Patents

Literature

2203 results about "Co extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

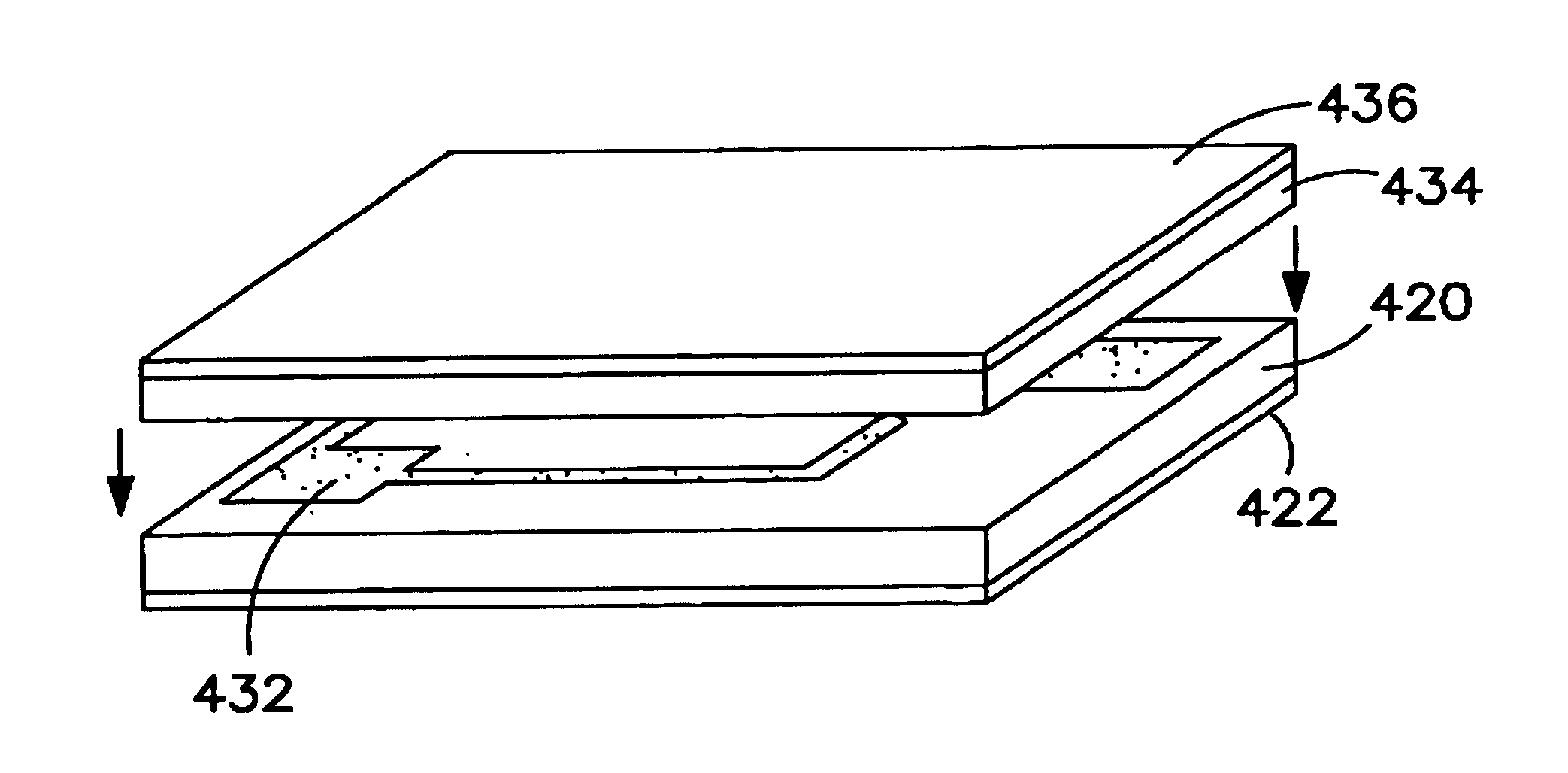

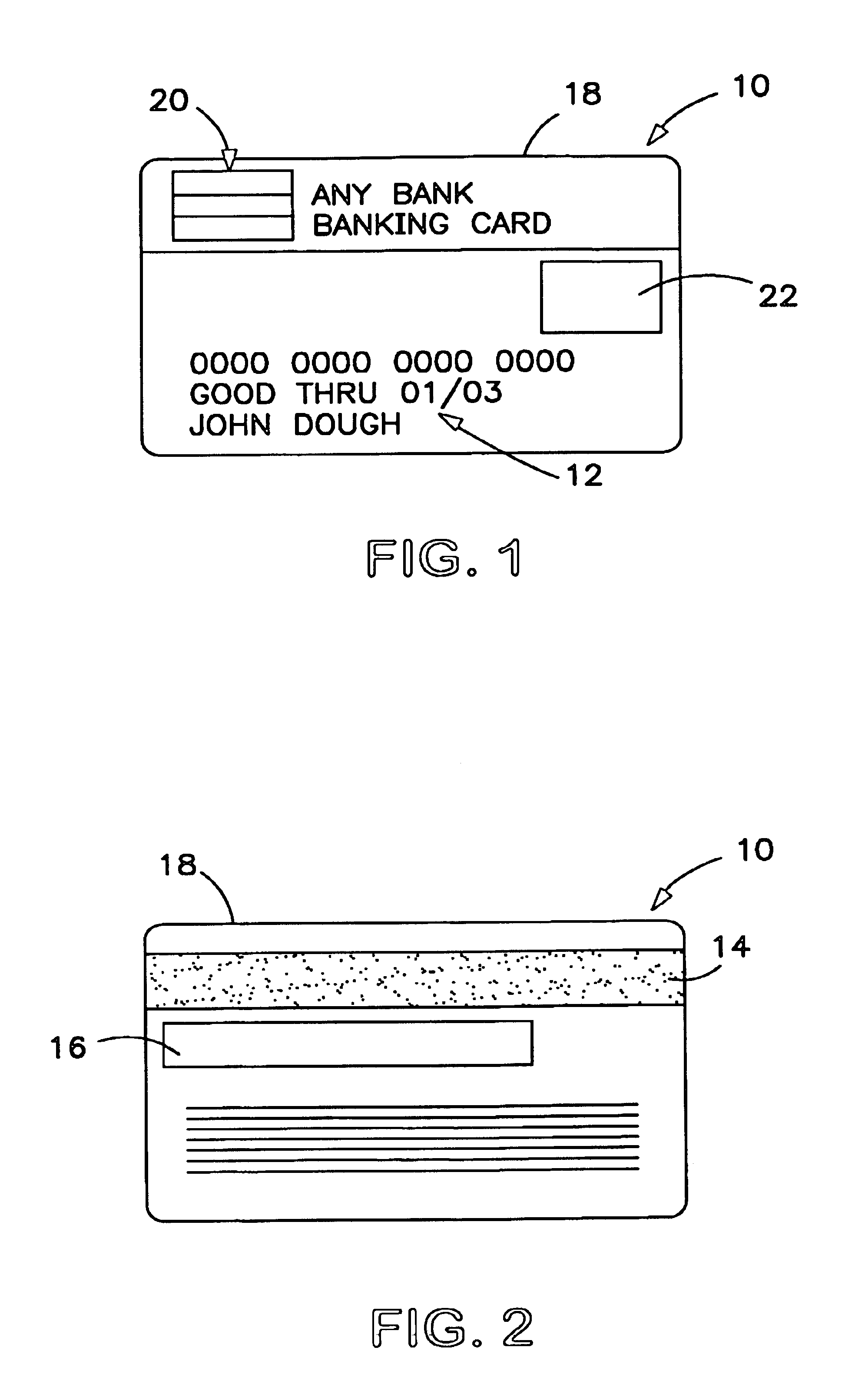

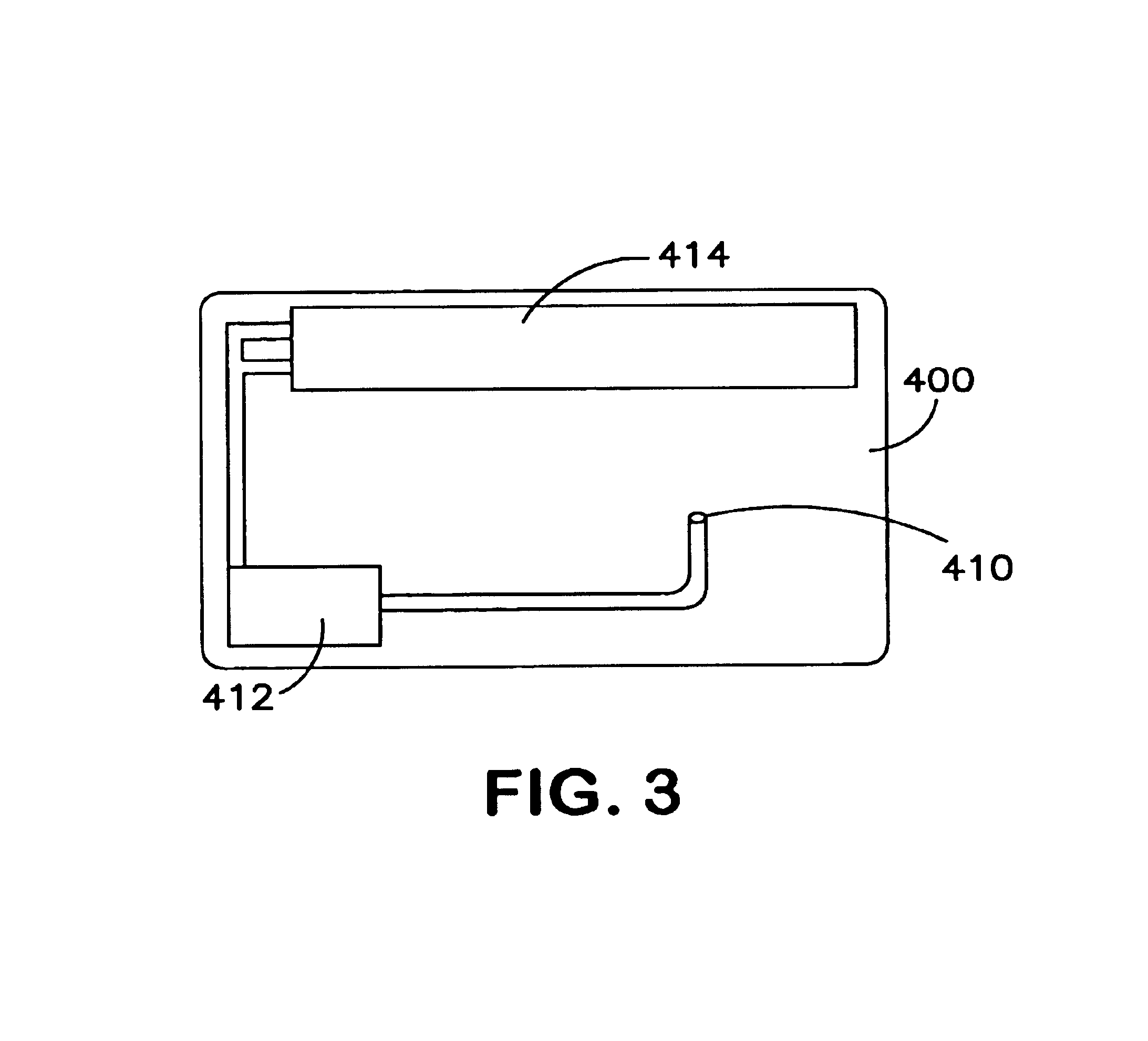

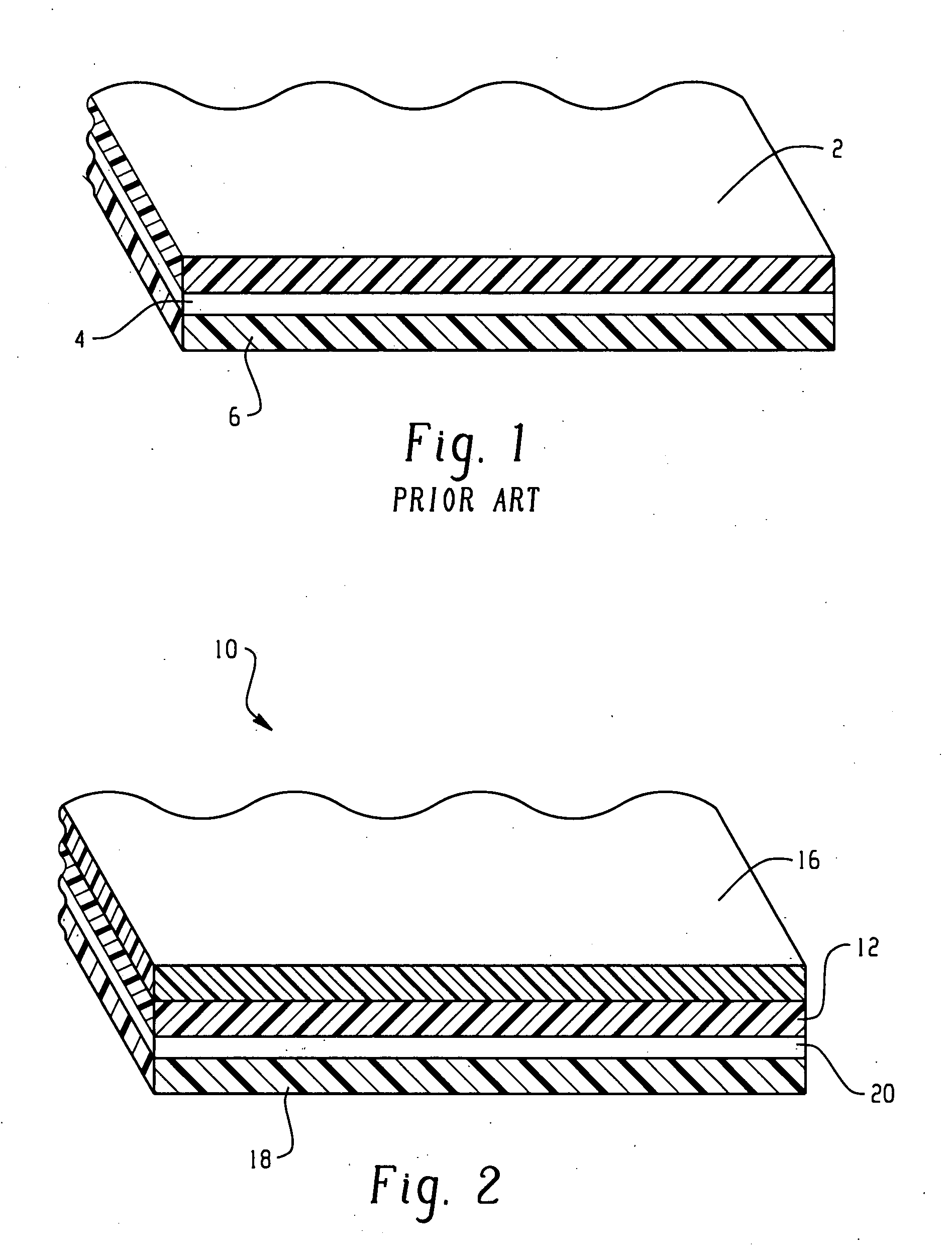

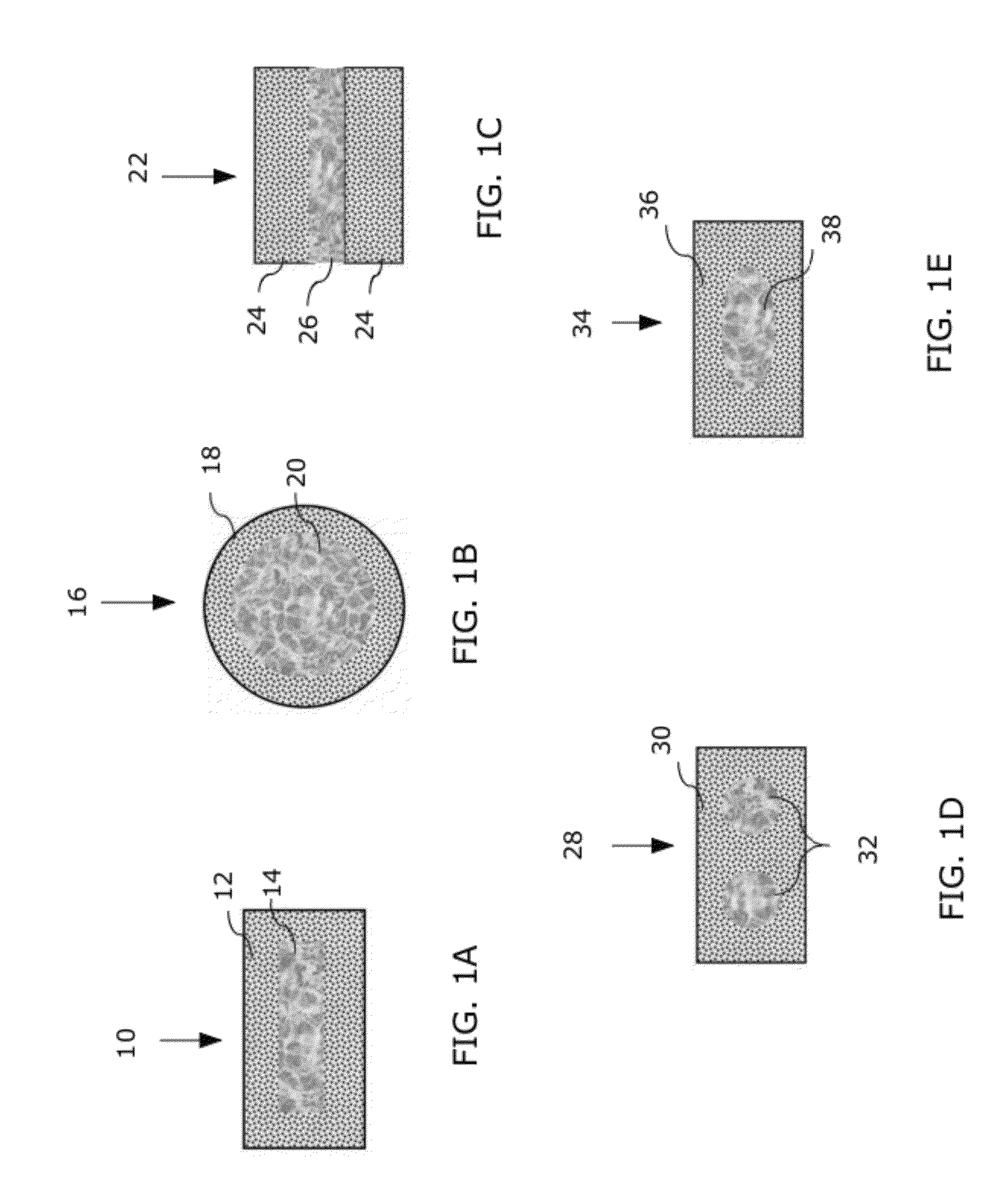

Method for making a financial transaction card with embedded electronic circuitry

InactiveUS6902116B2Complete banking machinesOther printing matterComputer hardwareFinancial transaction

Financial transaction and similar cards are fabricated with a split core adapted to received embedded electronic circuitry. The card core has two or more laminated layers. The cavity is milled into one or more of the layers to receive the electronic circuitry. The core layers are then laminated together, along with protective overlays. Alternative fabrication methods include co-extrusion and injection molding.

Owner:INNOVATIVE CARD TECH

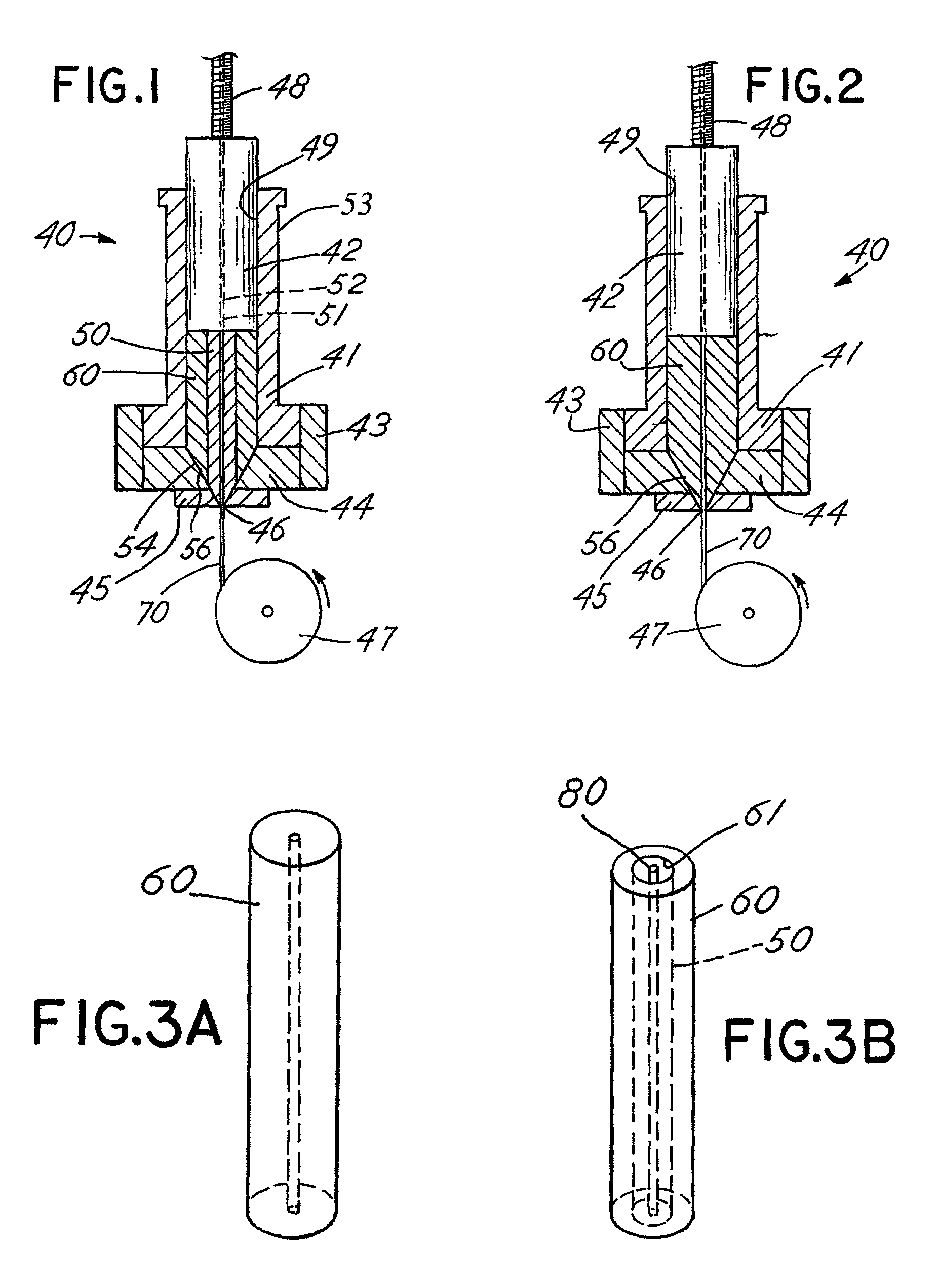

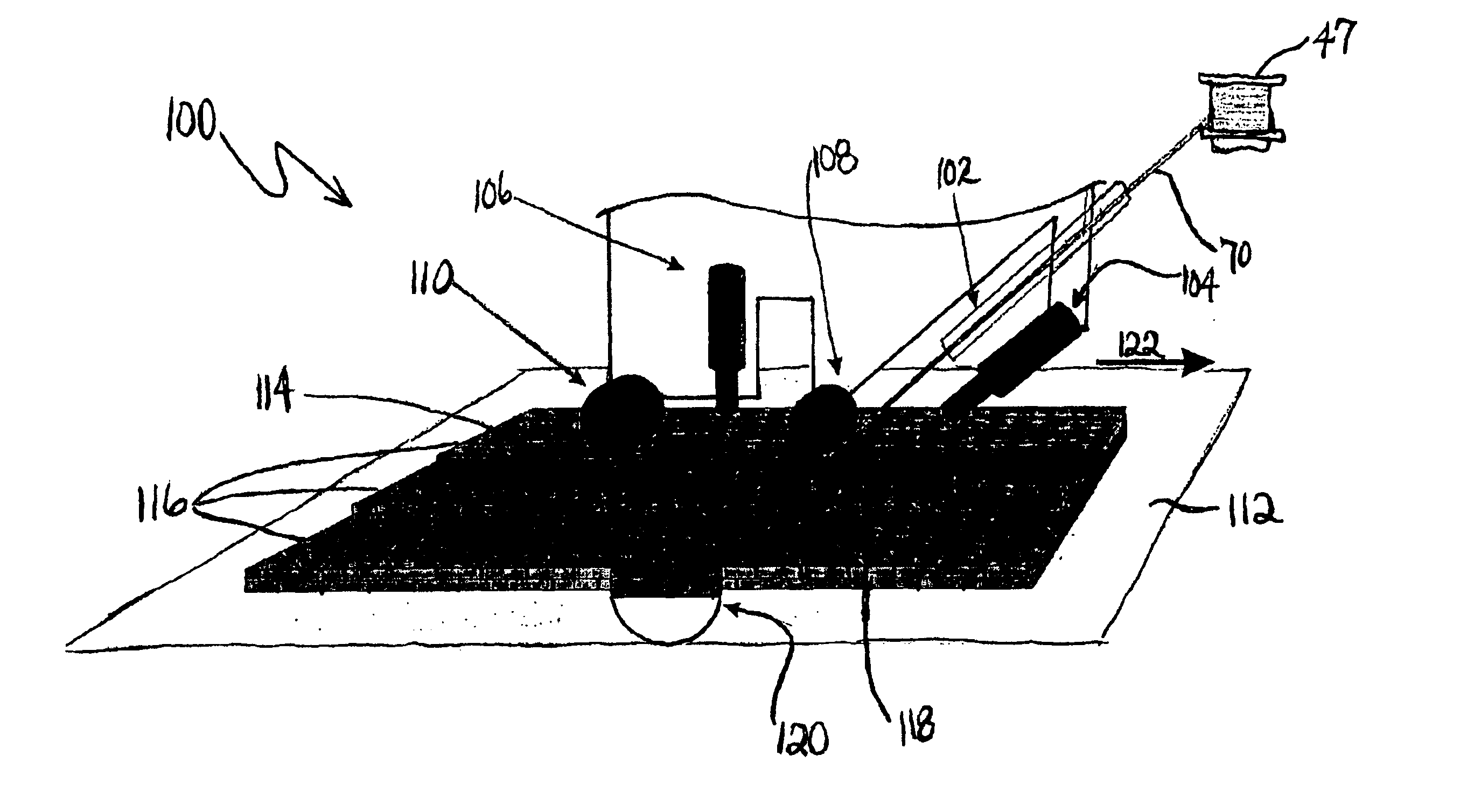

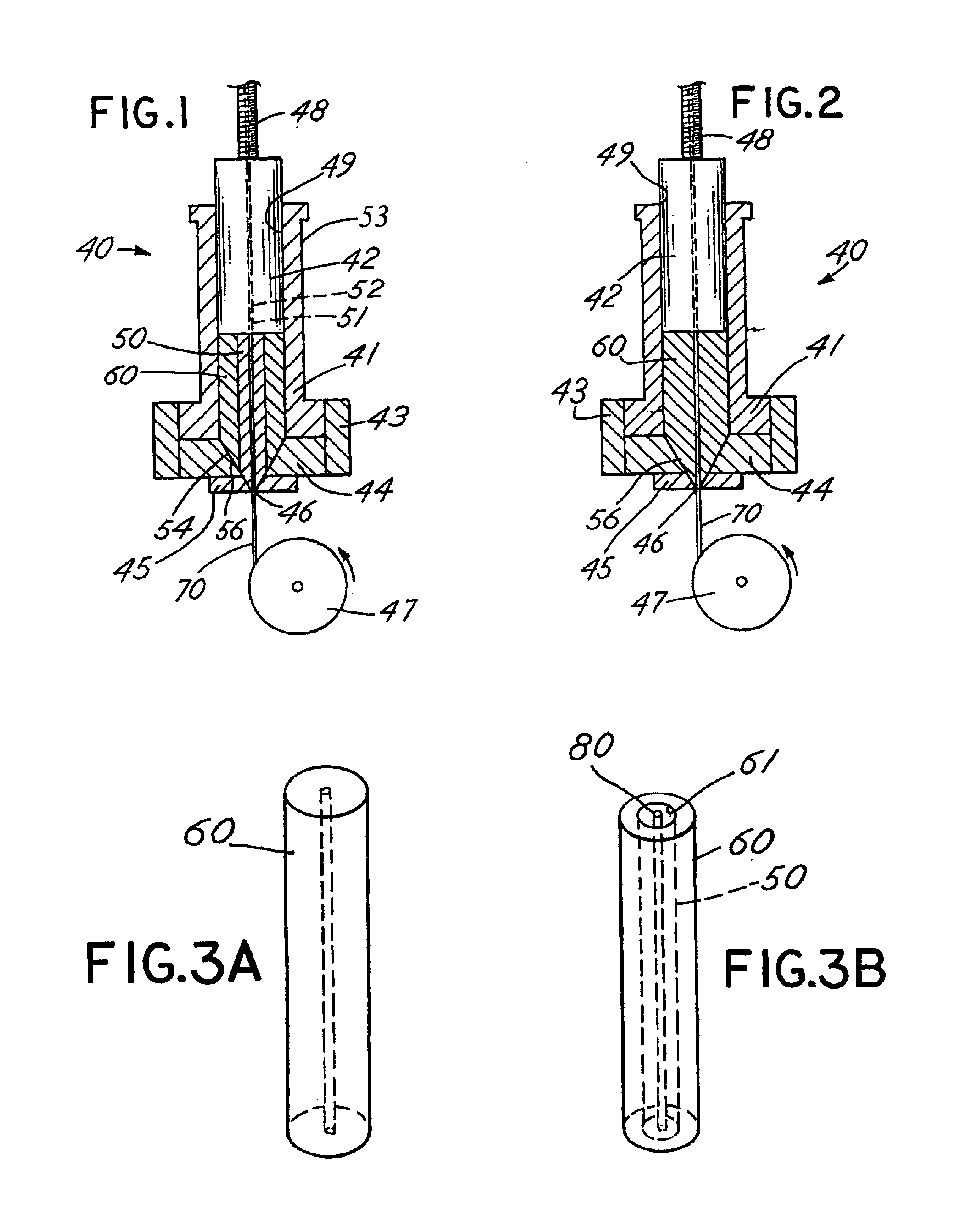

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

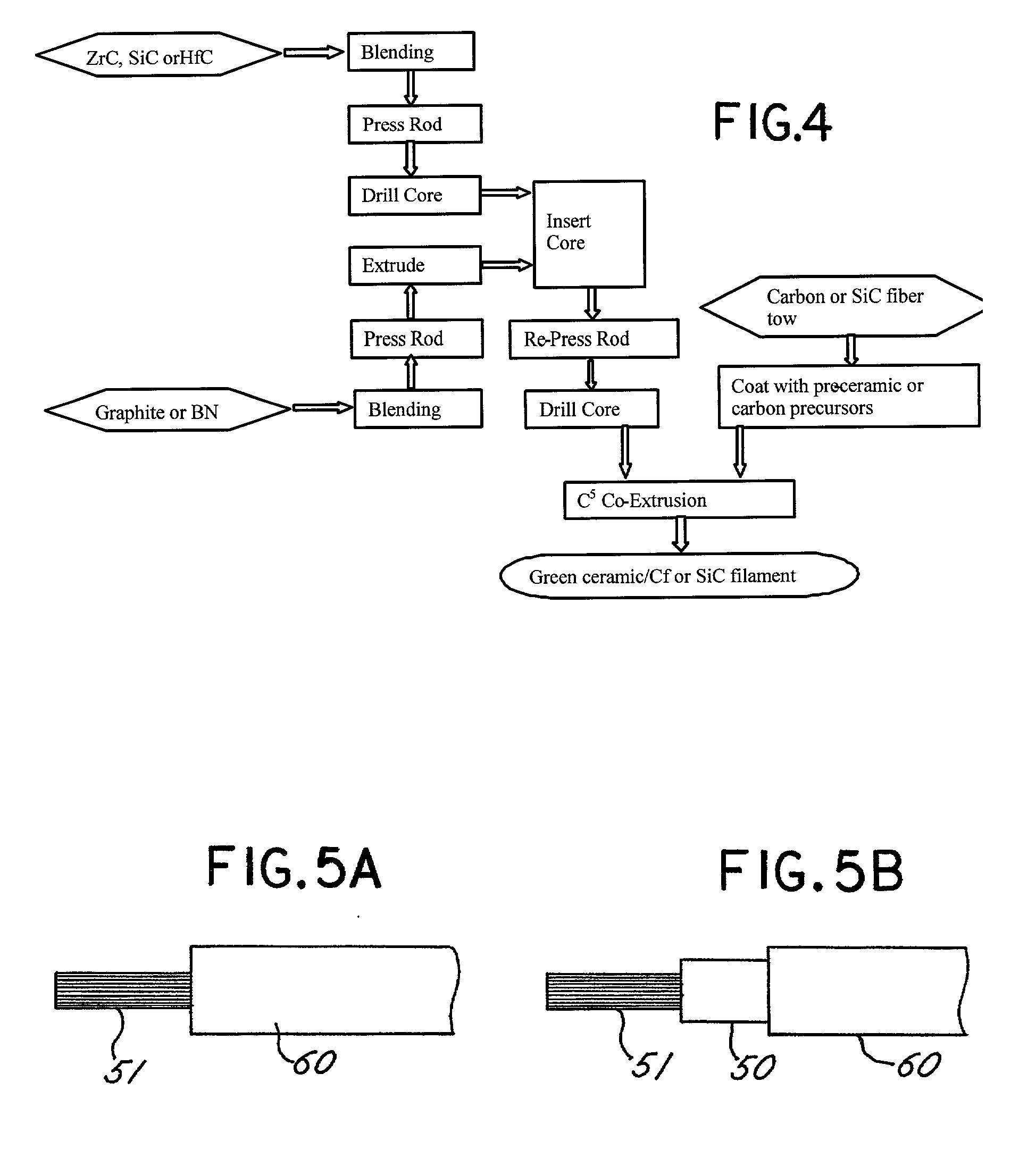

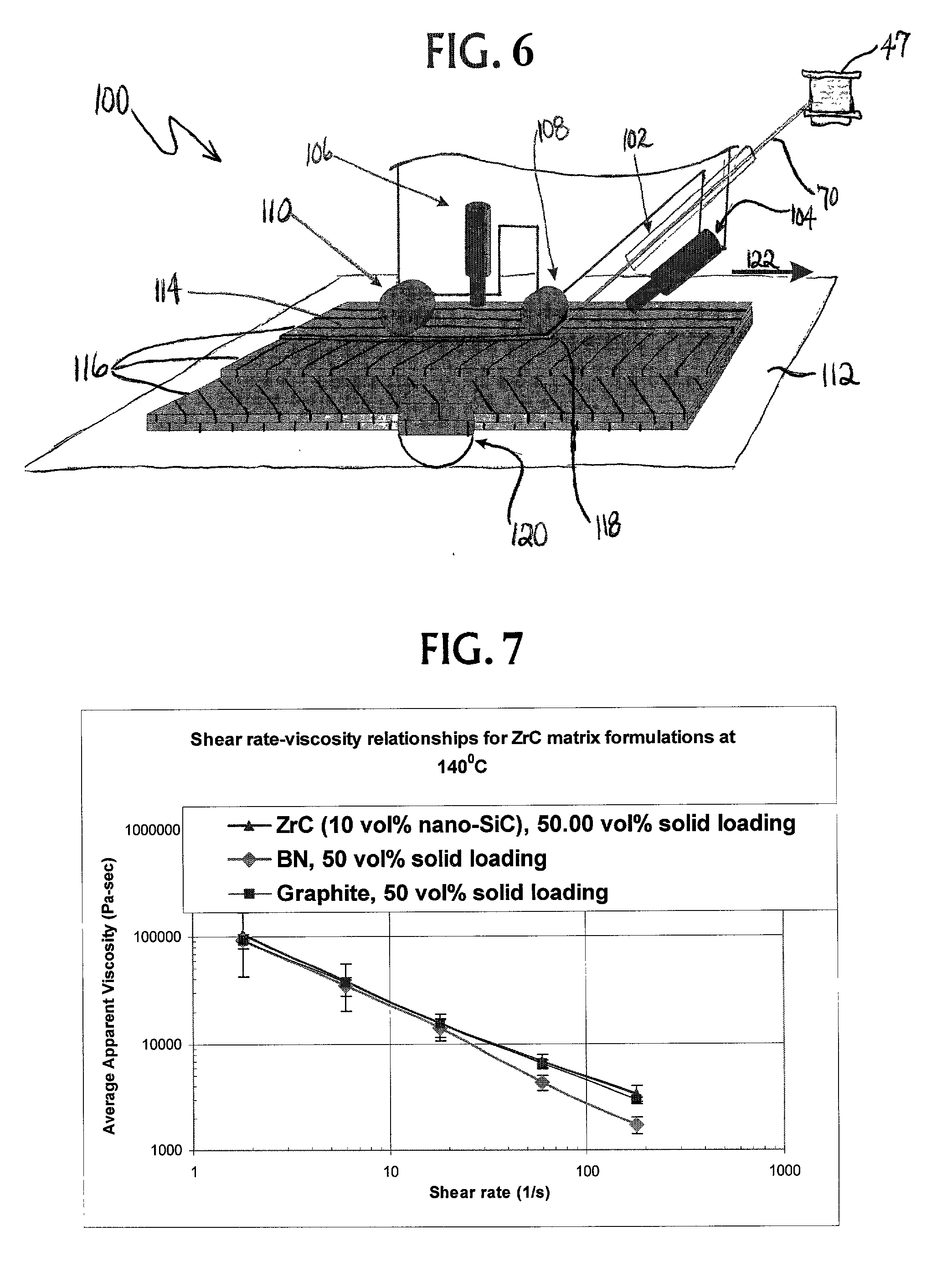

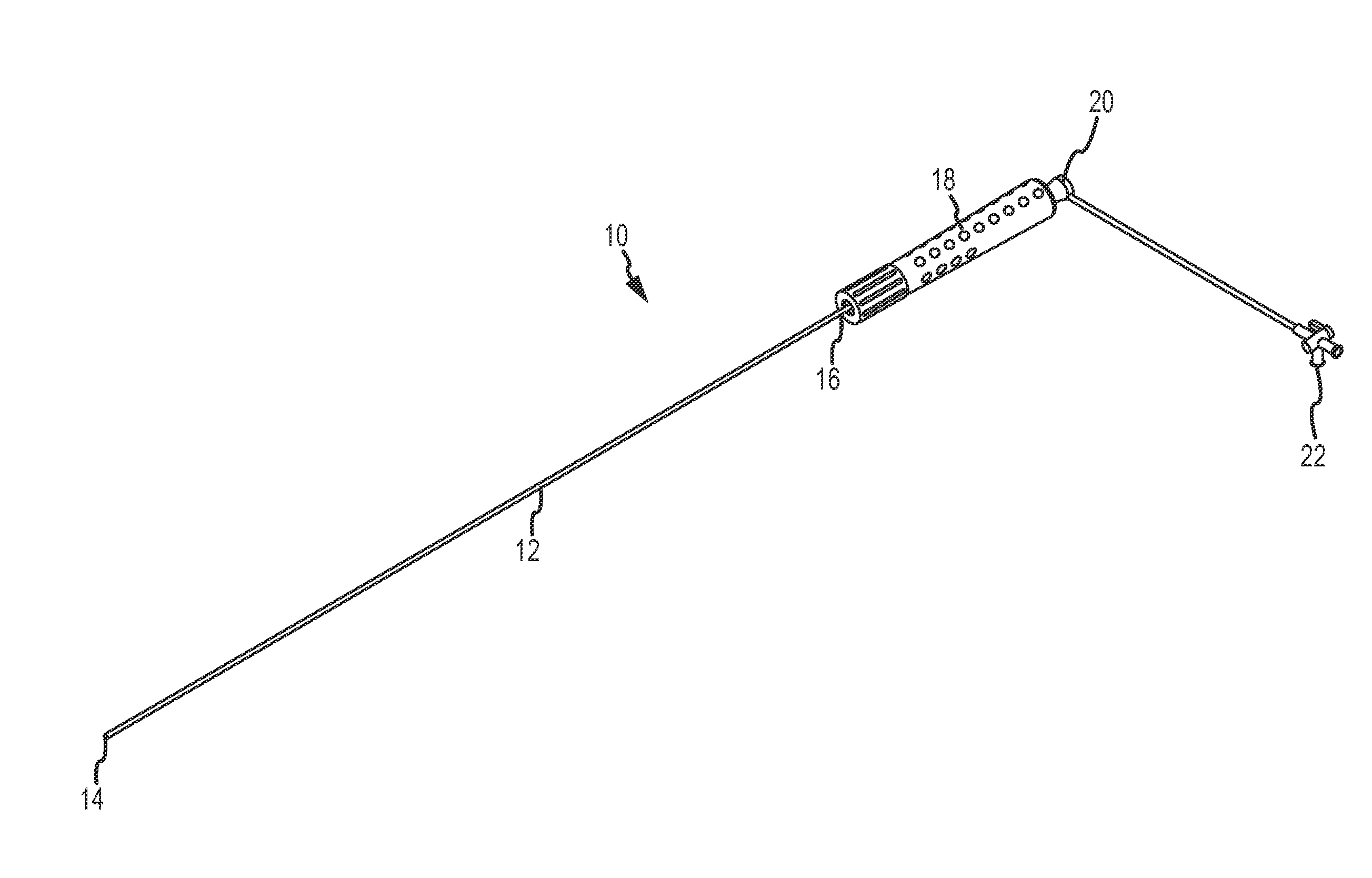

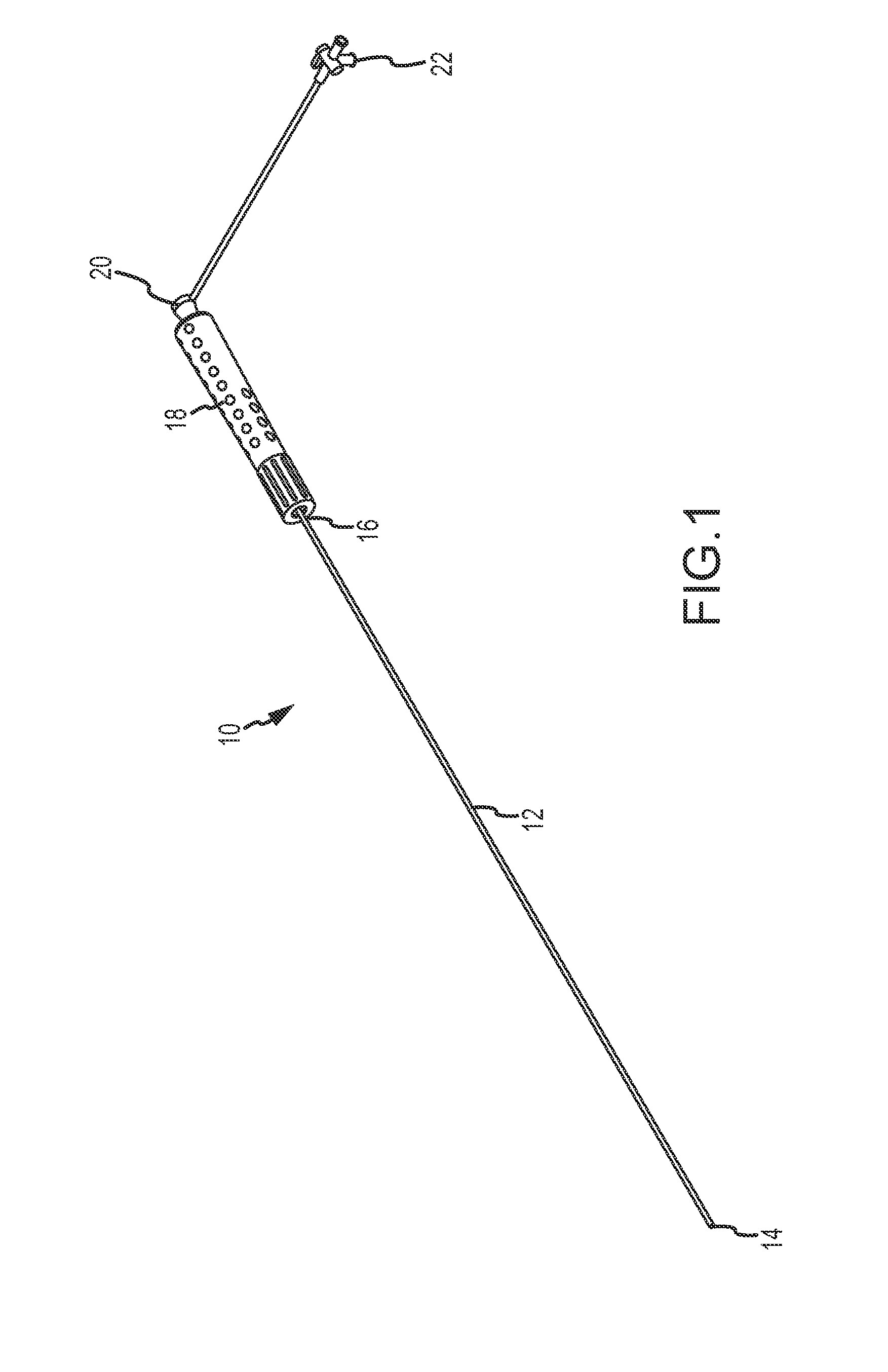

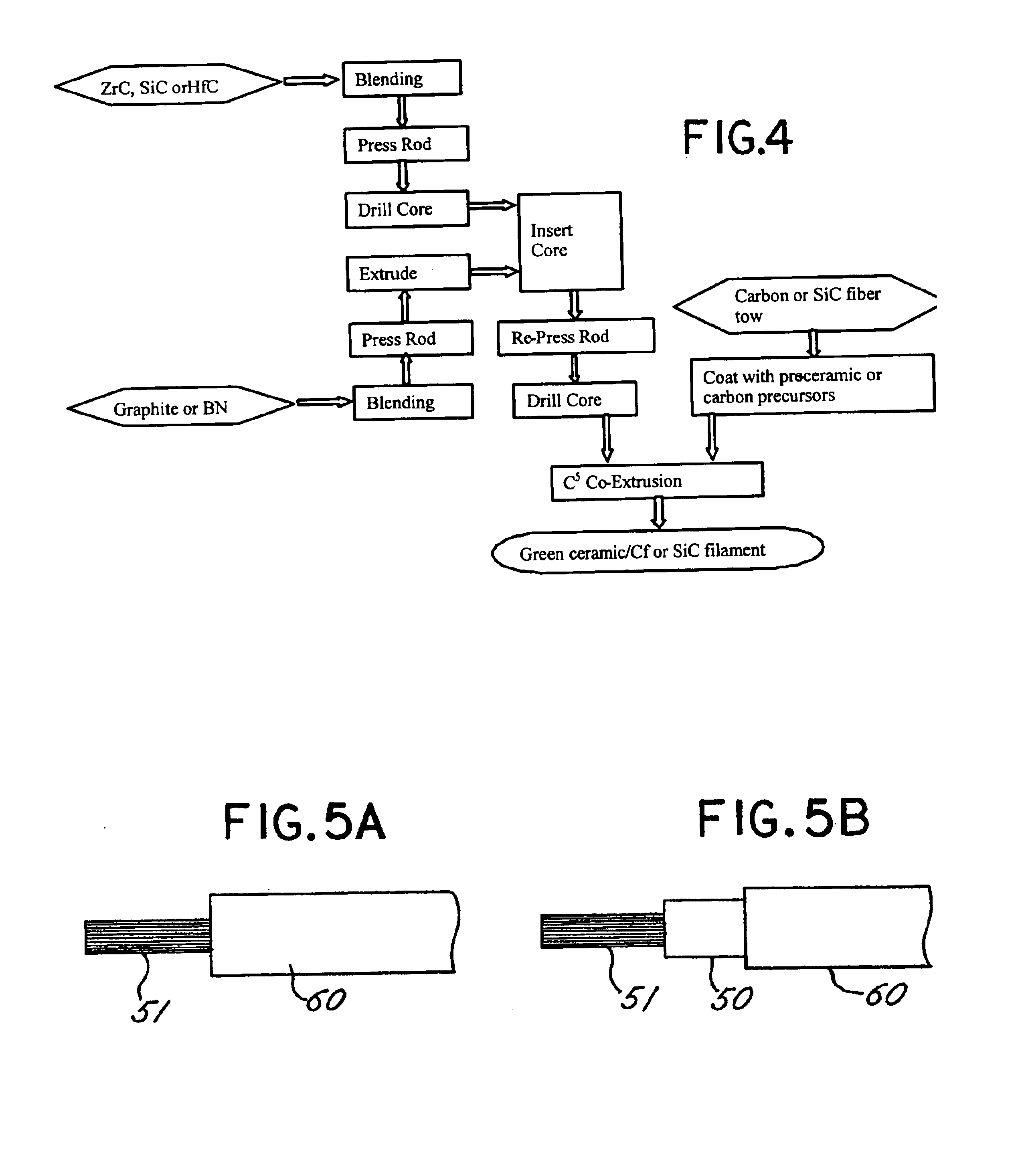

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

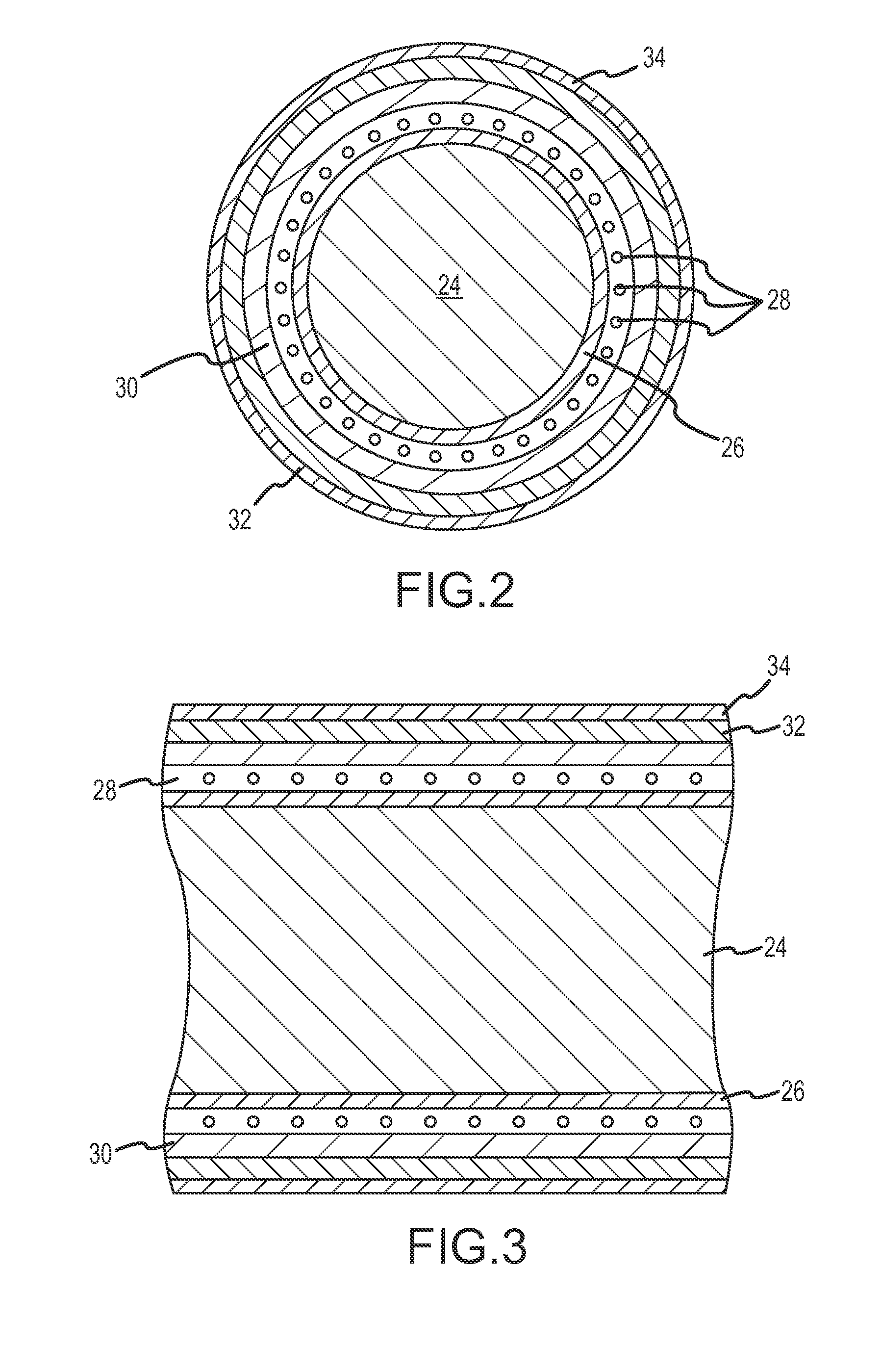

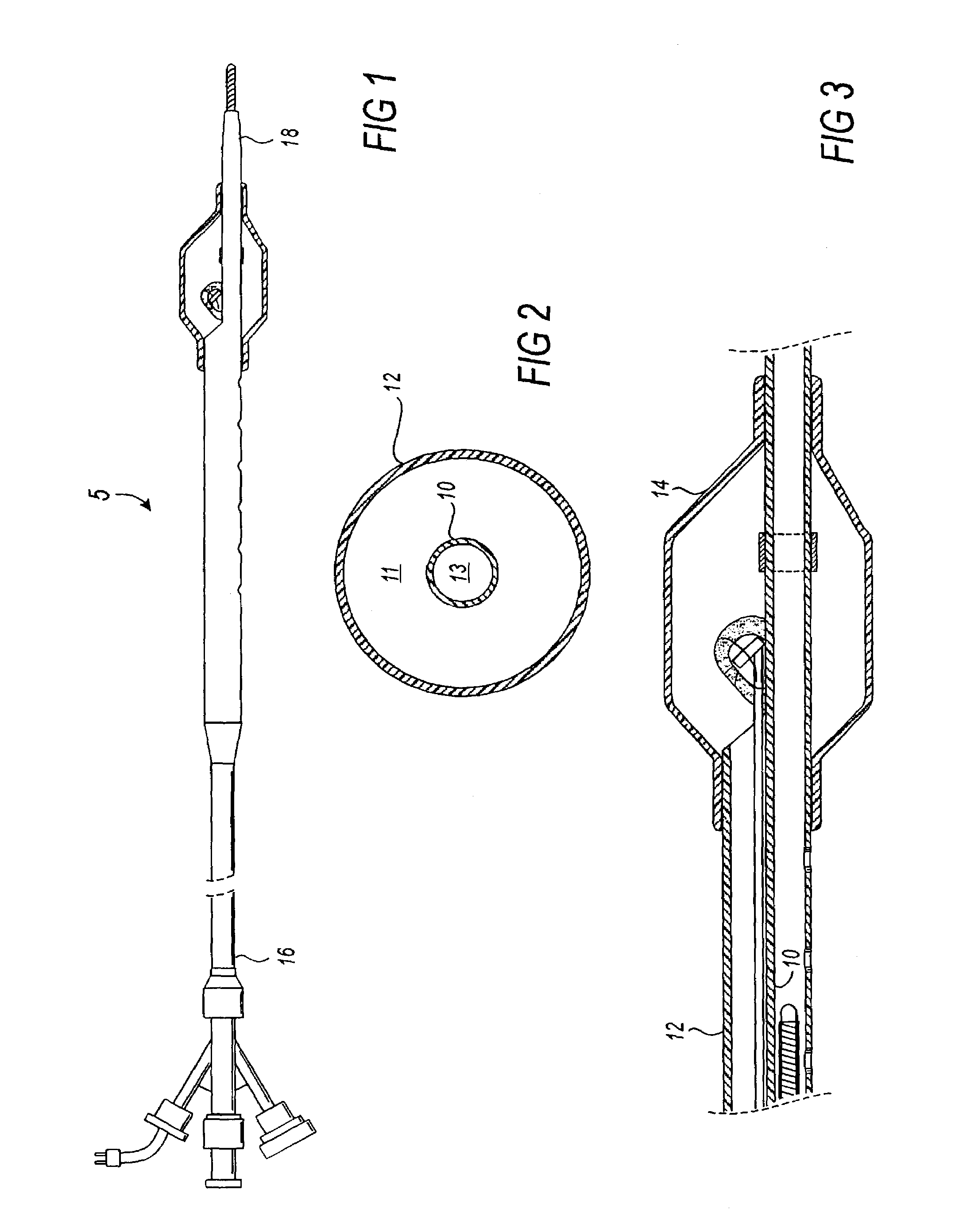

Catheter Shaft and Method of its Manufacture

ActiveUS20090166913A1Increase flexibilityIncrease resistanceMedical devicesLaminationHardnessCo extrusion

A method of manufacturing a catheter shaft includes the steps of forming an inner layer of a first polymeric material, forming a plait matrix layer including a second polymeric material about the inner layer, and forming an outer layer of a third polymeric material about the plait matrix layer. The plait matrix layer includes a braided wire mesh partially or fully embedded within the second polymeric material, which is different from at least one of the first polymeric material forming the inner layer and the third polymeric material forming the outer layer. The second polymeric material has a higher yield strain and / or a lower hardness than at least the first polymeric material, and preferably both the first and the third polymeric materials. The first polymeric material and the third polymeric material may be different or the same. The catheter shaft may be formed by stepwise extrusion, co-extrusion, and / or reflow processes.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

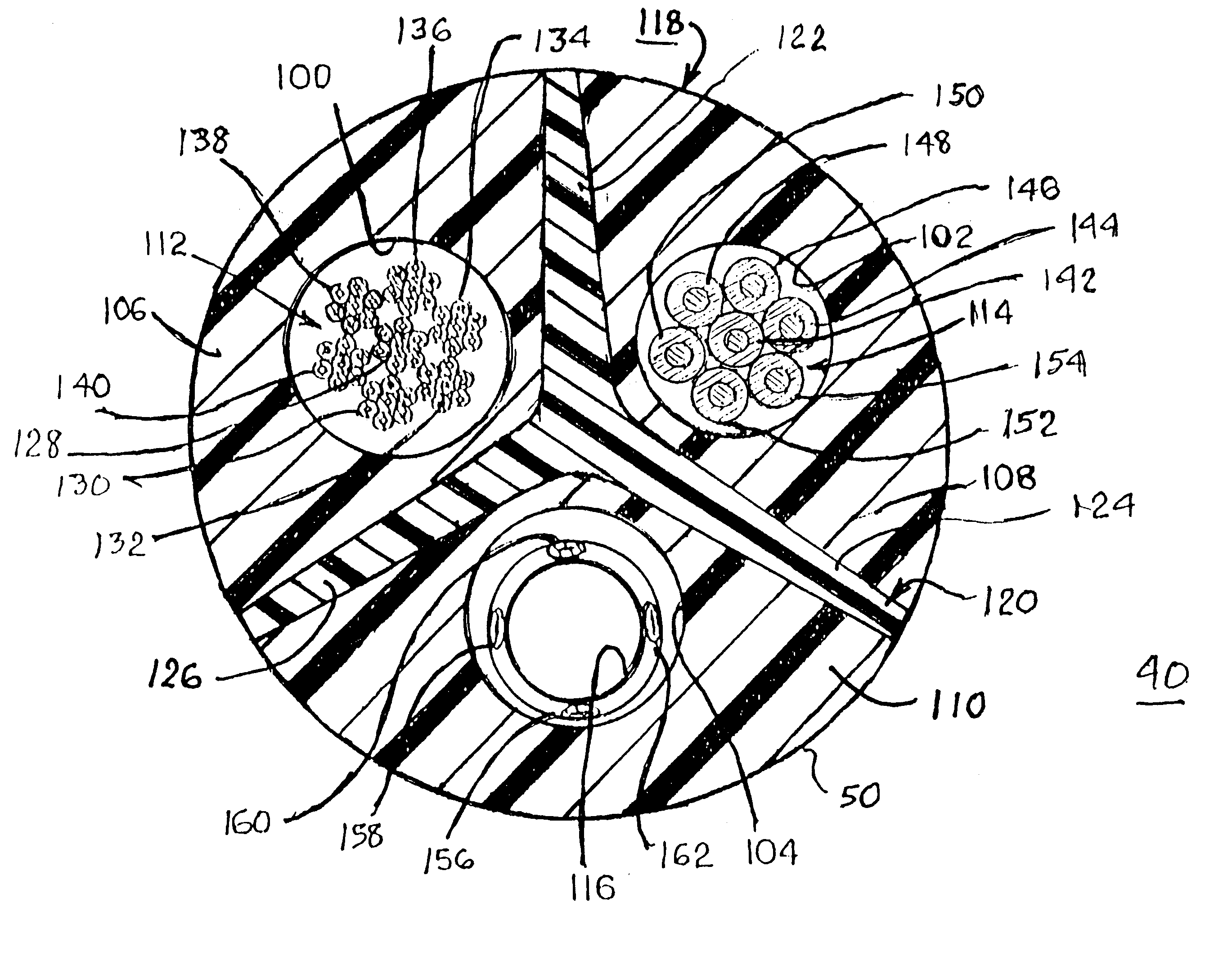

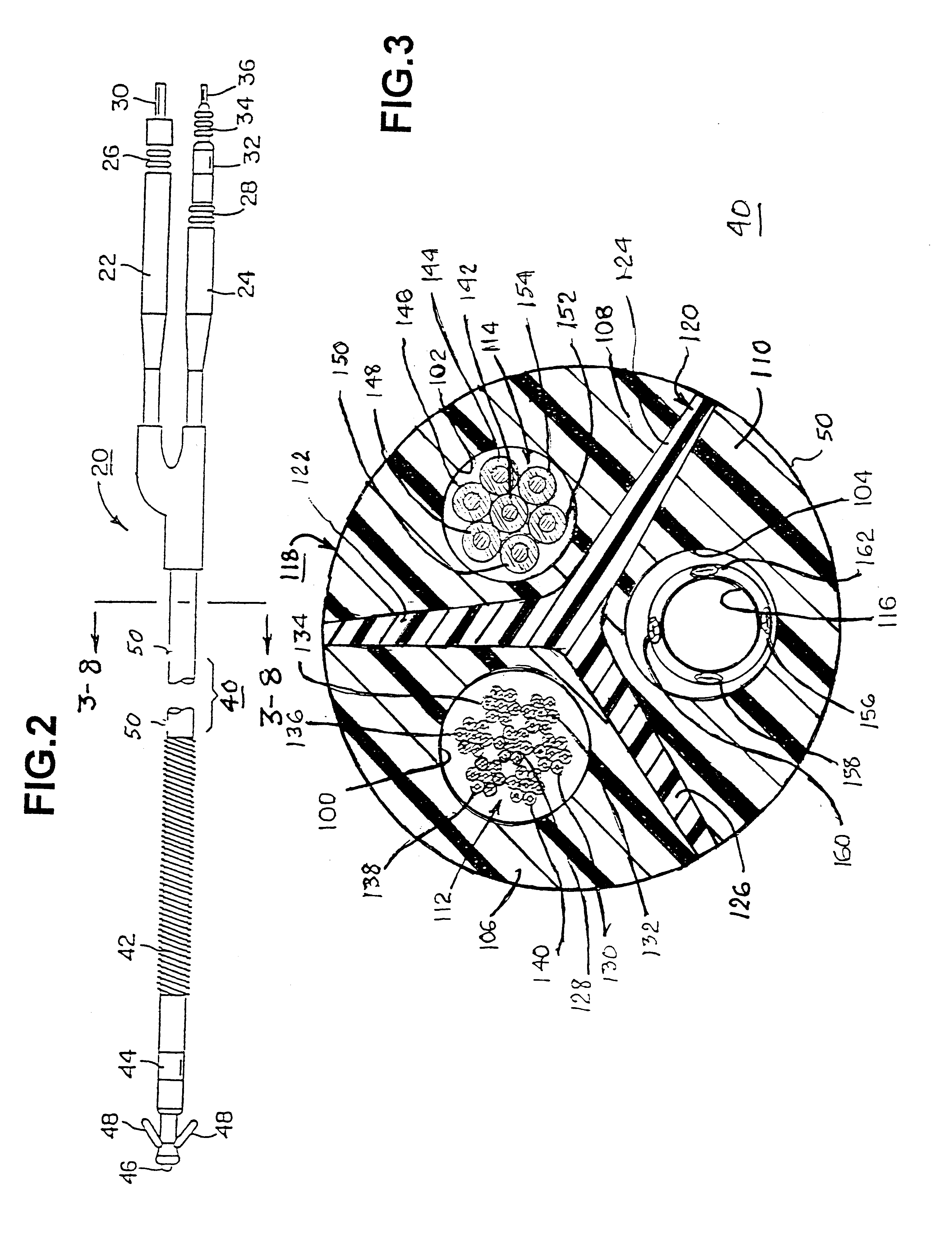

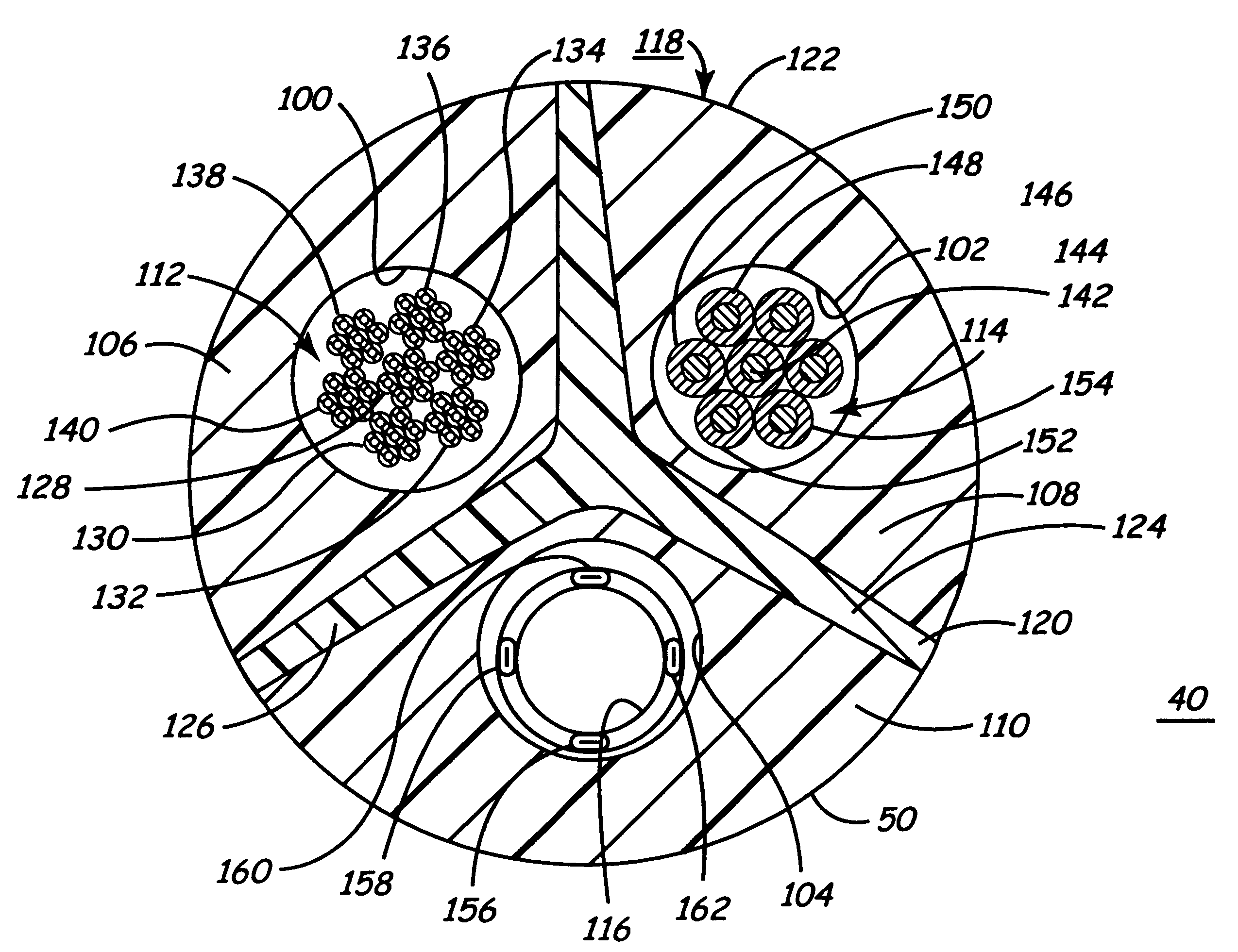

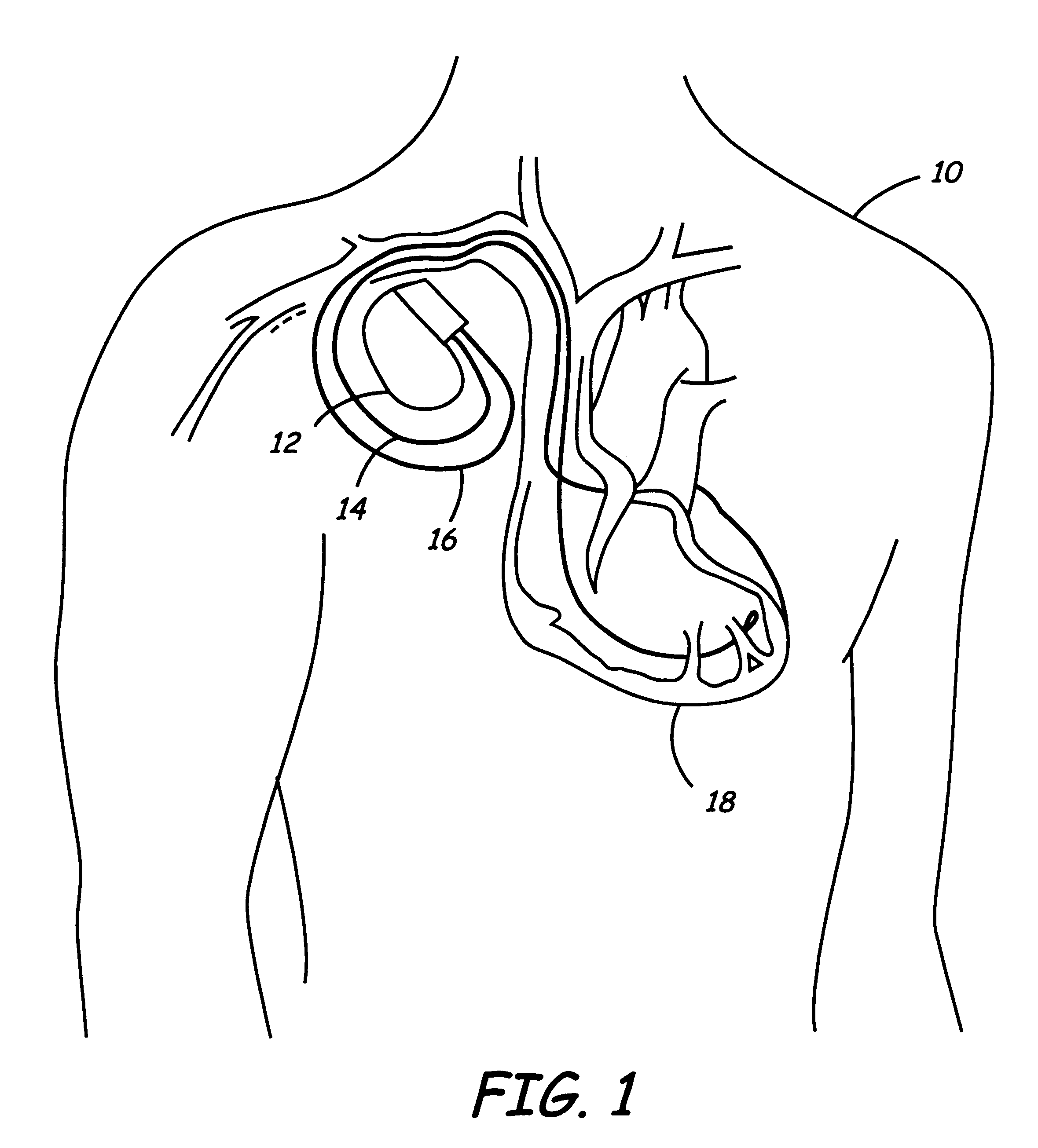

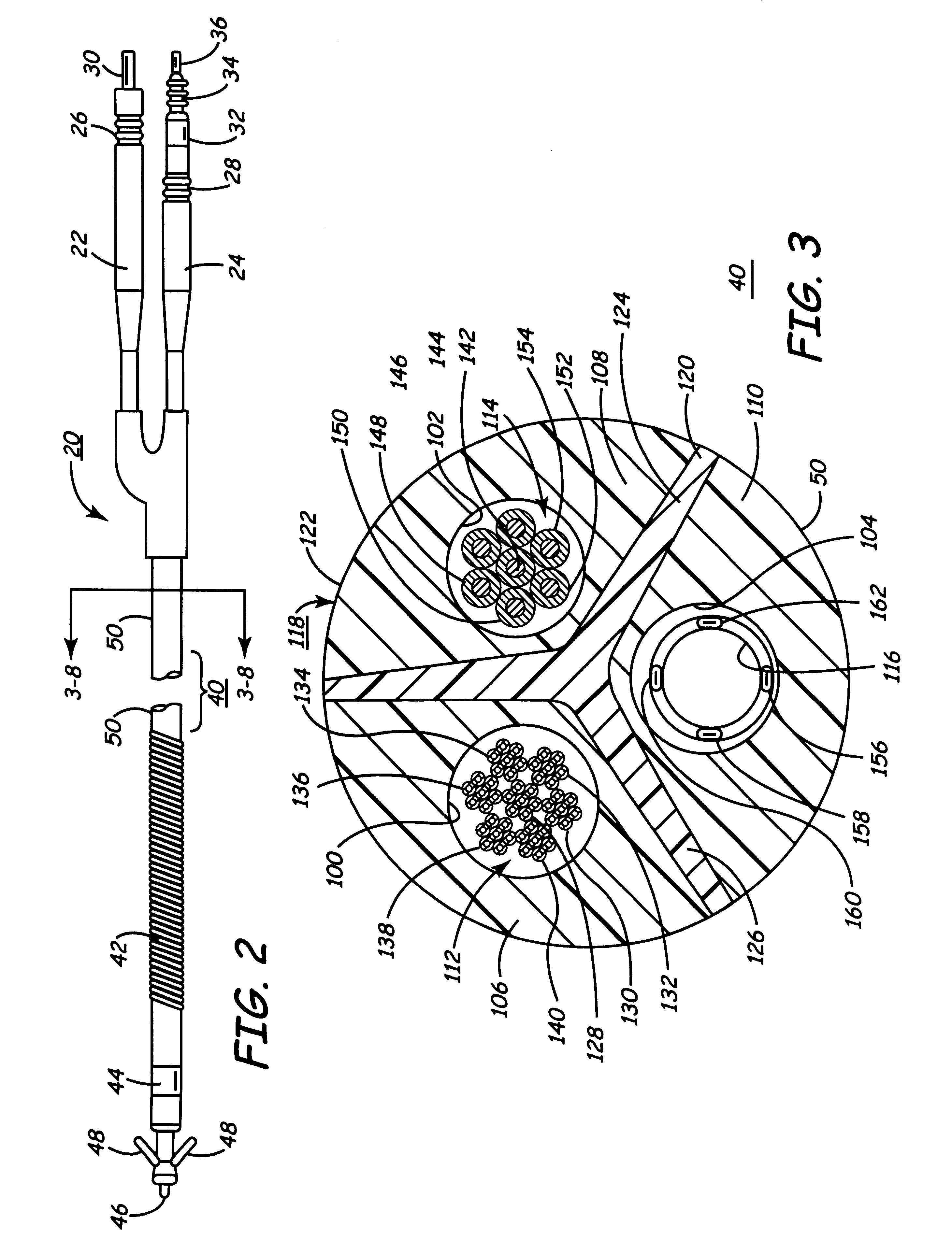

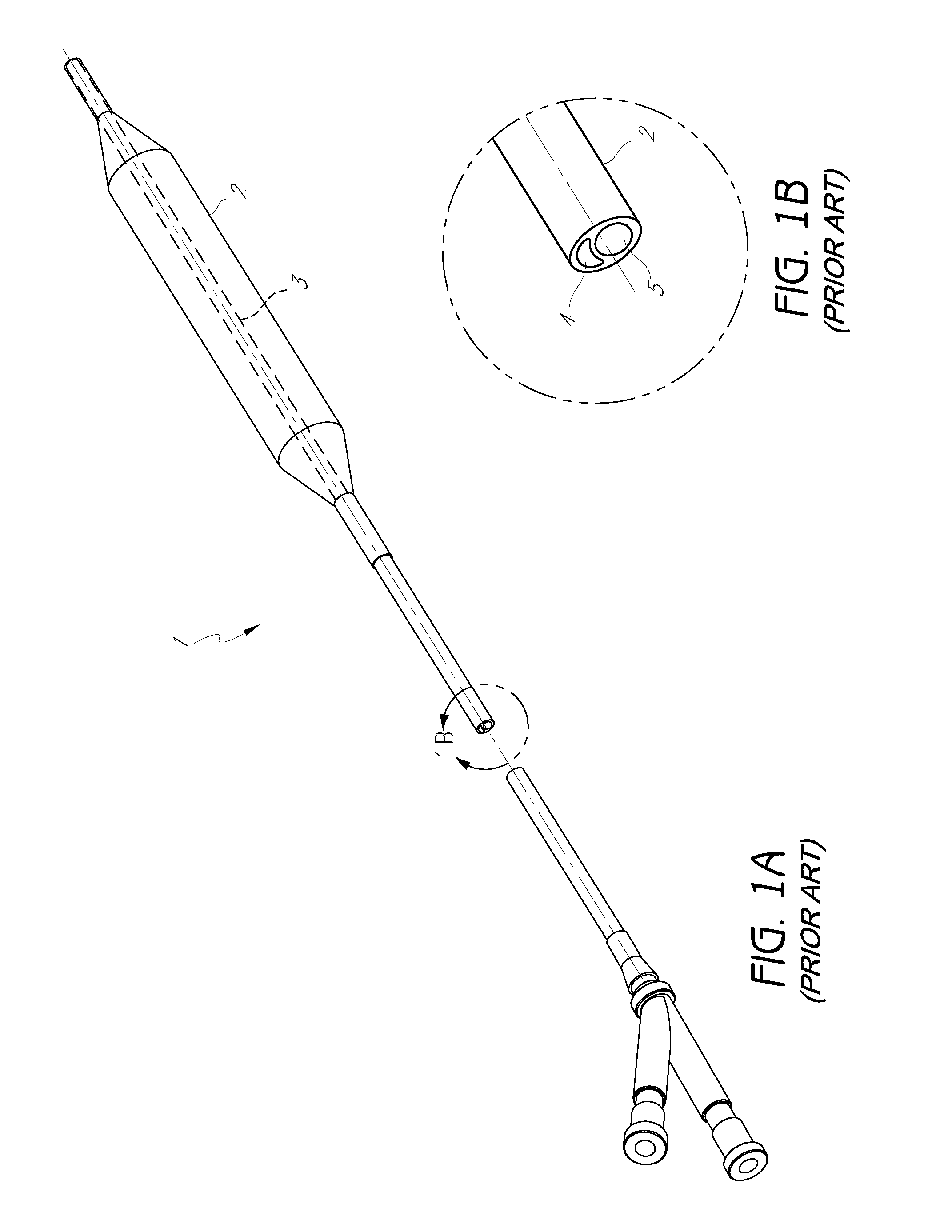

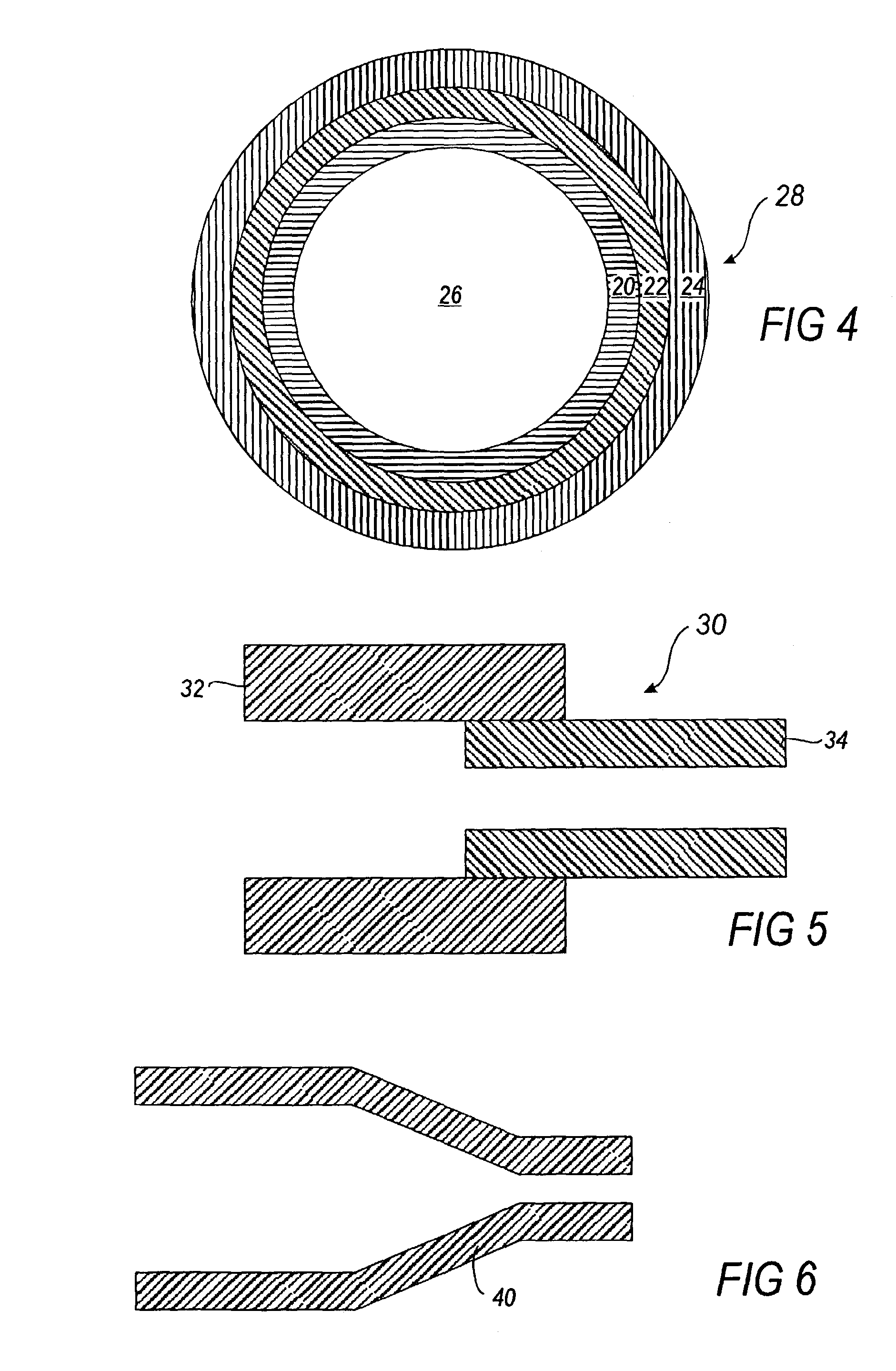

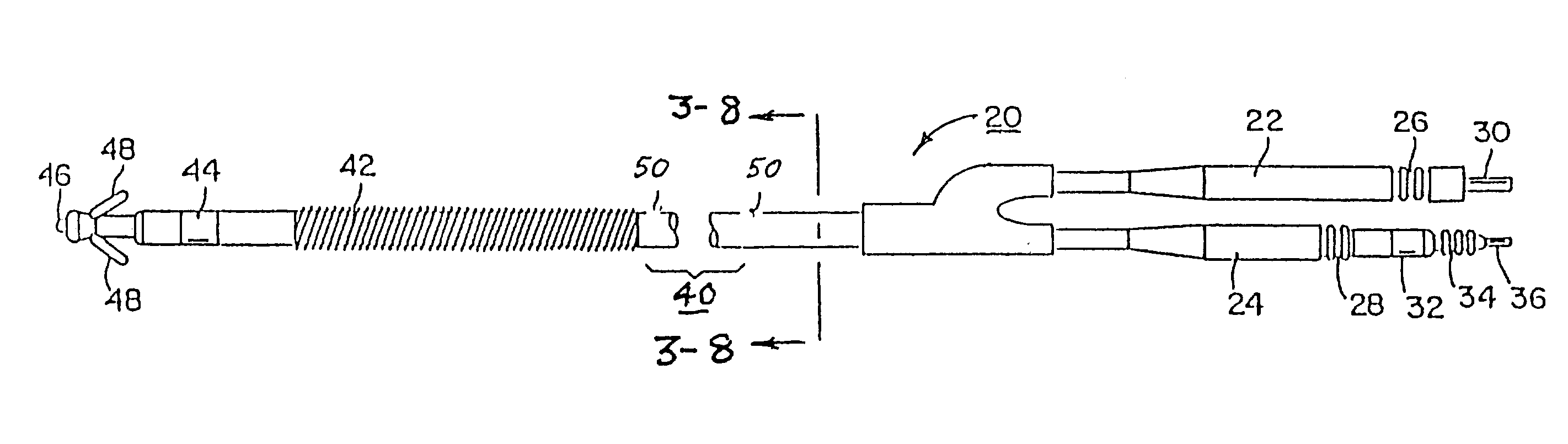

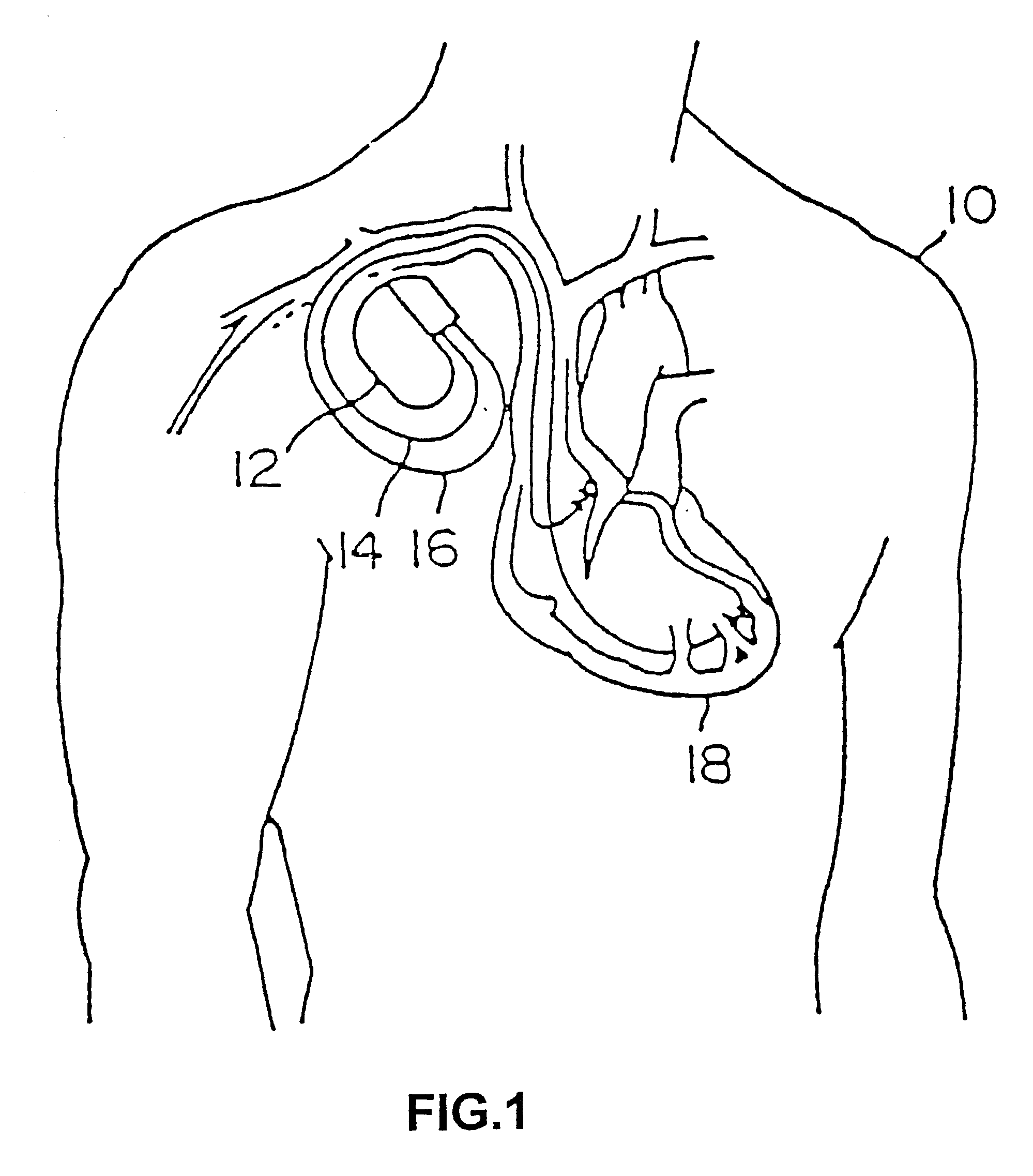

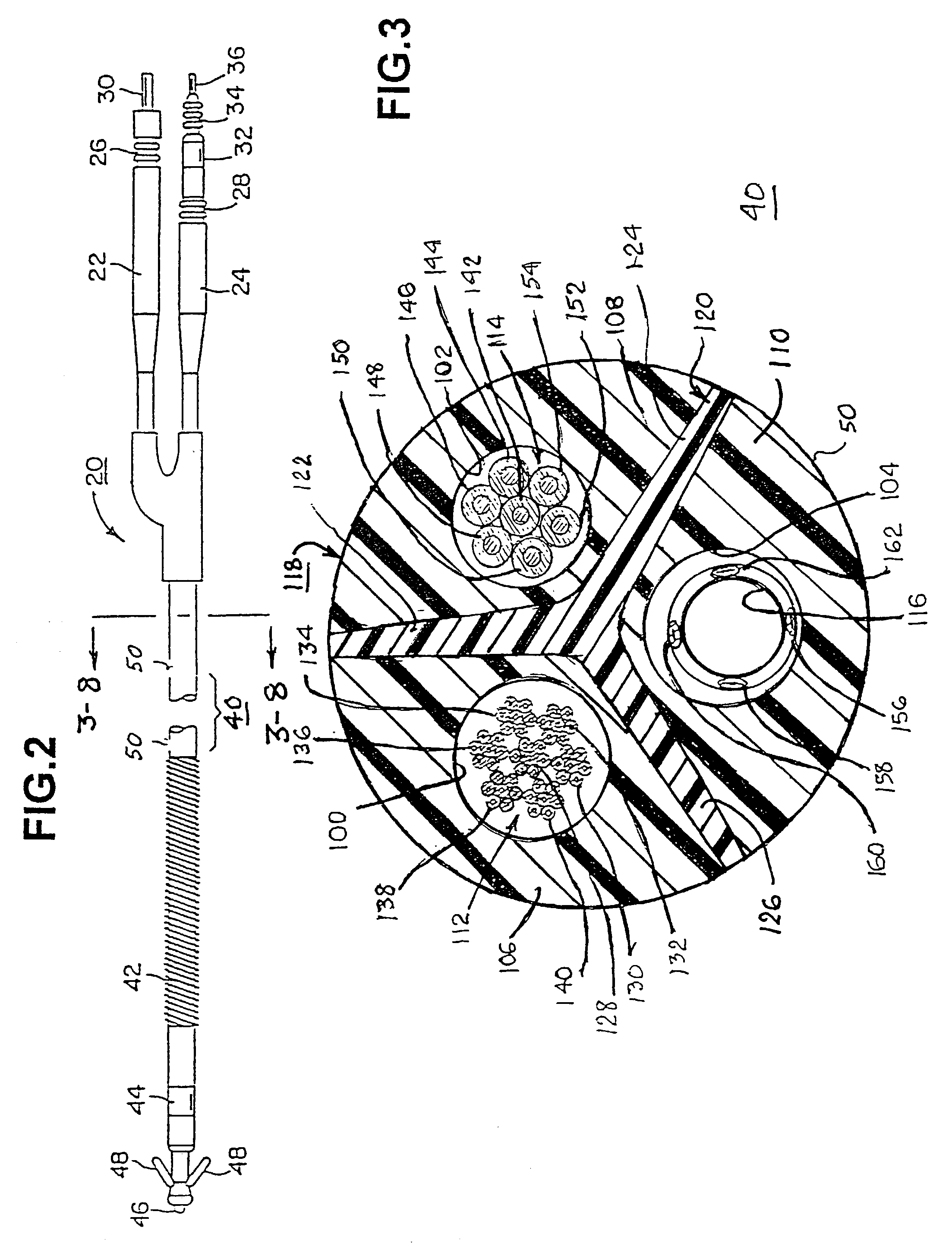

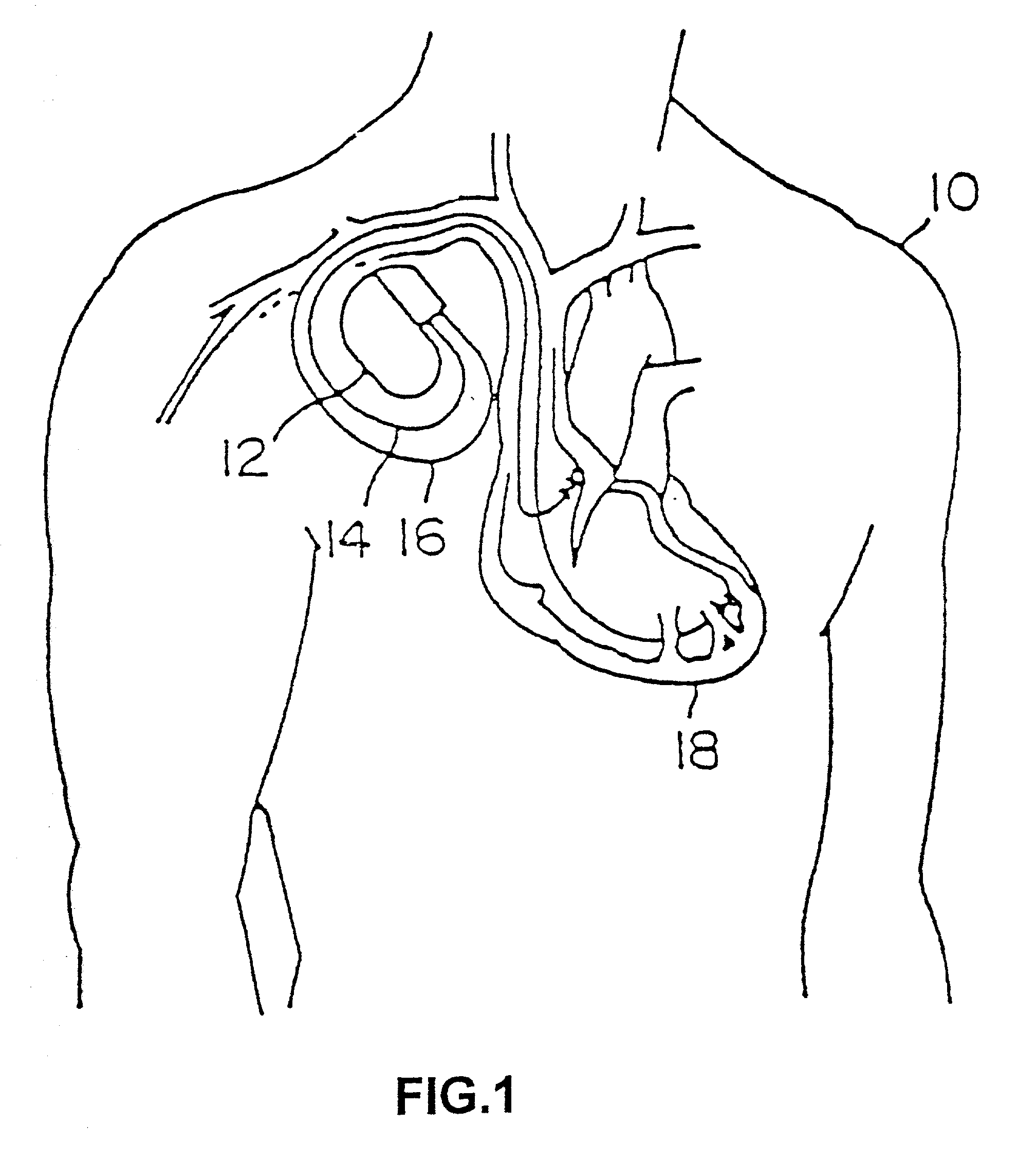

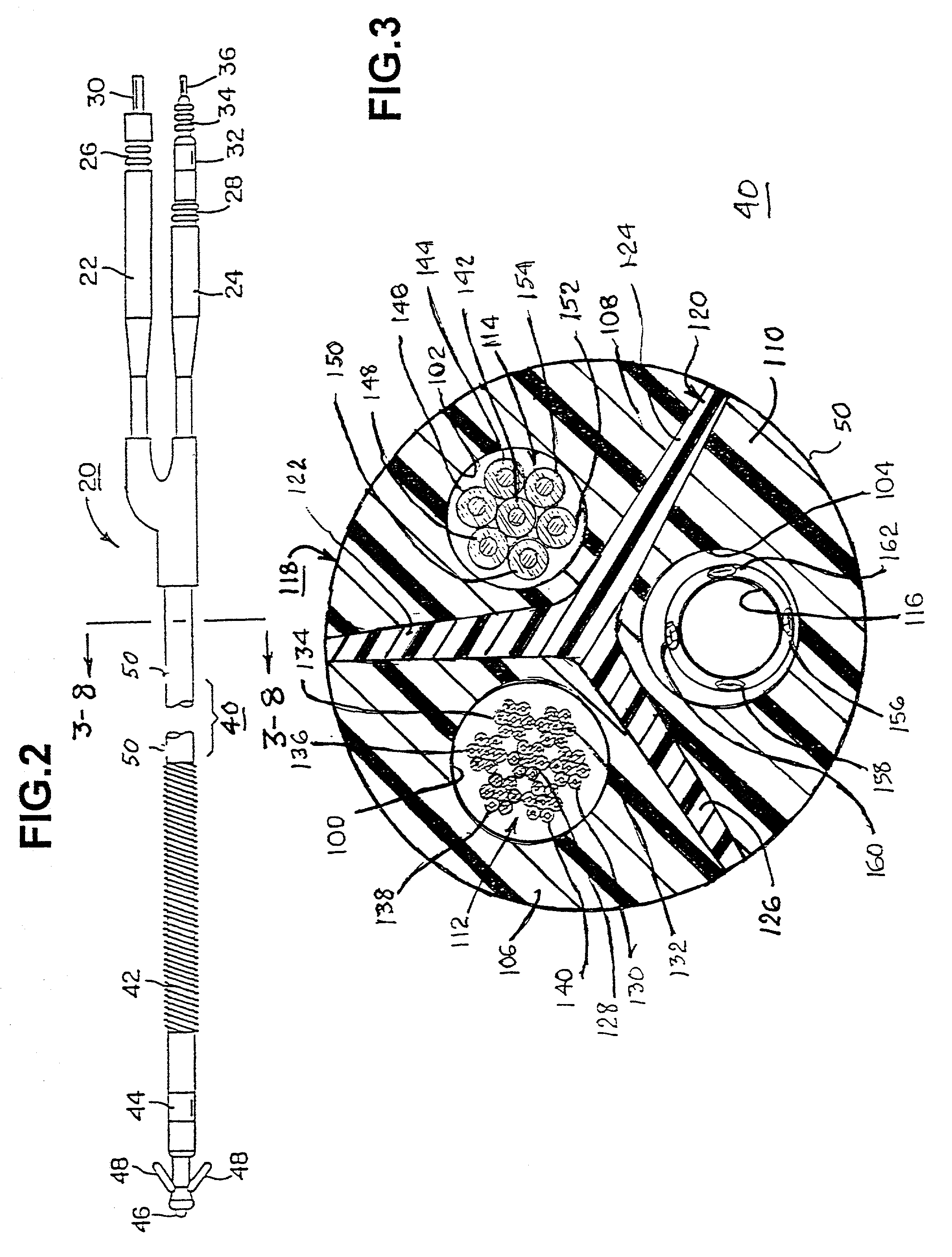

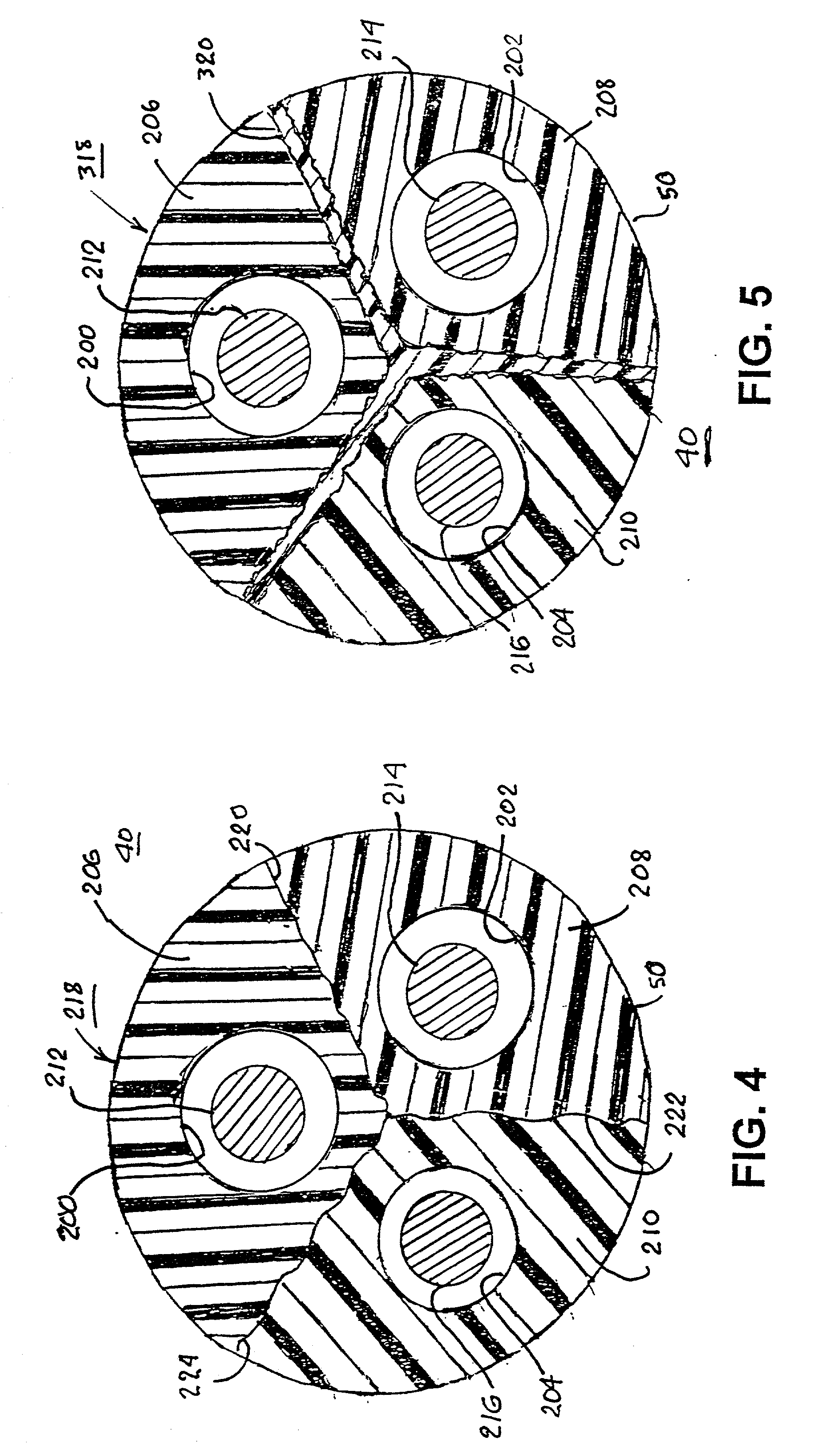

Co-extruded, multi-lumen medical lead

InactiveUS6434430B2Transvascular endocardial electrodesDiagnostic recording/measuringElectrical stimulationsBending stiffness

Owner:MEDTRONIC INC

Co-extruded, multi-lumen medical lead

InactiveUS6400992B1Transvascular endocardial electrodesExternal electrodesElectrical stimulationsBending stiffness

Medical electrical leads for sensing or electrical stimulation of body organs or tissues, particularly implantable cardiac leads for delivering pacing pulses and cardioversion / defibrillation shocks, and / or sensing the cardiac electrogram (EGM) or other physiologic data and their methods of fabrication are disclosed. A lead body sheath is co-extruded in a co-extrusion process using bio-compatible, electrically insulating, materials of differing durometers in differing axial sections thereof, resulting in a unitary lead body sheath having differing stiffness sections including axial segments or webs or lumen encircling rings or other structures in its cross-section. The lead body sheath is co-extruded to have an outer surface adapted to be exposed to the environment or to be enclosed within an outer sheath and to have a plurality of lead conductor lumens for receiving and enclosing a like plurality of lead conductors of the same or differing types. The lead body sheath can be co-extruded of a plurality of sheath segments containing a lead conductor lumen and formed of a first durometer material or of differing durometer materials. A web of a further durometer material can be co-extruded extending between the adjoining boundaries of the axial sheath segments and bonding the adjacent segments together. The lead body sheath can be tailored to exhibit differing bending stiffnesses away from the lead body sheath axis in selected polar directions around 360° circumference of the sheath body.

Owner:MEDTRONIC INC

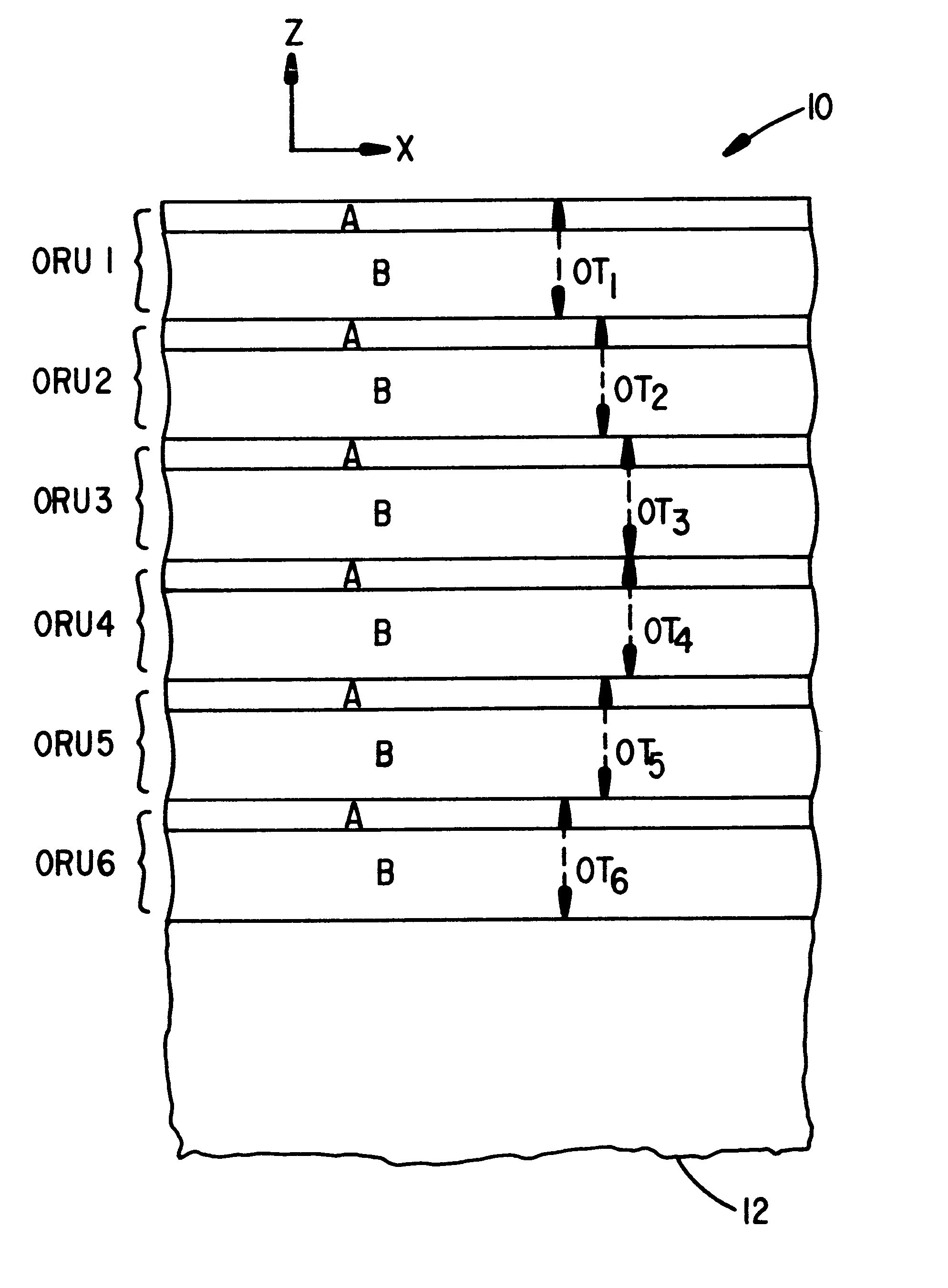

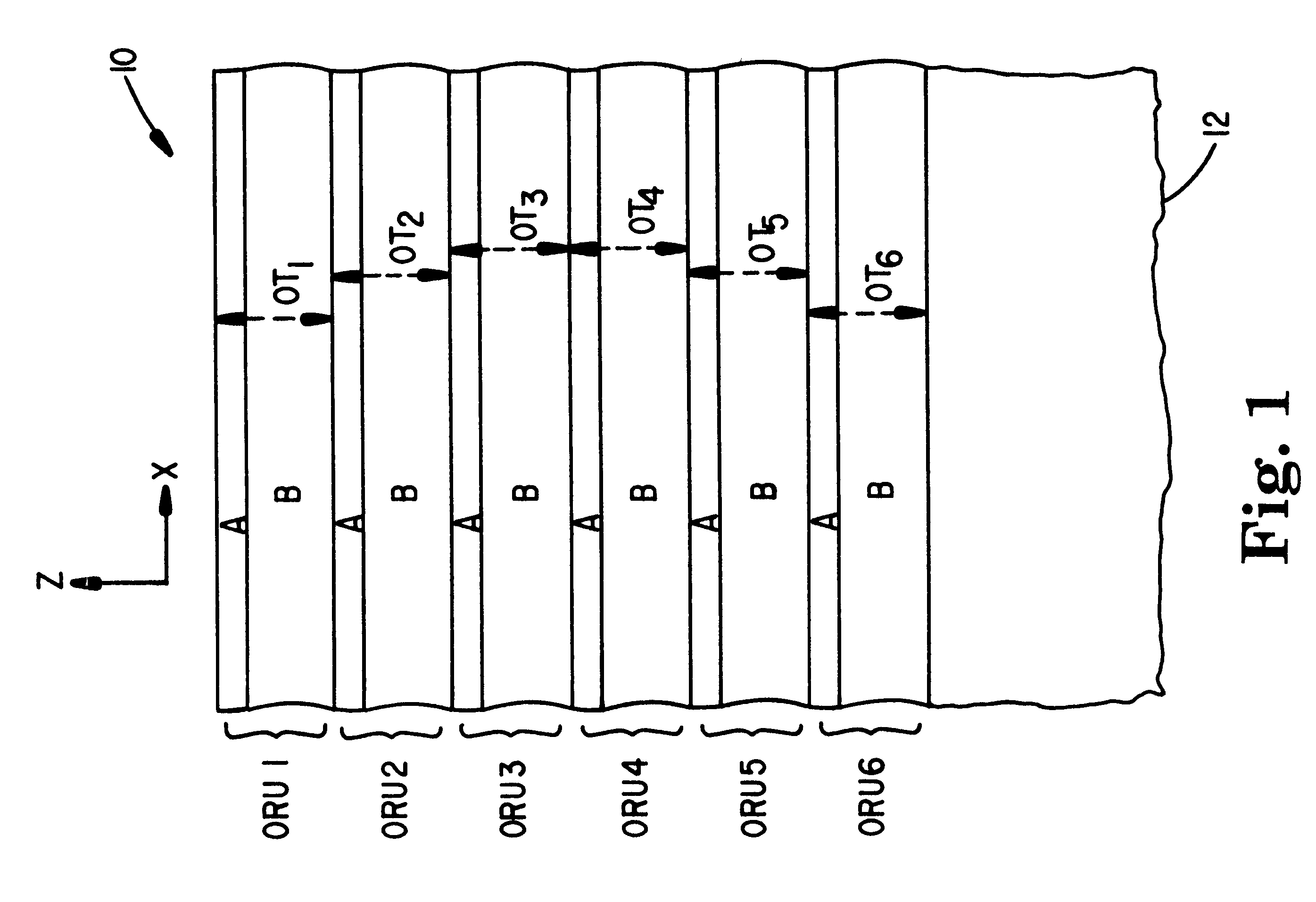

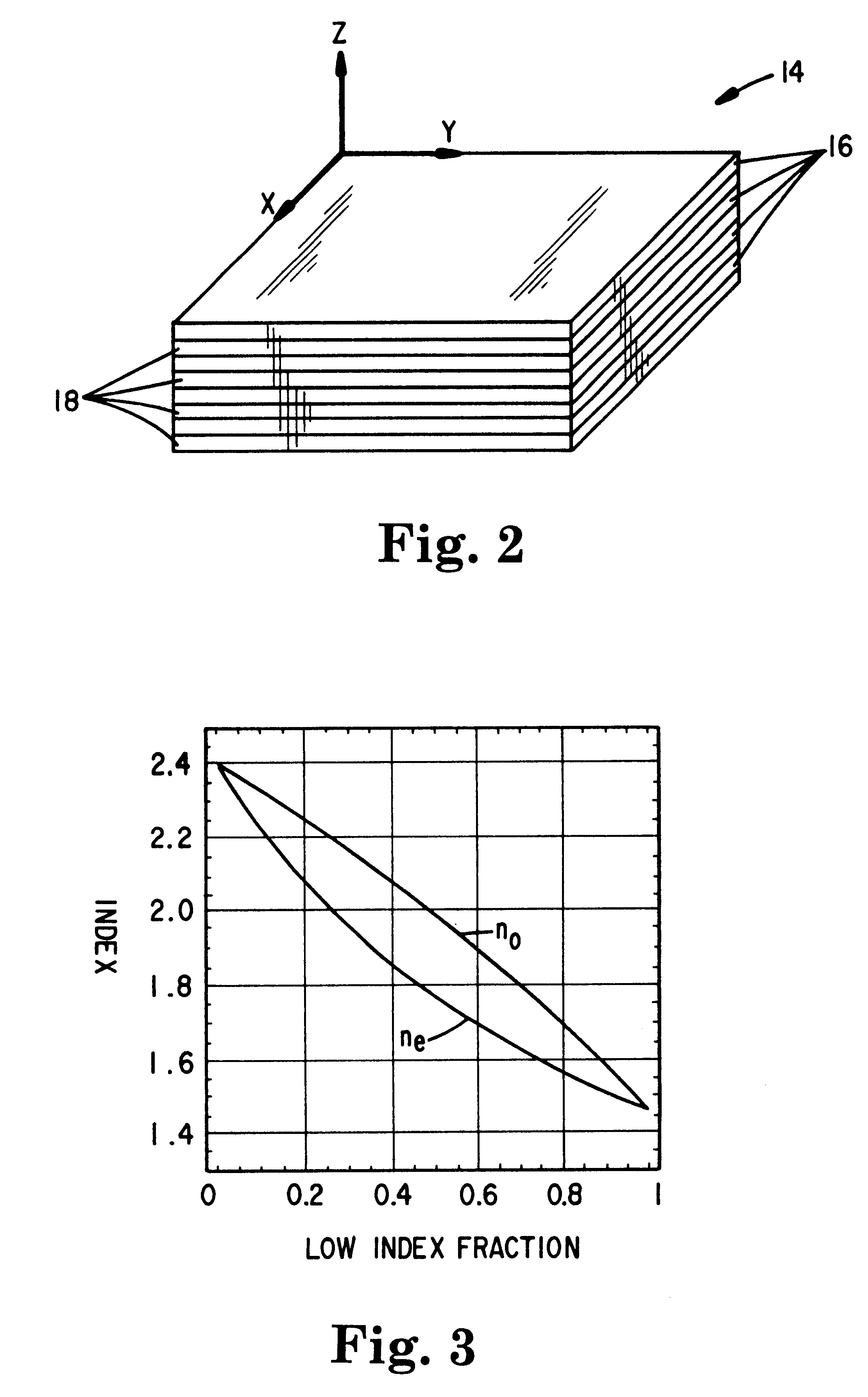

Birefringent reflectors using isotropic materials and form birefringence

Multilayer thin film reflectors, such as mirrors and reflective polarizers, are described in which form birefringent optical layers are incorporated into a plurality of optical repeat units in the film. The form birefringent layers exhibit birefringence as a result of microscopic structures that have a dimension that is small compared to the wavelength of light but large compared to molecular distances. The optical layers within the optical repeat units have out-of-plane indices of refraction that are tailored to produce desired effects as a function of incidence angle for p-polarized light. The multilayer reflectors can be made by conventional vacuum deposition techniques using known inorganic optical materials, but can also be made entirely with polymeric materials by co-extrusion or other processes.

Owner:3M INNOVATIVE PROPERTIES CO

Continuous fiber reinforced composites and methods, apparatuses, and compositions for making the same

InactiveUS6899777B2Improved non-brittle failure characteristicFast preparationCeramic shaping apparatusCoatingsMetal fiberPolymer science

A process for continuous composite coextrusion comprising: (a) forming first a material-laden composition comprising a thermoplastic polymer and at least about 40 volume % of a ceramic or metallic particulate in a manner such that the composition has a substantially cylindrical geometry and thus can be used as a substantially cylindrical feed rod; (b) forming a hole down the symmetrical axis of the feed rod; (c) inserting the start of a continuous spool of ceramic fiber, metal fiber or carbon fiber through the hole in the feed rod; (d) extruding the feed rod and spool simultaneously to form a continuous filament consisting of a green matrix material completely surrounding a dense fiber reinforcement and said filament having an average diameter that is less than the average diameter of the feed rod; and (e) depositing the continuous filament into a desired architecture which preferably is determined from specific loading conditions of the desired object and CAD design of the object to provide a green fiber reinforced composite object.

Owner:ADVANCED CERAMICS

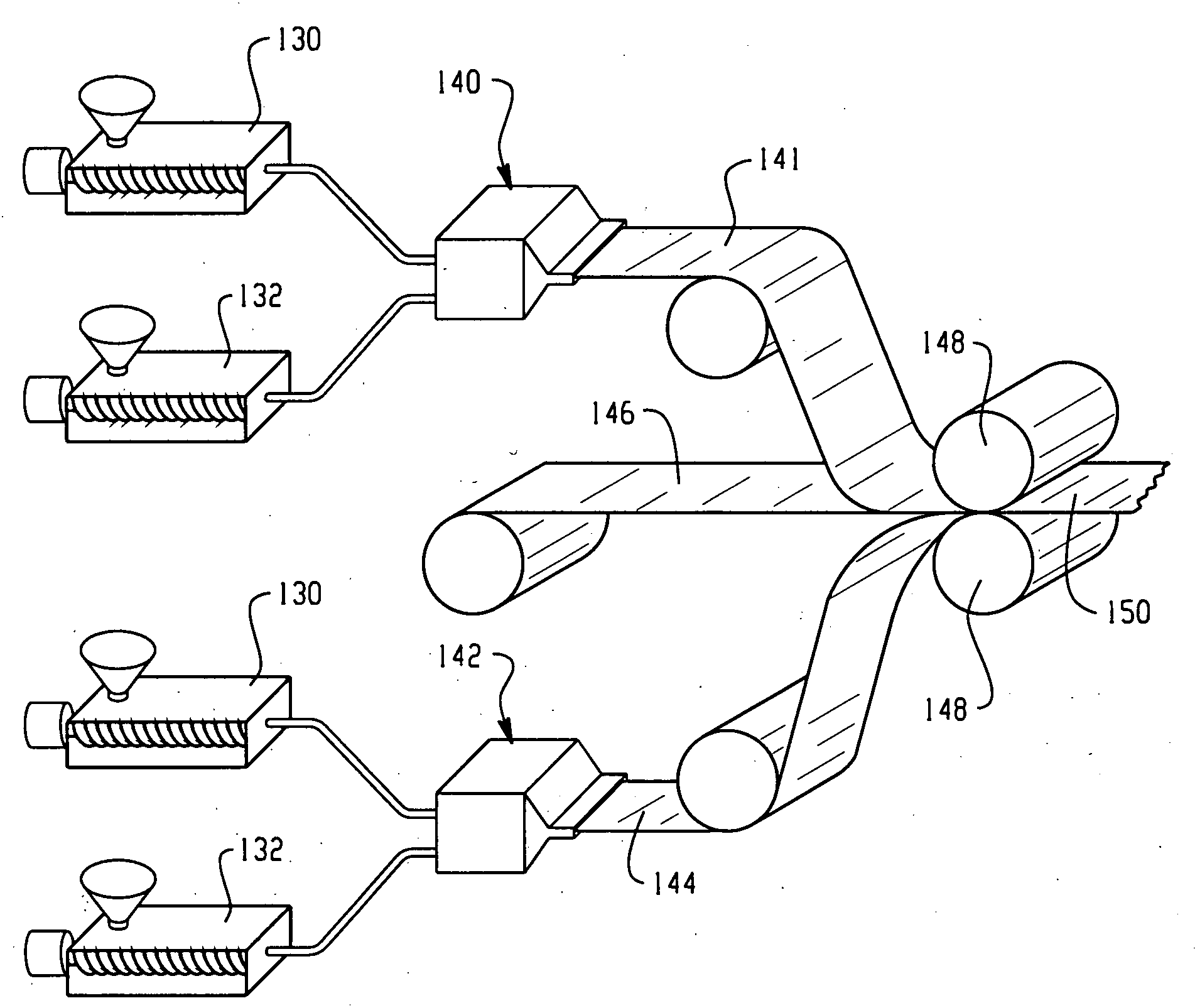

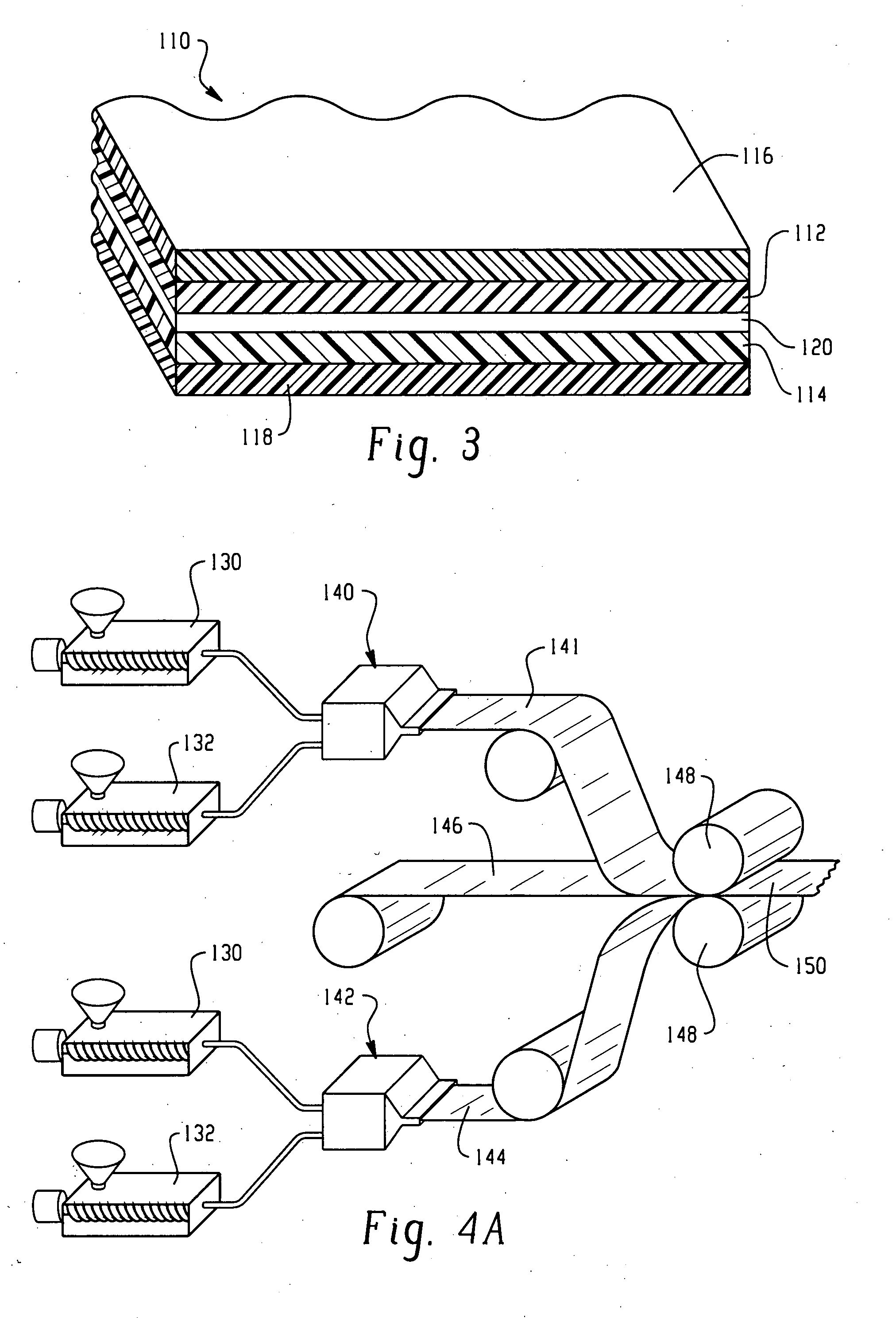

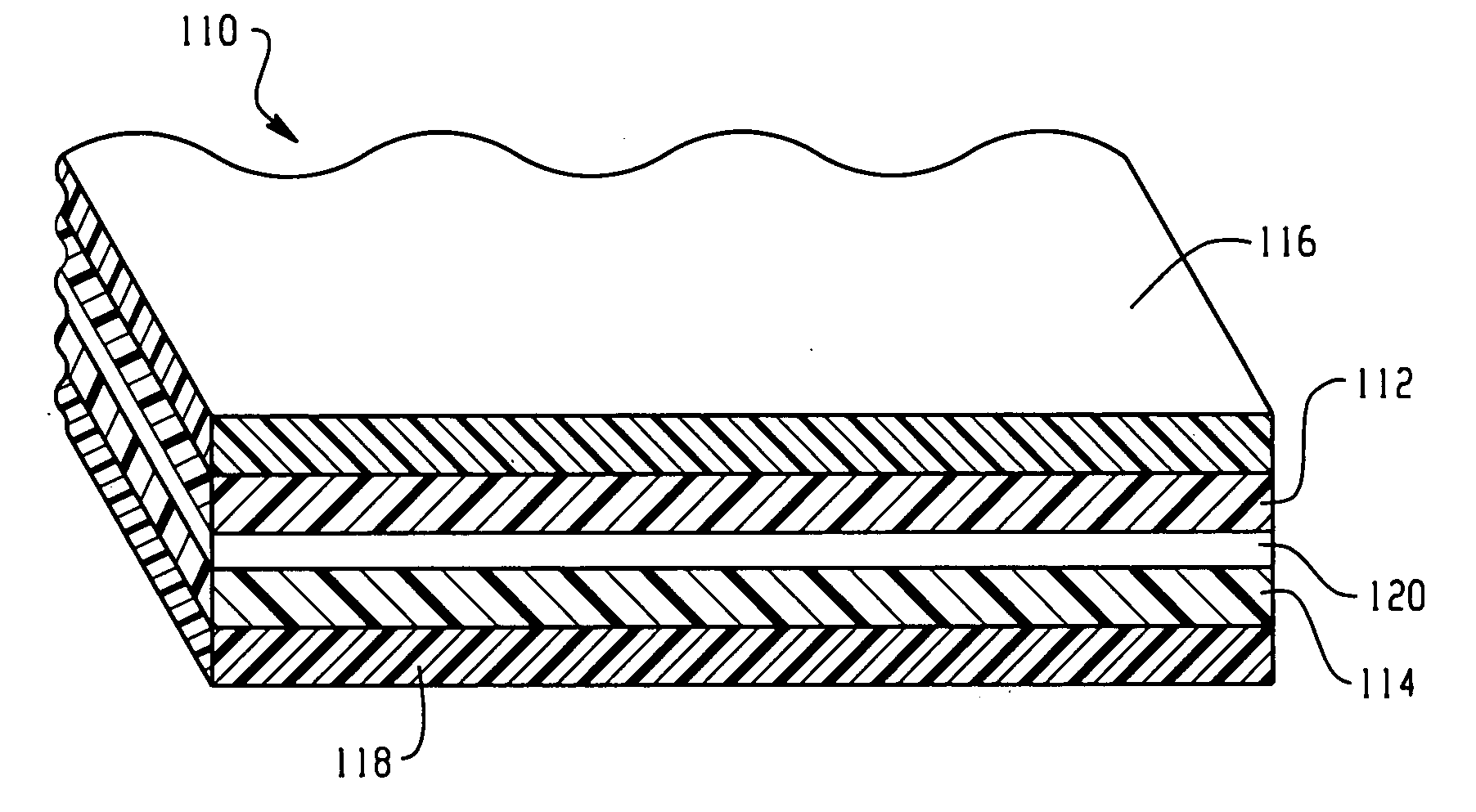

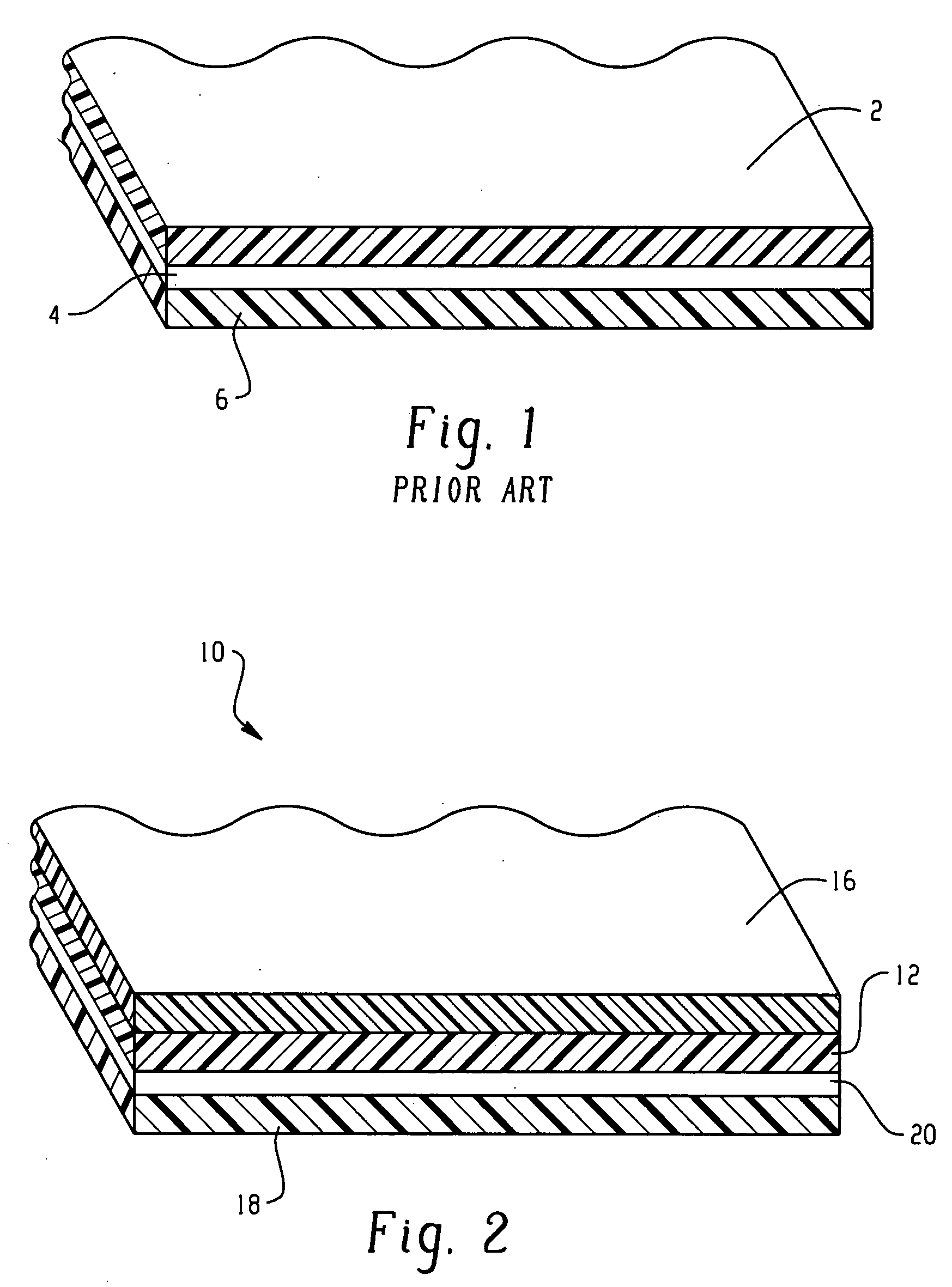

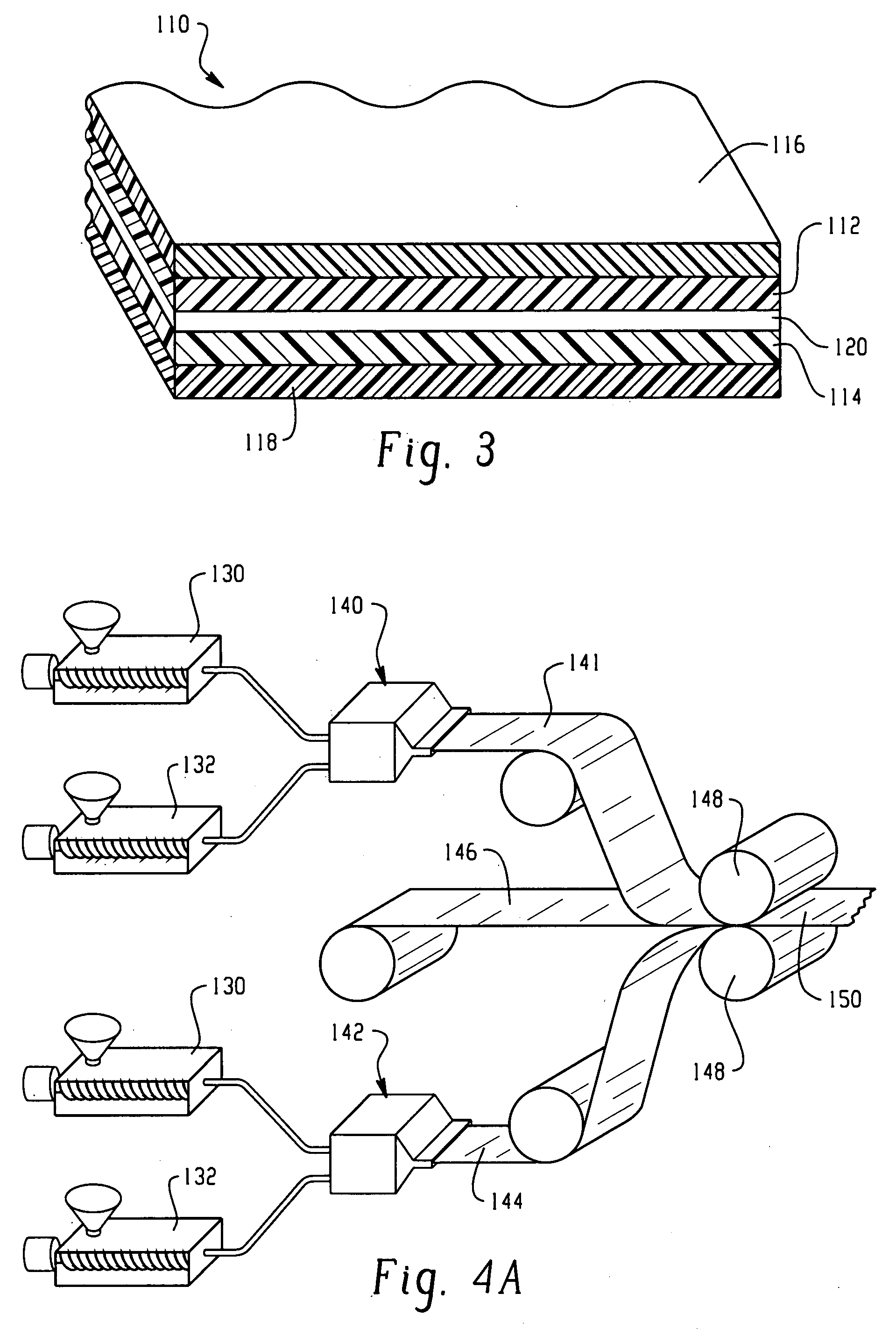

Co-extrusion process for preparing roofing membranes

InactiveUS20070194482A1Roof covering using flexible materialsSynthetic resin layered productsCo extrusionBiomedical engineering

A process for preparing a multi-layer roofing or structural membrane is provided including a top sheet including co-extruding a cap and inner layer and bonding the top sheet to a bottom sheet. The use of the co-extrusion process allows for multi-layer sheets that reduce the need for expensive fillers in all but a cap layer of the membrane. A scrim reinforcement layer is optionally embedded in the membrane. When installed on a roof substrate, the membrane can be sealed by heat welding the seams of the membrane sheets or by other means.

Owner:FIRESTONE BUILDING PRODS

Multi-layer co-extruded roofing membrane

A multi-layer roofing membrane is provided including a top sheet including a co-extruded cap and inner layer and a bottom sheet. The use of a co-extrusion die allows for multi-layer sheets that reduce the need for expensive fillers in all but a cap layer of the membrane. A scrim reinforcement layer is optionally embedded in the membrane. When installed on a roof substrate, the membrane can be sealed by heat welding the seams of the membrane sheets or by other means.

Owner:HOLCIM

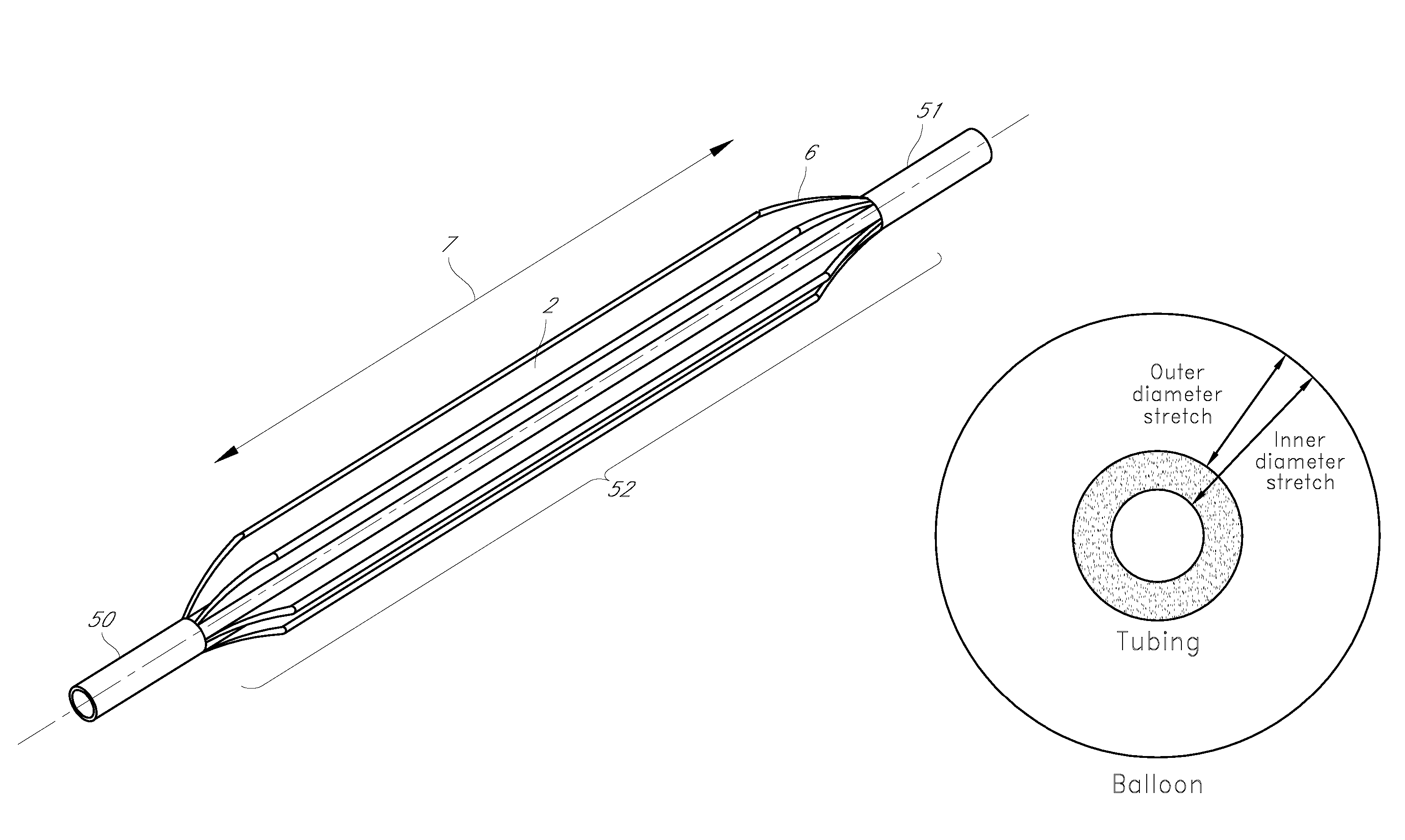

Multi-layer balloons for medical applications and methods for manufacturing the same

ActiveUS7942847B2High pressure rating and toughnessExcellent folding propertiesBalloon catheterLayered productsMedicineCo extrusion

A multi-layered balloon is provided where each layer is formed such that each layer is made from tubing that optimizes the inner wall stretch thus providing maximum balloon strength. The high pressure, multi-layer balloon is provided with layers that allow for slipping, such that the balloon has a very high pressure rating and toughness, yet excellent folding characteristics. Methods for producing such multi-layer balloons using existing balloon forming equipment are also provided. The multi-layer balloons can have alternating structural and lubricating layers, or layers with low-friction surfaces. The multi-layer balloons are preferably manufactured using a variety of methods including nesting, co-extrusion, or a combination of nesting and co-extrusion. The multi-layer balloons have balloon layers having substantially similar, or the same, high degree of biaxial orientation of their polymer molecules such that each balloon layer of the multi-layer balloon will fail at approximately the same applied pressure.

Owner:CONFLUENT MEDICAL TECH INC

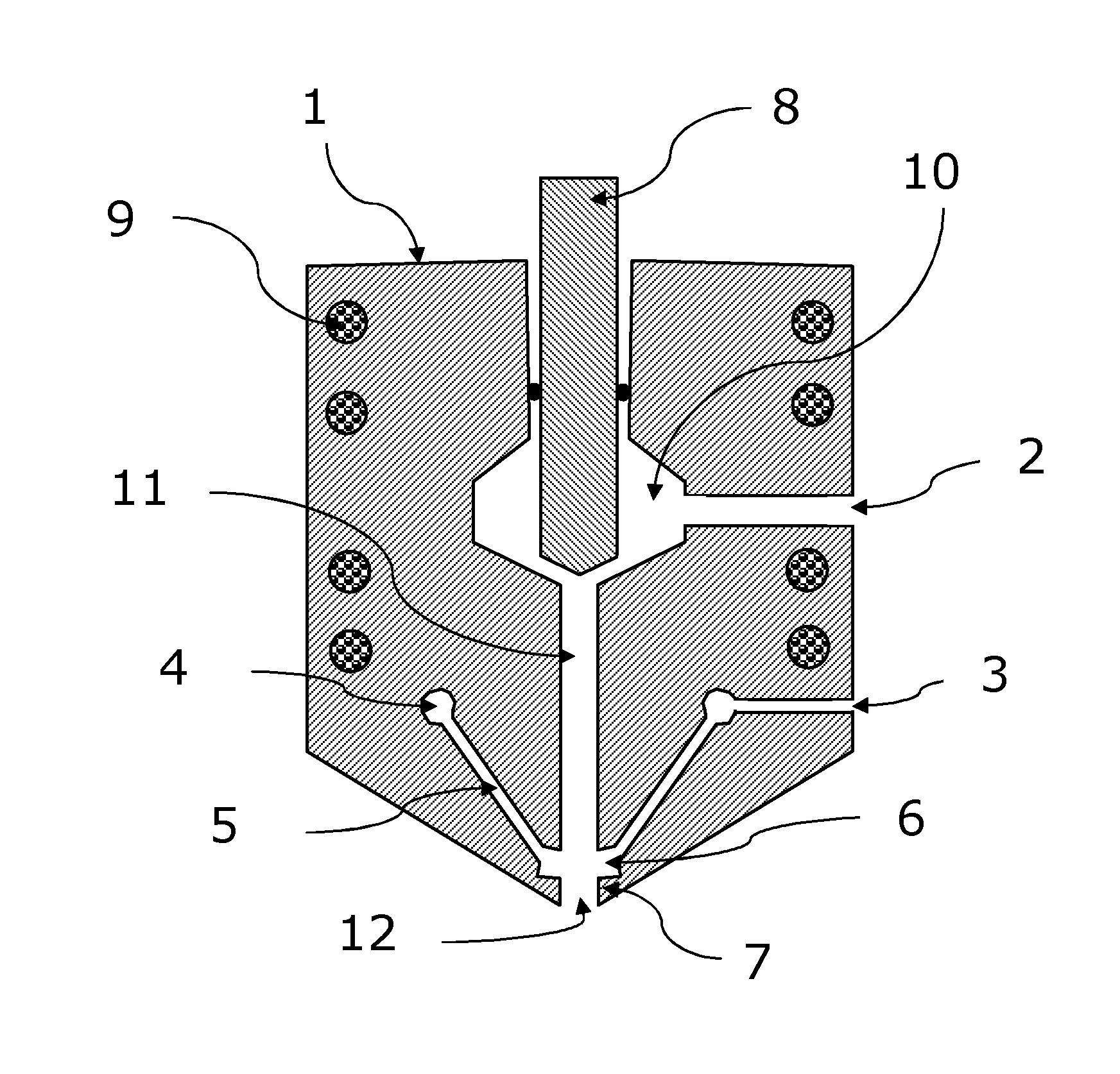

Integrated multi-zonal cage/core implants as bone graft substitutes and apparatus and method for their fabrication

A surgical implant including a cage having a first porosity and a first modulus; and a core bounded by said cage, said core having a second porosity that is higher than said first porosity of said cage, and said core having a second modulus that is lower than said first modulus of said cage. The implant may be functionally graded in a transverse direction, a longitudinal direction, or a radial direction thereof. The implant is made by preparing a first formulation for the cage within a first extruder and a second formulation for the core within a second extruder, extruding the first formulation through a co-extrusion die while simultaneously extruding said second formulation through the co-extrusion die so as to form an extrudate that includes said cage component and said core component bounded by said cage component.

Owner:STEVENS INSTITUTE OF TECHNOLOGY

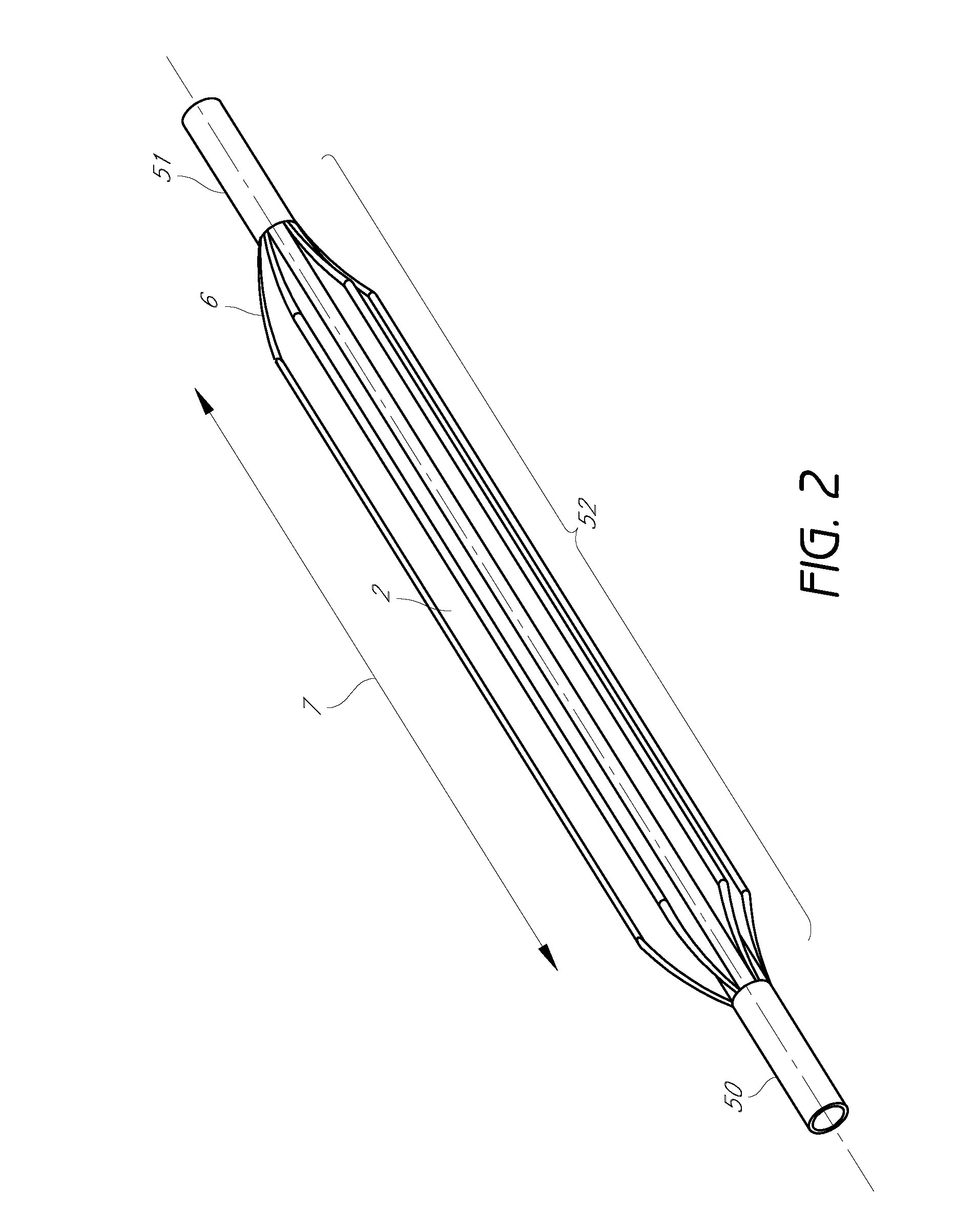

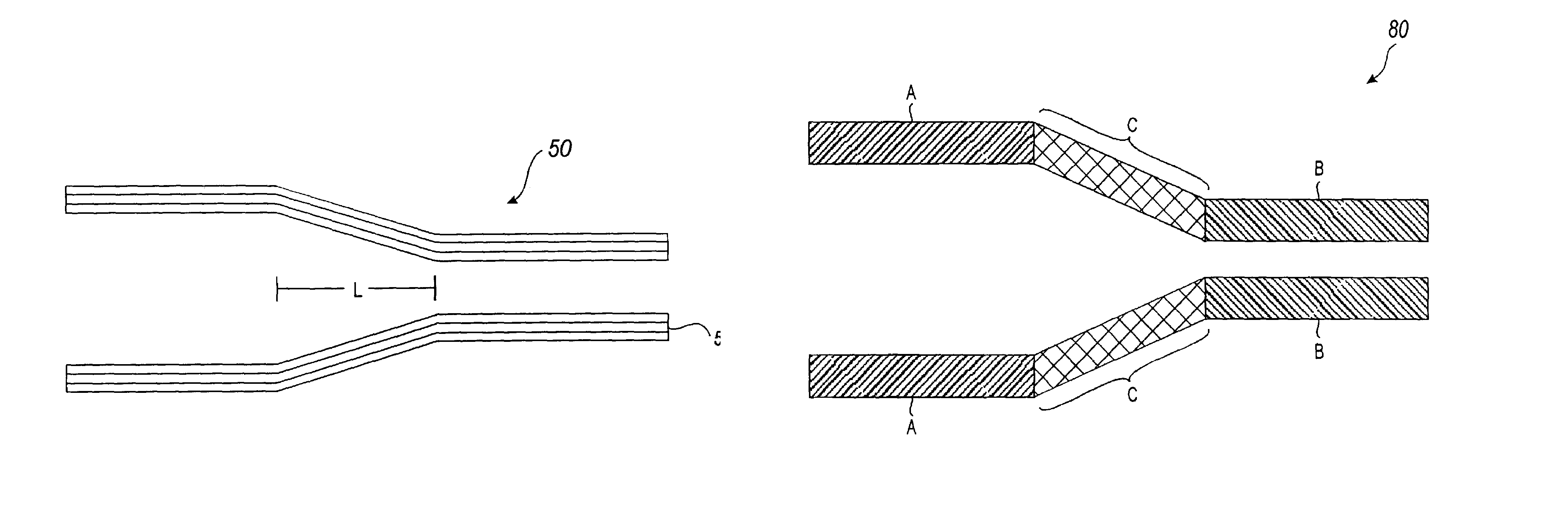

Co-extruded taper shaft

An apparatus and method for providing a co-extruded, tapered multi-layer shaft. A co-extruded, tapered multi-layer shaft may be fabricated by selecting a first material for the inner layer of the shaft and a second material for the outer layer of the shaft. The first and second materials are then co-extruded by a co-extrusion system including a puller with programmable tapering capabilities. The system forms a hollow tubing having an inner layer and an outer layer, wherein the tubing has the desired tapered characteristics. The result is a tapered tubular shaft having an inner layer and an outer layer.

Owner:ABBOTT CARDIOVASCULAR

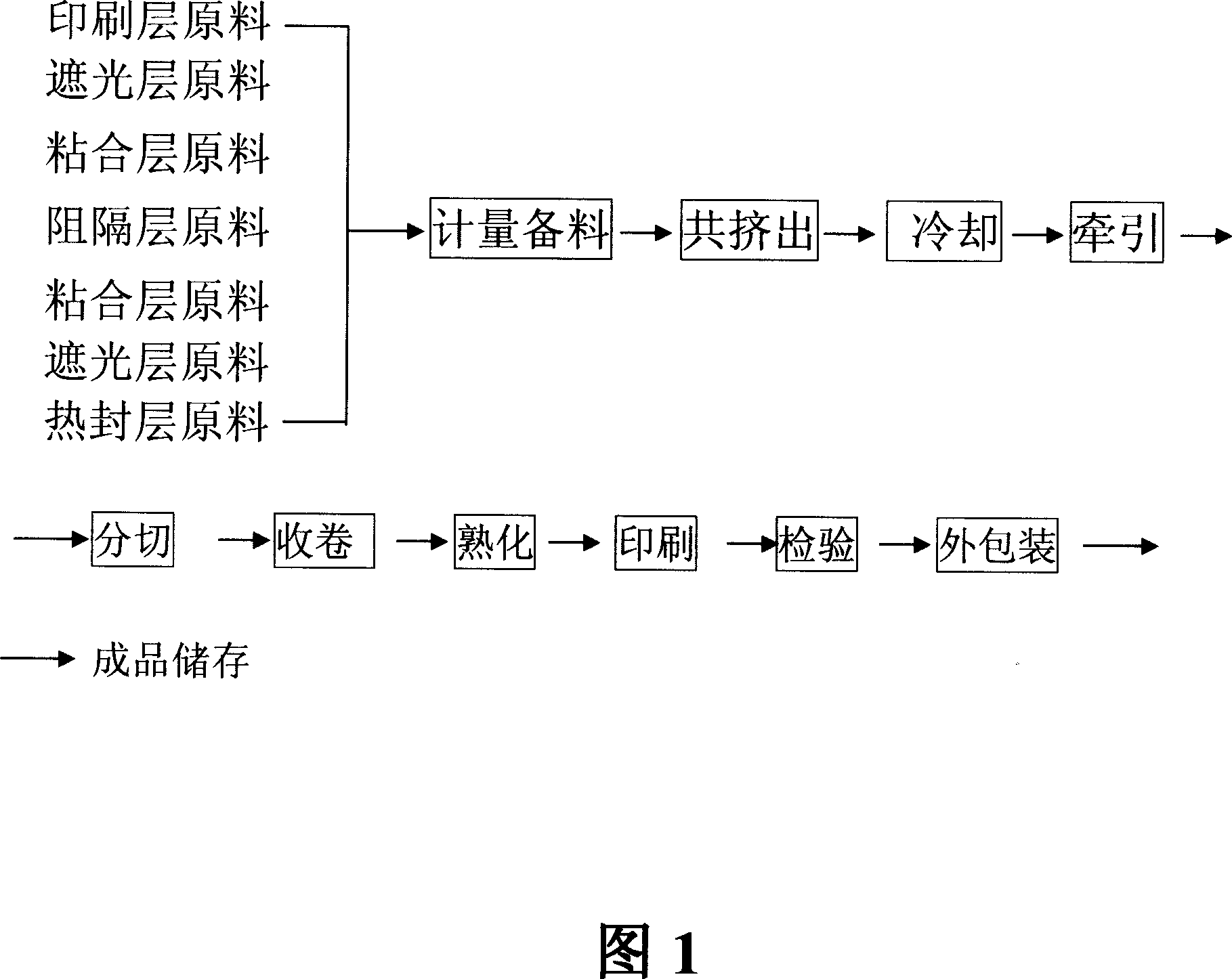

Biaxial tension co-extrusion high-obstruct base material membrane and process for preparing the same

InactiveCN1733397AImprove barrier propertiesImprove qualityTurning toolsHeat deflection temperaturePolyolefin

This invention provides biaxial tension coextrude resistive base material membrane and preparation method. Wherein, the membrane comprises at least a resistive layer that is at least one of PA, PVA, PVDC and MAD6, a splice layer belonged to EAA, EEA, ethylenemethacrylic acid copolymerized resin or polyolefin and neolyn resin that can combine the other tow layers, and a heat-sealing layer that is at least one of the polyolefin resin, EVA and PET; besides, there is nano inorganic material in resistive layer and or heat-sealing layer to improve performance. The product fits to package for all kinds goods.

Owner:朱春蕾 +4

Multicomponent whitening compositions and containers

InactiveUS20070231277A1Cosmetic preparationsToilet preparationsWhitening AgentsEnzymatic degradation

The present invention is directed to a container for housing and dispensing dentifrice compositions and that includes a first chamber containing therein a first dentifrice composition that includes a non-abrasive whitening agent and at least one thickener, a second chamber containing therein a second dentifrice composition that includes an abrasive polishing material, at least one thickener, a proteolytic enzyme and a rheology modifier that is not susceptible to enzymatic degradation, where the first and second dentifrice compositions are isolated one from the other until the substantially simultaneous co-extrusion from the container, and to whitening compositions containing the co-extruded first and second dentifrice compositions.

Owner:MCNEIL PPC INC

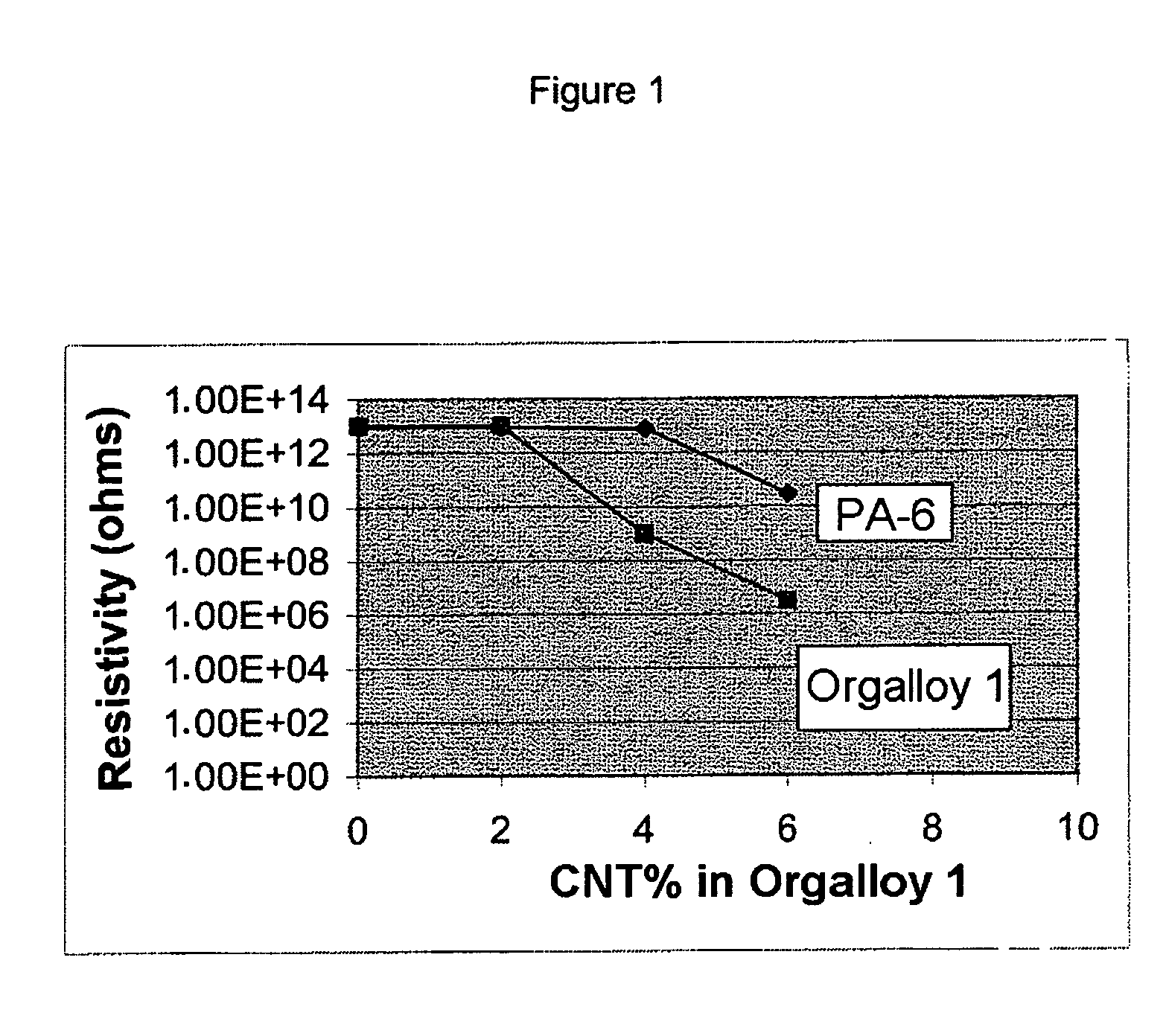

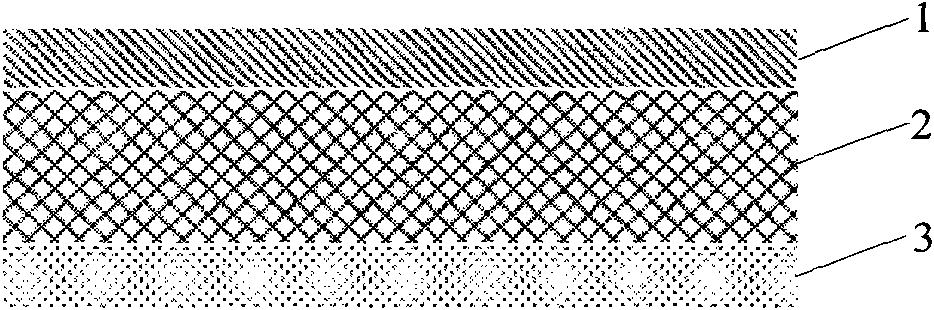

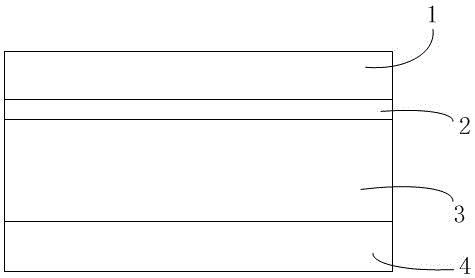

Polyamide/polyolefin blends containing carbon nanotubes

The present invention relates to polyamide / polyolefin blends containing carbon nanotubes. The invention also relates to structures comprising at least one layer of these blends and optionally at least one layer of another material. These structures may be in the form of bottles, tanks, containers, hoses, pipes and vessels of any kind. These structures may be manufactured using the standard techniques for thermoplastics, such as injection moulding, extrusion-blow moulding and coextrusion. The present invention, according to one embodiment, relates to a multilayer tube comprising, in its radial direction from the outside inwards: an outer layer (1) formed from a polyamide chosen from PA-11 and PA-12; a layer (2) formed from a tie; an optional layer (3) formed from an EVOH; optionally, a tie layer (this does not exist if no layer (3) is present); an inner layer (4) formed from a polyamide (A) / polyolefin (B) blend having a polyamide matrix and containing carbon nanotubes; with the layers being successive and adhering to one another in their respective areas of contact.

Owner:ARKEMA FRANCE SA

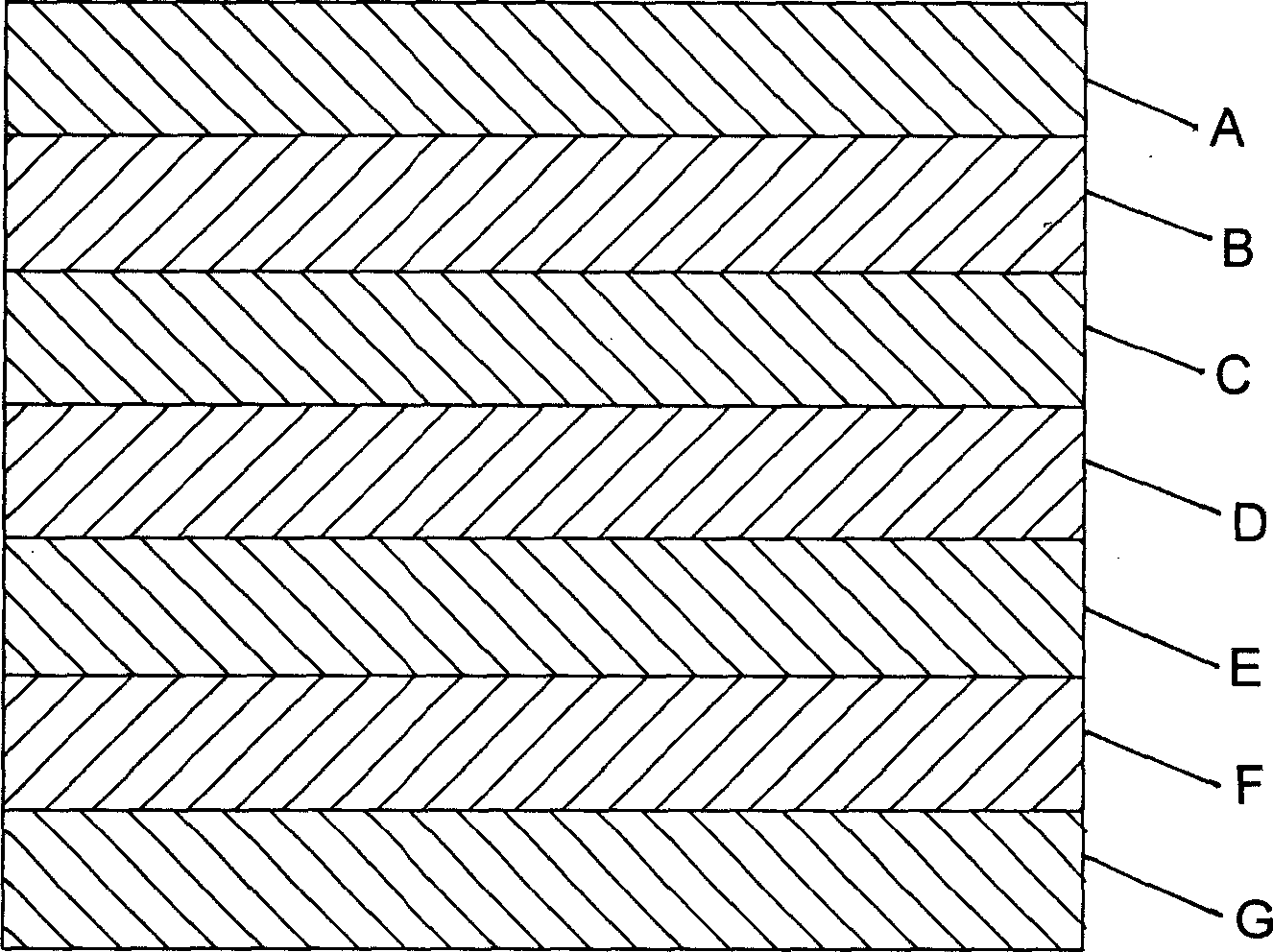

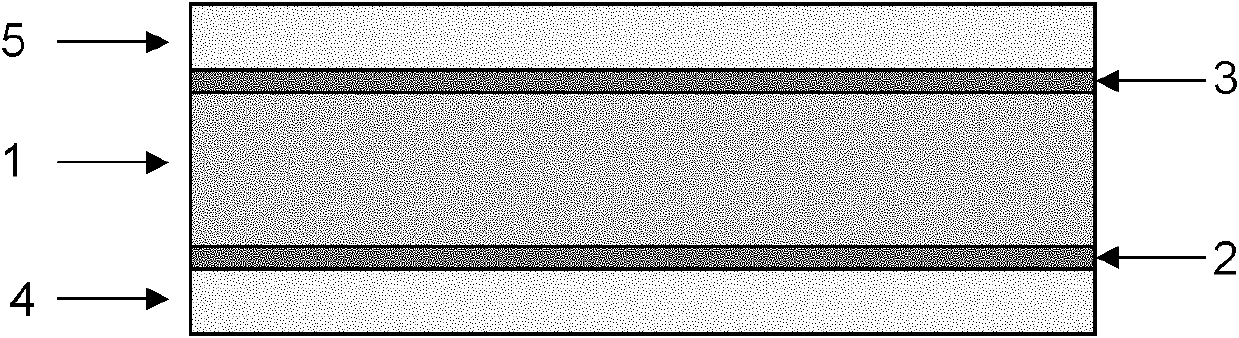

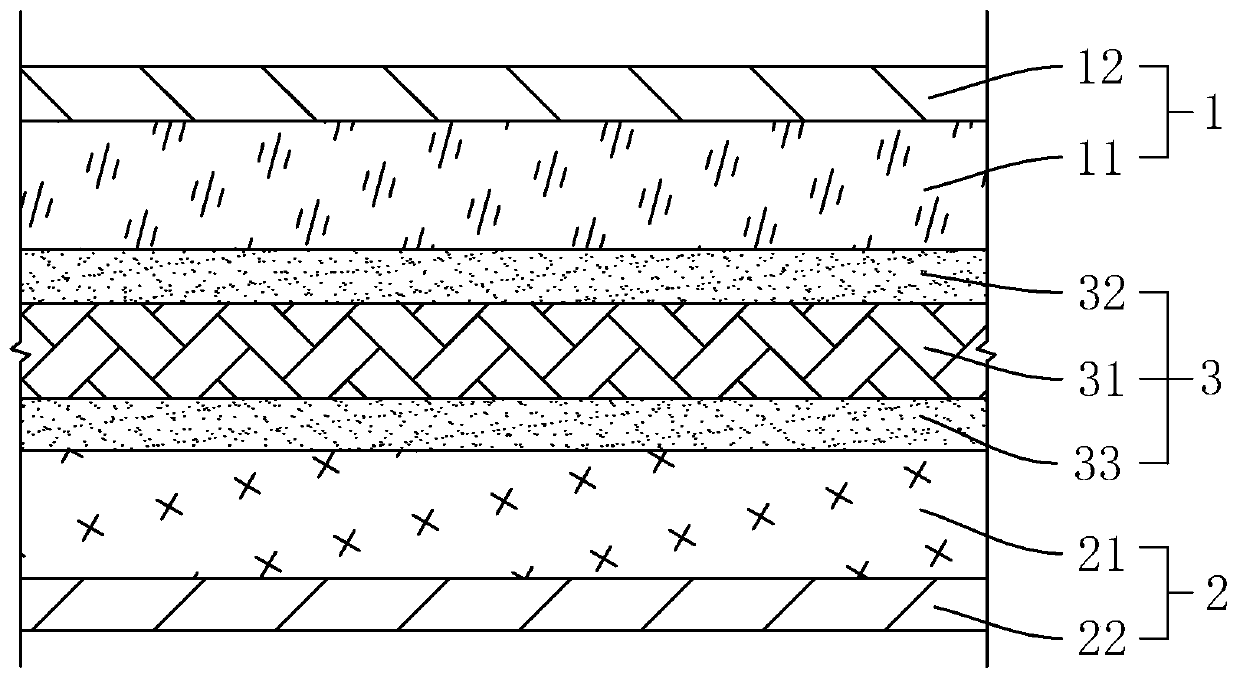

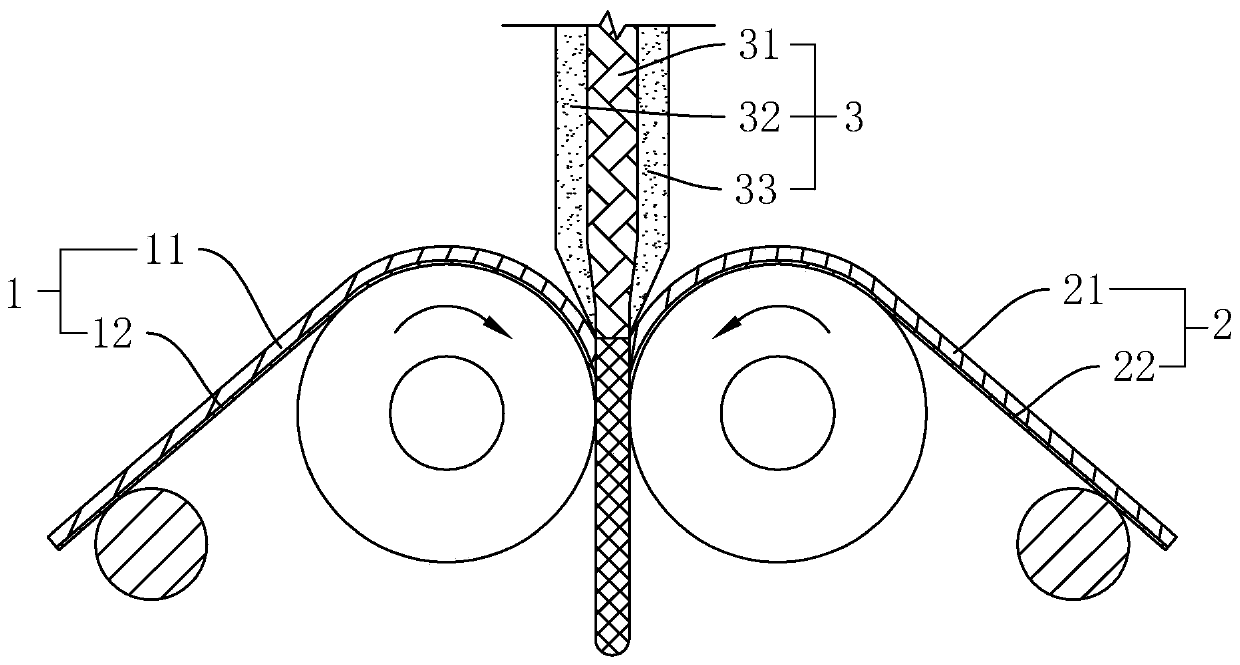

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

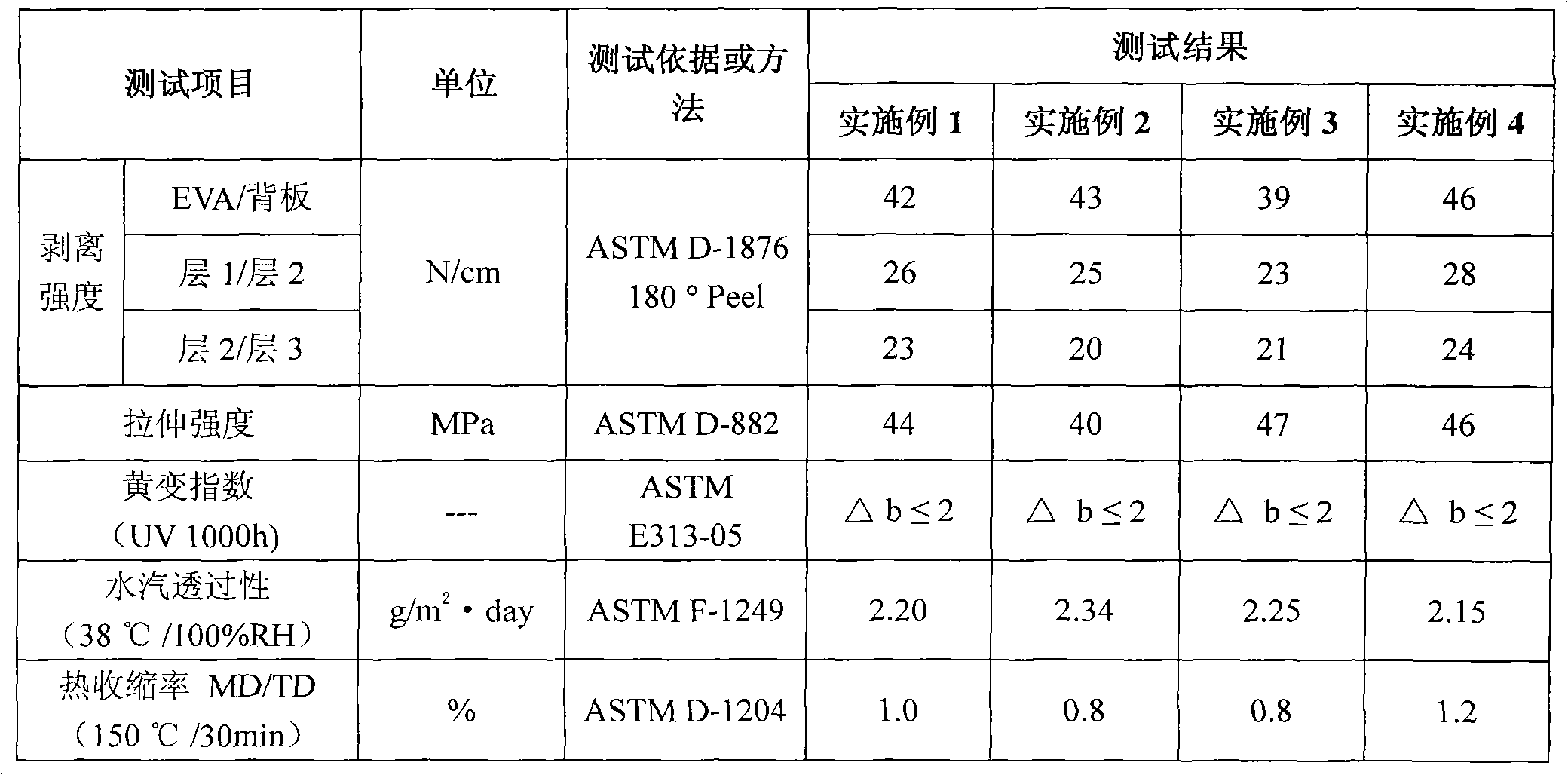

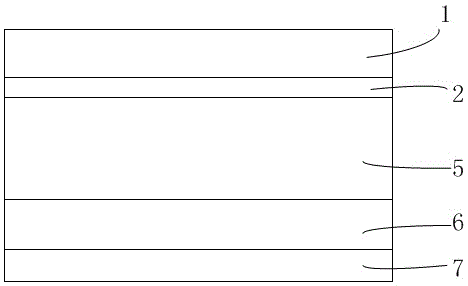

Back panel of solar cell and preparation method thereof

ActiveCN102157591AExtended service lifeMeet the requirementsFinal product manufactureSynthetic resin layered productsComposite filmPolyethylene terephthalate glycol

The invention relates to a back panel of a solar cell and a preparation method thereof. The solar back panel is provided with three polymer film layers from top to bottom, namely an adhesive weatherable layer, an adhesive reinforcing layer and an adhesive moisture-retarding layer, wherein the adhesive weatherable layer is a PVDF(polyvinylidene fluoride) / EVA (ethylene vinyl acetate) alloy layer, the adhesive reinforcing layer is a PET (polyethylene terephthalate) / PMMA (polymethyl methacrylate) alloy layer, and the adhesive moisture-retarding layer is a PVDF / PVB (polyvinyl butyral) alloy layer. In the preparation method, a multi-layer melting and co-extrusion method is adopted for realizing interface-free fusion of the three film layers, and a composite film can achieve good dimensional stability by online high-temperature shaping. The structure of the back panel of the solar cell only comprises the three layers, an adhesive layer does not need to be used, the preparation process is simple, the steps of sizing and hot-pressing are omitted, and the production efficiency is high; and simultaneously, the back panel has excellent performances and is in line with the packaging requirements of the solar cell.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Co-extruded, multi-lumen medical lead

InactiveUS20020183824A1Transvascular endocardial electrodesExternal electrodesElectrical stimulationsBending stiffness

Medical electrical leads for sensing or electrical stimulation of body organs or tissues, particularly implantable cardiac leads for delivering pacing pulses and cardioversion / defibrillation shocks, and / or sensing the cardiac electrogram (EGM) or other physiologic data and their methods of fabrication are disclosed. A lead body sheath is co-extruded in a co-extrusion process using bio-compatible, electrically insulating, materials of differing durometers in differing axial sections thereof, resulting in a unitary lead body sheath having differing stiffness sections including axial segments or webs or lumen encircling rings or other structures in its cross-section. The lead body sheath is co-extruded to have an outer surface adapted to be exposed to the environment or to be enclosed within an outer sheath and to have a plurality of lead conductor lumens for receiving and enclosing a like plurality of lead conductors of the same or differing types. The lead body sheath can be co-extruded of a plurality of sheath segments containing a lead conductor lumen and formed of a first durometer material or of differing durometer materials. A web of a further durometer material can be co-extruded extending between the adjoining boundaries of the axial sheath segments and bonding the adjacent segments together. The lead body sheath can be tailored to exhibit differing bending stiffnesses away from the lead body sheath axis in selected polar directions around the 360° circumference of the sheath body.

Owner:MEDTRONIC INC

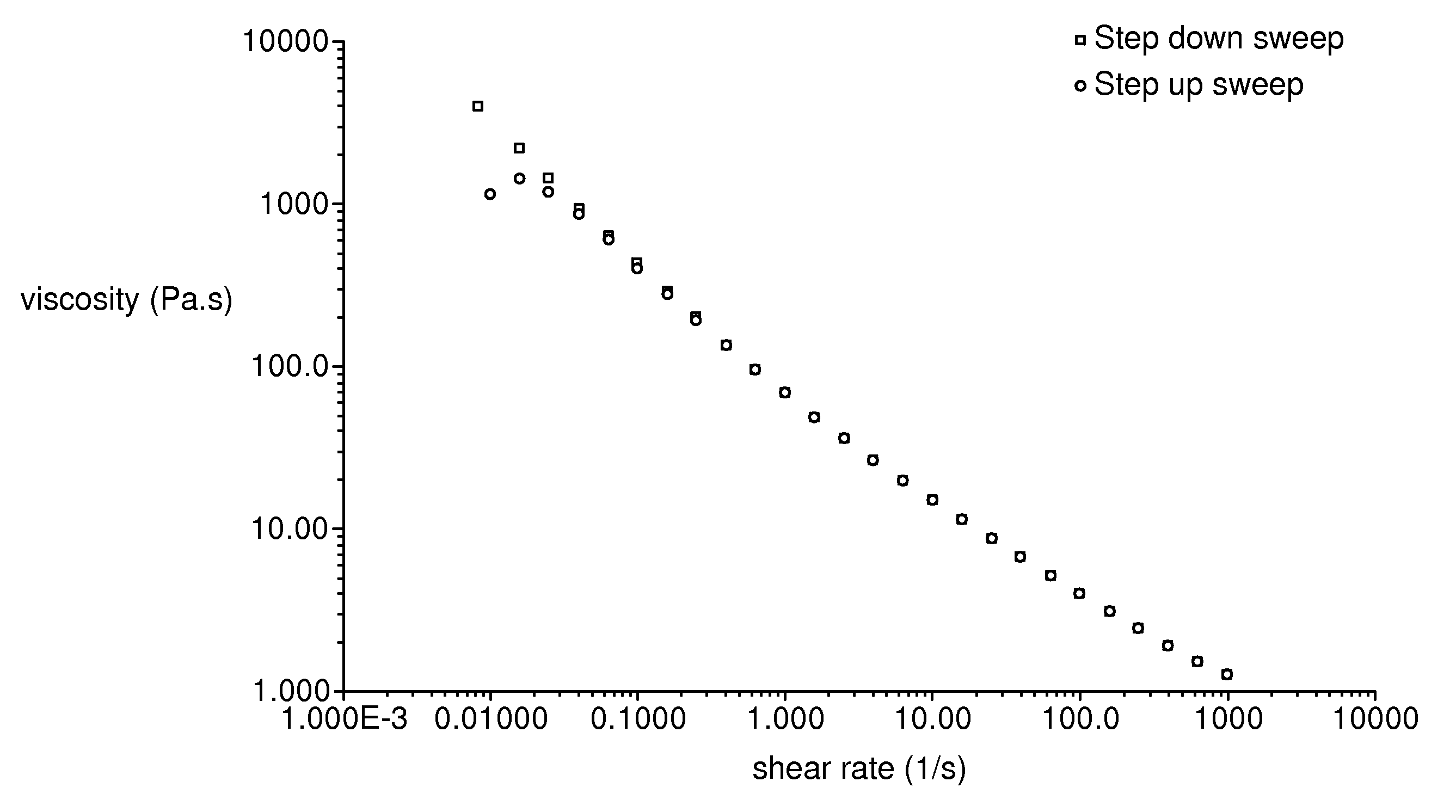

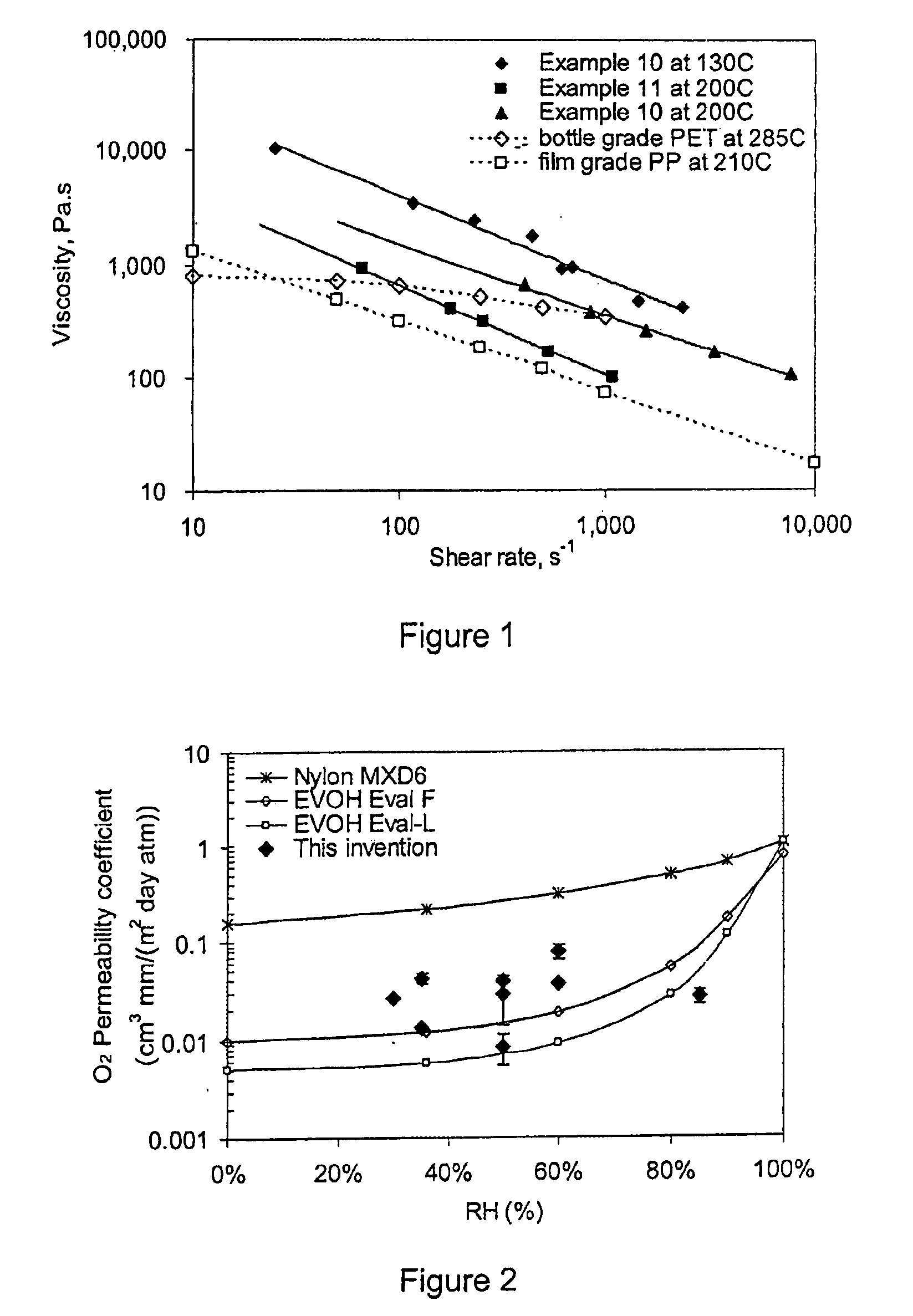

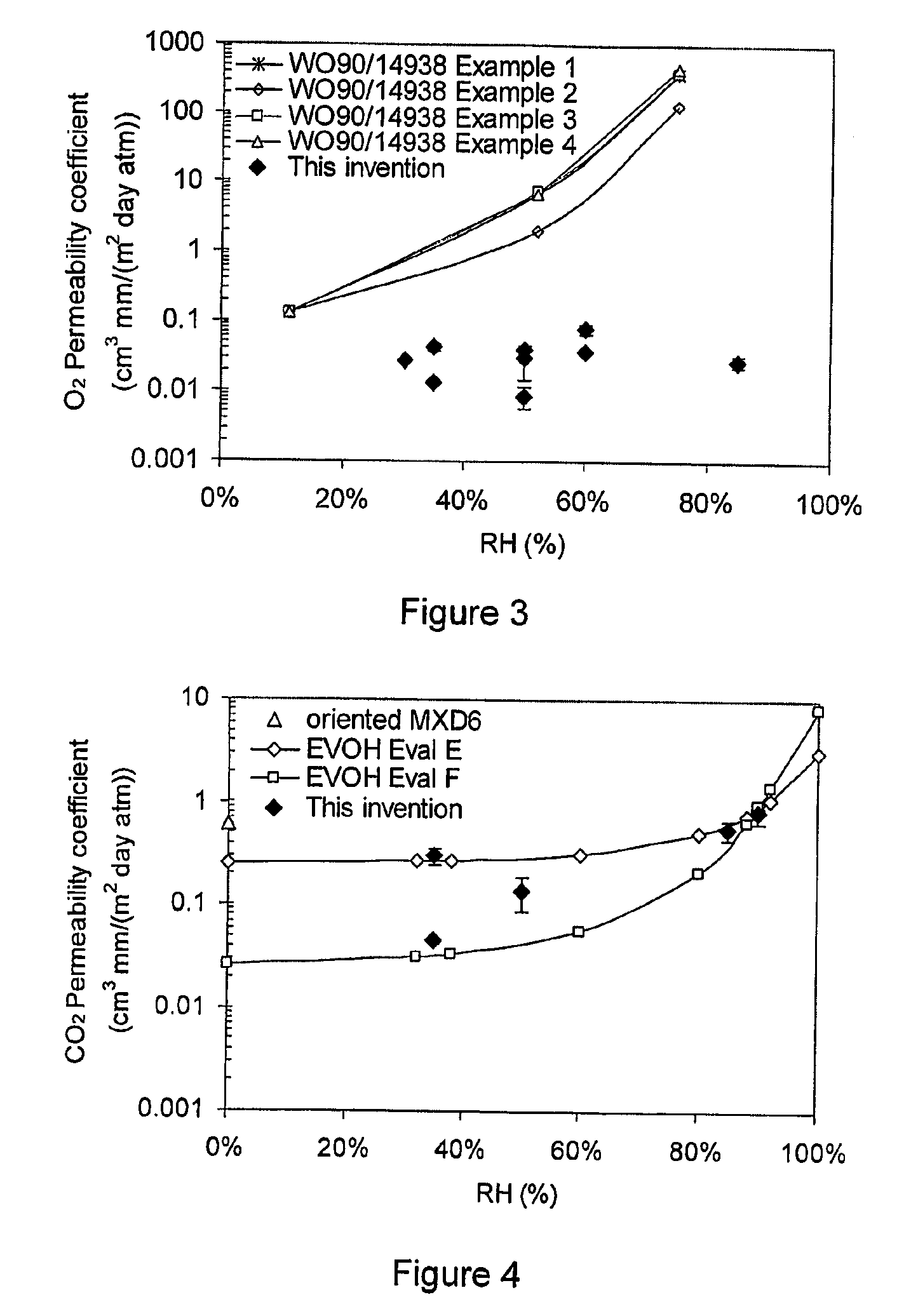

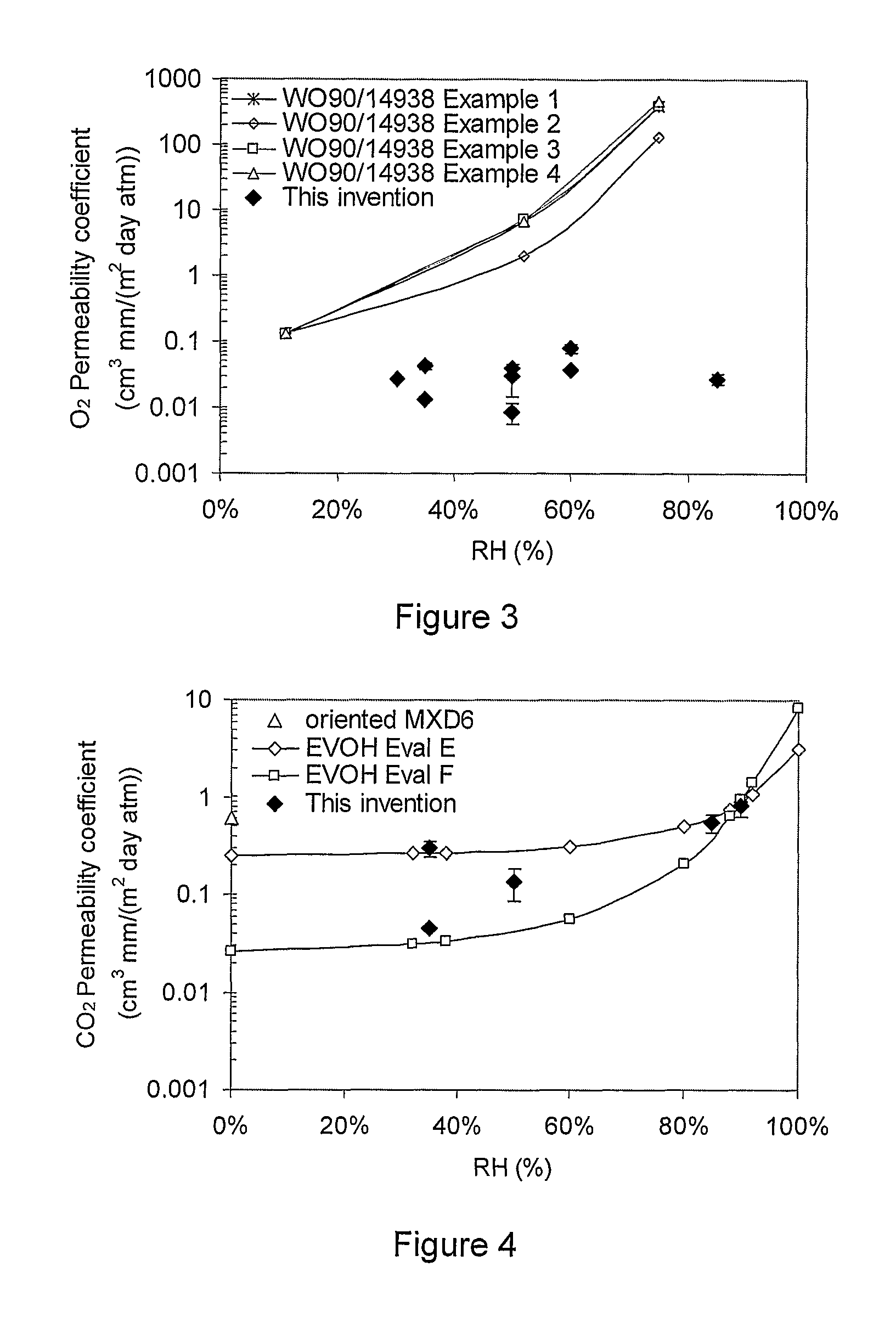

Barrier film

InactiveUS20090110942A1Stable mechanical propertiesImprove homogeneityFireproof paintsFibre treatmentMolten statePolyethylene oxide

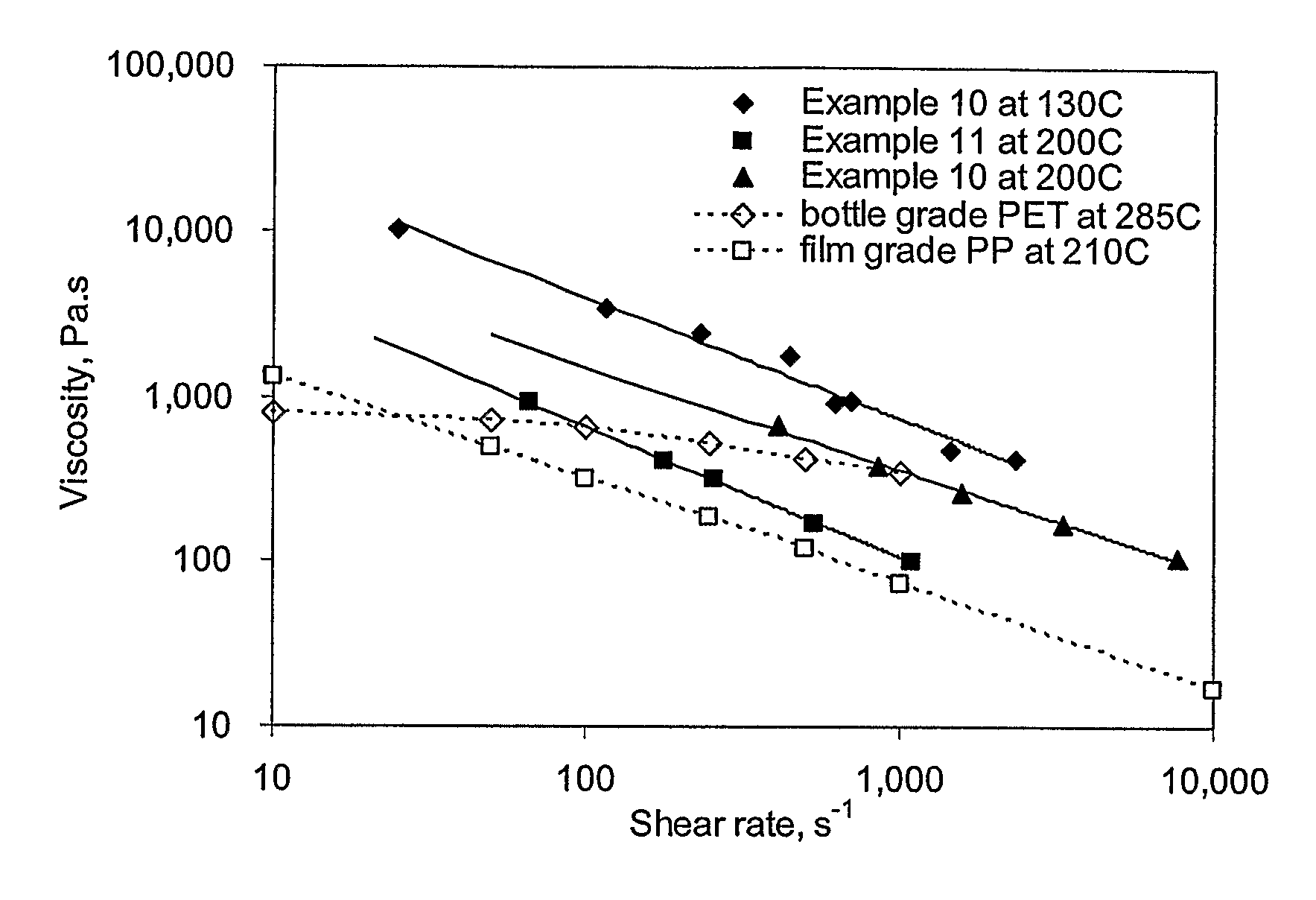

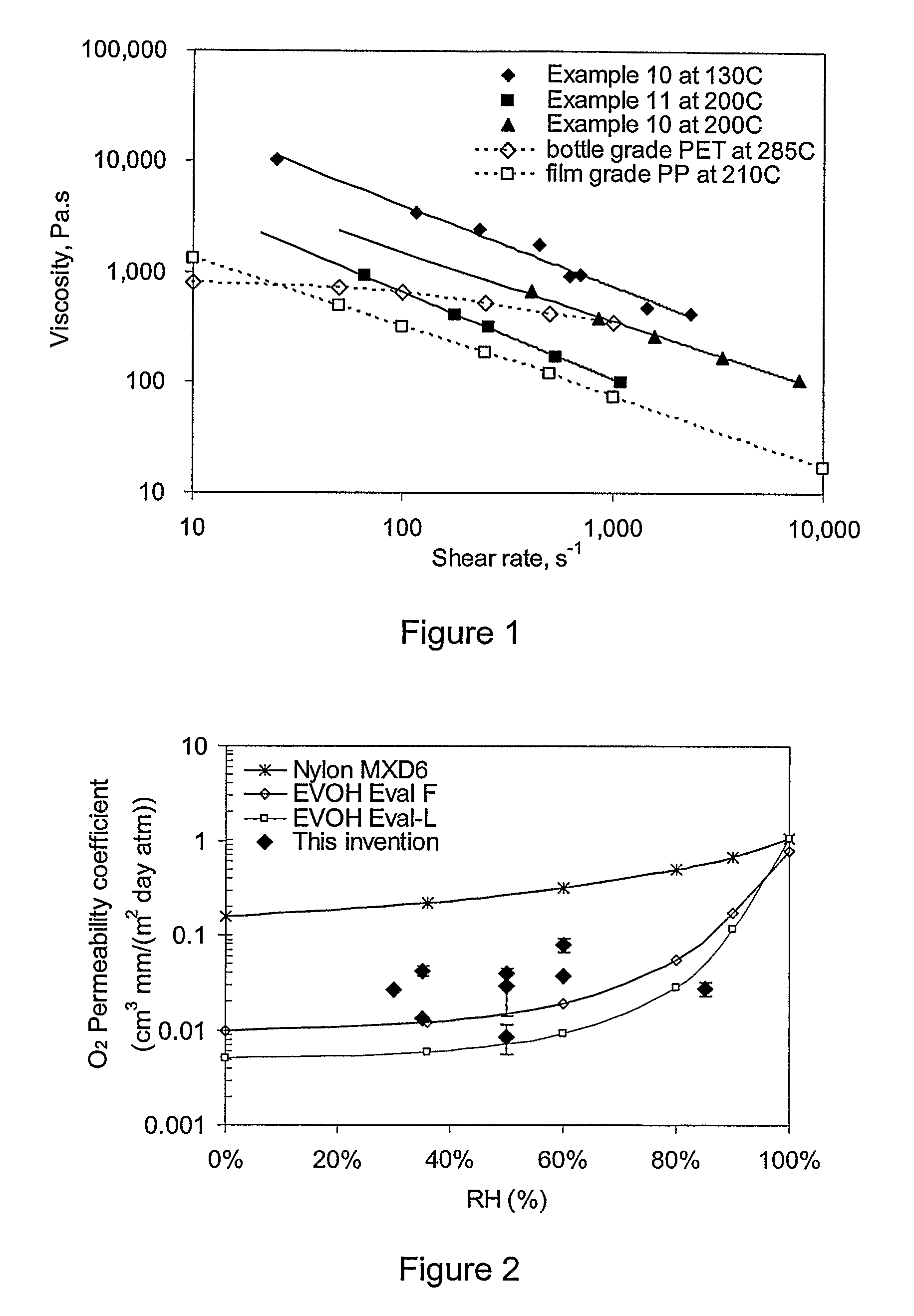

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5 % by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

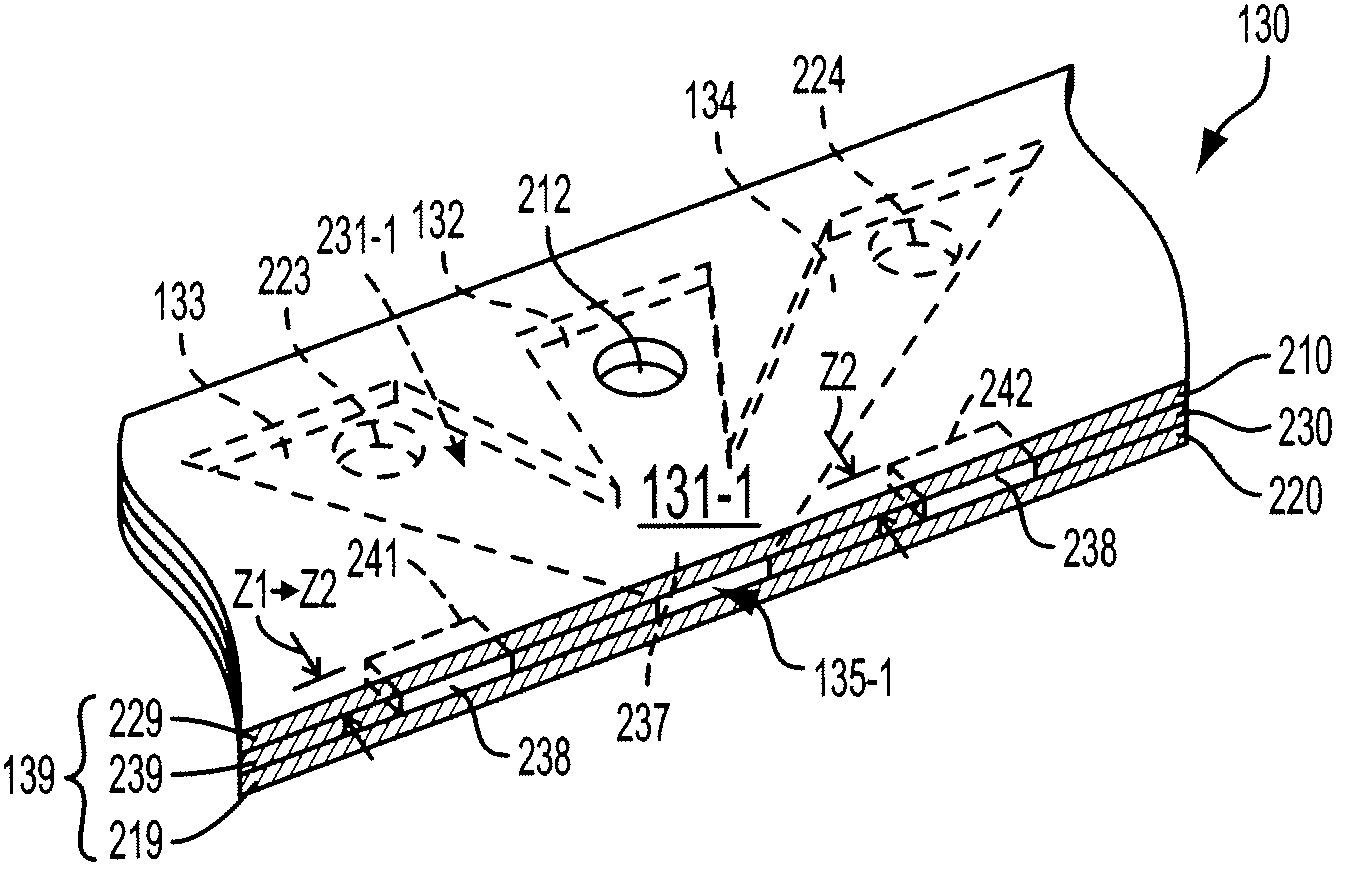

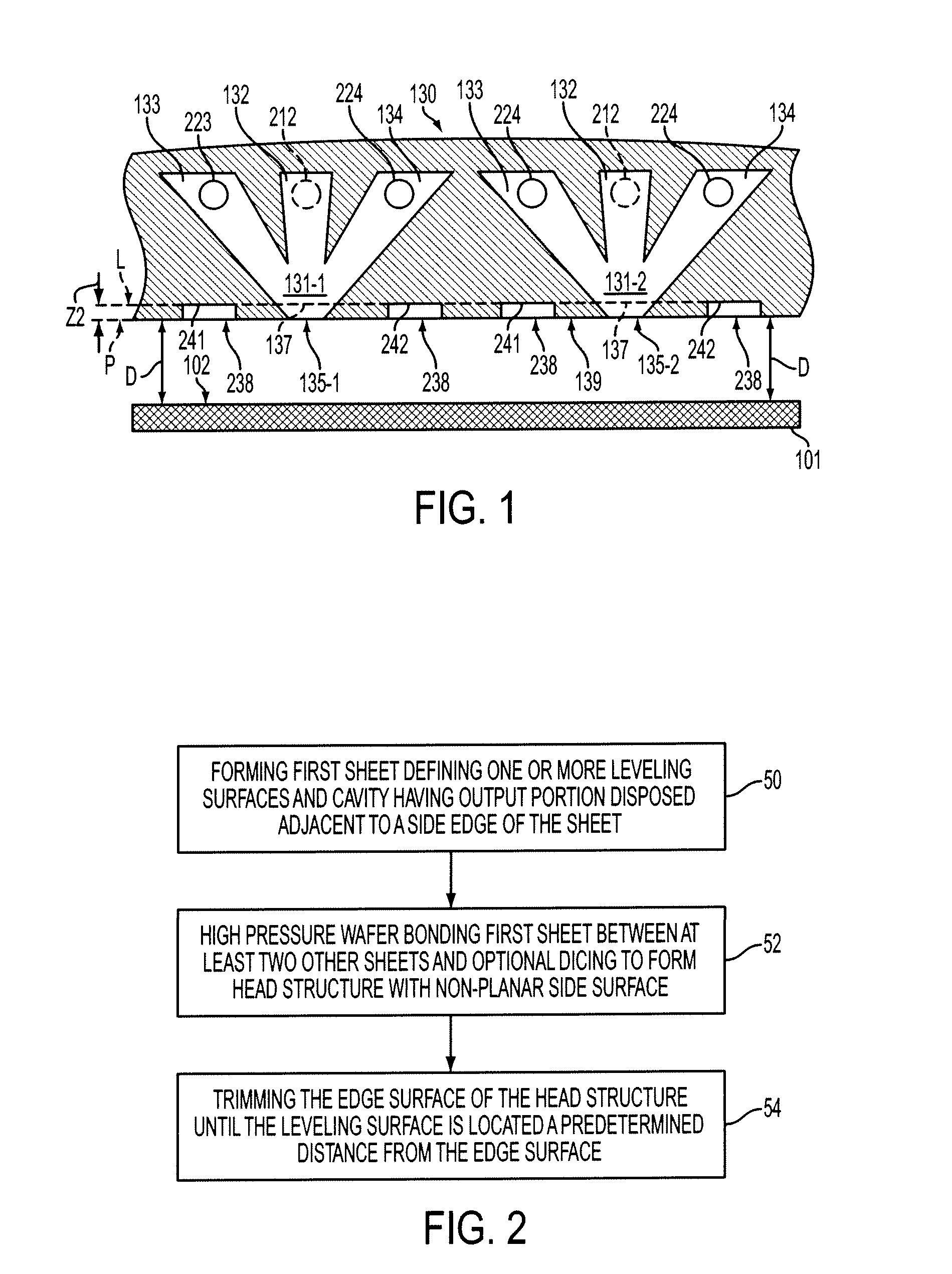

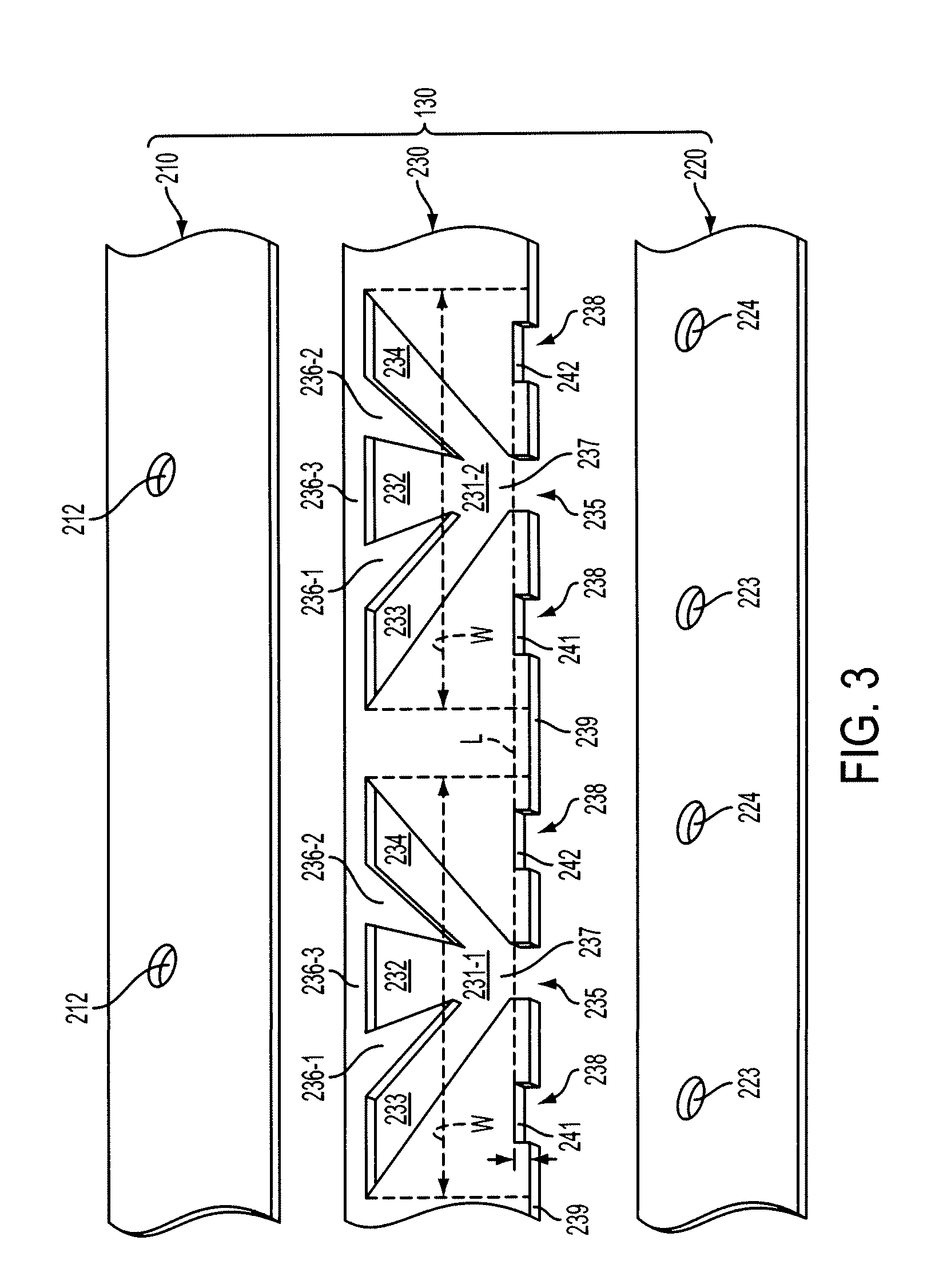

Extrusion head with planarized edge surface

InactiveUS7780812B2Easy to trimUnified positionConfectioneryCeramic shaping apparatusEdge surfaceHigh pressure

A co-extrusion head for forming high-aspect ratio gridline structures in a micro extrusion apparatus includes multiple sheets (e.g., metal plates) that are machined and assembled to define three-part fluidic channels having associated outlet orifice disposed along an edge surface of the head. Reference surfaces are also etched in the sheets and are aligned in a straight line that intersects output junctions of the three-channel cavities. After assembly (e.g., using high pressure bonding techniques), each reference surface is located inside a notch defined in the edge surface. The edge surface of the co-extrusion head is then trimmed (e.g., machined by wire EDM) using the reference surfaces as a precise guide, thereby producing uniform length outlet orifices with uniform flow impedance.

Owner:SOLARWORLD INNOVATIONS

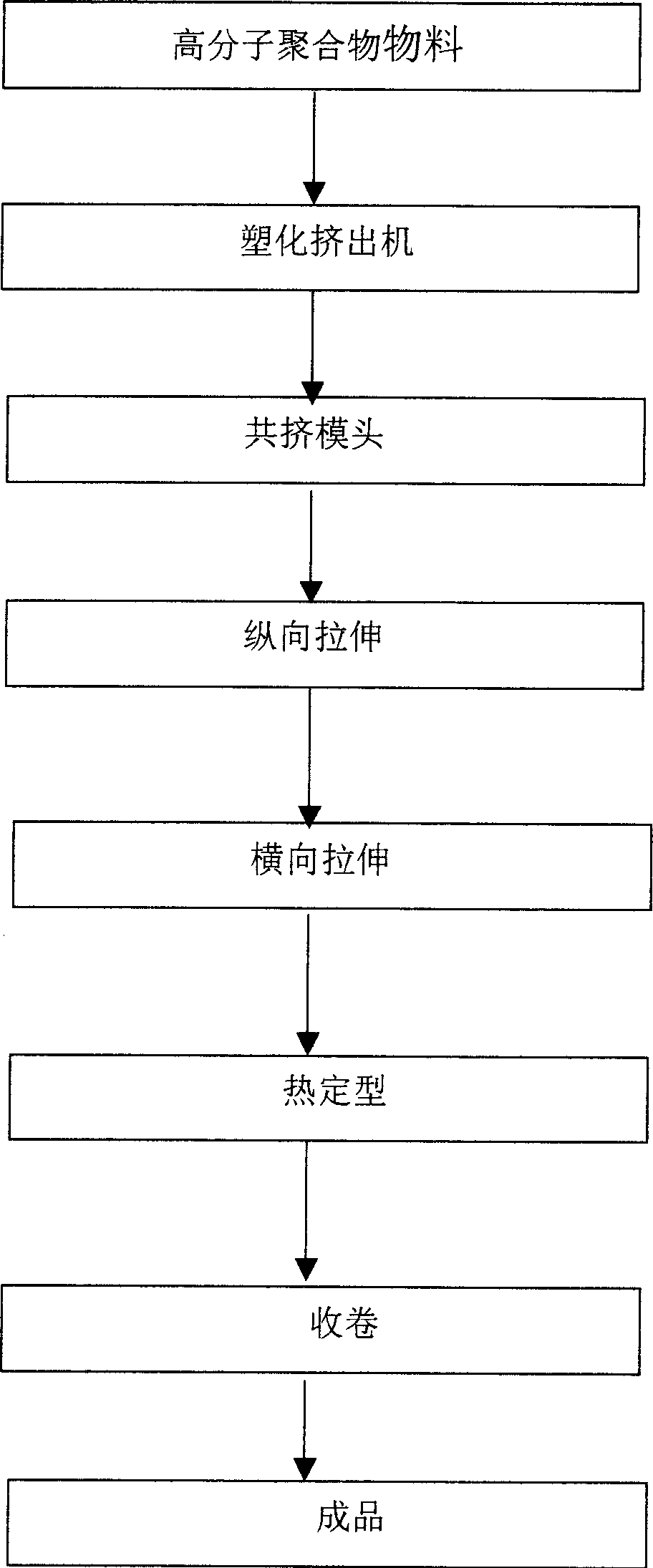

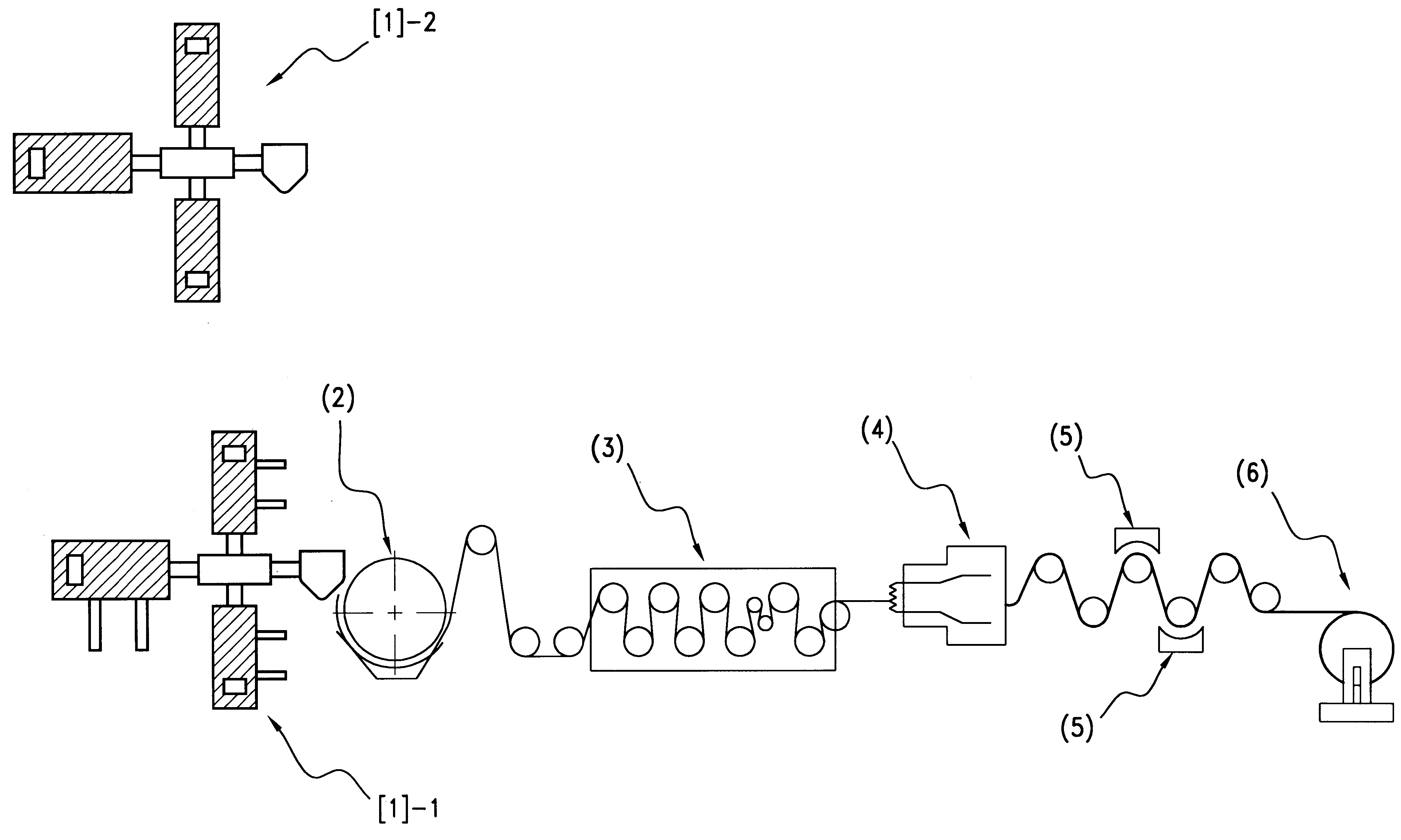

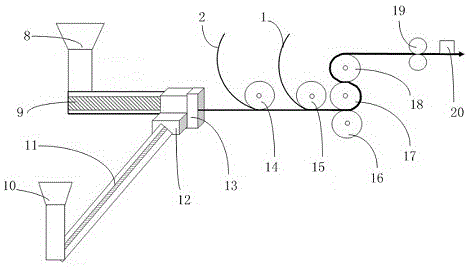

Process for producing a 3-layer co-extruded biaxial-oriented polypropylene synthetic paper and transparent film for in-mold label

InactiveUS6379605B1Low production costLow costLamination ancillary operationsElectric heatingCardboardEngineering

Disclosed is a process for producing a three layers co-extrusion biaxially oriented polypropylene (hereinafter as BOPP) synthetic paper and transparent film for in-mold label. More particularly, the invention relates to a process for producing a three layers biaxially oriented PP synthetic paper by means of three layers co-extrusion wherein three different PP resin compositions are separately extruded by one primary and two secondary extruders first, and then are co-flowed by a same T-die to form a three layers coating sheet. Thus, the three layers structure of said three layers co-extrusion coating sheet can be made into resin layer / foamed intermediate or resin layer / resin layer, and then through cooling, biaxial orientation, corona treatment and winding to form a three layers co-extrusion synthetic paper of haze paper sheet layer / foamed intermediate layer / adhesive layer, gloss paper sheet layer / foamed intermediate layer / adhesive layer, or a three layers co-extrusion synthetic transparent film of resin layer / resin layer / adhesive layer

Owner:NANYA PLASTICS CORP

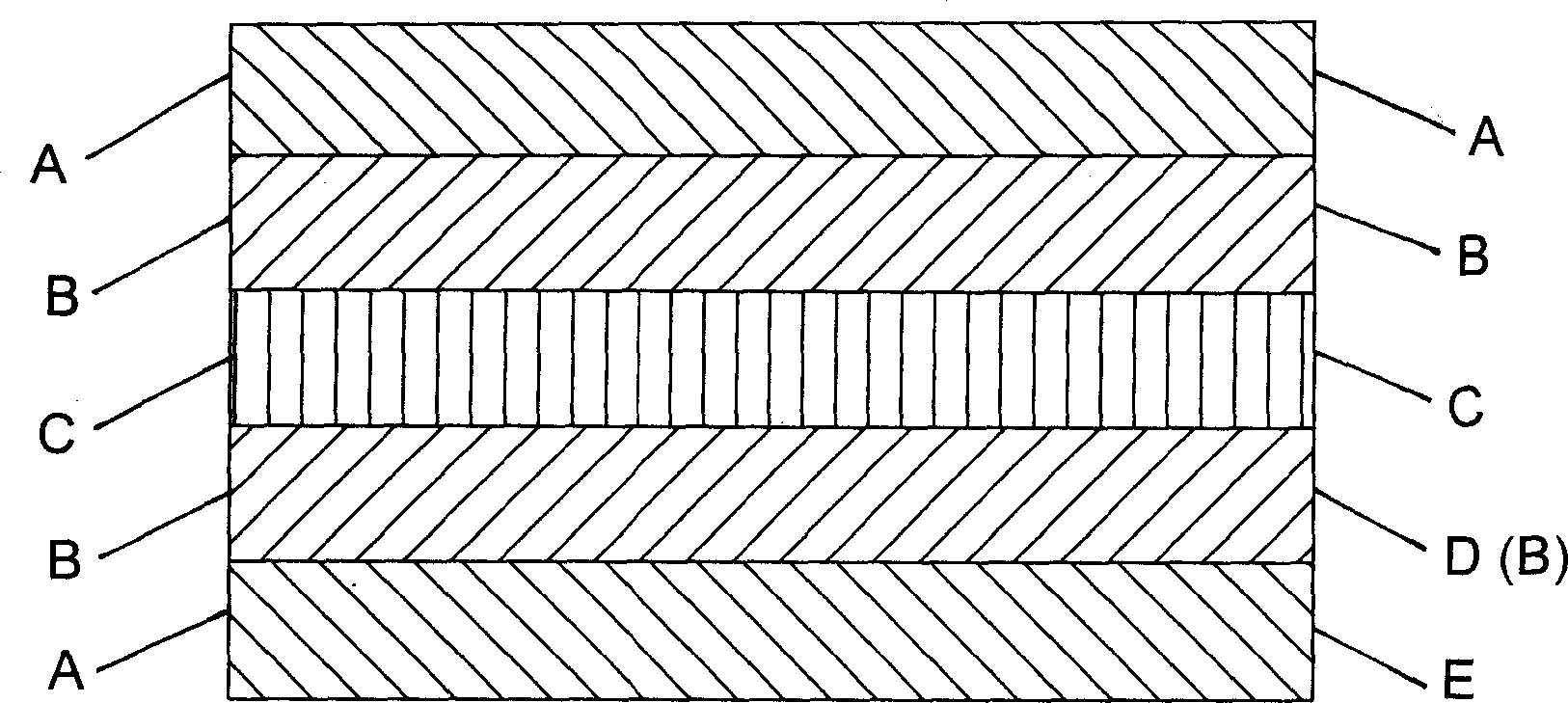

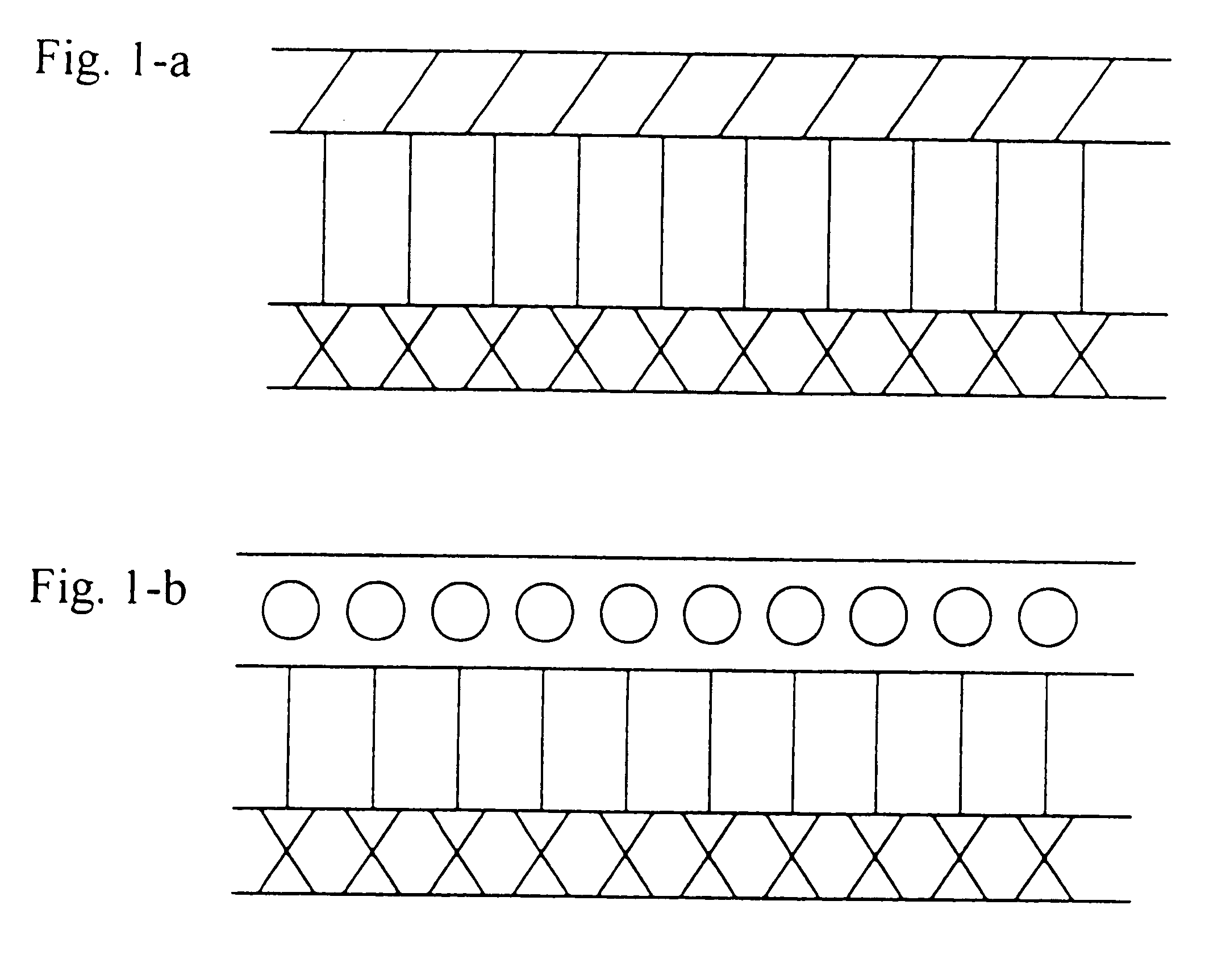

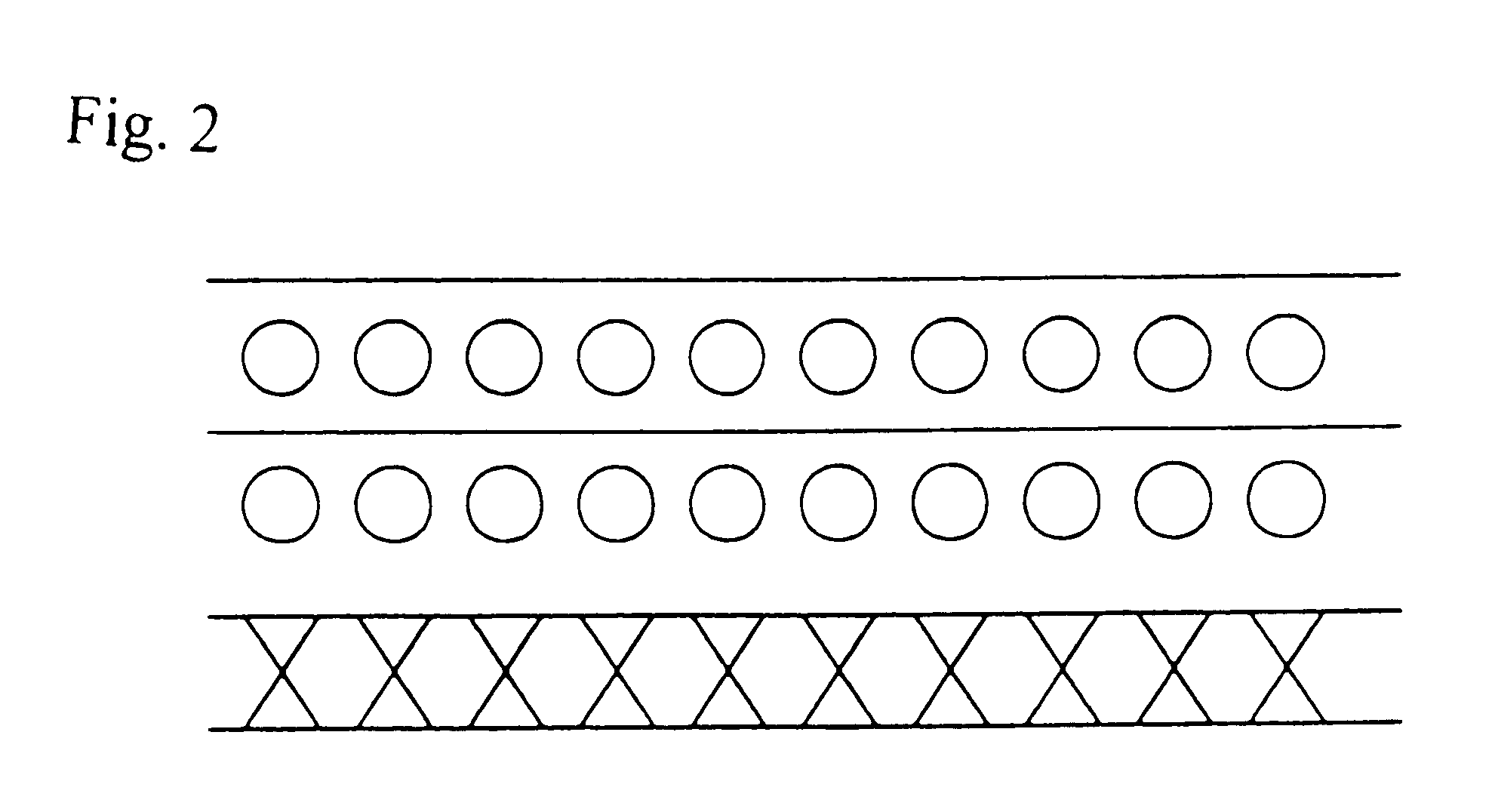

Seven-layer co-extrusion high-isolating packaging film

The seven layer high obstruct packing film includes the first printing layer made of LLDPE, LDPE and FSU; the second shading layer made of white color, LLDPE and LDPE; the third adhering layer of adhesive Tie; the fourth obstructing layer comprising EVOH; the fifth adhering layer of adhesive Tie; the sixth shading layer made of black color, LLDPE and LDPE; and the seventh thermal sealing layer made of LLDP, LDPE and FSU. The present invention possesses the advantages of non-toxicity, high humidity resistance, high oxygen resistance, high heat resistance, high flexibility, high cold resistance and high thermal sealing strength, and is used in packing milk without need of adding preservative and being cold stored.

Owner:郭瑞林

Co-extruded composite stone-plastic polyvinyl chloride (PVC) floor

ActiveCN105908946AReduce releaseHarm reductionSynthetic resin layered productsLaminationPolyvinyl chlorideEngineering

Owner:HUIZHOU WEIKANG NEW BUILDING MATERIALS CO LTD

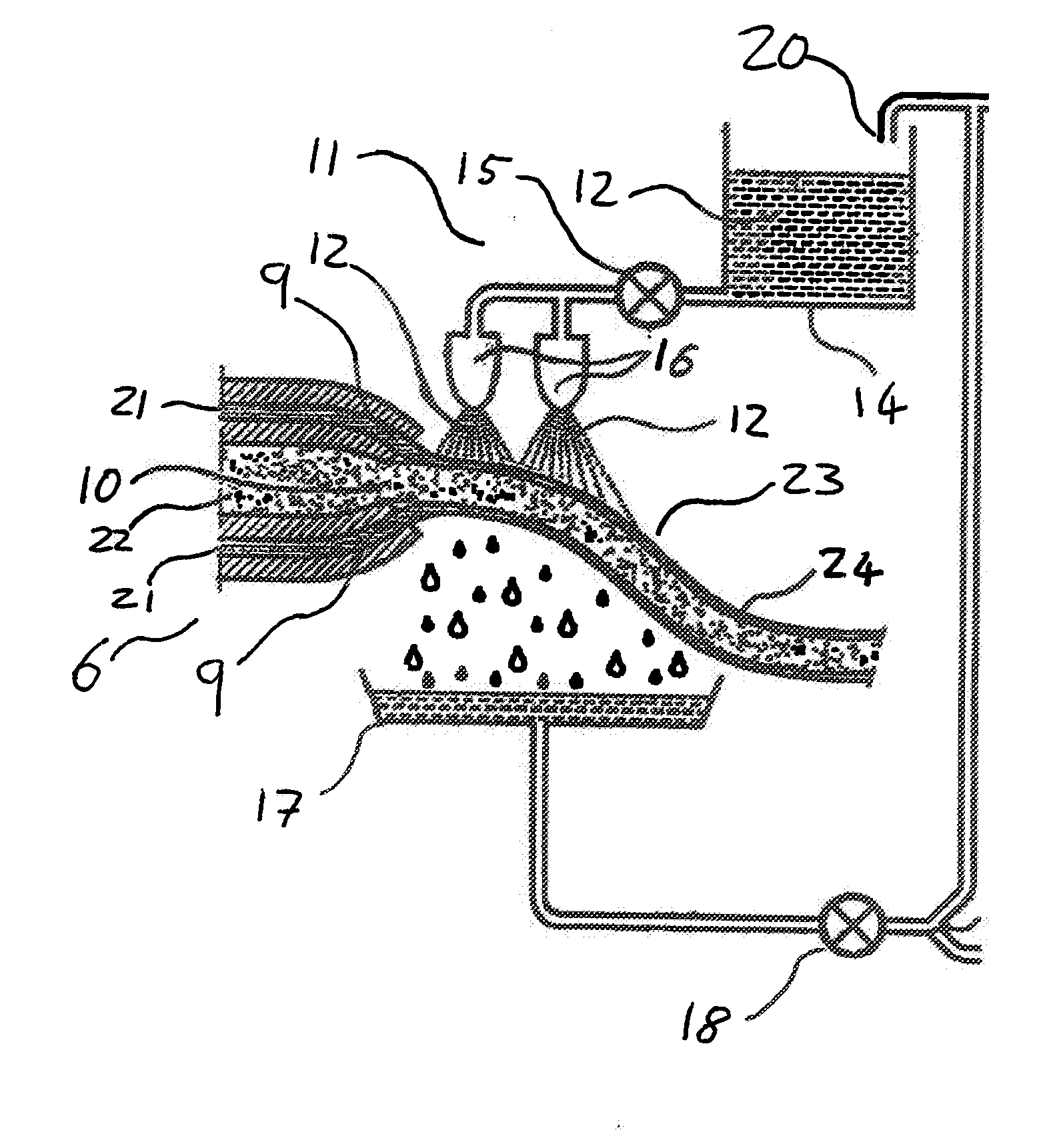

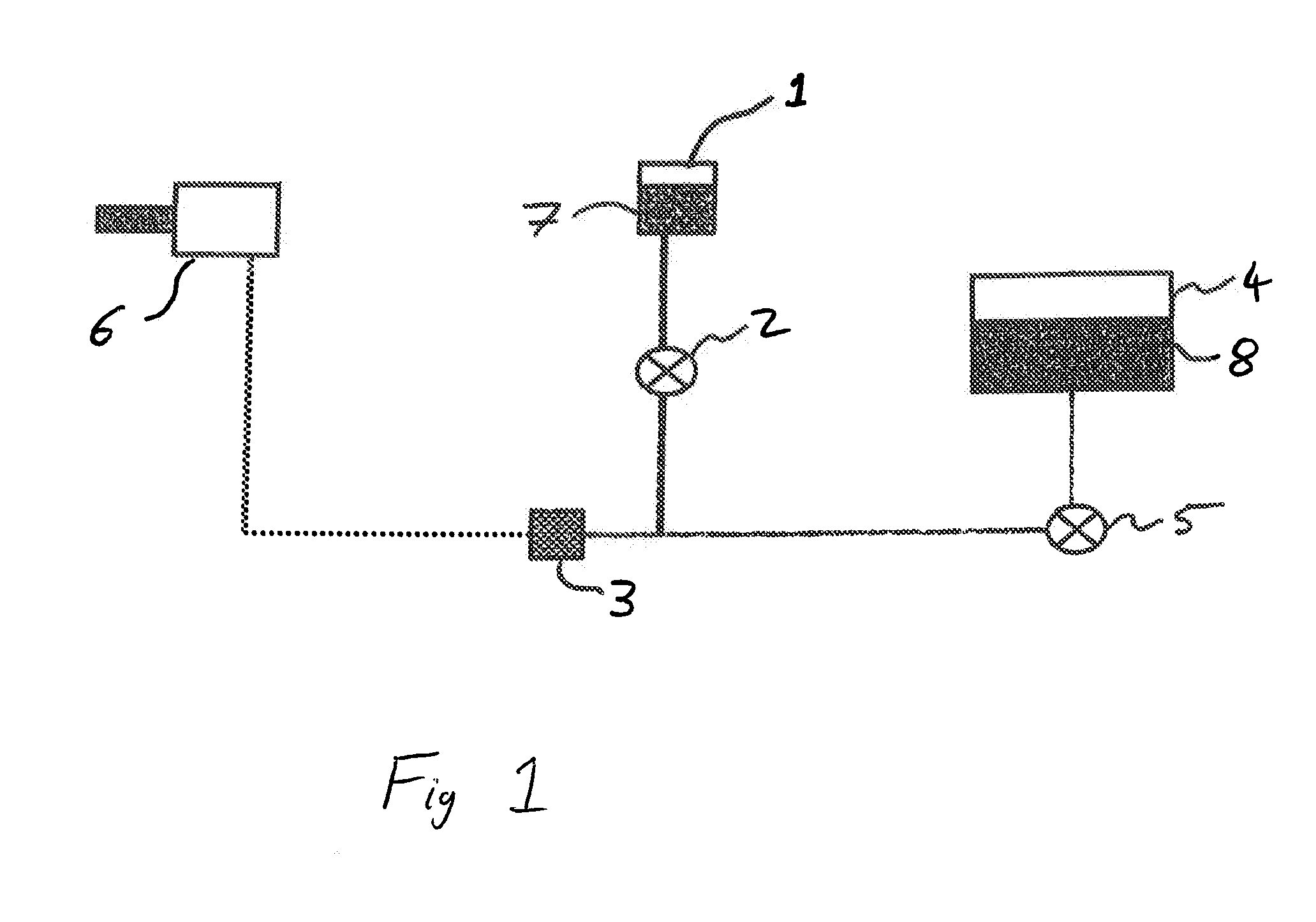

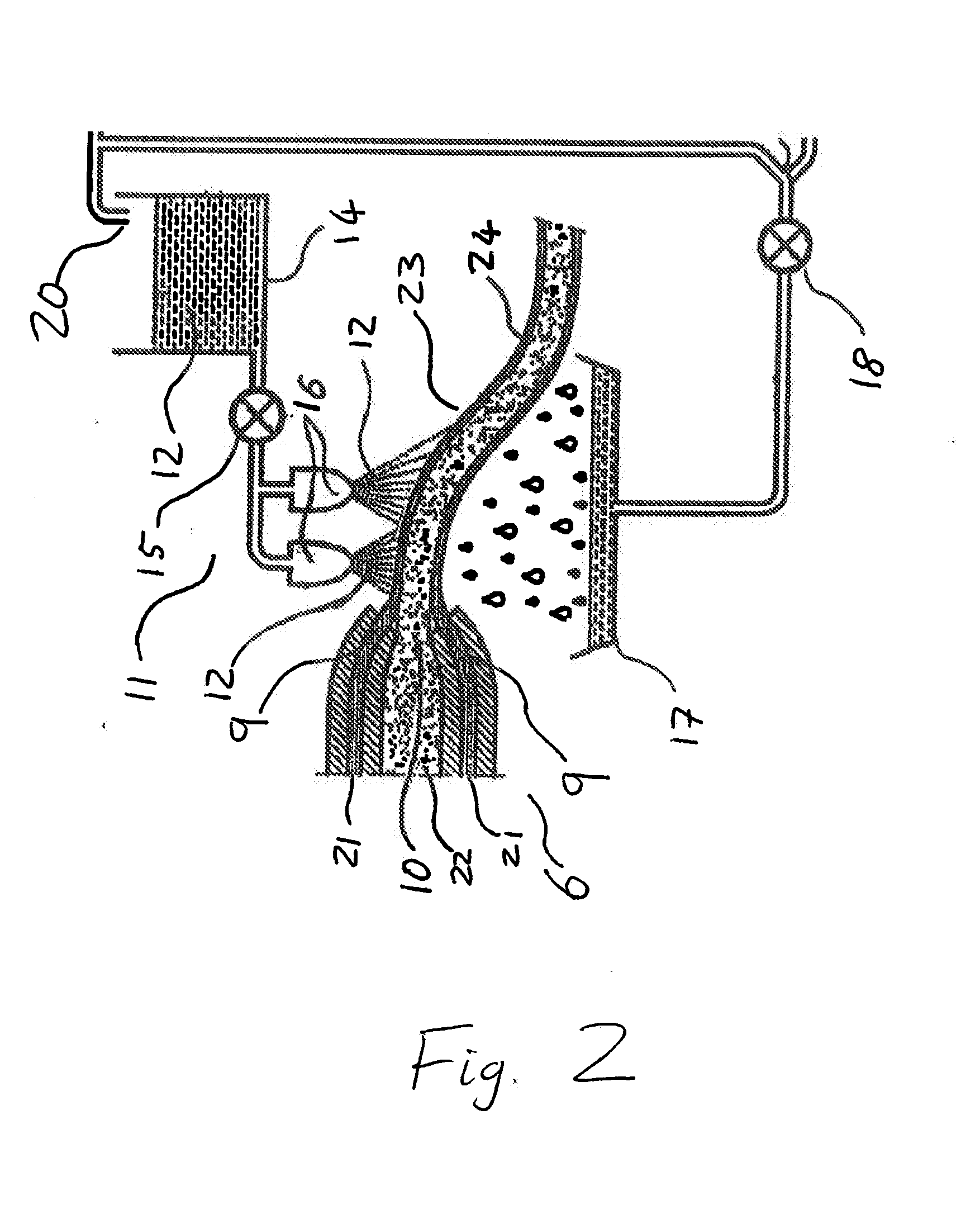

Equipment and method for frozen confectionery product with layered structure having external coating

ActiveUS20150157042A1Mitigate such drawbackMeat/fish preservationFrozen sweetsCo extrusionLayered structure

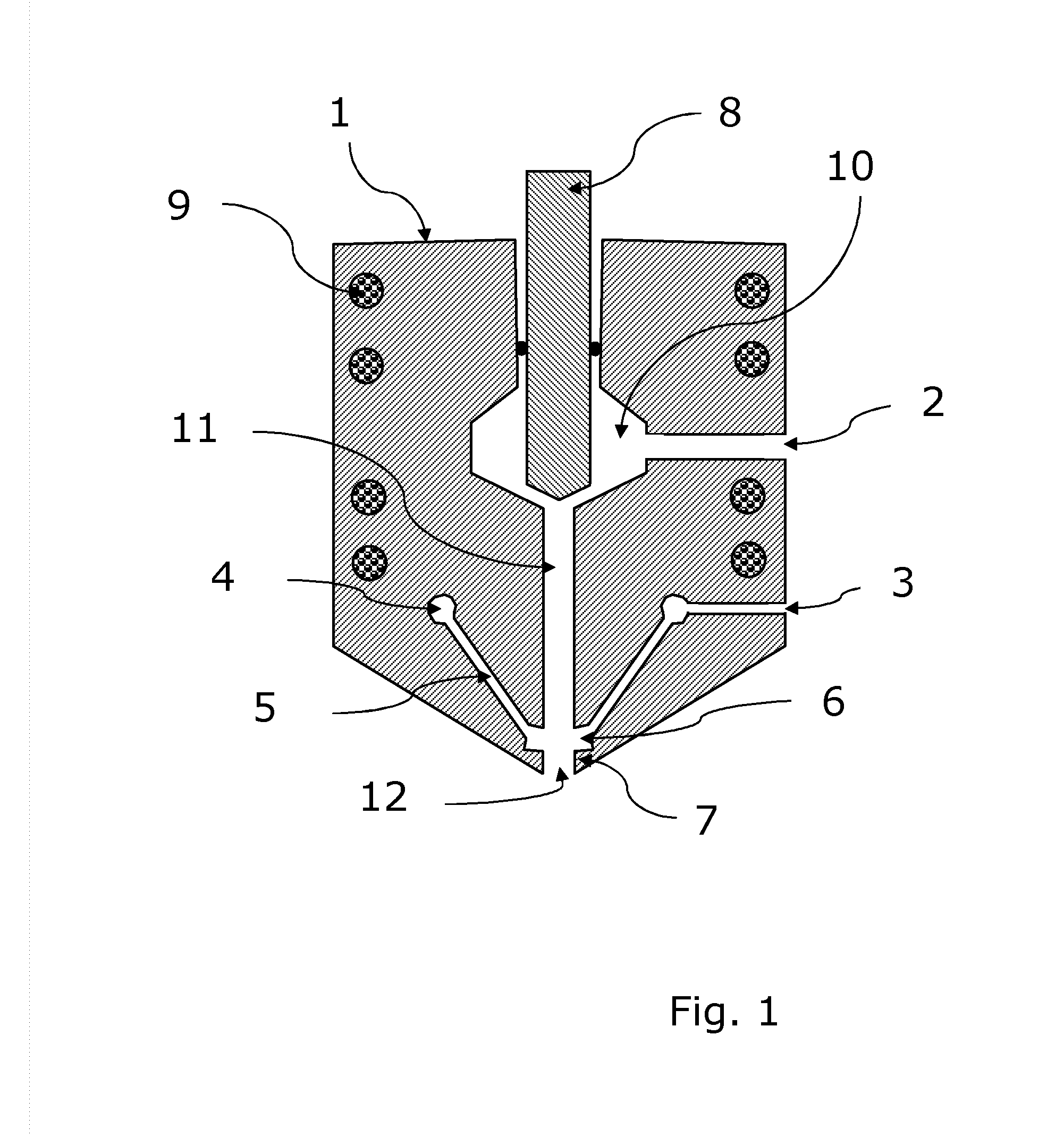

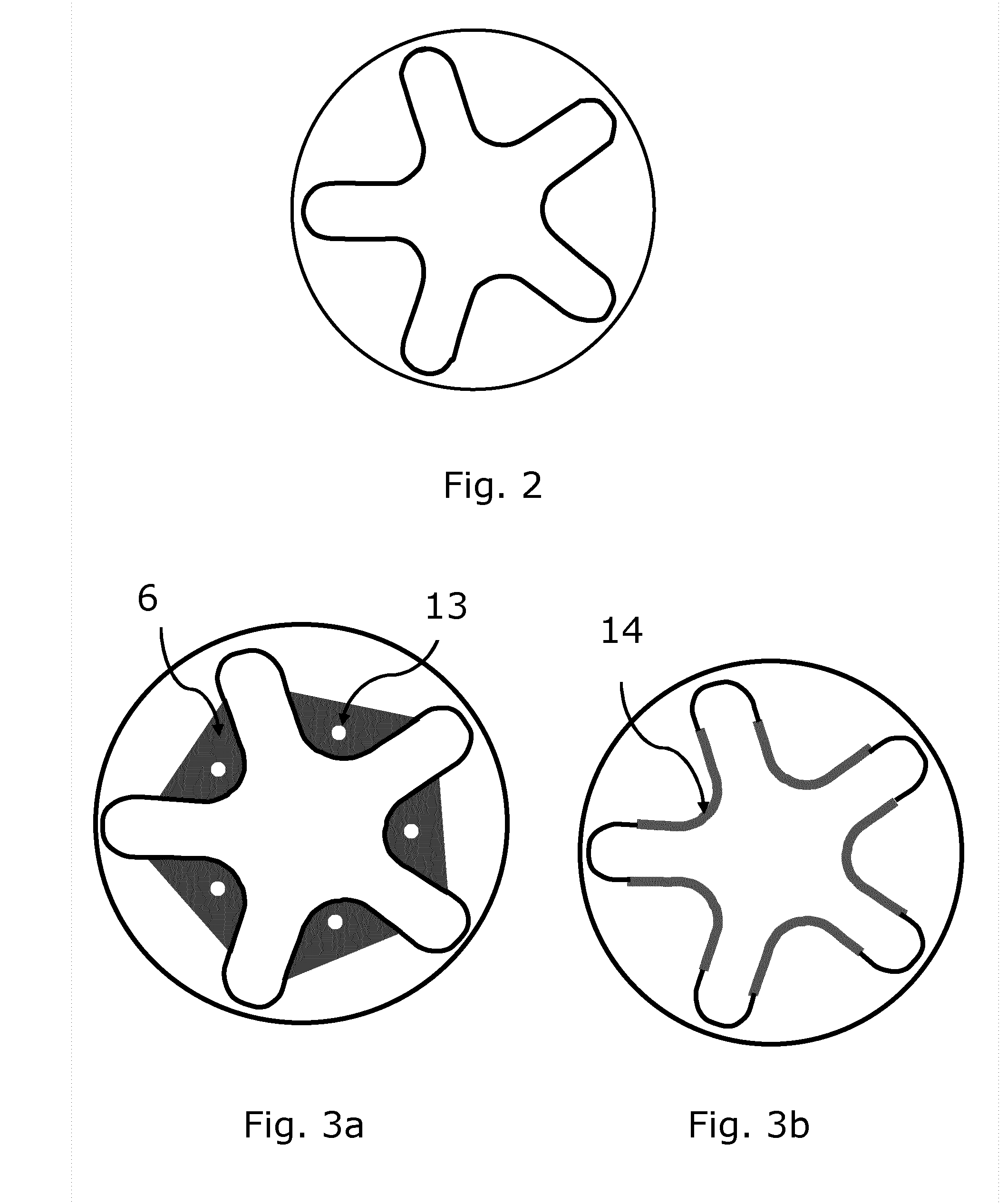

The present invention is concerned with an apparatus for making a coated frozen confectionery product by co-extrusion of a frozen confection and a coating substance, and in particular a nozzle body forming part of the apparatus. The nozzle body according to the invention has a nozzle exit, through which the coated confectionery product is discharged as stream; the stream of coated confectionery product being the frozen confectionery product at least partially coated with the coating substance. The nozzle body preferably comprises: a frozen confection product channel communicating with at least one frozen confectionery inlet port and leading to the nozzle exit, at least one coating supply channel communication with at least one coating inlet port and leading to at least one coating application chamber opening into the frozen confection product channel at a position upstream of the nozzle exit, and a spreading tongue arranged downstream of the at least one coating application chamber and upstream of or forms part of the nozzle exit, said spreading tongue being adapted to distribute the coating substance onto the surface of the frozen confection and define the cross sectional shape of the stream of coated confectionery product. The invention also relates to a method for making a coated frozen confectionery product by co-extrusion.

Owner:SOC DES PROD NESTLE SA

Barrier film

InactiveUS7854994B2Improve the level ofImprove homogeneityFibre treatmentBottlesPolyethylene terephthalate glycolPolyethylene oxide

A barrier composition which is injection mouldable and able to be made into a transparent film or incorporated (by co-extrusion and / or lamination) into multi-layer film products, the composition on dry basis: a) from 45 to 90% by weight of a starch and / or a modified starch selected from starches modified by reaction with a hydroxyl alkyl group, an acetate or a dicarboxylic acid anhydride or a grafting polymer; b) from 4 to 12% by weight of a water soluble polymer selected from polyvinyl alcohol, polyvinylacetate, and copolymers of ethylene and vinylalcohol which have a melting point compatible with the molten state of the starch components c) from 5 to 45% by weight of a non-crystallising mixture of sorbitol and at least one other plasticizer selected from glycerol, maltitol, xylitol, mannitol, glycerol trioleate, epoxidised linseed or soybean oil, tributyl citrate, acetyl tri-ethyl citrate, glyceryl triacetate, 2,2,4-trimethyl-1,3-pentanediol diisobutyrate; polyethylene oxide or polyethylene glycol; d) from 0.3 to 2.5% by weight of a C12-22 fatty acid or salt; e) from 0.25% to 3% of an emulsifier system having a hydrophilic lipophilic balance value between 2 and 10. The barrier film may be co-injection moulded with polyethylene terephthalate (PET) or polylactic acid (PLA) for blow moulding into beverage bottles, with polyethylene (PE) or polypropylene (PP) or biodegradable polymers for high gas-barrier containers or closures, or may be co-extruded with polyethylene, polypropylene or polylactic acid for thin film packaging applications or for blow-moulded containers.

Owner:PLANTIC TECH

Food Product Having a Casing

ActiveUS20090317522A1Less prone to weakening over timeTimely controlMilk preparationAlcoholic beverage preparationCo extrusionFood products

The present invention is directed to a process for preparing a food product having a casing, the process comprising the step of applying a casing paste comprising alginate and a sparingly soluble calcium salt by co-extrusion to the exterior of a material to be cased to form a co-extruded product, and contacting the co-extruded product with a solution comprising calcium ions, thereby causing the alginate to gel.

Owner:DUPONT NUTRITION USA INC

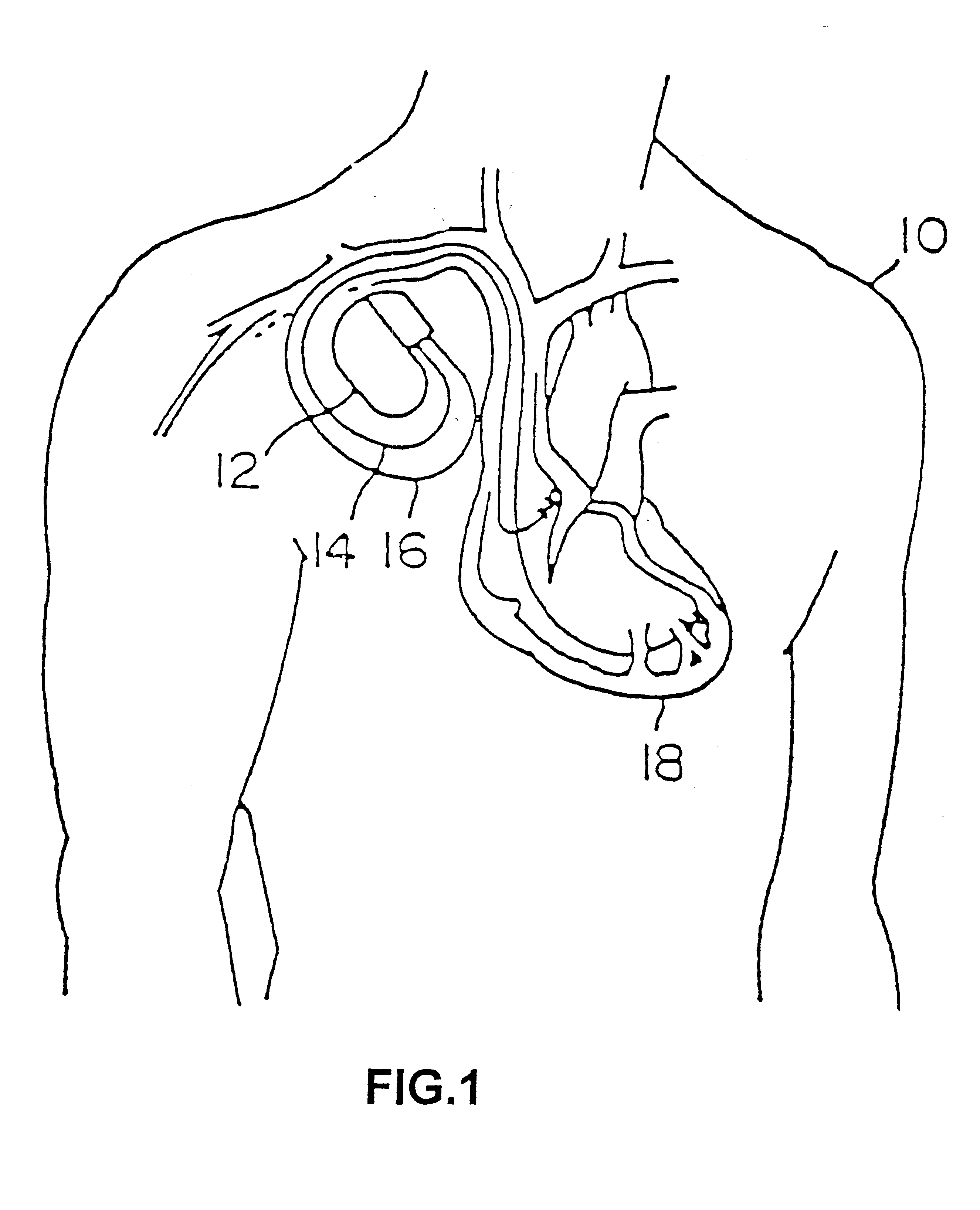

Co-extruded, multi-lumen medical lead

InactiveUS20010018607A1Transvascular endocardial electrodesDiagnostic recording/measuringElectrical stimulationsBending stiffness

Medical electrical leads for sensing or electrical stimulation of body organs or tissues, particularly implantable cardiac leads for delivering pacing pulses and cardioversion / defibrillation shocks, and / or sensing the cardiac electrogram (EGM) or other physiologic data and their methods of fabrication are disclosed. A lead body sheath is co-extruded in a co-extrusion process using biocompatible, electrically insulating, materials of differing durometers in differing axial sections thereof, resulting in a unitary lead body sheath having differing stiffness sections including axial segments or webs or lumen encircling rings or other structures in its cross-section. The lead body sheath is co-extruded to have an outer surface adapted to be exposed to the environment or to be enclosed within an outer sheath and to have a plurality of lead conductor lumens for receiving and enclosing a like plurality of lead conductors of the same or differing types. The lead body sheath can be co-extruded of a plurality of sheath segments containing a lead conductor lumen and formed of a first durometer material or of differing durometer materials. A web of a further durometer material can be co-extruded extending between the adjoining boundaries of the axial sheath segments and bonding the adjacent segments together. The lead body sheath can be tailored to exhibit differing bending stiffnesses away from the lead body sheath axis in selected polar directions around the 360° circumference of the sheath body.

Owner:MEDTRONIC INC

Tire having tread with colored groove configuration

InactiveUS20020174924A1Improve performanceSpecial tyresTyre tread bands/patternsElastomerEngineering

The present invention relates to a tire having a rubber tread of a lug and groove configuration and of a co-extruded cap / base construction; wherein the tread cap is of a rubber composition which contains carbon black and is thereby of a black color; wherein a visible surface of at least one groove is of a rubber composition exclusive of carbon black and is of a non-black color and wherein said visible non-black colored rubber composition is a rubber layer which underlies said tread cap. Said visible non-black colored rubber is exclusive of any appreciable portion of, and preferably exclusive of, the surface of said tread lugs intended to be ground-contacting. In one aspect of the invention, said non-black colored rubber composition contains an amorphous precipitated silica reinforcement, preferably a pre-hydrophobated precipitated silica. In another aspect of the invention, said non-black colored rubber composition, and alternately, carbon black containing black colored rubber compositions adjoining said non-black colored rubber composition, is comprised a blend of at least one diene based elastomer and a brominated copolymer of isobutylene and p-methylstyrene together with an organo phosphite.

Owner:GENERAL ELECTRIC CO +1

Wood-plastic coated solid wood composite material and preparation method thereof

InactiveCN104228236AHigh mechanical strengthImprove impact resistanceWood layered productsSolid woodCo extrusion

The invention discloses a wood-plastic coated solid wood composite material and a preparation method thereof and aims at solving the problems in the prior art that the combination of a wood-plastic composite material and a solid wood material is poor in firmness, the end of a sectional material is unclosed, the wood-plastic composite material is prone to creep deformation and low in tenacity, and the solid wood material is prone to decaying, hygroscopic deformation and cracking. The wood-plastic coated solid wood composite material is made by wrapping a solid wood core with a wood-plastic composite material. The method comprises the following steps: firstly, processing a groove in the side of solid wood to obtain the solid wood core; secondly, coating the surface of the solid wood core with the wood-plastic composite material through a co-extrusion method and filling the side groove with the wood-plastic composite material to obtain a wood-plastic coated solid wood composite sectional material; and thirdly, sealing the wood-plastic coated solid wood composite sectional material by virtue of the wood-plastic composite material to obtain the wood-plastic coated solid wood composite material. The wood-plastic coated solid wood composite material disclosed by the invention is used for manufacturing a door or window and furniture, and also can be used as a bearing structure material.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

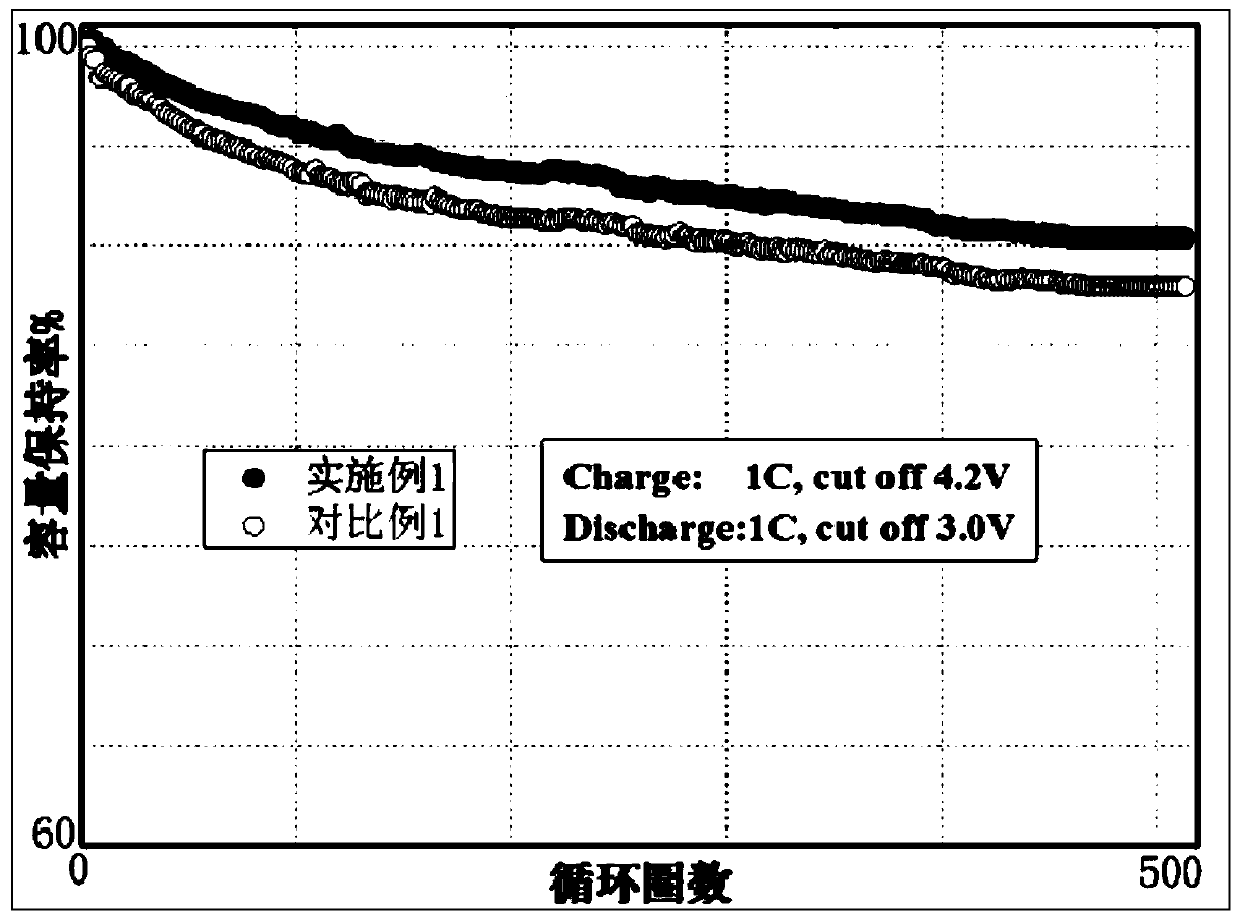

Hybrid solid-liquid electrolyte lithium storage battery

InactiveCN109768318AHigh mechanical strengthImprove securitySolid electrolytesFinal product manufactureSolid state electrolyteEngineering

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com