Heat sealing type biaxial-tension polypropylene film

A polypropylene film, biaxially oriented technology, used in flexible coverings, packaging, layered products, etc., can solve the problems of high environmental protection requirements, high production costs, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

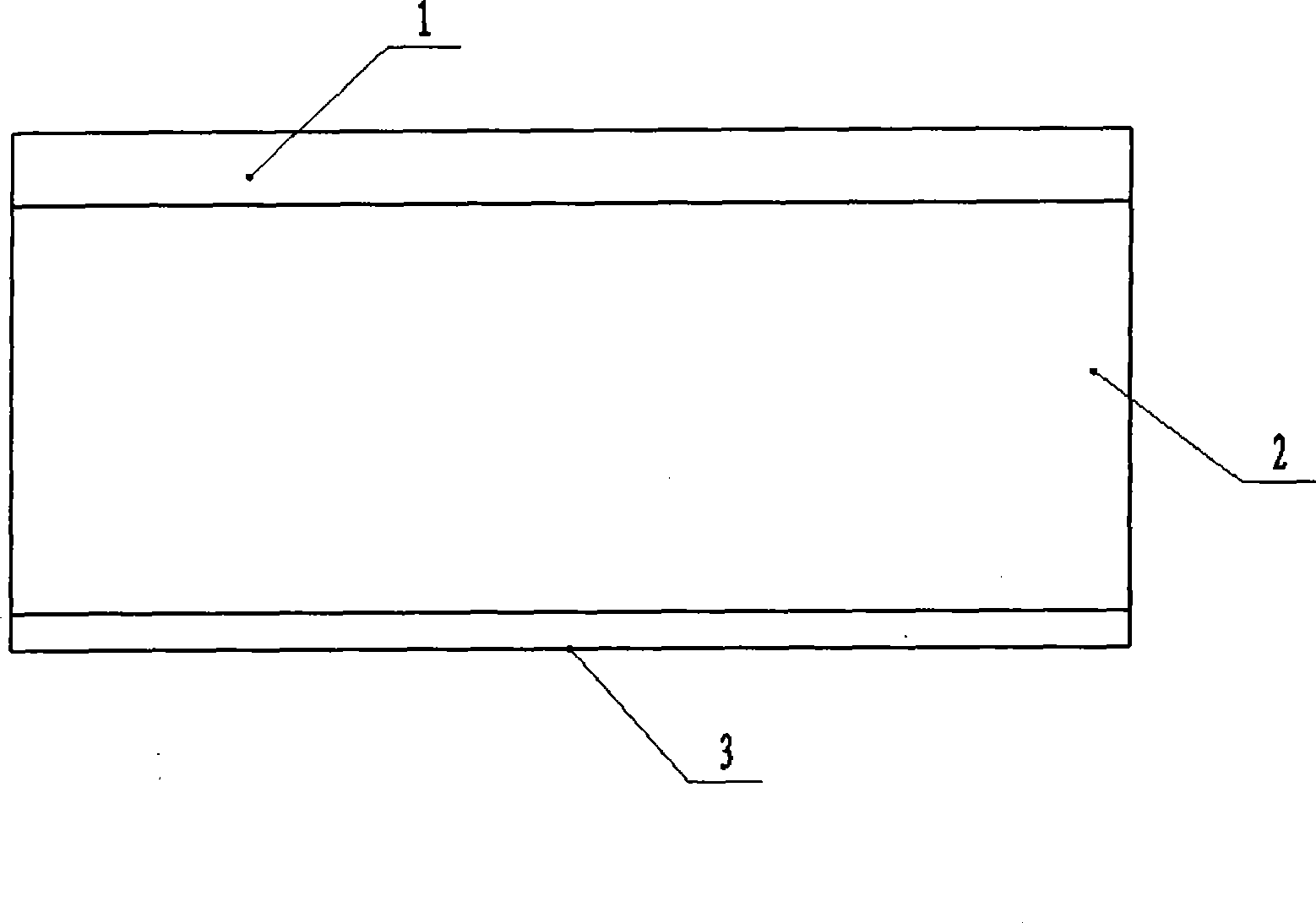

[0018] Embodiment one: adopt co-extrusion process to produce 35 micron BOPP film, wherein add 47% ternary copolymerization polypropylene, 50% propylene-butene copolymer and 3% siliceous lime and erucic acid in 1 surface layer of BOPP film Amide anti-blocking slip agent (effective content is 1500PPM), the extruded thickness of the surface layer is 2 microns, forming a heat-sealing layer 1; adding 15% propylene-butene copolymer and 85% homopolymer Propylene forms the core layer 2; and corona treatment is carried out on the non-heat-sealing layer 3, and the treatment value of the day is 41 dynes, and the prepared BOPP film has good heat-sealing performance. Its heat sealing strength is 9N / 15mm at 0.3 seconds.

Embodiment 2

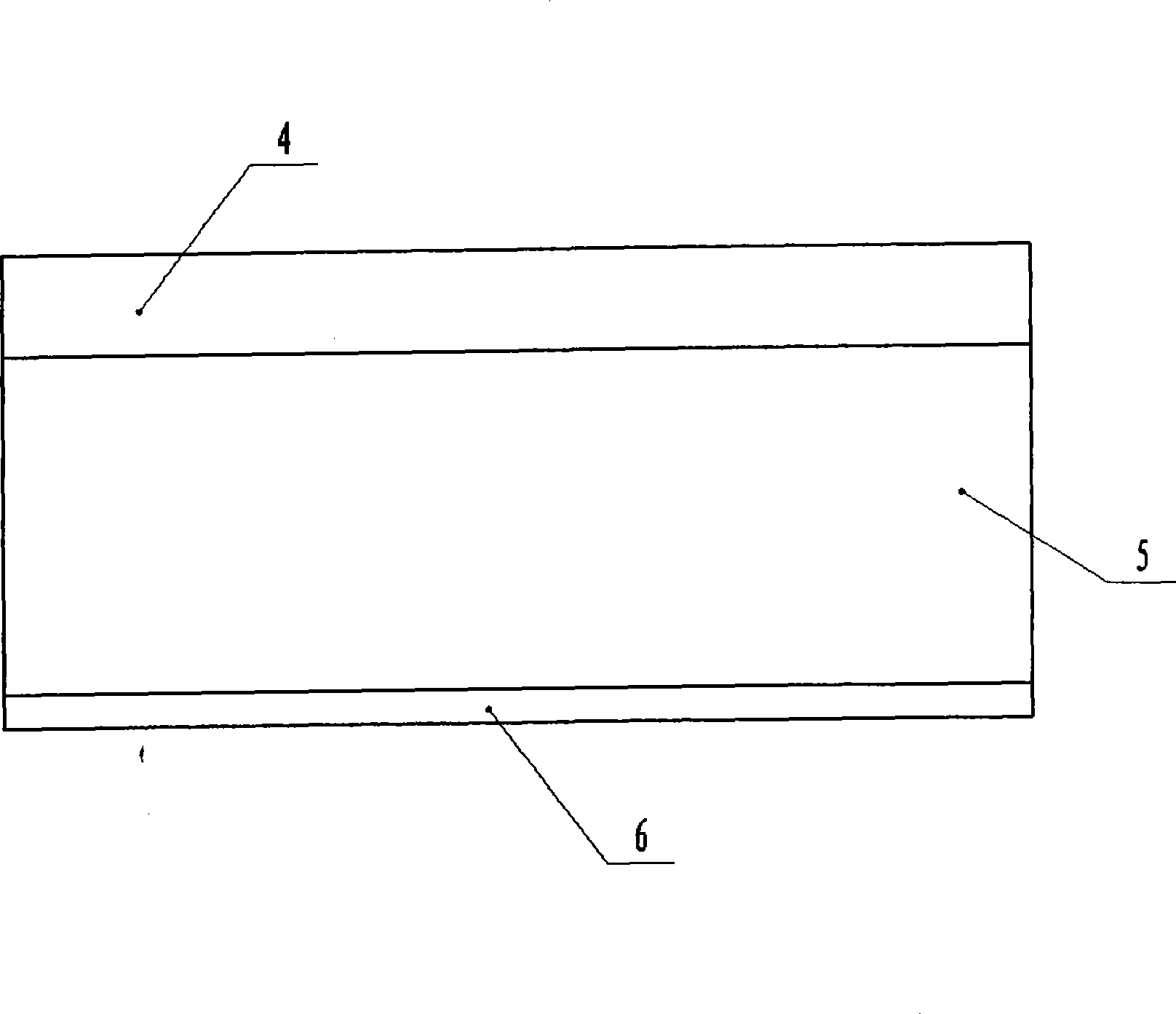

[0019] Embodiment two: adopt co-extrusion process to produce 35 micron BOPP film, wherein all add 84% ternary copolymerization polypropylene, 13% propylene-butylene copolymer and 3% erucamide class antibacterial to the two surface layers of BOPP film Adhesive slip agent (effective content is 1500PPM), the extruded thickness of both surface layers is 3 microns, forming heat-sealing layer 4 and heat-sealing layer 6; Add 10% propylene-butylene copolymer and 90% The homopolypropylene forms the core layer 5; and corona treatment is performed on the two heat-sealing layers. Polyvinyl alcohol (PVOH) coating. The prepared BOPP film has excellent heat-sealing performance and ultra-high oxygen barrier performance. When the heat-sealing temperature is 130°C and the heat-sealing time is 0.3 seconds, its heat-sealing strength is 11N / 15mm; when the PVOH coating is 3um , at a relative humidity of 0%, and at 23°C, its oxygen transmission rate is ≤1.0ml / m 2 .24hr.

Embodiment 3

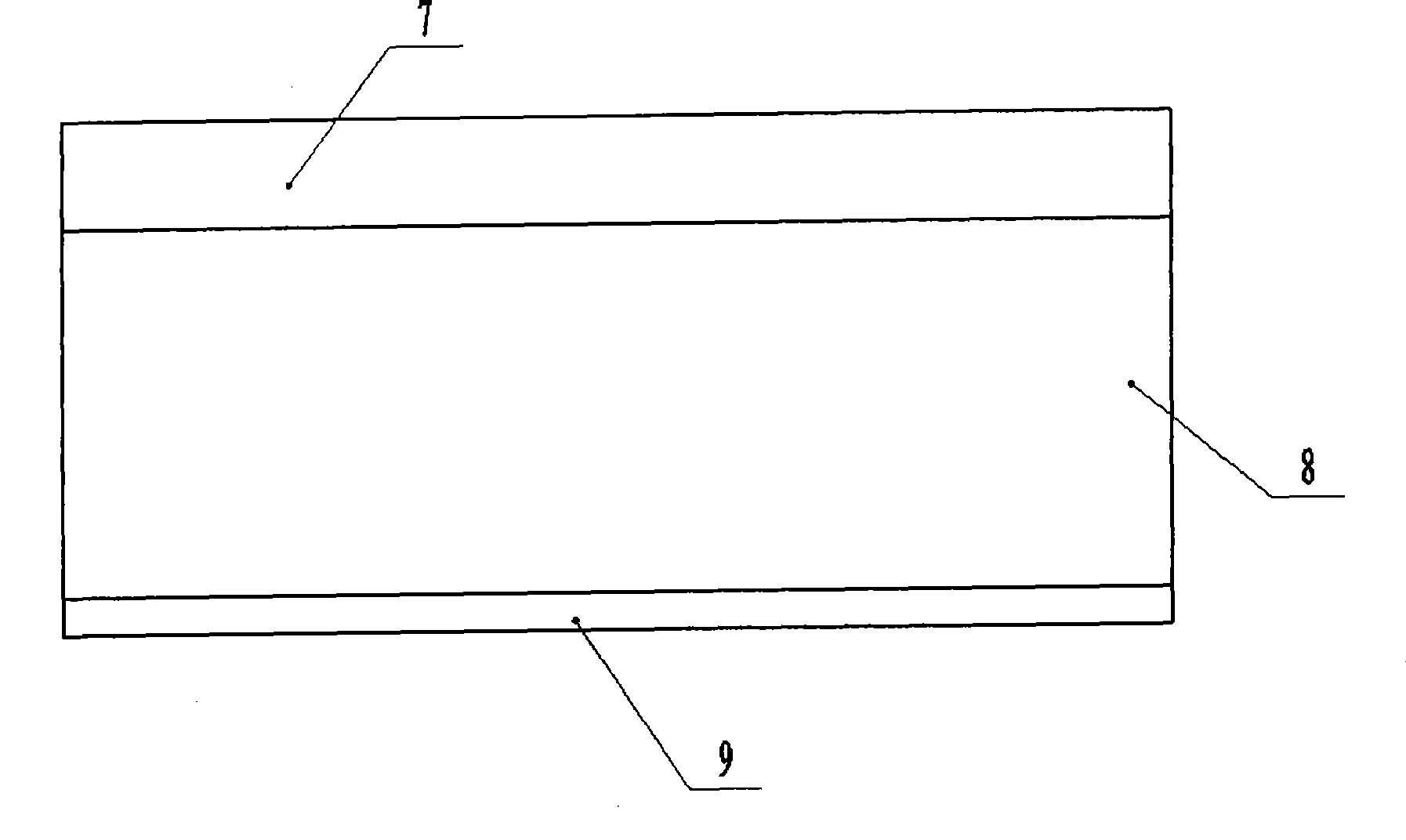

[0020] Embodiment three: adopt co-extrusion process to produce 35 micron BOPP films, wherein 25% binary copolymerized polypropylene, 60% terpolymerized polypropylene, 12% propylene-butene copolymer are added to 1 surface layer of BOPP film And 3% erucamide anti-blocking slippery agent (effective content is 1500PPM), the extruded thickness of this surface layer is 2 microns, forms heat-seal layer 7; Corona treatment is carried out to non-heat-seal layer 9, and the processing value of the same day is 41 Dyne, adding 15% propylene-butene copolymer and 85% homopolypropylene into the core layer to form the core layer 8; and coating the surface of the non-thermal layer 9 with a PVDC coating. The prepared BOPP film has good heat-sealing properties and oxygen and water vapor barrier properties. When the heat-sealing temperature is 130°C and the heat-sealing time is 0.3 seconds, its heat-sealing strength is 8N / 15mm; when the PVDC coating is 3um , at a relative humidity of 90%, and at 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com