Printer nozzle cleaning and flying ink suction device

A technology of printers and nozzles, applied in printing devices, printing, etc., can solve the problems of complex overall design, increase the load of the lifting motor, increase the lifting weight of the machine head, etc., and achieve the effect of shortening the length of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

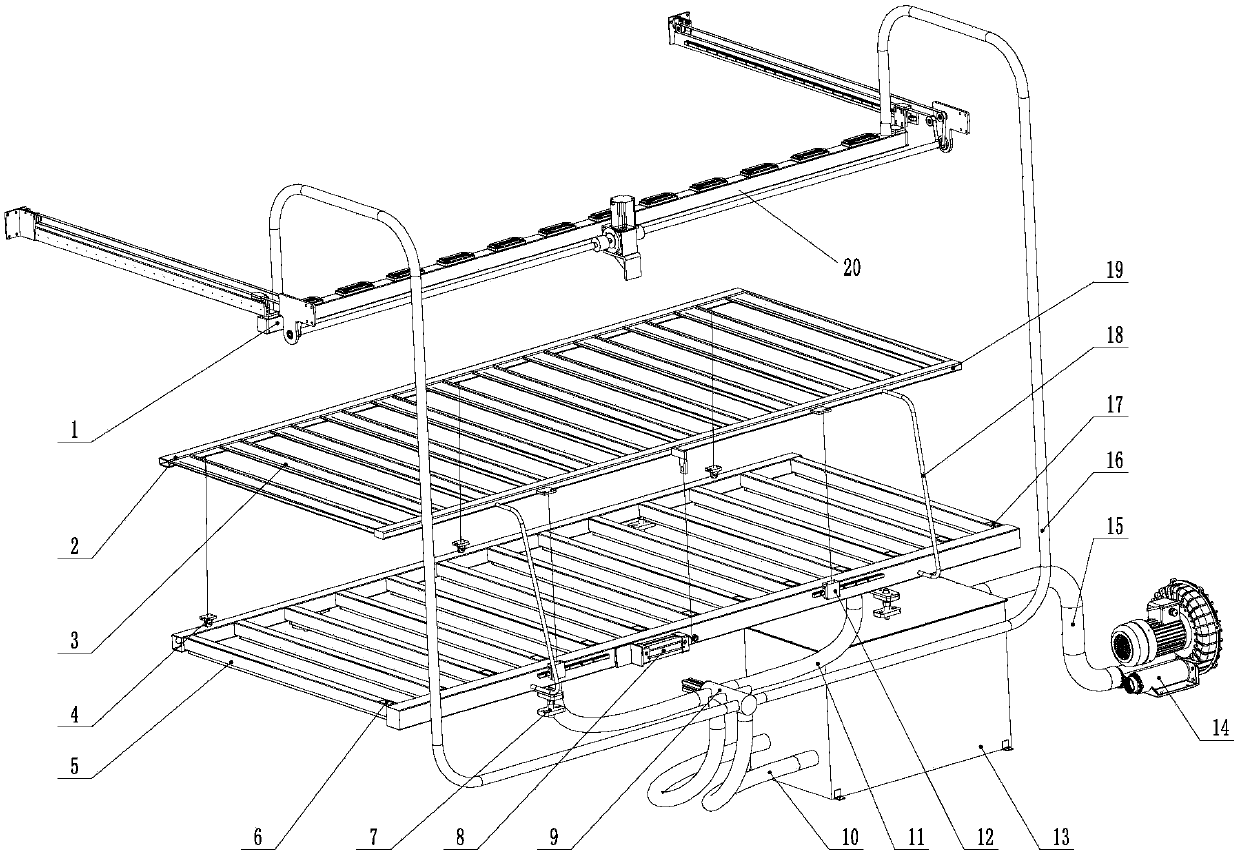

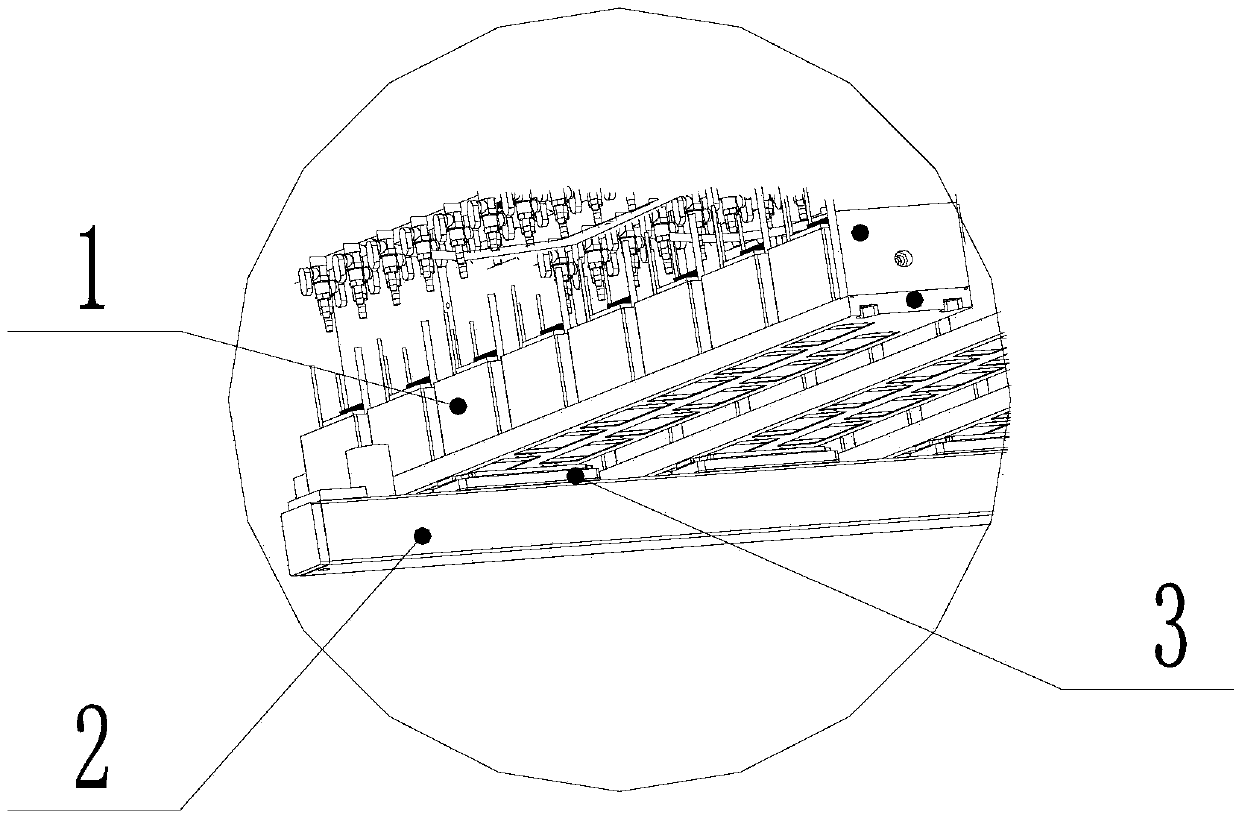

[0024] The invention provides a printer nozzle cleaning and ink flying device, such as figure 1 As shown, it includes nozzle cleaning beam assembly, ink receiving assembly, suction groove assembly, suction switching valve assembly and centrifugal fan; said nozzle cleaning beam assembly includes nozzle cleaning component 1, fixed beam 20 and cleaning suction pipe 16, wherein , the fixed crossbeam 20 is fixedly connected on the frame, and the upper surface of the nozzle cleaning part 1 is provided with a slit. The so-called upper surface refers to the upper surface in the direction shown in the figure, that is, when the nozzle is cleaned, the surface facing the nozzle , the slit is for sucking ink on the surface of the nozzle, the nozzle cleaning part includes a hollow cavity, and the inside of the fixed beam 20 also includes a hollow cavity, and the above two hollow cavities communicate, so that all The nozzle cleaning component 1 communicates with the fixed beam 20 , so when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com