Patents

Literature

1743results about How to "Improve thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

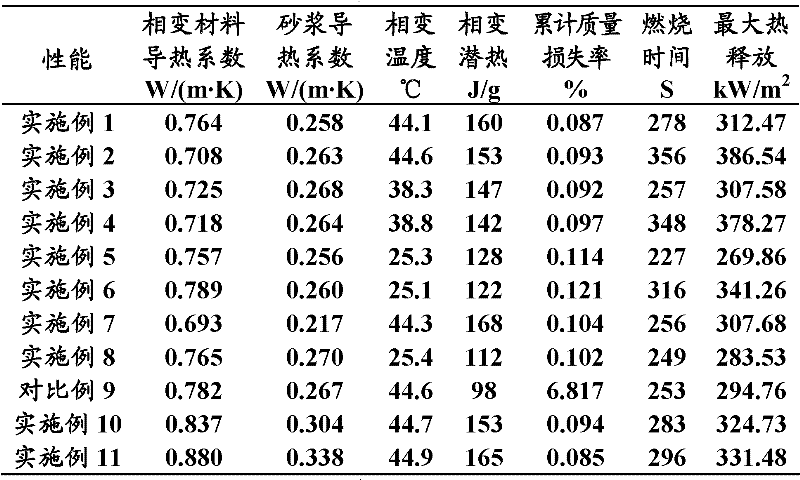

Phase-transition composite material, preparation method and application thereof

ActiveCN102408877APhase transition temperature is suitableLarge latent heat of phase changeClimate change adaptationHeat proofingParaffin waxThermal insulation

The invention relates to a phase-transition composite material which comprises: A) 30-65% of phase-transition materials which are low melting point paraffin with a melting point of 25-45 DEG C and / or dodecanol; B) 25-45% of carrier materials which are high density polyethylane and / or ethane-vinylacetate copolymer; C) 5-15% of inorganic fillers which are porous substances and are selected from one or two of expanded perlite and expandable graphite; D) 1-10% of heat-conduction reinforcing agents; and E) 1-10% of fire retardants. The composite material has an appropriate phase transition temperature which matches the building ambient temperature, has great phase transition latent heat, excellent heat-preservation and heat-insulation performance, is fireproof and flame-retardant, is easy to process, and has greatly reduced phase-transition material leakage. The invention also relates to a method for preparing the phase-transition composite material, which comprises the thermal insulation mortar of the phase-transition composite material and a method of heat preservation of a wall by using the mortar.

Owner:BEIJING UNIV OF CHEM TECH +1

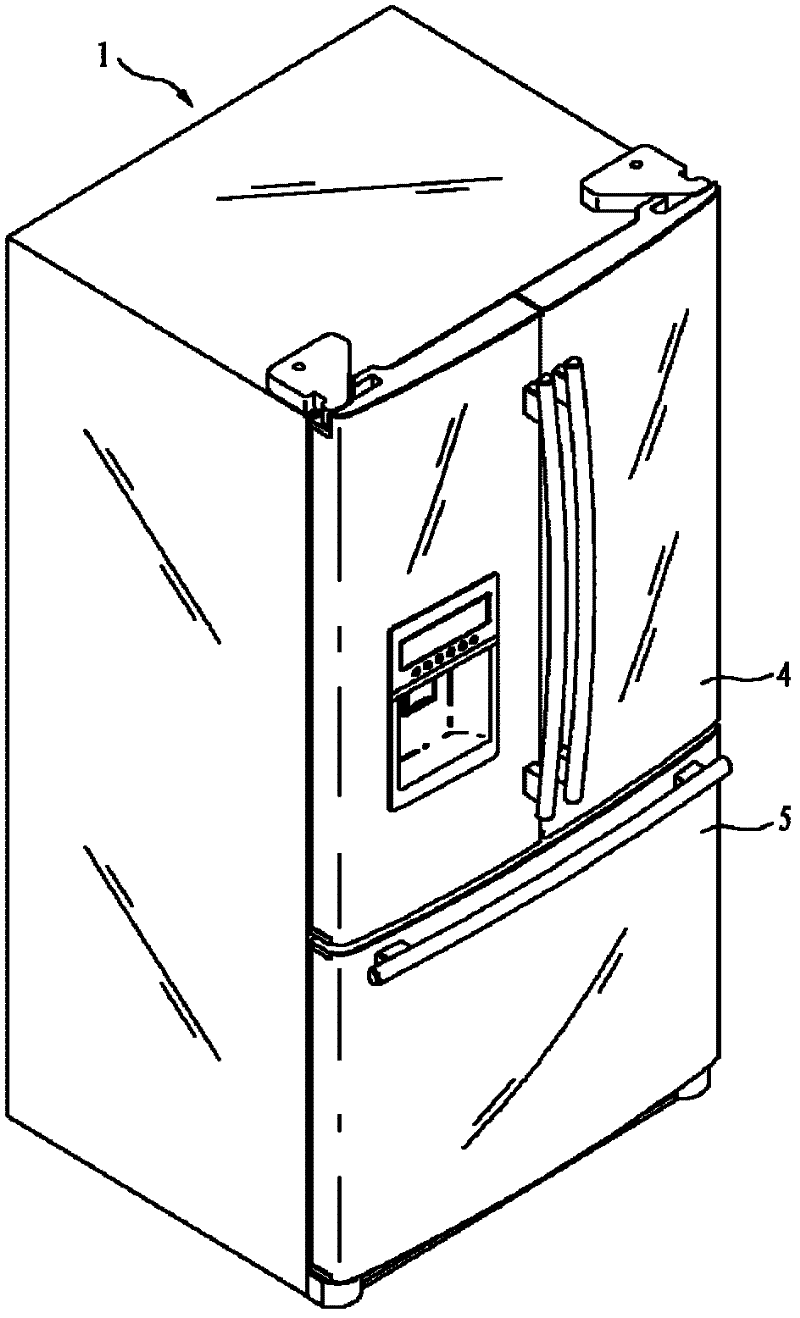

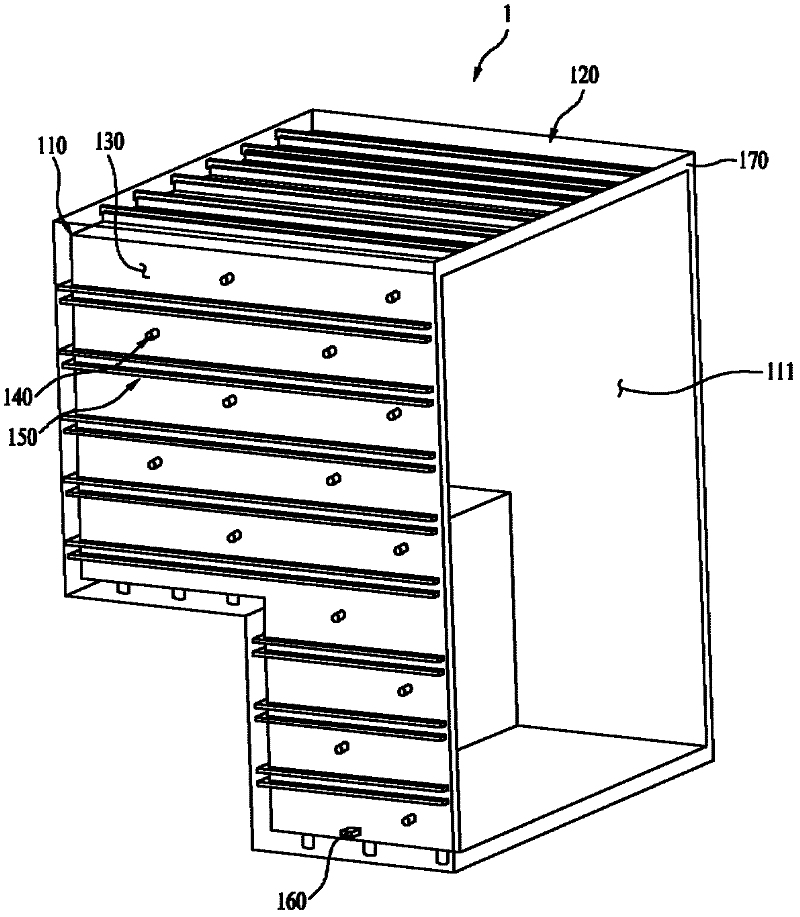

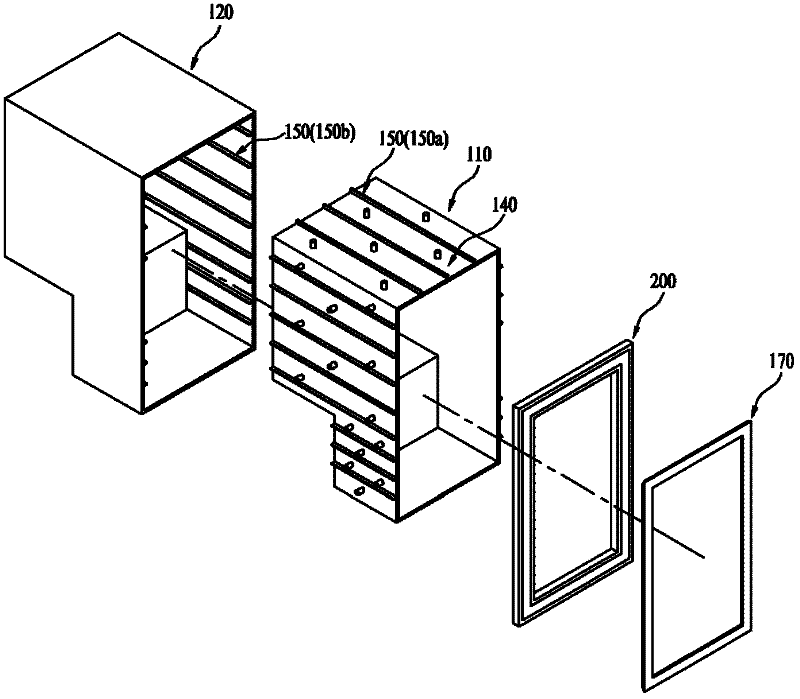

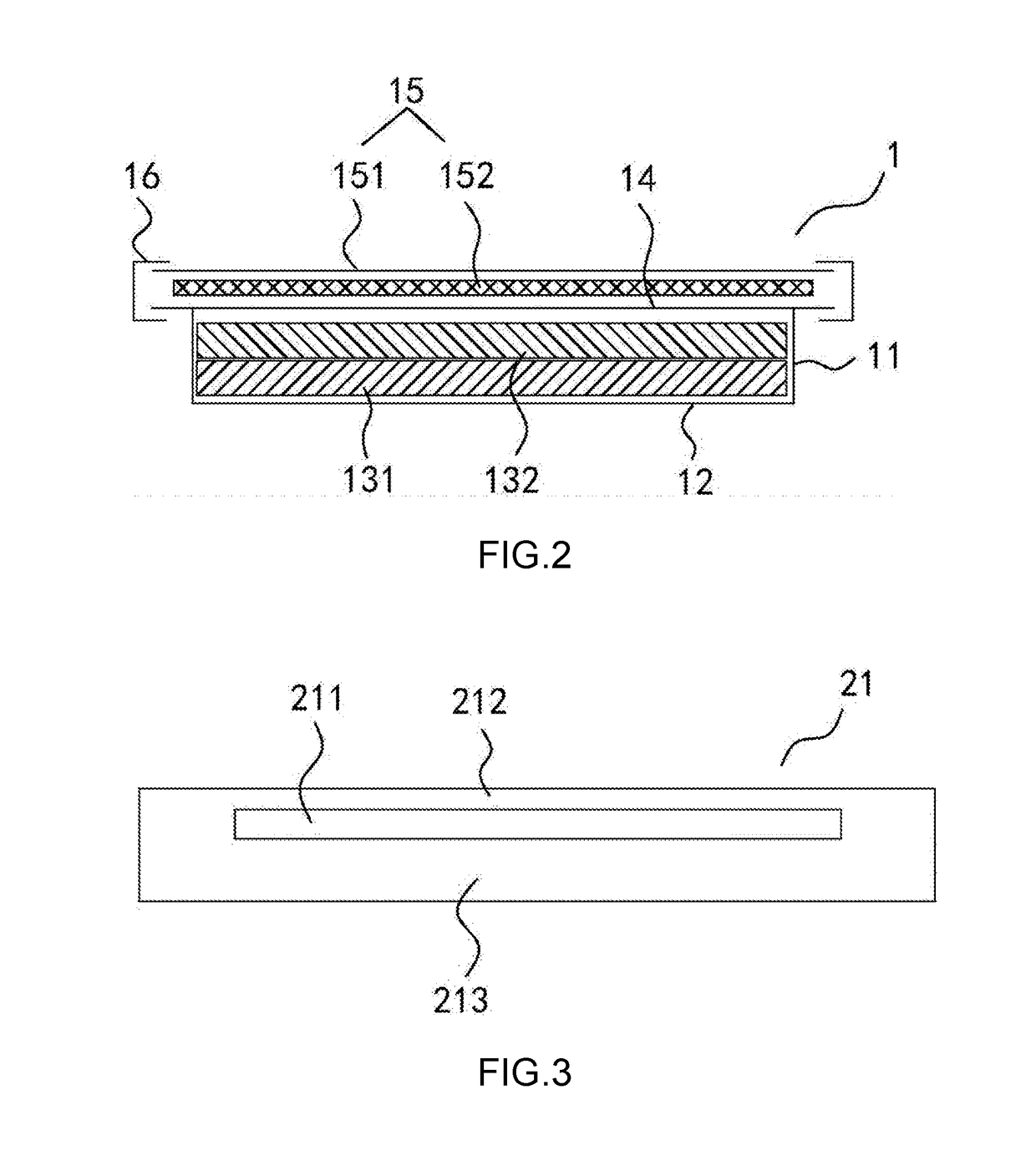

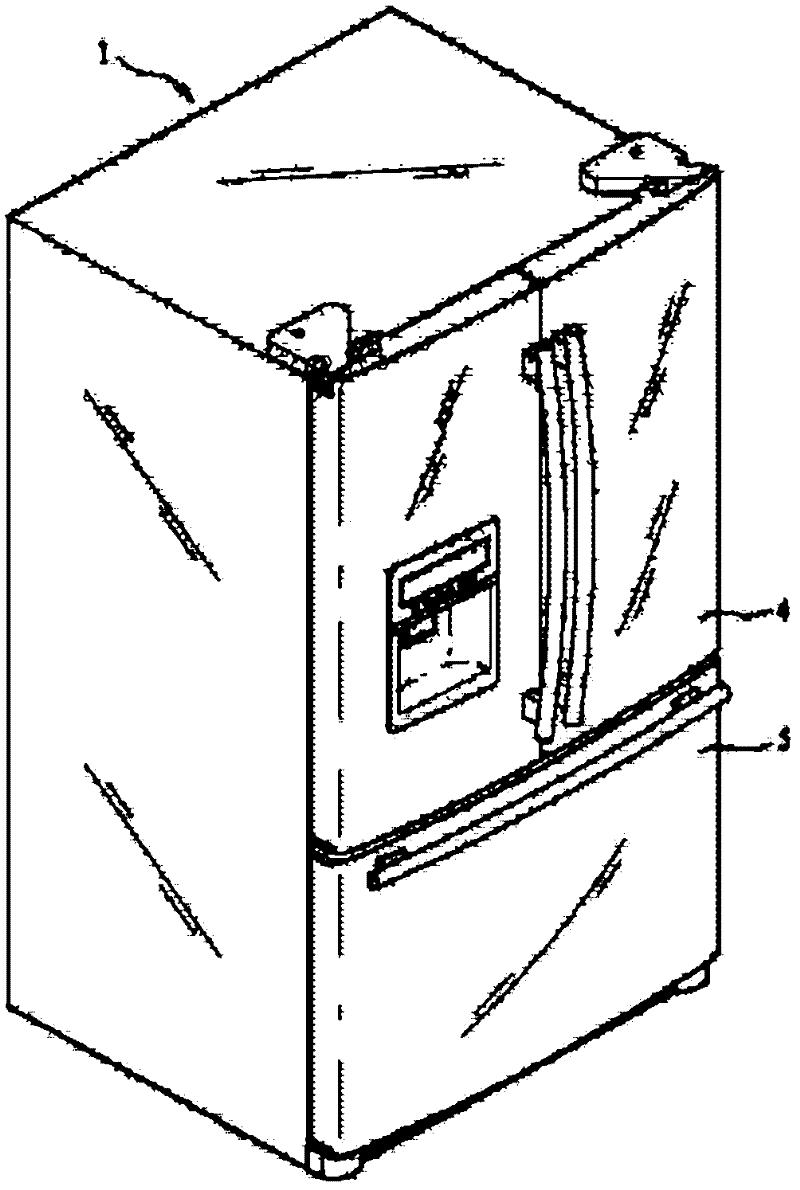

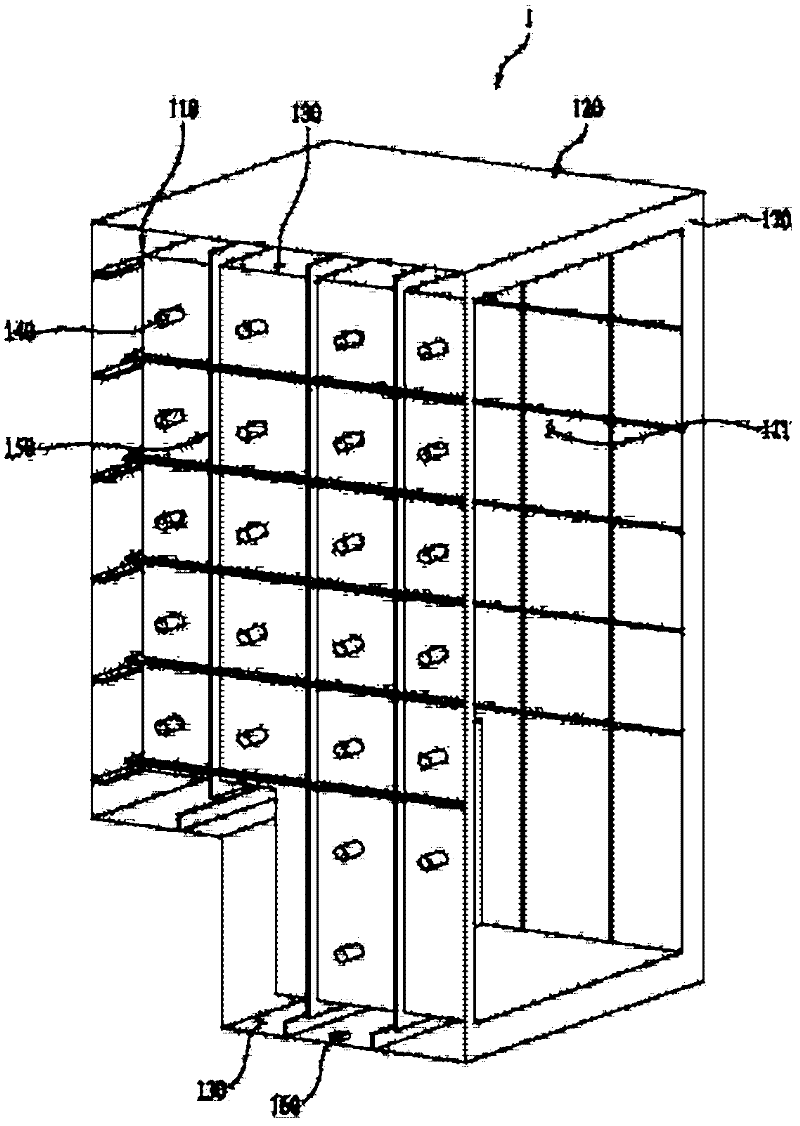

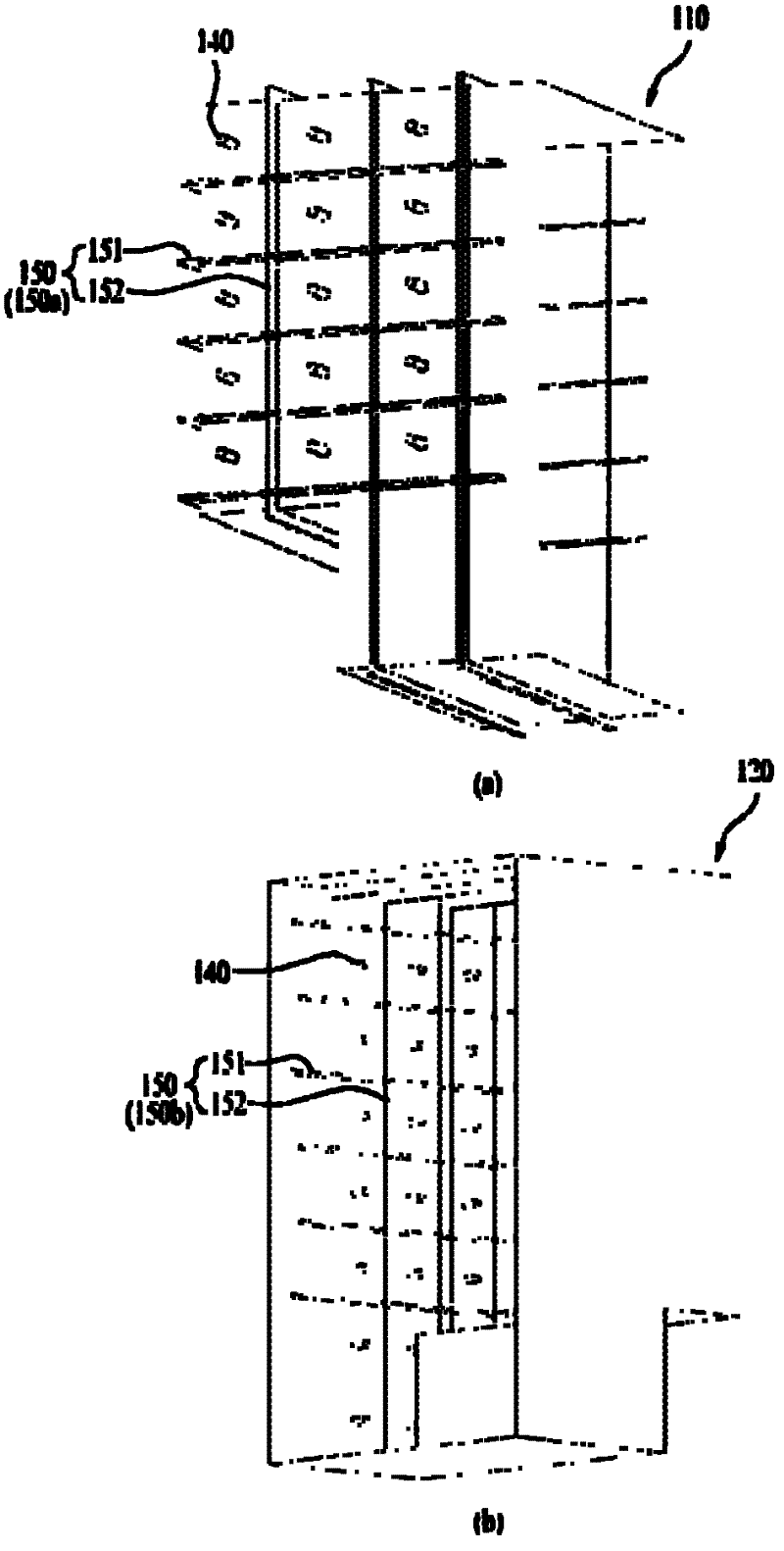

Refrigerator comprising vacuum space

ActiveCN102455105ACompact exteriorImprove thermal insulationLighting and heating apparatusInsulation for cooling apparatusEngineeringMechanical engineering

The refrigerator includes a body having a storage space for storing a predetermined storage object, wherein the body includes an inner case having the storage space, an outer case having an inside surface spaced a predetermined gap from an inside surface of the inner case to house the inner case, a vacuum space provided between the inner case and the outer case enclosed to maintain a vacuum state for heat insulating between the inner case and the outer case, and a sealing unit for sealing a front of the vacuum space formed between a front of the inner case and a front of the outer case and reducing a heat transfer rate between the inner case and the outer case.

Owner:LG ELECTRONICS INC

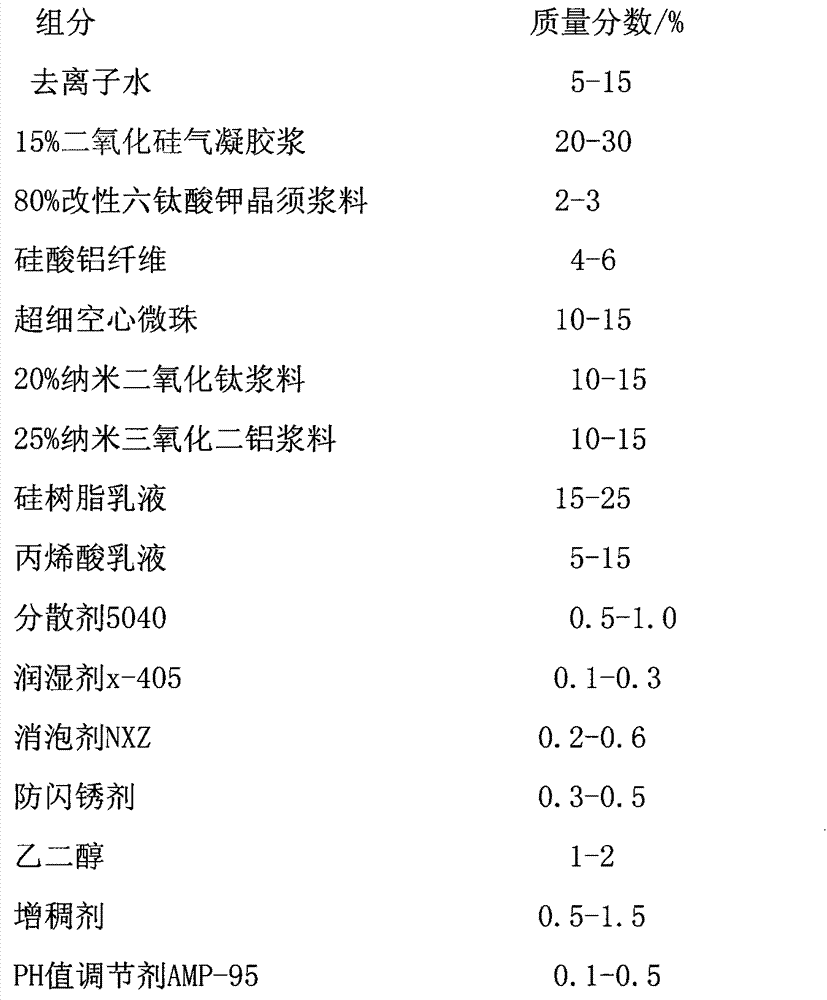

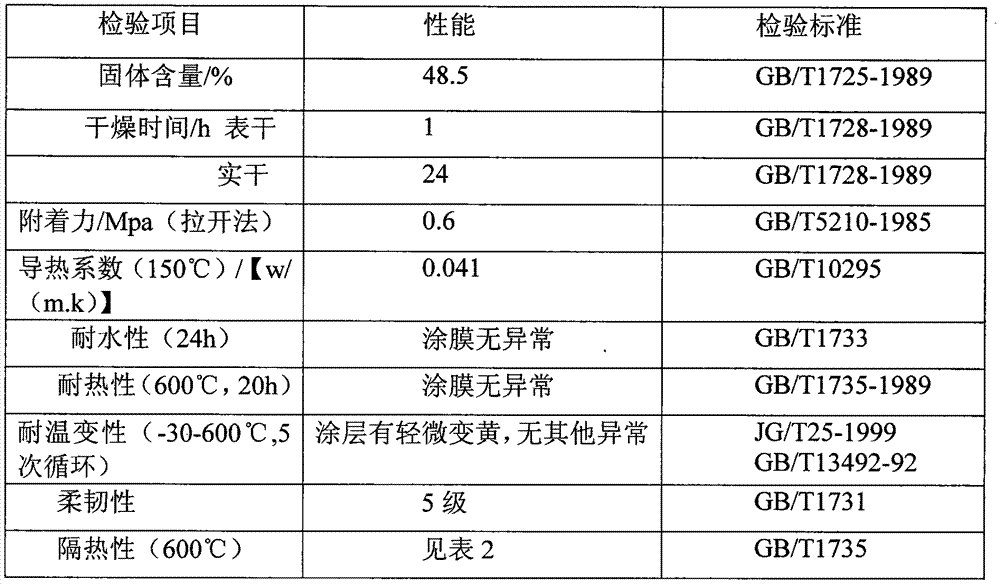

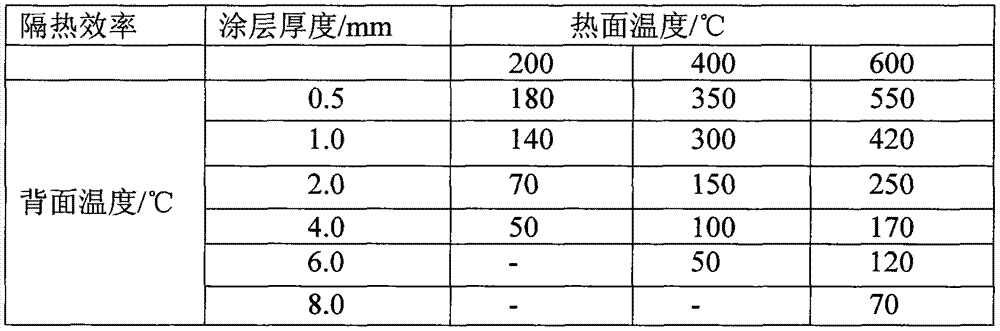

Nanometer high temperature resistant thermal insulation and prevention coating

The invention discloses a nanometer high temperature resistant thermal insulation and prevention coating. SiO2 aerogel, modified potassium hexatitanate whisker, aluminum silicate fiber, ultra-fine cenosphere, nanometer TiO2 and nanometer Al2O3 are used as a thermal insulation filler. A vacuum thermal insulation layer is formed by nano porous structures of SiO2 aerogel and cenosphere. The aluminum silicate fiber is used as a reinforcing and toughening material. The infrared shading performance of potassium hexatitanate whisker, nanometer TiO2 and nanometer Al2O3 are used as a thermal radiation shielding layer. A silicon resin emulsion and an acrylic emulsion are compounded to be an adhesive. Therefore, the nanometer 600 DEG C temperature resistant thermal insulation and prevention coating is prepared with matching of a variety of functional additives. The nanometer high temperature resistant thermal insulation and prevention coating has the characteristics of scumbling, thermal insulation, waterproofing, anti-crack, anti-corrosion, high temperature resistance, weather-proofing, durability and the like and is applicable to the field of industrial high temperature resistant thermal insulation energy conservation.

Owner:株洲中铁中南制造有限公司

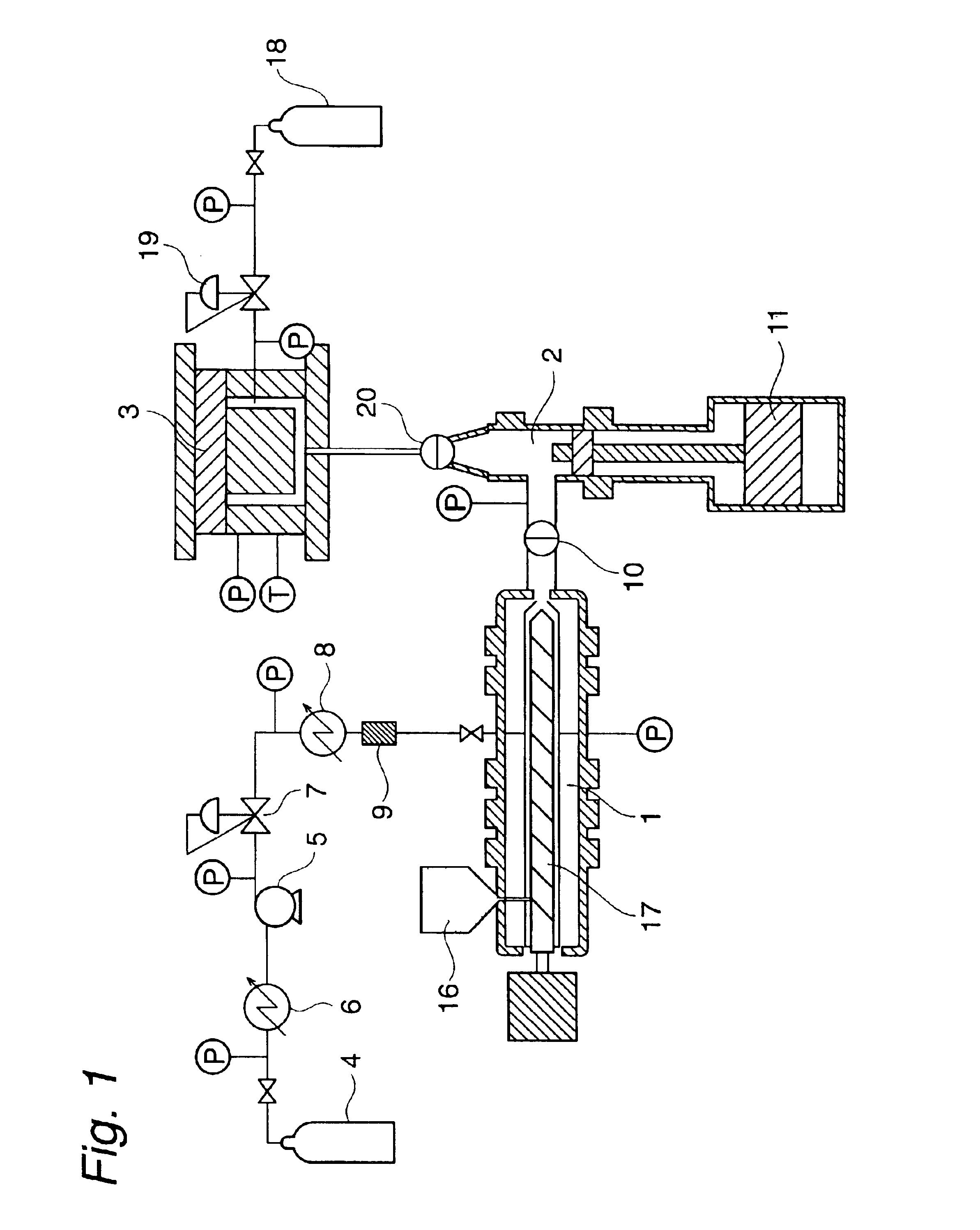

Foam of thermoplastic urethane elastomer composition and process for producing the foam

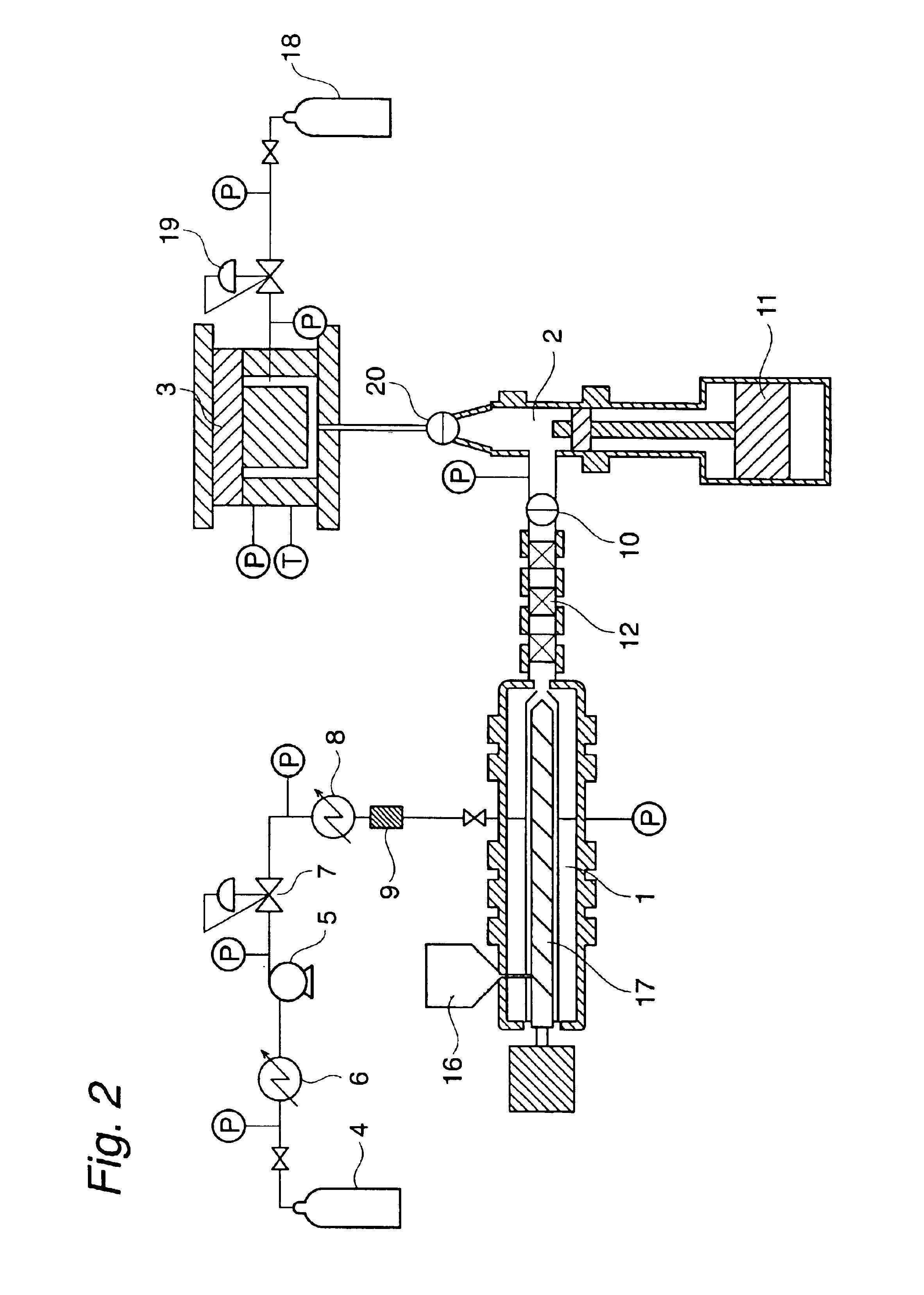

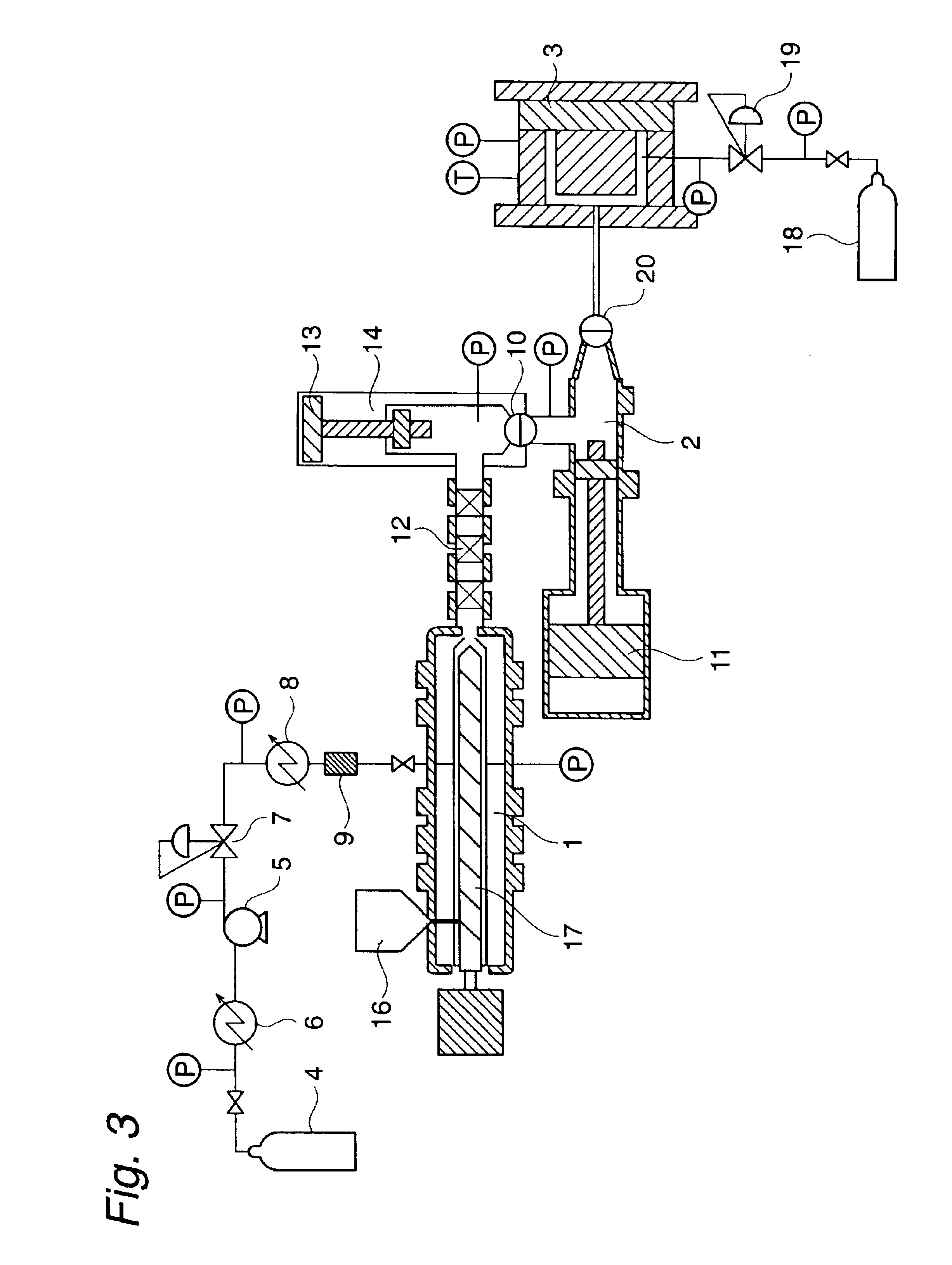

The method of the present invention for producing a urethane-based thermoplastic elastomer composition foam comprises the steps of:adding and mixing 0.1 to 30 parts by weight of carbon dioxide (B) to 100 parts by weight of a urethane-based thermoplastic elastomer composition (A) in a molten state, wherein said urethane-based thermoplastic elastomer composition (A) comprises a urethane-based thermoplastic elastomer (A-1) and other thermoplastic elastomer (A-2) in an (A-1) / (A-2) ratio of 20 / 80 to 99 / 1 by weight, to form a molten urethane-based thermoplastic elastomer composition (C) which is in a state of a mixture of the urethane-based thermoplastic elastomer composition (A) and the carbon dioxide (B) (gas dissolving step); andlowering a temperature of said molten urethane-based thermoplastic elastomer composition (C) (cooling step).The present invention can produce the urethane-based thermoplastic elastomer foam of stable quality over a range from low foamed product to highly foamed product by adding a given quantity of carbon dioxide in the molten urethane-based thermoplastic elastomer quantitatively and stably. It can also produce the foam excellent in flexibility, thermal insulation and surface appearances. It is also excellent in safety, because of use of carbon dioxide in place of the common foaming agent of fluorochlorohydrocarbon or butane, thus causing no air pollution or destruction of the ozone layer.

Owner:MITSUI CHEM INC

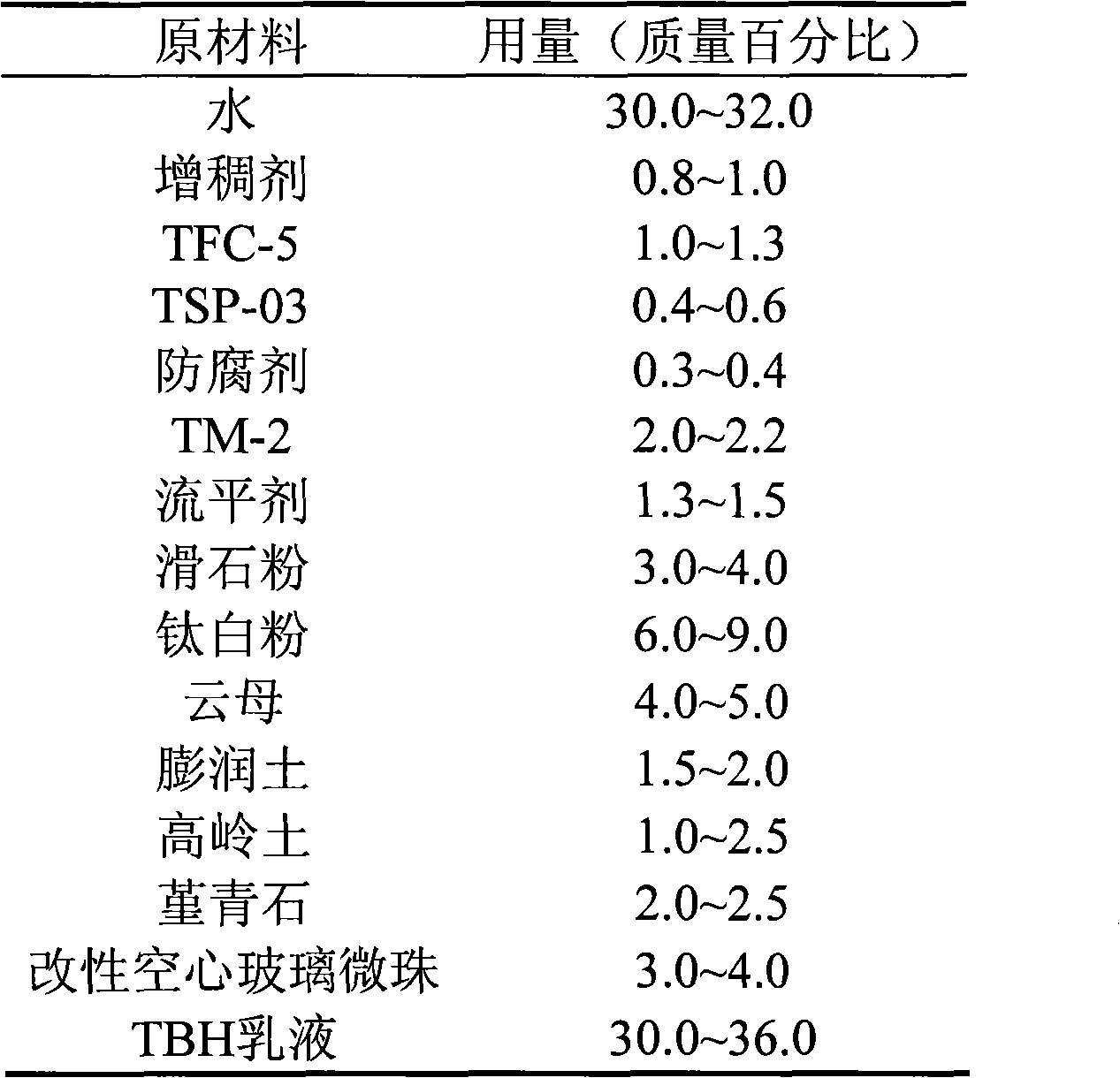

All-in-one water-borne inorganic-organic hybrid architectural coating and preparation method thereof

ActiveCN102408220AWaterproof and breathableIncrease viscosityEmulsion paintsThermal insulationOragene

The invention relates to an all-in-one water-borne inorganic-organic hybrid architectural coating and a preparation method thereof, wherein the all-in-one water-borne inorganic-organic hybrid architectural coating is prepared by taking a compounded product of a water-borne inorganic film-forming matter and an organic polymer emulsion as a base material through the steps of adding various pigments / fillers and auxiliaries into the base material, then carrying out beating, grinding and paint mixing on the obtained mixture. In the invention, through a Si-O-Si polymer net structure which can be formed by compounding alkali metal silicates and small-particle-size silica sols in the process of film forming, the early water resistance of a paint film is greatly increased, and the eventual hardness, scraping resistance and stain resistance of the paint film are greatly increased; and through adding the organic polymer emulsion, the film-forming performance of the coating can be improved, and the defects that the traditional two-component inorganic coating is easy to crack, bad in decorative properties, poor in storage stability, and the like are overcome. The coating prepared by using the method disclosed by the invention has various functions of environmental friendliness, non-toxicity, thermal insulation, ultra scrubbing resistance, abrasion resistance, yellowing resistance, ageing resistance, fouling resistance, good air permeability, sound insulation, and the like.

Owner:SOUTH CHINA UNIV OF TECH

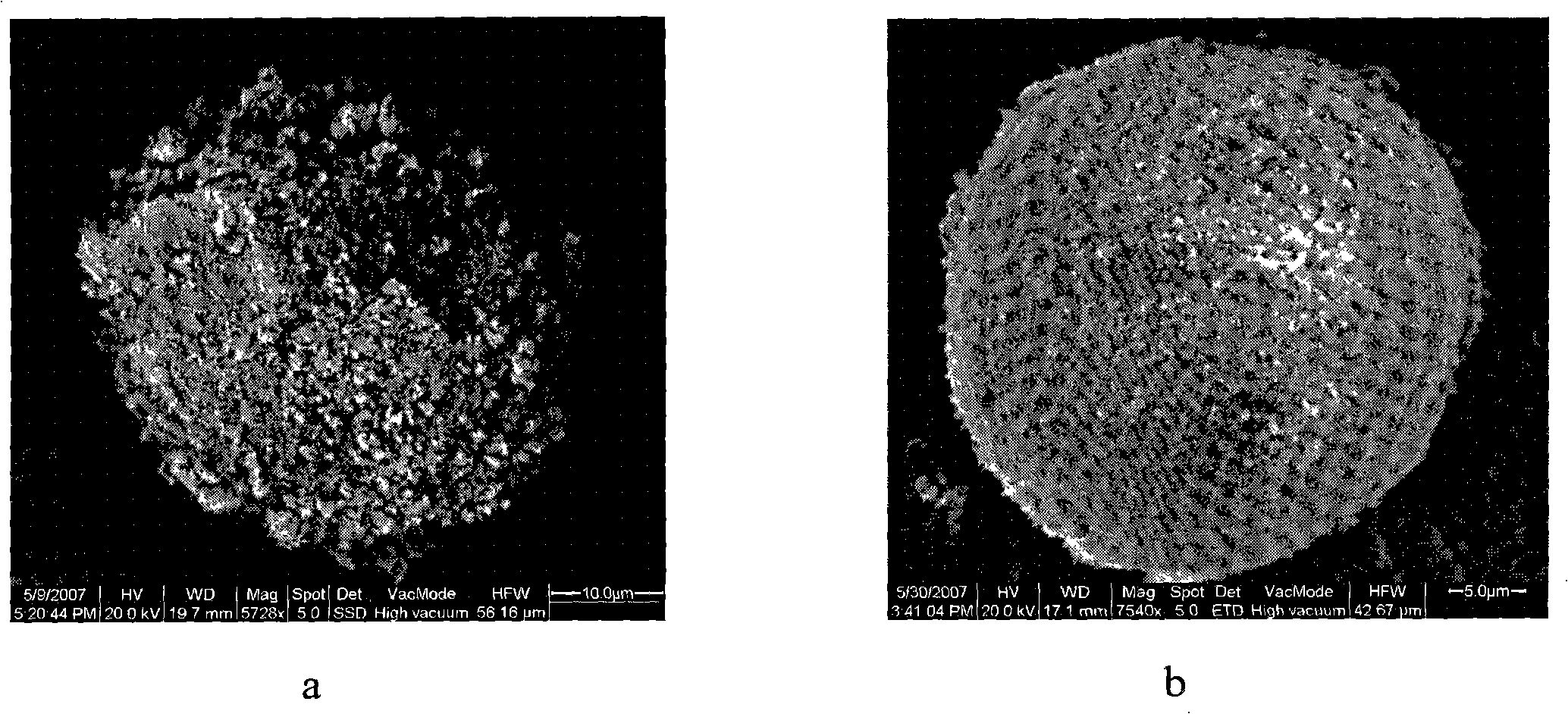

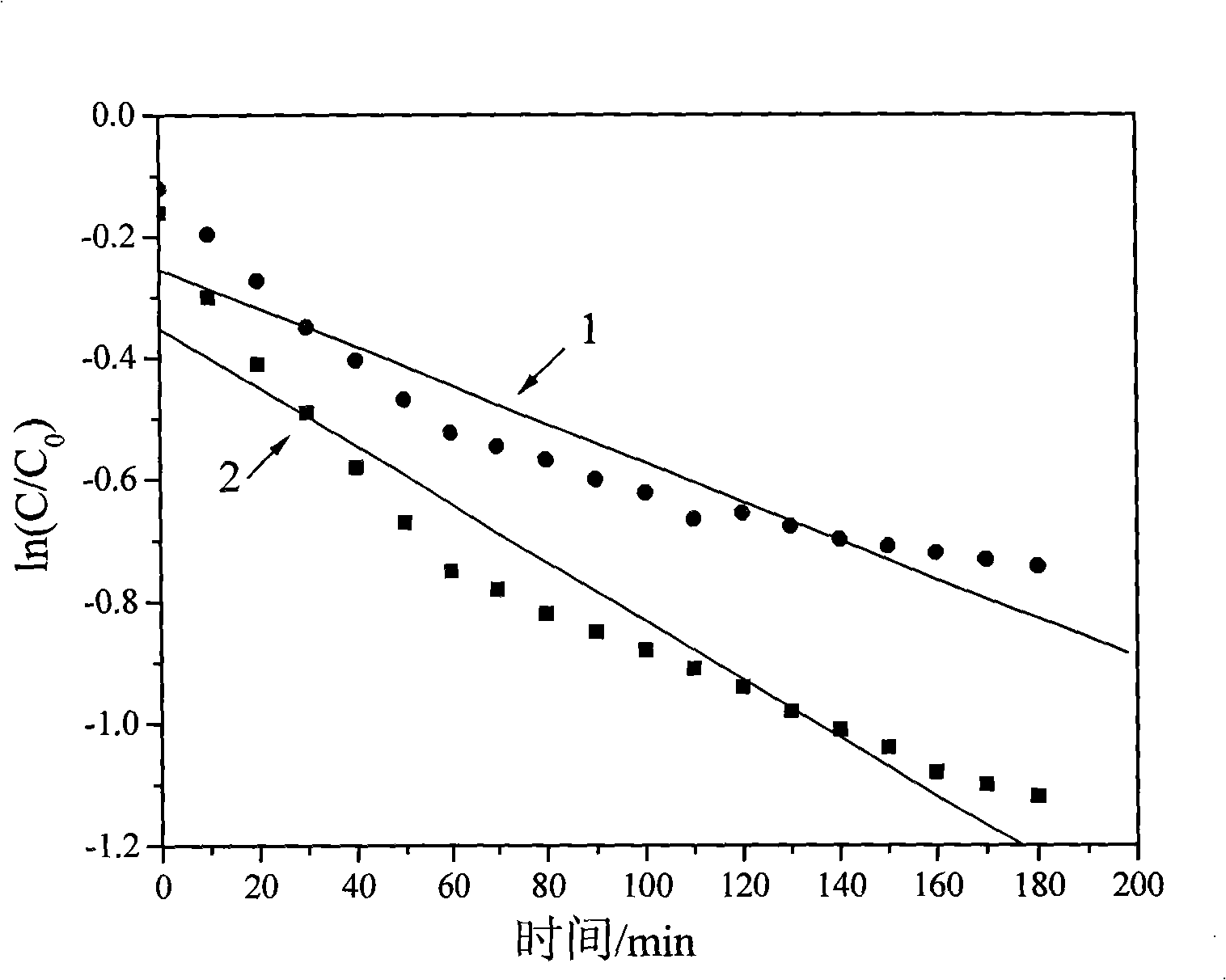

Surface modification method for hollow glass tiny bead and uses thereof

The invention provides a modification method of a hollow glass microballoon surface. Titanium dioxide coating layers are uniformly clad on the hollow glass microballoon surface by adopting a titanium salt back dripping method, so that the heat insulating property of the hollow glass microballoon can be improved obviously, and the production process is simplified. The method can fully bring into play the characteristics of the hollow glass microballoon and titanium dioxide in performance, make the best of the two and lead to synergistic effect. Therefore, the filling material of the hollow glass microballoon, after being modified, has diverse filling functions and the advantages of heat resistance, heat reflection, photocatalysis etc., so as to meet different needs. The invention also provides the application of the method in the manufacture of head insulating coatings.

Owner:NANTONG JUREN NEW MATERIAL TECH

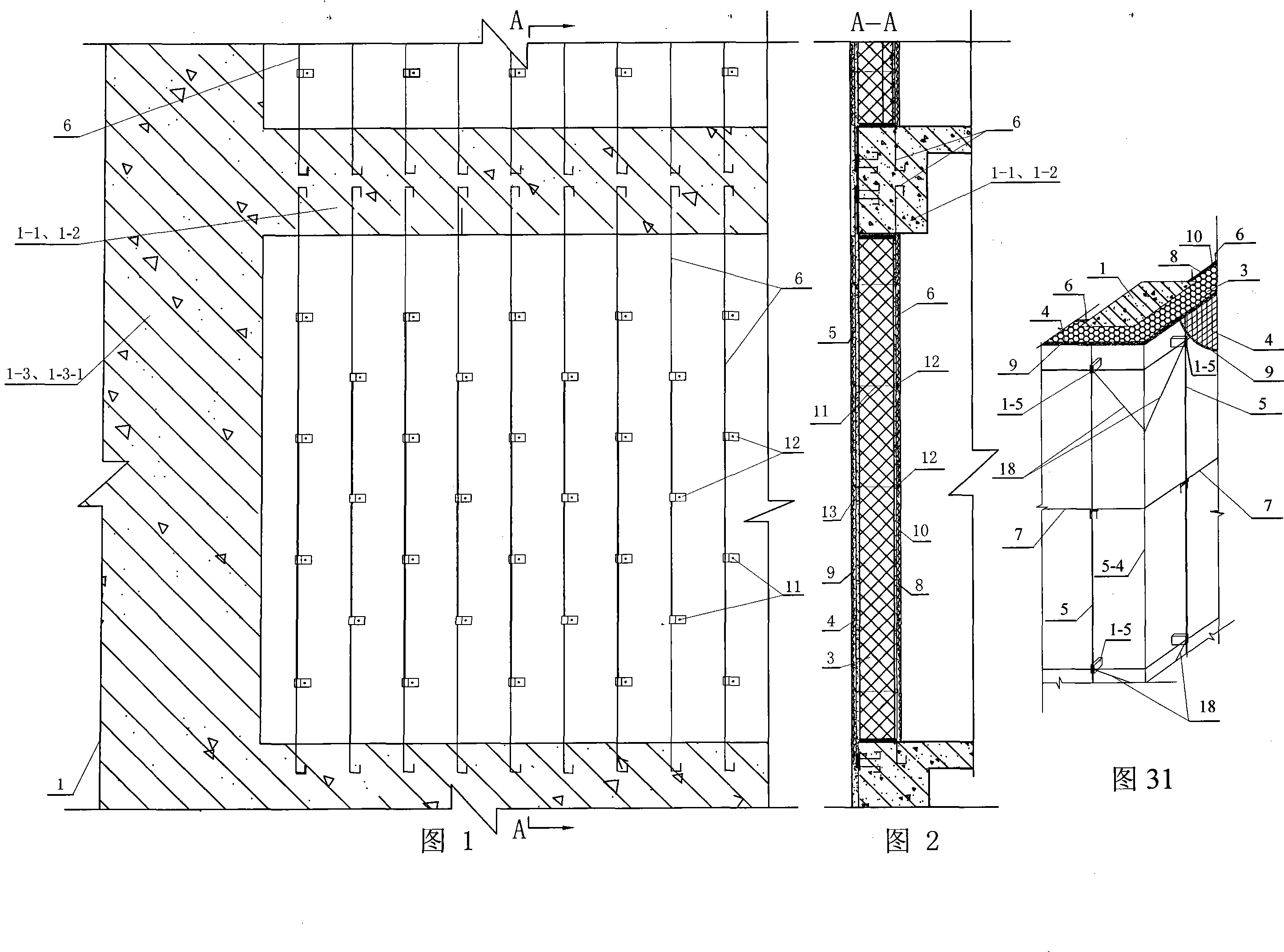

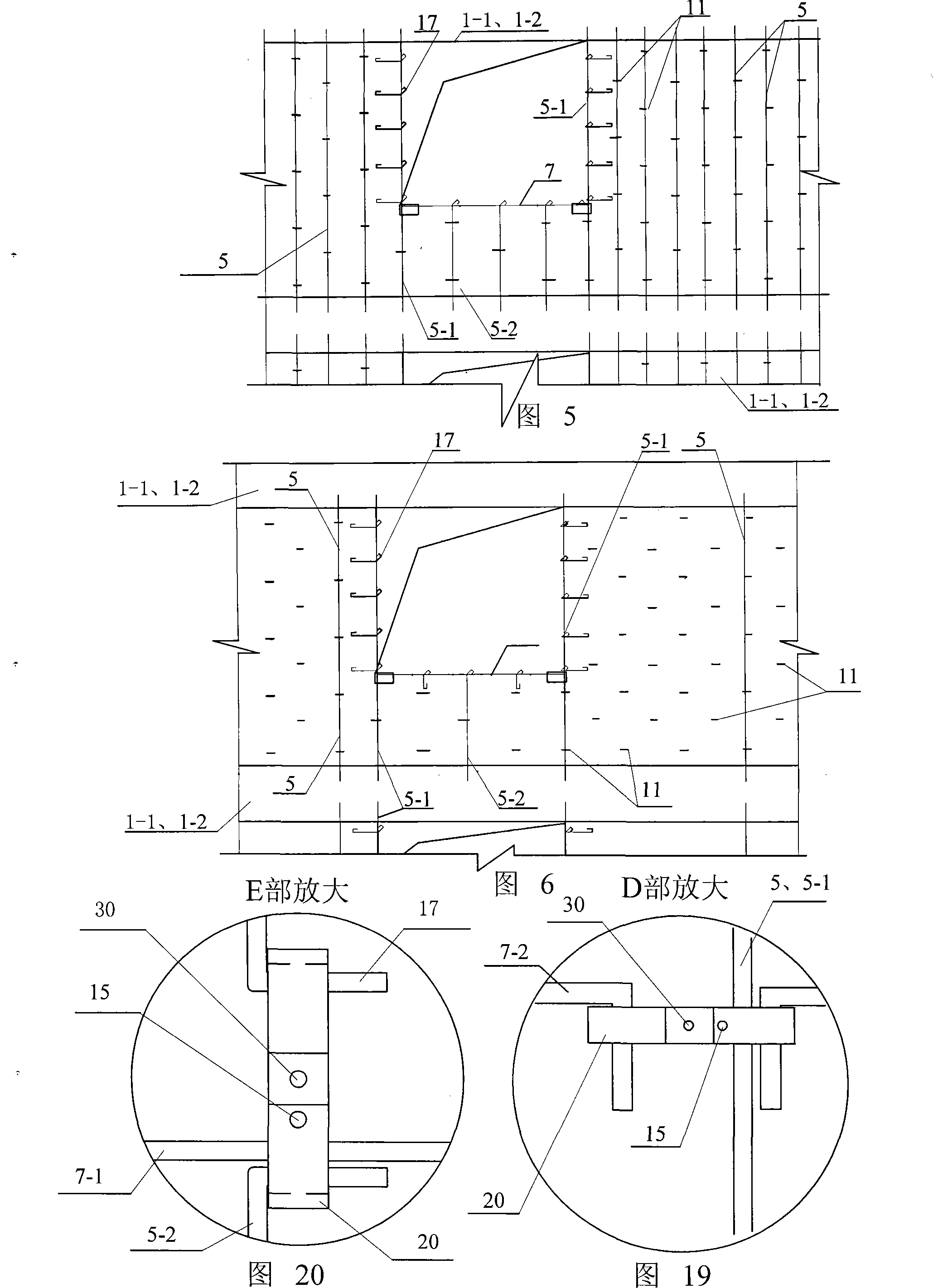

Plastering composite wall with reinforcing steel bar and/or metal net equipped at inter and outer or two-side

InactiveCN101168977AImprove securityImprove mechanical performanceCovering/liningsWallsFloor slabRebar

The utility model relates to a compound wall with reinforcing bars and / or metal mesh plastering on the inside and outside or on both sides, which relates to a building compound wall. Aiming at the incomplete structure of the bundled composite thermal insulation wall with support. Option 1: Outdoor vertical steel bars (5) and indoor vertical steel bars (6) are fixed to the outside and inside of the load-bearing member (1) of the main building structure, and the inner and outer sides of the core layer (3) are provided with inner and outer protection plan 2: the vertical steel bar (5-2) under the outdoor window sill and the vertical steel bar (6-2) under the indoor window sill are fixed to the cantilever plate (1-2); plan 3: indoor The vertical reinforcement (6) is fixed to the indoor floor of the load-bearing member (1) of the main structure of the building; scheme 4: the indoor vertical reinforcement (6) on both sides of the air layer, and the inner and outer sides of the indoor metal mesh are provided with protective layers (10 -1), the air layer (3-1) is located between the protective layers (10-1) on both sides. The invention has the advantages of good earthquake resistance, good wind load resistance, low cost, convenient construction, good safety of the outer decorative surface layer, increased indoor usable area, and meets the requirements of low energy consumption buildings.

Owner:吴淑环

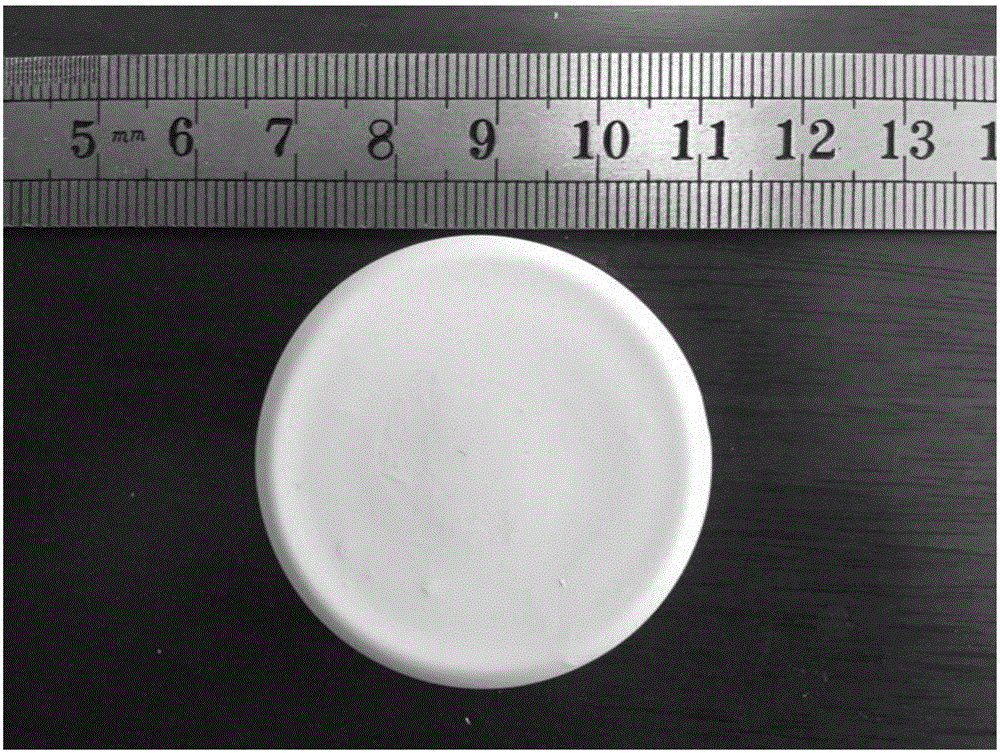

Heat-insulation slurry composition and applications thereof

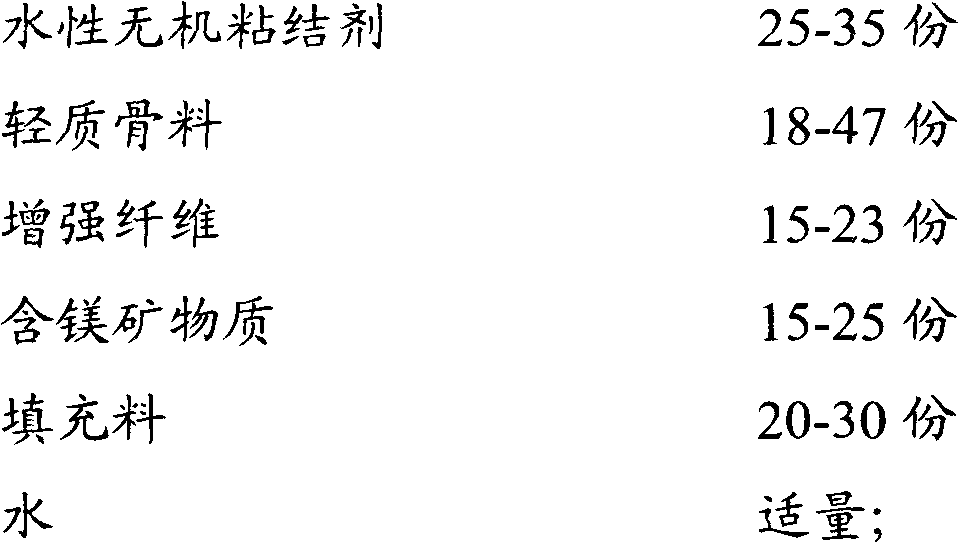

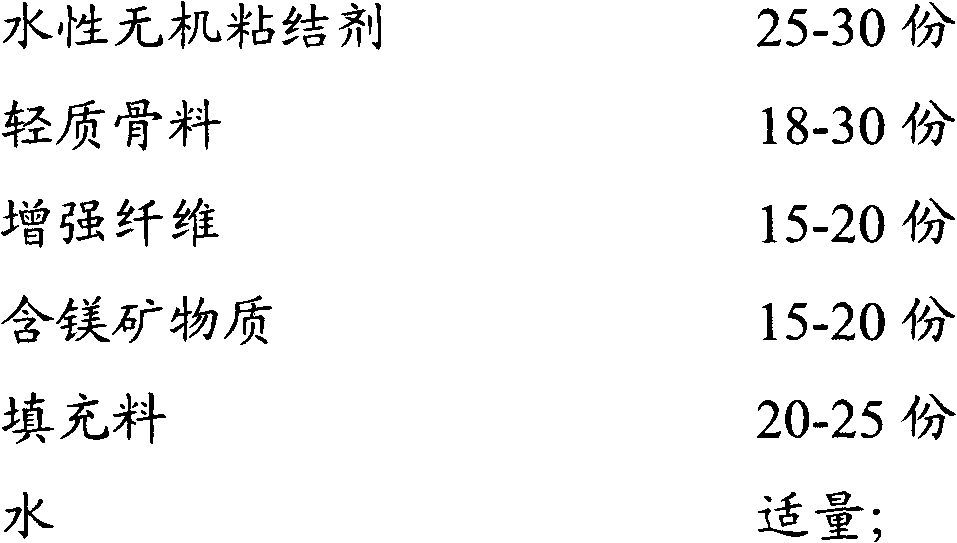

ActiveCN103030357ALight weightHigh mechanical strengthHeat proofingSpecific gravityEnvironmental standard

The invention provides a heat-insulation slurry composition which comprises the following components in parts by weight: 25-35 parts of waterborne inorganic binder, 18-47 parts of lightweight aggregates, 15-23 parts of reinforcing fibers, 15-25 parts of magnesium-containing minerals, 20-30 parts of fillers and a proper amount of water, wherein the waterborne inorganic binder comprises the following main components in parts by weight: 20-25 parts of colloidal silica, 5-8 parts of inorganic waterproof agent and 1.5-2.0 parts of thickening water-retaining agent. The invention also provides a method for preparing a heat-insulation plate by the heat-insulation slurry composition. According to the heat-insulation slurry composition provided by the invention, the main raw materials are inorganic materials, a prepared plate is light and high in mechanical strength, the heat-insulation performance is excellent, the plate is not inflammable, can be made into various specifications of products with the thickness of 6-120mm, the maximum length of 1200mm and the maximum width of 800mm and can be directly adhered to a wall surface, and the product conforms to the national environmental standard.

Owner:深圳市爱思宝科技发展有限公司

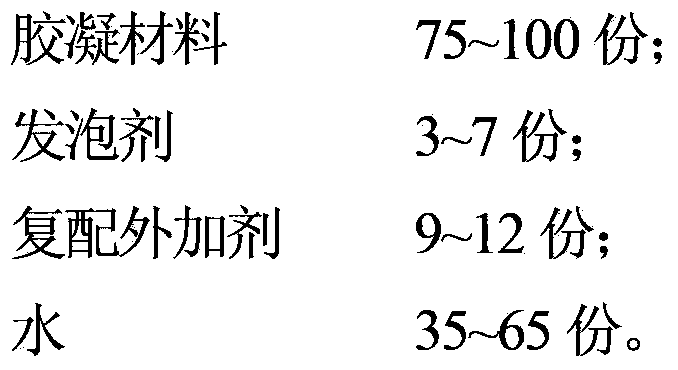

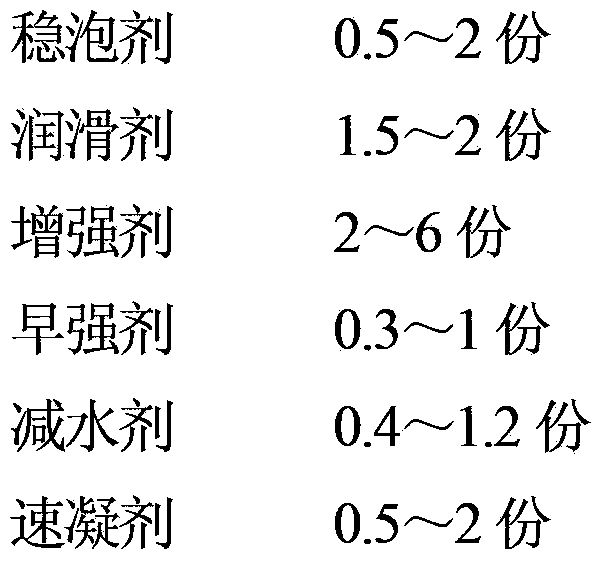

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

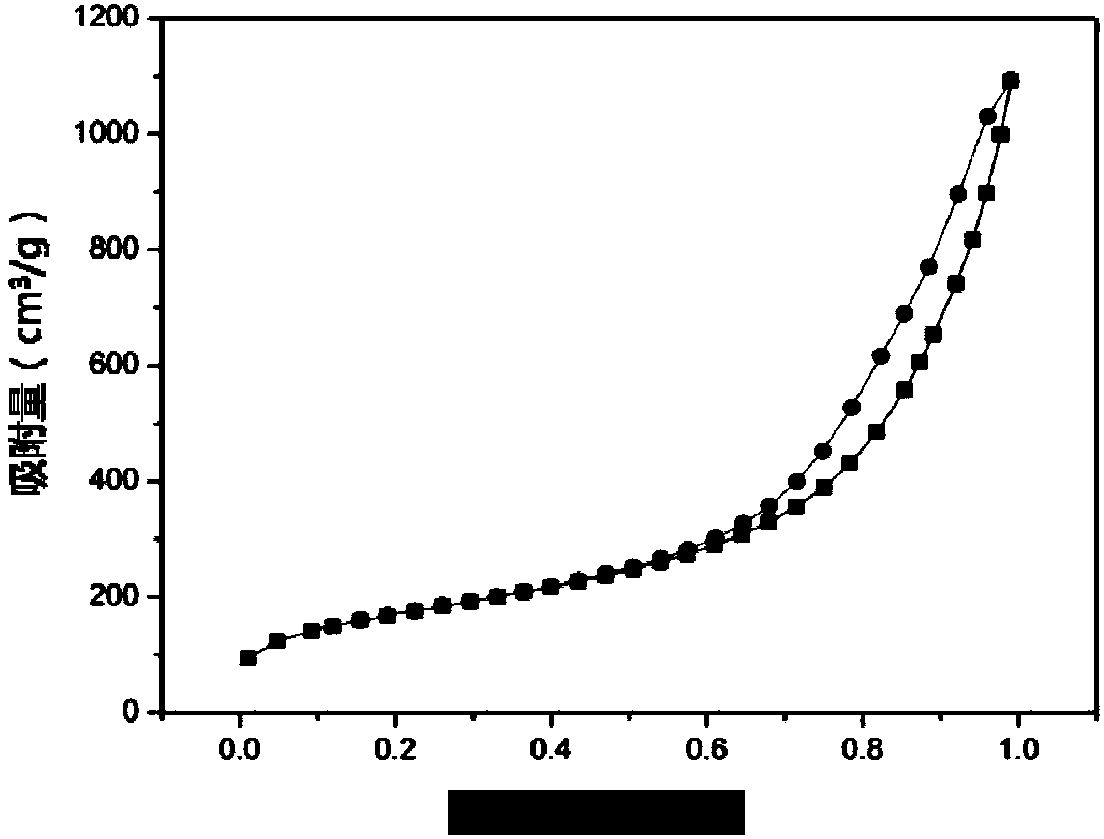

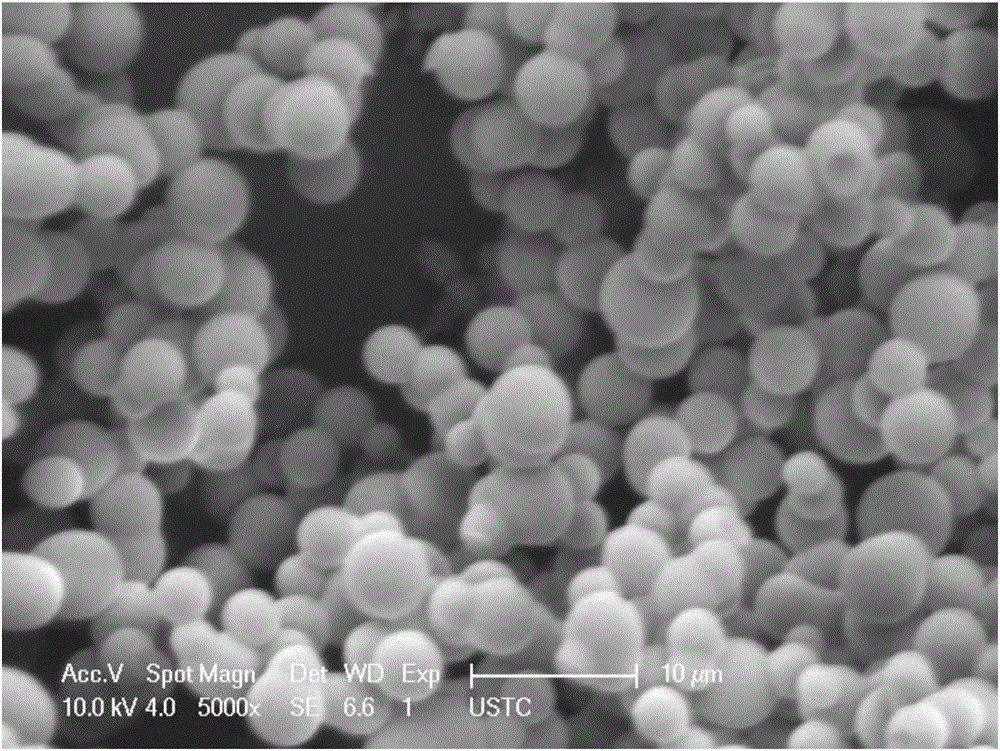

Aerogel micro powder and preparation method thereof

InactiveCN108689412AImprove drying efficiencyShorten freeze-drying timeChemical industryFerric oxidesPorosityOrganic solvent

The invention discloses aerogel micro powder and a preparation method thereof. The method comprises the following steps: a hydrogel is provided, and fragmentation is carried out on the hydrogel and dispersing the hydrogel to obtain gel fluid or gel dispersion liquid; an atomizing device is employed for performing atomization on the gel fluid or the gel dispersion liquid, gel droplets are formed, the gel droplets are collected by a low-temperature container, and the gel freezing particles are obtained; the freeze drying is carried out, and the aerogel micro powder is obtained. The aerogel micropowder can realize integration of granulation and refrigeration, pre-refrigeration is not required, rapid and continuous production of the aerogel micro powder can be realized, organic solvent displacement is not required, the preparation method has the advantages of simple process, short production period, low cost, energy saving, and environmental protection, the preparation process can be amplified to industrial production, and the obtained aerogel micro powder has the excellent physical properties of controllable morphology, uniform particle size, large specific surface area, high porosity amount, and low thermal conductivity.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Concrete cement foaming insulation brick and manufacturing method thereof

The present invention discloses a concrete cement foaming insulation brick, taking a concrete perforated brick as a main body. The concrete perforated brick is injected with a cement foam material, so that the cement foam material and the concrete perforated brick are fully combined. By adjusting the formulation and improving the process, the present invention makes full use of industrial wastes such as fly ash and coal gangue, does not need autoclaved curing, and is small in investment and simple in process. The foaming brick produced by the present invention has excellent heat insulation and sound insulation properties, and is high in strength, good in impact resistance, low in moisture absorption, light in weight, compression resistant, good in weather resistance, environmental-friendly and energy-saving, and non-toxic. The brick has great market space and development prospects in the application field of building energy efficiency.

Owner:嵊州市万顺新型墙体材料有限公司

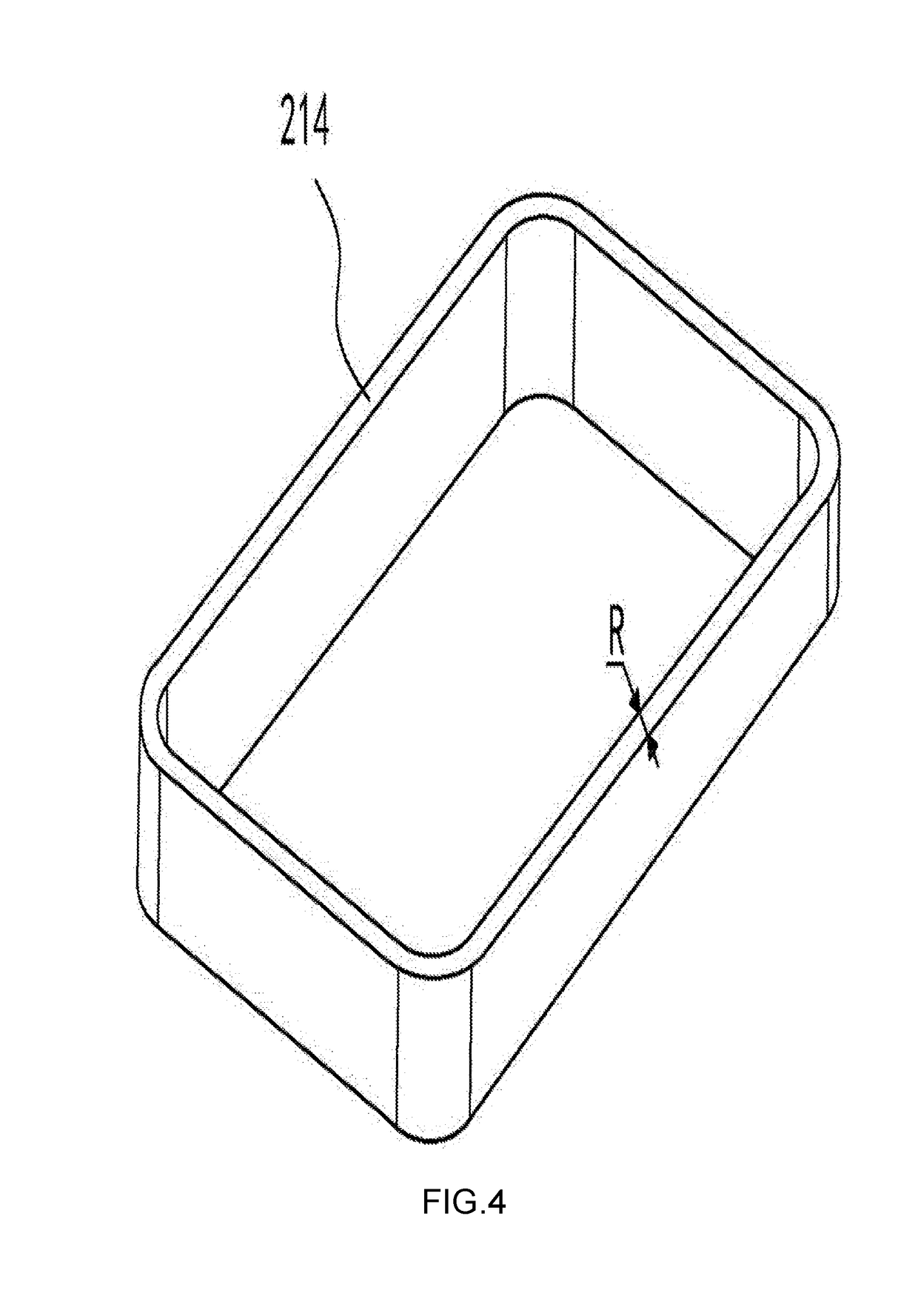

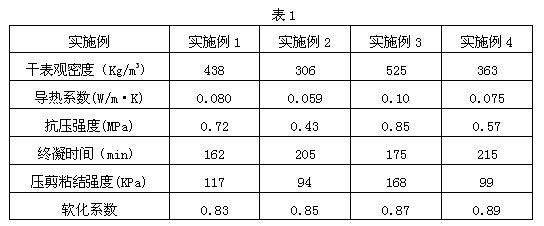

A thermal bag

ActiveUS20180370710A1Improve thermal insulationSimple structureDomestic cooling apparatusLighting and heating apparatusEngineering

Owner:LUO BINGHUA

Heat insulating mortar powder and its prepn process

The heat insulating mortar powder contains cementing material, foamed modified polystyrene grain, modified expanded pearlite, cementing material modifier and fiber. The foamed modified polystyrene grain contains foamed polystyrene grain, foamed polystyrene modifier and flyash; the modified expanded pearlite contains expanded pearlite, expanded pearlite modifier and sodium hydroxide; and the cementing material modifier contains polymer adhesive, air entraining and water reducing agent and flyash activator. The preparation process includes preparing foamed modified polystyrene grain, preparing modified expanded pearlite, preparing cementing material modifier, and mixing all the materials in certain proportion. The present invention has the advantages of small heat conducting coefficient, high compression strength, good construction performance, high adhering strength, etc.

Owner:爱福家居(江苏)有限公司

Thin and thermal insulation inner wall paint, preparation method and construction method thereof

ActiveCN101085892AImprove the decorative effectLow costFireproof paintsEmulsion paintsPolymer scienceMicrosphere

The invention discloses a kind of thin thermal insulating inner wall paint. The comprised components and their weight proportion are as follows: styrene-acrylic emulsion 28- 35%, titanium dioxide 8- 13%, fillings 10- 18%, borosilicate hollow microsphere 6- 12%, water- brone nanometer anti- pollution agent 0.5- 2%, defoaming agent 0.3- 0.5%. Said hollow microsphere is hollow white spherical powder with thin wall, the main component is silicon dioxide and diboron trioxide, the real density is small and heat conductive coefficient is 0.04- 0.08 w / m.k. The invention aslo discloses the preparation and construction method for said paint. It employs high pressure airless painting process for construction, the aperture of employed gunjet nozzle is 0.6- 0.8 mm, atomization pressure is 15- 18 Mpa, and when the coating layer is 0.3- 1.0 mm, the coating layer is homogeneous and tight, and the thermal insulating effect is good. The paint is especially suitable for building inner wall and ceiling painting.

Owner:上海秀珀化工有限公司

Thermal insulation mortar

InactiveCN102010174AGood volume stabilityStrong water resistanceSolid waste managementPolystyreneTime control

The invention discloses thermal insulation mortar which comprises the following components in percentage by weight: 20 to 60 percent of caustic calcined magnesia, 1 to 25 percent of fly ash, 5 to 35 percent of thickening time control agent, 0 to 40 percent of enhanced thickener, 1 to 20 percent of kieselguhr, 5 to 35 percent of expanded aggregate, 0 to 5 percent of polystyrene foam particles, 0 to 0.2 percent of polypropylene fiber, 0.5 to 8 percent of water-resisting admixture, and 0 to 2 percent of water reducing agent. The thermal insulation mortar has the characteristics of capability of coagulating and hardening quickly and having strong binding capacity with base materials, good volume stability, capability of producing volume micro-expansion in the process of coagulating and hardening, no crack, no splitting, strong water resistance, ageing resistance, long service life, light weight, and good heat preservation and heat insulation performance, wherein the coefficient of thermal conductivity is 0.05 to 0.30 W / m.k. The thermal insulation mortar has the advantages of no toxicity, odourlessness, zero radioactivity, no harm to human bodies, no pollution to environments, energy conservation, environmental friendliness and low production cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

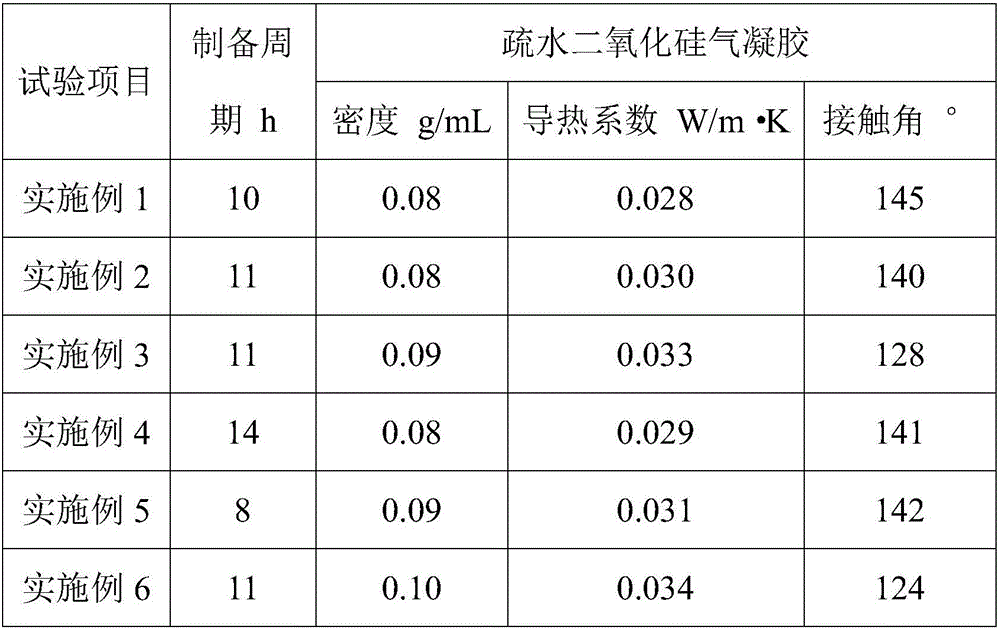

Method for quickly preparing hydrophobic silicon dioxide aerogel at low cost

InactiveCN106745004AAvoid pollutionReduce surface tensionSilicaNanotechnologyPhysical chemistryAmbient pressure

The invention discloses a method for quickly preparing hydrophobic silicon dioxide aerogel at low cost. The method comprises the following steps of (S1) mixing a silicon source, water and a surfactant evenly to obtain a precursor solution, adding an acid catalyst to the precursor solution, adjusting the pH value to be 3-4, and then hydrolyzing to obtain sol; and (S2) dropwise adding an alkali catalyst to the sol obtained in the step (S1), continuously stirring in the dropwise adding process, adjusting the pH value to be 6-7, and carrying out gel standing, ageing and ambient pressure drying to obtain the hydrophobic silicon dioxide aerogel. The method is low in cost, free of solvent exchange, short in production cycle and free of environmental pollution; and the prepared hydrophobic silicon dioxide aerogel has good heat preservation and heat insulation properties, hydrophobicity and flexibility.

Owner:ECONANO TECH LTD BEIJING

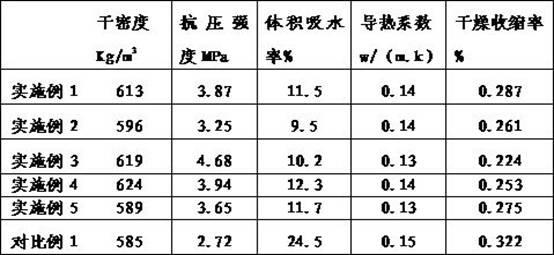

Straw cement based compound porous self-heat-insulating material and preparation method thereof

InactiveCN101941849AImprove thermal insulation performanceImprove thermal insulationSolid waste managementCeramicwareWater reducerMaterials science

The invention discloses a straw cement based compound porous self-heat-insulating material which is a new-type light, high-strength and porous building self-heat-insulating material prepared by foaming farmland straw, cement, industrial residue, foaming agent, waterproofing agent, coagulant, water reducer and water, and then mixing with gelled material slurry. The self-heat-insulating material comprises the following components by mass percent: 0.12-14.83% of farmland straw, 28.70-72.08% of cement, 0.40-43.52% of industrial residue, 0.04-0.40% of foaming agent, 0.06-0.89% of waterproof agent, 0.11-1.45% of coagulant, 0.06-0.13% of water reducer and 23.65-33.97% of water. The main raw materials, such as farmland straw, and industrial residue and other wastes used by the self-heat-insulating material prepared by the invention have wide resources, low cost and convenient preparation process, do not need high-temperature maintenance, simultaneously have excellent heat insulating performance, high mechanical strength, and have the outstanding properties of energy conservation, environmental protection, waste utilization, regeneration and the like.

Owner:SOUTHEAST UNIV

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Foam cement insulation board containing industrial solid waste and preparation method thereof

he invention relates to a foam cement insulation board and a preparation method thereof, and provides a foam cement insulation board containing industrial solid wastes and a preparation method thereof. The foam cement insulation board is composed of a mixture A and a mixture B. The mixture A comprises 55-65% of cement, 10-20% of gypsum powder, 8 -15% of hydrogen peroxide,3-4% of a flocculant, 1-2% of a water reducing agent, 1-2% of a coagulant, 2-3% of a cement waterproof agent, 1-2% of lithium carbonate, 1-2% of fiber, and 1-2% of solid master batch. The mixture B comprises 35-47% of a base material, 35-39% of a magnesium chloride solution, 10-15% of magnesium oxide, 2-5% of a binding agent, 2-3% of industrial hydrogen peroxide, 1-2% of lanthanide rare earth and 5-7% of an additive. The Foam cement insulation board provided by the invention has advantages of fireproof, waterproof, light weight, compressive and flexural resistance and high strength, and effectively utilizes industrial solid waste, facilitates environmental protection, and truly realizes turning wastes into treasures.

Owner:ZHENJIANG ZHONGRUI ENERGY SAVING TECH

Refrigerator comprising vacuum space

ActiveCN102455103AImprove thermal insulationReduced external volumeLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

This invention relates to refrigerators, and more particularly to a refrigerator in which a vacuum space is formed between an outer case and an inner case of a body thereof for enhancing a heat insulating function. The refrigerator includes a body having a storage space for storing a predetermined storage object, wherein the body includes an inner case having the storage space, an outer case having an inside surface spaced a predetermined gap from an outside surface of the inner case to house the inner case, and a vacuum space provided between the inner case and the outer case sealed to maintain a vacuum state for heat insulating between the inner case and the outer case.

Owner:LG ELECTRONICS INC

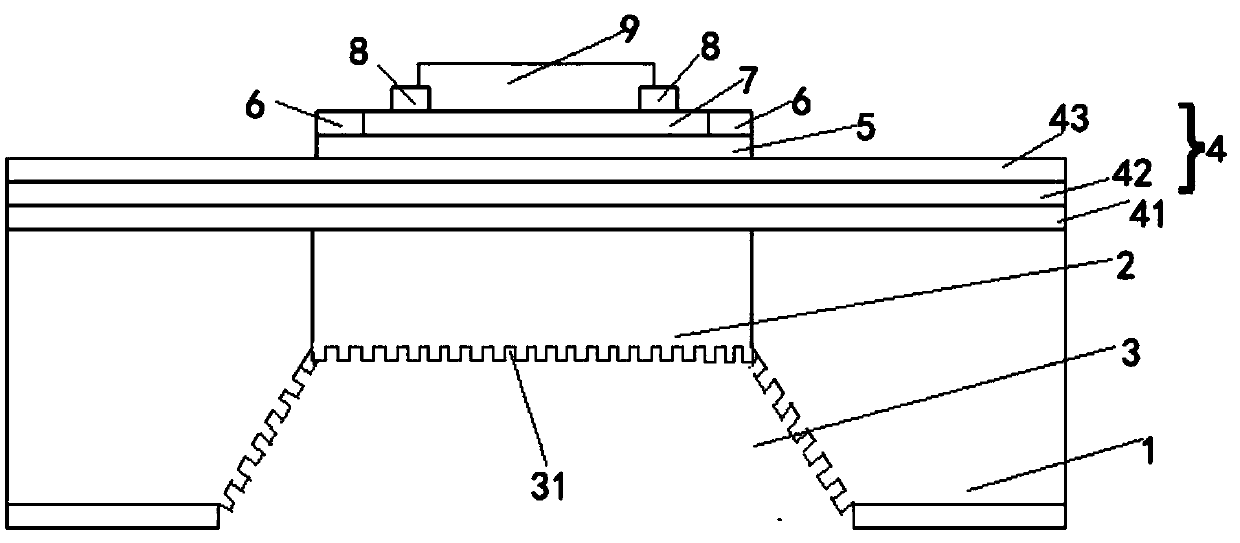

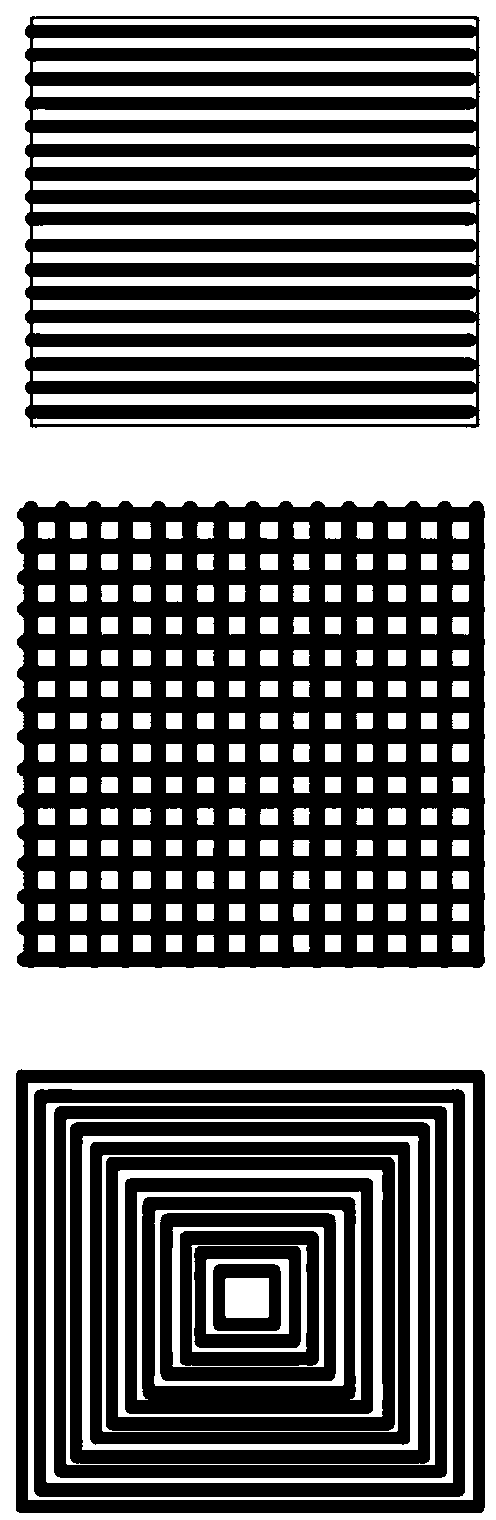

MEMS gas sensor and manufacturing method thereof

ActiveCN104181203AAvoid failureInhibit sheddingDecorative surface effectsSolid-state devicesInsulation layerSilicon dioxide

The invention relates to the technical field of gas detection, and in particular relates to an MEMS gas sensor. The MEMS gas sensor comprises a monocrystalline silicon substrate, a porous silicon layer which is formed on the upper surface of the monocrystalline silicon substrate and has thickness downwards, a heat insulation trough formed on the lower surface of the monocrystalline silicon substrate in an inverse manner, a lower insulation layer, a heating layer, an upper insulation layer and a gas sensitive layer, wherein the bottom surface of the heat insulation trough is positioned just under the porous silicon layer; the heat insulation trough comprises one or multiple trench groups; the lower insulation layer covers the porous silicon layer and the upper surface of the monocrystalline silicon substrate and comprises a first silicon dioxide layer, a second silicon dioxide layer and a silicon nitride layer from bottom to top in sequence; the heating layer, the upper insulation layer and the gas sensitive layer are arranged above the lower insulation layer. The invention also correspondingly discloses a manufacturing method of the MEMS gas sensor. By virtue of the structures of porous silicon and the heat insulation trough, the heat insulation effect is enhanced; the lower insulation layer effectively prevents the heat insulation layer warping to break away from the heating layer at high temperature; meanwhile, under the supporting of the porous silicon layer, deformation and cracks, which are caused by non-uniform stress, of the lower insulation layer are prevented, and thus the service life of the gas sensor is prolonged.

Owner:SUZHOU LEANSTAR ELECTRONICS TECH

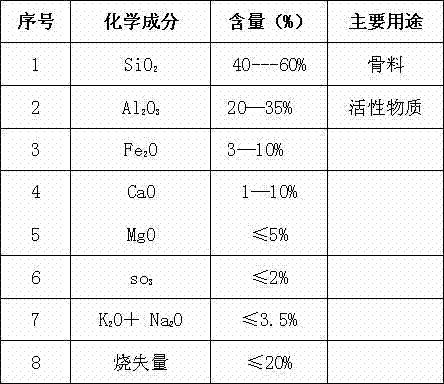

Autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and preparation method thereof

InactiveCN103193447AStable compressive strength"Light weightSolid waste managementCeramicwareBrickAluminium powder

The invention provides an autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and a preparation method thereof. The brick is prepared from the following materials by weight percent: 65%-68% of pulverized fuel ash, 17%-23% of lime, 6%-10% of cement, 2%-4% of desulfurization gypsum, 1%-1.5% of water-soluble aluminum powder, 0.5% of fatty acid soap and 0.5% of gleditsia sinensis powder. The preparation method comprises steps of: adding water to pulverized fuel ash and desulfurization gypsum which are screened mechanically and grinding together to form slurry, wherein the fineness of the pulverized fuel ash has to reach the condition that the residual of a 0.08mm square hoe sieve is not more than 15%; carrying out stirring, pouring, cutting and thermal, static and suspension curing on the slurry together with the lime, the cement and the aluminum powder suspension liquid which are weighed according to a weight ratio of a formula; utilizing an autoclave with good sealing for heating with 180-200 DEG C saturated steam under proper pressure (1.0-1.2Mpa); and steam curing for 8-10 hours so as to produce the aerated concrete brick. The aerated concrete brick has the characteristics of light weight, high strength, good heat insulation performance, good fire resistance and sound absorption, labor saving and energy saving, waste recycling and the like; and the aerated concrete brick meets constructional engineering requirements and environment protection requirements, and the wastes of enterprises are reasonably used.

Owner:SHIYAN JINSHA WALL MATERIALS

Method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder

The invention discloses a method for preparing microcrystalline foam glass by using high titanium blast furnace slag and waste glass powder. The method comprises the following steps: grinding the high titanium blast furnace slag and waste glass powder, uniformly and fully mixing the high titanium blast furnace slag, the waste glass powder, a fluxing agent, a foaming agent and a foam stabilizer, pressing into a block, adding the mixture block into a heating device and preparing the microcrystalline foam glass at a low temperature according to a specific heat treatment process by using a one-step sintering method. According to the characteristic that the high titanium blast furnace slag which is rich in TiO2 can serve as a nucleation agent, the low-melting-point waste glass powder serves as a silicious raw material, a proper amount of corresponding fluxing agent and sintering process are matched, the preparation temperature is greatly reduced, and the preparation can be finished through one-step sintering; and therefore, the energy consumption can be reduced, the process is simplified, the cycle is shortened, the cost is saved, the product which is uniform in cells, moderate in cell diameter, low in volume density, low in water absorption rate, good in thermal insulation effect and high in mechanical strength can be obtained, and the additional value of high titanium blast furnace slag utilization is improved.

Owner:SICHUAN UNIV

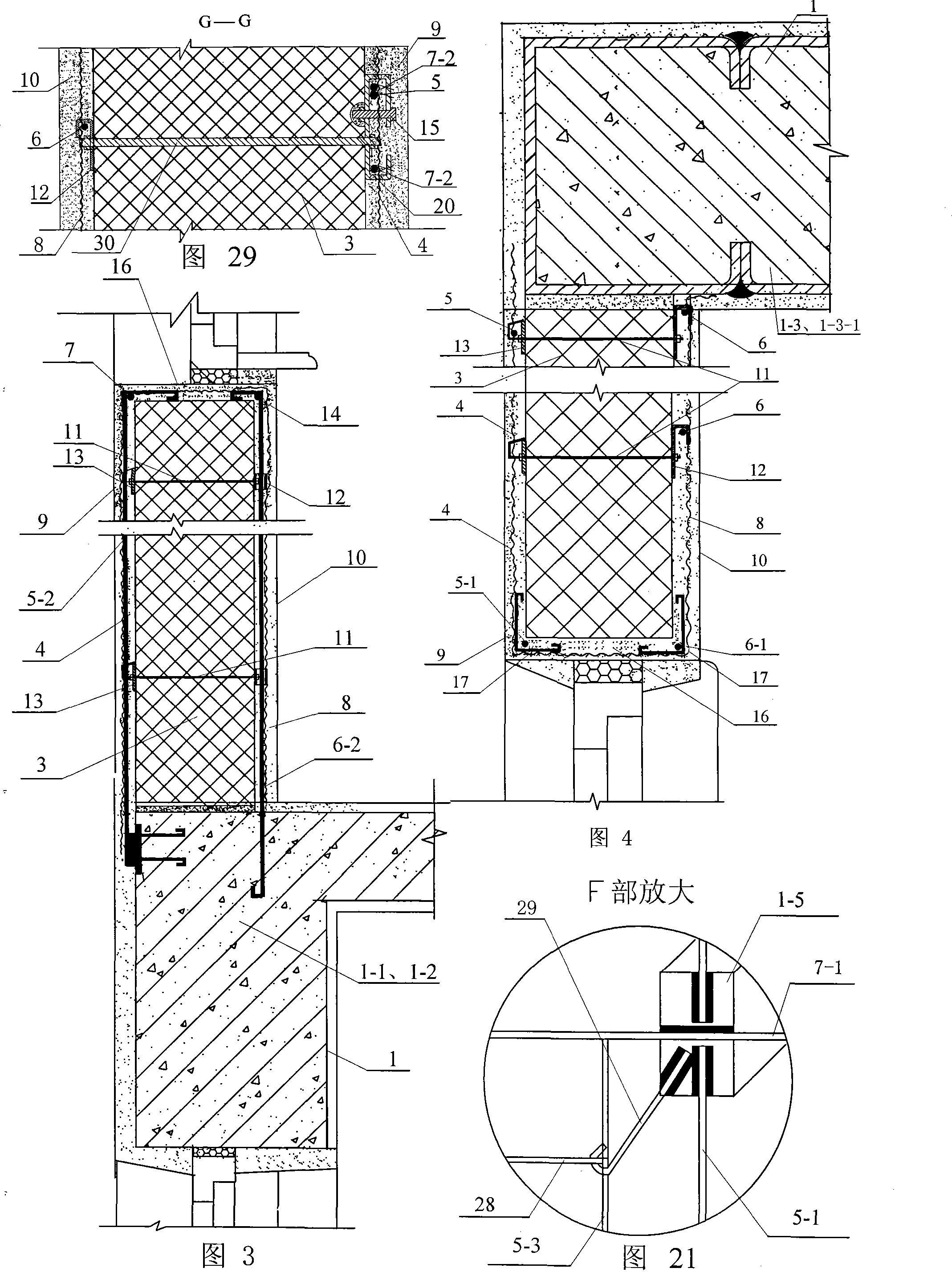

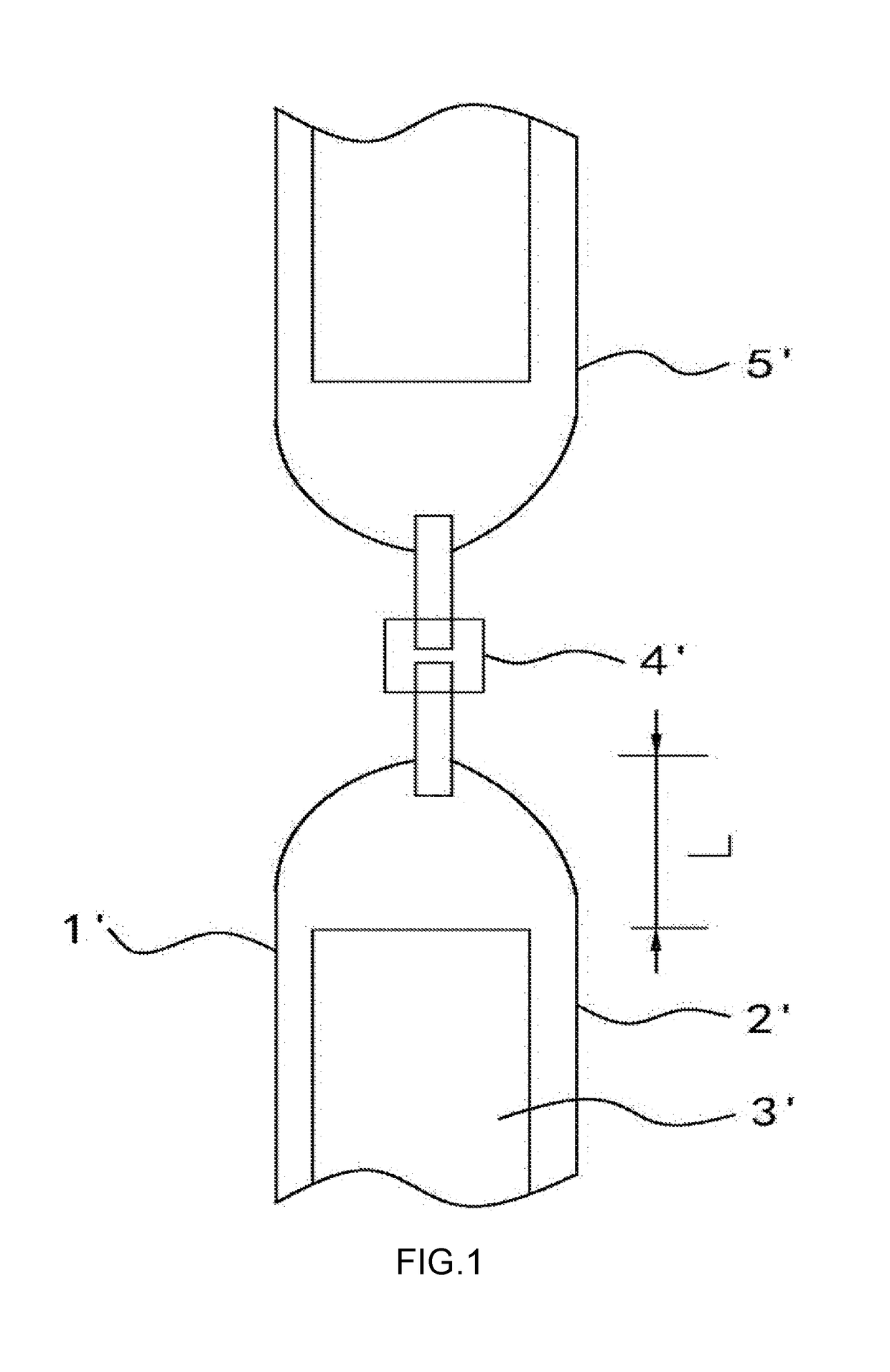

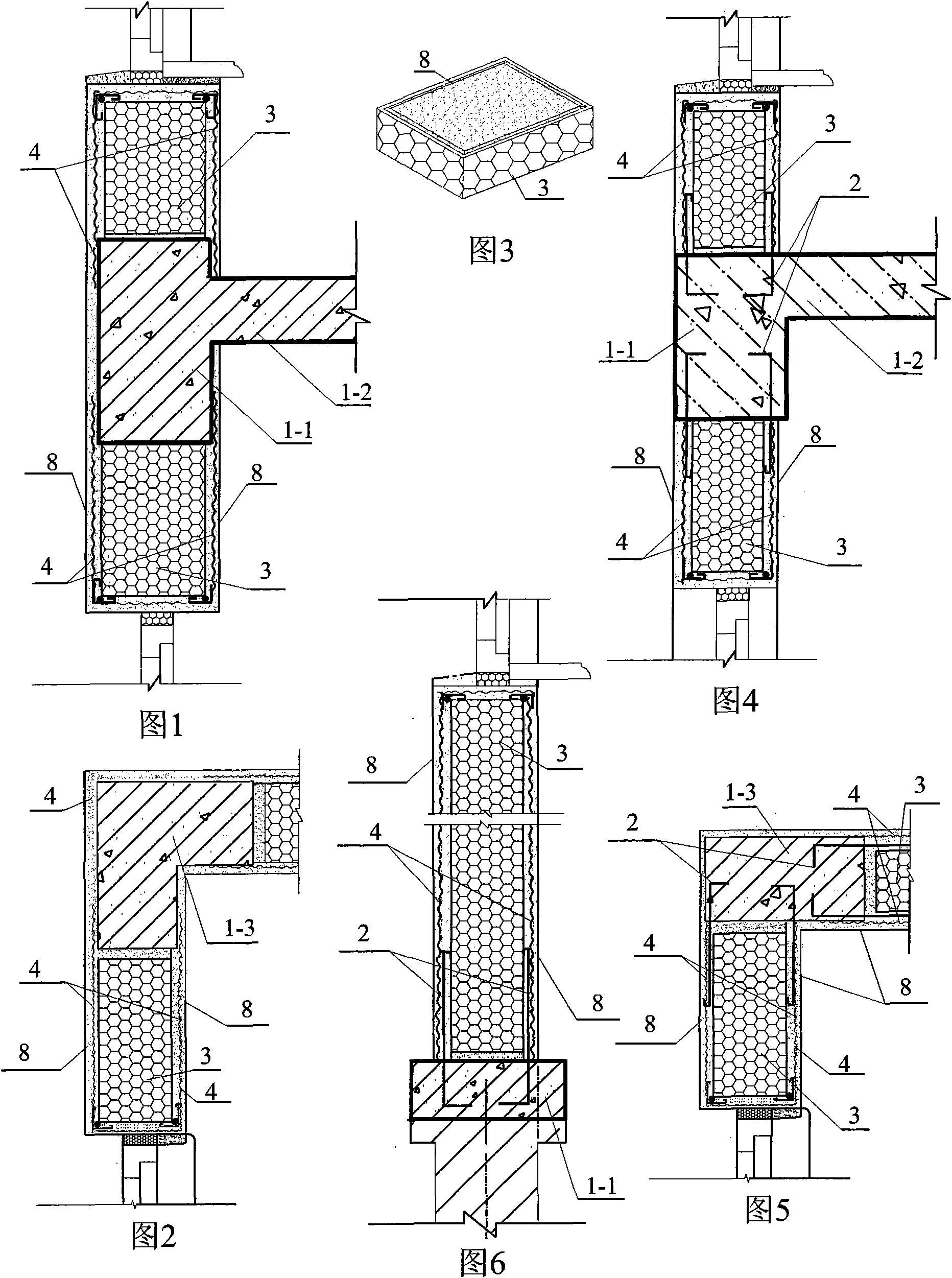

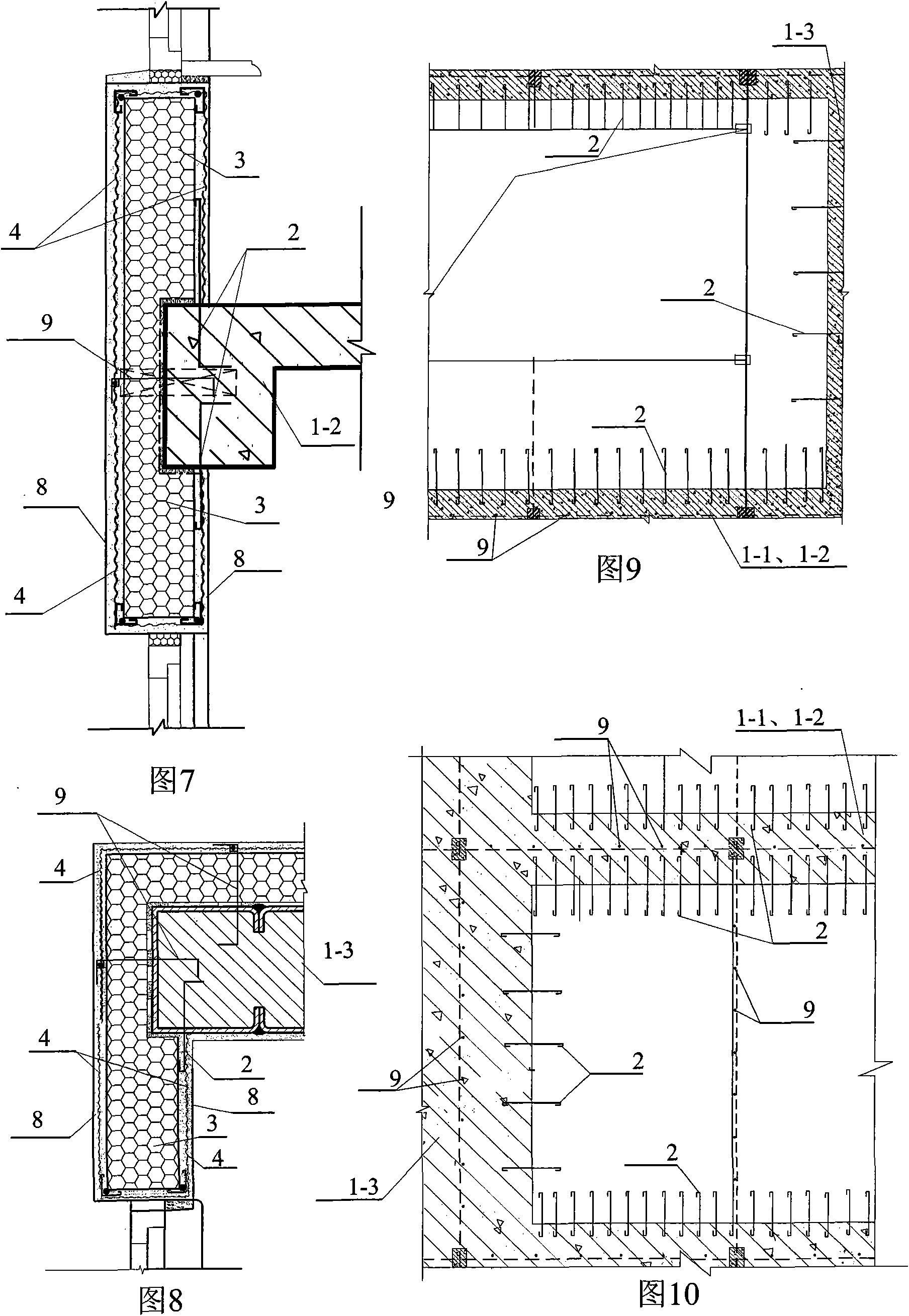

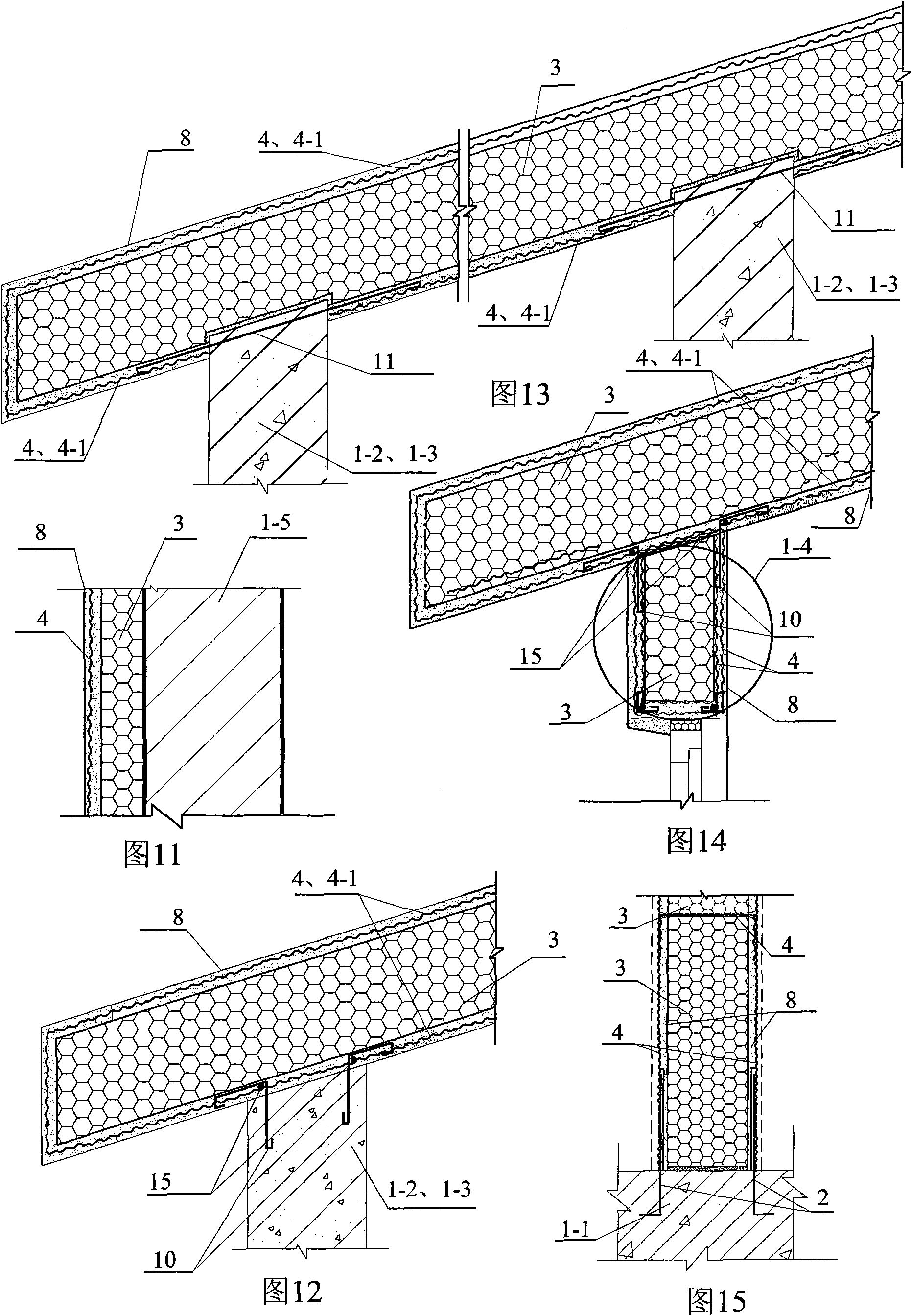

Composite component of alkaline-resisting mesh cloth plastering

InactiveCN101570981AReduce weightGood wind and shock resistanceRoof covering using slabs/sheetsStrutsMoisture barrierProtection layer

The invention relates to a composite component of alkaline-resisting mesh cloth plastering, relating to a building composite component and aiming at the problems of high construction cost, inconvenient construction and the like of the current energy-saving wall body. The structure one is as follows: a sandwich layer 3 is struck to the interior of a beam column frame of a load-carrying member 1; the interior and the exterior the sandwich layer 3 have cement mortar protective courses 8; an alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8 and is connected with the load-carrying member 1 in a sticking way. The structure two is as follows: the sandwich layer 3 is struck to a basic unit wall 1-5; the exterior of the sandwich layer 3 has the cement mortar protective courses 8; the alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8. The structure three is as follows: the sandwich layer 3 is positioned between the upper and lower cement mortar protective courses 8; the lower cement mortar protective course 8 is positioned on a building major structure 1; the upper protective course 8 covers the sandwich layer 3; the alkaline-resisting mesh cloth 4 is embedded in the interior of the protective courses 8. The method of construction is as follows: an interface agent is painted on the sandwich layer or cement mortar to stick the alkaline-resisting mesh cloth 4; when the interface agent is damp, the cement mortar ash is carried out; the glass is used as a waterproof and dampproof moisture barrier; a caking agent is struck to the surface of a structural cement to serve as the waterproof and dampproof moisture barrier. The method has the advantages of low construction cost, convenient construction, etc.

Owner:吴淑环

Chemical foaming cement building material prepared by utilizing light particles and preparation method thereof

The invention relates to a chemical foaming cement building material prepared by utilizing light particles and a preparation method of the cement building material. According to the chemical foaming cement building material, light particles, cement, coal ash, a foam stabilizer, fibers, a foaming agent, a gauging water, silicon powder and slag powder are used as raw materials; and three sets of foaming systems are adopted, that is to say, three foaming systems of quite stable light particle pre- foaming, physical foaming generated in a stirring process and cement chemical foaming with poor stability are combined, so that the foam breaking rate and the film collapse rate of the chemical foaming cement are greatly reduced. The chemical foaming cement building material has a more excellent insulating performance compared with independent chemical foaming cement, meanwhile, the application prospect of the light particles is expanded, and the pollution problem caused by partial industrial waste light particles is solved.

Owner:北京鸿锐嘉科技发展有限公司

Desulfurization gypsum-based thermal insulation mortar and preparation method thereof

The invention relates to a desulfurization gypsum-based thermal insulation mortar and a preparation method of the mortar, belonging to the technical fields of solid waste comprehensive utilization and building material. The desulfurization gypsum-based thermal insulation mortar comprises the components in parts by weight: 1000 parts of desulfurization gypsum, 3-10 parts of white cement, 350-450 parts of glass beads, 5-15 parts of redispersible latex powder, 1-5 parts of wood fiber, 5-25 parts of sepiolite fiber, 1.5-5 parts of polypropylene (PP) fiber, 1-8 parts of polyvinyl alcohol, 1-5 parts of hydrophobic agent, 0.4-3 parts of retarder, 1-5 parts of water reducing agent and 2-6 parts of thickening agent. The desulfurization gypsum-based thermal insulation mortar is convenient to transport and has very strong thermal insulation performance and fireproof performance.

Owner:上海复培新材料科技有限公司

Elastic thin layer thermal insulation coat

ActiveCN1919945ADelayed reflective decayGood stain resistanceFireproof paintsHeat proofingThermal insulationEmulsion

The invention discloses an elastic thin-layer insulating coating layer on the base of building wall or metal surface, which comprises the following parts: base, middle layer, surface layer and protective layer, wherein the base is epoxy zinc-rich paint, which is hydraulic sealed paint; the protective layer is transparent dirt-proof aging-tolerance liquid; the middle layer contains elastic emulsion of film acroleic acid, hollow filler of modified insulating silicate, solar reflecting dye; the surface layer concludes elastic emulsion of membrane acroleic acid, infrared irradiation ceramic filler, hollow filler of modified insulating silicate, solar reflecting dye, which coordinate.

Owner:江苏晨光涂料有限公司

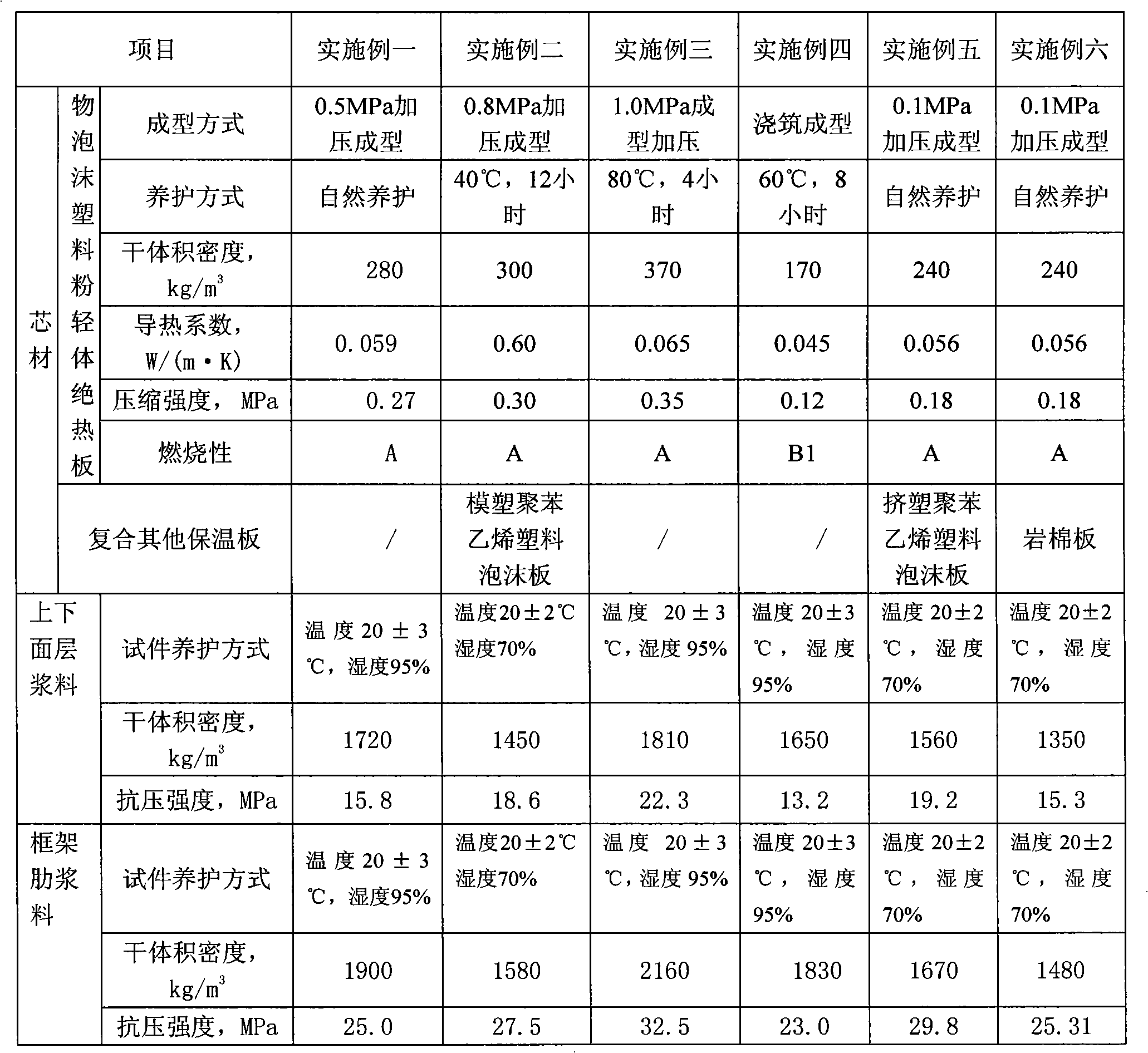

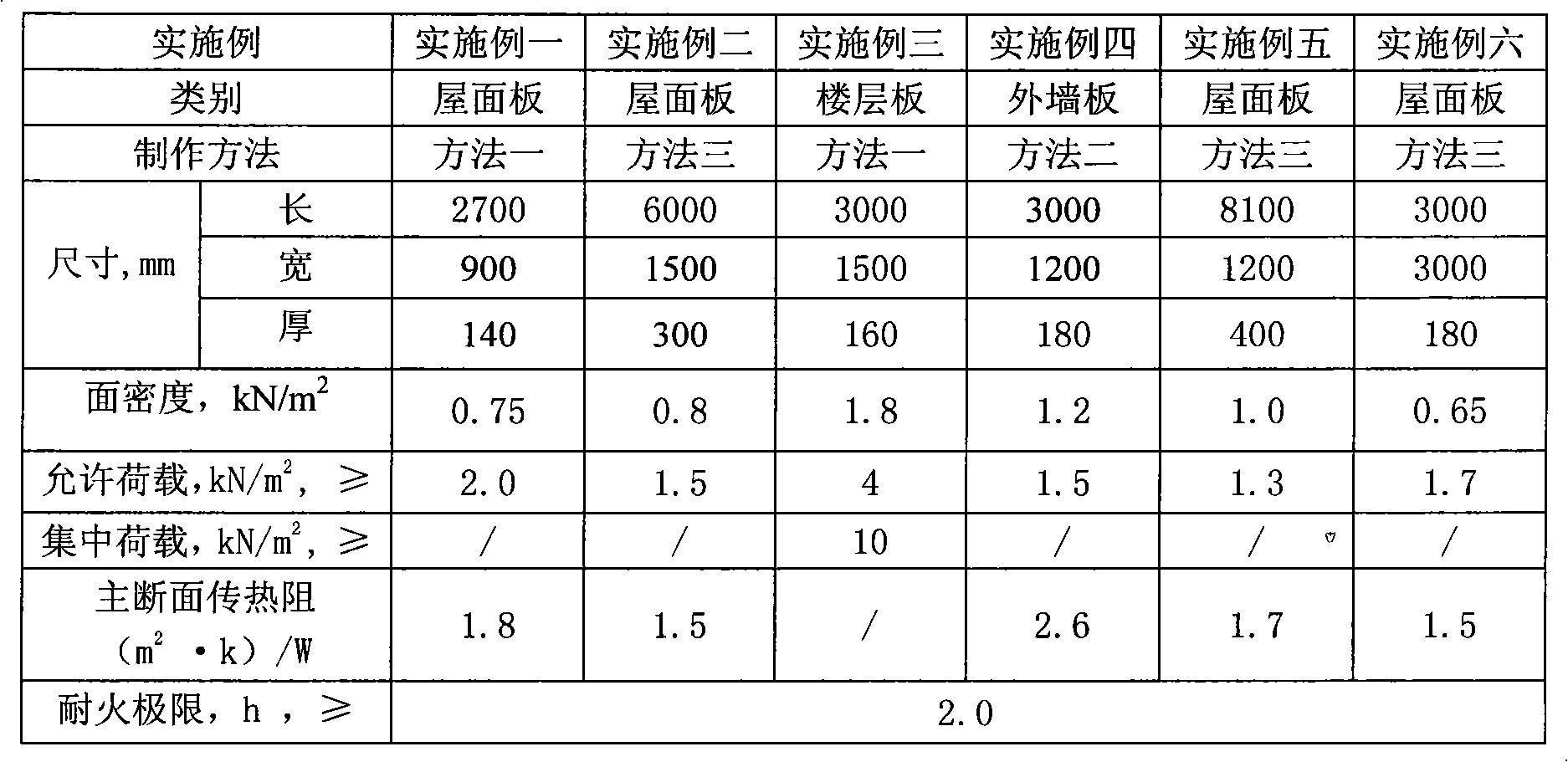

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

Diatom ooze environment-friendly decorating material

The invention relates to a diatom ooze environment-friendly decorating material, belonging to the technical field of building materials. The diatom ooze environment-friendly decorating material is composed of the following components in parts by weight: 4-90 parts of kieselguhr, 20-60 parts of bentonite, 10-40 parts of kaolin, 5-30 parts of atlapulgite, 10-60 parts of quartz sand, 5-40 parts of meerschaum, 5-40 parts of calcium carbonate, 5-30 parts of medical stone powder, 2-20 parts of nano titanium dioxide powder, 0.1-1.5 parts of wood fiber, 0.3-1.5 parts of chopped fiber, 4.5-40 parts of attapulgite, 2-20 parts of hydroxypropyl methylcellulose and 1-20 parts of inorganic pigment. The diatom ooze environment-friendly decorating material can purify air and eliminate peculiar smell, has the advantages of fire resistance, flame retardant, humidity regulation, noise absorption and reduction and heat insulation, and can release negative oxygen ions.

Owner:沈承舟

Aerated brick

The invention discloses an aerated brick. The aerated brick is prepared from the following raw materials by the conventional process for preparing the aerated brick: 30 to 35 weight parts of iron ore tailing, 5 to 10 weight parts of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano powder, 5 to 10 weight parts of broken glass powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.002 to 0.008 weight part of Chinese honey locust powder, 0.03 to 0.08 weight part of tea seed cake powder, 0.003 to 0.005 weight part of soda ash, 0.5 to 0.8 weight part of calcium stearate, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of calcium chloride, 0.05 to 0.1 weight part of white emulsion and an appropriate amount of water. By adding nano mineral powder, the volume weight of the brick, and the energy consumption are reduced; the brick is high in thermal insulation performance and sound insulation performance; and compared with the conventional aerated brick, the aerated brick has the advantage that the thermal insulation performance and the sound insulation performance are improved obviously. Meanwhile, the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com