Reactive powder concrete straddle track beam and precasting technological process thereof

A technology of active powder and technological process, applied in the field of traffic engineering, can solve the problems of increasing the number of rail beams and substructures, increasing the workload of supporting beams and other components, and increasing the project cost, achieving good volume stability and reducing bridge piers. Amount of base material, effect of reducing section size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

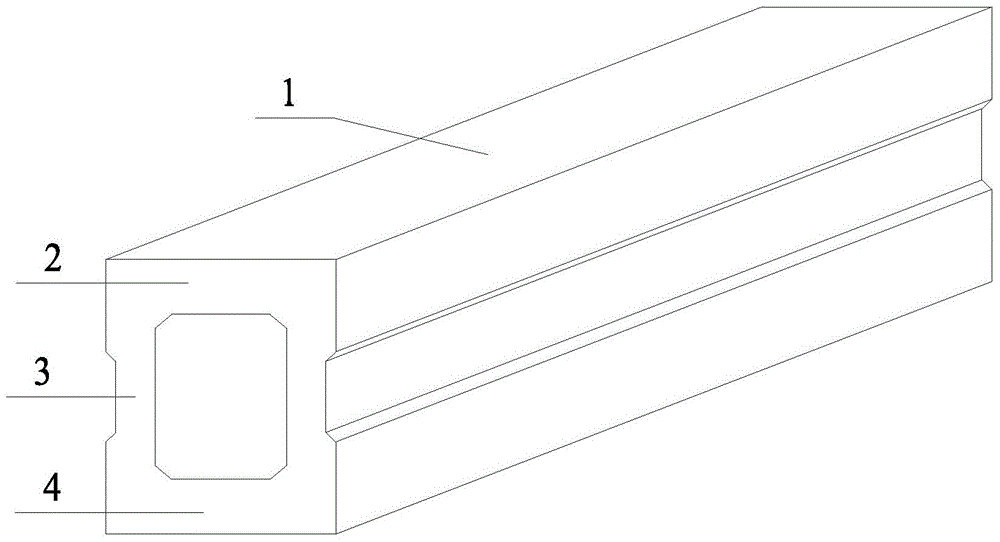

[0028] like figure 1 As shown, the structure of the straddle track beam of the present invention is similar to that of the prior art, including an integrally formed track beam main body 1, top plate 2, web 3 and bottom plate 4. The key point is that the straddle track beam of the present invention is made of RPC high The material is prefabricated, based on the elasticity of RPC high-strength materials, in reducing the cross-sectional size of the track beams and reducing the amount of basic materials sent, it also improves the structural strength, durability and stability.

[0029] In order to better implement the present invention, the prefabrication process flow of the active powder concrete straddling track beam is also disclosed, including the following steps:

[0030] S1. Prepare the prefabricated formwork to ensure the shape and siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com