Pressure balanced spool poppet valves with printed actuator coils

a technology of actuator coils and valves, applied in the field of valves, can solve the problems of large losses of energy and system noise, high system parasitic losses, and valve types that cannot be completely pressure balanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

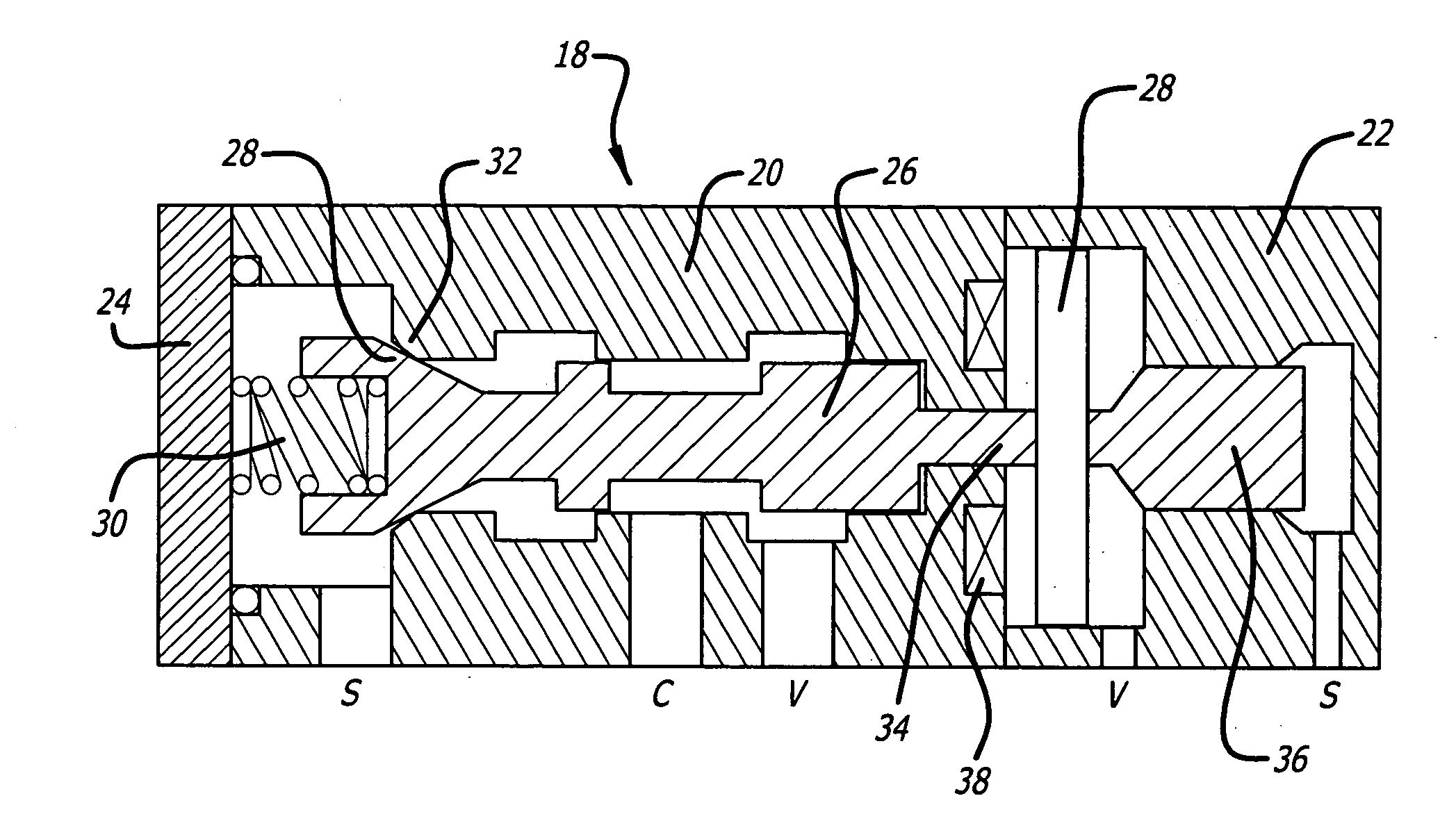

[0019] First referring to FIG. 1, a cross-section of a spool poppet valve in accordance with an embodiment of the present invention may be seen. The valve shown is a three-way valve, in that it may connect a control port C to a supply port S or to a vent port V. The valve includes a housing 20 and cap 22, both of which are of magnetic materials, and an end cap 24, which may or may not be fabricated of a magnetic material. Located within the housing 20 is a spool 26 having a poppet valve 28 at the left end thereof, with a coil spring 30 encouraging the spool and poppet valve to the right position, as shown. In this position, the control port C is coupled to the vent port V, with the poppet valve being firmly seated on seat 32 on the housing to seal the high pressure fluid in the source port S from the control port C.

[0020] At the right end of spool 26 is a magnetic armature 28 urged against end 34 of the spool by a pressure balance piston 36, the right end of which is also subjected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com