Patents

Literature

113 results about "Chain fall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

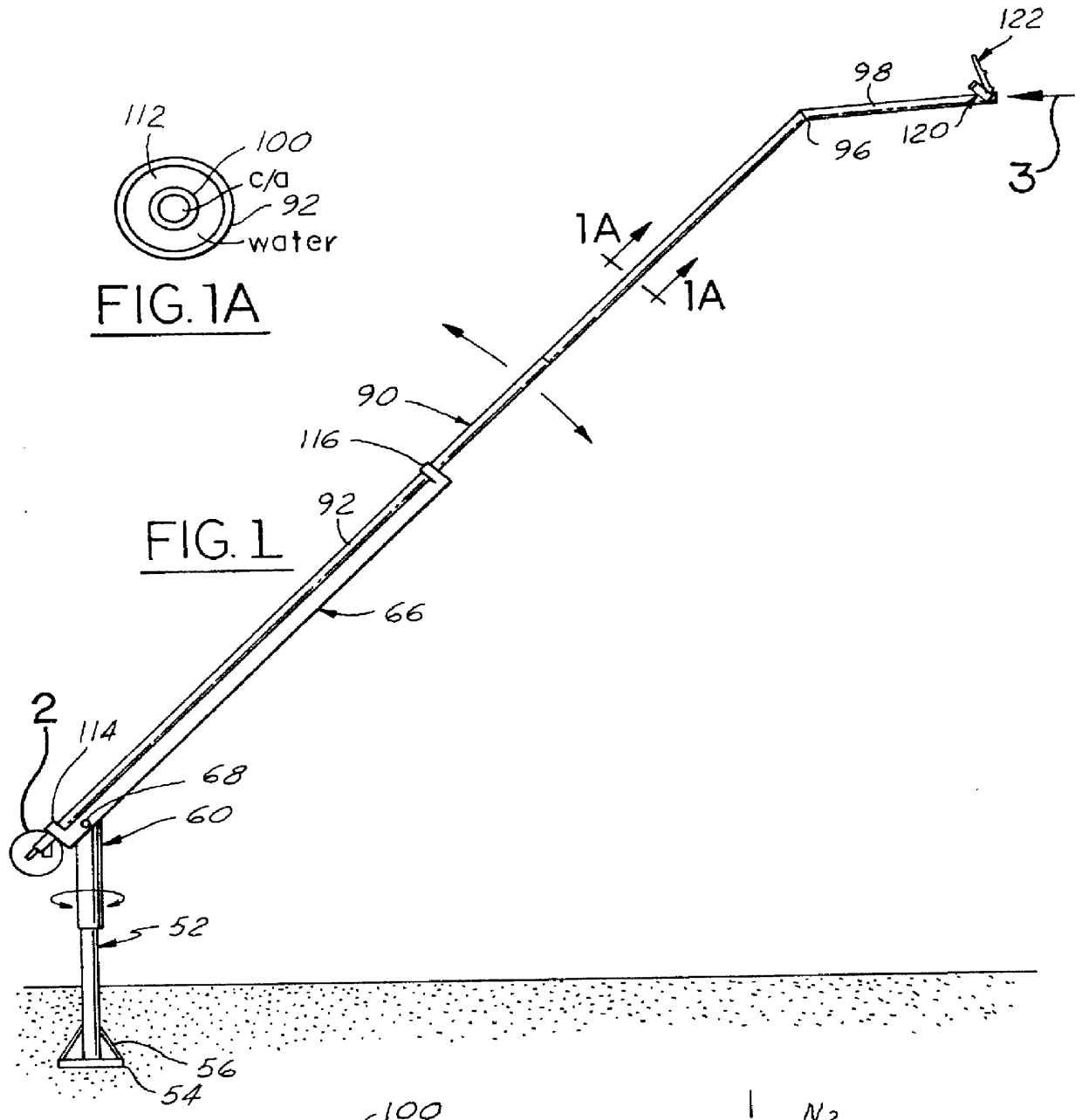

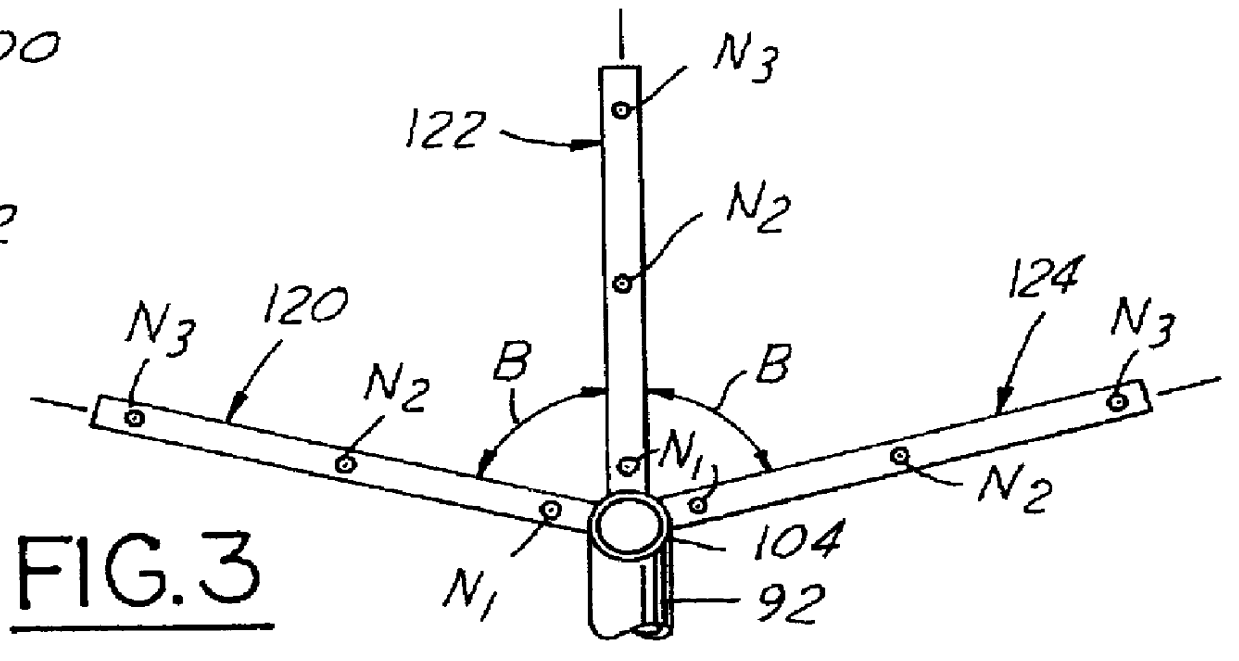

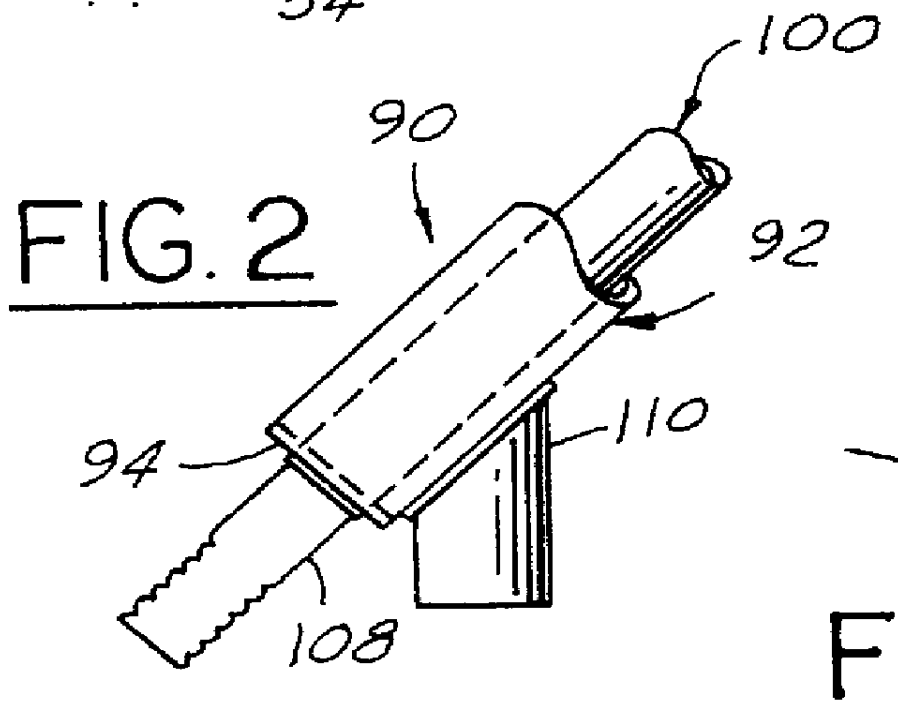

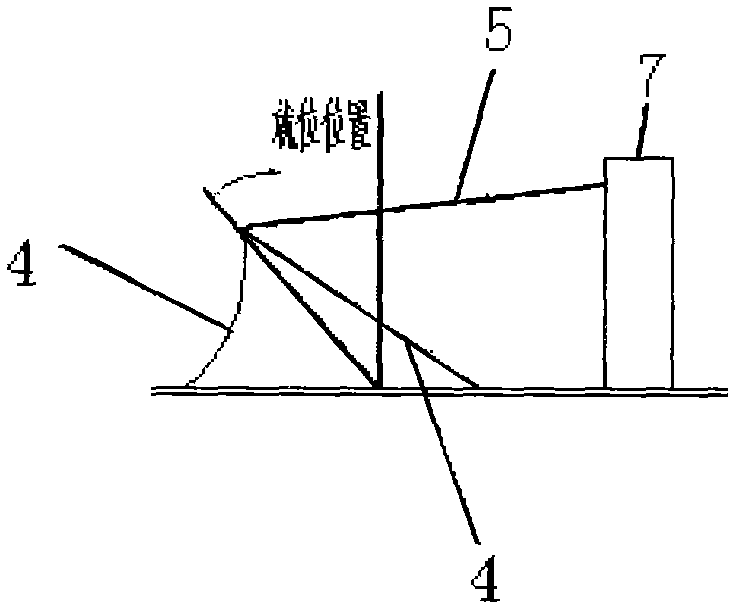

Adjustable snow making tower

InactiveUS6161769AIncrease flexibilityOptimize quantityLiquid surface applicatorsStands/trestlesBlock and tackleEngineering

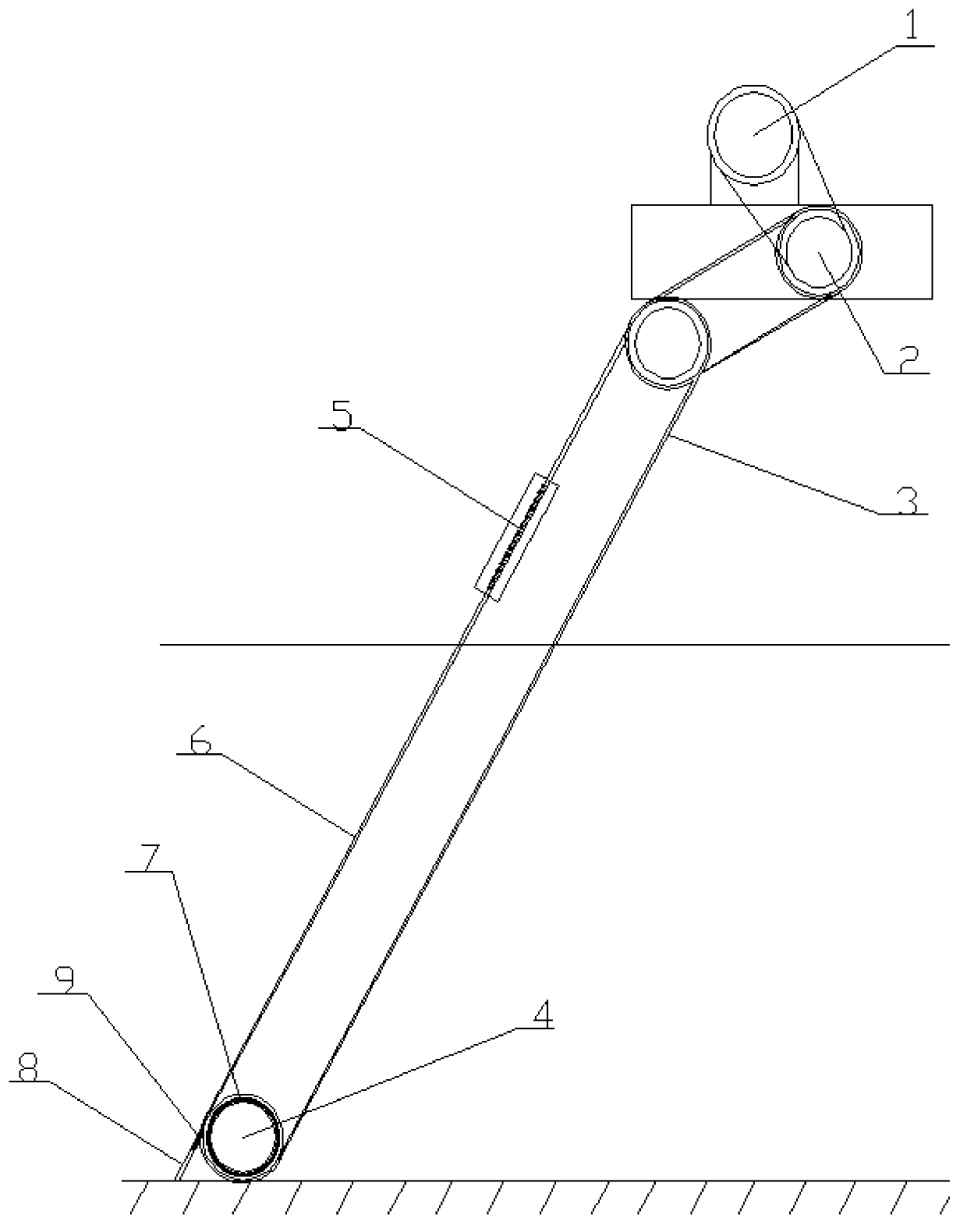

Method and apparatus for making snow by generating water spray from a triple array of multiple nozzle sub-boom branch-pipes transversely protruding from the upper end of a main boom of a pivotably adjustable snow making pipe tower. Three air jet streams, one for each branch pipe, are simultaneously discharged under high pressure into and sequentially through the throats of each associated multiple stack of water sprays issuing from each set of branch pipe nozzles to thereby form multiple spray plumes of atomized and seeded water all directed forwardly from the upper end of the tower pipe. The water pipe may be an elliptical aluminum extrusion with two interior air tubes respectively controllably feeding large and small diameter air jet arrays to thereby provide a range of air jet water spray interaction. The pipe tower may be pivotally raised and lowered by a block-and-tackle or chain fall type drive mechanism that may be recoupled to the tops of a lifting pole and tower pipe for bodily raising the entire tower pipe and its support pipe telescopically on a ground support pole. Spreader-supported guy wires may be used to brace the tower pipe and also provide an electrical deicing circuit. Air jet control, blow-out valving and water drain conduit arrangements are disclosed, and also universally adjustable ground support systems for the pipe tower, including an underground-fed combined telescopic hydraulic ram forming air and water conduits.

Owner:BOYNE USA +1

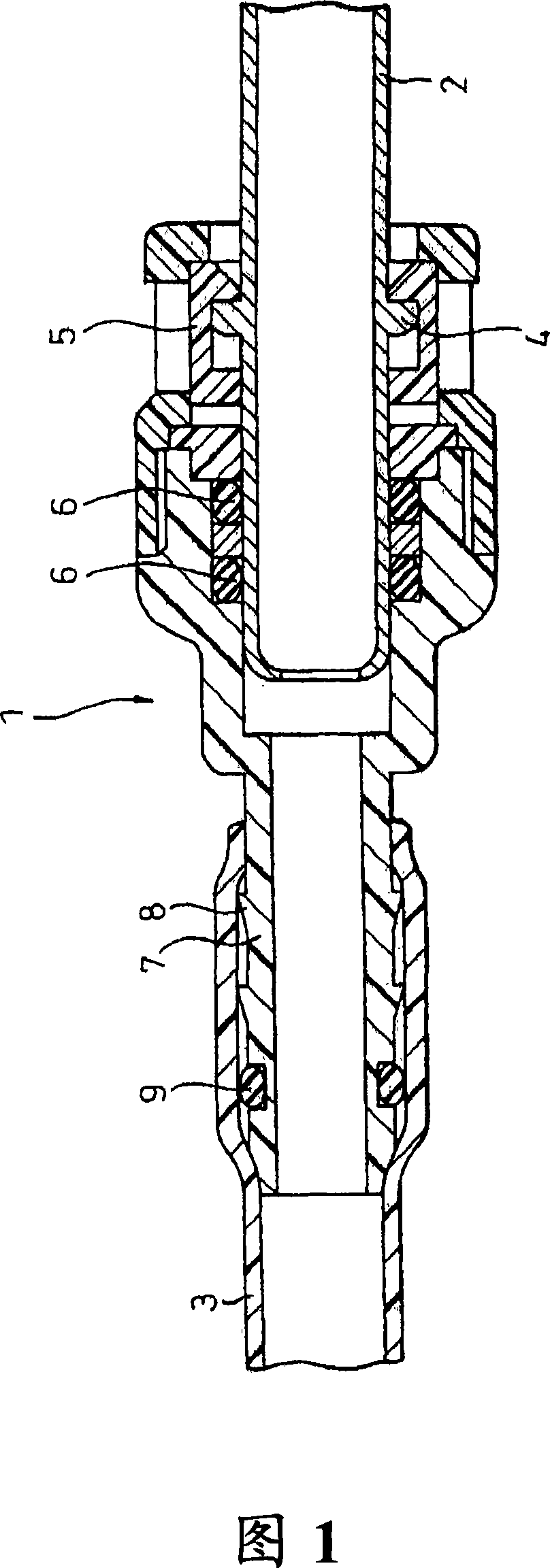

Semi-aromatic polyamide resin

ActiveCN101175791AImprove hot water resistanceGood chemical resistanceSynthetic resin layered productsThin material handlingResidenceAramides

The present invention provides a semi-aromatic polyamide resin having high residence stability, hot water resistance and chemical resistance and also having excellent adhesion property to and compatibility with other resin or the like. [MEANS FOR SOLVING PROBLEMS] The semi-aromatic polyamide resin has dicarboxylate units in which aromatic dicarboxylate units comprise 50 to 100 mol% of the dicarboxylate units and diamine units in which aliphatic diamine units having 9 to 13 carbon atoms comprises 60 to 100 mol% of the diamine units. In the resin, at least 10% of the terminal groups present in the molecular chain are end-capped with an end-capping agent, and the amount of the terminal amino groups present in the molecular chain falls within the range from 60 [mu]-equivalents / g to 120 [mu]-equivalents / g inclusive and satisfies the equation: [NH2] / [COOH]=6 wherein [NH2] ([mu]-equivalent / g) represents the amount of the terminal amino groups and [COOH] ([mu]-equivalent / g) represents the amount of the terminal carboxyl groups.

Owner:KURARAY CO LTD

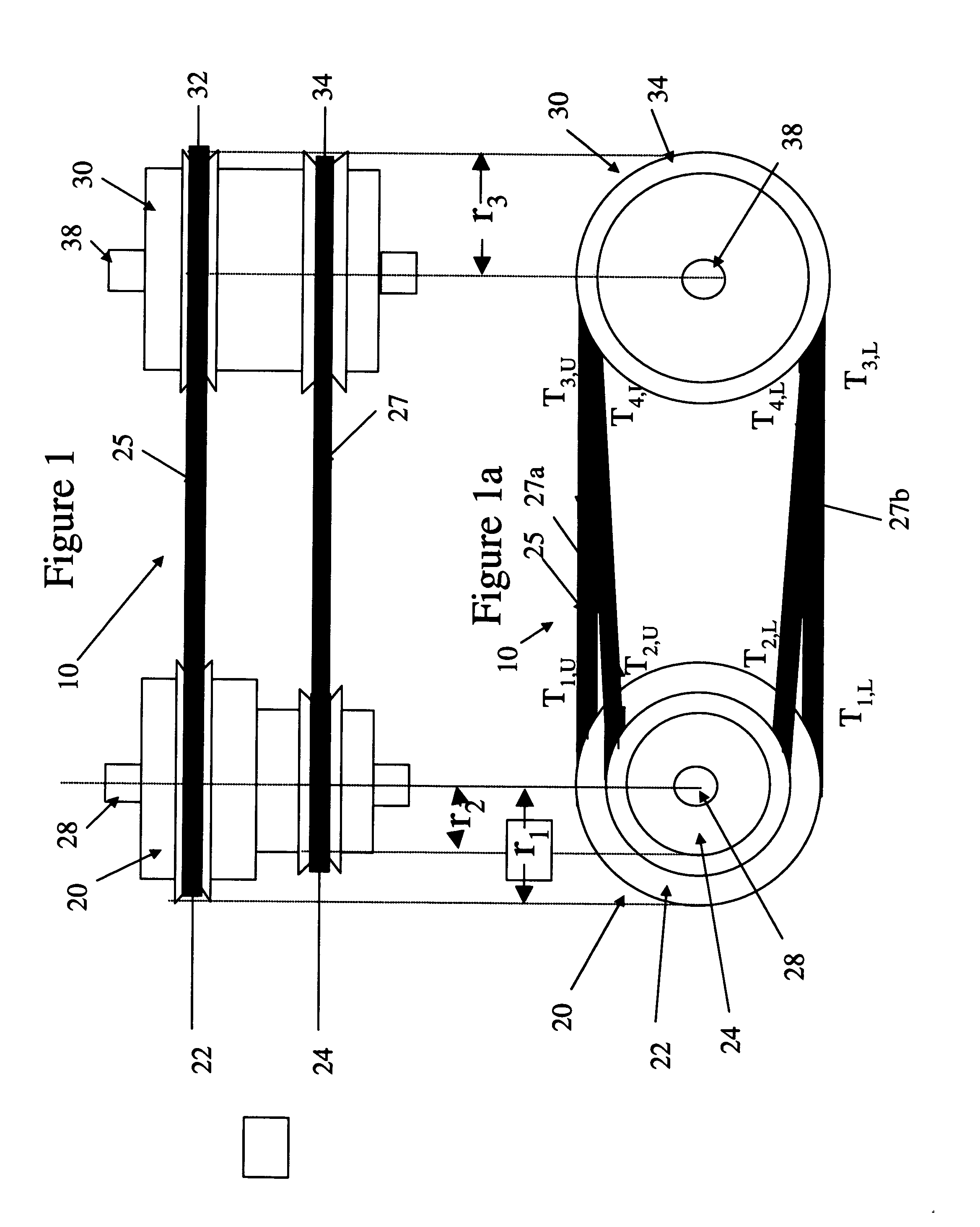

Solid state thermal engine

InactiveUS20050039452A1Reduce tensionGearingClosed-cycle gas positive displacement engine plantEngineeringPulley

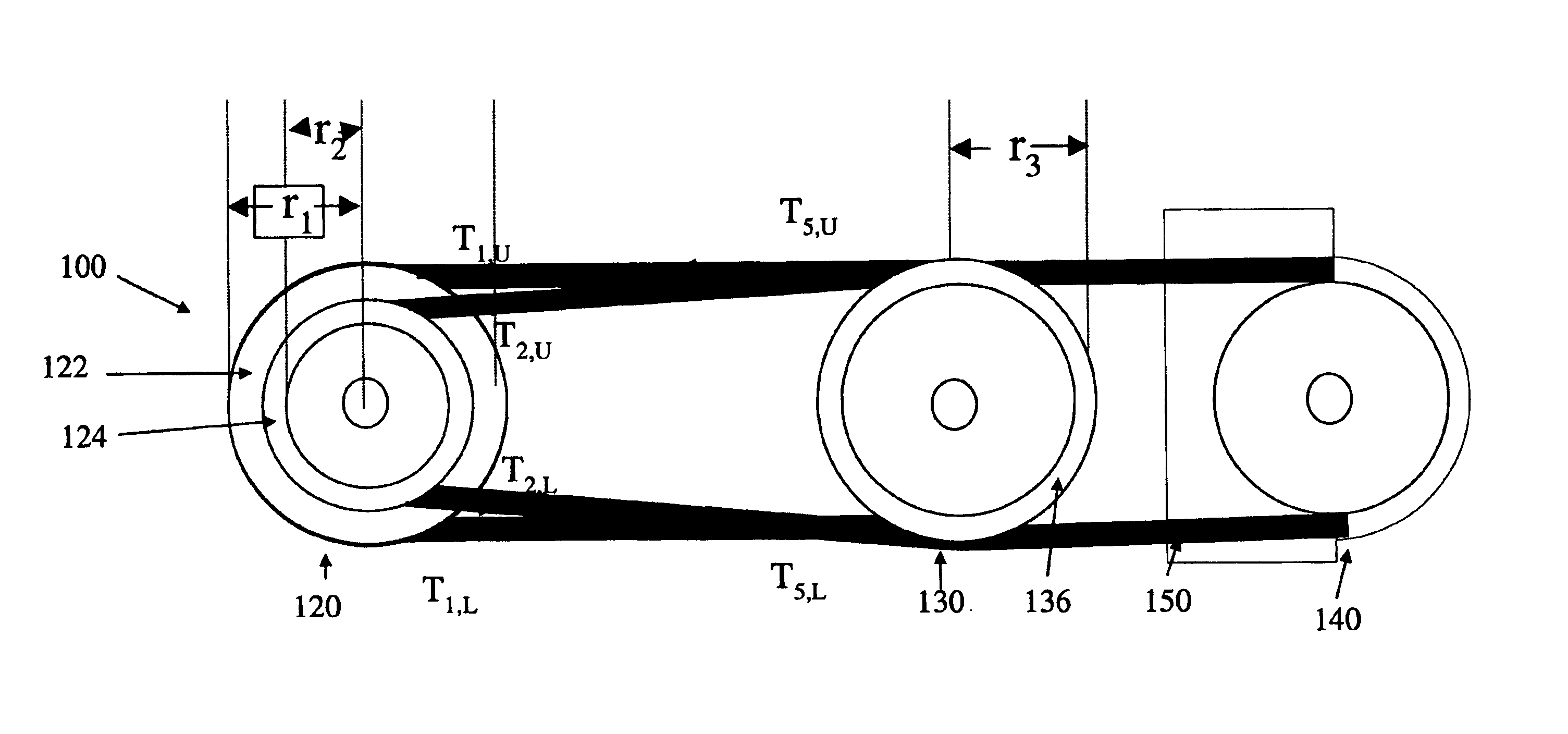

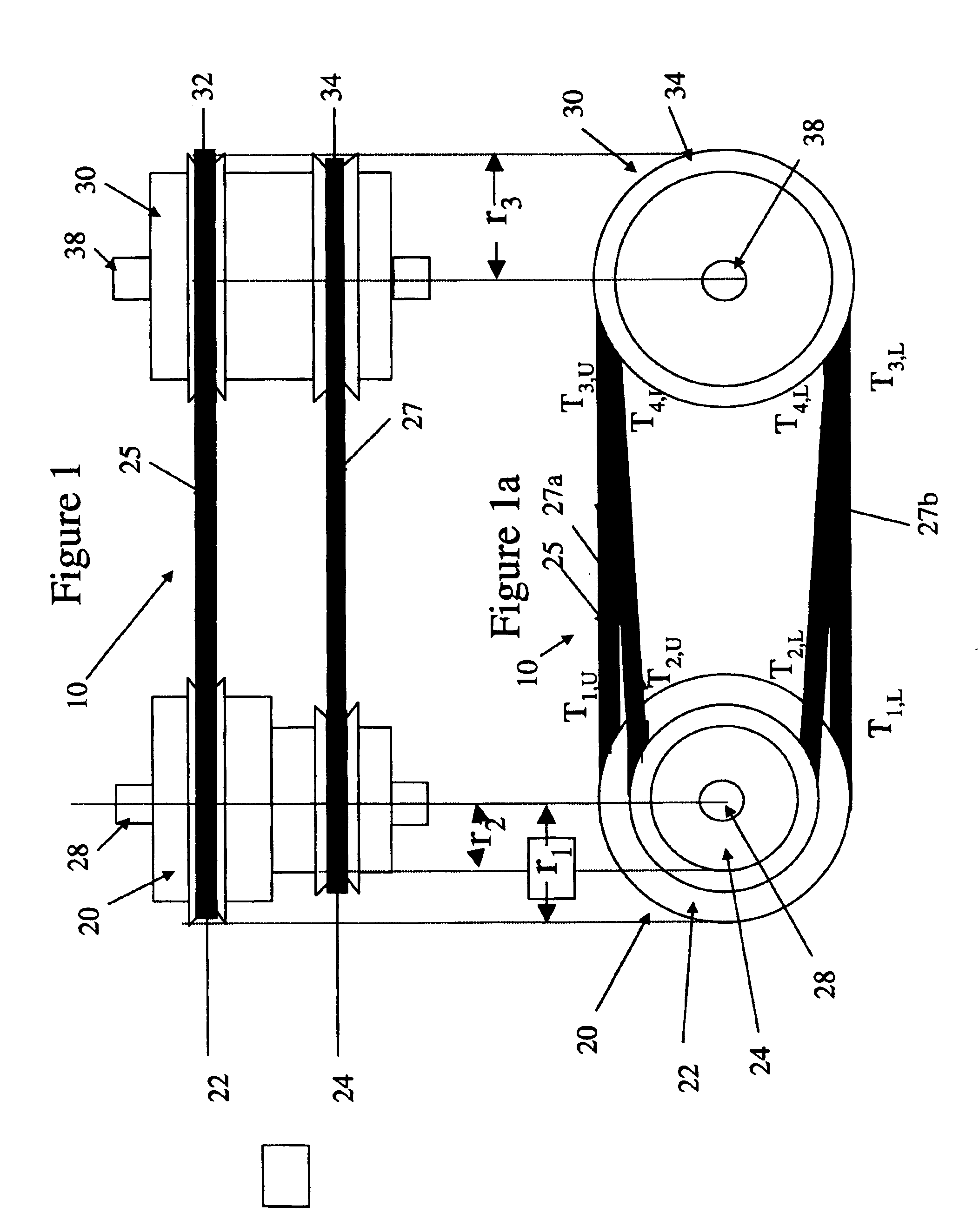

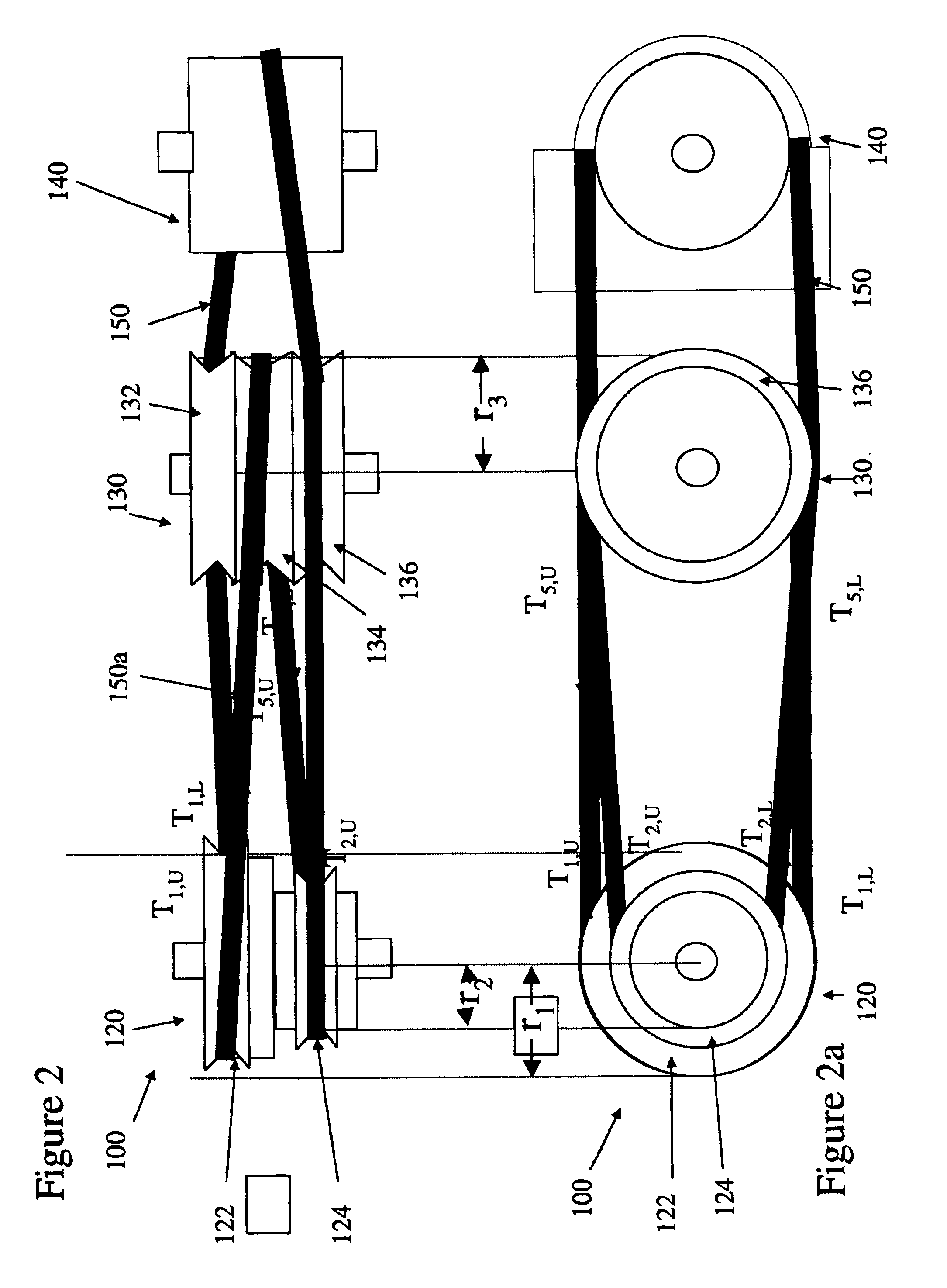

A solid state thermal engine has two drums, each drum having two pulleys positioned thereon. Each pulley on the one drum is coupled to its counterpart pulley on the other drum via a belt, chain or other connector. One of the belts, referred to as the active belt, is heated which causes the active belt to expand. The expansion decreases the tension on the active belt, and further causes the active belt and the pulleys on which it is positioned to rotate. In a preferred embodiment, the active belt is manufactured out of a memory metal such as NITINOL. In another embodiment, a system of several drums and pulleys are used to implement a chain fall device.

Owner:LOCKHEED MARTIN CORP

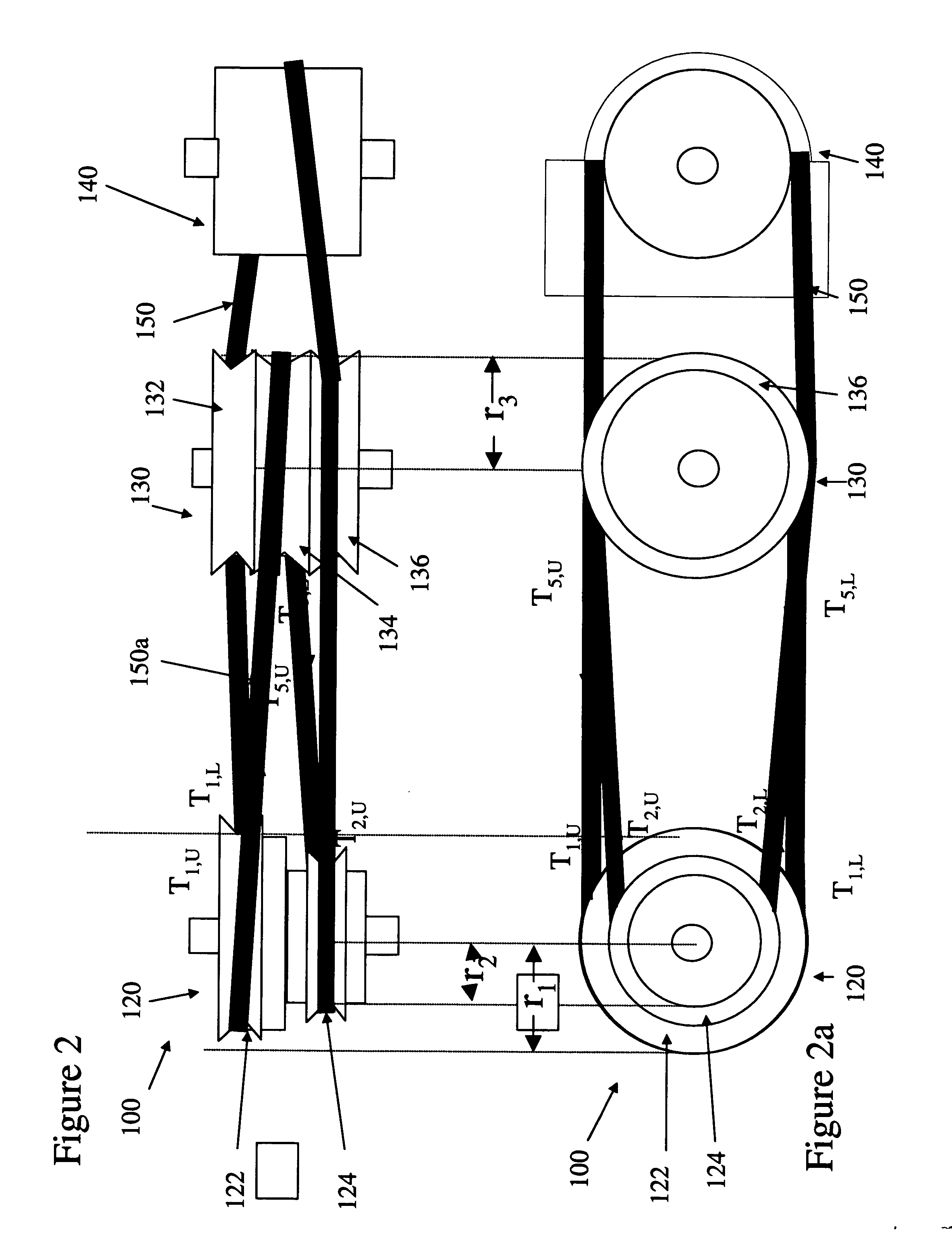

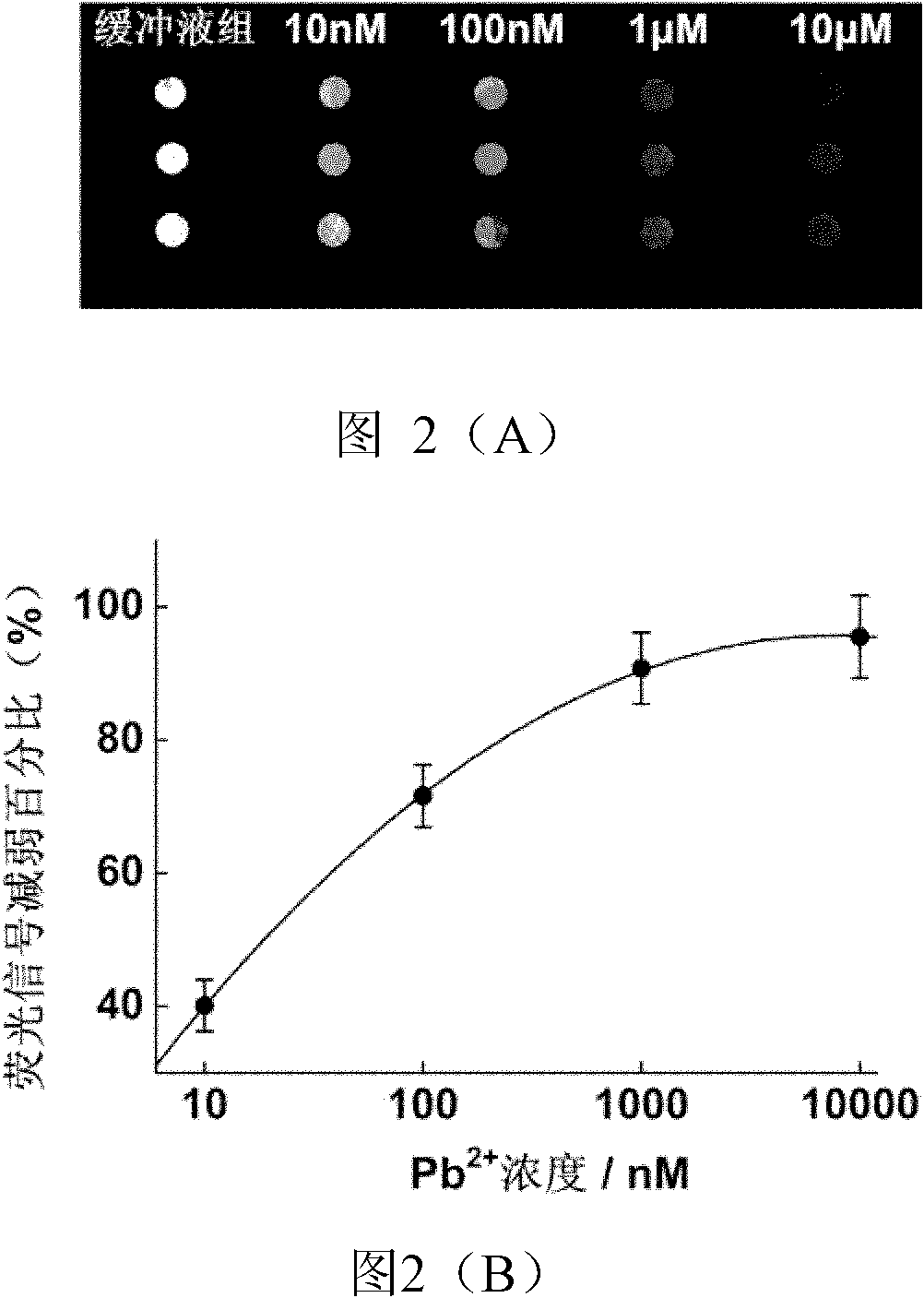

Lead ion detection chip based on deoxyribonuclease as well as making and application methods

ActiveCN102031284AEasy to prepareSimple manufacturing methodMicrobiological testing/measurementFluorescence/phosphorescenceDNase activityFluorescent labelling

The invention relates to a Pb<2+> detection chip based on deoxyribonuclease as well as making and application methods. The invention is characterized in that a 17DS substrate chain of a 17E enzyme chain of deoxyribonuclease 8-17 with strong specificity response is cut off, so that part or all of the cut-off 17DS substrate chain falls off. Since the 17DS substrate chain is previously labeled by fluorescence, the cut-off operation weakens the fluorescence signal. The application method is characterized by comprising the following steps: when the lead ion detection chip is used for lead ion detection, putting the sample to be detected on the chip, holding for a period of time, scanning the chip by using a chip signal analysis system, and analyzing the fluorescence signal. The Pb<2+> is detected through the variation of the fluorescence signal; and the fluorescence signal gets weakened as the concentration of Pb<2+> in the sample gets higher. The detection range of the concentration of Pb<2+> is 1nM-10mu M.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

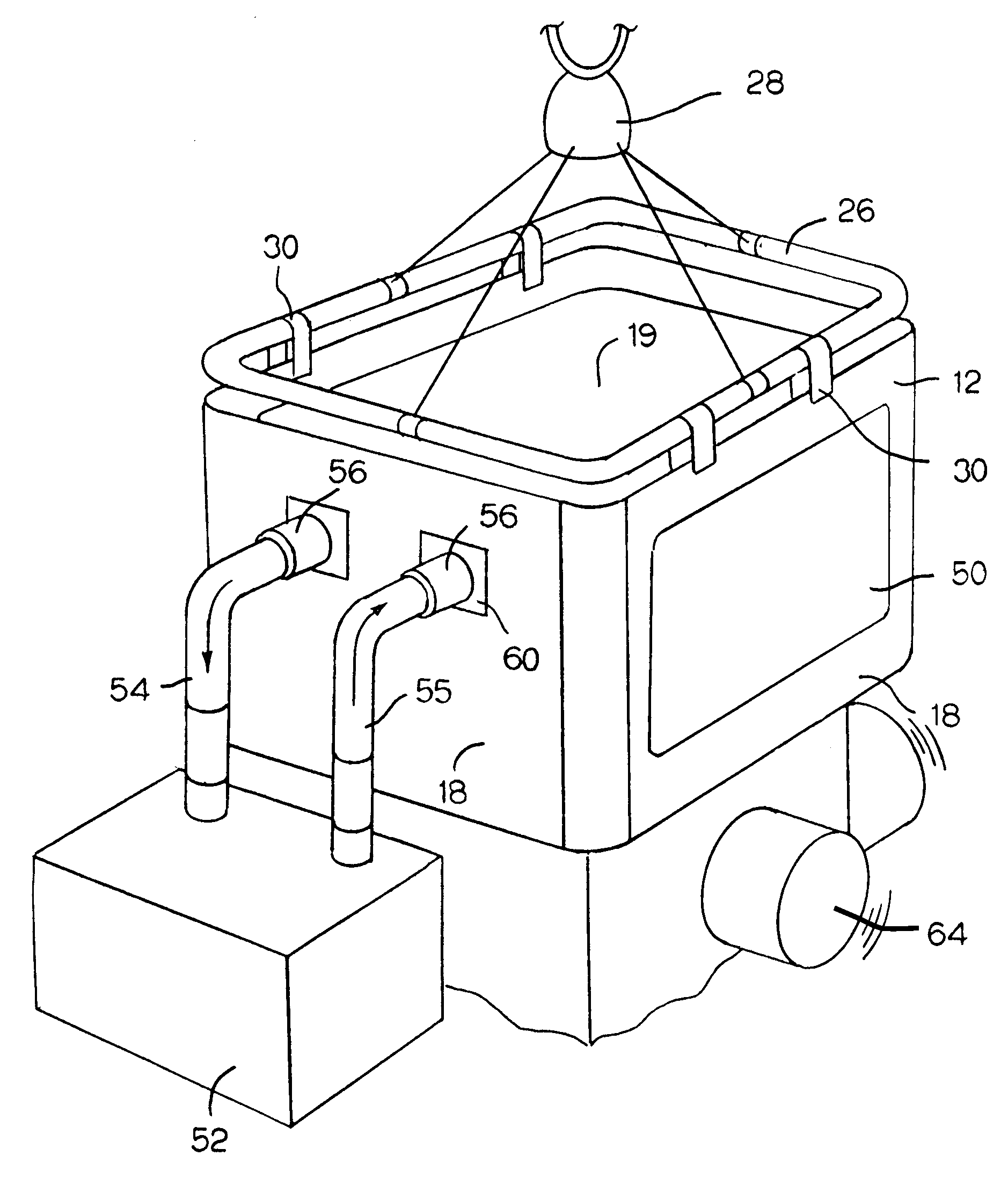

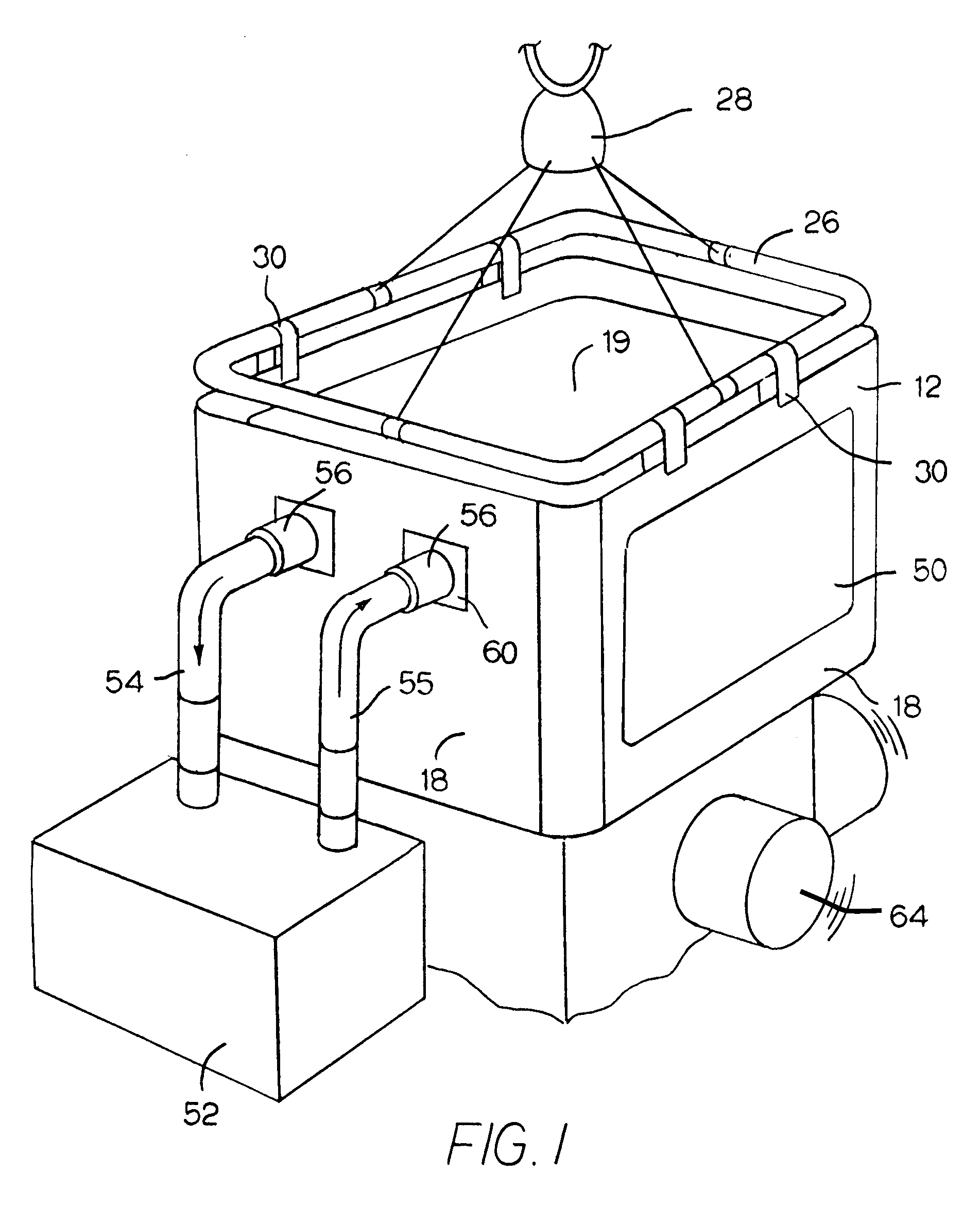

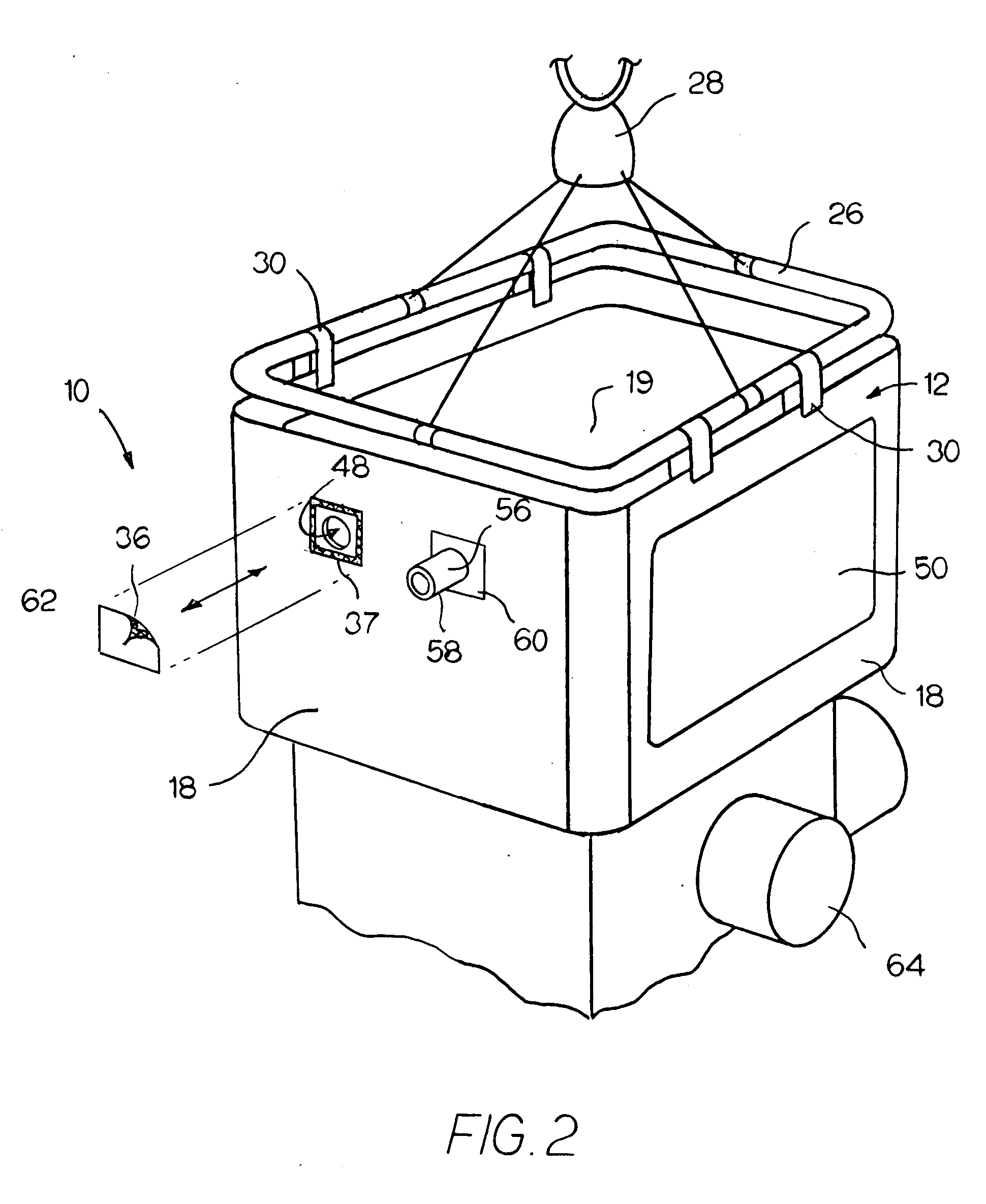

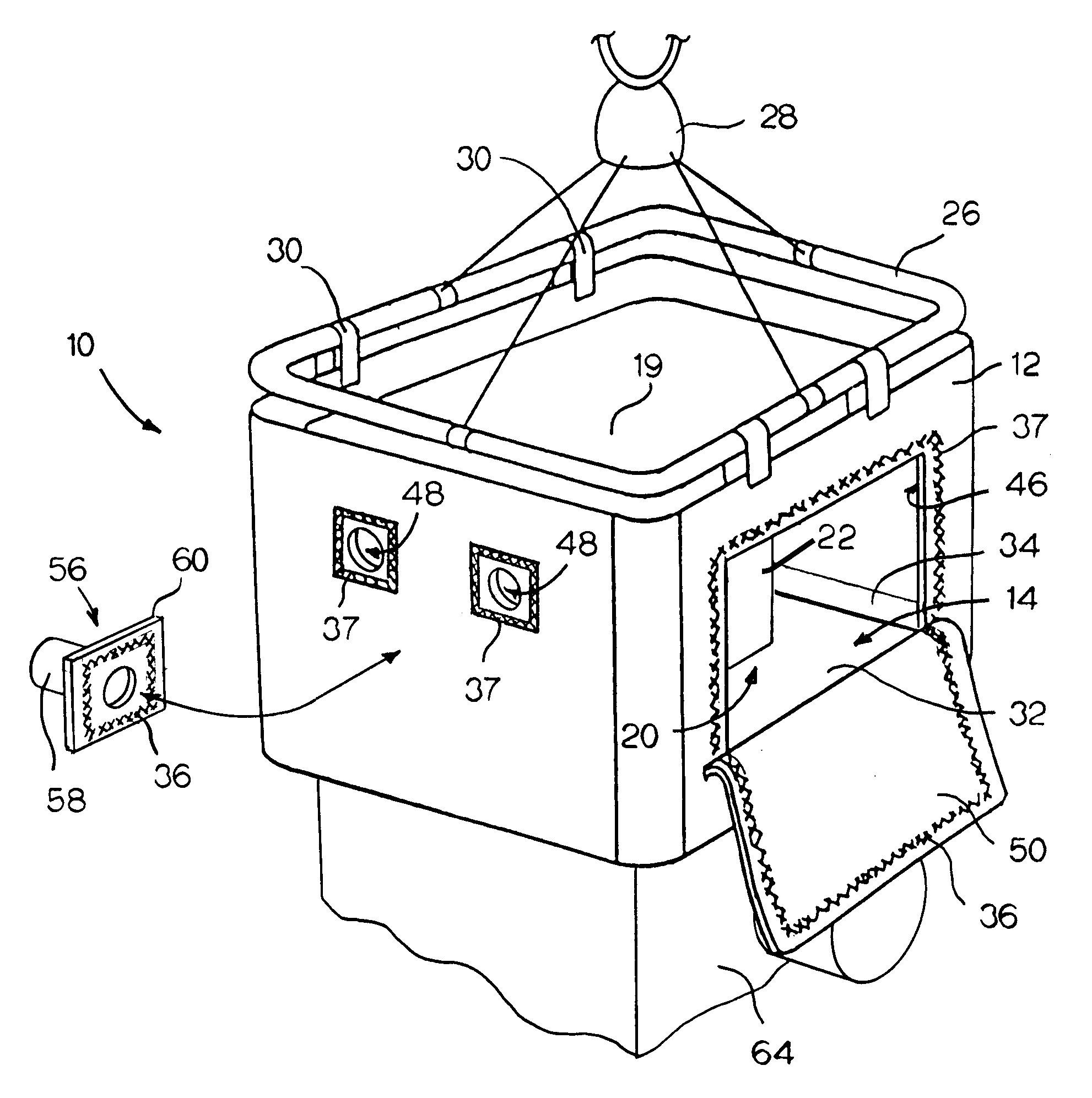

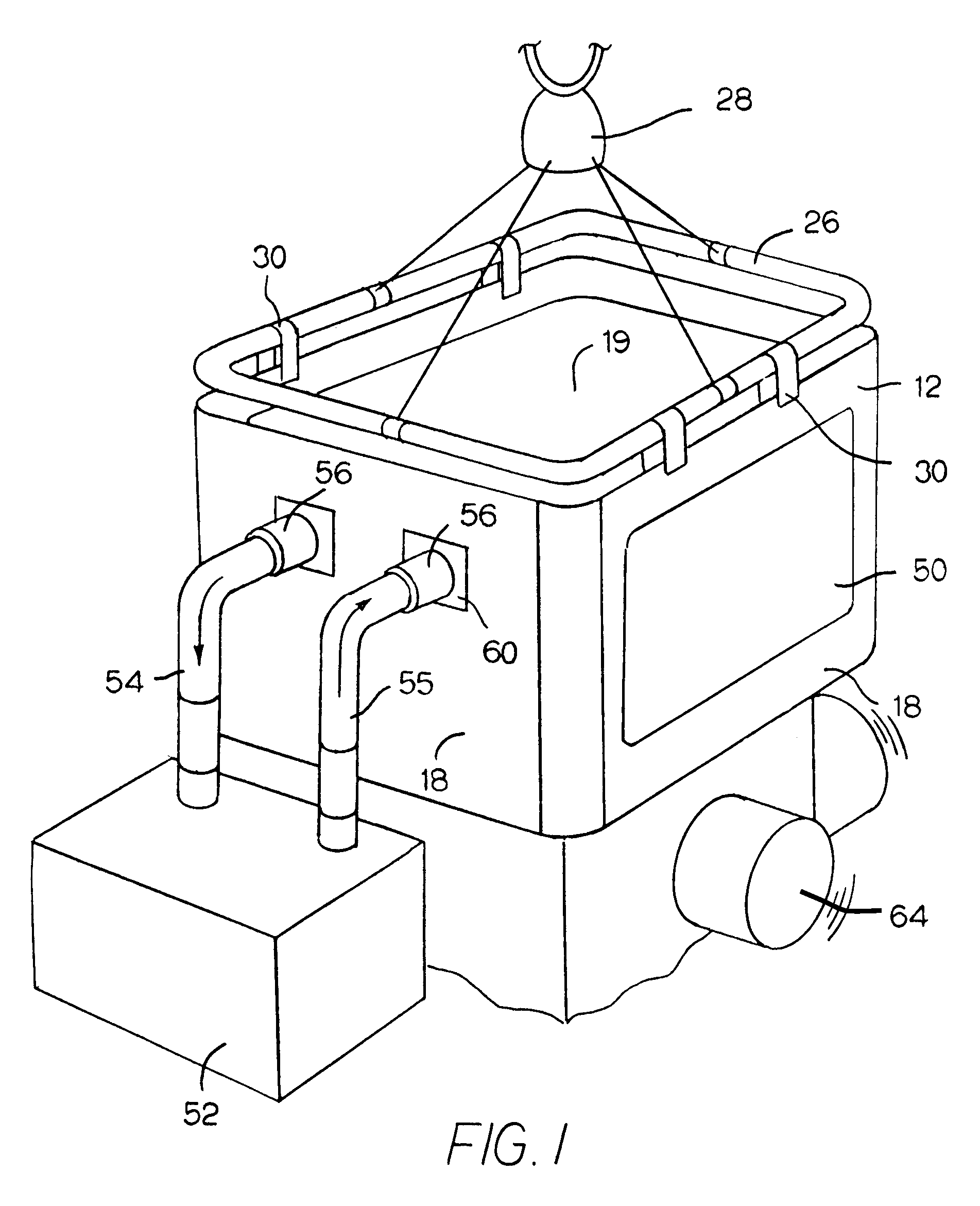

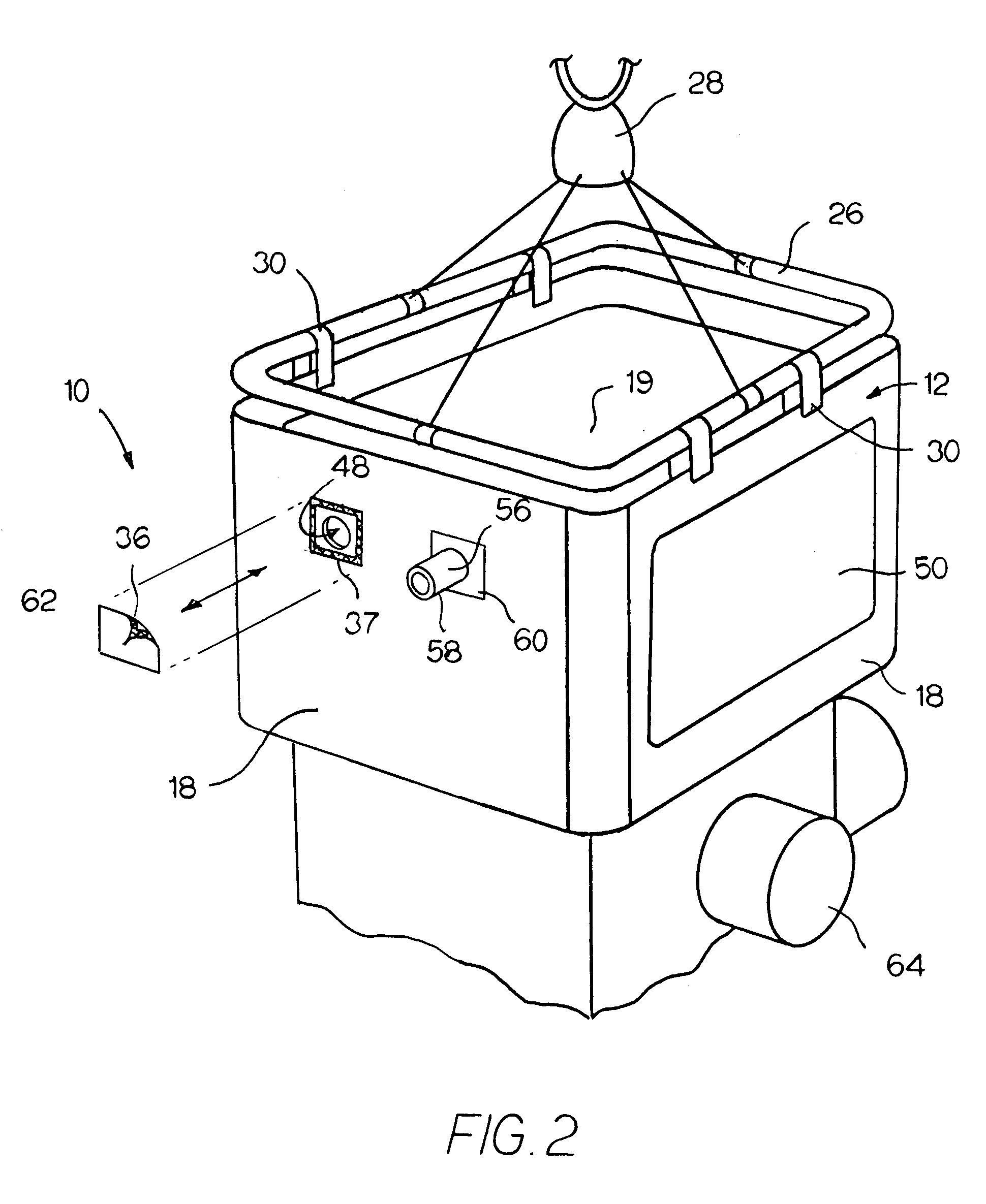

Thermal test chamber

ActiveUS20120297904A1Readily mountable upon shaker test tableQuick changeMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceTest chamberOverhead crane

A soft-sided thermal test chamber that is readily mountable upon / over a shaker test table. The test chamber includes four interconnected insulated side walls and a top which define an enclosure. A two-piece bottom receives the side walls to fully enclose the test object upon the table. The two-piece bottom includes an interchangeable center piece which is sized to accommodate various tables or test objects. The side and top pieces are hung from a frame that is readily lifted using an overhead crane or chain fall hoist to allow easy access to the table during set up. The bottom and side walls are interconnected via hook and loop fasteners, which allows for rapid alteration of the set up of the test equipment while maintaining a thermally sealed chamber.

Owner:PICKEL MICHAEL B

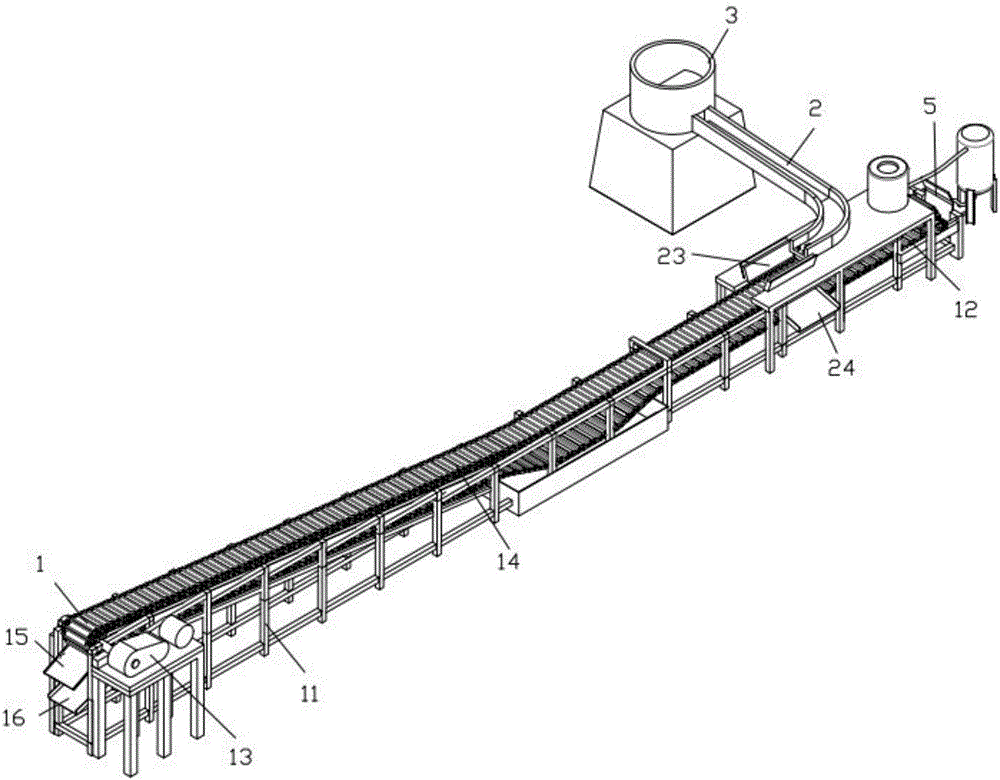

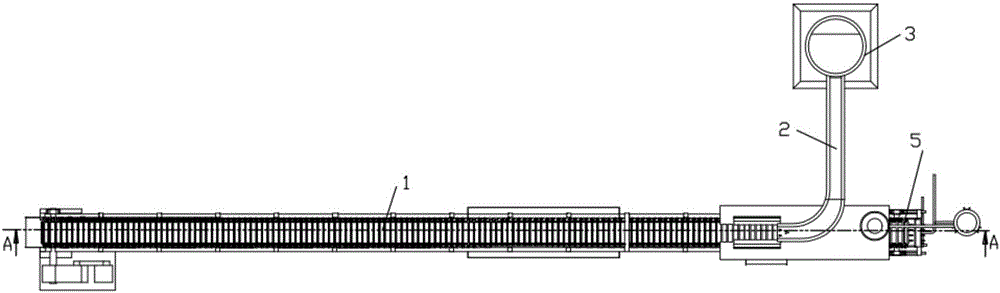

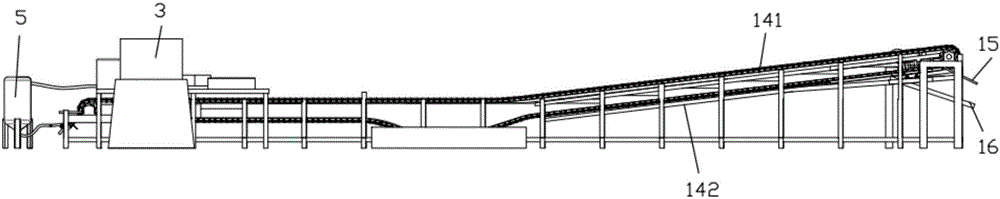

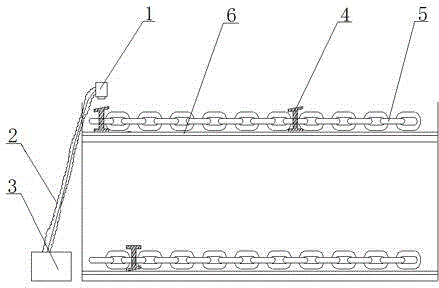

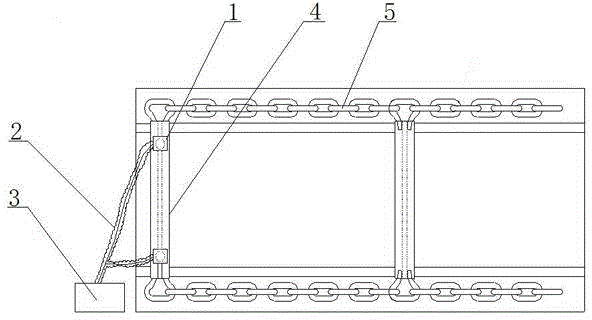

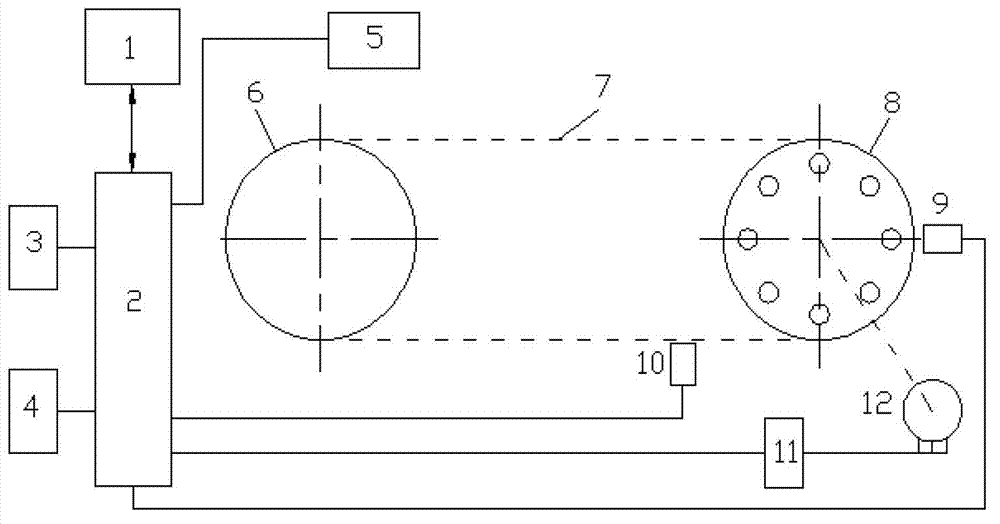

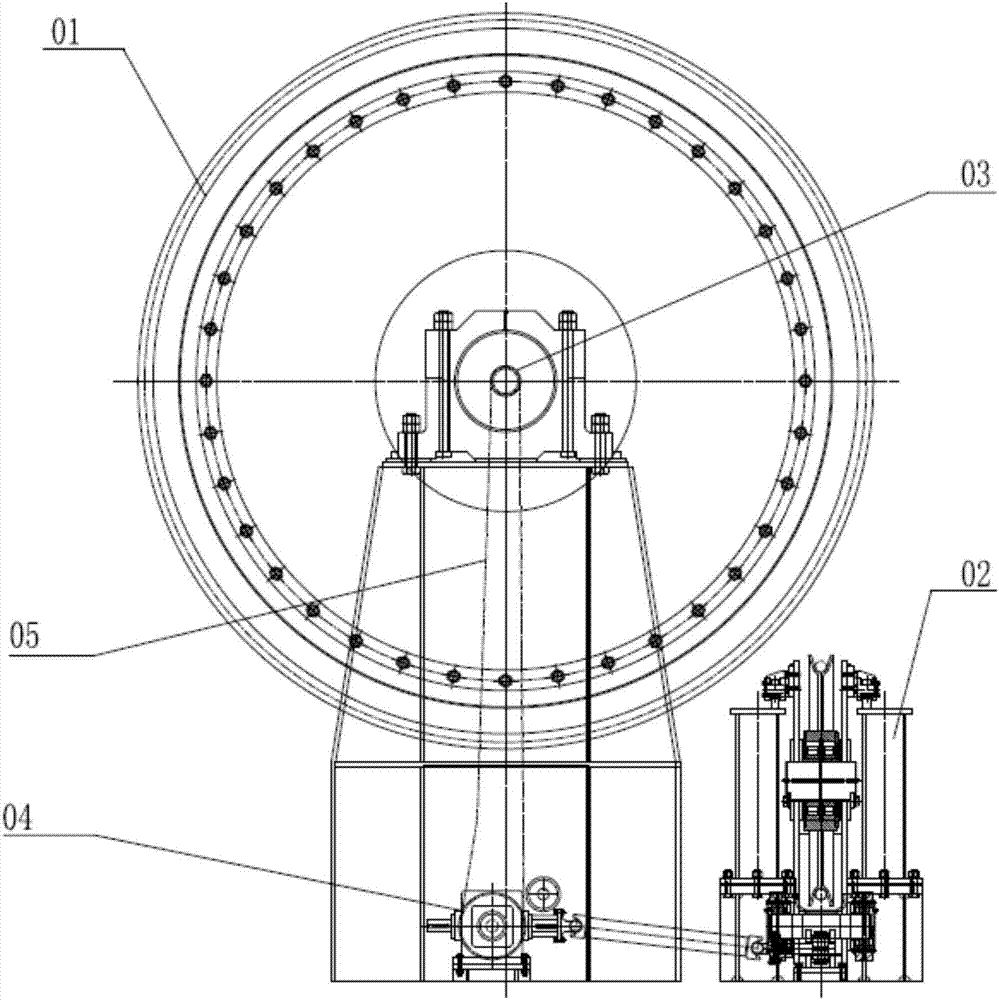

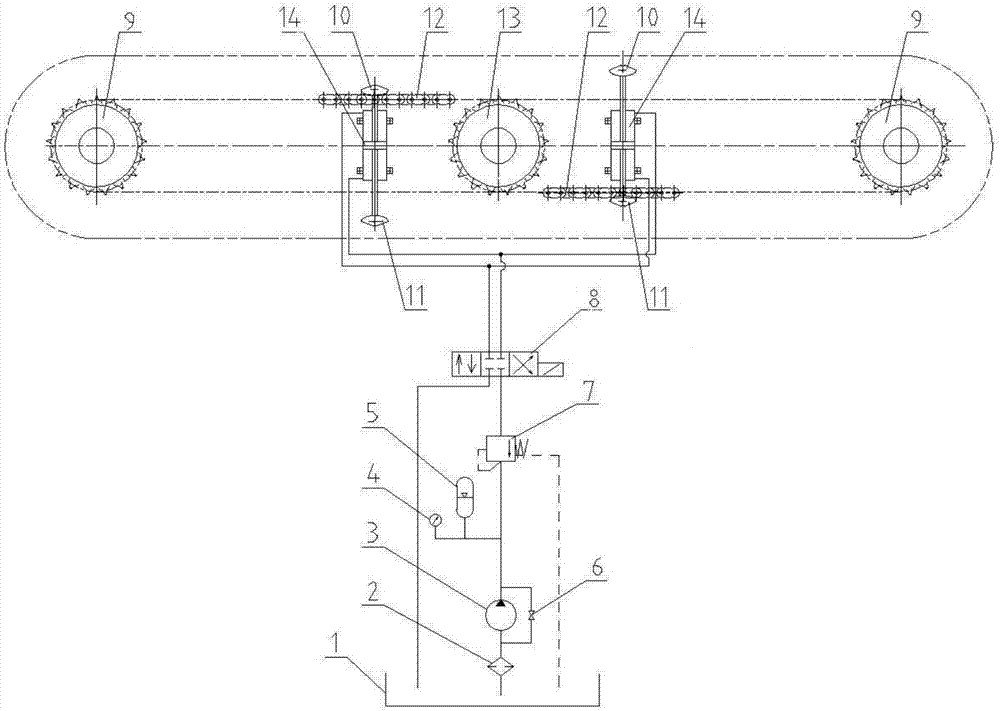

Self-vibration type continuous casting system

A self-vibration type continuous casting system comprises a casting machine, a flow dividing device, a molten pool and a self-vibration device. One end of the flow dividing device is connected with the molten pool, and the other end of the flow dividing device is connected with the casting machine; the casting machine comprises a supporting frame, a machine head, a machine tail and a casting portion, wherein the machine head, the machine tail and the casting portion are fixed on the supporting frame; the casting portion comprises a transmission chain; one end of the flow dividing device is connected with the molten pool, and the other end of the flow dividing device is connected with the casting portion; and the self-vibration device is installed below the up transmission chain of the casting portion, and the up transmission chain is vibrated and struck through vibration of the self-vibration device, so that ingot metal in a casting mould of the up transmission chain falls off. According to the self-vibration type continuous casting system, the self-vibration device is installed below the up transmission chain and makes contact with the back surface of the casting mould, and the self-vibration device vibrates and strikes the back surface of the casting mould through self-vibration, so that the ingot metal and the casting mould become loose, and the ingot metal falls off automatically.

Owner:宁夏铸源机械制造有限公司

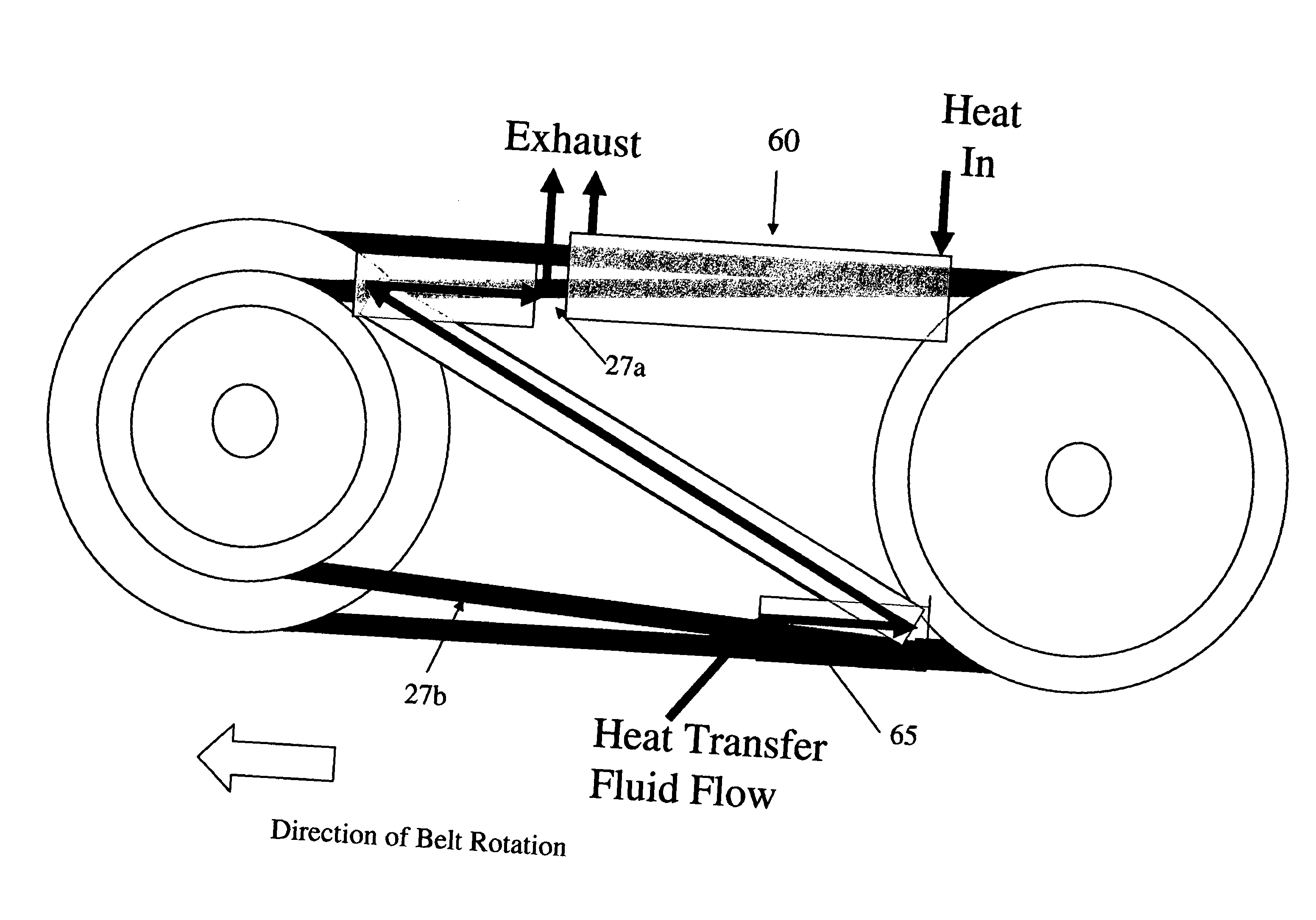

Solid state thermal engine

InactiveUS6880336B2Reduce tensionGearingClosed-cycle gas positive displacement engine plantEngineeringPulley

A solid state thermal engine has two drums, each drum having two pulleys positioned thereon. Each pulley on the one drum is coupled to its counterpart pulley on the other drum via a belt, chain or other connector. One of the belts, referred to as the active belt, is heated which causes the active belt to expand. The expansion decreases the tension on the active belt, and further causes the active belt and the pulleys on which it is positioned to rotate. In a preferred embodiment, the active belt is manufactured out of a memory metal such as NITINOL. In another embodiment, a system of several drums and pulleys are used to implement a chain fall device.

Owner:LOCKHEED MARTIN CORP

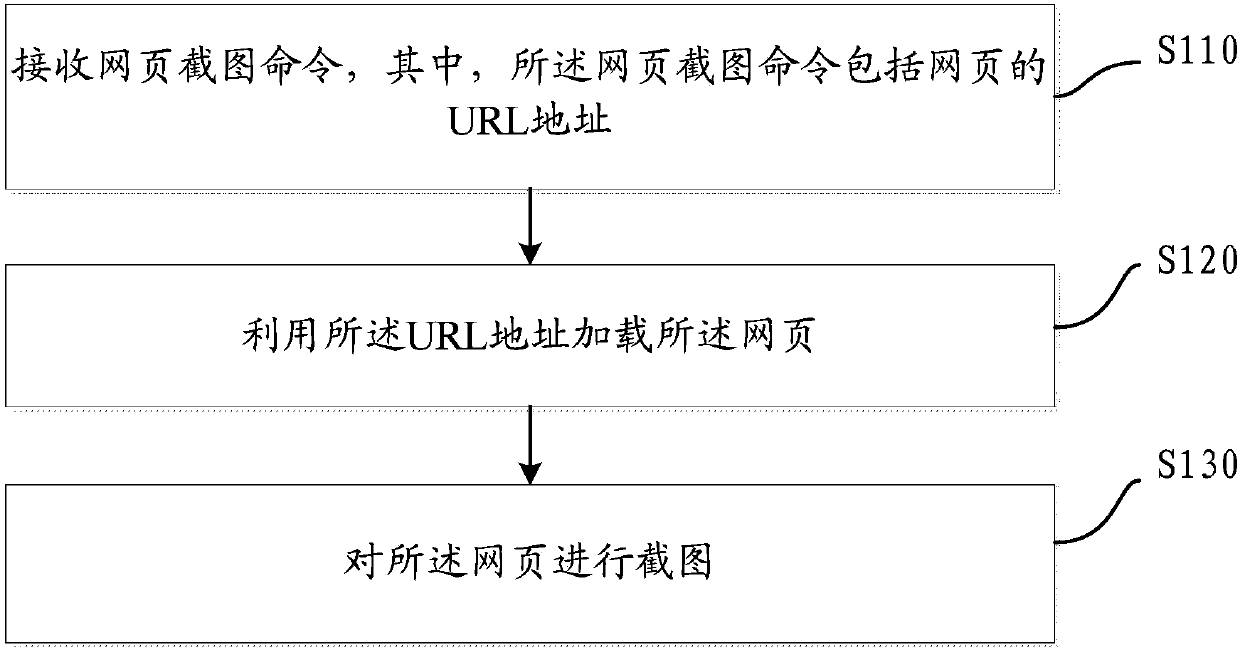

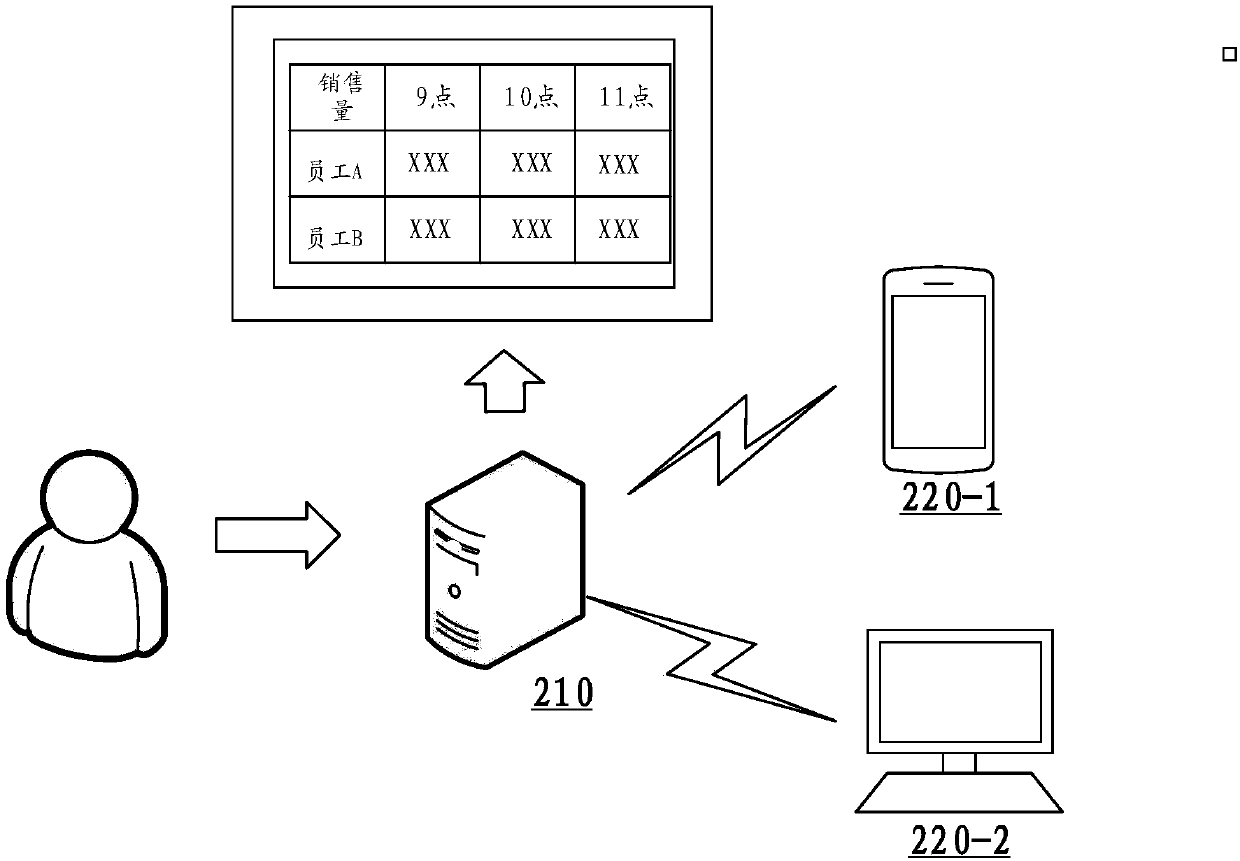

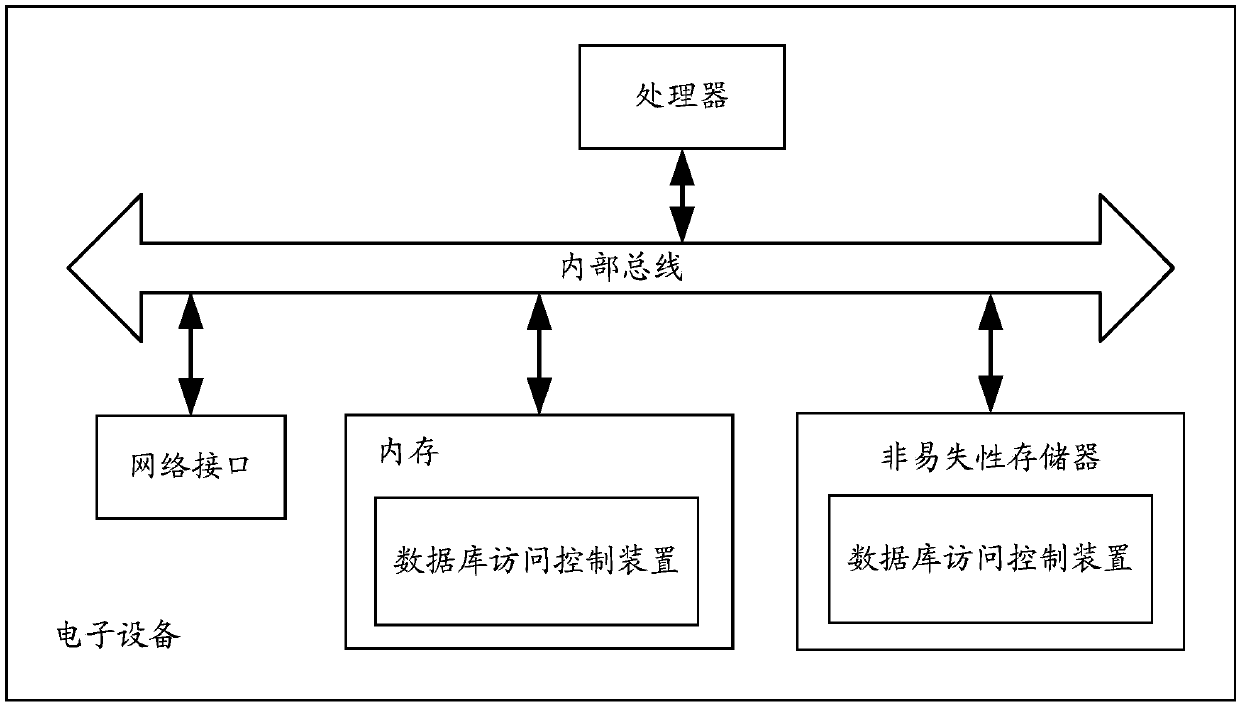

Webpage screenshot method and device

PendingCN110020231AReduce waiting timeSave human effortExecution for user interfacesSpecial data processing applicationsUniform resource locatorWeb page

The invention discloses a webpage screenshot method and device. The method comprises: receiving a webpage screenshot command, wherein the webpage screenshot command comprises a URL address of a webpage; loading the webpage by utilizing the URL address; and carrying out screenshot on the webpage. According to the invention, the waiting time of related personnel can be saved, the safety problem caused by chain falling is prevented, the related personnel can visually see the data report, and the manpower is saved.

Owner:ALIBABA GRP HLDG LTD

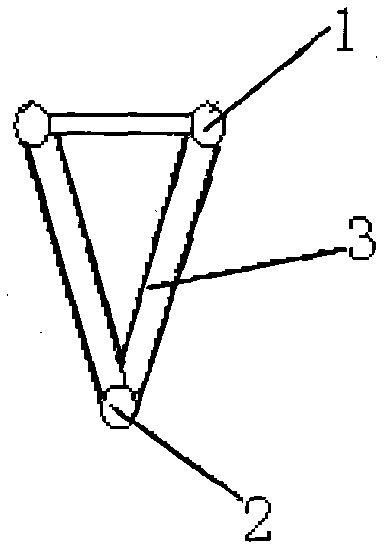

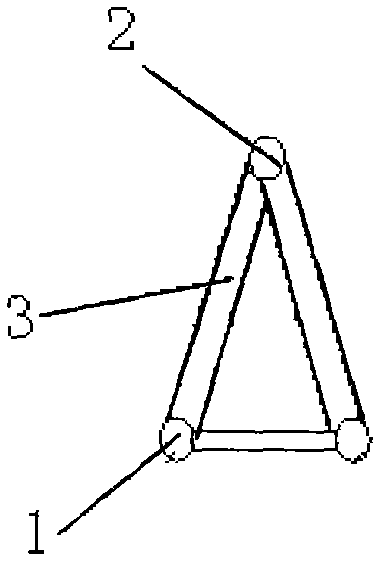

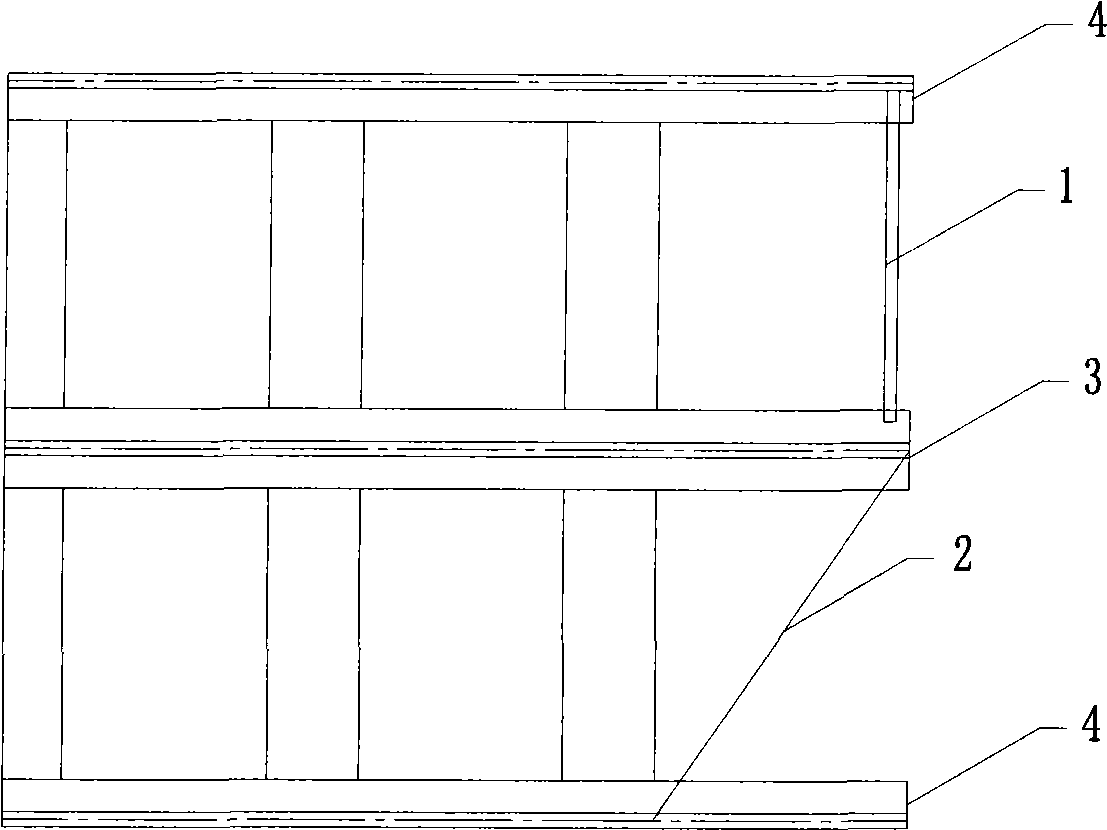

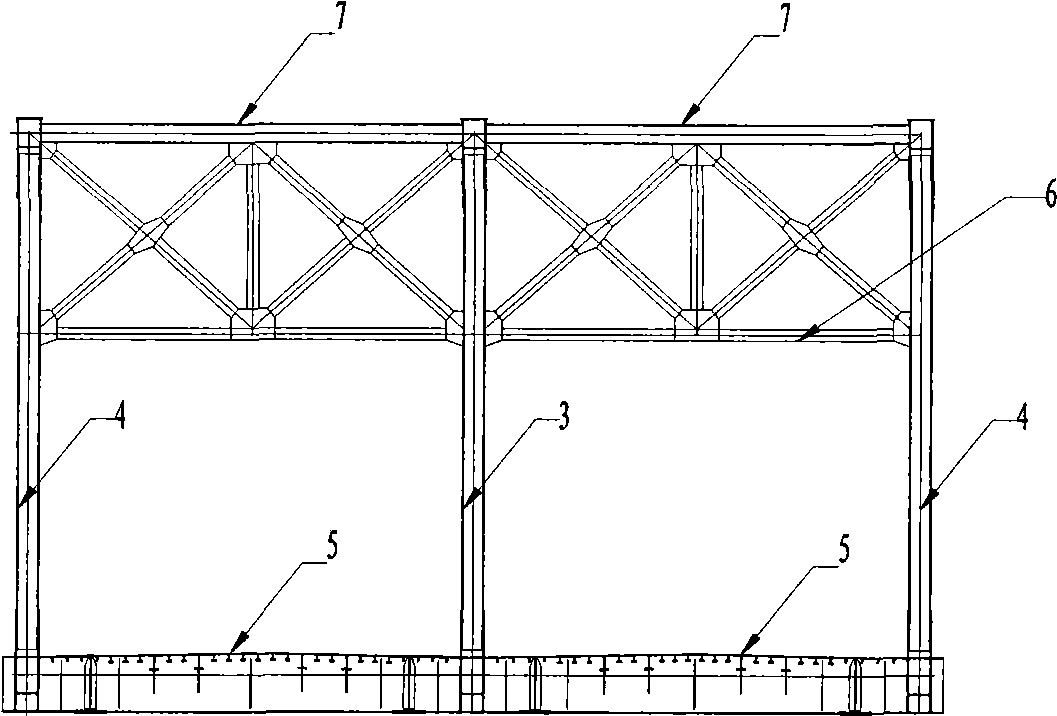

Longspan pipe truss pulling bar lifting and overhead rotating emplacing construction method

The invention discloses a longspan pipe truss pulling bar lifting and overhead rotating emplacing construction method which includes the following steps: 1), truss manufacturing and assembling, 2), pipe truss hoisting, 3), pulling bar moving, and 4), pulling bar removing. When a truss is assembled, an included angle of 30 degrees is formed between the truss and an installation positioning axis, the truss is lifted to exceed a concrete structure in height, and then rotated by 30 degrees to a design axis. The axis of the truss is rotated by 30 degrees to enable the truss to reach the position same as the position of the installation axis through the pulling bar erecting process, and therefore the pulling bar lifting and overhead rotating emplacing is achieved. The traditional single-foot pulling bar which is simple and flexible is adopted, in-place installation is achieved through pulley blocks, chain fall, winching and the like, an independent single-foot pulling bar can be adopted for hoisting in the hoisting construction for large components at certain special positions or on the situation that large hoisting machinery can not be adopted or the adoption of the large hoisting machinery can cause extremely large increase of construction cost, and the longspan pipe truss pulling bar lifting and overhead rotating emplacing construction method is high in work efficiency and low in cost.

Owner:安徽跨宇钢结构网架工程有限公司

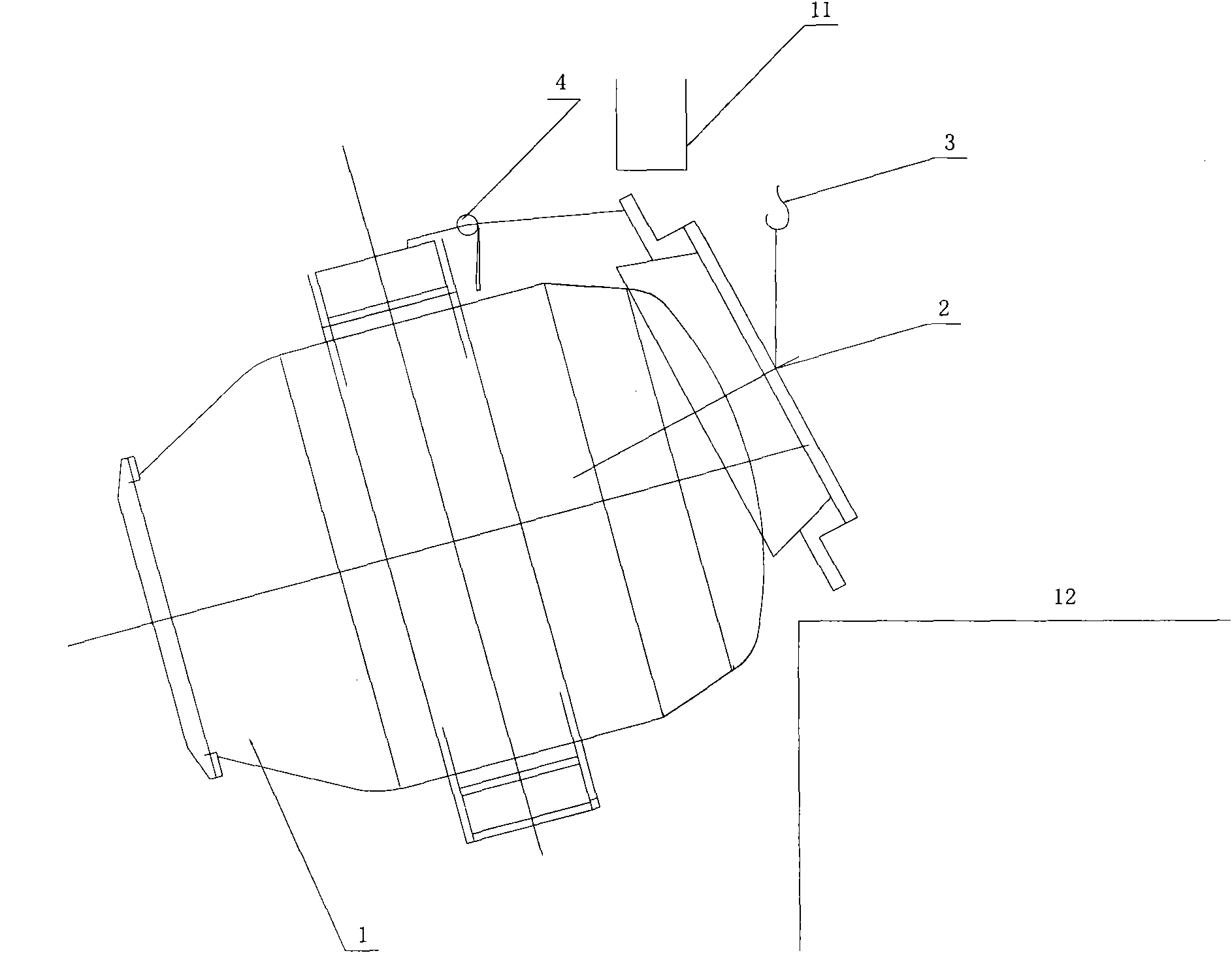

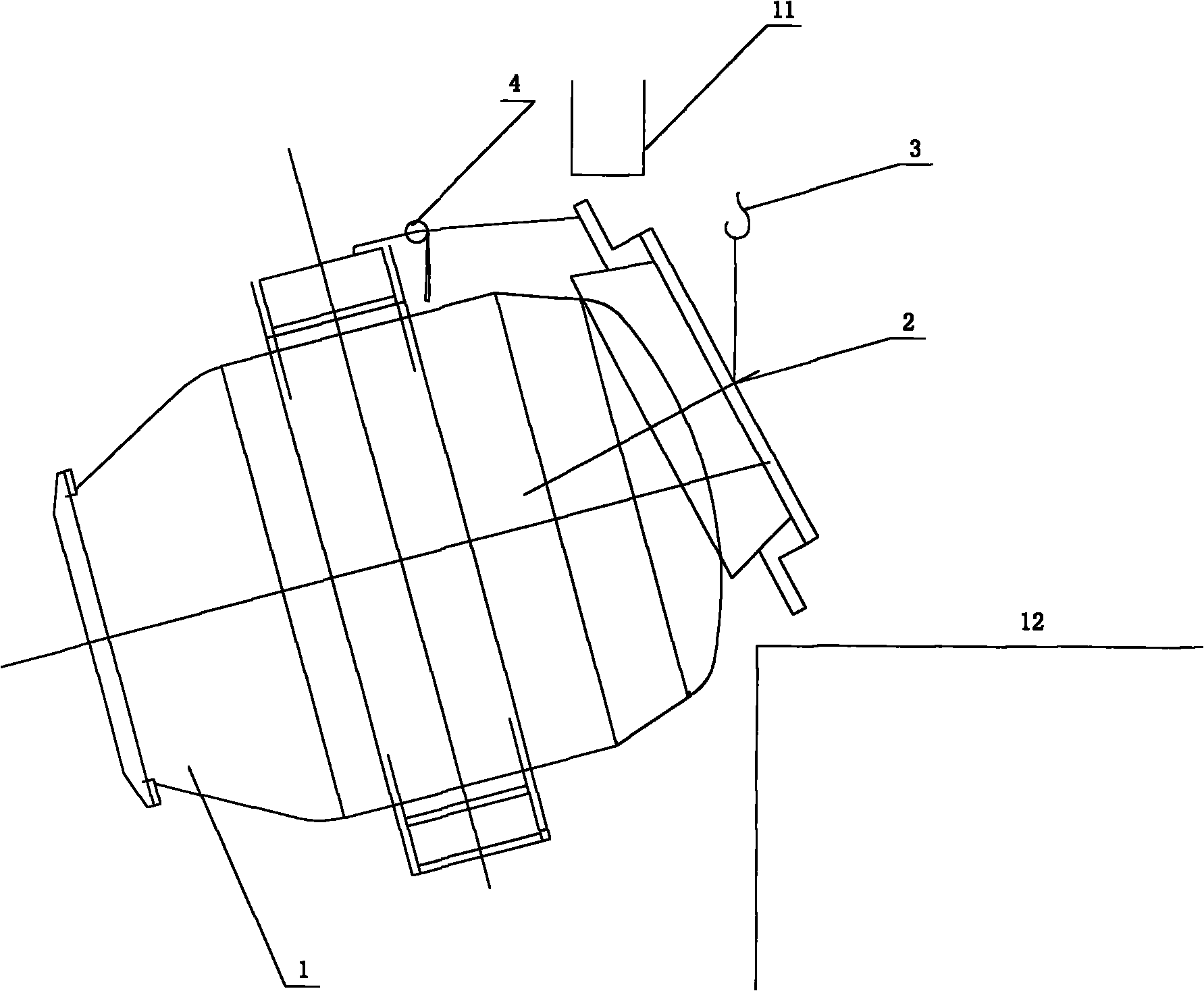

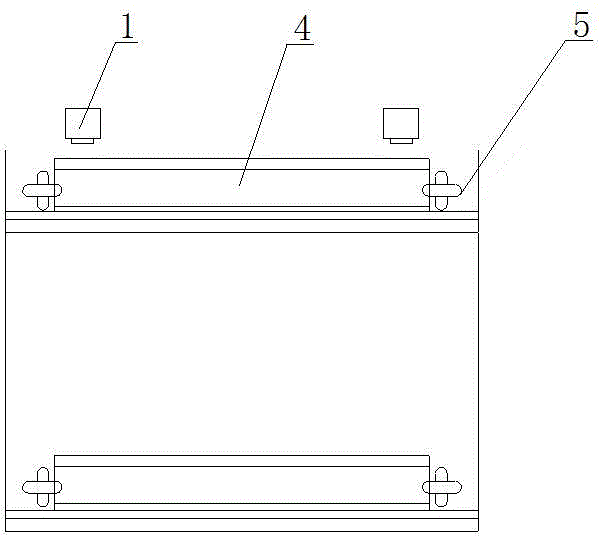

Fast change method of large-scale converter movable gas hood

InactiveCN101851694AQuick changeSimple stepsManufacturing convertersIncreasing energy efficiencyProcess engineeringWater pipe

The invention relates to the field of exhaust or separation devices of gas or smoke dusts in converters for processing and treating pig irons and discloses a fast change method of a large-scale converter movable gas hood. After a fixed gas hood is disassembled, the method sequentially comprises the following steps of: firstly, disassembling a cooling water pipe and rocking a converter (1) until the furnace bottom is arranged upwards; secondly, fixing a movable gas hood (2) on the converter (1) through a chain fall (4); thirdly, hoisting the movable gas hood (2) down through a crane (3); fourthly, hoisting a new movable gas hood onto the furnace bottom of the converter (1) through the crane (3) and fixing the new movable gas hood through the chain fall (4); fifthly, rocking the converter (1) until the furnace bottom is arranged upwards; and sixthly, reassembling a lifting chain of a hoisting device of the movable gas hood (2) and removing the chain fall (4). The invention has the advantages of simple steps, convenient operation, short construction period, less influence to production and high production efficiency.

Owner:SHANGHAI BAOYE GRP CORP

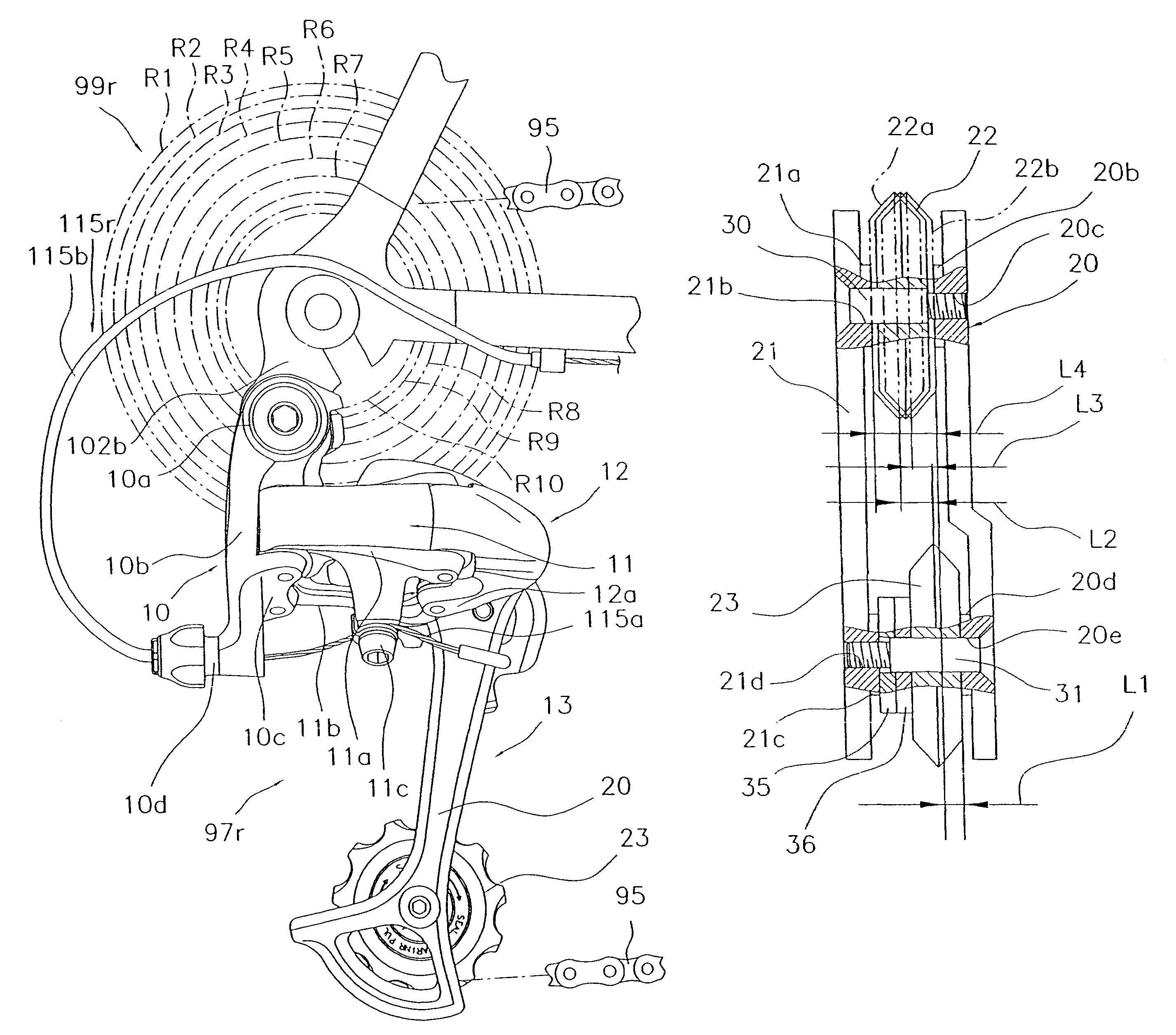

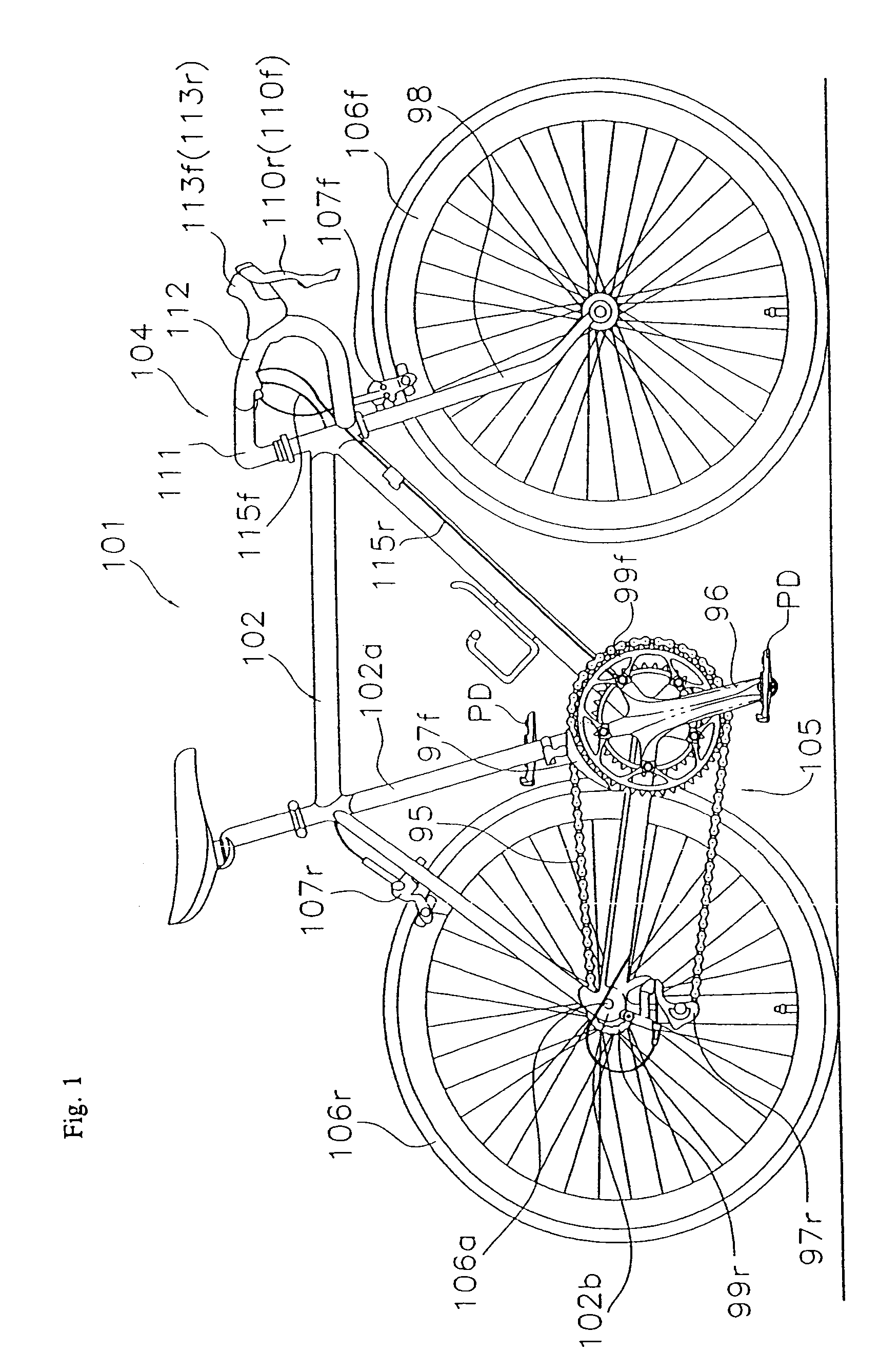

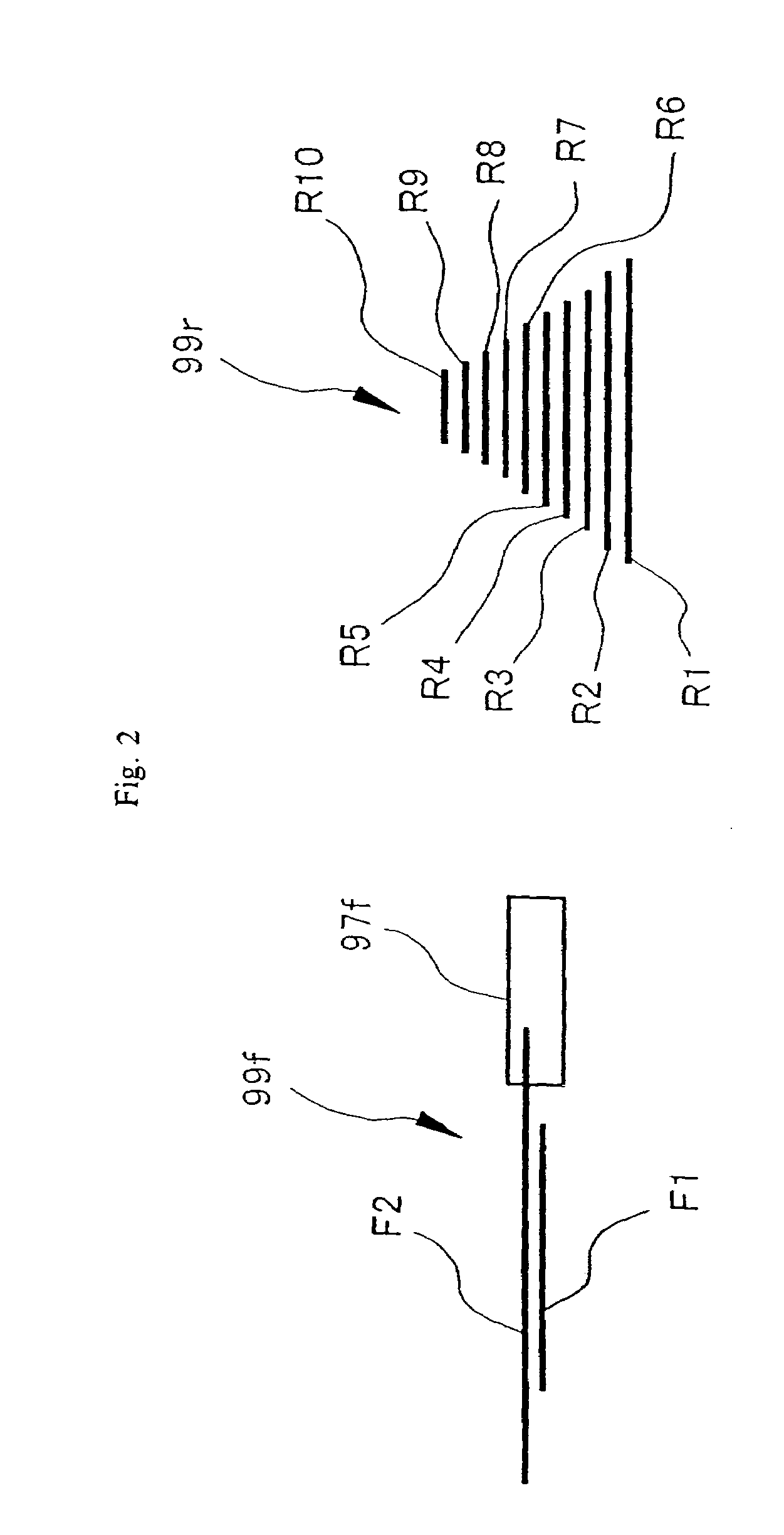

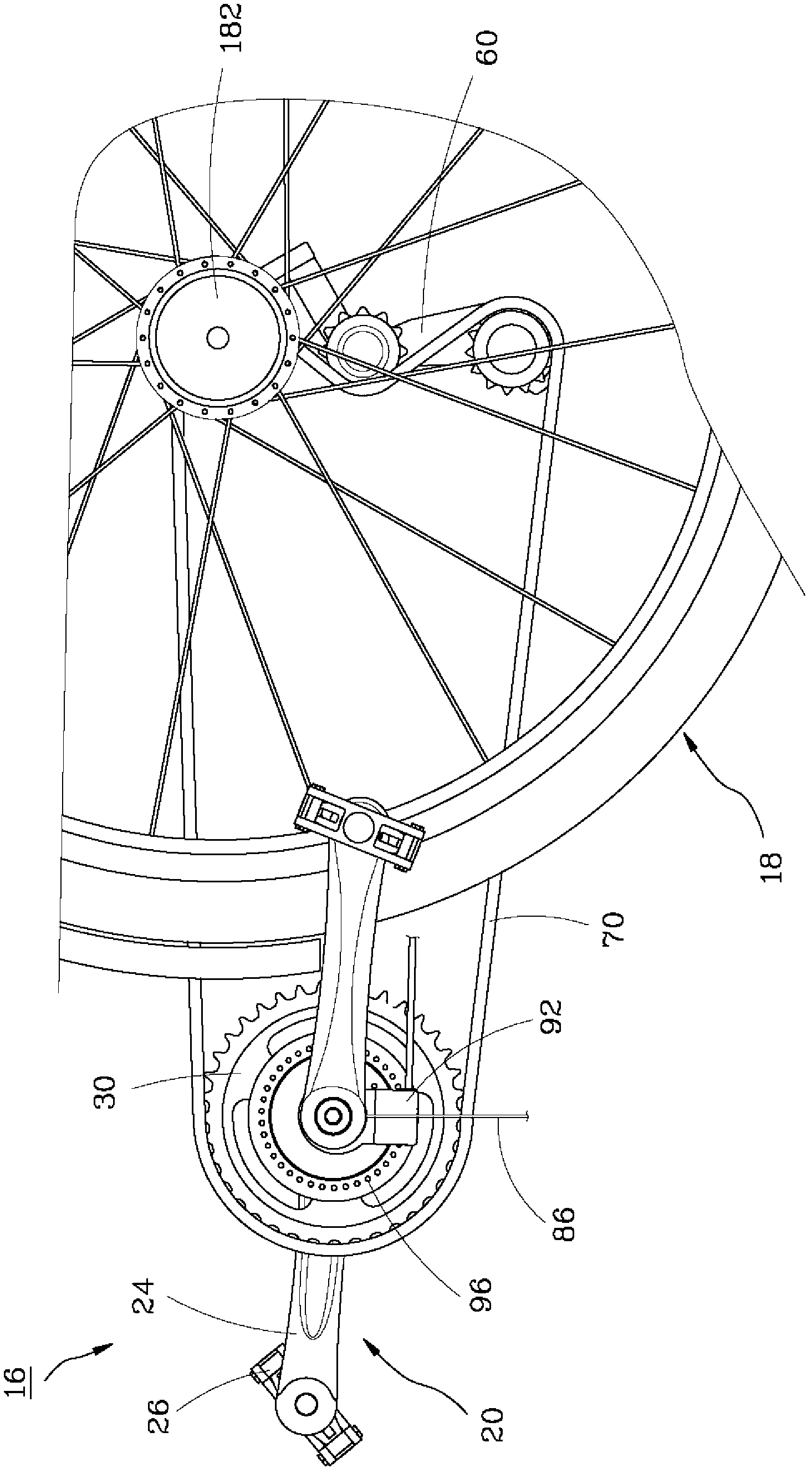

Bicycle derailleur

Owner:SHIMANO INC

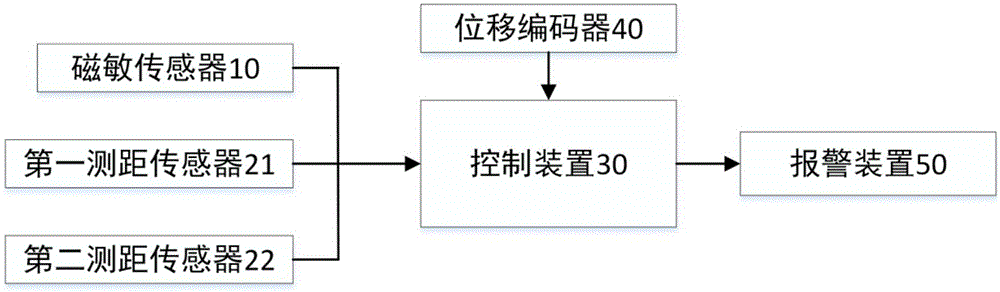

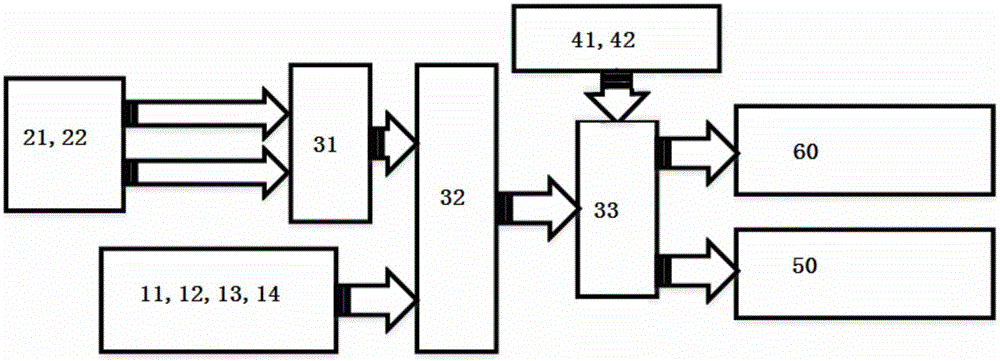

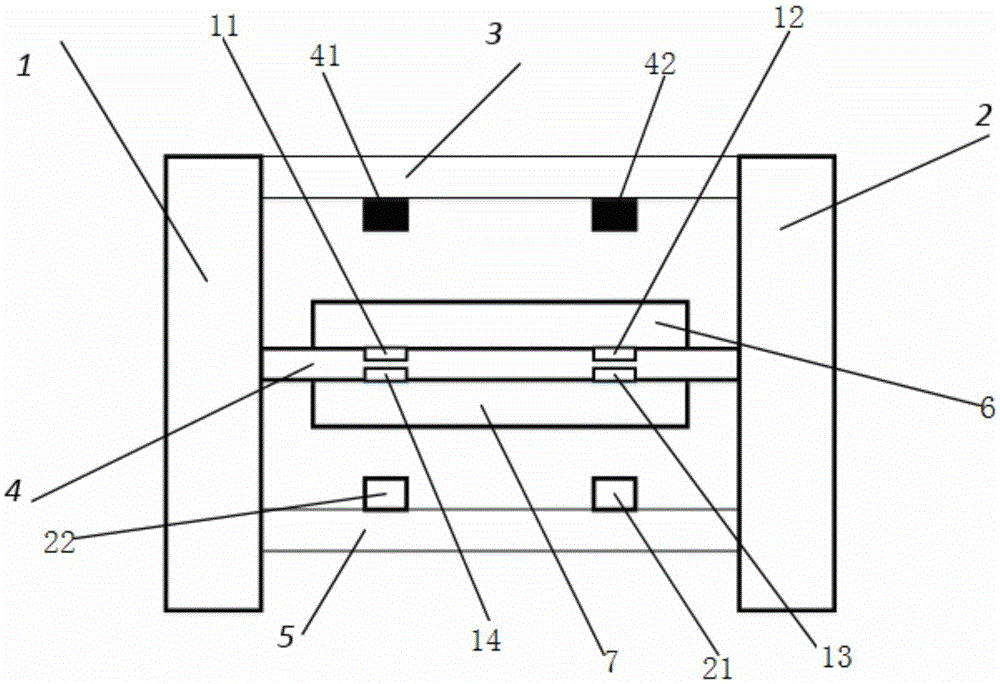

Chain breaking, dislocation and chain falling comprehensive protection device of scraper conveyor

InactiveCN104555341AAvoid bumpingReduce lossesConveyorsControl devices for conveyorsEngineeringDislocation

The invention relates to an automatic monitoring comprehensive protection device of a scraper conveyor, in particular to a chain breaking, dislocation and chain falling comprehensive protection device of a scraper conveyor, which is applied to the field of coal mine machinery. Parallel chains are arranged on both sides of the scraper conveyor placed in parallel; scraping plates are uniformly and vertically arranged on each chain along the length direction of the chain; the chains are operated to a tail pulley from a head pulley of the scraper conveyor; a first proximity switch and a second proximity switch are arranged above the scraping plates; the first proximity switch and the second proximity switch are respectively connected with a monitoring device in parallel through signal wires in a heat shrinkage pipe. The comprehensive protection device disclosed by the invention has the advantages of high automation degree, little influence to the scraper conveyor and relatively wide application range and is simple and reliable.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

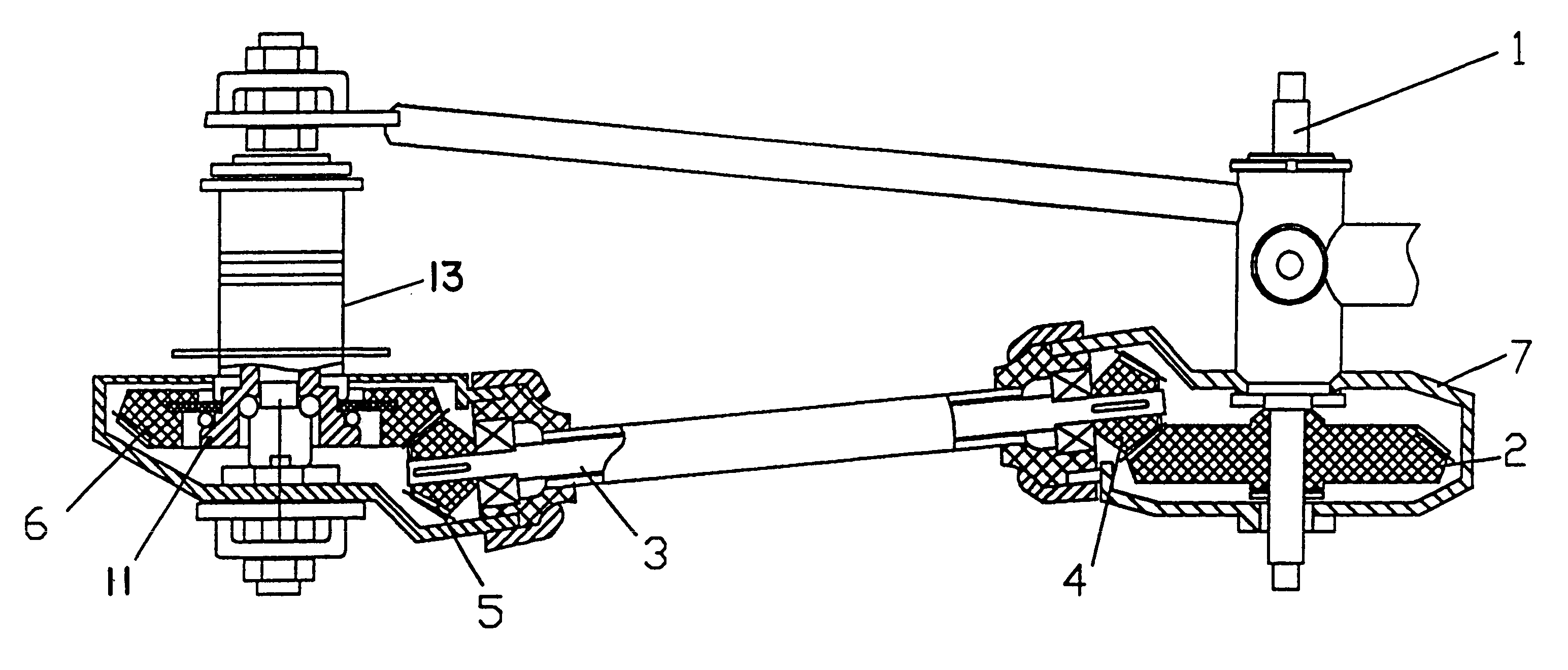

Three-joist trussed steel beam linear control method

ActiveCN101509232AGuaranteed alignmentMeet the requirements of forceBridge erection/assemblyPunchingLinear control

The invention relates to a steel truss girder linear control method of the bridge upper structure construction field and provides a three-truss steel truss girder linear control method. The control method comprises vertical control and plane linear control. The vertical control comprises A1. a main truss rod component between two adjacent steel truss girders and other rod components are assembled, the diameter of a punching nail is 0.3-0.5mm less than theoretical aperture; A2. the altitude difference caused by the uneven settlement of a temporary bearing is adjusted in advance by adjusting a pivot of next segment; the altitude difference caused by uneven load is adjusted by applying external force by the punching nail through the clearance of the aperture; the plane linear control adjusts and positions the midline of a middle truss according to the design line shape by a chain fall; and the midline of two lateral trusses is adjusted within the range of standard requirement with the midline of the middle truss as a reference line by adjustable profile steel. During the spanning process, the invention can control and adjust the altitude, the altitude difference and the plane line shape of three trusses effectively in time and ensures that the integral line shape and truss width of three trusses meet the requirement, thereby ensuring that three trusses are jointed successfully.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

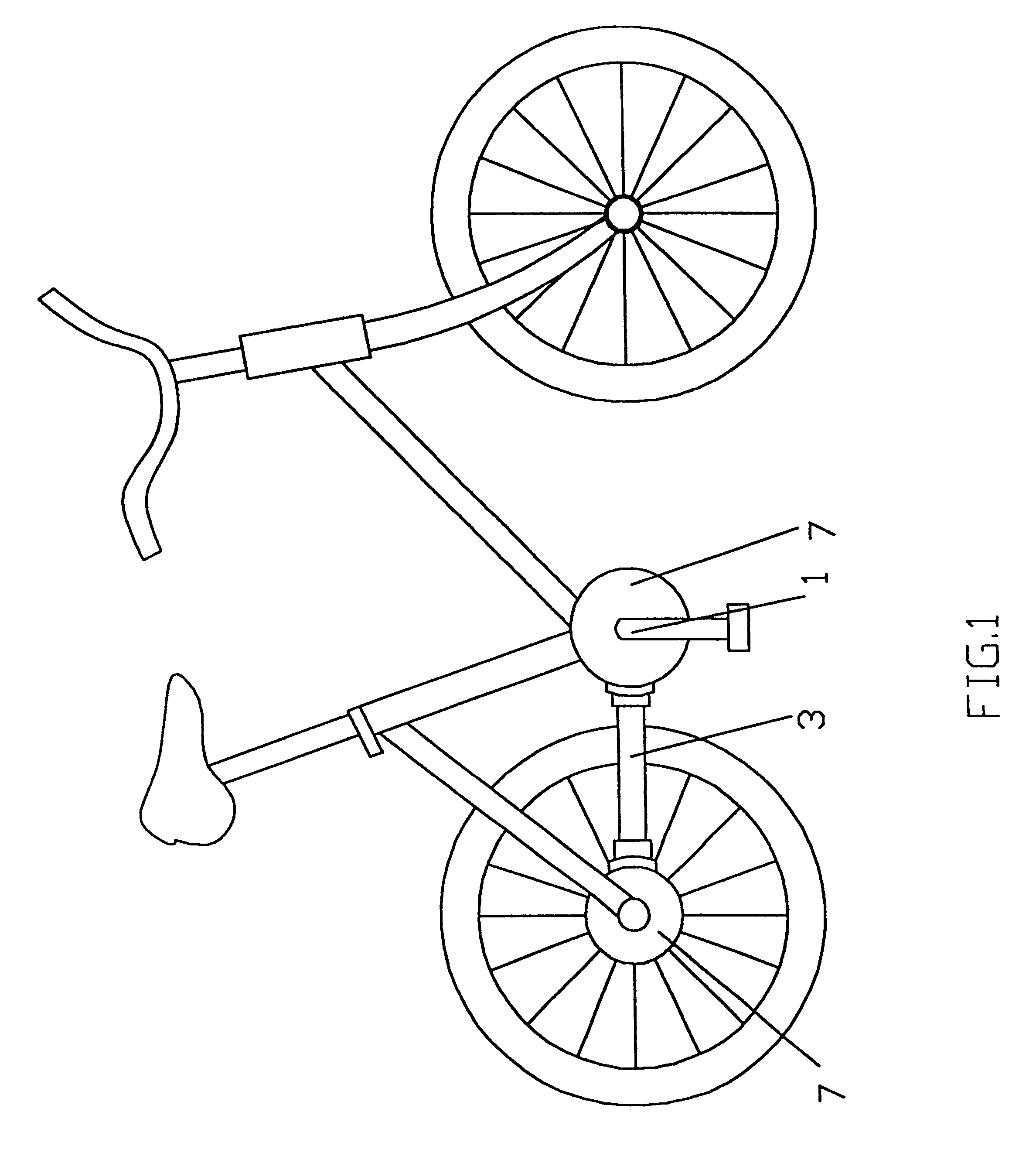

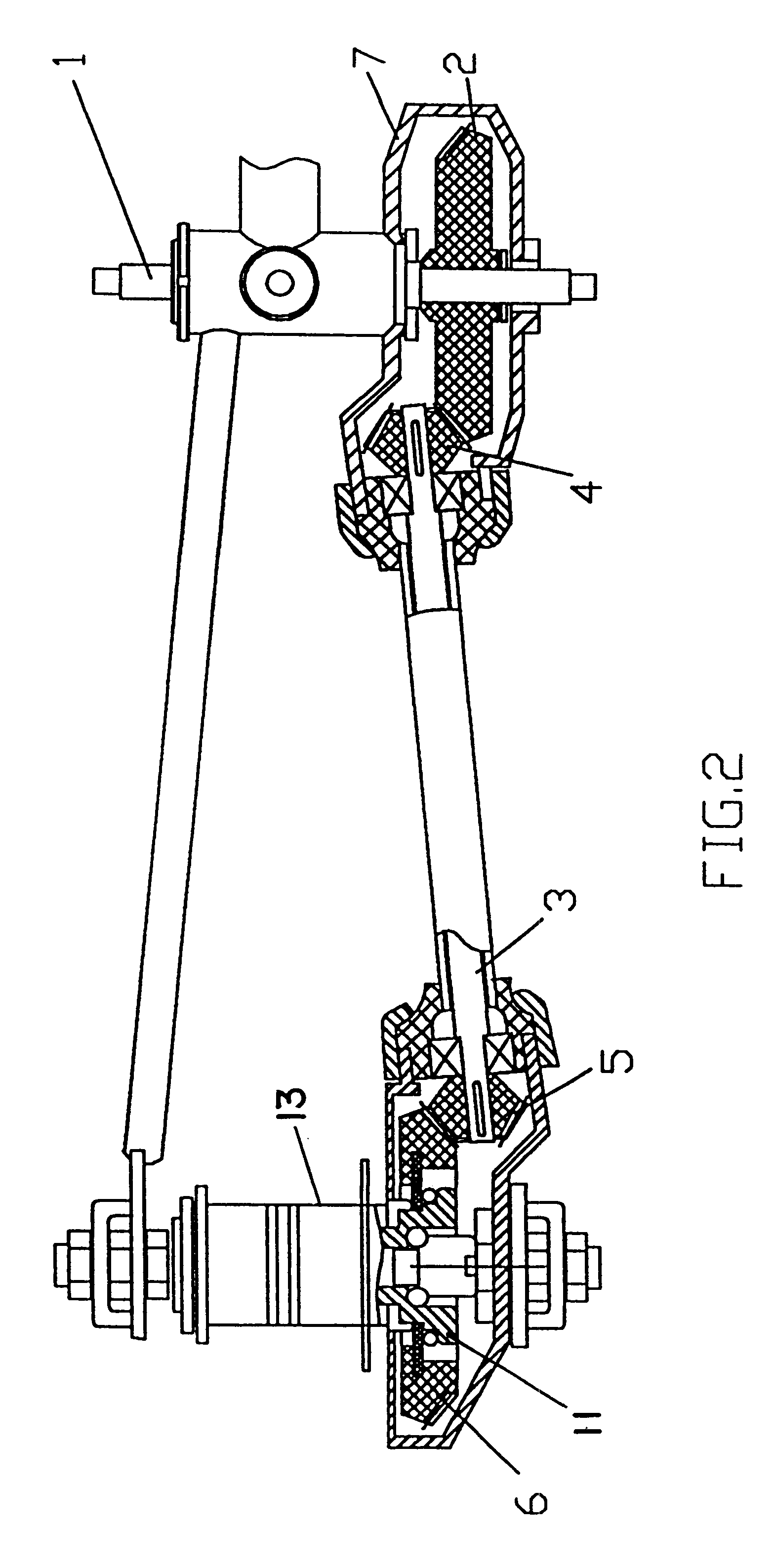

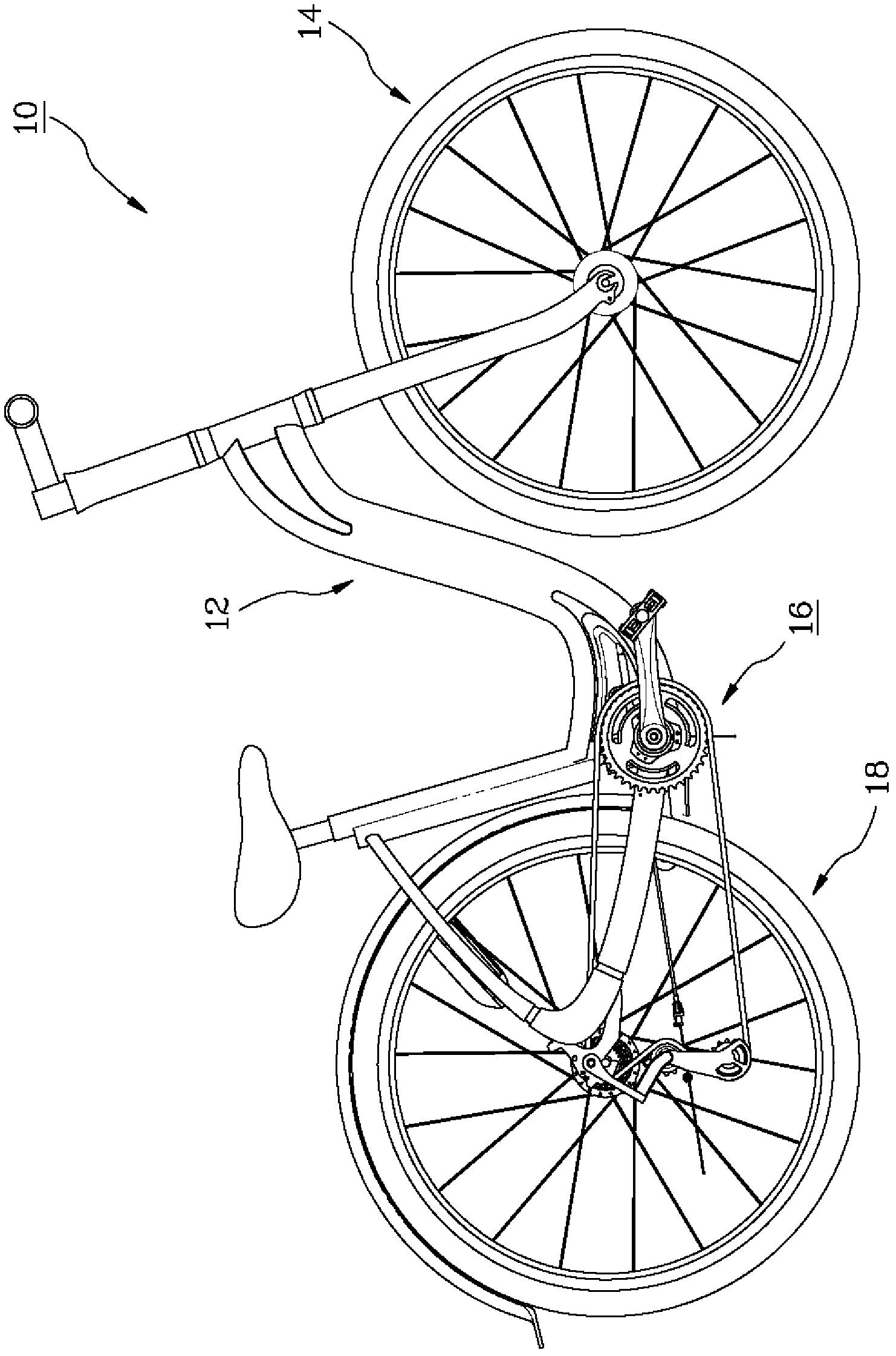

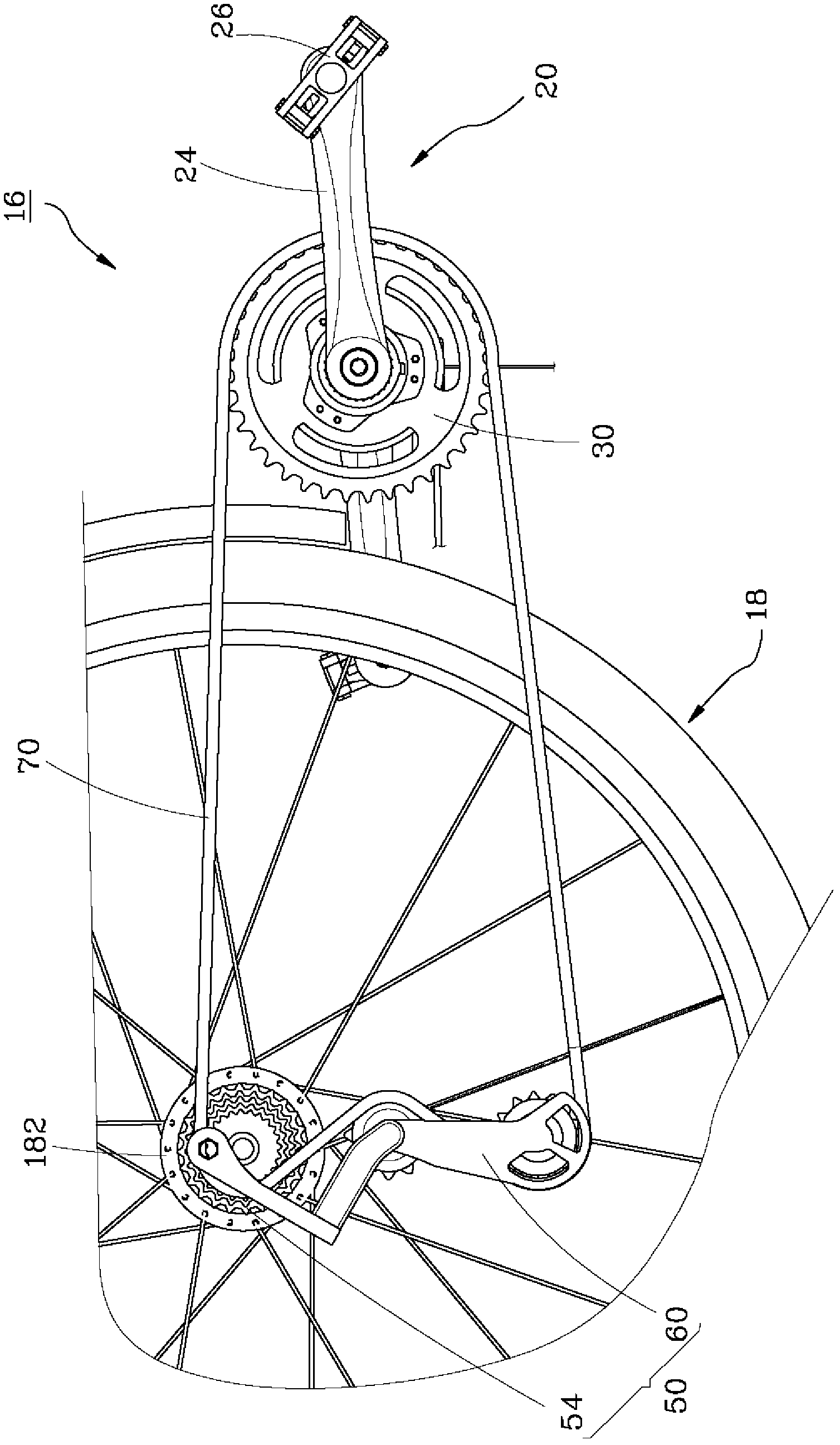

Bicycle with bevel gear drive for children

InactiveUS6446995B1Clean and safe for useEasy maintenanceWheel based transmissionChildren cyclesGear wheelEngineering

A children's bicycle with a bevel gear driving device that includes a pedal intermediate axle, characterized in that the pedal intermediate axle is connected with a drive bevel gear, which drives a connecting rod having bevel gears on both ends thereof, that the bevel gear on the other end of the connecting rod drives the rear wheel bevel gear, and that protecting hoods are provided over the driving bevel gear, the connecting rod with bevel gears, and the rear wheel bevel gear. The driving device avoids the problem of chain falling-off and allows safer use.

Owner:BAOLIN BICYCLE SHANGHAI

Outer speed change mechanism of electric bicycle

InactiveCN103183102AAppropriate tightnessAvoid falling chain situationsChain/belt transmissionRider propulsionAutomatic controlEngineering

The invention relates to an outer speed change mechanism of an electric bicycle. The outer speed change mechanism of the electric bicycle mainly adopts the structure that a one-way device is arranged between a large fluted disc and a crank shaft; the one-way device is driven by cranks to drive the large fluted disc to perform unidirectional rotation so as to enable a rear wheel, the larger fluted disc and a chain to keep rotation at the same rotational speed; besides, a sensing device is used for sensing the size of the rotating speed of the real wheel, the large fluted disc or the chain; and once the rotating speed is too low, an electronic derailleur stops move, during which a rider can not realize gear shift by using a manual control method or an automatic control method, so as to ensure that a shift cable can remain in a appropriate tightness, and avoid the situation of chain falling at the same time.

Owner:J D COMPONENTS CO LTD

Scraper conveyer detecting device and method

InactiveCN105035647AEasy maintenanceConveyorsControl devices for conveyorsStress concentrationEngineering

The invention relates to the field of scraper conveyer detection and discloses a scraper conveyer detecting device and method. The normal component of a magnetic signal in a stress concentration area of a scraper is acquired through magnetic sensors, whether the scraper of a scraper conveyer is to be broken or has been broken is judged according to the intensity of a gradient signal of the normal component, the distances between distance measuring sensors and the scraper are measured through the distance measuring sensors, and whether chain falling or chain breaking occurs to the scraper is judged according to the distances. By the adoption of the scraper conveyer detecting device and method, maintenance staff can be informed in time for maintenance when the scraper is broken or to be broken or chain falling or chain breaking occurs to the scraper, and then accidents such as coal leakage and coal piling are prevented.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

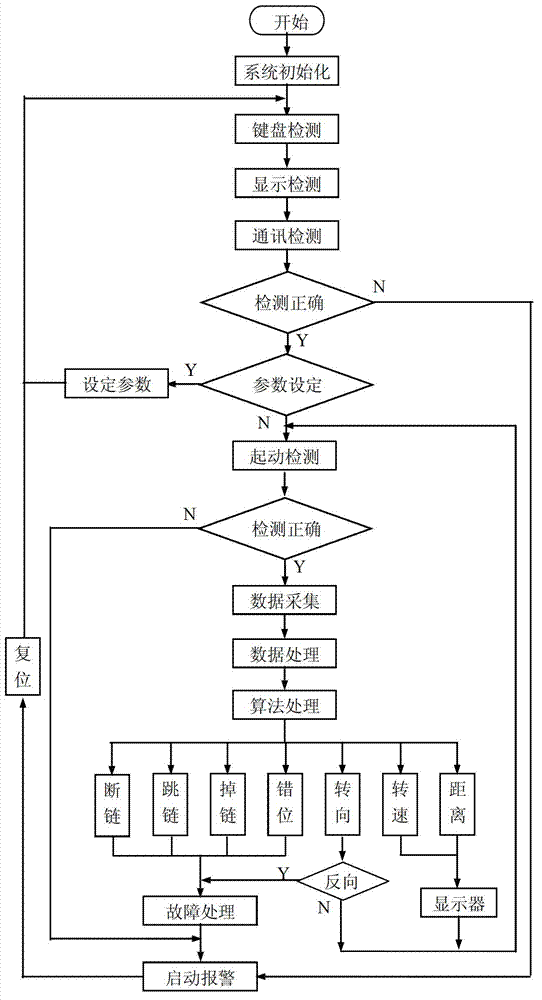

Integrated monitoring device for conveying chain of coal sorting machine

ActiveCN103246269ASimple structureEasy to installSolid separationTotal factory controlMain processing unitIntegrated monitoring

The invention provides an integrated monitoring device for the conveying chain of a coal sorting machine, and belongs to a conveying chain monitoring device. The upper monitor computer of the monitoring device monitors the performance of the main processing unit, the main processing unit receives and handles signals sent by the detecting unit, and controls a shutdown circuit and an alarm circuit; the speed detection unit detects the running speed and the direction of the conveying chain, the fault detection unit detects the faults of the two conveying chains, such as chain scission, chain falling, chain skipping, scraper plate dislocation and the like; the alarm circuit and the shutdown circuit conduct sound-light alarm and stop dragging motor order sent by the main controlling unit; the main controlling unit conducts self-locking after fault signal processing, and the reset of the main controlling unit is conducted by the reset circuit. According to the device provided by the invention, the running parameter of the conveying chain is detected in real time, and the conveying chain fault can be detected timely to stop dragging motor, the damage to the scraper plate and the fluidizer caused by continuous running of the motor after chain scission, chain falling is avoided effectively, and the staff allocation of the system operation and the workload maintenance are decreased.

Owner:CHINA UNIV OF MINING & TECH

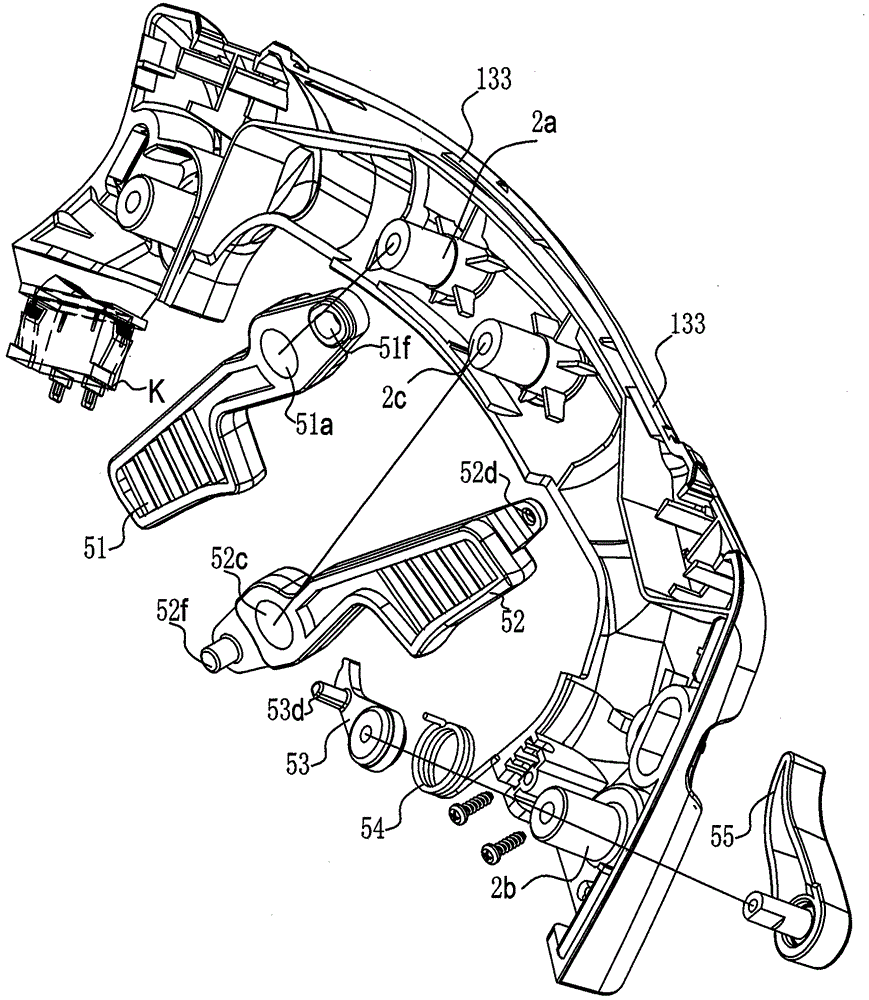

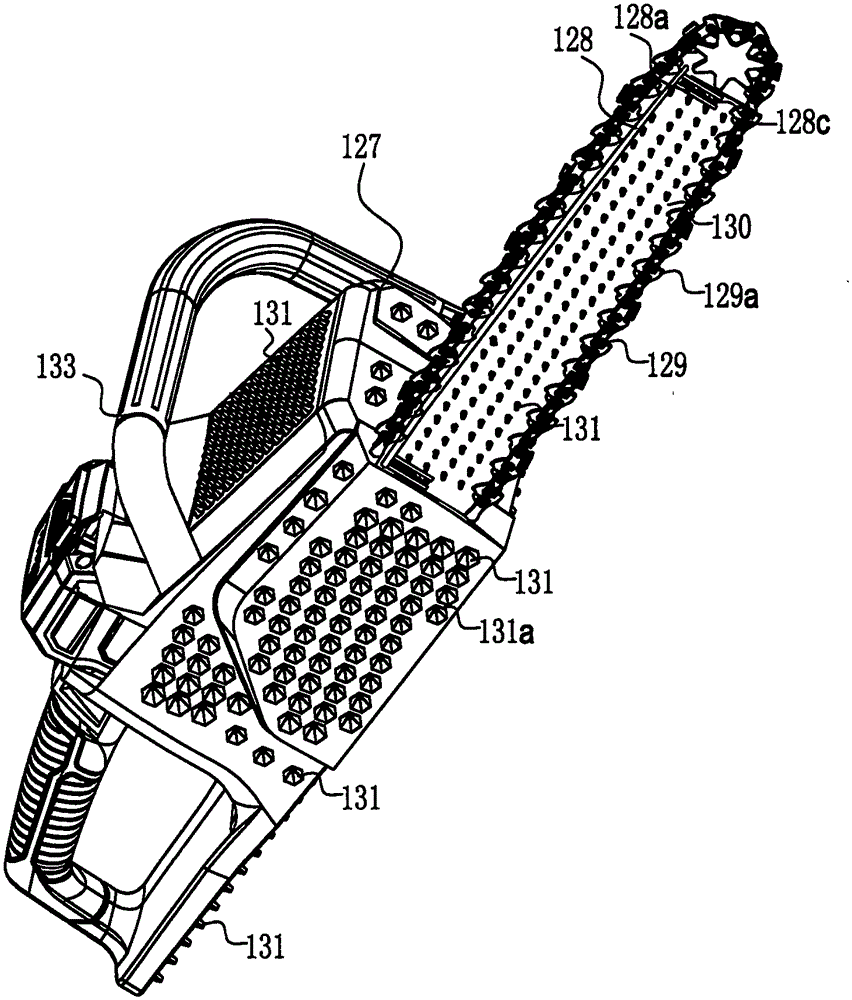

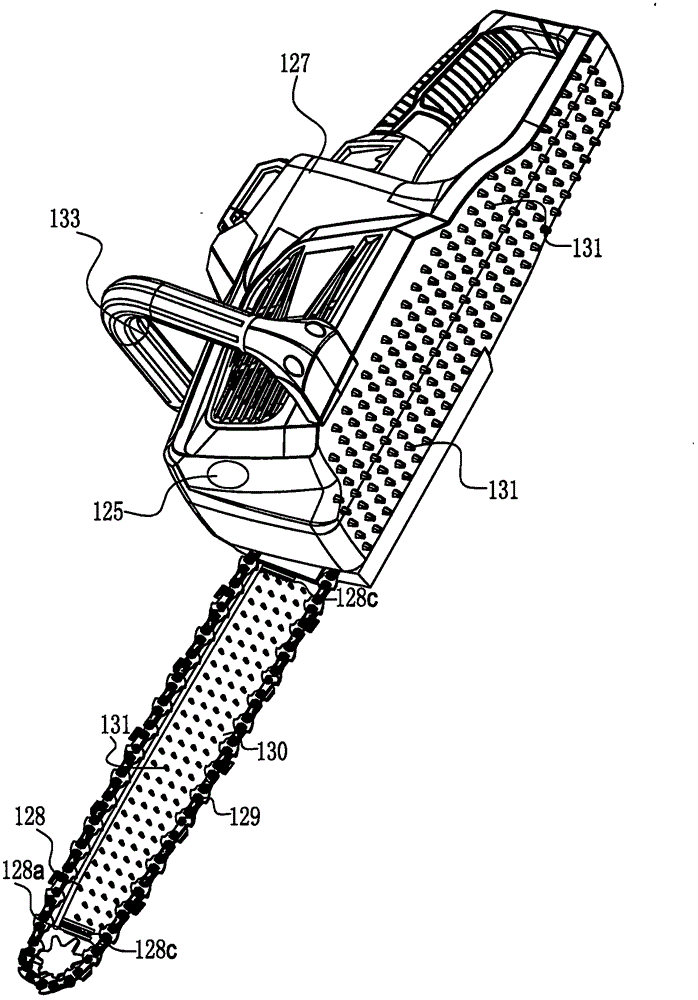

Electric chain saw with linked-lever latched damping handles for grip change of both hands

The invention relates to an electric chain saw with linked-lever latched damping handles for grip change of both hands. Chain falling prevention and hand changing operation are long-standing problems, and an innovation is made at present. According to the electric chain saw, the operation is facilitated during work, and a switch can be controlled to work by only gripping a left linked lever handle (51) and a right linked lever handle (52) by the both hands, or changing to use a left hand to grip the left linked lever handle (51), or changing to use a right hand to grip the right linked lever handle (52), or carrying out latching by using a latching turn handle (55), so that the electric chain saw with the linked-lever latched damping handles for the grip change of the both hands is formed, and manufacturing is facilitated.

Owner:NINGBO DAYE GARDEN EQUIP

Thermal test chamber

ActiveUS8479597B2Readily mountable upon shaker test tableQuick changeMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceOverhead craneEngineering

A soft-sided thermal test chamber that is readily mountable upon / over a shaker test table. The test chamber includes four interconnected insulated side walls and a top which define an enclosure. A two-piece bottom receives the side walls to fully enclose the test object upon the table. The two-piece bottom includes an interchangeable center piece which is sized to accommodate various tables or test objects. The side and top pieces are hung from a frame that is readily lifted using an overhead crane or chain fall hoist to allow easy access to the table during set up. The bottom and side walls are interconnected via hook and loop fasteners, which allows for rapid alteration of the set up of the test equipment while maintaining a thermally sealed chamber.

Owner:PICKEL MICHAEL B

Method for making pile foundation construction follow long steel pile casing construction in karst area

ActiveCN102286976AShorten the construction processReduce construction costsBulkheads/pilesArchitectural engineeringPipe

The invention discloses a method for making pile foundation construction follow long steel pile casing construction in a karst area. The method comprises the following steps of: drawing a pattern of a steel pipe bracket for supporting a steel pile casing by using graphics software; welding section steel and a steel pipe according to drawing paper to form a bracket for supporting the steel pile casing; during field application, treating a bracket foundation; putting the bracket at an orifice; making the steel pile casing follow segmentally by using a chain fall; and in the falling process of the steel pile casing, checking whether the verticality and the like are consistent with the specification and design requirements. The method has the characteristics of rapidness and safety when applied to pile foundation construction in the karst area; and moreover, the steel pipe bracket used during construction can be used repeatedly, the construction process is shortened, and the construction cost is saved.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

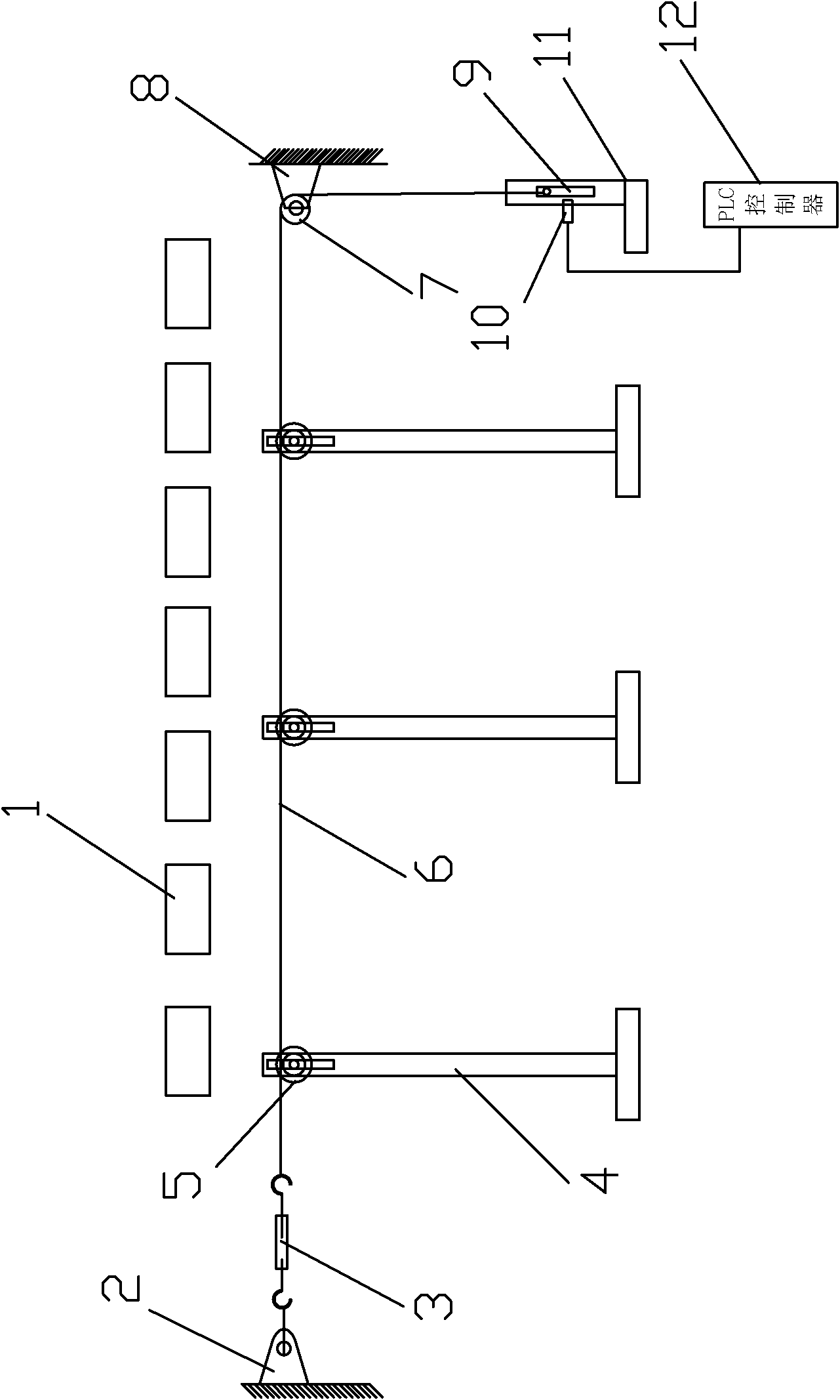

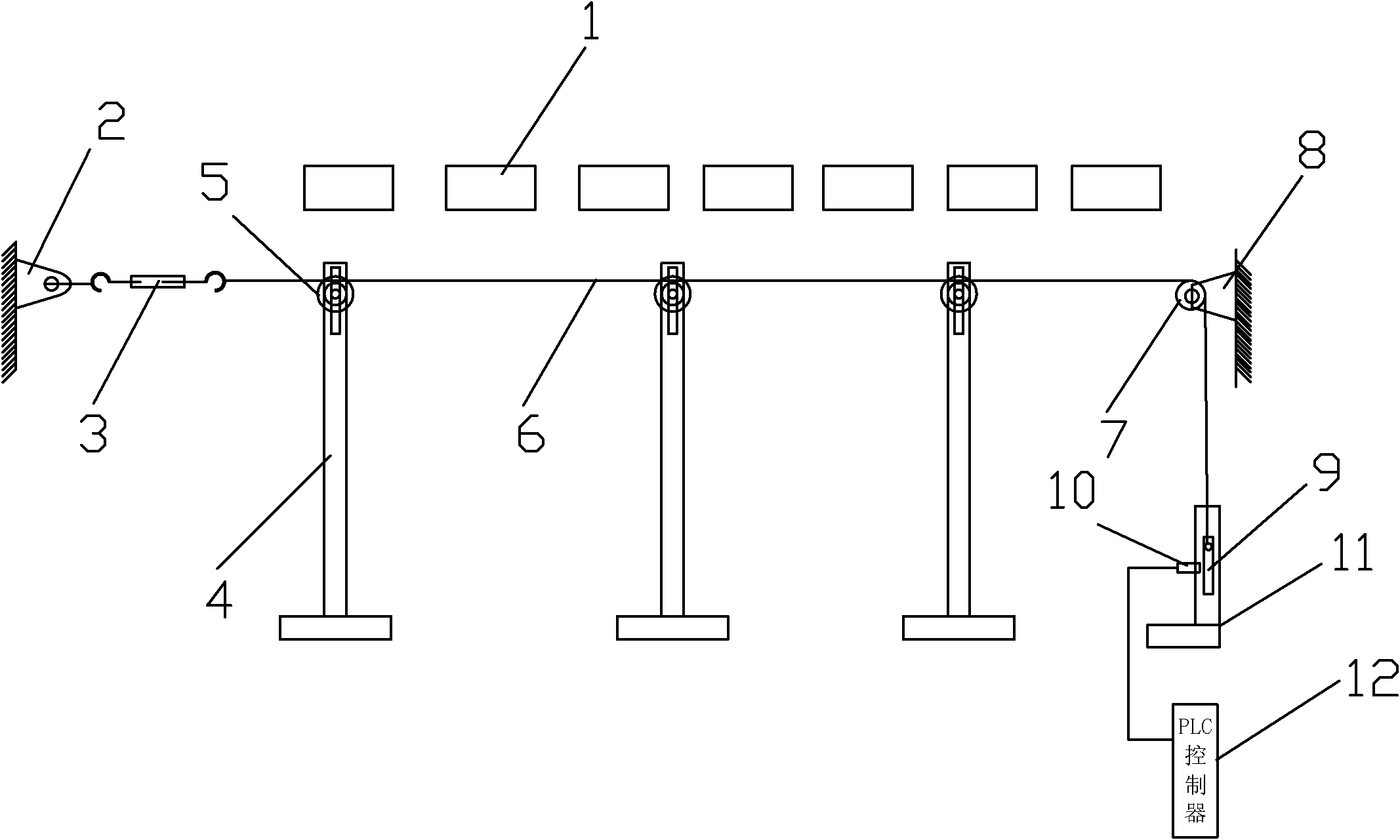

Method for detecting broken chains of swaying rack chain fall

ActiveCN102180343AAvoid being pulled and deformedInhibit sheddingControl devices for conveyorsSteering wheelProgrammable logic controller

The invention discloses a method for detecting broken chains of a swaying rack. A swaying rack is provided with a plurality of chains, wherein the chains are connected with a drive motor; the drive motor is connected with one PLC (Programmable Logic Controller); the PLC controls the drive motor to drive the chains to move back and forth; a steel wire rope is arranged below the chains; one end of the steel wire rope is fixed, and the other end of the steel wire rope is connected with a steel plate capable of sliding up and down via one steering wheel; one side of the steel plate is provided with a proximity limit sensor corresponding to the steel plate; and the proximity limit sensor is connected with the PLC controller. According to the device, maintenance staff can be reminded of overhauling chains on the swaying rack in time so as to avoid the problems of pulling deformation, falling and destroy of a chain track in a broken chain, thereby effectively shortening chain overhauling time, saving manpower and materials, lowering production cost, improving overhauling efficiency and ensuring normal production.

Owner:MCC BAOSTEEL TECH SERVICE

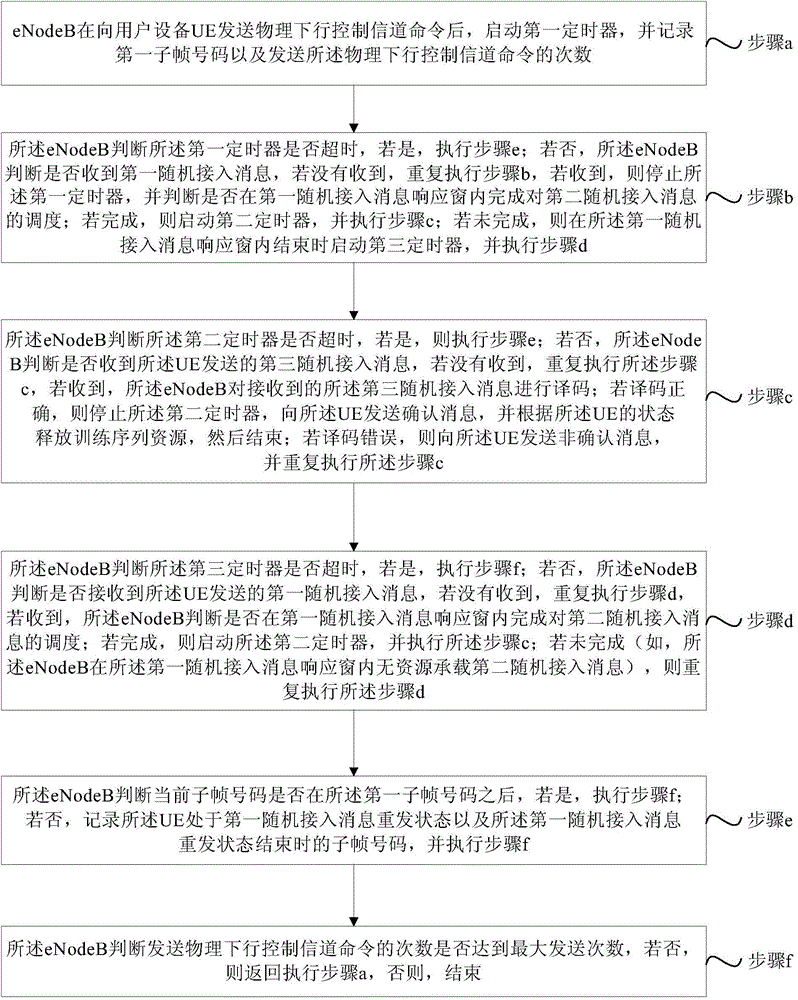

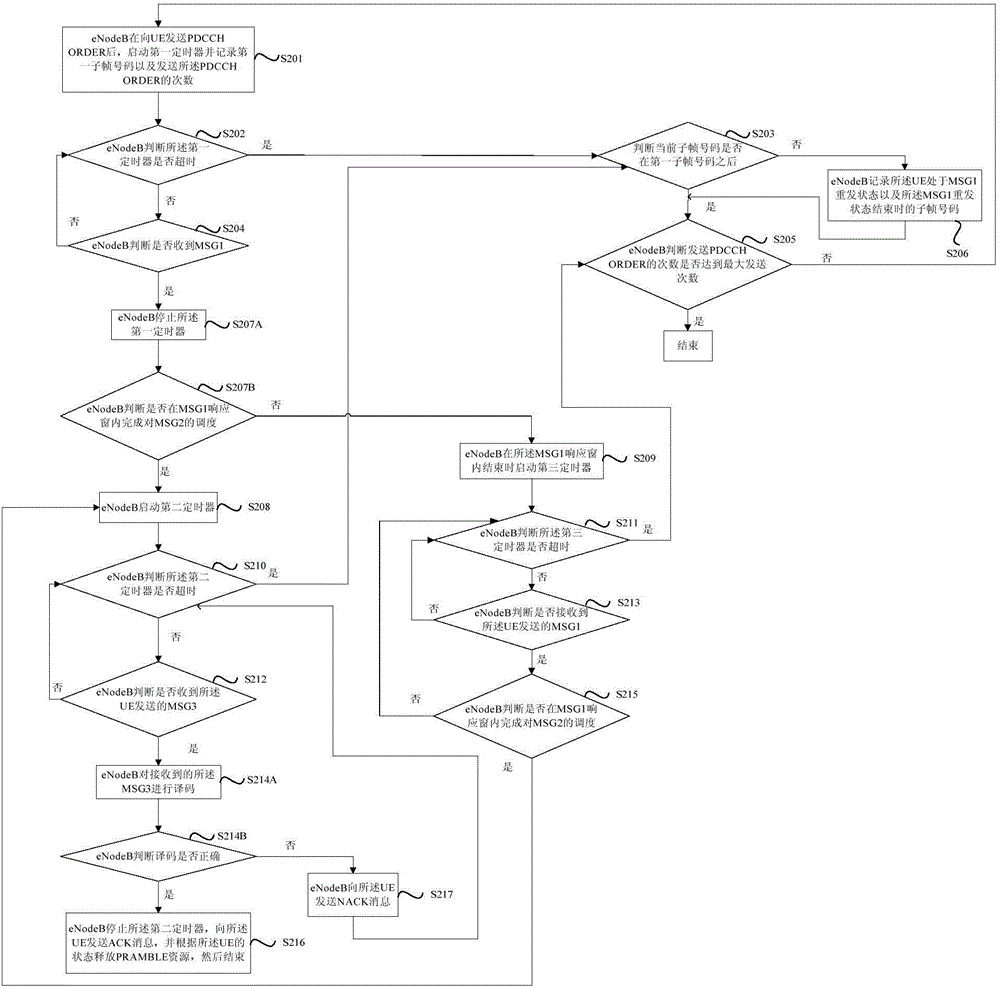

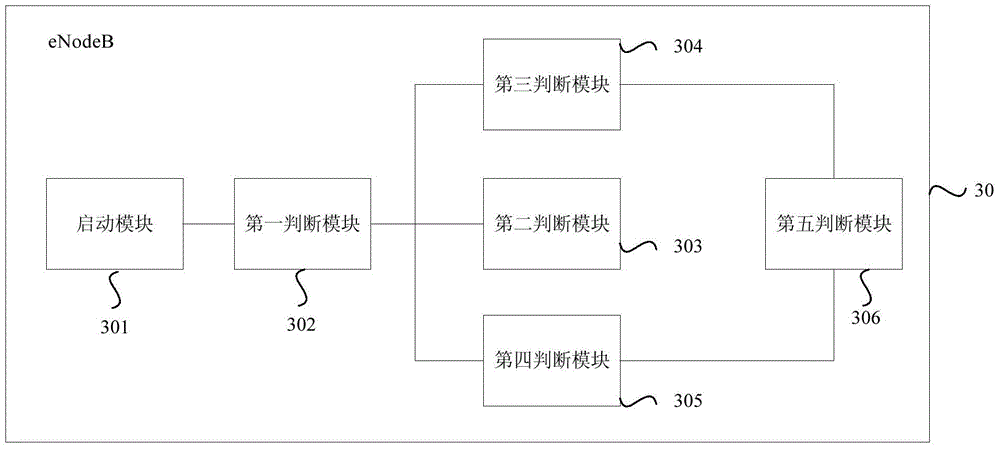

Non-competitive random access method and device

Embodiments of the present invention provide a non-contention random access method and device. In the non-contention random access method of the present invention, eNodeB sets different timers according to the states of different stages of non-contention random access, so that not only The synchronization delay of the UE and the saving of physical resources can also completely solve the problems of UE link loss and RRC reconstruction.

Owner:CHENGDU TD TECH LTD

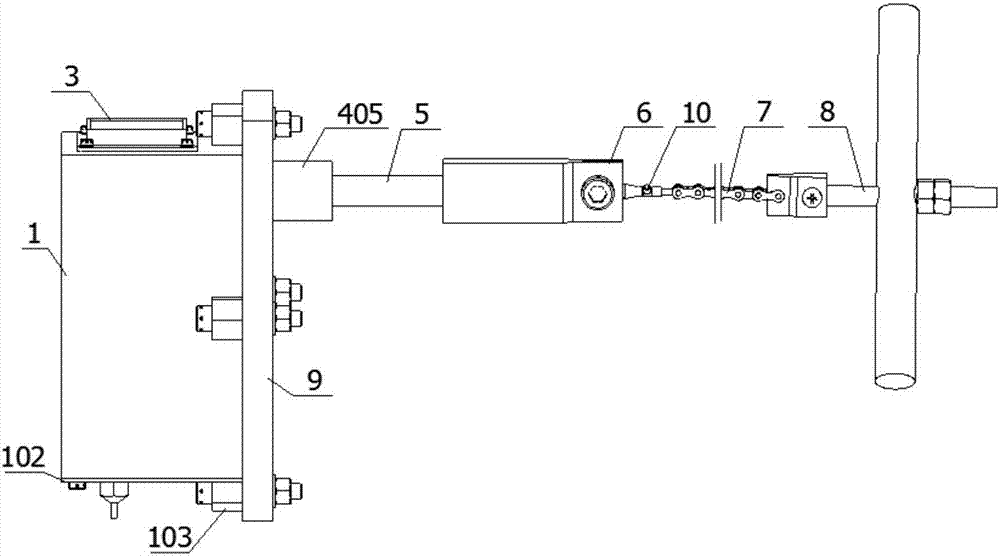

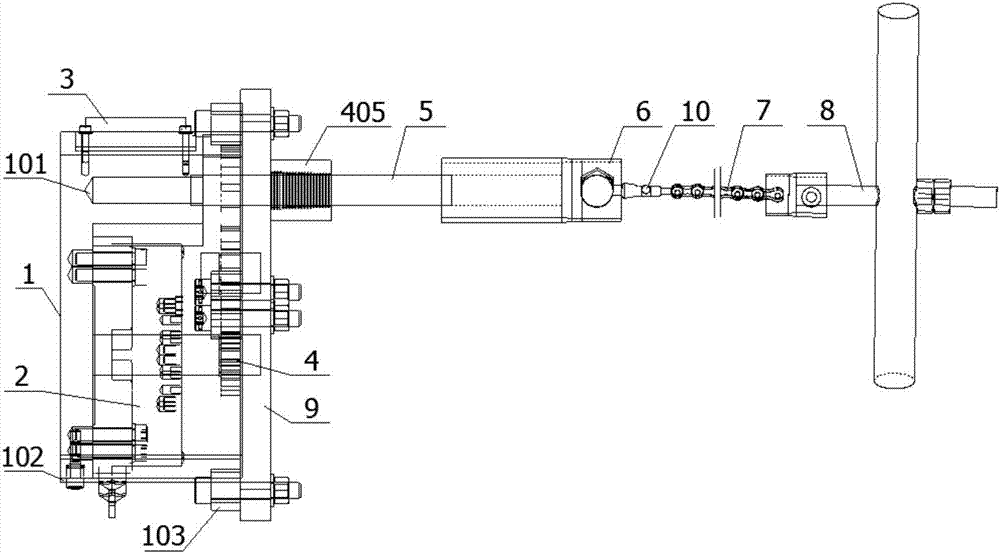

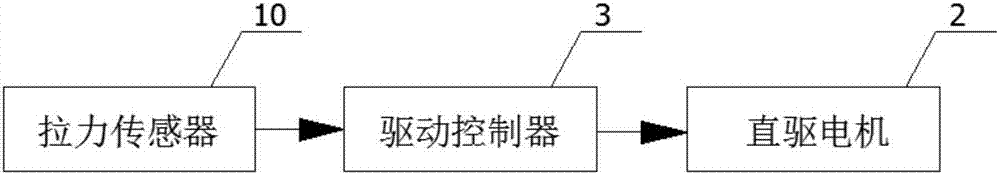

Chain tensioning adjusting mechanism

ActiveCN106931110AImprove driving precisionAvoid chain dropGearingElectric machineryWorking environment

The invention relates to a chain tensioning adjusting mechanism which comprises a shell, a direct drive motor, a drive controller, a transmission device, a transmission lead screw, a first connector device, a chain and a second connector device. The direct drive motor is arranged in the shell, and the drive controller is arranged at the upper end of the shell and is connected with the direct drive motor through a line; a supporting plate is arranged on the outer side of the shell, the transmission device is arranged on the side, close to the shell, of the supporting plate, and the direct drive motor is connected with the transmission device; one end of the transmission lead screw penetrates the supporting plate to be connected with the output end of the transmission device, and the other end of the transmission lead screw is connected with one end of the first connector device; the other end of the first connector device is connected with the second connector device through a chain; and a tension sensor is arranged at the connecting position of the first connector device and the chain and is connected with the drive controller through a line. By means of the chain tensioning adjusting mechanism, automatic chain tensioning is achieved, the chain driving accuracy is improved, chain falling is prevented, the chain tensioning adjusting mechanism can adapt to the wicked work environment, and the reliability coefficient is high.

Owner:GUILIN UNIV OF ELECTRONIC TECH

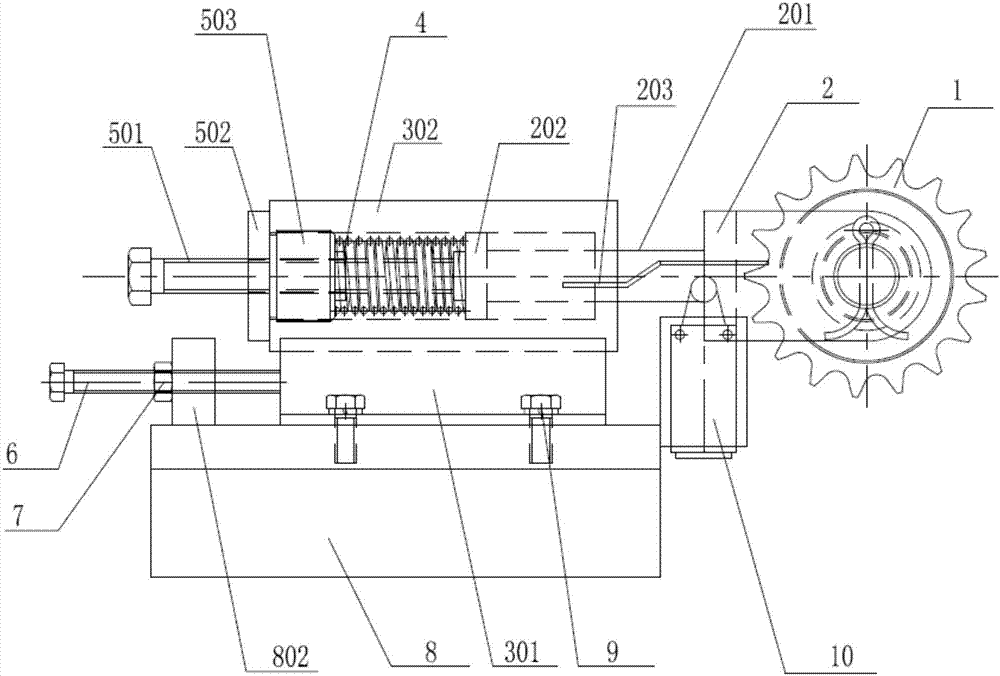

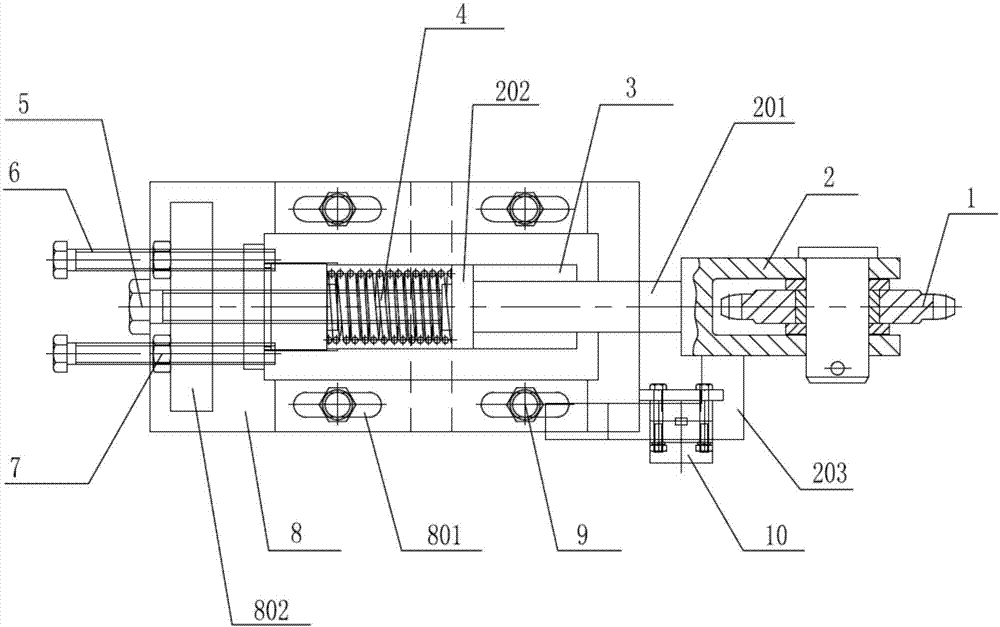

Tensioning chain wheel and chain breaking detection device

InactiveCN107120398AImprove safety and reliabilityAccurate detectionMachine gearing/transmission testingGearingAgricultural engineeringSprocket

A tensioning sprocket and a broken chain detection device, including a base, a sleeve device, a spring, a tensioning sprocket, a sprocket frame, a tensioning sprocket adjustment device, and a limit switch; the sleeve device includes a sleeve base and a sleeve The sleeve, the base of the sleeve is connected with the base; the spring is installed inside the sleeve; the tensioning sprocket is installed on the sprocket frame, the left end of the sprocket frame is provided with a sliding shaft, the sliding shaft is inserted into the right end of the sleeve, and the spring at the left end of the sliding shaft The right pressure plate is connected with the right end of the spring; the tensioning sprocket adjustment device includes a sprocket adjustment bolt, a screw plug, and a spring left pressure plate. The left end of the spring is connected; the limit switch is installed at the right end of the base; the front end of the sprocket frame is provided with a limit switch strike plate. The device of the invention can not only realize the function of chain rotation and tensioning the sprocket, but also can detect whether the transmission chain is detached or broken, thereby improving the safety and reliability of the chain transmission.

Owner:QINGDAO HAIXI HEAVY DUTY MASCH CO LTD

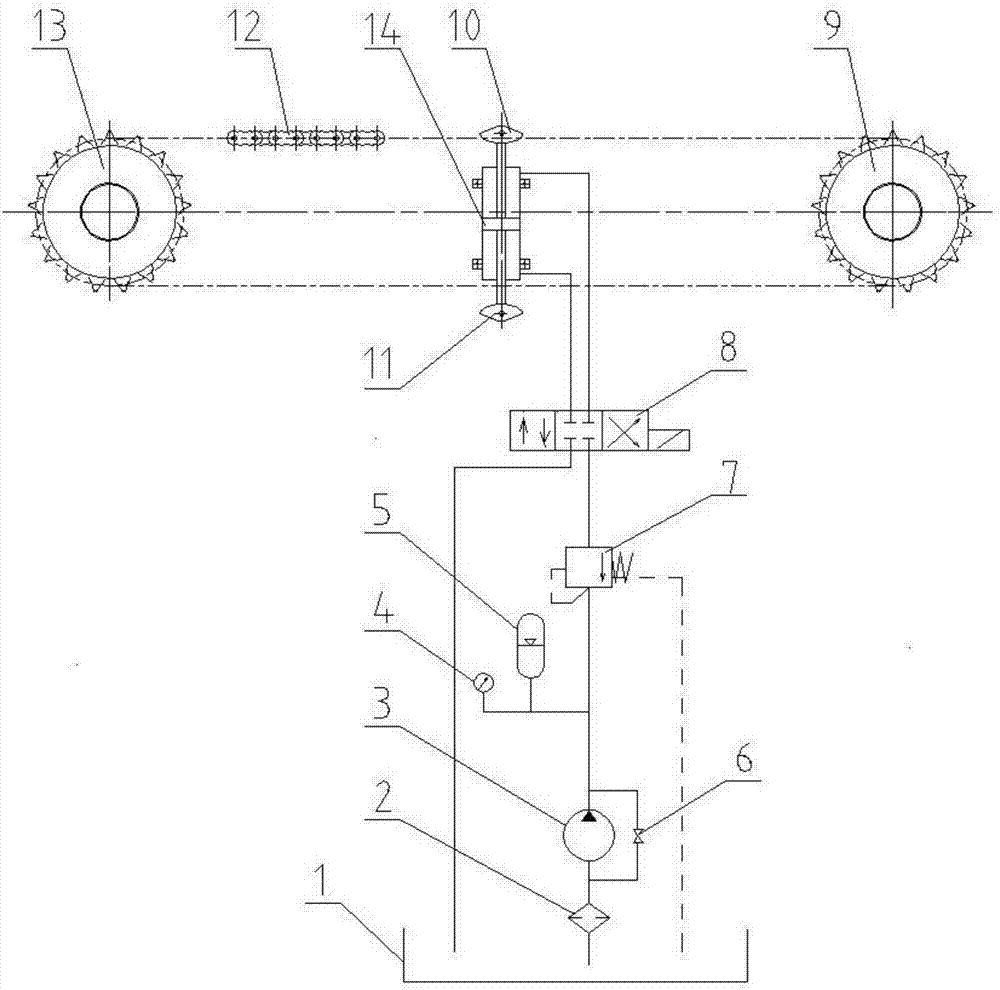

Forward-reverse-rotation transmission chain tensioning device and land leveler balance box

The invention relates to chain transmission and provides a forward-reverse-rotation transmission chain tensioning device in order to solve the problem that existing chain transmission is prone to generating tooth jumping and chain falling. The forward-reverse-rotation transmission chain tensioning device comprises a driving sprocket and driven sprockets which are rotatably connected through chains in the same direction and is characterized in that the forward-reverse-rotation transmission chain tensioning device further comprises upper tensioning sliding seats, lower tensioning sliding seats and two-way acting hydraulic oil cylinders; the two-way acting hydraulic oil cylinders push the upper tensioning sliding seats and the lower tensioning sliding seats to move in the perpendicular direction of the upper edges of the perpendicular chains, so that the upper tensioning sliding seats downwards compress the upper edges of the chains or the lower tensioning sliding seats upwards compress the lower edges of the chains; and the two-way acting hydraulic oil cylinders are connected with a chain tensioning control system. Engaged wrap angles of the chains and the driving sprocket are increased, the contact areas of the sprockets abraded after the long-term use and the chains are increased, when the chains are in forward-rotation transmission or reverse-rotation transmission, the phenomena such as shaking, skidding, floating, tooth jumping and chain falling of the transmission chains are overcome, the reliability of chain transmission is greatly improved, and the life of the chains is prolonged.

Owner:GUANGXI LIUGONG MASCH CO LTD

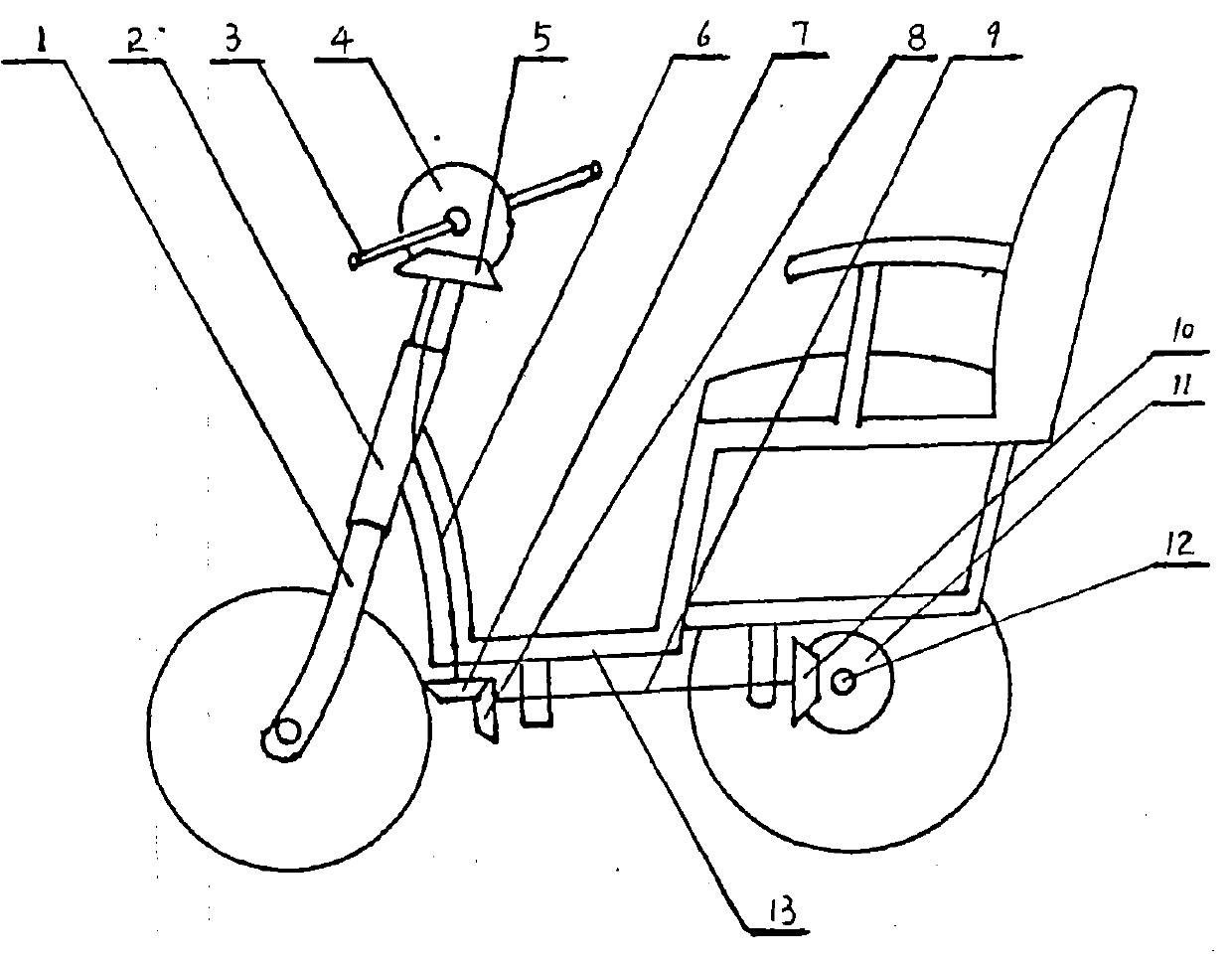

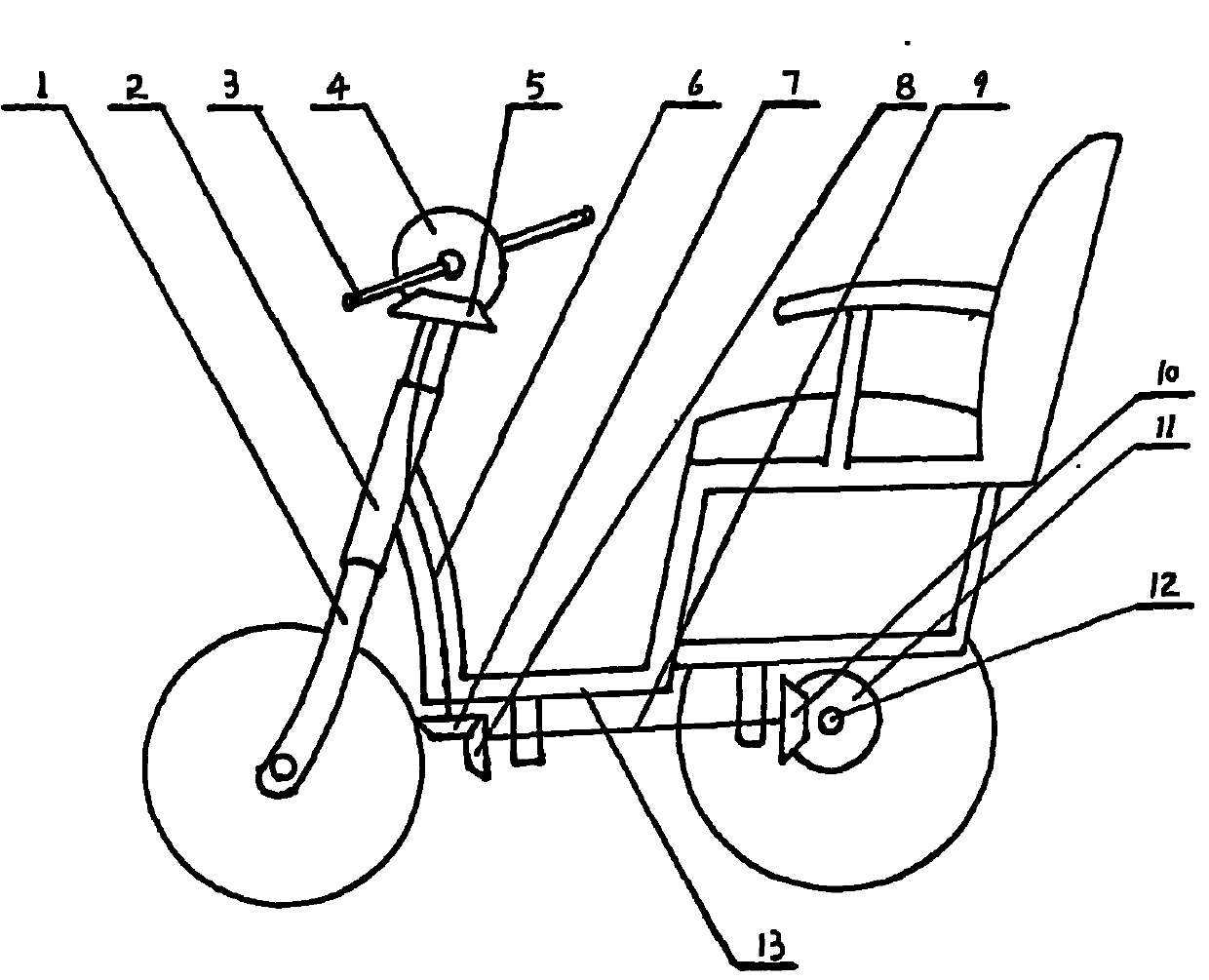

Transmission shaft type tricycle

InactiveCN101913405AEasy to useAdvance and retreat freelyWheel based transmissionRider propulsionDrive shaftGear wheel

The invention relates to a transmission shaft type tricycle comprising a rotary handle, a front fork shaft, a front fork frame which are sequentially connected, wherein the bottom end of the front fork frame is provided with a front wheel; the upper end of the front fork frame is connected with the rotary handle and a conical power input bevel gear through a rotary handle shaft; the conical power input bevel gear is sequentially connected with a conical power output bevel gear, a flexible transmission shaft which transmits vertically, a conical redirecting active bevel gear, a redirecting passive bevel gear, a horizontal transmission shaft, a conical axle active bevel gear and a conical axle passive bevel gear for rotation; the conical axle passive bevel gear is fixed between two rear wheels of the tricycle through horizontal axles; and a tricycle frame is positioned on the conical axle passive bevel gear. The transmission shaft type tricycle is free to advance or retreat when in use, is convenient to use, solves the problem of easy chain falling and has great popularization value.

Owner:于吉振

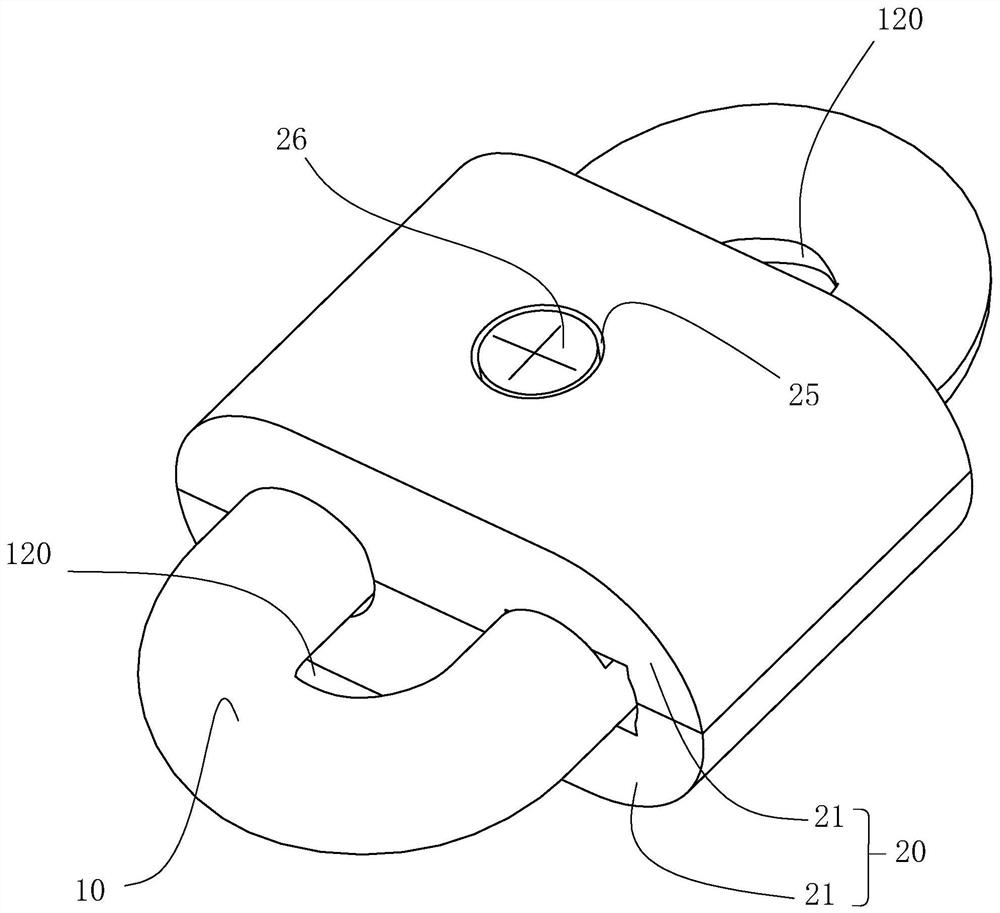

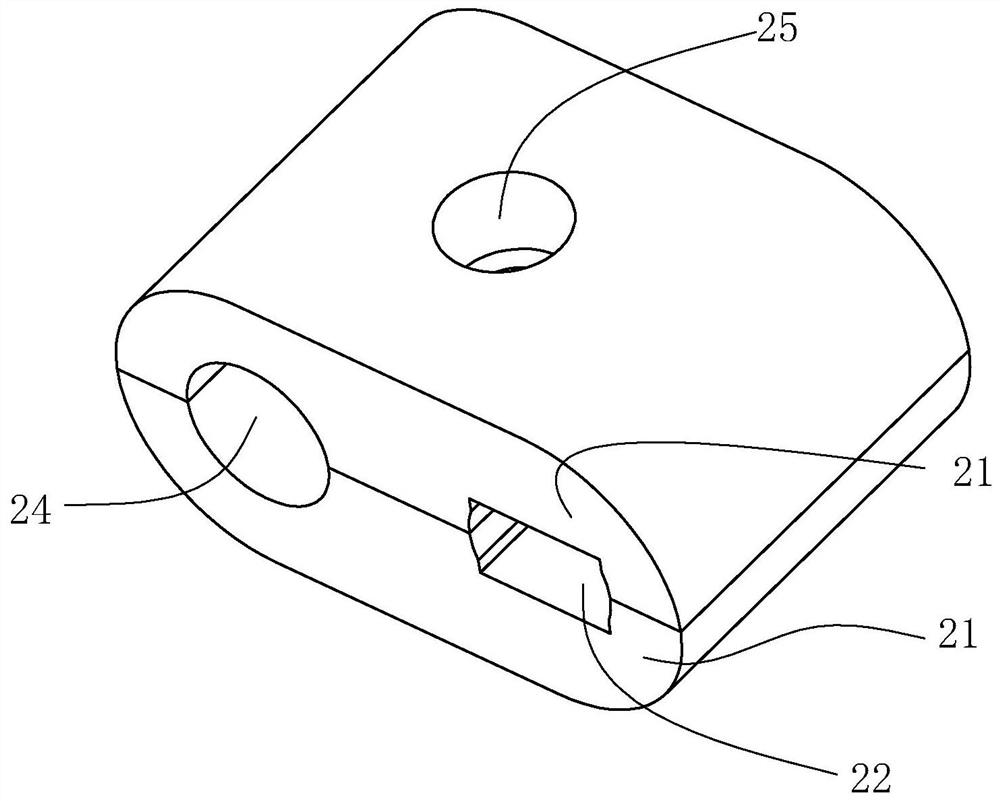

Connector used for connecting chains in series

The invention relates to a connector used for connecting chains in series. The connector used for connecting the chains in series comprises a connecting ring, the connecting ring is provided with an opening for allowing a chain link of an external chain to clamp into the connecting ring and hook parts positioned on two sides of the opening, the hook parts are used for being connected with the chain link of the chain, a gap space between two connecting ends of the connecting ring forms the opening, and the connector further comprises a locking piece detachably connected to the connecting ring.The locking piece can be connected with the two connecting ends of the connecting ring in a locking manner, so that the connecting ring is in a closed state at the opening position, and the two connecting ends of the connecting ring are locked together by the locking piece, so that the connecting ring is not easy to deform even if the connecting ring bears larger tension, the overall strength of the connector is effectively improved, and on the other hand, the locking piece is connected to the opening position of the connecting ring, so that the whole connecting ring is in a closed state, theproblem that the chain link of the chain fall off from the connecting ring is effectively avoided, and the use reliability of the connector is improved.

Owner:ZHEJIANG PUJIANG BOHU CHAIN

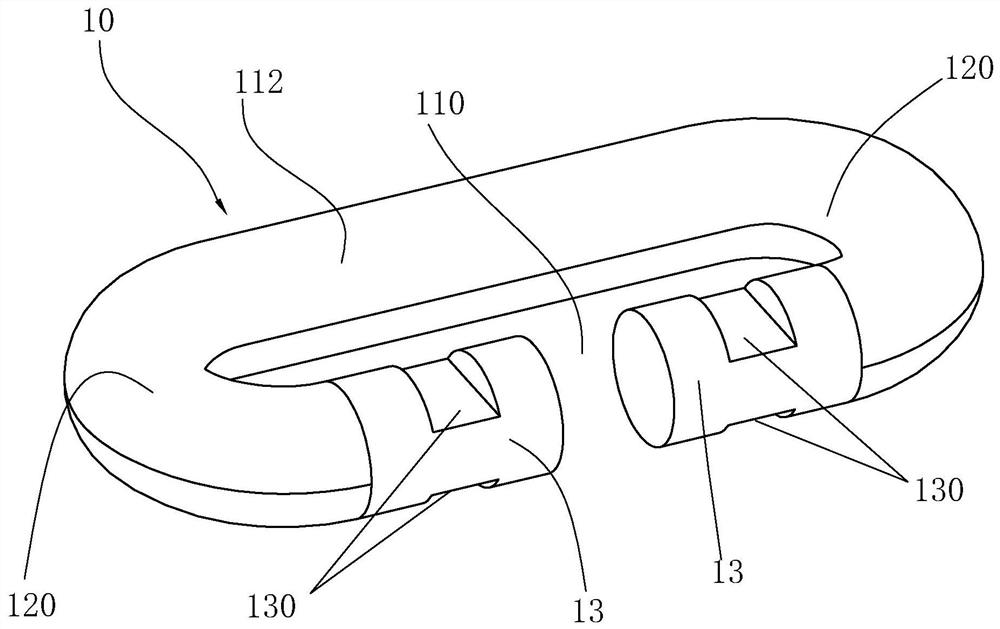

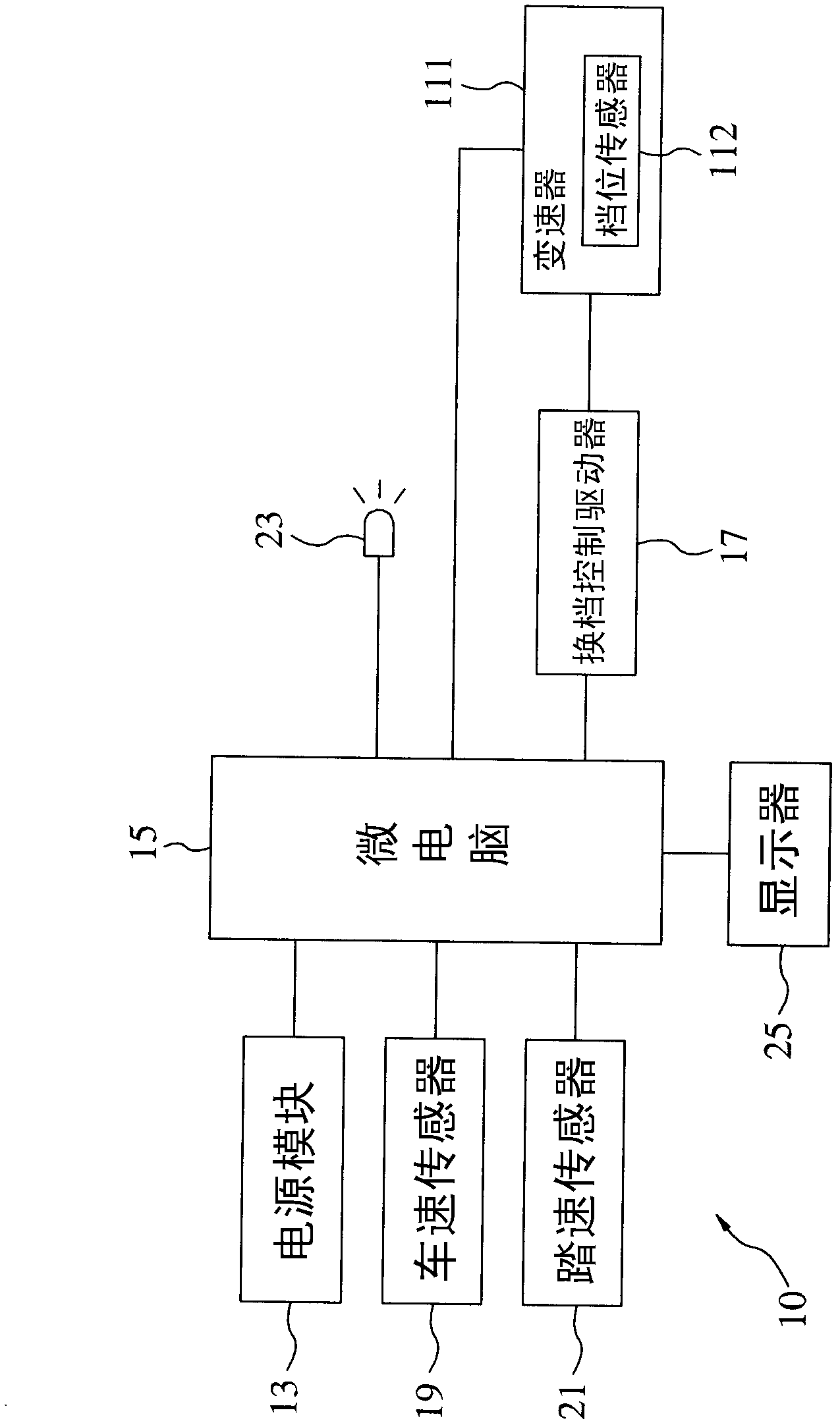

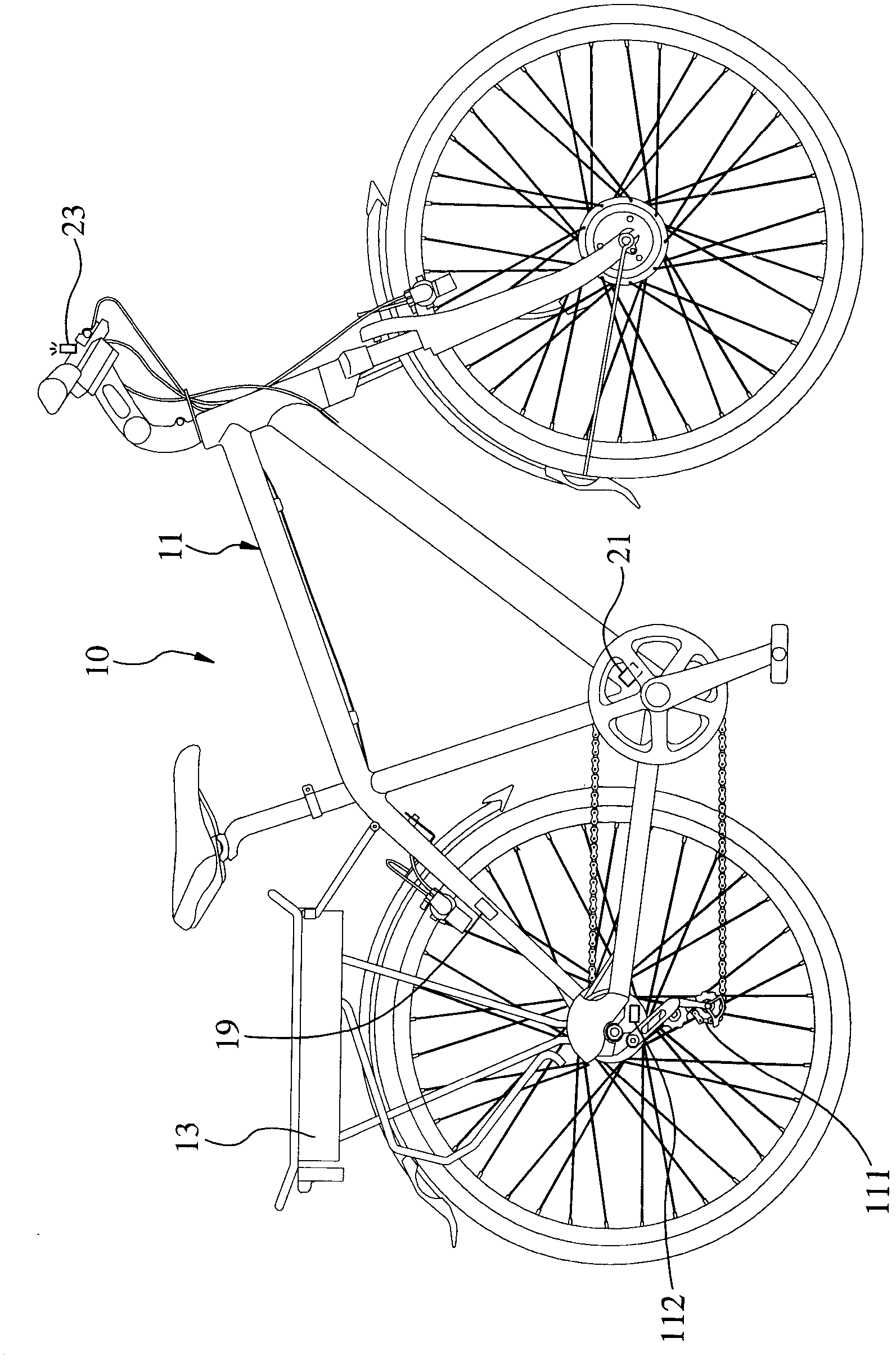

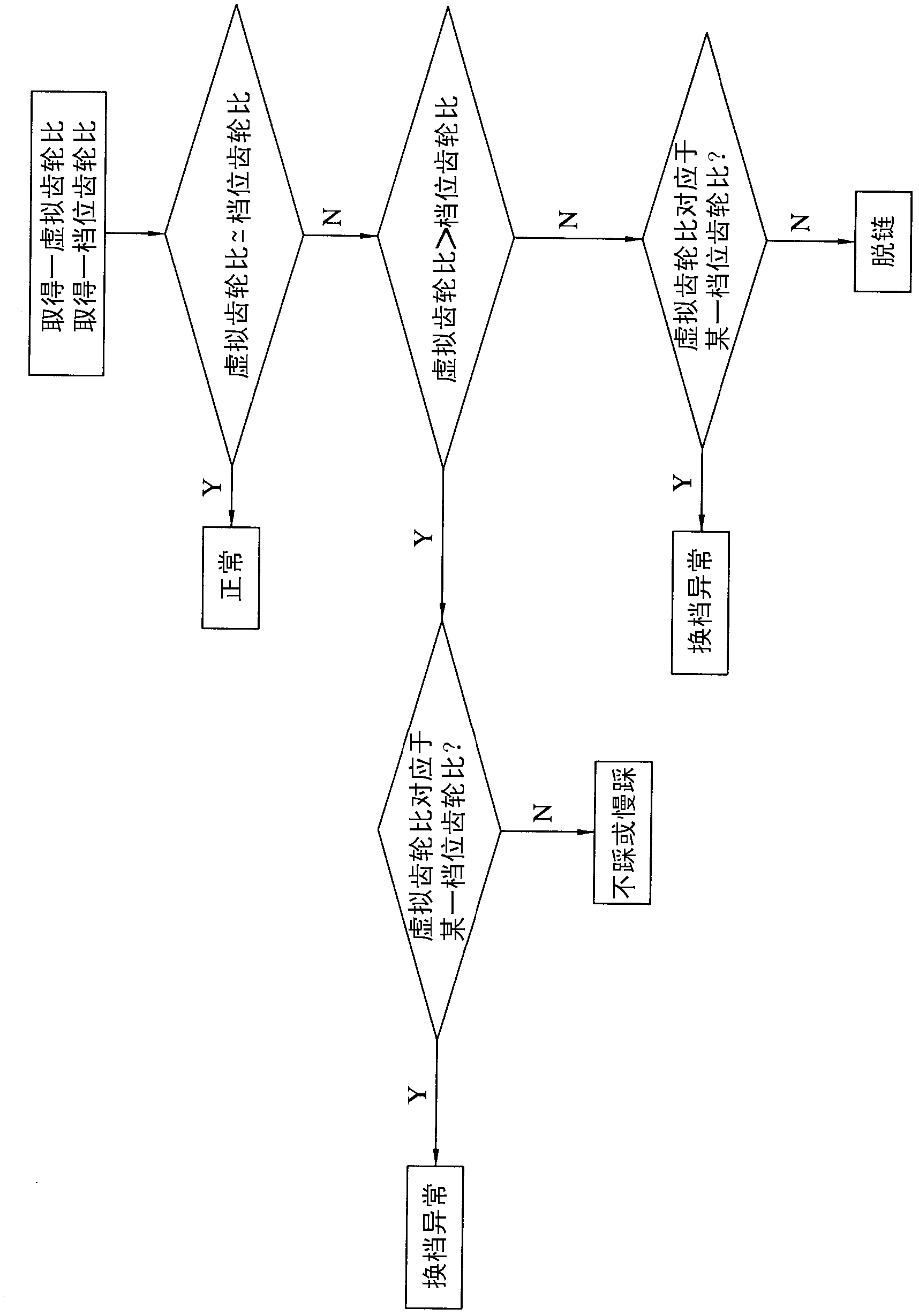

Variable-speed bicycle capable of identifying unusual conditions and identifying method of bicycle

The invention discloses a variable-speed bicycle capable of identifying unusual conditions and an identifying method of the bicycle. The bicycle comprises a transmission on the bicycle, a power supply module, a microcomputer, a gear check table which is stored inside the microcomputer, a gear shifting control driver, a vehicle speed sensor, a treading speed sensor and an alarming device, wherein gear identification is conducted through combination of the assemblies, during identification, the microcomputer obtains a virtual gear ratio through the ratio of the vehicle speed to the treading speed and inquires the gear check table according to actual gear information provided by the transmission to obtain a gear shifting-gear ratio, the microcomputer compares the virtual gear ratio with the gear shifting-gear ratio to determine whether gears are unusual or a chain falls down, and a rider is informed when unusual conditions occur.

Owner:J D COMPONENTS CO LTD

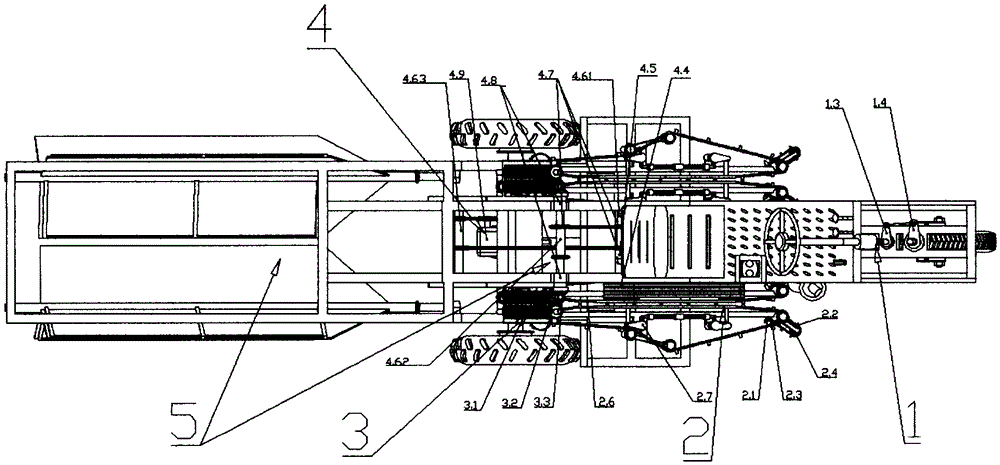

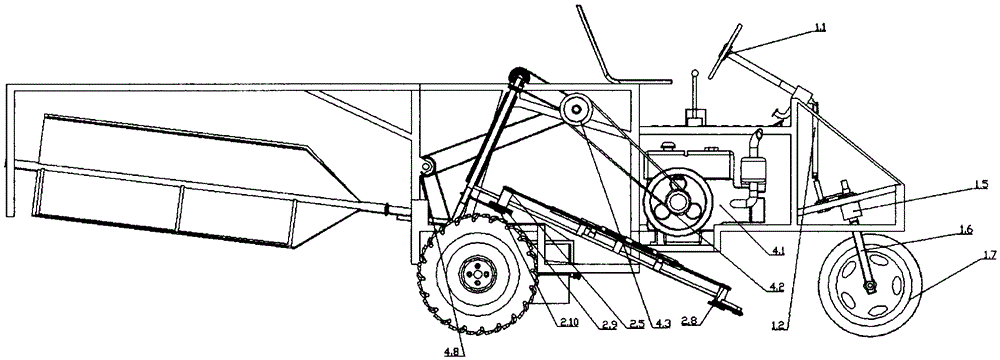

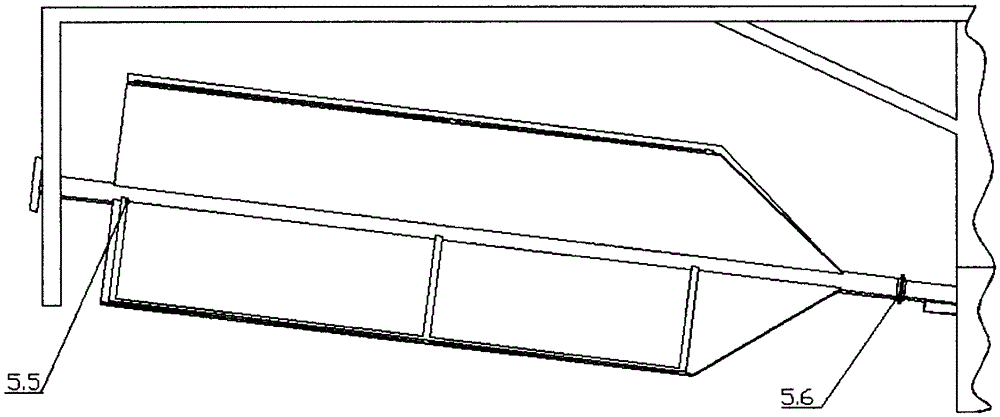

Sugarcane harvester

The invention relates to the technical field of agricultural machinery, particularity a sugarcane harvester. The sugarcane harvester comprises a frame, and a front wheel steering mechanism, a clamping and transporting part, a leaf peeling part, a power transfer system and a leaf and stick collecting and binding part which are mounted on the frame, wherein the leaf peeling part comprises a leaf peeling roll, a first gear and a bevel gear which are mounted in a bearing pedestal on the frame; the leaf and stick collecting and binding part comprises a box rack, a box body, a ratchet wheel, an active ratchet wheel, a sector plate, a first sprocket, a second gear and a sensor connector. By adopting the technical scheme, the sugarcane harvester provided by the invention has the beneficial effects that the sugarcane harvester is technically reasonable and is simpler in integral structure; the production cost is lowered; the work efficiency is improved; the height of the sugarcane harvester is reduced; the sugarcane harvester as a whole is compact in structure, small in size, stable to work and flexible to operate, and avoids phenomena of chain falling, chain cracking and grass entangling; by designing a leaf collecting box and a stick collecting mechanism by virtue of a sensor technology, the sugarcane harvester is advanced in technology and good in piling effect.

Owner:南宁市鼎天机械制造有限公司

Grille cleaner

The invention discloses a grille cleaner and relates to cleaning equipment. The grille cleaner mainly comprises a motor, a transmission mechanism, a chain belt, a driven guide wheel and a tooth harrow, wherein the motor is connected with the transmission mechanism; the transmission mechanism drives the chain belt; the chain belt is connected with the driven guide wheel under water; the tooth harrow is arranged on the chain belt and made of a nylon or stainless steel material; the interval of each two teeth of the tooth harrow is 1 mm; a full rotary grille surface is formed; a brush is arranged on an outer ring of the driven guide wheel; a baffle is arranged at the bottom of an underwater working region of the whole cleaner; a brush is arranged on the baffle and is in contact with the rotary grille surface; and the brushes are scrubbing brushes. The grille cleaner is simple in structure, reasonable in design, safe and reliable in operation, and good in effect; the brush on the baffle is used for primary protection; the brush on the outer ring of the driven guide wheel is used for secondary protection of the cleaner; and the phenomena of chain falling and blocking are prevented.

Owner:ANHUI TONGDU FLOW TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com