Patents

Literature

50 results about "Spontaneous reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

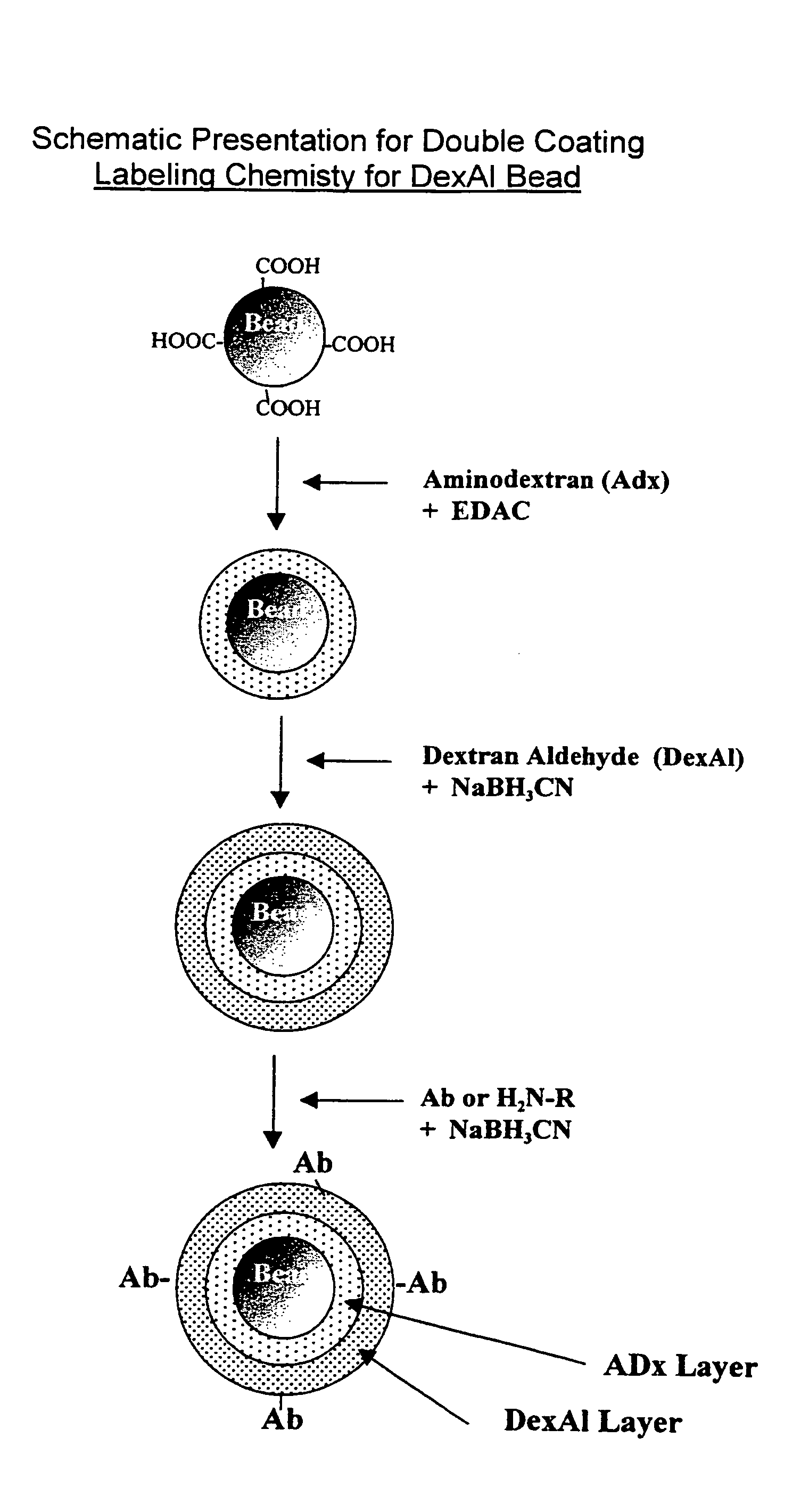

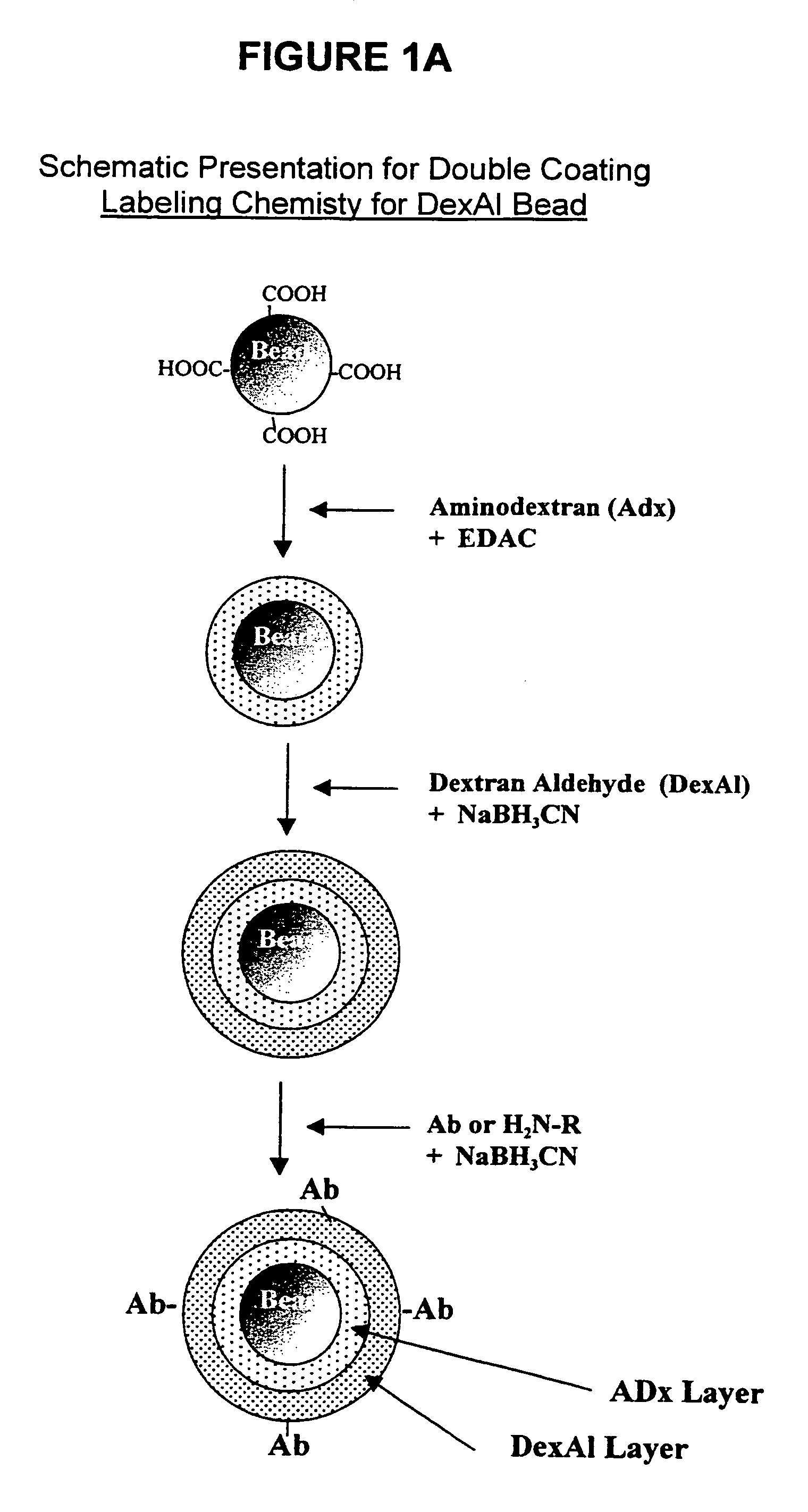

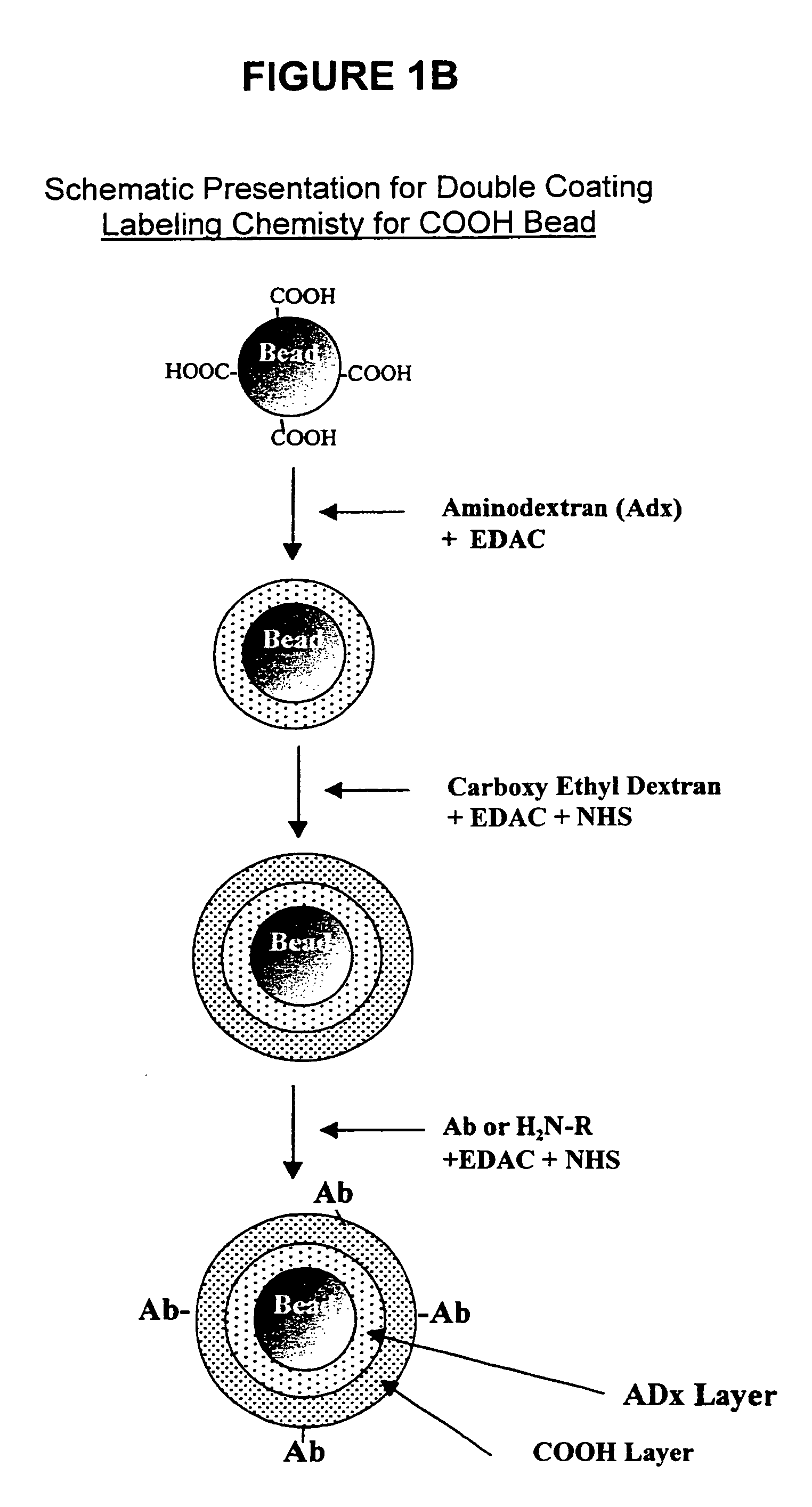

Carriers coated with polysaccharides, their preparation and use

InactiveUS7179660B1Increase coverageMinimizes unspecific bindingBioreactor/fermenter combinationsBiological substance pretreatmentsPolysaccharideSpontaneous reaction

A polysaccharide coated carrier having a coating of at least two successive layers of polysaccharide. The first polysaccharide layer spontaneously associates with a second polysaccharide layer and, optionally, the carrier. Each successive layer of polysaccharide spontaneously associates with a preceding layer. Spontaneous association occurs due to the presence of oppositely charged functional groups on each layer of polysaccharide or due to a spontaneous reaction between the functional groups the layers. The carrier may be any surface such as a tube, microtitration plate, bead, particle or the like and is suitable for use in diagnostic or therapeutic methods.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS PRODS

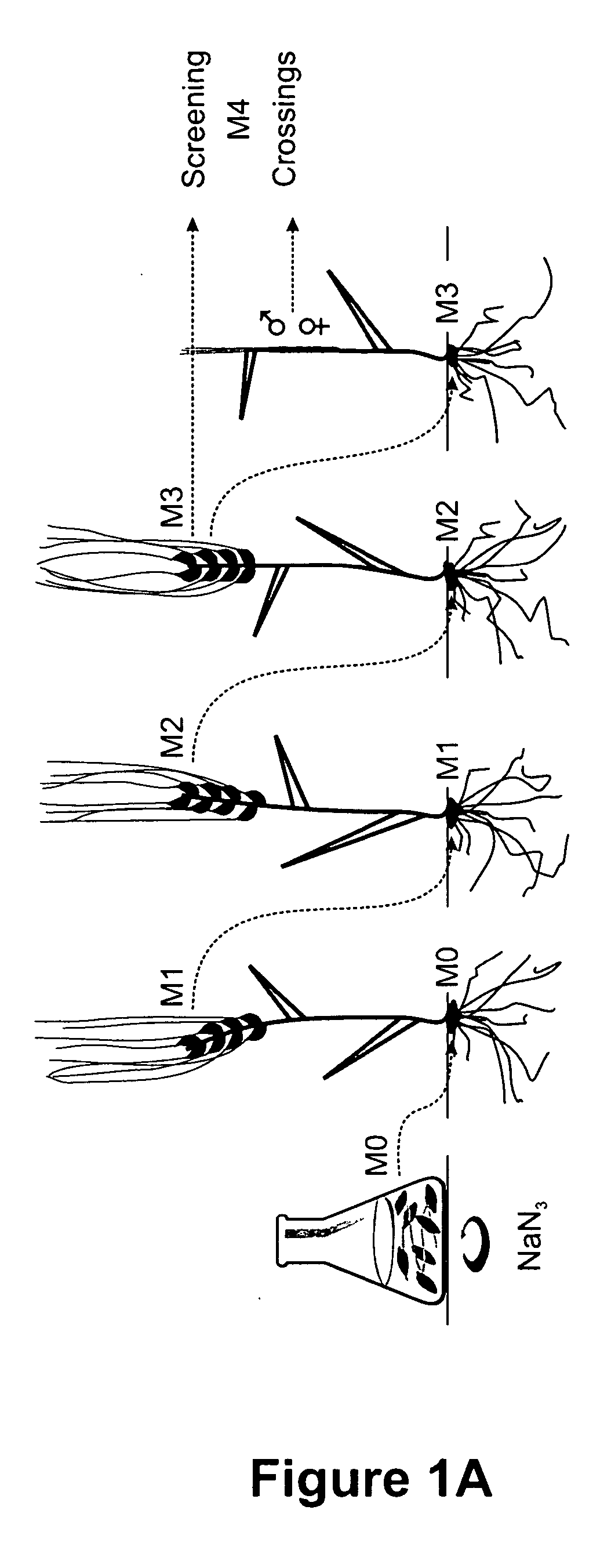

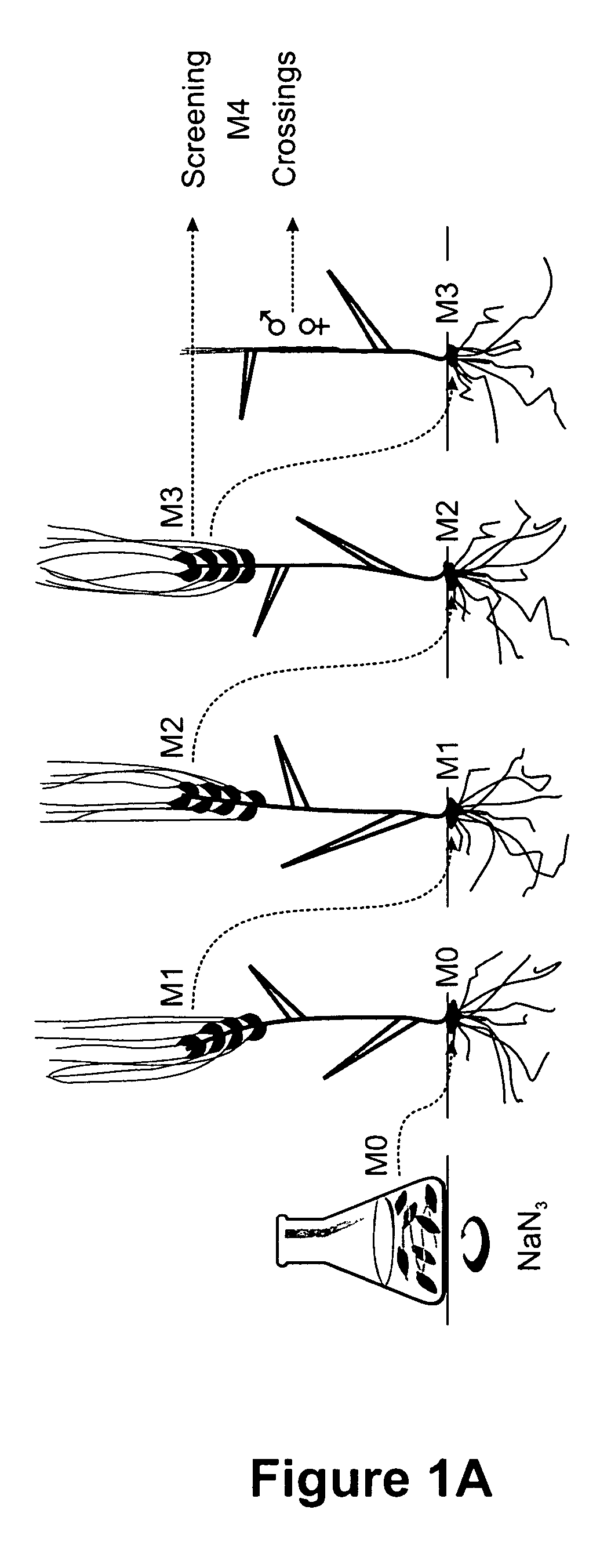

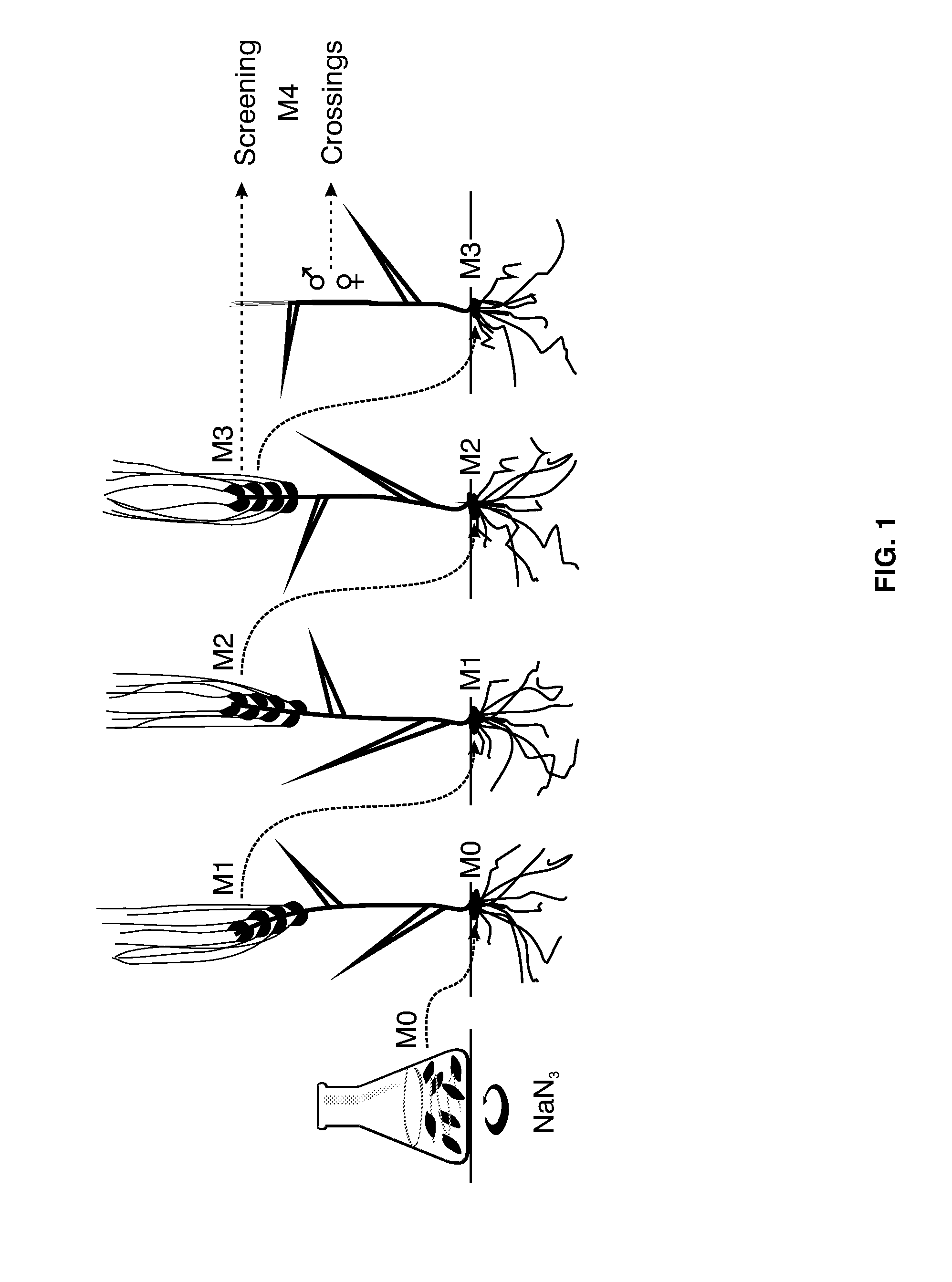

Barley for production of flavor-stable beverage

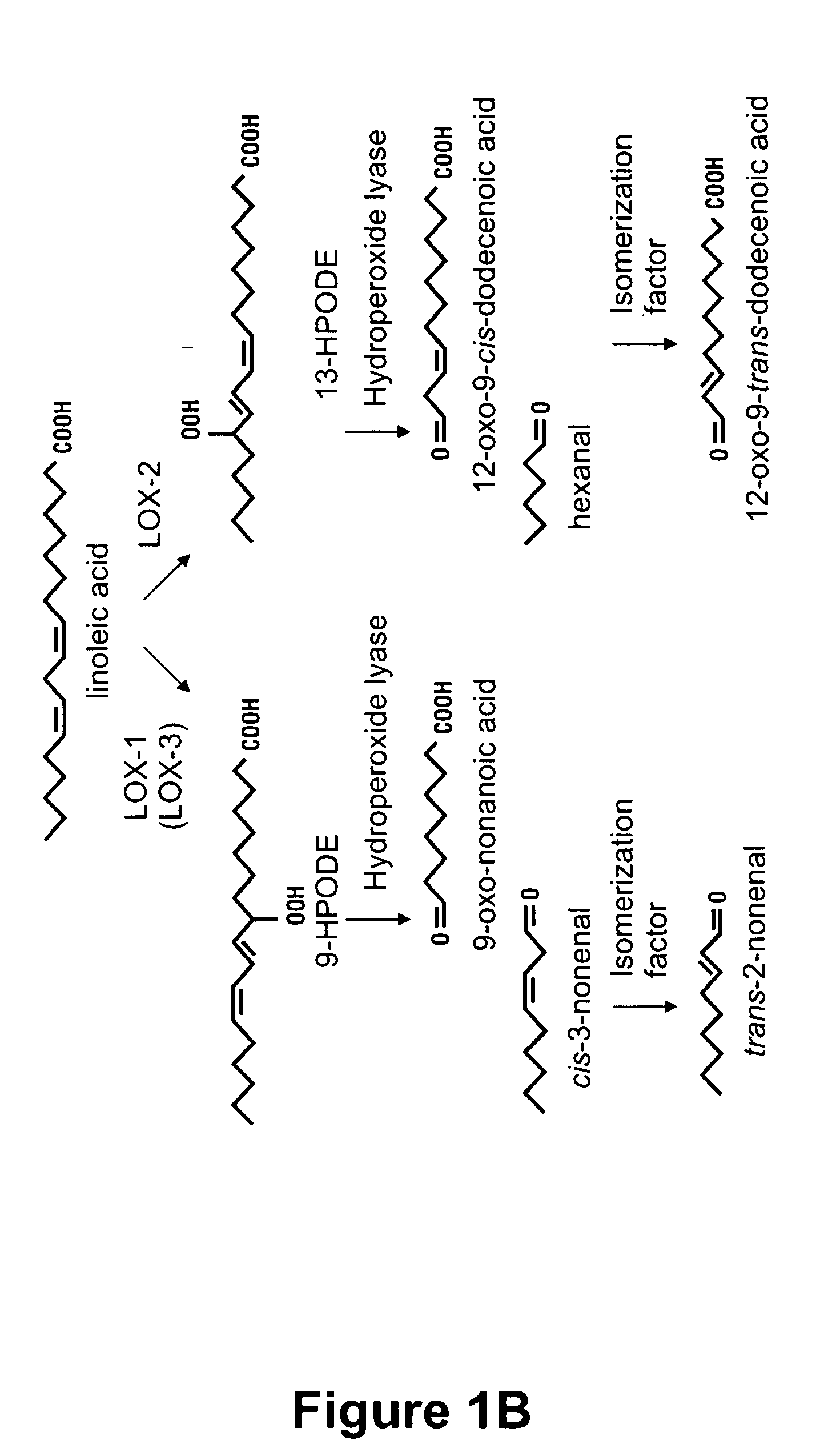

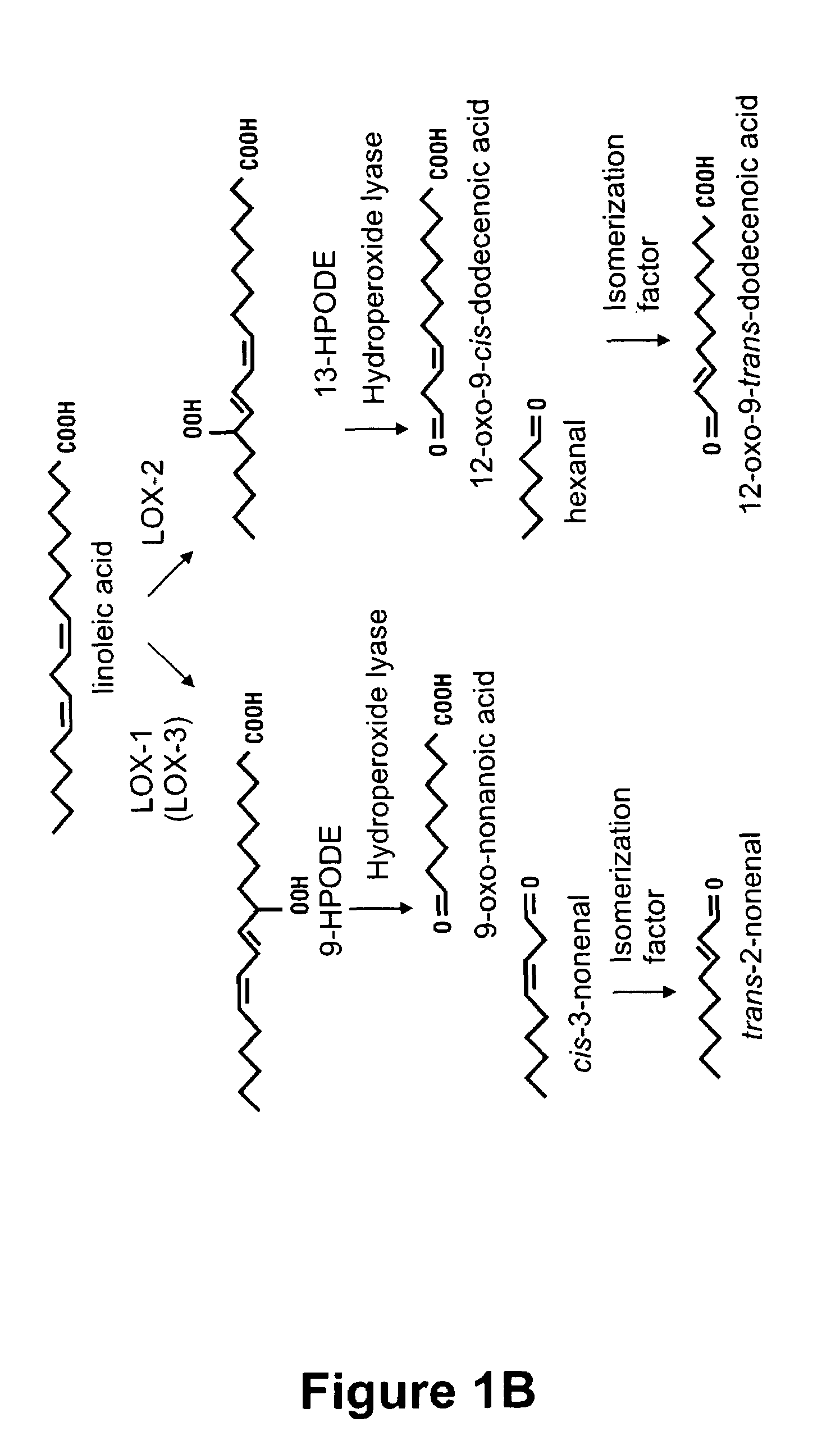

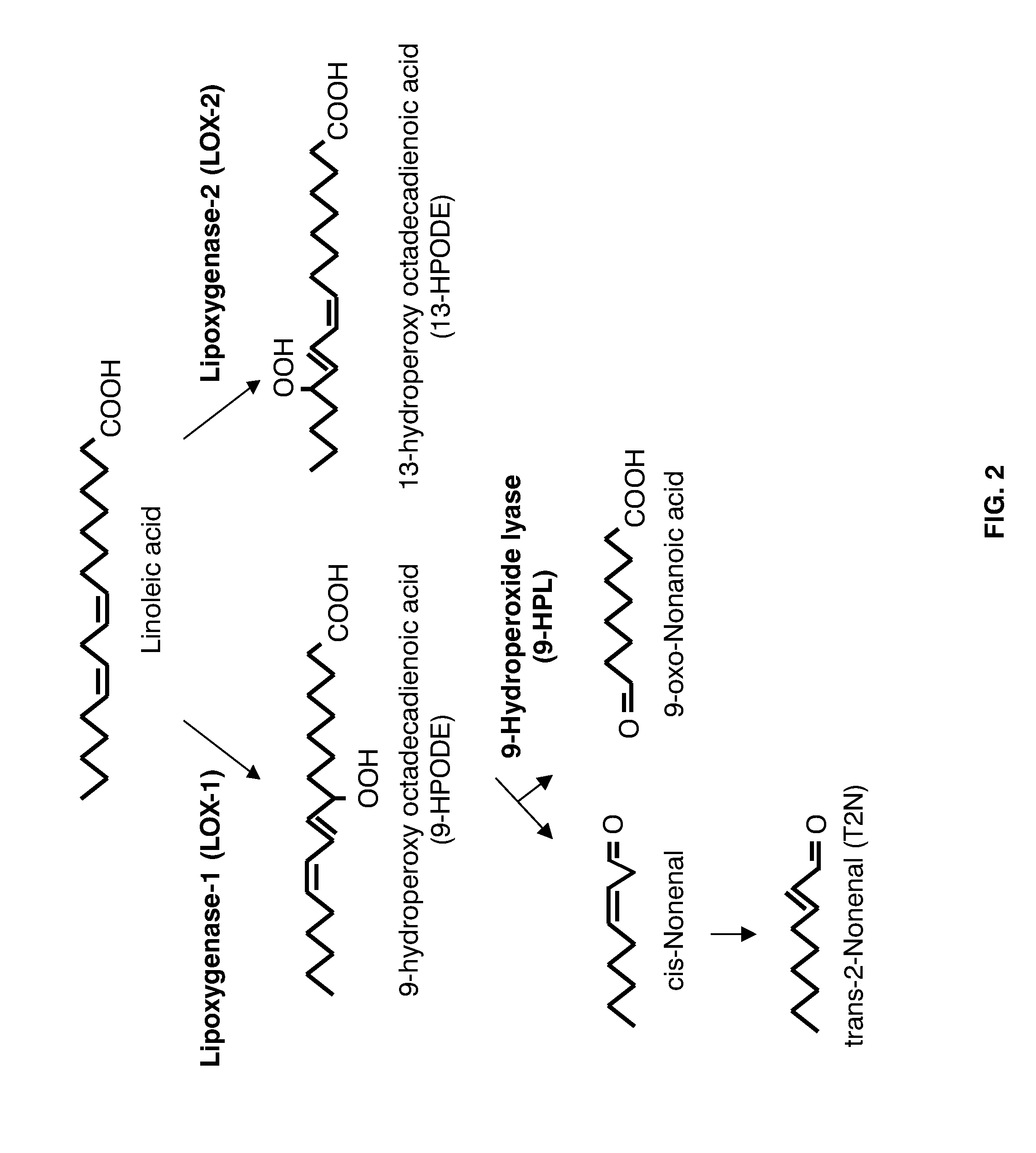

According to the invention, there is provided null-LOX-1 barley and plant products produced thereof, such as malt manufactured by using barley kernels defective in synthesis of the fatty acid-converting enzyme lipoxygenase-1. Said enzyme accounts for the principal activity related to conversion of linoleic acid into 9-hydroperoxy octadecadienoic acid, a lipoxygenase pathway metabolite, which—through further enzymatic or spontaneous reactions—may lead to the appearance of trans-2-nonenal. The invention enables brewers to produce a beer devoid of detectable trans-2-nonenal-specific off-flavors, even after prolonged storage of the beverage.

Owner:CARLSBERG BREWERIES AS

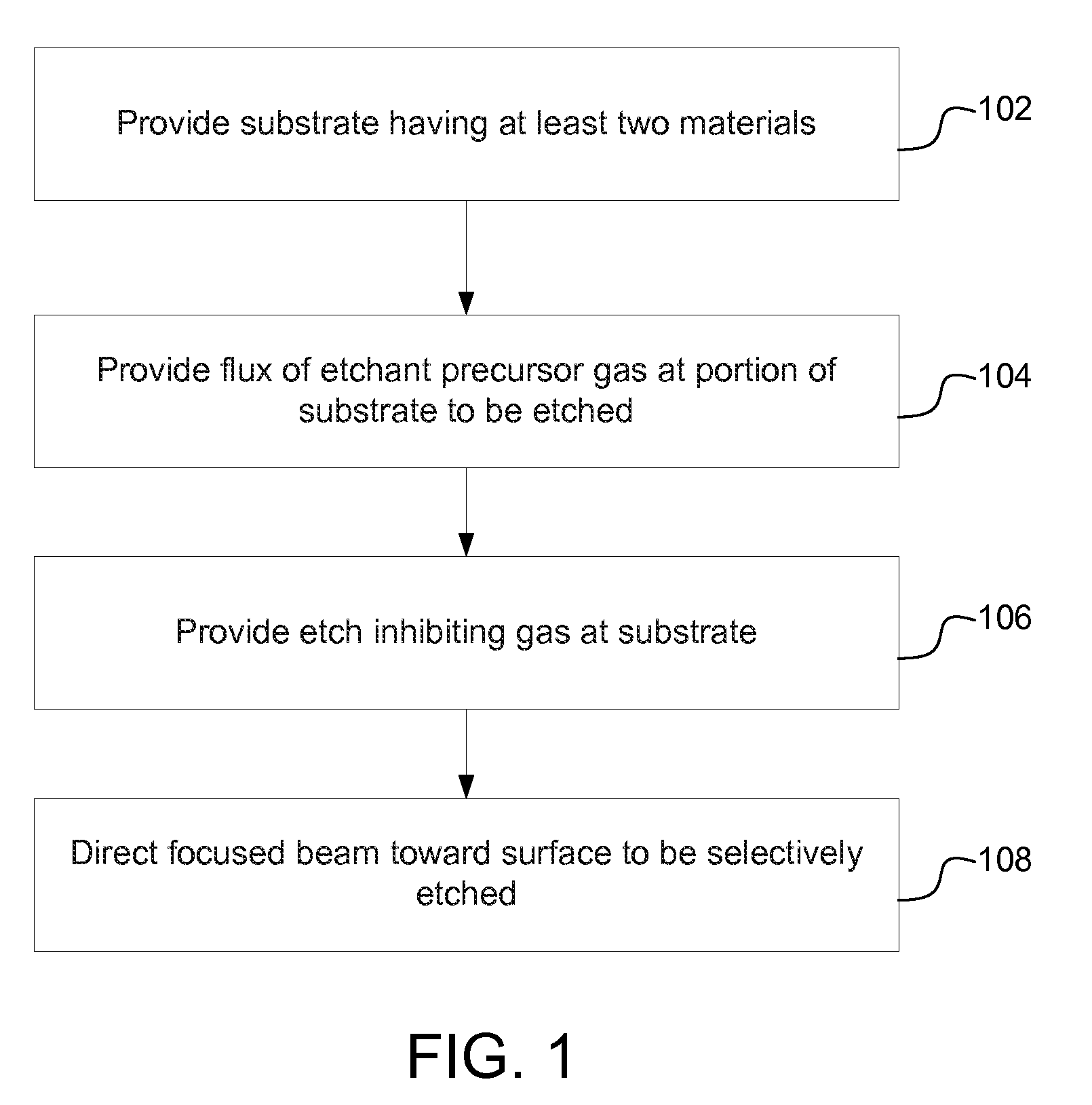

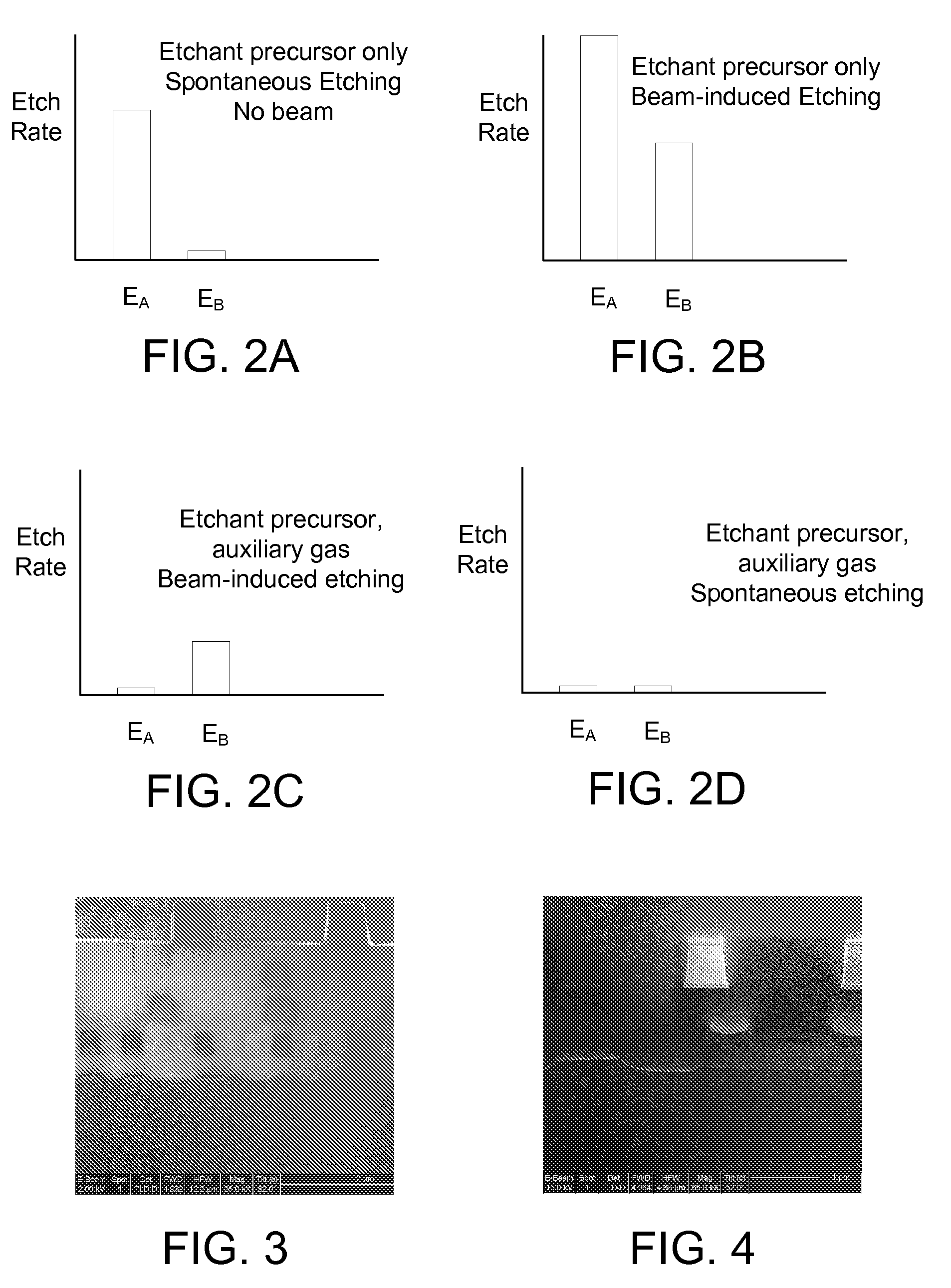

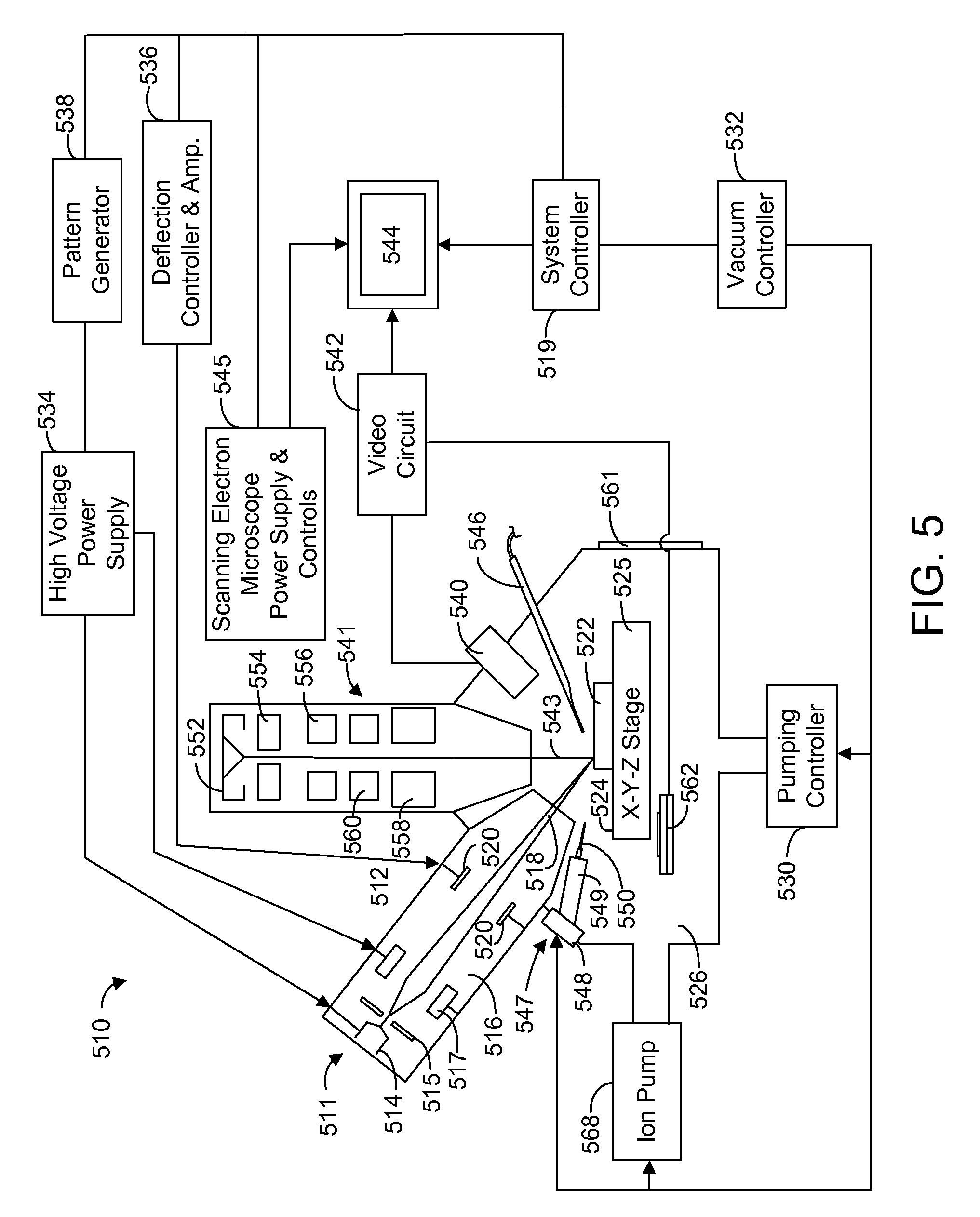

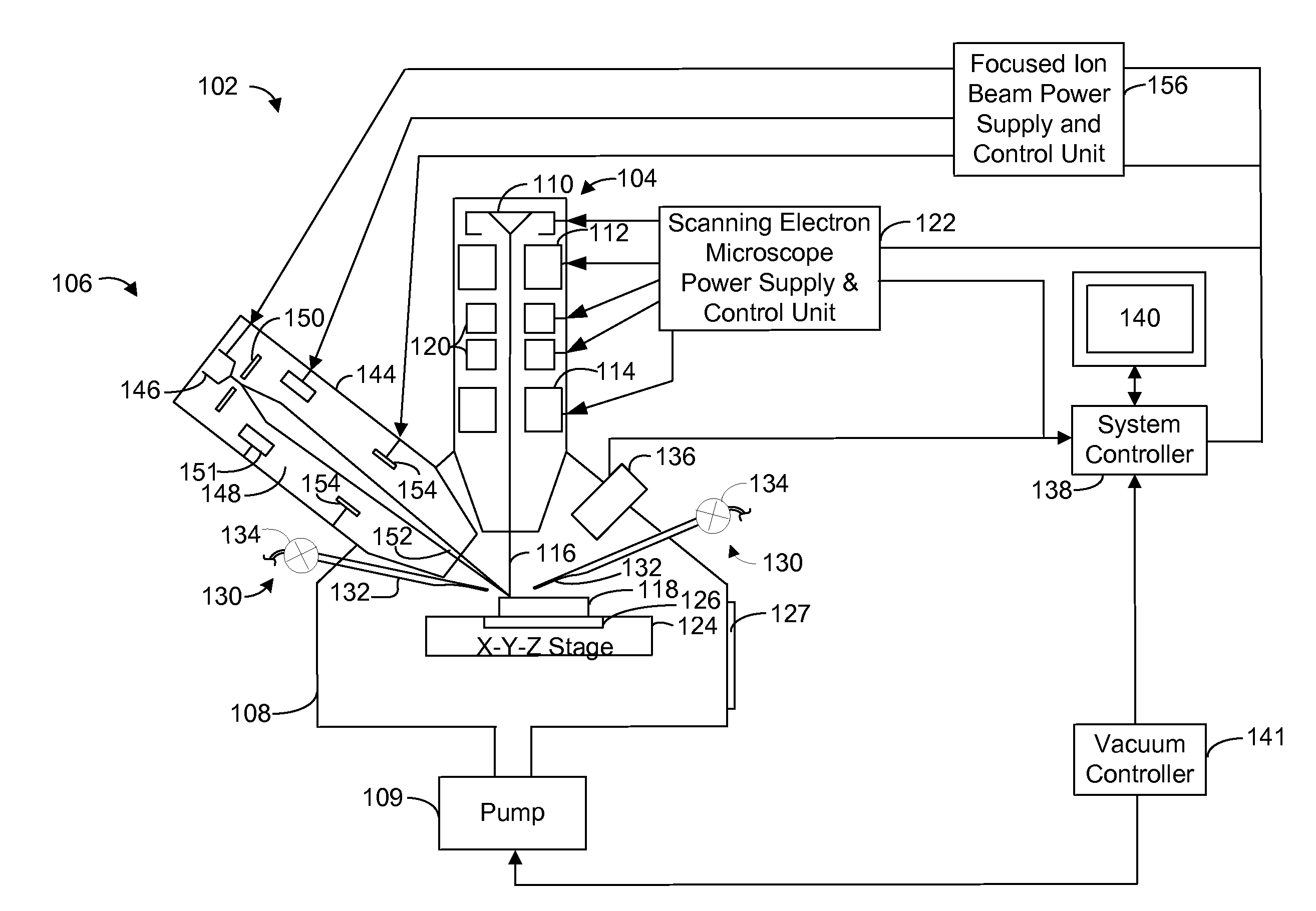

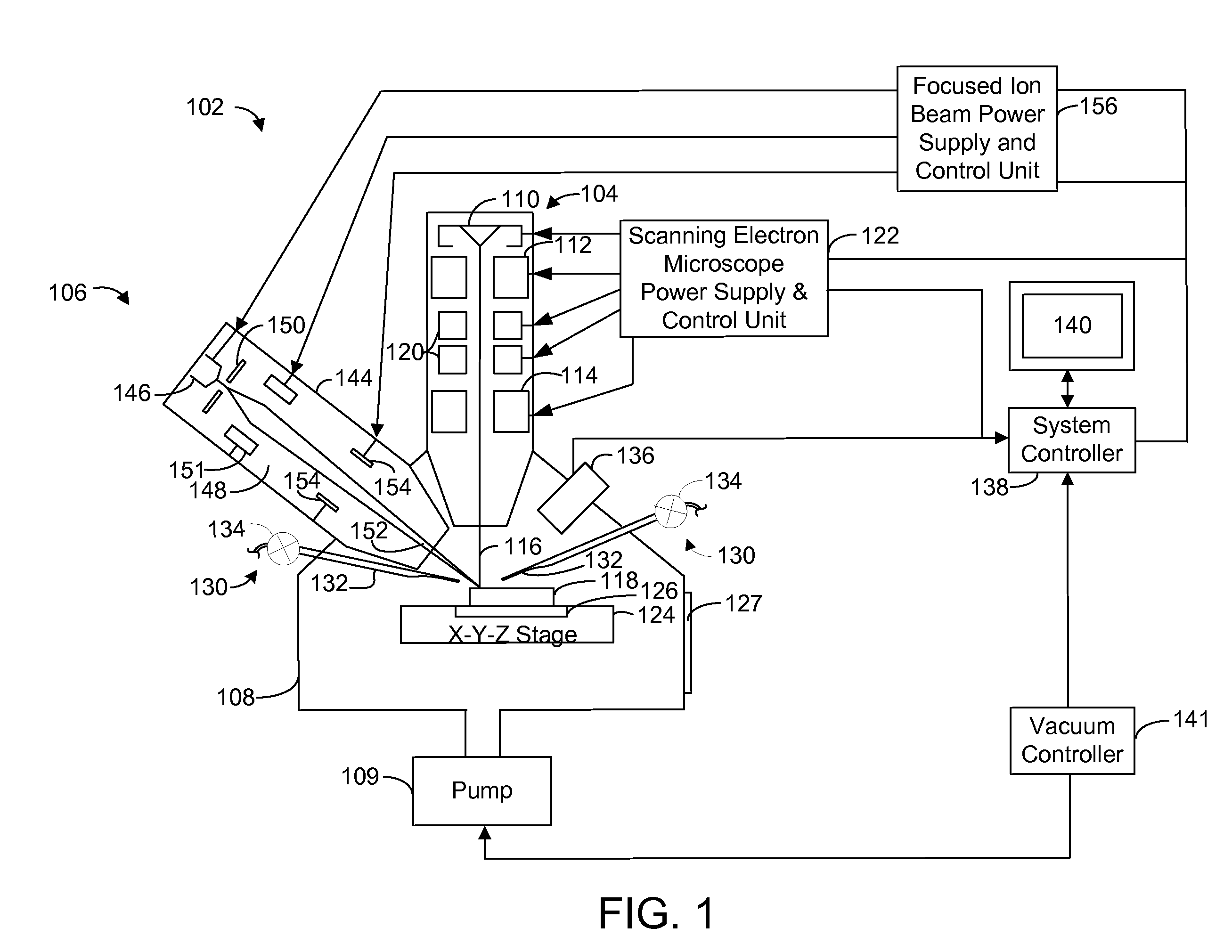

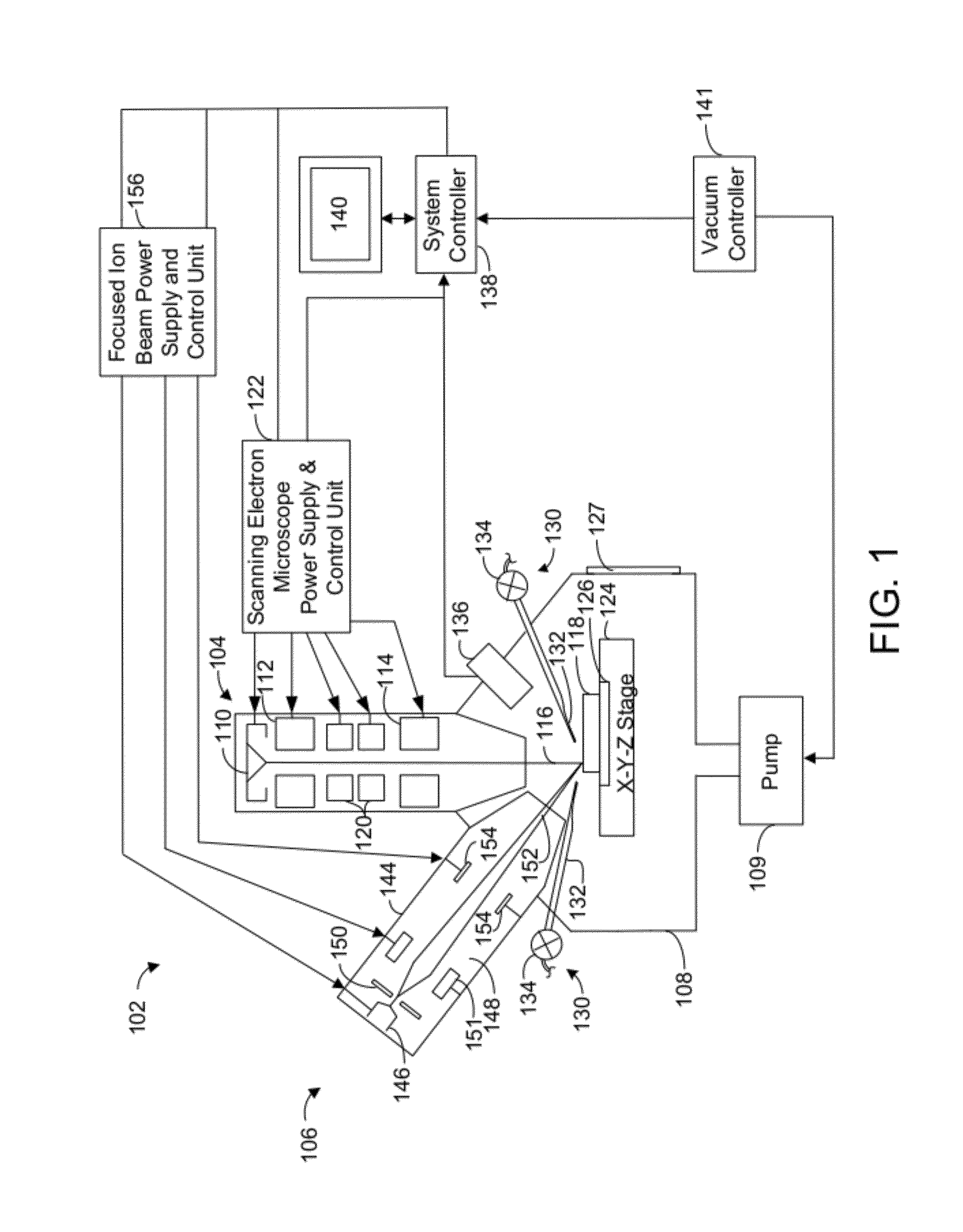

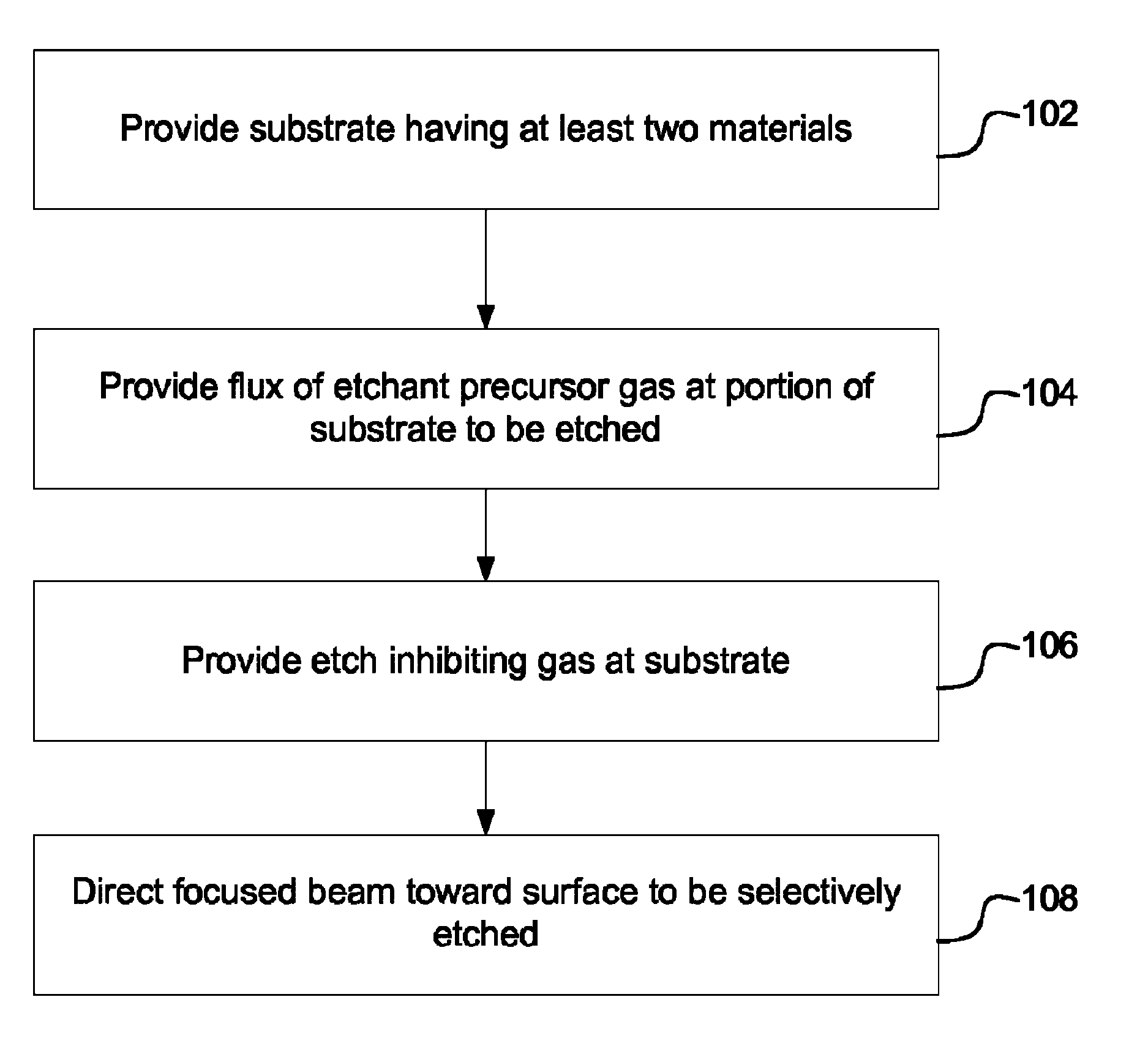

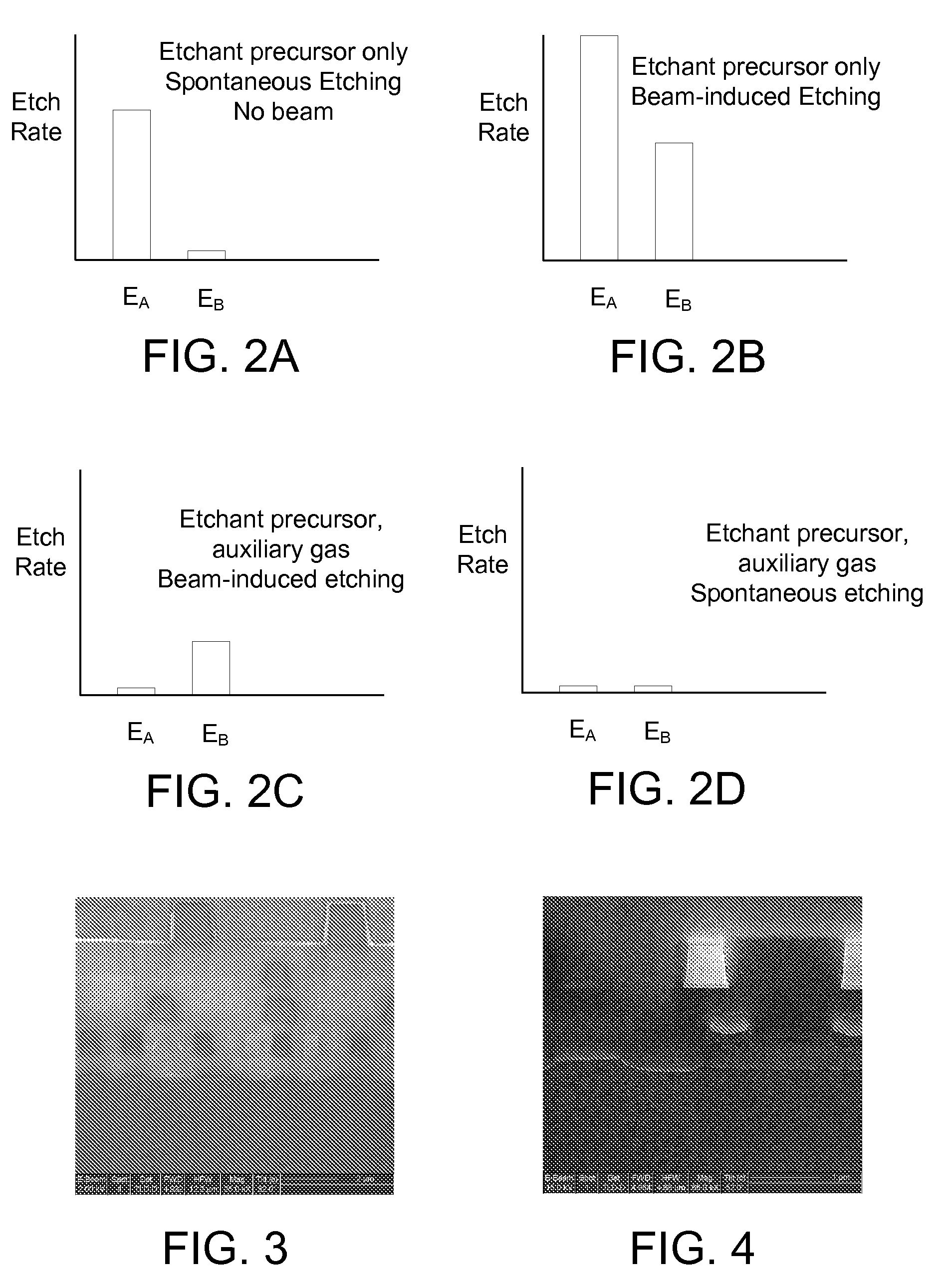

High selectivity, low damage electron-beam delineation etch

ActiveUS20100197142A1Simple methodSemiconductor/solid-state device manufacturingSpontaneous reactionHigh selectivity

A method and apparatus for selective etching a substrate using a focused beam. For example, multiple gases may be used that are involved in competing beam-induced and spontaneous reactions, with the result depending on the materials on the substrate. The gases may include, for example, an etchant gas and an auxiliary gas that inhibits etching.

Owner:FEI COMPANY

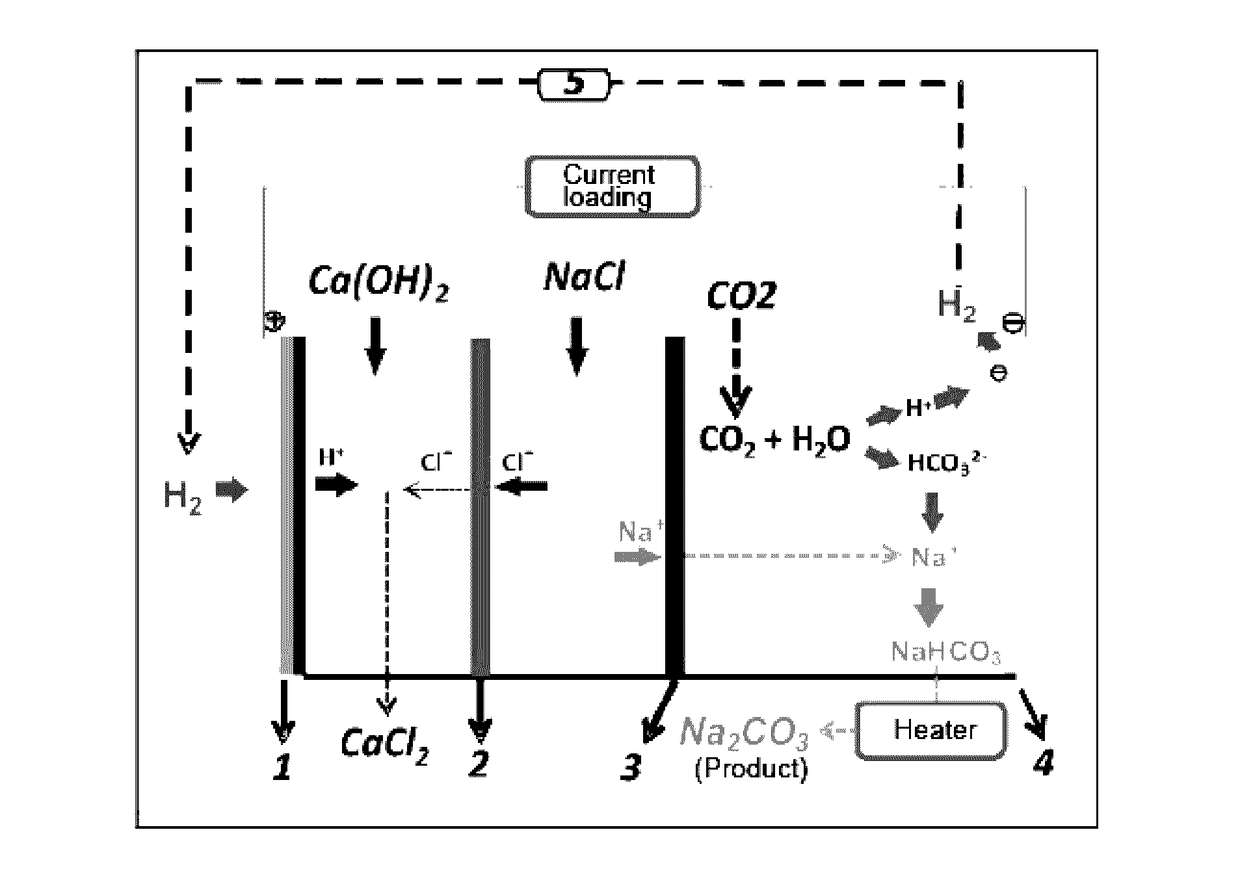

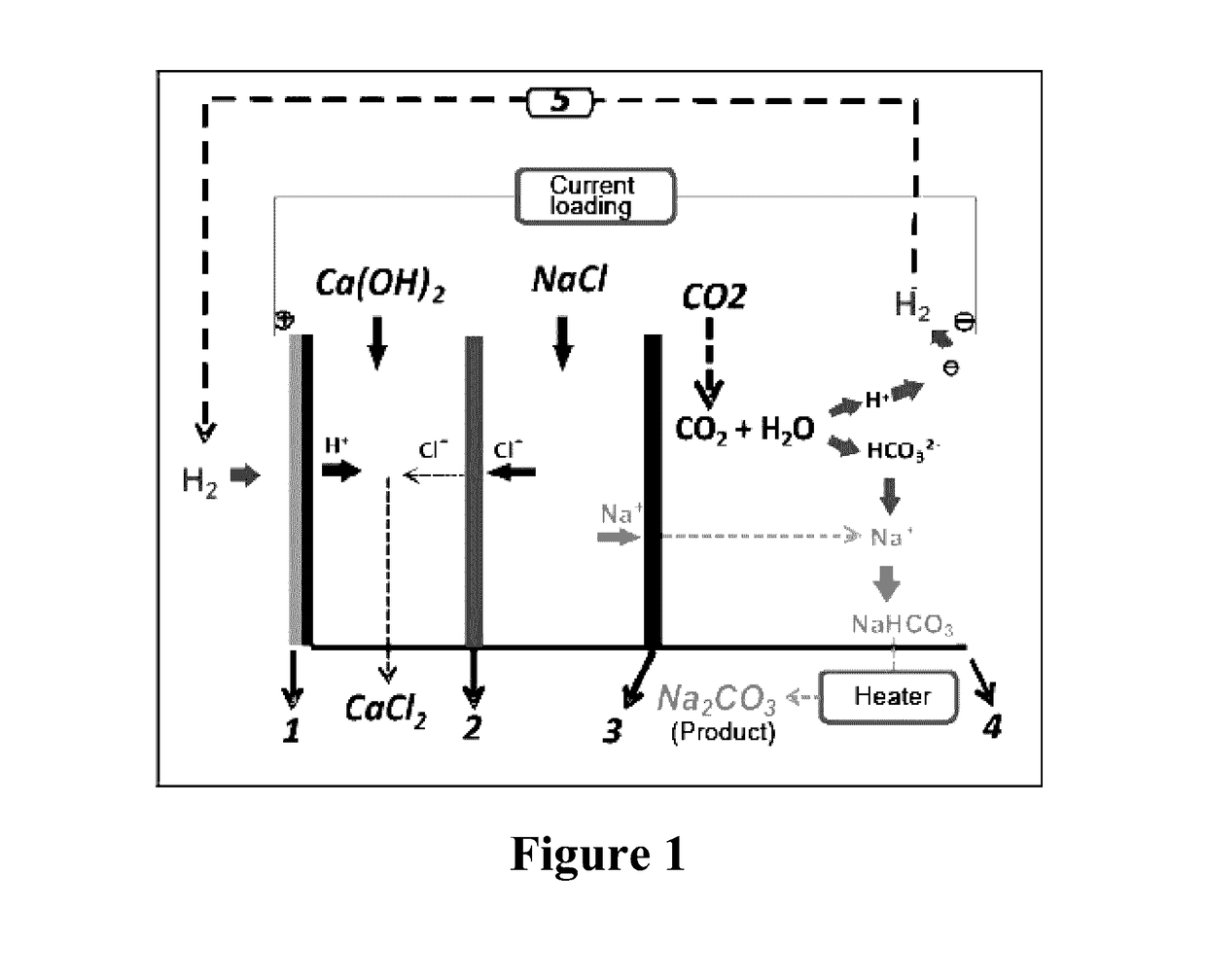

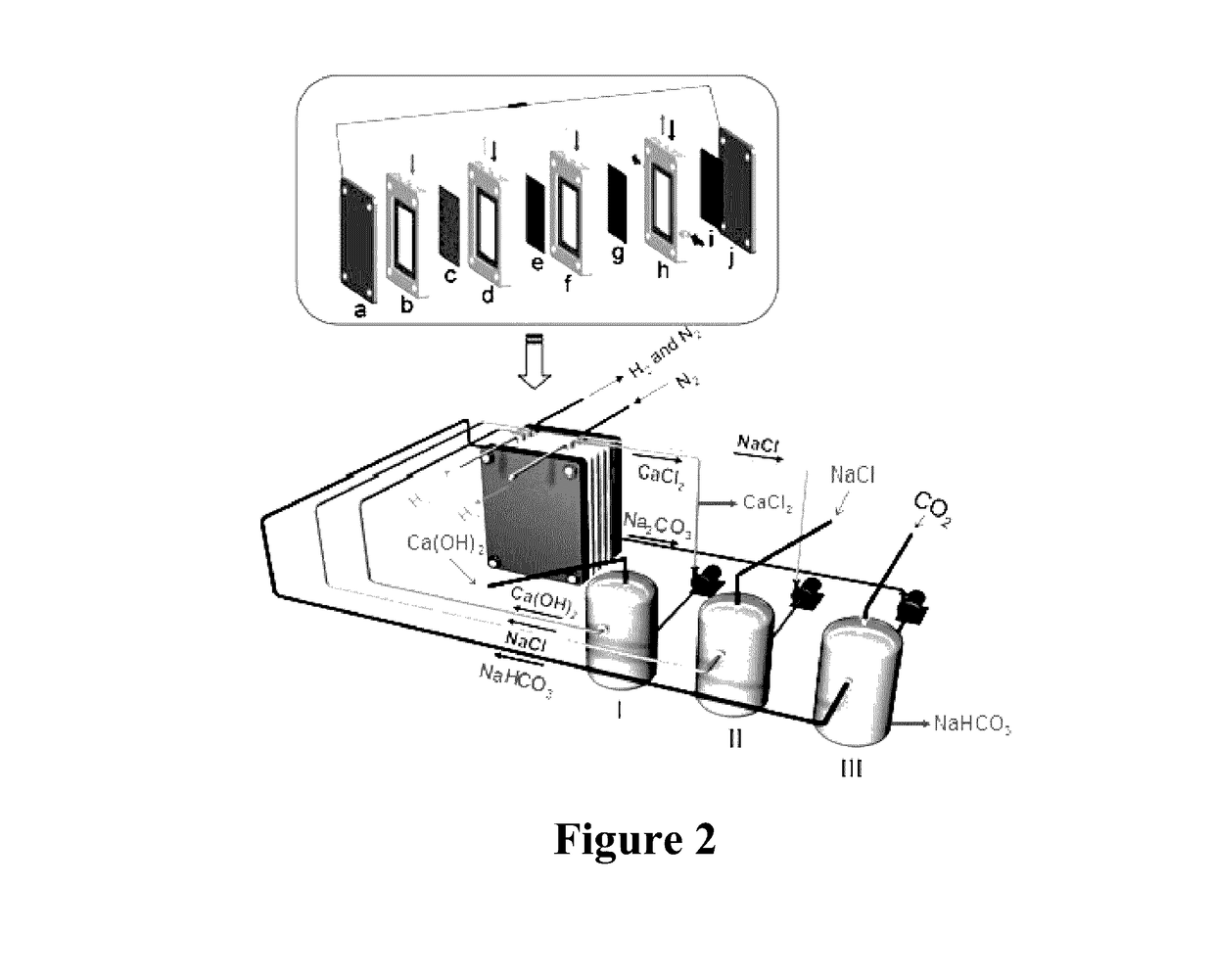

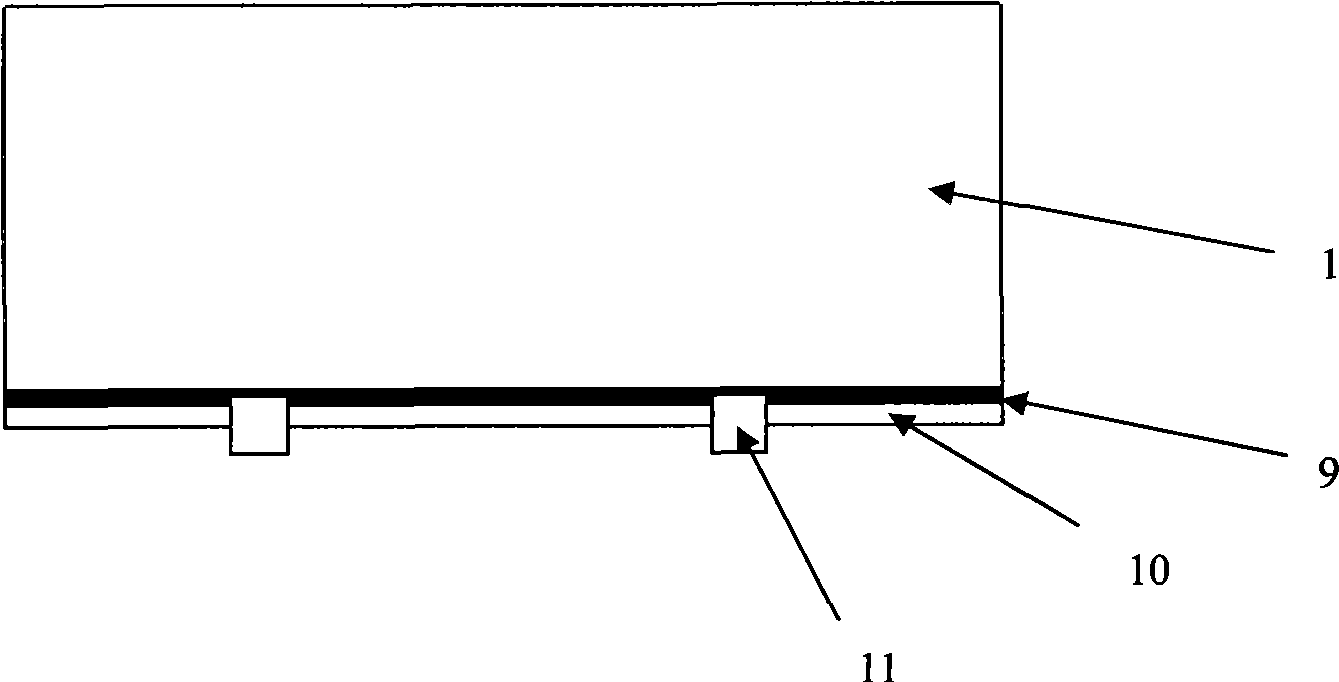

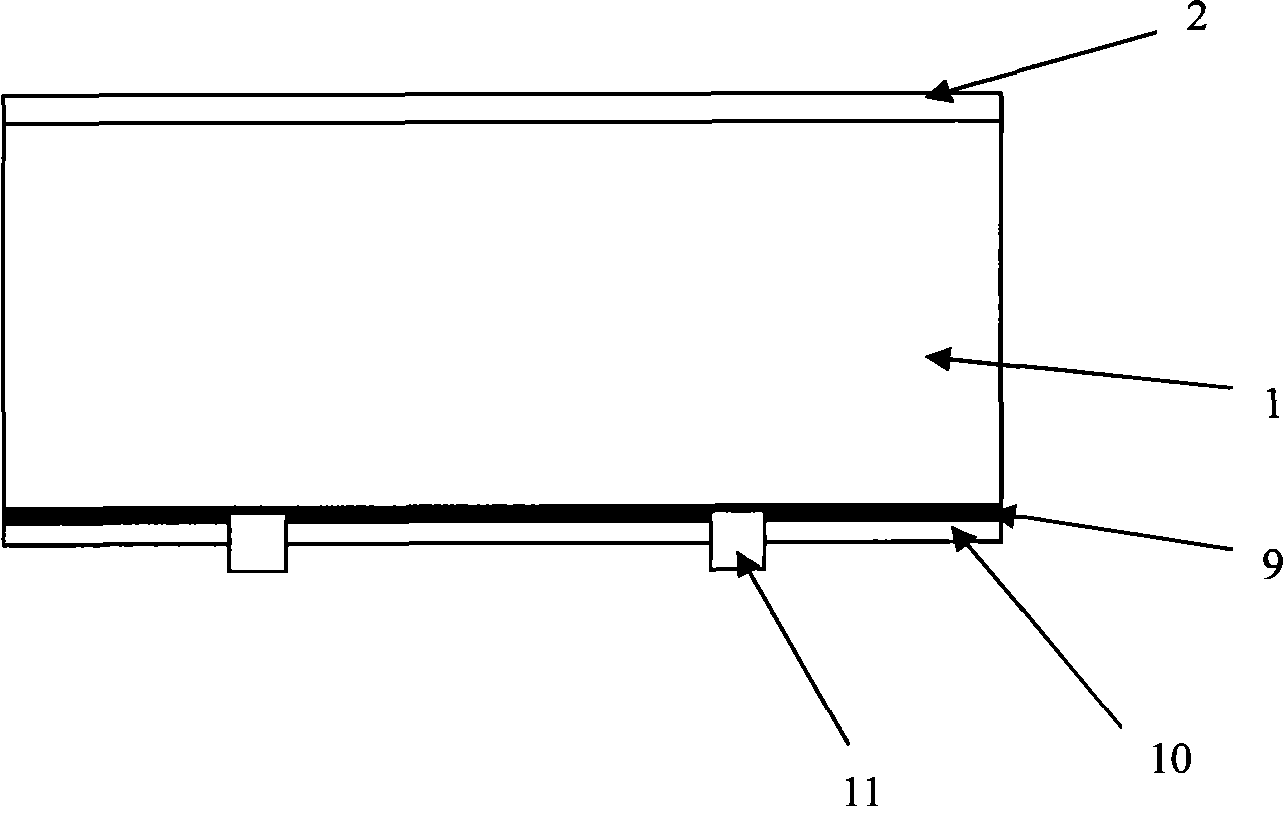

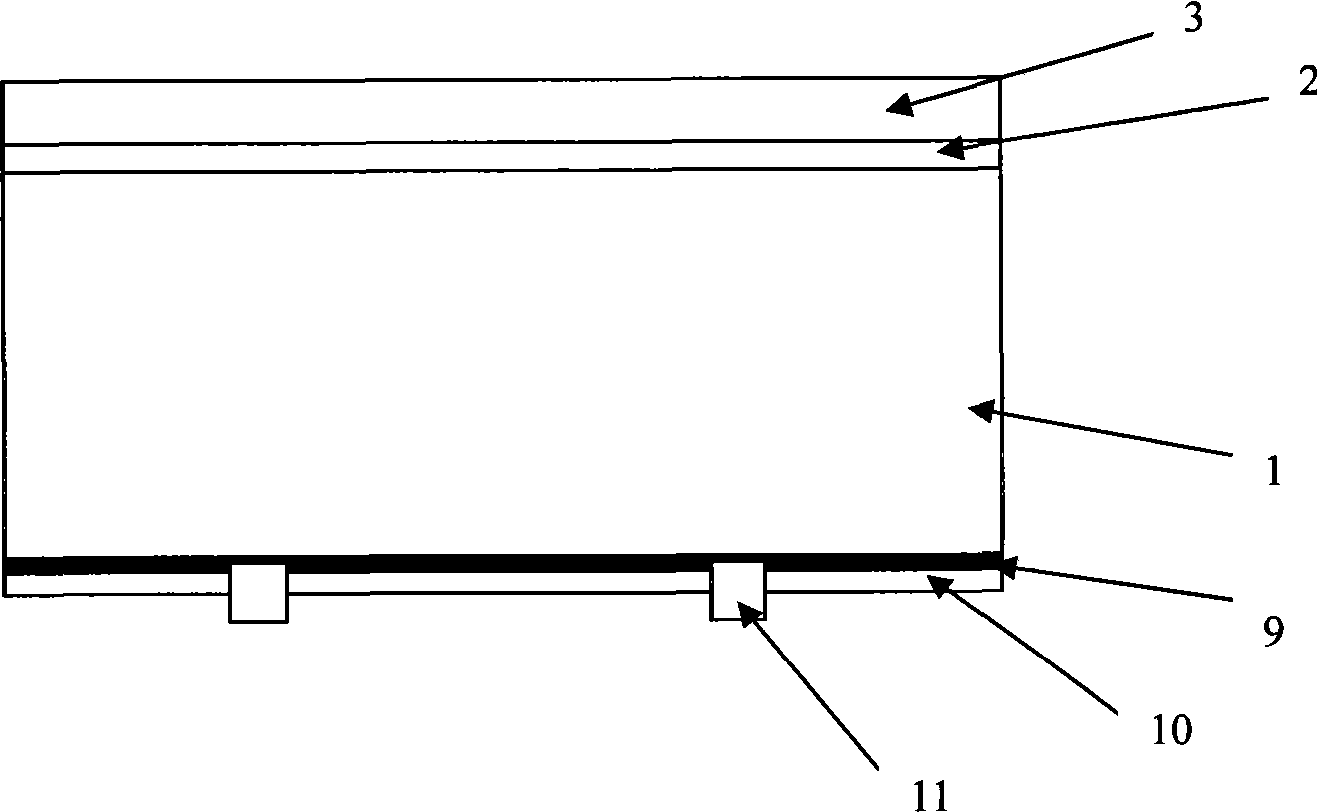

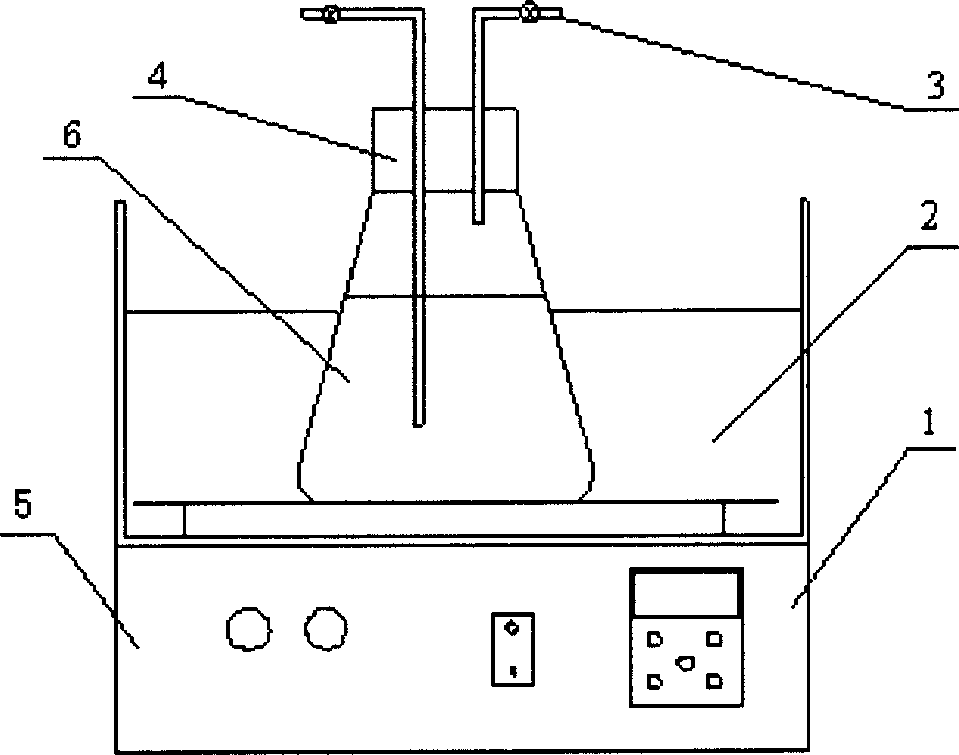

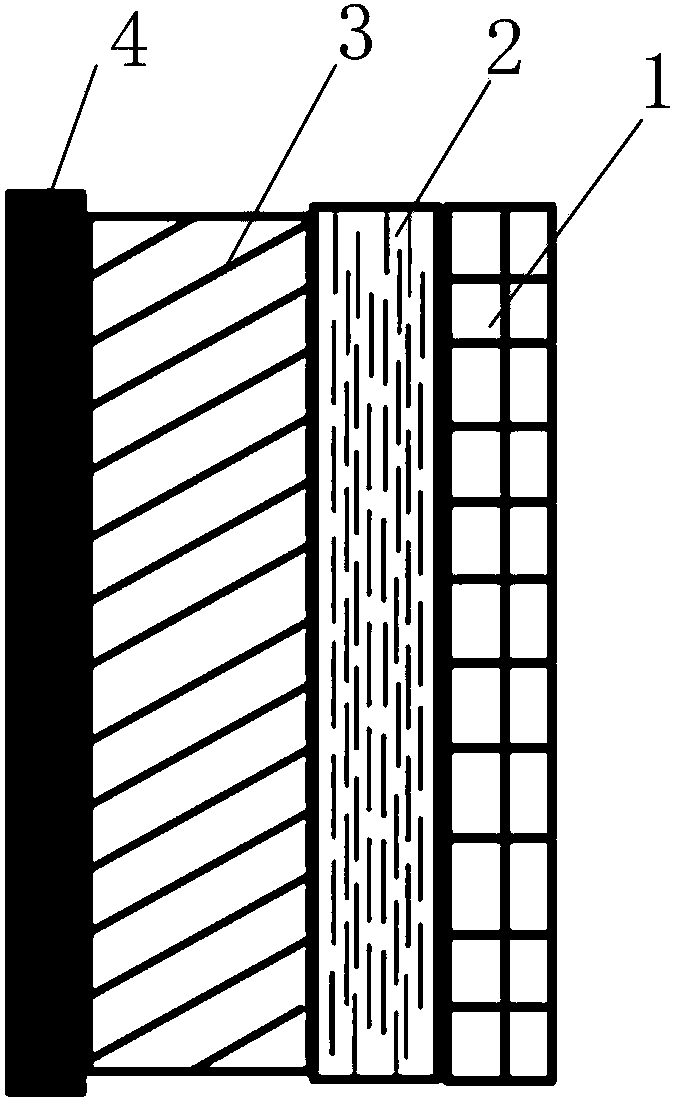

Method and device for using co2 mineralization to produce sodium bicarbonate or sodium carbonate and output electric energy

ActiveUS20170137951A1Facilitate spontaneous reaction and separationImprove conductivityCellsCell electrodesSodium bicarbonateElectrolysis

Disclosed are a method and device for using CO2 mineralization to produce sodium bicarbonate or sodium carbonate and output electric energy. The device comprises an anode area, an intermediate area, and a cathode area. The anode area and the intermediate area are spaced by a negative ion exchange membrane (2). The intermediate area and the cathode area are spaced by a positive ion exchange membrane (3). The anode area, the intermediate area, and the cathode area can accommodate corresponding electrolytes. An anode electrode (1) is disposed in the anode area, a cathode electrode (4) is disposed in the cathode area, and the cathode electrode and the anode electrode are connected through a circuit. A raw material hydrogen gas inlet is disposed in the anode area, and a CO2 inlet and a product hydrogen gas outlet are disposed in the cathode area. The method is based on the principle of CO2 mineralization and utilization, combines the membrane electrolysis technology, facilitates spontaneous reaction by using the acidity of CO2 and the alkalinity of the reaction solution and realizes separation of the products, and converts through a membrane electrolysis apparatus the energy released by the reaction into electric energy at the same time when producing the sodium bicarbonate or sodium carbonate and outputs the electric energy. The method and device have low energy consumption, high utilization rate of raw materials and little environmental pollution, and can output electric energy while producing sodium carbonate at the same time.

Owner:SICHUAN UNIV

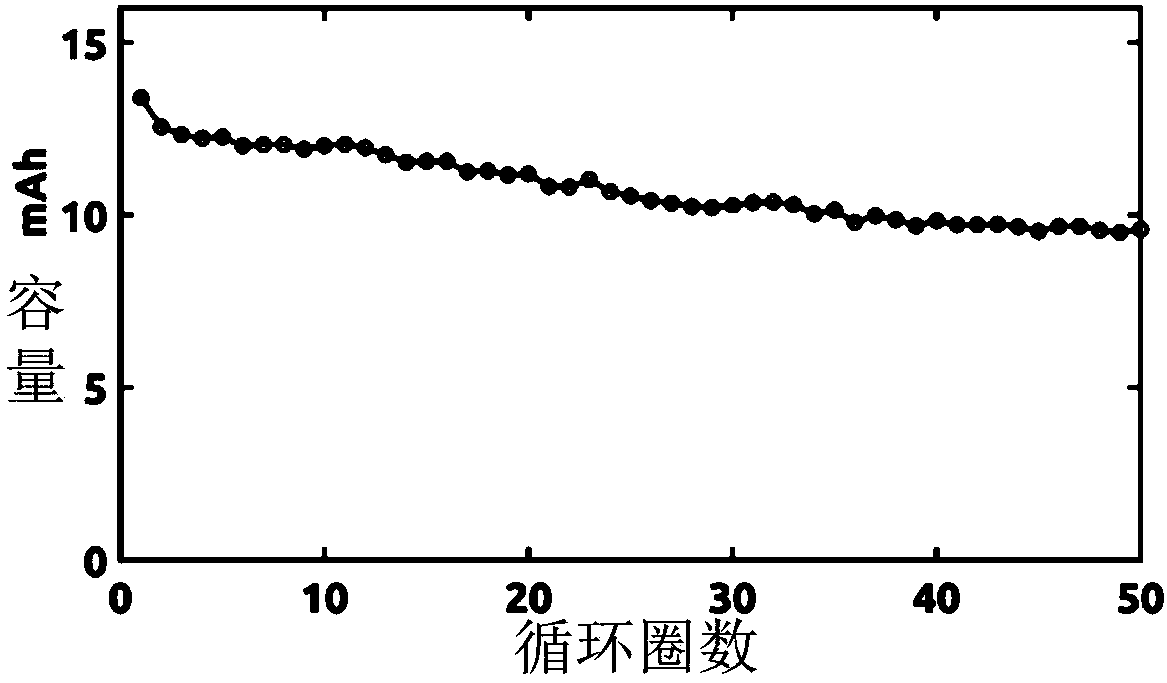

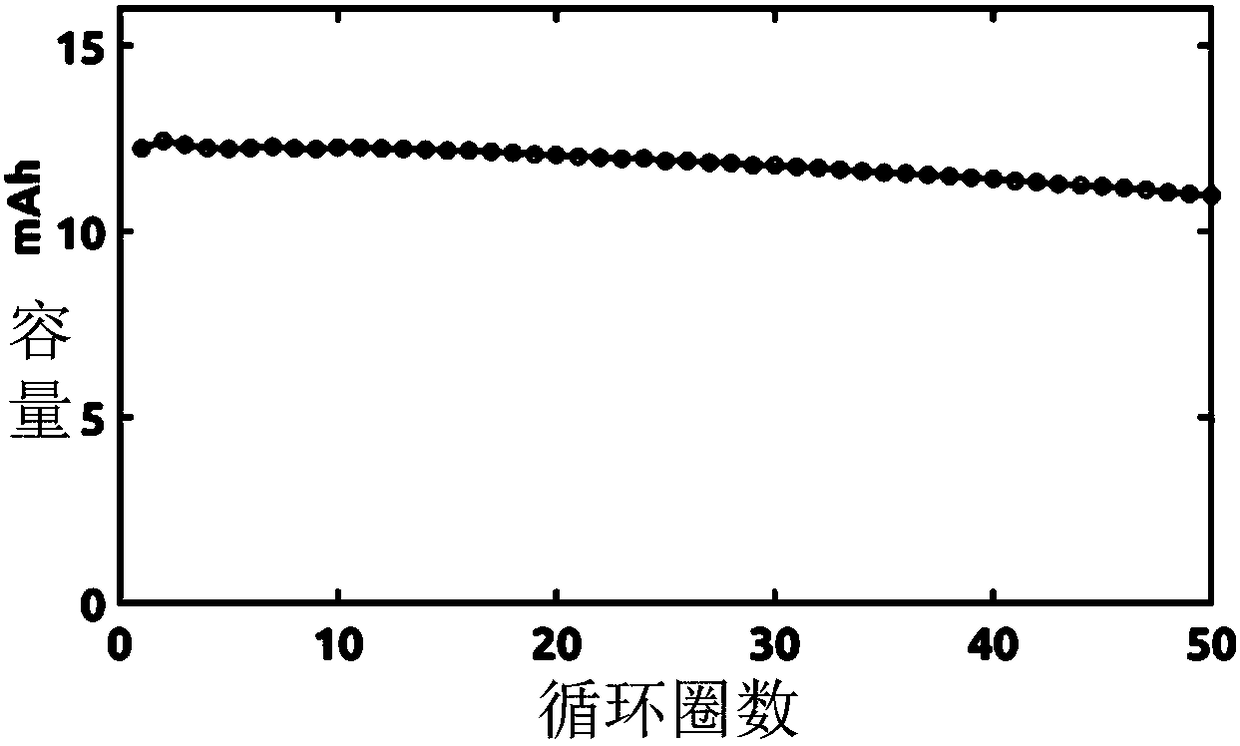

Sodium vanadium fluorophosphate as well as low-temperature environment-friendly preparation method and use thereof

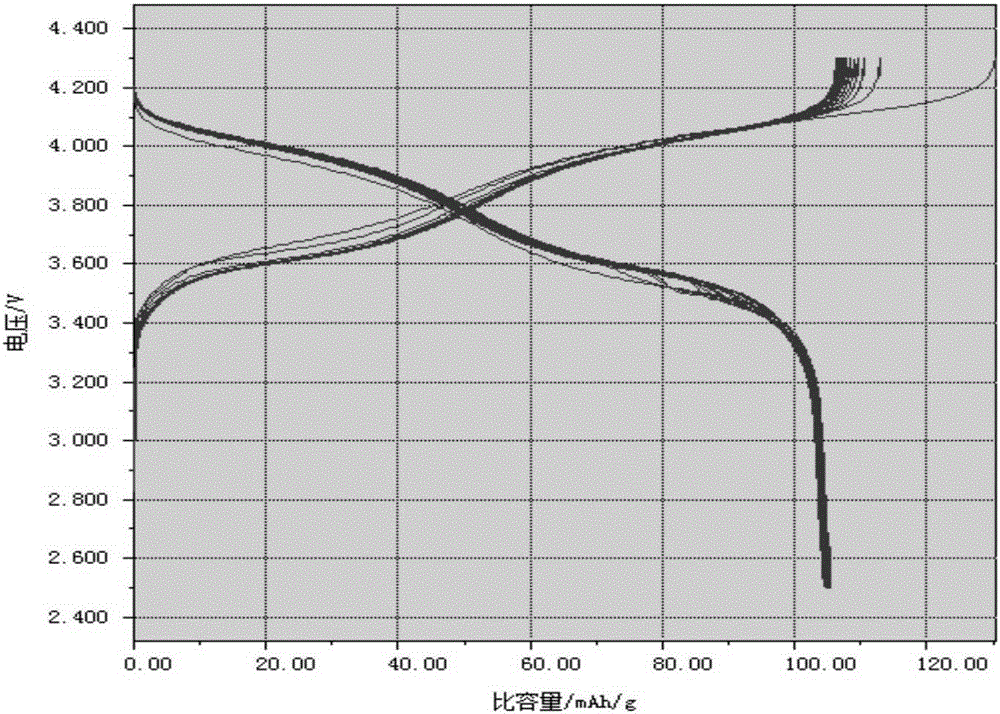

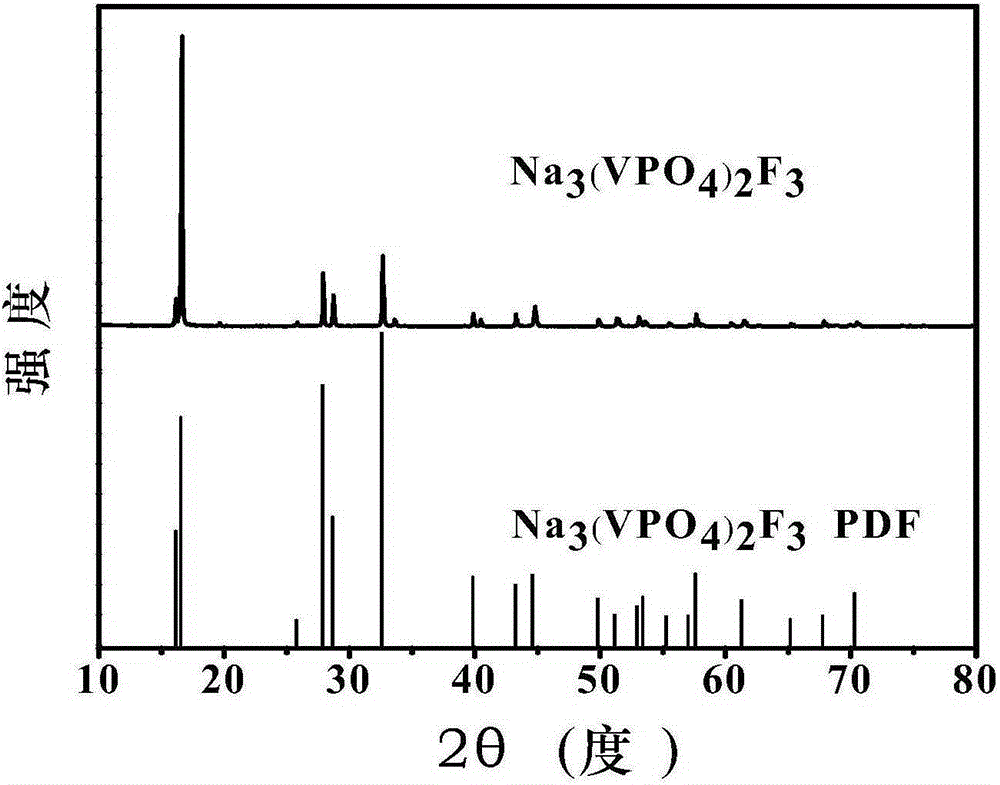

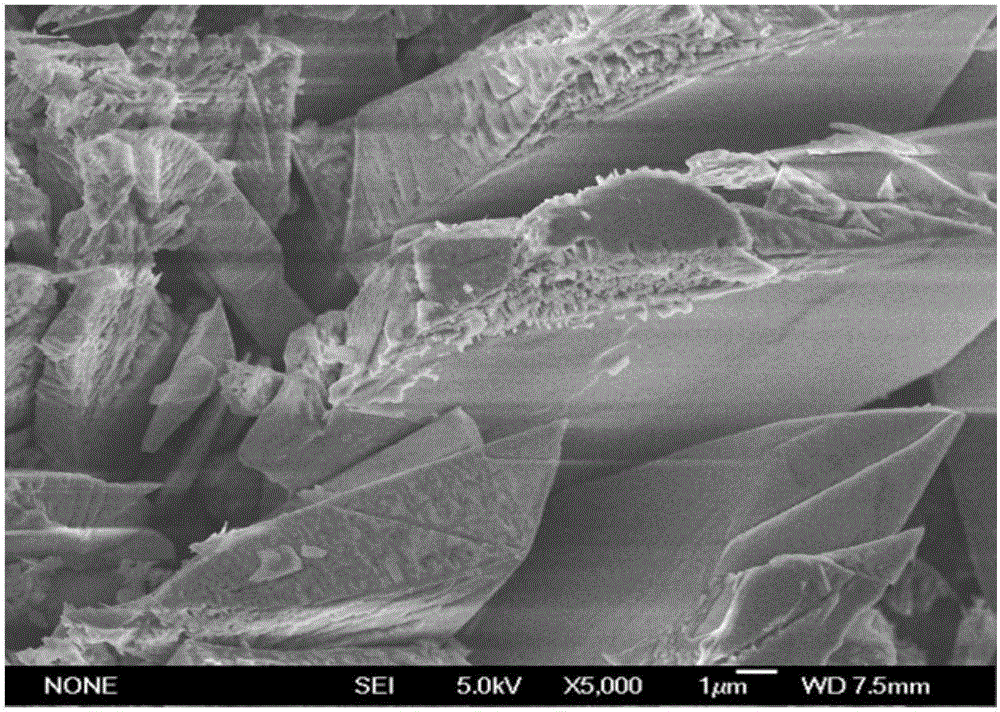

InactiveCN106495124AImprove electrochemical performanceSynthesis temperature is lowCell electrodesPhosphorus compoundsAqueous solutionSpecific discharge

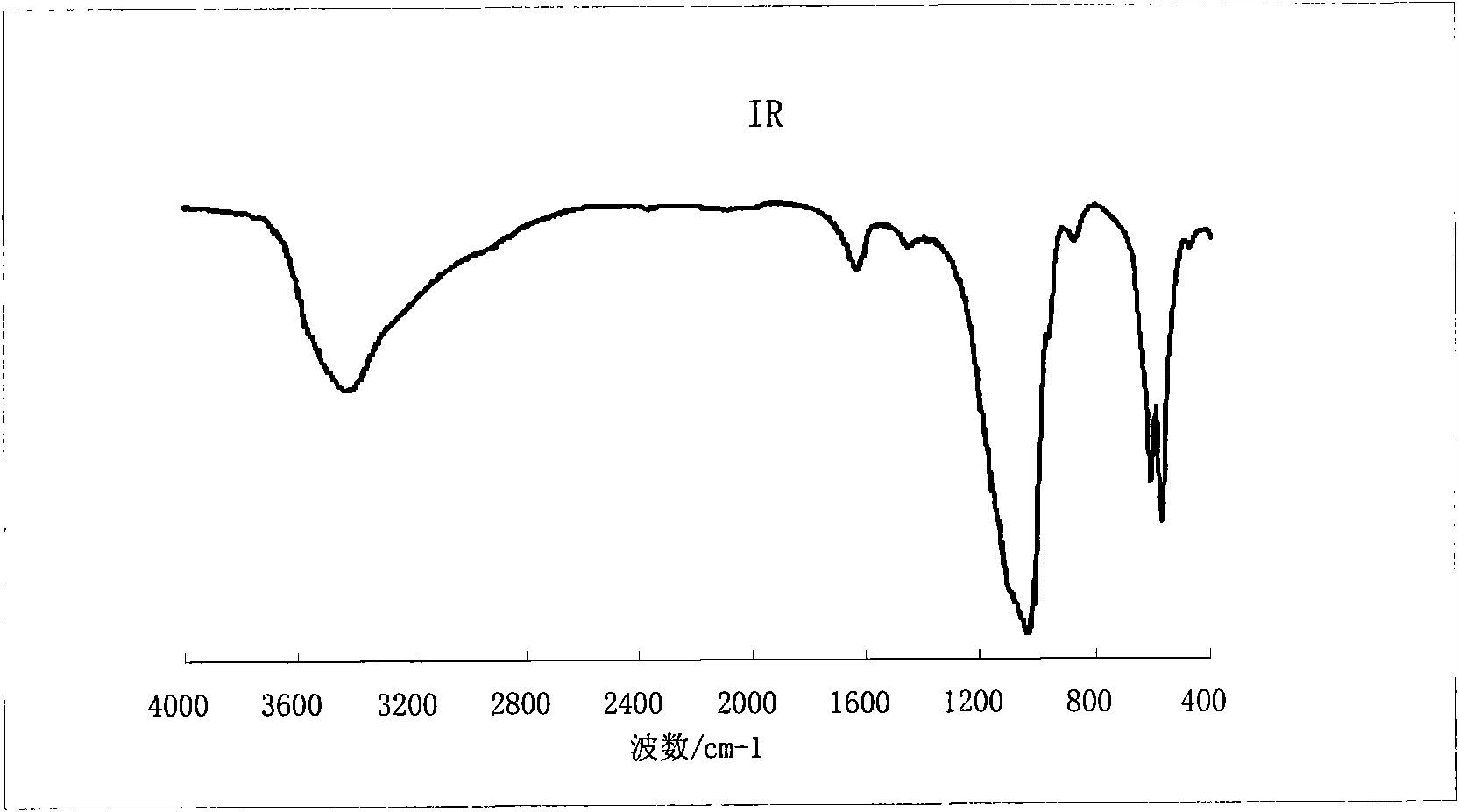

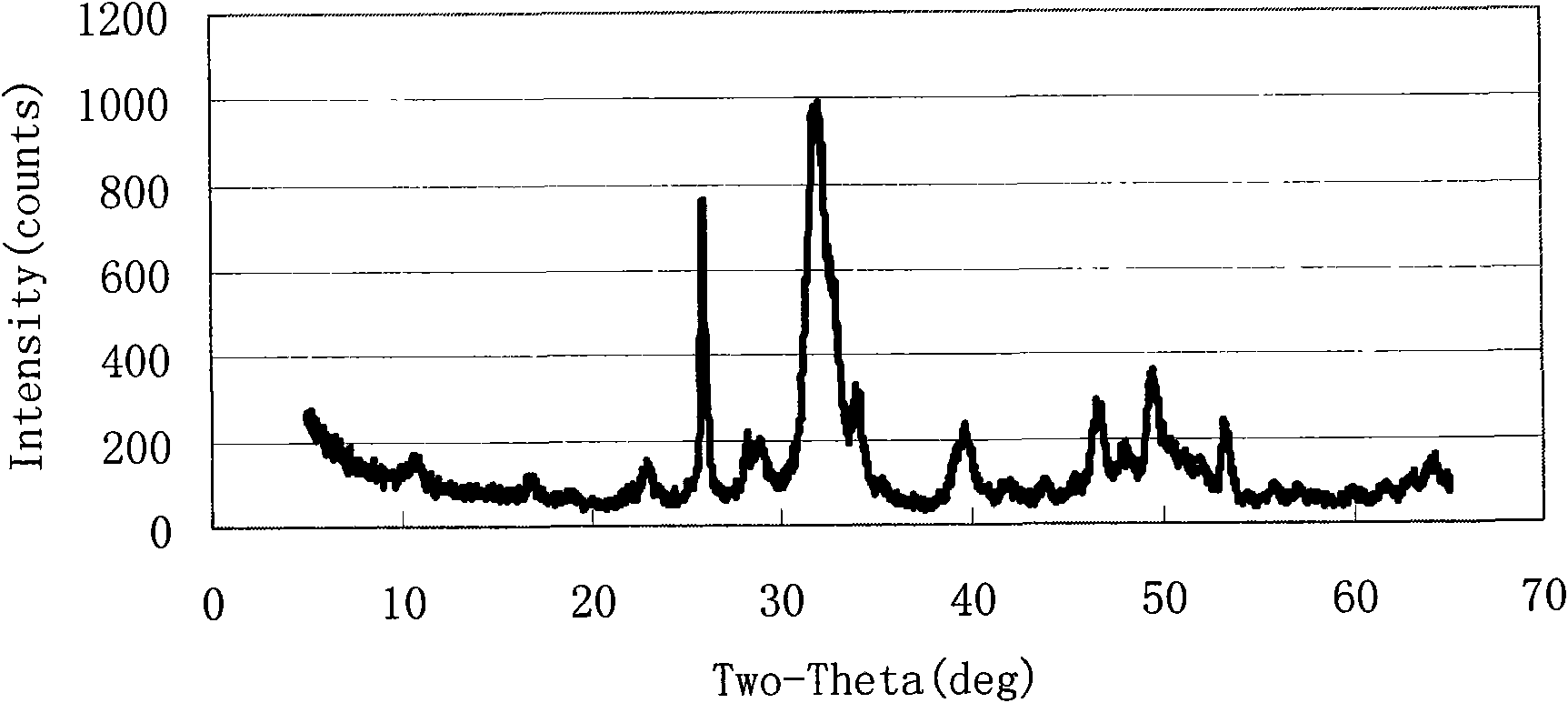

The invention belongs to the technical field of electrode materials and relates to sodium vanadium fluorophosphate as well as a low-temperature environment-friendly preparation method and use thereof. The preparation method comprises the steps of preparing a mixed water solution of a sodium source, a vanadium source, a phosphorus source and a fluorine source, reacting by virtue of the mixed water solution at 20-180 DEG C to obtain sodium vanadium fluorophosphate, wherein the vanadium source is a trivalent vanadium source and / or a tetravalent vanadium source; the chemical constitution of sodium vanadium fluorophosphate is Na3(VOxPO4)2F3-2x, and x is more than or equal to 0 and less than or equal to 1. According to the low-temperature environment-friendly preparation method, the mixed water solution of the sodium source, thephosphorus source, the fluorine source and the trivalent vanadium source and / or a tetravalent vanadium source can generate spontaneous reaction at 20-35 DEG C, the reaction can be accelerated at a temperature high than 35 DEG C and lower than 180 DEG C, and well-crystallized sodium vanadium fluorophosphate can be obtained. Sodium vanadium fluorophosphate can be used as an anode to be assembled into a battery, the specific discharge capacity is not lower than 100mAh / g, and the cycling stability is good.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Barley for production of flavor-stable beverage

Owner:CARLSBERG BREWERIES AS

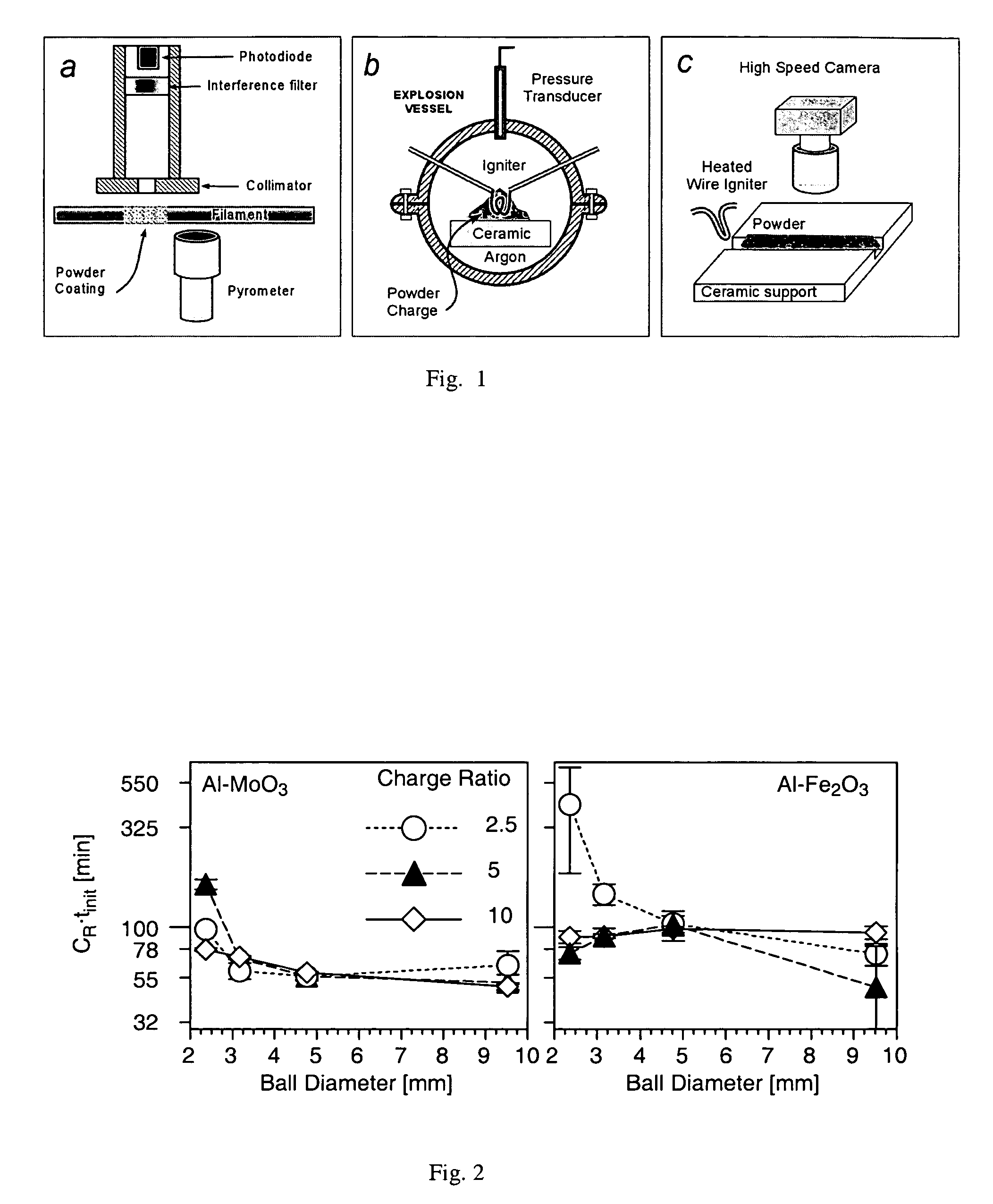

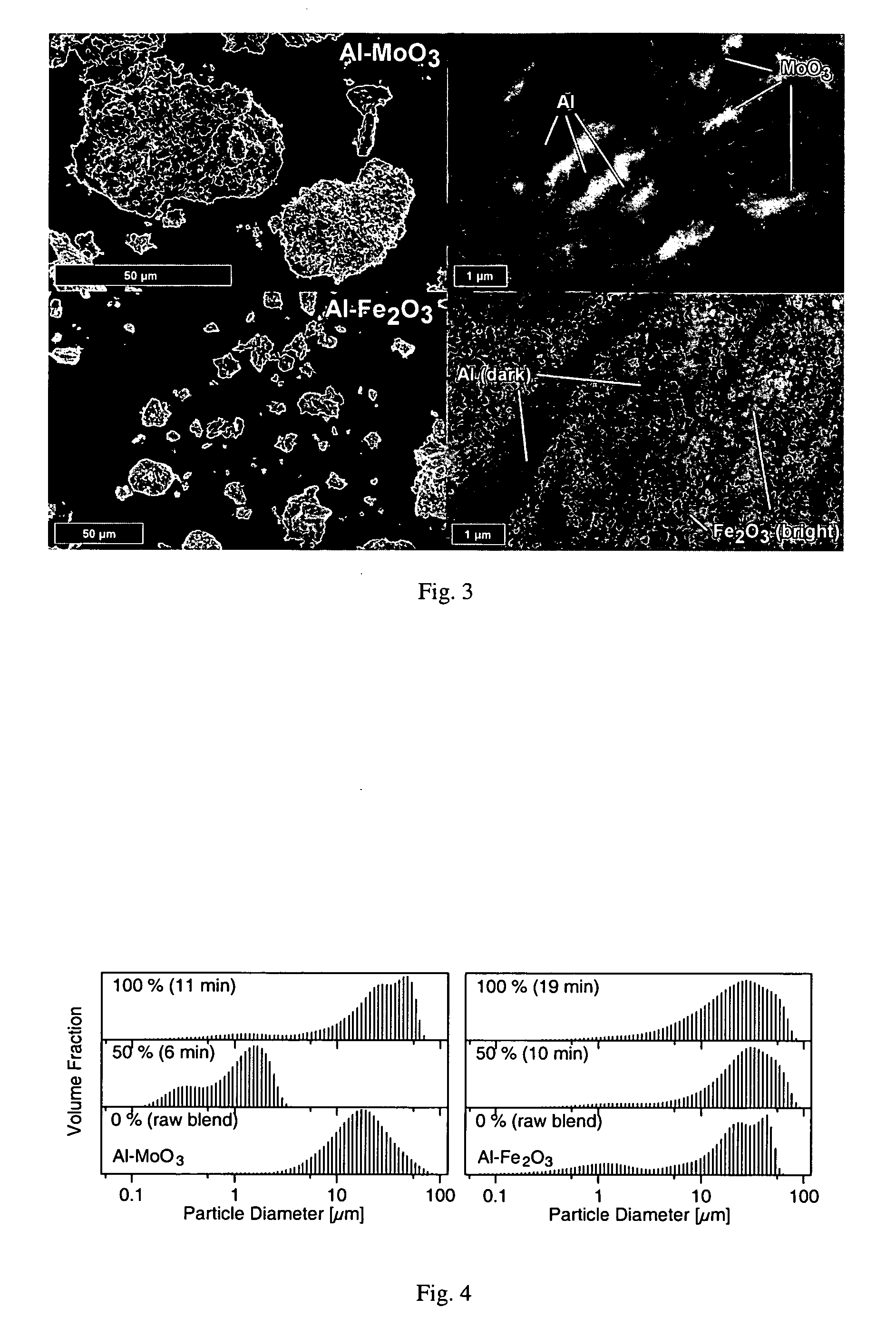

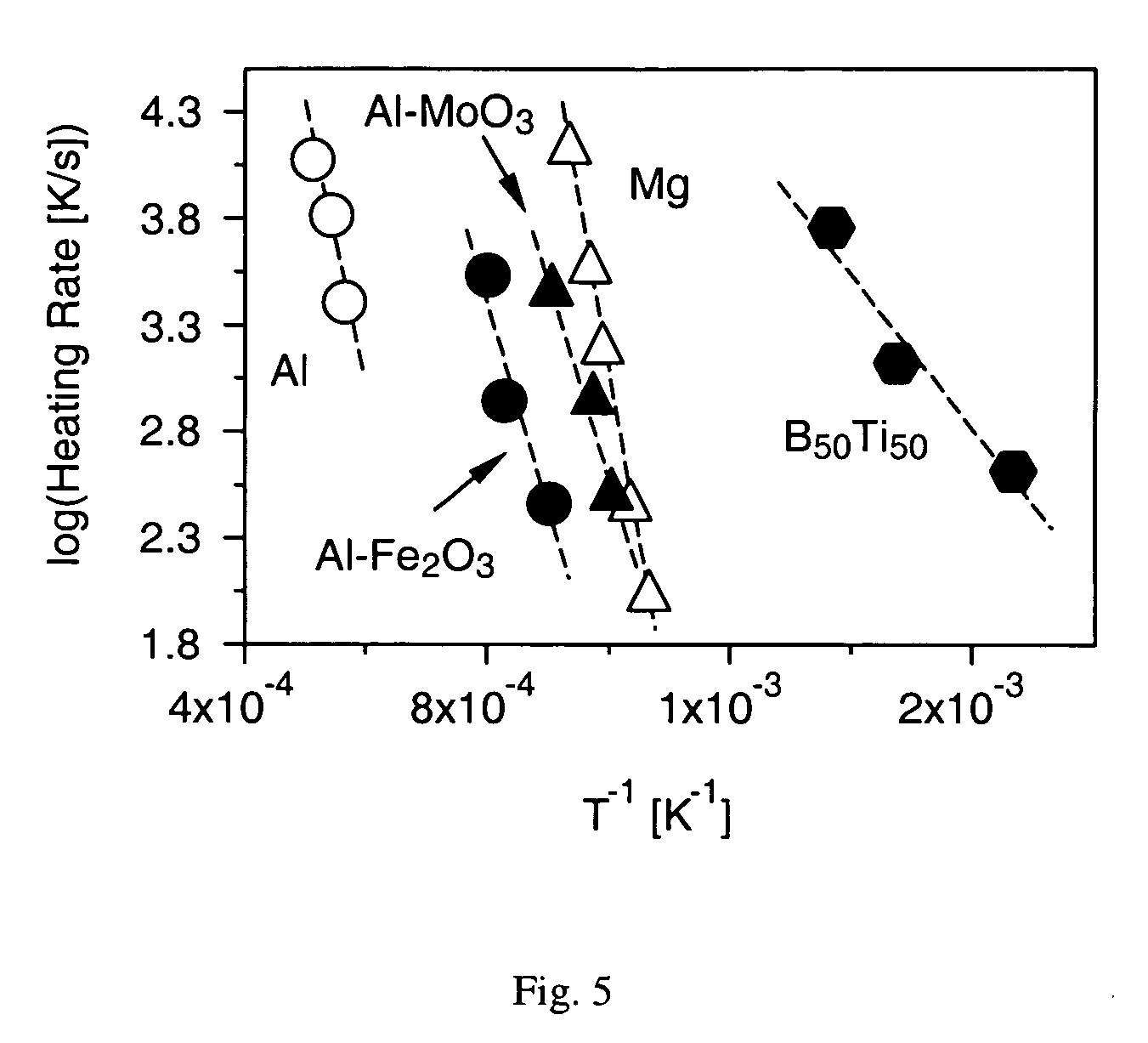

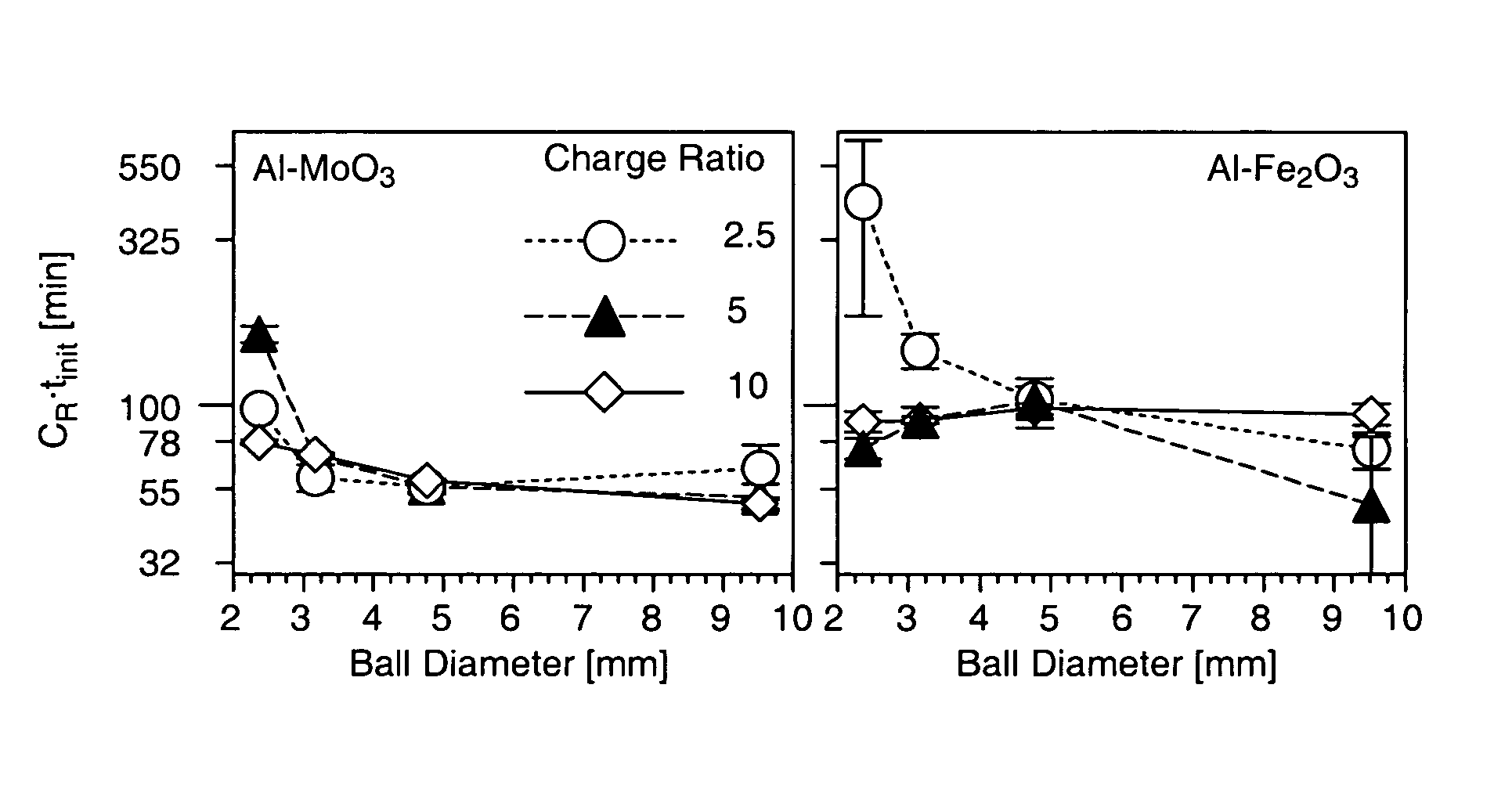

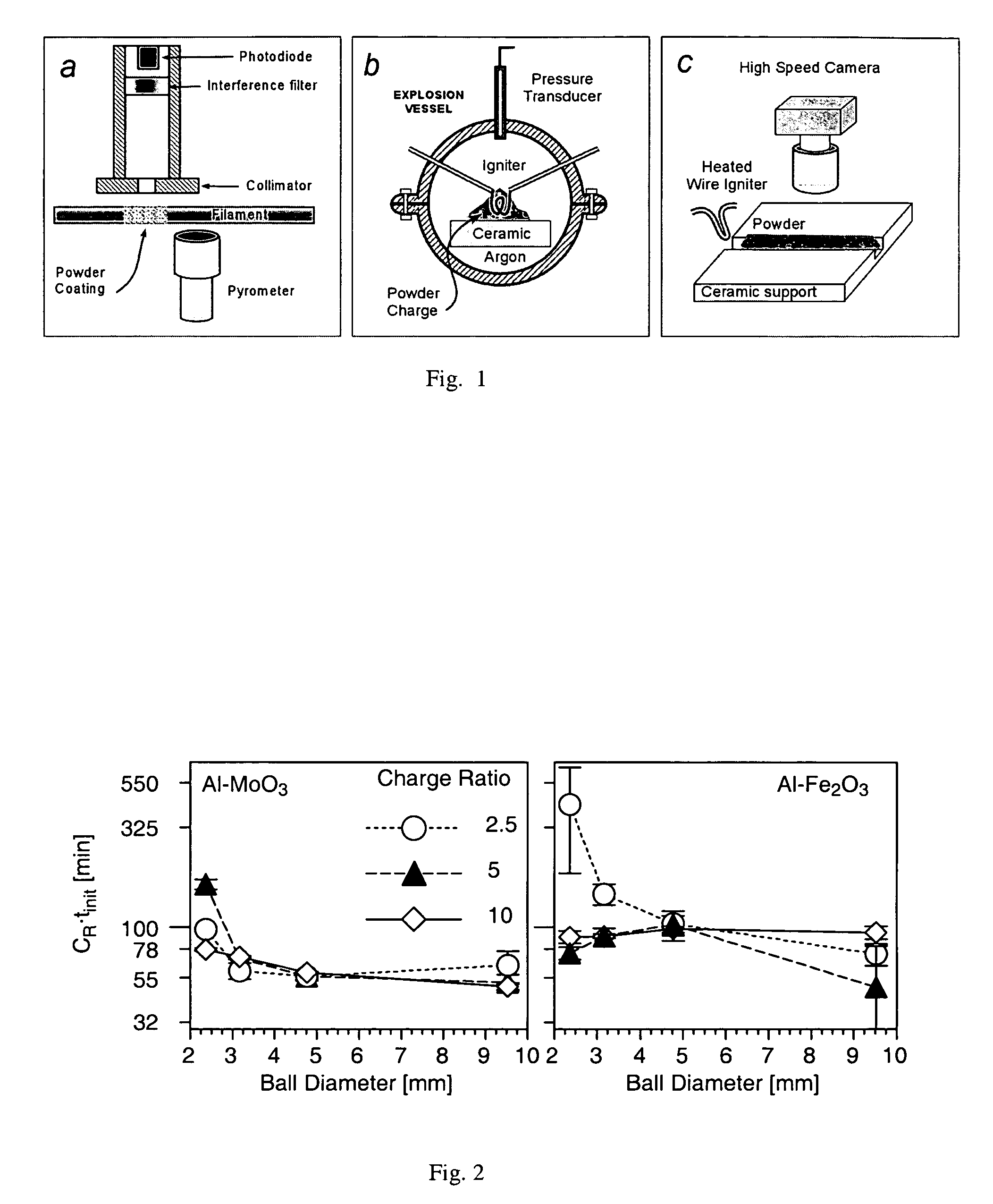

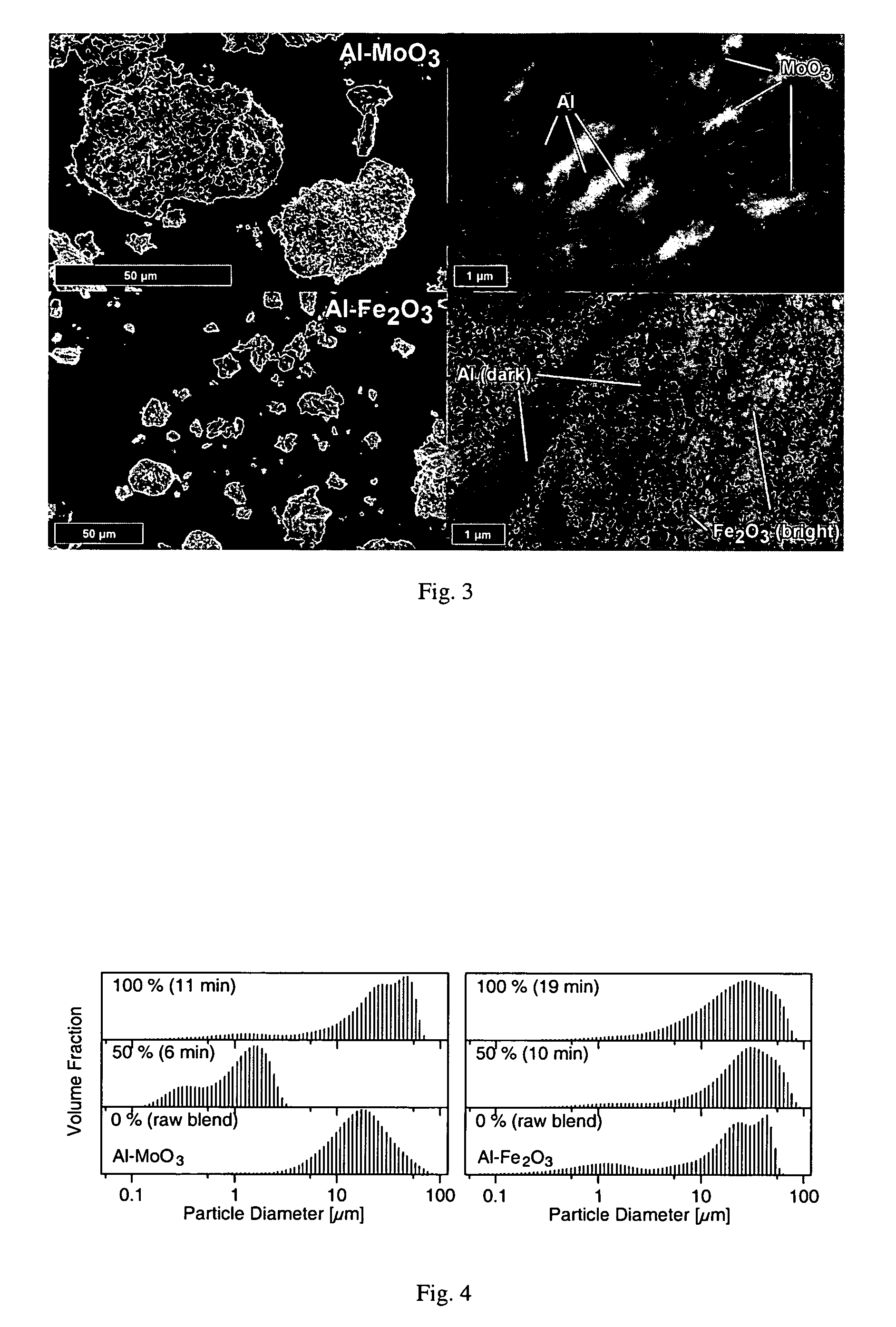

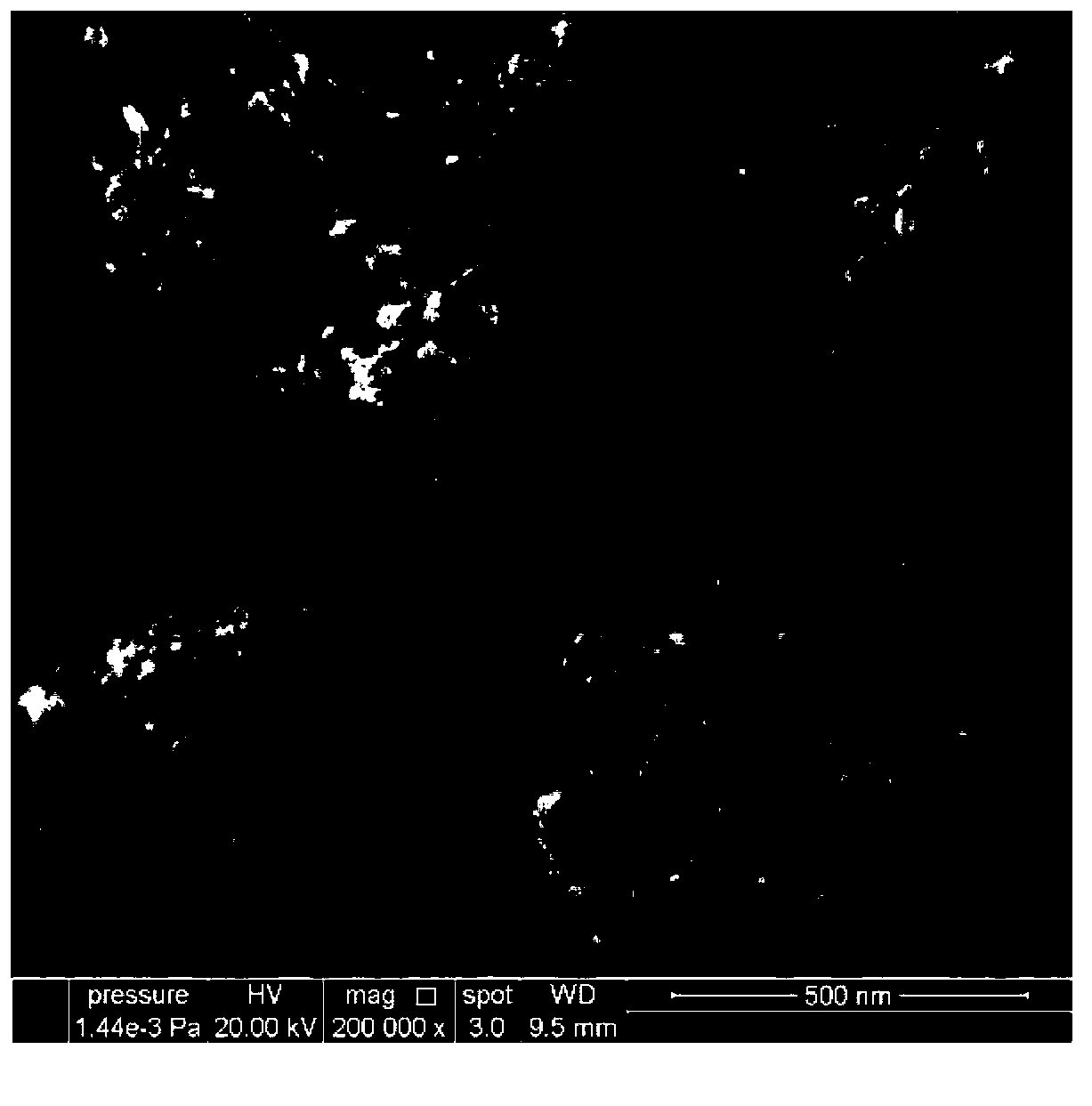

Nano-composite energetic powders prepared by arrested reactive milling

A method is disclosed for producing an energetic metastable nano-composite material. Under pre-selected milling conditions a mixture of powdered components are reactively milled. These components will spontaneously react at a known duration of the pre-selected milling conditions. The milling is stopped at a time at which the components have been compositionally homogenized to produce nanocomposite powder, but prior to said known duration, and thereby before the spontaneous reaction occurs. The milled powder is recovered as a highly reactive nanostructured composite for subsequent use by controllably initiating destabilization thereof.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

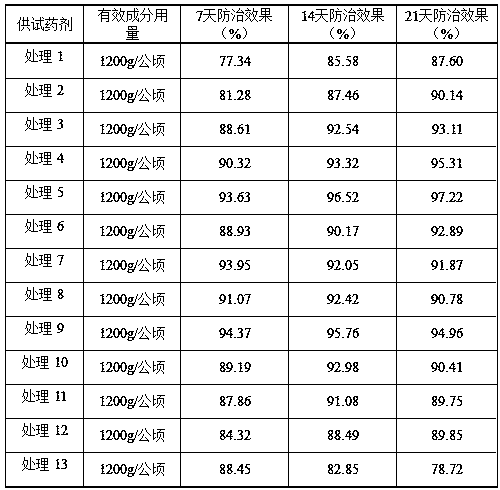

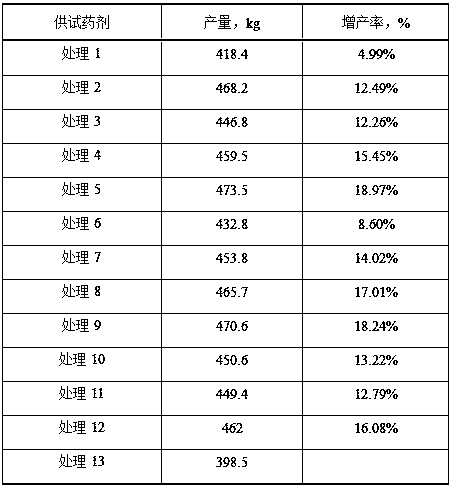

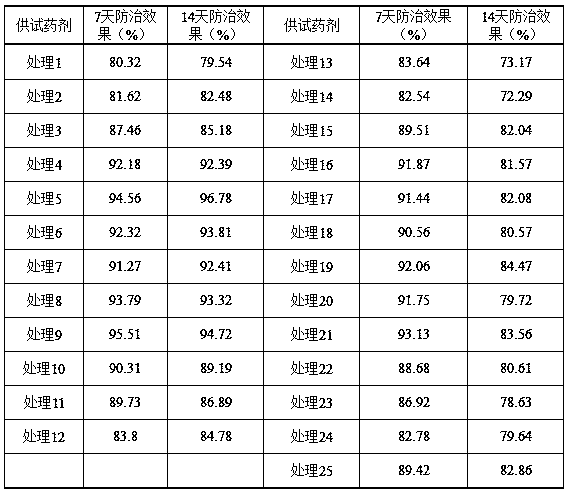

Release-controlled medicine fertilizer composition and preparation method thereof

InactiveCN109438071AImprove fertilizer efficiencyImprove weed control effectBiocideAnimal repellantsBULK ACTIVE INGREDIENTSolvent

The invention provides a release-controlled medicine fertilizer composition and a preparation method thereof. The medicine fertilizer composition is prepared from the following raw materials in percentage: 5 to 30 percent of weeding agents, 5 to 40 percent of fertilizers, 10 to 30 percent of surfactants, 0.5 to 3 percent of photoinitiators, 5 to 20 percent of prepolymers and the balance of solvents. The medicine fertilizer composition has the advantages that the medicine does not need to be prepared into a microcapsule preparation; and through the addition of the specific photoinitiator to bemixed with the prepolymers, medicine fertilizer can perform spontaneous reaction under the illumination condition after spraying use so as to form the medicine fertilizer composition with a slow-release effect. The medicine fertilizer active ingredient stability and effect-lasting period are improved.

Owner:四川赛华睿科技有限责任公司

Method for preparing point contact electrode at back of solar cell by utilizing laser induced thermit reaction

InactiveCN101546790AAvoid damageReduce compound rateFinal product manufactureSemiconductor devicesBack surface fieldMaterials science

The invention discloses a method for preparing a point contact electrode at the back of a solar cell by utilizing laser induced thermit reaction, which comprises the following steps in sequence: plating a passivation media layer on the back of a silicon substrate; steam-plating an aluminum layer on the passivation media layer; printing or coating thermite on the aluminum layer; and igniting the thermite by the radiation of laser to result in the thermit reaction for generating high temperature so that the aluminum layer and the silicon substrate are molten and then are crystallized and form better ohmic contact and aluminum back surface field. The invention adopts laser to indirectly sinter an electrode, i.e. the laser is used to induce spontaneous reaction of the thermite, high temperature generated by the reaction make aluminum and the silicon from better ohm contact, therefore, the prepared solar cell has smaller series resistance; meanwhile, the aluminum and the silico forms the aluminum back surface field, and the prepared solar cell has bigger short circuit current. By adopting the method of the invention, the laser does not directly radiate a metallic film, which reduces the damage to the silicon to be lowest and further improves the short circuit current of the solar cell.

Owner:SUN YAT SEN UNIV

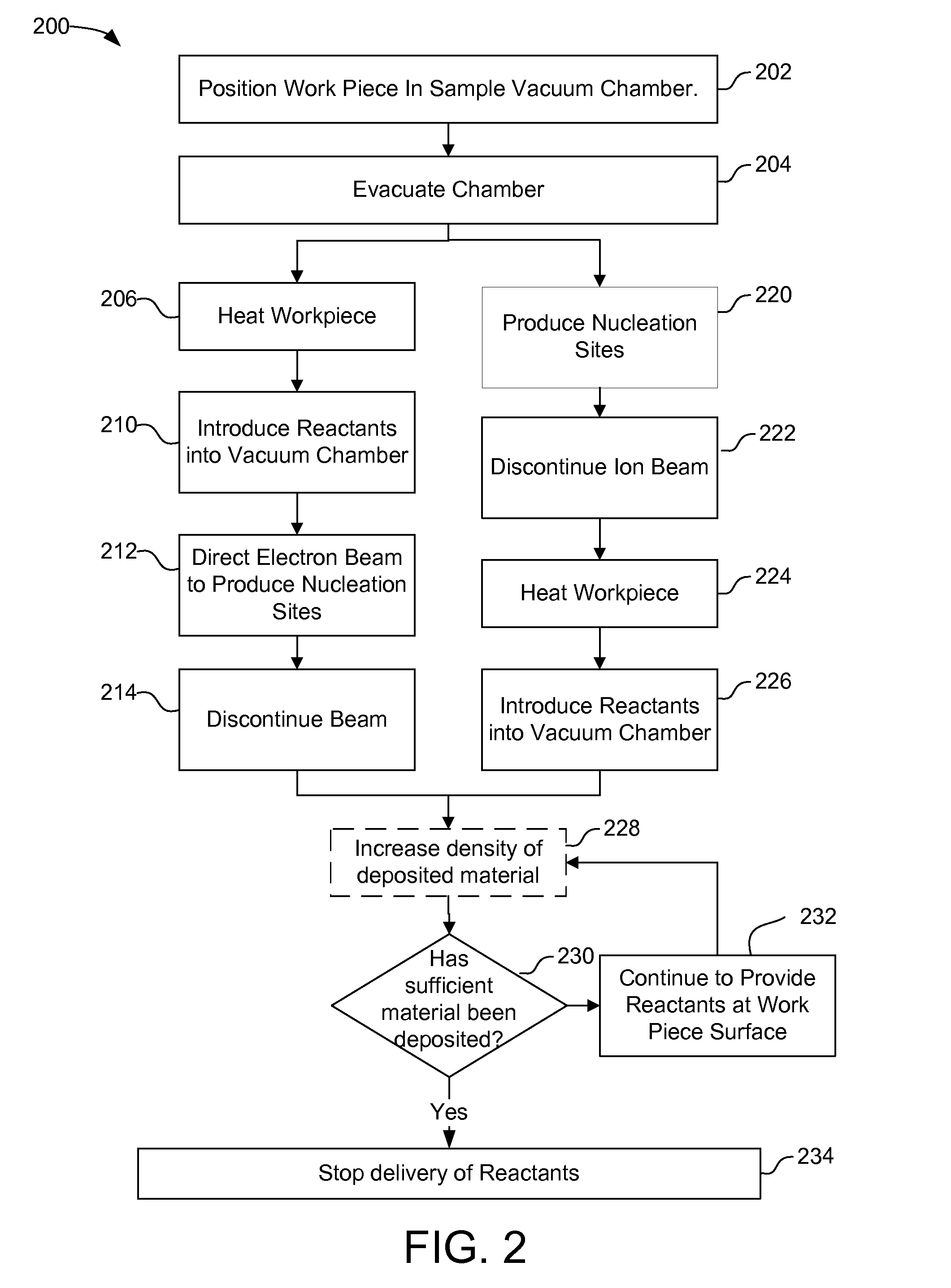

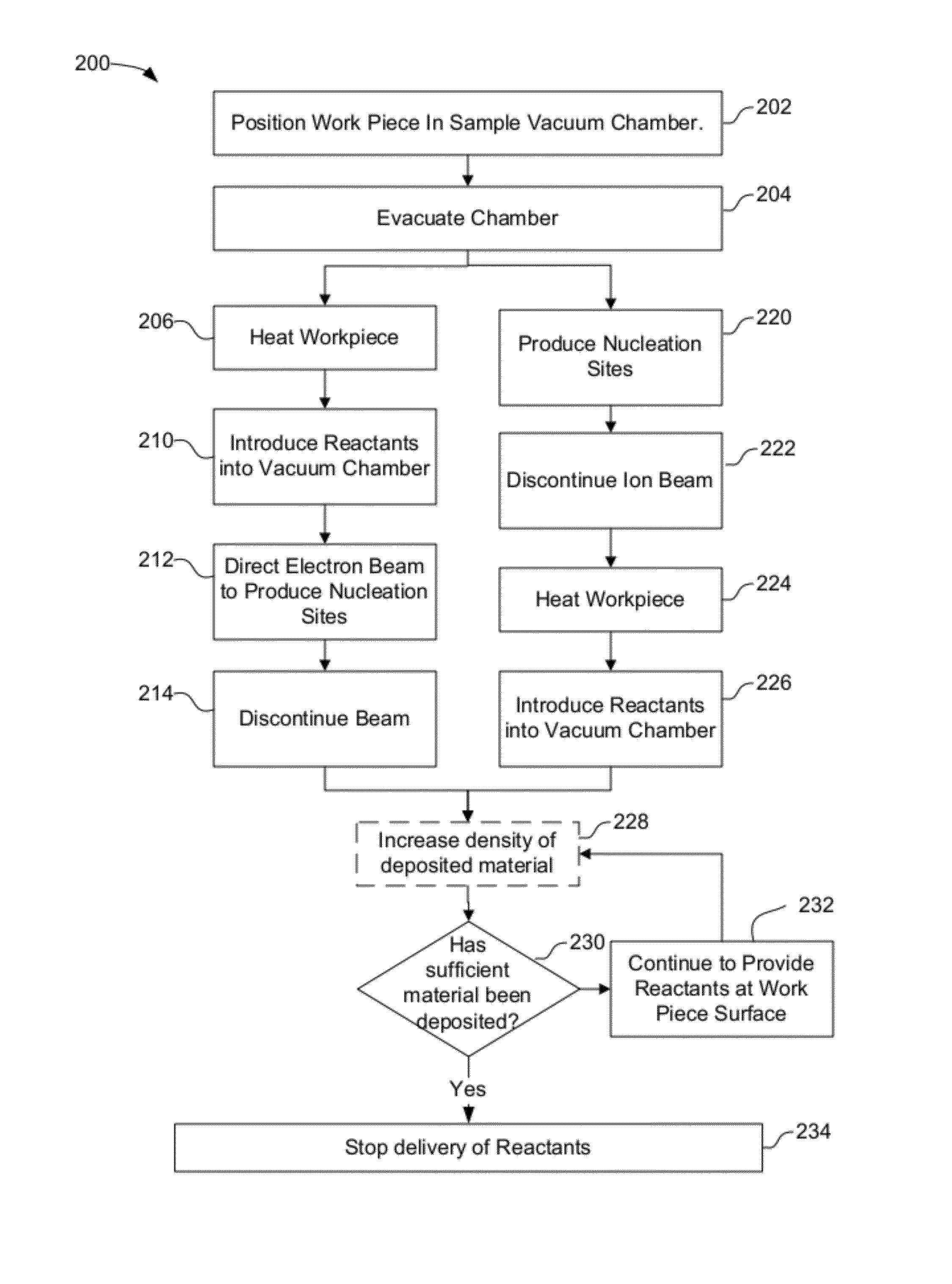

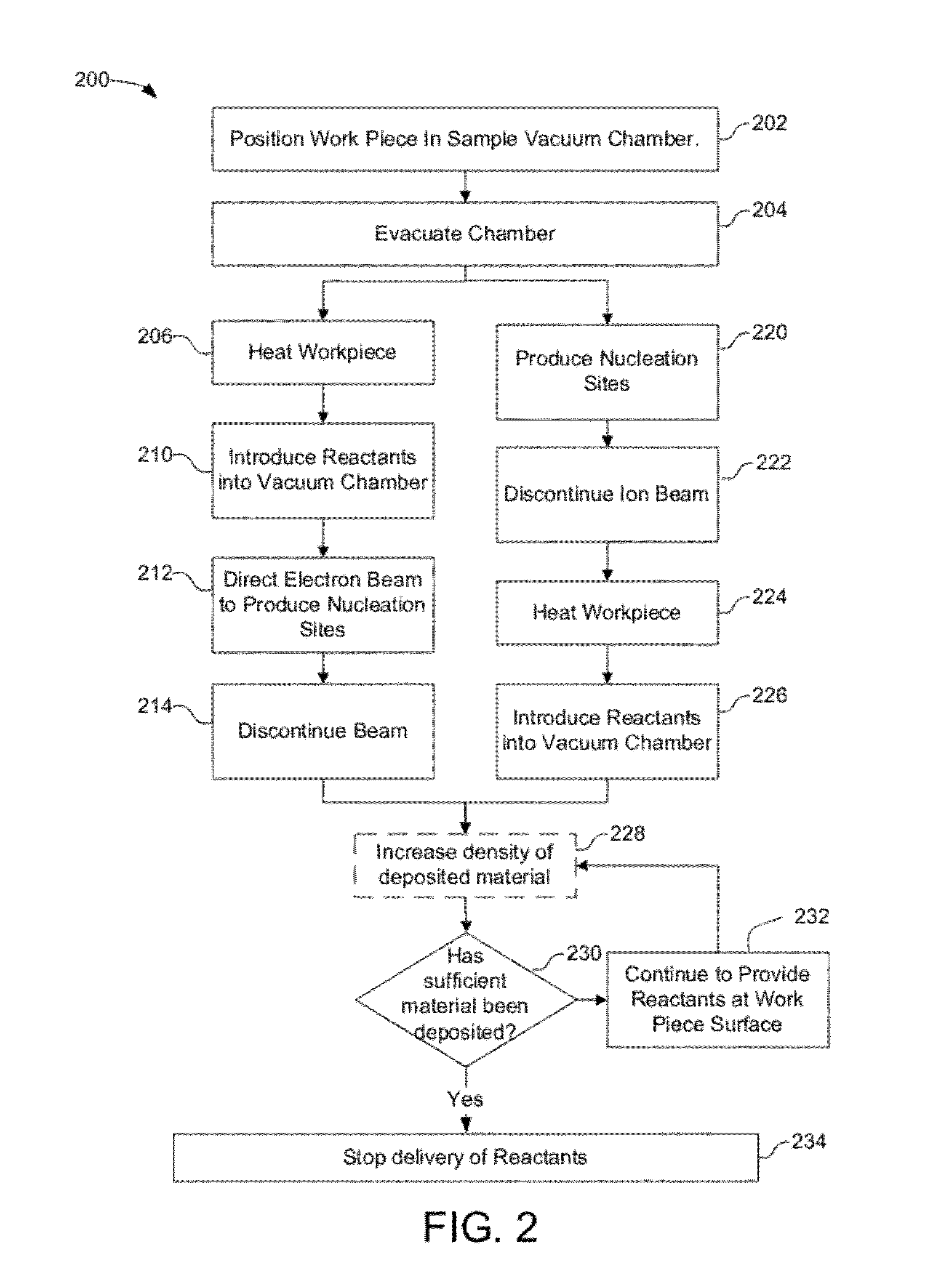

Method of Depositing Material

ActiveUS20120196440A1Deposition process is enhancedReduce adsorptionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSpontaneous reactionPhysics

Material is deposited in a desired pattern by spontaneous deposition of precursor gas at regions of a surface that are prepared using a beam to provide conditions to support the initiation of the spontaneous reaction. One the reaction is initiated, it continues in the absence of the beam at the regions of the surface at which the reaction was initiated.

Owner:FEI CO

Coating method for preventing bird from building nest

InactiveCN101651305ABright colorHigh light perceptionOverhead installationCoatingsEngineeringSpontaneous reaction

The invention relates to a coating method for preventing birds from building nests, in particular to a method which is capable of effectively preventing birds from building nests on power transmissionand transformation circuits and equipment. The coating method for preventing birds from building nests adopts coating of any two or three of a red colour system, a yellow colour system and a blue colour system to carry out interval coating. The invention applies the characteristics of biological spontaneous reaction and utilizes the sensitivity of the birds to colors to prevent the birds from building the nests and prevent bird damage. Meanwhile, the coating method has no environmental pollution or chemical pollution, and simple and convenient construction.

Owner:HENAN SUNSHINE ANTICORROSIVE PAINTING CO LTD

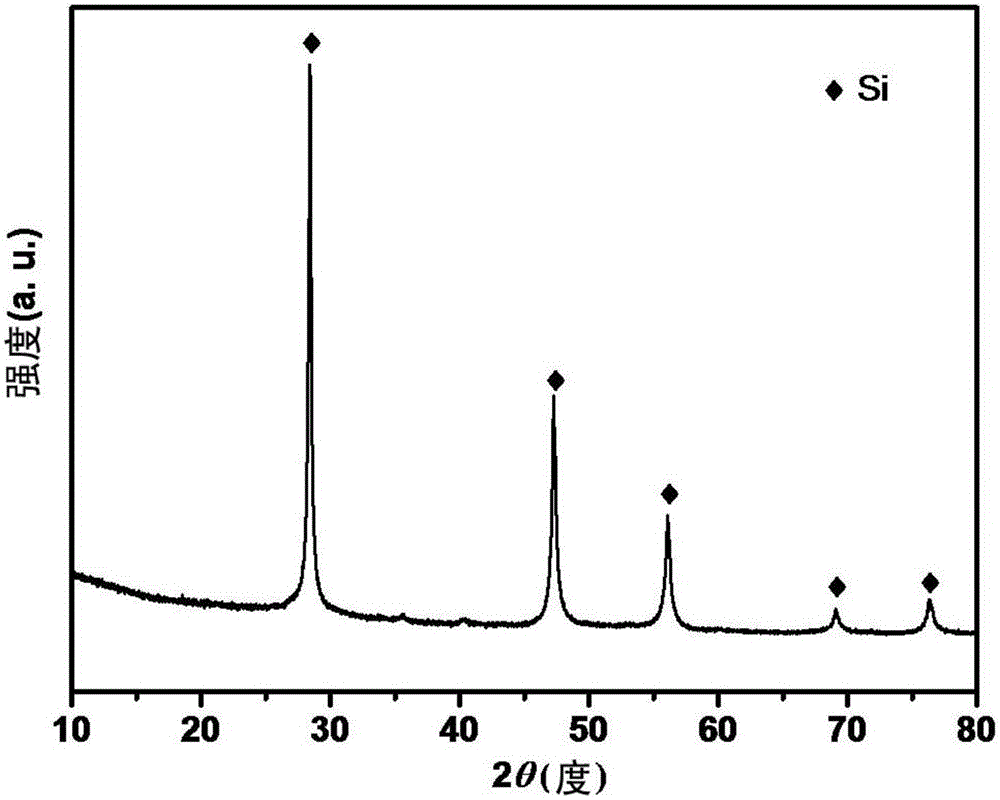

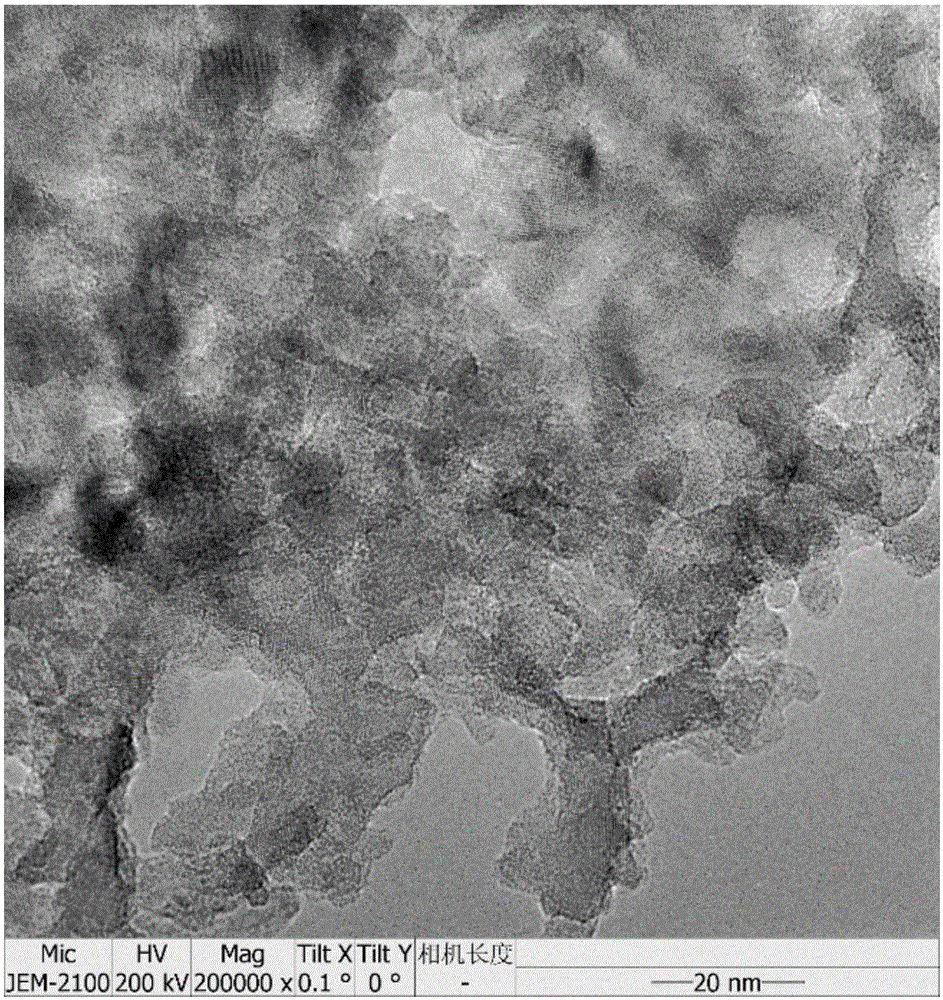

Novel method for preparing nanometer silicon from silicon dioxide

InactiveCN106044777AHigh puritySmall sizeMaterial nanotechnologySilicon compoundsRoom temperatureSilicon particle

The invention discloses a novel method for preparing nanometer silicon from silicon dioxide. The method is based on the principle that magnesiothermic reduction of SiO2 is achieved through spontaneous reaction based on heat release, reaction is triggered through low-rotating-speed ball milling at room temperature, spontaneous proceeding of reaction is maintained through heat release, and reaction can be finished basically within 10 min. Raw materials are easy to obtain, operation is quite easy, and the method has the advantages that operation is easy and fast, yield is high, cost is low, reaction product purity is high, and amplification is easy. Prepared nanometer silicon particles are small in size and uniform in distribution, are of a porous structure, can be applied to lithium ion battery cathode materials, sensors, optical devices and other fields, and have broad industrial application prospects.

Owner:PEKING UNIV

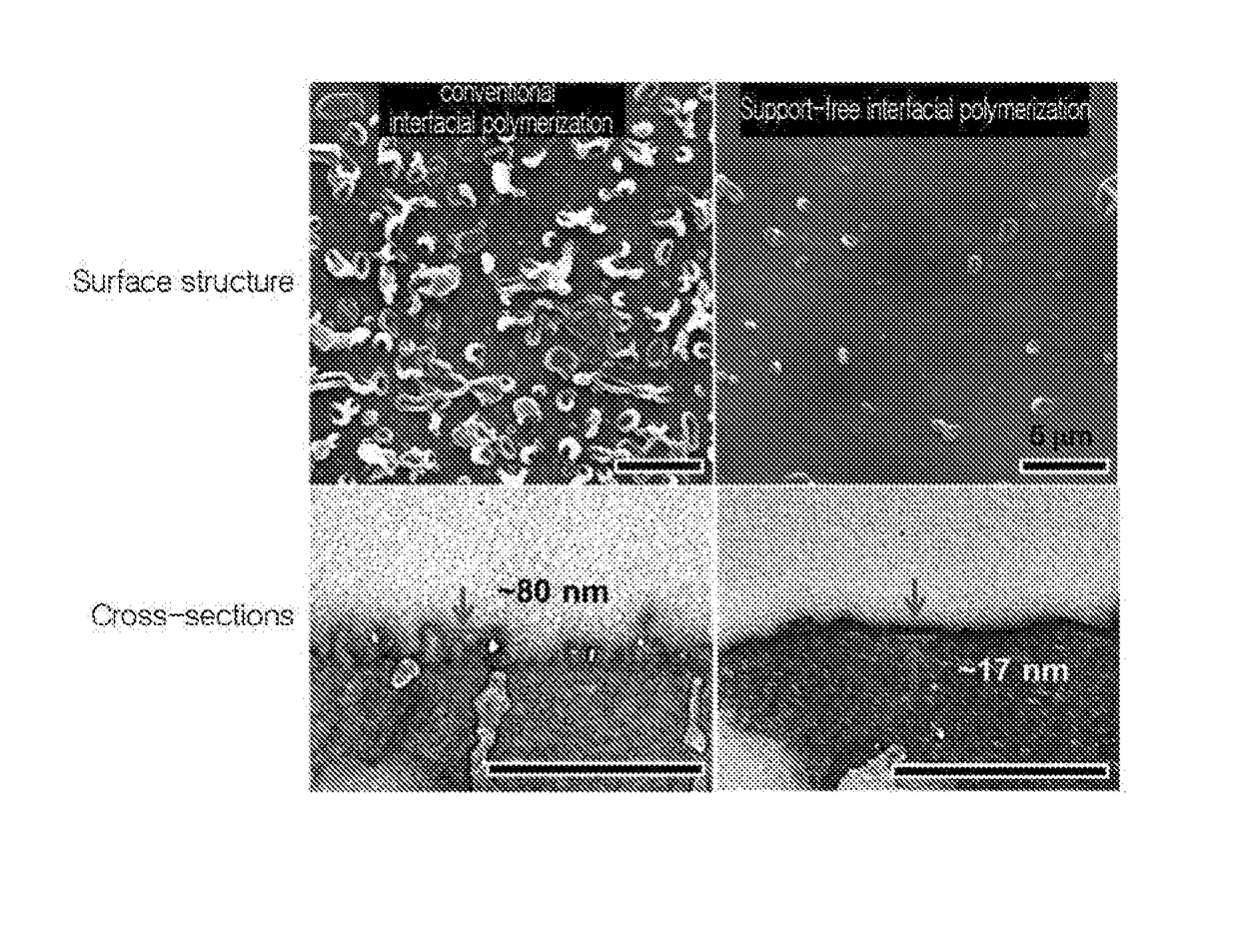

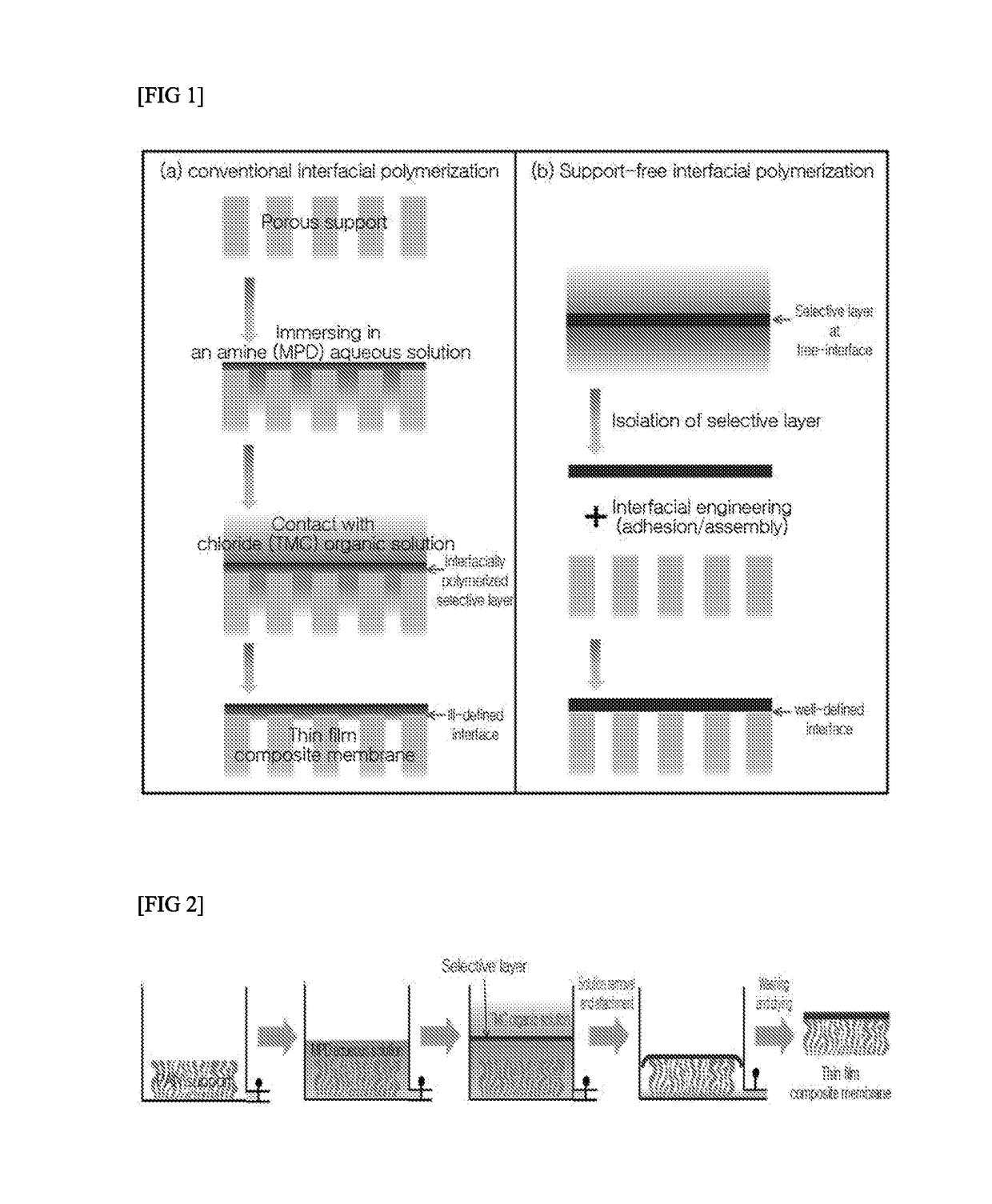

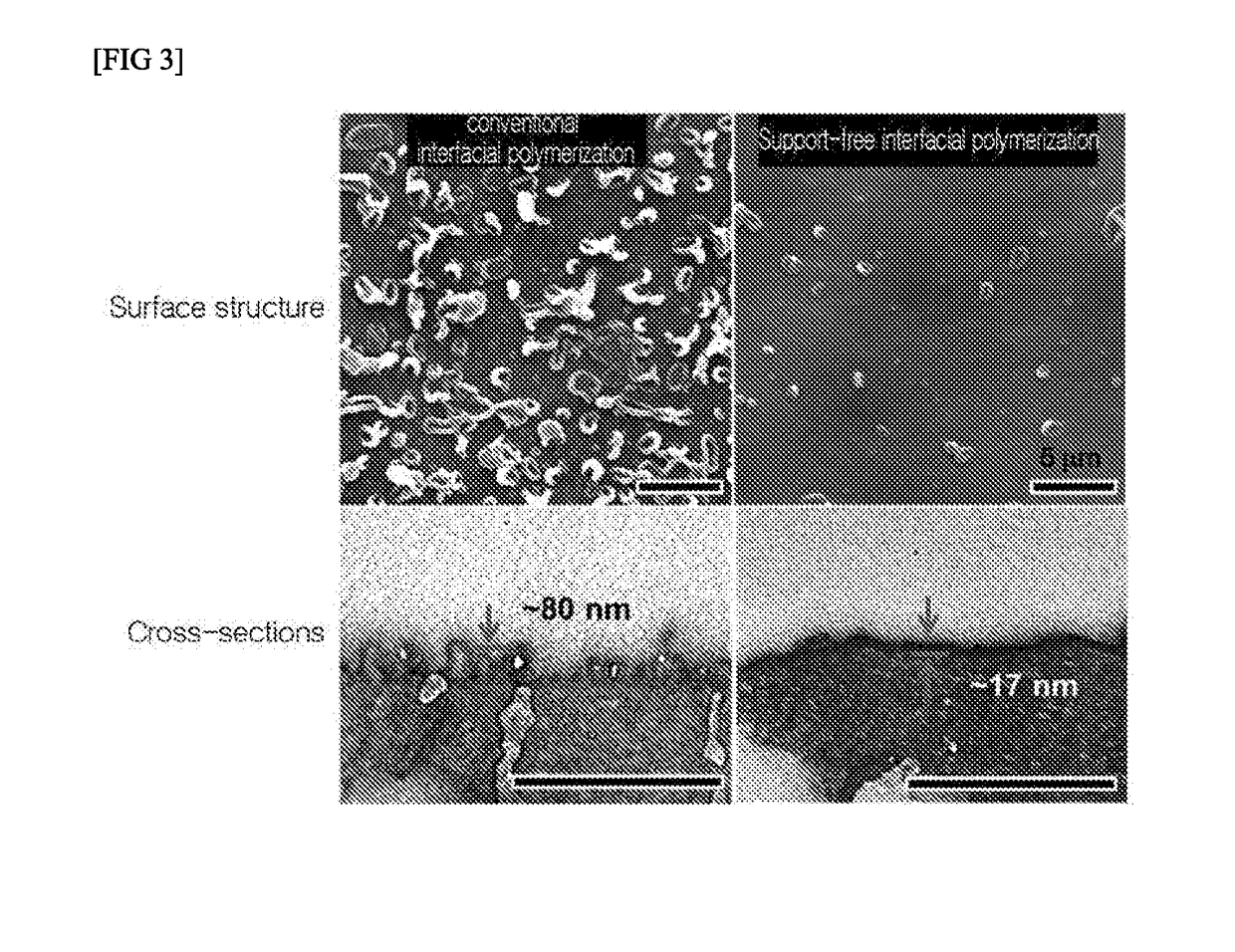

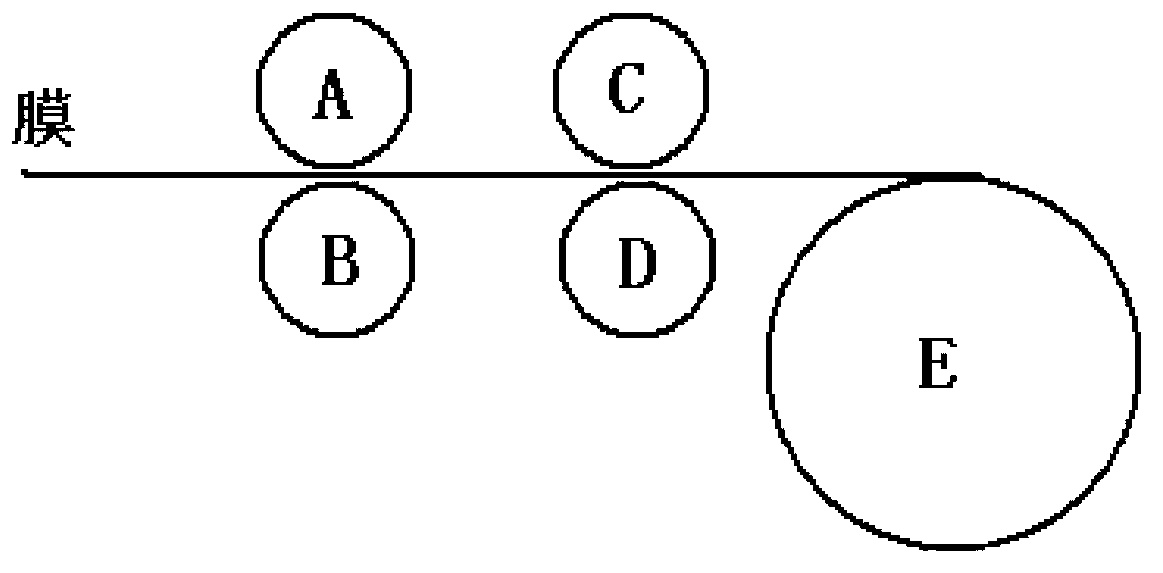

Method for manufacturing membrane using selective layer prepared through support-free interfacial polymerization

ActiveUS20180141831A1General water supply conservationSeawater treatmentFree interfaceSpontaneous reaction

The present invention relates to a method for manufacturing a composite membrane using a selective layer prepared through the interfacial polymerization (support-free interfacial polymerization) on a free interface without a support and, more specifically, to a method for manufacturing a composite membrane comprising a reverse osmotic membrane, which is obtained by preparing a selective layer through a spontaneous reaction of two organic monomers on an interface between two immiscible solutions and allowing the selective layer to adhere to a support. By employing the method for manufacturing a composite membrane having a selective layer prepared through the support-free interfacial polymerization according to the present invention, a high-functional reverse osmotic membrane can be prepared using various supports other than a conventional polysulfone support, thereby extending the application range of the reverse osmotic membrane, which has been restricted due to low chemical resistance of polysulfone. In addition, the preparation method for the selective layer can be controlled more precisely than a conventional method, and the analysis of components (selective layer, support, and interface) of the composite membrane is easy.

Owner:KOREA UNIV RES & BUSINESS FOUND

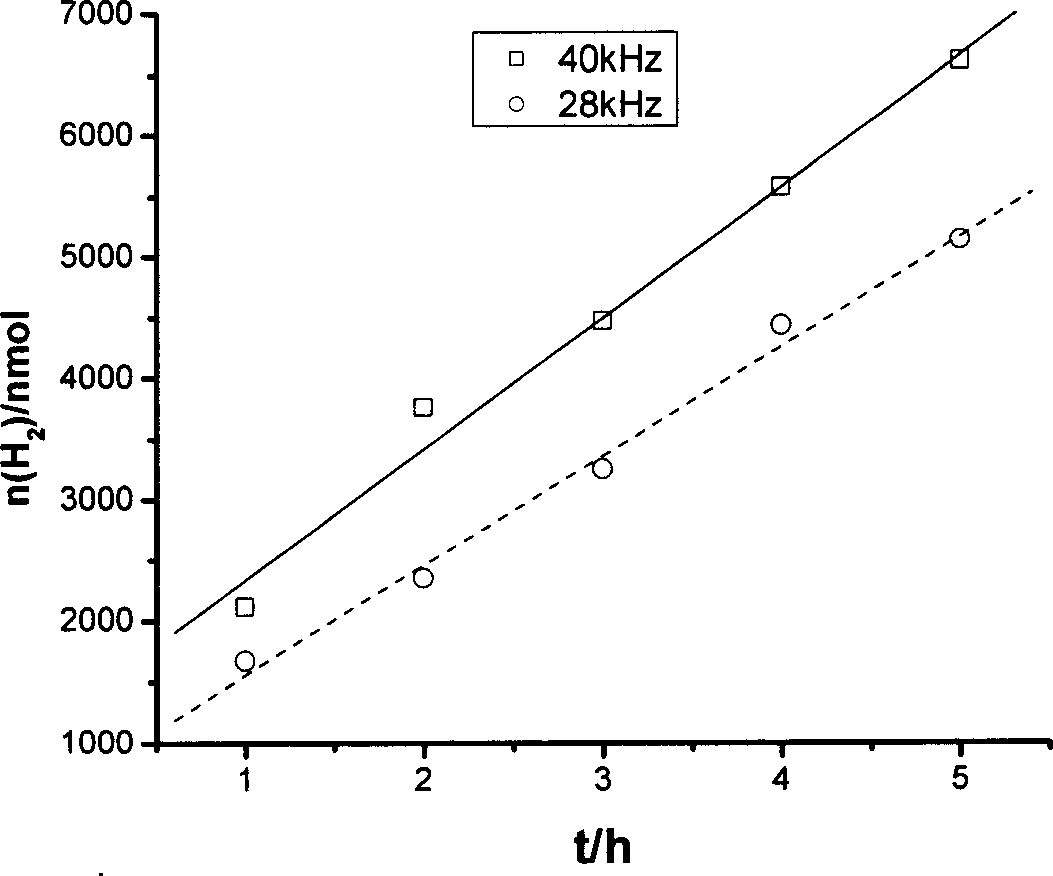

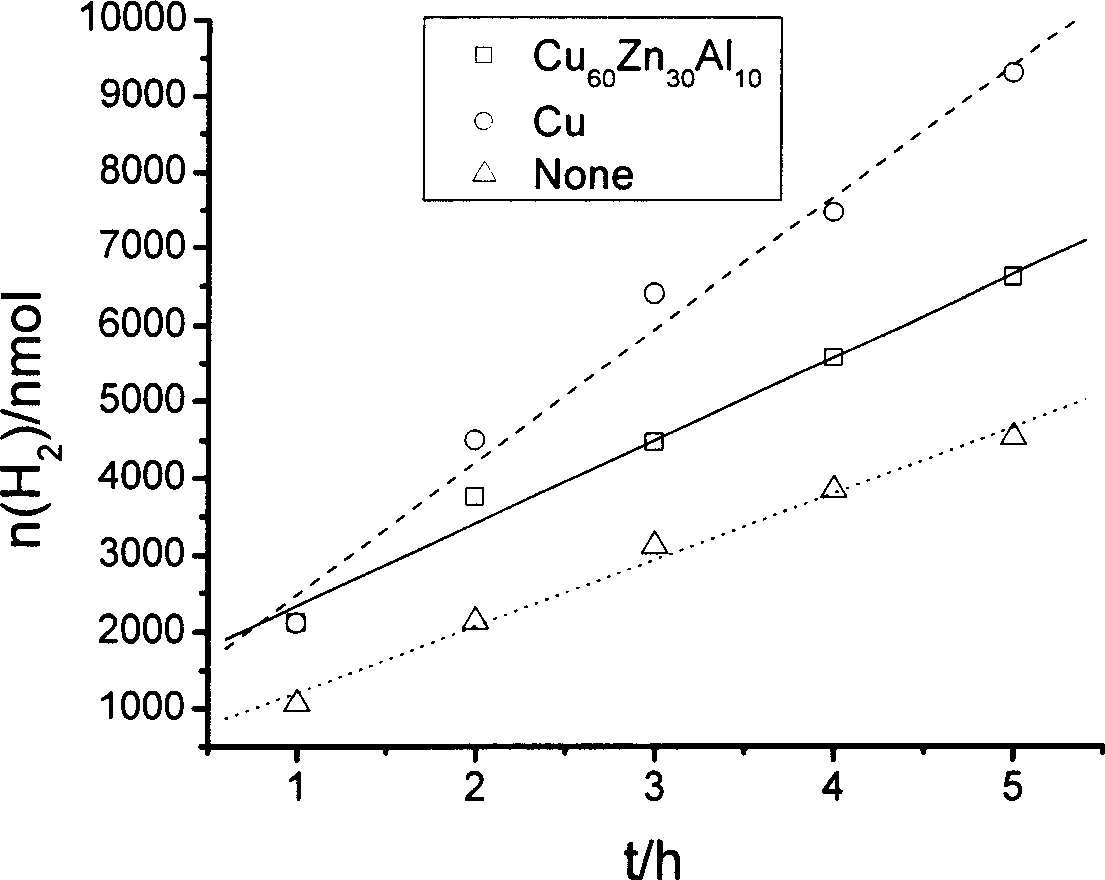

Method for preparing hydrogen from methanol

InactiveCN1899954AImprove the conditions of the hydrogen production reactionLower requirementHydrogenHydrogenCavitation

The method of preparing hydrogen with methanol is to react with methanol solution of 50-75 % concentration in ultrasonic device of 28 kHz or 40 kHz and 100-1000 W power. The present invention is water vapor reforming reaction of methanol and ultrasonic wave is used to produce vibrating and cavitation effect on the methanol solution. The reaction has highest macro temperature lower than critical temperature for spontaneous reaction, and hydrogen may be produced at normal temperature or even lower temperature. The present invention has improved methanol reacting hydrogen preparing condition, lowered reaction temperature and relaxed requirement on catalyst.

Owner:XI AN JIAOTONG UNIV

Method of depositing material

ActiveUS8853078B2Reduce adsorptionReaction is suppressedPolycrystalline material growthSemiconductor/solid-state device manufacturingSpontaneous reactionPhysics

Material is deposited in a desired pattern by spontaneous deposition of precursor gas at regions of a surface that are prepared using a beam to provide conditions to support the initiation of the spontaneous reaction. Once the reaction is initiated, it continues in the absence of the beam at the regions of the surface at which the reaction was initiated.

Owner:FEI CO

Nano-composite energetic powders prepared by arrested reactive milling

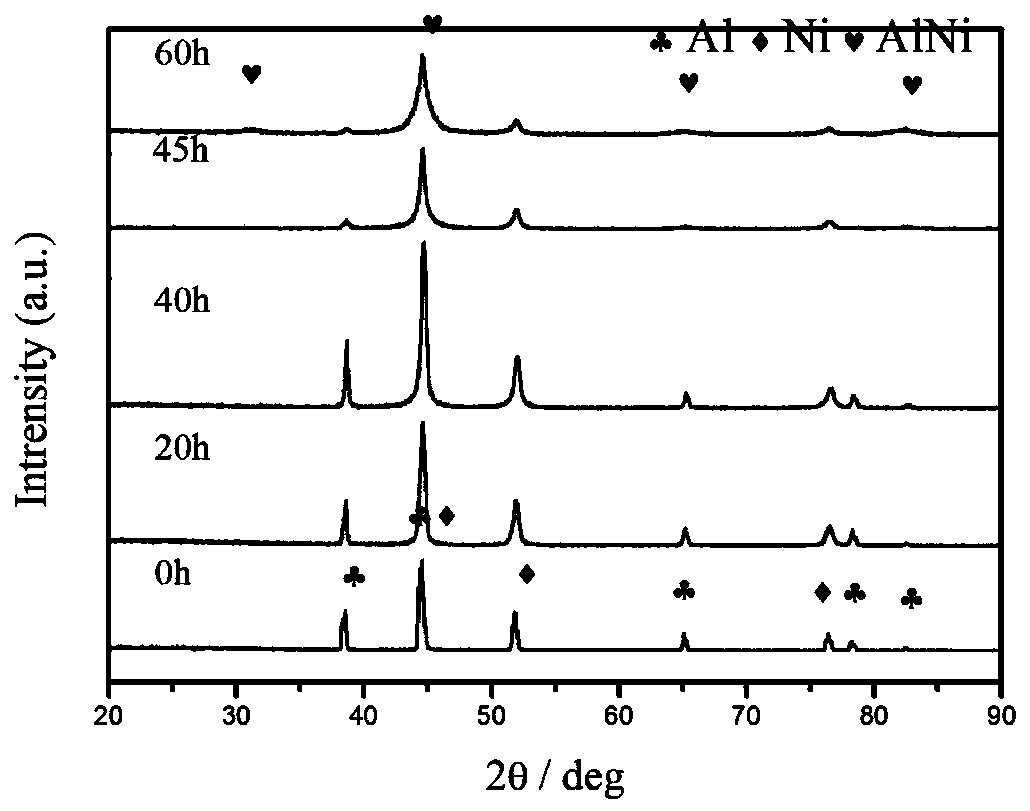

InactiveUS7524355B2Explosive working-up apparatusManufacturing convertersSpontaneous reactionNanostructured composites

A method is disclosed for producing an energetic metastable nano-composite material. Under pre-selected milling conditions a mixture of powdered components are reactively milled. These components will spontaneously react at a known duration of the pre-selected milling conditions. The milling is stopped at a time at which the components have been compositionally homogenized to produce nanocomposite powder, but prior to said known duration, and thereby before the spontaneous reaction occurs. The milled powder is recovered as a highly reactive nanostructured composite for subsequent use by controllably initiating destabilization thereof.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Method for welding between metal plates

ActiveCN110587112AImprove connection strengthSolve welding defects such as insufficient heat inputLaser beam welding apparatusNon-electric welding apparatusButt jointLap joint

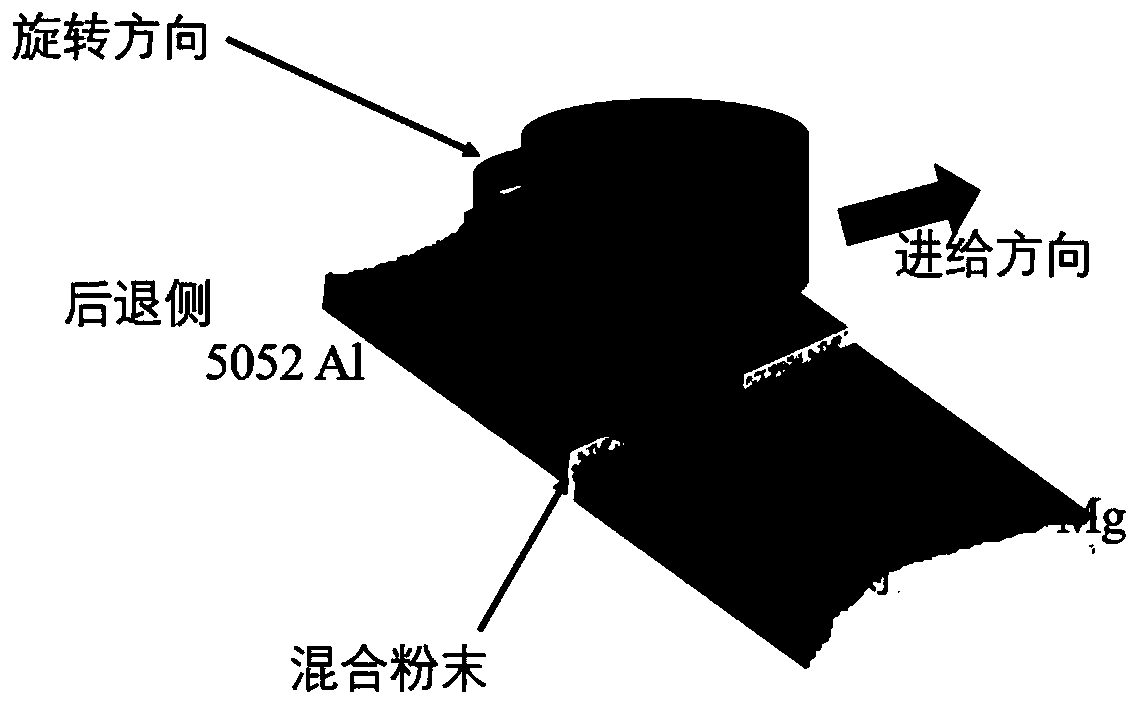

The invention belongs to the field of welding, and relates to a process for welding between same metal plates or dissimilar metal plates, in particular to a method for welding between the metal plates. The method for welding between the metal plates comprises the following steps that, after the first metal plate and the second metal plate are in overlapped lap joint or butt joint, a proper amountof metastable self-propagating reaction metal mixed powder is placed at the lap joint or but joint position, welding is carried out, the self-propagating reaction of the metal mixed powder is triggered, and the first metal plate and the second metal plate are welded together with the aid of heat released by the self-propagating reaction. According to the method for welding between the metal plates, a large amount of heat generated during welding is utilized to trigger the metastable self-propagating reaction metal mixed powder for spontaneous reaction, and the first metal plate and the secondmetal plate are bonded together under the action of instantaneous heat released by the self-reaction. The method for welding between the metal plates is especially suitable for welding between the high-melting-point metal plates, and can overcome welding defects such as insufficient heat input of a high-melting-point alloy.

Owner:HUBEI UNIV OF TECH

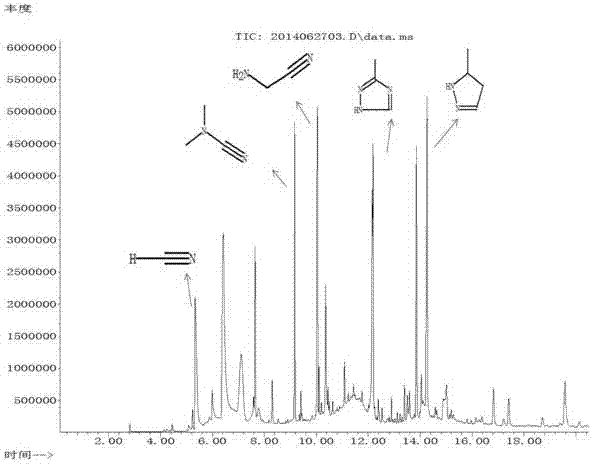

Method for preparing aminoacetonitrile and N,N-dimethylcyanamide from methane and ammonia gas through plasma synthesis

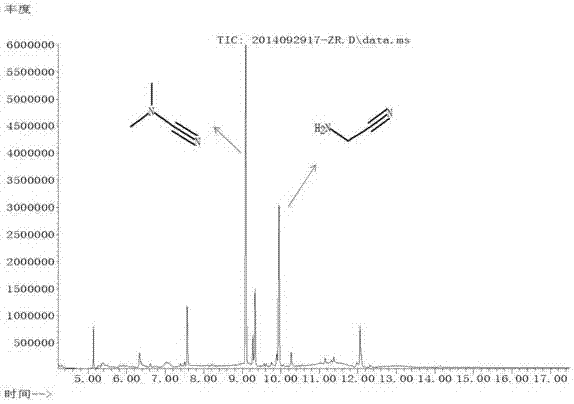

InactiveCN104725271ASimple methodNo pollution in the processOrganic compound preparationPreparation by hydrocarbon ammoxidationEthylenediamineAlkane

The invention relates to a method for synthesizing aminoacetonitrile and N,N-dimethylcyanamide by using methane and ammonia gas as raw materials, which is characterized by comprising the following steps: performing non-equilibrium plasma activation on methane and ammonia gas to generate carbon-containing and nitrogen-containing free radical active species, and performing one-step spontaneous reaction on the species to generate the target products. The method belongs to a one-step direct synthesis process, has the advantages of simplicity and cheap raw materials, does not use solvent and causes no pollution. Besides, the method is also applicable to synthesis of organic compounds from various C1-5 alkane, olefin and alkyne and ammonia gas. Moreover, in addition to the aminoacetonitrile and N,N-dimethylcyanamide, acetonitrile, ethylenediamine, 4,5-dihydro-5-methylpyrazole, aminopyrazole and other products can be also obtained through the plasma synthesis method.

Owner:DALIAN UNIV OF TECH

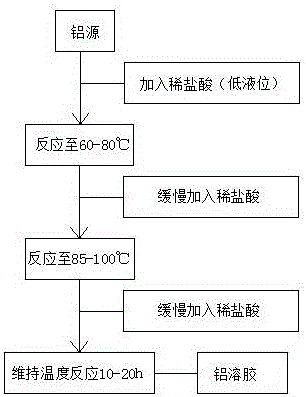

Aluminum soil production method

ActiveCN106268549AReduce investmentFully control the reaction rateAluminium chloridesSol preparationChemical industryHydrogen

The invention relates to the technical field of chemical industry and in particular relates to an aluminum soil production method. A single-kettle charge production manner is adopted; a reaction kettle internally comprises a stock bin for containing an aluminum source; in a production process, the aluminum source is added into the stock bin and the first part of diluted hydrochloric acid is added into a kettle body, wherein the adding amount is one-tenth to one-third of the total mass; the diluted hydrochloric acid reacts with the aluminum source at the lower part of the stock bin; after reaction temperature is stabilized to 60 DEG C to 80 DEG C, the temperature is kept for 15min to 30min; then the second part of diluted hydrochloric acid is slowly added; after the reaction temperature reaches 85 DEG C to 100 DEG C, the third part of diluted hydrochloric acid is slowly added; the reaction temperature is stabilized to 85 DEG C to 100 DEG C through the speed of adding the third part of diluted hydrochloric acid; after reaction is carried out for 12h to 20h, aluminum soil with the Al / Cl mass ratio of 1.0 to 2.0 and the pH (Potential of Hydrogen) of 2.4 to 3.2 is finally obtained, and total acid adding time is controlled to be 3h to 10h. According to the aluminum soil production method, an intermittent production process is adopted and a normal-pressure spontaneous reaction is carried out; a reaction speed is sufficiently controlled in a reaction process and spontaneous heat generated by the reaction is reasonably utilized; in a whole production process, stirring and steam heating are not needed, so that the energy consumption can be reduced by 80 percent or more when being compared with that of a traditional production process.

Owner:REZEL CATALYSTS CORP

High selectivity, low damage electron-beam delineation etch

A method and apparatus for selective etching a substrate using a focused beam. For example, multiple gases may be used that are involved in competing beam-induced and spontaneous reactions, with the result depending on the materials on the substrate. The gases may include, for example, an etchant gas and an auxiliary gas that inhibits etching.

Owner:FEI CO

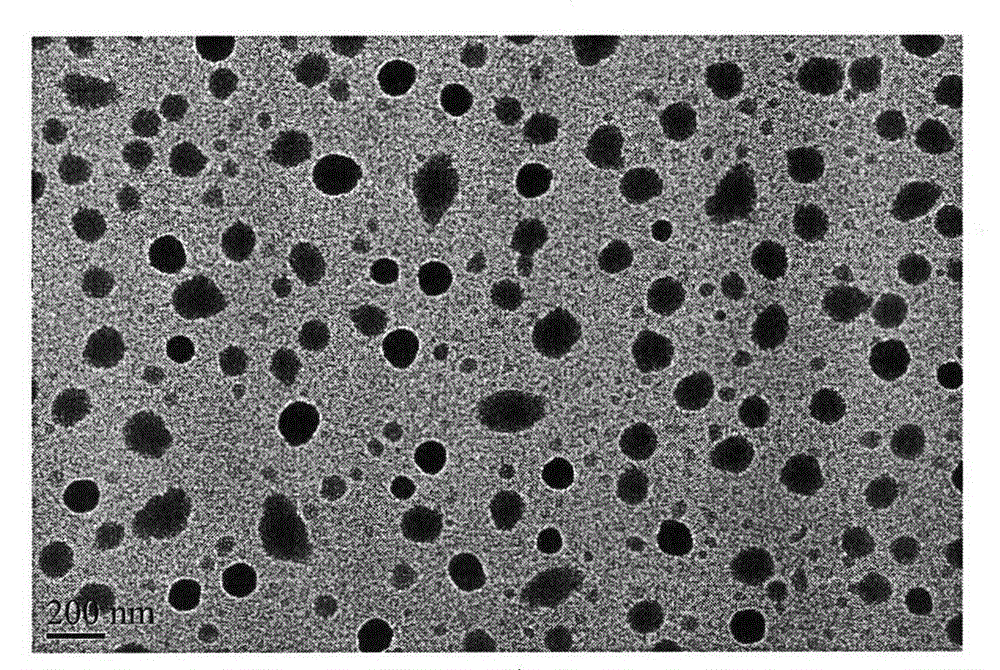

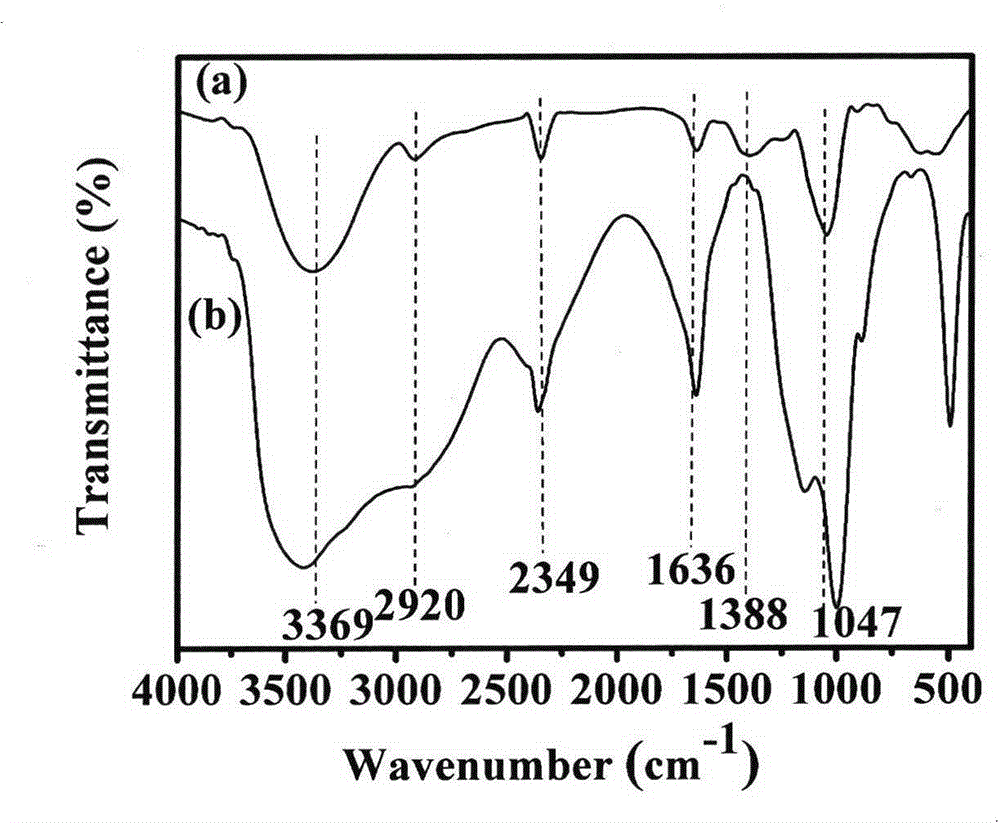

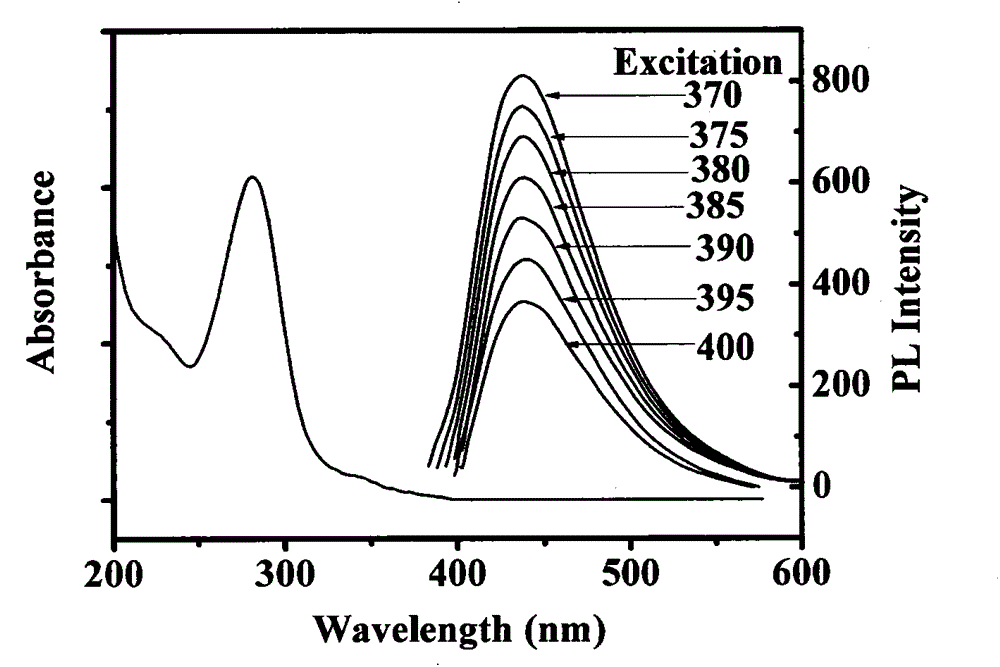

New preparation method of fluorescent carbon nanoparticles and application in biological samples

InactiveCN104787745AHigh affinityImprove processing efficiencyNanotechnologyFluorescence/phosphorescenceBiological pumpPhosphate

The invention relates to preparation of novel fluorescent carbon nanoparticles and an application in biological samples and belongs to the technical field of pharmaceutical analysis. By a phosphorus pentoxide dehydration method, a carbohydrate compound is used as a carbon source and reactants are simply mixed to prepare carbon nanoparticles with fluorescent property by a one-step method. The preparation process is a process of a spontaneous reaction. Without external heating or complex operations, a lot of carbon nanoparticles can be rapidly produced. The prepared carbon nanoparticles are characterized in that emission wavelength is fixed and will not change with excitation wavelength. In a phosphate buffered solution, fluorescence intensity of the carbon nanoparticles is obviously reduced with increasing of concentration of quercetin, and influence of other coexisting substances on fluorescence intensity of the carbon nanoparticles is little. Under optimized conditions, a good linear relationship between fluorescence intensity of the carbon nanoparticles and the concentration of quercetin is shown. The preparation method is pollution-free, simple, reliable and low-cost, and the prepared fluorescent carbon nanoparticles have a wide application prospect in aspects of detection of traces of pharmaceuticals in complex biological samples and detection and control of heavy metal in the environment.

Owner:CHINA PHARM UNIV

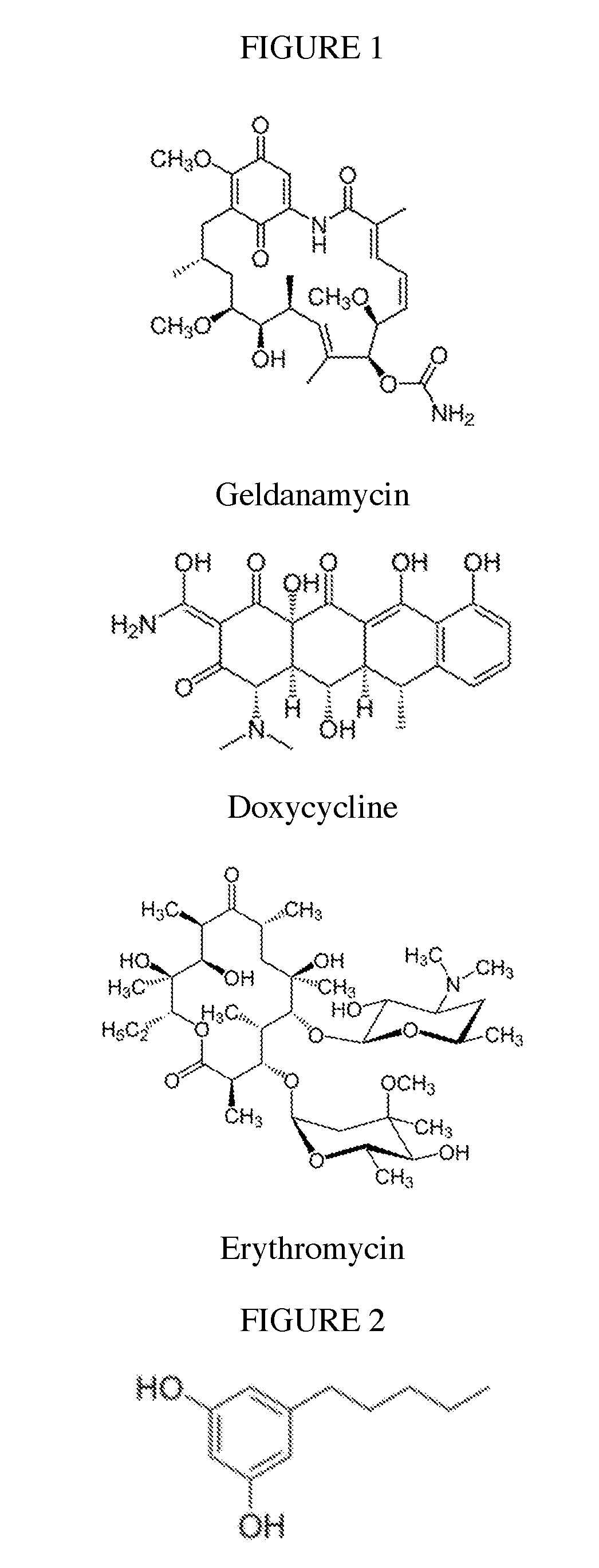

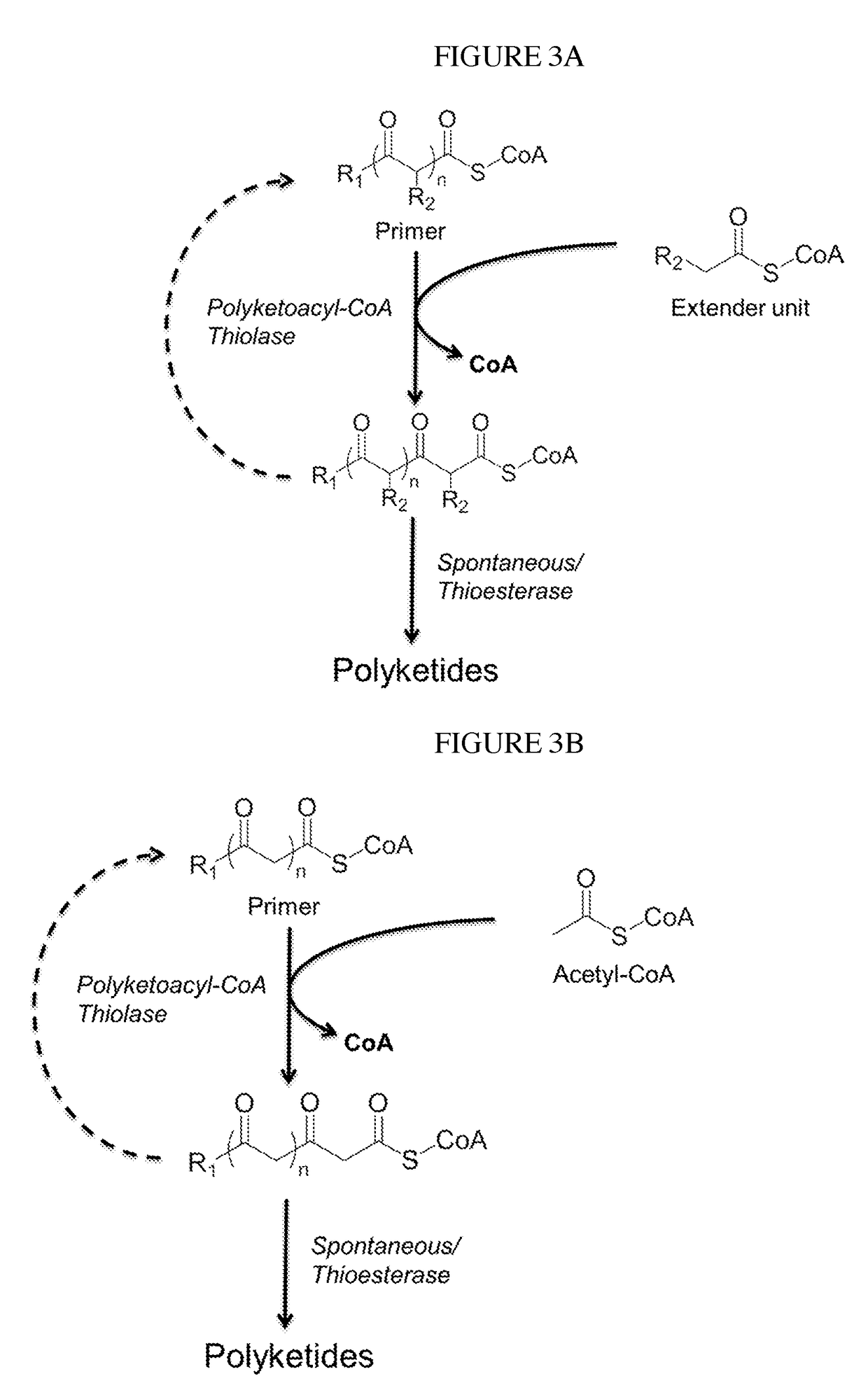

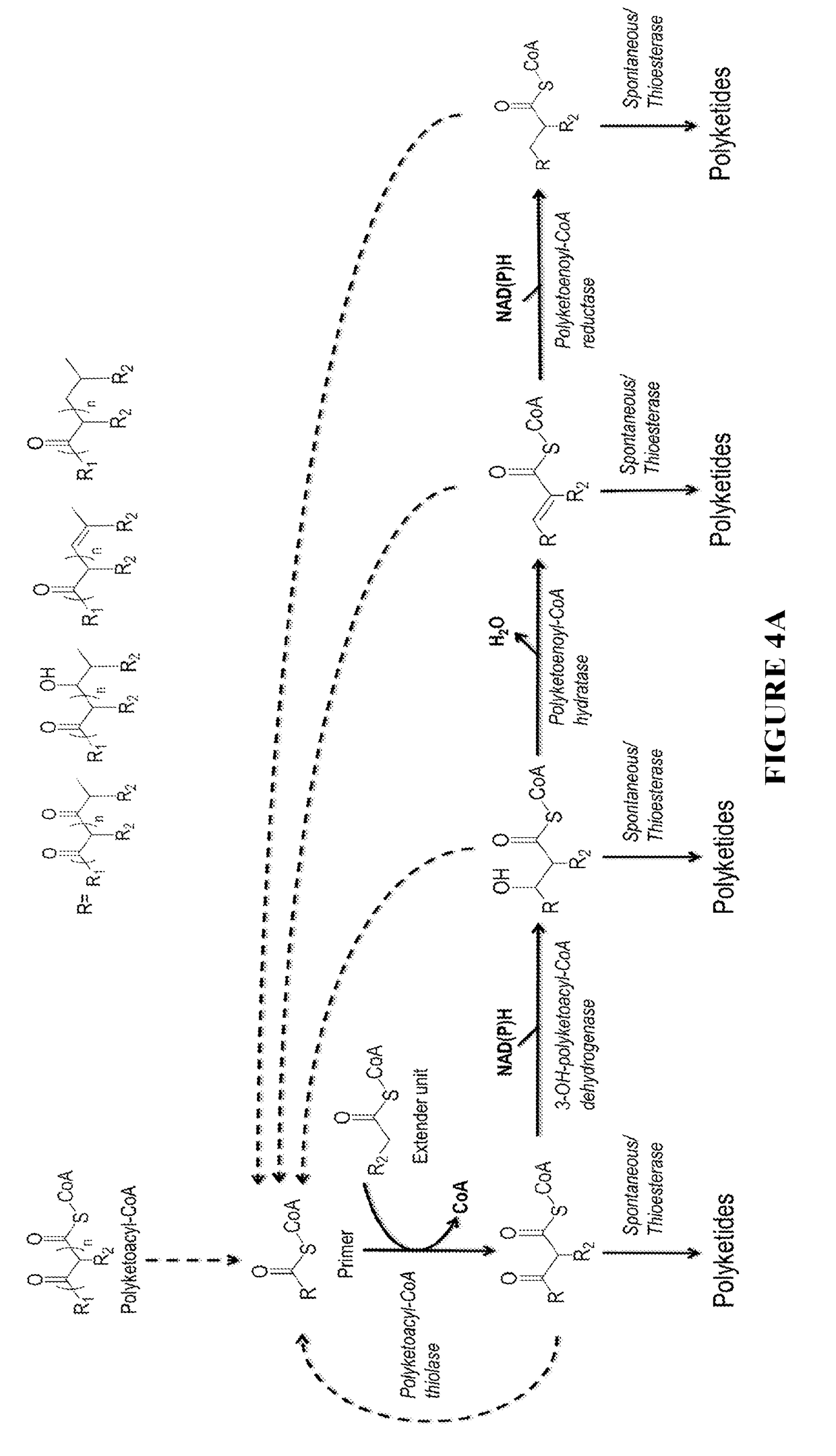

Biosynthesis of polyketides

InactiveUS20190002848A1Increase diversityWide-ranging product diversityAcyltransferasesFermentationClaisen condensationPolyketide biosynthesis

This disclosure generally relates to the use of microorganisms to make various functionalized polyketides through polyketoacyl-CoA thiolase-catalyzed non-decarboxylative condensation reactions instead of decarboxylative reactions catalyzed by polyketide synthases. Native or engineered polyketoacyl-CoA thiolases catalyze the non-decarboxylative Claisen condensation in an iterative manner (i.e. multiple rounds) between two either unsubstituted or functionalized ketoacyl-CoAs (and polyketoacyl-CoAs) serving as the primers and acyl-CoAs serving as the extender unit to generate (and elongate) polyketoacyl-CoAs. Before the next round of polyketoacyl-CoA thiolase reaction, the β-keto group of the polyketide chain of polyketoacyl-CoA can be reduced and modified step-wise by 3-OH-polyketoacyl-CoA dehydrogenase or polyketoenoyl-CoA hydratase or polyketoenoyl-CoA reductase. Dehydrogenase converts the β-keto group to β-hydroxy group. Hydratase converts the β-hydroxy group to α-β-double-bond. Reductase converts the α-β-double-bond to single bond. Spontaneous or thioesterase catalyzed termination reaction terminates the elongation of polyketide chain of polyketoacyl-CoA at any point through CoA removal and spontaneous reactions rearrange the structure, generating the final functional polyketide products.

Owner:GONZALEZ RAMON

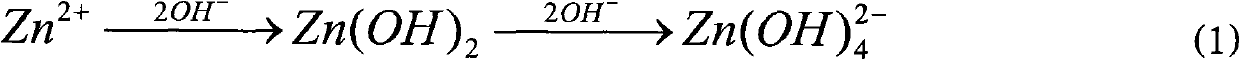

High-performance gas sensor

InactiveCN102608170AImprove performanceMany active sitesMaterial resistanceChemical reactionSpecific chemical reaction

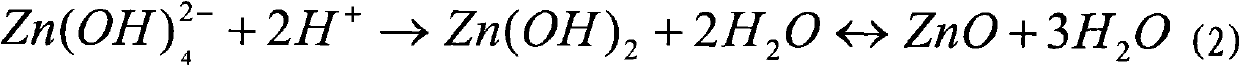

The invention relates to a high-performance gas sensor, which is characterized by comprising the following steps of preparing a sensitive material of a sensor, designing and manufacturing a sensor structure, and measuring and representing a sensor. The sensitive material is prepared at normal temperature and normal pressure mainly by regulating a chemical balance method, wherein the specific chemical reaction is as follows: equations as shown in an original PDF, and zinc acetate contains Zn<2+> ions and can be dissolved in strong alkaline solution. On the presence of a large amount of hydroxyl radicals, Zn(OH)4<2-> can be generated, which can be seen in an equation (1). A matter Zn(OH)4<2-> has high chemical energy in neutral solution, is unstable and carries out a spontaneous reaction to generate low-energy and stable Zn(OH)2. Absolute ethyl alcohol is added and H<+> is provided so that the H<+> and excessive OH<-> generate a neutralization reaction, and a solution changes from alkaline to be neutral; and simultaneously, the chemical equation moves rightwards to generate Zn(OH)2, which can be seen in an equation (2). According to a sensitive material coating method, different structures of gas sensors are manufactured, including bypass type gas sensors, plane type gas sensors and the like.

Owner:BEIJING ZHONGKE MICRO NANO NETWORKING SCI TECH

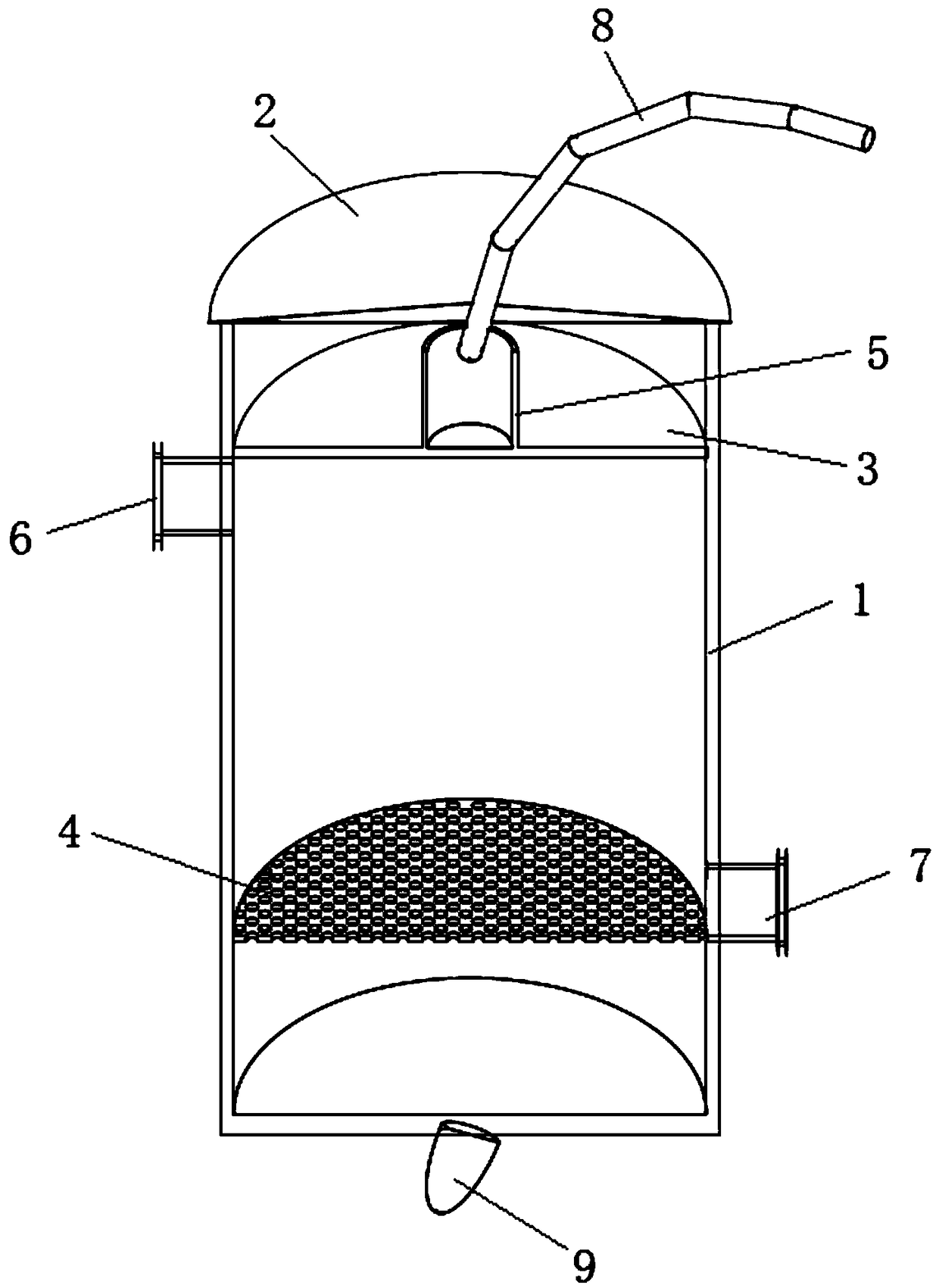

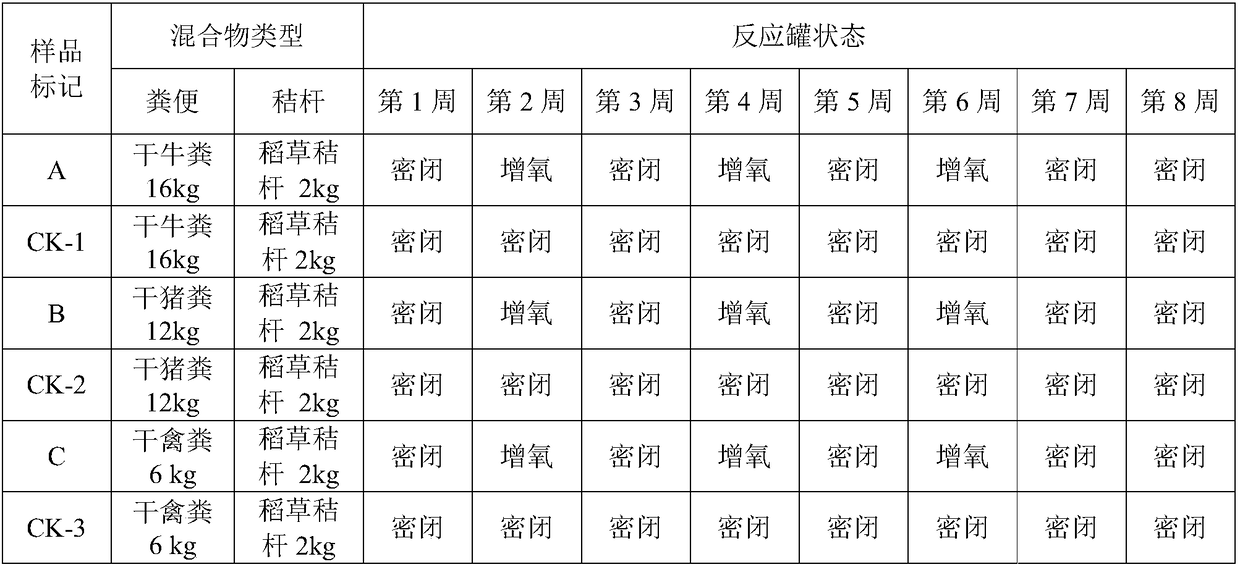

Method for producing organic fertilizer by using livestock manure

InactiveCN109400269AAccelerate the rate of decaySuppression of reduction lossCalcareous fertilisersBio-organic fraction processingAnaerobic decompositionLivestock manure

The invention discloses a method for producing organic fertilizer by using livestock manure. The method comprises the following steps: S1, mixing livestock manure and crop straws according to a givenweight ratio; S2, before a compost mixture is placed into a reaction tank, adding a given amount of water into the compost mixture; and S3, placing the compost mixture into the reaction tank, performing the spontaneous reaction of the compost mixture for one week in a closed state of the reaction tank; placing a given amount of oxygenation agent on the bottom of the compost mixture in the reactiontank about every two weeks, and enabling the compost mixture to continuously perform the aerobic reaction; after the temperature in the reaction kettle is stable, stopping placing the oxygenation agent into the reaction tank; and after the feeding of the oxygenation agent is stopped, keeping the closed state of the reaction tank for one week. According to the method of the invention, not only canthe anaerobic decomposition and degradation reaction be performed for the compost mixture, but also the oxygenation agent is placed into the reaction tank to perform the aerobic decomposition and degradation reaction, the decomposition speed for converting the organic matters into organic fertilizer can be increased, and the fertilizer effect conversion rate can be increased.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

Lithium metal electrode surface oxidized composite protective layer structure and preparation method thereof

ActiveCN108565397AInhibitionSmall volume changeNon-aqueous electrolyte accumulator electrodesLithium metalSolvent

The invention belongs to the technical field of lithium metal electrode oxidation protection and discloses a lithium metal electrode surface oxidized composite protective layer structure and a preparation method thereof. The lithium metal electrode surface oxidized composite protective layer structure comprises a plurality of electronic insulated two-dimensional lamellar structural layers; a phenyl sulfide conducting layer is arranged between every two adjacent two-dimensional lamellar structural layers; the preparation method comprises the steps of A, dispersing graphene oxide powder fully inan organic solvent to obtain a dispersion; B, adding thioether with benzene functional groups into the dispersion, mixing well for dissolving to obtain a coating solution; C, spraying the coating solution to a battery diaphragm substrate, evaporatively drying the solvent to obtain a diaphragm with an even coating. Organic phenyl sulfide small molecules are introduced among the multiple two-dimensional lamellar structural layers; lithium ion transfer passages formed by S-S crosslinked structure that the resultant forms through spontaneous reaction; electrolyte and lithium metal can be isolatedfrom direct contact; cycle stability of lithium metal is improved.

Owner:四川华昆能源有限责任公司

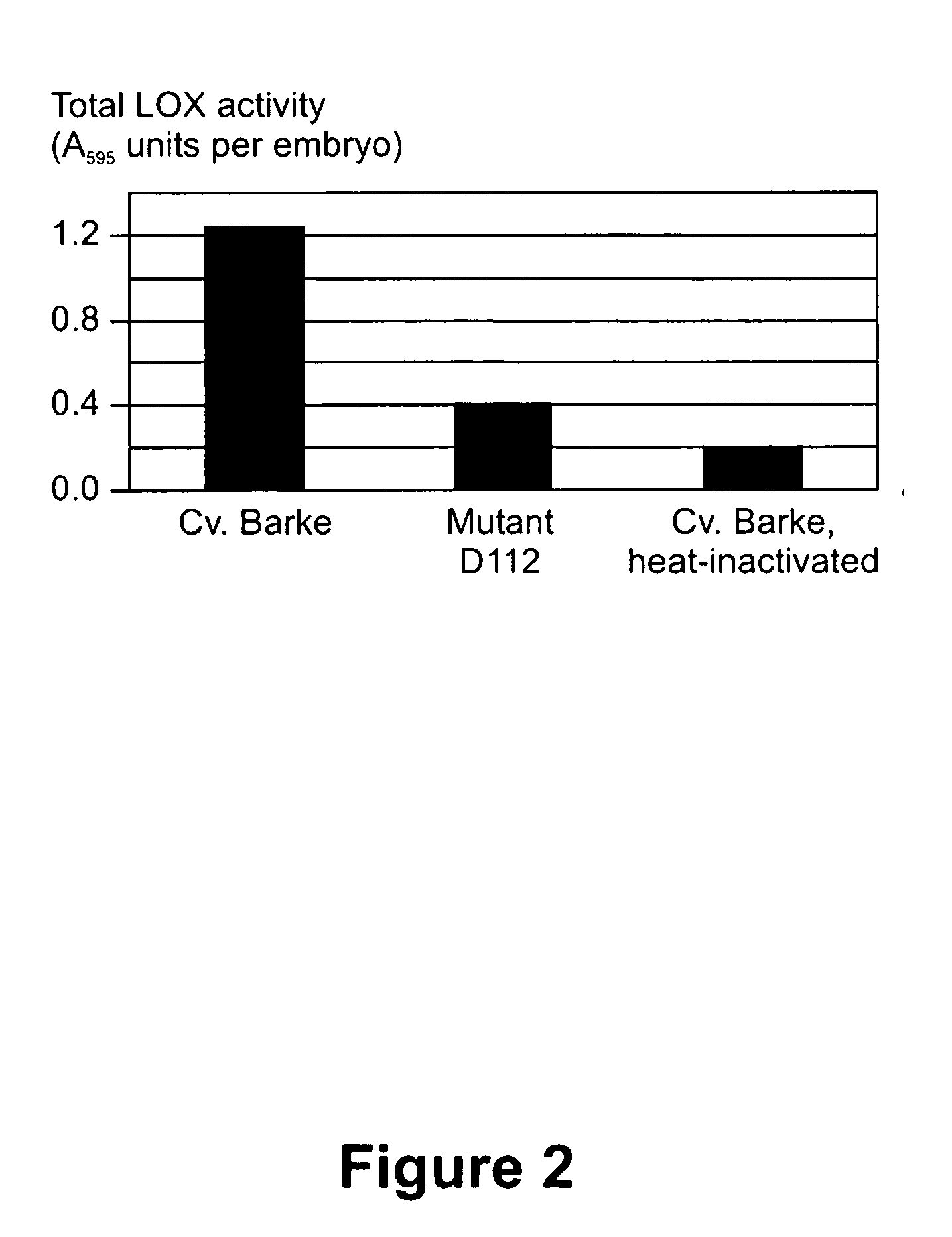

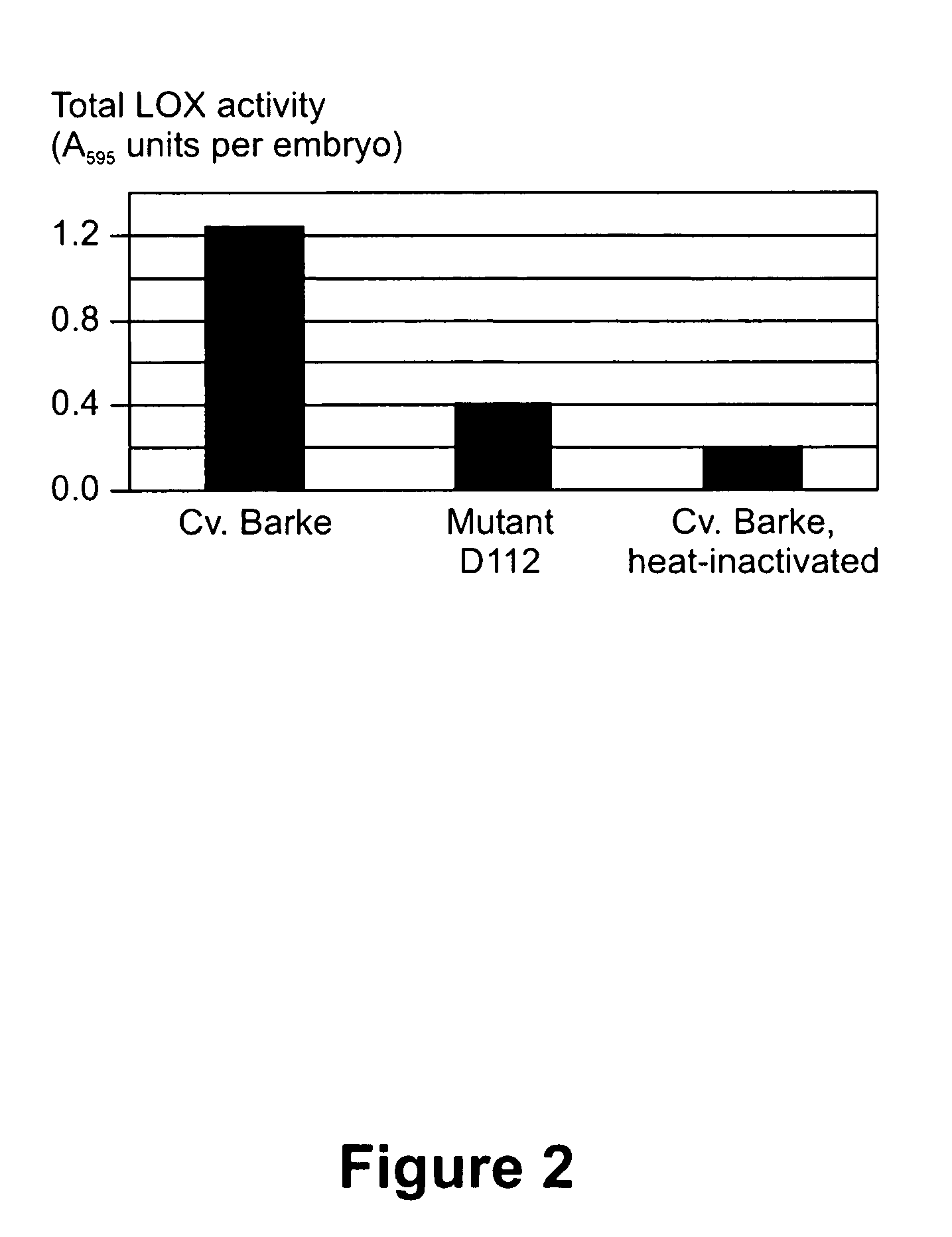

Barley with reduced lipoxygenase activity and beverage prepared therefrom

According to the invention, there is provided barley with total loss of functional lipoxygenase (LOX)-1 and LOX-2 enzymes, and plant products produced thereof, such as malt manufactured by using barley kernels defective in the synthesis of the fatty acid-dioxygenating enzymes LOX-1 and LOX-2. Said enzymes account for the principal activities related to dioxygenation of linoleic acid into 9- and 13-hydroperoxy octadecadienoic acid, respectively. 9-Hydroperoxy octadecadienoic acid represents a LOX pathway metabolite, which—through further enzymatic or spontaneous reactions—may lead to the appearance of trans-2-nonenal (T2N). The invention enables brewers to produce a beer having insignificant levels of stale, T2N-specific off-flavors, even after prolonged storage of the beverage.

Owner:CARLSBERG BREWERIES AS +1

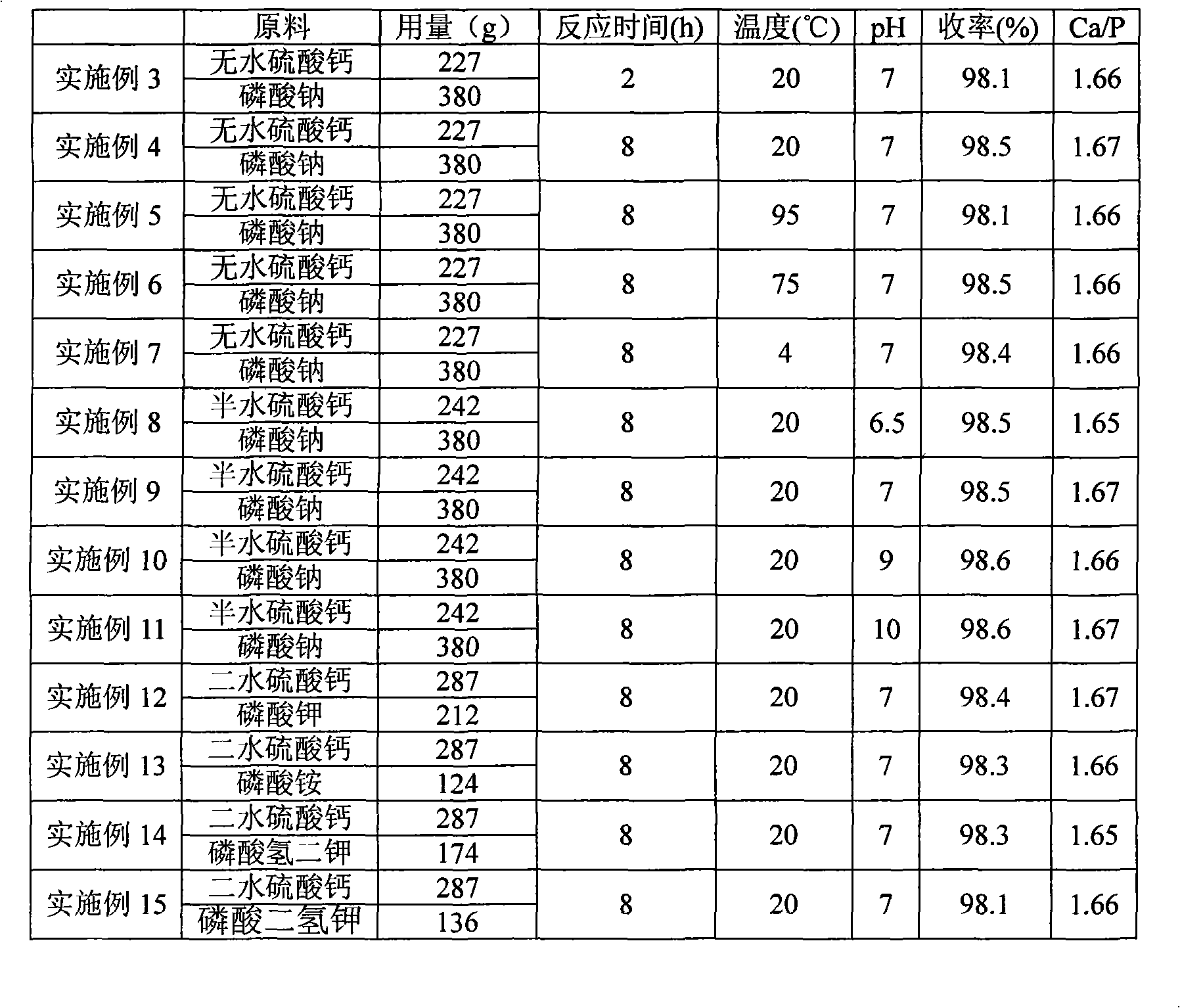

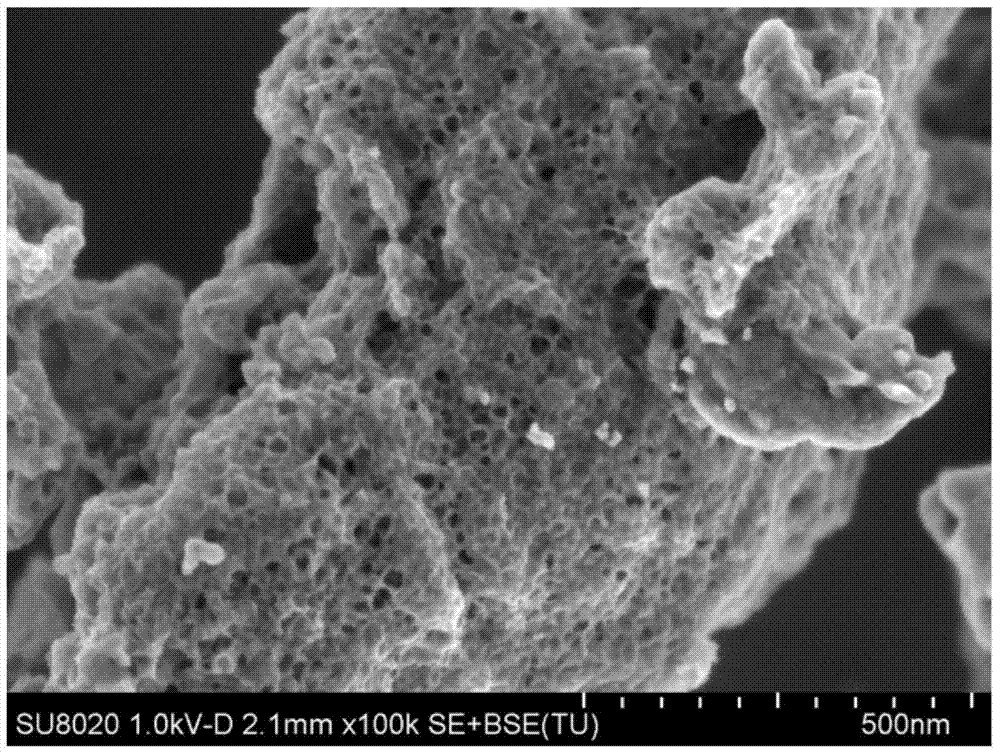

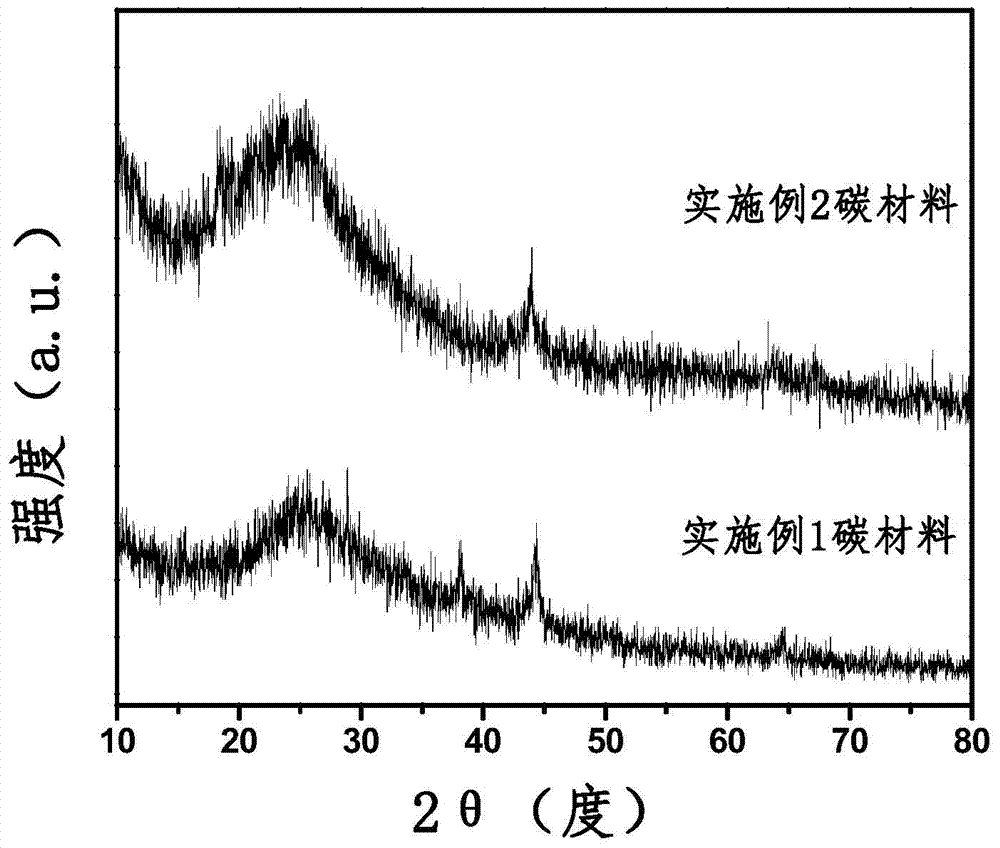

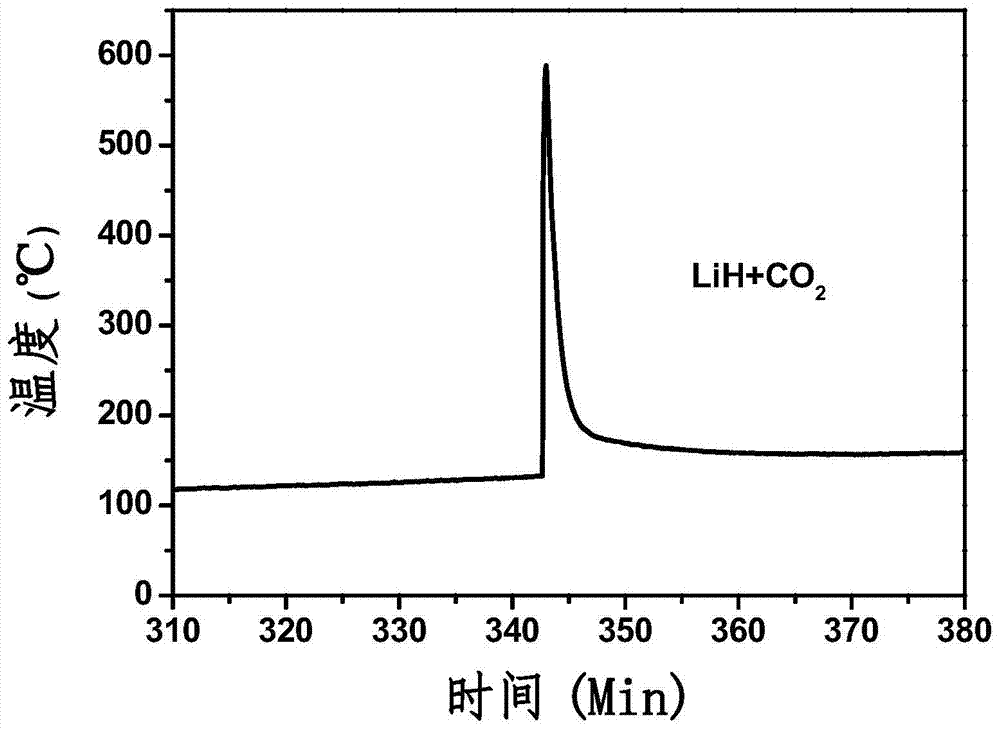

Method for preparing bone-like apatite controlled by thermodynamics

The invention relates to a method for preparing bone-like apatite controlled by thermodynamics. Water micro-soluble calcium salts with a Ksp value larger than that of bone-like apatite, such as calcium sulphate or hydrate thereof and the like, are taken as raw materials and react in a water solution of a water-soluble phosphate, thus obtaining the bone-like apatite; the yield of the product is above 95 percent, and the molar ratio of Ca / P is consistent with the theoretical computation of the raw materials. The method is characterized in that the reaction process is thermodynamic spontaneous reaction controlled by thermodynamics instead of dynamics; therefore, reaction condition does not affect the final composition and property of the product, and the product is stable and has less impurities; the prepared nano bone-like apatite sizing material can be directly applied to preparing corresponding nano biomimetic composite bone repairing and substituting materials and the like or used for obtaining corresponding bone-like apatite powder after being dried.

Owner:SICHUAN GUONA TECH

Method for producing fire-resistant insulated castable by self-foaming thermal reaction hardened forming

InactiveCN101817691ASimple production processEnergy saving and environmental protection in the production processCeramicwareBrickGranularity

The invention discloses a method for producing a fire-resistant insulated castable by self-foaming thermal reaction hardened forming, which is characterized by comprising the following steps of: pre-mixing and stirring 60 to 70 percent of refractory aggregate with the granularity between 0.5 and 5mm, 20 to 30 percent of refractory powder with the granularity between 0 and 0.5mm and 3 to 10 percent of aluminum powder with granularity between 0 and 0.1mm, and adding 50 percent phosphoric acid solution in a certain proportion; fully stirring, injecting the castable into a specified mold so as to perform spontaneous reaction foaming forming; and after fully reacting and continuously raising the temperature to the constant temperature of over 60 DEG C for about 1 hour, and curing and hardening into a molded fire-resistant insulated material with certain intensity. The prepared fire-resistant insulated material has hardness and intensity indexes equivalent to those of the light-weight refractory brick, simple production technology, energy-saving and environment-friendly production process, and significance for industrial application.

Owner:柯东杰

A way to convert greenhouse gases into carbon

ActiveCN105271178BThe method is simple and controllableEfficient methodCarbon preparation/purificationMetallic aluminumMetallic hydrogen

A method for converting greenhouse gas into carbon includes the steps that 1, under protective atmosphere and a room temperature, a metallic hydrogen-containing compound and the greenhouse gas make sufficient contact in a dry reactor, the greenhouse gas includes one or more of CO2, CO and CH4, and certain triggering energy is given so that effective components in the metallic hydrogen-containing compound and greenhouse gas can generate spontaneous reaction; the metallic hydrogen-containing compound is one or a mixture or composite of two or more of metal hydride, metallic aluminum hydride, metallic borohydride and metallic nitrogen hydride; 2, after reaction is completed and cooling is performed, the gas in the reactor is collected, then a reaction product is taken out of the reactor and soaked through acidic substances, and the carbon can be obtained through filtering, rinsing and drying. The method is simple, easy to control, efficient and low in energy consumption, and industrialized production is easy to achieve.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of inorganically filled lithium ion battery diaphragm

ActiveCN103199211AEvenly dispersedImprove mechanical propertiesCell component detailsPorosityLithium-ion battery

The invention discloses a preparation method of an inorganically filled lithium ion battery diaphragm. The preparation method comprises the following steps of adding tetrabutyl titanate into suspension liquid prepared from ultrahigh molecular weight polyethylene and a diluent, extruding the mixture to form a diaphragm, stretching the diaphragm, and extracting the diluent; and then carrying out spontaneous reaction on the tetrabutyl titanate in the diaphragm and water in a circulating water tank to generate titanium dioxide, enabling the titanium dioxide to enter a heat treatment device to be shaped, and finally enabling the thickness of the diaphragm to be uniform through thermal rolling. The preparation method can introduce titanium dioxide particles into the diaphragm by utilizing the reaction of the tetrabutyl titanate and the water, and is favorable for enhancing multiple mechanical properties and heat resistance performance of the diaphragm. The preparation method has the advantages of simplicity in operation, energy conservation, environmental protection, high safety and high production efficiency. The porosity of the diaphragm prepared by the preparation method is high, and the intensity of the diaphragm is qualified, and the shrinkage ratio of the diaphragm is smaller than 8% after the diaphragm shrinks at 150 DEG C for one hour. The lithium ion battery diaphragm obtained by the preparation method is good in the heat resistance performance and standard in mechanical properties, and can be used as a large-power lithium-ion battery diaphragm.

Owner:SHANGHAI SHUANGAO ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com