Co-extruded composite stone-plastic polyvinyl chloride (PVC) floor

A co-extrusion composite and stone-plastic technology, applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problems of endangering the health of workers, toxic and harmful substances in glue, and poor mute effect, so as to reduce the number of workers Harm to health, reduce VOC release, and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

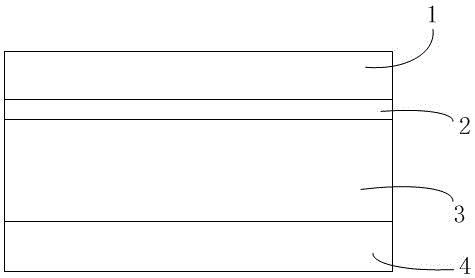

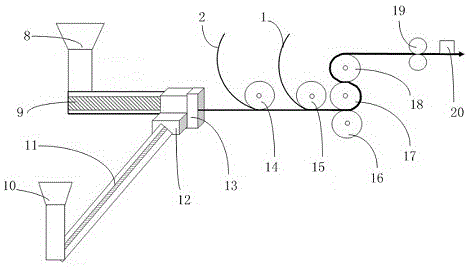

[0049] Such as figure 1 and figure 2 As shown, a double-layer co-extruded composite stone-plastic PVC floor, from top to bottom is wear-resistant layer 1, printing layer 2, stone-plastic layer 3 and PVC foam sound-absorbing layer 4, wherein stone-plastic layer 3 and PVC foam The foam sound-absorbing layer 4 is co-extruded to form a stone-plastic PVC co-extrusion layer, the above-mentioned printing layer 2 is hot-pressed on the stone-plastic layer 3 , and the wear-resistant layer 1 is hot-pressed on the printing layer 2 .

[0050] Among them, the stone plastic layer 3 is a non-foaming material, including the following components in parts by weight: 45 parts of PVC, 120 parts of stone powder (light calcium or heavy calcium or composite calcium), 5 parts of calcium zinc stabilizer, polyethylene glycol 1 part of distearate (G60), 1 part of PE wax, 5 parts of chlorinated polyethylene (CPE), 3 parts of ACR impact modifier.

[0051] The PVC foam sound-absorbing layer 4 contains th...

Embodiment 2

[0062] The structure of each layer of this embodiment is the same as that of Embodiment 1. The stone-plastic layer 3 is a micro-foaming material, including the following components in parts by weight: 75 parts of PVC, 130 parts of stone powder (light calcium or heavy calcium or composite calcium), 0.8 parts of foaming agent (wherein azo foaming 0.4 parts of sodium bicarbonate foaming agent), 8 parts of foam regulator, 6 parts of calcium zinc stabilizer, 1 part of polyethylene glycol distearate, 1 part of PE wax, 6 parts of chlorinated polyethylene parts, ACR impact modifier 3 parts, chlorinated polyvinyl chloride 6 parts.

[0063] The other raw material formulas and preparation methods and steps are the same as in Example 1, and will not be described in detail here.

[0064] The double-layer co-extruded composite stone-plastic PVC floor of this embodiment has low production cost, good stability, and good anti-sag performance. There is a PVC foam sound-absorbing layer at the b...

Embodiment 3

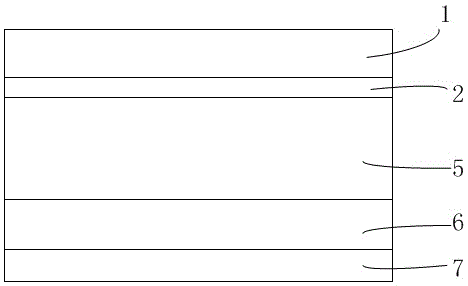

[0066] Such as image 3 , Figure 4 and Figure 5 As shown, a three-layer co-extruded composite stone-plastic PVC floor, from top to bottom is a wear-resistant layer 1, a printing layer 2, a PVC primer layer 5, a stone-plastic micro-foaming layer 6 and a second PVC foaming sound-absorbing layer. Layer 7, wherein the PVC primer layer 5, the stone-plastic micro-foaming layer 6 and the second PVC foam sound-absorbing layer 7 are co-extruded to form a stone-plastic PVC co-extrusion layer, and the printing layer is hot-pressed on the stone-plastic PVC co-extrusion layer , the wear-resistant layer is heat-pressed on the printing layer.

[0067] The PVC primer layer 5 contains the following components in parts by weight: 100 parts of PVC, 550 parts of stone powder, 1.5 parts of calcium zinc stabilizer, 35 parts of plasticizer, and 1 part of PE wax.

[0068] The stone plastic micro-foaming layer 6 contains the following components in parts by weight: 75 parts of PVC, 130 parts of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com