Patents

Literature

106results about How to "Reduce lifting weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

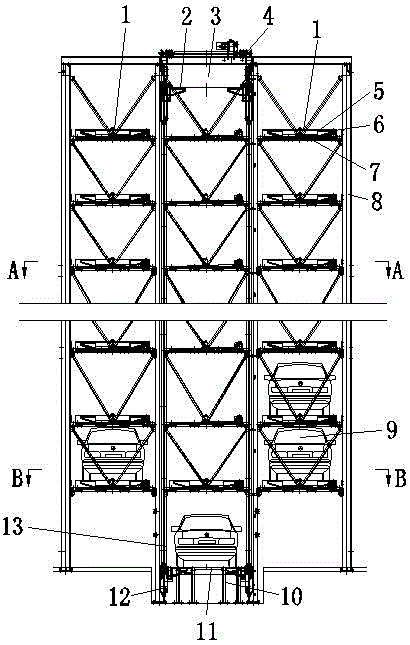

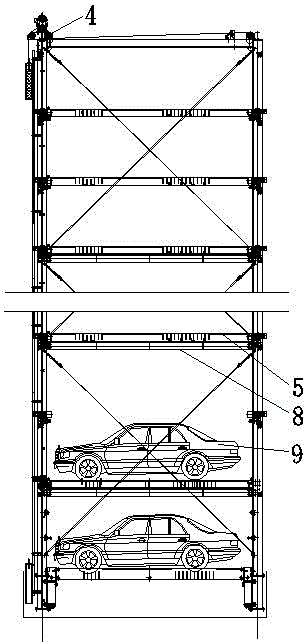

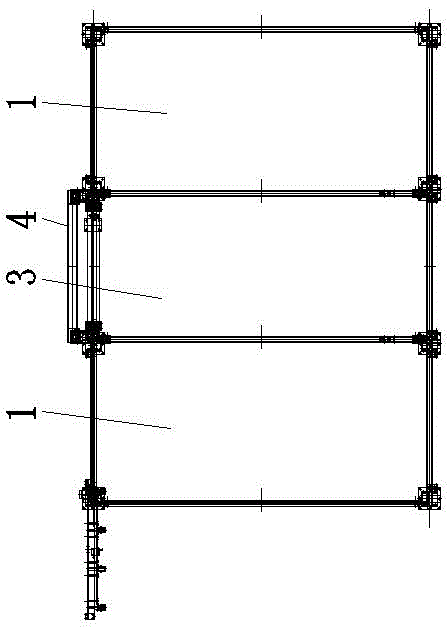

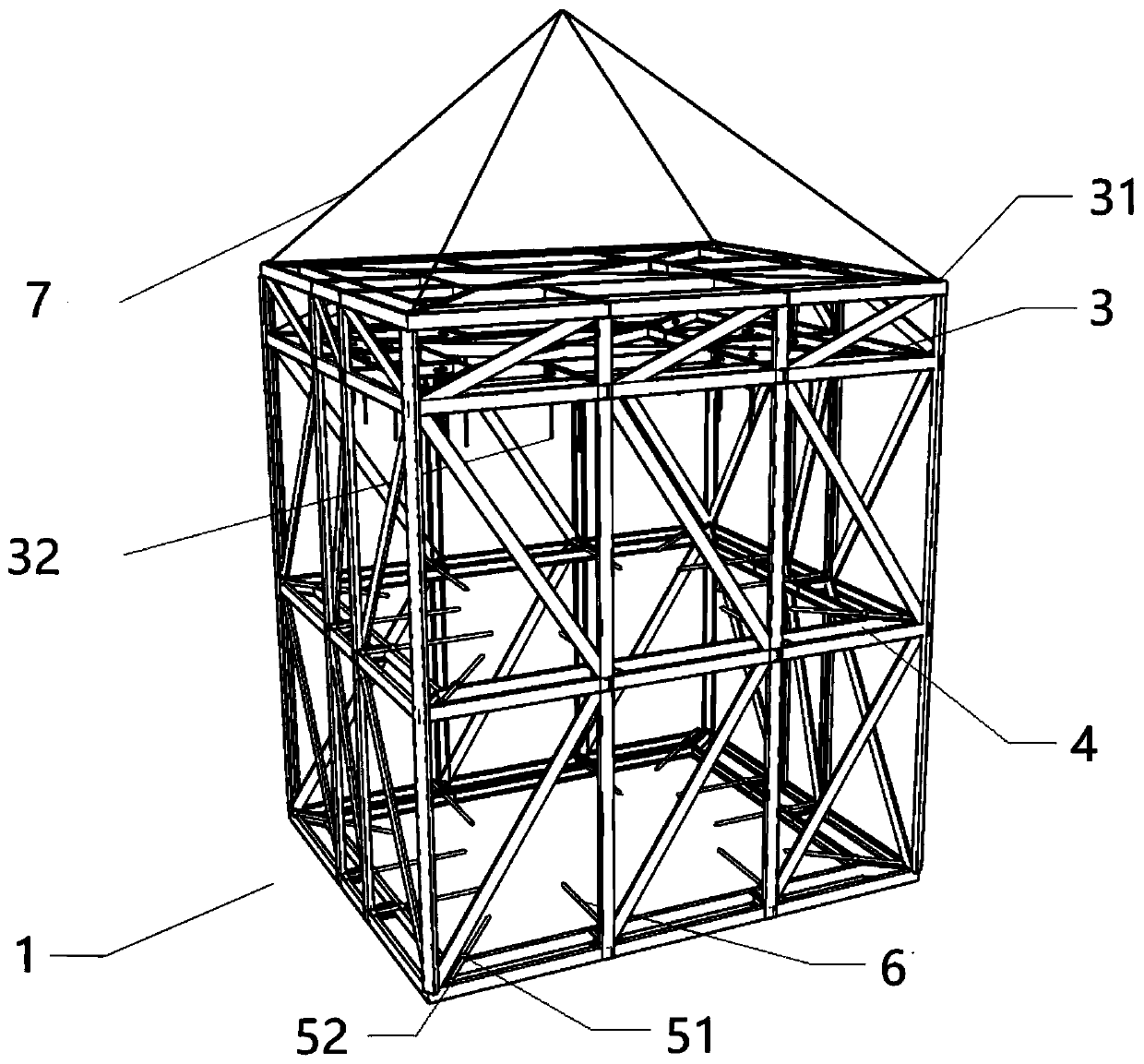

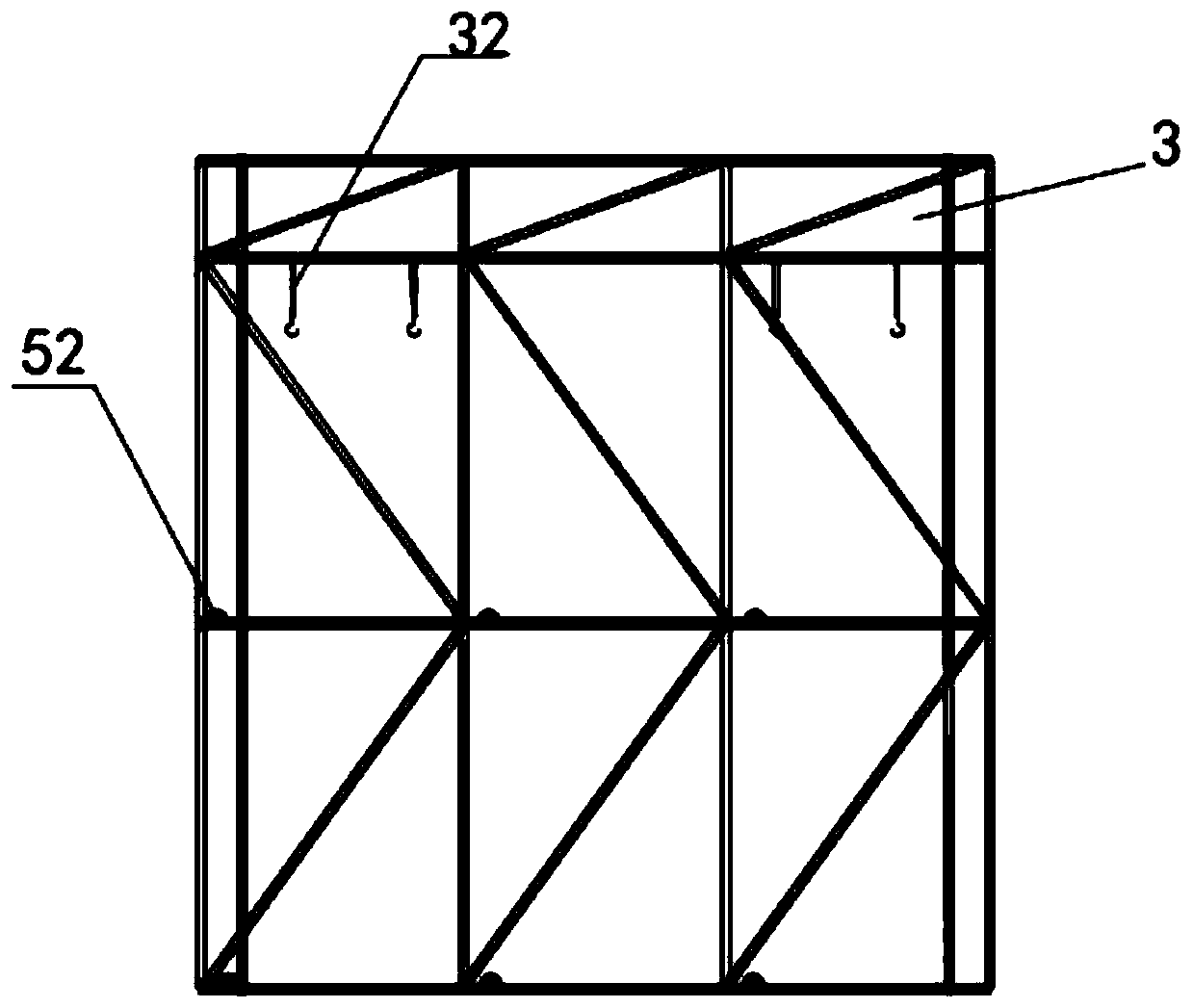

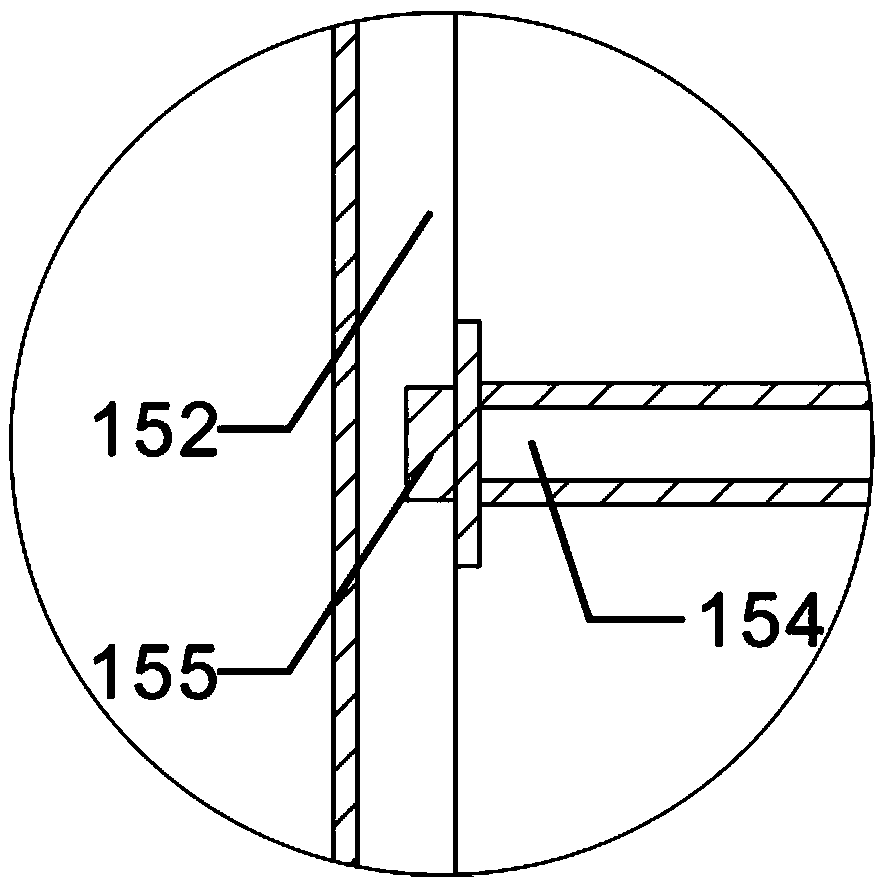

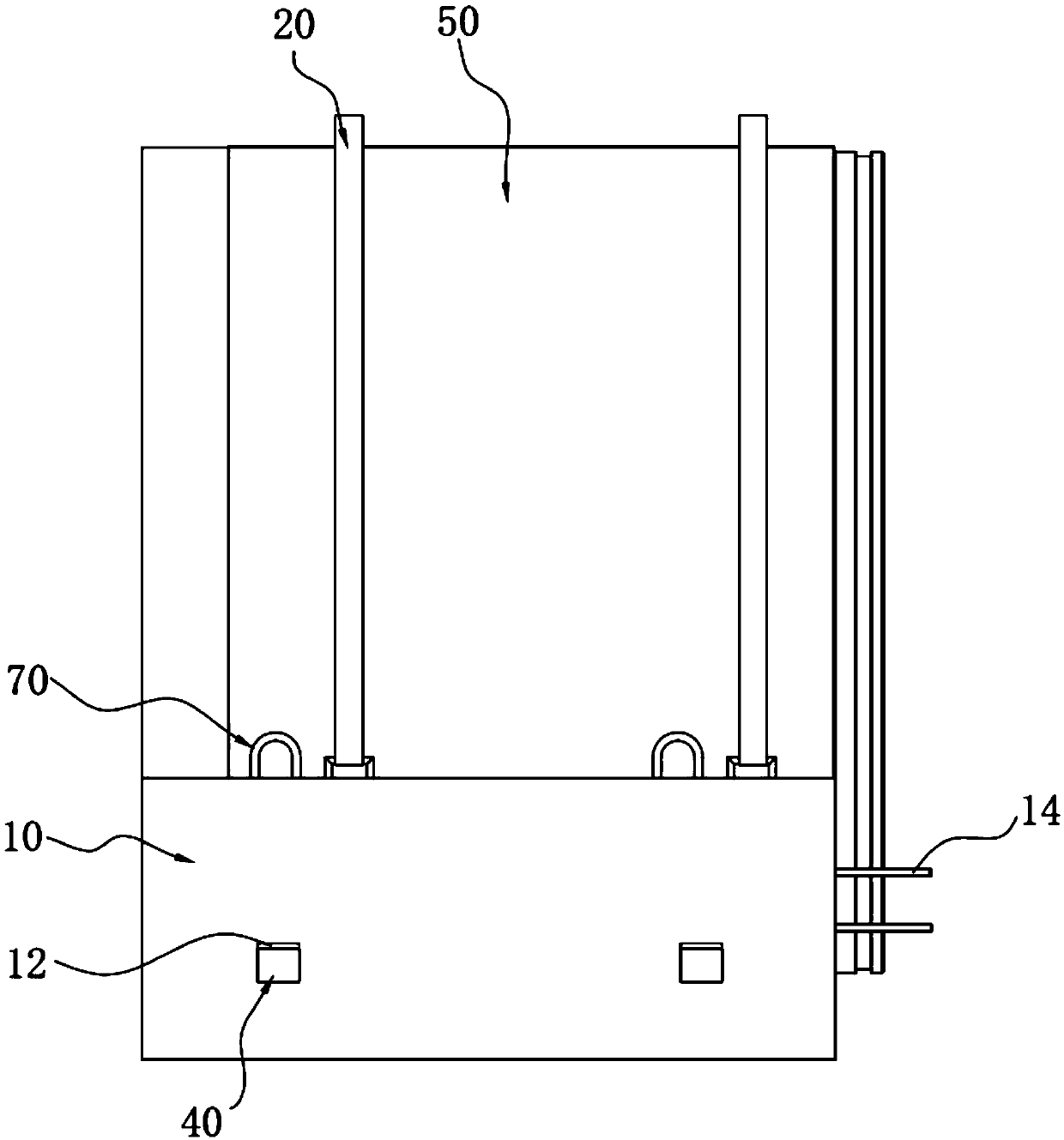

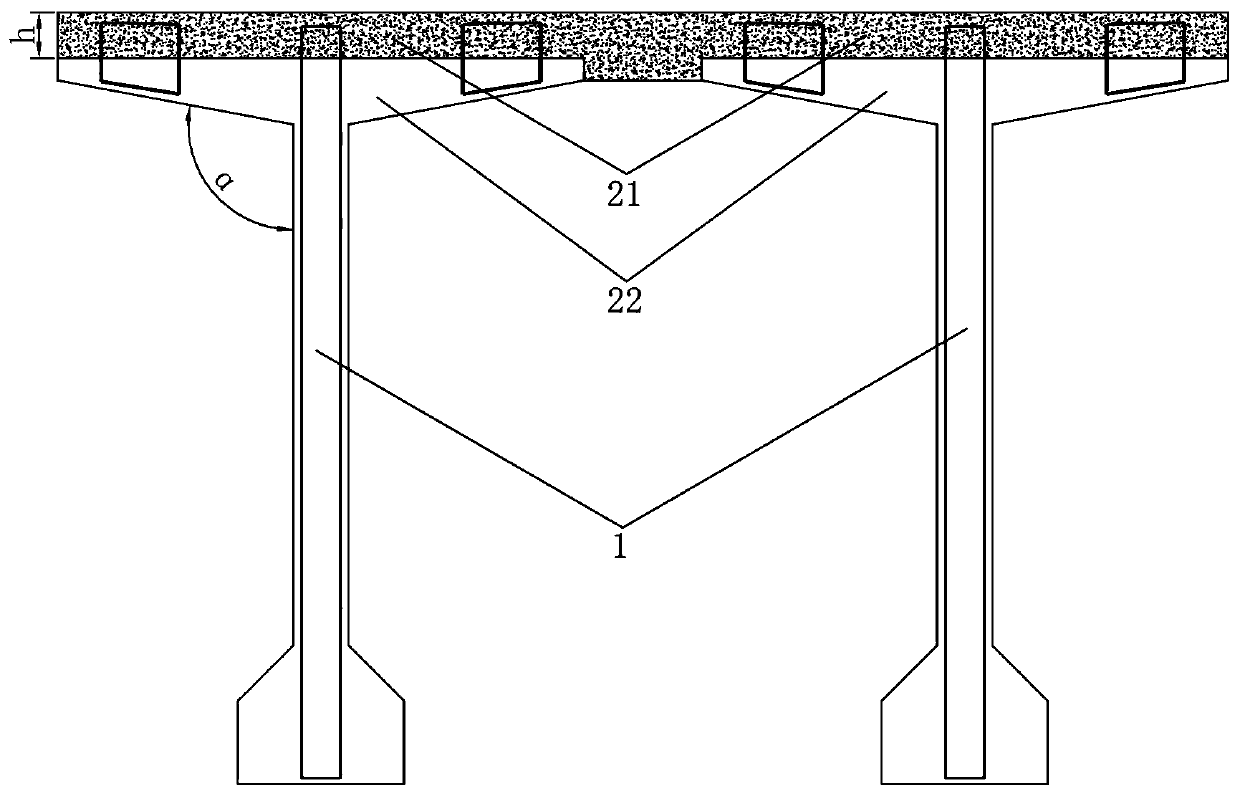

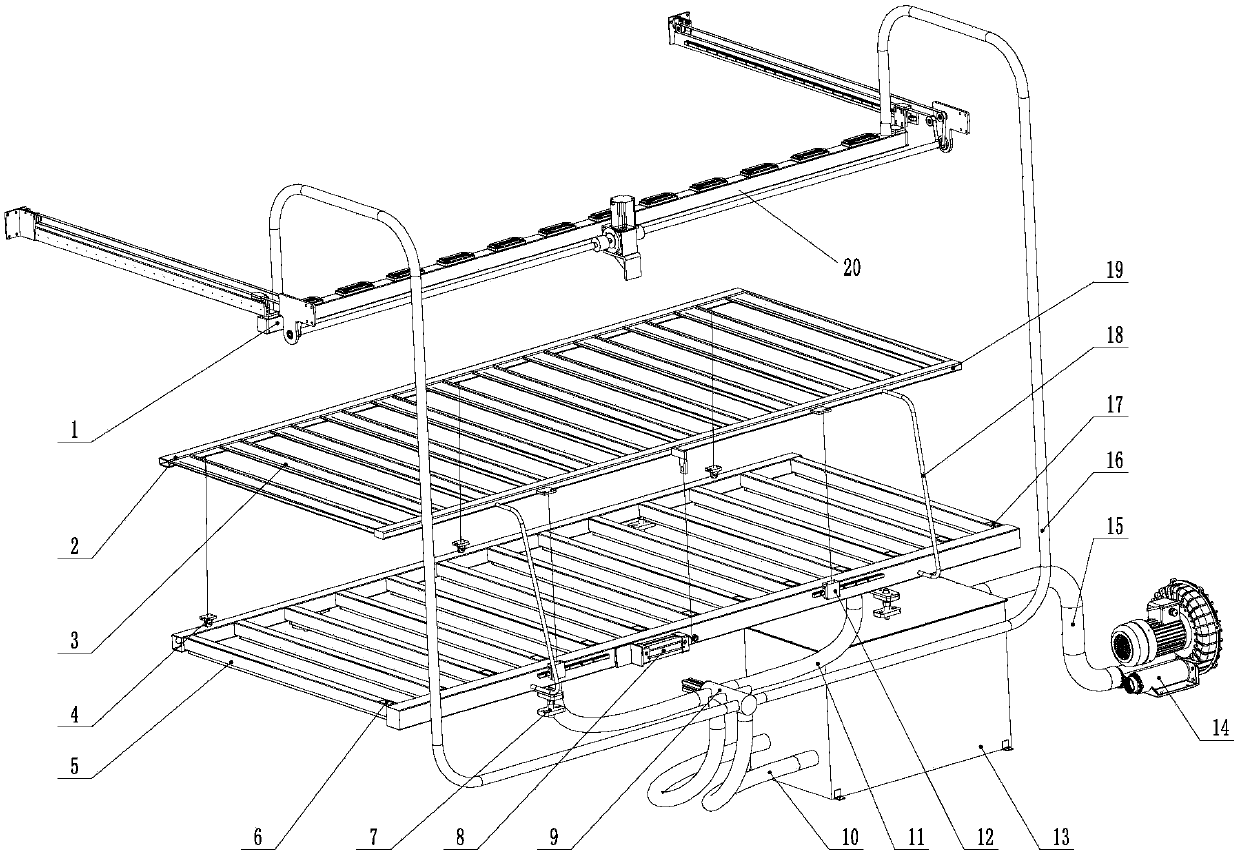

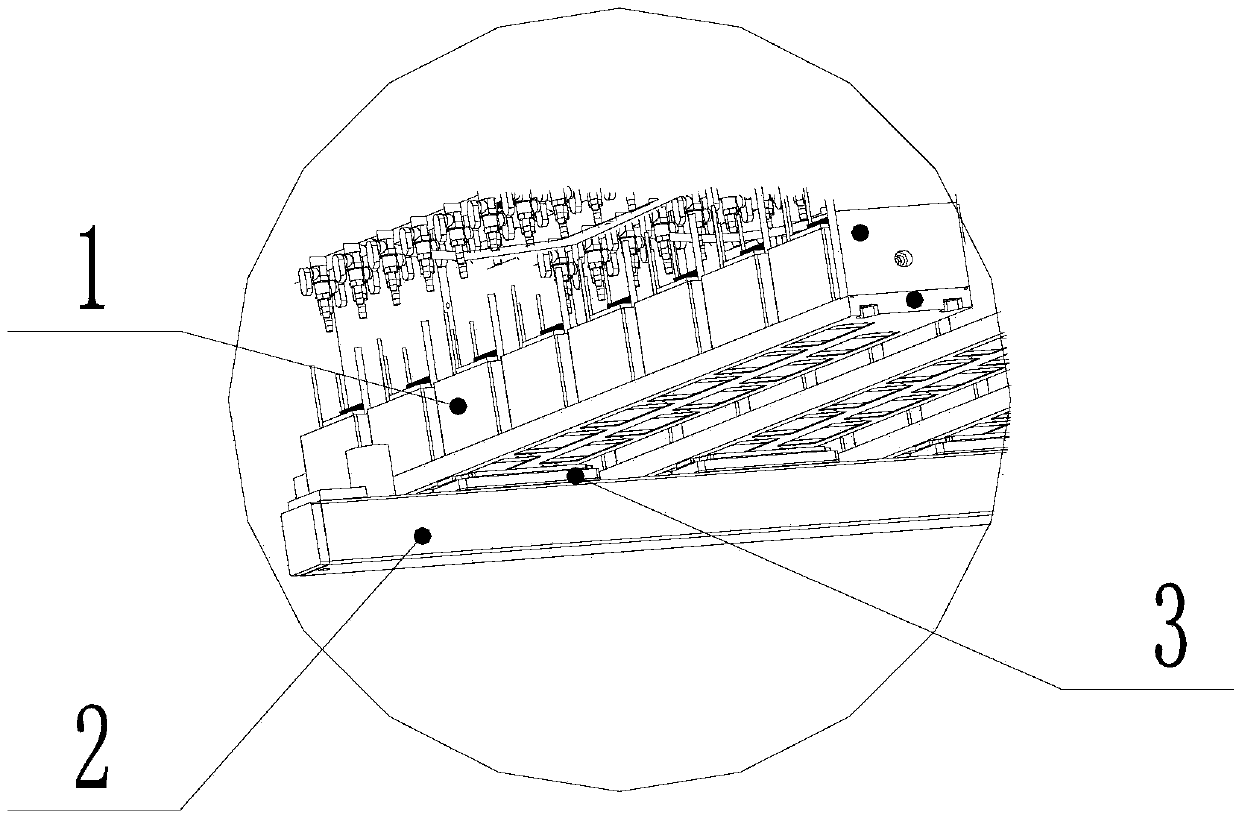

Comb tooth exchange type stereoscopic garage

The invention provides a comb tooth exchange type stereoscopic garage which comprises frame assemblies, lifting channels and vertical lifting devices. The vertical lifting devices are positioned in the lifting channels. The comb tooth exchange type stereoscopic garage has the advantages that when vehicles are accessed, only left lifting frames and right lifting frames in the vertical lifting devices need to ascend and descend without shifting vehicle carrying plates, so that the vehicles can ascend and descend, hoisting weights of hoisting mechanisms can be effectively reduced, and the hoisting stability and the hoisting safety can be improved; when running into the vehicle carrying plates, the vehicles are only in contact with the vehicle carrying plates, and the vehicle carrying plates are directly fixed onto the ground by the aid of support frameworks and are good in stability, so that the stability of the integral garage cannot be affected by movement of the vehicles; the left lifting frames, the right lifting frames, traverse tables and the vehicle carrying plates transfer the vehicles by the aid of comb tooth exchange structures, and accordingly the structure of the integral garage can be effectively simplified; the vehicles can enter the comb tooth exchange type stereoscopic garage and exit from the comb tooth exchange type stereoscopic garage conveniently and quickly, and accordingly the comb tooth exchange type stereoscopic garage is high in operation efficiency.

Owner:青岛齐星车库有限公司

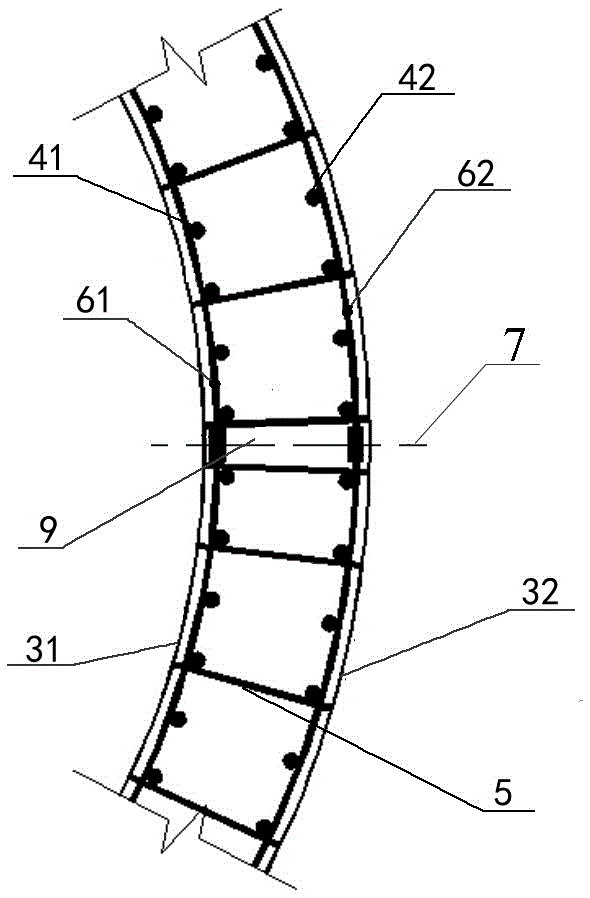

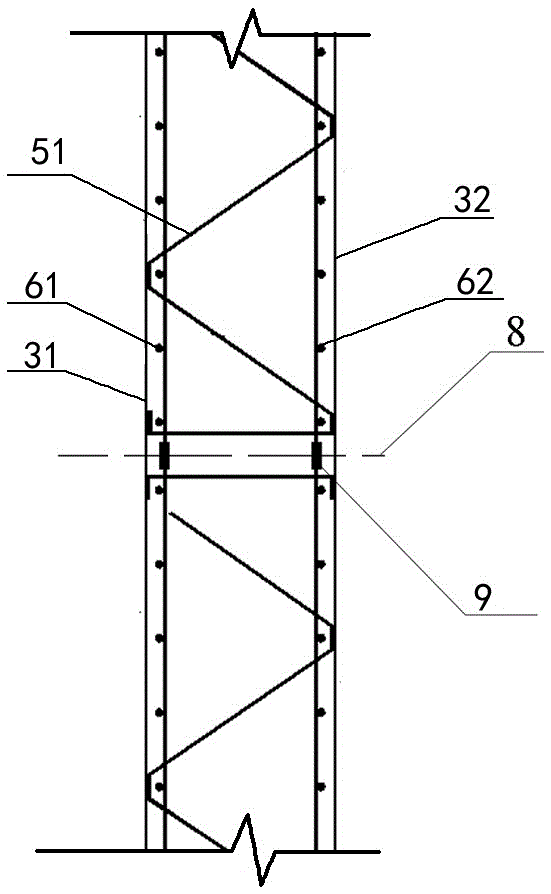

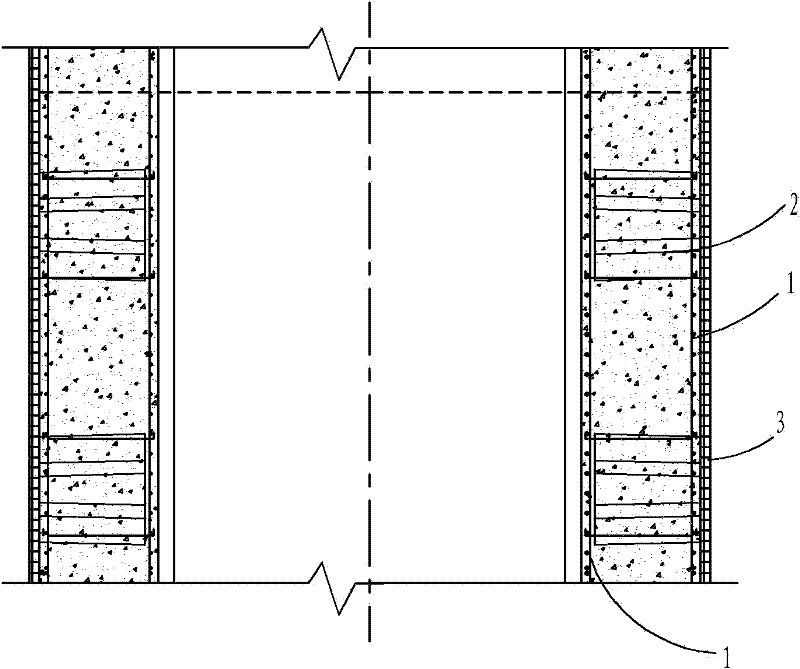

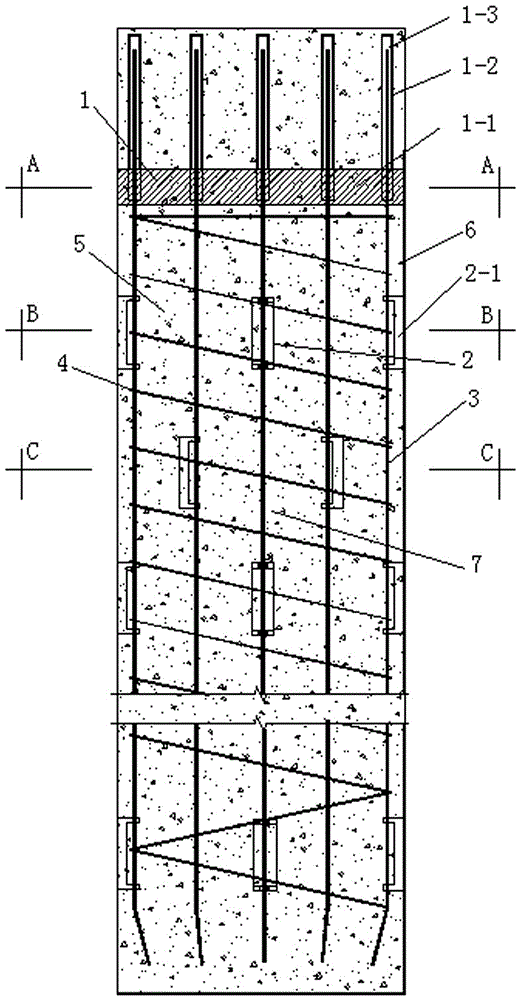

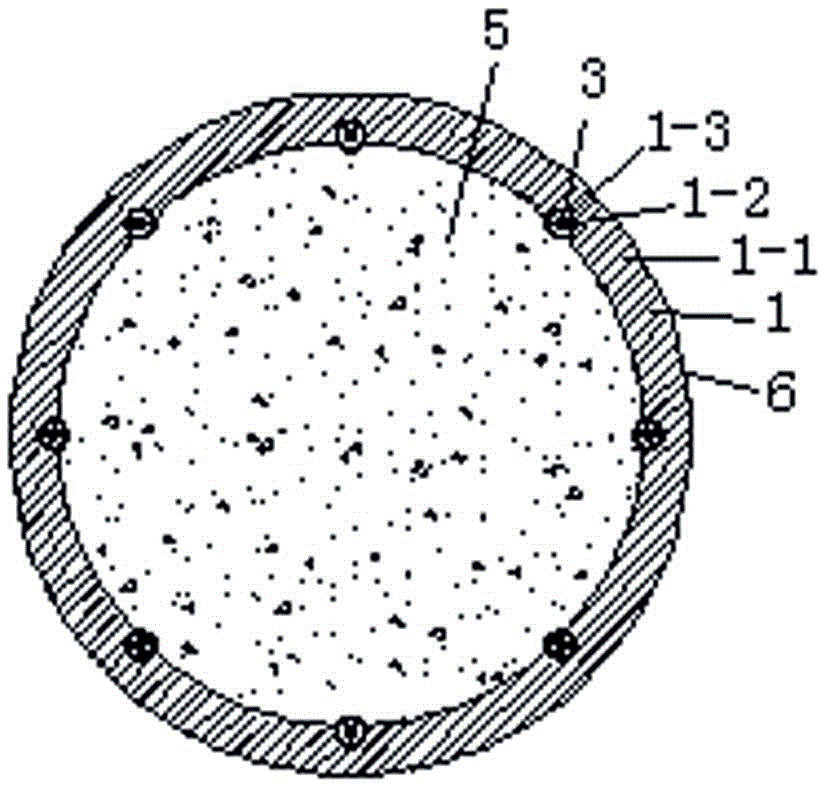

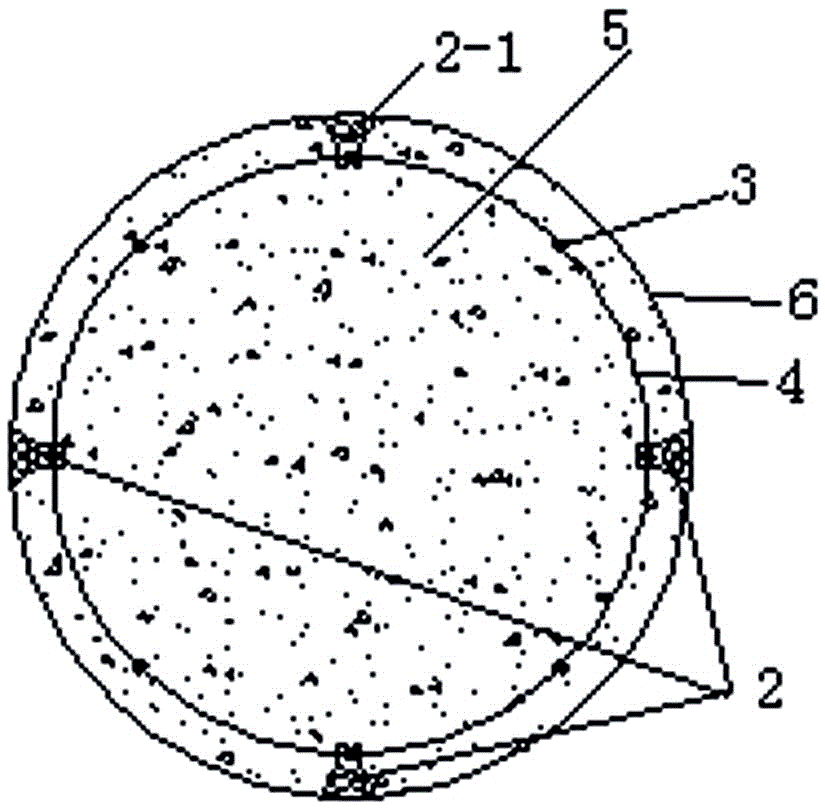

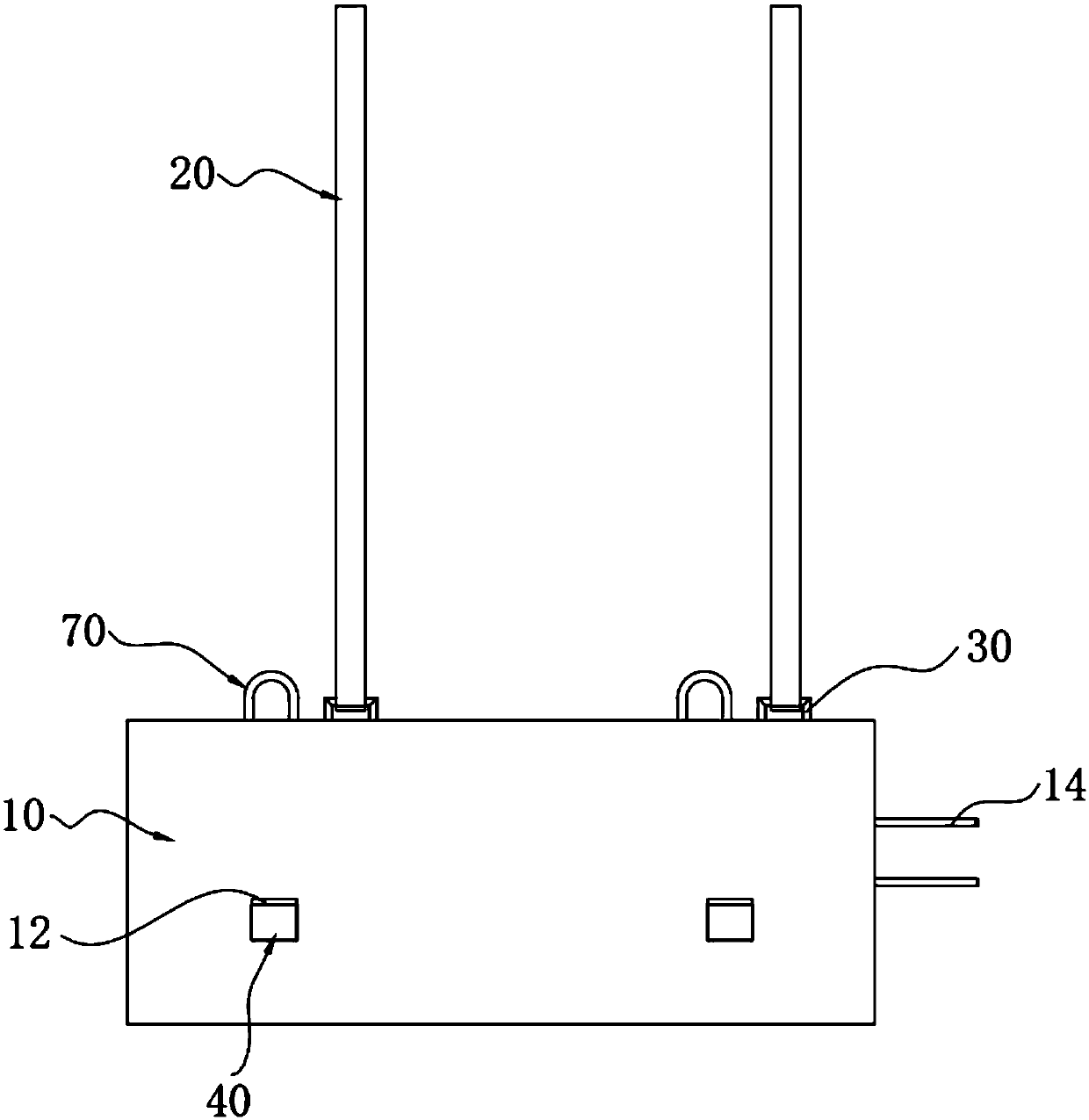

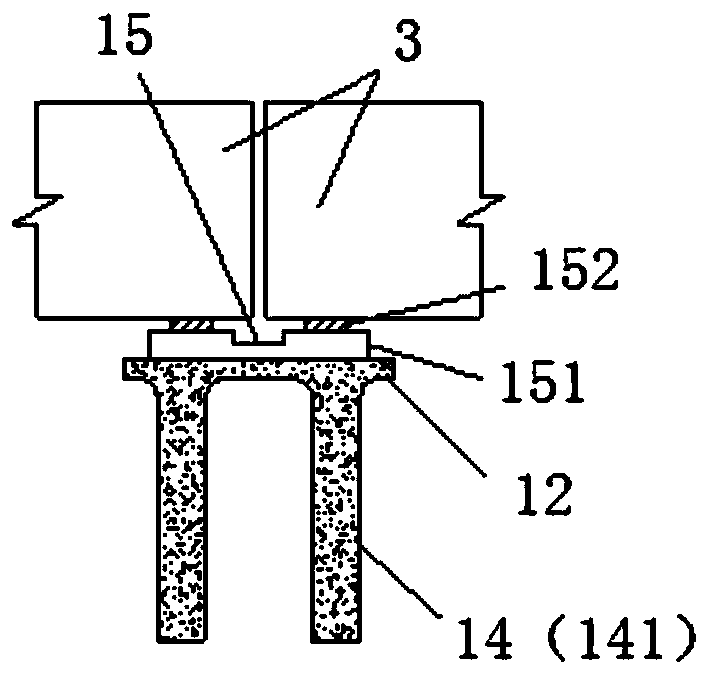

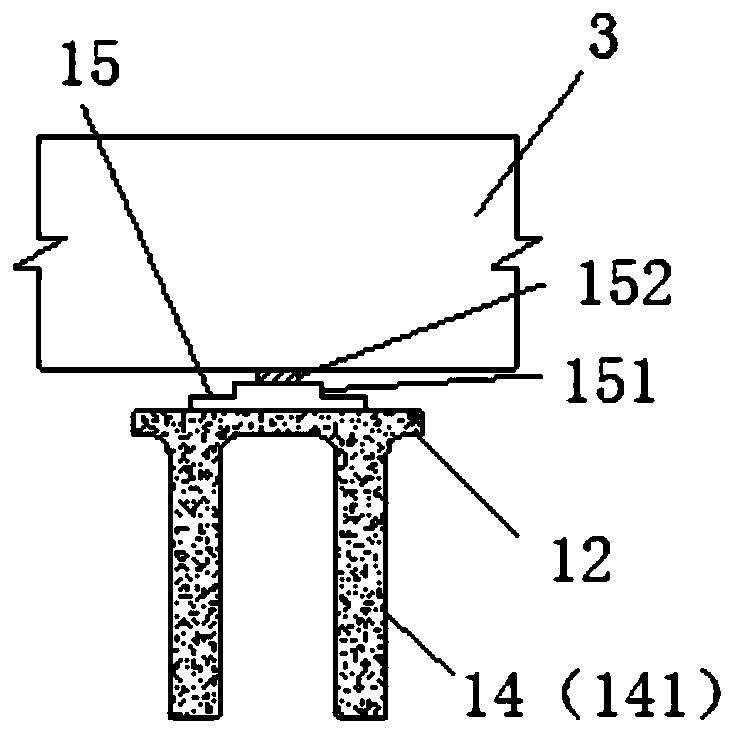

Cast-in-place concrete tower with prefabricated spatial steel bar truss formwork and construction method of cast-in-place concrete tower

ActiveCN106088780ASmall tonnageReduce lifting weightForms/shuttering/falseworksTowersHorizontal stressSUSPENDING VEHICLE

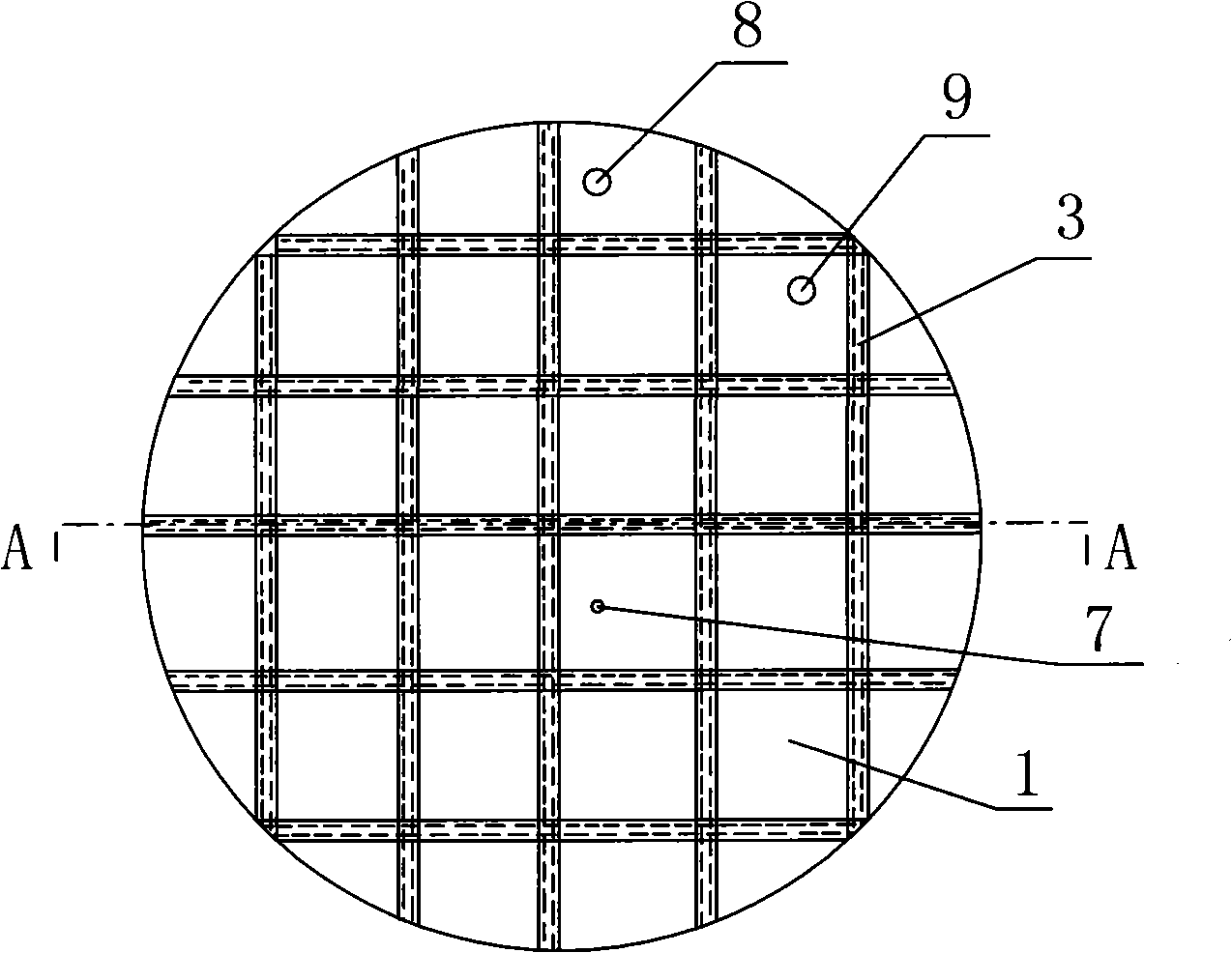

The invention discloses a cast-in-place concrete tower with a prefabricated spatial steel bar truss formwork and a construction method of the cast-in-place concrete tower. The cast-in-place concrete tower comprises the spatial steel bar truss formwork and concrete cast into the spatial steel bar truss formwork in place, and is characterized in that the spatial steel bar truss formwork is a disposable prefabricated formwork, is formed by splicing a plurality of spatial steel bar truss formwork units and is in a cylinder shape; each spatial steel bar truss formwork unit is of an arc-shaped sheet structure and comprises reinforcing bars in the middle and disposable steel formworks attached to the inner and outer sides of the reinforcing bars respectively, wherein the reinforcing bars comprise an inner layer of evenly-arranged vertical stressed steel bars, an outer layer of evenly-arranged vertical stressed steel bars, horizontal stressed steel bars used for tying the vertical stressed steel bars on the same layer, and tie stirrups arranged in a radial mode and used for tying the inner layer of vertical stressed steel bars, the outer layer of vertical stressed steel bars and the horizontal stressed steel bars at the same time. By adopting the technology, it is only needed to install the spatial steel bar truss formwork in a hoisting mode in site construction, the hoisting weight is greatly reduced, the needed crane tonnage is greatly reduced, and the construction cost is greatly reduced.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

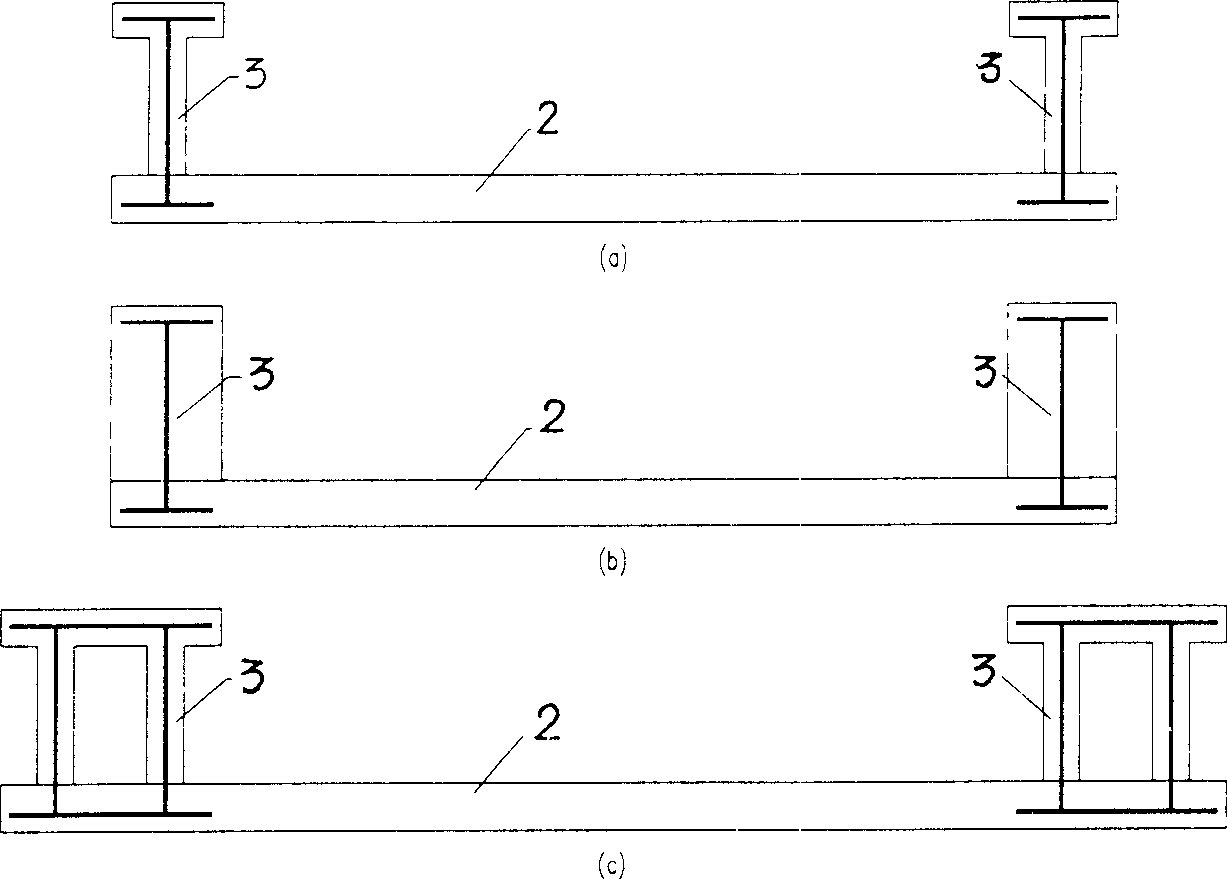

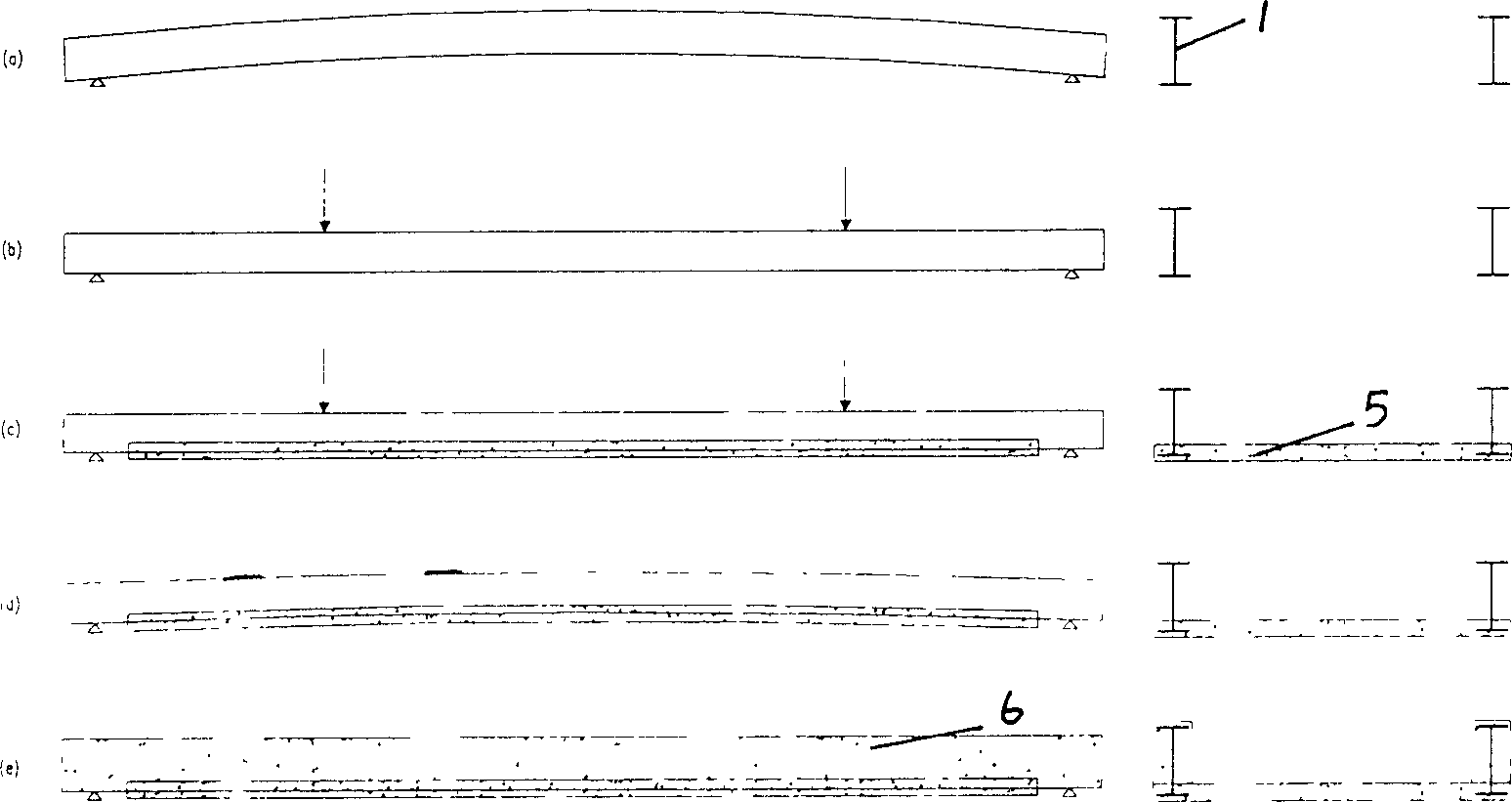

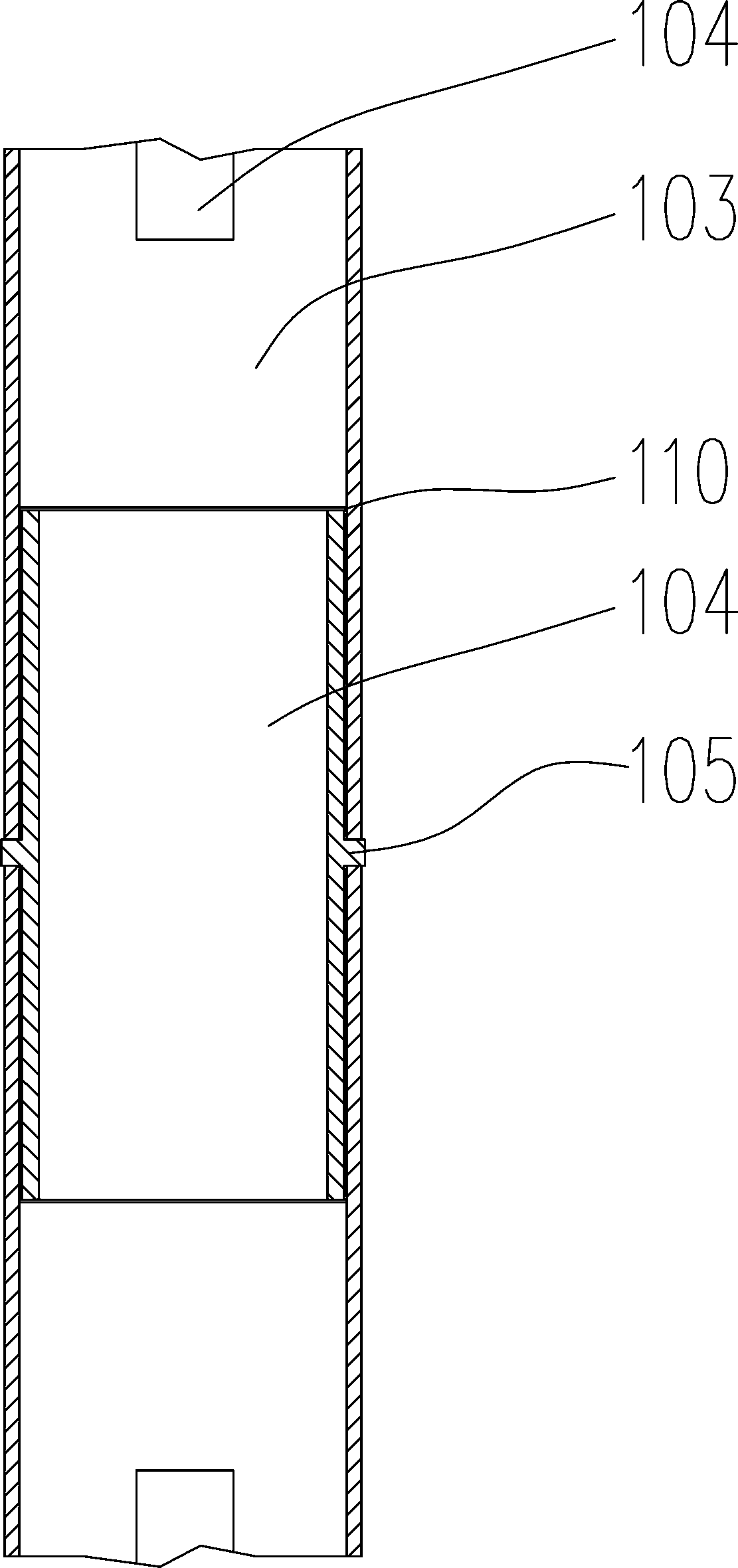

Preflex prestressed concrete channel beam and its making method

InactiveCN1730858AImprove fatigue resistanceImprove seismic performanceLoad-supporting elementsBuilding material handlingConcrete beamsPre stress

The present invention is one kind of pre-bent pre-stressed concrete channel beam and its making process, and features that the concrete beam in channel shape or U shape consists of bottom plate and two side web plates. The web plates are concrete coated steel beam with welded shear keys, and the web plate and the steel beam have I-shaped, rectangular or box cross section. The making process of the concrete channel beam includes the five steps of: making steel beam, pre-pressing the steel beam, depositing the first concrete layer, releasing pre-bending force, and depositing the second concrete layer. Compared with available technology, the present invention has the advantages of large span, low building height, easy construction, excellent fatigue and vibration resistance, etc. and is especially suitable for use in condition with limited building height.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

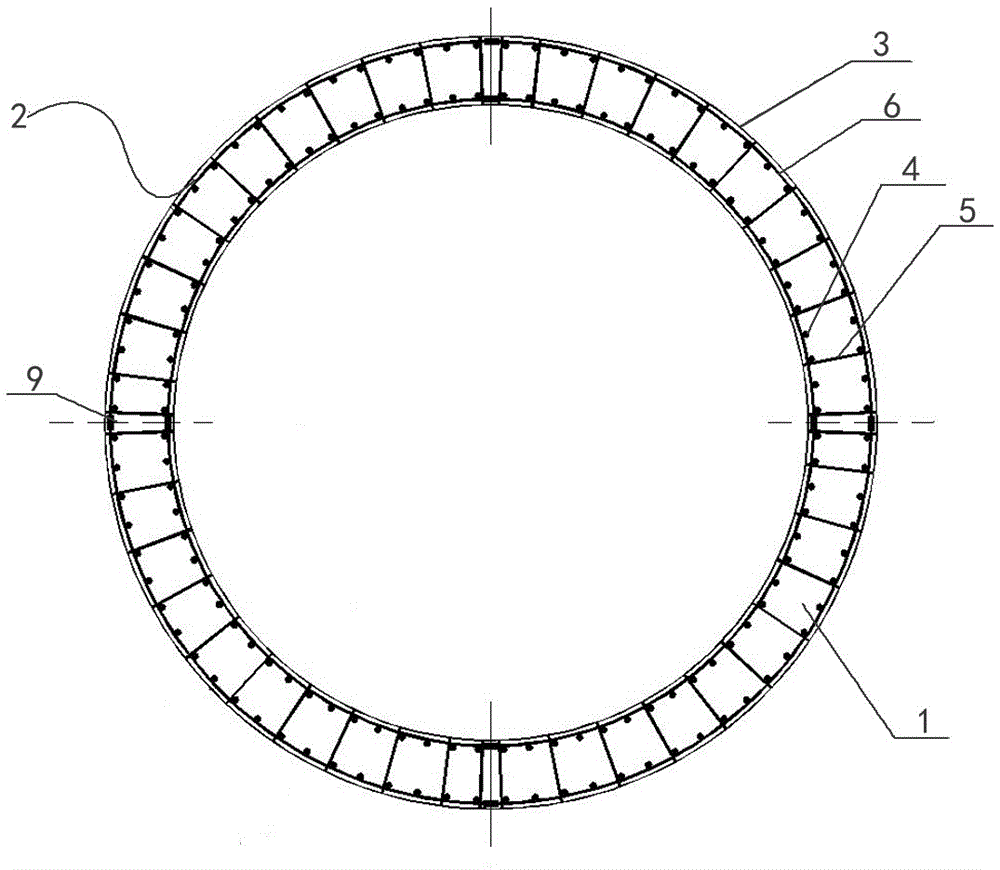

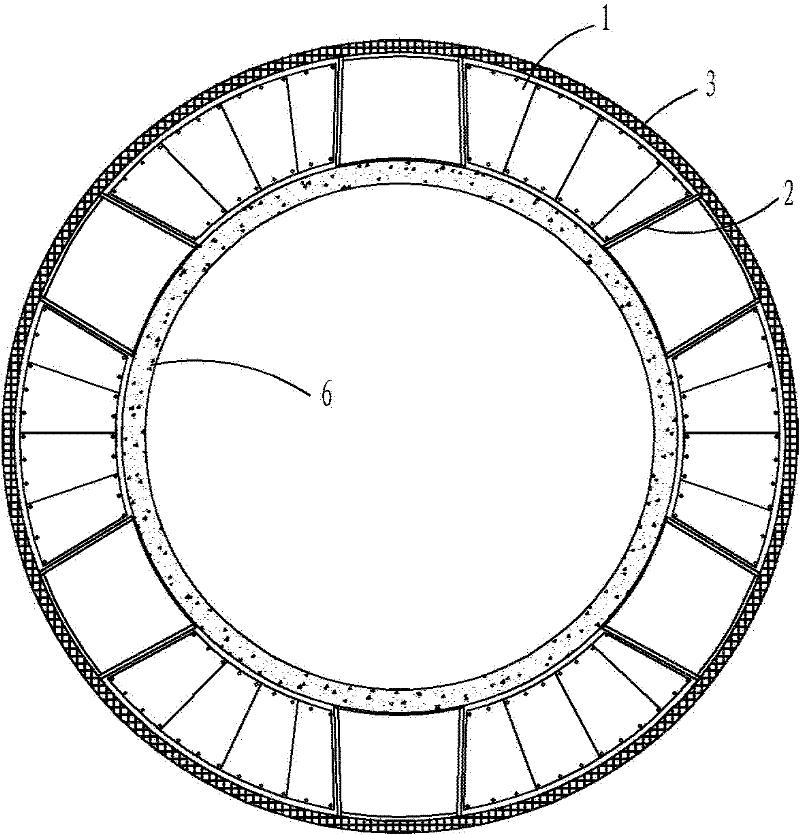

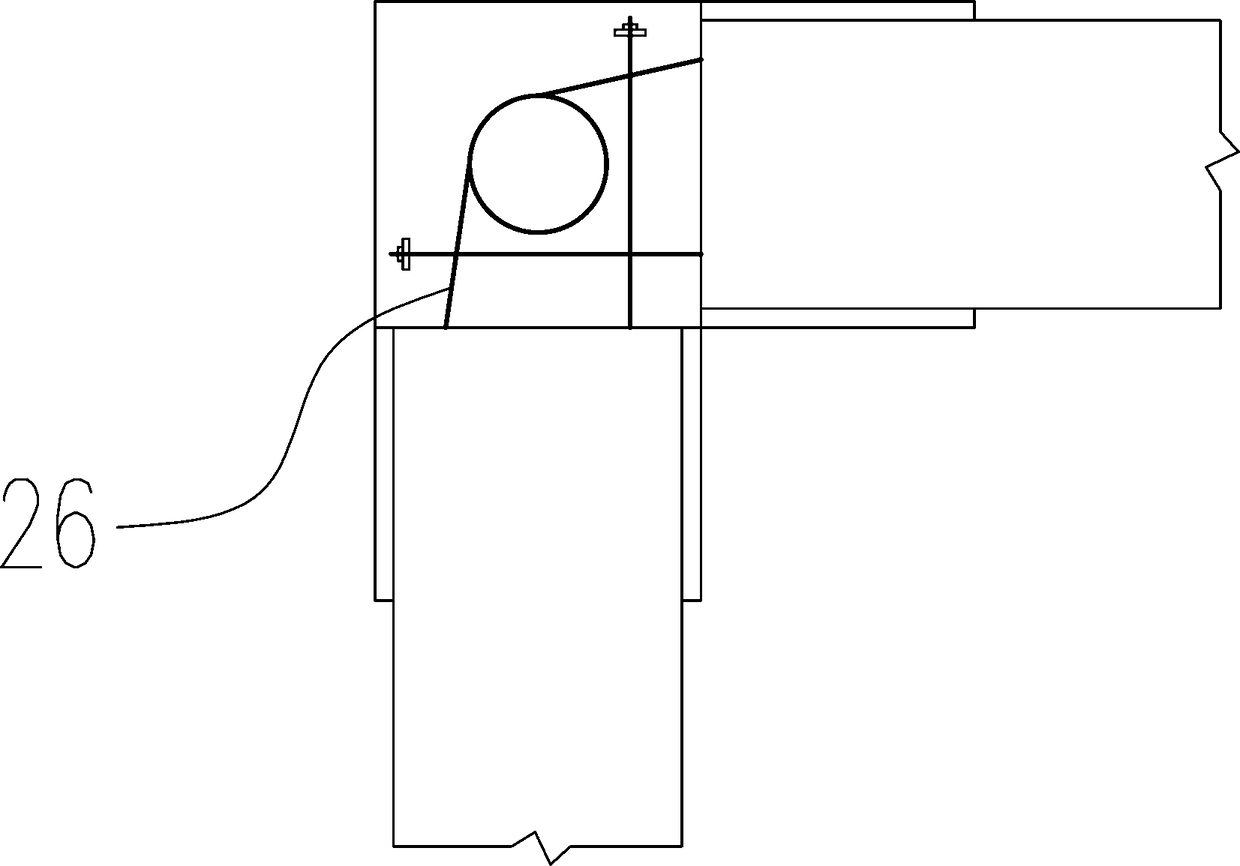

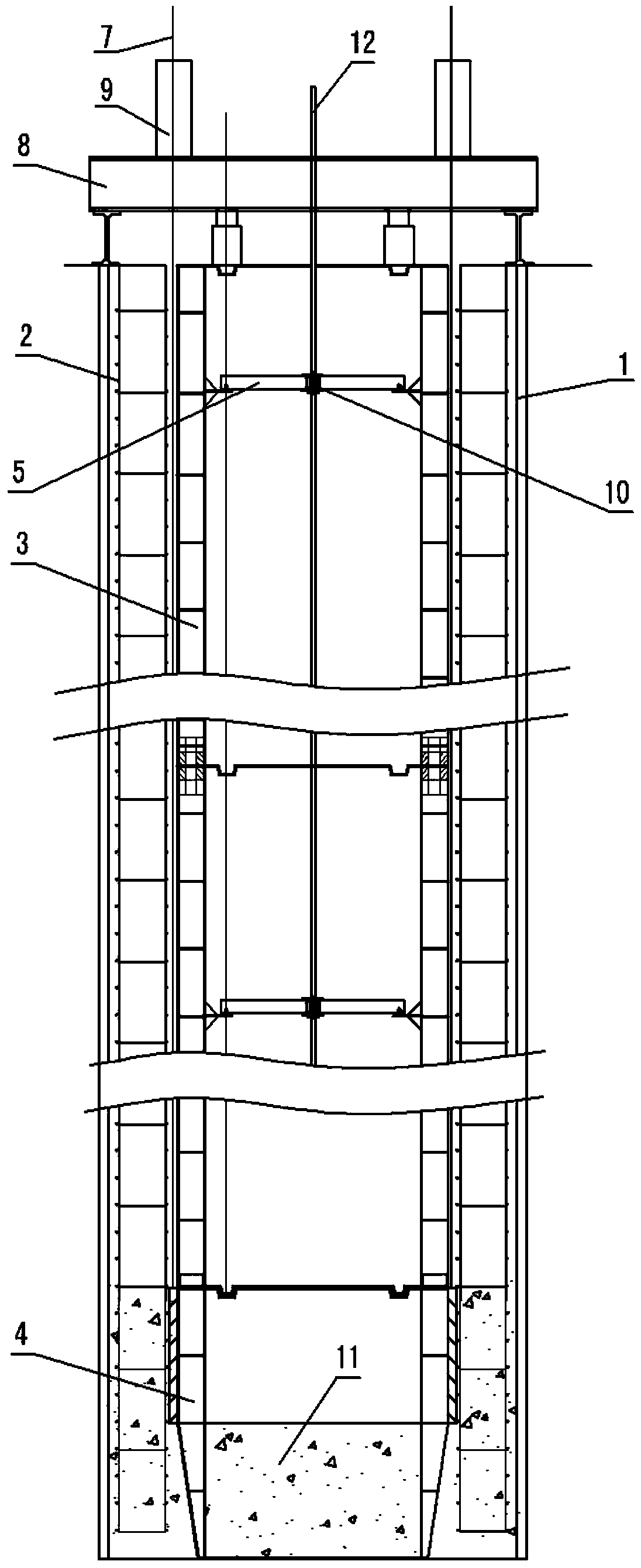

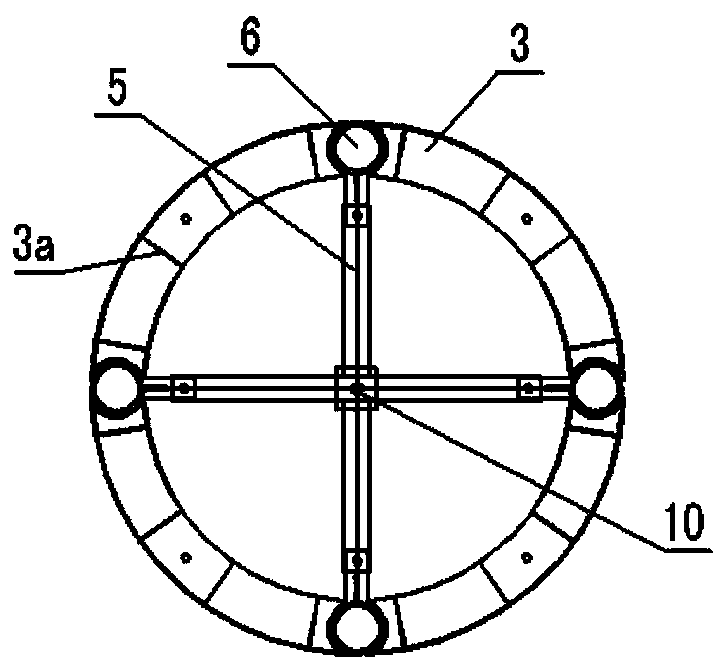

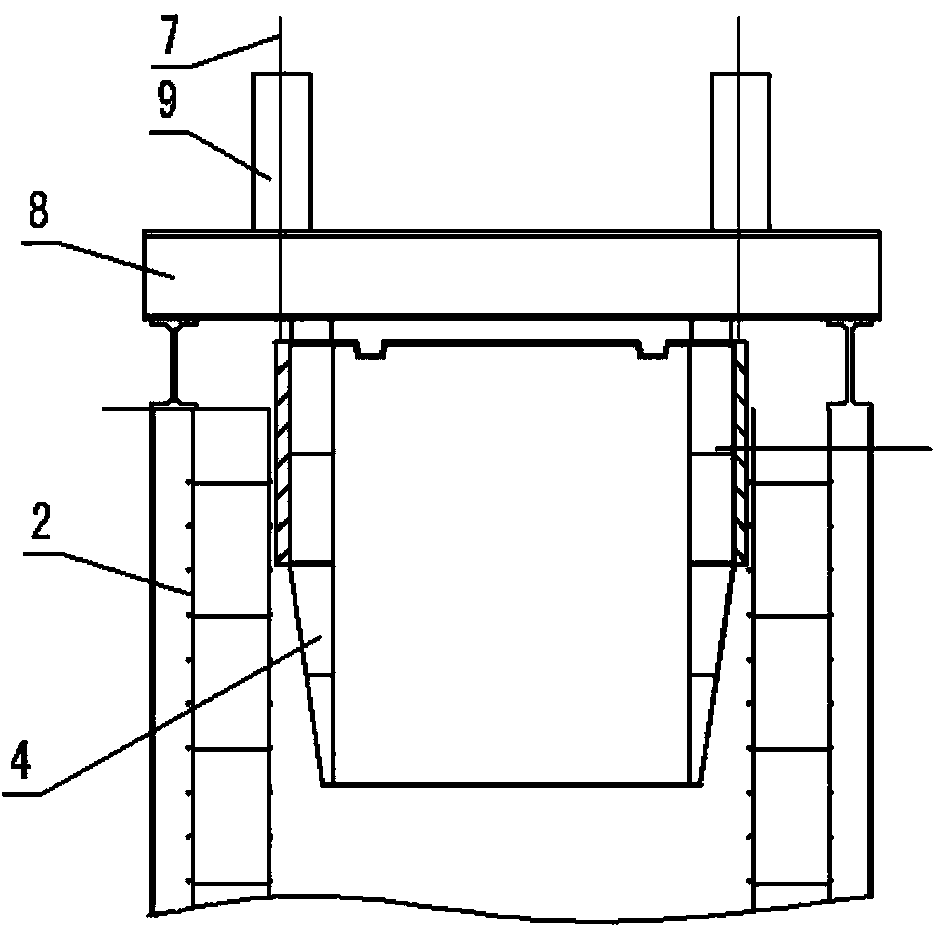

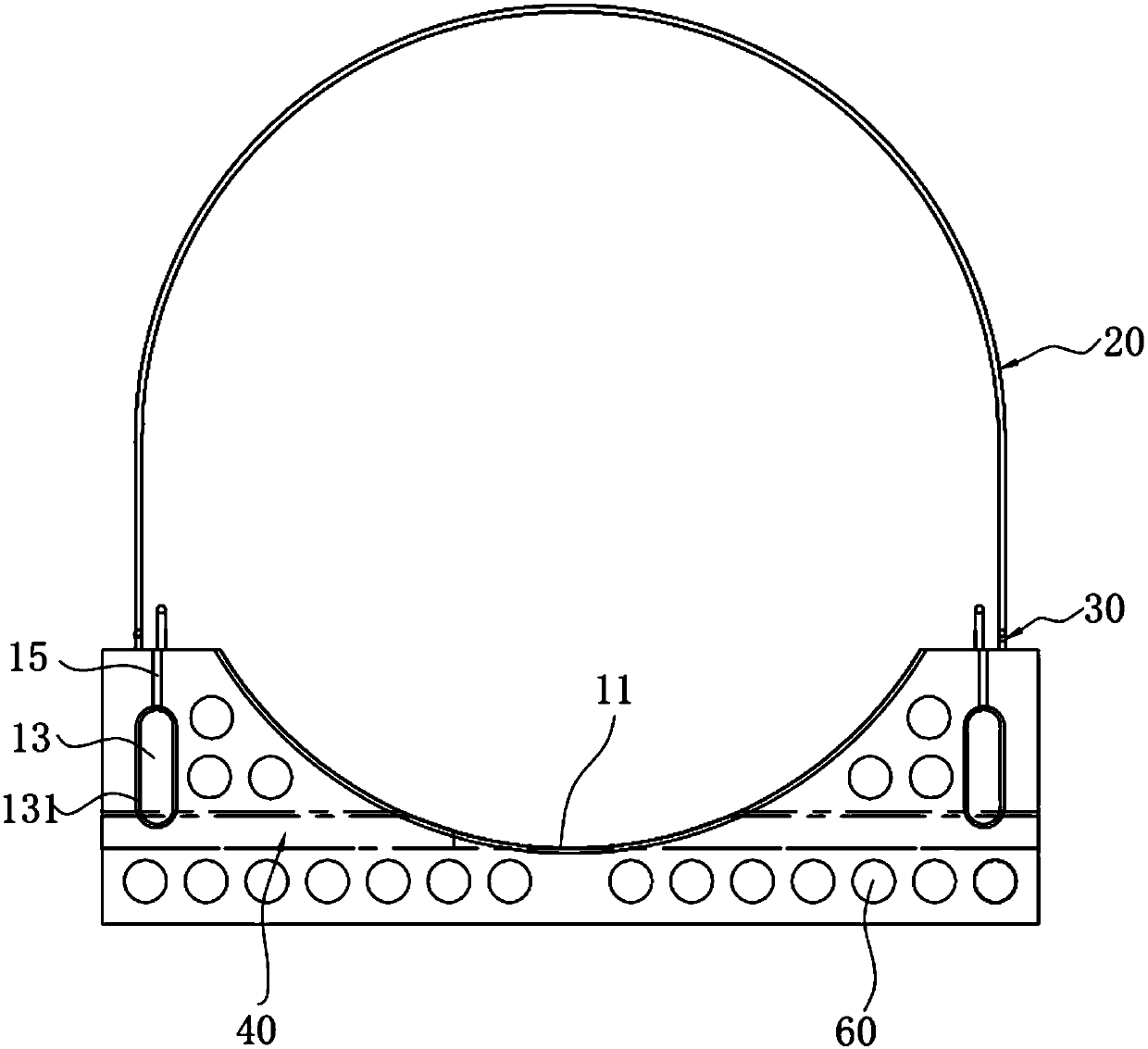

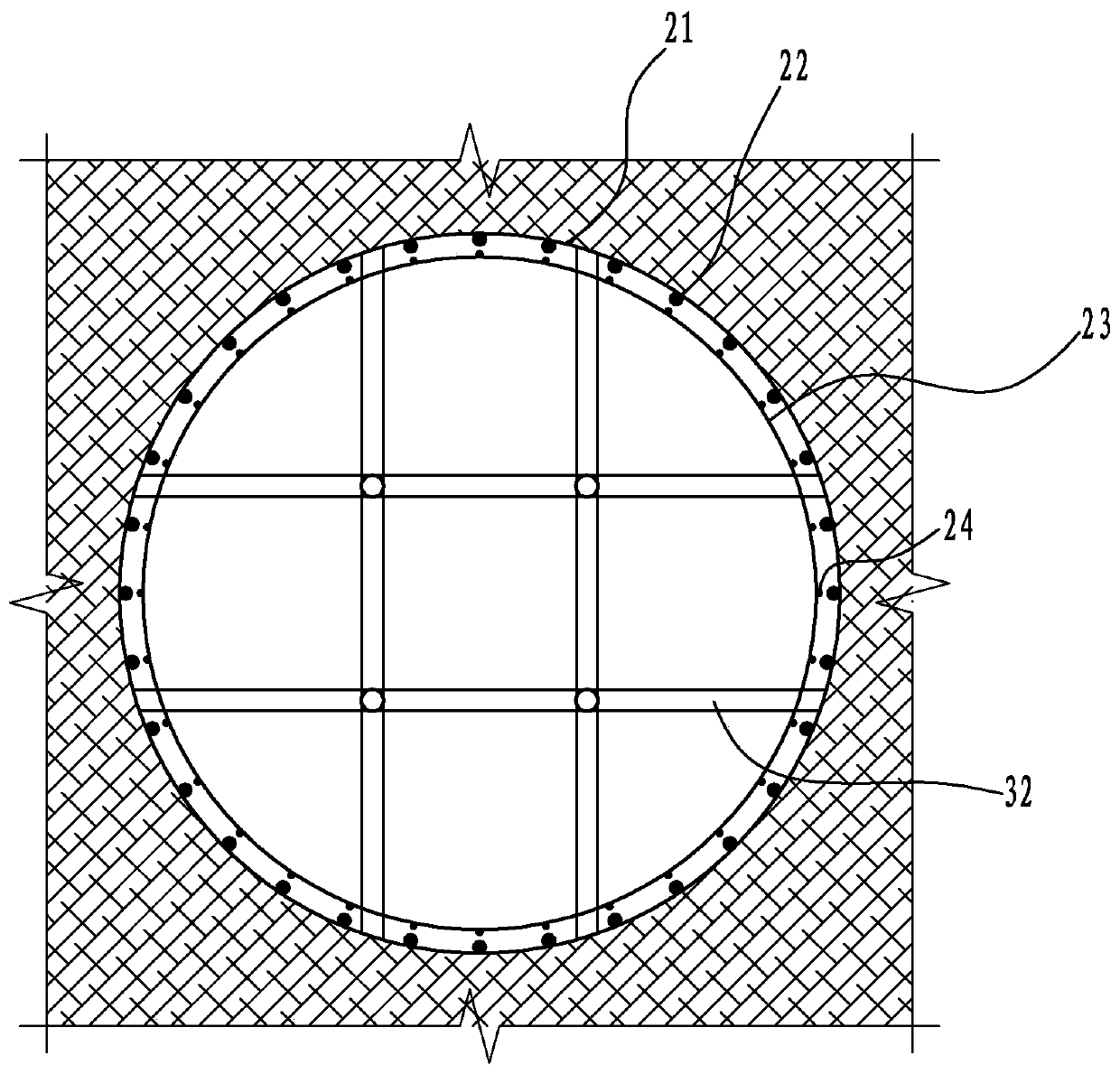

Modular cast-in-place construction method for large-diameter root foundation

InactiveCN102359110ACombined structure is light in weightSolve transportation difficultiesBulkheads/pilesFiberRebar

The invention discloses a modular cast-in-place construction method for a large-diameter root foundation, which is characterized by comprises the following steps of: firstly, constructing a pile formation hole at the position of a set root foundation by a drilling machine; sectionally manufacturing each section of FRP (Fiber Reinforce Plastic) combination structure, sequentially placing each section of FRP combination structure into the pile formation hole, welding adjacent sections of FRP combination structures by reinforcing bars or connecting adjacent sections of FRP combination structures by direct screw thread sleeves, winding FRP on the peripheries of the junctions to form a hollow pile cylinder, forming a pile cylinder concrete inner wall in the hollow pile cylinder, and pouring pile cylinder bottom plate concrete to carry out bottom sealing so as to form a ring-shaped cylinder with the sealed bottom; ejecting a root key into each root key steel bushing; and finally pouring lining concrete on the periphery of the pile cylinder concrete inner wall and pouring a top cover after the strength of the lining concrete is met so as to form a foundation platform. Due to the adoption of the modular cast-in-place construction method for the large-diameter root foundation, the construction can be effectively and conveniently carried out and the construction efficiency is improved.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

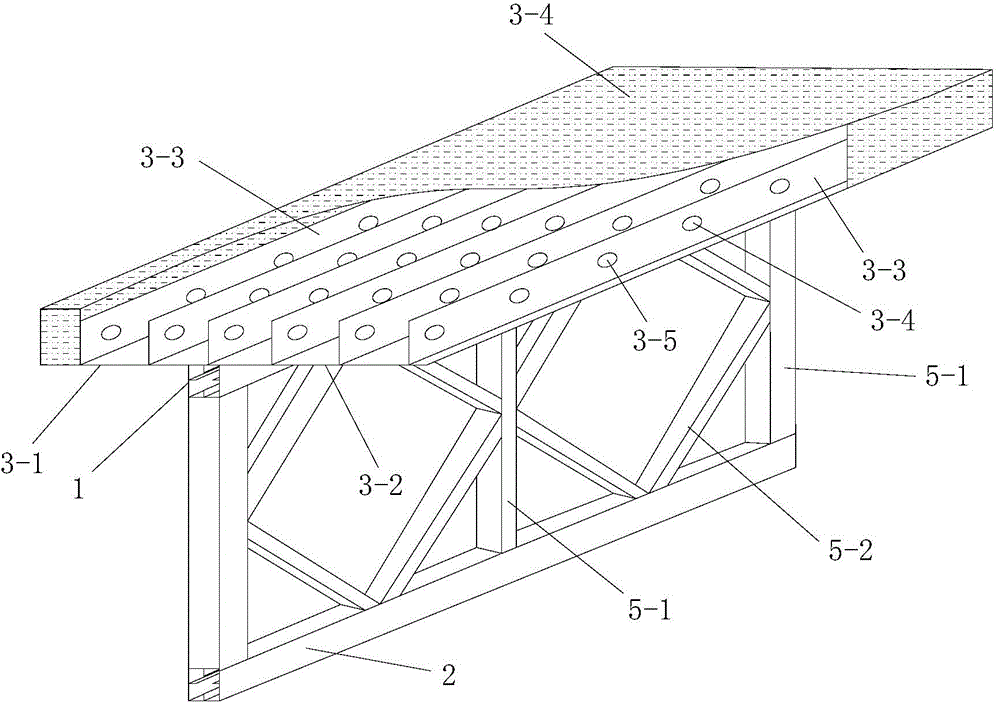

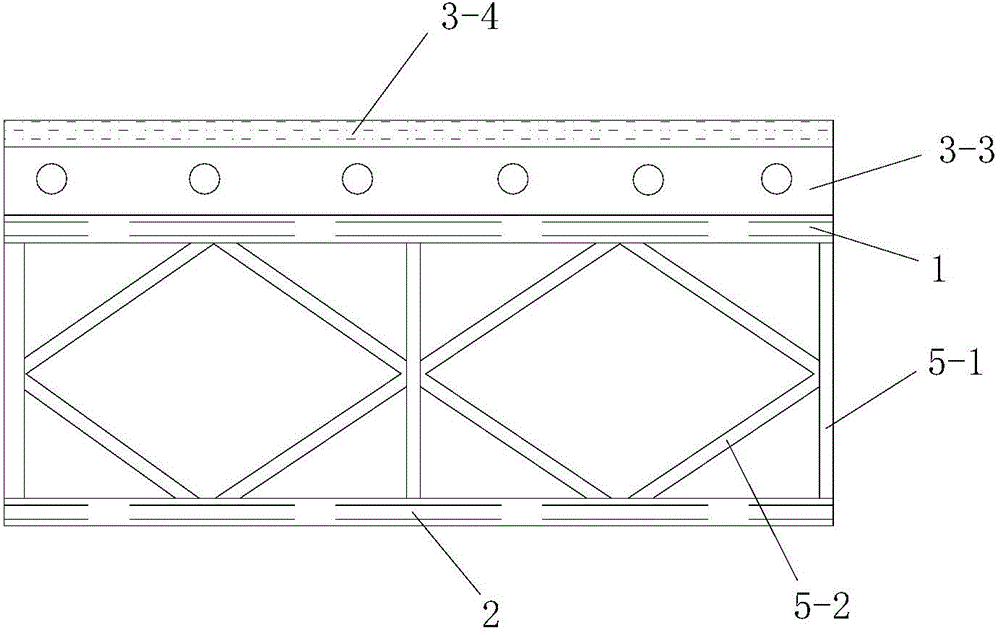

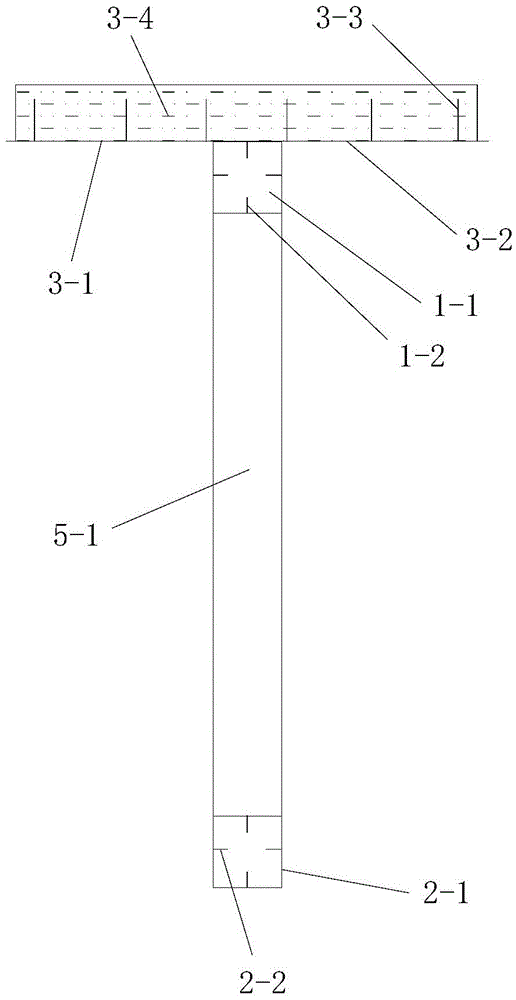

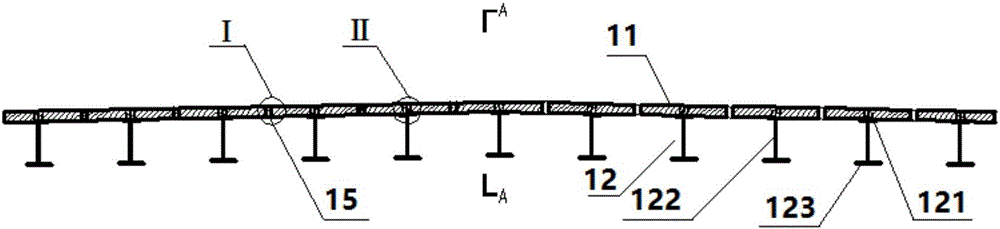

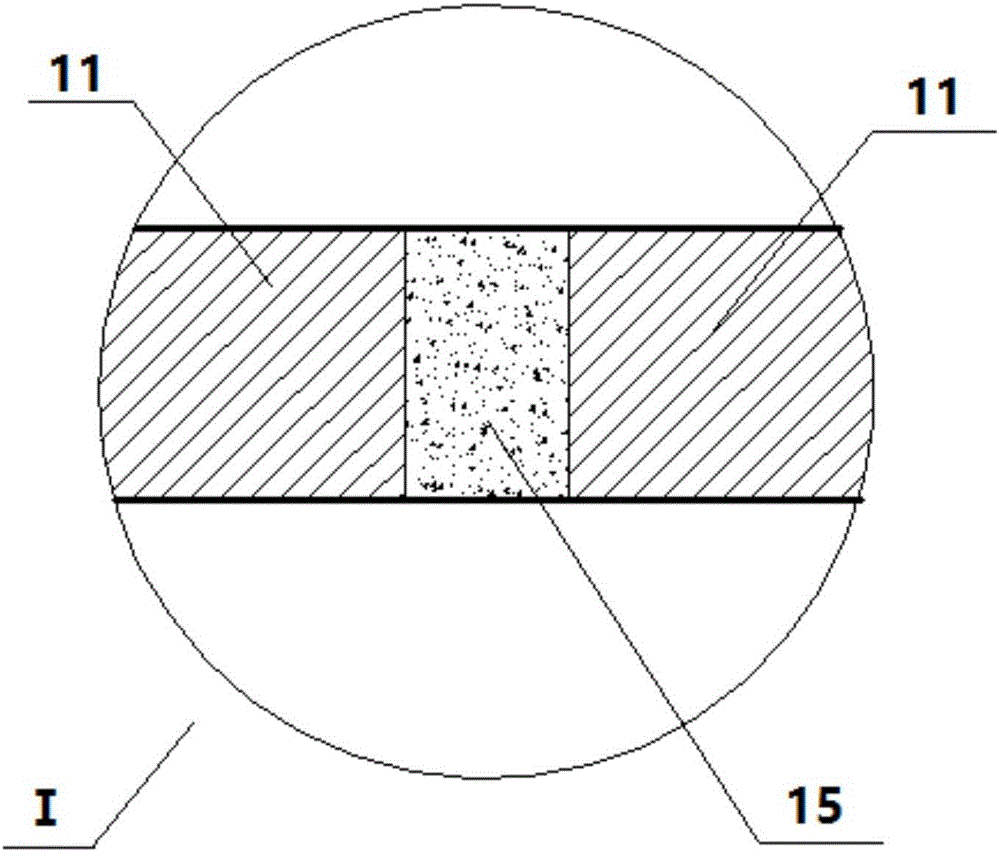

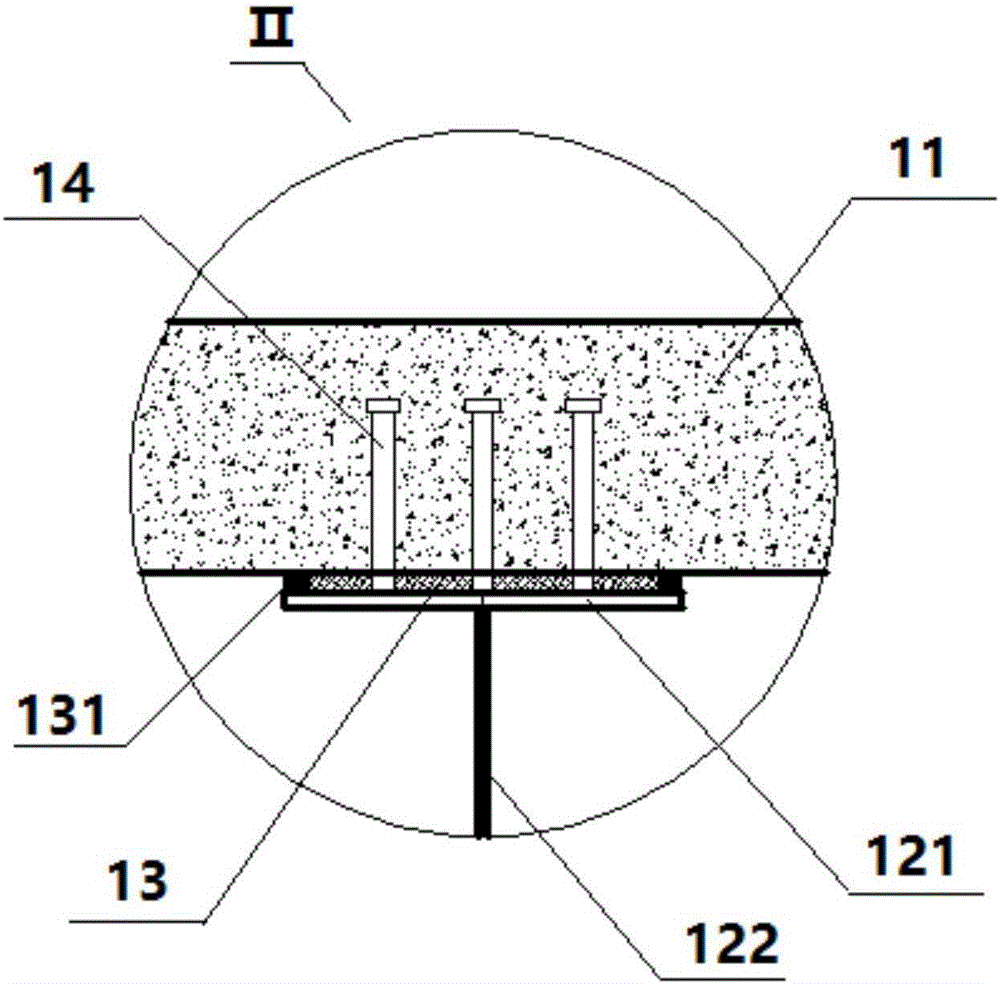

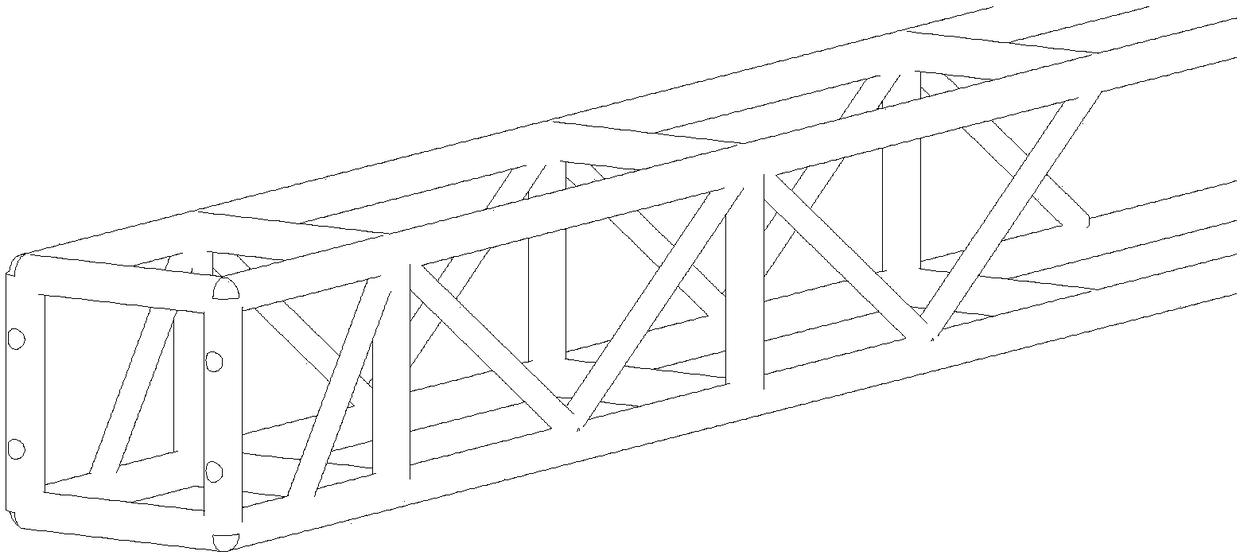

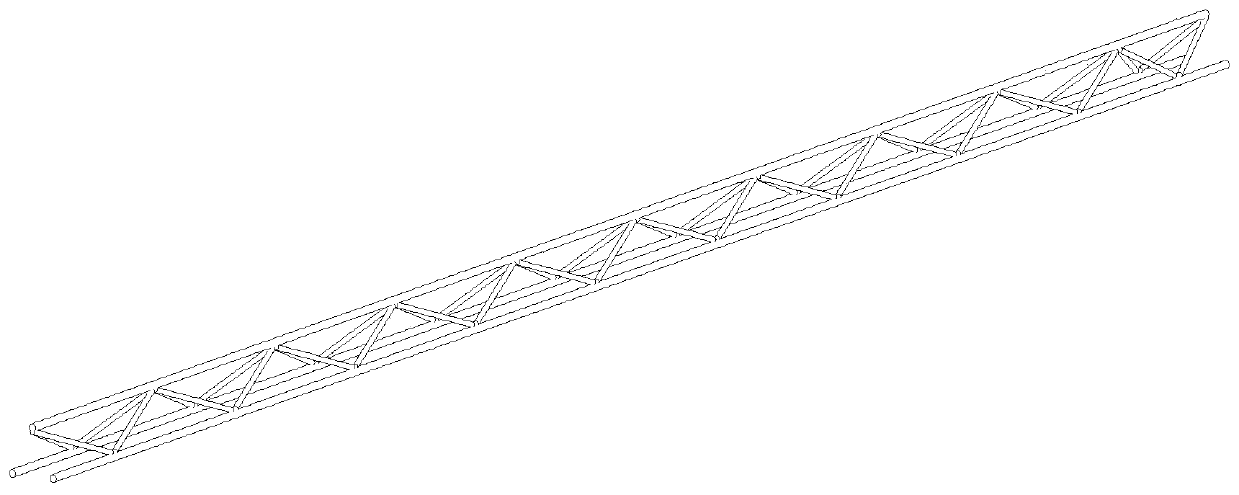

T-shaped plate girder segment prefabricating unit based on steel truss and combined bridge deck slab

InactiveCN104088221ASimple structureReasonable designBridge structural detailsSheet steelBridge deck

The invention discloses a T-shaped plate girder segment prefabricating unit based on a steel truss and a combined bridge deck slab. The T-shaped plate girder segment prefabricating unit comprises a lower force bearing structure and the combined bridge deck slab arranged on the lower force bearing structure, and the combined bridge deck slab and the lower force bearing structure are both arranged in the longitudinal bridge direction; the lower force bearing structure is a planar truss composed of an upper chord rod, a lower chord rod and a web rod, the upper chord rod comprises a first rectangular steel tube, and the lower chord rod comprises a second rectangular steel tube; the combined bridge deck slab comprises a bottom supporting steel plate, a plurality of upper longitudinal ribs arranged on the bottom supporting steel plate, and a concrete bridge deck slab arranged on the bottom supporting steel plate in a pouring mode, the upper longitudinal ribs are arranged in the concrete bridge deck slab in a pouring mode, and the upper longitudinal ribs are long-strip-shaped steel plates with the middles provided with a plurality of through holes; the bottom supporting steel plate is a rectangular supporting steel plate formed by connecting a left extension steel plate, a right extension steel plate and a first rectangular steel tube. The T-shaped plate girder segment prefabricating unit is simple in structure, reasonable in design, easy and convenient to construct, good in overall mechanical property and capable of improving the structure accuracy and construction convenience of a steel and concrete combined bridge.

Owner:CHANGAN UNIV

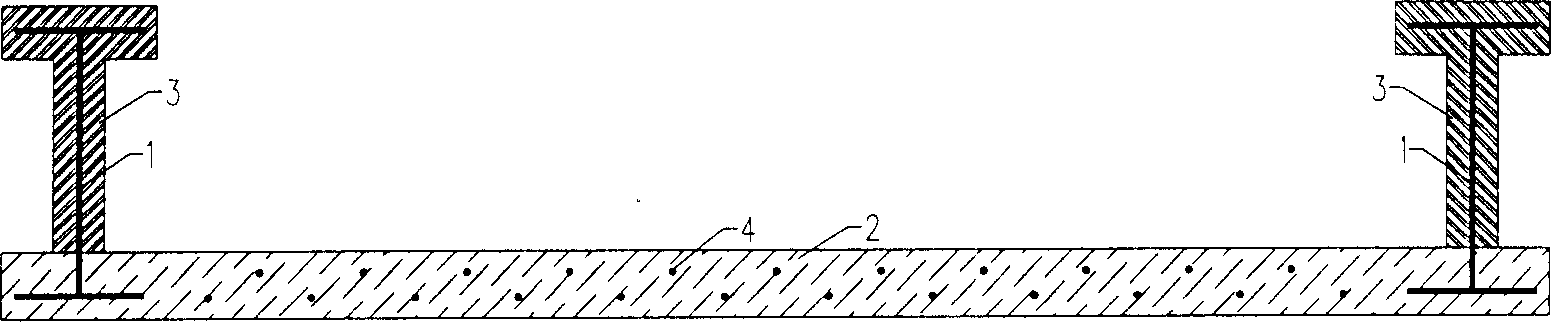

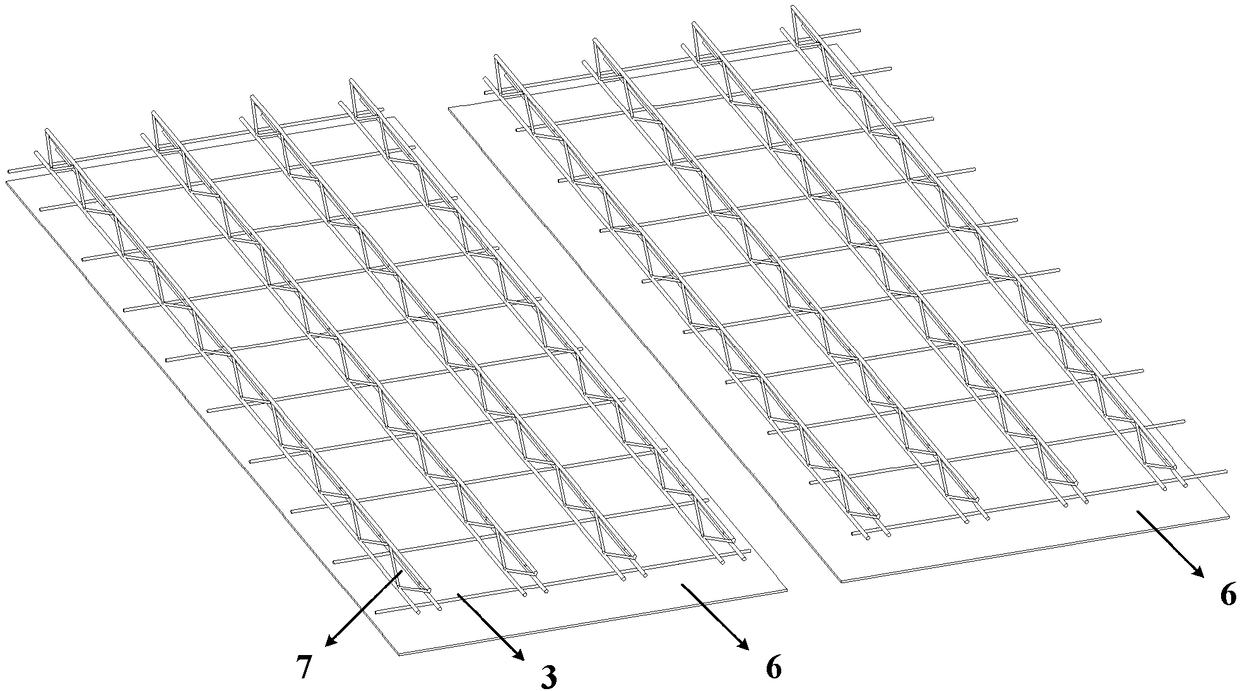

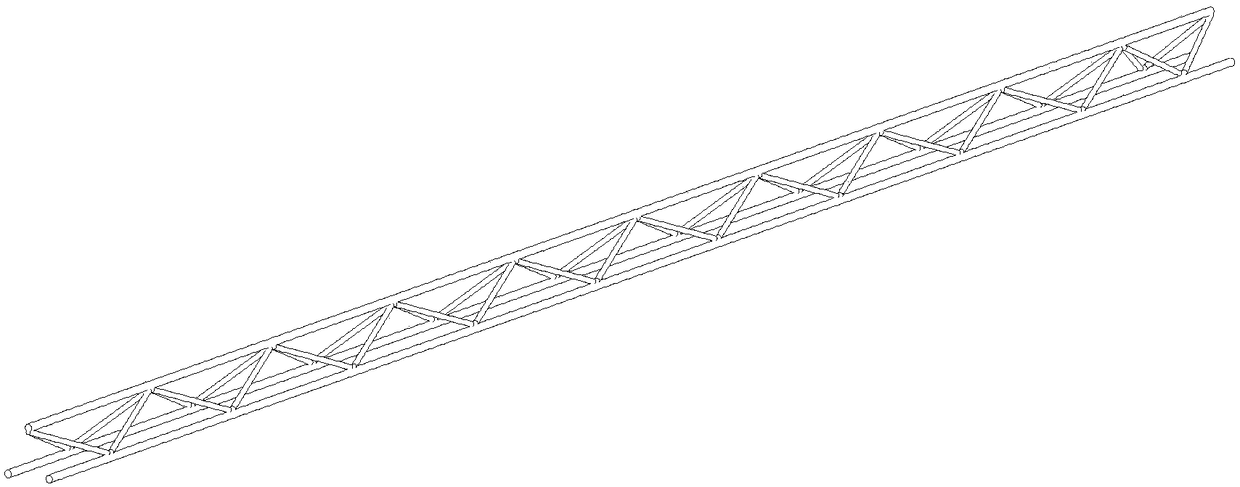

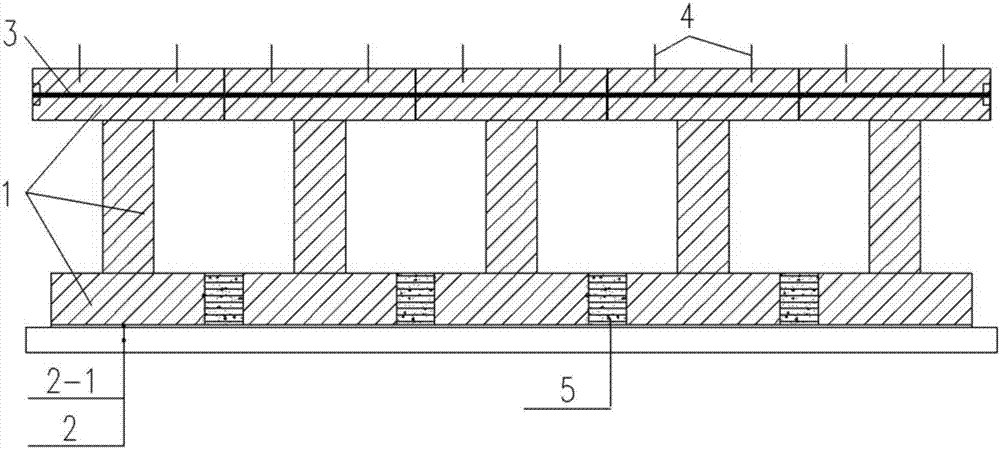

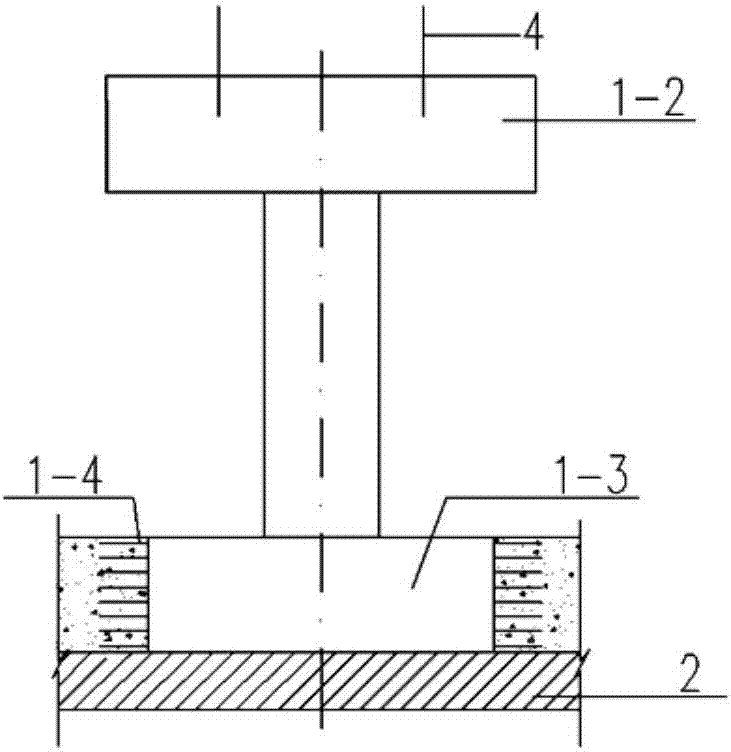

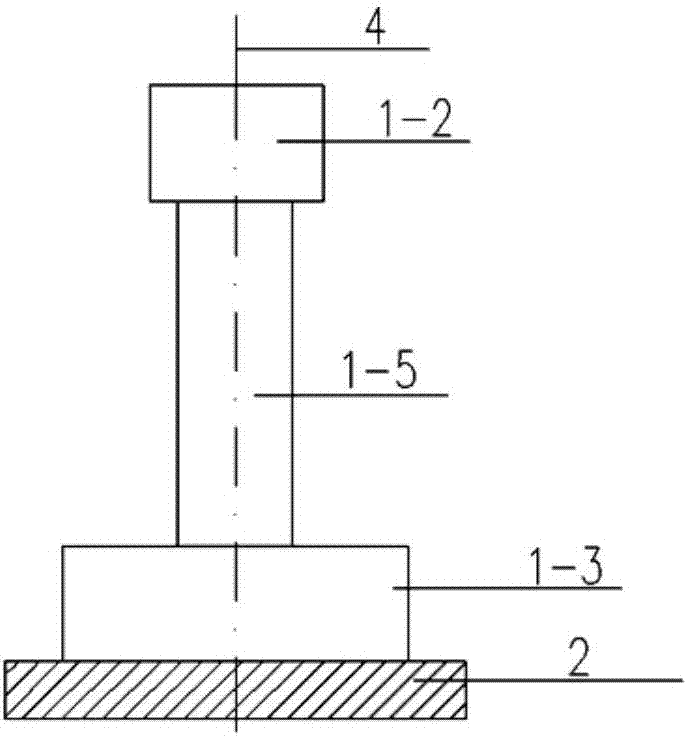

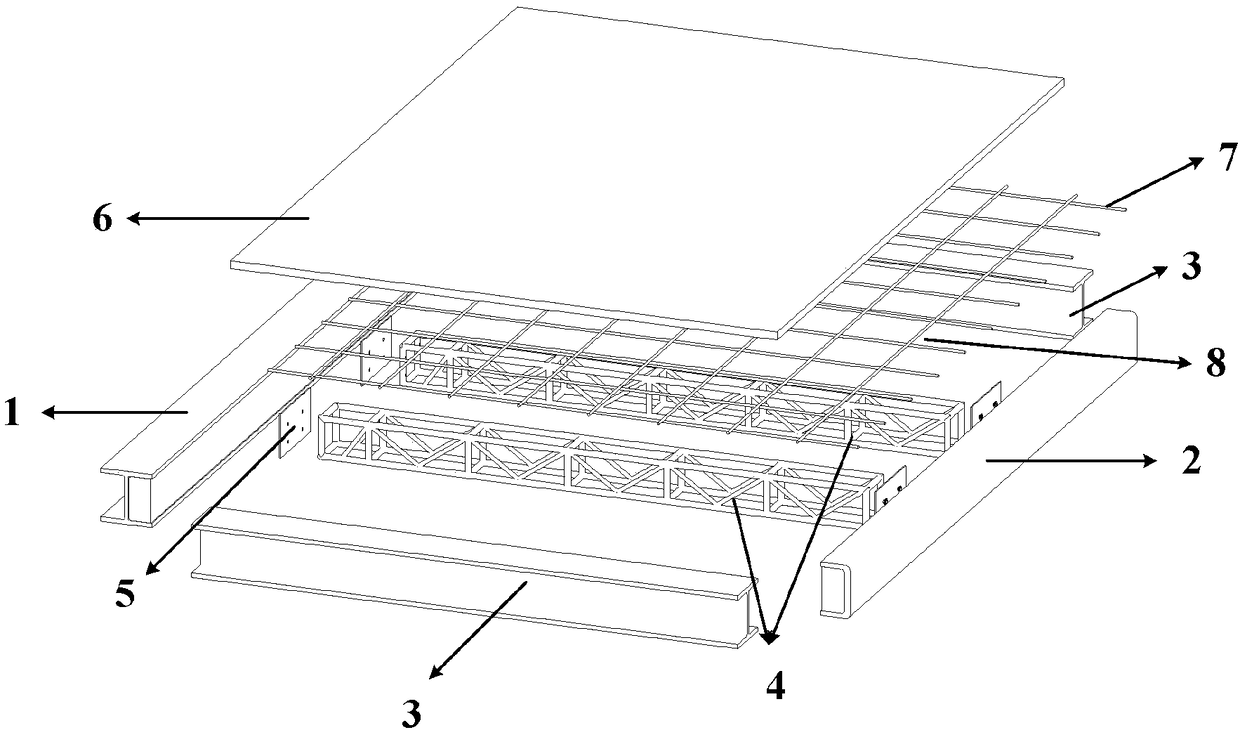

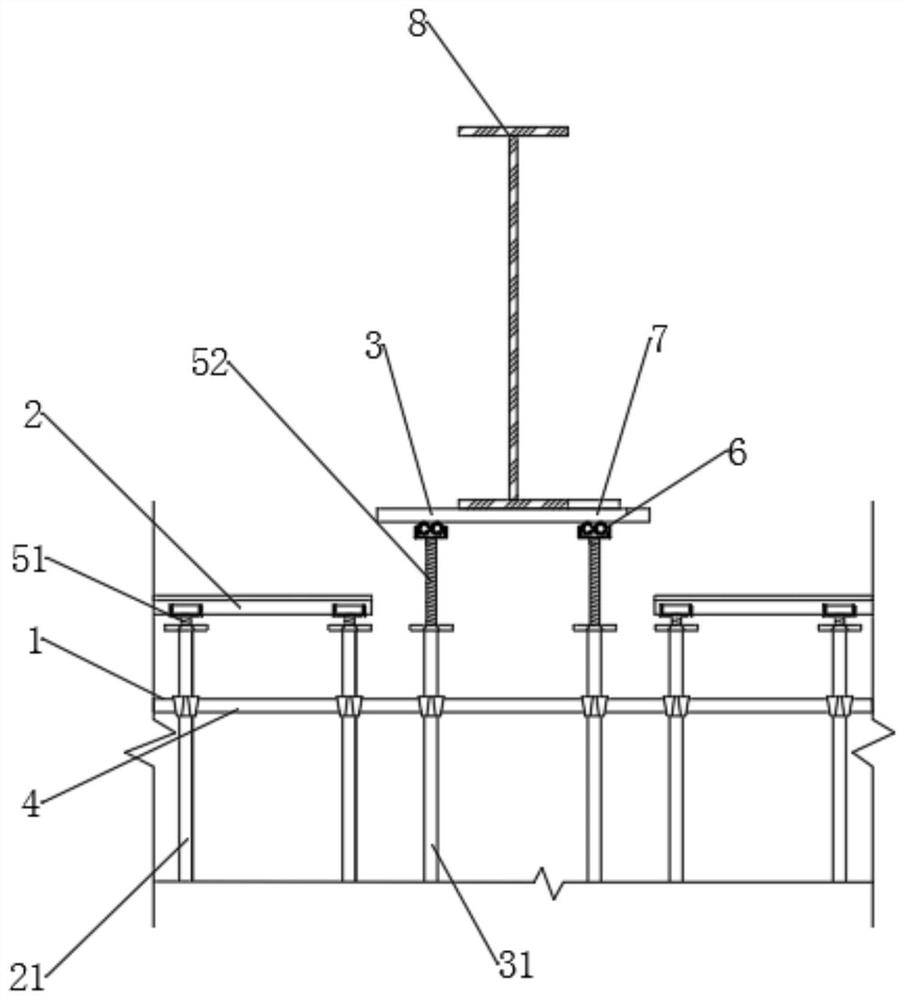

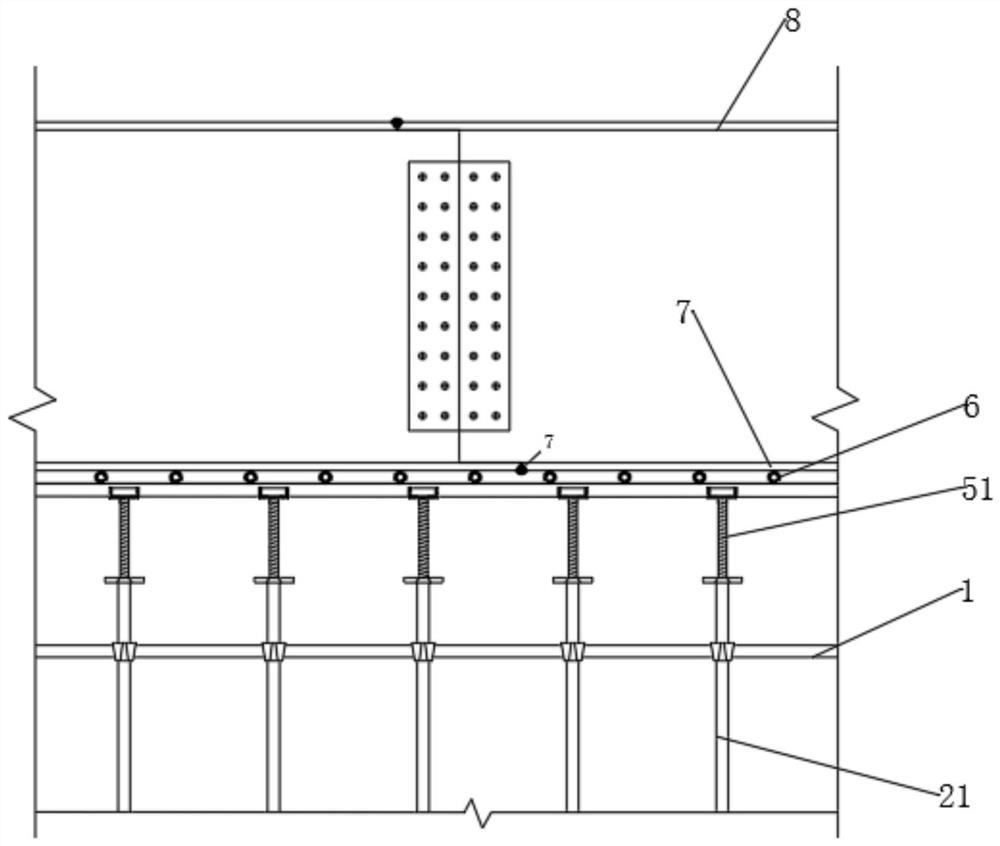

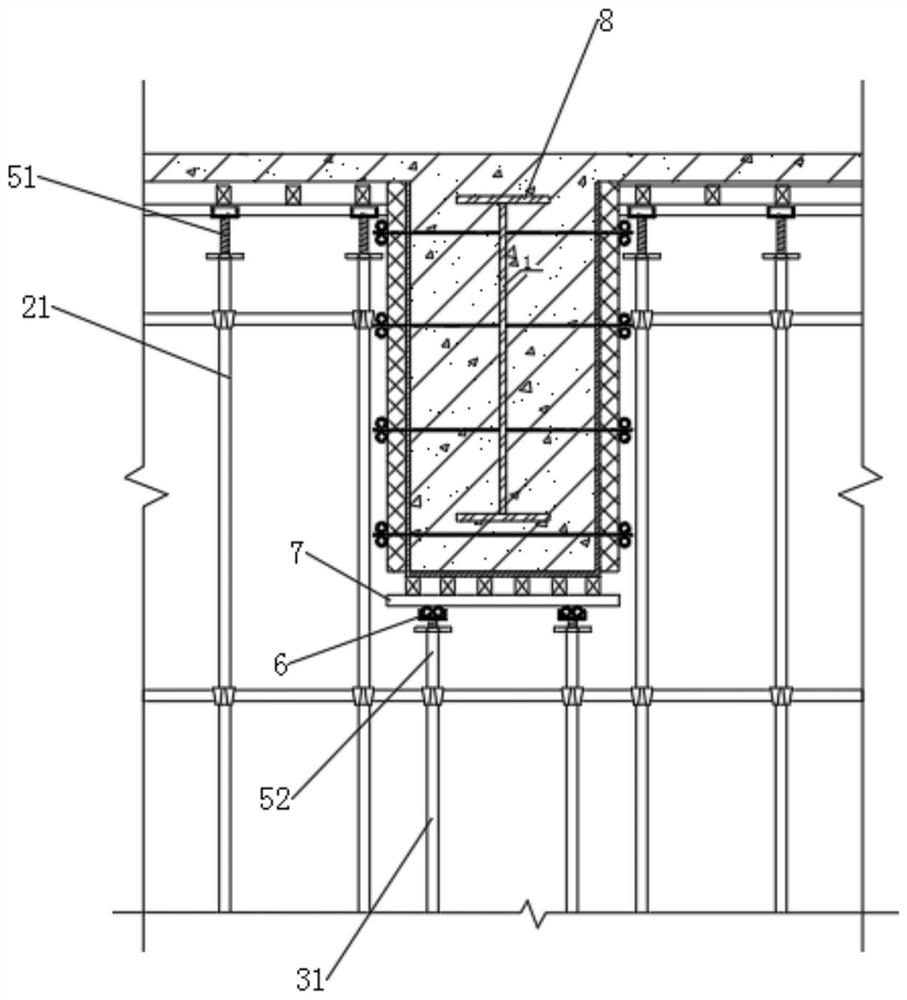

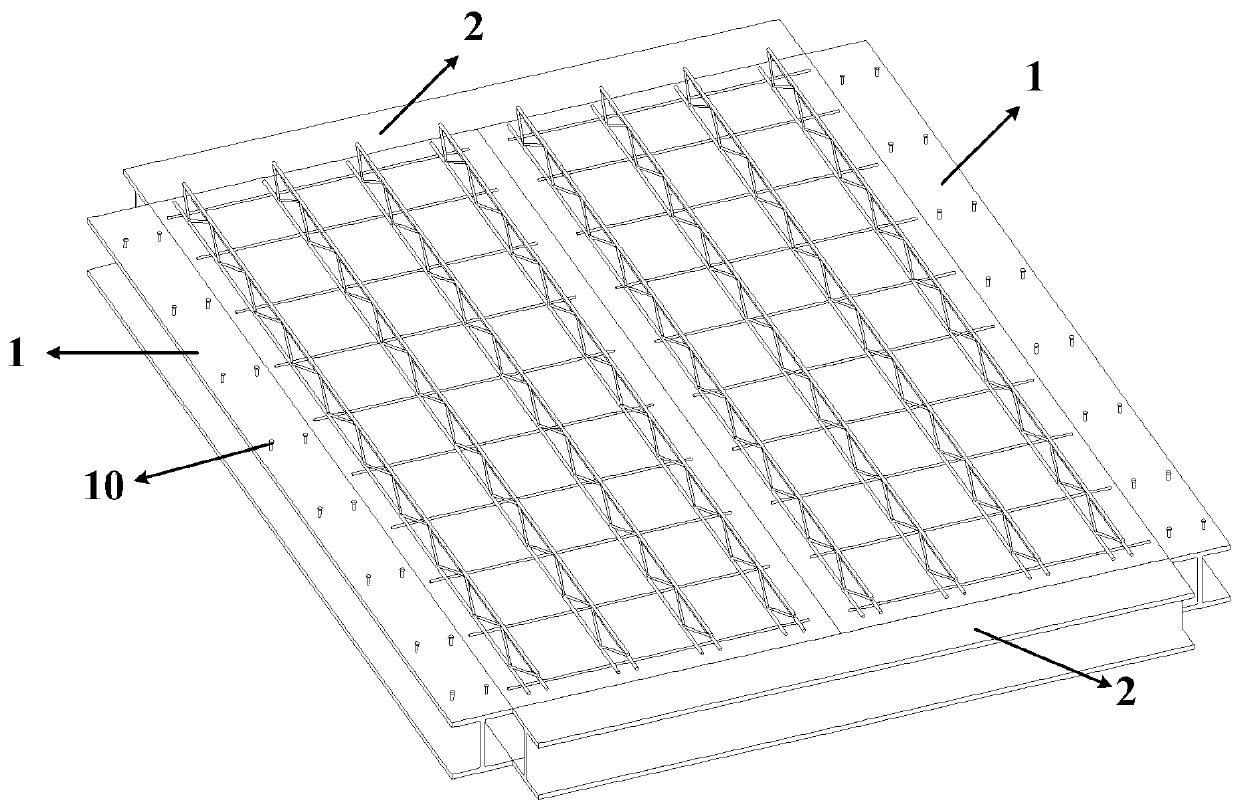

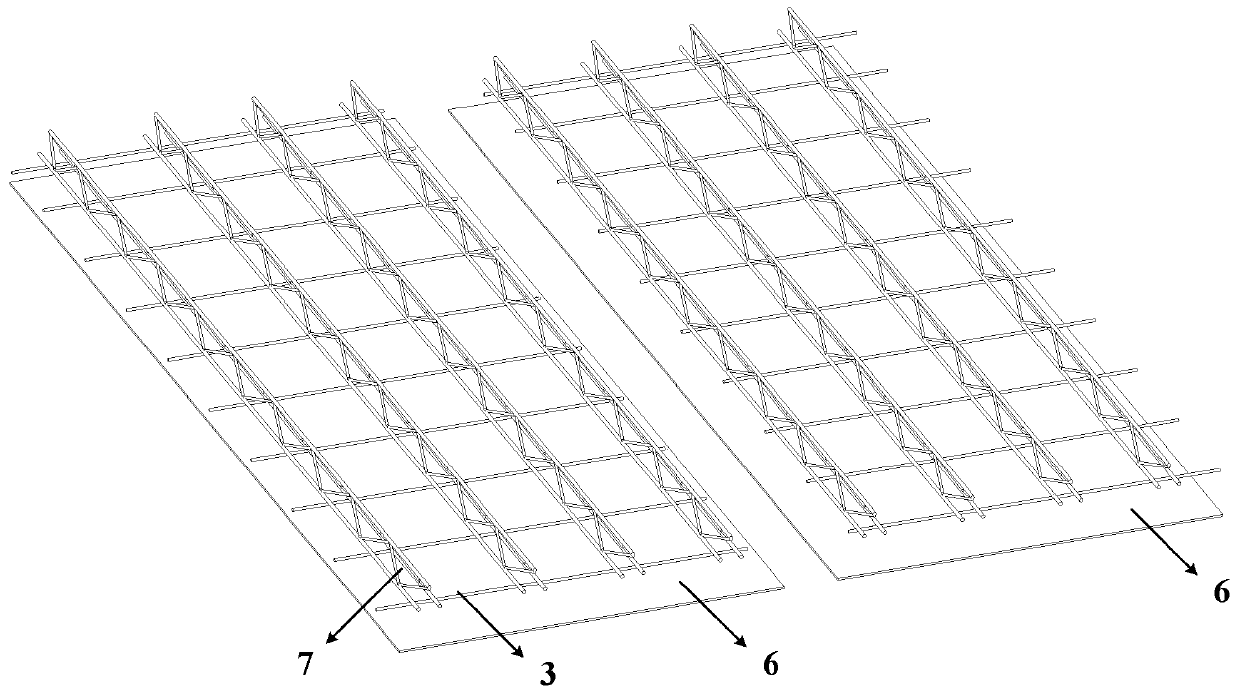

Prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab

The invention discloses a prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab, and belongs to the technical field of structural engineering. The basiccomposition of a composite beam-slab structure comprises shape steel beams, three-dimensional truss temporary supports, connecting plates, triangular reinforcing steel bar trusses, prefabricated short bars and prefabricated concrete slabs, wherein the shape steel beams are welded to the connecting plates, and the prefabricated short bars, the reinforcing steel bar trusses and the prefabricated floor slab are poured into a whole. The beams, the temporary supports and precast concrete floor slabs are hoisted in place and connected by bolts, reinforcing steel bars are paved in a penetrating mode, and the beams, the temporary supports and precast concrete floor slabs are poured with remaining concrete. The prefabricated concrete ultra-thin type two-way stress fabricated steel bar truss composite floor slab with temporary supports is used, the problem of integrity of the floor slab is solved, the reliability of the floor slab in the construction stage is guaranteed, a post-pouring strip ofthe fabricated floor slab is avoided, the field work efficiency is improved, the thickness of the prefabricated concrete slab is reduced, the weight of the hoisting is reduced, and the fabricated accuracy is improved.

Owner:BEIJING UNIV OF TECH

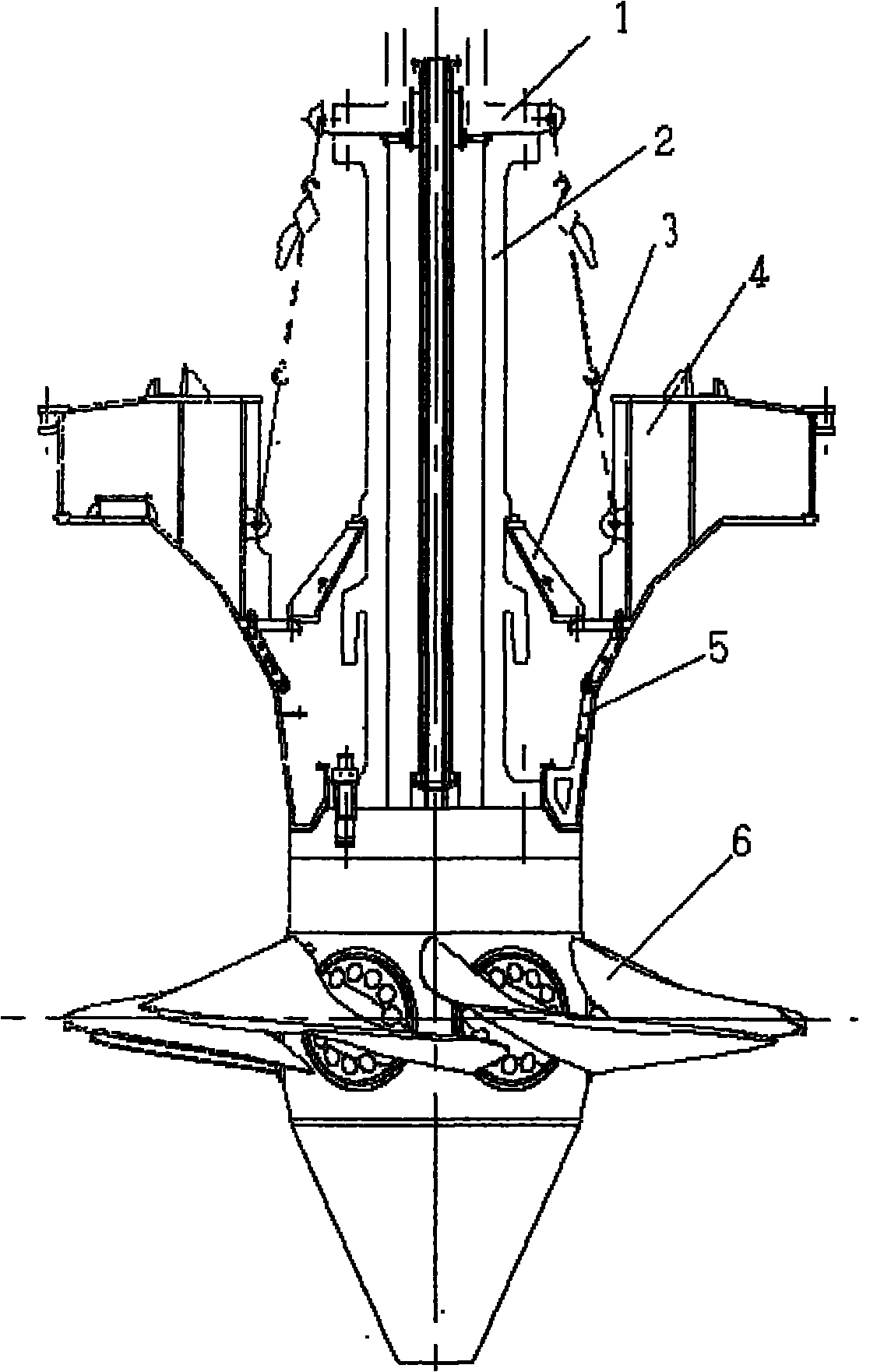

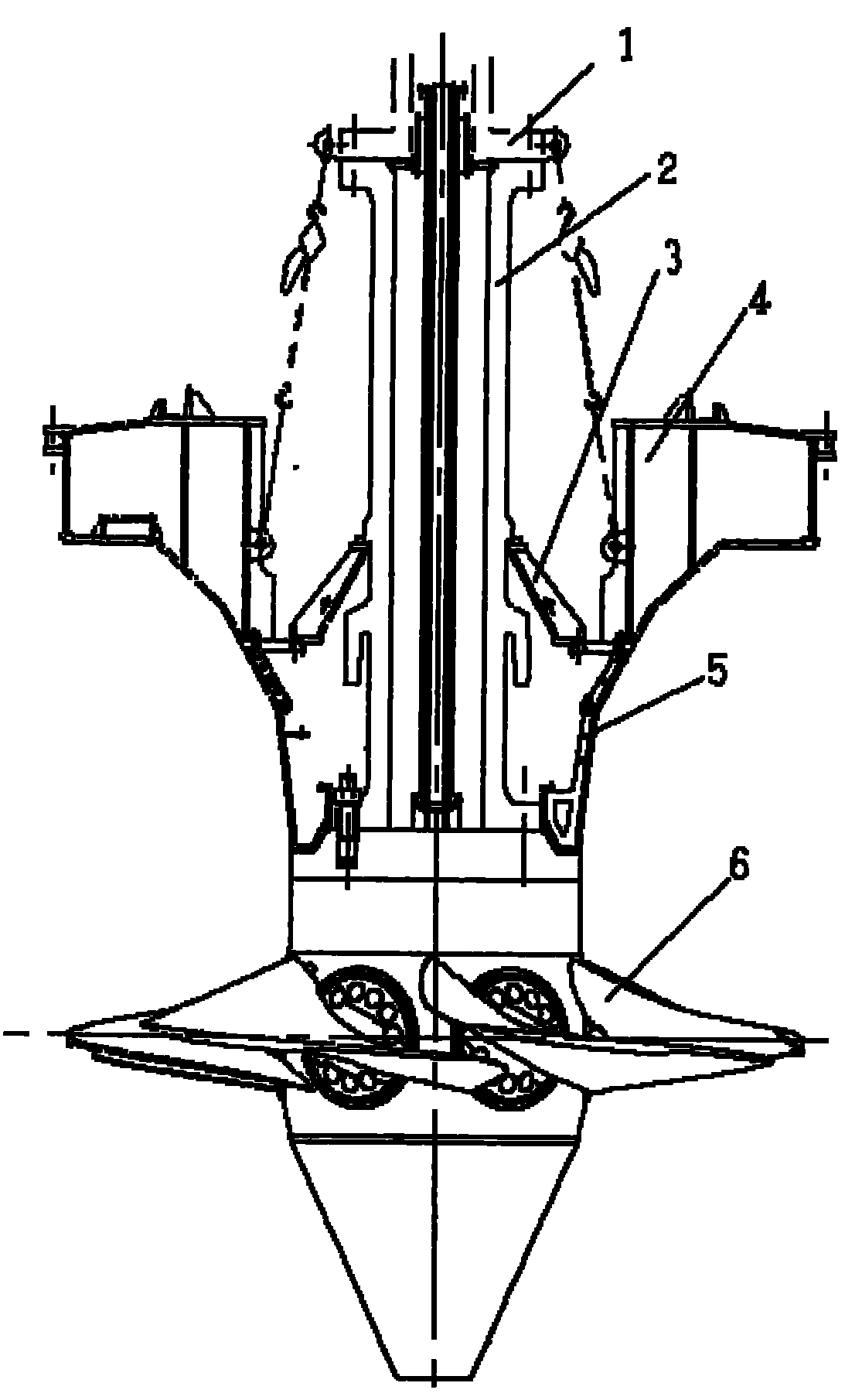

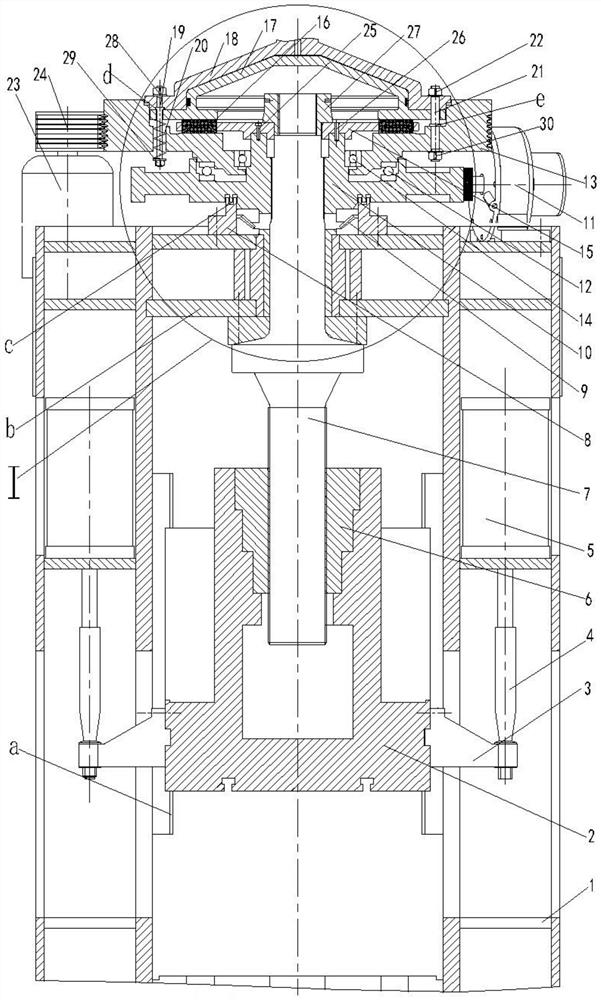

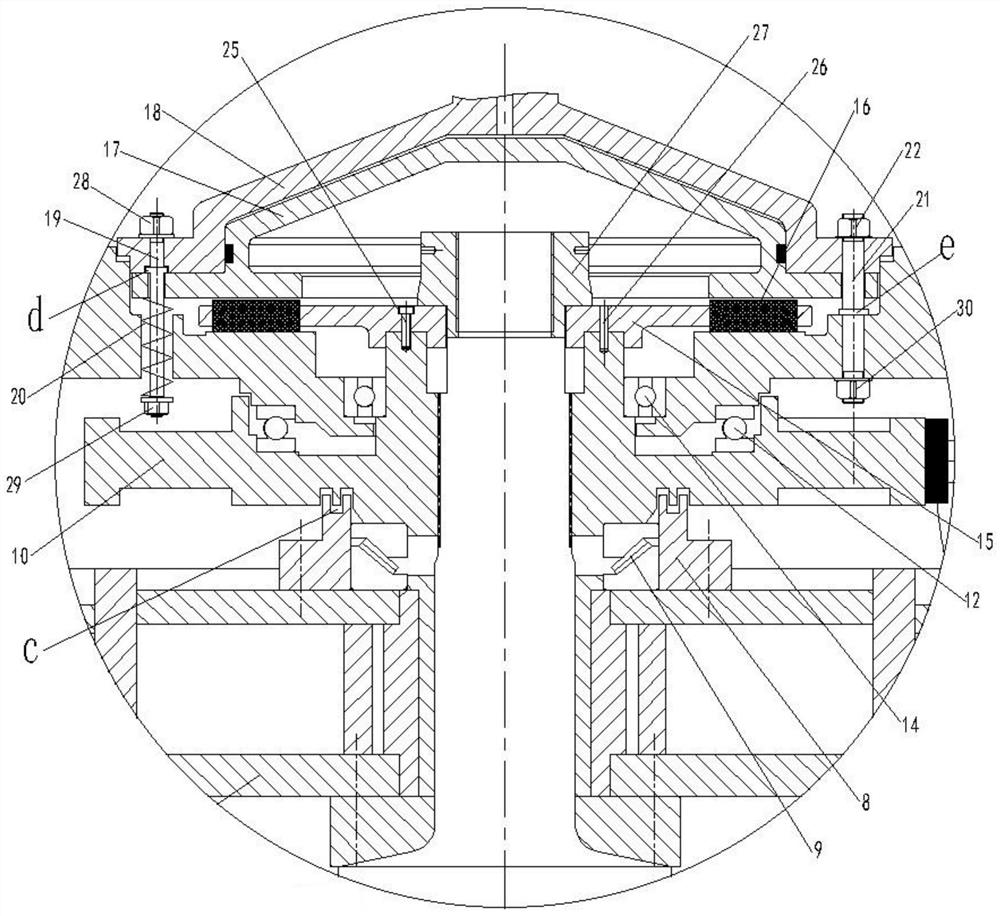

Hoisting process for rotating wheel of vertical shaft axial flow hydraulic turbine

InactiveCN102060252ASealing has no effectReduce lifting weightLifting devicesHoisting equipmentsCouplingEngineering

The invention relates to a hoisting process for a rotating wheel of a vertical shaft axial flow hydraulic turbine, which comprises the following steps of: 1, arranging a small convex plate at the appropriate position on a main shaft; 2, putting an installed rotating wheel on a platform in an installation room, allowing blades to be in the complete shut-down position, and adjusting the horizontal of an upper flange surface of the rotating wheel by 0.02mm / m; 3, hoisting a combining piece of the main shaft and an operating oil tube, connecting the operating oil tube with an operating oil tube of the rotating wheel, connecting the main shaft with the rotating wheel, and connecting the rotating wheel with a bolt and pretightening; 4, sleeving the combination body into the main shaft after combining a support cover and a flow guiding cone or combining the support cover and the flow guiding cone after sleeving the support cover and the flow guiding cone into the main shaft respectively, and putting the combination body on an upper flange or a rotating wheel cover of a rotating wheel body; 5, arranging a partitioned bearing on the support cover or the flow guiding cone, and arranging a divided clamping ring on the top of the bearing; 6, adjusting the height of combination body of the support cover and the flow guiding cone by using a hoist and conducting the safe and protective action when the combination body is hoisted in a turbine pit integrally; 7, reserving an axial gap between the convex plate on the main shaft in the installation room and the clamping ring, wherein the gap is 2 to 5 millimeters greater than the sum of a reverse machine lift value and a bayonet value of the main shaft, and the value is 2 to 5 millimeters greater than the bayonet value of the main shaft, so that the coupling is convenient; and 8, arranging a hanger, and hoisting the combination body in the turbine pit to be put in place.

Owner:浙江富春江水电设备股份有限公司

Upper structure of prefabricated cover-beam-free type combined steel plate bridge and assembling construction method of upper structure

ActiveCN106638259AIncrease headroomReduce restrictionsBridge structural detailsBridge erection/assemblySheet steelSupport point

The invention discloses an upper structure of a prefabricated cover-beam-free type combined steel plate bridge and an assembling construction method of the upper structure. The upper structure comprises a plurality of paths of combined steel plate longitudinal beams and supporting point concrete transverse beams; the plurality of paths of combined steel plate longitudinal beams are assembled along the transverse direction of the bridge to form a bridge-spanning main beam; and one path of the supporting point concrete transverse beam is arranged at each of two ends of each bridge-spanning main beam. According to the upper structure disclosed by the invention, the quantity of components in the upper structure of the bridge can be reduced and the weight of the components is reduced; the hoisting difficulty of field construction is reduced and the construction cost of buildings is saved; and a cover beam is not arranged, so that the defects in the prior art that the clearance under the bridge is low, the traffic limit under the bridge is great and the bridge landscape is poor are improved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

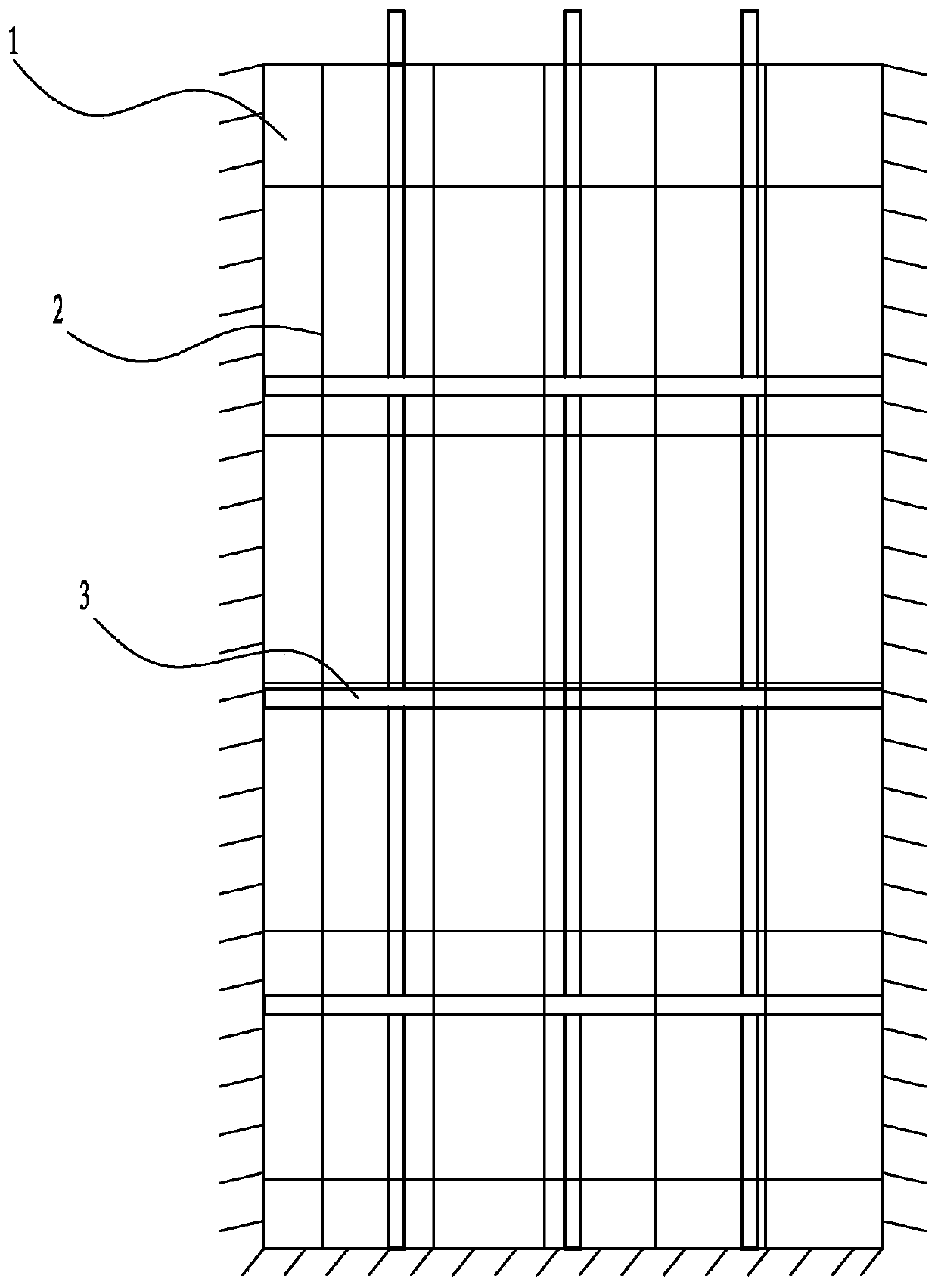

Construction method of connecting beam type spliced building structure

InactiveCN108729541AImprove seismic performanceLow transportation costFloorsProtective buildings/sheltersStress concentrationCompressive strength

The invention provides a construction method of a connecting beam type spliced building structure. The construction method comprises the following steps that members are prefabricated in a workshop, including at least inner layers and outer layers of columns, cross beams, slabs and shear walls; joints of the columns are located at the positions among the slabs; the columns are hoisted; the shear walls are installed; the cross beams are hoisted and arranged on bracket supports of the columns, wherein the cross beams are prestressed beams; the ends of the cross beams are connected with one another or are connected with the columns by connecting tension steel wires ropes; the slabs are hoisted on the cross beams; a spliced building is obtained by repeating the steps in sequence. The problem can be solved that an existing assembled structure is poor in compressive strength and easily produces stress concentration, the problem of poor anti-seismic property of a cast-in-place concrete structure can be also solved, and the influence on a linear construction period is not large. Members can be decreased by 30%-50%, the hoisting weight can be reduced by 20%-35%, and the construction periodis remarkably shortened compared with a cast-in-place structure. The overall anti-seismic property of the building is effectively improved.

Owner:HUBEI PEI HAN CONSTR CO LTD

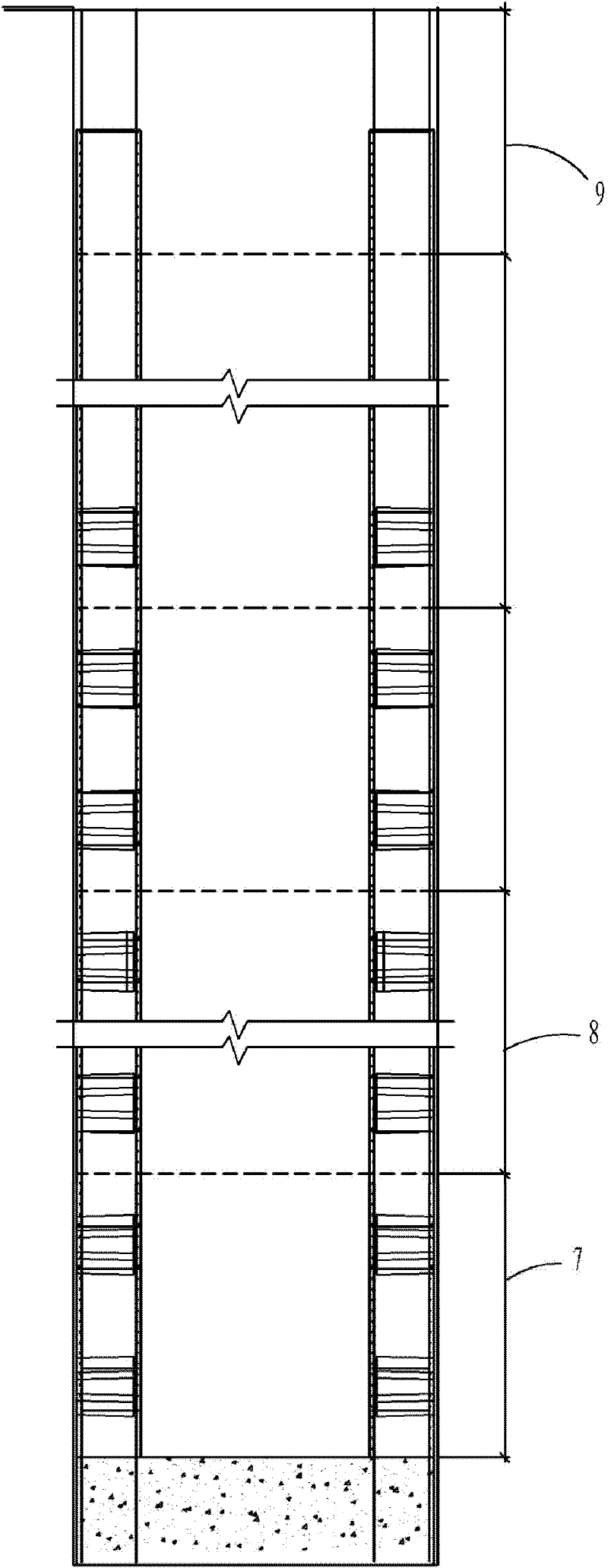

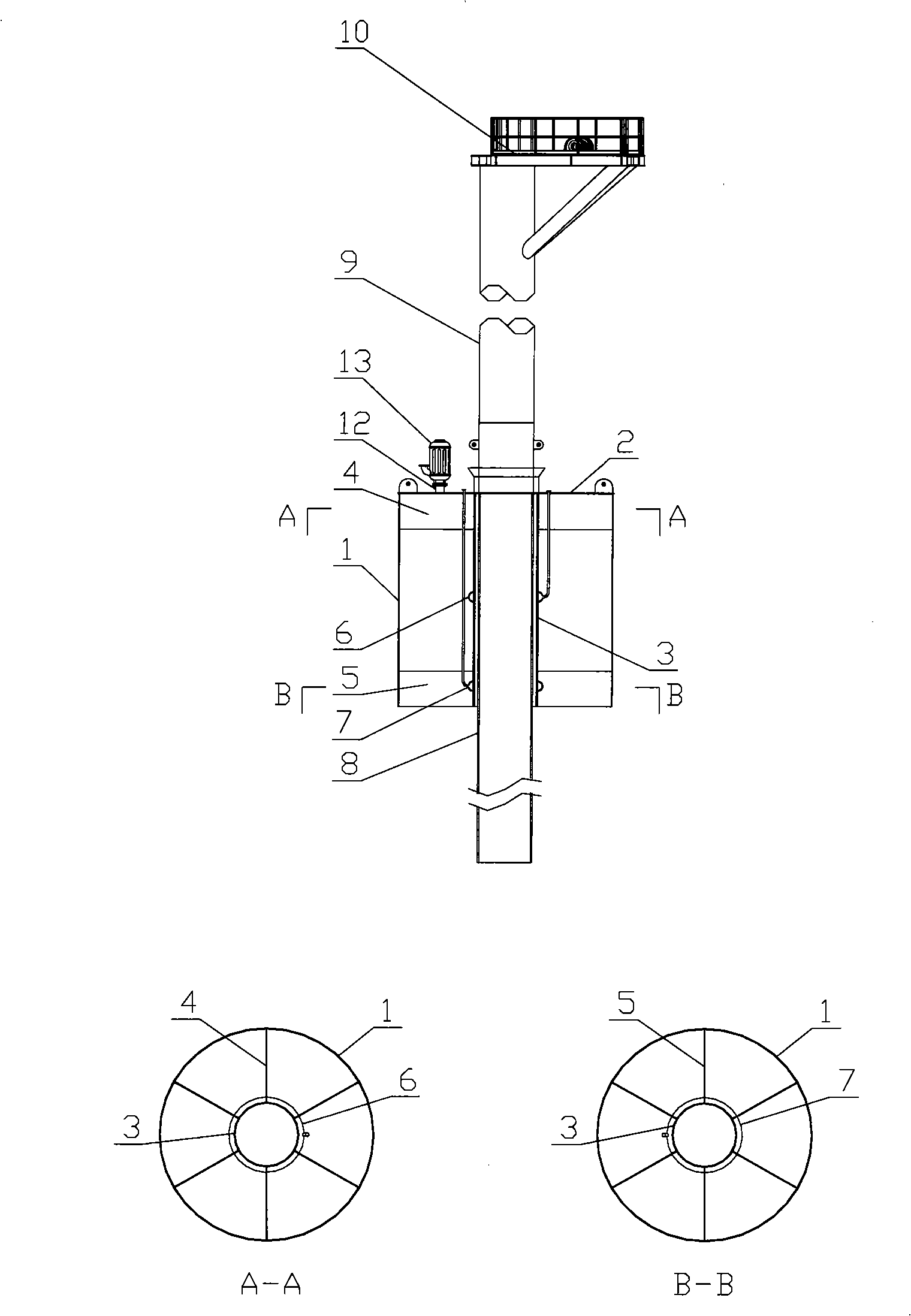

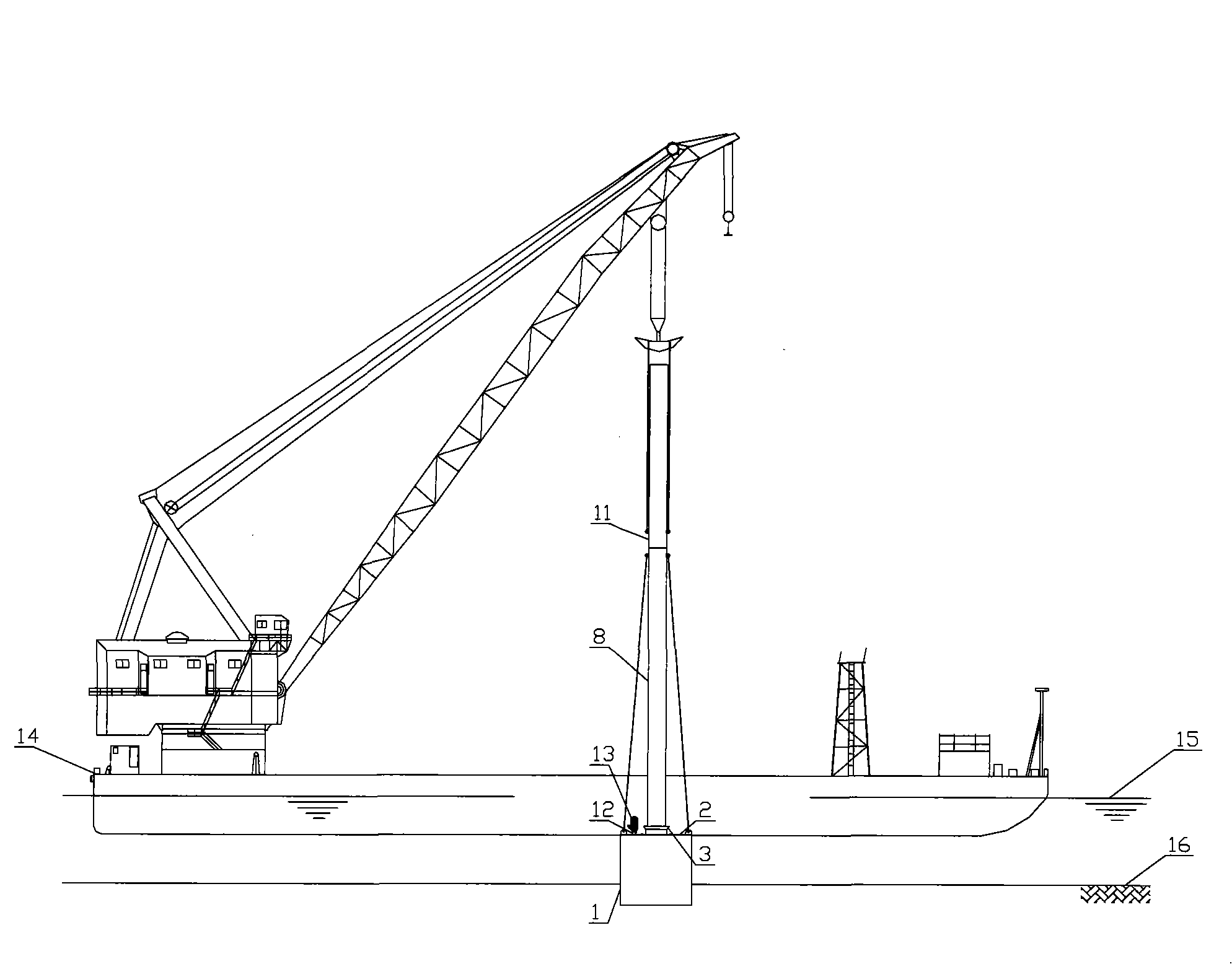

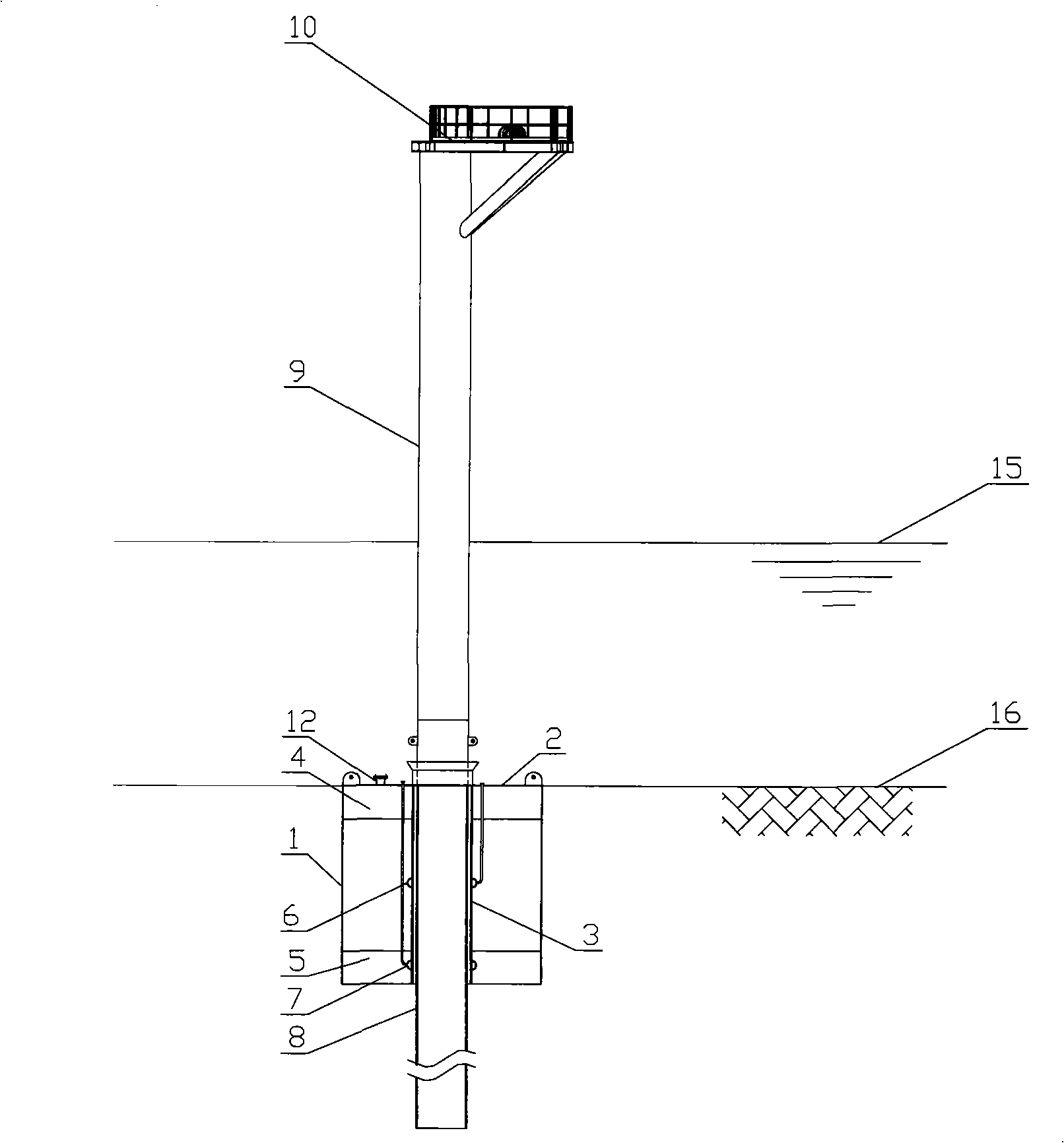

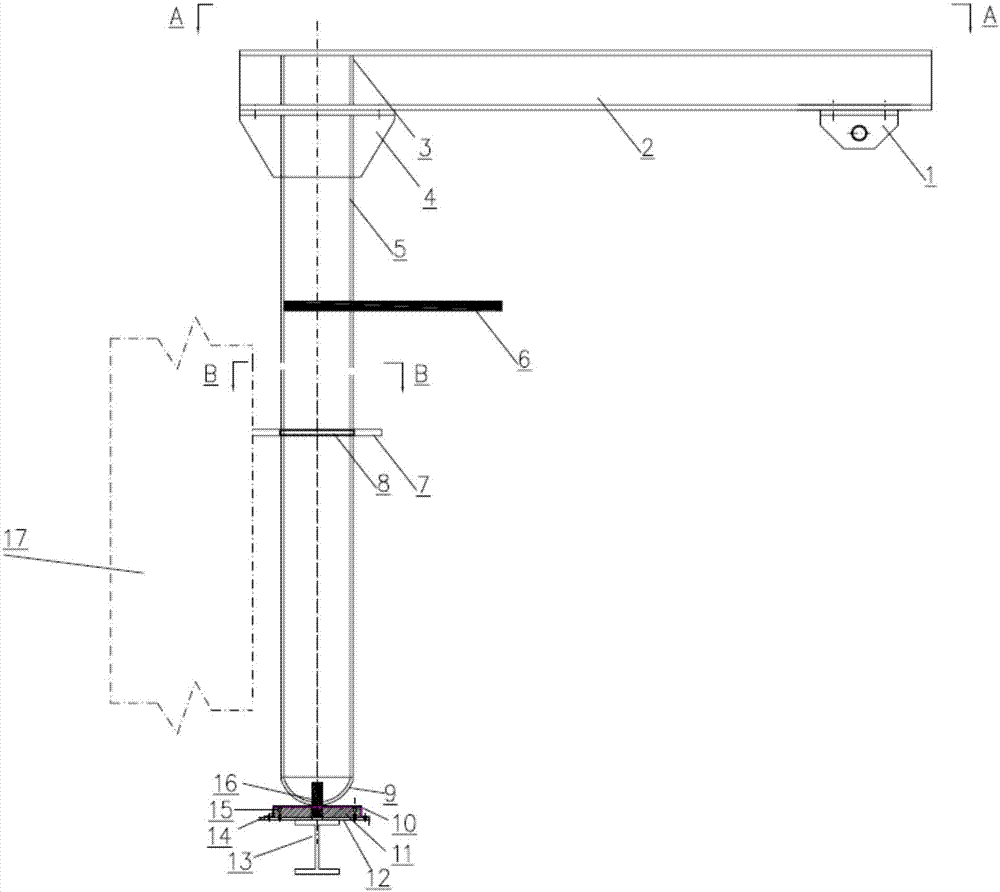

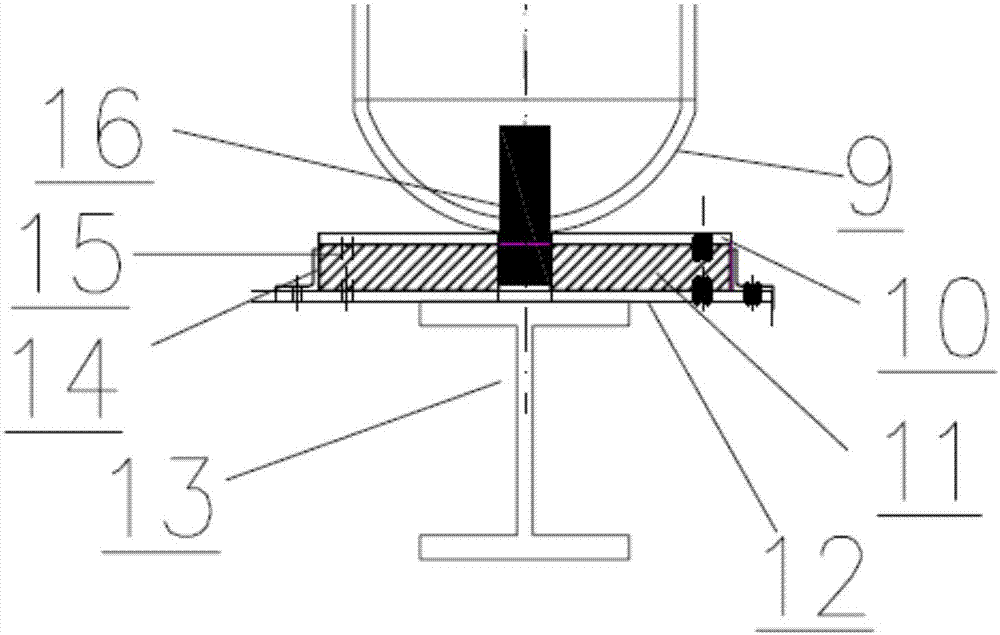

Novel single pillar structure and mounting method thereof

ActiveCN101298765AImprove structural strengthLower requirementArtificial islandsUnderwater structuresHorizontal forceSurface layer

A new single post structure and an installation method thereof are disclosed, the structure is composed by a suction pile + driven pile 8, a central vertical post 9 and a small platform 10, characterized in that the structure adopts a combination basic of suction type + driven type, the small platform 10 forms an integrative structure with the central vertical post 9 by welding. A central guide cylinder 3 is located in centre of the cylinder body 1, upper end is higher than a top cover 2 with a bell-mouthed shape, the lower end is horizontal to bottom end of the cylinder body 1. A mud-cleaning jetting ring 7 is provided in middle of a lower rib plate 5 of the central guide cylinder 3 and a grouting jetting ring is provided in the middle of the central guide cylinder 3. The top cover 2 is provided with a pump hole 12 for installing an underwater pump 13 or a pneumatic pump. The invention has the advantages that the new single post structure varies P-Y curve of surface layer soil, which is in favour of reduction of displacement under horizontal force, and meanwhile enhances structural intensity of the post. During the construction, the combination basic of the new single post structure lessens hoisting weight, in the meantime, the suction pile assists and positions the driven pile.

Owner:NEPTUNE OFFSHORE ENG DEV

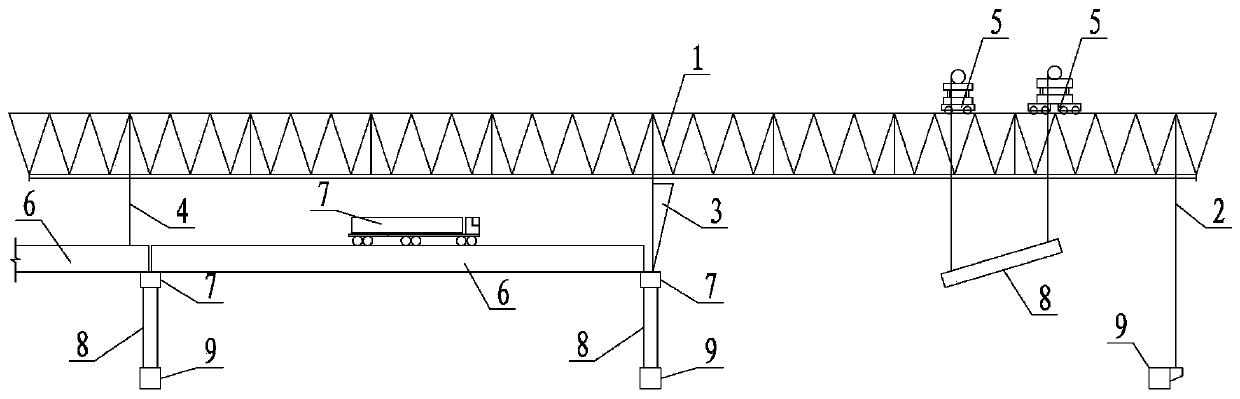

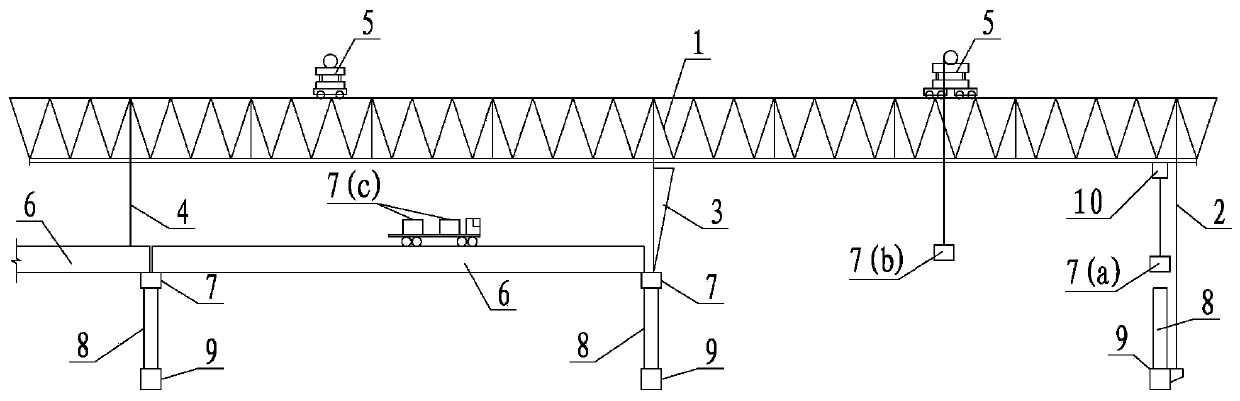

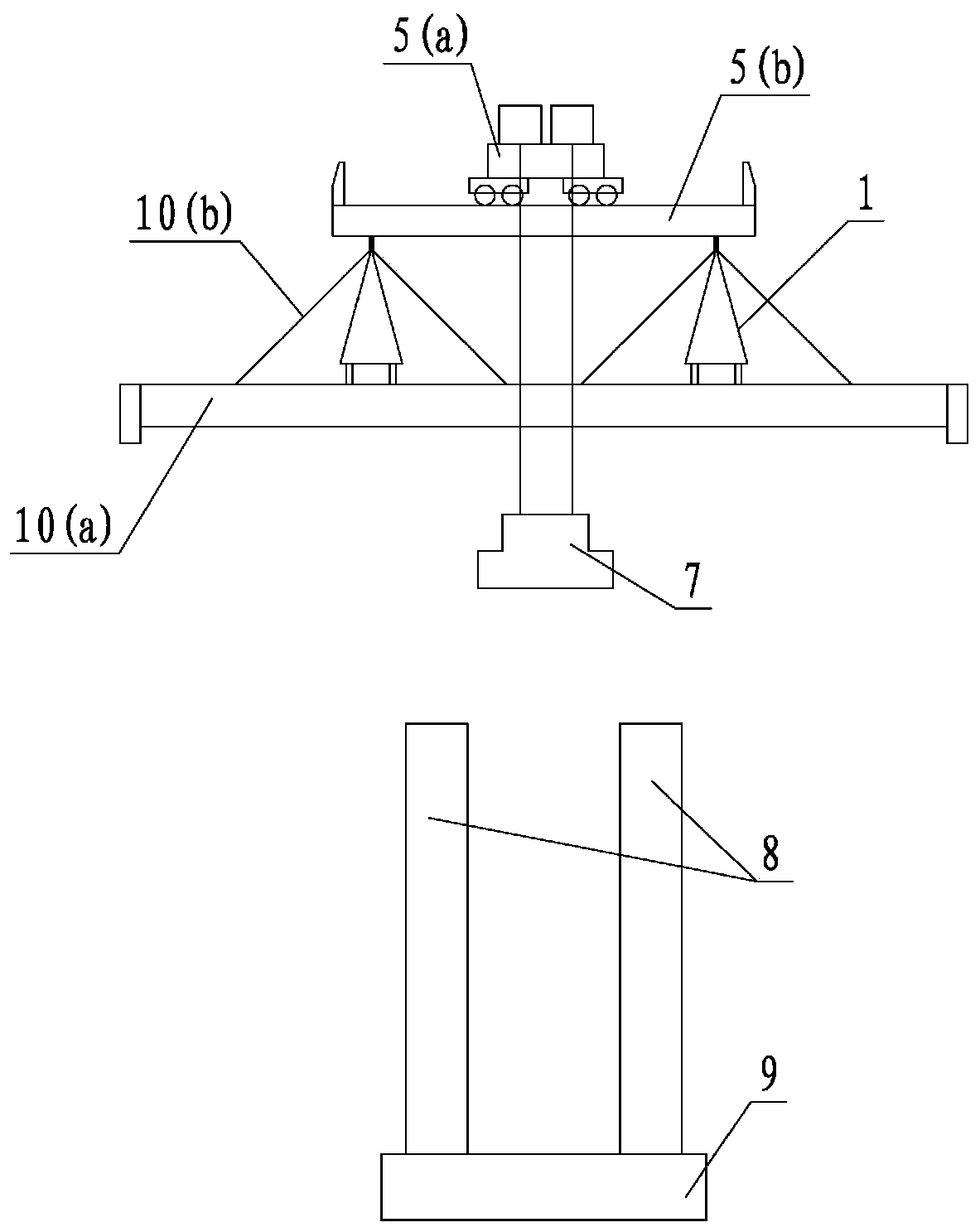

Three-working-face bridge erecting machine capable of achieving longitudinal and transverse splicing and bent cap shortcut-free segment splicing method

PendingCN110093862AReduce lifting weightReduce riskBridge erection/assemblyStructural engineeringStructural stability

The invention discloses a three-working-face bridge erecting machine capable of achieving longitudinal and transverse splicing and a bent cap shortcut-free segment splicing method. Double-working-surface erection of a bridge pier stand column and an upper structure main beam is realized and a prefabricated bent cap segment transverse assembly working face is additionally arranged, so assembly of the shortcut-free segment of the bent cap can be achieved through the working face, and in other words, in the bent cap segment assembly process, the structural stability and positioning accuracy of the bent cap segment can be guaranteed without arranging temporary shortcuts or brackets and the like. According to the invention, it can be achieved that the prefabricated pier column can be erected inthe vertical direction, the prefabricated bent cap segments can be transversely spliced, the prefabricated main beams can be longitudinally erected, and repeated disassembling and assembling of facilities such as temporary shortcuts or brackets are not required for transverse splicing of the bent cap segments.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

Obstructing pulling method pile digging construction device and method

InactiveCN106400804AGuaranteed to be vertical without deflectionPrecise positioningBulkheads/pilesRebarProtection layer

The invention relates to an obstructing pulling method pile digging construction device and method. The device comprises reinforcement cage main ribs and reinforcement cage stirrups, the reinforcement cage main ribs are equally distributed in a surrounding manner and are annularly, spirally, sequentially and fixedly wound with the reinforcement cage stirrups to form a reinforcement cage, the reinforcement cage is placed into a bored pile formed hole and is provided with reinforcement cage protection layer devices, and a concrete pre-separation device is arranged at the top end of the reinforcement cage; the reinforcement cage protection layer devices are arranged in the length direction of the reinforcement cage every 3 m, and protection layers are arranged on ach reinforcement cage protection layer device every 90 degrees along the circumference; the concrete pre-separation device is composed of vertical reinforcement isolation sleeves, annular protection layer isolation rings and filler, the reinforcement cage main ribs, located at the pile top, of the reinforcement cage are provided with the vertical reinforcement isolation sleeves one by one, and the two ends are closed; and the annular protection layer isolation rings are installed at the bottoms of the vertical reinforcement isolation sleeves. The obstructing pulling method pile digging construction device and method have the beneficial effects of saving labor and being rapid and environment-friendly.

Owner:NINGBO MUNICIPAL ENG CONSTR GROUP

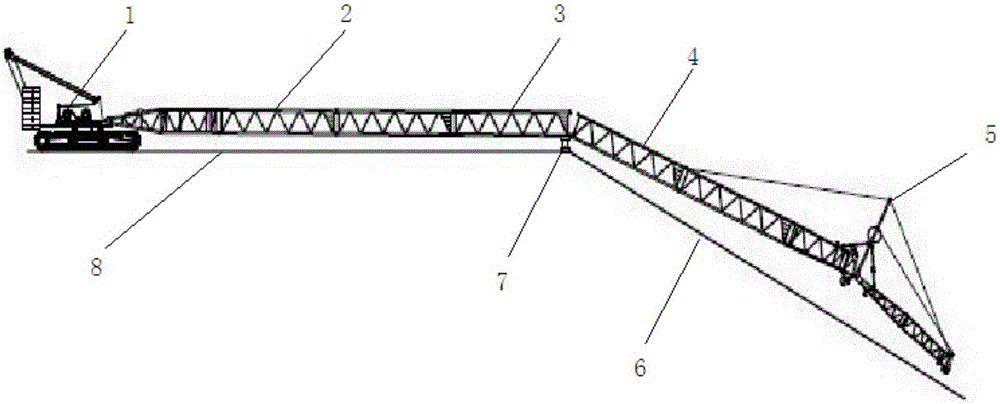

Construction method for assemble cargo boom of crawling crane through breaking-off method

The invention discloses a construction method for assemble a cargo boom of a crawling crane through a breaking-off method. When the cargo boom is assembled on the ground at the same height with the platform where a main crane of the crawling crane is located, all boom joint units are connected sequentially through upper hinge pins and lower hinge pins starting from the root joint. When the cargo boom is assembled to the ground downhill position, a support device is placed on the ground near the downhill position and is used for supporting assembled cargo boom units, then the lower portion of the boom joint unit in the position and the lower portion of the next boom joint unit only through a lower hinge pin, and then along the ground slope, the all next boom joint units are connected sequentially through lower hinge pins and lower hinge pins. When the head position is lifted gradually to be on the same horizontal line with the root segment of the cargo boom, the upper hinge pins of the two boom joint units in the downhill position, and thus pull rods of the two boom joint units are connected in a butt joint mode. After all installation work is completed, a main lifting machine of the crane is started, and assembly of the cargo boom is completed.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD +1

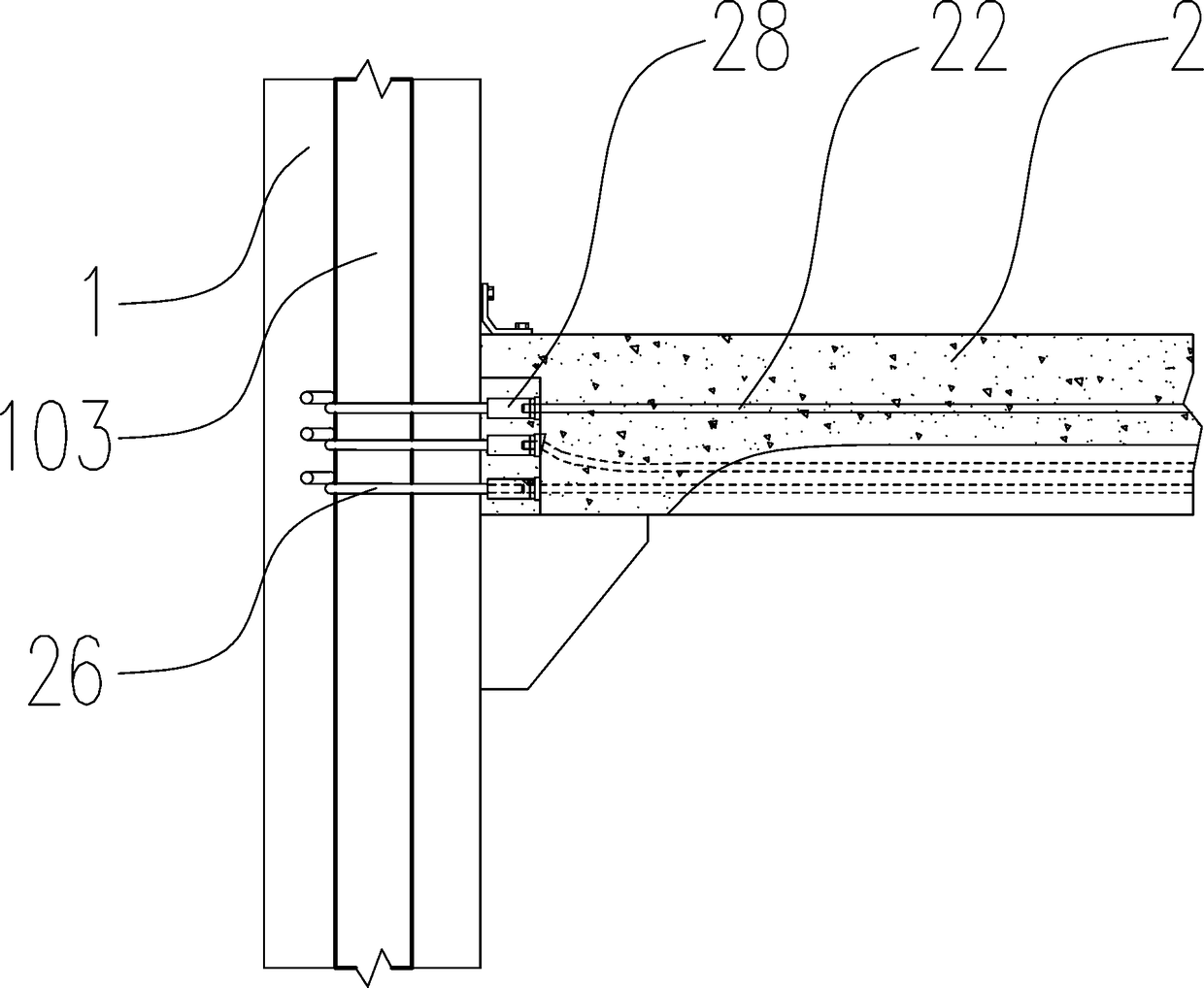

Underwater pouring root type foundation with retaining wall and construction method thereof

ActiveCN103911989AHigh strength to mass ratioHigh stiffness-to-mass ratioBulkheads/pilesReinforced concreteUnderwater

The invention discloses an underwater pouring root type foundation with a retaining wall and a construction method thereof. The underwater pouring root type foundation with the retaining wall is characterized in that a retaining wall layer formed by pouring underwater quick set materials is arranged between a cast-in-place reinforcing concrete tubular column and the pore-forming inner wall, the side wall of the concrete tubular column is provided with root keys in the radial direction of the tubular column, the bottom of the concrete tubular column is provided with a concrete back cover, and a top cover is arranged on the top of the concrete tubular column in a pouring mode so that the underwater pouring root type foundation with the retaining wall can be formed. The underwater pouring root type foundation can be effectively applied to civil engineering, bridge buildings and water conservancy project structures, and the construction efficiency is improved.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

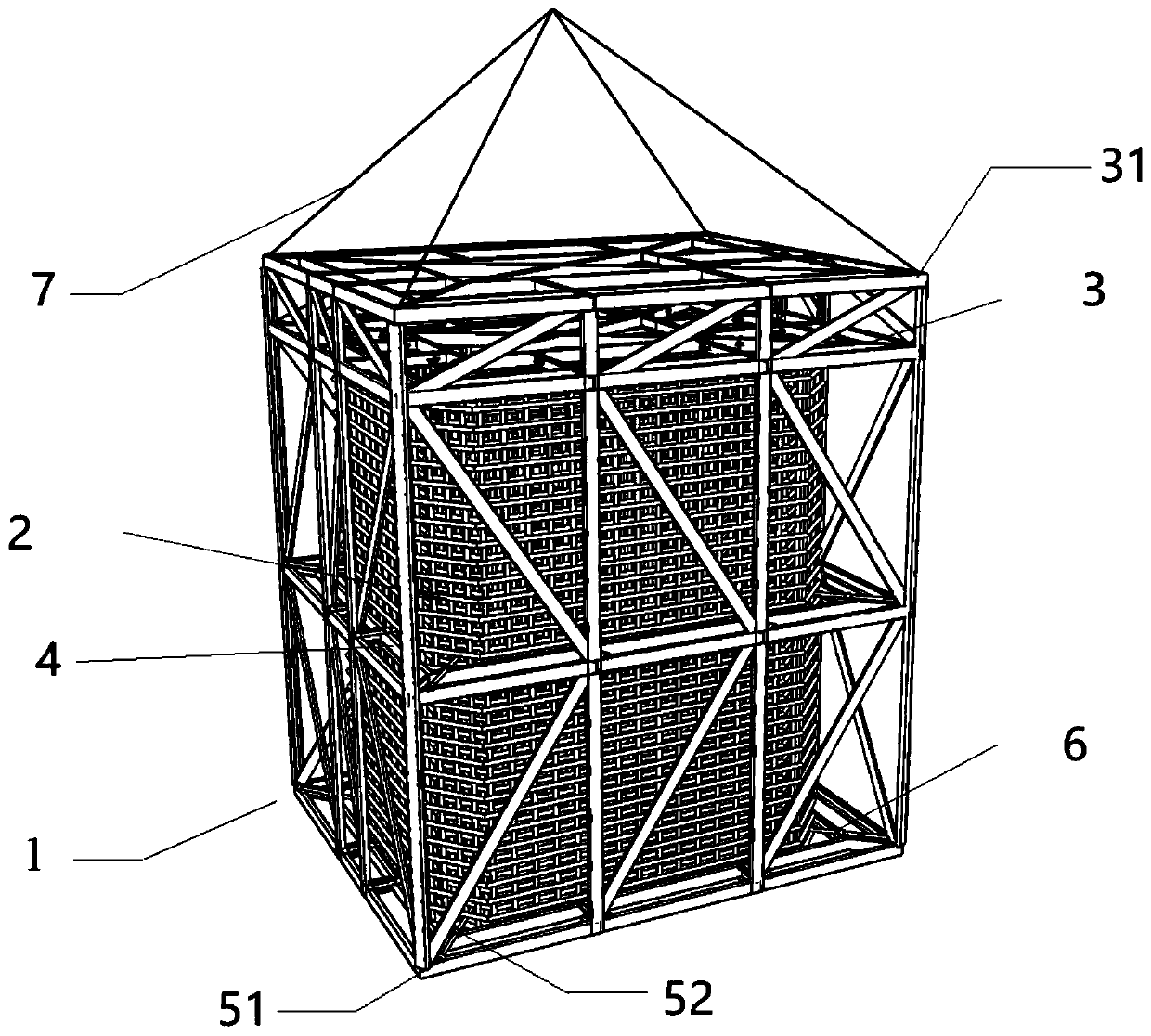

Hanger-integrated stiff skeleton integrated device and reinforcement cage lifting construction method

ActiveCN110747736AIncrease stiffnessAvoid cracking etc.Bridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a hanger-integrated stiff skeleton integrated device which comprises a stiff skeleton. The stiff skeleton is of a cube structure with the lower end open. A reinforcement cage is sleeved with the stiff skeleton and is detachably connected with the stiff skeleton. A hoisting mechanism is arranged on the stiff skeleton. A reinforcement cage lifting construction method using the integrated structure comprises the steps that the dimension of the stiff skeleton is determined according to the shape of the reinforcement cage, box iron of difference types is selected, spliced and welded; the hoisting mechanism is arranged at the top of the stiff skeleton; the outer side of the reinforcement cage is sleeved with the stiff skeleton from top to bottom, and the stiff skeleton isdetachably connected with the reinforcement cage; the integrated device is hoisted up by a crane, and the reinforcement cage is transported onto a pier stud and connected with steel bars of a pouredsection; the integrated device is detached and hoisted out, templates are installed outside the reinforcement cage, and concrete is poured. The integrated device has the characteristics of being convenient and fast in construction and capable of being recycled, and can be widely applied to the technical field of bridge construction.

Owner:中交二航局第一工程有限公司

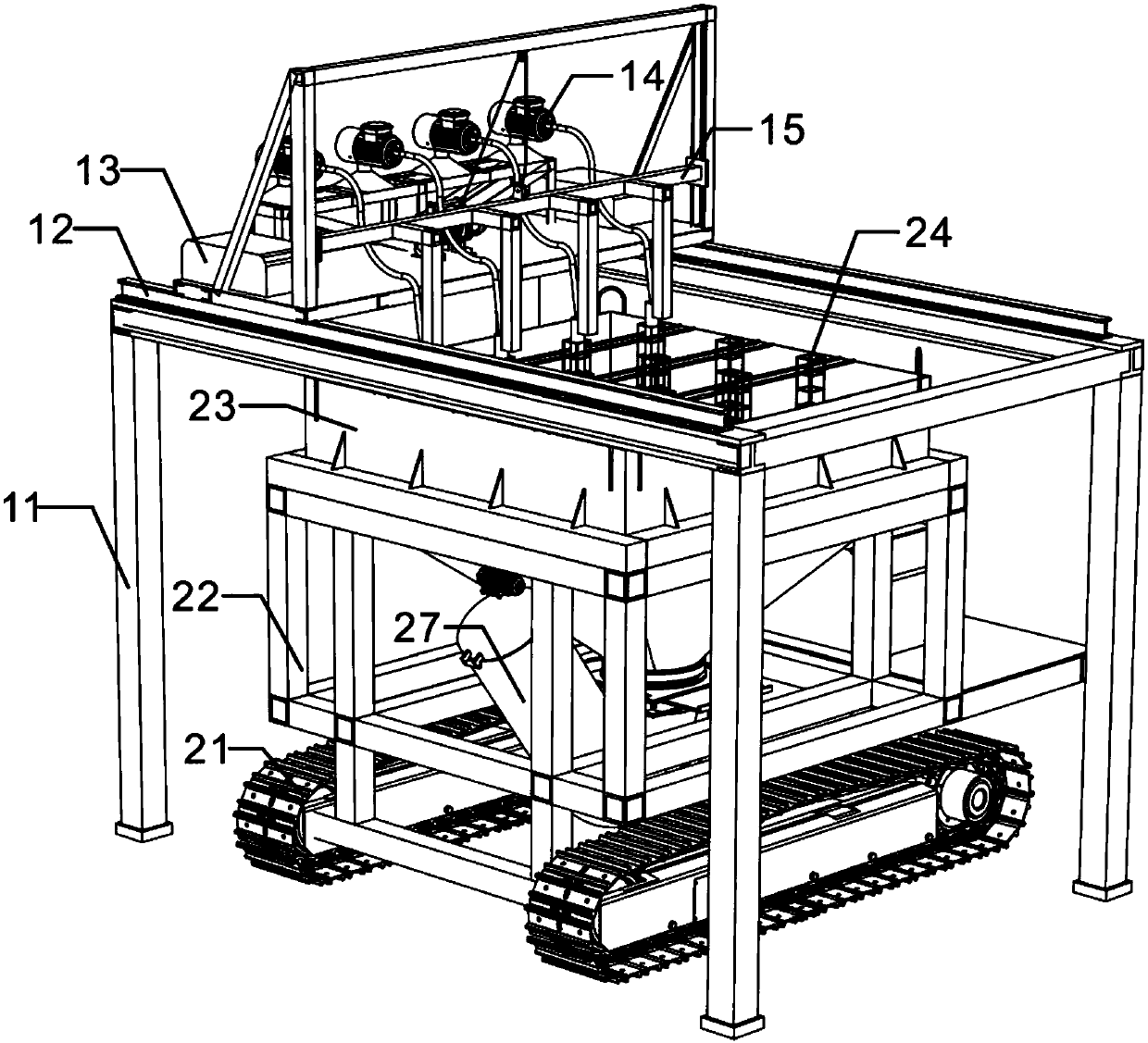

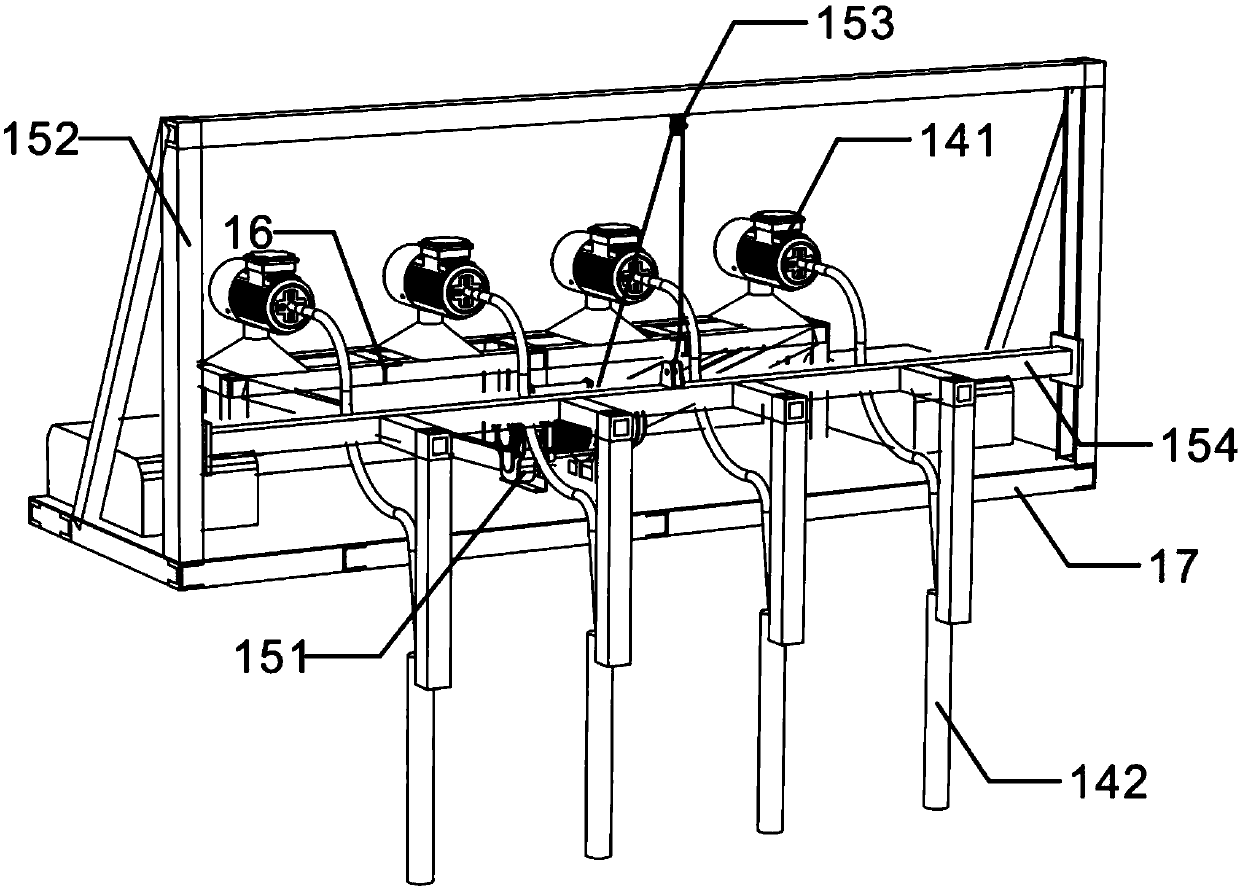

Self-moving type recycled block body discharging, mixing and vibrating device

PendingCN109680953AAccurately control the dosageImprove the efficiency of mixing and vibratingBuilding material handlingOperation pointEngineering

The invention discloses a self-moving type recycled block body discharging, mixing and vibrating device which comprises a vibrating supporting frame, rails, a walking trolley, a plurality of vibrators, a walking driver system, a hopper, a plurality of vibrating guiding devices and an articulated chute, wherein the rails are arranged at the top of the vibrating supporting frame in parallel, the walking trolley slides along the rails in a reciprocating mode, the vibrators are transversely arranged on the walking trolley at equal intervals, the hopper is arranged on the walking driver system, thevibrating guiding devices extend into the hopper from an opening above the hopper, and the articulated chute is connected with a discharge opening of the hopper. According to the self-moving type recycled block body discharging, mixing and vibrating device disclosed by the invention, the hopper is sequentially filled with cast-in-place concrete and the recycled block body in a material storage yard, the plurality of the vibrators are utilized to fully vibrate and mix the cast-in-place concrete and the recycled block body, then the walking driver system can self move to a construction site, and the hopper is lifted to an operation point by lifting equipment to discharge materials. The device has the advantages of good mixing effect, convenience in loading and unloading, self movement, highdischarging efficiency and more important effect on propelling recycled block body concrete to be applied to engineering on a large scale.

Owner:SOUTH CHINA UNIV OF TECH

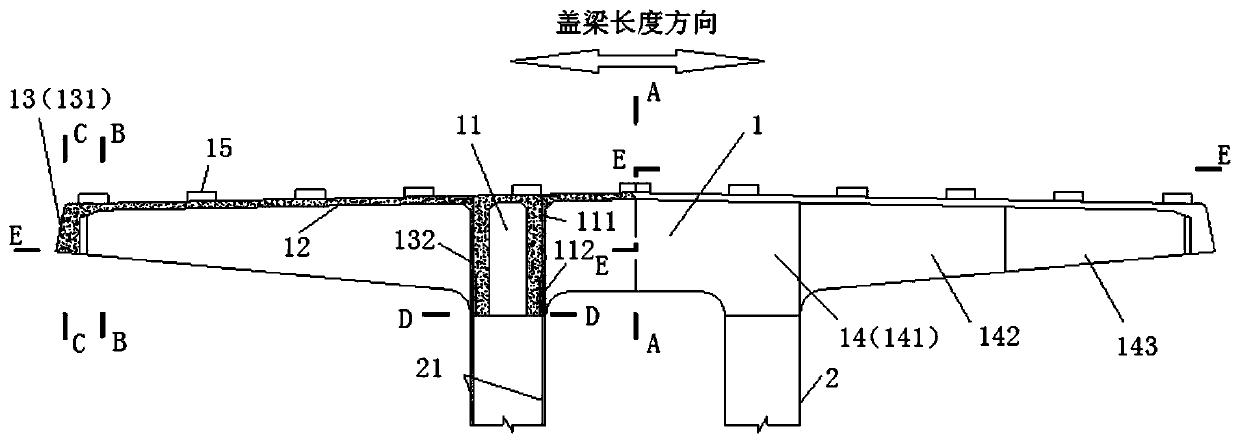

Total precast lower structure of bridge and construction method

ActiveCN107165038ASatisfy the height limitFulfil requirementsBridge structural detailsBridge erection/assemblyPre stressHigh intensity

The invention discloses a total precast lower structure of a bridge and a construction method. The structure is mainly composed of single whole precast lower components, a precast base plate, a prestressed steel strand and aseismic ribbed bars; single precast components which are precast in a factory overall are composed of cover beams, pier columns and enlarged foundations; the cover beams of the whole single precast components are reserved with corrugated pipes, and the prestressed steel strand is connected with the components in series through the reserved corrugated pipes in site assembly; concrete cast-in-site segments are arranged between the enlarged foundations of the single precast components, and the enlarged foundations of the single precast components are integrally connected in site construction; the whole precast base plate is arranged on the bottom of a whole foundation; when main beams to be precast is reserved on the tops of the cover beams of the precast components, the tops of the cover beams extend into the aseismic ribbed bars of main beam reserved holes. According to the total precast lower structure of the bridge and the construction method, the mode is simple, and the structure is suitable for a high intensity seismic zone.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Pipeline installing method

The invention discloses a pipeline installing method. The pipeline installing method comprises the steps that a fastening belt is adopted for achieving temporary fastening of a first pipe base and a first pipe joint, and a first pipe base and pipe joint unit is formed; the first pipe base and pipe joint unit is hoisted into a base groove; the pipe inner bottom elevation of the first pipe joint inthe base groove is measured; gaps on the two sides between the first pipe joint and the first pipe base are closed; the preparing work for second pipe base and pipe joint unit installation is conducted; a second inserting port of a second pipe joint is inserted in a first port of the first pipe joint; the bell mouth end elevation of the position of a second bell mouth of the second pipe joint in the base groove is measured; a gap on the second bell mouth side between the second pipe joint and the second pipe base is closed; the steps from the fifth step to the eighth step are repeatedly conducted, and subsequent pipe base and pipe joint unit installation is finished; and cement mortar is poured into the positions between the pipe joints and the pipe bases in the same pipe base and pipe joint units and between the pipe bases between the adjacent pipe base and pipe joint units. According to the pipeline installing method, the hoisting frequency can be effectively reduced, and the advantage that construction is safe and reliable is achieved.

Owner:KUNSHAN YUTENG MUNICIPAL ENG

Large-diameter pile base reinforcing steel bar in-hole layering and bundling construction method

ActiveCN110616706AEasy to set upControl the lifting weightBuilding material handlingBulkheads/pilesEngineeringRebar

The invention discloses a large-diameter pile base reinforcing steel bar in-hole layering and bundling construction method. The large-diameter pile base reinforcing steel bar in-hole layering and bundling construction method comprises the following steps: layering a reinforcement cage, limiting and manufacturing a reinforcement reinforcing cage and an operating frame, fixing and hoisting the operating frame and the reinforcement reinforcing cage into pile holes. The large-diameter pile base reinforcing steel bar in-hole layering and bundling construction method positions the reinforcement cage, and provides an operation platform for a constructor, so that hoisting weight is effectively controlled; and meanwhile, time of arranging the operating frame in the pile holes is reduced, and the operating frame is conveniently arranged. The construction method breaks through an existing common reinforcement cage construction way; and the reinforcement cage is bundled in the pile holes, so thatthe defects that the large-diameter reinforcement construction difficulty is great, hoisting is difficult, hoisting quality is not easily controlled, and potential safety hazards are easily generatedin the prior art are solved.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

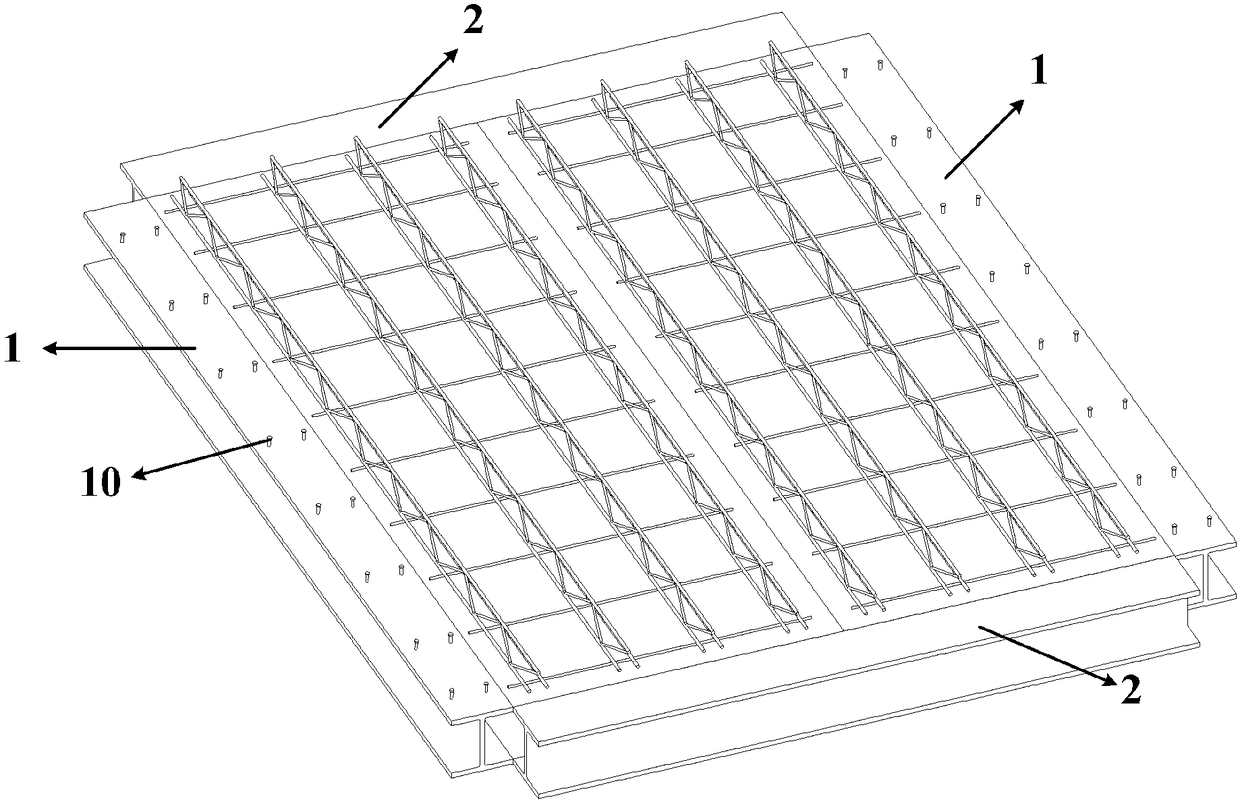

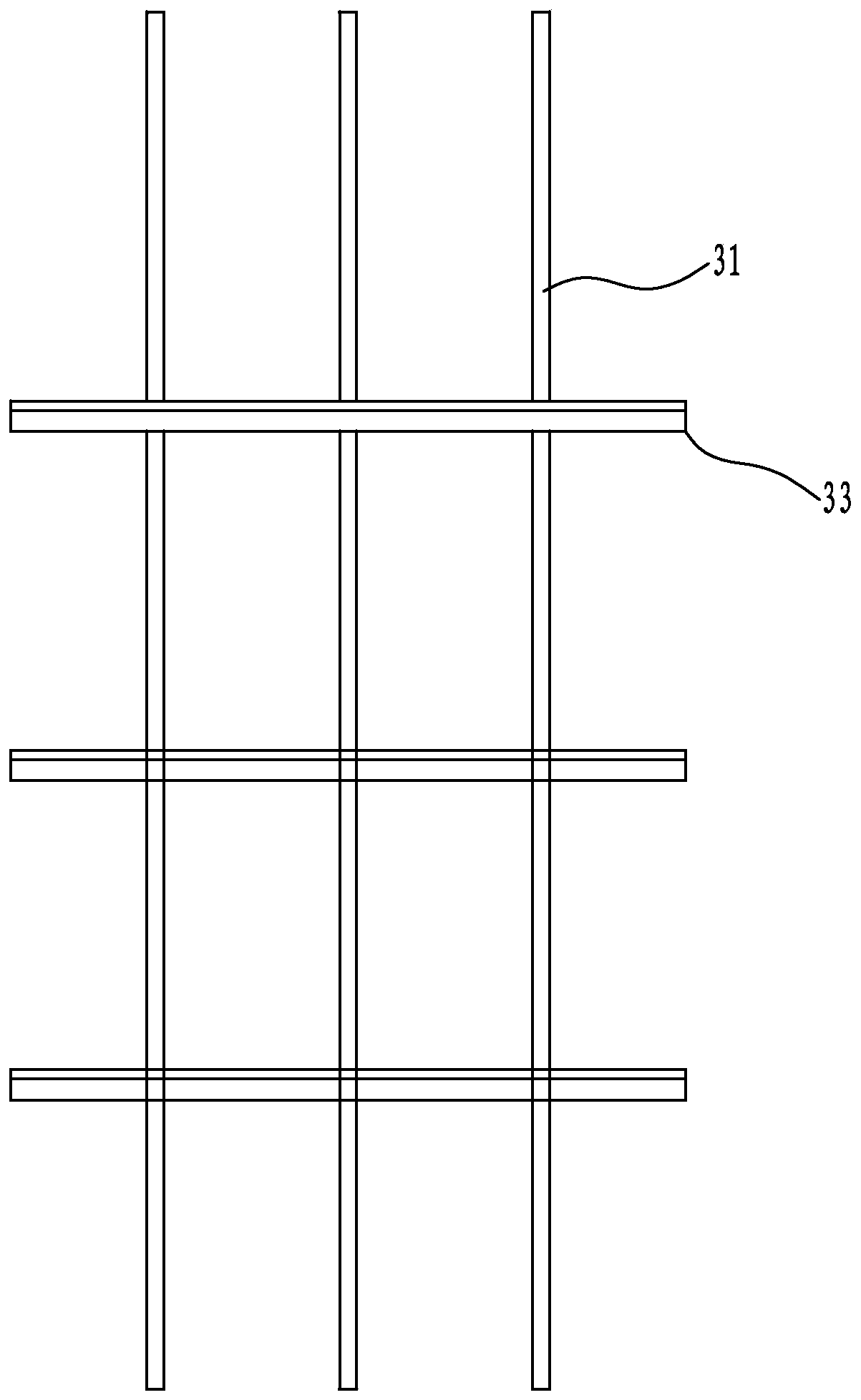

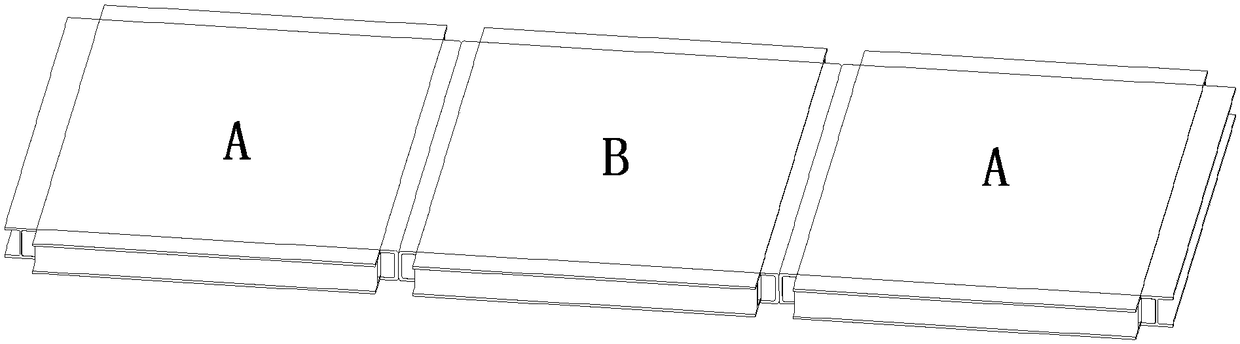

Assembly type big module overlapped beam and slab structure with three-dimensional truss temporary supports

The invention discloses an assembly type big module overlapped beam and slab structure with three-dimensional truss temporary supports. A temporary whole is formed by connecting quadrangular three-dimensional truss temporary supports and beams through connecting plates and bolts. A reinforcing mesh is paved on the temporary supports, a prefabricated concrete layer is poured after the reinforcing mesh is paved, and a whole is formed by pouring concrete at the inner sides of flanges of the beams during pouring. The assembly type big module overlapped beam and slab structure with the three-dimensional truss temporary supports is hoisted in place after prefabrication and processing, an overlapped slab is formed by paving a slab upper layer reinforcing mesh piece on the upper part of the prefabricated concrete layer according to the design and pouring the rest of slab concrete. When the slab maintenance is finished, the bolts are disassembled, the temporary supports are removed, and the assembly type overlapped slab construction is completed. The assembly type big module overlapped beam and slab structure with the three-dimensional truss temporary supports can solve the problem of slabintegrity, lifting weight is reduced, and the assembly accuracy and construction efficiency are improved.

Owner:BEIJING UNIV OF TECH

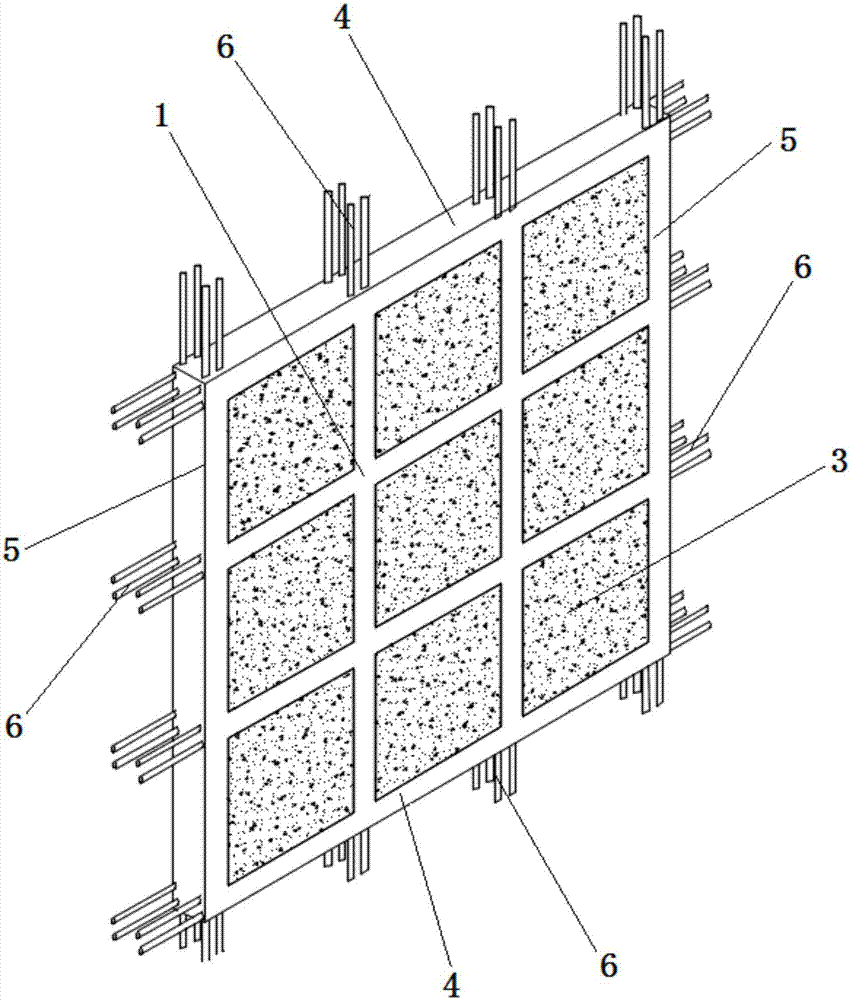

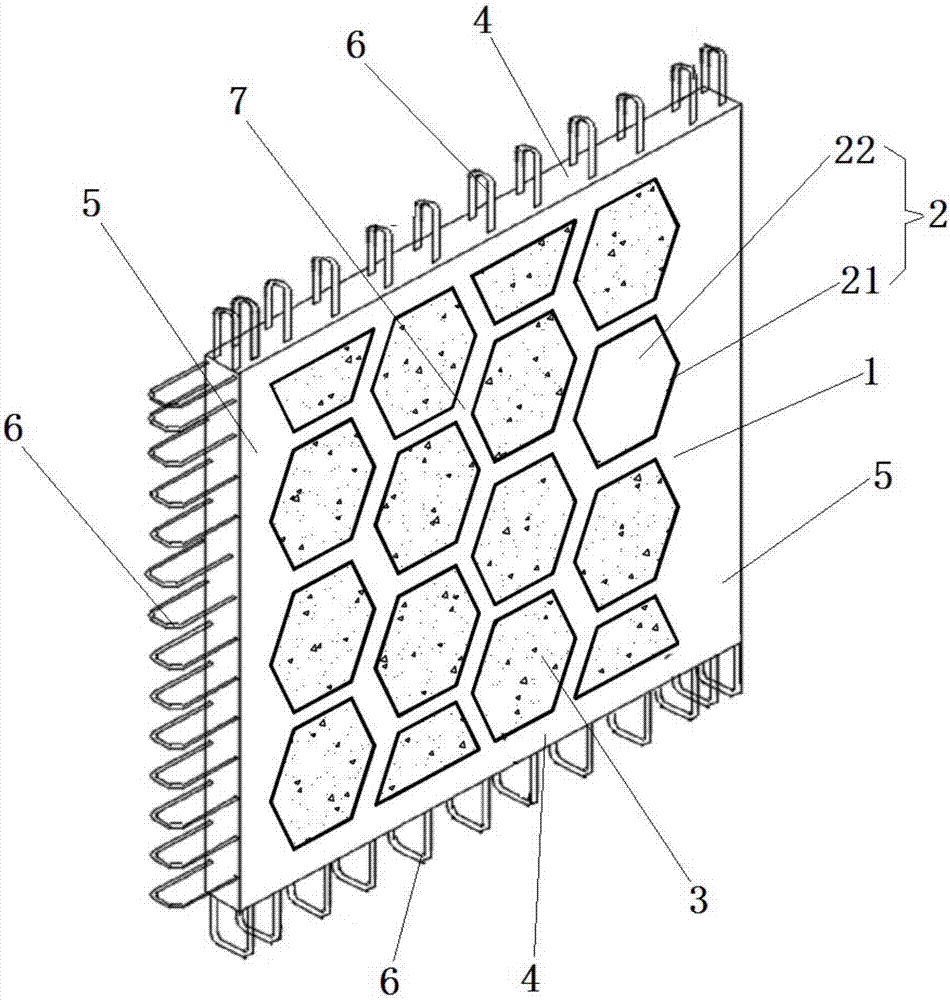

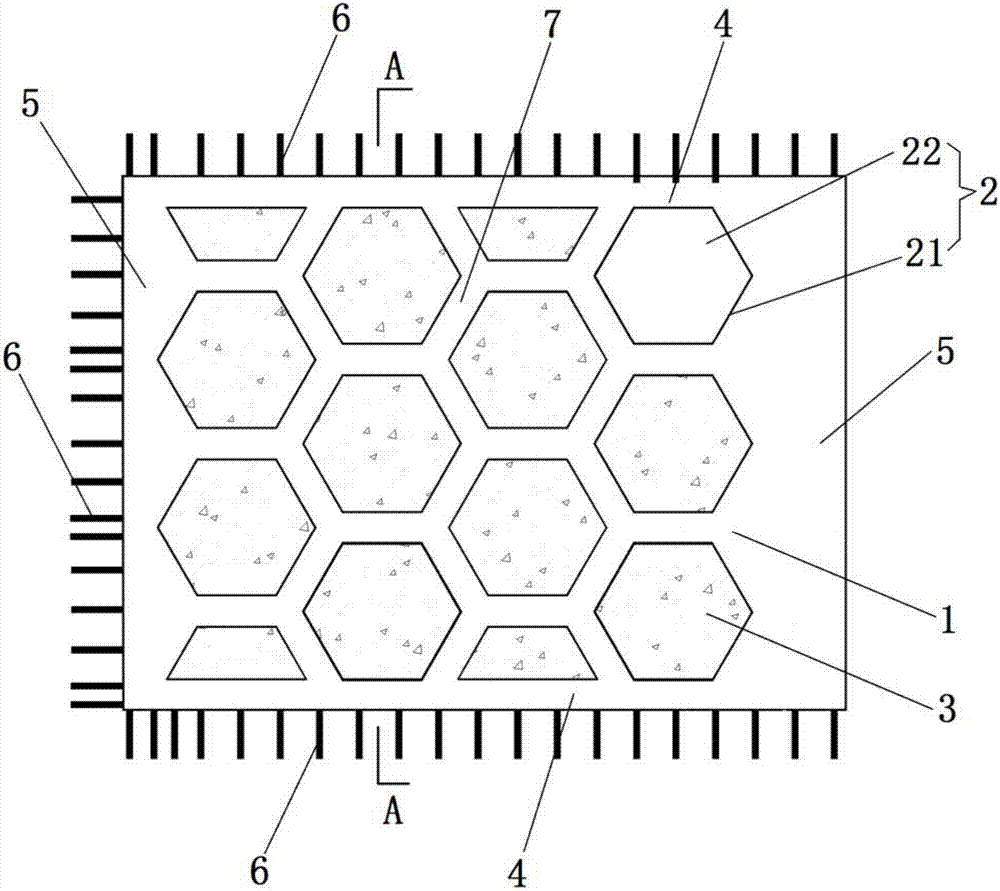

Prefabricated honeycomb composite structure wallboard

InactiveCN107083819AReasonable structureEasy to manufactureBuilding componentsHoneycomb structureMaterials science

The invention discloses a prefabricated honeycomb composite structural wallboard which comprises a platy cubic wallboard body provided with at least six surfaces. A plurality of honeycomb structure units distributed in a honeycomb shape are arranged in the wallboard body. Each honeycomb structure unit comprises a polygonal honeycomb wall which is formed by connecting at least six edges or a tubular honeycomb wall composed of arc edges, a honeycomb hole and filler, wherein the honeycomb hole is formed by the honeycomb wall, and the filler is arranged in the honeycomb hole. The periphery of the honeycomb structure unit located in the middle is adjacent to at least four additional honeycomb structure units. The prefabricated honeycomb composite structural wallboard is easy and convenient to manufacture, the polygonal or arc-shaped honeycomb structure units formed by at least six sides are adopted and distributed in the wallboard in the honeycomb shape so that the wallboard of a composite structure can be formed, the bearing capacity of the assembled wallboard is improved so that the stress of the wallboard can be more uniform and reasonable, the safety performance of the wallboard is improved, and the economical efficiency is remarkable.

Owner:刘祥锦

Mounting method of deep well high pressure aeration reactor steel drum

InactiveCN101344004AReduce lifting weightPrevent hole collapseFlow mixersMixing methodsInstabilityEngineering

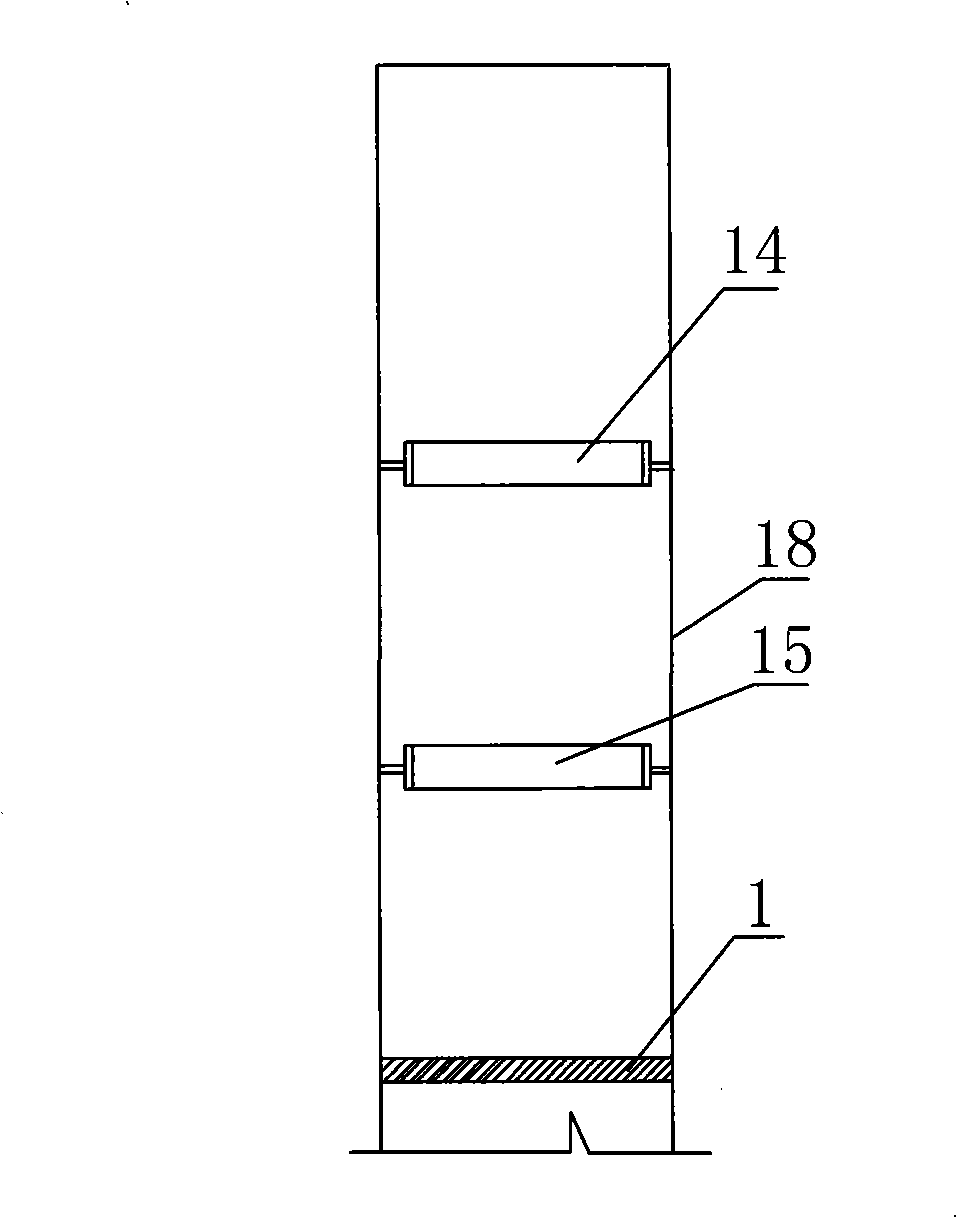

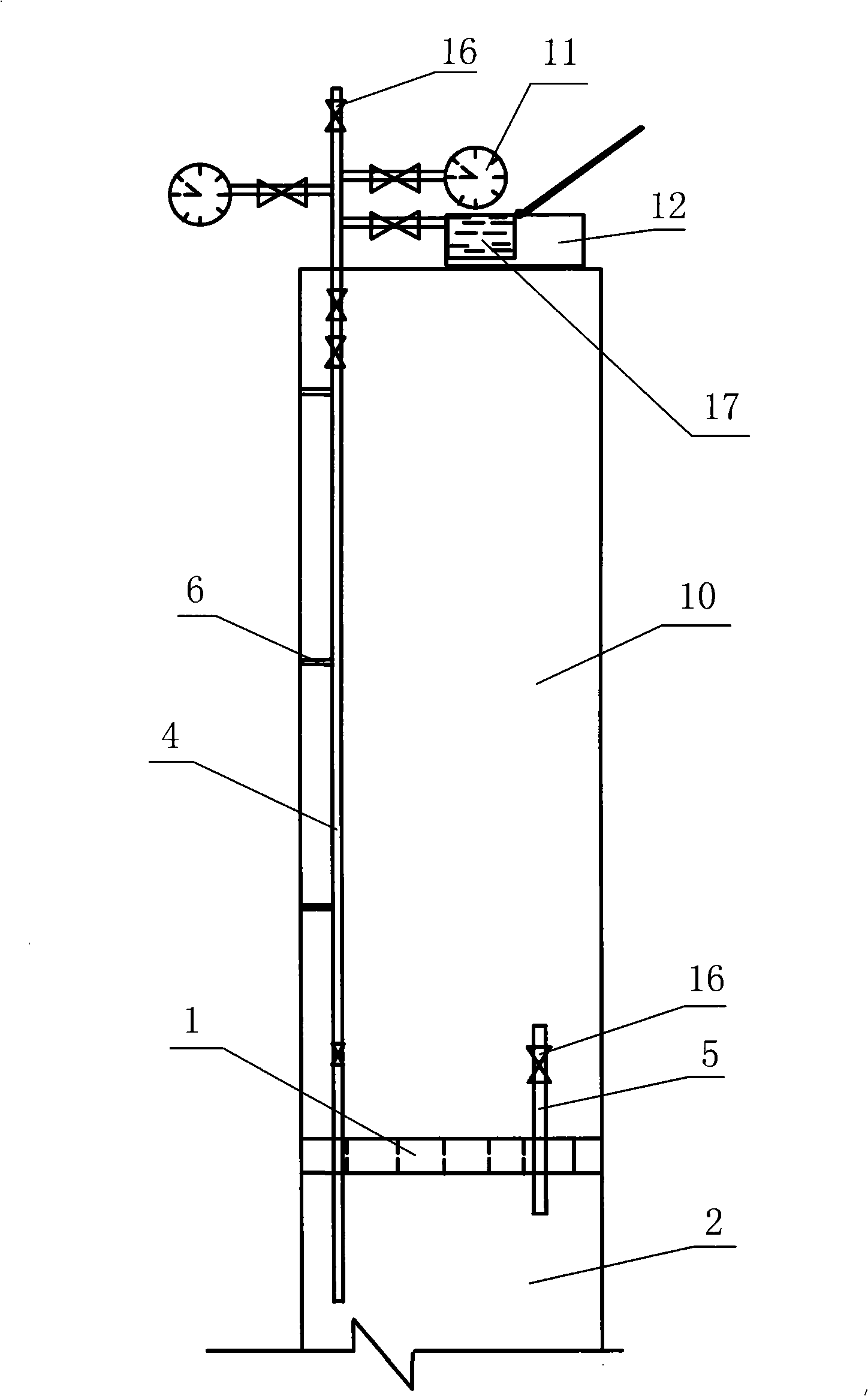

The invention discloses an installation method for a steel cylinder of a high-pressure aeration reactor of a deep well, comprising the following steps of: processing and manufacturing an inner baffle; determining the installation position of the inner baffle: the steel cylinder consists of a plurality of groups of steel cylinder sections from bottom to top, the inner baffle is arranged on the steel cylinder section with the number of M and the length ratio of the upper part and the lower part of the inner baffle is 2.5 to 4.0 : 6.0 to 7.5; installing a plurality of groups of steel cylinder sections of the lower part of the inner baffle in sequence from bottom to top; installing the inner baffle; sinking and temporarily fixing the steel cylinder section with the number of M+1; sinking and installing the steel cylinder section with the number of M+2 after the pressure in the cylinder is transmitted up uniformly and installing a plurality of groups of steel cylinder sections of the upper part in sequence according to the installation method thereof; pouring concrete or mortar to the outside of the steel cylinder; releasing the pressure and carrying out cutting recovery of the inner baffle. The invention can solve the lifting problem of the steel cylinder and the instability and distortion problem of the steel cylinder under the effect of the side pressure of the slurry outside of the cylinder, can ensure that the steel cylinder sinks to the designed elevation safely and smoothly and can save the construction cost.

Owner:陈定平

Novel cable bent tower intersection section structure and construction method thereof

ActiveCN106522094ASolve the problem of needing to build high-altitude support formworkReduce difficultyBridge structural detailsBridge erection/assemblyReinforced concreteTower

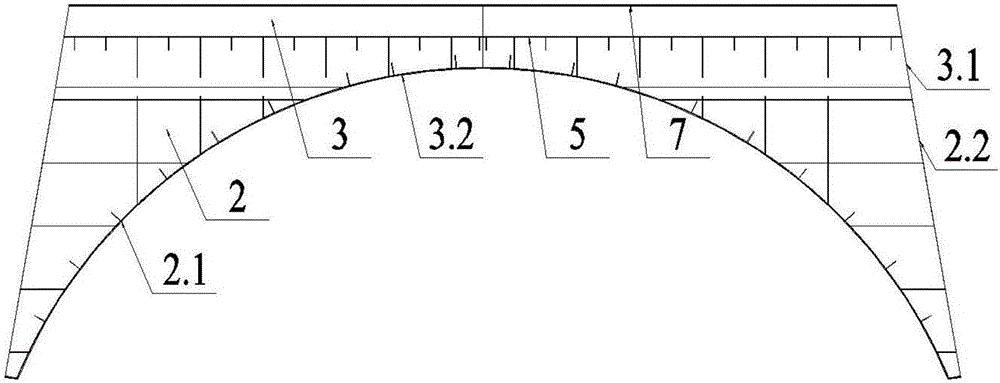

The invention relates to the field of bridge design and construction technology, specifically a novel cable bent tower intersection section structure and a construction method thereof. The novel cable bent tower intersection section structure comprises a cross beam which is arranged between two tower columns, wherein the cross beam comprises a steel box arranged between the two tower columns; the steel box is at least one box body structure, which is open at the upper end and formed by assembling and connecting a plurality of box body units; two ends, in a transverse bridge direction, of the steel box are fixed between the two tower columns through anchoring structures arranged on the side walls of the tower columns; the lower end surface of the steel box is a circular arc arch rib structure; arch supports on the two sides in the transverse bridge direction are fixed on the side walls of the tower columns; and reinforced concrete is poured into the internal side chamber body of the steel box. The invention is advantaged in that the construction process of the cross beam is simple, convenient and fast, the construction difficulty of the cable bent tower intersection section can be greatly reduced, the cross beam construction efficiency is increased through adoption of the steel box structure, the structural strength of the cross beam is enhanced and extremely great promotion value is obtained.

Owner:CCCC SECOND HARBOR ENG

Prefabricated T-beam and construction method

InactiveCN110359352AReduced bearing capacity requirementsReduce lifting weightBridge erection/assemblyT-beamArchitectural engineering

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Platform hoisting device capable of rotating by 180 degrees

The invention discloses a platform hoisting device capable of rotating by 180 degrees. The device comprises a barrel, a hemisphere mounted at the bottom of the barrel, and a rotating portion mounted at the bottom of the hemisphere, wherein the barrel is sleeved with a supporting plate, and the supporting plate is mounted on an existing platform supporting structure; a rotating handle is arranged on the barrel; and the rotating portion is provided with a pin roll mounted on the hemisphere, and the pin roll is inserted into a base plate and is located in a middle opening of a bottom lubricating plate. The platform hoisting device is simple in structure, low-weight and frequently-used living goods and production stocks can be hoisted on a platform, and problems of hoisting of small objects on the platform are solved; in addition, the device can be arranged in a place with a small space and a small hoisting weight, and the occupied space and production cost are reduced; and meanwhile, time and labor are saved, and the operating efficiency is greatly improved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Printer nozzle cleaning and flying ink suction device

ActiveCN111361292AShorten the lengthSimple designOther printing apparatusComputer printingEngineering

The invention relates to a printer nozzle cleaning and flying ink suction device. The printer nozzle cleaning and flying ink suction device comprises a nozzle cleaning cross beam assembly, an ink receiving assembly, an air suction groove assembly, an air suction switching valve assembly and a centrifugal fan. The ink receiving assembly comprises a plurality of ink receiving discs. The ink receiving discs are fixed to an ink receiving disc collecting pipe. The ink receiving disc assembly is contained in a machine head channel, the space of a whole machine is greatly utilized, and the length ofthe whole machine is reduced. The air suction groove assembly and the ink receiving disc assembly are fixed in a whole set, the lifting weight of a machine head is reduced, and the load of a lifting motor is reduced. The printer nozzle cleaning and flying ink suction device further comprises a gas-liquid separation box, all ink is collected into the gas-liquid separation box to be treated, then treated gas is exhausted to the atmosphere through the centrifugal fan, and therefore pollution to the environment is reduced.

Owner:KEDA INDUSTRIAL GROUP CO LTD

High-speed clutch type spiral closed punch press

InactiveCN111716785AAccelerating mass is smallSensitive stroke controlPress ramPunch pressBall bearing

The invention relates to a high-speed clutch type spiral closed punch press. The high-speed clutch type spiral closed punch press comprises a press body, a sliding block, lifting supporting arms, lifting rods, pneumatic return cylinders, a copper nut, a screw rod, a radial cylindrical roller bearing seat, a radial cylindrical roller bearing, a brake disc, a brake cylinder, a one-way ball bearing,a belt wheel type large flywheel, a deep groove ball bearing, a friction clutch disc, friction blocks, a piston, a cylinder body, a spring piston guide screw rod, a piston return spring, a piston guide screw rod, a right upper fastening nut, a motor and a small belt pulley. According to the high-speed clutch type spiral closed punch press, the sliding block stroke is automatically adjusted, the motor power is reduced, power is saved, and energy saving is remarkable; the sliding block can stop at any position of the press stroke, the service life of a die is long, the unbalance loading resistance is high, and multi-station die forging can be achieved; the sliding block rapidly returns, the production efficiency is high, and the output energy is high; and the sliding block striking speed ishigh, the striking force is large, environmental friendliness is achieved, the overload safety protection effect is achieved, and operation is reliable. The high-speed clutch type spiral closed punchpress can be widely applied to the forge piece pressure forming process, in particular to the stamping process.

Owner:青岛浩源益友锻压机械有限公司

Dual-purpose large-span stiff beam construction structure and construction method thereof

ActiveCN112324131AReduce lifting weightReduce the risk of hoistingForms/shuttering/falseworksSteel tubePipe support

The invention discloses a dual-purpose large-span stiff beam construction structure and a construction method thereof, and belongs to the technical field of stiff beam construction. The dual-purpose large-span stiff beam construction structure comprises a support system, wherein the support system comprises a plurality of sets of first support assemblies which are arranged at equal intervals and asecond support assembly, each first support assembly comprises a set of first tool type steel pipes which are arranged at equal intervals, the second support assembly comprises a set of second tool type steel pipes which are arranged at equal intervals, and the adjacent first tool type steel pipes and second tool type steel pipes, the two adjacent first tool type steel pipes and the two adjacentsecond tool type steel pipes are connected through a plurality of cross rods. According to the dual-purpose large-span stiff beam construction structure, sectional steel beams are hoisted in sections,so that the hoisting risk is reduced, the structure and components are protected conveniently, and the safety is higher; tool type steel pipe supports are erected, and the purpose that one support has two purposes is achieved through an adjustable jacking; andthe construction method is simple, easy to operate and good in integrity, shortens the construction period and reduces the cost.

Owner:杭州二建建设集团有限公司

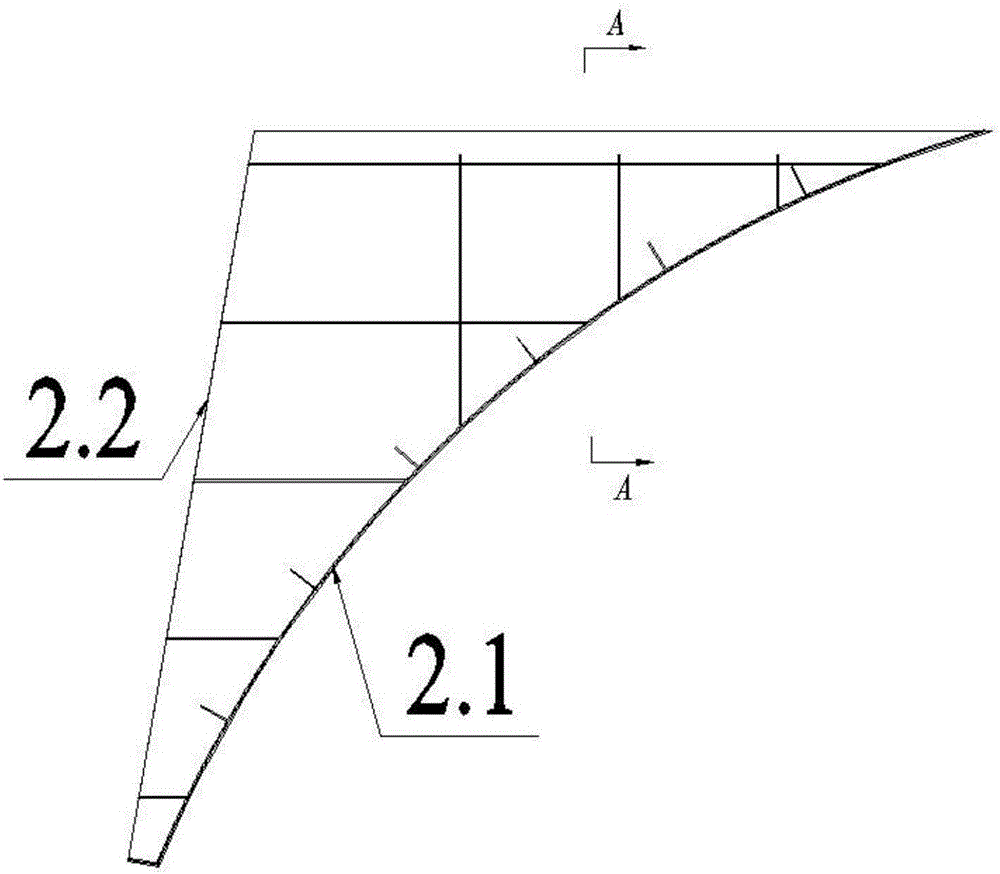

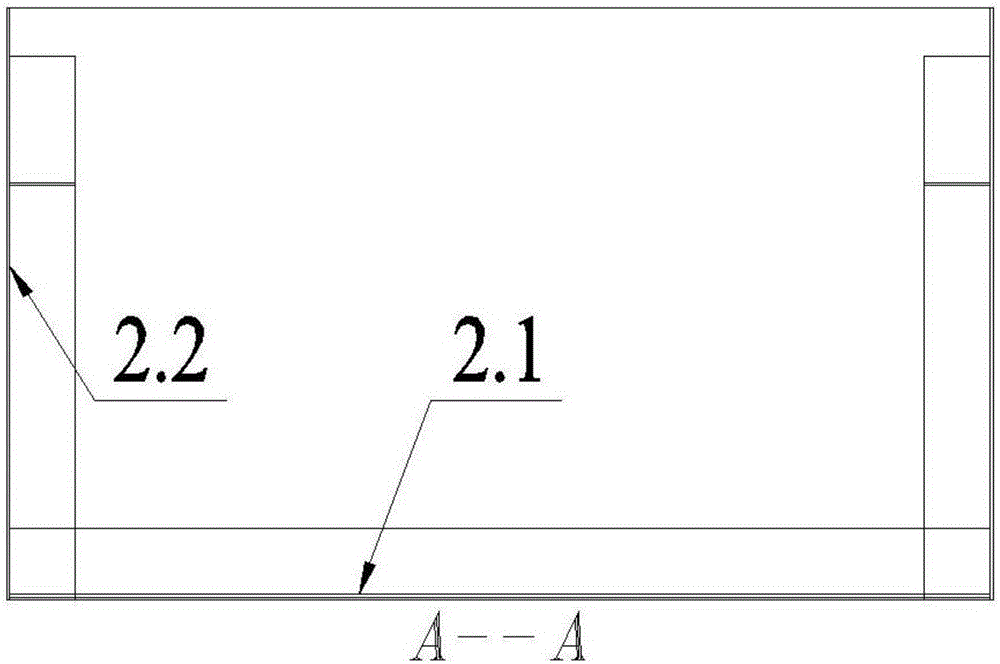

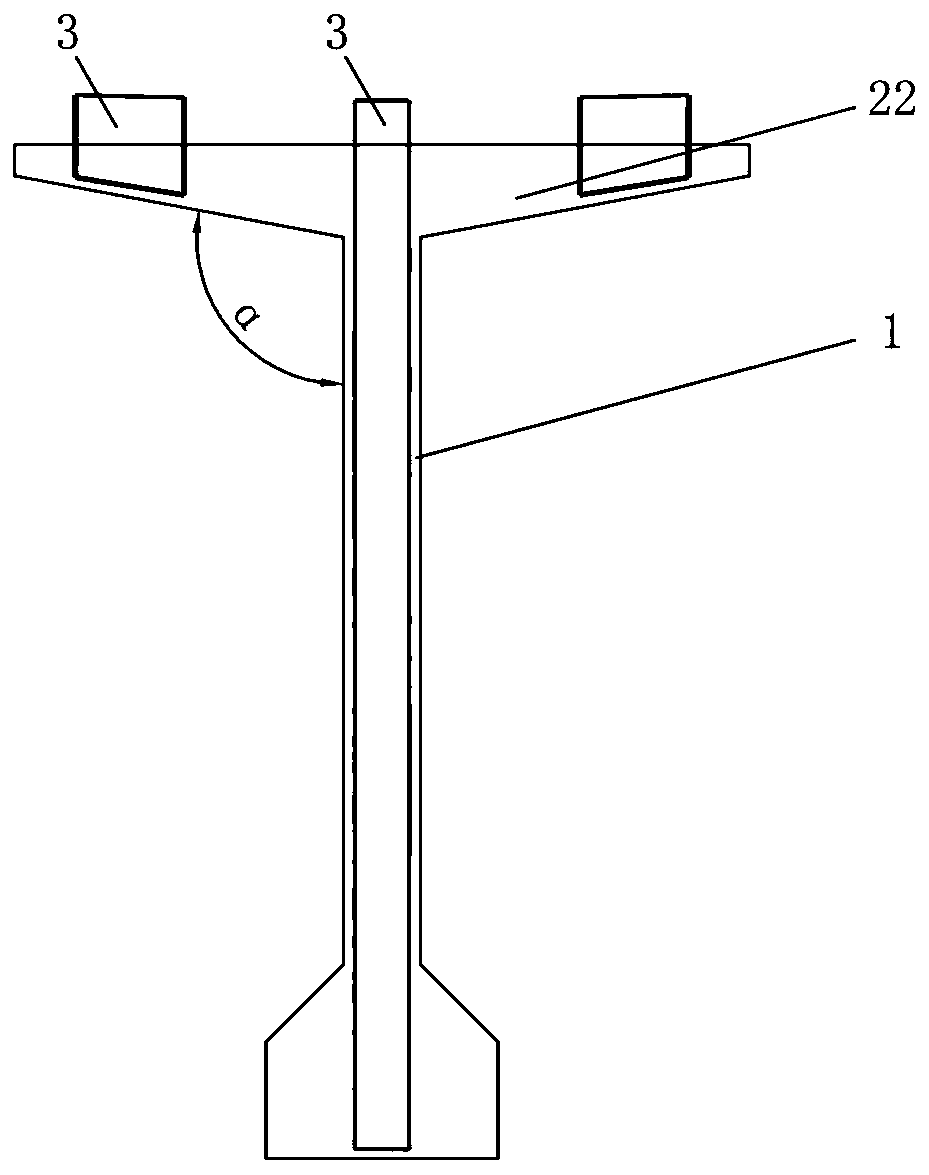

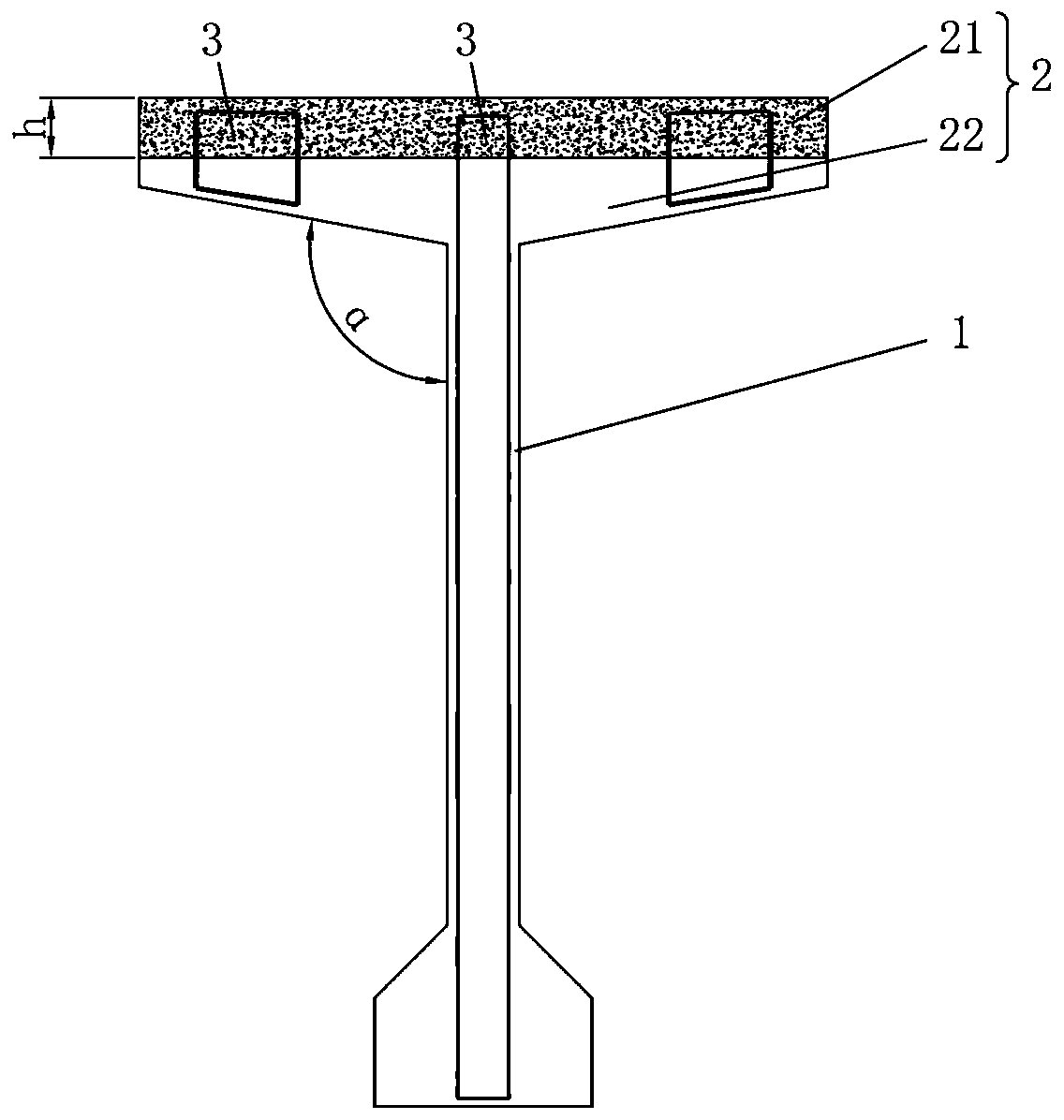

Pi-shaped cross section prefabricated capping beam adopting internal prestressed steel bar and prefabricated method thereof

PendingCN109881575AReduce road impactReduce lifting weightCeramic shaping apparatusBridgesRebarEngineering

The invention discloses a prefabricated UHPC capping beam structure with a pi-shaped cross section and a prefabricated method thereof. The capping beam comprises a top plate and two web plates, wherein a part of the web plates covering between two upright post piers is a thickened section, and parts of the web plates outside two sides of the two upright post piers are a gradual change section andan equal thickness section; the lengths of the gradual change section and the equal thickness section on the web plates are the same, the equal thickness section is close to an end of the web plates,the gradual change section is between the thickened section and the equal thickness section; the thickness of the gradual change section is linearly gradual, and the thicknesses of both ends are matched with the thickened section and the equal thickness section respectively; and a plurality of top plate prestressed steel bars and a plurality of web plate prestressed steel bars are respectively arranged inside the top plate and inside the two webs plates. During a prefabrication, vibrating and compacting are carried out by an attached vibrator, a prefabrication element is cured by adopting steam, and finally, the top plate prestressed steel bars and the web plate prestressed steel bars are stretched in a symmetrical stretching mode at two ends. The prefabricated UHPC capping beam structurewith the pi-shaped cross section and the prefabricated method thereof further reduce an overall weight of the capping beam and are expected to reduce weight by more than 55% relative to a solid capping beam.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com