Patents

Literature

191 results about "Advanced materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed-metal oxide particles by liquid feed flame spray pyrolysis of oxide precursors in oxygenated solvents

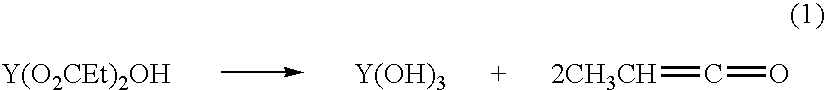

Liquid feed flame spray pyrolysis of solutions of a metal oxide precursor which is an alkoxide or C1-6 carboxylate and at least one second metal oxide precursor and / or second metal compound dissolved in oxygenated solvent by combustion with oxygen lead to the formation of sub-micron mixed-metal oxide powders not accessible by other processes or by the pyrolysis of metal chlorides or nitrates. The powders have numerous uses in advanced materials applications including particulate solid state lasers, advanced ceramic materials, and as catalysts in organic synthesis and automobile exhaust systems.

Owner:TAL MATERIALS +1

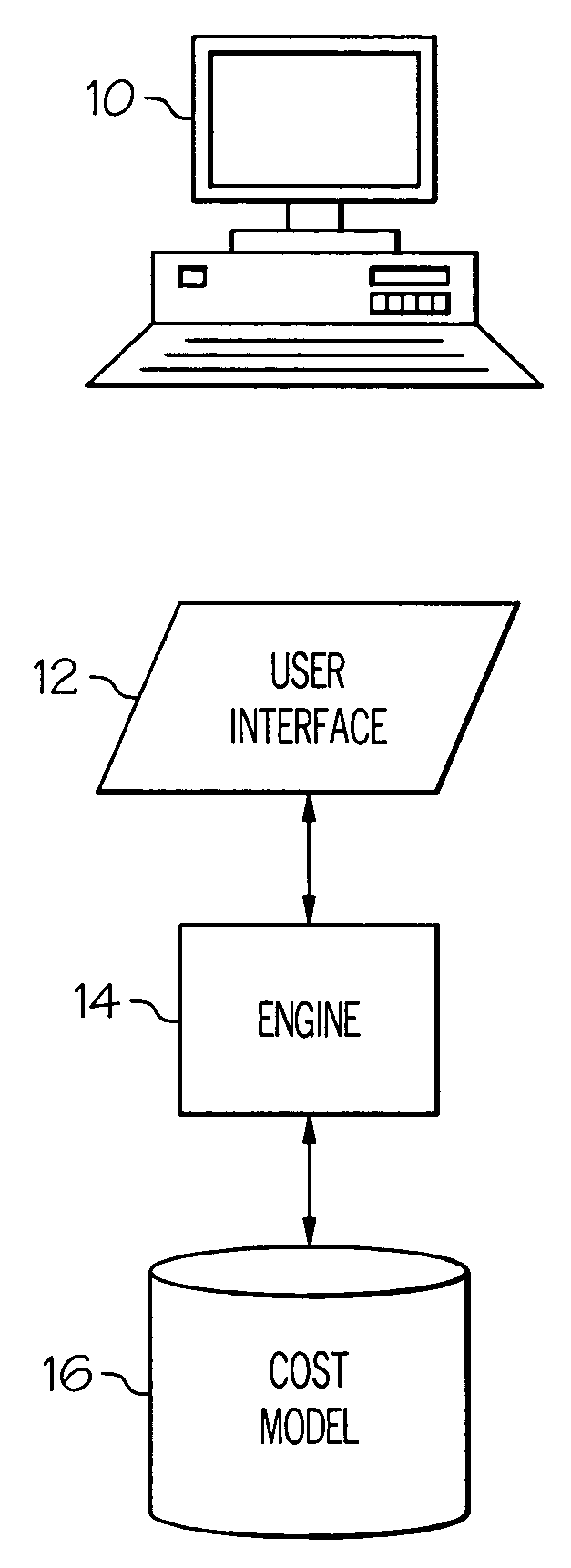

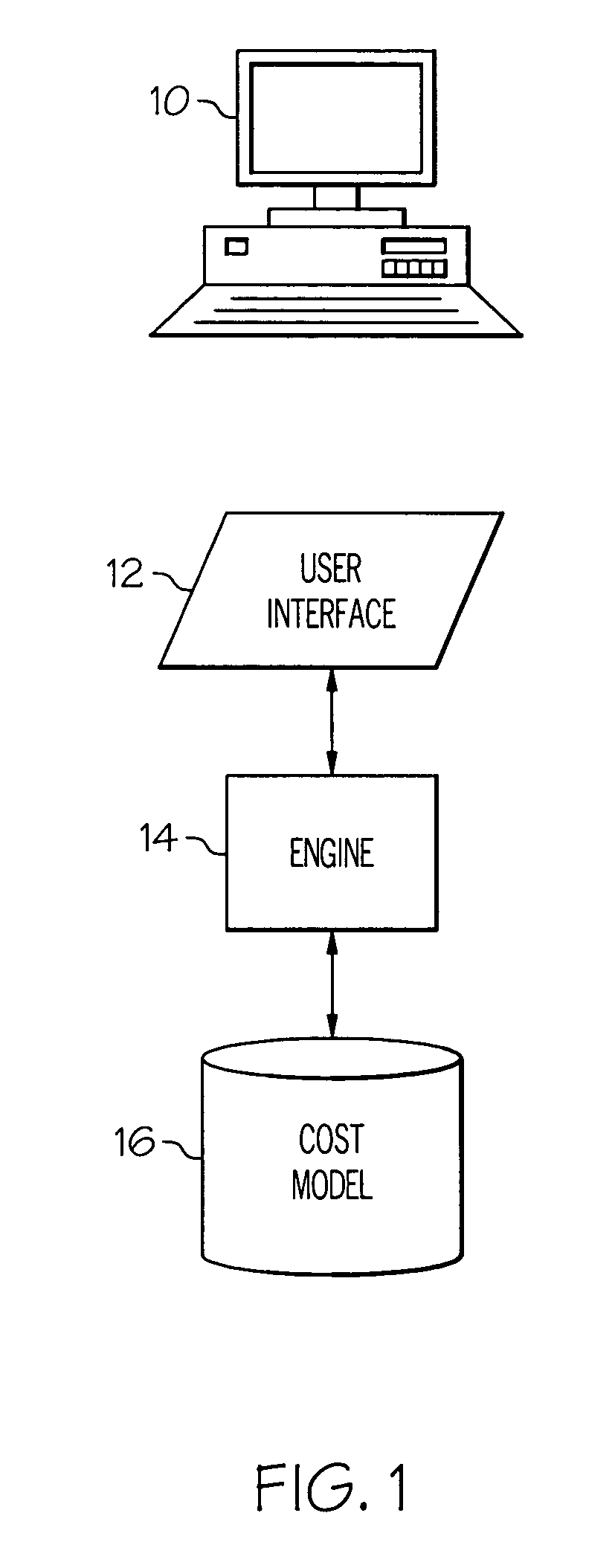

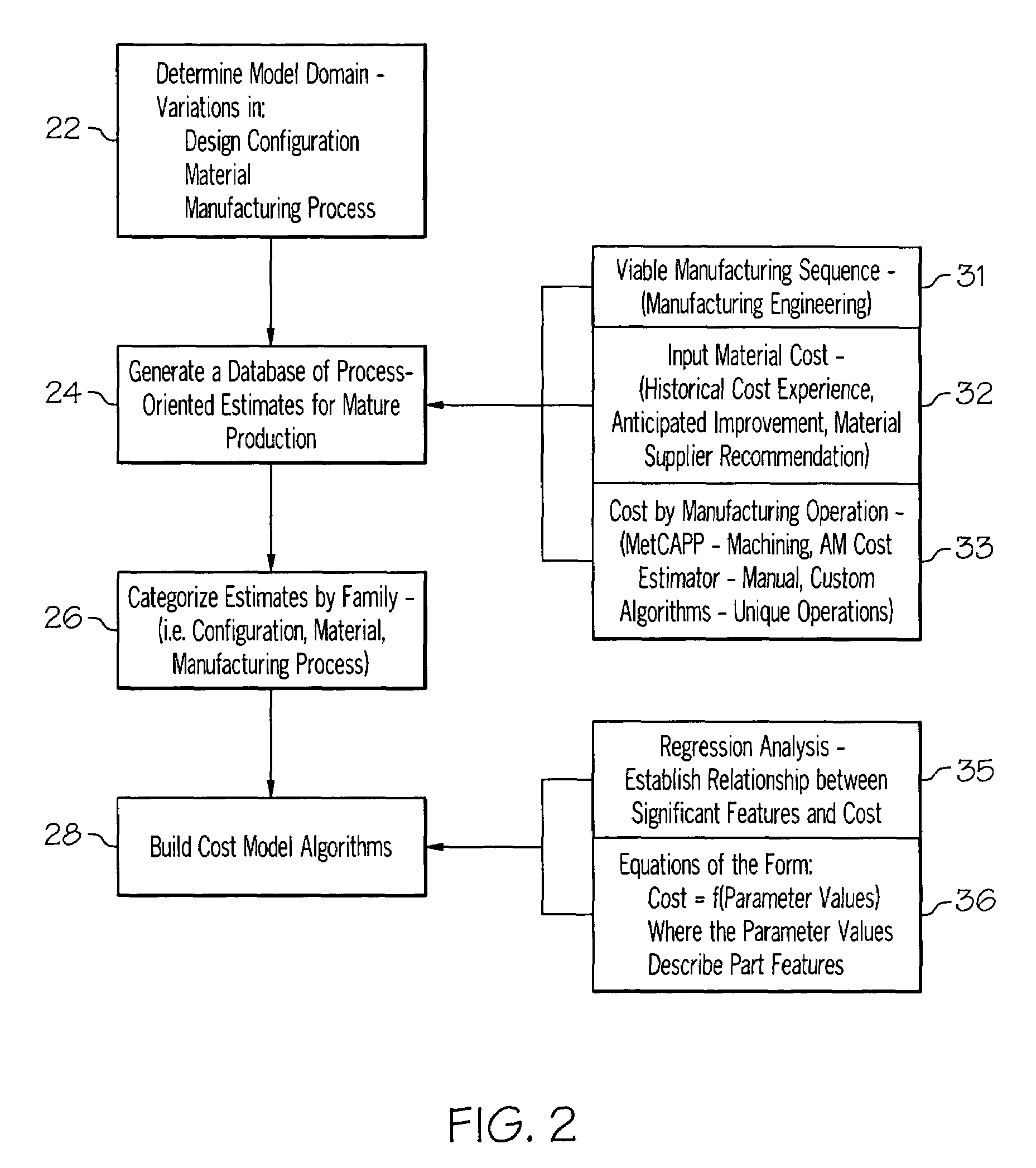

Method and system for estimating manufacturing costs

InactiveUS7292965B1Easily expandableEasily modifiableComputation using non-denominational number representationBuying/selling/leasing transactionsProcess orientedRelational database

A method and system estimates manufacturing costs for conventional and advanced materials and processes based on process-oriented approach. A computer system input display for selecting one or more designs and one or more design parameters. Cost models are based upon process-oriented manufacturing cost estimates for a plurality of designs utilizing materials and manufacturing processes. Software is programmed to receive selected designs and selected design parameters from the input display and pass the selected designs and design parameters to the cost models. An output display shows the manufacturing costs estimated by the cost models for the selected designs and design parameters. A manufacturing process flow simulation model highlights and quantifies the magnitude of the manufacturing process cost drivers. An architecture including a relational database is also disclosed, and input and editing modules can be utilized to modify the cost model equations or to provide input from other software applications.

Owner:AMERICAN TECH & SERVICES

Advanced materials and design for low temperature sofcs

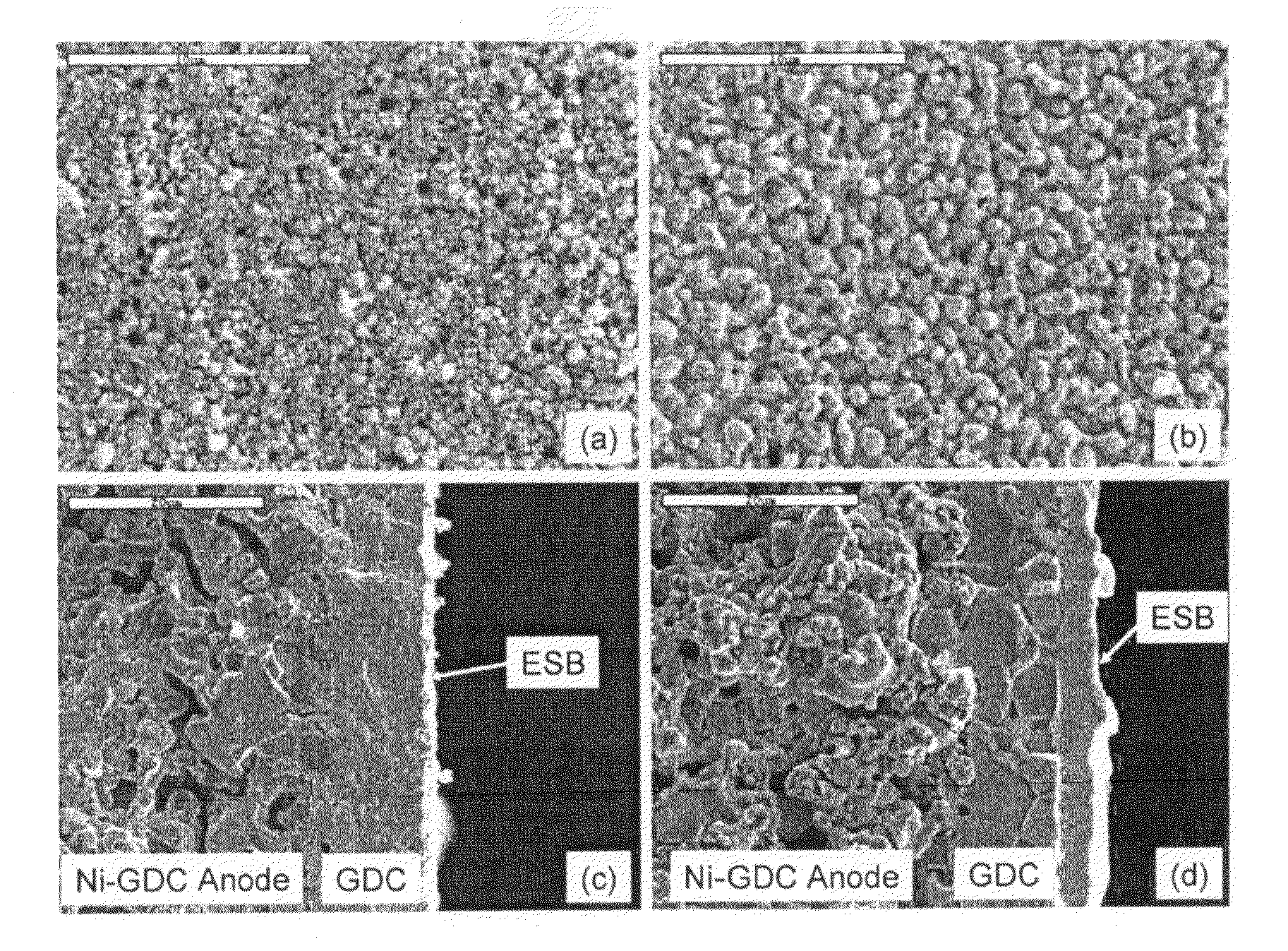

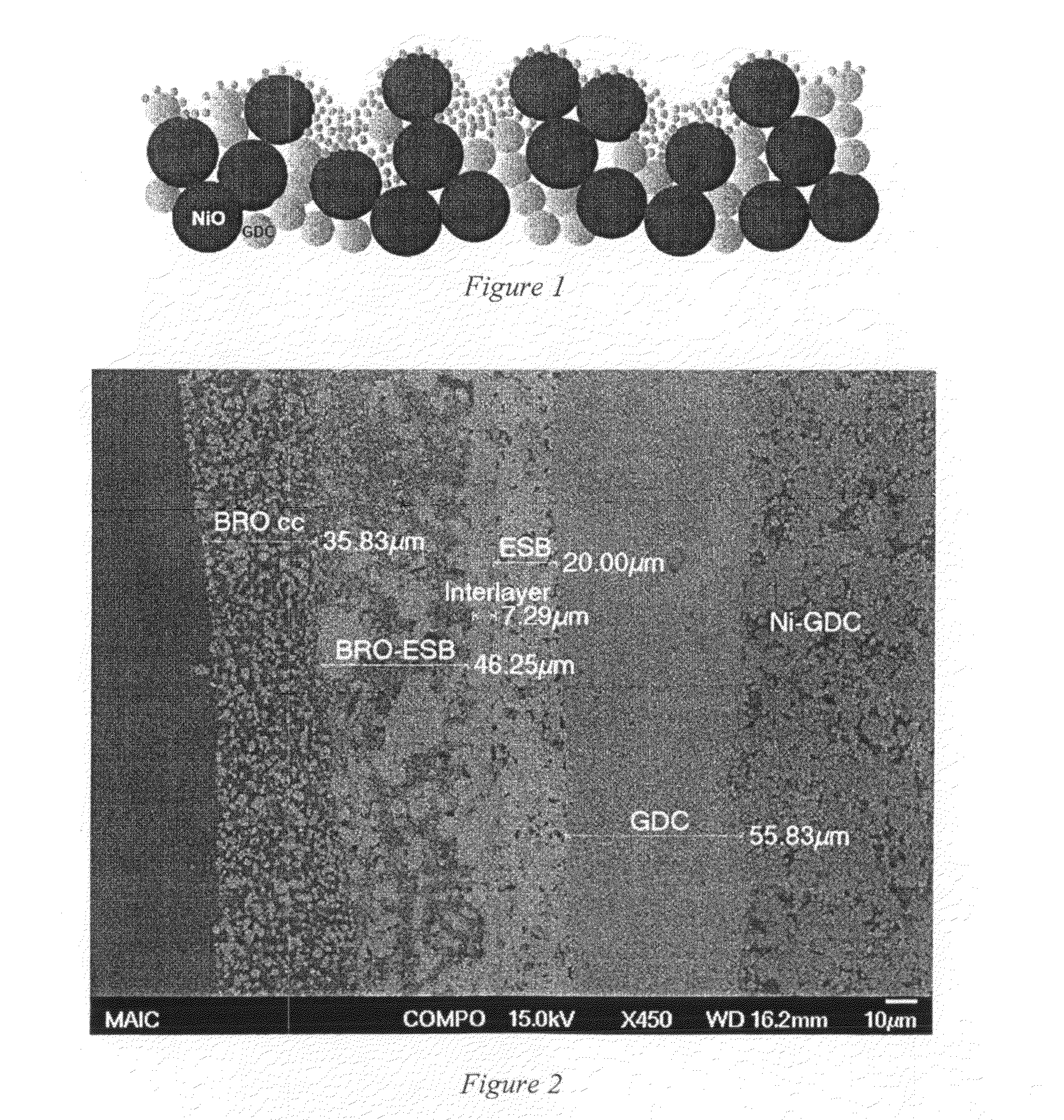

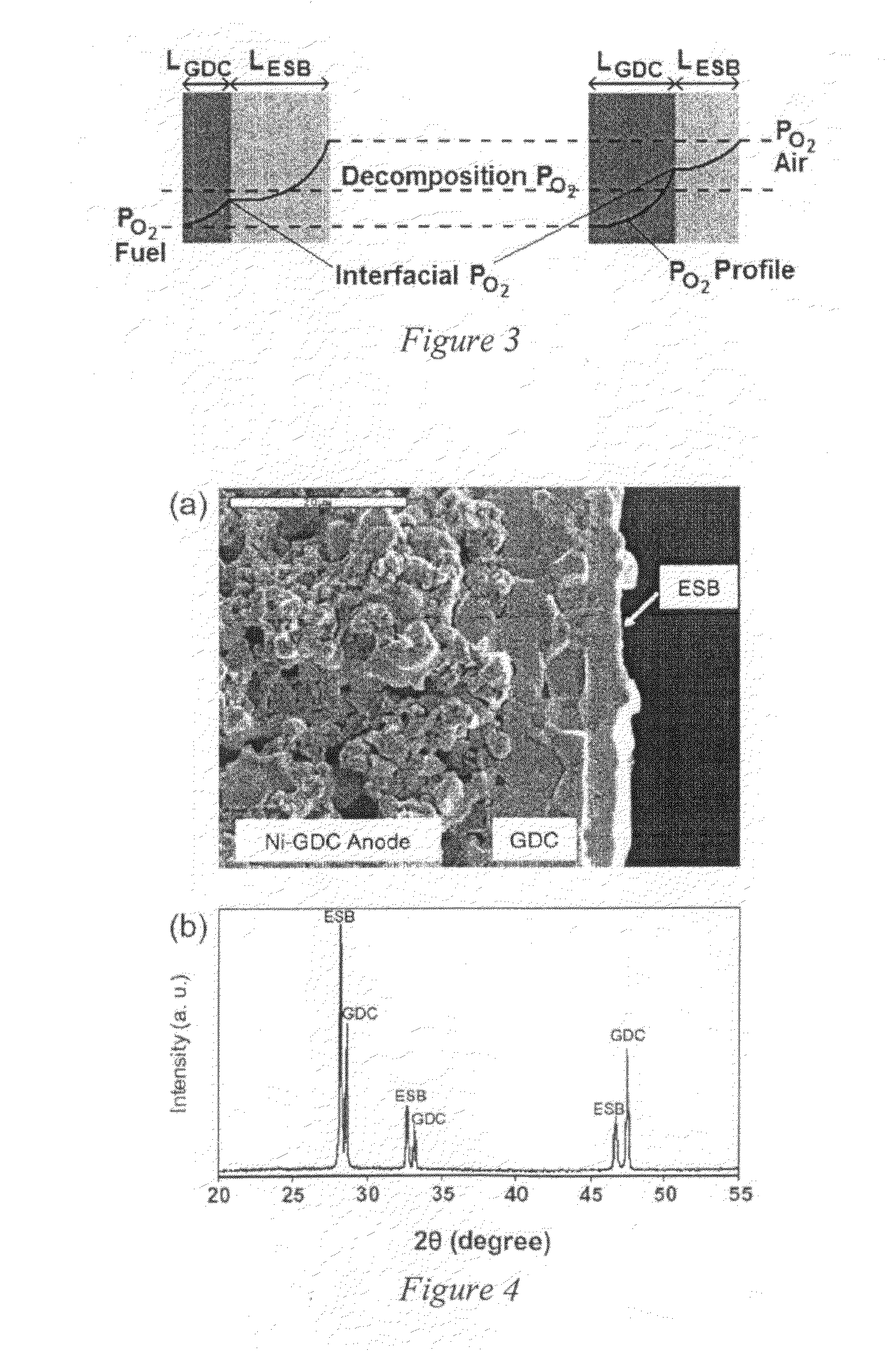

ActiveUS20110200910A1Small particle sizeOxide/hydroxide preparationElectric discharge heatingPorous ceramicsMaterials science

Embodiments of the invention are directed to SOFC with a multilayer structure comprising a porous ceramic cathode, optionally a cathodic triple phase boundary layer, a bilayer electrolyte comprising a cerium oxide comprising layer and a bismuth oxide comprising layer, an anion functional layer, and a porous ceramic anode with electrical interconnects, wherein the SOFC displays a very high power density at temperatures below 700° C. with hydrogen or hydrocarbon fuels. The low temperature conversion of chemical energy to electrical energy allows the fabrication of the fuel cells using stainless steel or other metal alloys rather than ceramic conductive oxides as the interconnects.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

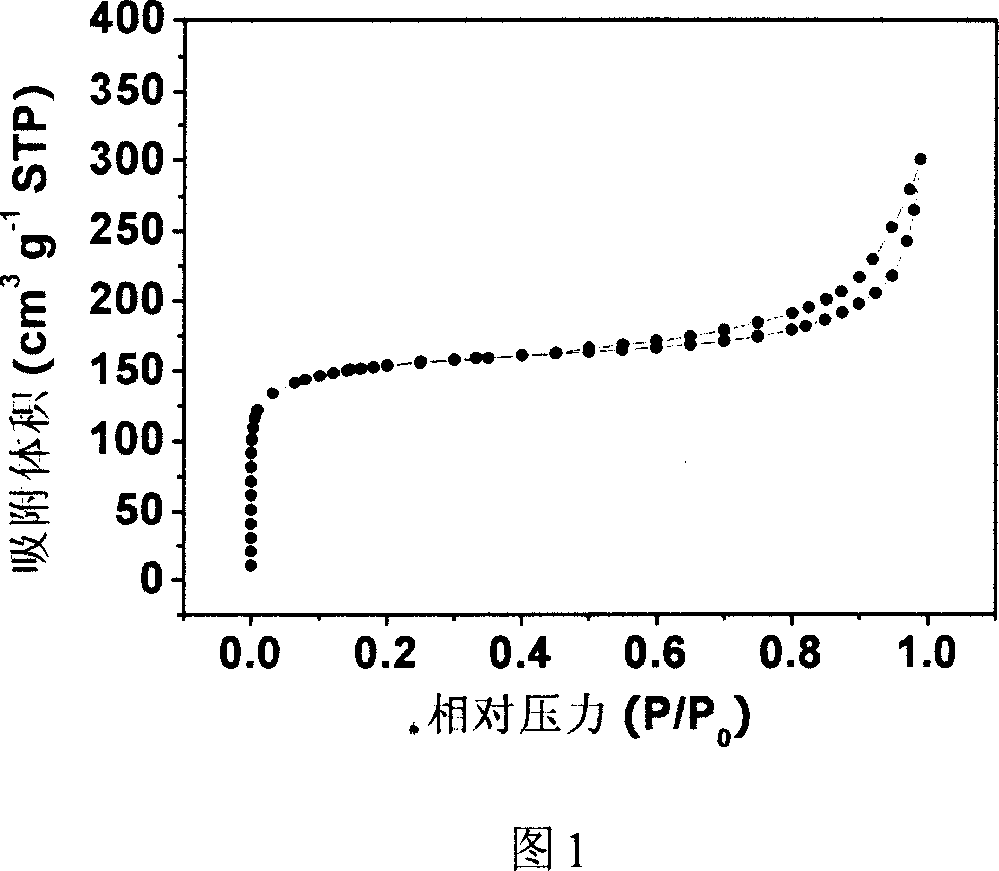

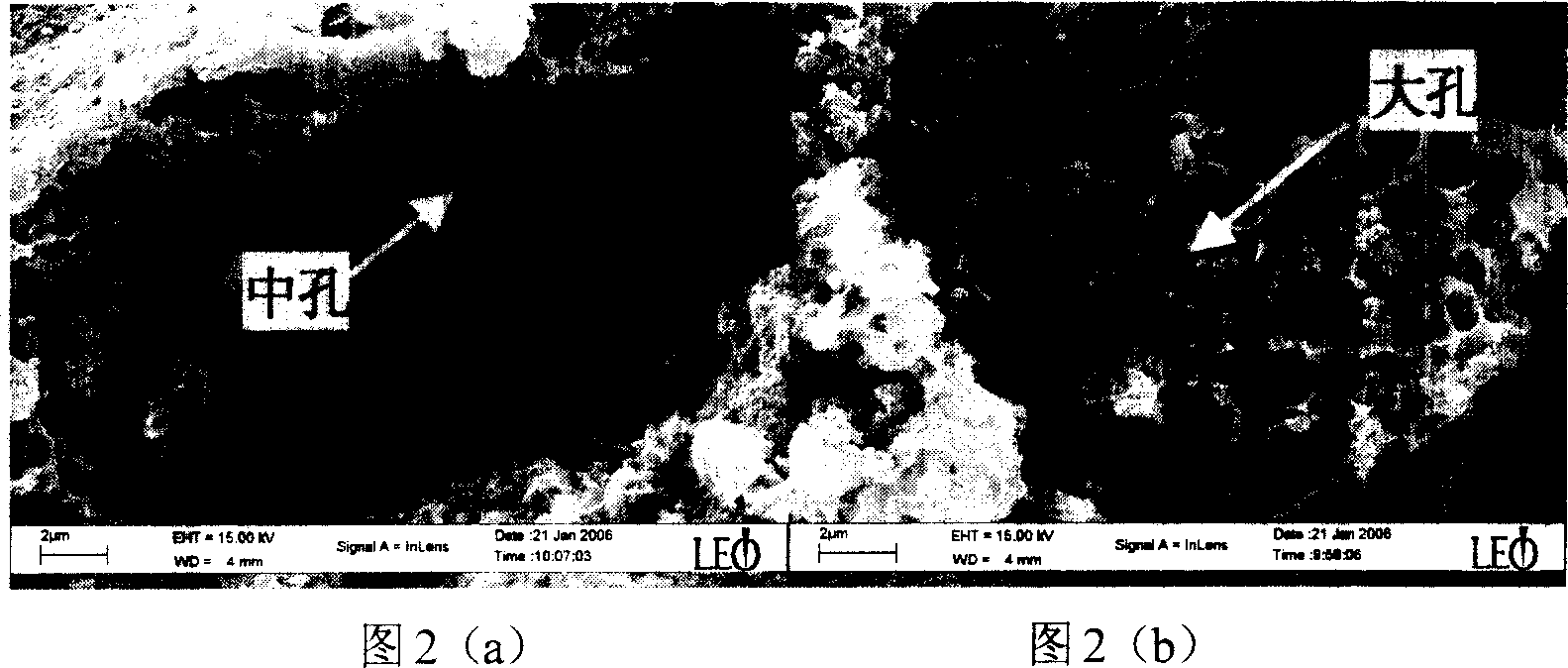

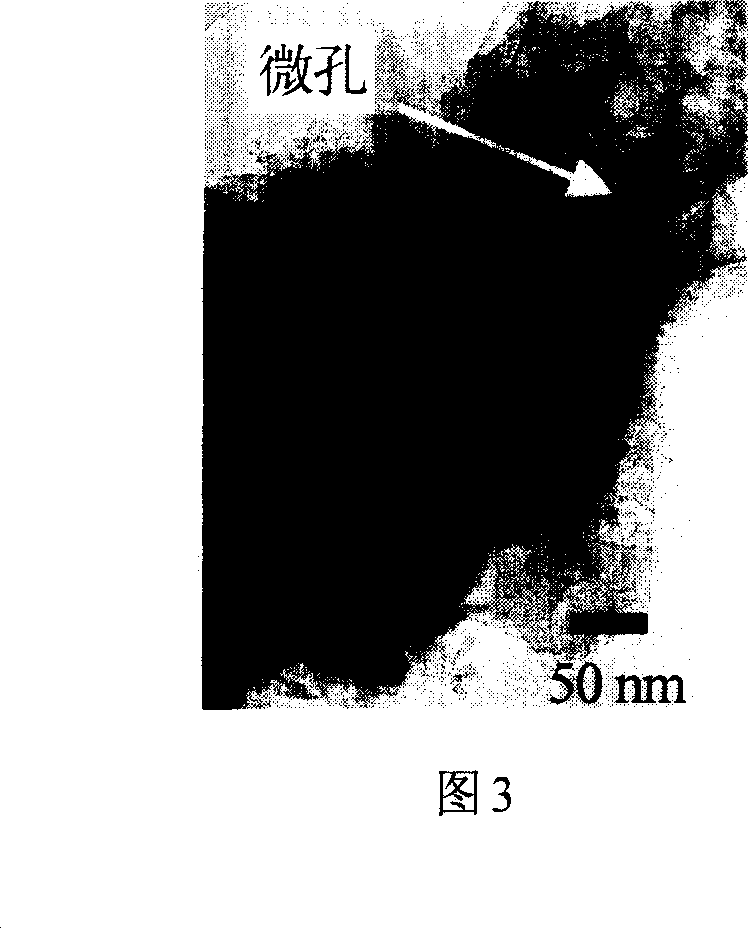

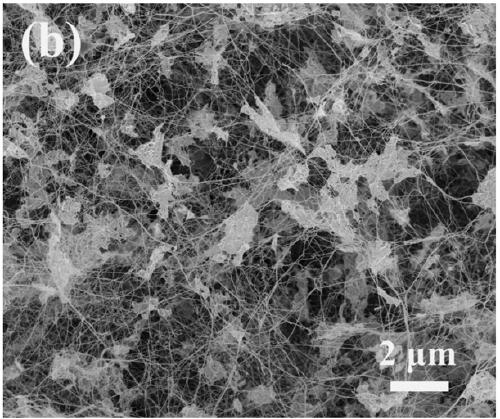

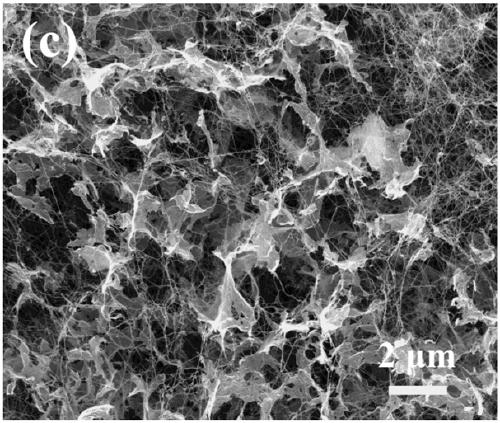

Layer combination controllable carbon material with nano pole of different scale, preparation method and application

The invention relates to a method for design advanced materials with nano-scaled structure and techniques for preparing same. In particular, the invention relates to a carbon material capable of controllable laminated combination with the nano-holes of variable sizes and preparation and application thereof. The method comprises the steps of: preparing metal oxide sol in the alkali solution system, which is then mixed with an alcohol solution of an alcohol-soluble resin; the oxide sol being used as the template and water being the resin precipitation agent during the process to directly prepare resin / oxide sol composite system. After solvent removal, carbonization, activation and template removal processes, the carbon material with laminated nano-holes combination is prepared which is of controllable micro-holes proportion, controllable medium-holes aperture and proportion, controllable big-holes aperture and propotion and concentrated distribution of medium-holes and big-holes apertures. The carbon material capable of controllable laminated combination with the nano-holes of variable sizes prepared in the invention is characterized in laminated holes structure, excellent ion transfer performances and high electrochemical active specific surface area and the material is expected to be used as high energy density high power density electrochemical capacitor used electrode material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

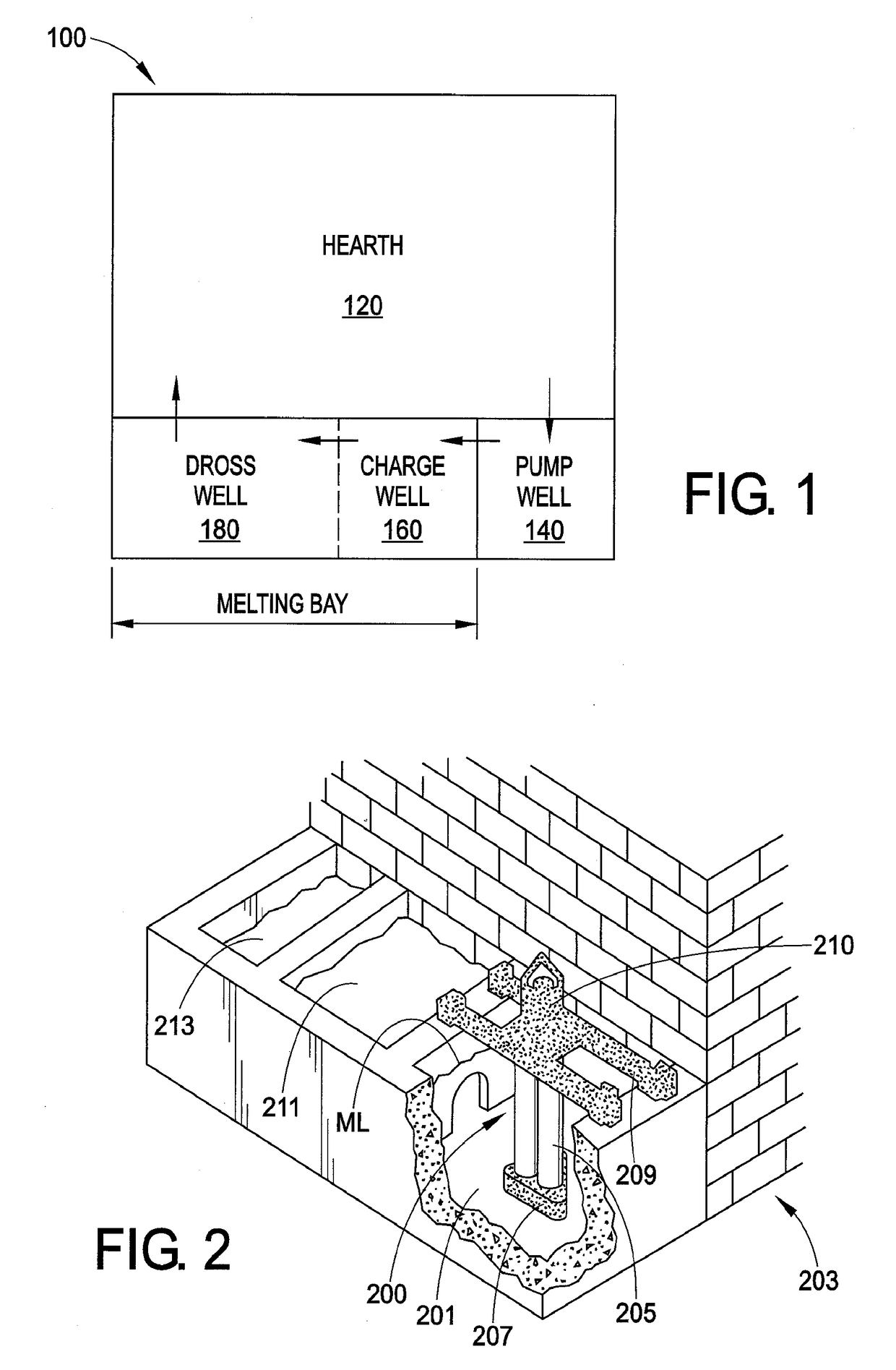

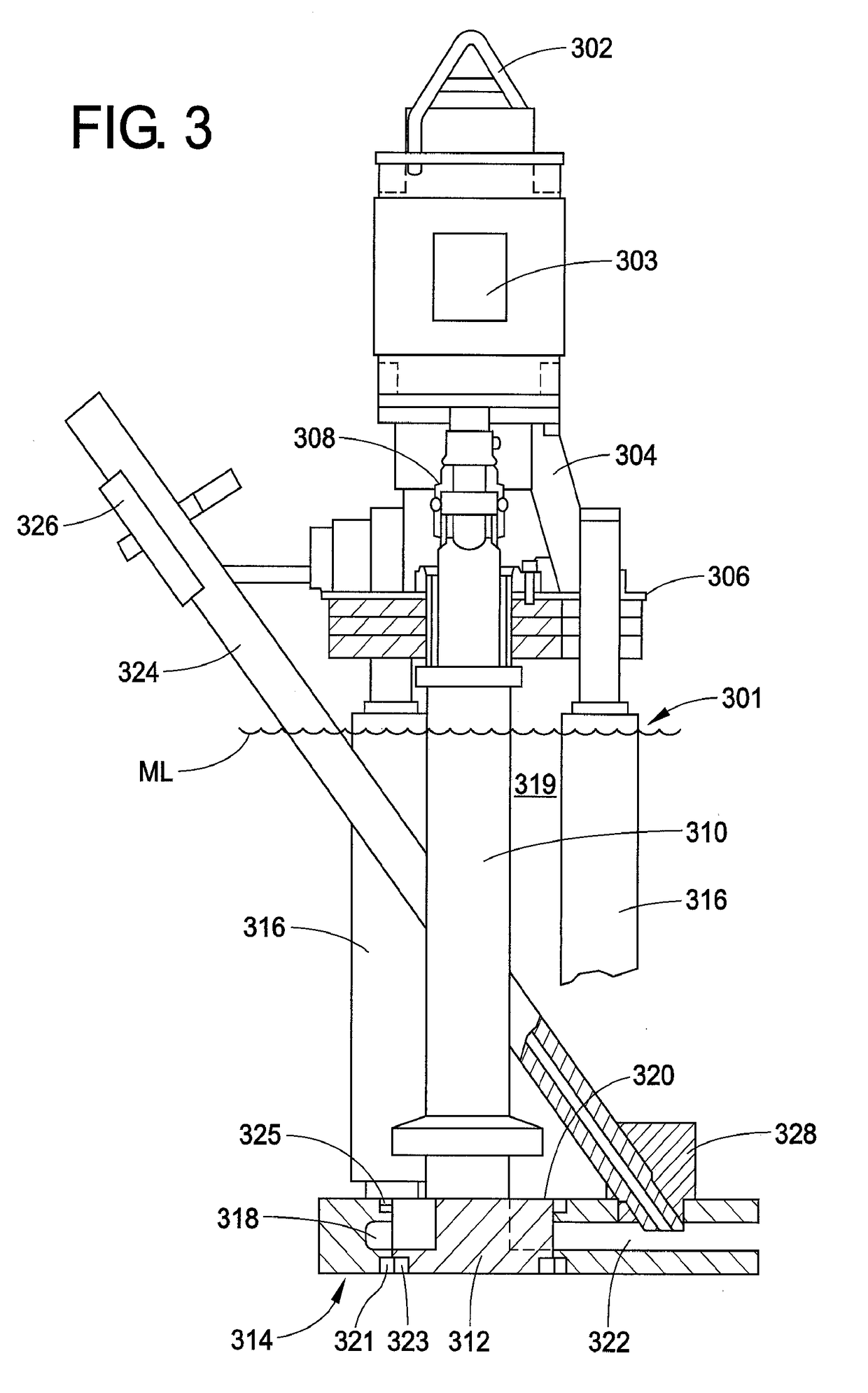

Advanced material for molten metal processing equipment

A molten metal processing apparatus selected from a pump, a degasser, a flux injector, and a scrap submergence device constructed to include at least one element comprised of C / C composite.

Owner:PYROTECK INC

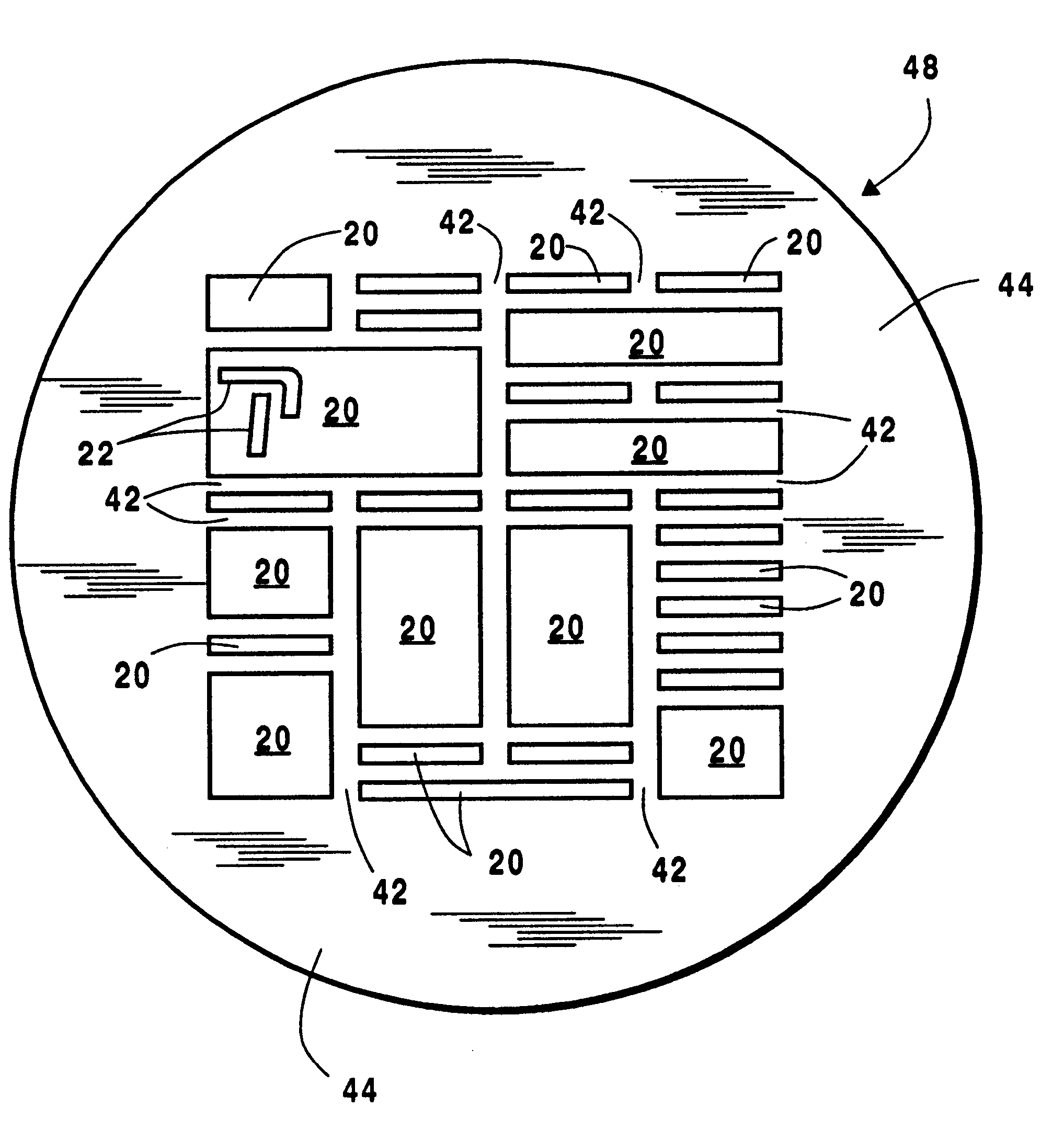

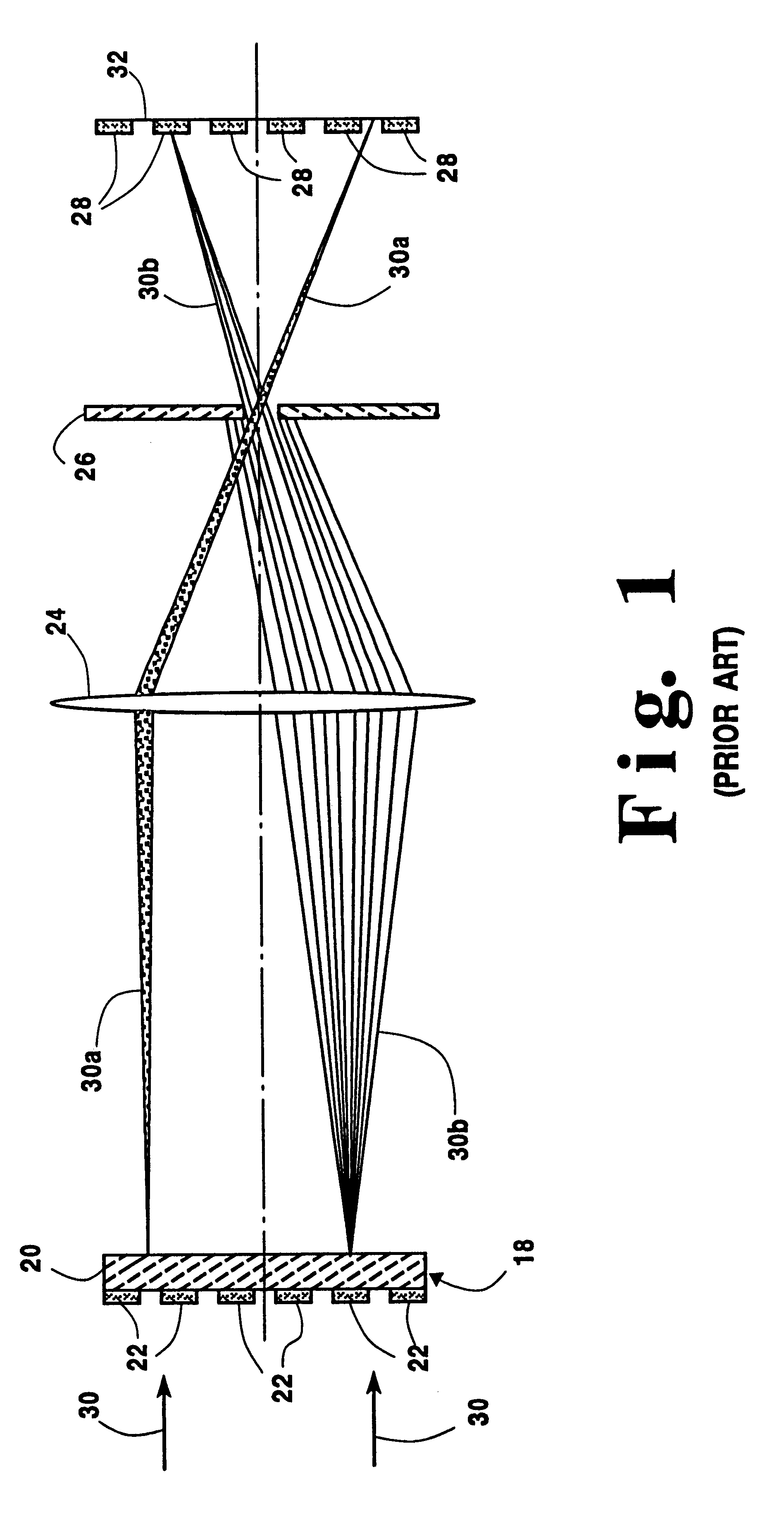

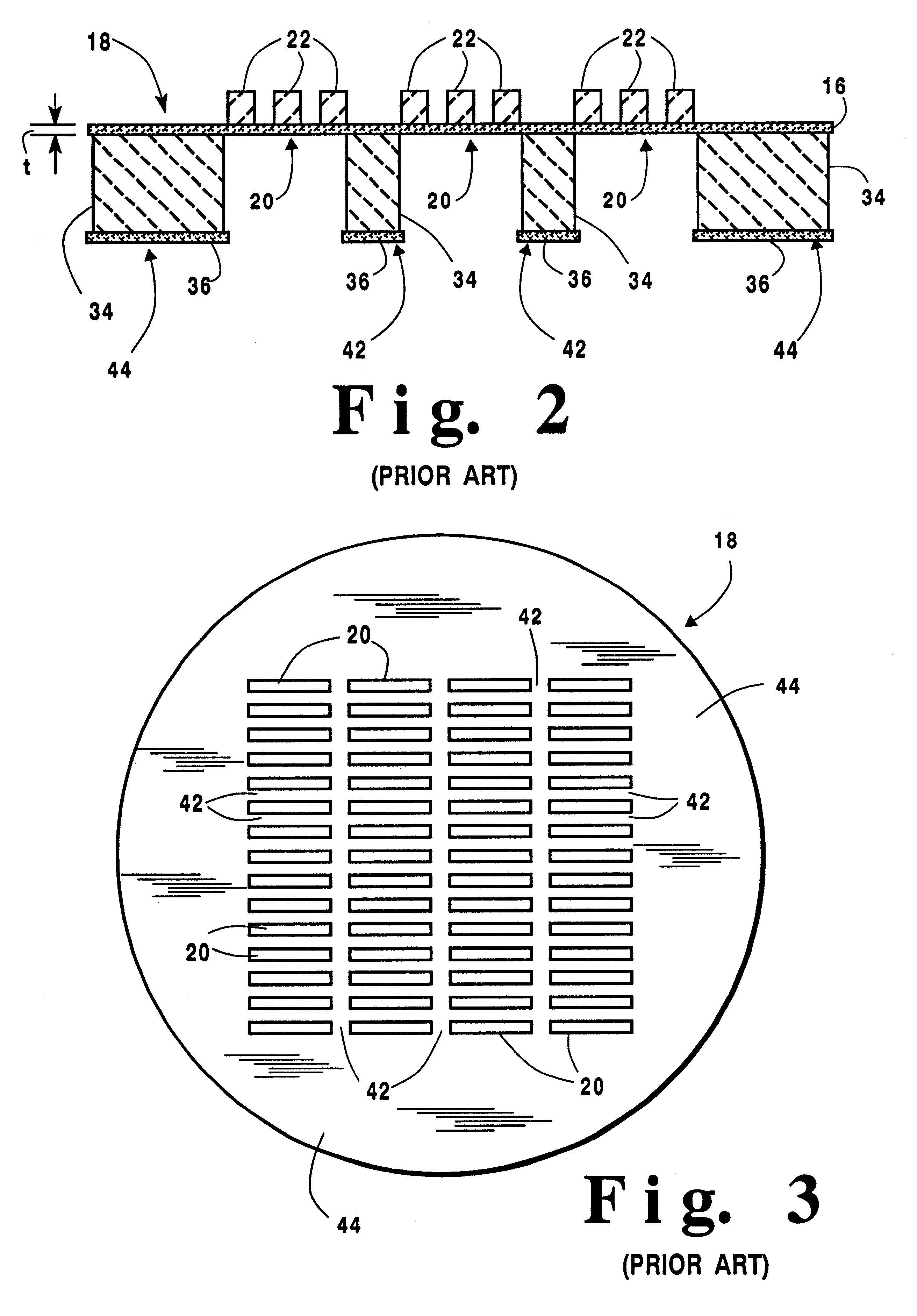

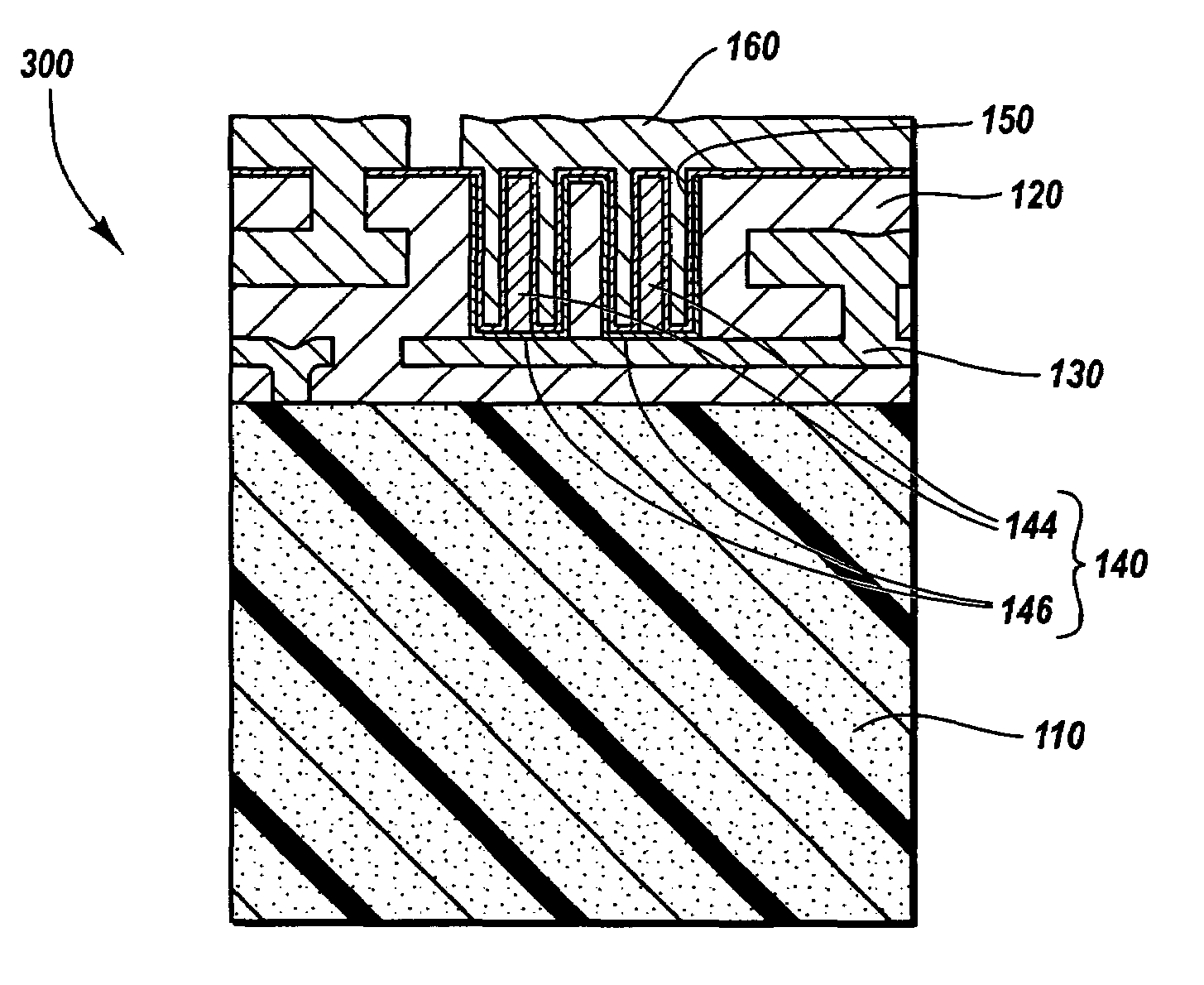

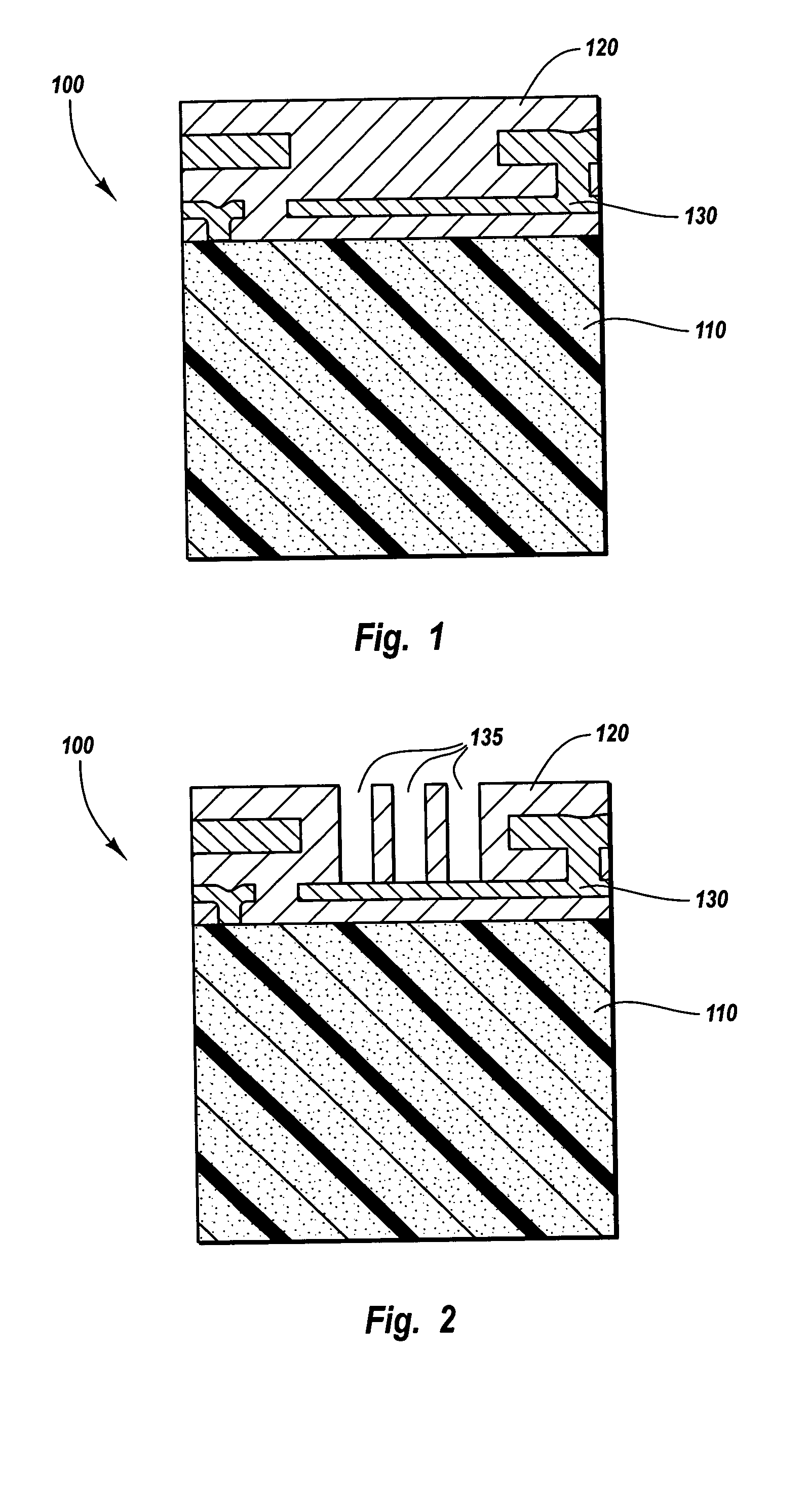

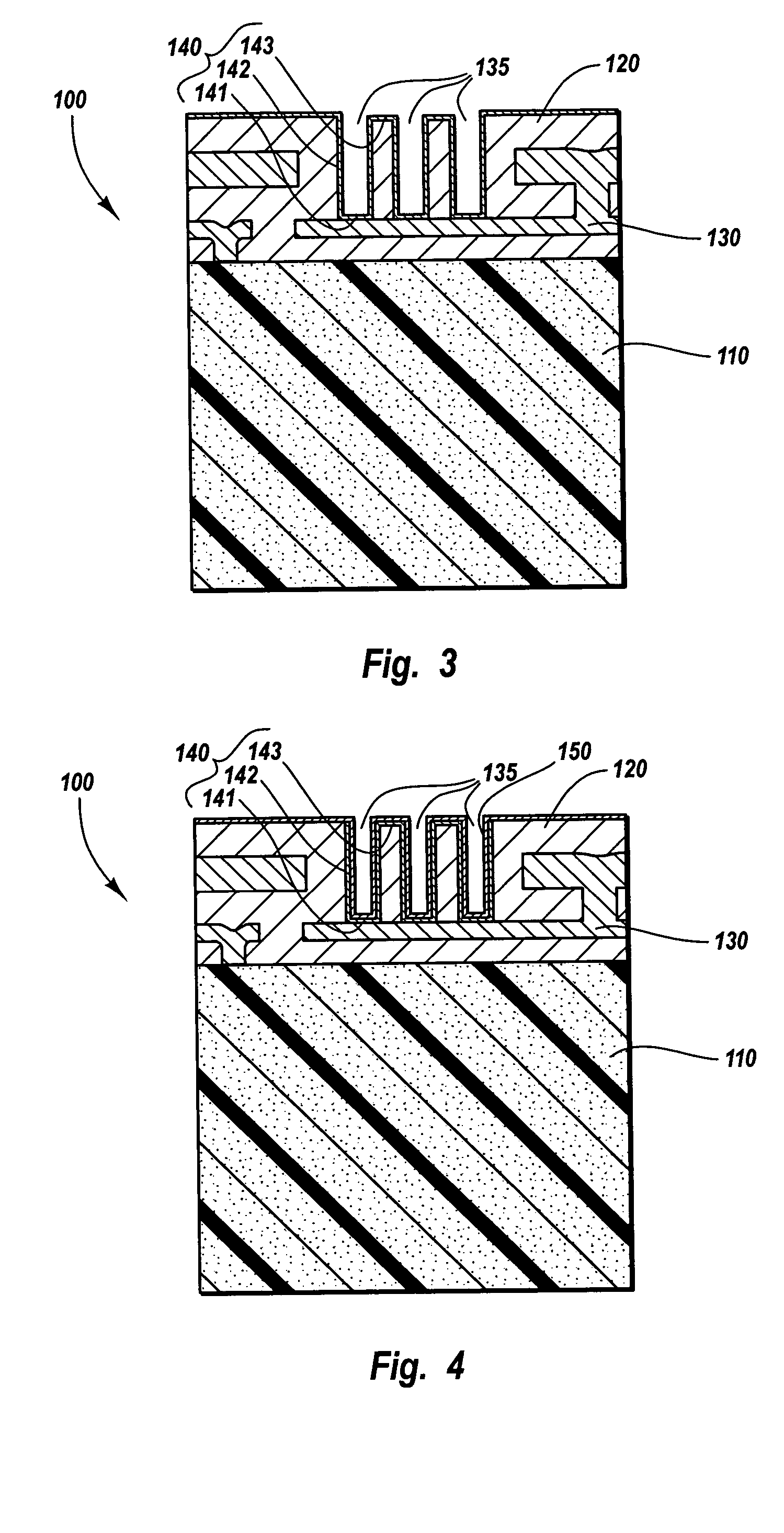

Projection electron-beam lithography masks using advanced materials and membrane size

InactiveUS6261726B1Without limiting strengthElectric discharge tubesSemiconductor/solid-state device manufacturingDiamond-like carbonYoung's modulus

A stencil or scatterer mask for use with charged particle beam lithography such as projection electron-beam lithography comprises a membrane layer of a material having a Young's modulus of at least about 400 GPa and support struts supporting a surface of the membrane. The struts form and surrounding a plurality of discrete membrane areas of different aspect ratios aligned to design regions of an integrated circuit. The discrete membrane areas have different aspect ratios range from about 1:1 to about 12:1, and the discrete membrane areas have different size surface areas. The membrane is preferably silicon carbide, diamond, diamond-like carbon, amorphous carbon, carbon nitride or boron nitride. When used in scatterer masks, the ratio of discrete membrane area to membrane thickness is at least about 0.18 mm2 / nm. When used in stencil masks, the ratio of discrete membrane area to membrane thickness is at least about 1.0 mm2 / nm. The stencil mask is made by depositing a diamond membrane film patterned with a hardmask layer on a substrate, depositing an etch stop layer adjacent the diamond film, and forming supporting struts surrounding a plurality of discrete areas of the membrane film. The method then includes depositing a pattern over the membrane film within the discrete membrane film areas, the pattern conforming to one or more desired circuit elements, and etching the membrane film with a reactive ion etch containing oxygen to form openings in the membrane film.

Owner:IBM CORP

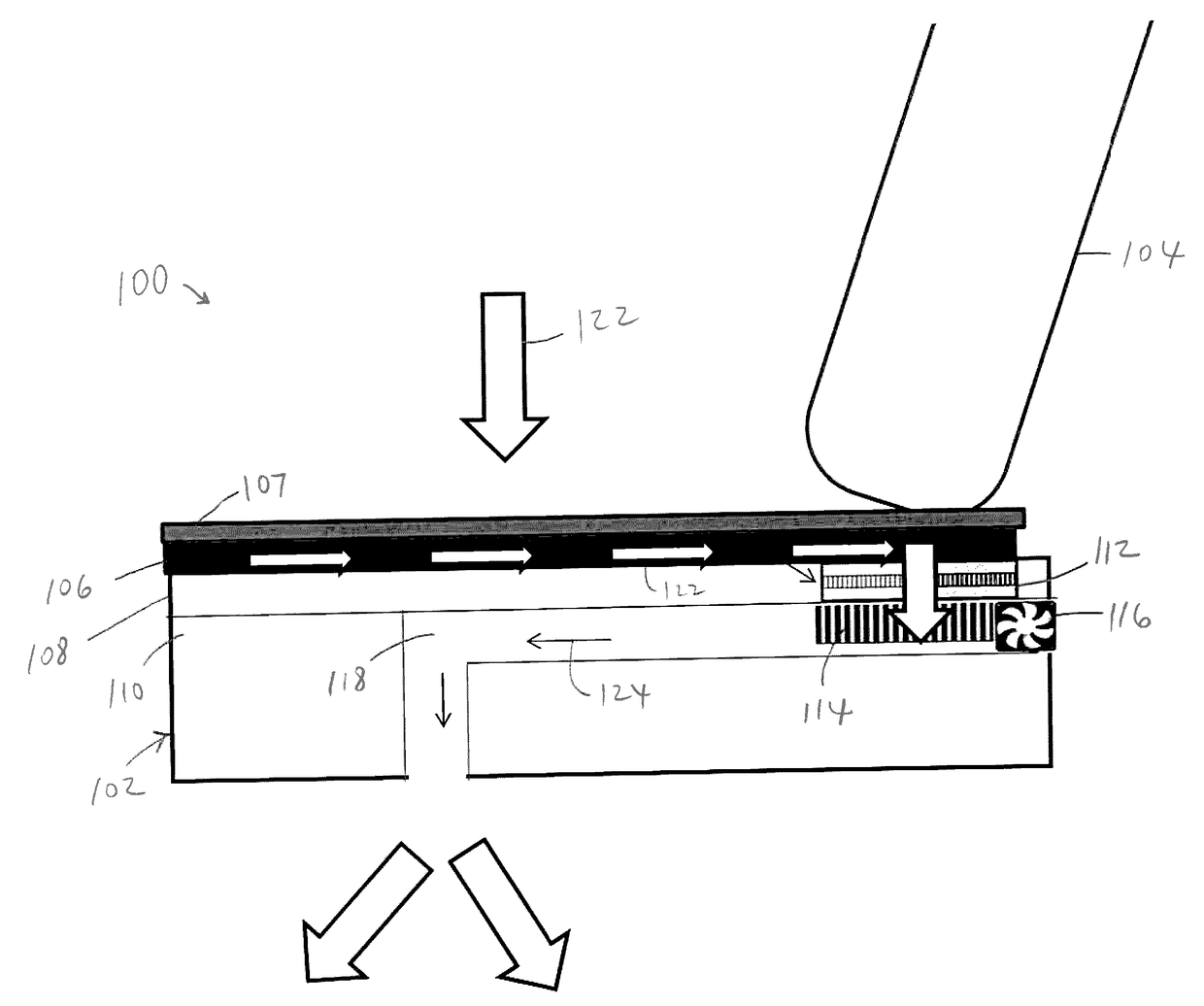

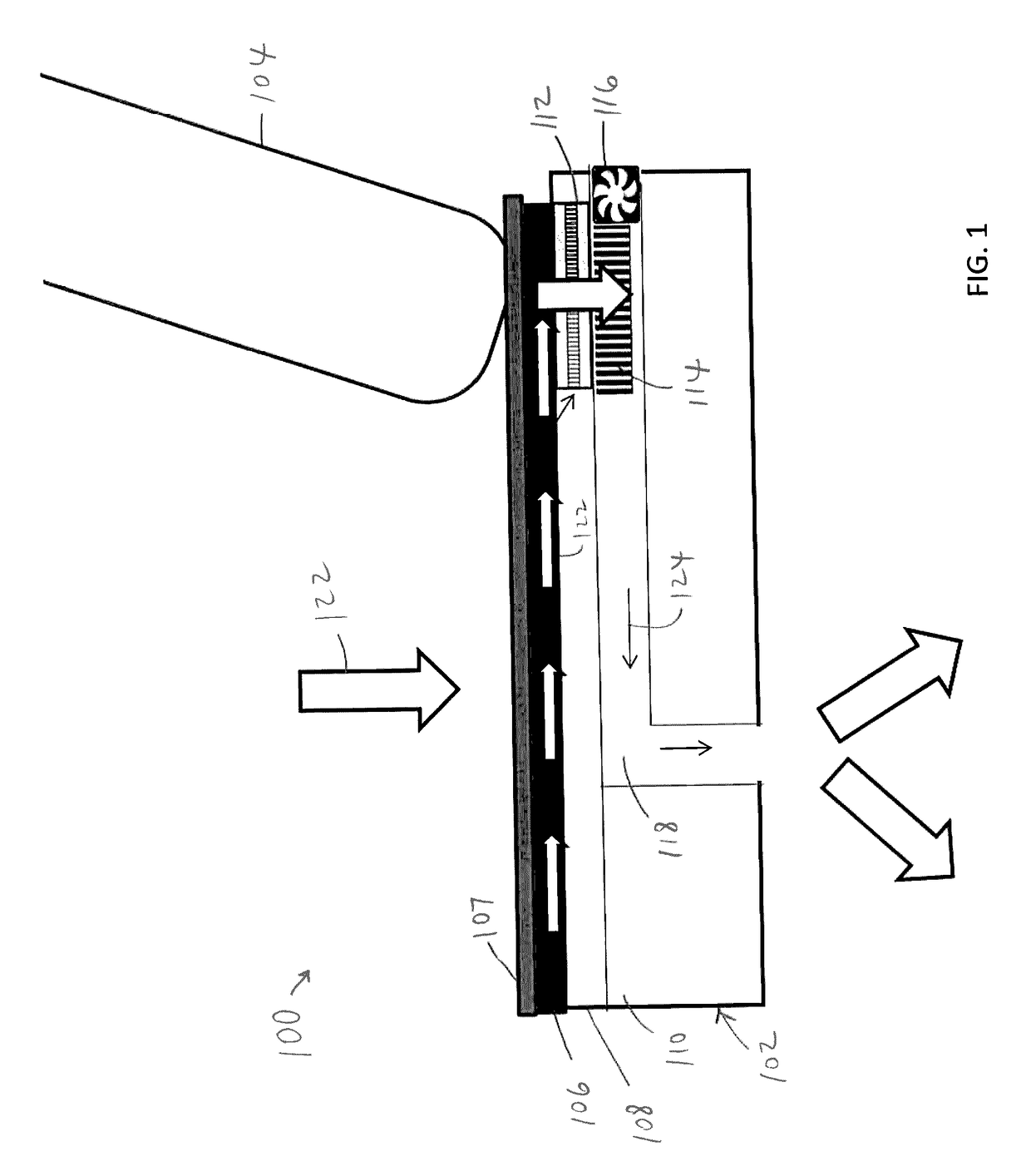

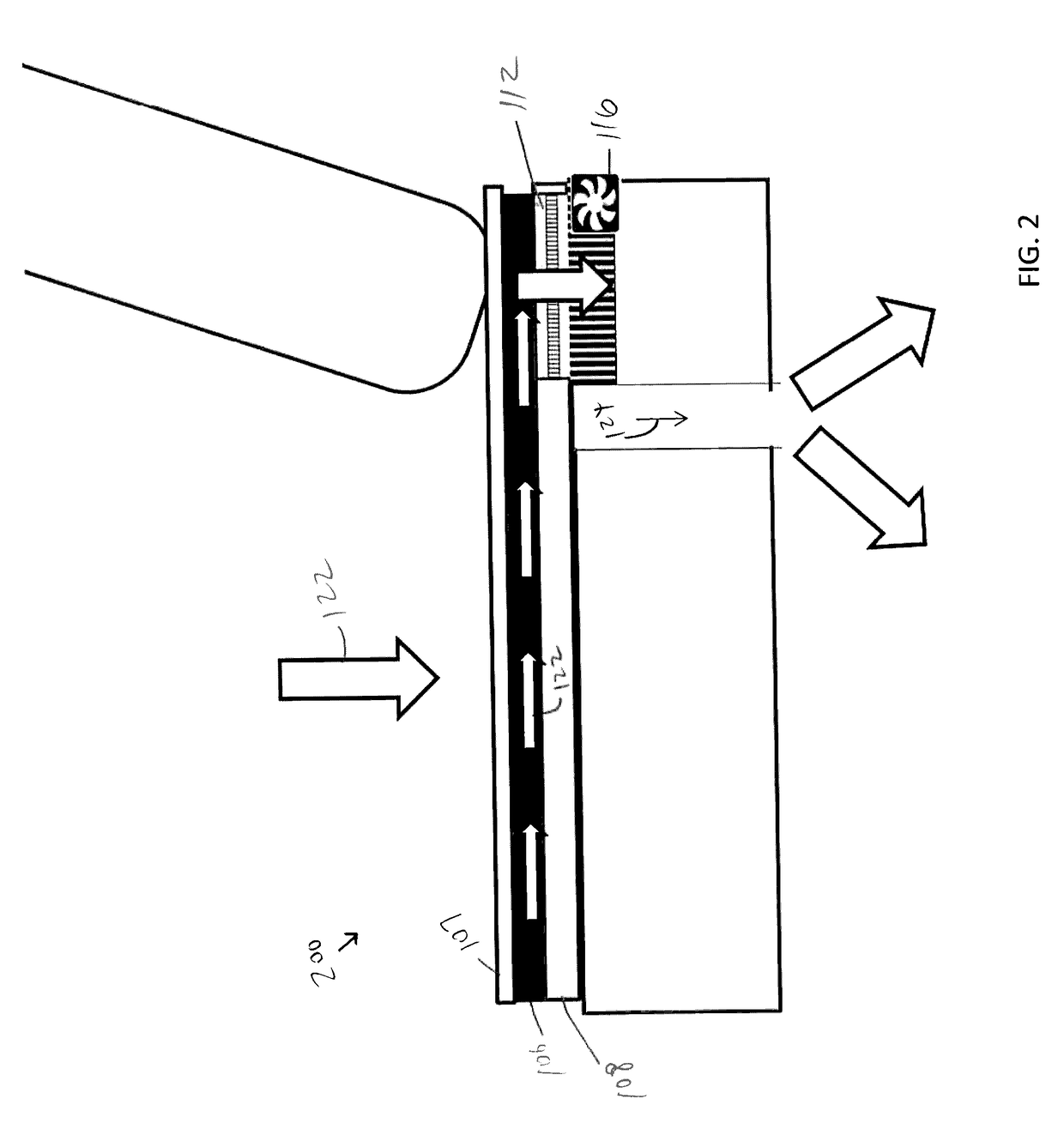

Methods and systems for heating and cooling seats and other user items utilizing thermally conductive sheet with one or more thermoelectric devices

A cooling and heating system for seats and other user items utilizes a thermally conductive sheet with one or more thermoelectric devices. This thermally conductive sheet has high thermal conductivity and is flexible, and may comprise polyimide, graphite, PGS graphite, carbon fiber, or more advanced materials such as graphene or carbon nanotubes or other high thermal conductivity material such as copper or aluminum sheet or mesh. The thermally conductive flexible sheet with remote thermoelectric device provides good temperature uniformity across the seat, quick response time, and excellent performance in extreme ambient temperatures. The high thermal conductivity sheet can be placed in the seat area between the upholstery and seat cushion with thermoelectric devices thermally connected to the thermally conductive sheet away from the occupant seating area to provide comfortable and durable seating with thermal comfort control. Heat rejection may be accomplished using a heat sink (with or without a fan) or a heat pipe connected to a heat sink (with or without a fan) or other heat rejection mechanisms.

Owner:NOVUS ENERGY TECH INC

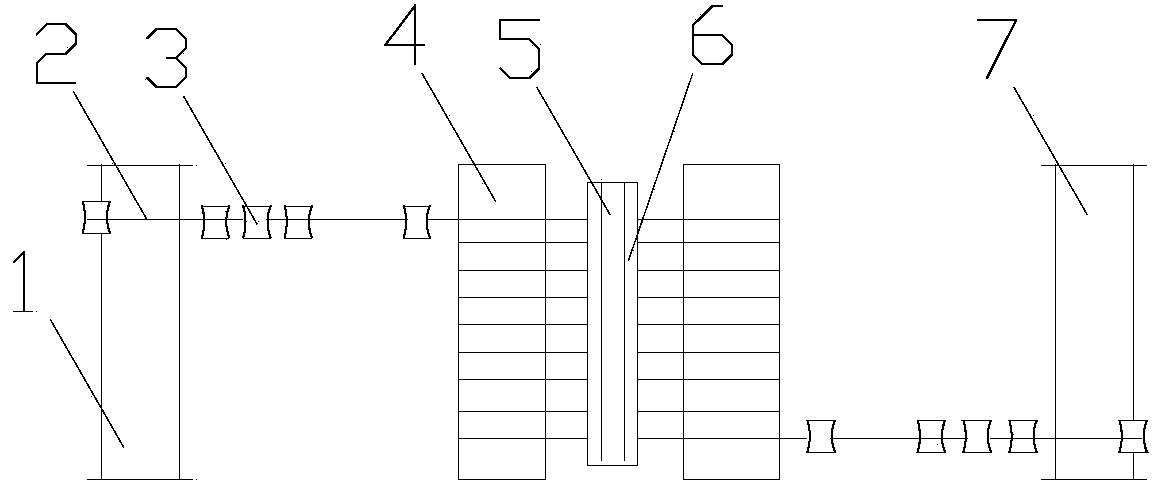

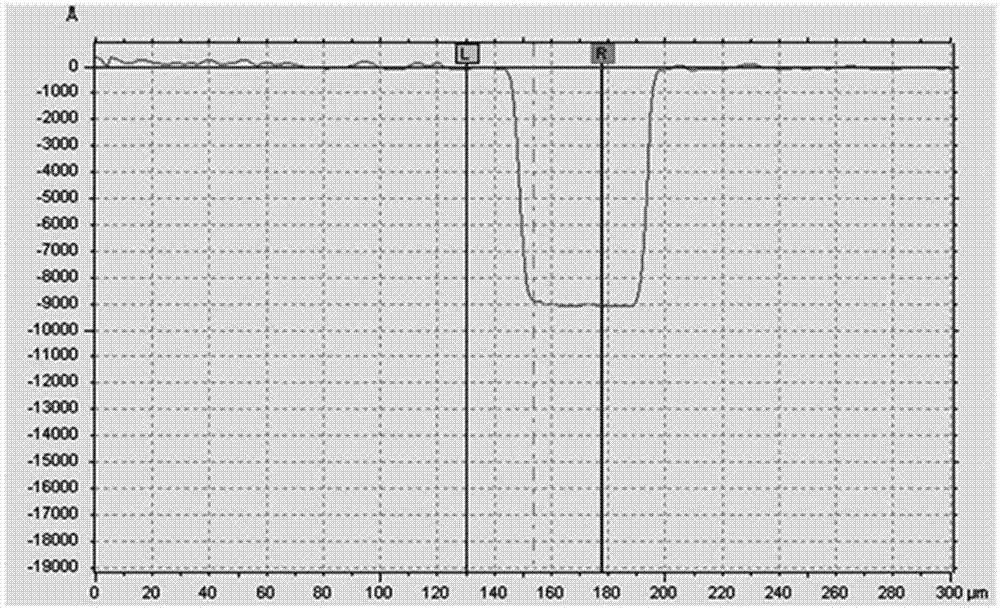

Method and equipment for cutting large-diameter silicon carbide single crystals by aid of diamond wires

The invention belongs to the field of technologies for processing advanced materials, and particularly provides a method and equipment for efficiently cutting large-diameter single crystals by the aid of diamond wires. The method and the equipment have the advantages that the equipment is convenient to operate and is provided with a multi-wire cutting machine and the diamond cutting wires, the diameters of the diamond cutting wires range from 120 micrometers to 400 micrometers, diamond particles are plated on outer layers of the diamond cutting wires, multiple pieces of large-diameter SiC crystal bars can be cut by the aid of reciprocating high-speed cutting movement of the diamond cutting wires, the surface roughness, the bending and the total thicknesses of cut SiC wafers hardly vary, and a plurality of target crystals can be cut in each procedure; the crystal can be cut at high speeds, crystal cutting elapsed time is short, and accordingly the silicon carbide wafers can be efficiently cut by the aid of the method and the equipment.

Owner:SICC CO LTD

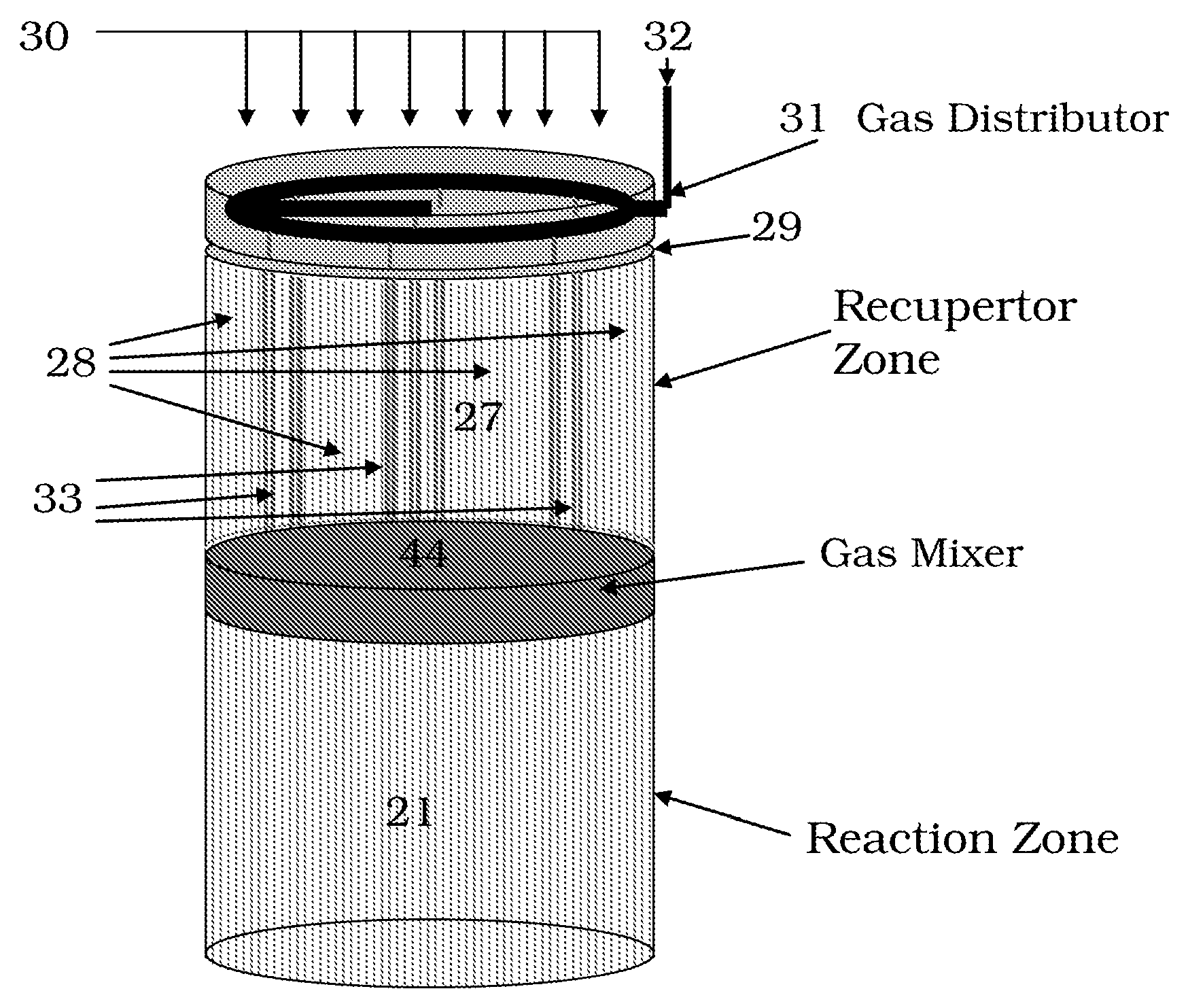

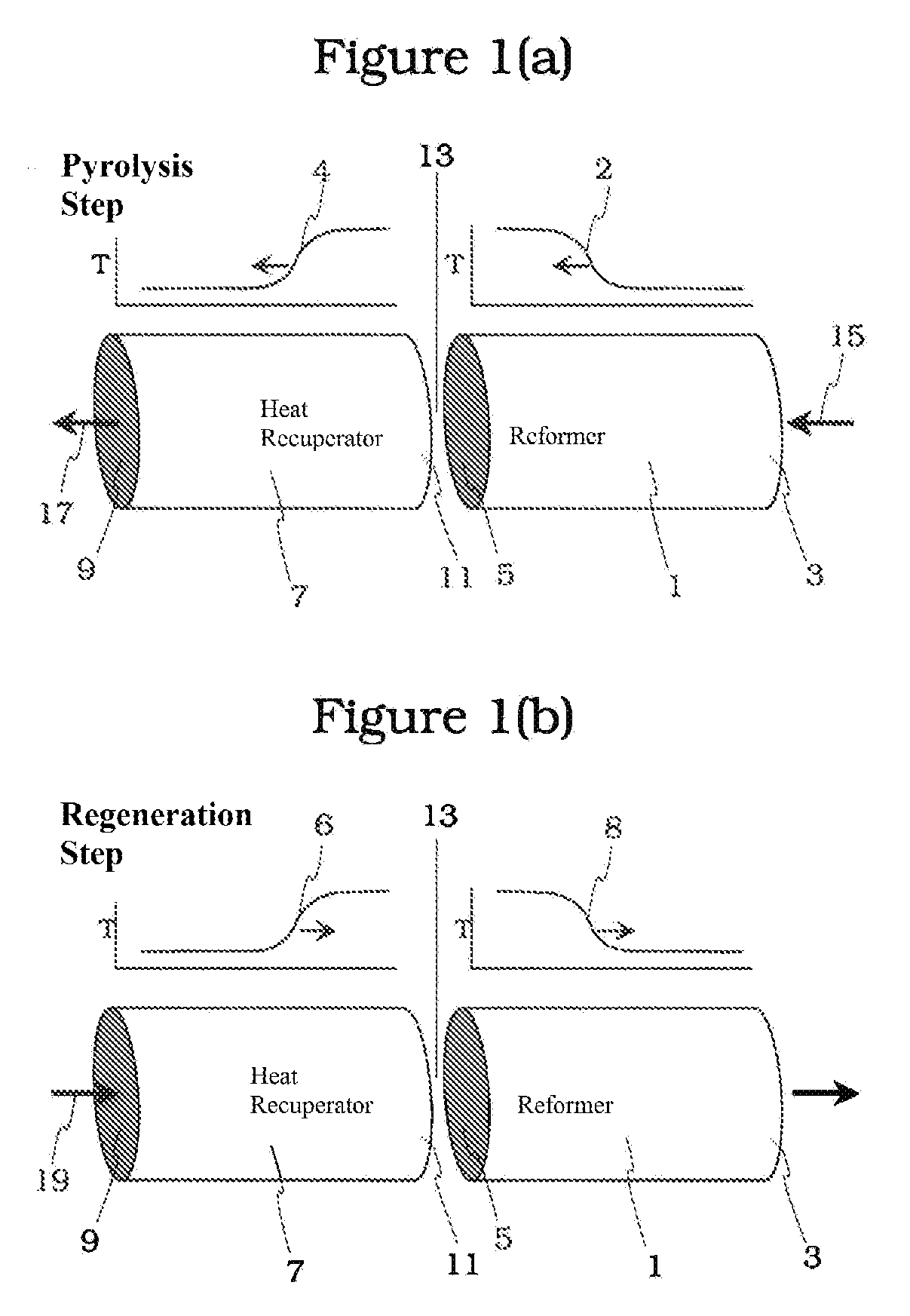

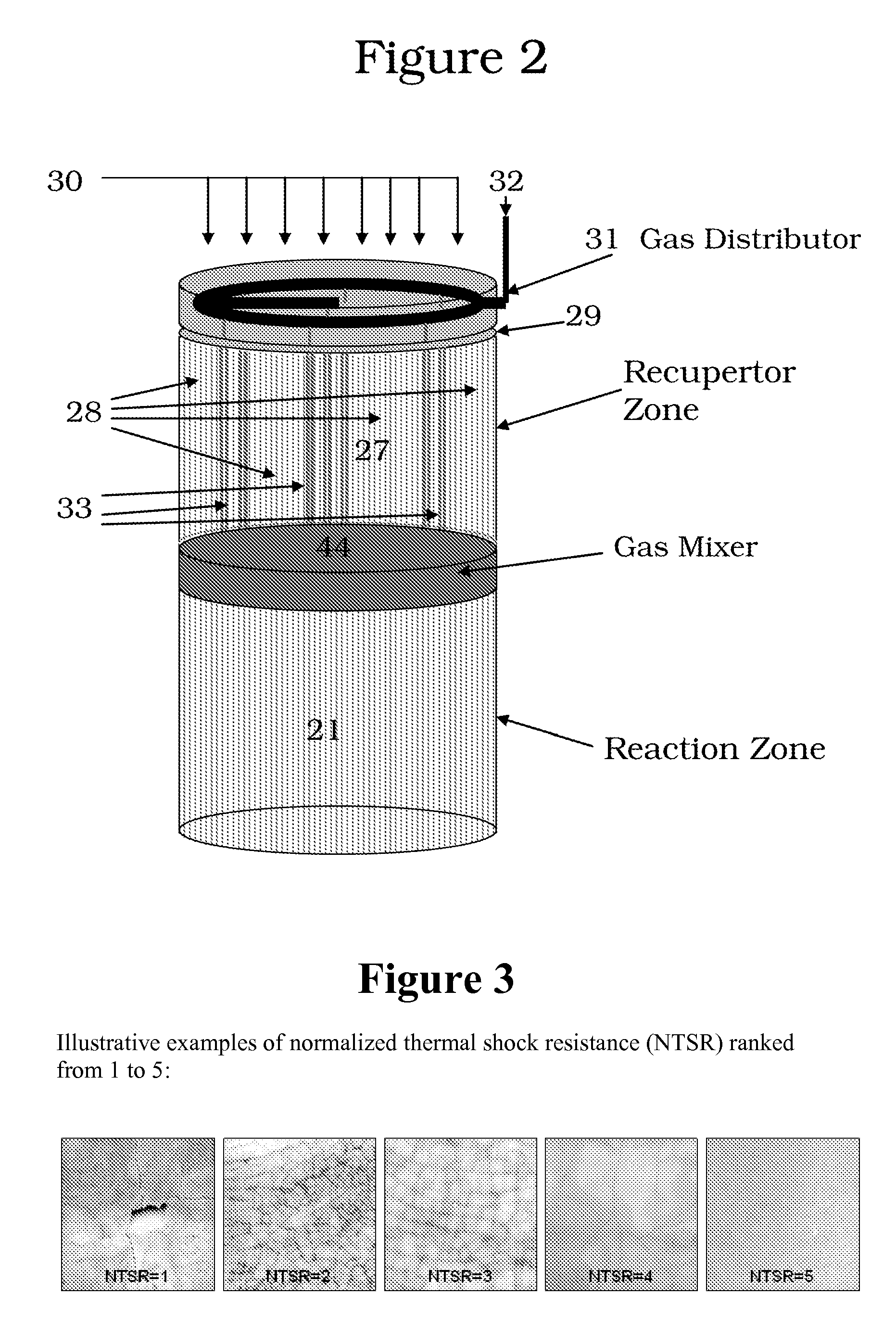

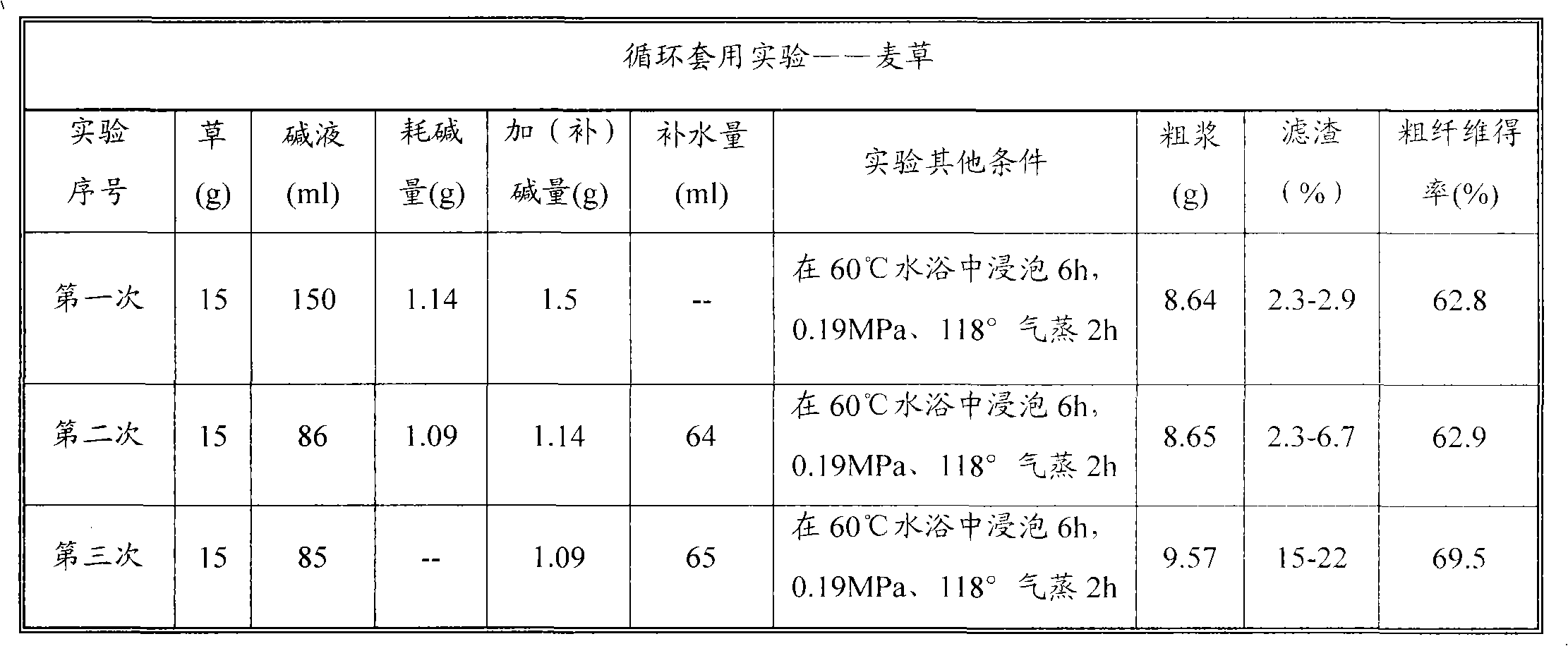

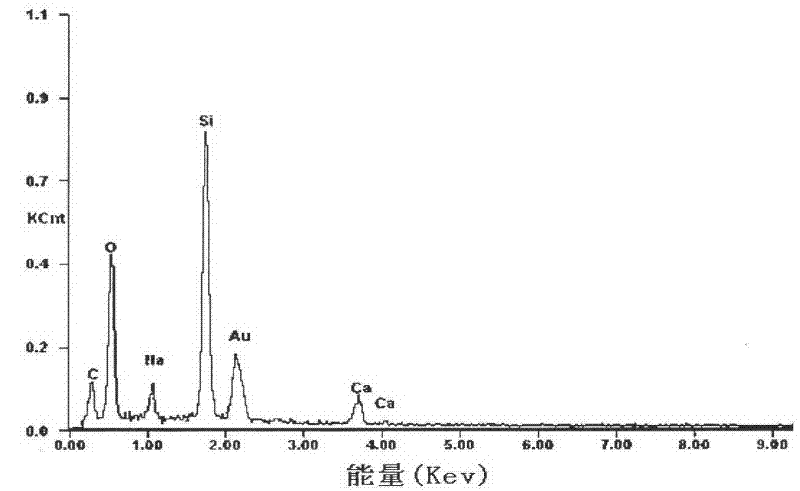

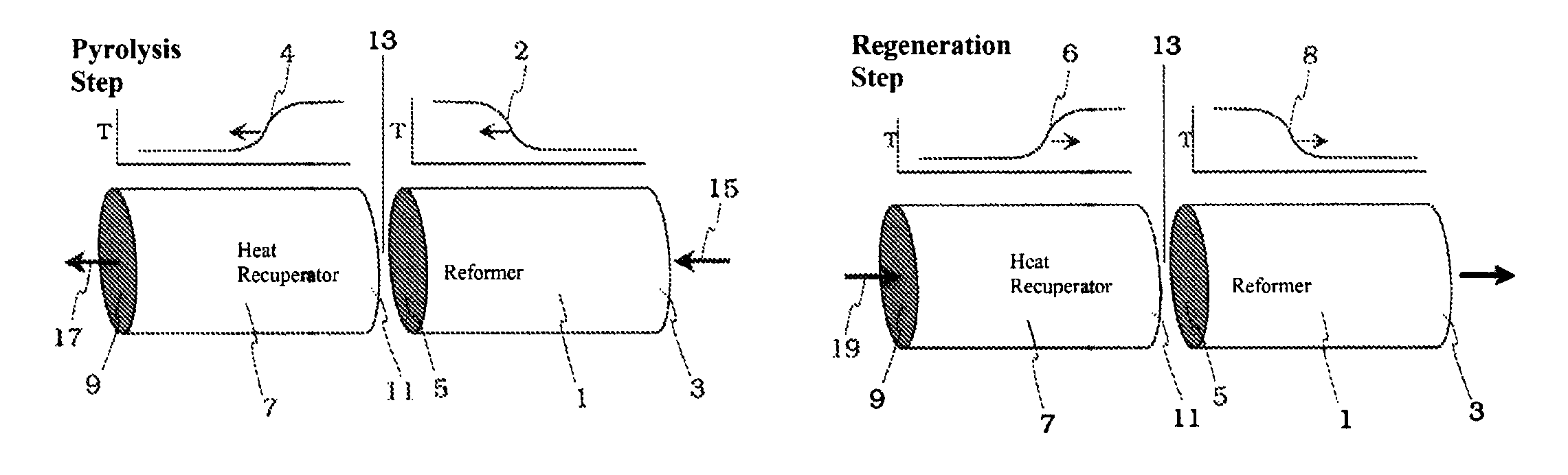

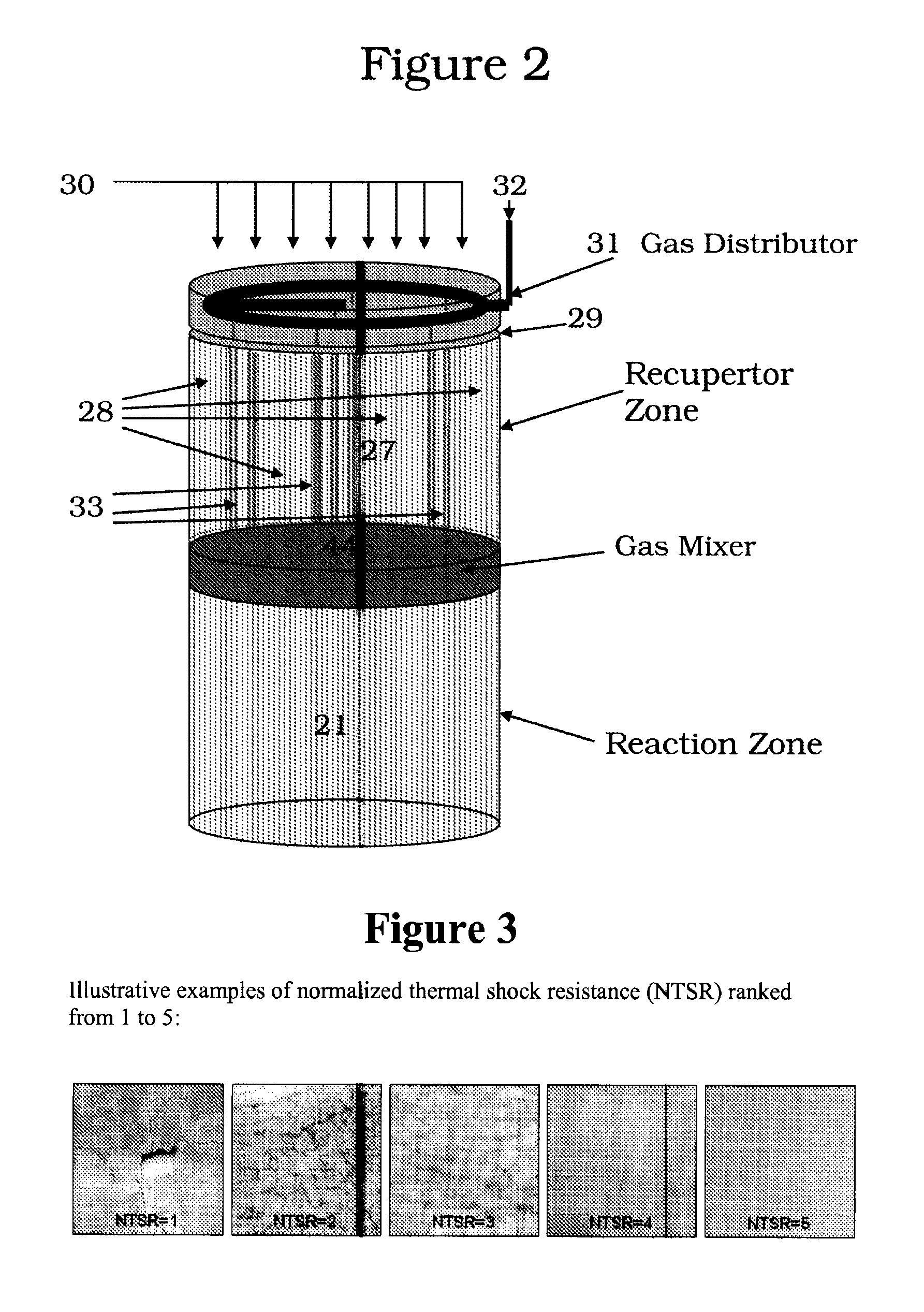

Advanced Materials for Regenerative Pyrolysis Reactors, Methods, and Reactors Using the Same

ActiveUS20090250377A1Improve propertiesThermal non-catalytic crackingCatalytic crackingReactor systemReaction zone

In one aspect, the invention includes an apparatus for pyrolyzing a hydrocarbon feedstock in a regenerative pyrolysis reactor system, the apparatus comprising a regenerative pyrolysis reactor comprising a stabilized refractory grade zirconia in a reactive region of the reactor system. In another aspect, this invention includes a method for pyrolyzing a hydrocarbon feedstock using a reverse flow regenerative pyrolysis reactor comprising the steps of providing a reverse flow regenerative pyrolysis reactor including a stabilized refractory grade zirconia in a heated reaction zone of the reactor; and pyrolyzing a hydrocarbon feedstock within the reactive region.

Owner:EXXONMOBIL CHEM PAT INC

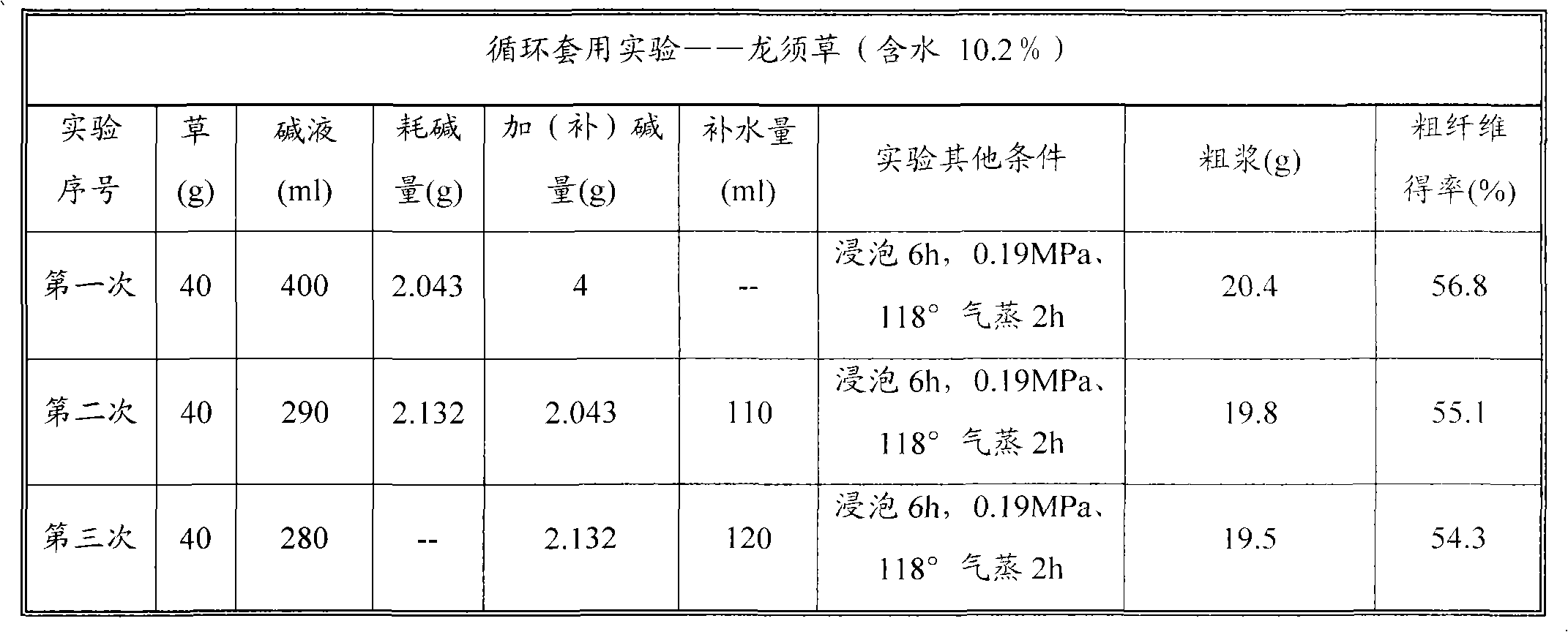

Green process for extracting fibers from plants

ActiveCN101899794ATime consuming to overcomeOvercome efficiencyDigestersPulping with inorganic basesFiberSlag

The invention relates to a sectional green process for extracting fibers from plant raw materials with high efficiency and high yield, which comprises the steps of: firstly, infiltrating or / and soaking plant raw materials with lime water (or carbide slag water solution) or dilute alkali; then steaming or boiling the raw materials; and finally, beating or steaming discharge and pulp washing to prepare fibers. The green process can also be comprehensively used for exploiting the utilization of lignin and extract, so as to realize the full-rate development of plants. The extract in the process can be recycled as a nutrient source for organisms such as plants, microbes, alga and the like, which breaks through the key technical bottleneck of the green and ecological industry, has significant theoretic and application values on the recycling economy, the sustainable development strategy and acquisition of energy sources, advanced materials and biological nutrient source from biomasses, and has extremely profound social benefits, economic benefits and ecological benefits.

Owner:BEIJING INSIGHT BIOMASS

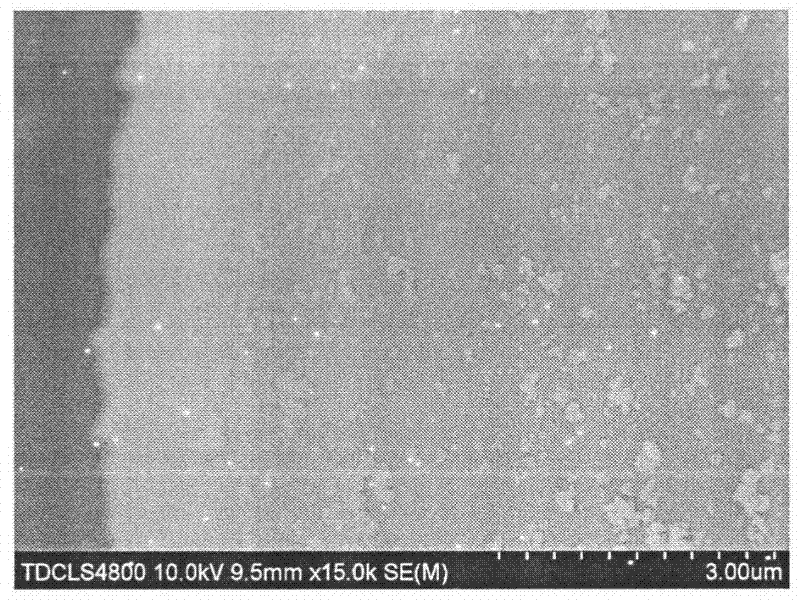

Epoxy resin/carbon nanotube high-strength lightweight composite material, and preparation method thereof

The invention relates to an epoxy resin / carbon nanotube high-strength lightweight composite material, and a preparation method thereof. The material comprises components of, by mass: 100 parts of epoxy resin, 30 parts of a curing agent, 10 to 60 parts of hollow glass microballoons, 1.0 to 6.0 parts of carboxylated carbon nanotubes, and 0.75 to 1.5 parts of an aminosilane coupling agent. The carboxylated carbon nanotubes are grafted on the surfaces of the hollow glass microballoons through chemical methods, and the materials are composed into epoxy resin. With good dispersibility of the hollowglass microballoons in epoxy resin, a dispersion problem of carbon nanotubes in epoxy resin is effectively solved, and mechanical intensity and conductivity of the composite material are improved. With the lightweight of the hollow glass microballoons, the density of the composite material is substantially reduced. The high-strength lightweight composite material produced with the method can be applied in the advanced material fields of aerospace, deep sea buoyancy materials, and wind power blades.

Owner:HEBEI BEISU PIPE IND

Advanced materials for regenerative pyrolysis reactors, methods, and reactors using the same

In one aspect, the invention includes an apparatus for pyrolyzing a hydrocarbon feedstock in a regenerative pyrolysis reactor system, the apparatus comprising a regenerative pyrolysis reactor comprising a stabilized refractory grade zirconia in a reactive region of the reactor system. In another aspect, this invention includes a method for pyrolyzing a hydrocarbon feedstock using a reverse flow regenerative pyrolysis reactor comprising the steps of providing a reverse flow regenerative pyrolysis reactor including a stabilized refractory grade zirconia in a heated reaction zone of the reactor; and pyrolyzing a hydrocarbon feedstock within the reactive region.

Owner:EXXONMOBIL CHEM PAT INC

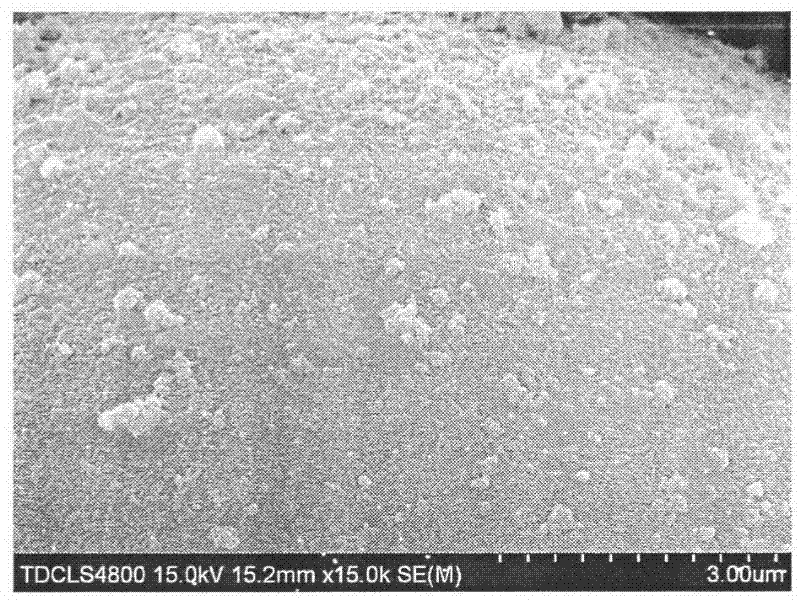

Nano-crystal large poresize mesopore oxide material and its preparation method

InactiveCN1948161AWell-ordered pore structureHighly ordered pore structureTantalum compoundsTitanium dioxideSpace groupOrganic solvent

Owner:FUDAN UNIV

MIM multilayer capacitor

Disclosed is a high-performance, RF-capable MIM capacitor structure and process for the manufacture thereof, which are compatible with discrete or integrated processes. The invention is compatible with standard semiconductor processing techniques and provides increased capacitance per unit area for a wide variety of capacitor requirements. The invention exploits vertical dimensions, reduces the chip area required for capacitors, and facilitates the use of advanced materials, such as high-k dielectric materials.

Owner:AMERICAN SEMICON

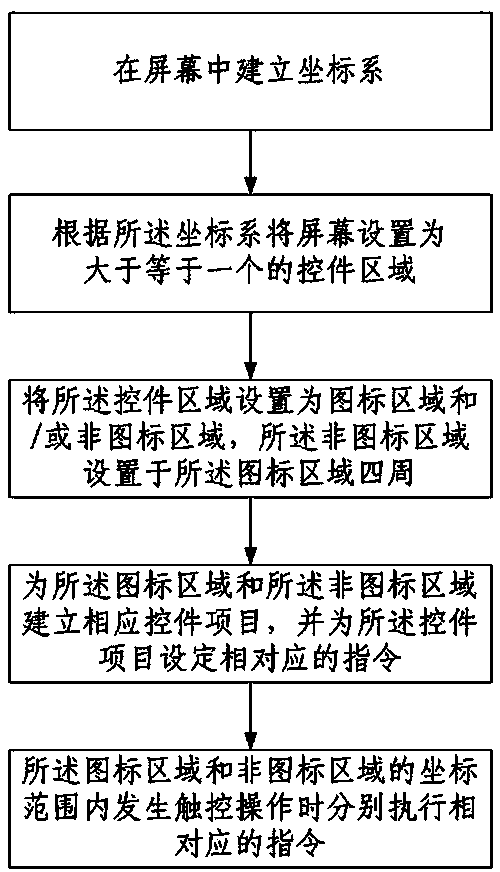

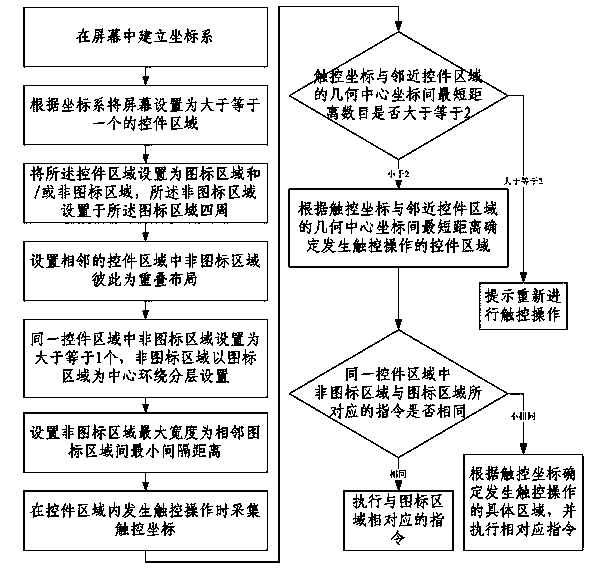

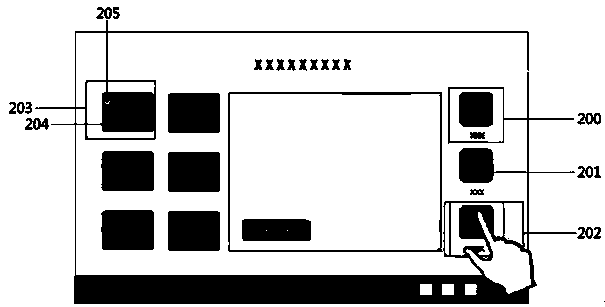

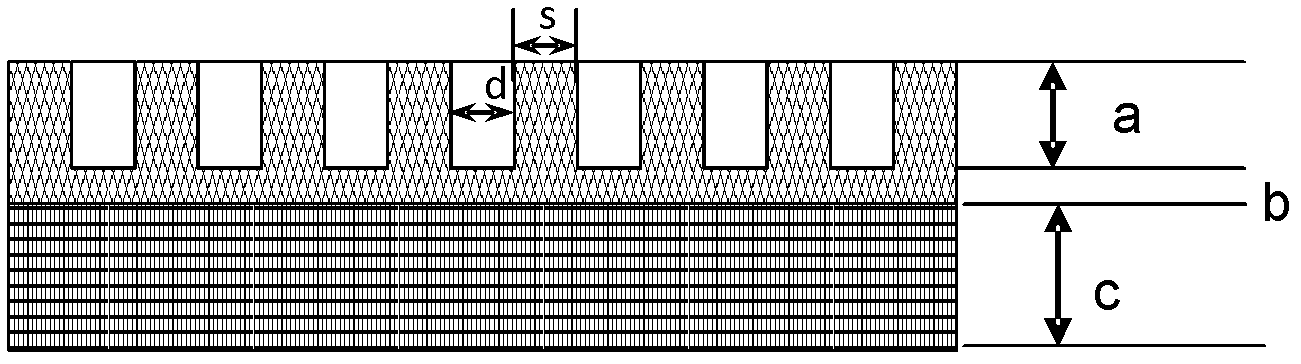

Method and device for achieving touch interface

InactiveCN103617002AIncrease the effective touch areaImprove touch accuracyInput/output processes for data processingComputer hardwareComputer graphics (images)

The invention relates to a method and device for achieving a touch interface. A control piece area is set to be an icon display area and a transparent area, and the transparent area is arranged at the periphery of the icon display area. According to the method, on the premise that an icon of a touch screen device is not required to be expanded or changed, the actual use area of the icon is expanded, the accuracy of a touch screen is improved in use, and the technical problem that the functions of the touch screen can be improved only by using a screen made of advanced materials with the high resolution, accuracy and sensitivity is solved, the production cost is reduced, and the product practicability is improved. The device for achieving the method of the touch interface also has the advantages of the method.

Owner:EDAN INSTR

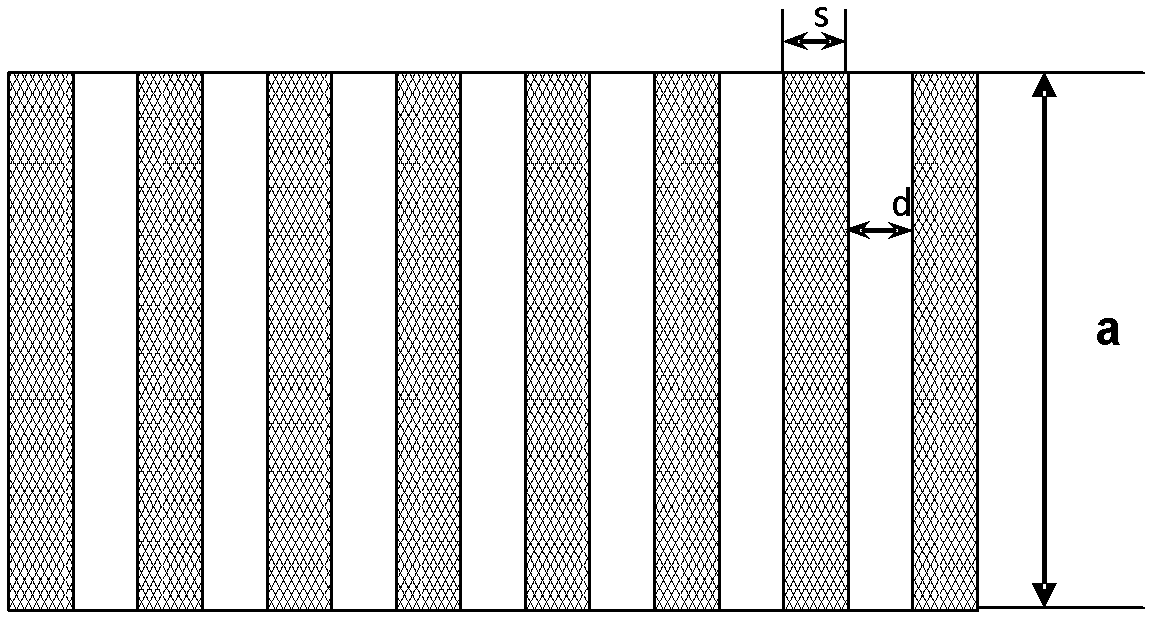

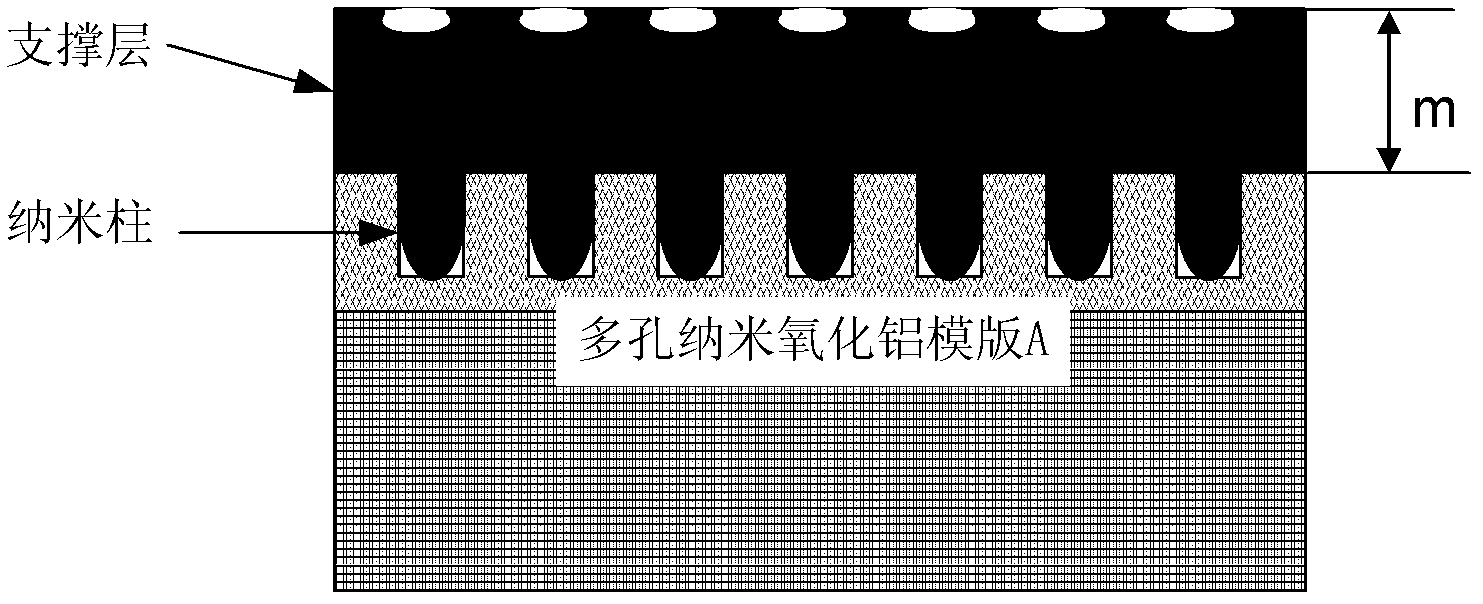

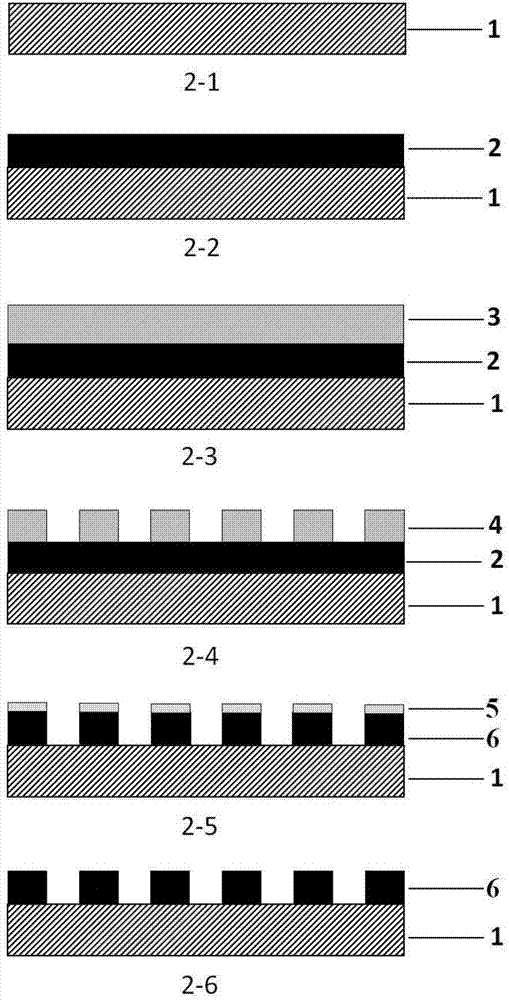

Preparation method and application of nanoimprint template

InactiveCN102431962ALow costReduce manufacturing costDecorative surface effectsPhotomechanical apparatusNanowireAdvanced materials

The invention discloses a preparation method and application of a nanoimprint template and belongs to the technical field of processing of advanced materials and nano structures. The preparation method of the nanoimprint template comprises the following steps: preparing a nano post and a surface supporting layer; preparing a transition layer on another substrate; firmly bonding the transition layer and the surface supporting layer; and etching off a porous nano aluminum oxide template, thus forming the nanoimprint template with a regular and protruded nano post structure. The characteristic dimension of the nanoimprint template can be as small as 5 nanometers; and the template can be used for preparing large-area defect-free regularly arrayed nano wires or nano tubes with different cross-sectional shapes in batches at low cost.

Owner:BEIHANG UNIV

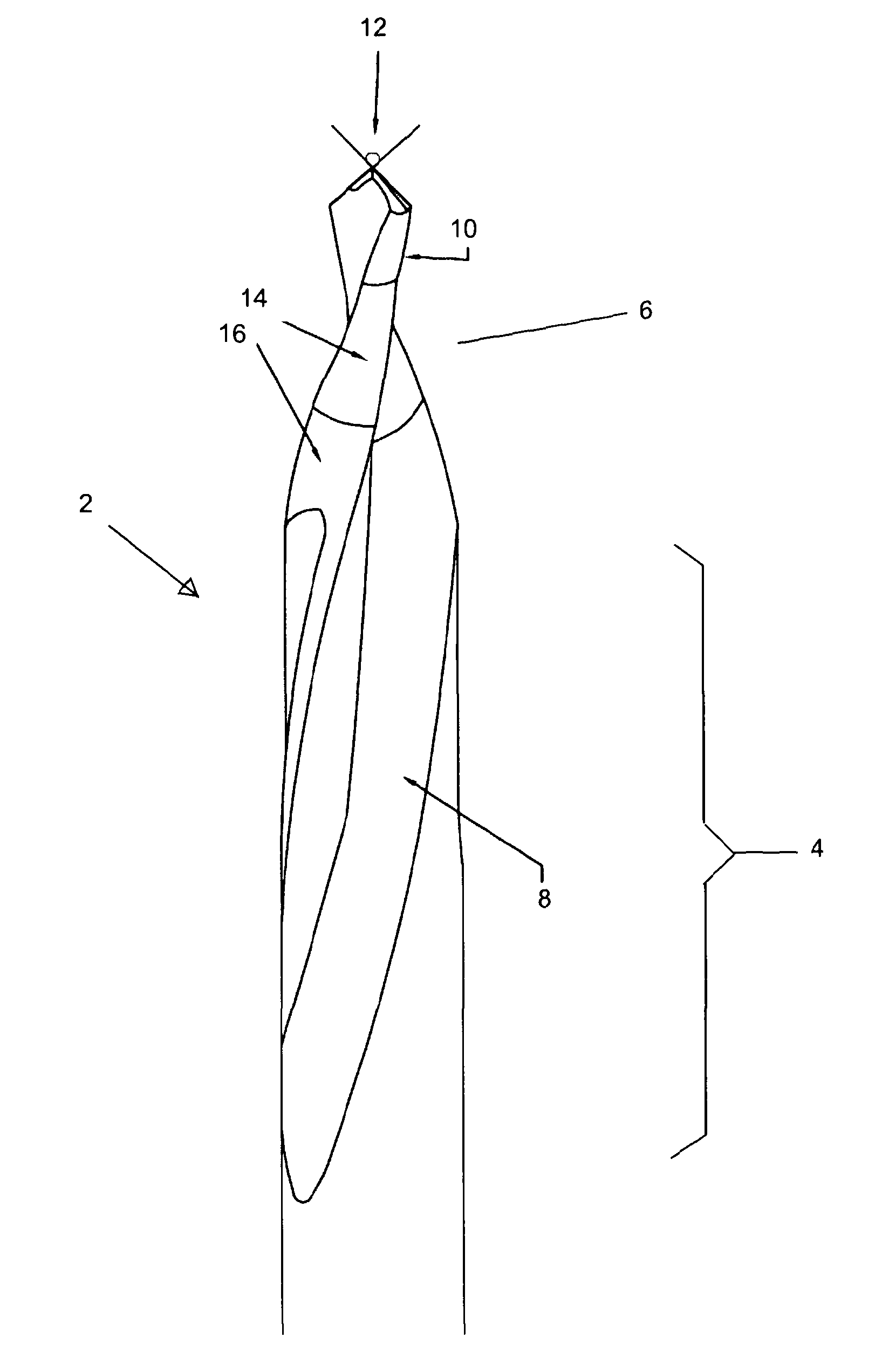

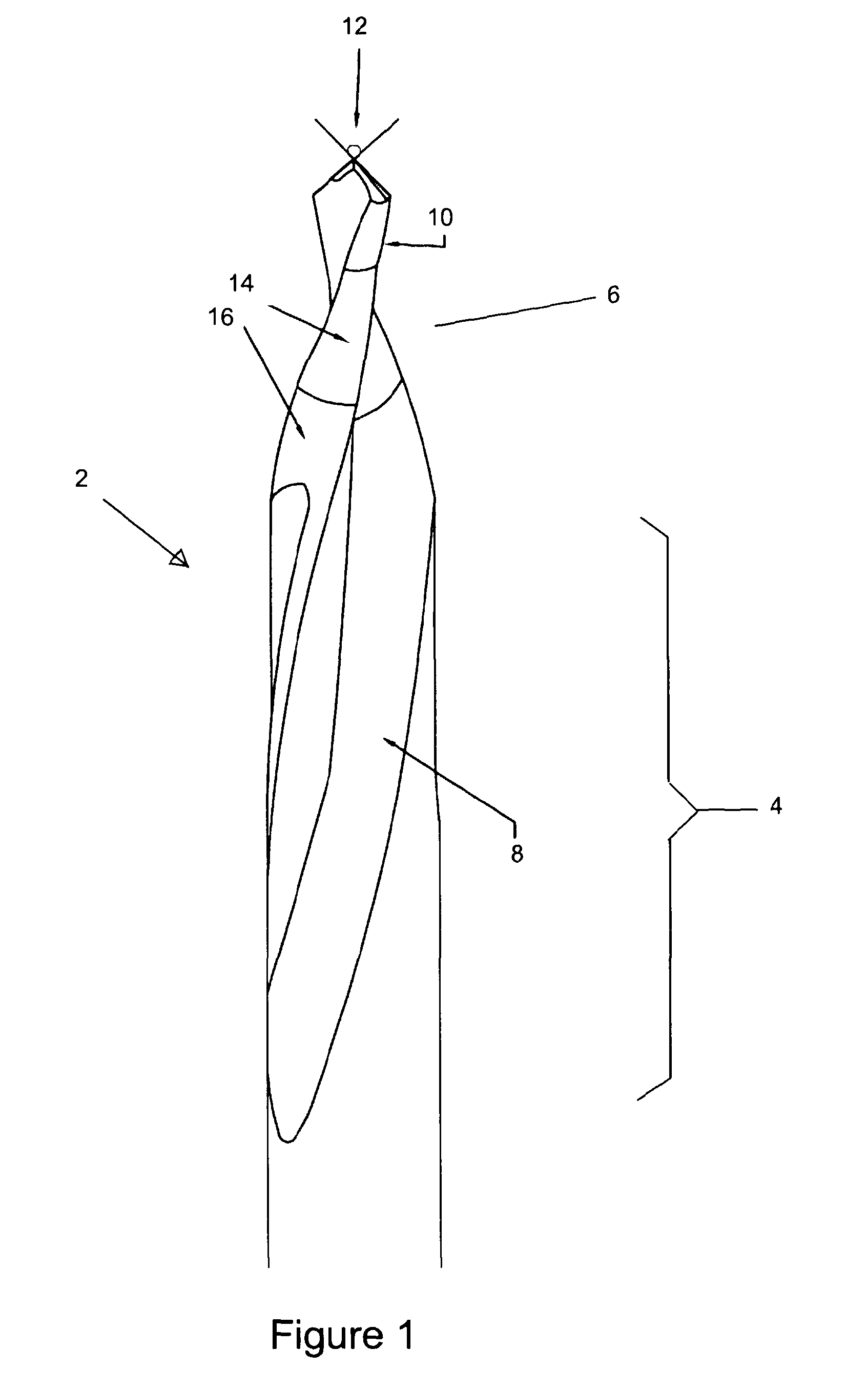

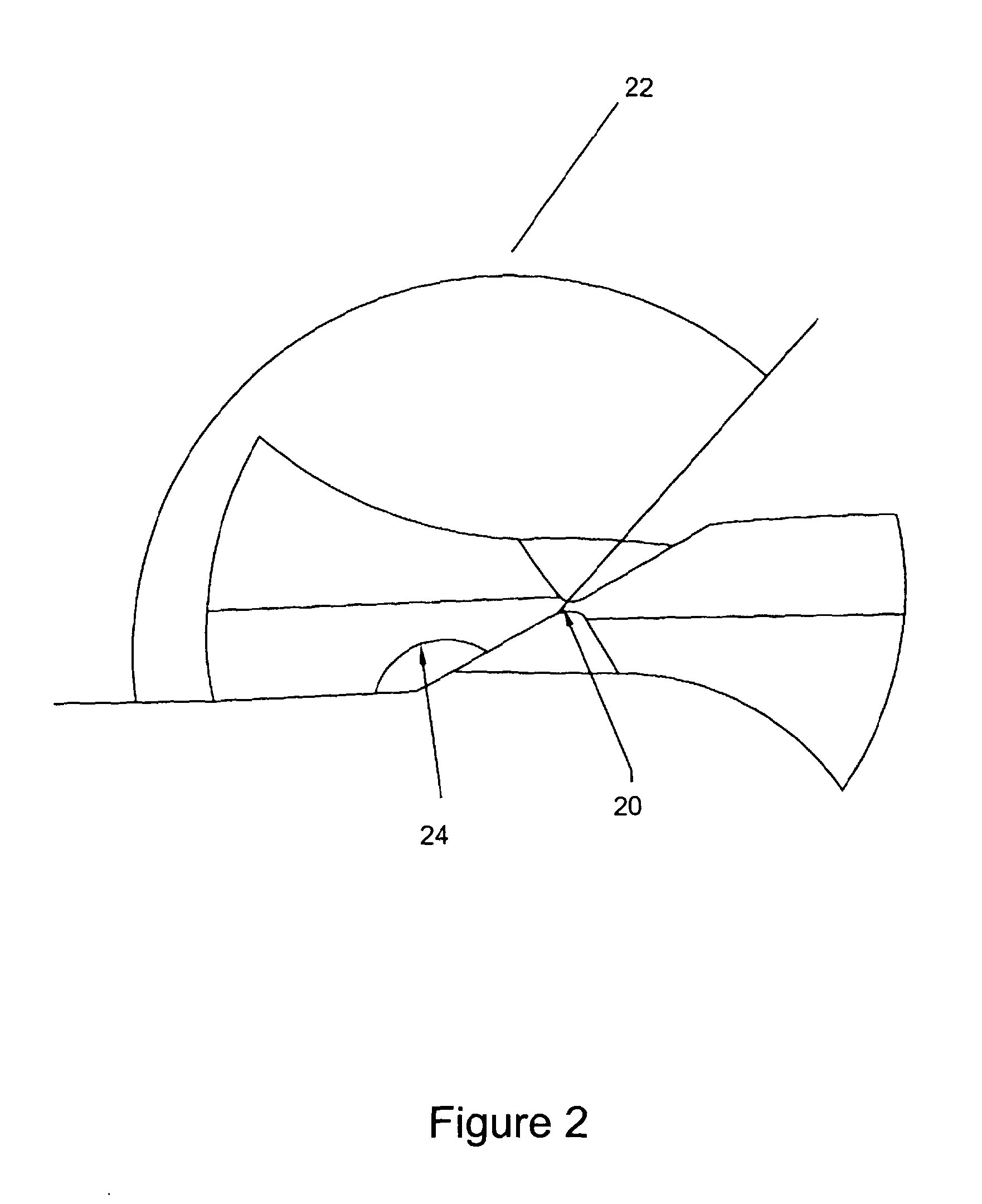

Twist drill for advanced materials

ActiveUS20130039709A1Improve hole qualityMinimize thrust forceWood turning toolsTransportation and packagingFiberGlass fiber

The present invention is concerned with twist drills for drilling of composite materials such as carbon fibre reinforced plastic (CFRP) and glass fibre reinforced plastic (GFRP). The present invention proposes that a twist drill (2) is provided with a variable helix having a defined start and finish helix angle, in combination with primary and secondary relief angles such that the drill (2) is adapted to minimise thrust force, particularly when used for drilling fibre—containing composite materials and especially for hand drilling. Start and finish helix angles of 50° and 10°; 50° and 30°; and 30° and 10° have been shown to provide excellent cutting performance and exit hole quality. A large secondary chisel edge angle (24) has also been found to contribute to excellent performance with composite materials, including stack machining.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

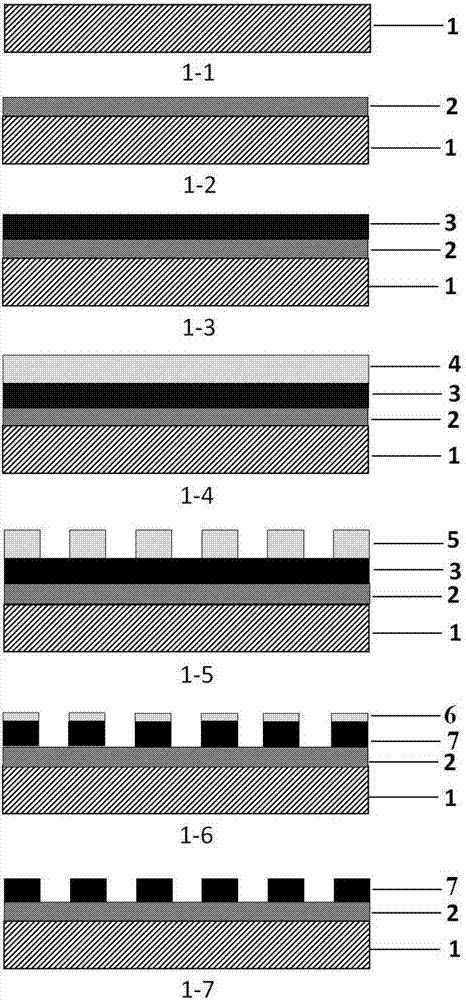

Manufacturing method of micro-nano structure capable of accurately controlling depth

InactiveCN104326440AImprove uniformityImprove reliabilityDecorative surface effectsNanotechnologyMicro nanoResist

The invention relates to a manufacturing method of a micro-nano structure capable of accurately controlling depth, which belongs to the technical field of processing of advanced materials and micro-nano structures. The manufacturing method comprises the following steps: selecting an etching resistant material to form an etching cutoff layer, and forming a structural material layer with the thickness being target depth on the surface of the etching cutoff layer by utilizing a film technique; then coating the surface of the structural layer with a layer of etching resistant agent, and manufacturing the required micro-nano structure on the etching resistant agent by utilizing a micro-nano processing technique; with the micro-nano structure on the etching resistant agent as a mask, transferring the micro-nano structure onto the structural material layer by utilizing an etching transferring process until the micro-nano structure reaches the etching cutoff layer with etching resistance, and stopping etching; and removing the etching resistant agent which remains on the structural layer so as to obtain the micro-nano structure of which the depth is up to a target value, wherein the depth precision is increased to + / -5 nanometers. The manufacturing method has the advantages of low cost, large local processing figure area, high precision and good uniformity, and wide application of high-precision optical devices to scientific research and production is promoted.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

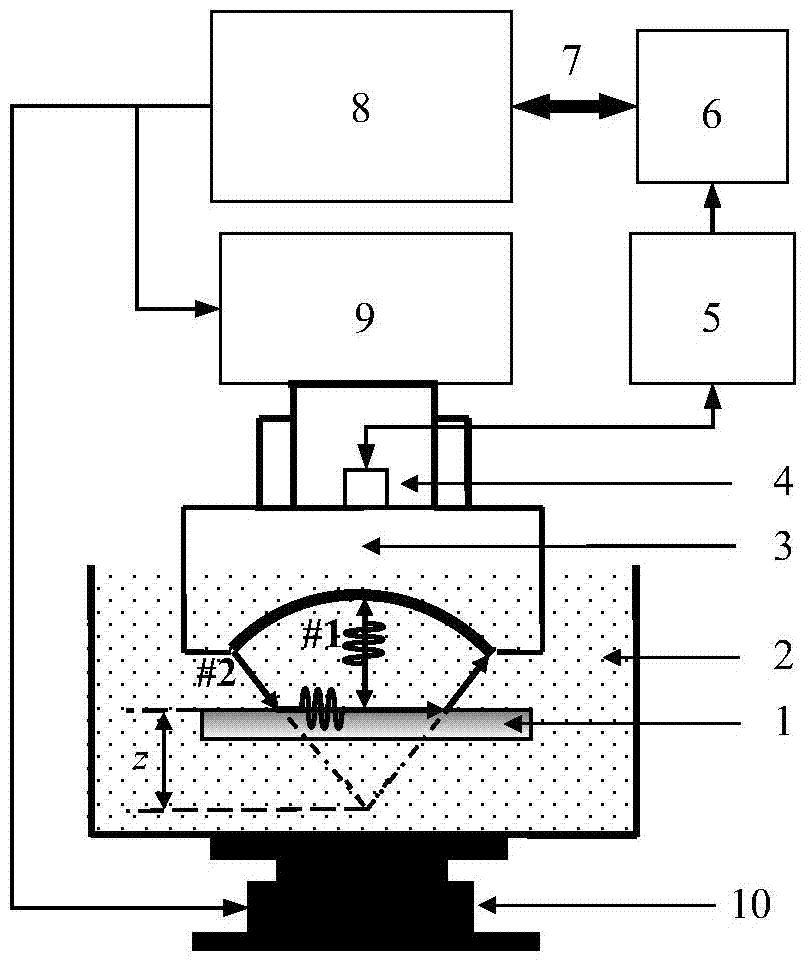

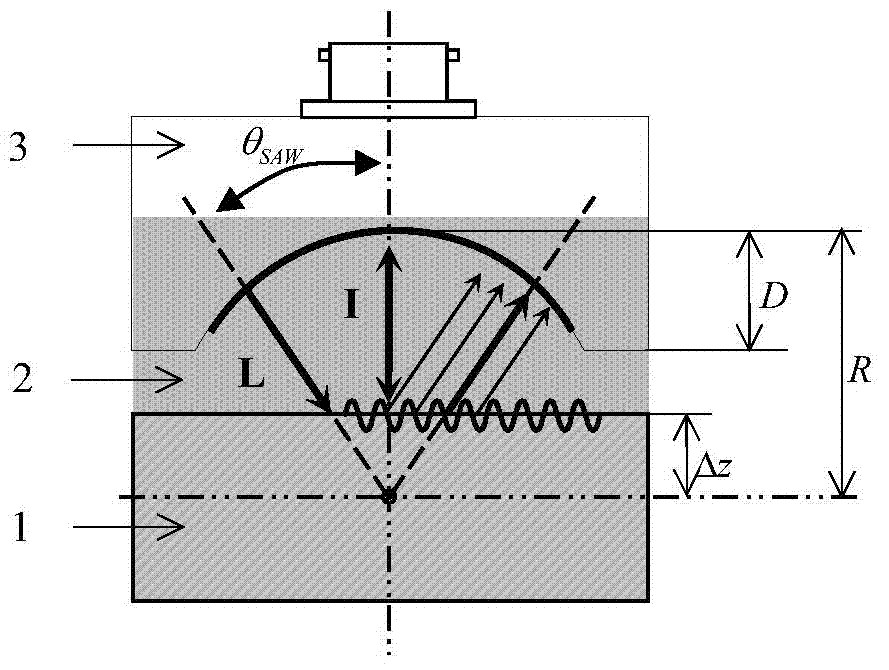

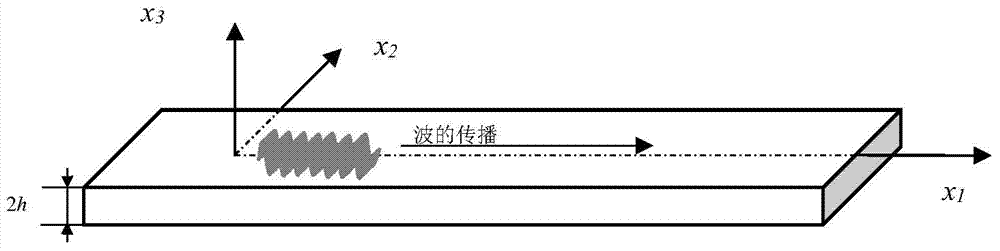

Method for obtaining elastic property of isotropous sheet material based on simplex method

ActiveCN103926315AAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalWave velocityDeterminant

The invention discloses a method for obtaining the elastic property of an isotropous sheet material based on a simplex method and belongs to the field of ultrasonic guided-wave nondestructive testing and evaluation. Based on an acoustic microscope technology and according to a self-developed ultrasonic system for measuring the elastic coefficient of a material, a line focusing polyvinylidene fluoride (PVDF) probe is adopted, the velocity of longitudinal waves and surface waves is simultaneously measured, and nondestructive testing of the elastic coefficient of the material can be realized. According to a novel inverse algorithm, the elastic property of the sheet material is obtained by virtue of the line focusing probe. According to the method, an objective function is induced into a coefficient matrix determinant of a frequency dispersion characteristic equation based on the simplex method, and the elastic property and the sample density can be obtained through acoustical properties and the measured density. The method can be used for extracting the wave velocity of the isotropous sheet material and is an advanced material wave velocity extraction method.

Owner:BEIJING UNIV OF TECH

Compositions with polymers for advanced materials

InactiveUS20050154105A1Fixed capacitor dielectricPrinted resistor incorporationElectrical conductorAdhesive

A composition comprising: a polymer with a glass transition temperature greater than 250° C. and a water absorption of 2% or less; one or more metals or metal compounds; and an organic solvent. The polymer can optionally include sites that can crosslink with one or more crosslinking agents. The compositions can be used to produce electronic components such as resistors, discrete or planar capacitors, conductive adhesives and electrical and thermal conductors. The invention is also directed to a composition comprising a polymer with a glass transition temperature greater than 250° C. and a water absorption of 2% or less, and an organic solvent. These compositions can also be used in a number of electronic applications such as an encapsulant and as an integrated circuit packaging material.

Owner:EI DU PONT DE NEMOURS & CO

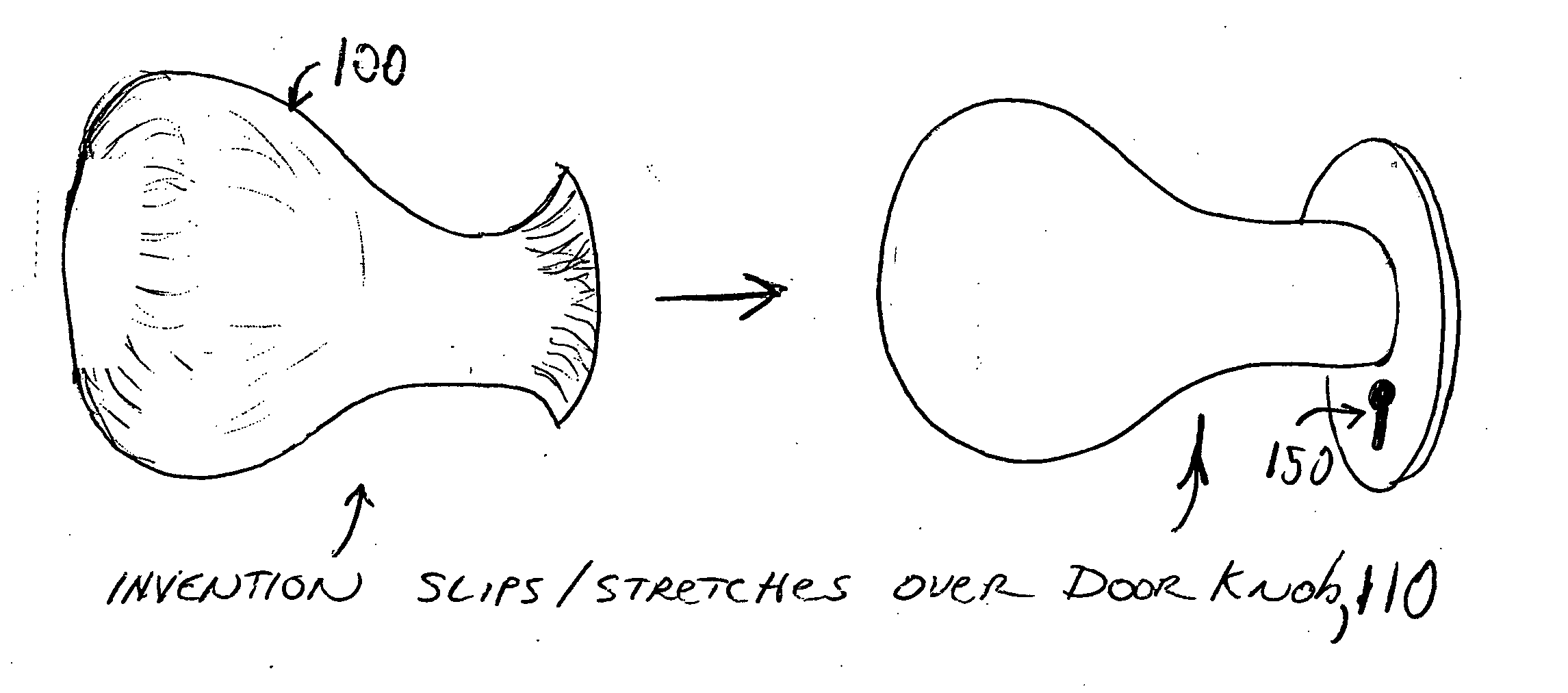

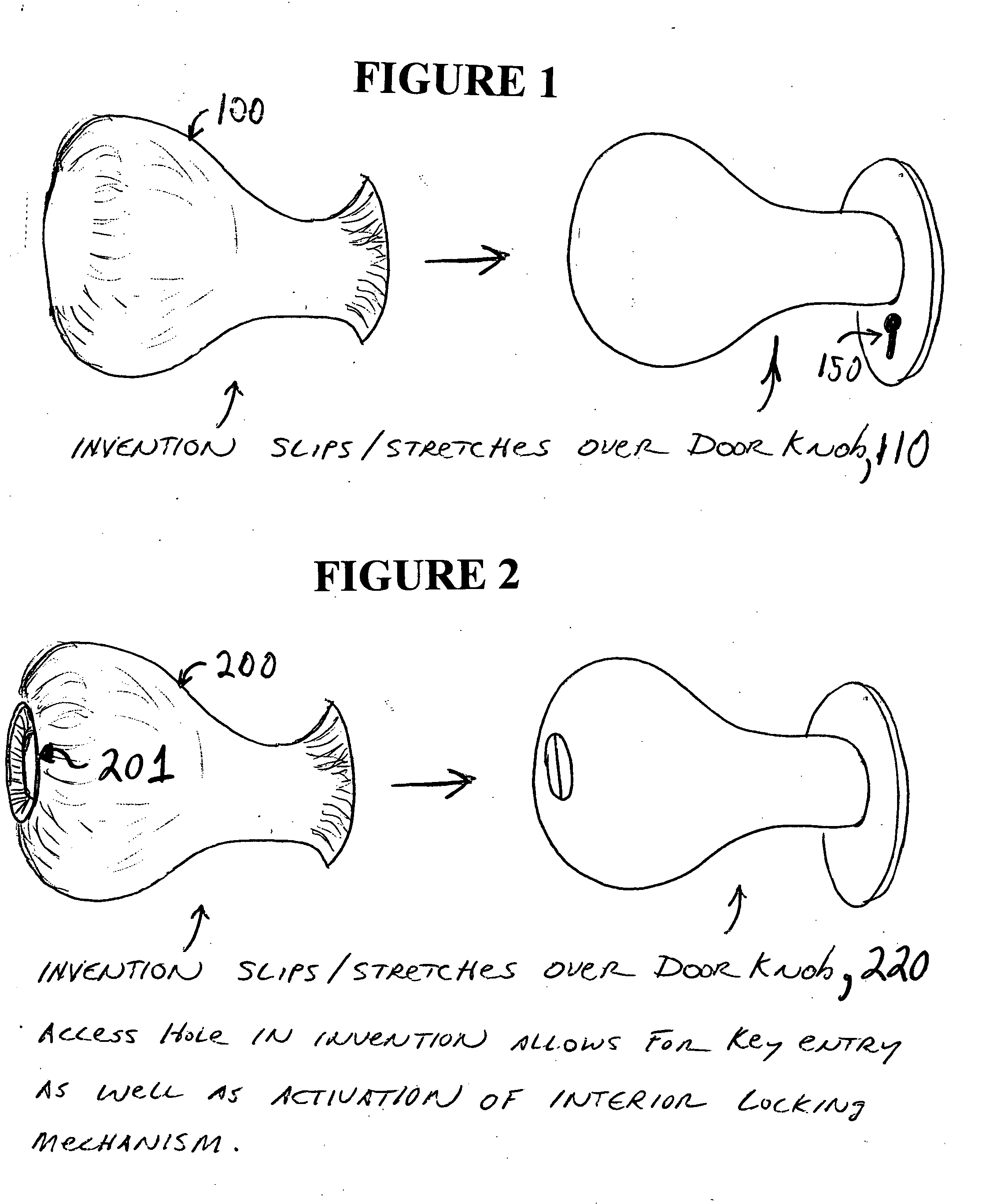

Door knob insulator

An insulated elastic cover that slips snuggly over interior or exterior door knob. It is constructed in a manner that allows locking and unlocking actions, as well as the ability to turn the door knob. Invention takes advantage of state-of-the-art materials to maximize insulating properties while minimizing bulk. Additionally, material is impregnated with anti-bacteriological medium that destroys hand-borne bacteria transferred from hand to door knob.

Owner:THE GOVERNMENT OF THE US SEC THE AIR FORCE

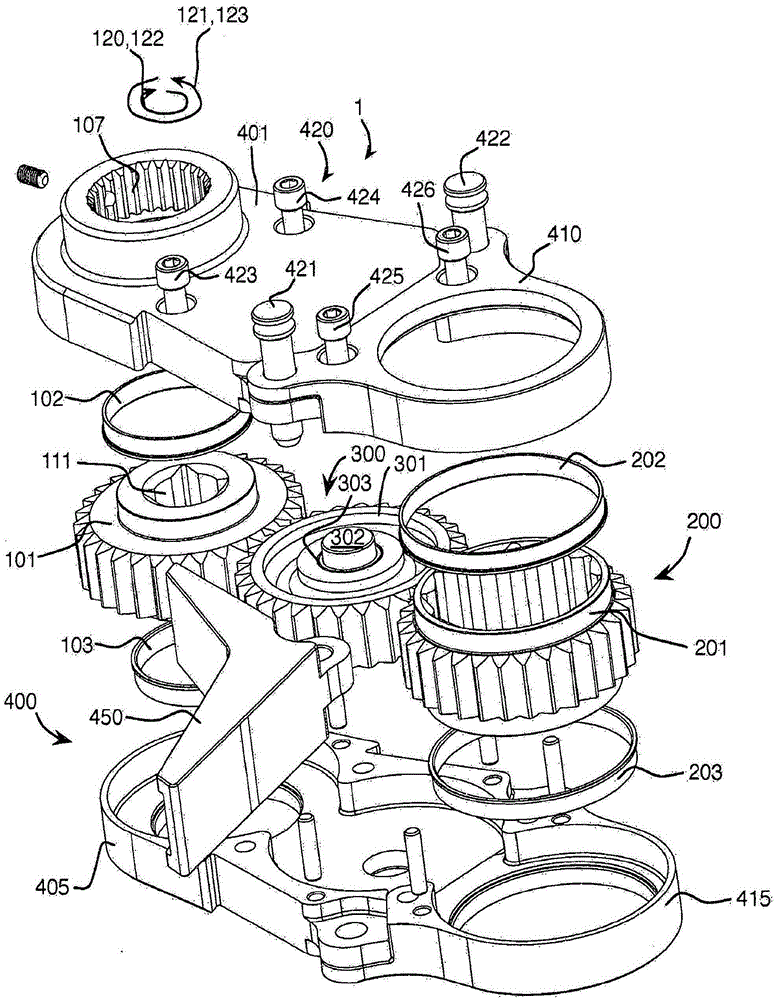

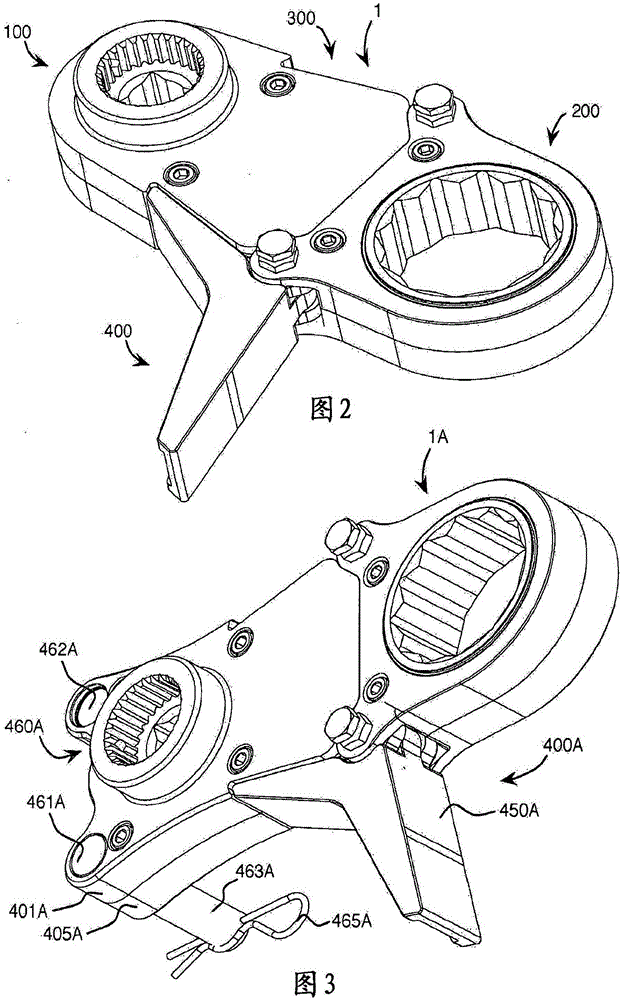

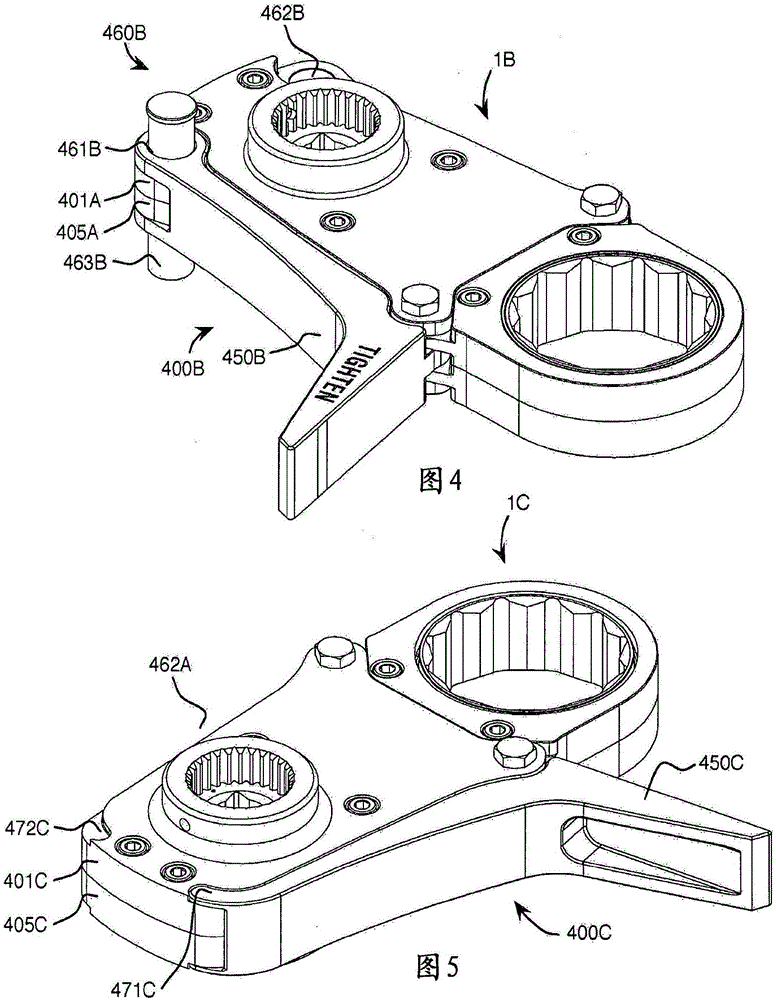

Apparatus for tightening threaded fasteners

ActiveCN105283272ASatisfy connected application characteristicsMeet the application characteristicsPliersSpannersEngineeringPower tool

An offset drive link assembly for transmission and multiplication of torque from a power tool for tightening or loosening a threaded fastener includes: a drive force input assembly; a drive force output assembly; and a reaction force assembly. Advantageously the offset drive link assembly: allows access to previously unreachable fasteners due to, for example protruding threads, limited clearances and obstructions; makes practical previously unusable devices driven either electrically, hydraulically, manually and / or pneumatically; makes feasible previously unusable advanced materials, such as, for example aircraft-grade aluminum; creates modular components, such as, for example hex-reducing and -increasing drive bushings, male to female drive adaptors, to meet bolting application characteristics; yields accurate and customizable torque multiplication; tames drive force and reaction force application; overcomes corrosion, thread and facial deformation; avoids bolt thread galling; nullifies side load; ensures balanced bolt load for symmetrical joint compression; simplifies link and tool use; minimizes risk of operator error; and maximizes bolting safety.

Owner:HYTORC DIV UNEX CORP

Graphene/bacterial cellulose composite material with gradient structure and preparation method thereof

ActiveCN109097420AMaintain a unique structureThickness is easy to controlMicroorganism based processesFermentationGradient materialMembrane surface

The invention discloses a preparation method of a graphene / bacterial cellulose composite material with a gradient structure. A membrane liquid interface culture method is adopted. The preparation method mainly comprises preparing a culture medium and preparing a base membrane for culturing graphene / bacterial cellulose as a membrane liquid interface; preparing mixed media of graphene / nonvaccinatedmedia in various volume ratios (concentrations); spraying the mixed media of the grapheme in different concentrations in the mist form to the base membrane for multiple times according to the change of the concentration of the graphene in the mixed media from low to high based on the spraying sequence to achieve membrane and liquid contact. The next spraying is conducted each time after the mixedmedia on the membrane surface are consumed, so that the grapheme / bacterial cellulose composite material with the ratio of the graphene and the bacterial cellulose in the gradient change in the thickness direction is formed. The composite material can provide materials for preparing novel advanced materials such as biomimetic biomaterials, electromagnetic gradient materials and conductive gradientfunctional materials.

Owner:EAST CHINA JIAOTONG UNIVERSITY

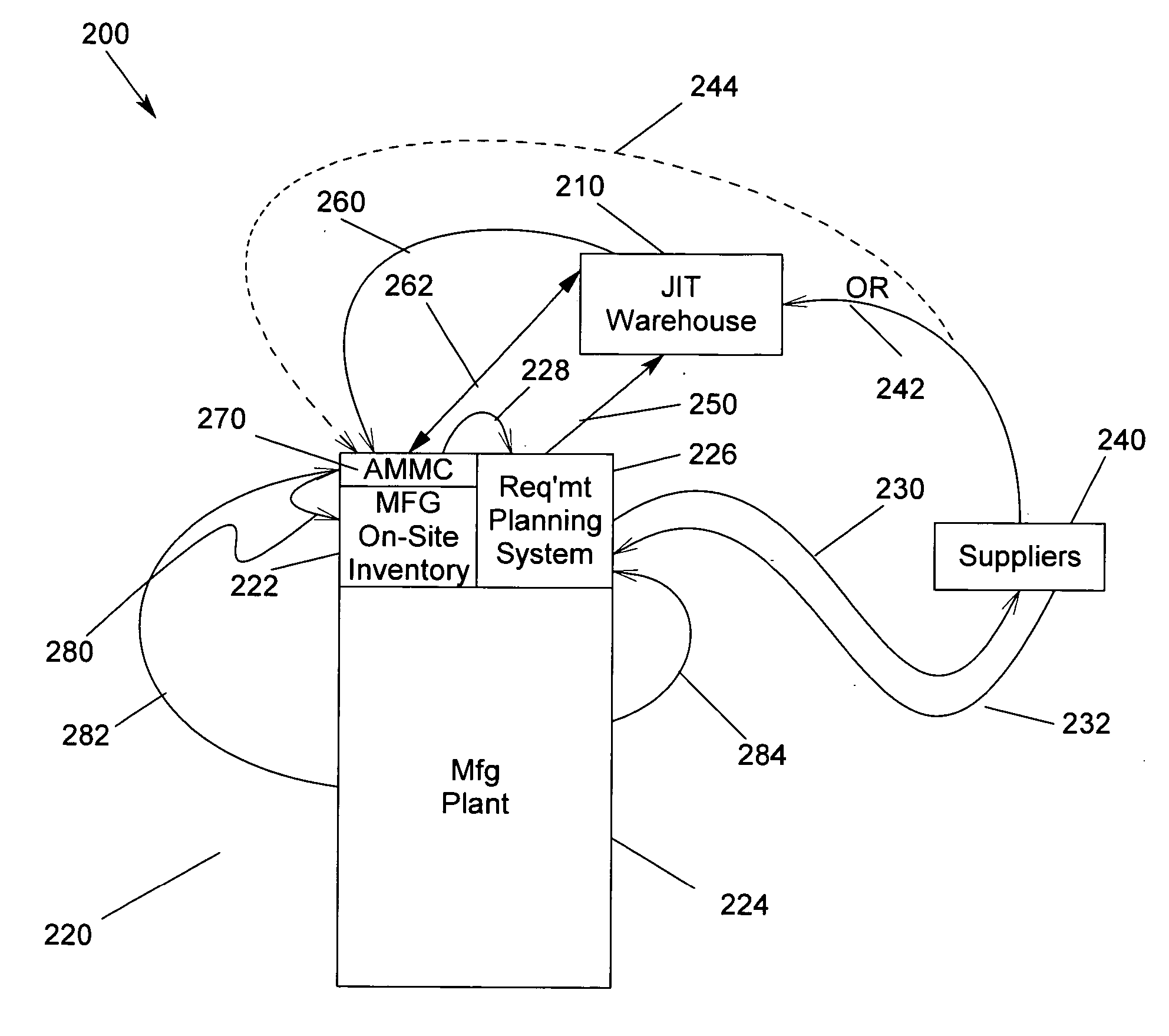

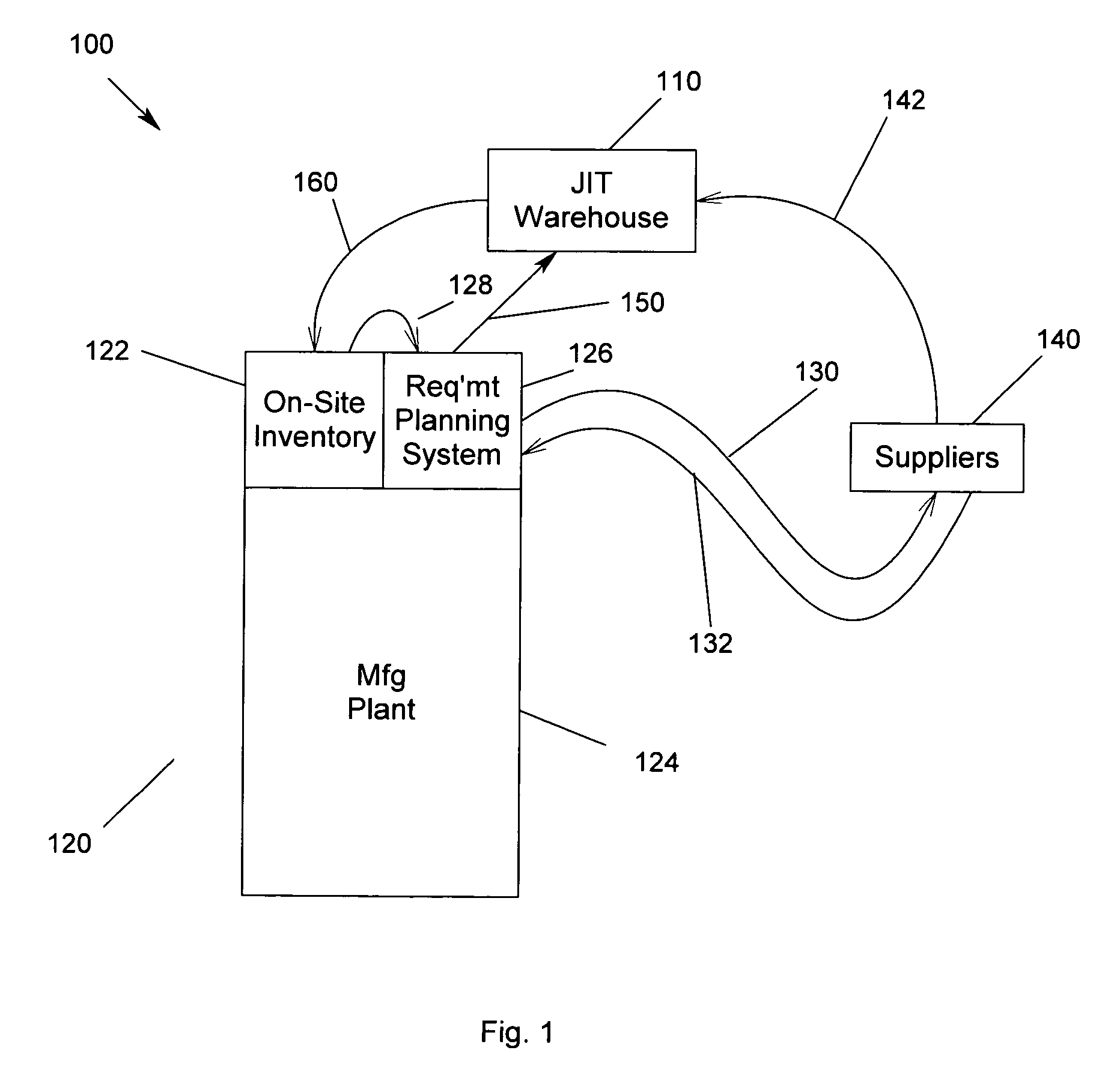

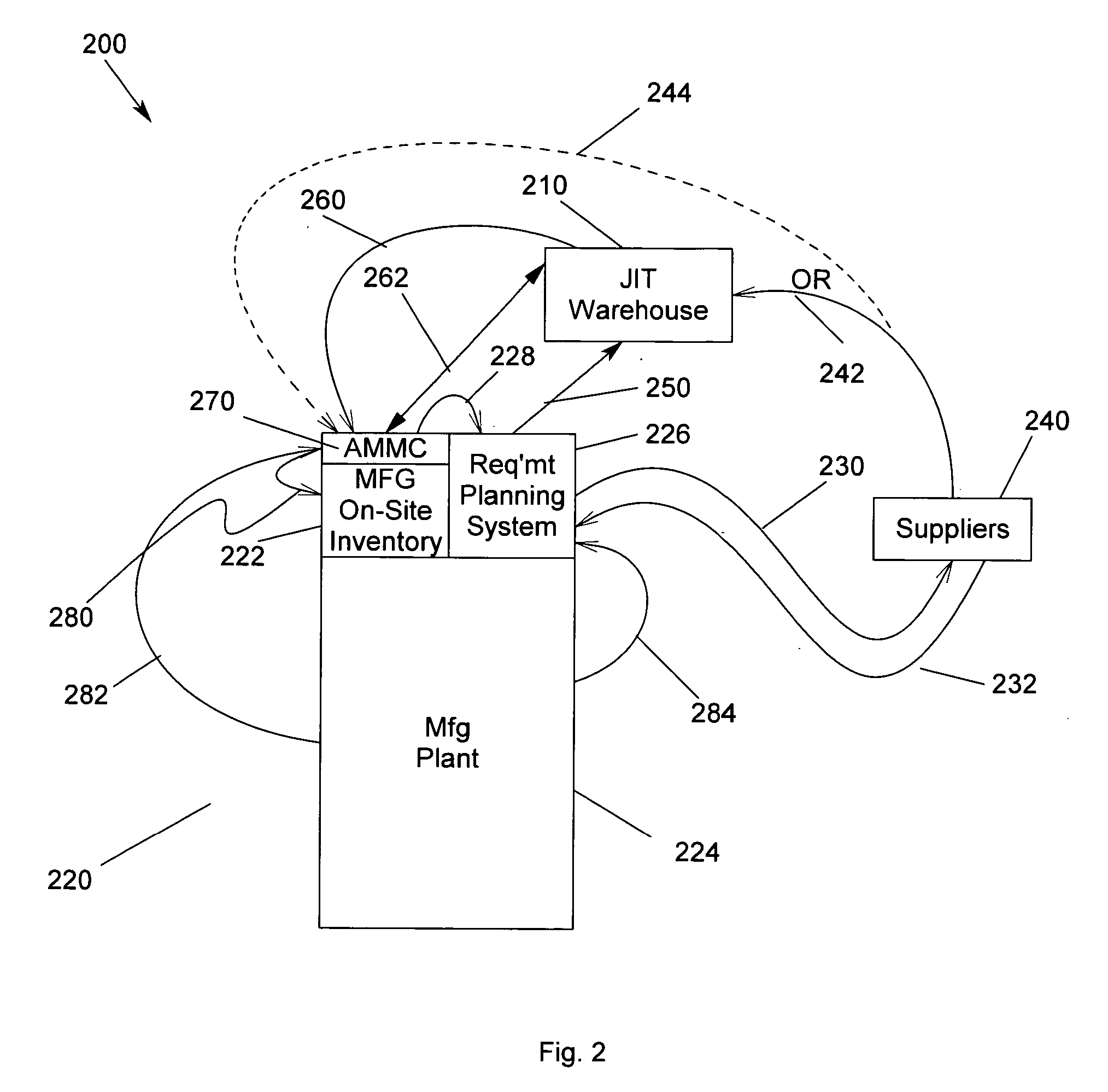

Method, apparatus and program storage device for providing an advanced material management center

InactiveUS20060229756A1Overcome excessive storage spaceEasy maintenanceHand manipulated computer devicesDigital data processing detailsEngineeringAdvanced materials

A method, apparatus and program storage device for providing an advanced material management center is disclosed. A segregated delivery delay / component buffer area is maintained at a manufacturing site for holding material before transfer to the manufacturer. The content of the buffer area is owned by the supplier. Materials may be provided to the buffer area by a just-in-time warehouse or by a supplier. The quantity of any particular material at the buffer area is smaller than normally held at the just-in-time warehouse or provided by a supplier and therefore requires much less storage space. However, the buffer area provides quick availability to inventory and allows for improved maintenance and availability of inventory.

Owner:WESTERN DIGITAL TECH INC

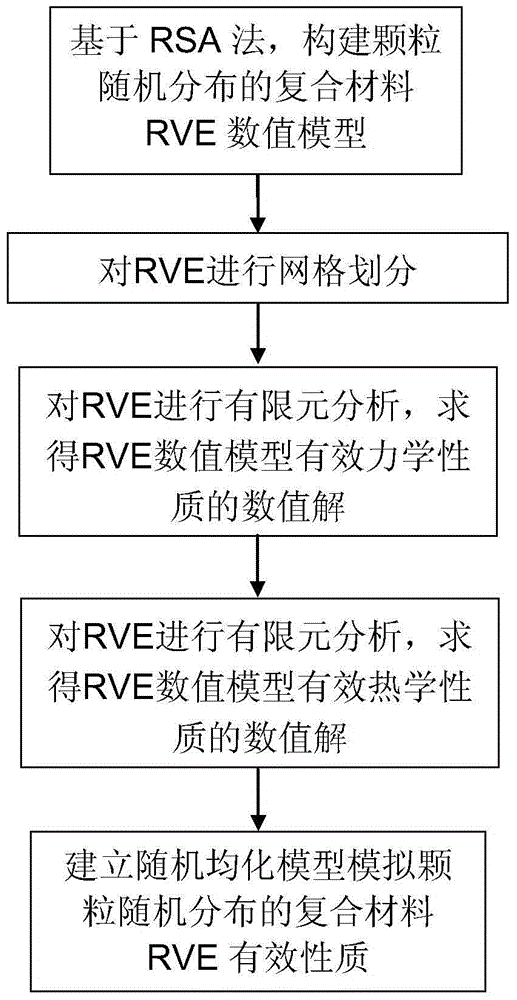

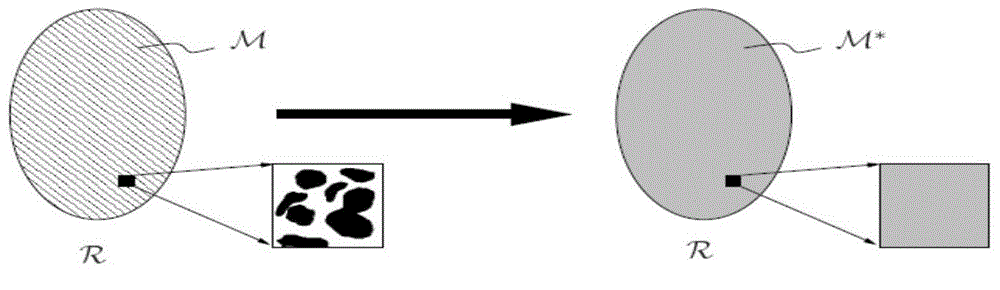

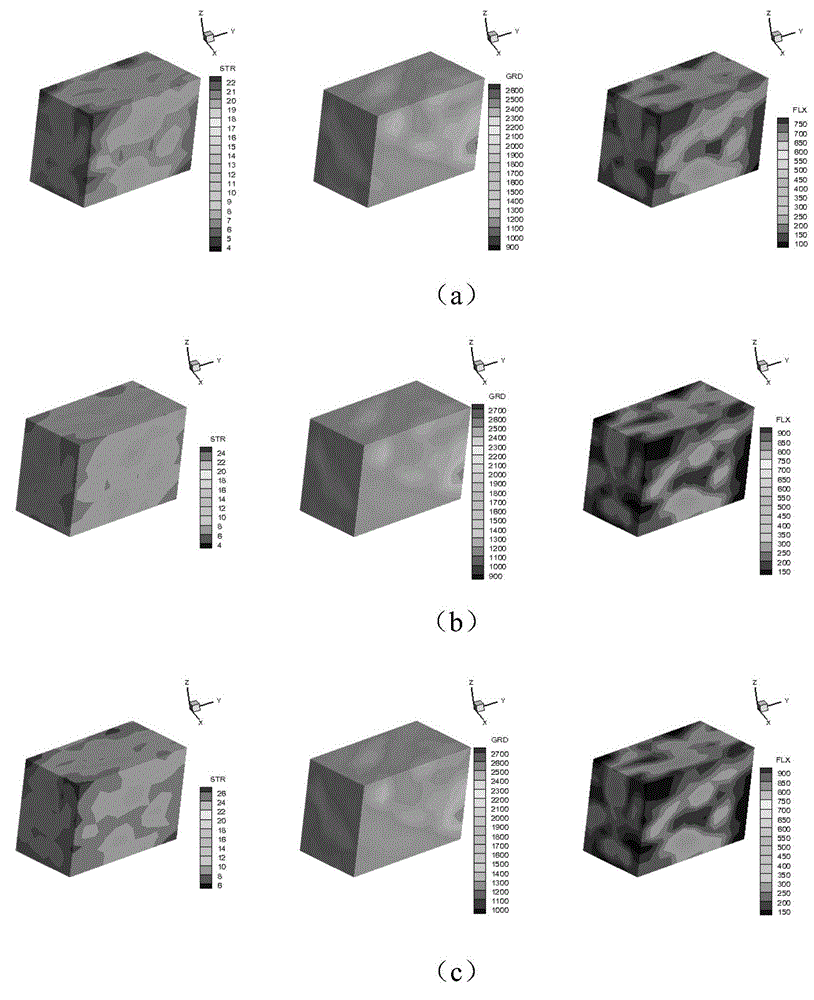

Thermoelasticity homogenizing method for three-dimensional random heterogeneous material under finite deformation

ActiveCN105069203ASolving Numerical Modeling ChallengesThe calculation result is accurateSpecial data processing applicationsElement analysisInhomogeneous material

The invention discloses a thermoelasticity homogenizing method for a three-dimensional random heterogeneous material under finite deformation. The method comprises the steps as follows: 1) establishing a composite material representative volume element three-dimensional RVE numerical model with randomly distributed particles based on random sequence adding RSA method and removing a particle overlapping phenomenon while the particle volume fraction is relative large; 2) performing finite element analysis calculation on the composite material three-dimensional RVE numerical model under a thermoelasticity environment to obtain an arithmetic solution of effective property of the RVE numerical model; 3) establishing a random homogenizing model to calculate macroscopic effective property of a composite material and using the macroscopic effective property of the composite material as an actual and effective property. The method of the invention provides a more reliable homogenizing result for the macroscopic effective property of the composite material, and provides sufficient basis for the optimization design of structure and the use of new advanced materials.

Owner:XIDIAN UNIV

Method for printing combustion chamber lining by using GRCop-42 spherical powder

ActiveCN111515391AImprove conductivityGood thermal expansionAdditive manufacturing apparatusTransportation and packagingCombustion chamberSand blasting

The invention discloses a method for printing a combustion chamber lining by using GRCop-42 spherical powder. The GRCop-42 alloy spherical powder comprises the following chemical components in percentage by weight: 2-4wt% of Cu, 2-4wt% of Cr and Nb. The method comprises the following steps of: 1) heating the spherical powder in vacuum, cooling the spherical powder along with a furnace, then performing ultrasonic vibration, screening the spherical powder and preparing to discharge the spherical powder into the furnace; 2) establishing a process model of a part, and slicing the model in layers to form a laser scanning path of each layer; 3) setting process parameters of powder laying and printing equipment, placing a rear bottom plate substrate, and fully laying the GRCop-42 spherical powderin a powder cylinder; 4) starting the equipment and starting printing and forming; 5) after laser scans one layer, descending a forming cylinder by one layer, then ascending the powder cylinder by one layer, laying a layer of copper powder on the processed layer surface by using the powder in the powder cylinder through a scraper, then descending the powder cylinder, and repeating the steps on each layer until the printing of the structure is finished; 6) performing annealing treatment; and 7) cutting and separating the structure from the substrate, and performing sand blasting on the surfaceof the structure. The method solves the problem of domestic application of advanced materials, and meets the preparation requirement of an aerospace copper alloy structure.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

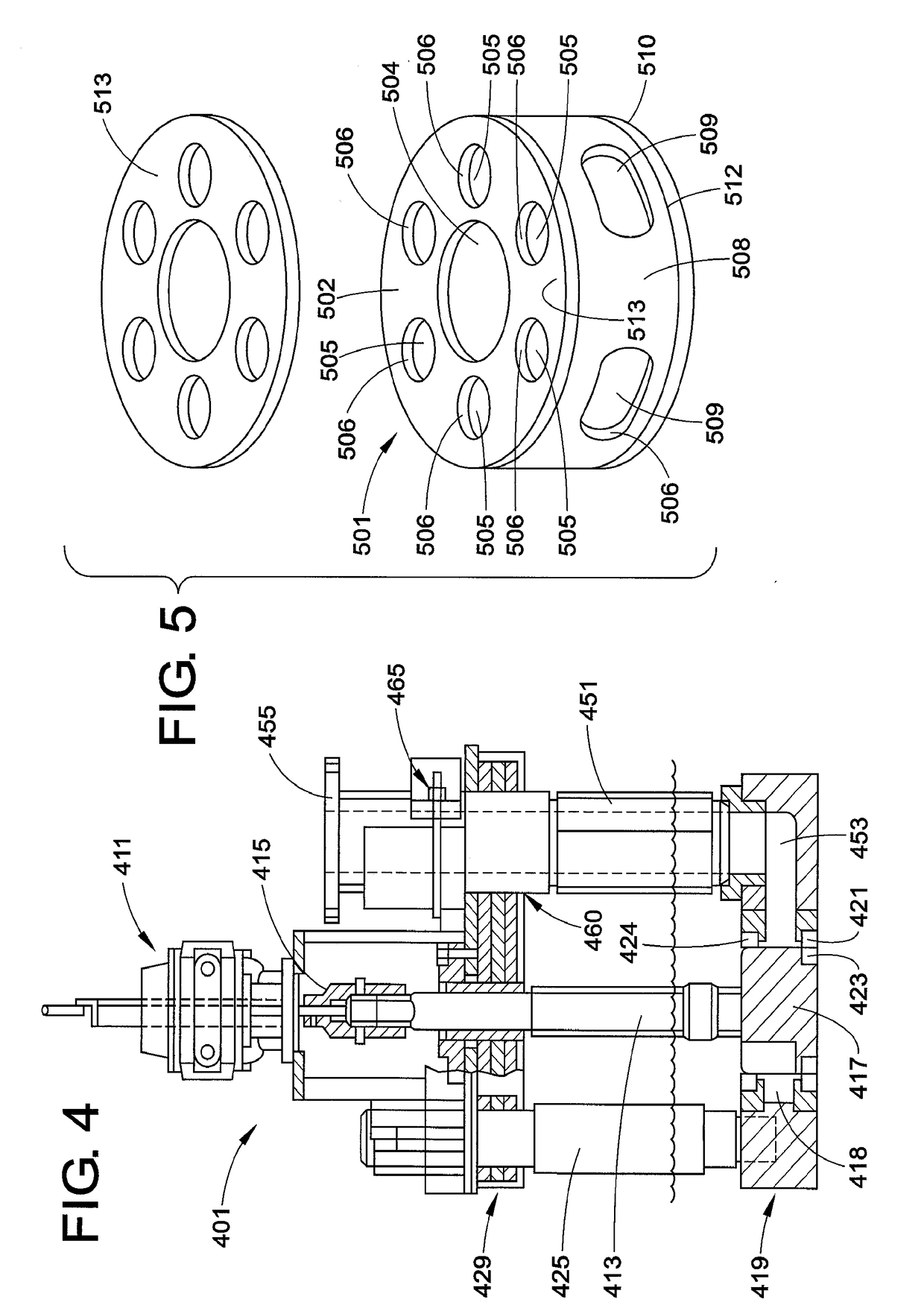

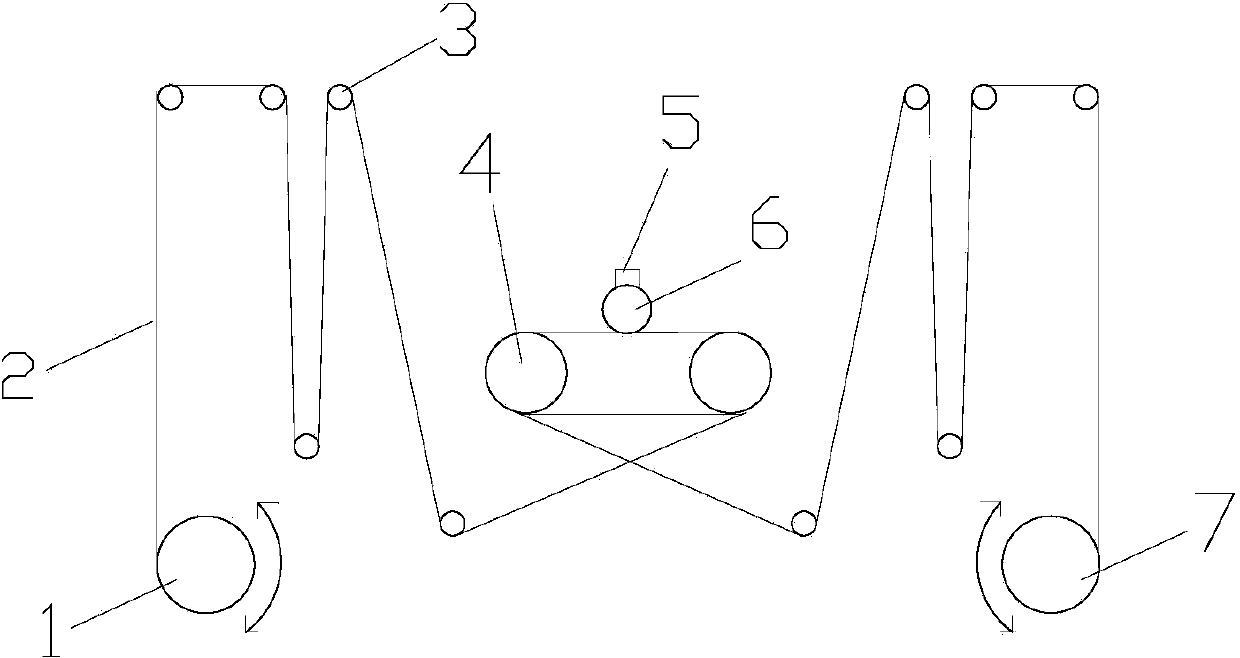

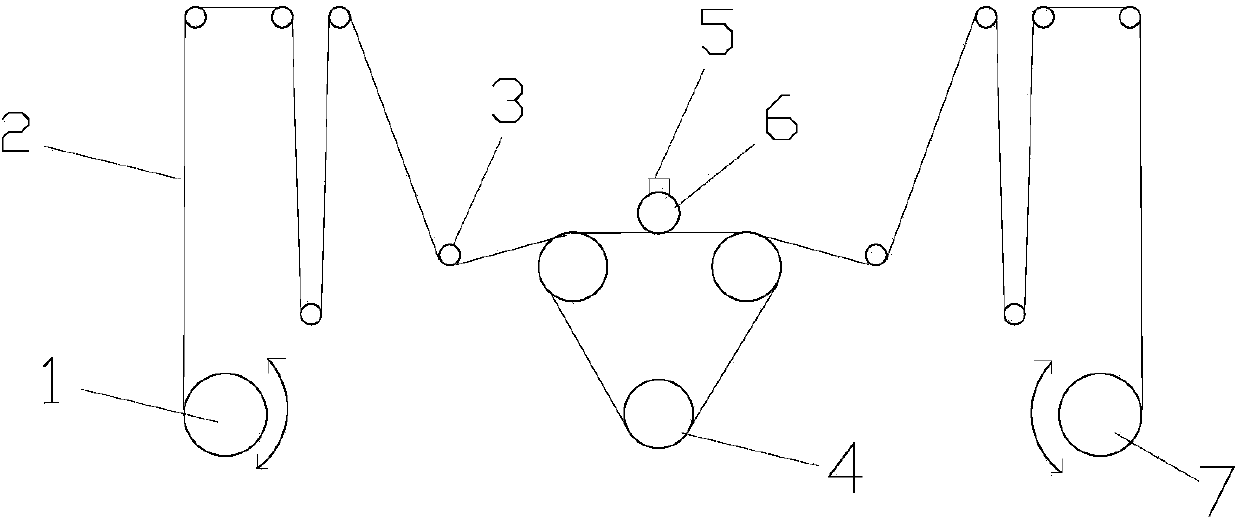

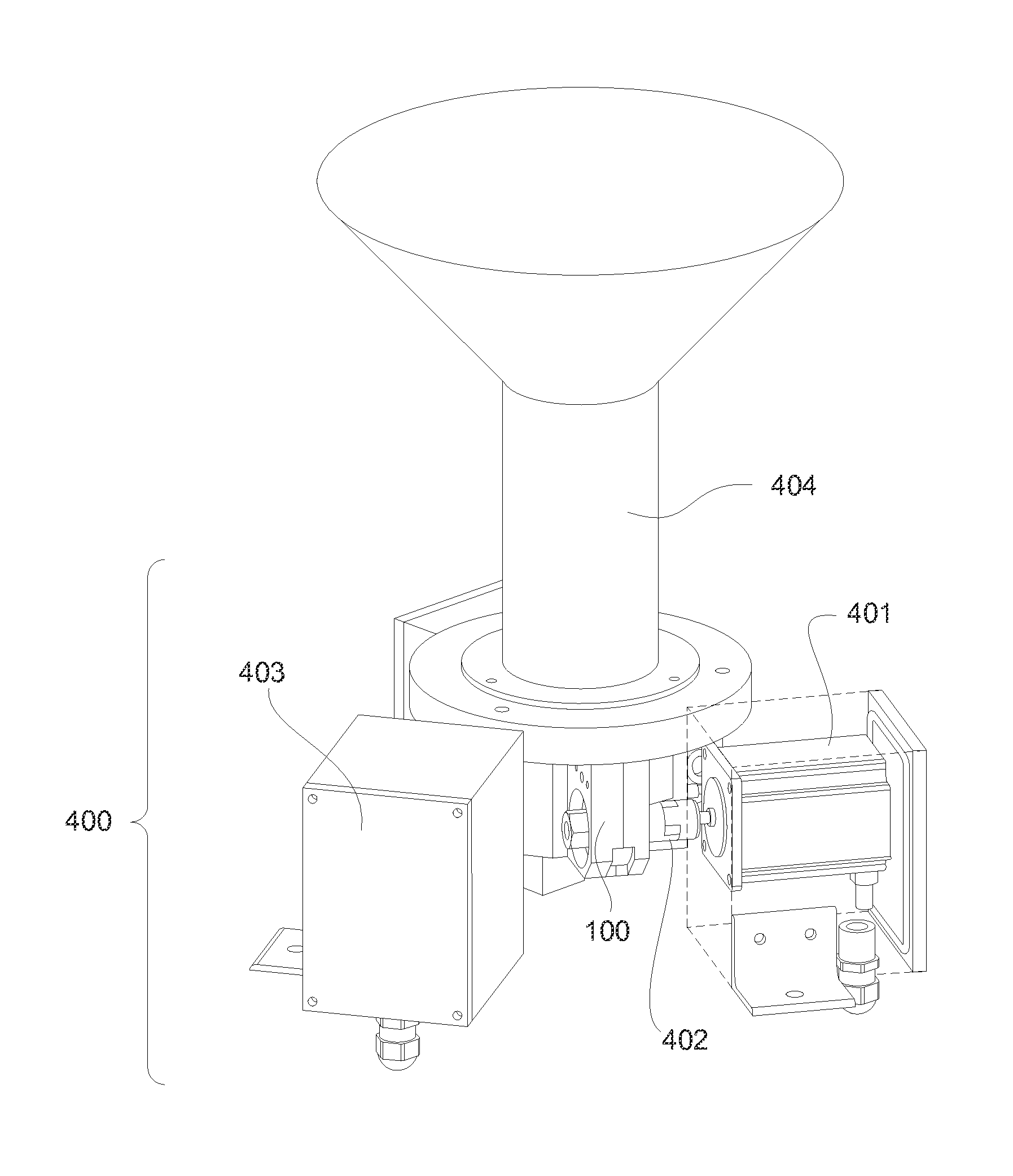

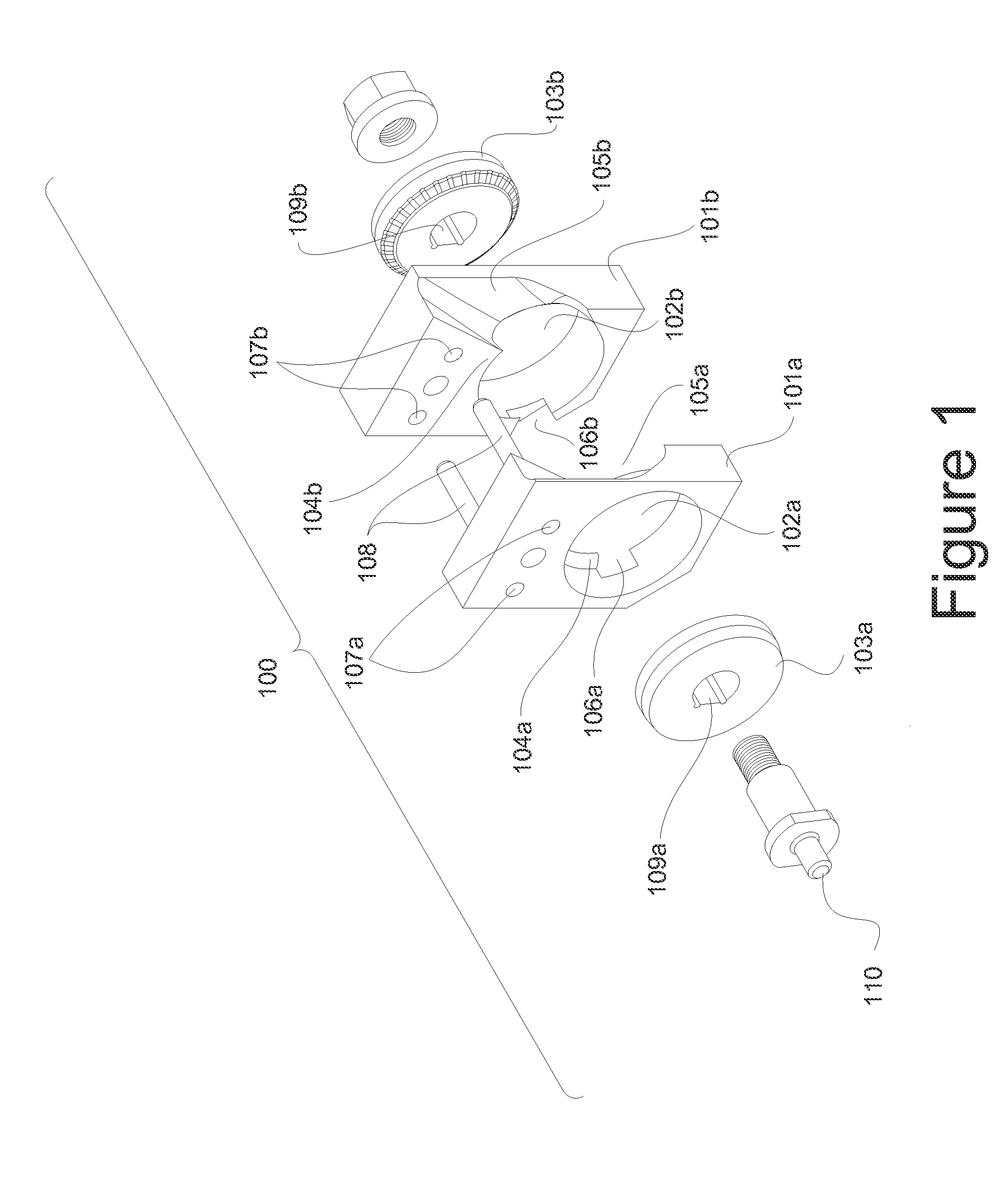

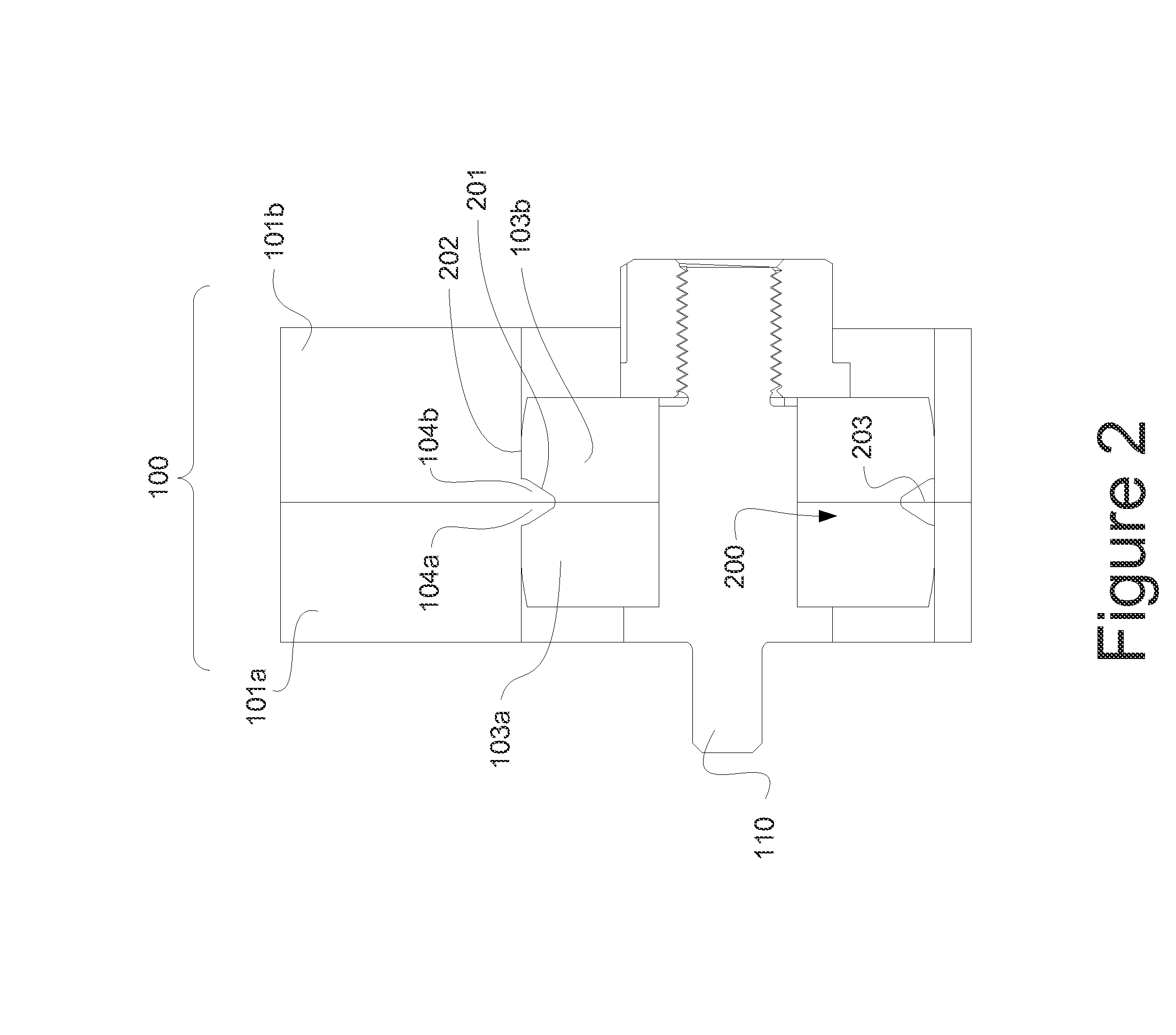

Material Feeder System and Method of Use

ActiveUS20130284520A1AmmunitionWeighing apparatus for materials with special property/formParticulatesEngineering

This invention relates to a material feeder system and method of use. The present invention relates particularly to a particulate feeder system that includes, among other features, one or more: feeder assemblies for advancing material that incorporate a spool having a channel disposed within its outer circumference for advancing material, the spool having a plurality of circumferentially spaced contours configured so as to not form transverse barriers within the channel; motors configured to connect to the feeder assemblies; and scales for weighing advanced material. The system also includes a computer in communication with the one or more motors and scales, and capable of performing operations to advance a predetermined material weight as well as various related operations. The invention also includes a method using the above.

Owner:CJC HLDG

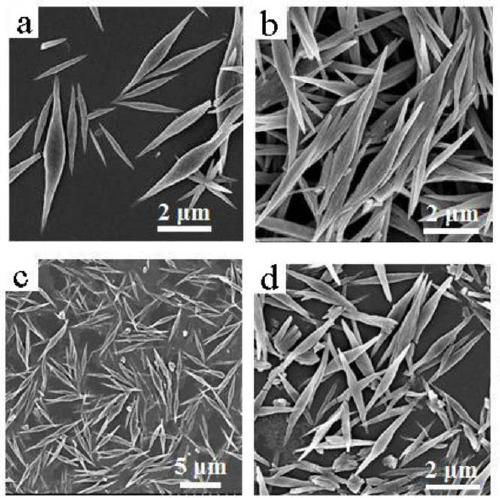

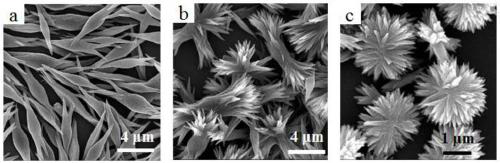

Metal-plant polyphenol complex crystal material and preparation method

The invention discloses a metal-plant polyphenol complex crystal material and a preparation method and belongs to the technical field of advanced materials. The preparation method comprises the step of adopting metal ions for crosslinking plant polyphenol, thereby forming a metal-polyphenol complex crystal, wherein morphology (such as shuttle shape and sea urchin shape) of the metal-polyphenol complex crystal is regulated by regulating volume of ammonium hydroxide, and the components of the metal-polyphenol complex crystal are controlled by adding different metal precursors. The plant polyphenol adopted by the method has the characteristics of low cost, non-toxicity, easiness in acquiring raw materials, and the like; the plant polyphenol is a reproducible precursor; the synthesis step of the metal-polyphenol complex crystal is simple; the preparation method is high in universality and is easy for large-scale preparation.

Owner:XI AN JIAOTONG UNIV

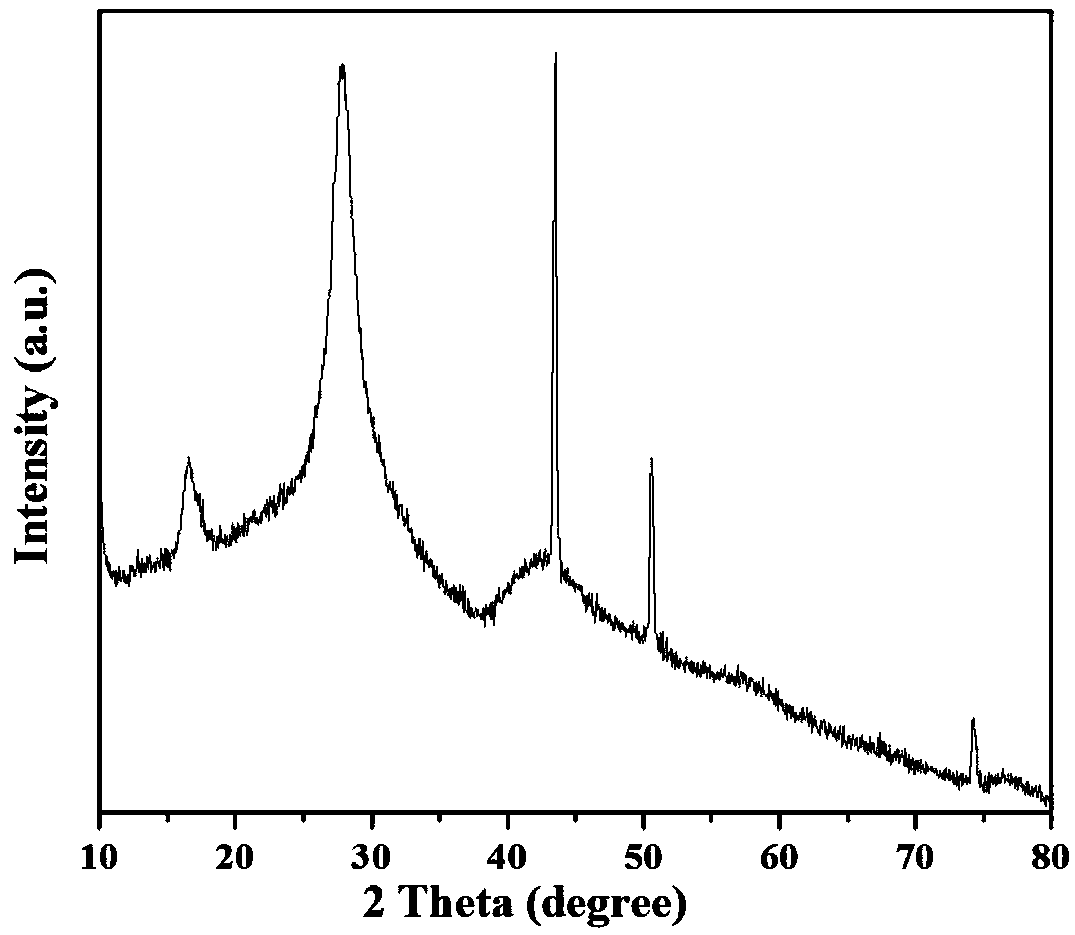

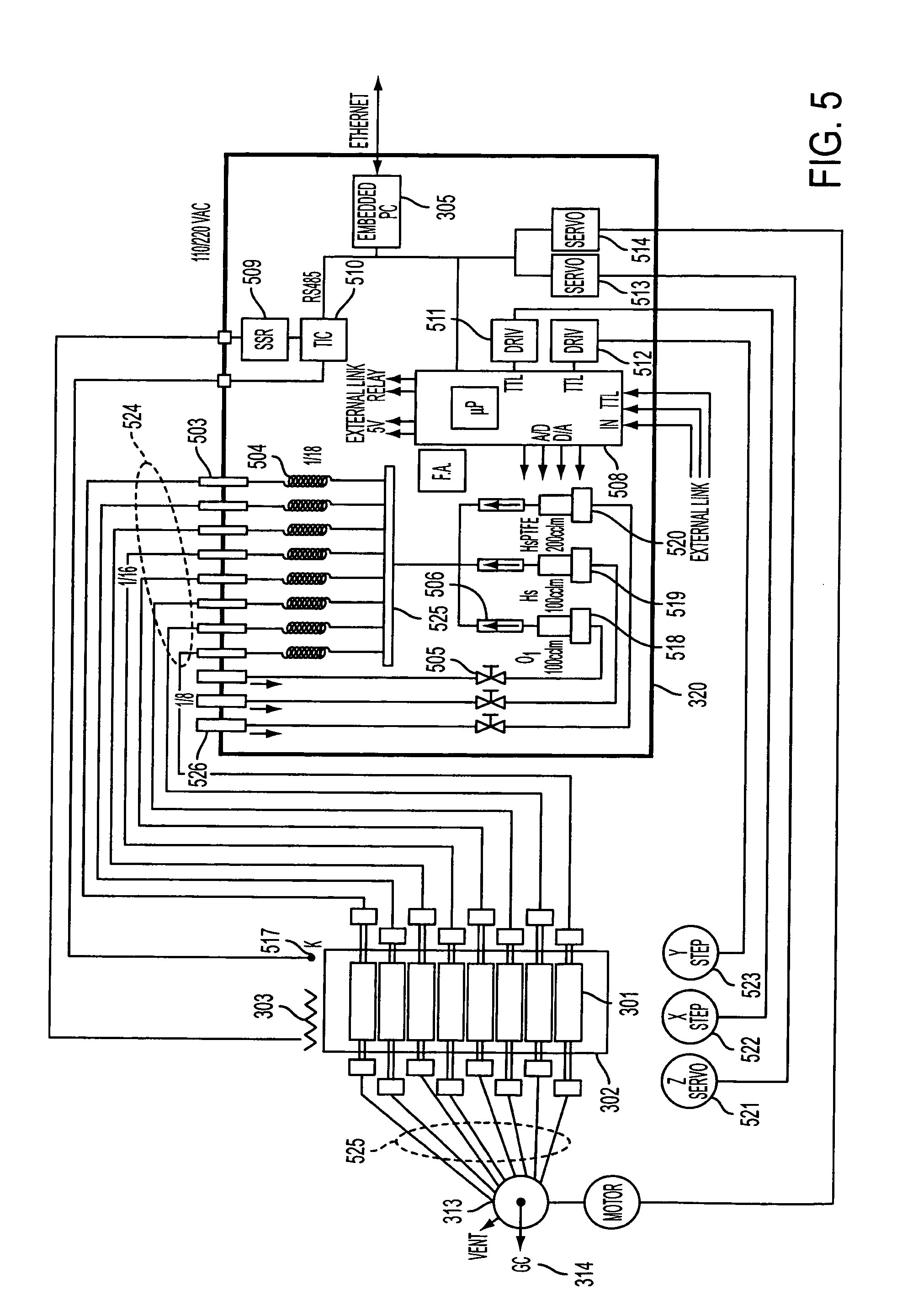

Smart combinatorial operando spectroscopy catalytic system

InactiveUS20070243556A1Easy to findLow costBioreactor/fermenter combinationsSequential/parallel process reactionsOperando spectroscopyAdvanced materials

A device and combinatorial method is disclosed for screening a plurality of catalytic materials simultaneously while determining the dynamic bulk and surface nature of the catalytic materials being screened under reaction conditions and surface chemical kinetic and mechanistic information for determining the structure-activity / selectivity relationship of the catalytic materials, and for collecting information on the dynamic structures of the catalytic materials as well as surface species. The discovery process of novel materials may thereby be accelerated, the associated costs may be reduced, and the information may also lead to the design of improved and advanced materials.

Owner:CATALYST DESIGN INC

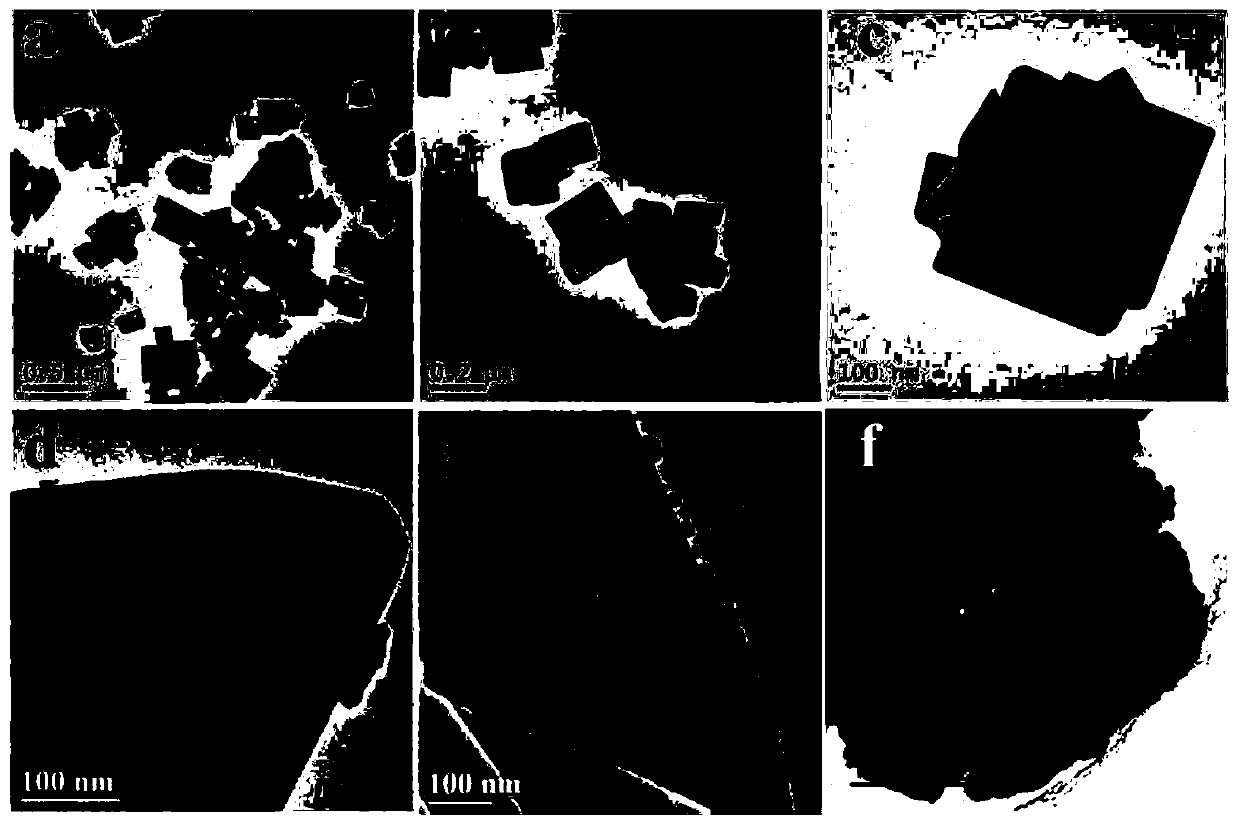

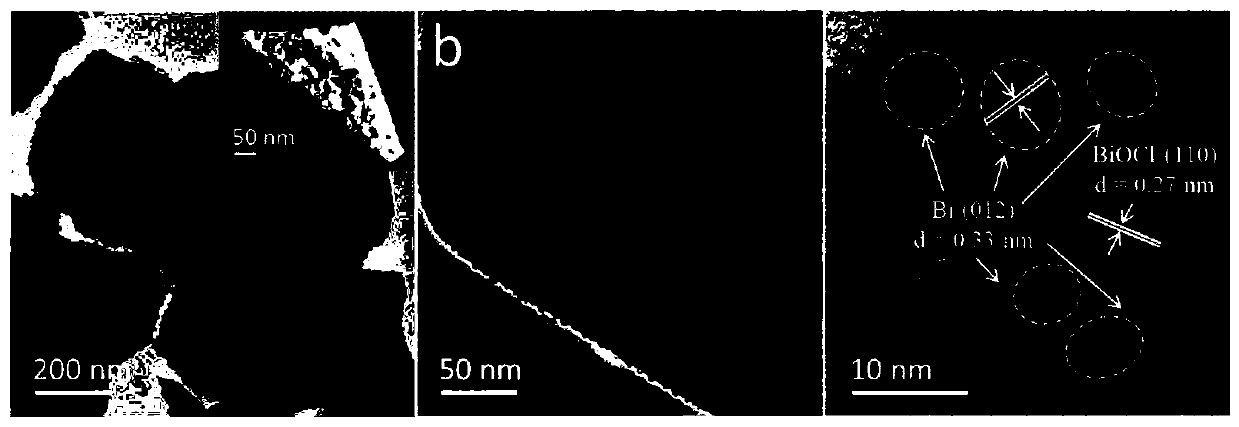

Ultra-fast preparation method of Bi nanoparticles and surface defects co-modified BiOCl nanosheets

InactiveCN110540239ABroaden the optical absorption bandwidthHigh photothermal performanceMaterial nanotechnologyBismuth compoundsFreeze-dryingOxygen

The invention discloses an ultra-fast preparation method of Bi nanoparticles and surface defects co-modified BiOCl nanosheets. The preparation method comprises the following steps: (1) adding the prepared BiOCl nanosheets and a certain amount of NaN3 into deionized water, magnetically stirring the mixture for 30 minutes for uniform mixing, slowly pouring the mixture into liquid nitrogen for rapidfreezing, and carrying out freeze-drying; and (2) after the drying is finished, placing a BiOCl and NaN3 mixture in a closed high-temperature reaction kettle, filling the kettle with nitrogen protection gas, carrying out a deflagration reaction on the NaN3 by adopting a heating wire heating mode, repeatedly cleaning products by using the deionized water after the reaction is finished, carrying outdrying, and finally obtaining the Bi nanoparticles and surface defects co-modified BiOCl nanosheets. The preparation method has the advantages of short reaction time, simultaneous completion of formation of BiOCl oxygen defects and doping of Bi nanoparticles, controllable defect and doping amount, high yield and the like; and moreover, the method is simple, the operation is simple and convenient,the universality is good, and the method can be used for preparing other advanced materials.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com