Control method and device for antislip of train

A control method and brake device technology, applied in the direction of brakes, etc., to achieve the effect of fast dynamic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

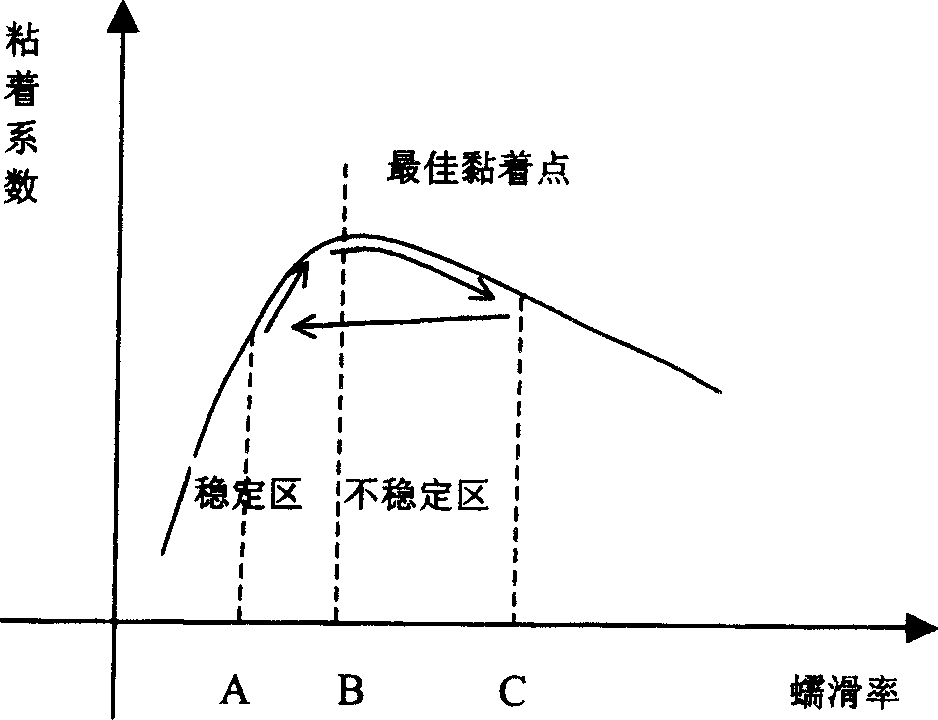

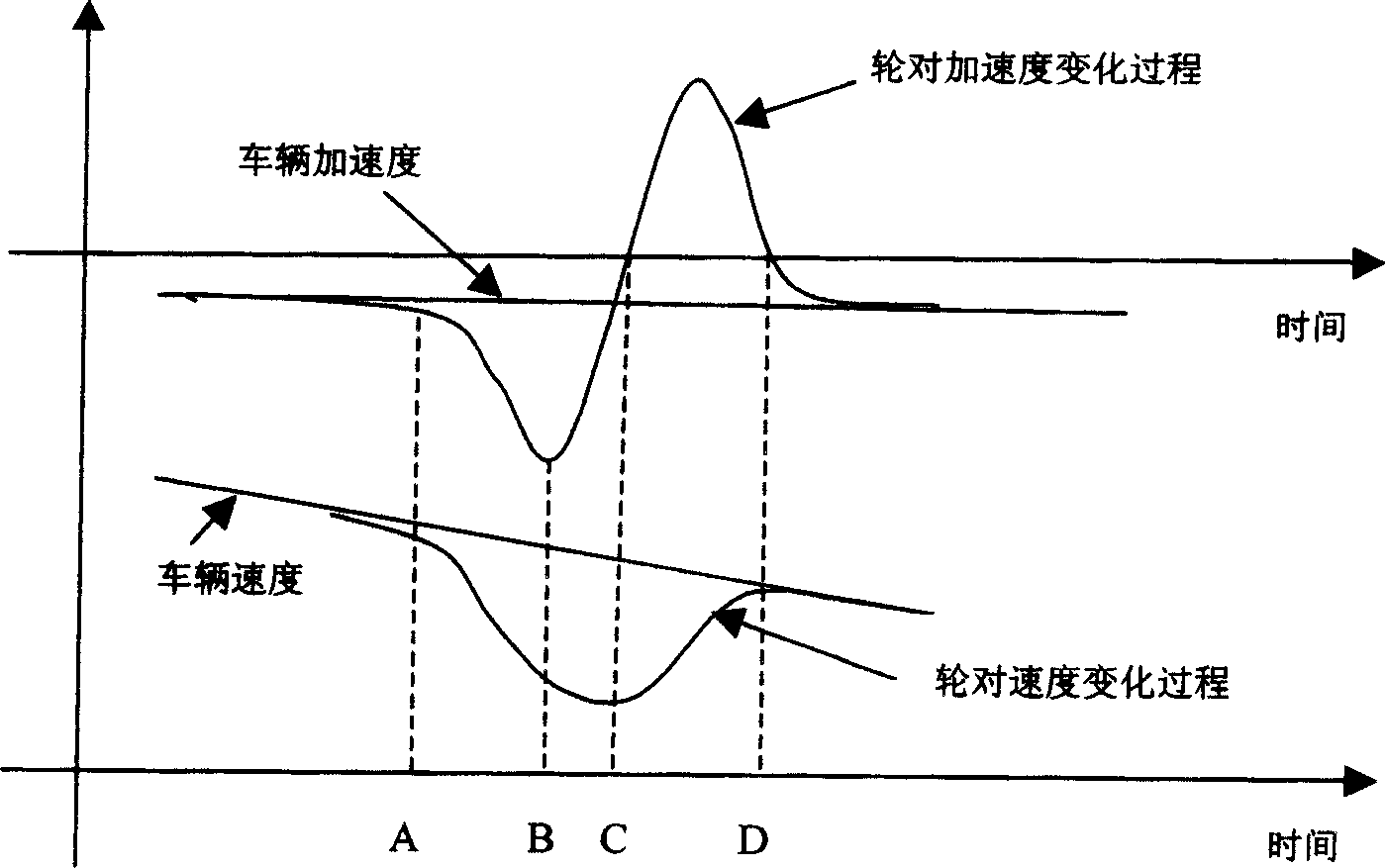

Problems solved by technology

Method used

Image

Examples

Embodiment 1

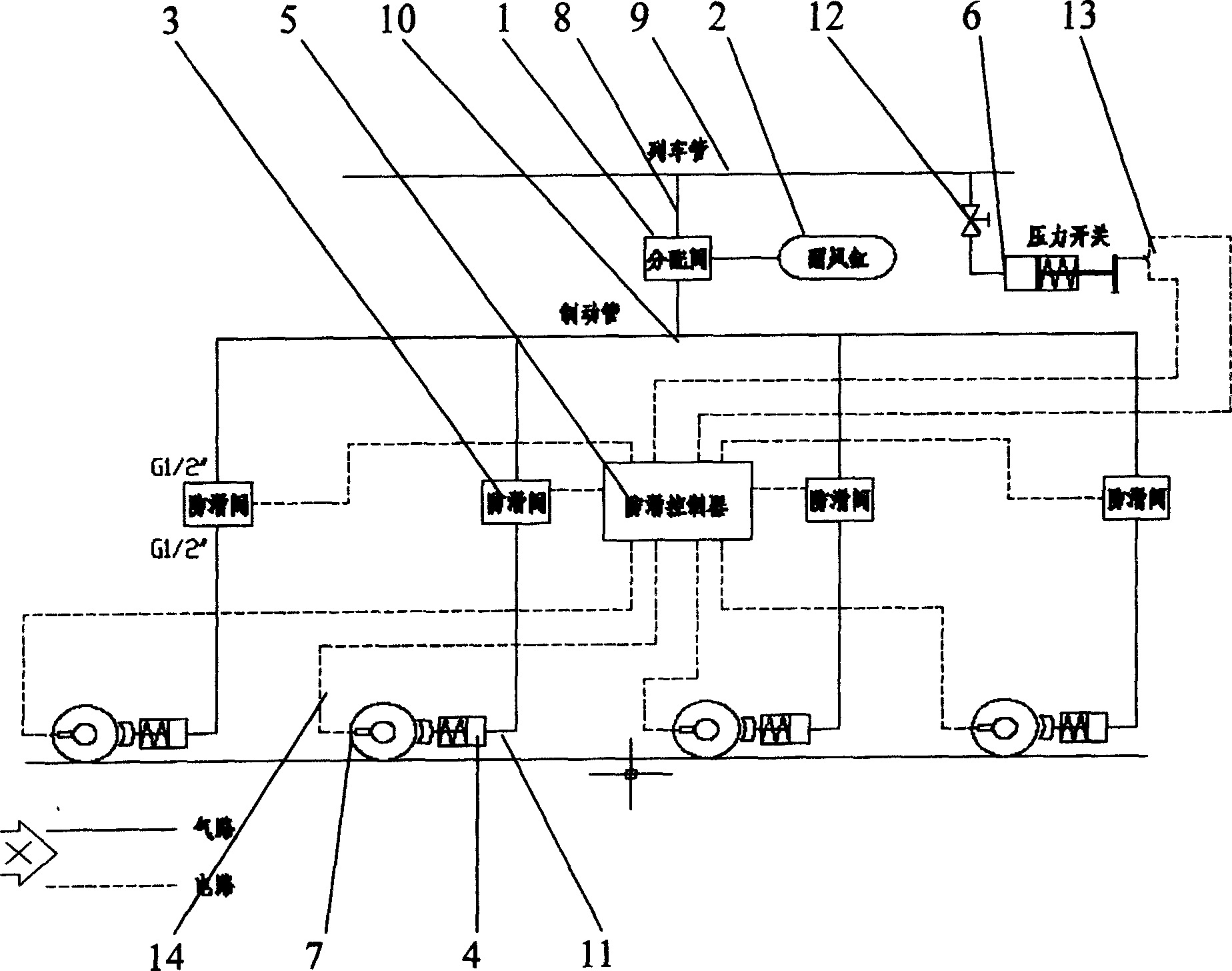

[0061] An anti-skid device for passenger cars mainly includes three parts: an anti-skid controller, four anti-skid valves and four speed sensor assemblies. The shaft control method is adopted, the anti-skid valve is connected with the anti-skid controller circuit, connected with the air circuit of the brake device, and controlled by the anti-skid controller; the anti-skid controller is electrically connected with the speed sensor component, and receives the speed electrical signal of the speed sensor component . It is used to prevent the wheels from locking and sliding due to insufficient adhesion between the wheels and rails when the air brake is used during the operation of the train.

[0062] The anti-skid controller is the core component of the control system. The box body is a standard 3U chassis with three installation methods: vertical installation, horizontal installation and embedded installation. The installation method can be determined according to the actual insta...

Embodiment 2

[0088] The method and structure of embodiment two are the same as embodiment one but the selected weighted proportional coefficient is different from embodiment one, is the data obtained according to the test, and the setting coefficient is as follows:

[0089] KAS1=13.0-20.0 Wheelset speed and vehicle calculation speed difference weighting coefficient

[0090] KAS2=1.8-3.2 acceleration weighting coefficient

[0091] KAS3=4.2-7.5 Creep rate weighting coefficient

[0092] KA84=2.2-4.5 Vehicle calculation speed and vehicle speed difference weighting coefficient

[0093] KAS5=0.5-1.5 Speed calculation weighting coefficient

[0094] The comprehensive index value (Z) is calculated as follows:

[0095] Z=KAS1*ΔV 轮对 +KAS3*η+KAS4*ΔV 车辆 +KAS2*α-KAS5*V 车辆计算

[0096] The control variables are explained as follows:

[0097] ΔV 轮对 Calculation of speed and wheel-to-line speed difference for the vehicle

[0098] η is the creep rate, equal to

[0099] ΔV 车辆 Compute the dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com