Hydraulic chain tensioner

A tensioner, hydraulic technology, applied in belt/chain/gear, mechanical equipment, transmission, etc., can solve the problems of occupying engine space, low added value, and high noise of the tensioner, and achieve a one-way sealing structure. Good effect, better wear resistance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

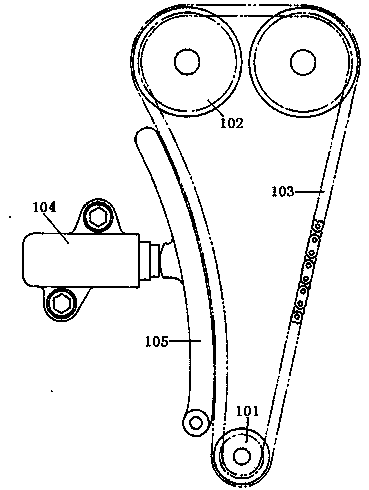

[0031] see figure 1 , shows the hydraulic chain tensioner of the present invention.

[0032] The transmission chain 103 between the drive sprocket 101 and the driven sprocket 102 installed on the crankshaft of the engine is tensioned by the hydraulic chain tensioner 104 through the arc pressure plate 105, and the hydraulic chain tensioner 104 is installed on on the engine body of the vehicle.

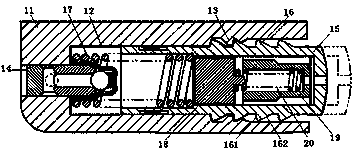

[0033] see figure 2 , showing the specific structure of the hydraulic chain tensioner 104, the hydraulic chain tensioner 104 includes a cylinder 11 with an open front end, and the cylinder 11 is provided with a front opening that can move along the inner surface of the cylinder 11 The plunger 15, the rear side of the plunger 15 is provided with a hydraulic chamber 12, the rear end of the cylinder 11 is provided with an oil inlet, the oil inlet is connected with an oil injection chamber 14, and the oil injection chamber 14 A one-way valve is provided to provide one-way oil inlet of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com