Patents

Literature

2506results about How to "Improve sound absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

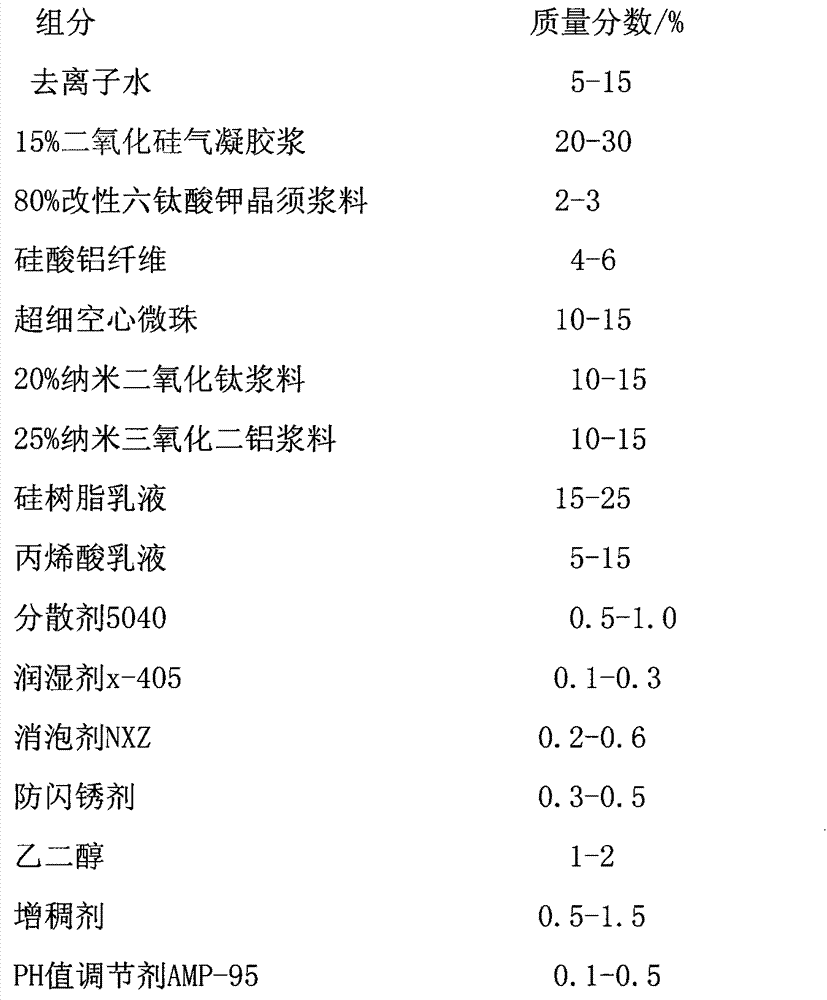

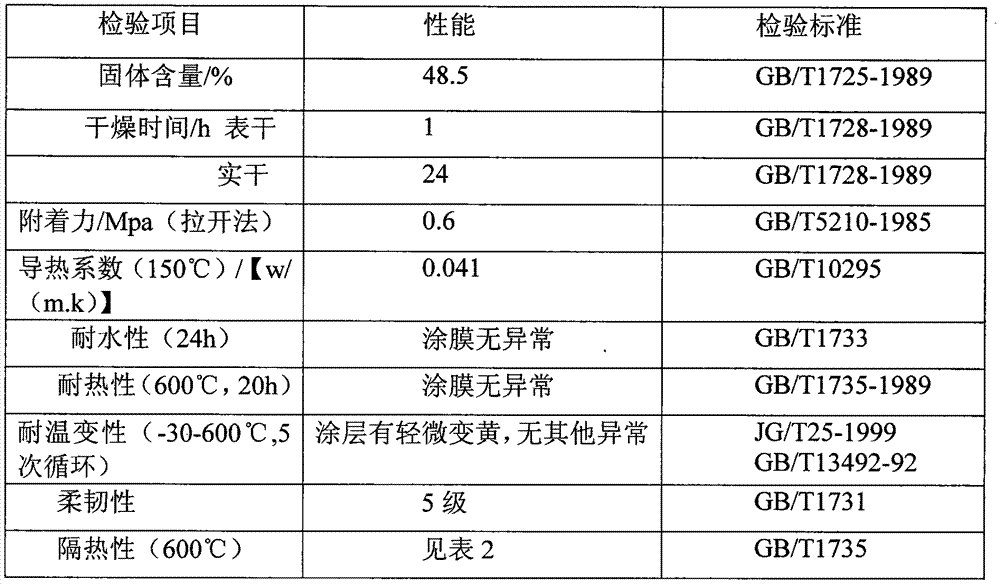

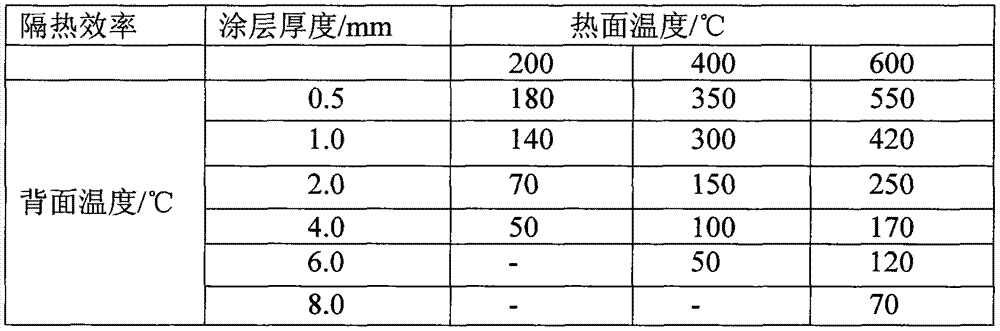

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

Acoustical gypsum board panel and method of making it

ActiveUS20080299413A1Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

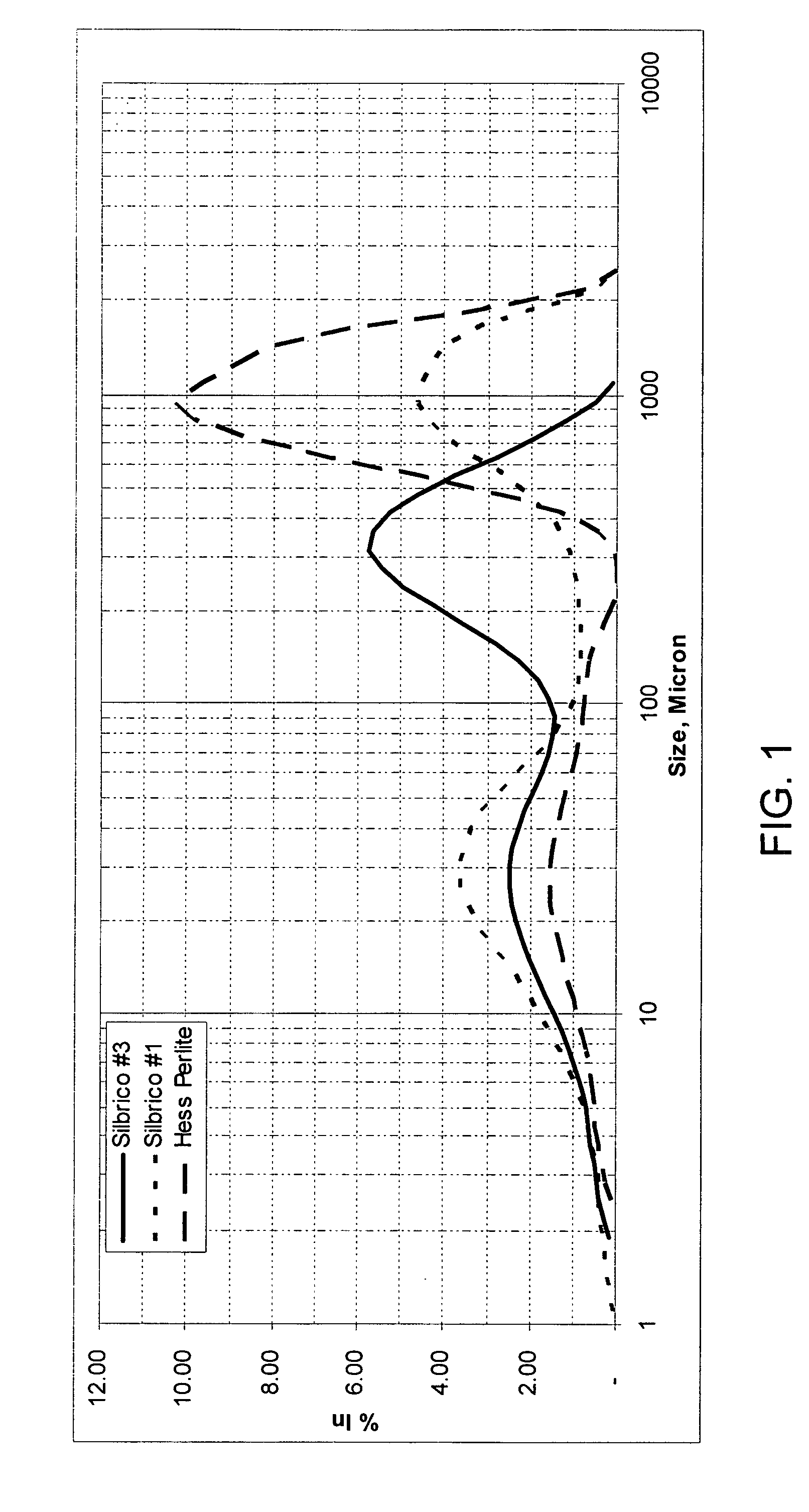

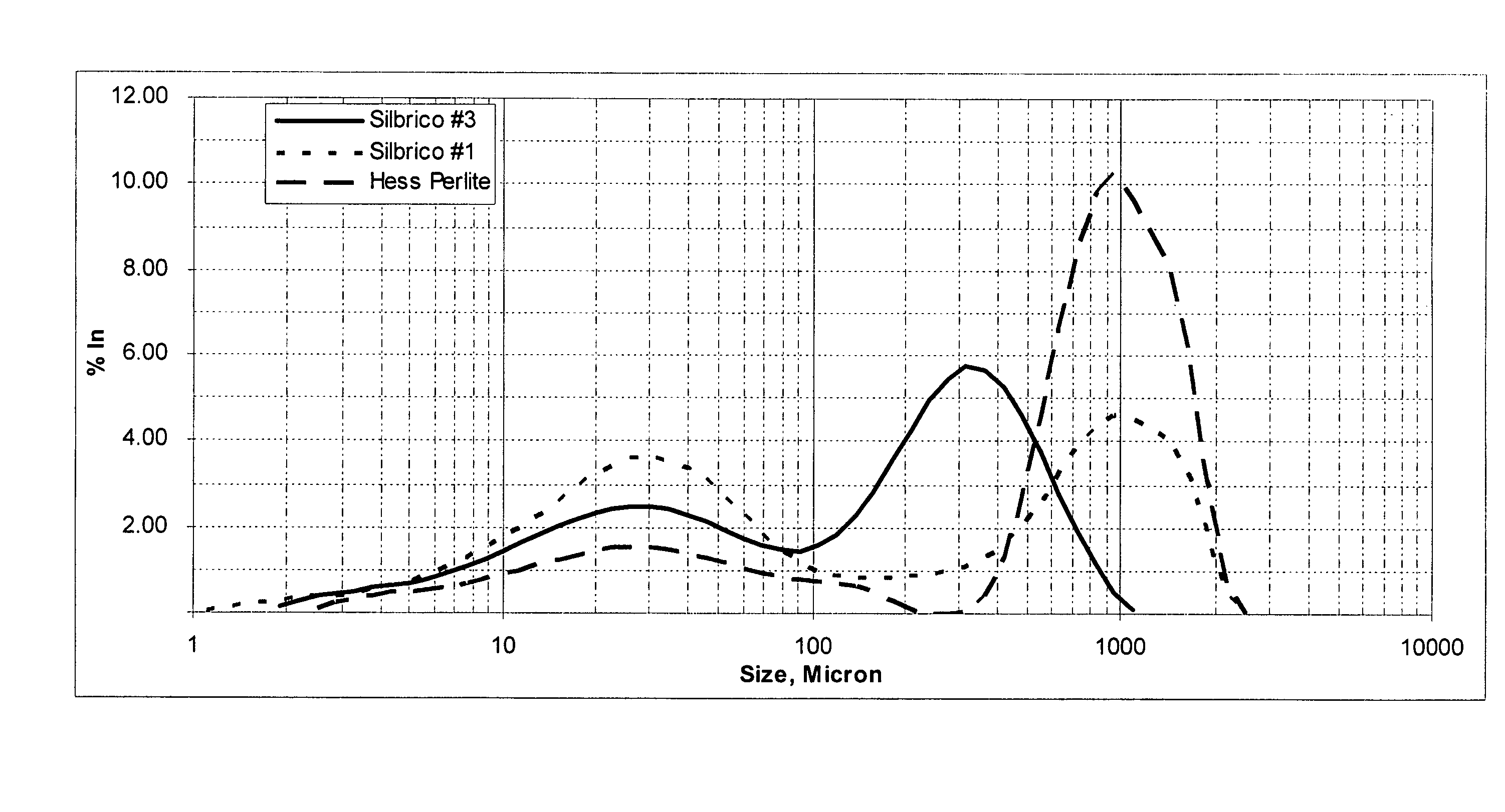

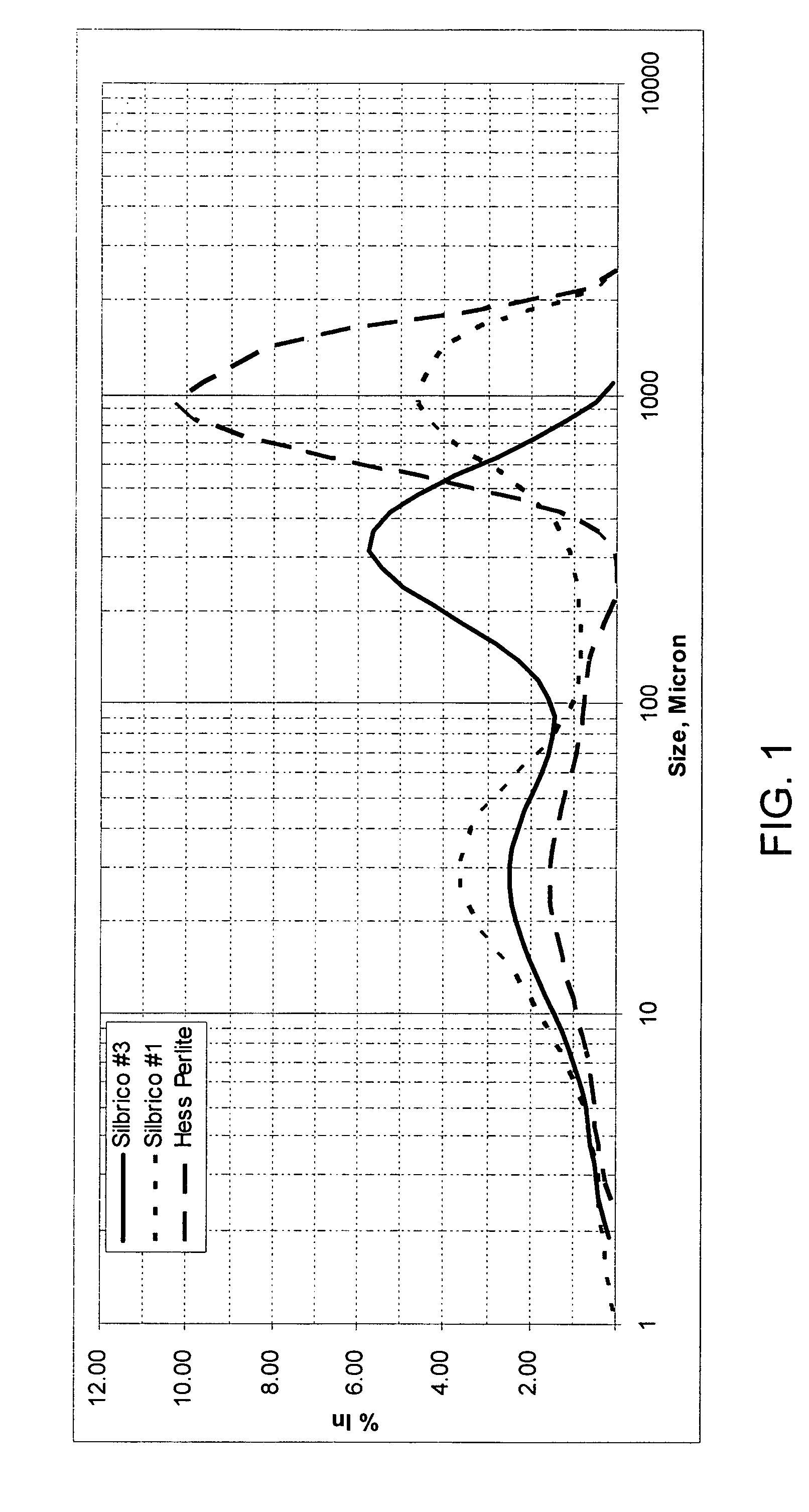

The acoustical product of the present invention comprises an acoustical product including a matrix of calcium sulfate dihydrate crystals and expanded perlite distributed throughout the matrix. The expanded perlite has a particle size distribution with at least 10% of the perlite having a particle diameter of 700 microns or more, and the amount of expanded perlite to calcium sulfate dihydrate is about 35% to about 75% by weight, based upon the dry weight of the calcium sulfate dihydrate. A dispersing agent and glass fibers having a particle length of about ¼ inch to about 1 inch are dispersed throughout the gypsum matrix.

Owner:UNITED STATES GYPSUM CO

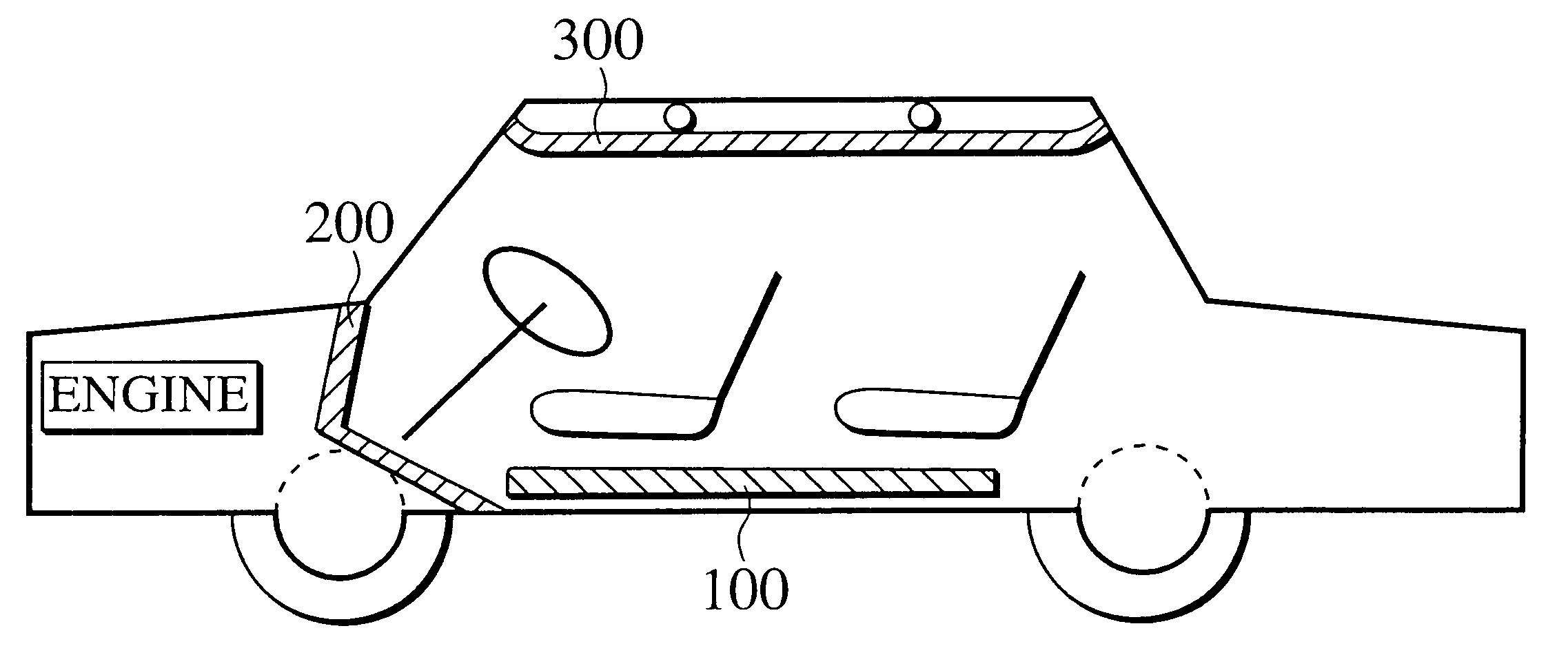

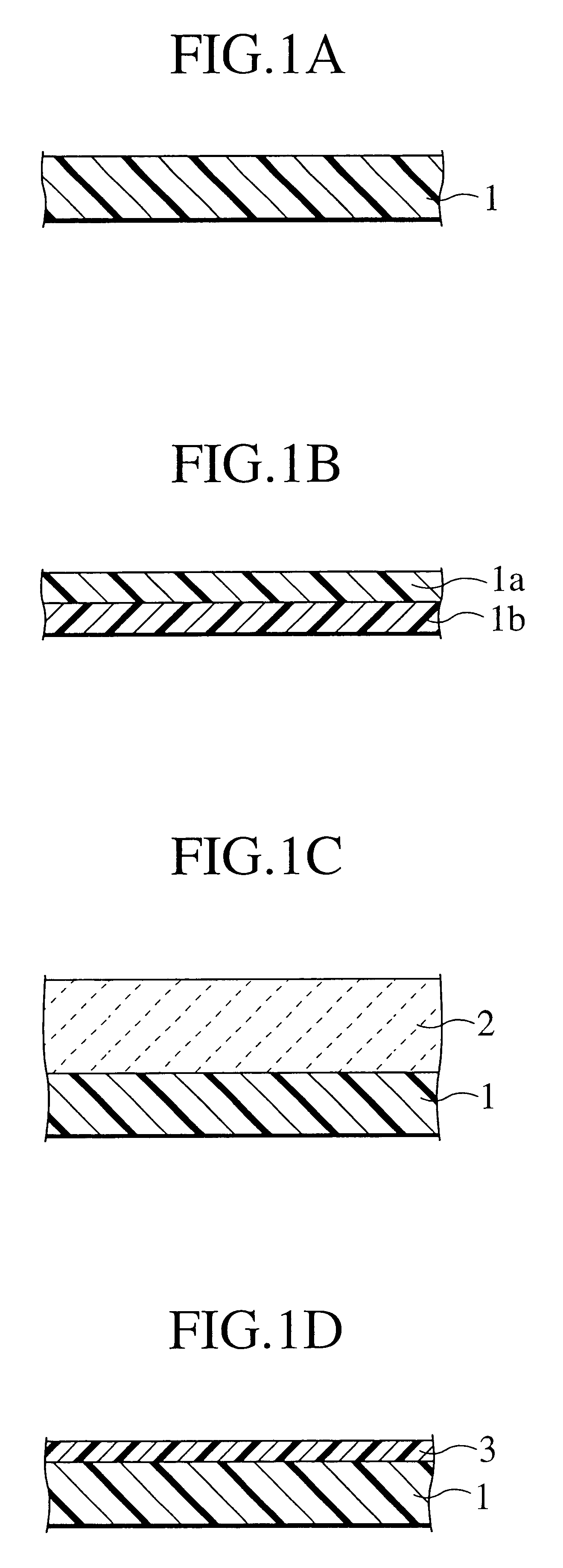

Sound absorbing-insulating structure for vehicles

InactiveUS6524691B2Improve sound absorptionLow costFibreboardWallsCellulose fiberVolumetric Mass Density

Owner:NISSAN MOTOR CO LTD

Low cost and high efficient soundproof material and manufacturing method thereof

InactiveCN103897262AImprove heat and aging resistanceExcellent ozone resistanceSound producing devicesRelaxation effectFilling materials

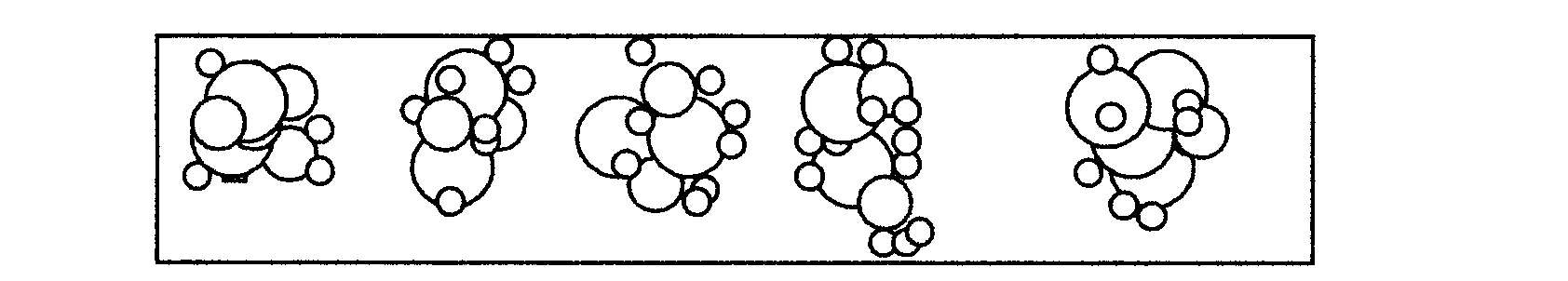

The invention relates to a low cost and high efficient soundproof material and a manufacturing method thereof, relates to the field of soundproof materials, solves the problems that in the prior art, soundproof materials do not have a prominent soundproofing effect, generate harmful gas, which can harm the human health, and have a high cost; and provides a low cost and high efficient soundproof material. The soundproof material comprises thermoplastic resin and an inorganic filling material, wherein the surface of the inorganic filling material has been processed by a coupling agent processing liquid, the inorganic filling material accounts for 15 to 80 wt% of the total weight of the soundproof material, and the balance being thermoplastic resin. In the soundproof material, the connections among the particles are abnormal, thus the internal friction of the incident sound waves is increased by the structure of the soundproof material, and a relaxation effect is generated to absorb the sound waves. Filling materials with different particle sizes are corresponding to waves in different wavelengths or frequencies, so the soundproof material can reduce sounds in different frequencies. Moreover the soundproof material has a good soundproof effect and is suitable for being promoted and used.

Owner:浙江艾迪雅科技有限责任公司

Nano porous concrete taking thixotropic colloid as template agent and preparation method

InactiveCN105294141AHas a three-dimensional network microporous structureNo pollution in the processCeramicwareBrickThixotropy

The invention relates to porous concrete and a preparation method thereof, in particular to novel nano porous concrete which is prepared by taking thixotropic colloid as a template agent to form a uniform-water-phase three-dimensional network nano porous structure and adding cementing materials, fine aggregate, coarse aggregate, an admixture and an additive. The nano porous concrete has the characteristics of being light, high in strength and low in heat conductivity, can be prefabricated into bricks, building blocks, plates, and assembly type stairs, wallboards, balcony slabs and roof panel parts in a factory, can be also cast on a construction site, and further can be prepared into mortar, thereby having remarkable practical significance on promotion of development of housing industrialization and green building concrete material in our country.

Owner:浙江圣润纳米科技有限公司

Acoustical gypsum board panel and method of making it

ActiveUS8057915B2Reduce fatigueReduce installation costsSynthetic resin layered productsLaminationGlass fiberCalcium Sulfate Dihydrate

Owner:UNITED STATES GYPSUM CO

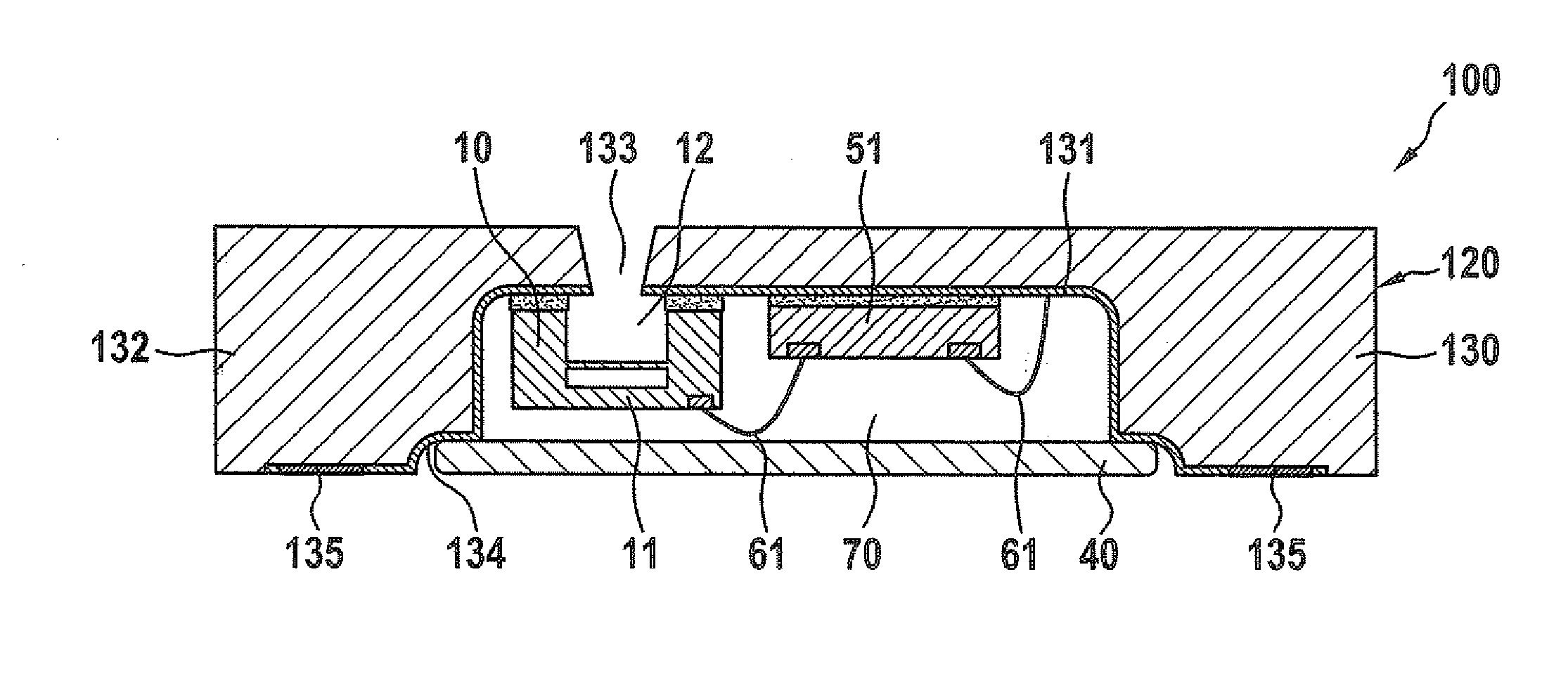

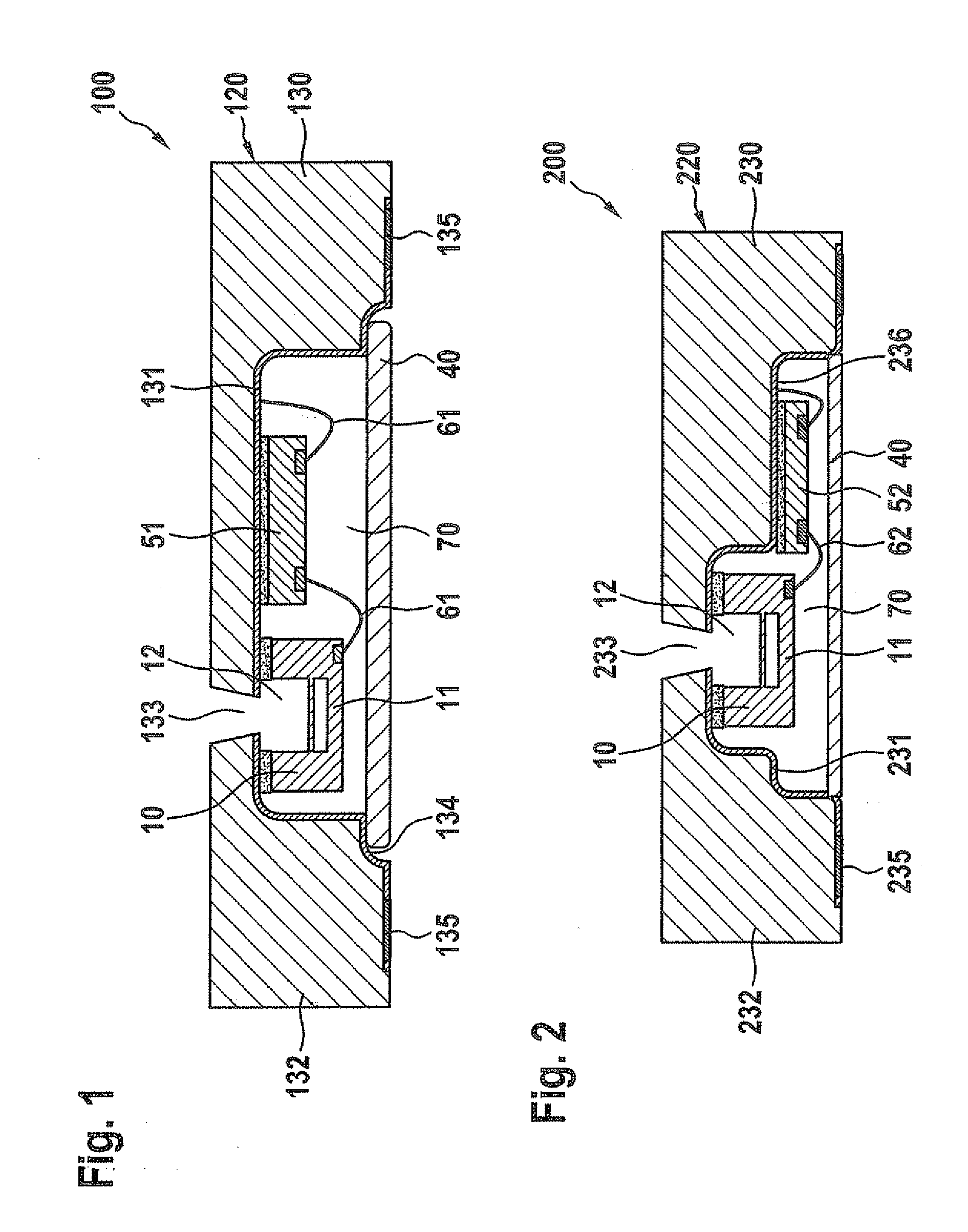

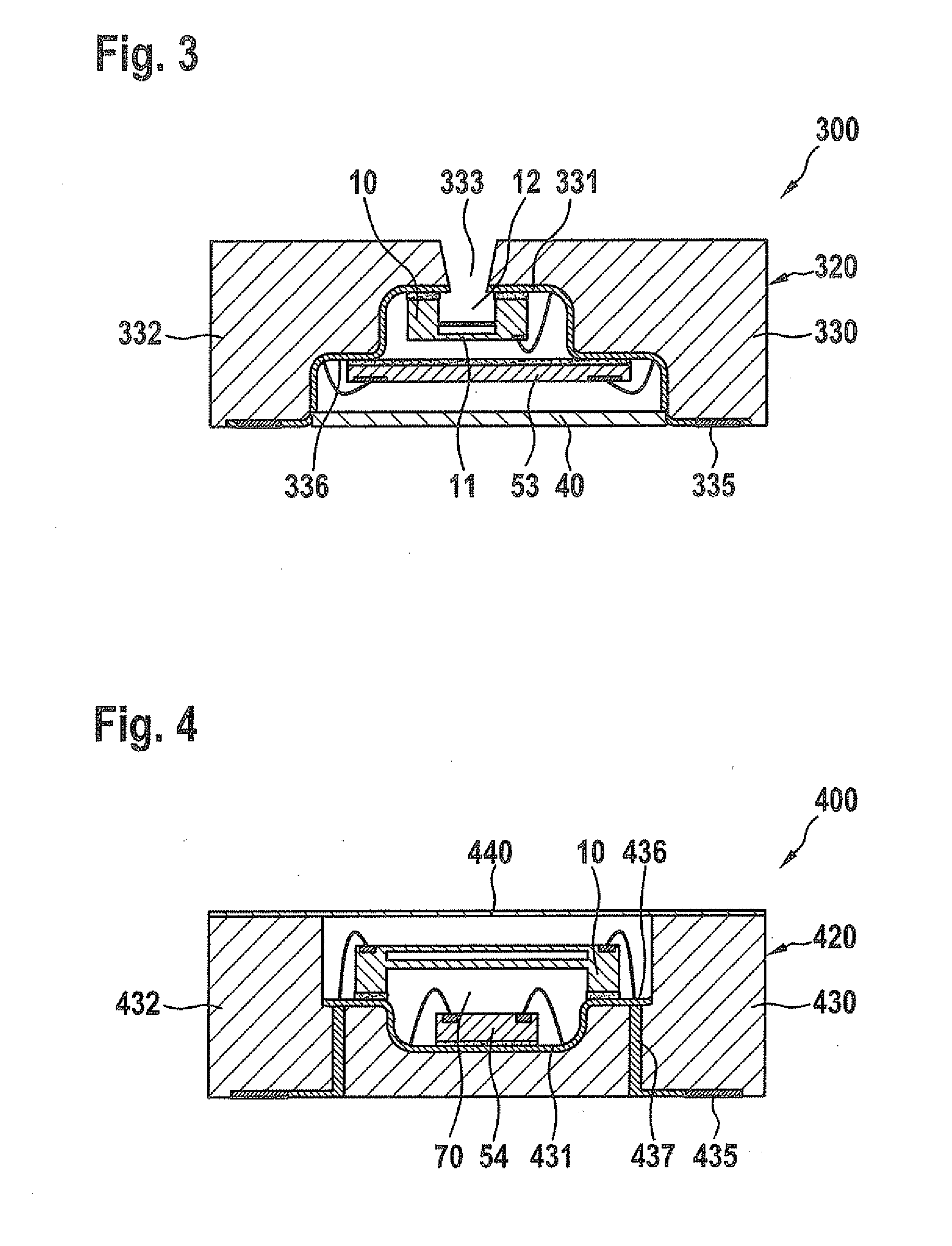

Component support and assembly having a mems component on such a component support

ActiveUS20120212925A1Well formedSimplifies electrical contactTransducer detailsSemiconductor electrostatic transducersMechanical engineeringLow stress

Owner:ROBERT BOSCH GMBH

Lightweight acoustical paint and preparation method thereof

The present invention discloses one kind of light sound absorbing paint and its preparation process. The paint consists of acrylate emulsion of average grain size of 0.15-0.5 micron as the adhesive, open-pored expanded perlite as light aggregate, pigment, stuffing and assistants combined together. It is prepared through pre-mixing, dispersing grinding and blending via fast stirring. It has low density, non-toxicity, no smell, environment friendship, simple production, simple application, coating of 1-5 mm thickness, average sound absorbing coefficient higher than 0.4 and other advantages, and is suitable for use in household, meeting room, concert hall, theater, etc.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

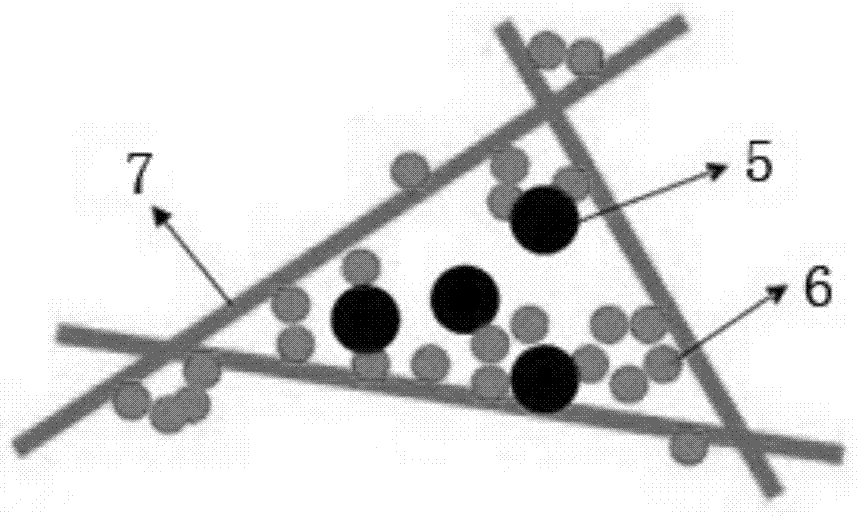

Preparation method of sound absorbing material, the sound absorbing material and filling method of same

ActiveCN105237033ARich microscopic pore structureImprove mass transfer efficiencyTransducer detailsSound producing devicesMetallurgySlurry

Owner:GOERTEK INC

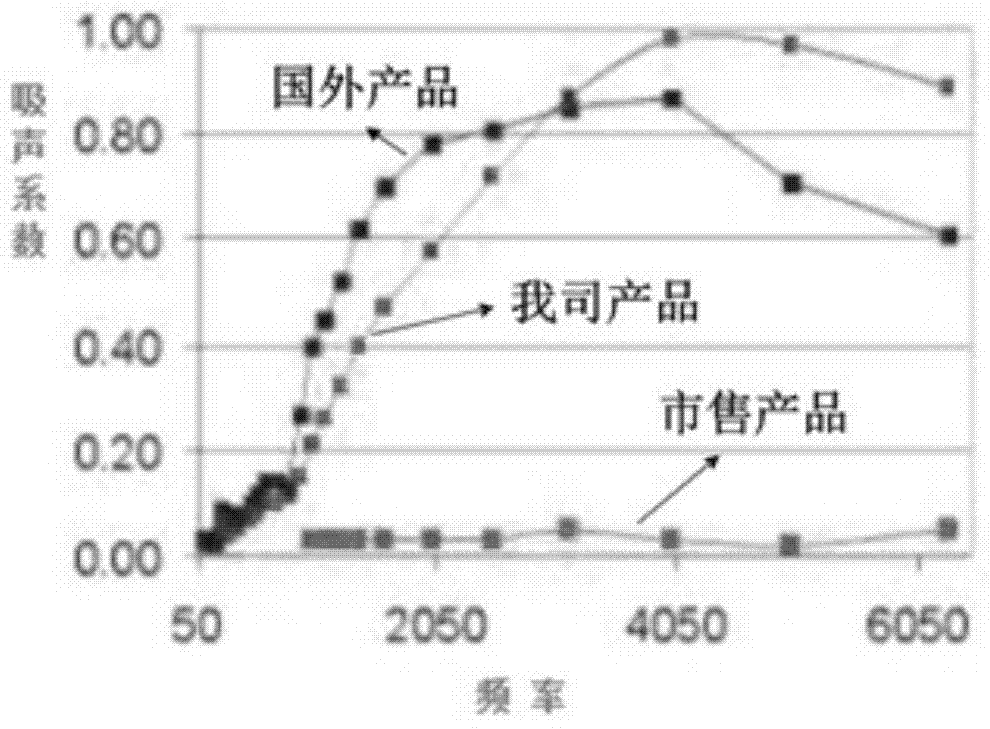

Micro-particle sound-absorbing board and preparation method thereof

ActiveCN104108902AGuaranteed structural strengthImprove the sound absorption coefficientSolid waste managementSound producing devicesFilm-coated tabletAngular coefficient

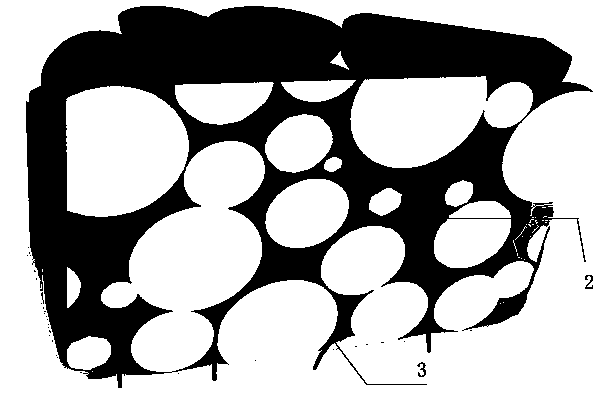

The invention discloses a micro-particle sound-absorbing board and a preparation method thereof. The micro-particle sound-absorbing board comprises a binding agent and sound-absorbing particles, wherein the outer surfaces of the sound-absorbing particles is coated with a layer of the binding agent; the angular coefficient of the particles coated with the binding agent is less than 1.3; the sound-absorbing particles comprise skeleton particles and filling particles; the skeleton particles are used for forming a skeleton of the sound-absorbing board; the filling particles enter pores among the skeleton particles to form sound-absorbing gaps; the average diameter of a cross section of the sound-absorbing gap is 0.07mm. Meanwhile, a two-section manufacturing process namely first-film-coating and second-curing-shaping of the sound-absorbing board can be used for avoiding an excessive amount of the binding agent from blocking the gap among the particles and further improving the angular coefficient of the particles. Therefore, the micro-particle sound-absorbing board and the preparation method of the micro-particle sound-absorbing board can be used for ensuring the structural strength of the sound-absorbing board and improving the sound-absorbing coefficient of the sound-absorbing board at the same time, and can obtain relatively good sound-absorbing effects.

Owner:ZISEN ENVIRONMENTAL TECHNOLOGY CO LTD

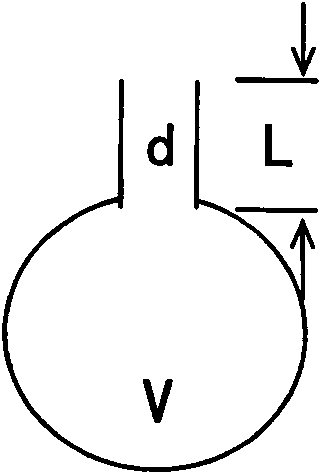

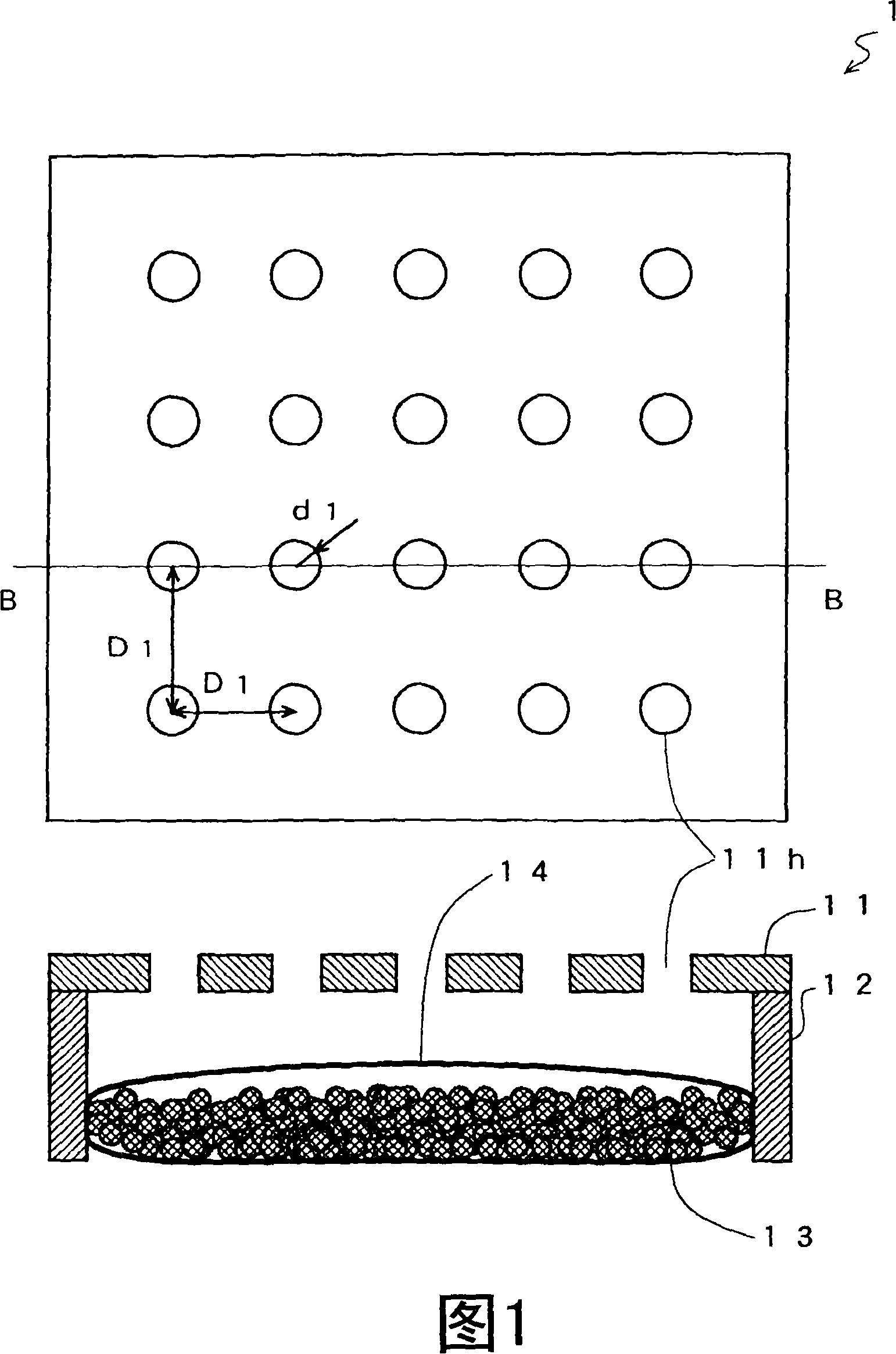

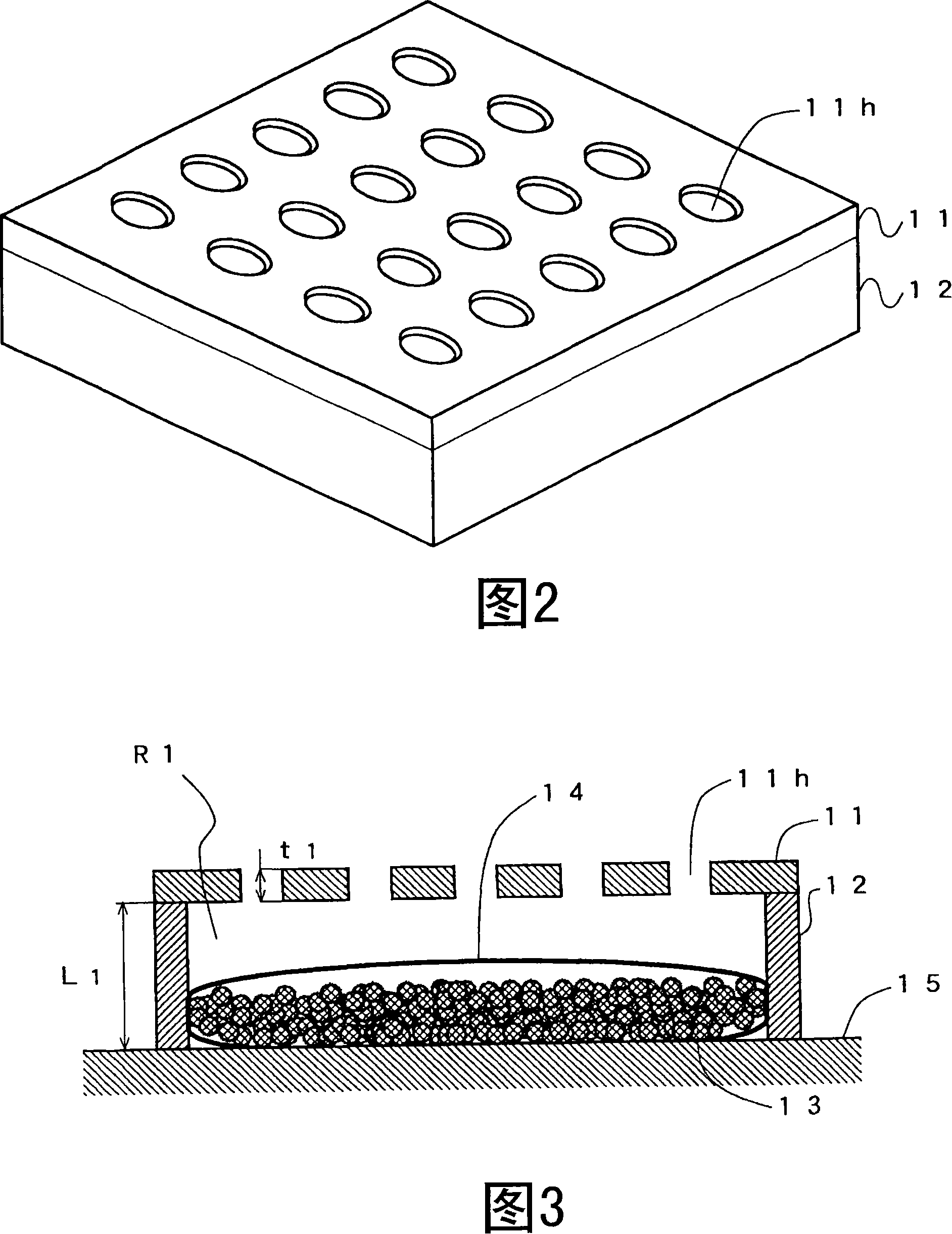

Composite sound absorbing device with built-in resonant cavity

ActiveCN101727894AIncrease sound resistanceIncrease acoustic reactanceSound proofingSound producing devicesResonant cavityResonance

The invention relates to a composite sound absorbing device with a built-in resonant cavity. The device comprises a perforated plate with a plurality of first holes, a back plate and a side plate, wherein a sealed cavity is formed by the perforated plate, the back plate and the side plate. The device is characterized in that at least one or more resonant cavities are placed in the sealed cavity; the resonant cavity is provided with at least one or more second holes; at least one of the second holes is communicated with the sealed cavity; the volume V of the resonant cavity is equal to 10mm3-1*1,010mm3, and the thickness of the wall of the cavity is 0.05 to 10 mm; and the aperture d, of the second hole on the cavity is equal to 0.05 to 100 mm, and the perforated percentage sigma, is 0.01 to 30 percent. The device forms acoustic scattering in the sealed cavity through the resonant cavity; and the second hole increases the acoustic resistance and the multi-cavity coupling resonance. The device has a flexible design and contributes to improving sound absorbing effect and expanding the sound absorbing frequency band.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

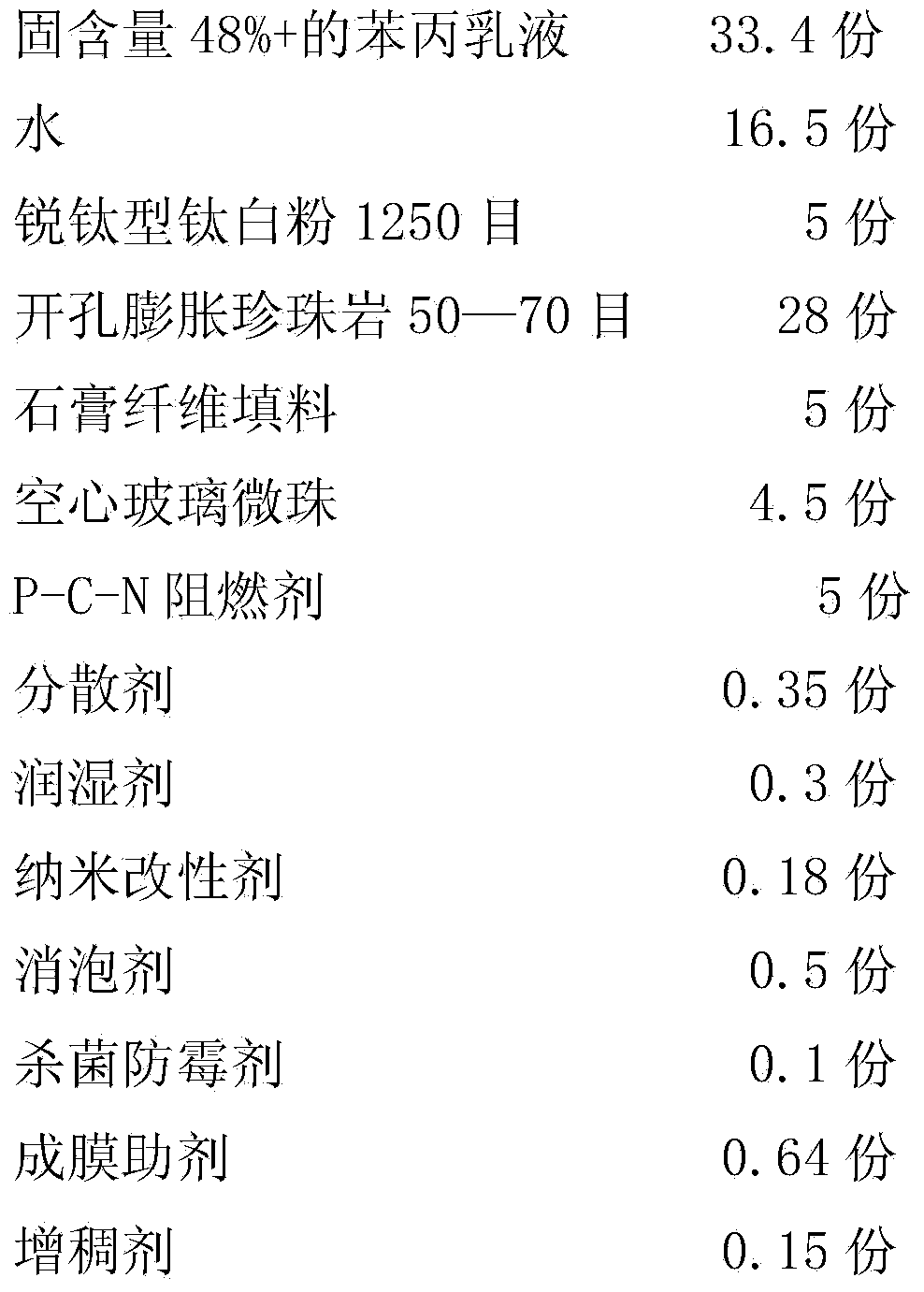

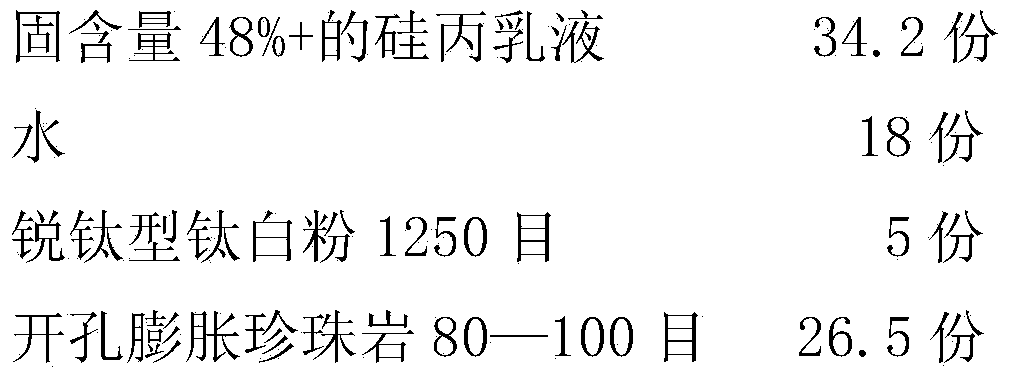

Nano modified water-base multifunctional sound-absorbing paint and preparation method thereof

InactiveCN103980771ABasic mechanicsBasic sound-absorbing functionCoatingsWater basedThermal insulation

The invention discloses a nano modified water-base multifunctional sound-absorbing paint and a preparation method thereof. The paint is composed of the following components in parts by weight: 28-38 parts of emulsion, 2-10 parts of pigment, 30-45 parts of filler, 15-25 parts of water, 4-8 parts of flame retardant and 2.25-5.43 parts of assistant. By optimizing the paint system structure, the polymer and filler are selected, modified and proportioned to ensure the basic mechanical properties and sound-absorbing function, and the paint has high-value service properties, such as thermal insulation, moisture resistance, fire resistance, aging resistance, fouling resistance, sterilization, air purification and the like, and is especially suitable for rooms and other occasions with higher environmental requirements.

Owner:南京创宁空间新材料科技有限公司

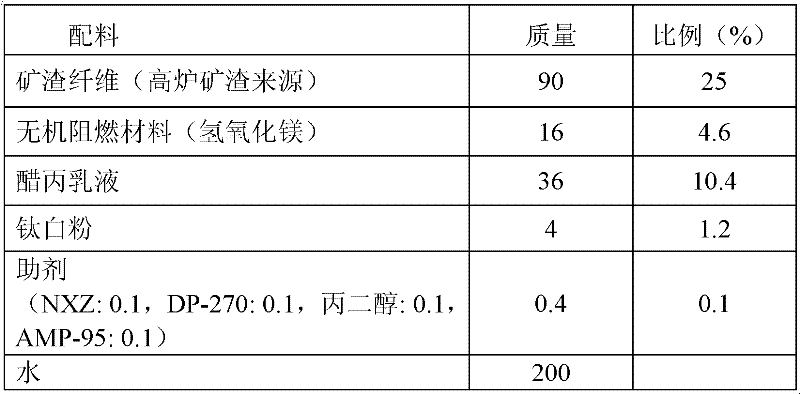

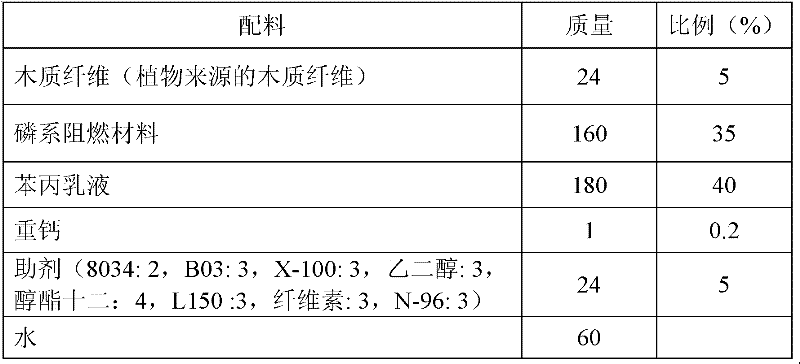

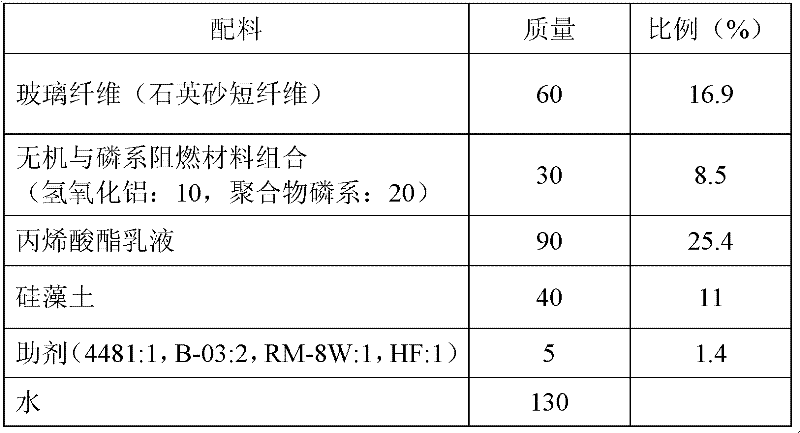

Sound-absorbing coating material and preparation method thereof

ActiveCN102533016AImprove sound absorptionNon-combustibleCoatingsNoise reduction coefficientGlass fiber

The invention discloses a sound-absorbing coating material, wherein every 100 parts by mass of coating contains 5-50 parts by mass of sound-absorbing function materials, 0.1-35 parts by mass of flame retardant materials, 10-40 parts by mass of binding materials, and the balance of an inorganic filling, an assistant and water in a common coating. The sound-absorbing function materials are selected from one or composite of some of materials such as slag fibers, mineral fibers, glass fibers and wood fibers, with fiber structures, and the sound-absorbing function materials are subjected to waterproof modification treatment. According to the invention, NRC (Noise Reduction Coefficient) of the coating material is tested to be more than 0.4 by using a standing wave tube method, and the sound-absorbing coating material has a good sound-absorbing denoising performance, excellent flame resistance and low heat conductivity coefficient, can be used for reducing the energy consumption of a building, is an environmental-friendly functional sound-absorbing coating material integrated with functions of sound absorption, flame resistance and decoration, and can be used on the surface of the building.

Owner:CHINA BUILDING MATERIALS ACAD

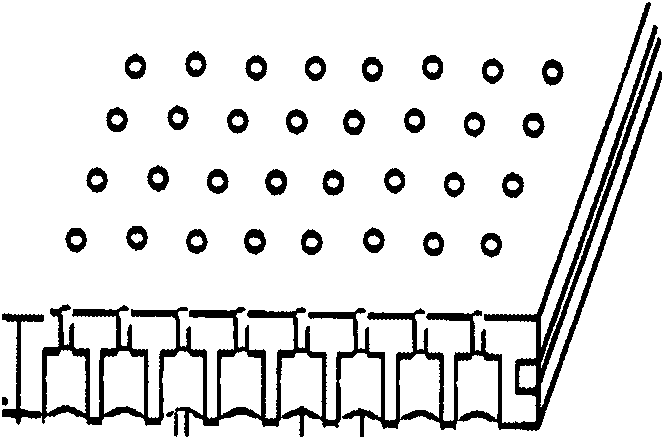

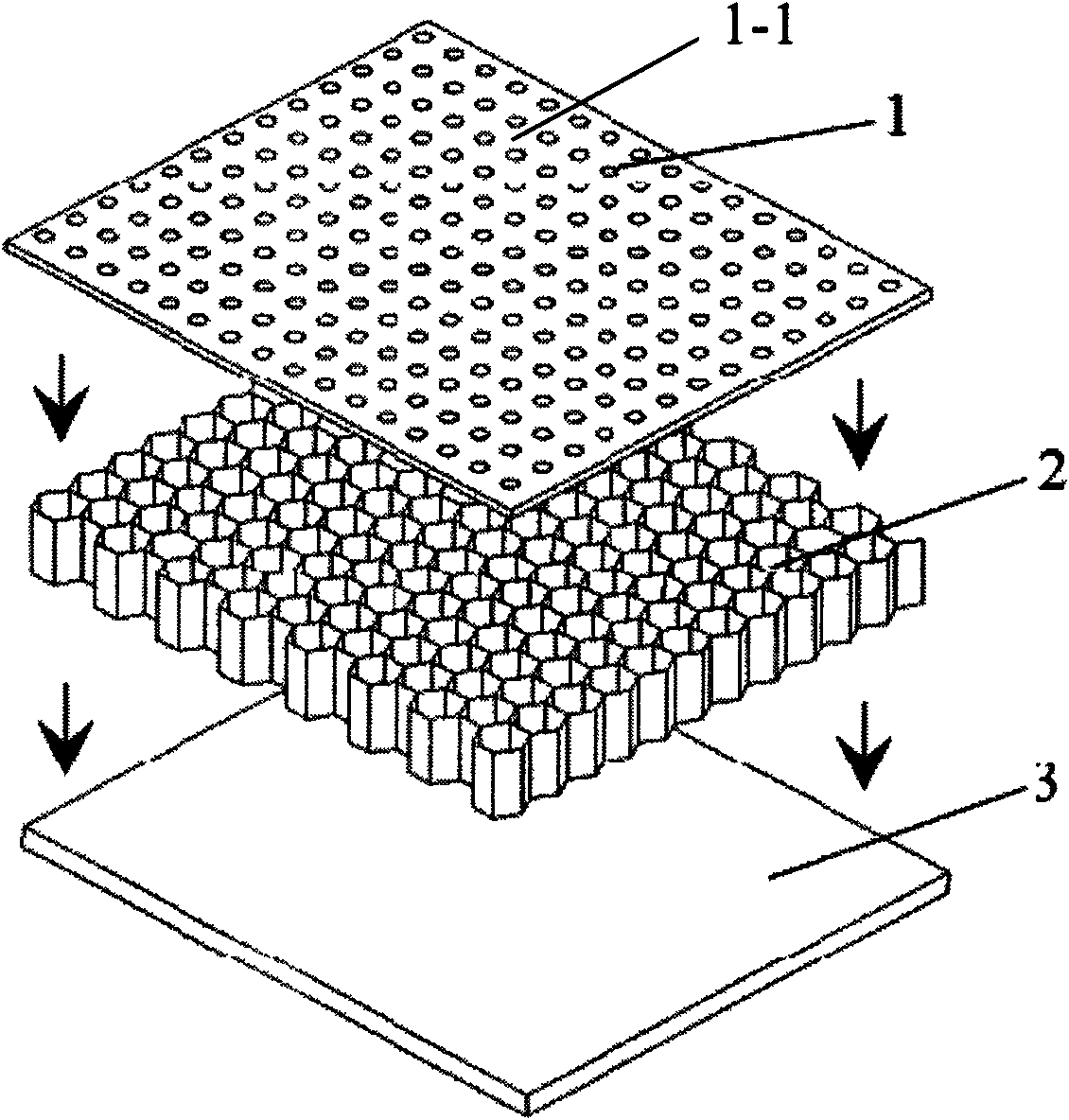

Multiple helmholtz resonator parallel cellular sandwich wood sound absorption plate

InactiveCN101962980AOvercome wasteStrong pressure resistanceCovering/liningsLayered productsCell cavityHelmholtz resonator

The invention relates to a multiple helmholtz resonator parallel cellular sandwich wood sound absorption plate, belonging to the field of sound absorption technologies. The invention solves the problems of small chamber volume ratio, narrow sound absorption frequency band and poor sound absorption effect in the traditional sound absorption panels. Technical essential is characterized in that a sandwich layer is a cellular sandwich layer; the cellular sandwich layer is formed from splicing a plurality of cylinder bodies with hexagonal cross sections; an inner cavity of each hexagonal cylinder body is a cell cavity chamber; the chamber volume ratio of the sandwich layer is larger than 90%; the area of perforation shape surrounded by contour lines of each perforation is less than a half of the hexagonal area of corresponding sandwich layer; and each small through hole on a panel is communicated with the cell cavity chamber at the corresponding position of the sandwich layer. The invention has wider sound absorption frequency band and better medium high frequency sound absorption performance, and the sanding wave tube method sound absorption coefficients respectively reach 0.8, 0.9 and 0.7 at 500Hz, 1000Hz and 2000Hz. In addition, the invention also has the characteristics of light weight, high ratio of strength to weight, good decorative effect, and the like; and wood resources can be saved, preparation process is simple, and cost is low.

Owner:NORTHEAST FORESTRY UNIVERSITY

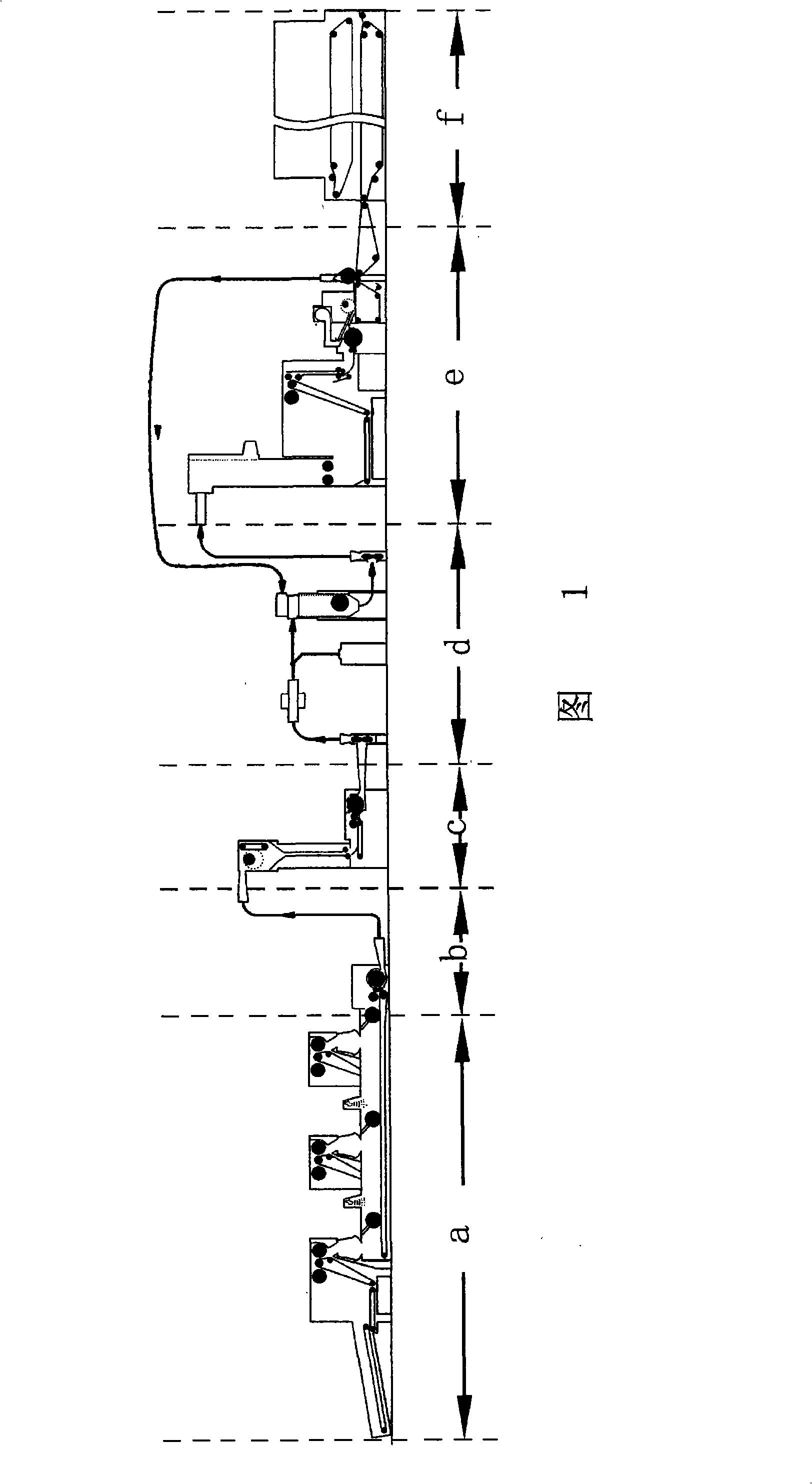

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

Method for producing ceramic tile using polished waste material

The waste material collected from polish waste water and waste slag via deposition, press filtering and ageing is mixed with high temperature sand, kaolin and low temperature sand. The mixture is wet milled in a ball mill, 250-mesh sieved, iron eliminated and spray dried to form powdered material; the powdered material is dry formed into ceramic tile adobe in a ceramic press; and the ceramic tile adobe is baked in a roller hearth kiln at 1140-1200 deg.c in 40-75 min. The said method utilizes the waste reasonably and the product has excellent performance.

Owner:FOSHAN OCEANO CERAMICS

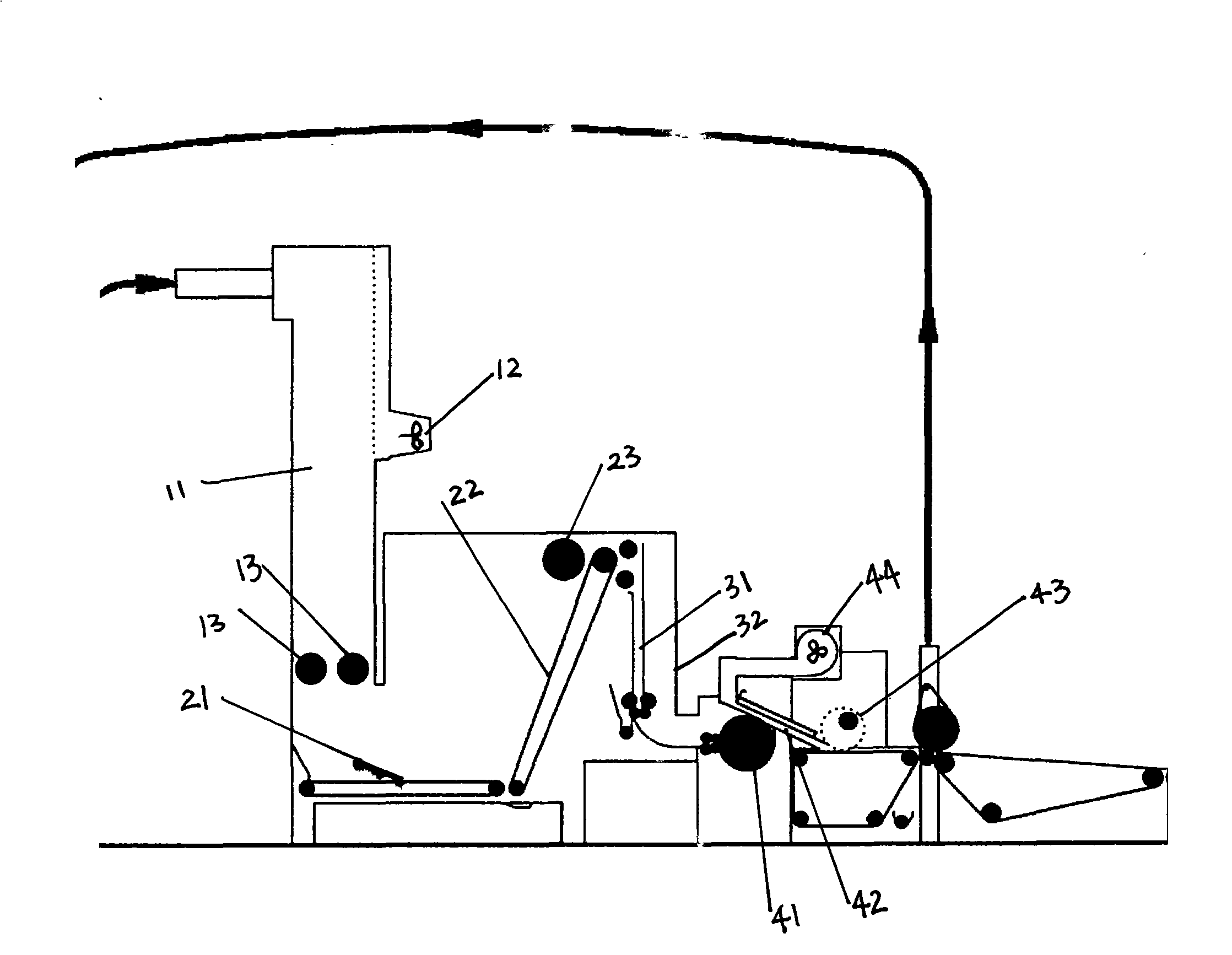

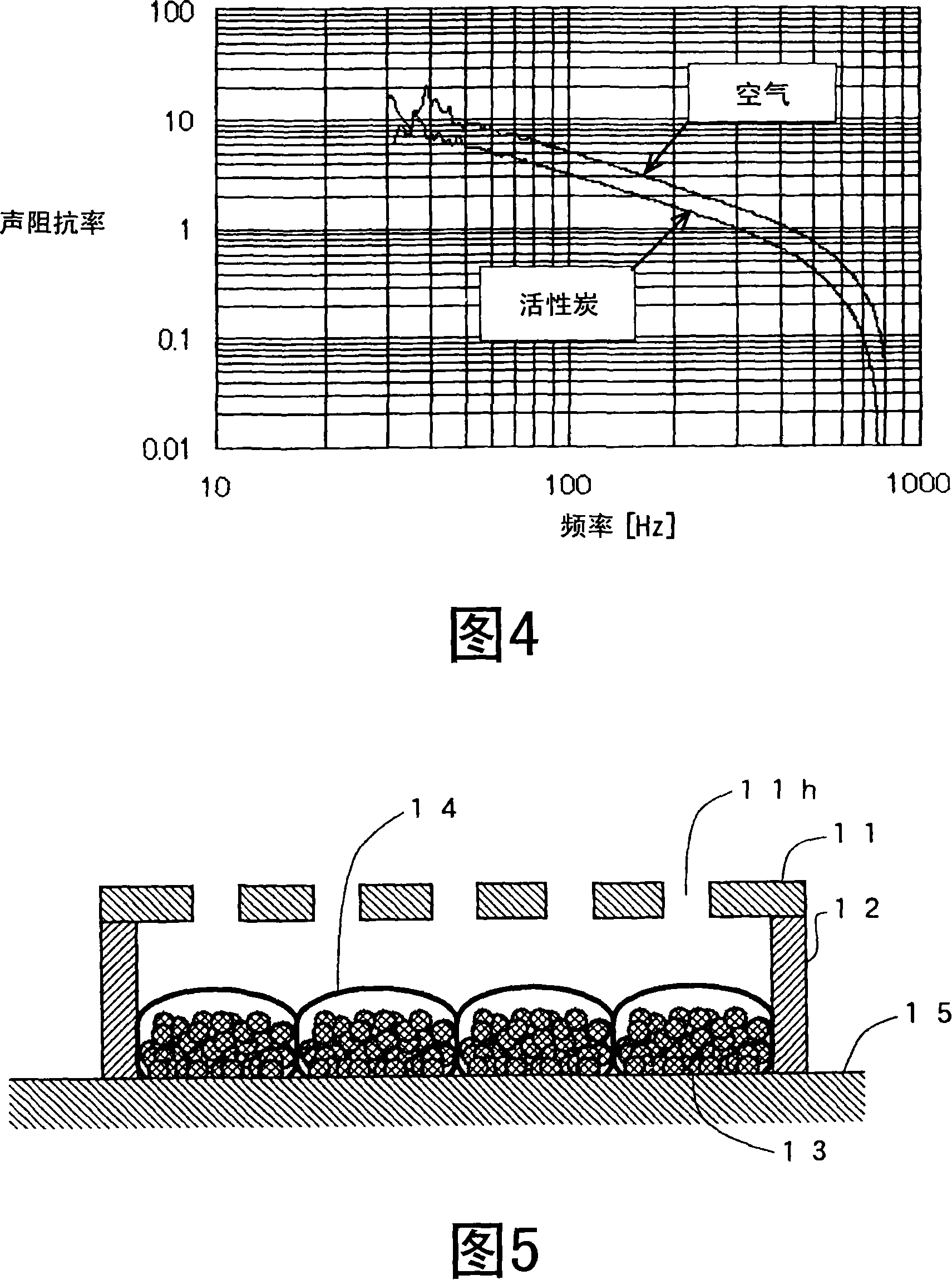

Sound absorption structure body

ActiveCN101151417AStrong physical adsorption capacityLow resonance frequencyNoise reduction constructionAxle-box lubricationMiniaturizationEngineering

A sound absorption structure body has a housing has a front side and a side face raised at at least a part of an outer edge section of the front face, a gas adsorption body placed in the internal space, surrounded by the front face and the side face, of the housing and physically adsorbing gas in the internal space, a sealing means for sealing the gas adsorption body from the outside, and an acoustic connection section provided at at least either the front face or the side face and functioning as an acoustic mass for acoustically connecting the internal space of the housing and the space outside the housing. The sound absorption structure body achieves both sound absorption in a low -pitched sound range and downsizing of the sound absorption structure body itself.

Owner:GOERTEK INC

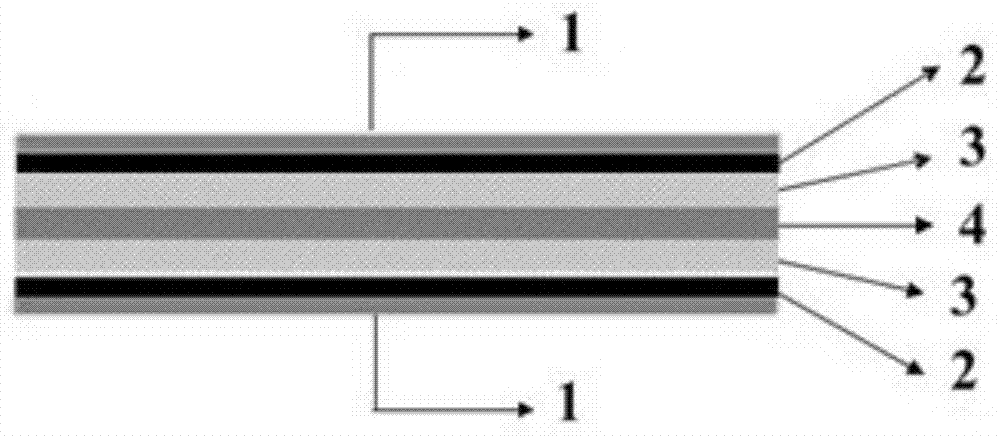

Light fiber-reinforced thermoplastic plate used for high-performance passenger vehicle bottom protection plate and preparation technology thereof

ActiveCN103692990AImprove impact resistanceImprove sound absorptionDeflectorsSynthetic resin layered productsThermoplasticPunching

The invention relates to the field of composite materials for automobile exterior trimming parts, in particular to a light fiber-reinforced thermoplastic plate used for a high-performance passenger vehicle bottom protection plate and a preparation technology thereof. The plate comprises a surface material layer, a netty hot melt adhesive film, an anti-impact inflaming retarding layer, a sound absorbing layer, an anti-impact inflaming retarding layer, a netty hot melt adhesive film and a surface material layer from top to bottom in sequence. According to the technology, after thermoplastic resin fibers and reinforced fibers in different proportions are subjected to opening by an opener, cross lapping is carried out, mixed powder of polyolefin rubber powder and inflaming retarding filler in different proportions is added by a powder distributor, 140-degree infrared roasting is carried out, and finally, a fiber-reinforced thermoplastic felt and the like are obtained after the needling of different needle punching technologies. The light fiber-reinforced thermoplastic plate has excellent anti-impact, sound-absorbing and inflaming retarding performances, and effectively solves various problems which are encountered when the existing common bottom protection plates in the market are used; the preparation technology is simple, convenient, feasible, flexible and varied, the performances of products are designed according to the practical application needs, and the production efficiency is optimized.

Owner:浙江华江科技股份有限公司

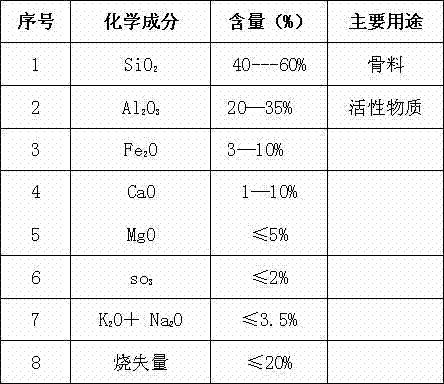

Autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and preparation method thereof

InactiveCN103193447AStable compressive strength"Light weightSolid waste managementCeramicwareBrickAluminium powder

The invention provides an autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and a preparation method thereof. The brick is prepared from the following materials by weight percent: 65%-68% of pulverized fuel ash, 17%-23% of lime, 6%-10% of cement, 2%-4% of desulfurization gypsum, 1%-1.5% of water-soluble aluminum powder, 0.5% of fatty acid soap and 0.5% of gleditsia sinensis powder. The preparation method comprises steps of: adding water to pulverized fuel ash and desulfurization gypsum which are screened mechanically and grinding together to form slurry, wherein the fineness of the pulverized fuel ash has to reach the condition that the residual of a 0.08mm square hoe sieve is not more than 15%; carrying out stirring, pouring, cutting and thermal, static and suspension curing on the slurry together with the lime, the cement and the aluminum powder suspension liquid which are weighed according to a weight ratio of a formula; utilizing an autoclave with good sealing for heating with 180-200 DEG C saturated steam under proper pressure (1.0-1.2Mpa); and steam curing for 8-10 hours so as to produce the aerated concrete brick. The aerated concrete brick has the characteristics of light weight, high strength, good heat insulation performance, good fire resistance and sound absorption, labor saving and energy saving, waste recycling and the like; and the aerated concrete brick meets constructional engineering requirements and environment protection requirements, and the wastes of enterprises are reasonably used.

Owner:SHIYAN JINSHA WALL MATERIALS

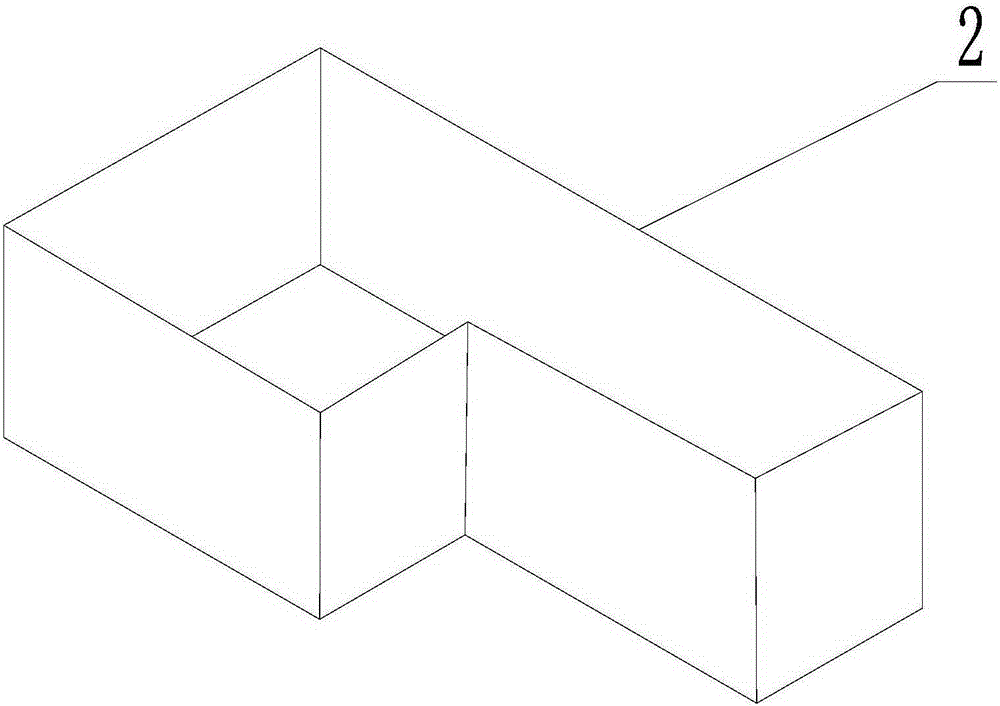

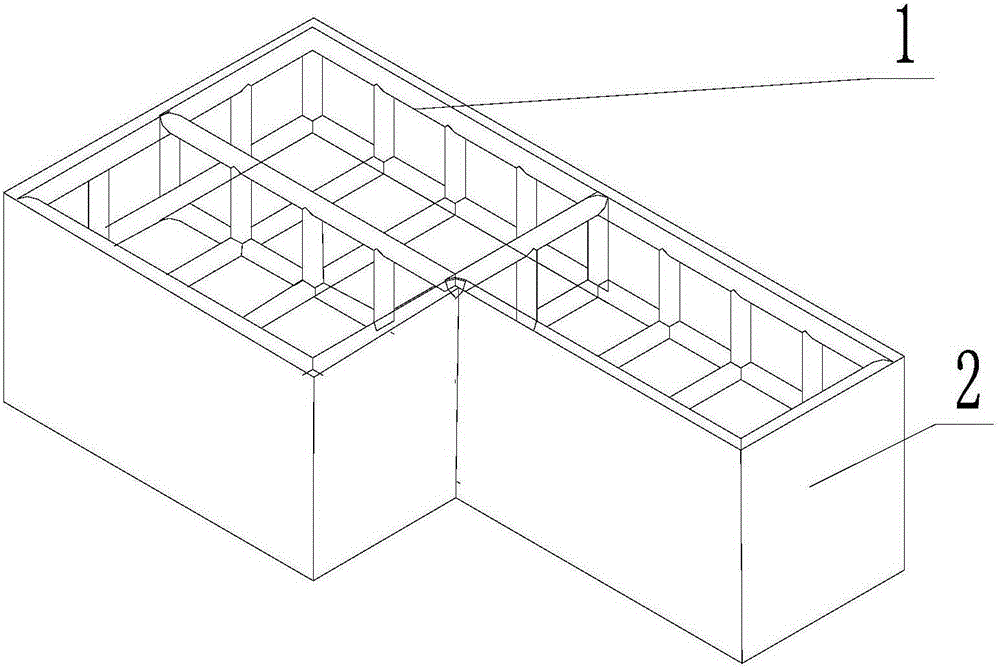

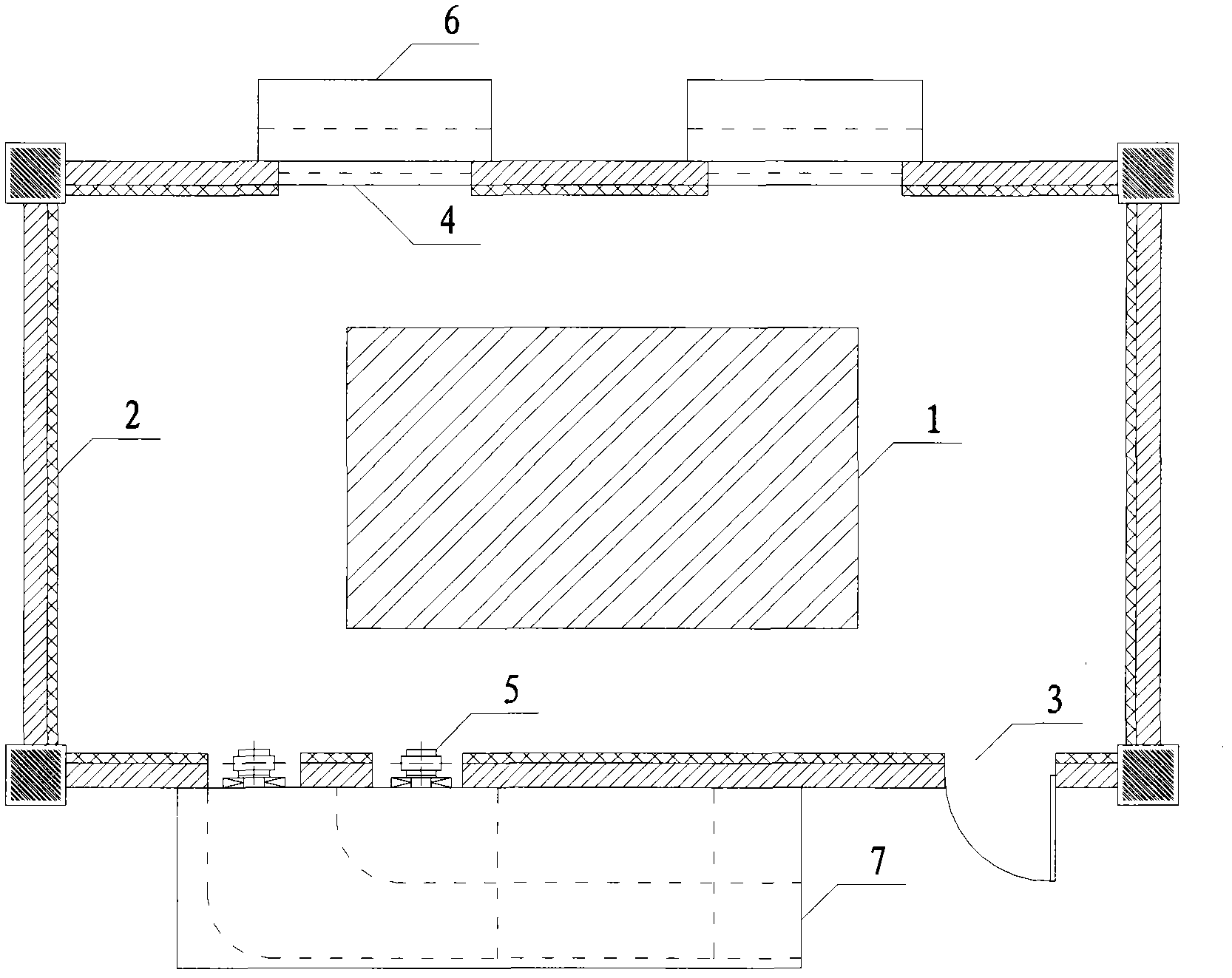

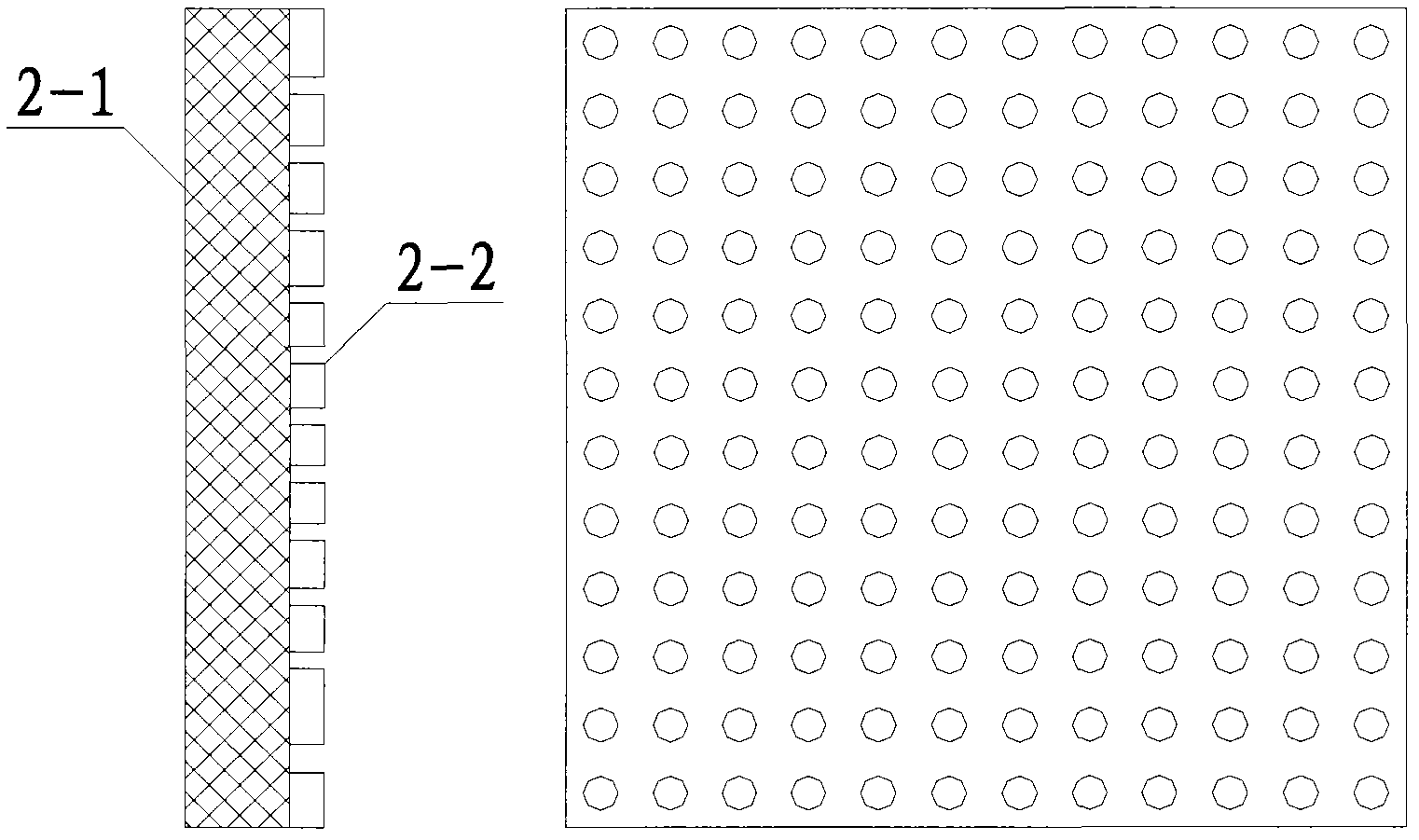

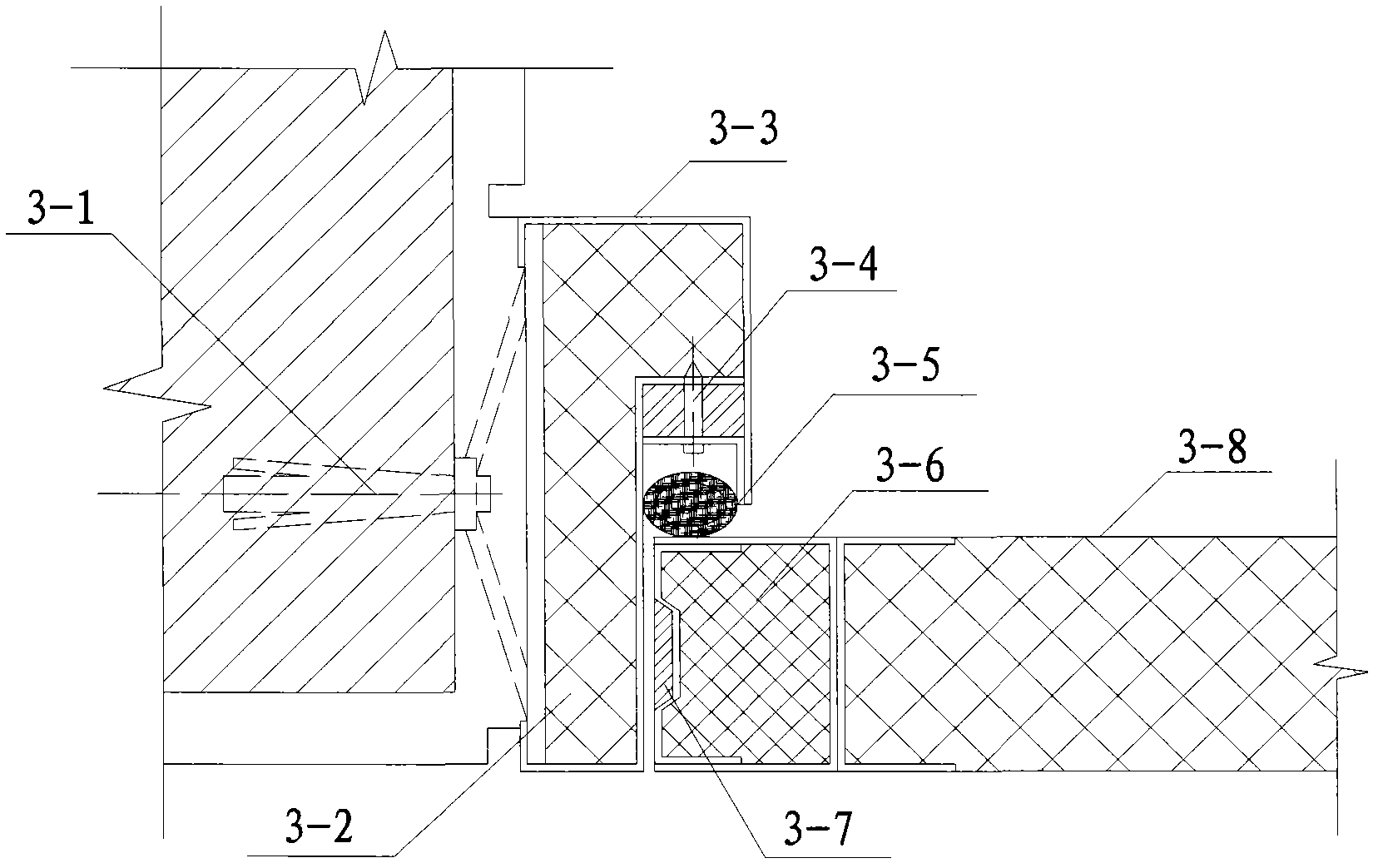

Noise reduction structure of main noise resources of urban indoor substation

The invention relates to a noise reduction structure of main noise resources of an urban indoor substation, belonging to the technical field of noise pollution control in environmental engineering. The noise reduction structure is mainly used for reducing the noise resources of the urban indoor substation, including noise radiated by a main transformer and a reactor 1. The noise reduction structure comprises a wall perforated plate resonance sound absorption structure 2, a sound isolation door 3, a ventilating shutter 4, a low-noise axial flow fan 5, an air intake silencer 6 and an air exhaust silencer 7, wherein the wall perforated plate resonance absorption structure 2 is located inside the wall and comprises a perforated gypsum plate and acrylic cotton; the sound isolation door 3 is filled with glass coated intermediate glass cotton fiber, and the gap of a door frame is filled with sealing strips; the ventilating shutter 4 and the low-noise axial flow fan 5 are used for ventilating and dissipating heat to ensure the safe and stable operation of the main transformer and the reactor; the air intake silencer 6 is installed on the outer part of the ventilating shutter 4, the upper part is a lighting sound-isolating window cover, and the lower part is an air flow channel covering the sound absorption material; and the air exhaust silencer 7 is installed outside a ventilating fan hole, and the interior is an air flow channel covering the sound absorption material.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST +1

Light weight wall brick and method of manufacturing the same

The invention relates to a light-weight wall brick and a method for manufacturing the same. The light-weight wall brick comprises a light-weight material body and a decorative layer, wherein the decorative layer is coated on at least one surface of the light-weight material body and consists of an aggregate and a bonding agent cladding the aggregate; and the light-weight material body is made of a light-weight material. The method comprises the following steps: using the bonding agent to bond and clad the aggregate so as to form the decorative layer; forming the light-weight material body with the light-weight material; and coating the decorative layer on at least one surface of the light-weight material body. The wall brick has the advantages of light weight, sound absorption, good heat preservation effect, and the reduction of the manufacturing cost. Simultaneously, the decorative layer comprises high-strength quartz sand, glass microballoon, and the like, thus the strength of the brick is improved, and the decorative layer can also be formed with patterns with various colors and types which play a role in decorating the light-weight wall brick. Besides, because the light-weight wall brick has a simple structure, the manufacturing process is simple and convenient.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

PET (polyethylene glycol terephthalate) fiber/teflon fiber composite sound absorbing cotton and preparation method of PET fiber/teflon fiber composite sound absorbing cotton

InactiveCN102965843AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsDiphenyl phosphatePolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / teflon fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of teflon fibers, 10 to 15 parts of emulsifying agents OP-30, 5 to 10 parts of peregal O-20, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of HIPS (high impact polystyrene), 15 to 20 parts of activated clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of dioctyl adipate, 4 to 6 parts of cresyl diphenyl phosphate, 2 to 3 parts of liquid paraffin, 1 to 2 parts of 3-aminopropyltrimethoxysilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of barium stearate, 0.5 to 1.5 parts of anti-aging agents RD and 1 to 2 parts of antioxidants DLTP (dilauryl thiodipropionate). The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

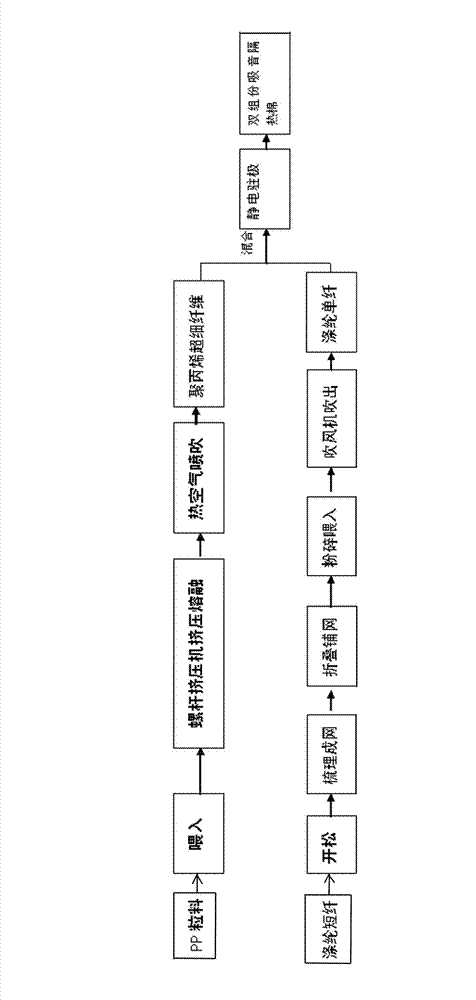

Two-component sound absorption and heat insulation cotton based on polypropylene superfine fibers and polyester staple fibers and preparation method thereof

InactiveCN103088549AFluffy structureHas a three-dimensional network structureNon-woven fabricsPolyesterPolymer science

The invention relates to two-component superfine fiber material used for heat insulation and sound absorption based on polypropylene superfine fibers and polyester staple fibers and a preparation method thereof, in particular to two-component sound absorption and heat insulation cotton based on the polypropylene superfine fibers and the polyester staple fibers and a preparation method thereof. The material is specially designed for reducing noise power in a high-noise environment, and has the effects of sound absorption and heat insulation particularly in the aspects of automobiles, high speed trains and the like. The material is also suitable for the aspects of pocket-type or plate-and-frame type filters of heating and ventilating systems, household air cleaners and vacuum dust catchers, factory purification and the like. The two-component sound absorption and heat insulation cotton based on the polypropylene superfine fibers and the polyester staple fibers comprises the polypropylene superfine fibers and the polyester staple fibers, wherein the average fineness of the polypropylene superfine fibers is 1-2 micrometers, and the fineness of the polyester staple fibers is 25-35 micrometers. The two-component material formed by mixing of the polypropylene superfine fibers and the polyester staple fibers is processed through electrostatic electrets, and then the two-component sound absorption and heat insulation cotton is formed.

Owner:SHANGHAI LIUXIN NEW MATERIAL

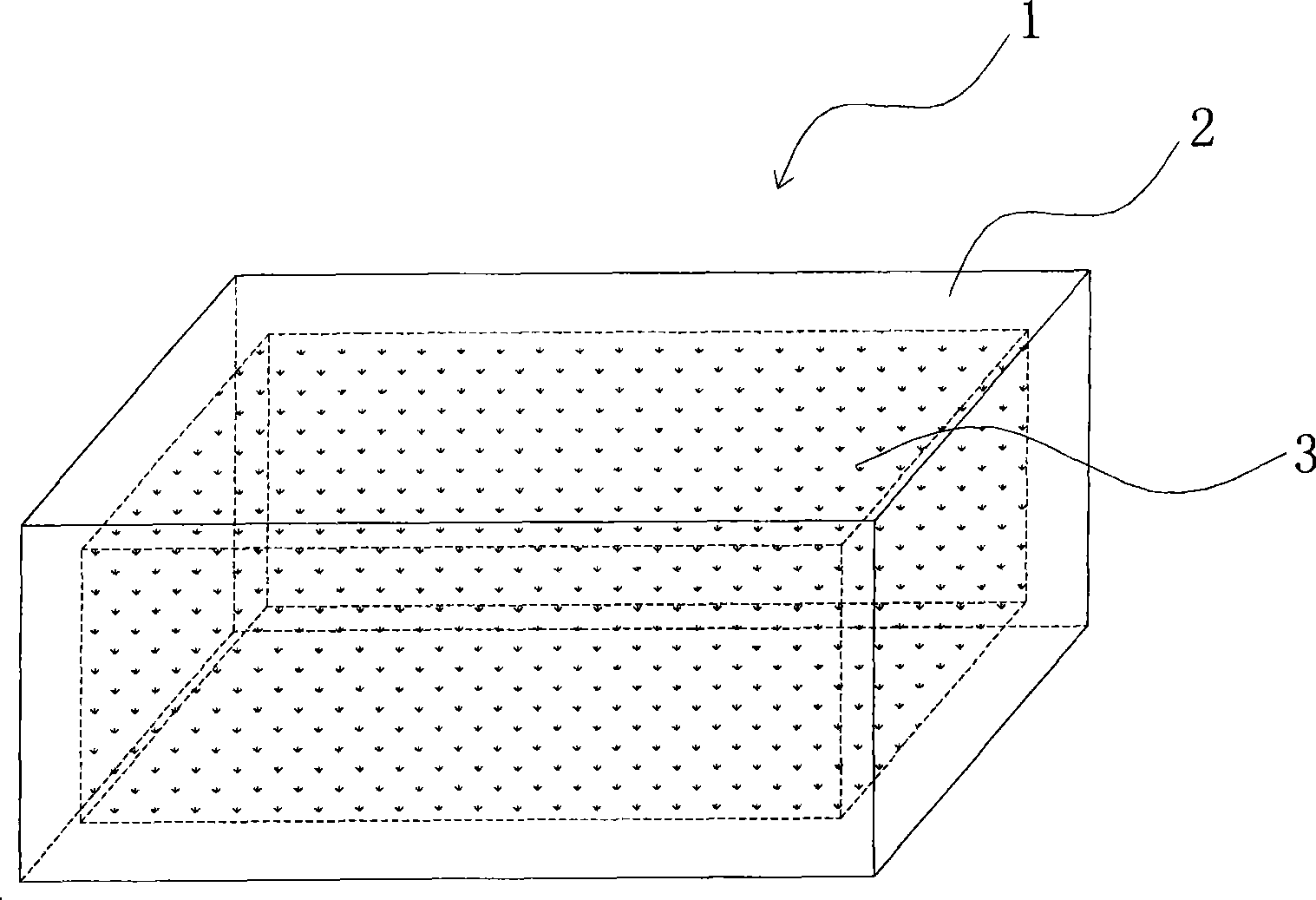

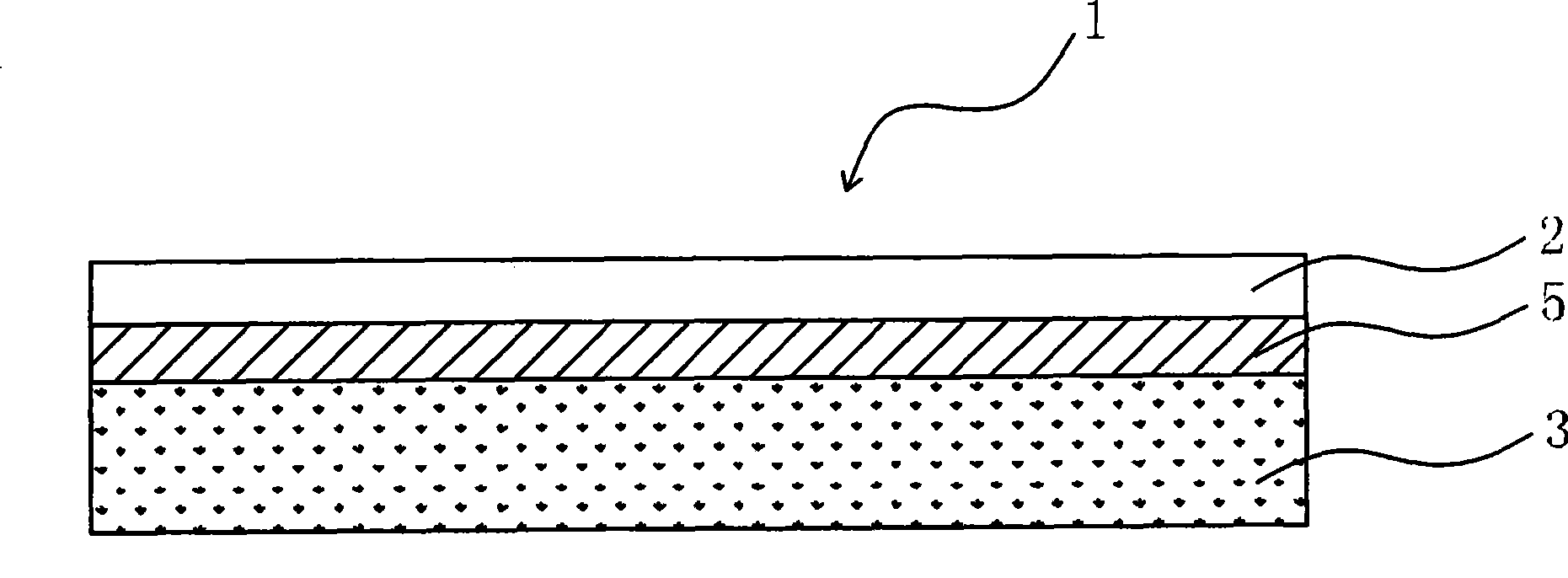

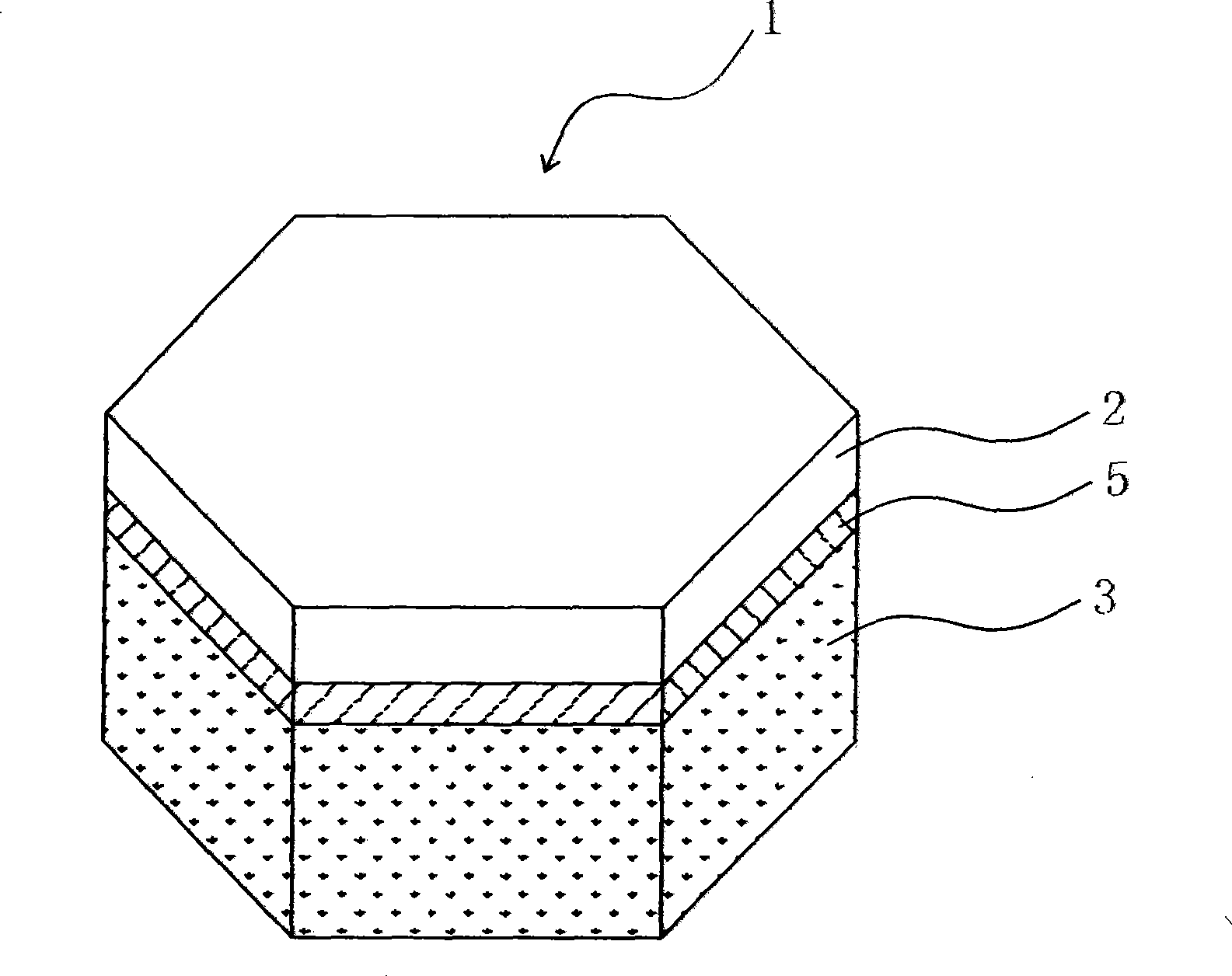

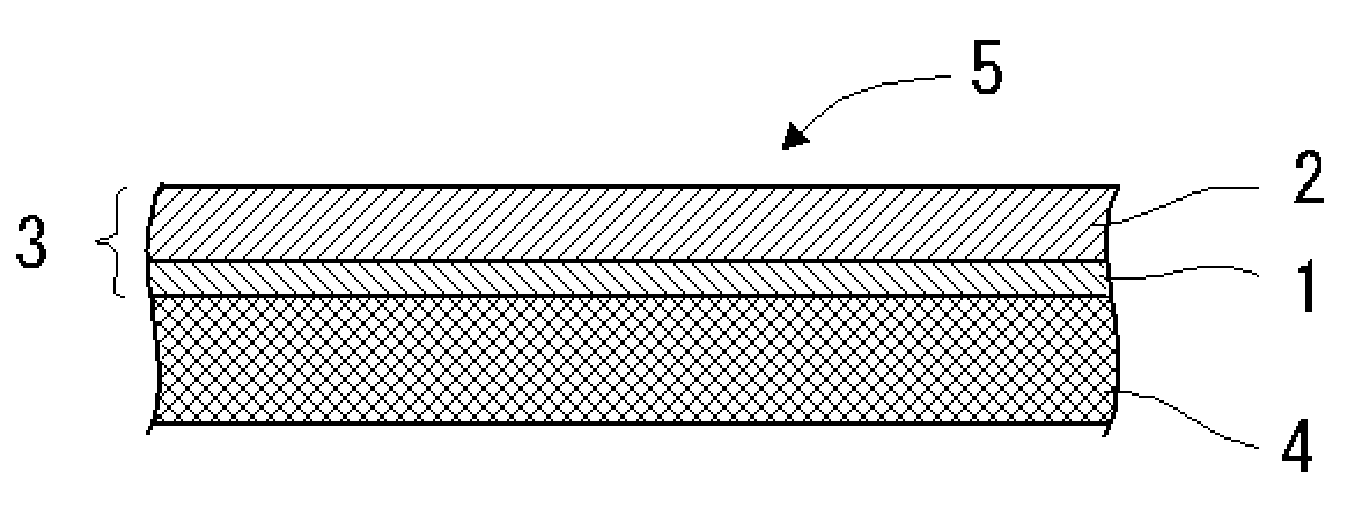

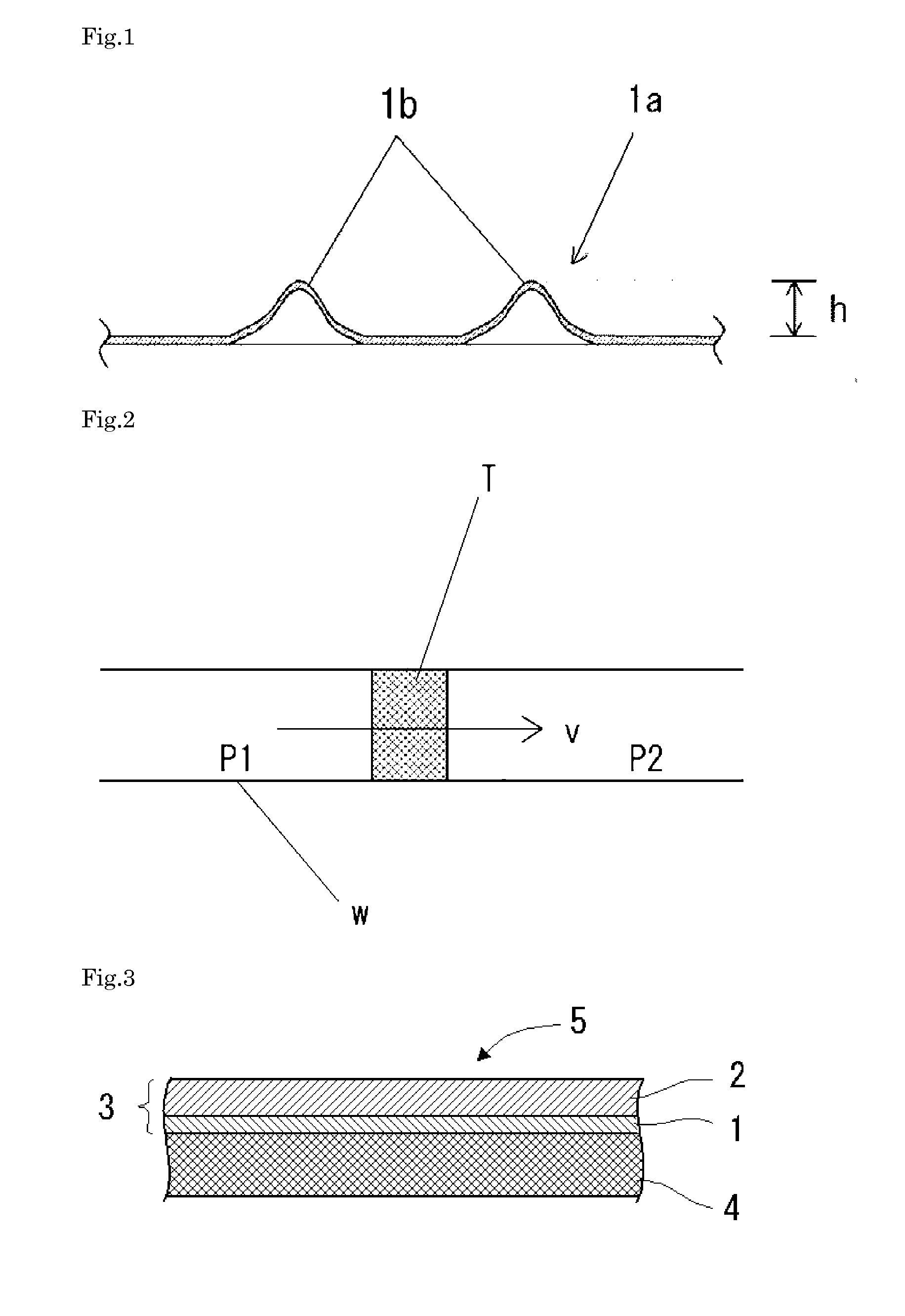

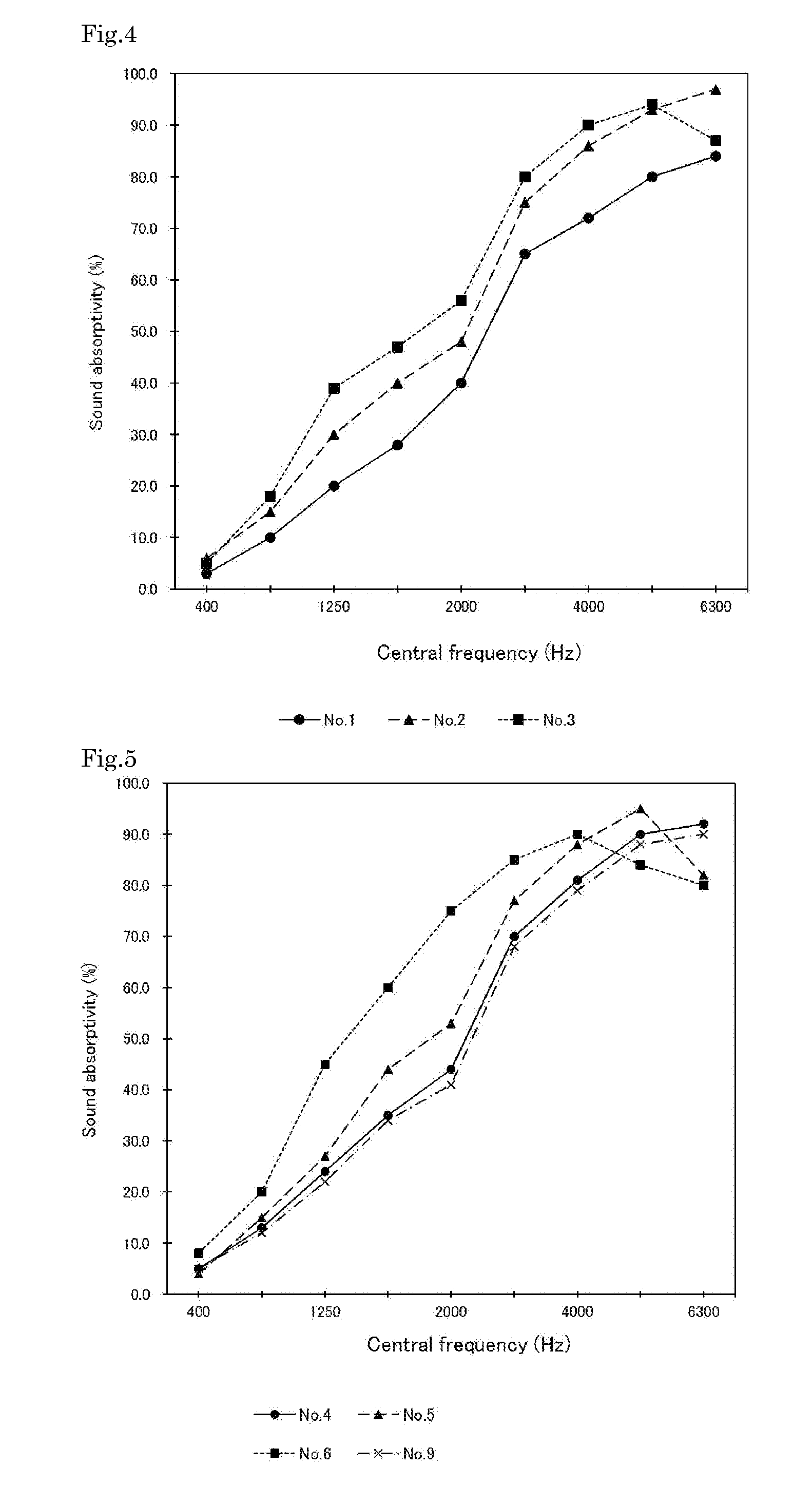

Sound absorbing material, multilayer sound absorbing material, molded product of multilayer sound absorbing material, sound absorbing interior material, and sound absorbing floor covering material

ActiveUS20110186381A1Poor sound absorb propertyInferior in moldabilityWallsLayered productsAirflowPorous fiber

The object of the present invention is to provide a sound absorbing material having a light weight and excellent sound absorbing performance, and a sound absorbing material consisting of a fiber sheet made of fibers containing at least 50% by mass of a porous fiber having many minute pores, each minute pore opening onto the surface of the porous fiber, and having an airflow resistance in the range of between 0.05 and 3.0 kPa·s / m.The porous fiber having many minute pores, each one opening onto the surface of the porous fiber, has air-permeability, and so a sound absorbing property in itself, and a sheet made of the porous fiber having air-permeability and sound absorbing property has even further sound absorbing properties created by the spaces between the porous fibers, resulting in the sheet becoming a sound absorbing material with extremely great sound absorbing efficiency.

Owner:NAGOYA OIL CHEM CO LTD

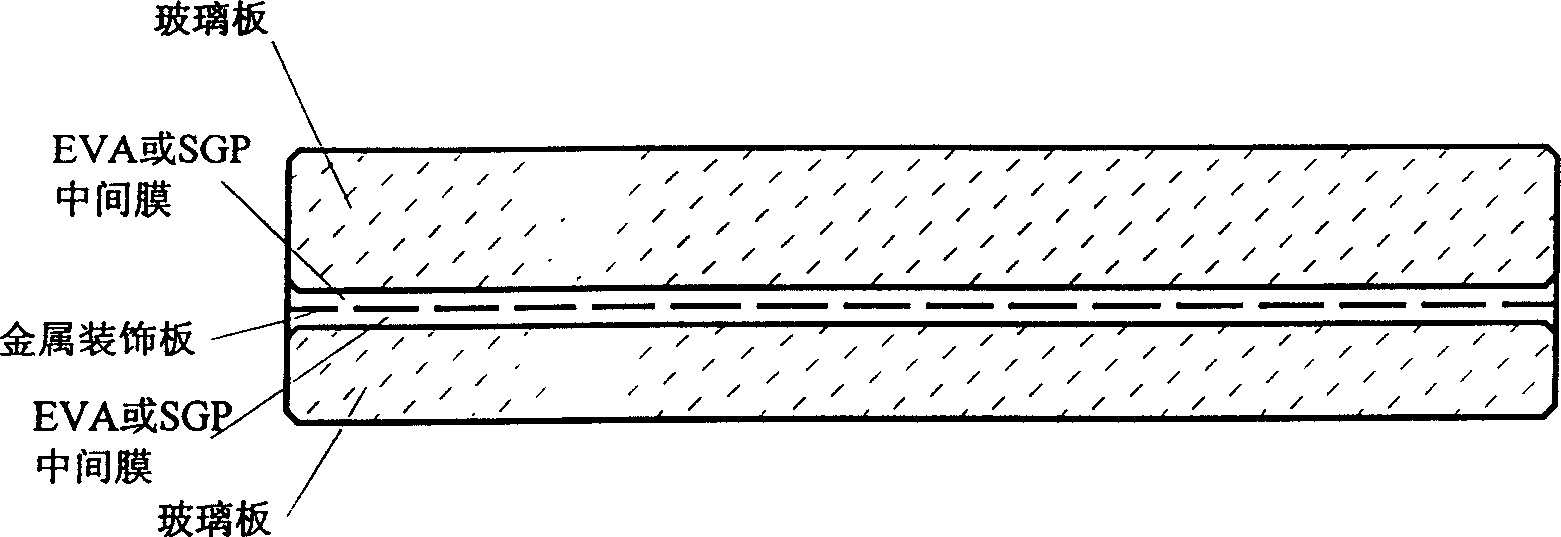

Glass with metal decorative sheet as interlayer and its production process

The invention provides metal sandwiched glass with intermediate film which comprises a glass plate, intermediate film having surface gluing material EVA or SGP, a metallic decorative thin panel, an intermediate film of organic gluing material EVA or SGP, and a glass plate. And the secondary rolling production process comprises glass cleaning, hot-air drying, sheet combining, first heating, first rolling precompression, second heating, second rolling precompression, quality inspection, final forming in autoclave, and packaging.

Owner:SHANGHAI YAOHUA PILKINGTON GLASS GROUP +1

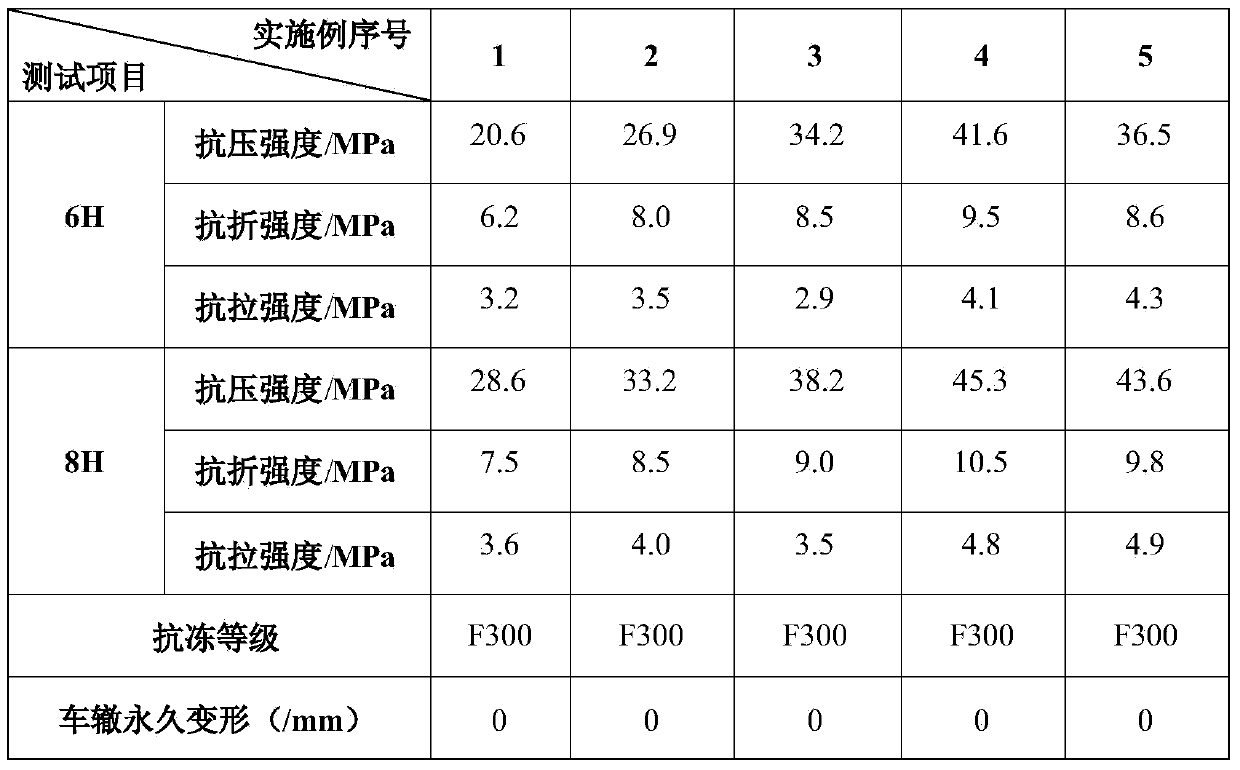

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

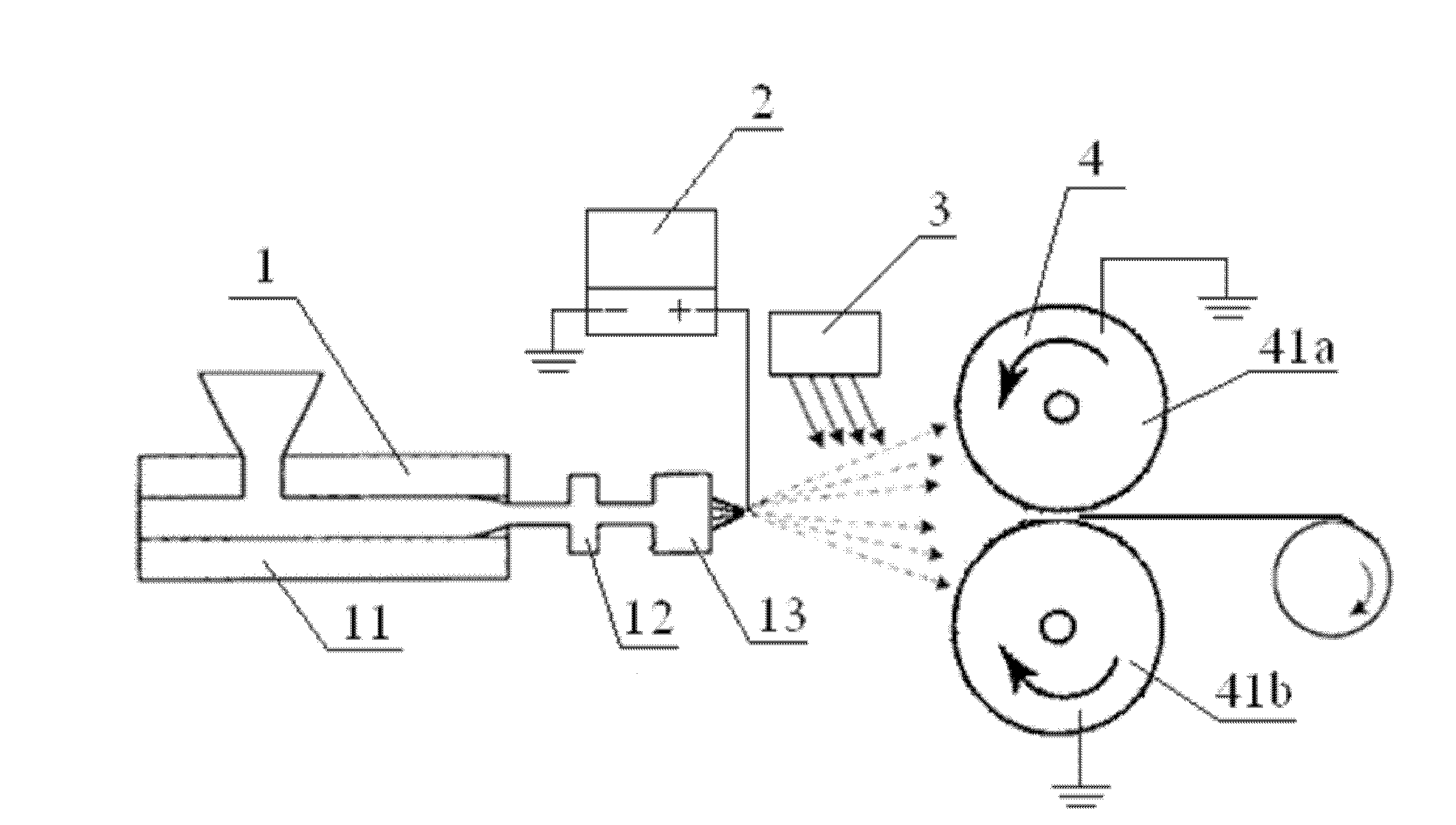

Non-woven fabric and preparation method thereof and production device thereof

ActiveCN103161032AReduce energy consumptionReduce compactnessNon-woven fabricsEngineeringHigh pressure

The invention relates to a preparation method for non-woven fabric and a non-woven fabric production device used for performing the method. The method comprises enabling melt-blown fiber formed through a melt-blown device to have high voltage static electricity, mixing the melt-blown fiber with the high voltage static electricity with artificial short fiber, obtaining composite fiber, collecting the composite fiber and forming the non-woven fabric. The non-woven fabric prepared through the non-woven fabric production device and according to the preparation method for the non-woven fabric is low in density so that the non-woven fabric has improved sound absorption and insulation effects.

Owner:BYD CO LTD

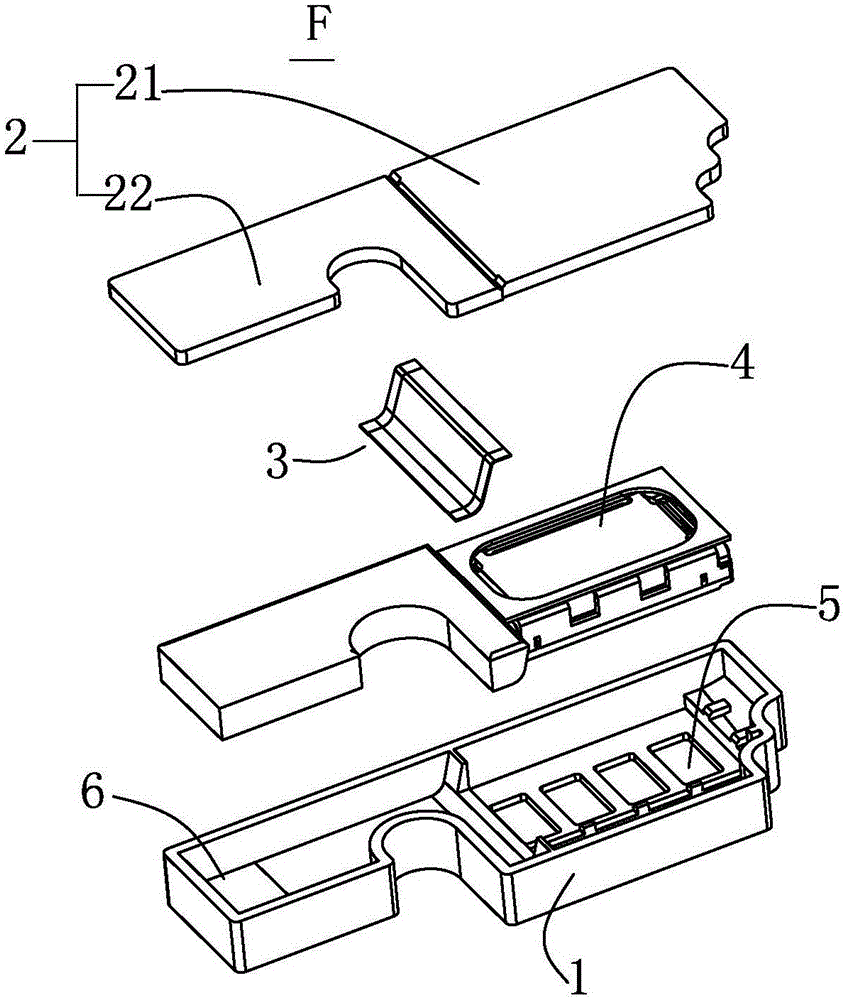

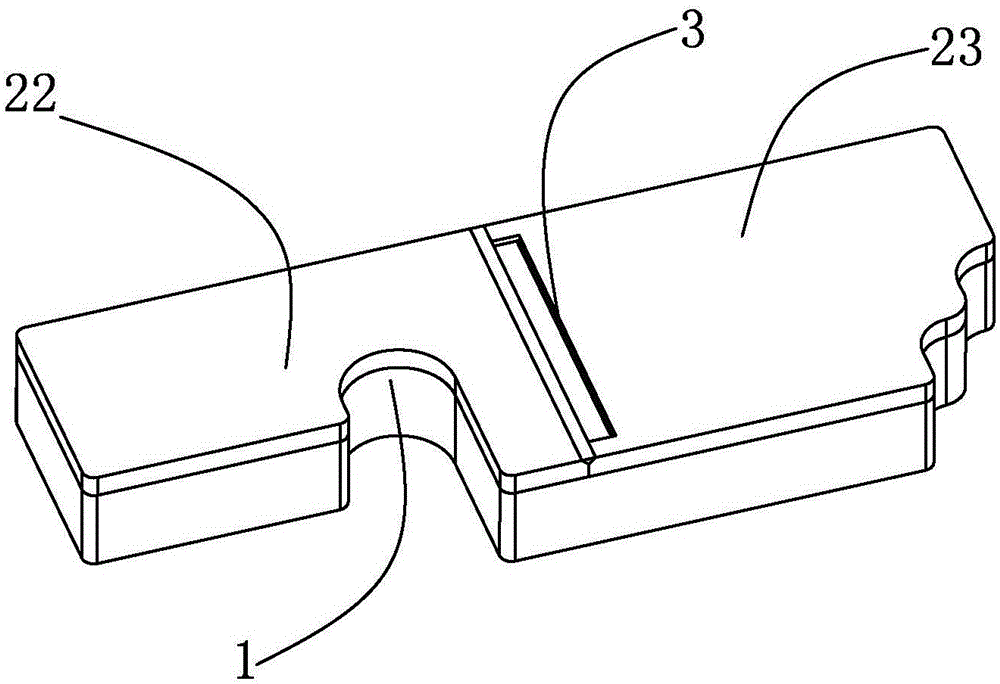

Sounding device and installation method thereof

ActiveCN105101036AImprove sound absorptionImprove sound transmission qualityElectrical transducersEngineeringSounds device

The invention discloses a sounding device and an installation method thereof. The sounding device comprises a casing, a cover plate, an accommodation space, a single sounder unit, a sound absorbing material and an isolation net, wherein the cover plate covers the casing, the accommodation space is formed by the casing and the cover plate, the single sounder unit and the sound absorbing material are accommodated in the accommodation space, and the isolation net is accommodated in the accommodation space. The isolation net divides the accommodation space into a front cavity and a rear cavity ventilated with the front cavity, the single sounder unit is accommodated in the front cavity, and the sound absorbing material is accommodated in the rear cavity. The cover plate comprises a front cover plate body which covers the front cavity and a rear cover plate body which covers the rear cavity. The installation method comprises the following steps that the single sounder body is accommodated in the front cavity; the front cover plate body covers the front cavity body; the isolation net is placed between the front cavity and the rear cavity; the sound absorbing material is mounted in the rear cavity; the rear cover plate body covers the rear cavity; and the front and rear cover plate bodies are sealed with the casing to form the sounding device. Thus, assembling is convenient.

Owner:AAC MICROTECH CHANGZHOU

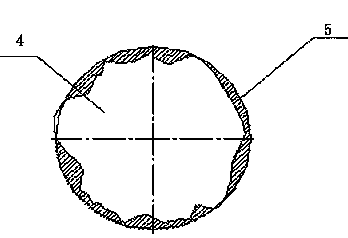

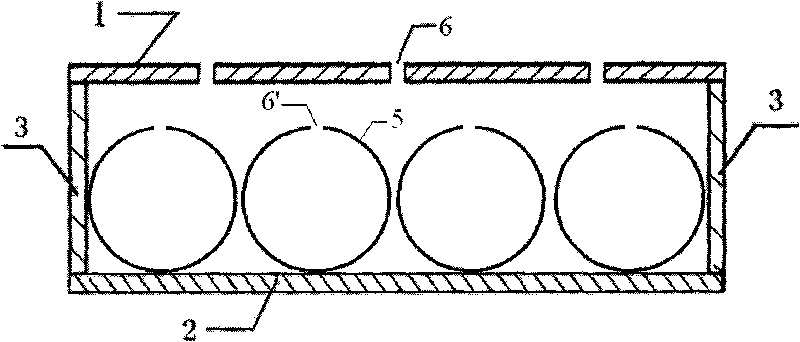

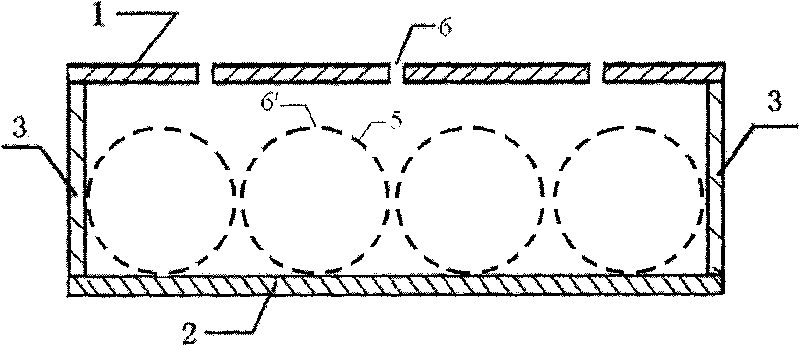

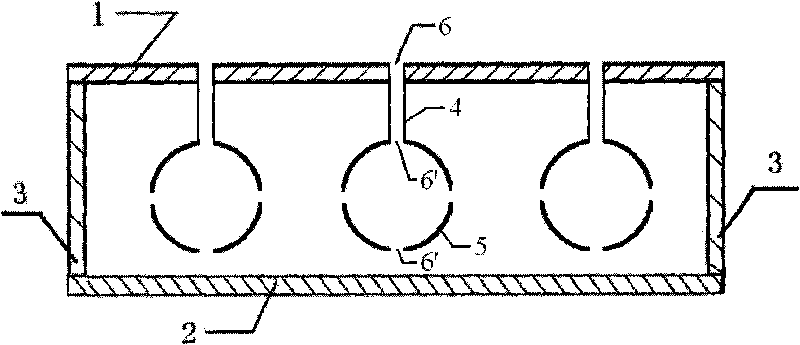

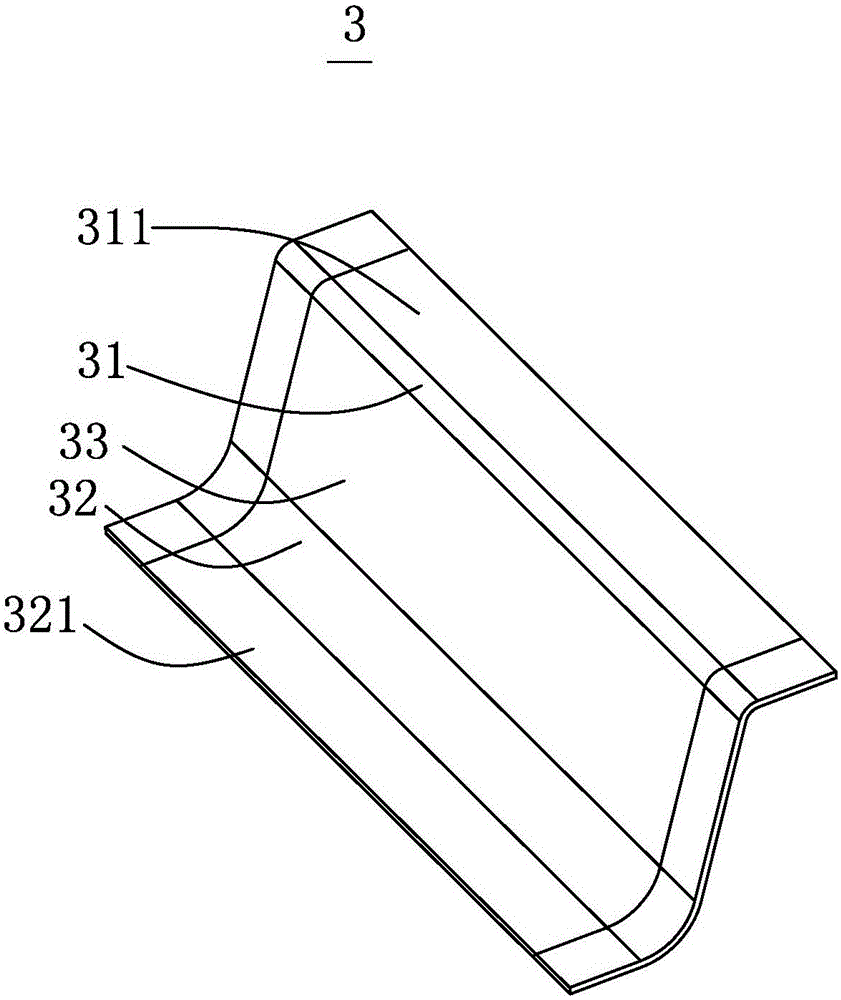

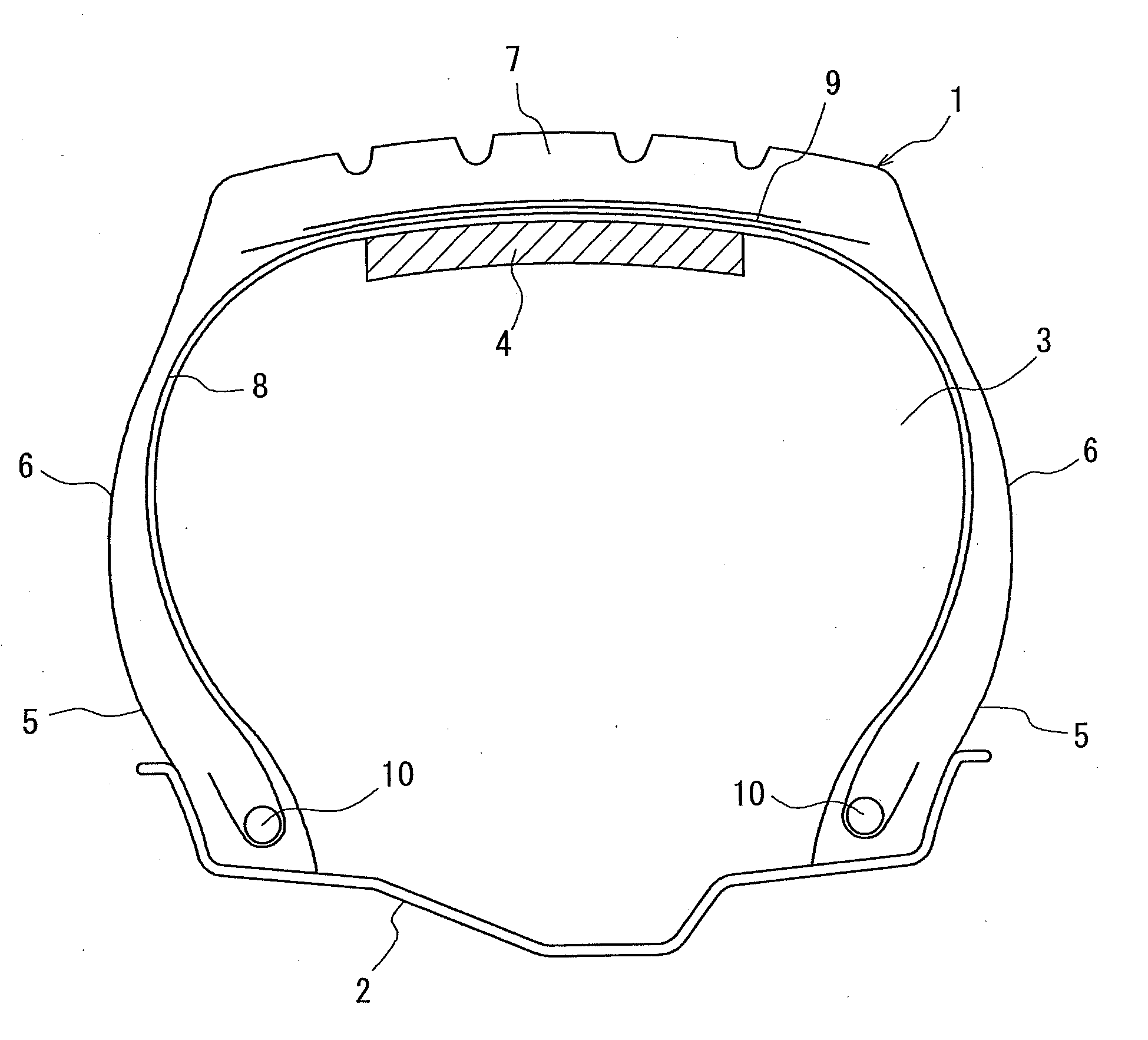

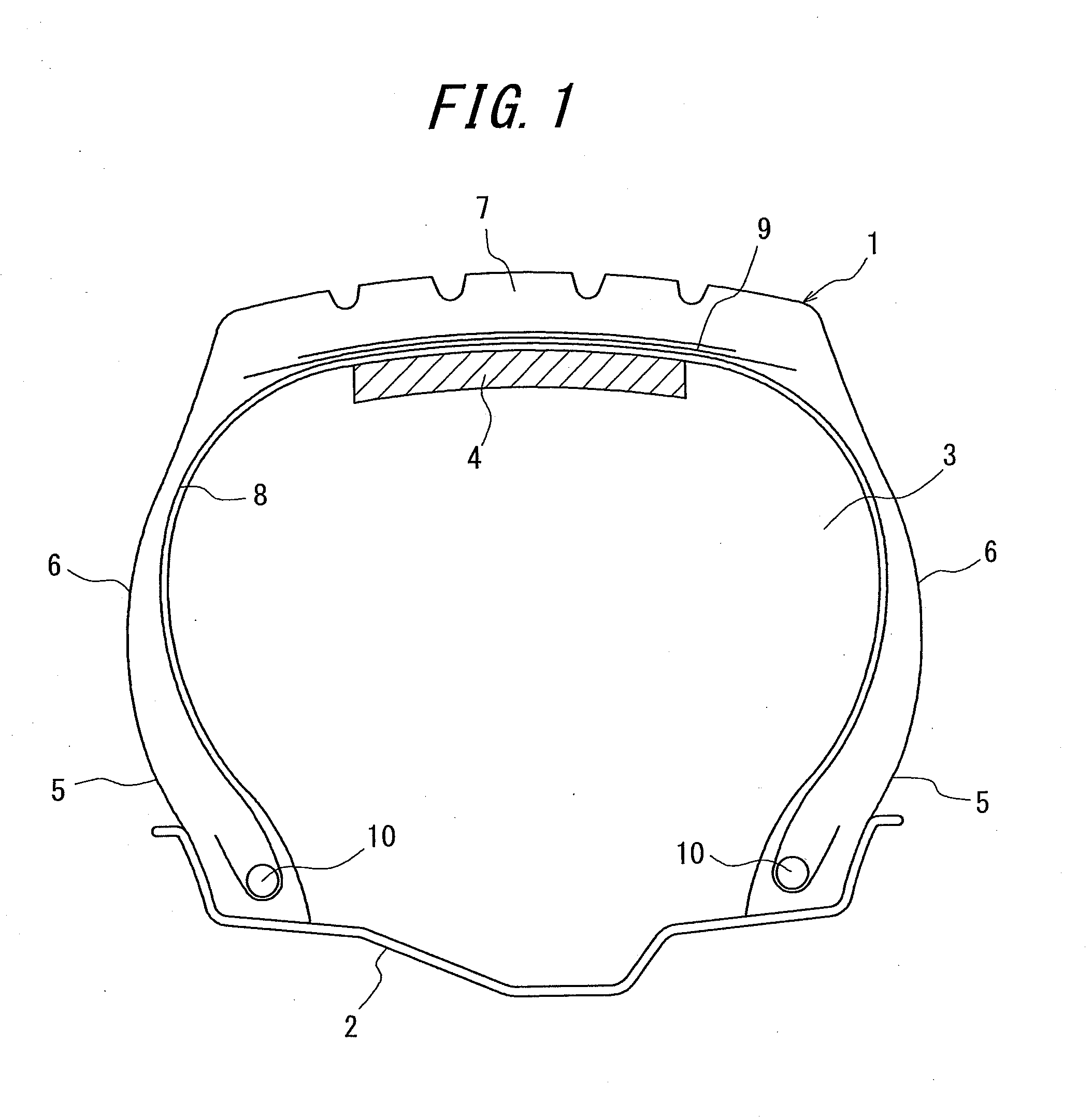

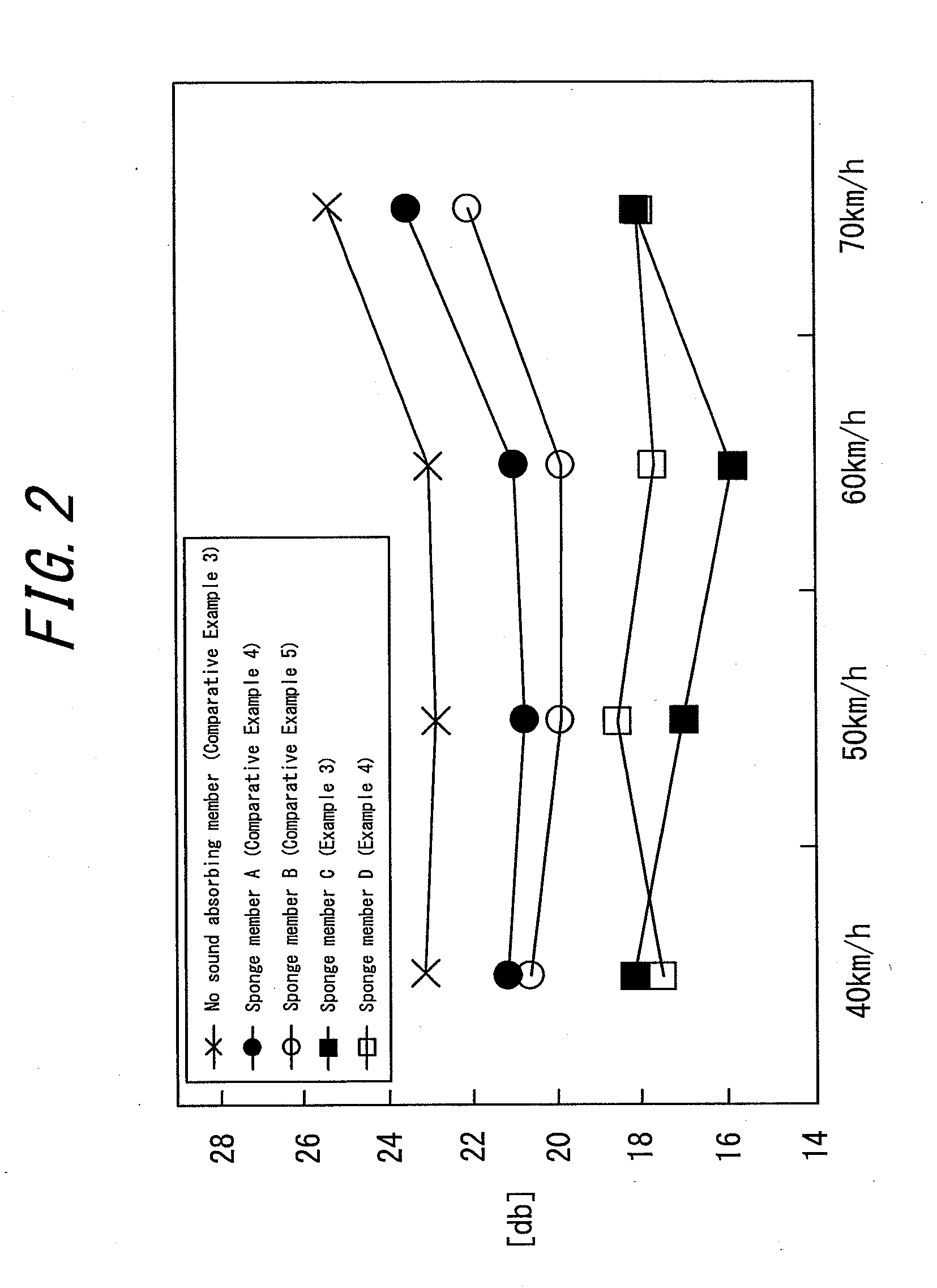

Tire-rim assembly and sponge member used in the same

ActiveUS20100038005A1Reduce road noiseEasy to produceInflatable tyresWheelsEngineeringInternal cavity

This invention relates to a tire-rim assembly which is easily produced at low cost, excellent in durability and capable of notably reducing road noise, and more particularly to a tire-rim assembly comprising a pneumatic tire (1), a rim (2) and a sponge member (4) disposed in a tire internal cavity (3) defined by the pneumatic tire (1) and the rim (2), characterized in that the sponge member (4) has a specific gravity of higher than 0.06 but not higher than 0.25 and / or an air permeability of not higher than 5 cc / cm2 / sec.

Owner:BRIDGESTONE CORP

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com