Patents

Literature

1182 results about "Reduction ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reduction ratio. [ri′dək·shən ‚rā·shō] (engineering) Ratio of feed size to product size for a mill (crushing or grinding) operation; measured by lump and sieve sizes.

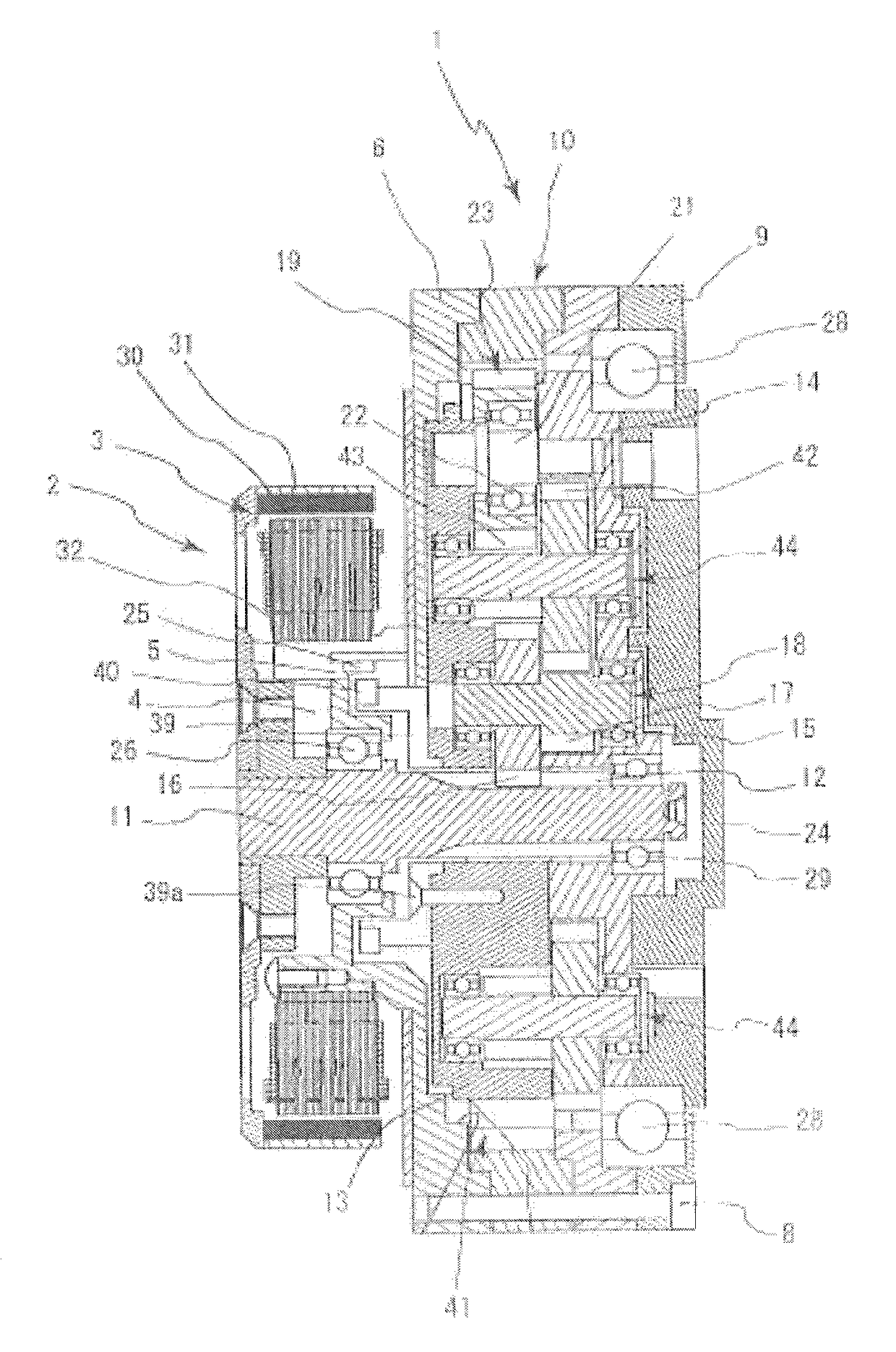

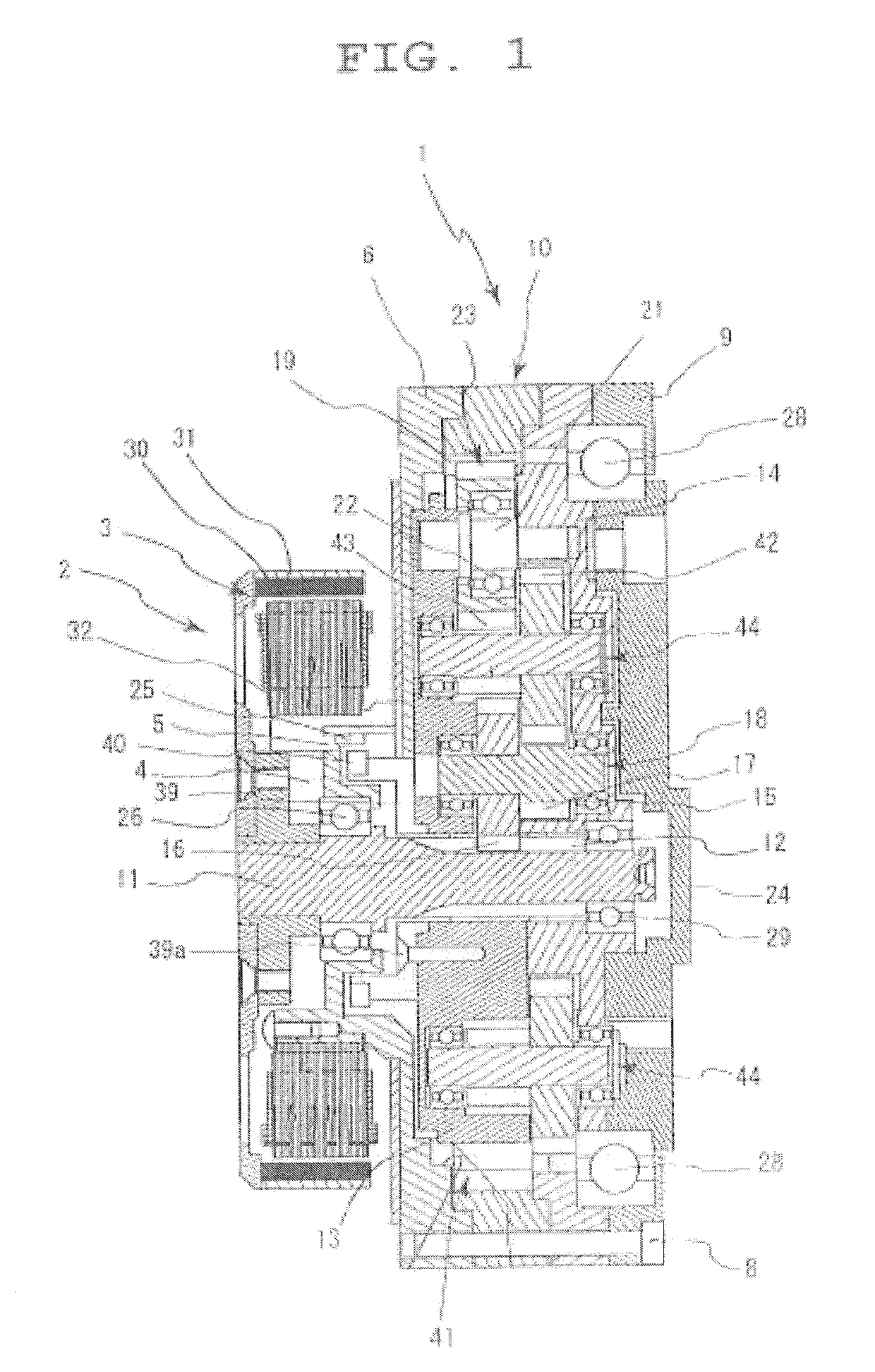

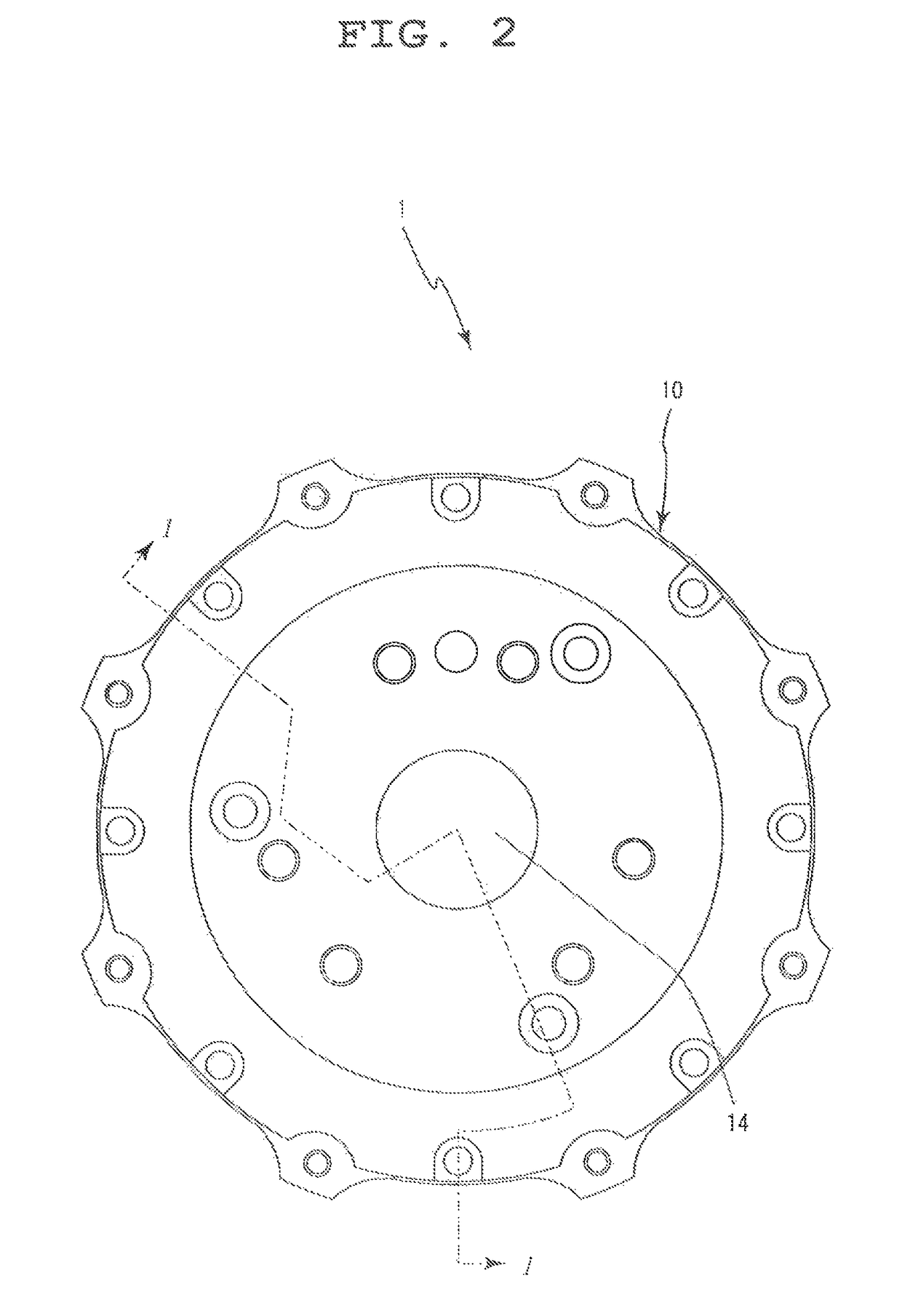

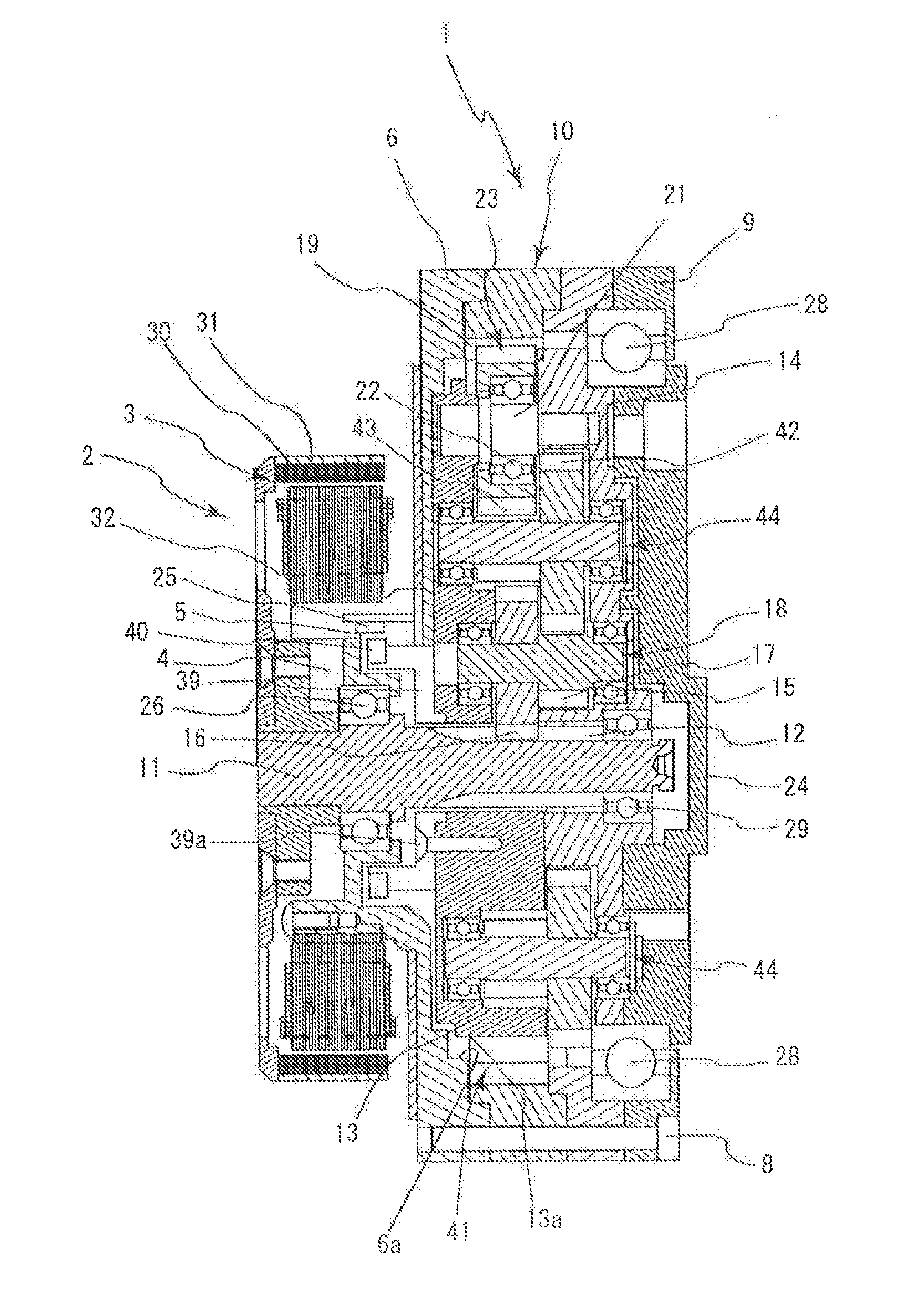

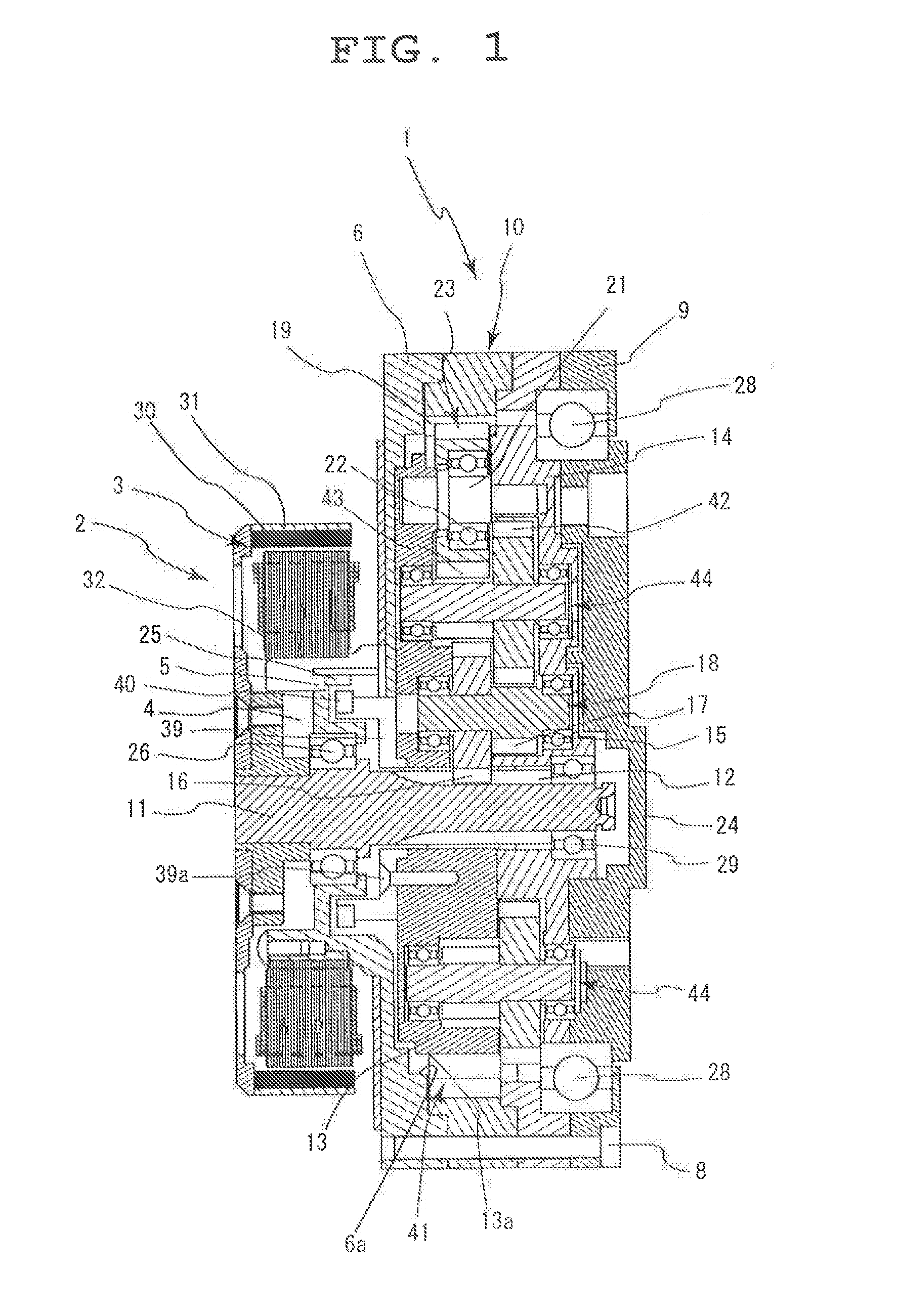

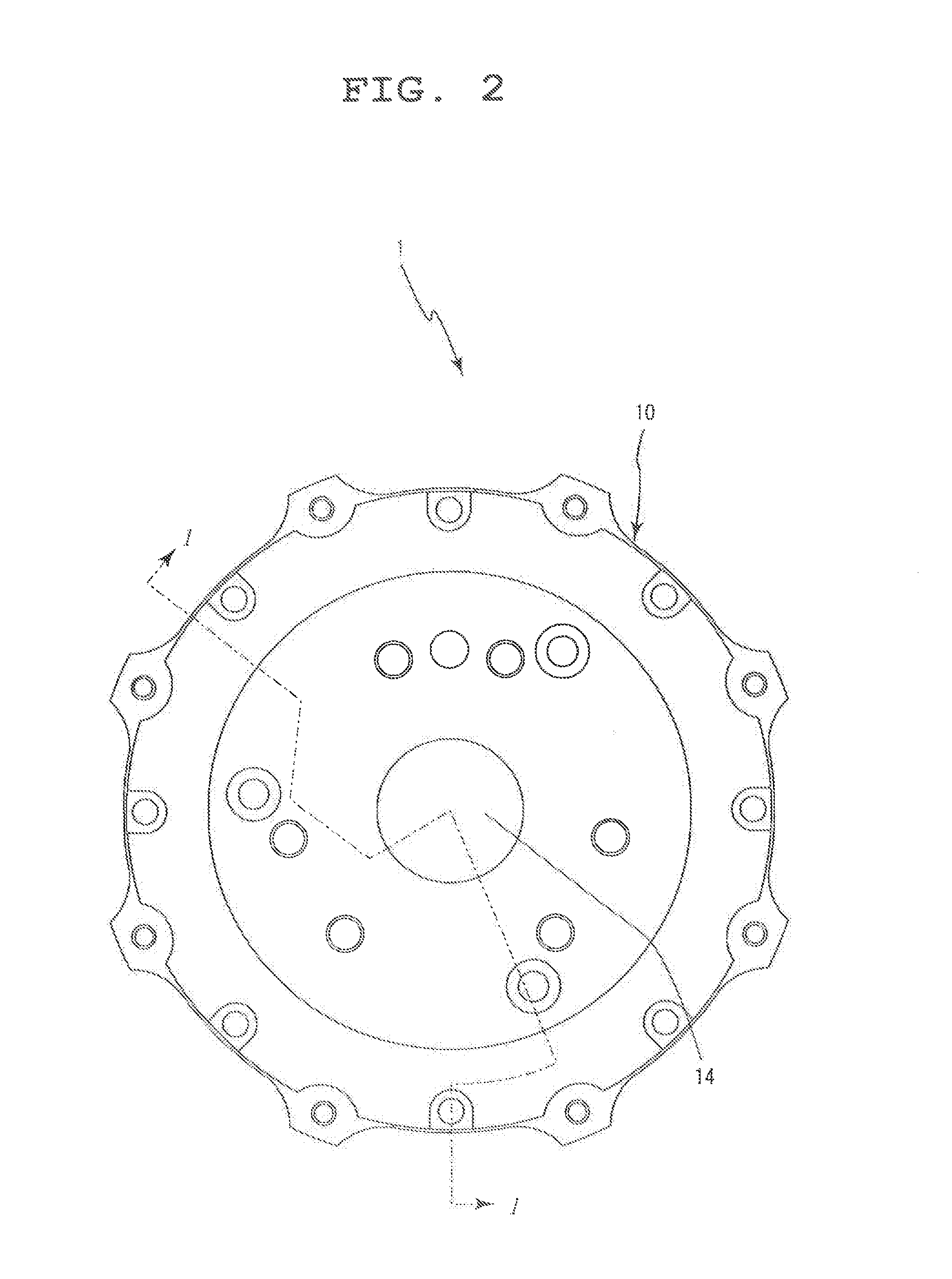

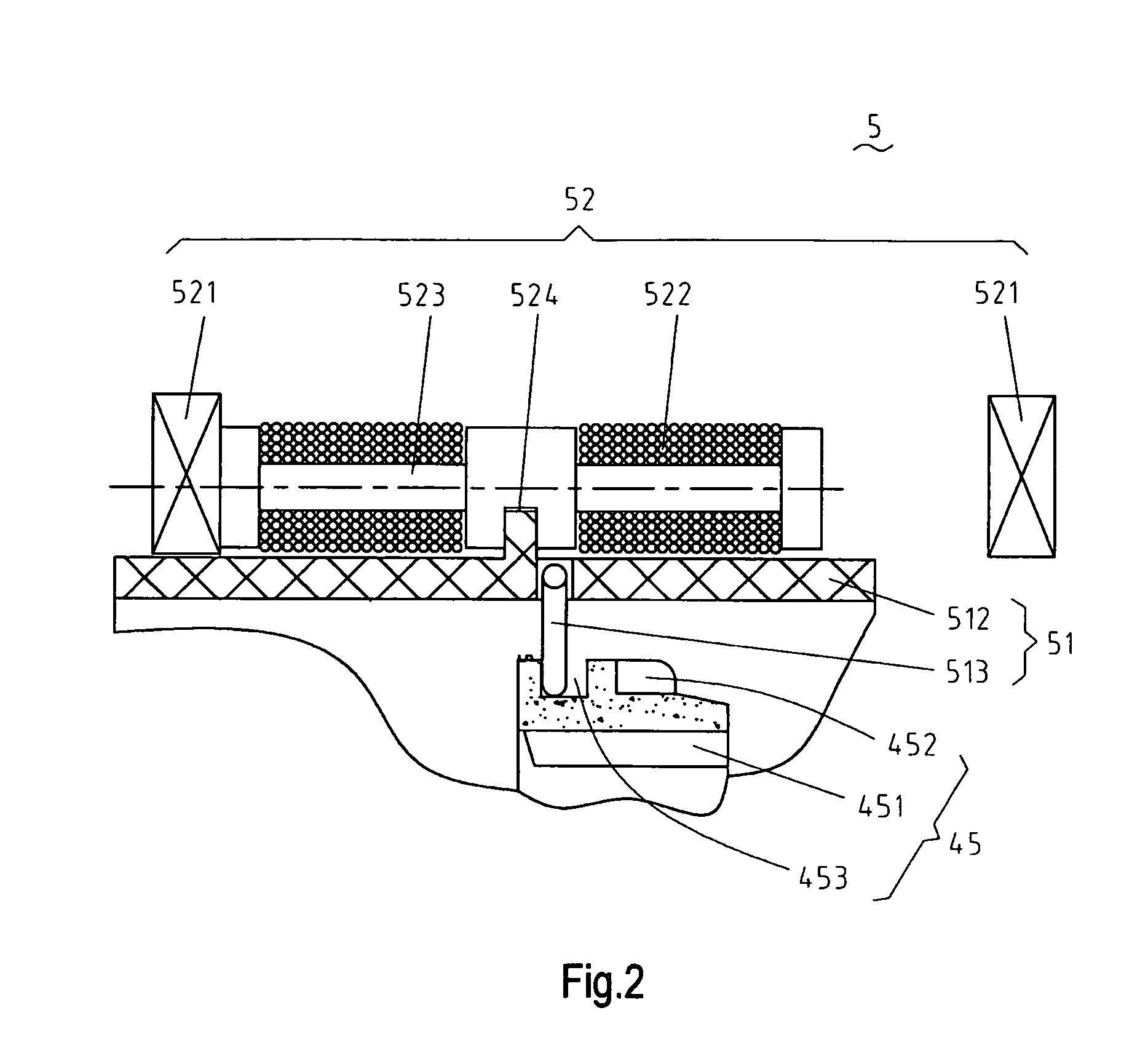

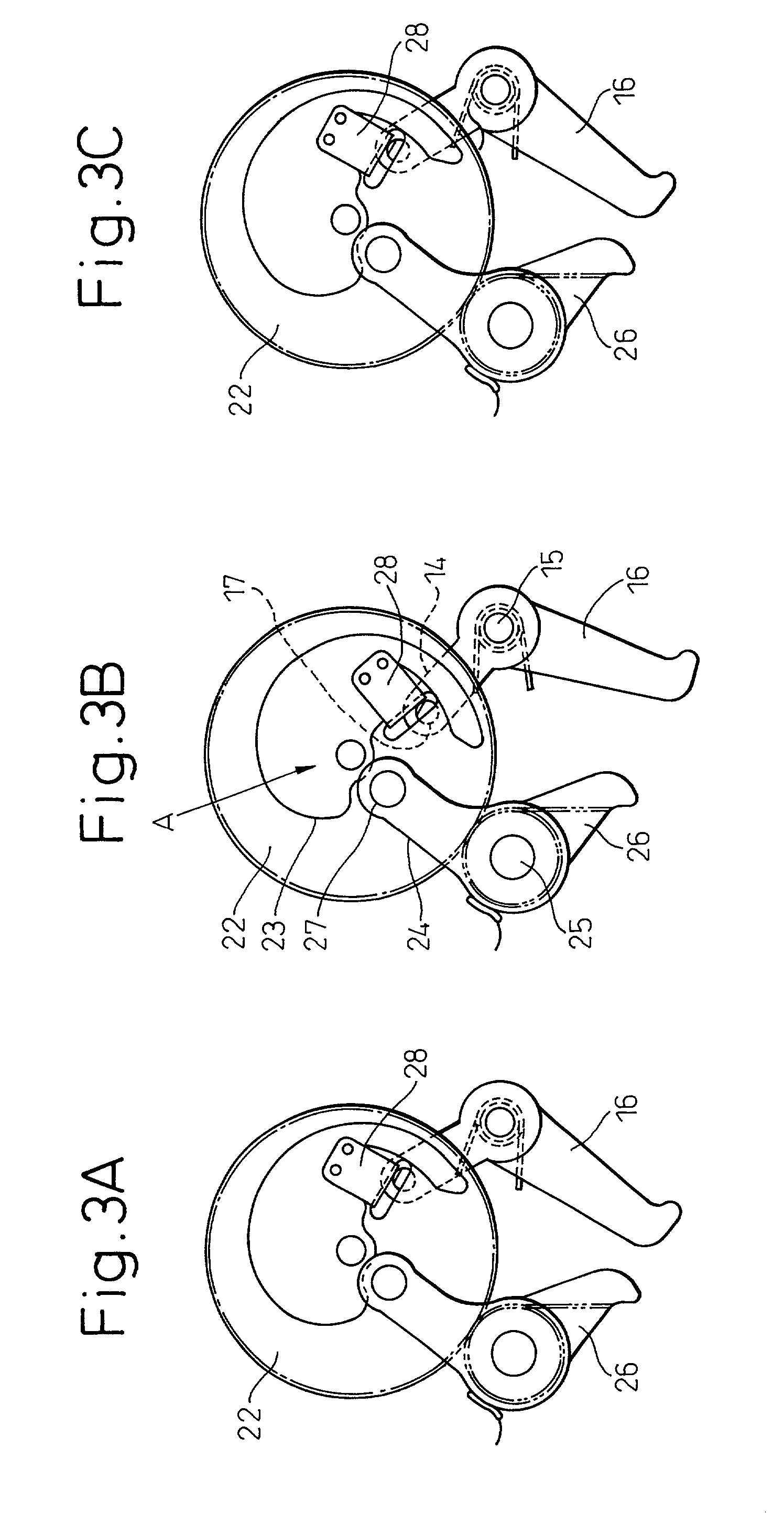

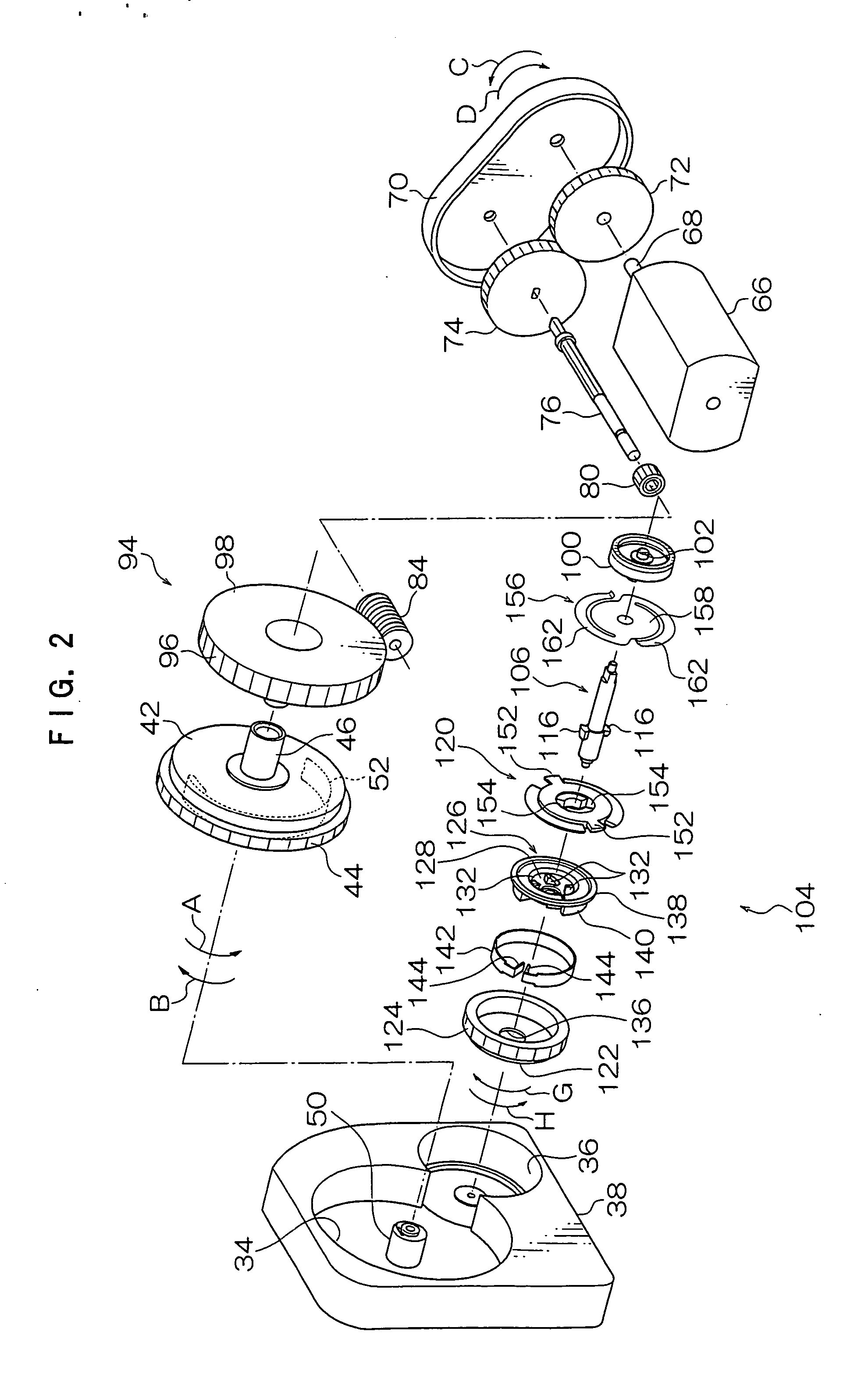

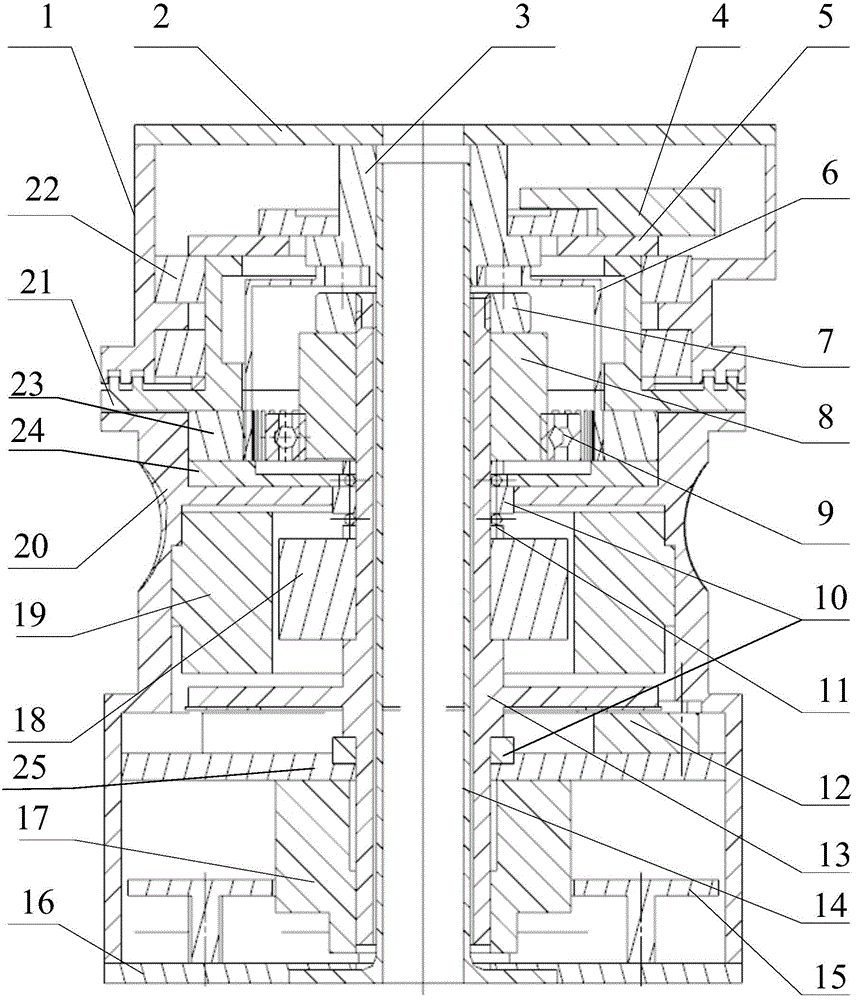

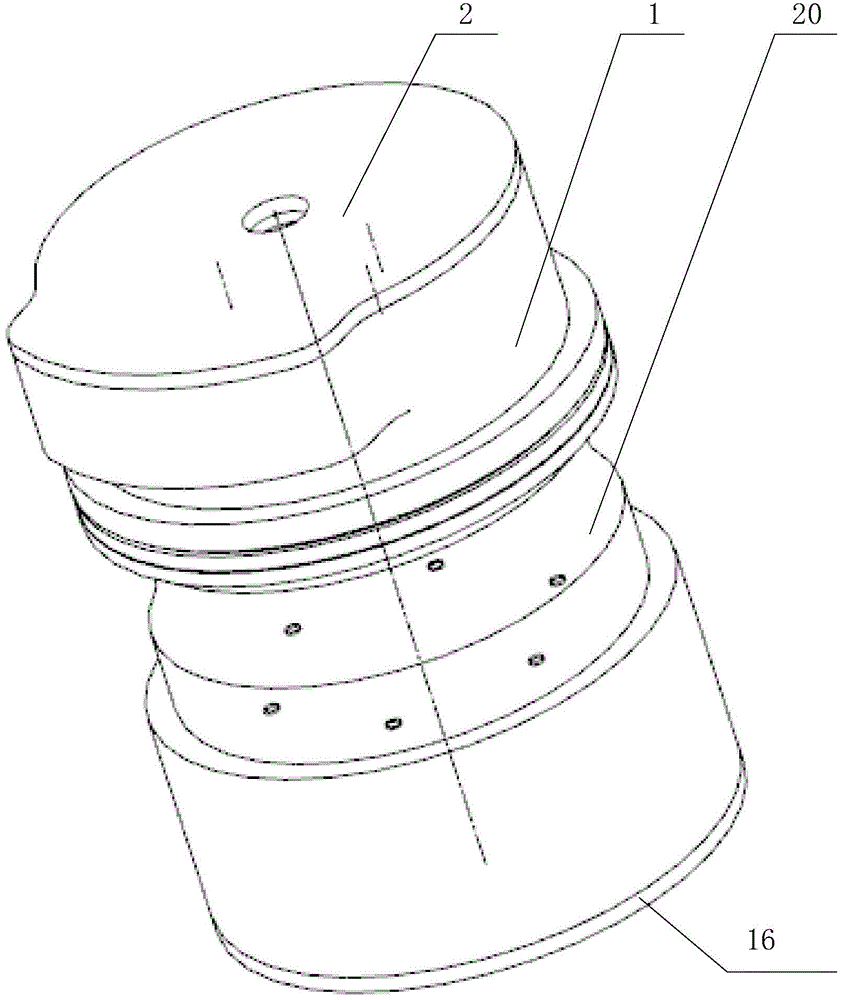

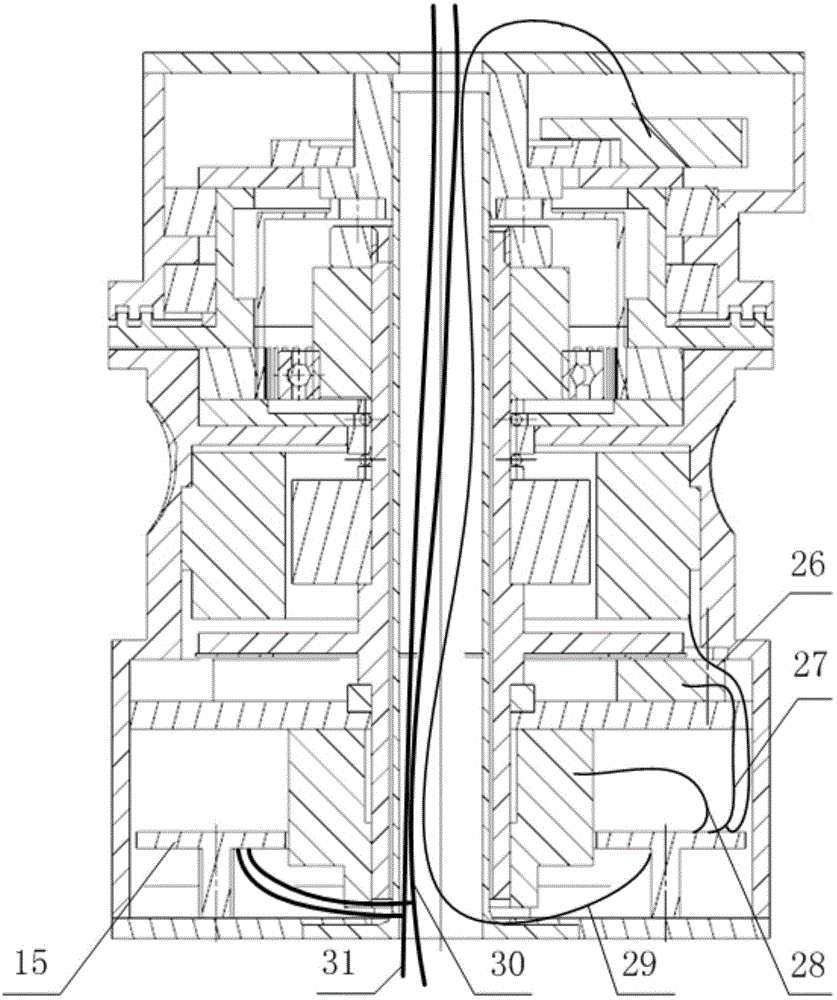

Gear motor including reduction mechanism

ActiveUS9689466B2Thinness and size and weight reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can he achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

Gear motor including reduction mechanism

ActiveUS20160238108A1Thinness and size and weight reduction of reductionAvoid instabilityToothed gearingsMechanical energy handlingBall bearingReduction ratio

The present invention provides a reduction mechanism in which high torque output can be achieved, thinness and size and weight reduction can be achieved, and the number of teeth of a gear and reduction ratio can be freely set. In a gear motor that includes a reduction mechanism in which a planetary two-stage gear is arrayed between a sun gear of a planetary gear mechanism and an internal gear of a planetary gear mechanism, the reduction mechanism has at least a single planetary two-stage gear arrayed such as to be positioned between the sun gear and the internal gear and including a small gear or a large gear that meshes together with a large gear or a small gear of the planetary two-stage gear, and both end portions of the at least a single planetary two-stage gear are supported by ball bearings.

Owner:COPAL ELECTRON CO LTD

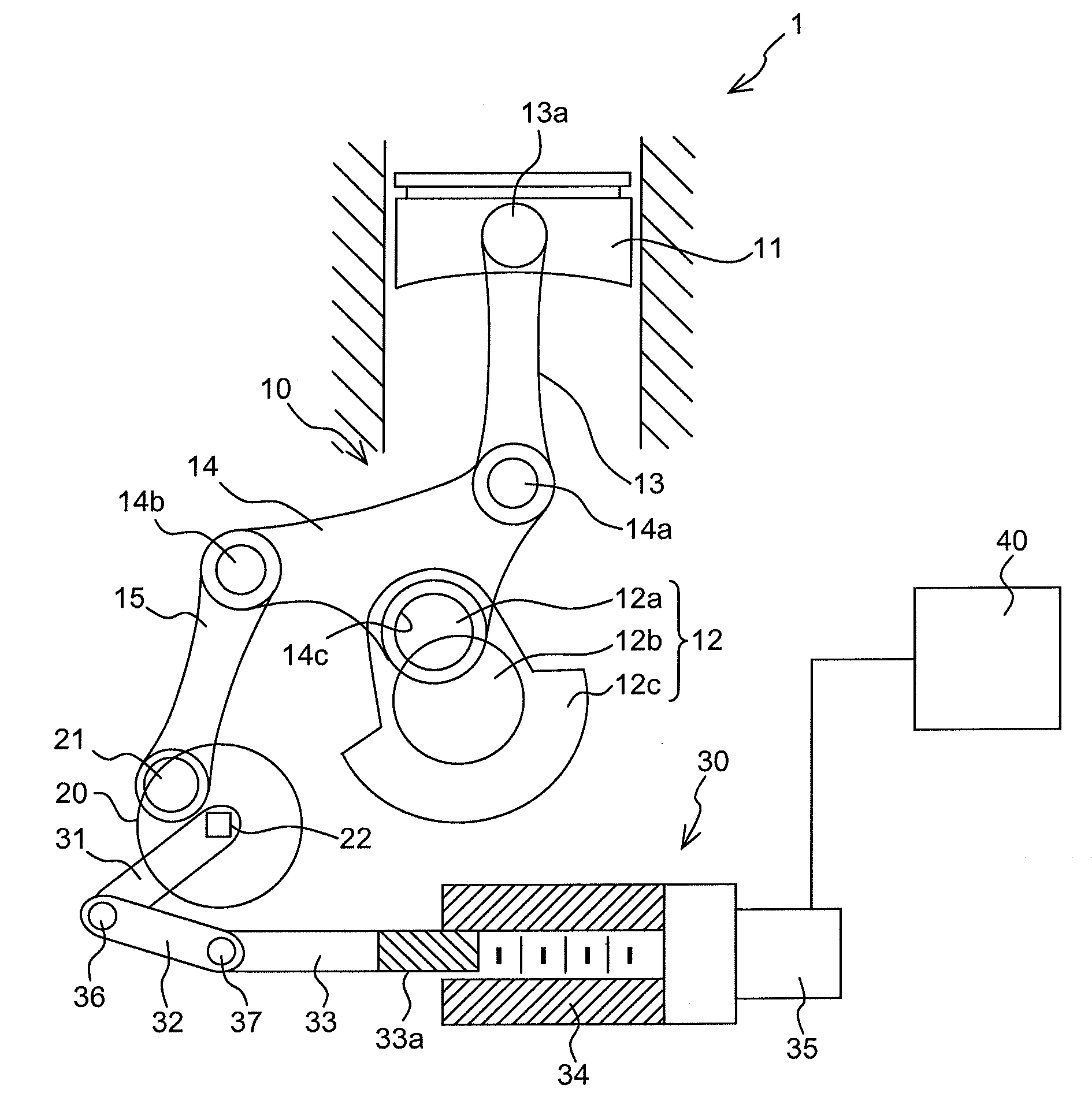

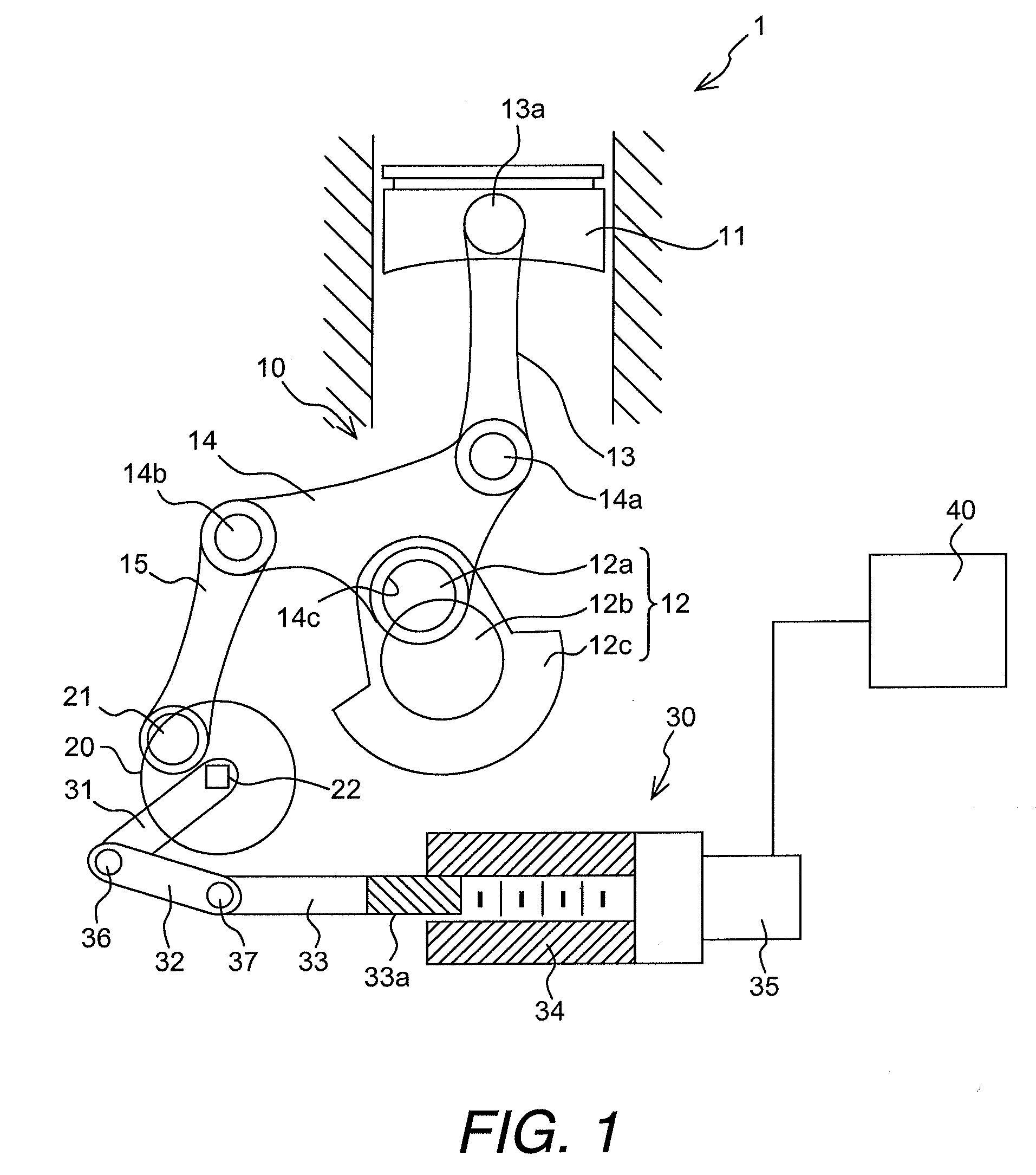

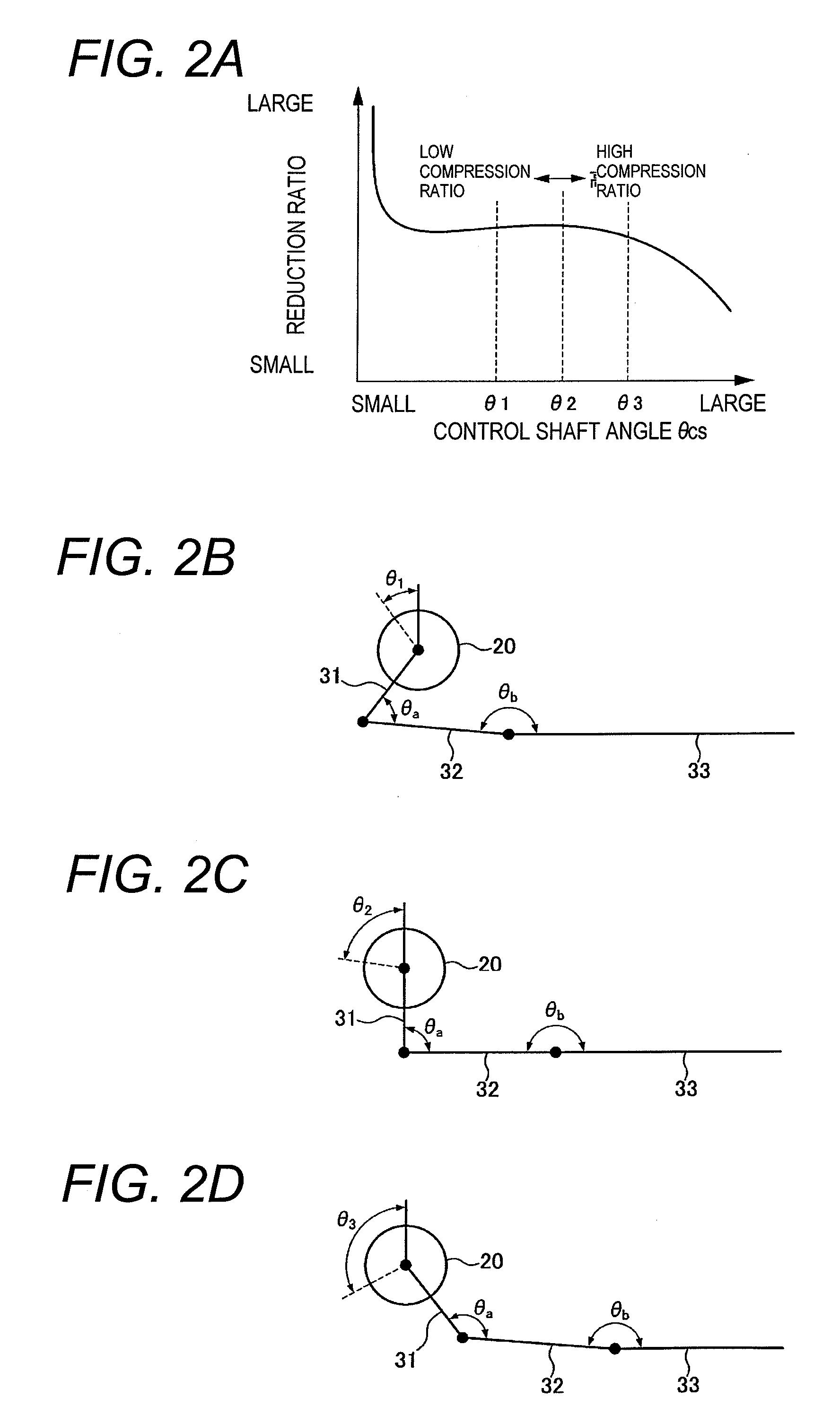

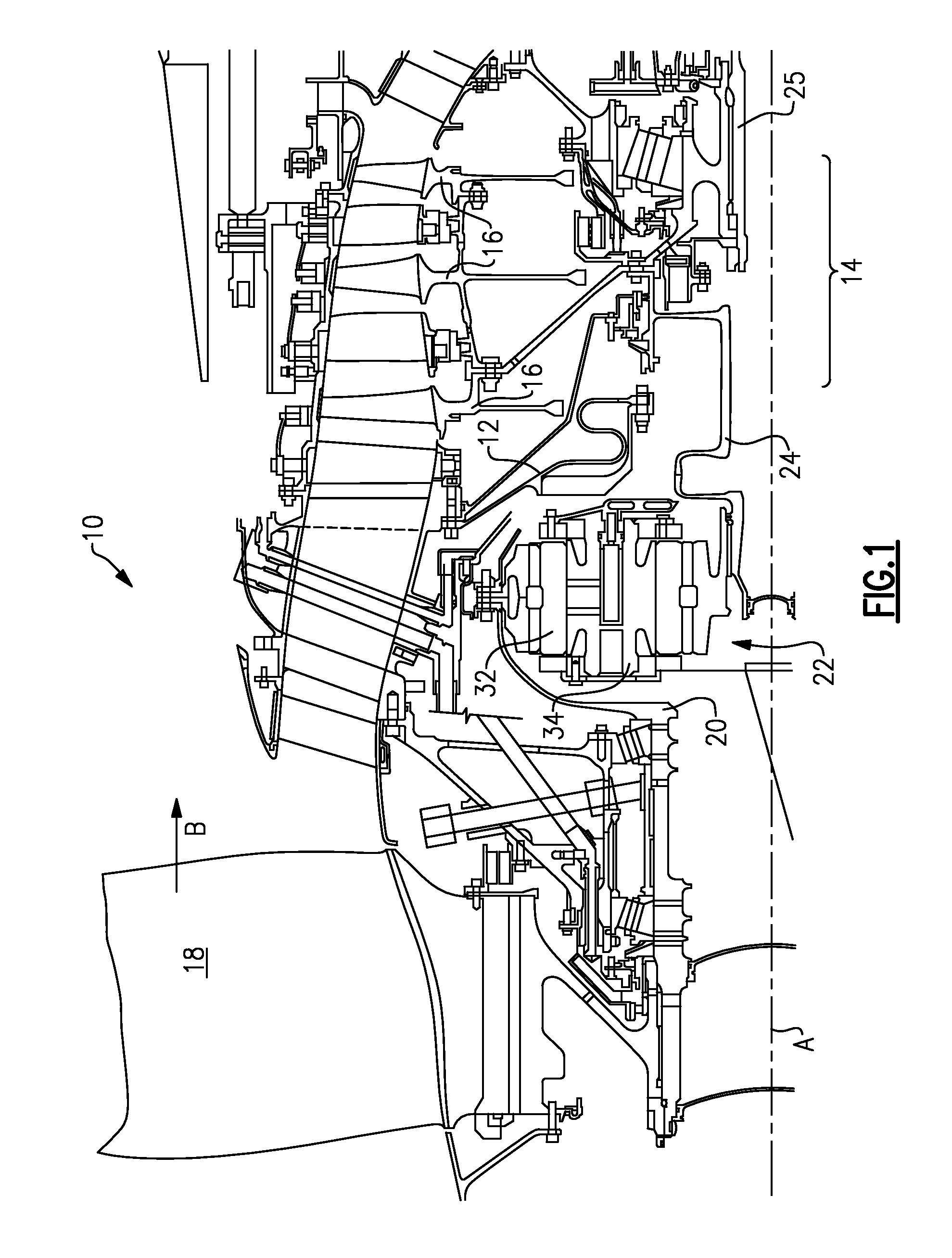

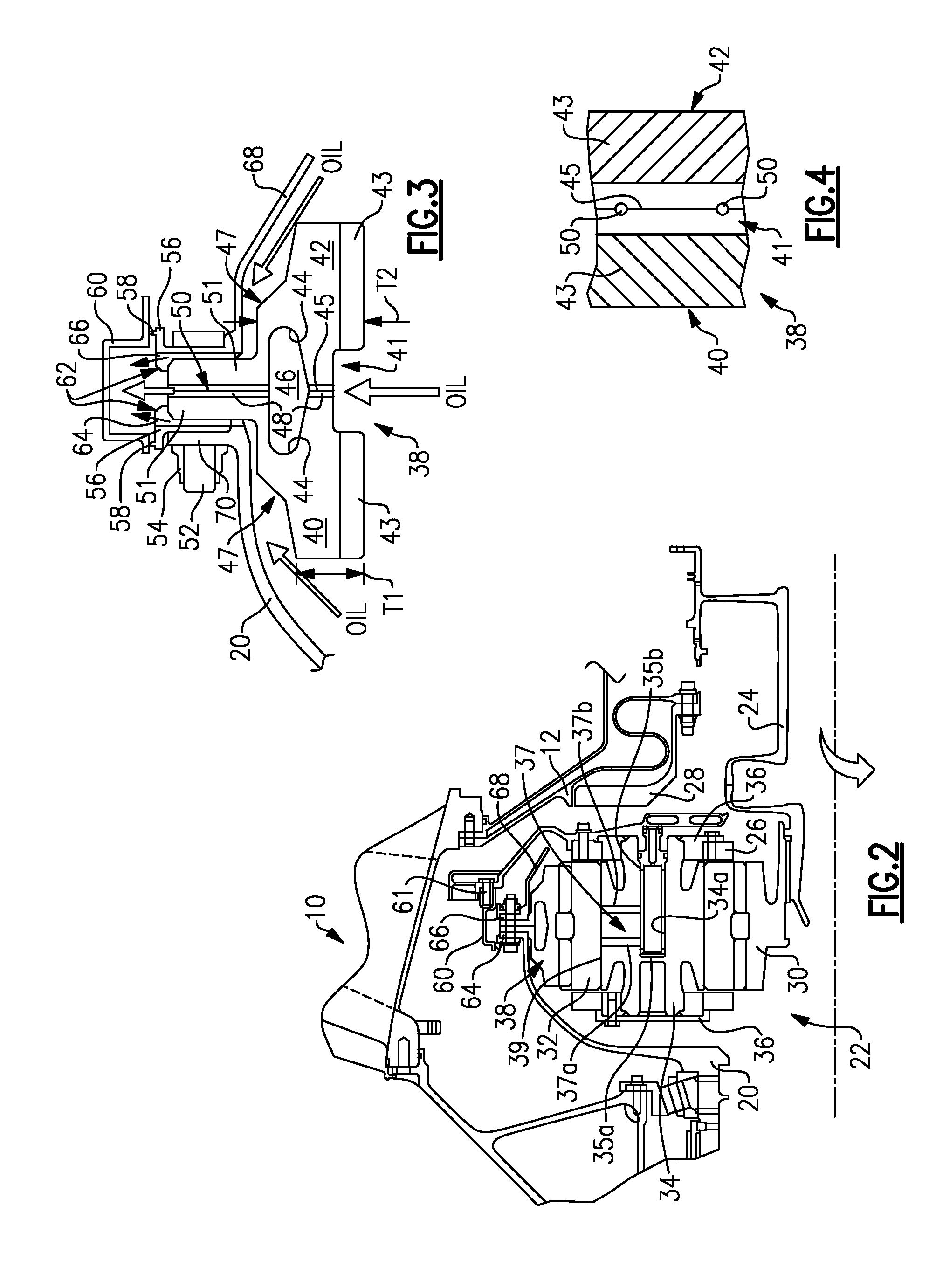

Multi-link variable compression ratio engine

ActiveUS20090107454A1Frequently knockedInhibitionConnecting rodsMachines/enginesTop dead centerReduction ratio

A multi-link variable compression ratio engine is provided with a crankshaft, a piston, a control shaft, a linkage, a motor and a reduction mechanism. The crankshaft moves the piston within an engine cylinder. The control shaft has an eccentric axle eccentric relative to its center-axis. The linkage operatively connects the piston to the crankshaft and the crankshaft to the eccentric axle of the control shaft. The motor rotates the control shaft so a top-dead-center position of the piston changes to vary compression ratios by changing the positions of the eccentric axle and the linkage. The reduction mechanism couples the motor to the control shaft to transmit a reduced rotation of the motor to the control shaft so a reduction ratio of a rotation angle of the motor to a rotation angle of the control shaft is less at high-compression ratios than at intermediate compression ratios.

Owner:NISSAN MOTOR CO LTD

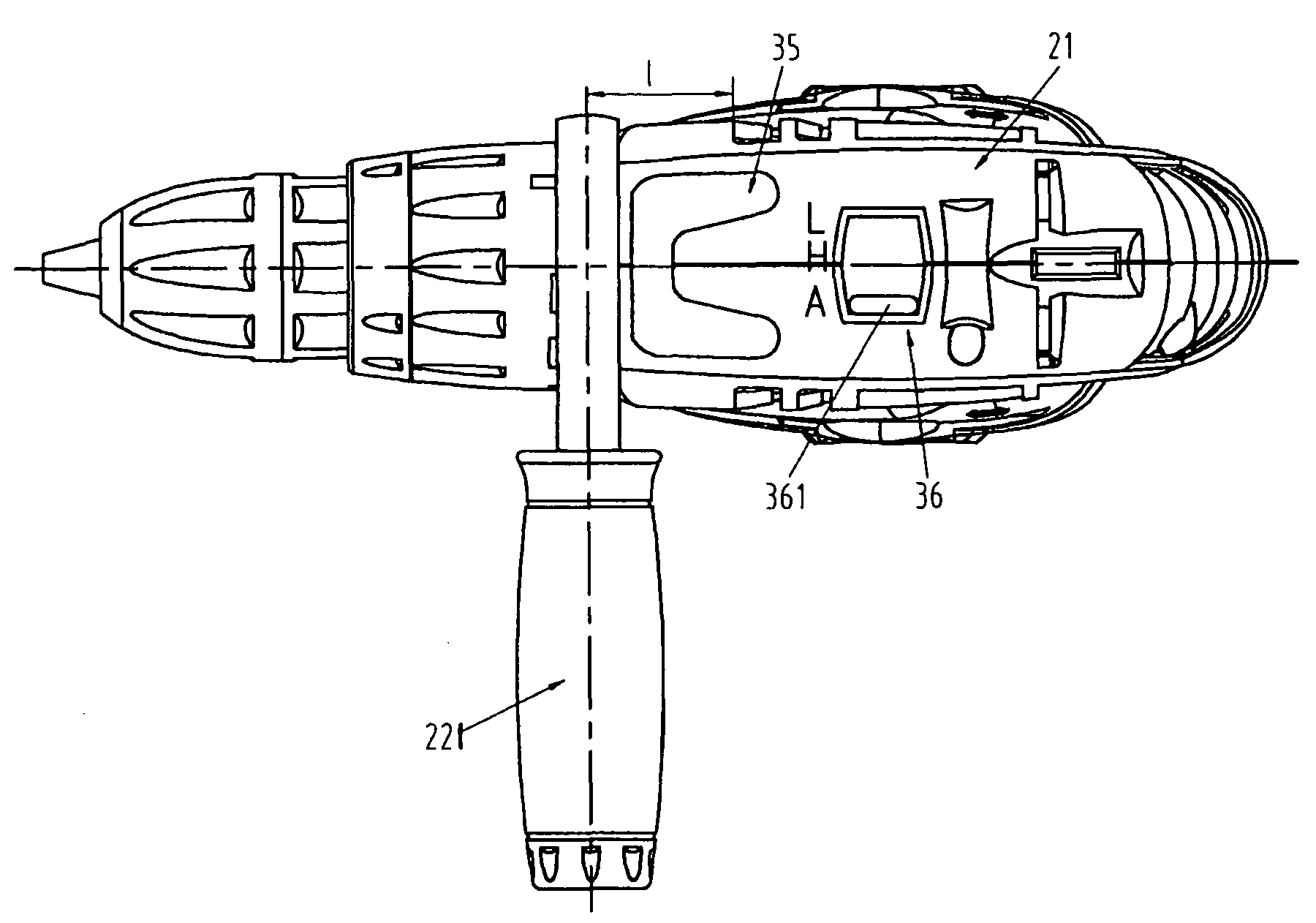

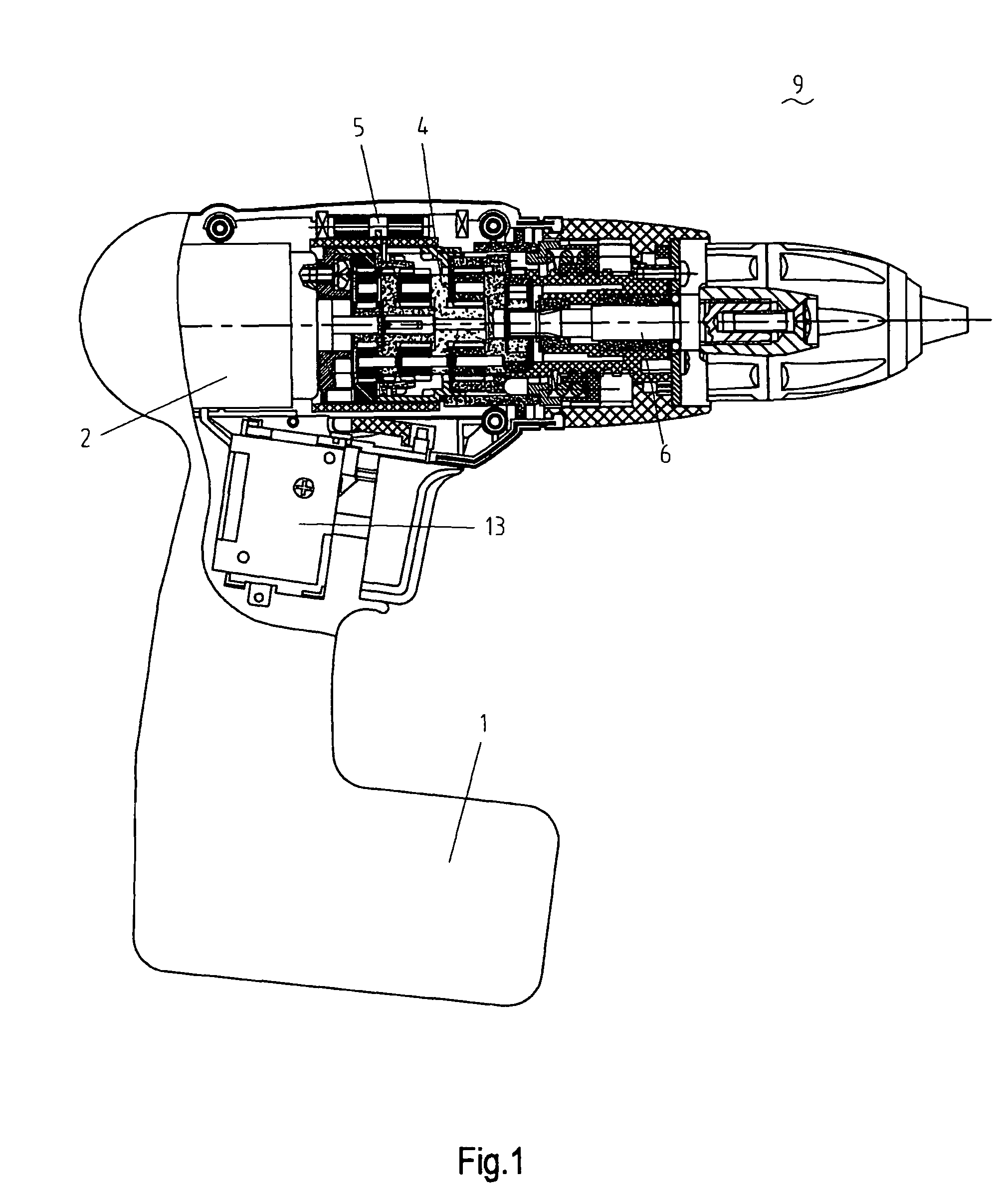

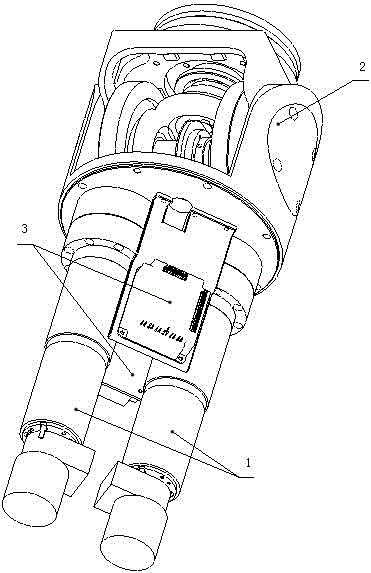

Power tool with signal generator

A power tool includes a housing, a motor, an output shaft, a gear transmission mechanism and a control system. The gear transmission mechanism is connected between the motor and the output shaft to transmit the rotary power of the motor to the output shaft. The power tool includes a signal generator and a control system electrically coupled to the signal generator and operatively engaged with the gear transmission mechanism such that when the signal generator is manually activated, an electric signal is generated and transmitted to the control system to cause the gear transmission mechanism to vary the gear reduction ratio.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

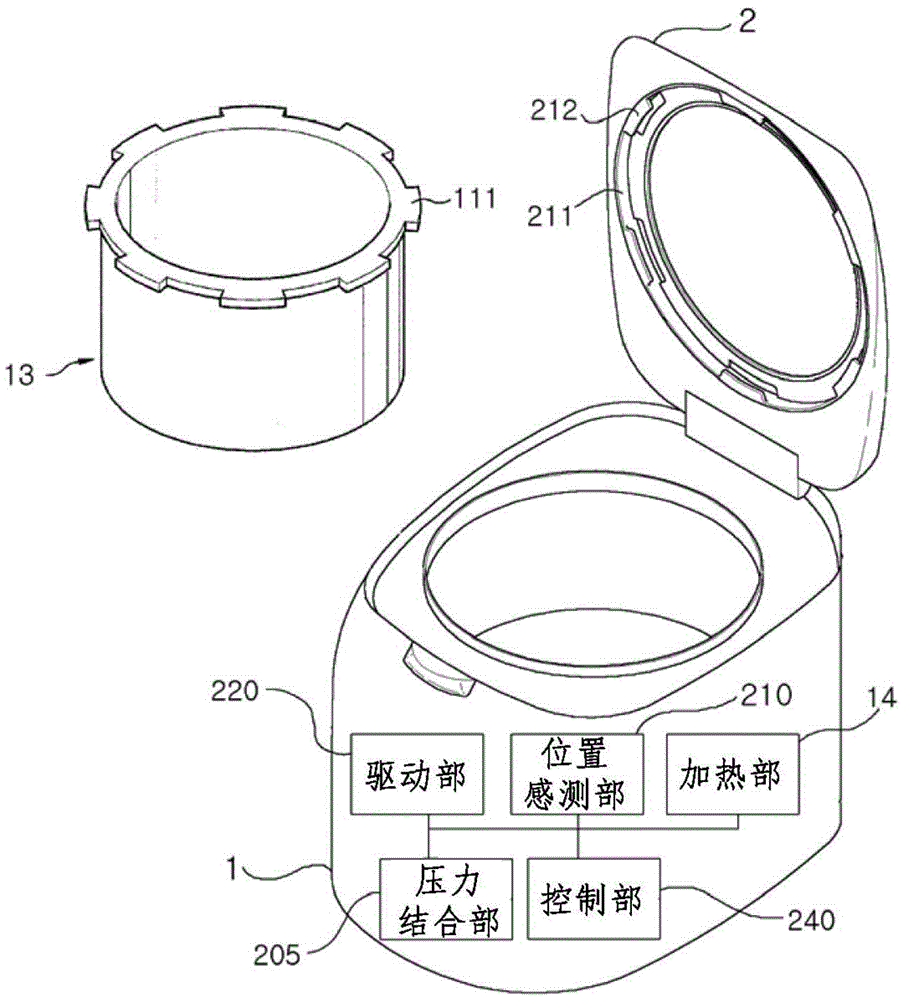

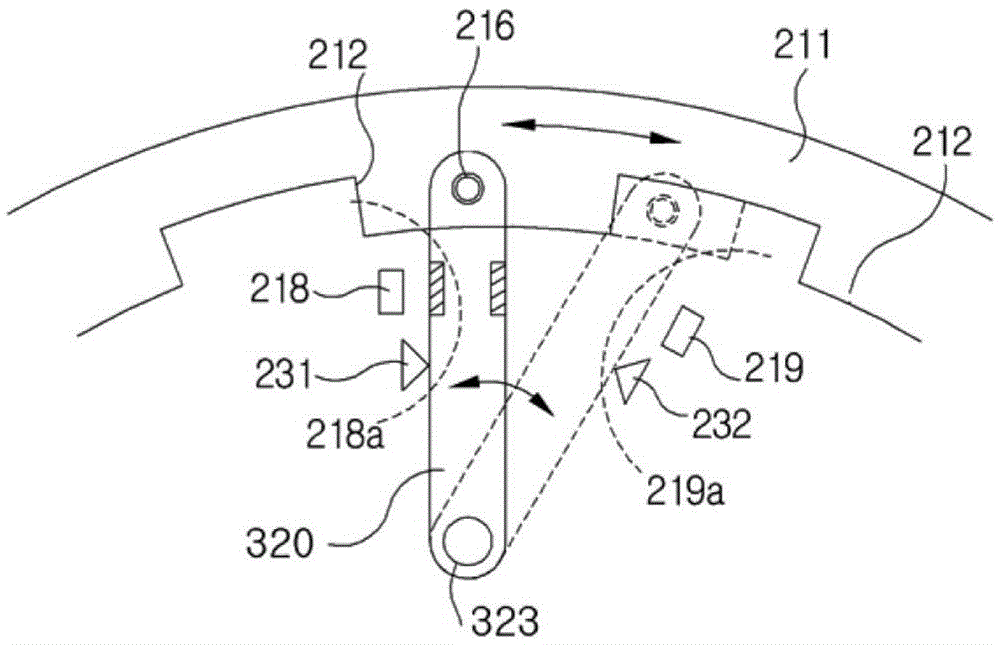

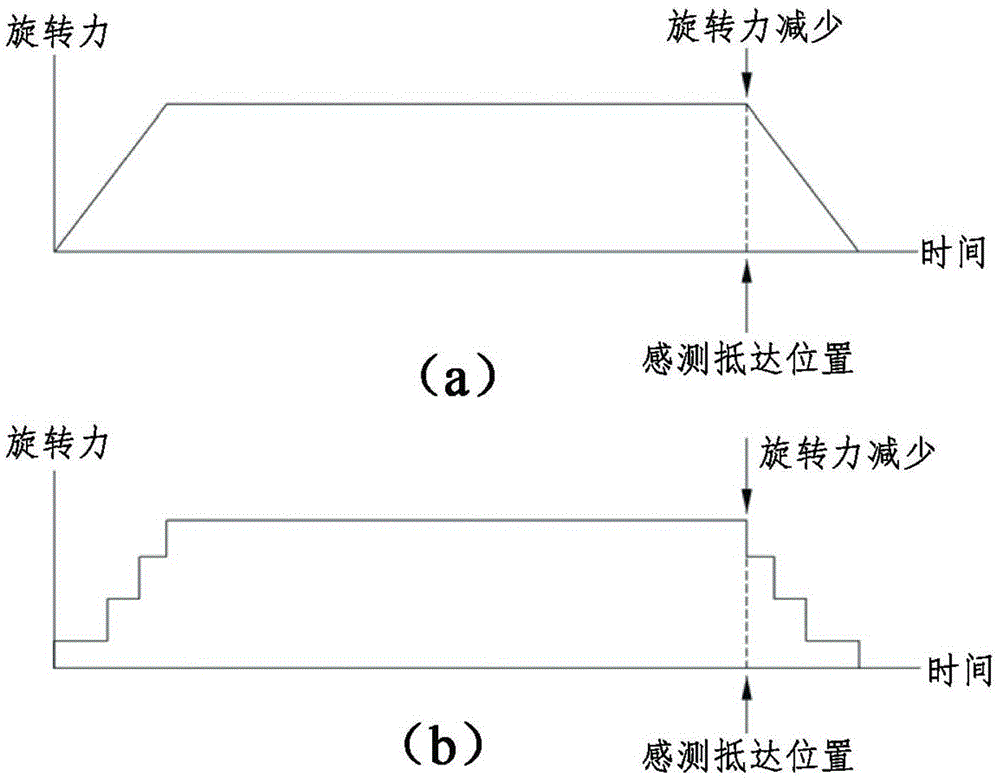

ELECTRIC PRESSURE RICE COOKER, AUTO LOCKING DEVICE, automatic pressure locking function control method

ActiveCN105662127AWith automatic pressure lock functionStop precisePressure-cookersCookerReduction ratio

The invention provides an electric pressure rice cooker with an automatic pressure locking function, an automatic pressure locking function control method for the electric pressure rice cooker, and an auto looking device for the electric pressure rice cooker. The auto looking device includes an inner cooker forming hanging projections, an outer cooker, a cover and a pressure combination part including a locking wheel provided with a plurality of hanging grooves; in the state that the cover covers the outer cooler. The hanging grooves are joint with the hanging projections at a second position (i.e., a pressure locking state), and the hanging grooves releases the hanging projections at a first position (i.e., a pressure locking releasing state); a position sensing portion is used for sensing the locking wheel; the driving portion is used for providing a rotary force for allowing the locking wheel to rotate; and a control portion is used for controlling cooking actions and reducing the rotary force of the driving portion at a certain reduction ratio and finally allowing the locking wheel to stop rotation completely when it is sensed that the locking wheel rotates near the first position or the second position.

Owner:(株)酷晨

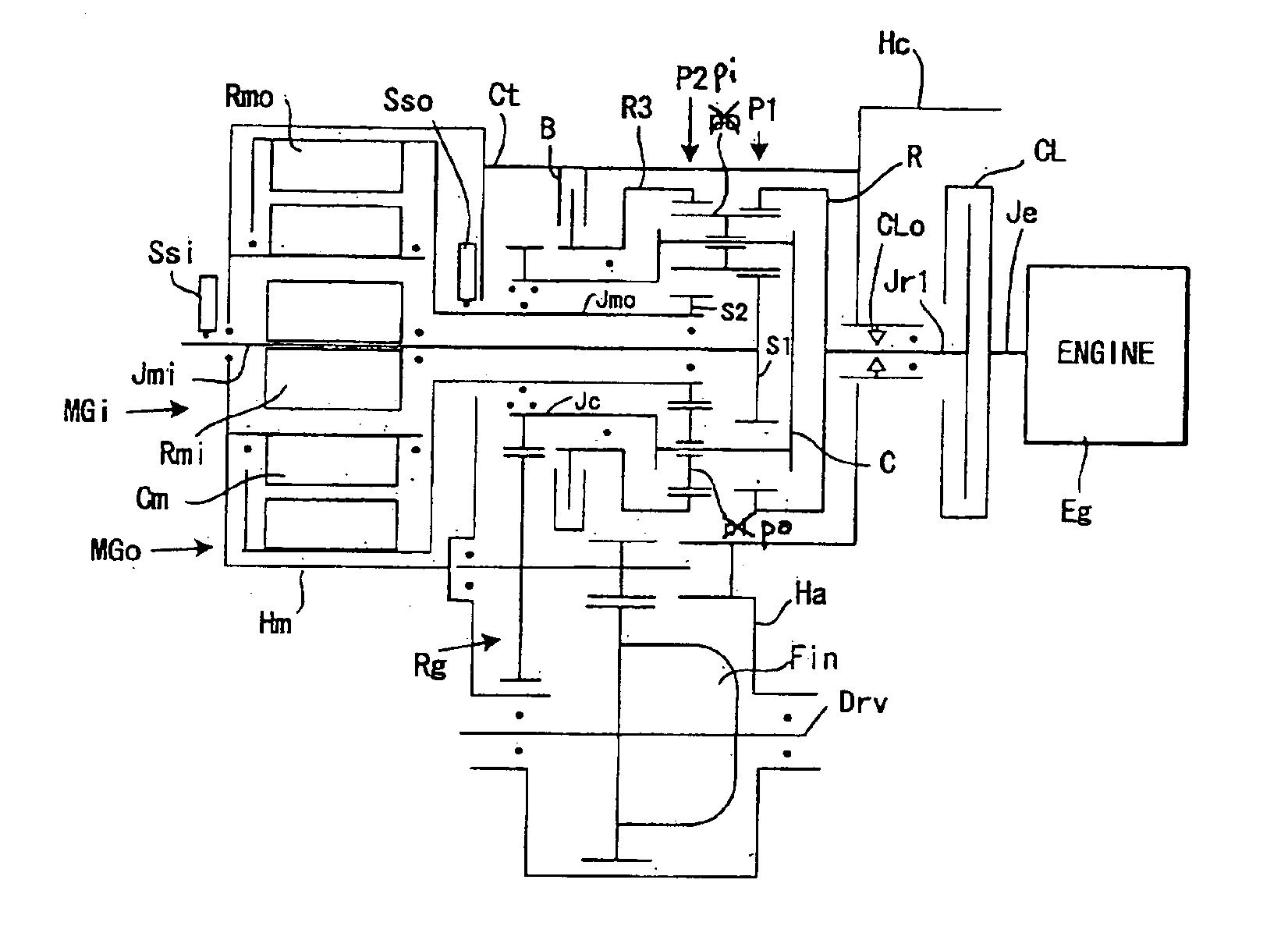

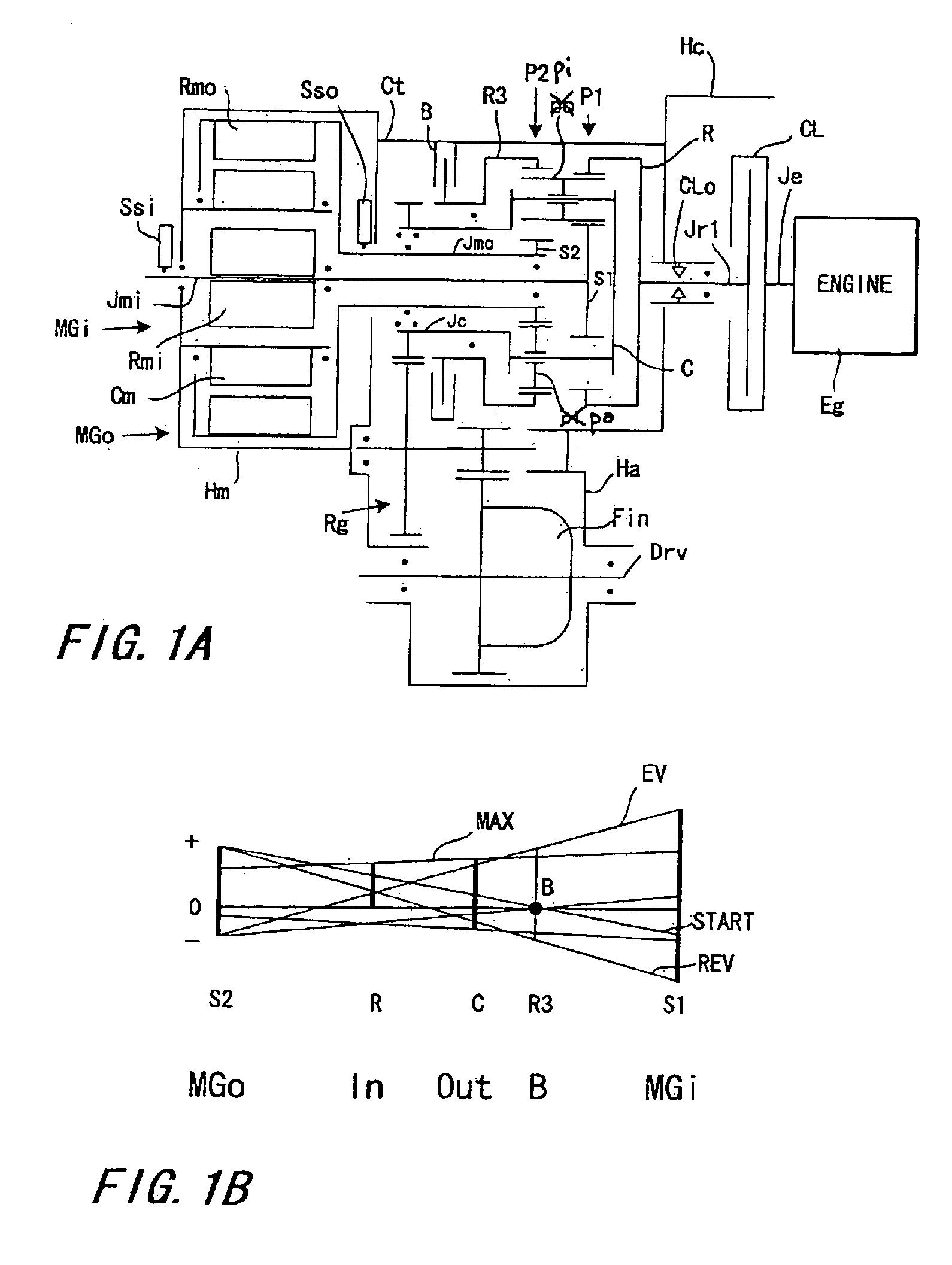

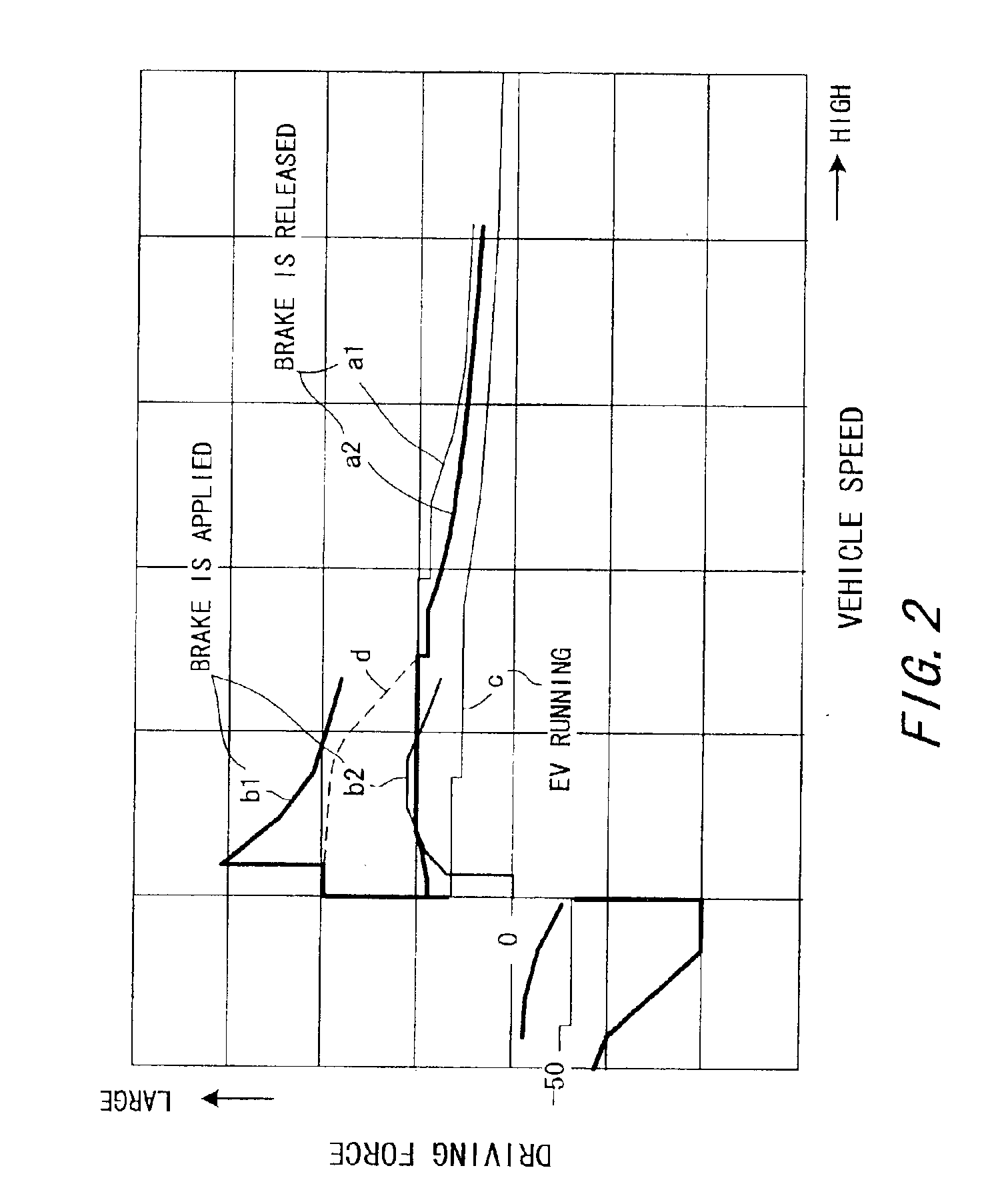

Drivetrain for a vehicle

InactiveUS7004868B2High energyIncrease in sizeHybrid vehiclesElectric propulsion mountingDrive shaftDrivetrain

The drivetrain includes a differential mechanism having four or more input / output elements and having two degrees of freedom. The input In from an engine, the output Out to a drive shaft, and two motor-generators MGi and MGo are assigned to the elements, and one of the elements other than the element to which the output assigned is provided with brakes B. By braking the element other than the output with the brakes, a large reduction ratio can be achieved, so startability can be improved without enlarging the capacities of the motor-generators.

Owner:NISSAN MOTOR CO LTD +1

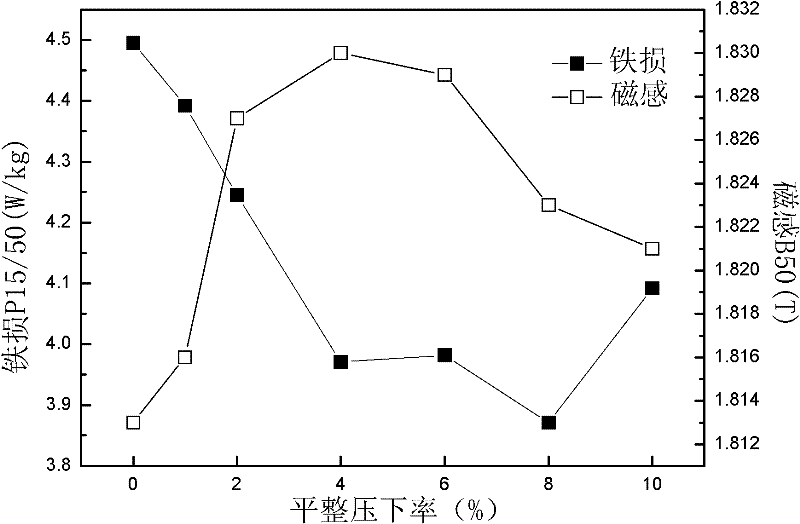

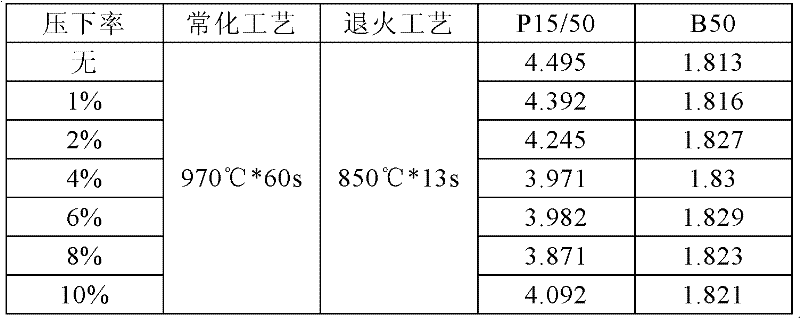

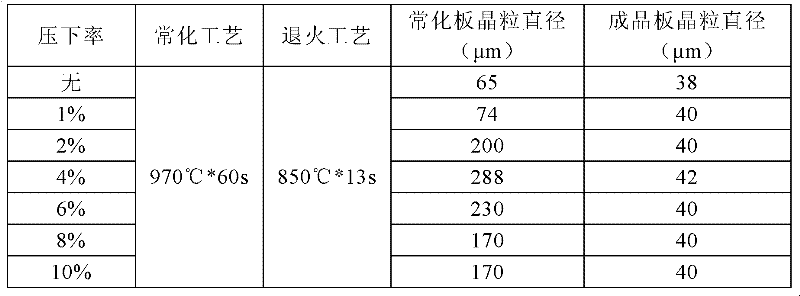

Method for preparing non-oriented silicon steel with high magnetic induction

ActiveCN102453837AHigh magnetic inductionGuaranteed iron lossInorganic material magnetismMetal rolling arrangementsReduction ratioSlow cooling

Owner:BAOSHAN IRON & STEEL CO LTD

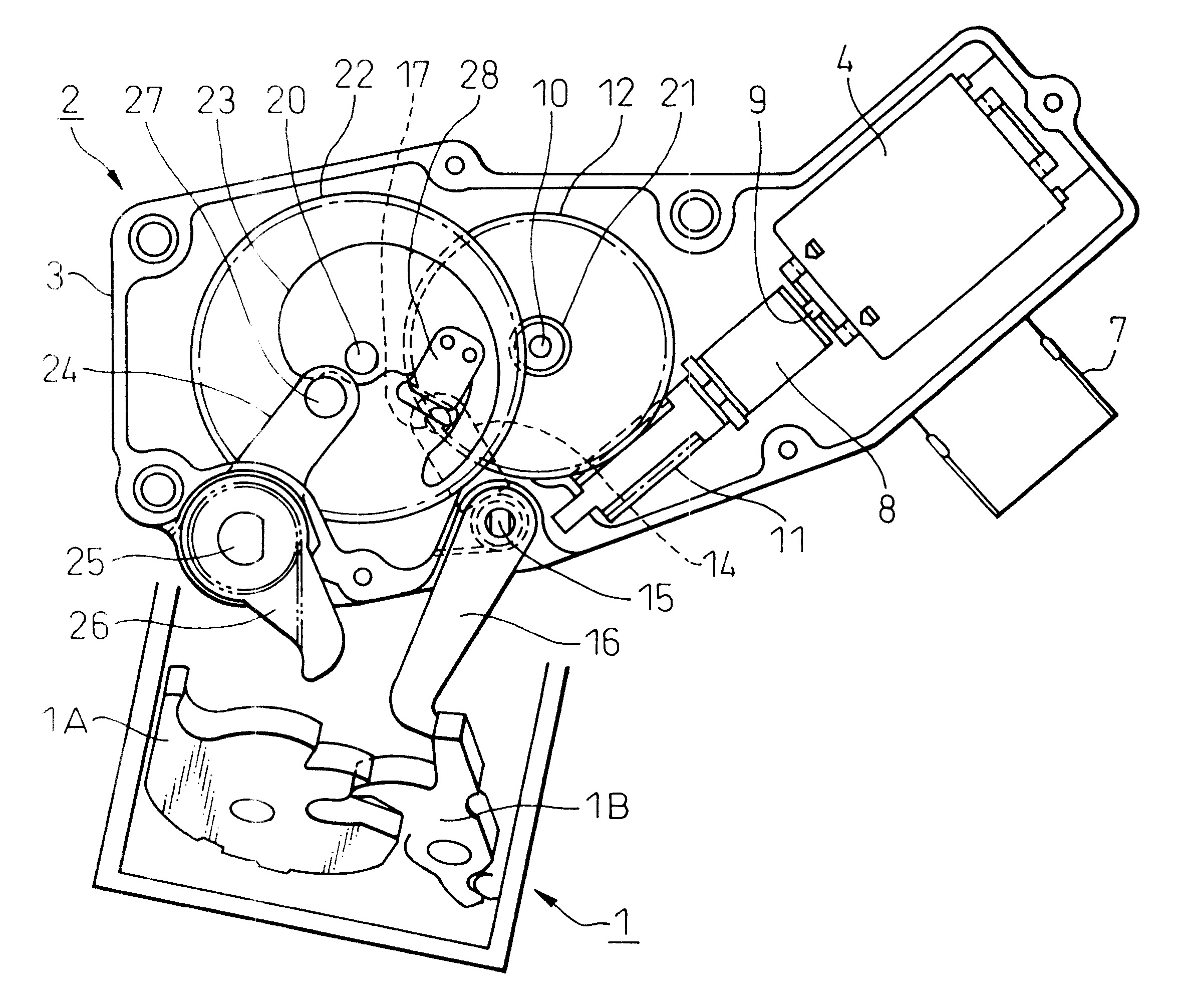

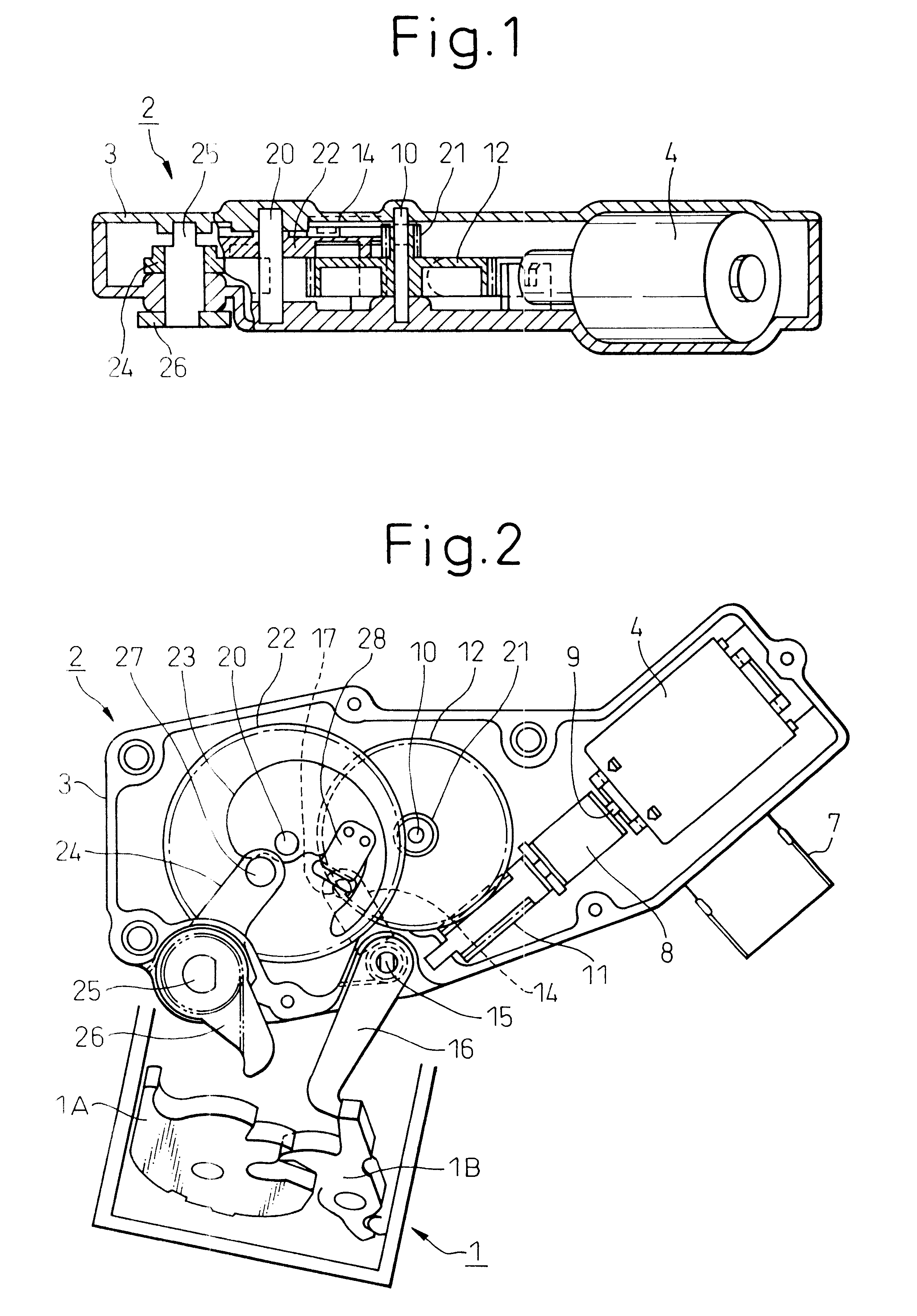

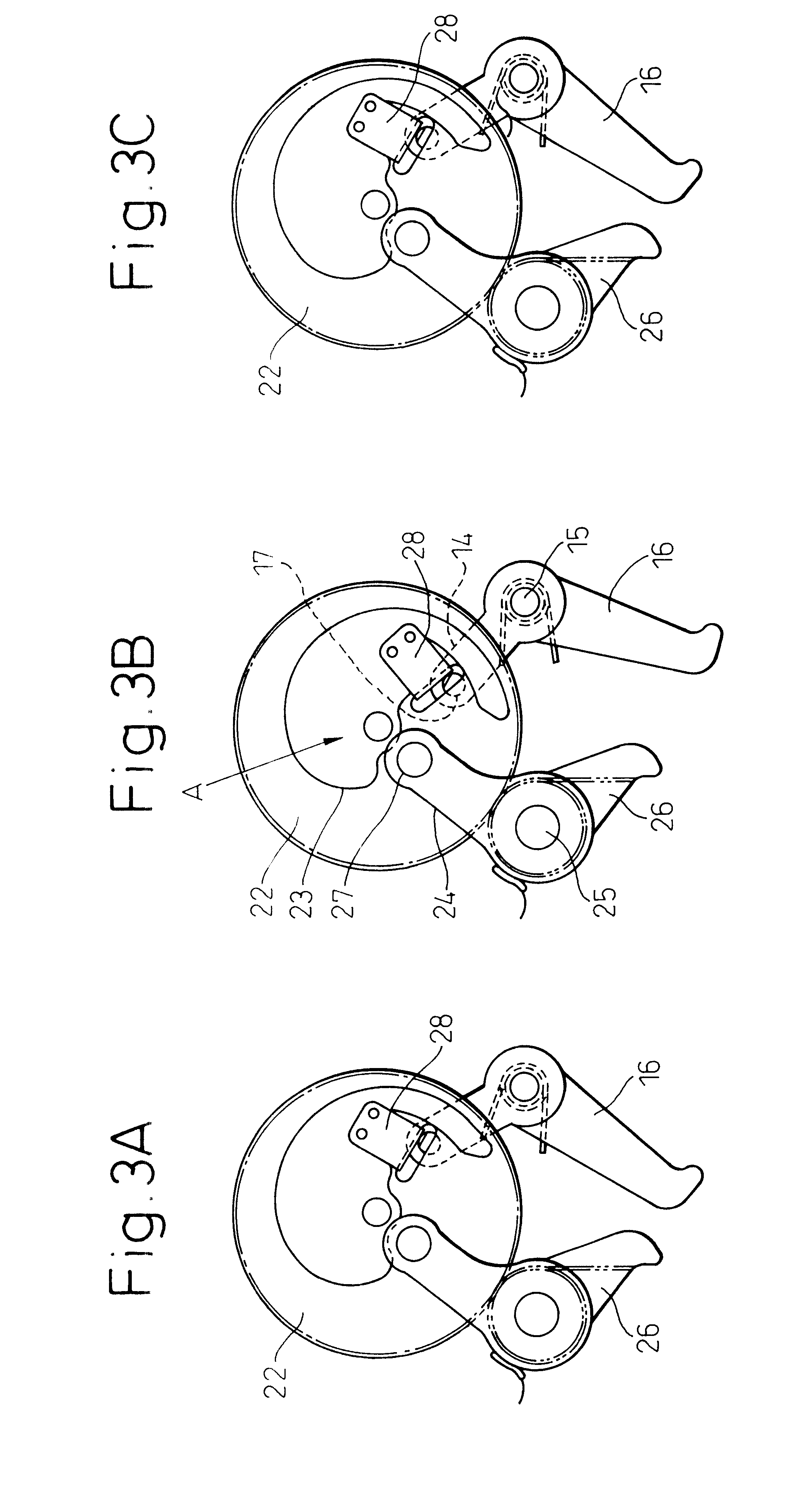

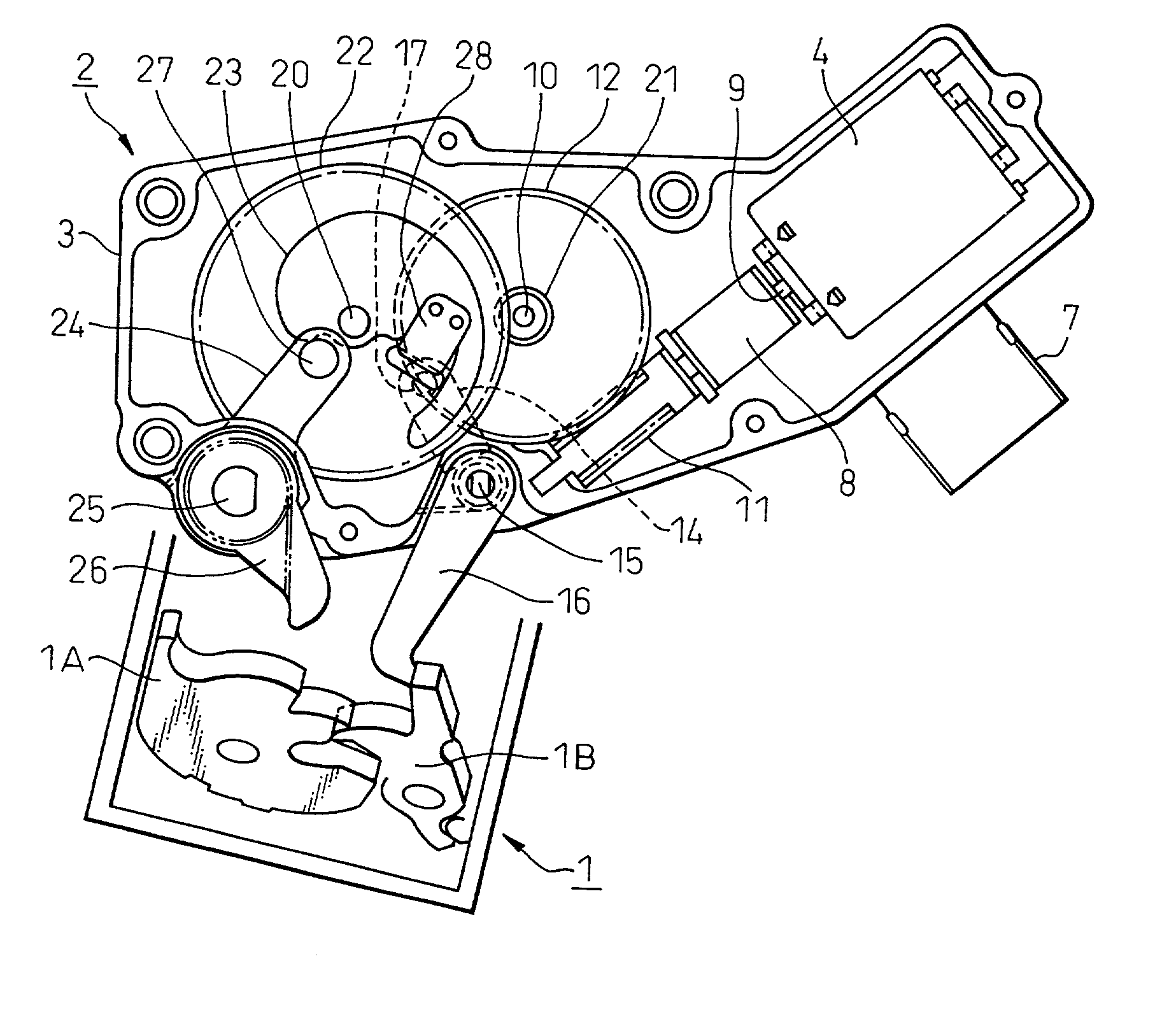

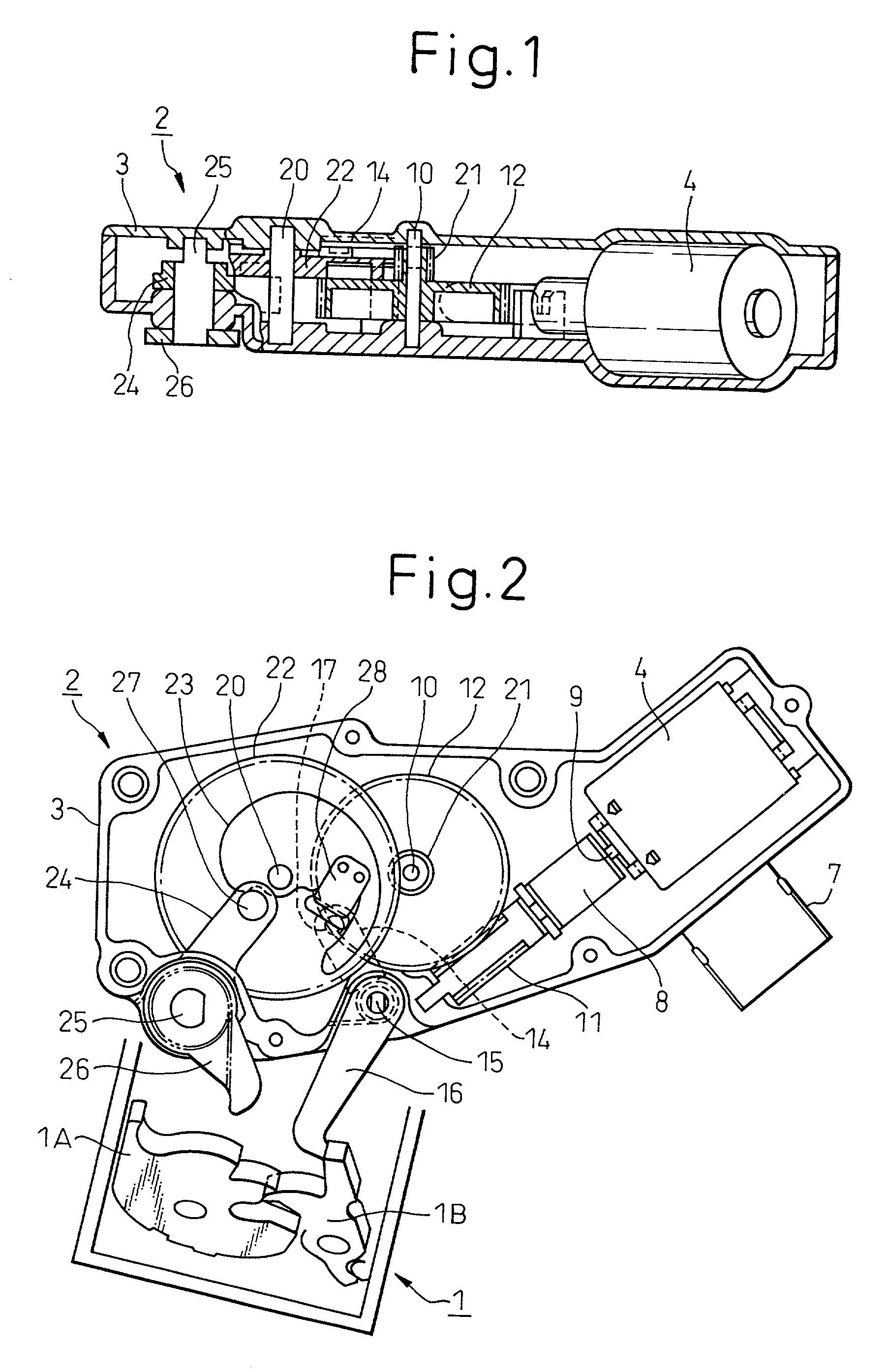

Door lock drive unit

InactiveUS6557910B2Safety can be ensuredSmall sizeNon-mechanical controlsConstruction fastening devicesReduction ratioElectric motor

A rotating speed of the motor 4 is reduced at a high reduction ratio by using a reduction gear (the first and the second reduction gear), and the unlatch mechanism for conducting unlatch operation of the door lock 1 and the closer mechanism for conducting closer operation of the door lock 1 are separated from each other by the normal and the reverse rotating direction of the second reduction gear. Due to the foregoing, even in the middle of a closing operation conducted by the reverse rotation of the second reduction gear, when the closing operation is stopped and then the motor 4 is normally rotated, it is possible to switch from the stopping position of the closing operation to unlatch operation.

Owner:DENSO CORP

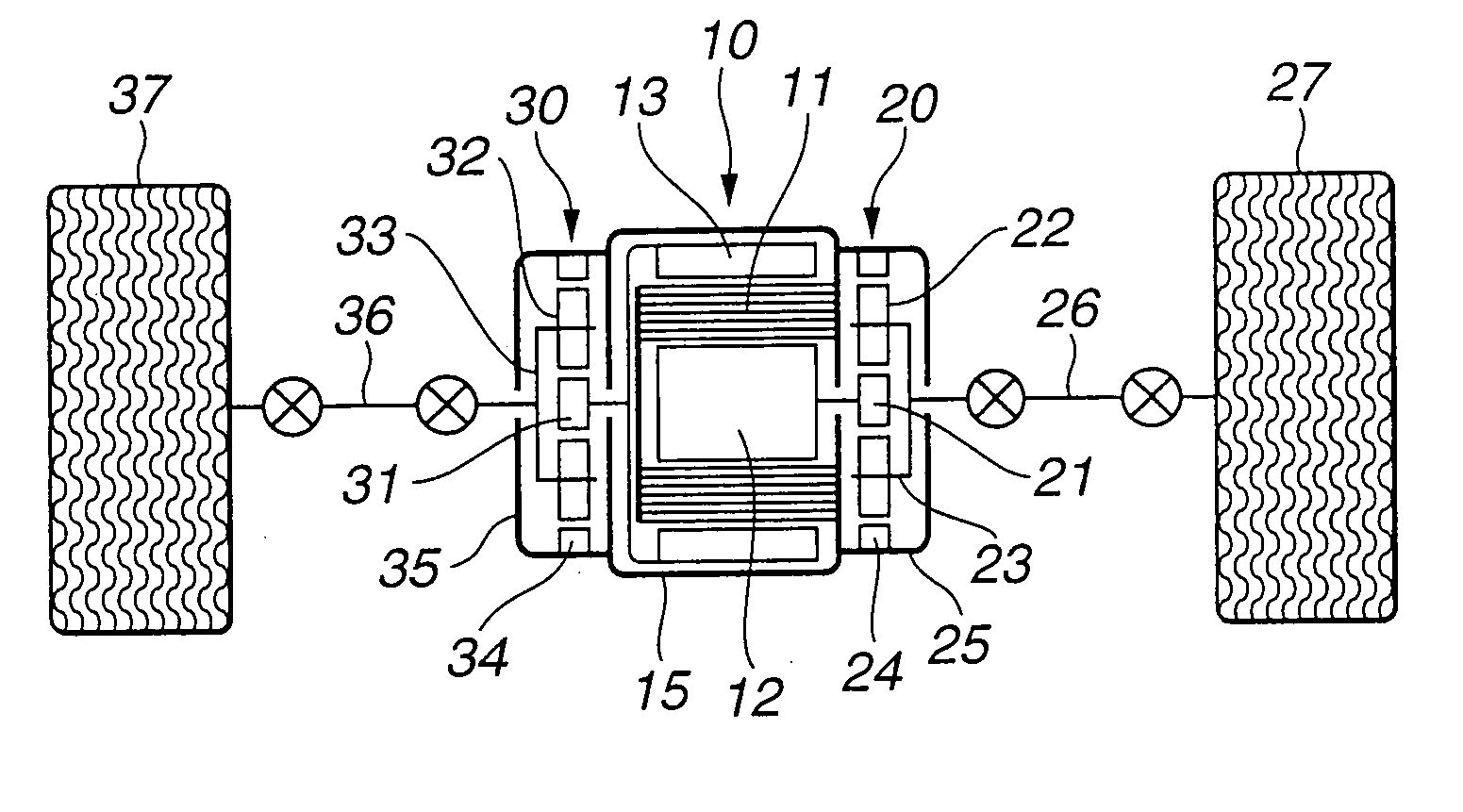

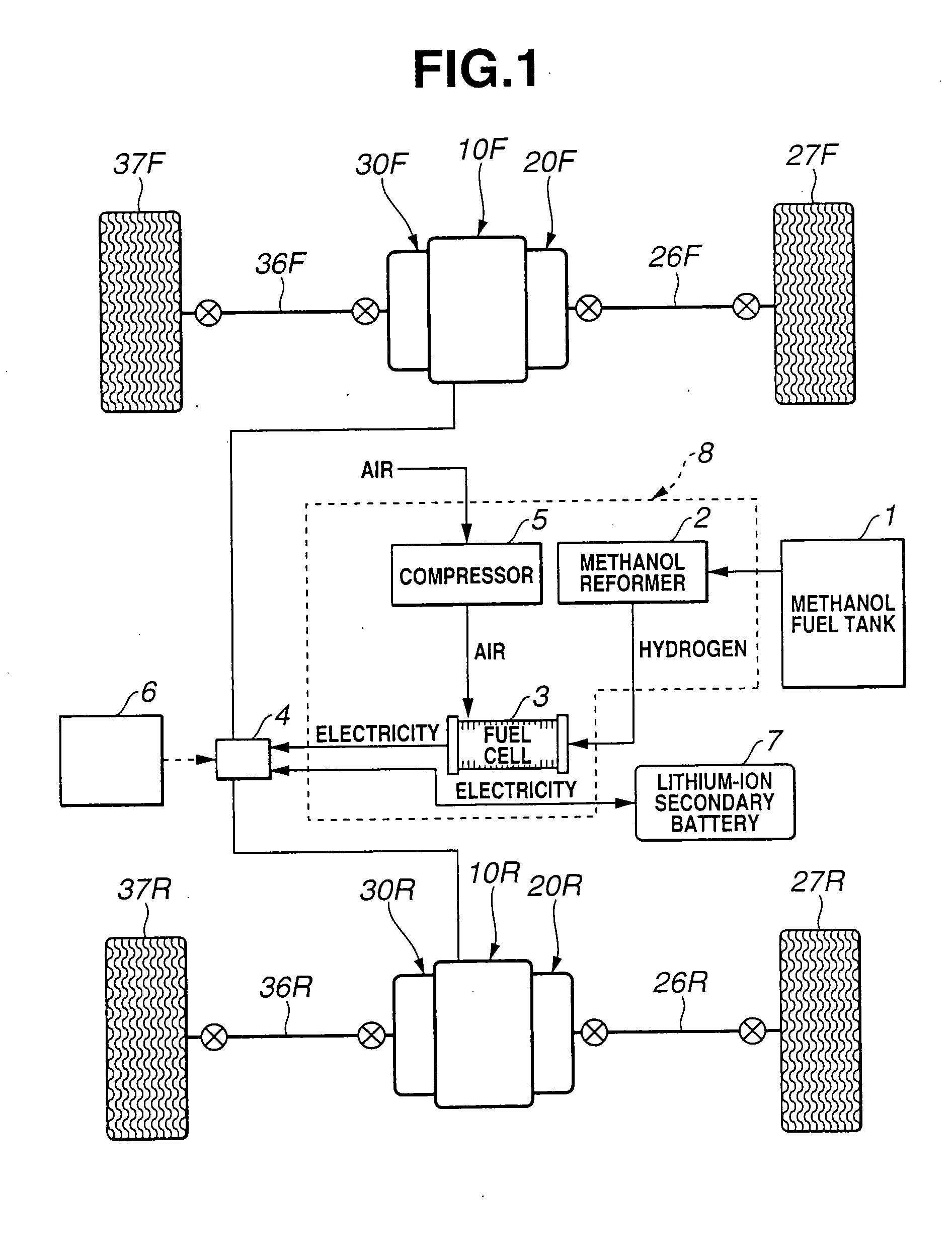

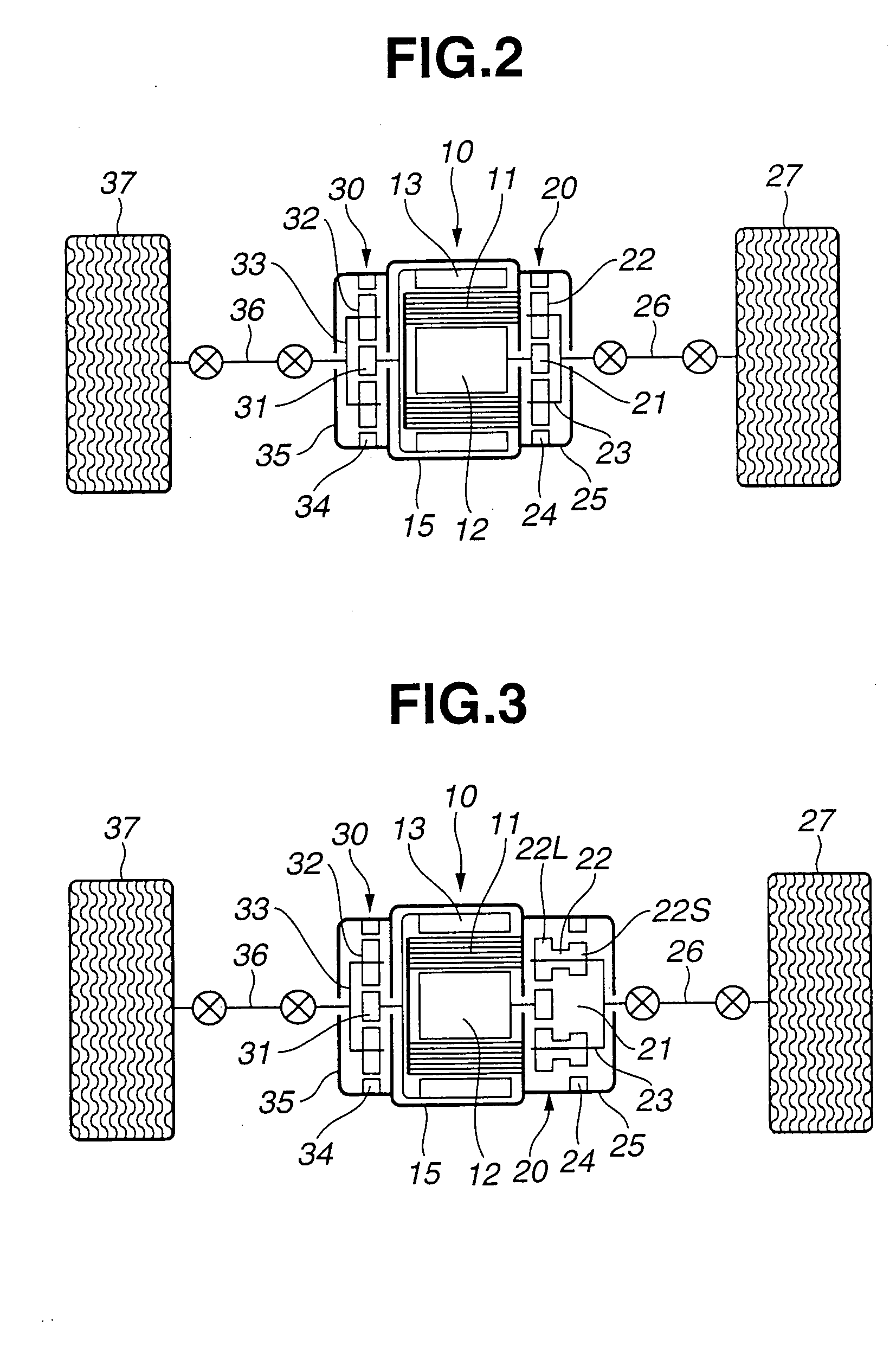

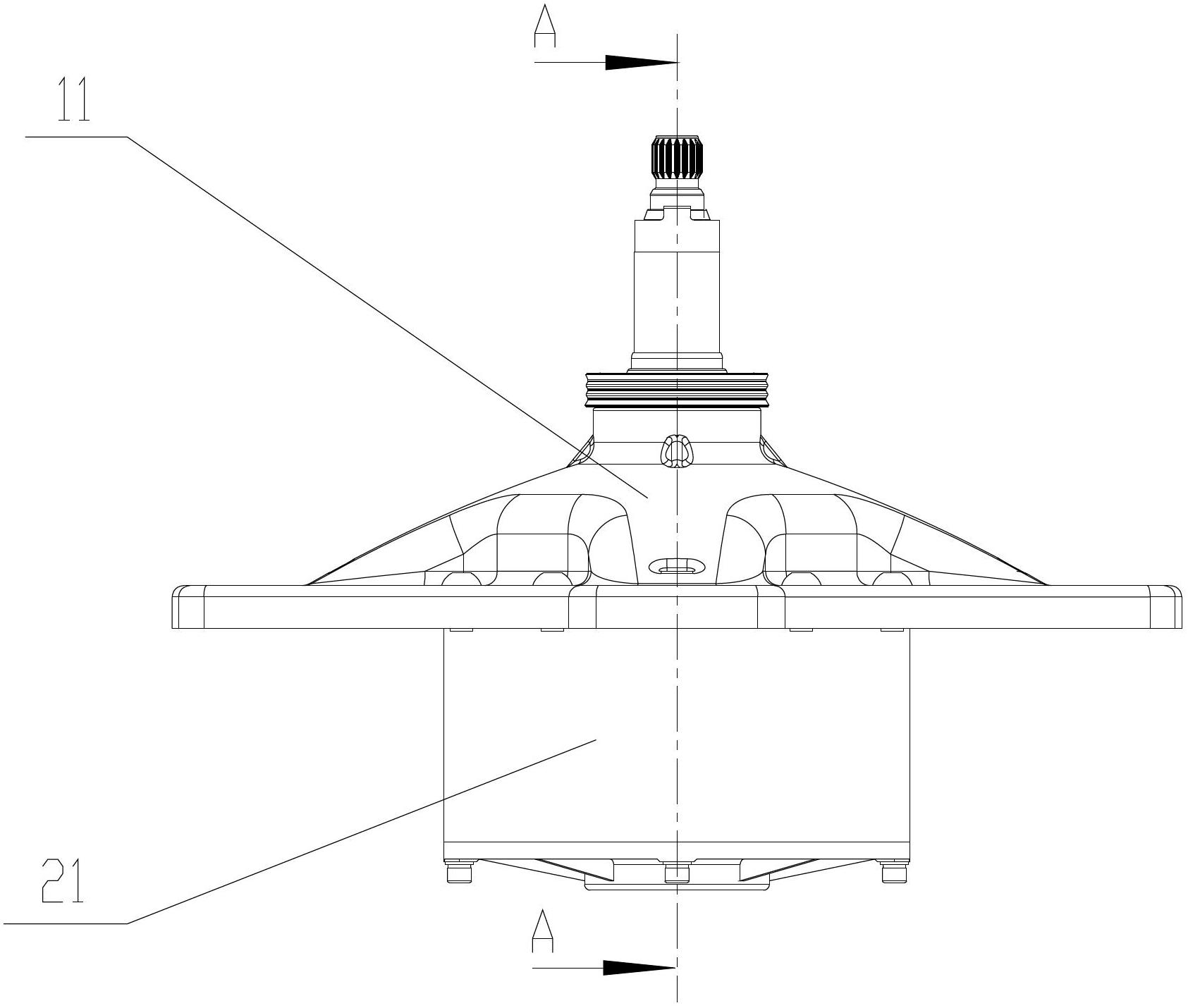

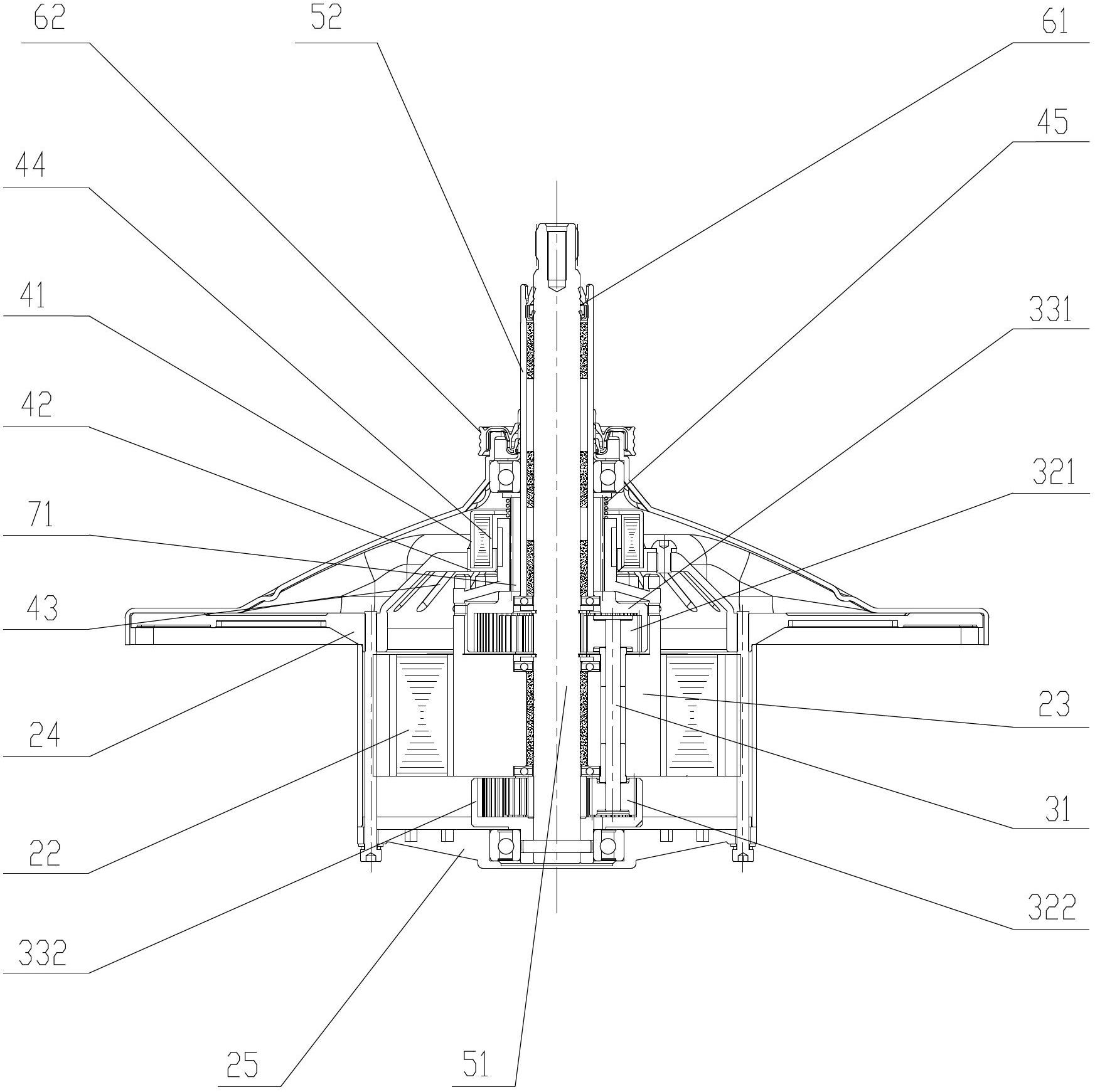

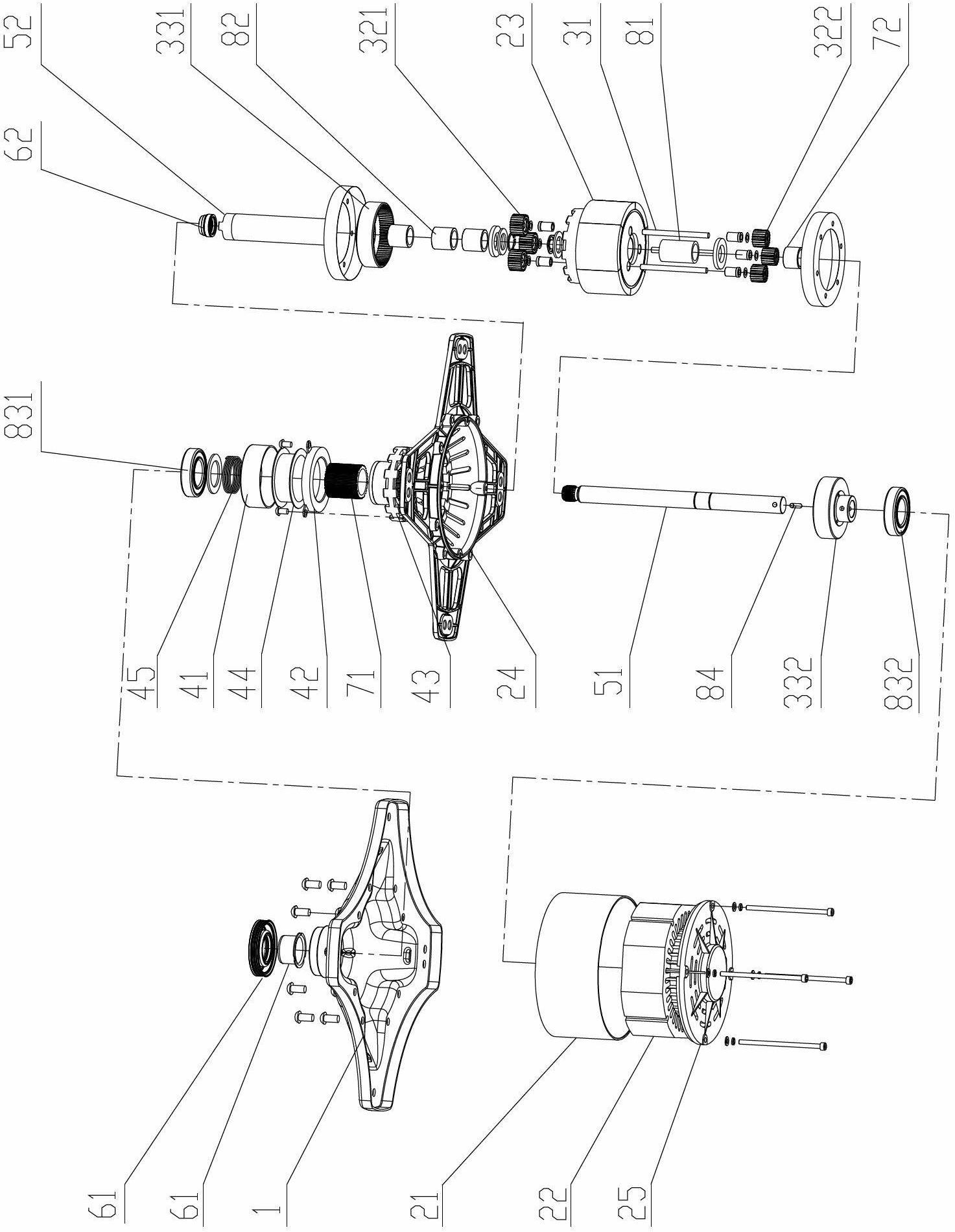

Wheel drive system for independently driving right and left wheels of vehicle

InactiveUS20050124451A1High vehicle installation abilityImprove compactnessFuel cell auxillariesPower to auxillary motorsDrive shaftGear wheel

A wheel drive system for independently driving right and left wheels of a vehicle is disposed between right and left wheels of the vehicle, and is comprised of a coaxial three-layer motor which includes an inner rotor, an outer rotor and a stator which are coaxially arranged; a first planetary gear reduction mechanism whose input is connected to the inner rotor, and whose output is connected to a first drive shaft of one of right and left wheels; and a second planetary gear reduction mechanism whose input is connected to the outer rotor and whose output is connected to a second drive shaft of the other of the right and left wheels. A reduction ratio of the first planetary gear reduction mechanism is greater than a reduction ratio of the second planetary gear reduction mechanism.

Owner:NISSAN MOTOR CO LTD

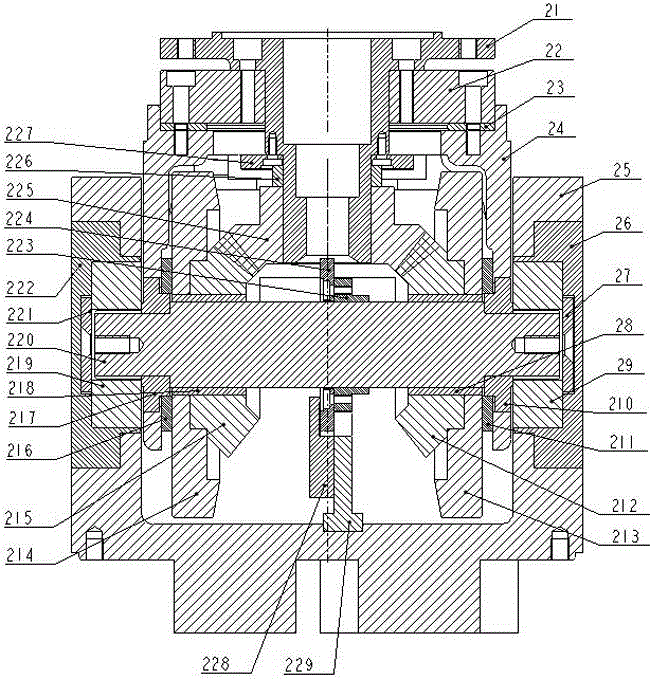

Washing machine driver

InactiveCN102677427AReduce axial sizeCompact structureMechanical apparatusOther washing machinesReduction ratioMechanical engineering

The invention discloses a washing machine driver which comprises a motor, a washing shaft, a dehydration shaft sleeve sleeved on the washing shaft and a gear speed reduction mechanism. The washing shaft is coaxially arranged inside a motor rotor of the motor and is fixedly connected with an output gear of the gear speed reduction mechanism; and an input gear shaft of the gear speed reduction mechanism is inserted in a shaft hole of the motor rotor. The input gear shaft of the gear speed reduction mechanism is inserted in the shaft hole of the motor rotor, and thus, the gear speed reduction mechanism and the motor are effectively integrated by the motor rotor serving as a gear holder of the gear speed reduction mechanism, so that the axial size of the washing machine driver is reduced and the washing machine driver has a simple and compact structure and occupies a small space. Moreover, the gear speed reduction mechanism has a large transmission ratio range, and thus, the large reduction ratio output can be implemented.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Door lock drive unit

InactiveUS20020063430A1Safety can be ensuredSmall sizeNon-mechanical controlsConstruction fastening devicesReduction ratioEngineering

A rotating speed of the motor 4 is reduced at a high reduction ratio by using a reduction gear (the first and the second reduction gear), and the unlatch mechanism for conducting unlatch operation of the door lock 1 and the closer mechanism for conducting closer operation of the door lock 1 are separated from each other by the normal and the reverse rotating direction of the second reduction gear. Due to the foregoing, even in the middle of a closing operation conducted by the reverse rotation of the second reduction gear, when the closing operation is stopped and then the motor 4 is normally rotated, it is possible to switch from the stopping position of the closing operation to unlatch operation.

Owner:DENSO CORP

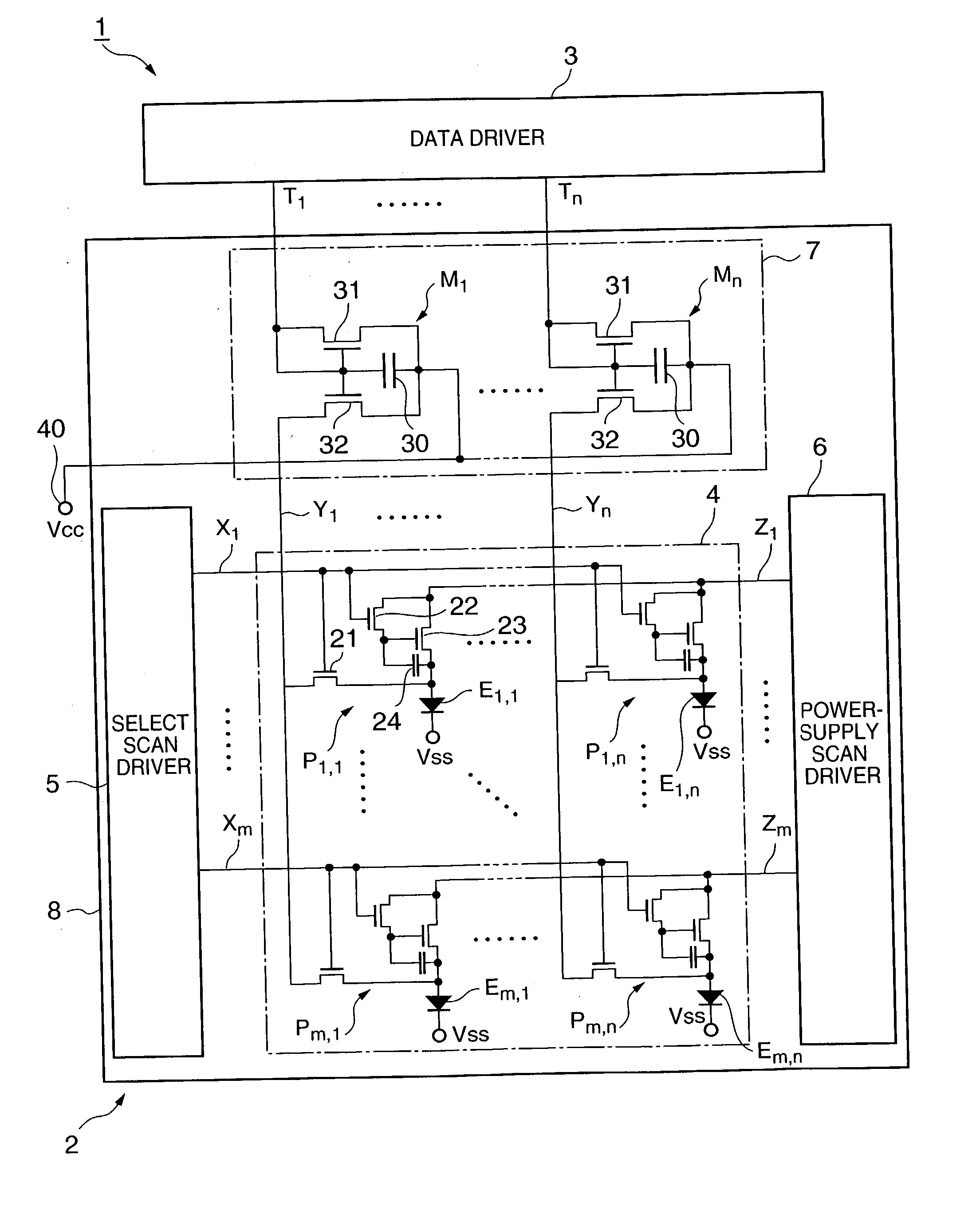

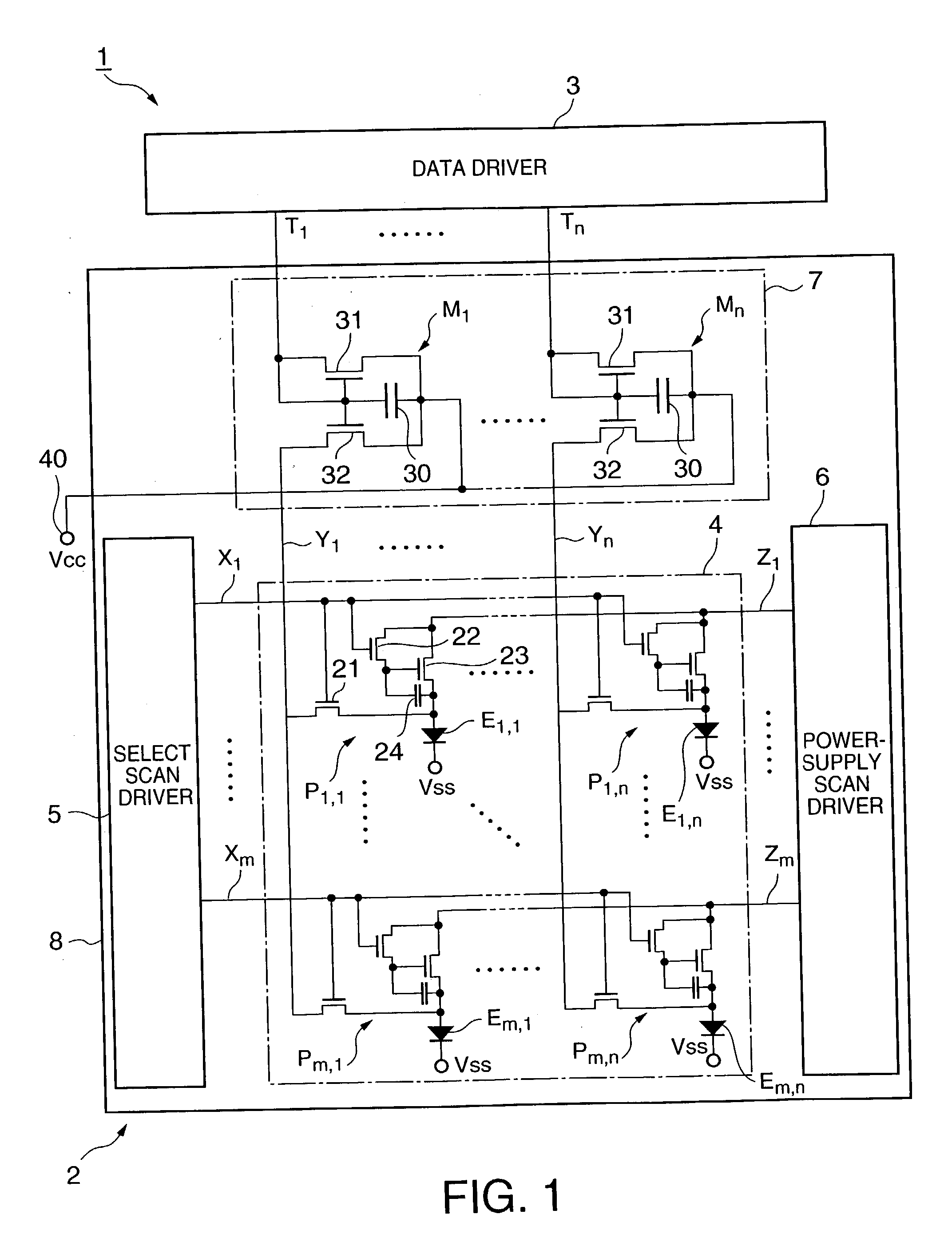

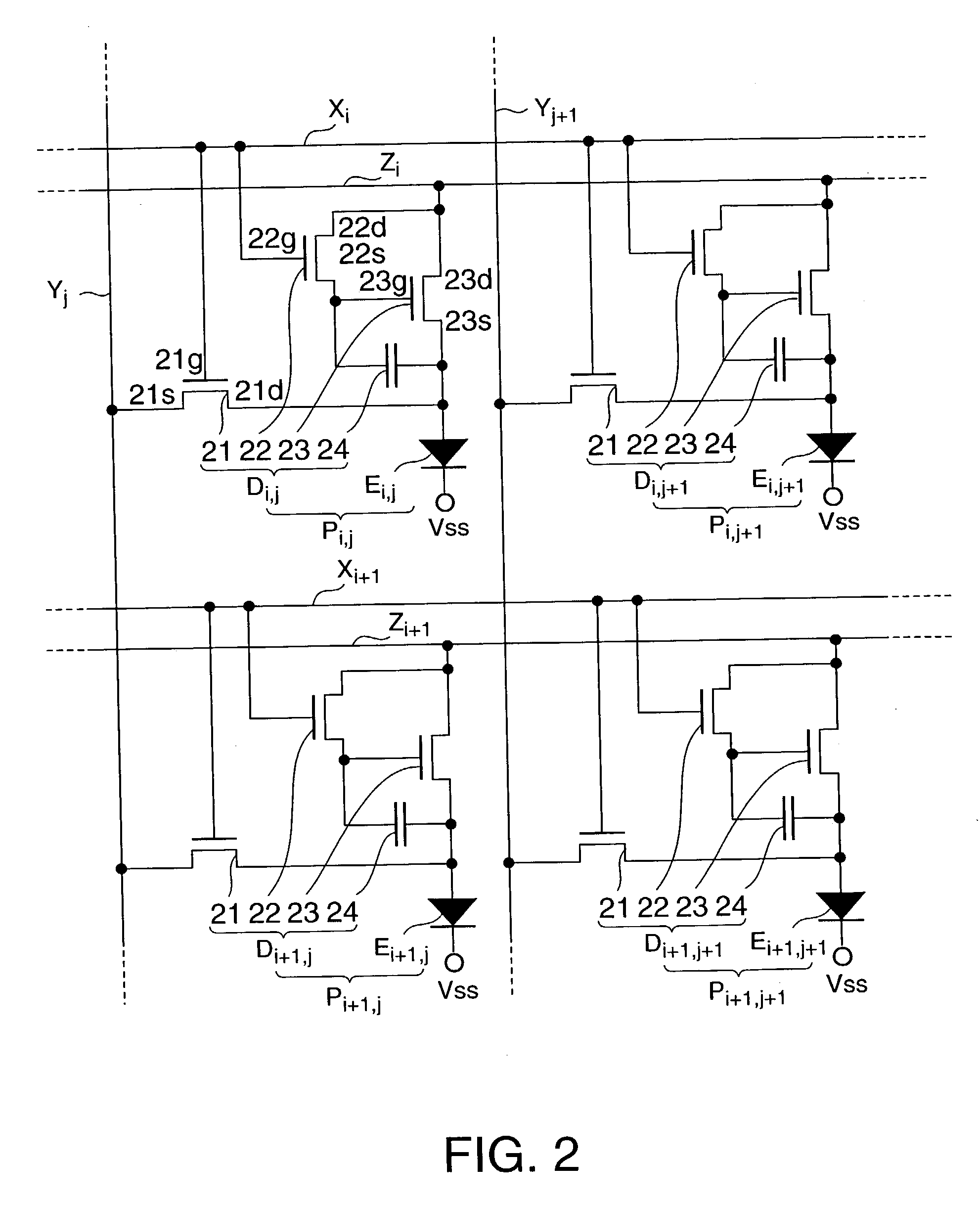

Display apparatus and drive method therefor

ActiveUS20060214890A1Easy to manufactureRaise the ratioStatic indicating devicesElectroluminescent light sourcesDriving currentReduction ratio

Disclosed is a high-definition display apparatus which allows a write current having an adequate value to flow. The display apparatus comprises a plurality of signal lines, a plurality of optical elements which presents display as a drive current equal in value to a write current flowing in the signal lines flows, and a current control driver which is connected to one ends of the signal lines, reduces the current value of a gradation signal by a current reduction ratio and lets the write current flow in the signal lines.

Owner:SOLAS OLED LTD

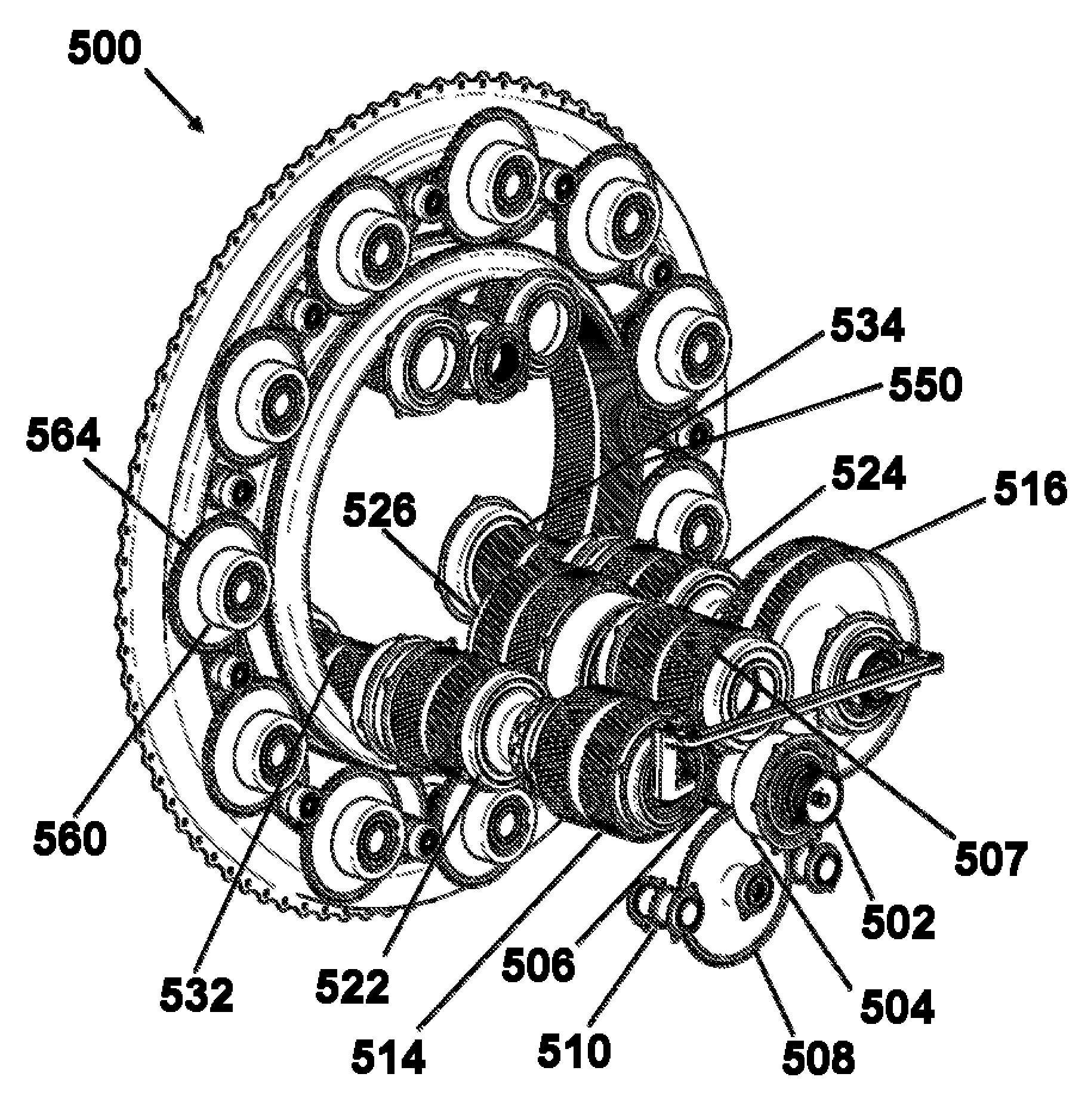

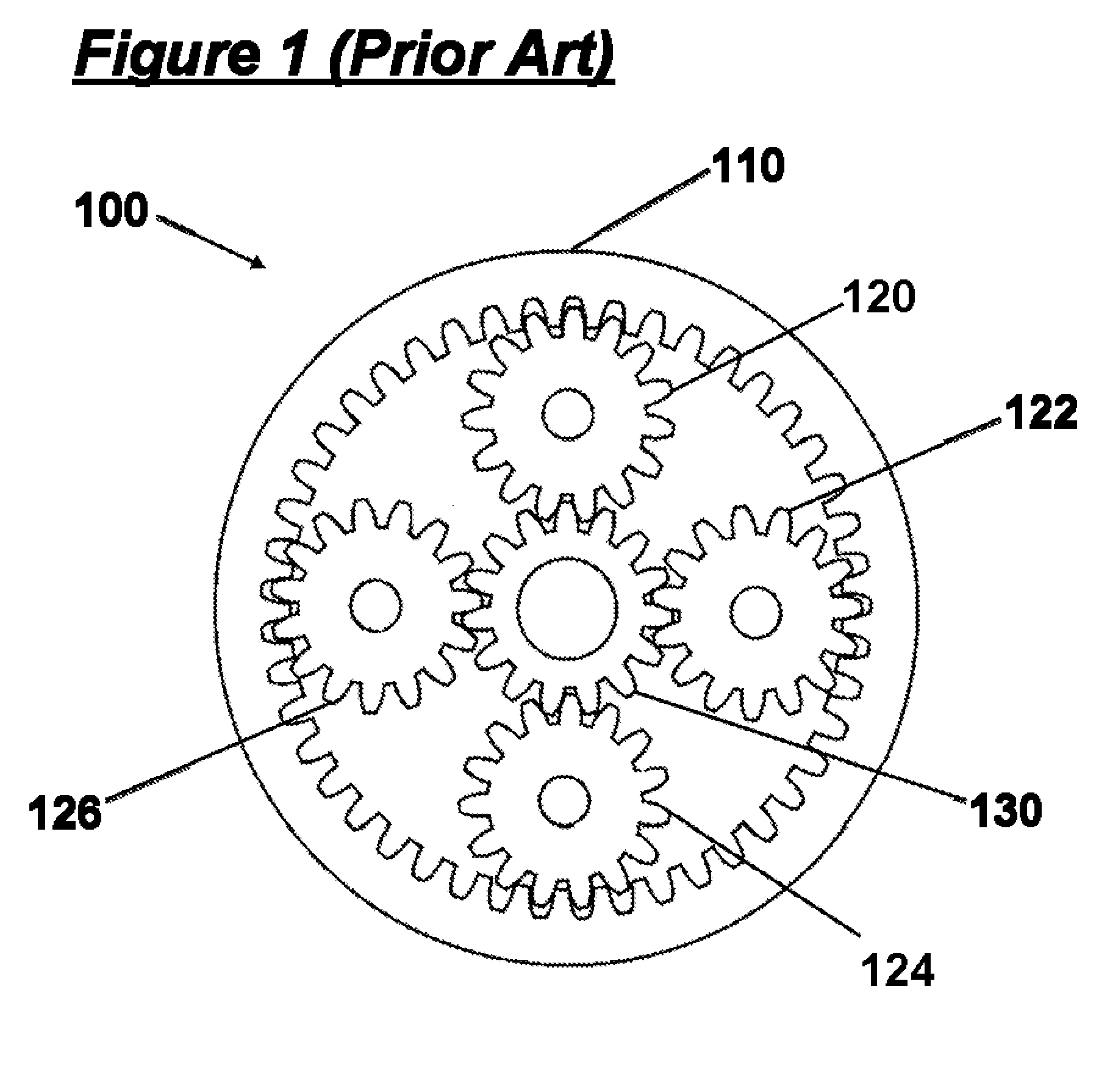

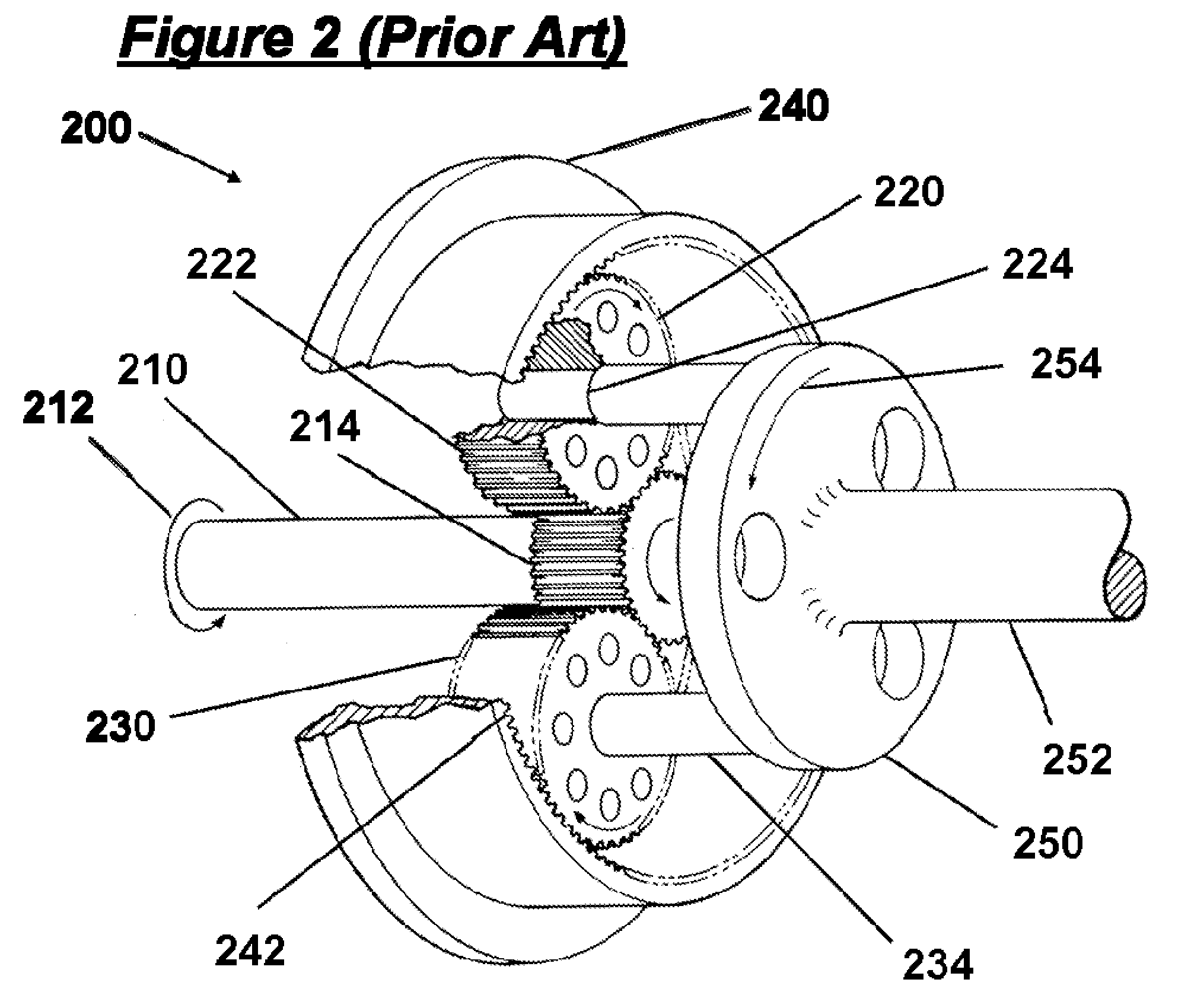

Torque Balancing Gearbox

ActiveUS20090227415A1Reduction in power-to-weight ratioEvenly loadedToothed gearingsAircraft power transmissionGear wheelReduction ratio

A gearbox comprising a gearset is able to transmit high output torques at high numerical reduction ratios at a power-to-weight ratio higher than previously attainable with existing designs. A distributor gear is disposed relative to a spur gear in order to produce automatic torque balancing. The distributor gear can be advantageously configured as an input floatring gear, for which support in all directions is provided by gear tooth mesh forces rather than bearings. Automatic torque balancing is achieved by configuring the distributor gear with first and second rows of helical teeth on the external circumference, and with a set of double helical teeth disposed on the internal circumference of the distributor gear. This allows for the placement of up to 50 or more planet gears in a countershaft arrangement with one end having helical teeth and the other end having spur teeth.

Owner:KAREM AIRCRAFT INC

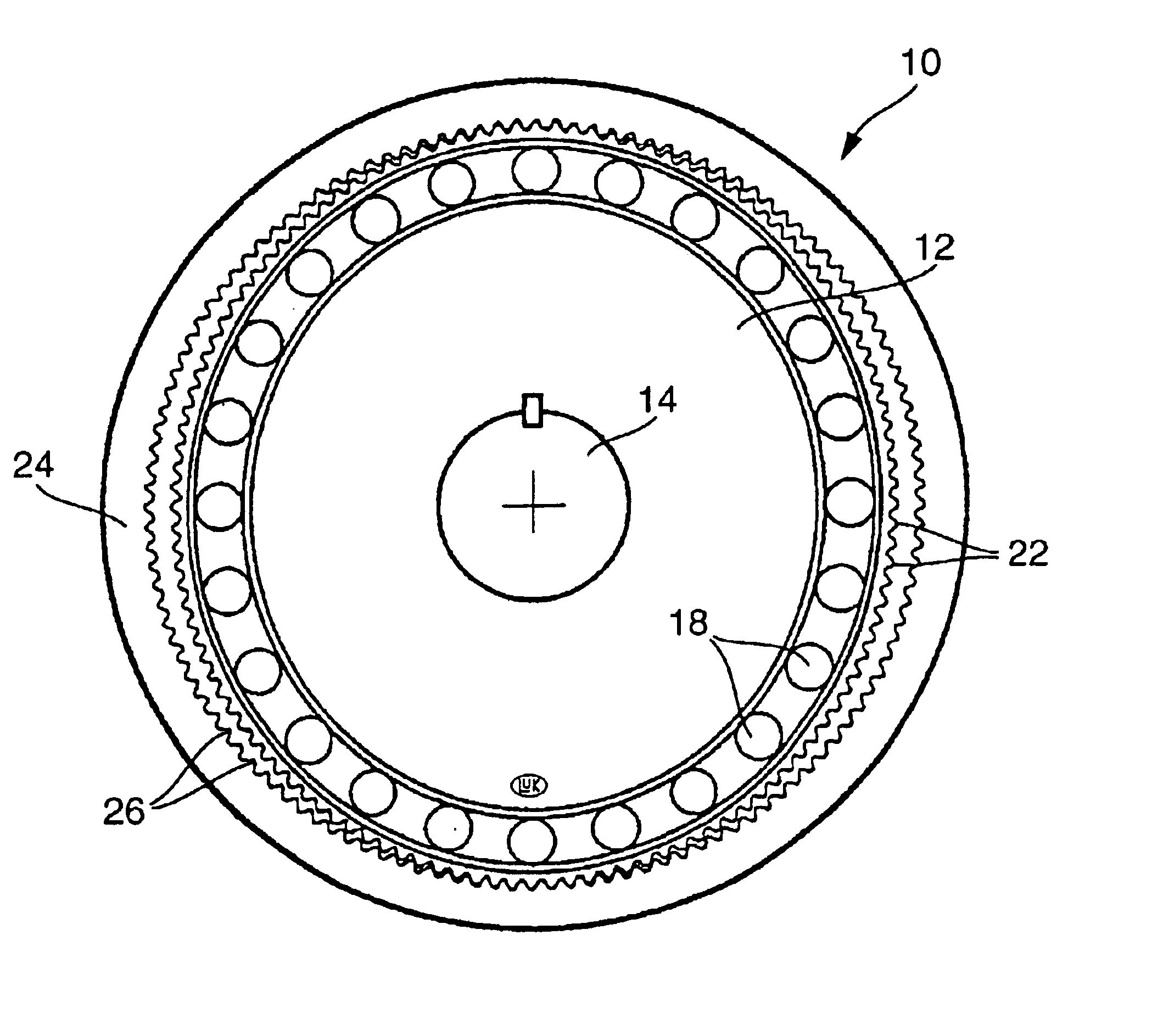

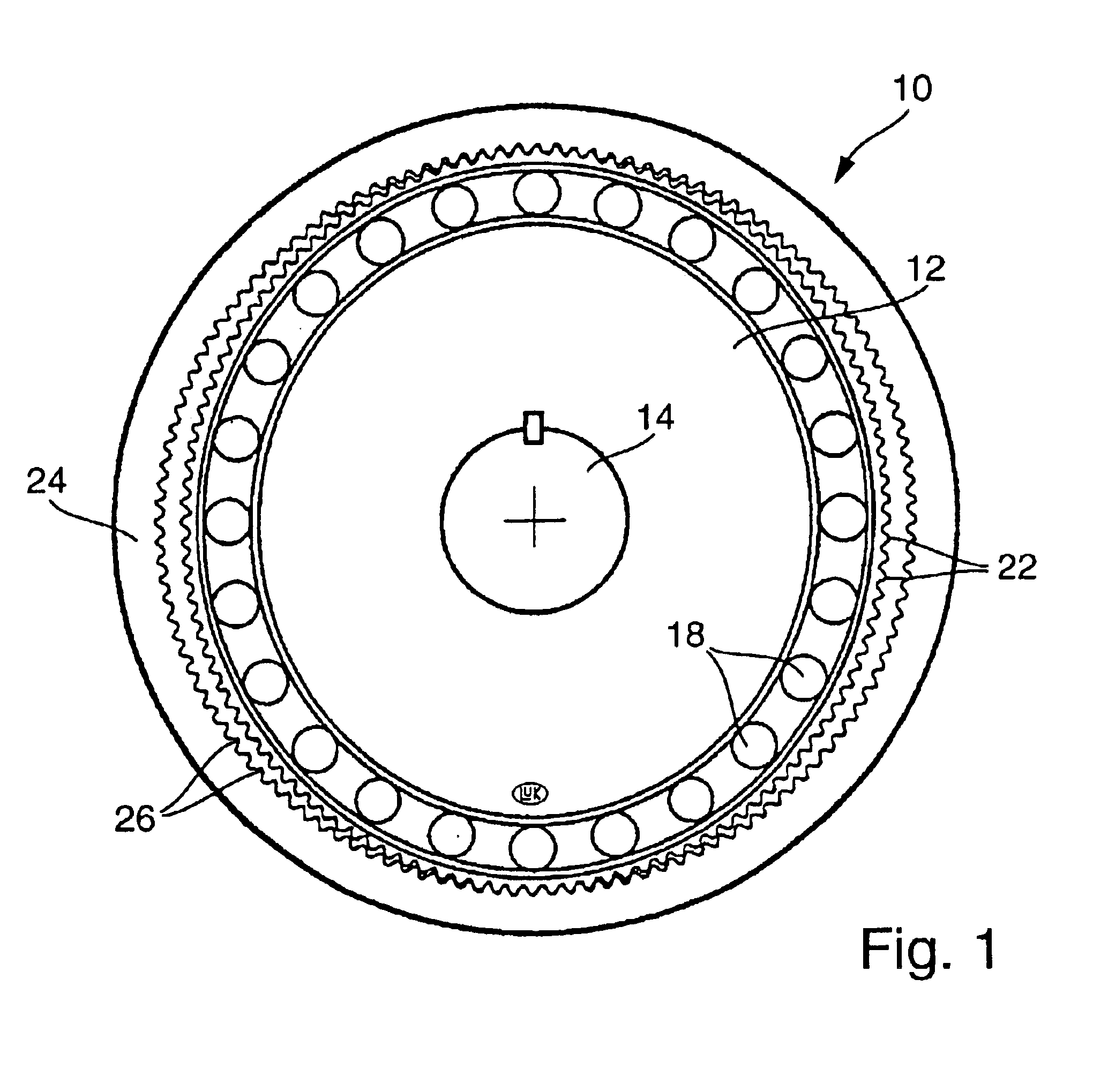

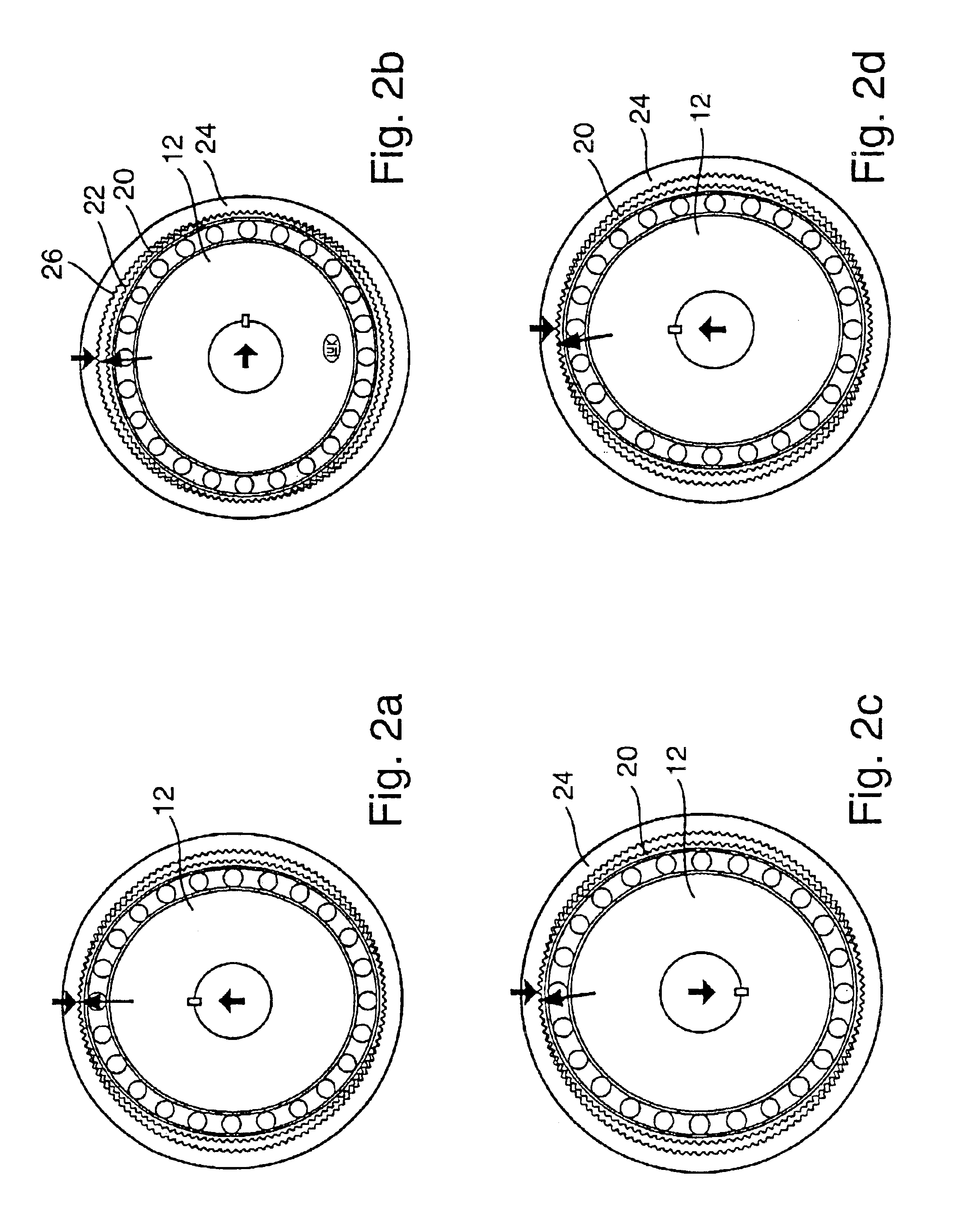

Transmission actuator driven by an electric motor

InactiveUS6893371B2Compact spaceSimple and cost-effective to manufactureGearboxesToothed gearingsReduction ratioEngineering

An actuator for a motor vehicle transmission has a shift cylinder performing rotary actuating movements. An electric motor is arranged inside the shift cylinder and drives the latter either through a harmonic drive mechanism or a planetary drive mechanism. The arrangement provides a high reduction ratio and an efficient use of limited space.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

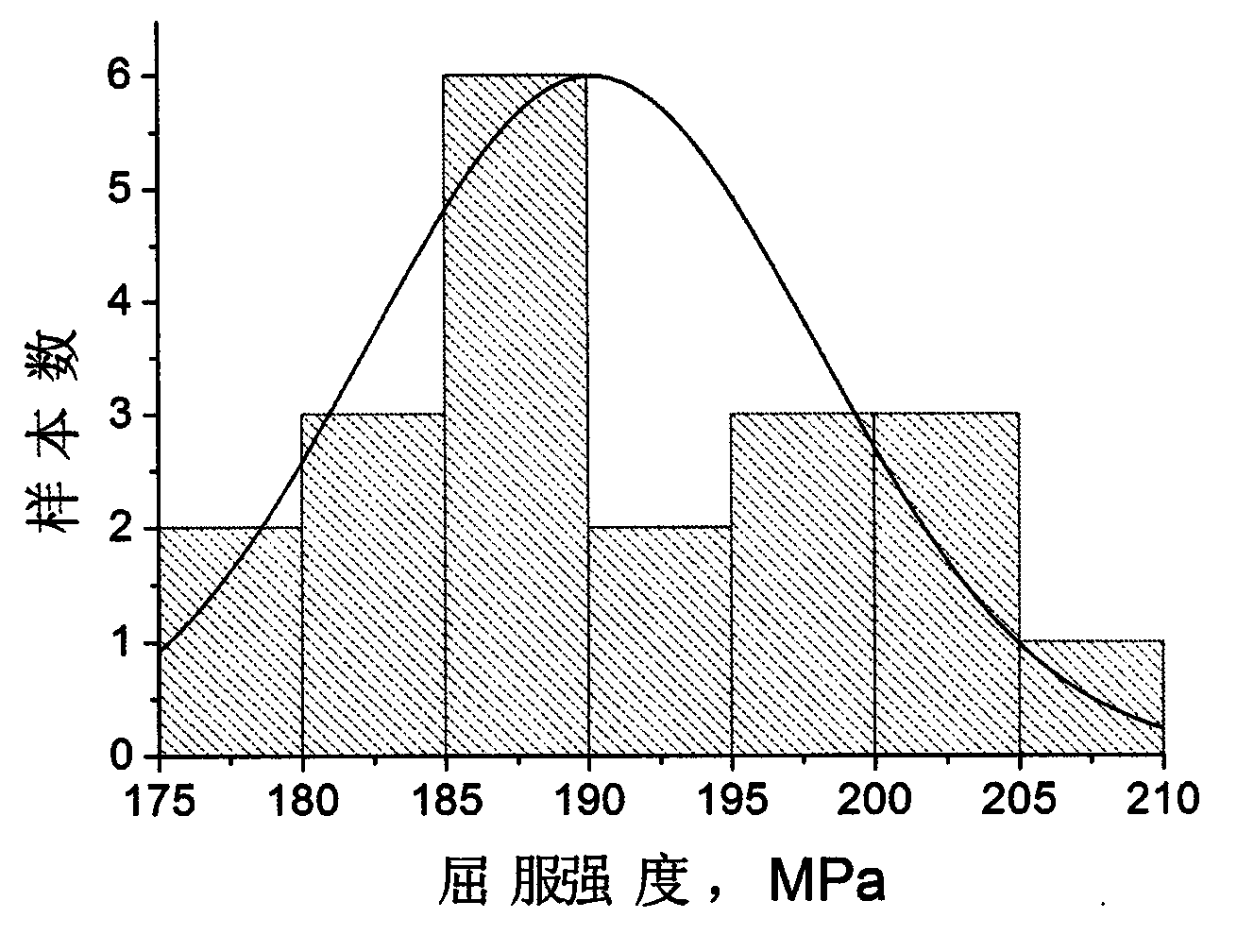

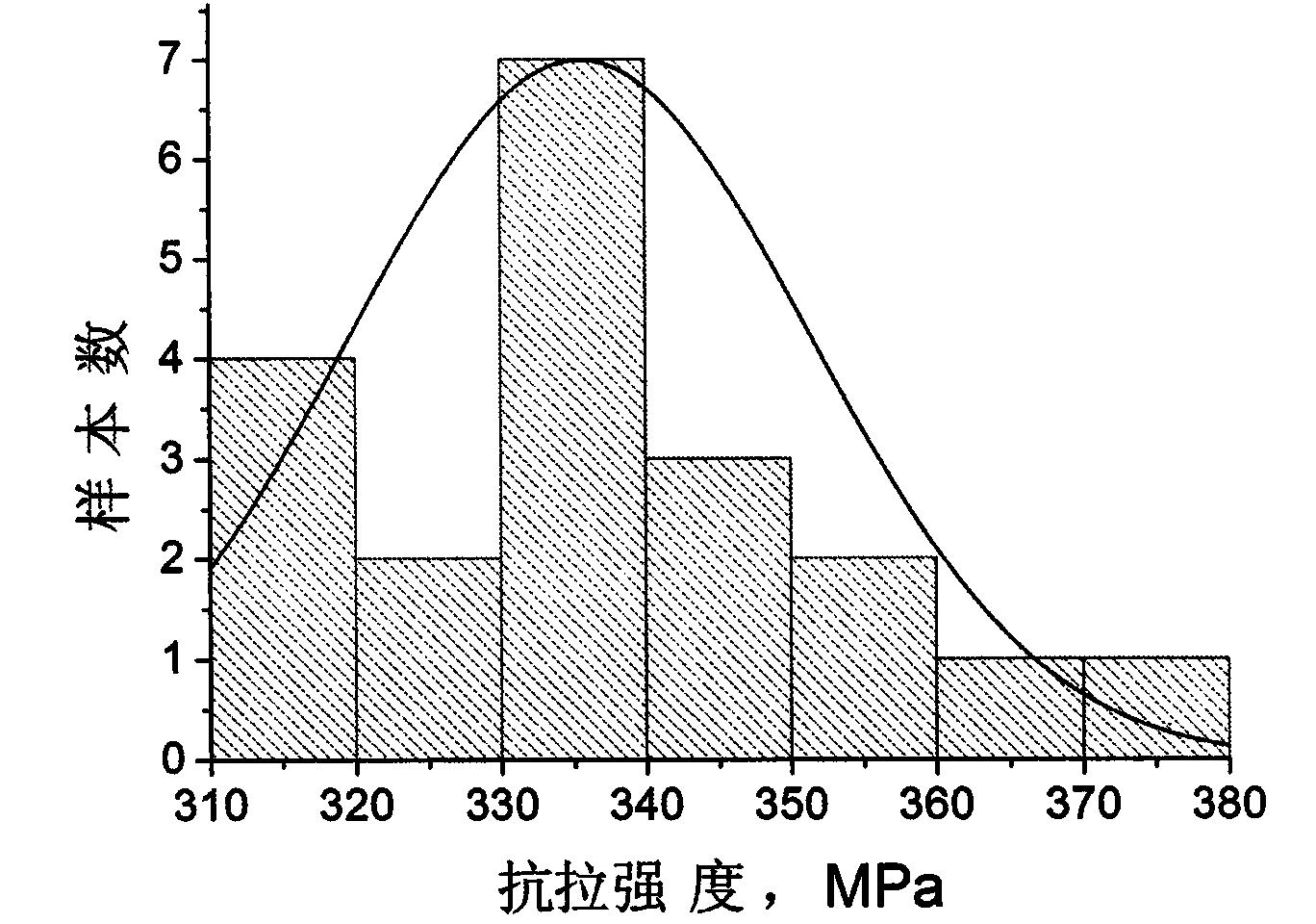

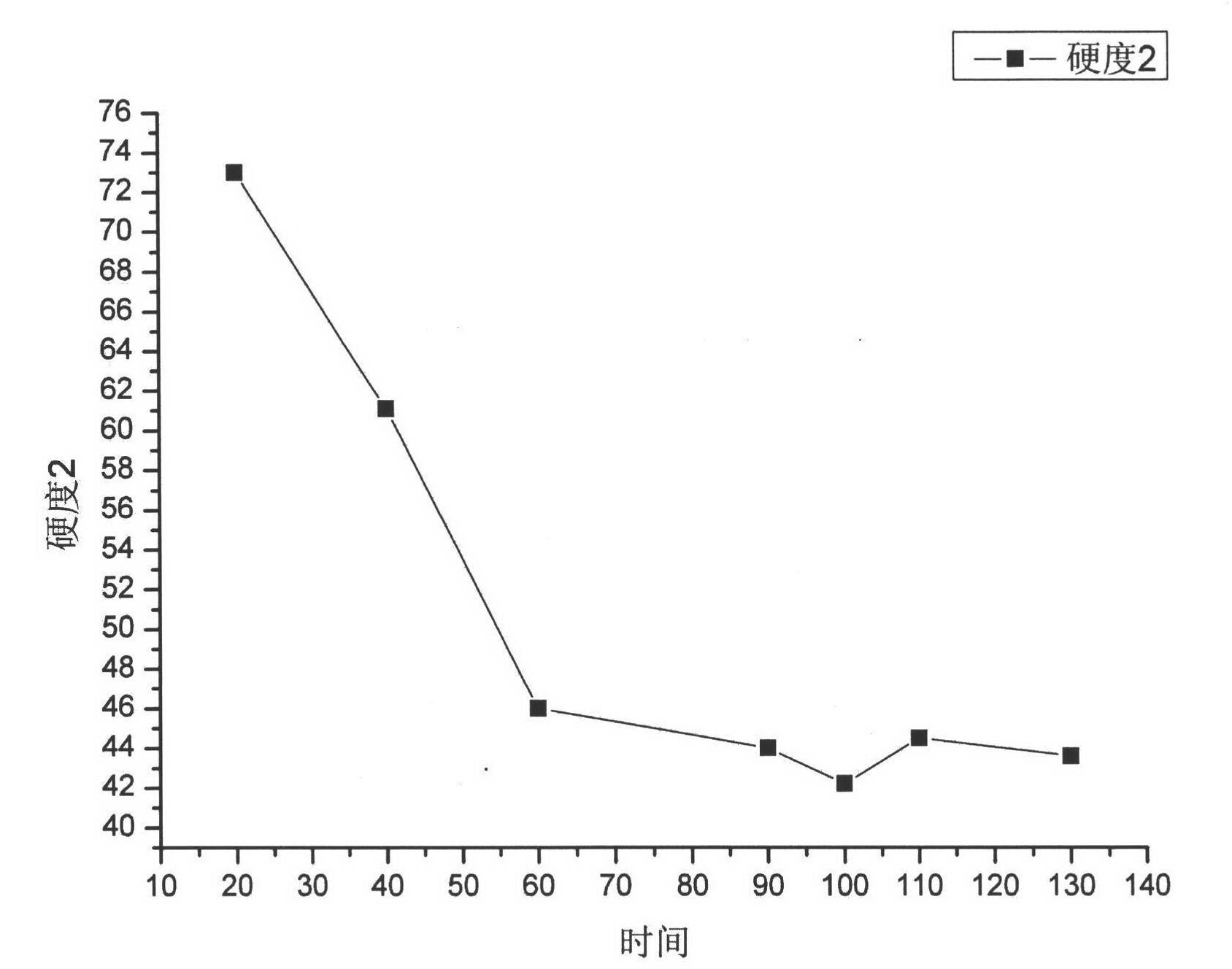

Continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles

The invention relates to a continuous annealing method of DC01 steel plate with low yield and high tensile strength for automobiles, belonging to the field of metallic materials processing. The chemical composition of the steel plate is as follows by mass percentage: 0.02-0.04% of C, 0.2-0.35% of Mn, less than or equal to 0.03% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.02-0.06% of Als, 0.0020-0.0050%of N, and the rest being Fe. The hot rolling parameter is as follows: heating temperature at 1250+ / -30 DEG C; finishing temperature at 930+ / -20 DEG C; coiling temperature at 730+ / -20 DEG C; cold rolling reduction ratio being controlled at 75-85%; soaking time for 50-100s; annealing temperature at 780+ / -20 DEG C; outlet temperature of the slow-cooling section at 675+ / -20 DEG C; outlet temperature of the rapid-cooling section at 400+ / -20 DEG C; overaging temperature at 350+ / -20 DEG C; and level elongate ratio being 0.9+ / -0.3%. The generated steel plate has the advantages of low yield strength, high tensile strength, fine formability, high product quality and considerable economic benefit.

Owner:SHOUGANG CORPORATION

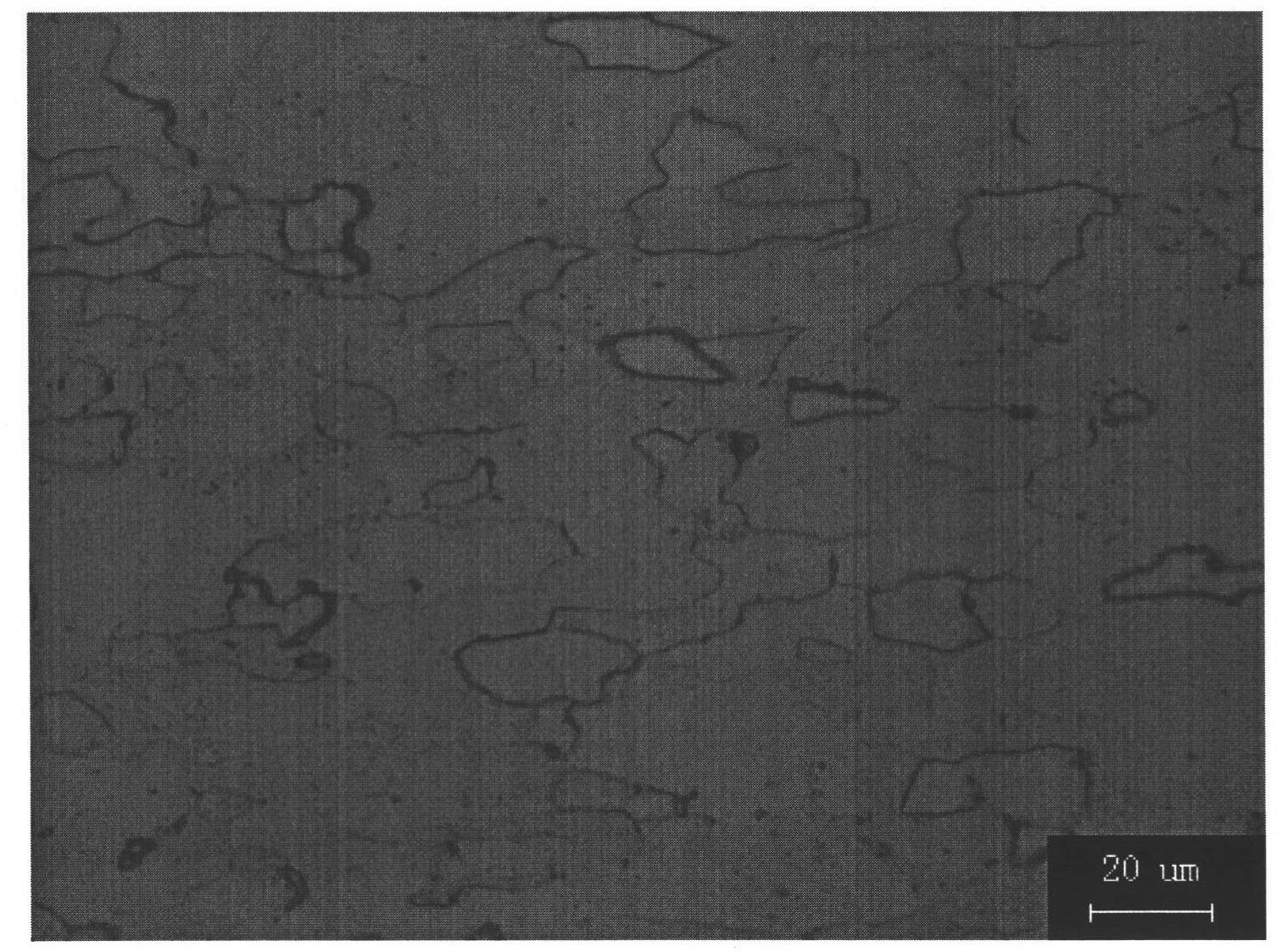

Austenitic stainless steel tube excellent in steam oxidation resistance and a manufacturing method thereof

ActiveUS20030231976A1Excellent in steam oxidation resistanceFurnace typesHeat treatment furnacesAustenite grainReduction ratio

The present invention provides an austenitic stainless steel tube with a uniform fine grained structure of regular grains, which is not changed to a coarse structure and the steam oxidation resistance is maintained even if the tube is subjected to a high temperature reheating during welding and high temperature bending working. The austenitic stainless steel tube consists of, by mass %, C: 0.03-0.12%, Si: 0.1-0.9%, Mn: 0.1-2%, Cr: 15-22%, Ni: 8-15%, Ti: 0.002-0.05%, Nb: 0.3-1.5%, sol. Al: 0.0005-0.03%, N: 0.005-0.2% and O (oxygen): 0.001-0.008%, and the balance Fe and impurities, the austenitic stainless steel tube having austenitic grain size number of 7 or more and a mixed grain ratio of preferably 10% or less. The present invention also provide a method of manufacturing the austenitic stainless steel tube comprising the following steps: (a) heating an austenitic steel tube at 1100-1350° C. and maintaining the temperature, and cooling at a cooling ratio of 0.25° C. / sec; (b) working by cross-sectional reduction ratio of 10% or more at a temperature range of 500° C. or less; and (c) heating at a temperature range of 1050-1300° C. and at a temperature of lower by 10° C. or more than the heating temperature in the step(a).

Owner:NIPPON STEEL CORP

Epicyclic gear train

An epicyclic gear train includes a carrier that supports star gears that mesh with a sun gear. A ring gear surrounds and meshes with the star gears. Each of the star gears is supported on a respective journal bearing. Each journal bearing includes an internal central cavity and at least one passage that extends radially from the internal cavity to a peripheral journal surface of the respective journal bearing. The epicyclic gear train has a gear reduction ratio of greater than or equal to about 2.3.

Owner:MCCUNE MICHAEL E +2

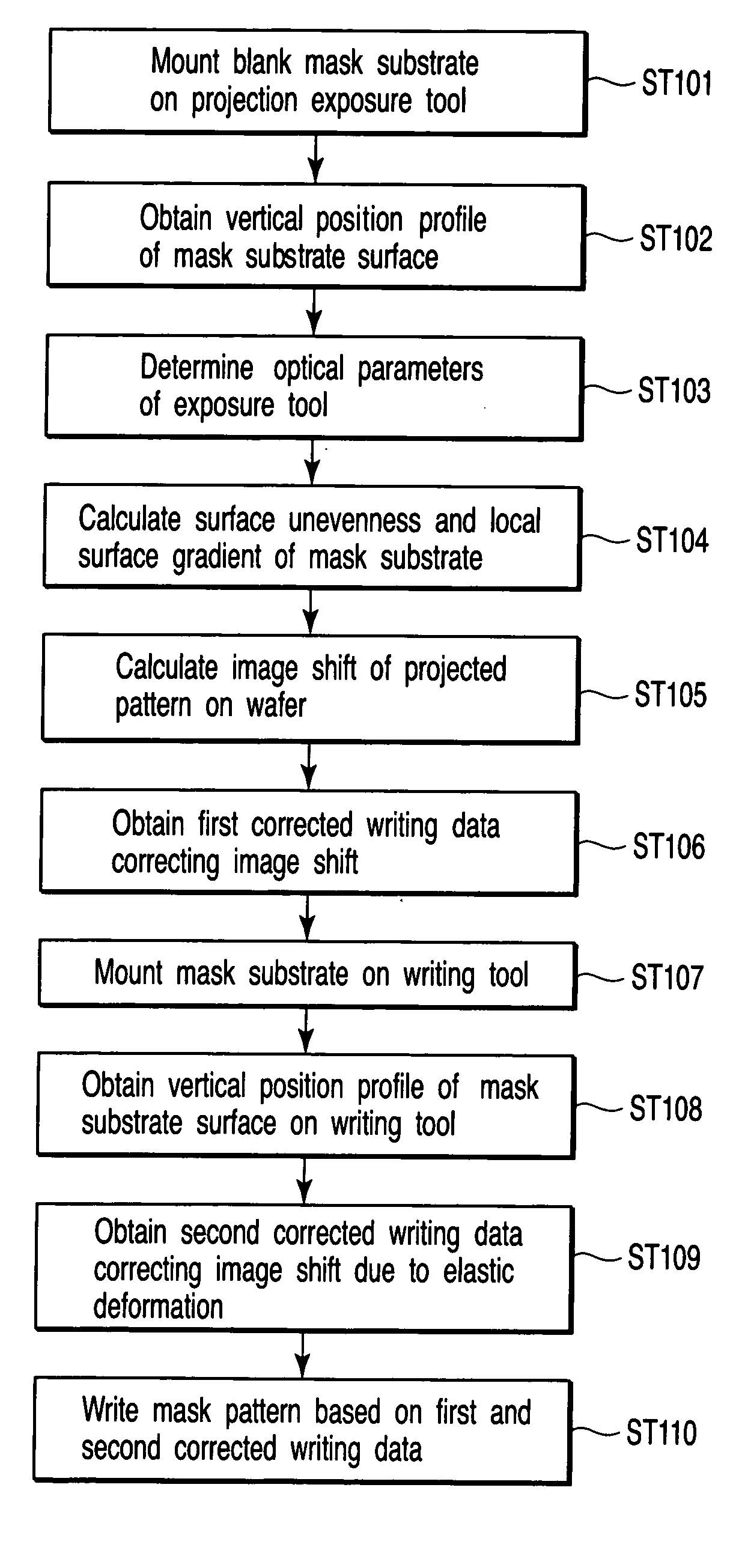

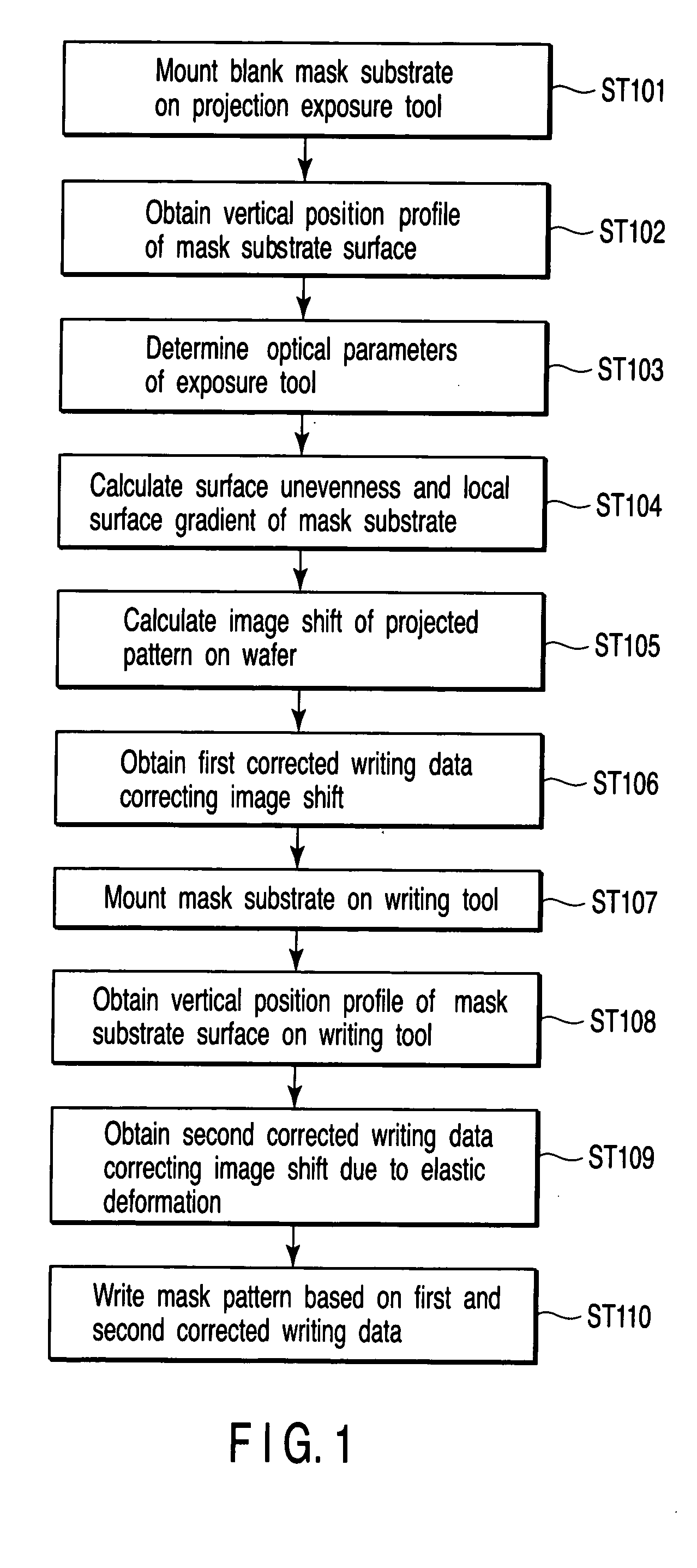

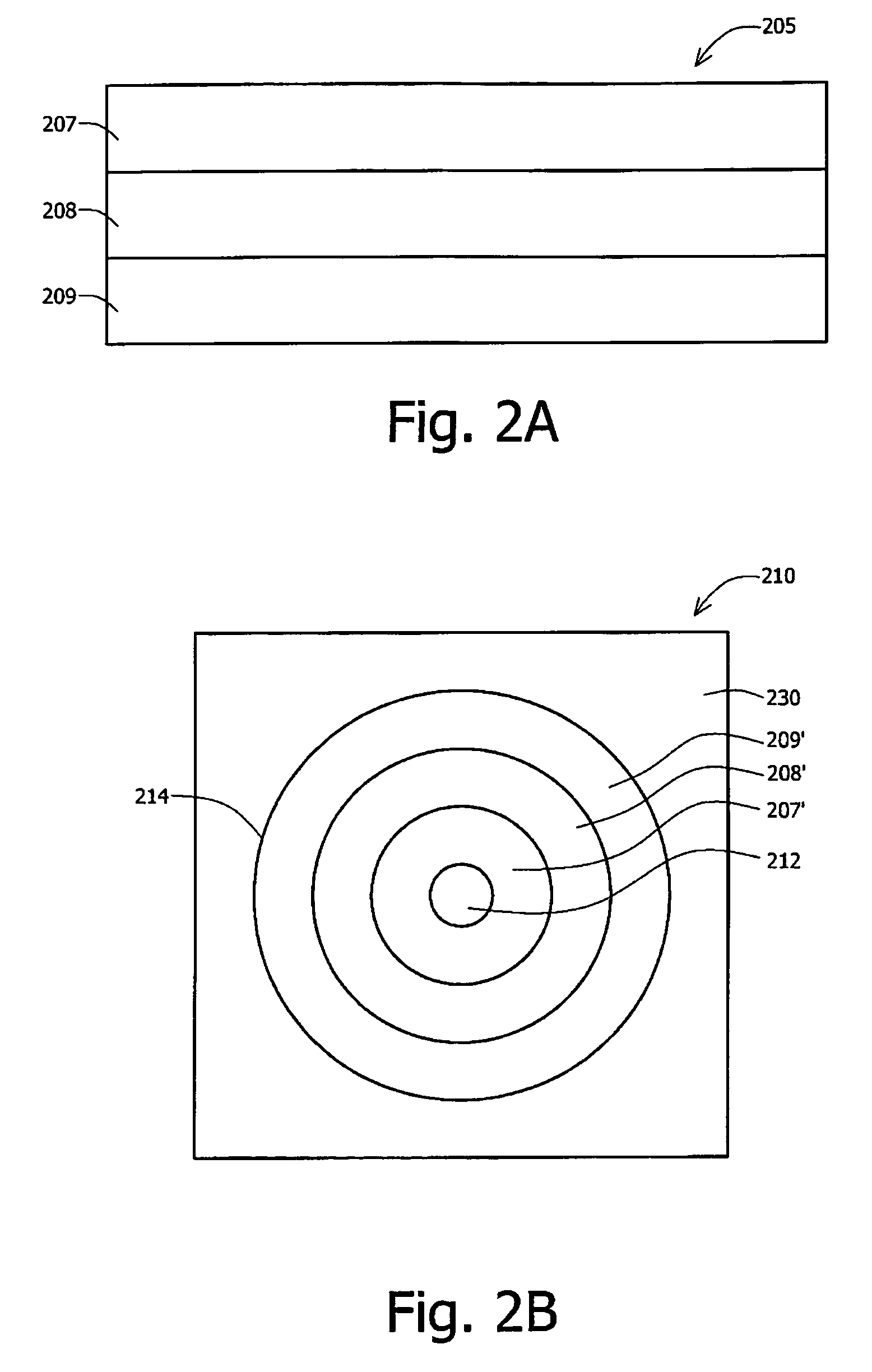

Method of generating writing pattern data of mask and method of writing mask

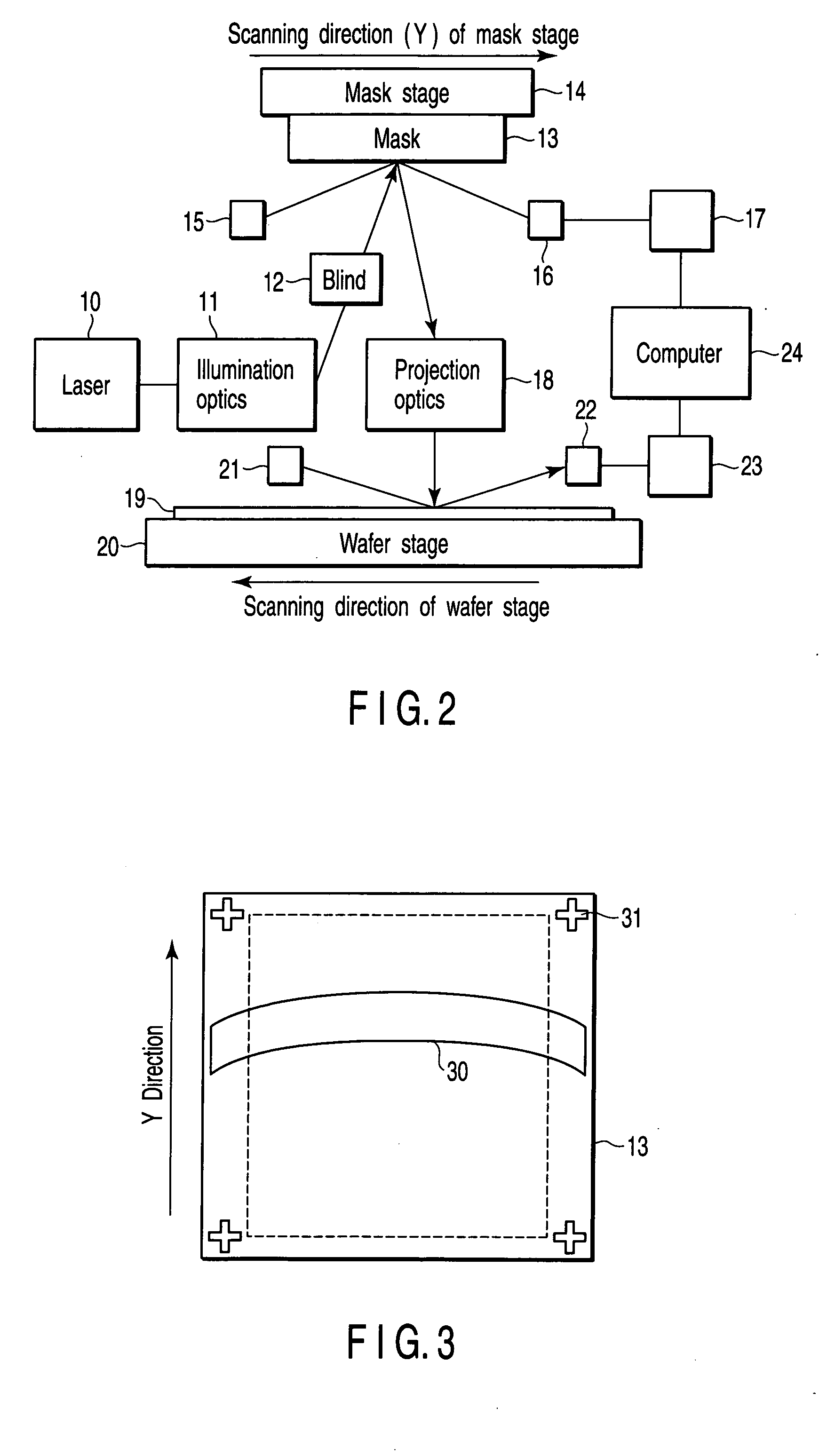

A method of generating writing pattern data of a reflective mask for use in a non-telecentric exposure tool comprises obtaining a vertical position profile by measuring vertical positions of a plurality of X, Y coordinates arbitrarily set on the surface of a blank mask substrate when mounted on a mask stage, or by measuring and calculating a flatness profile, calculating unevenness of the blank mask substrate surface from the vertical position profile, calculating a shift amount of an image position, generated in a wafer mounted on a wafer stage of the exposure tool, in accordance with the unevenness of the blank mask substrate and parameters of a non-telecentric optics of the exposure tool, and obtaining corrected writing pattern data by correcting design pattern data of the reflective mask based on the shift amount of the image position and a reduction ratio of a projection optics of the exposure tool.

Owner:KIOXIA CORP

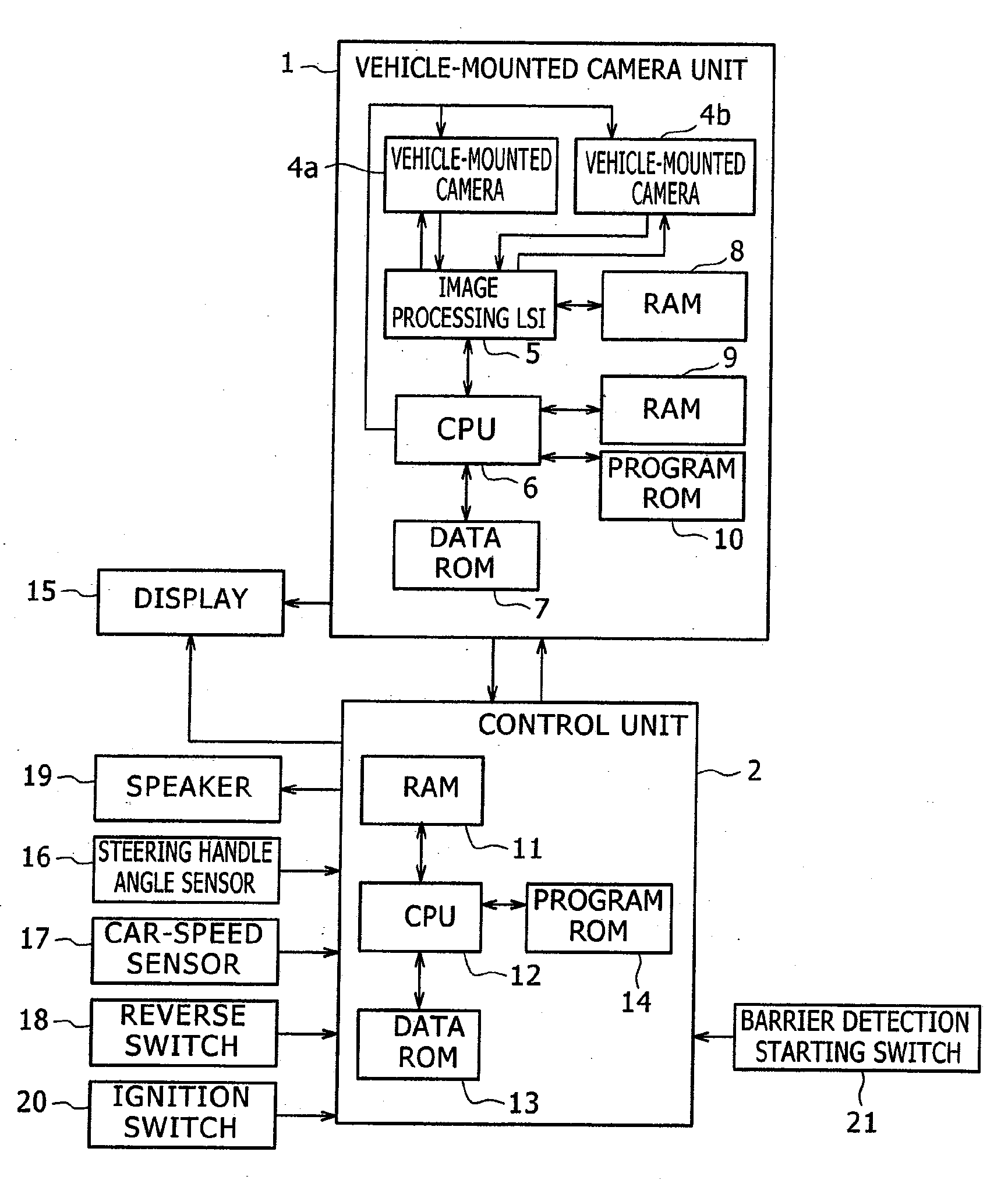

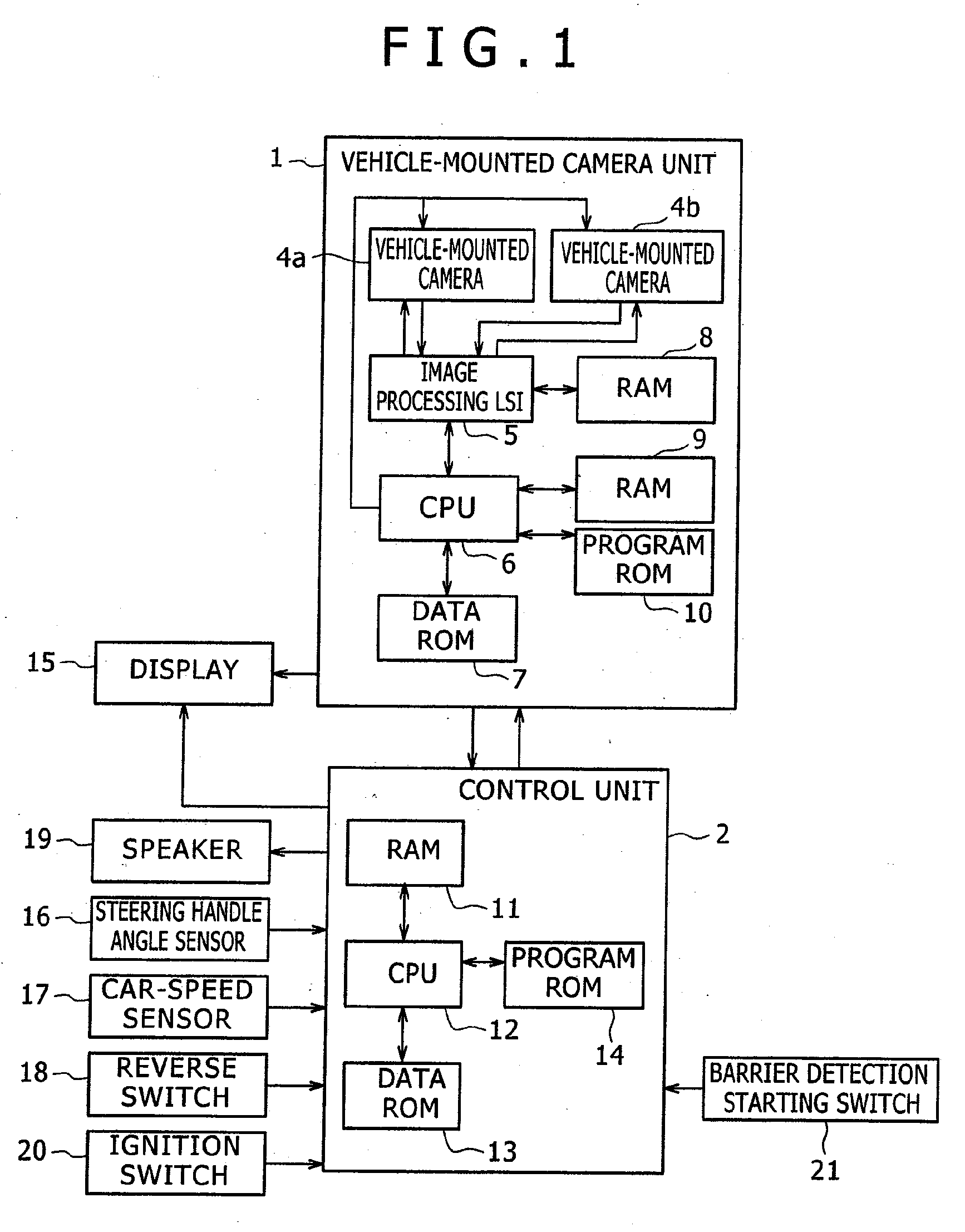

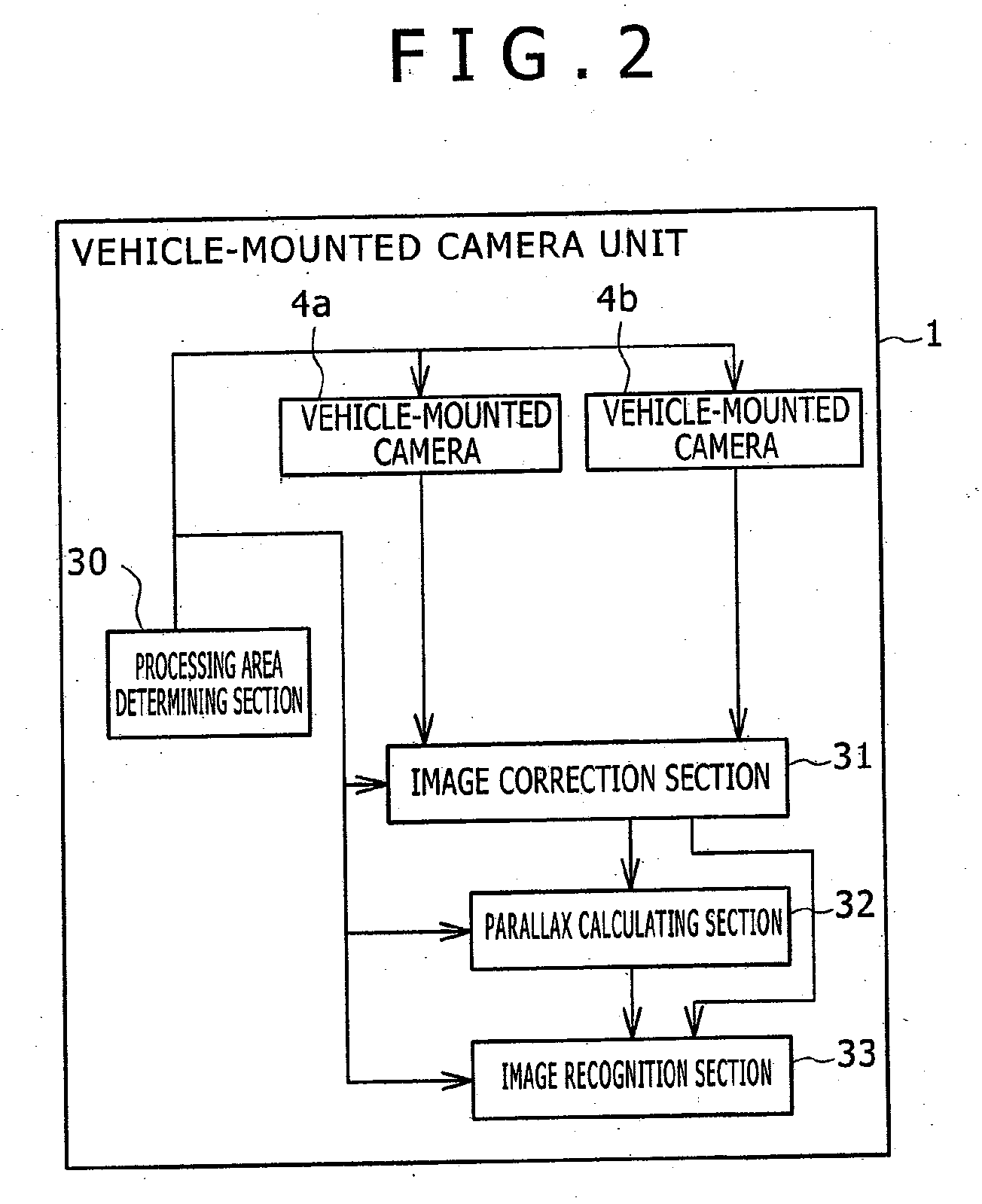

Stereo Camera Device

A stereo camera device includes: plural picture image taking sections, an image correction section which makes correction of picture images taken, a parallax calculating section which calculates parallax, an amount of dislocation between the left and right images, and an image recognition section which carries out image recognition processing using both the image taken and the calculated parallax, or either of them. The stereo camera device further includes: a processing area setting up section which sets up the image area to be processed and reduction ratio differently depending on the driving environment of the vehicle on which the stereo camera device is mounted, wherein, by using the image area and the reduction ratio set up by the processing area setting up section, the image correction section makes correction to the picture image, the parallax calculating section calculates parallax, and the image recognition section carries out processing of image recognition.

Owner:HITACHI ASTEMO LTD

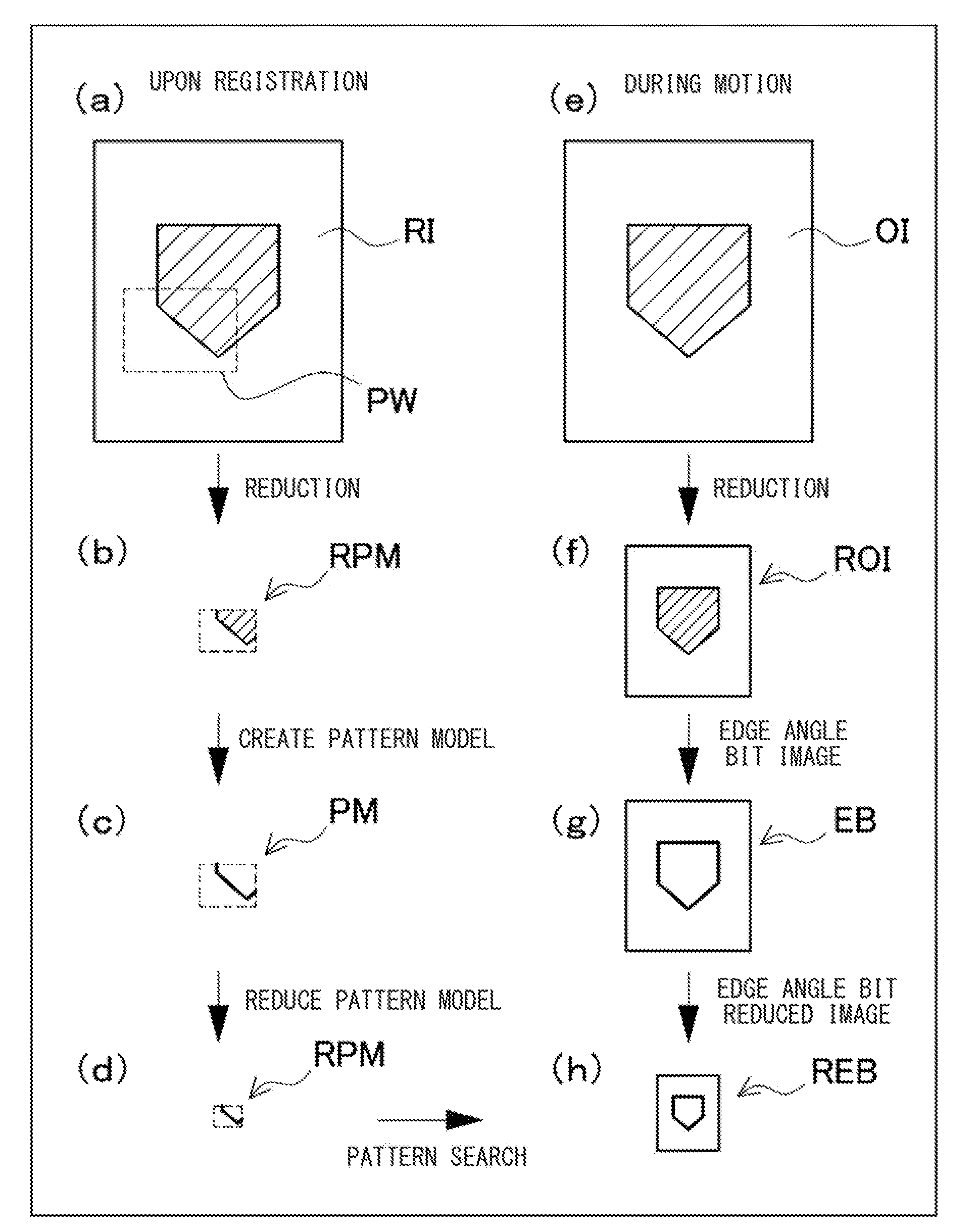

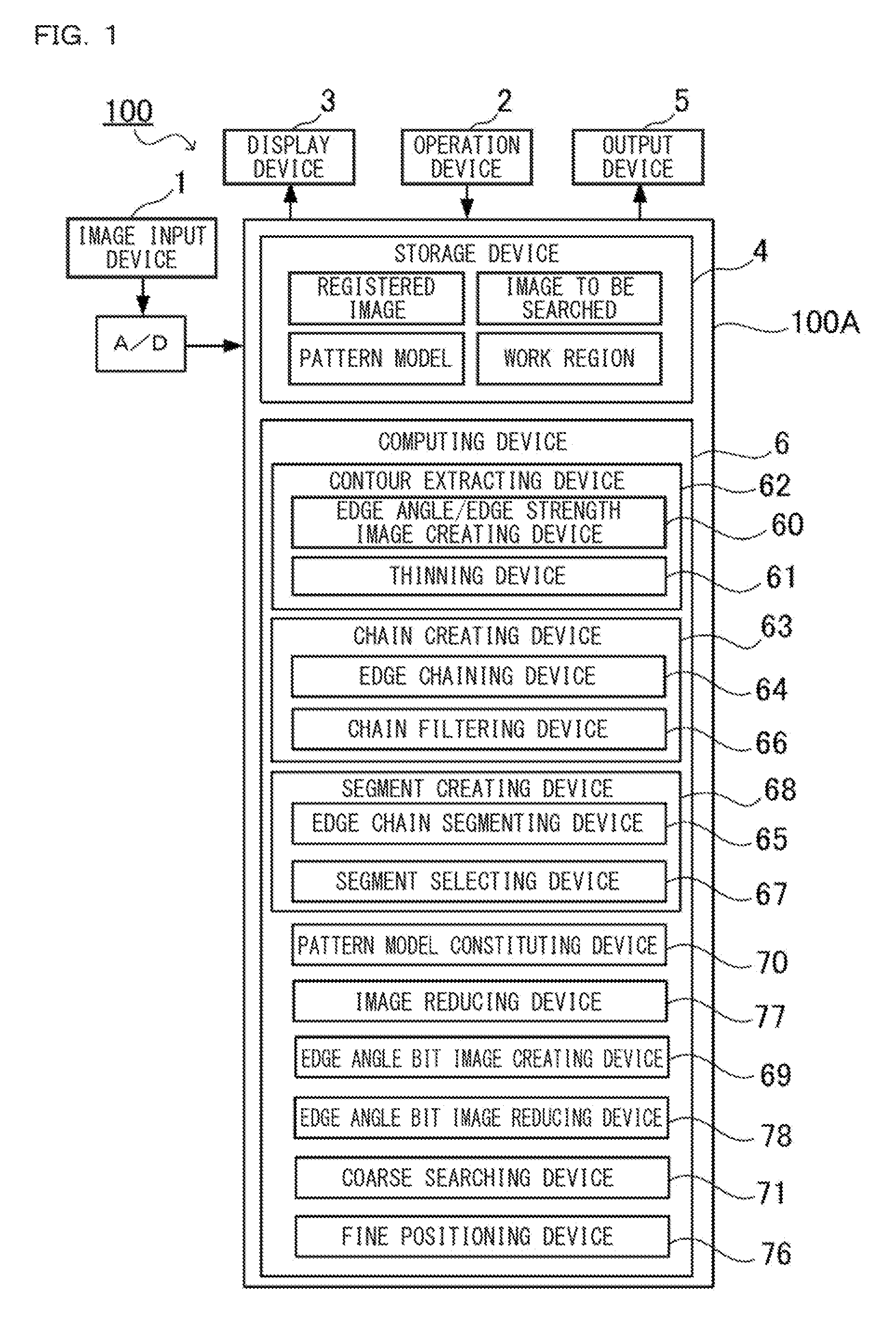

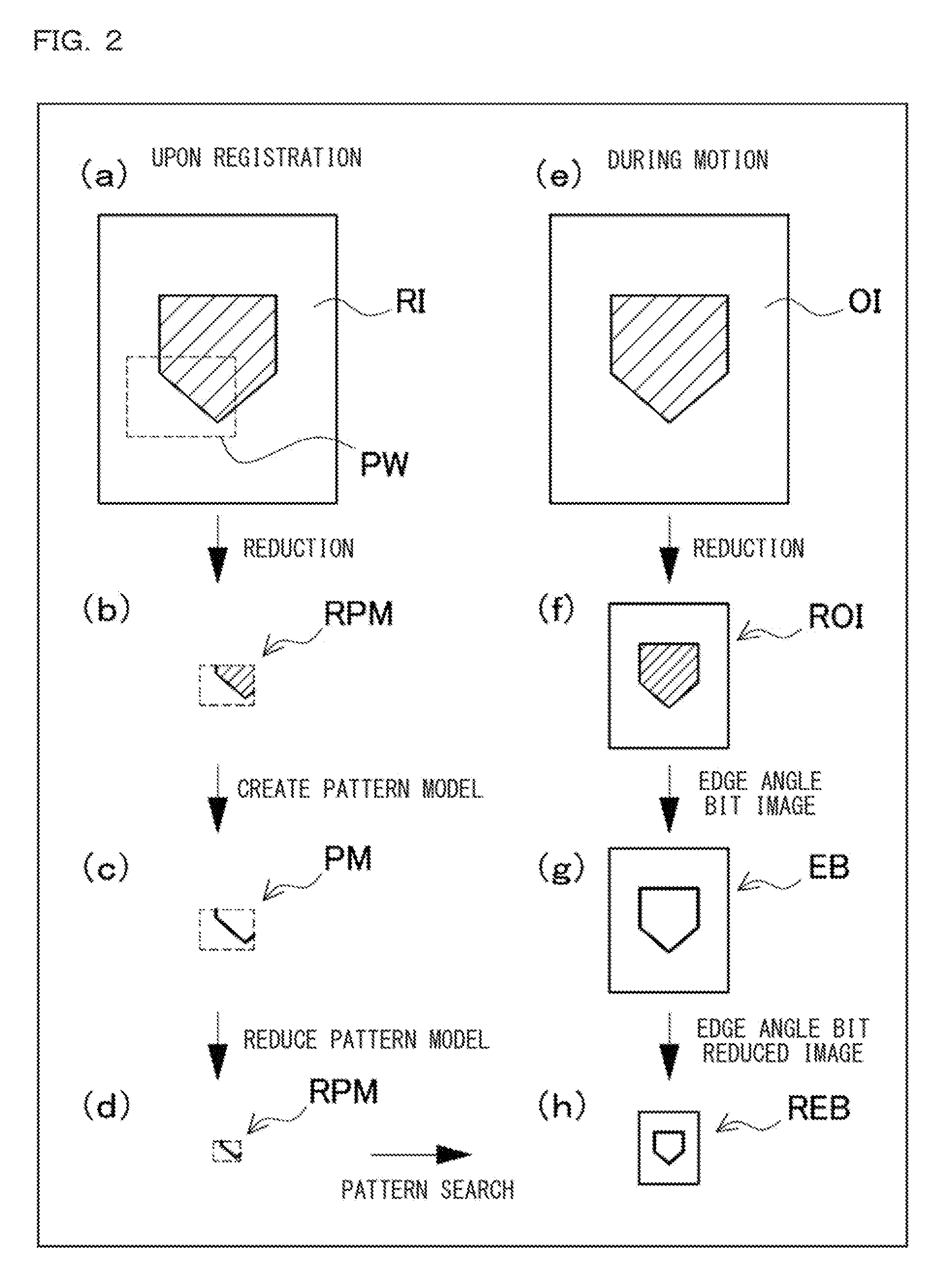

Image Data Compression Method, Pattern Model Positioning Method in Image Processing, Image Processing Apparatus, Image Processing Program, and Computer Readable Recording Medium

InactiveUS20100034476A1Accurately perform adjustmentPrecise positioningCharacter and pattern recognitionData compressionImaging processing

There is provided a data compression method for increasing a reduction ratio, while keeping a sufficient characteristic amount, to seek speeding up of processing, the method being for compressing image data in pattern model positioning in image processing of searching out of an image to be searched and positioning a pattern model corresponding to a pre-registered image. The method includes the steps of computing an edge strength image having edge strength information and an edge angle image having edge angle information with respect to each pixel constituting an image; transforming the edge angle image of each pixel into an edge angle bit image expressed by an edge angle bit indicating an angle with a pre-defined fixed width; and compressing the edge angle bit image to create an edge angle bit reduced image by taking a sum with respect to each edge angle bit.

Owner:KEYENCE

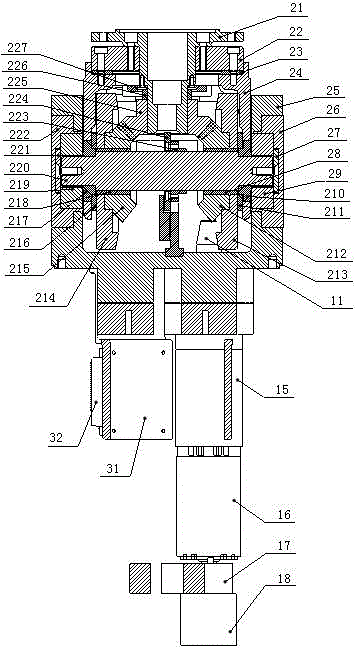

Two-degree-of-freedom joint of space robot

The invention discloses a two-degree-of-freedom joint of a space robot. The two-degree-of-freedom joint comprises two joint driving assemblies and a joint transmission assembly. Two-degree-of-freedom movement of the joint can be achieved. Three movement modes of pitching, rotating and combining of pitching and rotating can be achieved by adjusting the rotating speeds and the rotating angles of two motors. The joint transmission assembly is a differential movement mechanism formed by two input bevel gears and an output bevel gear. The two input bevel gears are fixedly connected with corresponding hypoid gears respectively, and an output flange is fixedly connected with the output bevel gear. First-stage speed reduction is carried out on the torque of the motors through planetary reducers connected with the motors, then second-stage speed reduction is carried out through the hypoid gears, and finally the torque is transmitted to the output end through the bevel gear differential mechanism. As the reduction ratios of two stages of speed reduction are large, the output torque of the mechanism is large, and the high load capacity is achieved.

Owner:SHANGHAI AEROSPACE SYST ENG INST

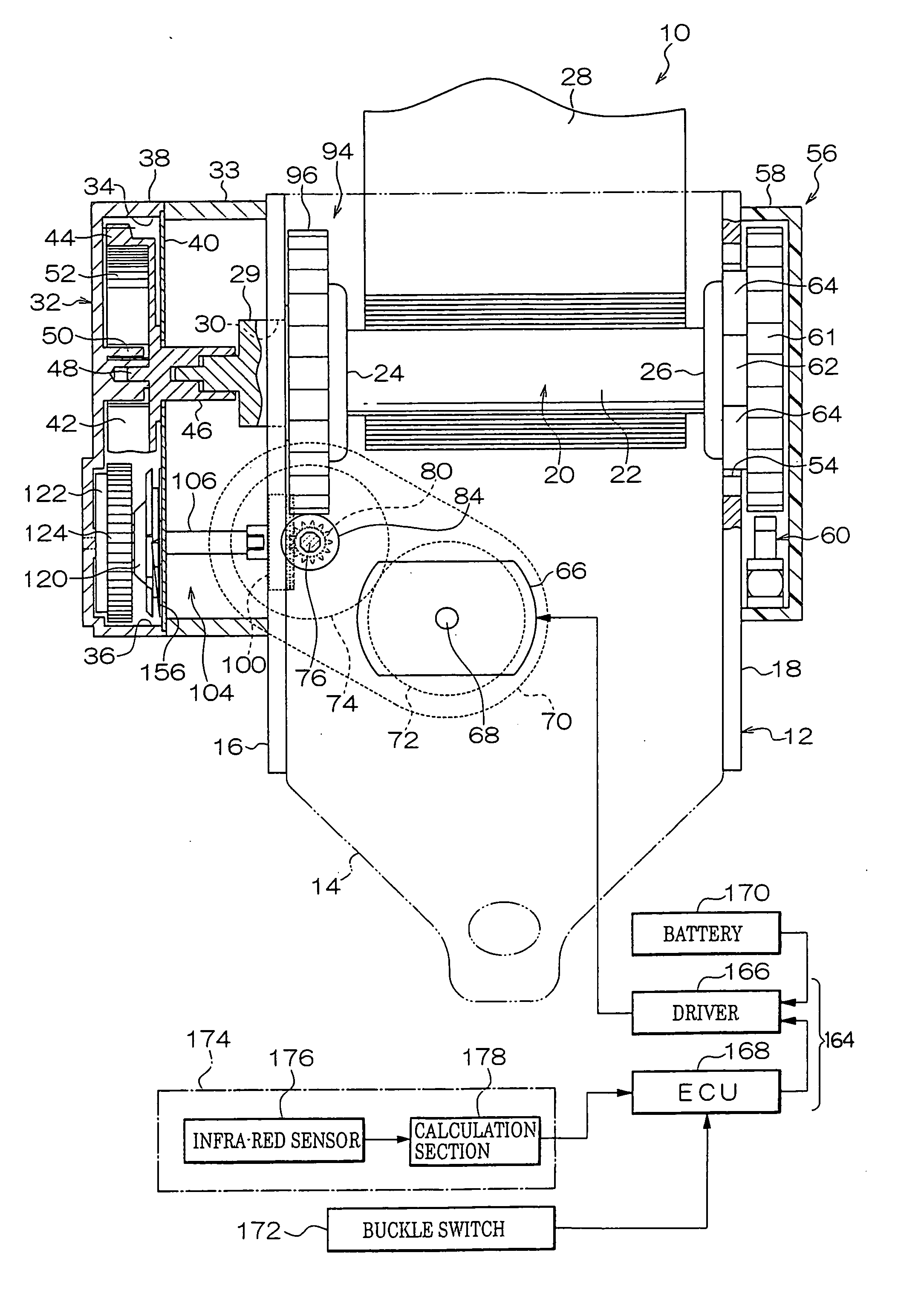

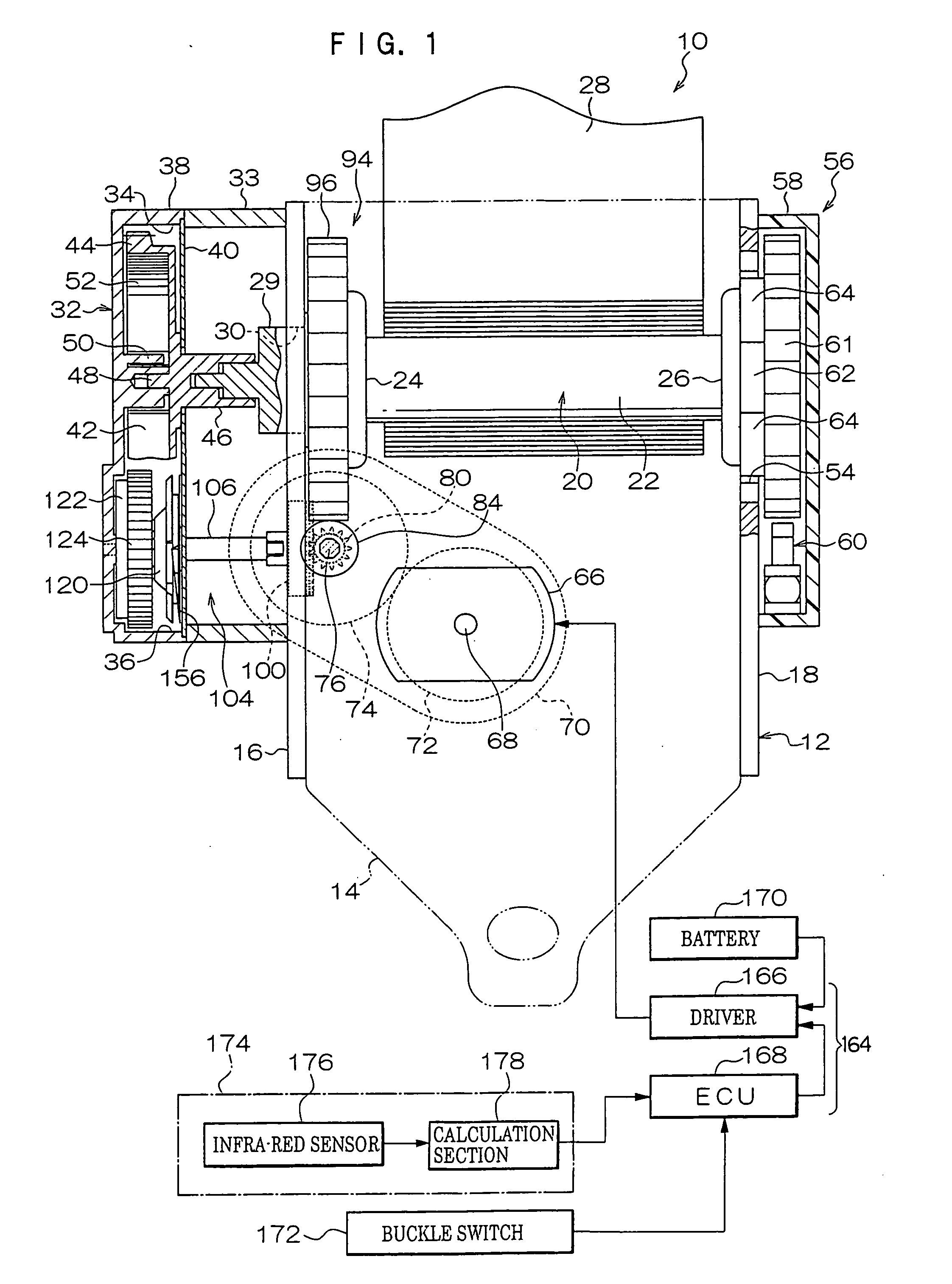

Motorized retractor

ActiveUS20050224621A1Increase torqueAvoid using forceBelt retractorsBelt control systemsSpool valveReduction ratio

A motorized retractor which includes a spool with a webbing wound therearound, a reversible motor, a forward and a reverse driving force transmission mechanisms. The forward and the reverse driving force transmission mechanisms are provided between the spool and an output shaft of the motor, respectively. The forward driving force transmission mechanism reduces forward rotation of the output shaft by a predetermined reduction ratio and transmits this rotation to the spool for rotating the spool in a winding direction. The reverse driving force transmission mechanism reduces reverse direction rotation of the output shaft by a reduction ratio which is lower than the predetermined reduction ratio of the forward driving force transmission mechanism, and transmits this rotation to the spool for rotating the spool in the winding direction. The forward and the reverse driving force transmission mechanisms both block transmission to the output shaft of rotations generated at the spool side.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

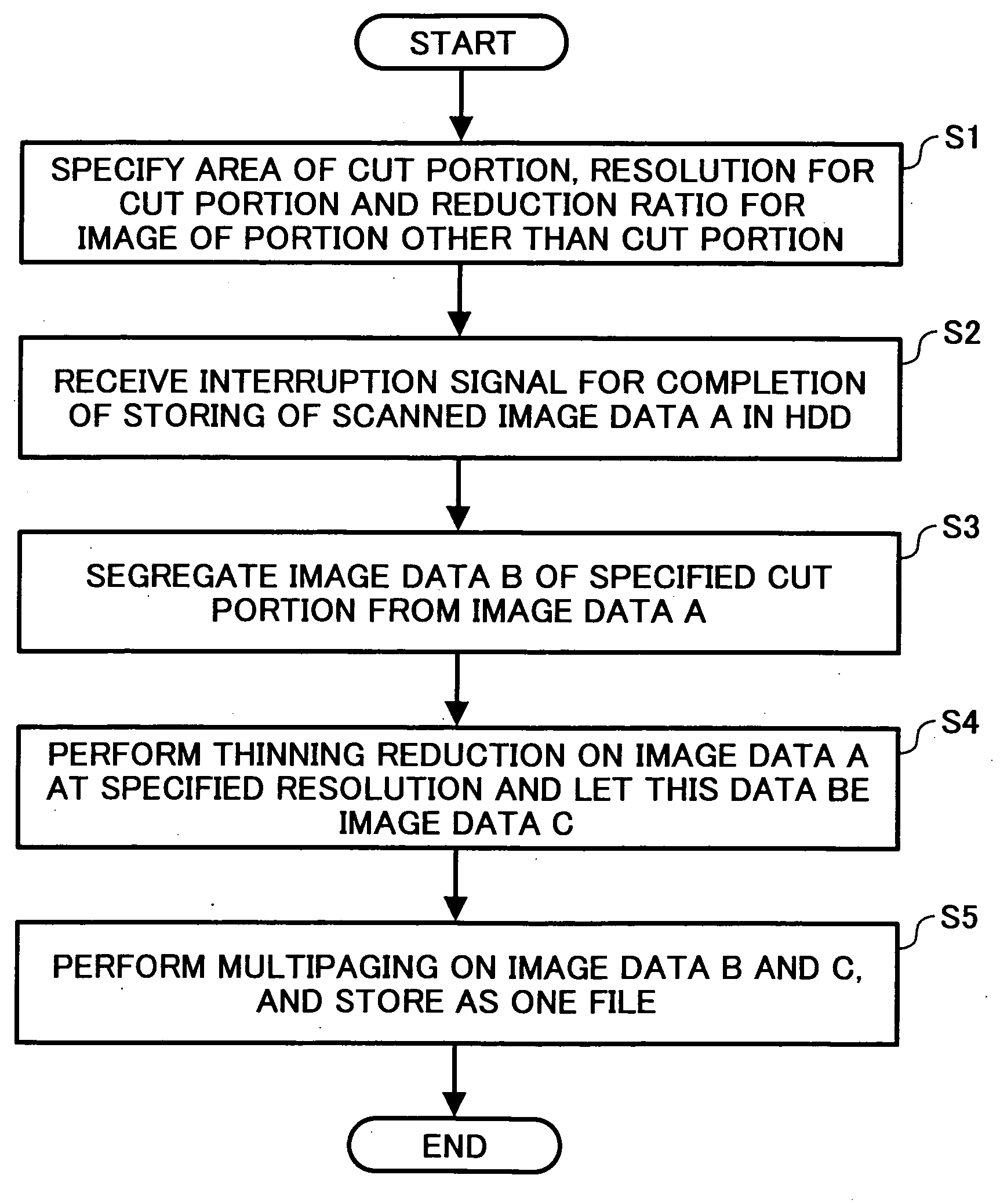

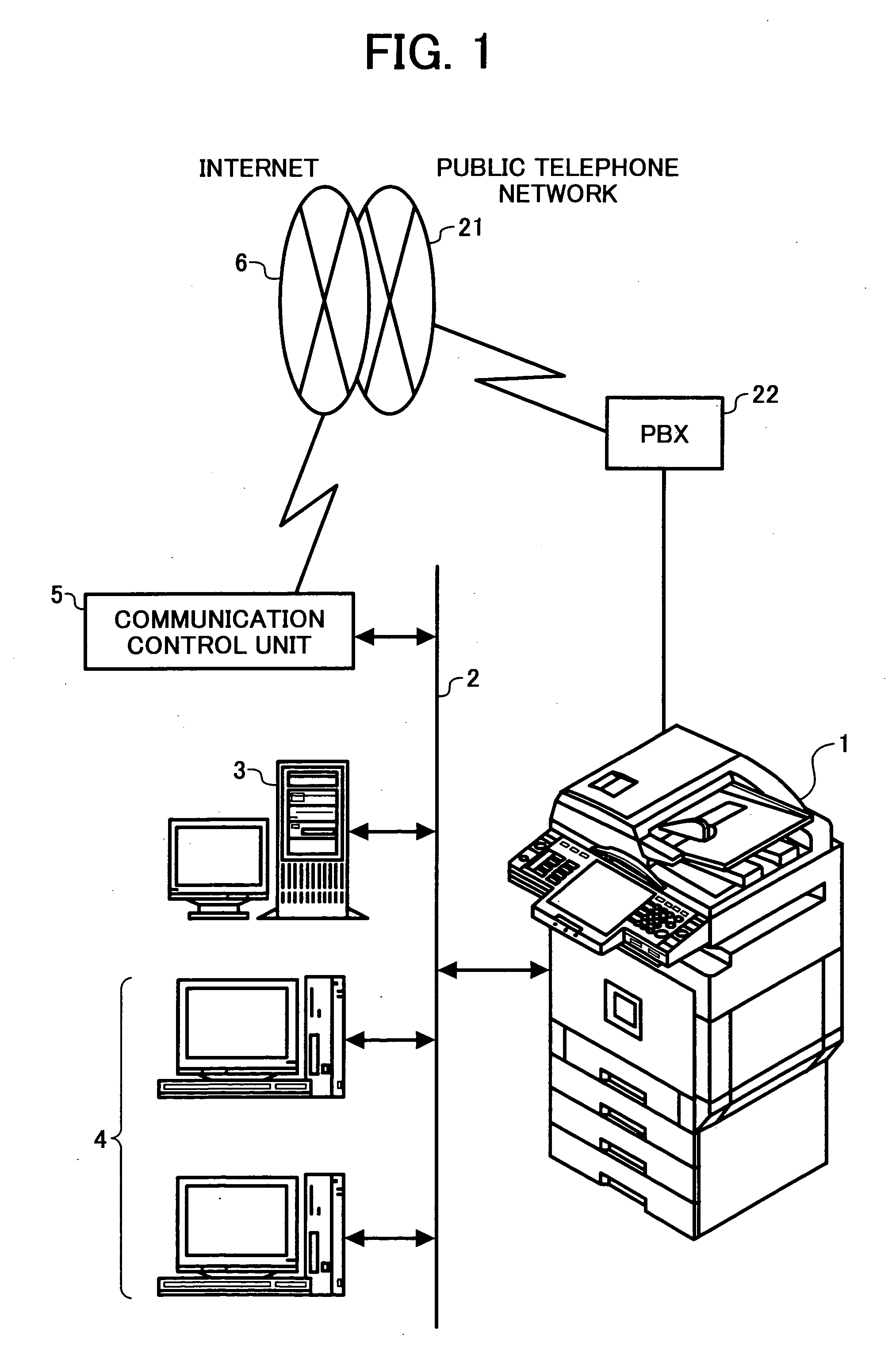

Image processing apparatus, and computer product

InactiveUS20050062991A1Solve problemsDigitally marking record carriersVisual presentation using printersImaging processingImage resolution

A desired area, a desired resolution of the desired area, and a desired reduction ratio of an area other than the desired area are specified. An image data of the desired area is extracted from an image data of a document read at the desired resolution. A changed image data is created by changing the image data of the document based on the desired reduction ratio. The image data of the desired area and the changed image data are subjected to multi-page filing and saved as one file.

Owner:RICOH KK

High-integrality robot joint

The invention relates to a high-integrality robot joint. The high-integrality robot joint comprises a mechanical system, a joint electrical system and a sensor system, wherein the mechanical system, the joint electrical system and the sensor system are integrated in the joint; the mechanical system comprises a power-off brake; the joint adopts a large hollow shaft structure, and wires in the joint are all arranged in hollow inside space. The high-integrality robot joint has the benefits as follows: the high-integrality robot joint has the characteristics of small size, small dead weight, high load capacity and high integrality; output performance requirements for a motor are reduced while output torque is increased through a large reduction ratio of a harmonic reducer; meanwhile, slide control of the motor is realized through a motor encoder, the high-precision characteristic of output of the joint is guaranteed through an absolute joint encoder, position keeping of a robot is realized through the power-off brake under the power failure condition, and safety of the robot during movement is improved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

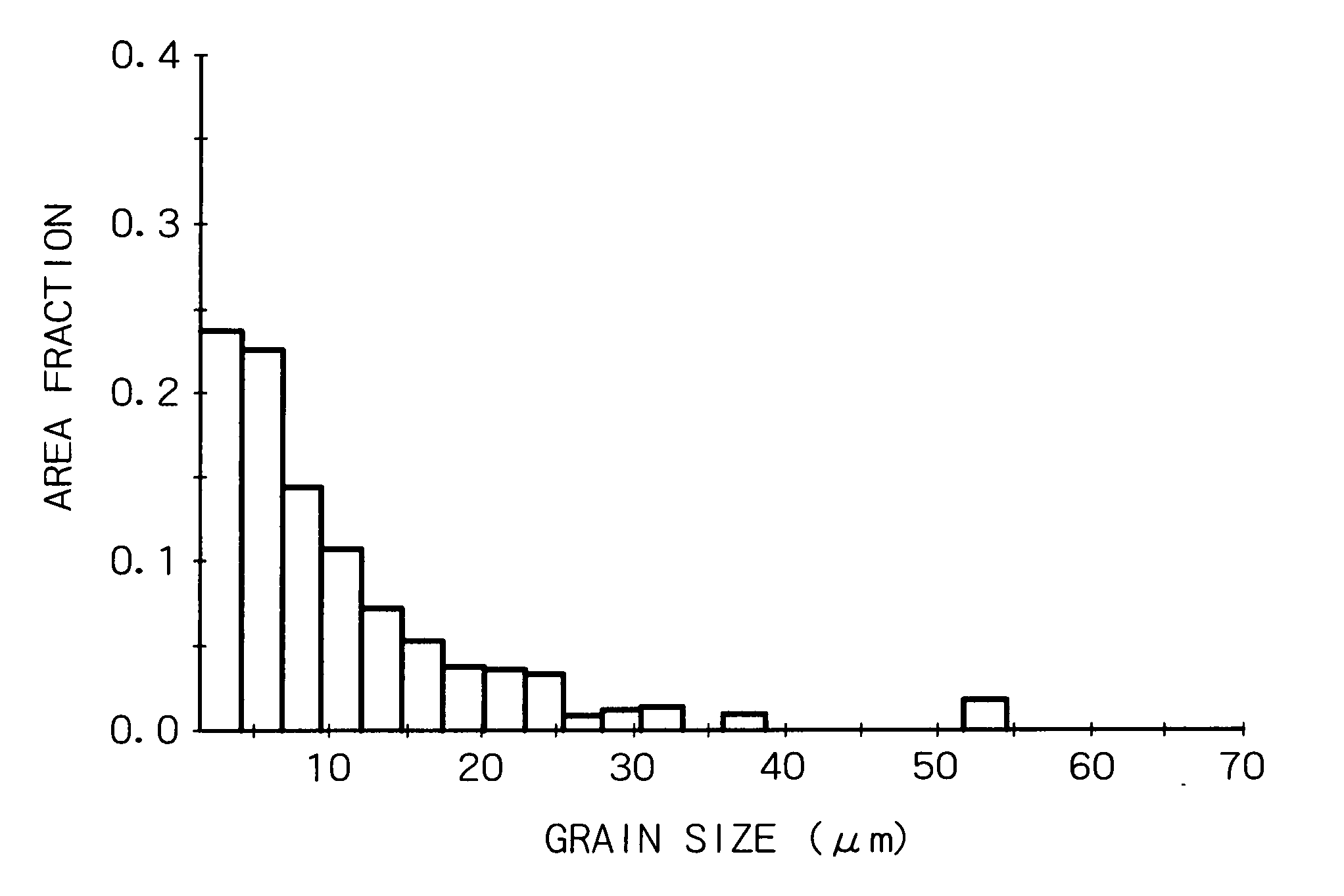

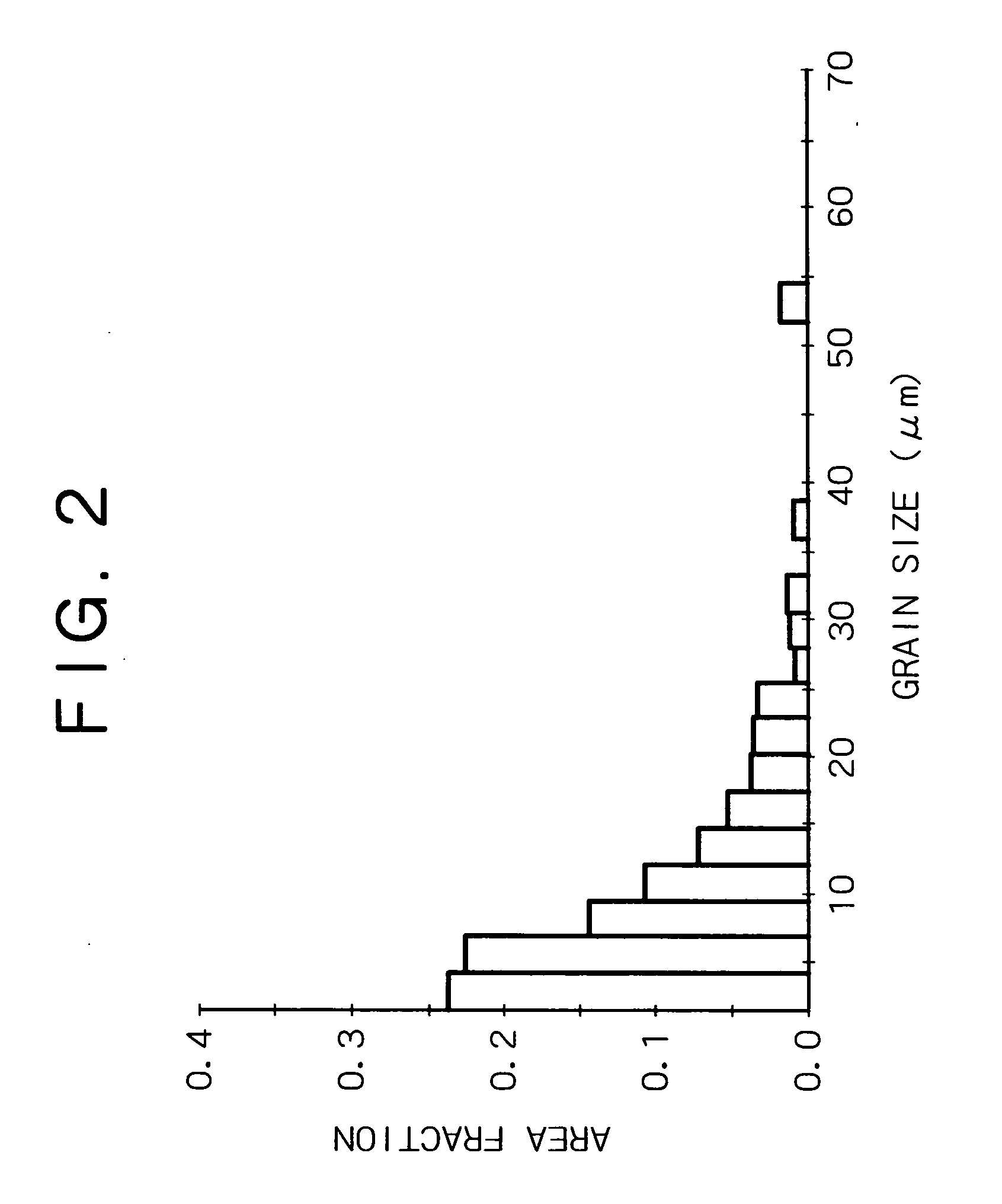

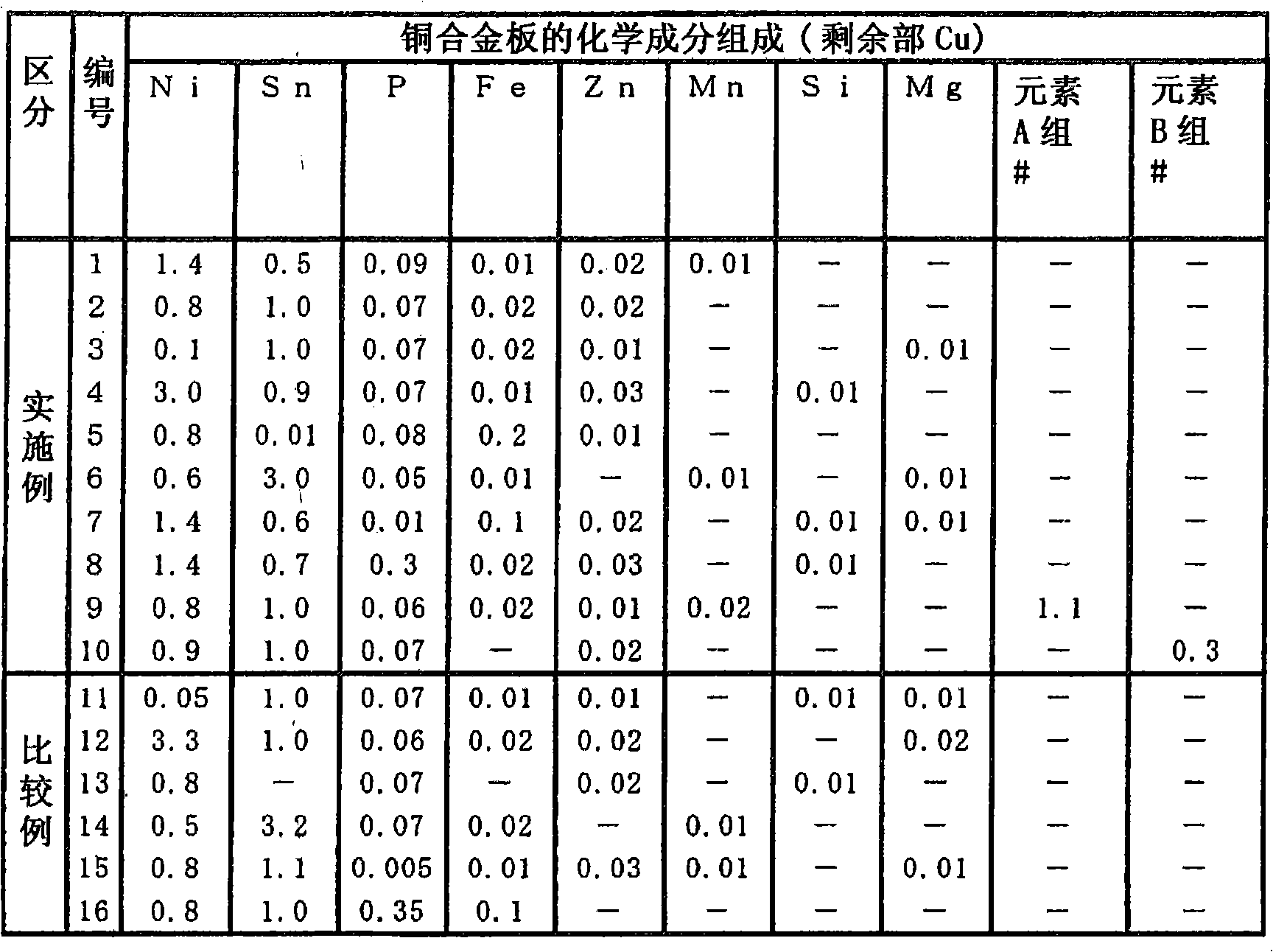

Softening-resistant copper alloy and method of forming sheet of the same

InactiveUS20050092404A1Improve softening resistanceReduced strengthMetal rolling arrangementsWork cycleReduction ratio

A softening-resistant copper alloy contains Fe in an Fe content in the range of 0.01 to 4.0% by mass. The copper alloy has a cube orientation density of 50% or below and a mean grain size of 30 μm or below after being annealed at 500° C. for 1 min. A copper alloy sheet forming method of forming a copper alloy sheet comprises, in successive steps: a hot rolling process for hot-rolling a copper alloy sheet of the copper alloy according to any one of claims 1 to 4, at least two working cycles each of a cold rolling process and an annealing process, and a finish cold rolling process. Reduction ratio for each of the cold rolling processes of the working cycles is in the range of 50 to 80%, and reduction ratio for the finish cold rolling process is in the range of 30 to 85%.

Owner:KOBE STEEL LTD

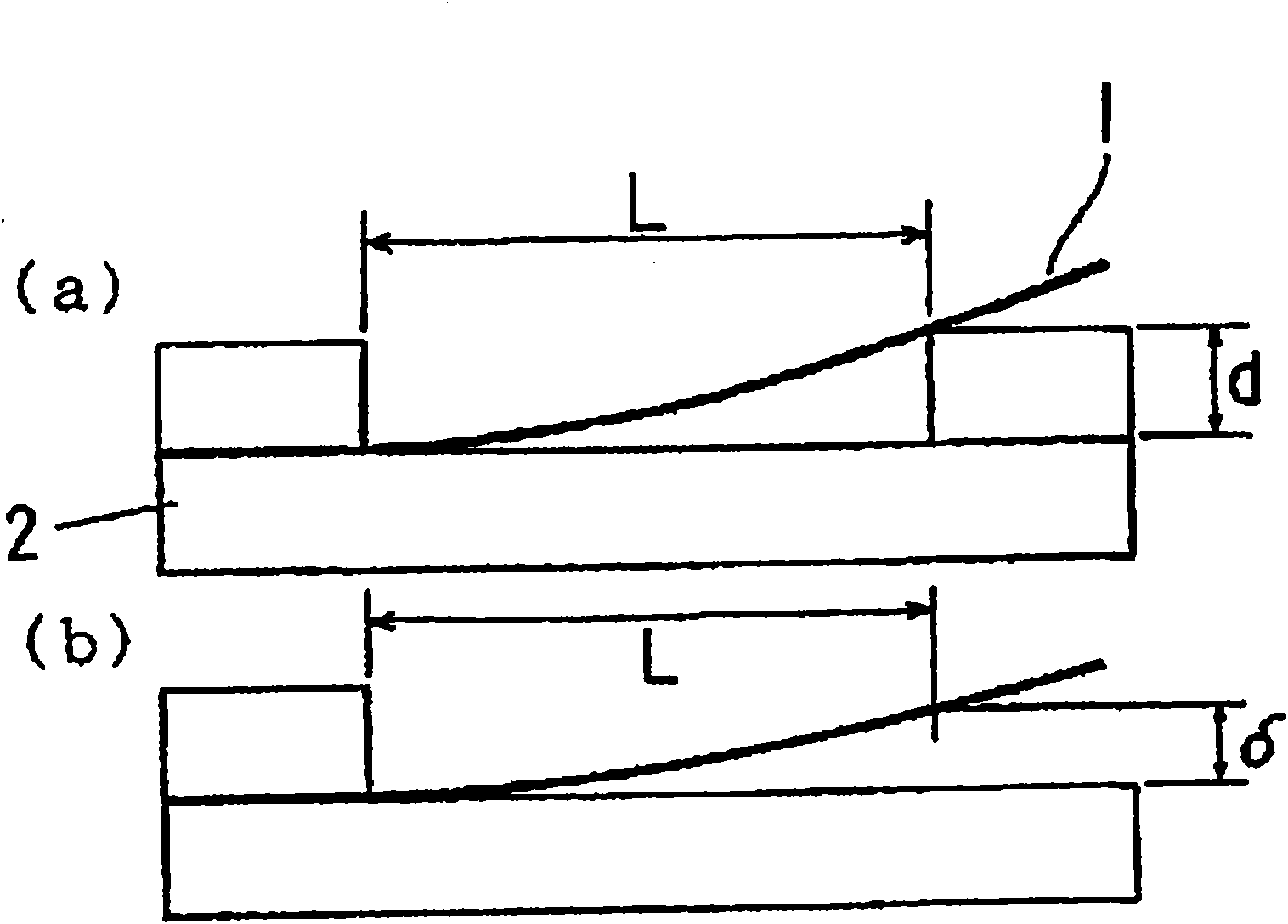

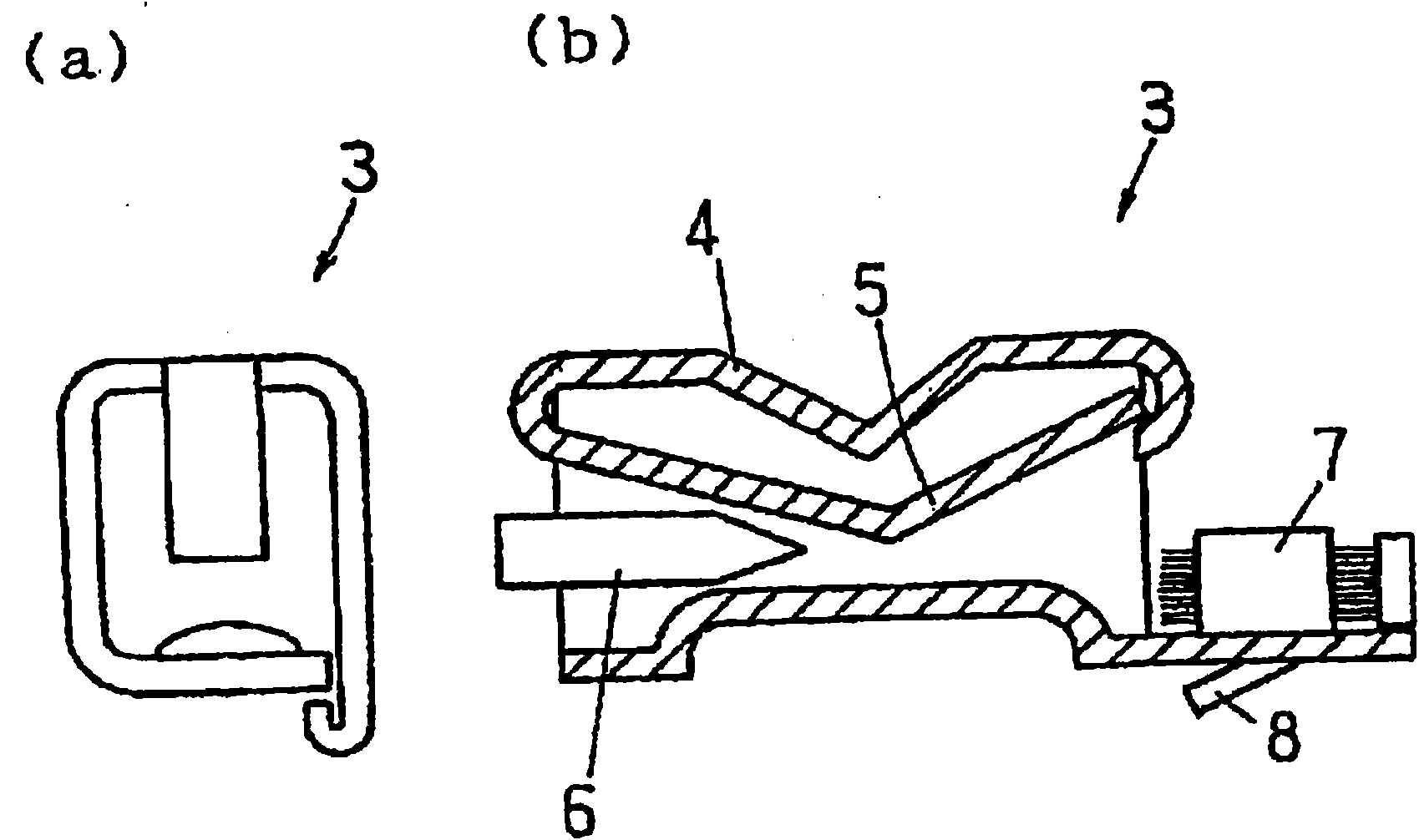

Copper alloy plate having excellent anti-stress relaxation properties

The invention provides a Cu-Ni-Sn-P alloy sheet satisfying the resistance property of stress relaxation in the direction perpendicular to the rolling direction and excellent in the other necessary properties as terminals and connectors. The invention relates to analloy sheet having a specific composition, which is made to contain specific atomic clusters containing at least any of an Ni atom or a P atom, as detected with a three-dimensional atom probe field ion microscope, in a specific density, by increasing the reduction ratio in the final cold rolling and by intentionally shortening the time for the rolling and the time to be taken before the final annealing at low temperature, and of which the necessary properties as a terminal or connector 3 are improved in that the resistance property of stress relaxation thereof in the direction perpendicular to the rolling direction is enhanced and the difference (anisotropy) in the resistance property of stress relaxation thereof between the parallel direction and the perpendicular direction to the rolling direction is reduced.

Owner:KOBE STEEL LTD

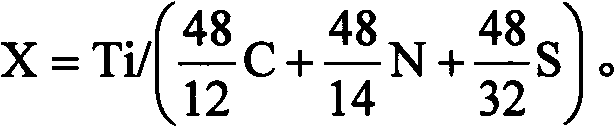

Low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and production method thereof

ActiveCN102653839ALower recrystallization temperatureRealize the structureChemical compositionReduction ratio

The invention relates to a low-temperature continuous-annealing interstitial-free atom cold-rolled steel plate and a production method thereof and belongs to the technical field of iron-based alloys. The production method of the cold-rolled steel plate comprises the following steps of: controlling the components of the cold-rolled steel plate in percentage by mass: 0.0005-0.0025% of C, less than or equal to 0.03% of Si, 0.05-0.15% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, less than or equal to 0.0025% of O, less than or equal to 0.0025% of N, 0.015-0.050% of Al, 0.03-0.07% of Ti, and the balance of Fe and inevitable mixed elements; and meanwhile, controlling the continuous-annealing temperature of the cold-rolled steel plate to be 710-740 DEG C, and controlling the cold-rolling reduction ratio to be not less than 80%. According to the cold-rolled steel plate and the production method thereof, the reasonable chemical components and the suitable control of cold-rolling reduction are adopted, the recrystallization temperature is lowered, full-old-rolled microstructures are formed, and a lower continuous-annealing temperature can be adapted, so that the equipment cost and energy consumption are reduced, the control difficulty of a production process is reduced, the product defects and production accidents are avoided.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

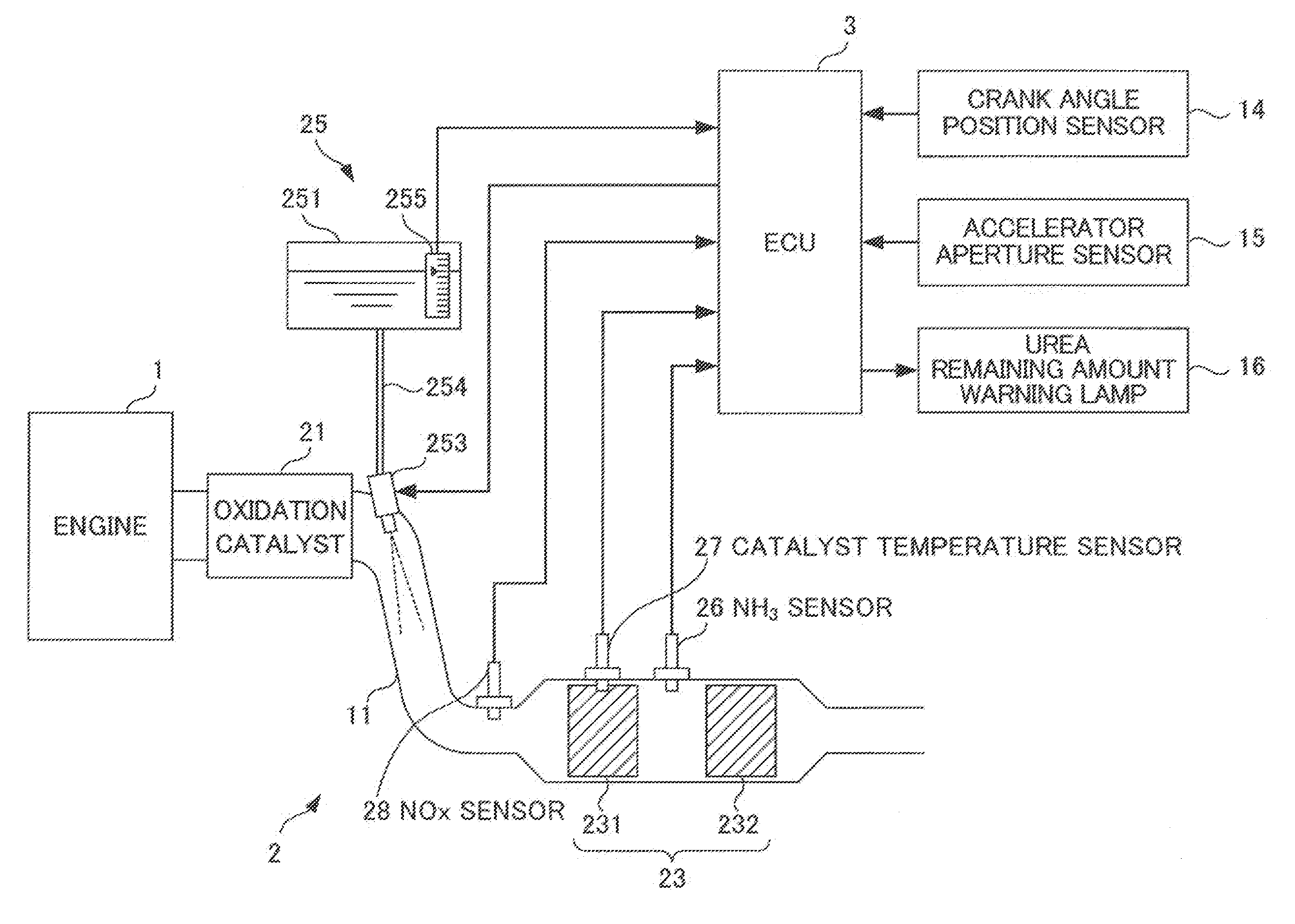

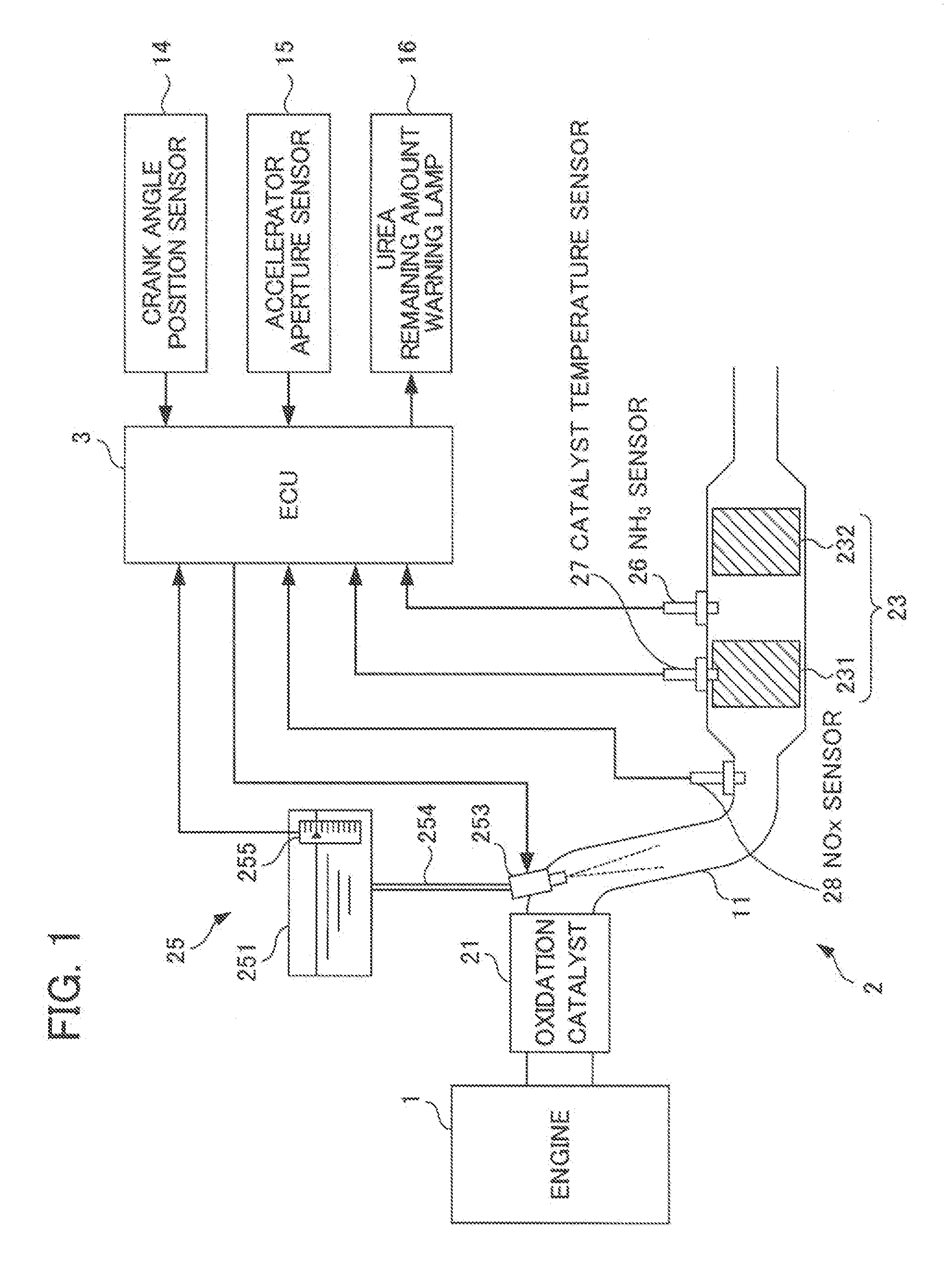

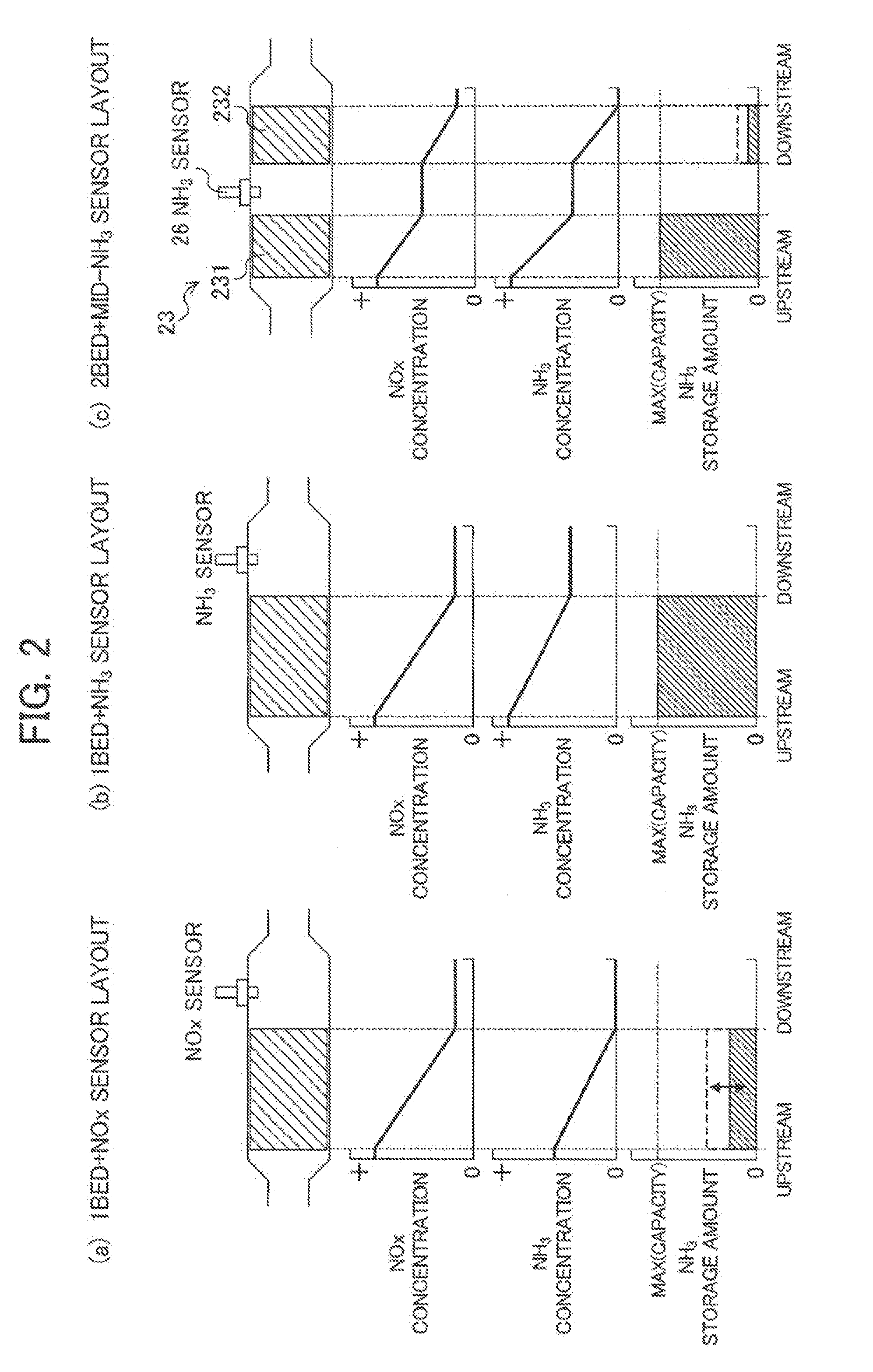

Exhaust purification apparatus for internal combustion engine

InactiveUS20110041480A1High NOx reduction rateReduce probabilityInternal combustion piston enginesExhaust apparatusReduction ratioEnvironmental engineering

An exhaust purification apparatus for internal combustion engine having a selective reduction catalyst that while maintaining a high NOx reduction ratio, inhibits any ammonia discharge downstream of the selective reduction catalyst. In the exhaust purification apparatus (2), a urea selective reduction catalyst (23) comprises a first selective reduction catalyst (231) and, provided downstream of the first selective reduction catalyst (231) in an exhaust passageway (11), a second selective reduction catalyst (232). Further, the exhaust purification apparatus (2) includes a urea injection unit (25) for feeding of a reducing agent upstream of the urea selective reduction catalyst (23) in the exhaust passageway (11) and an ammonia sensor (26) for detection of the ammonia concentration at a site between the first selective reduction catalyst (231) and the second selective reduction catalyst (232) in the exhaust passageway (11). The rate of urea injection, GUREA, by the urea injection unit (25) is determined so that the value of ammonia concentration, NH3CONS, detected by the ammonia sensor (26) is greater than “0.”

Owner:HONDA MOTOR CO LTD

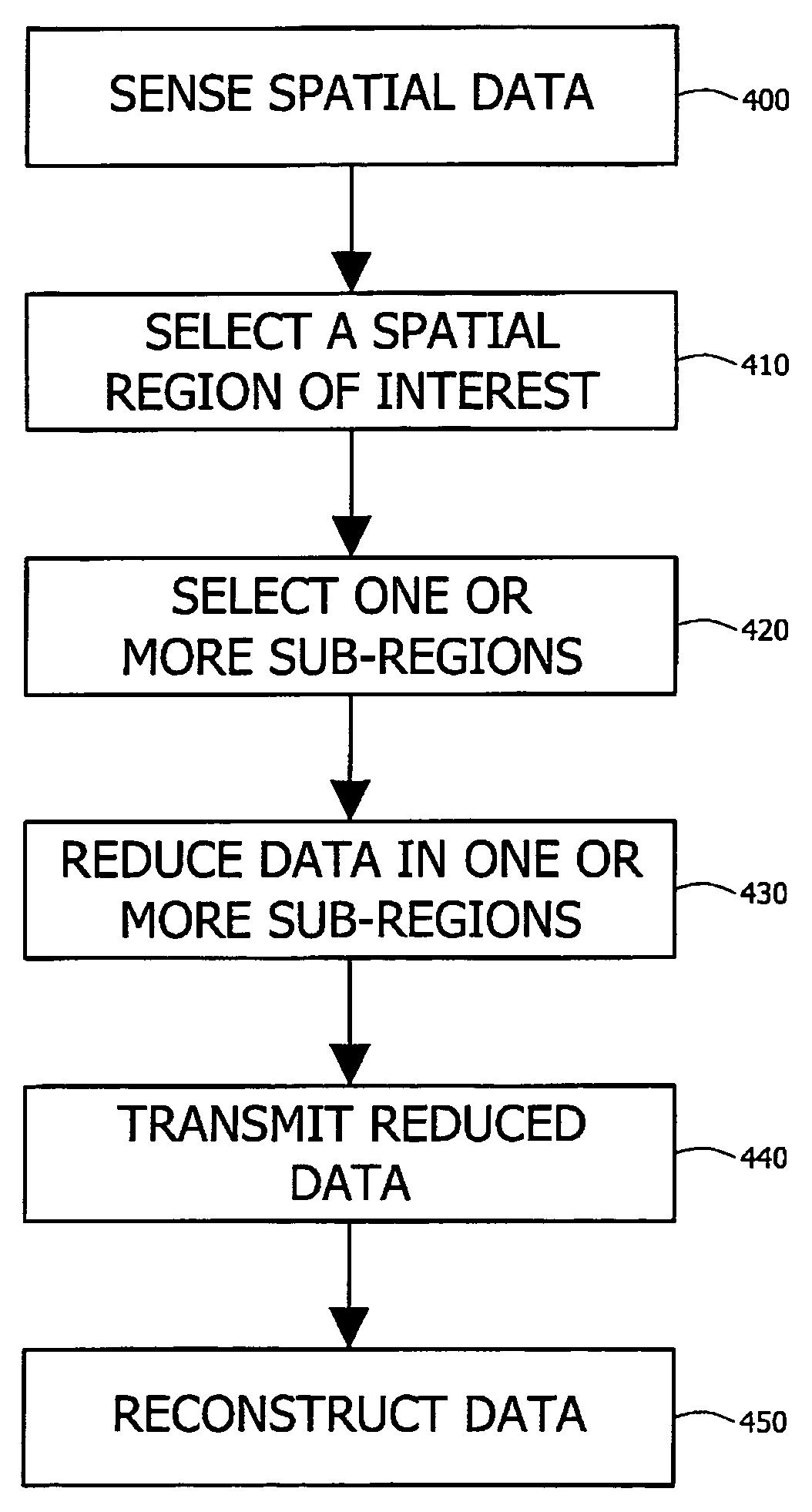

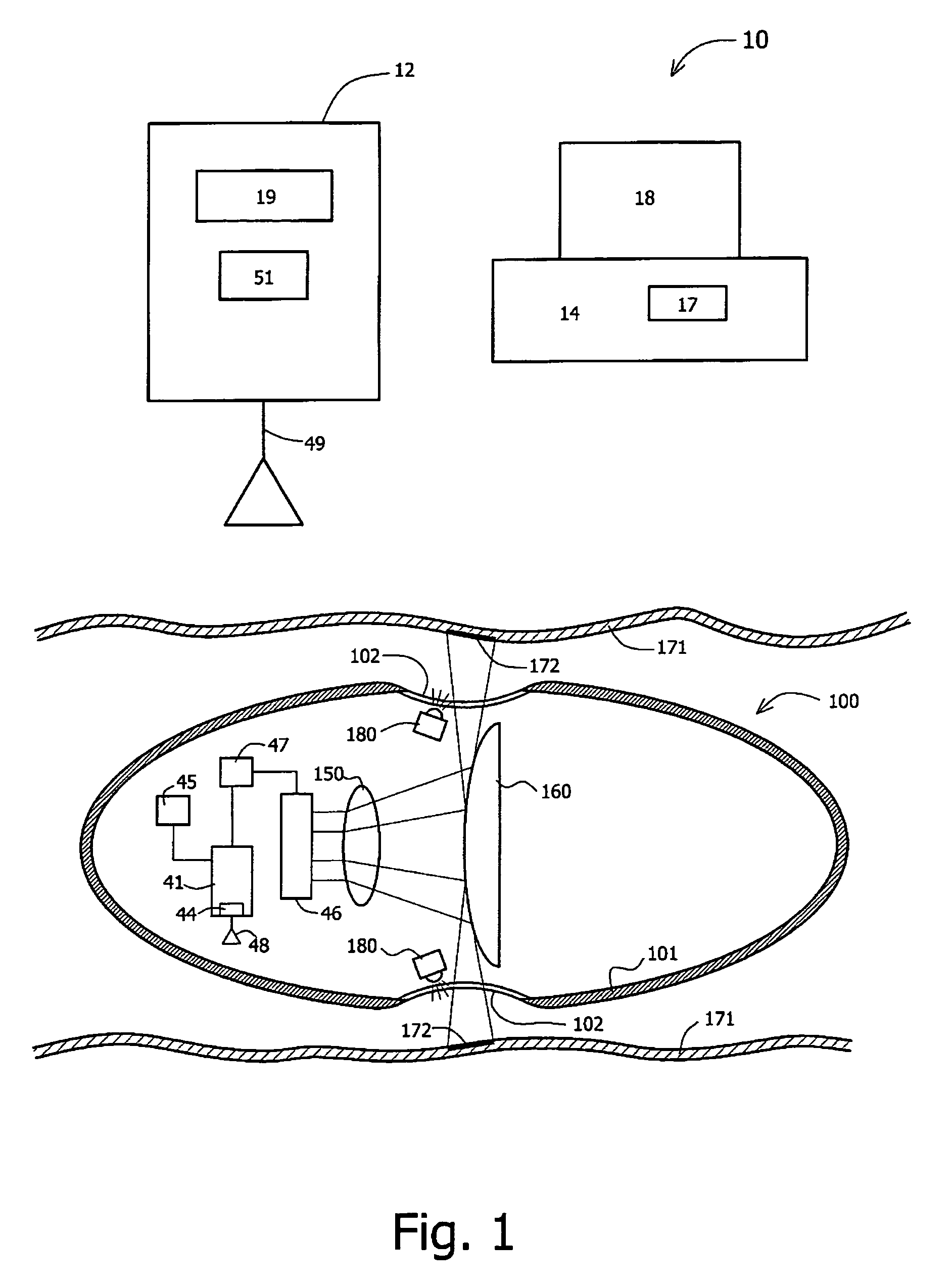

Device, system, and method for reducing image data captured in-vivo

A device, system, and method for reducing image data using spatially varying reduction are described. Images may be captured from an in-vivo device, while the reduced images may be transmitted via wireless communications. Reduction may be achieved by selecting a spatial area of interest on an image frame, dividing the spatial area of interest into one or more sub-regions, reducing each sub-region by a defined reduction ratio according to the spatial properties of said sub-region, and transmitting image data from spatial area of interest.

Owner:GIVEN IMAGING LTD

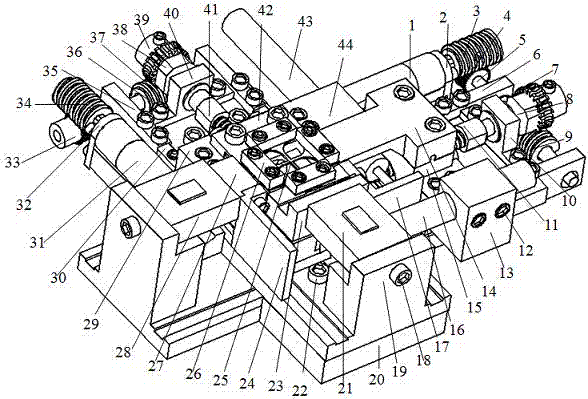

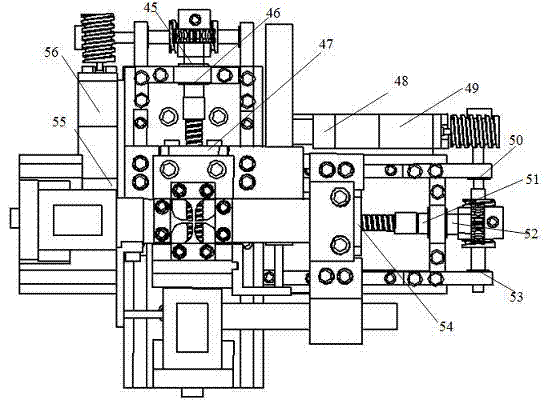

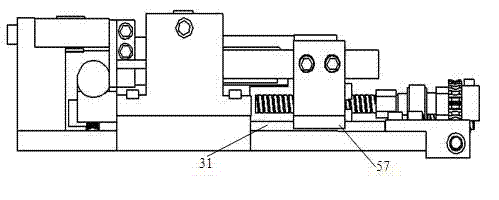

Biaxial stretching/compression mode scanning electron microscope mechanical test device

InactiveCN102645370AApplication rate controllableApplied independentlyMaterial strength using tensile/compressive forcesThree levelBall screw

The invention relates to a biaxial stretching / compression mode scanning electron microscope mechanical test device belonging to an electromechanical material performance test instrument. The biaxial stretching / compression mode scanning electron microscope mechanical test device comprises a biaxial loading and transmission unit composed of a high-precision direct current servo motor, a three-level large-reduction-ratio reducing mechanism, a small-lead ball screw nut pair and a guide rail. With the adoption of the biaxial stretching / compression mode scanning electron microscope mechanical test device, precise application of load can be realized in a quasi-static mode at an extremely low velocity, a plurality of types of material performance test modes containing a uniaxial stretching / compression mode, a biaxial constant speed / variable speed synchronous stretching / compression mode, or a biaxial constant speed / variable speed asynchronous stretching / compression mode, and the like can be started by synchronization precision acquisition of four paths of load / displacement signals and combining a closed-loop control strategy taking a load, displacement or deformation signal as a feedback source, and drive units, transmission units and detection units of each shaft are independent and are not interfered with one another. The biaxial stretching / compression mode scanning electron microscope mechanical test device has a compact and exquisite structure and good compatibility with imaging instruments, such as a scanning electron microscope.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com