Patents

Literature

143 results about "Biaxial tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

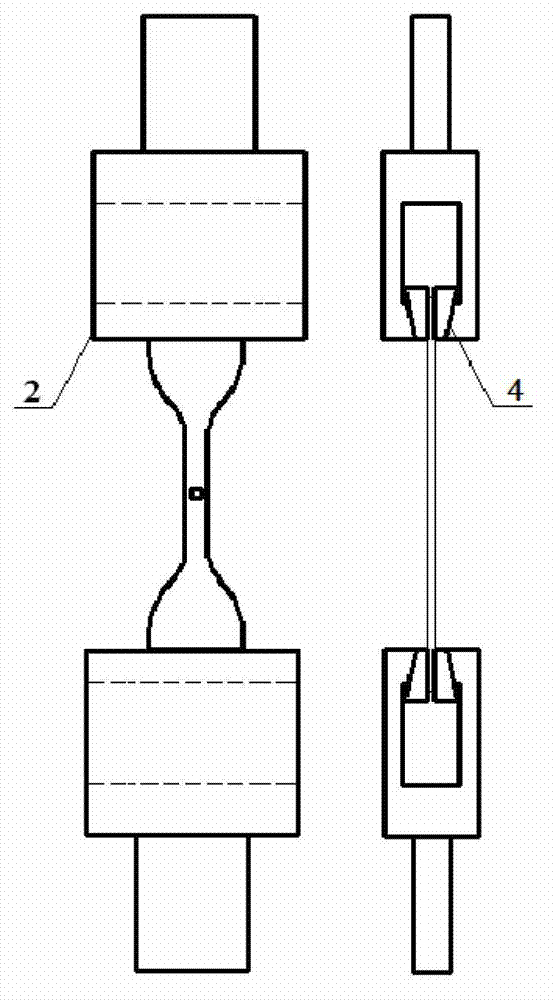

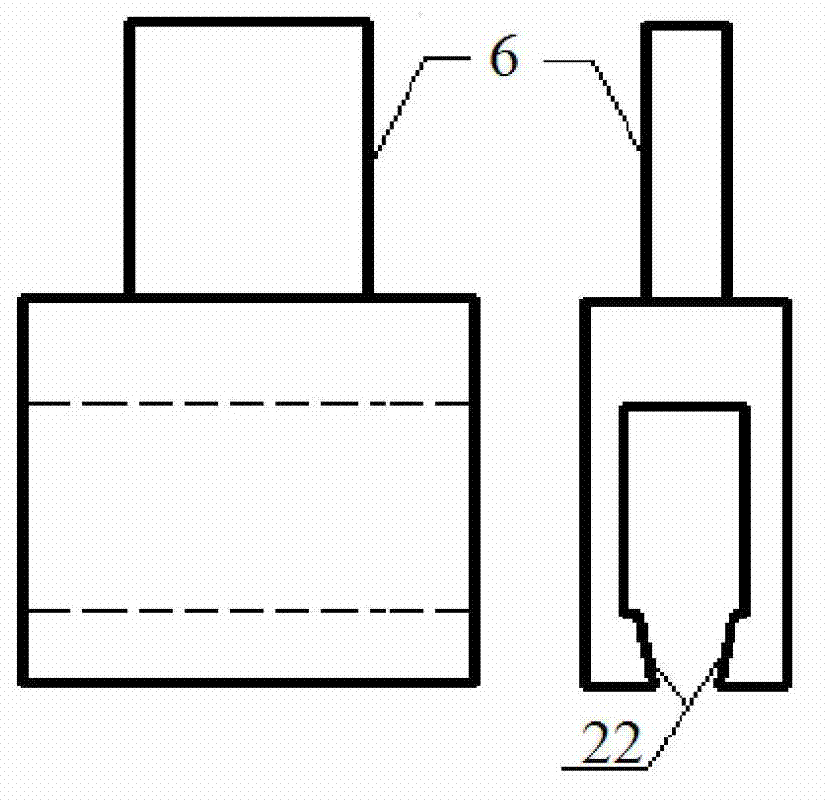

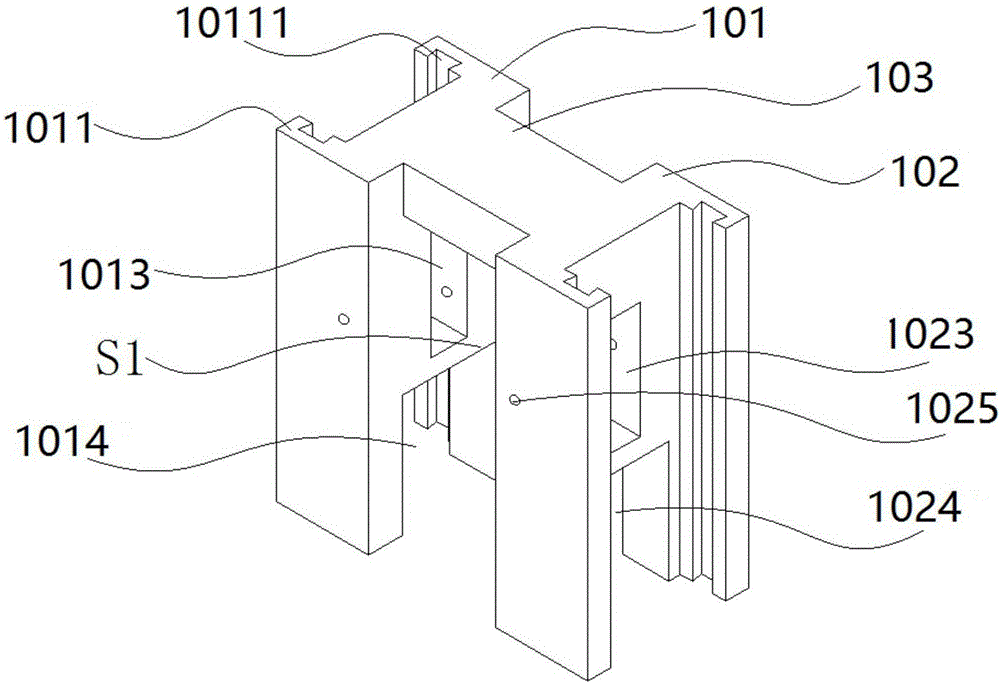

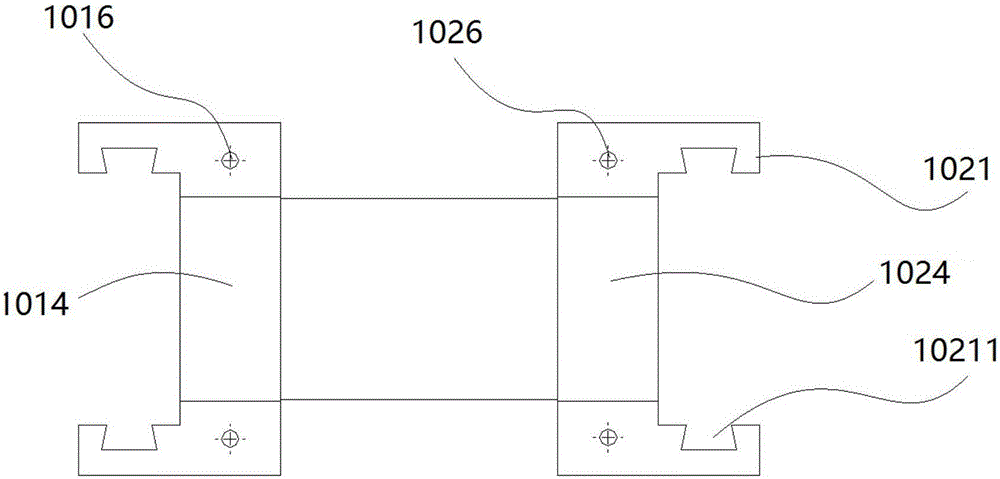

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

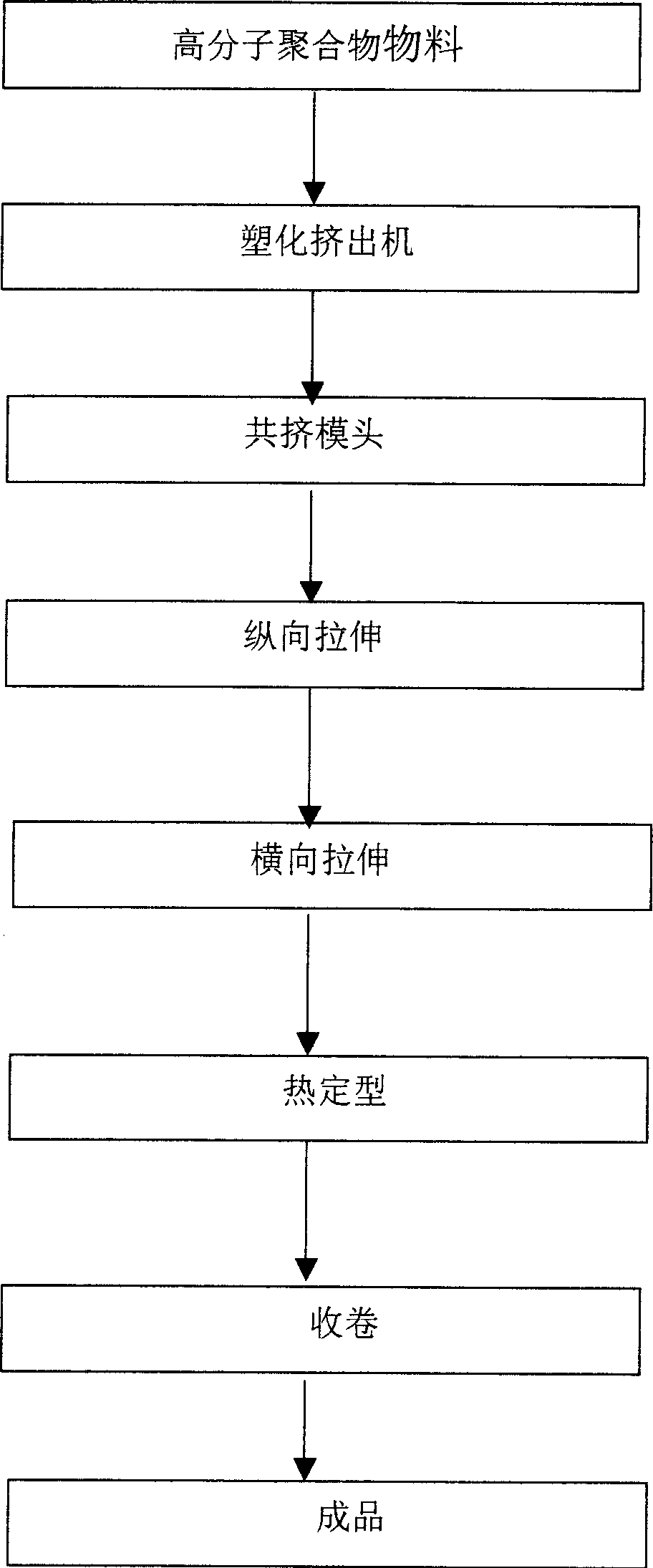

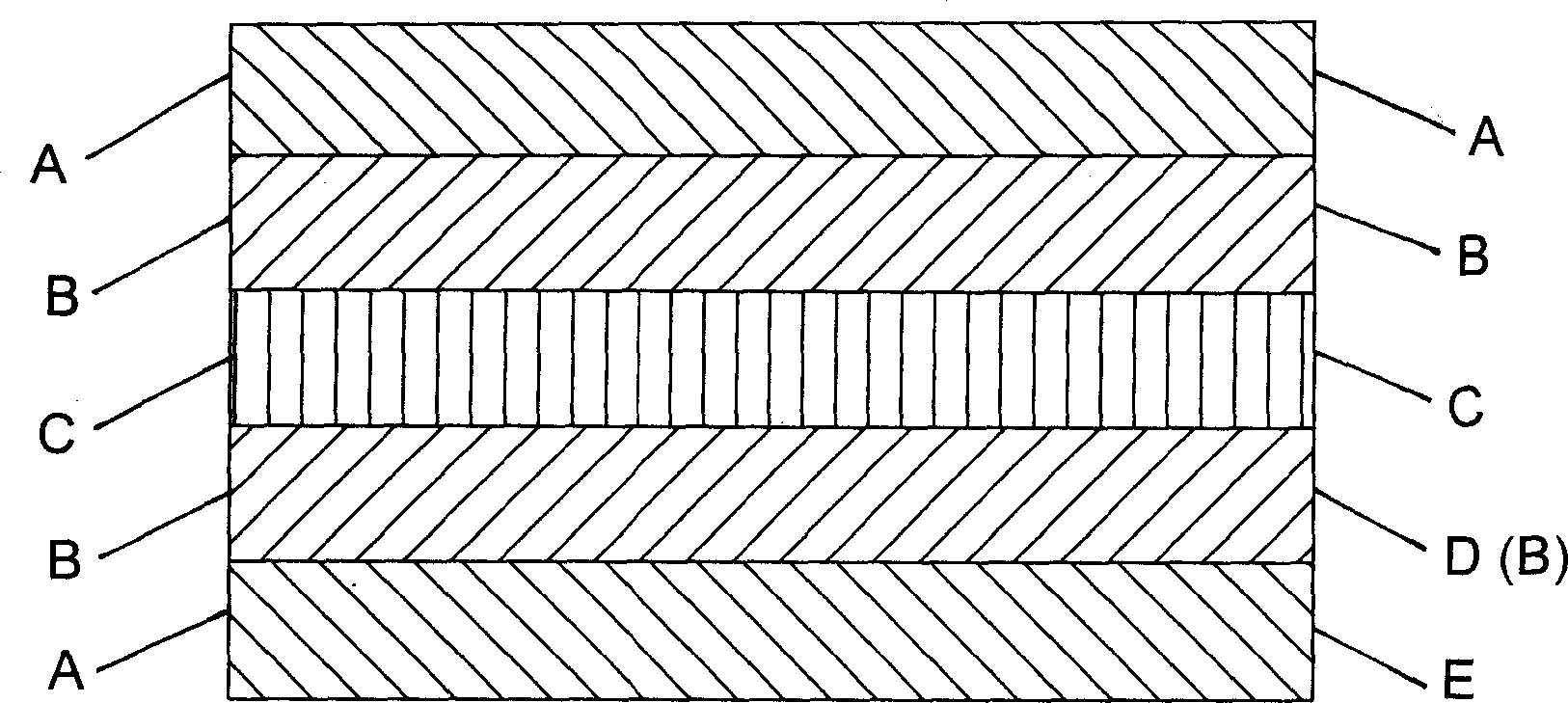

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

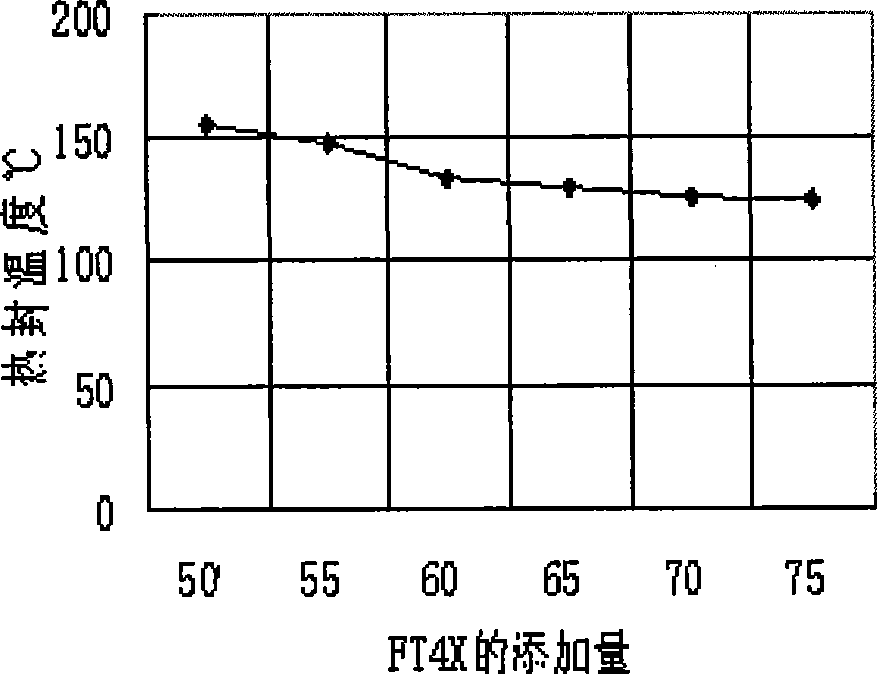

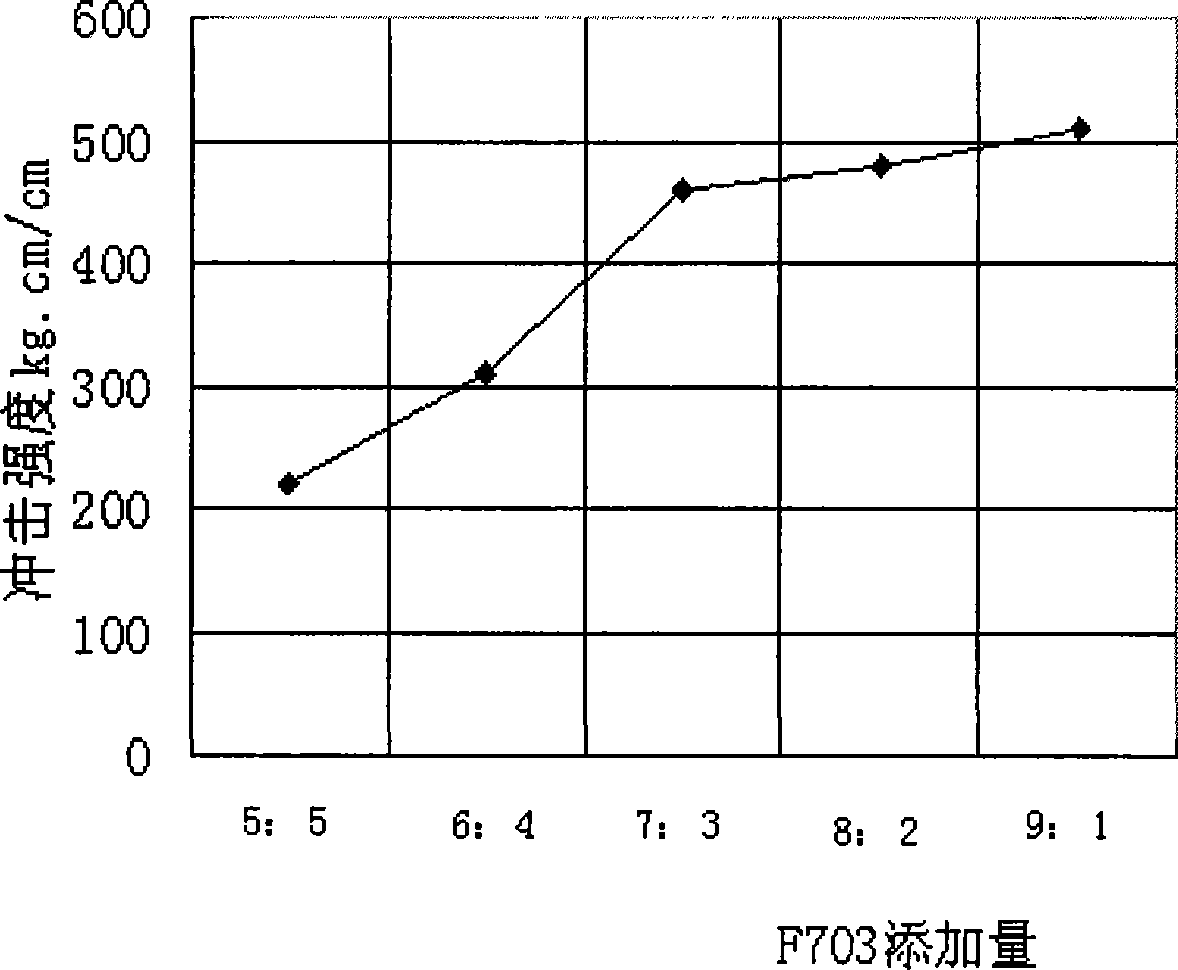

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

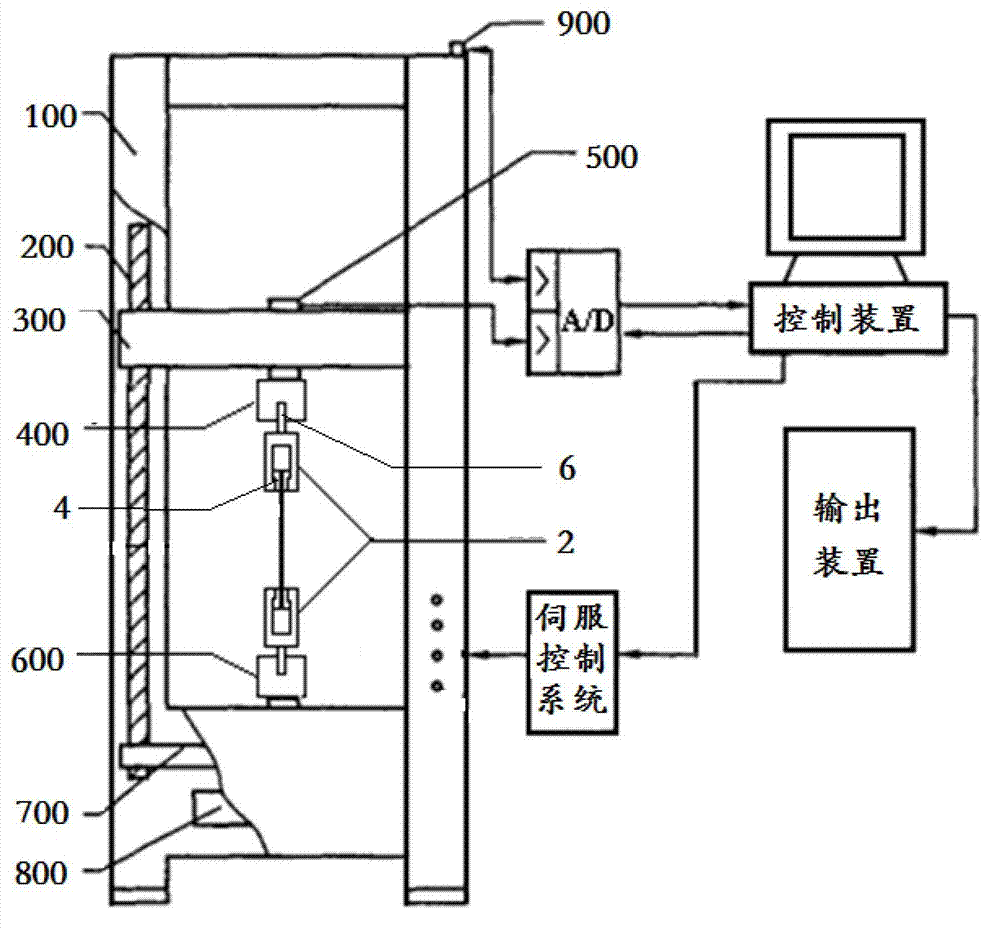

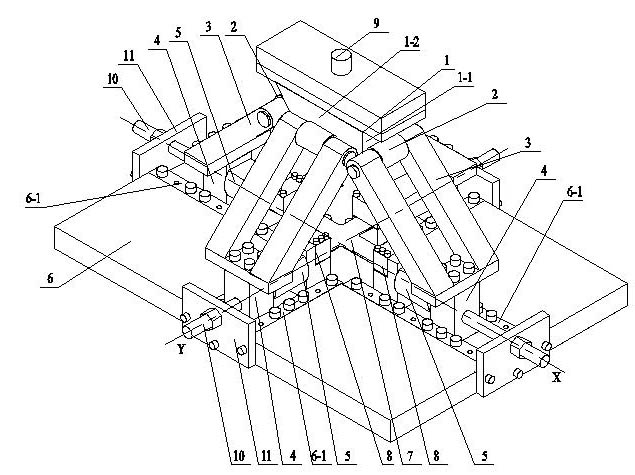

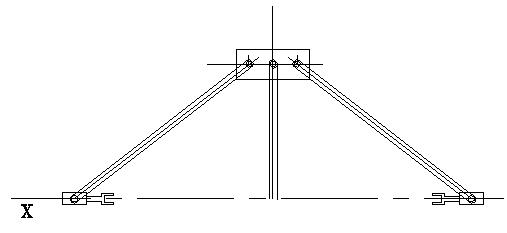

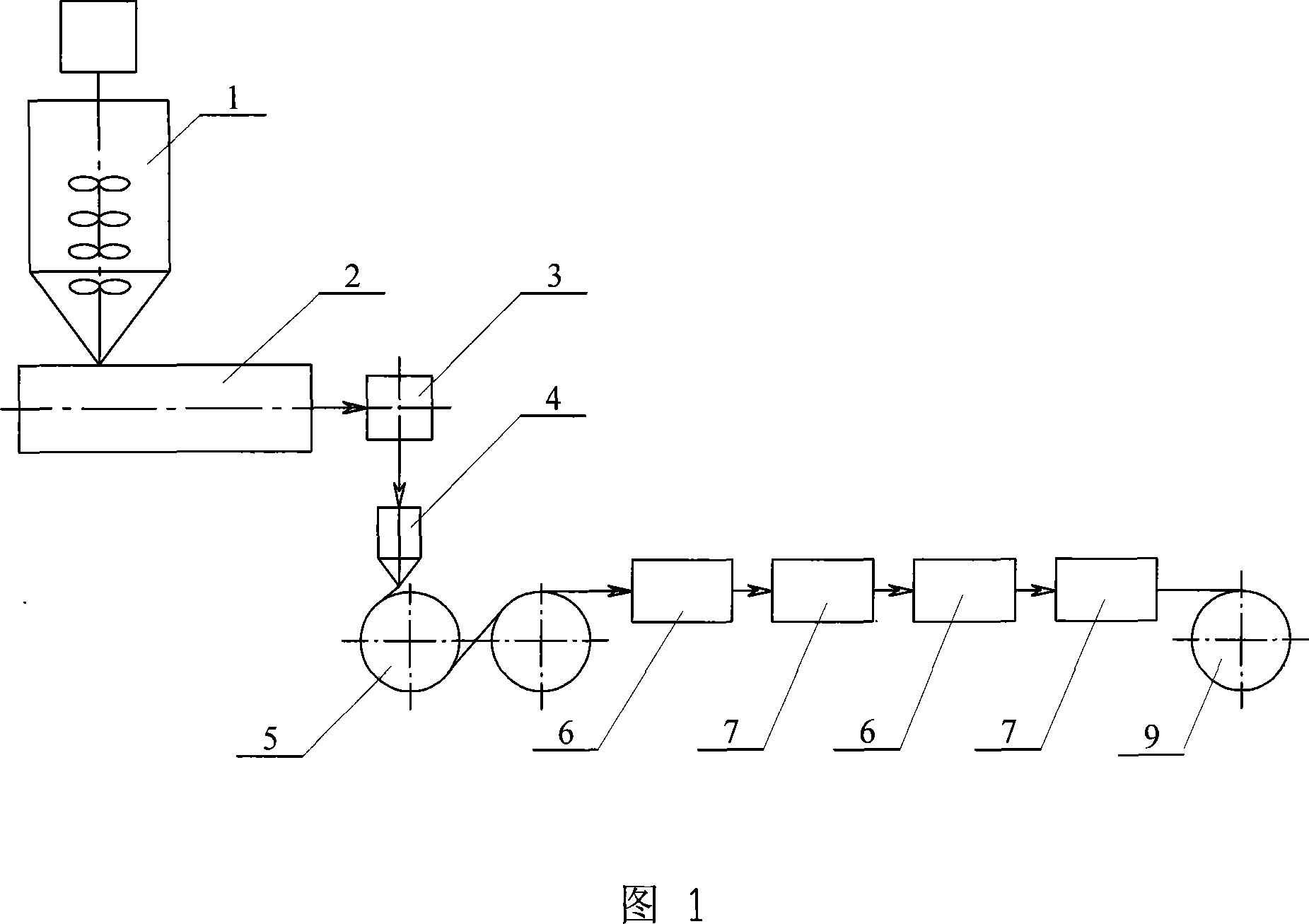

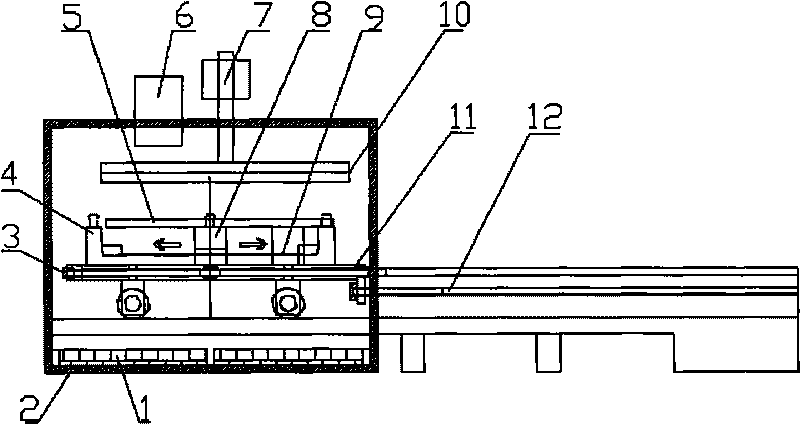

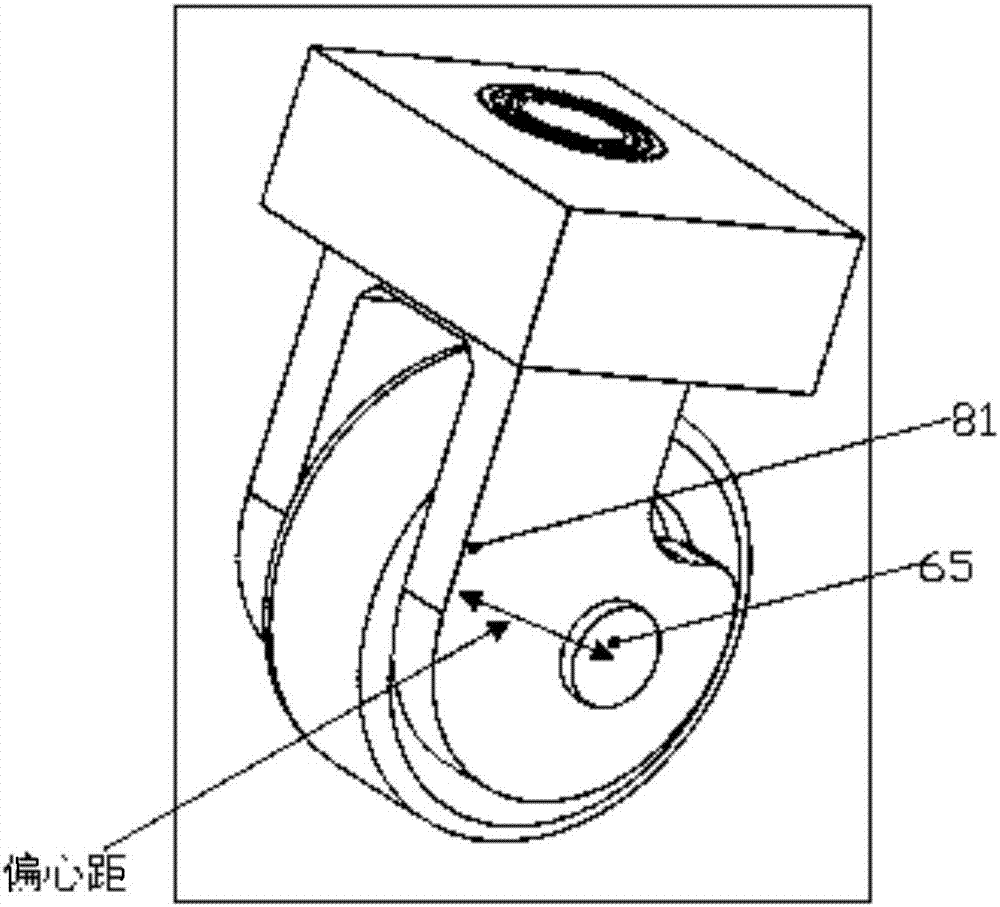

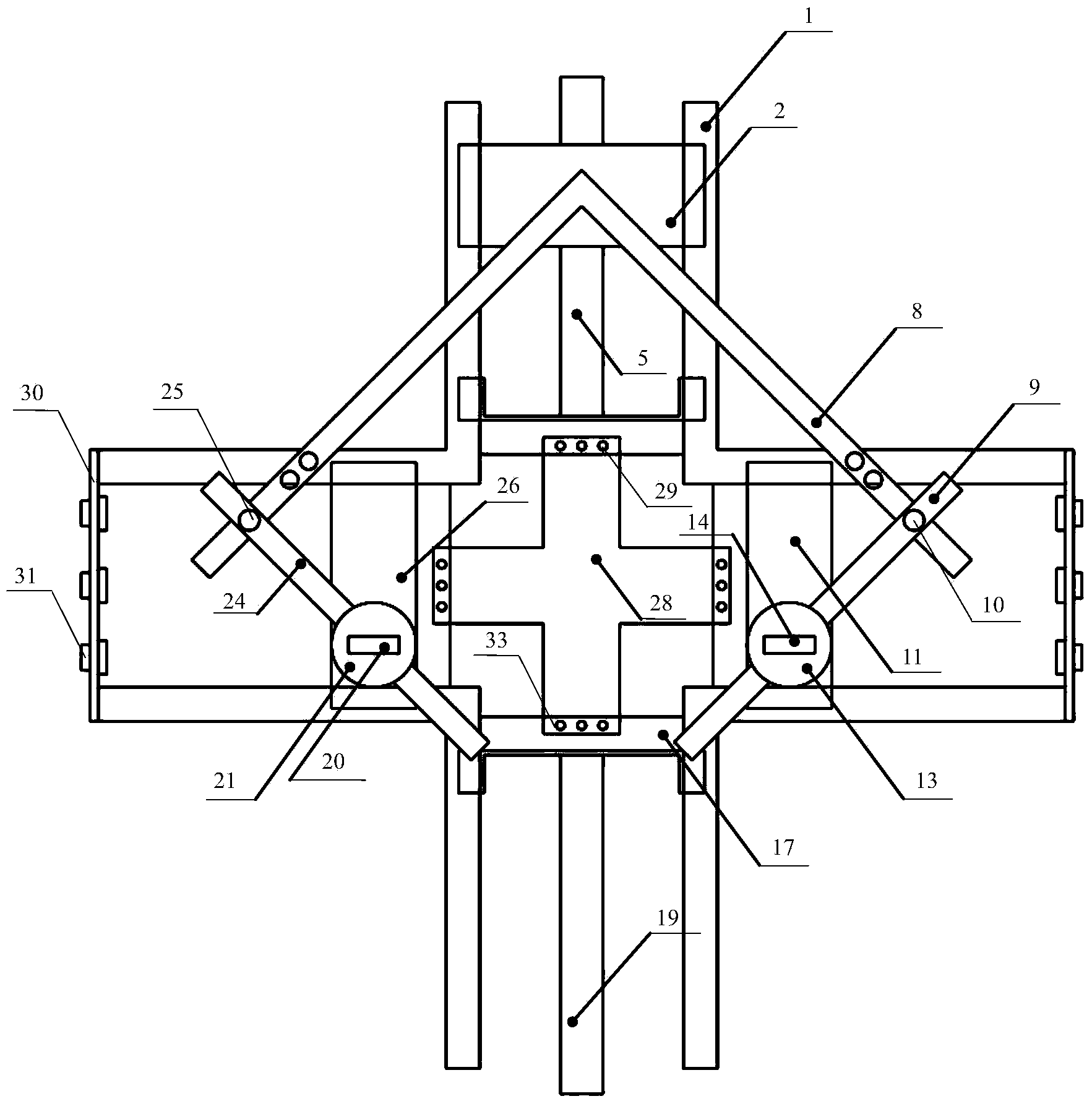

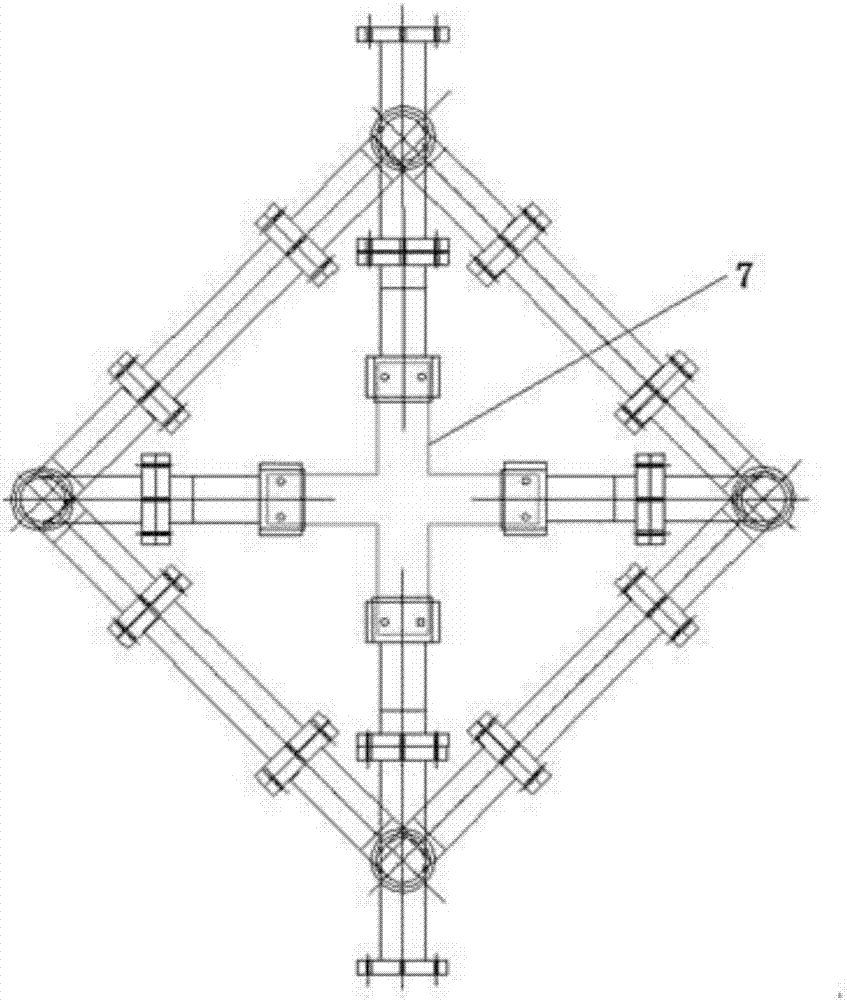

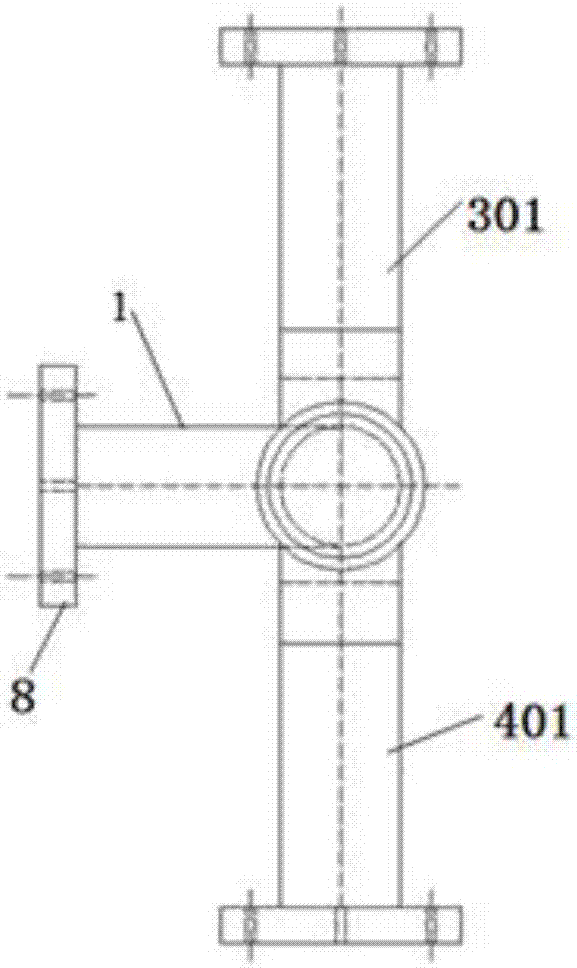

Mechanical biaxial tension tester with variable proportion loading

InactiveCN101907538AReduce frictionRatio unchangedMaterial strength using tensile/compressive forcesCruciformTension compression

The invention discloses a mechanical biaxial tension tester with variable proportion loading, relating to a biaxial tension tester. The invention solves the problem that the traditional biaxial tension testing device can not realize variable proportion loading under a complex loading path. In the invention, a slanting slide block is an inverted trapezoidal quadrangular frustum pyramid, a workbench is provided with a cruciform chute, a cruciform test piece is arranged above the cruciform chute, four ends of the cruciform test piece are respectively and fixedly connected with a clamping head, a tension-compression sensor is fixedly connected to the outer end surface of each clamping head, the outer end of each tension-compression sensor is fixedly connected with a horizontal slide block, each horizontal slide block is installed on the workbench, the lower end of each slant beam is fixedly connected with a horizontal slide block, a rolling bearing is installed at the upper end of each slant beam, and each rolling bearing is contacted with a corresponding trapezoidal inclined plane of each slant beam and rolls on the corresponding trapezoidal inclined plane of each slant beam. The invention is suitable for a tension test of the cruciform test piece.

Owner:HARBIN INST OF TECH

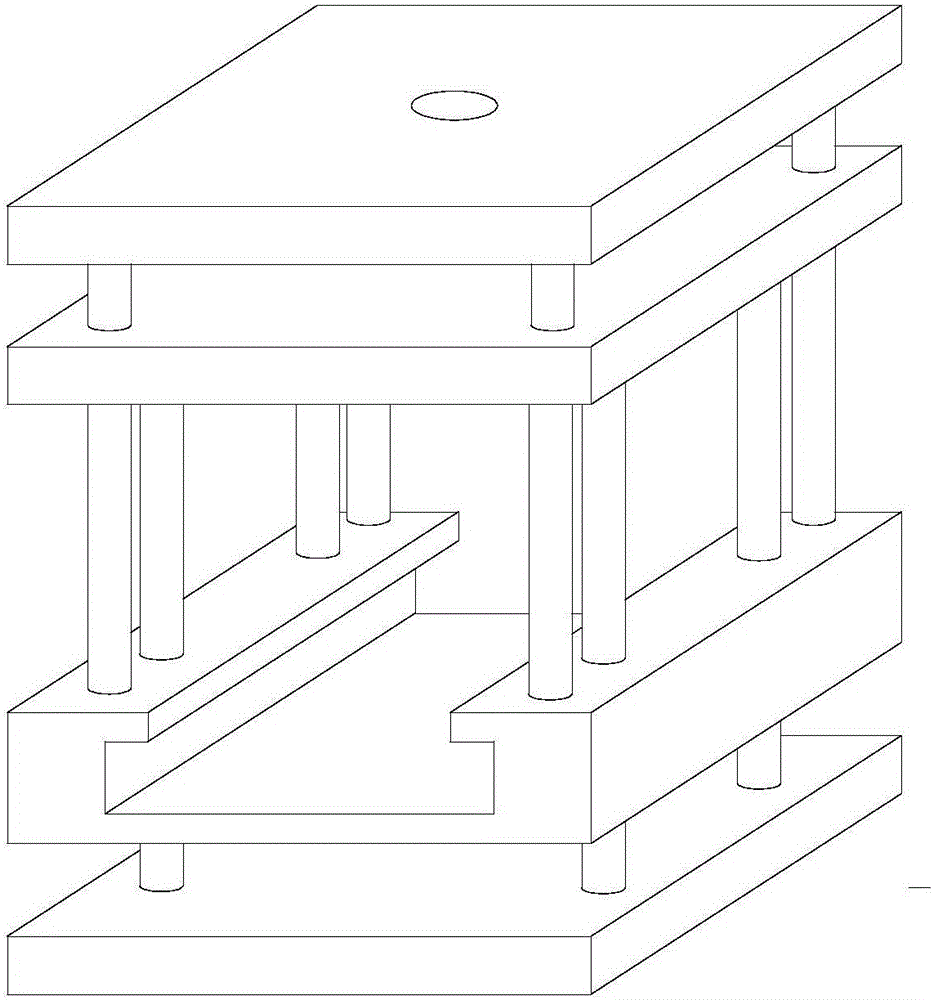

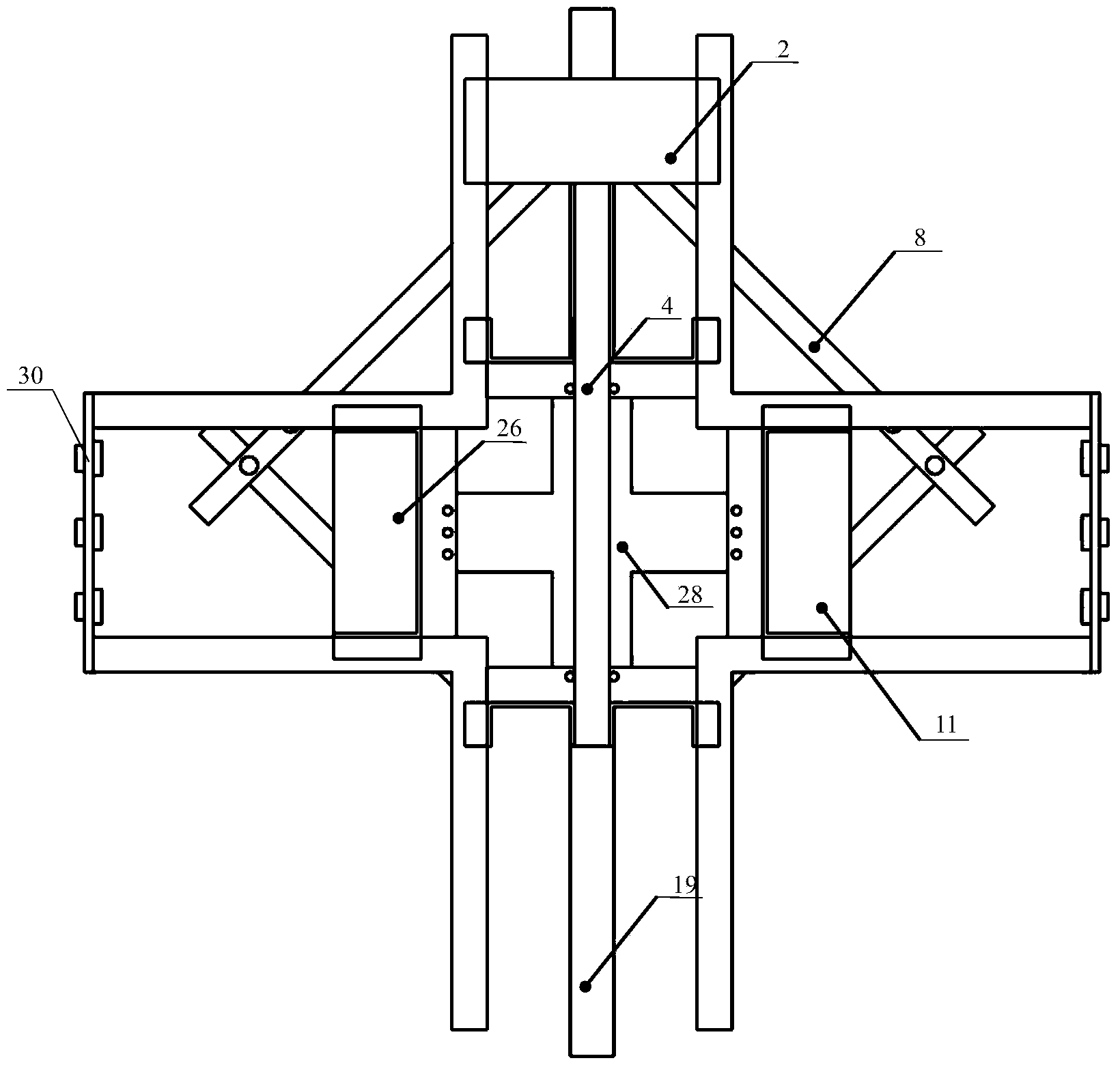

Biaxial tension test device for testing performance of sheet metal

InactiveCN102706731ASimple structureEasy maintenanceUsing optical meansStrength propertiesSoftware engineeringEngineering

The invention discloses a biaxial tension test device for testing the performance of sheet metal. The biaxial tension test device comprises an upper connecting structure, a lower connecting structure, a proportion adjusting mechanism, a fixture slide block mechanism and connecting rods. The biaxial tension test device with a simple pure mechanical structure is easy to maintain and mount, requires a relatively low cost and can effectively achieve a biaxial tension goal; besides, the loading proportion in two mutually vertical directions is convenient to adjust, and each connecting bolt can be adjusted to be horizontal with a chassis, so as to guarantee that specimens are in horizontal positions; and the biaxial tension test device has relatively high test accuracy and can effectively control failure time of the specimens.

Owner:HENAN POLYTECHNIC UNIV

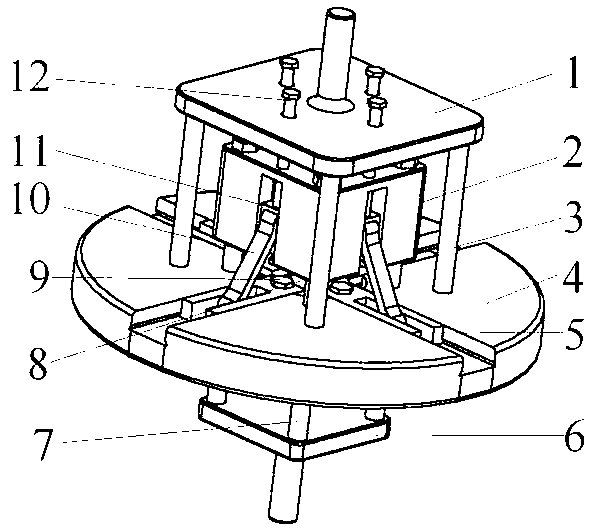

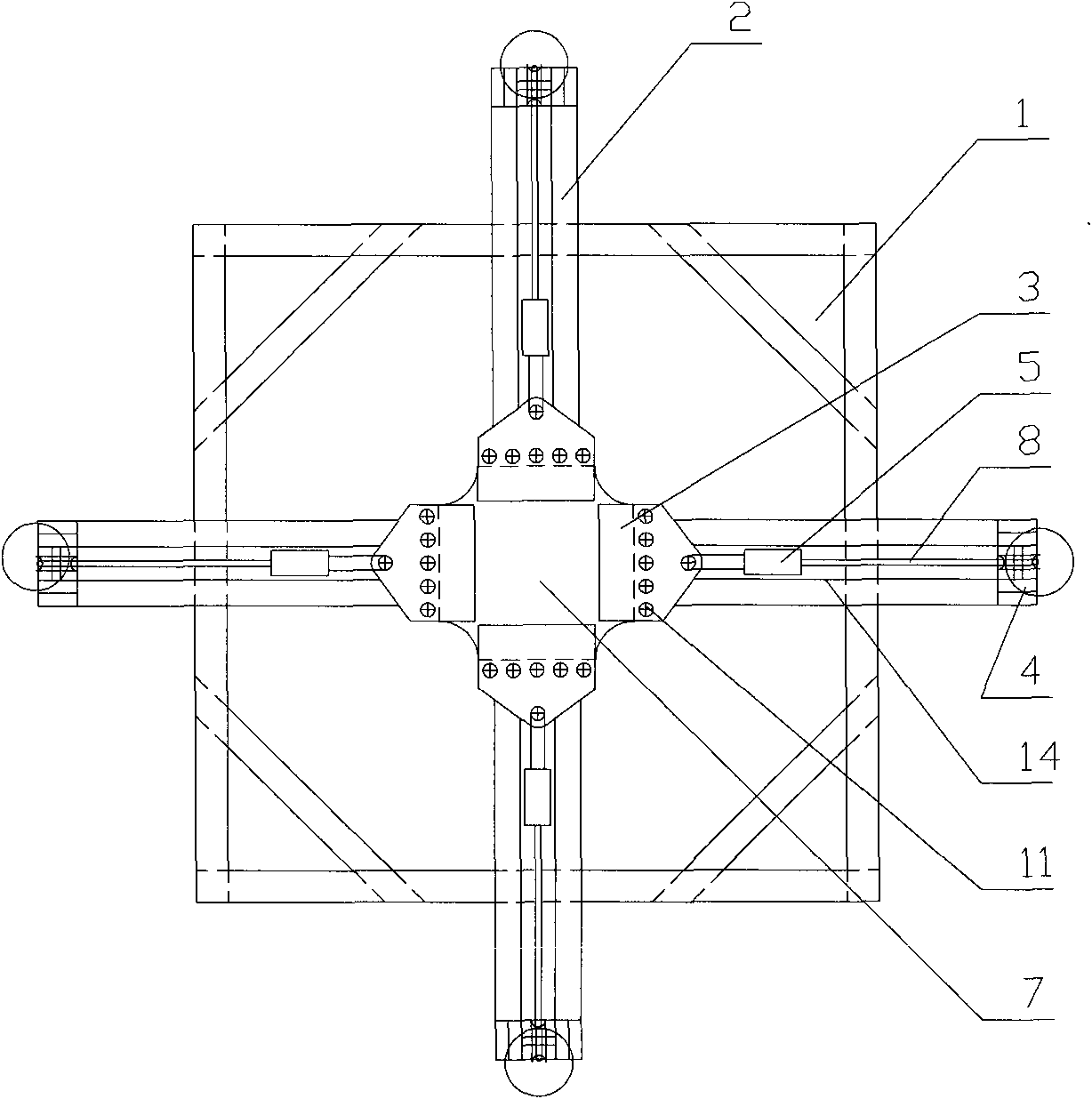

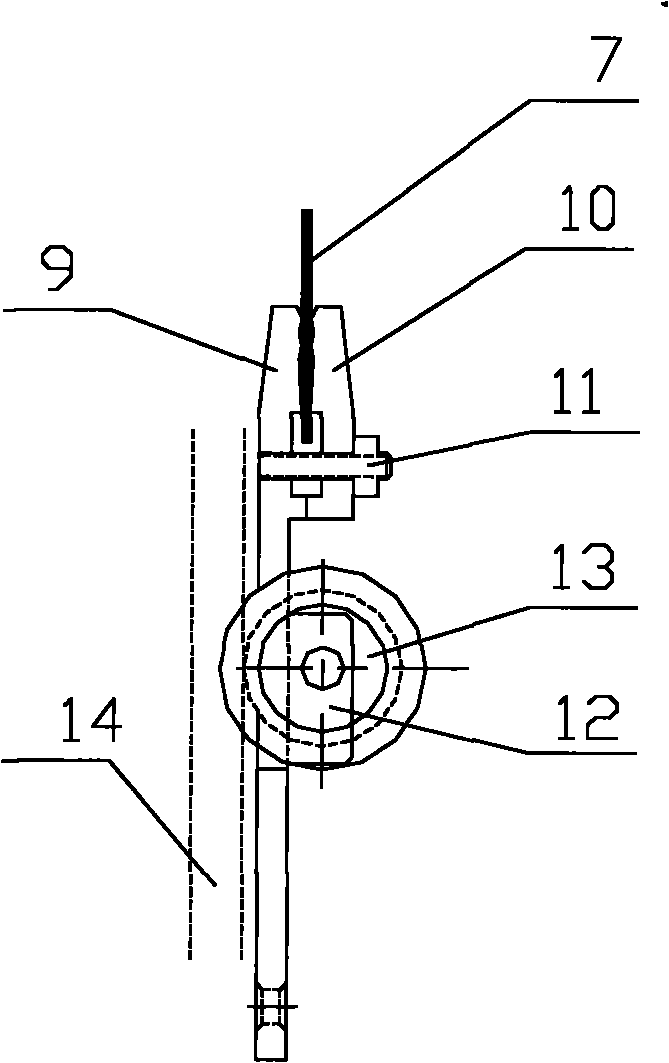

Material micro-mechanical property biaxial tension-fatigue test system and test method thereof

ActiveCN104913974ANovel structureCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFatigue loadingScientific instrument

The invention relates to a material micro-mechanical property biaxial tension-fatigue test system and a test method thereof, and belongs to the field of precise scientific instruments. The test method is characterized in that orthogonal tensile load is applied to a test piece to make two mutually vertical tensions exist in one plane, and fatigue load can also be applied to the test piece on the basis of the tensile load in order to research the micro-mechanical properties of a material under different load forms and load sizes. The system is composed of a precise loading-transmitting unit, a fatigue unit, a mechanics and deformation signal detection unit, and a test piece clamping unit. The test system has the advantages of novel and compact structure, respective realization of uniaxial tension test, biaxial tension test, uniaxial tension-fatigue test and biaxial tension-fatigue test, good compatibility with an optical microscope, and dynamic research of the relationship between the microstructure of the material and the deformation damage mechanism under tension-fatigue load conditions.

Owner:JILIN UNIV

Biaxial tension polypropylene synthetic paper and manufacture method thereof

InactiveCN101015974AReduce adhesionLow densityFlexible coversWrappersPolypropylene compositesPolymer science

A method for producing bidirectional drawing polypropylene composite paper is characterized in foam or specific porous thin layer. The inventive bidirectional drawing polypropylene composite paper has three-layer extrusion, while two surface layers are pearl layer or extinction layer, the pearl layer is PP and adhesive resistant, the extinction layer is extinction mother material, the corn layer is inorganic foaming layer which comprises polypropylene resin, pearl mother material and static resistant. The invention fuses and extrudes corn layer and surface layer, while the extruded corn layer fusion is extruded via a metering pump to be filtered via a filter network to enter into mould head, and the extruded surface material fusion is directly fed into the mould head, to be cooled and shaped via a cooling roller, and the sheets are fed into longitudinal drawer and transverse drawer, the membrane enters into a drawer to be flattened and on-line measured at thickness, to adjust the thickness, cut edge, and corona, to be coiled, cut, checked and packed.

Owner:QUANZHOU LICHANG PLASTIC

Continuous polyethylene dissolving process in a double screw extructor to prepare lithium ion cell diaphragm

The present invention is continuous polyethylene dissolving process in a double screw extruder to prepare diaphragm for lithium ion cell. The preparation process includes dissolving super high molecular weight polyethylene and high density polyethylene in mineral oil, extruding out through a slot to form belt, mineral oil extraction, biaxial tension, mineral oil extraction for the second time and settling to form the diaphragm. The diaphragm has the features of homogeneous pores, high porosity and high strength, and the process is simple and low in cost.

Owner:HARBIN COSLIGHT POWER CO LTD

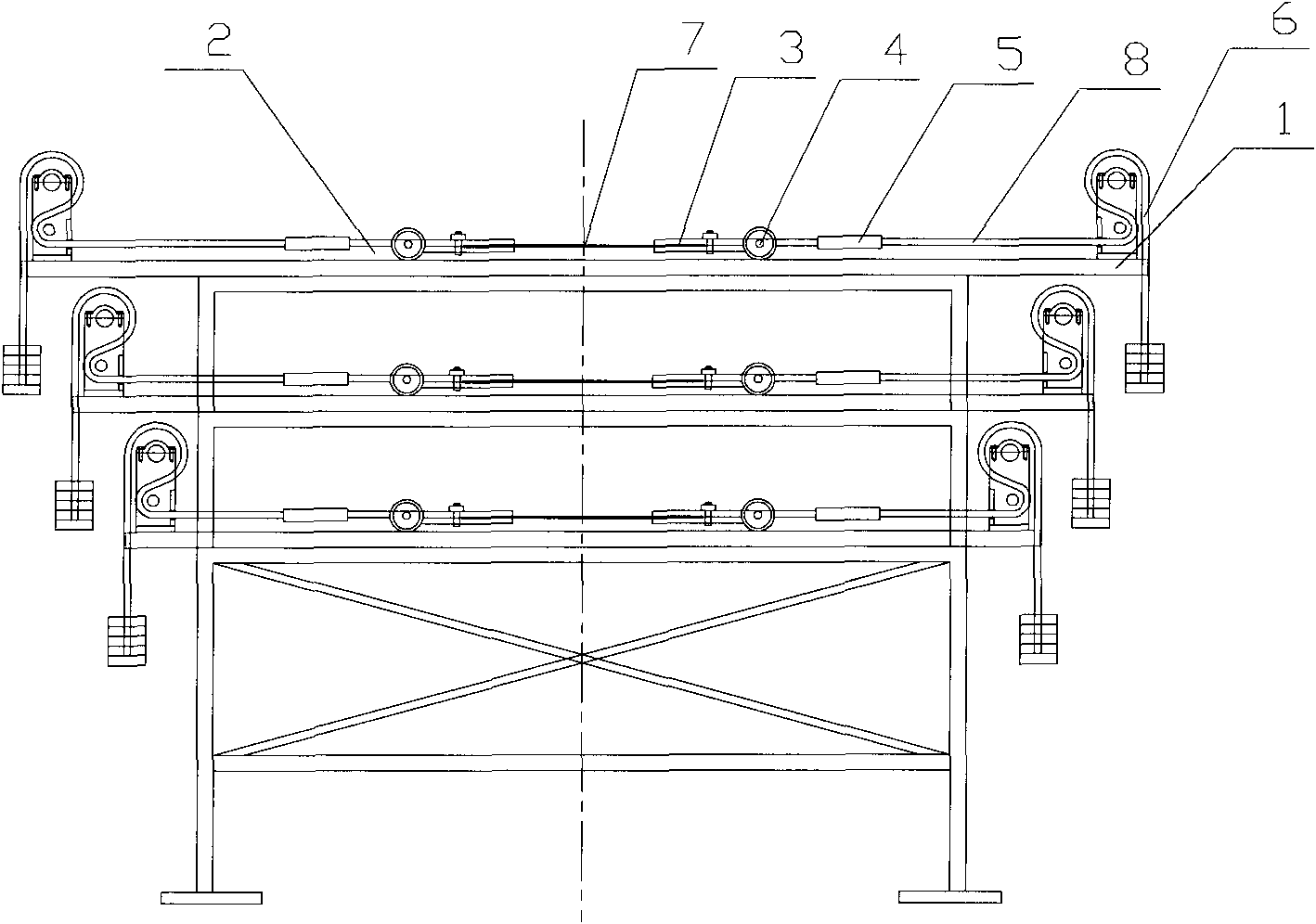

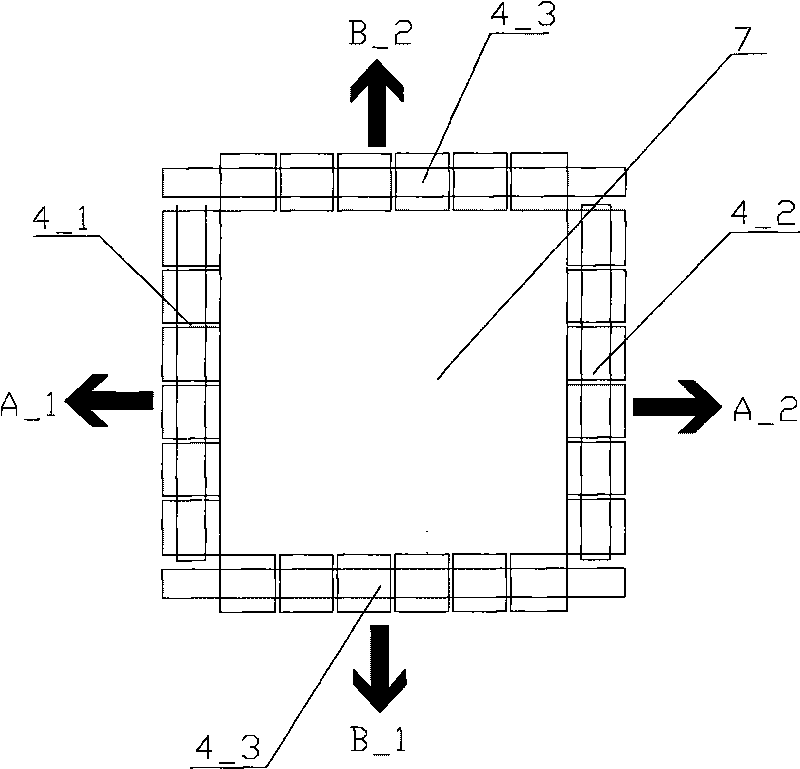

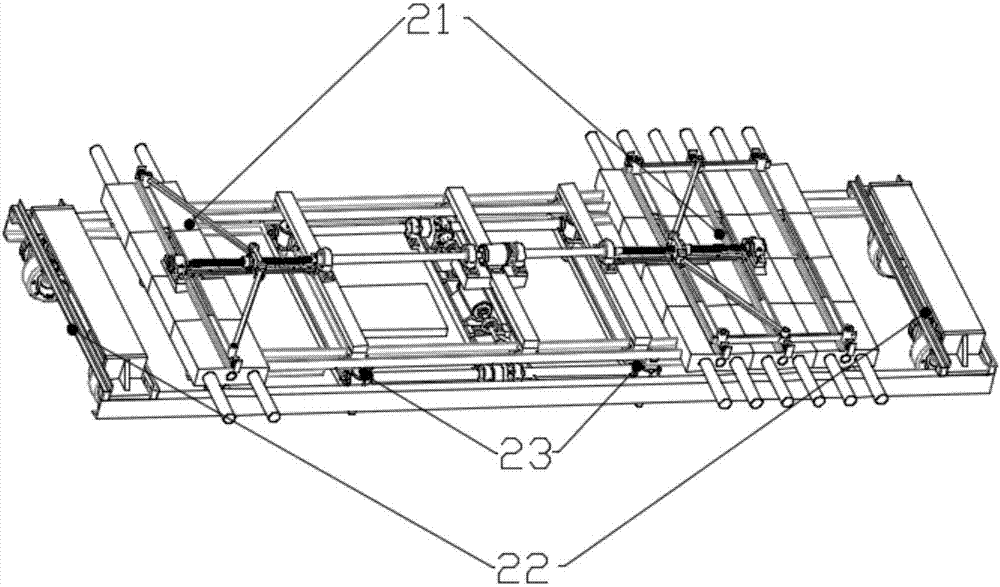

Geosynthetic biaxial tension creep tester

InactiveCN101776553ASolve the problem of long time-consuming and low efficiency of creep testImprove long-term stabilityMaterial strength using tensile/compressive forcesEngineeringGeosynthetics

The invention provides a geosynthetic biaxial tension creep tester. The tester comprises a main frame platform and a cross-shaped tensile testing device arranged on the main frame platform, wherein the cross-shaped tensile testing device comprises four groups of clamping devices, four groups of guiding devices, four groups of displacement sensors and four force-applying devices; the clamping devices are used to clamp the four edges of a test-piece placed in the middle of the cross-shaped tensile testing device and separately connected with the four force-applying devices arranged at the four ends of the cross-shaped tensile testing device through steel cables; the four groups of clamping devices can slide to the force-applying devices separately along the four groups of guiding devices; and the displacement sensors are separately arranged between the clamping devices and the force-applying devices. The geosynthetic biaxial tension creep tester of the invention can be used to perform creep test in any complex stress-strain loading path under the action of biaxial tensile loading, and compared with the easy uniaxial tension test, the creep test is more similar to the actual stress-strain state in engineers.

Owner:HOHAI UNIV

Pre-coating film and preparation method for the same

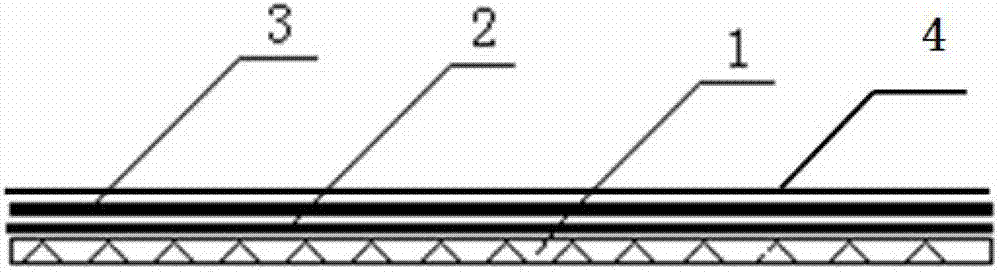

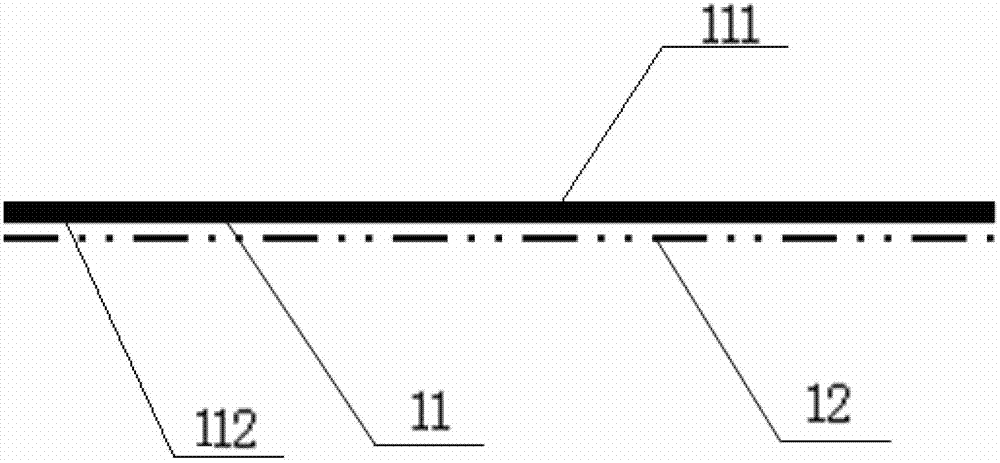

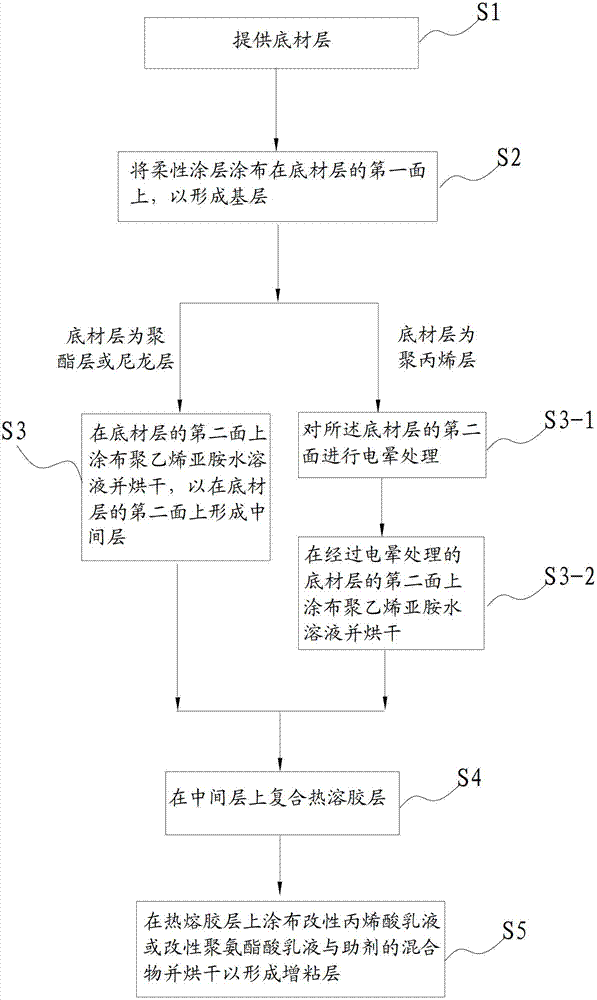

ActiveCN102732174AImprove adhesionMeet the requirements of subsequent processing proceduresFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyesterPolyurethane dispersion

The present invention provides a pre-coating film and a preparation method for the pre-coating film. The pre-coating film comprises: a substrate layer, wherein the substrate layer comprises a bottom material layer and a flexible coat, wherein the bottom material layer is a biaxial tension polyester layer, a biaxial tension nylon layer or a biaxial tension polypropylene layer, and the flexible coat is arranged on the first surface of the bottom material layer, and is formed from a mixture comprising a polyurethane dispersion and a curing agent; a middle layer, wherein the middle layer is arranged on the second surface of the bottom material layer, and is formed from a polyethylenimine aqueous solution; a hot melt adhesive layer, wherein the hot melt adhesive layer is arranged on the middle layer, and is formed from EVA, EEA, EAA or EMA; and a viscosity increasing layer, wherein the viscosity increasing layer is arranged on the hot melt adhesive layer, and is formed from a mixture comprising a modified acrylic acid emulsion or a modified polyurethane emulsion and an assistant agent. According to the present invention, with arrangement of the flexible coat, the surface of the pre-coating film has a soft touch feeling; with the viscosity increasing layer, the adhesion between the pre-coating film and the printed product can be enhanced, the requirements of the subsequent processing steps are met, and the use range of the pre-coating film is expanded.

Owner:张家港保税区康得菲尔实业有限公司

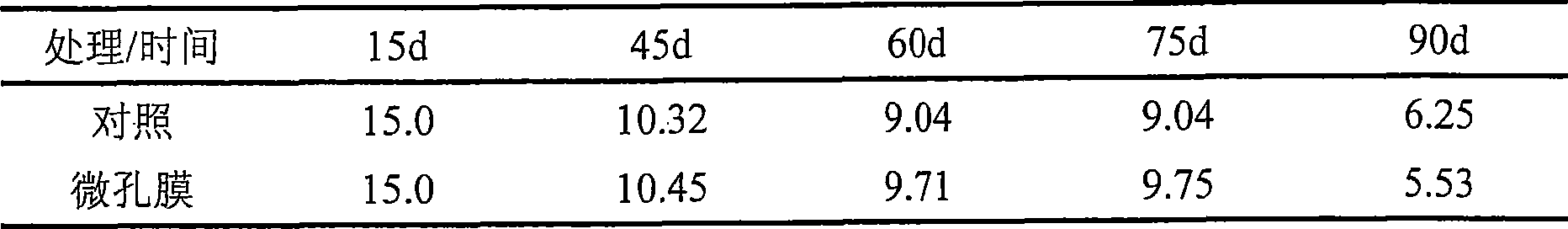

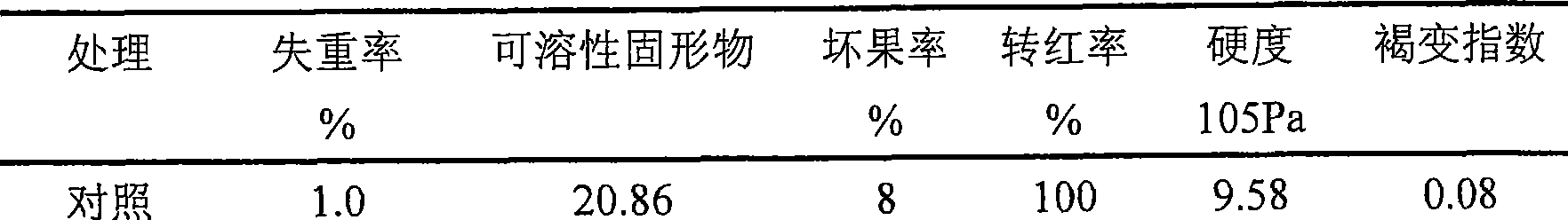

Micropore preservative film for garden stuff

InactiveCN101497712AEffective regulationStable stateFlat articlesFruits/vegetable preservation by coatingLow-density polyethylenePorosity

A fruit and vegetable millipore preservative film comprises the following components of 100 portions of low-density polyethylene resin, 20 portions of ethene-vinyl acetate resin, 10 portions of linear polyethylene resin, 13 portions of superfine calcium carbonate, 8 portions of superfine medical stone, one portion of Tween 80, 0.5-1.5 portions of antifogging agent, 1.5 portions of SWJU-1 anlistatig, 0.5 portions of antioxidizer1076 and 0.6 portions of polyethylene wax. After organized processing by acetic acid, inorganic functional materials are used to prepare master batch together with polyethylene base material and other functional components by coextrusion; the materials are mixed through diatexis according to the proportion; blow molding is carried out on a single screw extruder; a film is formed through bidirectional biaxial tension in a longitudinal and transverse way; and the rotate speed of the screw and the traction speed are adjusted to ensure that the aperture of the millipore of the formed film is 0.1-3 microns, and the poriness is 40-55 percent. The manufactured film has bidirectional adjusting ability of O2 and CO2, and therefore, when used for small-package storage, the film can spontaneously adjust air and has good moisture permeability without condensation of moisture in the bag.

Owner:天津市食品加工工程中心 +1

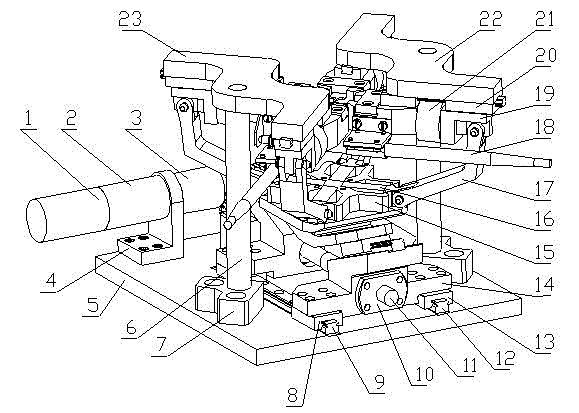

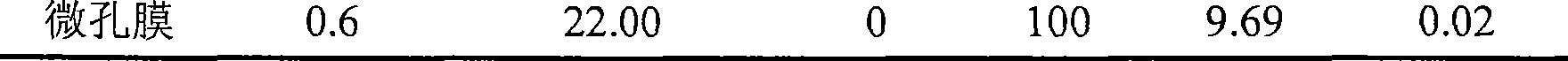

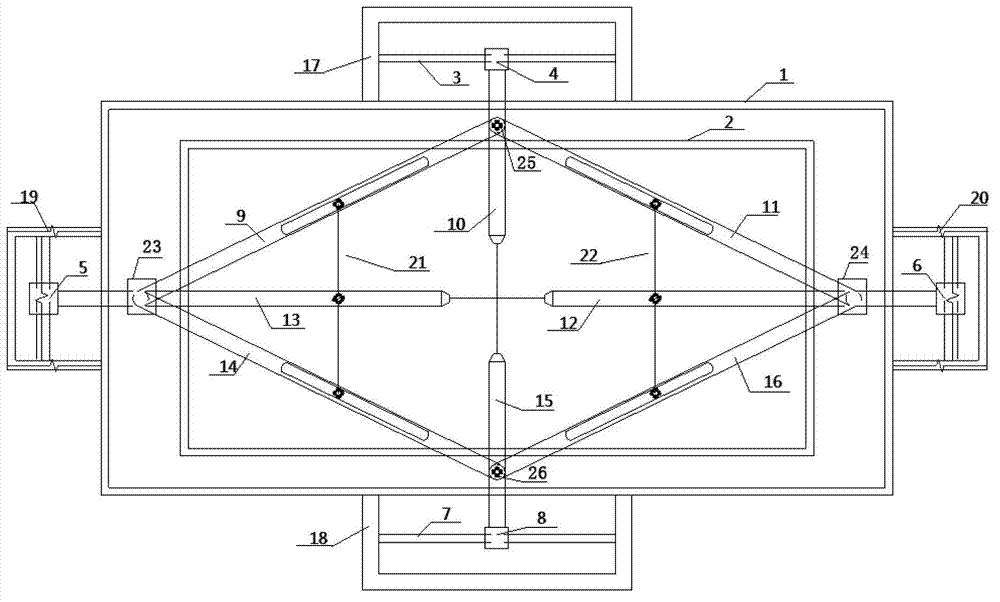

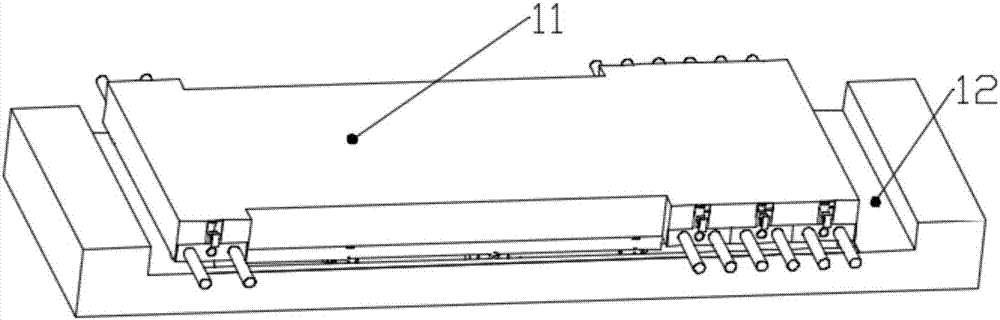

Small-size self-centering one-way loading biaxial tension-compression test device

InactiveCN102928295APrevent off-centerReal physical and mechanical propertiesMaterial strength using tensile/compressive forcesElectric machineryEngineering

The invention discloses a small-size self-centering one-way loading biaxial tension-compression test device. The device is characterized by comprising a loading transmission device and a combined type framework, wherein the combined framework is composed of a main framework 1 and a suspension framework 2, the loading transmission device comprises transverse loading shafts (12 and 13), vertical loading shafts (10 and 15), inclined rigid rods (9, 11, 14 and 16), transverse sliding rods (3 and 7), sliding connectors (4 and 8), stepping motors (5 and 6), fixing and sliding dual-use hinged supports (23 and 24) and fixing hinged supports (25 and 26). According to the small-size self-centering one-way loading biaxial tension-compression test device, the function of biaxial tension and compression can be achieved by means of one-way loading; and simultaneously, problems that the fluctuation process that the center of a test piece is deviated and goes back to the center of the loading device happens in the test process always and the test piece is difficult to clamp and adjust are solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

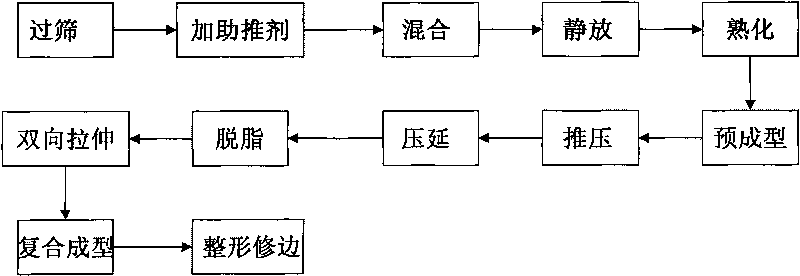

Method for manufacturing expanded polytetrafluoroethylene plate

A method for manufacturing an expanded polytetrafluoroethylene (PTFE) plate comprises the following steps: sieving PTFE dispersion resins, adding a propellant and mixing the two materials, placing the mixed materials for 24h and then carrying out aging treatment, then carrying out pre-press shaping and extruding blanks, carrying out calendaring with two rollers, removing the propellant, carrying out composite shaping after biaxial tension and carrying out reshaping and trimming to finally manufacture the expanded PTFE plate. The expanded PTFE plate is a great breakthrough in the manufacturingprocess of molded plates and turning plates. The compression resilience, the tensile strength and the low stress relaxation rate of the expanded PTFE plate are obviously increased and the expanded PTFE plate obviously improves the performance defects of the fluoroplastics, thus meeting the demand of the use functions of the sealing elements and propelling the fluoroplastics to be one of the substitutes of the asbestos materials widely used at present in the sealing material field.

Owner:四会市生料带厂有限公司

Biaxial tension polyethylene film and preparation method thereof

InactiveCN102173156AAvoid stickingSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a biaxial tension polyethylene film and a preparation method thereof. The biaxial tension polyethylene film comprises at least one film layer, wherein the at least one film layer comprises the following components in percentages by weight: 90-99.5% of metallocene linear low-density polyethylene resin, 0-10% of antistatic agent, 0-5% of antiblocking agent, 0-5% of slipping agent and 0-5% of antioxidant. A packaging material has the advantages of high heat-sealing strength, puncture resistance strength, stiffness and tensile strength, excellent low temperature resistance, durable wetting tension, small use thickness, low cost, energy saving and environment friendliness.

Owner:FSPG HI TECH

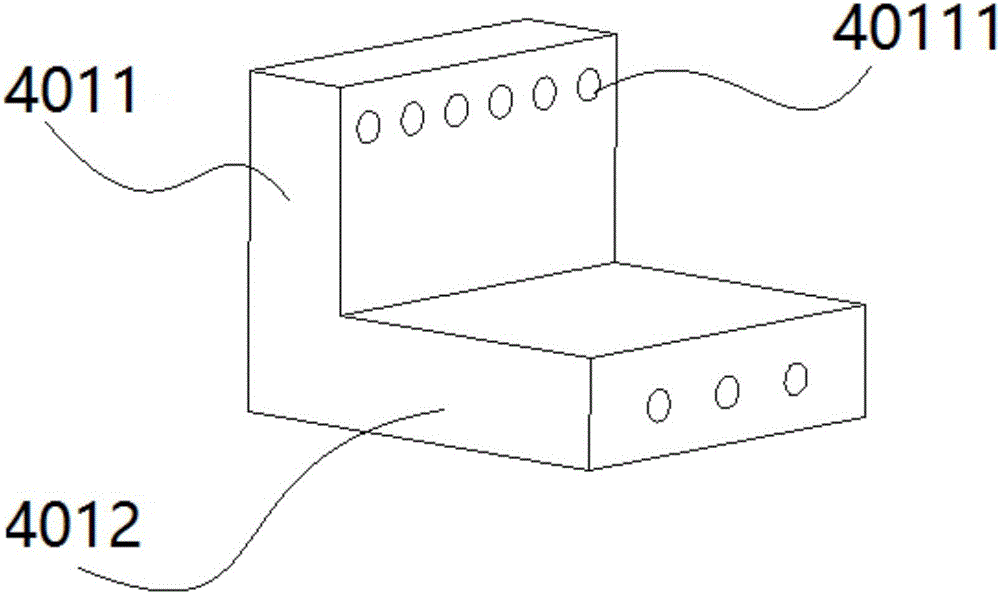

Novel stereo garage AGV (automatic guided vehicle)

ActiveCN107217892ARealize fully automatic high-efficiency accessGet rid of restrictionsVehicular energy storageParkingsLinear motionMotor drive

The invention discloses a novel stereo garage AGV (automatic guided vehicle) which comprises an upper frame and a lower frame. A traveling mechanism is mounted at the bottom of the lower frame, a four-point synchronous spiral lifting mechanism and a four-point guide device are mounted in the middle of the lower frame and drive the upper frame to vertically move, a comb tooth extending and shrinking centering mechanism is mounted on the upper frame and comprises a biaxial tension direct-current motor mounted at the center of the upper frame, the biaxial tension direct-current motor drives two transmission shafts, the two transmission shafts drive two lead screws to rotate, lead screw nuts are mounted on the two lead screws, each lead screw nut is connected with two push connecting rods, each push connecting rod pushes a comb tooth push rod to move, the comb tooth push rods push comb tooth connectors to move along a guide axis, comb teeth are arranged on the comb tooth connectors, and a centering detection plate is pushed. According to the automatic guided vehicle, the motor drives lead screw nuts matched with the front lead screw and the rear lead screw to make constant-speed reverse linear motion, so that the comb teeth positioned at the front end and the rear end of the upper frame to synchronously extend and shrink.

Owner:SHANDONG UNIV

Bidirectional stretching heat-sealing extinction film used for package and manufacturing method thereof

InactiveCN101125595AReduce manufacturing costReduce pollutionFlexible coversWrappersSurface layerExtinction

The present invention relates to a biaxial tension heat-sealing type extinction membrane used for foods packing and a production method, wherein, a basement membrane of the extinction membrane is provided with an upper surface layer, a middle core layer and a lower surface layer which are packed into a whole through heat melt and jostling together. The upper surface layer is an extinction layer and the lower surface layer is a heat-sealing layer. The production method is mainly that the lower surface of the extinction has the heat-sealing performance by changing the materials that the lower surface uses, and the extinction collects the heat-sealing performance and extinction performance as a whole. Taking the basement membrane as food packing membrane is able to simplify the processing procedure of back procedure, reduce the cost in the backward position production process, decrease the pollution to environments, and simultaneously high heat-sealing intensity and fancy flat gloss pictures are provided.

Owner:DAQING PETROLEUM ADMINISTRATION

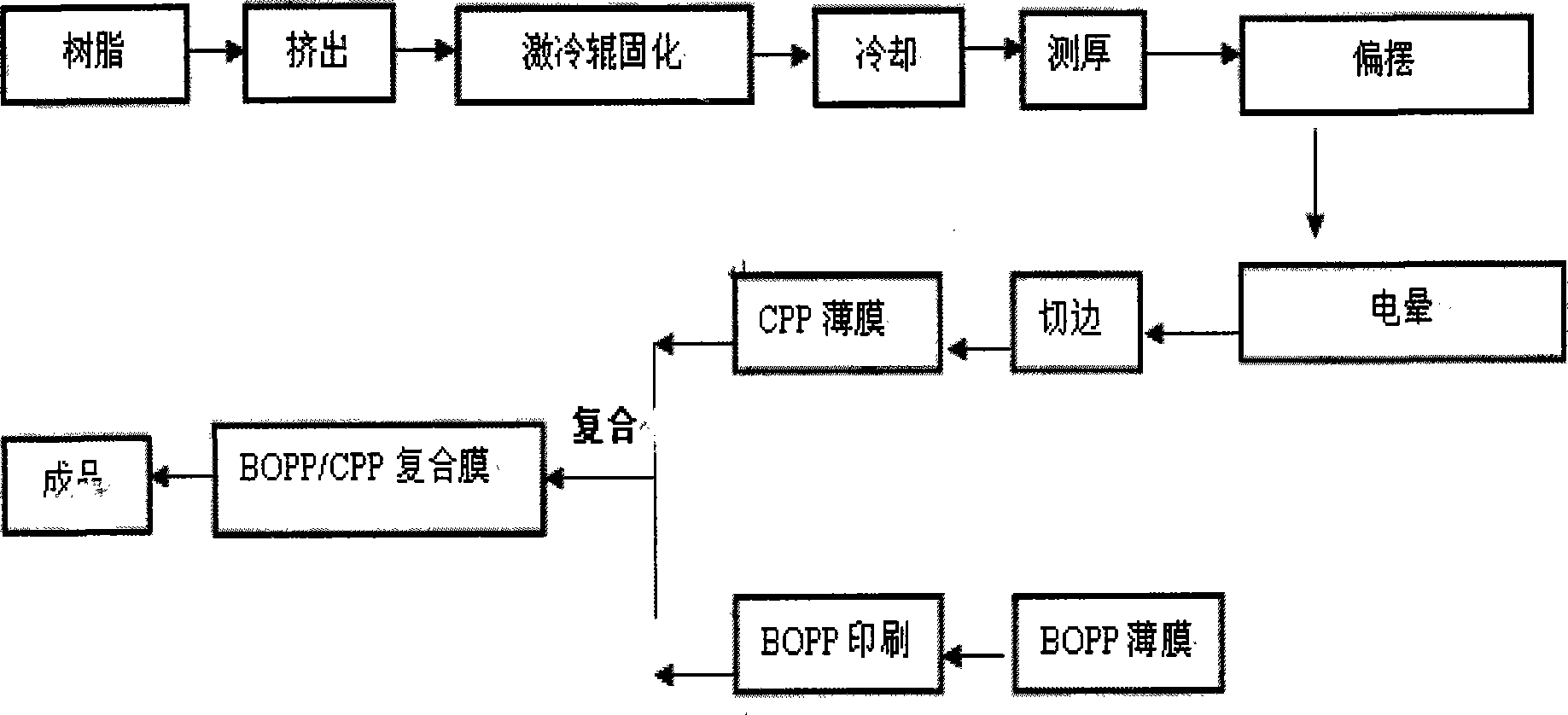

Antifreezing speed-sealing film and preparation method thereof

The invention discloses an anti-freezing film capable of being quickly sealed and a preparation method thereof. The film is formed by composition of biaxial tension polypropylene and a polypropylene film, wherein the polypropylene film consists of a corona layer, an intermediate layer and a heat-sealing layer; the heat-sealing layer comprises metallocene three-element blocking polypropylene, an ethylene elastomer, an antitackiness agent and a slip agent the weight ratio of which is 50-86.5: 18-20: 1-2: 1-1.5. The preparation method comprises the following steps in turn: a step of extrusion, a step of solidifying a sharp cooling roller, a step of cooling, a step of thickness measurement, a step of corona, a step of swing, a step of edge cutting, a step of composition of BOPP and CPP and a step of forming a spiral-wound film through cutting. Compared with the prior art, the anti-freezing film capable of being quickly sealed has the characteristics of good anti-freezing property, cold resistance and mechanical performance, obvious shock resistance effect and penetration resistance effect, low initial sealing temperature, short heat-sealing time and high sealing intensity, and is suitable for a modern quick automatic packaging unit.

Owner:HUANGSHAN NOVEL

Optical polyester thin film and preparation method thereof

ActiveCN102514275AImprove adhesionPrevent Interfering Rainbow PatternsSynthetic resin layered productsOptical elementsSolid componentPolyester

The invention relates to an optical polyester thin film and a preparation method thereof. The thin film comprises a biaxial tension polyester base film and a bottom coating layer coated on at least a surface of the polyester base film, wherein the bottom coating layer contains a filler with a refractive index of 1.55-2.50, and the coating liquid for forming the bottom coating layer comprises 5-10% by weight of a solid component content. The optical polyester thin film of the present invention has the following advantages that: the optical polyester thin film has high transparency, good adhesion and easy winding property; the generation of the interference rainbow fringe after the hard coating processing can be effectively solved; and the optical polyester thin film is applicable for various optical functional films for LCD, high-grade IMD film interior decoration processing and other high-end film material fields.

Owner:HEFEI LUCKY SCI & TECH IND +2

Pipe material modified with ultrahigh molecular weight polyethylene and its prepn

The present invention is modified ultrahigh molecular weight polyethylene pipe material and its preparation process. The modified ultrahigh molecular weight polyethylene pipe material consists of ultrahigh molecular weight polyethylene 105-165 weight portions, polyethylene wax 3-7 weight portions, graphite 1.2-4 weight portions, hollow glass bead 3-10 weight portions, antistatic agent 1.2-4.5 weight portions and flame retardant 1.8-5.6 weight portions. It has tensile strength higher than 46 MPa. Its preparation process includes the steps of compounding material, mixing, heating, extruding, forming, biaxial tension, cooling to settle and cutting. The modified ultrahigh molecular weight polyethylene pipe material has low cost, high wear resistance, excellent self-lubricating performance, high impact strength, excellent fire resistance, etc.

Owner:王好占

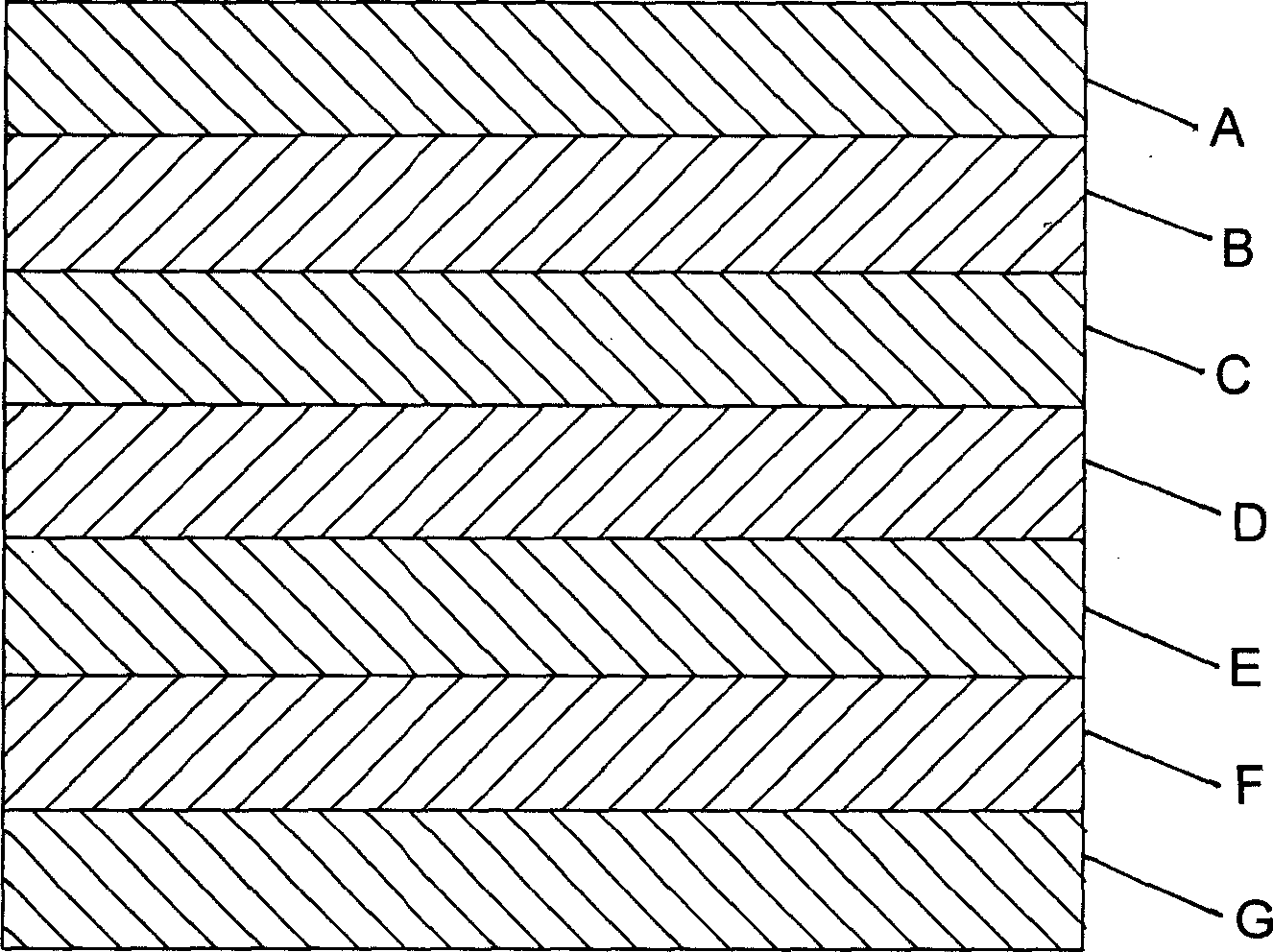

Heat sealing type biaxial-tension polypropylene film

ActiveCN101428699AHigh packaging requirementsReduce manufacturing costFlexible coversWrappersSurface layerAntistatic agent

A heat-sealing type two-way stretching polypropylene film is prepared by forming a heat-sealing layer with a heat-sealing strength on the surface layer of the two-way stretching polypropylene film by a co-extrusion process. The heat-sealing layer can be formed above or below the two-way stretching polypropylene film, or formed on both the upper and the lower surfaces of two-way stretching polypropylene film at the same time. The adopted heat-sealing material comprises mixing materials of heat-sealing type materials like biopolymer polypropylene or terpolymer polypropylene, propylene-butylene copolymer or known alkene copolymer and the like; heat-sealing materials like 3% to 60% of propylene butylene copolymer or known alkene copolymer and the like, or elastic body, 40% to 97% of homopolymerization polypropylene, and 1% to 20% of an anti-static agent are added to a core layer. The interface heat-seal package or the couple-seal package can be directly performed to the product without being compounded with the PE or CPP heat-sealing film; the surface of the product can be printed and coated, or coated after being printed according to the operating requirements; the product integrates package and decoration as a whole, and can replace partial composite products. The product has the remarkable advantage of low cost, and reduces the environmental pollution.

Owner:HAINAN SHINER IND

Biaxially oriented polypropylene adhesive-free film

InactiveCN101722702AImprove puncture resistanceFlexible coversWrappersLow-density polyethylenePolymer science

The invention belongs to the technical field of packaging materials, in particular to a film for packaging. The biaxially oriented polypropylene adhesive-free film is characterized by consisting of a surface layer, a core layer and a secondary surface layer, wherein the core layer is positioned between the surface layer and the secondary surface layer; the surface layer, the core layer and the secondary surface layer are co-extruded and form a whole by biaxial tension; the material of the surface layer consists of the following components in percentage by weight: 90 percent of low-density polythene, 5 percent of anti-adhesive agent and 5 percent of slipping agent; the core layer is made of low-density polythene, metallocene polyethylene and ethylene propylene diene methylene; and the secondary surface layer is made of ethylene-polythene copolymer, paraffin, hydrogenated resin, low-density polythene and antioxidant. The invention has the characteristics of low compound temperature (60-95 DEG C) with paper and favorable puncture resistance.

Owner:HUBEI FIRSTA MATERIALS SCI & TECH GRP

Method for preparing multiple layers of polyolefin microporous film

The invention discloses a method for preparing multiple layers of polyolefin microporous film and is used for preparing a polyethylene microporous film by utilizing a wet method. In the method disclosed by the invention, more than two polyolefin resin combinations with low hole closing temperature and high film breaking temperature are adopted; the polyolefin resin with low hole closing temperature and high film breaking temperature and one solvent in long paraffin, mineral oil, vegetable oil and benzoate are mixed into a solution; the polyethylene resin with high film breaking temperature and the solvent which is prepared by blending two or more than two solvents selected from the long paraffin, the mineral oil, the vegetable oil and the benzoate are mixed into a solution; and the polyolefin microporous film is prepared through the steps such as coextrusion, biaxial tension, solvent elution and the like. By the selection of the solvents, the method disclosed by the invention enables the polyolefin resin and the solvents to be easily fused and mixed, has good separation effect and can better control the aperture and thickness of the prepared film. The prepared film has the advantages of low hole closing temperature, high film breaking temperature and high intensity.

Owner:康辉南通新材料科技有限公司

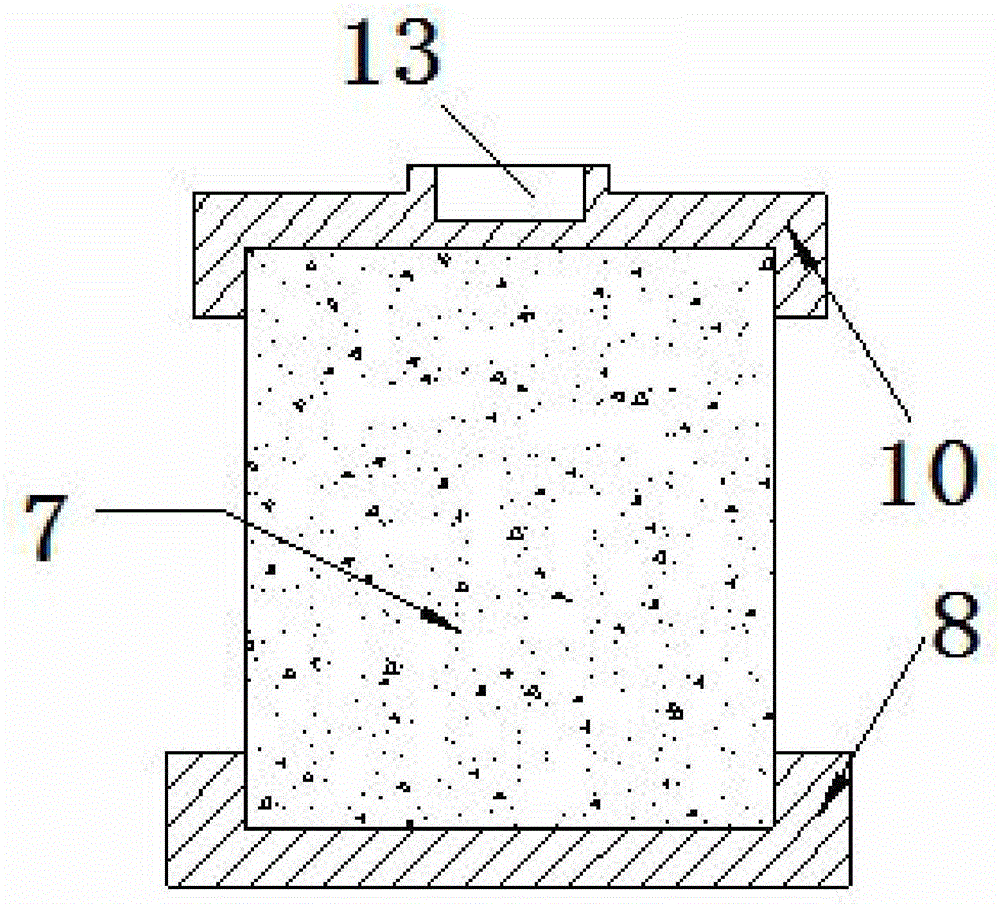

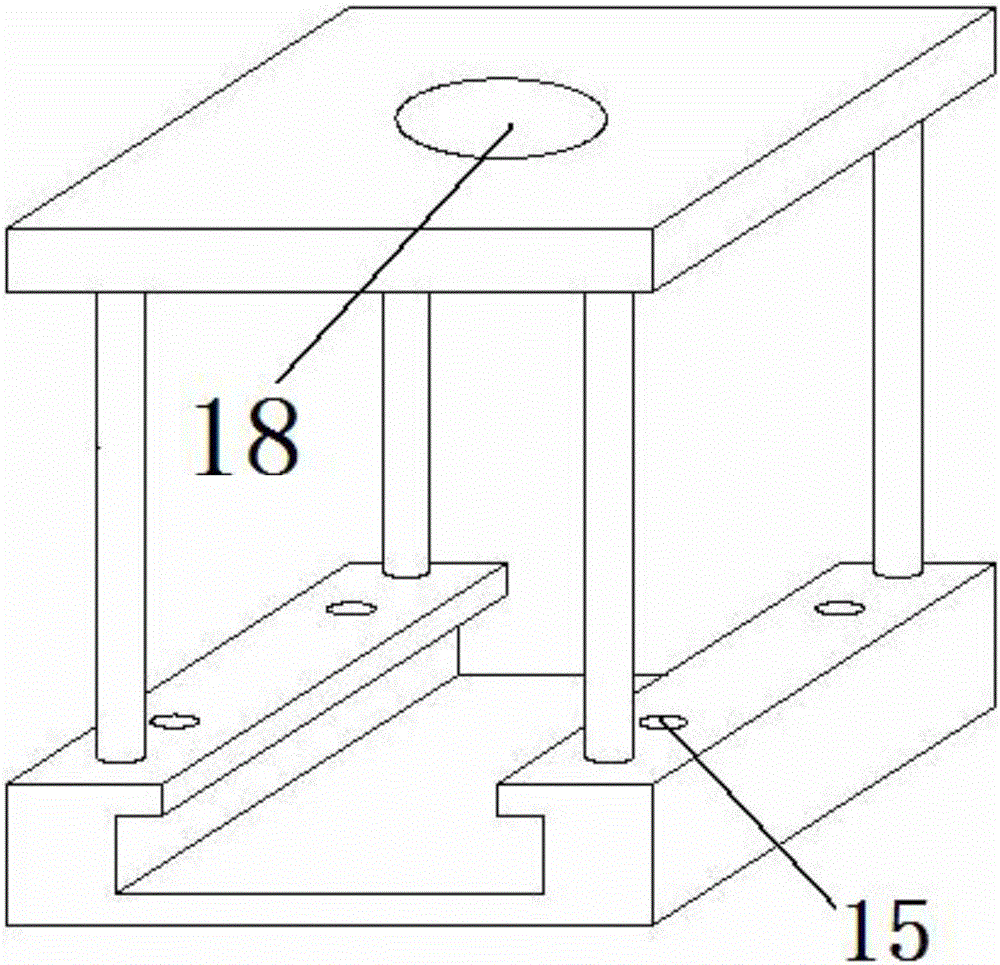

Device for utilizing real triaxial testing machine to realize rock biaxial tension test

InactiveCN105865925AGuaranteed forcePrecise alignmentMaterial strength using tensile/compressive forcesTriaxial shear testEngineering

The invention relates to a device for utilizing a real triaxial testing machine to realize a rock biaxial tension test. The device comprises a sample bonding component, a stretching component and a supporting component, wherein the sample bonding component comprises an upper slot plate and a lower slot plate; a screw hole is formed at the center of the upper slot plate; the stretching component comprises a first top plate, a first base plate and a connecting rod; the connecting rod is located on slot walls on the two sides of a slot of the first base plate; first through holes are formed on the slot walls on the two sides of the slot of the first base plate; the supporting component comprises a bolt, a second top plate, a second base plate and a brace; a bolt mounting hole is formed at the center of the second top plate; the brace is mounted in each of the first through holes of the stretching component; a second through hole is formed on the second top plate; the connecting rod of the stretching component is mounted in the second through hole; the bolt is mounted on the bolt mounting hole and the screw hole. The device provided by the invention can utilize the real triaxial testing machine to accurately measure the strength and deformation of the rock material under a biaxial tension condition.

Owner:GUANGXI UNIV

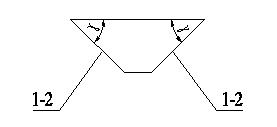

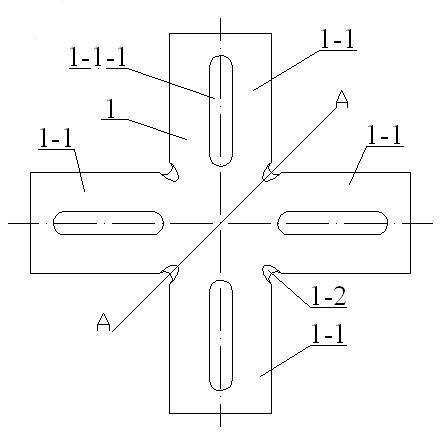

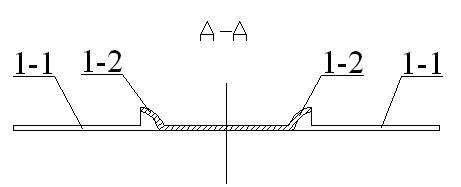

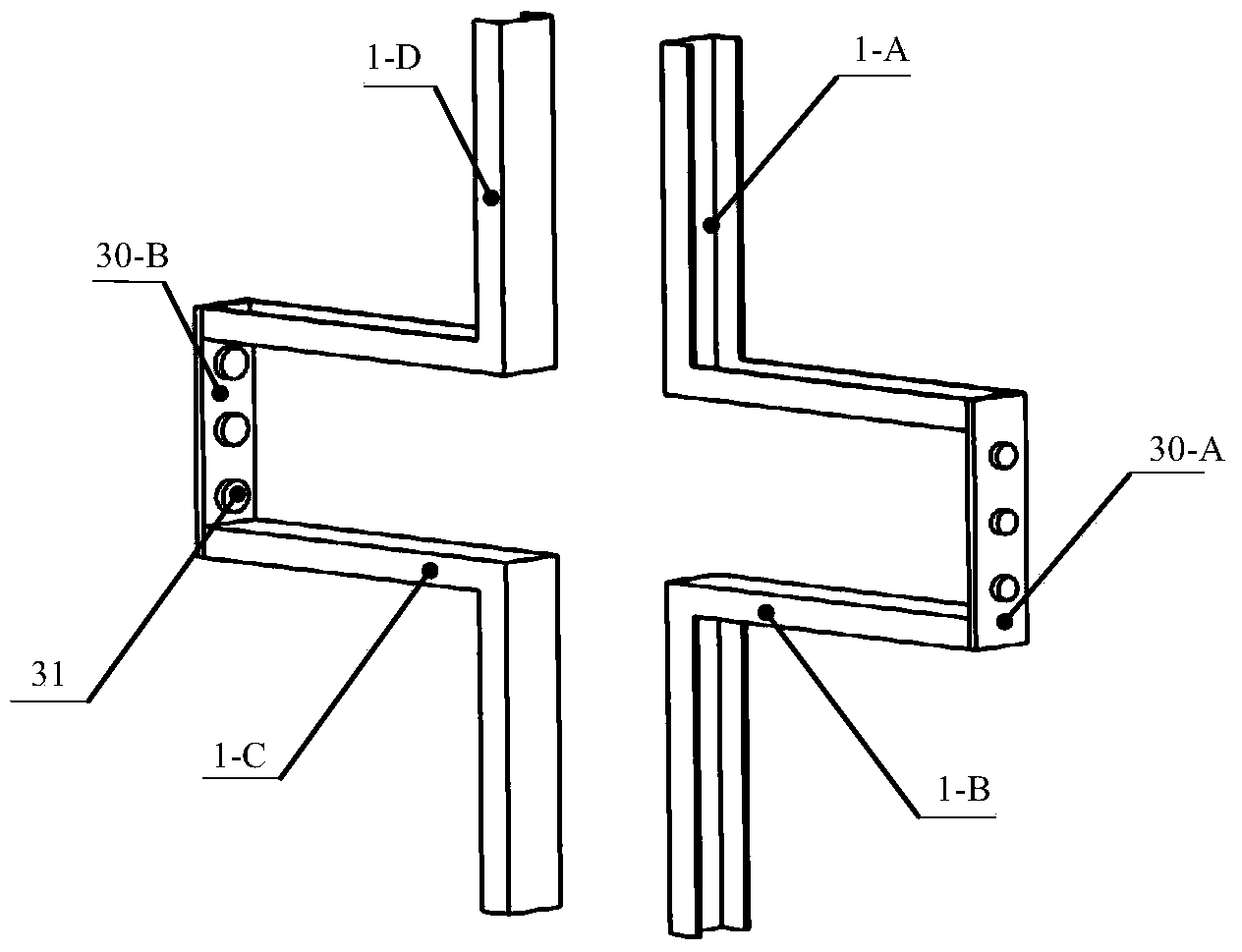

Three-dimensional cross-shaped biaxial tension test piece

InactiveCN101893532AReduce the impactSolve the force problemStrength propertiesEngineeringLarge deformation

The invention provides a three-dimensional cross-shaped biaxial tension test piece. The invention relates to a biaxial tension test piece. The invention solves the problems that stress at the center of the existing cross-shaped test piece is nonuniform and large deformation can not be achieved. The invention is composed of one cross-shaped tension piece (1), the end face at the junction of each two adjacent arms of the four arms (1-1) on the cross-shaped tension piece (1) is provided with a pit (1-2), and the four pits (1-2) are arranged on the same side of the cross-shaped tension piece (1). The invention is used for providing a biaxial tension test piece, so as to test the biaxial tension property of plate and obtain accurate material model.

Owner:HARBIN INST OF TECH

Casting compound type CPP aluminum-base plated film

InactiveCN101774289AEasy to changeImprove adhesionSynthetic resin layered productsAdhesion forceProduction line

The invention relates to a casting compound type CPP aluminum-base plated film. The film consists of a layer A, a layer B and a layer C which form an integral body through hot melting, co-extrusion and biaxial tension, wherein the layer A is a heat-sealing layer, the layer B is a core layer, the layer C is an aluminized layer, and each layer comprises the following raw material components in percentage by weight: 95 percent of co-polypropylene and 5 percent of anti-sticking agent for the layer A; 100 percent of homo-polypropylene for the layer B; 75 to 93 percent of the co-polypropylene, 5 to 20 percent of reinforcing agent and 2 to 5 percent of the anti-sticking agent for the layer C, wherein the reinforcing agent is an ethylene methyl acrylate copolymer WH303. Because the formula of the layer C (the aluminized layer) is added with an aluminizing reinforcing agent, the adhesion force of an aluminized aluminum layer is greatly increased to ensure that the aluminum layer cannot be peeled off when the CPP aluminized film is in casting compounding. Besides, the casting compound type CPP aluminum-base plated film can be produced on the existing production line and can be produced in bulk without changing equipment.

Owner:GUANGDONG WEIFU PACKAGING MATERIAL

Rock-like material tension-shear and biaxial tension-compression testing device and use method thereof

ActiveCN106644708ASimple structureReduce testing costsMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringCompression test

The invention provides a rock-like material tension-shear and biaxial tension-compression testing device and a use method thereof. The device comprises a frame I, a frame II, an upper pressing plate, a pull head I, a pull head II, a base plate, a tester loading head I, a tester loading head II, a tester loading head III and a tester loading head IV; the frame II can move along a vertical direction to convert vertical pressure of a tester into tension; a sample freely deforms in a horizontal pressure direction. The device is simple in structure, a test result is accurate, the aims of performing a tension-shear test and a biaxial tension-compression test on a biaxial tester can be achieved, and the test cost is greatly lowered.

Owner:HEBEI UNIV OF TECH

Super-slide type biaxial tension polypropylene thin film for easy-quit package retraction tobacco

The invention relates to a super-smooth type dual-direction extension polypropylene film used by a retractable cigarette with the package easy to be taken down, comprising a structure of an upper layer, an intermediate layer and a lower layer. The upper layer is added with macromolecular silicone accounting for 1 to 3 percent Mw (namely more than 100,000) of the total weight of polypropylene biopolymer basal material as lubricant and 0.1 to 0.5 percent of cross-link methyl acrylate as anti-adhesiveness agent. The intermediate layer is added with hydrogen oil resin accounting for 10 to 30 percent of the total weight of the polypropylene basal material as erection strengthening agent and 0.2-1.0 percent of alkyl (C14-18) double (2-hydroxyethyl group) amine as anti-static agent. The lower layer is added with macromolecular silicone accounting for 1 to 3 percent Mw (namely more than 100,000) of the total weight of polypropylene triopolymer basal material as lubricant and 0.1 to 0.5 percent of cross-link methyl acrylate as anti-adhesiveness agent. The film has small internal friction and good erection and static electricity prevention, and can enable the cigarette package to be easily taken down from the film.

Owner:江苏恒创包装材料有限公司

High-temperature biaxial tension device

InactiveCN104359767ASimple structureEconomical priceMaterial strength using tensile/compressive forcesEngineeringBiaxial tension

The invention discloses a high-temperature biaxial tension device and solves problems that devices in the prior art cannot perform tensioning at the high temperature, cannot realize biaxial variable-proportion loading, are not constant in tension speed and the like. The device comprises a support, a tension mechanism, a transmission mechanism and a gear control mechanism, wherein a No.1 support, a No.2 support, a No.3 support and a No.4 support of the support are sequentially arranged on a same plane, every two adjacent supports are symmetrical and identical, a right support fixing plate of the support is welded at right ends of the No.1 support and the No.2 support, and a left support fixing plate is welded at left ends of the No.3 support and the No.4 support; the tension mechanism is mounted and glidingly connected onto the support; the transmission mechanism is mounted and glidingly connected tonto the support through a power transmission block of the transmission mechanism, the lower end of a power transmission rod of the transmission mechanism is welded on a lower sliding block of the tension mechanism, a right power output rod and a left power output rod of the transmission mechanism are glidingly connected with the gear control mechanism, and the gear control mechanism is mounted on a right rotating shaft and a left rotating shaft of the tension mechanism through bearings.

Owner:JILIN UNIV

Production technology for heat shrinkable polyester film

ActiveCN103640237AEasy to recycleImprove mechanical propertiesFlat articlesPolymer sciencePolyethylene terephthalate glycol

The invention discloses a production technology for a heat shrinkable polyester film and relates to the package material field. The production technology comprises the following technologies: slicing, vacuum drying, melt extrusion, quenching slice casting, biaxial tension, cooling and rolling slitting. Amorphous polyethylene glycol terephthalate is selected as a raw material, amorphous polyethylene glycol terephthalate is easy to recycle, nontoxic and odourless, has good mechanical properties, and meets environment protection requirements. Heat is transferred to materials to be dried through a drier shell under the vacuum environment, and therefore the purpose of drying reinforcement is achieved. The softening point of polymers is raised effectively, adhesion and agglomeration of resin particles are avoided during the drying and melt extrusion processes, moisture in resins can be removed, and hydrolytic degradation and bubble generation of polymers containing ester groups are prevented during the melt extrusion process. The ways of segmented heating and segmented processing are beneficial for fusion of molecules, and avoid material deterioration caused by too fast heating. the intensity of the produced shrinkable film is raised, and the shrinkable film has impact resistance.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

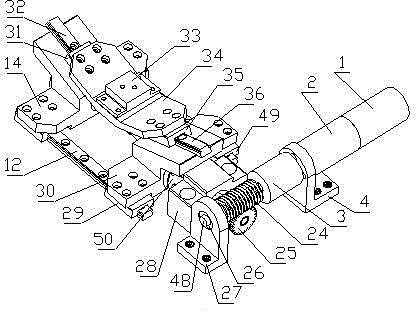

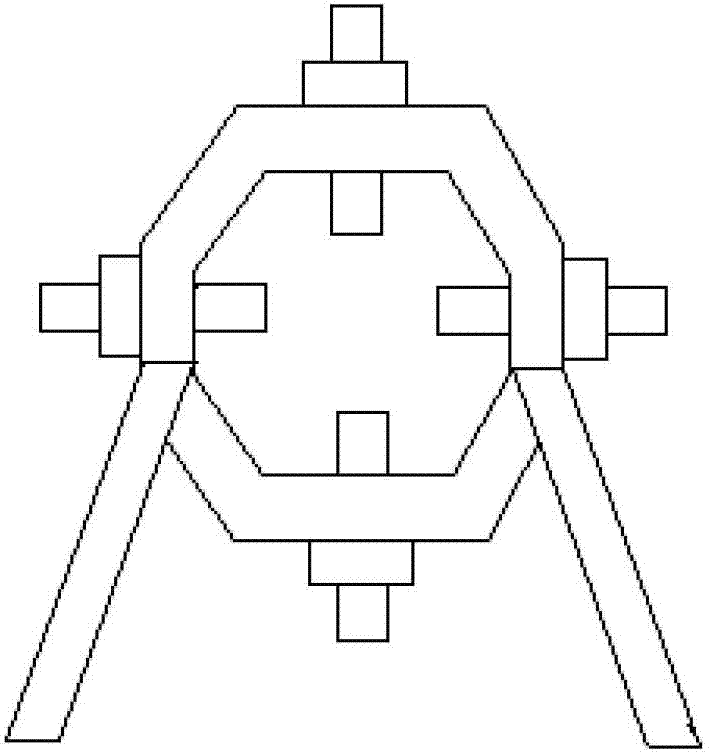

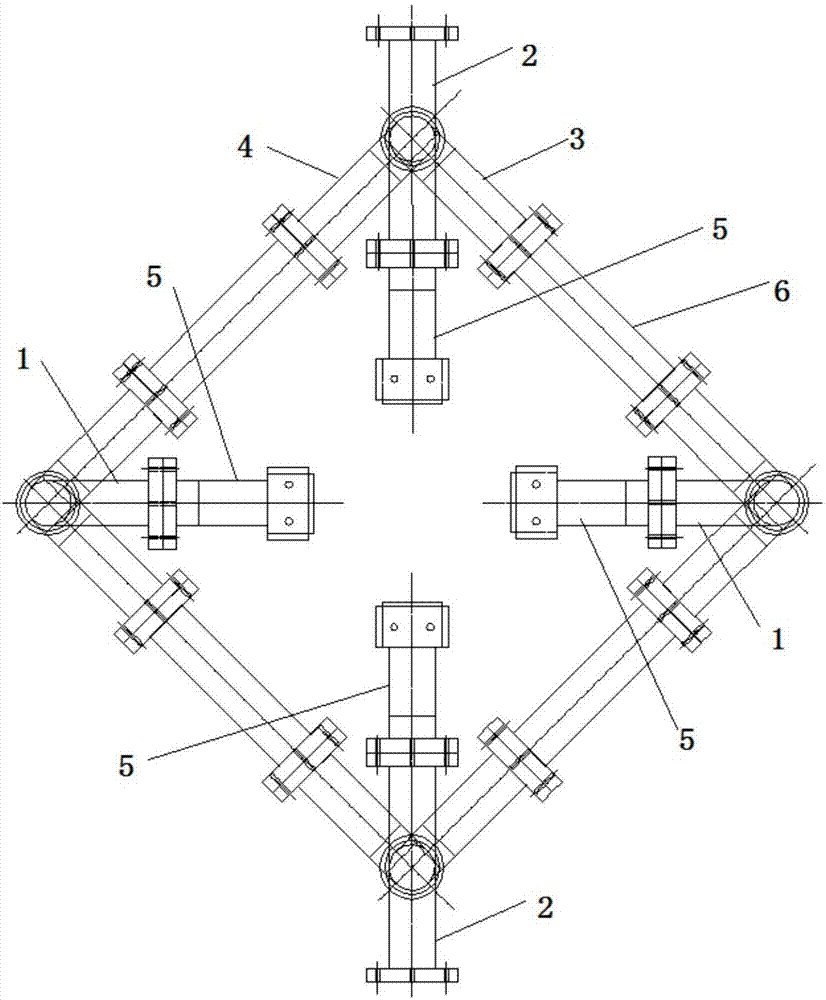

Biaxial fatigue test clamp

PendingCN107389440AResolve synchronizationThe principle is simpleMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a biaxial fatigue test clamp, which is characterized in that T-shaped clamp joints and cross-shaped clamp joints are formed by movably connecting two rotating arms to two wings of one T-shaped or cross-shaped bracket; a movable quadrilateral frame is formed by connecting the rotating arms of two T-shaped clamp joints and two cross-shaped clamp joints end to end; one rotating arm on the corresponding cross-shaped clamp joint is connected with one clamp chuck respectively; the other rotating arm of the corresponding cross-shaped clamp joint is connected with a uniaxial fatigue tester. The biaxial fatigue test clamp can be used for realizing a biaxial tension-compression fatigue test by utilizing a conventional uniaxial fatigue tester. The physical structure of the clamp determines the loading frequency in the directions x and y to be strictly consistent; the synchronization problem occurring in a biaxial fatigue tester is avoided. The biaxial fatigue test clamp is simple in principle, clear in structure and convenient to use. An extension rod can be quite conveniently replaced according to the size of a test sample.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

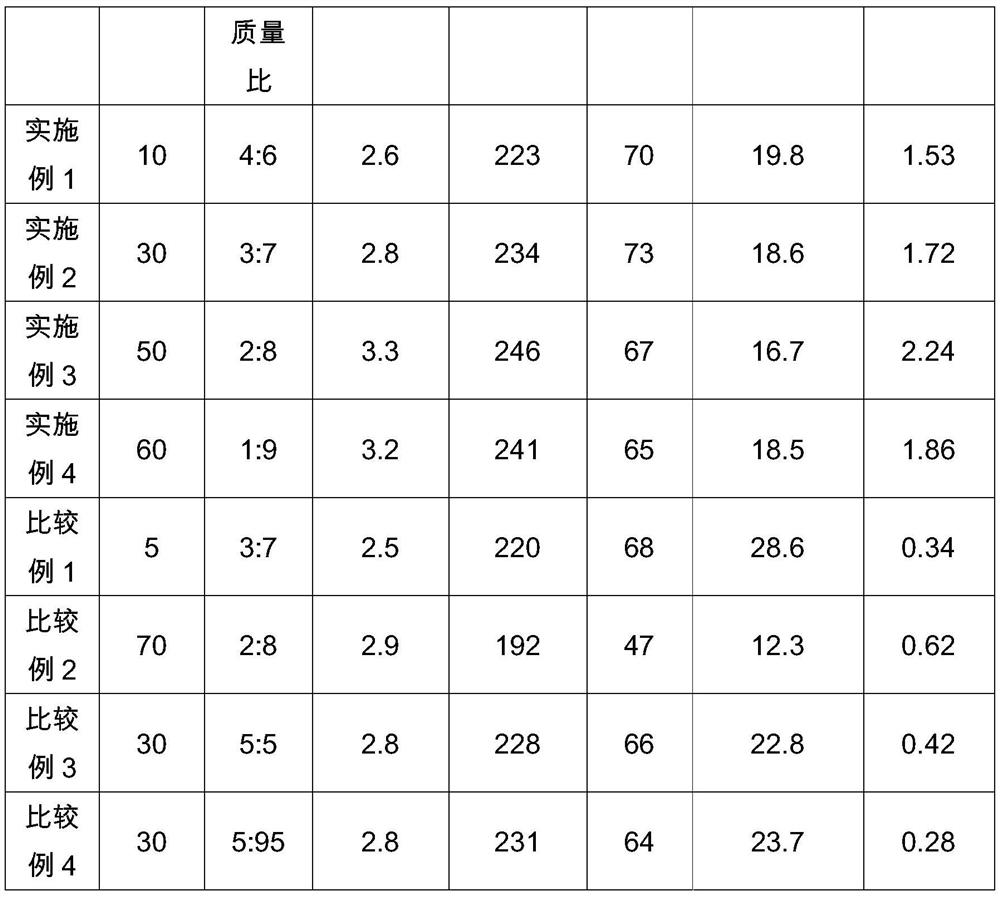

Preparation method of polyimide film and polyimide film

ActiveCN111793206AGuaranteed mechanical propertiesSmall coefficient of thermal expansionHeat-exchange elementsThermal dilatationImide

The invention discloses a polyimide film and a preparation method thereof. The preparation method of the polyimide film comprises the following steps: S1, preparing a heat-conducting filler dispersionliquid, namely mixing clay treated by a first silane coupling agent and a nano-scale inorganic filler treated by a second silane coupling agent in a solvent to form the heat-conducting filler dispersion liquid, the particle size of the clay being micron-sized; S2, adding a diamine monomer and a dianhydride monomer into the heat-conducting filler dispersion liquid to generate a polyamide acid resin solution; wherein the heat-conducting filler dispersion liquid forms a heat-conducting filler structure with a three-dimensional network structure in the polyamide acid resin solution; and S3, casting the polyamide acid resin solution, and carrying out imidization and biaxial tension to obtain the polyimide film. The heat-conducting filler structure with a three-dimensional network structure isformed in the polyimide film through micron-sized clay and nano-sized inorganic filler, so that the polyimide film maintains mechanical properties, the coefficient of thermal expansion of the film isreduced, and the heat-conducting property of the film is improved.

Owner:ZHONGTIAN ELECTRONICS MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com