Biaxial stretching/compression mode scanning electron microscope mechanical test device

A compression mode, SEM technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of SEM vacuum compatibility and electromagnetic compatibility cannot be determined, SEM structure is compatible, and the overall size of the machine is large, etc. problem, to achieve the effect of controllable application sequence, independent application method and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

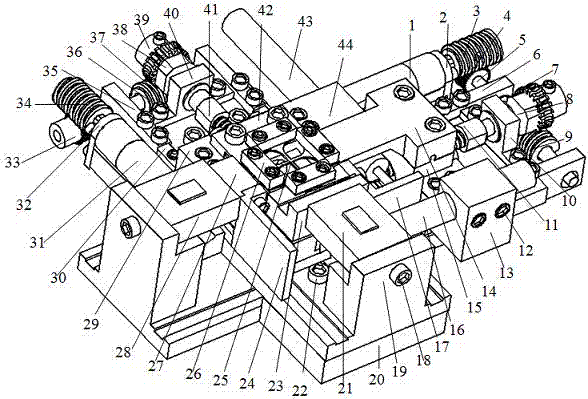

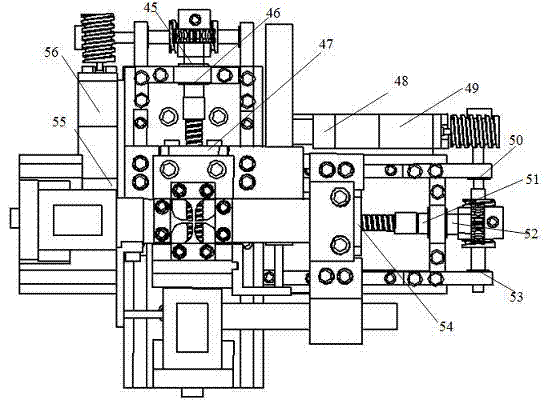

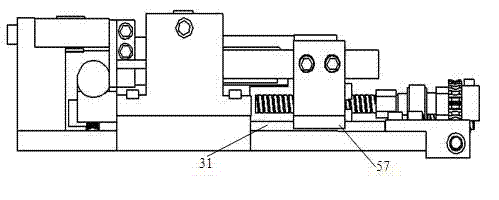

[0029] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0030] see Figure 1 to Figure 5 , the mechanical testing device under the biaxial tension / compression mode scanning electron microscope of the present invention includes a bidirectional loading and transmission unit, a bidirectional signal detection and control unit, a clip body unit and a base unit, and the bidirectional loading and transmission unit includes Precision DC servo motor, three-stage deceleration mechanism, ball screw nut-rail transmission mechanism, taking one-way drive loading as an example, the precise rotary motion output by DC servo motor-Ⅰ1 can reduce the speed and increase the torque through the three-stage deceleration mechanism, And the rotary motion is converted into precise linear motion through the precision ball screw nut-rail transmission mechanism; the precision ball screw nut-rail tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com