Thermal insulation mortar

A technology of thermal insulation mortar and mortar, which is applied in the field of construction engineering, can solve the problems of poor frost resistance, low strength, and long construction period, and achieve the effects of good thermal insulation performance, good volume stability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

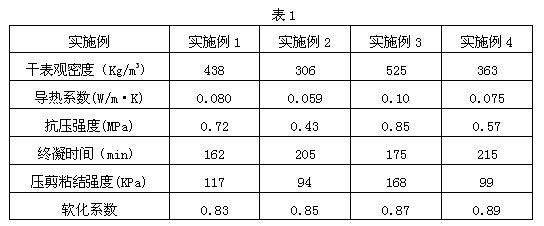

Examples

Embodiment 1

[0023] Example 1: The components of the thermal insulation mortar in this example and their percentages by weight are: 38% of bischofite partial pyrolysis light-burned magnesia, 12.0% of dry fly ash, 14.3% of coagulation regulator, enhanced thickening 9.6% additive, 4.8% diatomite, 14.3% closed-cell expanded perlite, 1.9% polystyrene foam particles, 0.1% polypropylene fiber, 4.0% water-resistant admixture, and 1.0% water-reducing agent;

[0024] Among them: the coagulation regulator is anhydrous magnesium chloride, the reinforcing thickener is magnesium carbonate, the diatomite is the original diatomite powder, the water-resistant additive is sodium metaphosphate, and the water reducing agent is commercially available calcium lignosulfonate; The particle size of styrene foam particles is 0.5mm~5.0mm; the length of polypropylene fiber is 3mm~20mm, and the diameter is 10um~50um;

[0025] Preparation method: weigh each component according to the above weight percentage, fully mix...

Embodiment 2

[0027] Example 2: The components of the thermal insulation mortar in this example and their weight percentages are: bischofite-pyrolytic method light-burned magnesium oxide 20.0%, dry fly ash 24.9%, coagulation regulator 5.0%, enhanced thickening 12.0% additive, 2.0% diatomaceous earth, 34.9% open-cell expanded perlite, 0.45% polystyrene foam particles, 0.05% polypropylene fiber, 0.5% water-resistant admixture, and 0.2% water-reducing agent;

[0028] Among them: the coagulation agent is anhydrous magnesium sulfate, the thickening agent is magnesium silicate, the diatomite is calcined diatomite powder, and the anti-water additive is sodium dihydrogen phosphate and ferrous sulfate according to the ratio of 1:4 (weight). The water reducer is a naphthalene-based high-efficiency water reducer; the particle size of polystyrene foam particles is 0.5mm to 5.0mm; the length of polypropylene fibers is 3mm to 20mm, and the diameter is 10um to 50um;

[0029] The method of preparation and ...

Embodiment 3

[0030] Example 3: The components of the thermal insulation mortar in this example and their weight percentages are: 33.6% of calcined magnesite light-burned magnesia, 9.6% of dry fly ash, 24.0% of coagulation regulator, and 19.2% of reinforcing thickener , diatomite 1.9%, closed-cell expanded vermiculite 5.0%, polystyrene foam particles 1.9%, polypropylene fiber 0.2%, water-resistant admixture 2.7%, water-reducing agent 1.9%;

[0031] Among them: the coagulation agent is a mixture of magnesium chloride hexahydrate and anhydrous magnesium sulfate at a ratio of 1:1 (by weight), the reinforcing thickener is a mixture of magnesium carbonate and magnesium silicate at a ratio of 1:2 (by weight), and diatomaceous earth is calcined Diatomaceous earth powder, the anti-water additive is a mixture of calcium phosphate, gypsum and silica fume at a ratio of 1:2:4 (by weight), and the water reducing agent is calcium lignosulfonate and naphthalene-based high-efficiency water reducer at a rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com