Three-working-face bridge erecting machine capable of achieving longitudinal and transverse splicing and bent cap shortcut-free segment splicing method

A technology of working face and bridge erection machine, which is applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of increasing the force of the main girder, difficult to hoist, difficult to achieve, etc., and achieves strong adaptability, high efficiency and high benefit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

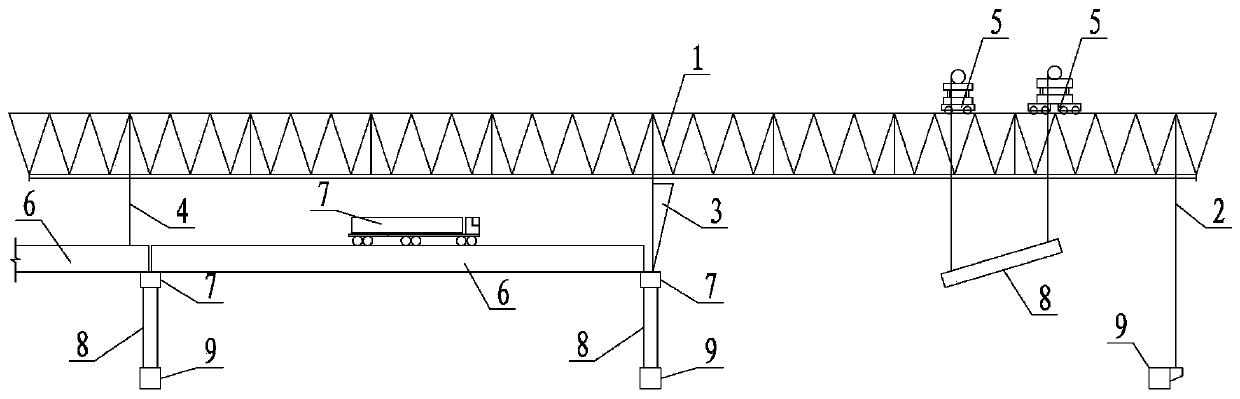

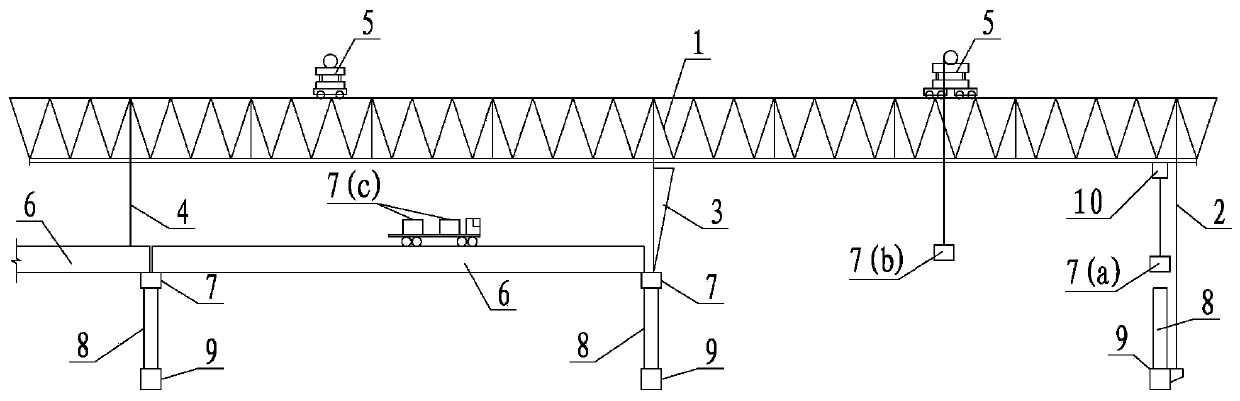

[0049] The following is a case to describe the assembly method of the cover beam without access road segment using this three-face bridge erection machine. The specific steps are as follows:

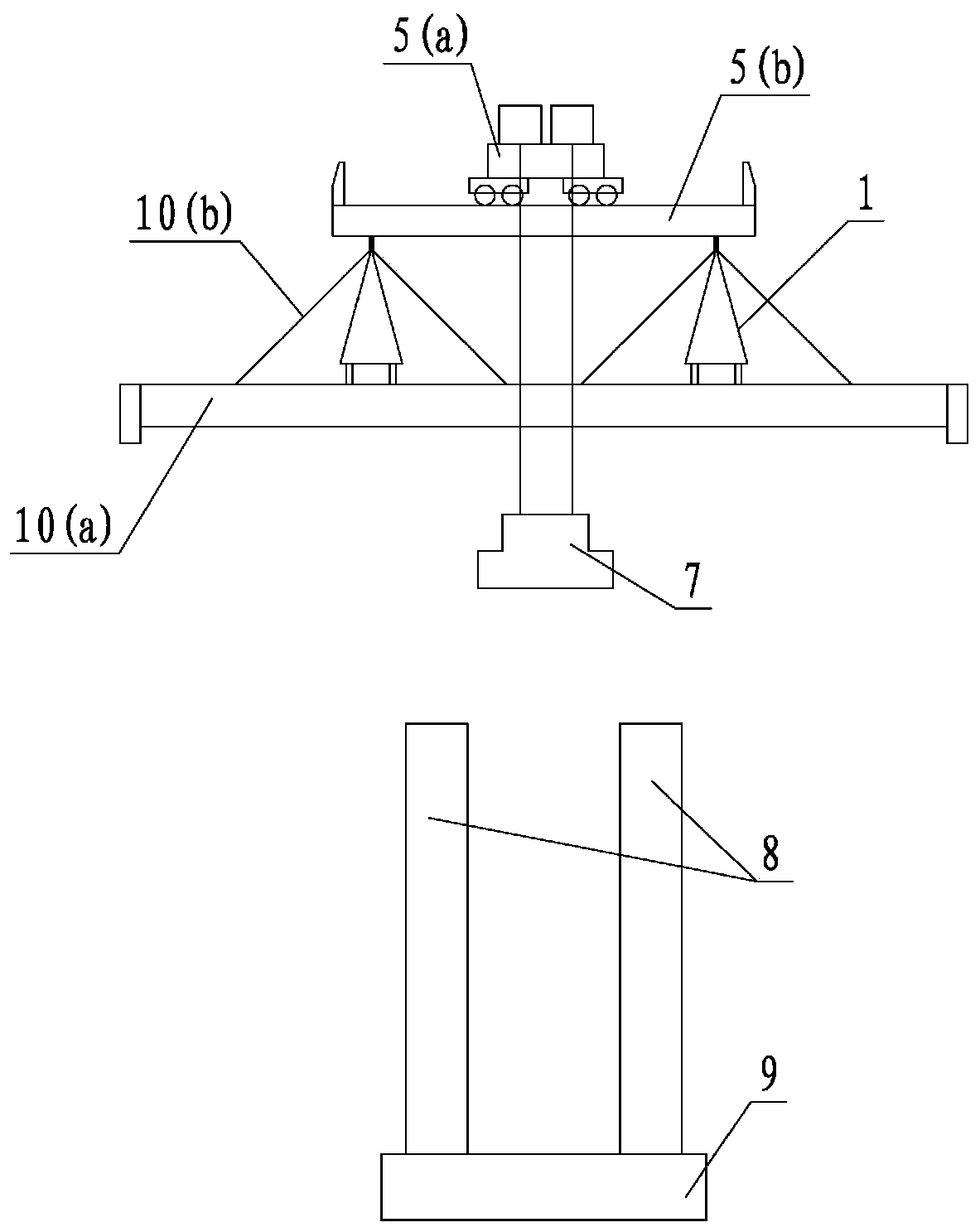

[0050] Step 1: As shown in Figure 5(a), after the erection of the prefabricated piers 8 is completed, the prefabricated cover girder segment N1 is transported through the bridge deck, hoisted by the bridge erection crane 5 and transported longitudinally to the transverse direction of the prefabricated cover girder segment. Assemble the work surface.

[0051] Step 2: As shown in Figure 5(b), the cover beam segment N1 is transferred to the beam 10(a) through the mechanical transfer device of the transverse beam, and the segment N1 is moved laterally to the beam 10(a) through the rail of the beam 10(a). When the crane 5 of the bridge erecting machine moves back and lifts the next segment N2, the above process can be performed synchronously to improve the erection efficiency.

[0052] Step ...

Embodiment 2

[0058] The three-face bridge erecting machine of the present invention can be adapted to different types of cover beam segment assembly processes, such as Figure 6(a) ~ Figure 6(f) As shown, this embodiment is different from the aforementioned balanced cantilever lateral assembling method. This method adopts the all-plastic assembling method, uses slings as temporary supports, and finally tensions all the prestressing beams at one time. The construction accuracy is required to be high, and the specific steps are as follows:

[0059] Step 1: As shown in Figure 6(a), after the erection of the prefabricated piers 8 is completed, the prefabricated cover beam segment N1 is transported through the bridge deck, and is lifted by the bridge erection crane 5 and transported longitudinally to the horizontal direction of the prefabricated cover beam segment. Assemble the work surface.

[0060] Step 2: As shown in Fig. 6(b), the cover beam segment N1 is transferred to the beam 10(a) thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com