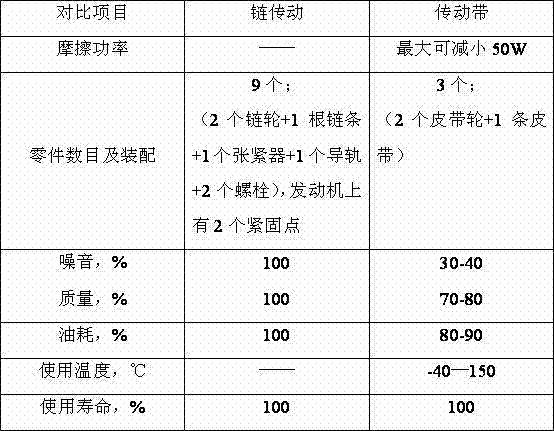

Patents

Literature

148 results about "Timing belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A timing belt, timing chain, or cambelt is a part of an internal combustion engine that synchronizes the rotation of the crankshaft and the camshaft(s) so that the engine's valves open and close at the proper times during each cylinder's intake and exhaust strokes. In an interference engine the timing belt or chain is also critical to preventing the piston from striking the valves. A timing belt is usually a toothed belt—a drive belt with teeth on the inside surface. A timing chain is a roller chain.

Power transmission belt and method

A power transmission belt, and more particularly a toothed power transmission belt, comprising a longitudinally extending tensile member composed of one or more carbon fiber cords, wherein the belt exhibits belt growth of not more than 0.1% based on its original length after 48 hours under High Temperature Belt Growth Analysis performed at 100° C., a method for producing such belts exhibiting reduced belt growth, and a method for reducing the angular vibration of a camshaft in relation to a crankshaft in an internal combustion engine wherein the camshaft is driven by a timing belt.

Owner:THE GATES CORP

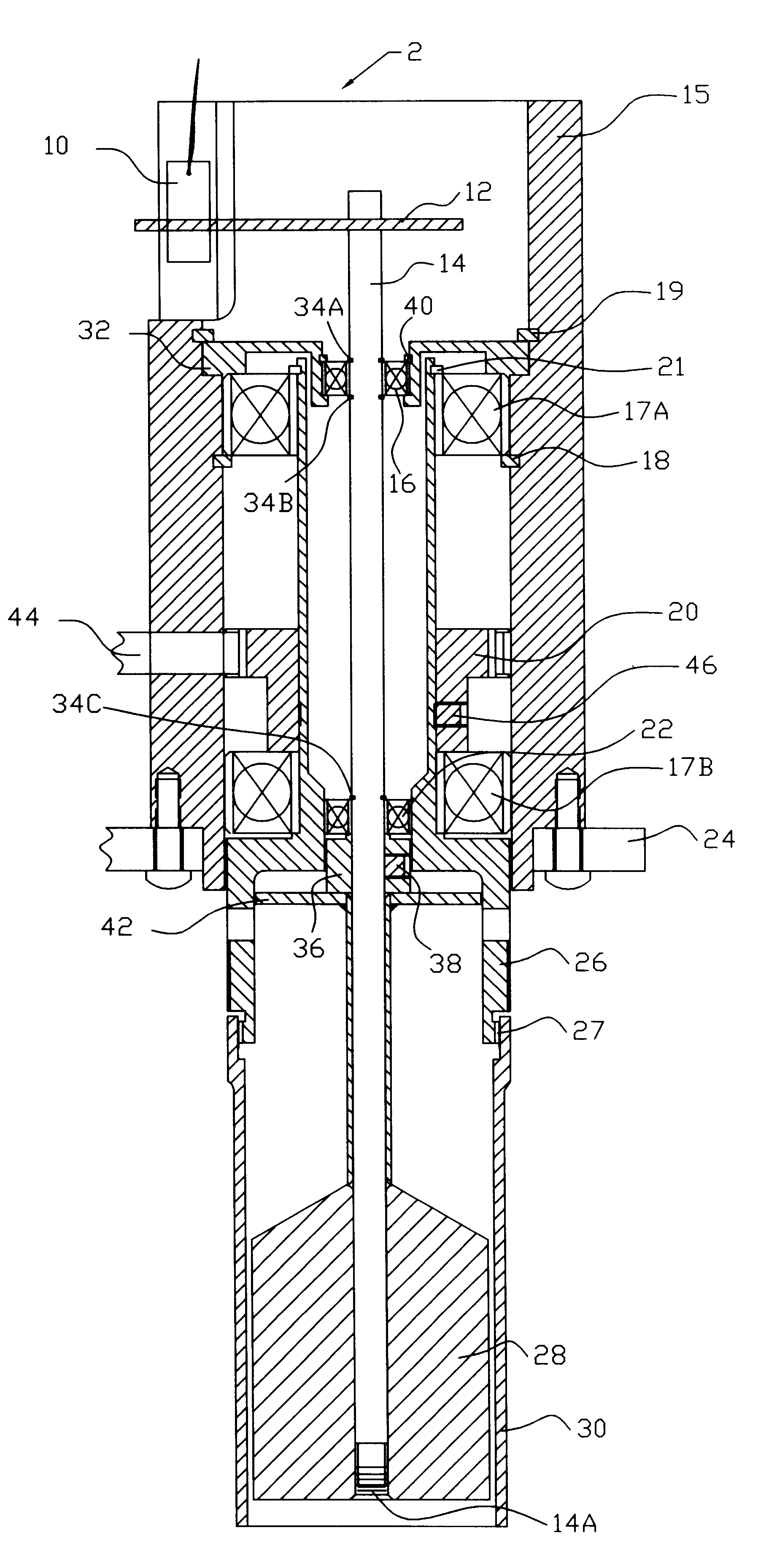

Digital viscometer with arm and force sensor to measure torque

Viscometer (2) with a sleeve (30) rotatable by a sprocket (20) and a timing belt (44) to shear a tested fluid thus imparting torque to a bob (28) mounted on a shaft (14) supported via axially spaced bearings (16, 22), an arm (12) connecting to the top of the shaft (14) applies force to a force sensor (10) which is proportional to the torque applied to the bob.

Owner:BI HONGFENG

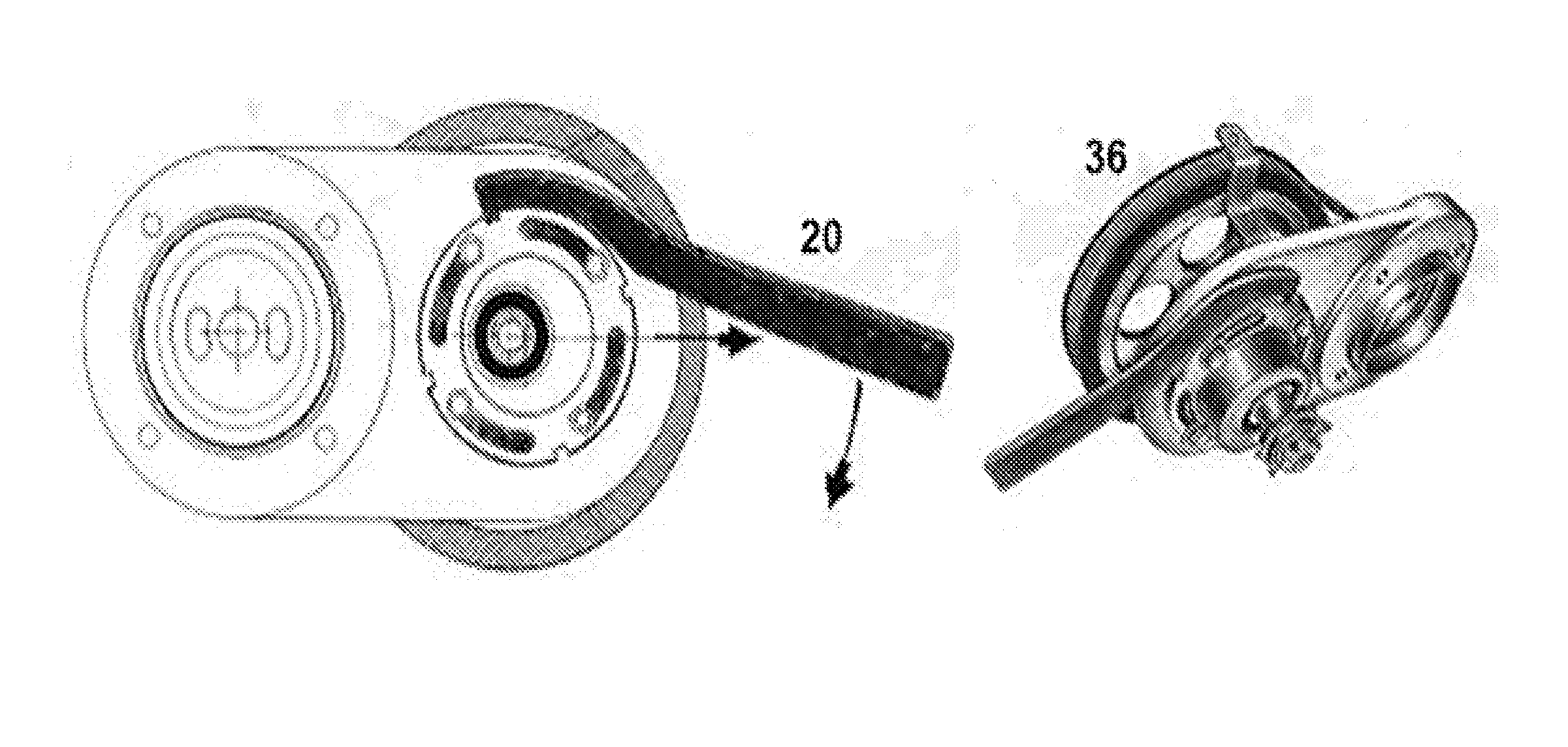

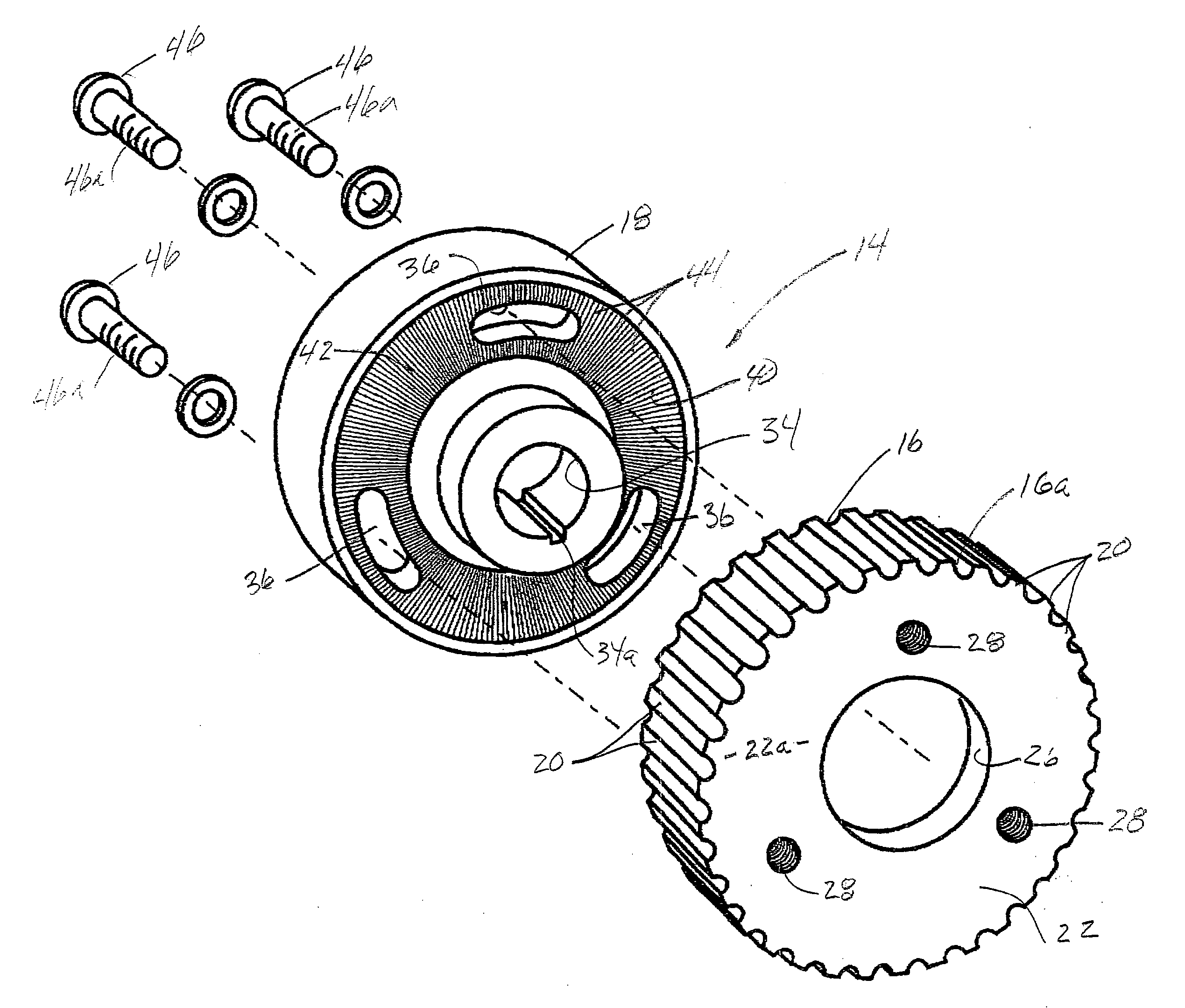

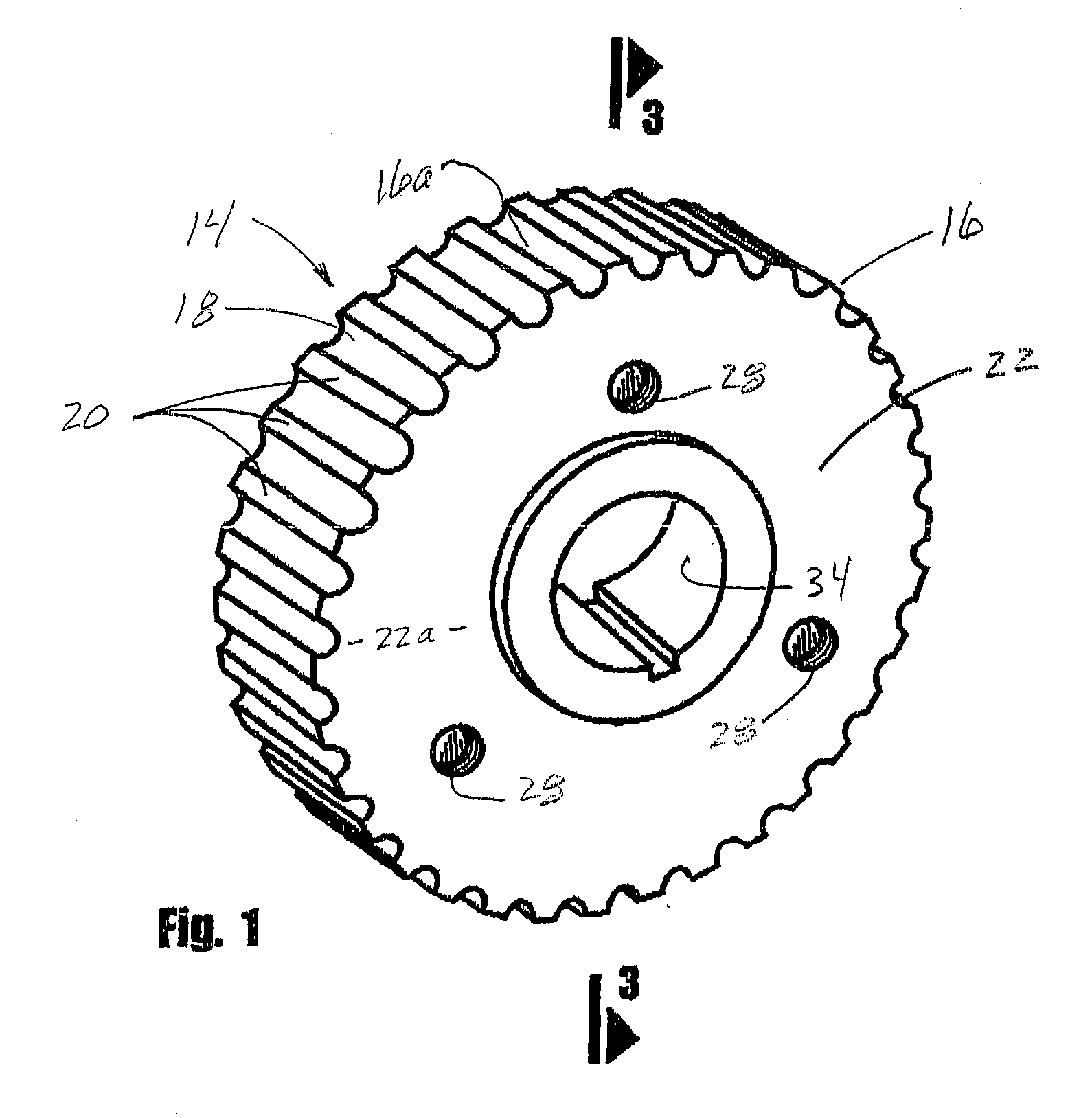

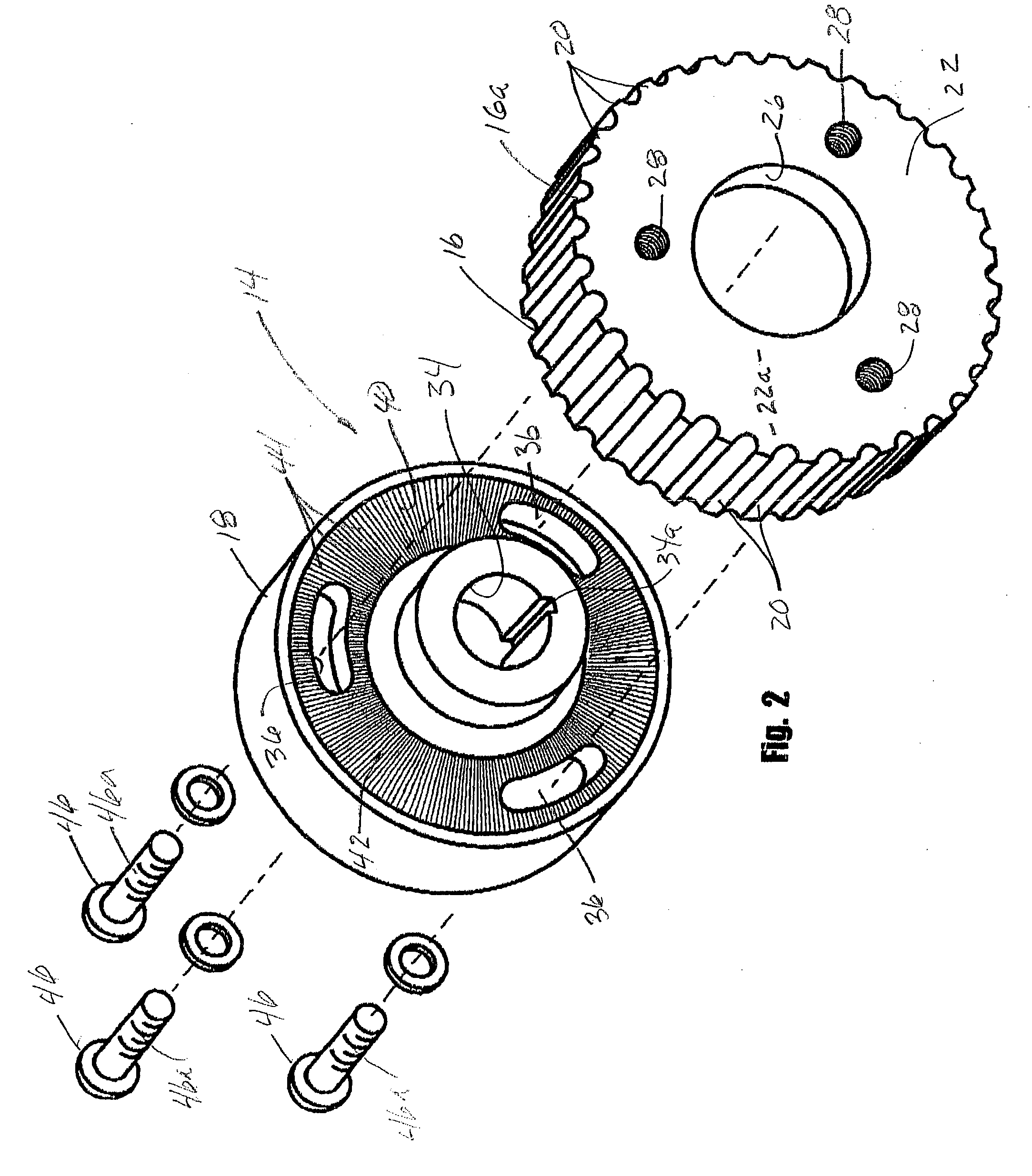

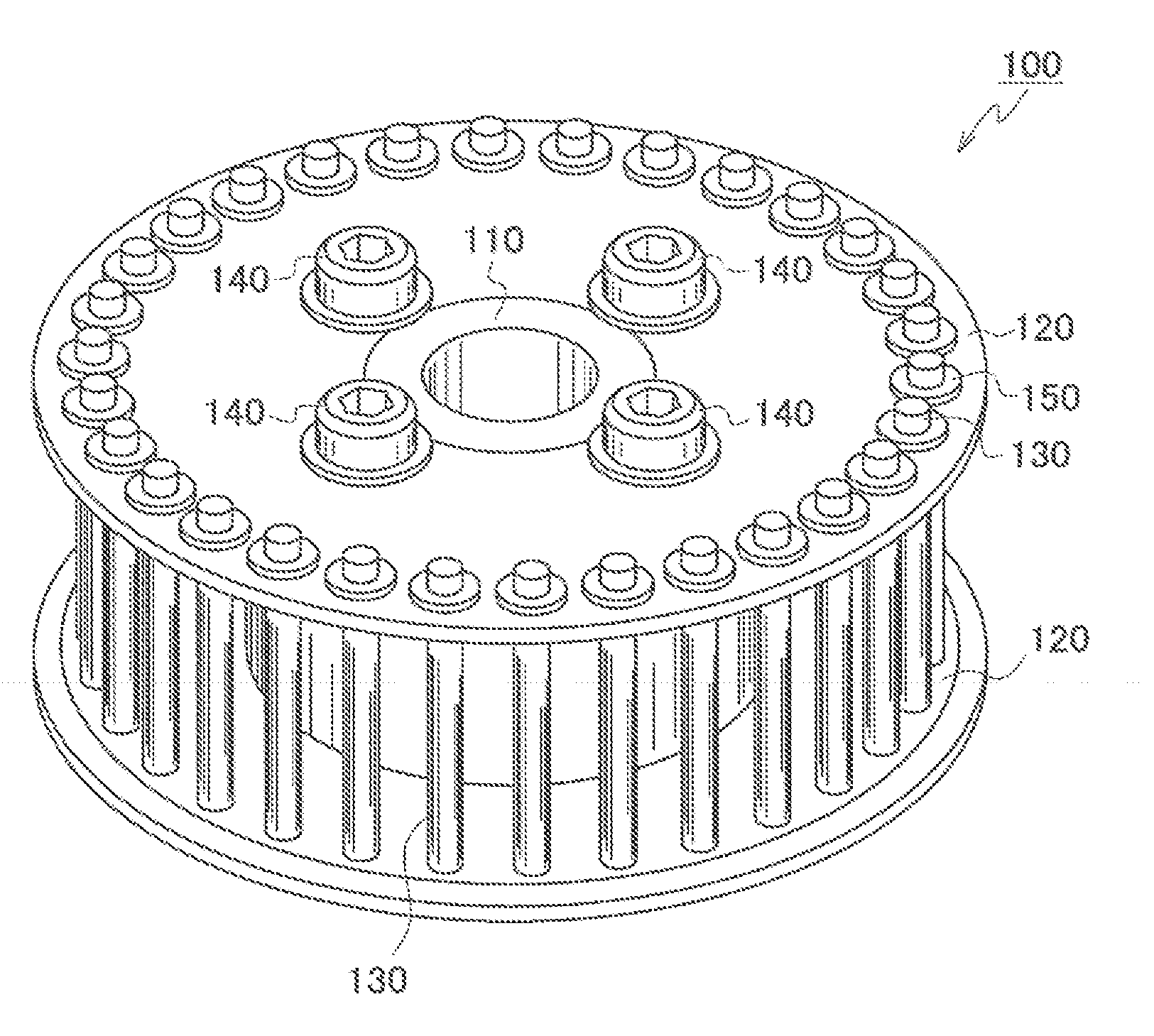

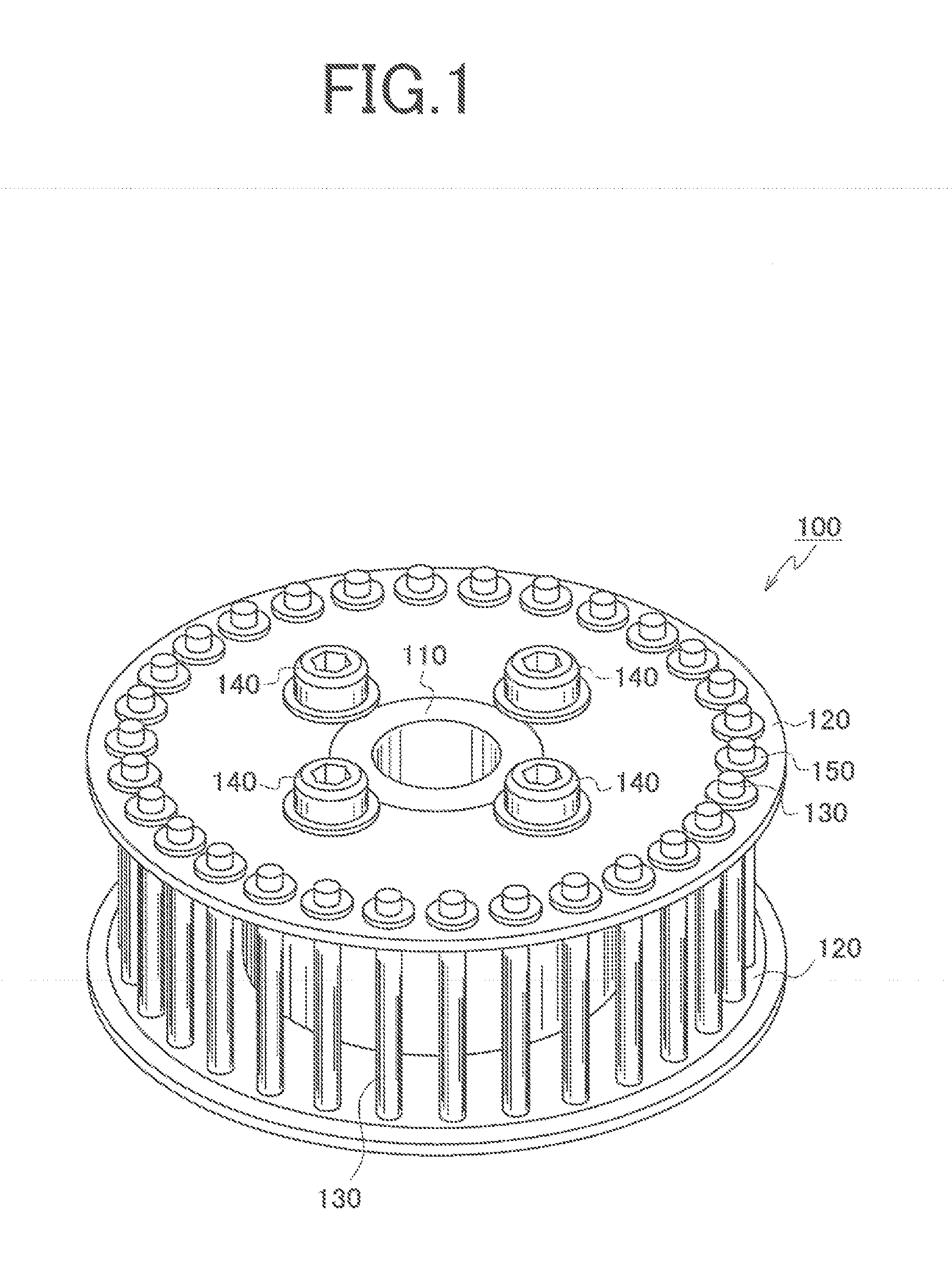

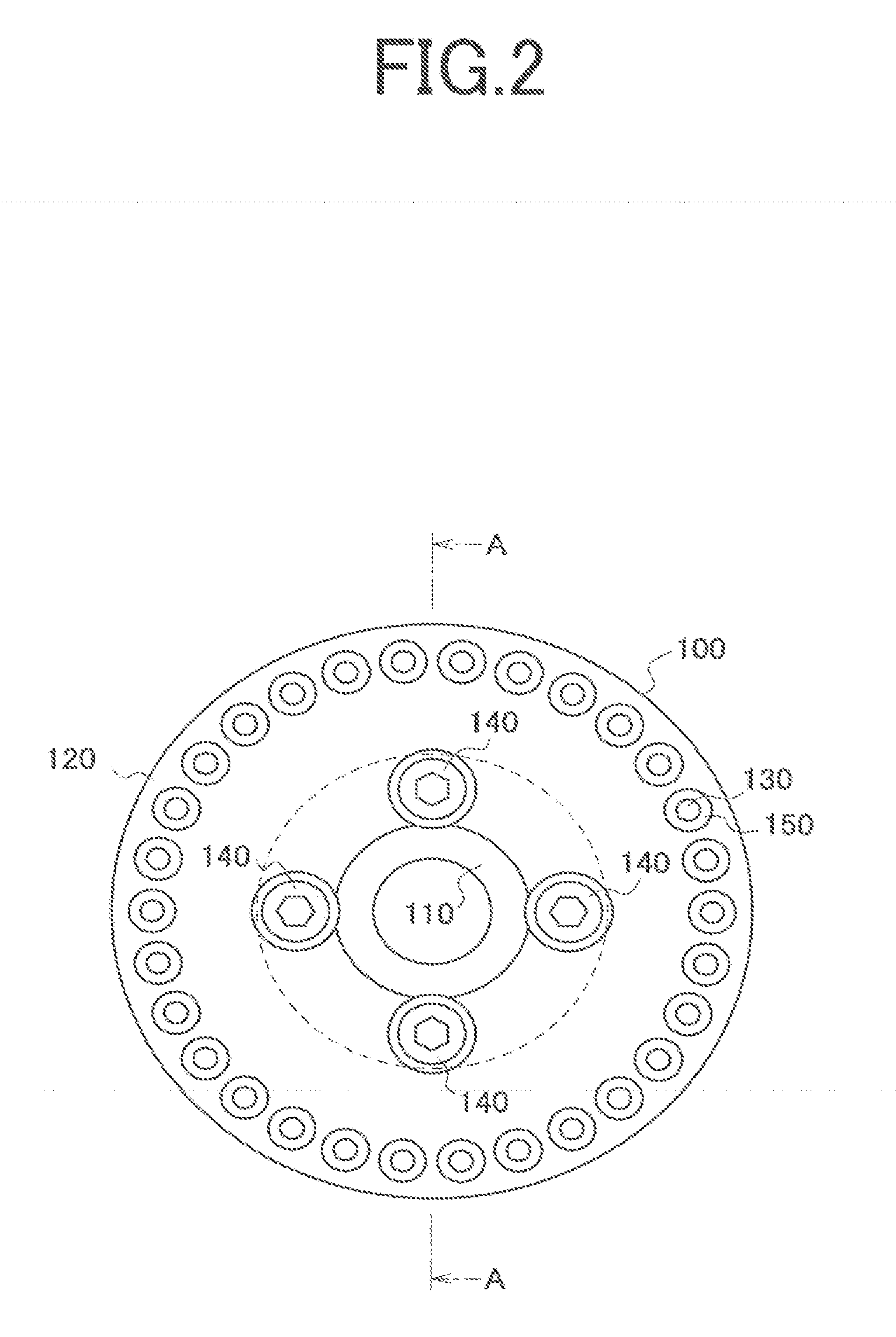

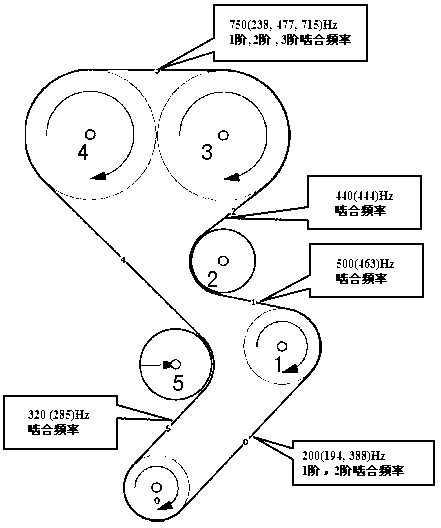

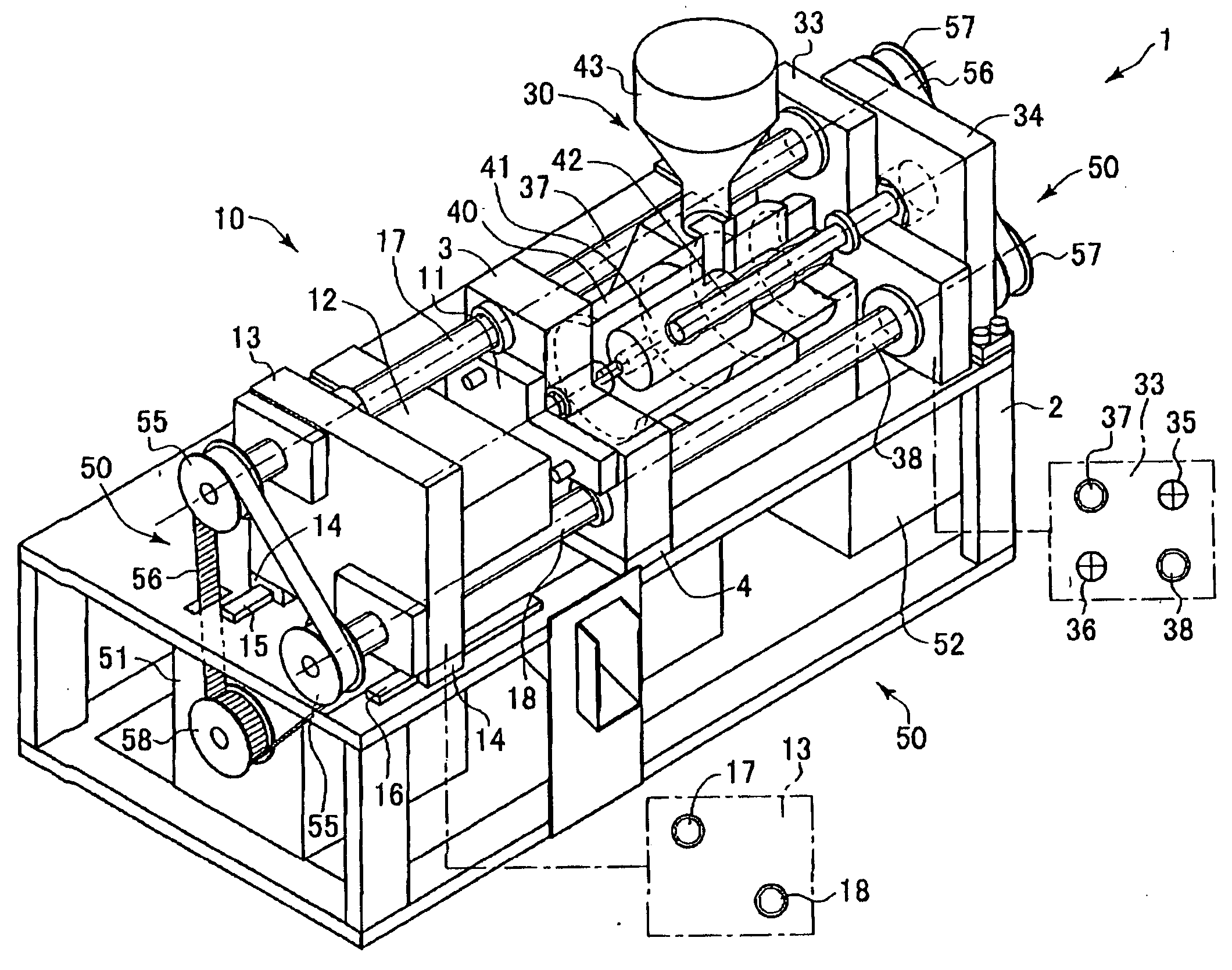

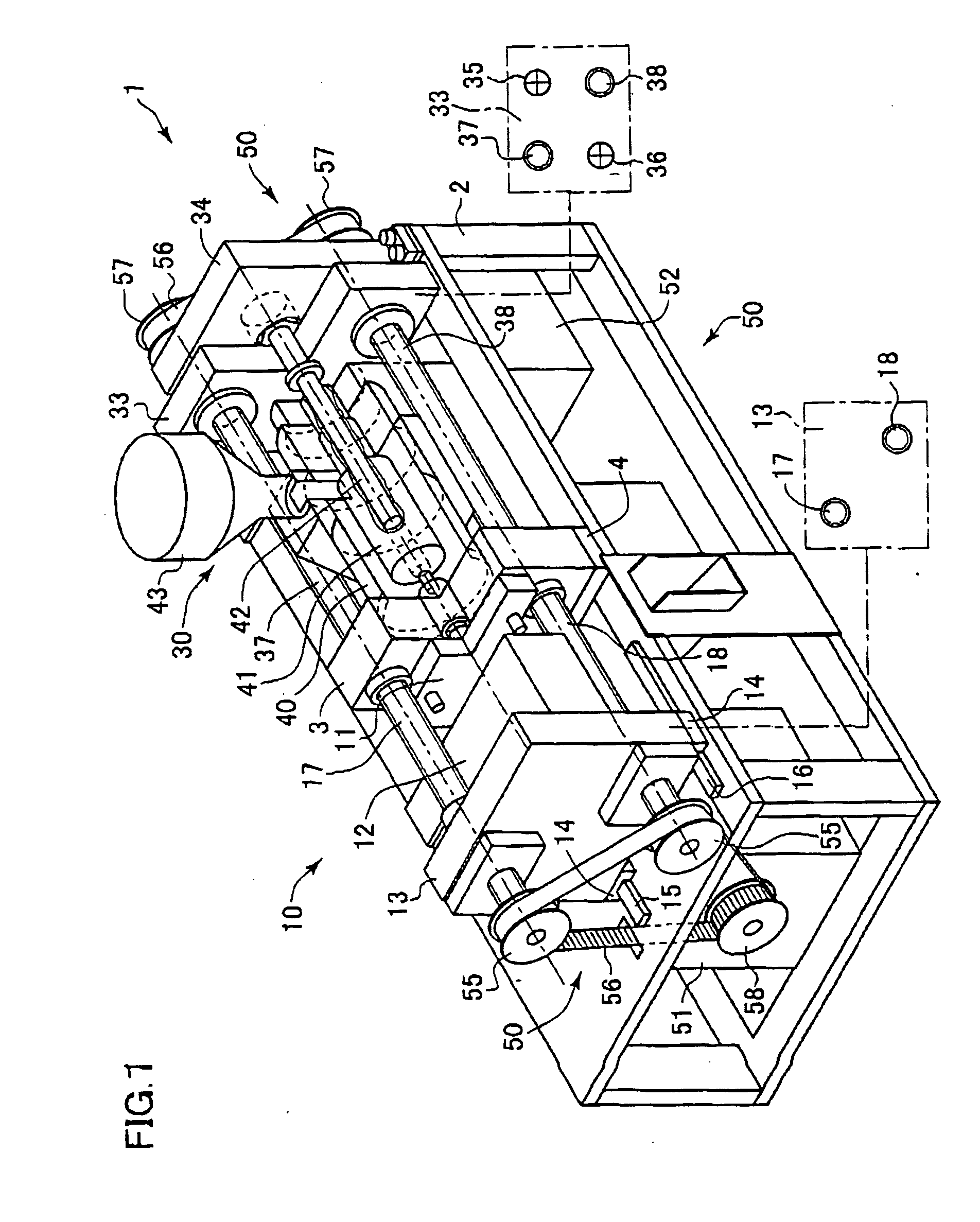

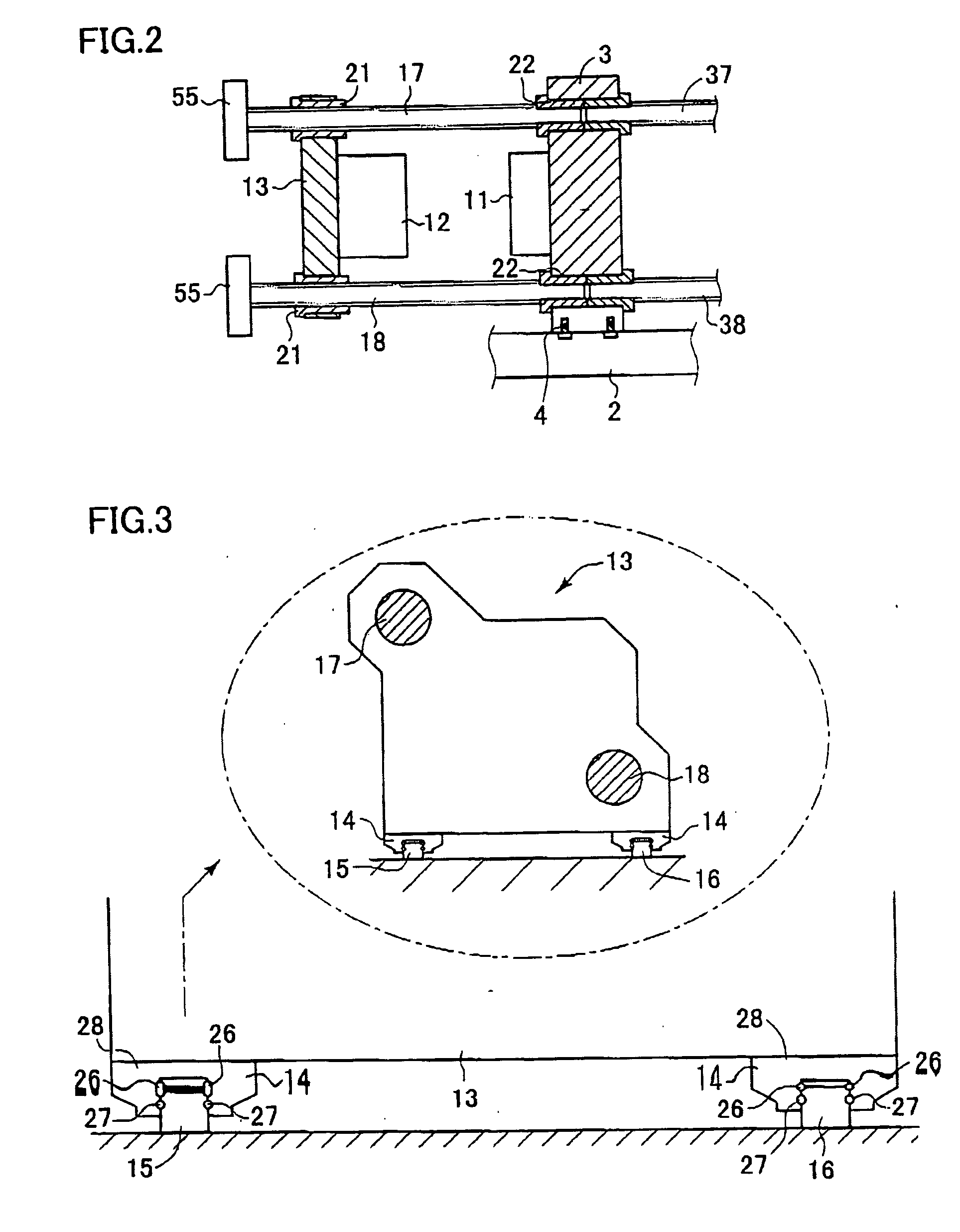

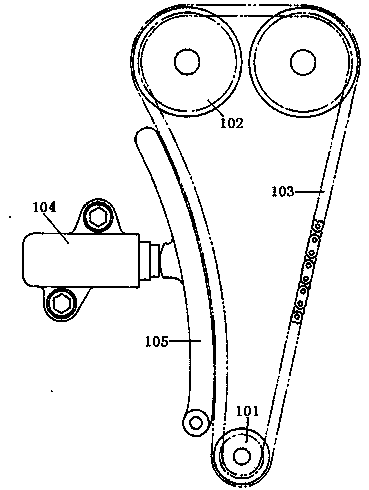

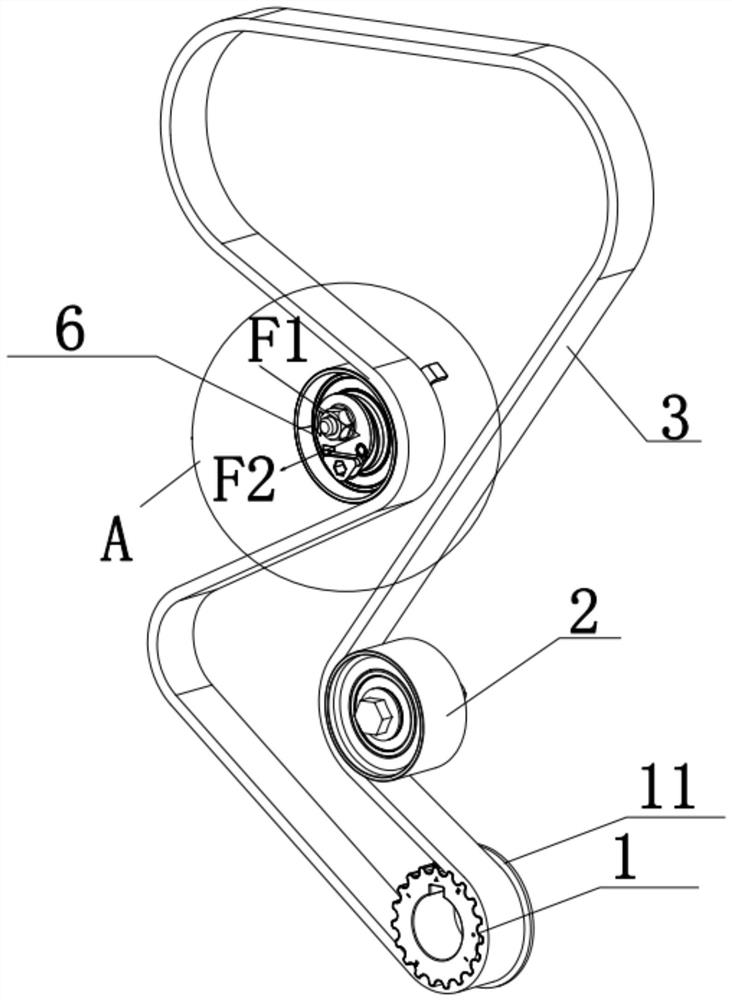

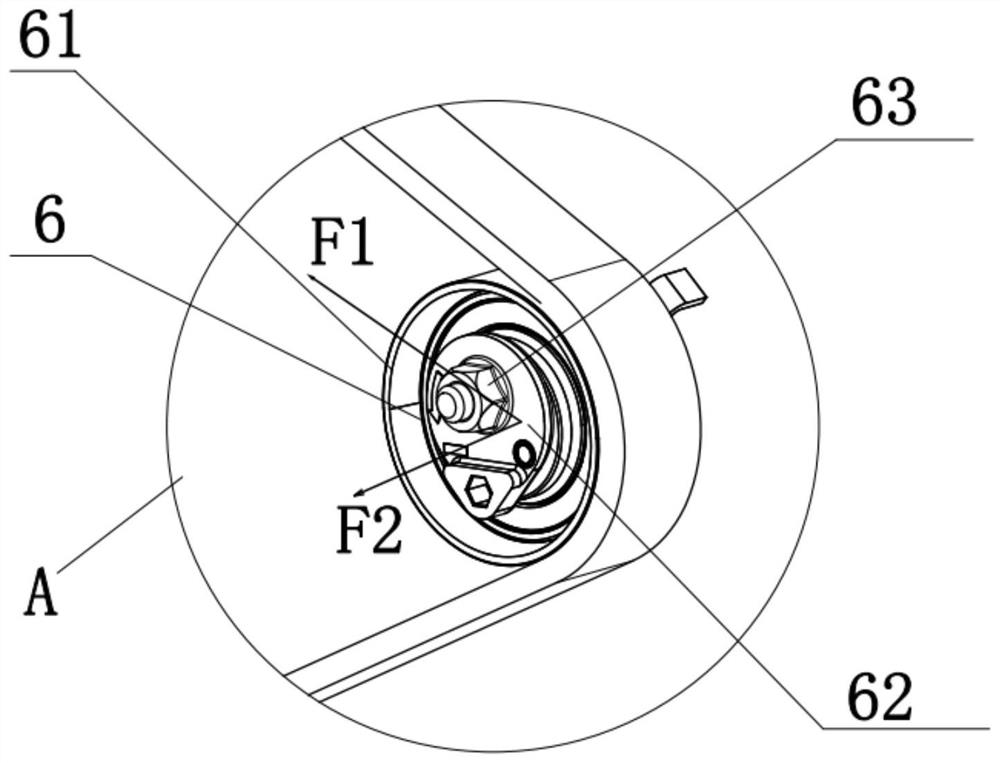

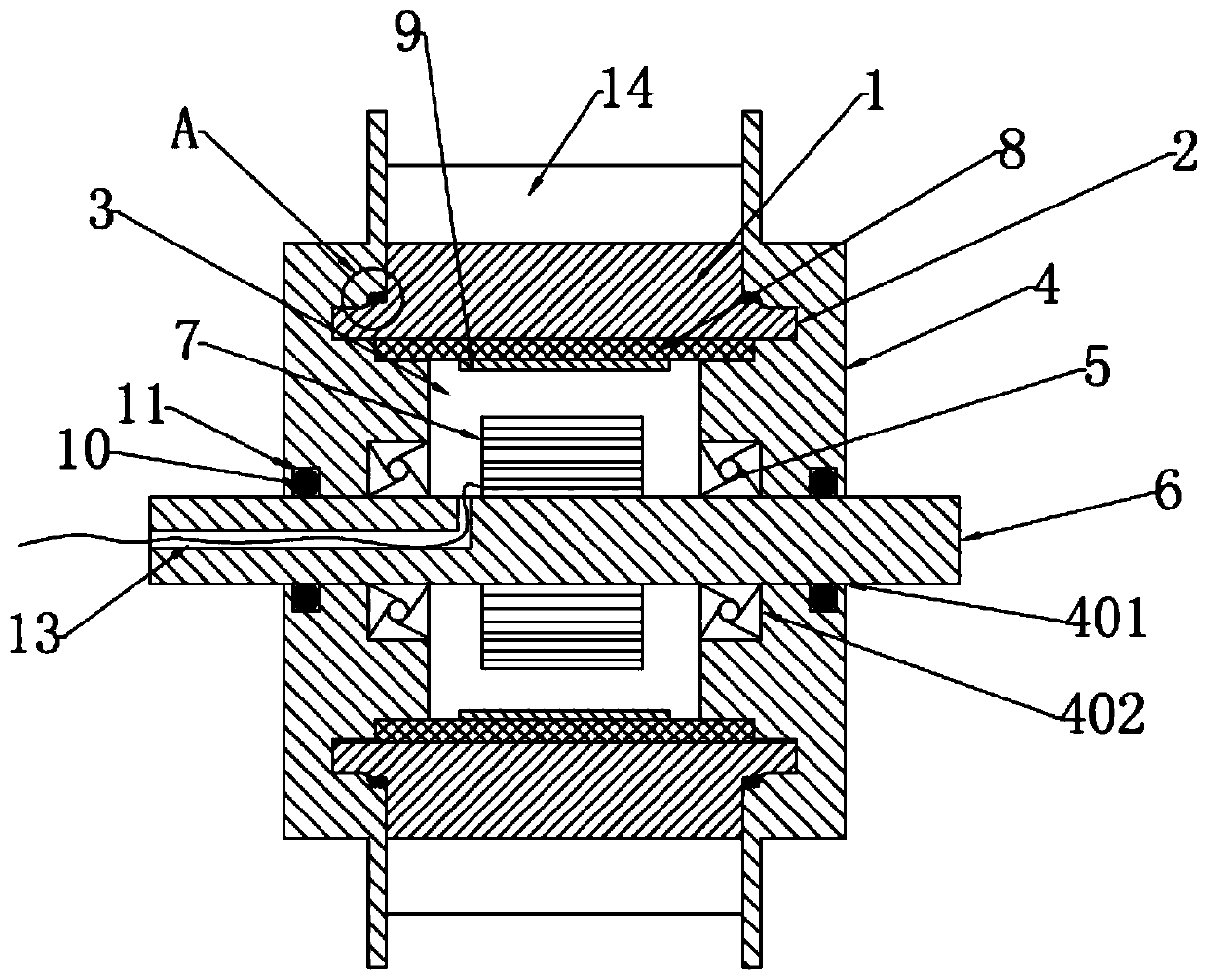

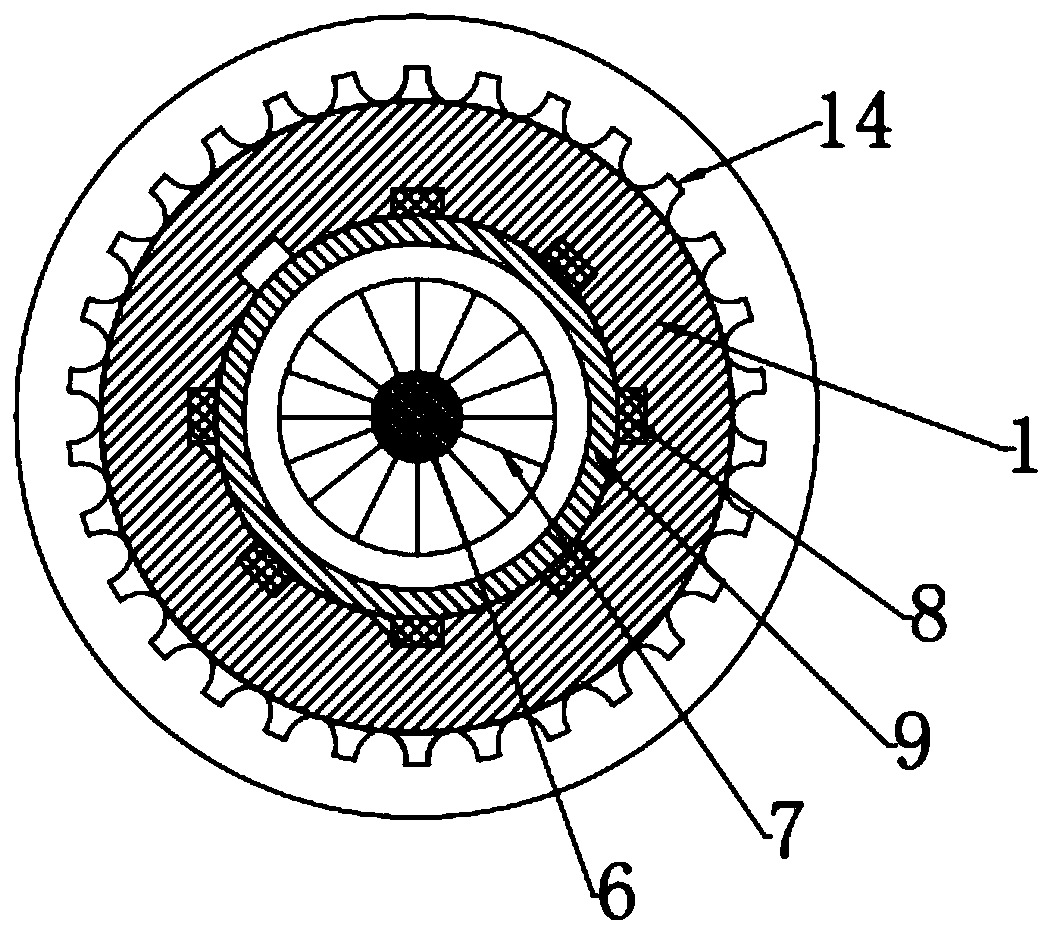

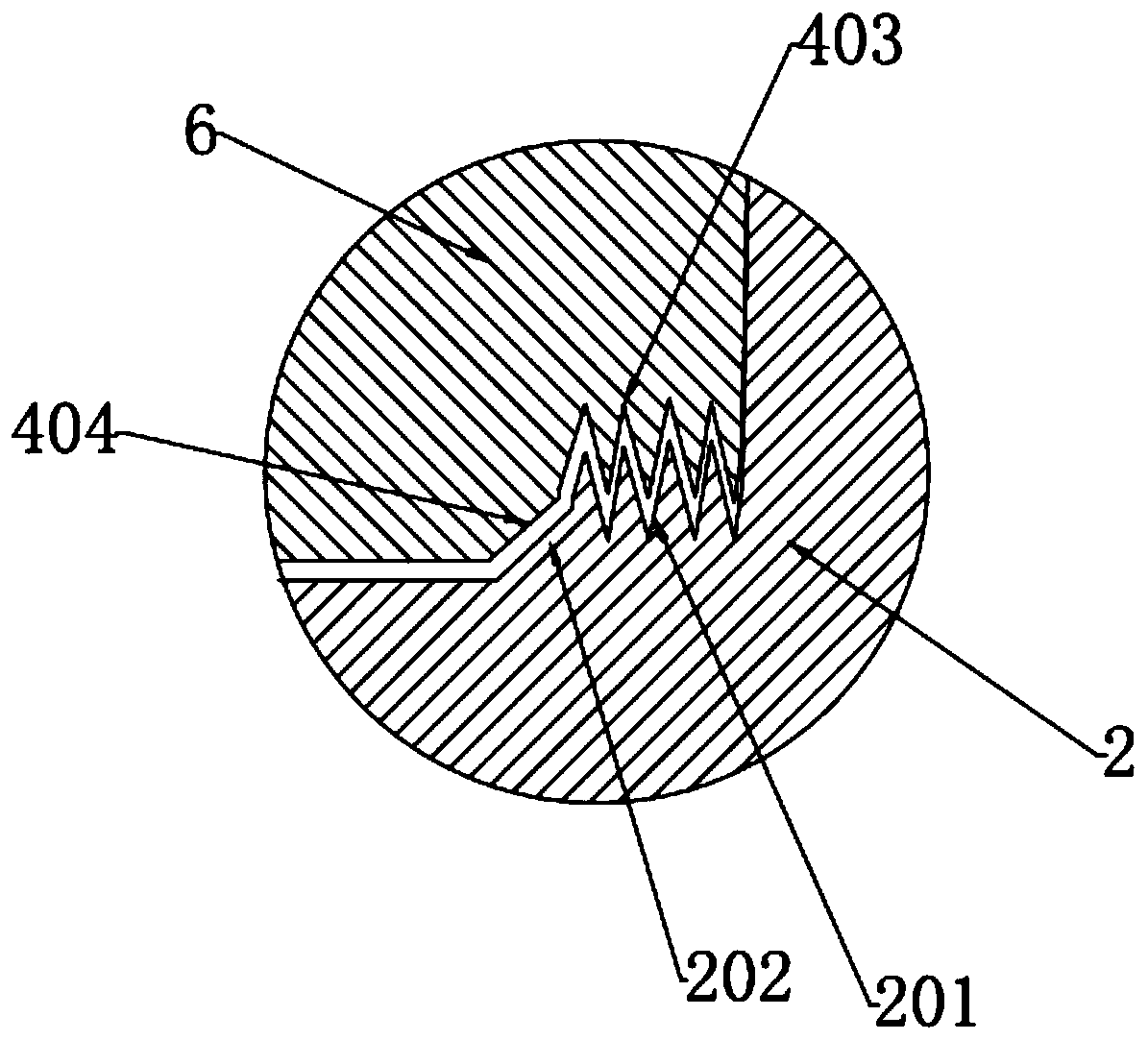

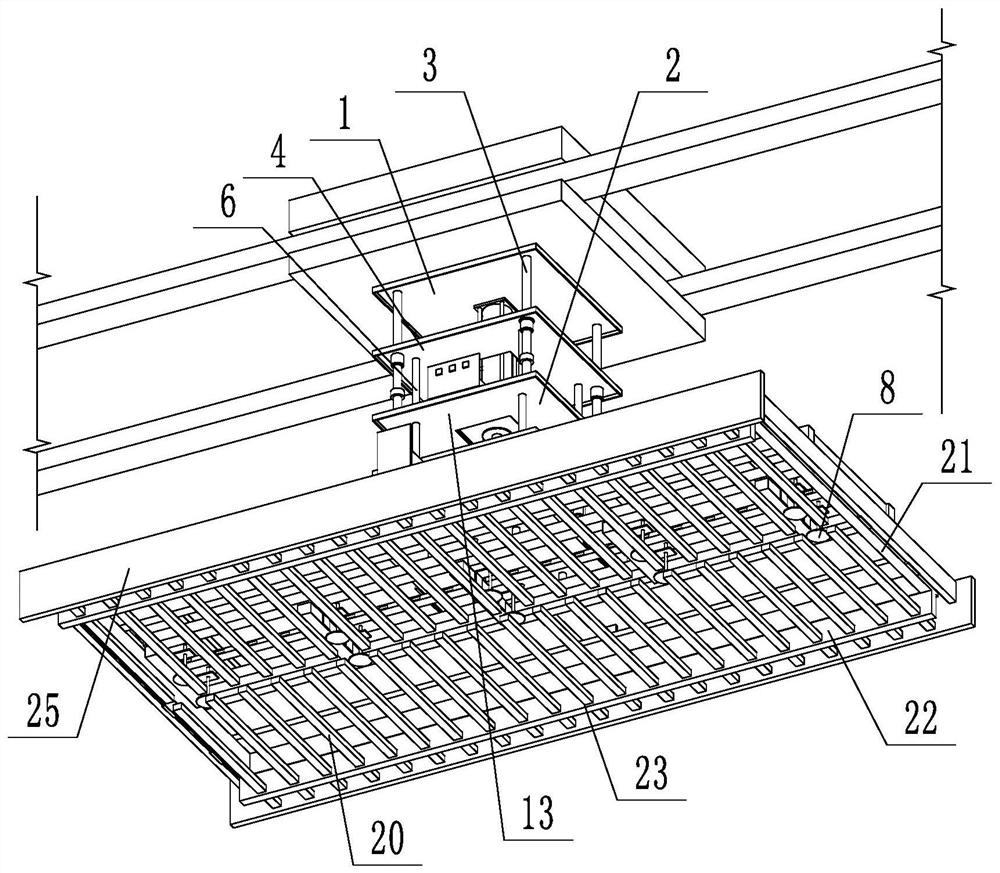

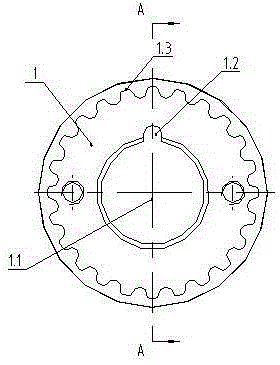

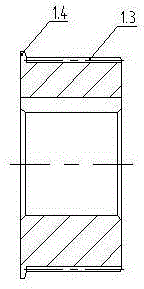

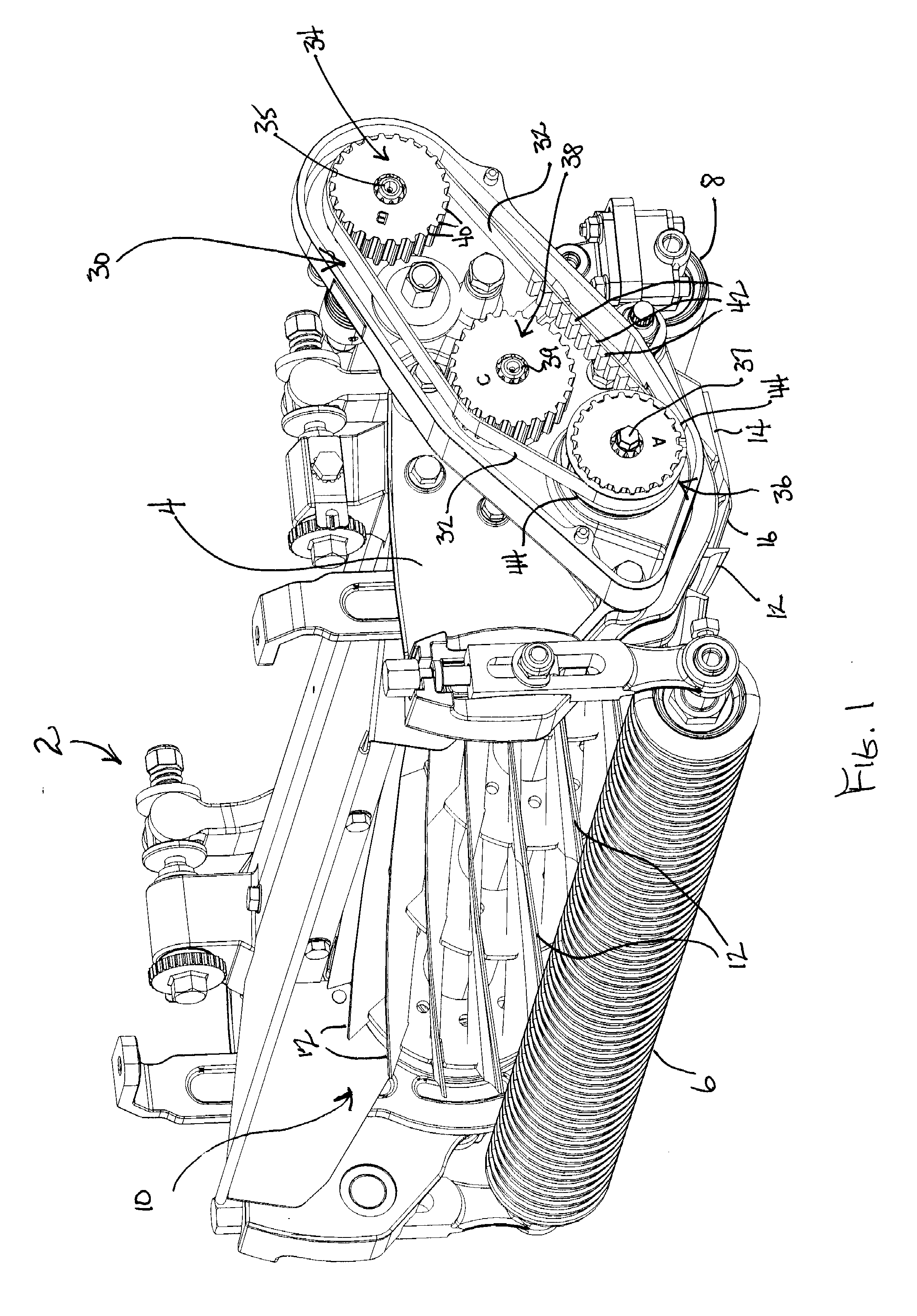

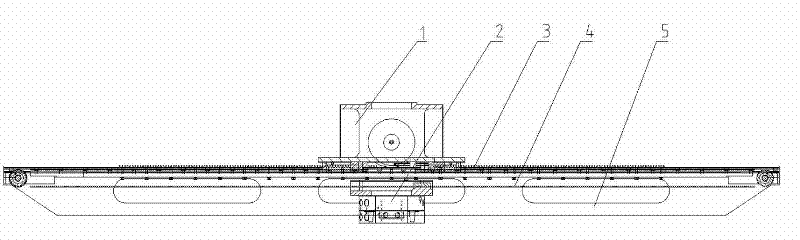

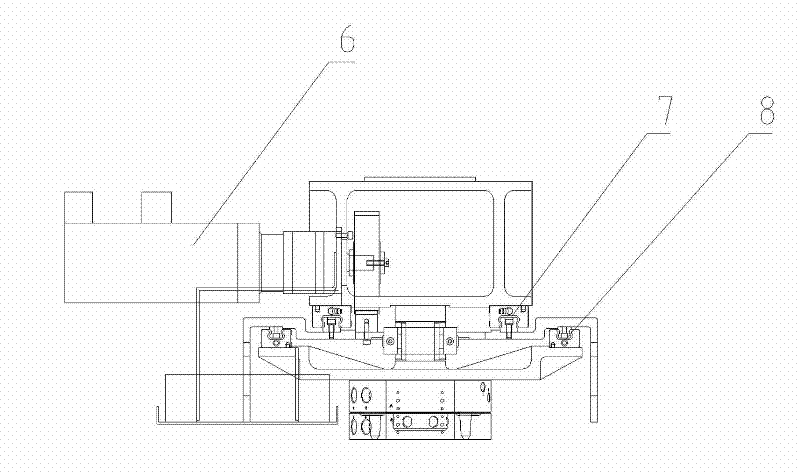

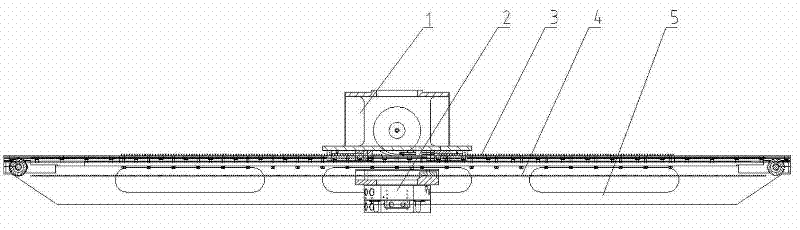

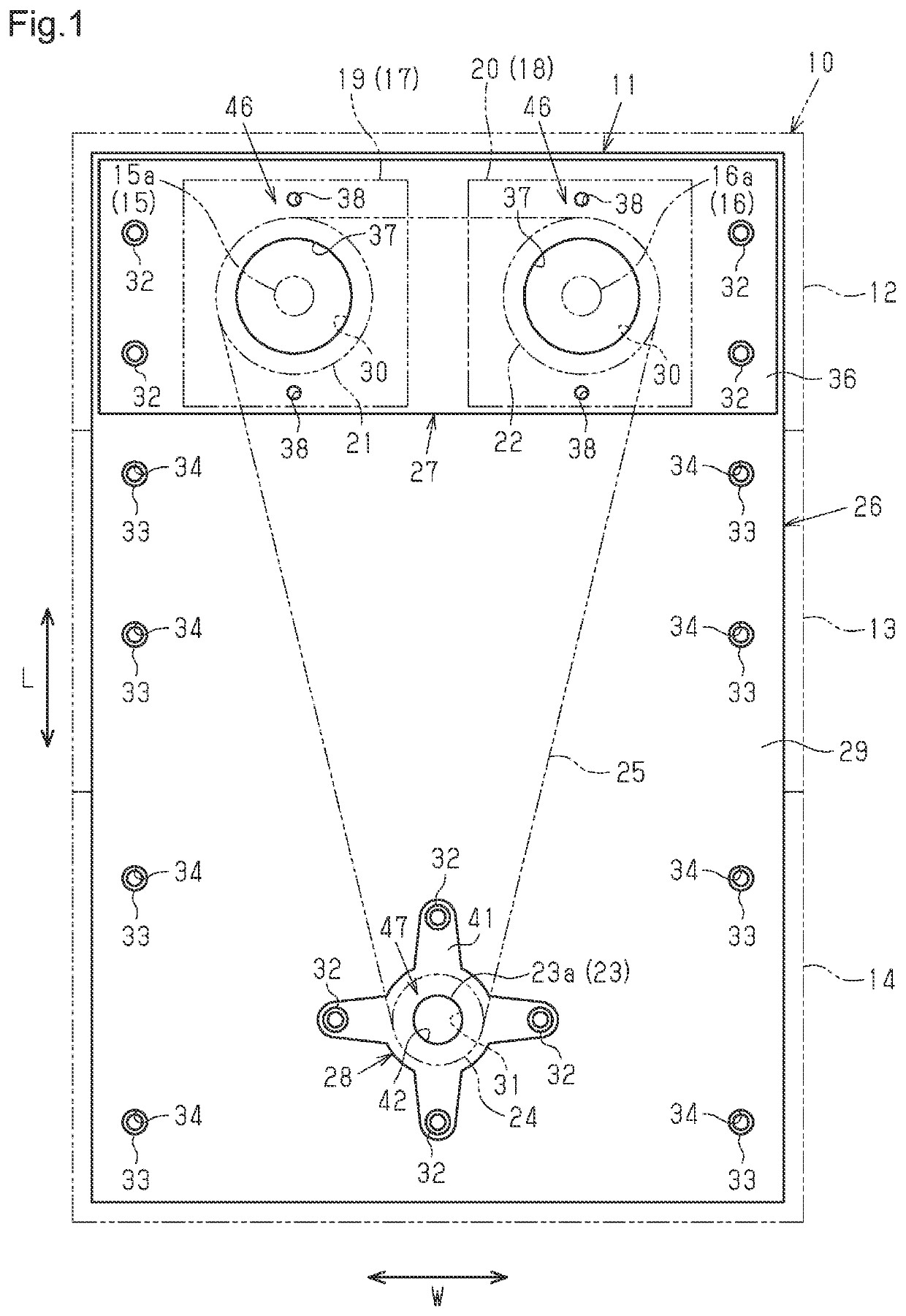

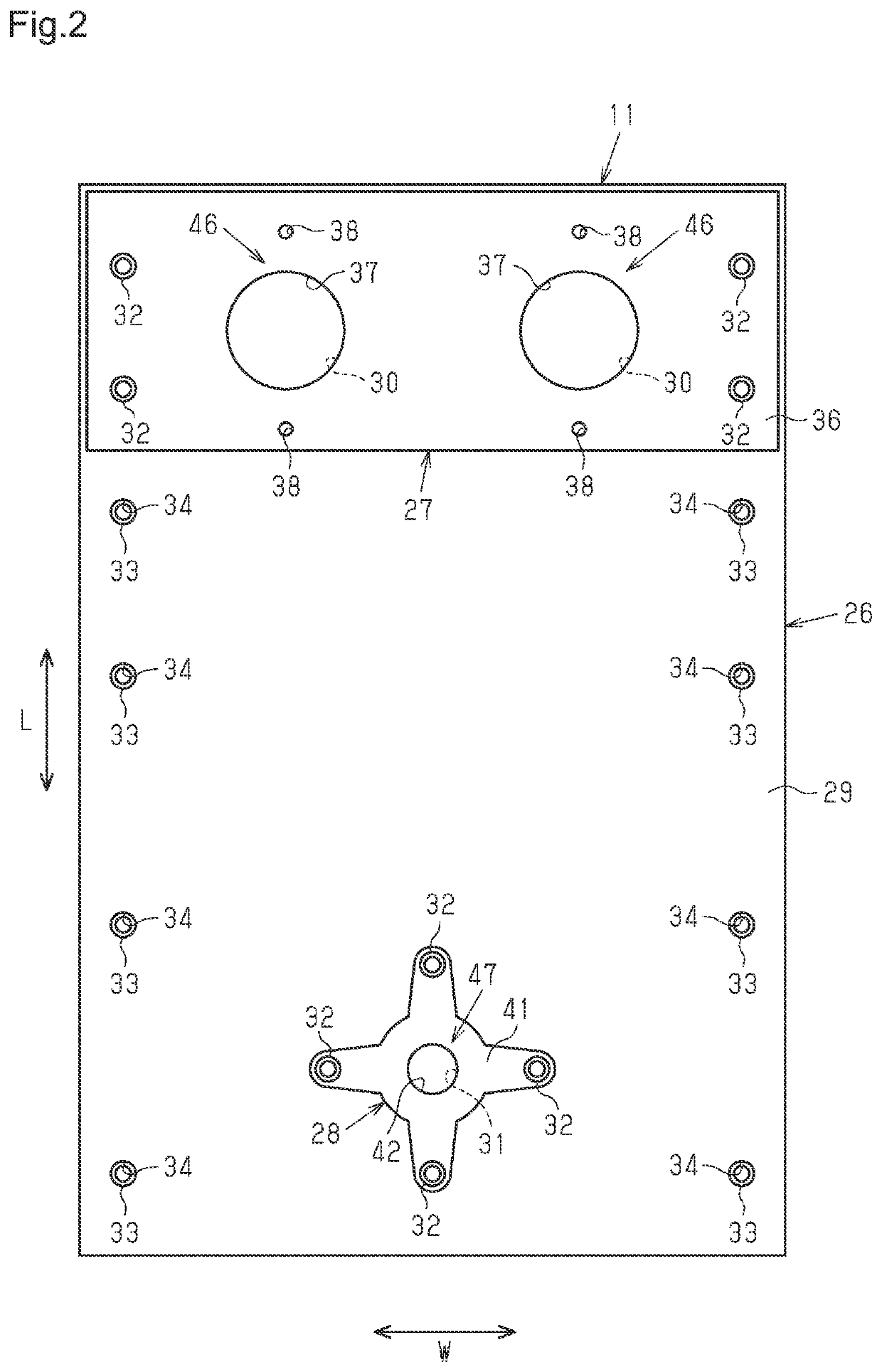

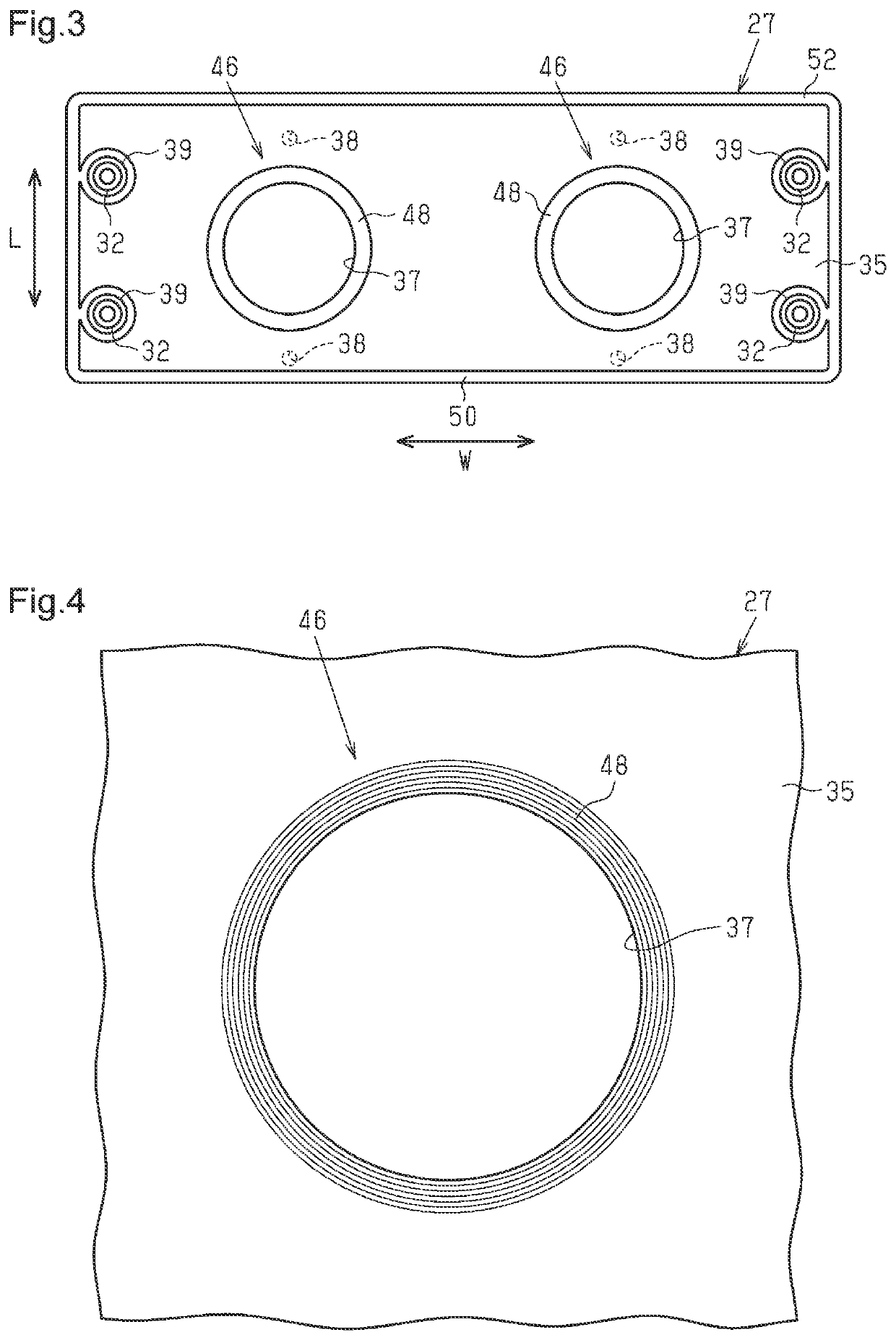

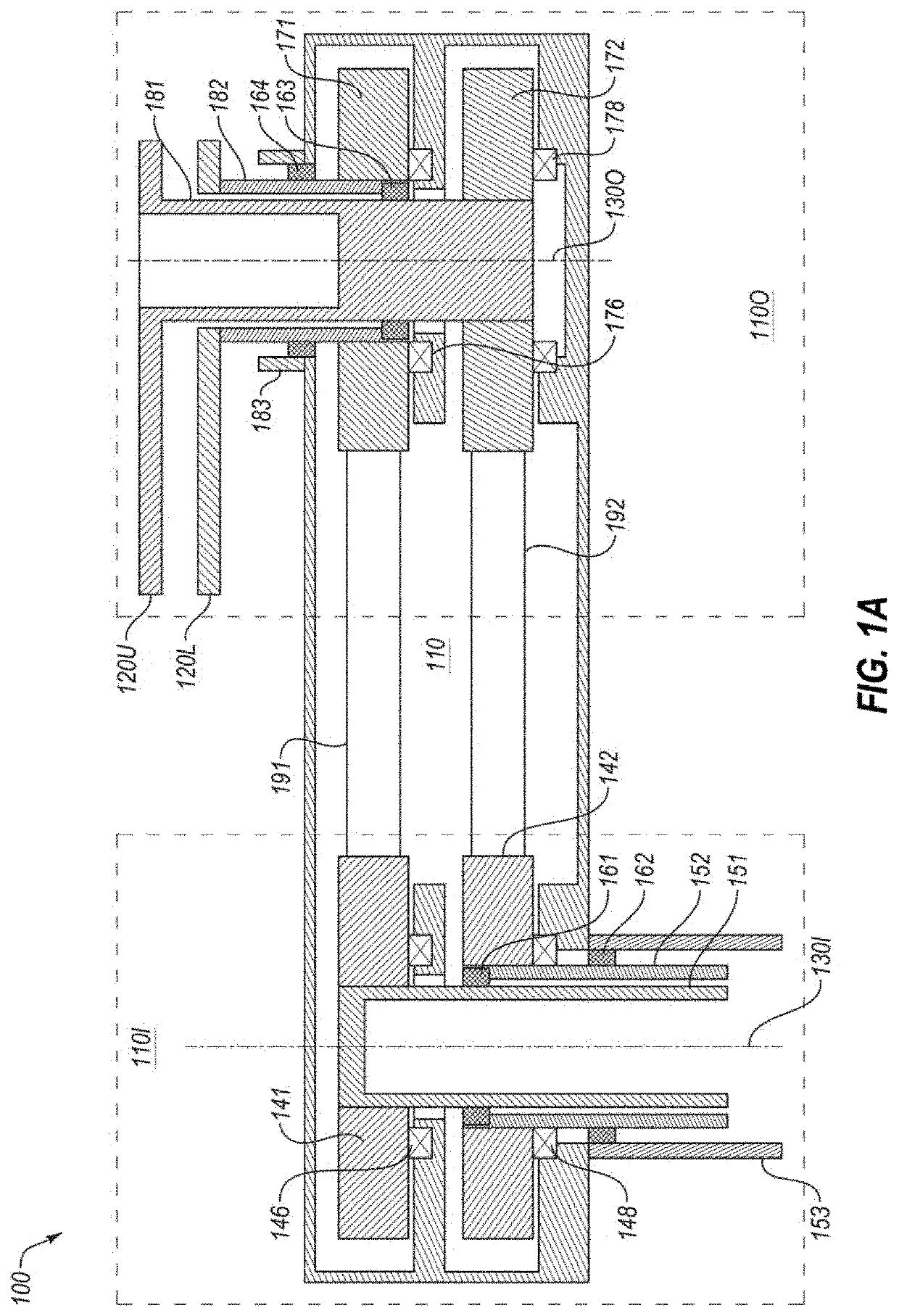

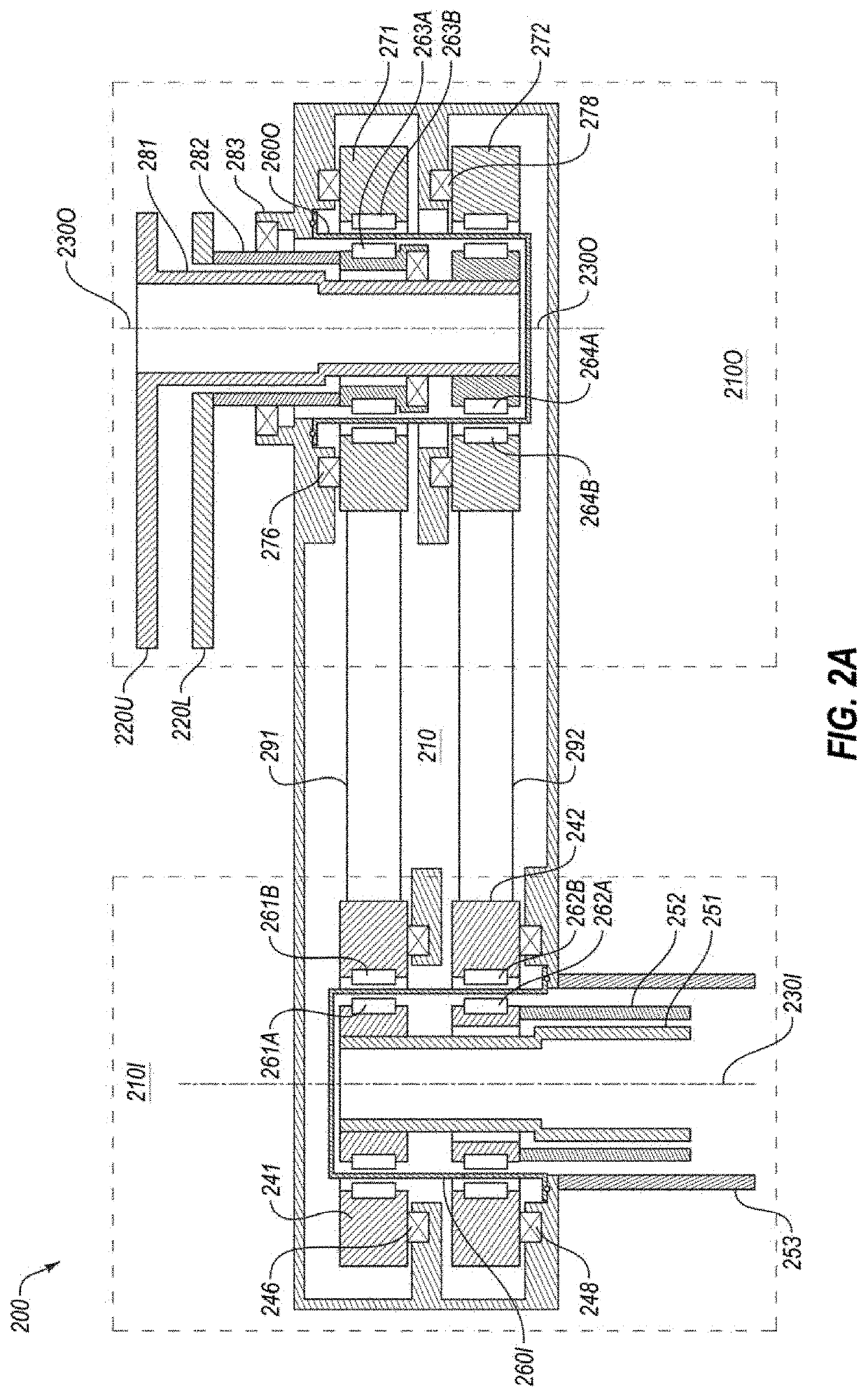

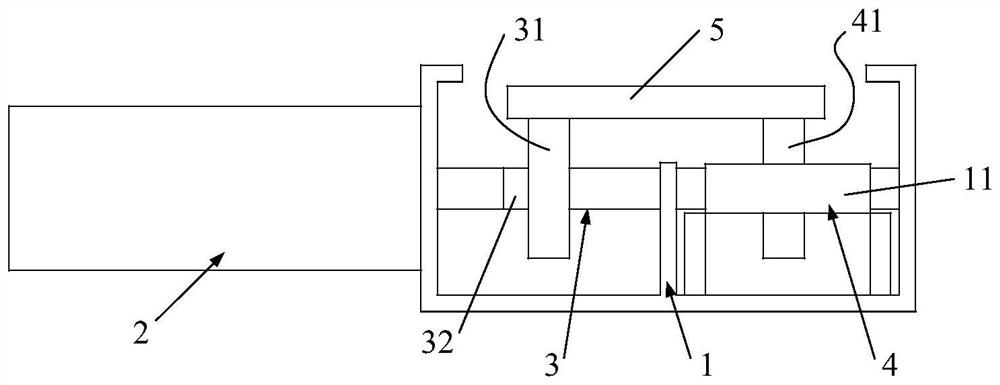

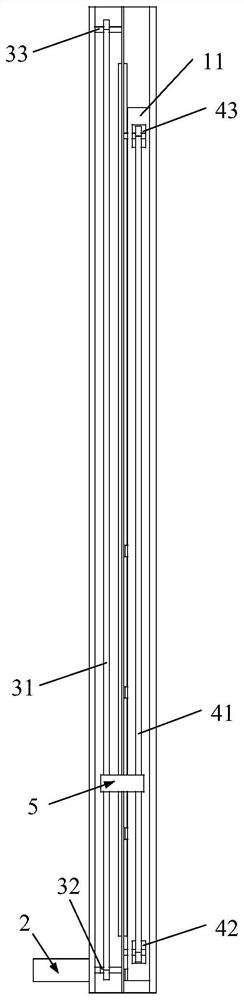

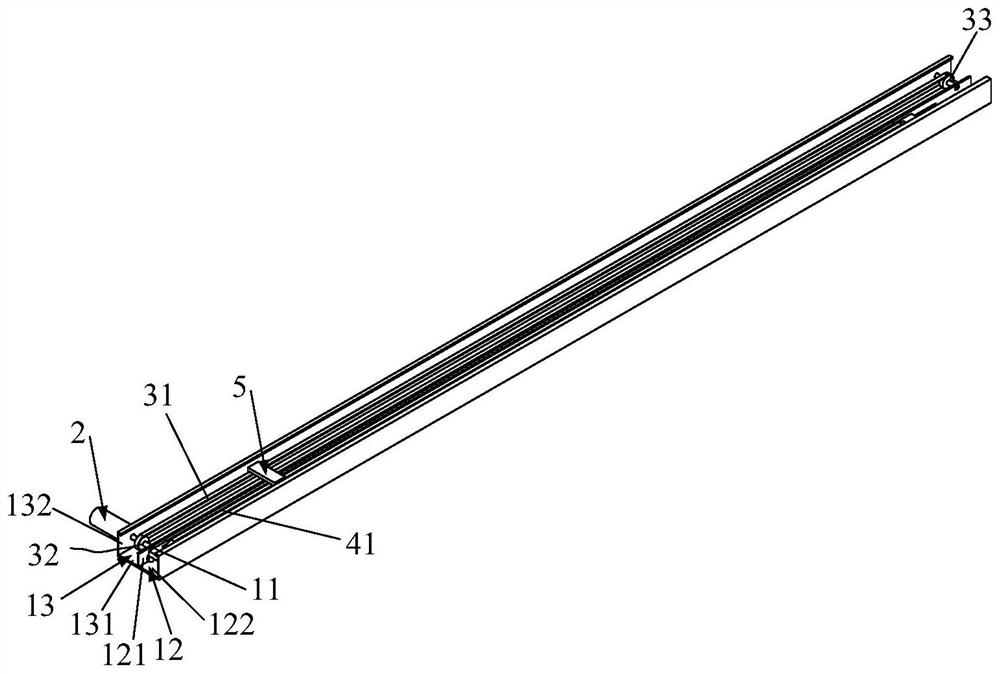

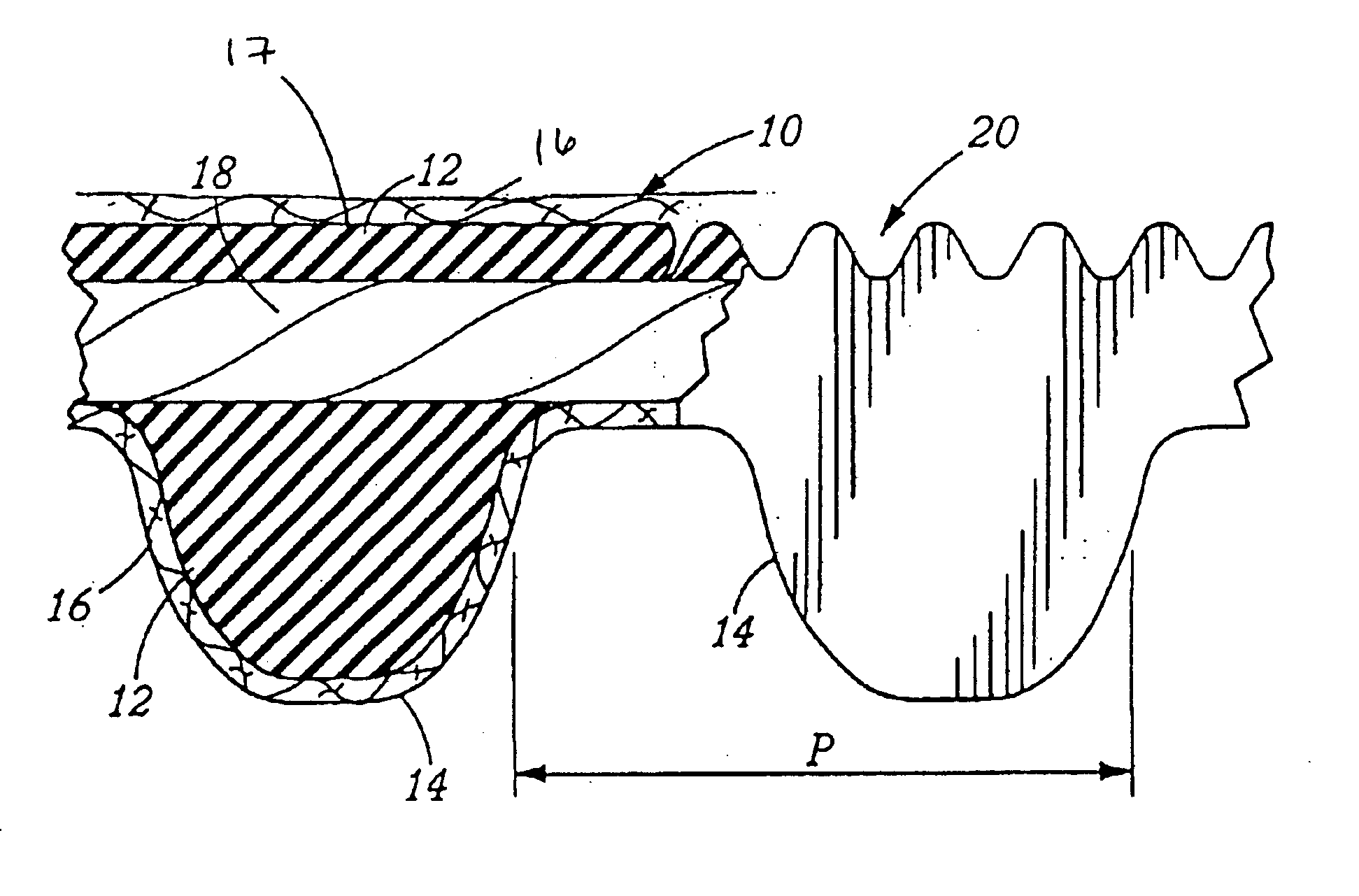

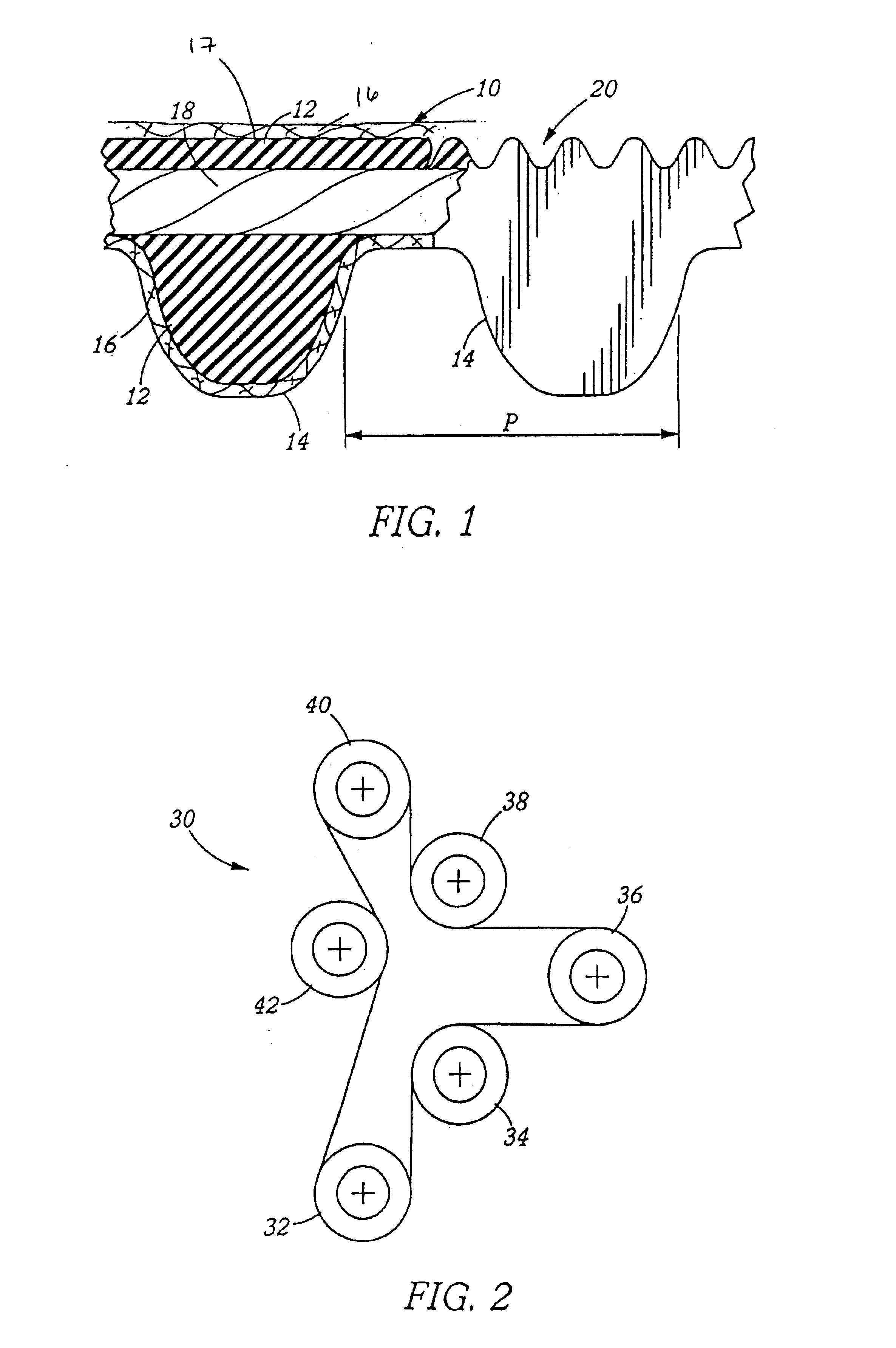

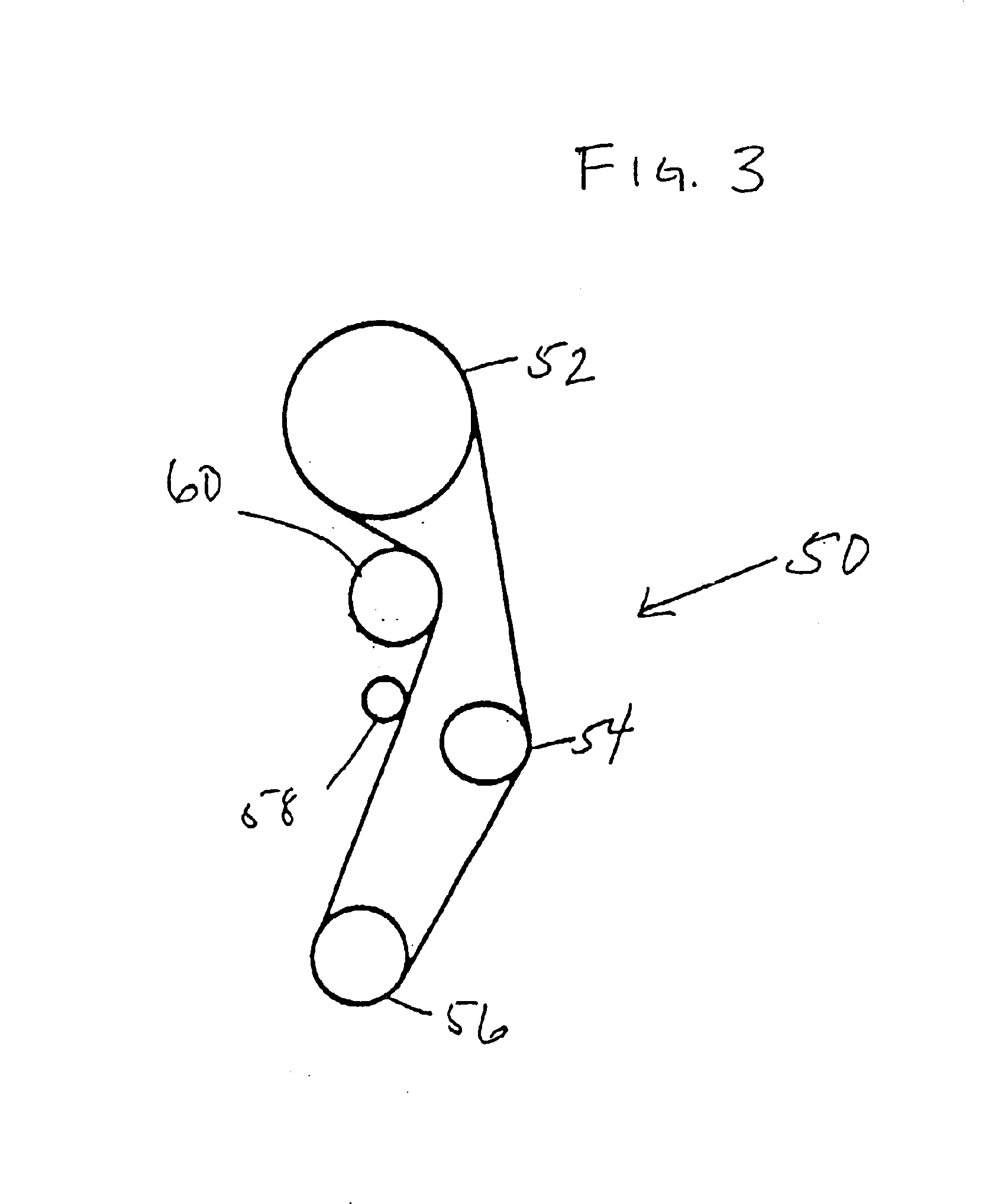

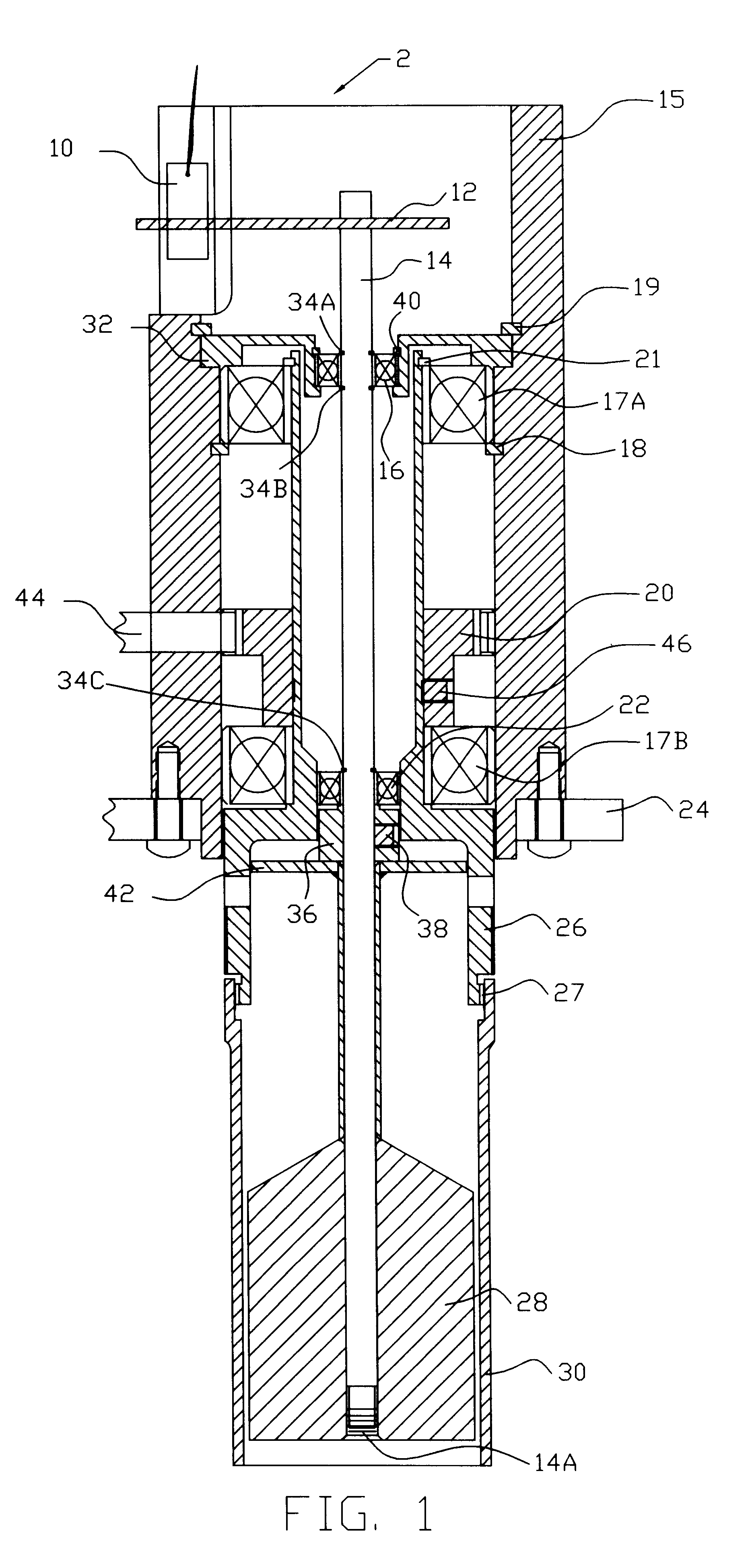

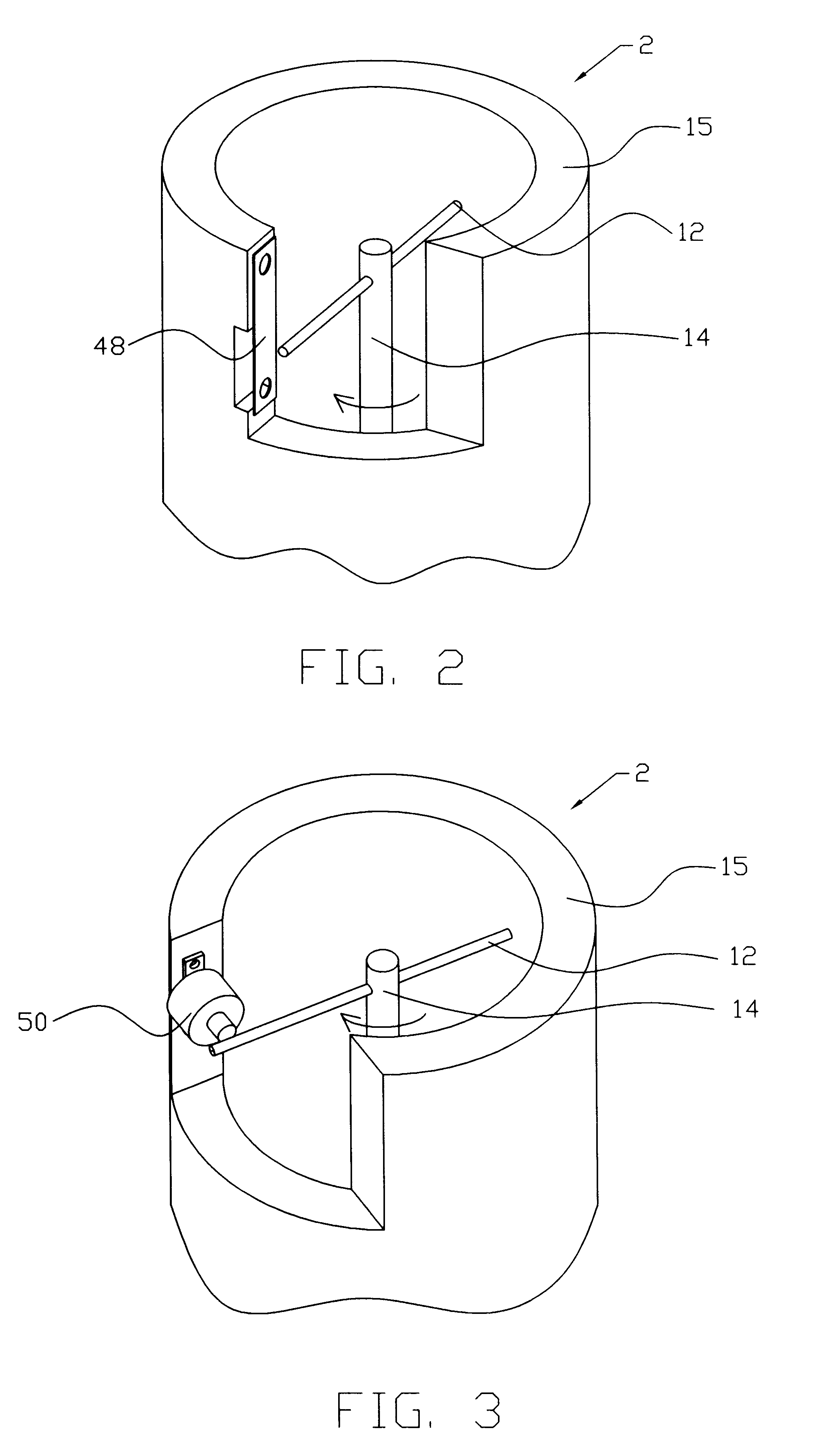

[Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys]

This hybrid pulley assembly is comprised of two outer driven synchronized timing pulleys and a centerpiece inner driver timing pulley. This pulley assembly operates in such a manner where the input driving timing belt mounted on the centerpiece timing pulley positively drives the outer synchronized timing pulleys. An outer driven timing belt, which is mounted on the outer driven timing pulleys and across the centerpiece driver timing belt, is partially supported by the centerpiece driver timing belt top surface in the area enclosed by the two outer synchronized timing pulleys. This configuration allows this hybrid pulley assembly to be driven from within. This alleviates the need of conventional drive train systems where a timing driven belt is driven through an axial input to the driven timing pulley.

Owner:QUANTUM ENG INT

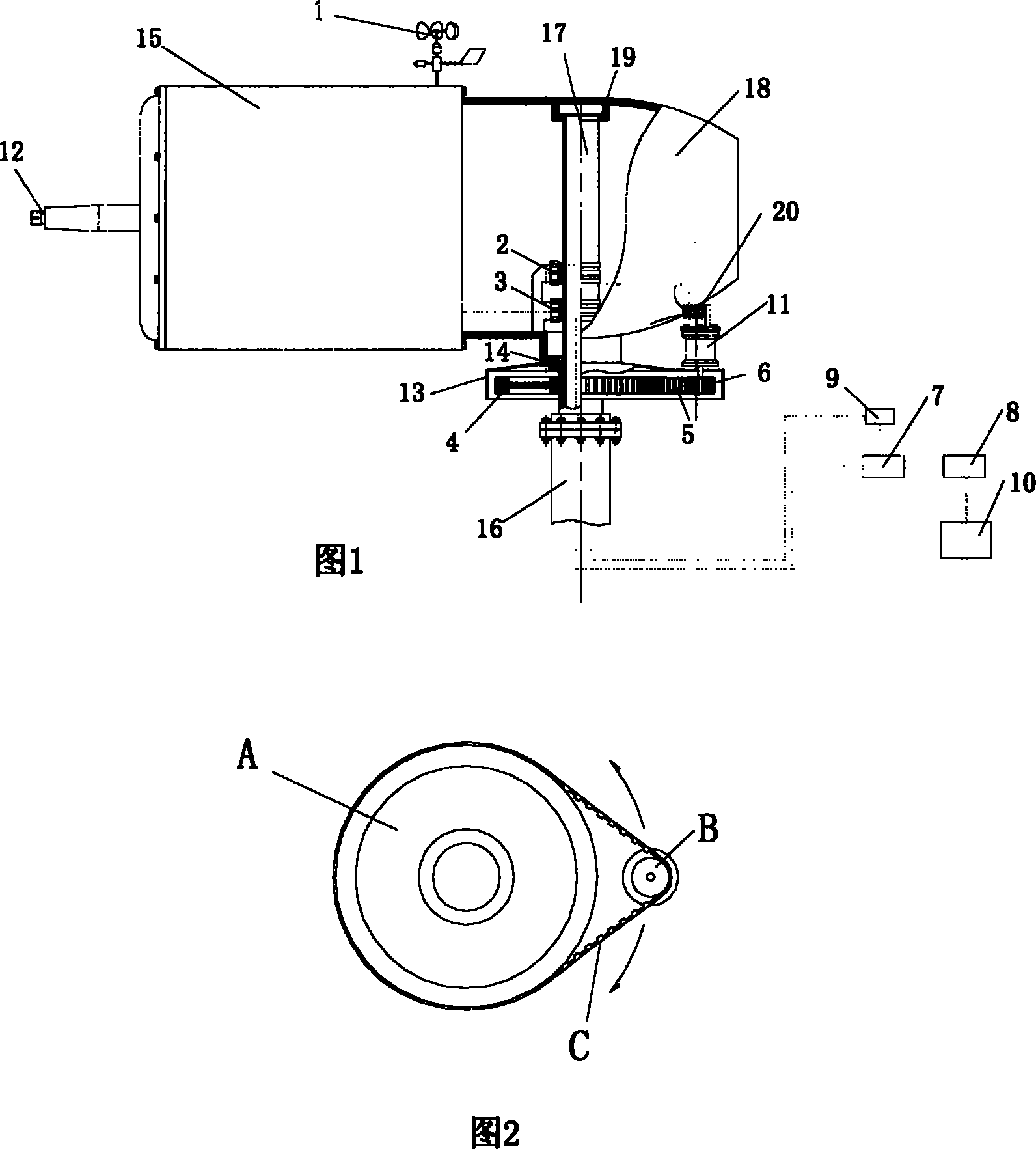

Wind-driven generator synchronous belt transmission automatic wind-aiming drift device

InactiveCN101122279ARealize speed regulationImplement speed limitWind motor controlMachines/enginesWind drivenElectricity

The invention is a timing belt transmission automatic wind opposing deviation device of a wind power generator. A power generator (15) is connected with a revolving body (engine cabin) (18). The revolving body shaft (17) is connected with a pole (16). The shaft (17) is provided with a carbon brush (2), a carbon brush (3) and a large synchronous belt pulley (4). The shaft (17) cooperates with the engine cabin (8) via a cone gear (14) and a deep groove ball bearing (19). The engine cabin (18) is equipped with a timing belt tension spring (20) outside, which is connected with a stepped electric motor (11). The stepped electric motor (11) is connected with a small synchronous belt pulley (6). Thus, the revolving body can drive the small synchronous belt pulley (6) to rotate circumferentially around the large synchronous belt pulley (4) on the revolving body shaft (17) via a timing belt (5). The carbon brush (2) is responsible to input the externally stored electric current into the stepped electric motor (11), while the carbon brush (3) is responsible to output the power generated by the generator (15). The advantage of the wind deviation device is that when the wind power generator is working, the device can oppose the wind automatically and deviates from the wind in the case of a strong wind, so as to reach the purpose of automatic speed controlling and limiting and achieve the self-protection function of the wind power generator. The device avoids large tail fins of a wind power generator in the past. With the device, a wind power generator can be controlled and operated intelligently, is more reliable in the work, and is free of maintenance for a long time.

Owner:ZHEJIANG BIHUALI ELECTRIC TECH

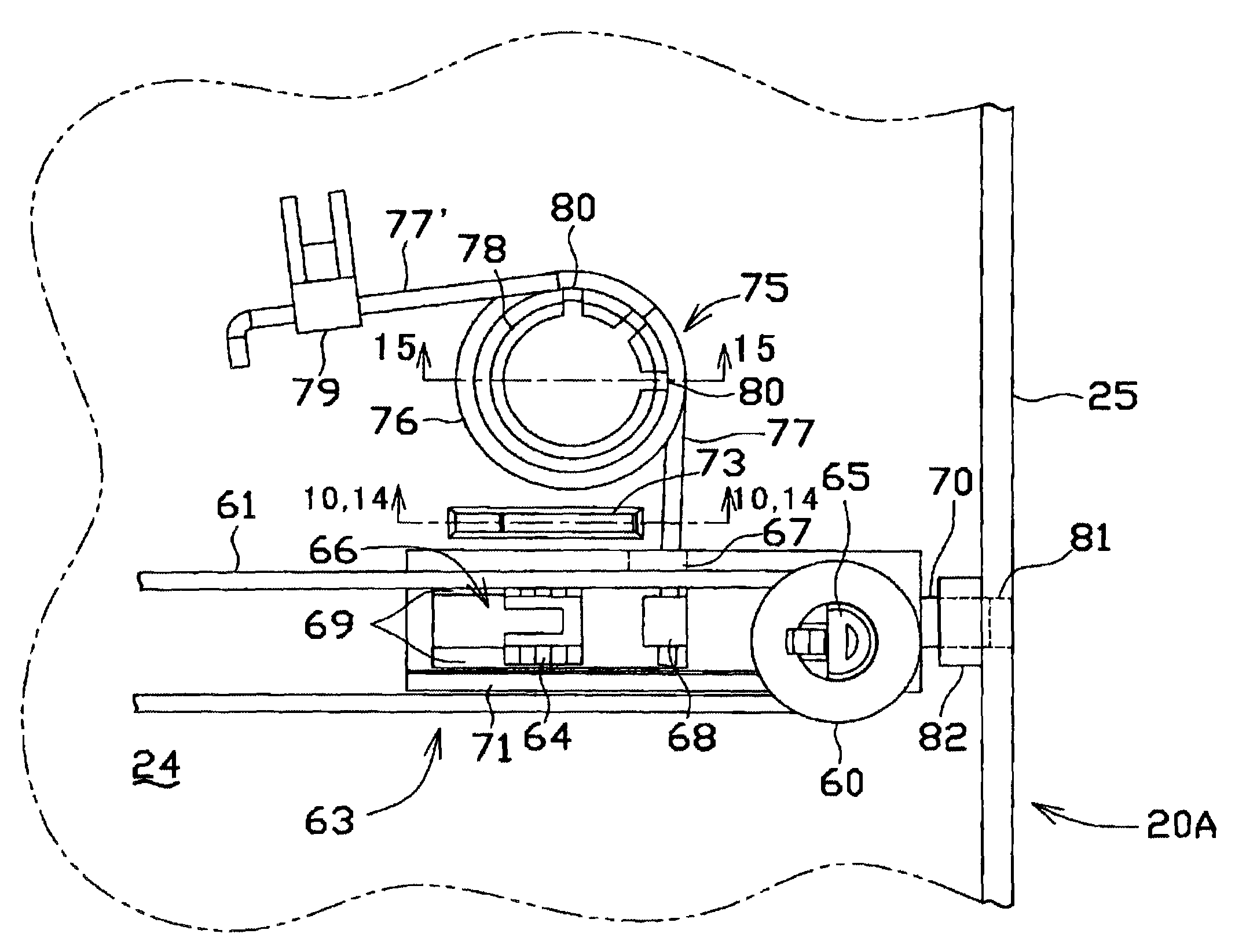

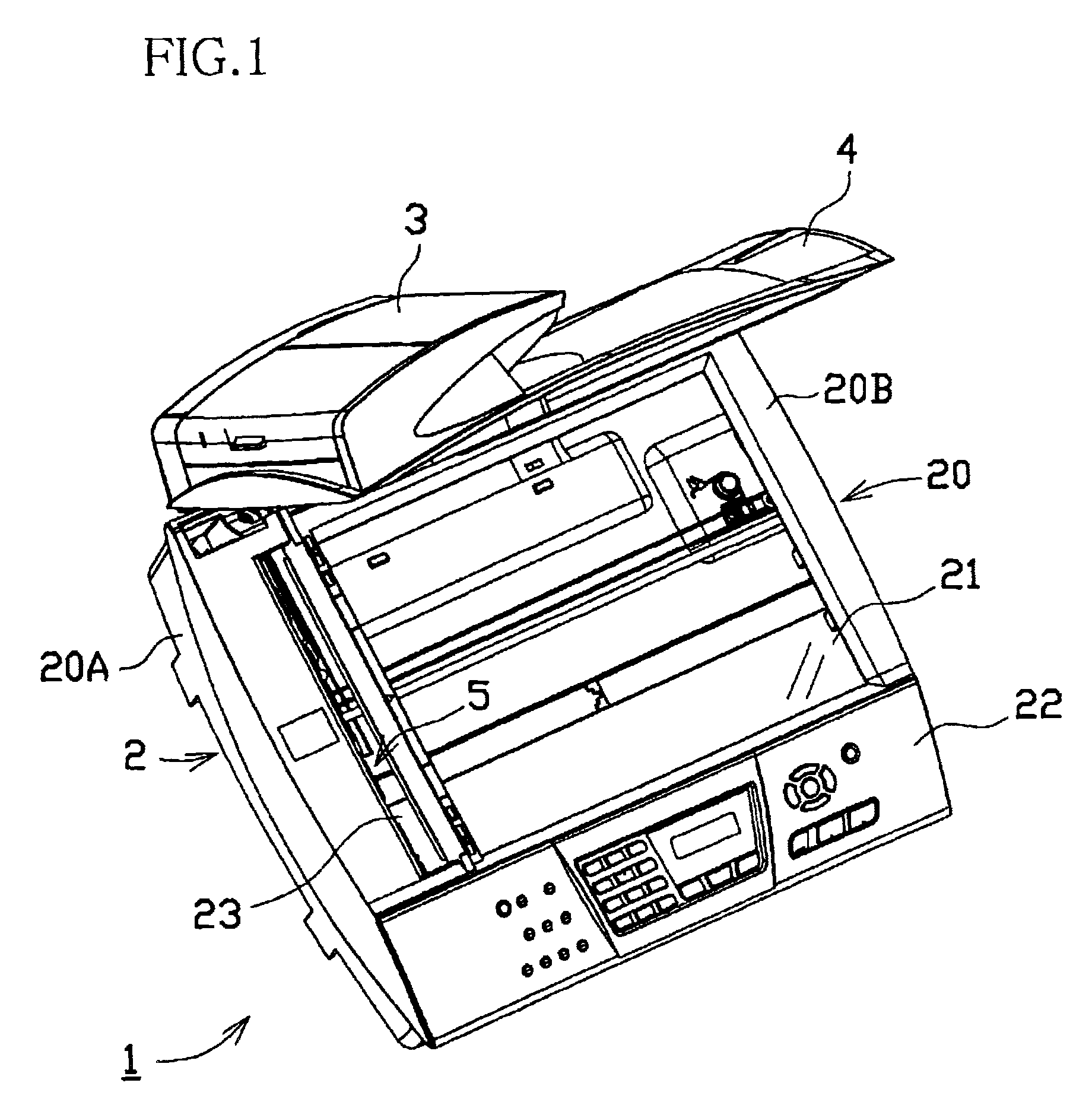

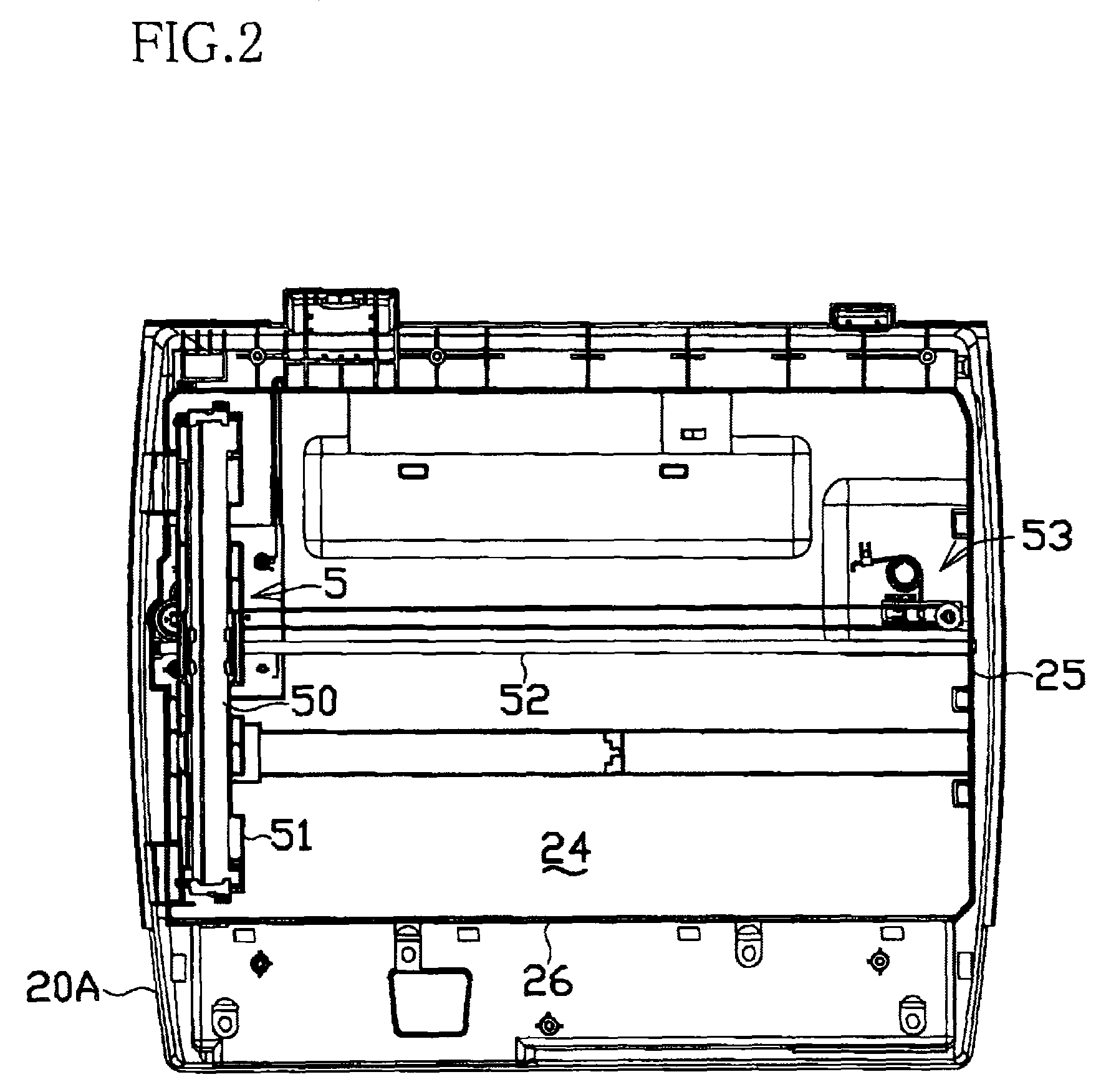

Carriage driving apparatus and image reading apparatus and image recording apparatus using the same

ActiveUS7758460B2Simple structurePrevent disengagementSpacing mechanismsGearingImage recordingEngineering

A carriage driving apparatus includes: a biaser which biases a pulley holder in a tensioning direction to tension a timing belt; and a biaser holder which holds the biaser such that the pulley holder is allowed to move to the slackening position when the biaser is not held by the biaser holder, and the pulley holder is biased by the biaser in the tensioning direction when the biaser is held by the biaser holder, the biaser holder limiting movement of the pulley holder in a slackening direction to slacken the timing belt, to a disengagement inhibit position between the slackening position and the tensioning position.

Owner:BROTHER KOGYO KK

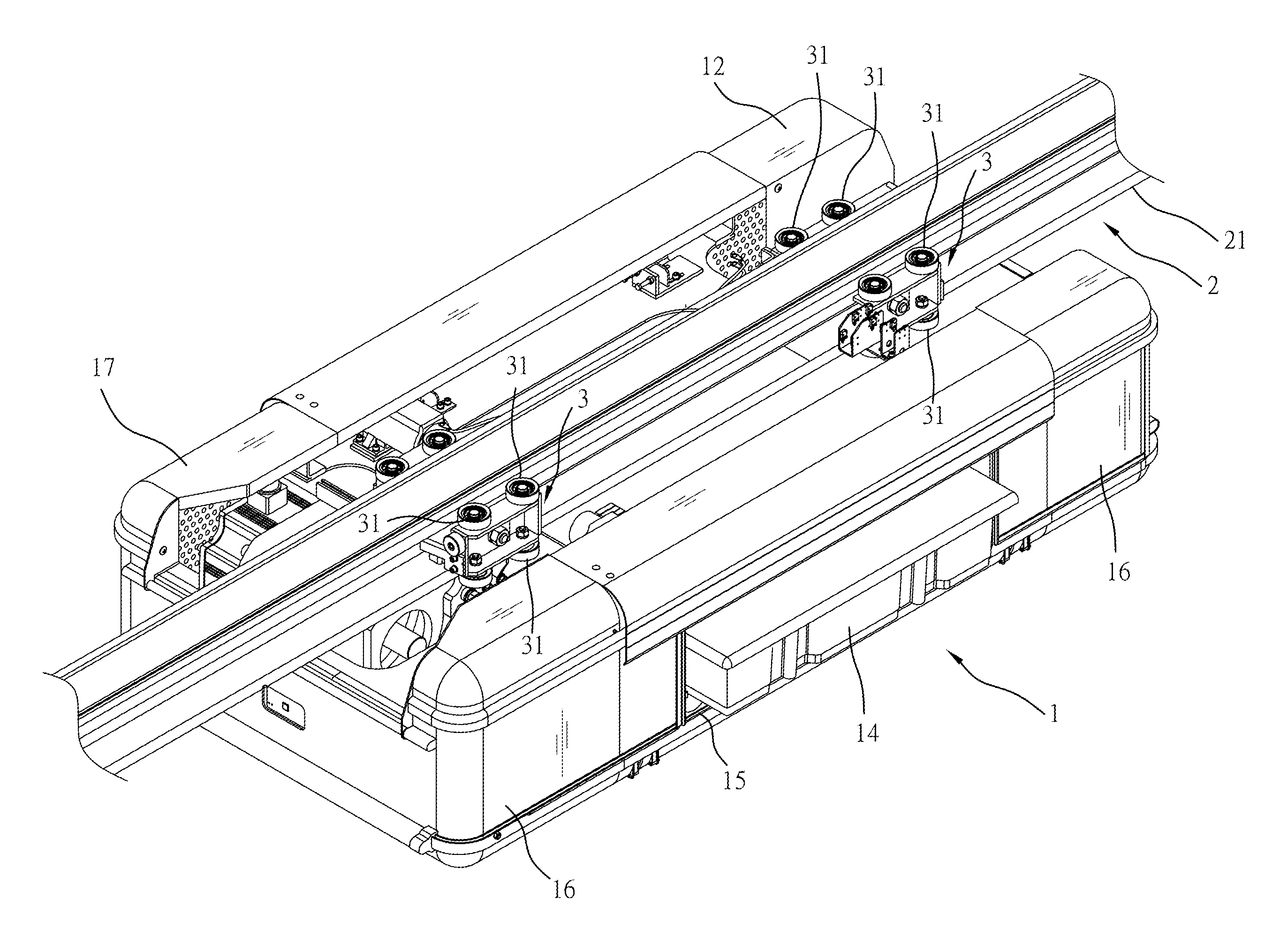

Autonomous mobile robot

ActiveUS20110144849A1Simple structureEasy to installElevated railway with suspended vehicleVehicle position/course/altitude controlRight-SidedEngineering

An autonomous mobile robot includes a housing mounted on a track and controllable to move along the track and to stop at each selected location, two side covers pivotally mounted on the left and right sides of the housing and movable by a respective driving motor to close / open the left or right side of the housing, and a mechanism consisting of a motor roller, a driven roller, timing pulleys and timing belts to move a material carrier horizontally leftwards or rightwards to the outside of the housing after opening of the left-sided or right-sided side cover.

Owner:WANG CHIN HSIUNG

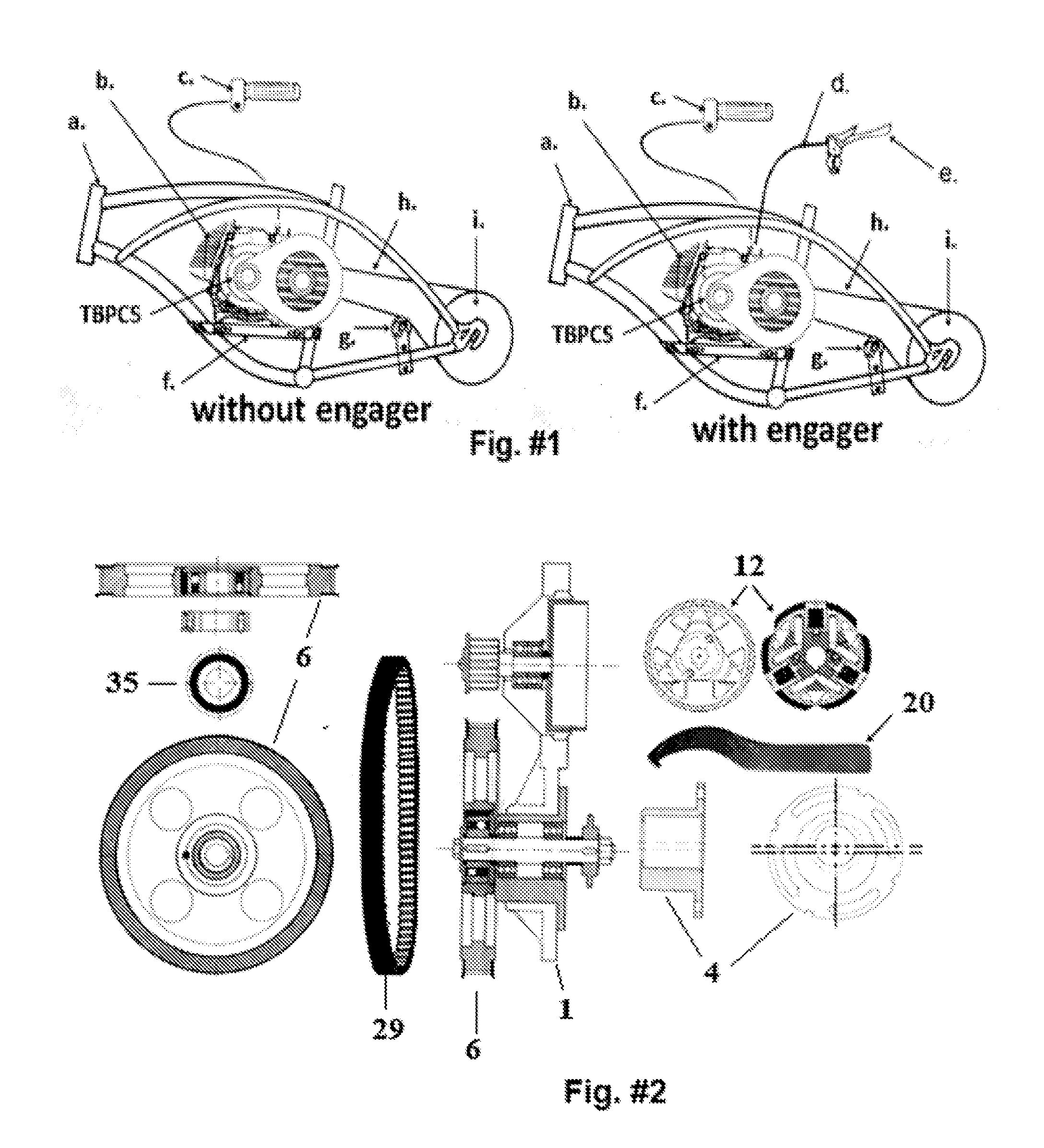

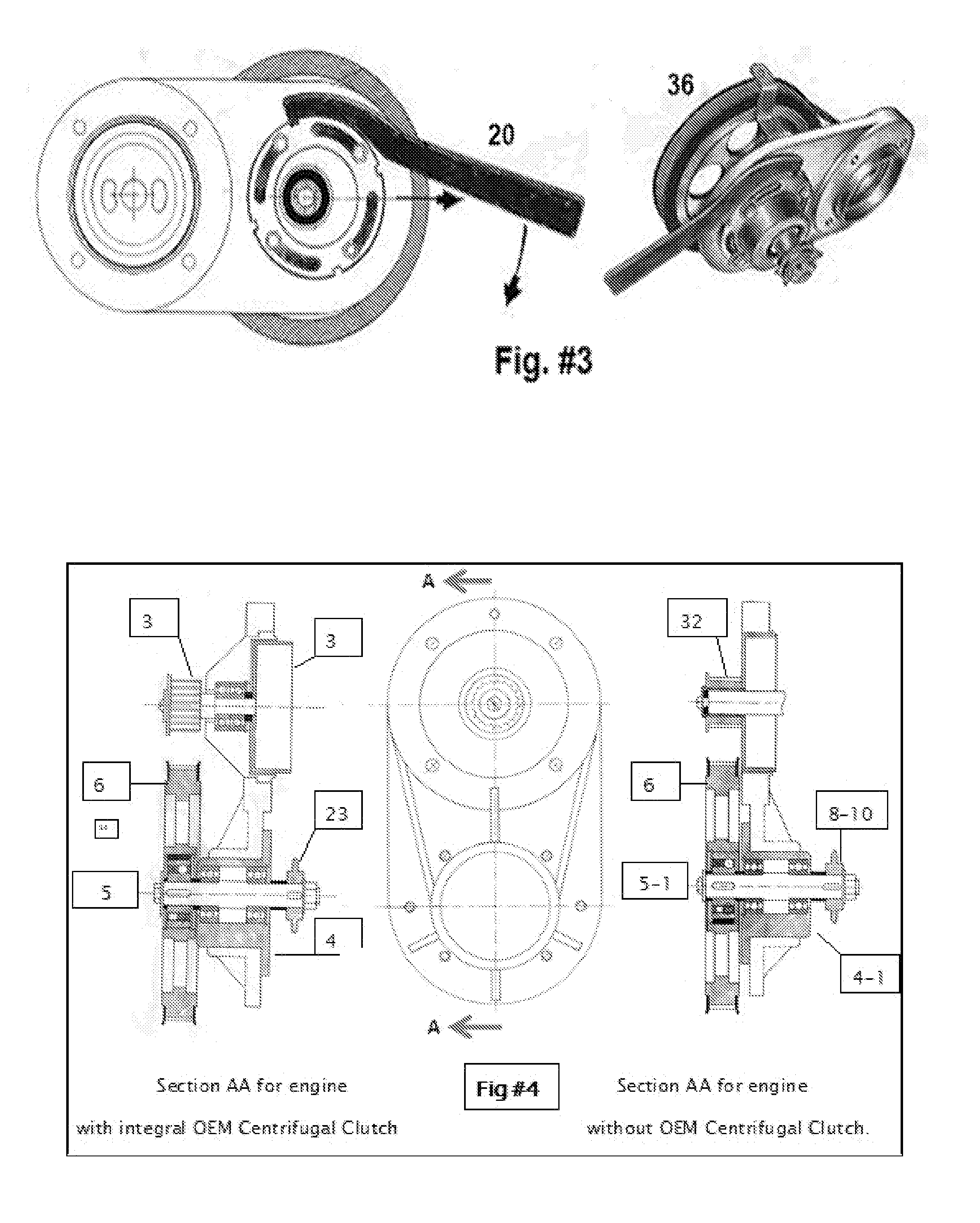

Centrifugal clutch timing belt power transmission control system for a small gasoline engine

A T belt power control system is disclosed to consist of a centrifugal clutch integral bell drum, or in the case of a straight shaft engine such as a Honda GXH50 a non integral bell drum, a T belt drive pulley affixed to a bell drum, an automotive type timing belt, a driven pulley cylindrical cam lock assembly consisting of a larger driven pulley with a one-way bearing for speed reduction and torque enhancement, a non concentric cylindrical housing and an output jackshaft with or without an engine power engaging system to a primary drive sprocket for chain operation. The T Belt tension is secured and maintained by rotating the cam lock assembly with a spanner wrench and then held tight by four bolts. If the T belt power control system is made without an engager system the power is transmitted as soon as the centrifugal clutch latches with the bell drum. If with an engager system the engagement and disengagement of engine power is done by an integral engager remotely controlled by steel cable and hand lever. A motorized vehicle is disclosed as consisting of a standard bicycle frame or modified bicycle frame, a tricycle frame, a go-cart frame, and a paddle wheel boat frame all with the T belt power control system of present invention installed on a gasoline four cycle engine.

Owner:GRUBE DONALD BARTON

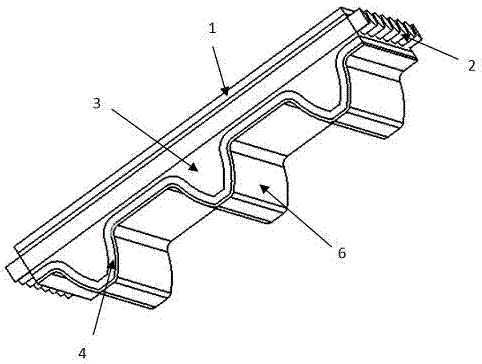

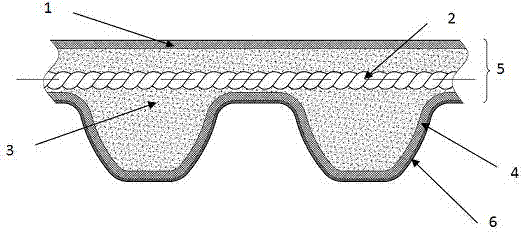

Automobile timing driving belt for oil immersion

ActiveCN103075464AMeet different job requirementsSimple structureFibre typesDriving beltsElastomerNitrile rubber

The invention relates to a timing belt, in particular to an automobile timing driving belt for oil immersion, which can be dipped in automobile engine oil for use. The automobile timing driving belt for the oil immersion comprises an annular belt body, a plurality of tooth parts and a core wire, wherein the tooth parts are formed at intervals along the inner surrounding surface of the belt body; the core wire is embedded along the periphery of the belt body; the outer surrounding surface of the belt body is provided with a back fabric layer; the inner surrounding surface of the belt body is provided with a tooth-shaped fabric layer covered above the tooth parts; and the back fabric layer and the tooth-shaped fabric layer are canvases subjected to dipping treatment by dipping mucilage of which the main ingredient is the same with the main ingredient (hydrogenated butadiene-acrylonitrile rubber) of the main body of the belt body. According to the automobile timing driving belt for the oil immersion, which is disclosed by the invention, the belt body is made of elastomer material with excellent oil resistance, the back of the belt body is provided with one layer of back fabric layer subjected to deoiling treatment, the middle of the belt body is provided with the core wire subjected to oil resistance treatment, and the inner surrounding surface of the belt body is provided with a plurality of tooth parts covered by the tooth-shaped fabric layer to serve as a transmission area.

Owner:NINGBO FENGMAO FAR EAST RUBBER

Cam timer adjuster

An adjustable timing gear assembly and the method of making same that can readily be adjusted in the field in a manner to permit precise cam timing adjustments without having to remove the engine timing belt from the gear member of the apparatus. Importantly, the gear assembly includes strategically located and configured mating serrations that function to positively prevent accidental relative rotation between the gear member and the hub member of the device which is connected to the engine camshaft

Owner:BOURNE EDWARD T +1

Timing pulley

There is provided a timing pulley whose noise is low, which is light-weight, whose pulley structure is simple and which excels in workability. The timing pulley comprises a cylindrical timing hub which is fitted around a power transmitting shaft, a pair of flange members provided apart on both end portions of the timing hub and a plurality of engagement pins disposed on peripheral edge portions of the pair of flange members in the circumferential direction thereof so as to extend between and through each of the flange members and so as to engage with mating teeth of a timing belt.

Owner:TSUBAKIMOTO CHAIN CO

Active pay-off tension control device and wire winding method thereof

The invention provides an active pay-off tension control device and a winding method thereof. Including: bottom plate, ceramic eye mounting plate, synchronous belt and synchronous pulley, floating roller and fixed roller, two guide wheels, countersunk screws, nuts, moving plate, slider, linear guide rail, fixed plate, damper and its housing , and the speed motor. The guide wheel, fixed roller and synchronous pulley are fixed on the bottom plate by nuts, the ceramic eye plate and linear guide rail are fixed on the bottom plate by countersunk head screws, the slider is stuck on the linear guide rail groove, and the moving plate and slider are connected by countersunk head screws , Connect the fixed plate and the moving plate through countersunk screws and nuts, the fixed and moving plates clamp the timing belt, and fix the floating roller on the moving plate through nuts. The beneficial result of the invention is that the tension feedback device has a novel structure, is easy to implement, and is simple to assemble, can effectively control the tension of the wire during the winding and unwinding process, and improve production efficiency. The winding method of the active pay-off tension control device applied in the present invention is convenient to implement and the tension is precisely controlled.

Owner:CHINA JILIANG UNIV

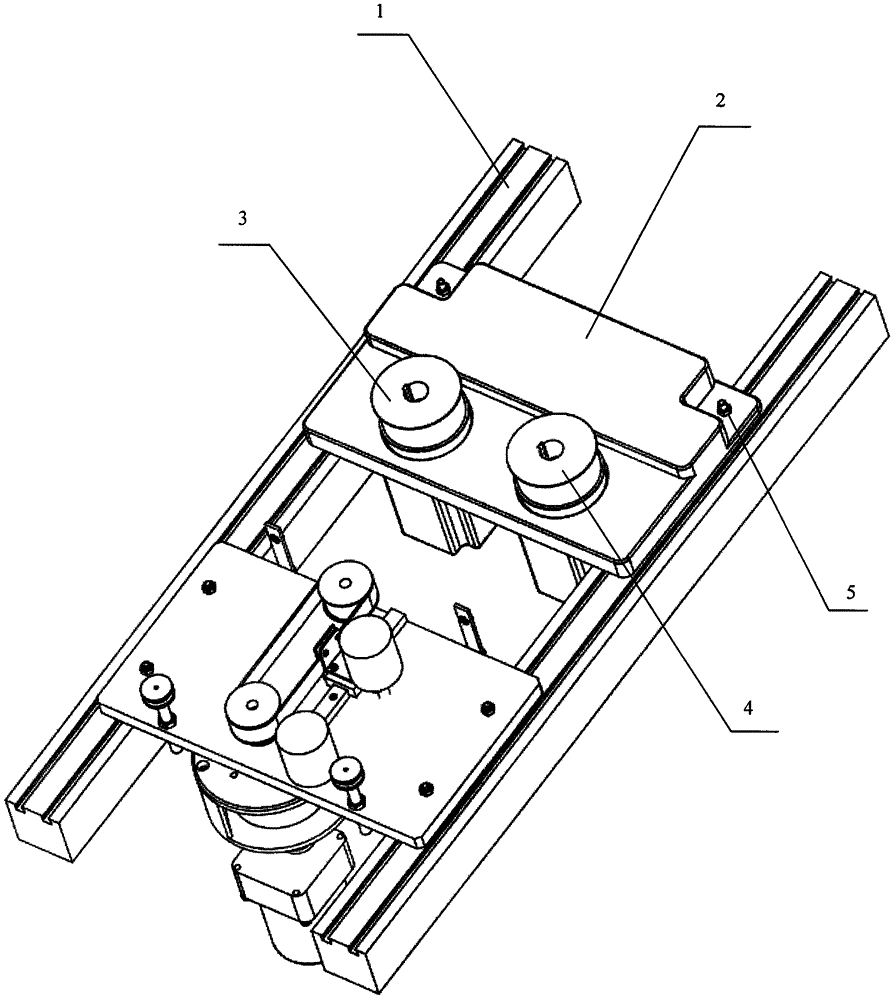

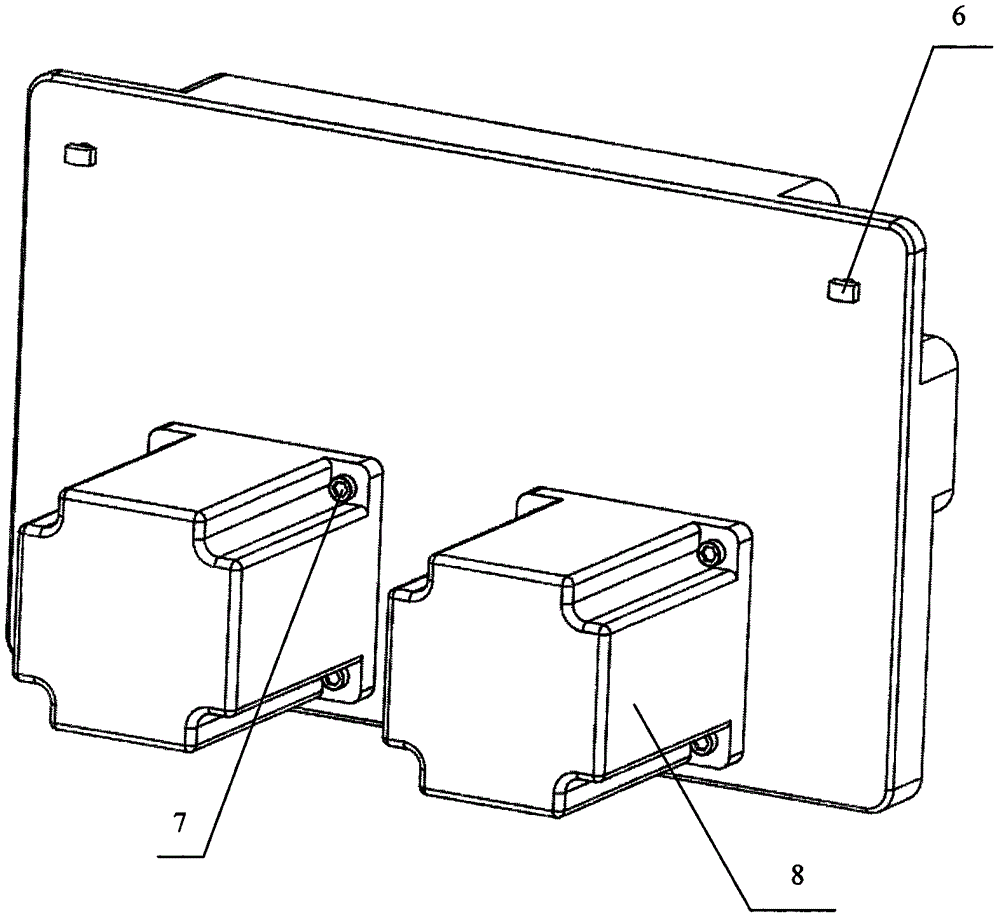

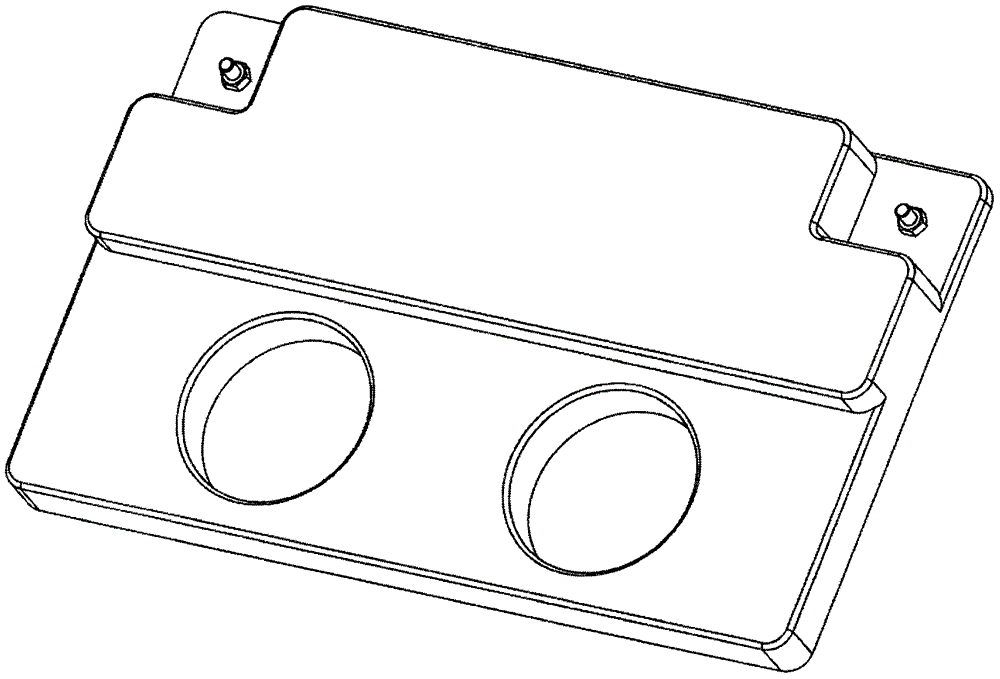

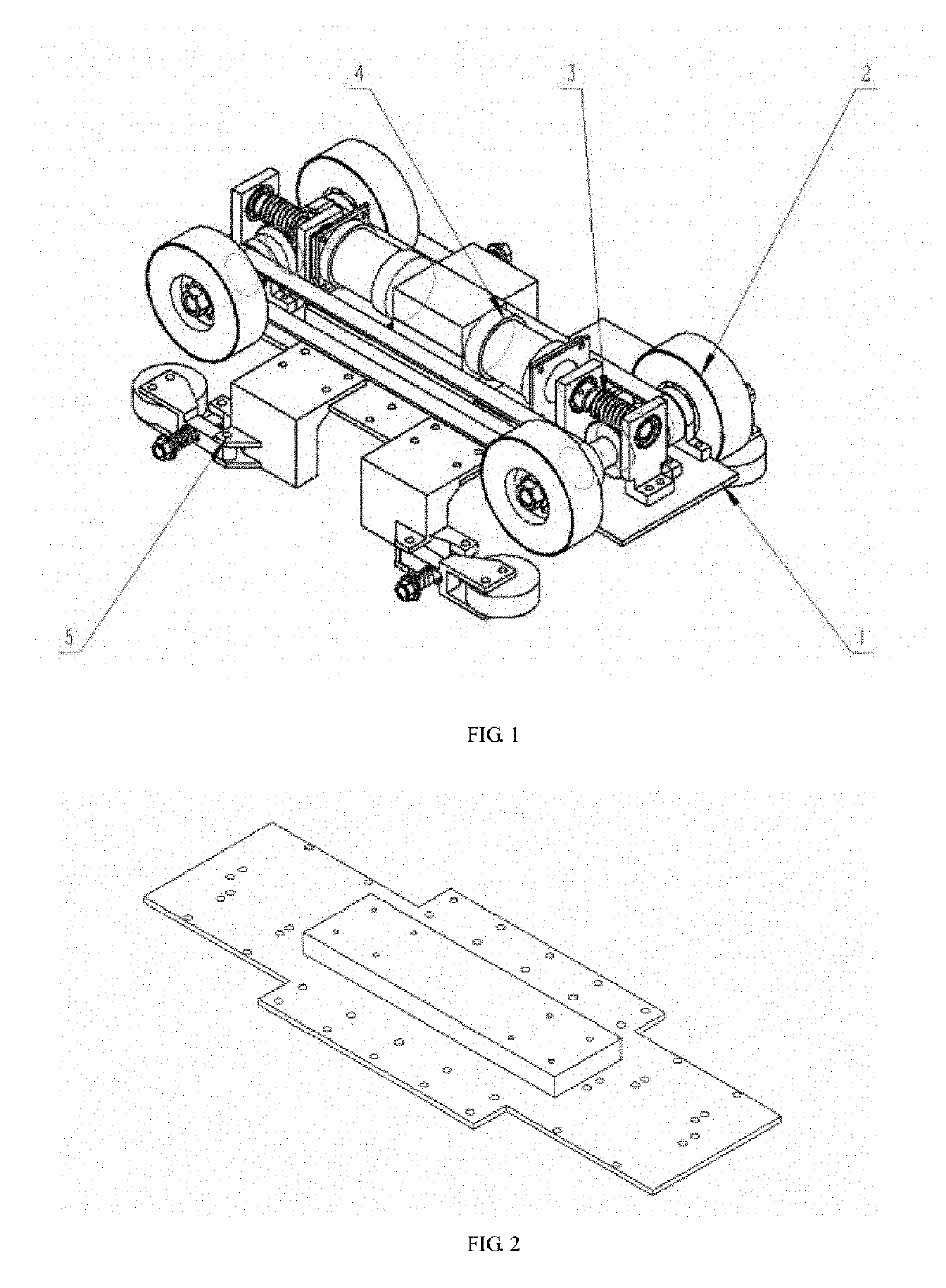

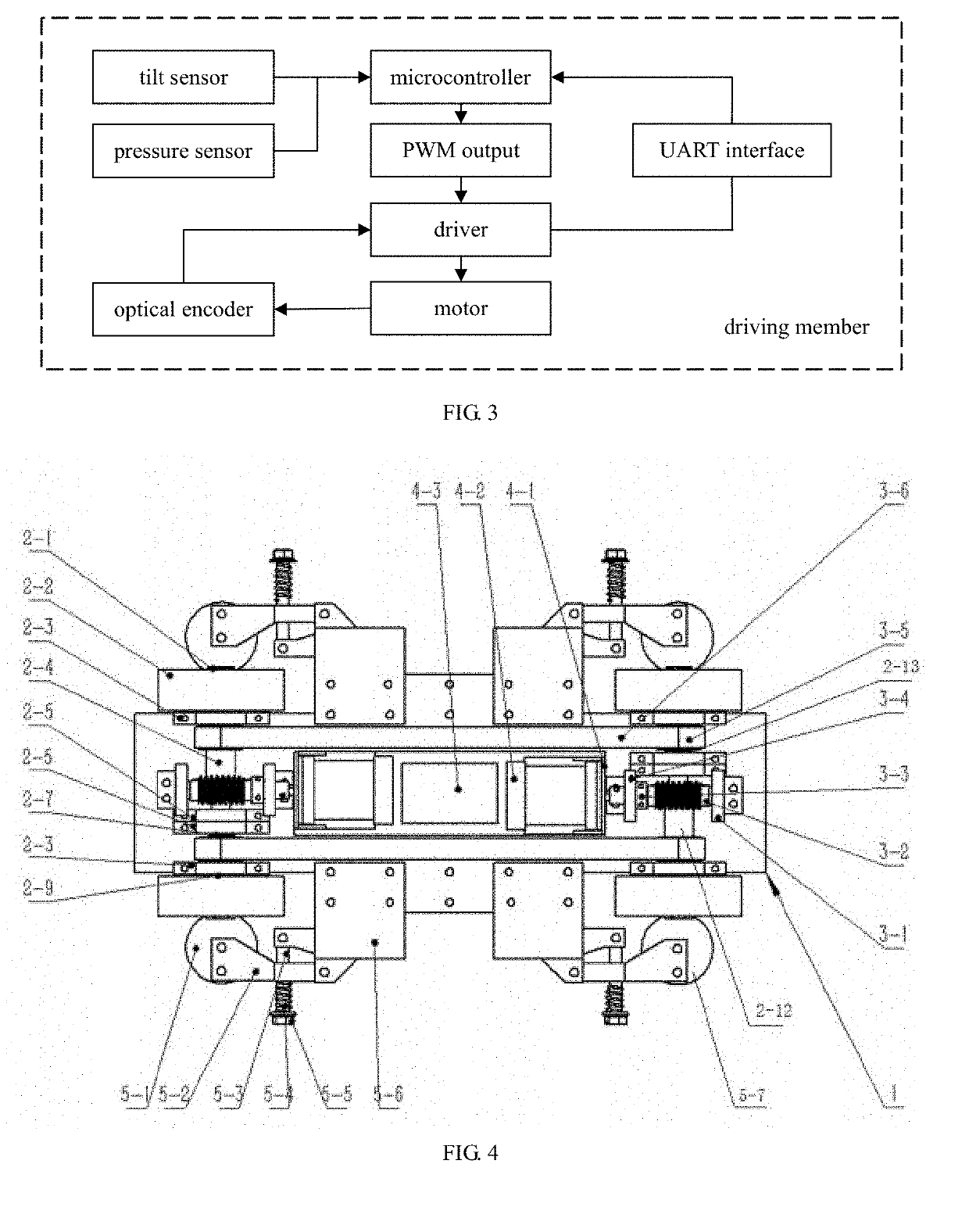

Device and method for periodically inspecting rigid guide

ActiveUS20190225287A1Increase speedShorten the timeMining devicesElevatorsMicrocontrollerEngineering

The present invention discloses an apparatus and method for patrol-inspection of a rigid cage channel. The patrol-inspection apparatus comprises a moving member, a transmission member, a driving member, a guide member, and a housing on a main bottom plate. The driving member comprises a tilt sensor and a pressure sensor connected to a microcontroller, the microcontroller is connected to a driver, the driver is connected to a brushless DC motor, and an output shaft of the brushless DC motor is provided with an optical encoder connected to the driver; The moving member comprises a driving output shaft and a driven output shaft, wheel flanges on the driving output shaft and the driven output shaft are each connected with a wheel hub, a permanent magnet is provided in the wheel hub, and a rubber skin is provided on the outer side of the wheel hub; The transmission member comprises a worm connected with the output shaft of the brushless DC motor, a worm wheel on the driving output shaft and meshed with the worm, timing pulleys on the driving output shaft and the driven output shaft, and a timing belt wound on the timing pulleys. The guide member comprises a guide wheel. The present invention increases inspection speed of the rigid cage channel and improves indirectly the production efficiency of the coal mine enterprise.

Owner:CHINA UNIV OF MINING & TECH

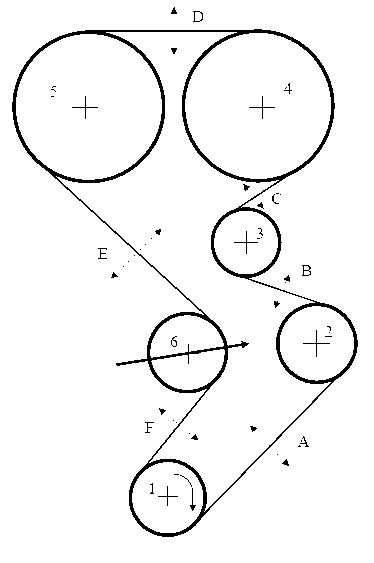

Low-noise automobile timing driving belt

The invention relates to a timing belt, in particular to a low-noise automobile timing driving belt. The low-noise automobile timing driving belt comprises an annular belt body, wherein the belt body is formed by binding a belt back and a meshed part, the meshed part is provided with a plurality of tooth parts which are spaced along the inner circumferential surface of the belt body, a core rope skeleton is embedded inside the meshed part along the circumferential direction of the belt body, an interlayer fabric is arranged between the belt back and the meshed part, and the inner circumferential surface of the meshed part is provided with a tooth-shaped fabric layer covering the tooth parts. Through the measurement, when the low-noise automobile timing driving belt is applied to a 1.8L top-mounted double-cam engine, the resonance phenomenon is eliminated, the noise is remarkably lowered, and the noise is hardly heard when a timing system protection shield is covered.

Owner:NINGBO FENGMAO FAR EAST RUBBER

Motor-driven injection molding apparatus

InactiveUS20050074517A1Reduce the number of partsSimple structureCeramic shaping apparatusFood shapingTiming beltBall screw

Owner:DAIWA KASEI IND CO LTD

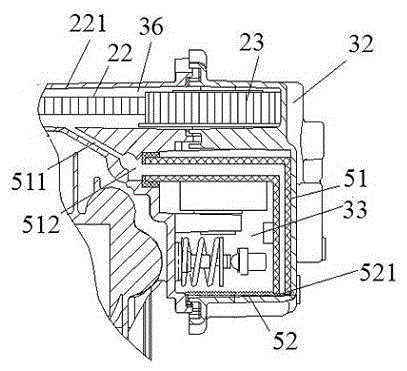

Four-stroke engine of vertical shaft OHC structure

InactiveCN104989522AReduce consumptionEasy dischargeValve drivesNon-pressurised lubricationExhaust valveTiming belt

The invention discloses a four-stroke engine of a vertical shaft OHC structure. The four-stroke engine of the vertical shaft OHC structure comprises an engine body and a timing transmission mechanism arranged above the engine body. The engine body mainly comprises a crankcase, a cylinder body and a cylinder head. The timing transmission mechanism is mainly composed of a driving belt wheel, a timing belt and a driven belt wheel which are located above the oil face of lubrication oil, and further mainly comprises a gas distribution mechanism, a lubrication mechanism and an oil-gas separation and lubrication oil recycling mechanism. The gas distribution mechanism is mainly composed of a cam, a cam rocker, a cam transmission shaft and an inlet and exhaust valve. The lubrication mechanism mainly comprises a lubrication oil mist generation mechanism and a lubrication channel. The oil-gas separation and lubrication oil recycling mechanism mainly comprises a cylinder head cavity, a partition board and a returned oil sucker. The novel vertical shaft OHC structure is adopted and the oil mist lubrication mode is adopted; the structural design is reasonable and compact; the cost is low; the consumption of the lubrication oil can be effectively reduced; engine emission is optimized; the operation reliability of the engine is improved.

Owner:JIANGSU LINHAI POWER MACHINERY GROUP

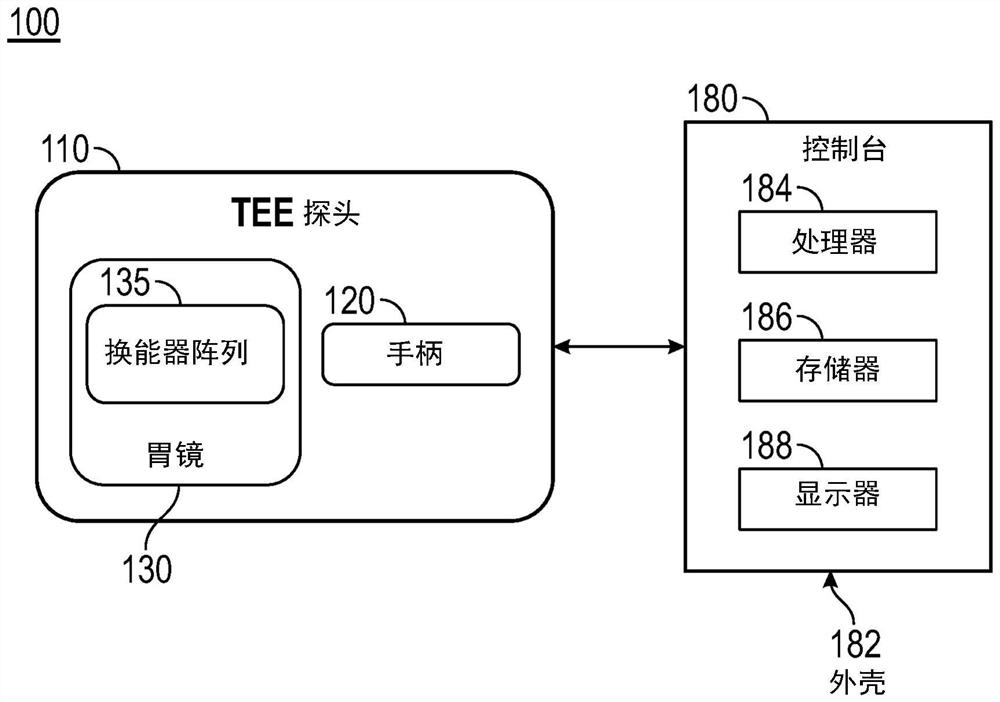

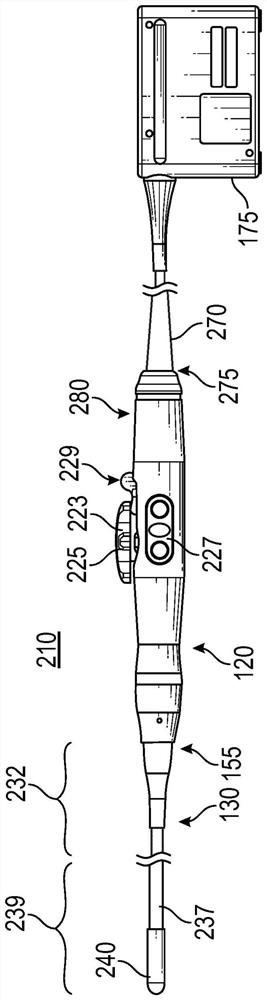

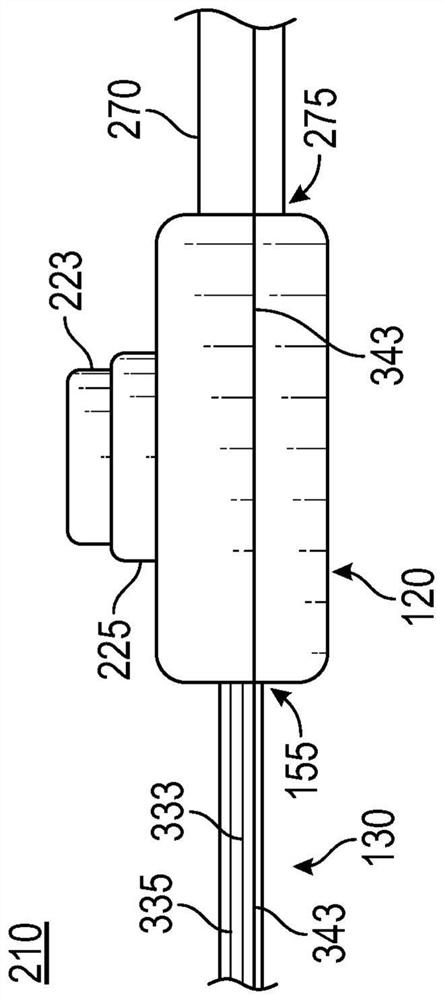

Handle assembly for transesophageal echocardiography

The present disclosure relates generally to a simplified transesophageal echocardiography (TEE) probe mid-handle assembly for actuating the pull cables that control the flexion of the distal end of the gastroscope portion of a TEE probe. The assembly includes a containment frame, two control wheels, two coaxial shafts each coupled to one of the control wheels, with an elongated flexible member wrapped around each shaft. The elongated flexible members may be friction belts, timing ladders, pulley cables, timing belts, or drive tapes to translate the rotational motion of the control wheels into linear motion of the gastroscope pull cables. The assembly may also include a brake switch that, when engaged, applies a resistance to rotation of the shafts and control wheels. In some embodiments, control wheels and containment frame are made of molded plastic, and the elongated flexible members are made of elastomeric compounds moulded over Kevlar, nylon, or metal reinforcement members to reduce stretch and increase life.

Owner:KONINKLJIJKE PHILIPS NV

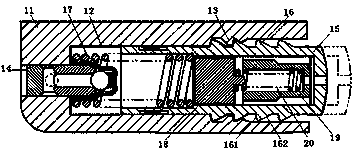

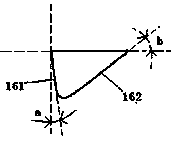

Hydraulic chain tensioner

A hydraulic chain tensioner comprises a cylinder with an opening at the front end, a plunger with an opening at the front end and capable of moving along the inner surface of the cylinder is arranged in the cylinder, a hydraulic cavity is formed in the rear side of the plunger, an oil inlet is arranged at the back end of the cylinder and communicated with an oil injection chamber, a one-way valve for providing one-way oil injection for the oil inlet is disposed in the oil injection chamber, an inner thread is arranged on the inner surface of the front end of the cylinder, an outer thread matched with the inner thread is arranged on the plunger and comprises a clamping surface and a deviating surface, the angle formed by the clamping surface and the longitudinal perpendicular line is smaller than that formed by the deviating surface and the longitudinal perpendicular line, a first compression spring is placed in the hydraulic cavity of the cylinder, one end of the first compression spring abuts against the bottom of the hydraulic cavity, and the other end of the first compression spring abuts against the plunger. The hydraulic chain tensioner is simple in structure, convenient to assemble and disassemble, good in tensioning effect and capable of effectively providing continuous and stable tensioning pressure for timing belts, timing chains and the like to improve the stability of vehicles.

Owner:JIANGSU SIXIANG SILK

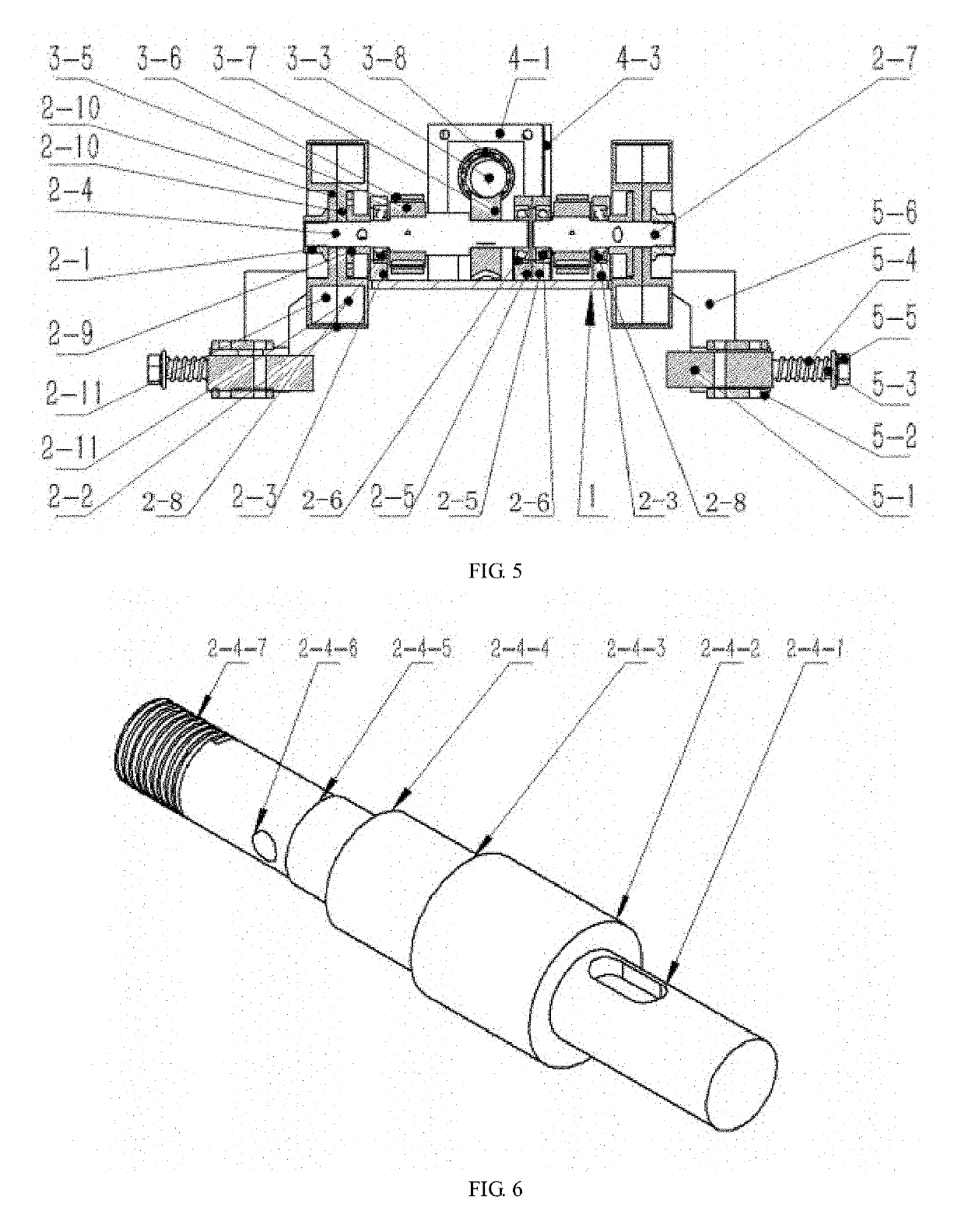

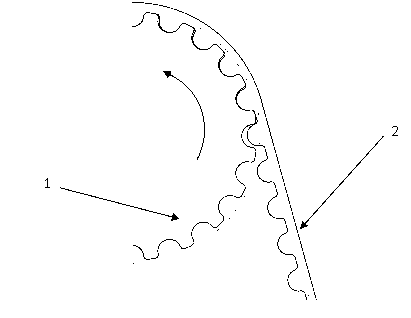

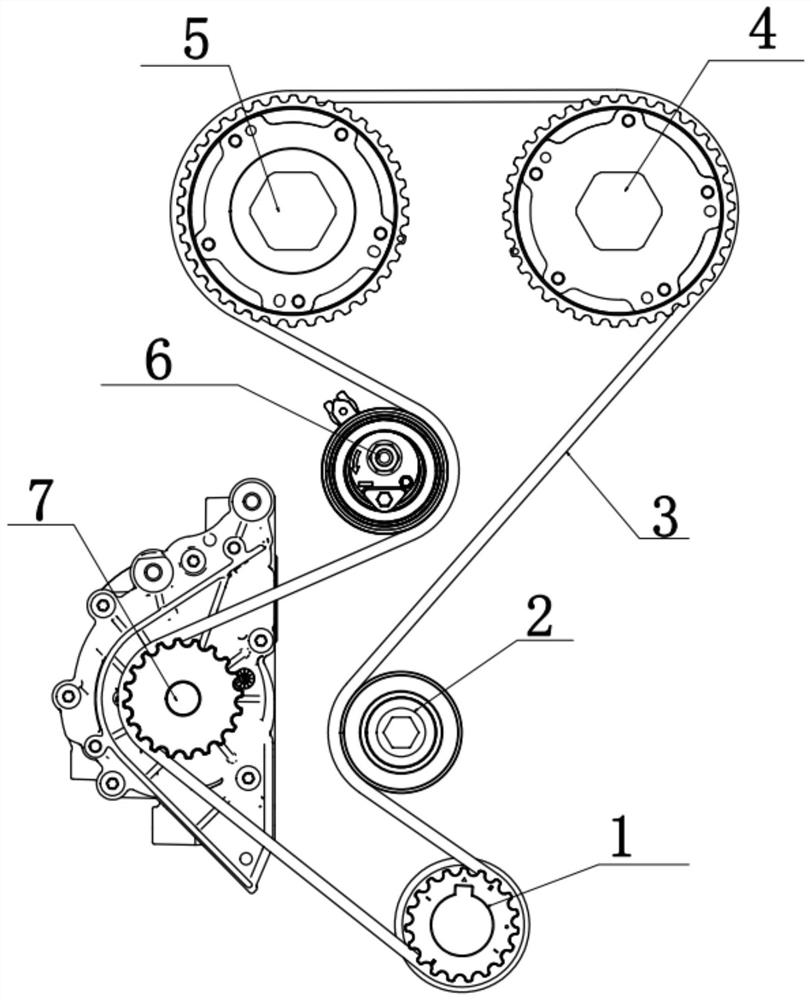

Testing device for belt deviation test

ActiveCN113358349AEnough lifeEasy to operateMachine part testingValve arrangementsTiming beltGear wheel

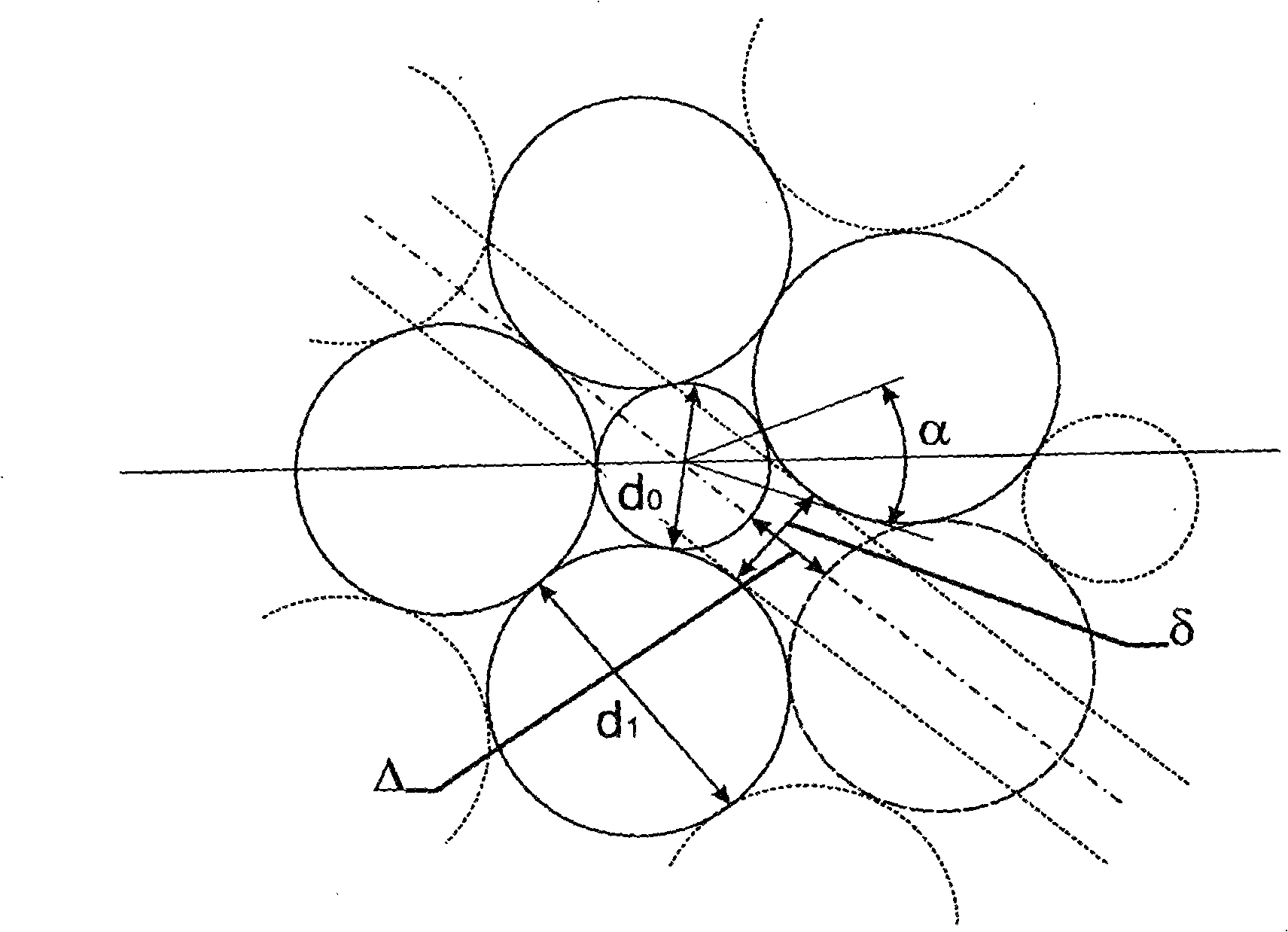

The invention relates to the technical field of belt detection, and discloses a testing device for a belt deviation test, which comprises a timing belt, and a crankshaft timing gear, a timing idle wheel, an intake camshaft gear, an exhaust camshaft gear and a timing tensioning wheel connected with the timing belt in a winding manner. The crankshaft timing gear is connected with an output shaft of an engine; the exhaust camshaft gear and the intake camshaft gear are positioned in the same horizontal plane; the timing tensioning wheel is located below the exhaust cam shaft gear; the crankshaft timing gear, the timing idle wheel, the intake camshaft gear and the exhaust camshaft gear are installed in the same vertical plane, an included angle alpha is formed between the axis of the timing tensioning wheel and the horizontal plane, a sensor used for detecting the deviation force of the timing belt is arranged on the crankshaft timing gear, and the deviation force of the timing belt is changed by adjusting the angle alpha. According to the technical scheme, the testing device for the belt deviation test can better meet the actual use condition of the timing belt, so that what is ensured is that the service life of the timing belt is reasonable, and failure of the timing belt is avoided.

Owner:DONGFENG LIUZHOU MOTOR

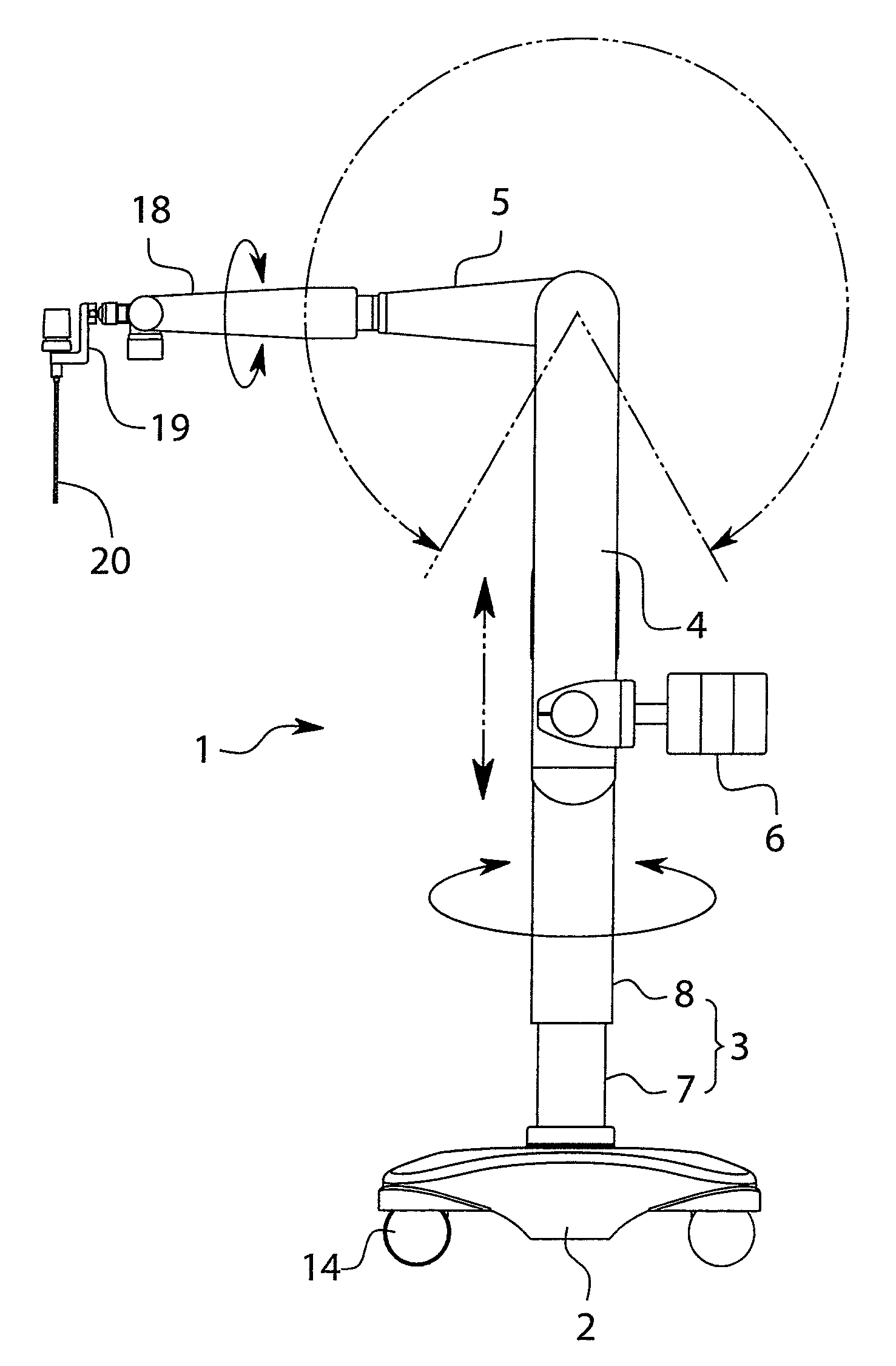

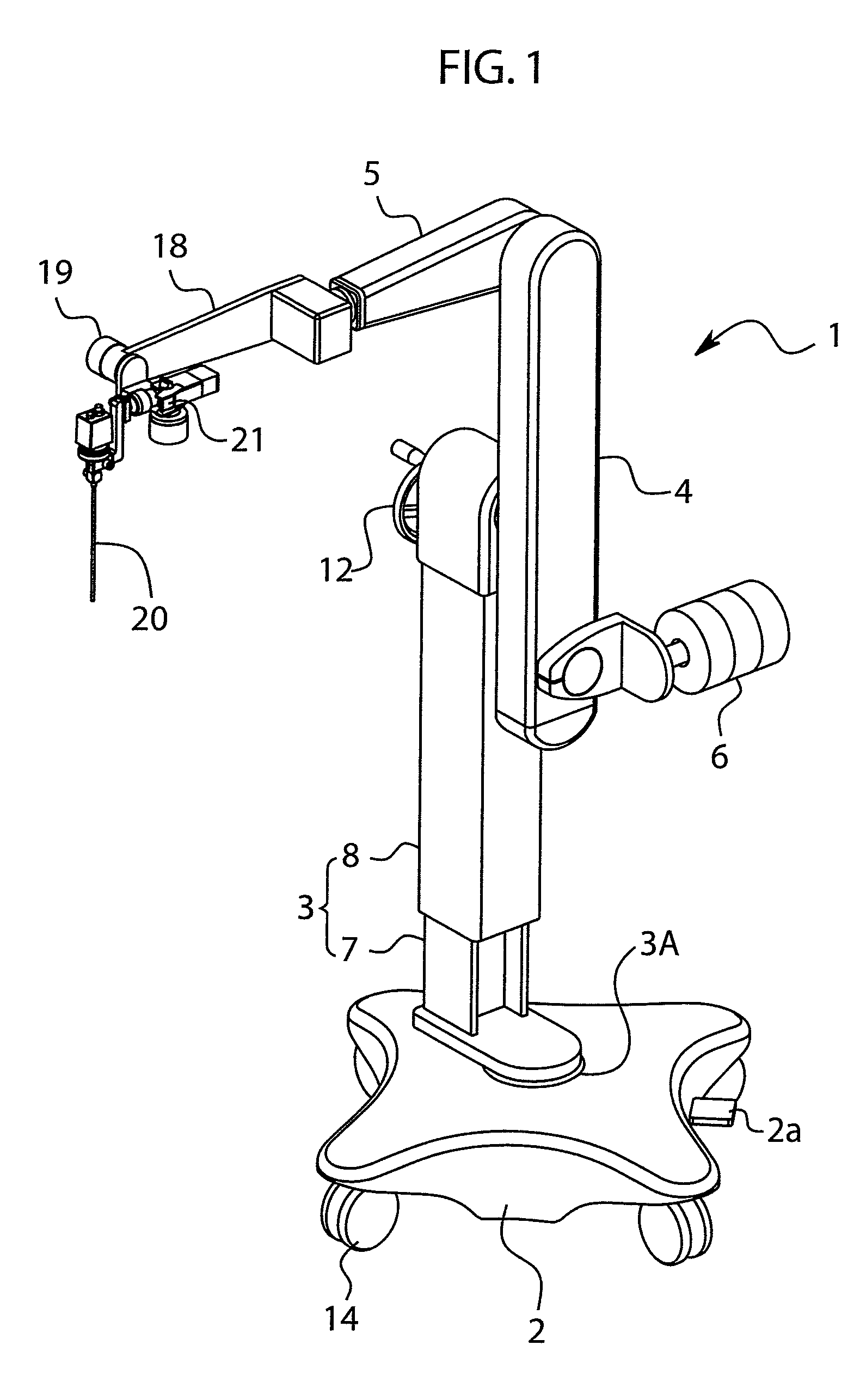

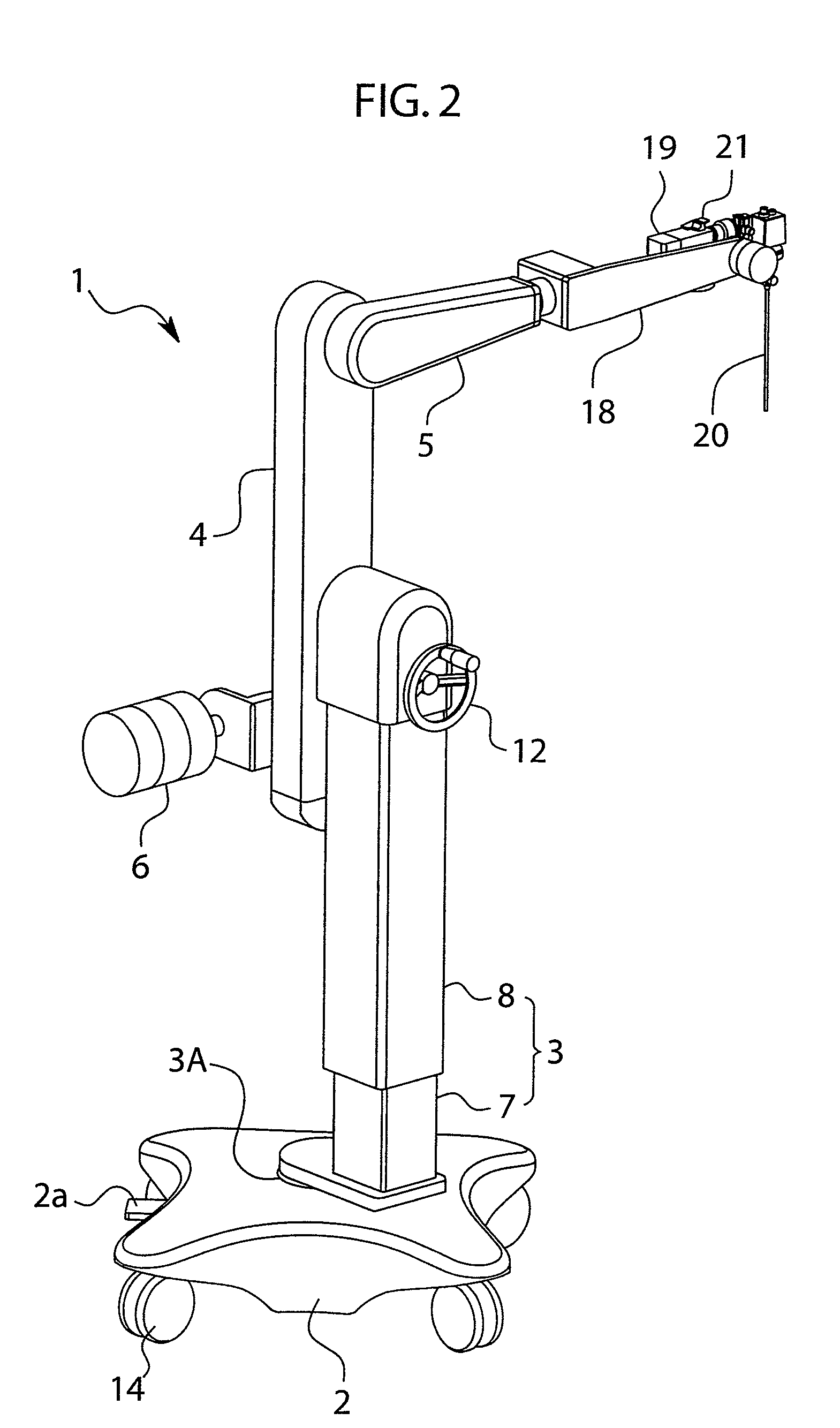

Holding arm apparatus for medical tool

Owner:MITAKA KOHKI

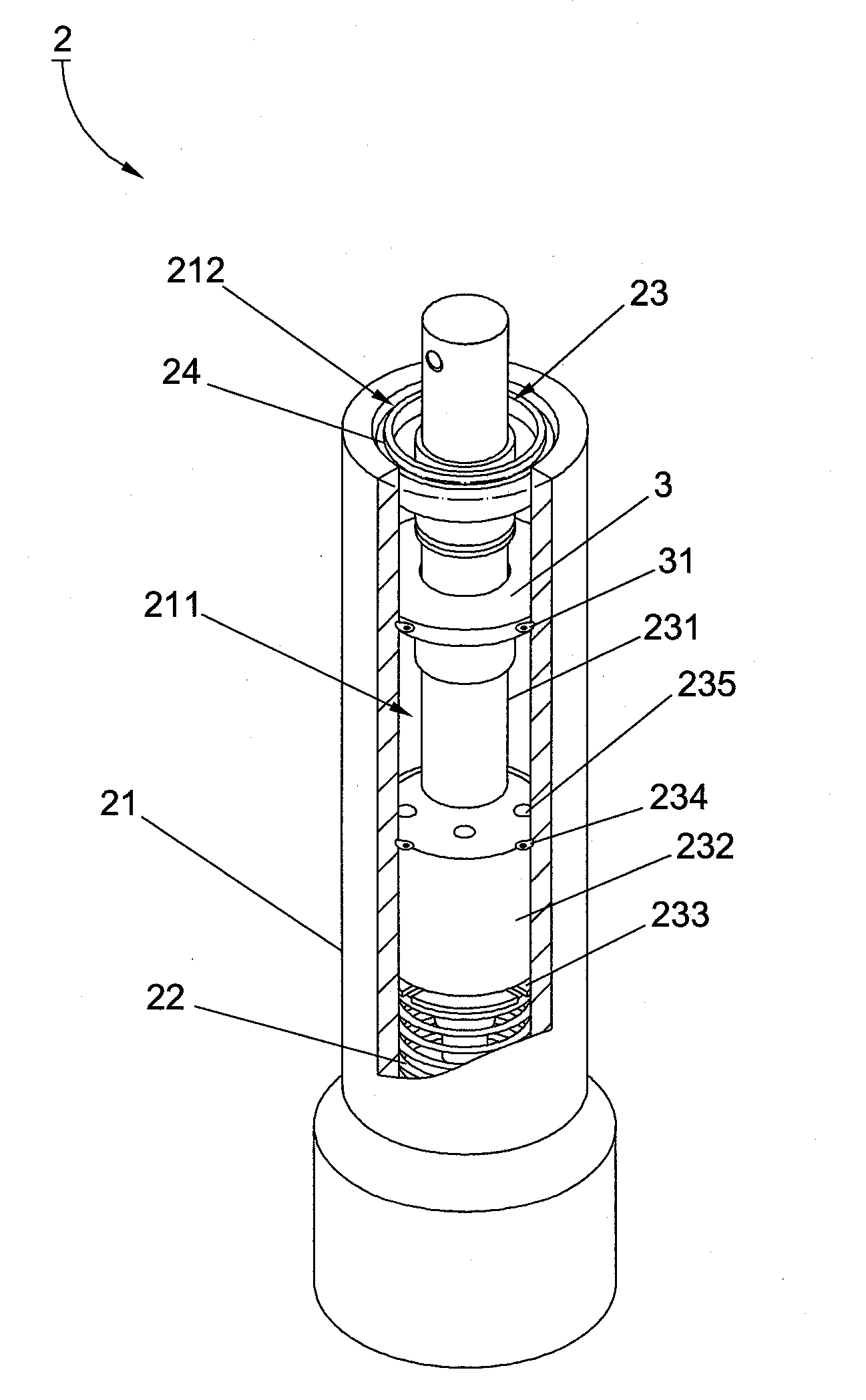

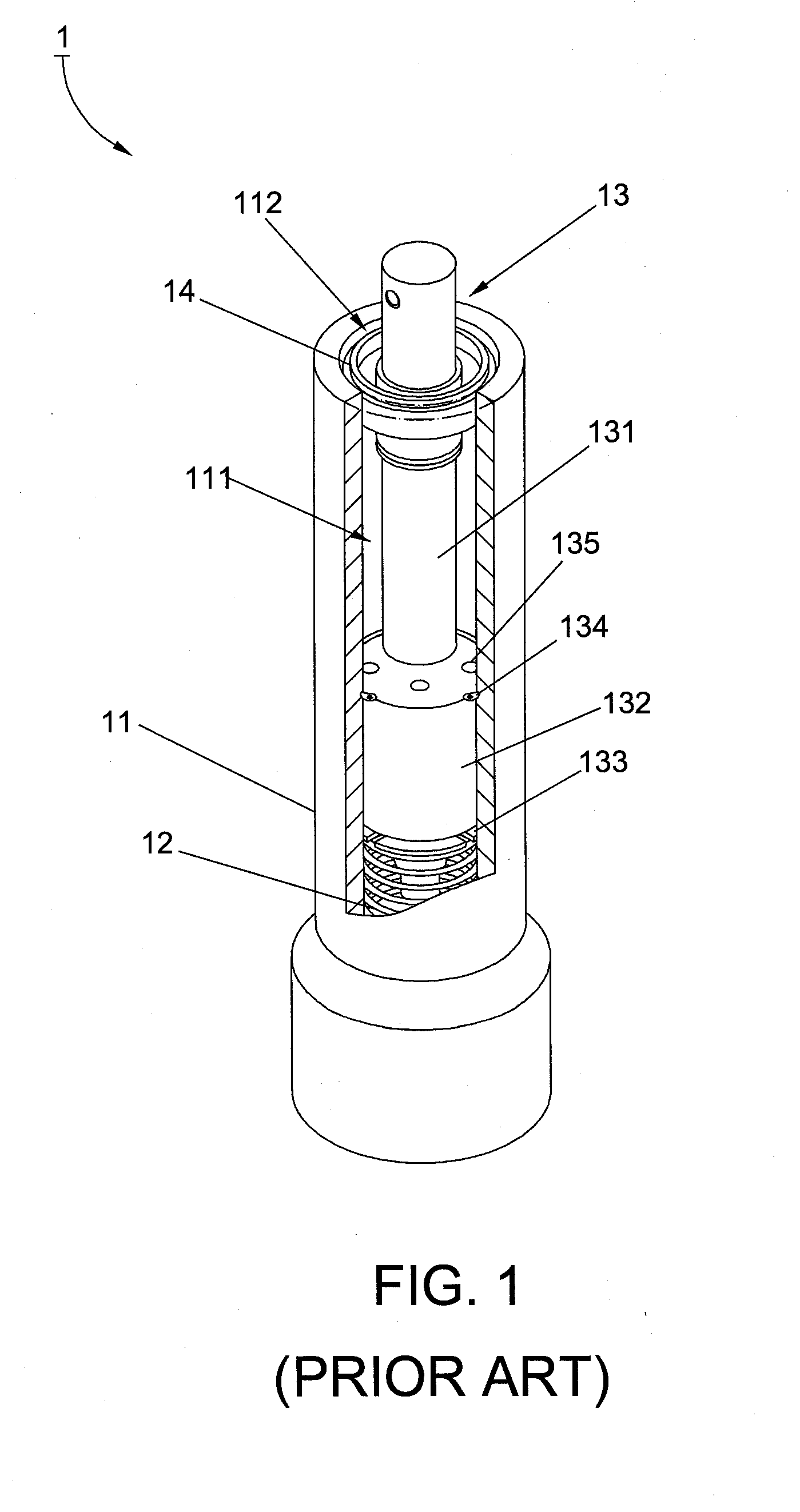

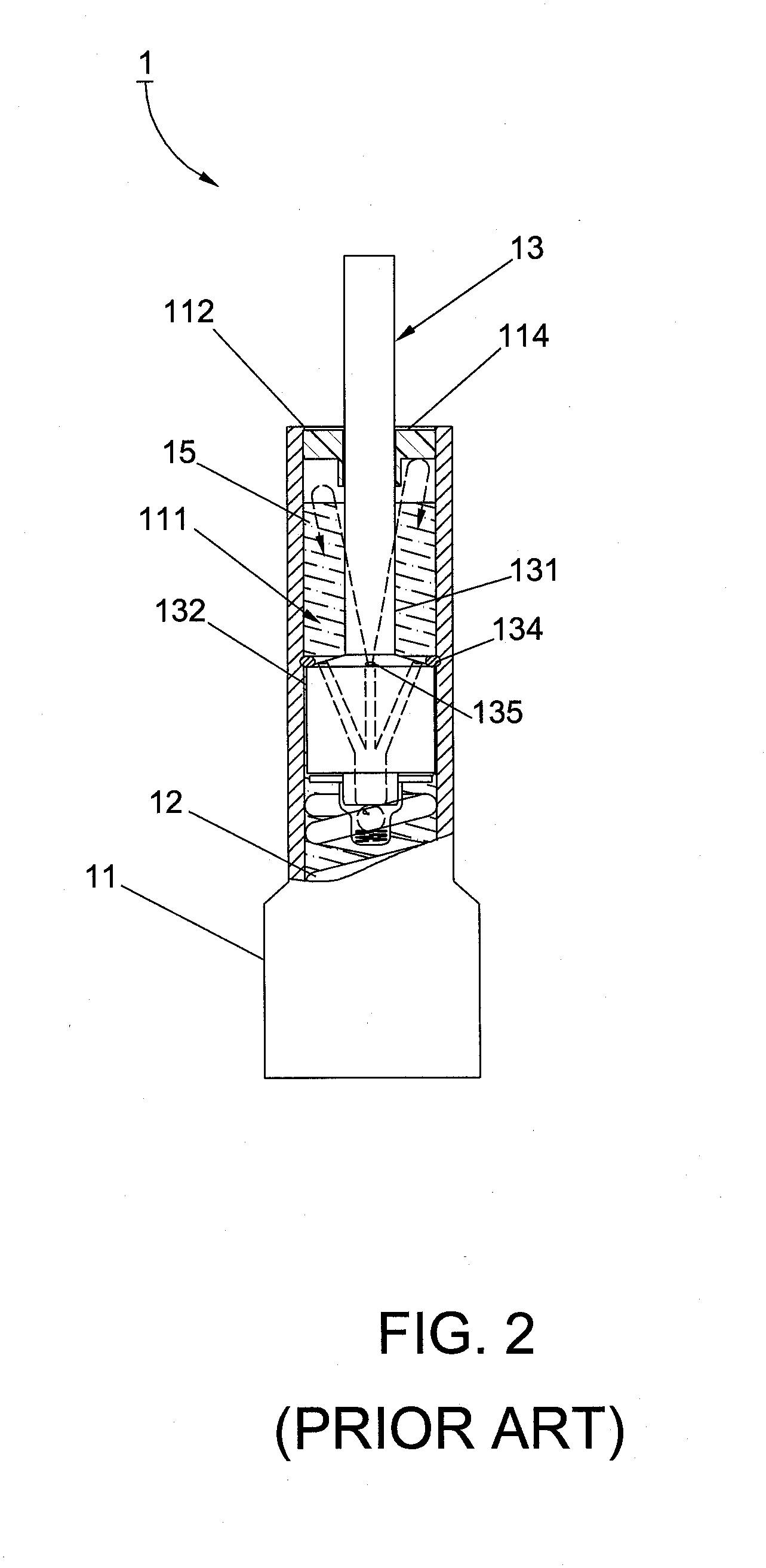

Tension regulator applied to a timing belt

InactiveUS20110098145A1Guaranteed uptimePromote driving safetyGearingEngineeringMechanical engineering

A tension regulator employs a first blocking member fixed between a plunger on a propelling member and the blocking device to permit a smooth sliding movement of the propelling member to be achieved via a stable support while the plunger driving the propelling member of the propelling device. Additionally, the reinforced limitation to the sliding movement of the plunger provided by the first blocking member could accordingly prevent the propelling member from an over-protruding incident. Thence, since hydraulic oil is properly blocked by the first blocking member, no leakage of the oil would adversely occur, and no air would unfavorably enter into the sliding space in time of the sliding. Thence, the tension regulator possesses a more stable operation, and a driving safety could be promoted.

Owner:GONG SHUN TECH

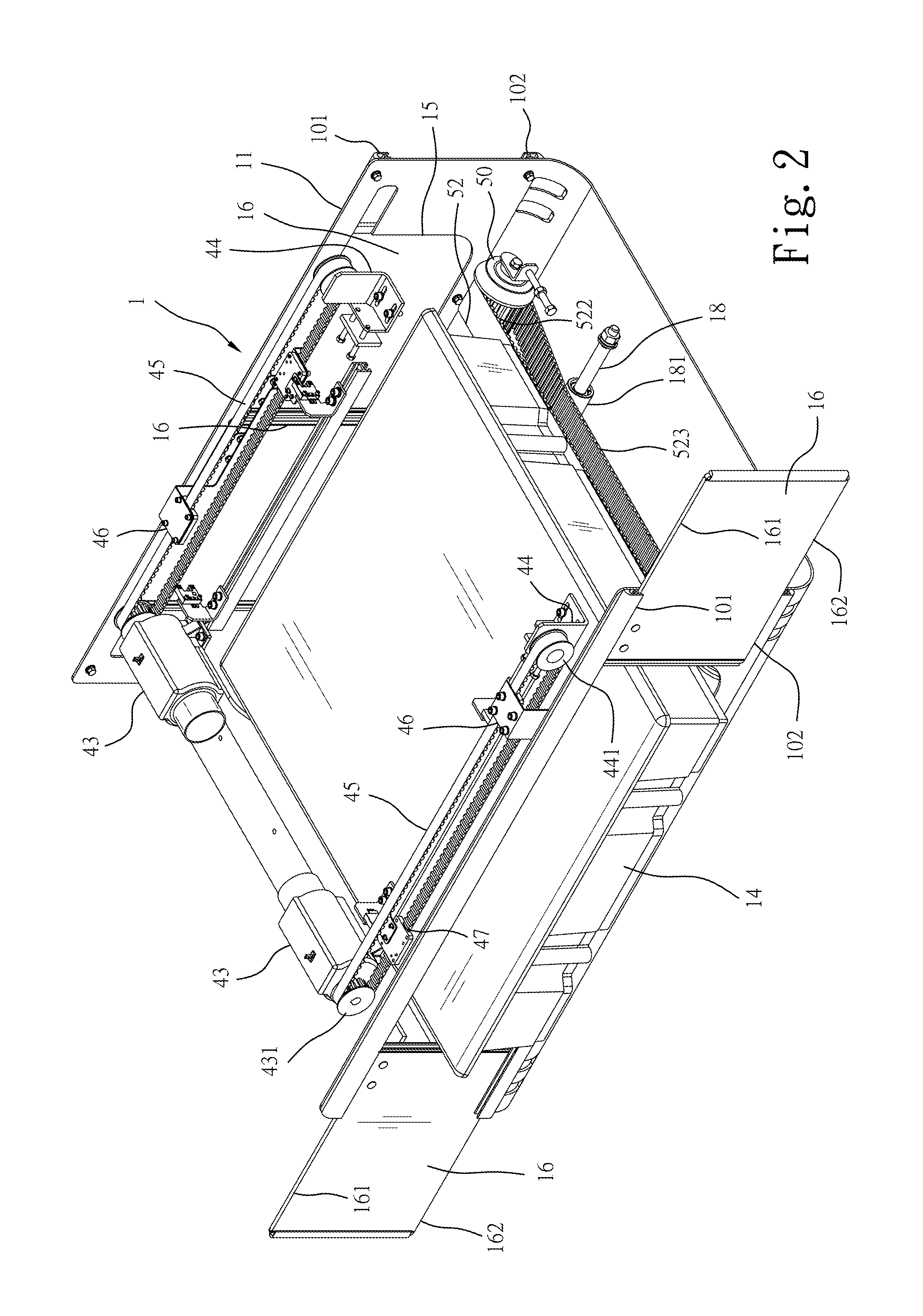

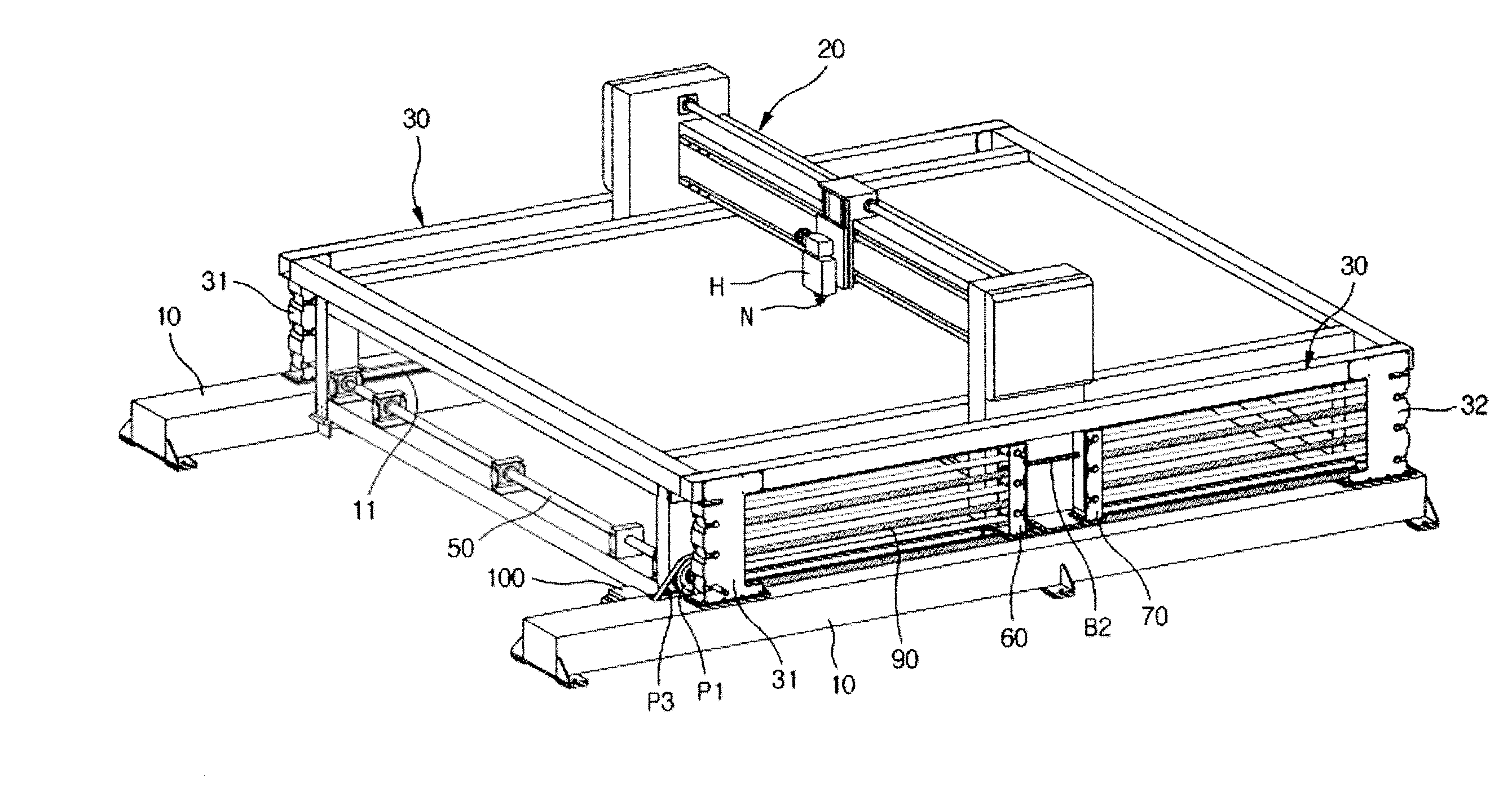

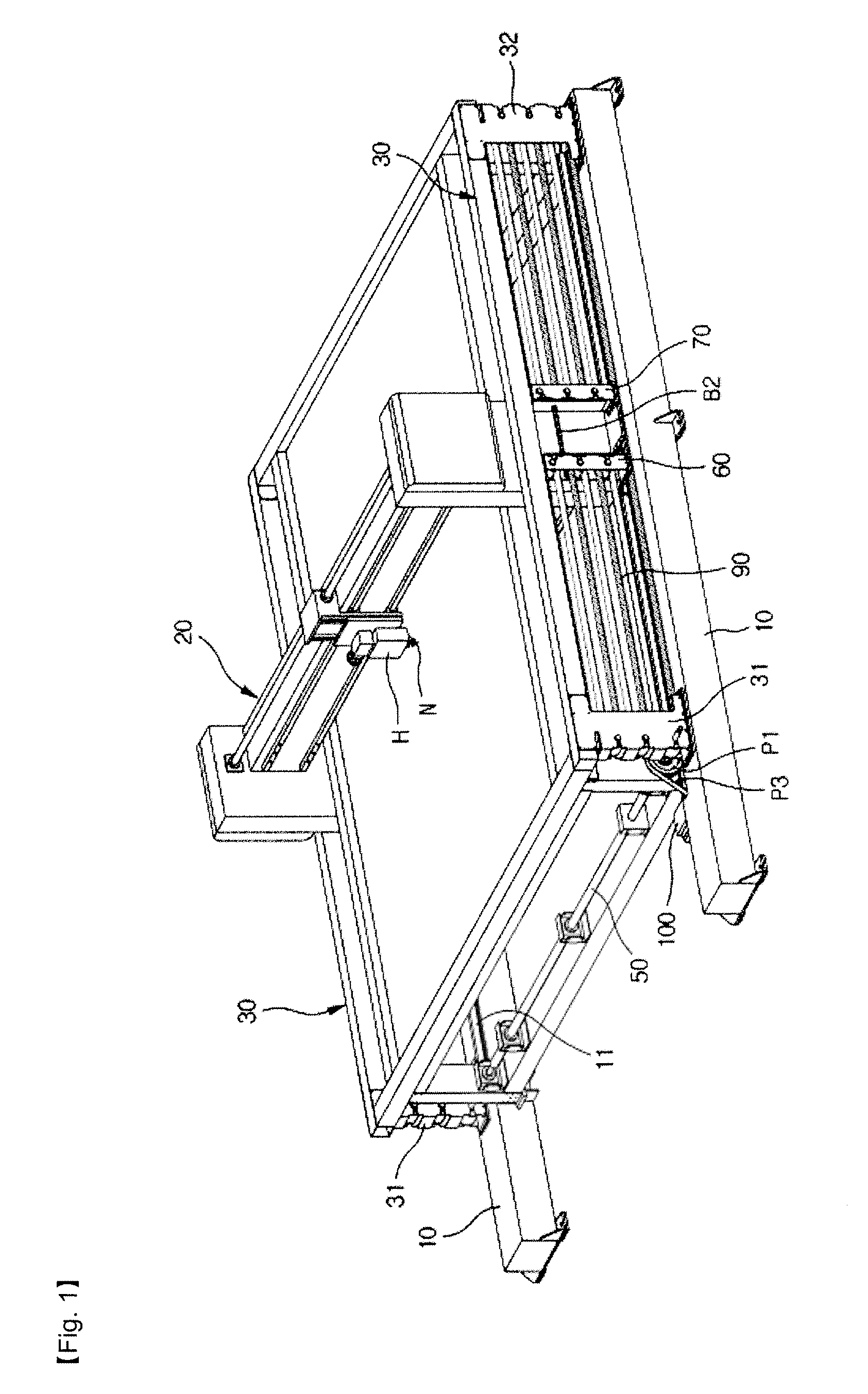

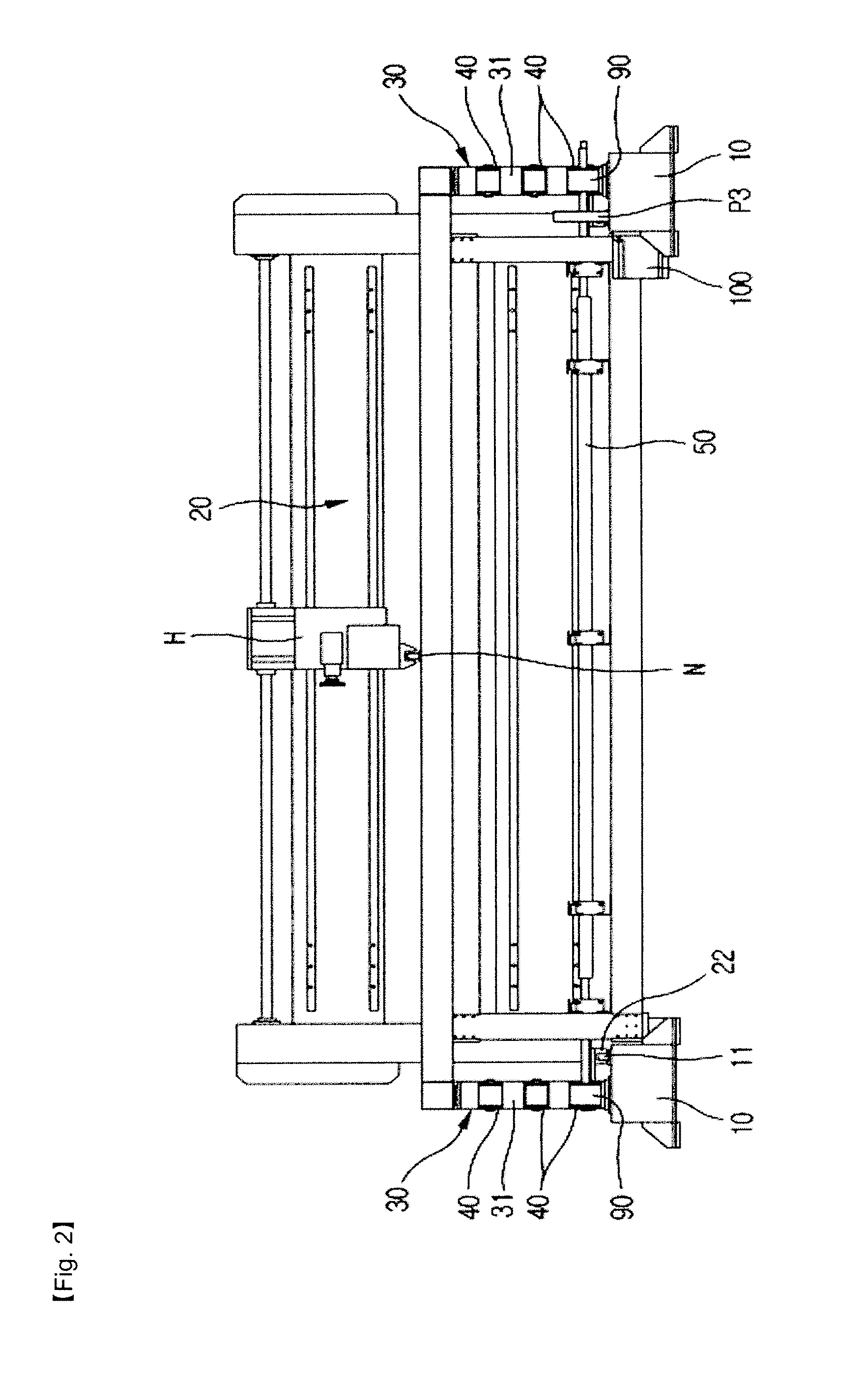

Apparatus for forward and backward movement of sewing machine

InactiveUS20100229771A1Smooth and precise movementIncrease productivityTufting apparatusSewing-machine control devicesVehicle frameGear wheel

Forward and backward movement apparatus for main body of sewing machine according to this invention comprises, in sewing machine comprising Main Body movable forward and backward and supported on both sides of a Base and Heads movable left and right and supported on the Main Body; Frame mounted on the Base; Timing Gears installed in the front and rear Fixed Frame of the Frame in multiple rows; Connecting Shat which connects Timing Gears beneath Front Fixed Frame; Forward and Backward Movement Frames is movable forward and backward on the Frame and connected to the Main Body; Rollers are installed in the Forward and Backward Movement Frames in multiple rows to correspond to the Timing Gears; Timing Belt which zigzags through Timing Gear and Roller and Timing Gear and Roller, and both ends of which are connected to the top of Front and Rear Fixed Frames; and electric motor which drives the Connecting Shat in forward and reverse directions.

Owner:DAE HUNG HITECH +1

Electric timing belt wheel

PendingCN111486216ASimple designAvoid enteringMagnetic circuit rotating partsPortable liftingProduction lineRotor magnets

The invention belongs to the technical field of mechanical equipment, and particularly relates to an electric timing belt wheel. The electric timing belt wheel comprises a belt wheel body provided with protrusions. A central circular hole penetrating through the belt wheel body and the protrusions is formed in the axis of the belt wheel body and the protrusions. End covers are arranged on the protrusions, and shaft holes communicated with the central circular hole are formed in the axis lines of the end covers. A bearing mounting hole is coaxially formed in one side, close to the belt wheel body, of the end cover with the shaft hole. Bearings are installed in the bearing mounting holes, and a stationary shaft is coaxially arranged on the two end covers through the bearings. The part in thecentral circular hole of the stationary shaft is provided with stator coils. Rotor magnet yokes are arranged on the inner side of the belt wheel body around the stator coils, and permanent magnets are arranged on the inner sides of the rotor magnet yokes around the stator coils. According to the electric timing belt wheel, a driving device and a motor are arranged in the belt wheel, so that spaceoccupation is reduced, convenience is provided for the design of equipment or production line and maintenance, and the automation and intelligence of production equipment are promoted.

Owner:上海亘本科技有限公司

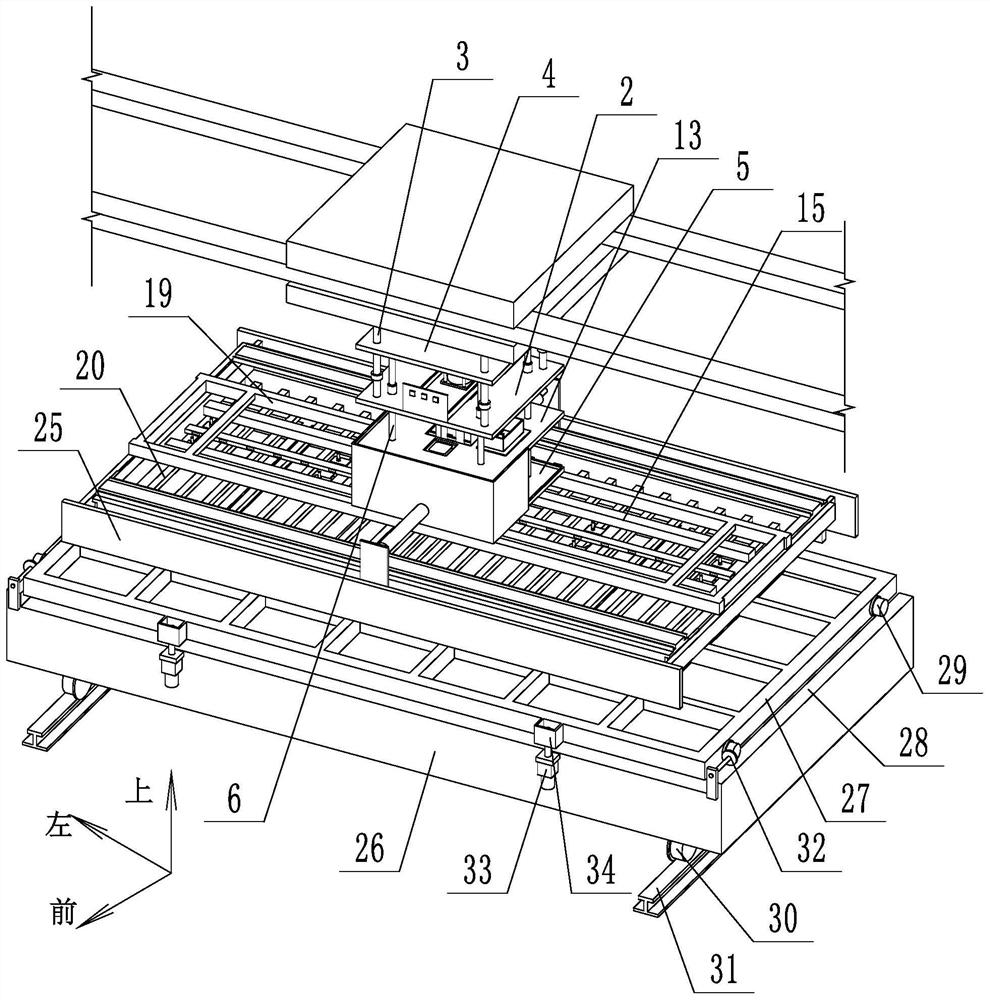

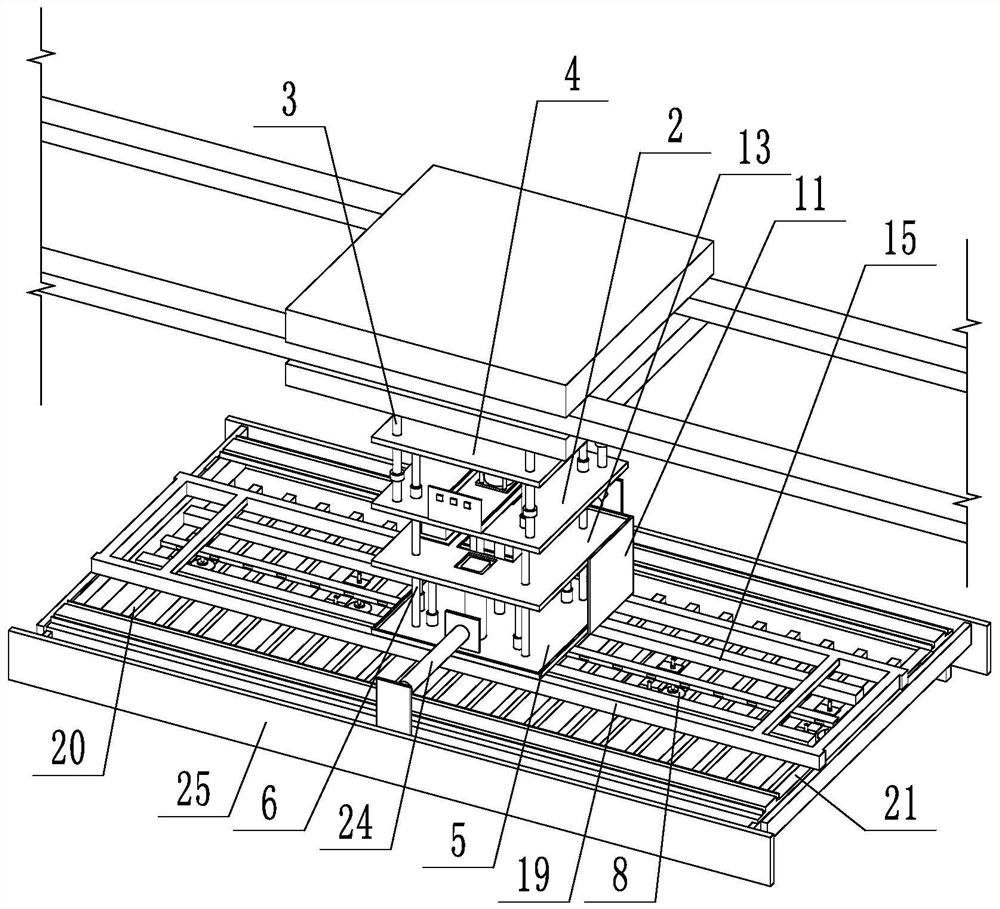

Automatic feeding and discharging machine for sheet materials

ActiveCN111717660AHigh mechanical strengthImprove flexibilityConveyorsStacking articlesTiming beltControl engineering

The invention discloses an automatic feeding and discharging machine for sheet materials. The automatic feeding and discharging machine comprises a flexible lifting device, a grasping mechanism and asupporting mechanism. The grasping mechanism is located at the lower end of the flexible lifting device, a driving mechanism for driving the flexible lifting device to move is arranged at the upper end of the flexible lifting device, the driving mechanism is driven by a servo motor and a timing belt, a track is arranged above the flexible lifting device, the flexible lifting device is driven to move forwards by the servo motor and timing belt, the walking torque is large, the positioning is accurate, the operation is stable, high-speed walking and positioning can be realized, the walking trackdoes not need to be subjected to finish machining, ordinary profiles can be used, and the automatic feeding and discharging machine is suitable for long-distance transportation of the sheet materials. The supporting mechanism is located under the grasping mechanism, the sheet materials are installed on the supporting mechanism, the sheet materials are grasped by the grasping mechanism, and then the driving mechanism drives the flexible lifting device to move to realize the automatic feeding of the sheet materials.

Owner:济南瑞开电气有限公司

Timing belt wheel for battery electric vehicle engine crankshaft and manufacturing method of timing belt wheel

InactiveCN105240487AHigh strengthAvoid being inPortable liftingGearing elementsGear wheelBattery electric vehicle

The invention discloses a timing belt wheel for a battery electric vehicle engine crankshaft. The timing belt wheel is a cylindrical gear body with powder metallurgy as a main body. The center of the gear body is provided with a center hole. A key groove is formed in the center hole. The outer peripheral wall of the gear body is provided with teeth formed in the center axis direction of the center hole. A flanged edge is arranged at the end of the gear body, integrally connected to the teeth and higher than the teeth. According to the improvement, the flanged edge is connected to tooth tops of the teeth through inclined edges; the bottom of the key groove is in an arc shape; and the surfaces of the teeth are provided with wear-proof composite layers. The invention further discloses a manufacturing method of the timing belt wheel for the battery electric vehicle engine crankshaft. The tooth structural strength is high, stress is low, and the service life is long.

Owner:TAIZHOU KECHENG AUTOMOBILE PARTS

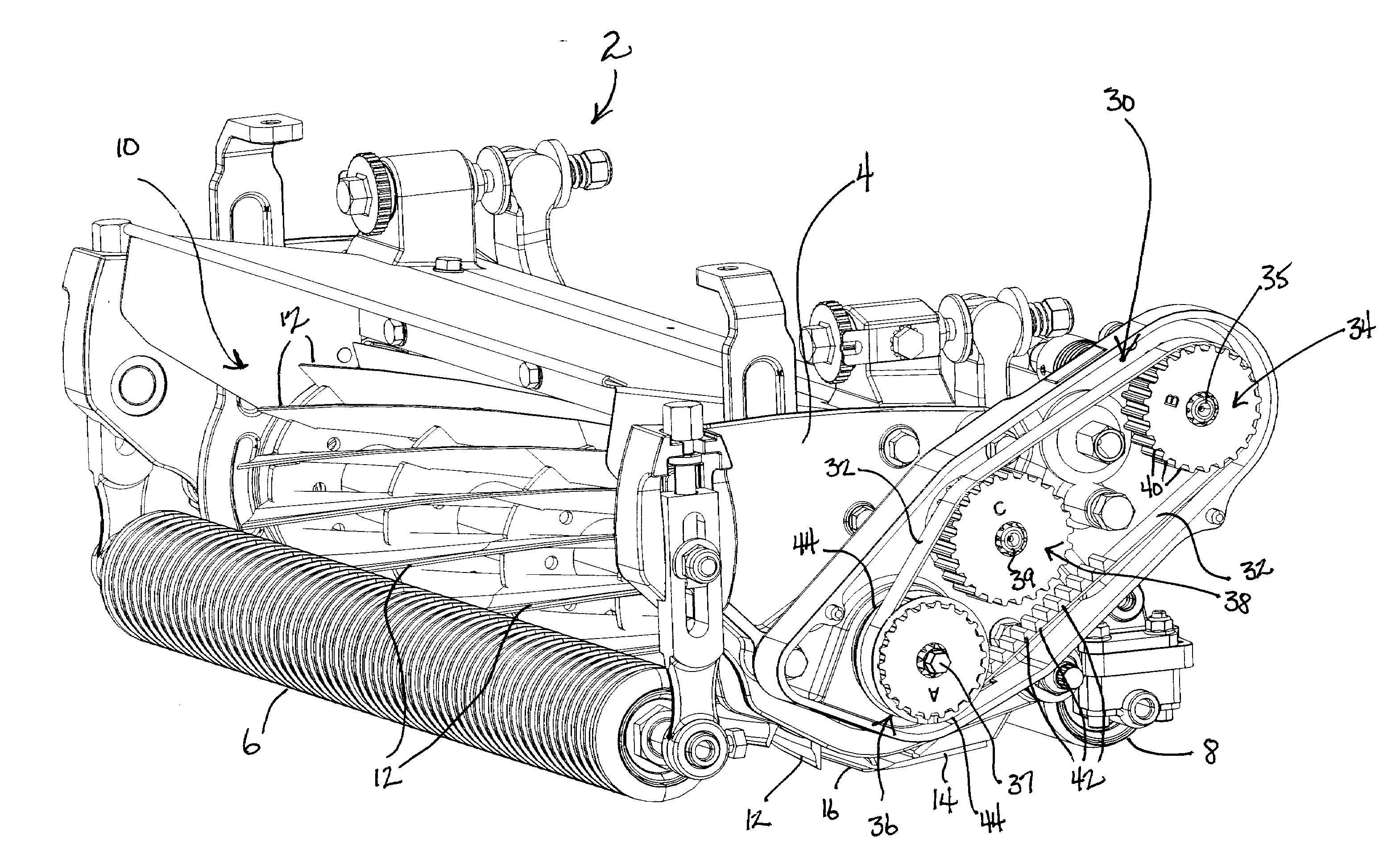

Clip control system for walk reel mower

A reel cutting unit of a reel mower is provided with a belt and pulley drive system for rotating the reel of the cutting unit at variable speeds when the ground speed of the reel cutting unit is substantially constant to provide different clips. The drive system has three pulleys of different diameter in engagement with the belt in drive, driven and idler positions. The pulleys can be interchangeably used in any of the positions by moving the pulleys around into the different positions in six different possible arrangements. The pulleys are selectively placed in one arrangement at a time to select the clip provided by that arrangement. A chain and sprocket drive system with different diameter sprockets may be used in place of the belt and pulley drive system. The belt and pulley drive system may comprise toothed pulleys and toothed timing belt.

Owner:TORO CO THE

Linear Servo Conveyor System

InactiveCN102295145AImproving the efficiency of automated stamping linesIncrease transmission speedConveyor partsMechanical conveyorsProduction lineTiming belt

The invention discloses a linear servo conveying system, comprising: a frame, which is arranged on a horizontal line, and synchronous pulleys are respectively arranged at both axial ends of the frame, and an endless conveyor belt surrounding the frame is wound between the synchronous pulleys, and the conveyor belt includes a section The rack and a section of timing belt located above the frame; the mounting support is connected with the robot, and the bottom of the mounting support is slidably connected above the frame through the upper linear guide device; the output shaft of the servo motor extends into the mounting support and drives A gear meshed with the rack is connected; the quick change device of the end effector is slidably connected under the frame through the lower linear guide device, and is connected with the synchronous belt. The beneficial effect of the invention is that the linear translation of the parts between the presses can be realized, and the transmission speed is increased, so that the efficiency of the automobile automatic stamping production line is improved and the production cost is reduced. In addition, the adaptability to the change of the press spacing is improved, which is of great significance to the transformation of the old press line.

Owner:JINAN AOTTO TECH

Single lay steel cord for elastomer reinforcement

ActiveCN101573489AImprove cost efficiencyRope making machinesThin material handlingElastomerElectrical and Electronics engineering

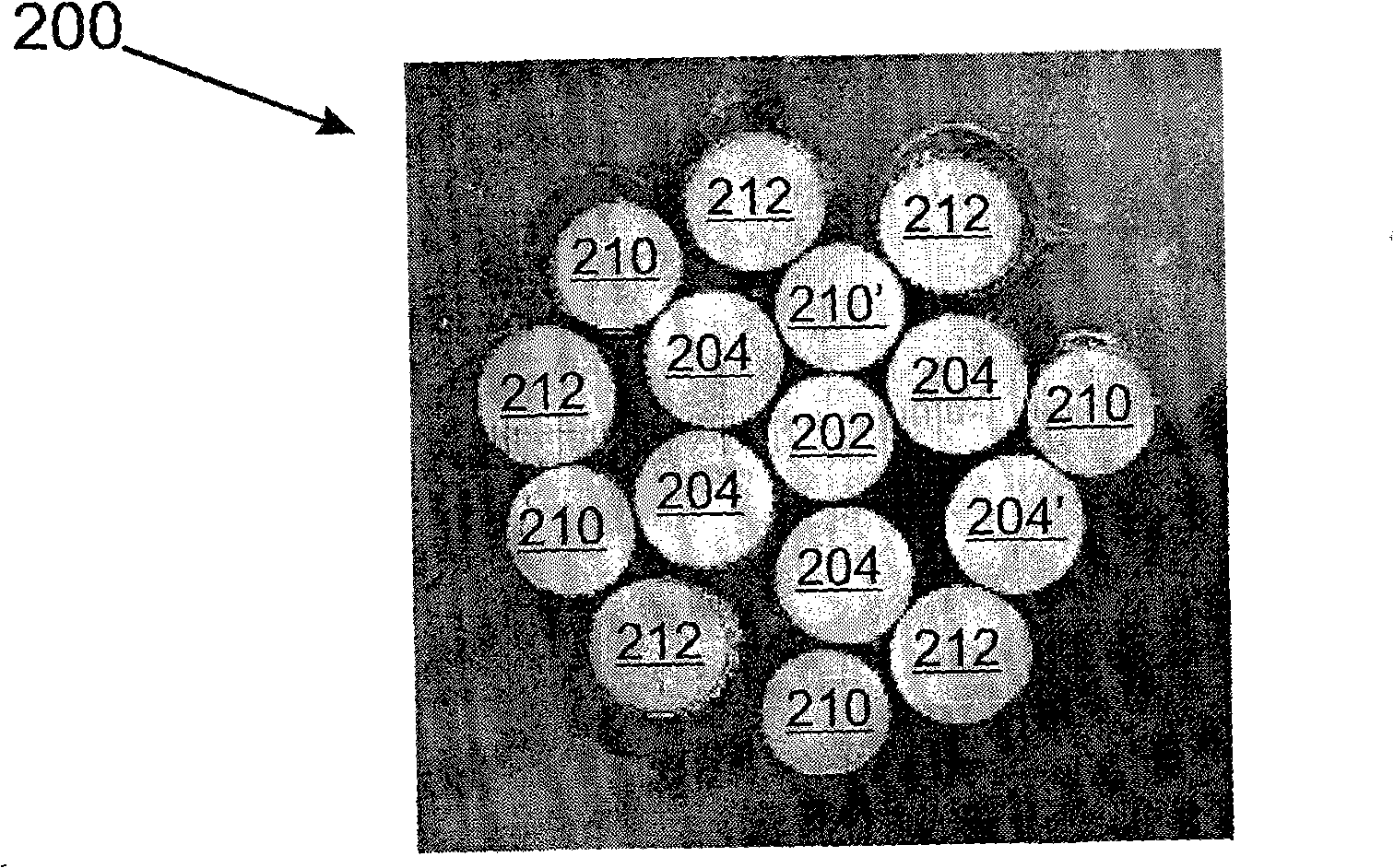

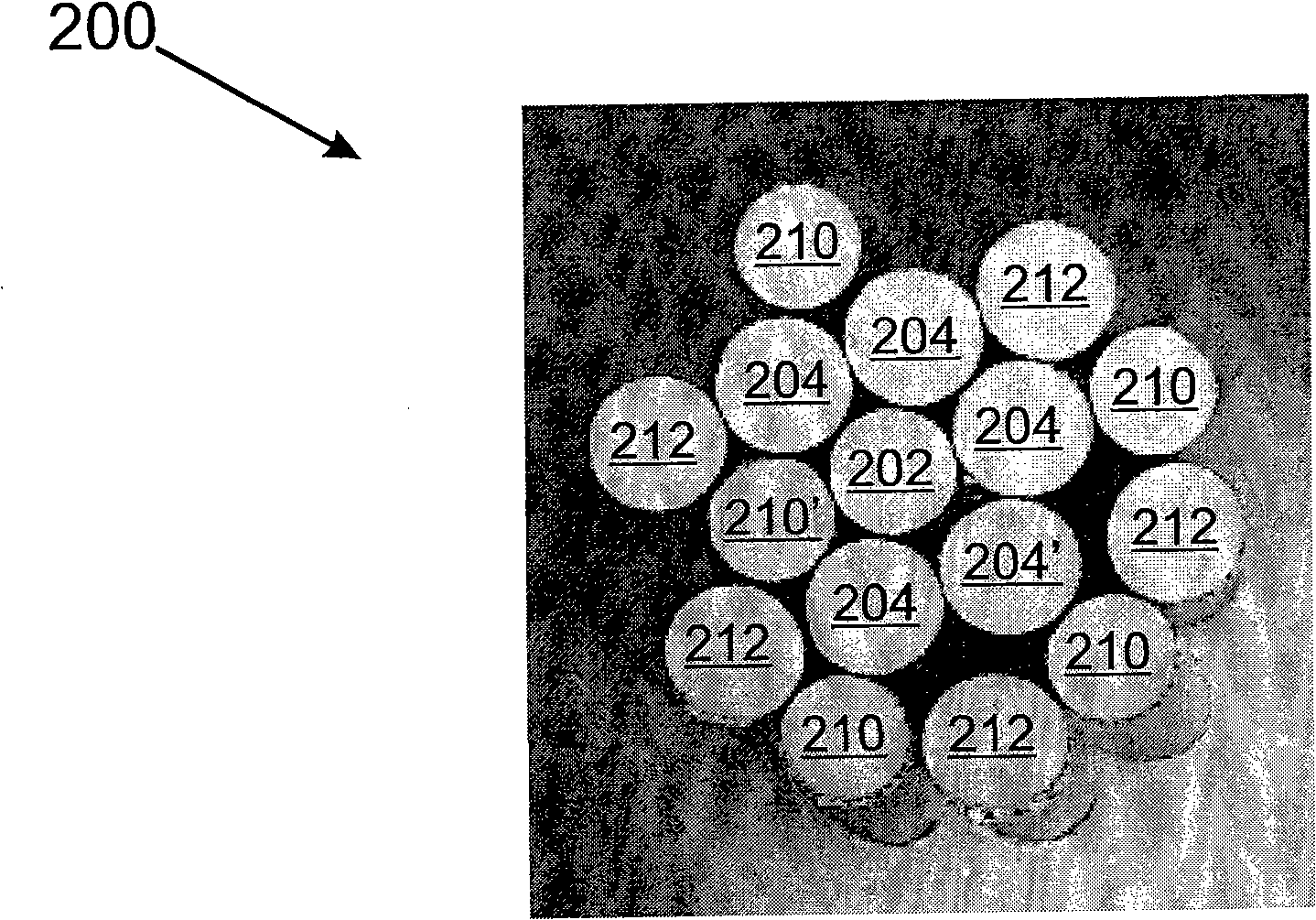

The present invention discloses a steel cord (200) that is simple and cost effective to produce while solving some particular problems for the reinforcement of elastomer belts such as timing belts or the like. The cord (200) is a single lay cord that comprises a core filament (202), around which a first layer and a second layer of filaments (204, 210, 212) is twisted, all filaments being twisted with the same lay length and direction. By appropriate choice of the lay length, the core filament diameter and the filament diameters of the first layer - the latter being larger or equal to the former - an aggregate gap can form in which intermittently a filament (210') of the second layer gets entrained. This aggregate gap must be between 40 and 70 % of the core filament diameter in order to obtain the desired effect of having a core filament (202) that is deformed with the same lay length and direction as the other filaments (204,210,212). A deformed core filament (202) suppresses the effect of core filament migration. In addition the exceptional rough aspect of the cord (200) leads to good mechanical anchorage in the elastomer. Also the load exerted on the cord (200) is better distributed over all filaments. The use of the cord is not limited to timing belts: an advantageous use of the cord in tyres, hoses, hoisting belts, drive belts and reinforcing strips is anticipated.

Owner:BEKAERT ADVANCED CORDS AALTER NV

Cover for internal combustion engine

A cover for an internal combustion engine is configured to be attached to an engine main body so as to cover a timing chain or a timing belt. The cover for the internal combustion engine includes insertion holes configured to receive a crankshaft or a camshaft. The cover for the internal combustion engine includes a first member made of a hard plastic and a second member made of a material different from the hard plastic. The first member is produced by insert molding with the second member embedded in the first member. A periphery of at least one of the insertion holes in the second member includes a joint surface that is joined to the first member. The joint surface includes annular grooves surrounding the insertion hole, the annular grooves being arranged in a radial direction of the insertion hole.

Owner:TOYOTA BOSHOKU KK

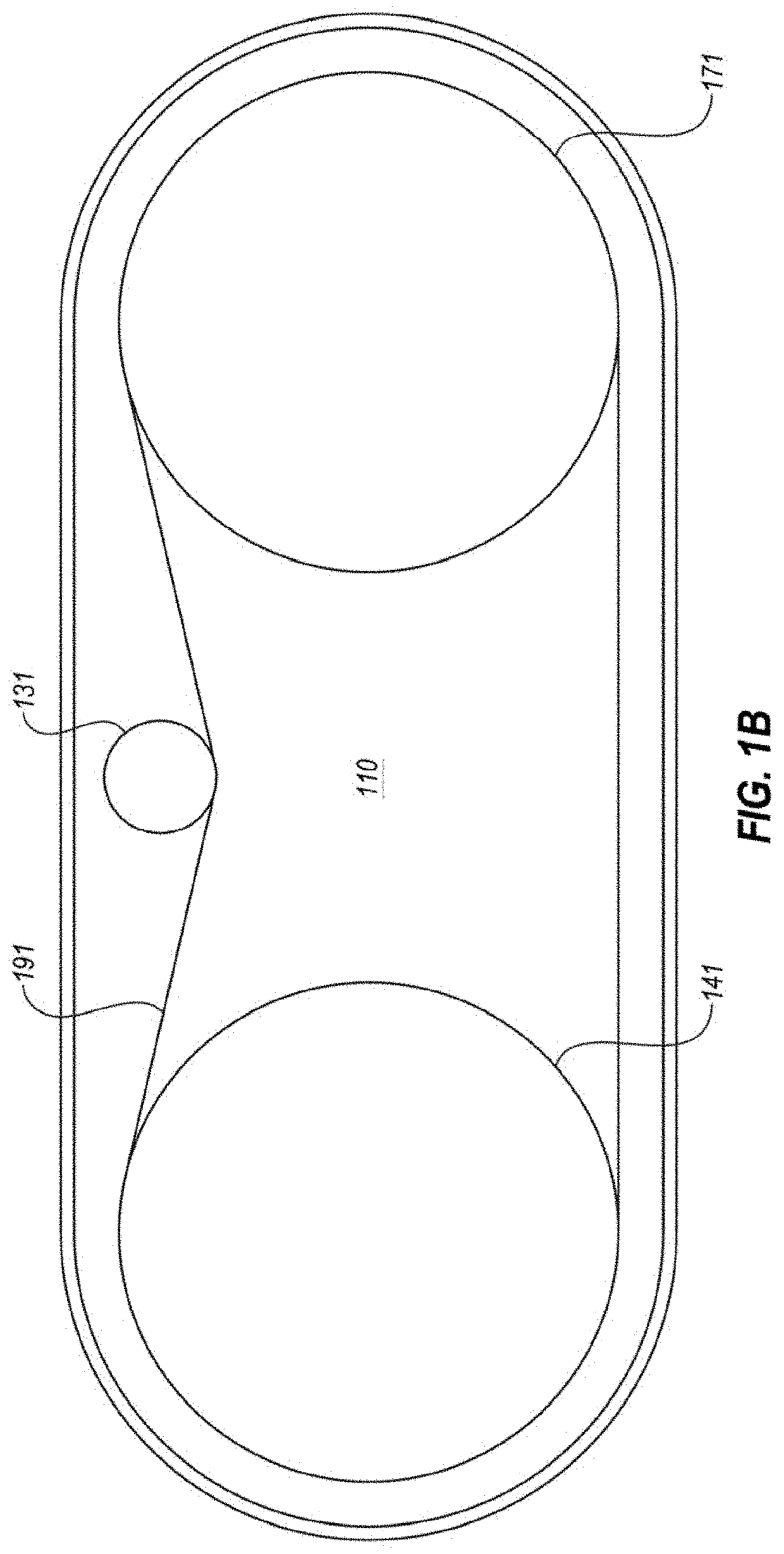

Infinite rotation of vacuum robot linkage through timing belt with isolated environment

Disclosed herein are a vacuum robot, vacuum robot linkages that may enclose driving assemblies in a sealed environment configured to isolate at least a portion of the driving assemblies from the outside environment, and methods of operation thereof. Drive assemblies that may be enclosed in the sealed environment of the vacuum robot linkage may be infinite rotation driving assemblies that enable a robot link member to have a rotation of at least 360 degrees about an axis. The vacuum robot linkage environment may be sealed through a magnetic liquid rotary seal and / or through a fixed vacuum seal.

Owner:APPLIED MATERIALS INC

Transmission mechanism and scanning table

ActiveCN110742766BLower the altitudeSave height spaceDiagnosticsOperating tablesTelecommunicationsTiming belt

Owner:SHANGHAI NEUSOFT MEDICAL TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys] [Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys]](https://images-eureka.patsnap.com/patent_img/d7546f47-6d15-4623-9595-e3d87966029e/US20050064972A1-20050324-D00000.png)

![[Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys] [Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys]](https://images-eureka.patsnap.com/patent_img/d7546f47-6d15-4623-9595-e3d87966029e/US20050064972A1-20050324-D00001.png)

![[Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys] [Three Piece Timing Pulley Assembly containing one Inner Positive Drive Hubless and Flangeless Timing Pulley and two Outer Driven, Positive Drive, and Synchronized Timing Pulleys]](https://images-eureka.patsnap.com/patent_img/d7546f47-6d15-4623-9595-e3d87966029e/US20050064972A1-20050324-D00002.png)