Epicyclic gear train

a gear train and cyclic technology, applied in the direction of gearing details, machines/engines, mechanical apparatuses, etc., can solve the problems of deterioration of balance, wear of splined connection between ring gear and spline ring, and difficulty in getting a repeatable balance of the turbo fan assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

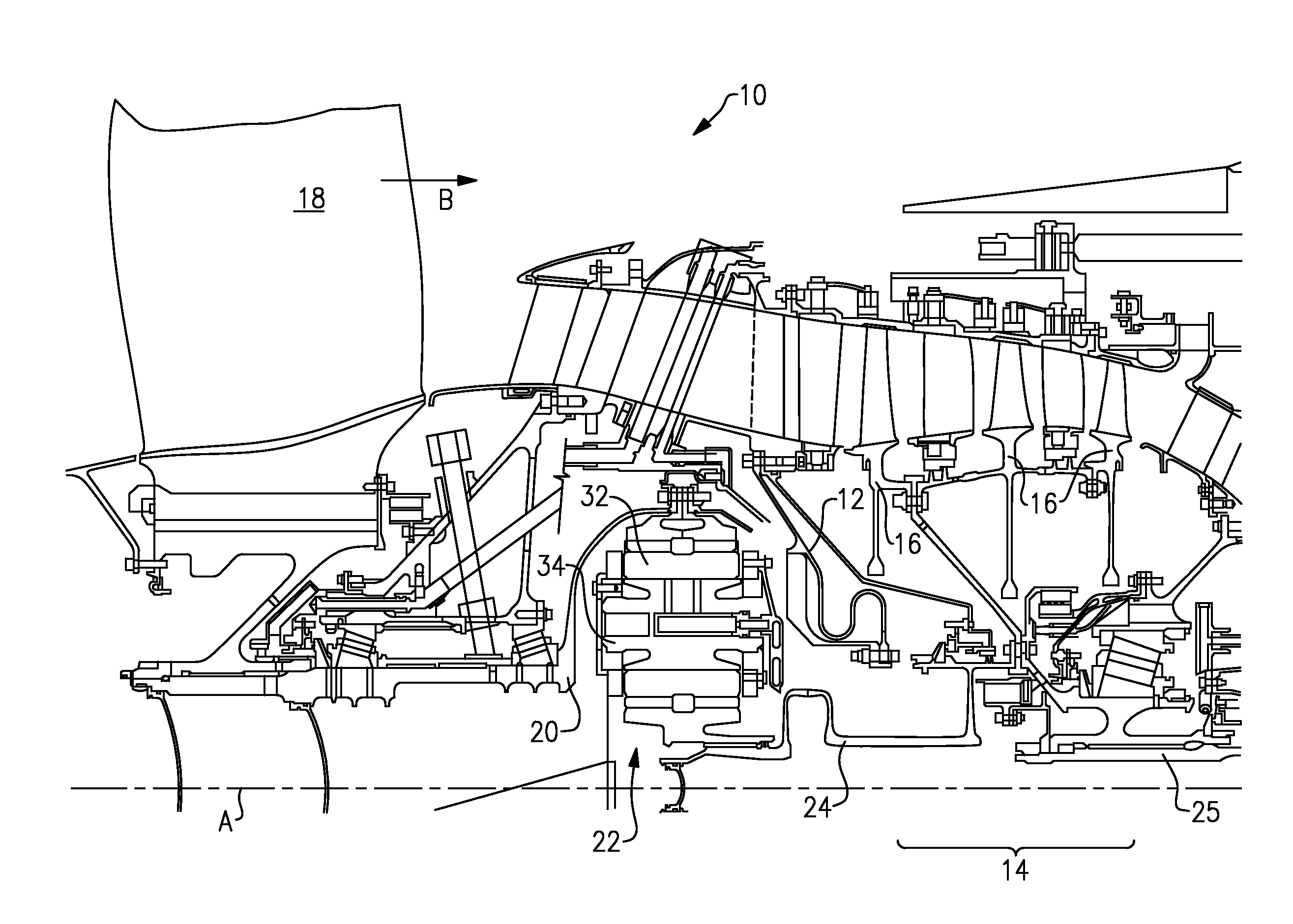

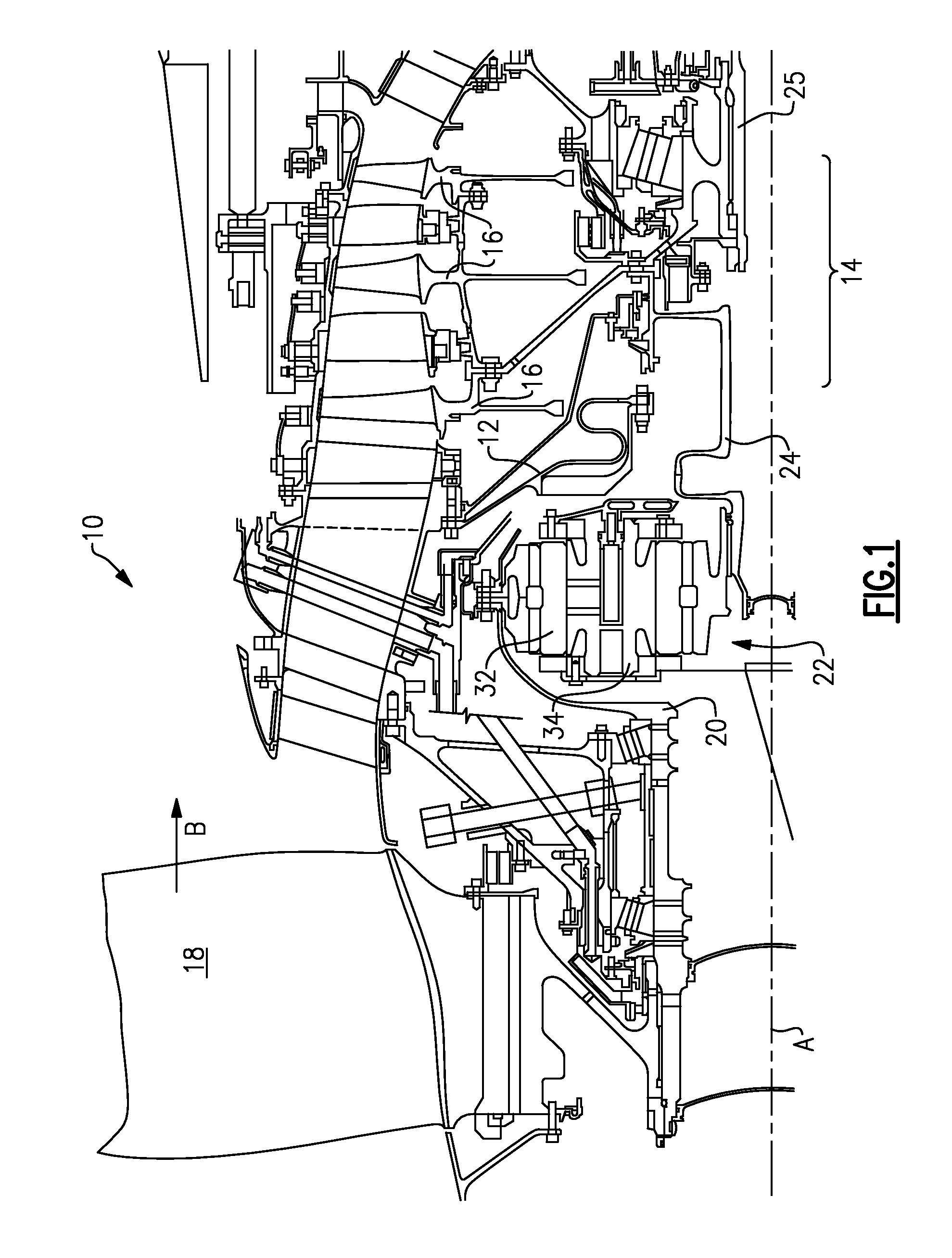

[0031]A portion of a gas turbine engine 10 is shown schematically in FIG. 1. The turbine engine 10 includes a fixed housing 12 that is constructed from numerous pieces secured to one another. A compressor section 14 having compressor hubs 16 with blades are driven by a turbine shaft 25 about an axis A. A turbo fan 18 is supported on a turbo fan shaft 20 that is driven by a compressor shaft 24, which supports the compressor hubs 16, through an epicyclic gear train 22.

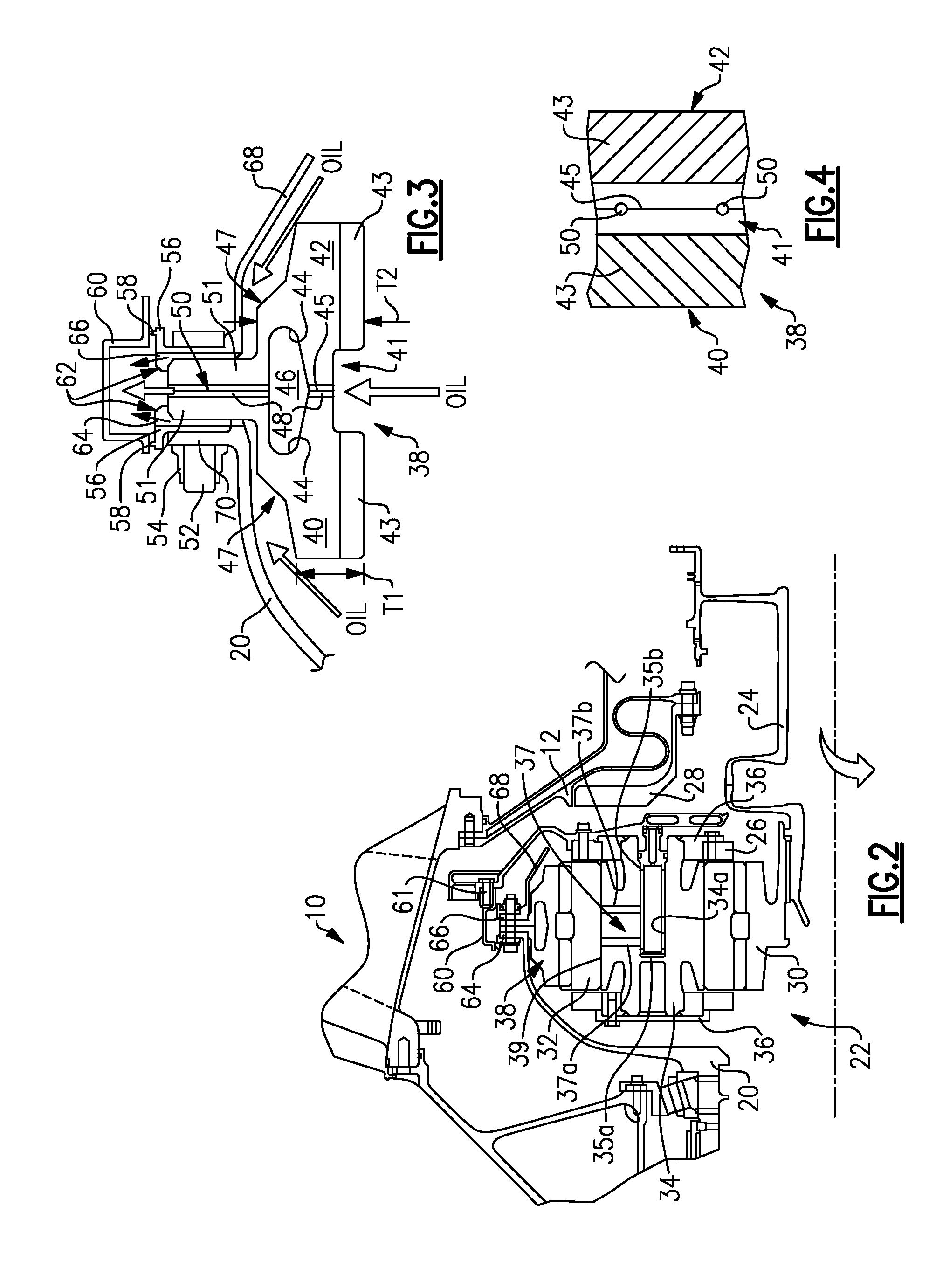

[0032]In the example arrangement shown, the epicyclic gear train 22 is a star gear train. Referring to FIG. 2, the epicyclic gear train 22 includes a sun gear 30 that is connected to the compressor shaft 24, which provides rotational input, by a splined connection. A carrier 26 is fixed to the housing 12 by a torque frame 28 using fingers (not shown) known in the art. The carrier 26 supports star gears 32 using journal bearings 34 that are coupled to the sun gear 30 by meshed interfaces between the teeth of sun and star ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com