Bismuth vanadate powder and preparation method thereof

A bismuth vanadate and powder technology, which is applied in chemical instruments and methods, bismuth compounds, vanadium compounds, etc., can solve the problems of special reactants, complex reaction conditions, and unsuitability for industrial production, and achieve low energy consumption and cost, The effect of high photocatalytic activity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

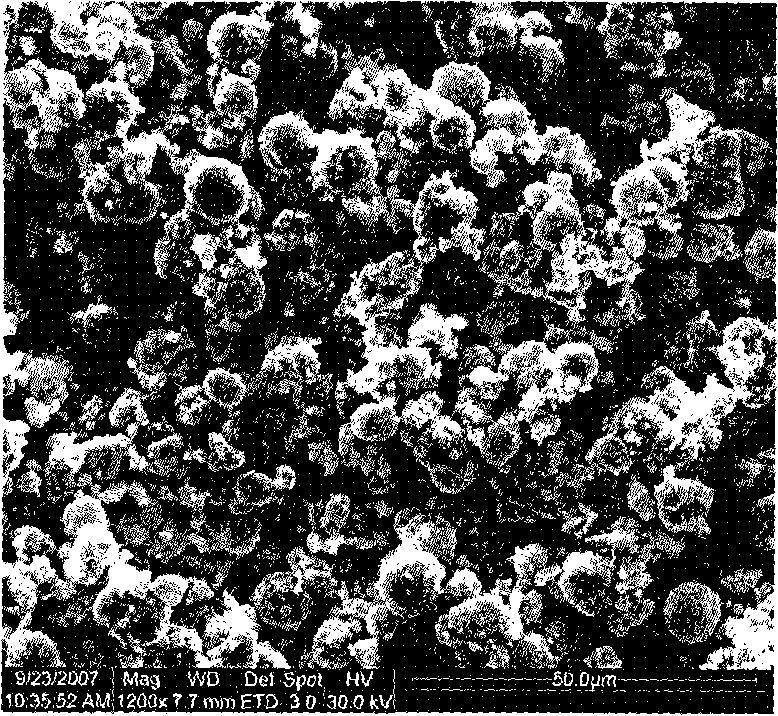

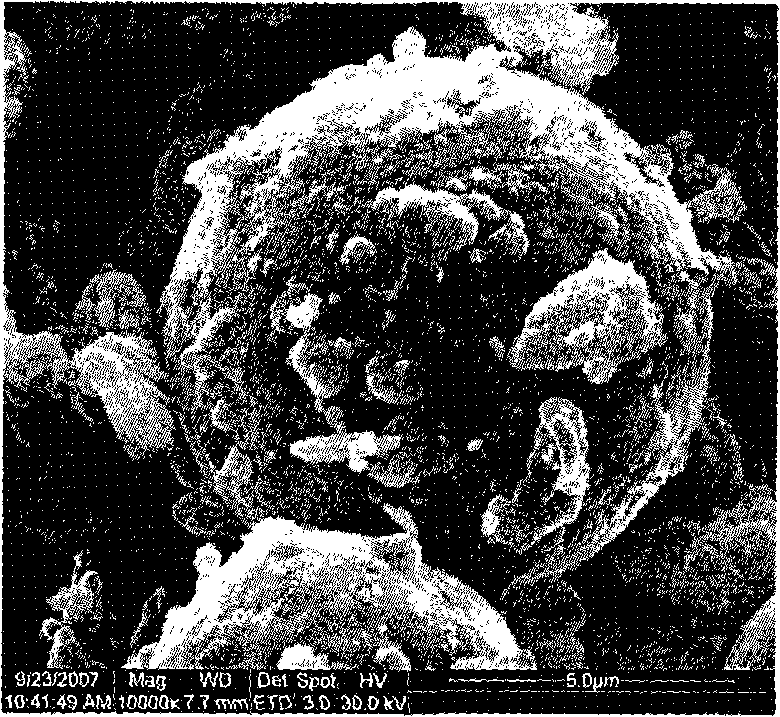

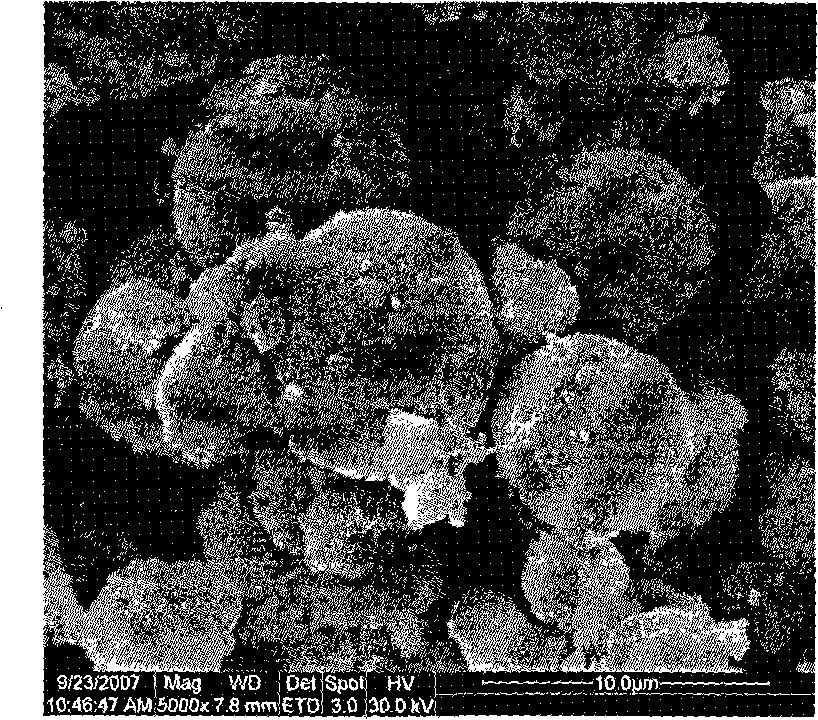

Image

Examples

Embodiment 1

[0024] Embodiment 1: take by weighing an appropriate amount of Bi(NO 3 ) 3 ·5H 2 O dissolved in 0.5mol / L HNO 3 solution, forming a colorless transparent solution. Weigh an appropriate amount of NH 4 VO 3 Soluble in 0.5mol / L HNO 3 solution, forming a reddish-brown solution. According to the bismuth: vanadium: nitric acid molar ratio of 1:1:2.5 will contain NH 4 VO 3 HNO 3 The solution was added dropwise to the Bi(NO 3 ) 3 HNO 3 In the solution, after magnetic stirring for 2 hours, the solution changed from reddish brown to yellow, and a yellow precipitate appeared. Adjust the pH of the above solution to 6.5 with ammonia water, and stir magnetically for 2 hours; according to the molar ratio of bismuth: vanadium: nitric acid: CTAB of 1:1:2.5:0.025, add CTAB to the above yellow solution, and stir magnetically for 2 hours to form BiVO 4 precursors. BiVO 4The precursors were put into the reactor and treated with hydrothermal treatment at 80°C for 72 hours. Centrifuge...

Embodiment 2

[0026] Embodiment 2: take by weighing an appropriate amount of Bi(NO 3 ) 3 ·5H 2 O dissolved in 0.5mol / L HNO 3 solution to form a colorless transparent solution, weigh an appropriate amount of NH 4 VO 3 Soluble in 0.5mol / L HNO 3 solution, forming a reddish-brown solution. According to the bismuth: vanadium: nitric acid molar ratio of 1:1:2.5 will contain NH 4 VO 3 HNO 3 The solution was added dropwise to the Bi(NO 3 ) 3 HNO 3 In the solution, after magnetic stirring for 2 hours, the solution changed from reddish brown to yellow, and a yellow precipitate appeared. Adjust the pH of the solution to 6.5 with ammonia water, and stir magnetically for 2 hours; according to the molar ratio of bismuth: vanadium: nitric acid: CTAB of 1:1:2.5:0.025, add CTAB to the above yellow solution, and stir magnetically for 2 hours to form BiVO 4 precursors. BiVO 4 The precursors were put into the reactor and treated with hydrothermal treatment at 120°C for 72 hours. After cooling, c...

Embodiment 3

[0028] Embodiment 3: take by weighing an appropriate amount of Bi(NO 3 ) 3 ·5H 2 O dissolved in 0.5mol / L HNO 3 solution, forming a colorless transparent solution. Weigh an appropriate amount of NH 4 VO 3 Soluble in 0.5mol / L HNO 3 solution, forming a reddish-brown solution; according to the bismuth: vanadium: nitric acid molar ratio of 1:1:2.5 will contain NH 4 VO 3 HNO 3 The solution was added dropwise to the Bi(NO 3 ) 3 HNO 3 In the solution, after magnetic stirring for 2 hours, the solution changed from reddish brown to yellow, and a yellow precipitate appeared. Adjust the pH of the solution to 6.5 with ammonia water, and stir magnetically for 2 hours; according to the molar ratio of bismuth: vanadium: nitric acid: CTAB of 1:1:2.5:0.025, add CTAB to the above yellow solution, and stir magnetically for 2 hours to form BiVO 4 precursors. BiVO 4 The precursors were put into the reactor and treated with hydrothermal treatment at 160°C for 72 hours. After cooling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average ball diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com