Patents

Literature

472 results about "Aluminum extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

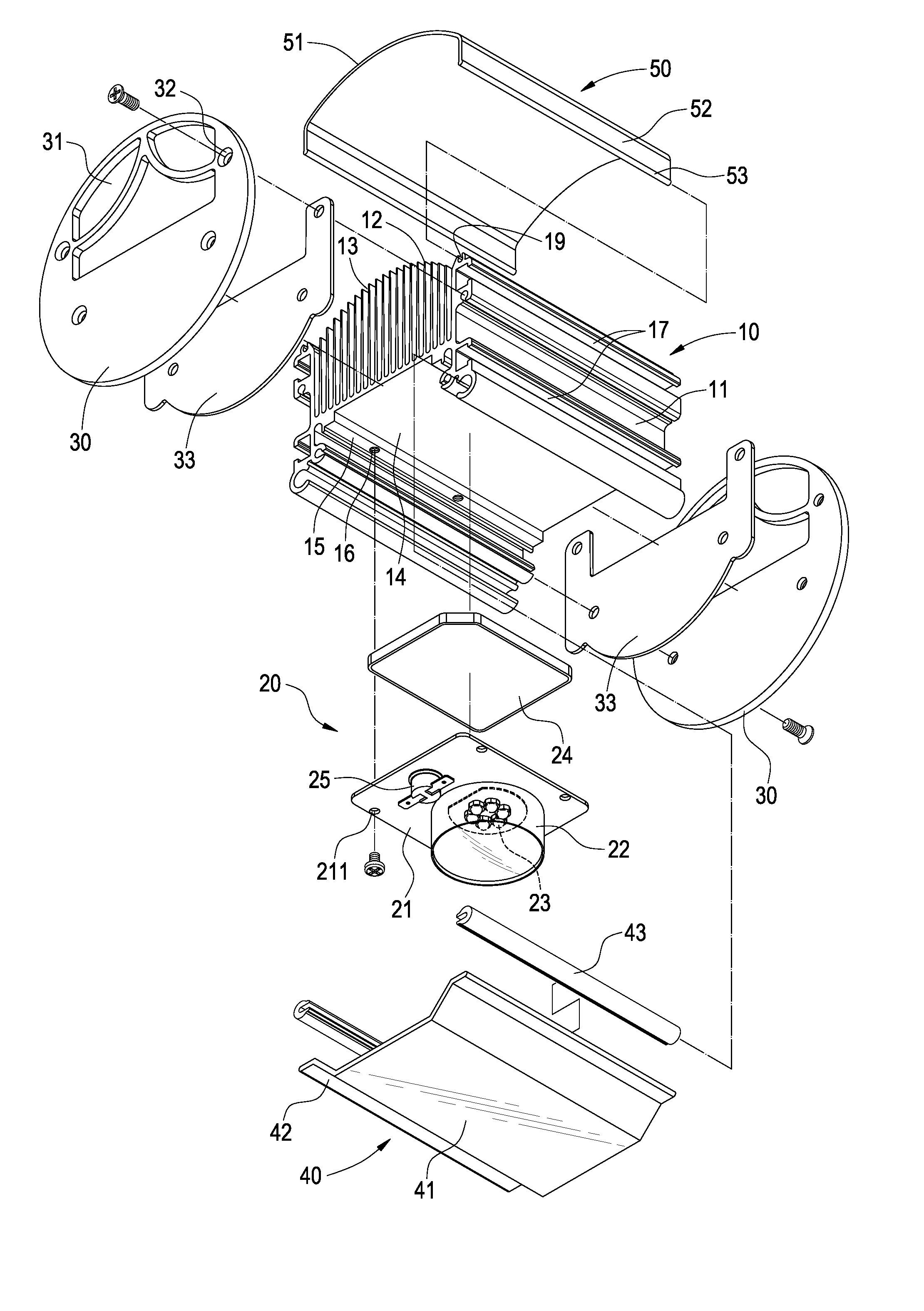

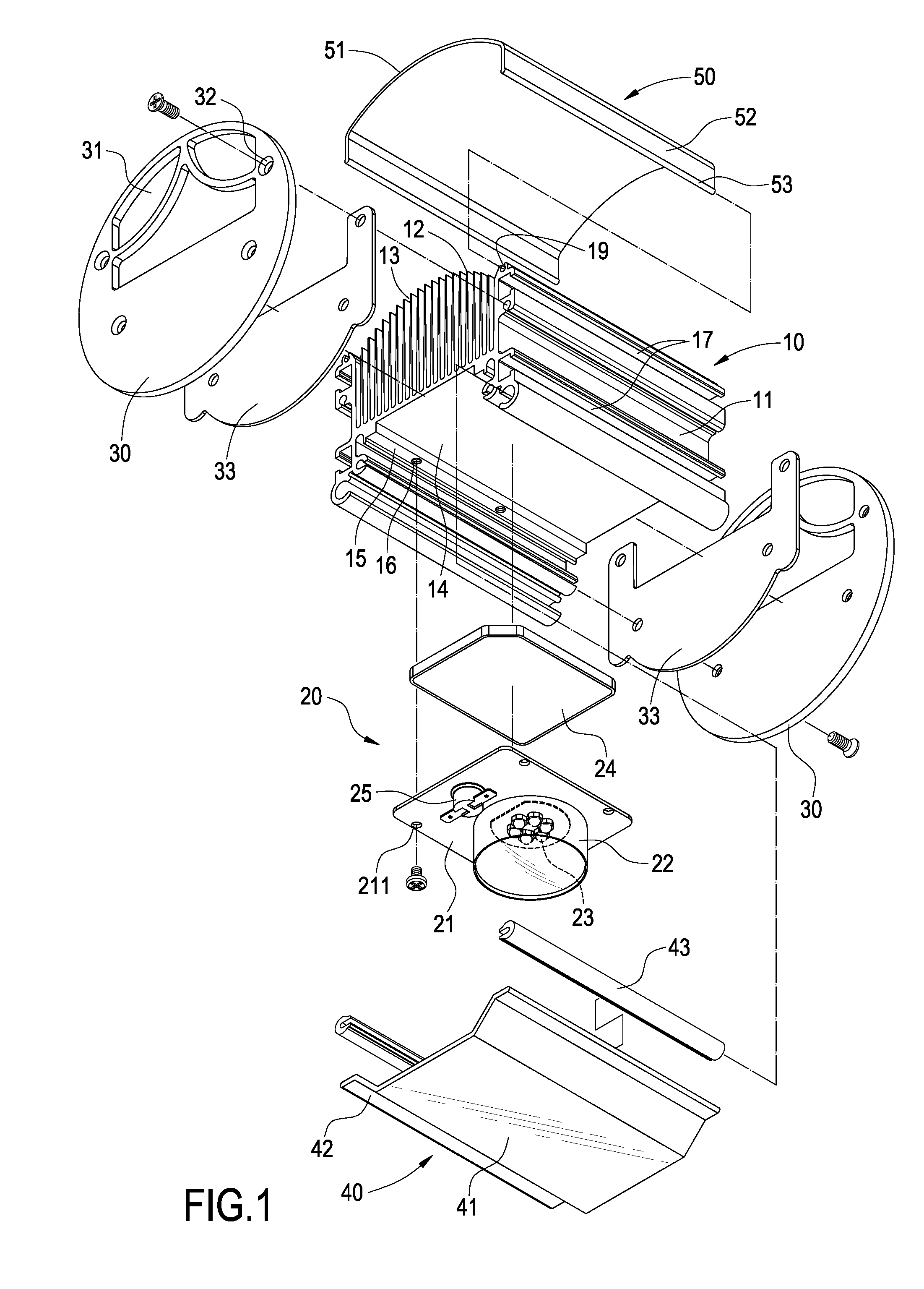

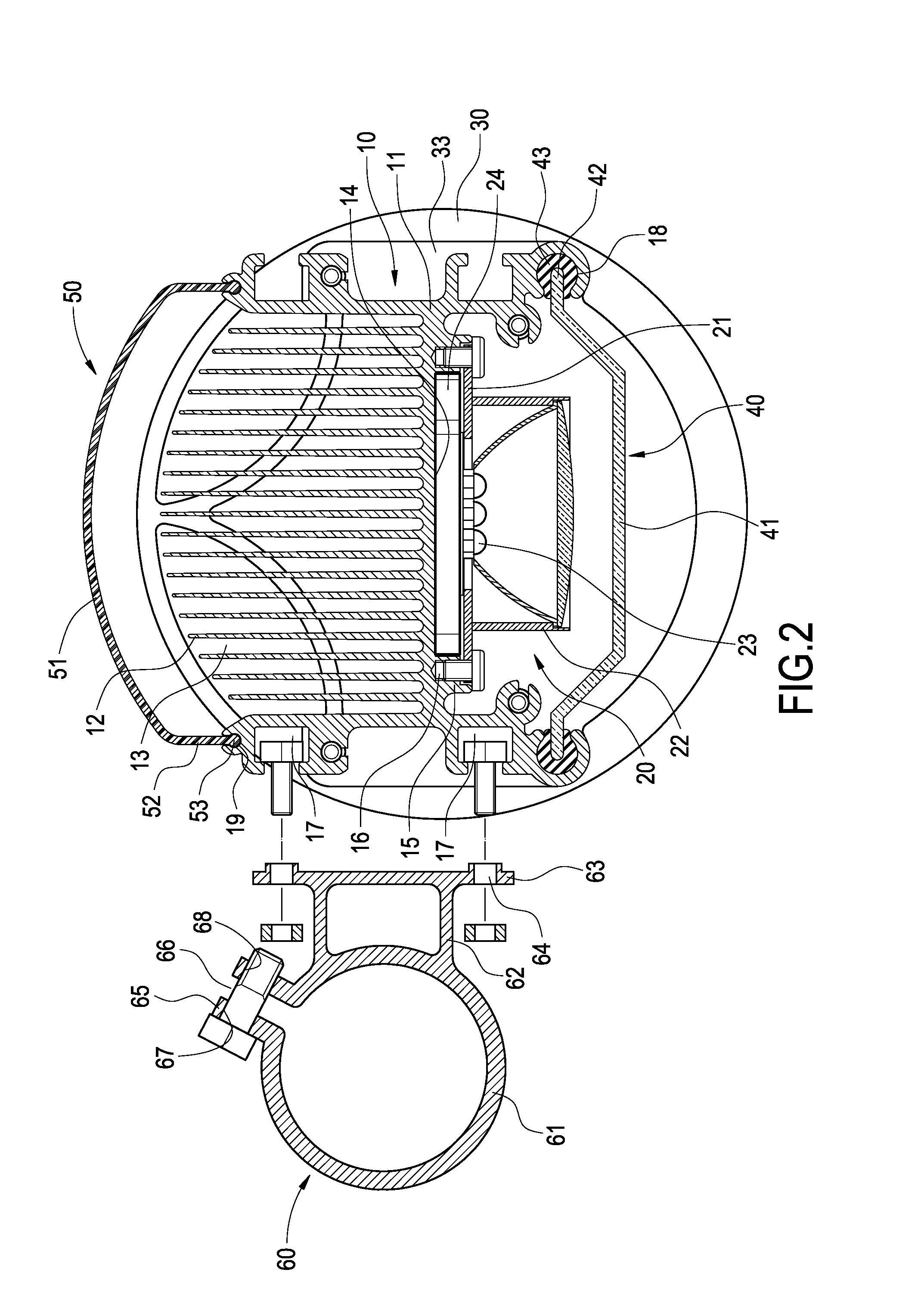

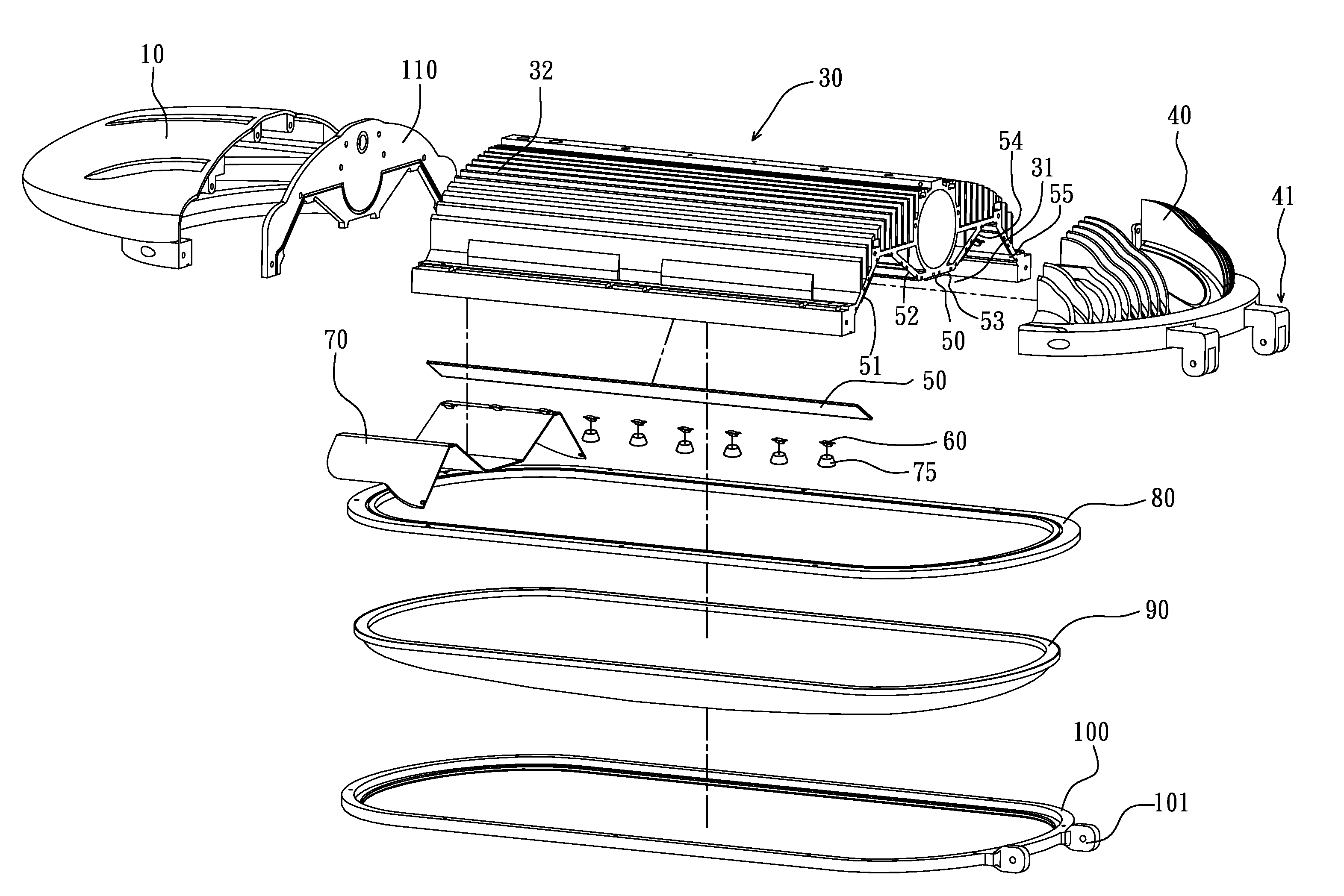

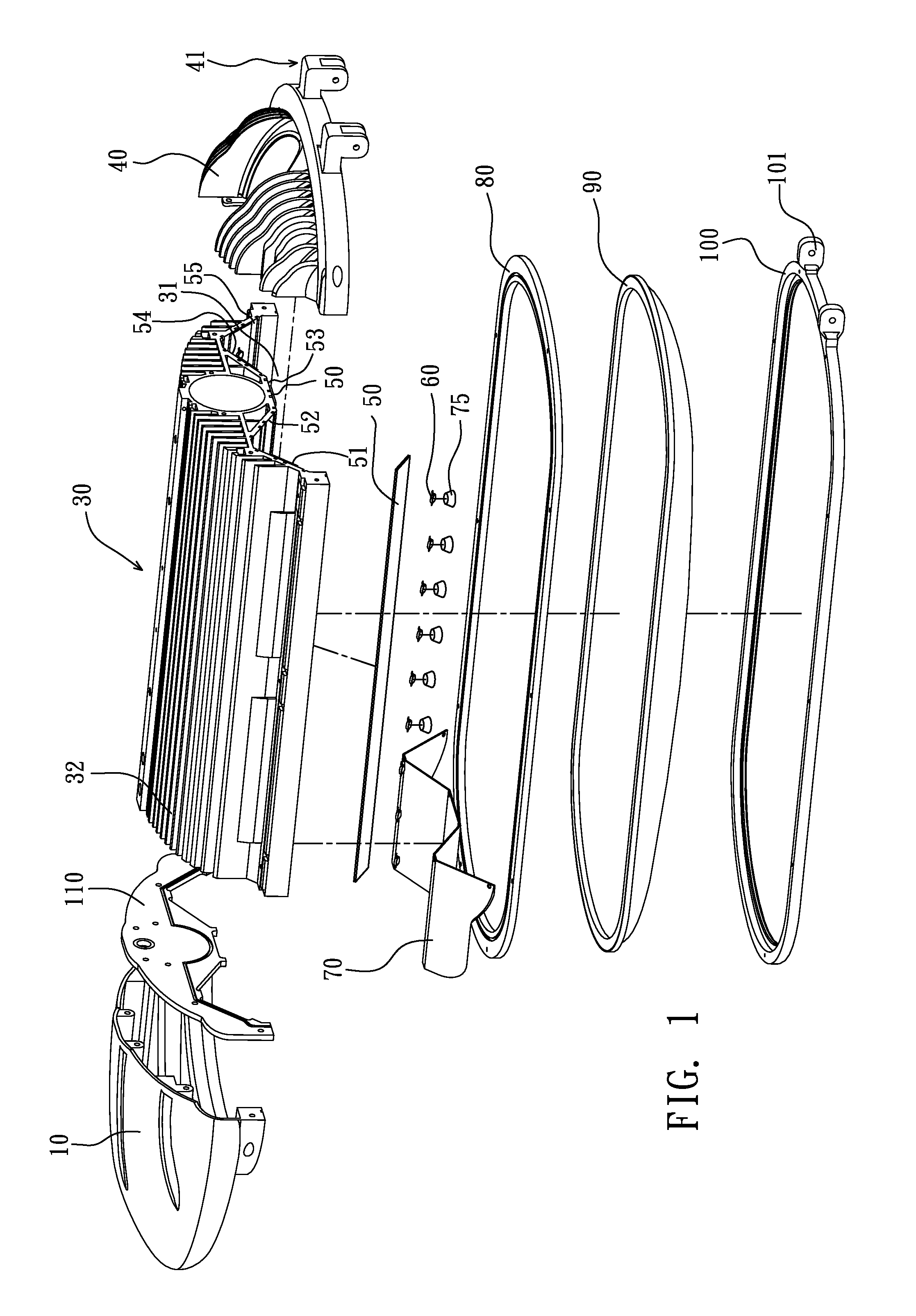

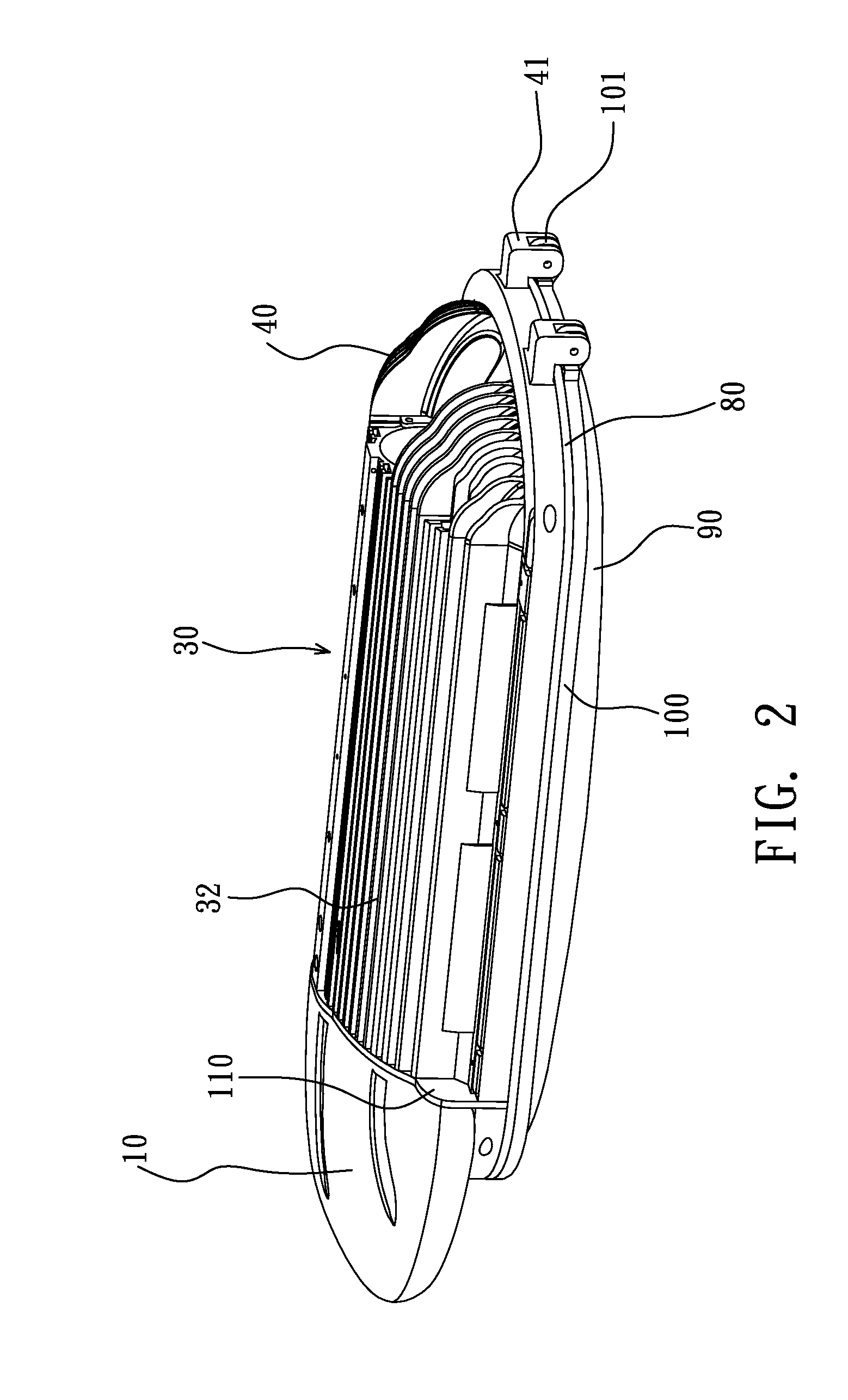

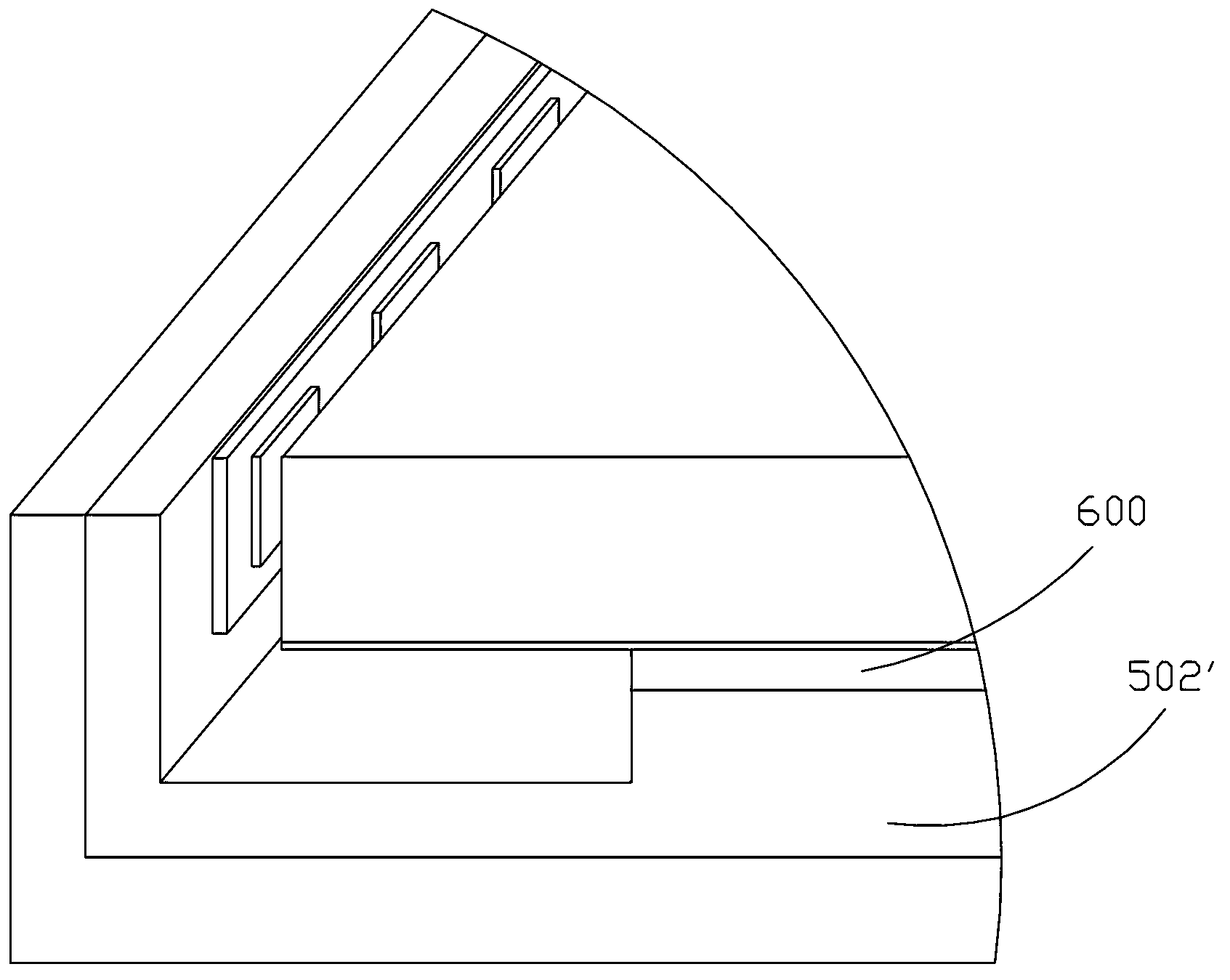

Lamp structure with adjustable projection angle

An LED lamp structure with adjustable projection angle includes an aluminum extrusion lamp housing, an LED module, and a rotating rack. The lamp housing has a base, a plurality of heat sinks extended from the base, and a receiving portion formed on an external side of the base. The LED module includes a fixing base, a lampshade on a side of the fixing base, and a plurality of LED lamps in the lampshade, and the fixing base is coupled in the base of the lamp housing. The rotating rack has a hollow cylindrical body, a fixing board extended from a side of the cylindrical body, and a connecting portion formed on the fixing board and connected to the corresponding receiving portion, so that the projection angle of the LED module can be adjusted according to the illumination requirements for different positions and provide the light required for the illumination area.

Owner:LEADER KEY +1

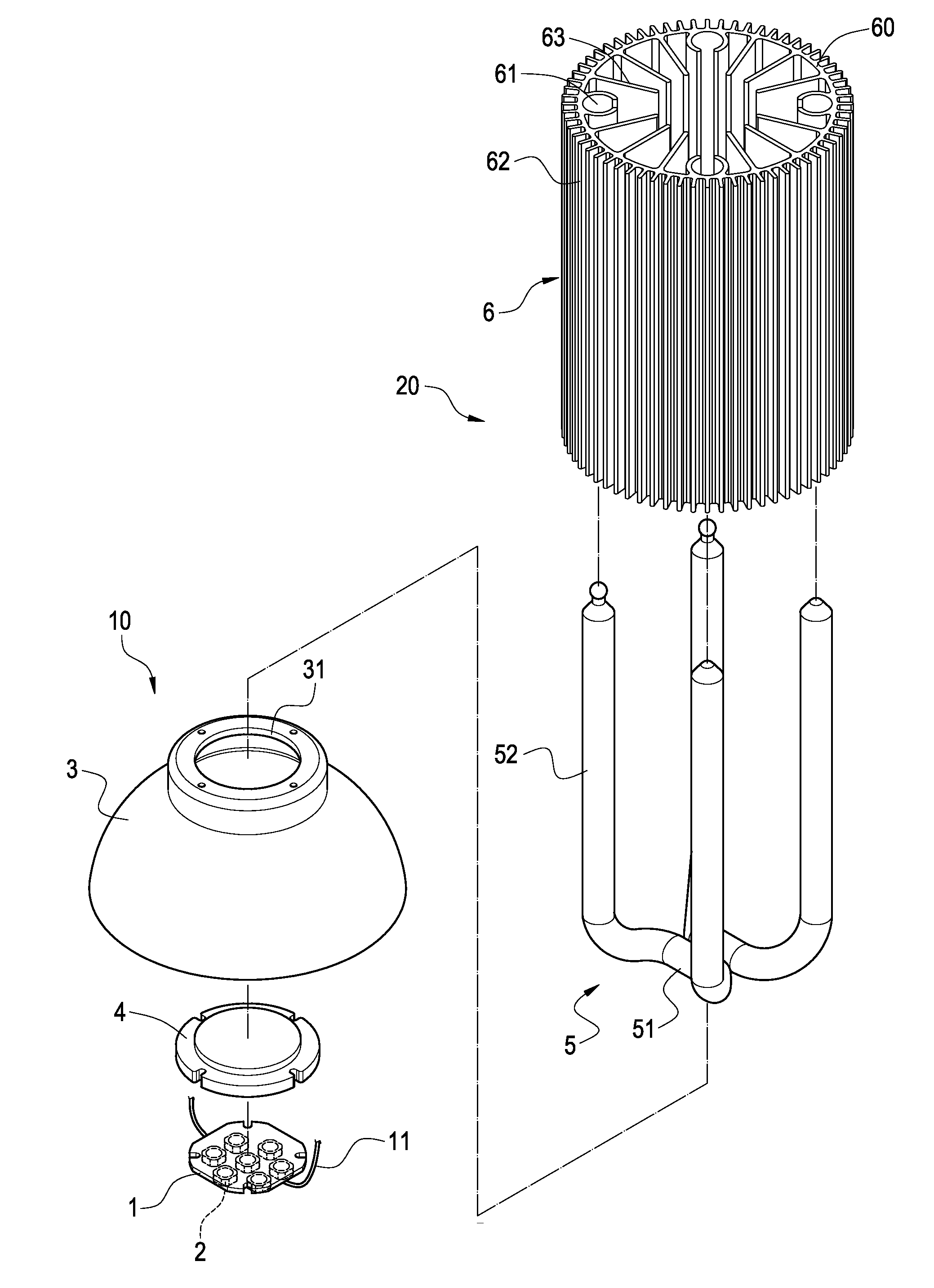

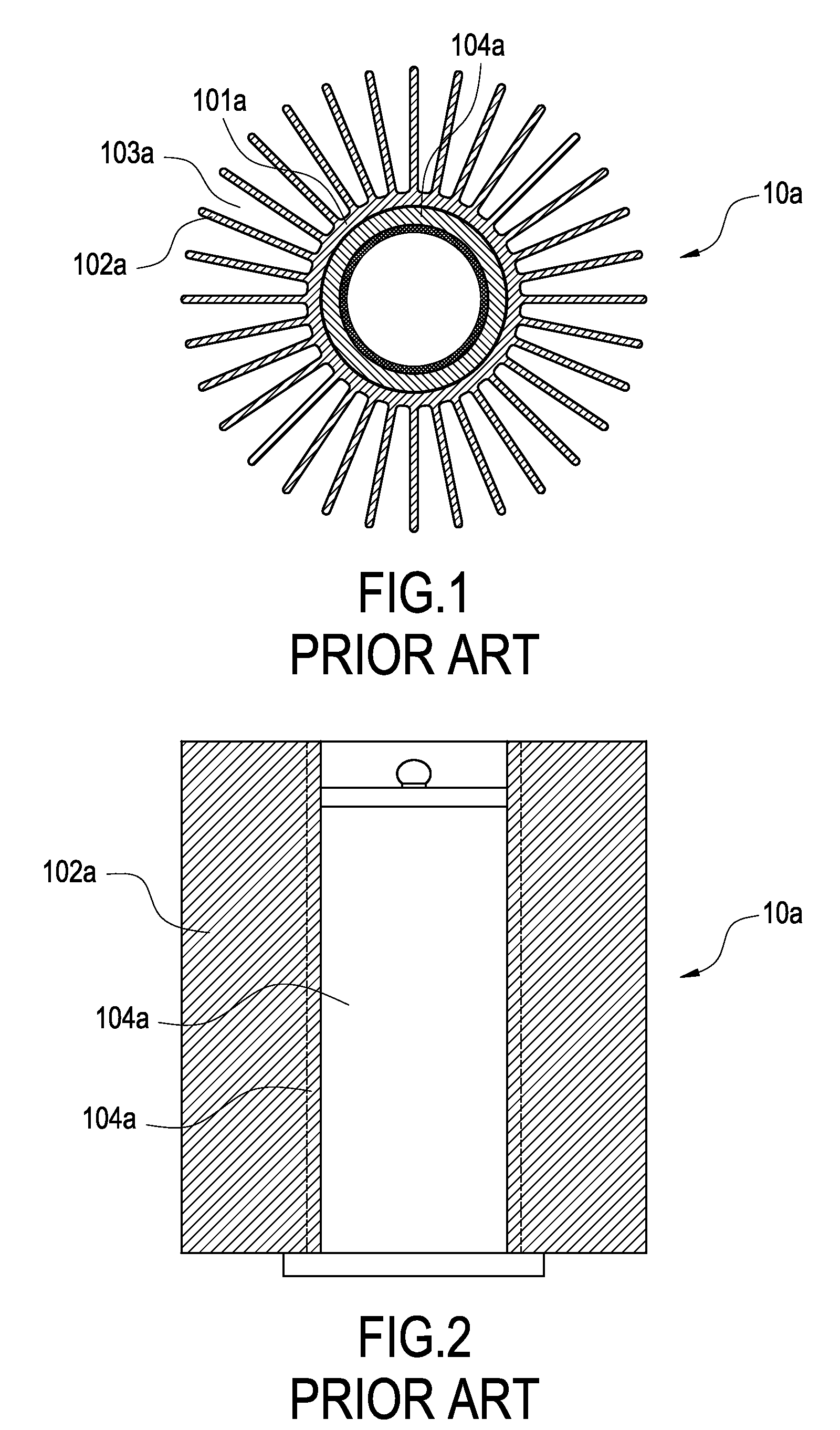

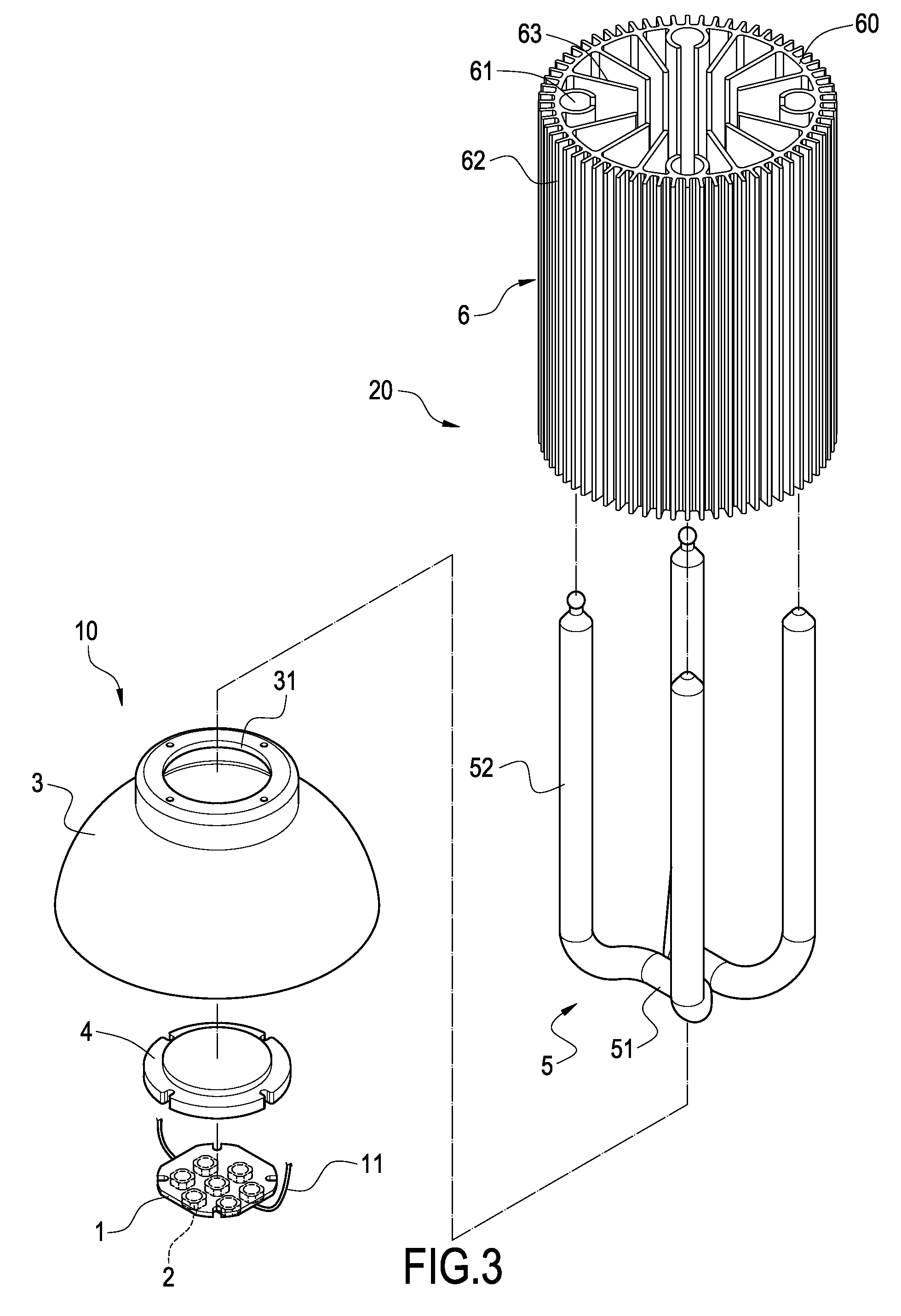

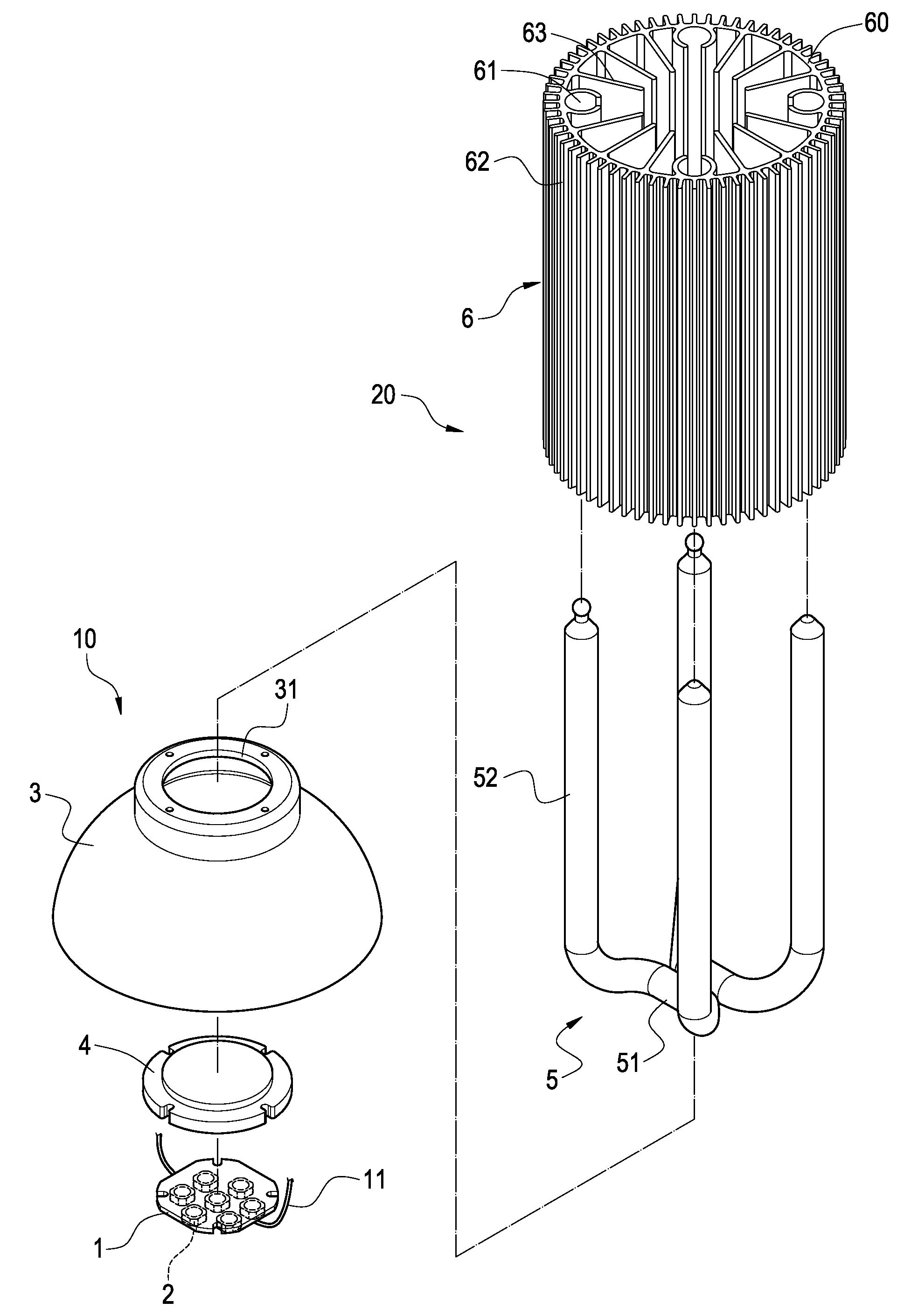

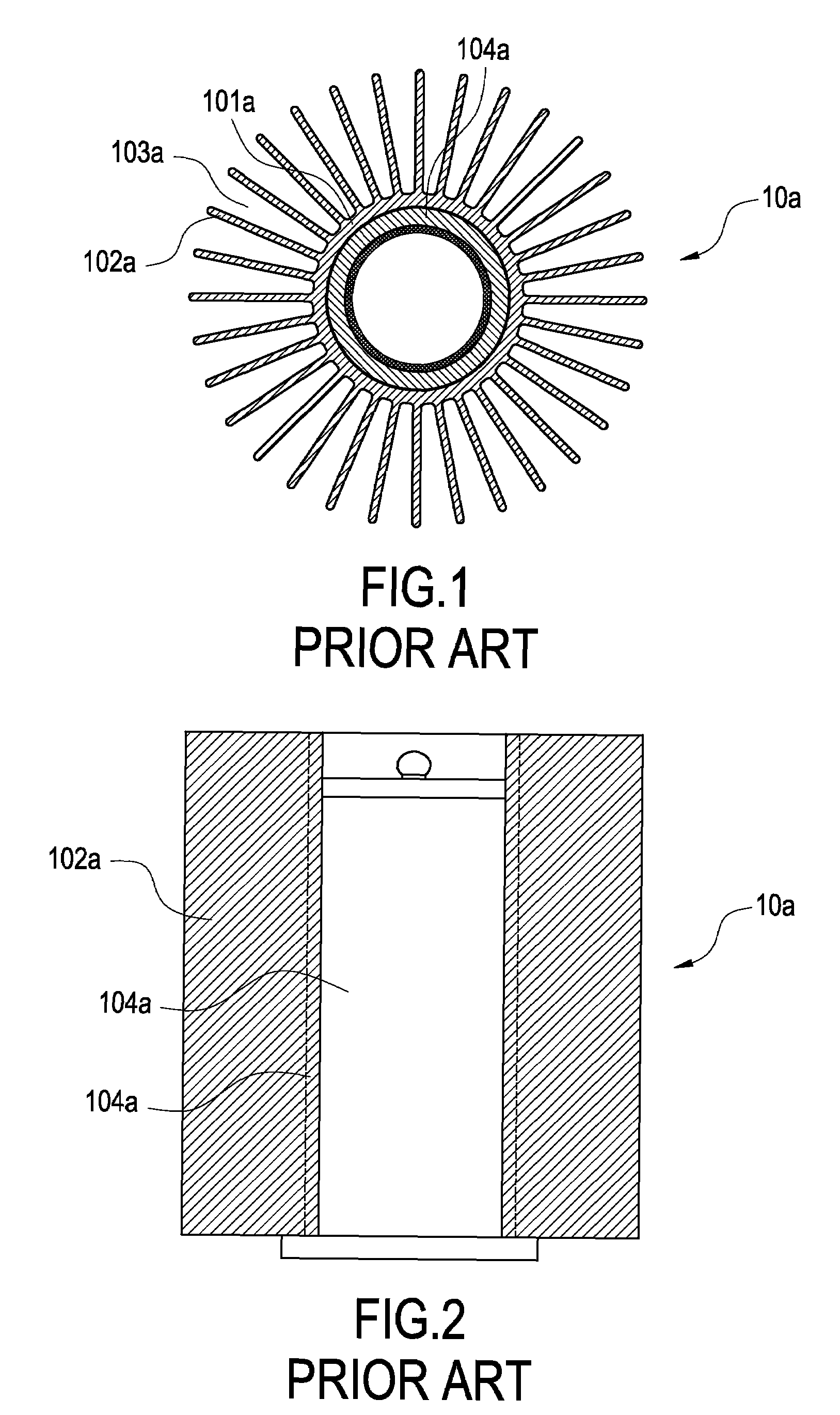

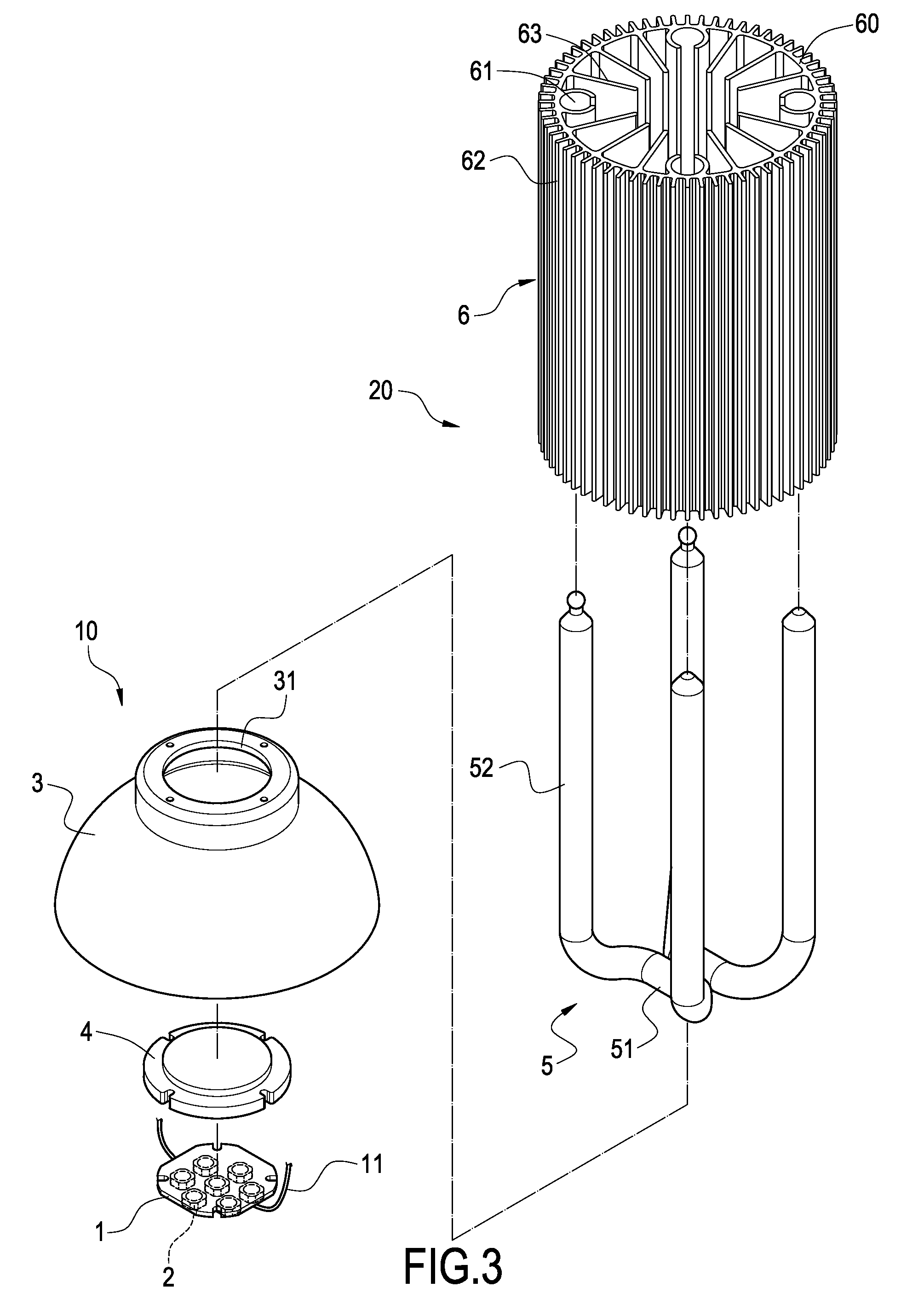

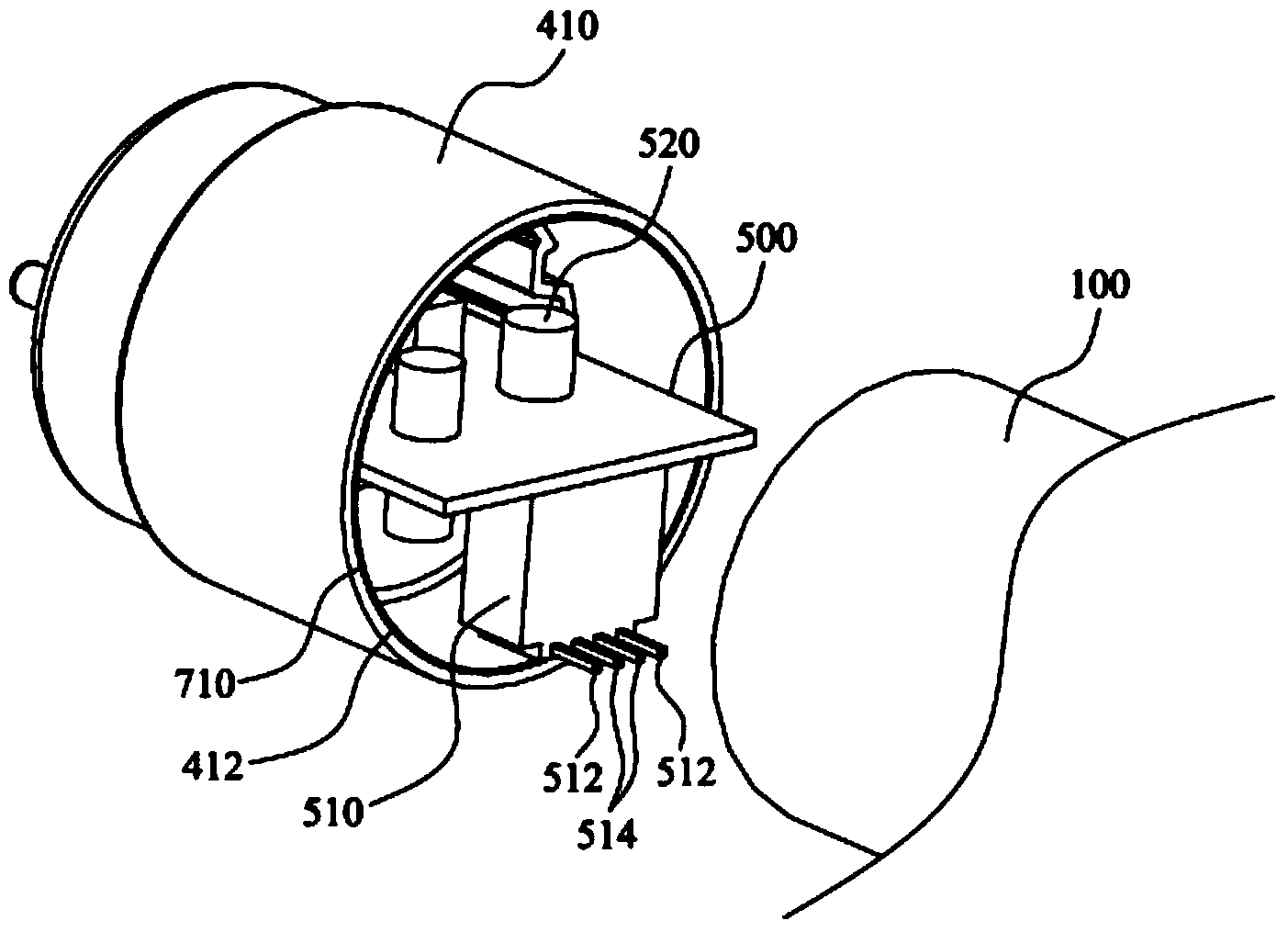

Heat-Dissipating Structure For LED Lamp

InactiveUS20080007954A1Increase contact areaFast conductionPoint-like light sourceLighting heating/cooling arrangementsHeat sinkAluminum extrusion

A heat-dissipating structure for a LED lamp includes a heat-dissipating base, a heat-dissipating body and a plurality of heat pipes. The heat-dissipating body has an outer cylinder formed into a hollow cylinder. The inside surface of the outer cylinder is provided with a plurality of accommodating grooves. The condensed ends of the plurality of heat pipes are inserted into the accommodating grooves. The end to be heated of the heat pipe is adhered to the heat-dissipating base. Further, the inside surface and the outside surface of the outer cylinder are formed with a plurality of heat-dissipating fins made by aluminum extrusion, so that the heat pipes are encircled by the heat-dissipating fins. In this way, the heat can be conducted by the plurality of heat pipes so as to increase the total contacting area. Thus, the heat can be rapidly conducted to the outer cylinder. Further, the heat can be rapidly dissipated to the outside by the heat-dissipating fins, thereby to substantially increase the efficiency in the heat dissipation.

Owner:JAFFE

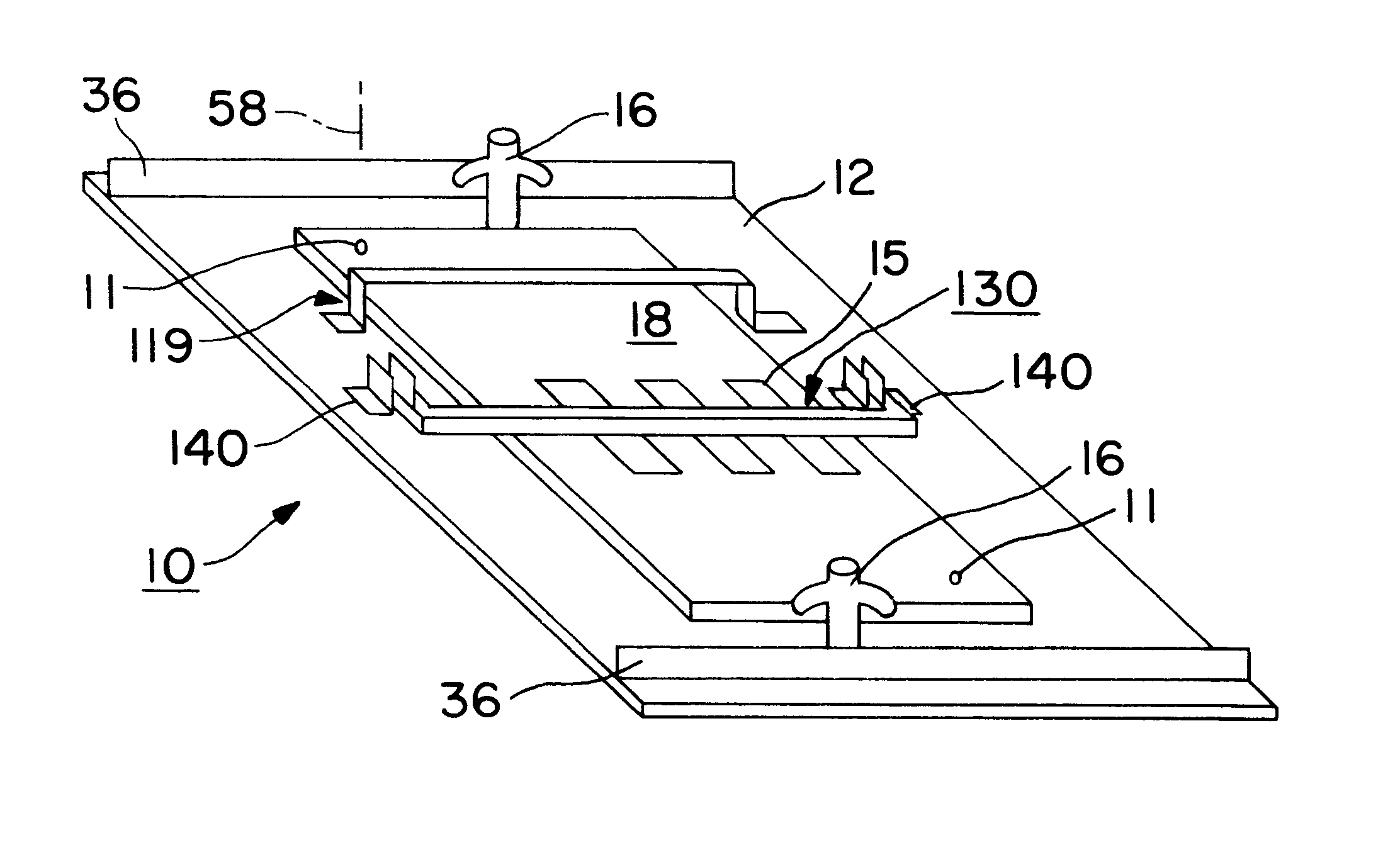

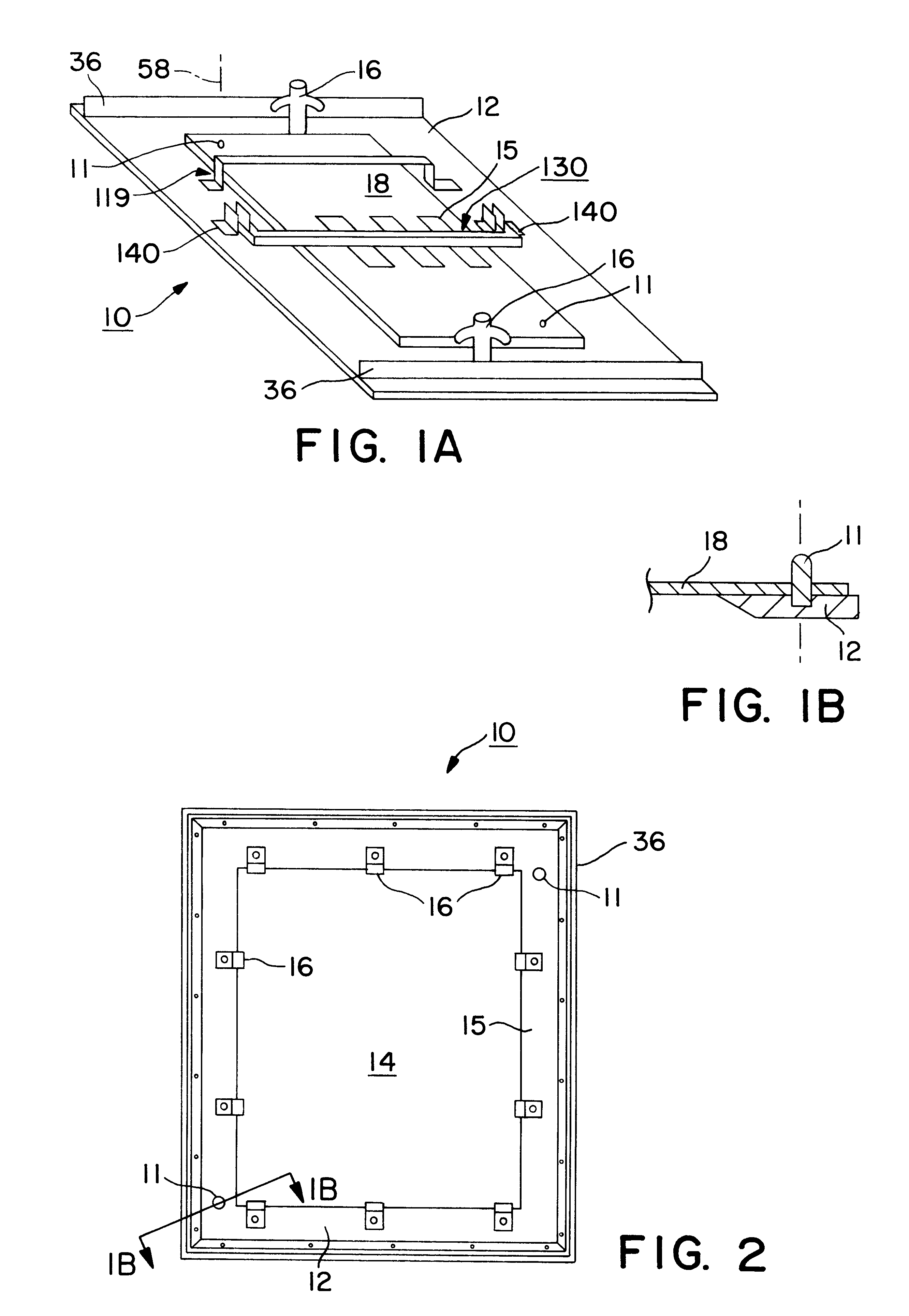

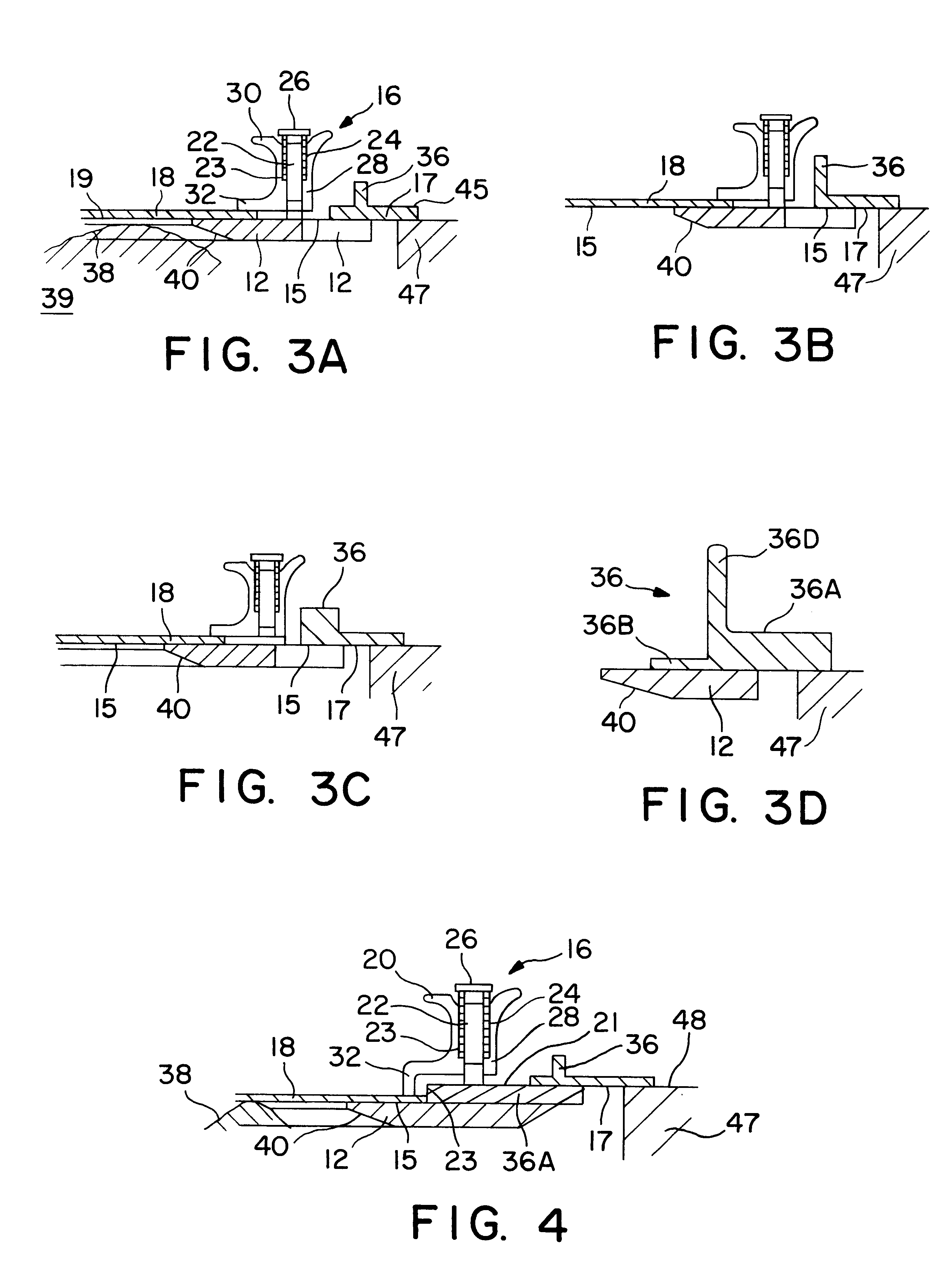

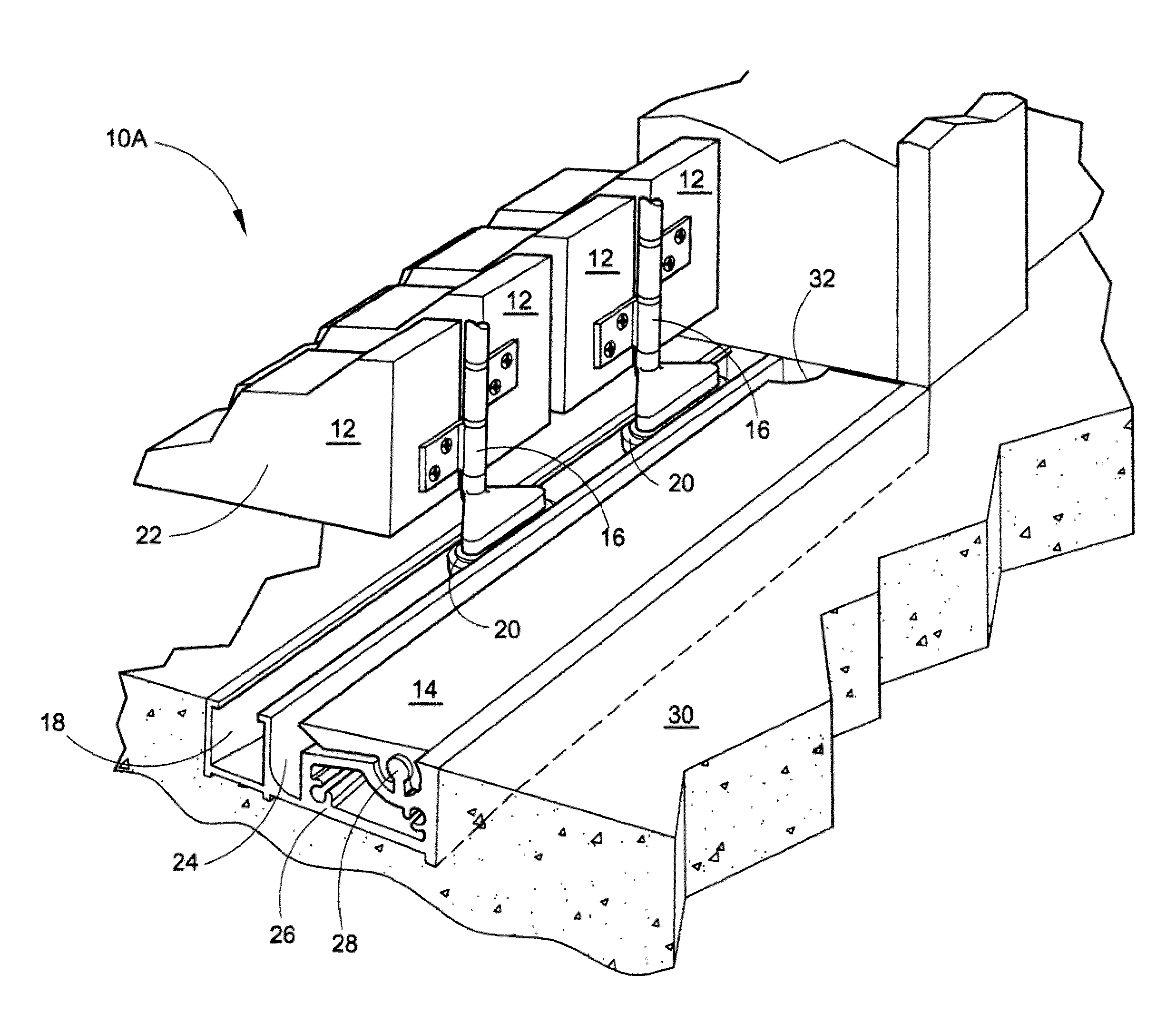

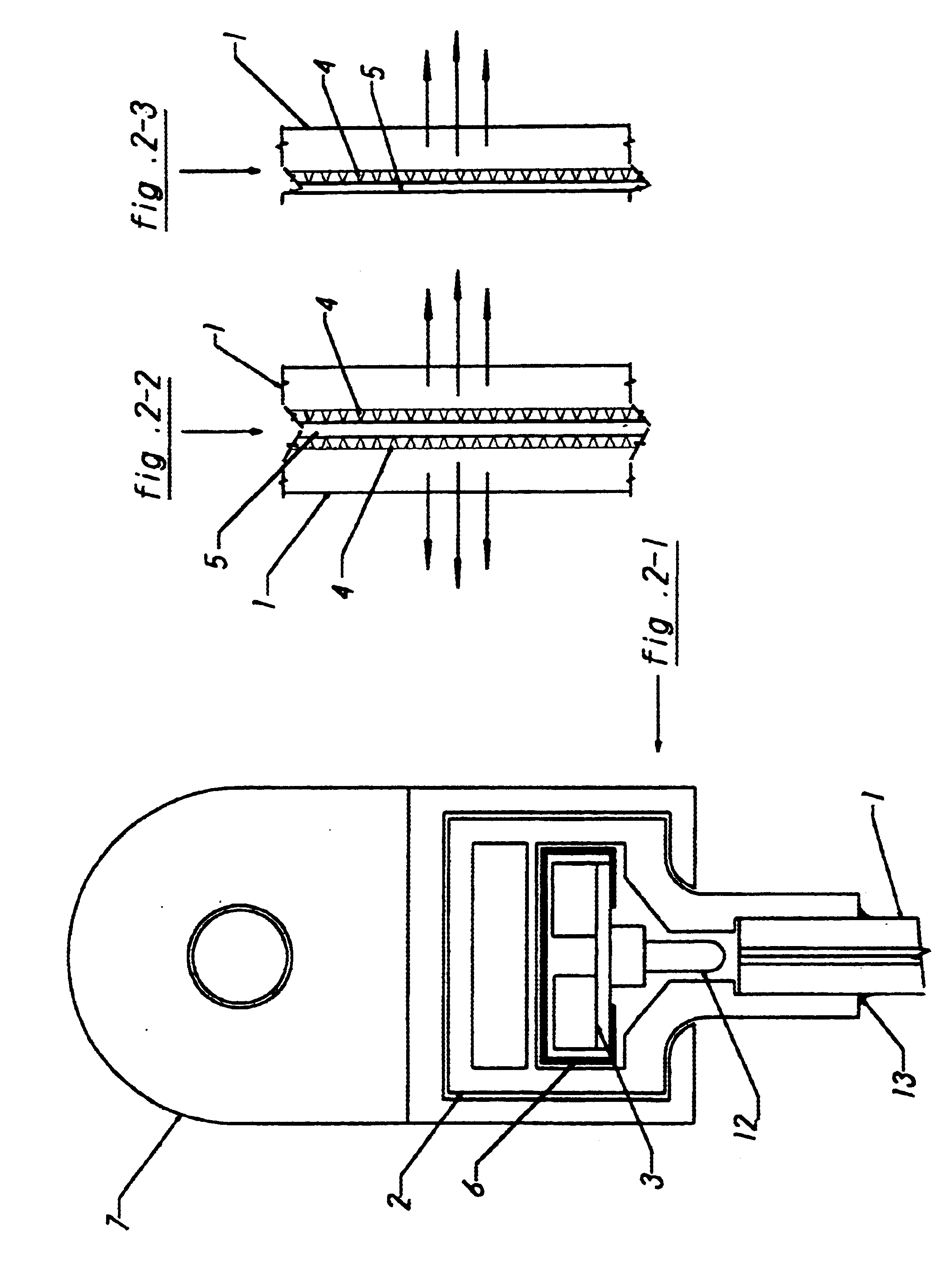

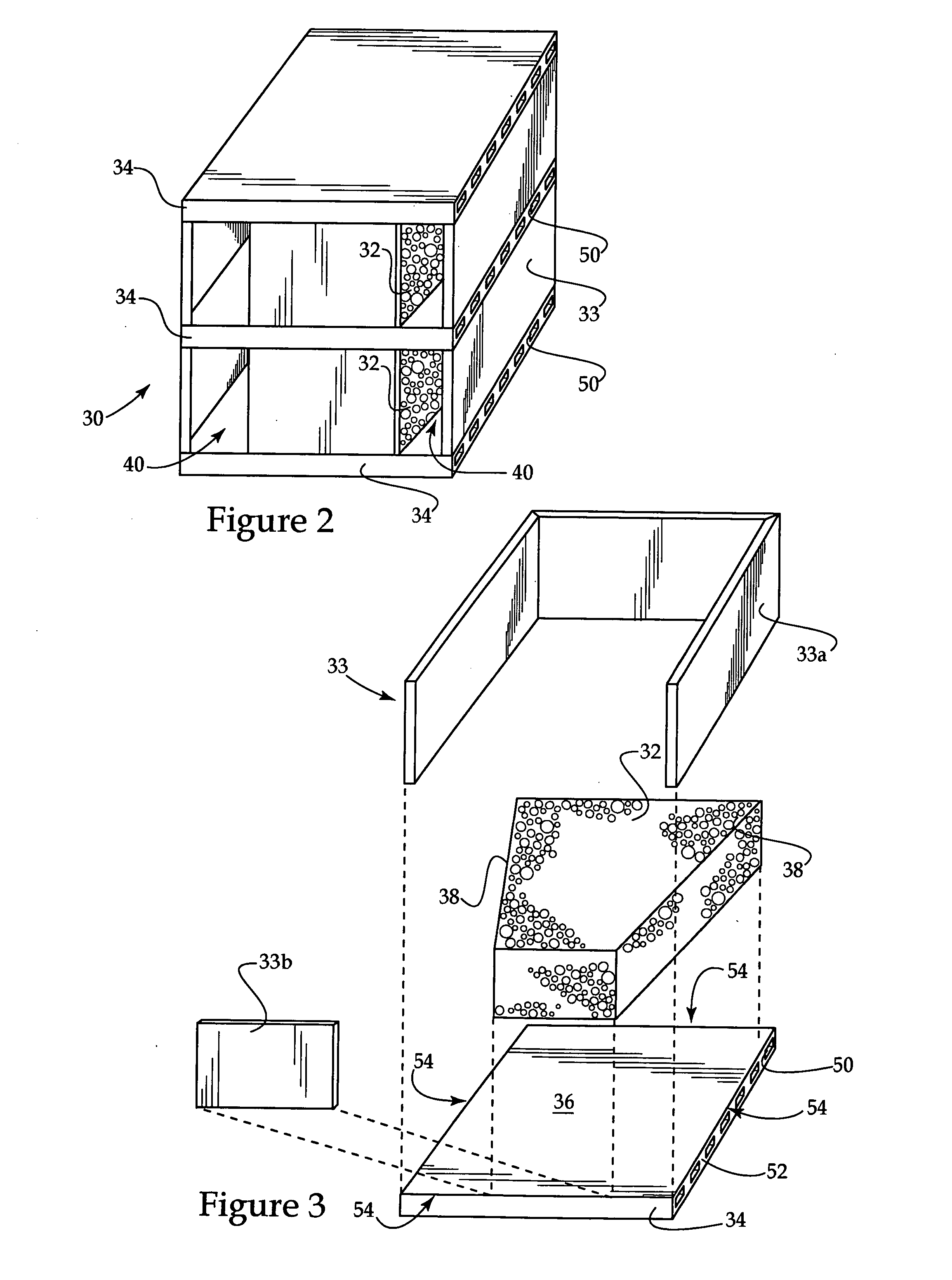

Wave soldering fixture

InactiveUS6237832B1Minimizing conductionMinimizing warpage/bowingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAluminum extrusion

An apparatus used in a process for supporting a printed circuit board during a wave soldering operation including a frame with a frame opening in which a surface of the frame supports the board and also serves as a reference surface for vertically positioning the board above the solder pool. The board is secured against the reference surface with spring loaded clamps. Stiffeners preferably being an aluminum extrusion having a Tee or angle cross section is mounted along the outside edge of the reference surface of the frame and has a second reference surface facing in a direction opposite the reference surface of the frame. The second reference surface on the extrusion is accessible for support by a slide rail so that the height of the reference surface of the frame above the surface of the pool is independent of the thickness of the board or frame. A board support bar for minimizing warpage of the board from heat is disclosed as well as a hold down bar that secures components on the board so that they do not float away when contacted by the solder wave.

Owner:CHUNG HENRY

Heat-dissipating structure for LED lamp

InactiveUS7494248B2Increase contact areaFast conductionPoint-like light sourceLighting heating/cooling arrangementsEngineeringHeat sink

A heat-dissipating structure for a LED lamp includes a heat-dissipating base, a heat-dissipating body and a plurality of heat pipes. The heat-dissipating body has an outer cylinder formed into a hollow cylinder. The inside surface of the outer cylinder is provided with a plurality of accommodating grooves. The condensed ends of the plurality of heat pipes are inserted into the accommodating grooves. The end to be heated of the heat pipe is adhered to the heat-dissipating base. Further, the inside surface and the outside surface of the outer cylinder are formed with a plurality of heat-dissipating fins made by aluminum extrusion, so that the heat pipes are encircled by the heat-dissipating fins. In this way, the heat can be conducted by the plurality of heat pipes so as to increase the total contacting area. Thus, the heat can be rapidly conducted to the outer cylinder. Further, the heat can be rapidly dissipated to the outside by the heat-dissipating fins, thereby to substantially increase the efficiency in the heat dissipation.

Owner:JAFFE

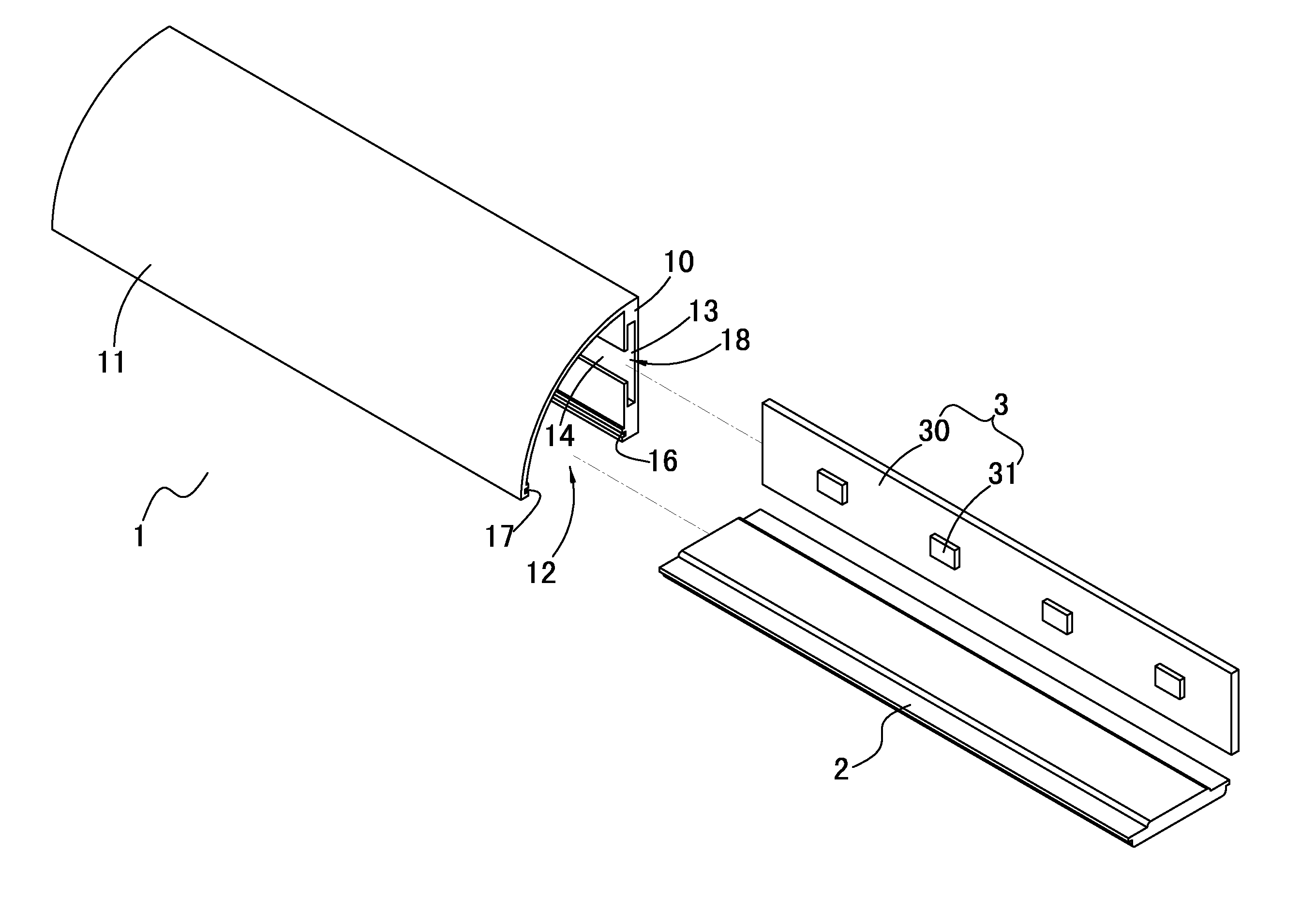

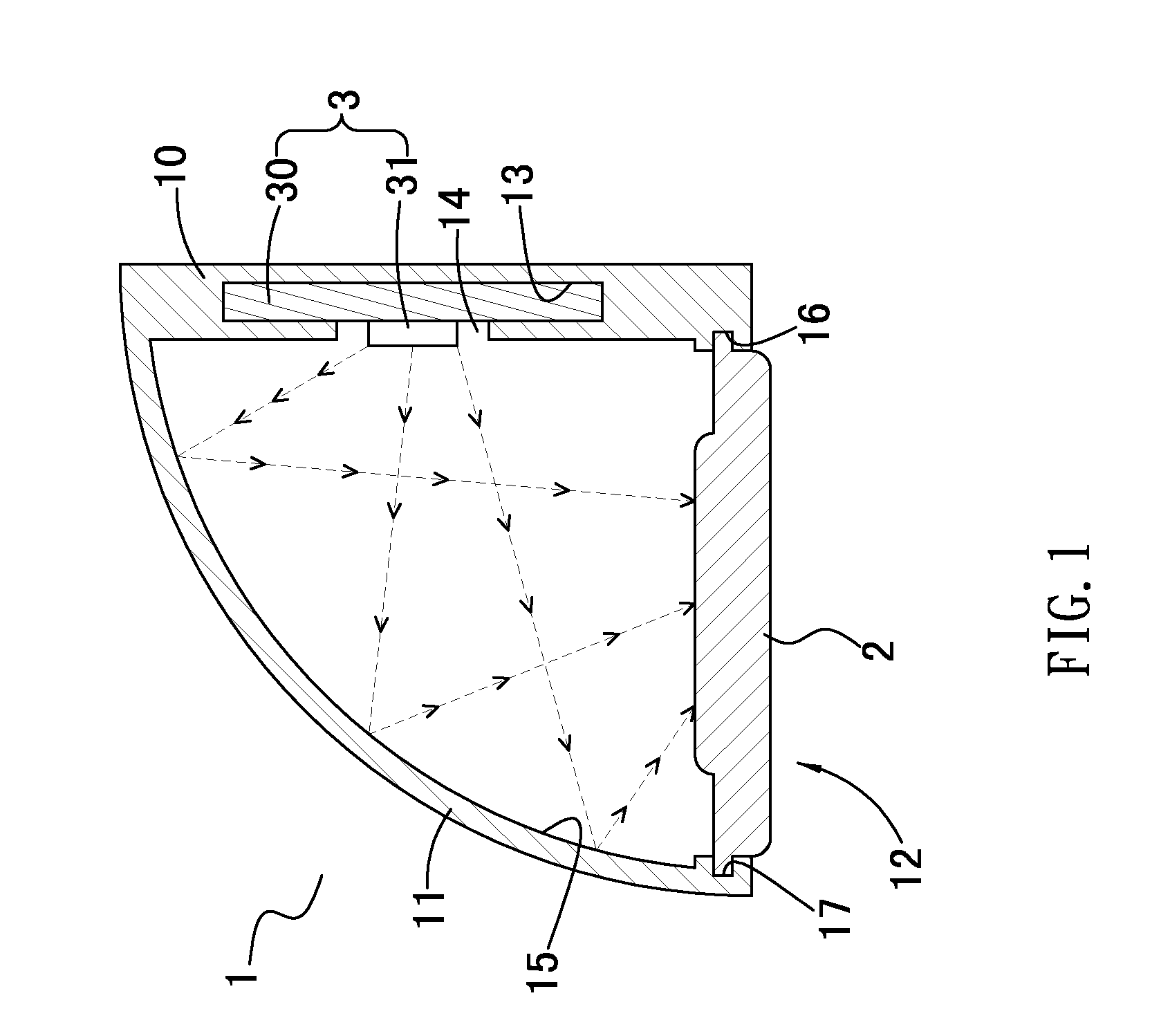

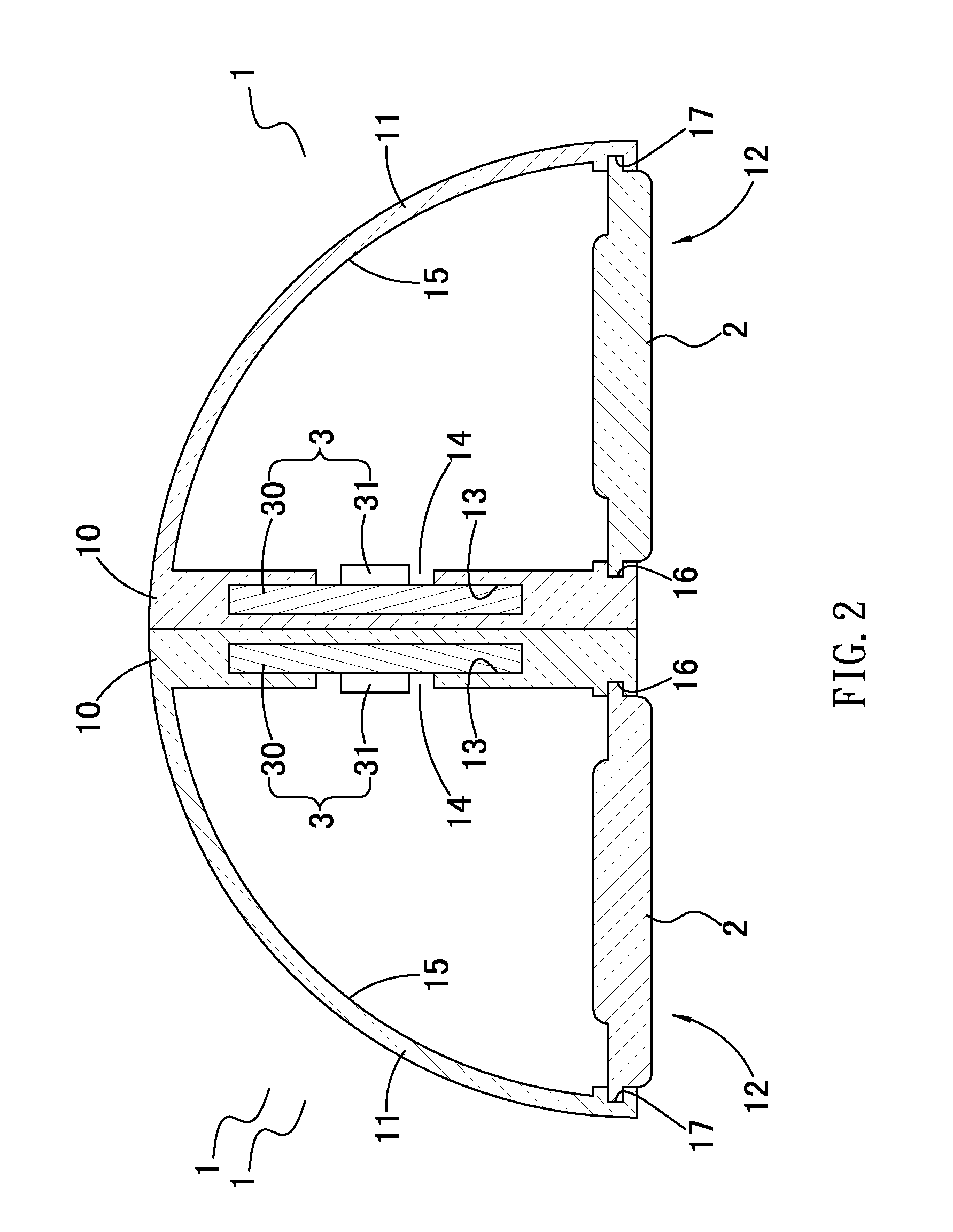

Even luminance, high heat dissipation efficiency, high power LED lamp structure

InactiveUS20100027269A1Solve the low heat dissipation efficiencyImprove cooling efficiencyPoint-like light sourceElongate light sourcesDie castingEngineering

An even luminance, high heat dissipation efficiency, high power LED lamp structure includes an aluminum extrusion body, an aluminum die cast front casing and an aluminum die cast rear casing respectively provided at two distal ends of the aluminum extrusion body, a PC board mounted inside the aluminum extrusion body, LEDs mounted in different LED mounting faces of the PC board at different angles, an inner cover plate decorating the inside of the aluminum die cast front casing, a transparent outer cover covering the bottom side of the aluminum extrusion body and sealed with a water seal, and a retaining device fastened to the aluminum extrusion body to secure the transparent outer cover in place.

Owner:LO WEI HUNG

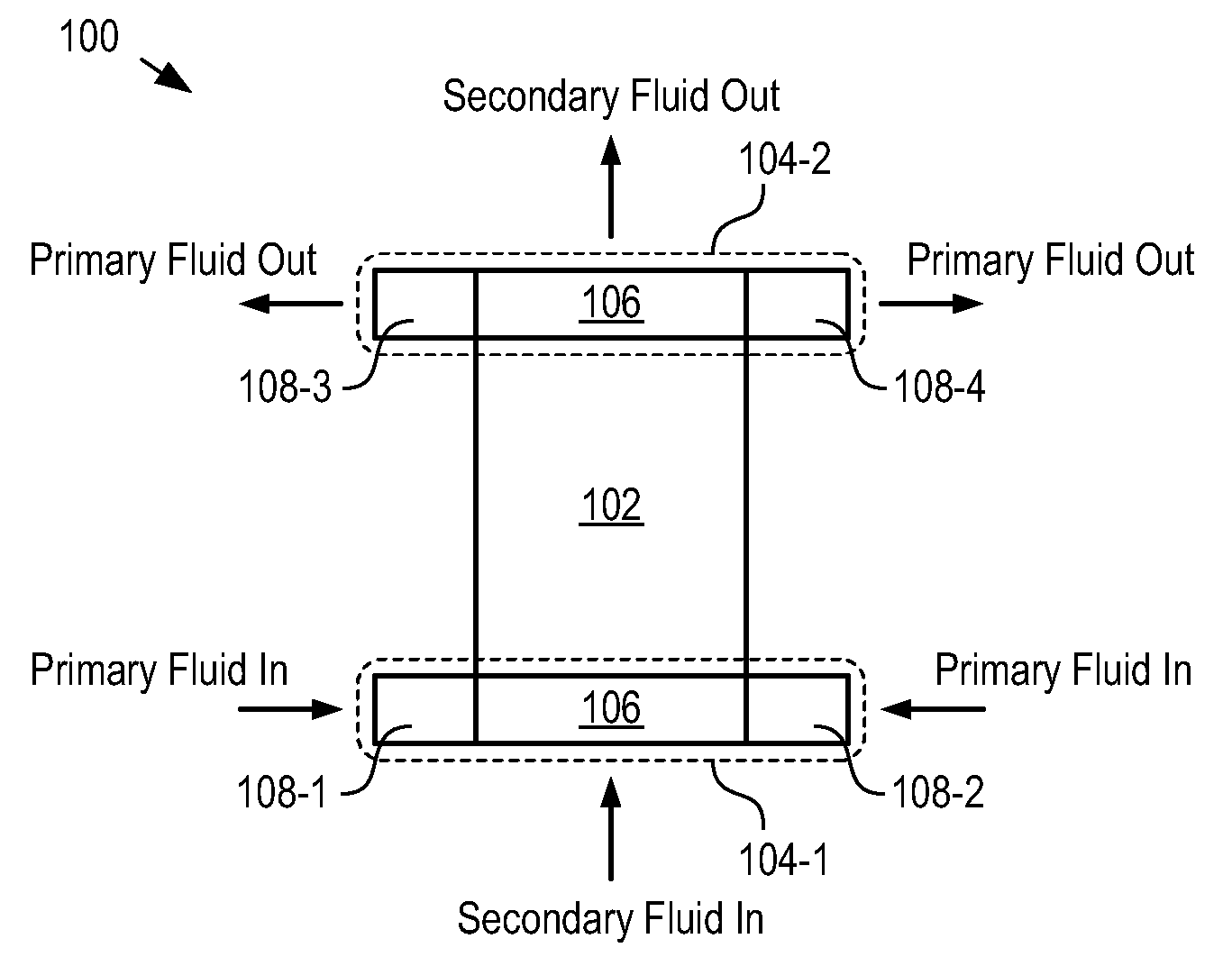

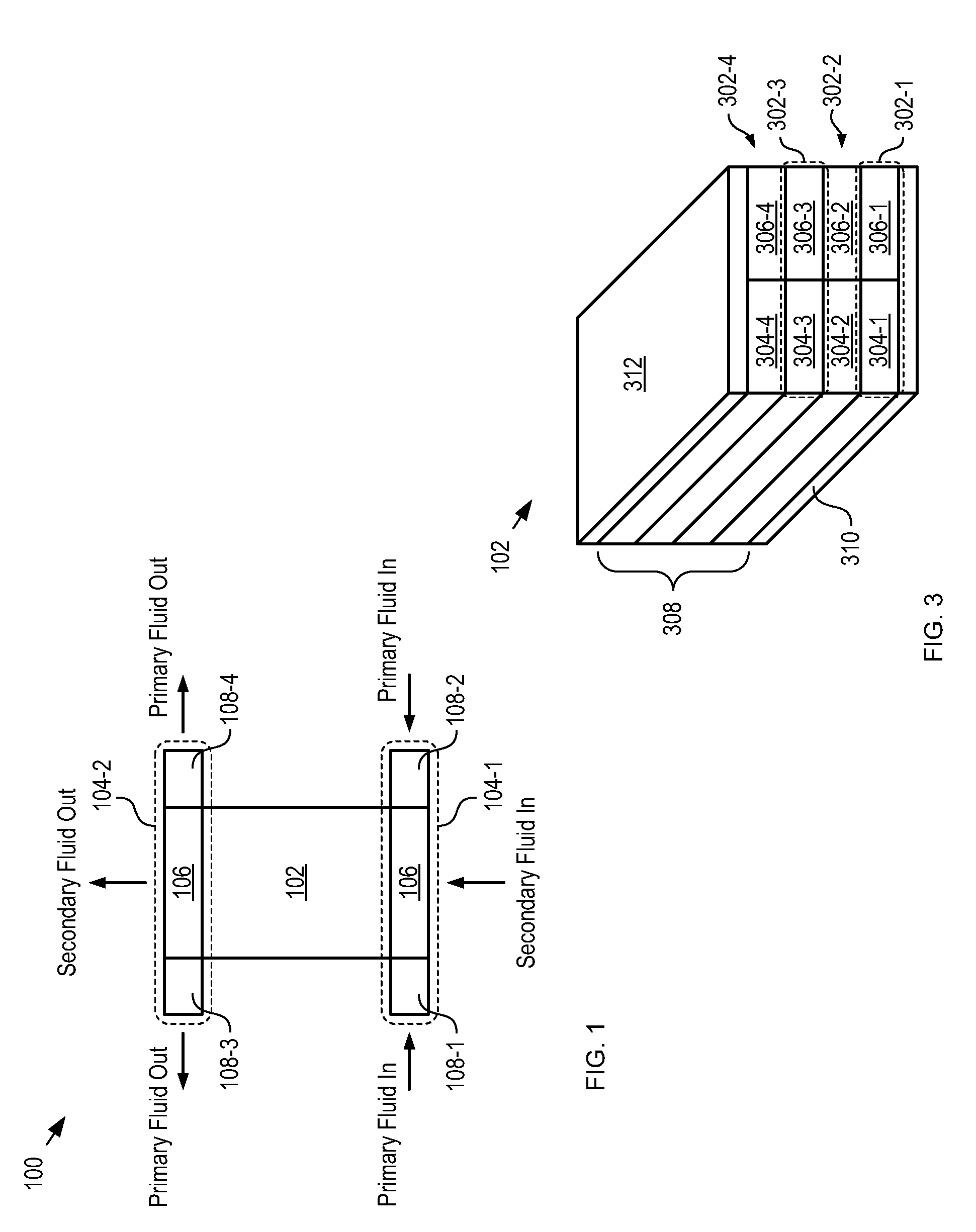

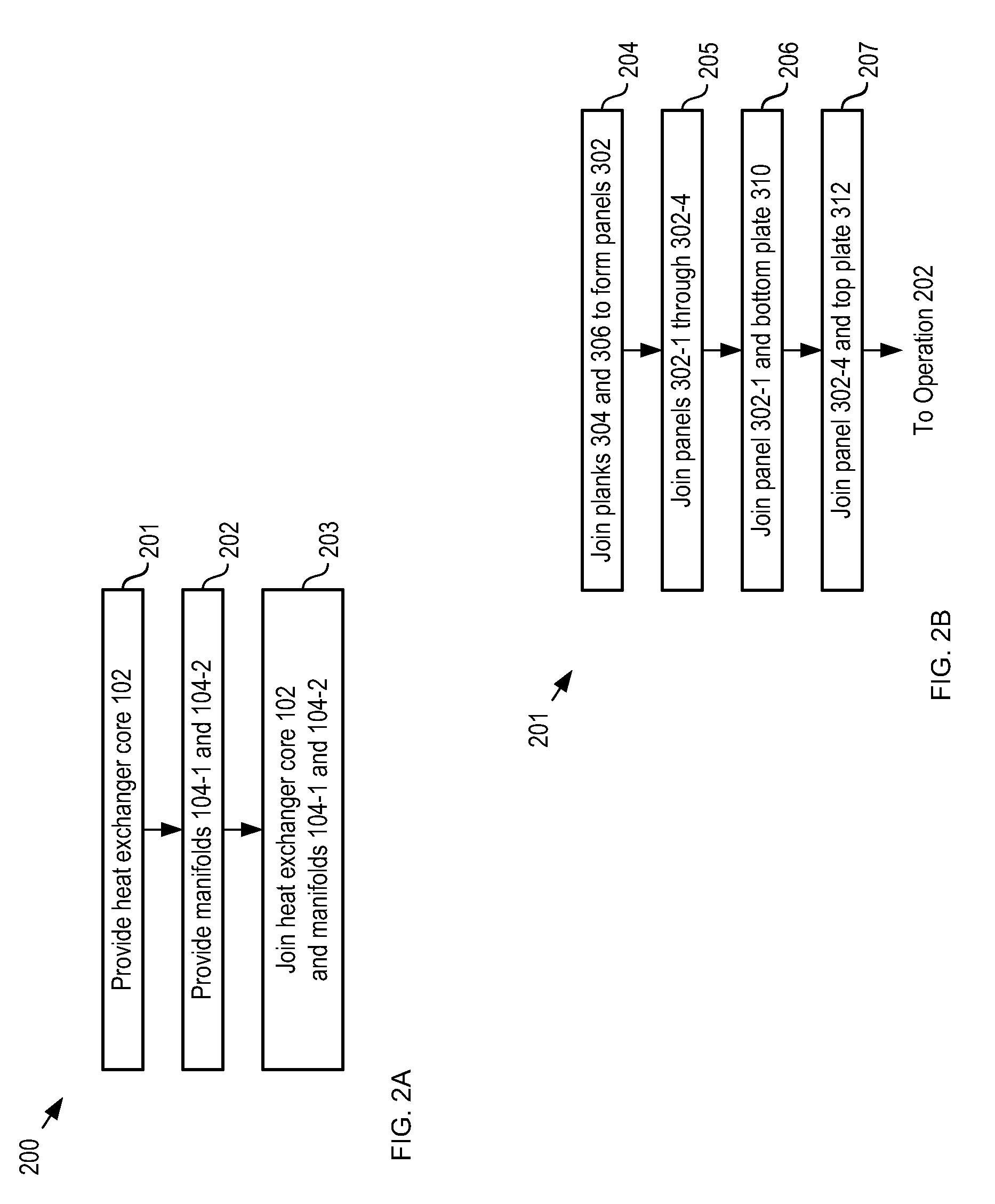

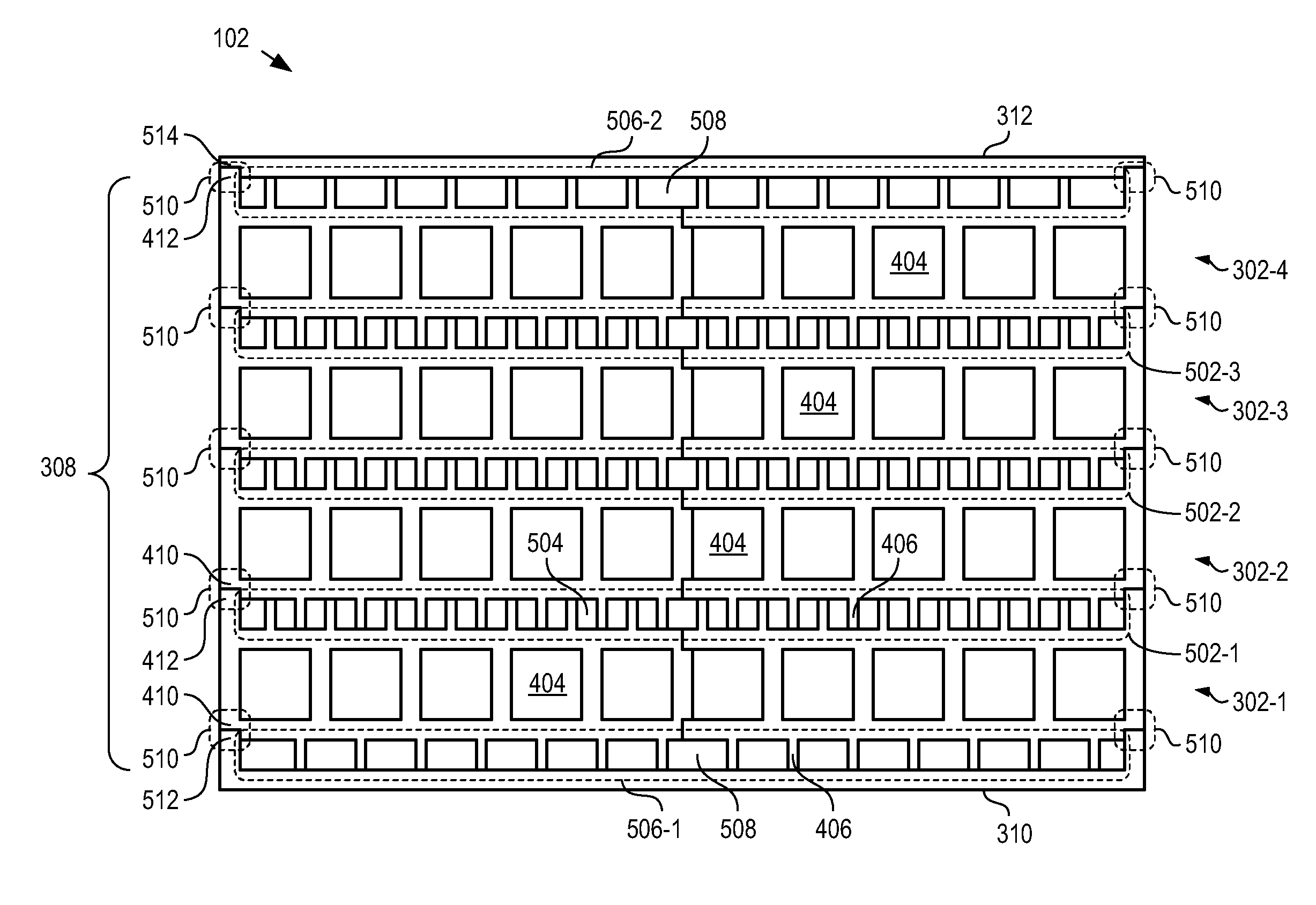

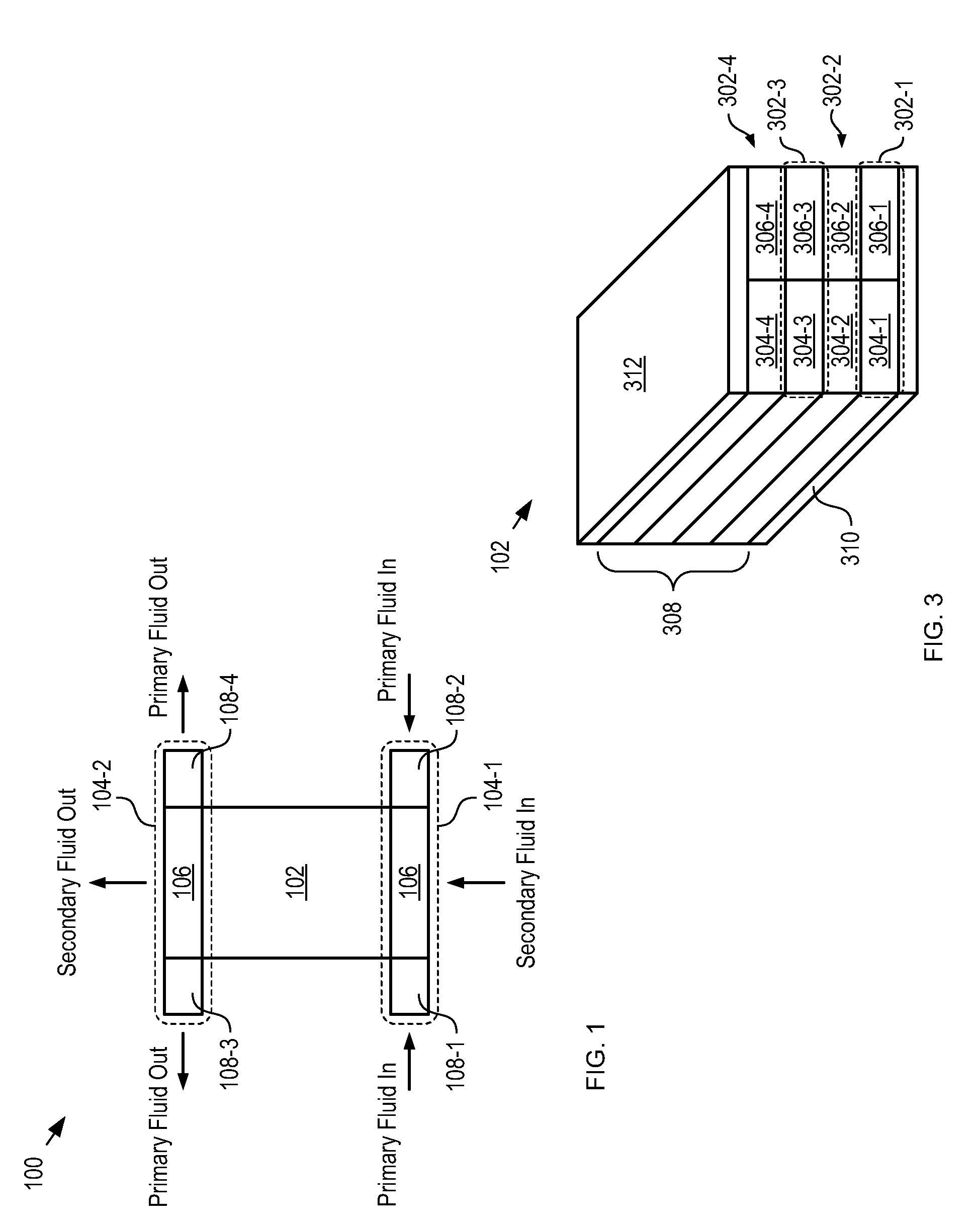

Heat Exchanger

ActiveUS20090308582A1Prevent materialAvoid introducingOther heat production devicesGeothermal energy generationFriction weldingPlate heat exchanger

A heat exchanger and a method for fabricating the heat exchanger are disclosed. The heat exchanger comprises a heat exchanger core that is formed from a plurality of stacked aluminum panels that are joined together via friction stir welding. Each panel in the core is formed from at least two aluminum extrusions that are joined to one another via friction stir welding.

Owner:LOCKHEED MARTIN CORP

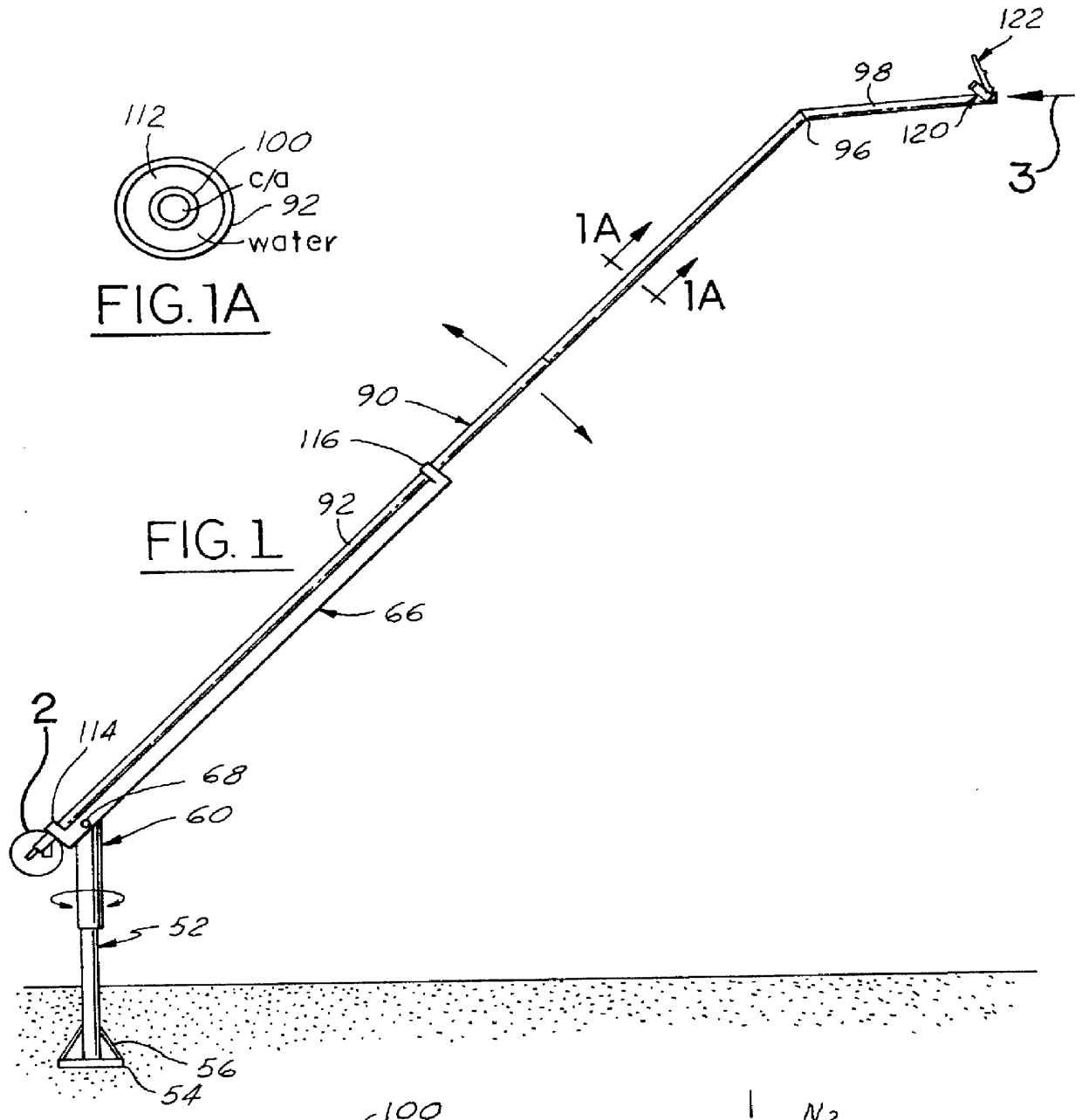

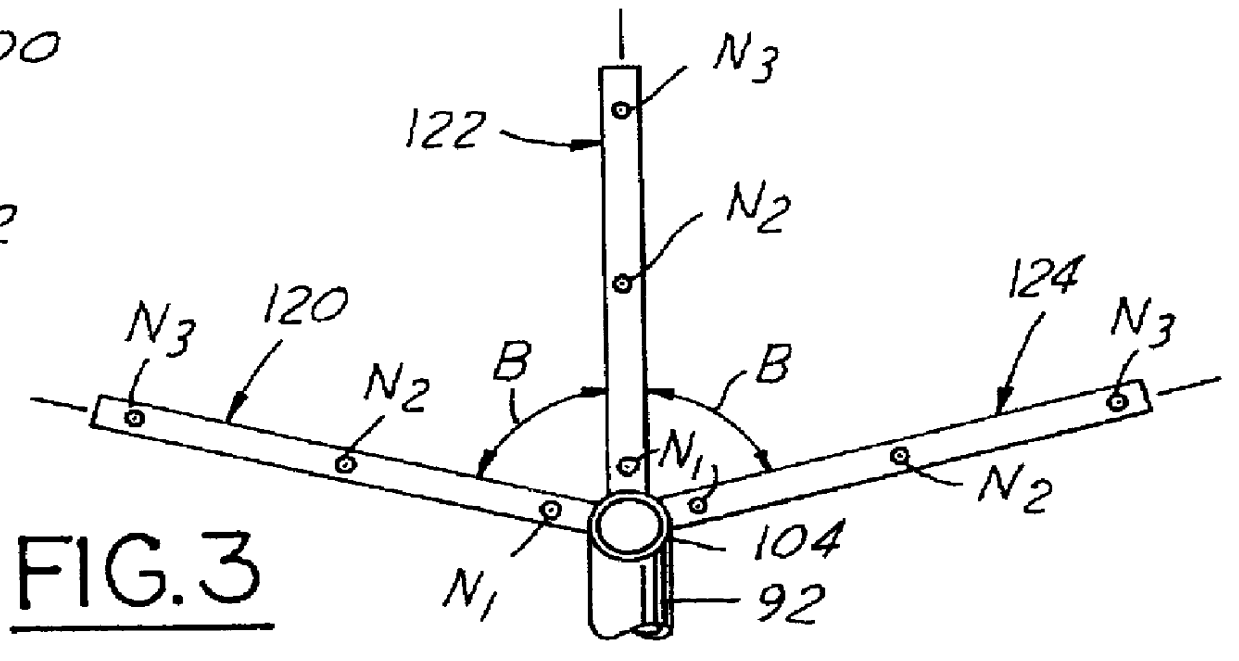

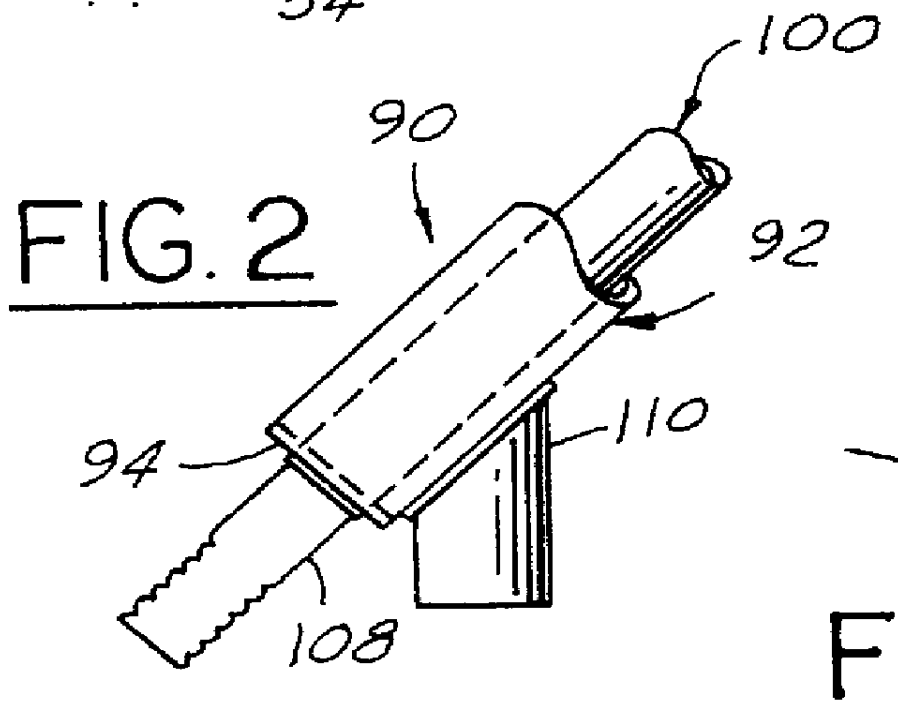

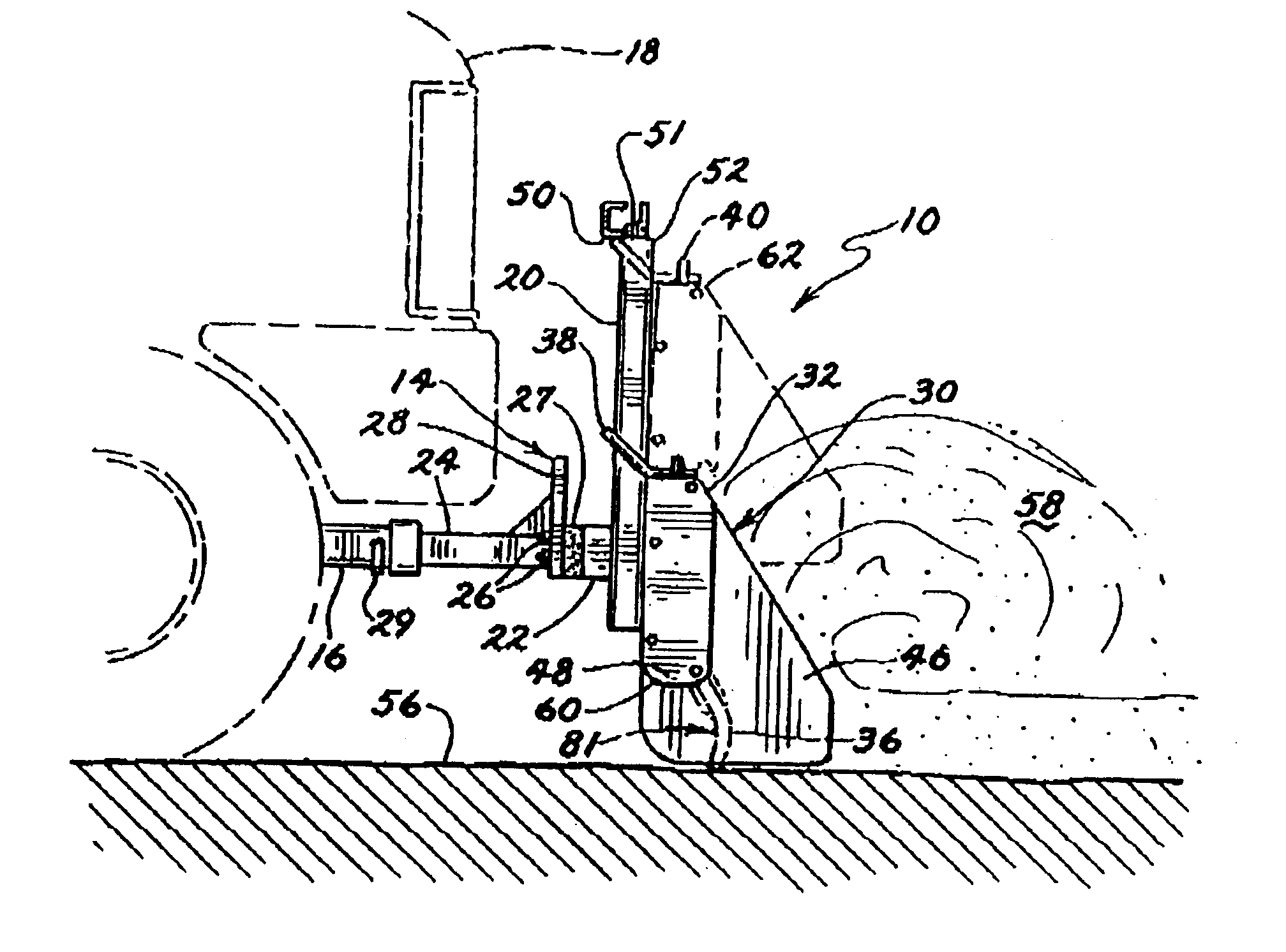

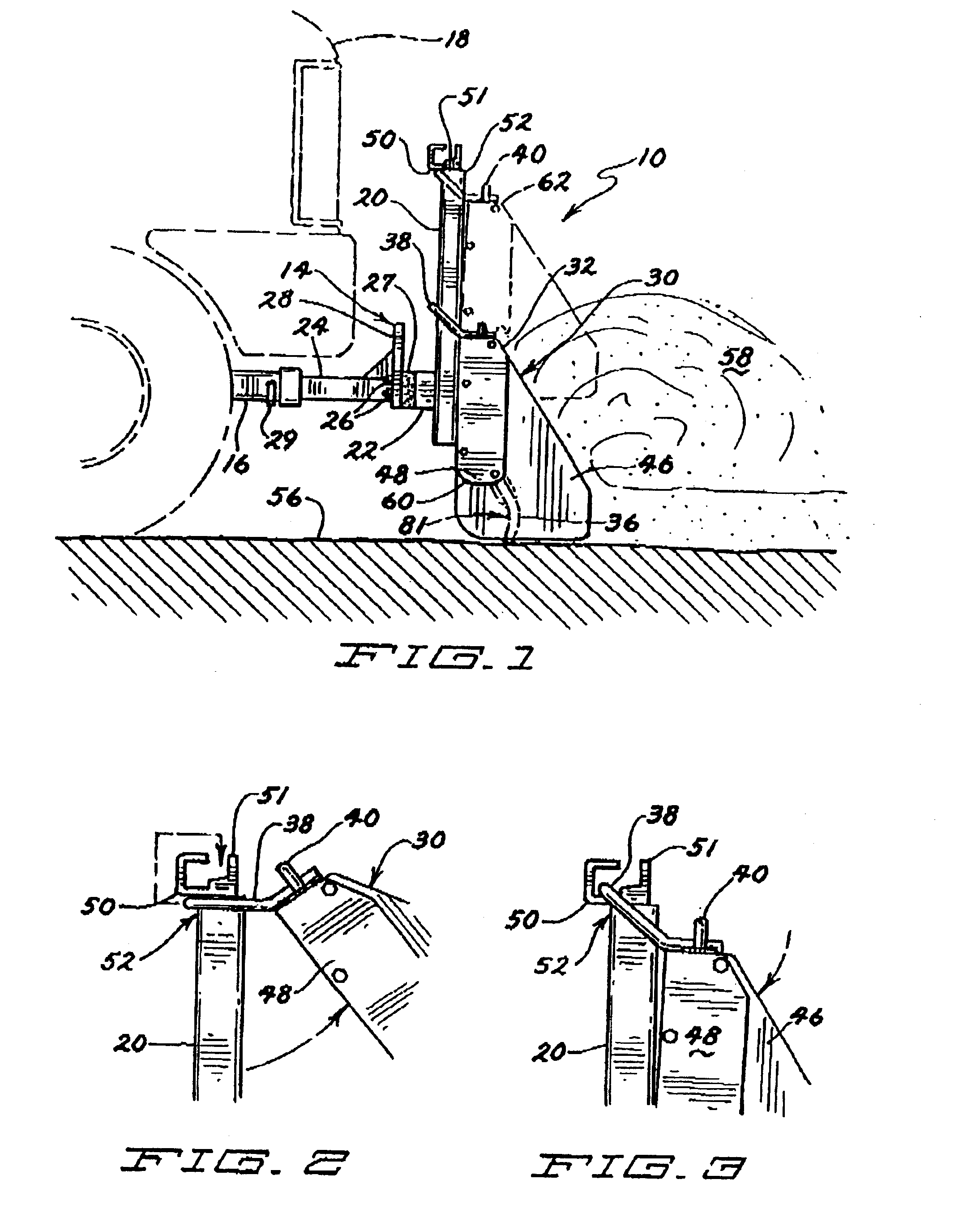

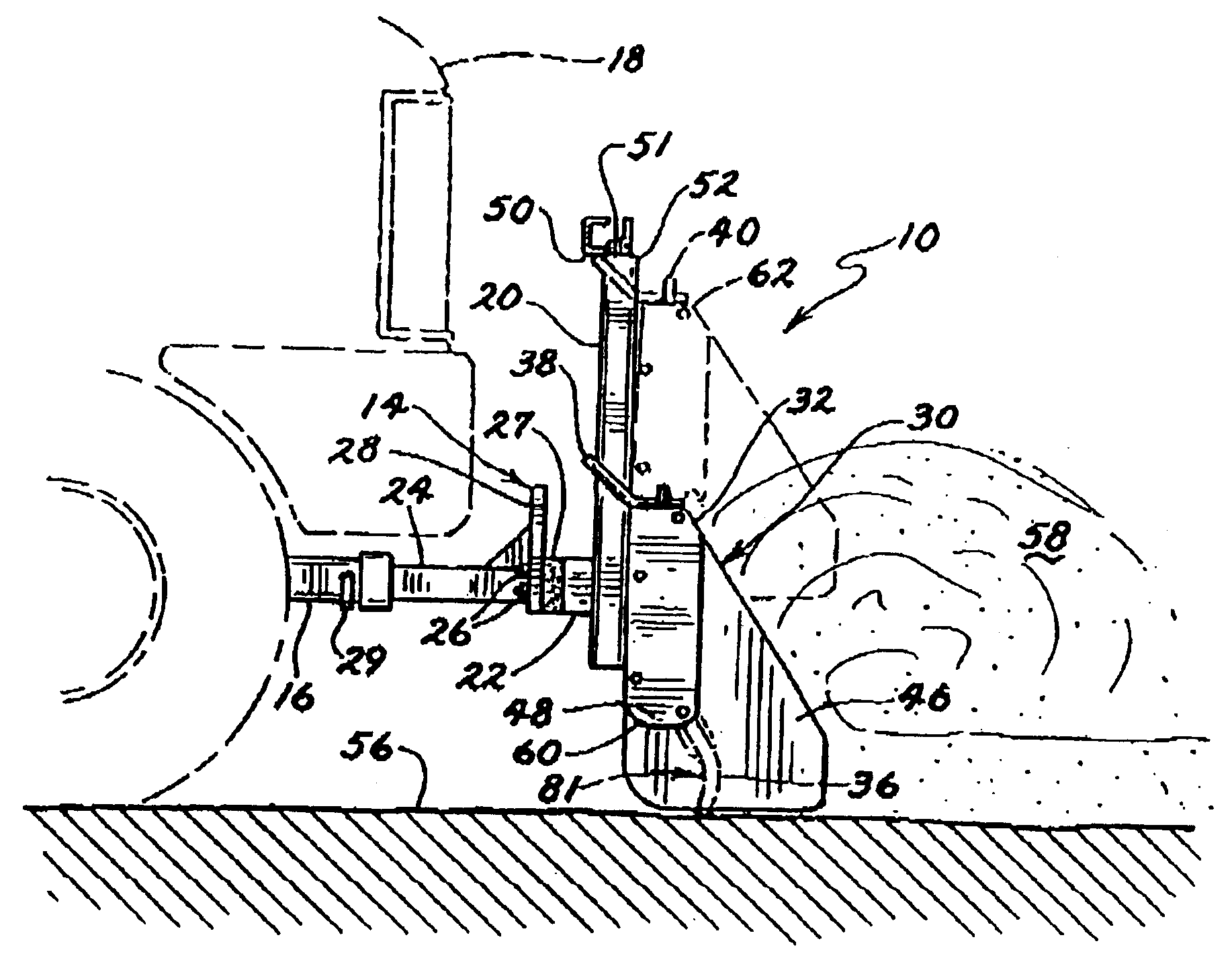

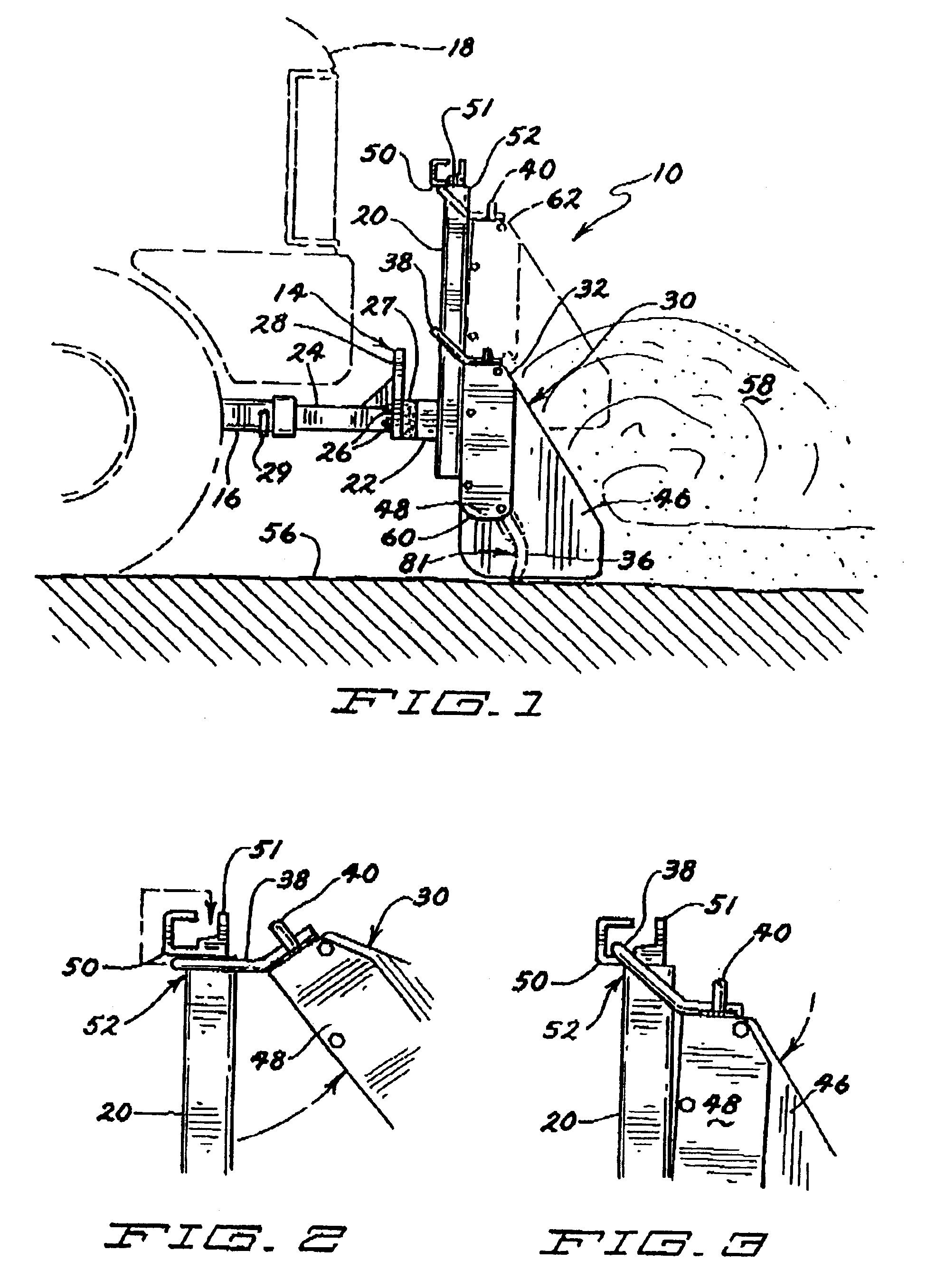

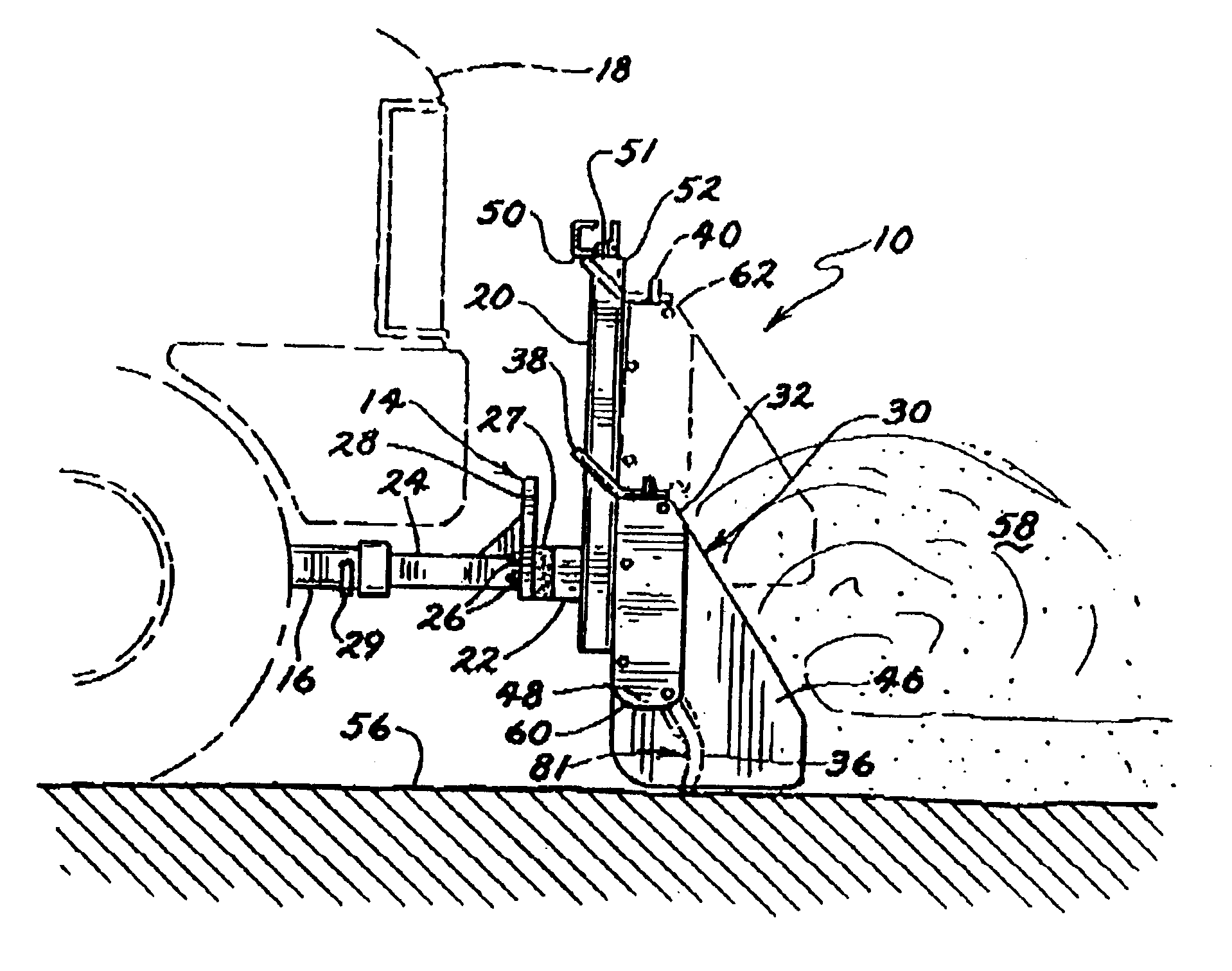

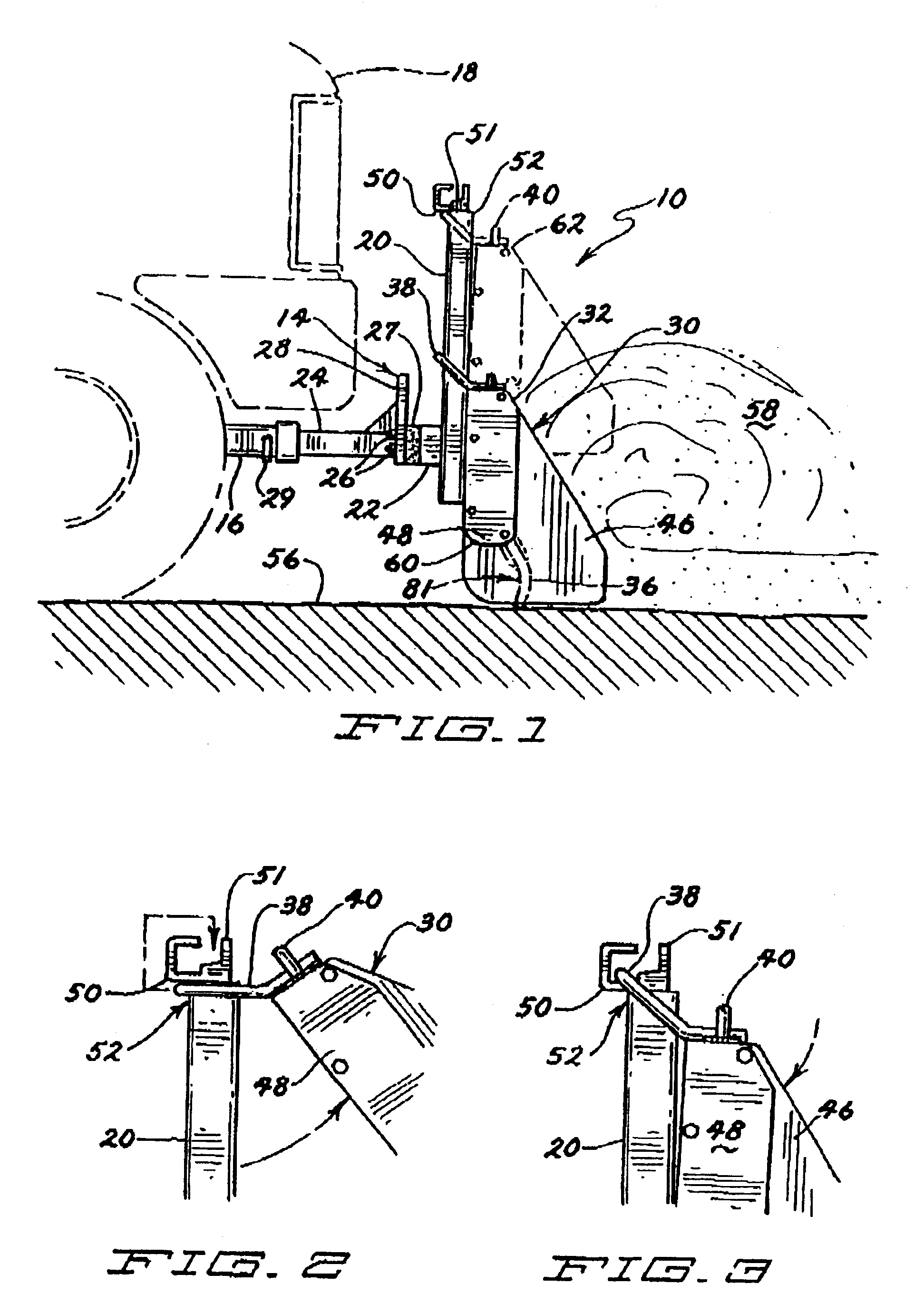

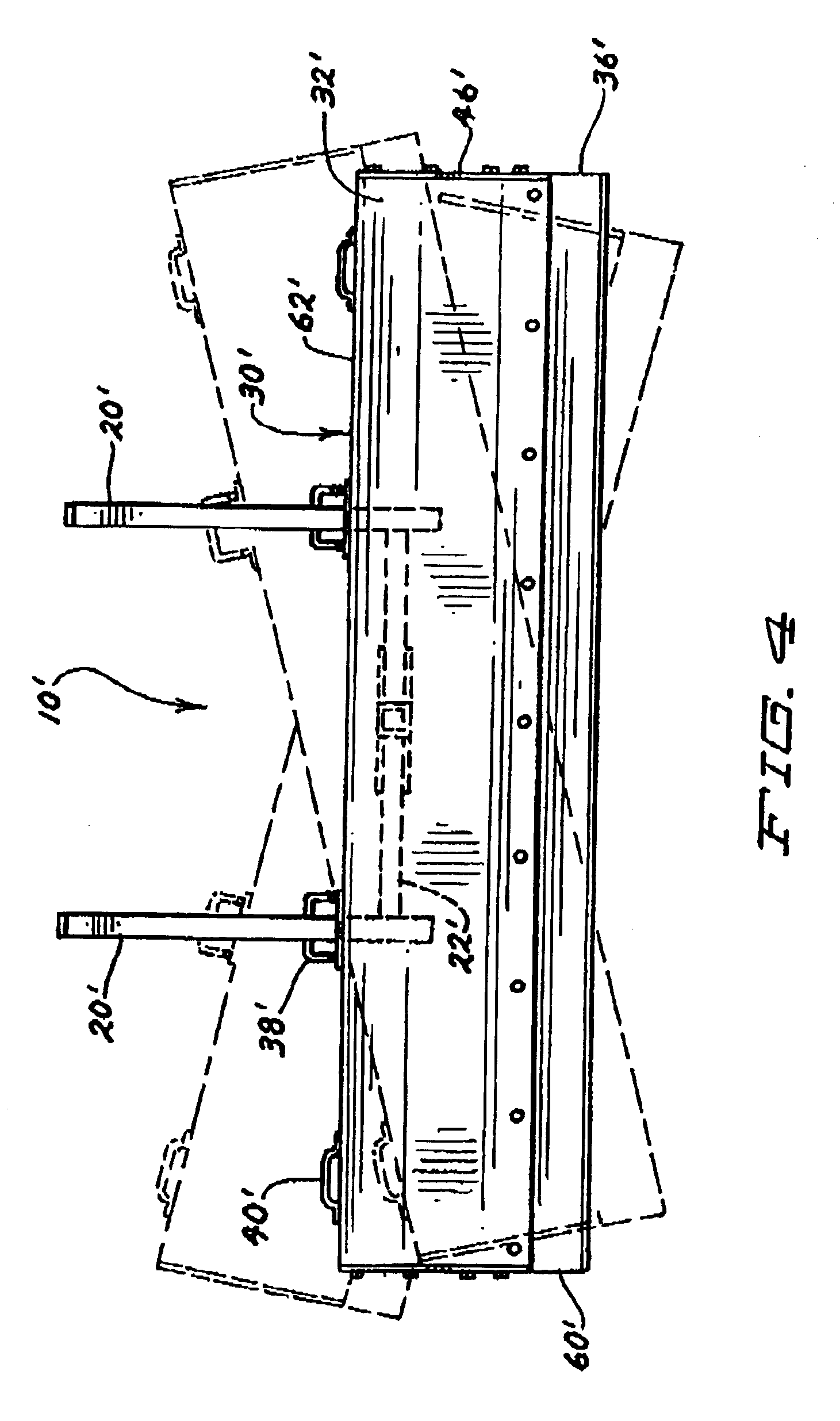

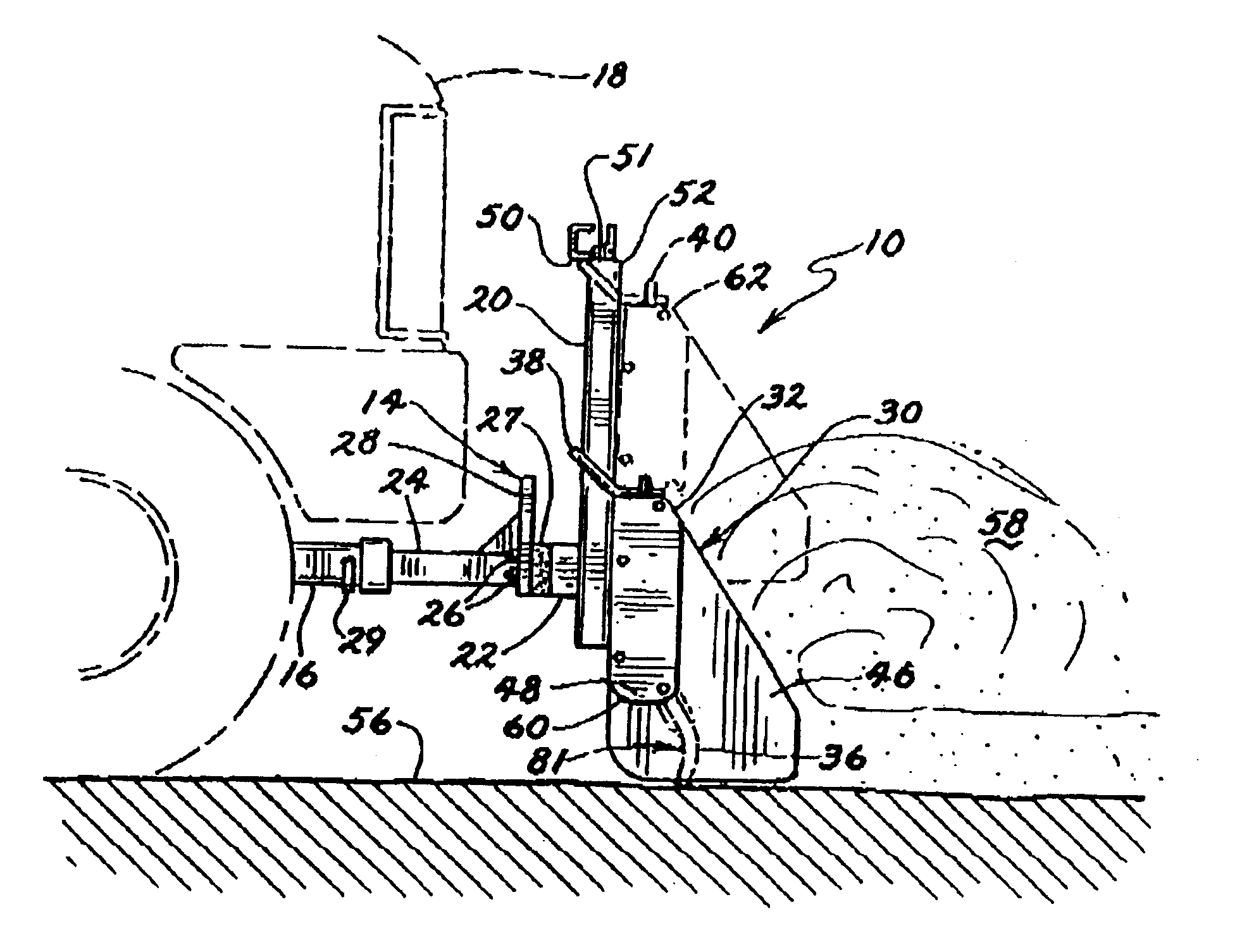

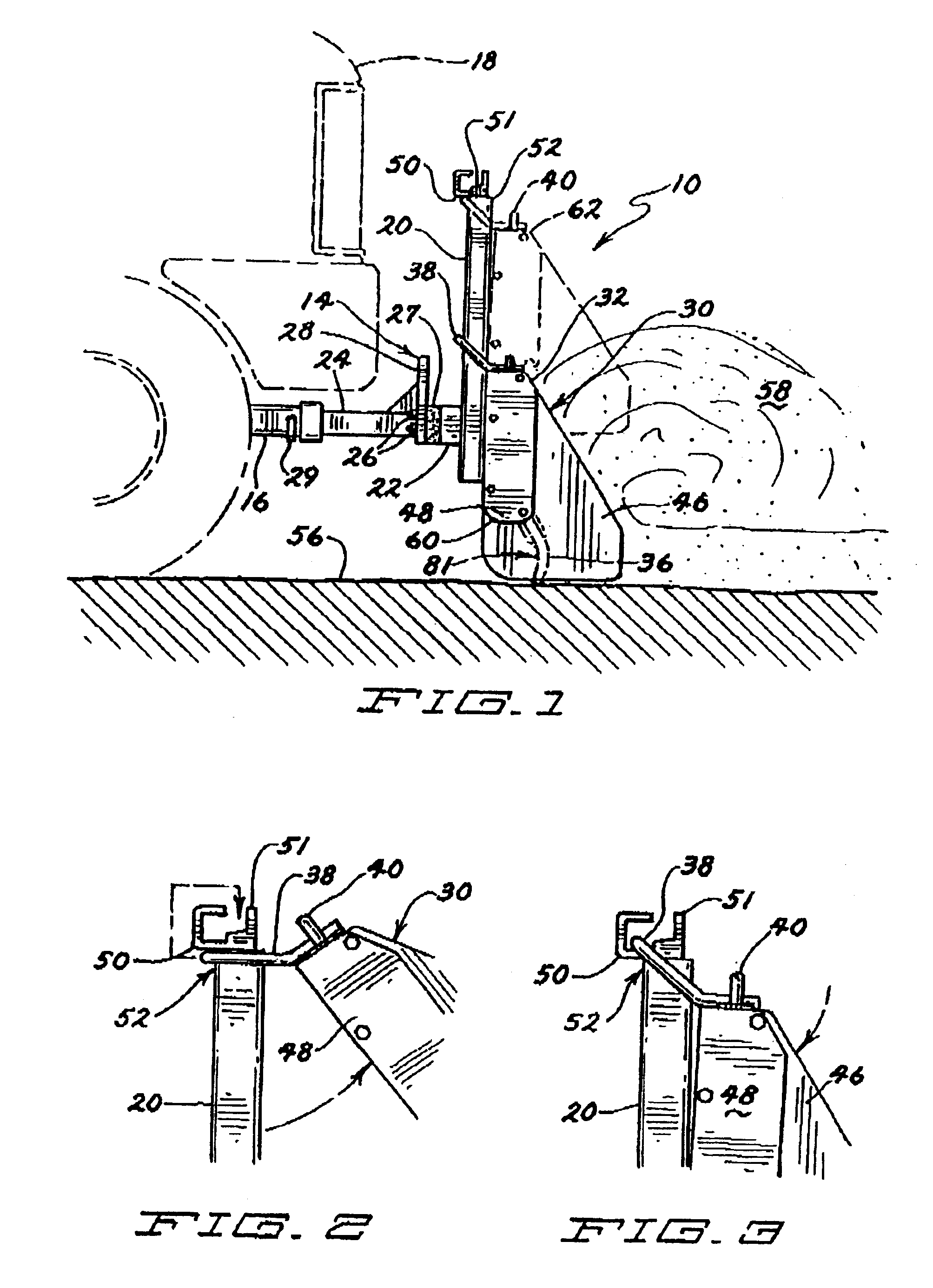

Adjustable snow making tower

InactiveUS6161769AIncrease flexibilityOptimize quantityLiquid surface applicatorsStands/trestlesBlock and tackleEngineering

Method and apparatus for making snow by generating water spray from a triple array of multiple nozzle sub-boom branch-pipes transversely protruding from the upper end of a main boom of a pivotably adjustable snow making pipe tower. Three air jet streams, one for each branch pipe, are simultaneously discharged under high pressure into and sequentially through the throats of each associated multiple stack of water sprays issuing from each set of branch pipe nozzles to thereby form multiple spray plumes of atomized and seeded water all directed forwardly from the upper end of the tower pipe. The water pipe may be an elliptical aluminum extrusion with two interior air tubes respectively controllably feeding large and small diameter air jet arrays to thereby provide a range of air jet water spray interaction. The pipe tower may be pivotally raised and lowered by a block-and-tackle or chain fall type drive mechanism that may be recoupled to the tops of a lifting pole and tower pipe for bodily raising the entire tower pipe and its support pipe telescopically on a ground support pole. Spreader-supported guy wires may be used to brace the tower pipe and also provide an electrical deicing circuit. Air jet control, blow-out valving and water drain conduit arrangements are disclosed, and also universally adjustable ground support systems for the pipe tower, including an underground-fed combined telescopic hydraulic ram forming air and water conduits.

Owner:BOYNE USA +1

Lamp structure

InactiveUS20110164417A1Low costEasy to assembleNon-electric lightingPoint-like light sourceFlexible circuitsLight reflection

A lamp structure comprises an aluminum extrusion pipe, a light transmission cover, and a light emitting member. The aluminum extrusion pipe is axially provided with at least one first sidewall, one second sidewall and one opening, the first sidewall is formed with at least an engaging groove in communication with a through hole in the first sidewall, the second sidewall is provided with at a light reflection surface. The light transmission cover is mounted on the aluminum extrusion pipe to cover the opening. The light emitting member includes a flexible circuit board and plural light sources, the light sources are arranged spaced apart on the flexible circuit board, the light of the light sources of the light emitting member are focused on the light transmission cover through reflection by the light reflection surface, and finally projected out of the aluminum extrusion pipe after passing through the light transmission cover.

Owner:HUANG YING FANG

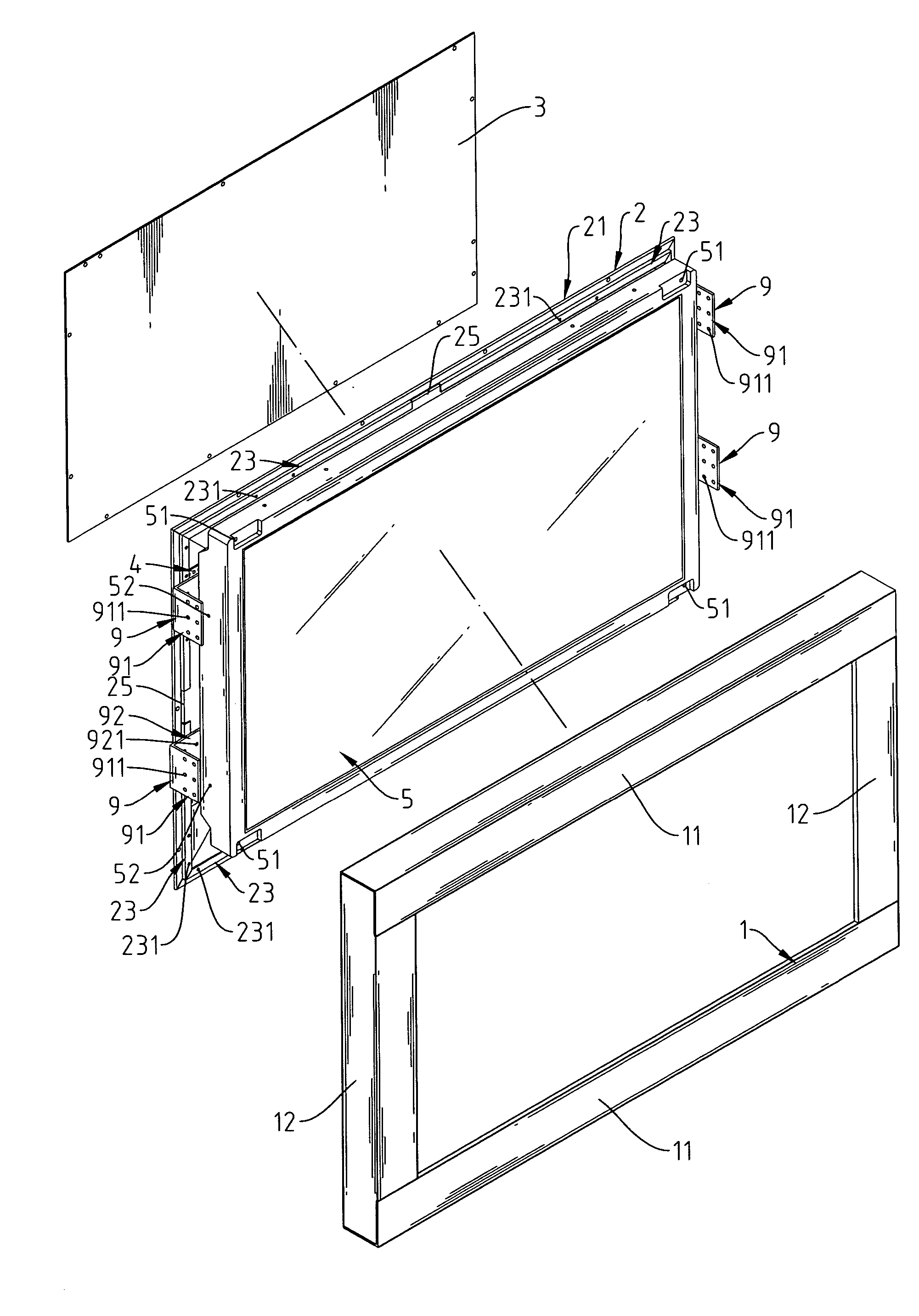

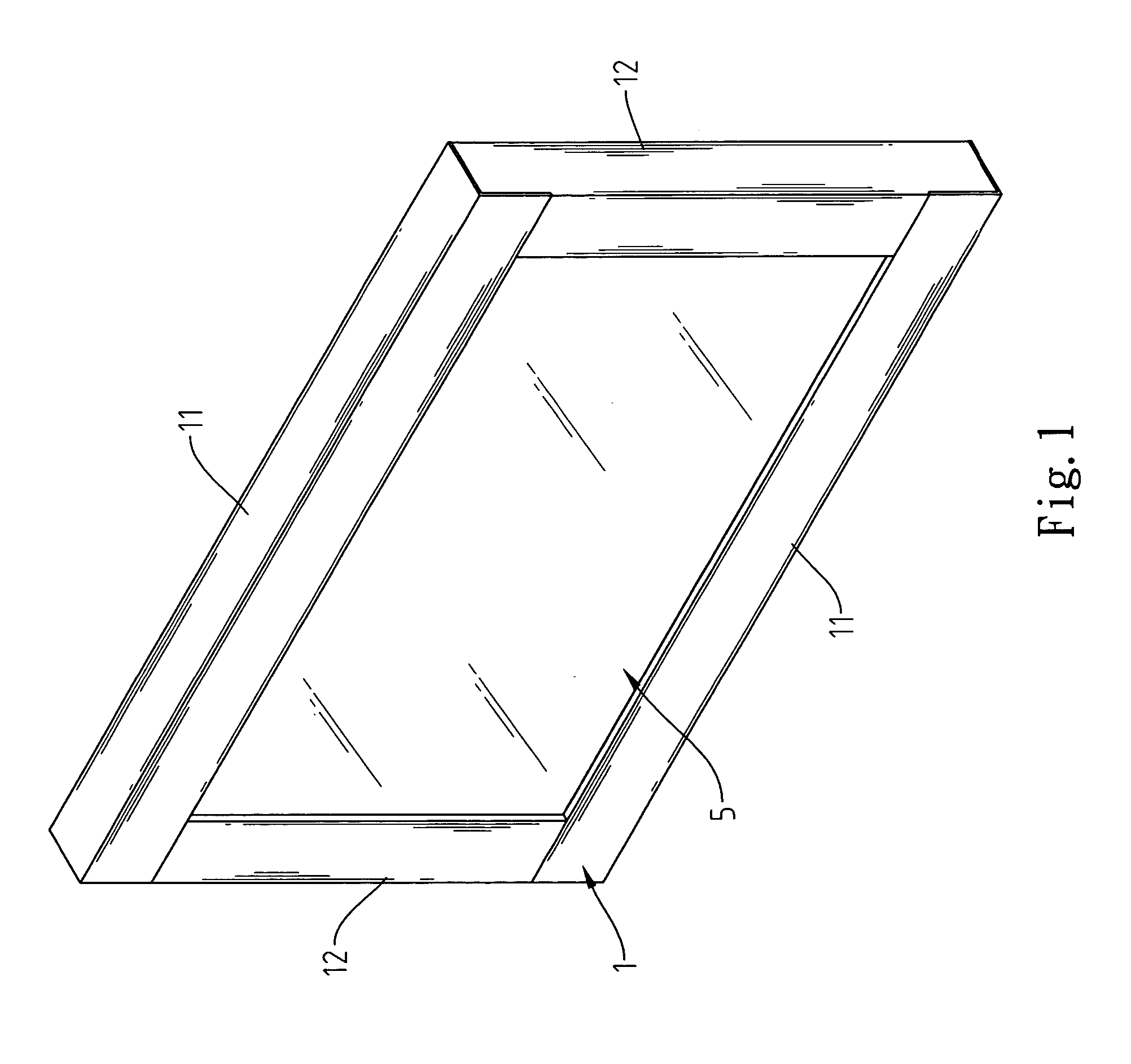

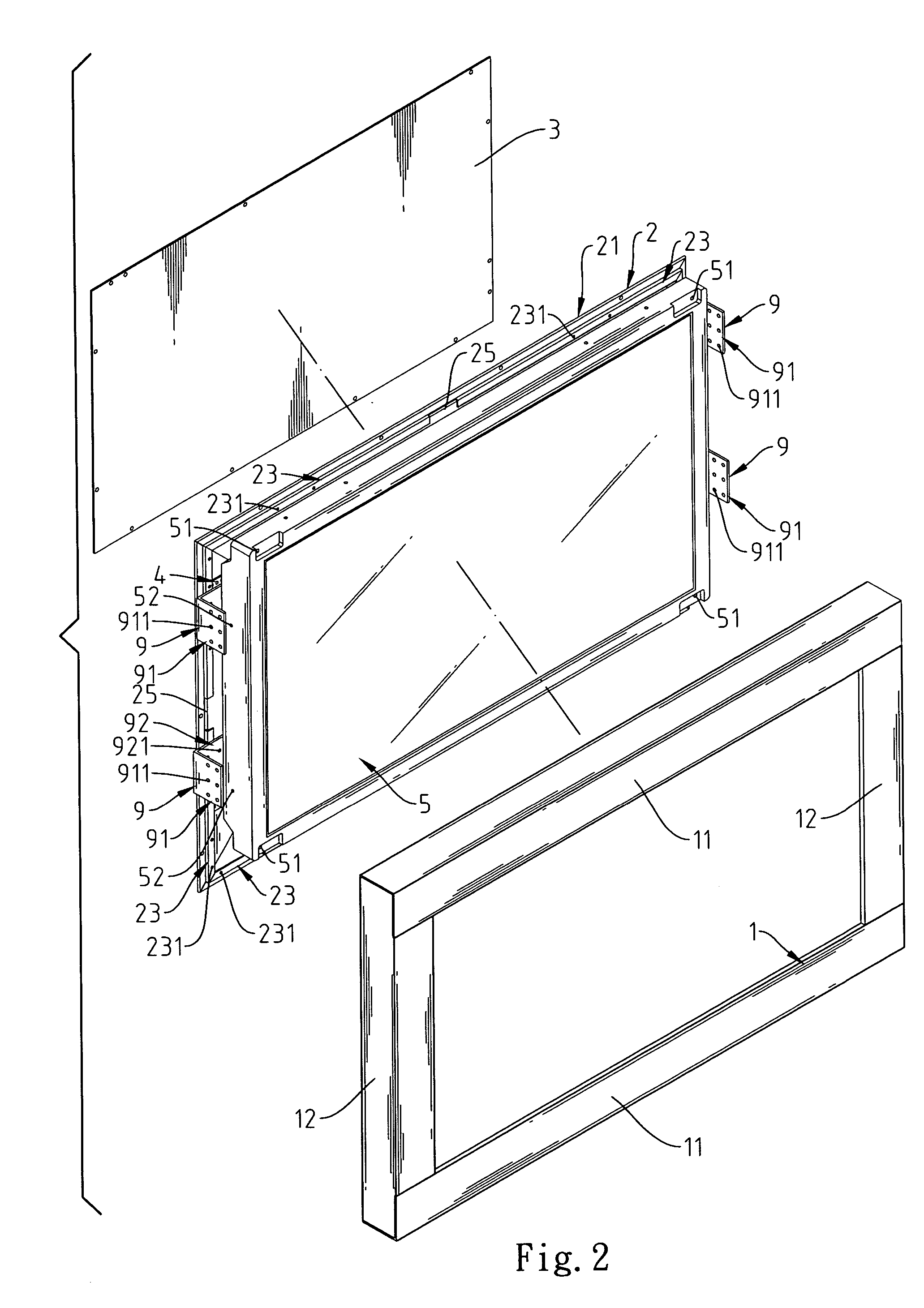

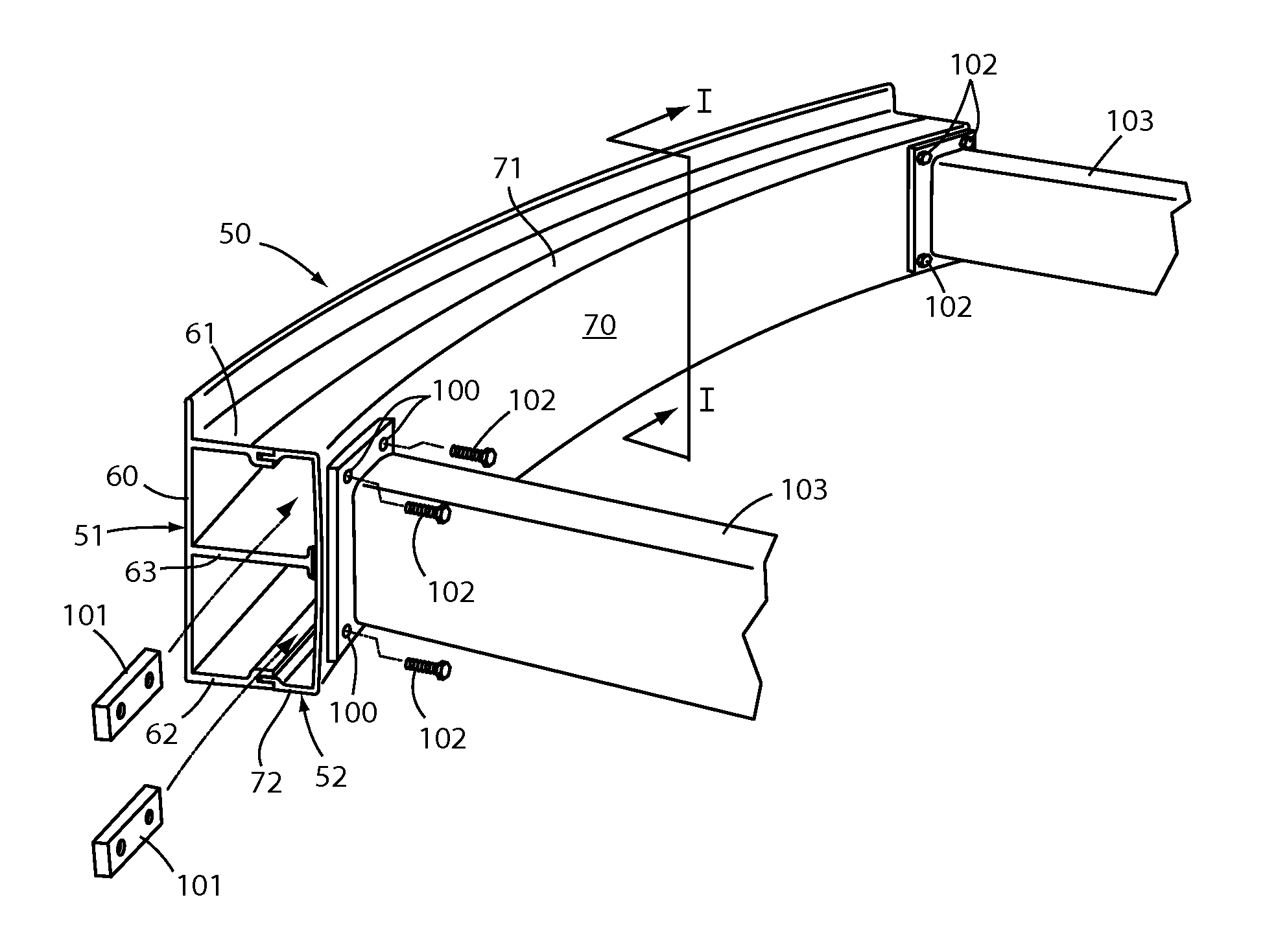

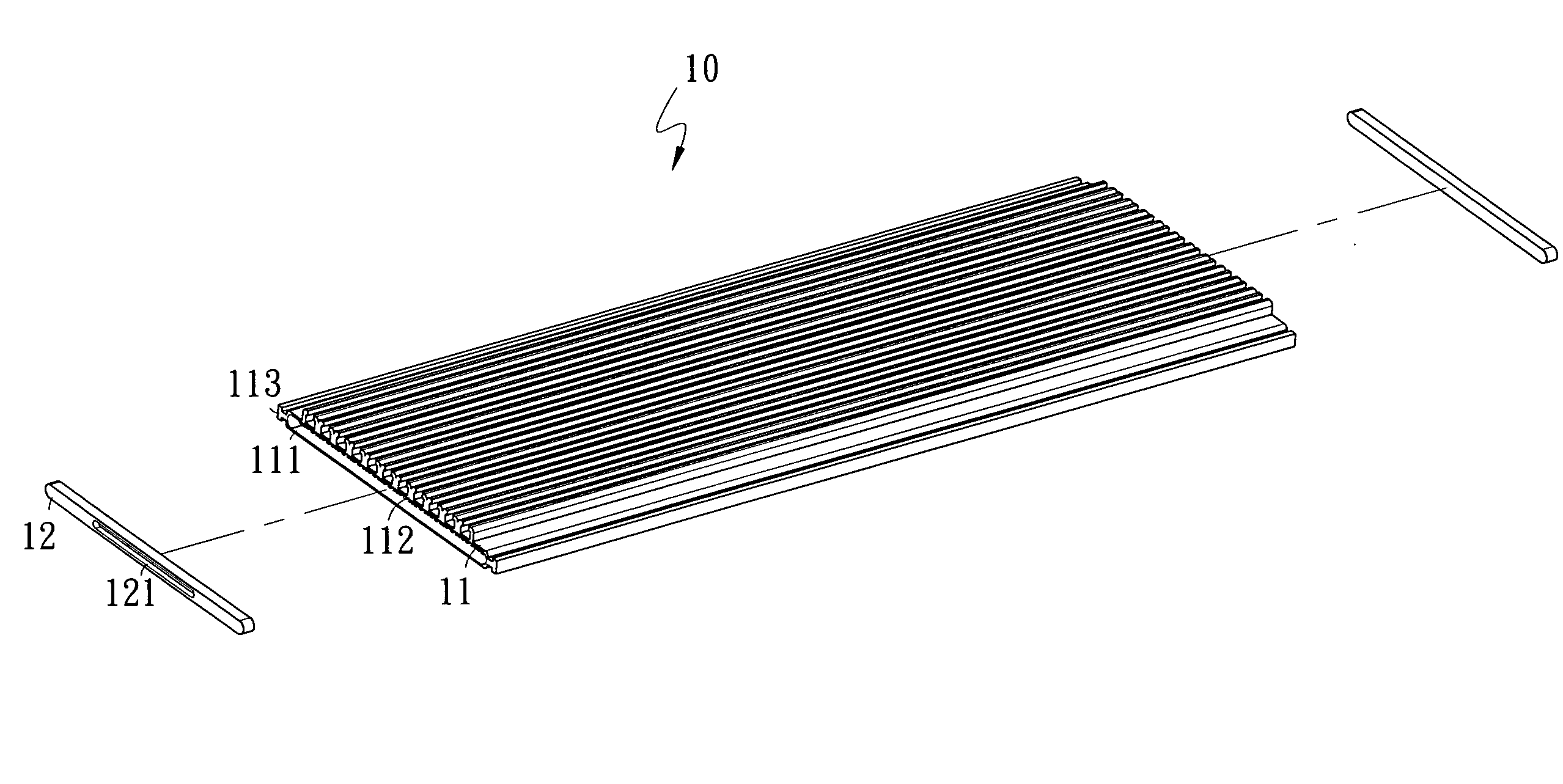

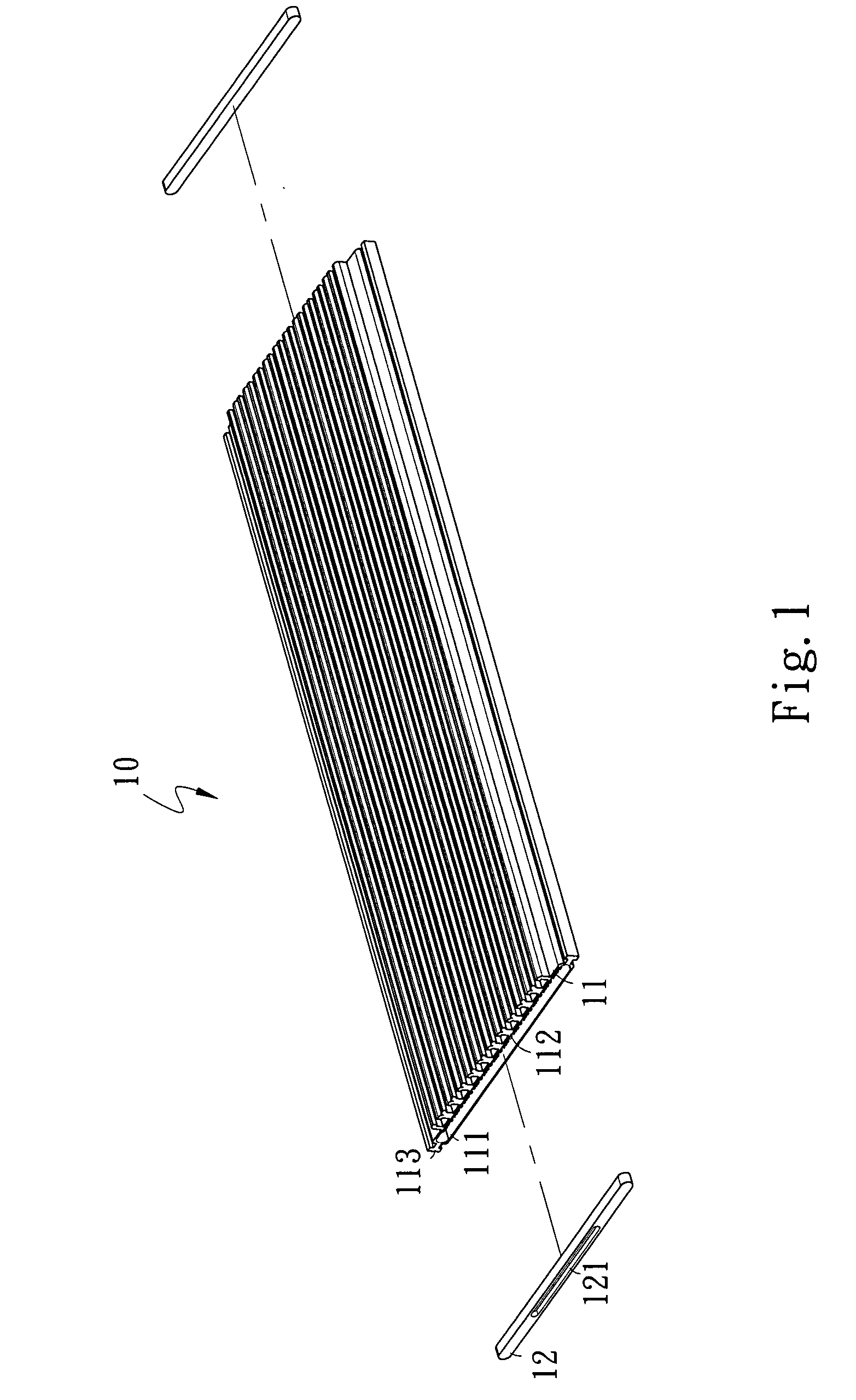

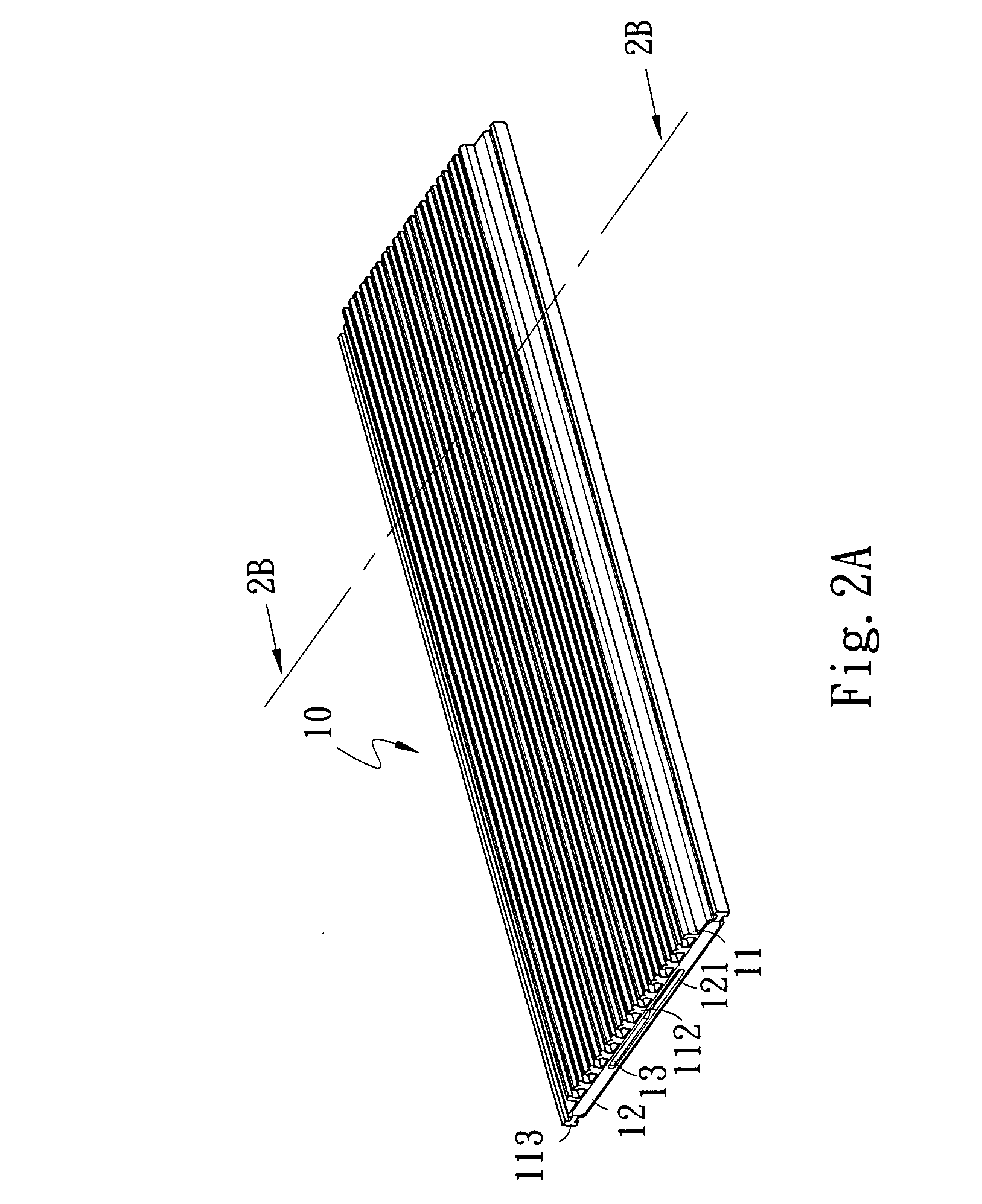

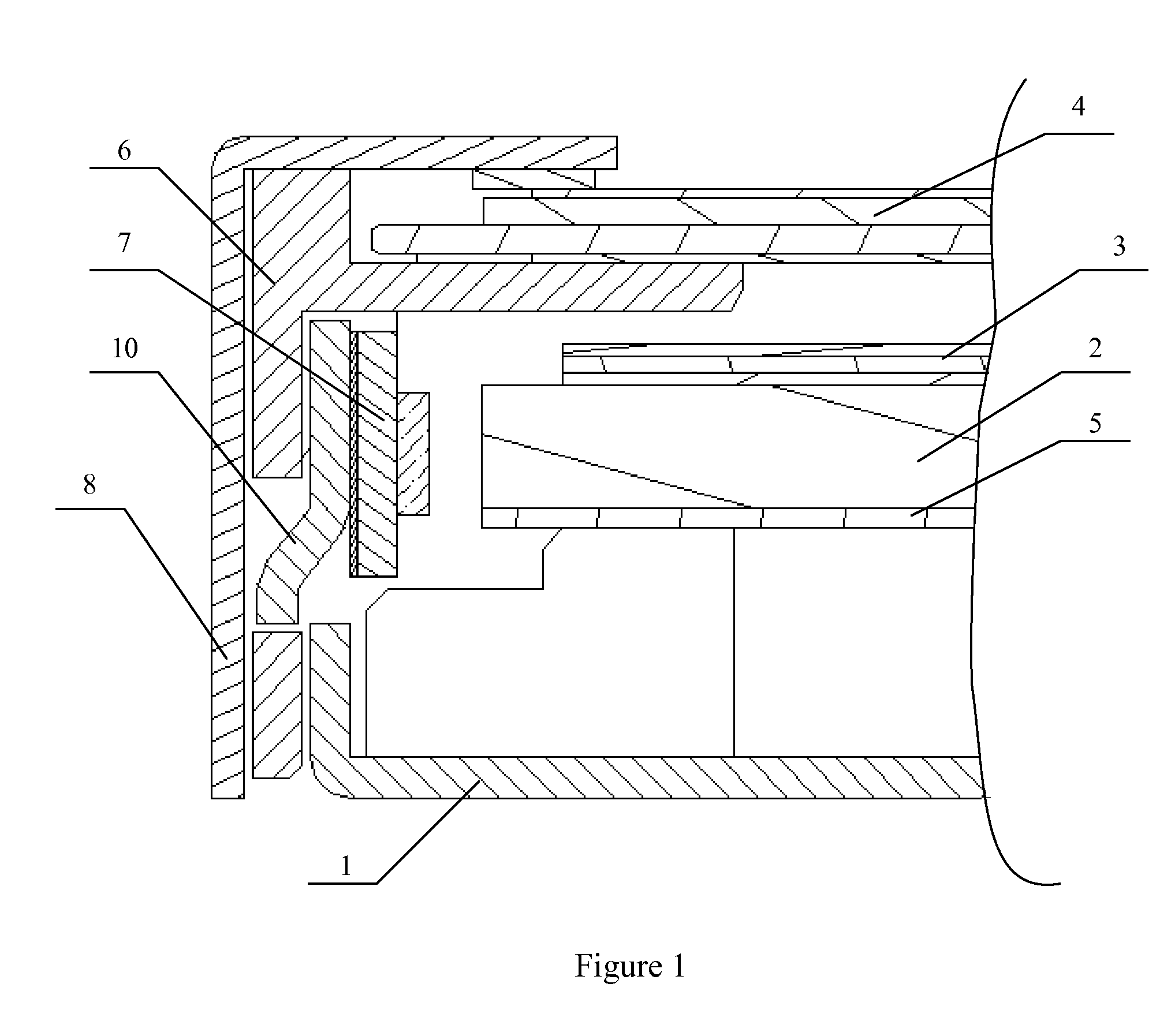

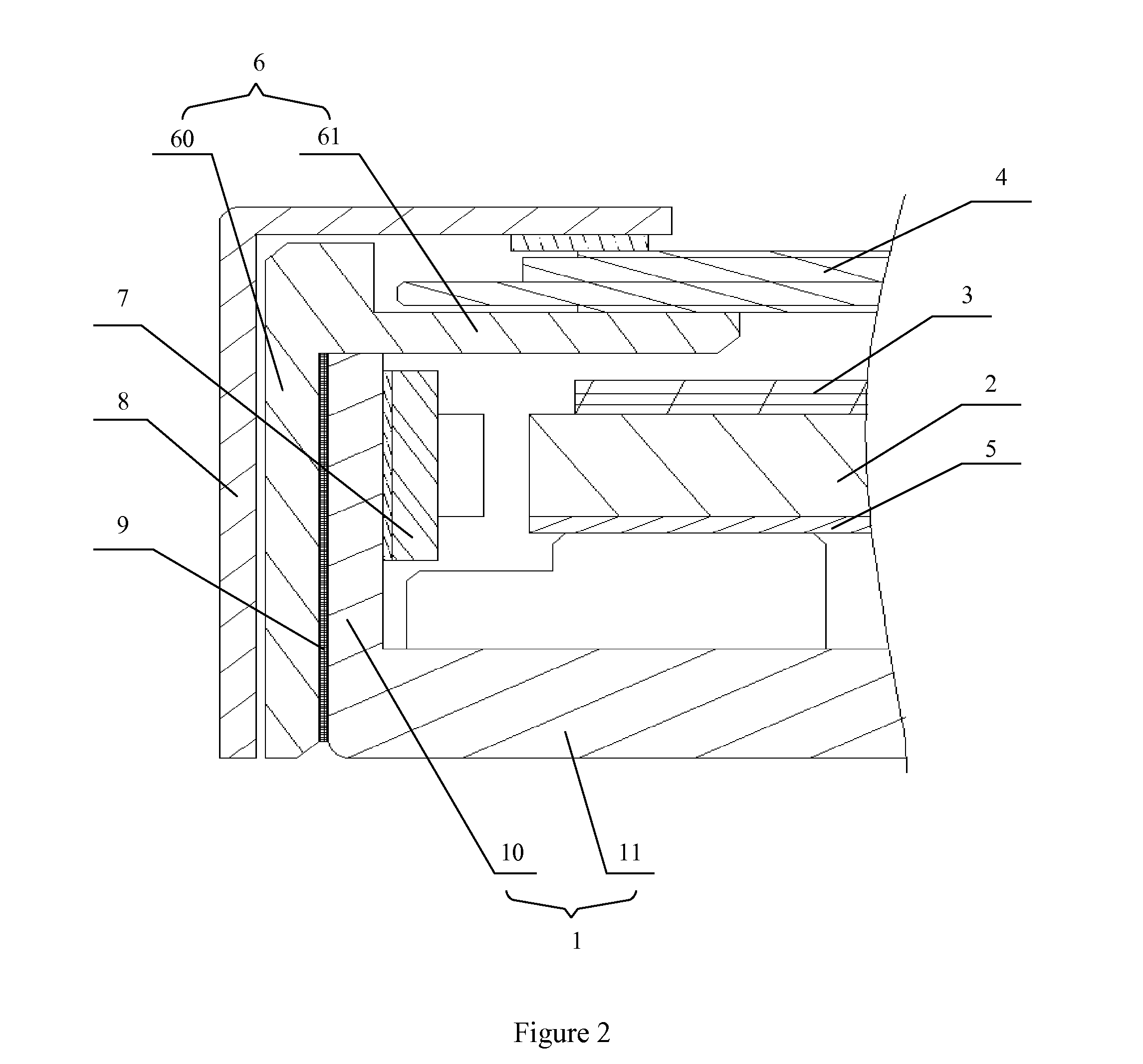

Composite structure of aluminum extrusion external framework of LCD monitor

InactiveUS7319499B2Digital data processing detailsElectrical apparatus contructional detailsLiquid-crystal displayEngineering

An aluminum extrusion external framework of LCD monitor primarily comprises a front frame cap, a back frame cap, and a sheathing, which are assembled with one another. Several movable laminas are mounted on the inside of the back frame cap, wherein the locking positions of the movable laminas are adjustable. The aluminum extrusion external framework of the LCD monitor is made of aluminum for lightening its weight and conforming to the recycle-based environmental protection so as to facilitate the heat sinking, reduce the production cost, and increase the product lifetime. Besides, the movable laminas are applied to the raised slideways around the inside of the back frame cap so as to be universally suitable for the existing LCD panel having various specifications and dimensions.

Owner:PENG CHING LUNG

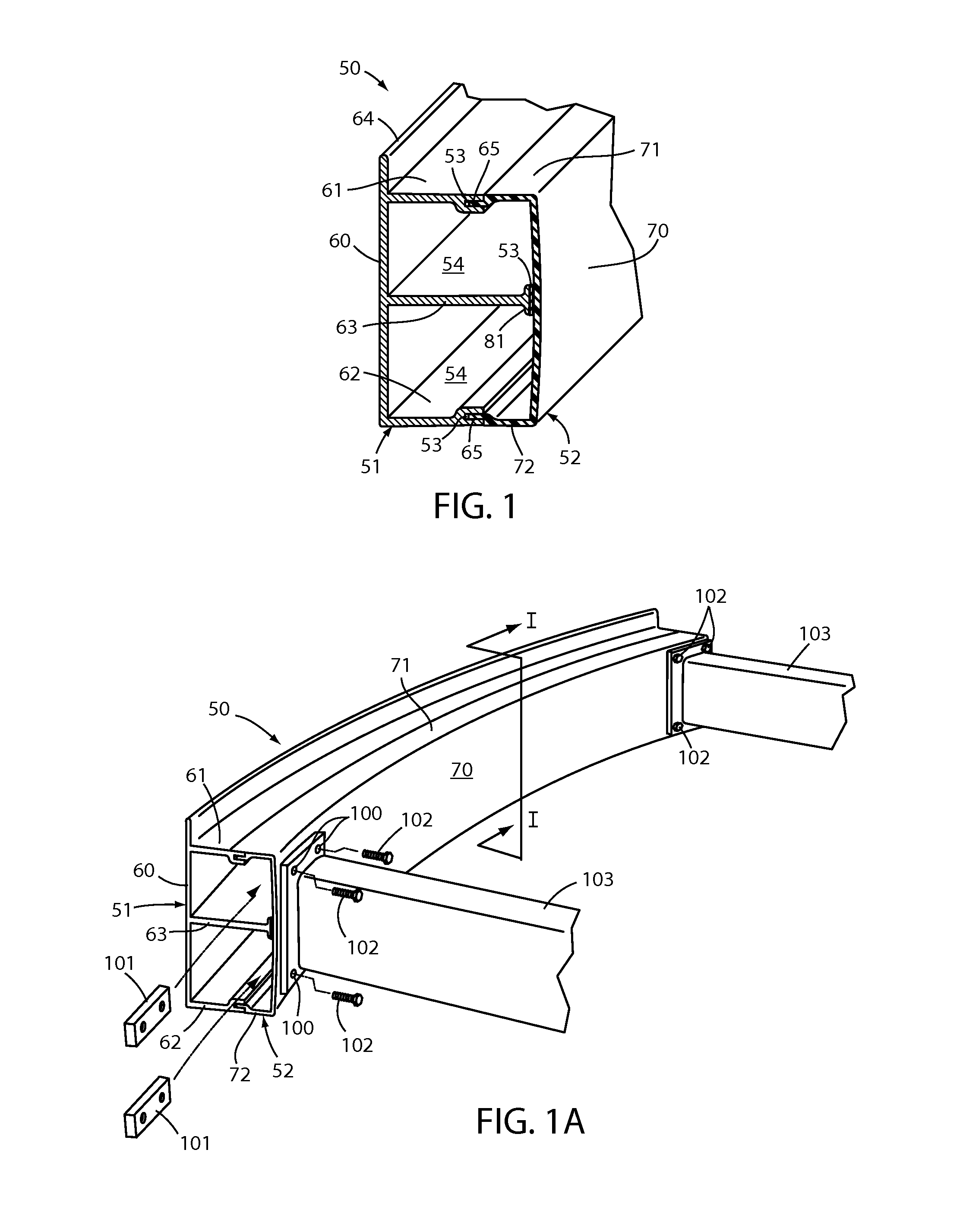

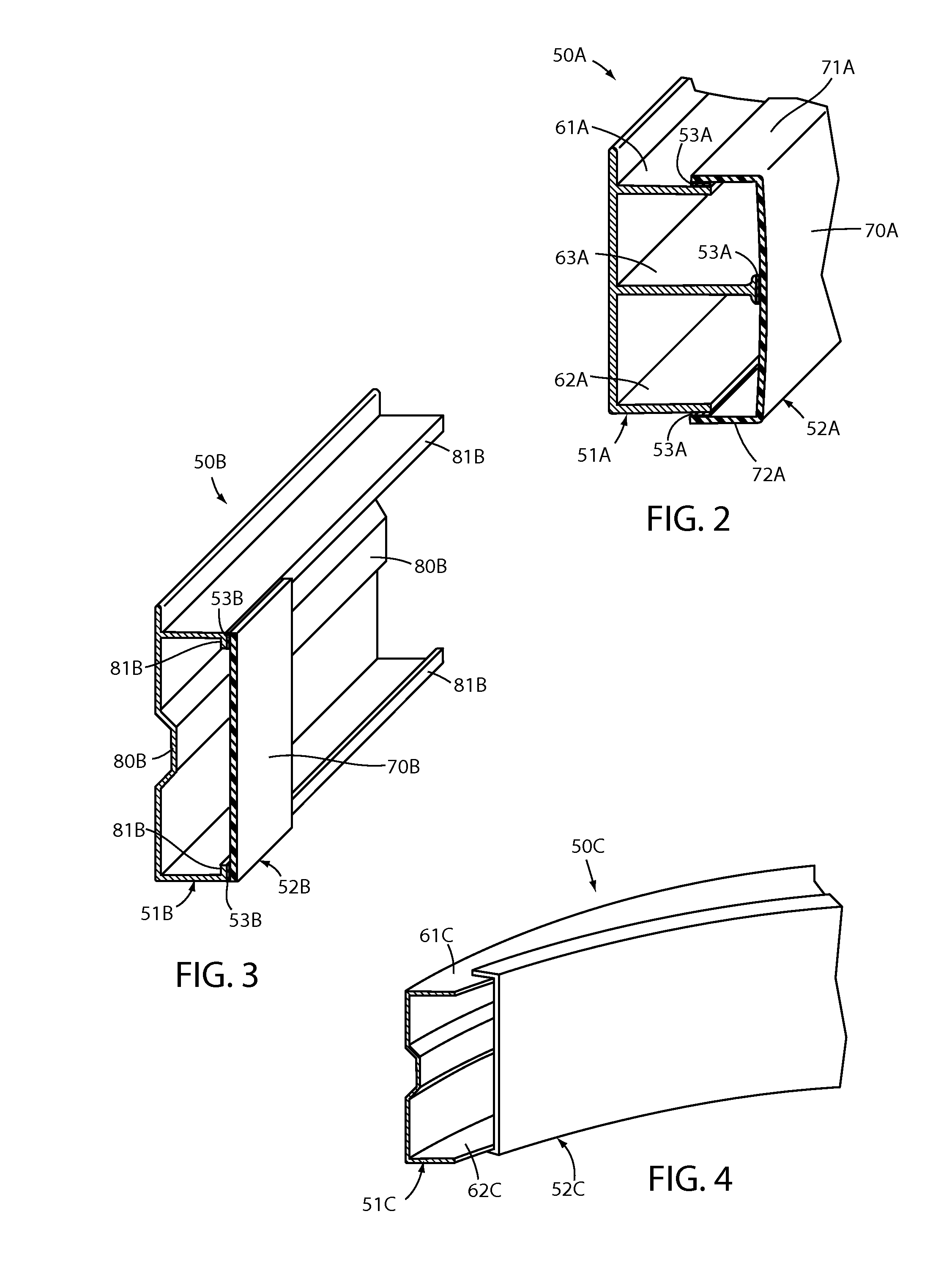

Beam incorporating aluminum extrusion and long-fiber reinforced plastic

InactiveUS20160159300A1Optimize locationReduce stressLaminationLamination apparatusCarbon fibersIn vehicle

A hybrid impact beam, suitable for use as a reinforced impact beam in vehicle bumpers, includes an extruded aluminum section, a fiber reinforced polymeric (FRP) section, and a structural adhesive bonding them together. The components are arranged so that during an impact, the aluminum section experiences compression and receives the direct impact, the FRP section experiences tension, and the adhesive experiences minimal stress by being on a neutral plane of the beam's bending moment. The extruded aluminum beam is preferably extruded as an open section, but becomes a closed section when the polymeric section is attached. The FRP section is preferably a continuous carbon fiber reinforced polymeric section, although different reinforcements can be used. A related method includes bonding an extruded aluminum and fiber-reinforced polymeric section together to form a closed bumper impact beam.

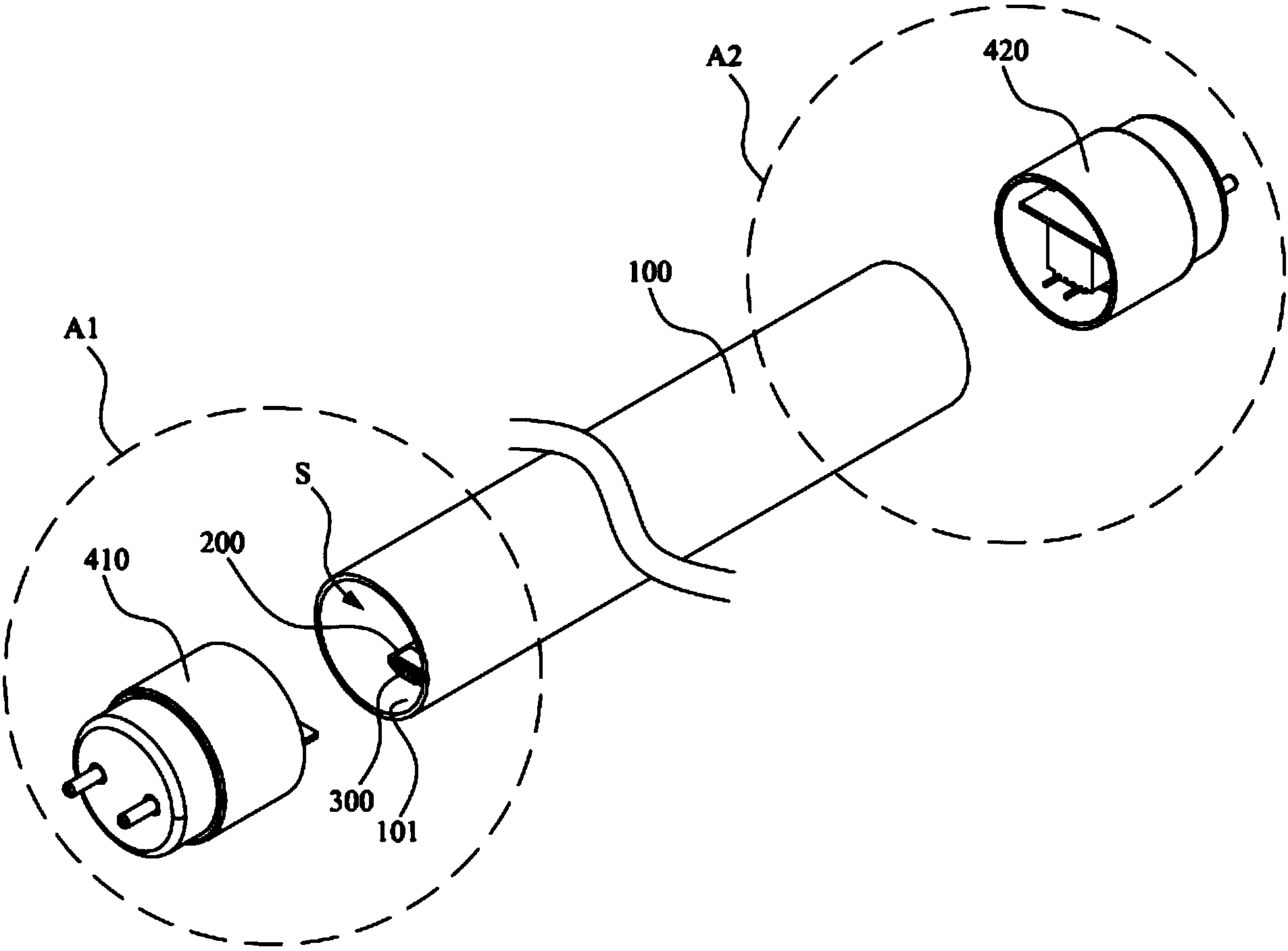

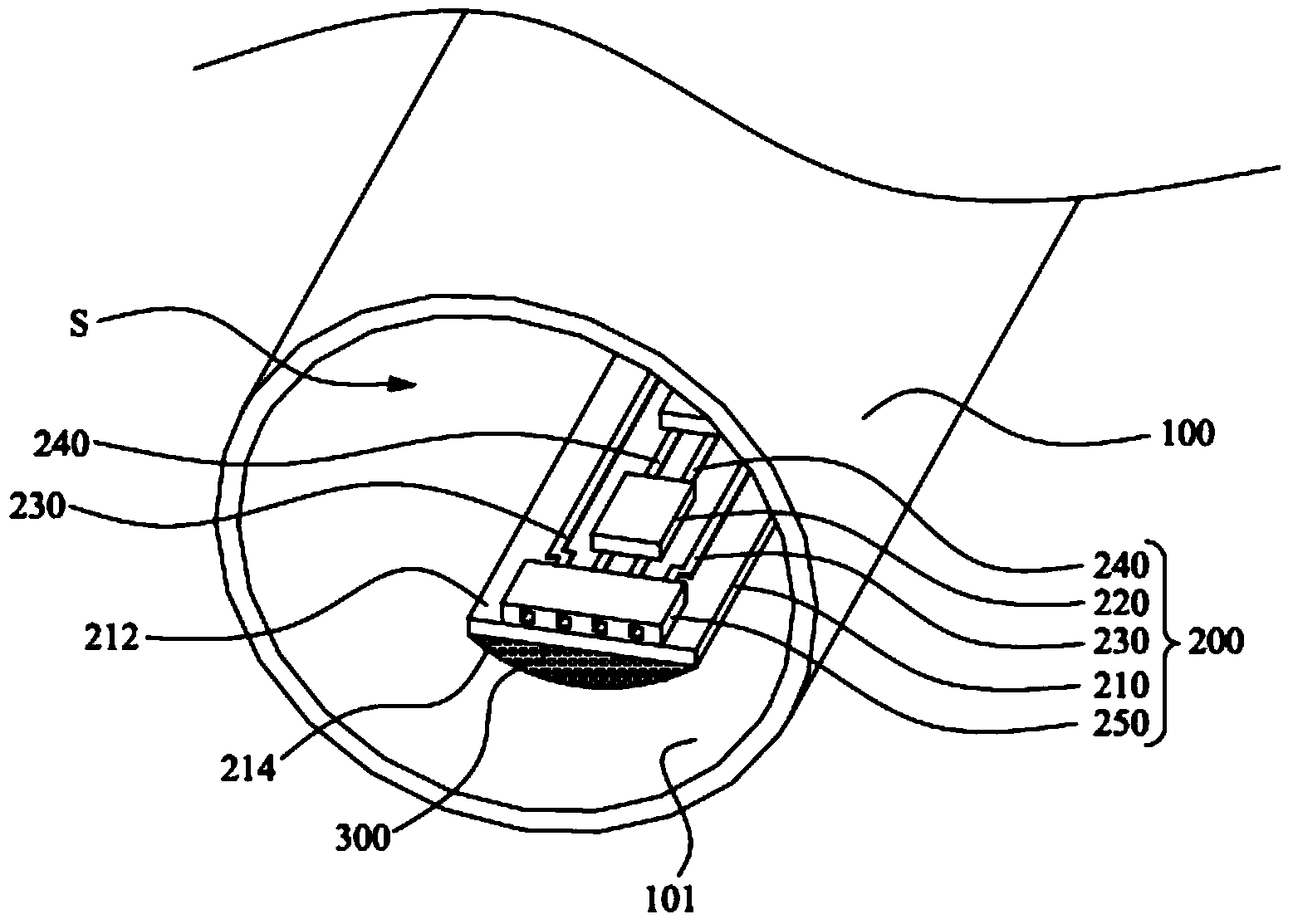

Lamp

The invention relates to a lamp which comprises a glass tube, a light emitting diode assembly and first adhesive. The glass tube is provided with an inner tube wall, and an accommodating space is defined by the inner tube wall. The light emitting diode assembly is positioned in the accommodating space and comprises a circuit board and at least one light emitting diode. The circuit board is provided with a front surface and a back surface opposite to the front surface. The back surface of the circuit board is adhered on the inner tube wall of the glass tube by the first adhesive. The light emitting diodes are arranged on the front surface of the circuit board. The lamp has the advantages that the glass tube is excellent in heat dissipation capability, the circuit board of the light emitting diode assembly is adhered on the inner tube wall of the glass tube by the first adhesive with a heat conduction function, accordingly, heat generated when the light emitting diodes emit light can be transmitted to an external environment by the aid of the first adhesive and the glass tube, and a heat dissipation effect can be realized without aluminum extrusion structures.

Owner:LEXTAR ELECTRONICS (SUZHOU) CORP +1

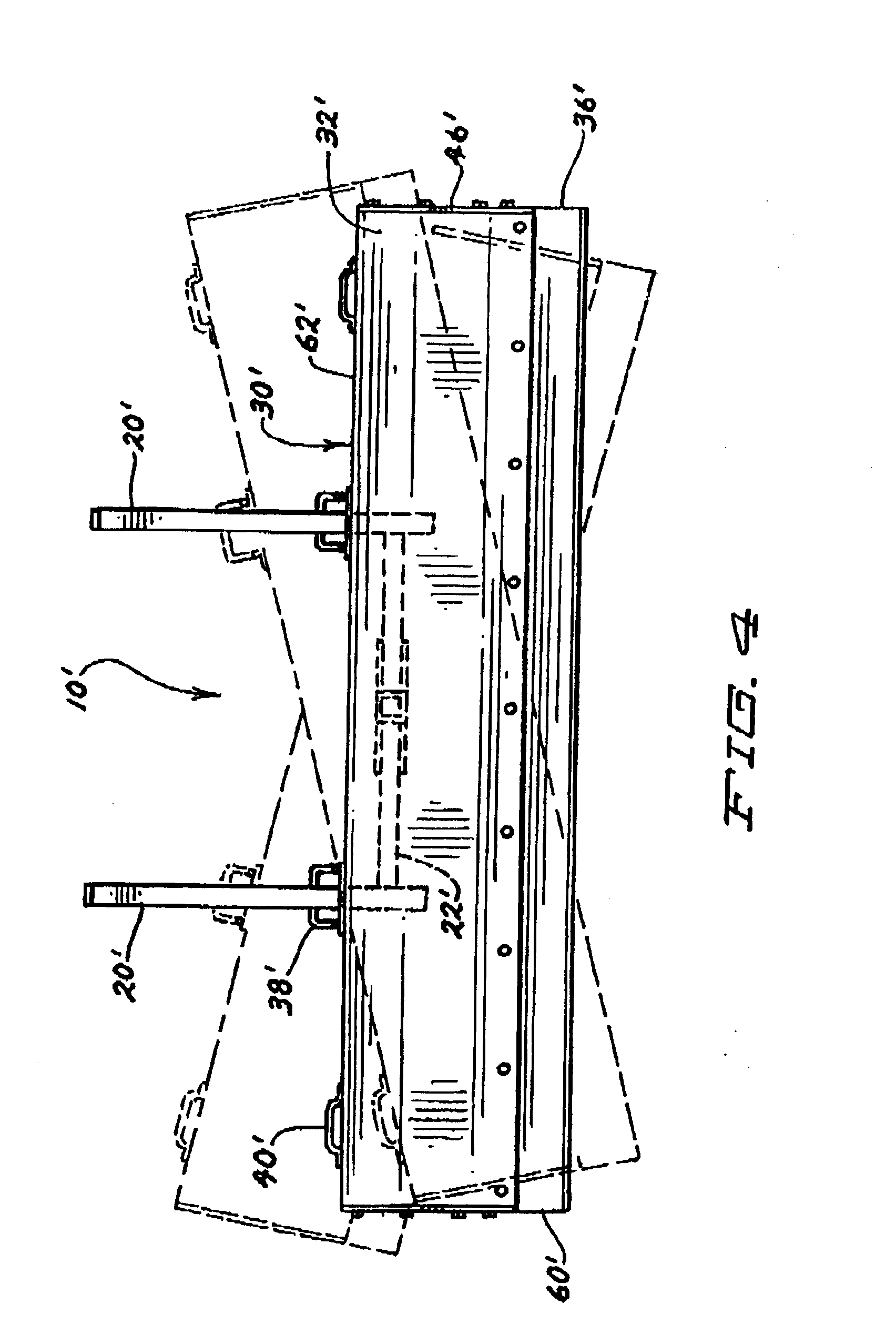

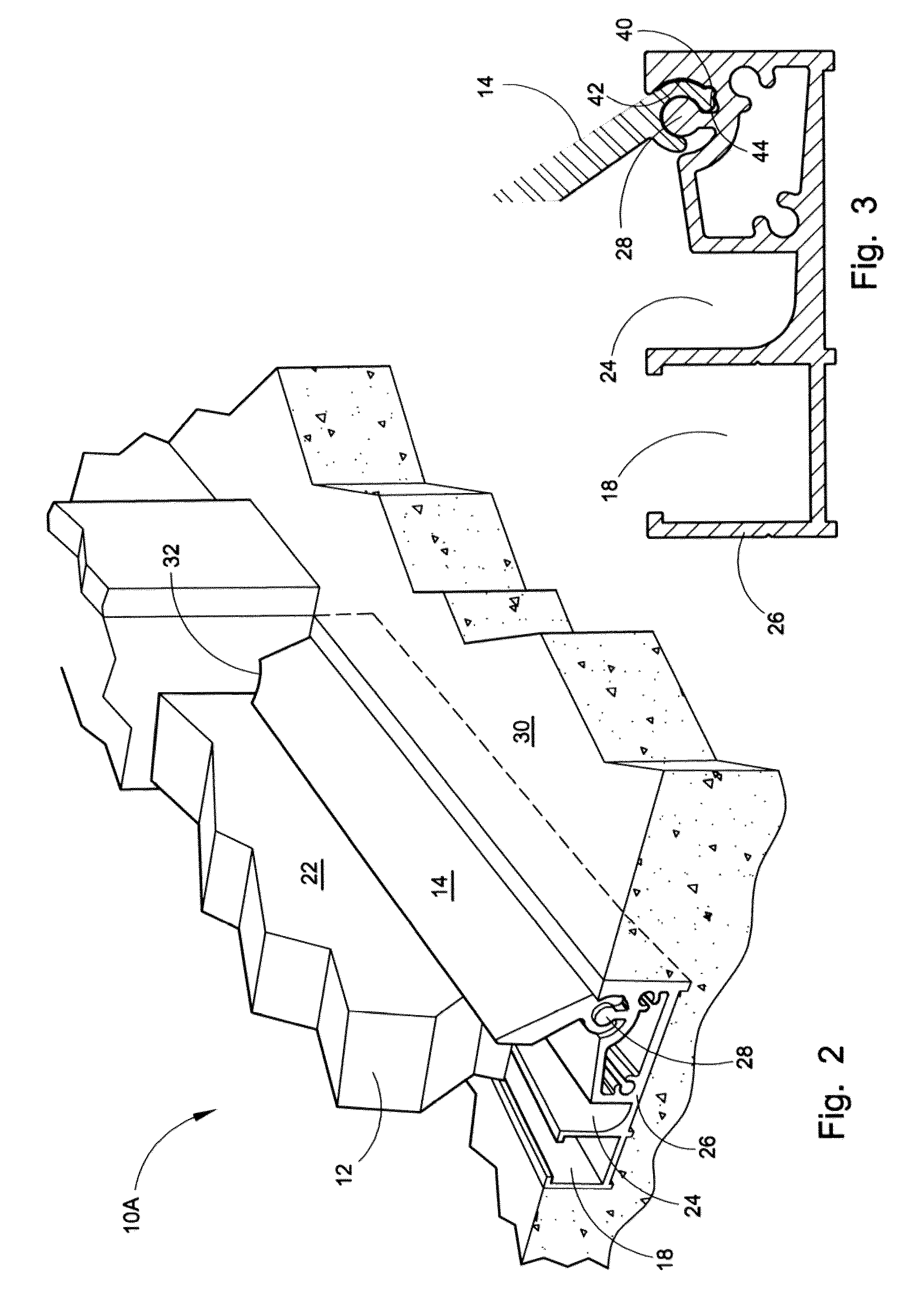

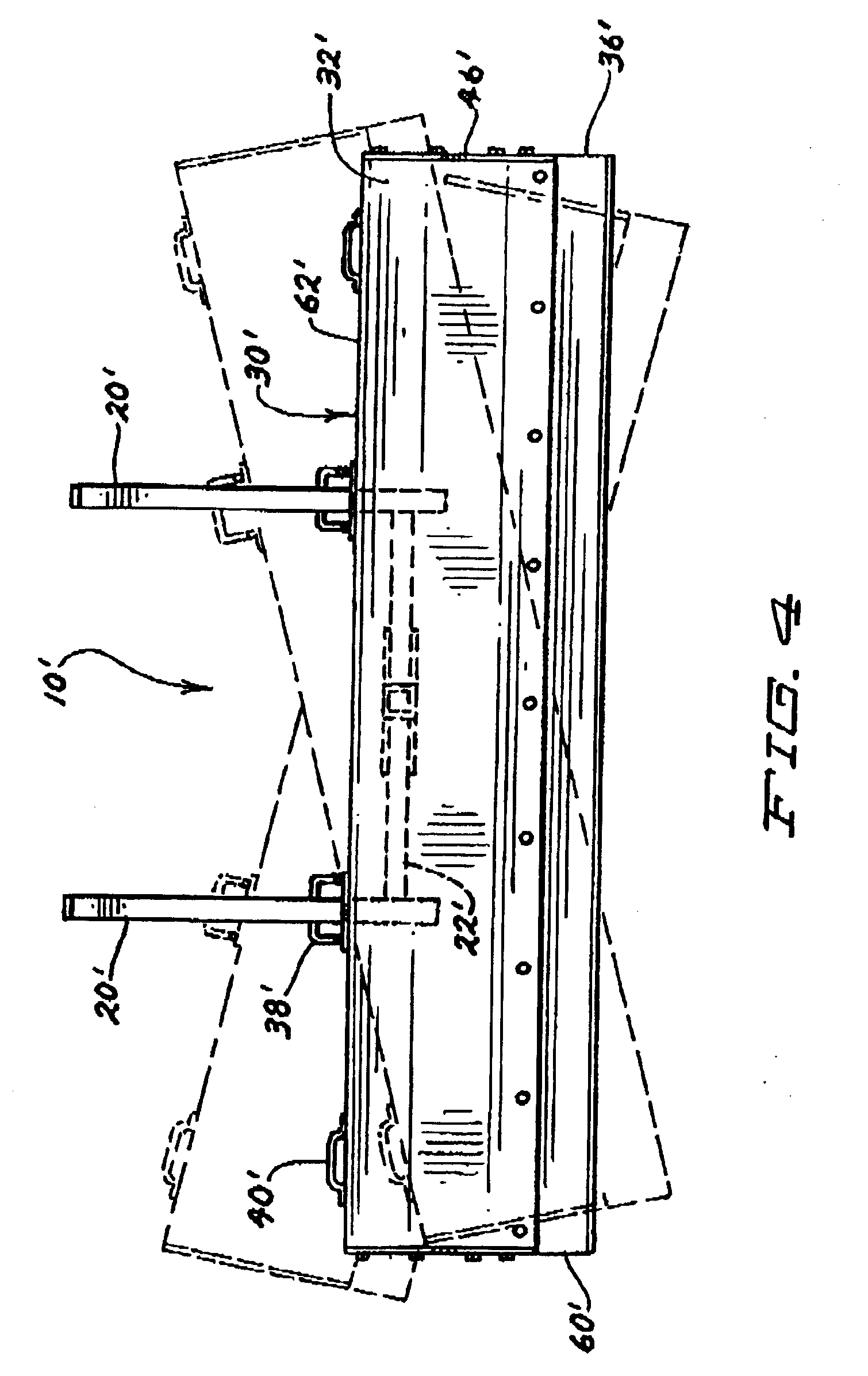

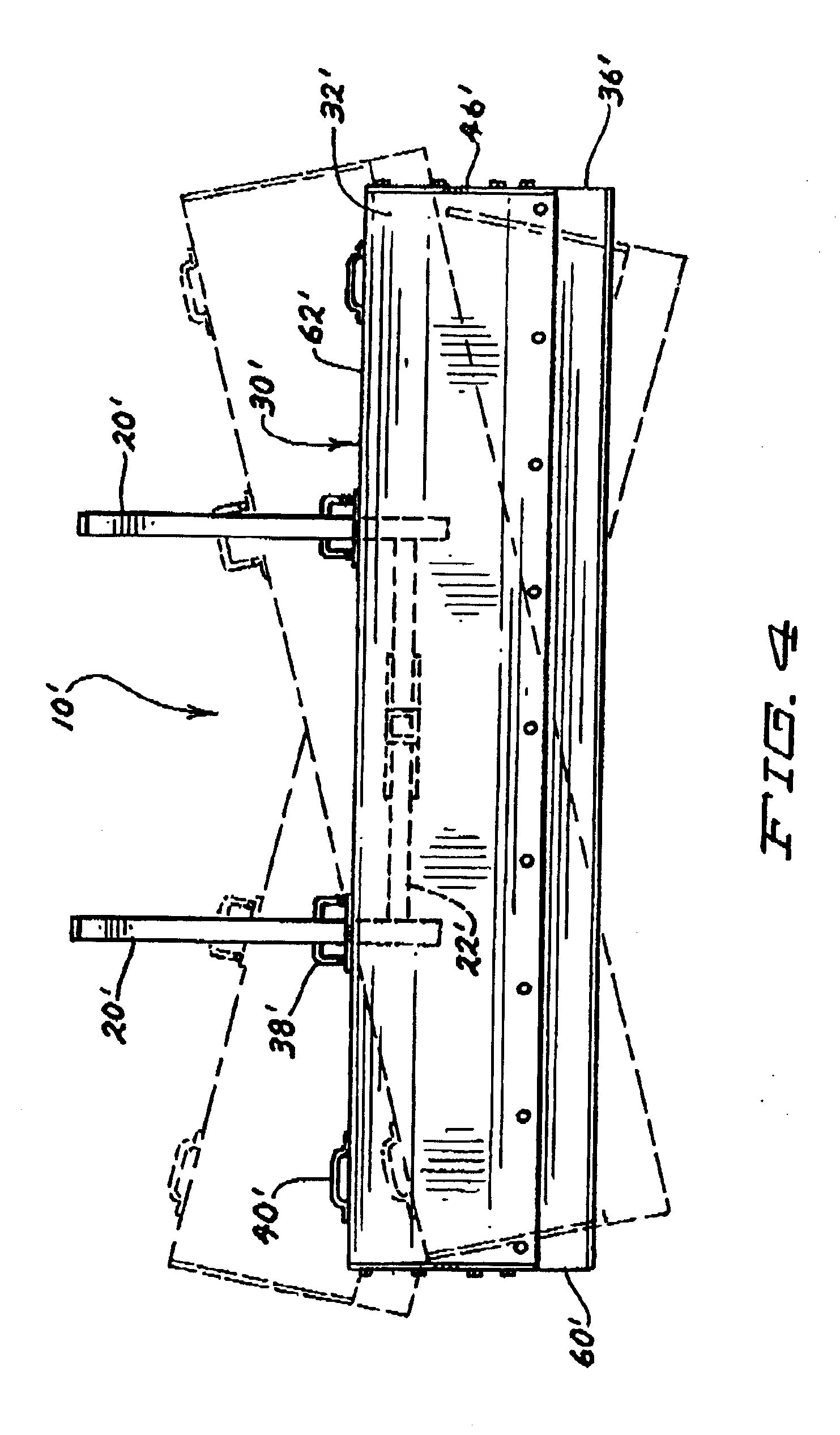

Snow plow having two-piece mold board

InactiveUS20070062072A1Improve practicalityEasy to liftMechanical machines/dredgersSoil-working equipmentsAgricultural engineeringAluminum extrusion

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a two piece mold board, the mold board preferably being an aluminum extrusion.

Owner:AGRI COVER

Heat plate

InactiveUS20080264611A1Solve the low heat dissipation efficiencyImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringAluminum extrusion

A heat plate mainly includes a hollow body and a plurality of caps. The hollow body is fabricated integrally by aluminum extrusion and has a hollow chamber inside. The hollow chamber has an inner side with a plurality of angular strips formed thereon to enhance heat dissipation efficiency and a plurality of spacing ribs to divide the hollow chamber into a plurality of housing space to hold a liquid to increase the heat dissipation efficiency. The hollow body has one surface with a plurality of sliding tracks formed thereon, a latch flute on the left side and right side to wedge in the sliding tracks of another heat plate to enhance the heat dissipation efficiency. The hollow body has another surface with a PCB circuit formed thereon. Electronic elements may be soldered on the PCB circuit to achieve optimal heat dissipation efficiency.

Owner:CHANG KUN JUNG +2

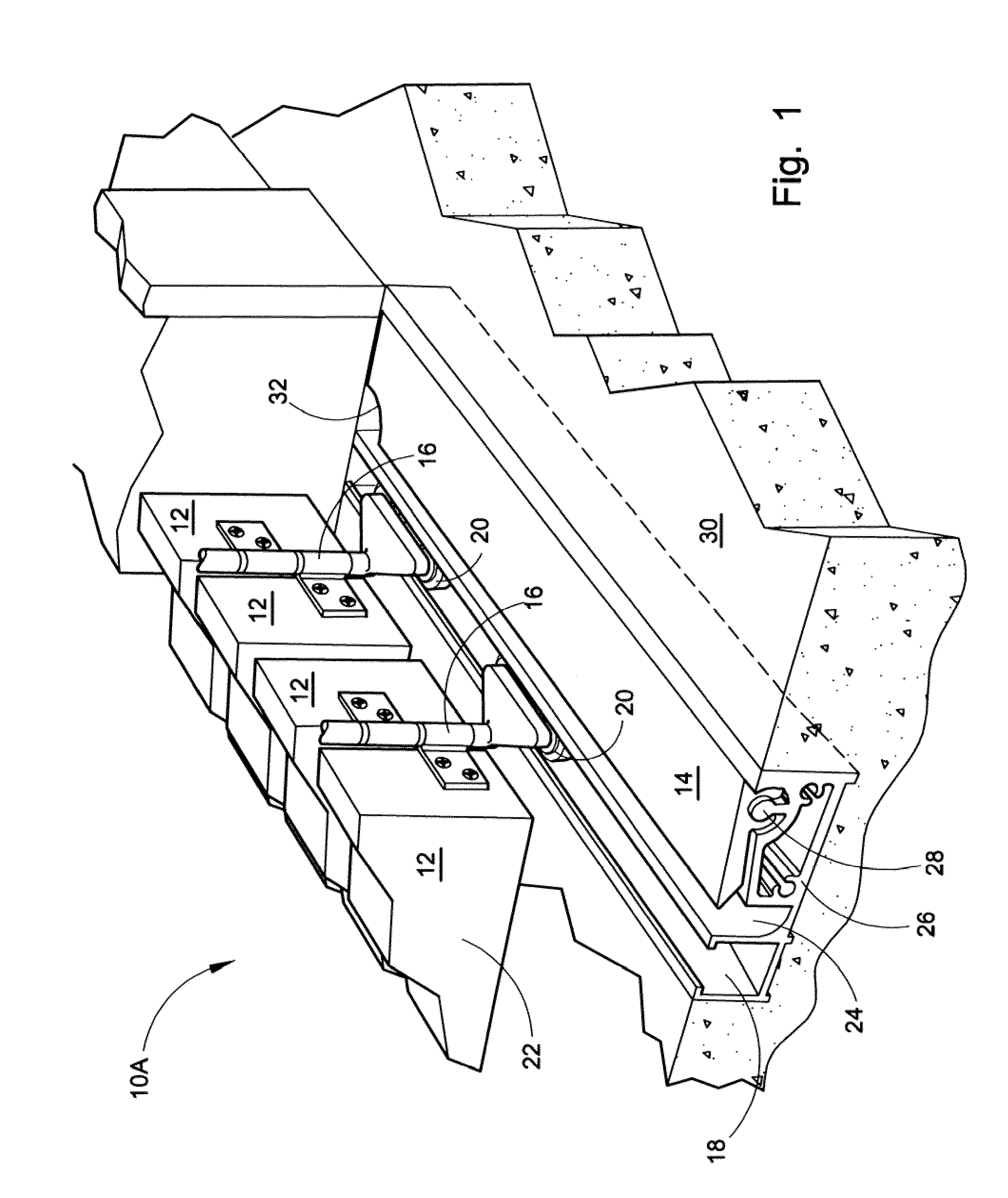

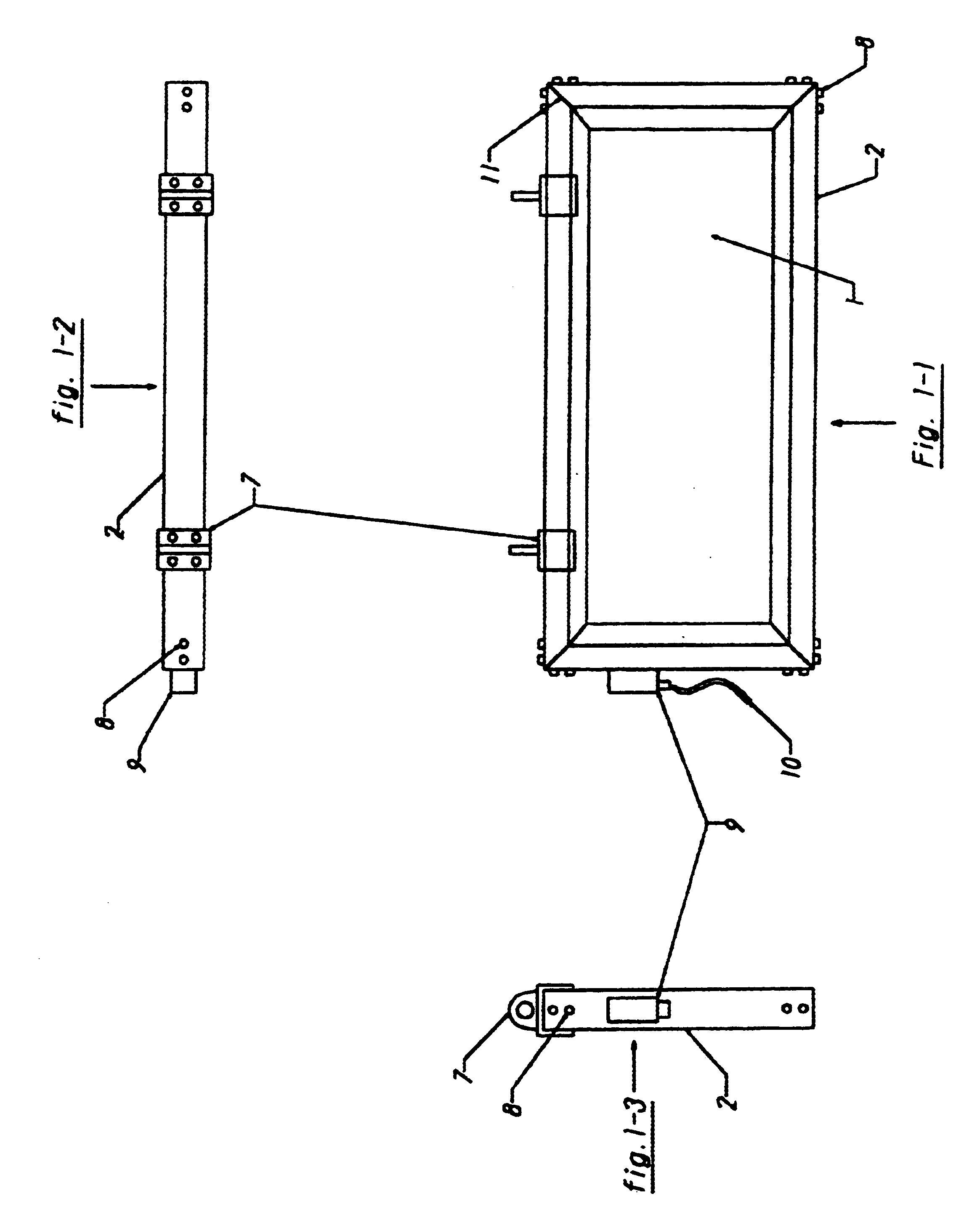

Zero step sill extruded flush threshold door seal system

The present application is directed to a manual or automatic flush threshold door seal system used on folding exterior doors along with an alternate embodiment for conventional exterior entryway doors that will not impede the passage of a wheelchair. A flexible weather seal can be put in a retracted or down position within an aluminum extrusion imbedded within the threshold providing a flush access surface and may be raised up into the upright position providing an adequate weather seal.

Owner:JELD-WEN

Plow blade having integrally formed attachment channel

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a mold board, the mold board preferably being an aluminum extrusion. The aluminum extrusion will preferably include at least one attachment channel, more preferably a plurality of attachment channels, in which parts of the snow blade can be secured or anchored. The plow blade preferably includes first and second attachment channels and the retention apparatus preferably includes at least one retention member anchored in at least one of the attachment channels.

Owner:AGRI COVER

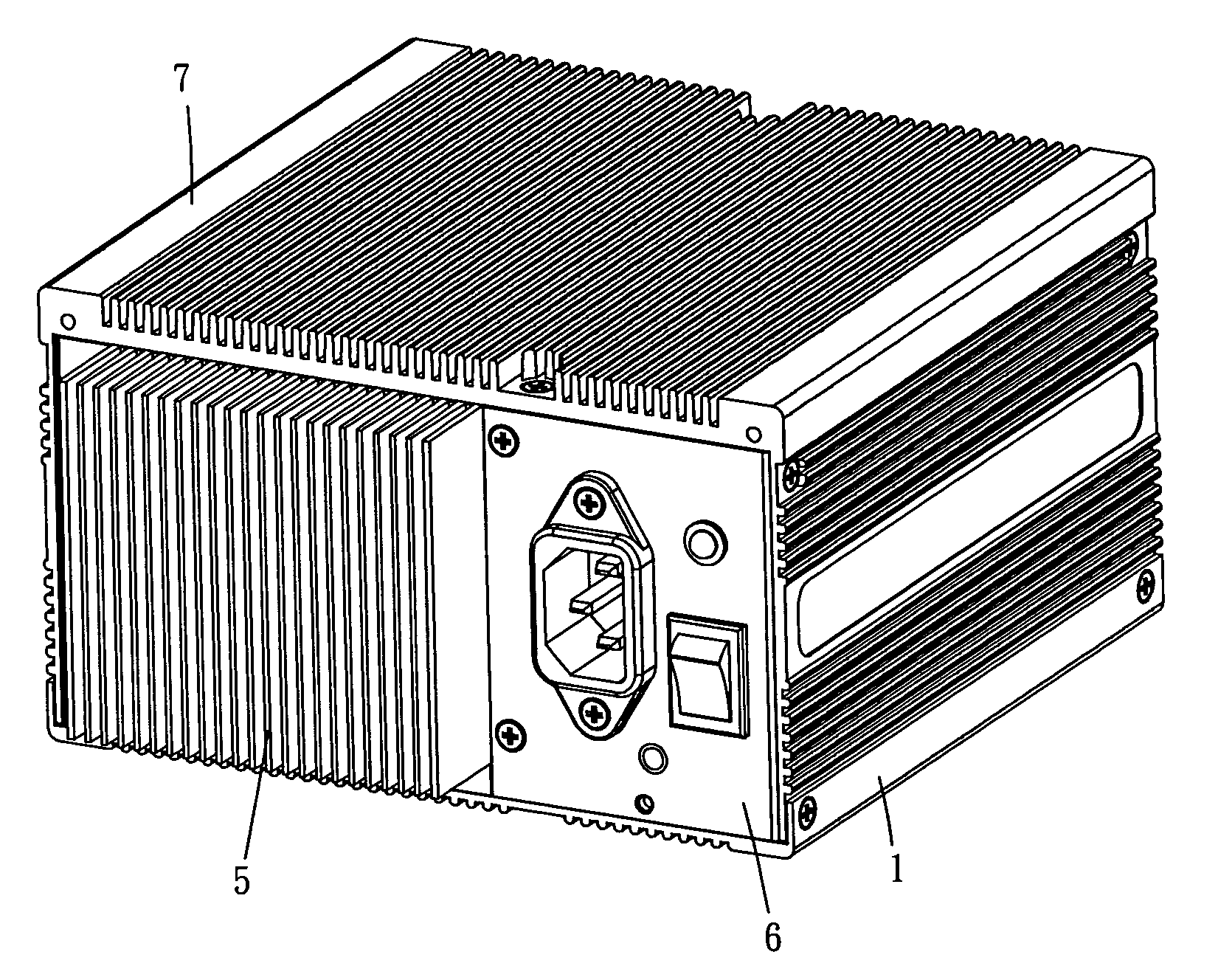

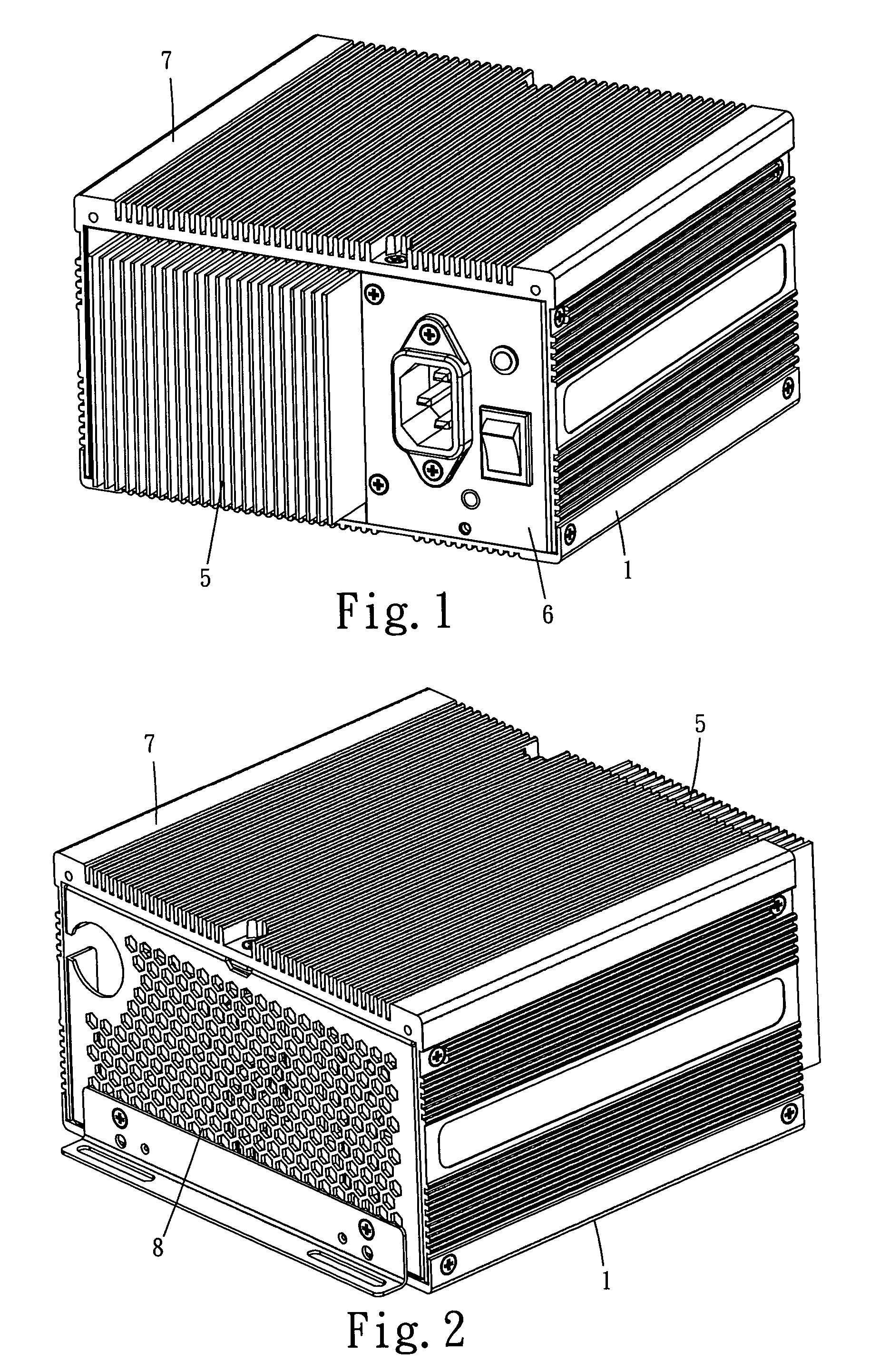

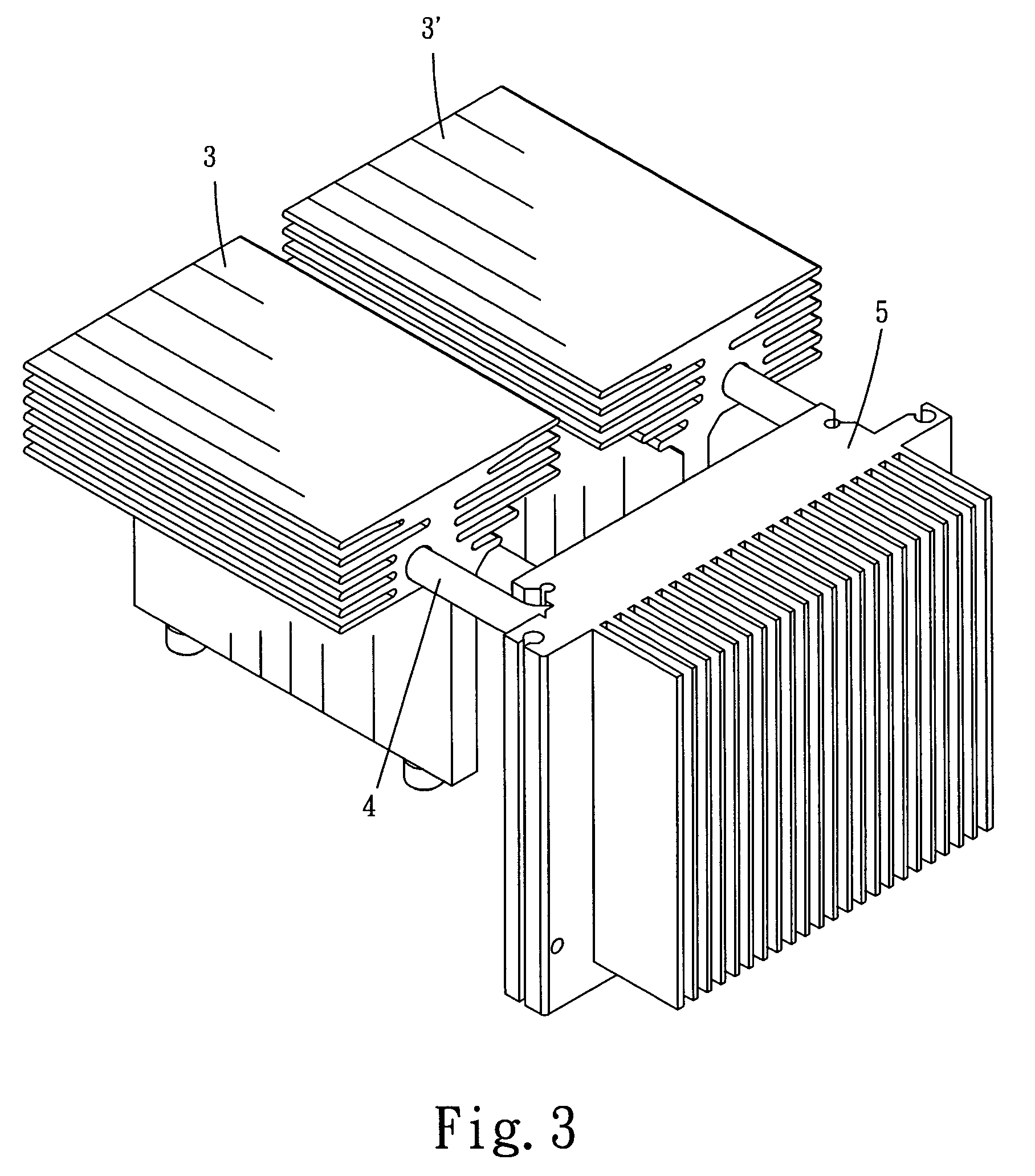

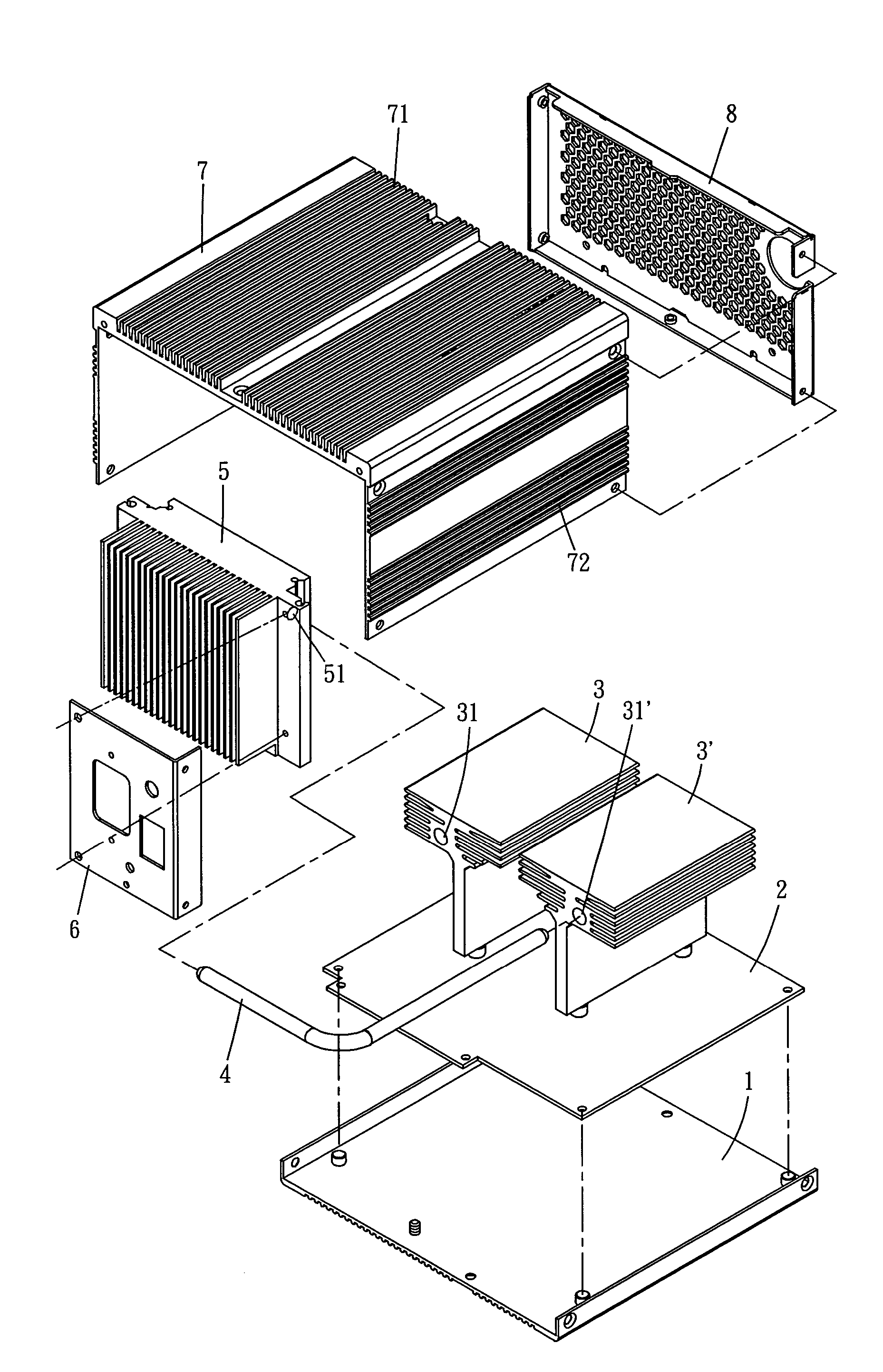

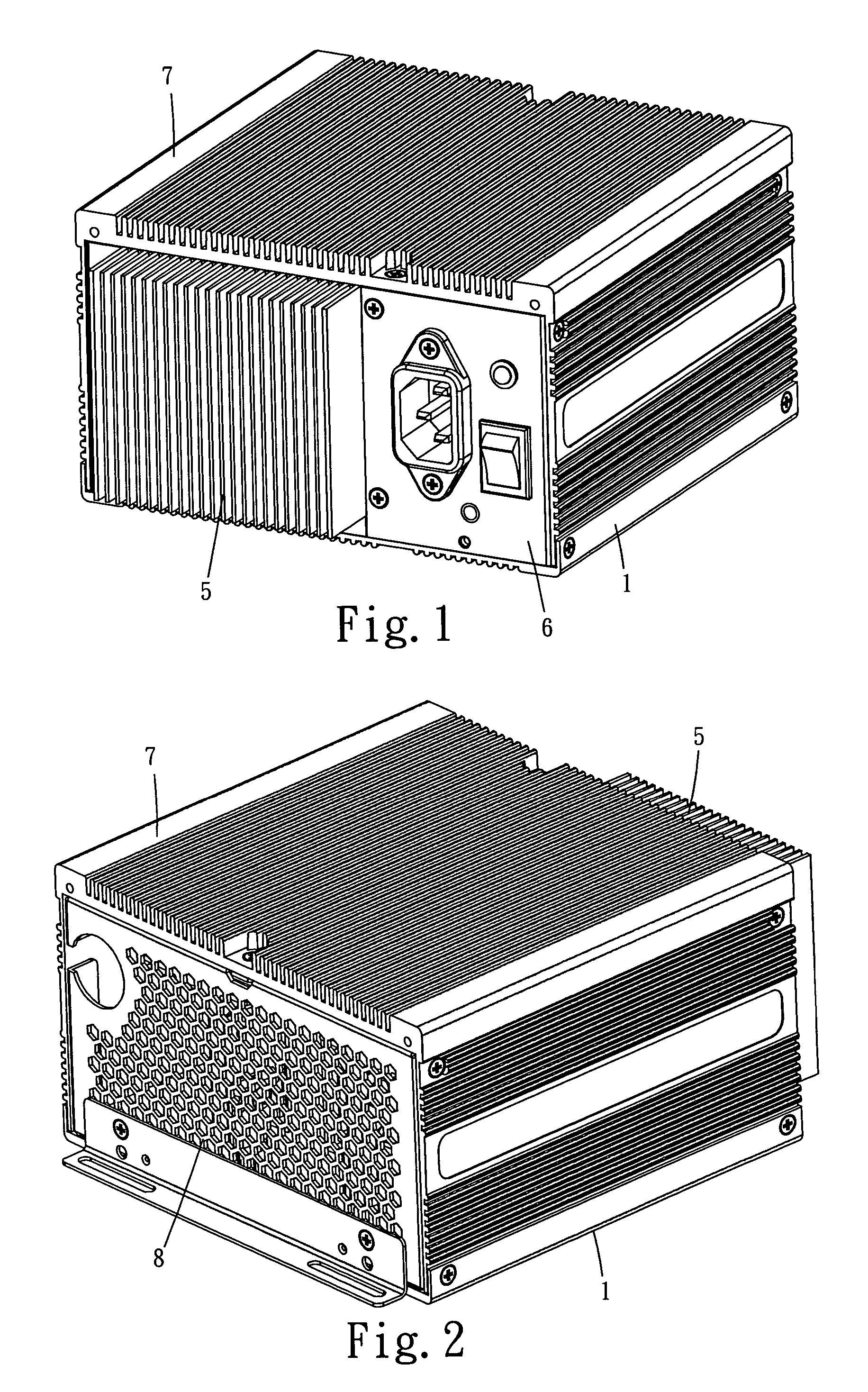

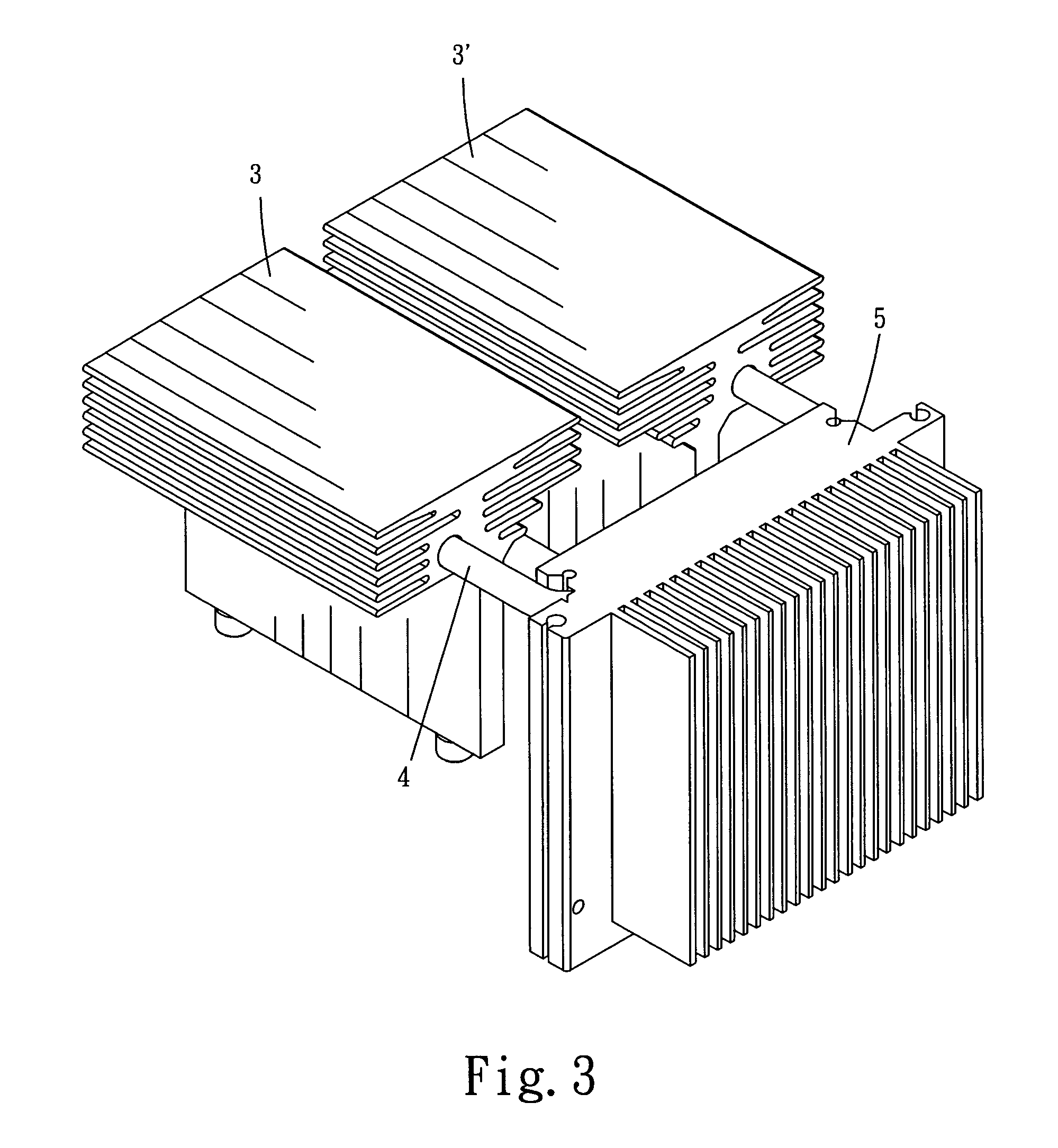

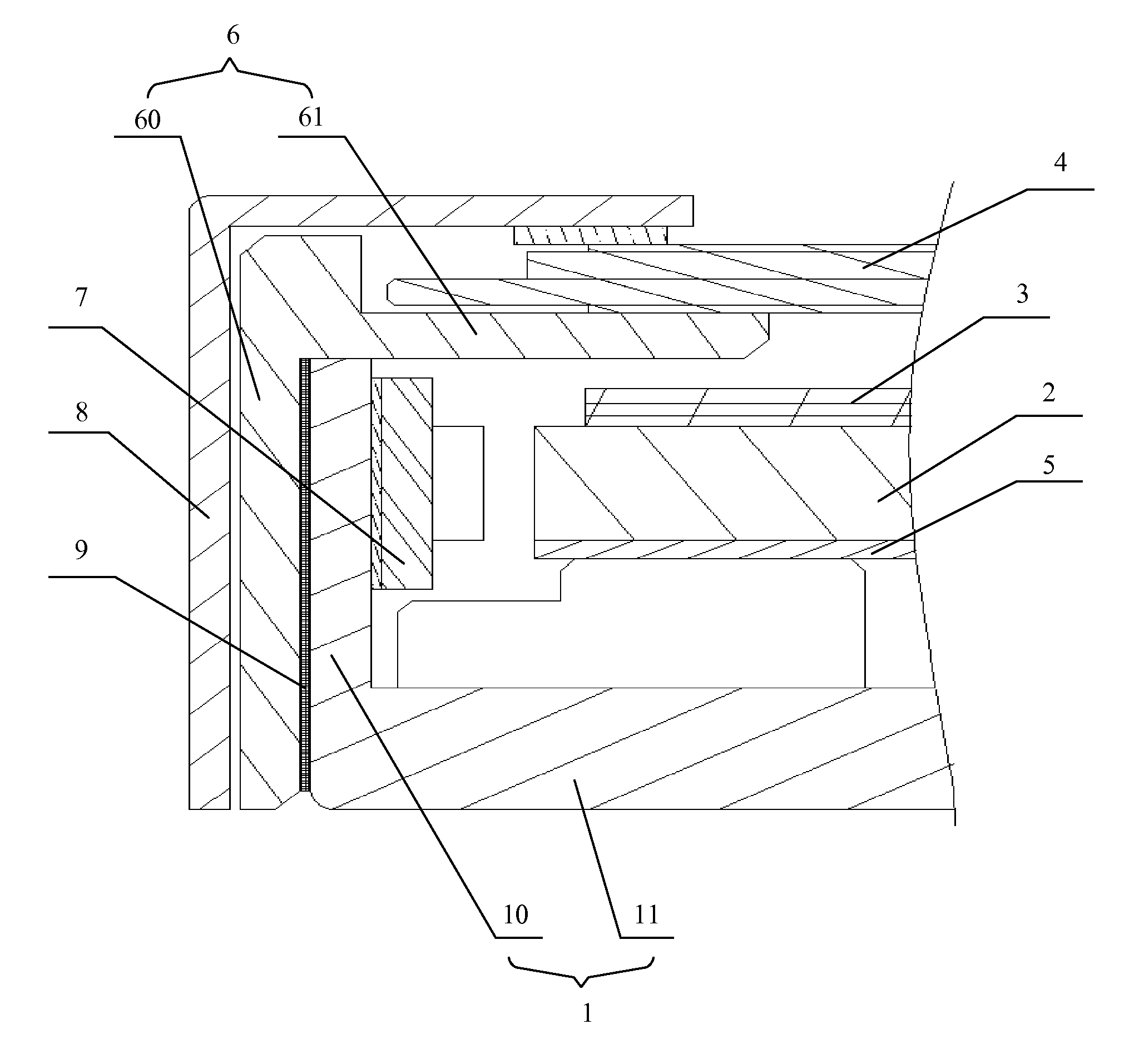

Power supply without cooling fan

InactiveUS7133284B2Improve efficiencyConsumes lotPower supply for data processingRack/frame constructionCooling effectHeat sink

The invention provides a power supply for a computer mainframe, which is cooled by a heat conduction method, and more particularly to a power supply without a cooling fan. The present invention features a highly effective heat pipe connecting a plurality of aluminum-extrusion heat sink fins and a plurality of aluminum-extrusion heat sinks, the aluminum-extrusion heat sink fins fixed above a cooling chip over a circuit board, and the aluminum-extrusion heat sinks fringed near the power supply, with a part of the heat sink fins exposed to the power supply. The heat of a chip is conducted out of the power supply by the aluminum-extrusion heat sink fins, the high-effect heat pipe, and the aluminum-extrusion heat sinks. Therefore, the power supply can reach an expected cooling effect without the cooling fan.

Owner:ETASIS ELECTRONICS

Snow plow having attachable biasing member

InactiveUS20070056194A1Improve practicalityEasy to liftSnow cleaningAgricultural engineeringEngineering

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a mold board, preferably, a two piece mold board being an aluminum extrusion. The preferred snow plow also includes an attachable biasing member secured between the plow blade and the mounting apparatus such that the biasing member resists upward movement of the plow blade when the plow blade is in a working orientation

Owner:AGRI COVER

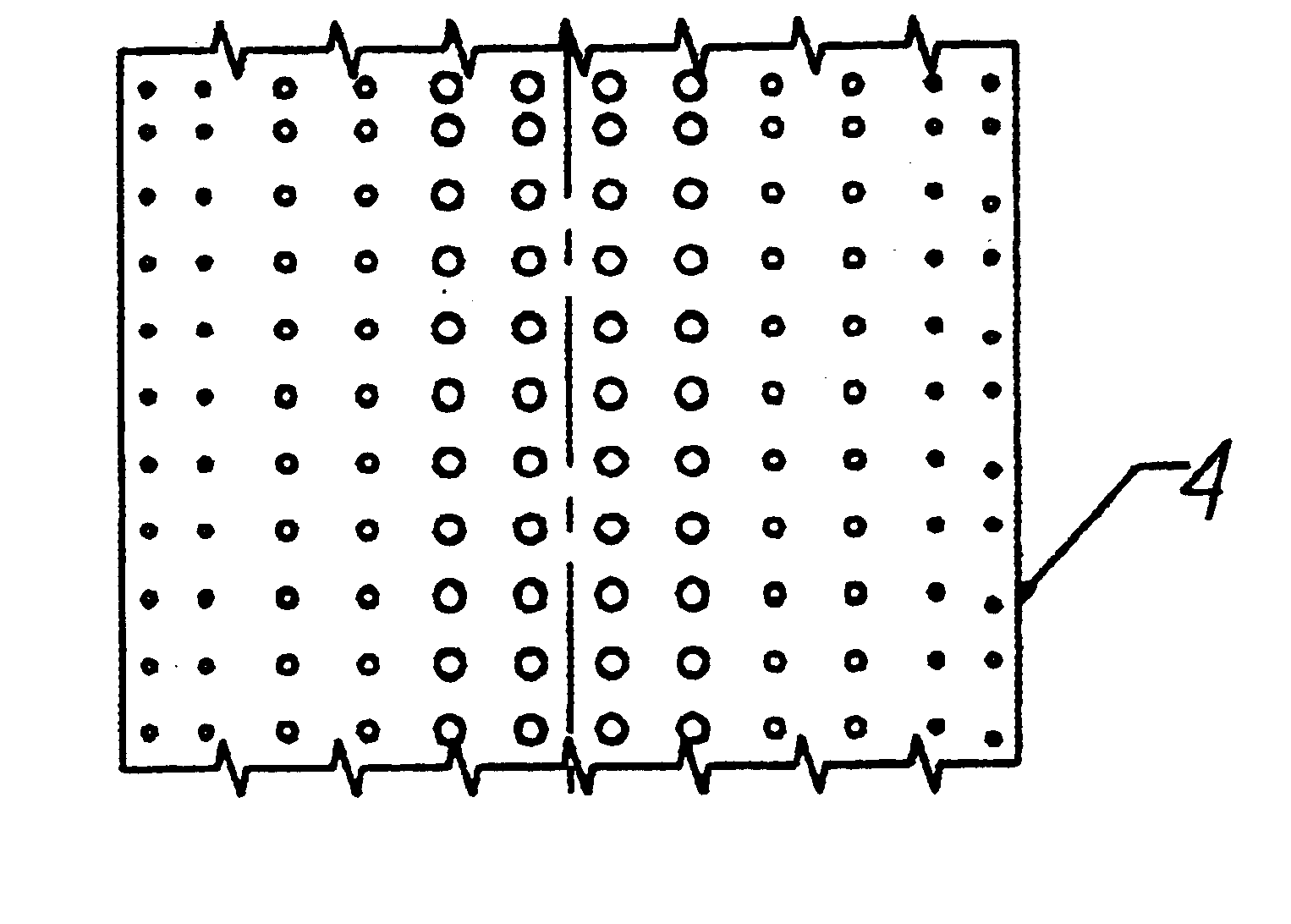

Snow plow having internally reinforced mold board

InactiveUS20070256334A1Efficient productionMechanical machines/dredgersSnow cleaningEngineeringAluminum extrusion

A snow plow for attachment to a vehicle, the snow plow including a mounting apparatus having a mounting frame, the mounting frame including at least one mounting upright. The snow plow further including a plow blade including a retention apparatus constructed and arranged to slidlingly and disengageably secure the plow blade to the mounting upright(s) when the plow blade is in a working orientation. The plow blade includes a mold board, preferably, a two piece mold board being an aluminum extrusion. The mold board will preferably include a front and a back and cells or compartments partially formed by support structures that extend between the front and the back of the mold board and along the width of the plow blade.

Owner:AGRI COVER

Visual display unit

A visual display unit comprising a panel and housing with said housing enclosed by an aluminum extrusion, said extrusion houses at least one printed circuit board and light emitting diodes which are attached to said at least one printed circuit board, said light emitting diodes are insulated and attached to said at least one printed circuit board, a bracket and junction box are attached to said aluminum extrusion, with power coming through said junction box, sealant is used between said aluminum extrusion and said panel, light is projected through said panel and reflected out.

Owner:VELEZ MICHAEL

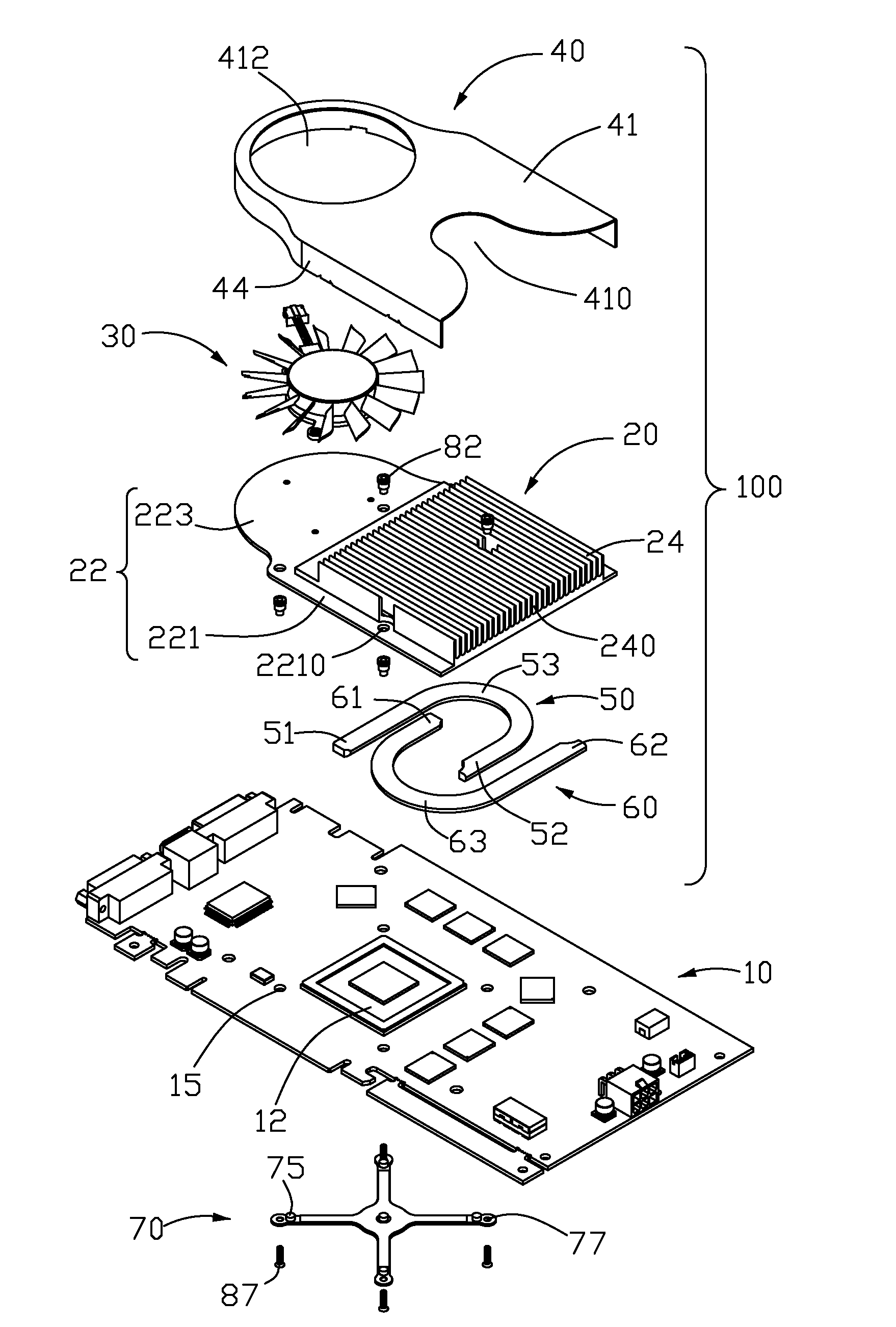

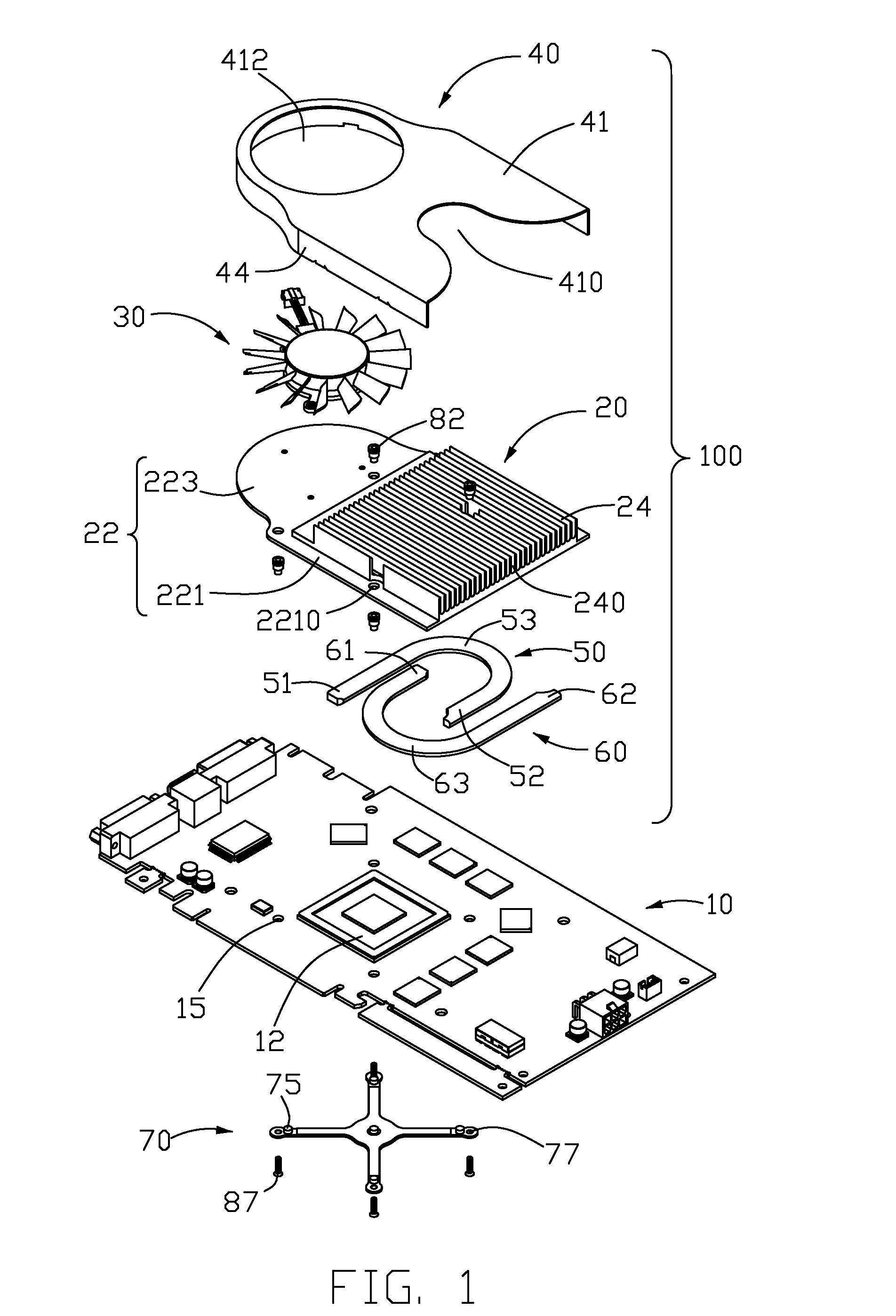

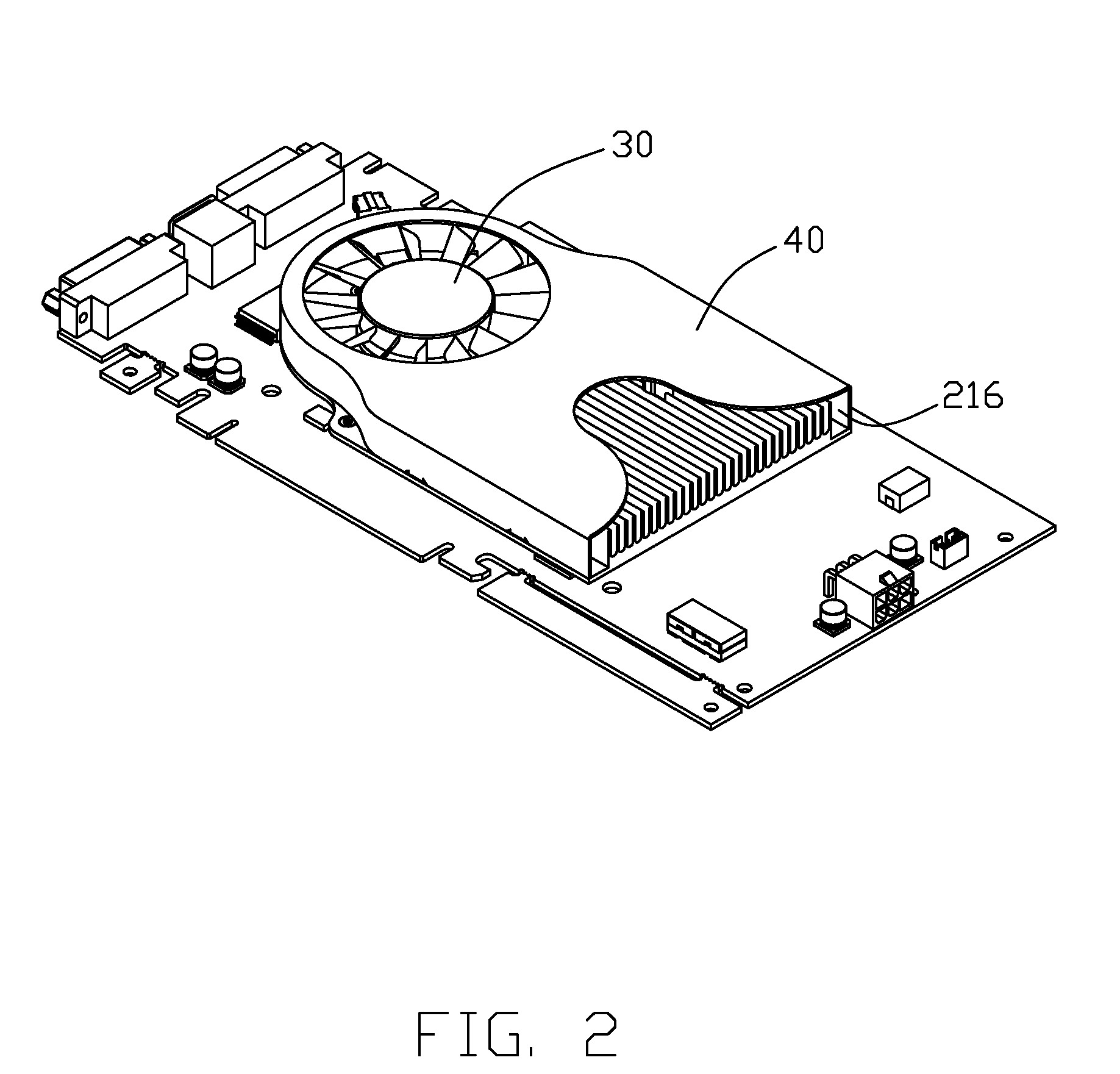

Heat dissipation device for computer add-on cards

InactiveUS20080158820A1Semiconductor/solid-state device detailsSolid-state devicesGraphicsGraphic card

A heat dissipation device (100) is mounted on a heat-generating device (12) of a graphics card (10) and comprises a heat sink (20), a fan (30), a cover (40) and a heat pipe (50). The heat sink (20) has a base (22) and a plurality of fins (24) on the base (22). The fan (30) is mounted on the base (22) of the heat sink (20) beside the fins (24). The cover (40) covers the heat sink (20) and the fan (30). The heat pipe (50) is embedded in a bottom surface of the base (22) of the heat sink (20) in direct contact with the heat-generating device (12). The heat pipe (50) has a bottom face coplanar with the bottom surface of the base (22). The base (22) and the fins (24) are integrally formed as a monolithic piece by aluminum extrusion.

Owner:HON HAI PRECISION IND CO LTD

Heat exchanger

ActiveUS8540012B2Prevent materialAvoid introducingOther heat production devicesMachines/enginesEngineeringAluminum extrusion

Owner:LOCKHEED MARTIN CORP

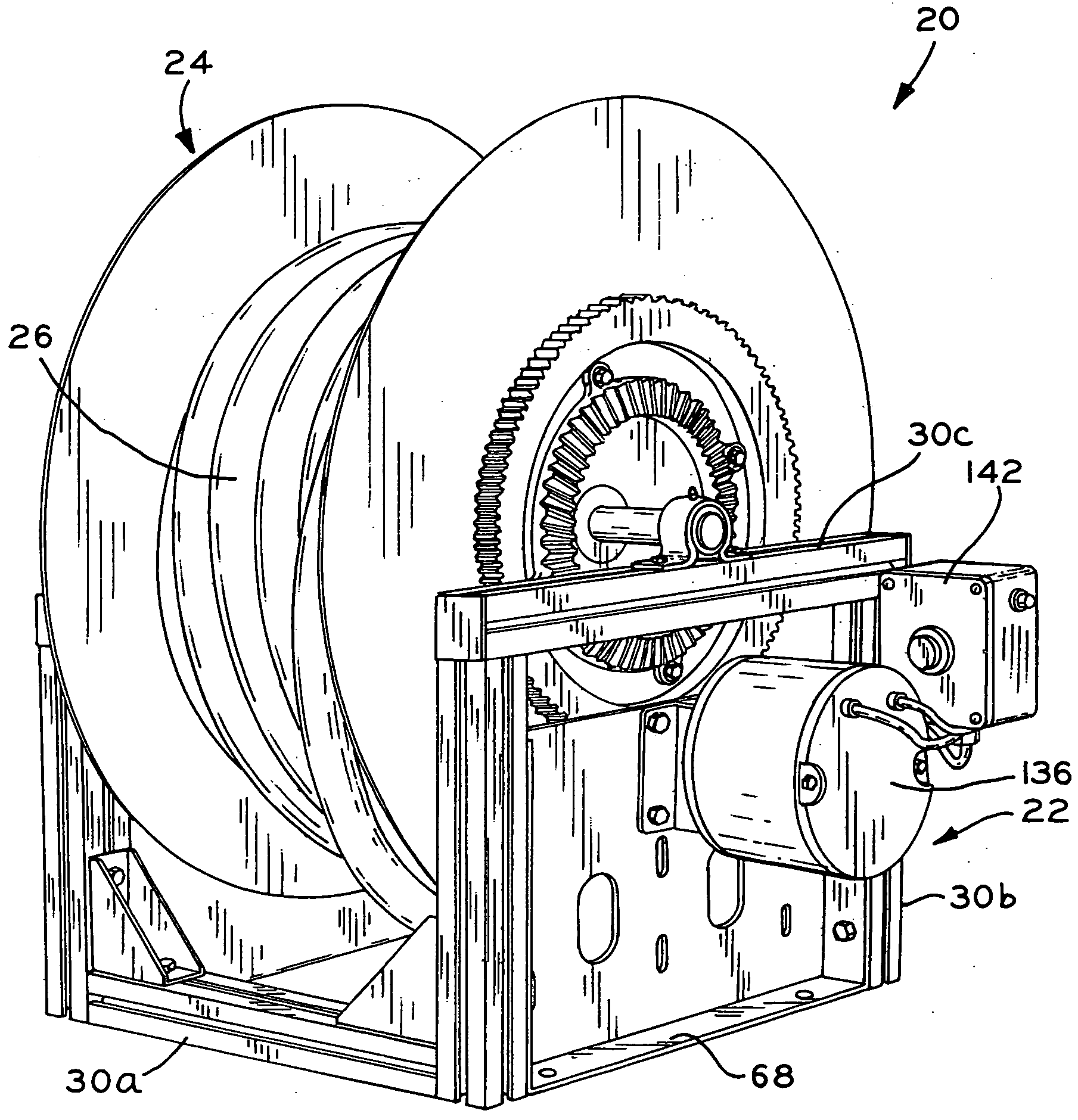

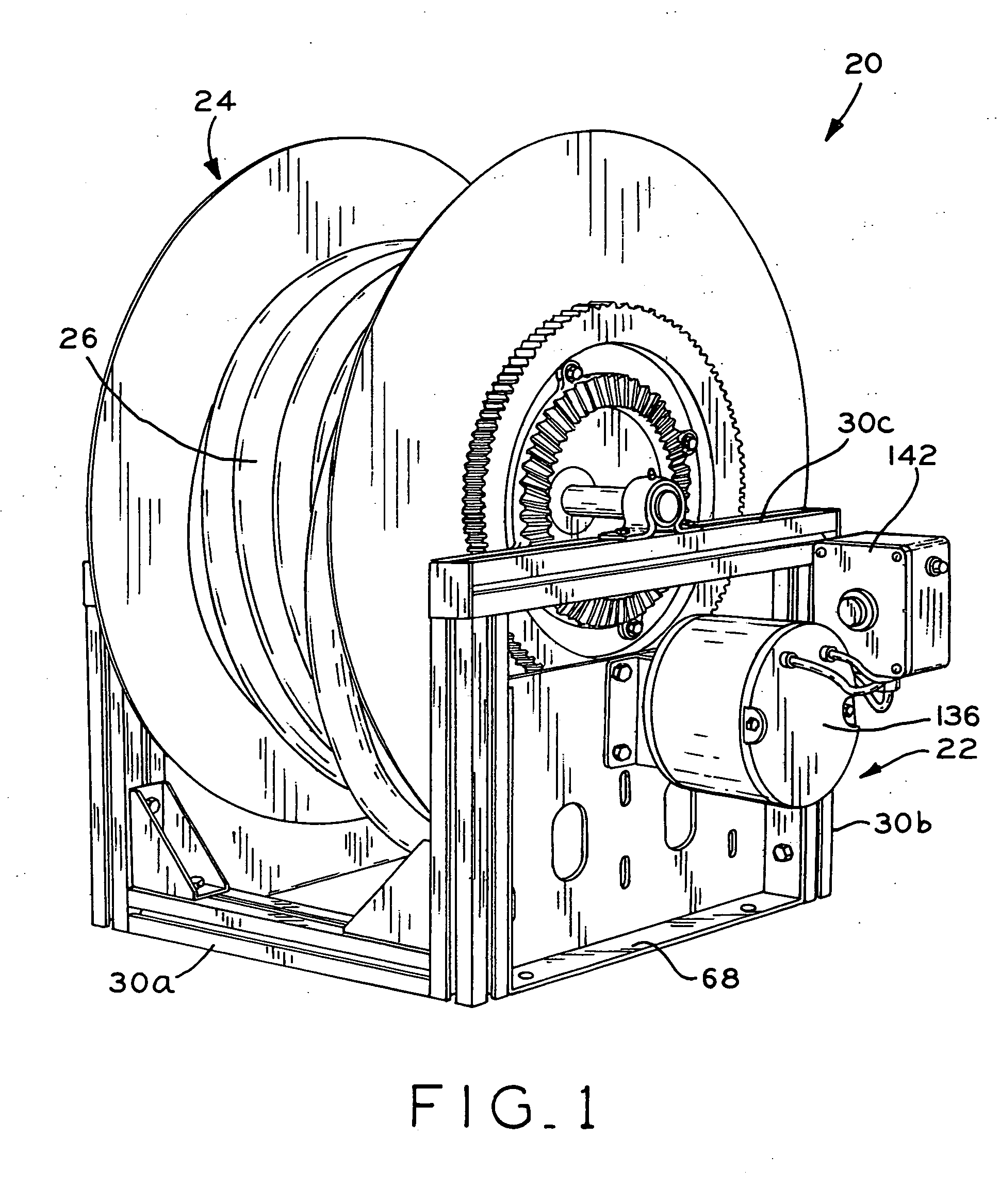

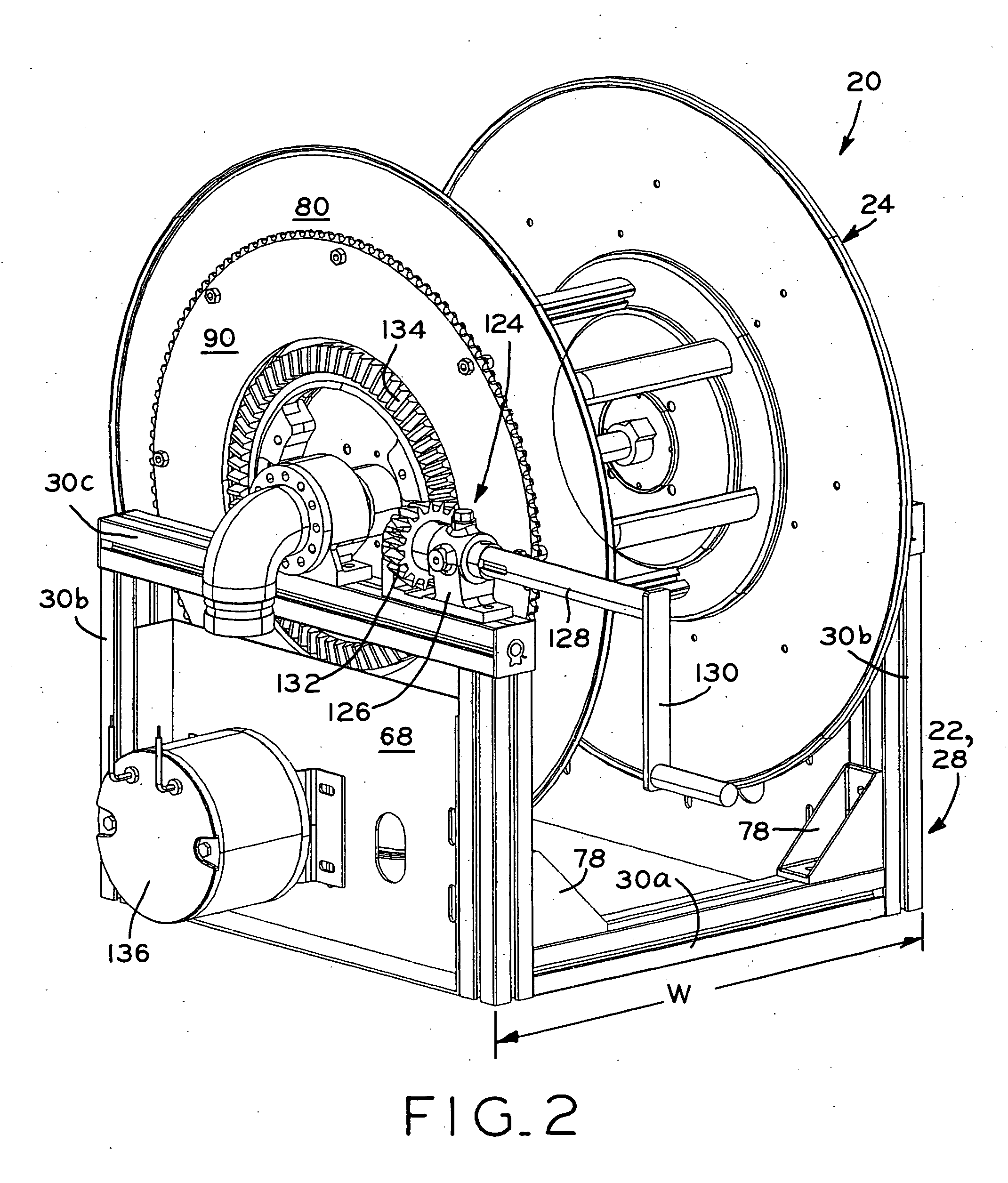

Modular hose reel

InactiveUS20050103918A1Easily custom manufactureConvenient lengthModularityGobio gobio obtusirostris

A reel, such as a hose reel, which includes a modular base assembly and a modular spool assembly. The base assembly includes a frame which is formed by a plurality of extruded frame components joined to one another by connecting members. The lengths of the frame components may be easily varied in order to in turn vary the overall width, depth, and height dimensions of the frame of the base assembly. The spool assembly includes a pair of side walls joined to one another by a plurality of spacer members. The length of the spacer members may be varied to in turn vary the width of the spool assembly. In one embodiment, the base assembly frame components and the spacer members are aluminum extrusions which are each cut to a selected length. In this manner, the width, depth, and height of the frame of the base assembly and the width of the spool assembly may be selectively varied to easily custom manufacture different reels having different overall sizes.

Owner:REELCRAFT INDS

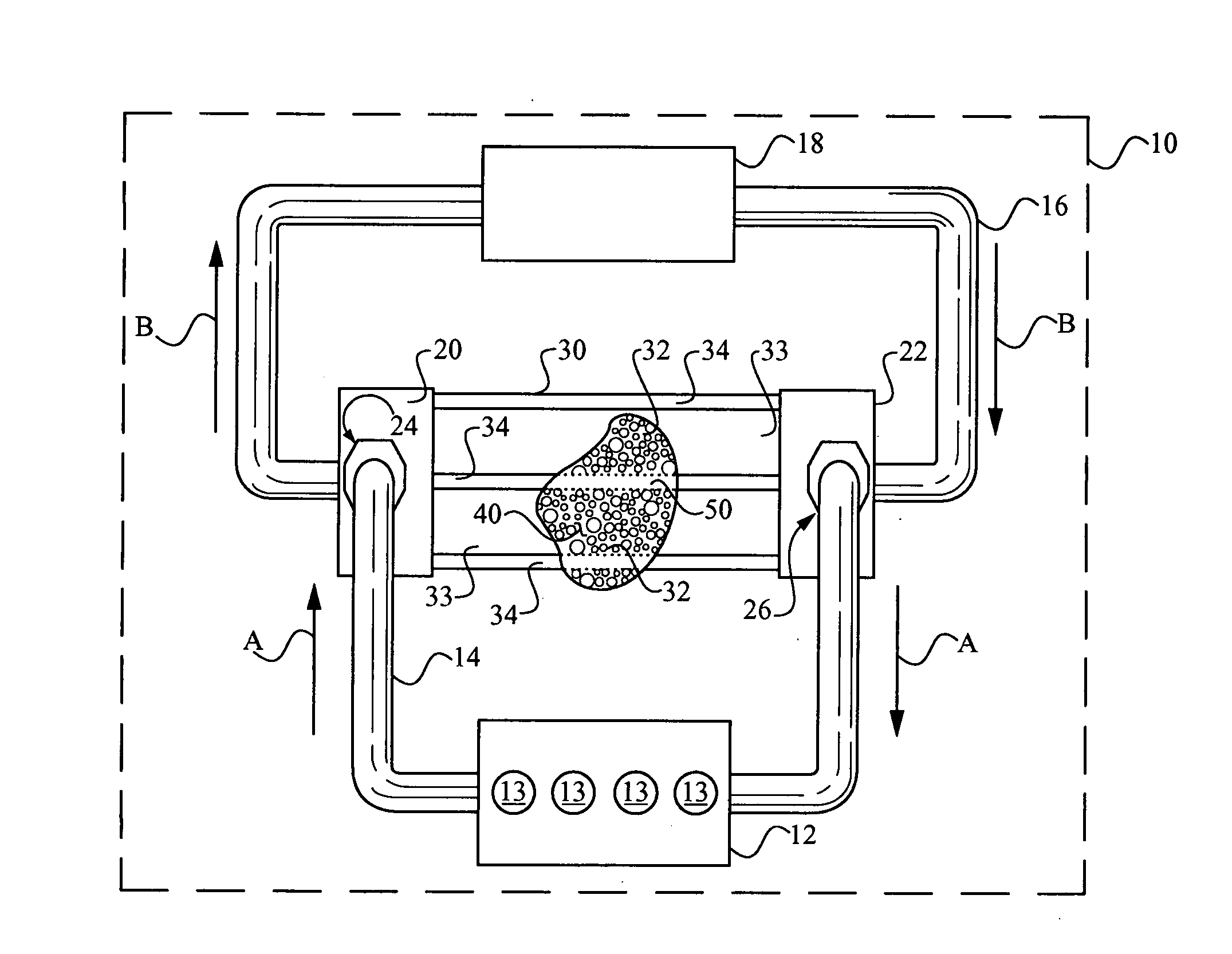

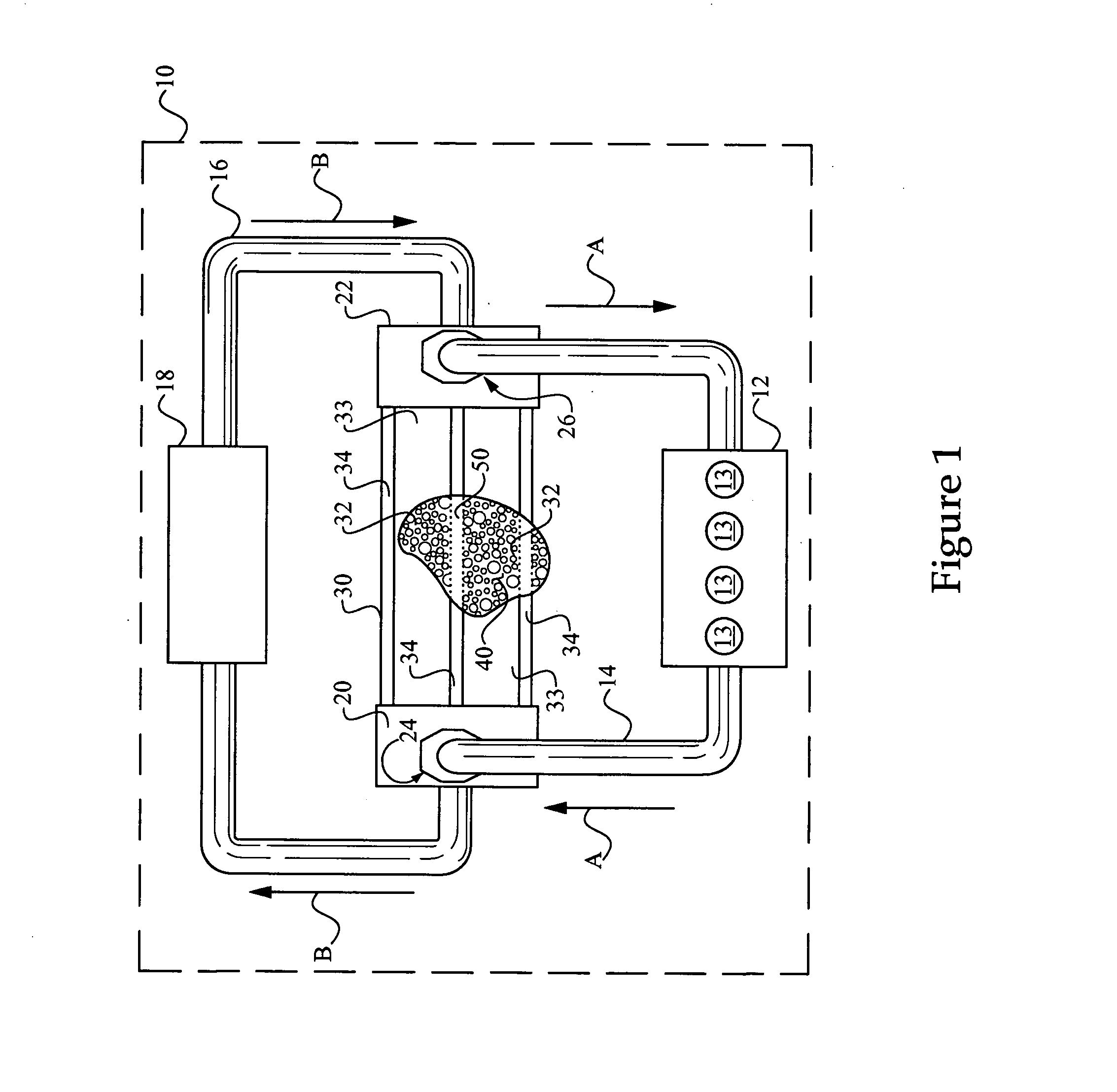

Method of manufacturing metallic foam based heat exchanger

InactiveUS20070228113A1Heat transfer modificationWelding apparatusInternal combustion engineAluminum extrusion

A method of manufacturing a metallic foam based heat exchanger includes positioning an aluminum foam block, for example, within a housing defining a first fluid passage, and placing the block in contact with a second portion of the housing defining at least one other fluid passage, the second housing portion being an extrusion. A brazing flux material and a brazing filler are applied to at least one of the foam and the extrusion, the foam being thermally coupled to the extrusion with the brazing filler via heating in a brazing furnace. A heat exchanger includes a housing having a fluid passage with a metallic foam such as an aluminum foam therein. The metallic foam is attached to a metallic extrusion such as an aluminum extrusion, and connected therewith via a thermally conducting brazing filler. A method of cooling oil in an internal combustion engine is further provided, including the step of passing high temperature oil through an aluminum foam in a fluid passage of a first housing portion, and passing low temperature fluid through a second passage in a second housing portion. Heat is exchanged between the high temperature oil and the low temperature fluid at least in part via a thermally conducting attachment material joining the aluminum foam with the second portion of the housing.

Owner:CATERPILLAR INC

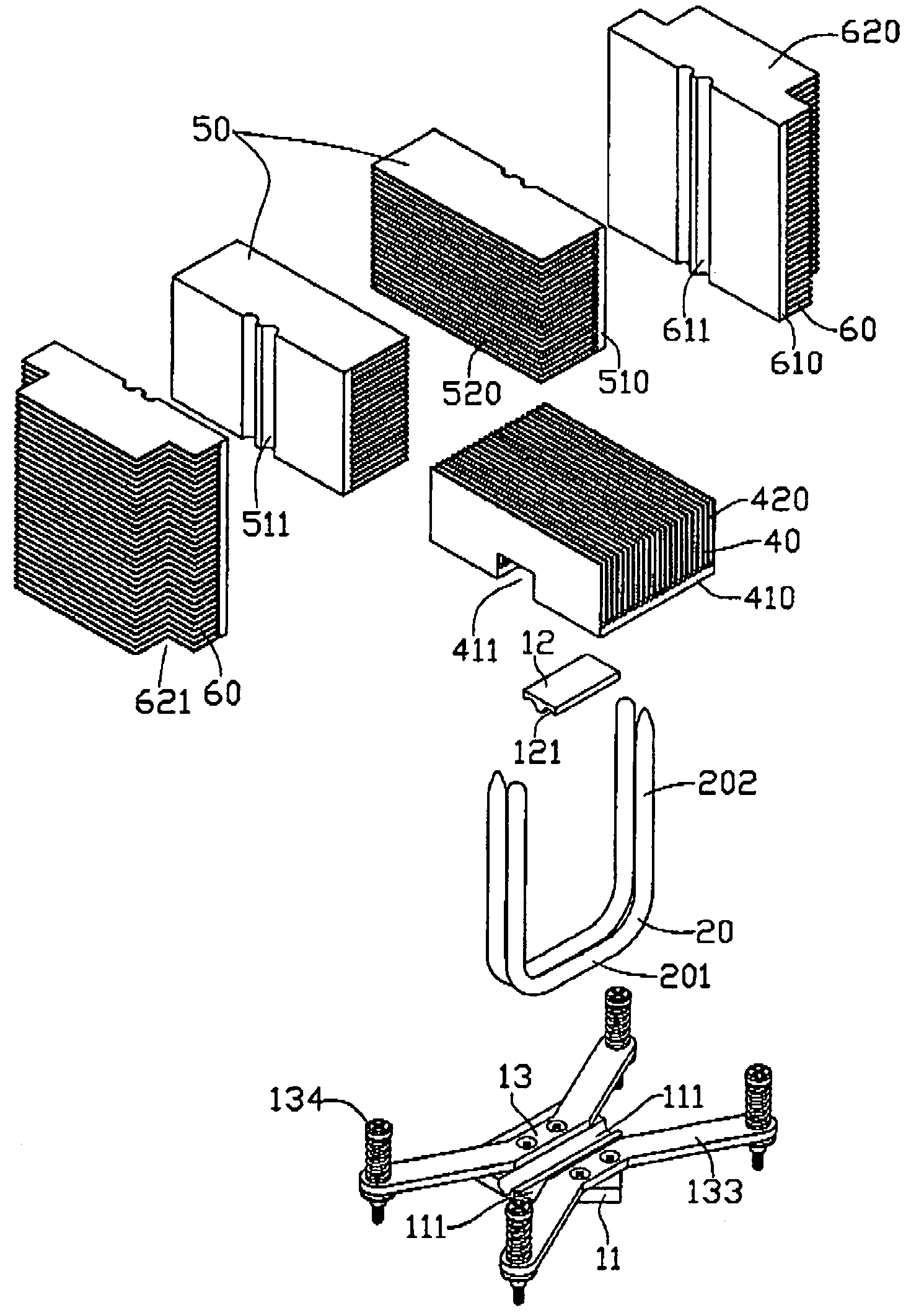

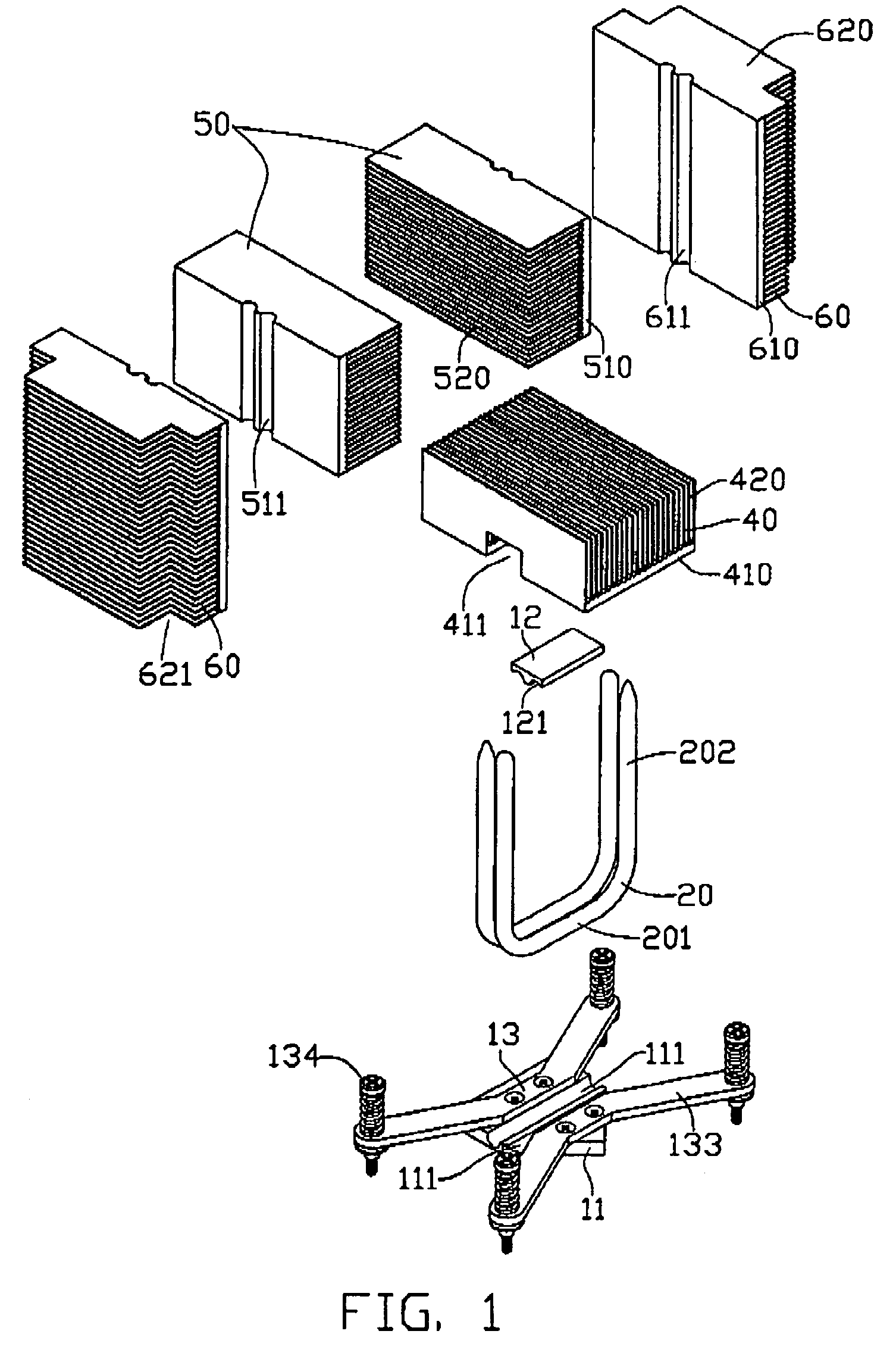

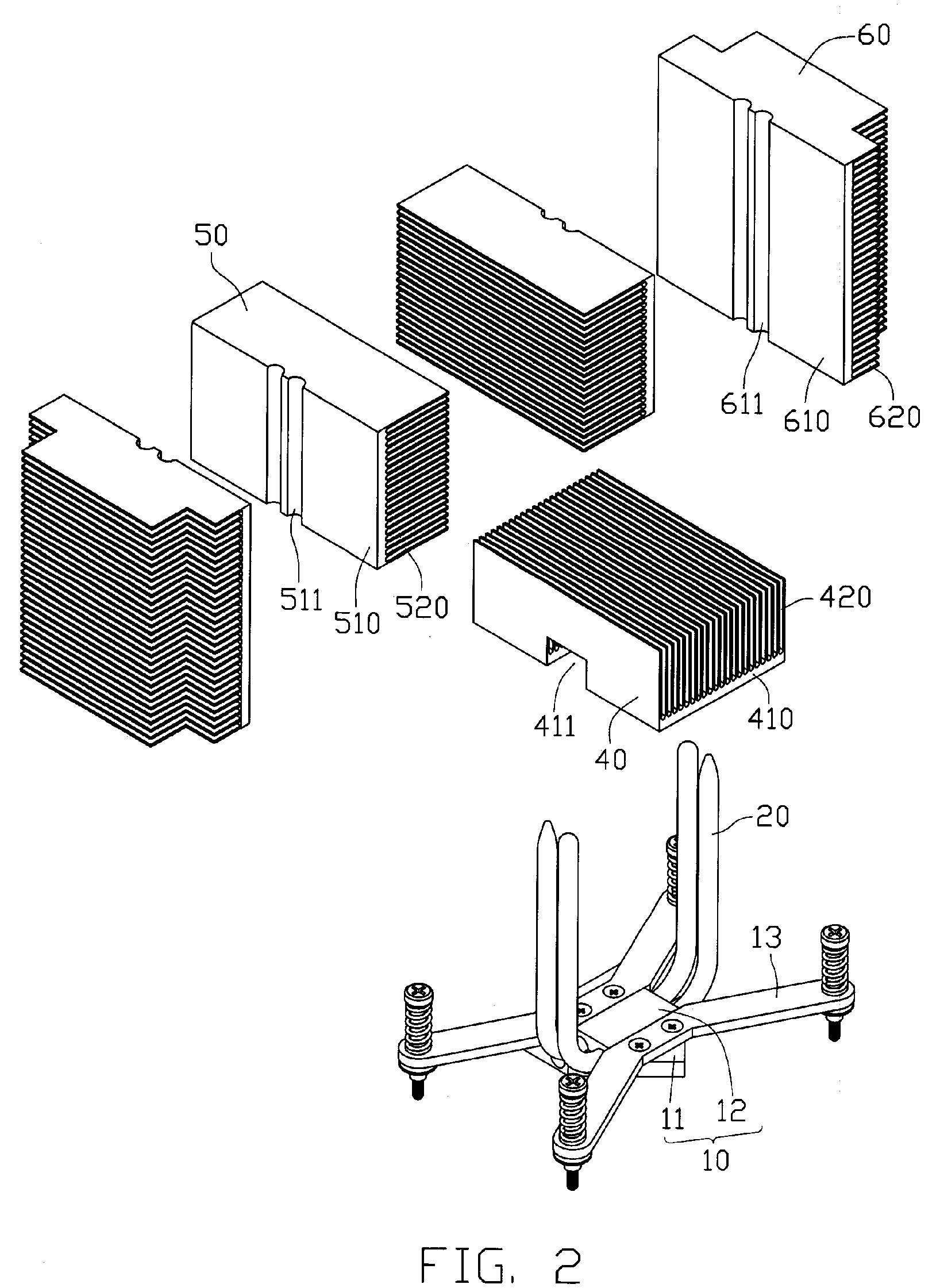

Heat dissipation device with heat pipes

InactiveUS7277287B2Improve cooling effectLow costCooking-vessel materialsSemiconductor/solid-state device detailsEngineeringAluminum extrusion

A heat dissipation device comprises a seat for absorbing heat from a heat generating device. At least a heat pipe has a first section thereof thermally combined to the seat, and two second sections thereof extending from the first section and remotely from the seat. Pluralities of heat sinks are located on the seat. Each of the pluralities of heat sinks has a base and a plurality of fins integrally extending from the base and is made of aluminum extrusion. The bases of the heat sinks thermally sandwich the two second sections of the at least a heat pipe therebetween. At least one of the bases of the heat sinks is angled or perpendicular to the seat.

Owner:HON HAI PRECISION IND CO LTD +1

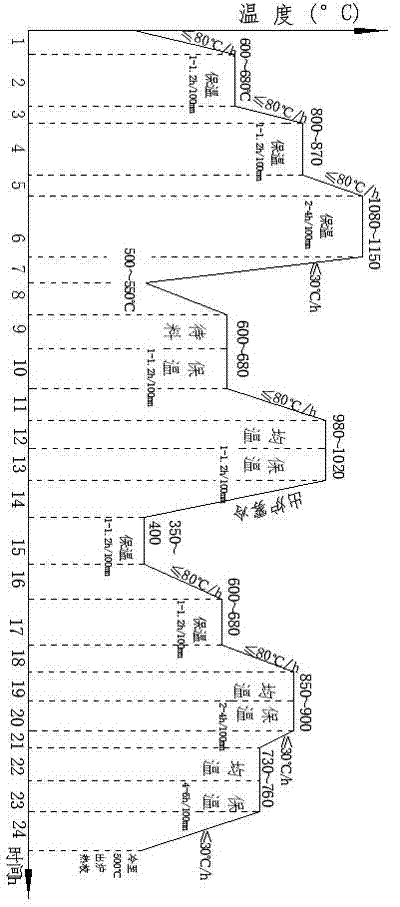

Thermal treatment process for improving microscopic coarse grains and microstructures of H13 forged piece

The invention relates to a thermal treatment process for improving microscopic coarse grains and microstructures of an H13 forged piece for an H13 aluminum extrusion mold with high requirements for microscopic and post-forge annealing structures. The process comprises high-temperature diffusion heating, high-temperature diffusion cooling, normalization heating, normalization cooling and isothermal spheroidizing, wherein two times of preheating is adopted in the high-temperature diffusion heating, and fog cooling is adopted in the normalization cooling. According to the process adopting a high-temperature diffusion, normalization and isothermal spheroidizing mode, local coarse grains are eliminated by high-temperature diffusion, so as to obtain relatively large and uniform grains and structures ready for subsequent normalization and isothermal spheroidizing; fog cooling is adopted in the normalization cooling to increase the cooling speed, so that the coarse grains produced by high-temperature diffusion are thinned, and netlike carbide structures are eliminated; and through the isothermal spheroidizing, fine and uniform globular pearlite and a small amount of diffused granular carbides are obtained, and the purpose of eliminating the microscopic coarse grains and the microstructures is achieved.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

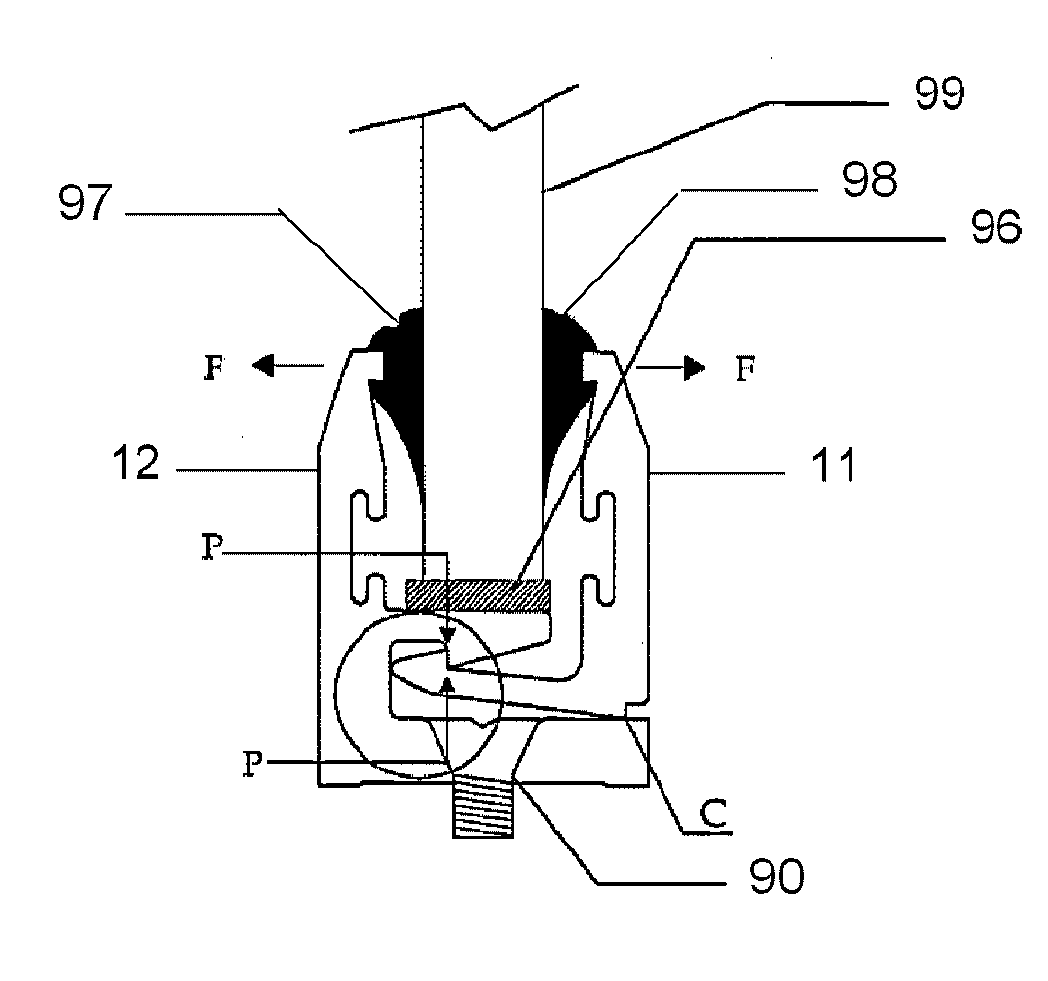

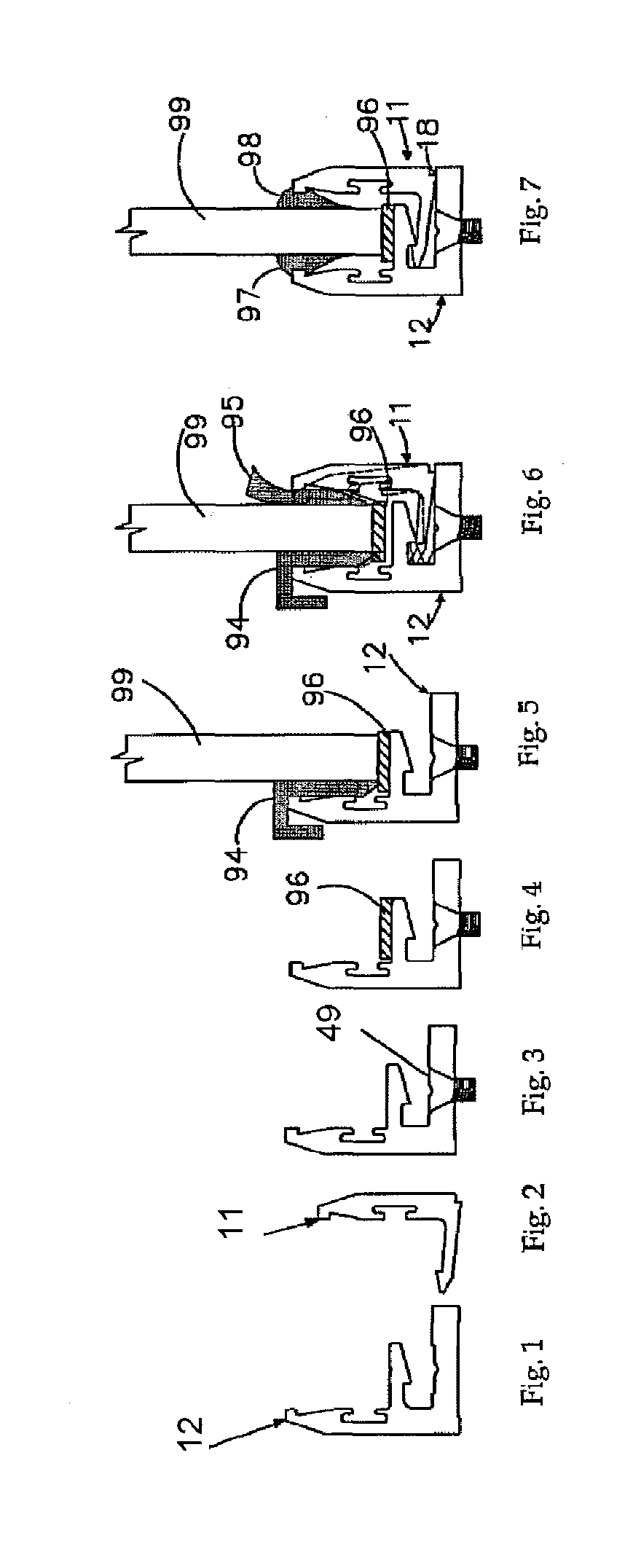

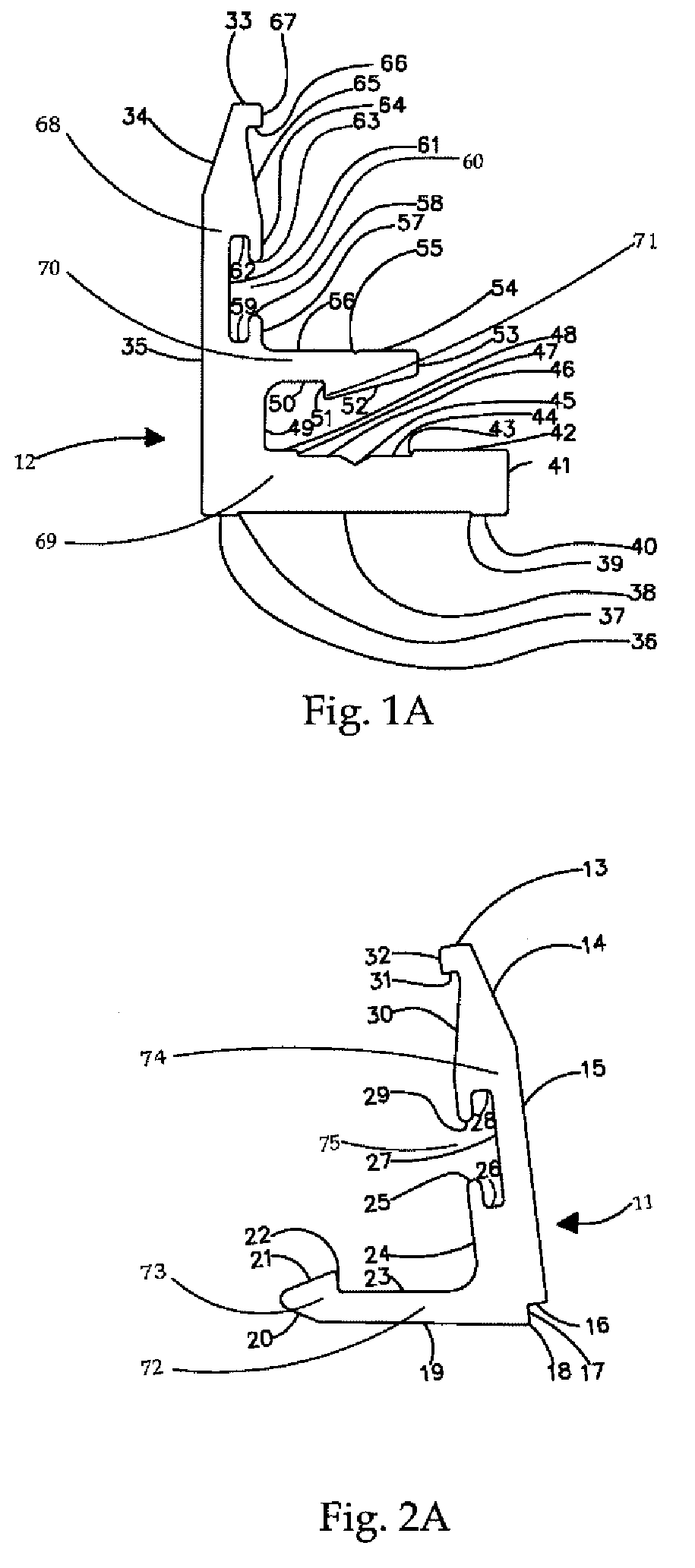

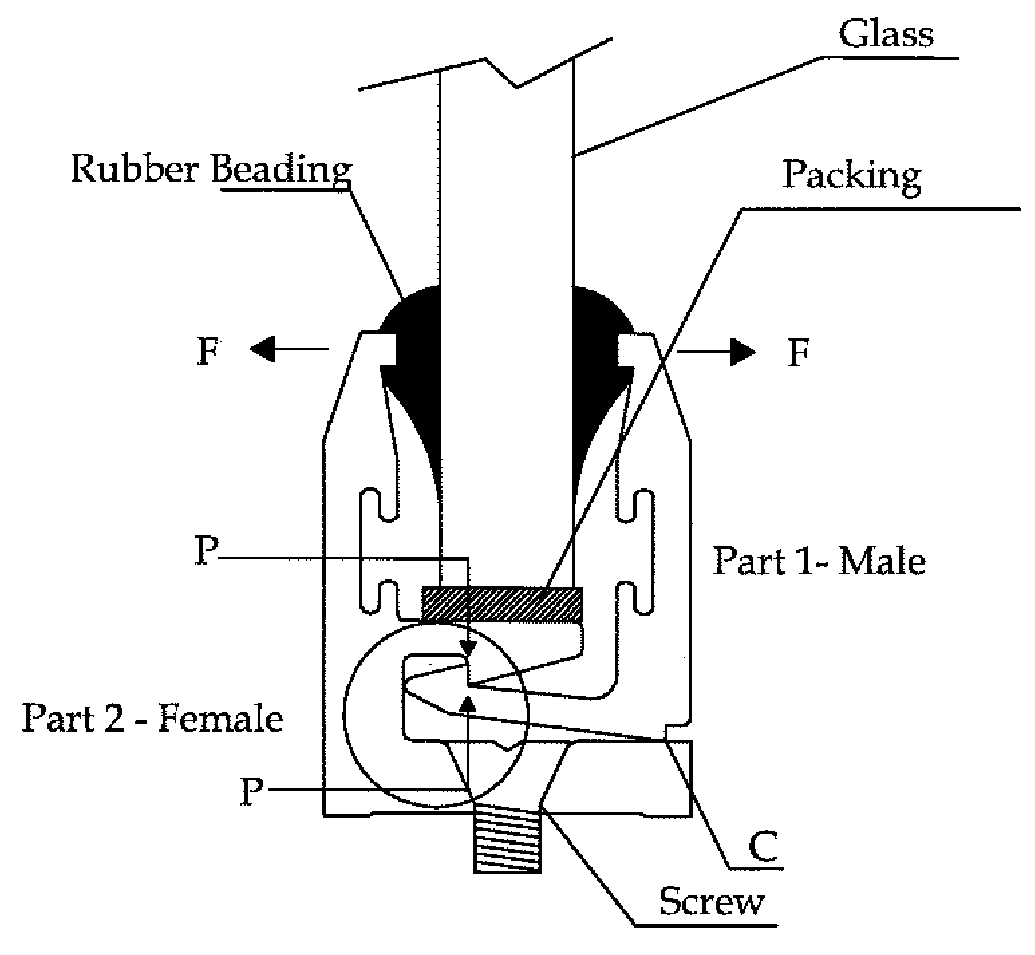

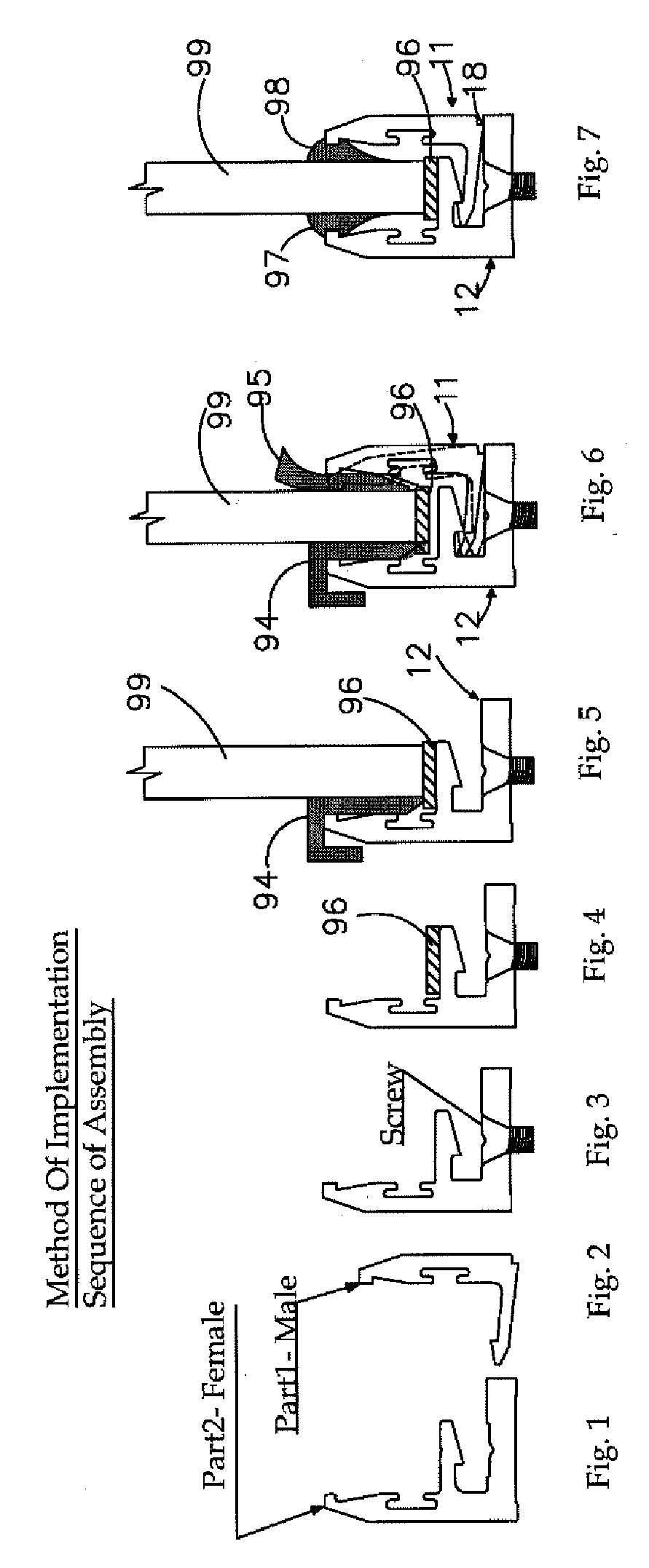

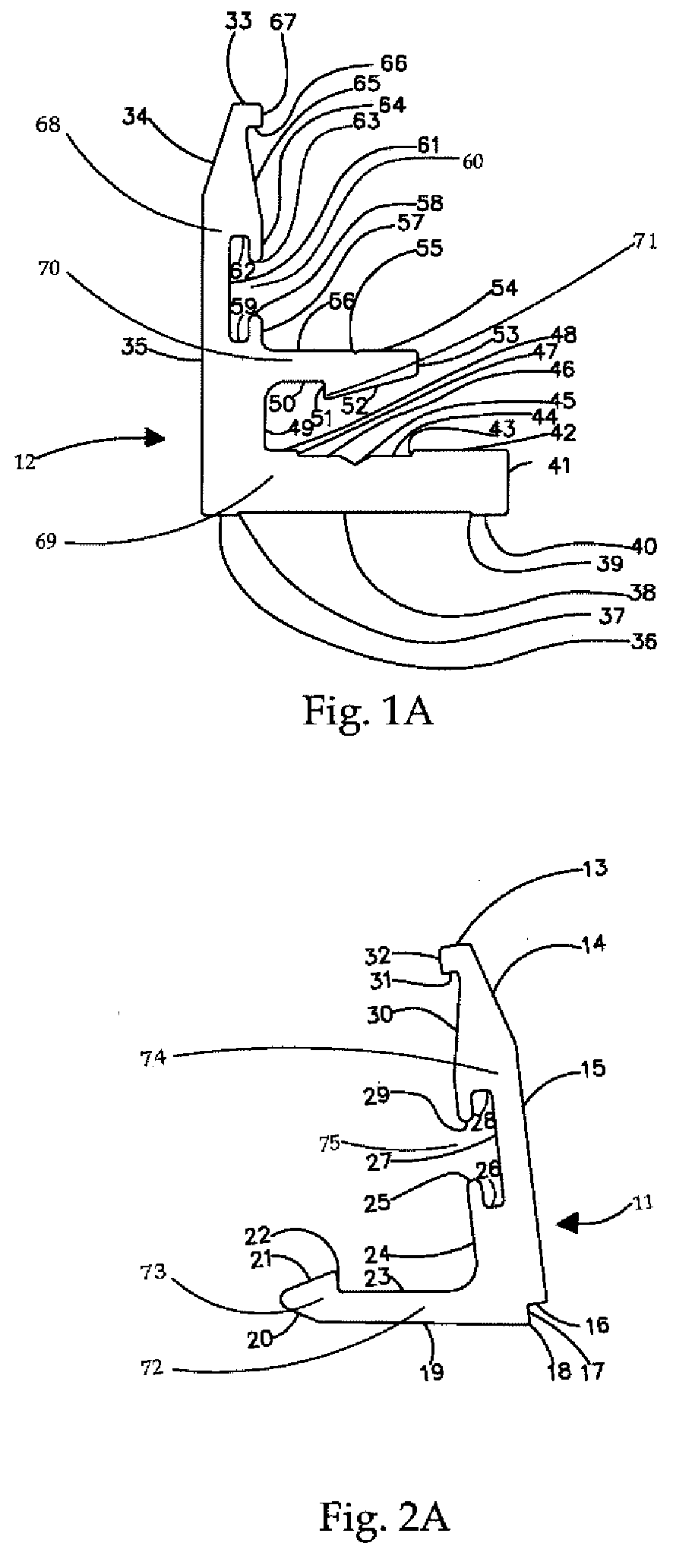

Glazing system

ActiveUS8621793B2Faster glazingEasy to installWindow/door framesGlass pane fixingEngineeringAluminum extrusion

A self-lock glazing mechanism of two aluminum extrusion profiles, a male profile and a female profile, to self-lock glass panels using beadings. The mechanism functions when a glass panel is positioned on setting blocks over the flat surface of the upper leg of the female profile—with spacers between the vertical leg of the female profile and the glass panel and the male profile with the locking tip facing upward on its horizontal leg inserted into the gap between the upper leg and the lower leg of the female profile against the female locking tip above. The locking tips of both male and female profiles are then engaged by tilting the vertical leg of the male profile outward about its built-in fulcrum, and inserting wedges into the space created between the glass panel and the vertical leg of the male profile, for keeping the glass panel locked in position. The mechanism further tightens grip on the edges of the glass panel when the spacers and wedges are replaced by rubber beading of appropriate resilience for glazing to avoid touching metal and to allow expansion and to absorb impacts.

Owner:CITY GLASS & GLAZING PTE LTD

Power supply without cooling fan

InactiveUS20050083660A1Improve efficiencyConsumes lotPower supply for data processingRack/frame constructionCooling effectAluminum extrusion

The invention provides a power supply for a computer mainframe, which is cooled by a heat conduction method, and more particularly to a power supply without a cooling fan. The present invention features a highly effective heat pipe connecting a plurality of aluminum-extrusion heat sink fins and a plurality of aluminum-extrusion heat sinks, the aluminum-extrusion heat sink fins fixed above a cooling chip over a circuit board, and the aluminum-extrusion heat sinks fringed near the power supply, with a part of the heat sink fins exposed to the power supply. The heat of a chip is conducted out of the power supply by the aluminum-extrusion heat sink fins, the high-effect heat pipe, and the aluminum-extrusion heat sinks. Therefore, the power supply can reach an expected cooling effect without the cooling fan.

Owner:ETASIS ELECTRONICS

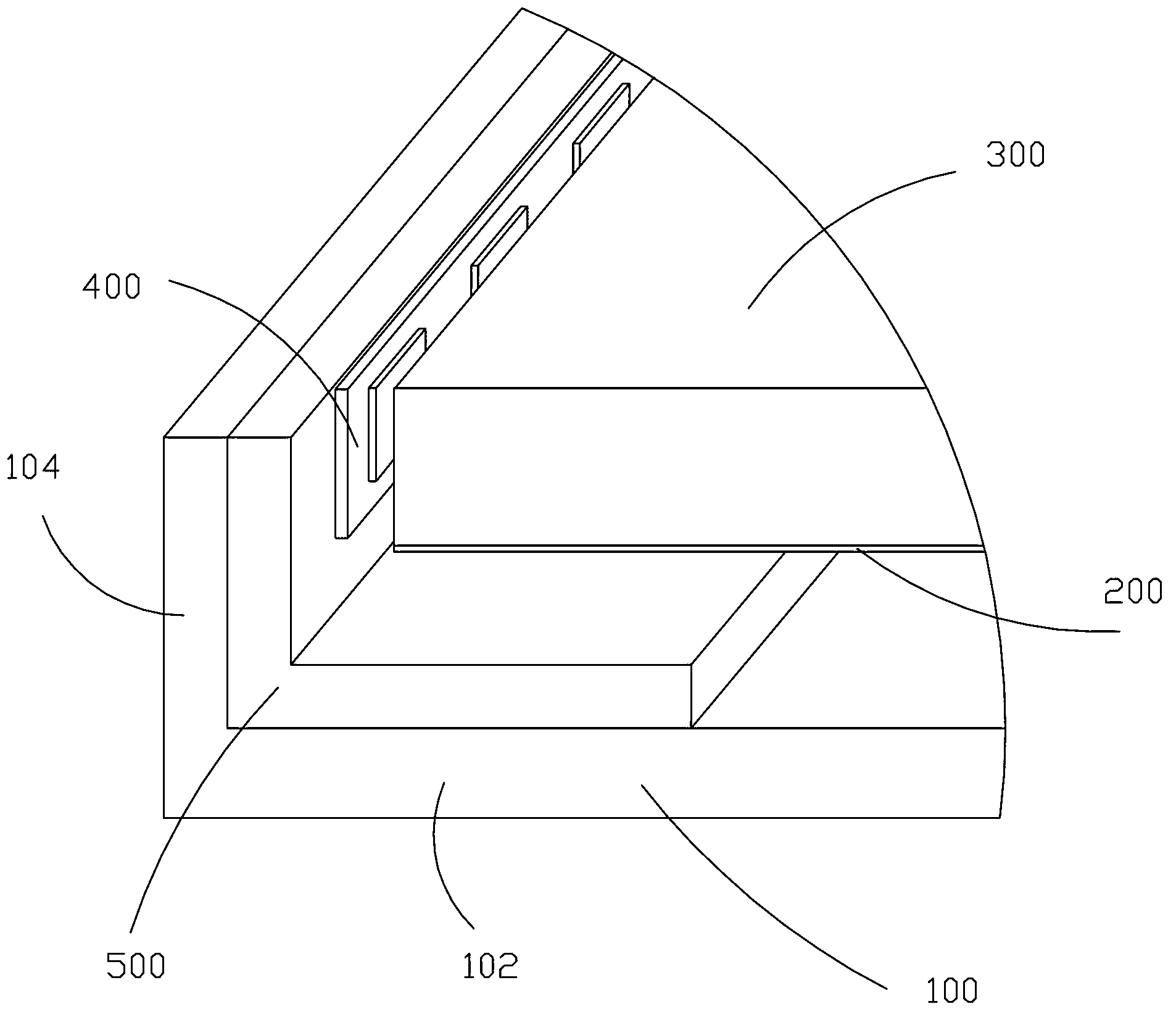

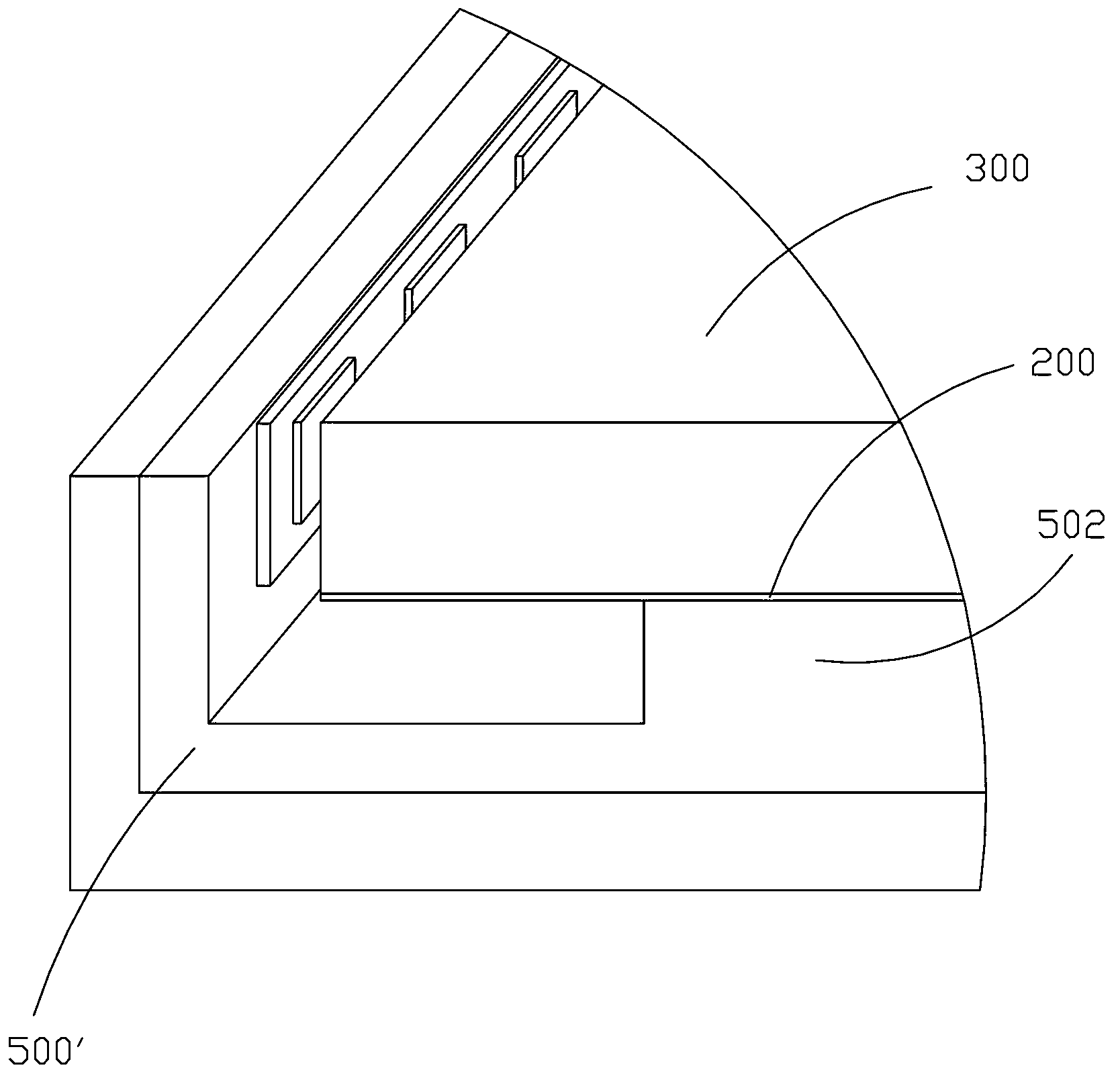

Edge type backlight module and liquid crystal display for preventing light leakage

InactiveUS20140176867A1Avoid light leakageMechanical apparatusLight guides for lighting systemsLiquid-crystal displayEdge type

An edge type backlight module for preventing light leakage is disclosed. The backlight module includes an aluminum extrusion, an edge type light source, an optical film set, and a plastic frame. The an adhesive bar is arranged at least partly in a space between the aluminum extrusion and the plastic frame to fix the aluminum extrusion and the plastic frame and to fill a gap between the aluminum extrusion and the plastic frame. A liquid crystal display with the above backlight module is also disclosed. With the configuration, the aluminum extrusion and the plastic frame may be easily fixed, and the light leakage may be avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Edge-lighting backlight module

ActiveCN102798044AImprove qualityImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsLight guideAdhesive

The invention provides an edge-lighting backlight module which comprises a back plate, a light guide plate arranged in the back plate and a backlight installed on the back plate, wherein the backlight comprises a circuit board and a plurality of LED (light-emitting diode) lights arranged on and electrically connected to the circuit board; the circuit board comprises an installation part and a bending part connected to the installation part; the LED (light-emitting diode) lights are arranged on the installation part; the bending part is connected to the back plate; and the light guide plate is supported on the bending part. According to the edge-lighting backlight module, since the metal-based printed circuit board provided with the bending part is adopted, the heat-dissipating mode in the prior art that the metal-based printed circuit board is pasted on an aluminum extrusion through a thermal conductive adhesive is replaced, a heat-dissipating effect is enhanced, and the quality of the backlight module is improved; and in addition, the bending part of the metal-based printed circuit board can be processed into various shapes so as to support the light guide plate and avoid the use of the aluminum extrusion in the prior art, so that the production cost can be reduced to a large extent.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Glazing system

ActiveUS20090113826A1Faster glazingEasy to installWindow/door framesGlass pane fixingEngineeringAluminum extrusion

The current invention relates to a unique and compact self-lock glazing mechanism for heavy glazing needs, composed of two aluminum extrusion profiles—a male profile and a female profile—designed in such a way to self-lock glass panels using rubber beading; the said glazing system functions when glass panel is placed on the setting blocks over the upper leg of the said female profile with a pair of spacers between the vertical tip of the said female profile and the said glass panel, and then the horizontal leg of the said male profile is inserted with its locking tip facing upward into the gap between the lower and upper legs of the said female profile; the locking tips of both the male and female profiles are then engaged by tilting the said male profile on its built-in fulcrum by pulling the vertical leg outward and introducing a pair of wedges into the space so created between the said glass panel and the said vertical tip of the male profile to keep the lock engaged and the said profiles get arrested; eventually the said glass panel is locked in the said glazing system; and the said mechanism further tightens its grip on the edges of the locked glass panel when the spacers and wedges are replaced by grooved rubber beadings of appropriate resilience which enables the said glass panel to remain in equilibrium throughout the life of the rubber beading; the introduction of the rubber beadings into the system lends a unique dynamism to the mechanism due to the built in fulcrum built in the said male profile, the inherent resilience of rubber causes a mating action in the said locking chamber and the resulting equal and opposite reaction keep the glass panel in an equilibrium; this balancing act of forces remains in the locking system throughout the life of the rubber beading as a dynamic phenomenon.

Owner:CITY GLASS & GLAZING PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com