Patents

Literature

1161results about "Bismuth compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ternary oxide nanostructures and methods of making same

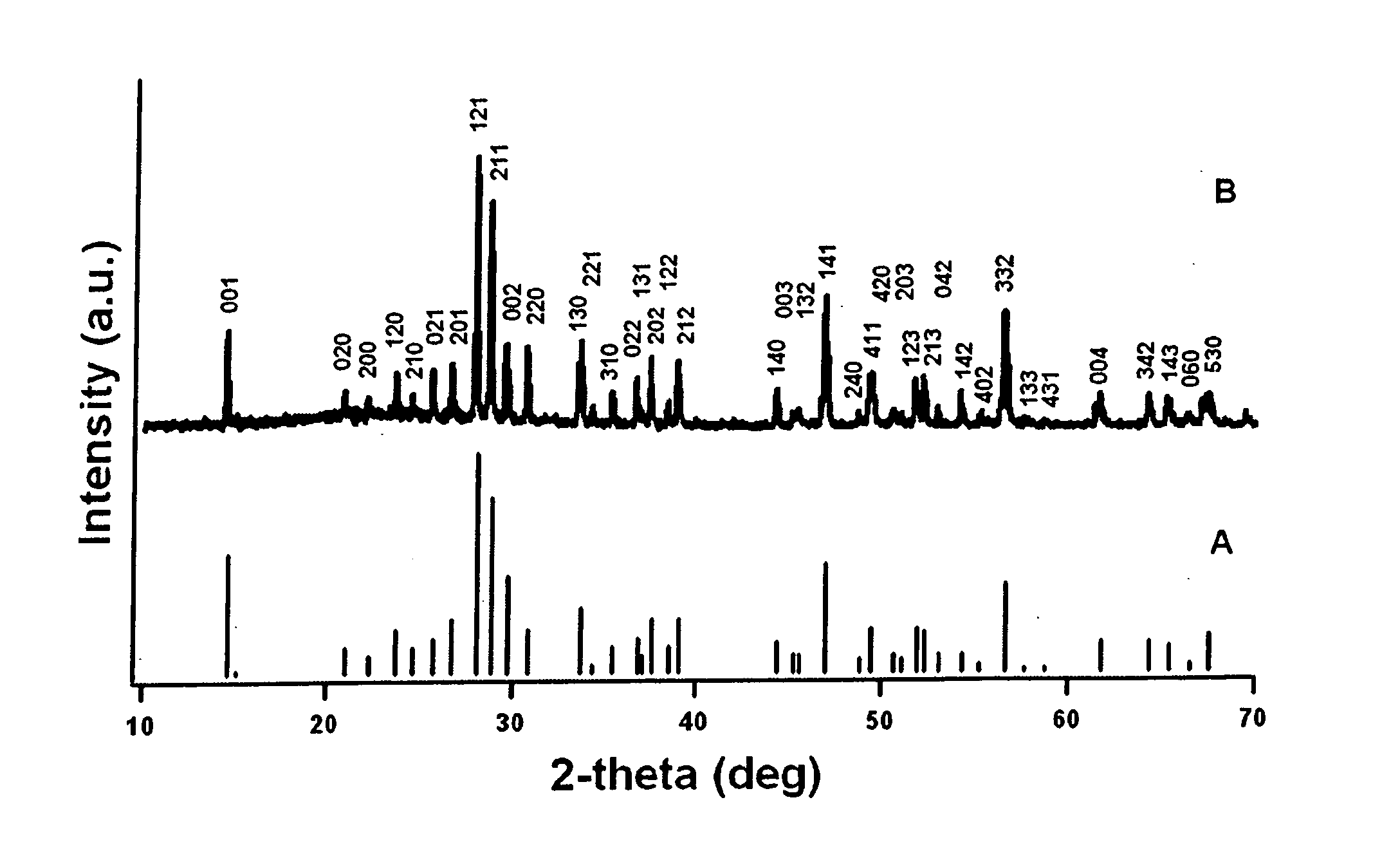

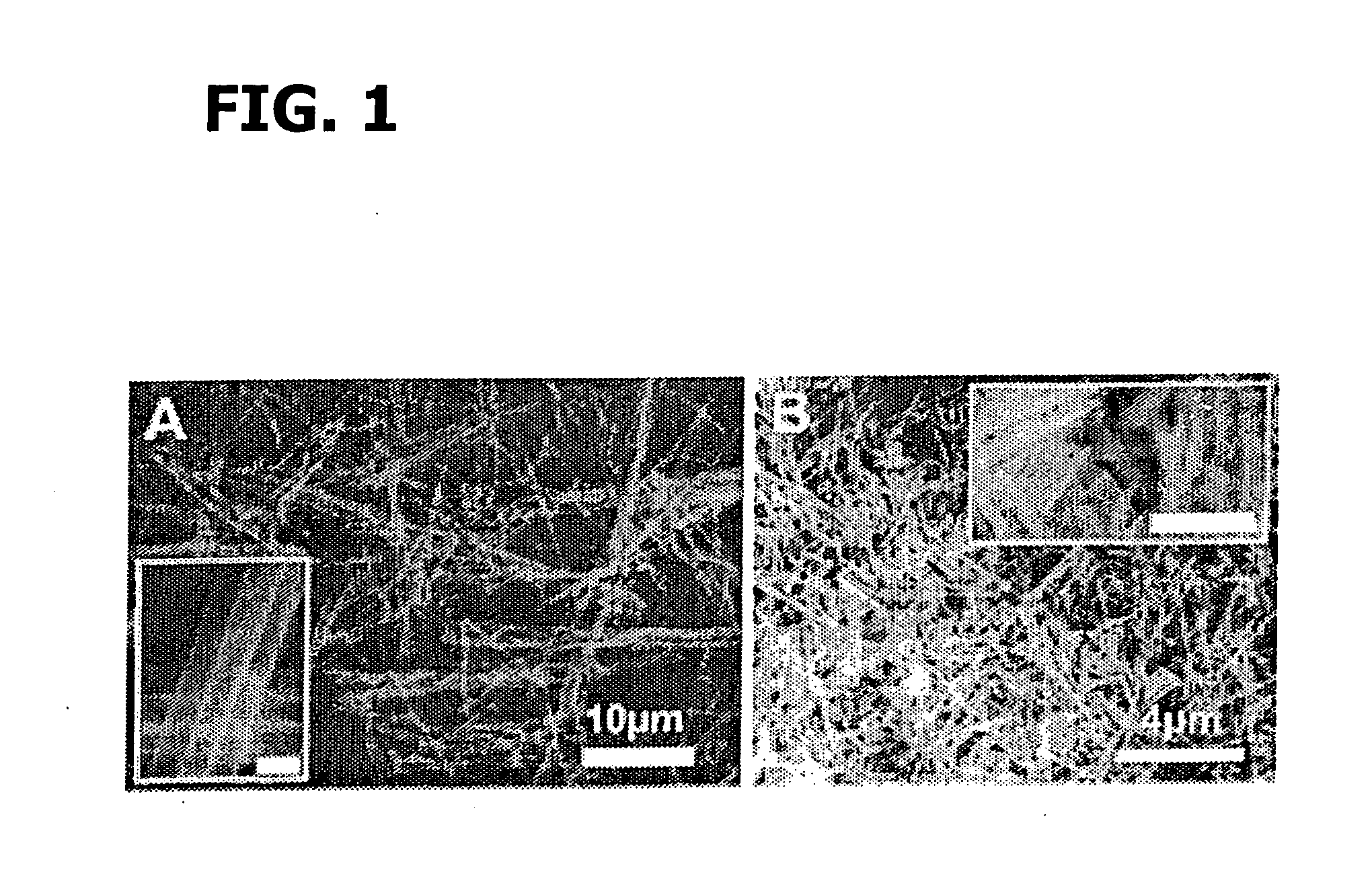

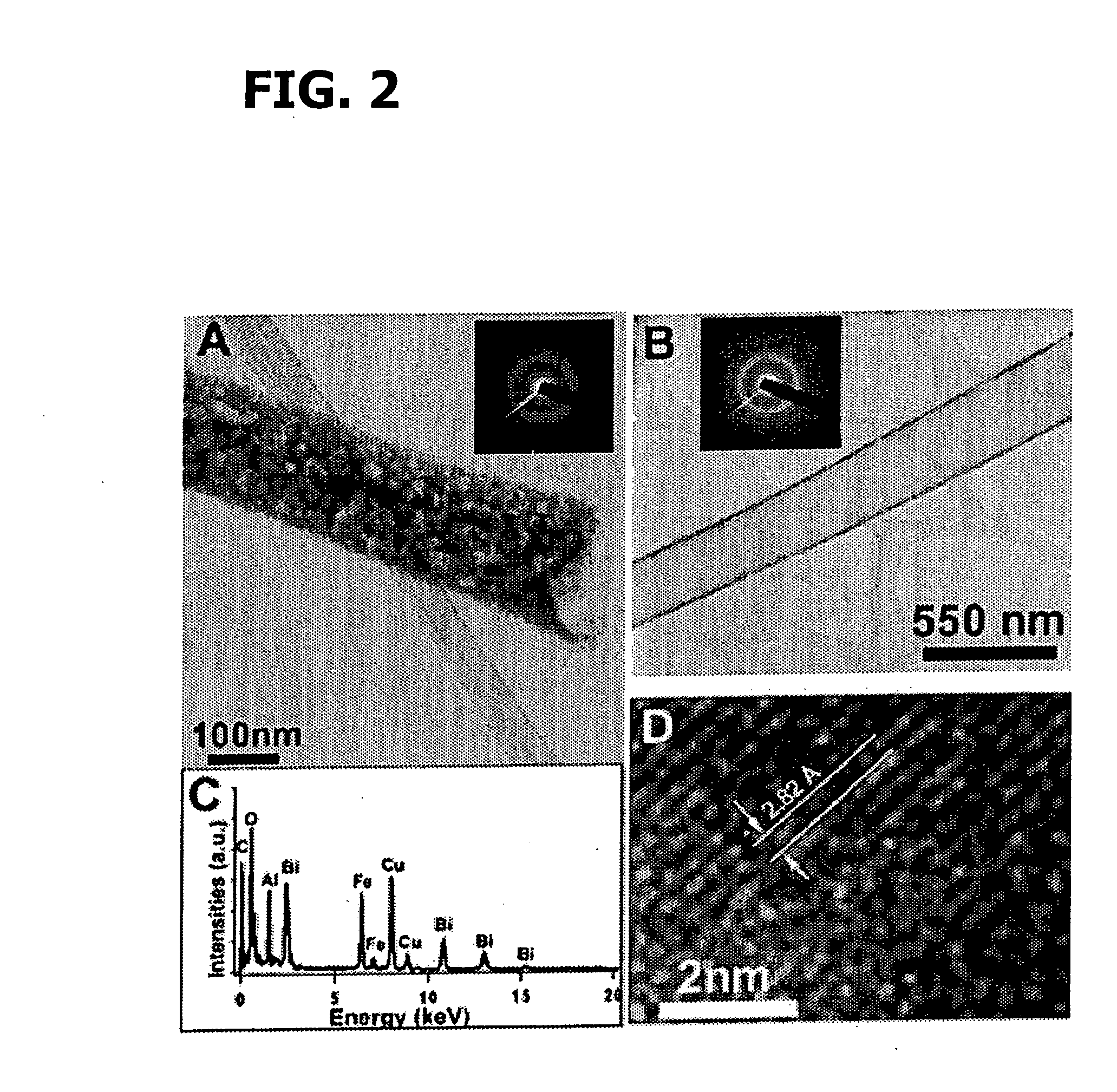

InactiveUS20070138459A1Suitable for preparationFrom gel stateAlkaline earth titanatesNanostructureDislocation

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Ti, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

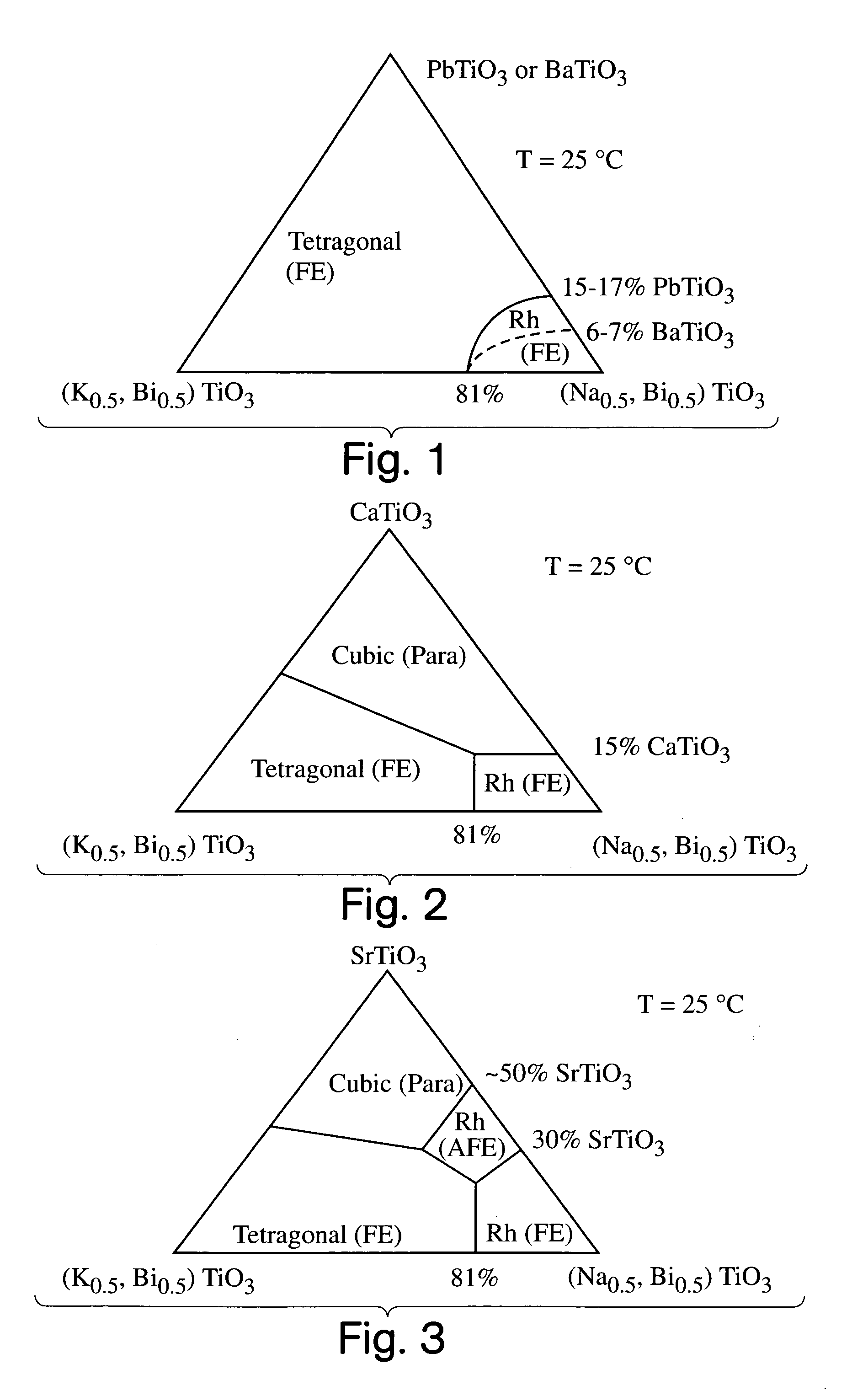

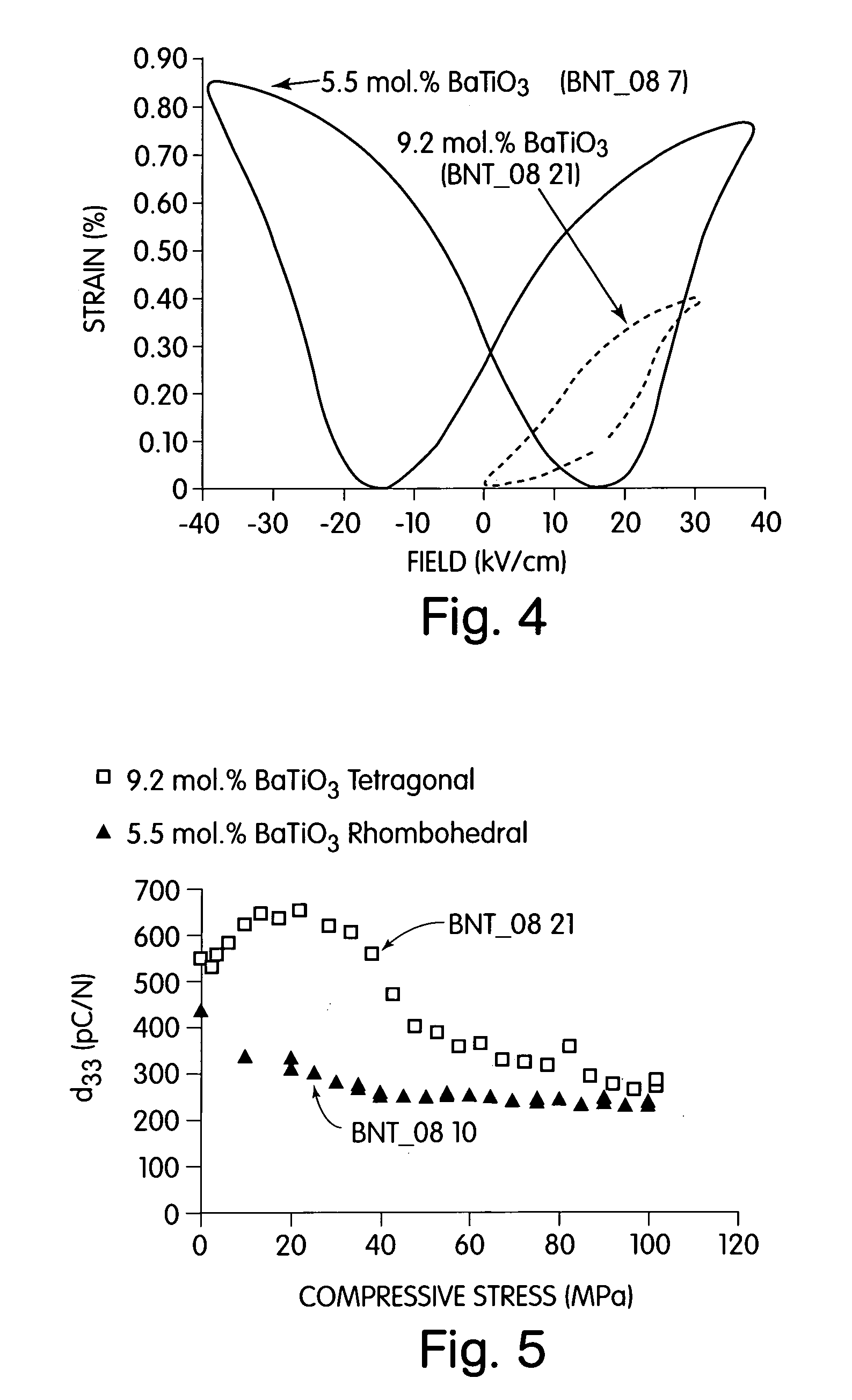

Electromechanical actuators

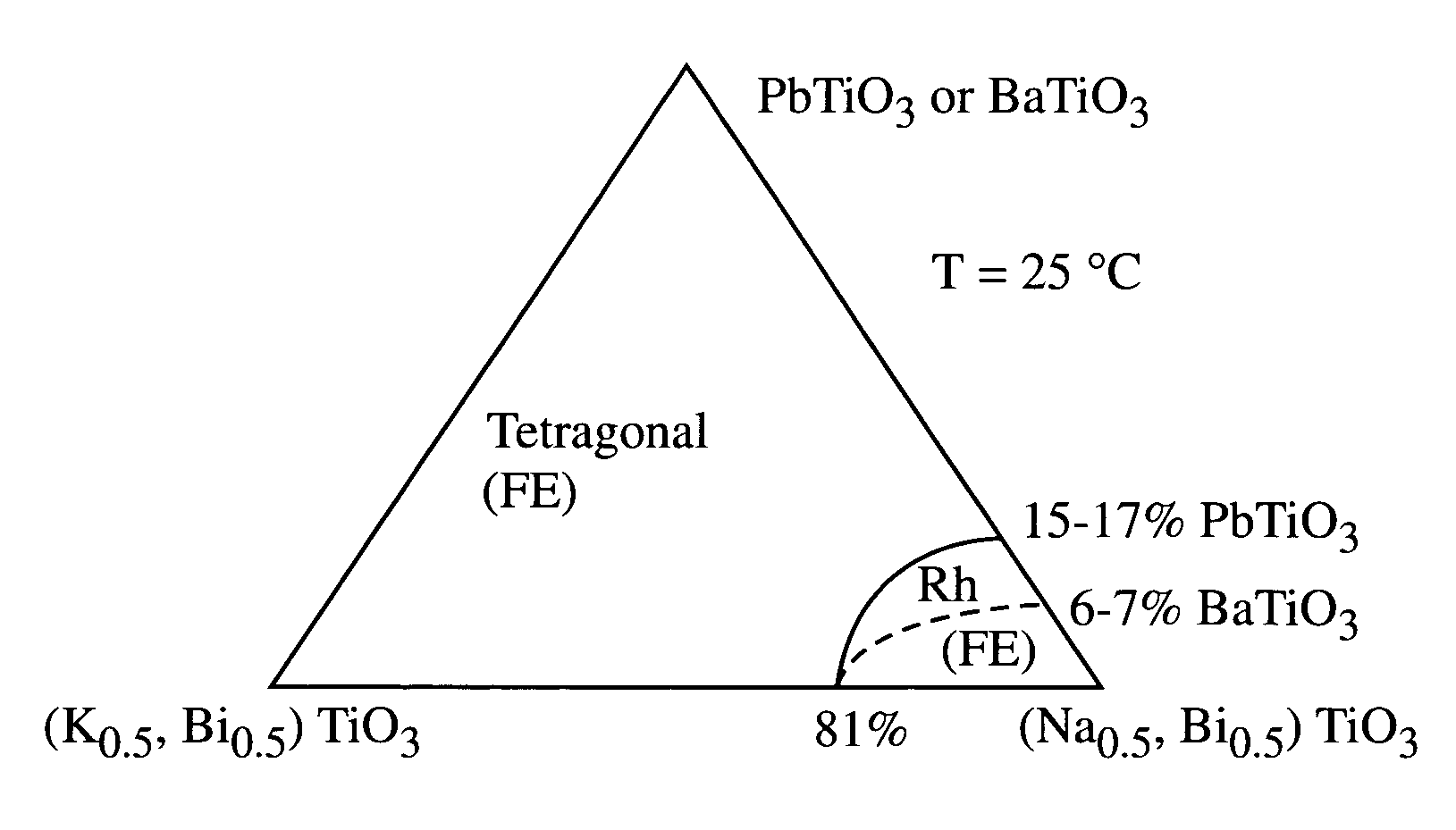

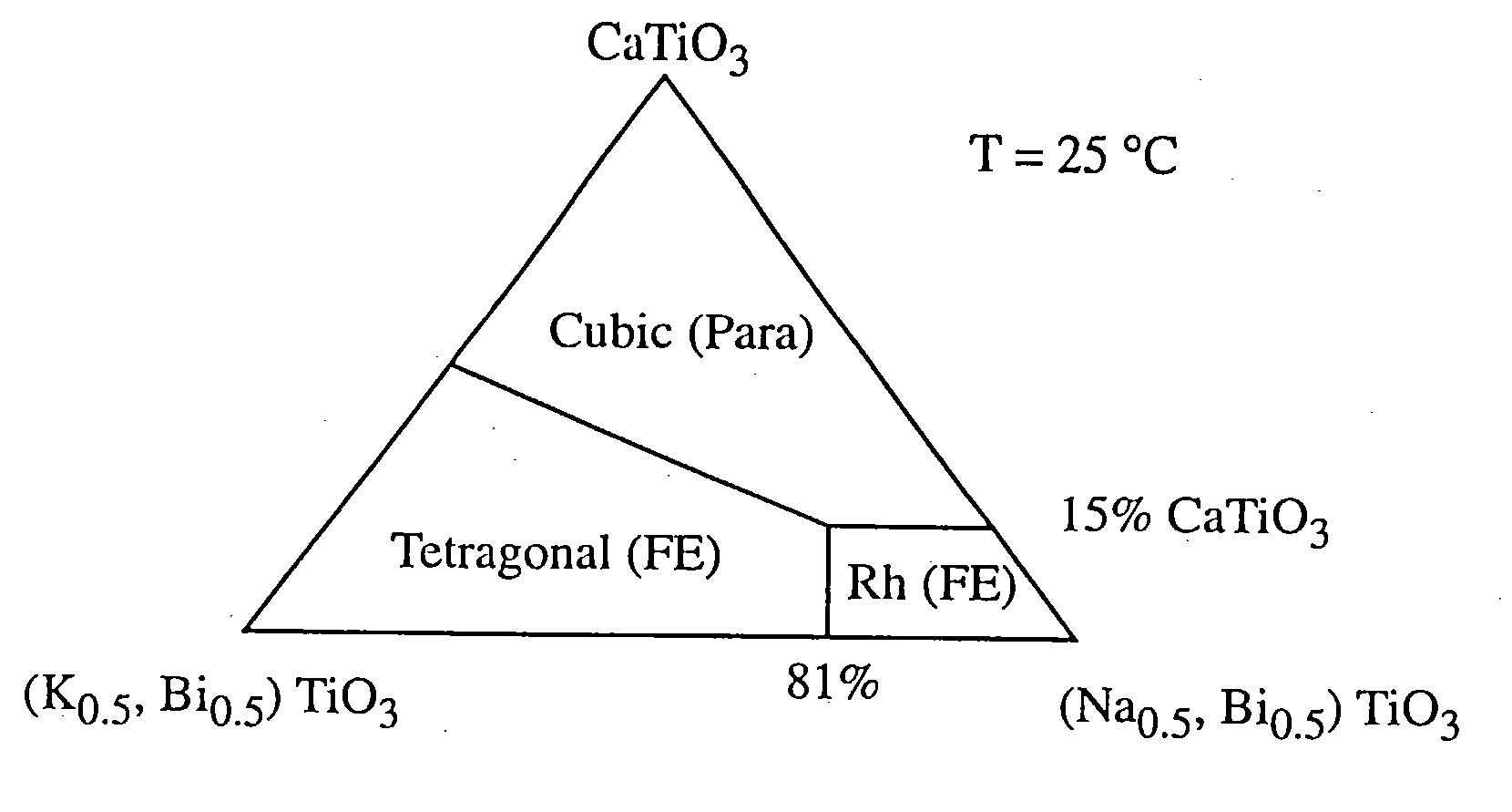

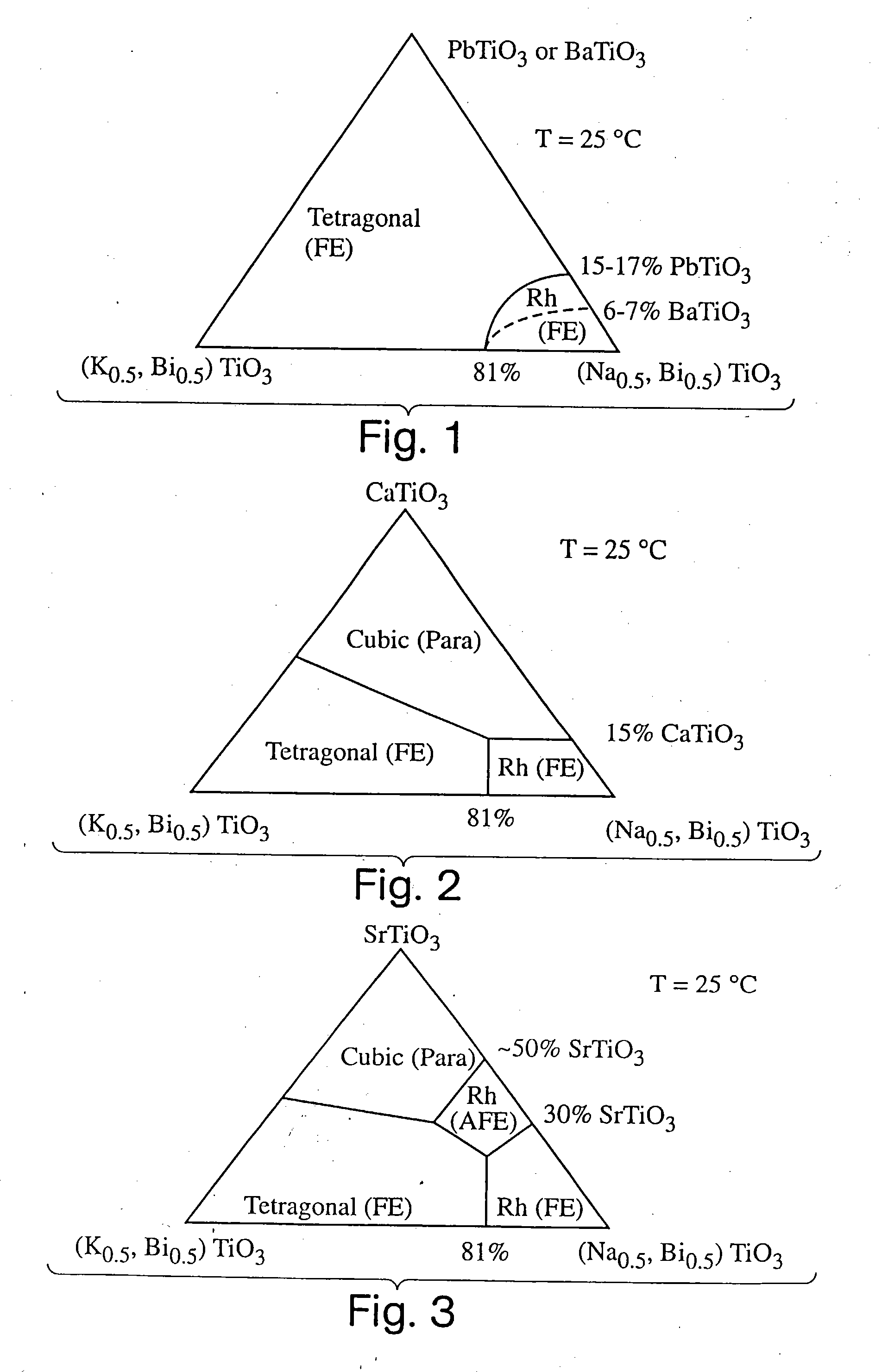

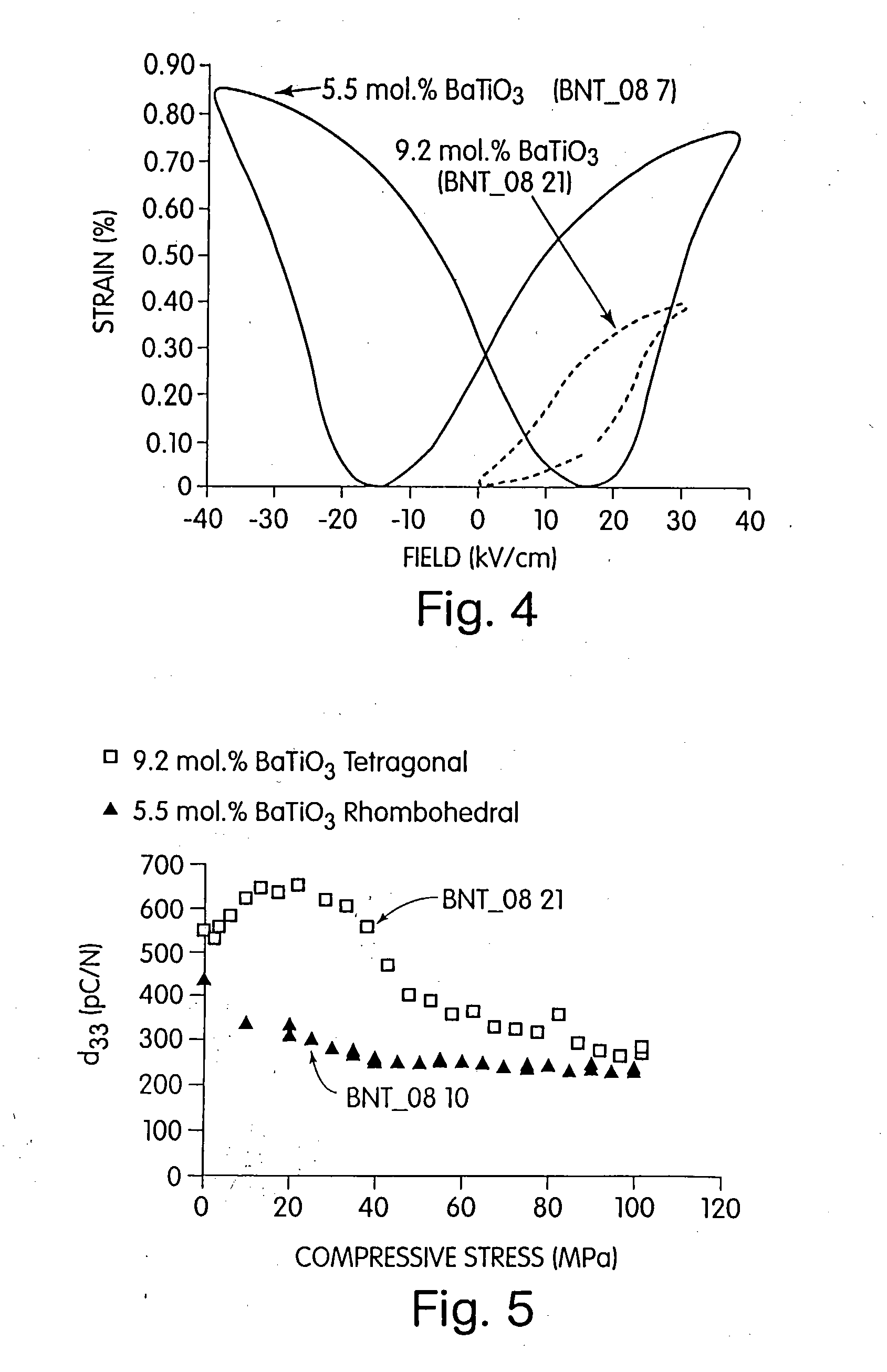

InactiveUS7090785B2Increased doping of BaTiOImprove propertiesAlkaline earth titanatesLighting support devicesElectroactive materialsMaterials science

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

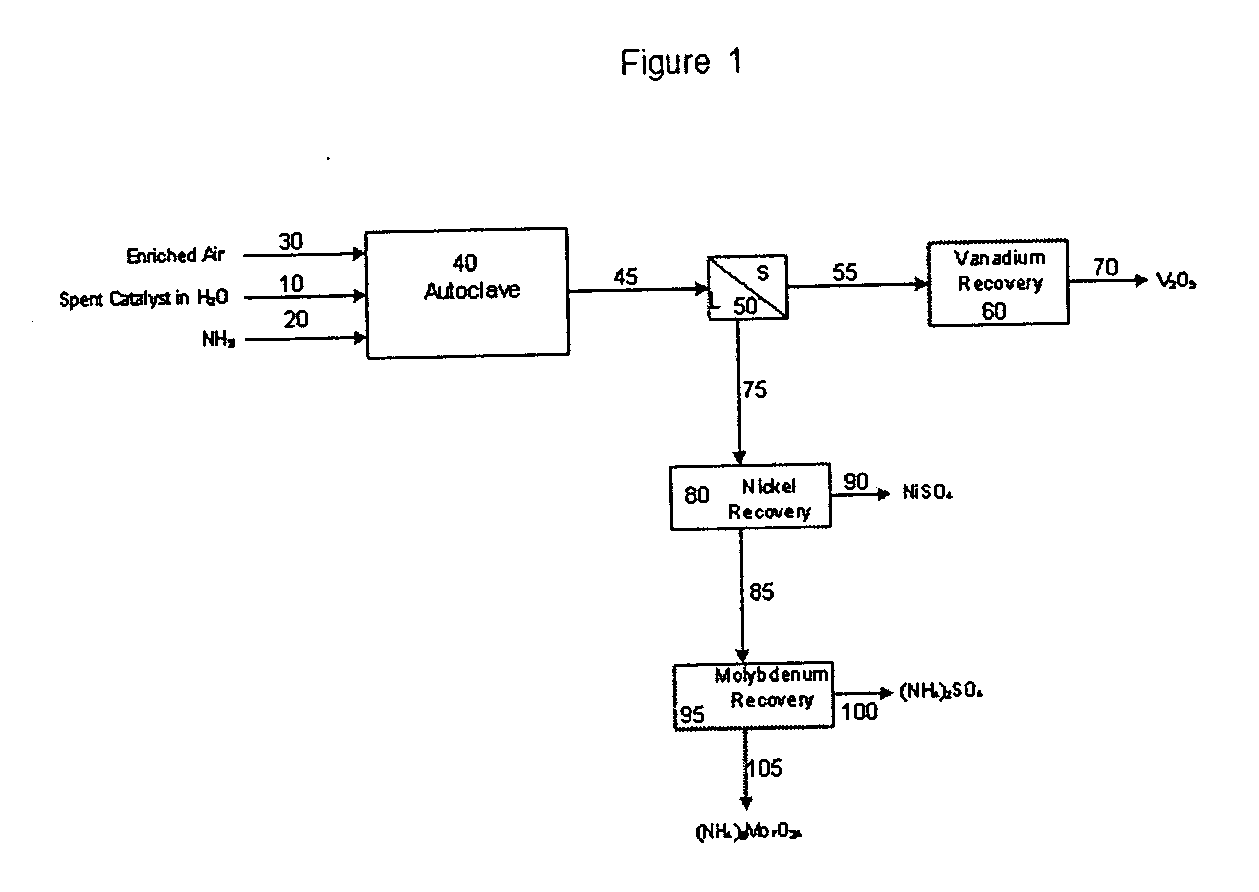

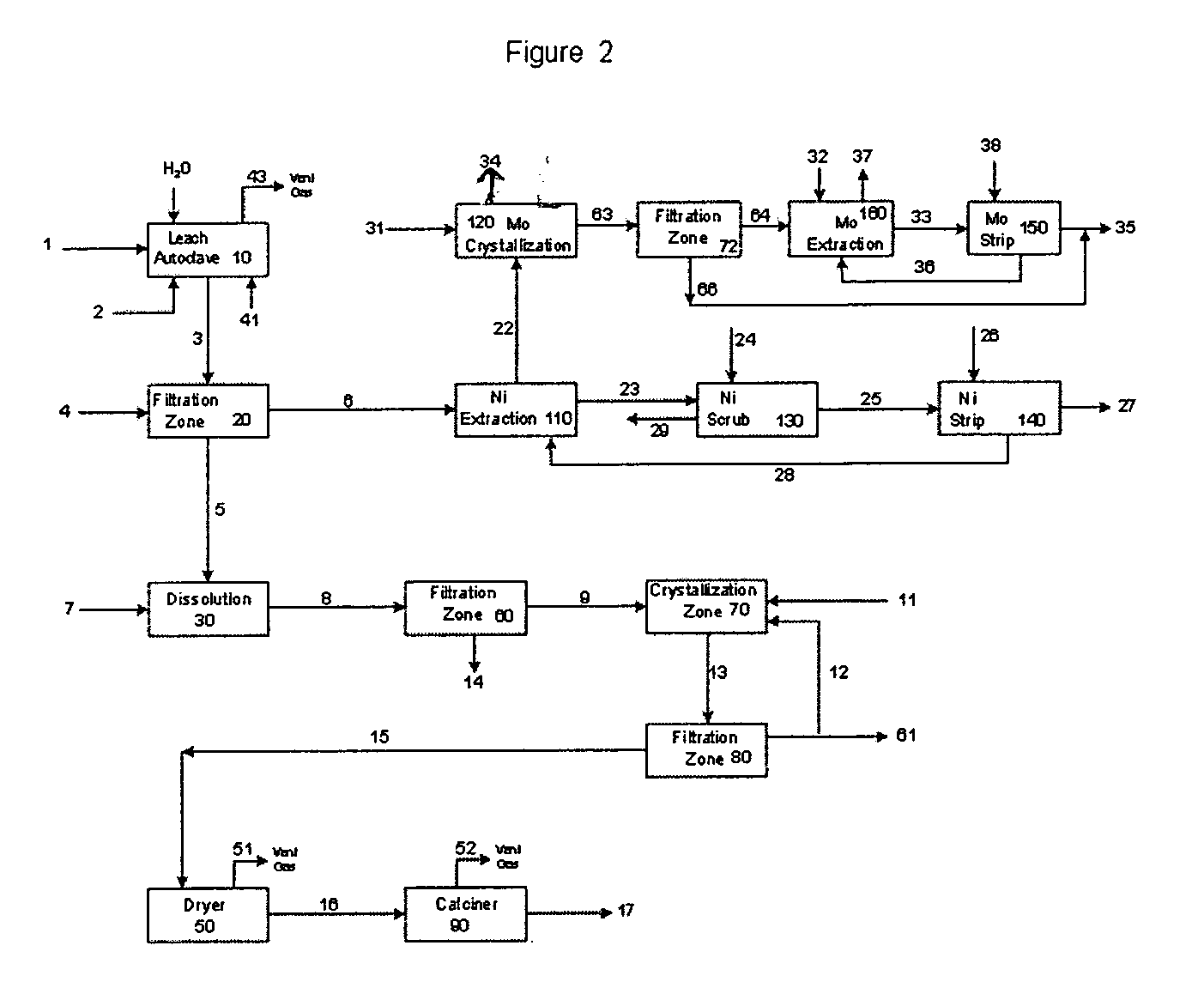

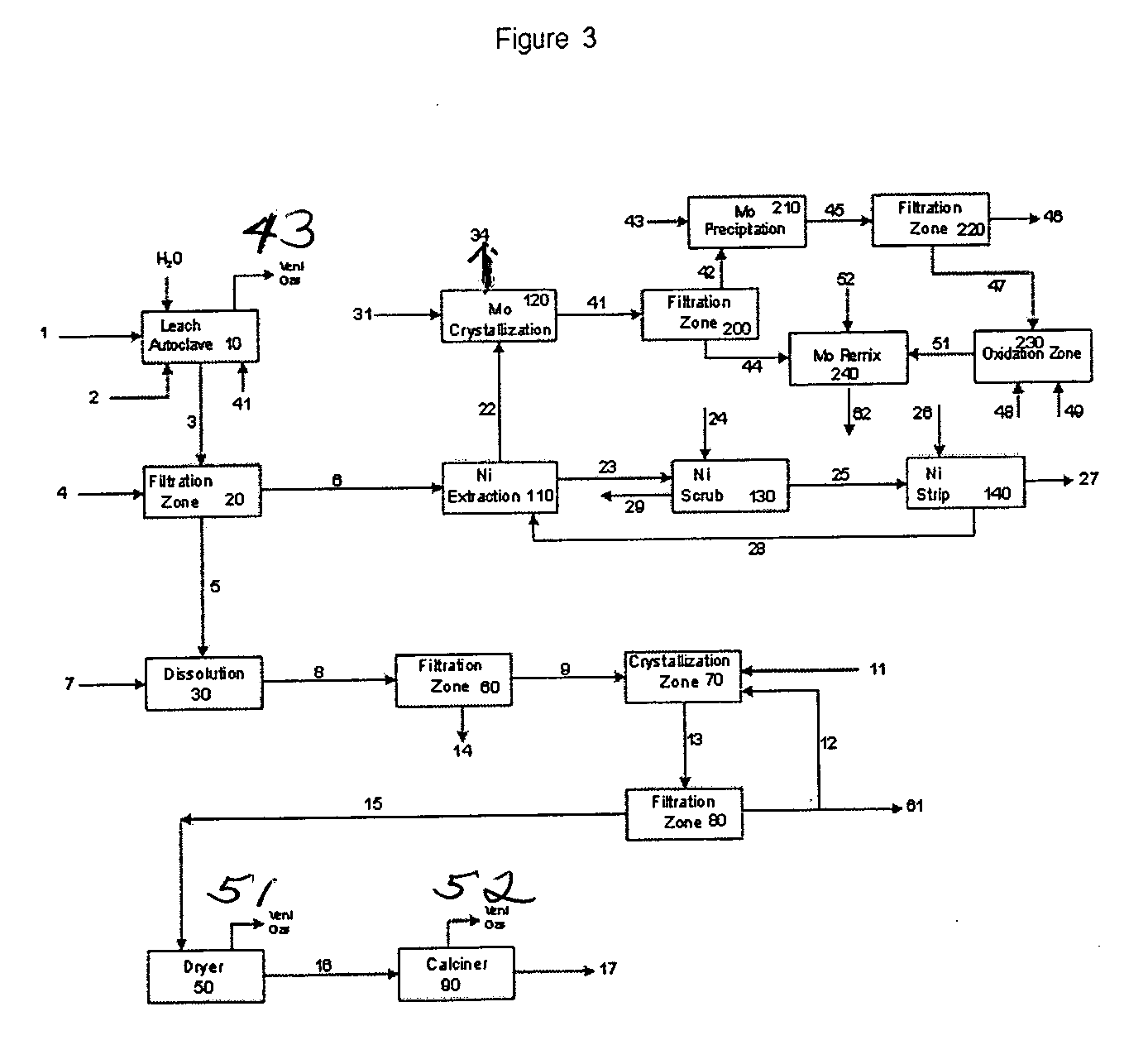

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

Synthesis of bis(fluorosulfonyl)imide

The present invention provides methods for producing bis(fluorosulfonyl) compounds of the formula:F—S(O)2—Z—S(O)2—F Iby contacting a nonfluorohalide compound of the formula:X—S(O)2—Z—S(O)2—Xwith bismuth trifluoride under conditions sufficient to produce the bis(fluorosulfonyl) compound of Formula I, where Z and X are those defined herein.

Owner:SES HLDG PTE LTD

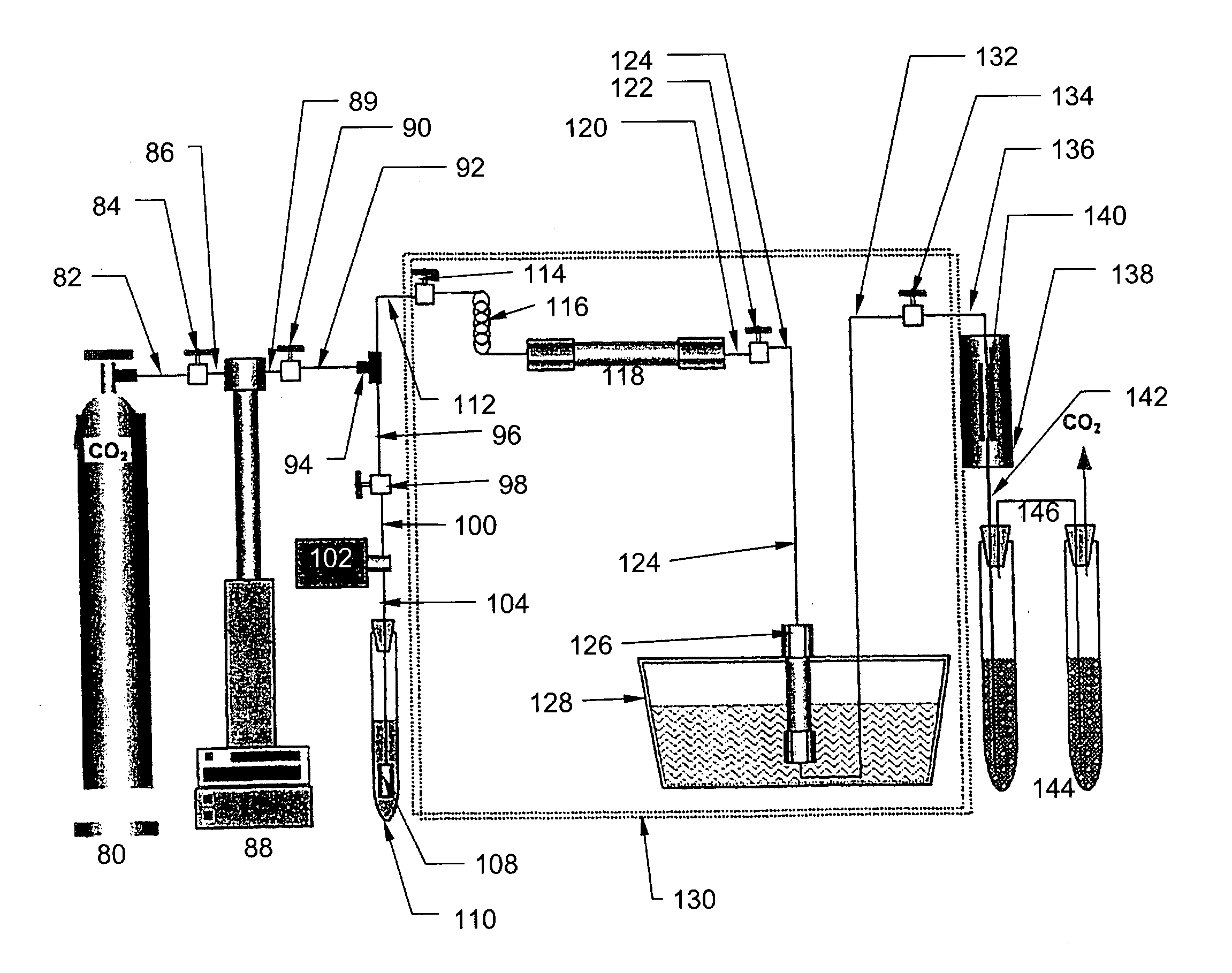

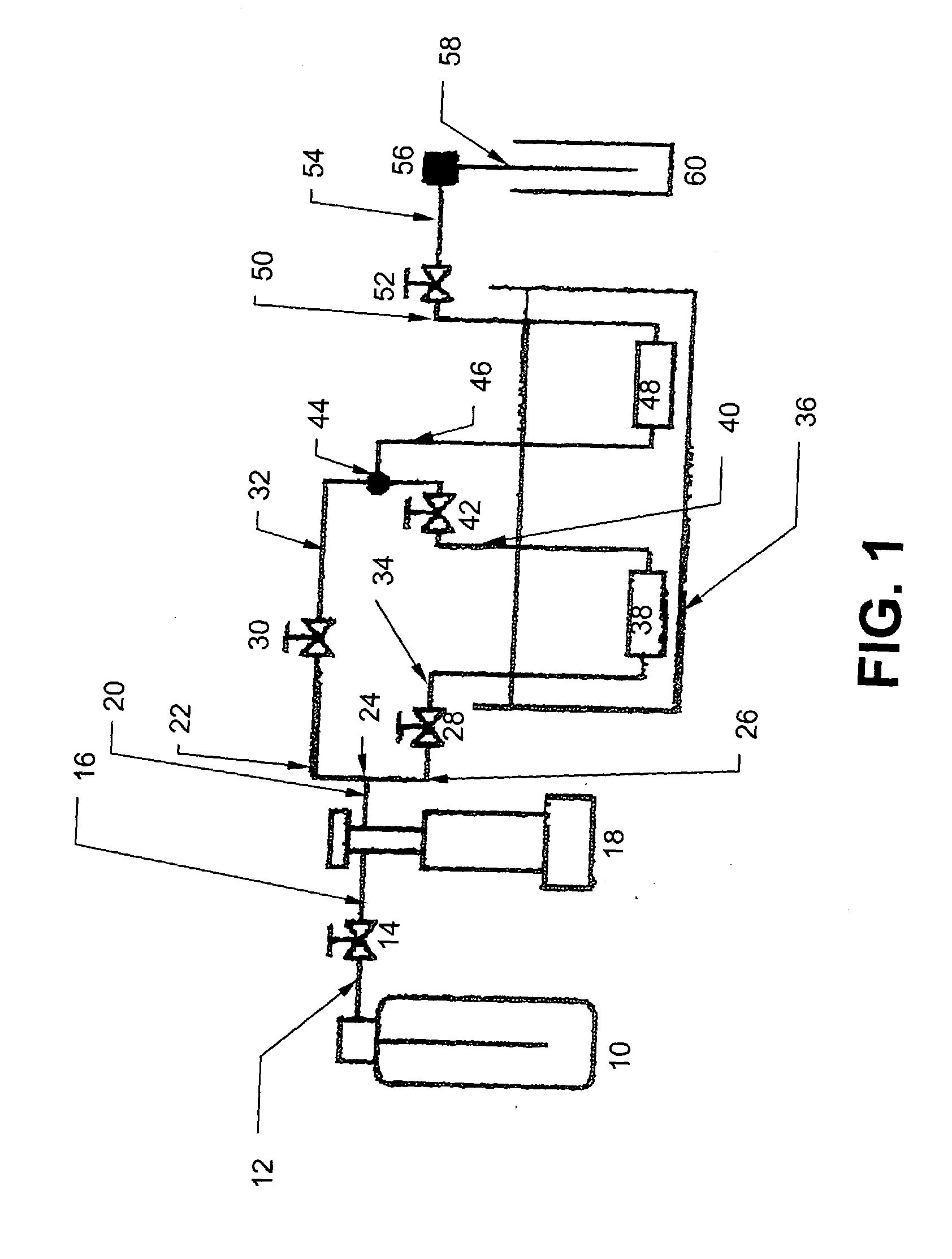

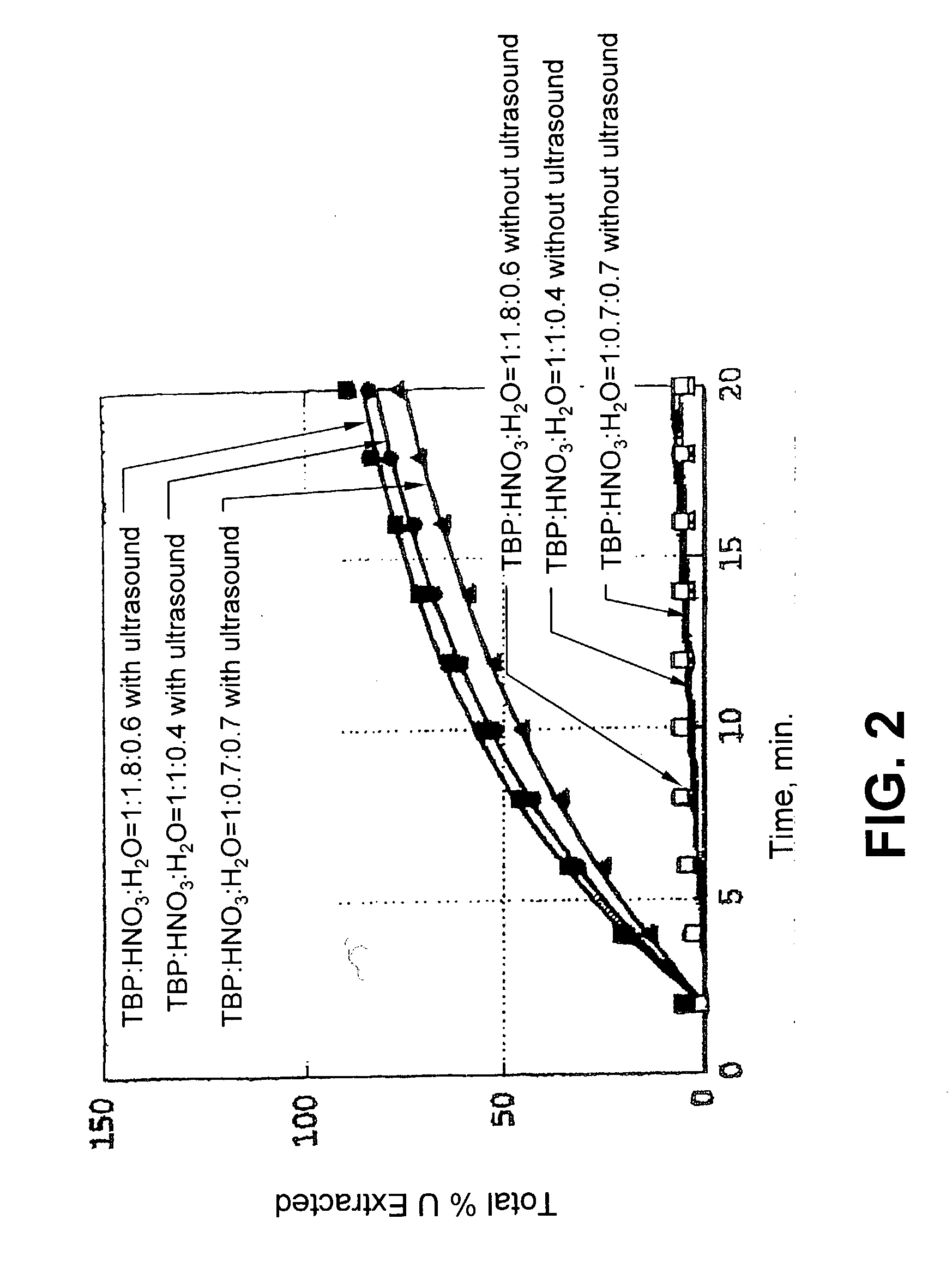

Ultrasound enhanced process for extracting metal species in supercritical fluids

InactiveUS20030183043A1Enhances rate and efficiencyReduce probabilitySolid sorbent liquid separationGold compoundsUranium oxidePresent method

Improved methods for the extraction or dissolution of metals, metalloids or their oxides, especially lanthanides, actinides, uranium or their oxides, into supercritical solvents containing an extractant are disclosed. The disclosed embodiments specifically include enhancing the extraction or dissolution efficiency with ultrasound. The present methods allow the direct, efficient dissolution of UO2 or other uranium oxides without generating any waste stream or by-products.

Owner:NAGOYA INDUSTRIAL SCIENCE RESEARCH INST +1

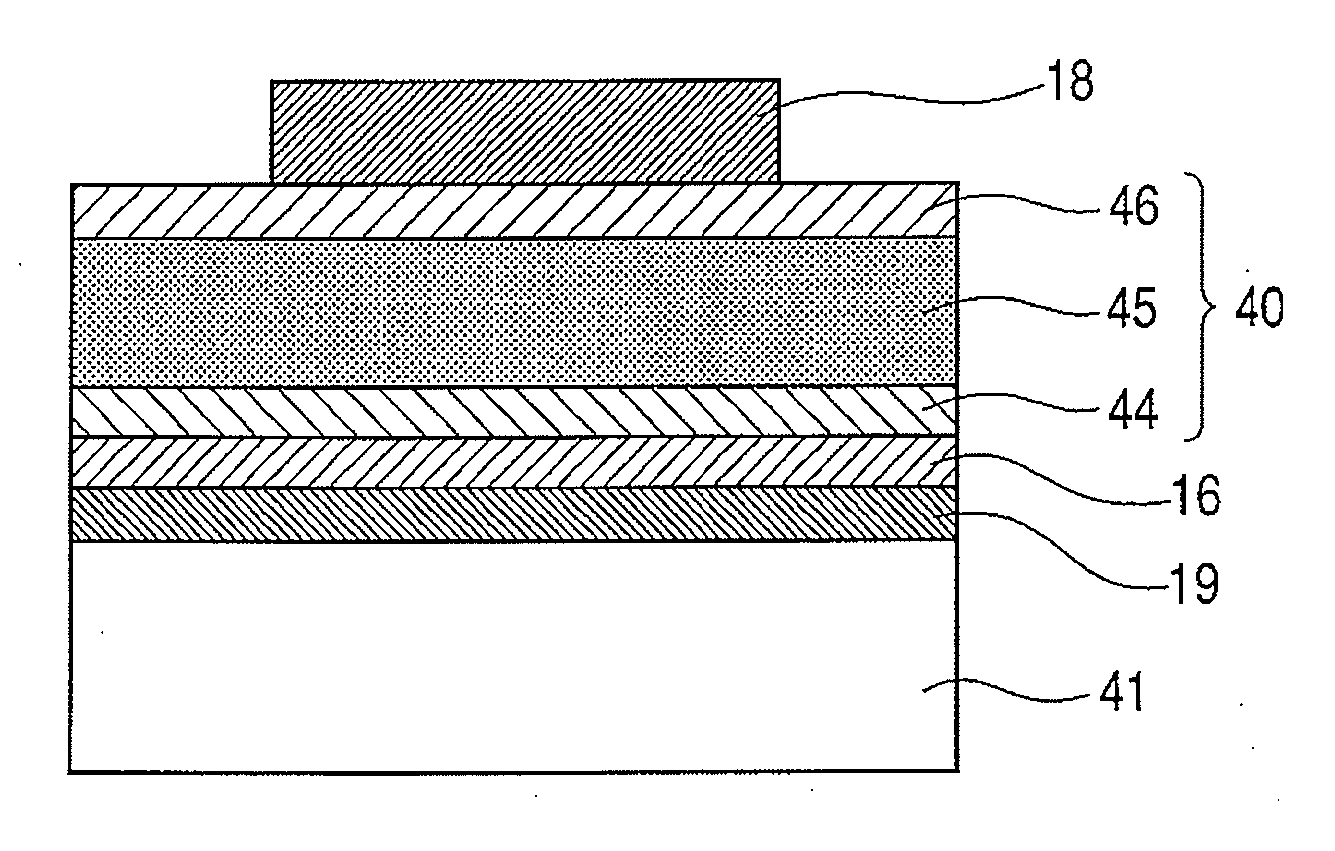

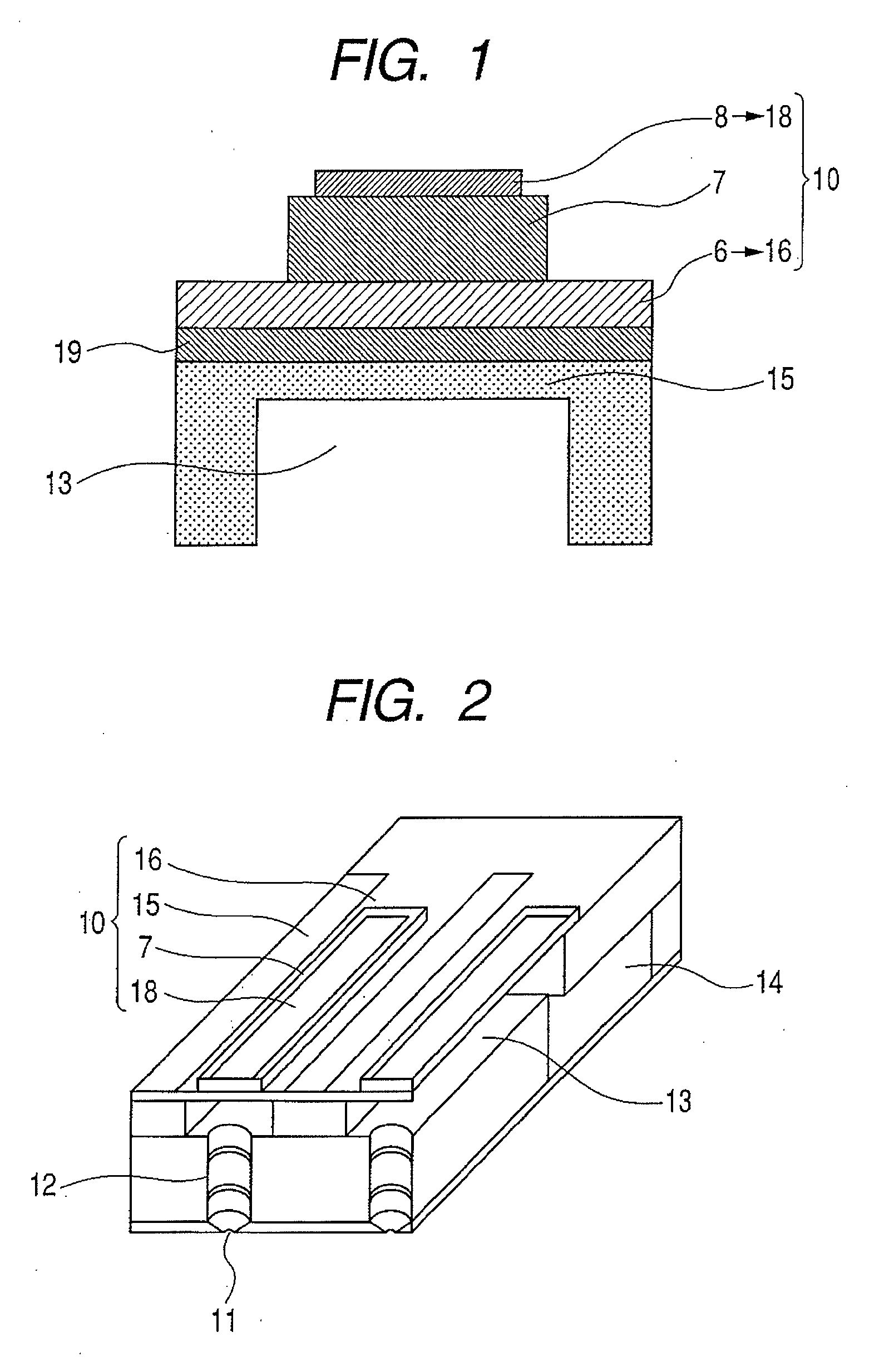

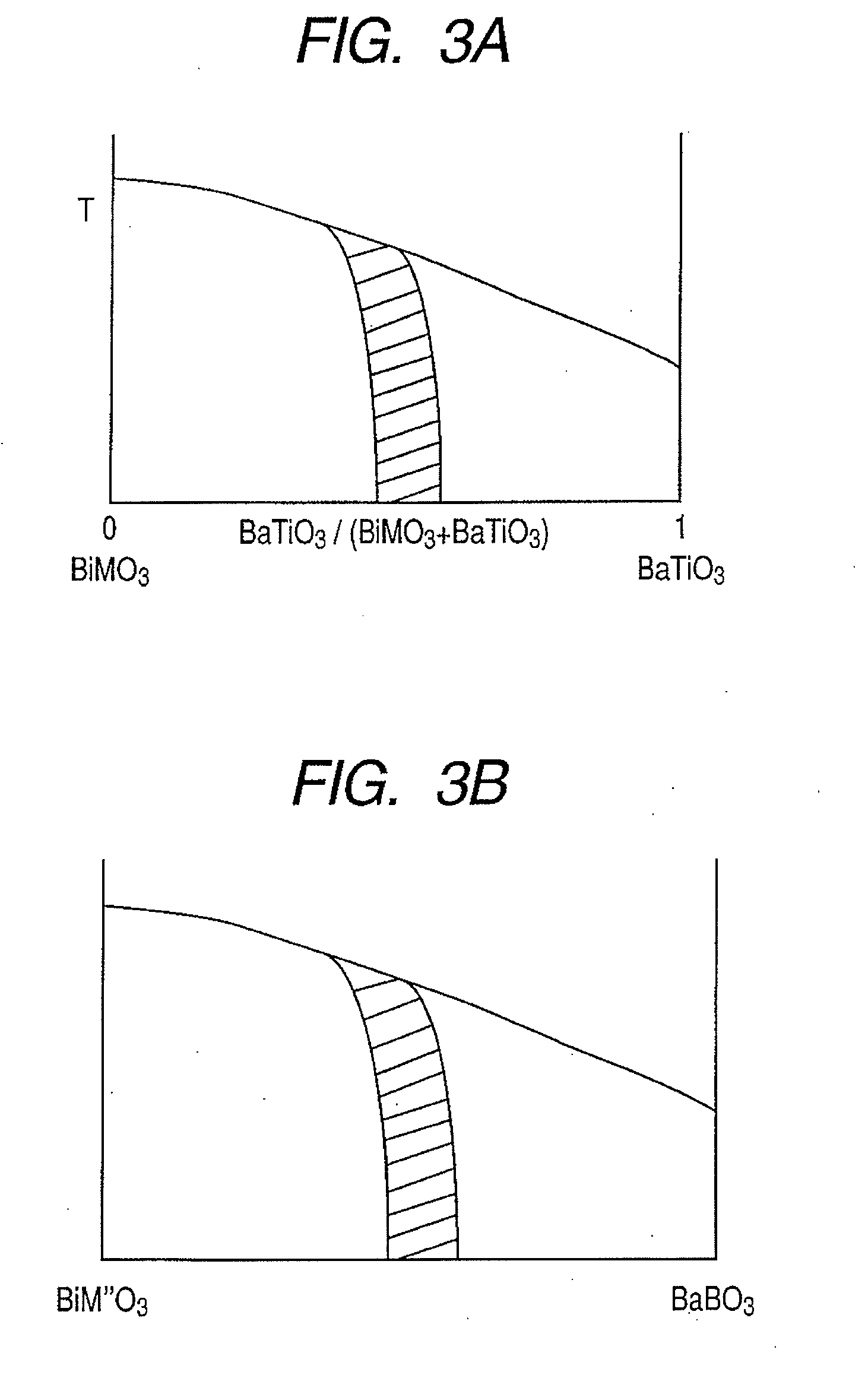

Piezoelectric element, and liquid jet head and ultrasonic motor using the piezoelectric element

InactiveUS20080067898A1Improve featuresInking apparatusPiezoelectric/electrostriction/magnetostriction machinesLiquid jetUltrasonic motor

There is disclosed a piezoelectric element having, on a substrate, a piezoelectric body and a pair of electrodes which come in contact with the piezoelectric body, wherein the piezoelectric body consists of a perovskite type oxide represented by the following formula (1):(Bi,Ba)(M,Ti)O3 (1)in which M is an atom of one element selected from the group consisting of Mn, Cr, Cu, Sc, In, Ga, Yb, Al, Mg, Zn, Co, Zr, Sn, Nb, Ta, and W, or a combination of the atoms of the plurality of elements.

Owner:CANON KK

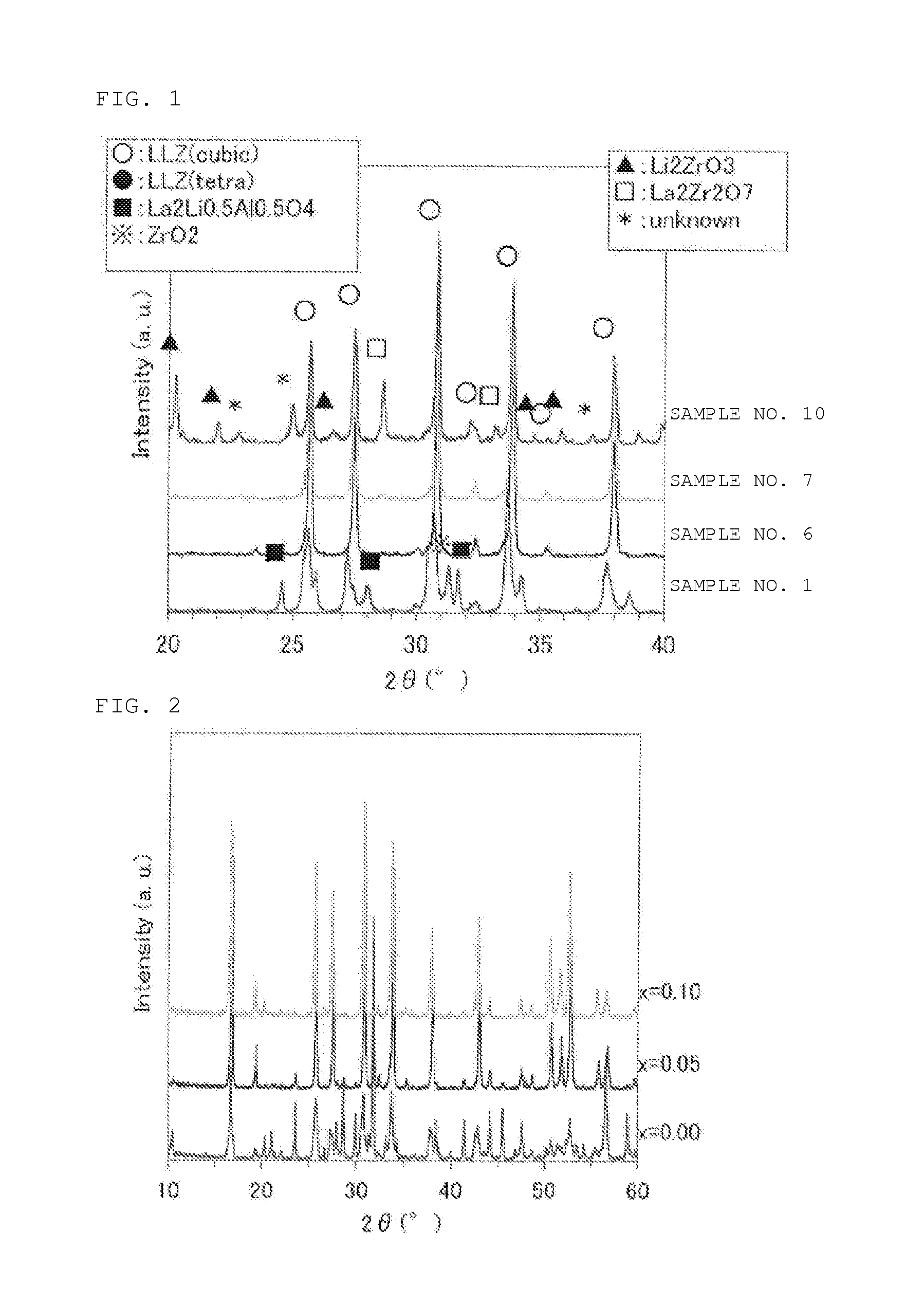

Material for solid electrolyte

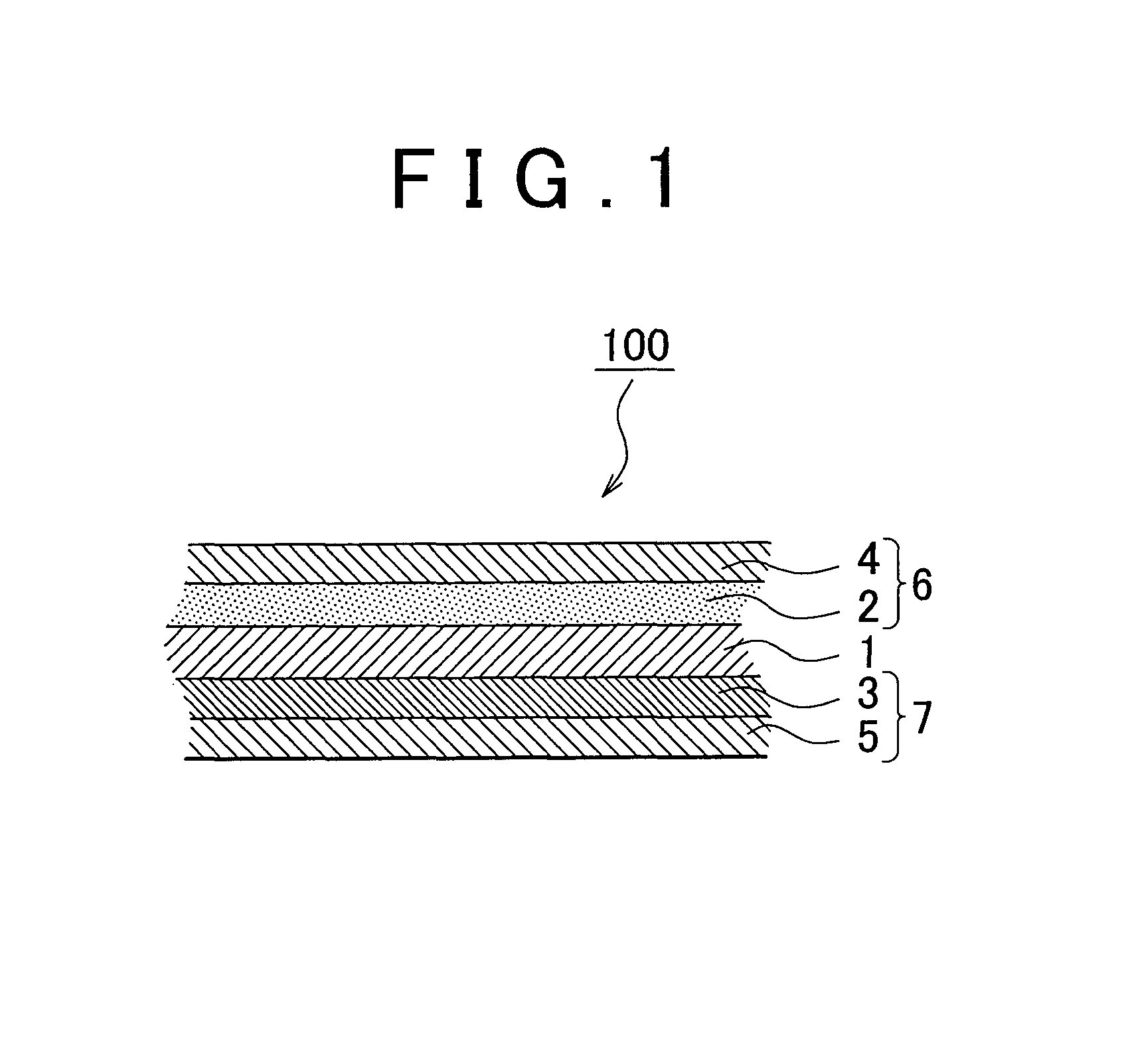

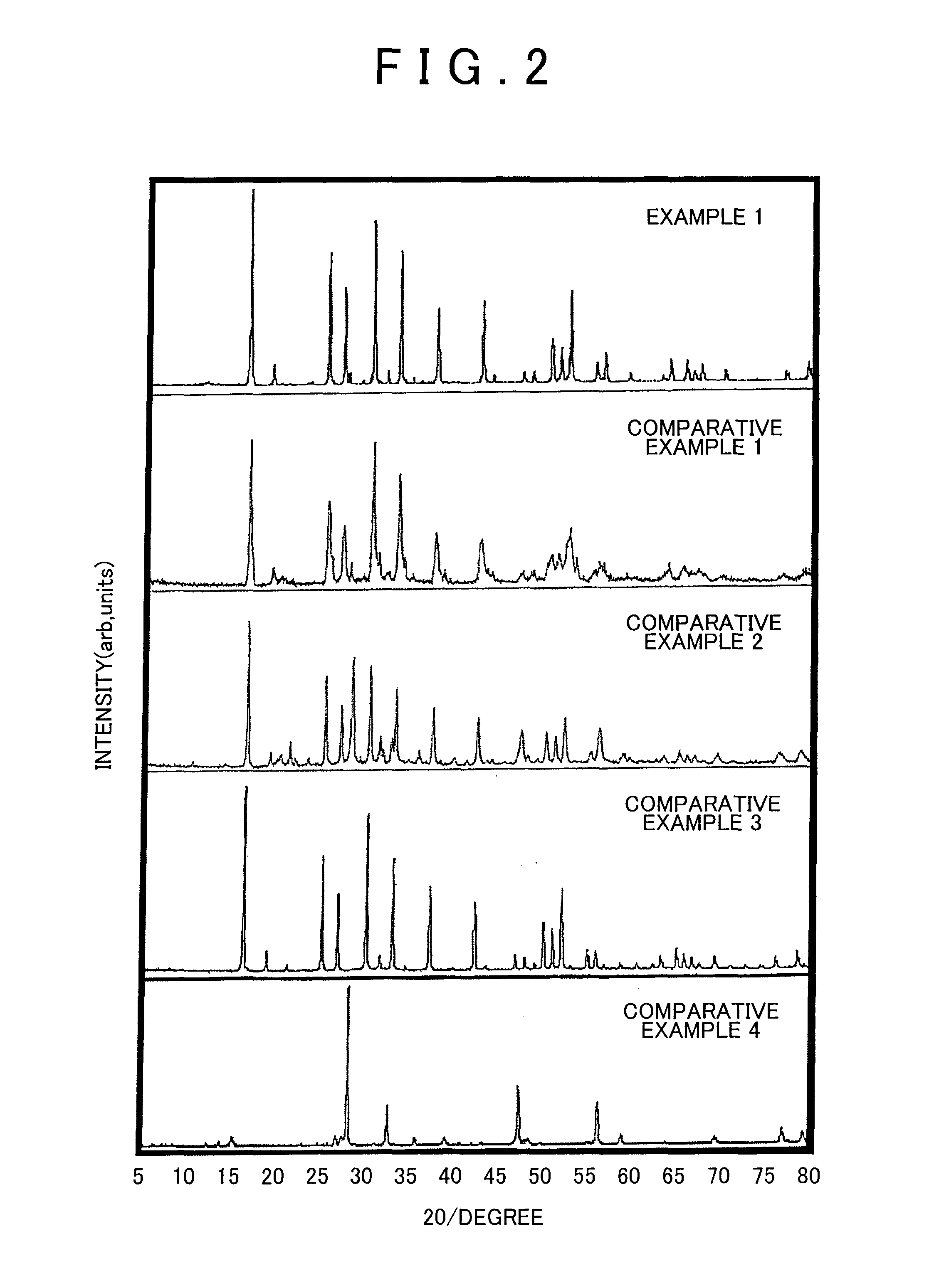

ActiveUS20140186720A1Suppress and prevent reactionShort timeFinal product manufactureZirconium compoundsSolid state electrolyteCrystal structure

A material capable of producing a sintered body of cubic system garnet type Li7La3Zr2O12 as a solid electrolyte having specified ion conductivity by firing at relatively low temperature in short time. The material for the solid electrolyte is an oxide containing Li, La, Zr and Bi, and the oxide has a cubic system garnet crystal structure where La sites are partly or entirely substituted by Bi.

Owner:MURATA MFG CO LTD

Thermoelectric material and thermoelectric converting element using the same

Compounds are expressed by general formula of AxBC2-y where 0<=x<=2 and 0<=y<1, and have CdI2 analogous layer structures; A-site is occupied by at least one element selected from the group consisting of Li, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, Ru, Rh, Pd, Ag, Cd, Hf, Ta, W, Re, Ir, Pt, Au, Sc, rare earth elements containing Y, B, Al, Ga, In, Tl, Sn, Pb and Bi; B-site is occupied by at least one element selected from the group consisting of Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, W, Ir, and Sn; C-site is occupied by at least one element selected from the group consisting of S, Se and Te; the compounds exhibit large figure of merit so as to be preferable for thermoelectric generator / refrigerator.

Owner:NEC CORP

Electromechanical actuators

InactiveUS20050109263A9Improve the overall coefficientImprove electromechanical performanceAlkaline earth titanatesLighting support devicesMaterials science

A perovskite compound of the formula, (Na1 / 2Bi1 / 2)1-xMx(Ti1-yM′y)O3±z, where M is one or more of Ca, Sr, Ba, Pb, Y, La, Pr, Nd, Sm, Eu, Gd, Th, Dy, Ho, Er, Tm, Yb and Lu; and M′ is one or more of Zr, Hf, Sn, Ge, Mg, Zn, Al, Sc, Ga, Nb, Mo, Sb, Ta, W, Cr, Mn, Fe, Co and Ni, and 0.01<x<0.3, and 0.01<y<0.3, and z<0.1 functions as an electromechanically active material. The material may possess electrostrictive or piezoelectric characteristics.

Owner:MASSACHUSETTS INST OF TECH

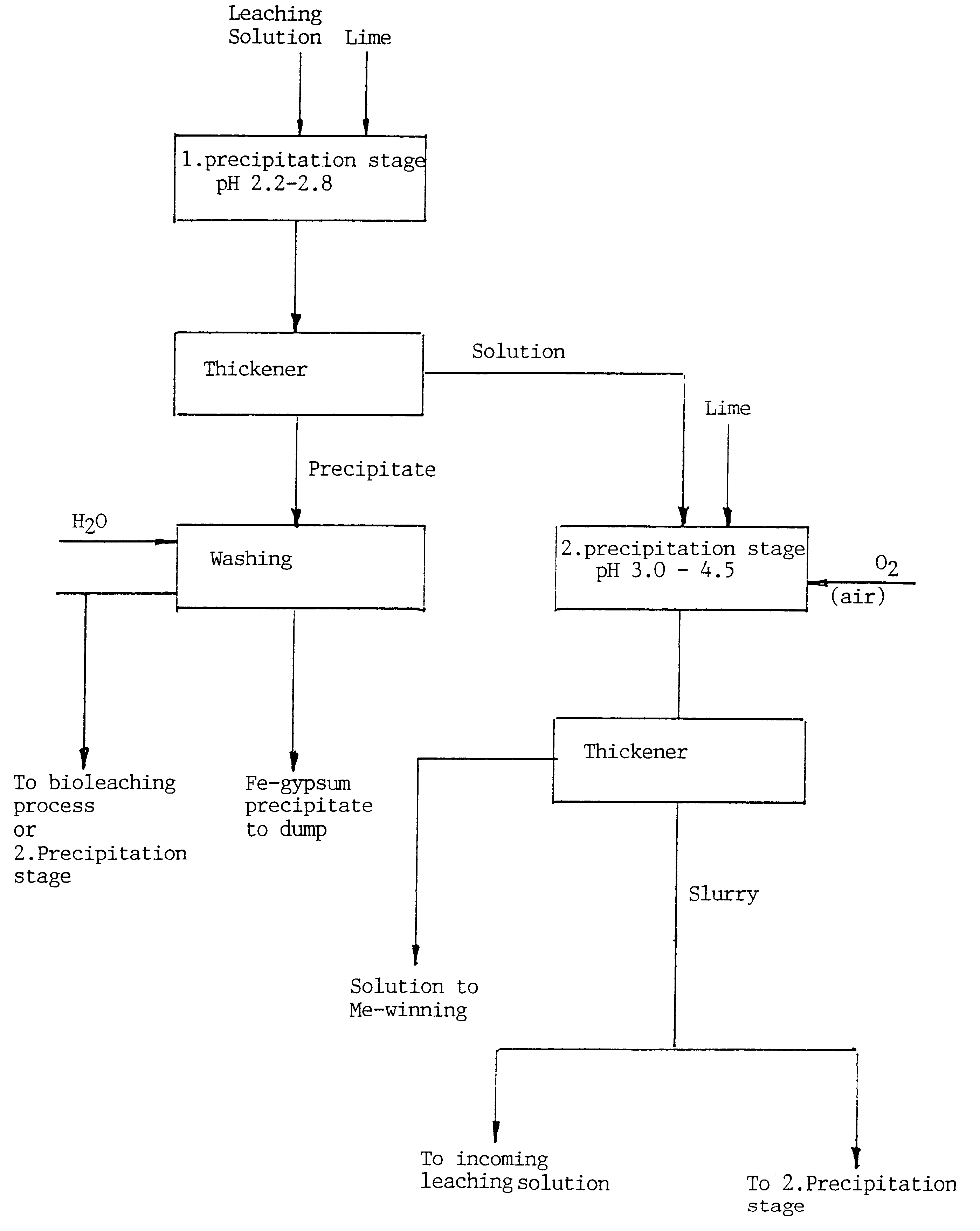

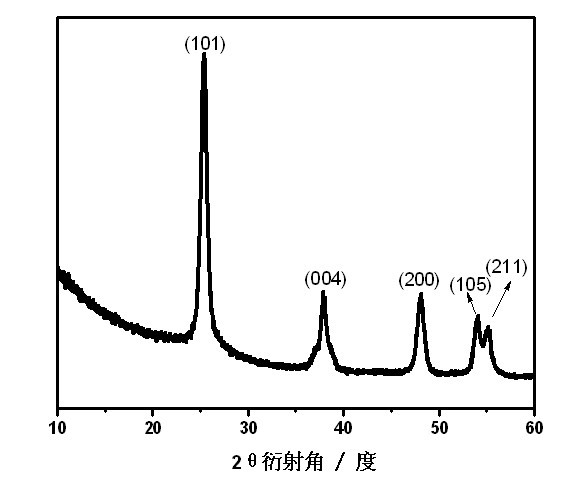

Method of purifying acid leaching solution by precipitation and oxidation

A method of purifying an acid leaching solution obtained by processing hydrometallurgically material that contains valuable metals and also Fe3+ and Fe2+, and possibly also arsenic in solution. The major part of the Fe3+-content and the arsenic is precipitated out in a first stage, by adding pH-elevating agent to the leaching solution. The precipitate formed in the first precipitation stage is extracted from the solution and removed from the process. The solution is oxidised in a second precipitation stage while adding a further pH-elevating agent for oxidation of Fe2+ and precipitation of resultant Fe3+ and any arsenic still present. The resultant precipitate and any residual solid pH-elevating agent are then extracted from the solution and returned in the process to more acid conditions, and the thus purified solution is then processed to win its valuable metal content in a manner per se. The pH is suitably raised during the first stage to a value in the range of 2.2-2.8, and in the second stage to a value in the range of 3.0-4.5. The oxidising process in the second stage is suitably effected by injecting air into the solution and by preferably using lime or limestone as the pH-elevating agent. Solid material extracted from the second stage is returned beneficially to the first stage. Some of the solid material taken from each precipitation stage can be recycled within respective stages as a nucleating agent.

Owner:BOLIDEN MINERAL

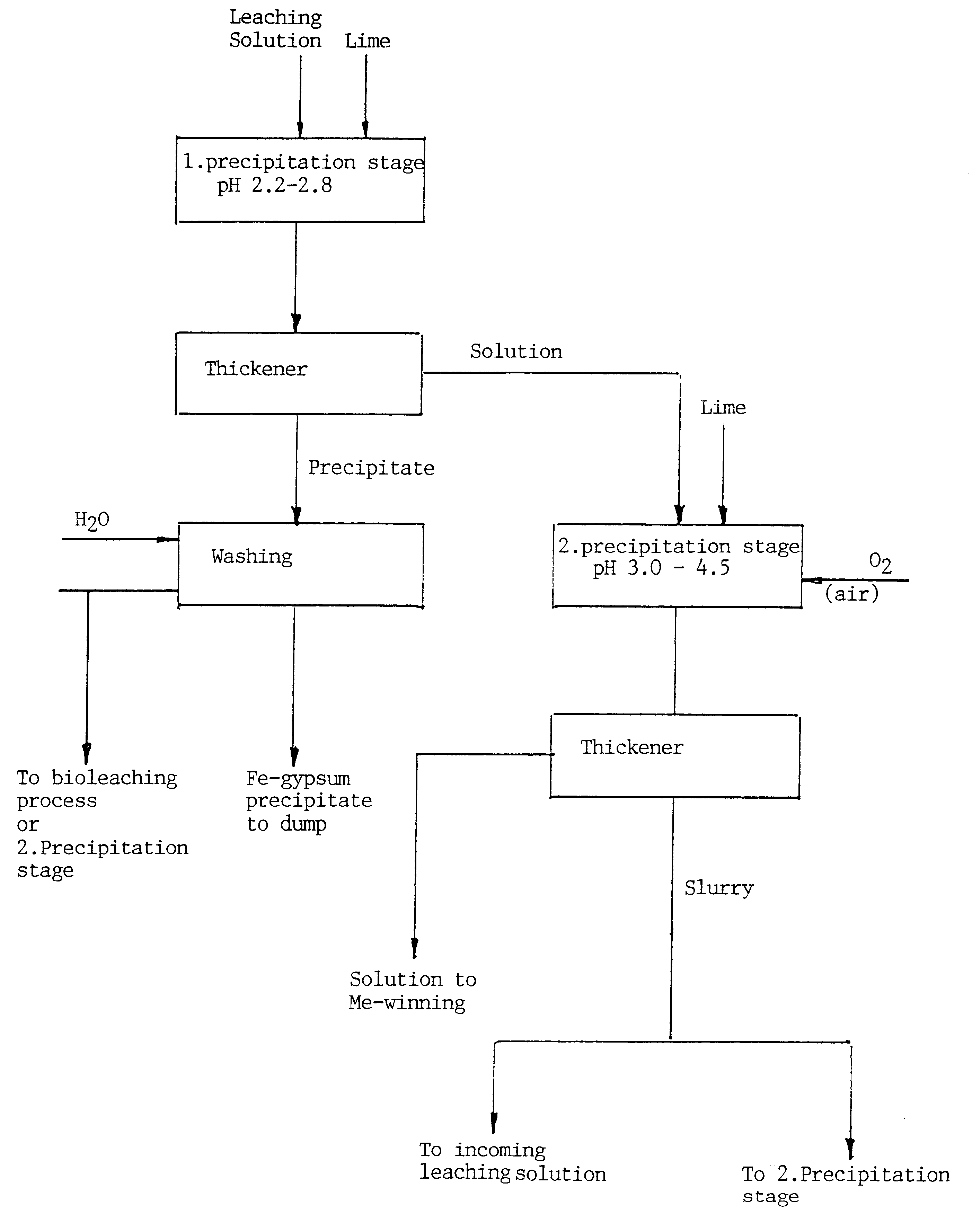

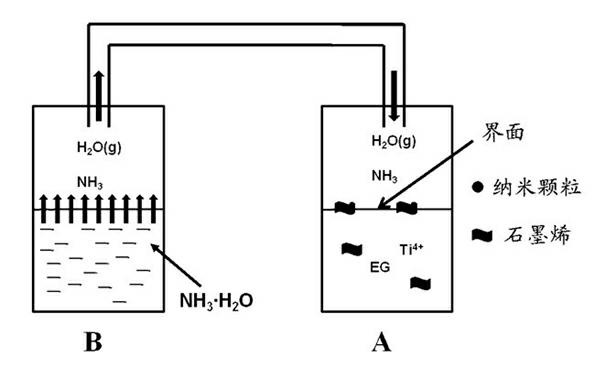

Preparation method of nitrogen doped graphene/ metal oxide nanometer composite material

ActiveCN102602917ASimple processLess investmentMaterial nanotechnologyCarbon compoundsNitrogenNitrogen doped graphene

The invention discloses a preparation method of a nitrogen doped graphene / metal oxide nanometer composite material. The preparation method comprises the following steps of: weighing graphene and metal salt the cation of which is trivalent or quadrivalent to be added in a dispersant, and then carrying out ultrasonic dispersion to obtain mixed liquor; (2), reacting the mixed liquor obtained in the step (1) with alkaline air on a gas-liquid interface for 3-12hours at the temperature of 60-200 DEG C, cooling, centrifuging, washing a precipitate and drying to obtain powder; and (3) introducing the alkaline air or a mixed gas of the alkaline air and inert gas, maintaining the powder to be at the constant temperature of 600-900 DEG C for 2-6 hours, and cooling to room temperature to obtain the nitrogen doped graphene / metal oxide nanometer composite material. According to the invention, the conductibility and interface action of the composite material obtained by the method provided by the invention are improved due to the doping of nitrogen; and the method provided by the invention has the advantages of simple process, cheap cost, high productive rate, short cycle and the like, and is environment-friendly, and can be suitable for industrialization large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

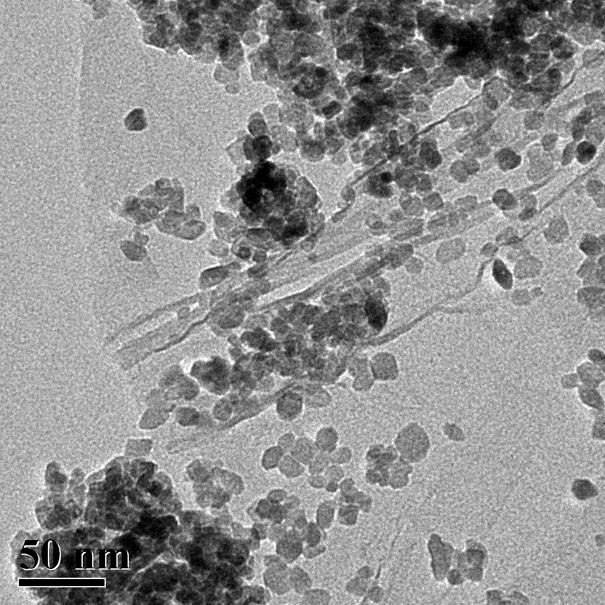

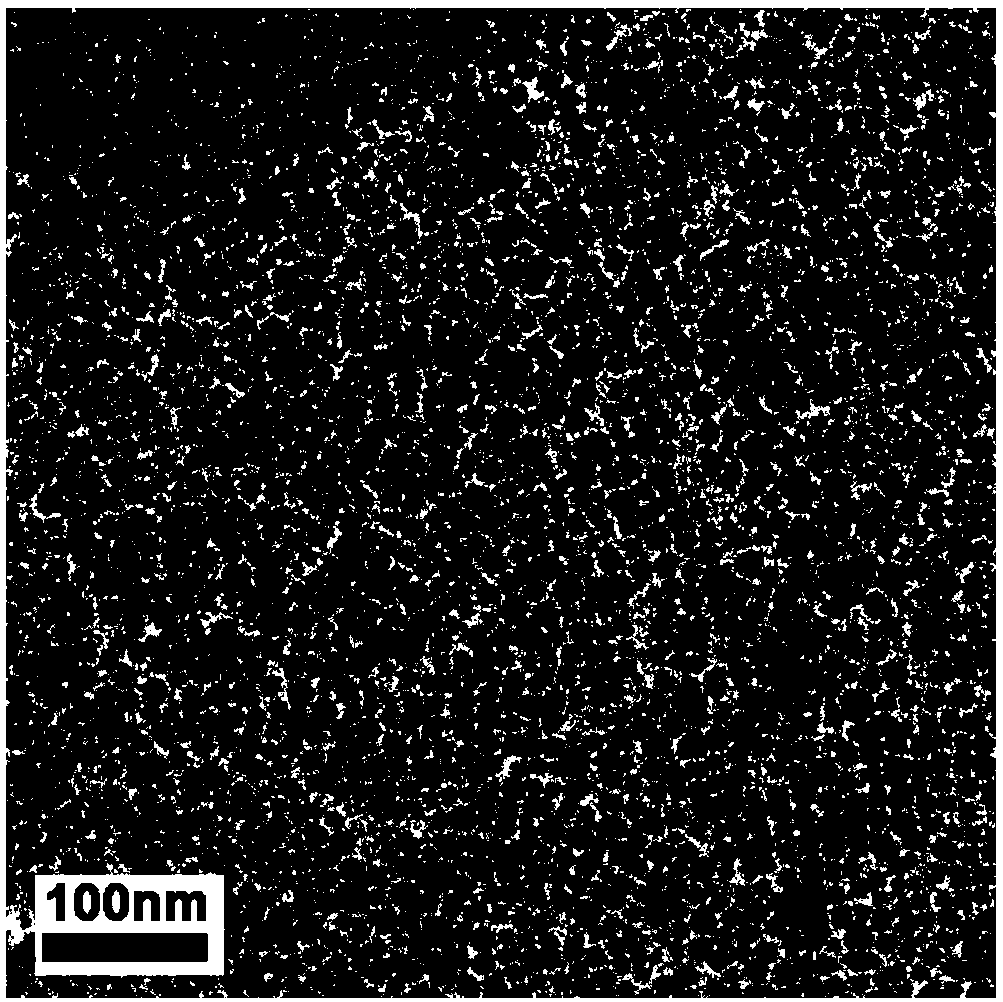

Preparation method of quantum dot self-assembling nano structural material

The invention discloses a preparation method of a super nanostructure material formed by quantum dots self-assembly. That the alcohols are used as solvent to prepare nano-metal oxides and sulphides or metal oxides and sulphides are reduced to get nano-metal is a widely used method. The super nanostructure material formed by the quantum dots self-assembly draws much attention because of the superior comprehensive properties. The application prospect is wide enough. The invention adopts a method of using the alcohols as the solvent that a super nanostructure with different appearances and is formed by the quantum dots self-assembly which is obtained by changing the condition under the existence condition of surfactant. According to the invention, precursor, namely organic metal compound is dissolved in the alcohol solvent by ultrasonic, stirring and being laid down quietly. Under the effect of the surfactant, the precursor has a nucleation and grows into a plurality of quantum dots, the size of which is similar to nano. Then the dots form a super nanostructure which has a certain shape or space structure along the defined growing direction of the surfactant.

Owner:HUAZHONG NORMAL UNIV

Ternary oxide nanostructures and methods of making same

InactiveUS7585474B2Suitable for preparationFrom gel stateAlkaline earth titanatesSingle crystalNanostructure

A single crystalline ternary nanostructure having the formula AxByOz, wherein x ranges from 0.25 to 24, and y ranges from 1.5 to 40, and wherein A and B are independently selected from the group consisting of Ag, Al, As, Au, B, Ba, Br, Ca, Cd, Ce, Cl, Cm, Co, Cr, Cs, Cu, Dy, Er, Eu, F, Fe, Ga, Gd, Ge, Hf, Ho, I, In, Ir, K, La, Li, Lu, Mg, Mn, Mo, Na, Nb, Nd, Ni, Os, P, Pb, Pd, Pr, Pt, Rb, Re, Rh, Ru, S, Sb, Sc, Se, Si, Sm, Sn, Sr, Ta, Tb, Tc, Te, Ti, Tl, Tm, U, V, W, Y, Yb, and Zn, wherein the nanostructure is at least 95% free of defects and / or dislocations.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Process for removing arsenic from aqueous streams

InactiveUS6863825B2Efficiently and effectively removedReduce the concentration of arsenicSolid sorbent liquid separationSedimentation separationCeriumOxidation state

Arsenic is removed from water and other aqueous feeds by (1) treating the feed with a compound containing cerium in the +4 oxidation state, preferably cerium dioxide, to oxidize arsenic in the +3 oxidation state to arsenic in the +5 oxidation state and (2) removing the arsenic in the +5 oxidation state from the aqueous phase, normally by contacting the treated feed with alumina or other precipitating agent containing cations in the +3 oxidation state.

Owner:SECURE NATURAL RESOURCES LLC

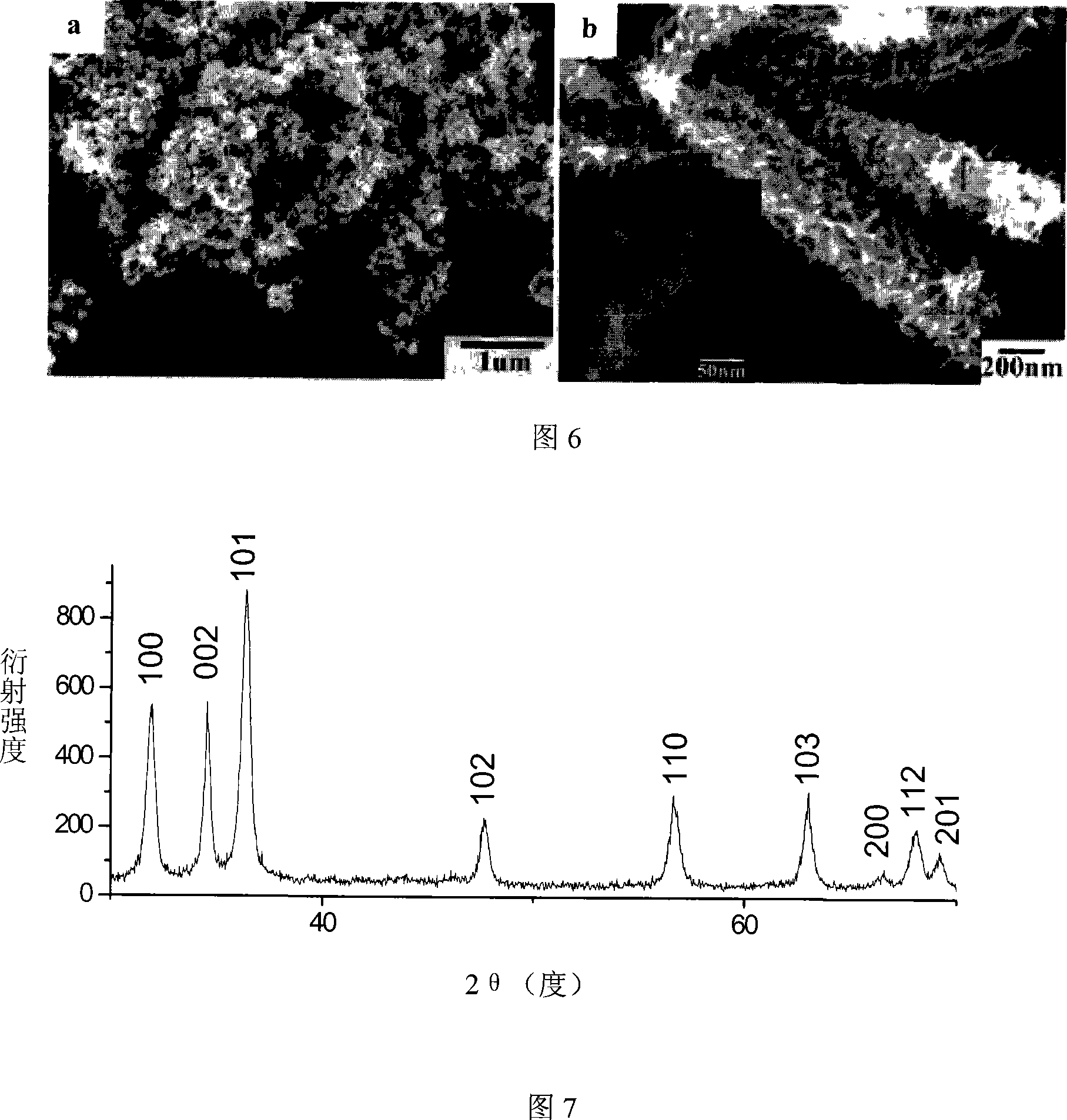

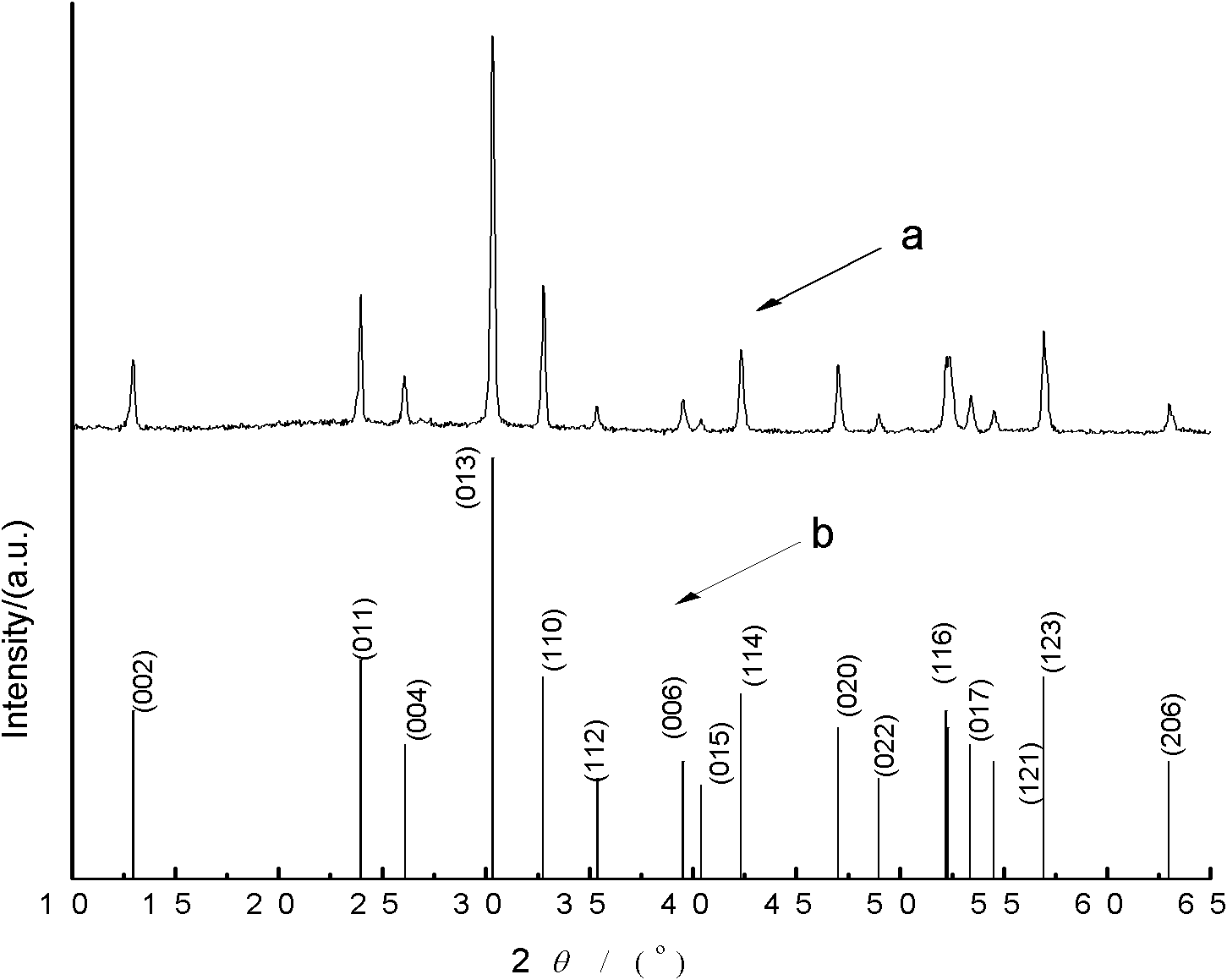

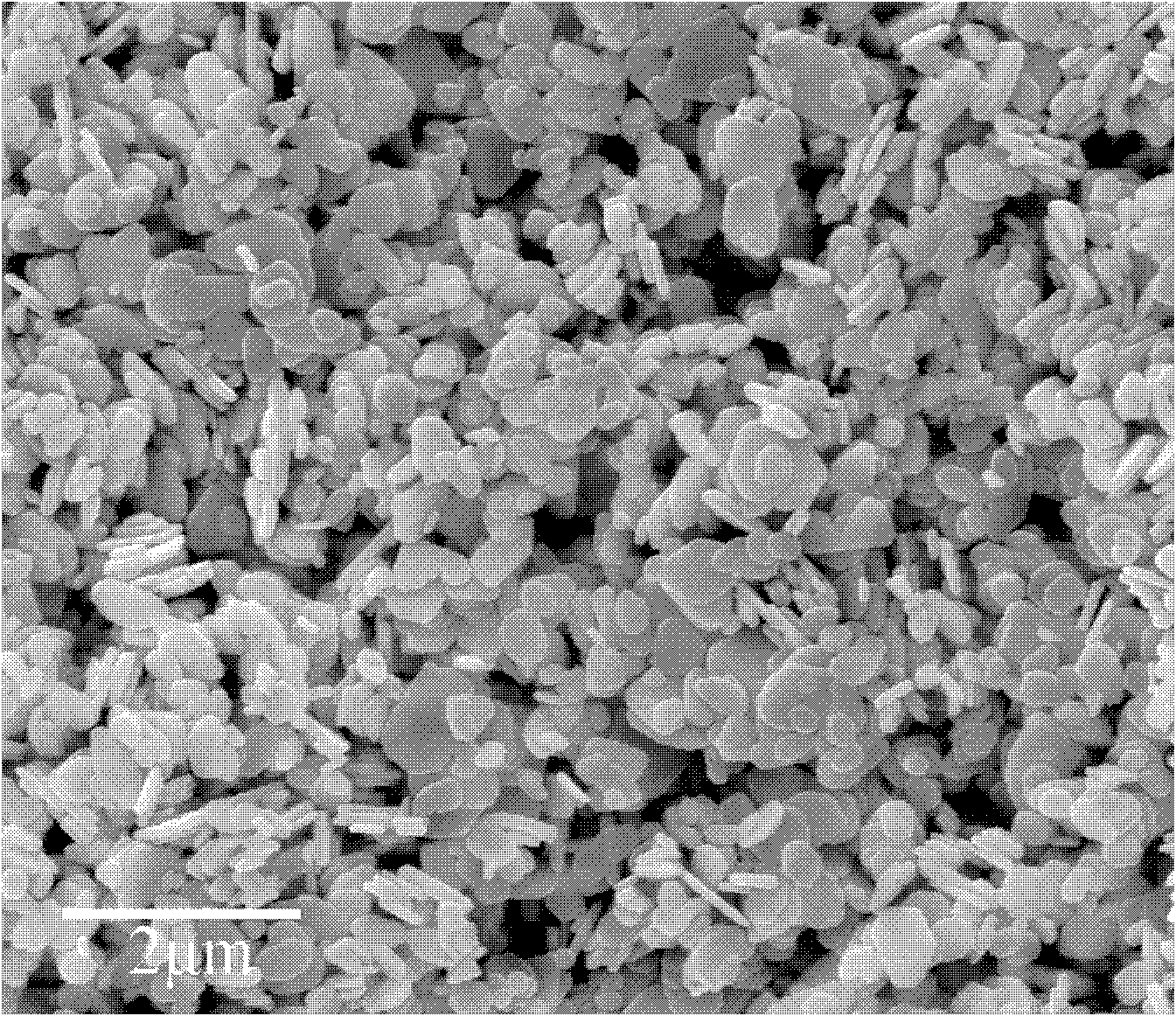

Bismuth vanadate powder and preparation method thereof

InactiveCN101318700AHigh activityImprove visible light absorptionVanadium compoundsBismuth compoundsBismuth vanadateIon exchange

The invention discloses bismuth vanadate powder and a preparation method thereof. The method comprises the following steps: firstly, bismuth-bearing compounds and vanadium-bearing compounds are respectively dissolved in a nitric acid, mixed and then added with a hexadecyl trimethyl ammonium bromide solution, the mol ratio of bismuth to vanadium to the nitric acid to hexadecyl trimethyl ammonium bromide is 1 to 1 to 2.5 to 0.025, and the mixture is stirred for 1 to 2 hours by magnetic force so as to form a bismuth vanadate precursor; the bismuth vanadate precursor is placed in a reaction kettle, undergoes hydrothermal treatment for 70 to 75 hours at a temperature of between 80 and 200 DEG C, cooled, centrifugally separated, and then added with a saturated sodium chloride solution of anhydrous ethanol and deionized water; ion-exchange is performed after the bismuth vanadate precursor is completely immersed, and then centrifugal separation is performed; and finally the bismuth vanadate precursor is washed for 3 to 5 times by mixture of the deionized water and ethanol, then the bismuth vanadate powder with microspheric and / or micro-flaky particles is prepared. The method has simple operation and mild conditions; and bismuth vanadate powder particles prepared are uniform, have large specific surface area, have the characteristics of good visible light response and high photocatalytic activity, and are suitable for industrialized production.

Owner:WUHAN UNIV

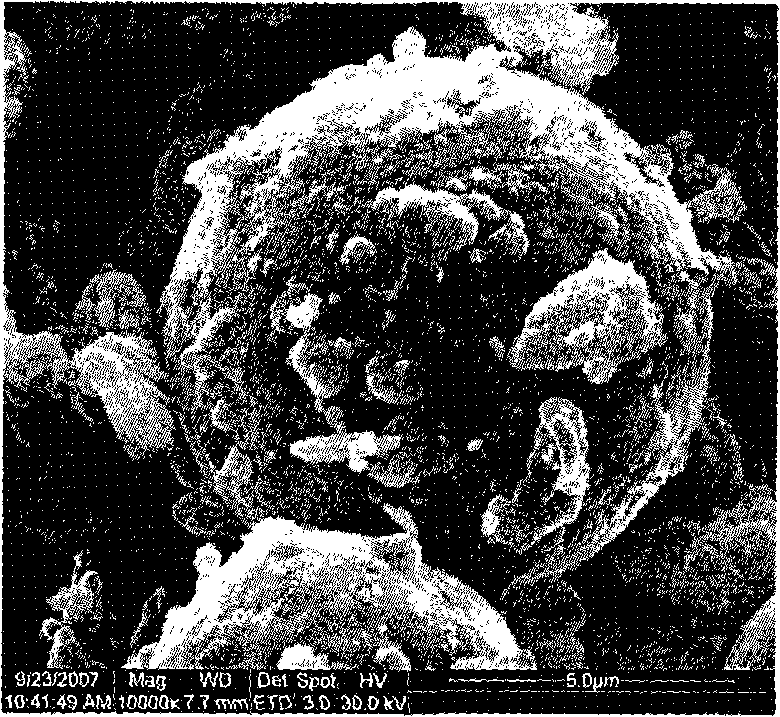

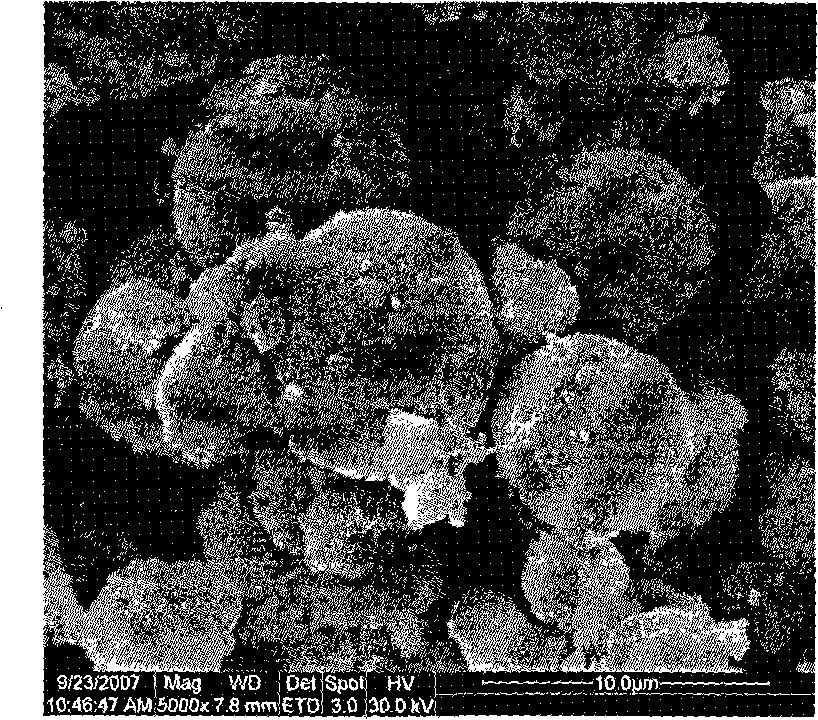

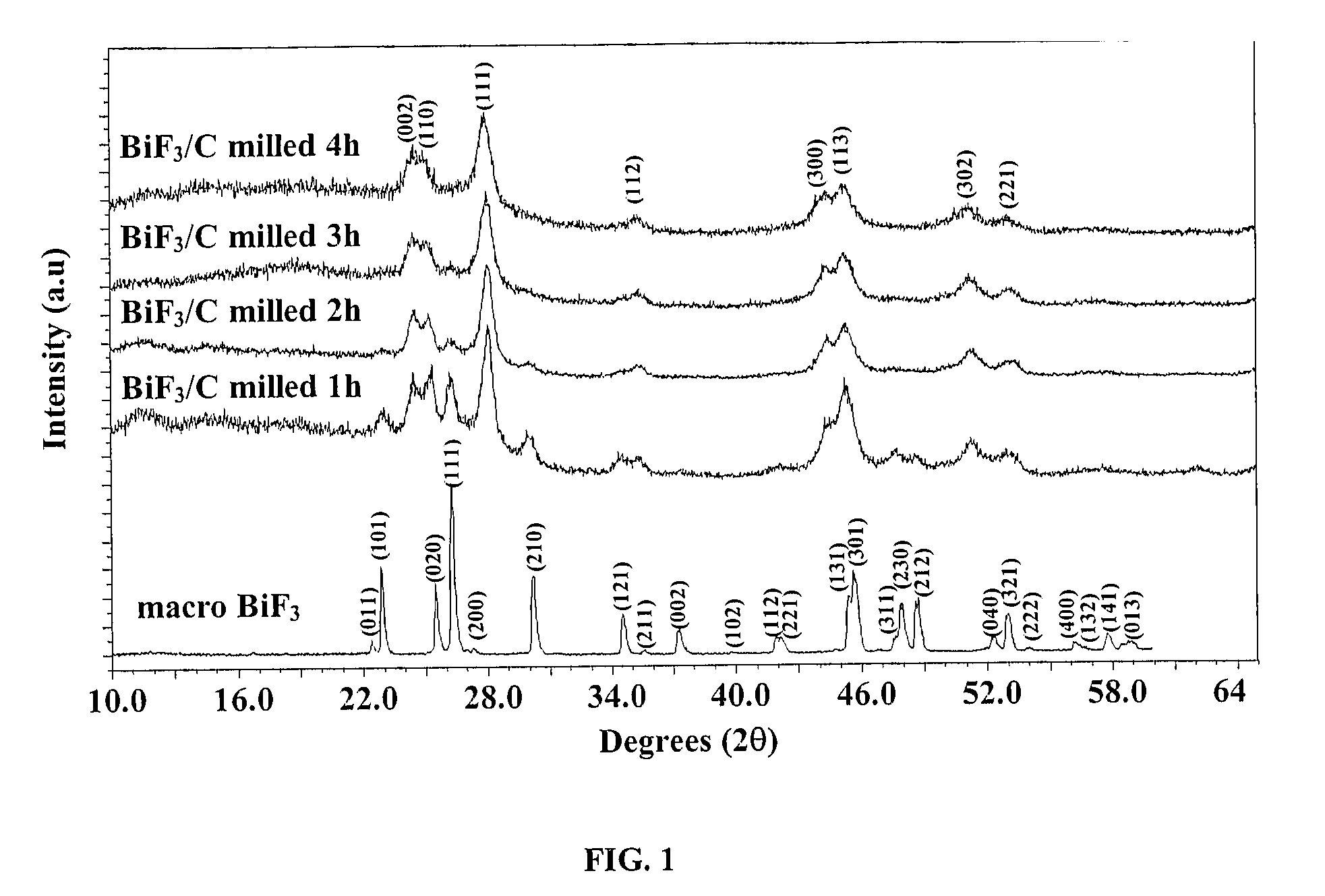

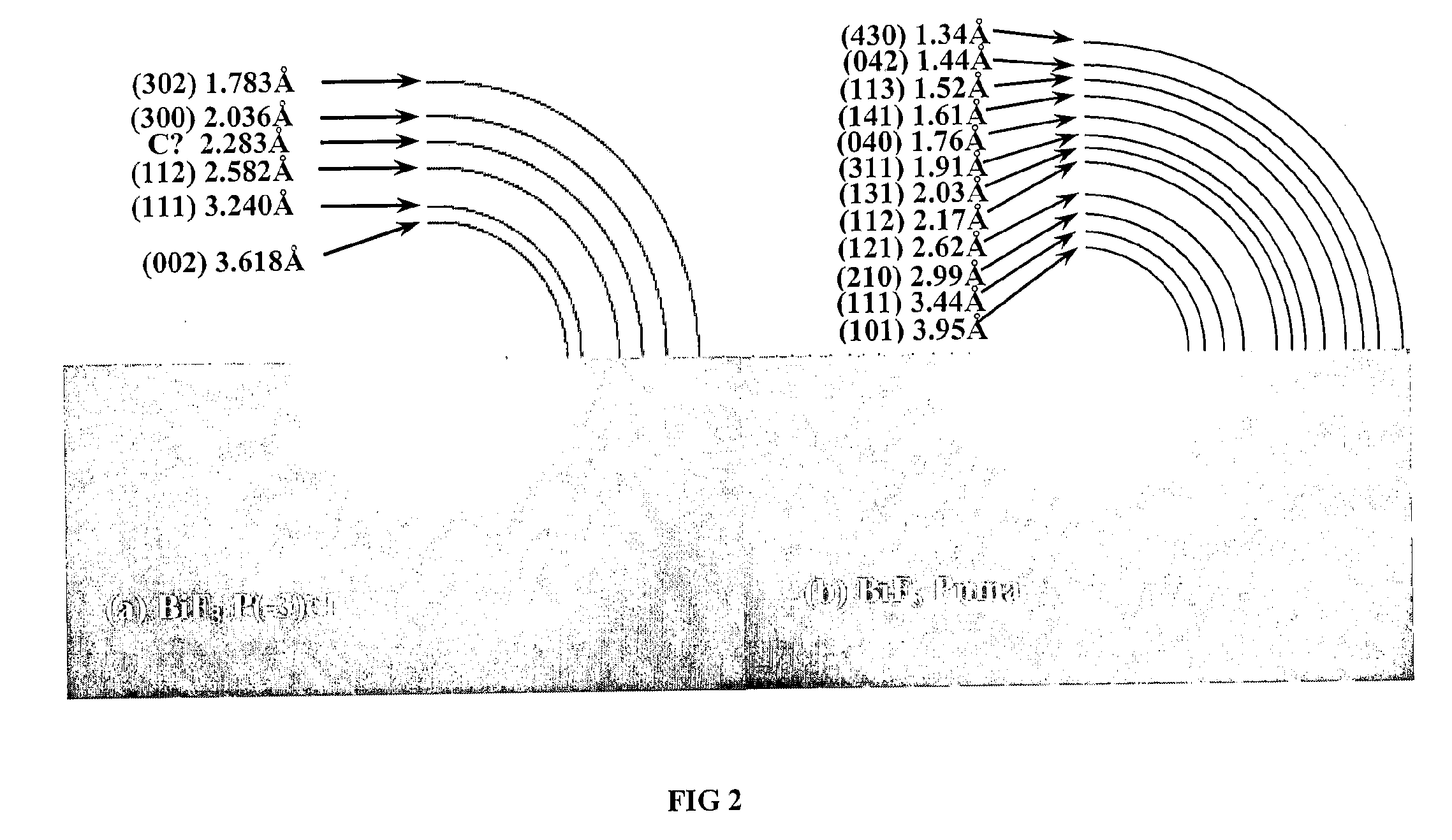

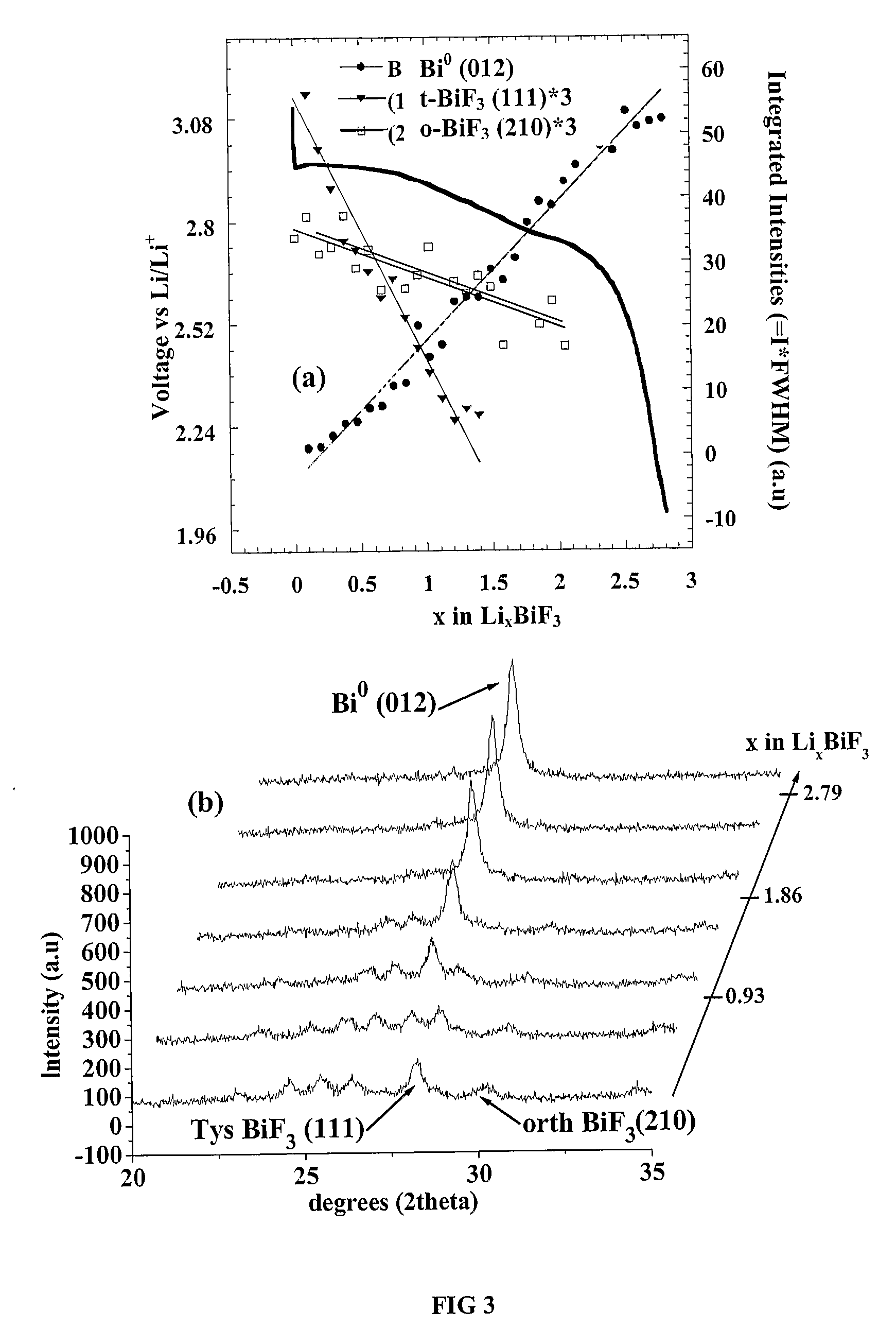

Bismuth Fluoride Based Nanocomposites as Electrode Materials

The present invention relates to primary and secondary electrochemical energy storage systems, particularly to such systems as battery cells, which use materials that take up and release ions as a means of storing and supplying electrical energy.

Owner:RUTGERS THE STATE UNIV

Garnet-type solid electrolyte, secondary battery containing garnet-type solid electrolyte, and method of producing garnet-type solid electrolyte

ActiveUS9034526B2Few crystal defectHigh crystallinityTin compoundsTantalum compoundsLithiumLanthanum

Owner:TOYOTA JIDOSHA KK +1

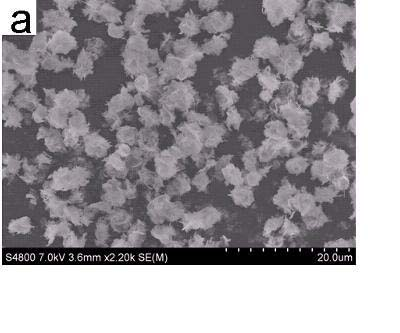

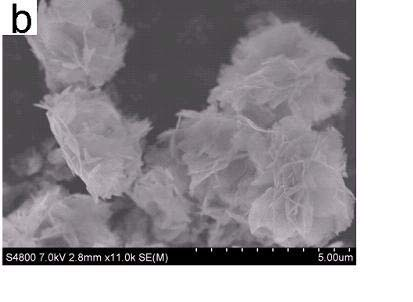

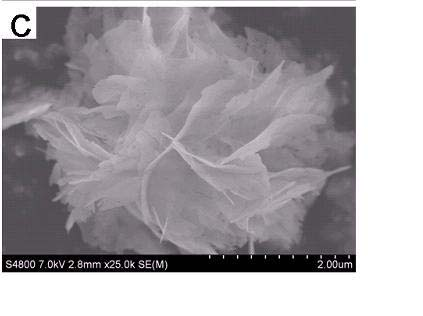

Bismuthyl carbonate micro flowery material with graded structure and preparation method thereof

The invention relates to a bismuthyl carbonate micro flowery material with a graded structure, which is structurally characterized in that two-dimensional nano flakes are staggered to form a flower shape, and the average diameter of the flakes is 3 to 4 microns. The material is prepared by fist dissolving bismuth nitrate into dilute nitric acid and then gradually dripping the dilute nitric acid into excessive sodium carbonate solution and reacting the solution. A preparation method can be implemented at the low temperature and the normal pressure, and has the advantages of short time consumption, low cost, simple equipment, easy operation and large-scale production. Because of a large specific surface area, the prepared bismuthyl carbonate micro flowery material with the graded structure has important practical application in the aspects of pharmacy and sterilization; and meanwhile, the material with the large specific surface area has good performance in the aspect of degrading organic pollutants by photocatalysis.

Owner:SHANDONG UNIV

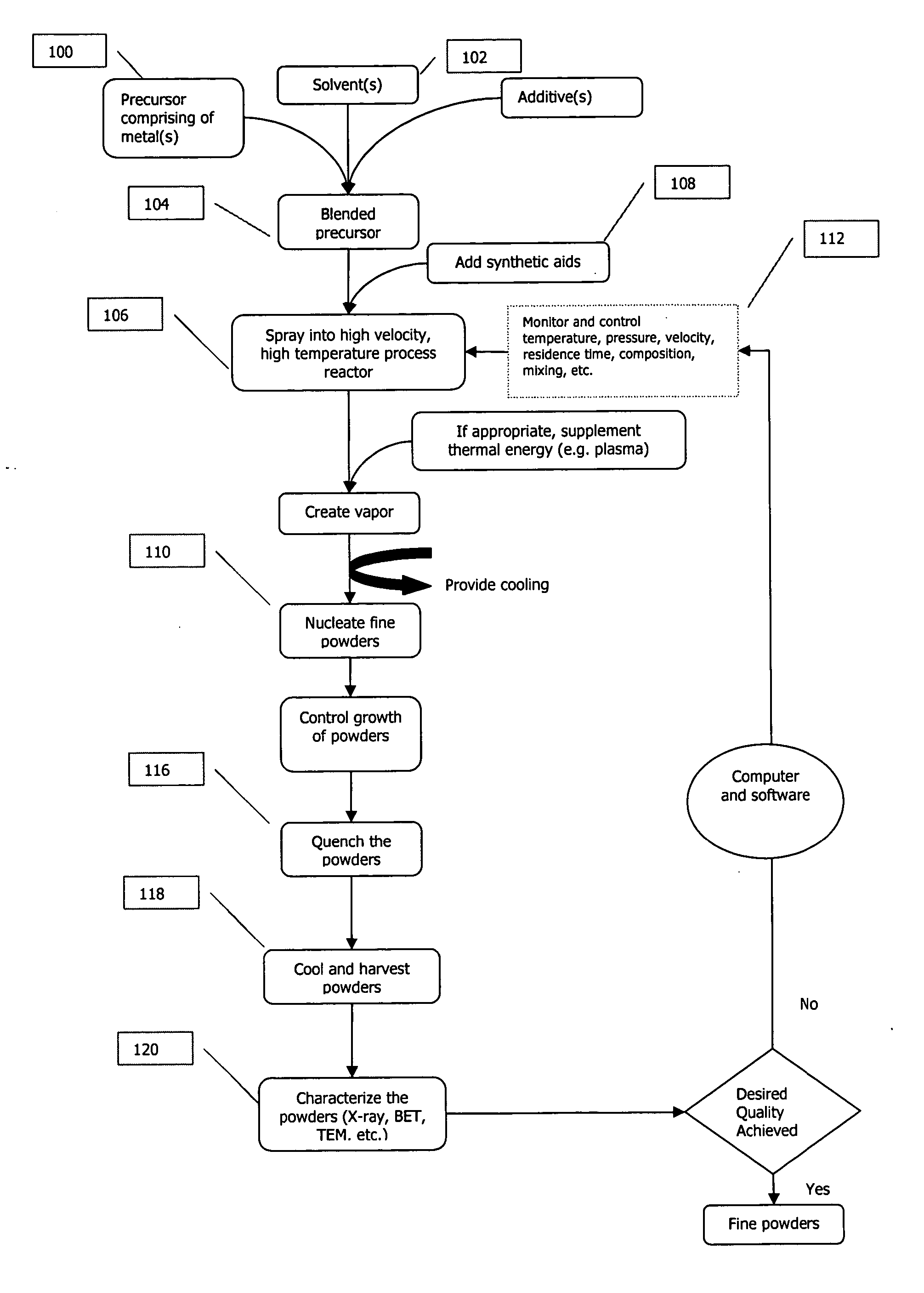

Manufacturing methods for nanomaterial dispersions and products thereof

InactiveUS20060016371A1Increase volumeLow cost productionMaterial nanotechnologyAlkaline earth titanatesManufactured nanomaterialsApplications of nanotechnology

Methods for manufacturing nanomaterial dispersions, such as nanomaterial concentrates, and related nanotechnology are provided. The nanomaterial concentrates provided can be more cheaply stored and transported compared to non-concentrate nanomaterial forms.

Owner:PPG IND OHIO INC

Preparation method of general-purpose multi-metal sulfide nano-material

InactiveCN102633297AHigh yieldAdjustable phaseTin compoundsGallium/indium/thallium compoundsPhenanthrolineDiethyldithiocarbamic Acid

The invention discloses a preparation method of a general-purpose multi-metal sulfide nano-material. The preparation method comprises the following steps of: taking two or more different metal diethyldithiocarbamates, or two or more different metal phenanthroline diethyldithiocarbamates, or the combination of the metal diethyldithiocarbamates and the metal phenanthroline diethyldithiocarbamates as reaction predecessors, performing co-thermal decomposition in a mixed solution of surfactants with different coordination properties, and performing nucleation and growth so as to prepare a high-quality multi-metal sulfide nano-material by one step. The multi-metal sulfide prepared by the preparation method disclosed by the invention has the advantages of pure phase state, adjustable composition, uniform and controllable appearance and size, high yield, low toxicity or no toxicity, better dispersivity in a non-polar organic solvent, easiness in control of reaction conditions, mild preparation conditions, simple operation, good repeatability and capability of realizing large-scale production.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Metal scavenging polymers and uses thereof

ActiveUS20110243819A1Dispersed particle filtrationSelenium/tellurium compundsWastewater systemsMonomer

Uses for a composition comprising a polymer derived from at least two monomers: acrylic-x and an alkylamine, wherein said polymer is modified to contain a functional group capable of scavenging one or more compositions containing one or more metals are disclosed. These polymers have many uses in various mediums, including wastewater systems.

Owner:ECOLAB USA INC

Electrode active material for secondary battery and method for preparing the same

ActiveUS20110311875A1Minimizing dead volumeHigh-capacity batteryMaterial nanotechnologyGallium/indium/thallium compoundsParticulatesLithium oxide

The disclosure relates to an electrode active material including: (a) first particulate of a metal (or metalloid) oxide alloyable with lithium; and (b) second particulate of an oxide containing lithium and the same metal (or metalloid) as that of the metal (or metalloid) oxide, and to a secondary battery including the electrode active material. When the electrode active material is used as an anode active material, reduced amounts of an irreversible phase such as a lithium oxide or a lithium metal oxide are produced during initial charge-discharge of a battery since lithium is already contained in the second particulate before the initial charge-discharge, and thus a dead volume on the side of the cathode can be minimized and a high-capacity battery can be fabricated.

Owner:LG ENERGY SOLUTION LTD

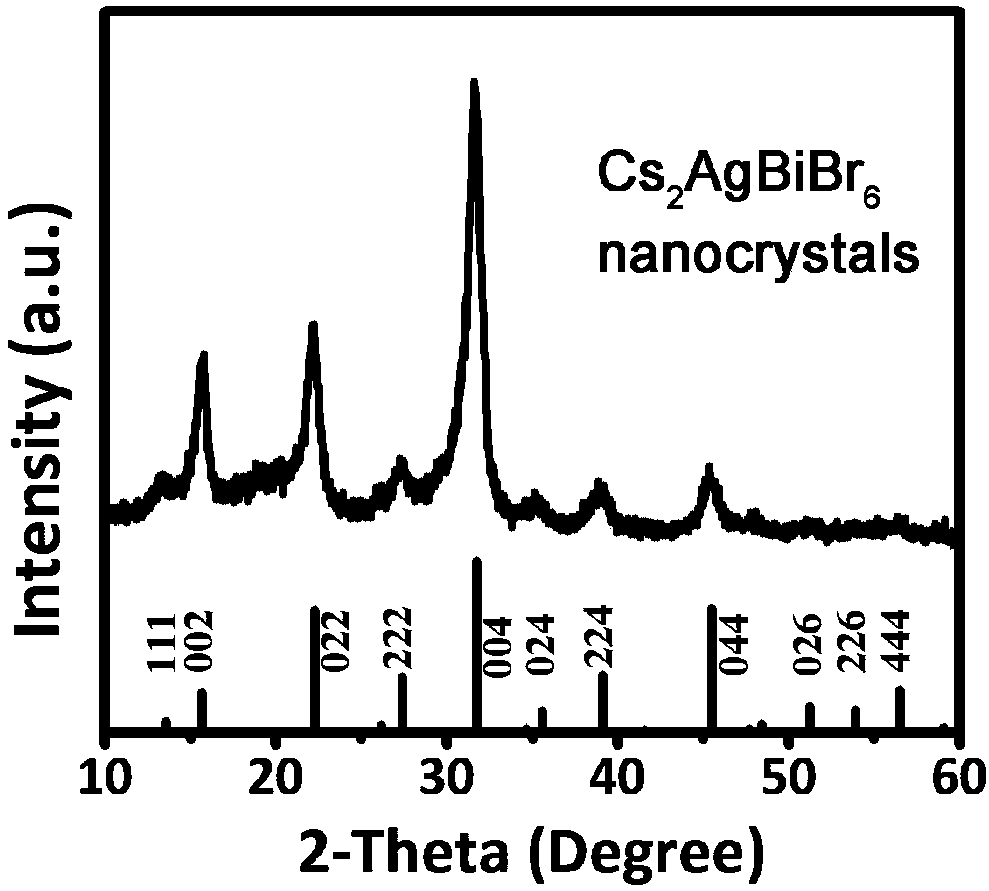

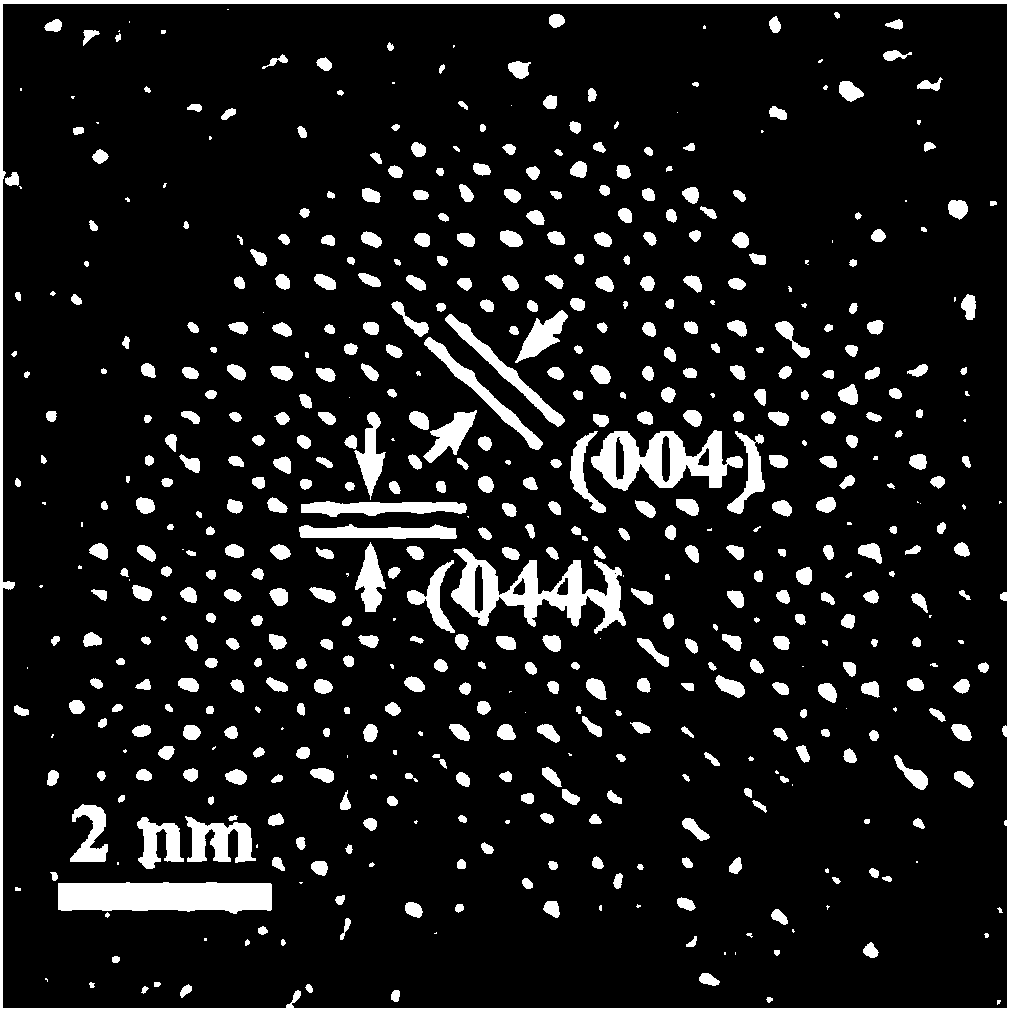

Preparation method of stable lead-free all-inorganic double perovskite A2BB'X6 nanocrystals

ActiveCN107934916AGood reproducibilityGood dispersionBromide preparationHydrocarbon from carbon oxidesReaction temperaturePhysical chemistry

The invention discloses a preparation method of stable lead-free all-inorganic double perovskite A2BB'X6 nanocrystals. The method adopts a thermal injection technology to synthesize the nanocrystals,and concretely comprises the following steps: mixing a metal precursor salt, a reaction solvent oleic acid, oleylamine, octadecene and other raw materials, carrying out vacuum heating and stirring ata certain temperature for a certain period of time, rising the temperature to a suitable reaction temperature under the protection of N2, rapidly injecting the obtained hot oleate solution of A into areaction system, and then rapidly cooling the system to room temperature by using ice bath to finally obtain the A2BB'X6 perovskite nanocrystals having a uniform size. The method has the advantages of simplicity, convenient, good reappearance and environmental protection, and the obtained product has the advantages of uniform size, good dispersion, high stability and excellent photocatalytic performance, and can be applied to the fields of photocatalysis, photodetectors, laser, solar cells and the like.

Owner:SUN YAT SEN UNIV

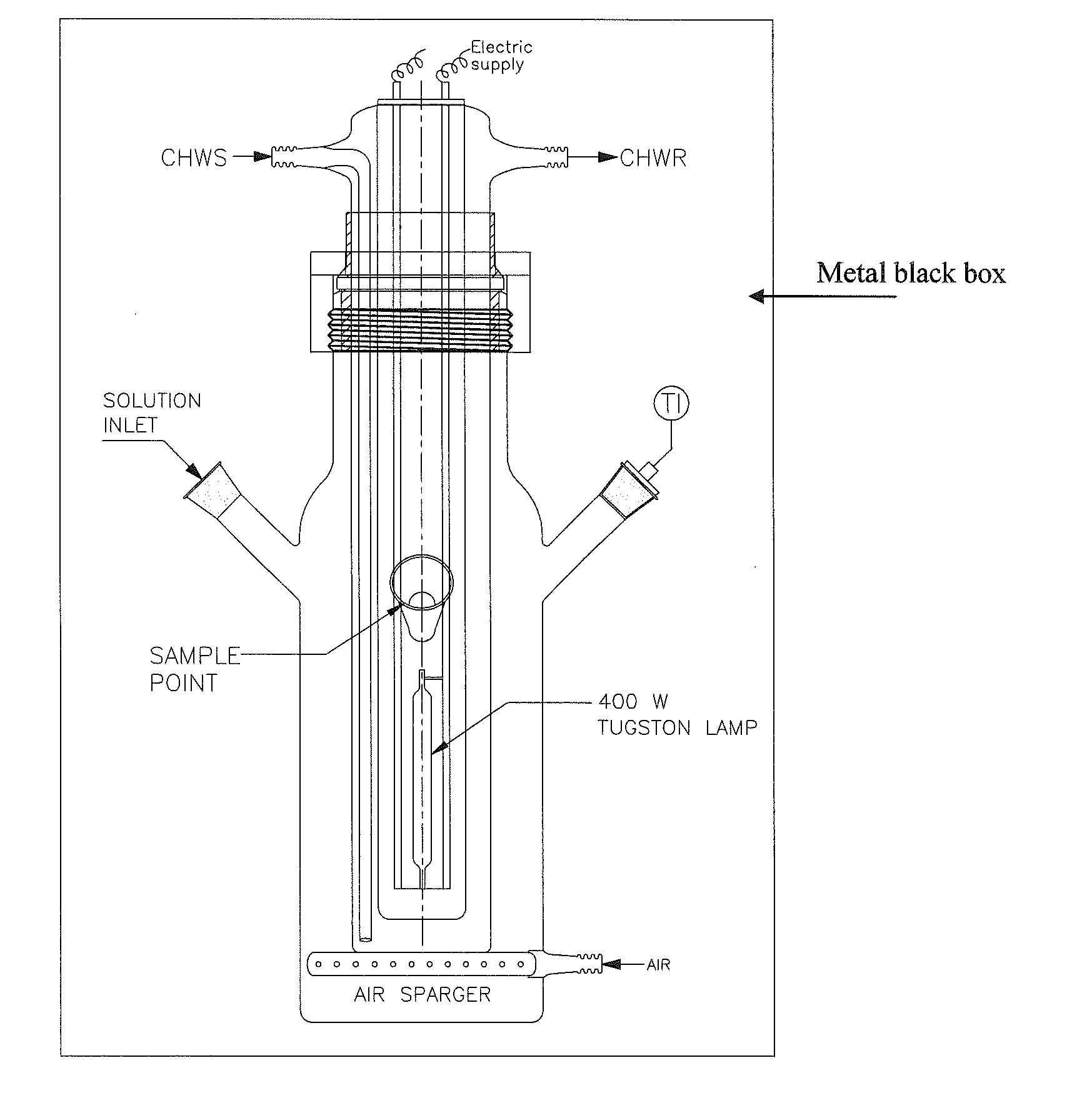

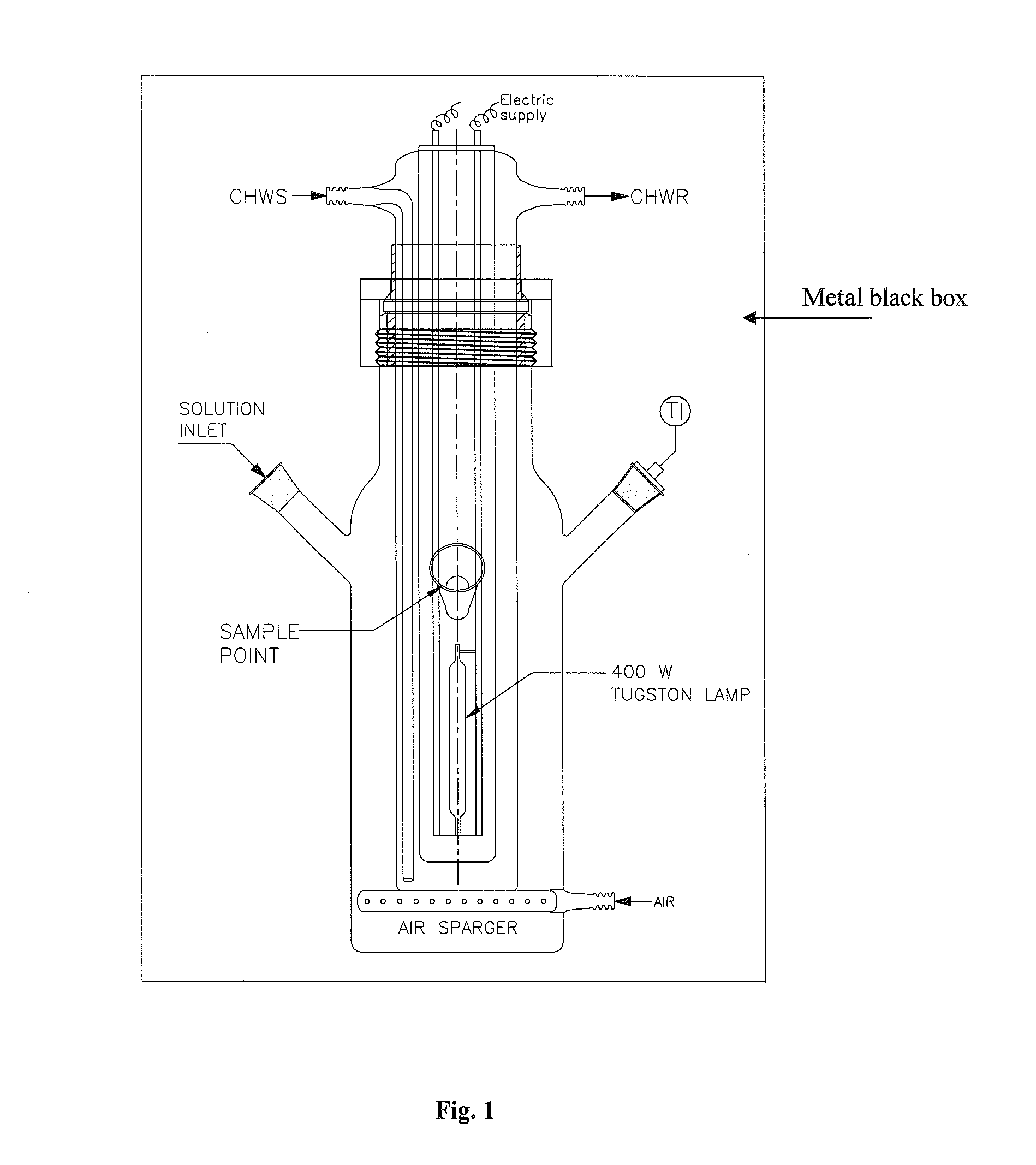

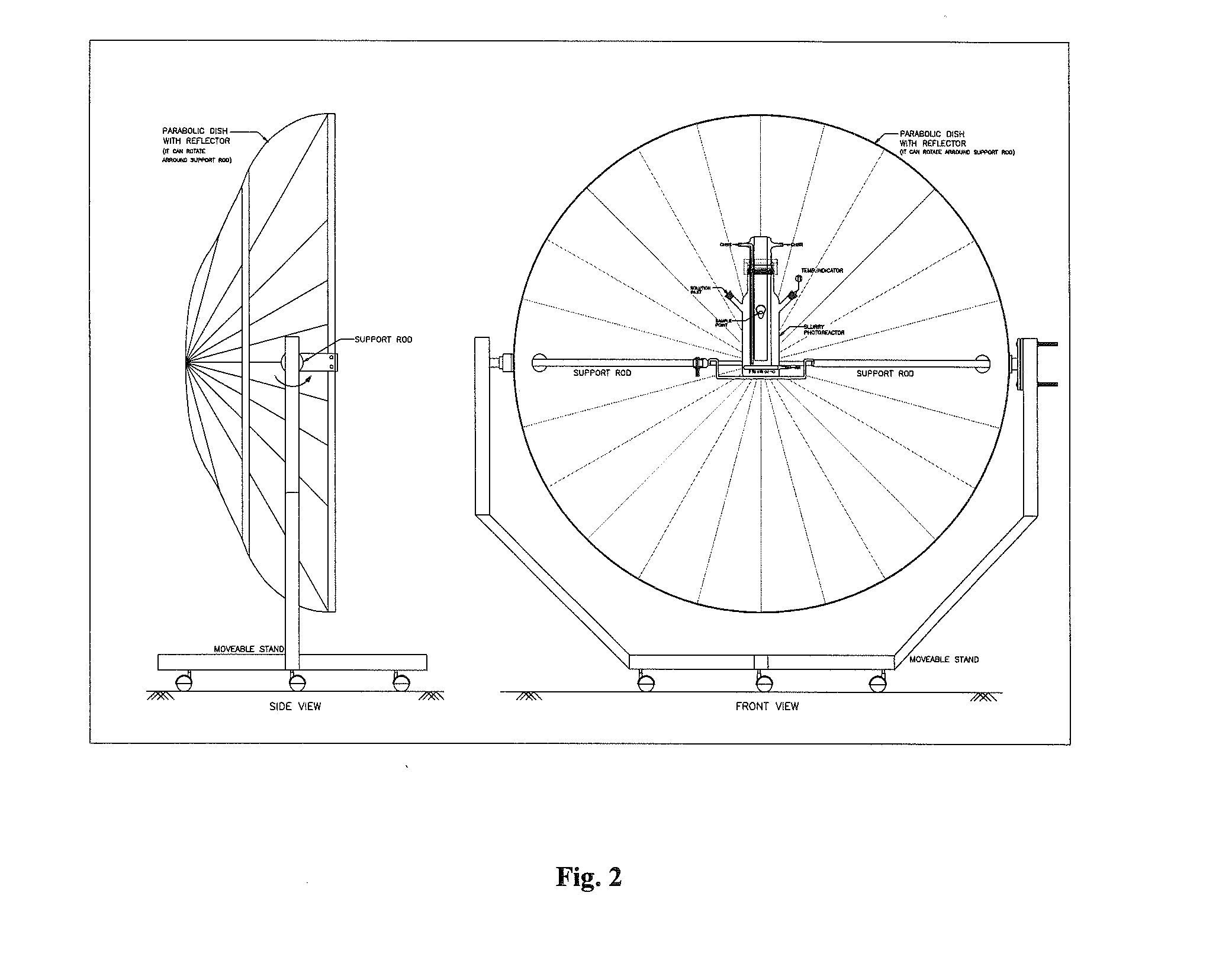

Photocatalytic degradation of pharmaceutical drugs and dyes using visible active biox photocatalyst

ActiveUS20160185615A1PhosphatesSulfate/bisulfate preparationPharmaceutical drugPhotocatalytic degradation

Provided is a visible active photocatalyst of formula BiOX wherein X=P or S and process of preparation and use thereof. Use of the catalyst is demonstrated in the photocatalytic degradation of pharmaceutical drug pollutants and pollutant dyes using solar radiation or artificial radiation.

Owner:COUNCIL OF SCI & IND RES

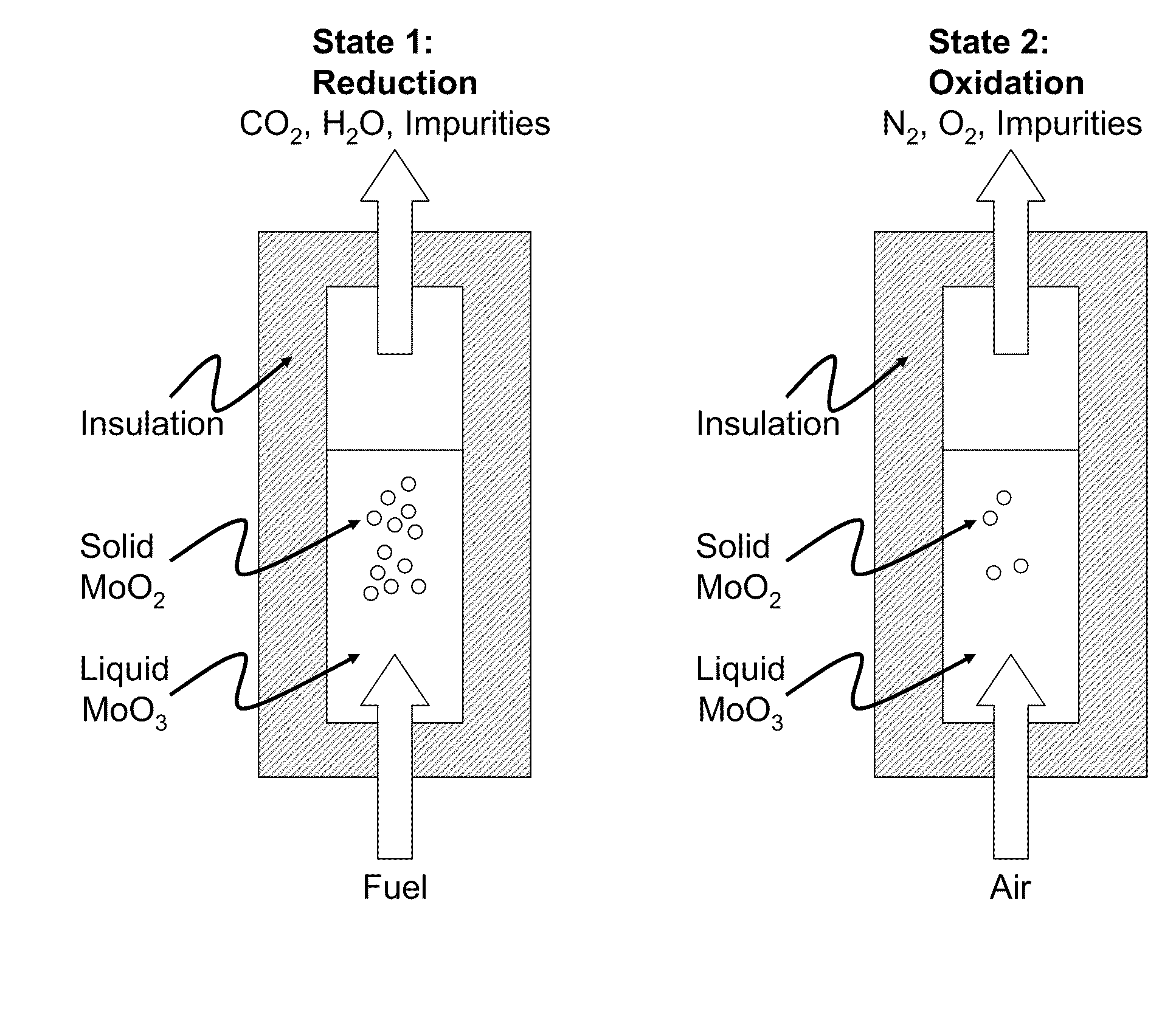

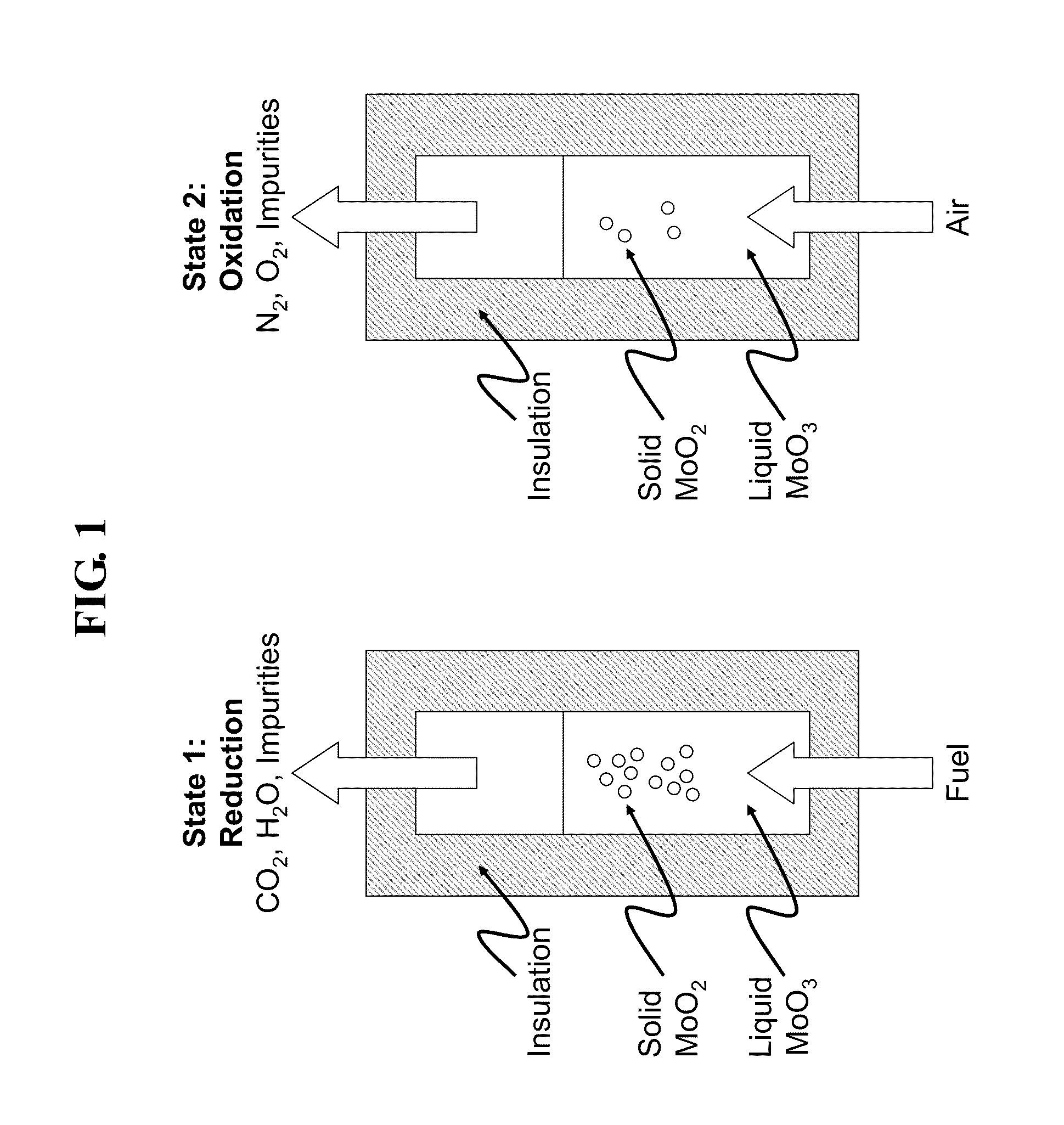

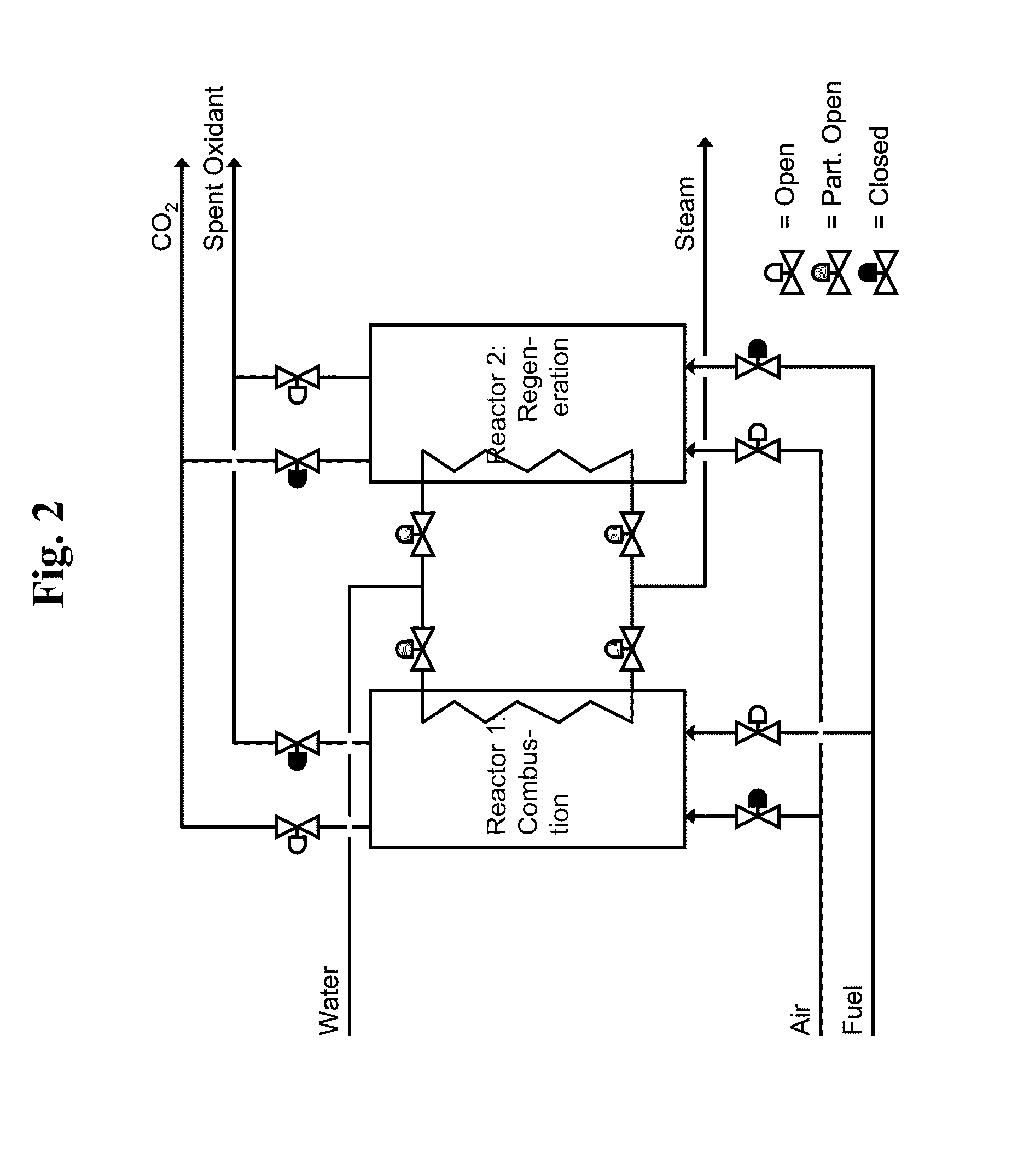

Liquid-phase chemical looping energy generator

Owner:PHILLIPS 66 CO

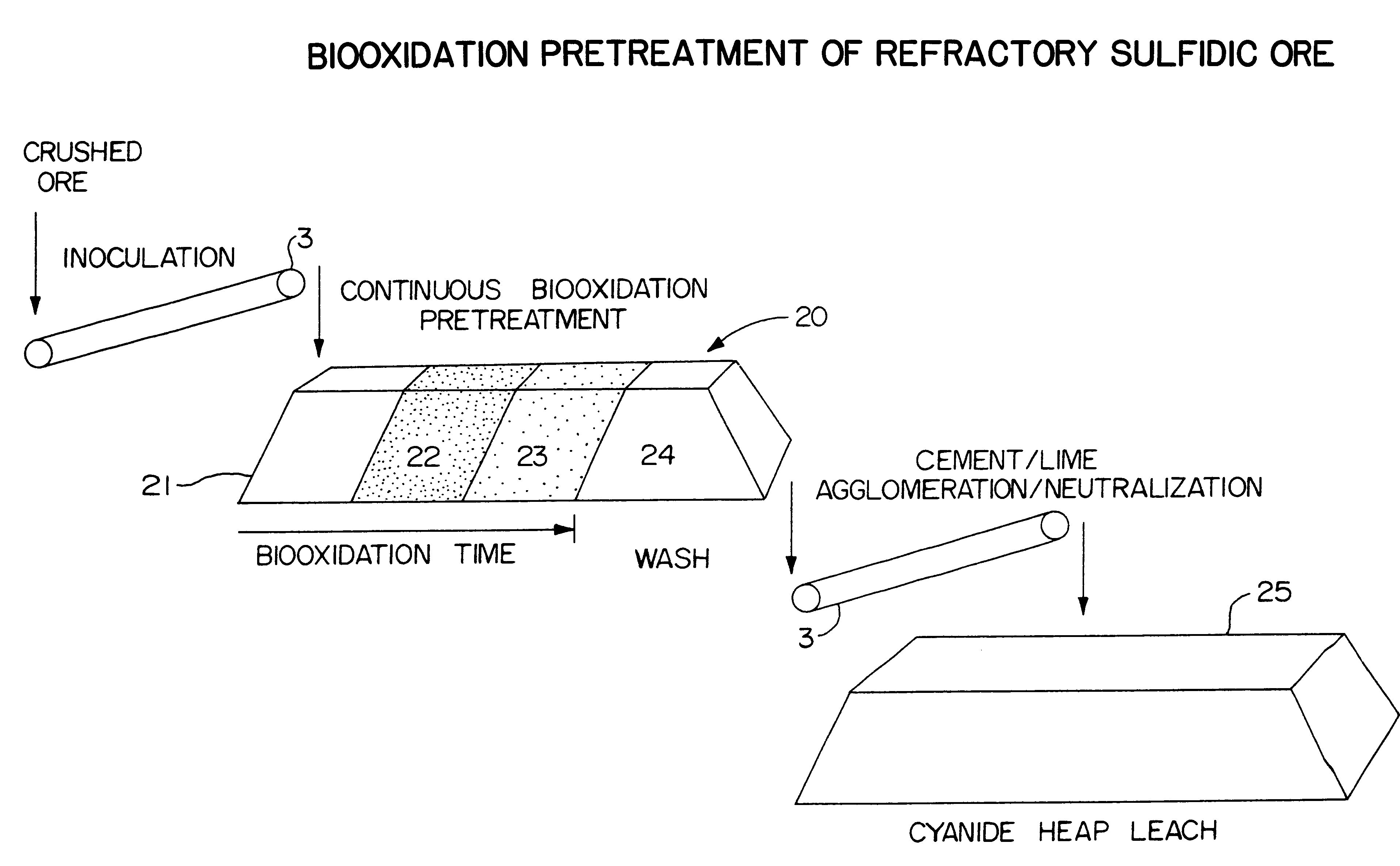

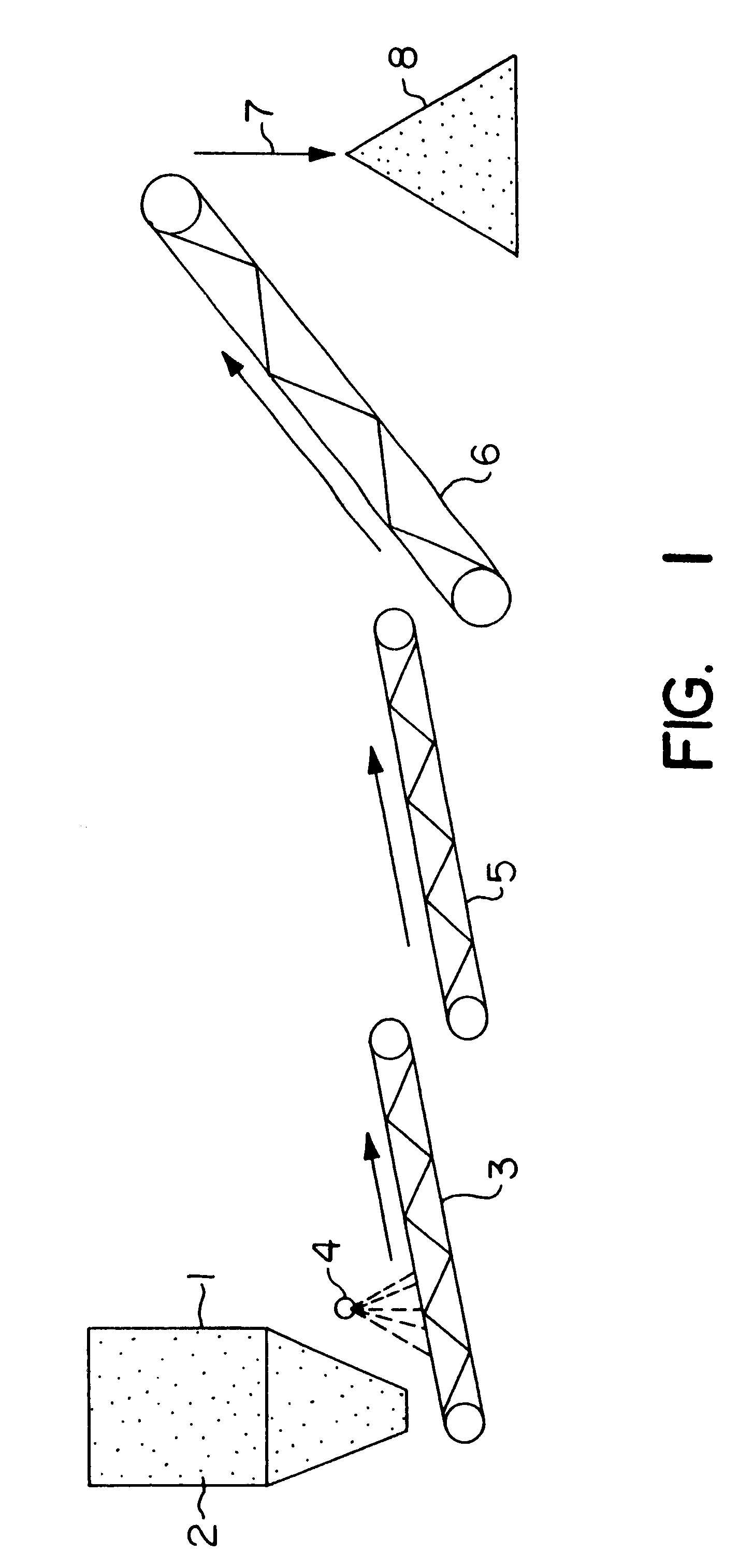

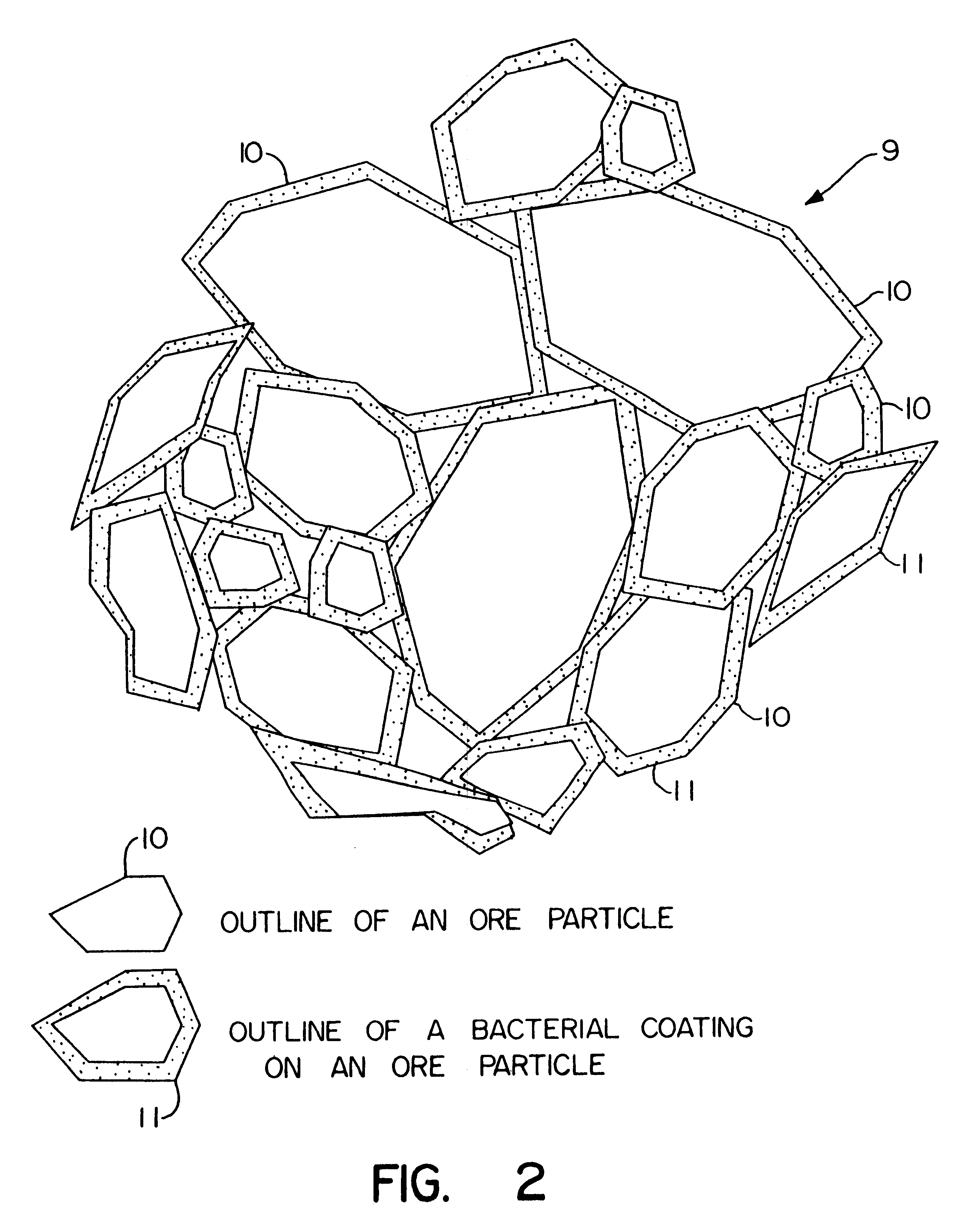

Biooxidation process for recovery of metal values from sulfur-containing ore materials

InactiveUS6383458B1Increase ratingsIncrease attractivenessTransuranic element compoundsSolvent extractionParticulatesPartial oxidation

A process for the recovery of one or more metal values from a metal ore material comprising those of one or more values and a matrix material having a sulfur content wherein the sulfur is present in an oxidation-reduction state of zero or less comprisinga. forming particulates from particles of said ore and an inoculate comprising bacteria capable of at least partially oxidizing the sulfur content;b. forming a heap of said particulates;c. biooxidizing the sulfur content andd. recovering those one or more metal values.

Owner:NEWMONT USA LTD

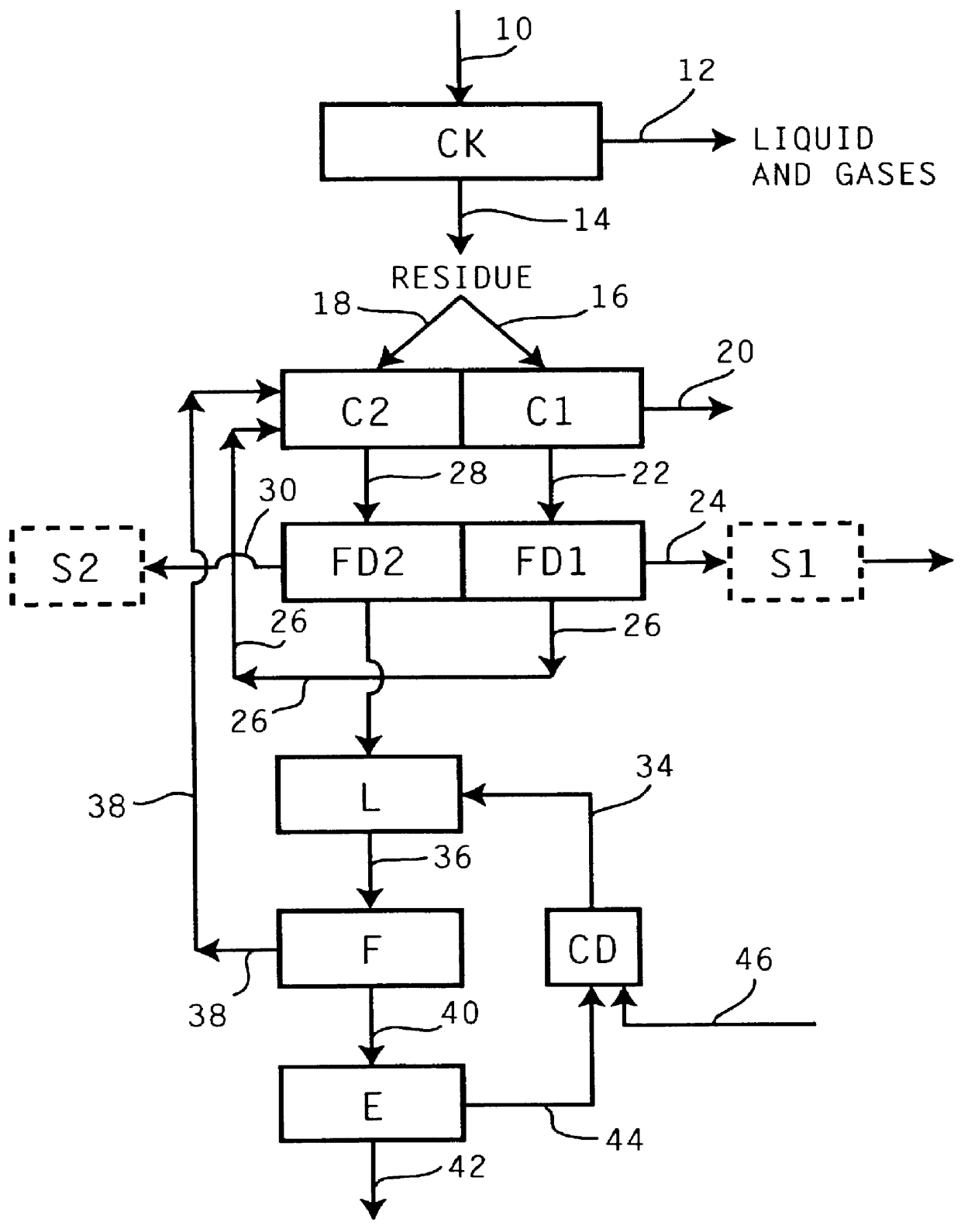

Recovery of the transition metal component of catalyst used in heavy feed hydroconversion

The invention relates to a process for recovering the transition metal component of catalysts used in the hydroconversion of heavy hydrocarbonaceous materials. In accordance with the invention, a slurry of a transition metal catalyst and hydrocarbon is catalytically desulfurized resulting in a desulfurized product and a solid residue containing the transition metal. The transition metal may be recovered by coking the residue and then dividing the coker residue into two portions are combusted with the flue dust from the first combustion zone being conducted to the second combustion zone. The flue dust from the second combustion zone is treated with ammonia and ammonium carbonate in order to obtain ammonium molybdate.

Owner:EXXON RES & ENG CO

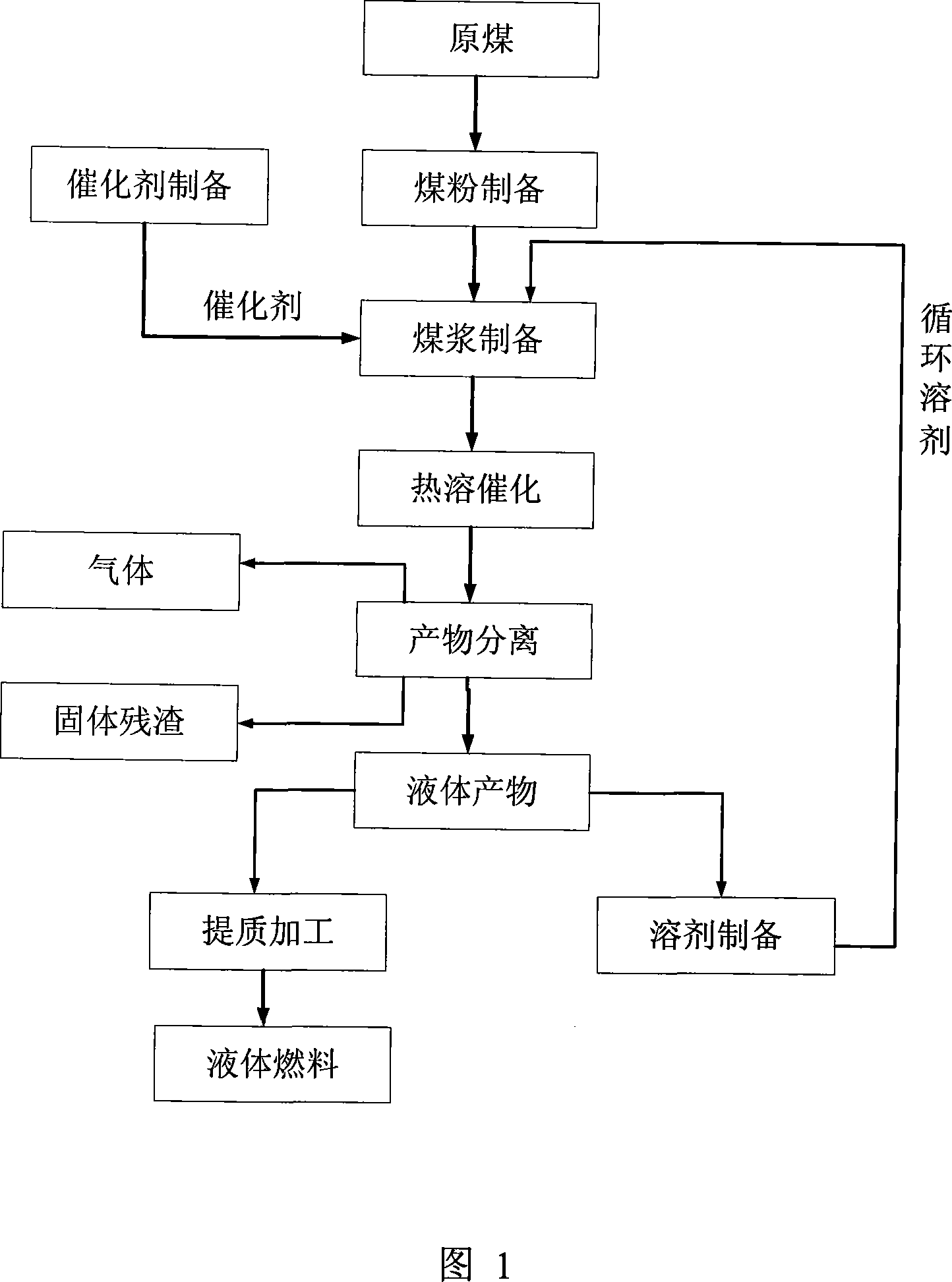

Thermally dissolving and catalytic method for preparing liquid fuel by lignite as well as catalyst and solvent used therefor

ActiveCN101182421AMild operating conditionsSimple preparation equipmentOrganic-compounds/hydrides/coordination-complexes catalystsMolybdeum compoundsLiquid productForming gas

The invention belongs to the technological field of coal chemical processing and discloses a heat dissolving and catalyzing method using brown coal to prepare liquid fuel. The method comprises the following steps: 1) the brown coal is smashed and dried to prepare pulverized coal; 2) the pulverized coal, solvent and catalyst are stirred and mixed well to prepare coal slurry; wherein, the weight percent of the pulverized coal is 30 percent to 40 percent; the weight percent of the solvent is 60 percent to 70 percent; the quantity of the added catalyst is 0.5 percent to 1 percent of the weight of the pulverized coal; 3) the coal slurry is dissolved by heat and catalyzed to prepare heat dissolved and liquefied products; wherein, the temperature is 390 DEG C to 450 DEG C; the pressure is 5.0MPa to 9.0MPa; the reaction time is 30 minutes to 60 minutes; 4) the heat dissolved and liquefied products are separated to form gas-phase, liquid-phase and solid-phase products; 5) the liquid products are extracted and processed to form liquid fuel. The invention also discloses catalyst and solvent used in the method. The operation condition of the method of the invention is mild; the conversion ratio of the organic substances in the brown coal can achieve a higher level; after being processed, the liquid fuel product can be used for preparing engine fuel suiting national standards; and the preparation equipment is simple; the investment is small; the cost is low; and the invention is a coal liquefaction method suiting the national conditions of China.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

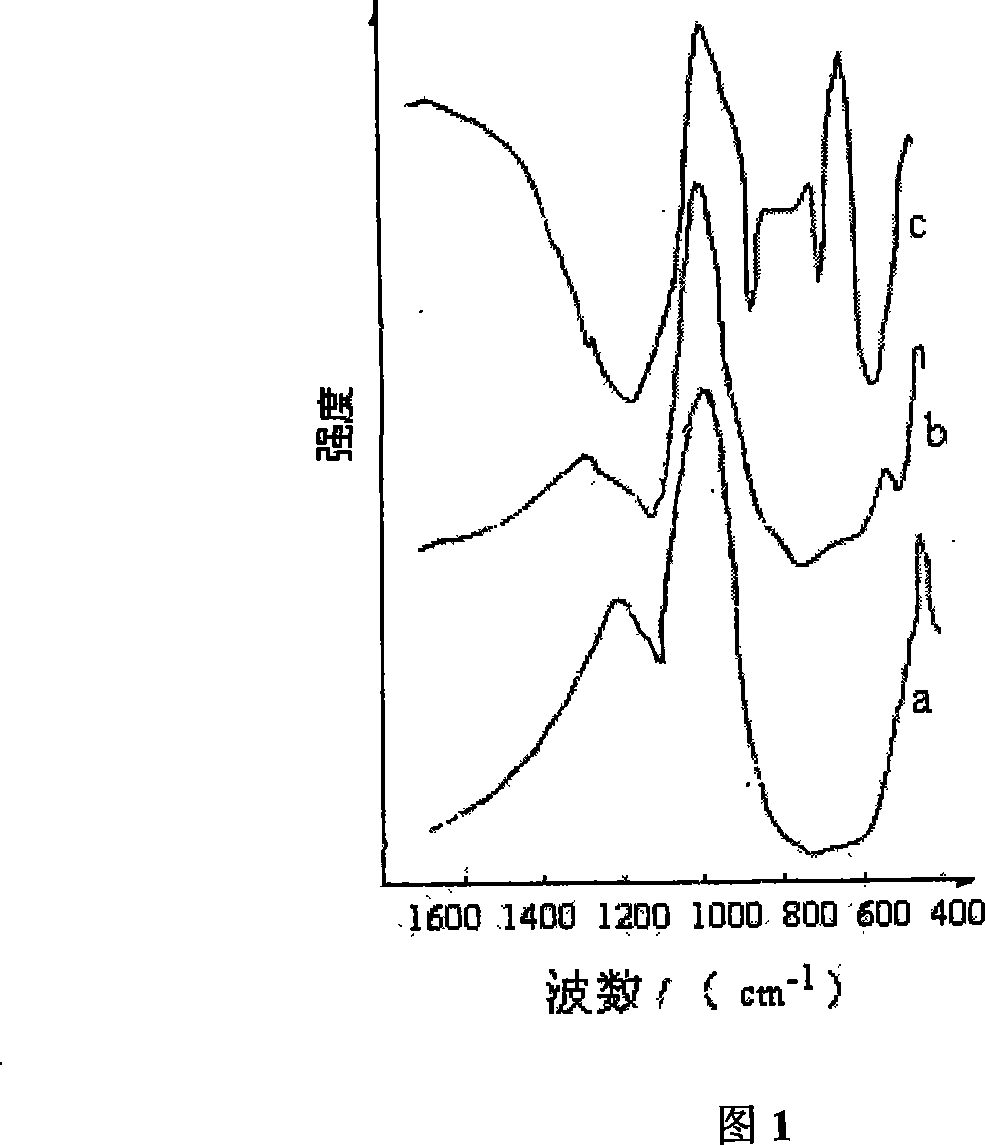

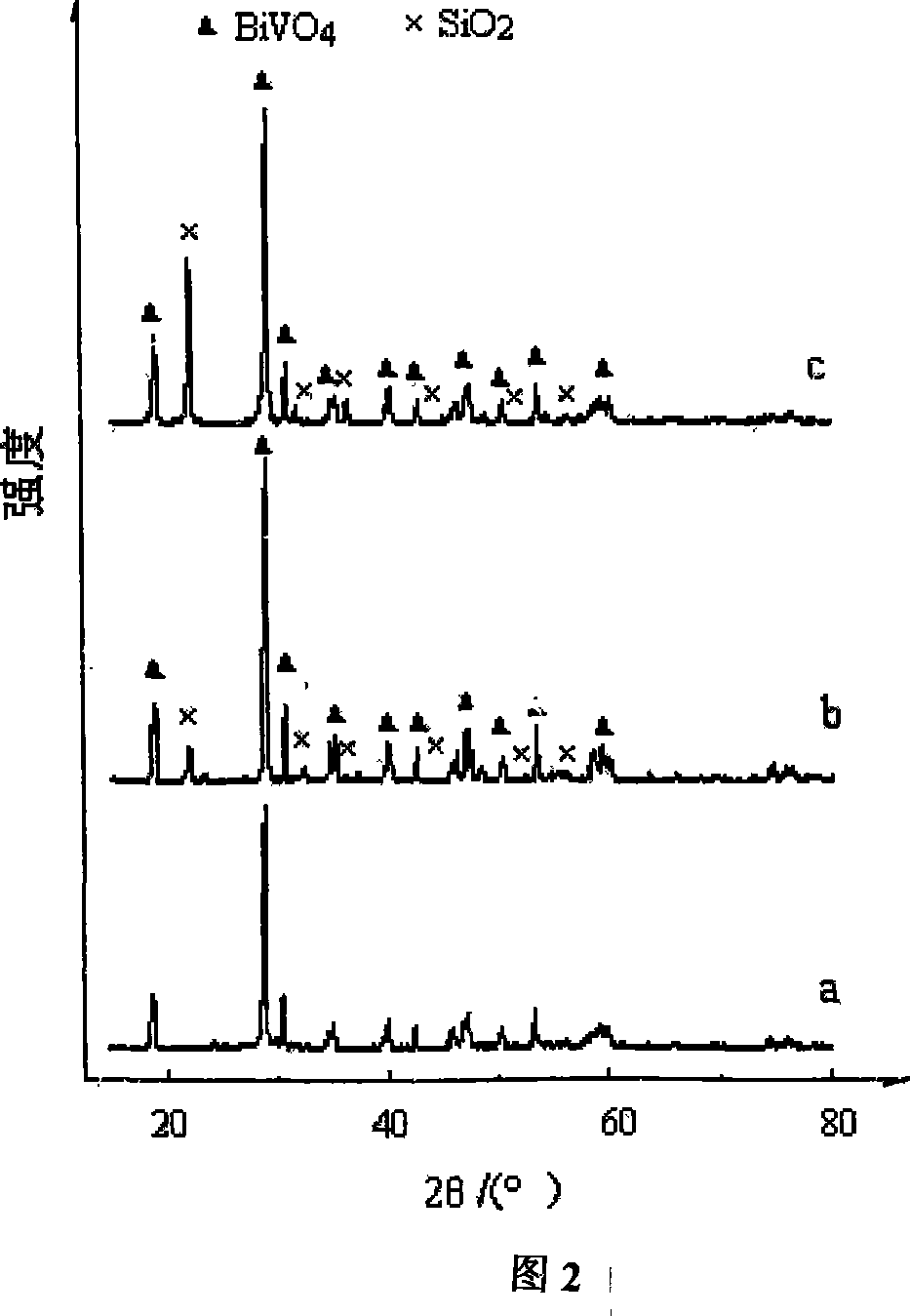

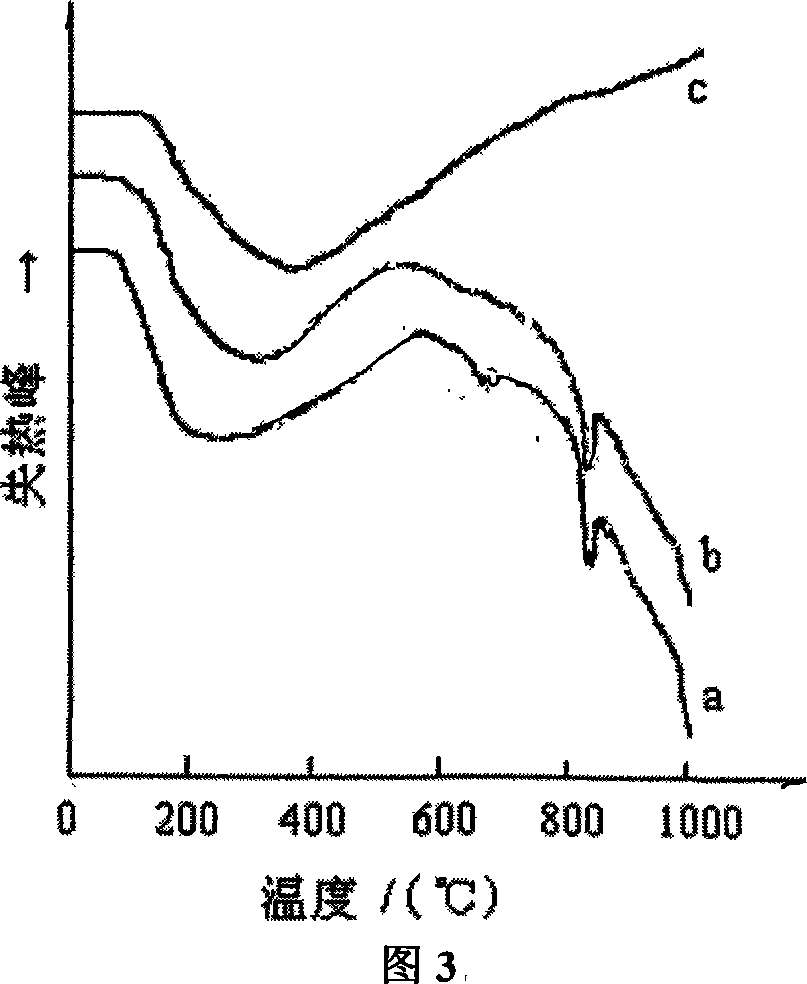

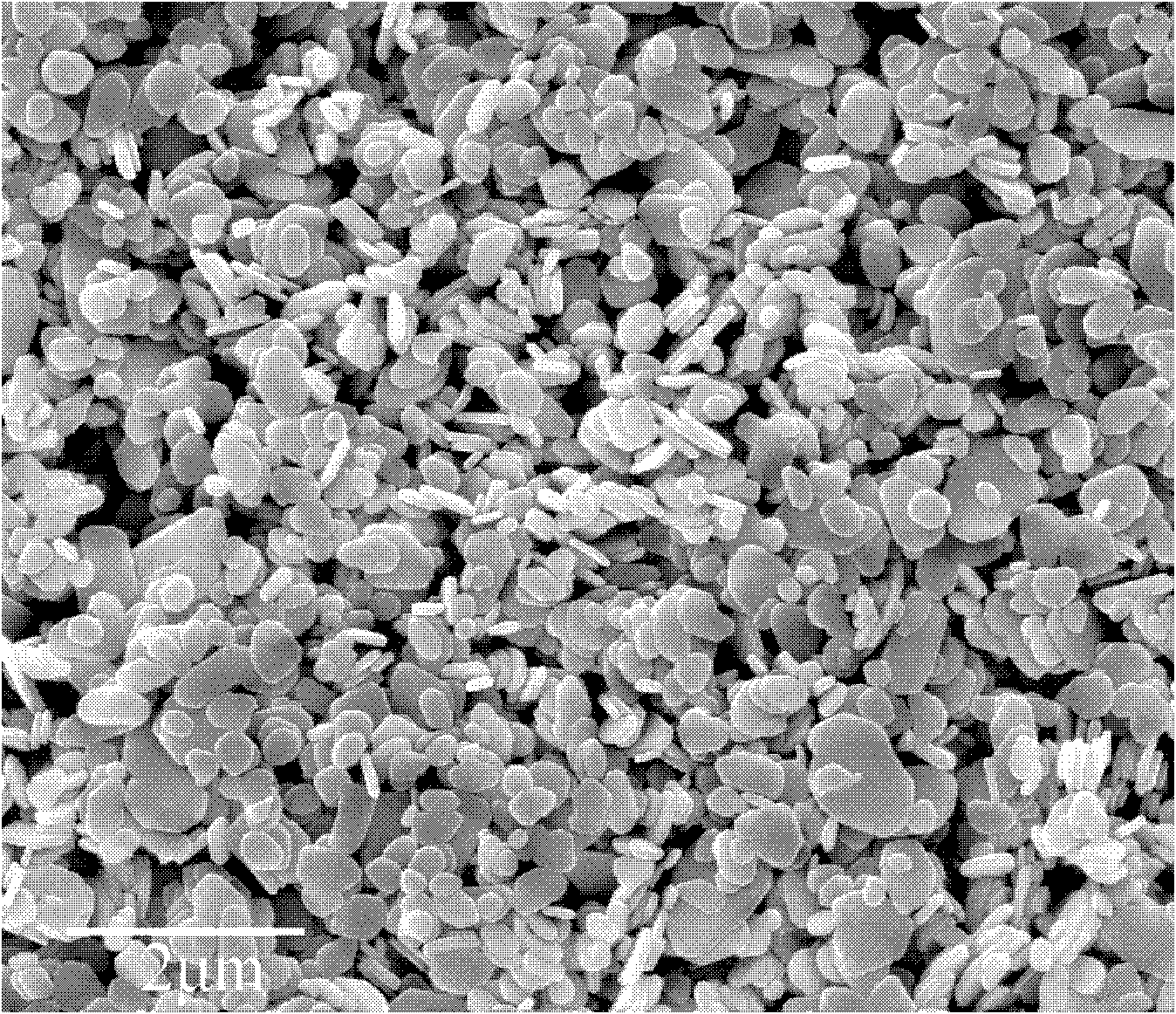

Production process of high-temp resistant bismuth vanadate yellow ceramic pigment

This invention relates to production process of pucherite yellow ceramic pigment, which takes sodium silicate as raw material to coat silicon dioxide. It takes sodium silicate as silicon source, coat silicon dioxide on surface of pucherite. For the strong inertia of silicon dioxide, it be able to withstand 1000 deg high temperature, and keep bright-colored after annealing of 1000 deg. This invention can eliminate harm to human body and pollution to environment in the process of production, solve the problem of heavy metal content are overproof in the export ceramic product of our country.

Owner:SHIJIAZHUANG UNIVERSITY

A kind of bismuth oxycarbonate material of nano-micro scale plate and its preparation method

The invention discloses a nano / micro-scale sheet bismuthyl carbonate material and a preparation method thereof. Micro-morphology of the nano / micro-scale sheet bismuthyl carbonate material is in the shape of a sheet-like particle. The particle size is in a range of 10 to 1000 nm. The preparation method comprises that urea is prepared into a urea aqueous solution; the urea aqueous solution and bismuth nitrate pentahydrate are mixed according to a certain proportion; the mixed solution is maintained at a temperature of 100 to 200 DEG C under the pressure above 3MPa for 1 to 4 hours to undergo a reaction; after the reaction, the reaction products are cooled in air to room temperature; and the cooled products are filtered by a pump, washed by water and dried at room temperature to form the nano / micro-scale sheet bismuthyl carbonate material. The nano / micro-scale sheet bismuthyl carbonate material has the advantages of good dispersibility, high purity, high bismuth recovery rate above 90%, no need of addition of any organic solvent in preparation, and no damage on human bodies and the environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com