Patents

Literature

74results about How to "Improve hot water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-aromatic polyamide resin

ActiveCN101175791AImprove hot water resistanceGood chemical resistanceSynthetic resin layered productsThin material handlingResidenceAramides

The present invention provides a semi-aromatic polyamide resin having high residence stability, hot water resistance and chemical resistance and also having excellent adhesion property to and compatibility with other resin or the like. [MEANS FOR SOLVING PROBLEMS] The semi-aromatic polyamide resin has dicarboxylate units in which aromatic dicarboxylate units comprise 50 to 100 mol% of the dicarboxylate units and diamine units in which aliphatic diamine units having 9 to 13 carbon atoms comprises 60 to 100 mol% of the diamine units. In the resin, at least 10% of the terminal groups present in the molecular chain are end-capped with an end-capping agent, and the amount of the terminal amino groups present in the molecular chain falls within the range from 60 [mu]-equivalents / g to 120 [mu]-equivalents / g inclusive and satisfies the equation: [NH2] / [COOH]=6 wherein [NH2] ([mu]-equivalent / g) represents the amount of the terminal amino groups and [COOH] ([mu]-equivalent / g) represents the amount of the terminal carboxyl groups.

Owner:KURARAY CO LTD

Ethylene-vinyl alcohol resin composition, multilayer structure, multilayer sheet, container, and packaging material

ActiveUS20150159005A1Excellent appearance characteristicsHigh mechanical strengthSynthetic resin layered productsFood preservationAldehydeEthylene vinyl alcohol copolymer

The present invention provides a resin composition containing: an ethylene-vinyl alcohol copolymer (A) having an ethylene content of 20 mol % or more and 60 mol % or less; a polyamide resin (B); a carboxylic acid metal salt (C); and an unsaturated aldehyde (D), the mass ratio (A / B) of the ethylene-vinyl alcohol copolymer (A) to the polyamide resin (B) being 60 / 40 or more and 95 / 5 or less, the content of the carboxylic acid metal salt (C) with respect to a resin content in terms of a metal element equivalent being 1 ppm or more and 500 ppm or less, and the content of the unsaturated aldehyde (D) with respect to the resin content being 0.05 ppm or more and 50 ppm or less.

Owner:KURARAY CO LTD

Absorbing material preparation method based on amination reinforced modified straw

InactiveCN103418353AImprove stabilityImprove heat resistanceOther chemical processesMaterials preparationSpecial design

The invention relates to an absorbing material preparation method based on amination reinforced modified straw. Through the special design of the technological steps of straw raw material fermentation pre-processing, cation-type modification processing, anion-type modification processing, alkalization, crosslink preparing and the like and the special optimization of relative parameters, the absorbing material preparation method solves the technical problem that through the methods like single ion modification in the prior art, an absorbing material which meets the requirement of absorbing performance is difficult to obtain, and has the advantages that straw materials are good, the absorbing quantity is large, the absorbing speed is high, the technological process cost is low, the technological operation is simple and the method is applicable to industrialized production and cannot generate secondary pollution.

Owner:SUZHOU ZHENGYECHANG INTELLIGENT TECH

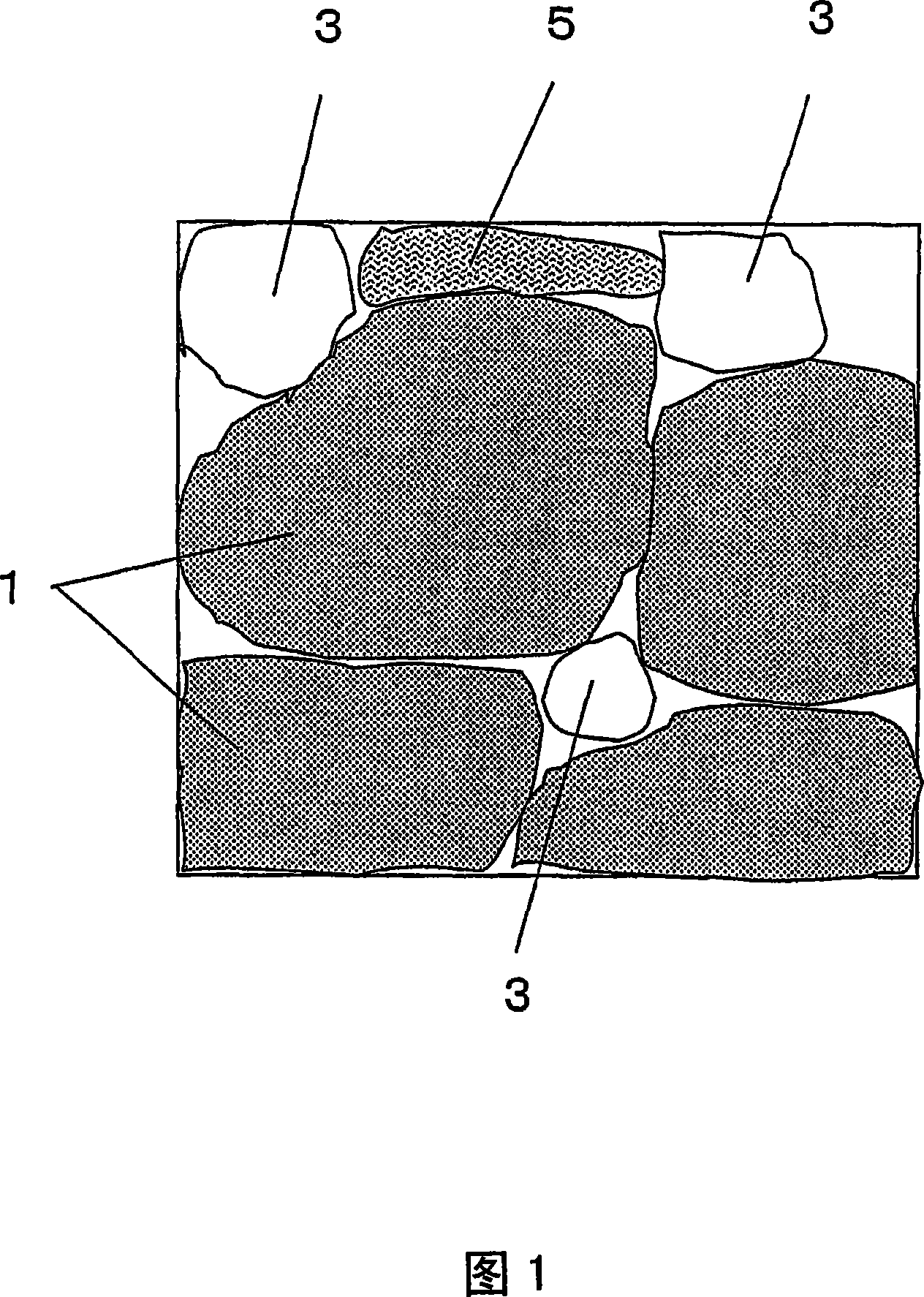

Composite ceramic and method for producing same

Disclosed is a composite ceramic which is composed of a bulk alumina crystal phase (A) having an aspect ratio of not more than 3, a bulk zirconia crystal phase (B) having an aspect ratio of not more than 3 and a columnar crystal (C) of a complex oxide containing an alkaline earth metal and aluminum element which has an aspect ratio of more than 3. This composite ceramic has excellent flexural strength, excellent toughness, high hardness, excellent hot water resistance, and high transverse strength after thermal degradation resistance test.

Owner:KYOCERA CORP

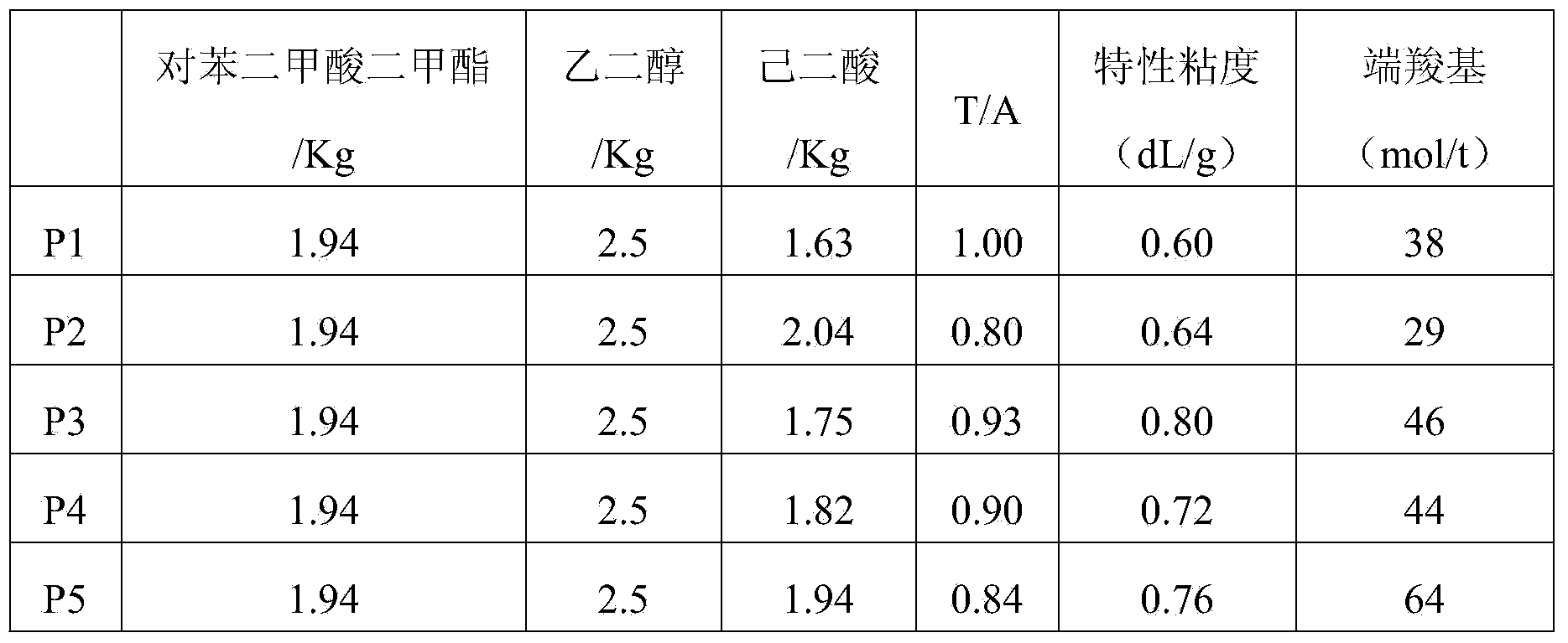

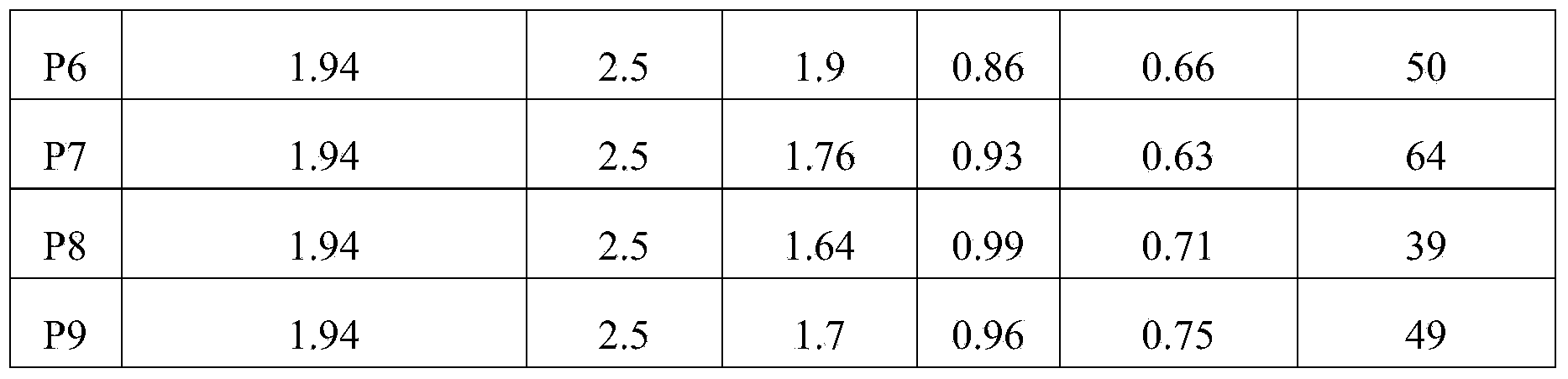

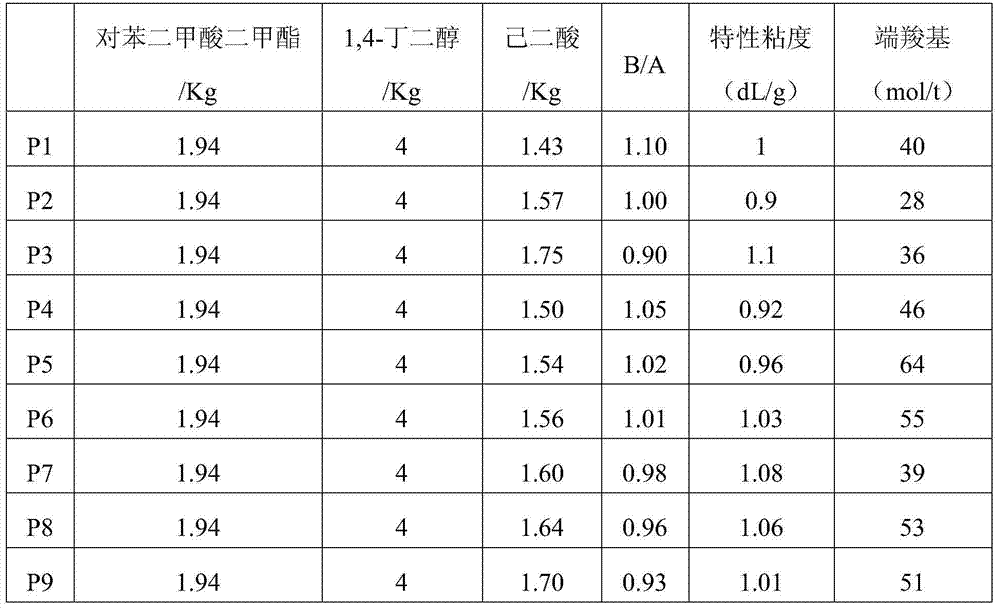

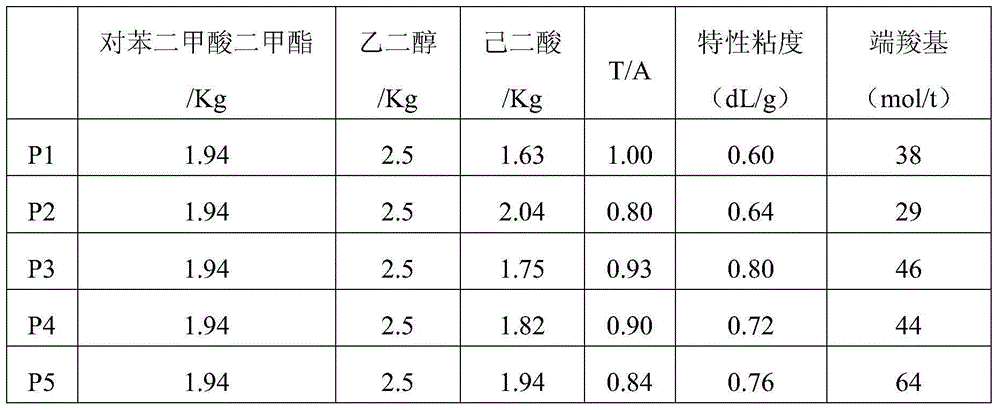

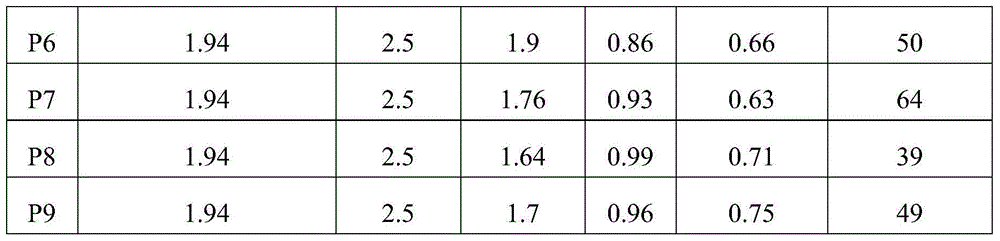

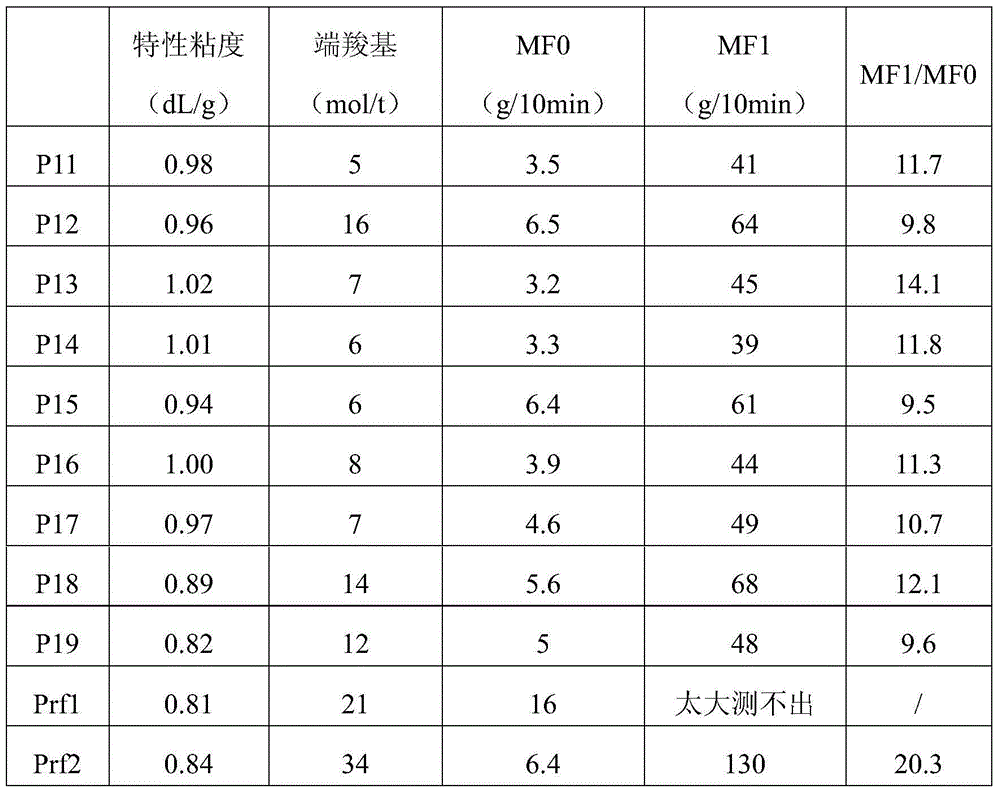

Modified PET copolyester and preparation method and application thereof

The invention belongs to the technical field of polyester preparation, and discloses a modified PET copolyester with high viscosity and a low terminal carboxyl group and a preparation method and application thereof. The copolyester contains the following ingredients in parts by weight: 100 parts of low-viscosity PET copolyester, 0.8-2.0 parts of oxazoline compound and 0.6-2.0 parts of a hydroxyl chain extender. The method prepares the high-viscosity modified PET copolyester by adding the oxazoline compound and the hydroxyl chain extender. The oxazoline compound is added to react with the terminal carboxyl group in resin, the terminal carboxyl group content of resin is reduced, therefore, the hot water resisting performance of resin is increased. The hydroxyl chain extender is added, the molecular weight of resin is increased, and the balance between a physical performance and a processing performance is achieved. The viscosity and the melt strength of the modified PET copolyester are increased, the content of terminal carboxyl group is reduced, and the hot water resisting performance is greatly increased. Moreover, the production method shortens the polycondensation time and the production cycle, effectively reduces the thermal degradation reaction, and also increases the output of equipment.

Owner:KINGFA SCI & TECH CO LTD

Coating composition

InactiveUS20110304817A1Avoid crackingImprove hot water resistanceCoatingsOptical partsOrganic solventMicroparticle

[Problem] To provide a coating composition for forming a hard coating which, by itself, favorably adheres to a plastic optical substrate, and effectively prevents the occurrence of cracks caused by the thermal hysteresis at the time of curing.[Means for Solution] The coating composition for forming a hard coating, contains a fine inorganic oxide particle, a hydrolyzable organosilicon compound, water, a curing catalyst and an organic solvent, wherein cyclic ketone is contained in an amount of 0.10 parts by mass to 30.00 parts by mass per 100 parts by mass of the total of the fine inorganic oxide particle and the hydrolyzable organosilicon compound.

Owner:TOKUYAMA CORP

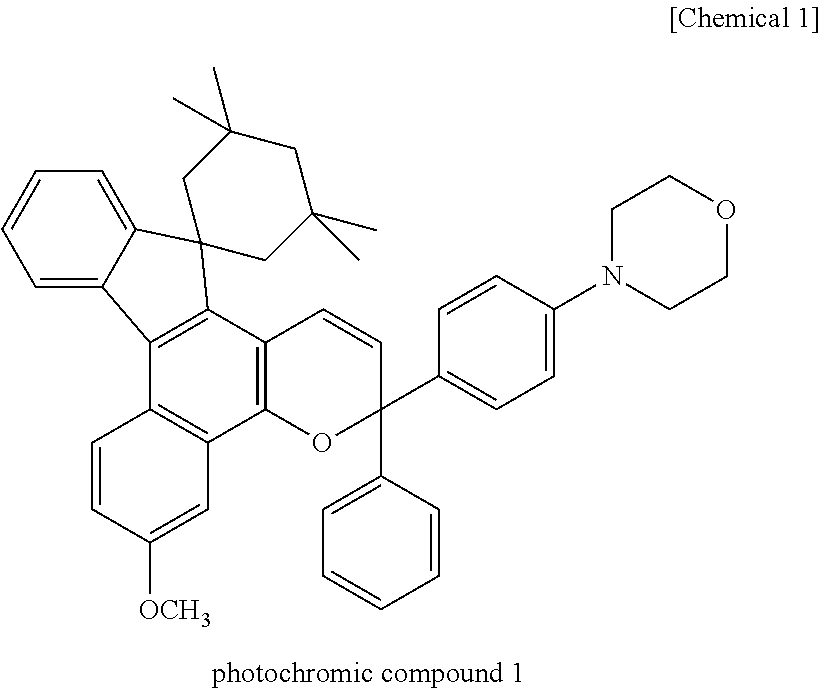

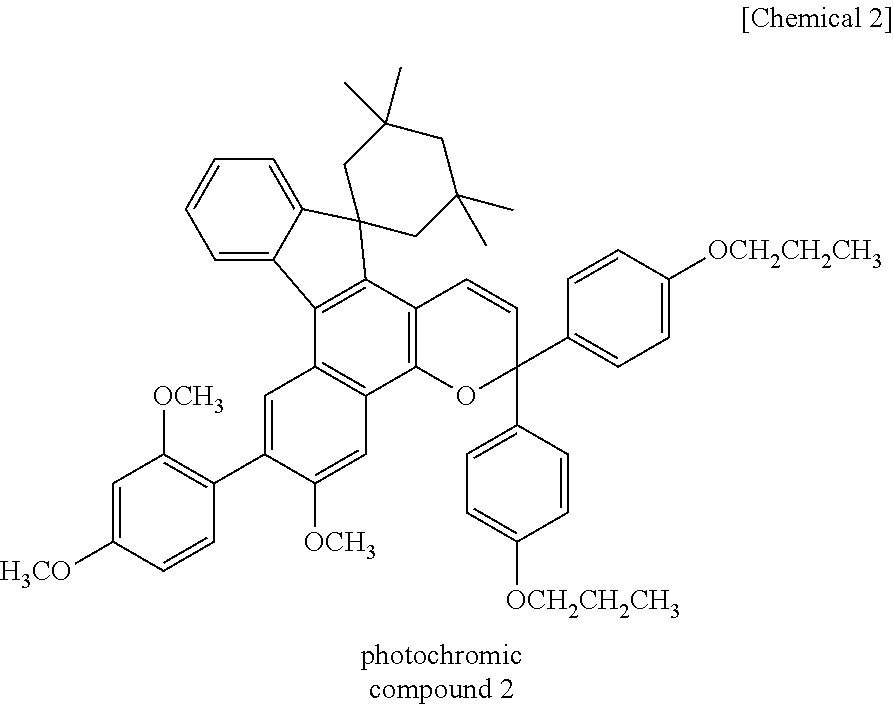

Modified aliphatic-aromatic copolyester and its preparation method and use

The invention belongs to the technical field of polyesters and discloses a modified aliphatic-aromatic copolyester having high viscosity and low carboxyl end group content and its preparation method and use. The modified aliphatic-aromatic copolyester comprises, by weight, 100 parts of a low-viscosity aliphatic-aromatic copolyester, 0.5-3 parts of an oxazoline compound and 0.4-2.5 parts of a hydroxyl chain extender. Through use of the oxazoline compound and the hydroxyl chain extender, the modified aliphatic-aromatic copolyester is prepared. The used oxazoline compound and the carboxyl end group in the resin undergo a reaction so that resin carboxyl end group content is reduced and resin hot-water resistance is improved. Through use of the hydroxyl chain extender, resin molecular weight is improved and the balance of physical properties and processing properties is realized. Viscosity and the melt-strength of the modified aliphatic-aromatic copolyester are improved, carboxyl end group content is reduced and hot-water resistance is improved. The preparation method has a short production period, reduces polycondensation time and effectively reduces thermal degradation reactions.

Owner:KINGFA SCI & TECH CO LTD

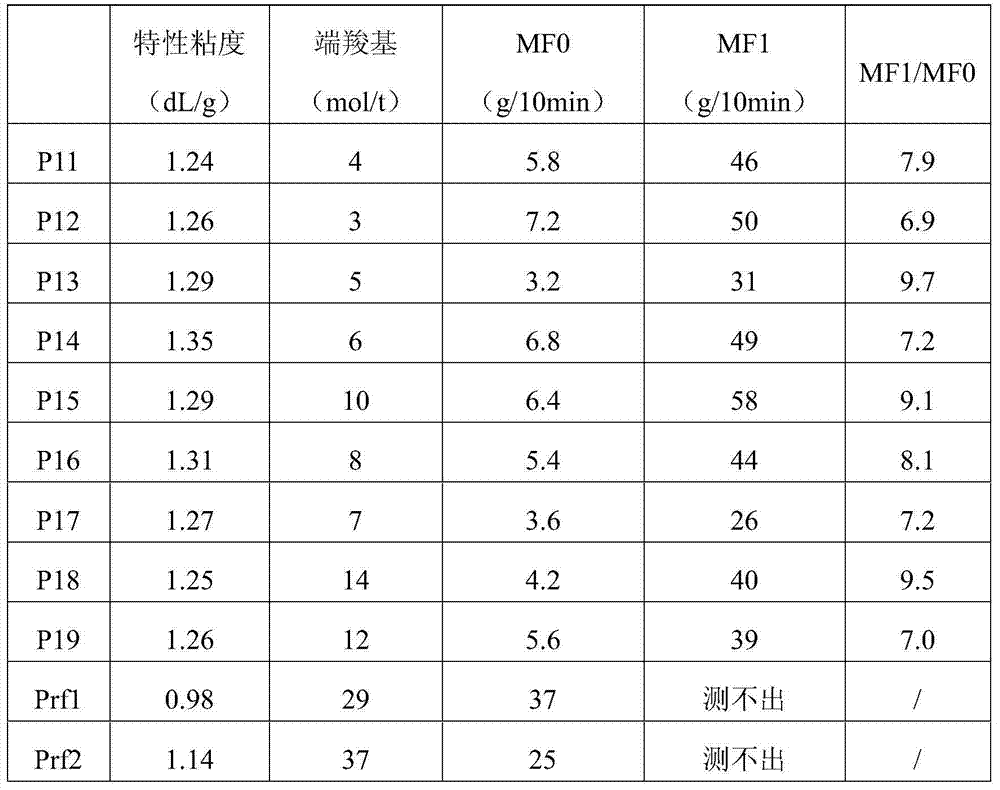

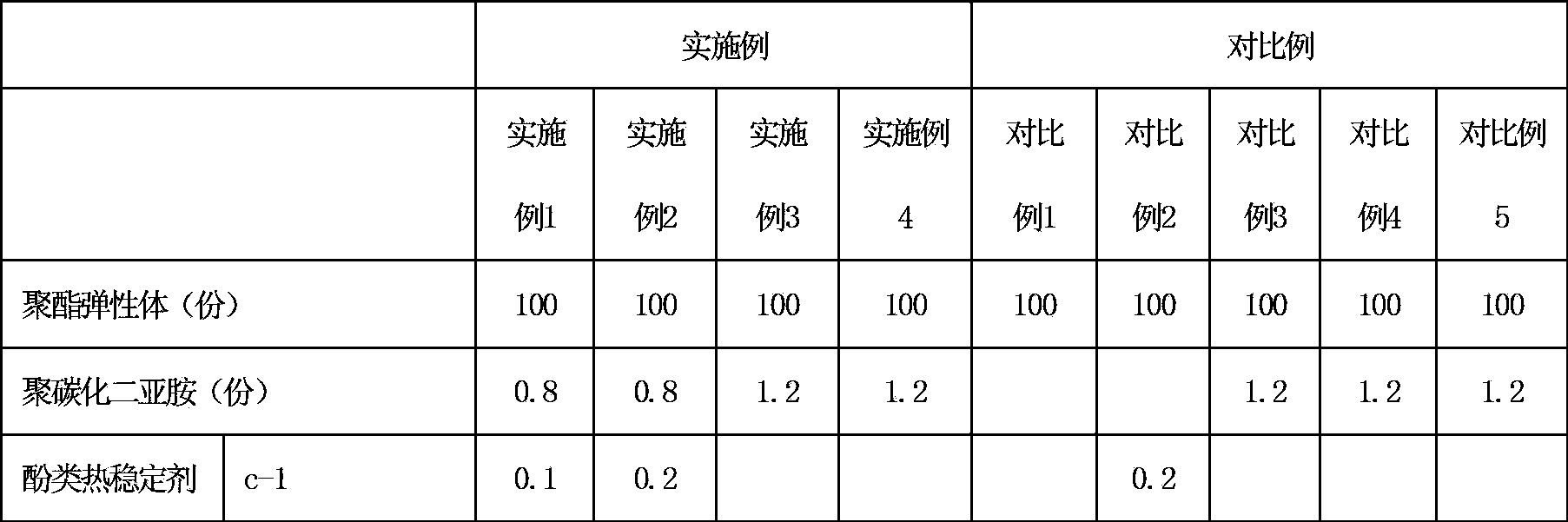

Hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition

The invention provides a hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition including 100 parts by weight of polyester elastomer (A); 0.01-10 parts by weight of poly carbodiimide (B); 0.01 to 0.5 part by weight of a phenolic heat stabilizer (C); 0.01 to 0.5 part by weight of a thio ester heat stabilizer (D); and 0.01 to 0.5 part by weight of an aromatic amine heat stabilizer (E). The hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition still can effectively maintain the tensile strength and elongation at break in the long time exposure to hygrothermal environment, after 90 days of hydrolysis resistance test of the composition dipping in hot water at the temperature of 95 DEG C, the tensile strength is maintained above 25Mpa, the elongation at break is remained above 482%; and after 168h of heat resistance test at the temperature of 158 DEG C, the tensile strength is maintained above 81%, so that the hydrolysis resistant high temperature resistant thermoplastic polyester elastomer composition can be applied in higher-end areas.

Owner:SINOTEX INVESTMENT & DEV CO LTD

Modified epoxy acrylate resin weather-proof exterior wall coating

The invention discloses a modified epoxy acrylate resin weather-proof exterior wall coating, which comprises raw materials with part by weight: modified epoxy acrylate resins 78 parts, polystyrene rubbers 41 parts, mica powder 7.5 parts, nanometer titanium dioxide 5.5 parts, nanometer magnesium hydroxide 3 parts, organophilic bentonite 2.5 parts, nanometer sea-foam stone powder 2 parts, diatomaceous earth 5.5 parts, talcum powder 6 parts, modified attapulgite 4 parts, titanate coupling agents 3 parts, styrene-acrylic emulsions 18 parts, chlorinated paraffin 2 parts, ethylene glycol 3.5 parts, 2,2,4-Trimethyl-1,3-pentanediolmono(2-methylpropanoate) 6 parts, sodium tripolyphosphate 4.5 parts, butyl acrylate resins 3.5 parts, ammonium dihydrogen phosphate 2 parts, diphenylamine 6 parts, deionized water 36 parts, carbamide 14 parts, polyacrylamide 9 parts, propylene glycol methyl ether acetate 6 parts, polyether modified polyester organic siloxane 5 parts and antioxidant trinitrophenyl groups (TNP) 7.5 parts. The modified epoxy acrylate resin weather-proof exterior wall coating has excellent water resistance, cohesive property and weather-proof performance.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

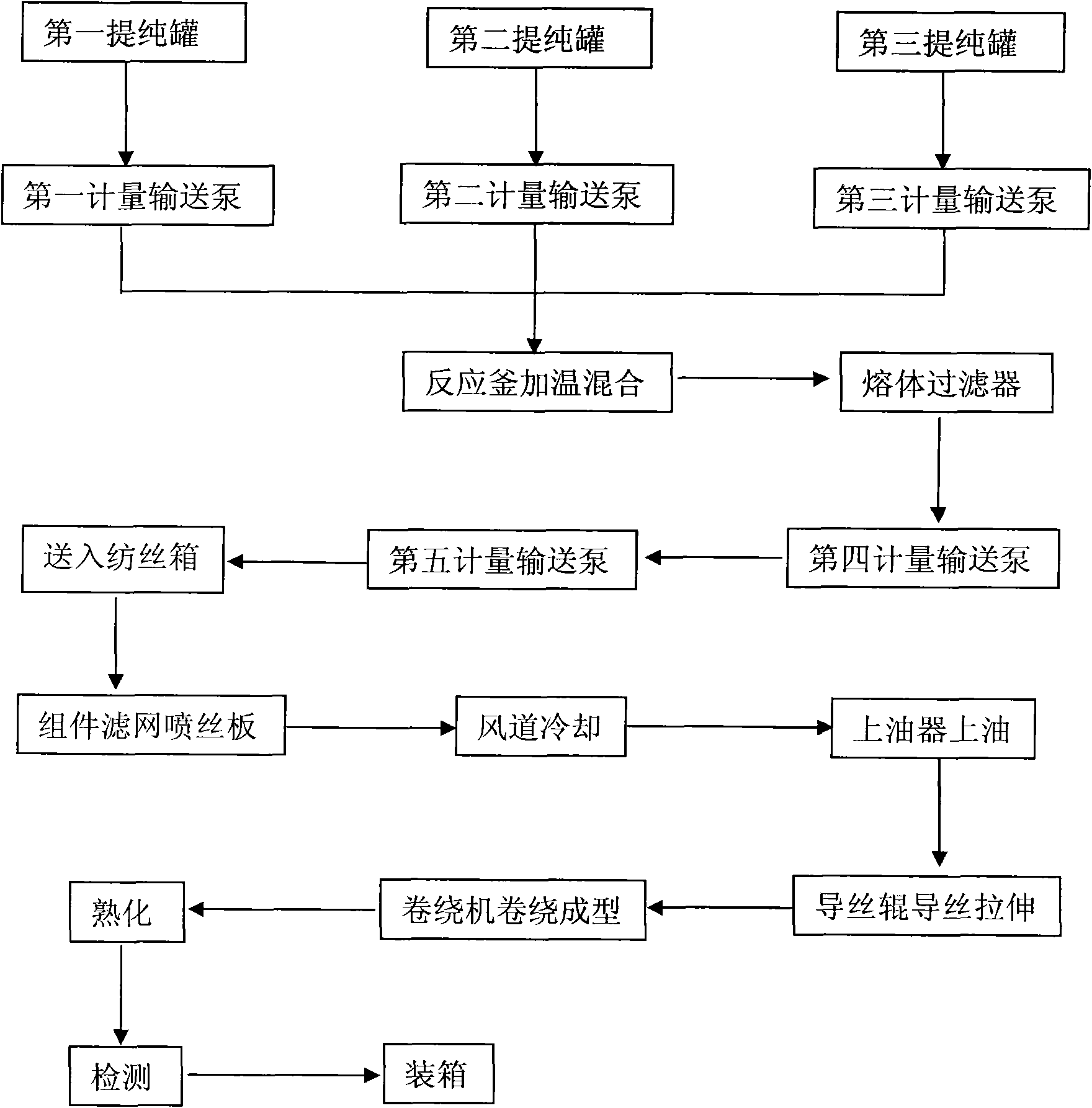

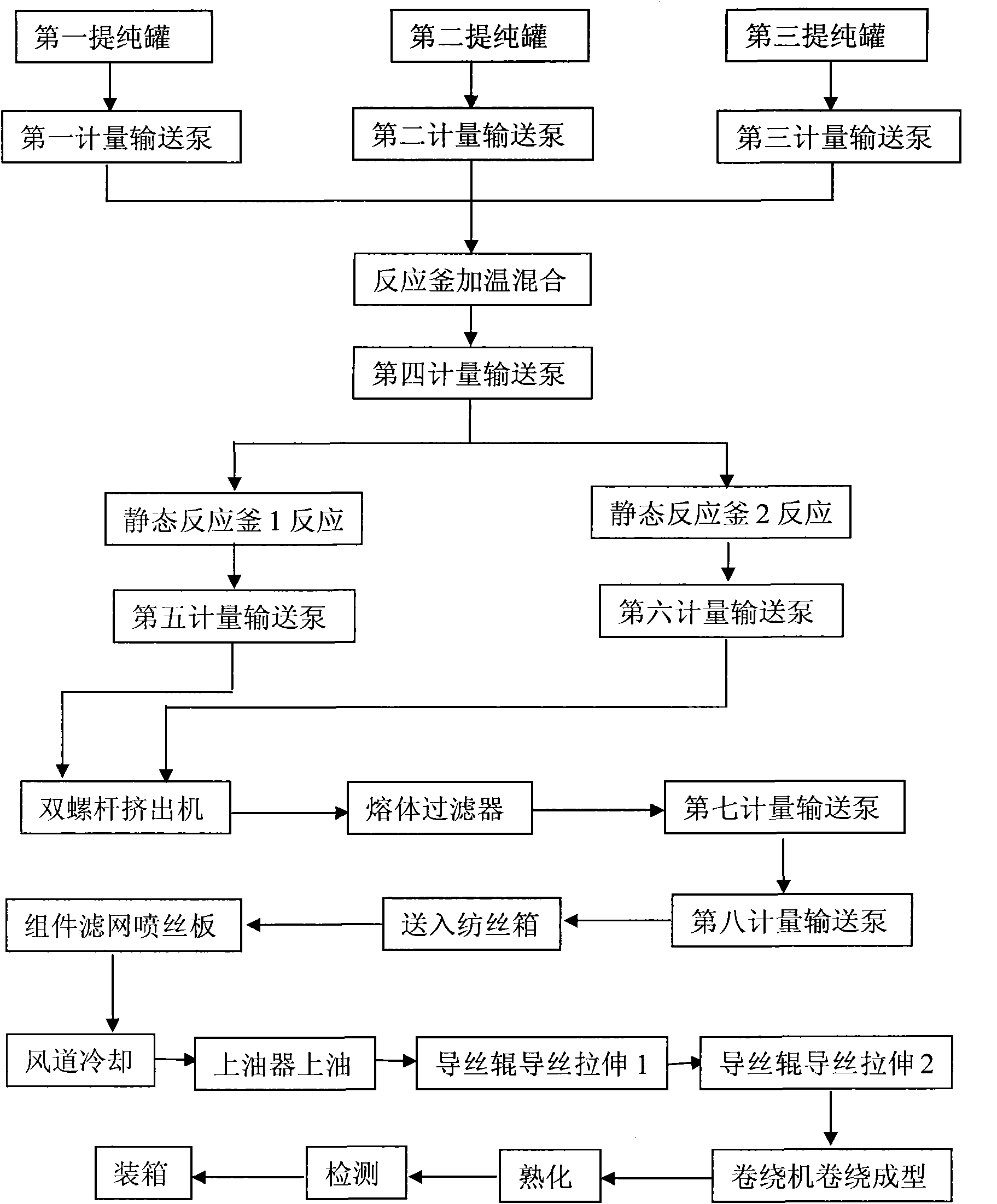

A processing process of high-modulus low-shrinkage high-colour-fastness polyester filament yarn by direct melt spinning and real-time injection

ActiveCN104294393AImproved elongation and uniformityLow bending stiffnessMelt spinning methodsFilament-forming treatmentLow modulusMelt spinning

The invention relates to a processing process of high-modulus low-shrinkage high-colour-fastness polyester filament yarn by direct melt spinning and real-time injection. By the special design of steps including subjecting a polyester raw material to shrinkage reducing processing, performing modulus-increasing blending and melting melt processing, performing low-frequency real-time compression and injection, subjecting the melt to multi-stage direct-melting and spinning, passing through a filter screen, spinning, cooling, applying oil, stretching, and the like, and by special optimization of related parameters, the technical difficult problems of fiber in the prior art, namely low modulus, low strength and poor natural-color fasteness are overcome, and the objective of purification, high color fasteness, high modulus and low shrinkage is achieved. Under the obvious improvement on the high color fasteness, the high modulus and the low shrinkage which are good properties, stability, thermal resistance, resistance to hot water, elasticity resilience, elongation and homogeneity are largely improved.

Owner:福建百宏聚纤科技实业有限公司

Modified gelatin fiber

ActiveCN106591992AImprove mechanical propertiesSimple processMonocomponent protein artificial filamentCellulose/protein filament chemical after-treatmentSolventMechanical properties of carbon nanotubes

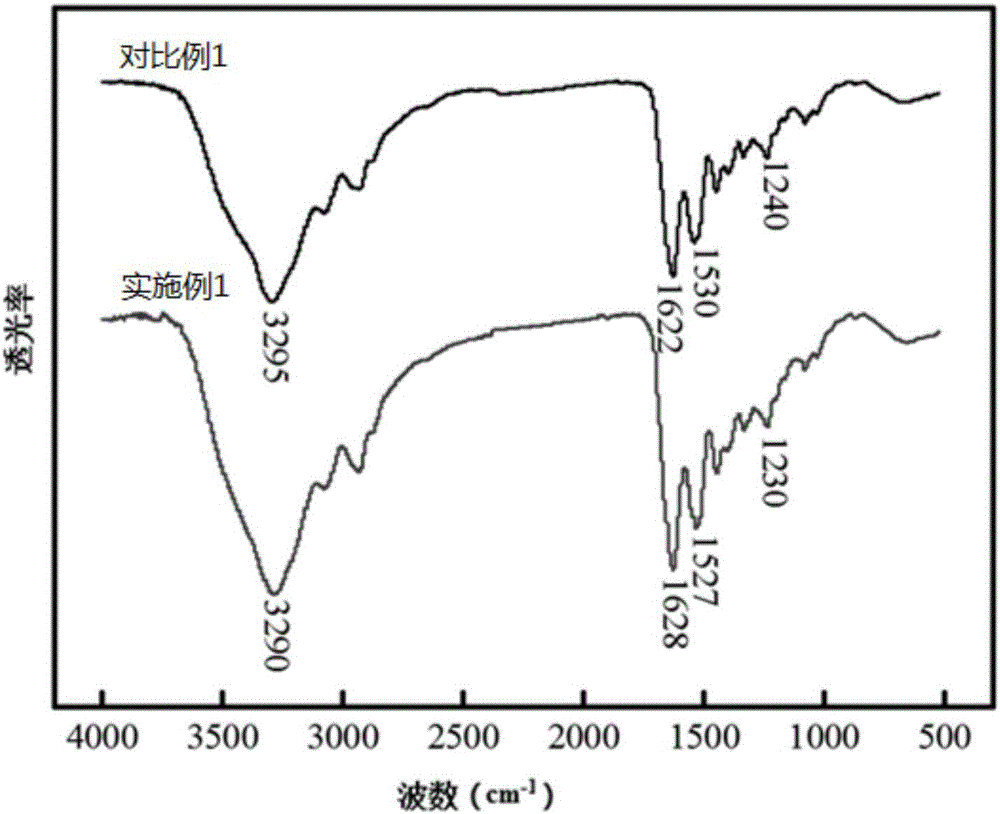

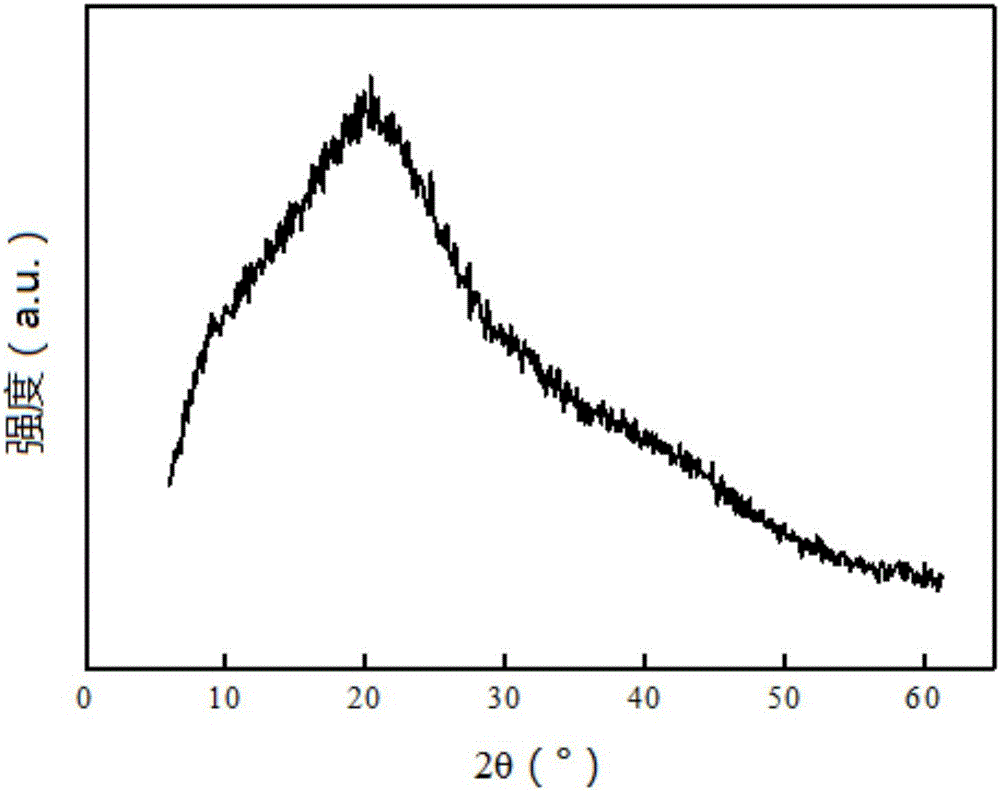

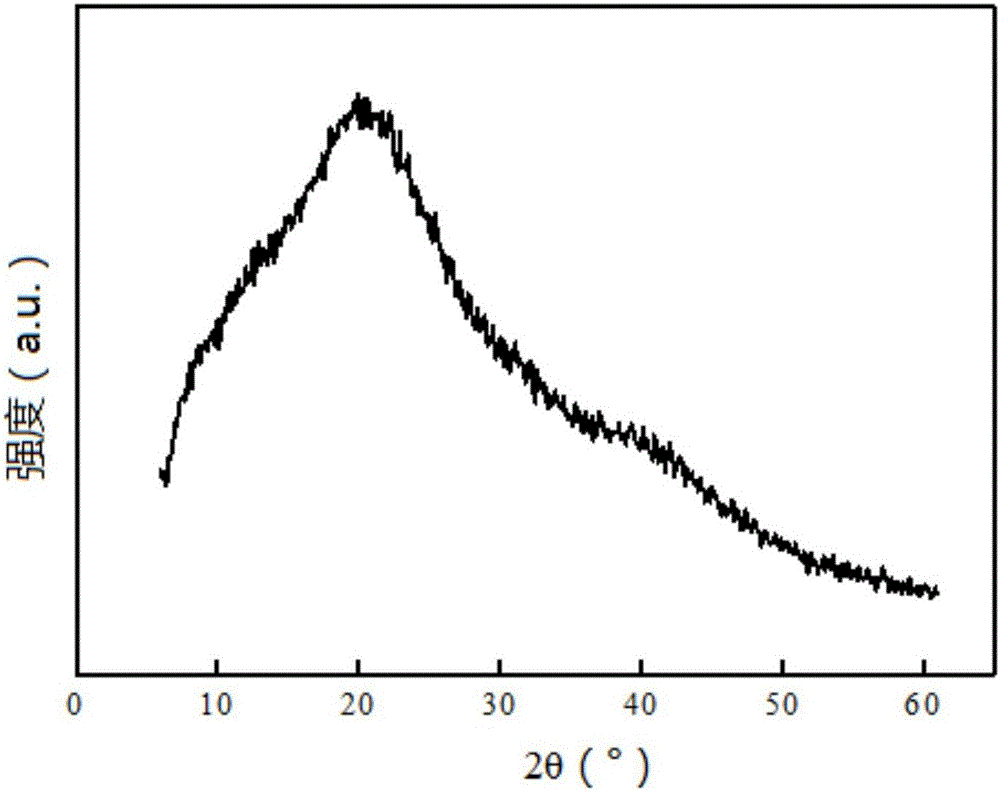

The invention discloses a modified gelatin fiber. Characteristic absorption peaks appear nearby 3290 cm<->, 1628 cm<->, 1527 cm<-> and 1230 cm<-> in the infrared spectrum of the gelatin fiber. The gelatin fiber is prepared by dissolving gelatin in a solvent for swelling and then to mixing with a cross-linking agent, then adding a mixed material obtained in the previous step into spinning equipment so as to obtain nascent fiber, and subjecting the nascent fiber to aftertreatment. According to the invention, transglutaminase is used as the cross-linking agent which is safe to use; and the prepared gelatin fiber has good stability in water and improved mechanical properties and is applicable to the fields of biology and medicine.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Composite material and preparation method thereof

The invention relates to a composite material and a preparation method thereof. The preparation method comprises the steps of slowly adding the following components in parts by weight: 80-90 parts of amination-enhanced modified straw, 1-10 parts of oxidized graphene and 1-10 parts of cyclodextrin into deionized water with the bath ratio of 1 to (10-20), and carrying out ultrasonic treatment for 1-24h; and then, carrying out freeze drying to obtain the amination-enhanced modified straw / oxidized graphene / cyclodextrin composite material. According to the invention, the amination-enhanced modified straw / oxidized graphene / cyclodextrin composite material is prepared by loading oxidized graphene and cyclodextrin on the amination-enhanced modified straw serving as a carrier, and then, carrying out freeze drying. The composite material has the advantages of environmental friendliness, good mechanical property, regular structure, high porosity and adsorption capacity, high adsorption speed, wide application range, simplicity in desorption, reutilization and the like.

Owner:桐乡市建春塑业股份有限公司

Anti-ultraviolet and anti-aging powder coating added with nano titanium dioxide

InactiveCN105462452AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPowdery paintsSilanesExtinction

The invention discloses an anti-ultraviolet and anti-aging powder coating added with nano titanium dioxide. The powder coating is prepared from the following raw materials: 52-54 parts of hydroxy polyester resin, 7-8 parts of fluorocarbon resin, 4-5 parts of triglycidyl isocyanurate, 13-15 parts of nano-aluminum oxide, 0.8-0.9 part of perfluorooctyl triethoxysilane, 25-30 parts of an ethanol solution with the concentration of 75wt%, 0.5-0.6 part of a silane coupling agent kh560, 15-17 parts of rutile type nano titanium dioxide, 0.2-0.25 part of an aluminum coupling agent F1, 3-4 parts of extinction micronized wax, 0.8-1 part of amorphous silica, 1.5-2 parts of carboxymethyl cellulose, 4-5 parts of low-melting glass powder and a proper amount of deionized water. In the preparation of the powder coating, the aluminate coupling agent-modified rutile type nano titanium dioxide is additionally added, so that the weatherability and the hydrophobicity are improved; the powder coating is used for corrosion protection of an outside pump valve, and has an excellent anti-aging effect.

Owner:TONGLING SIDE TECH

Epdm composition

InactiveUS20070021565A1Uniform characteristicsImproved compression set characteristicEngine sealsOther chemical processesVulcanizationCompression set

An EPDM composition, which comprises a blend rubber comprising 100 parts by weight of blend rubber consisting of 20-80% by weight of EPDM containing 5-ethylidene-2-norbornene [ENB] as one type of diene component and 80-20% by weight of EPDM containing dicyclopentadiene [DCPD] as another type of diene component, and 0.5-10 parts by weight of an organic peroxide. Seal parts obtained by vulcanization molding of the EPDM composition show well balanced characteristics, even if dipped in hot water at high temperatures such as 200° C. for 500 hours or 300° C. for 24 hours, particularly with improved compression set characteristics.

Owner:NOK CORP

Formalizing method of high-strength and high-modulus polyvinyl alcohol fiber

InactiveCN101812744AIncreased elongationImprove hot water resistanceSynthetic polymer filament chemical after-treatmentPolymer scienceFiber bundle

The invention discloses a formalizing method of high-strength and high-modulus polyvinyl alcohol fiber, which comprises the following steps: (1) preparing a swelling medium: dissolving 1-50 parts by weight of additive in 100 parts by weight of water and stirring to obtain the swelling medium; (2) pre-swelling the fiber: feeding the polyvinyl alcohol fiber bundle into the swelling medium to be swelled, wherein the temperature of the swelling medium is 20-80 DEG C and the swelling time is 10 to 60 minutes; and (3) formalizing the swelling fiber bundle: formalizing the swelled fiber bundle in an aldehyde condensation solution, wherein the formalizing temperature is 40-90 DEG C and the formalizing time is 10-40 min. The formalized polyvinyl alcohol fiber can be manufactured into short fiber or filament after being processed. The formalized high-strength and high-modulus polyvinyl alcohol fiber can be purely spun or blended with other fibers to manufacture textile threads and fabrics with various specifications, which are used for manufacturing high-strength wear-resistant work clothes, training clothes, tents, backpacks, ropes and the like, and has good popularization and application prospects.

Owner:SHANGHAI QUANYU BIOLOGICAL SCI & TECHSUIPING PHARMA

Hydrophobicity-enhanced powder coating for corrosion protection of pump valves

InactiveCN105440902AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPowdery paintsSilanesSesquioxide

The invention discloses hydrophobicity-enhanced powder coating for corrosion protection of pump valves. The hydrophobicity-enhanced powder coating is prepared from the following raw materials by weight: 52 to 54 parts of hydroxyl polyester resin, 7 to 8 parts of fluorine-carbon resin, 4 to 5 parts of triglycidyl isocyanurate, 13 to 15 parts of nano aluminum sesquioxide, 0.8 to 0.9 part of perfluoro octyl triethoxy silane, 25 to 30 parts of an ethanol solution of which the concentration is 75%, 0.5 to 0.6 part of a silane coupling agent kh560, 14 to 16 parts of calcium carbonate, 2.5 to 3.5 parts of stearic acid, 6 to 7 parts of nano-silicon sol, 2 to 3 parts of polyvinyl pyrrolidone, 1 to 1.2 parts of dibutyltin dilaurate, 0.9 to 1.1 parts of polydimethyl siloxane, and a proper amount of water. The prepared powder coating is high in leveling property, smooth in a formed coating layer, and high in corrosion resistance, is sprayed on the surface of a pump valve material via static electricity, and has the effects of resisting wiping, preventing shedding, and being long in service life.

Owner:TONGLING SIDE TECH

Special powder paint with good water resistance and weather resistance for pump valve

InactiveCN105440928AImprove corrosion resistanceGood weather resistancePolyurea/polyurethane coatingsPowdery paintsSilanesMaterials science

The invention discloses special powder paint with good water resistance and weather resistance for a pump valve. The powder paint is prepared from the following raw materials in parts by weight: 52-54 parts of hydroxyl polyester resin, 7-8 parts of fluorocarbon resin, 4-5 parts of triglycidyl isocyanurate, 13-15 parts of nano-aluminium oxide, 0.8-0.9 part of perfluoro octyl triethoxysilane, 25-30 parts of an ethanol solution with the concentration of 75 wt%, 0.5-0.6 part of a silane coupling agent kh560, 1.5-2 parts of an antioxidant 264, 0.8-0.9 part of a polyacrylate levelling agent, 2-2.5 parts of emulsified asphalt, 2-3 parts of iron oxide red, 7-9 parts of waste glass, 9-11 parts of superfine light calcium carbonate, 0.8-1 part of aminopropyltriethoxysilane and a proper amount of water. The powder paint is low in production cost, easy for powder coating, and good in water resistance and weather resistance, and has a good protection effect on the pump valve material working under permanently humid environment.

Owner:TONGLING SIDE TECH

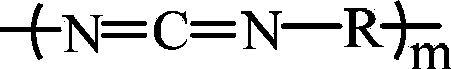

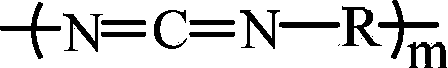

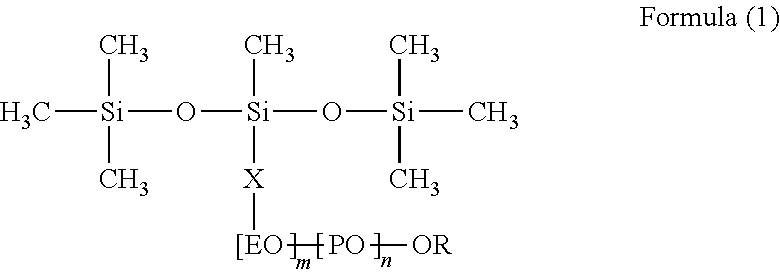

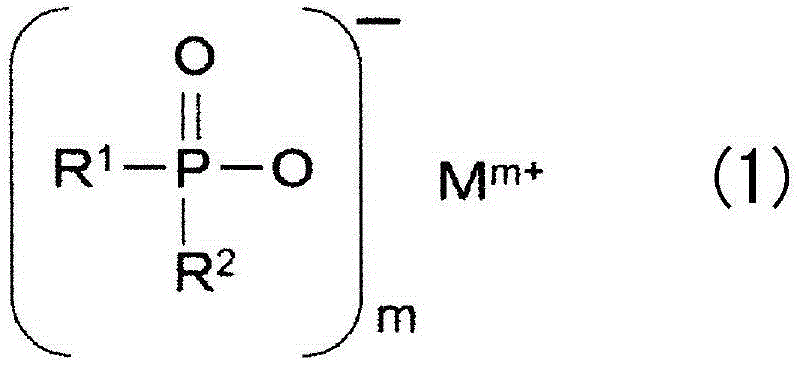

Membrane-electrode assembly for solid polymer electrolyte fuel cell

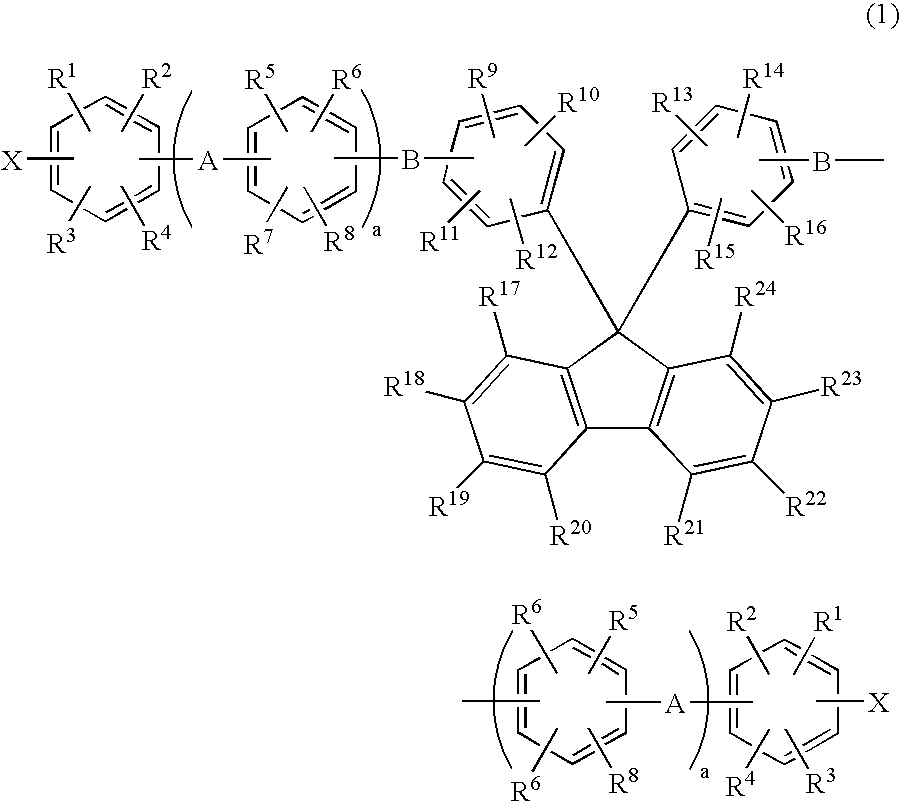

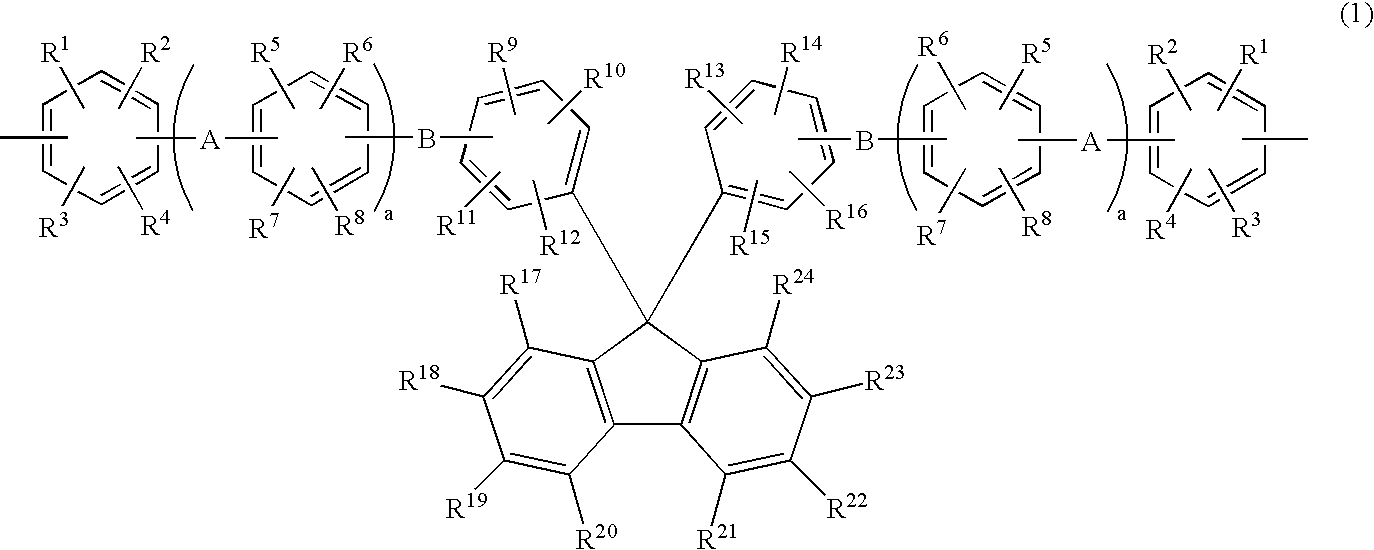

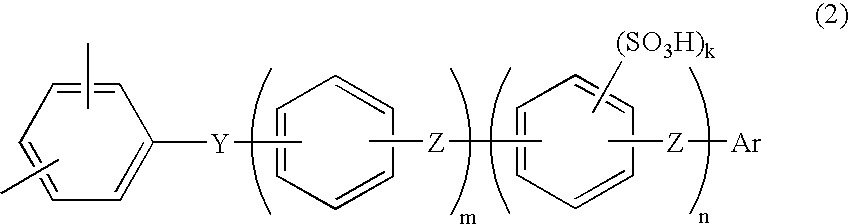

InactiveUS20060280991A1Improve mechanical propertiesImprove hot water resistanceSolid electrolyte fuel cellsPolymer scienceHydrogen atom

A membrane-electrode assembly having superior hot water resistance has a membrane containing an aromatic polymer having a repeating unit expressed by general formula (1): in which A represents independently either —CO— or —SO2—; B represents independently an oxygen atom or sulfur atom; R1 to R8, which may be identical or different from each other, represent a hydrogen atom, fluorine atom, alkyl group, phenyl group or nitrile group; R9 to R24, which may be identical or different from each other, represent a hydrogen atom, alkyl group or phenyl group; and ‘a’ represents an integer of 0 to 4.

Owner:HONDA MOTOR CO LTD

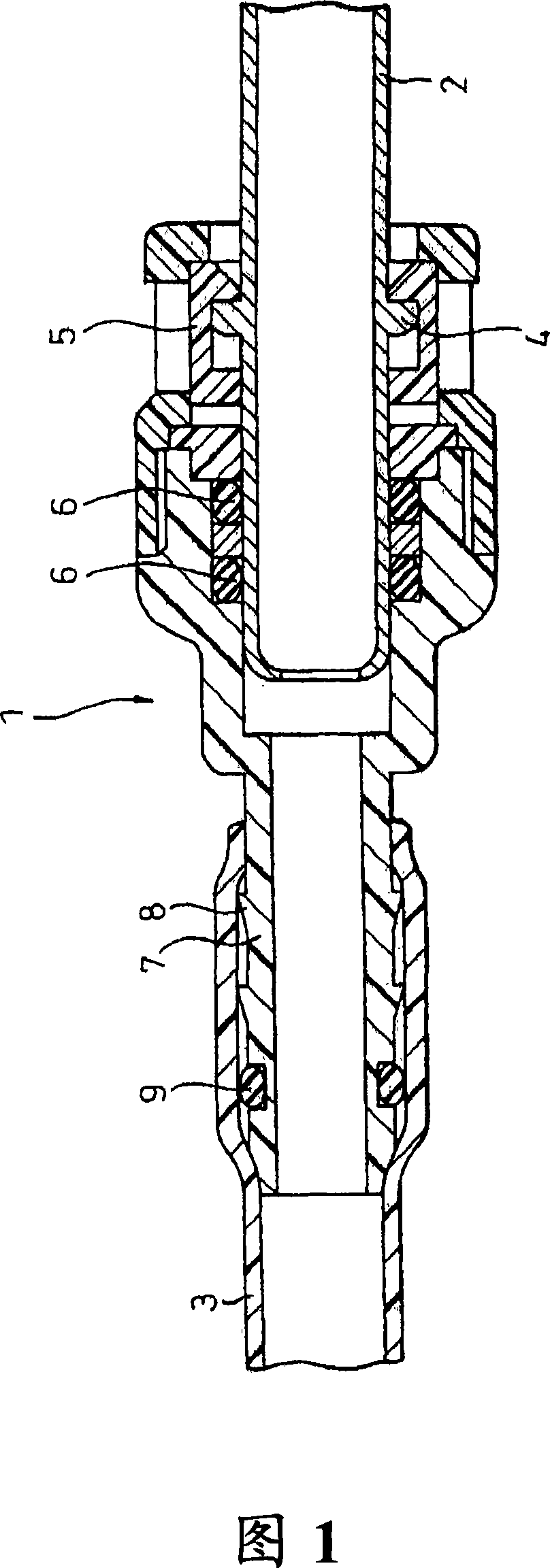

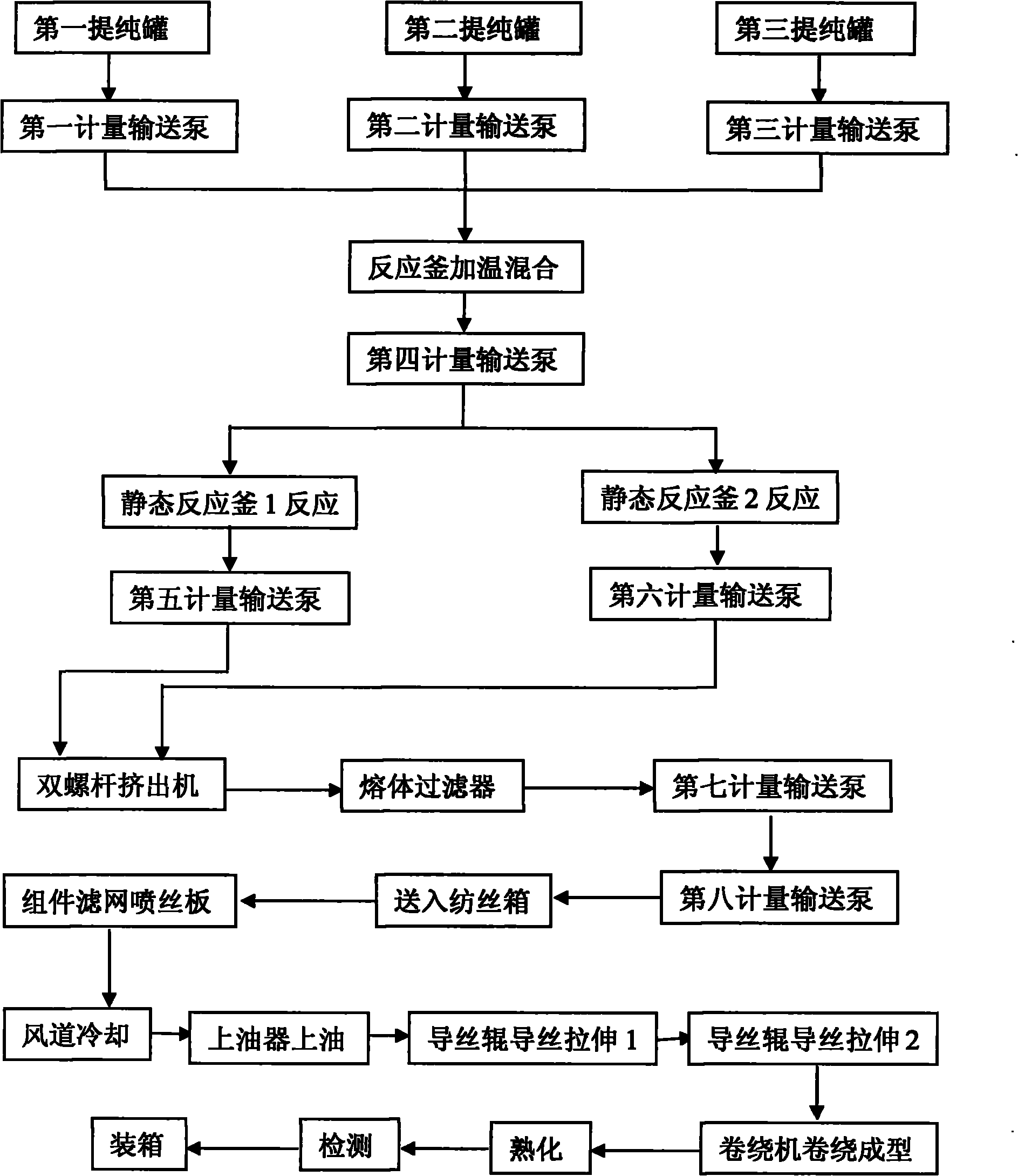

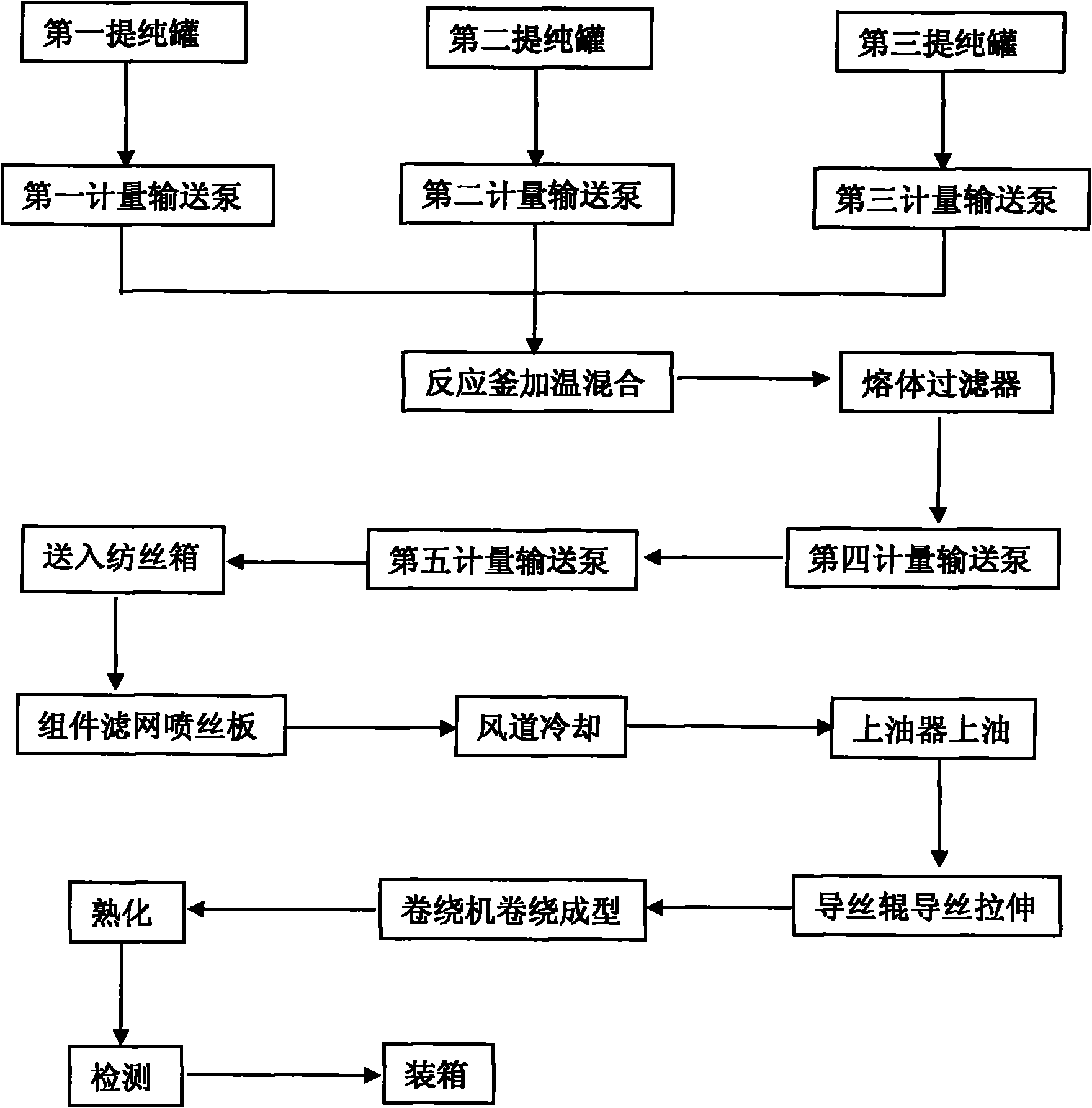

Melting and direct-spinning superfine denier (4.6-5.5 denier) high-elastic modulus polyurethane fiber equipment

InactiveCN102115919AImprove water absorptionIncrease fiber surface areaMonocomponent polyurethanes artificial filamentArtificial thread manufacturing machinesFiberHigh density

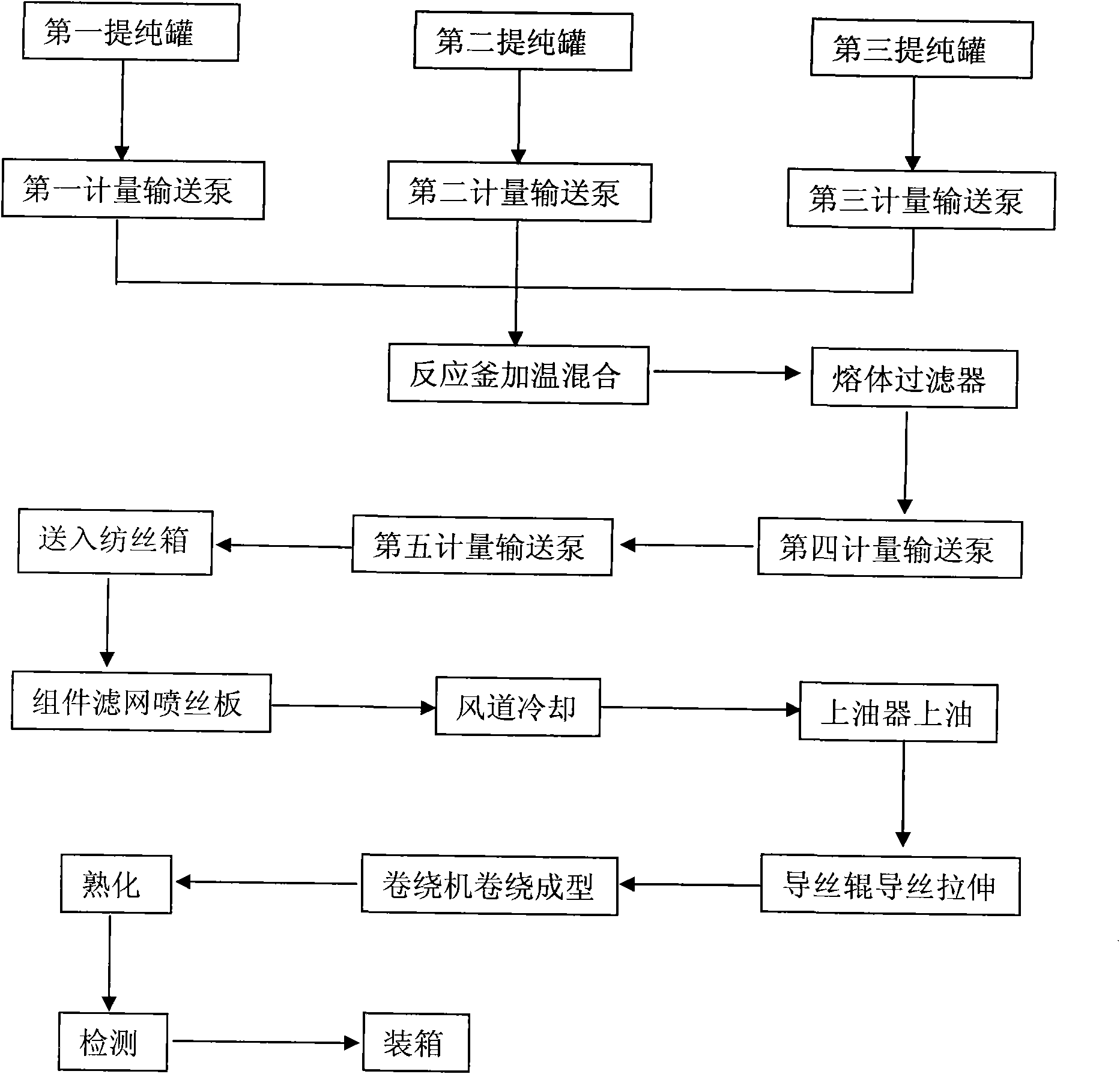

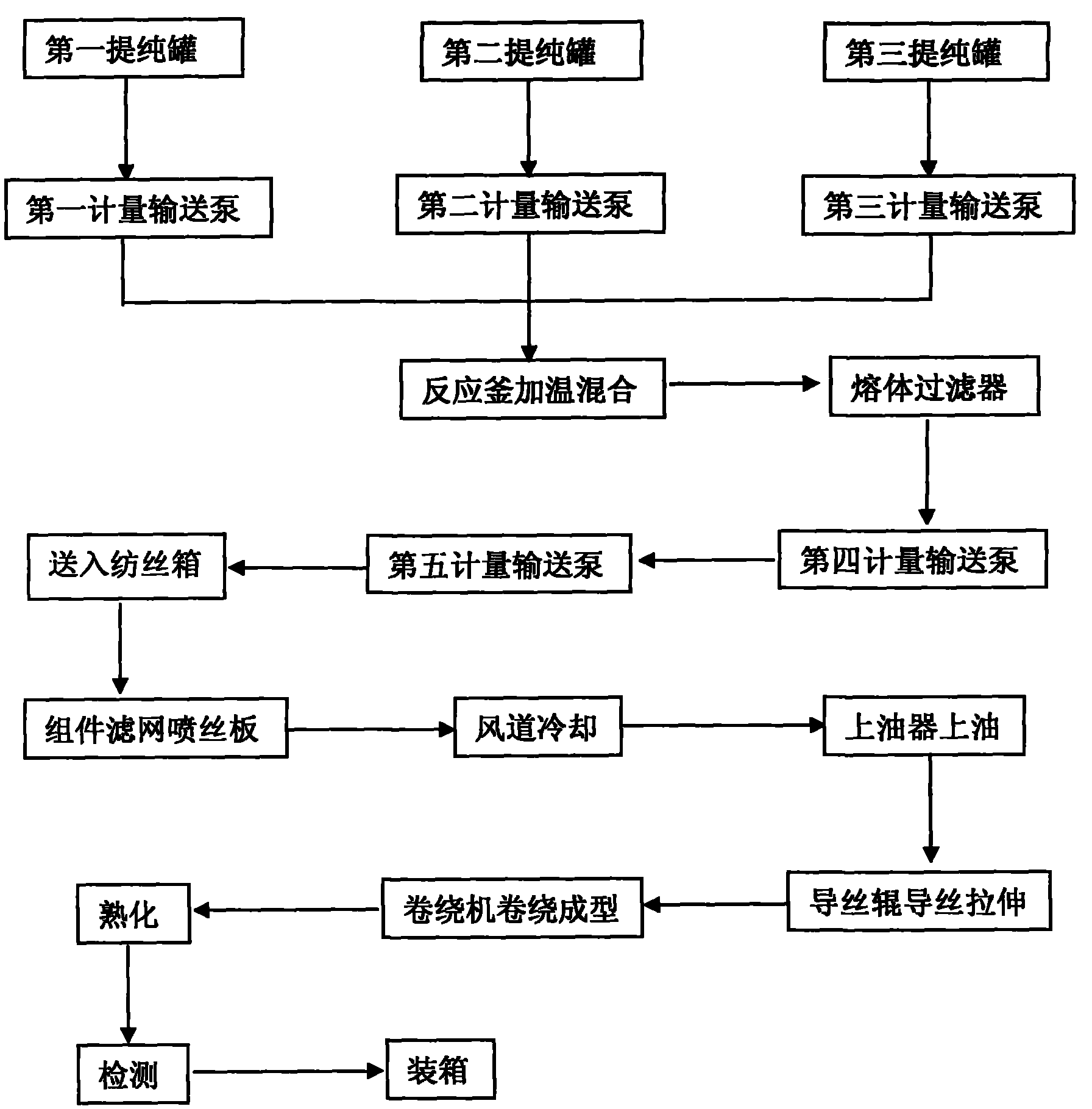

The invention discloses melting and direct-spinning superfine denier (4.6-5.5 denier) high-elastic modulus polyurethane fiber equipment. The equipment is characterized in that the equipment comprises a purification tank, a reaction tank, a metering and conveying pump, a reaction kettle warming mixer, a static reaction kettle, a double-screw extruder, a melt filter, a thread spinning box, a component filter screen spinneret plate, an air duct cooling system, an oiling device, a godet guide thread stretching device, and a winder winding and forming device. The equipment has the advantages that the produced superfine denier polyurethane fibers have very small bending rigidity and very soft hand feel; the surface areas of the fibers are very large, so that the spreadability, the bulkiness andthe heat retention property of fabrics are obviously improved, and the fabrics achieve a powerful cleaning function; when the superfine fibers are manufactured into super-high density fabrics, the size of gaps among the fibers is between the diameter of a water drop and the diameter of a water vapor droplet, so that the superfine fabrics have the waterproof and vapor-permeable effects; and when the superfine fibers are processed into fabrics like towels which can be wetted by water, the fabrics have high water absorbability, so that moisture of washed hair can be quickly absorbed by the towels, and the hair can be quickly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

Amination-enhanced modified straw based composite material and preparation method thereof

The invention relates to an amination-enhanced modified straw based composite material and a preparation method thereof. The preparation method comprises the following steps of slowly adding the following components in parts by weight: 80-90 parts of amination-enhanced modified straw, 1-10 parts of oxidized graphene and 1-10 parts of alginate into deionized water with the bath ratio of 1 to (10-20), and carrying out ultrasonic treatment for 1-24h; and then, carrying out calcium ion crosslinking and freeze drying to obtain the amination-enhanced modified straw / oxidized graphene / alginate composite material. According to the invention, the amination-enhanced modified straw / oxidized graphene / alginate composite material is prepared by loading oxidized graphene and the alginate on the amination-enhanced modified straw serving as a carrier, and then, carrying out calcium ion crosslinking and freeze drying. The composite material has the advantages of environmental friendliness, good mechanical property, regular structure, high porosity and adsorption capacity, high adsorption speed, wide application range, simplicity in desorption, reutilization and the like.

Owner:重庆鼎信塑料制品有限责任公司

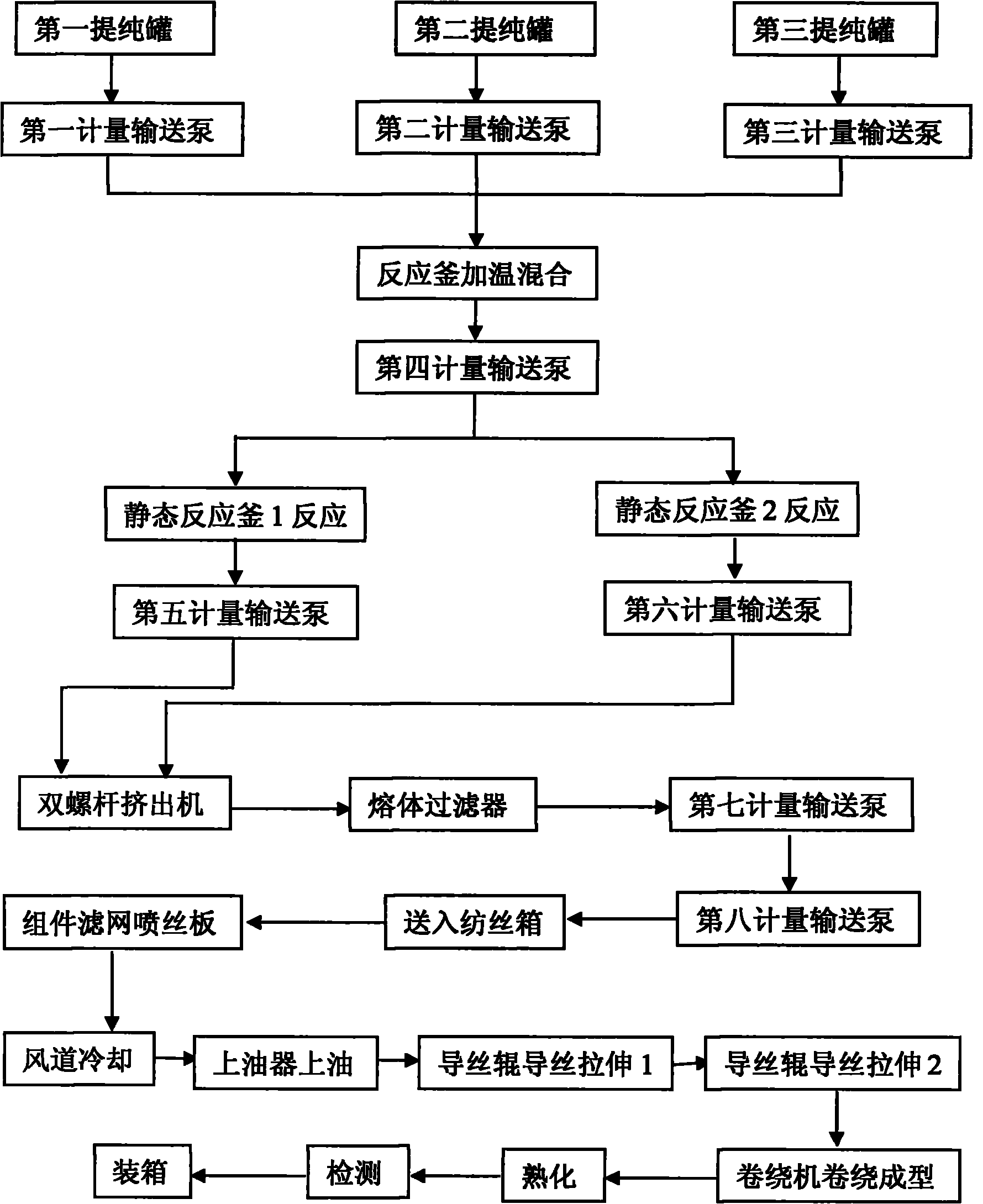

Method for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers

InactiveCN102051705AImproved elongation and uniformityLow bending stiffnessSpinnerette packsSpinning head liquid feederFlexural rigidityNitrogen pressure

The invention discloses a method for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers. The method is characterized by comprising the following steps of: proportioning raw material components, feeding materials under negative pressure, applying 0.8MPa nitrogen pressure, extruding by a twin-screw extruder, filtering by a melt filter, cooling spun filaments by an air channel, oiling by an oiling machine, curing by a drying room, and detecting and packing. The invention has the advantages that: the ultrafine denier polyurethane fibers have small bending stiffness, soft handfeel and large surface area; the coverage, bulkiness and heat retention of a fabric are remarkably improved, and the fabric has strong cleaning function; the ultrafine fibers are prepared into an ultra-dense fabric, a gap among the fibers is between the diameter of a water drop and the diameter of a water vapor microdrop, and the ultra-dense fabric has a waterproof and ventilated effect; and the ultrafine fibers are processed into a towel fabric which can be wetted by water, and the towel fabric has high water absorption, and water of washed hair can be rapidly absorbed by using the towel, so that the hair is rapidly dried. The method can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

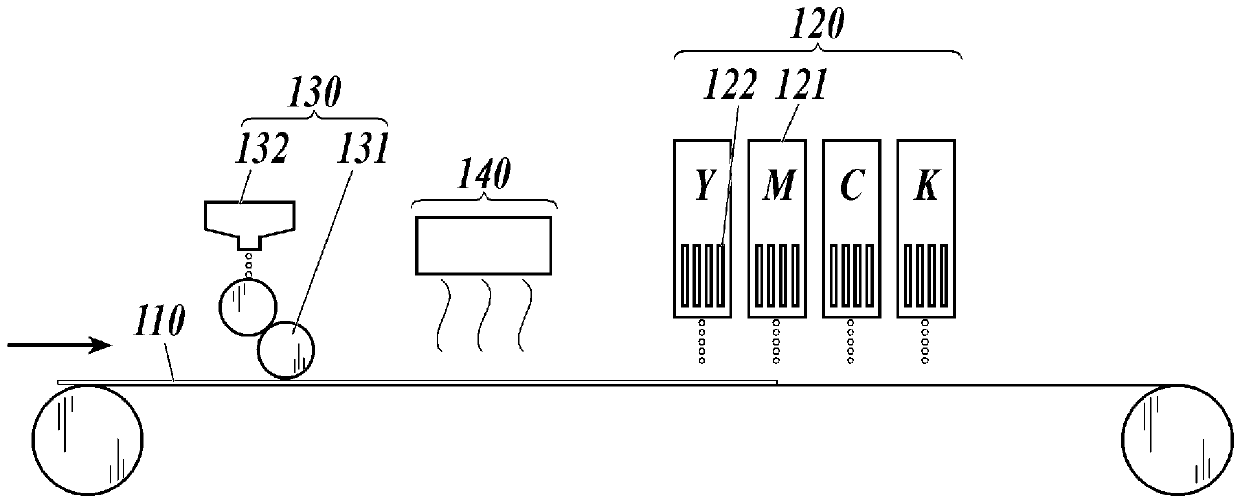

Inkjet recording liquid set, printed matter, and inkjet recording method

ActiveUS11447650B2Excellent hot water resistanceImprove hot water resistanceDuplicating/marking methodsInksOrganic solventActive agent

Owner:KONICA MINOLTA INC

Halogen-free flame-retardant insulated wire

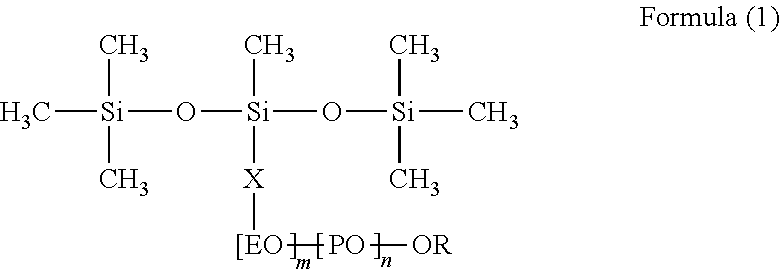

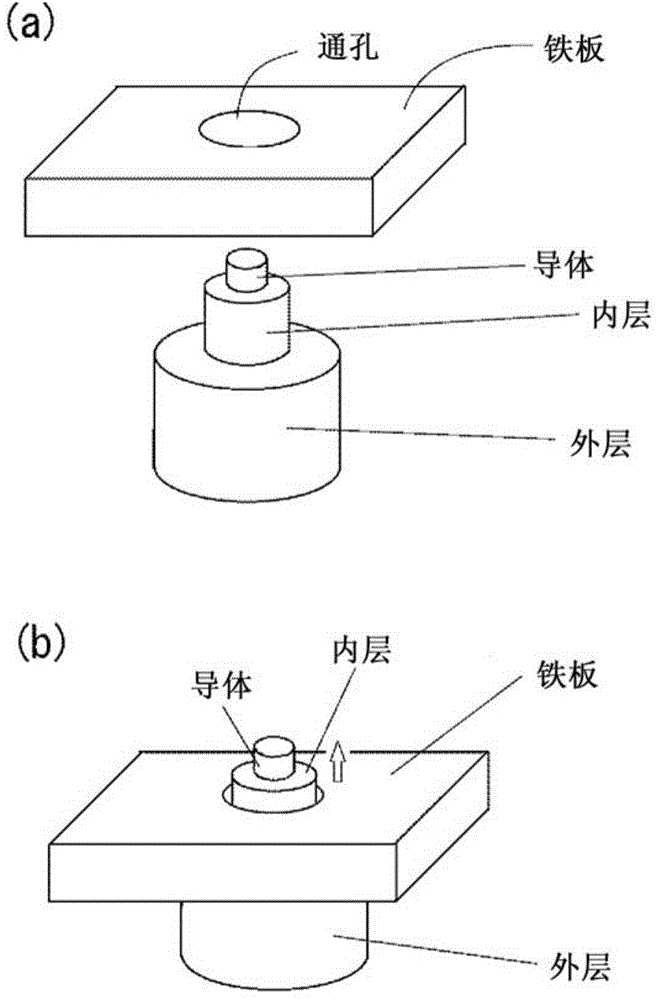

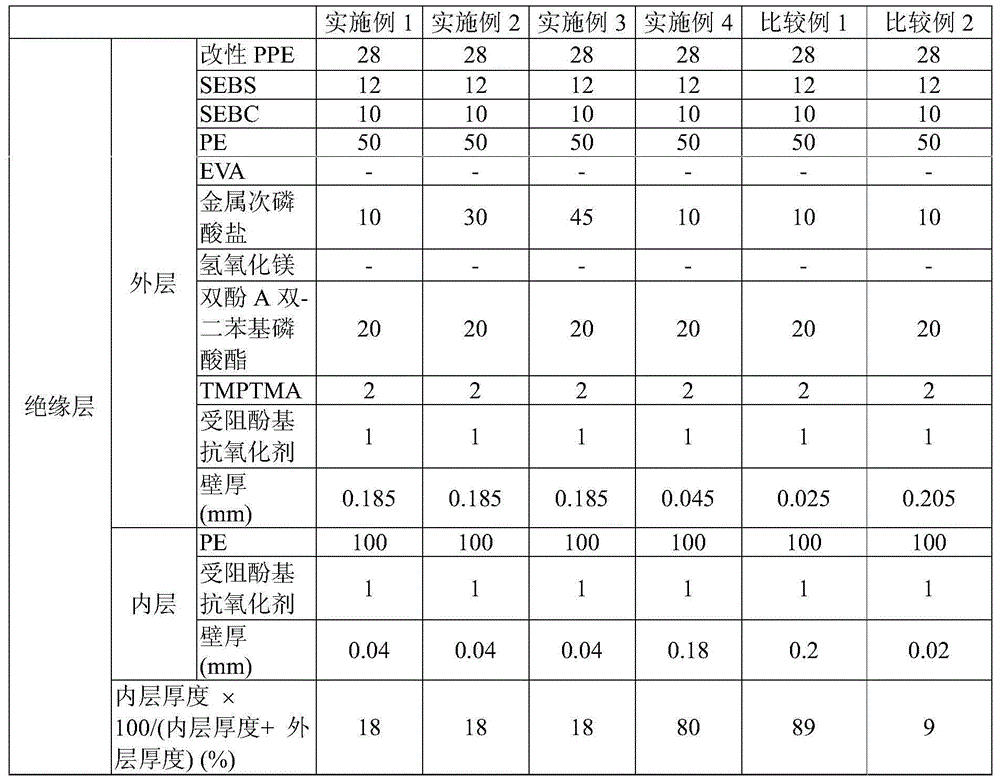

InactiveCN104813417AImprove hot water resistanceHighly balanced insulation resistanceRubber insulatorsPlastic/resin/waxes insulatorsPhosphoric Acid EstersElastomer

Provided is a halogen-free flame-retardant insulated wire which has high hot water resistance, while achieving a good balance among insulation resistance, flame retardancy, wear resistance and thermal deformation resistance at high levels. A halogen-free flame-retardant insulated wire which comprises a conductor and a halogen-free insulating layer that covers the conductor. The insulating layer has: an outer layer that is formed of a crosslinked body of a resin composition which contains 100 parts by mass in total of resin components, wherein 25-30 parts by mass of a polyphenylene ether resin and 10-30 parts by mass of a styrene elastomer are finely dispersed in 40-65 parts by mass of a high-density polyethylene having a melt flow rate of 0.60 or less, and 5-50% by mass of a metal phosphinate, 6-25% by mass of a phosphoric acid ester and 1-10% by mass of a polyfunctional monomer relative to the resin components; and an inner layer that is formed of a crosslinked polyethylene. The thickness of the inner layer is 10-85% of the total thickness of the inner layer and the outer layer.

Owner:SUMITOMO ELECTRIC IND LTD

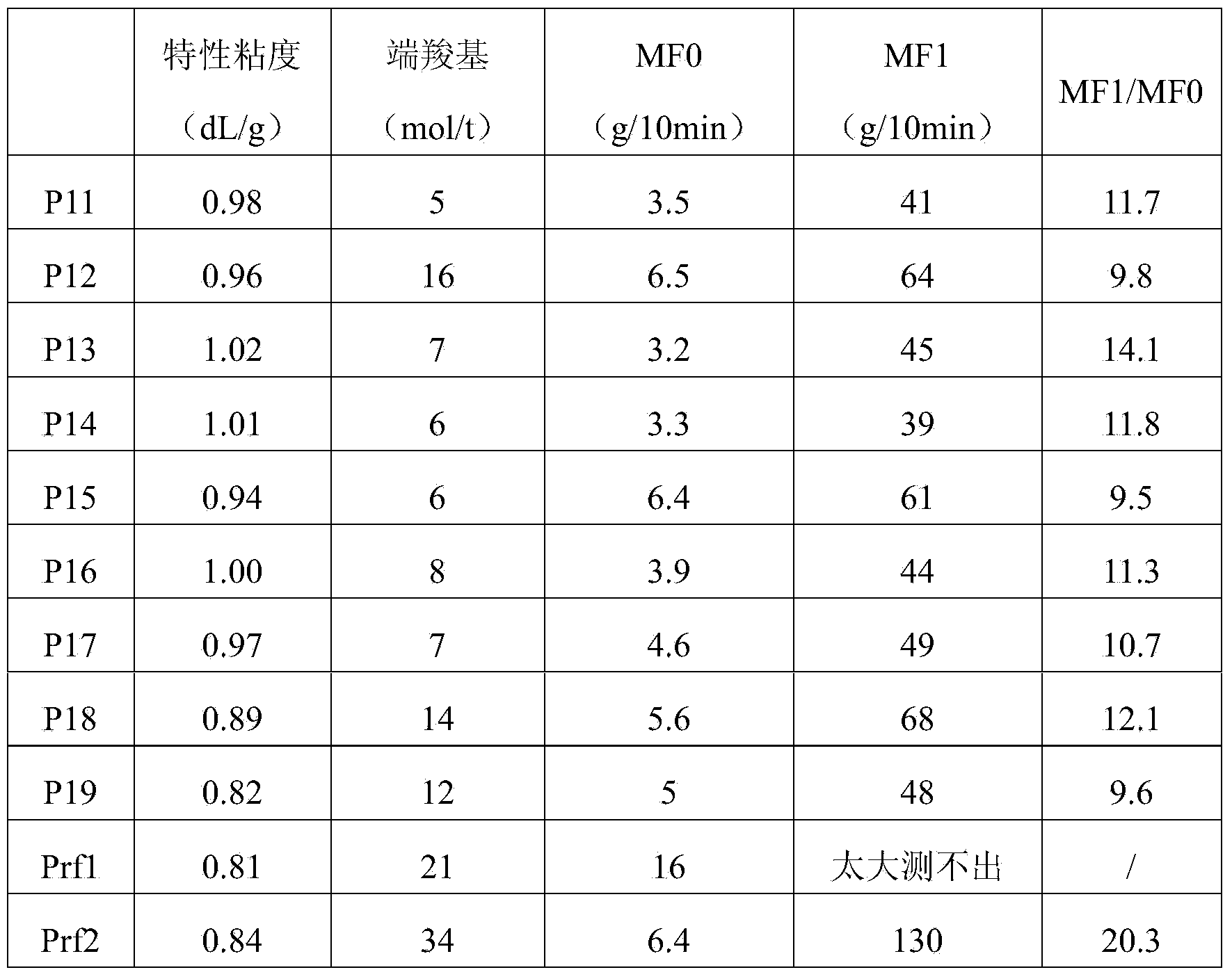

A kind of modified PET copolyester and its preparation method and application

The invention belongs to the technical field of polyester preparation, and discloses a modified PET copolyester with high viscosity and a low terminal carboxyl group and a preparation method and application thereof. The copolyester contains the following ingredients in parts by weight: 100 parts of low-viscosity PET copolyester, 0.8-2.0 parts of oxazoline compound and 0.6-2.0 parts of a hydroxyl chain extender. The method prepares the high-viscosity modified PET copolyester by adding the oxazoline compound and the hydroxyl chain extender. The oxazoline compound is added to react with the terminal carboxyl group in resin, the terminal carboxyl group content of resin is reduced, therefore, the hot water resisting performance of resin is increased. The hydroxyl chain extender is added, the molecular weight of resin is increased, and the balance between a physical performance and a processing performance is achieved. The viscosity and the melt strength of the modified PET copolyester are increased, the content of terminal carboxyl group is reduced, and the hot water resisting performance is greatly increased. Moreover, the production method shortens the polycondensation time and the production cycle, effectively reduces the thermal degradation reaction, and also increases the output of equipment.

Owner:KINGFA SCI & TECH CO LTD

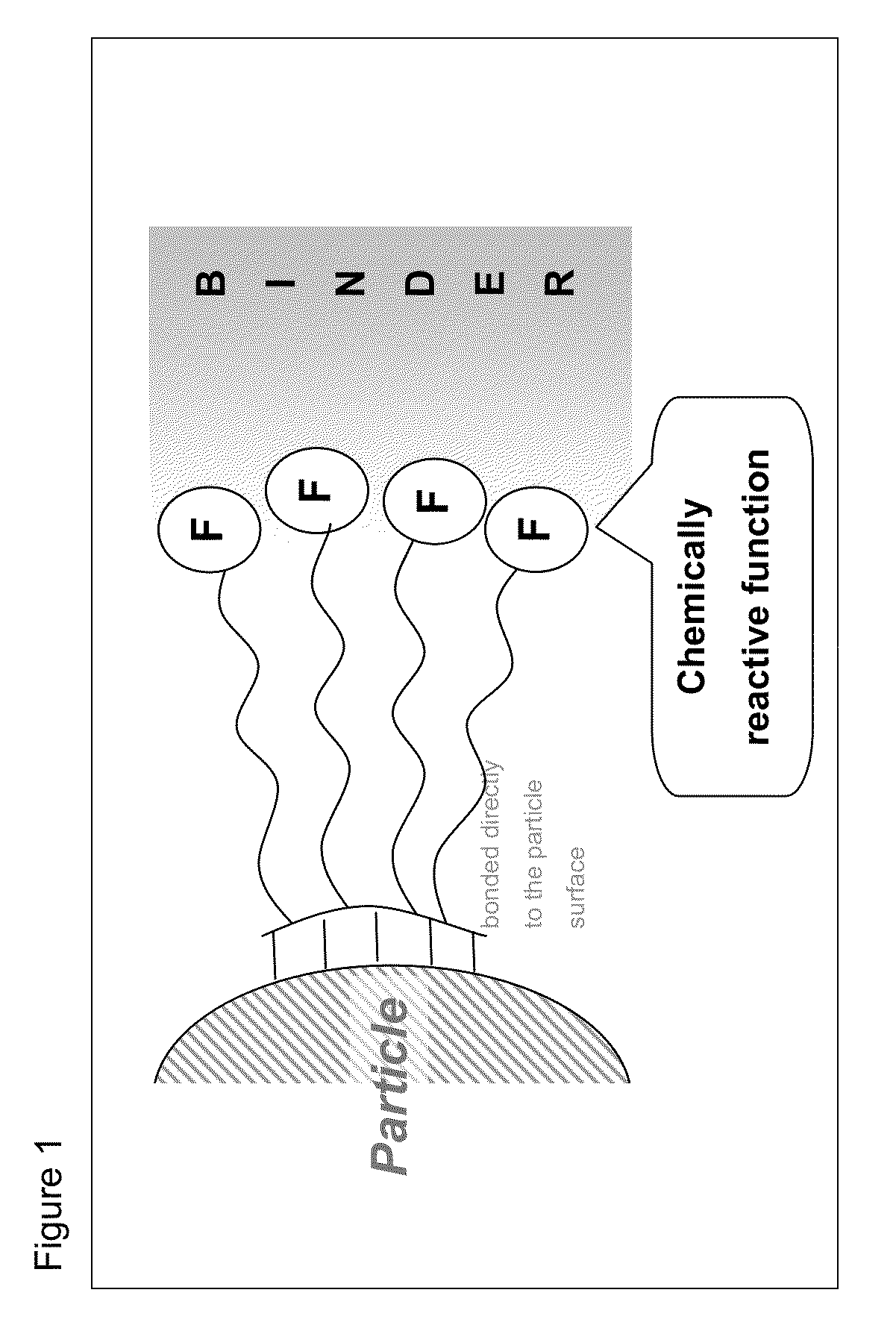

Functionalized particles and use thereof

InactiveUS9212194B2Improve propertiesHigh hiding powerMaterial nanotechnologyGlass/slag layered productsInorganic particleOligomer

A method of making a powder coating composition includes obtaining functionalized particles by reacting inorganic particles with alkoxysilanes having the general structural formula (I) R1Si(OR2)3, silane oligomers having the general structural formula (II) (R1)(OR2)2Si—O—[—Si(R1)(OR2)—O—]m−—Si(R1)(OR2)2 or mixtures thereof.

Owner:SACHTLEBEN CHEM GMBH

Powder coating having excellent antirust effect and used for pump valve

InactiveCN105440901AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPowdery paintsEnvironmental resistanceSilanes

The invention discloses powder coating having an excellent antirust effect and used for a pump valve. The powder coating is prepared from raw materials in parts by weight as follows: 52-54 parts of polyester resin, 7-8 parts of fluorocarbon resin, 4-5 parts of triglycidyl isocyanurate, 13-15 parts of nano aluminum oxide, 0.8-0.9 parts of perfluoro octyl triethoxysilicane, 25-30 parts of an ethanol solution with the concentration being 75wt%, 0.5-0.6 parts of a silane coupling agent kh560, 0.8-1 part of polyethylene wax, 1.2-1.5 parts of a polyacrylate leveling agent, 6-8 parts of superfine zinc powder, 2-3 parts of an ethylene-chlorotrifluoroethylene copolymer, 2-3 parts of polyvinylpyrrolidone, 13-15 parts of barium sulfate, 3-4 parts of mica iron oxide and a proper amount of water. The powder coating has excellent comprehensive performance, the film forming speed is high, the antirust effect of the powder coating is further improved due to addition of the superfine zinc powder and mica iron oxide, and a coating layer is tough and firm and not prone to peeling, has a smooth surface and is free of pinholes, safe and environment-friendly.

Owner:TONGLING SIDE TECH

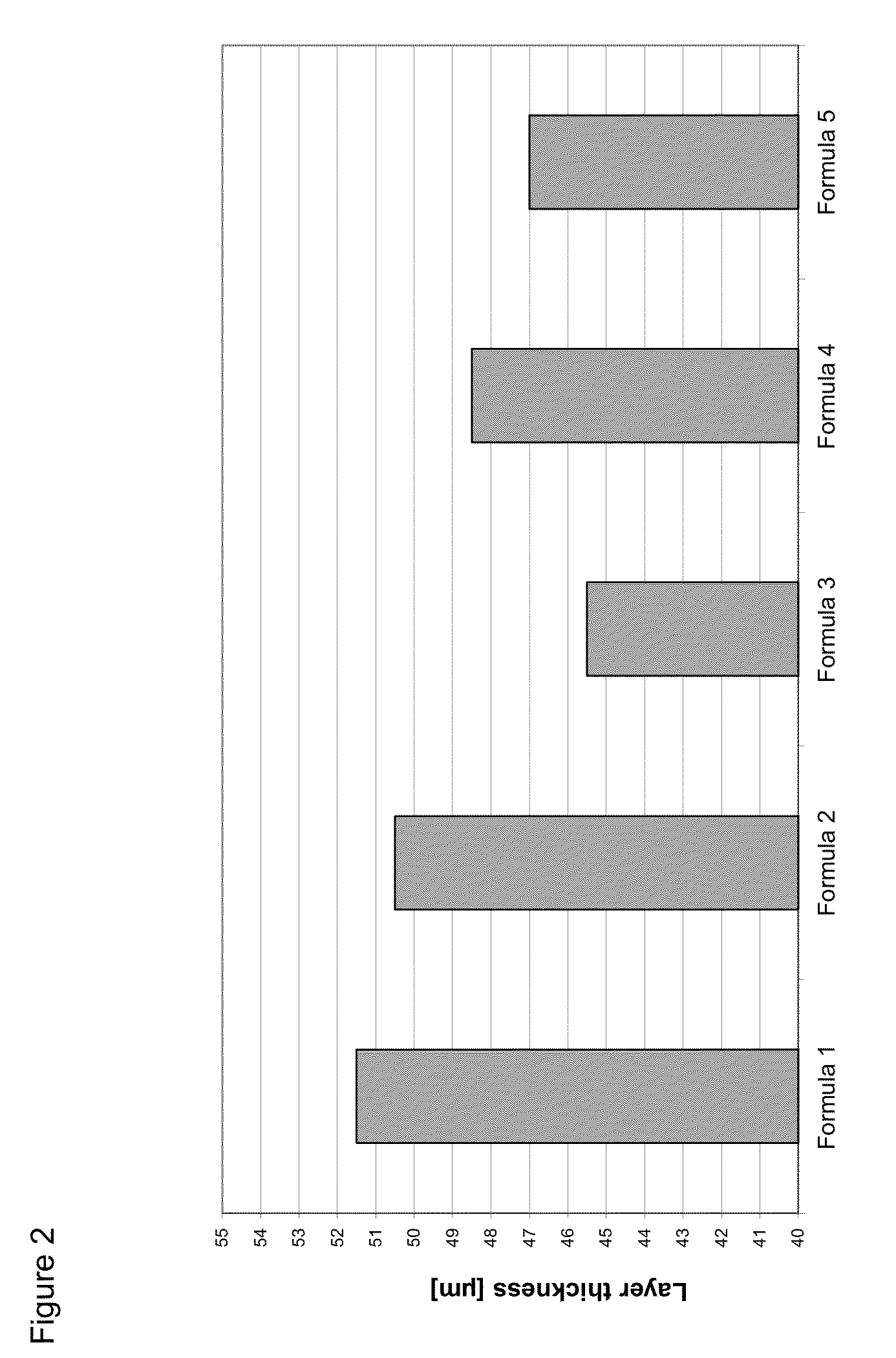

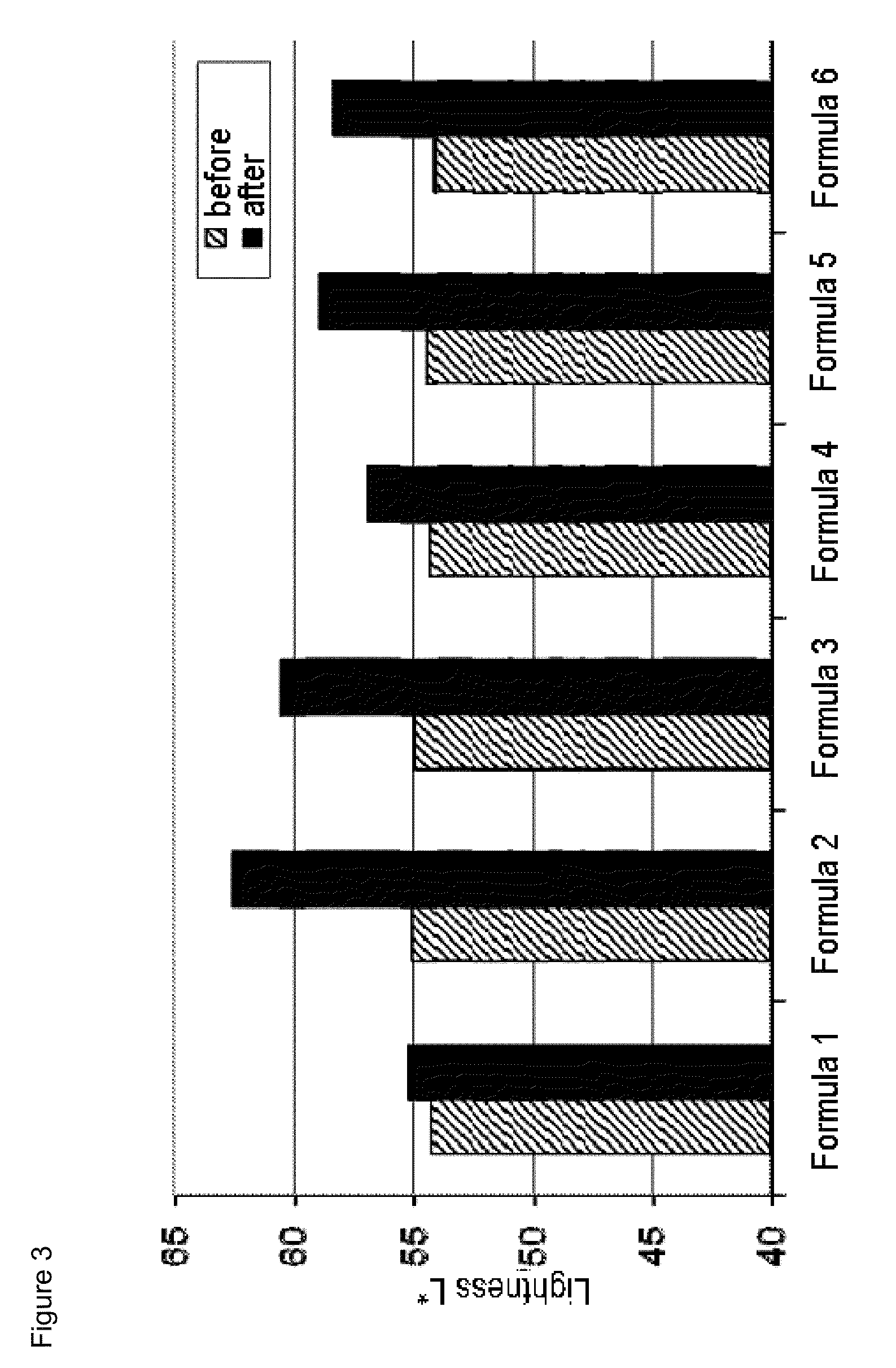

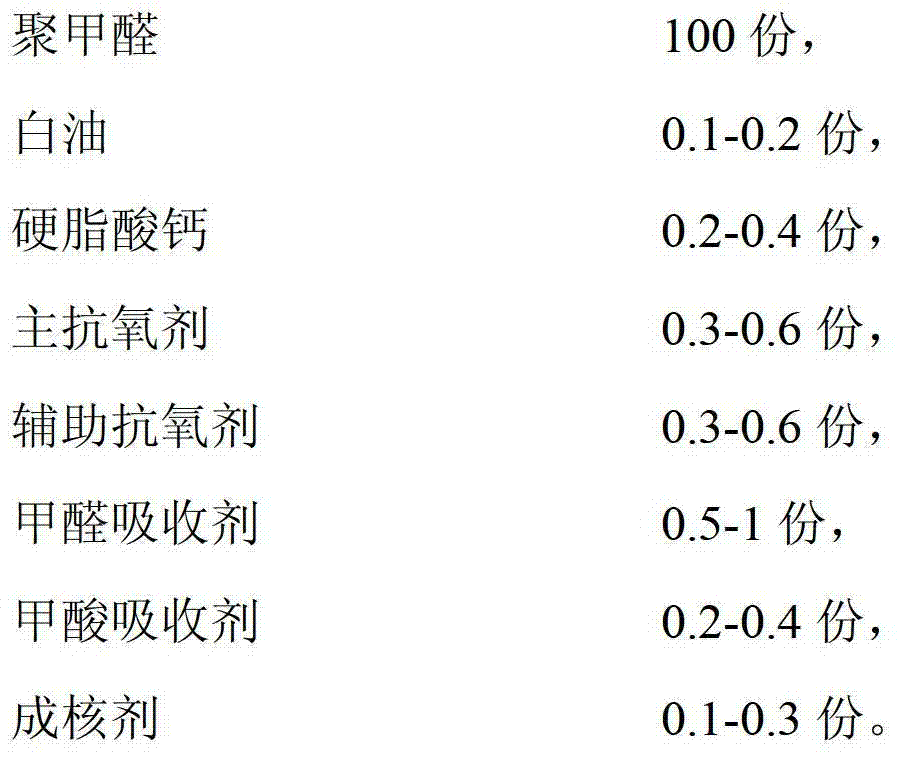

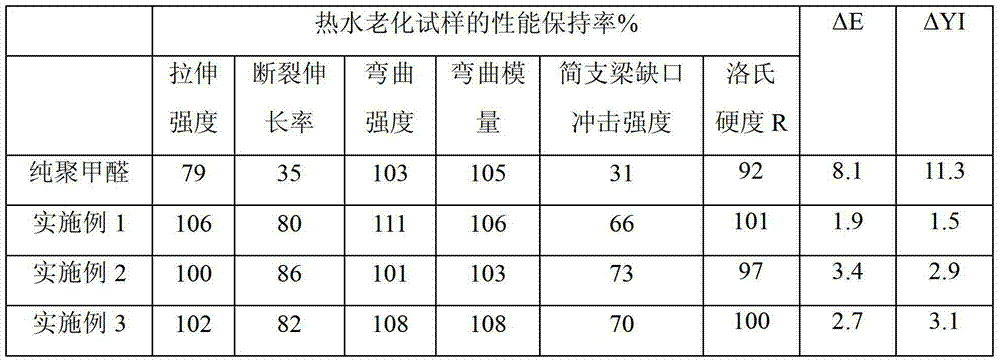

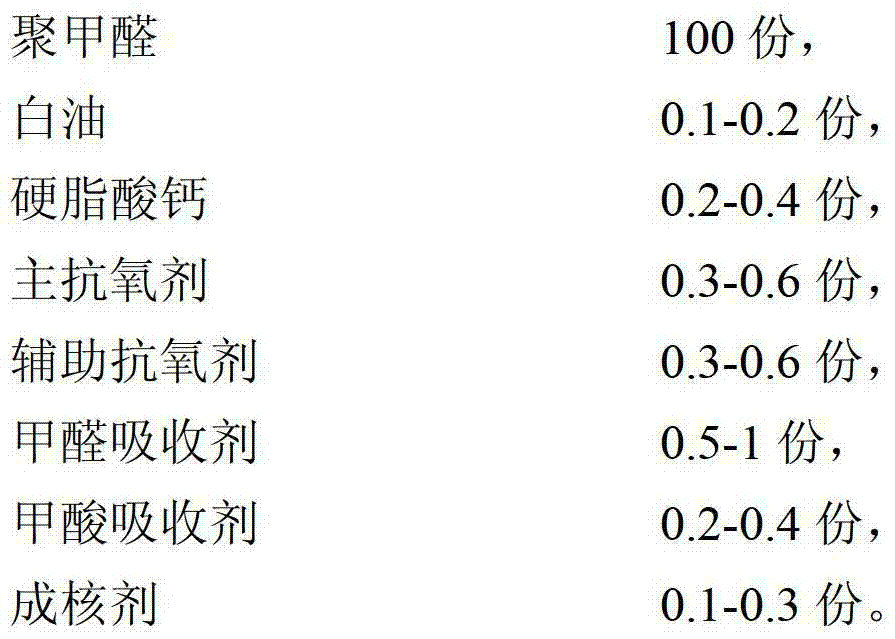

Hot-water resistance polyformaldehyde composition and preparation method thereof

The invention belongs to the technical field of material, and relates to a hot-water resistance polyformaldehyde composition and a preparation method thereof. The hot-water resistance polyformaldehyde composition comprises the following ingredients by weight part: 100 parts of polyformaldehyde, 0.1-0.2 parts of white oil, 0.2-0.4 parts of calcium stearate, 0.3-0.6 parts of main anti-oxidant, 0.3-0.6 parts of auxiliary anti-oxidant, 0.5-1 part of formaldehyde absorbent, 0.2-0.4 parts of formic acid absorbent and 0.1-0.3 parts of nucleating agent. Compared with the prior art, through the boiling by water and aging experiment of the prepared composition, the mechanical property conservation rate is high, aberration and yellowing index change are little, and the hot-water resistance is obviously increased.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers

InactiveCN102051698AImprove water absorptionIncrease fiber surface areaArtificial thread manufacturing machinesSpinning head liquid feederFiberFiltration

The invention discloses equipment for producing direct melt filtration fused direct spun ultrafine denier polyurethane fibers. The equipment comprises a purification tank, a reaction tank, a metering delivery pump, a reactor heating mixer, a melt filter, a spinning box, a component filter screen spinning plate, an air channel cooling system, an oiling machine, a guide wire roller guide wire stretching device and a winder winding forming device. The invention has the advantages that: the ultrafine denier polyurethane fibers have small bending stiffness, soft handfeel and large surface area; the coverage, bulkiness and heat retention of a fabric are remarkably improved, and the fabric has strong cleaning function; the ultrafine fibers are prepared into an ultra-dense fabric, a gap among the fibers is between the diameter of a water drop and the diameter of a water vapor microdrop, and the ultra-dense fabric has a waterproof and ventilated effect; and the ultrafine fibers are processed into a towel fabric which can be wetted by water, and the towel fabric has high water absorption, and water of washed hair can be rapidly absorbed by using the towel, so that the hair is rapidly dried. The equipment can be applied to various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

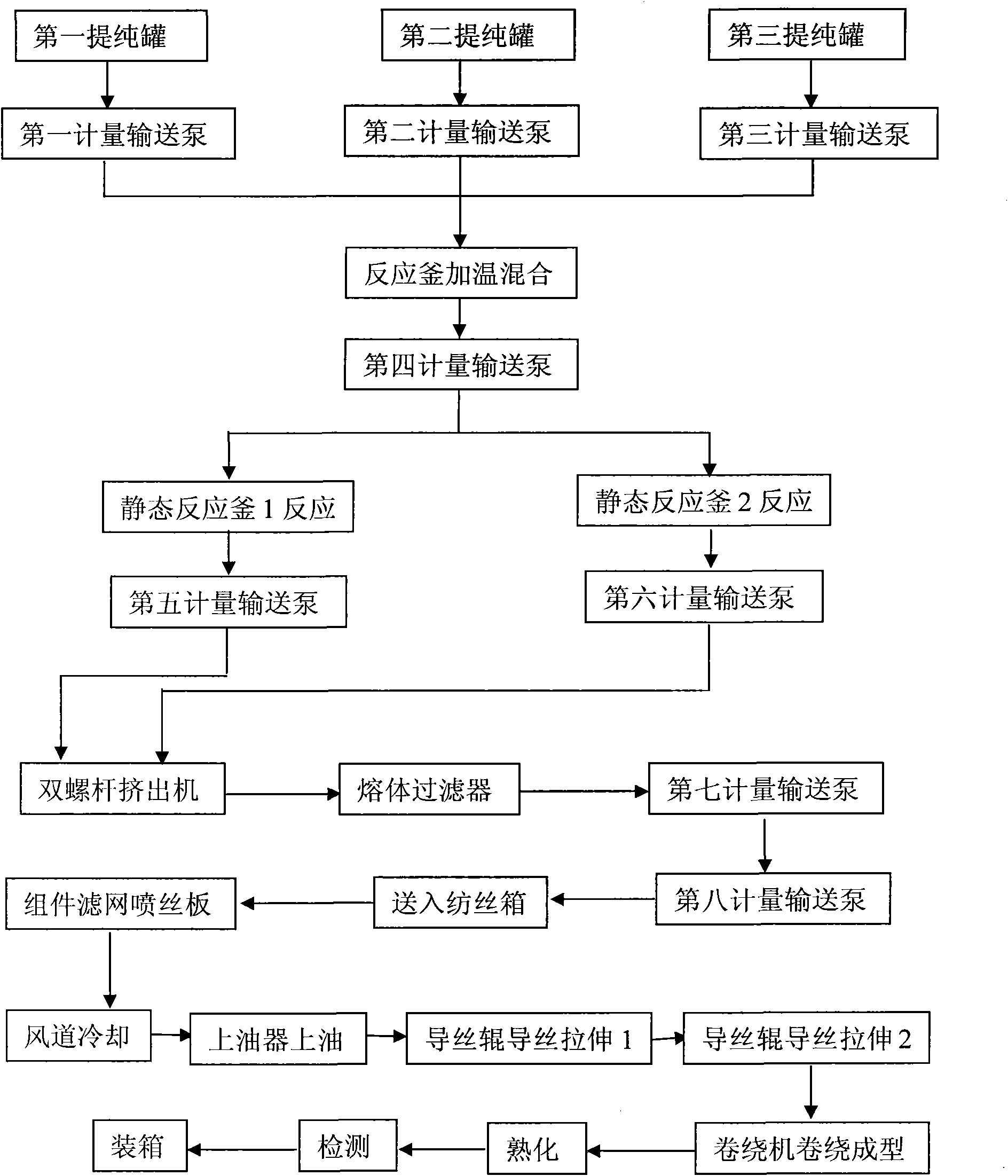

Method for producing melt direct spinning superfine (4.6-5.5) denier high elastic modulus polyurethane fibers

InactiveCN102021673AImproved elongation and uniformityLow bending stiffnessSpinning head liquid feederFilament/thread formingSpontaneous reactionMoisture

The invention provides a method for producing melt direct spinning superfine (4.6-5.5) denier high elastic modulus polyurethane fibers, which is characterized by comprising the following steps: raw materials, charging under negative pressure, addition of 0.8MPa nitrogen pressure, high-temperature spontaneous reaction in two static reactors in turn, a double-screw extruder, filtration in a melt filter, jetted yarn cooling in an air duct, oiling by an oiling machine, curing in a drying room and detecting and casing. The method has the following advantages: the superfine denier polyurethane fibers have low bending stiffness and quite soft feel; the surface areas of the fibers are large, thus obviously improving the coverage, bulkiness and heat retention of the fabrics and having extremely strong cleaning function; the superfine fibers are made into superhigh density fabrics and the size of the gaps between the fibers range from the diameter of the water drops to the diameter of the vapor droplets, thus having waterproof and non-airproof effects; and the superfine fibers are processed into such fabrics which can be moistened by water as towels and the towels have high water absorbability and can rapidly absorb the moisture of the washed hairs to rapidly dry the hairs. The method can be applied in various fields.

Owner:TAICANG JINXIANG SPANDEX FIBER

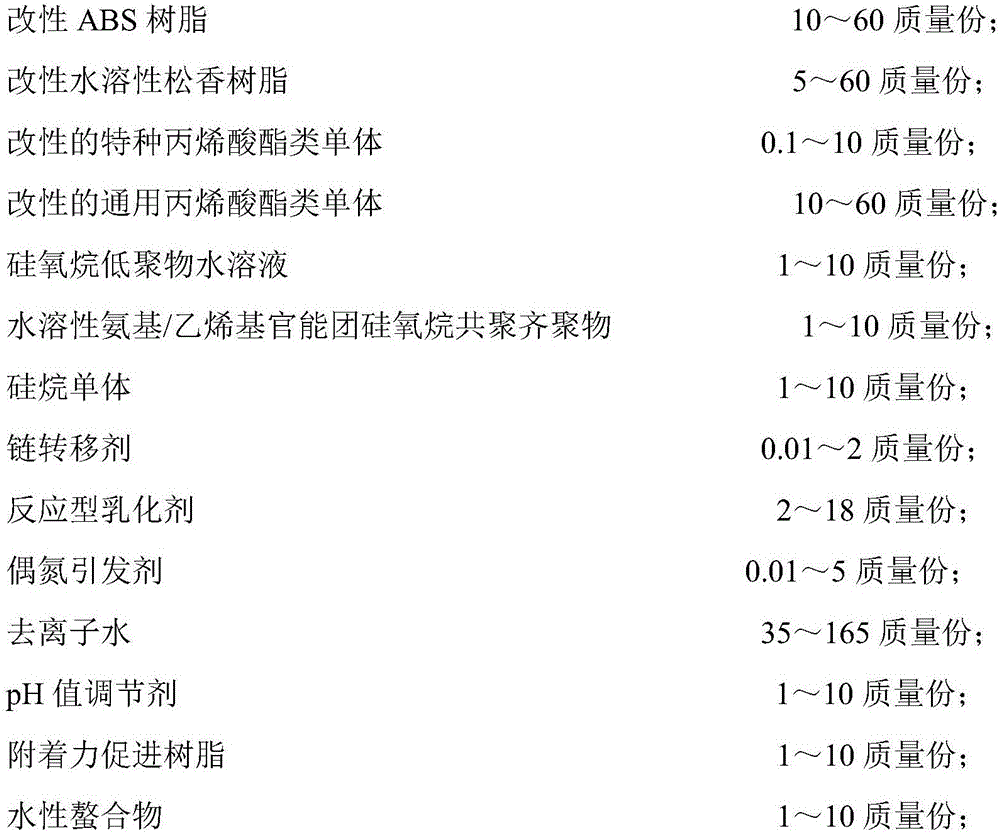

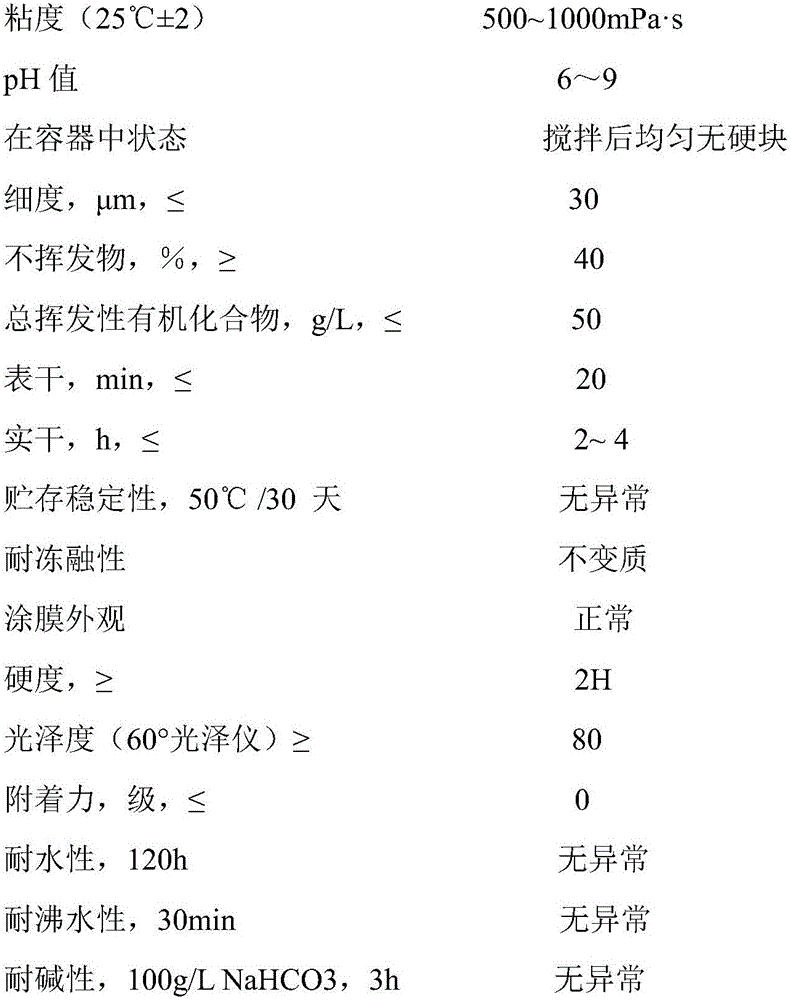

Water-based wood lacquer basic sticking material and preparation method of water-based wood lacquer basic sticking material

ActiveCN106752191AExtensive physicsWide range of chemical propertiesFireproof paintsWater basedLacquer

The invention provides a water-based wood lacquer basic sticking material. The water-based wood lacquer basic sticking material is prepared from the following components: modified ABS (Acrylonitrile Butadiene Styrene) resin, modified water-soluble rosin resin, a modified specific acrylate monomer, a modified general acrylate monomer, a siloxane low-polymer water solution, a water-soluble amino / vinyl functional group siloxane copolymerized oligomer, a siloxane monomer, a chain transfer agent, a reaction type emulsifier, an azo initiator, de-ionized water, a pH (Potential of Hydrogen) regulator, adhesion promoting resin, a water-based chelate and a water repellent agent. The invention further provides a preparation method of the water-based wood lacquer basic sticking material. By adopting the water-based wood lacquer basic sticking material provided by the invention, the quality effect can be get close to oily wood lacquer.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com