Patents

Literature

3172 results about "Magnesium Hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium hydroxide is the inorganic compound with the chemical formula Mg(OH)2. It occurs in nature as the mineral brucite. It is a white solid with low solubility in water (Ksp = 5.61×10−12).

Mercury adsorbents compatible as cement additives

InactiveUS20080134888A1Efficient removalReduce distractionsGas treatmentOther chemical processesAluminateSorbent

Solid adsorbents, following their use for mercury removal from flue gas, that do not interfere with the ability of air-entraining additives (such as surfactants) to form stable bubbles when added to fly ash containing the adsorbents. The interference is overcome by heating the materials used in the manufacture of the adsorbent so that magnesium hydroxide and / or one or more alkali compounds containing one or more silicate, aluminate, and / or phosphate moiety, added or already present in the materials, binds multivalent cations present in the materials that could otherwise interfere with the surfactant activity.

Owner:PRAXAIR TECH INC

Flame-Retardant Magnesium Hydroxide Compositions and Associated Methods of Manufacture and Use

InactiveUS20070176155A1Improve resistance performanceSuitable for usePigmenting treatmentGlass/slag layered productsParticulatesPolymer resin

The invention provides a submicron magnesium hydroxide particulate composition comprising a first distribution of magnesium hydroxide particles having a D50 of no more than about 0.30 μm, a D90 of no more than about 1.5 μm, and a BET surface area of at least about 35 m2 / g, which can be used as a flame-retardant additive for synthetic polymers, optionally in combination with other flame-retardant additives such as nanoclays and larger-sized magnesium hydroxide particulate compositions. Polymeric resins comprising the submicron magnesium hydroxide particles and methods of manufacturing submicron magnesium hydroxide particles are also provided.

Owner:MARTIN MARIETTA MATERIALS

A high flame retardant high thermal conductivity composite material component and its manufacturing method

InactiveCN102260413AImprove thermal conductivityImprove flame retardant performancePolymer sciencePhenol formaldehyde resin

The invention relates to a high-molecular composite material having performances of high heat conduction and high flame retardation, the invention is characterized in that the composite material does not contain any halogen or a non environmentally-friendly heavy metal fire retardant, the flame resistance is capable of reaching a UL94 V0 standard, simultaneously, the composite material has good heat conducting performance, the heat conduction coefficient is more than 0.5 W / m. DEG C. The composite material provided in the invention has good injection moulding performance, extruding performance and hot pressing performance. The composite material comprises the following basic components: 1) one or a plurality of metal hydroxides, such as aluminum hydroxide, magnesium hydroxide, zinc hydroxide and the like, wherein the weight content is 10-70%, 2) about 0.2%-60% of the weight content of expandable graphite flaky powder, the lamina size is more than 10 um, and the expandable coefficient is more than or equal to 20 times; 3) 15%-70% of the weight content of matrix resins, such as epoxy resin, organic silicone resin, phenolic resin, thermosetting polyester resin and thermoplastic resins of nylon 6, nylon 66, PBT, PP, HDP and the like. The composite material component of the invention can be directly used for radiators such as LED, electric appliances and electronic components, the heat can be radiated into colder environment so that the operating temperature of the electronic device can be reduced.

Owner:HEFU NEW MATERIAL TECH WUXI

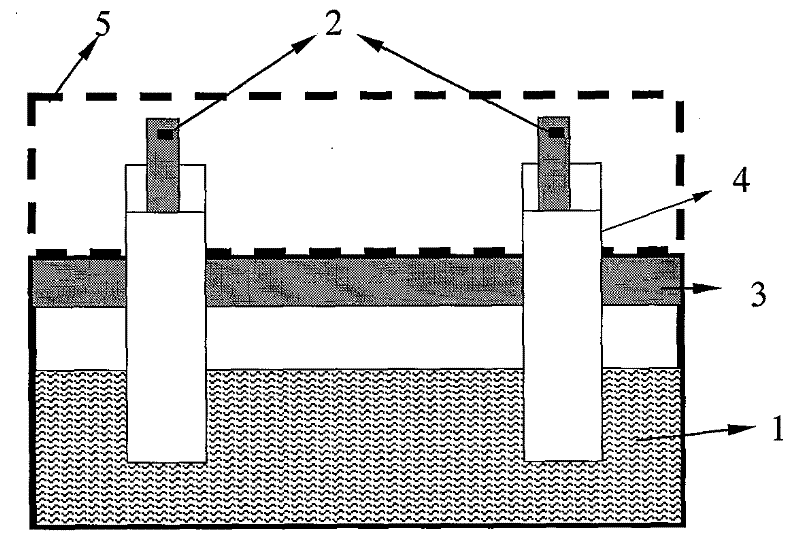

Modified magnesium oxysulfate cement for foaming and foam material thereof

InactiveCN105859166ASuppress generationPromote generationCeramicwareMagnesium sulphate heptahydrateCement

The invention relates to the field of cement and particularly relates to modified magnesium oxysulfate cement and a foam material prepared by adopting the magnesium oxysulfate cement. The modified magnesium oxysulfate cement is prepared from the raw materials in parts by weight: 100 parts of magnesium sulfate, 50-200 parts of magnesia, 0-500 parts of filler and 30-350 parts of water, wherein an admixture may be added. The invention also relates to the foam material prepared by adopting the magnesium oxysulfate cement. According to the modified magnesium oxysulfate cement and the foam material thereof, by adding the admixture, the generation of magnesium hydroxide in the cement is inhibited, so that the mechanical properties and water resistance of the magnesium oxysulfate cement are effectively improved; and meanwhile, the magnesium oxysulfate cement has the characteristics of heat resistance and no cracking.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Magnesium aluminate spinel foamed ceramic filter as well as preparation method thereof

ActiveCN103553686APrevent plastic crackingImprove high temperature stabilityCeramicwareMg alloysSlurry

The invention relates to a magnesium aluminate spinel foamed ceramic filter which is excellent in high-temperature chemical stability and thermal shock resistance. A preparation method of the magnesium aluminate spinel foamed ceramic filter comprises the following steps: firstly, using water-base resin, a dispersing agent and water as a solvent, forming ceramic powder by using magnesium aluminate spinel powder, aluminum oxide powder and magnesium hydroxide powder, and mechanically stirring to prepare slurry; soaking polyurethane porous sponge serving as a carrier in slurry, pressing to remove excessive slurry to prepare a preform body, drying and sintering to obtain the magnesium aluminate spinel foamed ceramic filter. The foamed ceramic filter disclosed by the invention can satisfy rigorous requirements of filtering of molten magnesium alloy, has good high-temperature stability, does not pollute the alloy, has good filtering and adsorbing effect on inorganic impurities in the molten magnesium alloy, and is good in filtering and purifying effect, small in fluid resistance, and large in filtration yield; and good using effect is obtained through trial in casting production of metal magnesium and magnesium alloy.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

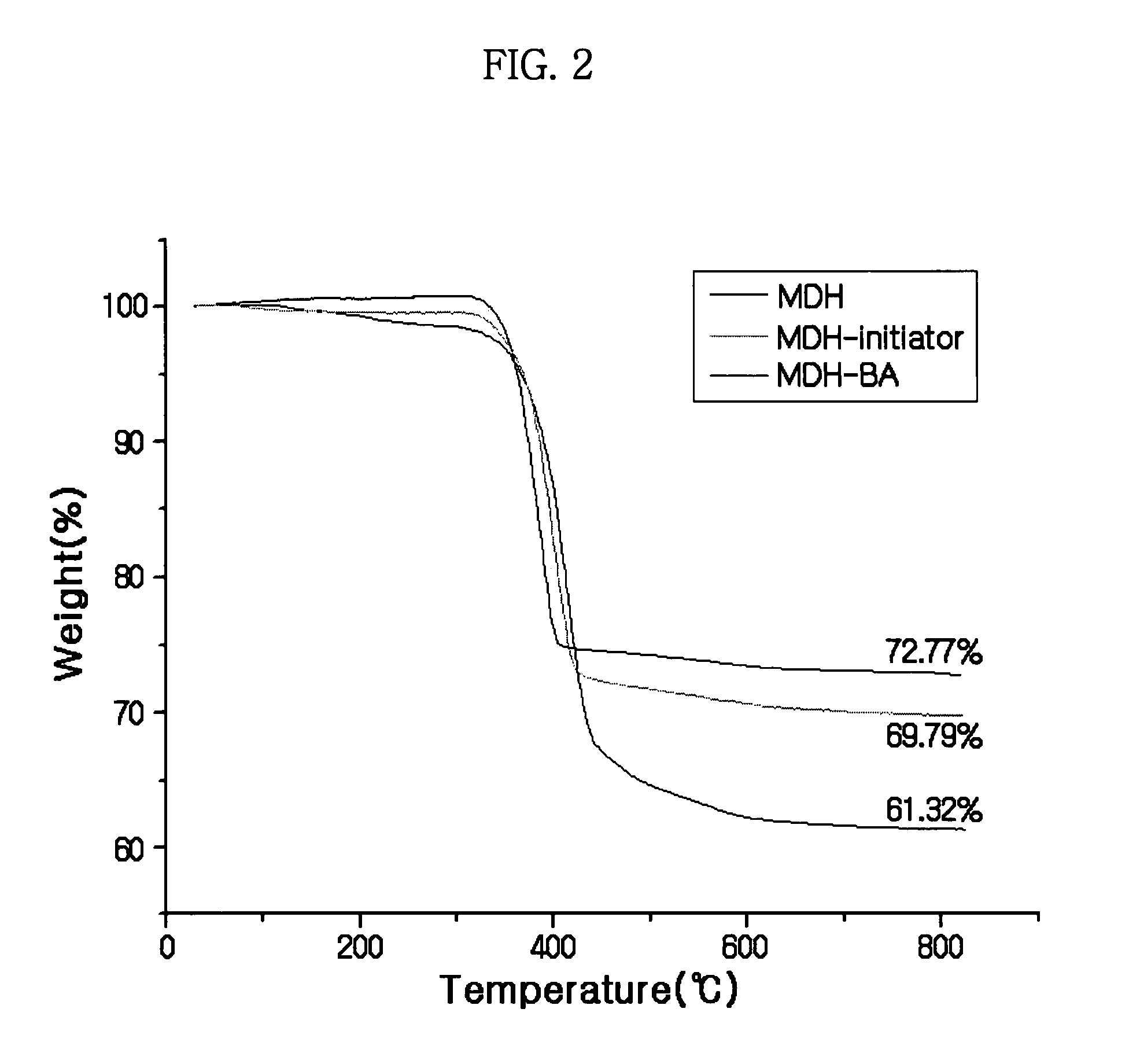

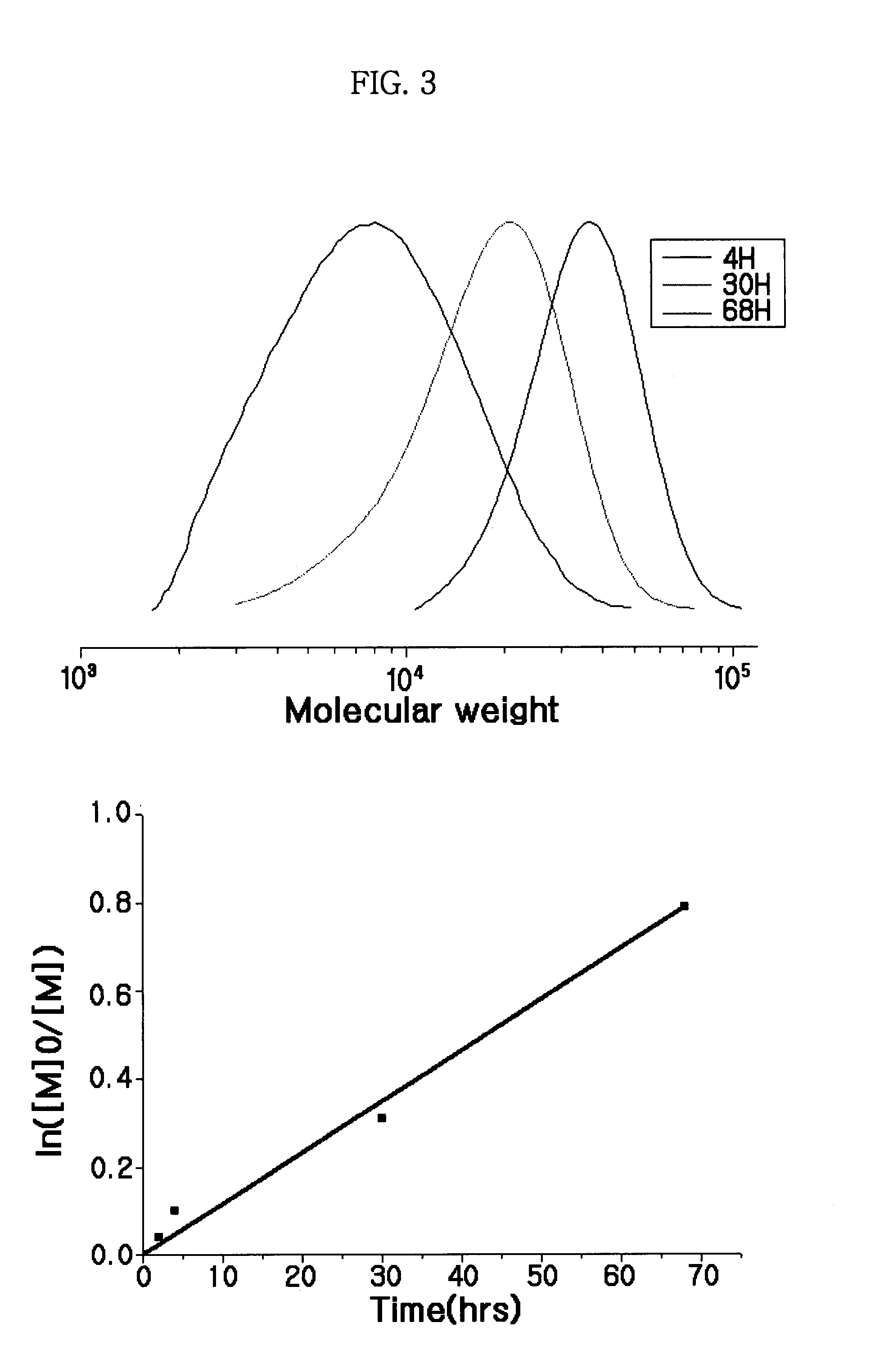

Synthesis of MDH-polymer hybrid particles

Disclosed is the preparation of organic / inorganic hybrid particles comprising magnesium hydroxide cores and tethered copolymer chains whose composition can be selected to allow dispersion in targeted plastic materials, thereby providing improved mechanical, electrical and flame retardant properties. Processes for preparing the same are also disclosed.

Owner:CARNEGIE MELLON UNIV +1

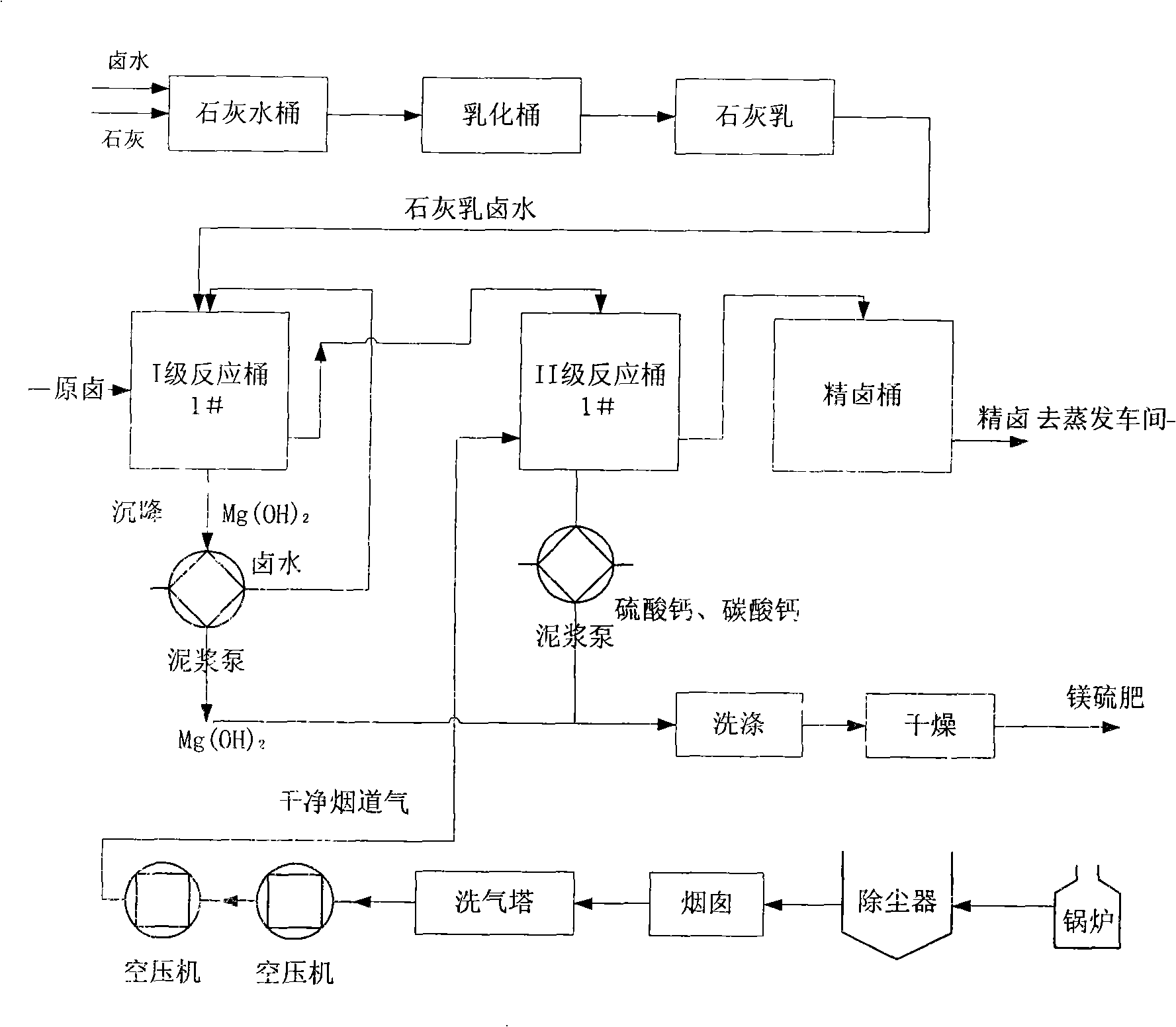

Technological process for purifying bittern

InactiveCN101289200AReduce purification costsImprove purification qualityAlkali metal chloridesSlurryCalcium carbonate precipitation

The invention provides a brine purification technical method which comprises that: a first step is that limewater is added into brine so that reaction happens to calcium hydroxide in the limewater and magnesian ion in the brine to generate magnesium hydrate sedimentation, the magnesian ion in the brine is removed, excessive calcium hydroxide is used for causticizing the sodium sulfate in the brine into sodium hydroxide; a second step is that flue gas is put into the brine after the magnesian ion is removed for carrying out reaction between carbon dioxide in the flue gas and the sodium hydroxide causticized in the brine to generate sodium carbonate which reacts with calcium ion in the brine to generate calcium carbonate sedimentation, the calcium ion in the brine is removed; a third step is that slurry produced in the first step and the second step is collected; and a fourth step is that refined brine after being treated by the first step and the second step is recycled. The technical method can reduce the pollution to environment, can save energy, and can reduce the consumption of raw brine and the purification cost of the brine at the same time, thereby conforming to the requirements of the strategy of sustainable development.

Owner:CHINA NATIONAL SALT INDUSTRY CORPORATION +1

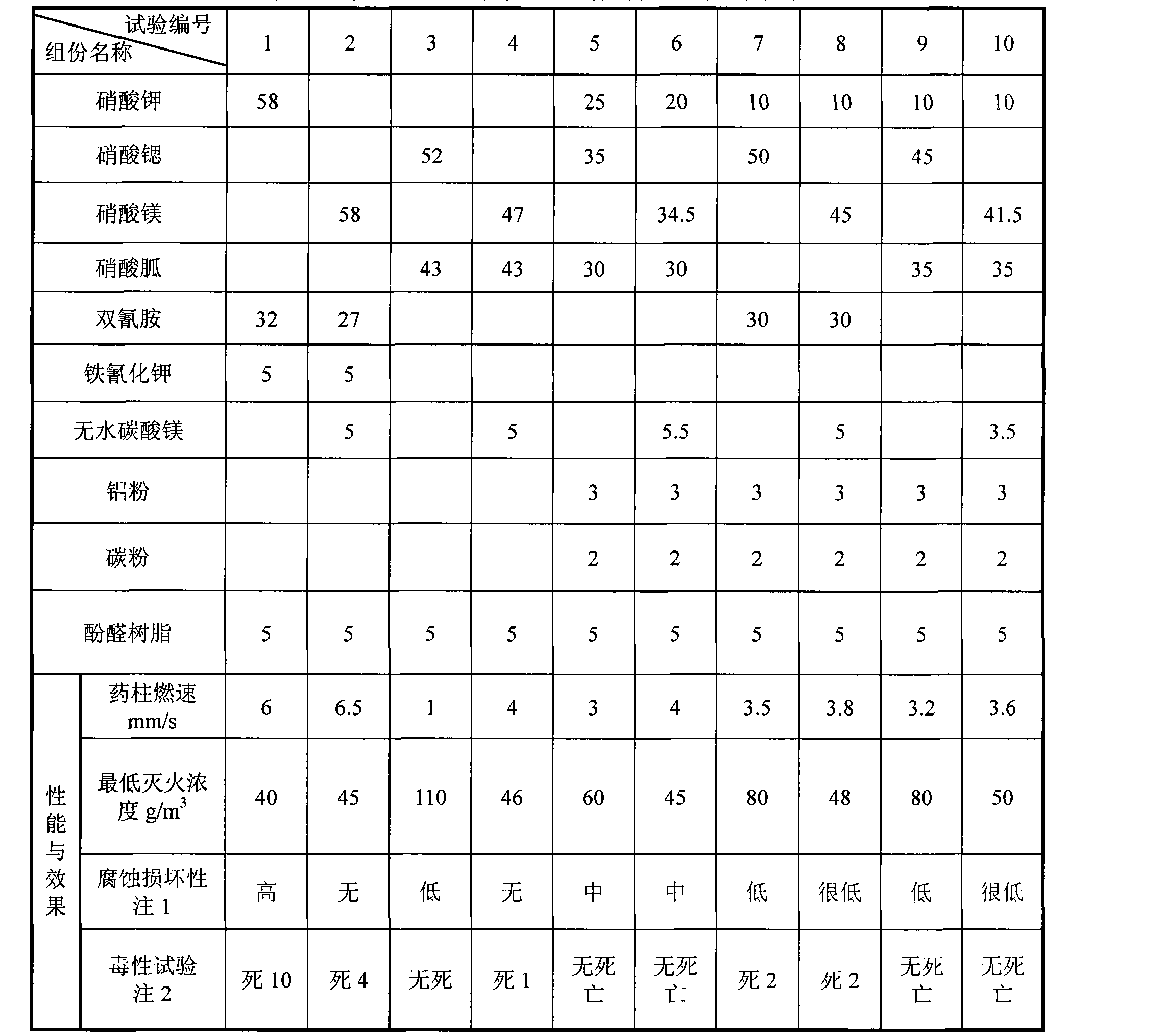

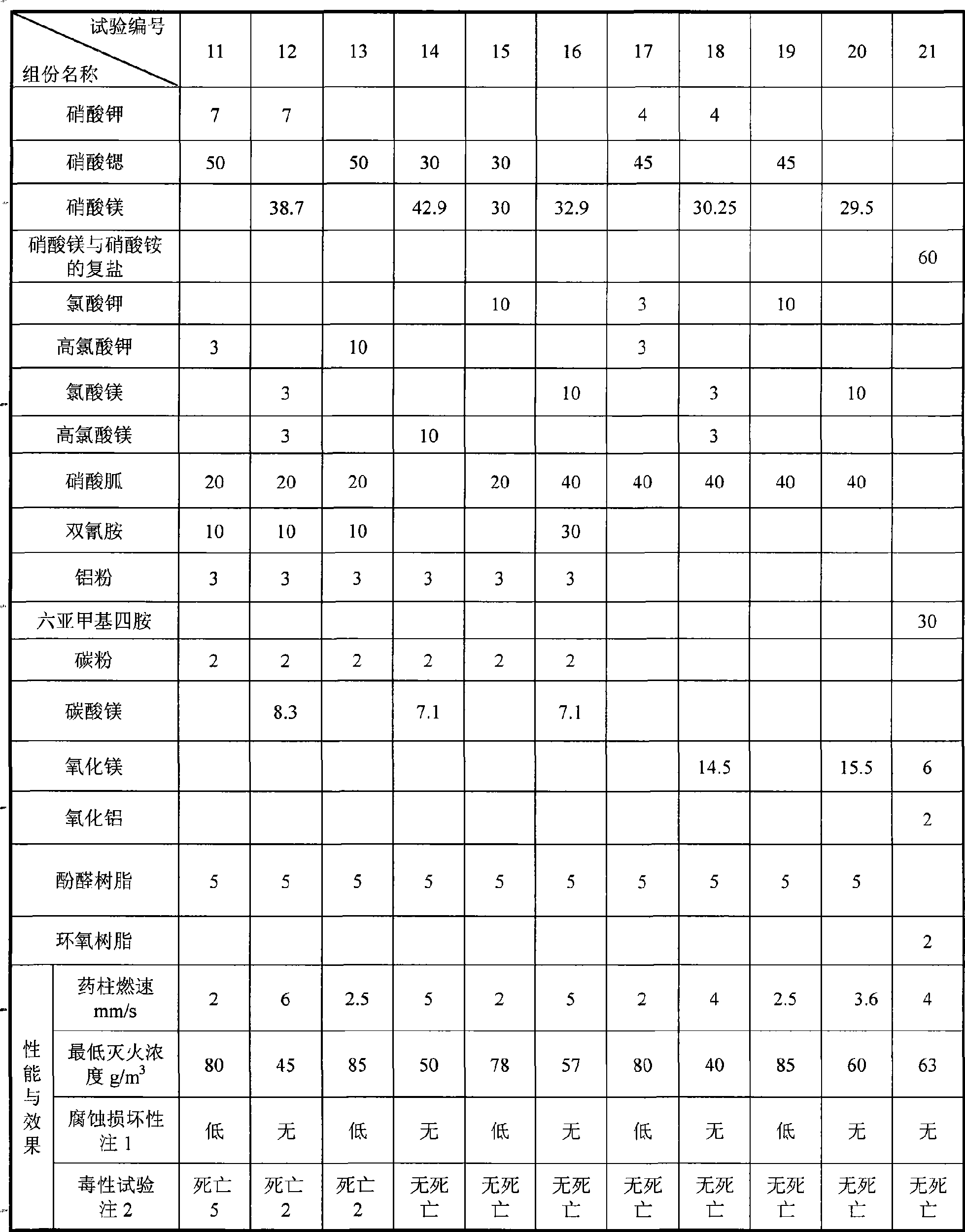

Extinguishment combination with hot gas sol

The invention provides ''a hot aerosol fire-extinguishing composition'' and relates to an oxidative magnesium salt hot aerosol fire-extinguishing composition represented by anhydrous magnesium nitrate. The composition is characterized in that the composition can be magnesium nitrate, magnesium carbonate, or other magnesium salt, and can also be a compound of magnesium nitrate, or other magnesium salt with potassium nitrate, strontium nitrate, or other potassium salt or strontium salt; a reducer can be one of or the combination of a plurality of ammonium carbamidine, dicyandiamide, red prussiate of potash, formamine, triazole, and tetrazole; a capability improver can be magnesium carbonate, manganous carbonate, aluminium powder, powdered carbon, magnesium hydrate, metal oxide, etc.; and the bond adopts phenolic resin, etc. The preparation of the magnesium salt comprises the continuous steps: medium temperature and low pressure dehydration, spray under the protection of nitrogen-oxygen flow or ultrafine grinding of grinded colloid, and microencapsulated hydrophobic treatment, etc. Compared with the prior art, the fire-extinguishing composition has the advantages of low price, extensive source, fire-extinguishing capability of K-type composition, and low causticity and toxicity of the ultimate product of combustion.

Owner:SHAANXI J&R FIRE FIGHTING CO LTD

Irradiation cross-linking low smoke halogen-free fire retardant polyolefin cable material

InactiveCN101286377ALow smoke productionImprove mechanical propertiesPlastic/resin/waxes insulatorsInsulated cablesCross-linkPolyolefin

The invention discloses a halogen-free cable material which is irradiation cross-linked, has less smoke and can retard the inflaming of polyolefine, and consists of the following components by mass: 30 to 50 percent of ethylene-vinyl acetate copolymer, 0 to 20 percent of high-density polyethylene, 30 to 60 percent of magnesium hydrate, 0 to 10 percent of red phosphorus, 1 to 5 percent of resin acceptor, 0.1 to 1.5 percent of cross linker, 1 to 5 percent of compatilizer, 0.1 to 1.5 percent of antioxidizer and 0.1 to 1.5 percent of lubricating agent. The halogen-free cable material which is irradiation cross-linked, has less smoke and can retard the inflaming of polyolefine overcomes the harm to the environment and the human bodies when retarding the inflaming of polyolefine material by using traditional halogen-containing flame retardants, has less smoke, innoxiousness, green and environment protection, and can ensure good mechanical performance, flame retarding performance and processing performance.

Owner:ZHEJIANG UNIV

Process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt

InactiveCN103436720ASolve the problem of ammonia nitrogen pollutionRealize green miningProcess efficiency improvementAmmoniacal nitrogenCalcium hydroxide

The invention relates to a process for leaching rare earth from ion-adsorption type rare earth ore without using ammonium salt. The process comprises the step of replacing ammonium salt by taking a mixture of calcium, magnesium and sodium salts as a leaching agent and taking non-ammonium salts, such as calcium hydroxide, magnesium hydrate or sodium hydroxide as a precipitator. According to the process disclosed by the invention, the ammonia nitrogen pollution problem in exploitation of ion-adsorption type rare earth is radically solved; environmental-friendly exploitation of the ion-adsorption type rare earth can be realized; the process disclosed by the invention has higher economic benefit and social benefit.

Owner:LONGNAN COUNTY NANYU RARE EARTH RESOURCES COMPREHENSIVE UTILIZATION CO LTD

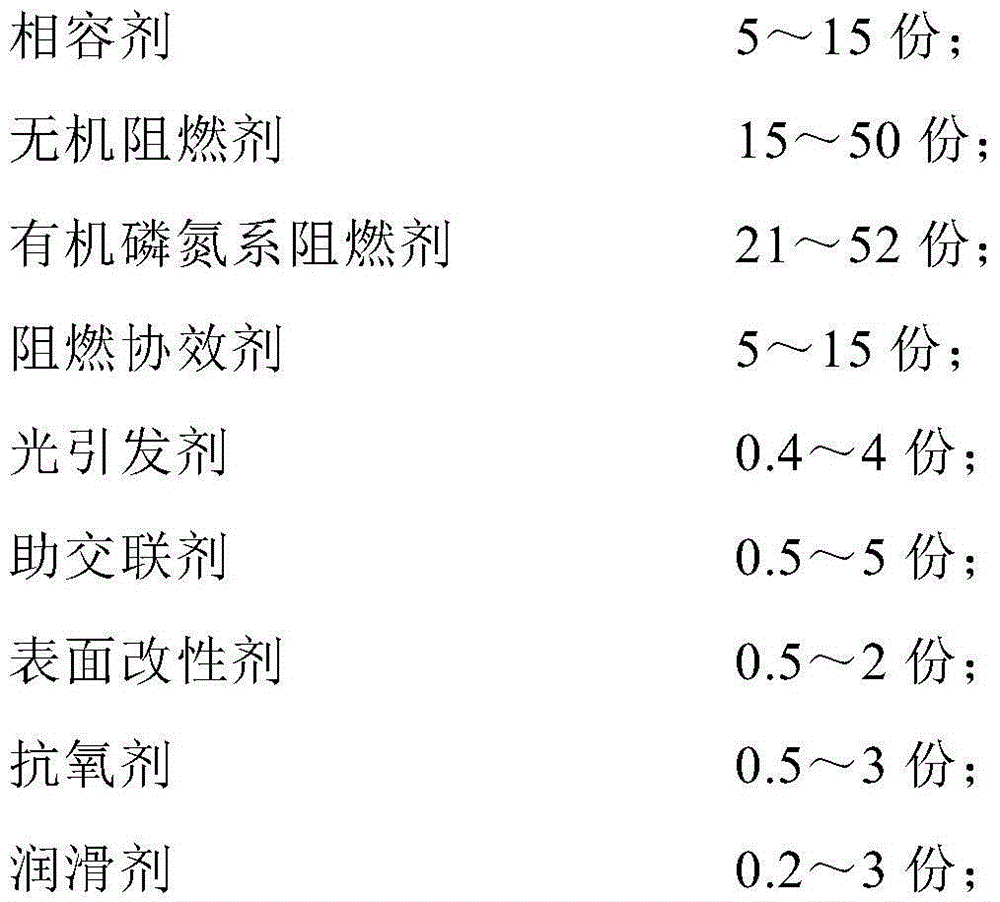

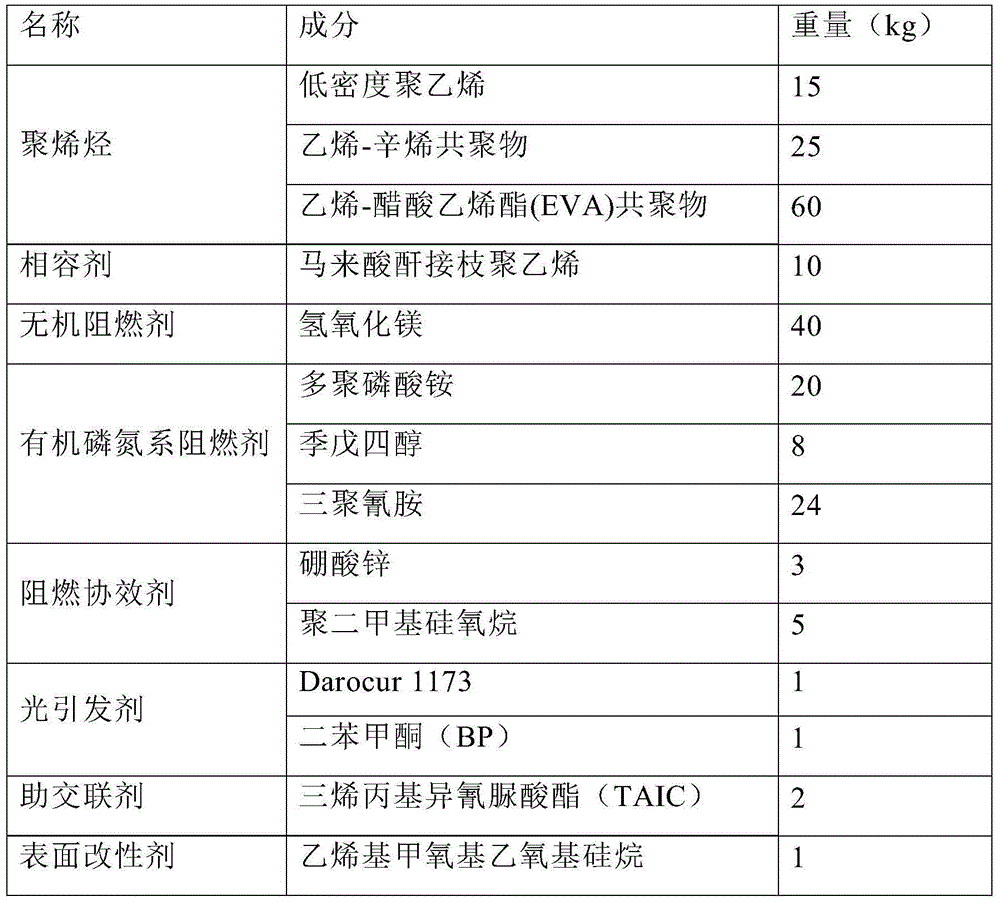

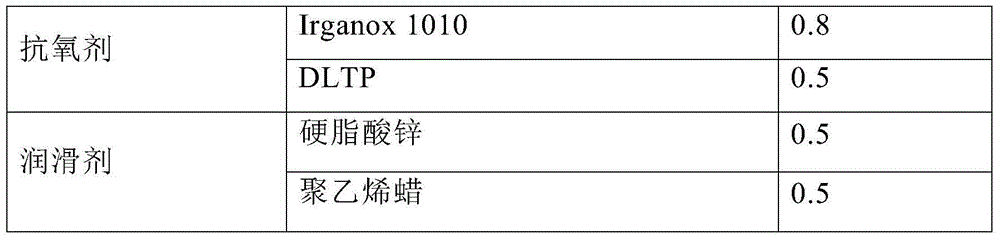

Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

ActiveCN104893088AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention provides an ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material. The cable material comprises polyolefin, a compatilizer, an inorganic flame retardant, an organic phosphorus-nitrogen-containing flame retardant, a flame-retardant synergist, a photoinitiator, an assistant crosslinker, a surfactant, an antioxidant and a lubricant, wherein polyolefin contains low-density polyethylene, an ethylene-octylene copolymer and an ethylene-vinyl acetate copolymer in the weight proportion being (10-25):(20-35):(55-65); the compatilizer is polyethylene for grafting of maleic anhydride; the inorganic flame retardant is selected from magnesium hydroxide and aluminum hydroxide; the organic phosphorus-nitrogen-containing flame retardant contains polyphosphoric acid, pentaerythritol and melamine in the weight proportion being (10-20): (4-8): (15-30); the flame-retardant synergist contains zinc borate and / or polydimethylsiloxane. The cable material has good thermal resistance and anti-aging performance, can be used at the temperature of 125 DEG C for a long time and is excellent in comprehensive mechanical performance and better in flame retardance.

Owner:上海至正新材料有限公司

Additive for plastic and plastic

InactiveUS20060188428A1Small amountCalcium/strontium/barium carbonatesMagnesium carbonatesCALCIUM CARBONATE/MAGNESIUM CARBONATEMagnesium carbonate / Magnesium Oxide

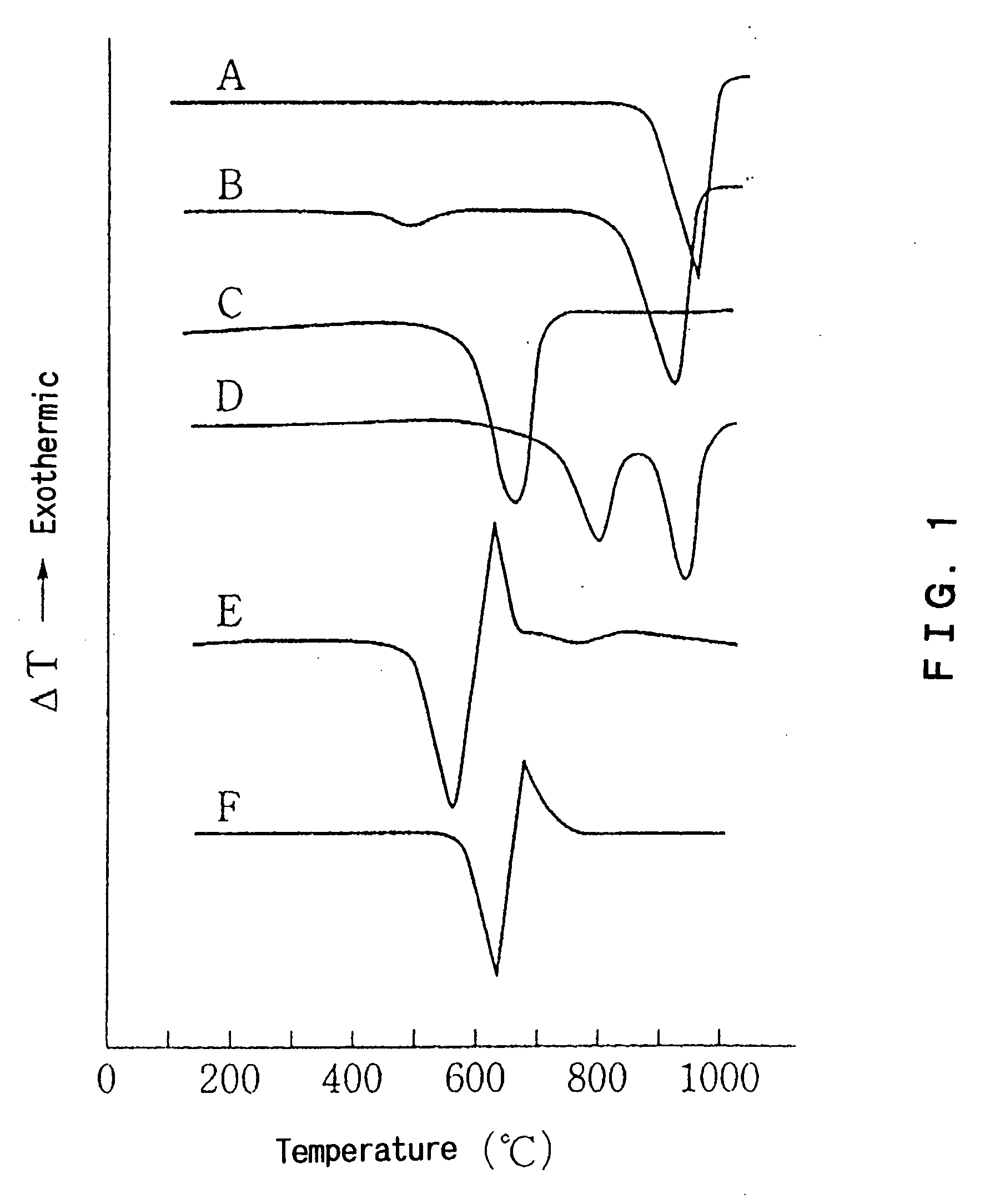

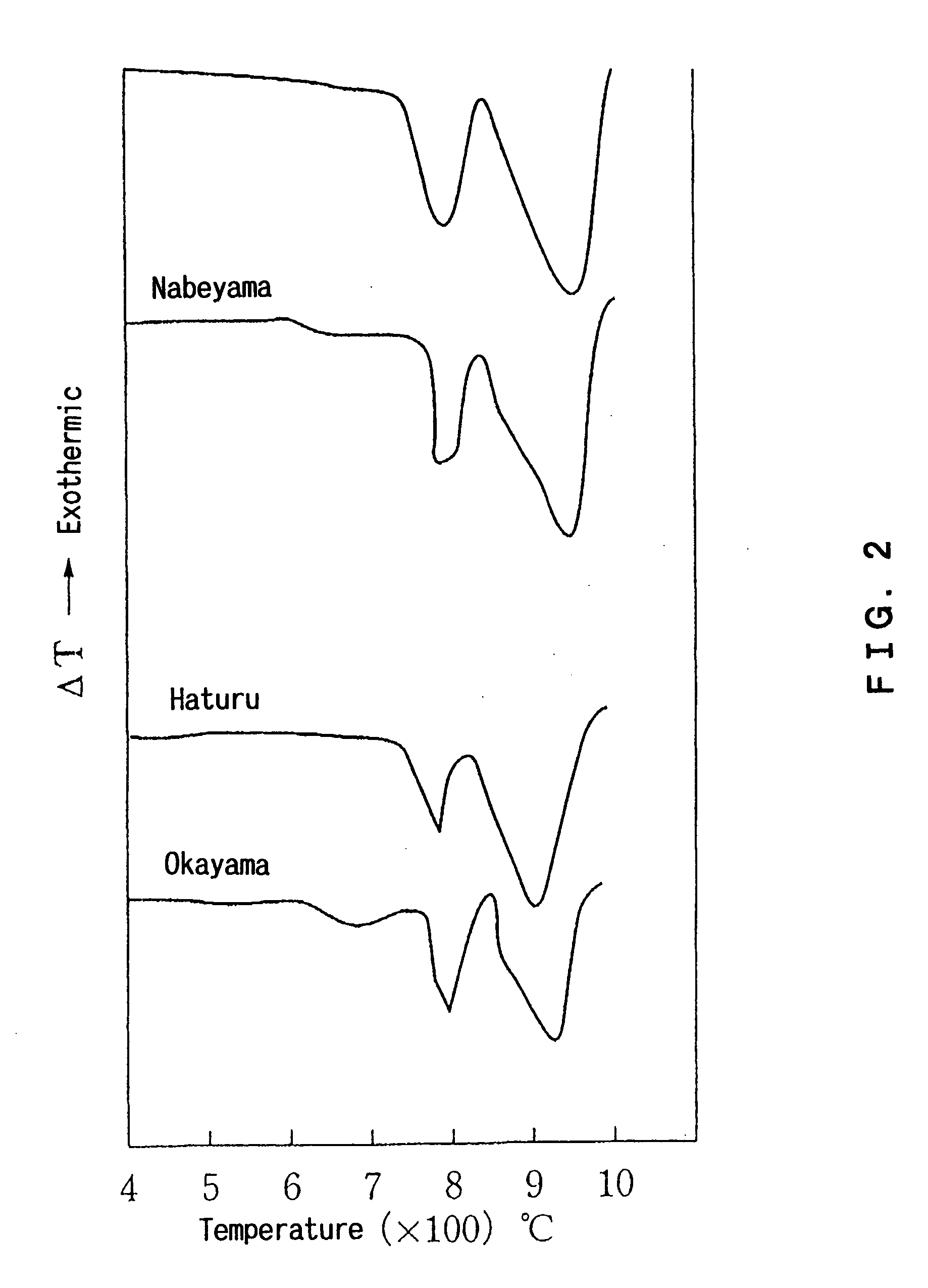

Disclosed is an additive for a plastic, comprising fine particles obtained by calcination and slaking of a dolomite which exhibits two endothermic peaks in the differential thermal analysis, said fine particles containing calcium carbonate, magnesium carbonate, magnesium oxide, calcium hydroxide and magnesium hydroxide as main chemical components and also containing an ignition loss component in an amount of 10 to 40% by weight based on the weight of said fine particles. A plastic hating hydrogen chloride scavenging properties and antimicrobial properties imparted by incorporating the additive for a plastic is also disclosed.

Owner:OSAKA MUNICIPAL TECHN RES INST +2

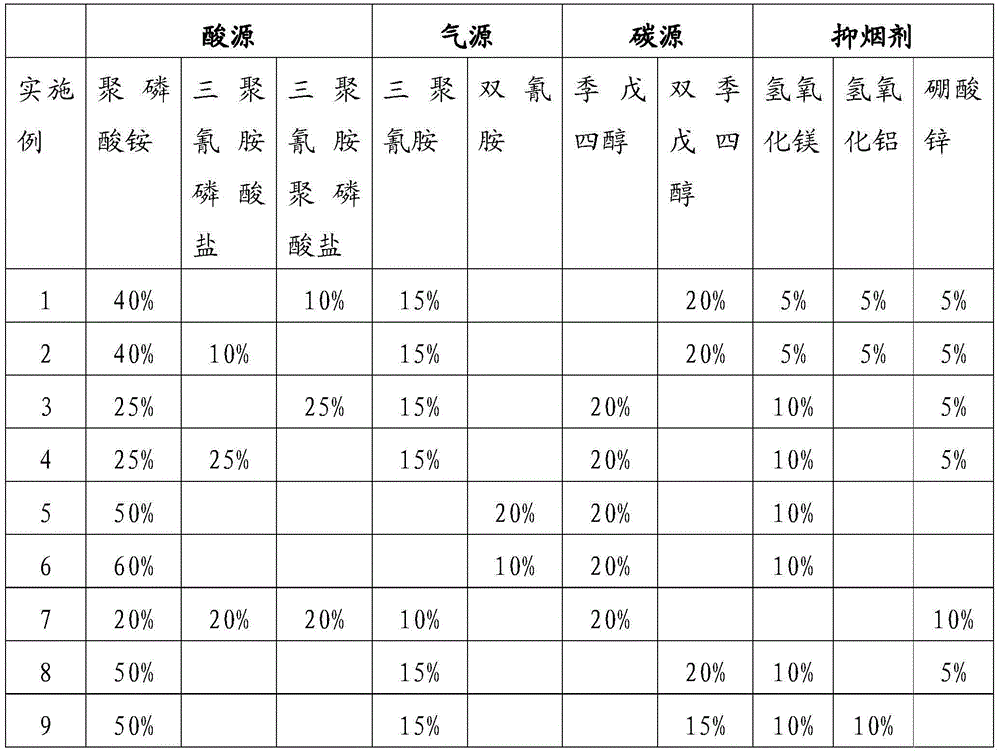

Composite intumescent flame retardant and preparation method thereof

InactiveCN104532588AReduce generationImprove flame retardant performanceFibre typesMelamine phosphateAluminium hydroxide

The invention discloses a composite intumescent flame retardant which is composed of the following components in percentage by weight: 50-65% of acid source, 10-20% of gas source, 15-20% of carbon source and 10-20% of smoke inhibitor. The acid source is composed of at least one of ammonium polyphosphate, melamine phosphate and melamine polyphosphate, wherein the ammonium polyphosphate is crystal II ammonium polyphosphate with the average degree of polymerization of greater than 1000; the gas source is composed of at least one of melamine and dicyandiamide; the carbon source is composed of at least one of pentaerythritol and bis pentaerythritol; and the smoke inhibitor is composed of at least one of magnesium hydroxide, aluminum hydroxide and zinc borate. The invention also discloses a preparation method of the composite intumescent flame retardant.

Owner:SHIFANG TAIFENG NEW FLAME RETARDANT

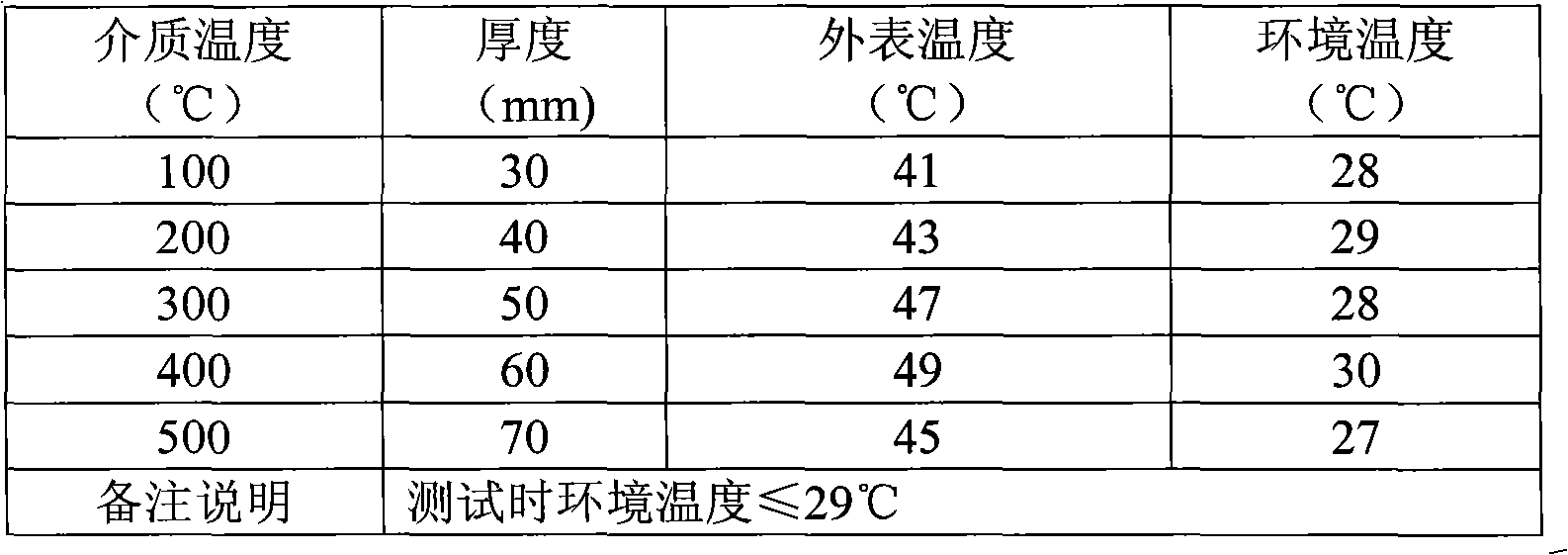

Inorganic heat-insulating material and preparation method thereof

InactiveCN101973750AImprove isolation abilityStrong anti-radiation heat conduction abilitySolid waste managementSodium BentoniteCarbon fibers

The invention relates to an inorganic heat-insulating material and a preparation method thereof. The inorganic heat-insulating material is prepared from the following raw materials in parts by weight: 15-37 parts of basic material, 45-70 percent of pigment and filler and 9-26 parts of auxiliary agent, wherein the basic material comprises the following raw materials in parts by weight: 10-20 partsof phosphoric acid, 3-8 parts of aluminium hydroxide, 2-8 parts of aluminum-silver slurry auxiliary agent, 0.5-5 parts of silicate and 1-5 parts of sodium carboxymethyl cellulose; the pigment and filler is one or a combination of potassium titanate whiskers, expanded perlite, ceramic microspheres, nano-silicon dioxide aerogel, heat-insulating powder, carbon fibers, meerschaum, needle-shaped wollastonite powder and magnesium hydrate; and the auxiliary agent is one or a combination of boron nitride, dichromium trioxide, glass powder, boric acid, nano-zirconia, calcium oxide and calcium-based bentonite. The invention inorganic heat-insulating material has strong insulating capability for solid conductive heat at high temperature (150-500 DEG C) and simultaneously also has strong insulating capability for radiation and flow conductive heat.

Owner:童金荣

105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking and preparation method thereof

InactiveCN103965541AImprove mechanical propertiesGood electrical performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolymer science

The invention provides a 105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking. The covering material comprises the following raw materials: an ethylene vinyl acetate copolymer, linear low density polyethylene, high density polyethylene, ethylene-octene copolymer elastomer, a maleic anhydride grafting material, silicone master batch, aluminium hydroxide, magnesium hydrate, zinc borate, a phosphorus-nitrogen type intumescent flame retardant, a silane coupling agent, a lubricating agent, a complex antioxidant, a light stabilizer, and an environment-friendly mice and ants preventing agent. The preparation method comprises the following steps: uniformly mixing the raw materials above through a high-speed mixer; and then extruding and granulating through a double-step single-screw reciprocating extruding unit to obtain the covering material. The covering material is scientific and reasonable in formula and matching, and advanced in process; the prepared 105 DEG C thermoplastic, halogen-free, low-smoke, fire-retardant and ultraviolet-resistant covering material capable of preventing mice and ants and resisting cracking is applicable to manufacture of cables, and the prepared cable is high in mechanical performance, flame retardant performance, electrical performance and low-temperature performance, outstanding in resistance to mice and ants, resistance to thermo-oxidative aging, and excellent in resistance to high-temperature cracking.

Owner:BAOSHENG SCI & TECH INNOVATION +1

Process for producing cavity type ZSM-5 modified zeolite molecular sieve

ActiveCN101428817ANarrow distributionRelatively low crystallinityMolecular sieve catalystsPentasil aluminosilicate zeoliteSodium bicarbonatePotassium hydroxide

The invention relates to a method for preparing hollow cavity type ZSM-5 modified zeolite molecular sieve, and aims to solve the problems that the microcellular structure diffusion admittance is narrow, the modified zeolite molecular sieve has lower relative degree of crystallinity, and the adjustable range of apertures inside molecular sieve is small, thereby facilitating macromolecule reaction limited by diffusion. The invention adopts at least one 0.1-8.5 mol / L acid solution of hydrochloric acid, nitric acid, sulphuric acid or acetic acid to treat ZSM-5 molecular sieve raw powder with the silica alumina ratio SiO2 / Al2O3 being 20-1000 and the particle size being 0.4-10 Mum for 1-8 h; then at least one 0.1-5.0 mol / L aqueous alkali of sodium hydroxide, magnesium hydrate, potassium hydroxide, sodium carbonate or sodium bicarbonate is used for treatment for 1-48 h at 20-90 DEG C; and at least one 0.1-8.5 mol / L acid solution of hydrochloric acid, nitric acid, sulphuric acid or acetic acid is used for treatment for 1-48 h at 20-90 DEG C to obtain the modified ZSM-5 molecular sieve. The problems are well solved, and the invention can be used in industrial production of macromolecule catalysis and transformation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technique for chemomechanical pulp-making of poplar wood

InactiveCN101230552AHigh yieldGood optical performancePretreatment with alkaline reacting compoundsChemical/chemomechanical pulpWastewaterPre treatment

The invention relates to a pulp technology of aspen by using a chemical-mechanical method. Aspen sizing agent which is decatized and is extruded and dispersed for a space is infused in peroxide using magnesium hydrate as an alkali source and is mechanically grinded by adopting the enzyme pretreatment technique, then the sizing agent high density storage bleaching is acted, finally, chemical-mechanical pulp with high whiteness and high yield is manufactured through a second stage jordaning production. The method of the invention realizes that the pulp yield and the optical performance are increased, the energy consumption for jordaning is lowered, the load of wastewater pollution is lowered, and the scale formation problem is eliminated.

Owner:QILU UNIV OF TECH

Halogen-free flame retardant polyamide 6 composition

The invention discloses a halogen-free flame-retardant polyamide 6 composition with high toughness and antistatic property. The composition comprises active magnesium hydrate, organic phosphate oligomer, zinc oxide crystal whisker, a macromolecular compatilizer, a plasticizer and an additive. The active magnesium hydrate and the organic phosphate oligomer are used to improve flame retardance; organic anlistatig and the zinc oxide crystal whisker are used to improve the antistatic property; and the macromolecular compatilizer is used to improve interaction among polyamide, the inorganic magnesium hydrate and the zinc oxide crystal whisker. The flame-retardant polyamide 6 composition has the advantages that compared with a sole magnesium hydrate flame-retardant polyamide 6, the use amount of the magnesium hydrate is reduced to below 50 mass percent; the impact strength of a gap is increased by over 80 percent; the breaking elongation rate is improved by approximately 20 times; the resistivity is reduced by 4 orders of magnitude; the flame retardant performance reaches UL94V-0 level; simultaneously, the toughness is basically maintained at the level of pure polyamide 6; the temperature for thermal deformation is much higher than 65 DEG C of the pure polyamide 6; and the molding shrinkage rate is reduced to 0.6 percent from 1.78 percent of the pure polyamide 6.

Owner:GUANGDONG XINHUI MEIDA NYLON

Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

ActiveCN101531789AImprove radiation resistanceThe ratio is scientific and reasonableRubber insulatorsSilanesNuclear power

The invention discloses a radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and a preparation method. The radiation-resistant halogen-free low smoke flame retardant insulating material is prepared from the following raw materials: ethylene propylene diene rubber, phenyl siloxane rubber, magnesium hydrate, aluminium hydroxide, zinc borate, white carbon black, cerium dioxide, zinc oxide, Bis(tert-butyldioxyisopropyl)benzene, tri allyl cyanurate, 2-mercaptobenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline, Aflux A-25, stearic acid, vinyl tris(beta-methoxyethoxy) silane, and paraffin oil by heating and mixing. The formulation and the mixture ratio are scientific and reasonable, and the process is advanced. The prepared insulating material has good radiation resistance, excellent mechanical property, good electrical property and long service life, and is a good radiation-resistant halogen-free low smoke flame retardant insulating material for manufacturing the cables of the nuclear power plants.

Owner:BAOSHENG SCI & TECH INNOVATION

Flame-retardant agent and flame-retardant resin composition

InactiveUS20140200292A1Improve flame retardant performanceFireproof paintsO-Phosphoric AcidSilicic acid

The present invention provides a composite flame retardant which can be produced without using any toxic metal such as antimony trioxide or any halogen such as bromine and chlorine and can exhibit excellent flame retardancy compared with magnesium hydroxide when added in a smaller amount; and a flame retardant resin composition having excellent flame retardancy and excellent physical properties. The present invention relates to a flame retardant including: (A) 100 parts by mass of a reaction product of piperazine with one phosphorus compound selected from phosphoric acid, pyrophosphoric acid, and polyphosphoric acid; (B) 10 to 1000 parts by mass of a reaction product of melamine with a polyacid selected from cyanuric acid, phosphoric acid, pyrophosphoric acid, and polyphosphoric acid; and (C) 0.1 to 100 parts by mass of a reaction product of calcium or magnesium with silicic acid.

Owner:SAKAI CHEM IND CO LTD

High efficiency composite flocculant, its preparation method and application

InactiveCN1785836AEasy to prepareLow costWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationCalcium hydroxideInorganic compound

The present invention relates to a high-effective compound flocculating agent, its preparation method and application. Said flocculating agent is composed of flocculating agent and coagulant aids, in which the flocculating agent mainly is polymeric aluminium iron or polymeric aluminium, and the coagulant aids mainly have two classes, one is inorganic compound, for example sodium silicate, calcium hydroxide, calcium carbonate, magnesium hydroxide and high-molecular coagulant aids, and another is organic substance, for example polyacrylamine, dodecyl dimethyl tertiary amine, dicyandiamide and modified chitosan. It can be used for treating dyeing waste water.

Owner:SHANGHAI UNIV OF ENG SCI

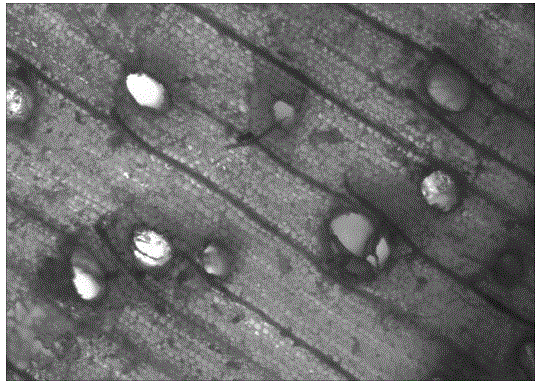

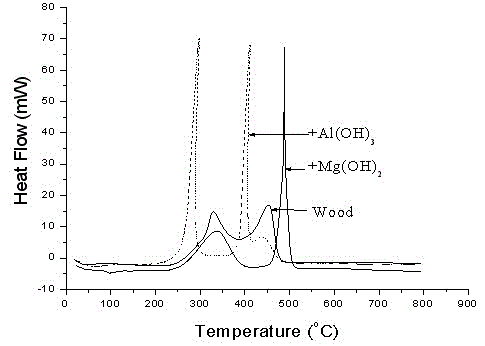

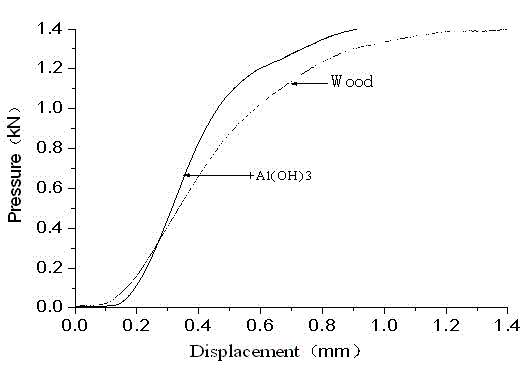

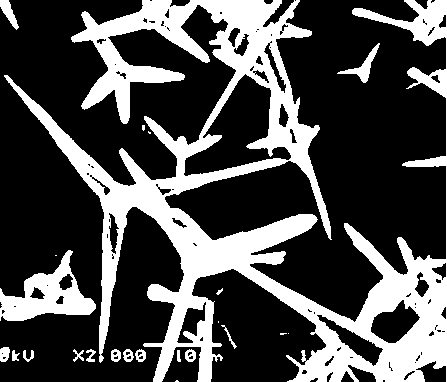

Nanometer hydroxide wood composite material and preparation method thereof

InactiveCN102873724AStrong mechanical propertiesImprove flame retardant performanceMaterial nanotechnologyWood impregnation detailsAluminum oxide hydroxideAluminium hydroxide

The invention discloses a nanometer hydroxide wood composite material. The nanometer hydroxide wood composite material is a high-quality composite wood material which consists of fast-growing wood serving as a base body and inorganic nanometer hydroxide serving as a reinforcing body. The inorganic nanometer hydroxide is uniformly filled in nanometer cavities among microfibers of the fast-growing wood, and is nanometer aluminum hydroxide, nanometer aluminum oxyhydroxide, nanometer magnesium hydroxide or nanometer magaldrate. The nanometer wood composite material is prepared from the fast-growing wood serving as the base body for the first time by a (microwave) hydrothermal method, surface activity and dispersion conditions of nanometer particles in a matrix and influence of a boundary structure on the mechanical property and the flame retardant property of the composite material are researched, so that filled wood is strengthened and has multiple functions of flame retardance, smoke suppression and the like, and the novel material with the excellent mechanical property and the good flame retardant property is obtained.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Process for preparing concentrated polyunsaturated fatty acid oil

ActiveUS20090176284A1Improve responseLow costFatty acid esterificationBacteria peptidesCalcium hydroxideAlcohol

The present invention provides a process for concentrated PUFA oil, characterized in that alcoholysis reaction using lipase is carried out in the presence of a small amount of water and at least one compound as an additive selected from magnesium oxide, magnesium hydroxide, calcium oxide and calcium hydroxide, and then separation is conducted to obtain a glyceride fraction.

Owner:NIPPON SUISAN KAISHA LTD

Nano-whisker-reinforced multifunctional diatom ooze coating

The invention relates to a nano-whisker-reinforced multifunctional diatom ooze coating. The nano-whisker-reinforced multifunctional diatom ooze coating is characterized in that 30 to 65wt% of diatomite, 0.5 to 2.5wt% of tetrapod-like nano-zinc oxide whiskers, 10 to 16wt% of superfine magnesium hydroxide, 5 to 15wt% of at least one crystalline aluminum salt, 10 to 40wt% of quartz sand, 0.5 to 1.5wt% of hydroxyethyl cellulose, 2 to 4.2wt% of one or two inorganic pigments and 0.5 to 3wt% of calcium hydroxide are mixed into the nano-whisker-reinforced multifunctional diatom ooze coating at a rotation rate of 500 to 800rpm. The nano-whisker-reinforced multifunctional diatom ooze coating has functions of resisting mildew and bacteria, purifying air in a room, and adjusting humidity. Compared with like products obtained by the existing technology, the nano-whisker-reinforced multifunctional diatom ooze coating has the advantages of strong adhesion to a wall surface, good durability, no falling-off of powder, no color fading and no cracking and falling-off, and is suitable for build interior decoration of airports, hospitals, office buildings, conference centers, hotels, villas, high-grade residential areas and entertainment places, and inner wall decoration of public places having forced flame-resistance requirements.

Owner:成都斯米利亚硅藻新材料有限公司

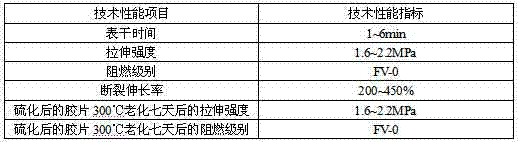

Halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber and preparation method thereof

InactiveCN103044922AFast curingExtensive adhesionNon-macromolecular adhesive additivesPolymer sciencePhosphate

The invention discloses a halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber and a preparation method thereof. Hydroxy-end-capped polydimethylsiloxane is used as the main body and is compounded with a thermal-resisting additive and a flame retardant additive, wherein the halogen-free flame retardant, high-temperature resisting and rapidly solidified deacetone silicon rubber comprises the following ingredients by weight: 100 parts of the hydroxy-end-capped polydimethylsiloxane serving as a main body, 1-50 parts of polydimethylsiloxane, 5-18 parts of silicon oxide, 5-15 parts of thermal-resisting additive, 50-200 parts of flame retardant additive, 0.5-2.5 parts of tackifier, 0.5-1 part of organic guanidine catalyst and 5-8 parts of deacetone siloxane cross-linking agent; the thermal-resisting additive is one or a mixture of several of iron oxide red, cerium oxide of which the purity is not less than 90% and tin oxide of rutile structure; and the flame retardant additive is one or a mixture of several of aluminum hydroxide, magnesium hydrate, zinc borate, phosphate ester, phosphonate, phosphine oxide and organic phosphorus. The deacetone silicon rubber has good thermal resistance, flame retardant effect and mechanical properties at 250-300 DEG C, and is simple in preparation method and high in production efficiency.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

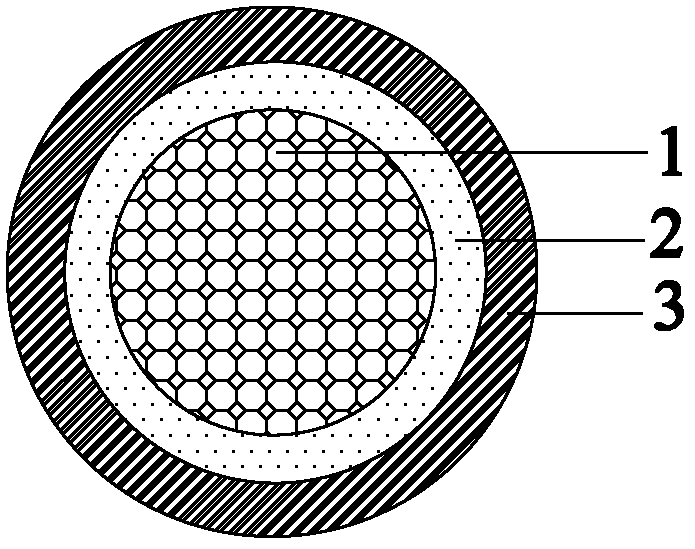

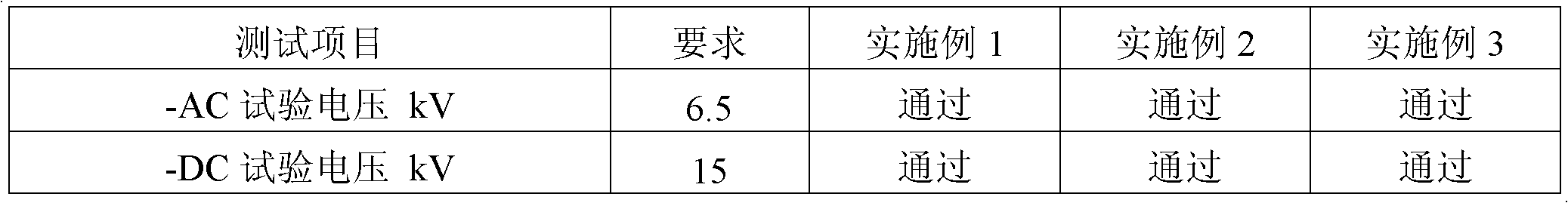

Photovoltaic cable and manufacturing method and application thereof

ActiveCN102610305AGood mechanical propertiesMeet environmental protection requirementsClimate change adaptationInsulated cablesThermal ageingCross-link

The invention discloses a photovoltaic cable and a manufacturing method and application thereof. The photovoltaic cable comprises an insulating layer and a jacket layer; the insulating layer comprises the following components: EVA (ethylene-vinyl acetate copolymer), LLDPE (linear low density polyethylene), EMA (ethylene-methyl acrylate), EVA-g-MAH (ethylene-vinyl acetate copolymer grafted maleic anhydride), magnesium hydrate, organic montmorillonoid, a cross-linked sensitizing agent, a lubricating agent, an antioxidant, a light stabilizer and a copper resisting agent; and the jacket comprisesthe following components: EVA, LLDPE, EMA, EVA-g-MAH, color masterbatch, magnesium hydrate, a phosphor series fire retardant, melamine chlorinated isocyanurates, zinc borate, a cross-linked sensitizing agent, a lubricating agent, an antioxidant, a light stabilizer and a copper resisting agent. According to the invention, the photovoltaic cable is manufactured by extruding insulating layer aggregates and jacket layer aggregates on a cable double-layer co-extrusion machine, wrapping the aggregates on the outer surface of a conductor in sequence and carrying out forming, air cooling, coiling andirradiation. The manufacturing method disclosed by the invention has the advantages of good machining property, favorable machining property and low cost and is suitable for industrial production; and the manufactured photovoltaic cable is environment-friendly and has excellent mechanical property, flame radiation resistance performance, thermal ageing property and weather fastness.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

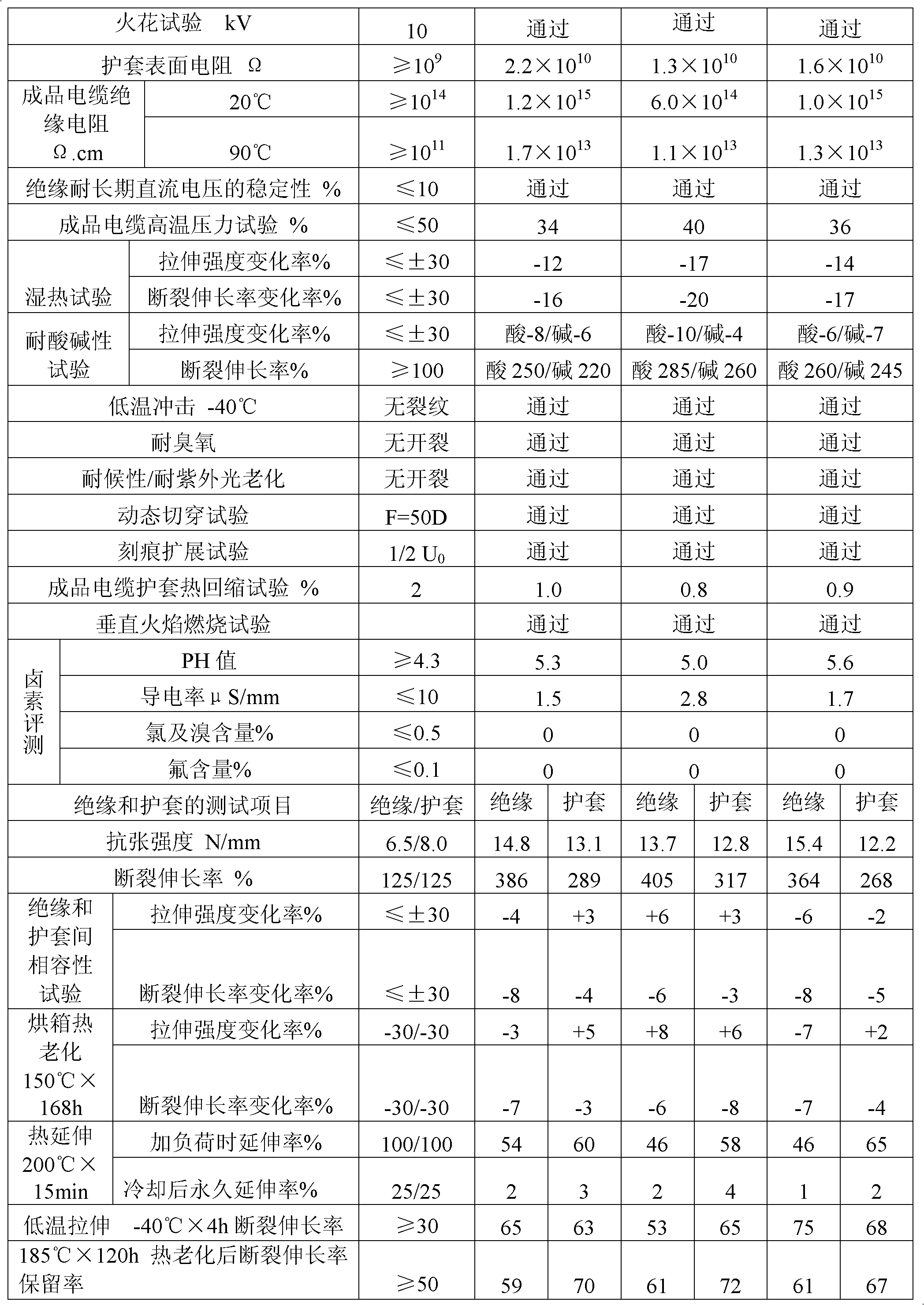

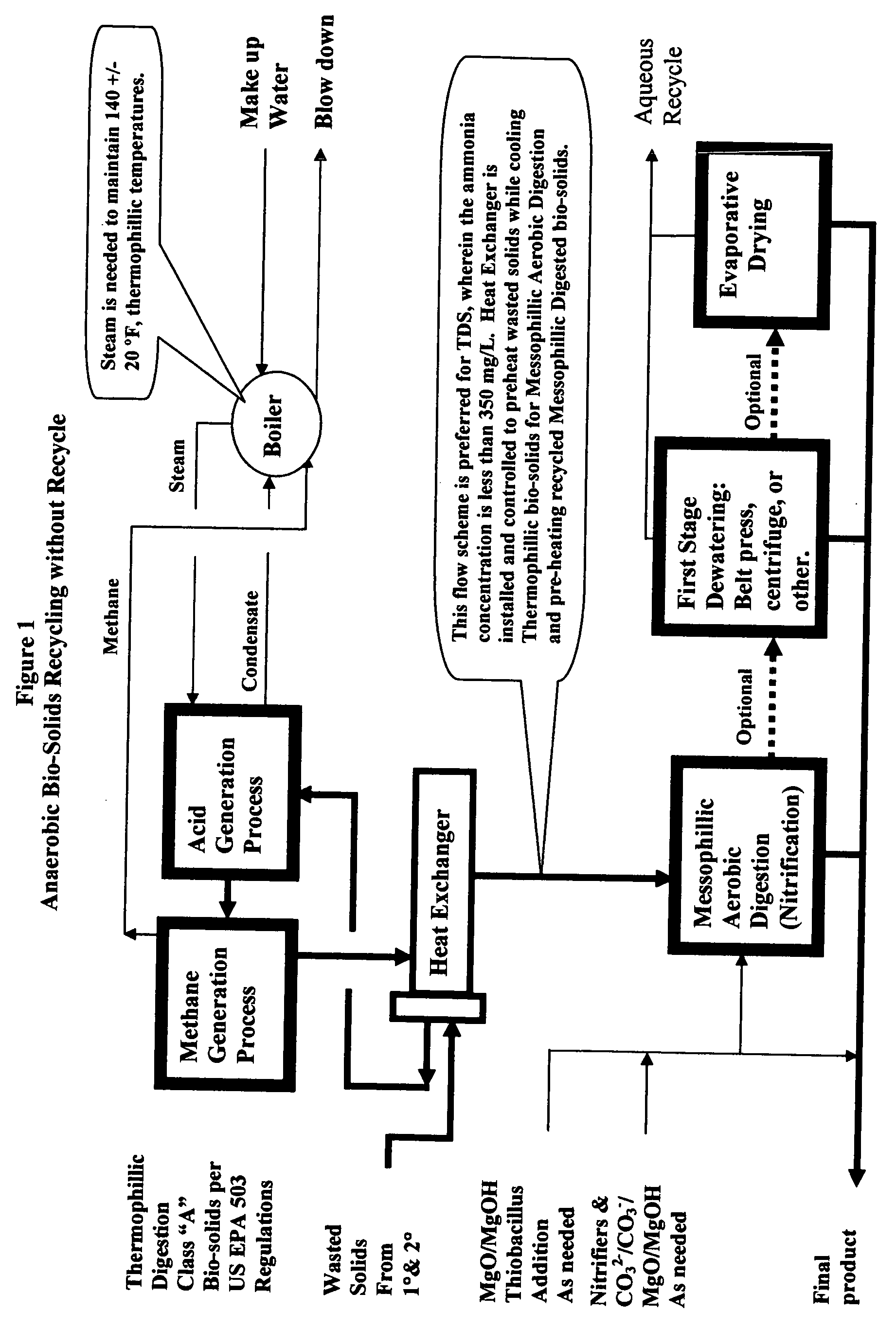

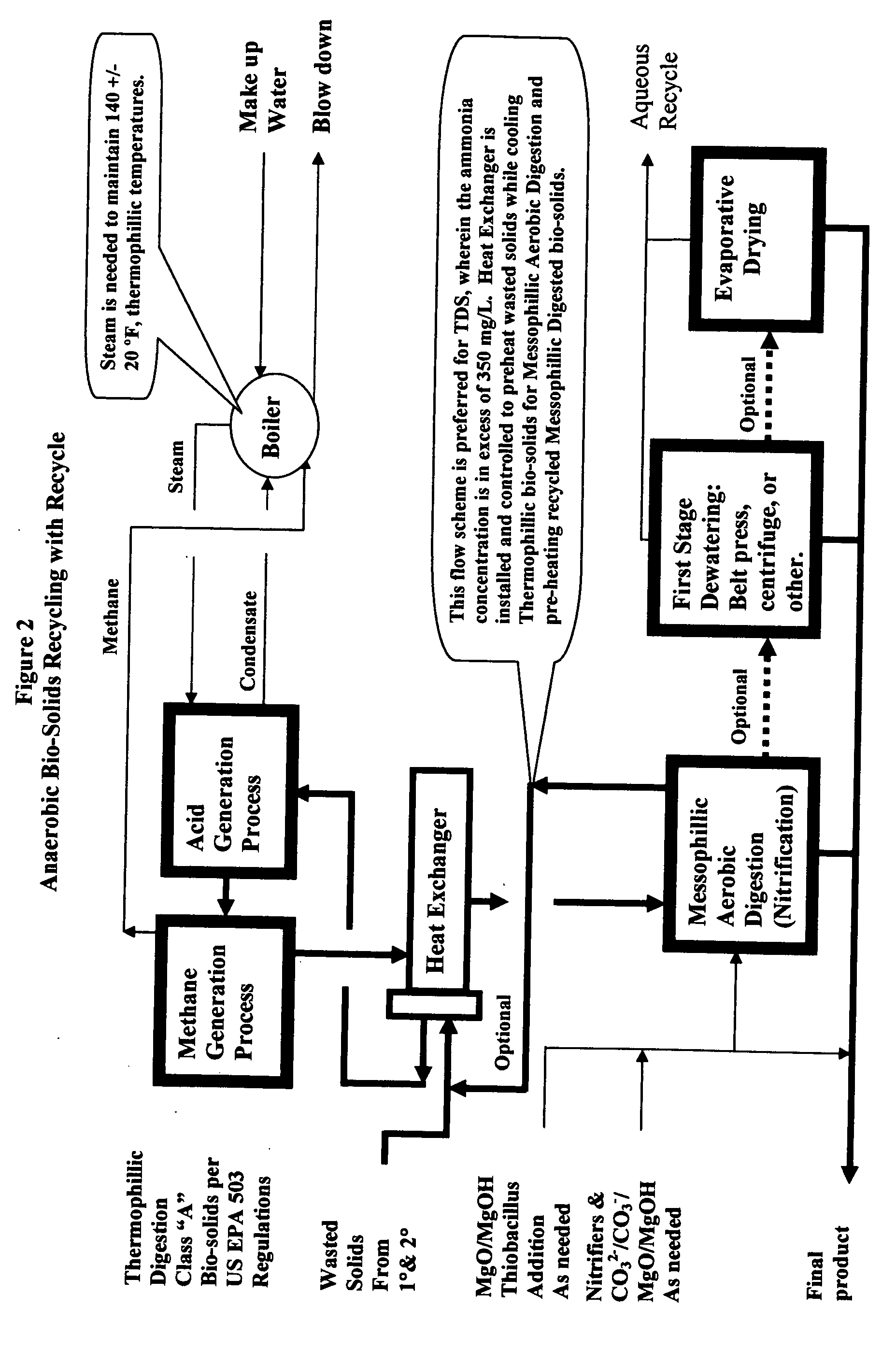

Methods, processes and apparatus for bio-solids recycling and the product of bio-solids from such methods, processes and apparatus

InactiveUS20050145566A1Effective, efficient and economically feasible digestionMinimal objectionable odorCalcareous fertilisersBio-organic fraction processingIron saltsDisinfectant

In the field of water treatment, this invention relates to economical methods, processes and apparatus for preparing Class A bio-solids wherein: dewatering costs and energy costs are efficient, the solids product has reduced ammonia and sulfide odor, and the concentration of solids in the aqueous solids may vary from approximately 3 to approximately 90 percent. This instant invention presents messophilic and thermophilic digestion in concert, wherein messophilic digestion incorporates strains of thiobacillus with nitrifiers to remove sulfide(s) and ammonia from bio-solids. Chemical dewatering of thermophilic digested bio-solids is accomplished incorporating a cationic, quaternized or an anionic polyacrylamide with at least one selected from a list consisting of: an aluminum salt, an iron salt, an amine comprising a quaternized nitrogen moiety and any combination therein. A quaternized polyacrylamide is presented alone. The use of magnesium oxide and / or magnesium hydroxide as a disinfectant / preservative for said bio-solids is also presented.

Owner:CLEARVALUE TECH

Ion-adsorption-type rare earth extracting method

ActiveCN103266224AImprove leaching rateIncrease sedimentation rateProcess efficiency improvementAluminum IonPollution

The invention relates to an ion-adsorption-type rare earth extracting method. The method comprises the following steps of: by taking an aqueous solution containing magnesium sulfate or the magnesium sulfate and / or ferric sulfate or the magnesium sulfate and / or aluminum sulfate as main components as an ore leaching agent, leaching ion-adsorption-type rare earth ore; dissolving rare earth ions in the rare earth ore with magnesium, ferric and aluminum ions and the like in an iron exchanging manner, thereby obtaining a leachate; and by taking magnesium hydrate or magnesium oxide or magnesium carbonate as a precipitator, thereby generating a rare earth hydrate or a rare earth carbonate. The method is simple in process and strong in raw material adaptability, and can be used for economically and effectively leaching the rare earth from the ion-adsorption-type rare earth ore, thereby completely avoiding the problem of ammonia nitrogen pollution caused by an existing leaching process. Therefore, the method is a sanitary production process.

Owner:JIANGXI UNIV OF SCI & TECH

PET (polyethylene glycol terephthalate) fiber/aramid fiber composite sound absorbing cotton and preparation method of PET fiber/aramid fiber composite sound absorbing cotton

InactiveCN102965839AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesEpoxyPolymer science

Owner:芜湖跃飞新型吸音材料股份有限公司

Preparation method of expansion graphite polystyrene board

InactiveCN102492232AAvoid generatingImprove flame retardant performanceThermal insulationPolystyrene

The invention provides a preparation method of an expansion graphite polystyrene board, belonging to the technical field of preparation methods of expansion graphite polystyrene boards. An organic-inorganic composite insulation board is prepared by using the thermal insulation, heat resistance and flame retardance of an inorganic material, so that the thermal insulation and halogen-free flame retardance of a polystyrene insulation board are enhanced. According to an adopted technical scheme, the method comprises the following steps of: performing surface modification on expansion graphite powder of 200-500 meshes and nano-scale magnesium hydrate with a surfactant; mixing with polystyrene resin monomer particles; uniformly stirring at the temperature of 110-135 DEG C for 25-45 minutes; extruding prepared particles with a double screw extruder; mixing the prepared particles with nano-talc powder and ethanol serving as a foaming agent; and stirring uniformly at the temperature of 80-110 DEG C, and adding into a plastic extruder for extruding and molding to obtain a composite material with high thermal insulation, heat preserving property and flame retardance.

Owner:王琼文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com