Novel method for preparing nanometer silicon from silicon dioxide

A silicon dioxide and nano-silicon technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of high energy consumption in high-temperature reactions, difficult to control reactions, self-accelerating reactions, etc., and achieve high purity and easy scale-up , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

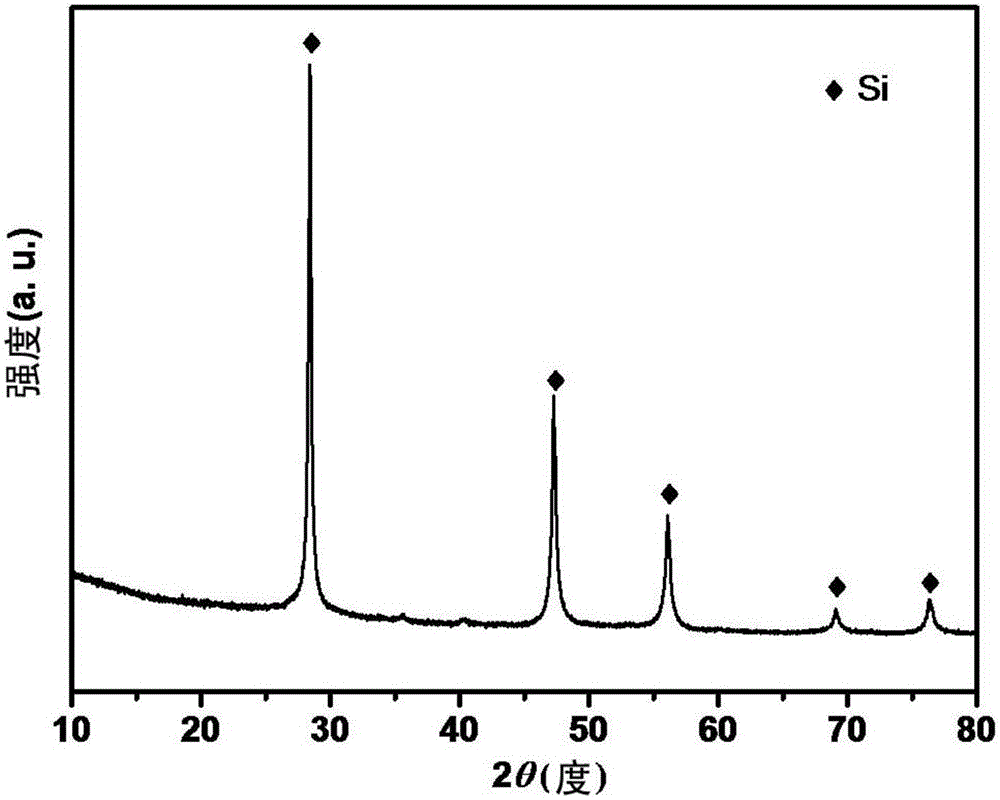

[0026] Amorphous SiO 2 Prepare nano-silicon by ball milling with a molar ratio of 1:2.1 to nano-magnesium powder (average particle size: 300nm)

[0027] (1) Take 10g of raw material of commercial amorphous SiO with a size of 50nm 2 And 8.4g of magnesium powder with an average particle size of 300nm, add 25 zirconia balls with a mass of 4g, and use a planetary ball mill to mill for 10min.

[0028] (2) Add hydrochloric acid to the mixture to remove MgO and generate MgCl 2 , 500rpm centrifugal separation of nano silicon, washed with deionized water to MgCl 2 After all of them were removed, they were washed with ethanol, heated and dried under vacuum at 150° C. for 1 h to obtain nano-silicon.

[0029] (3) The nano-silicon obtained in the previous step is etched with 20%wt HF solution, the surface oxide layer is removed, and the deionized water is washed to MgCl 2 After all of them were removed, they were washed with ethanol, and dried in a vacuum oven at 70° C. for 12 hours ov...

Embodiment 2

[0032] Preparation of nano-silicon by ball milling of mesoporous molecular sieve SBA-15 and nano-magnesium powder (average particle size 300nm) at a molar ratio of 1:2.5

[0033] (1) Take 5g of SBA-15 and 5g of nano-magnesium powder (average particle size: 300nm) as raw materials, add 10 zirconia balls with a mass of 4g, and use a planetary ball mill to mill for 30min.

[0034] (2) Add hydrochloric acid to the mixture to remove MgO and generate MgCl 2 , 10000rpm centrifugal separation of nano-silicon, washed with deionized water to MgCl 2 After all of them were removed, they were washed with ethanol, heated and dried at 50° C. under normal pressure for 36 hours to obtain nano-silicon.

[0035] (3) The nano-silicon obtained in the previous step is etched with 2%wt HF solution, the surface oxide layer is removed, and the deionized water is washed to MgCl 2 After all of them were removed, they were washed with ethanol, and dried in a vacuum oven at 70° C. for 12 hours overnight...

Embodiment 3

[0038] Diatomite and nano-magnesium powder (average particle size: 300nm) molar ratio of 1:3 ball milling to prepare nano-silicon

[0039] (1) Take 8g of diatomite and 12g of nano-magnesium powder (300nm) as raw materials, add 40 zirconia balls with a mass of 4g, and use a planetary ball mill to mill for 2 hours.

[0040] (2) Add hydrochloric acid to the mixture to remove MgO and generate MgCl 2 , 30000rpm centrifugal separation of nano-silicon, washed with deionized water to MgCl 2 After all of them were removed, they were washed with ethanol, heated and dried under vacuum at 100° C. for 12 hours to obtain nano-silicon.

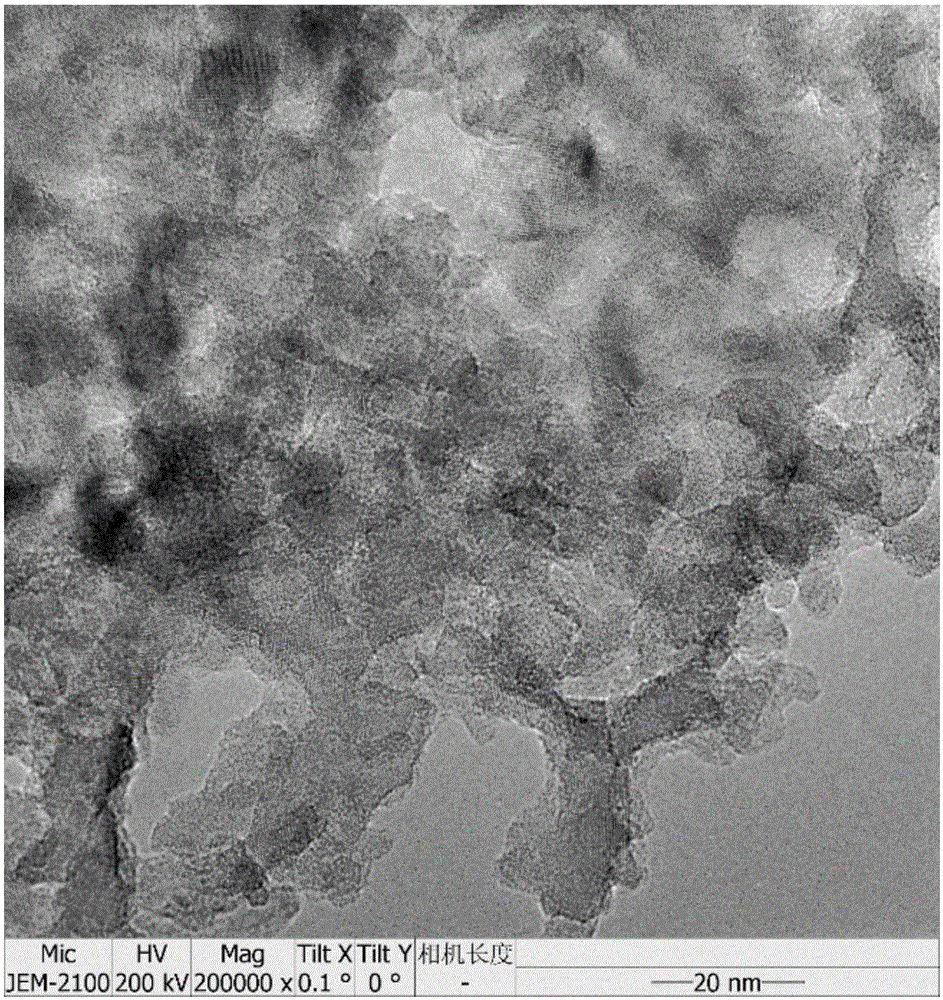

[0041] The high-purity nano-silicon obtained after the above two steps has good crystallinity, a particle size of about 5 μm, and a pore size of about 100 nm. The specific surface area of the sample obtained by nitrogen isothermal adsorption is 200m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com