Patents

Literature

15349 results about "Chain link" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

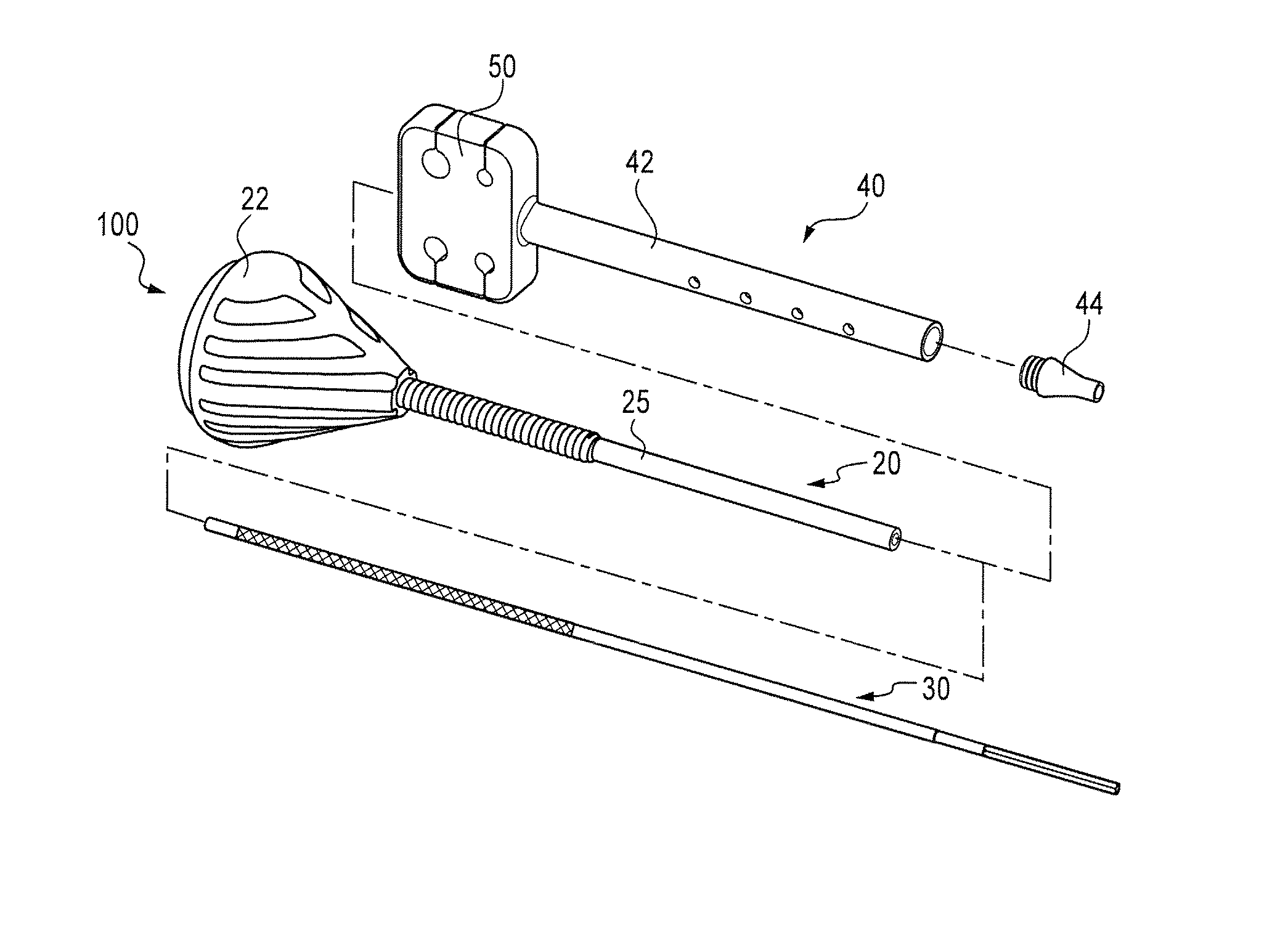

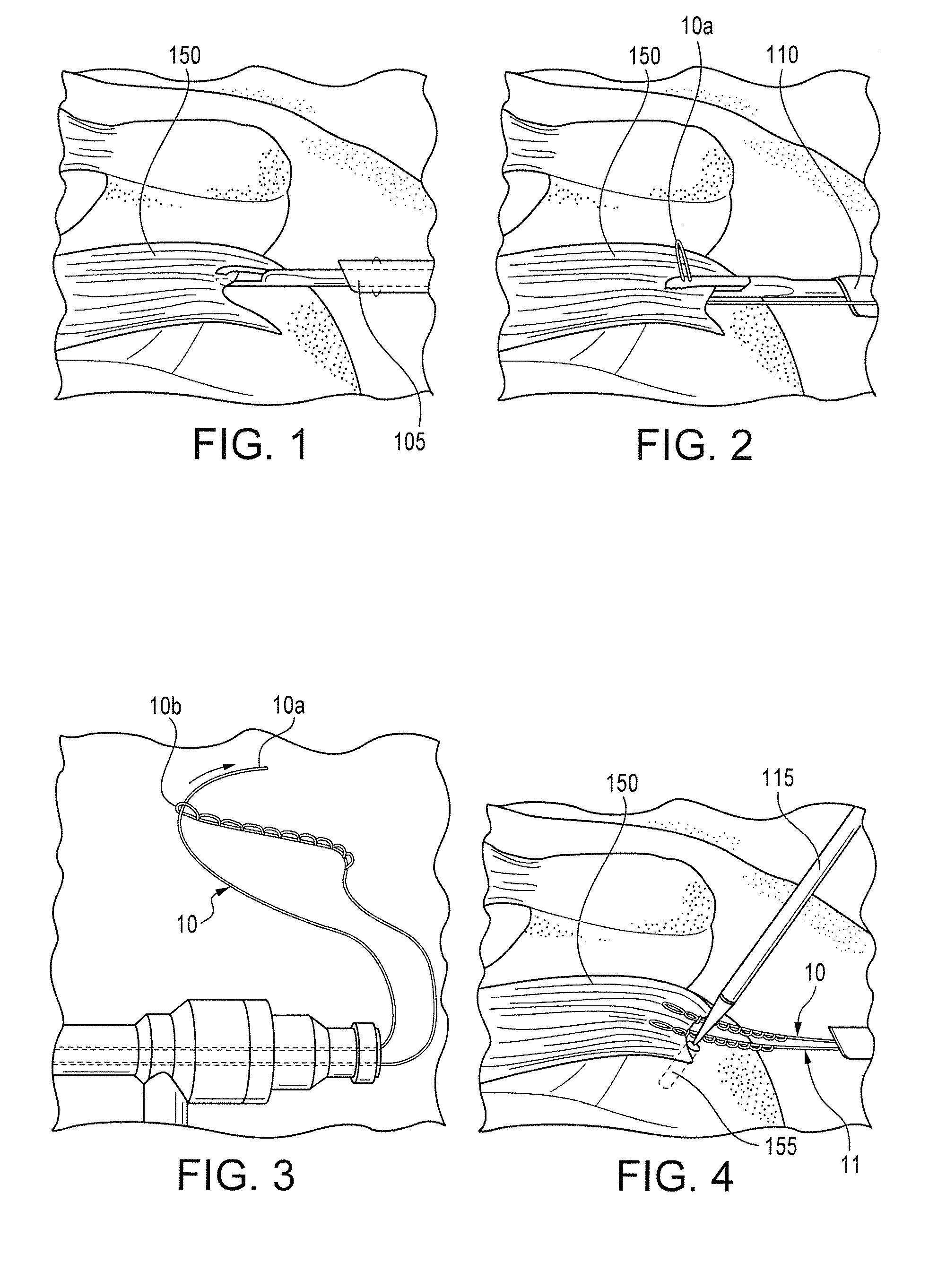

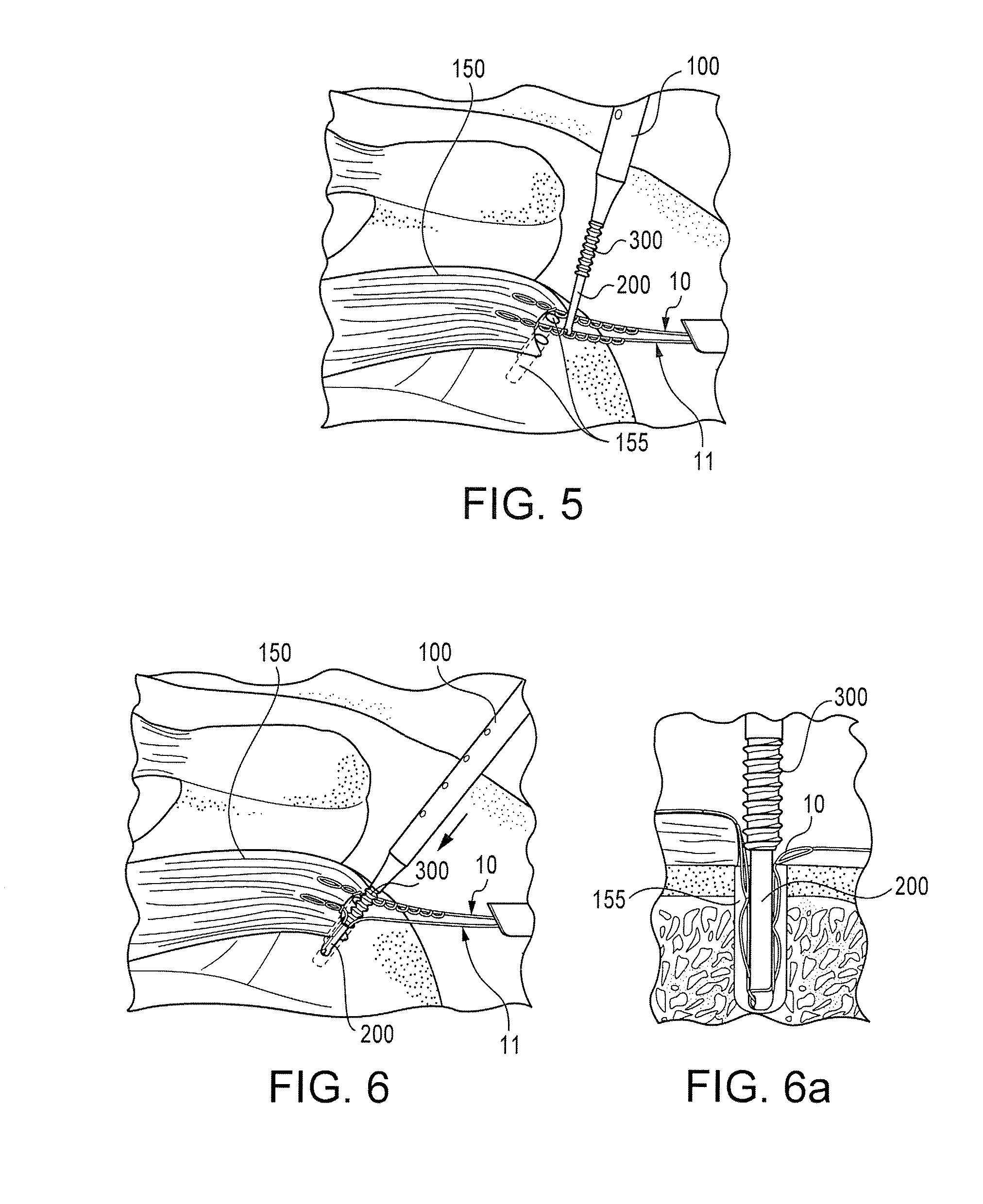

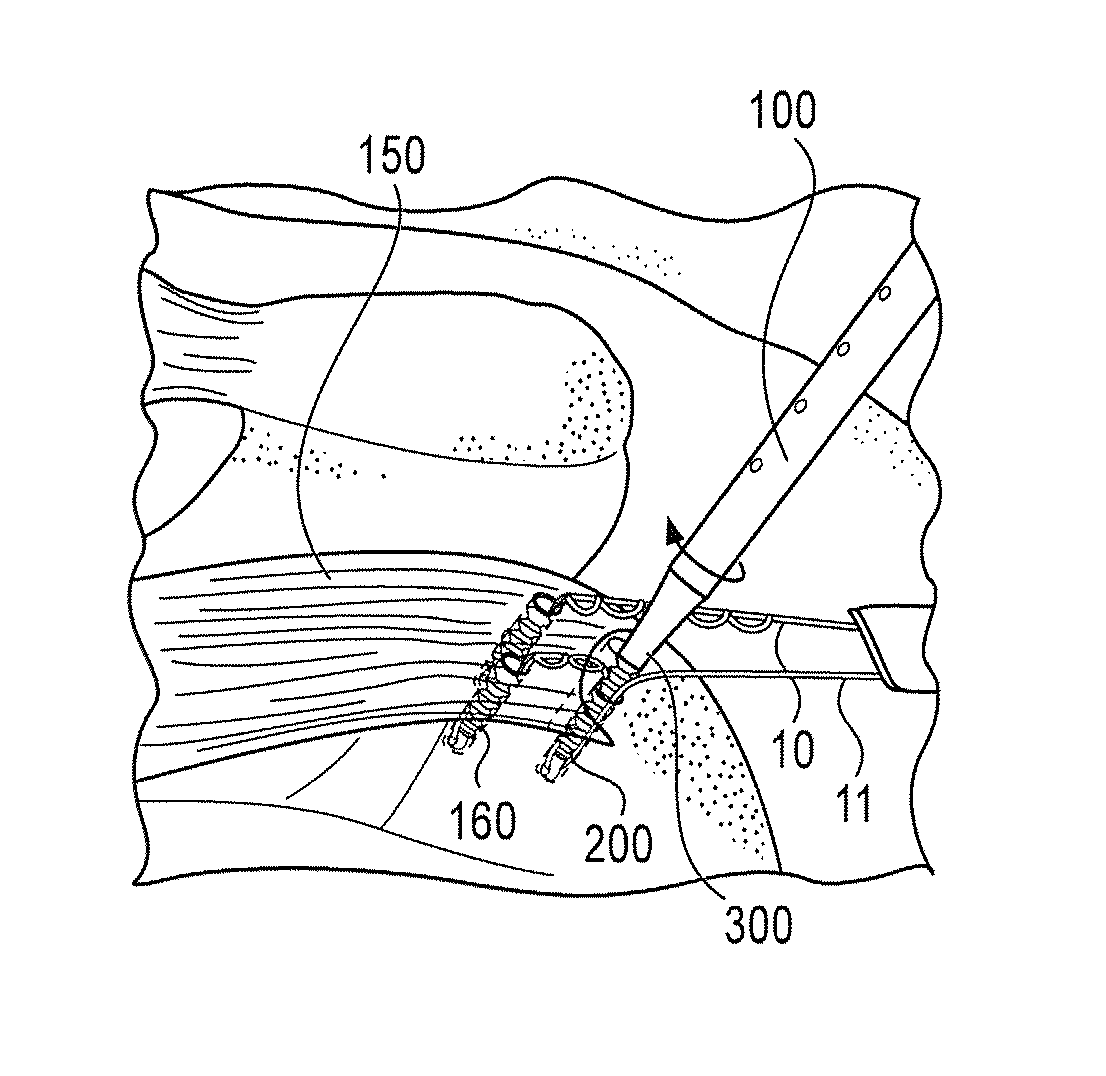

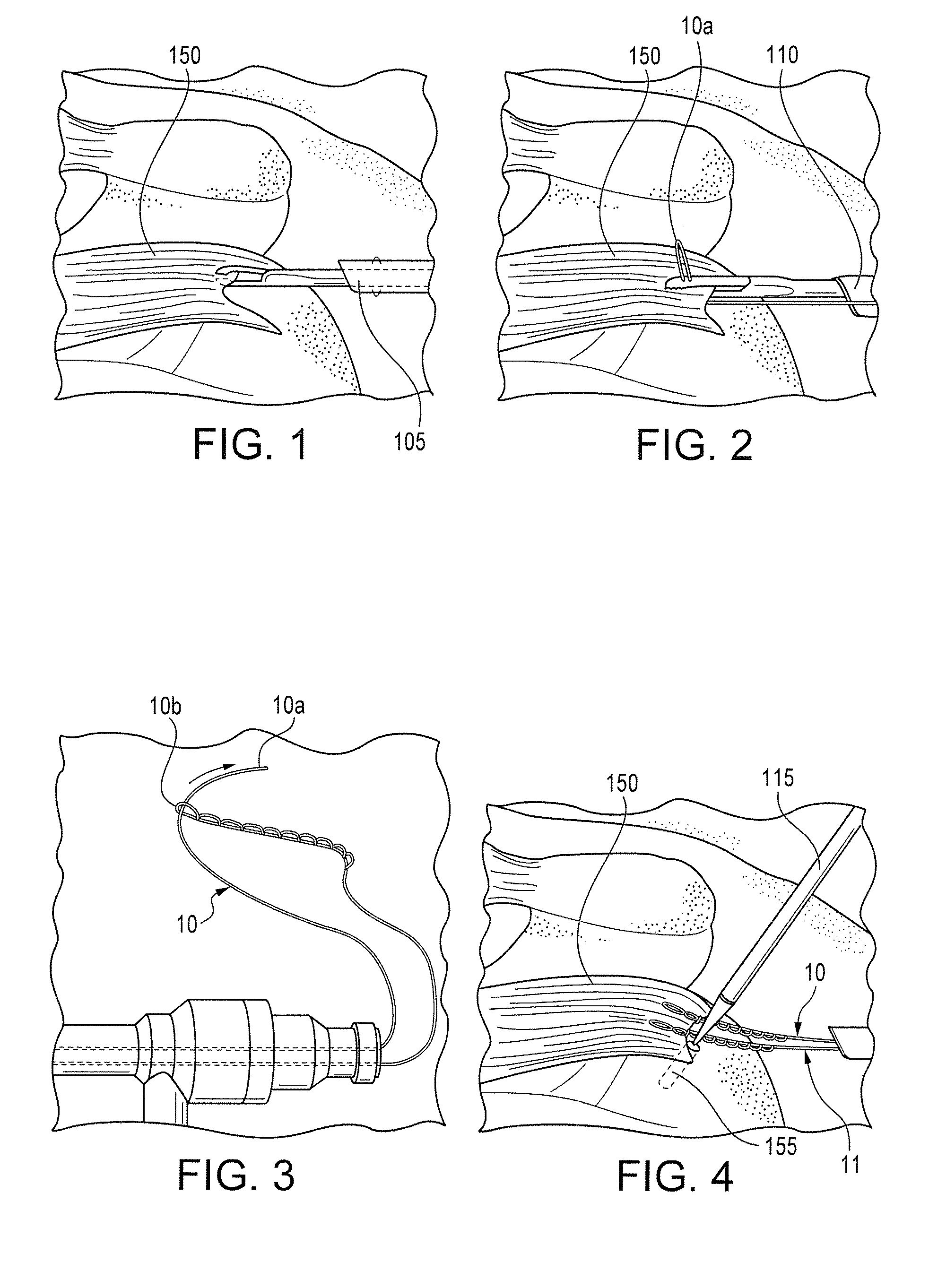

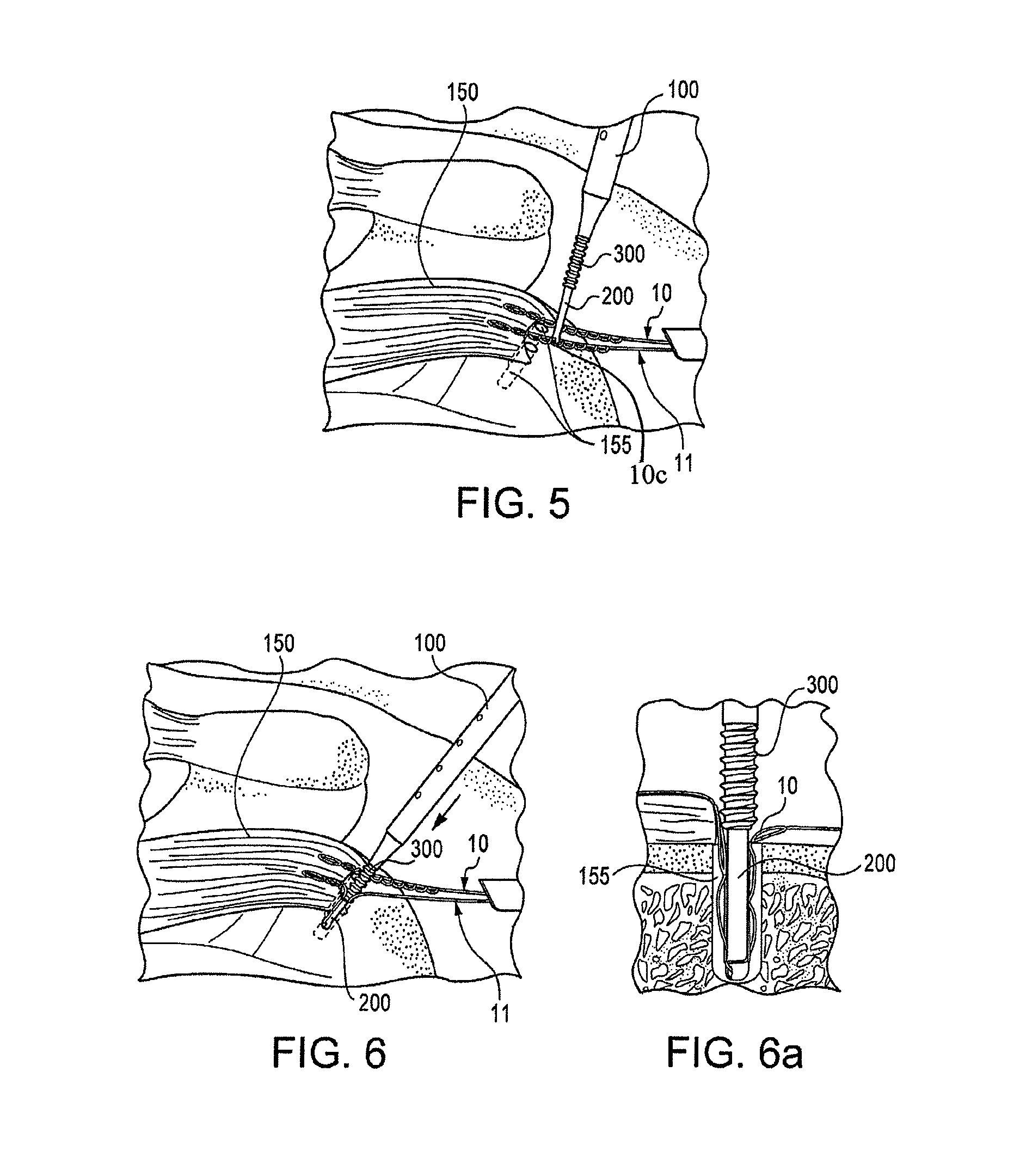

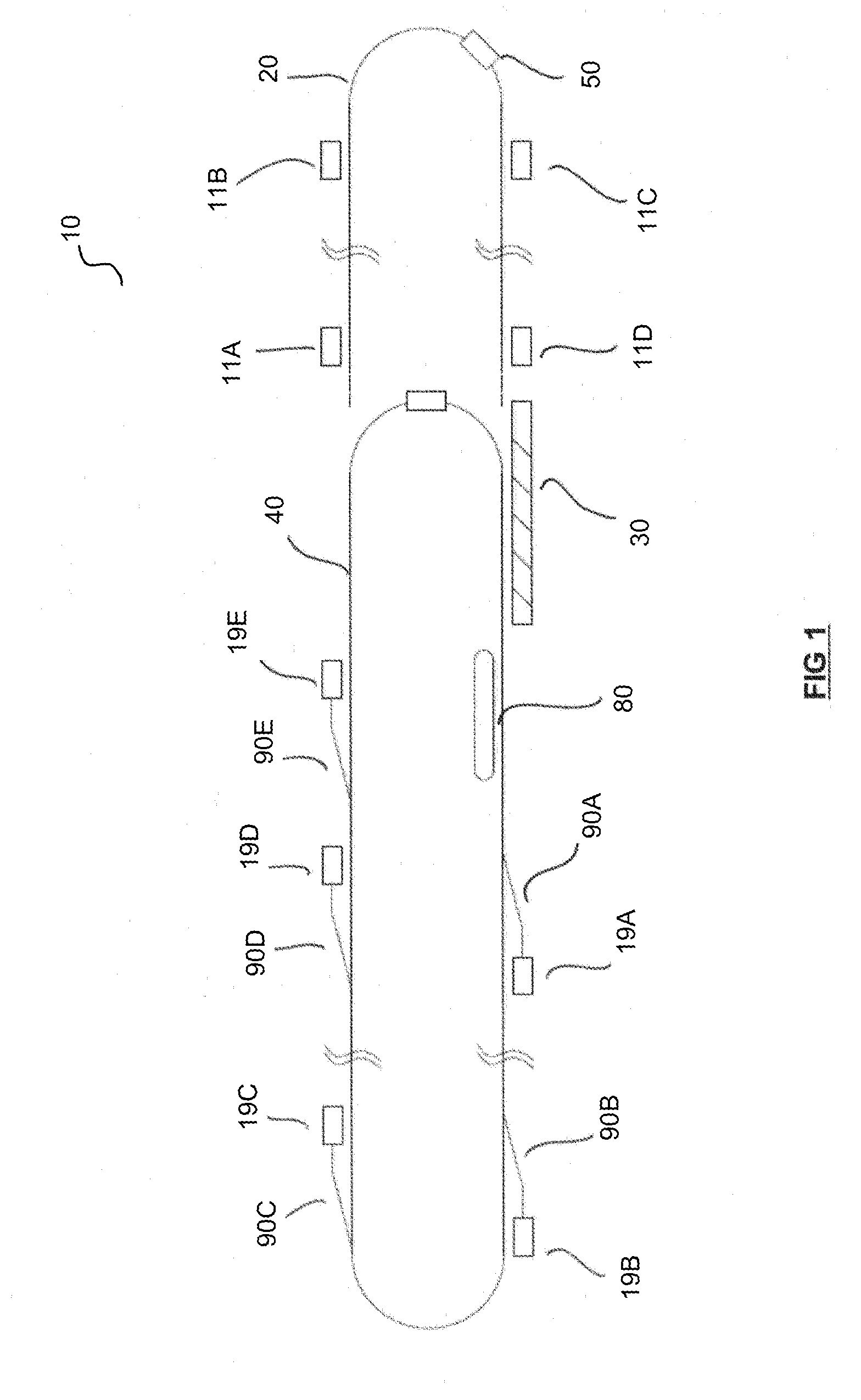

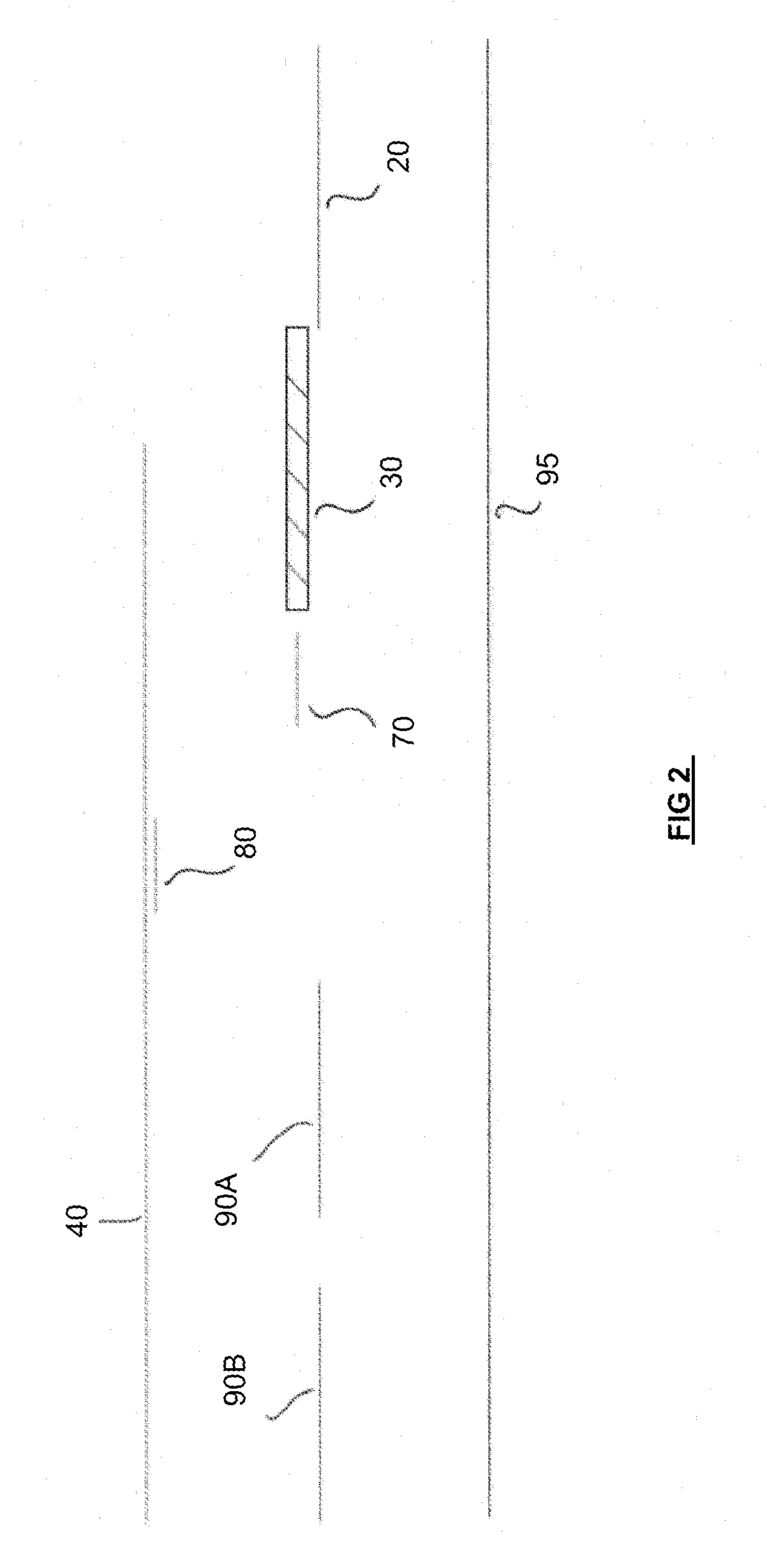

Swivel anchor and method for knotless fixation of tissue

A method and device for knotless fixation of tissue. A swivel anchor having a rotatable forked anchor tip is used to capture suture, such as a suture chain, for surgical tissue repair without requiring suture knots. Tension on the repair constructs is adjustable through the selection of the specific chain link or links of the suture chain captured by the forked anchor tip of the swivel anchor. The swivel anchor is secured in a hole in bone by advancing a fixation device, such as a cannulated interference screw, over the body of the anchor.

Owner:ARTHREX

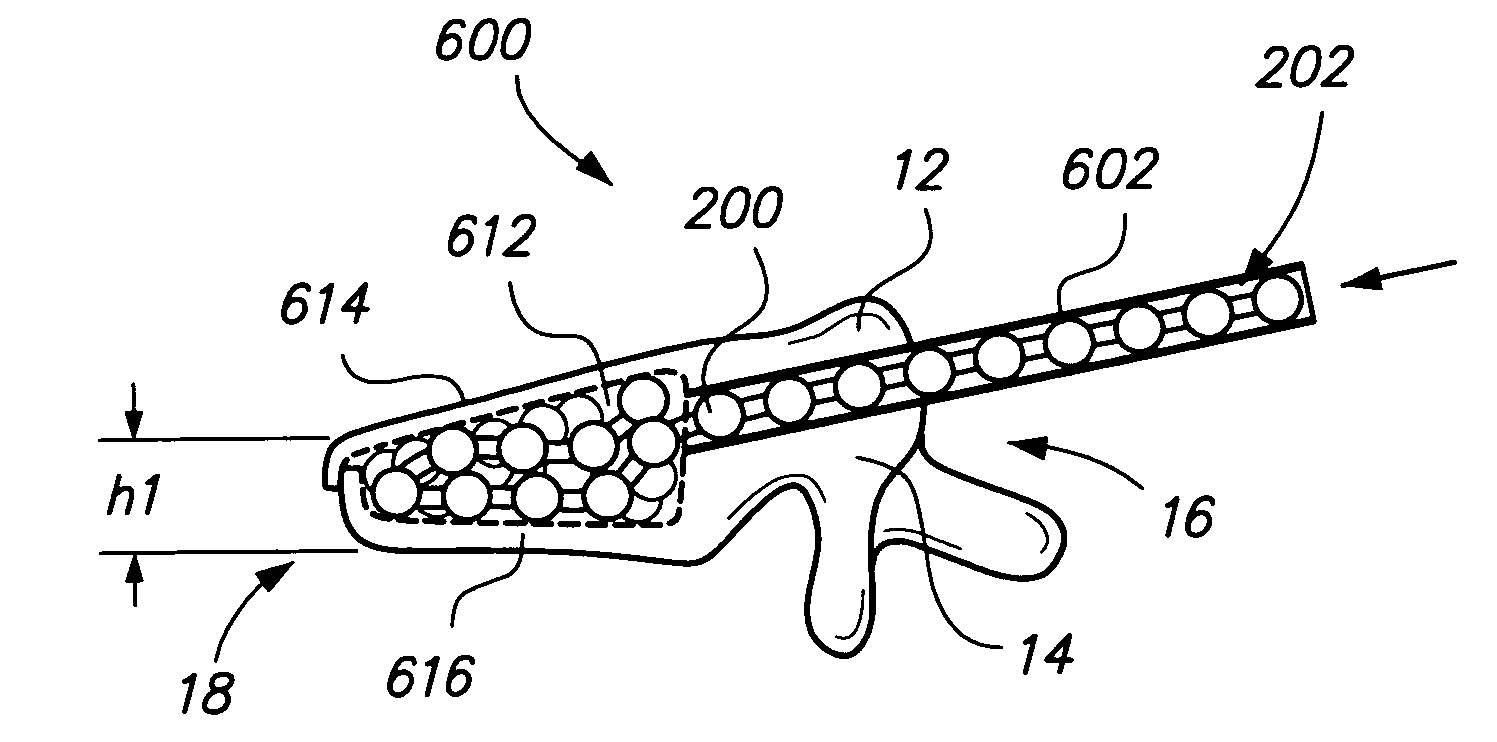

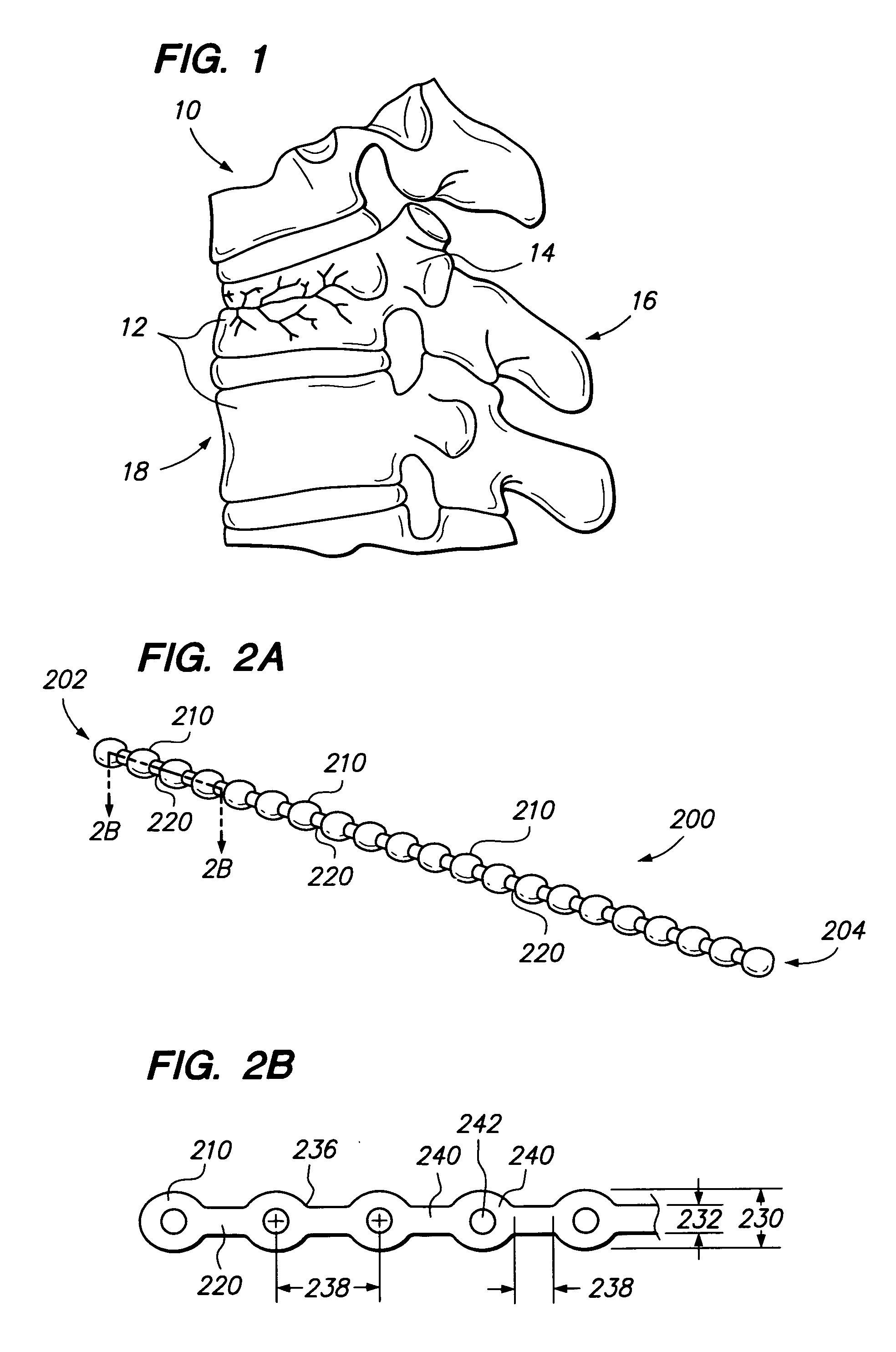

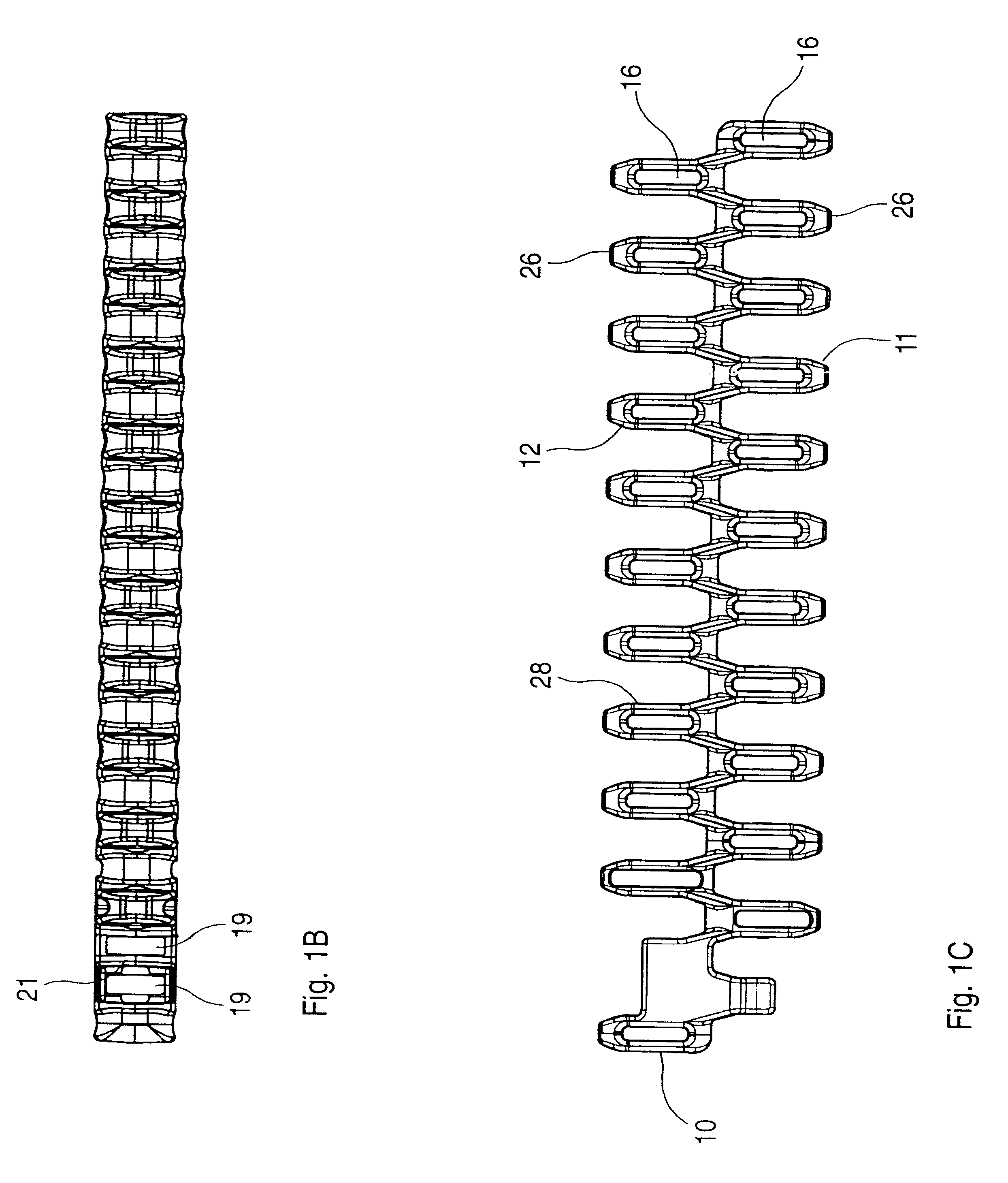

Flexible elongated chain implant and method of supporting body tissue with same

InactiveUS20070162132A1Internal osteosythesisSpinal implantsSurface layerMinimally invasive procedures

Implants and methods for augmentation, preferably by minimally invasive procedures and means, of body tissue, including in some embodiments repositioning of body tissue, for example, bone and, preferably vertebrae are described. The implant may comprise one or more chain linked bodies inserted into the interior of body tissue. As linked bodies are inserted into body tissue, they may fill a central portion thereof and for example in bone can push against the inner sides of the cortical exterior surface layer, for example the end plates of a vertebral body, thereby providing structural support and tending to restore the body tissue to its original or desired treatment height. A bone cement or other filler can be added to further augment and stabilize the body tissue. The preferred implant comprises a single flexible monolithic chain formed of allograft cortical bone having a plurality of substantially non-flexible bodies connected by substantially flexible links.

Owner:DEPUY SYNTHES PROD INC

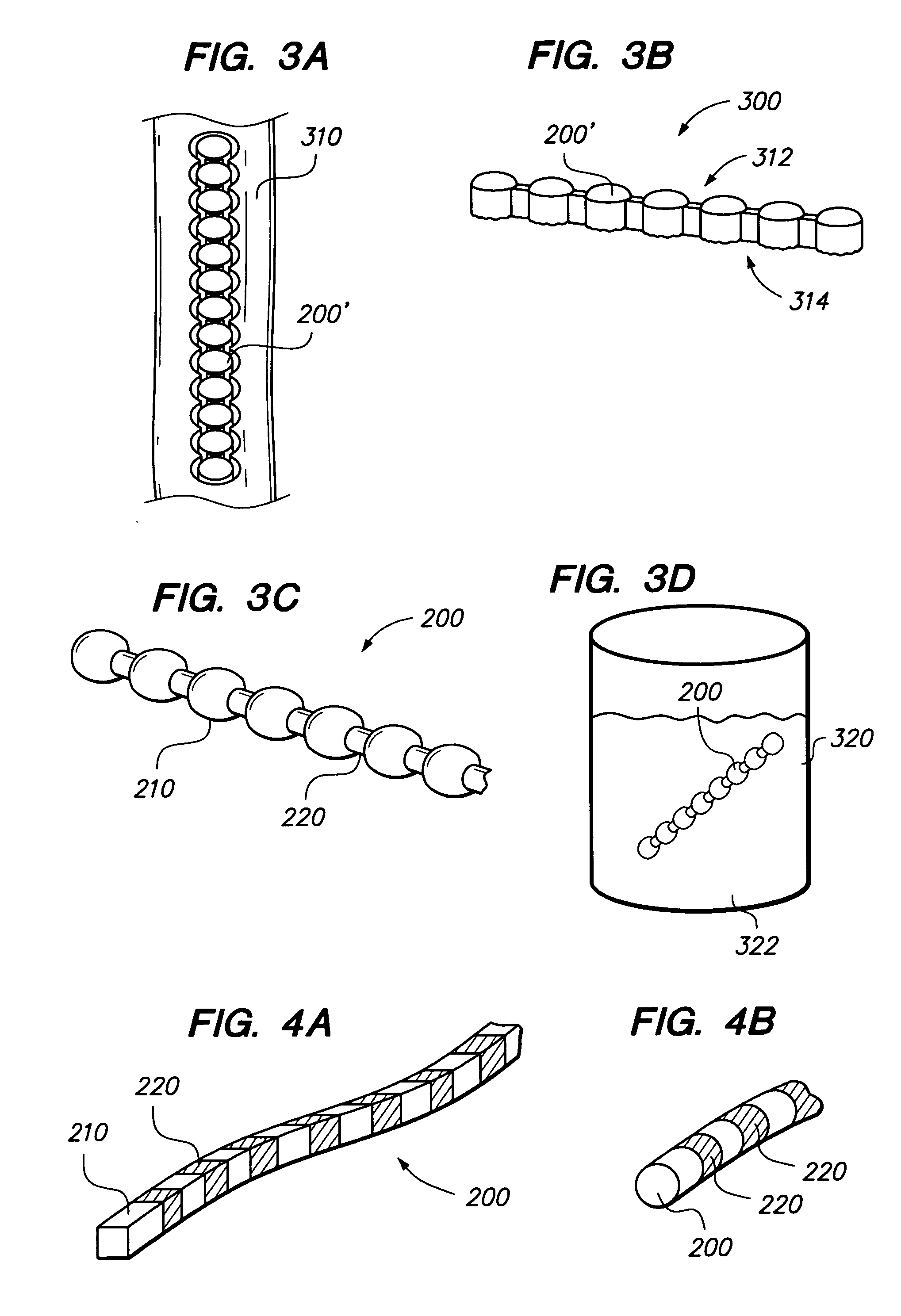

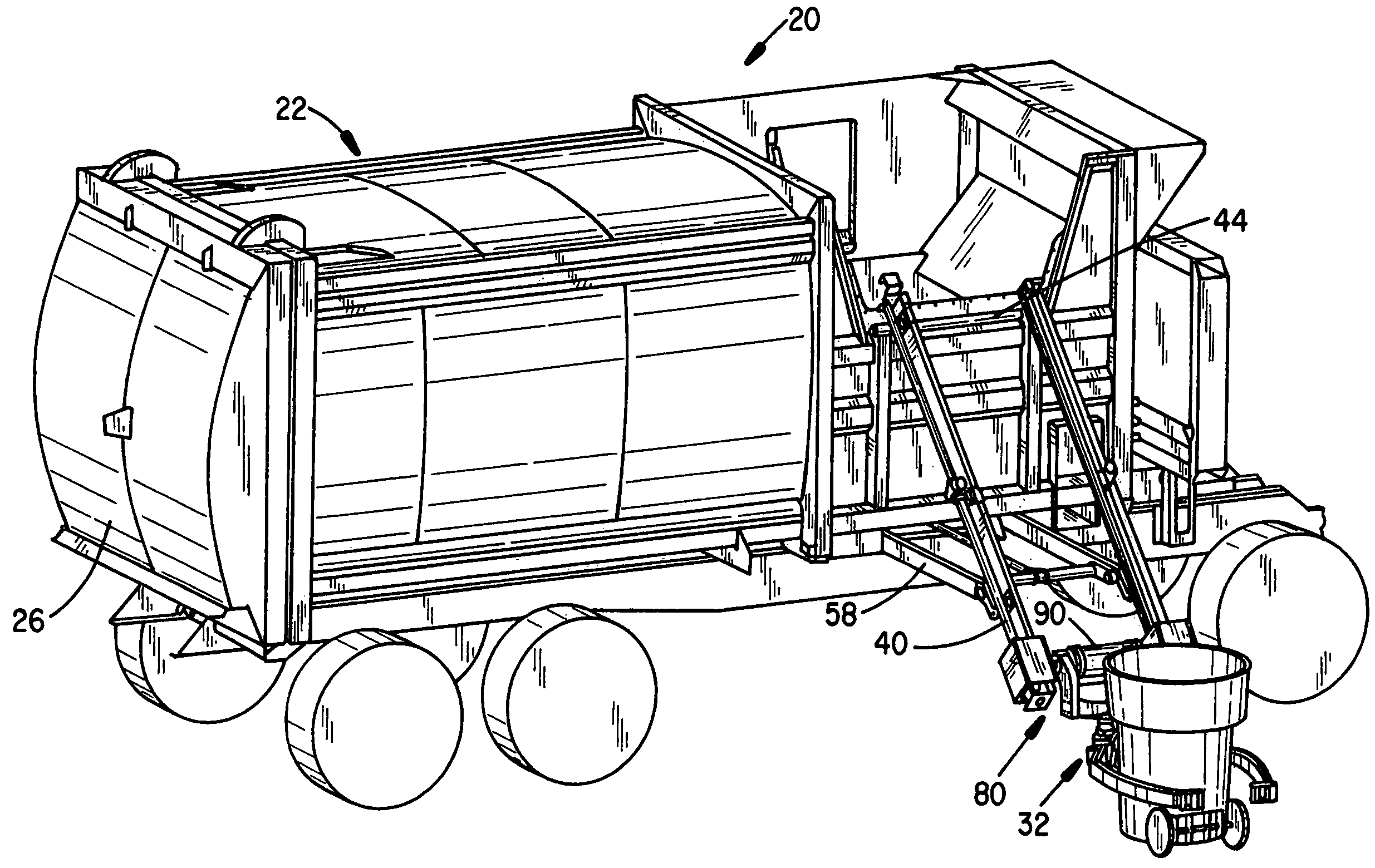

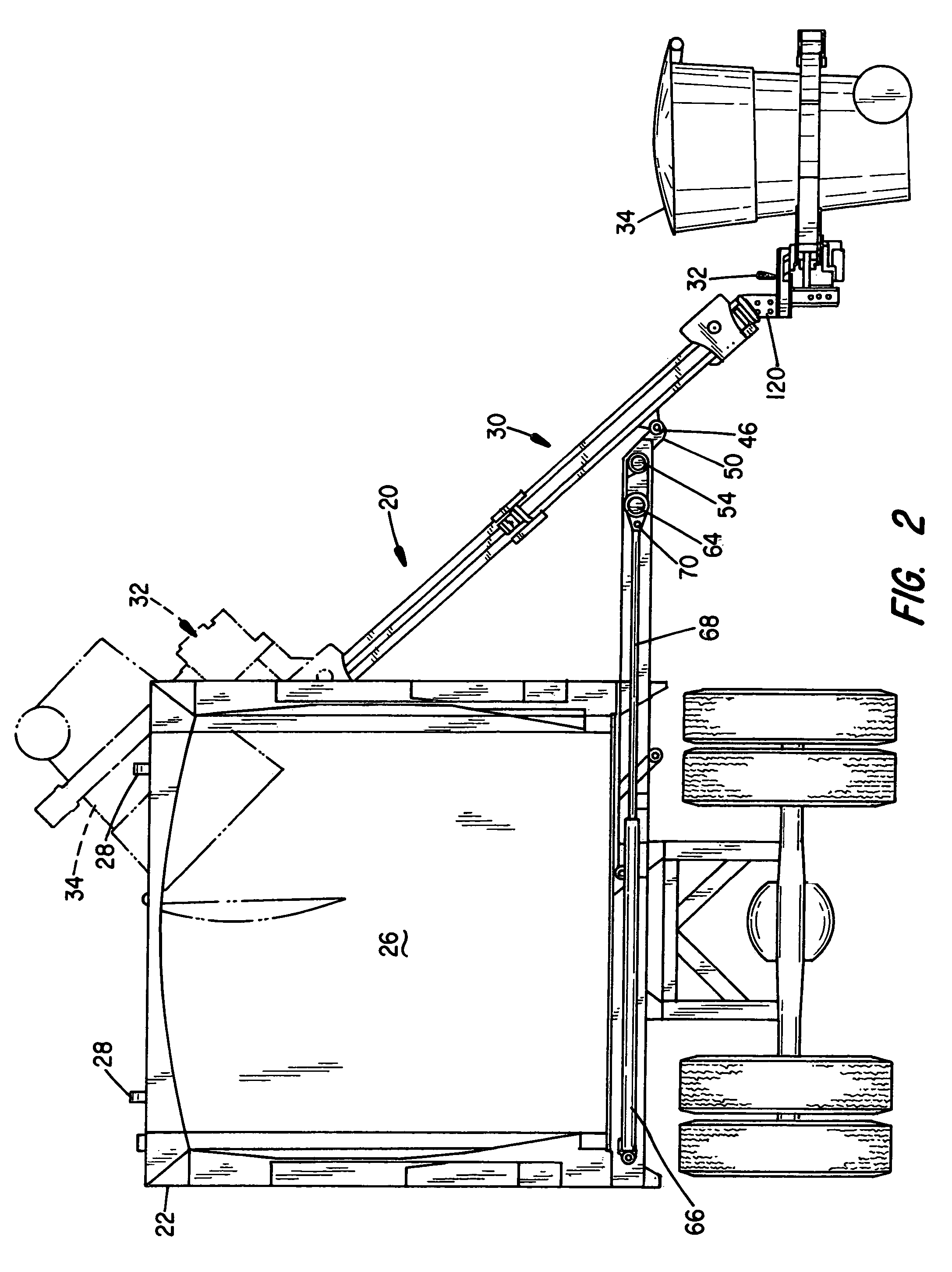

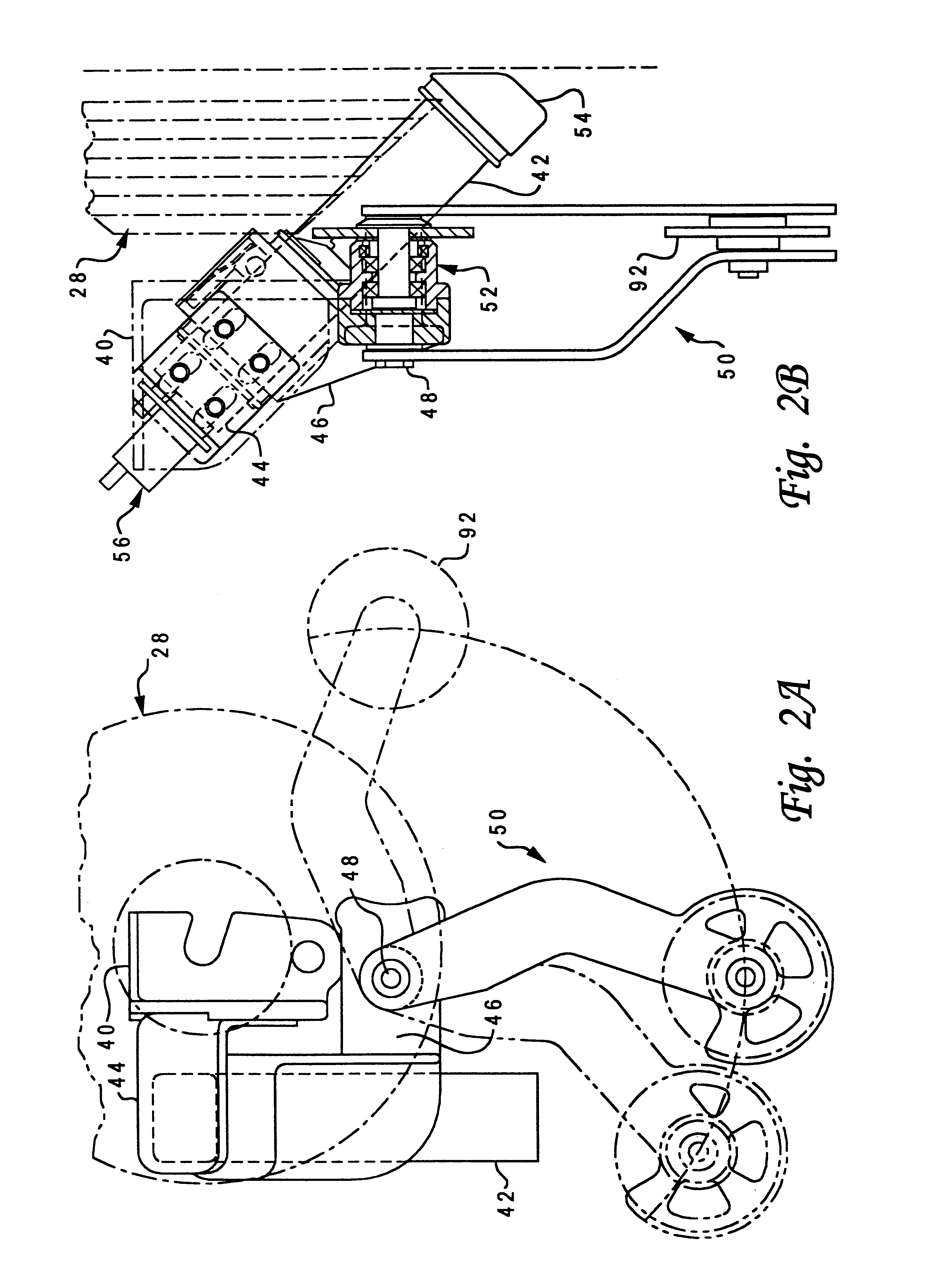

Automated loader

A container handling mechanism suitable for mounting on the side of a refuse vehicle for loading material from refuse containers is disclosed that includes a lift assembly, having a pair of spaced, generally parallel lift support members, attachable to a refuse vehicle, a carriage device reciprocally operable along the lift support members of the lift assembly, a container grabbing system carried by the carriage device and further including a pair of opposed grabber fingers and an actuator system for closing and opening the grabber fingers to engage and release containers of interest, the container grabbing system being vertically pivotable on a short radius for adjusting the position of and tipping a container. A chain and cylinder drive system operates the carriage device along the lift assembly, and a control system controls operation of the container handling mechanism.

Owner:MCNEILUS TRUCK & MFG INC

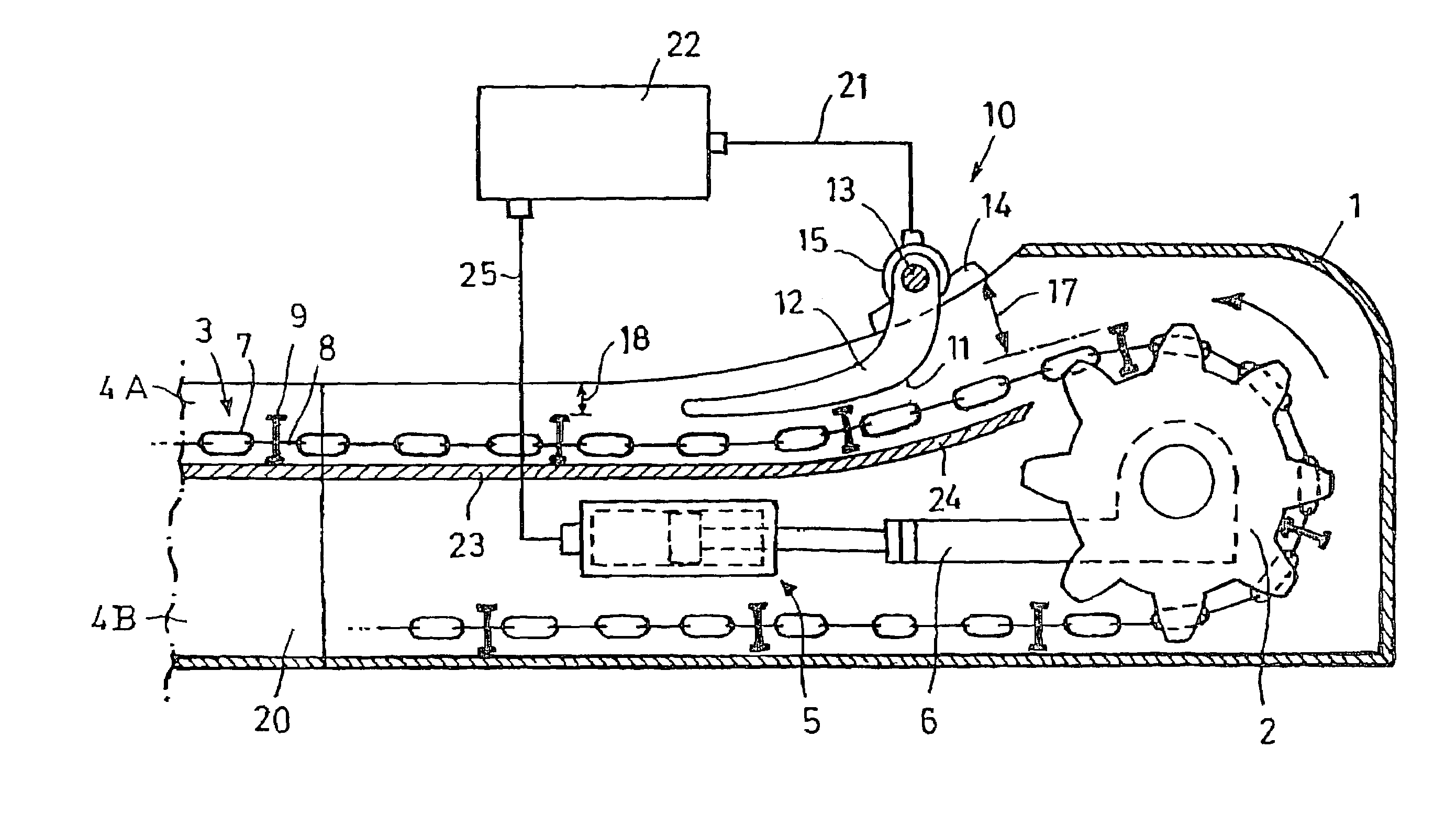

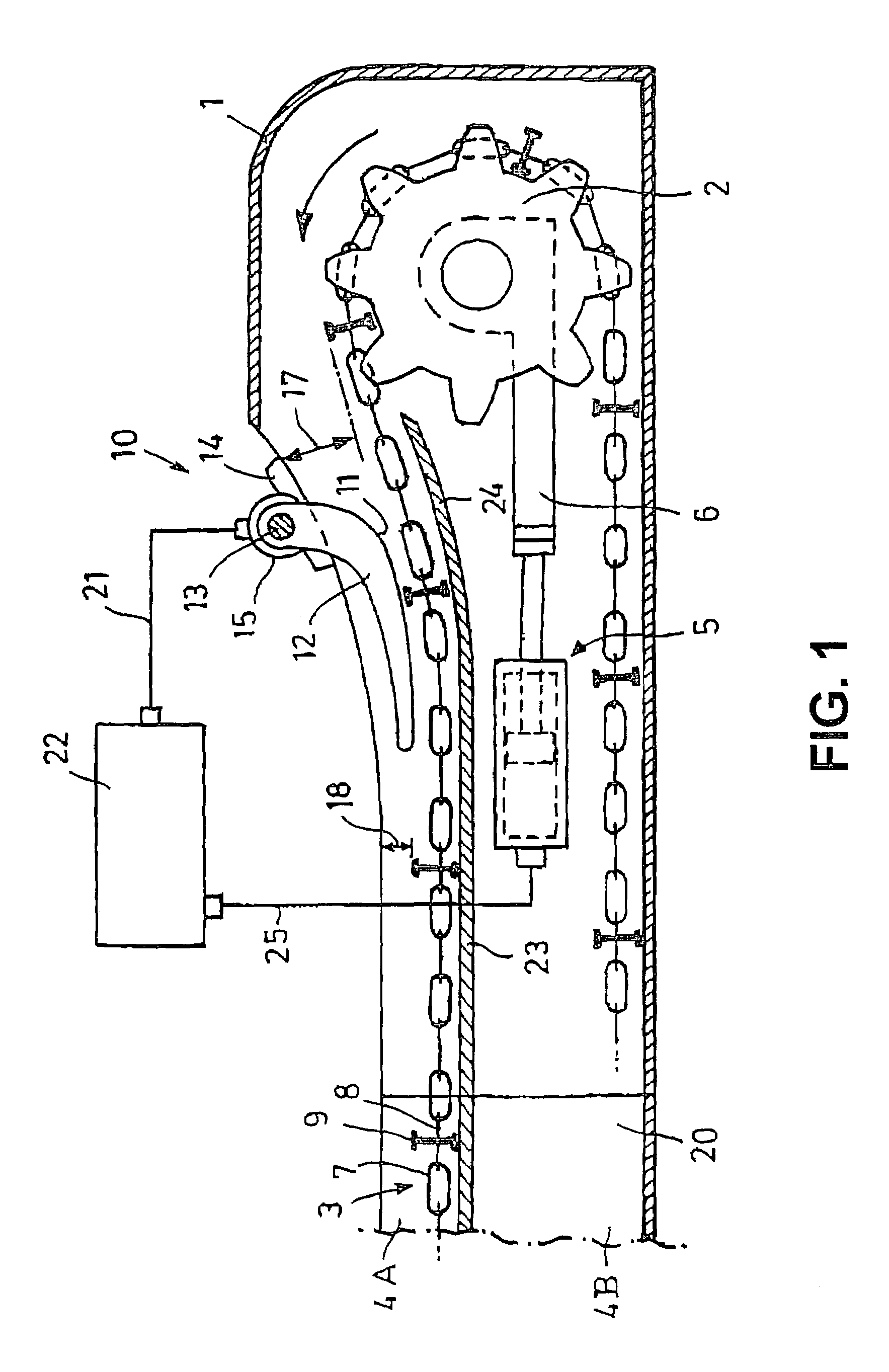

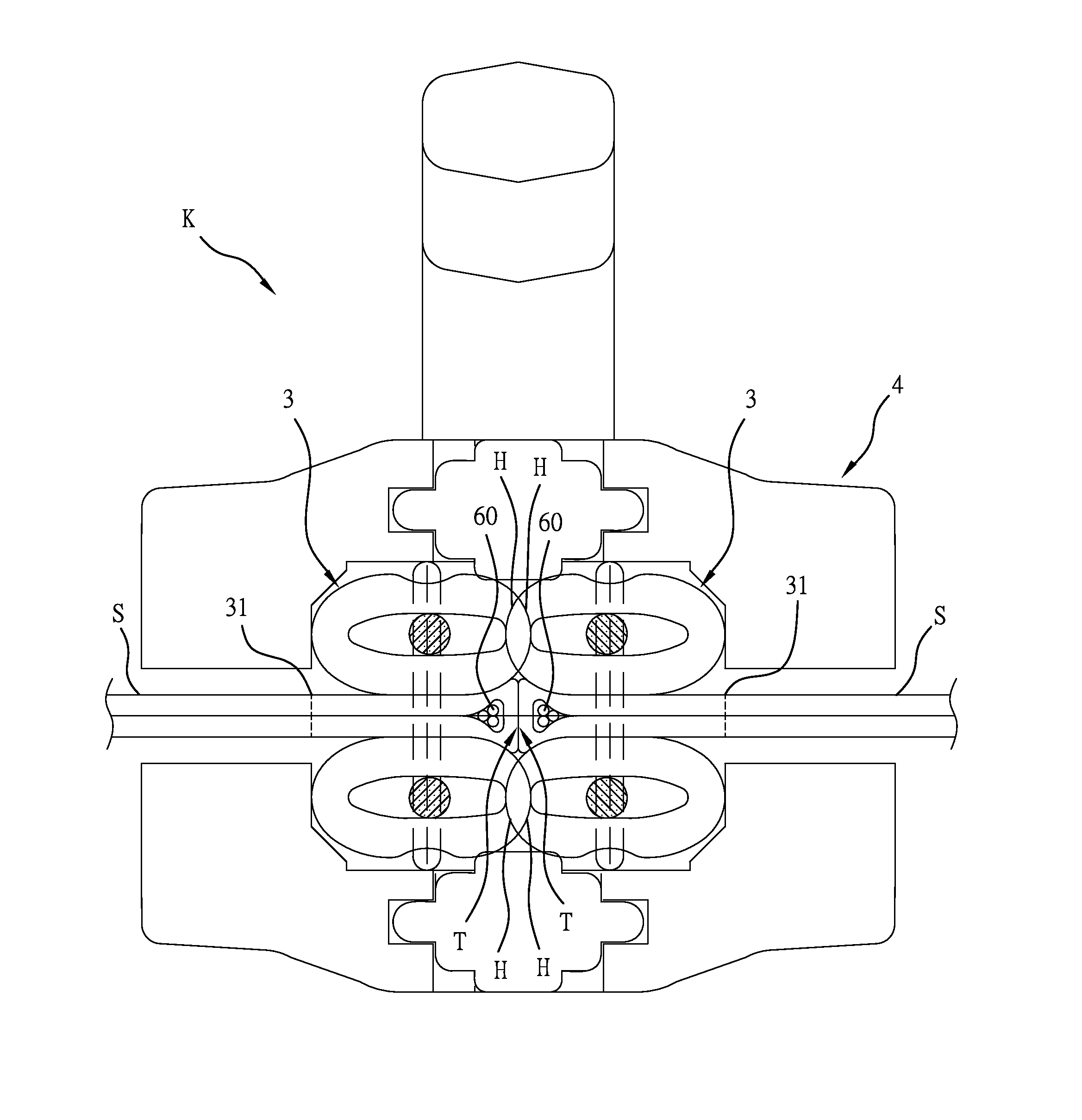

Device for detecting the tension of scraper chains

InactiveUS7117989B2Not easy to wearEasy to replaceConveyorsControl devices for conveyorsEngineeringChain conveyor

A device for detection and adjustment of the tension of a scraper chain of a chain conveyor, in particular of a face conveyor, having a tensionable return station, on which a spoked chainwheel to reverse the scraper chain, having chain links and scrapers attached thereto, is supported between the bottom race and the top race. The devices including a sensor which determines the tension of the scraper chain at the return station and the sensor having a swivellable sensor body coupled with a shaft encoder. The sensor body being in the top race and in contact with the upper face of the scraper chain in a measurement zone with provision being made in the measuring zone for vertical play for the run of the scrapers and / or the chain links.

Owner:DBT

Swivel anchor and method for knotless fixation of tissue

A method and device for knotless fixation of tissue. A swivel anchor having a rotatable forked anchor tip is used to capture suture, such as a suture chain, for surgical tissue repair without requiring suture knots. Tension on the repair constructs is adjustable through the selection of the specific chain link or links of the suture chain captured by the forked anchor tip of the swivel anchor. The swivel anchor is secured in a hole in bone by advancing a fixation device, such as a cannulated interference screw, over the body of the anchor.

Owner:ARTHREX

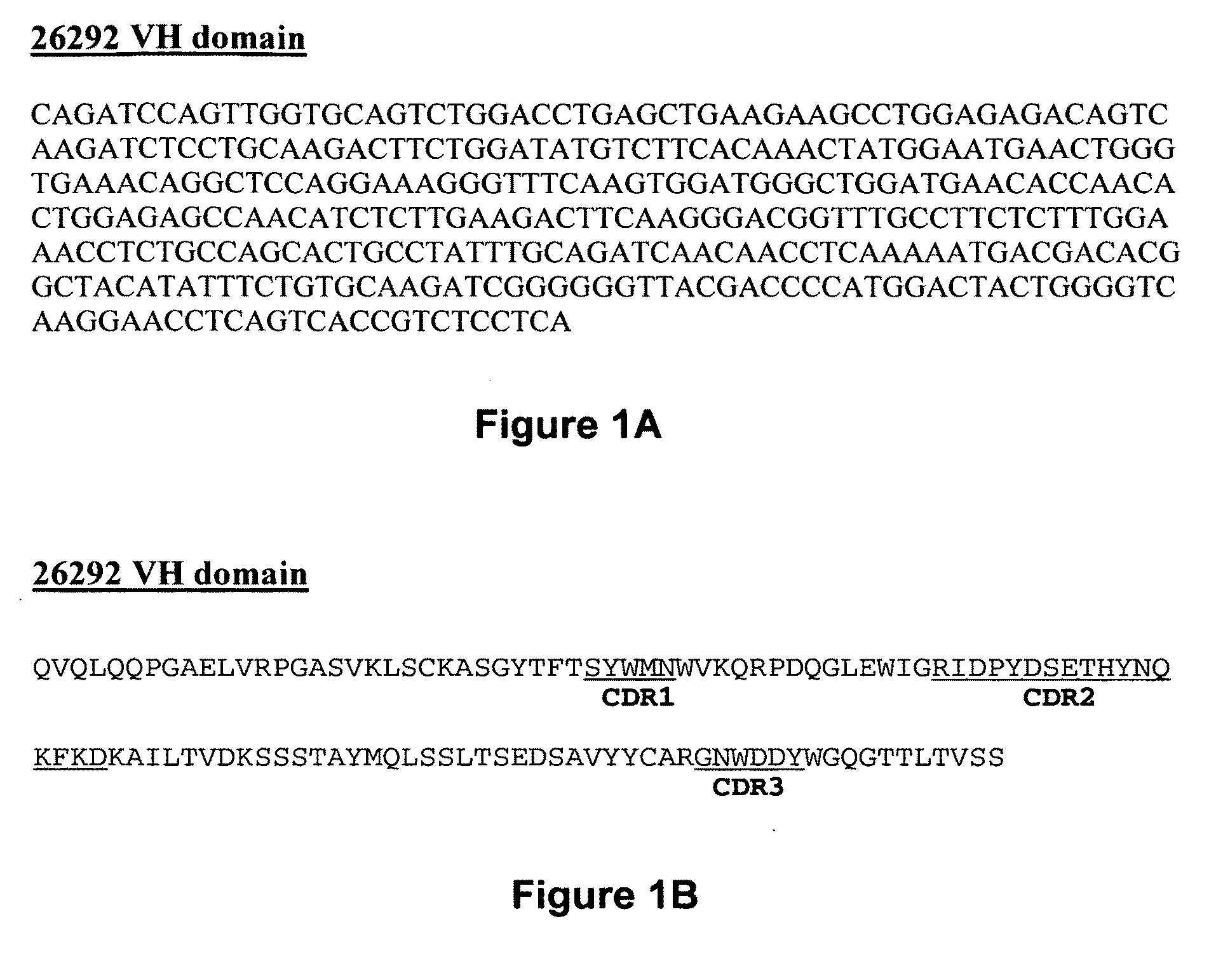

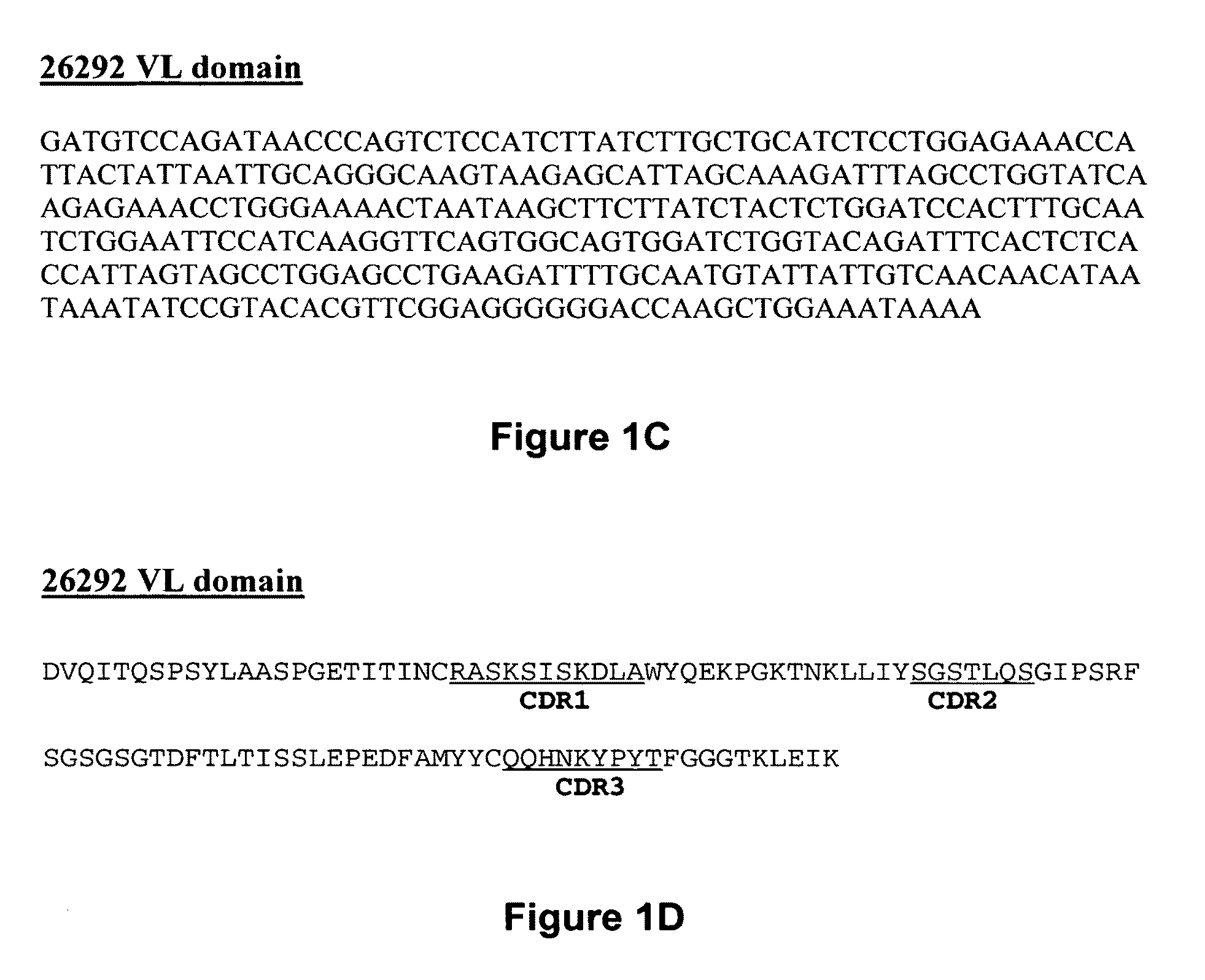

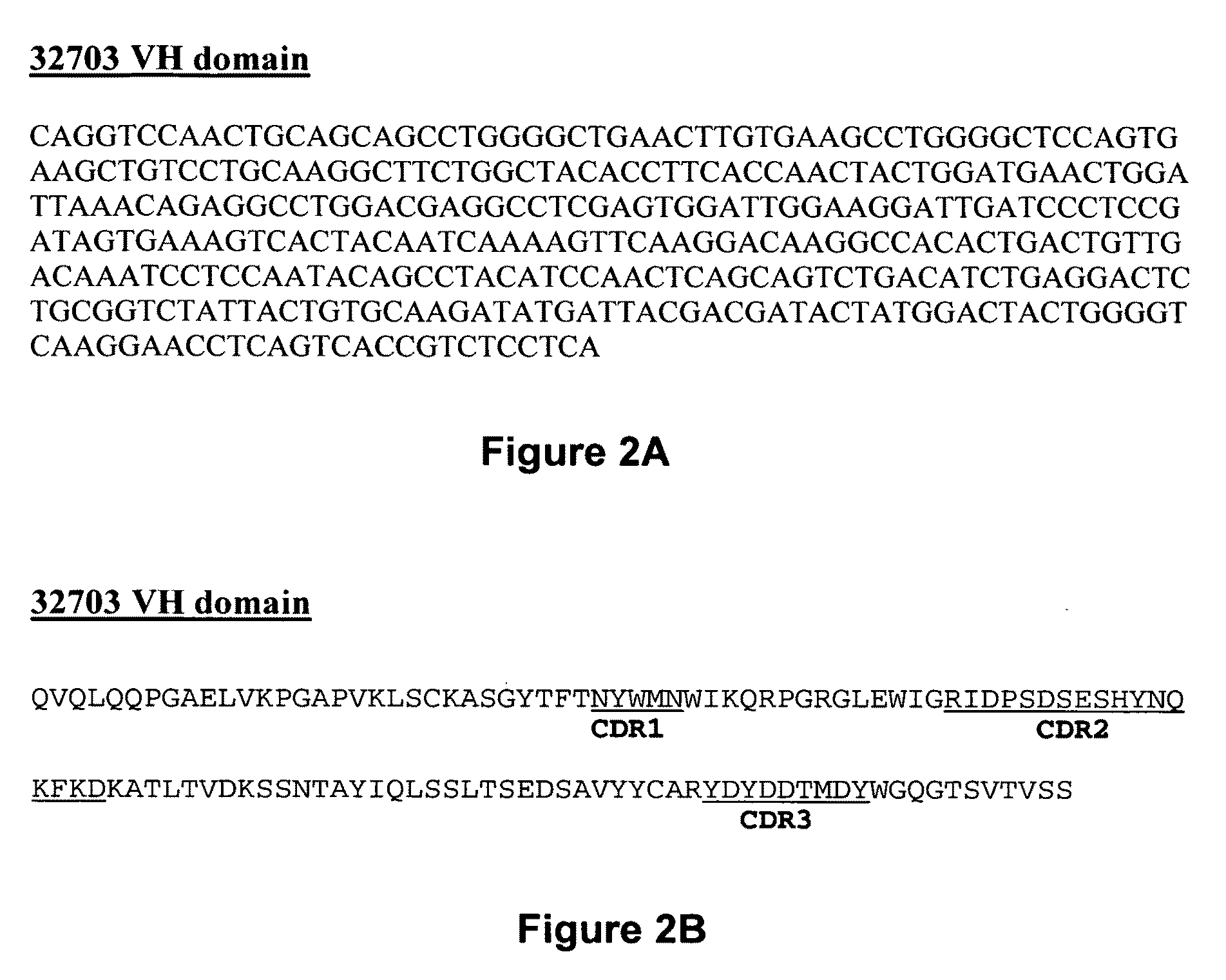

IL3Ralpha antibody conjugates and uses thereof

ActiveUS20090252742A1Shorten the durationReduce severitySugar derivativesMicrobiological testing/measurementCancer cellAntibody conjugate

The present invention provides antibodies that bind to the IL-3 receptor alpha subunit alpha (Il3Rα) chain, and compositions comprising such antibodies. The present invention provides methods for inhibiting or reducing an IL3Rα-expressing cell population, the methods comprising contacting a population of IL3Rα-expressing cells (e.g., cancer cells and / or cancer stem cells) with an antibody that binds to IL3Rα. The present invention also provides antibody conjugates comprising an antibody that binds to an IL3Rα chain linked to a cytotoxic agent or anticellular agent and compositions comprising such conjugates. The present invention also provides methods for preventing, treating and / or managing a disorder associated with IL3Rα-expressing cells (e.g., a hematological cancer), the methods comprising administering to a subject in need thereof an antibody that binds to IL3Rα.

Owner:STEMLINE THERAPEUTICS

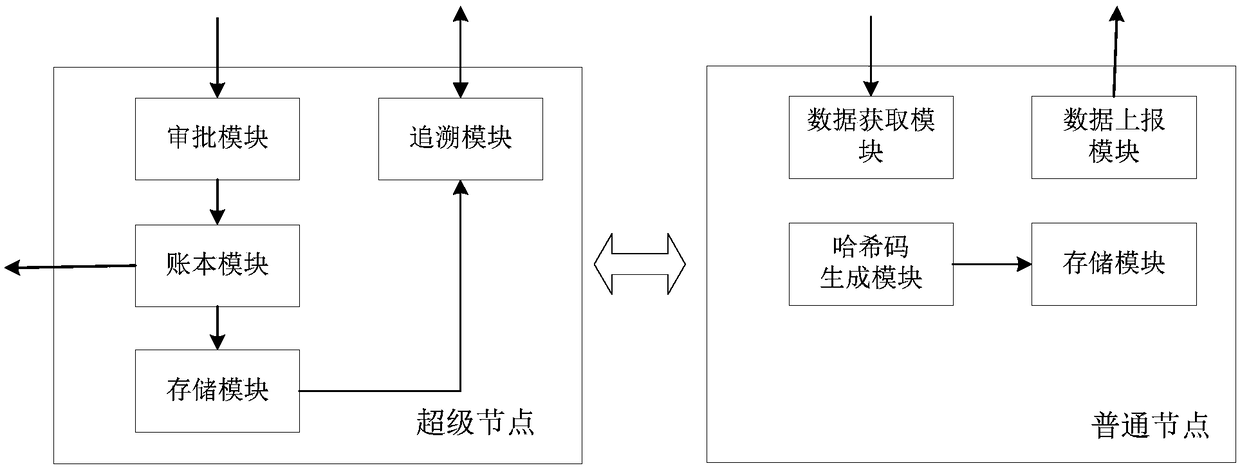

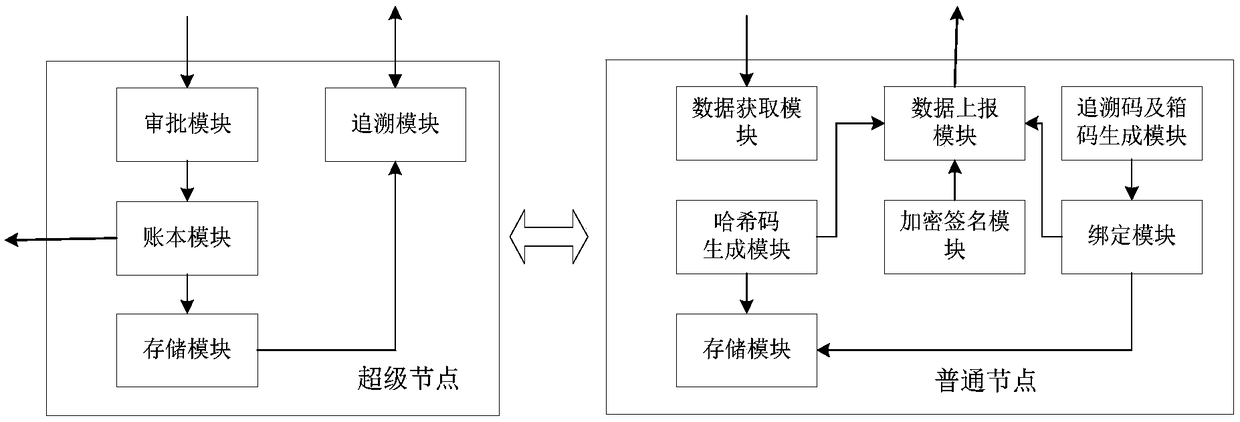

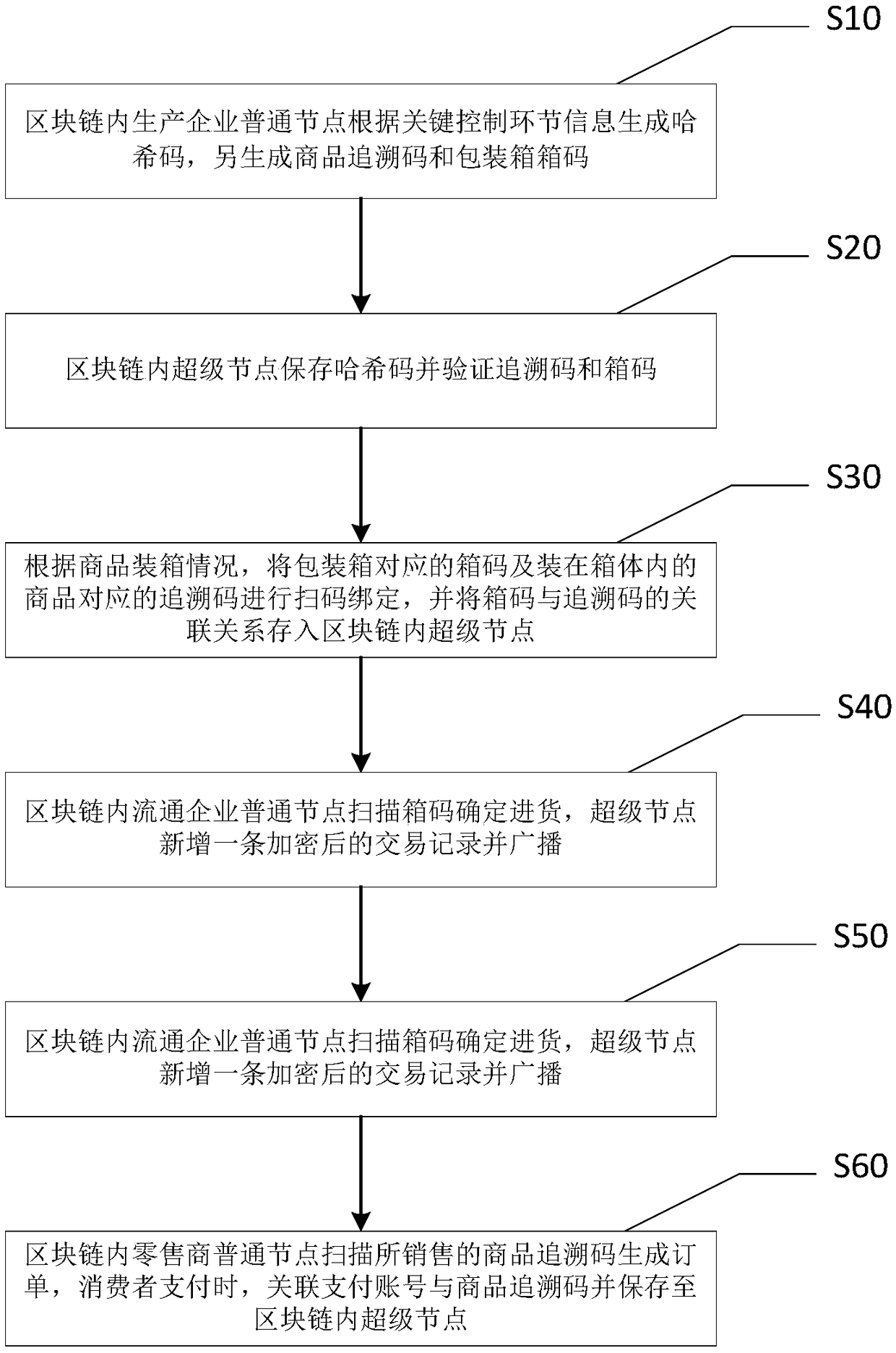

Data storage system, circulating method and tracing method of distributed commodities based on block chain

The invention discloses a data storage system, a circulating method and a tracing method of distributed commodities based on a block chain and relates to the field of data tracing. The system is deployed by adopting a league chain mode and comprises multiple super-nodes and multiple common nodes. The data storage system, the circulating method and the tracing method of the distributed commoditiesbased on the block chain solve the problem of non-transparent transaction data in current commodity production and circulation chains, reduce trust friction between enterprises and trust friction between enterprises and supervision departments by utilizing the characteristic that the block chain cannot be tampered, solves the problem of big storage pressure of a centralized tracing platform as thedetail information of the production and circulation links are stored in databases of each enterprise node dispersedly and guarantees the data to be not tampered arbitrarily by the enterprises through the Hash codes, solves the problem of tracing data incompleteness and responsibility positioning difficulty of a supply chain as all the information in the whole life cycle is recorded by regardingthe tracing codes as core and combining with means such as box code association and mobile payment, the responsible party can be positioned rapidly when a quality problem occurs and a recall notice can be sent to related enterprises and related consumers.

Owner:广州中科易德科技有限公司

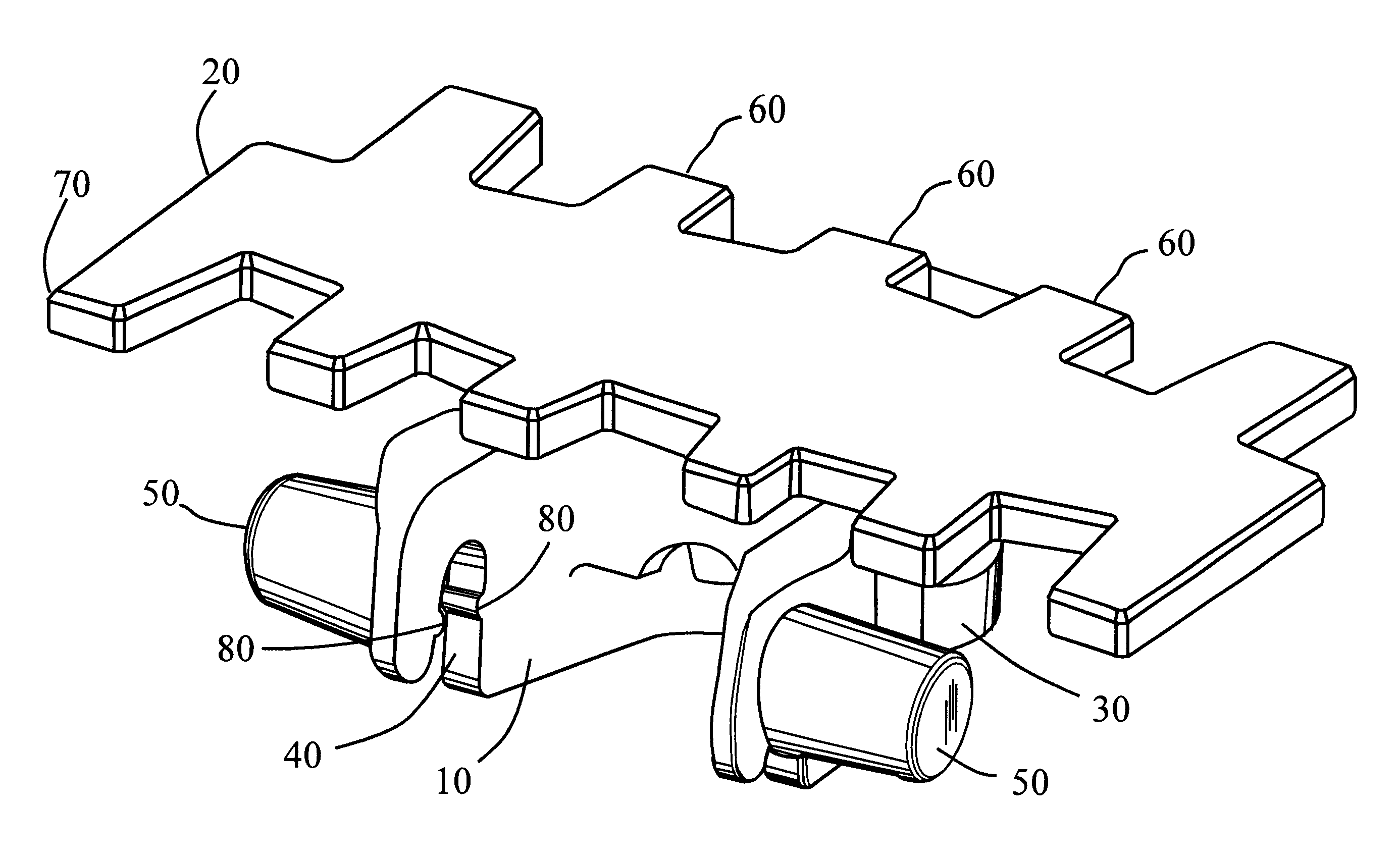

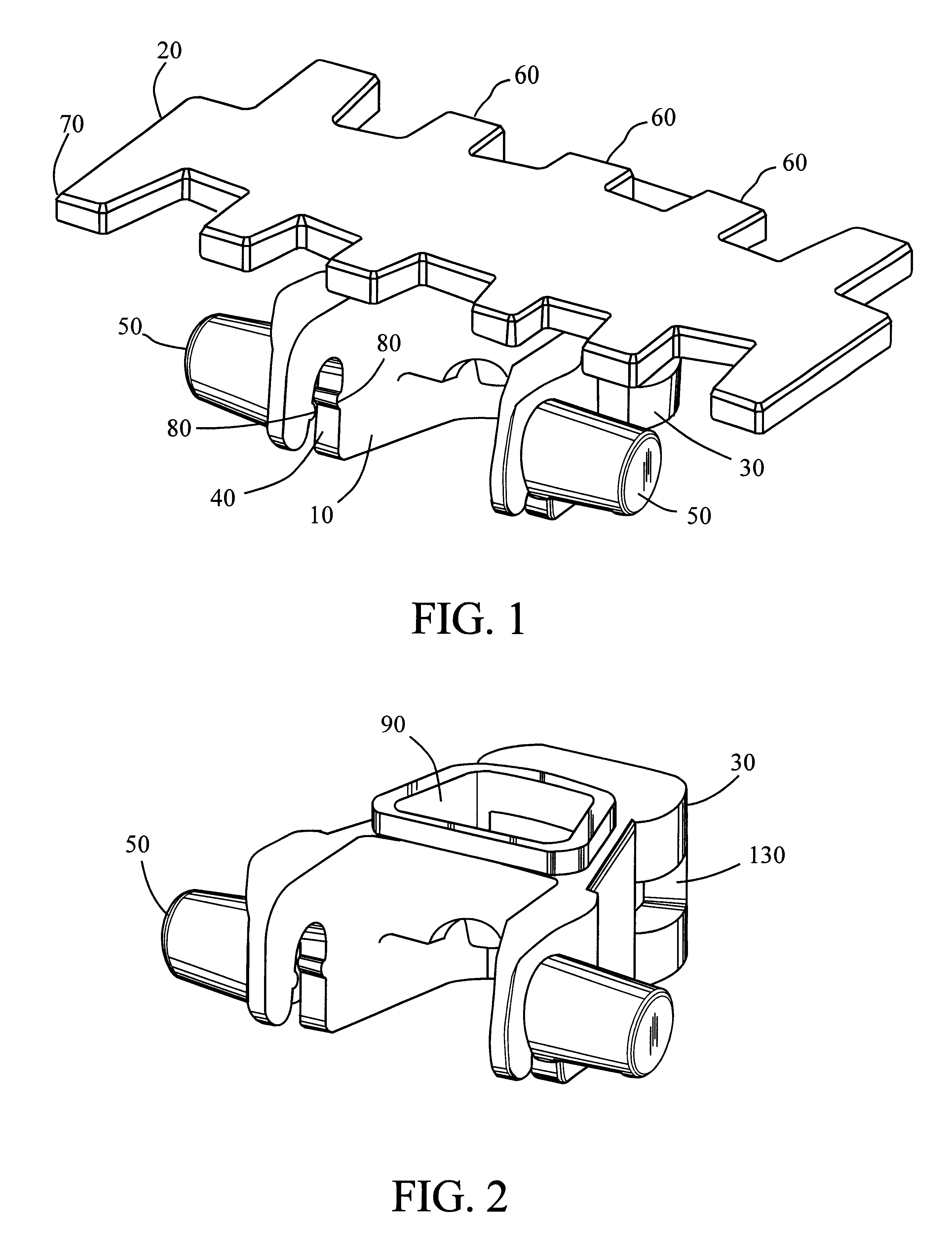

Conveyor chain link

A two piece pivot chain link which through its construction allows the top platform piece to be removably replaceable, additionally the pin attachment means can be frictionally placed in the main body of the pivot chain from the underside allowing for easy placement and removal.

Owner:RAMSEY EARL

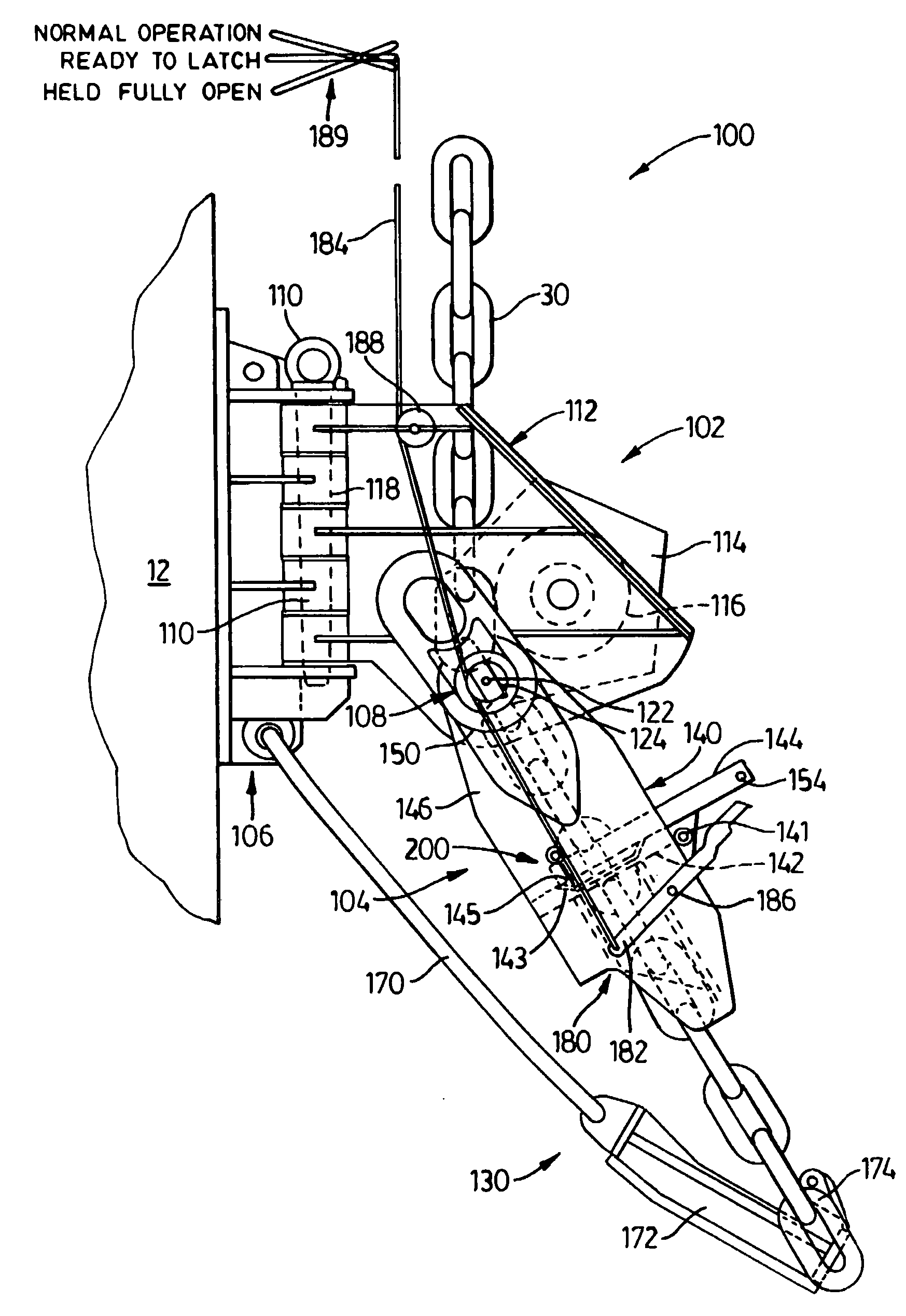

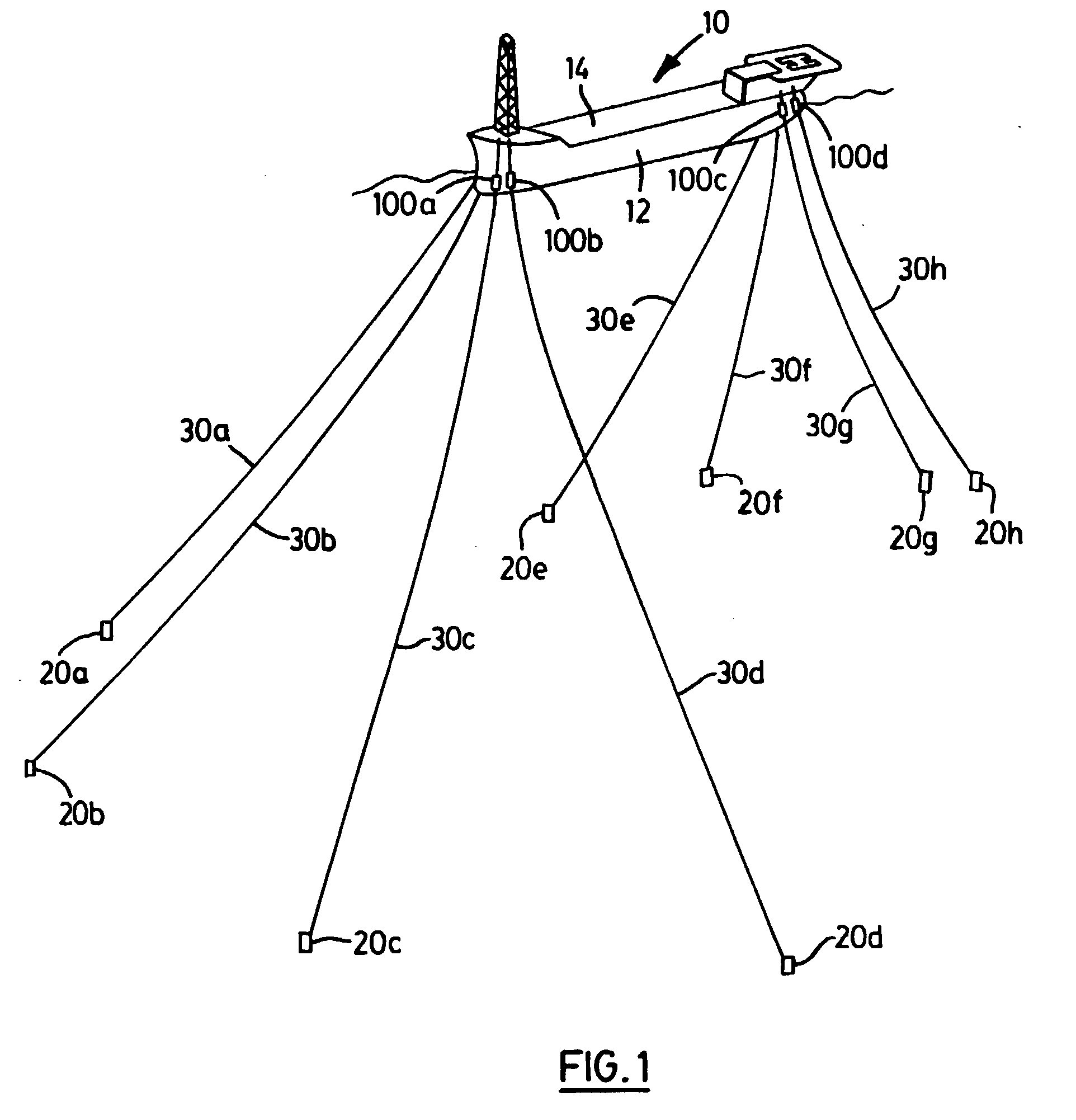

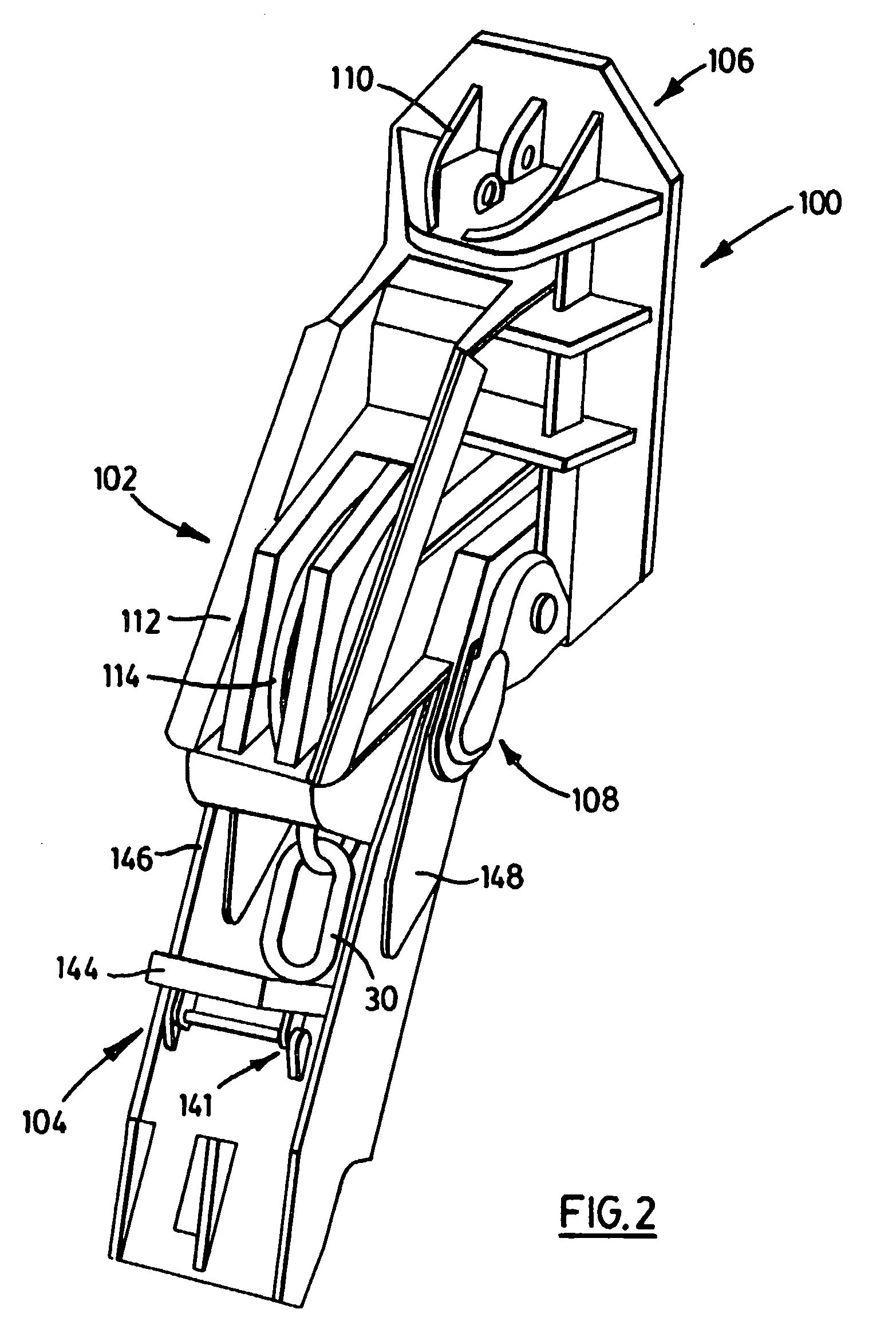

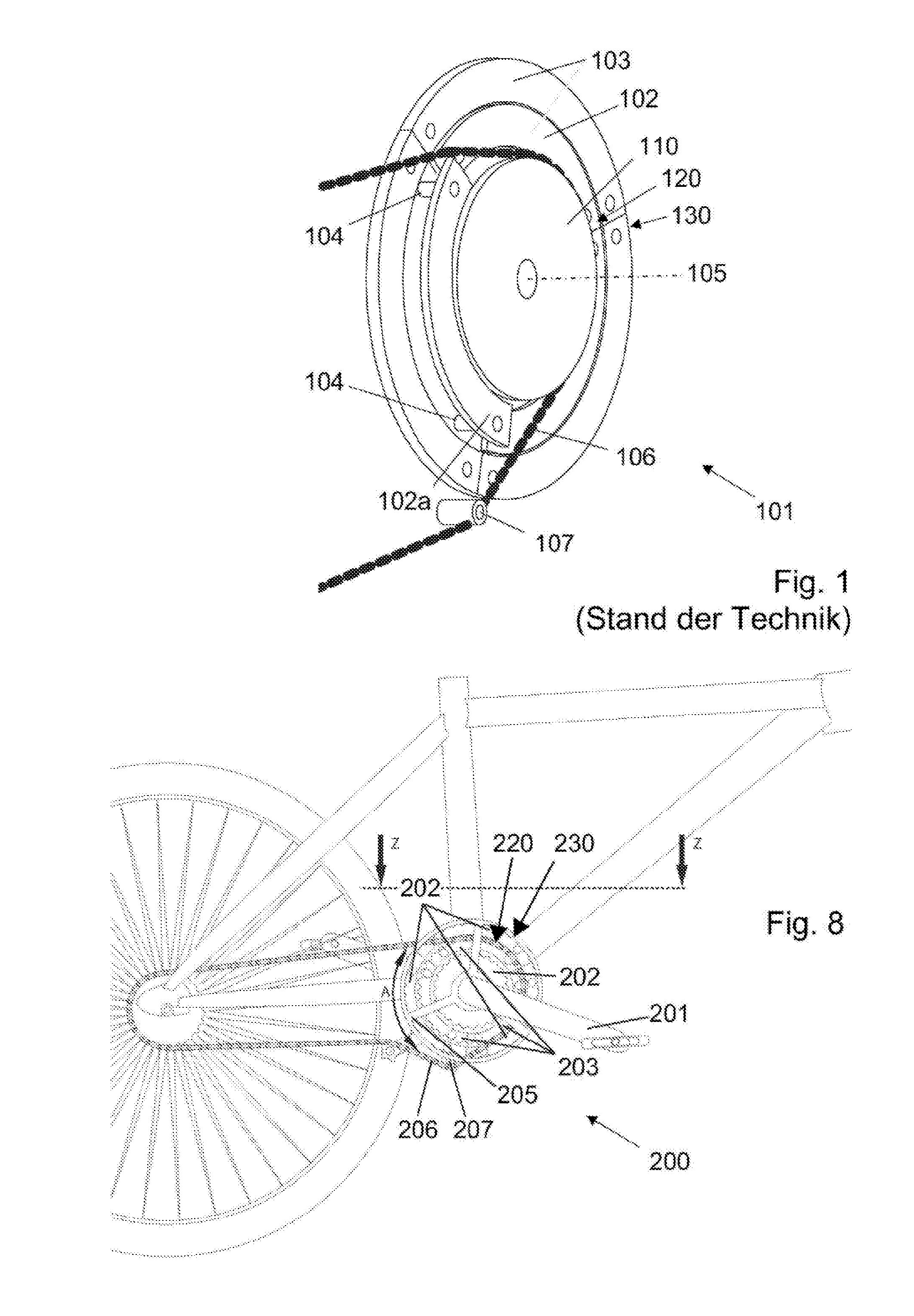

Underwater chain stopper and fairlead apparatus for anchoring offshore structures

ActiveUS20050241558A1Avoid large movementsChain fasteningsAnchoring arrangementsVertical planeSelf locking

An underwater chain stopper and fairlead apparatus for offshore structures, drilling platforms, ships or other vessels. The apparatus comprises a mounting member, a fairlead member and a chain stopper member. The mounting member is attached to an underwater surface of the offshore structure or vessel and includes a bracket for coupling the fairlead member. The bracket may comprise a hinge allowing the fairlead member to pivot in an approximately horizontal plane. The chain stopper member is coupled to the fairlead member through a hinge which allows the chain stopper member to pivot with respect to the fairlead member in an approximately vertical plane. The chain stopper member includes a chain stopper flapper having a horseshoe shaped opening at one end. The other end of the flapper is connected to the chain stopper member through a hinge which allows the flapper to swing between an open position and a closed position. In the open position, the chain links for the anchor chain are allowed to pass by the horseshoe shaped opening on the flapper. The horseshoe shaped opening also includes a chain link seat which stops movement of the anchor chain through the chain stopper member when the flapper is in the closed position. The chain stopper flapper moves to the closed position under the force of gravity to provide a self-locking chain stopper. A latch mechanism is provided for latching the chain stopper flapper in an open position.

Owner:TIMBERLAND EQUIP

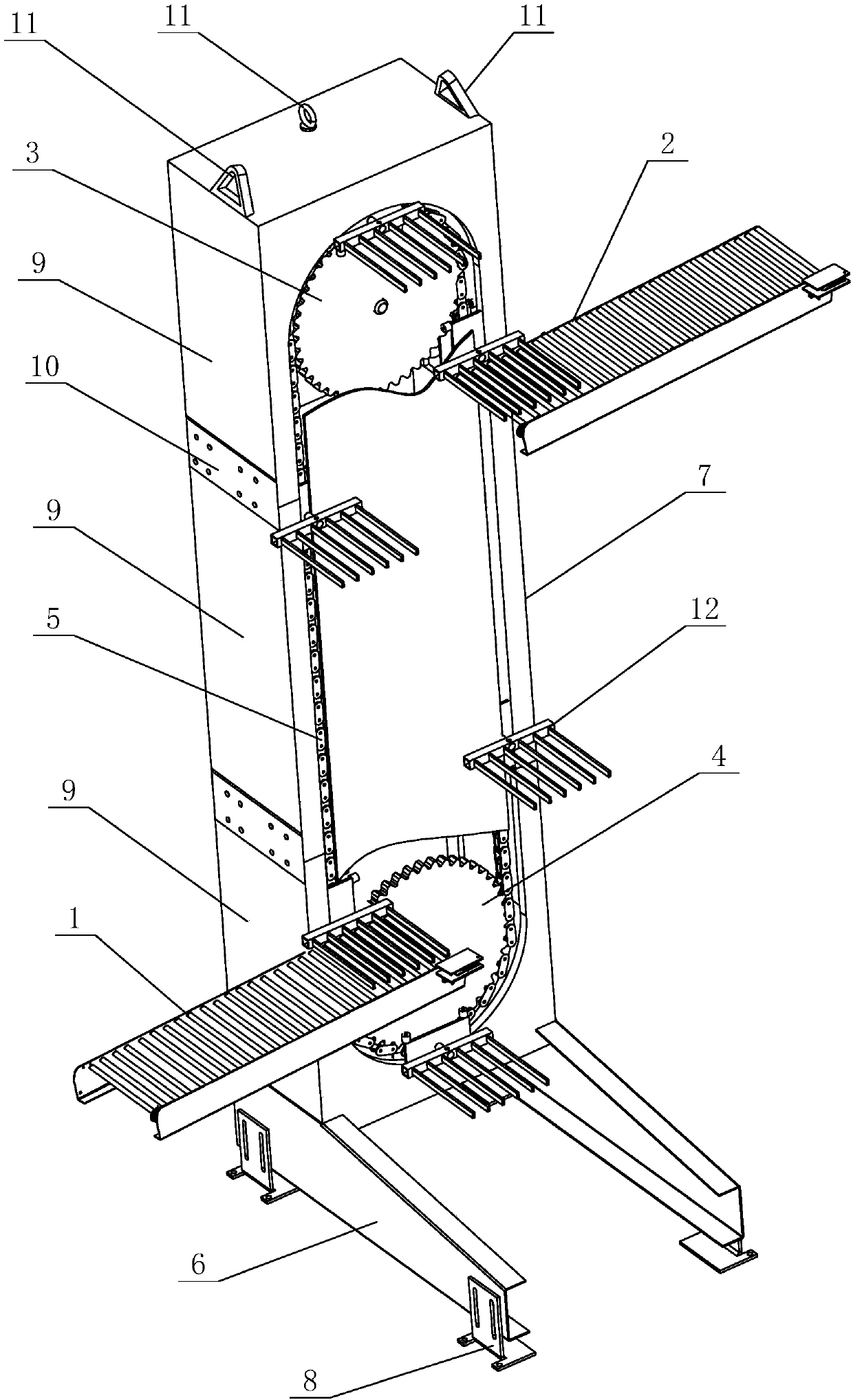

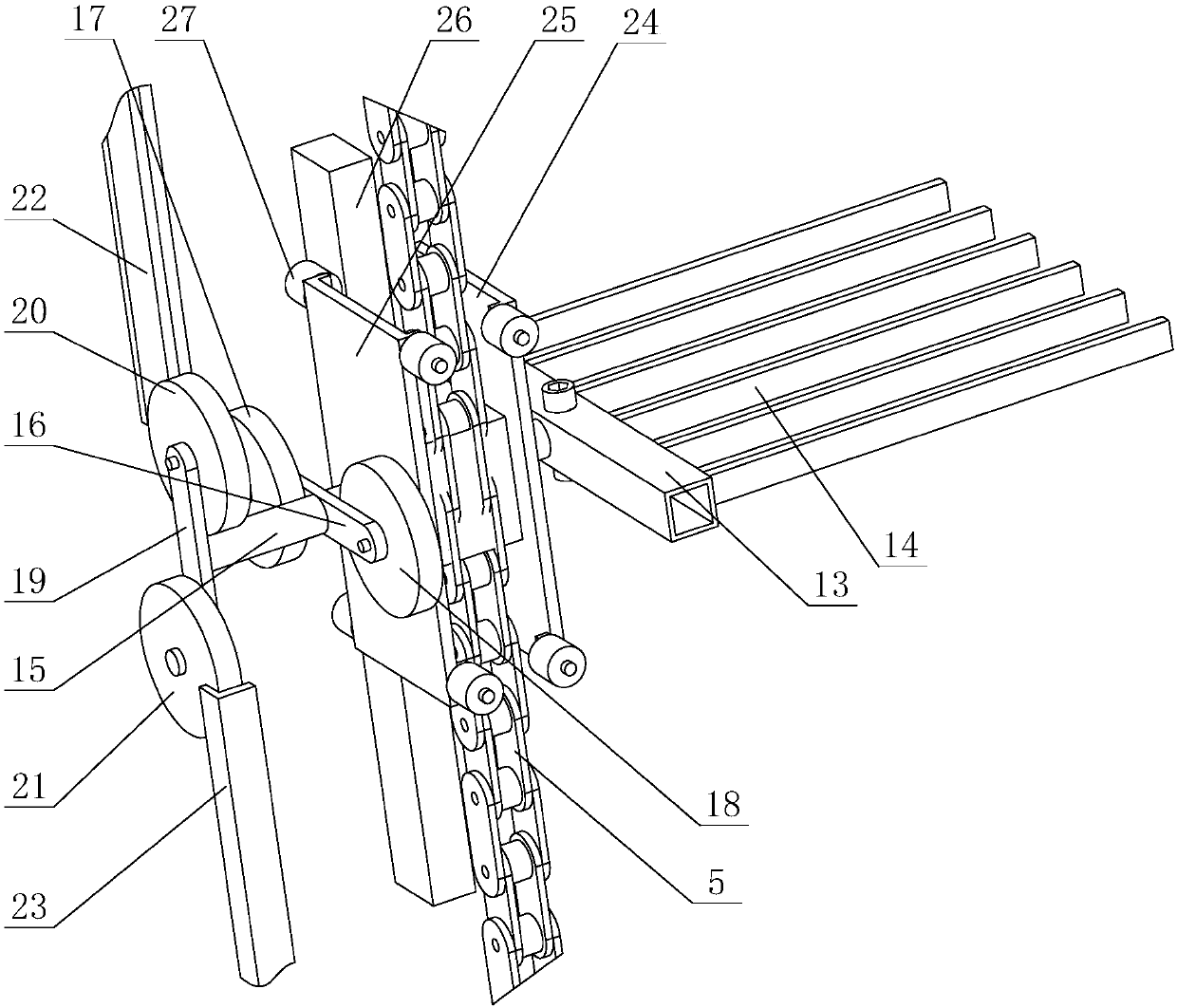

Cycle lifting mechanism

PendingCN107934340AAchieve accessSimple structureConveyorsStorage devicesControl engineeringElectric machinery

The invention discloses a cycle lifting mechanism. The cycle lifting mechanism comprises a cycle lifting machine, a coming material conveying line and a discharging material conveying line; the cyclelifting machine comprises a machine frame, a motor, a driving chain wheel, a driven chain wheel, and a transmission chain distributed on the driving chain wheel and the driven chain wheel in a circling manner; a plurality of lifting frames are connected onto the transmission chain; the lifting frames can be in butt joint with the discharging material conveying line to achieve goods discharging; horizontal holding mechanisms capable of enabling the lifting frames to be kept horizontally are connected onto the lifting frames. The cycle lifting mechanism is used for lifting goods through the lifting frames fixed on the transmission chain, and a stand column is not required to be arranged, and the cycle lifting mechanism has the characteristics of simple and compact structure and small volume,the lifting frames can turn around with the transmission chain, further cyclic goods fetching is further achieved, and the lifting frames are arranged on the transmission chain according to needs, sothat the efficiency is improved greatly.

Owner:ZHEJIANG GALAXIS TECH GRP CO LTD

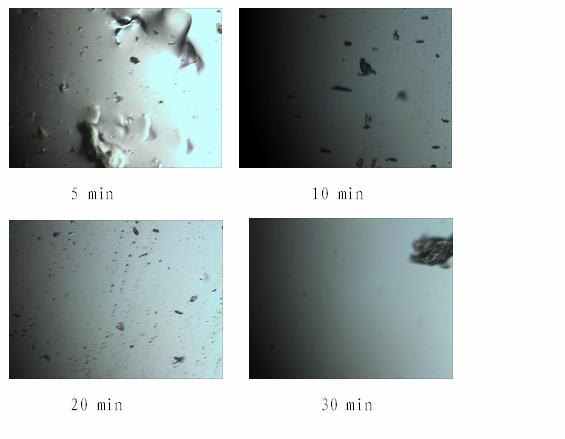

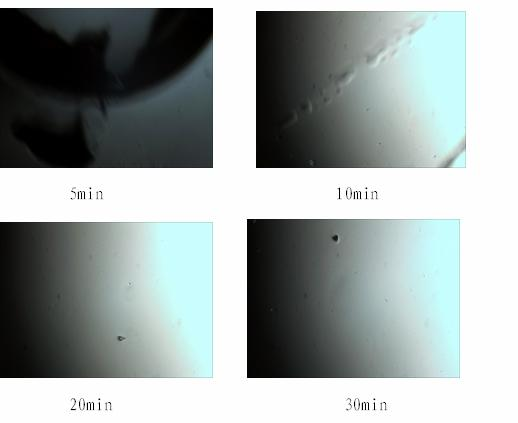

Preparation method of organic silicon rubber for encapsulating LED being convenient for vacuum defoamation

InactiveCN101880396AReduce surface tensionReduce defective rateOther chemical processesAdhesivesRoom temperatureTransmittance

Owner:HANGZHOU NORMAL UNIVERSITY

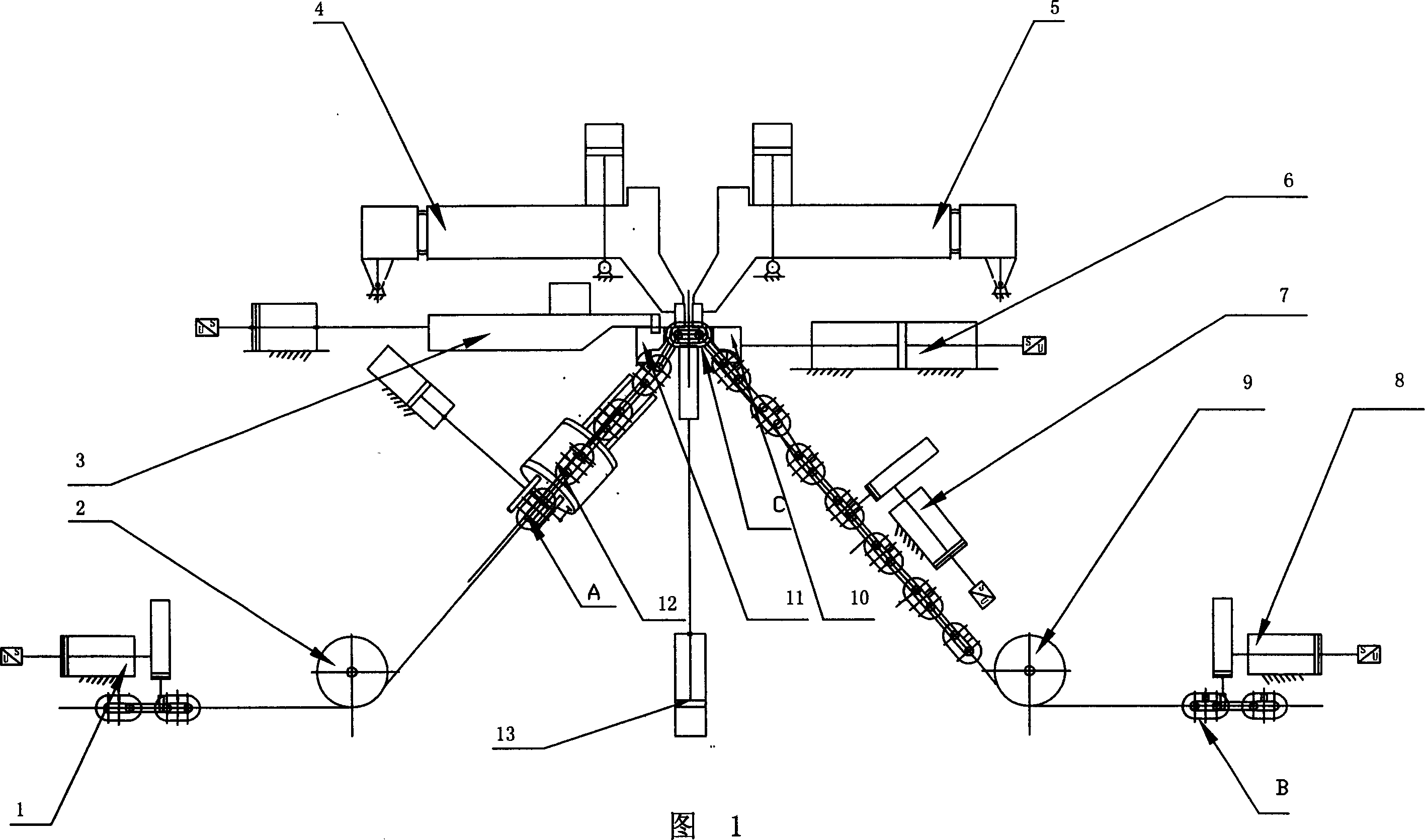

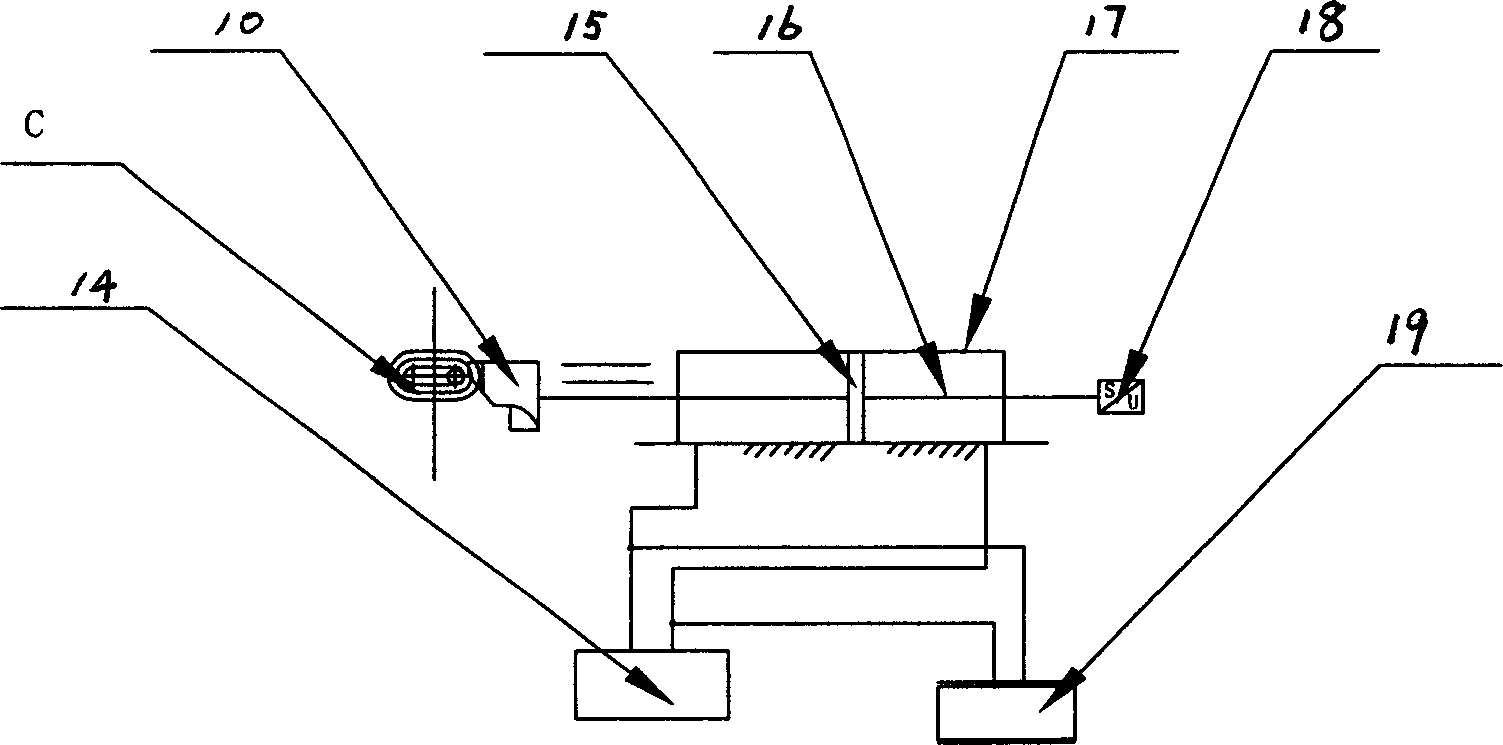

Full automatic hydraulic flash butt welding method of metal circular ring chain and apparatus thereof

ActiveCN1806992AHigh quality excisionFully automaticWelding/cutting auxillary devicesAuxillary welding devicesButt weldingTransducer

The invention relates the metallic bond full-automatic all-hydraulic flash butt welding method and device. The method is that the open of each chain link is automatically welded after the metallic bond is knitted to chain. The method comprises the following step: sending the chain link from left end of machine to position of welding under the combined action of main conveyer and subsidiary conveyer, controlling the hydraulic heading equipment with displacement transducer, servo valve and heading valve, preheating, burning, flashing and heading welding, auto removing the burrs, and exporting the finished chain link from the right end of machine. The whole process is the full-automatic all-hydraulic flash butt welding method. The invention possesses the characters of high automation level, high production efficiency, high product quality and high safe reliability. The said method and device will replace the national current fall behind electric milling cam type FBW method and device.

Owner:王洪军

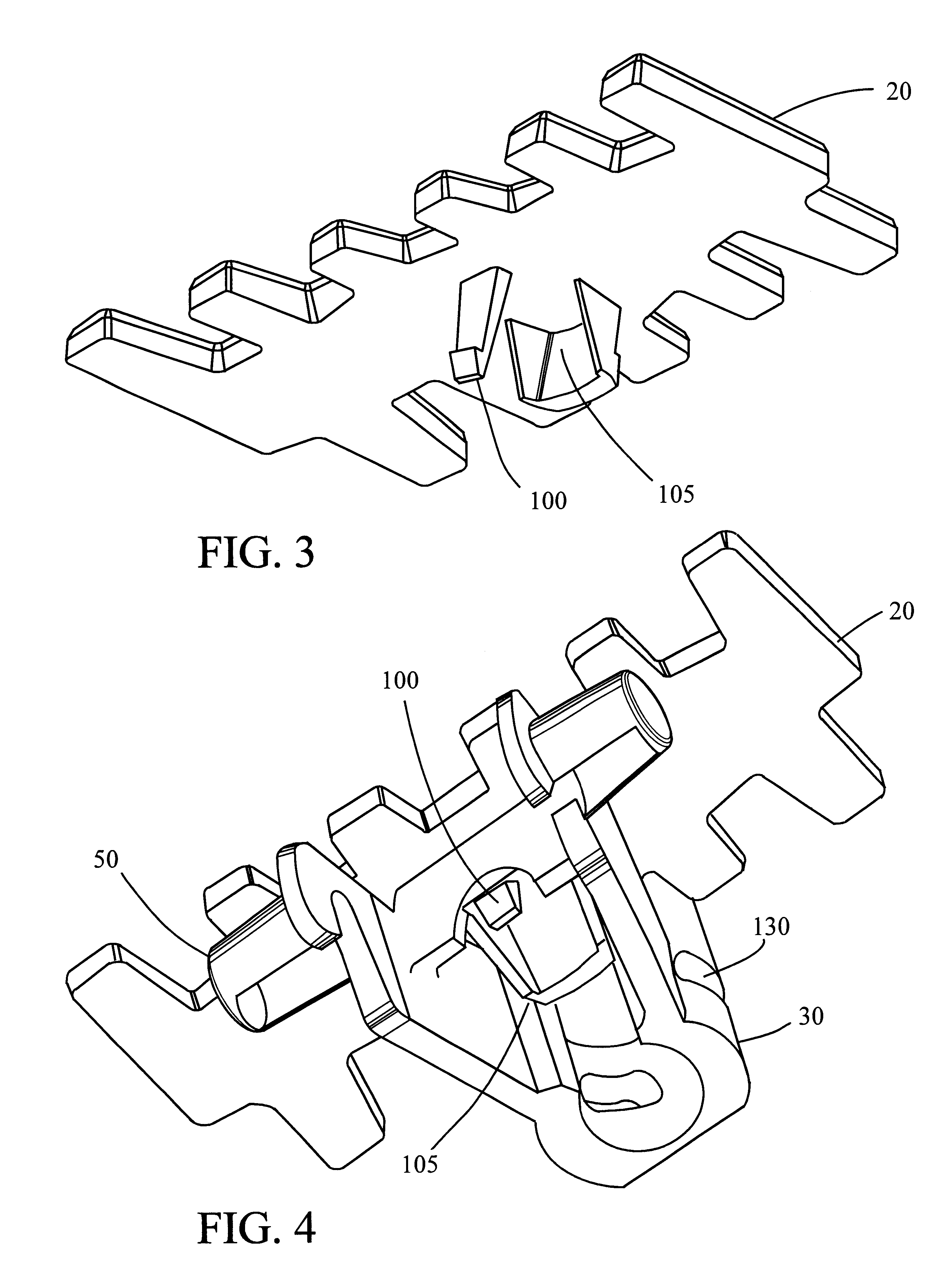

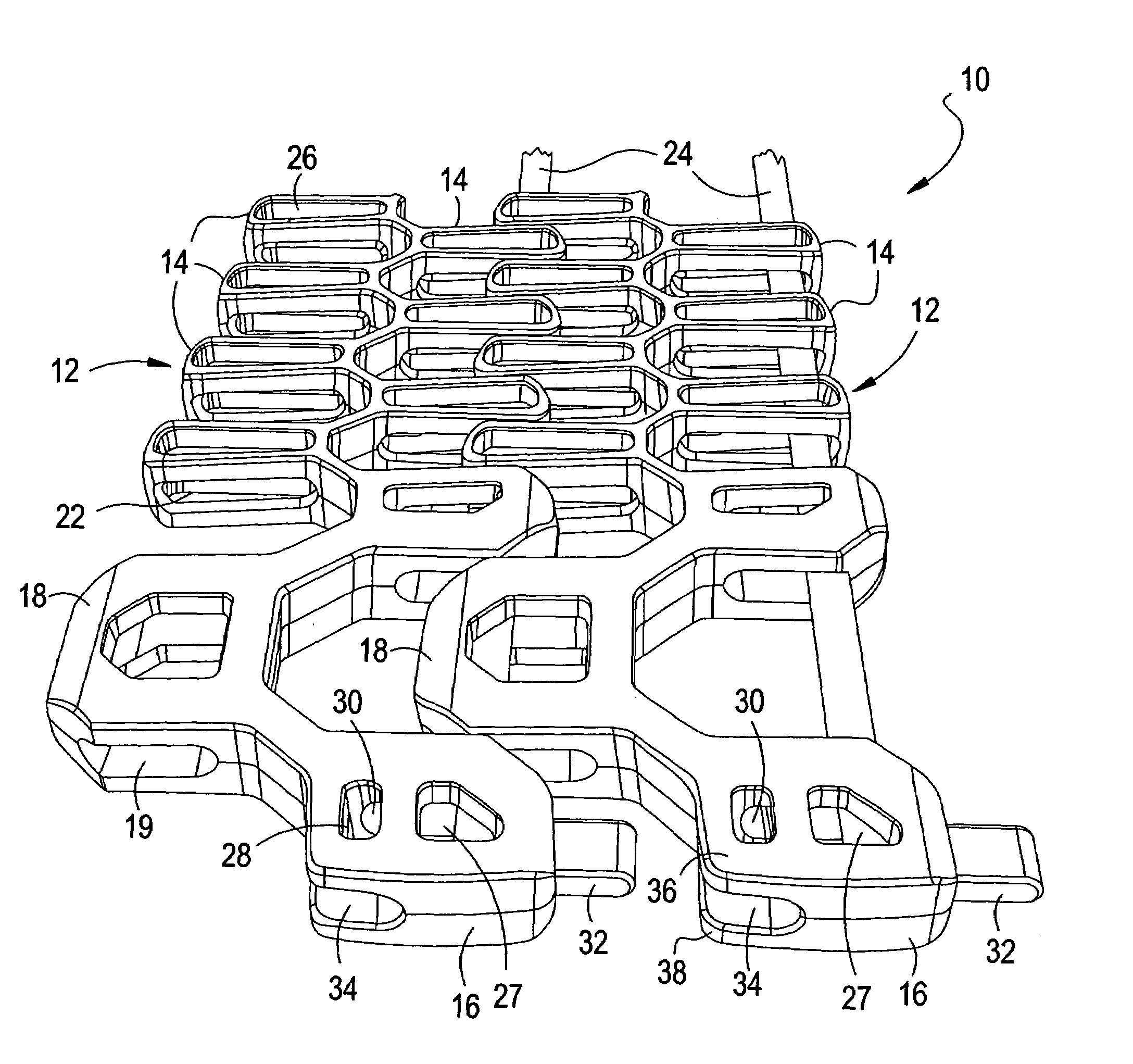

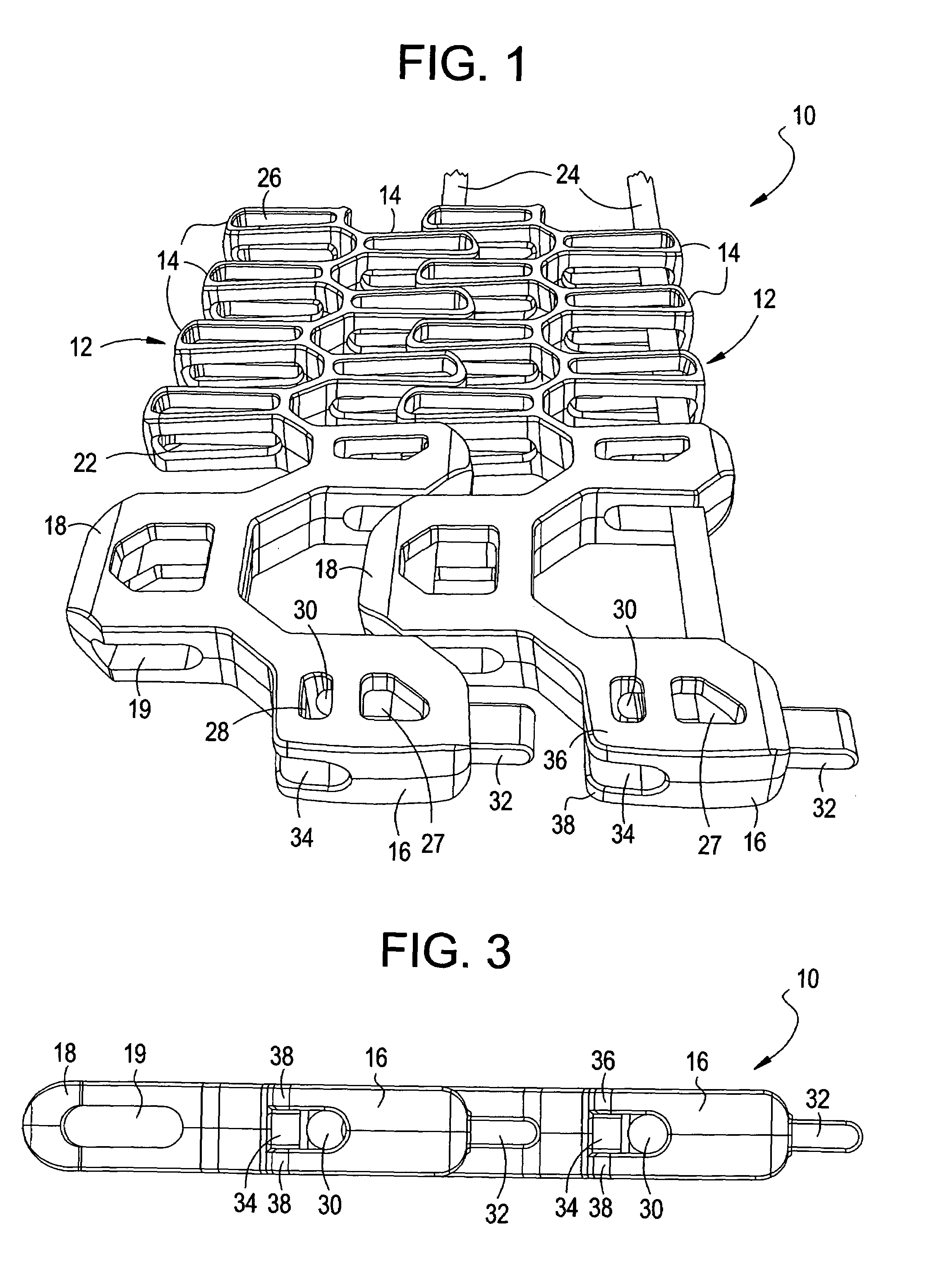

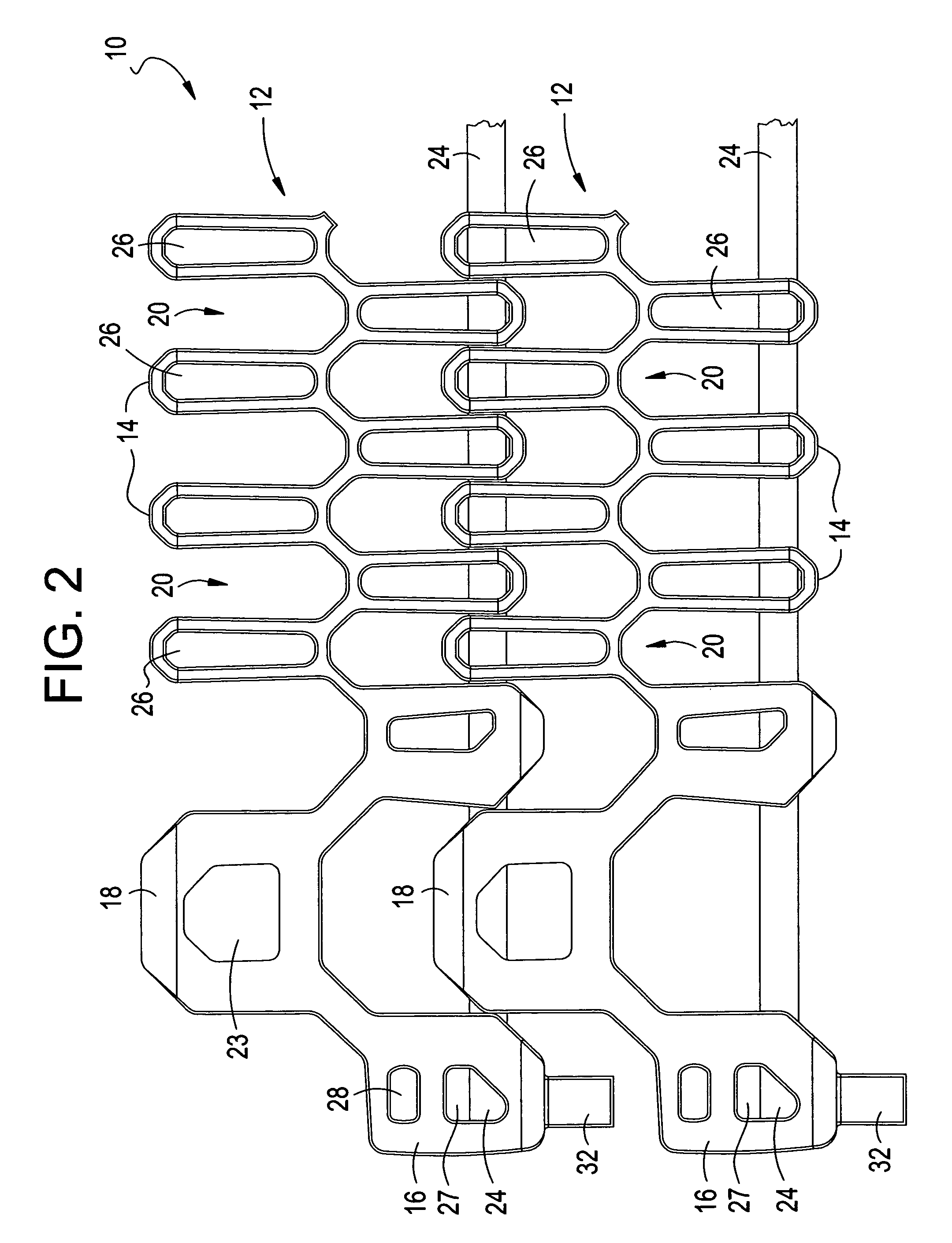

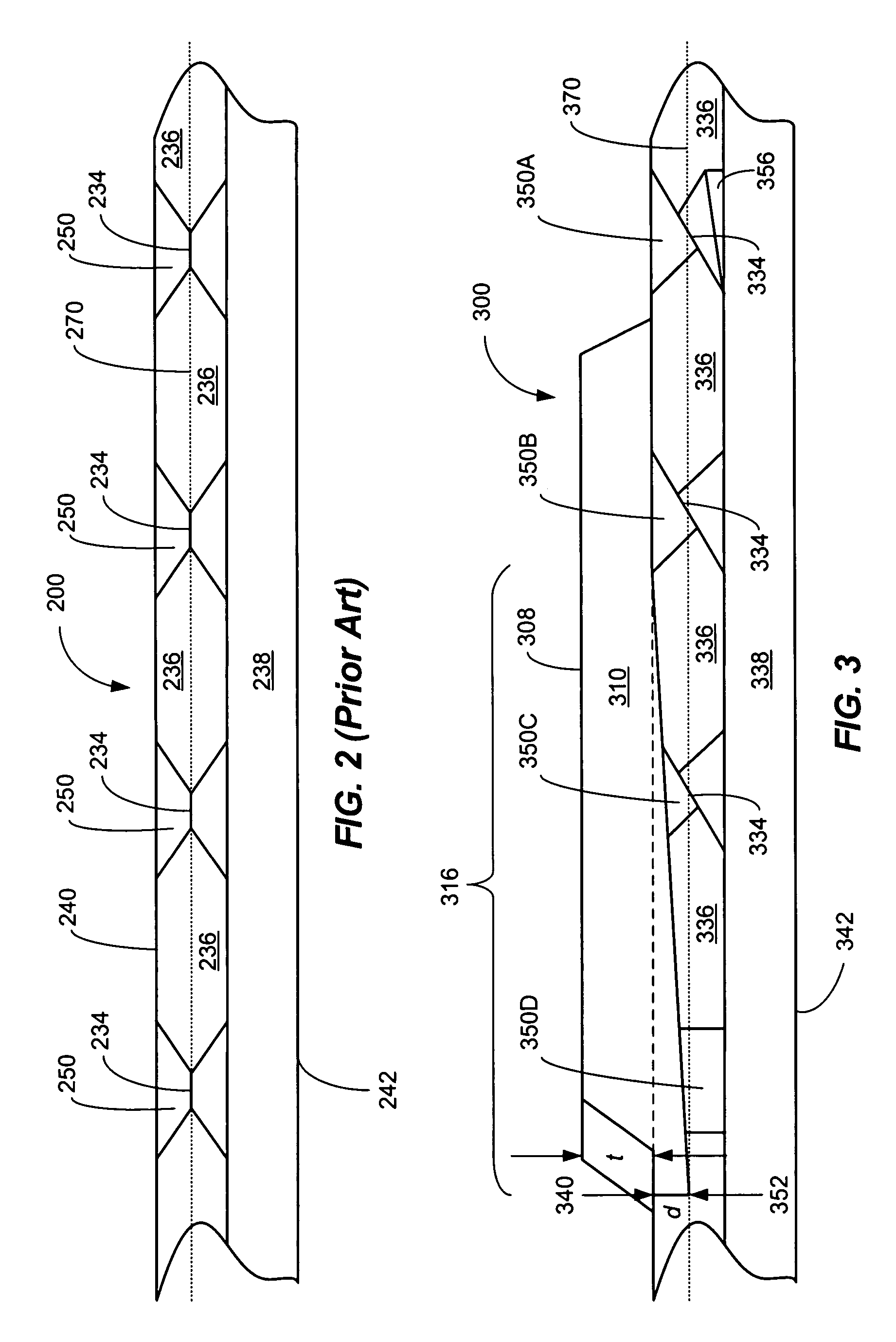

Conveyor belt and method of assembly

A conveyor belt and method for assembling a conveyor belt, the conveyor belt including a plurality of link elements and a plurality of pivot rods. Each link element includes a plurality of intermeshing extensions and at least one edge extension at a peripheral edge thereof. The plurality of intermeshing extensions form receiving compartments adapted to receive intermeshing extensions of an adjacent link element, and include transverse rod openings. The plurality of pivot rods are received in the transverse rod openings of the plurality of intermeshing extensions thereby interlinking adjacent link elements together. The edge extensions include an entry aperture sized to allow insertion of a pivot rod, and a rod receiving compartment to retain an end of the pivot rod.

Owner:ASHWORTH BROS

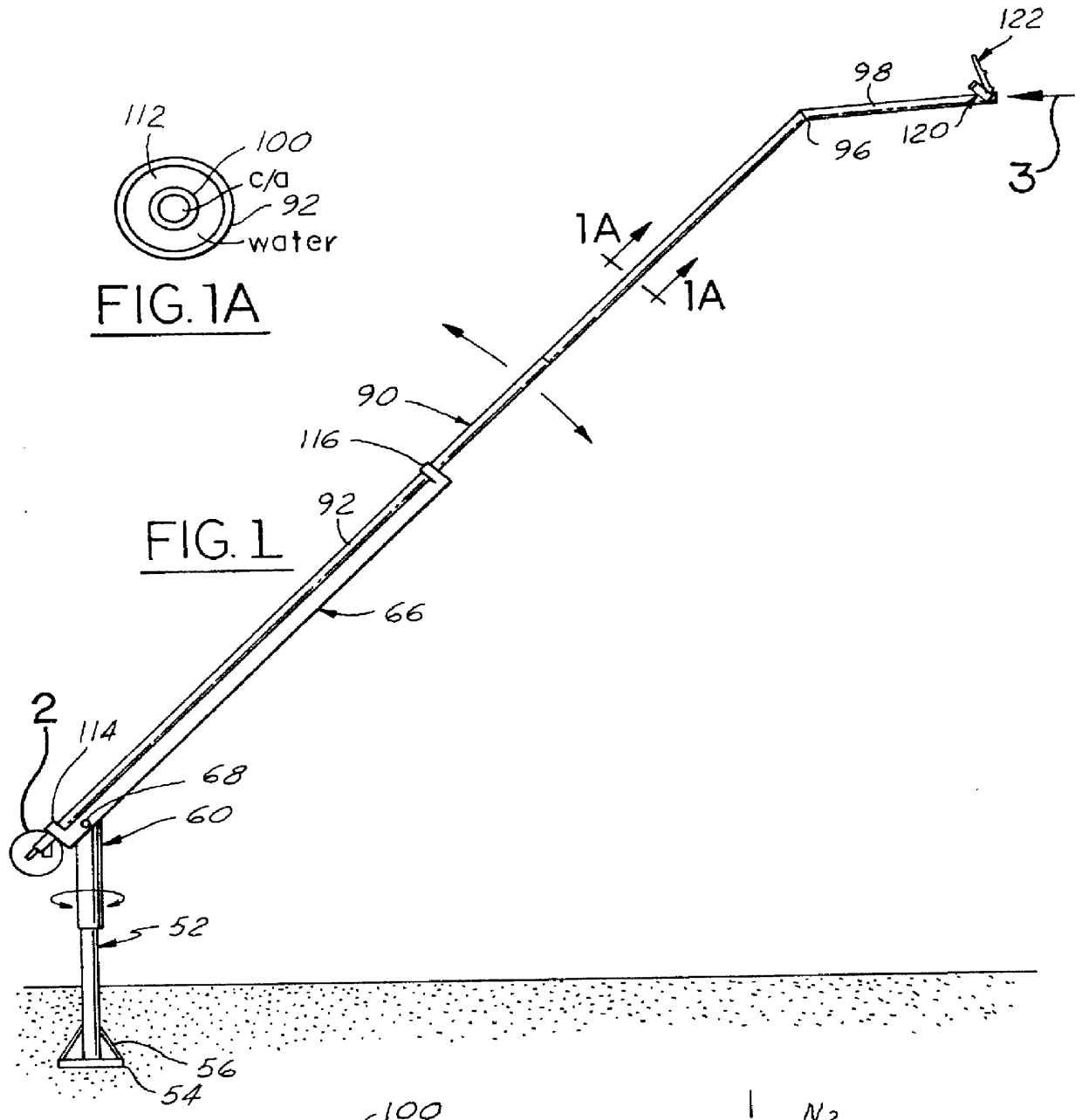

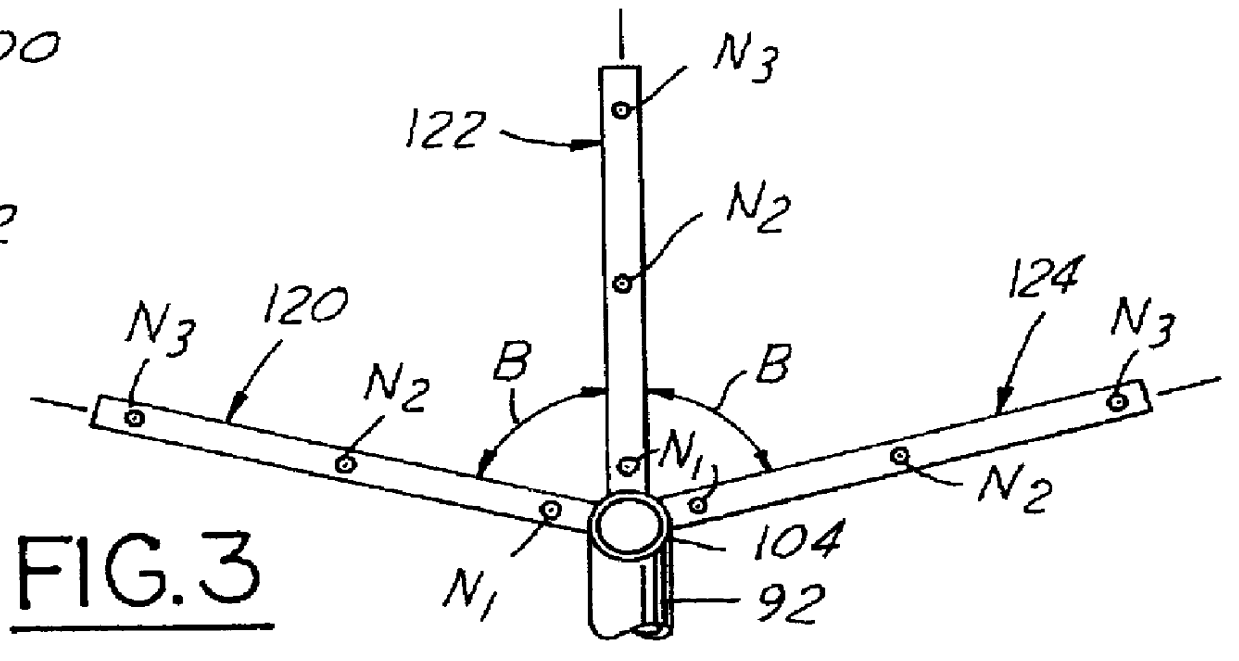

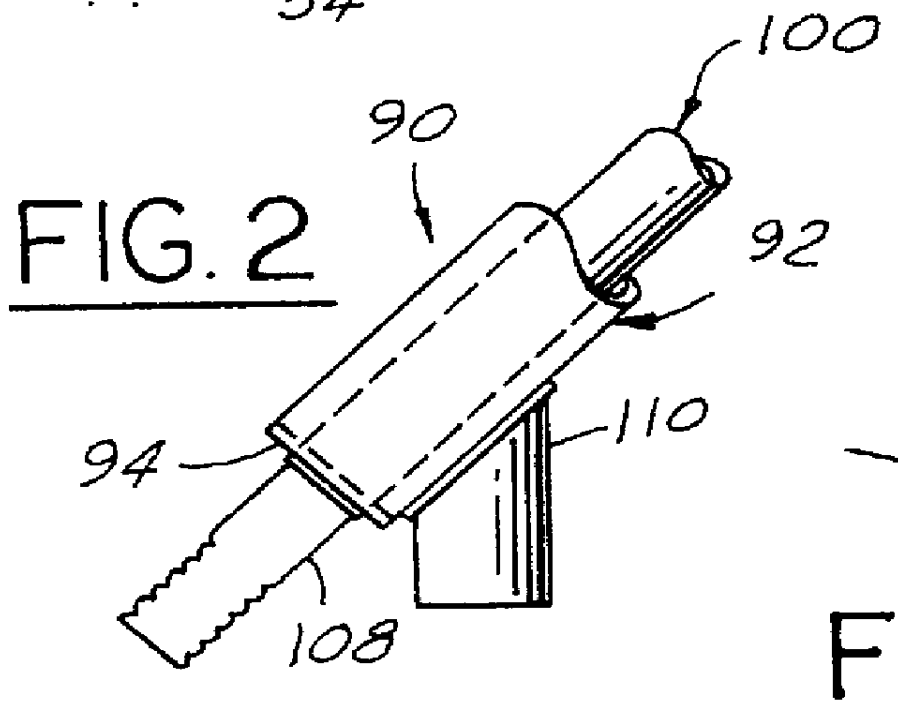

Adjustable snow making tower

InactiveUS6161769AIncrease flexibilityOptimize quantityLiquid surface applicatorsStands/trestlesBlock and tackleEngineering

Method and apparatus for making snow by generating water spray from a triple array of multiple nozzle sub-boom branch-pipes transversely protruding from the upper end of a main boom of a pivotably adjustable snow making pipe tower. Three air jet streams, one for each branch pipe, are simultaneously discharged under high pressure into and sequentially through the throats of each associated multiple stack of water sprays issuing from each set of branch pipe nozzles to thereby form multiple spray plumes of atomized and seeded water all directed forwardly from the upper end of the tower pipe. The water pipe may be an elliptical aluminum extrusion with two interior air tubes respectively controllably feeding large and small diameter air jet arrays to thereby provide a range of air jet water spray interaction. The pipe tower may be pivotally raised and lowered by a block-and-tackle or chain fall type drive mechanism that may be recoupled to the tops of a lifting pole and tower pipe for bodily raising the entire tower pipe and its support pipe telescopically on a ground support pole. Spreader-supported guy wires may be used to brace the tower pipe and also provide an electrical deicing circuit. Air jet control, blow-out valving and water drain conduit arrangements are disclosed, and also universally adjustable ground support systems for the pipe tower, including an underground-fed combined telescopic hydraulic ram forming air and water conduits.

Owner:BOYNE USA +1

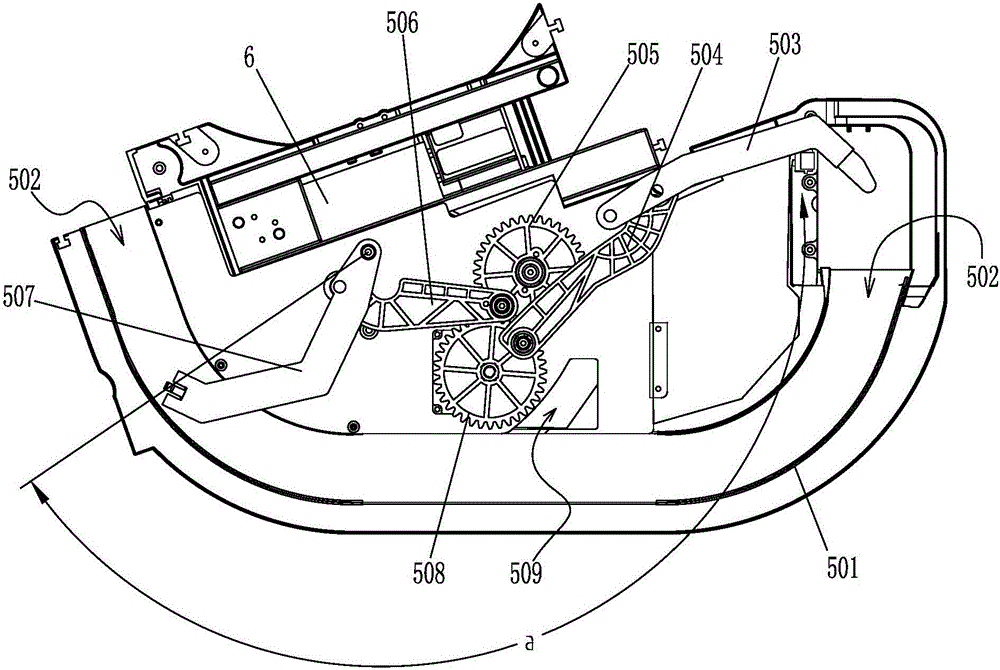

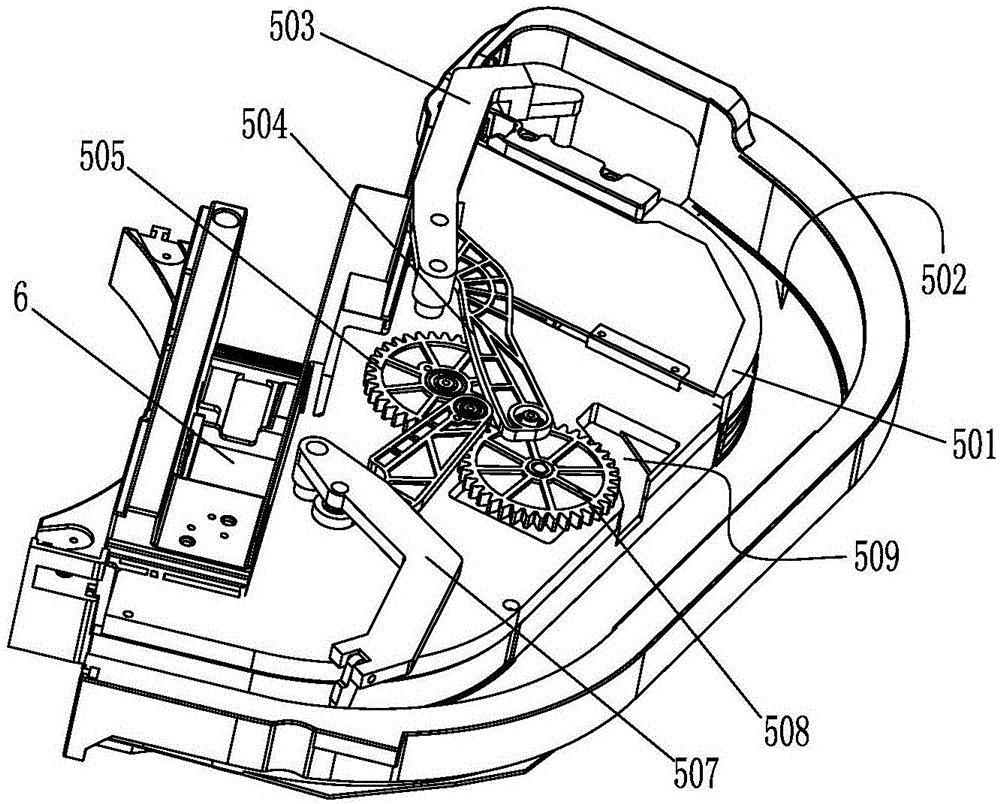

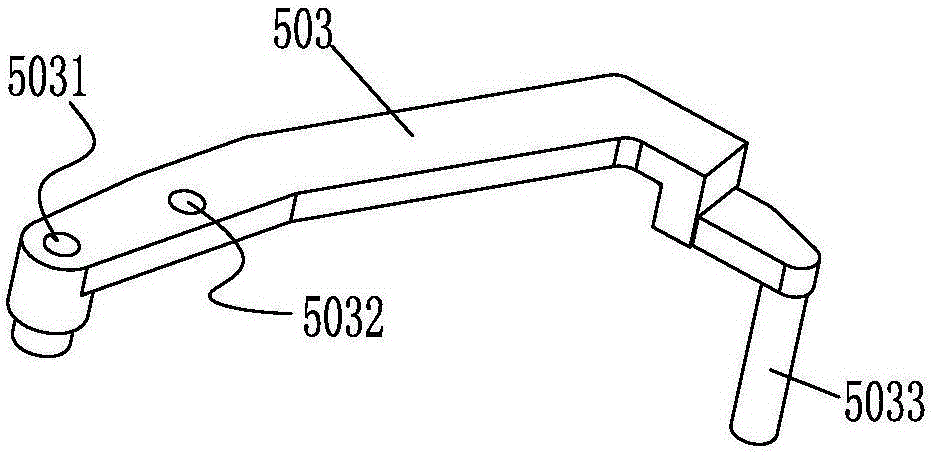

Mahjong machine, mahjong tile feeding component of mahjong machine and mahjong tile feeding drive mechanism of mahjong machine

ActiveCN106075897AAvoid high resistanceAvoid defects such as loud working noiseIndoor gamesEngineeringReciprocating motion

The invention discloses a mahjong machine, a mahjong tile feeding component of the mahjong machine and a mahjong tile feeding drive mechanism of the mahjong machine. The mahjong tile feeding component comprises a mahjong tile feeding support. The mahjong tile feeding support is provided with a mahjong tile storage groove, a first mahjong tile feeding push head and a second mahjong tile feeding push head. The inner lateral wall of the mahjong tile storage groove is provided with a notch in the middle. The mahjong tile storage groove is communicated with a reversing groove through the notch. The first mahjong tile feeding push head is driven by the mahjong tile feeding drive mechanism to move from the outside of the mahjong tile inlet of the mahjong tile storage groove to a position near the notch and returns. The second mahjong tile feeding push head is driven by the mahjong tile feeding drive mechanism to move from the outside of the mahjong tile outlet of the mahjong tile storage groove into the reversing groove and returns. The mahjong tile feeding drive mechanism comprises a first mahjong tile feeding push rod and a second mahjong tile feeding push rod which respectively move in a reciprocating manner and are coordinated with each other, the first mahjong tile feeding push head is arranged on the first mahjong tile feeding push rod, and the second mahjong tile feeding push head is arranged on the second mahjong tile feeding push rod. By the relay mahjong tile pushing manner of the two mahjong tile feeding push rods, the defects that the mahjong tile feeding push heads and guide rails are high in resistance, chains are large in noise, and the like in the prior art are overcome.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

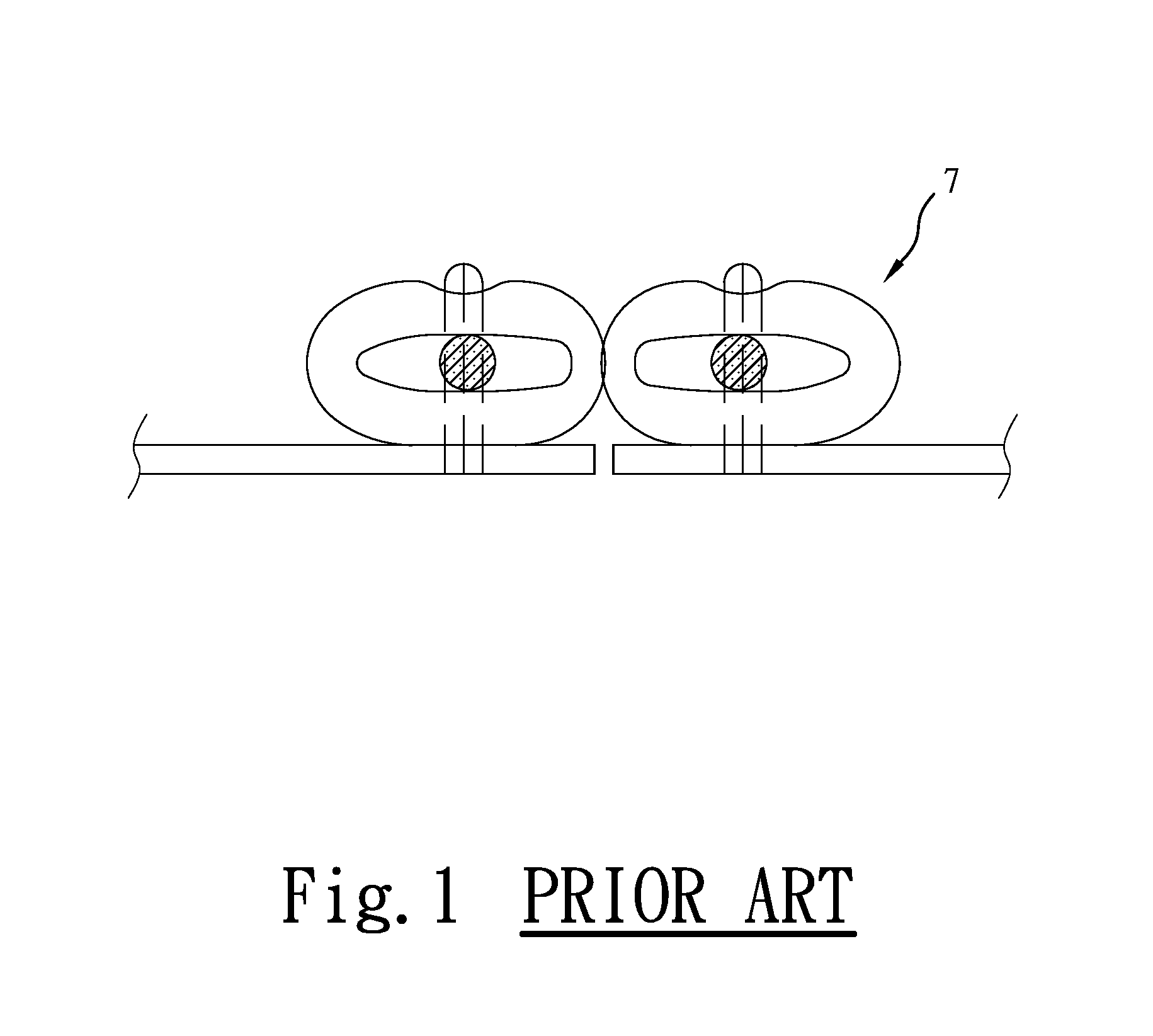

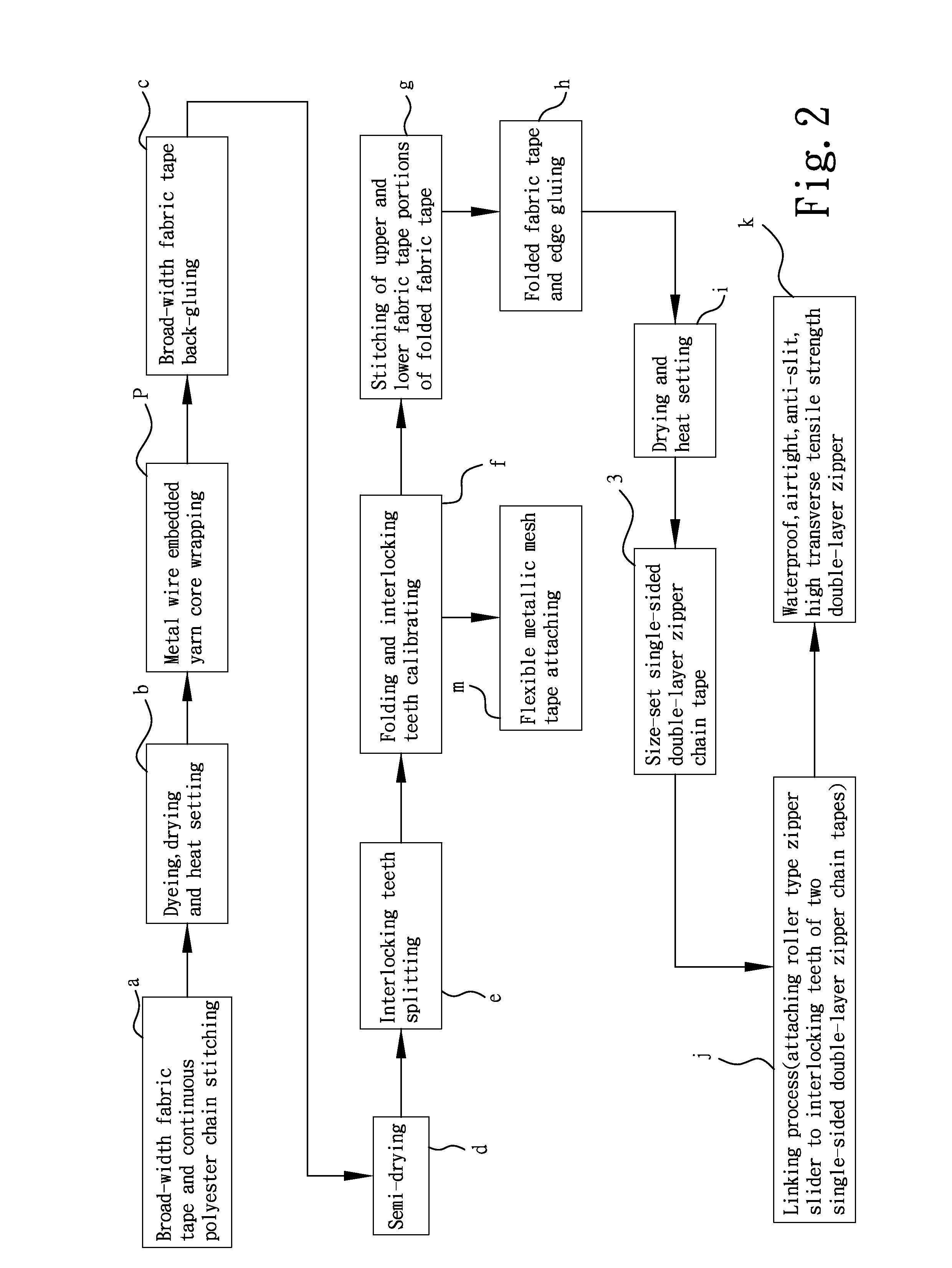

Waterproof, Anti-Split, High Transverse Tensile Strength Double-Layer Zipper and its Fabrication Method

ActiveUS20140359978A1Good for stable movementHigh strengthSnap fastenersWire articlesPolyesterHigh intensity

A waterproof, airtight, anti-slit, high transverse tensile strength double-layer zipper made by: stitching a continuous polyester chain to a middle part of a broad-width fabric tape and then separating the continuous polyester chain into left and right series of interlocking teeth after zipper chain tape dyeing and drying and gluing processes, and then folding up the zipper chain tape and stitching up the open side of the folded zipper chain tape so as to obtain a single-sided double-layer zipper chain tape, and then using a zipper slider to couple two single-sided double-layer zipper chain tapes, thereby obtaining a waterproof, airtight, anti-slit, high transverse tensile strength double-layer zipper. Alternatively, the continuous polyester chain can be stitched to the broad-width fabric tape near its one lateral side for making a high-strength double-layer zipper with less fabric consumption.

Owner:WANG LIEN CHOU

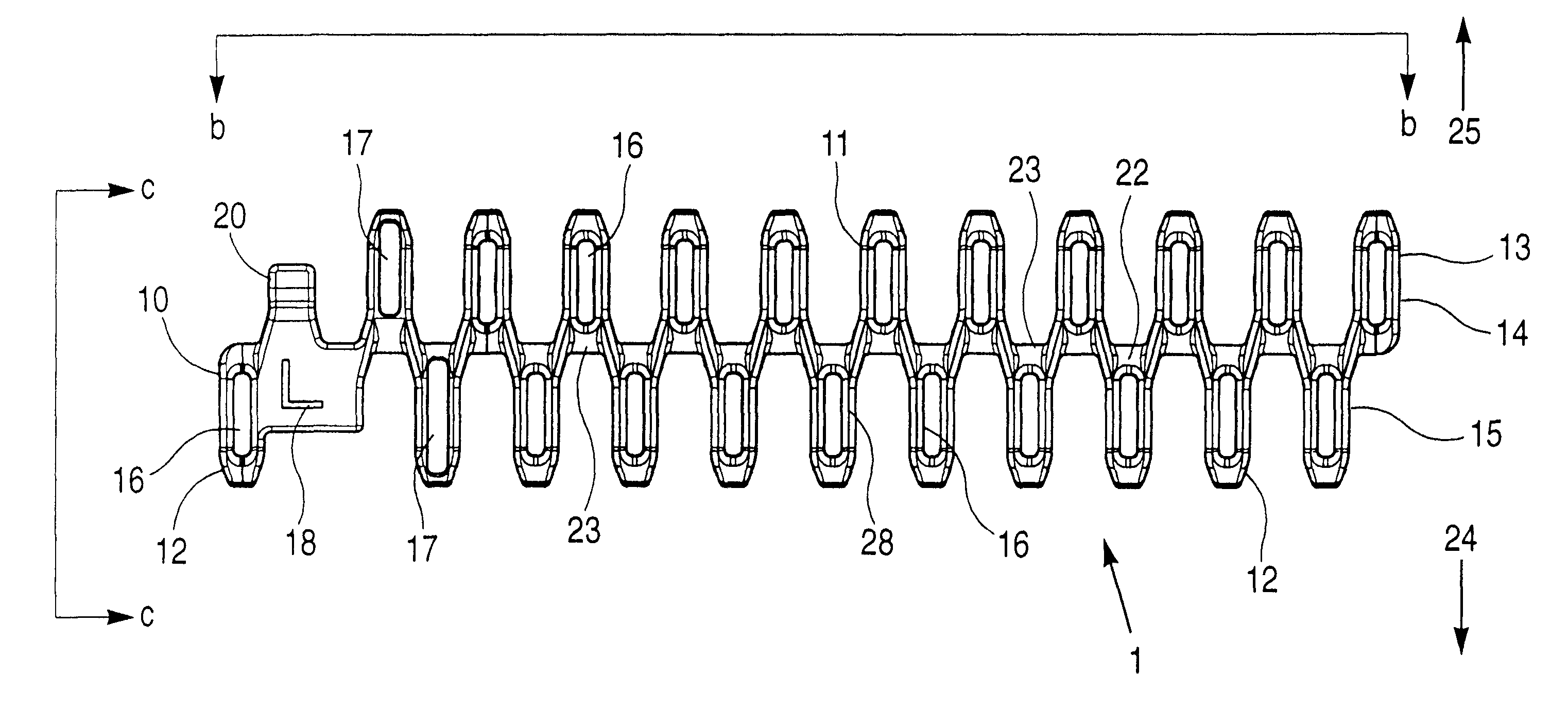

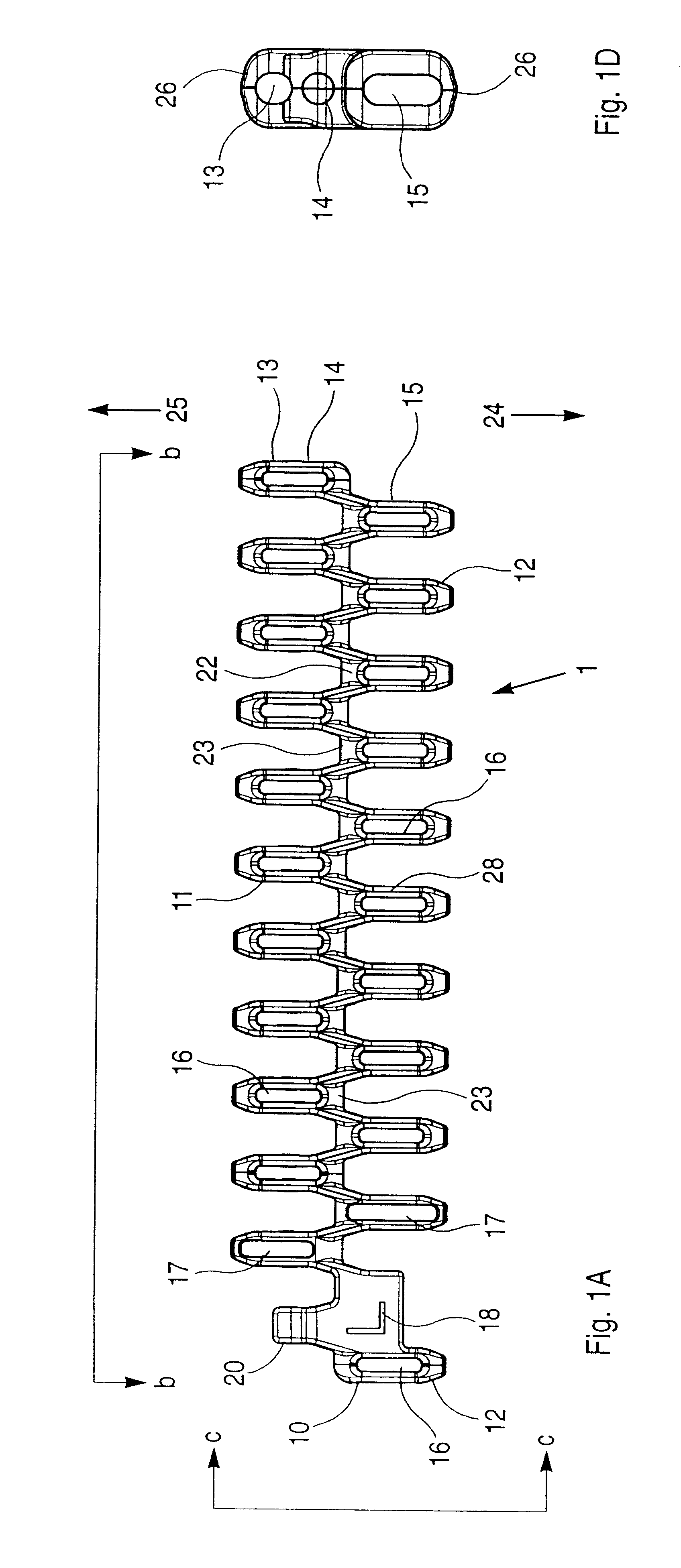

Side-flexing conveyor belt

Side-flexing conveyor belt built up of a number of chain links which are joined together in a hinge-like manner by means of transverse rods (5, 6) through openings in the individual chain links. Use is made of chain links of at least two types, i.e. edge chain links (1, 2) with one-sided reinforcement (18), and module chain links (3, 4) between the edge chain links. The chain links of both types can be configured in various module breadths, and the individual links are staggered in relation to one another. Each link has a first row of eye parts (12) with mutual intervals between them in the transverse direction, and with elongated holes in line with one another for the engagement of a transverse rod, and a second row of eye parts (11) disposed midway between the first-mentioned eye parts and with holes in line with one another for the engagement of a second transverse rod, and the two sets of eye parts are held together by a transversely-extending bridge part. The edge chain links' one-sided reinforcement (18) extends over at least one eye part for each row, so that at least one eye part is replaced by at least one traction side plate (7) in each link, in that said side plates have transverse openings corresponding to the eye part's openings and elongated holes and are in engagement with adjacent rods (5, 6).

Owner:AMMERAAL BELTECH MODULAR

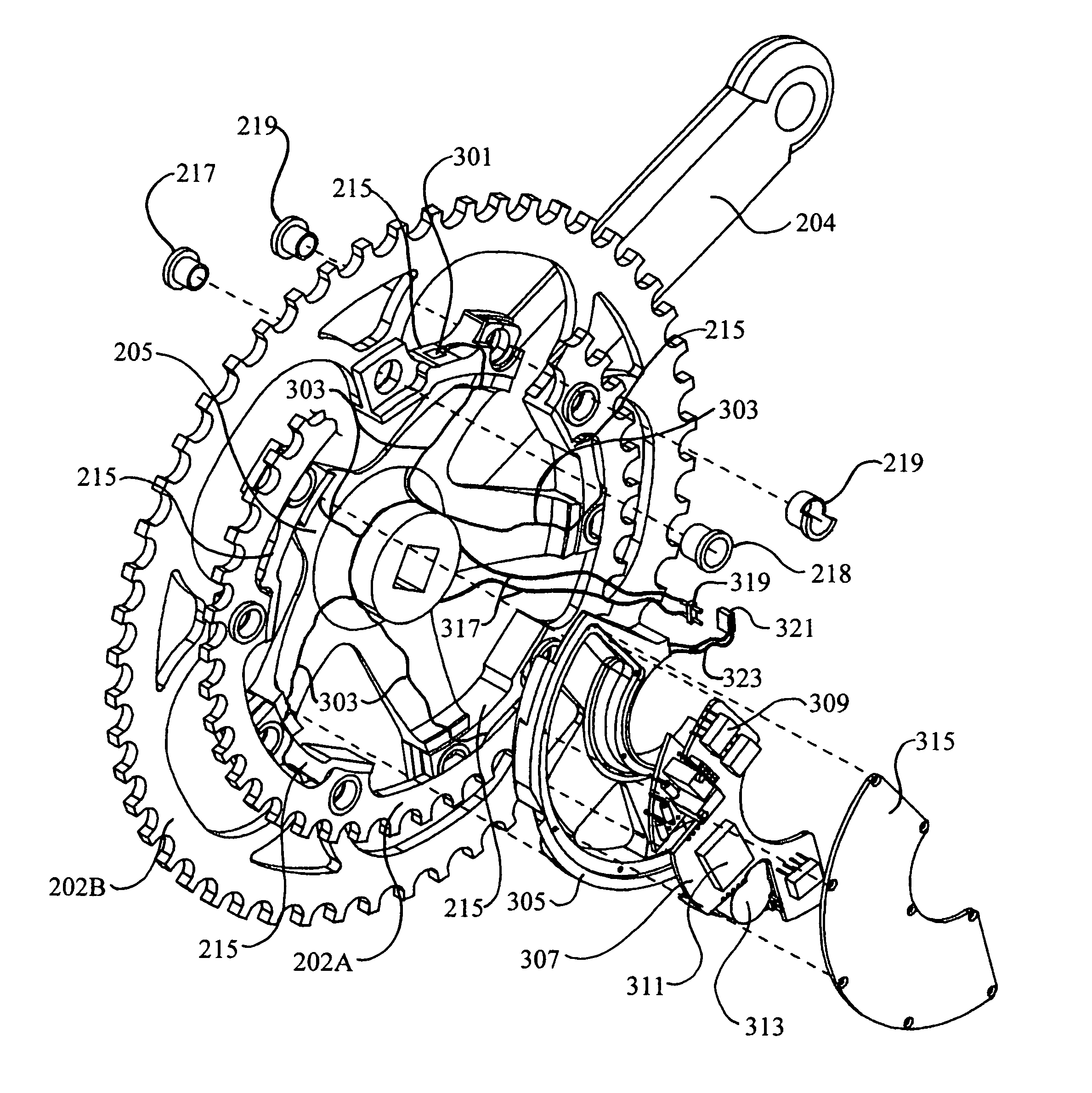

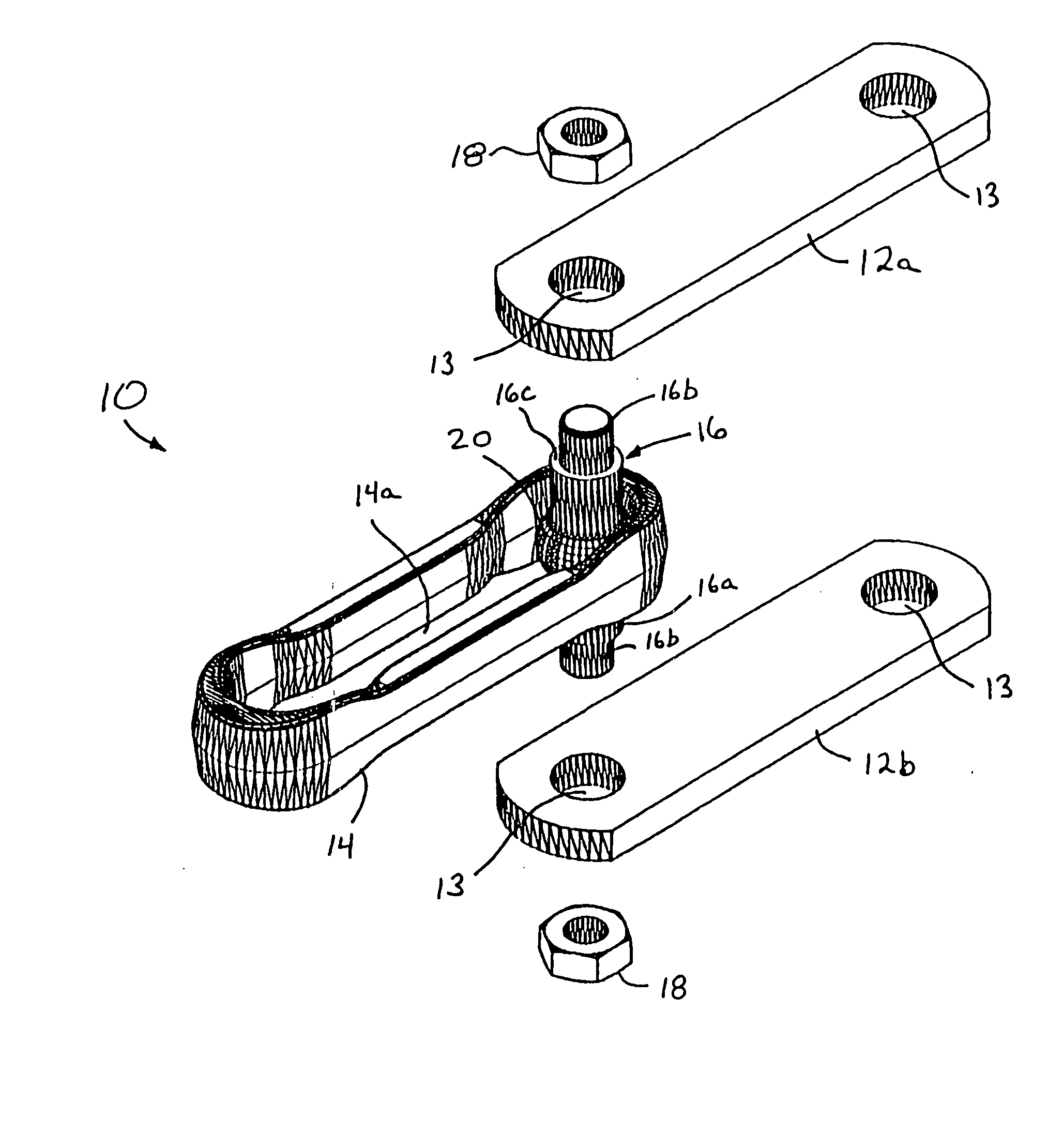

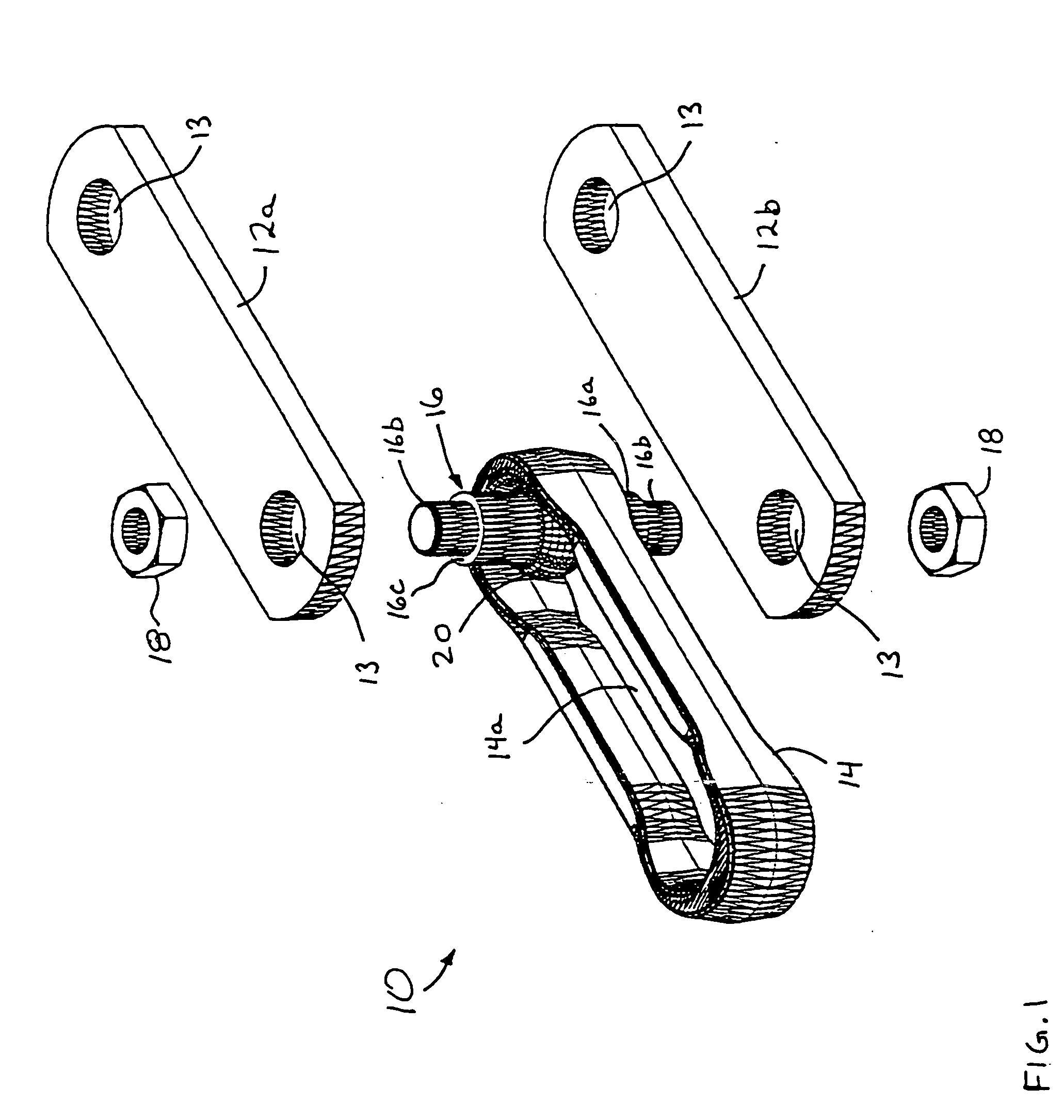

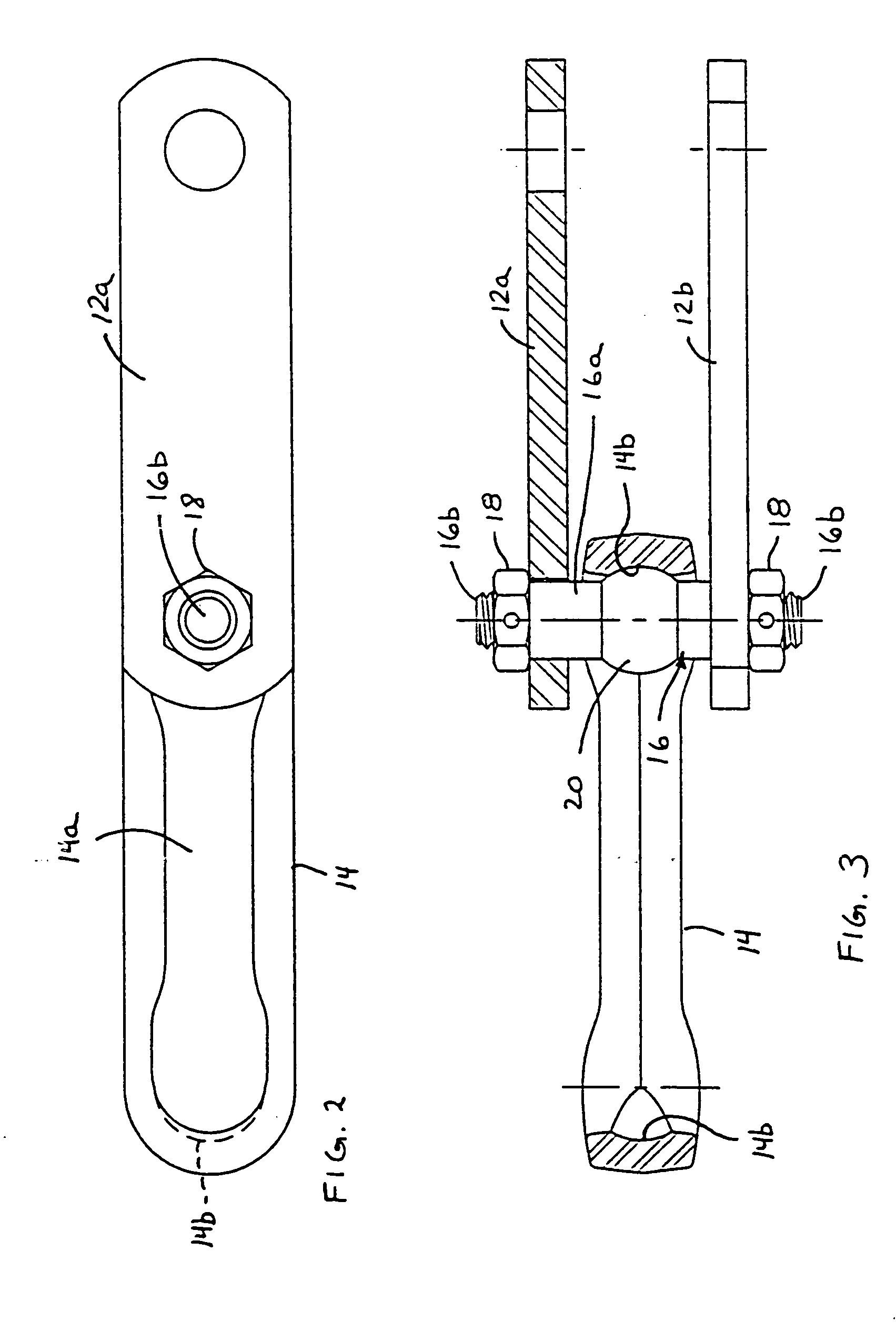

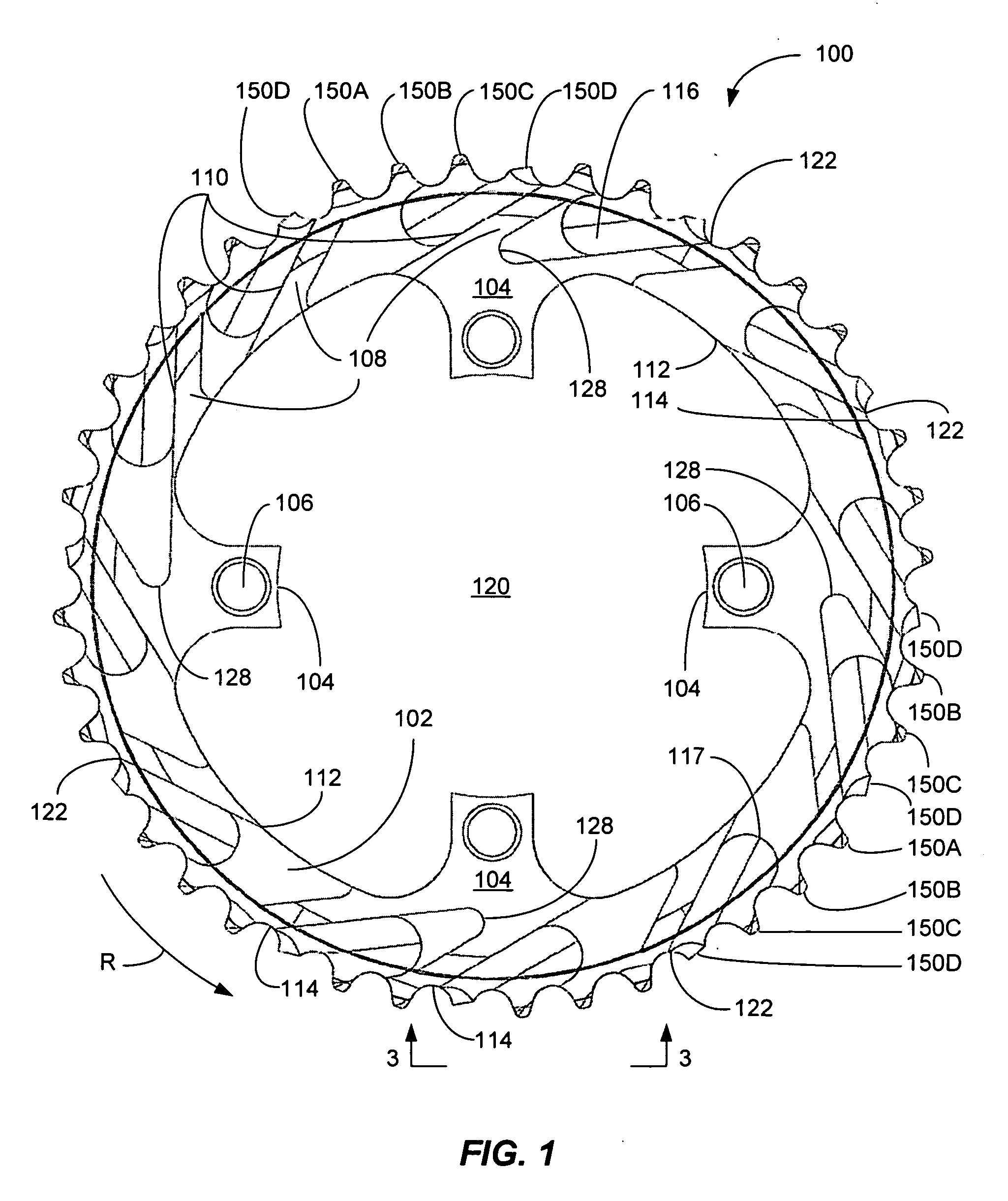

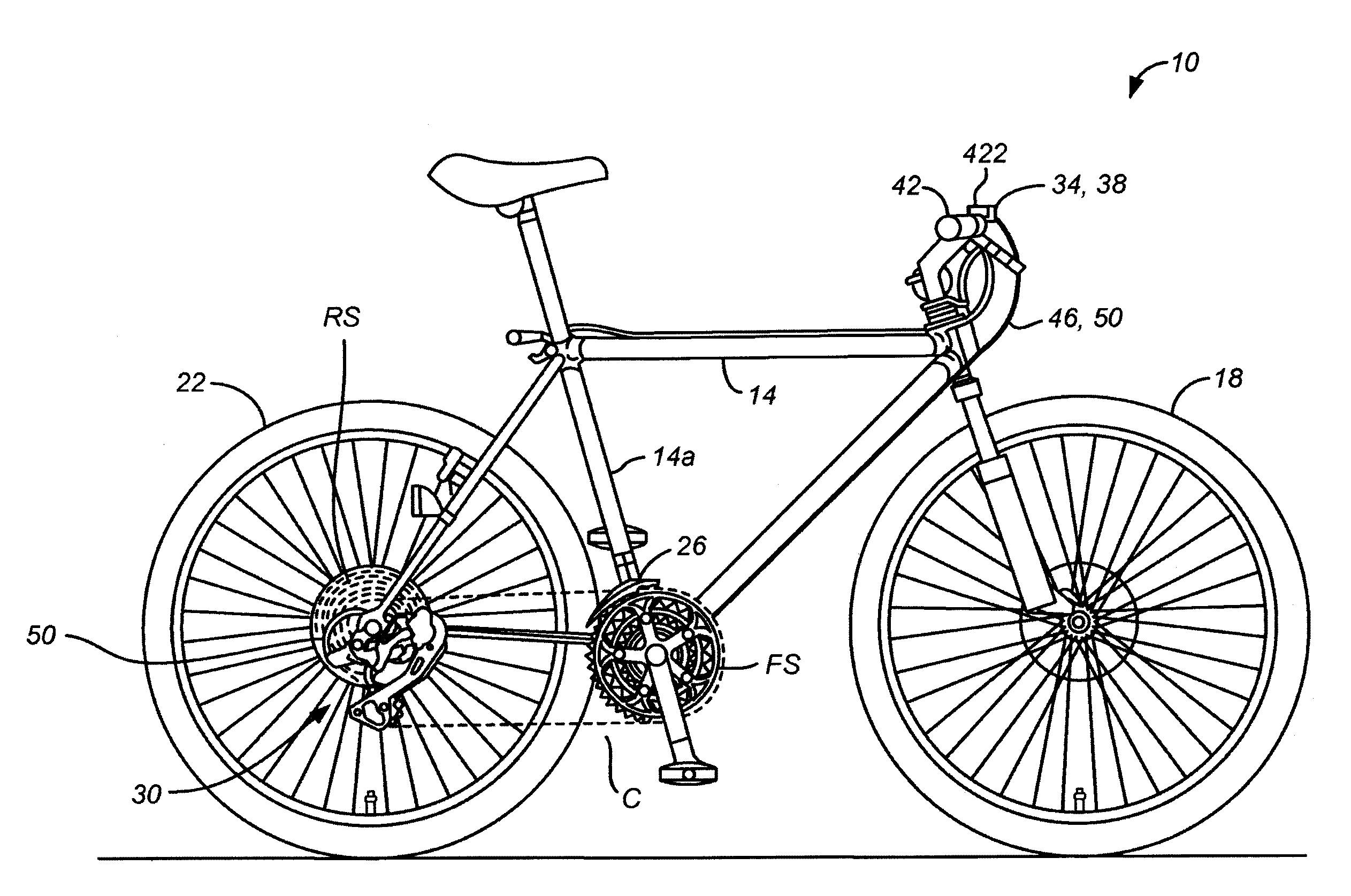

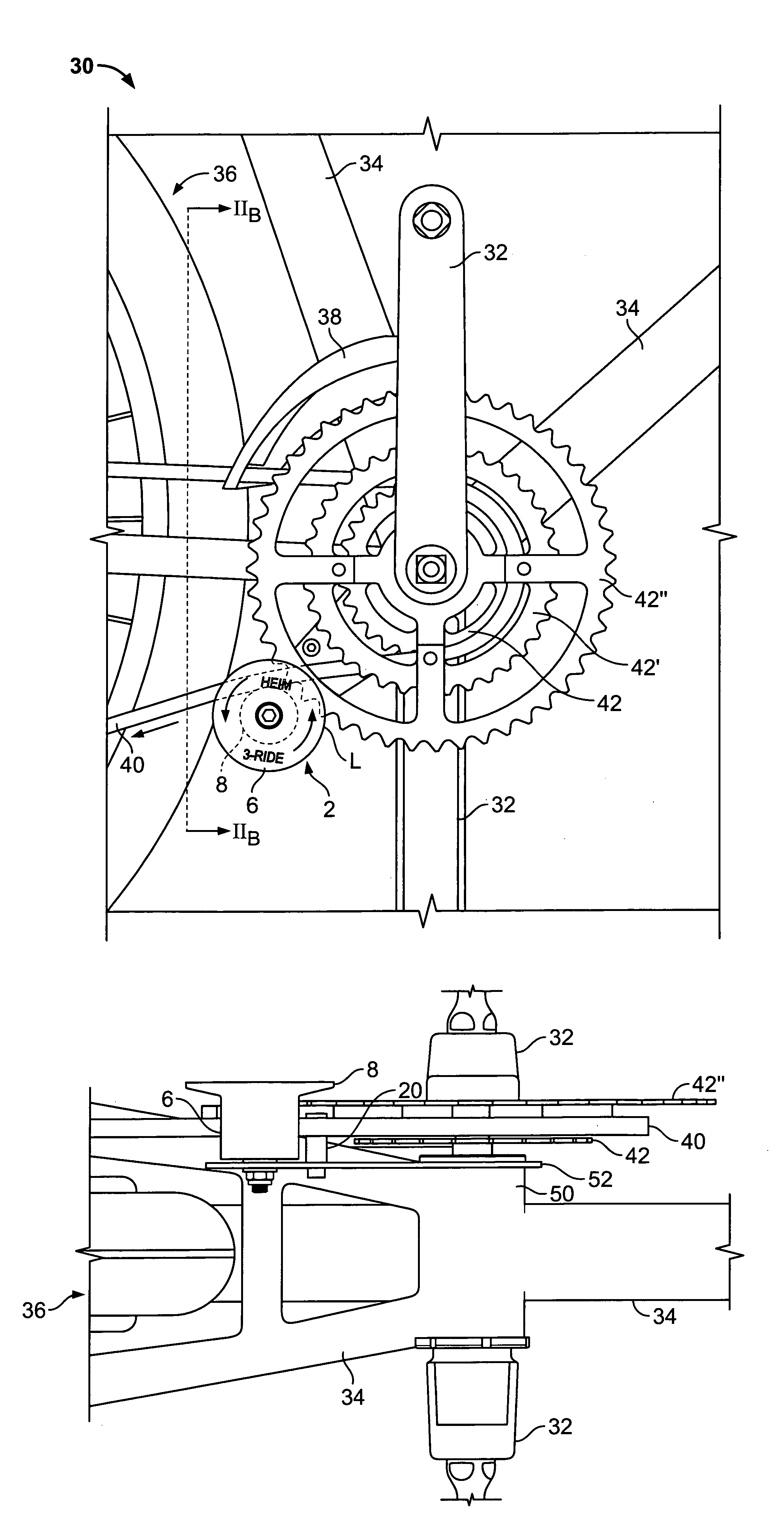

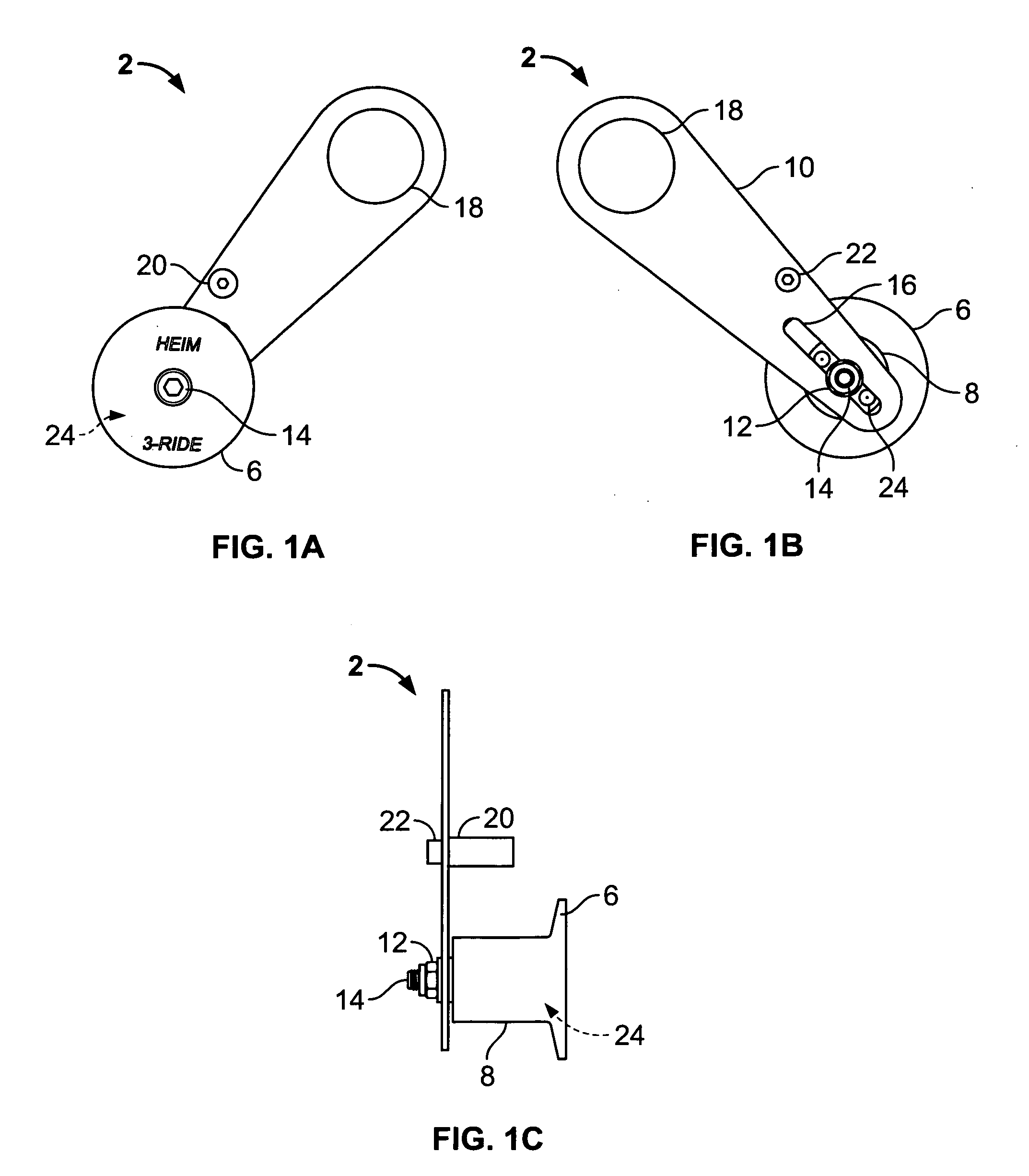

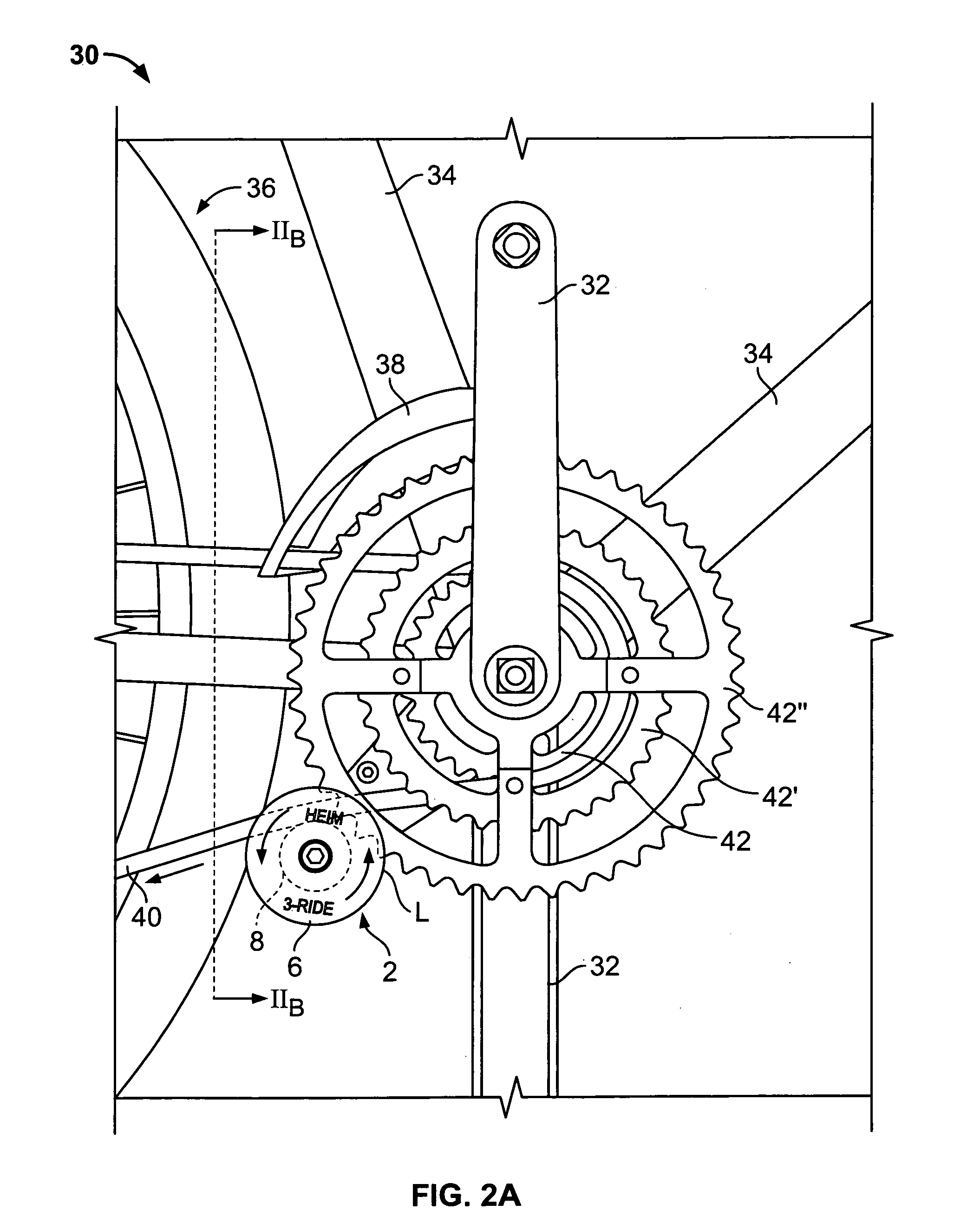

Load measurement apparatus and methods utilizing torque sensitive link for pedal powered devices

InactiveUS7047817B2Easy to installEasy maintenanceChain/belt transmissionForce measurementEngineeringChain link

Apparatus and methods for use in measurement of applied load at a chainring assemblage of a pedal powered device are provided. The apparatus includes a link adapted for interposition between a chainring attachment site located on a conventional chainring mount, or spider, and a corresponding chainring attachment locale at a conventional chainring. The link has a geometry and / or material composition selected to accommodate measurement of load exhibited between the attachment site and the corresponding chainring attachment locale. Means for measuring the load exhibited thereby is associated with the link.

Owner:FORZA

Conveyor chain

InactiveUS20050061636A1Increase flexibilityReducing and controlling wearConveyorsPackagingEngineeringChain link

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links. The pin may have a rotationally non-symmetrical shaft portion to provide different wear surfaces that engage a center link of the section of chain. The different wear surfaces may be sized and shaped to accommodate wear at the wear surface of the center link. The shaft portion may include a rotationally non-symmetrical ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialed to the next position or wear surface in response to an output of a wear measurement device or system.

Owner:FROST TECH

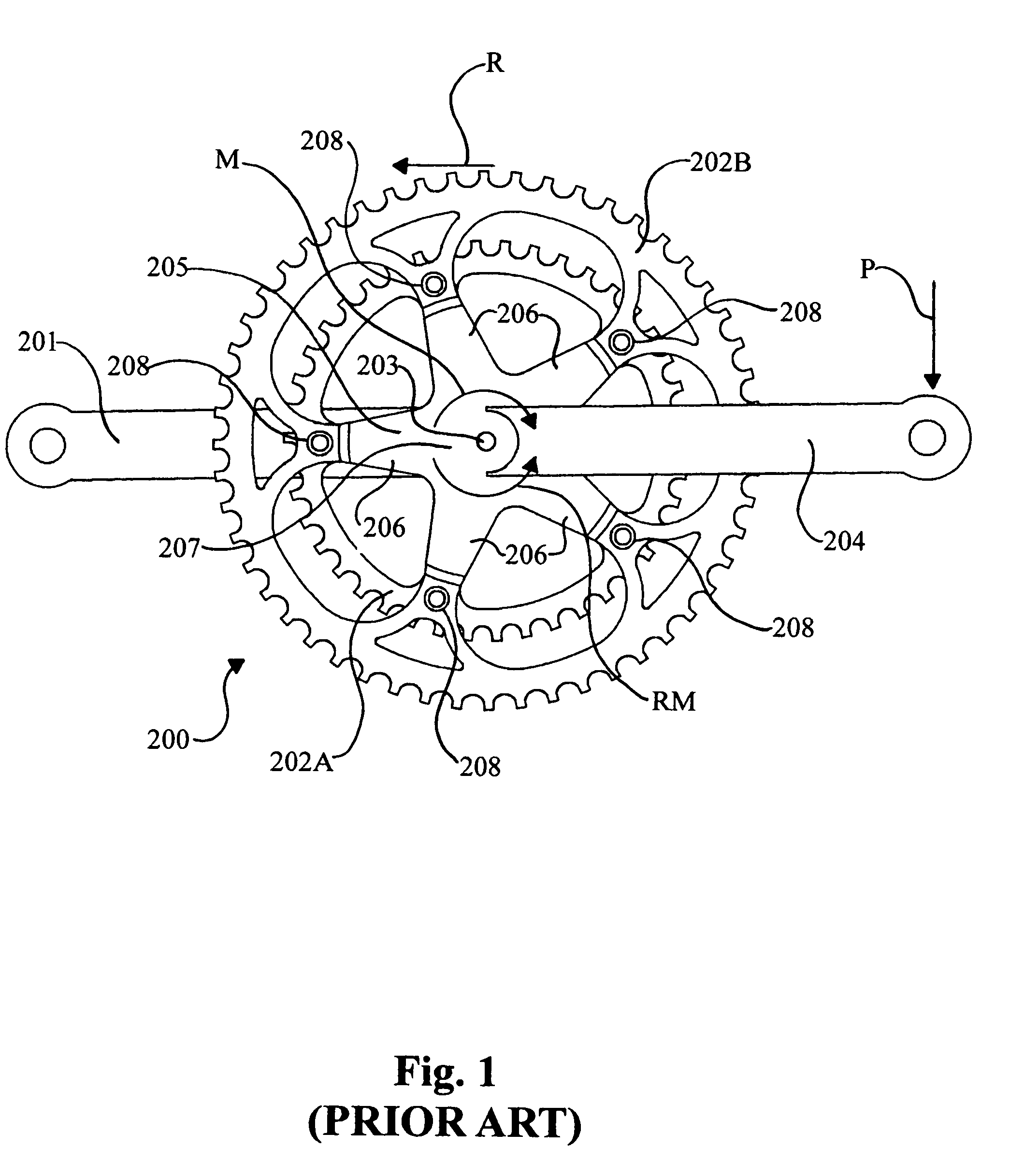

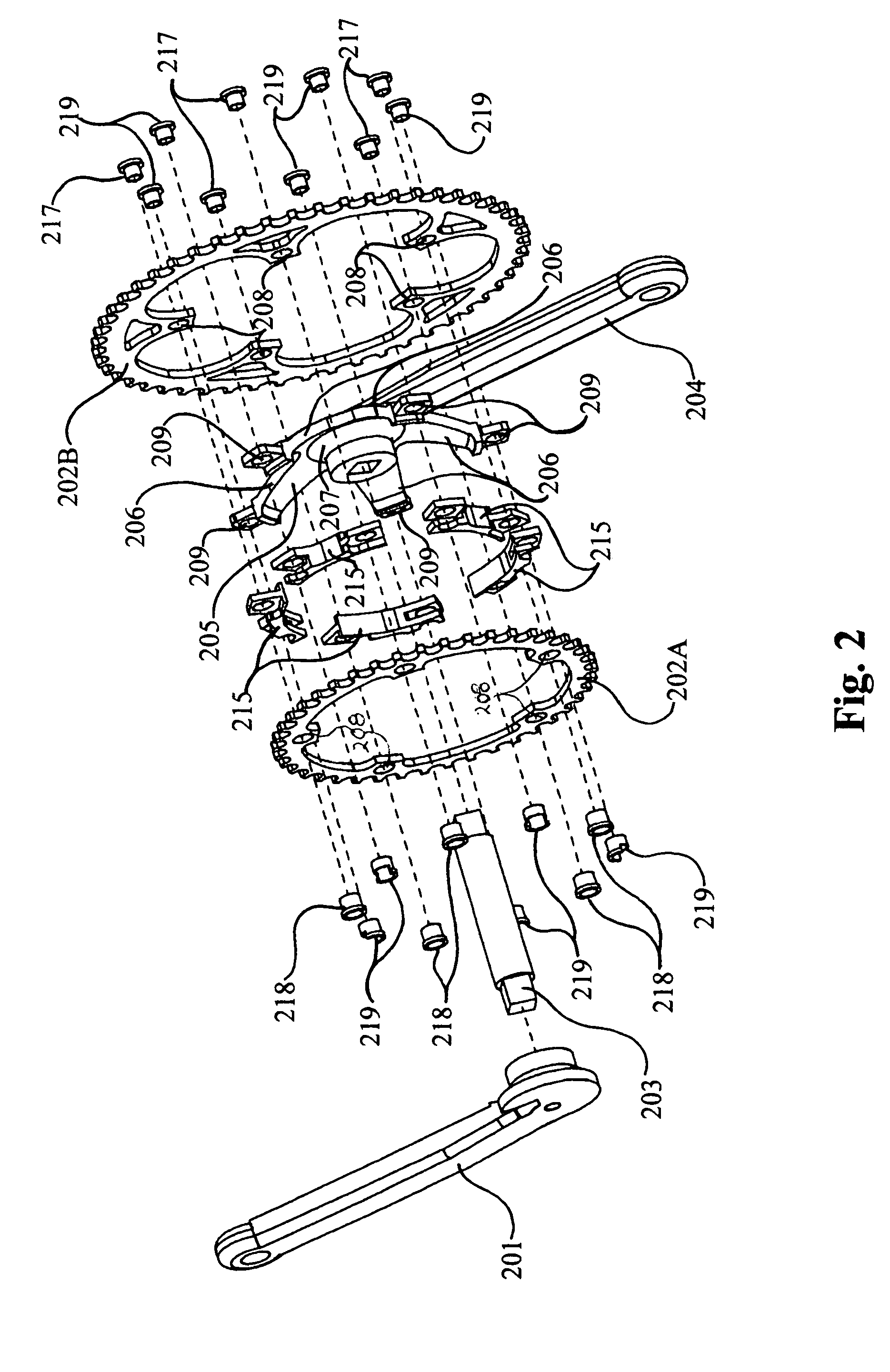

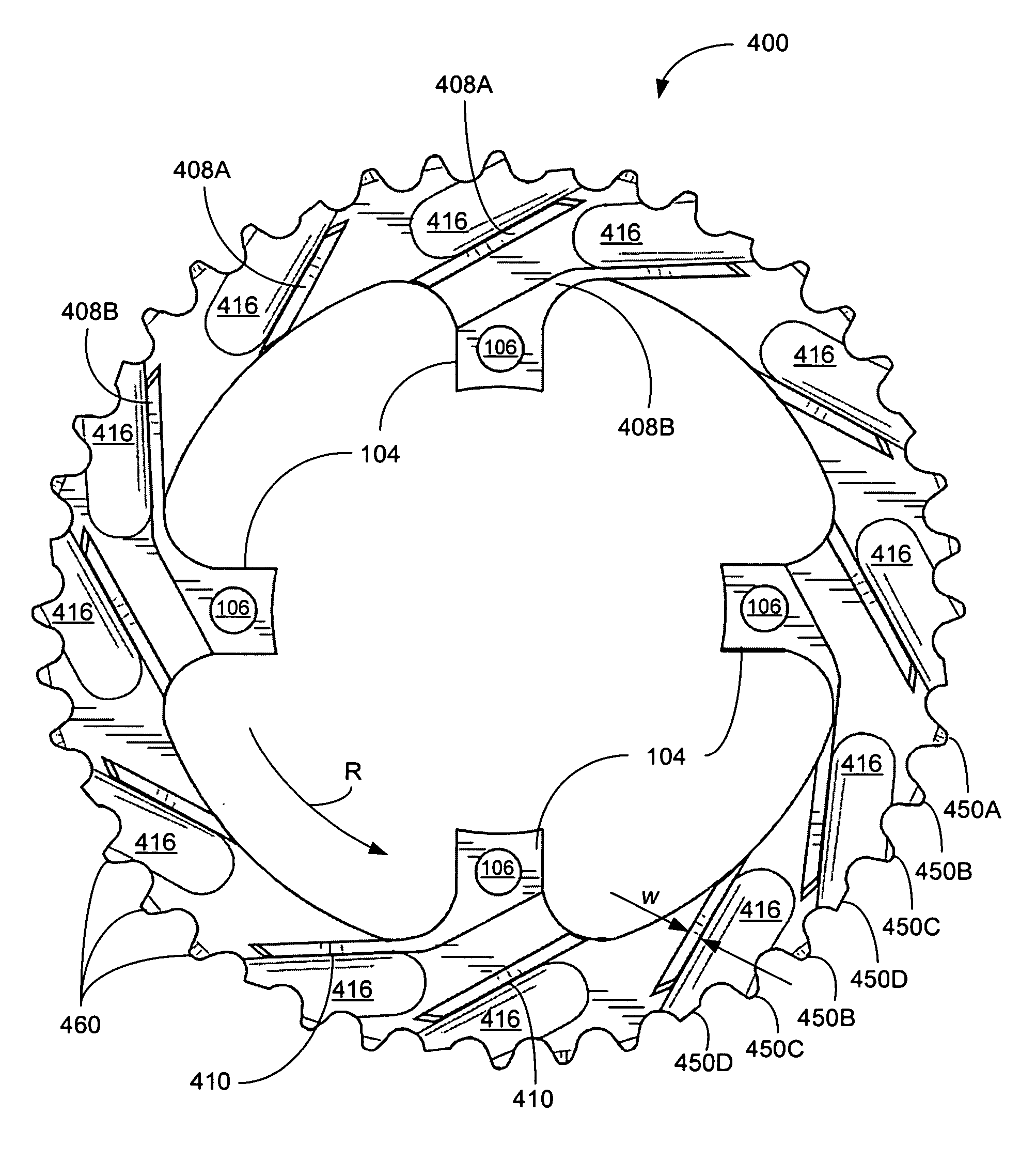

Bicycle chain rings

Owner:WICKWERKS

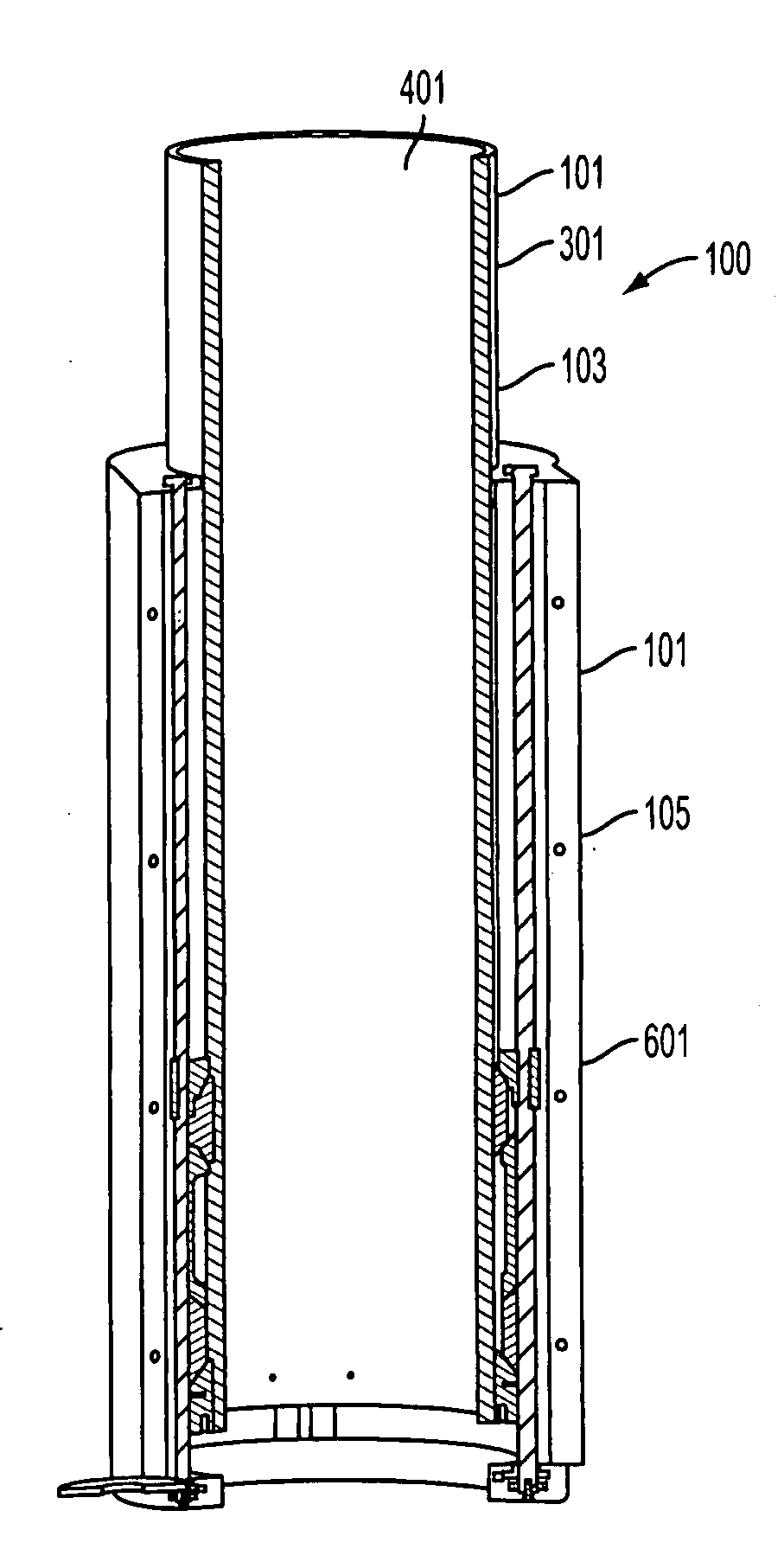

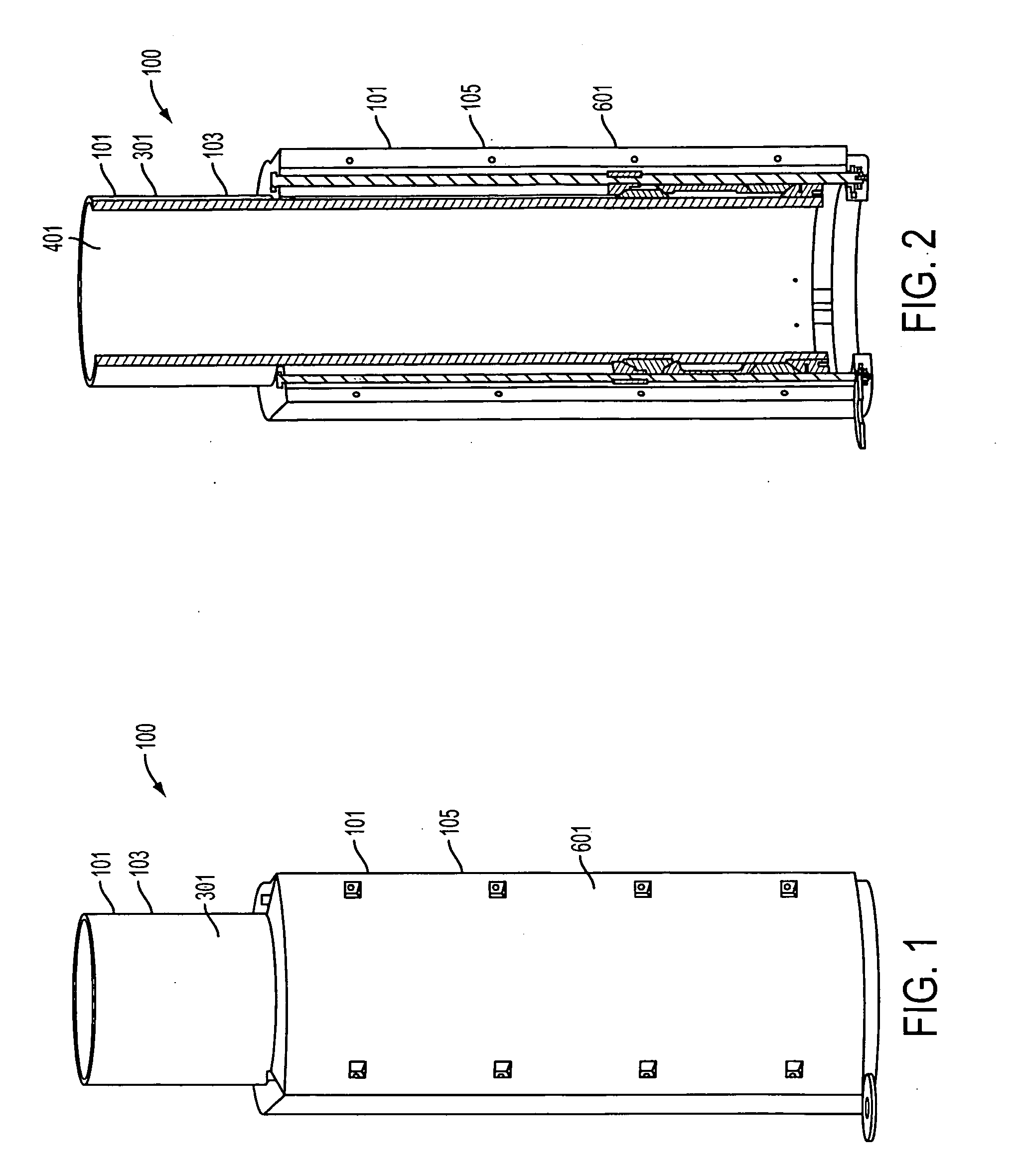

Telescoping mast having variable height locking and a chain erection mechanism with a cable management system

A telescoping mast for supporting and raising a load may be telescopically extended by a zipper-action chain extension system further comprising a system for the management of one or more cables, such as power or communication cables traversing the length of the mast, and is capable of being locked into a rigid formation along a range of telescopic lengths.

Owner:DRS SUSTAINMENT SYST

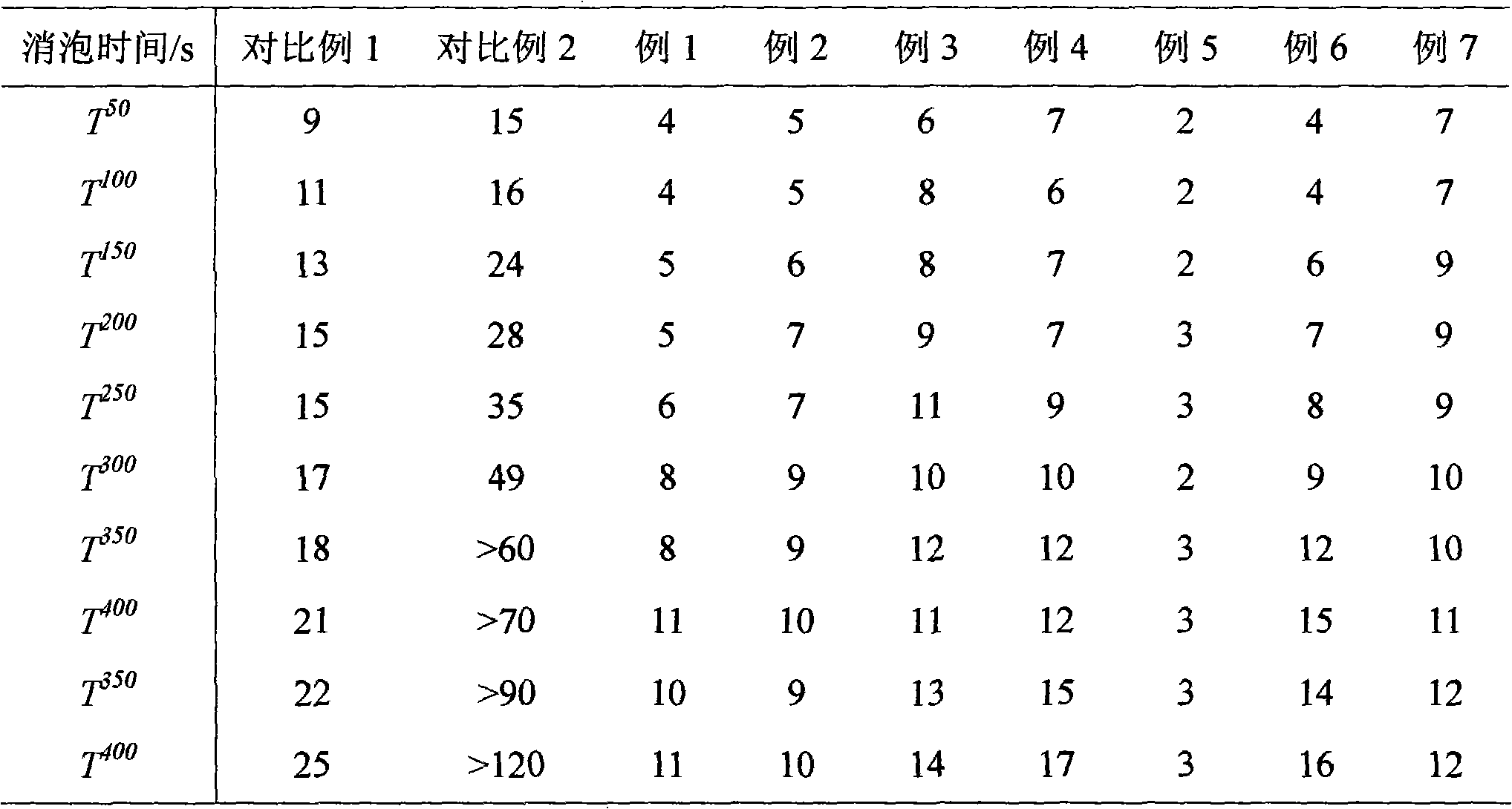

Method for preparing defoaming agent composition

The invention discloses a method for preparing a defoaming agent composition, belonging to the technical field of fine chemical preparation. The invention provides a defoaming agent composition widely used for removing harmful foams in industrial production. The defoaming agent composition comprises the following components: (1) polysiloxane RaSiO(4-a) / 2; (2) a coupling agent; (3) fine filler particles such as silicon dioxide and the like; (4) organic silicon resin; (5) polyether modified polysiloxane MDx(CH3GSiO)yM, wherein M is chain link R'2SiO1 / 2, D is chain link R'2SiO2 / 2, G is polyether radical-(CH2)z(EO)g(PO)hR'' and (6) an alkaline catalyst. The preparation method comprises the following steps: (1) heating the polysiloxane and the coupling agent together in a stirring machine, adding the alkaline catalyst to carry out a polymerization reaction at the temperature of 40-140 DEG C; (2) after crosslinking the mixture, adding the organic silicon resin and the polyether modified polysiloxane, carrying out a reaction again for 1-7 h at the temperature of 80-140 DEG C, and then adding the fine filler particles to mix uniformly, carrying out a reaction for 1-6 h at temperature of 90-180 DEG C; (3) after finishing the reaction, keeping the mixture for 0.1-1.5 h at the vacuum degree of -0.01 to -0.08 MPa, and finally, cooling to the room temperature to obtain white active materials that are defoaming agent compositions.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

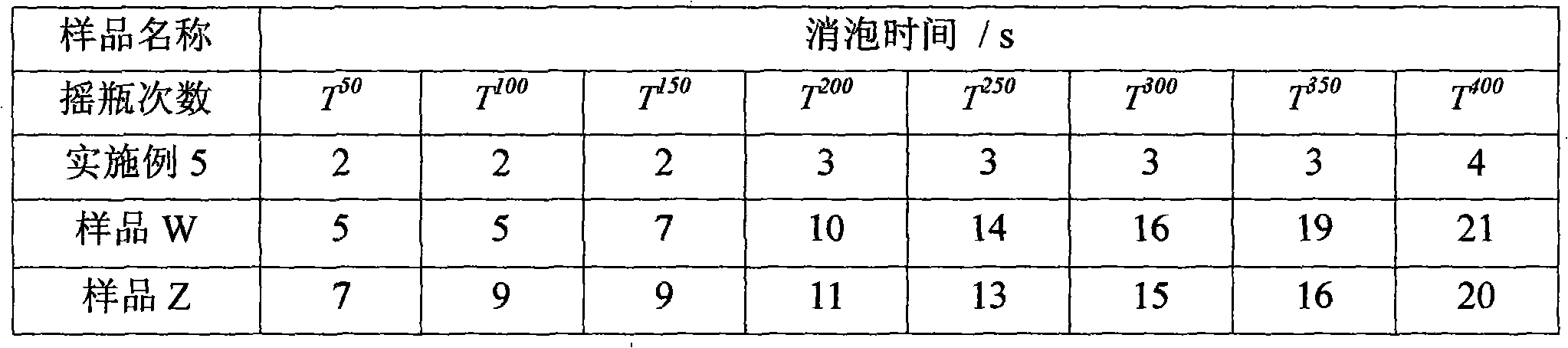

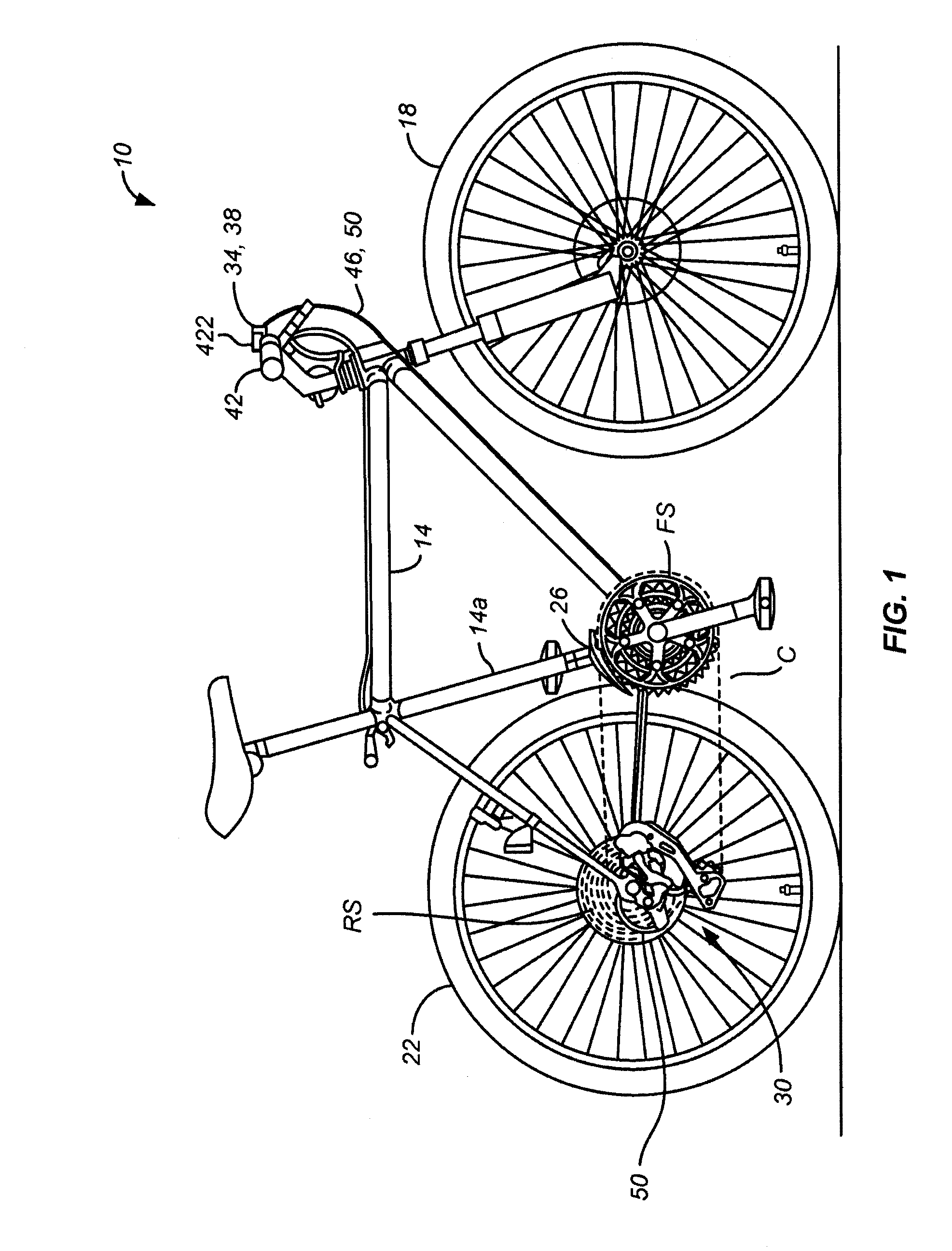

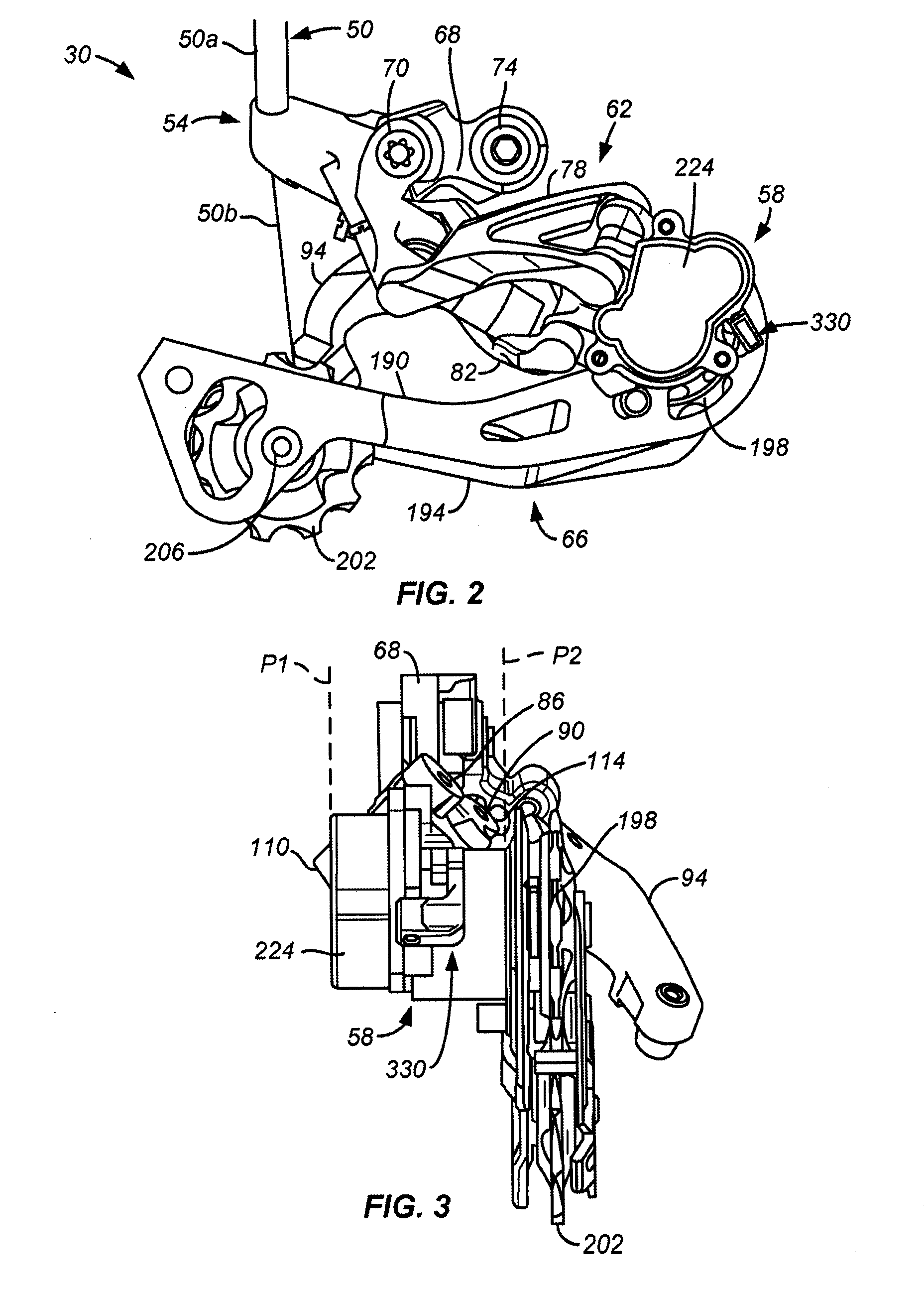

Bicycle derailleur with rotation resistance and resistance control

ActiveUS20130288834A1Avoid resistanceChain/belt transmissionGearingRotational axisElectrical resistance and conductance

A bicycle derailleur comprises a base member adapted to be mounted to a bicycle, a movable member movably coupled to the base member, a chain guide coupled to the movable member for rotation around a rotational axis, a resistance applying element that applies resistance to rotational movement of the chain guide, and a resistance control element. The resistance control element applies a force to the resistance applying element in a direction that is non-parallel with the rotational axis, without any manual operations, to prevent a reduction in the resistance to rotational movement of the chain guide applied by the resistance applying element.

Owner:SHIMANO INC

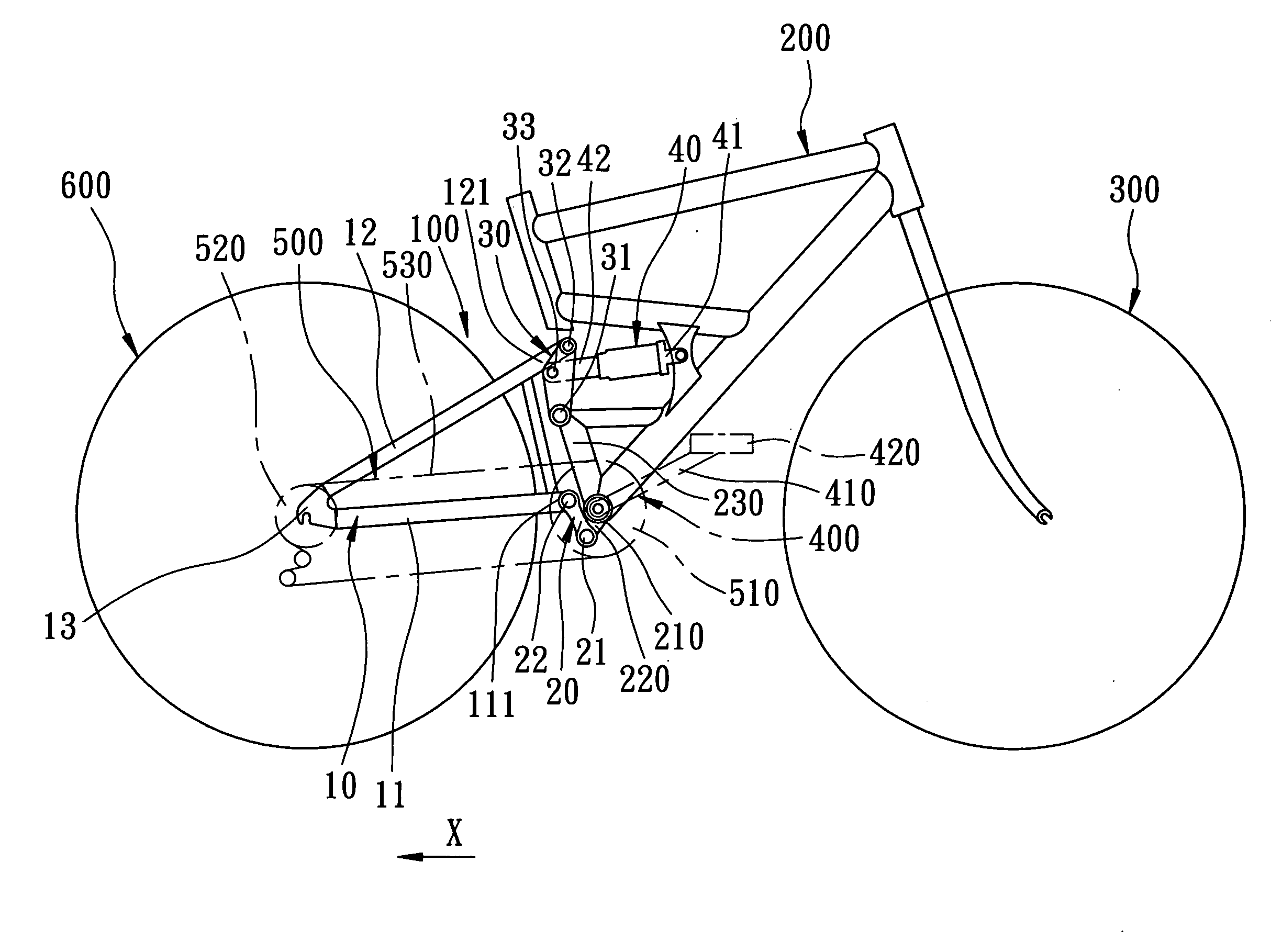

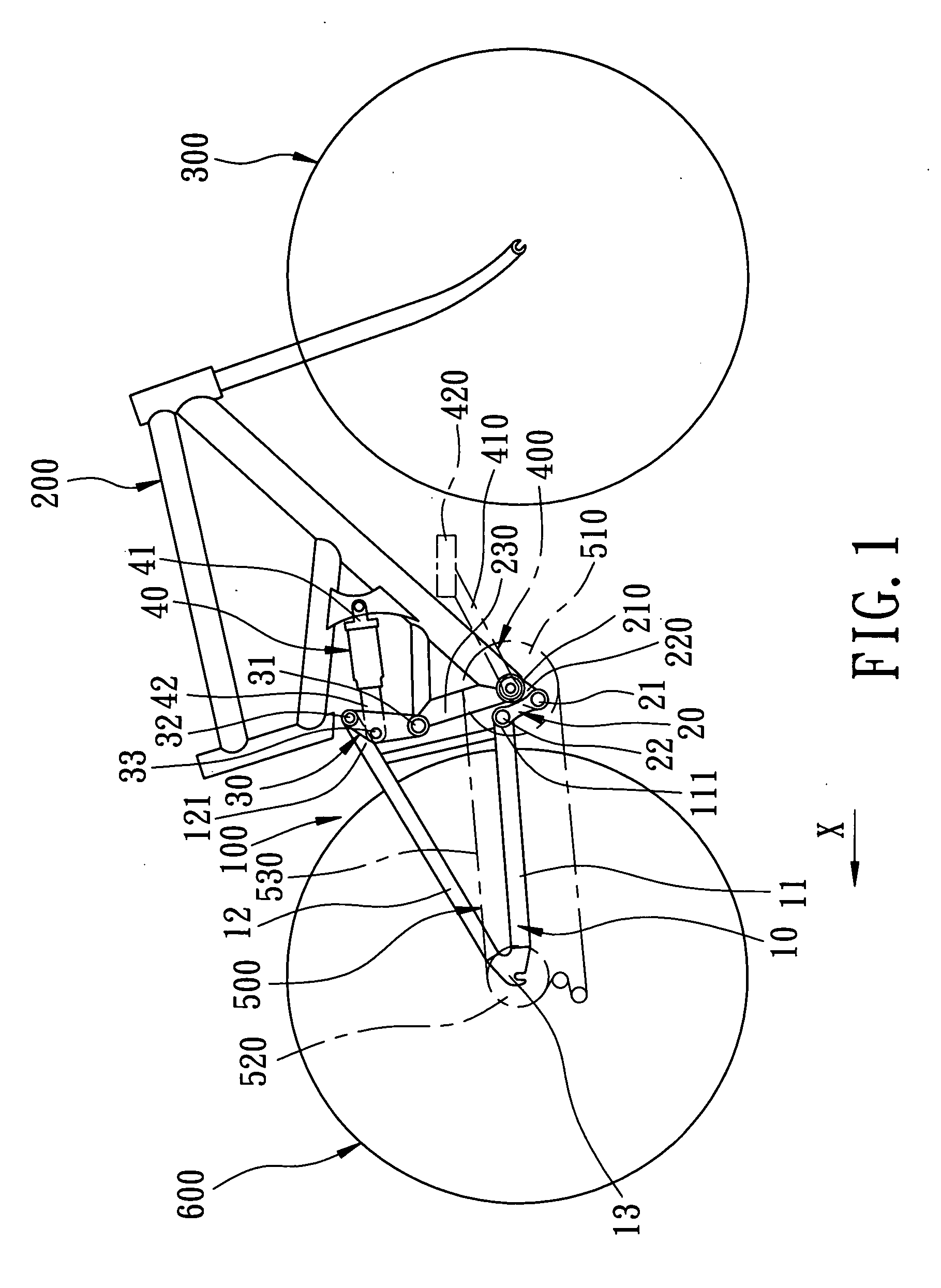

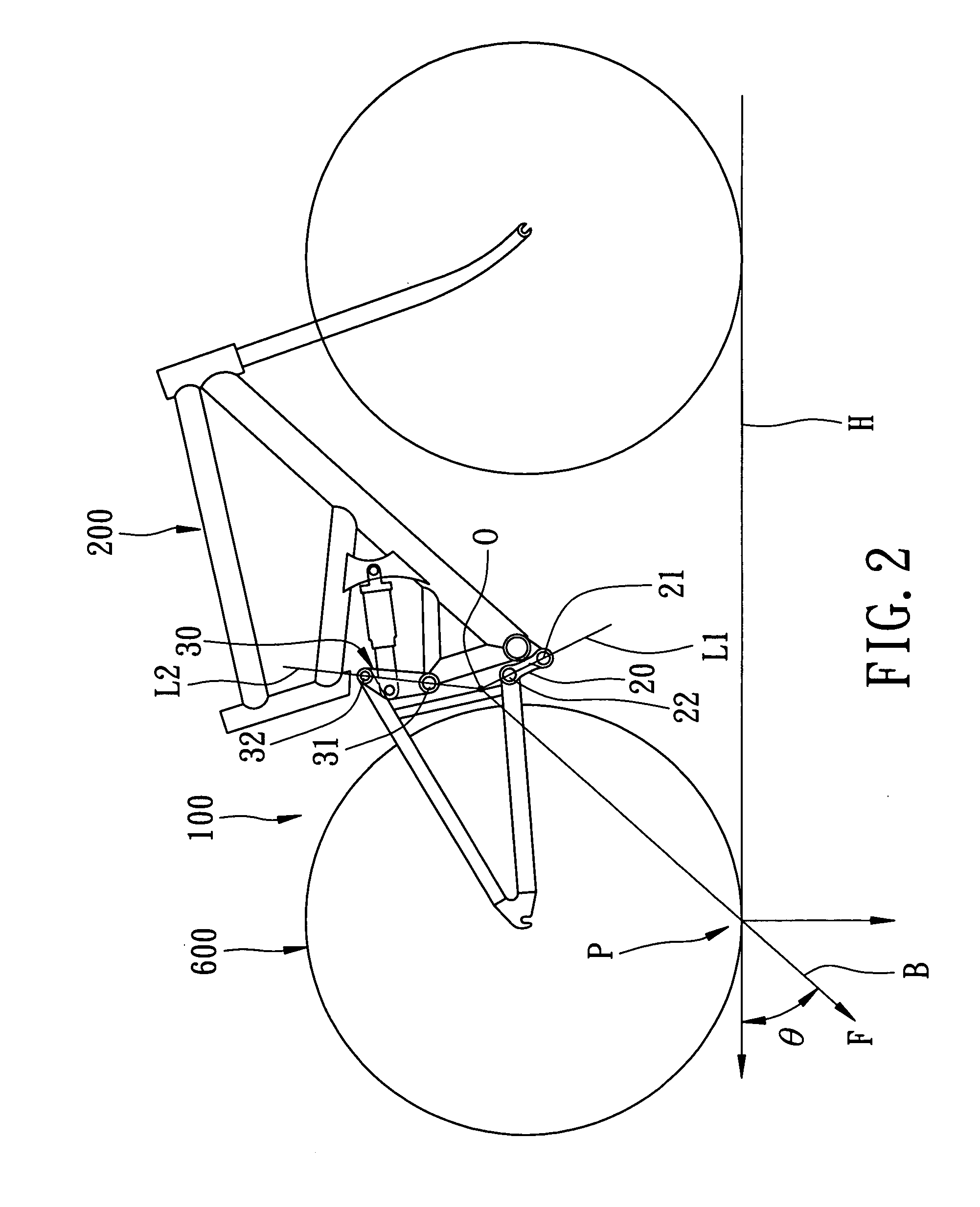

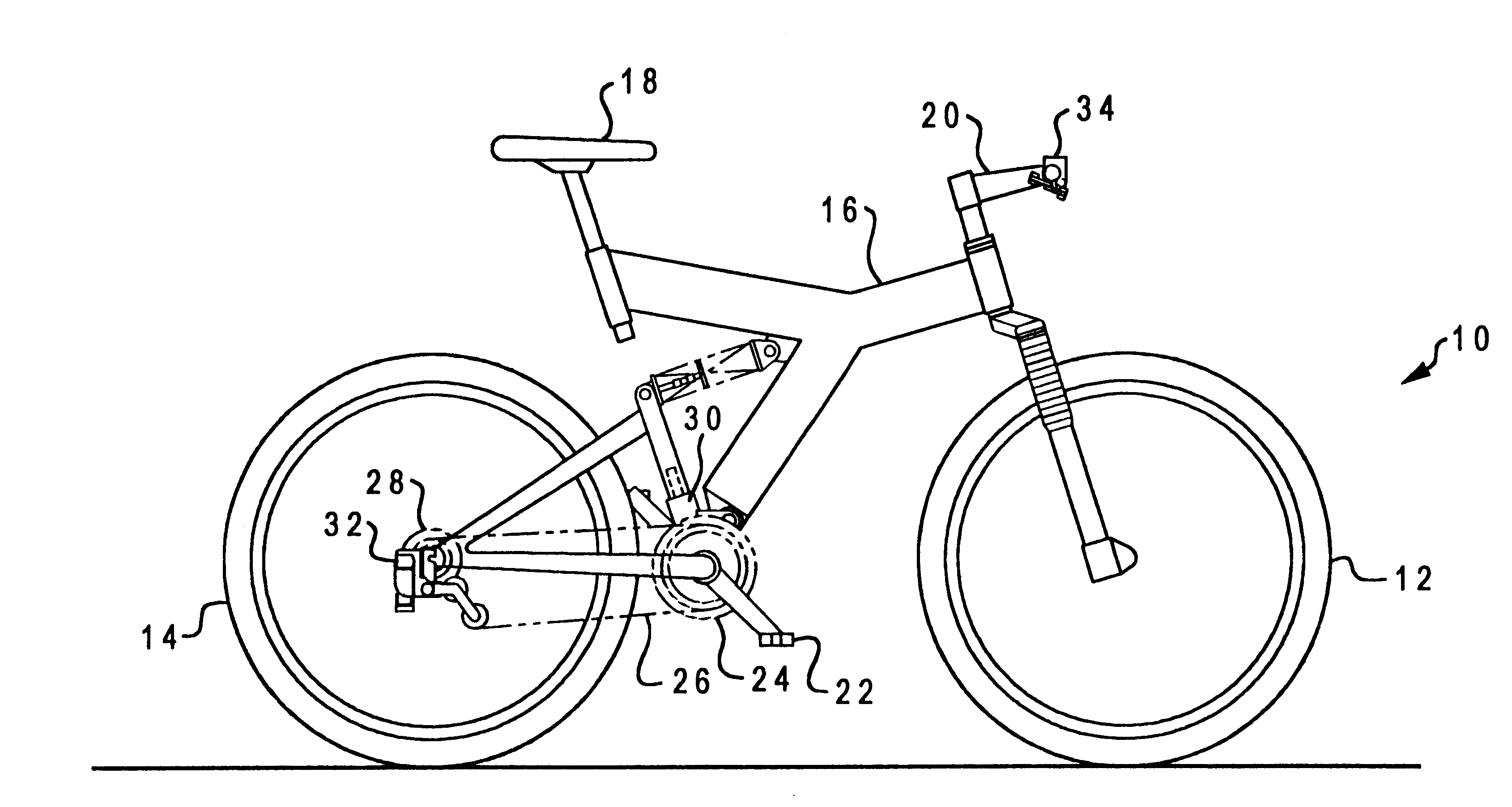

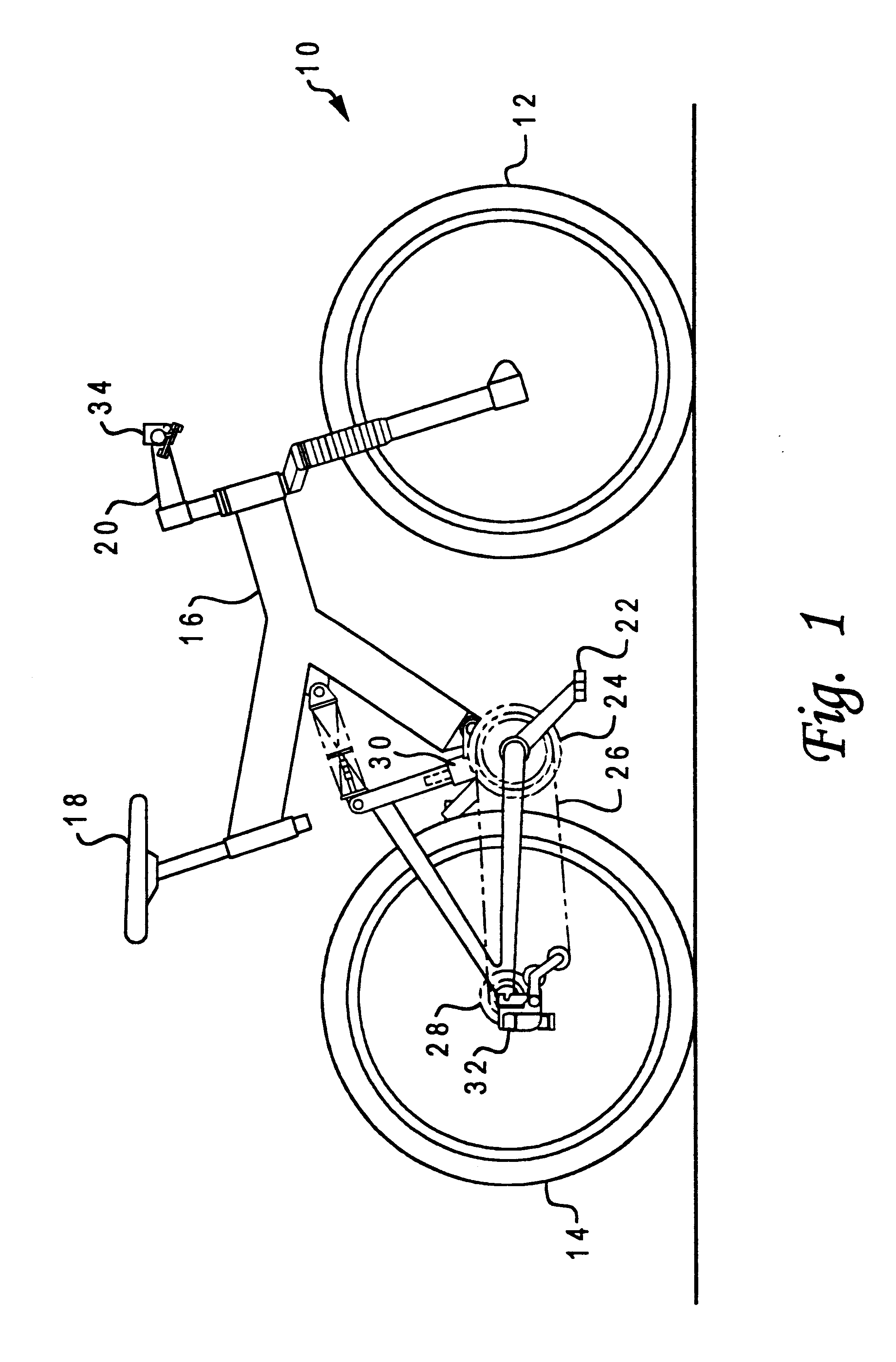

Bicycle rear suspension system

A bicycle rear suspension system has a virtual pivot point that is close to a junction between a chain and a front driving sprocket when a piston rod travels relative to a cylinder body by ¼ to ⅓ of a maximum displacement value, and that moves rearwardly when a rear wheel moves upwardly away from the ground. A line interconnecting an instant center of a rear triangular frame and a contacting point between a rear wheel and the ground forms an angle of about 45° with respect to a horizontal line.

Owner:GIANT MFG

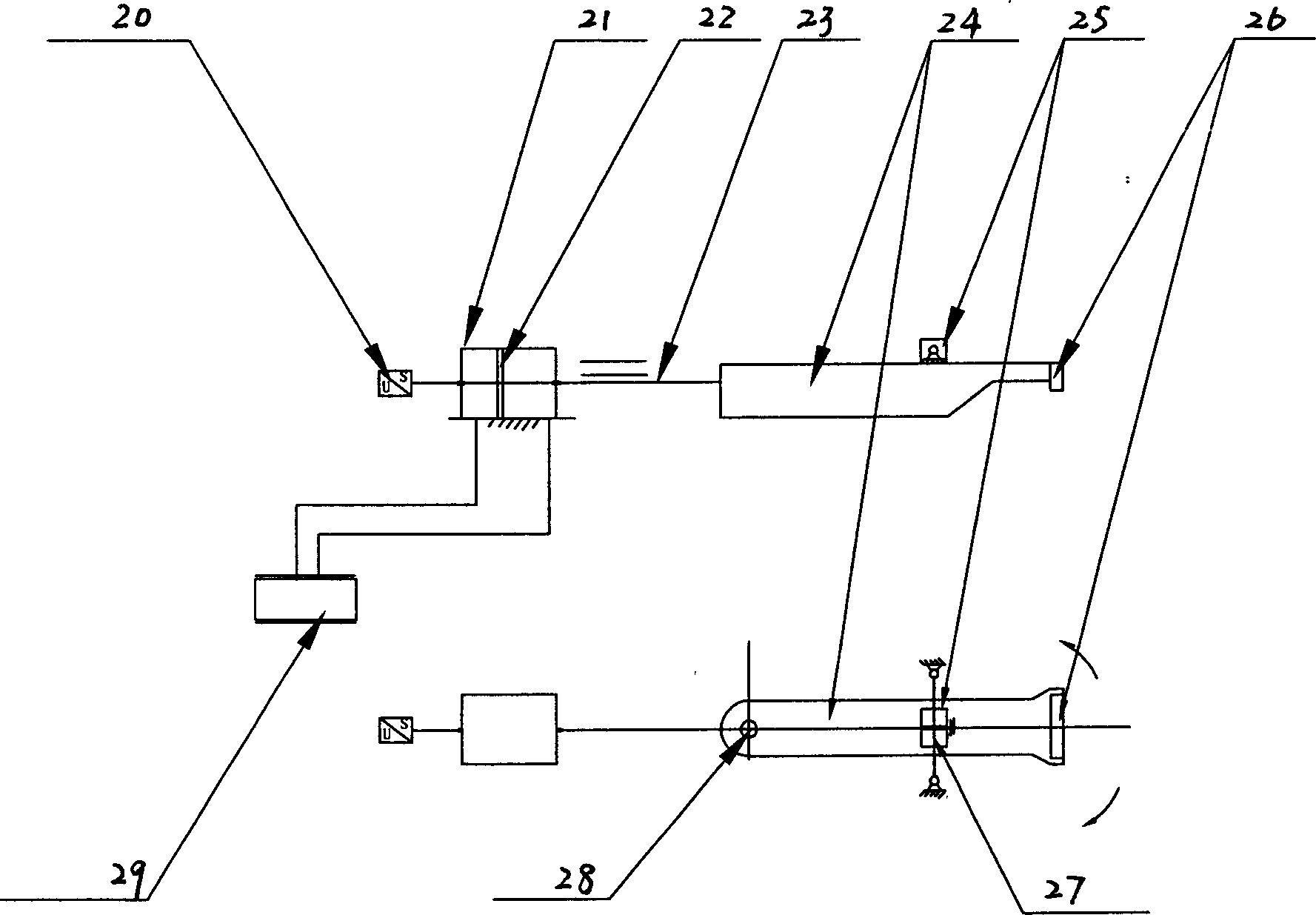

Hydraulically-operated bicycle shifting system with power shifting

InactiveUS6325733B1Compact designIncreased durabilityChain/belt transmissionGearingAutomatic controlComputer module

A family of new bicycle shifting systems incorporate improved derailleur designs that are controlled by sealed hydraulic actuators. The shifting systems (i) a hydraulically-actuated, manually-powered front and rear derailleur shifting system, (ii) a hydraulically-actuated, power-assisted front and rear derailleur shifting system with manual control, and (iii) a hydraulically-actuated, power-assisted front and rear derailleur shifting system in which the shifting sequence for the rear derailleur is controlled automatically by pedal speed. Each of these shifting systems utilize a totally sealed, inclined linear shifting path. Environmental contaminants are prevented from entering any of the critical derailleur or control elements. The linear, inclined shifting path provides precise chain shifting, more uniform chain wrap on the rear bicycle drive sprockets, and lower chain and sprocket wear. Several different shifting control units are disclosed. An integrated shifting and braking module is also disclosed.

Owner:PATTERSON RICHARD A +1

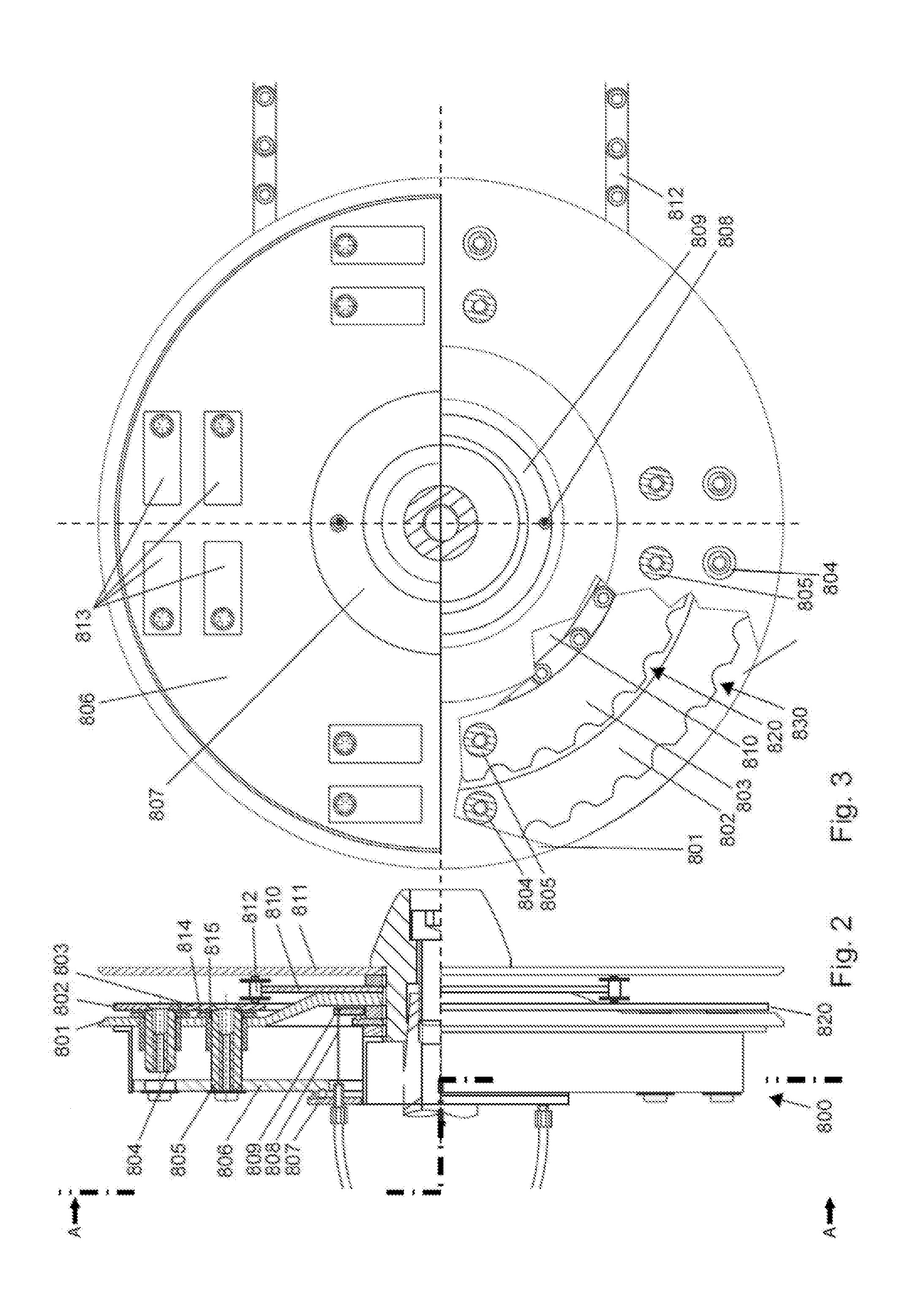

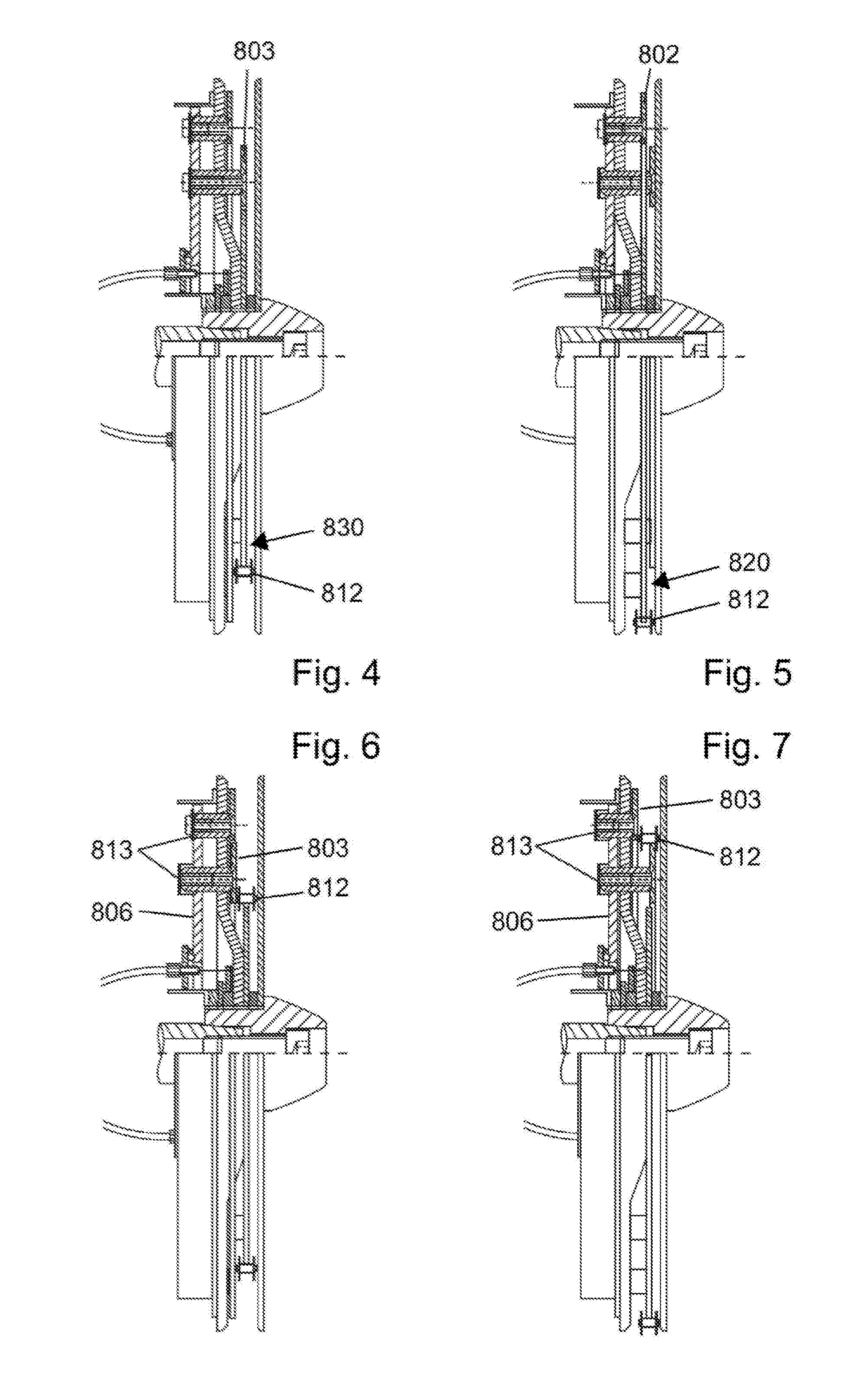

Mechanism for transmitting a rotary movement with variable transmission ratio

A control mechanism (800) for setting a transmission ratio between a traction means (812), in particular chain, and a wheel set that is rotatable about a wheel axle and includes two or more wheel blades (810, 820, 830), in particular sprocket blades, adjusts the wheel rim sectors relative to a fixed plane of the traction means in a direction transverse to the plane of alignment. At least one of the wheel blades is composed of a plurality of independently adjustable wheel rim sectors (802, 803). By means of a control component (807) mounted decoupled from a rotary movement of the wheel set, a plurality of co-rotating thrust elements (804, 805) are each displaced via rotation-free couplings between a first and a second position at least in the axial direction, wherein each of the wheel rim sectors is connected in a rotationally fixed manner to a respectively associated thrust element. The first position of a thrust element corresponds to the position of the associated wheel rim sector outside the plane of alignment, whereas a thrust element located in the second position exerts on the respective wheel rim sector, at least as long the latter is outside the plane of the traction means, a force for displacing the respective wheel rim sector into the plane of alignment, thus shifting the same into the plane.

Owner:PRAXIS WORKS

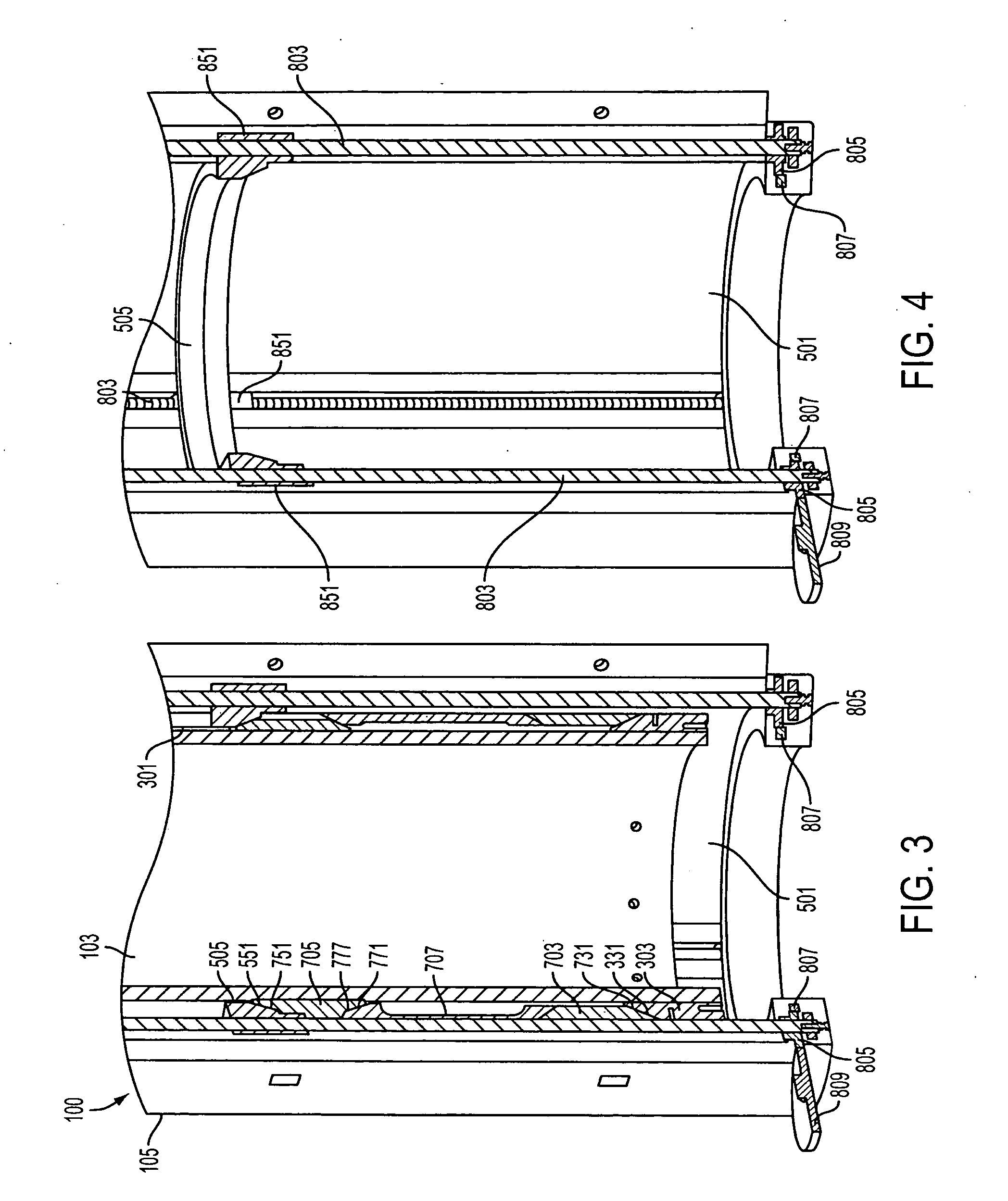

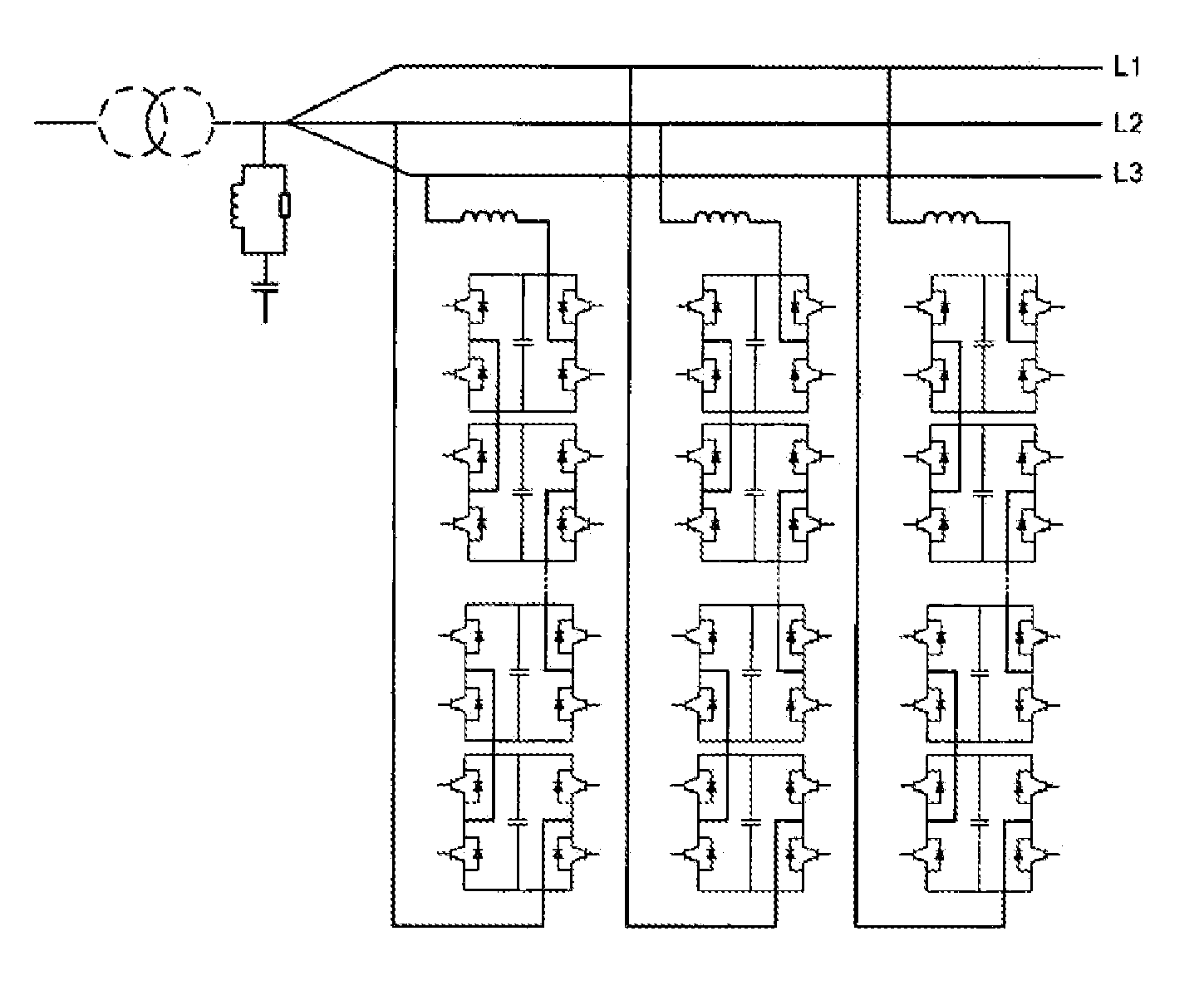

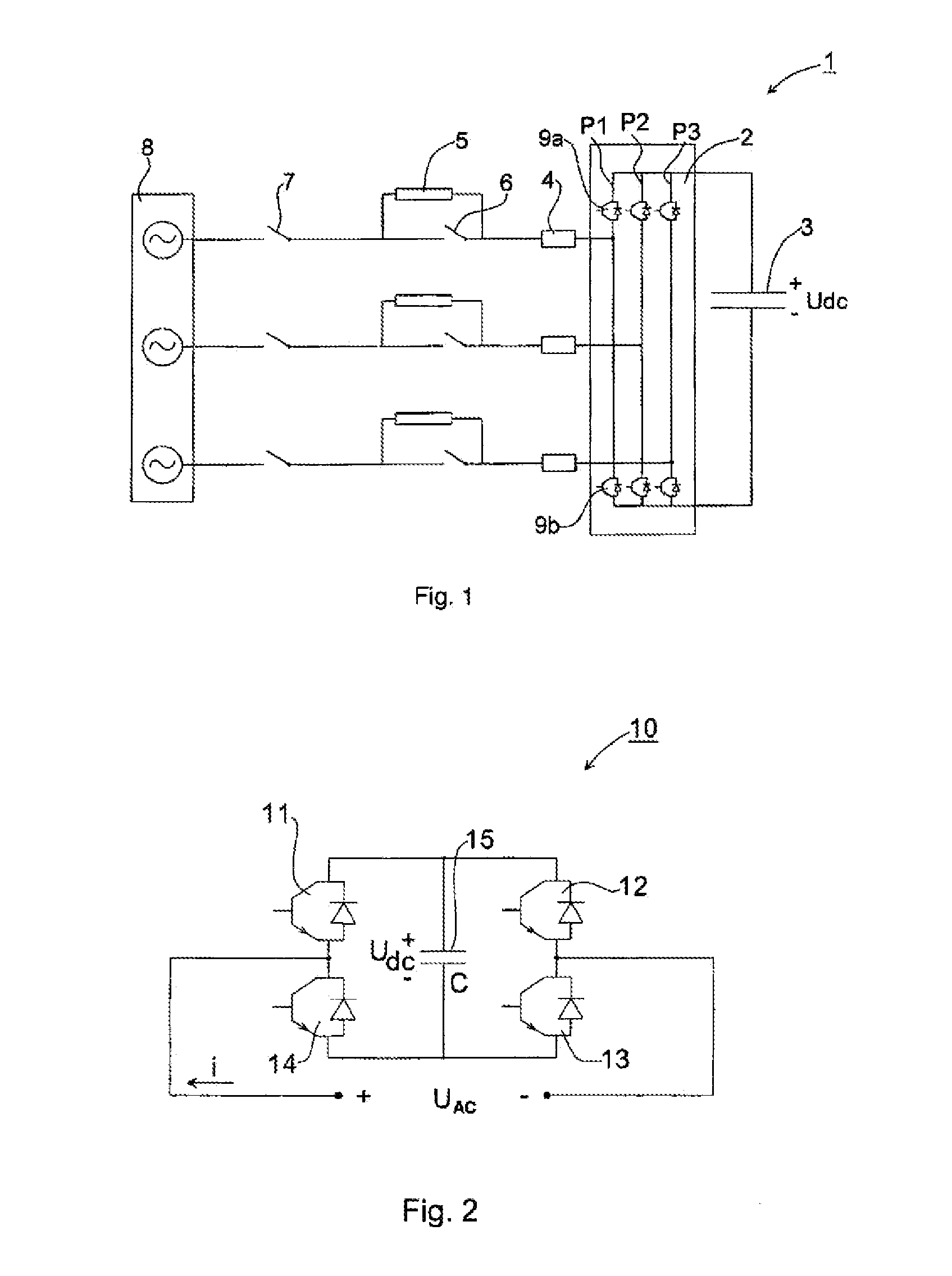

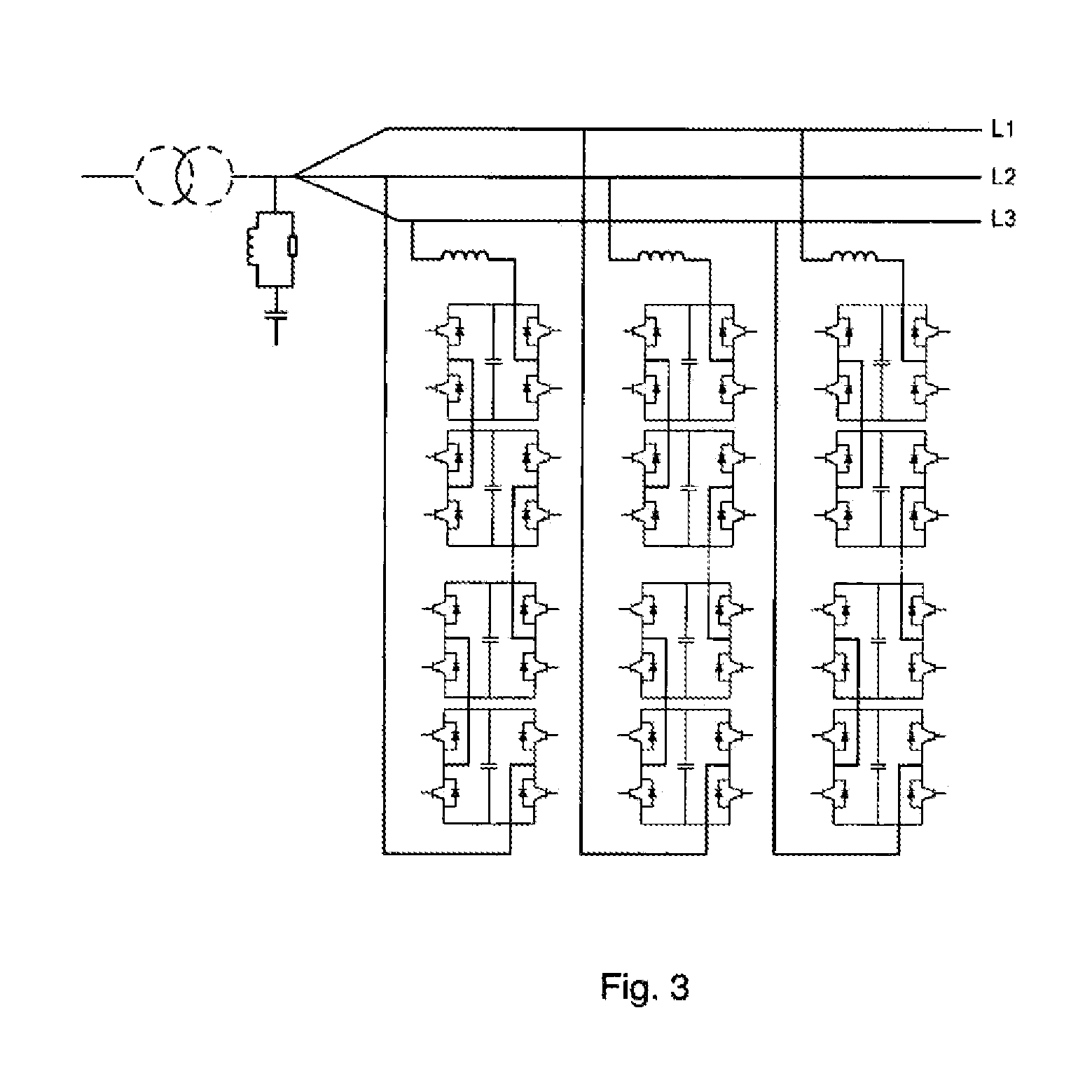

Modular Voltage Source Converter

Voltage source converter based on a chain-link cell topology including one or more phases, each of the phases having one or more series-connected chain-link cell modules connected to each other. The output voltage of the voltage source converter is controlled by control signals applied to the series-connected chain-link cell modules. In case of failure of a chain-link cell module, that module is controlled, by the control signals, such that zero output voltage is provided at its output voltage AC terminal.

Owner:HITACHI ENERGY SWITZERLAND AG

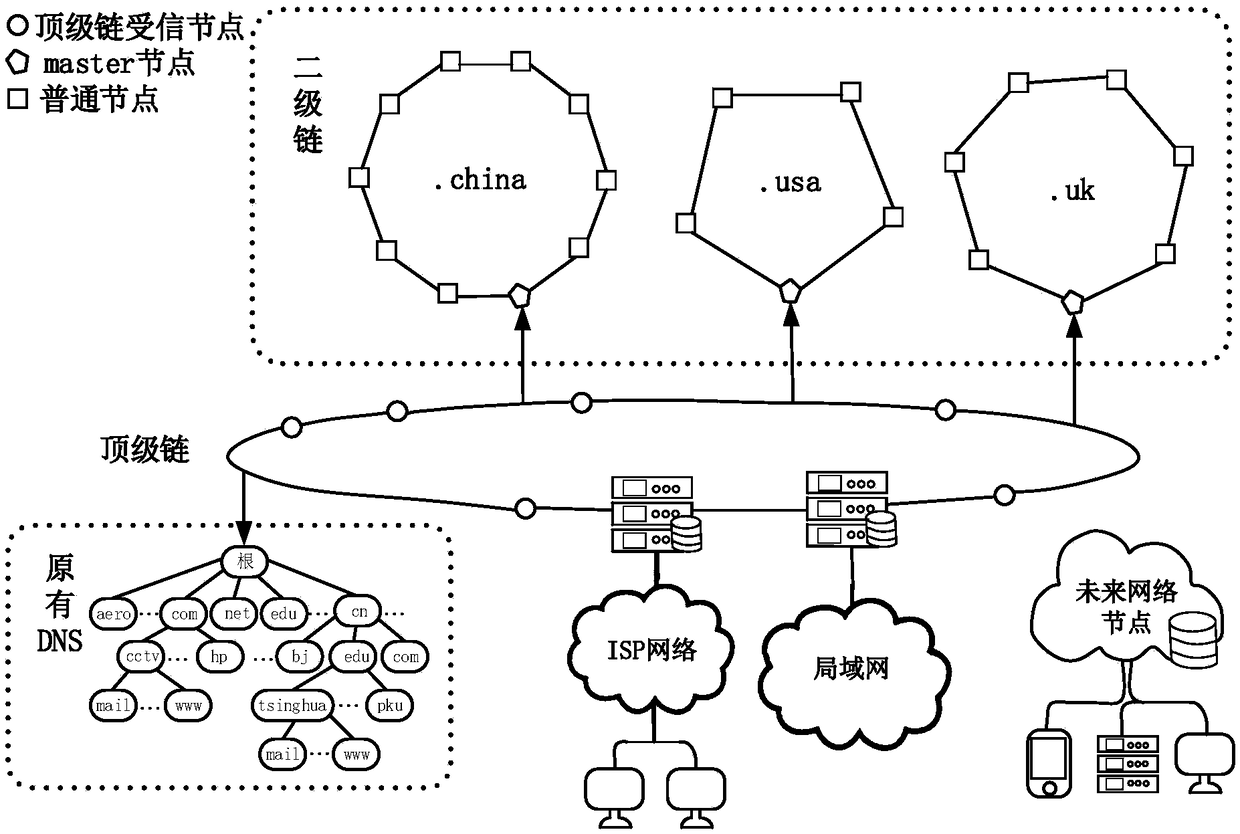

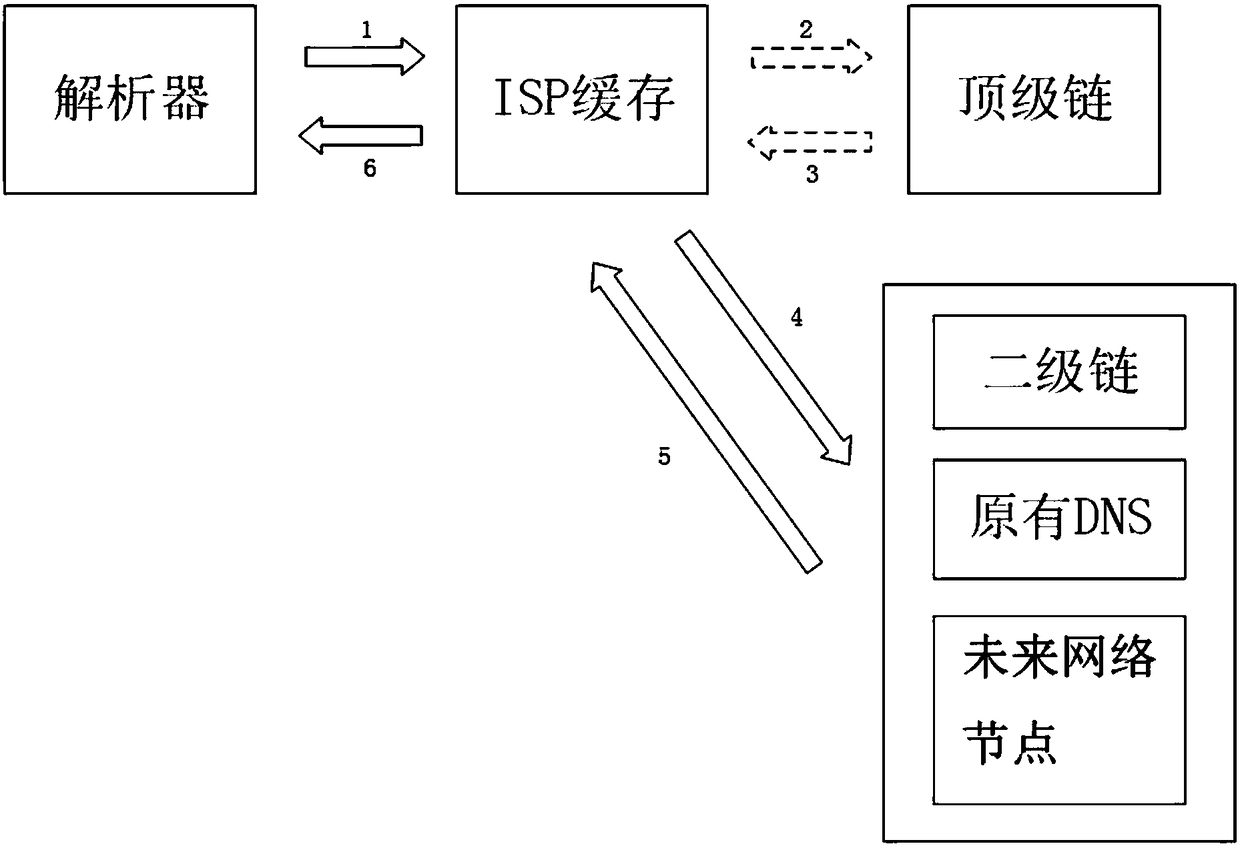

Blockchain-based domain name resolution system

ActiveCN108064444AImprove management efficiencyEfficient managementSecuring communicationChain networkChain link

The invention relates to a blockchain-based domain name resolution system. The domain name resolution system adopts a hierarchical structure, including a top-level domain name chain network, a second-level domain name chain network, a future network node and an original DNS system network, and the top-level domain name chain links the second-level domain name chain network, the future network nodeand the original DNS system network; the top-level domain name chain network is used for each professional organization to deploy reliable server nodes to form an allied blockchain network, each nodeserver records information about all current top-level domain names, second-level domain name chain nodes, future network nodes, and existing DNS system root nodes; the second-level domain name chainnetwork is used for domain name registration and management, and records a record of all second-level domain names and subdomain names to which they belong; the future network node is used for storing metadata and indexes thereof in the future network. The resolution request is reduced and the efficiency of domain name resolution is effectively improved.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

Multiple sprocket, multiple function chain guide

InactiveUS7059983B2Durability importantResistance importantChain/belt transmissionGearingGear wheelSprocket

Chain guides for the front sprockets of bicycles are disclosed. More particularly, the chain guides are adapted or configured for bicycles that have multiple (usually 2 or 3) sprockets / chain rings mounted to the crank assembly. The setup is provided to freely allow shifting between the gears. All of the chain guide variations presented are provided with an outer flange attached to a roller section so that these portions roll together with the chain they restrain. Additional optional features include aspects to do with roller positioning, bracket mounting, roller configuration and supplemental chain restrain means (including a stop / post member and inner roller flange.)

Owner:THE HIVE GLOBAL

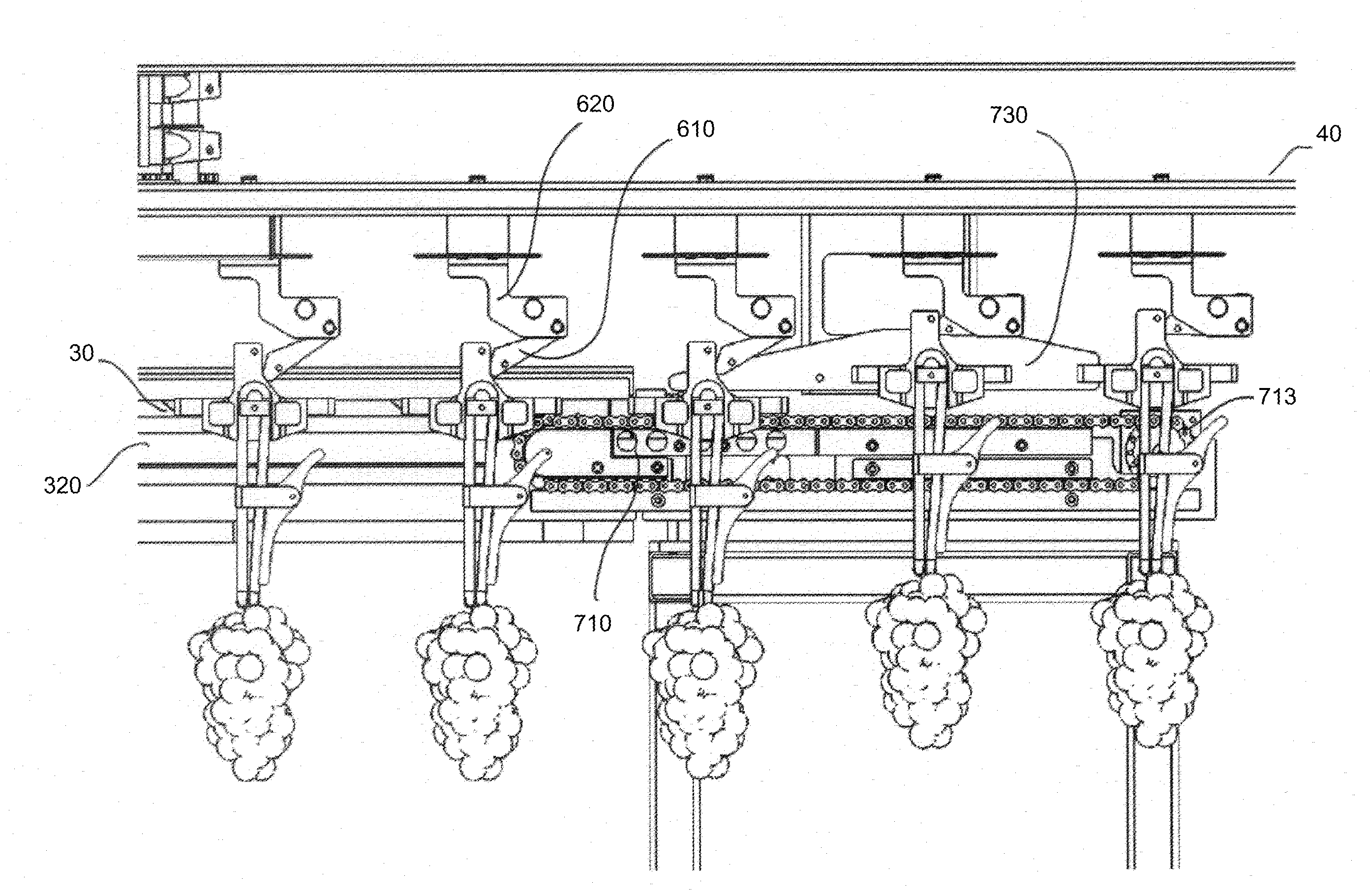

Methods, apparatuses, and systems for conveying and sorting produce

InactiveUS20110186405A1Improve throughputReduce labor costsControl devices for conveyorsColor television detailsGear wheelEngineering

Systems for conveying and sorting can include a plurality of clamps, a loading conveyor, an introduction screw, a sizing conveyor, and a plurality of outlet conveyor. Some systems can further include a weighing station, and imaging station, and a computer. A clamping apparatus can include an engagement block with a milling for slidable engagement with a chain, a nipple for engagement within a helical slot of a screw, and an opening for receiving a distal end of an elongate finger. The clamping apparatus can further include an elongate securing member for removably hanging a product there from. Imaging systems can include a rotation block, a gear wheel rotably coupled with the rotation block, a driving member, and at least one camera.

Owner:MAF IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com