Patents

Literature

343results about How to "Mild production conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

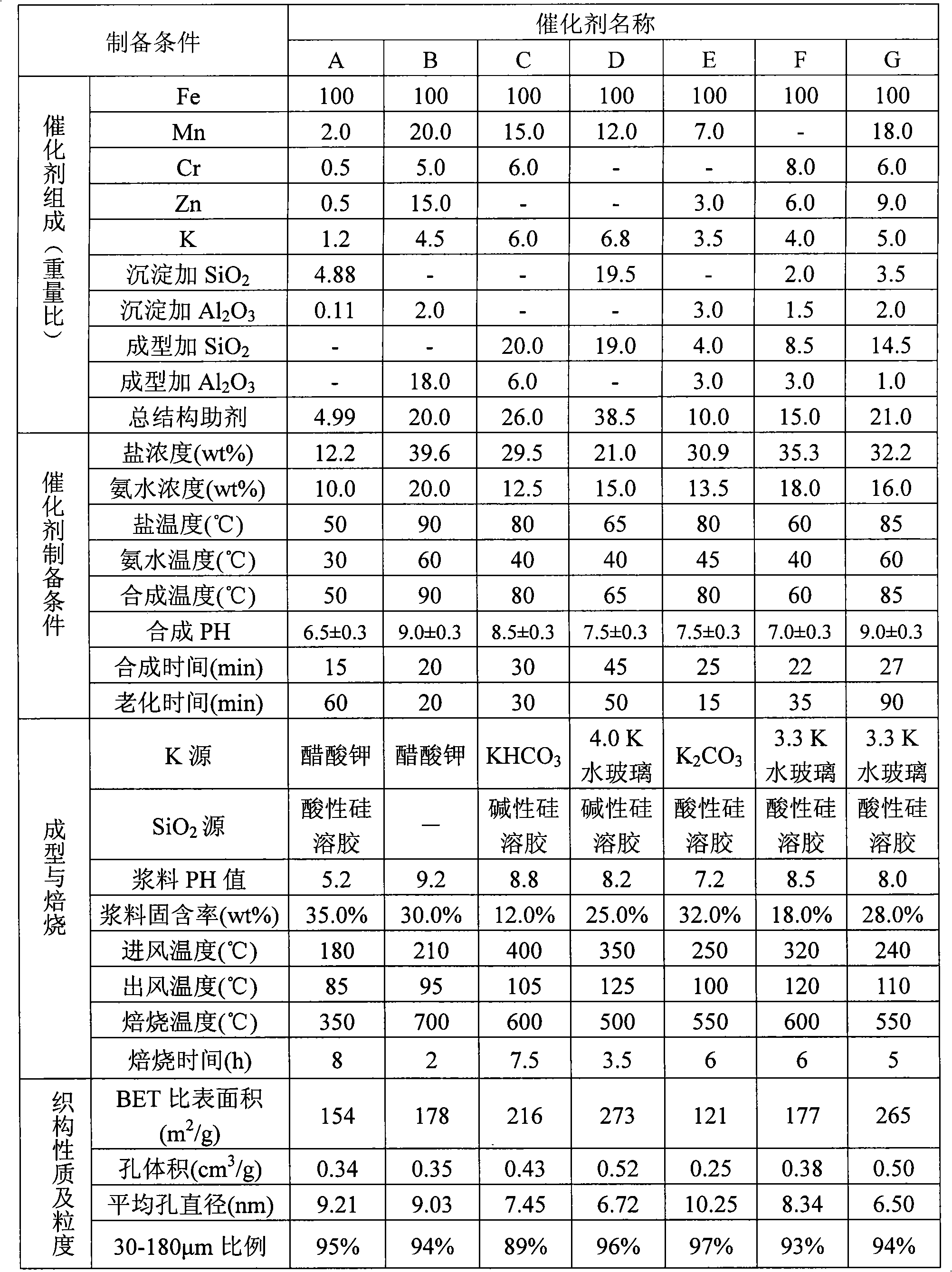

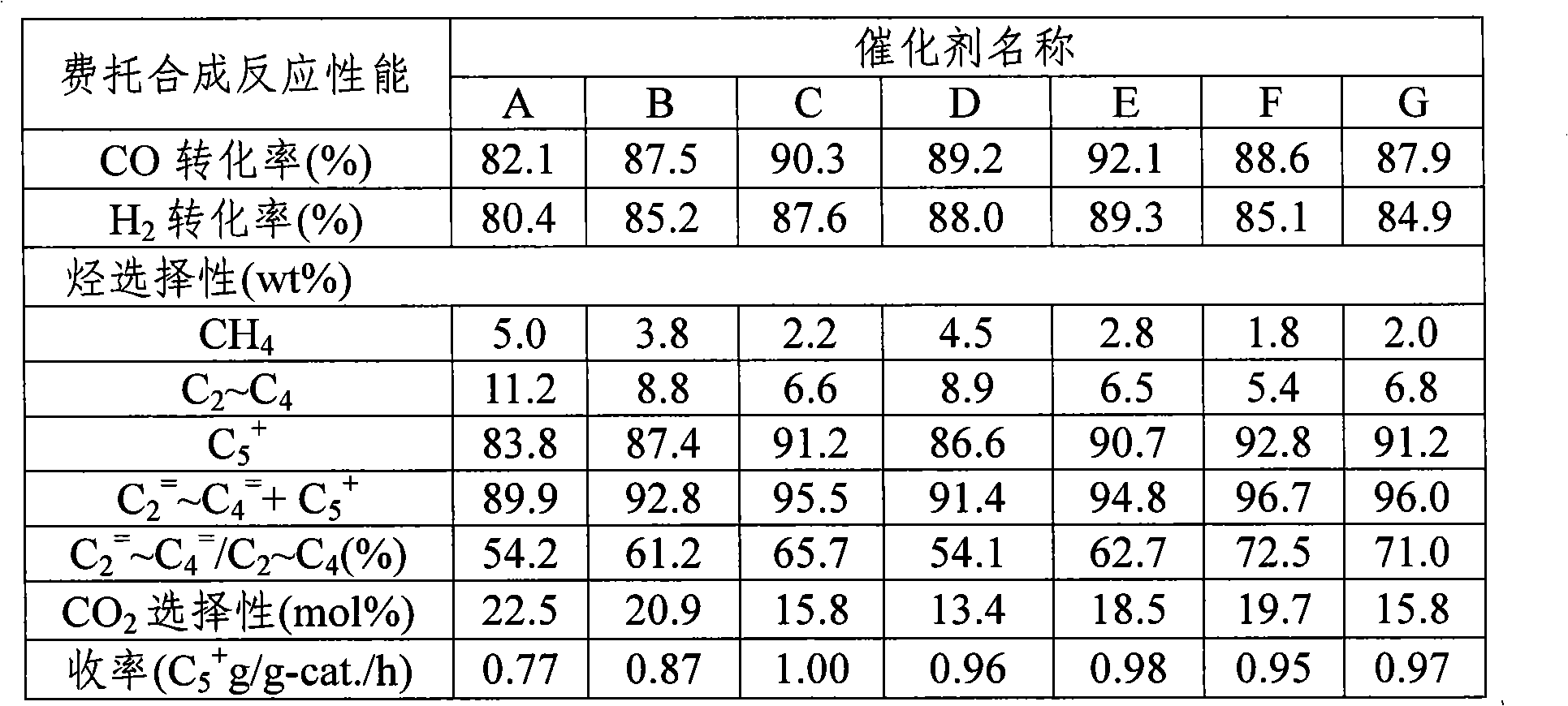

Fischer-Tropsch synthesis catalyst and preparation method and application thereof

InactiveCN101869840AHigh activityOptimize electronic structureHydrocarbon from carbon oxidesHeterogenous catalyst chemical elementsSlurry reactorPtru catalyst

The invention relates to a micro-spherical iron-based catalyst which contains transition metal additive, has high performance and is applicable to the Fischer-Tropsch synthesis of a slurry reactor, and a preparation method and the application thereof; and the weight composition of the catalyst is as follows: Fe: transition metal additive M: structural additive (SiO2 or / and Al2O3):K=100:1 to 50:1 to 50:0.5 to 10. The preparation method of the catalyst comprises the following steps: adding the structural additive into Fe / M mixed nitrate solution, co-precipitating with ammonia to prepare slurry; filtering and washing the slurry to obtain a filter cake; and adding the required amount of K additive and water into the filter cake, beating, spraying, drying and calcining to obtain the Fischer-Tropsch synthesis iron-based catalyst of the micro-spherical slurry reactor. The catalyst prepared by the method has good anti-wear performance, the distribution scope of the grain size of the catalyst is narrow, the synthesis gas conversion capability is high, the product selectivity is good and the time-space yield is high, and the Fischer-Tropsch synthesis reaction of the slurry reactor can be carried out within a wider scope of temperature simultaneously.

Owner:SYNFUELS CHINA TECH CO LTD

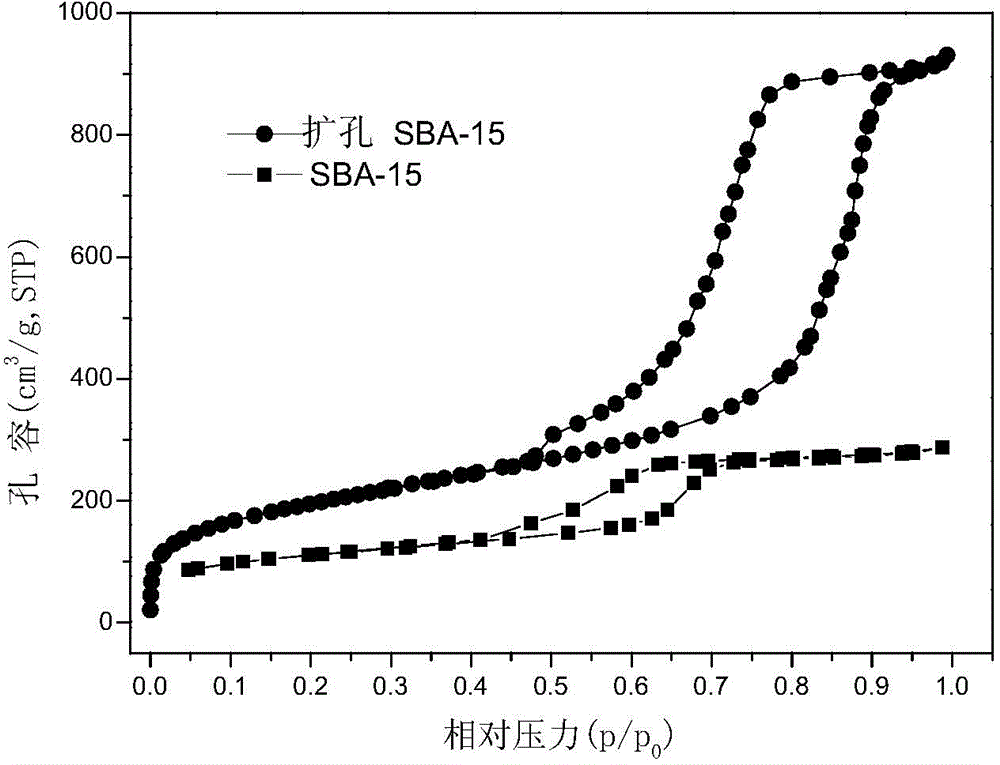

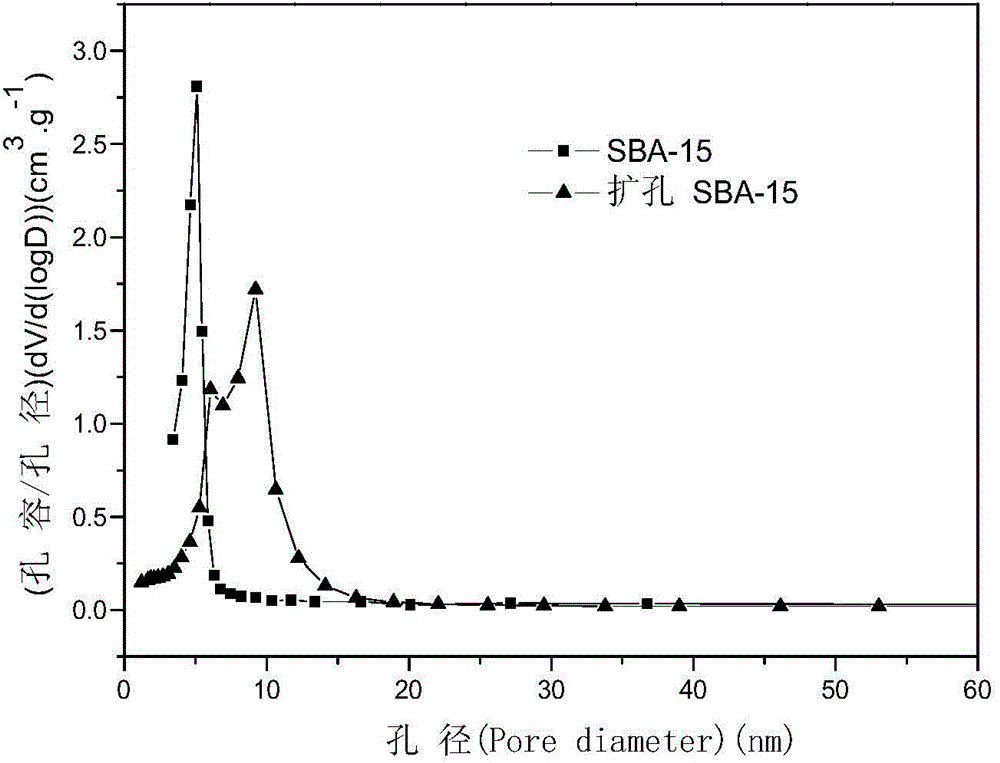

Method for preparing bifunctional mesoporous silica for adsorbing heavy metal ions in water

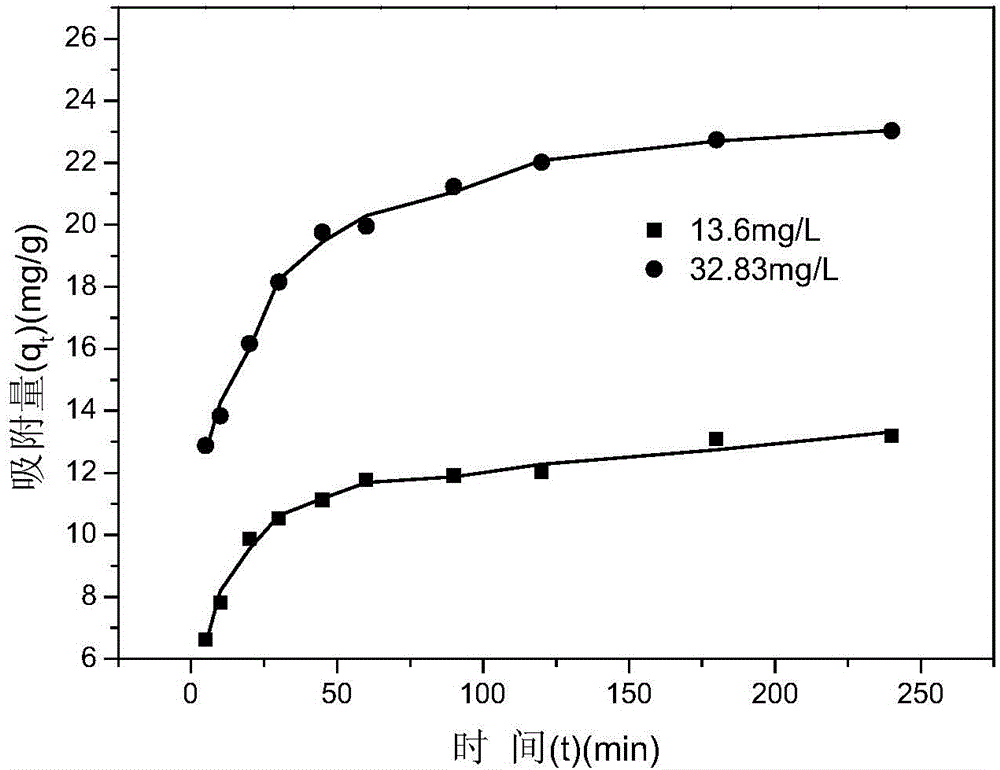

ActiveCN104148021AMild production conditionsGood adsorption effectOther chemical processesWater/sewage treatment by sorptionIonCompound (substance)

The invention discloses a method for preparing bifunctional mesoporous silica for adsorbing heavy metal ions in water. The method comprises the following steps: P123 is used as a structure-directing agent, mesitylene is used as a hole-enlarging agent, and mesoporous silica with large hole diameter is prepared by adopting a hydrothermal synthesis method; then, a post-grafting method is adopted, a triamine silane coupling agent (3-[2-(2-Aminoethylamino)ethylamino]propyl-trimethoxysilane) and disodium edetate dihydrate are successively used as a modifying agent, and finally the bifunctional mesoporous silica with the large hole diameter is synthesized. The adsorbent preparation process is mild in production condition and is conducted at room temperature, and other chemical reagents are not needed. The adsorption effect is good, and production cost is reduced. Meanwhile, environmental pollution is reduced, and the bifunctional mesoporous silica has a good application prospect.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Production method of high purity oligoxylose

ActiveCN1556110ARaw materials are cheap and easy to getIncrease valueOligosaccharidesUltrafiltrationMacromolecular Substances

Owner:河南益常青生物科技有限公司

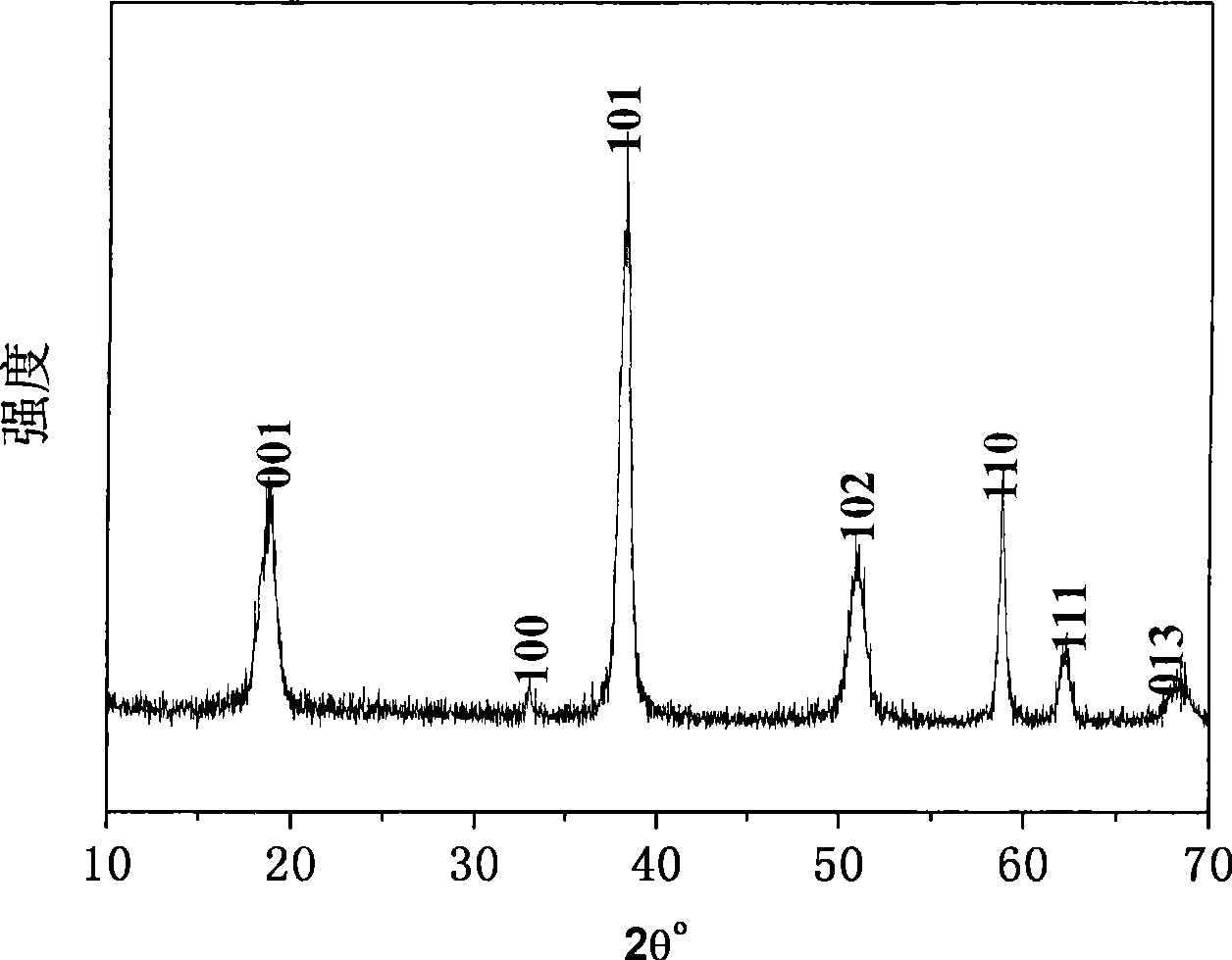

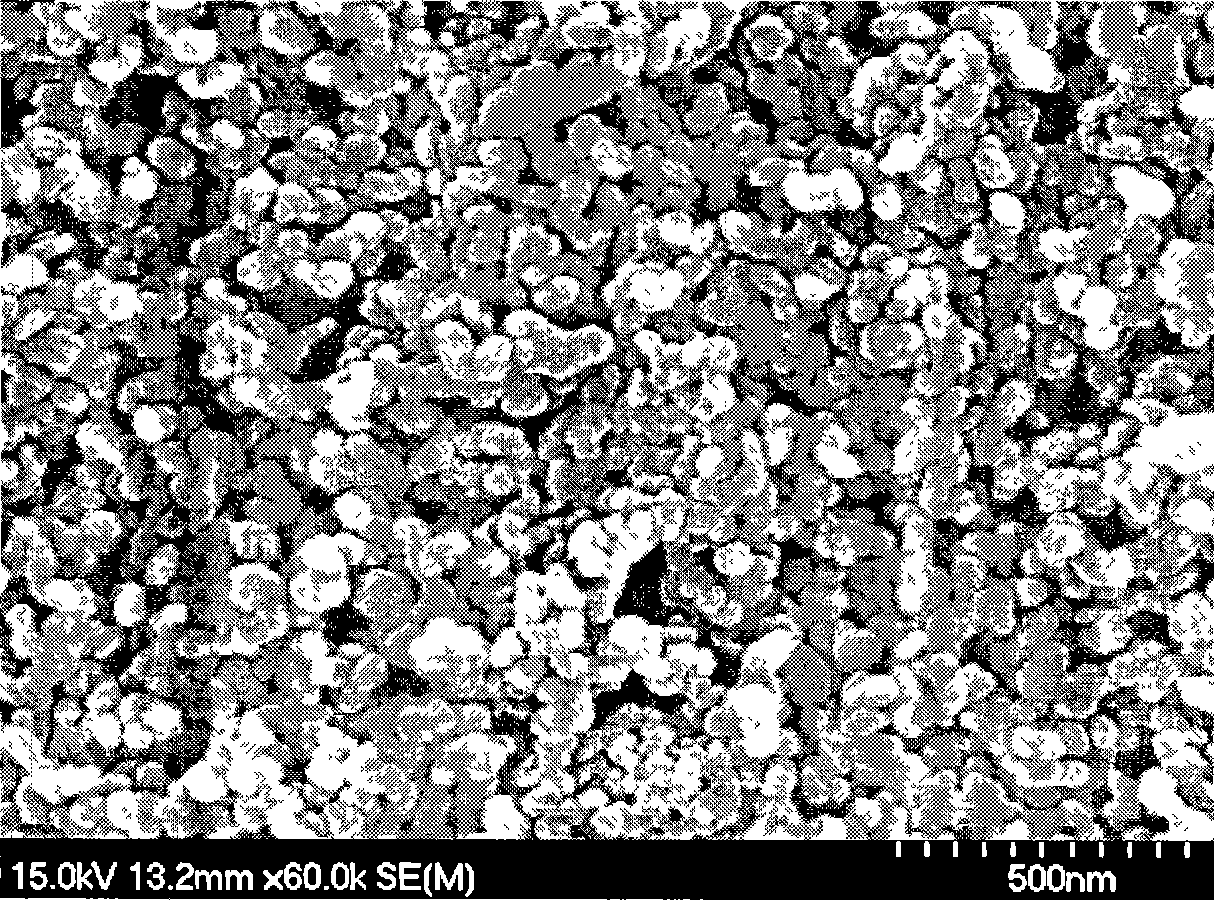

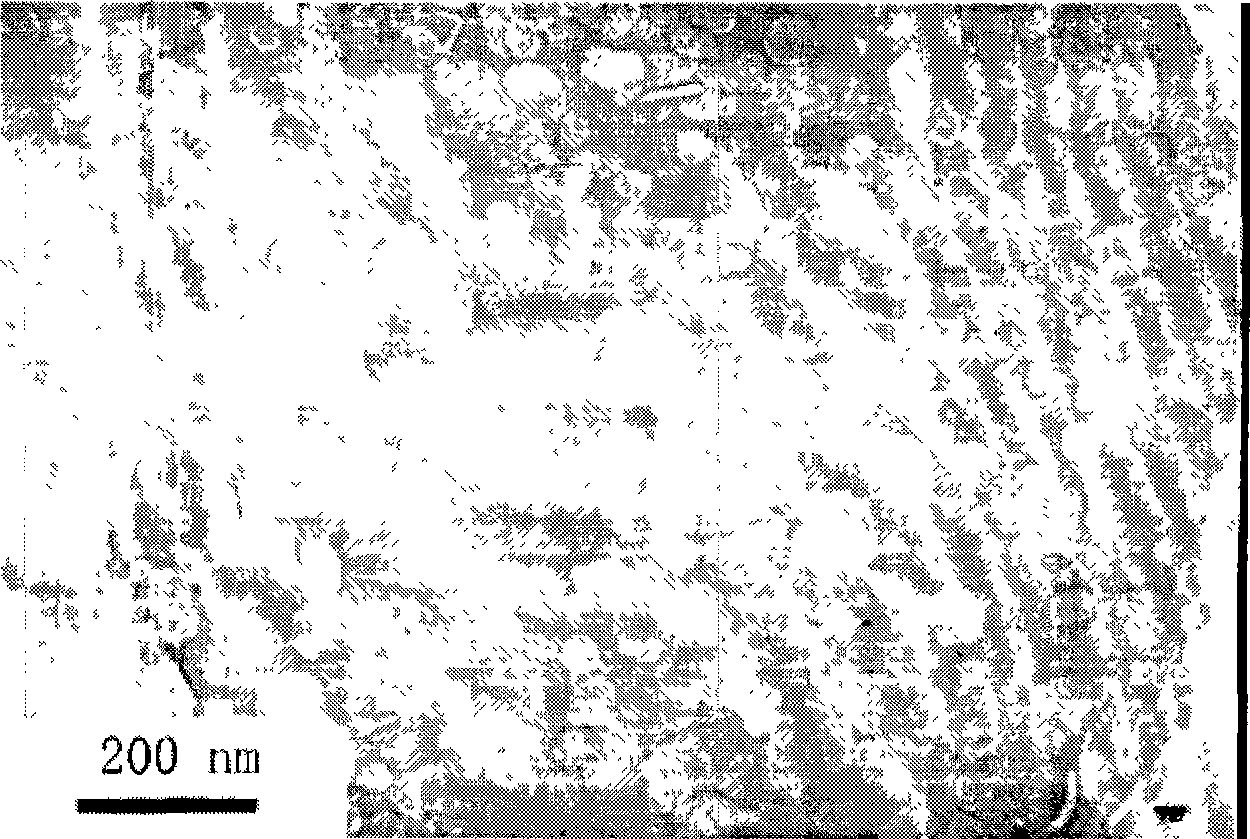

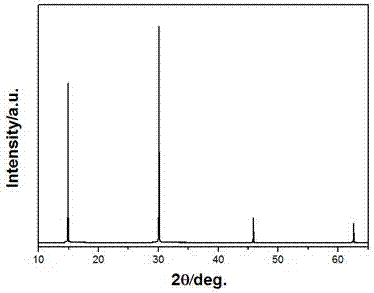

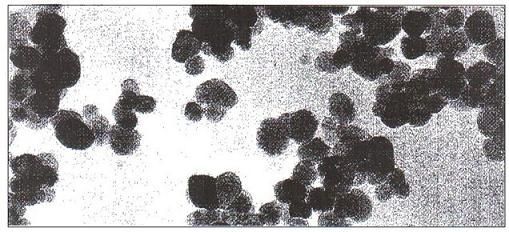

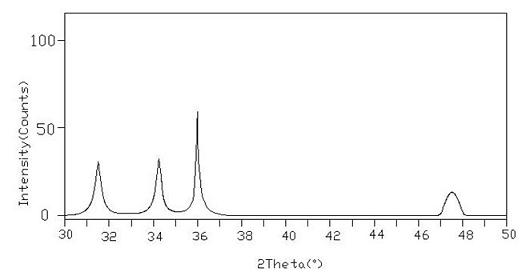

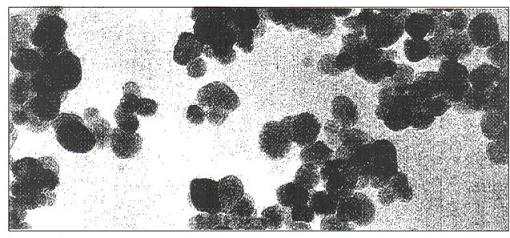

Preparation of nano magnesium hydrate

InactiveCN101376511AShorten aging timeHigh crystallinityNanostructure manufactureMagnesium hydroxideUltrasonic cavitationMagnesium salt

The invention relates to a preparation method of nano-sized magnesium hydroxide, which is characterized in that a soluble magnesium salt solution and soluble lye which are added with a dispersant react in a reactor which is put in an ultrasonic tank and provided with a stirrer to obtain magnesium hydrate suspension; the magnesium hydrate suspension is processed through ultrasonic ageing at room temperature; the magnesium hydrate which is processed through ageing is dried through heating to obtain nano-sized magnesium hydroxide powders after being filtered and washed. The ultrasonic wave which is exerted during the reaction process promotes the nucleation, inhibits crystal nucleus growth velocity, and controls the size and the distribution of particles; the ultrasonic cavitation avoids the occurrence of aggregate phenomenon, and increases the uniformity and the dispersibility of nano particles; the thermal effect of the ultrasonic wave increases the crystallinity degree of the nano particles and shortens the ageing time of samples. Therefore, the preparation method has the advantages of simple technology, short production period, mild production conditions, good product dispersibility, and even particle distribution.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

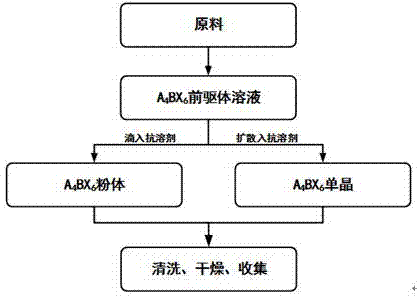

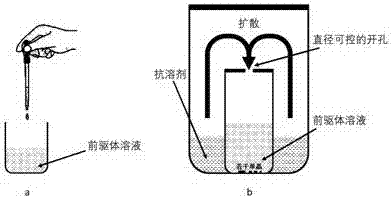

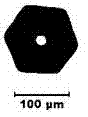

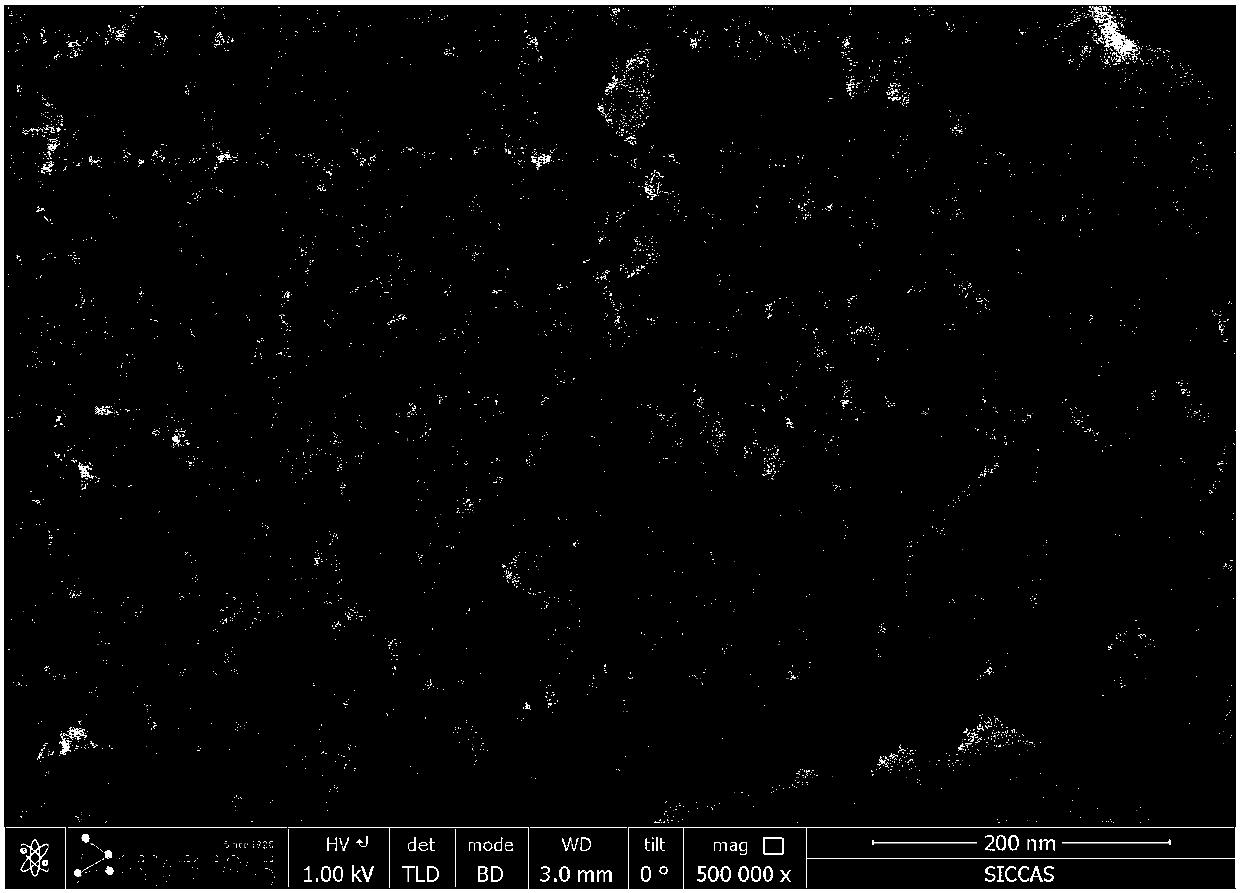

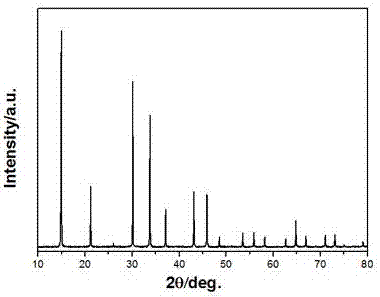

Zero dimension perovskite structure luminescent material A4BX6 and preparation method thereof

ActiveCN107267144AImprove luminous efficiencySingle crystal with few defectsPolycrystalline material growthTin compoundsSolubilityAnti solvent

The invention discloses a zero dimension perovskite structure luminescent material A4BX6 and a preparation method thereof. The preparation method comprises the steps of utilizing a principle that the solubility of a solute in a precursor solution can be reduced through an anti-solvent, dripping or slowly diffusing the anti-solvent into the precursor solution so as to prepare the zero dimension perovskite structure efficient luminescent material A4BX6 powder or a single crystal, and concretely, dissolving an A-containing halogen compound and a B-containing halogen compound or B-containing oxide into a solvent to obtain the precursor solution; slowly dripping or diffusing the precursor solution into the anti-solvent, and separating out the zero dimension perovskite structure luminescent material A4BX6 from the precursor solution. The method has the advantages that the obtained zero dimension perovskite structure luminescent material A4BX6 has high purity, the luminous efficiency is high, the requirement on the used equipment is simple, and the like.

Owner:KUNMING UNIV OF SCI & TECH

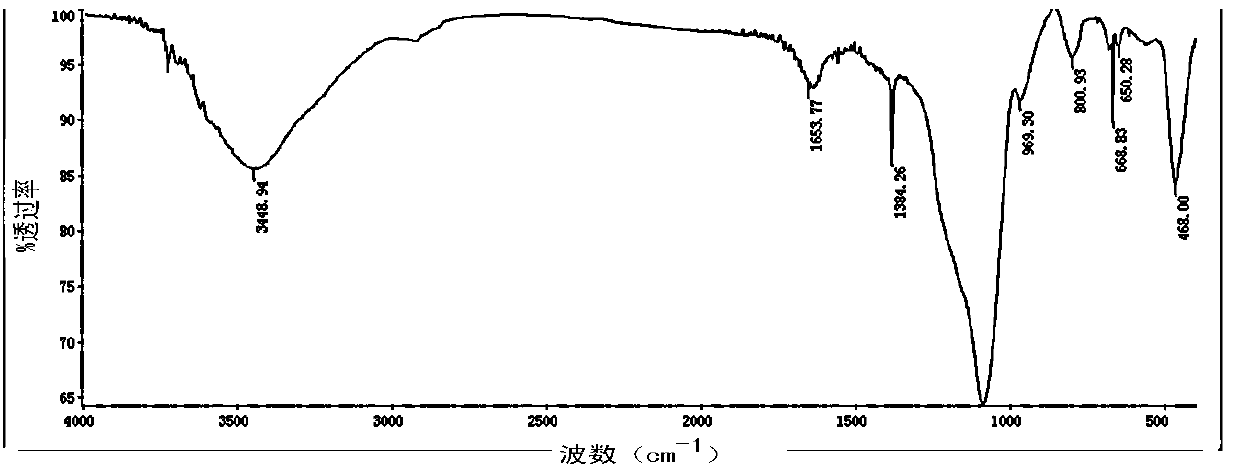

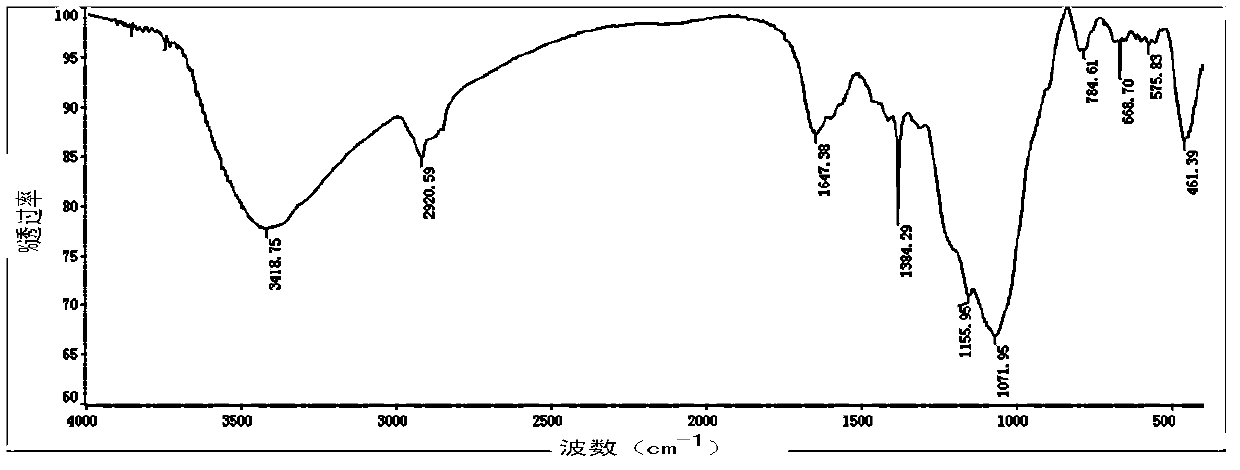

Silicon oxide-chitosan composite aerogel and preparation method thereof

The invention relates to a silicon oxide-chitosan composite aerogel and a preparation method thereof. The silicon oxide-chitosan composite aerogel comprises chitosan, a chitosan cross-linking agent and silicon oxide, wherein the mass fraction of the chitosan is 9%-65%, the mass fraction of the silicon oxide is 30%-90%, and the mass fraction of the chitosan cross-linking agent is 1%-5%.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-thermal-conductivity graphene-based composite film and preparation method thereof

ActiveCN108658615AImprove heat transfer performanceImprove mechanical propertiesCarbon compoundsComposite filmRoom temperature

The invention discloses a high-thermal-conductivity graphene-based composite film and a preparation method thereof. Based on the mass percentage of solid raw materials, the graphene-based composite film is prepared from the following raw materials: 40-70% of graphene oxide, 30-60% of stabilizer, 1-3% of surfactant and 1-10% of reinforcing agent; the preparation comprises the following steps: mixing a graphene oxide dispersion, the stabilizer, the surfactant and the reinforcing agent dispersion, performing ultrasonic treatment, and stirring uniformly to obtain a graphene oxide-based composite dispersion; obtaining a graphene oxide based composite film by a solution film forming process; finally, performing secondary hot-pressing reduction to obtain the graphene oxide-based composite film. Thickness of the graphene-based composite film disclosed by the invention is controllable at 10-50 microns, the thermal conductivity on the room-temperature surface is 800-1,600Wm<-1>k<-1>, the tensilestrength can reach 10-30MPa, and the graphene oxide-based composite film is not broken when bent at 180 DEG C.

Owner:SOUTH CHINA UNIV OF TECH +1

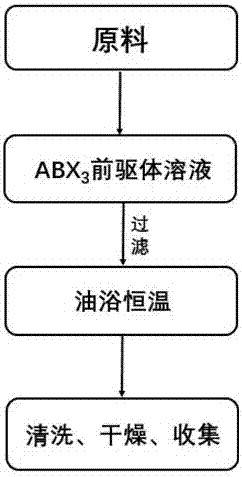

Process for preparing perovskite structure light-emitting material through temperature inversion method

InactiveCN107338044AImprove luminous efficiencyMild production conditionsOrganic compound preparationZinc compoundsHalogenPhysical chemistry

The invention discloses a process for preparing a perovskite structure light-emitting material through a temperature inversion method. The process comprises: 1, dissolving an A-containing halide and a B-containing metal halide or oxide in a solvent M, and filtering the obtained solution to obtain a precursor solution, wherein A is the mixture comprising one or a plurality of materials selected from CH3NH3<+>, Cs<+>, H2N-CH=NH2<+>, (CH3)4N<+>, C7H7<+> and C3H11SN3<2+>, B is the mixture comprising one or a plurality of materials selected from Pb, Ge and Sn, and X is the mixture comprising one or a plurality of halogen elements selected from Cl, Br and I; 2, placing the container filled with the precursor solution into an oil bath with a temperature of 50-200 DEG C for 0.5-5 h, and precipitating ABX3 at the bottom portion of the container; and 3, washing the precipitated ABX3 by using a solvent N, carrying out vacuum drying for 0.5-48 h at a temperature of 20-200 DEG C, and carrying out sealed storage. With the technical scheme of the present invention, the prepared perovskite structure light-emitting material ABX3 has advantages of high purity, high light-emitting efficiency, short production period, simple requirement on the equipment, and the like.

Owner:苏州虹霞晶体科技有限公司 +1

Mushroom instant food and production method thereof

ActiveCN102511782AImprove utilization efficiencyNothing producedFood preparationFiberShiitake mushrooms

The invention relates to a mushroom instant food and a production method thereof, and belongs to the field of food processing technology. Dried mushroom whole plants or mushroom handles are screened, removed with impurities and treated with rehydration, texture improvement, seasoning adsorption and changing temperature cooking, etc., so as to obtain the instant food with good palatability and strong mushroom fragrance. Dried mushroom whole plants or mushroom handles are used as raw materials and treated with rehydration, rinsing, immersion, blanching, rolling, texture improvement, seasoning adsorption, dehydration for drying and changing temperature cooking to prepare strip, sheet, soft thread or powdered mushroom instant food with special mushroom fragrance, loose, soft and crisp mouthfeel. The invention expands application scope of instant mushroom; and the product contains high protein, high meal fiber, low fat, low sugar and no starch or any artificial synthesized additive, can be eaten with rice or bread or instantly and is convenient, healthful and nutrient.

Owner:JILIN WEIYIKANG BIOLOGICAL SCI & TECH

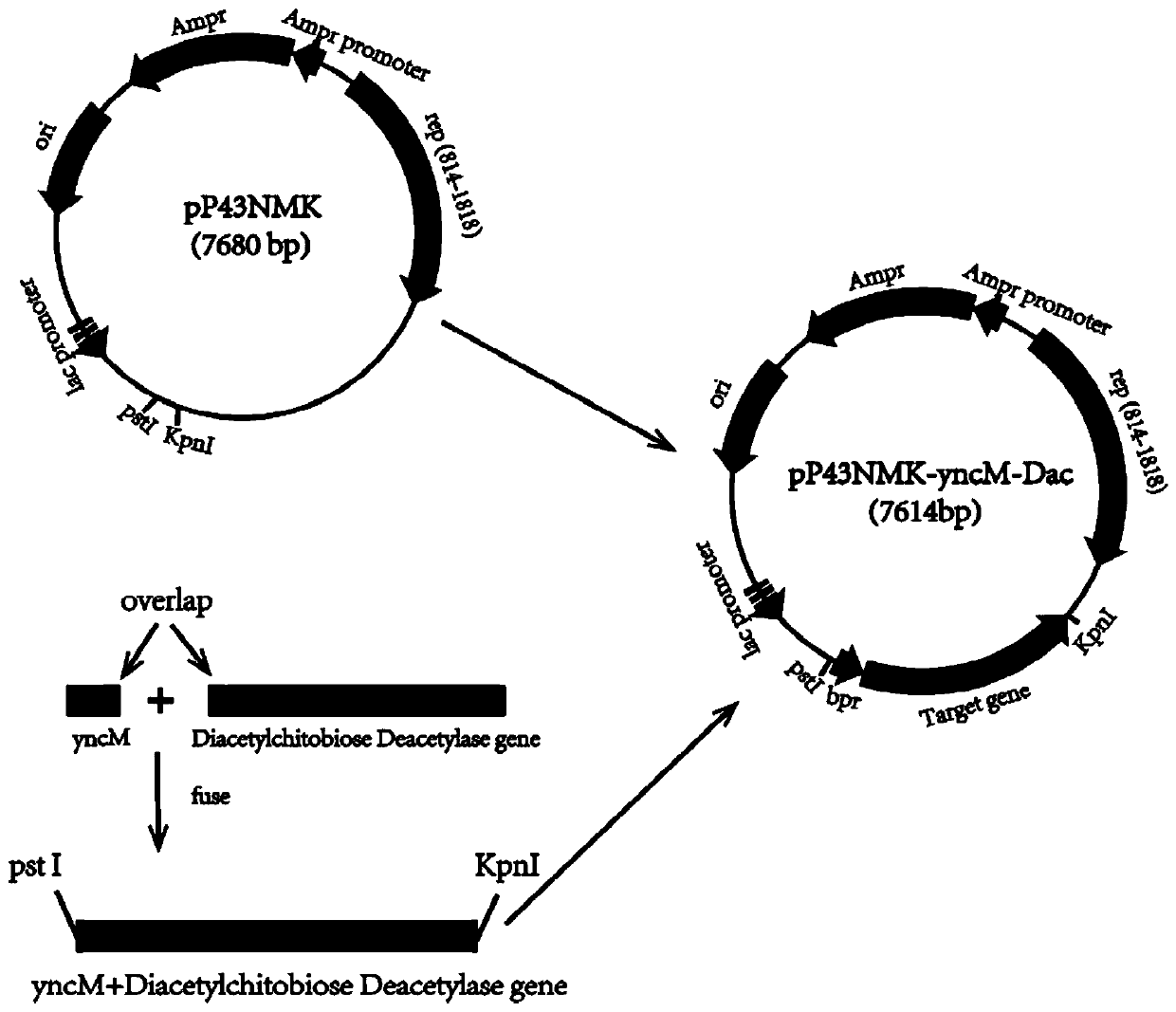

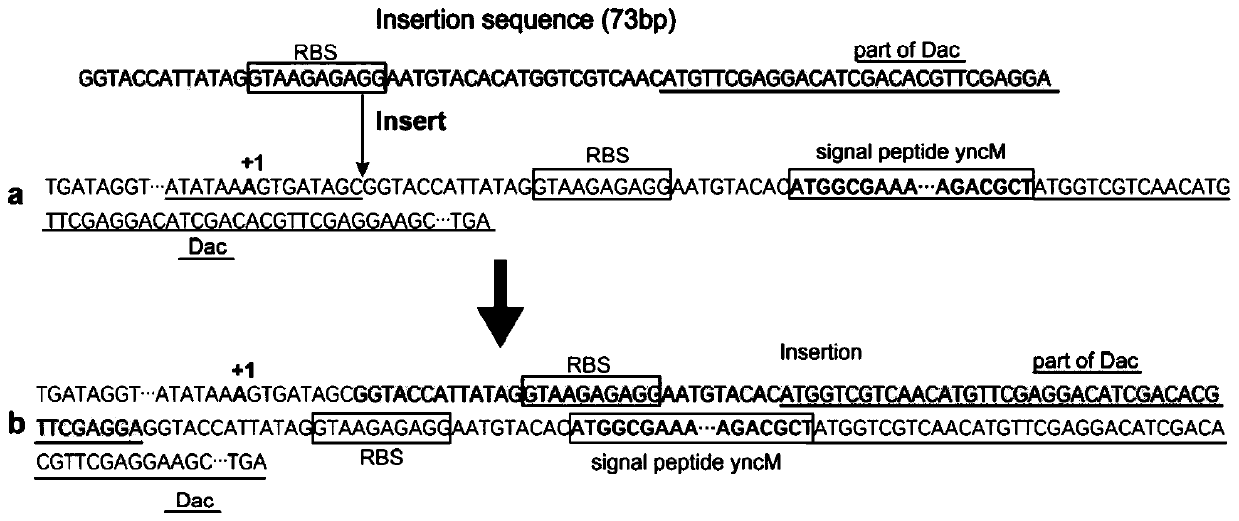

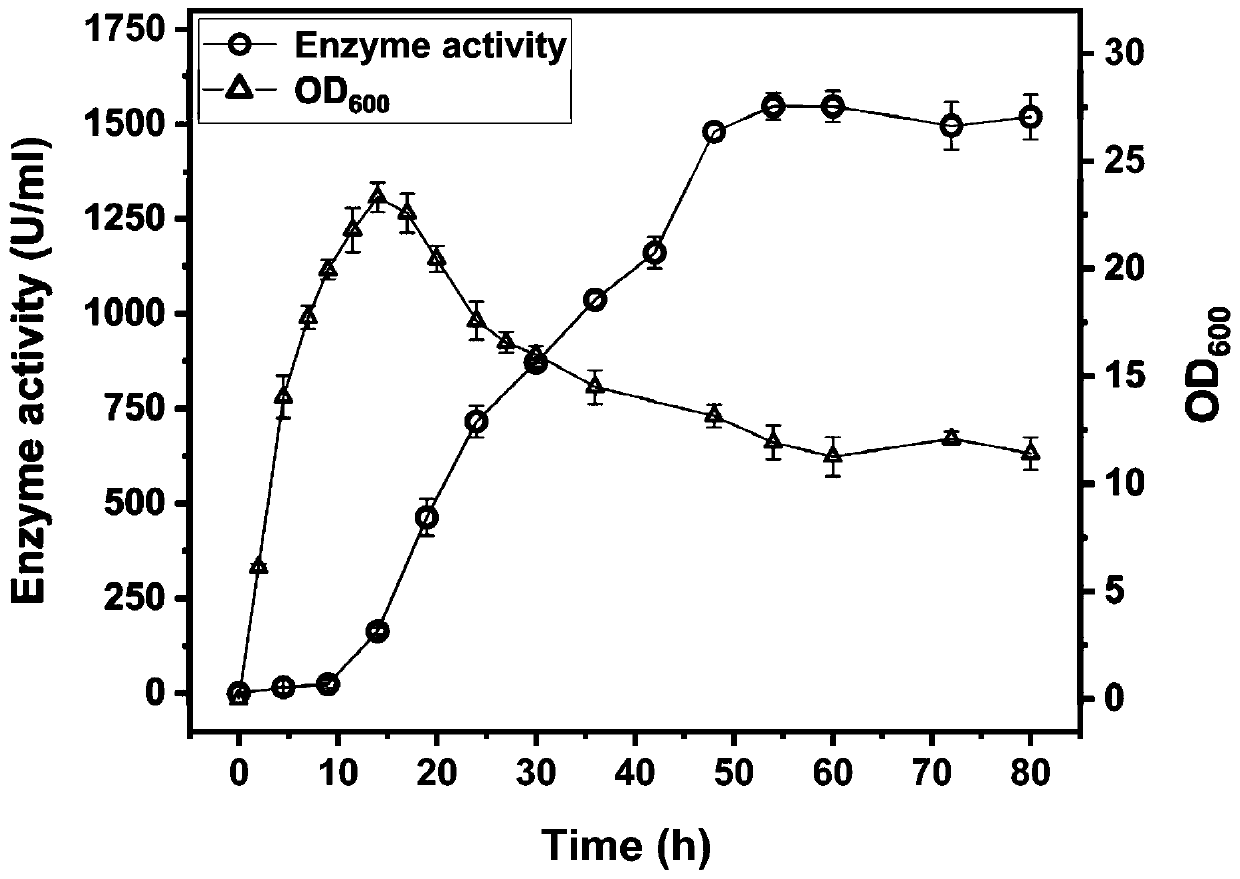

Construction and application of engineering bacteria secreting and expressing chitosan deacetylase

ActiveCN109777761AHigh expressionSimplify separation and purification stepsOrganic active ingredientsBacteriaHeterologousProtein target

The invention discloses a construction and application of an engineering bacteria secreting and expressing chitosan deacetylase, belonging to the technical field of fermentation engineering. The construction firstly constructs a recombinant Bacillus subtilis secreting and expressing chitosan deacetylase gene by a different source, and adds a signal peptide fragment yncM in the recombinant vector for a first time, wherein the signal peptide can secrete target protein chitosan deacetylase outside cells of the recombinant Bacillus subtilis, and obtain mutants in a non-translation region at 5' end, so that the expression of the target protein is significantly increased and steps of subsequent enzyme separation and purification are greatly simplified. The enzyme activity of obtained chitosan deacetylase is up to 1548.7 U / mL and the yield of chitosan deacetylase is up to 620 mg / L when fermentation medium is fermented and cultured for 50-60 hours. And meanwhile, the method has the advantages of low production cost, mild production conditions, simple purification process, safe operation and the like.

Owner:JIANGNAN UNIV +1

Hydroxymethylated lignin and application thereof

The invention relates to the technical field of organic chemical engineering, especially a hydroxymethylated lignin which is prepared by the following steps: after filtering lignin with black liquor, reacting with formaldehyde at 60-90 DEG C for 1-2 hours, adding acetone to continue the reaction for 1-2 hours, cooling to room temperature after the reaction finishes, carrying out acid precipitation, filtering and drying to obtain the hydroxymethylated lignin. The invention also relates to application of the hydroxymethylated lignin in preparing polyurethane foam. The used lignin is corn cob lignin black liquor, the production conditions are mild, and the lignin in the black liquor still has the structure of the natural lignin and has higher hydroxy content and higher compatibility with polyether glycol; and thus, the hydroxymethylated lignin has the advantages of higher activity, higher purity and higher dispersity. When being used for preparing polyurethane hard foam, the hydroxymethylated lignin lowers the production cost, has excellent properties and enhances the competitive power of the product.

Owner:JINAN SHENGQUAN GRP SHARE HLDG CO LTD

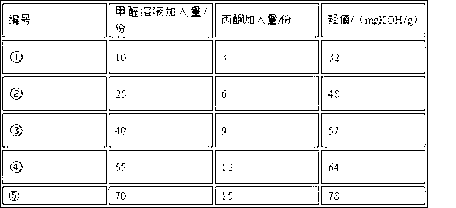

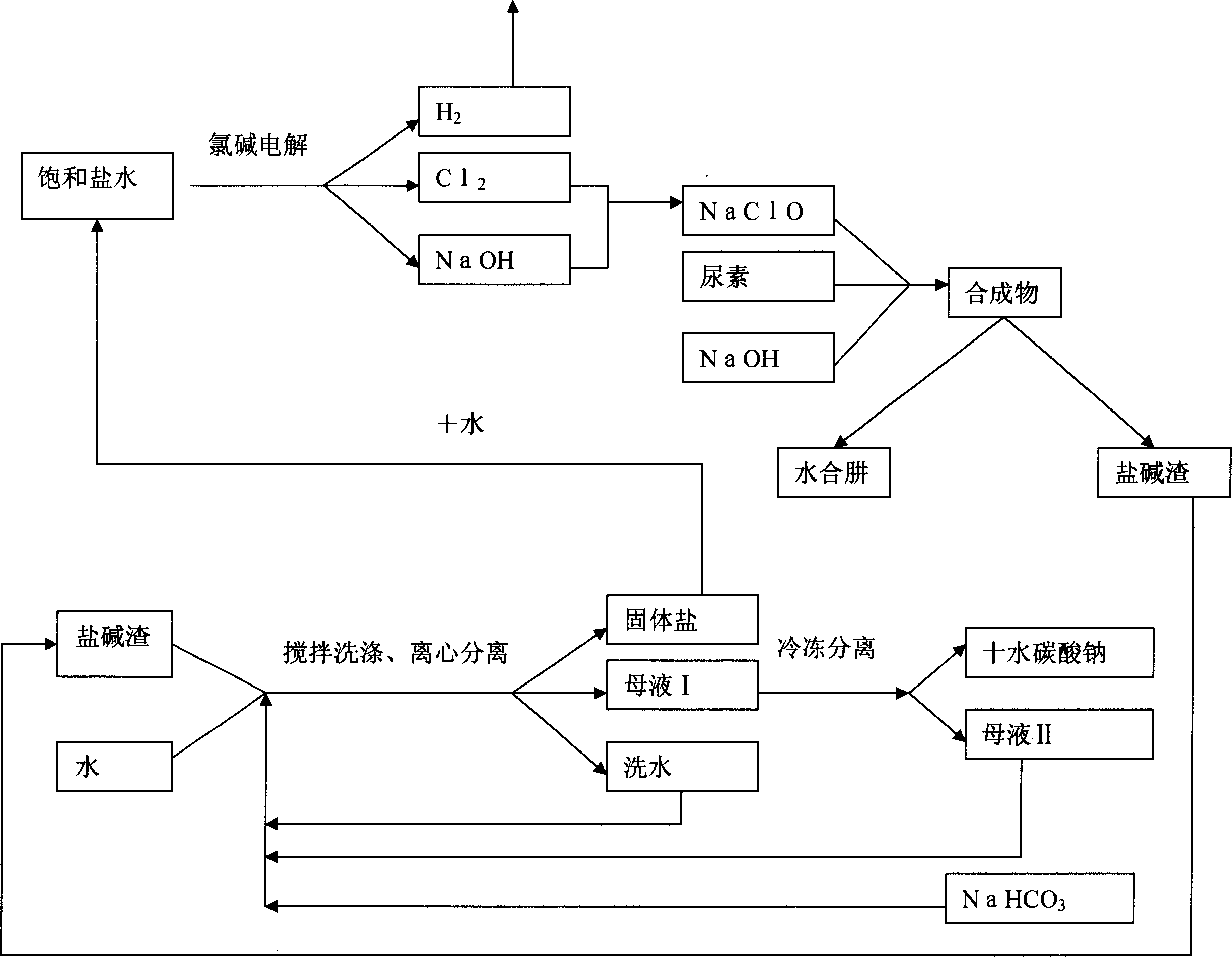

Separation of salt and alkali from waste salt and alkali residue in production of hydrazine hydrate and technique of cyclic utilization

InactiveCN1796280ANo pollutionNo need for external dischargeHydrazineAlkali metal chloridesSodium bicarbonateHydrazine compound

This invention describes a process for the recovery and recycle of industrial waste solids, especially the salt-alkali separation and recycle of the waste salt-alkali solids from the manufacturing of hydrated nitriles. This invention uses water, mother liquid and sodium bicarbonate to wash the waste salt-alkali solids from the manufacturing of hydrated nitriles, so that Na2CO3 and NaOH in the waste salt-alkali solids are washed into the solution. The washing solution is then cooled to 0-5deg.C, and filtrated and separated to obtain solid sodium carbonate decahydrate, which can be commercialized after washing. The mother liquid, after separating the solid alkali, is directed to the next process for washing the waste salt-alkali solids without discharge. During the circulatory washing of the waste salt-alkali solids, the table salt keeps in the solid state. After centrifugal separation, the table salt containing 3% of alkali can be obtained and used for sodium carbonate industry. The said table salt NaCl, after washing and separation to remove a small amount of hydrazine and amine, can be used for chlorine-alkali industry. Chlorine Cl2 and sodium hydroxide NaOH are raw materials for sodium hypochlorite NaClO, which is a raw material for producing hydrazine hydrate. In addition, sodium hydroxide is directly involved in the reaction for producing hydrazine hydrate N2H4íñH2O, thus constituting an internal recycling system of a manufacturing plant without discharging, which not only is environmentally friendly but also reduces transportation load and production cost. This invention describes a rational process for large-scale hydrazine hydrate manufacturing plants.

Owner:陈大元

Preparation of nano aluminum oxide without hard coacervation

InactiveCN1583567AEfficient removalEliminate hard agglomerationAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium nitrateNano al2o3

A process for preparing nano-alumina without hard conglomerations includes such steps as proportionally and respectively dissolving aluminium nitrate and ammonium carbonate in secondary distilled water to obtain their solutions, adding polyethanediol to them to obtain their composite solutions, mixing them together, stirring, centrifugal dewatering, drying, azeotropic distilling, and high-temp calcining.

Owner:WUHAN UNIV

Edible mushroom flavor paste and production method thereof

The invention relates to an edible mushroom flavor paste and a production method thereof, and belongs to a food processing technology. The entire plants of edible mushrooms are cleaned and screened to remove impurities, and then are subjected to washing, flavor-optimizing, limited-dehydrating, crushing, blending, sterilizing and other treatments so as to produce a sauce seasoning which has well palatability and intense aromas and flavor. The production method provided by the invention can be used for widening the application range of edible mushroom and increasing the varieties of the sauce seasonings; in addition, the product has high protein and high dietary fiber without any artificially synthesized additives, and is convenient, healthy and nutrient serving good item.

Owner:JILIN WEIYIKANG BIOLOGICAL SCI & TECH

Preparing process fibrous nano alumina powder

InactiveCN1986408ALarge specific surface areaLow costNanostructure manufactureAluminium oxide/hydroxide preparationNano al2o3Polyethylene glycol

The process of preparing fibrous nanometer alumina powder includes the following steps: dissolving ammonium aluminum sulfate and ammonium bicarbonate separately in double distilled water to compound solutions; adding polyglycol into the ammonium aluminum sulfate solution to prepare solution A of ammonium aluminum sulfate containing polyglycol, adding Span-80 into the ammonium bicarbonate solution to prepare solution B of ammonium bicarbonate containing Span-80 and regulating pH value, adding the solution A into the solution B via stirring, centrifuging, washing, azeotropic distillation to dewatering, and calcining at 850-900 deg.c or 1100-1150 deg.c to nanometer fibrous gamma-Al2O3 powder or nanometer fibrous alpha-Al2O3 powder. The process is simple and low in cost, and the prepared fibrous product with high specific surface area may be used in ceramic material, nanometer composite material, etc in different fields.

Owner:WUHAN UNIV

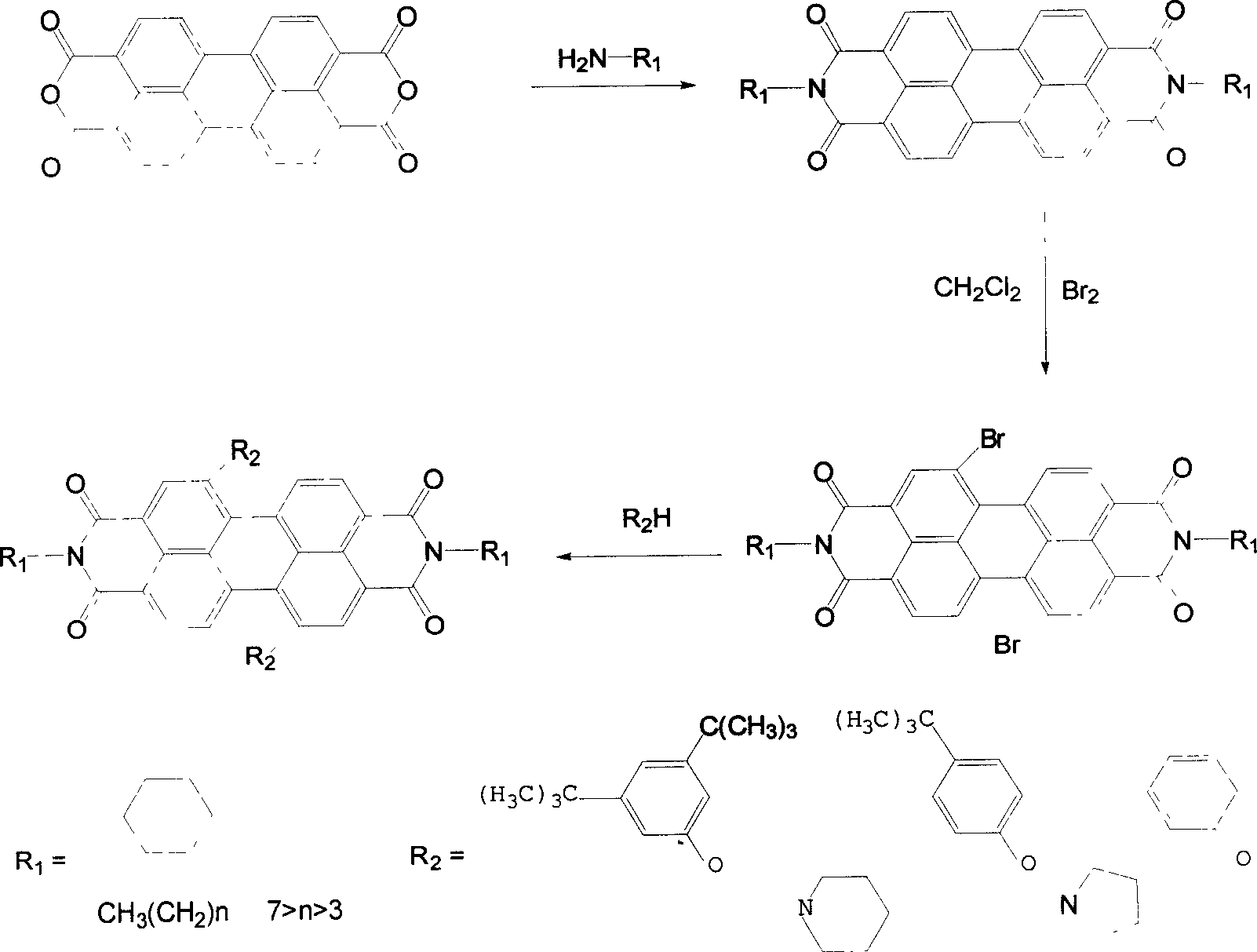

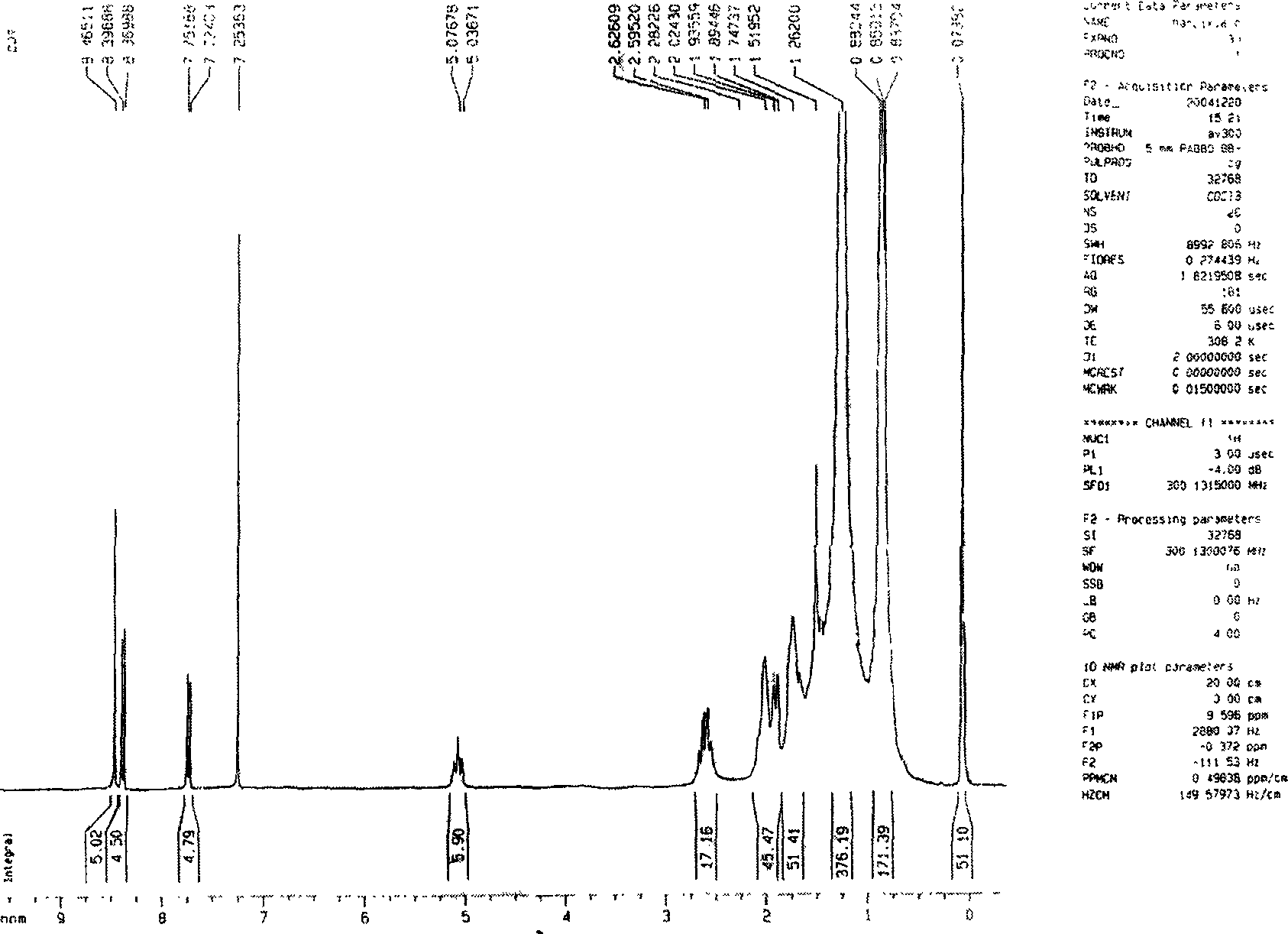

Synthesis process of 1,7-disubstituent-3,4:9,10-perylene bisimide

The present invention provides the synthesis process of 1, 7-disubstituent-3, 4: 9, 10-perylene bisimide. The synthesis process includes the following steps: A. refluxing perylene tetrabasic dihydride with first-order amine as solvent for 20-60 hr to produce perylene bisimide; B. refluxing perylene bisimide and liquid bromine in dichloromethane solvent for 10-60 hr to produce dibromoperylene bisimide; and C. reacting dibromoperylene bisimide and phenol inside N-methyl pyrrolidone in the presence of carbonate at 90-140 deg.c for 10-60 hr to produce 1, 7-diphenol-3, 4: 9, 10-perylene bisimide; or reacting dibromoperylene bisimide in second-order amine as solvent at 40-70 deg.c for 10-30 hr to produce 1, 7-diimido-3, 4: 9, 10-perylene bisimide.

Owner:SHANDONG NORMAL UNIV

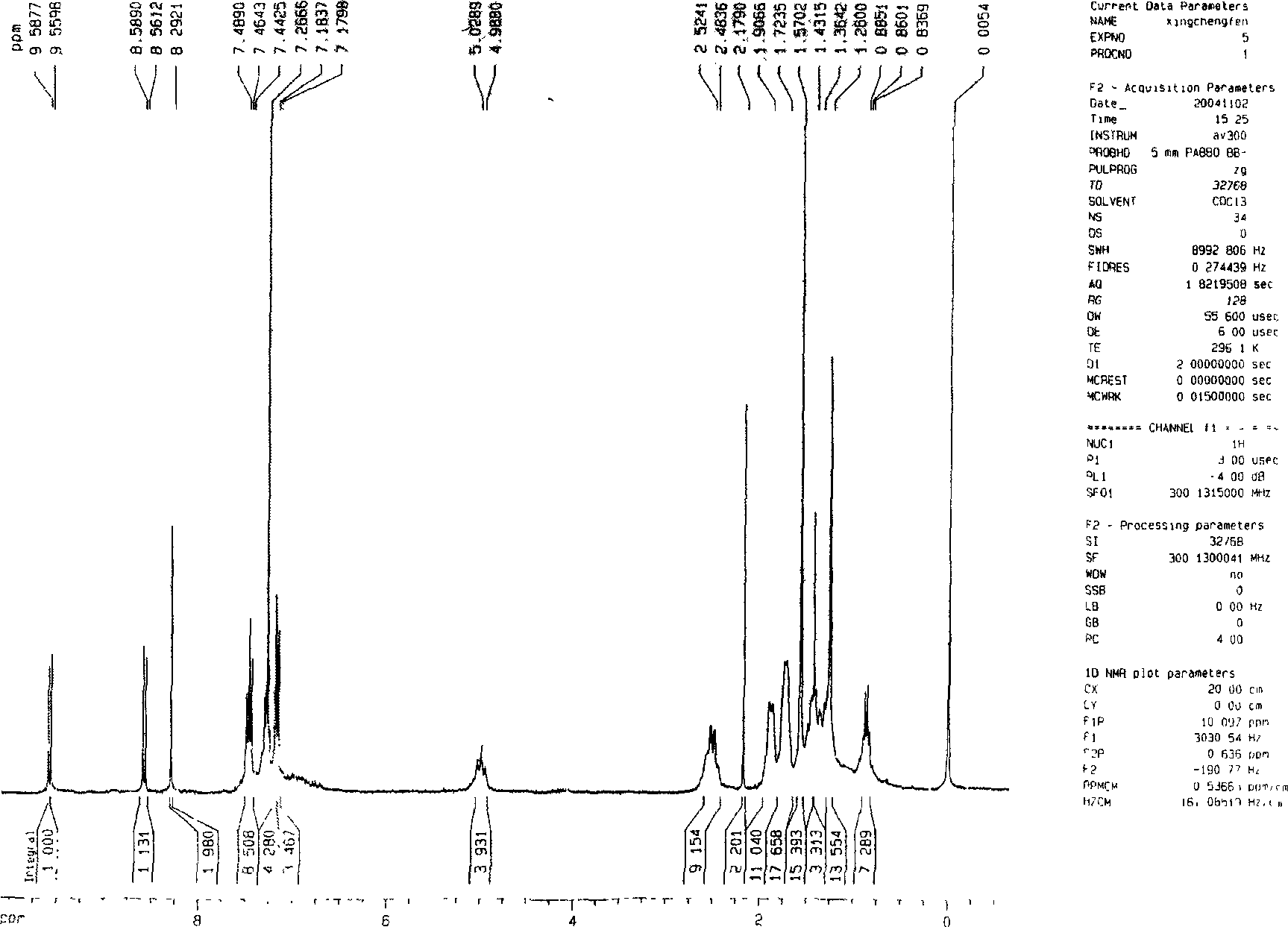

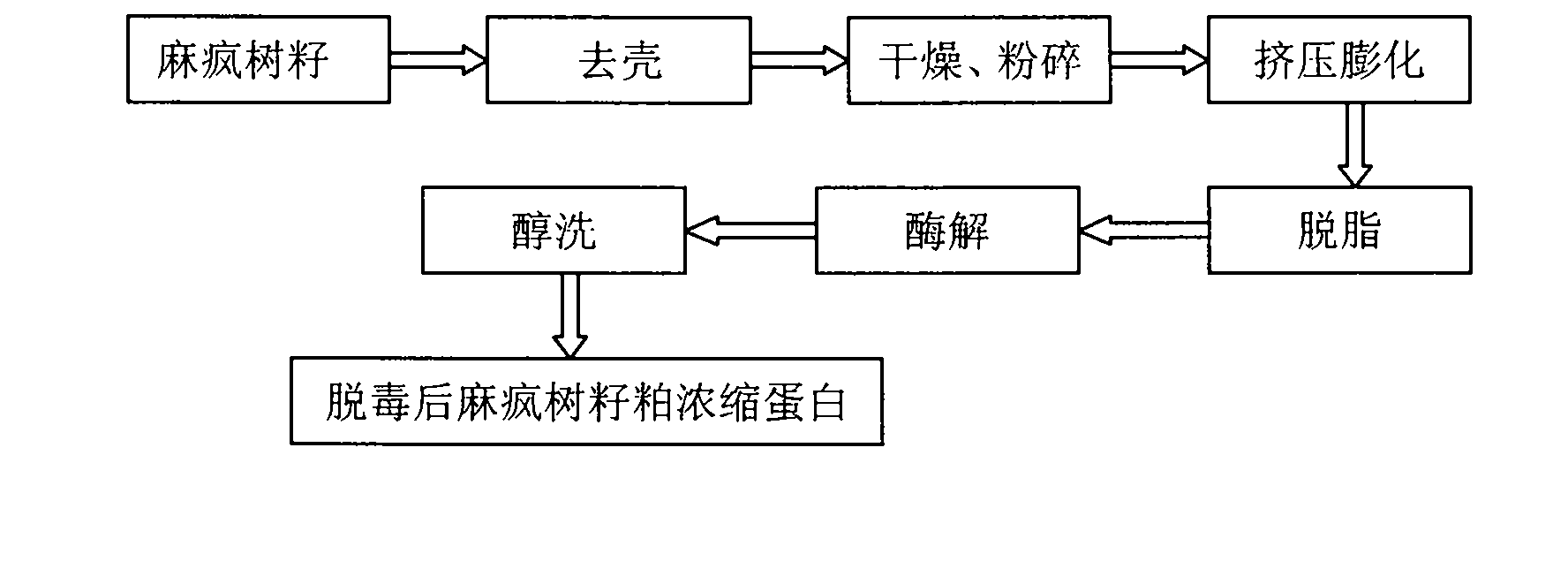

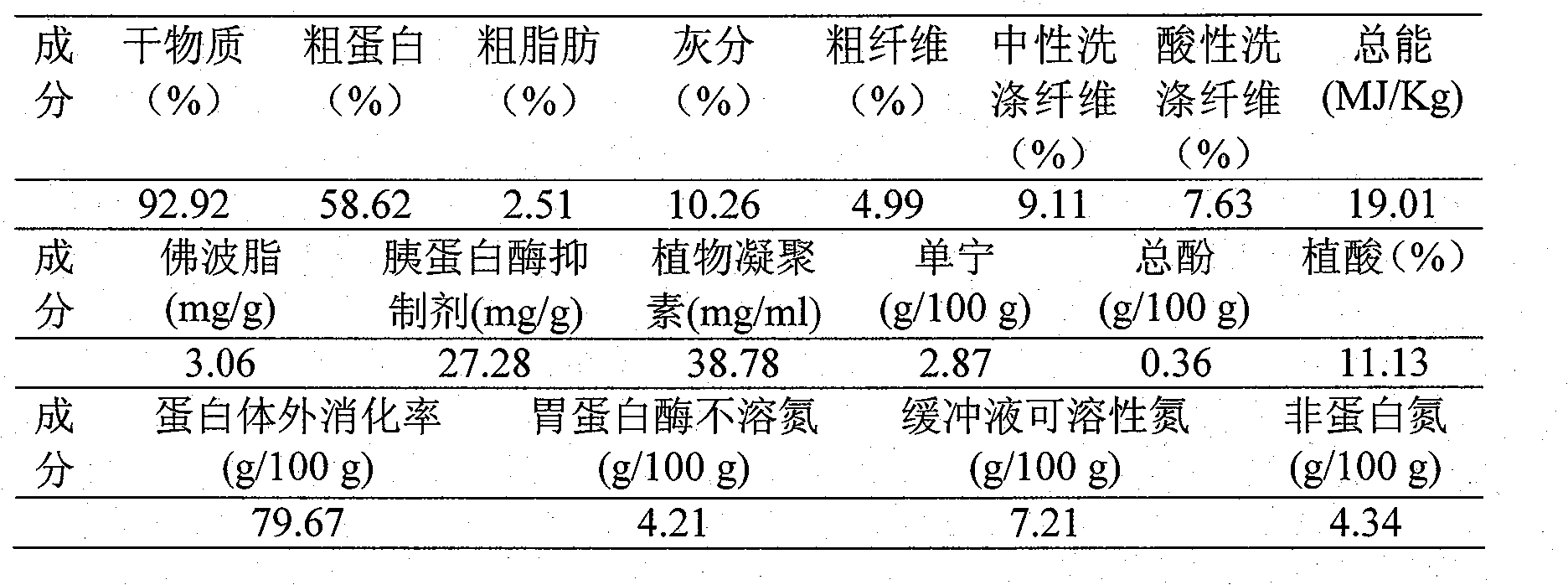

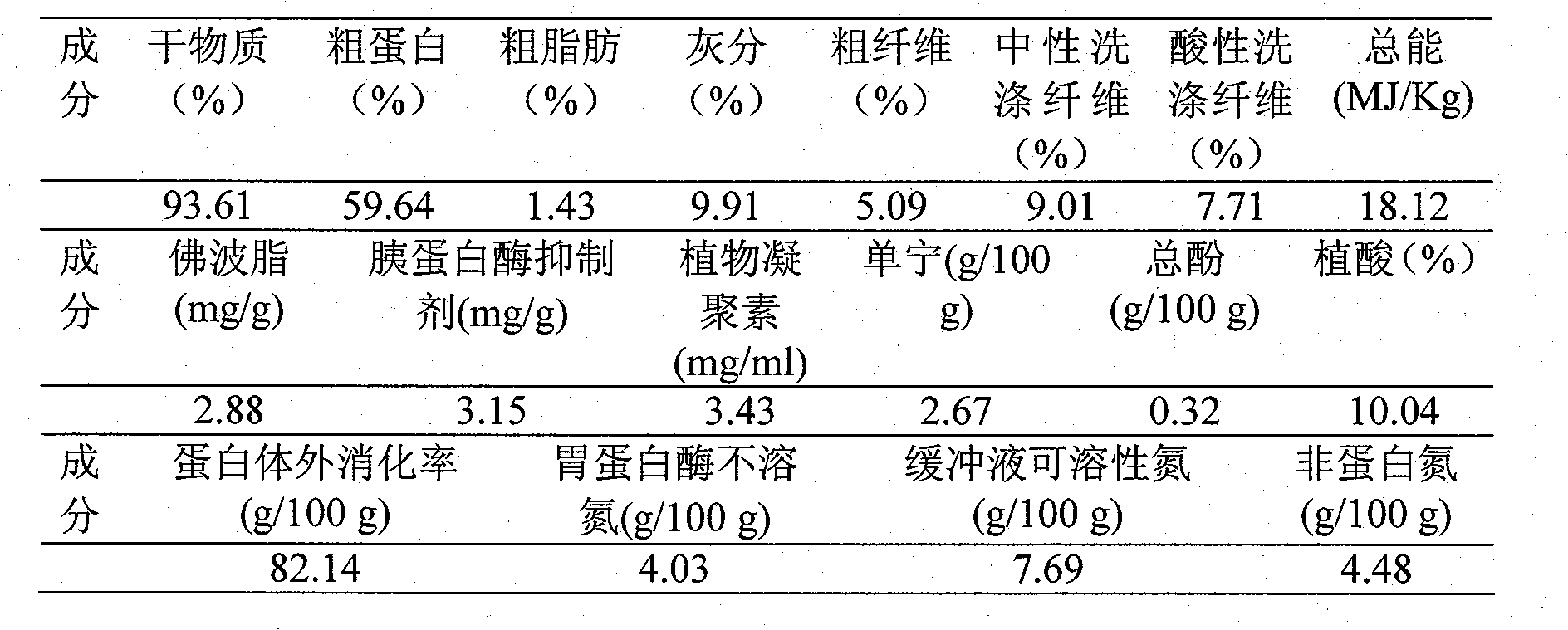

Method for detoxifying barbadosnut seed dregs and preparing protein concentrates

ActiveCN102090501ALow priceMeet the needs of the deep processing fieldProtein composition from vegetable seedsAnimal feeding stuffBiotechnologyTechnology development

The invention provides a method for detoxifying barbadosnut seed dregs and preparing protein concentrates, which belongs to the field of fine and further processing of barbadosnut seed dregs. The method comprises the following steps of: destroying plant cell walls by firstly using an extruding bulking machine as a reactor and then utilizing biological enzymolysis, then eluting by using alcohol with a proper concentration, thereby solving the problem of toxin residual of the barbadosnut seed dregs and simultaneously preparing the protein concentrates of the barbadosnut seed dregs; and finally, carrying out nutrition evaluation on the protein concentrates of the barbadosnut seed dregs. The method has the advantages of low requirement on equipment, simple production process, low production cost and environmental friendliness without using strong acid and strong base for treating the barbadosnut seed dregs, also has low cost of raw materials and low production cost and is suitable for large-scale industrial production. Meanwhile, the method also meets the requirements of fine and further processing field of agricultural products in the 'National Guideline on Medium- and Long-Term Program for Science and Technology Development' and has very obvious social and economic benefits and significance.

Owner:JIANGNAN UNIV

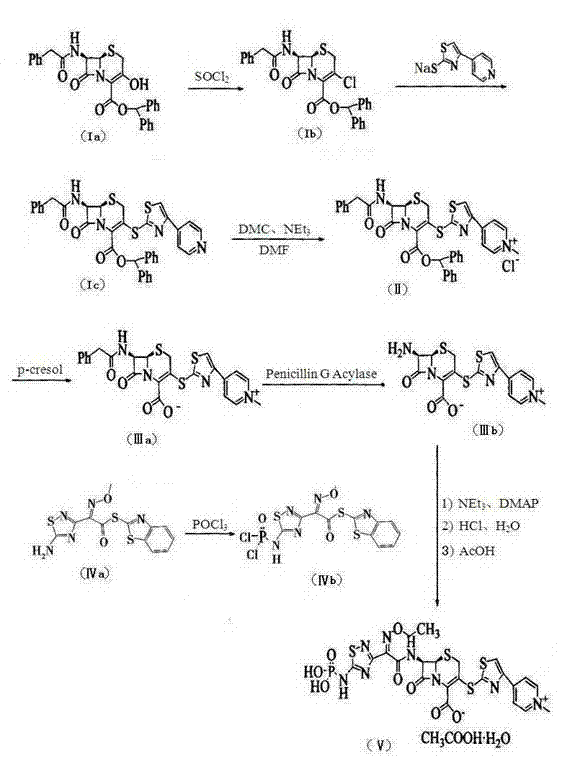

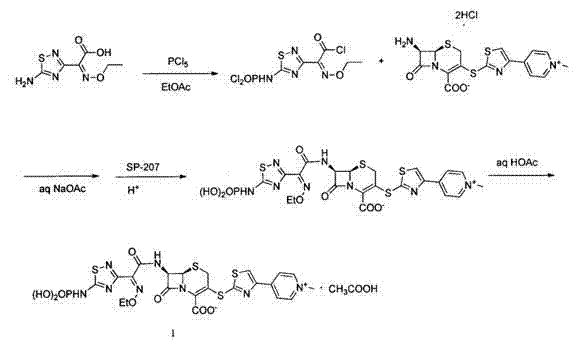

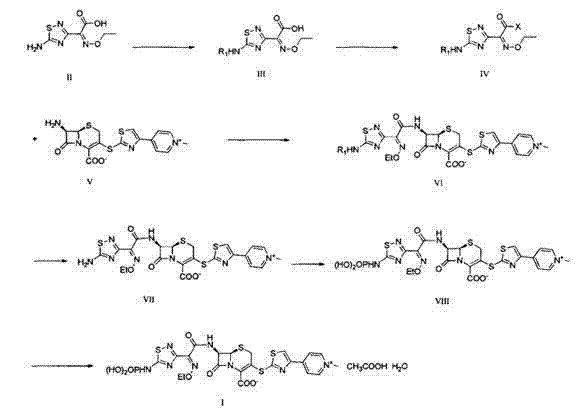

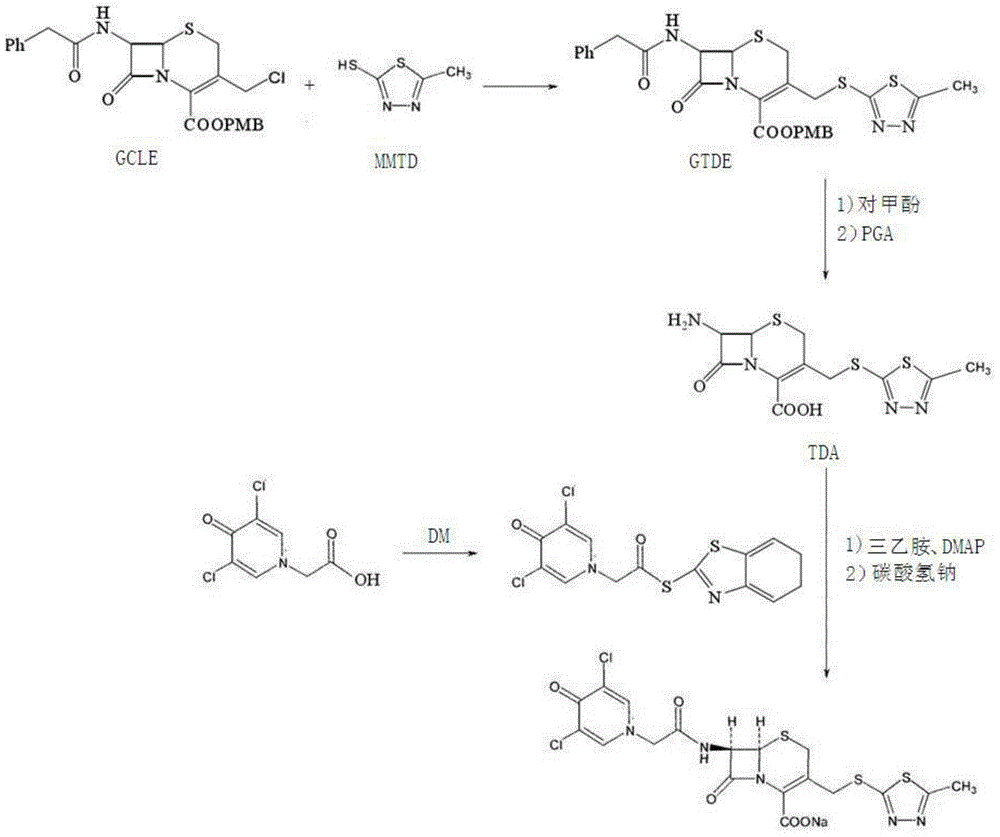

Preparation method for ceftaroline fosamil

ActiveCN104725425AMild reaction conditionsLess side effectsGroup 5/15 element organic compoundsBulk chemical productionCarboxylic groupG penicillin

The invention relates to a synthetic method for ceftaroline fosamil. According to the synthetic method, 7-phenylacetamide-3-hydroxy-3-cephalosporin-4-carboxylate-diphenylmethyl is selected as a raw material to be chloridized and reacts with 4-(4-pyridyl)-1,3-thiazole-2-thiol sodium salt at a C-3 site to obtain a thioether compound, p-cresol and immobilized penicillinase are adopted for removing carboxyl and amino protecting groups respectively, the thioether compound and the acylated AE-active ester are subjected to C-7 site condensation reaction, and crystallization in acetic acid is performed after hydrolyzation to prepare the ceftaroline fosamil successfully. The preparation method has the advantages that use of toxic and harmful substances such as trifluoroacetic acid and phosphorus pentachloride is avoided, reaction conditions are moderate, side reactions are few, technology is simple, yield and product purity are high, cost is low, raw materials are cheap and easy to obtain, and the preparation method is applicable to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

Method for comprehensively extracting protein, polysaccharide and polyphenol from avocado kernels

InactiveCN104523836AAvoid feesAvoid security issuesPeptide preparation methodsPlant peptidesSolventIsoelectric point

The invention provides a method for comprehensively extracting protein, polysaccharide and polyphenol from avocado kernels. The method provided by the invention comprises the following steps: (1) grinding, drying and degreasing avocado kernels, then performing extraction by using ethanol / water, concentrating, adjusting a pH value of an extracting solution to reach a protein isoelectric point so as to ensure that protein is precipitated, performing solid-liquid separation, and drying to obtain protein; (2) performing macroporous resin adsorption on supernatant liquor obtained by protein precipitation, and drying an outflow fluid to obtain polysaccharide with relatively high purity; and (3) eluting macroporous resin by using an ethanol solution, and concentrating and drying an eluant to obtain polyphenol with relatively high purity. According to the method provided by the invention, three products namely protein, polysaccharide and polyphenol are sequentially obtained from the avocado kernels; and moreover, the method is simple in process, mild in production condition and relatively high in purity of the obtained products, and is suitable for industrial production; and solvents used by the method are mainly water and ethanol, so that the method is small in environmental pollution and low in production cost.

Owner:GUANGXI POLYTECHNIC

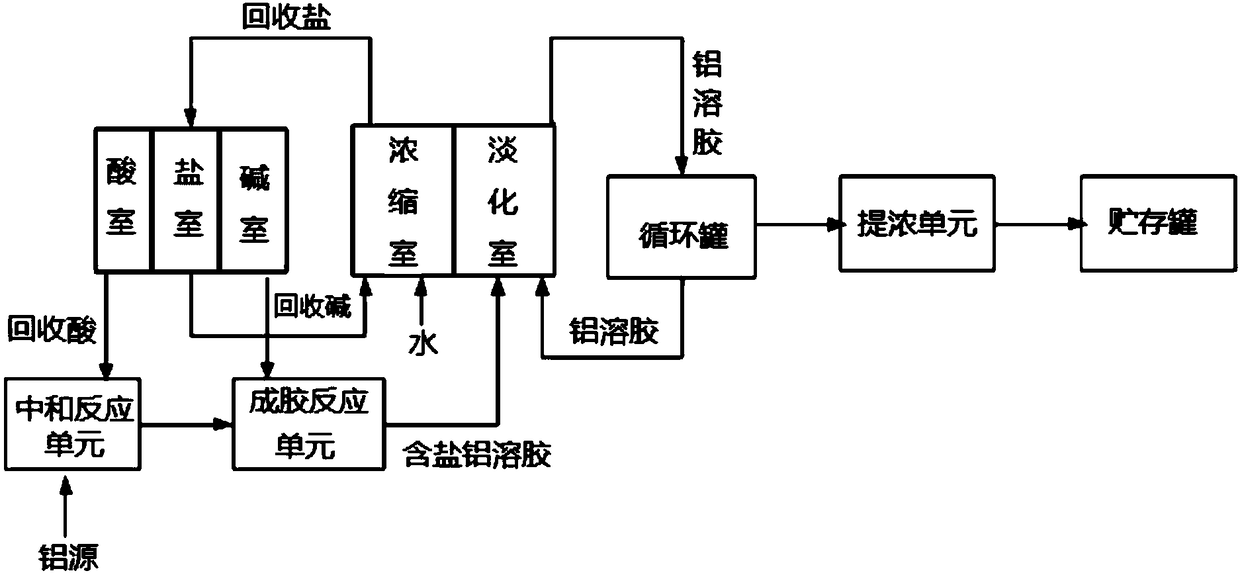

Aluminum sol production method and aluminum sol production system

ActiveCN108975370ALow priceIncrease profitAluminium chloridesSol preparationElectrodialysisUtilization rate

The invention discloses an aluminum sol production method and an aluminum sol production system. The an aluminum sol production method comprises: (1) making an aluminum source contact an acid to obtain a solution containing an aluminum salt; (2) making the solution containing the aluminum salt contact an alkali to obtain a salt-containing aluminum sol; (3) carrying out ordinary electrodialysis onthe salt-containing aluminum sol to obtain a desalted aluminum sol and a recovered salt; and (4) carrying out bipolar membrane electrodialysis on the recovered salt to respectively obtain a recoveredacid and a recovered alkali, wherein at least part of the recovered acid is recycled in the step (1), and at least part of the recovered alkali is recycled in the step (2). According to the present invention, with the production system and the production method, the raw materials have characteristics of low price and high utilization rate, the quality of the prepared aluminum sol is good, and thewhole production process has the mild condition, and is environmentally friendly.

Owner:CHINA PETROLEUM & CHEM CORP +1

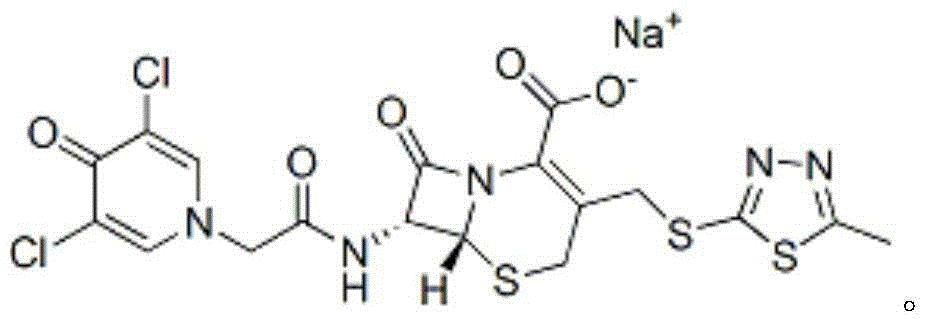

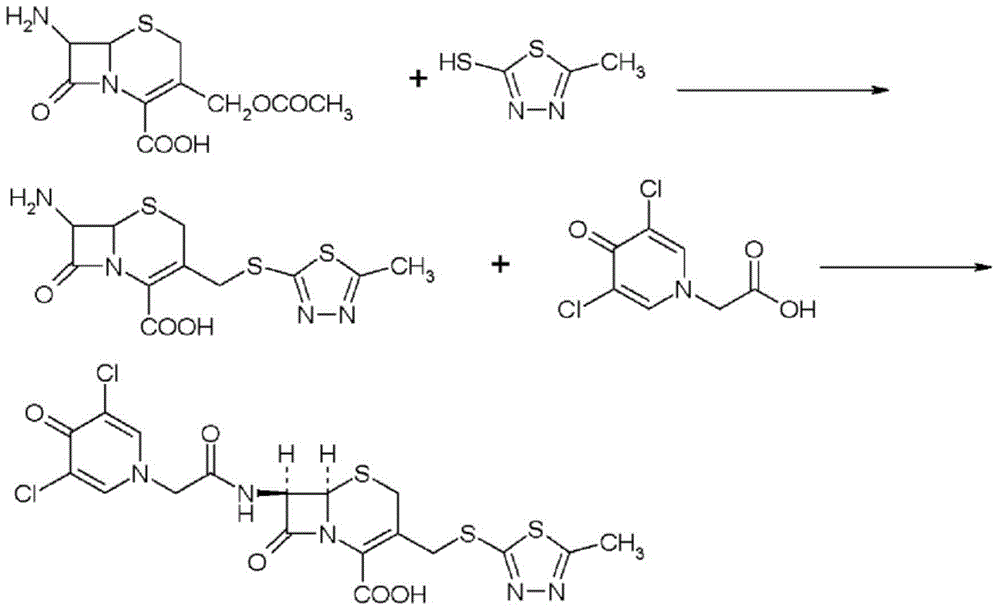

Preparation method for cephalosporin anti-infective drug

ActiveCN105017286ASimple preparation processReduce generationOrganic chemistry7-ACACefazedone sodium

The invention relates to a preparation method for a cephalosporin anti-infective drug-cefazedone sodium, belonging to the field of pharmaceutical synthesis. According to the invention, the method uses GCLE as a raw material to substitute 7-ACA and overcomes the defects of low yield, high pollution and the like in prior art; the preparation method with mild reaction conditions, little side reaction and simple process is provided; meanwhile, the method has the advantages of cheap and easily-available raw materials, low cost, high product yield, high product purity and applicability to industrial production.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD

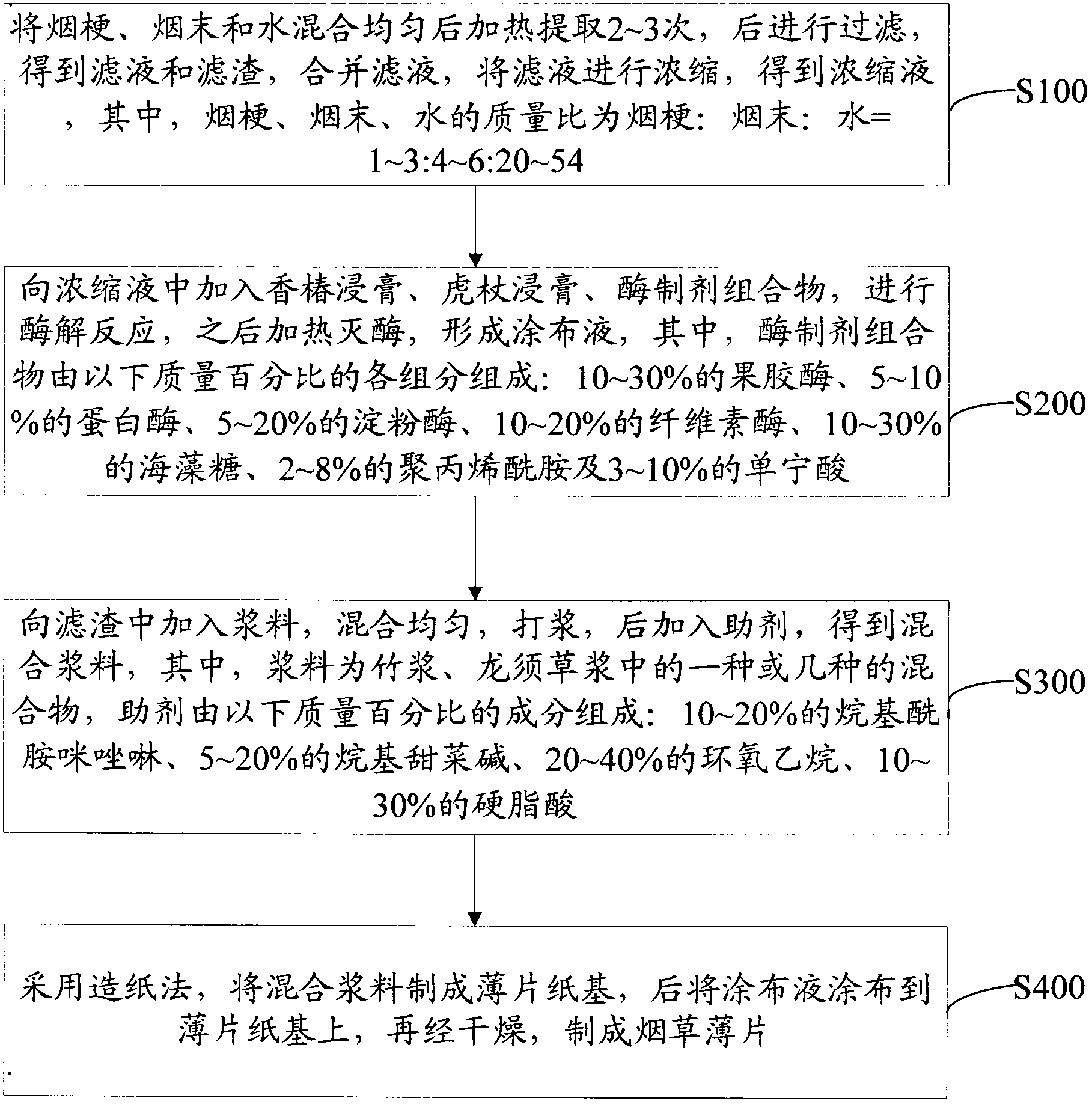

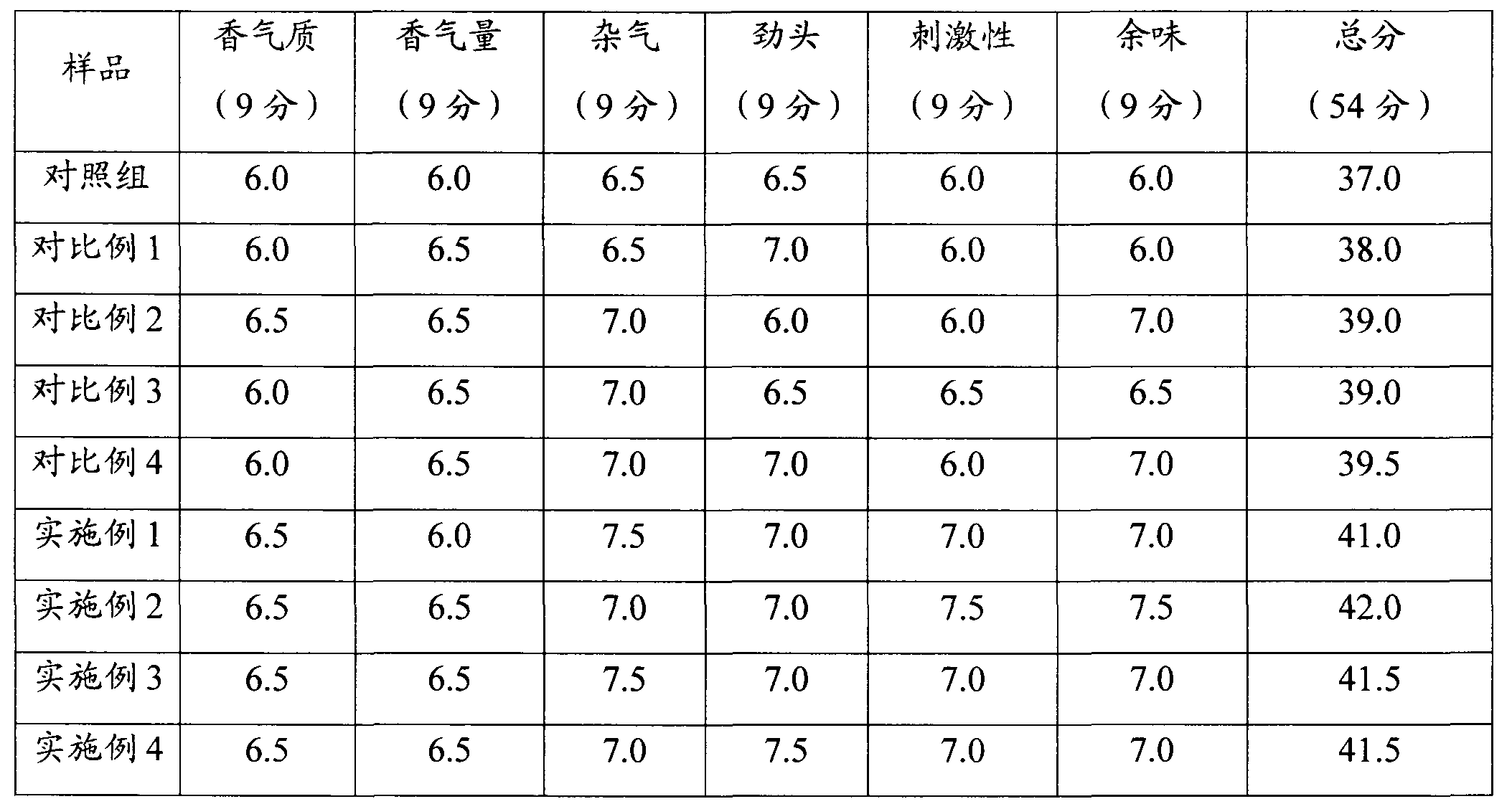

Production method of tobacco sheets

InactiveCN103238921AImprove stabilityGood repeatabilityTobacco preparationMethods of productionCedrela sinensis

The invention provides a production method of tobacco sheets. The production method of tobacco sheets includes the following steps: (1) mixing cabo, tobacco powder and water evenly, heating and extracting for 2-3 times, filtering to obtain filtrate and filter residue, combining the filtrate, and concentrating the filtrate to obtain a concentrated solution; (2) adding a composition of cedrela sinensis, giant knot weed extract and enzymic preparation in the concentrated solution, performing enzymatic reaction, and heating and deactivating enzyme to form coating liquid; (3) adding pulp in the filter residue, mixing evenly, pulping, and adding an addition agent to obtain mixed pulp; and (4) adopting a paper-making method, making the mixed pulp into sheet paper bases, coating the coating liquid on the sheet paper bases, drying, and manufacturing the tobacco sheets. The production method of reconstituted tobacco adopts a treatment process combining the enzymic preparation composition and the addition agent, can reduce content of lignin, and improves smoking effect.

Owner:SUZHOU KUNLAN BIOTECH

Process for co-production of collagen calcium and polypeptide in chondroitin sulfate production

InactiveCN104911240AHigh purityHigh economic valueConnective tissue peptidesPeptide preparation methodsUltrafiltrationFiltration

The invention discloses a process for co-production of collagen calcium and polypeptide in chondroitin sulfate production. The production process includes: conducting coarse crushing on shark cartilage to a massive size, performing soaking in an acid solution and then conducting filtering, subjecting the filtrate to calcification treatment and alcohol precipitation, conducting secondary washing with alcohol, and then carrying out spin-drying and drying to obtain collagen chelated calcium; subjecting the soaked cartilage to enzymolysis and filtration to obtain a chondroitin sulfate and collagen polypeptide aqueous solution and bone dreg, subjecting the aqueous solution to ultrafiltration separation to obtain a chondroitin sulfate concentrated solution, and performing alcohol precipitation to obtain chondroitin sulfate; and concentrating the ultrafiltrate, and then carrying out spray drying, thus obtaining collagen polypeptide. On the basis of co-production of chondroitin sulfate and collagen polypeptide, the invention also produces another high benefit product at the same time, i.e. collagen chelated calcium, makes full use of the resources in cartilage, performs high value utilization of bone calcium powder in treatment process, and improves the economic value.

Owner:JIAXING NUDIKON LIFE SCI

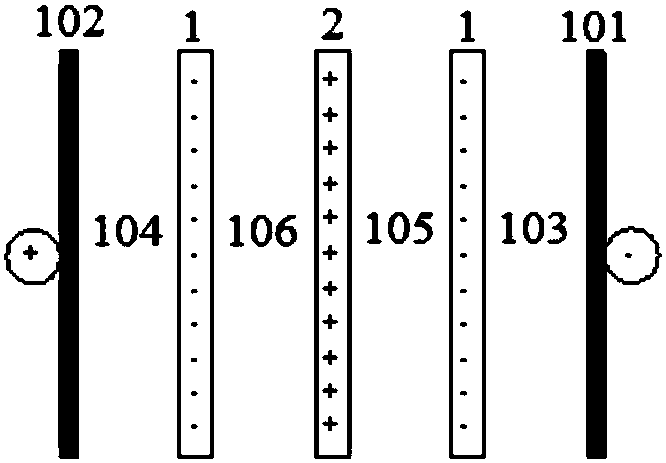

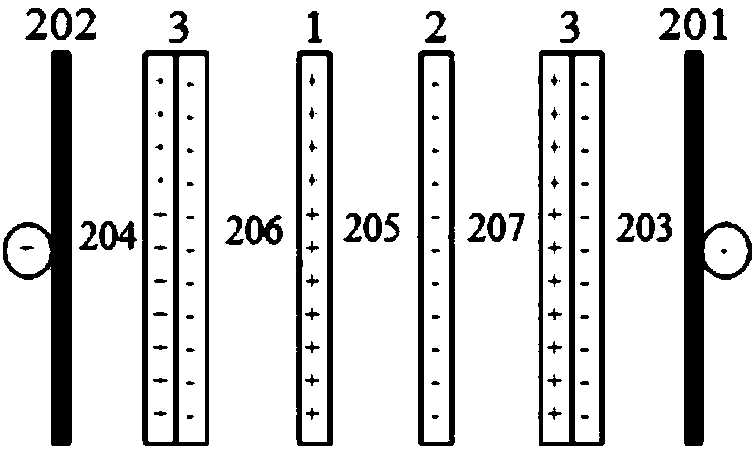

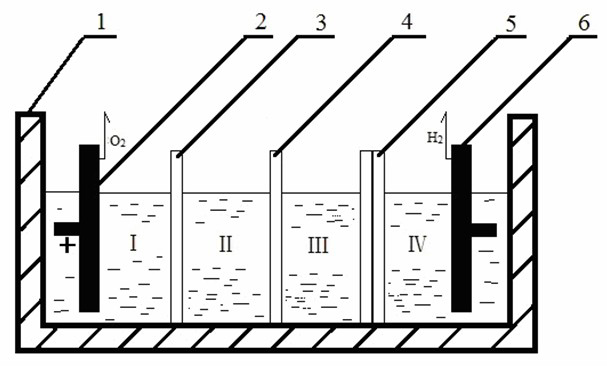

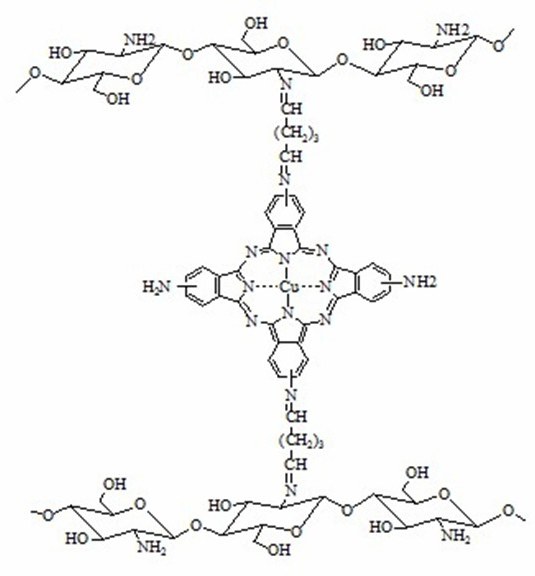

Three-membrane four-chamber chlorine-free alkali-producing electrolytic tank consisting of anion and cation exchange membranes and bipolar membrane

InactiveCN102304723AProcess environmental protectionMild production conditionsCellsOrganic diaphragmsElectrolysisChemical physics

The invention relates to an environment-friendly, high-efficiency and energy-saving electrolytic tank, in particular to a three-membrane four-chamber chlorine-free alkali-producing electrolytic tank modified by a metal phthalocyanine derivative, with a high ionic conductivity anion exchange membrane, a high ionic conductivity cation exchange membrane and a bipolar membrane and consisting of the anion exchange membrane, the cation exchange membrane and the bipolar membrane. The three-membrane four-chamber chlorine-free alkali-producing electrolytic tank is characterized in that: the anion exchange membrane, the cation exchange membrane and the bipolar membrane are arranged between the electrolytic tank anode and the electrolytic tank cathode sequentially; an electrolytic chamber I is arranged between the electrolytic tank anode and the anion exchange membrane; an electrolytic chamber II is arranged between the anion exchange membrane and the cation exchange membrane; an electrolytic chamber III is arranged between the cation exchange membrane and the bipolar membrane; and an electrolytic chamber IV is arranged between the bipolar membrane and the electrolytic tank cathode. According to the scheme, the electrode reaction on the anode is oxygen evolution; the electrode reaction on the cathode is hydrogen evolution; the oxygen evolution and the hydrogen evolution are non-toxic and chlorine evolution reaction is avoided; the environment-friendly, high-efficiency and energy-saving electrolytic tank is environment-friendly and mild in production condition; production can be performed at the temperature of between 20 and 65 DEG C; and the current efficiency is over 70 percent.

Owner:FUJIAN NORMAL UNIV

Two-component colorful flexible polysulfide ammonia ester sealant and preparation method thereof

InactiveCN105111996AColor stableNot easy to yellowNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention discloses a two-component colorful flexible polysulfide ammonia ester sealant and a preparation method thereof. The sealant consists of a component A and a component B; expressed by weight part, the component A is prepared from 15 to 60 parts of PSU type liquid rubber, 10 to 30 parts of a plasticizer, 10 to 60 parts of a filler, 0.1 to 5 parts of a tackifier, 0.1 to 5 parts of an antiager and 0.1 to 5 parts of a premature vulcanization retarder; the component B is prepared from 10 to 40 parts of a vulcanizing agent, 0.1 to 5 parts of a vulcanization accelerator, 10 to 50 parts of a plasticizer, 1 to 20 parts of a colorant and 10 to 50 parts of a filler; the mass ratio of the component A to the component B is 5 to (15 to 1). The component A and the component B are respectively ground to be pasty and then are mixed uniformly, thus obtaining a product. The product is stable in storage, excellent in physical and mechanical properties, and easy to blend into multiple colors, and the defect of color singleness of an existing flexible sealant is overcome.

Owner:HENAN YONGLI CHEM

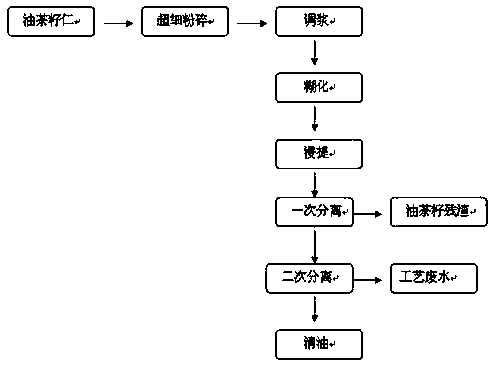

Method for extracting camellia oleosa seed oil by weak acid aqueous solution

ActiveCN103351945ASimple production processEasy to operateFatty-oils/fats productionCamellia oleiferaHigh energy

The invention relates to an edible oil production and processing technology, in particular to a method for extracting camellia oleosa seed oil by weak acid aqueous solution. The technical scheme adopted by the invention is that camellia oleosa seeds are taken as raw materials, and are added in the weak acid aqueous solution for slurry mixing after being subjected to superfine grinding, the constant temperature mixing and extracting are carried out on slurry after the slurry is gelatinized for a period of time, and the obtained extract liquid is subjected to two-step centrifugal separation to obtain the camellia oleosa seed oil. The camellia oleosa seed oil is clear, transparent, light yellow, and even golden yellow, does not contain benzo(a)pyrene, has no residual organic solvent, and can reach the national-level camellia oil edible safety standard without refining or after being subjected to simple refining. According to method, the production technology is simple, biological enzyme is not used during the production process, the processing temperature is low, the production cost of the camellia oleosa seed oil is lowered, so that the method is suitable for industrial large-scale production; meanwhile, the problems of low camellia oleosa seed oil yield, high energy consumption, existence of residual organic solvent, serious active nutritional ingredient loss and the like in a conventional production method are solved.

Owner:CHANGSHA HAORUI BIOLOGICAL SCI & TECH

Chemical preparation method of nanoscale zinc oxide powder

InactiveCN102531037AHigh puritySmall particle sizeZinc oxides/hydroxidesNanotechnologyZinc hydroxidePhysical chemistry

The invention discloses a chemical preparation method of nanoscale zinc oxide powder, and the method comprises the following steps of: (1) in a stirring container, adjusting the concentration of a zinc salt solution to be 0.5-2.0mol / L, heating to 20-80 DEG C, adding an alkali solution to cause the pH of the zinc salt solution to be 11-12, and reacting at the temperature of 20-80 DEG C for 1-2 hours, thus obtaining a zinc hydroxide precipitate and a zinc oxide precipitate; (2) filtering and separating to obtain a solid mixture of zinc hydroxide and zinc oxide, and washing the mixture of solid zinc hydroxide and zinc oxide until washing liquid contains no zinc salt anion; and (3) placing the mixture obtained by the step (2) into a flash dryer to be subjected to flashing and drying at the temperature of 150-250 DEG C, and smashing to obtain 96-99% nanoscale zinc oxide powder, wherein the grain diameter of the powder is 50-100nm, and the whiteness of the powder is higher than eighth level.

Owner:沭阳县飞宏金属新材料有限公司

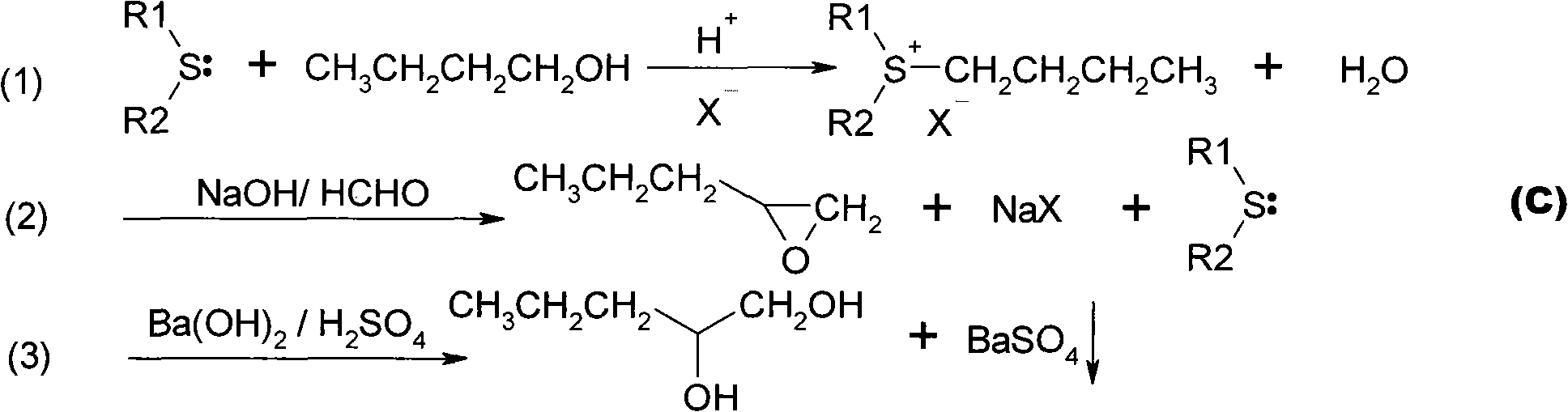

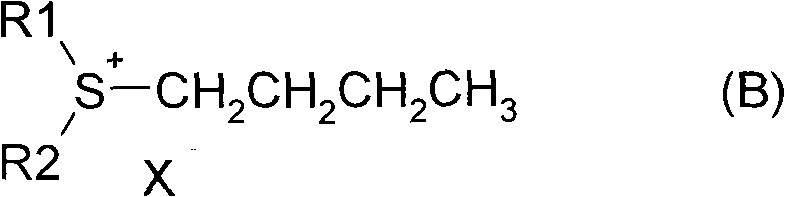

Method for synthesizing 1,2-pentanediol from n-butyl alcohol

InactiveCN101857524APromote safe productionMild production conditionsPreparation by hydrolysisStrong acidsN-Butyl Alcohol

The invention discloses a low-cost synthesis process for synthesizing 1,2-pentanediol from n-butyl alcohol. The method comprises the following steps of: synthesizing butyl sulfosalt from n-butyl alcohol and thioether in the presence of the catalysis of strong acid by adopting the n-butyl alcohol as a starting raw material; then reacting the butyl sulfosalt with methanal to obtain 1,2-epoxy pentane; and carrying out ring opening in the presence of the catalysis of barium hydroxide to obtain the 1,2-pentanediol. Compared with a process using n-amylene as a raw material, the method greatly reduces the production cost, has moderate and reliable production condition and is quite stable and safe.

Owner:王永军 +1

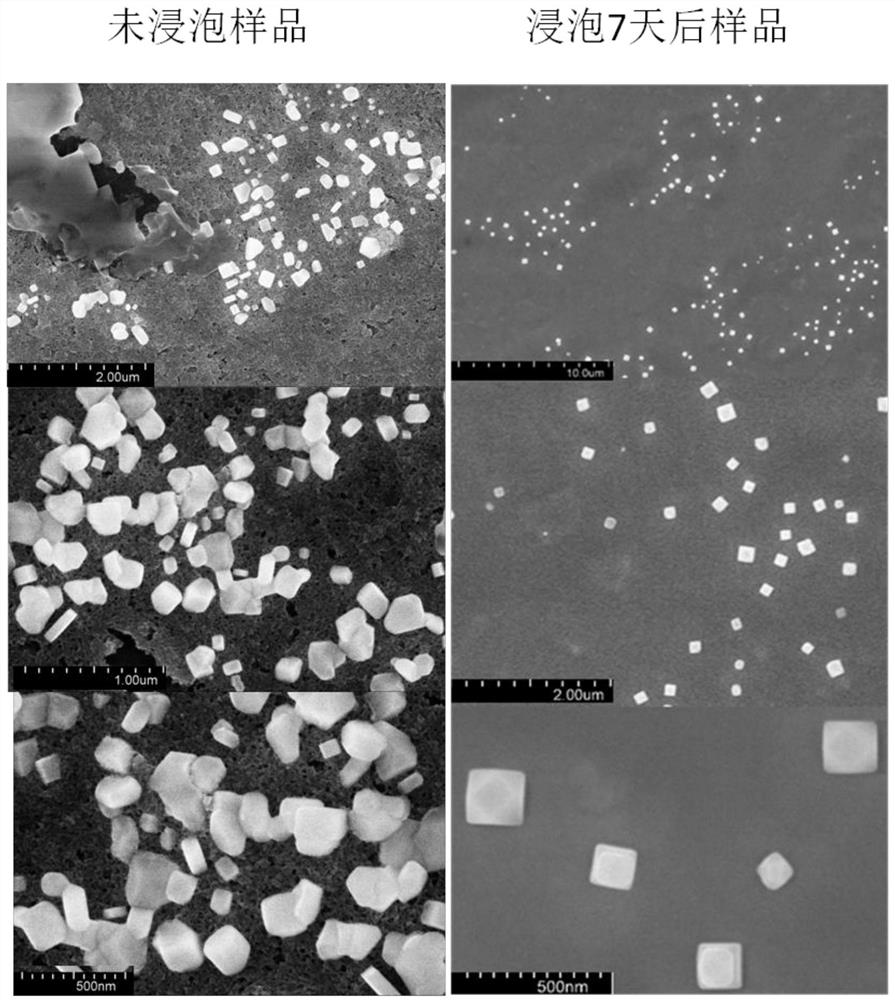

Water-insoluble cyclodextrin-based metal organic framework material and preparation method thereof

ActiveCN113750968AImprove water stabilityWide variety of sourcesOther chemical processesWater/sewage treatment by sorptionPtru catalystCyclodextrin

The invention relates to a water-insoluble cyclodextrin-based metal organic framework material and a preparation method thereof. The method comprises the steps: mixing cyclodextrin, sylvite and deionized water, carrying out ultrasonic treatment, dropwise adding an embedding substance active molecule solution, carrying out ultrasonic treatment, adding crystallization induction molecules, standing for crystallization, washing, drying, mixing the obtained crystal, a catalyst, a cross-linking agent and a solvent, and carrying out cross-linking reaction. The method is simple, mild in production condition and suitable for industrial application; and the prepared metal organic framework material has excellent structural stability, more active sites and high specific surface area, can realize efficient enrichment of pollutants in printing and dyeing wastewater, and is beneficial to rapid removal of the pollutants.

Owner:DONGHUA UNIV

Preparation method of sugar-free moon-cake syrup

InactiveCN102823801ASimple processMild production conditionsDough treatmentFood preparationFood additiveAdditive ingredient

The invention discloses a preparation method of sugar-free moon-cake syrup, and belongs to the field of food additives. The sugar-free moon-cake syrup is prepared from maltitol, xylitol and erythritol serving as raw materials by a specific process, and the process for producing the product does not require boiling sugar, so that labor and time are saved; and saccharification does not exist in in-vivo metabolism and is independent of insulin, so that the problems that a patient with diabetes mellitus cannot taste sweet foods can be solved, and glucose and insulin in blood are prevented from greatly fluctuating. The moon-cake produced by applying the syrup has smooth and fine surface, high nutrition and gold greasy color. The method for using the sugar-free moon-cake syrup comprises the step of doping with flour in a sugar-free moon-cake syrup-flour ratio of 4:5 to produce the Cantonese moon-cake crust when a Cantonese moon-cake is made.

Owner:JIANGSU HENGHUI FOOD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com