Patents

Literature

2253results about How to "Improve radiation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

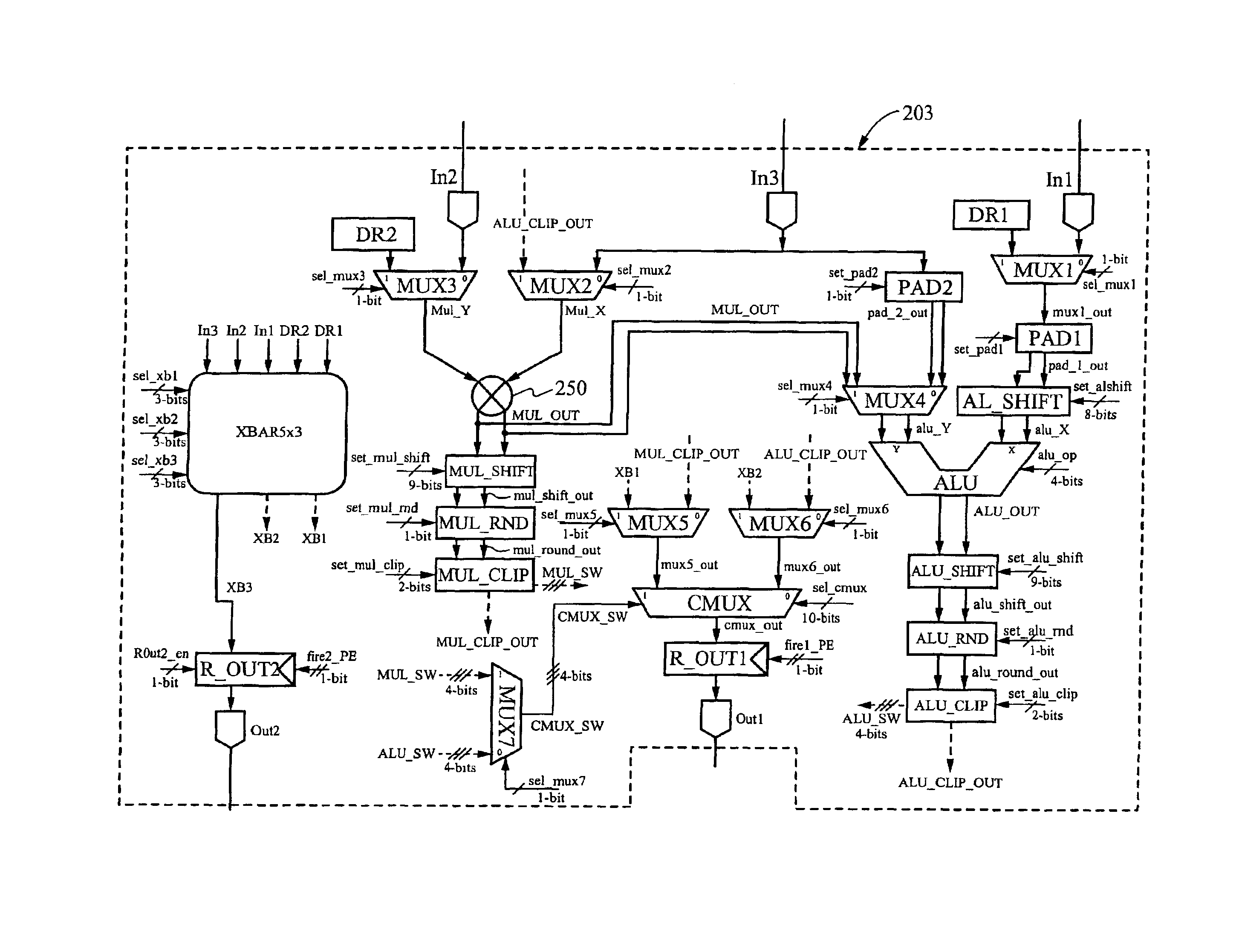

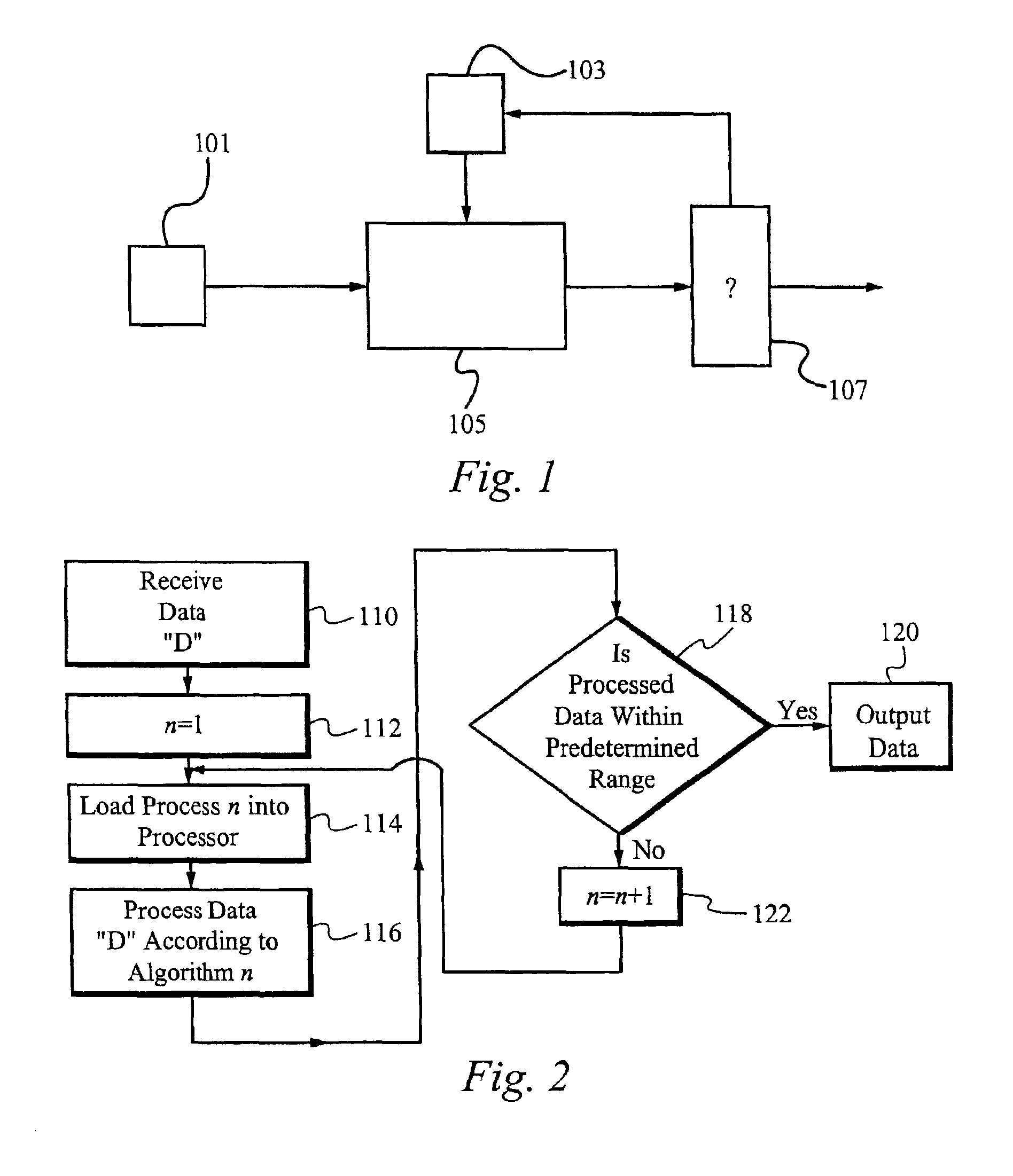

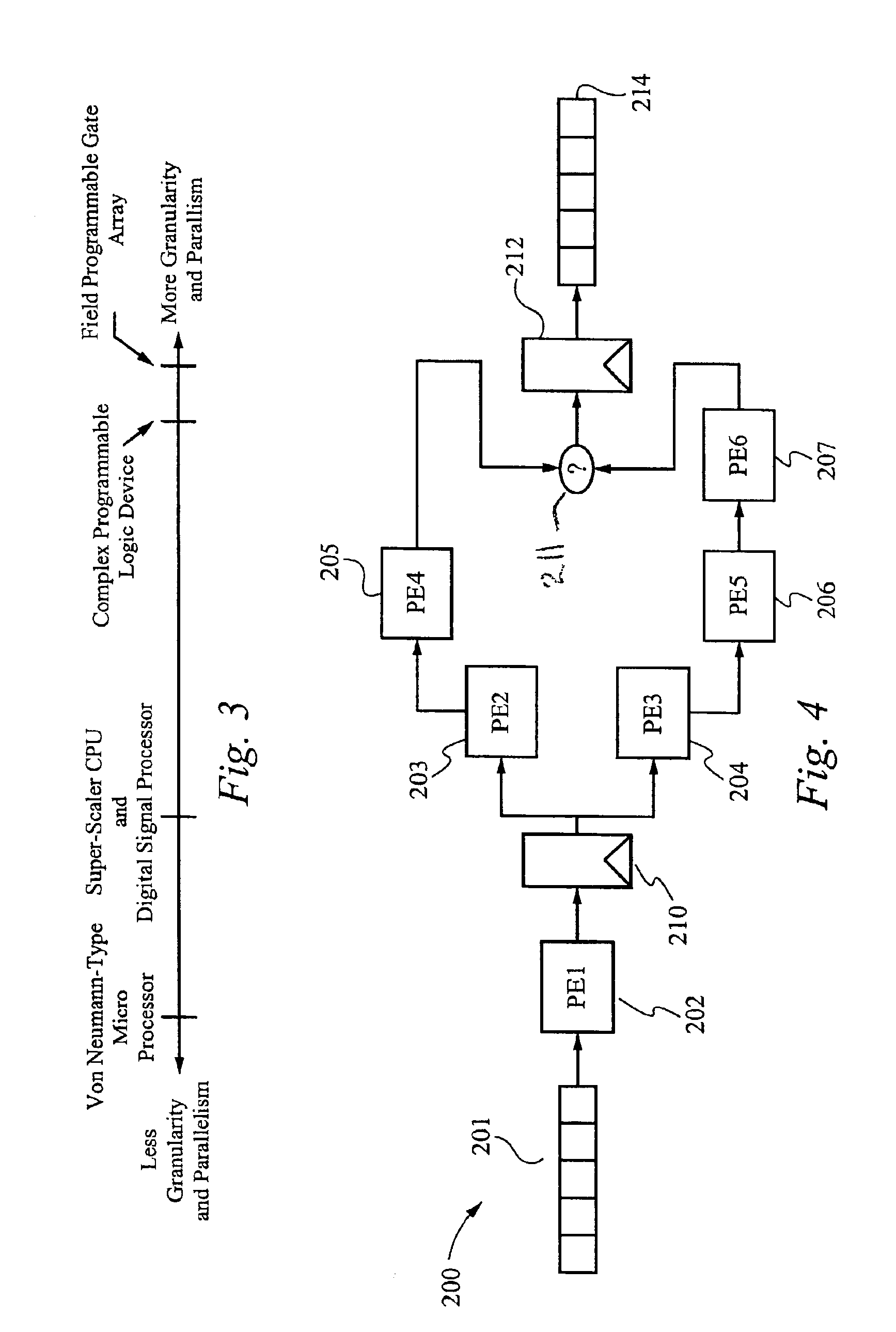

Reconfigurable data path processor

InactiveUS6883084B1Eliminates branchingCycle simpleEnergy efficient ICTConditional code generationMultiplexerProcessing element

A reconfigurable data path processor comprises a plurality of independent processing elements. Each of the processing elements advantageously comprising an identical architecture. Each processing element comprises a plurality of data processing means for generating a potential output. Each processor is also capable of through-putting an input as a potential output with little or no processing. Each processing element comprises a conditional multiplexer having a first conditional multiplexer input, a second conditional multiplexer input and a conditional multiplexer output. A first potential output value is transmitted to the first conditional multiplexer input, and a second potential output value is transmitted to the second conditional multiplexer output. The conditional multiplexer couples either the first conditional multiplexer input or the second conditional multiplexer input to the conditional multiplexer output, according to an output control command. The output control command is generated by processing a set of arithmetic status-bits through a logical mask. The conditional multiplexer output is coupled to a first processing element output. A first set of arithmetic bits are generated according to the processing of the first processable value. A second set of arithmetic bits may be generated from a second processing operation. The selection of the arithmetic status-bits is performed by an arithmetic-status bit multiplexer selects the desired set of arithmetic status bits from among the first and second set of arithmetic status bits. The conditional multiplexer evaluates the select arithmetic status bits according to logical mask defining an algorithm for evaluating the arithmetic status bits.

Owner:STC UNM +1

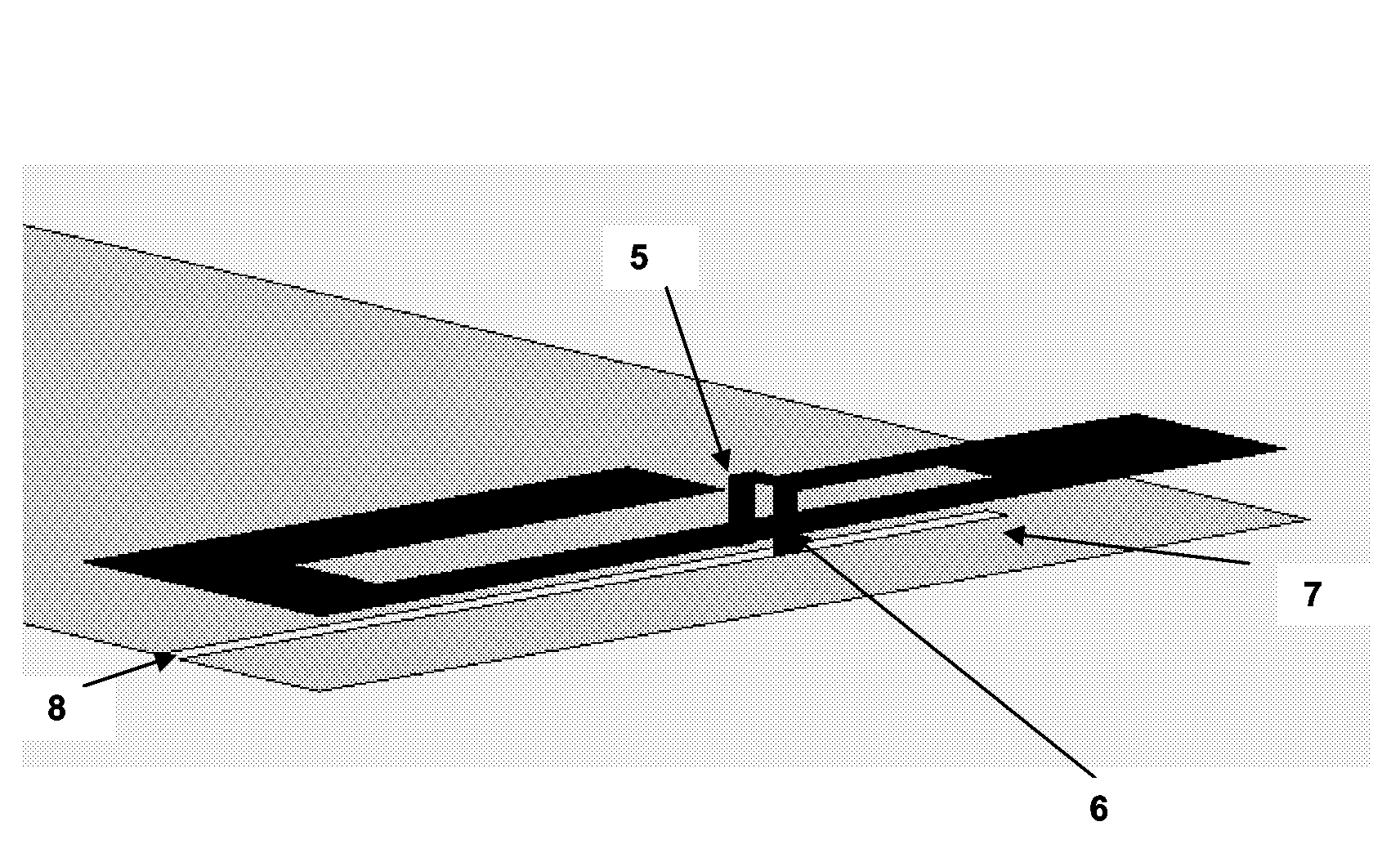

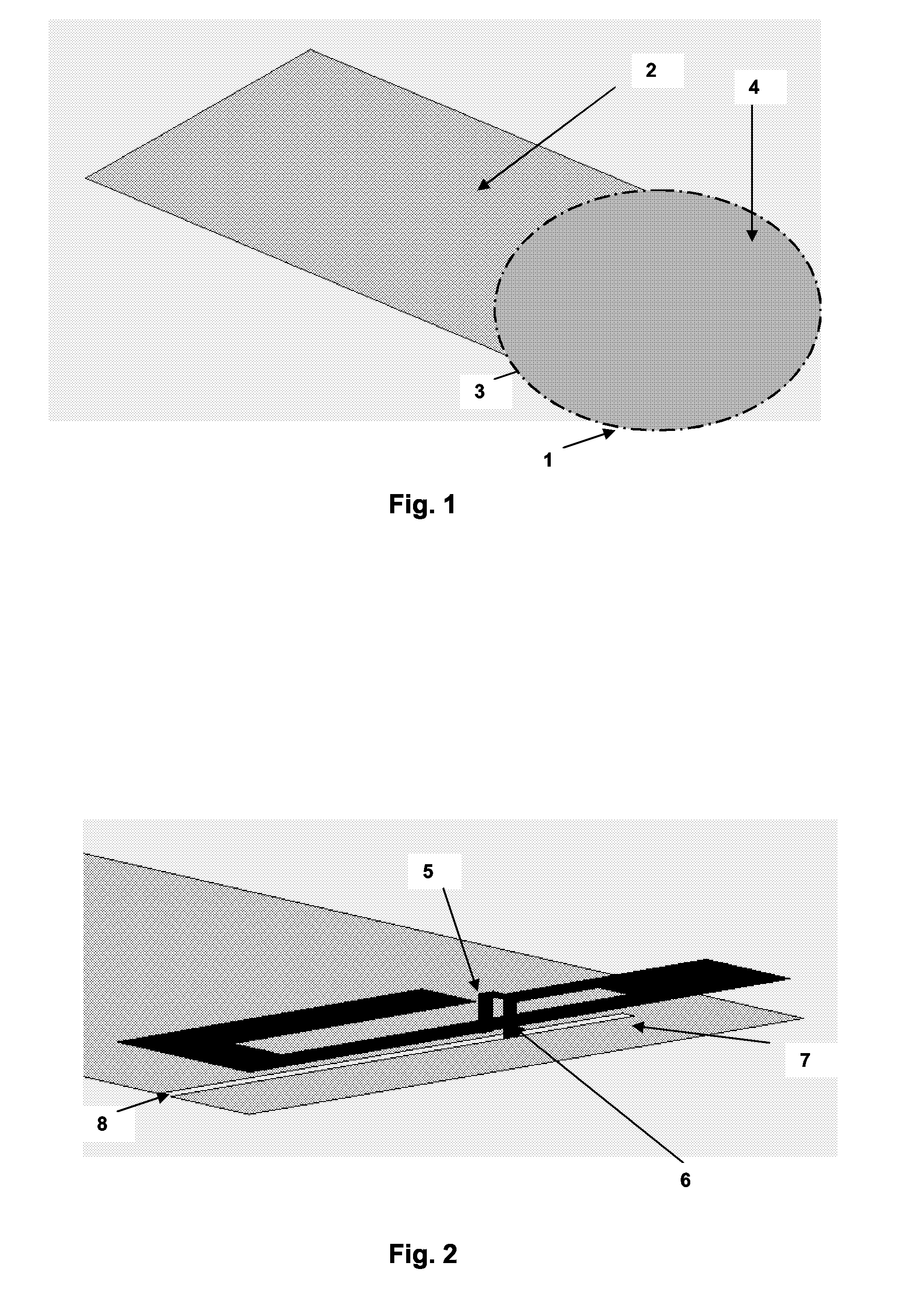

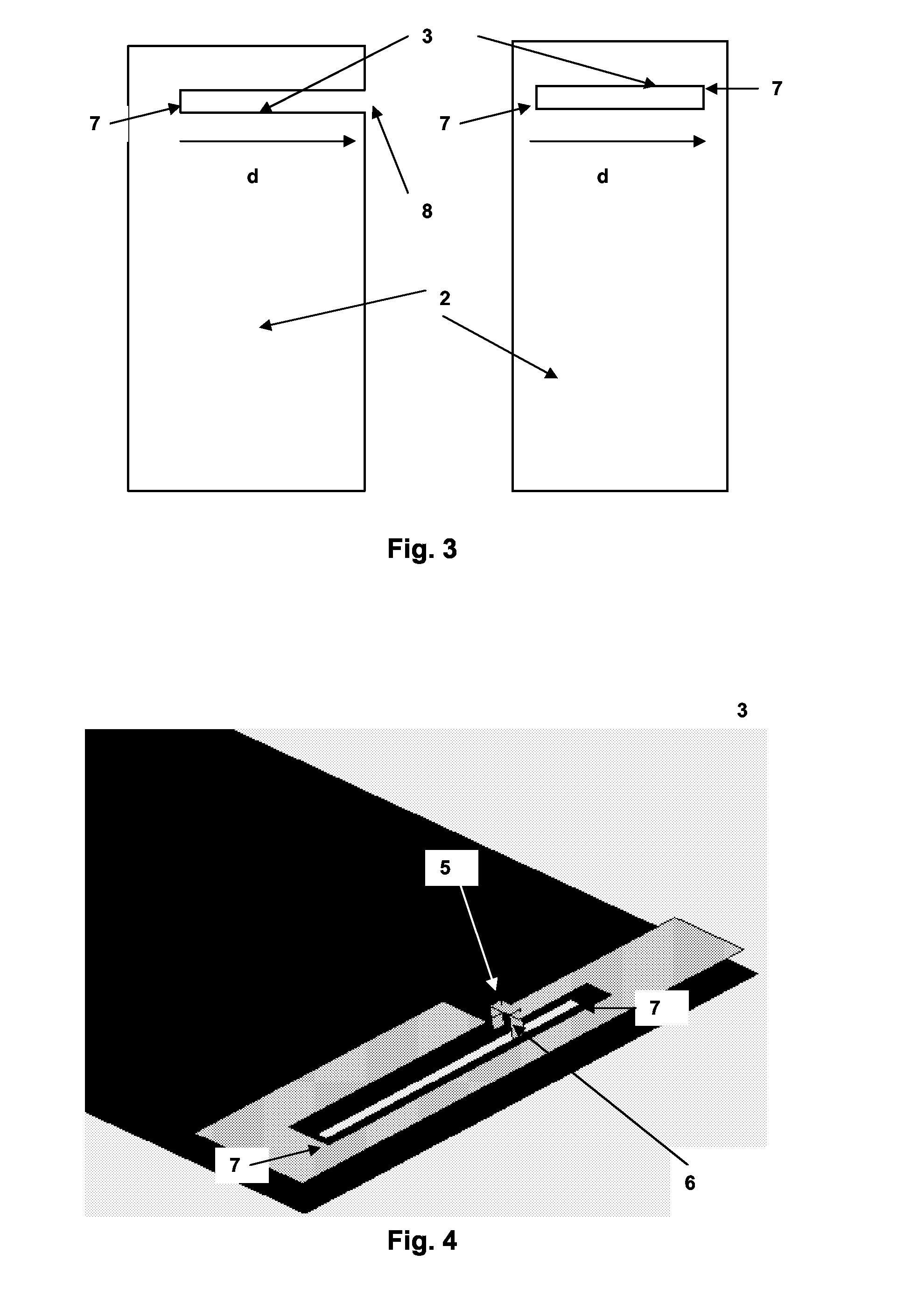

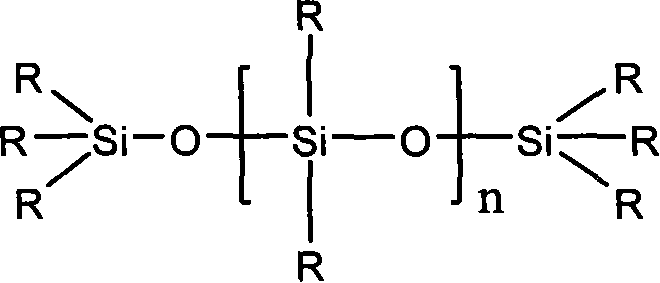

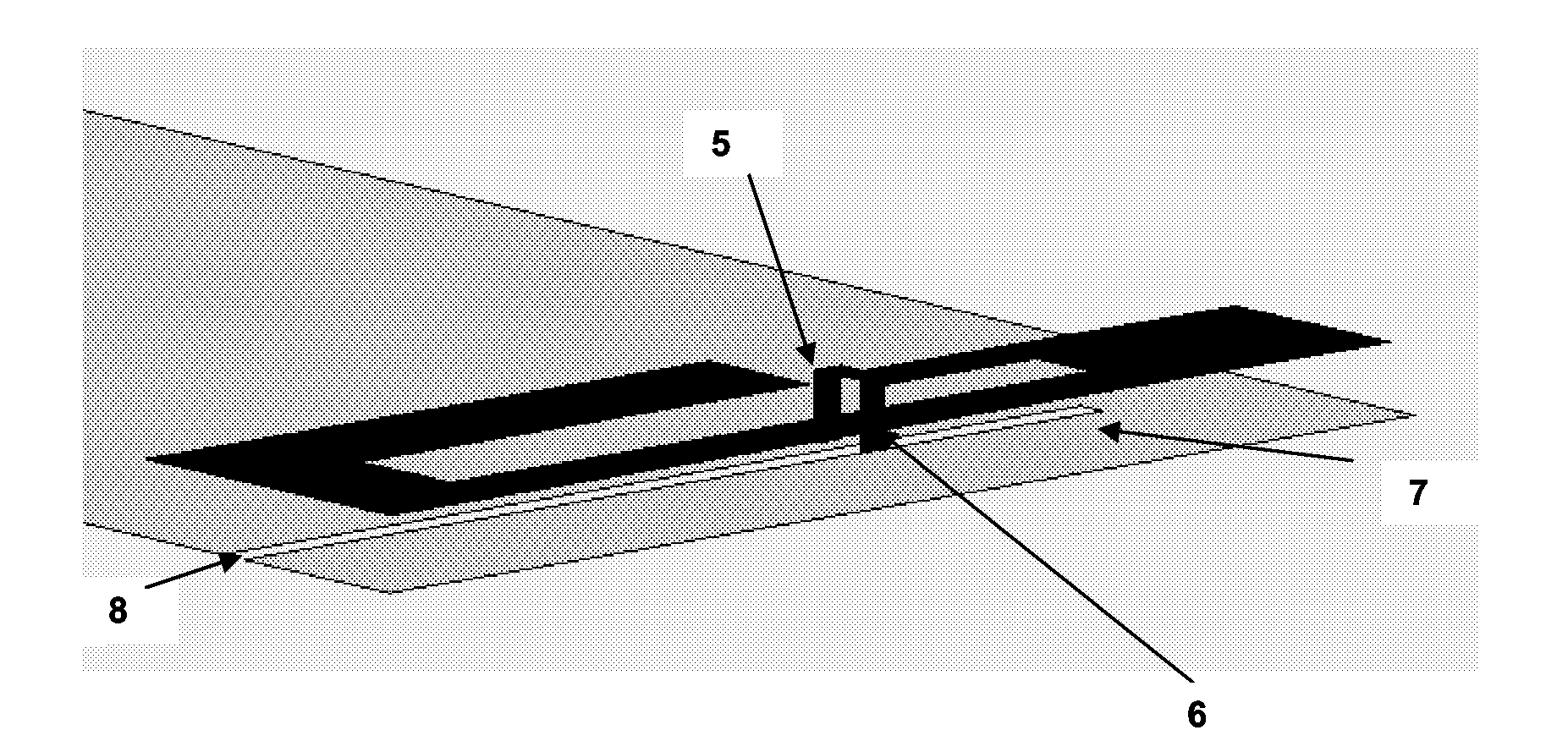

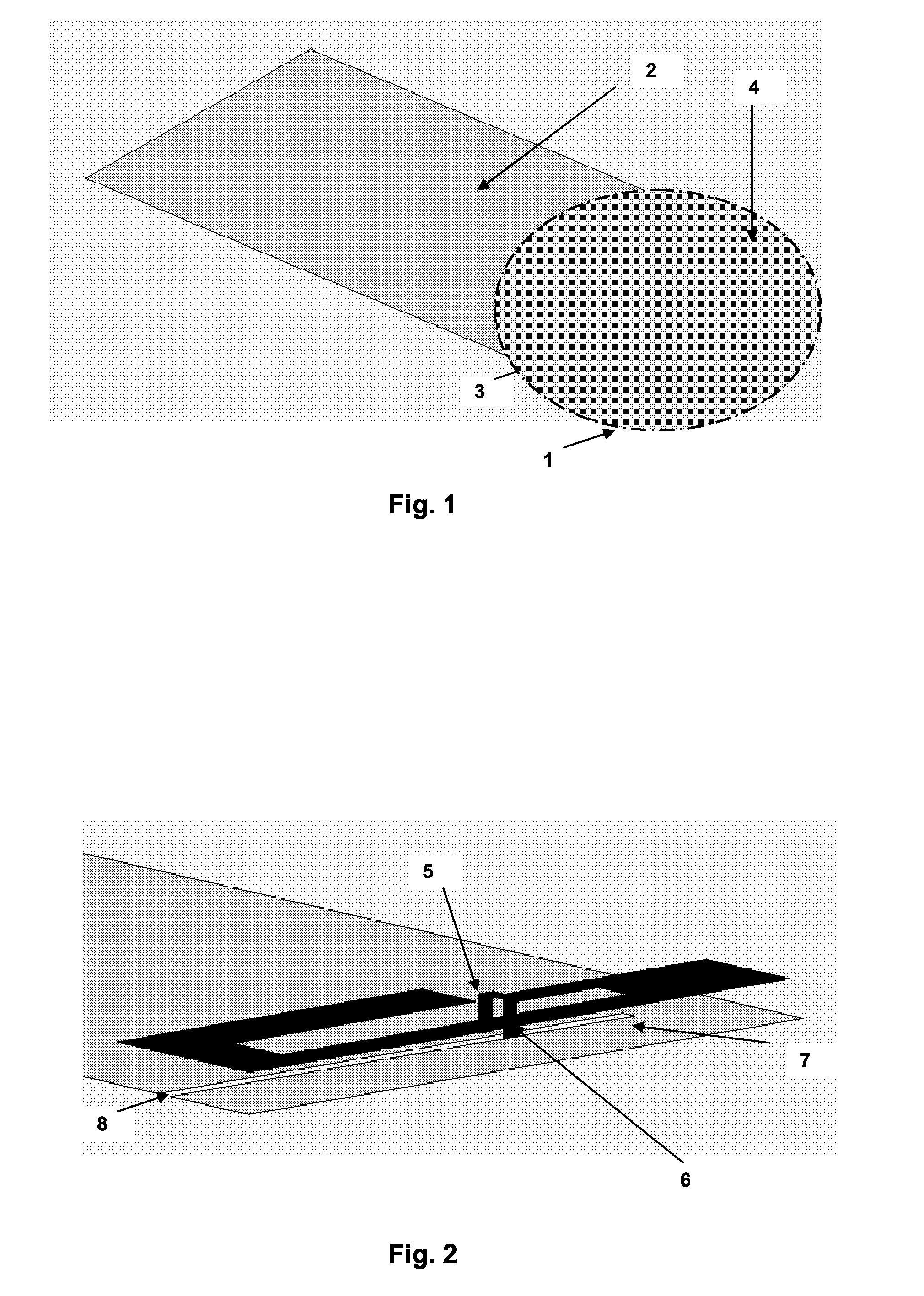

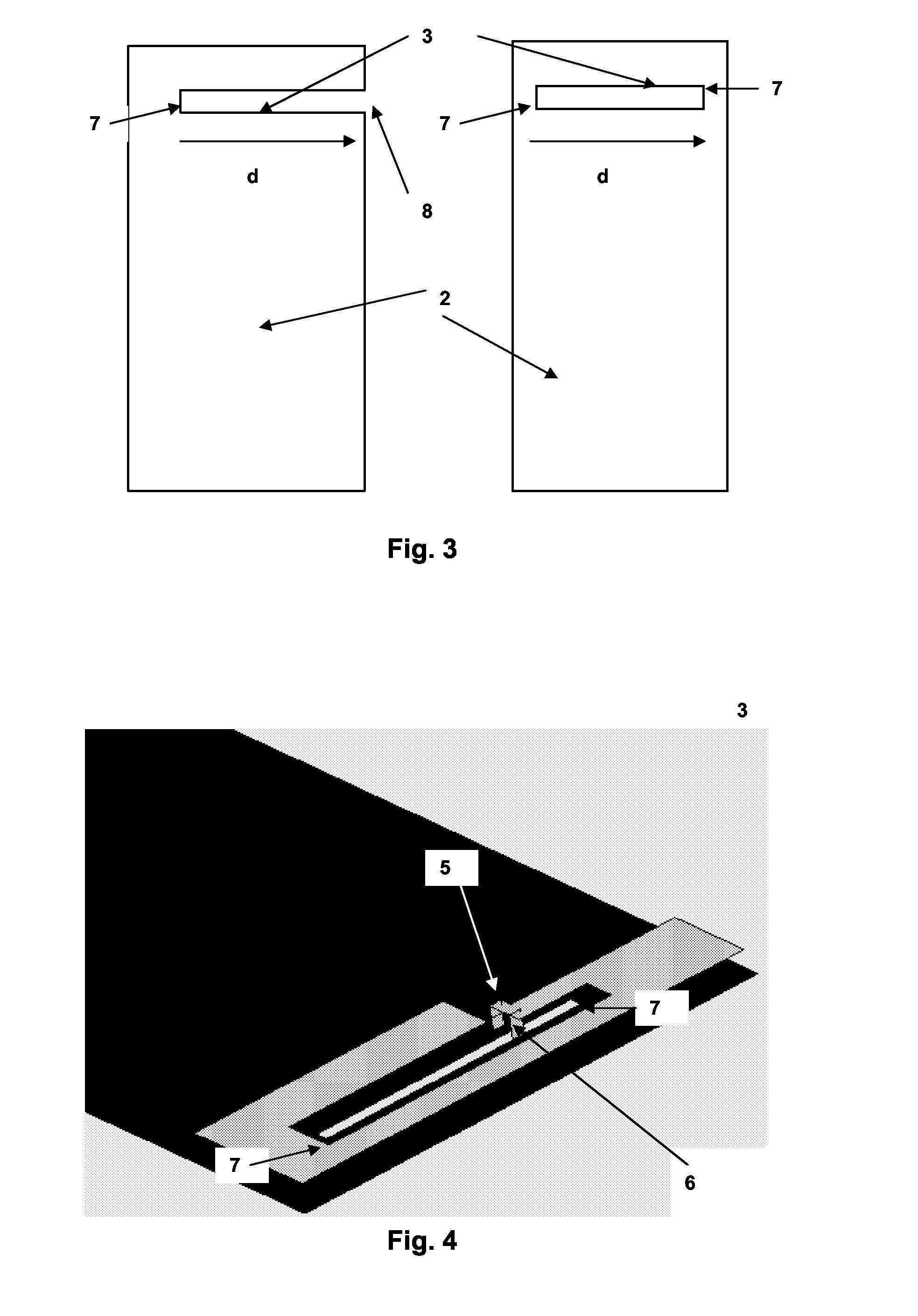

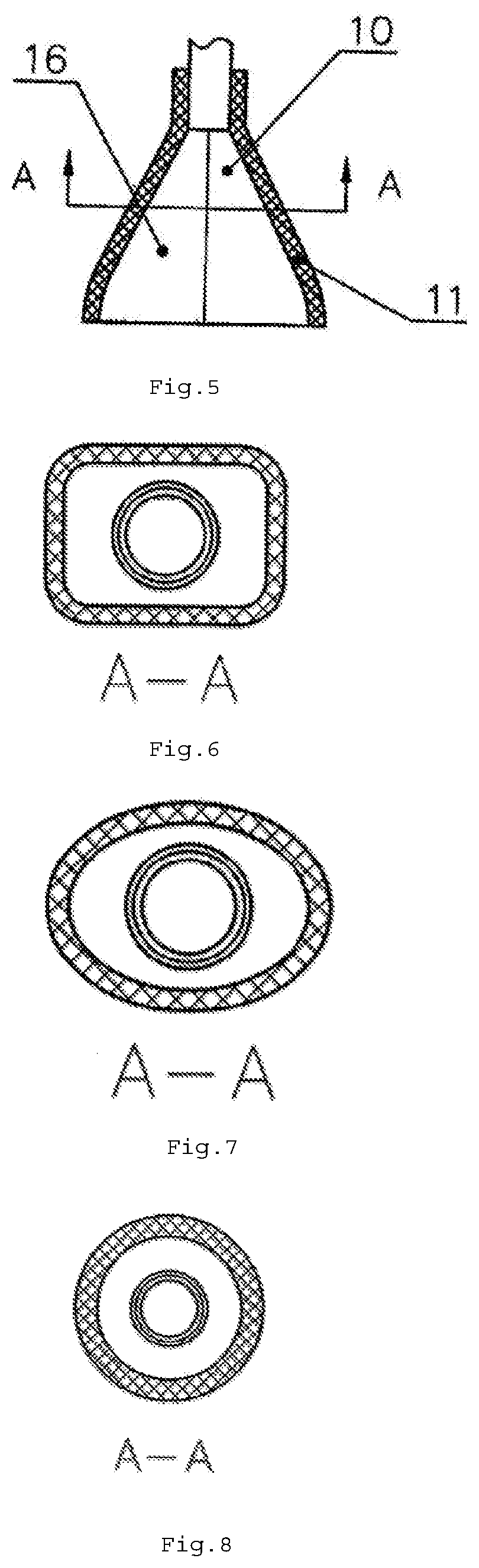

Shaped Ground Plane For Radio Apparatus

ActiveUS20080231521A1High degree of miniaturizationConducive to lightweightSimultaneous aerial operationsAntenna supports/mountingsRadio equipmentGround plane

This invention refers to an antenna structure for a wireless device comprising a ground plane and an antenna element, wherein the ground plane has a slot with at least a short end, an open end and a length substantially close to a quarter wavelength. The feeding and ground connections of the antenna structure are placed at the two different sides of said slot and the distance of at least one of them to the short end of the slot is equal or smaller than an eighth of the wavelength. The invention further refers to an antenna structure for a wireless device comprising a ground plane and an antenna element, wherein the ground plane has a slot with at least two short ends, and a length substantially close to half wavelength. The feeding and ground connections of the antenna structure are placed at the two different sides of said slot and the distance of at least one of them to a short end of the slot is equal or smaller than a quarter of the wavelength. Further the invention refers to a corresponding wireless device, a corresponding mobile phone and to a method for integrating such an antenna structure within a wireless device.

Owner:FRACTUS

Radiation-resistant and moisture-retention make-up base, lotion and water

InactiveCN102488627AImprove radiation resistanceImprove immunityCosmetic preparationsToilet preparationsPhysiologyImmunity

The invention discloses a radiation-resistant and moisture-retention sun-blocking skin-care product, which contains 2-5 wt% of oat beta-glucan. The radiation-resistant and moisture-retention sun-blocking skin-care product provided by the invention can be used to raise radiation resistance and immunity of the whole skin and construct healthy skin, has an anti-allergic effect, can effectively prevent / alleviate various inflammation and symptoms such as erythema, and can preserve moisture, minimize fine lines and smoothen skin.

Owner:上海宝姿生物科技有限公司

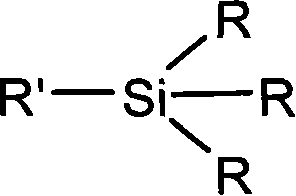

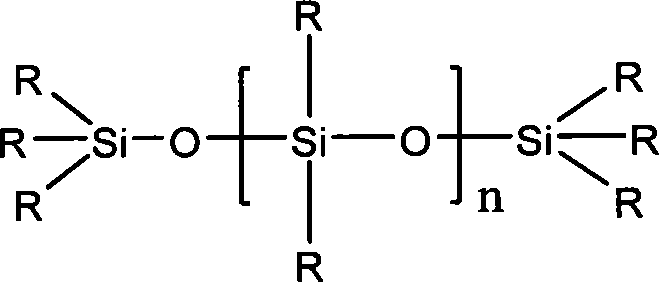

High heat conduction organosilicon filling and sealing gum

InactiveCN101054507AImprove mechanical propertiesGood electrical propertiesOther chemical processesAdhesivesHeat conductingCohesive strength

The invention discloses an organic silicon potting adhesive with a high heat conduction capacity. The curing time of the additive type organic silicon potting adhesive with a high heat conduction capacity can be controlled by the temperature and the amount of the catalyst. The condensate has good mechanical and electrical properties, especially outstanding cohesive strength, high and low temperature resistance and radiation resistance. The inventive heat-conducting organic silicon potting adhesive includes component A and B: said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, 3-20 shares of reinforced-filling, 1-10 shares of catalyst; said component A is mixed by following parts by weight: 100 shares of organic silica-base adhesive, 10-80 shares of heat-conducting filling, and 1-10 shares curing agent.

Owner:NANJING UNIV OF TECH

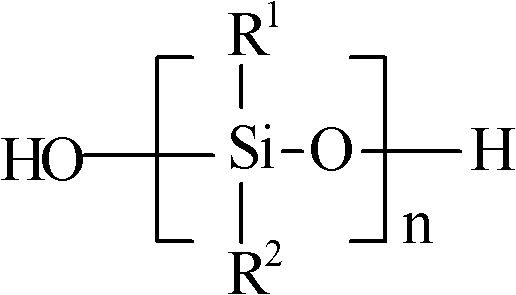

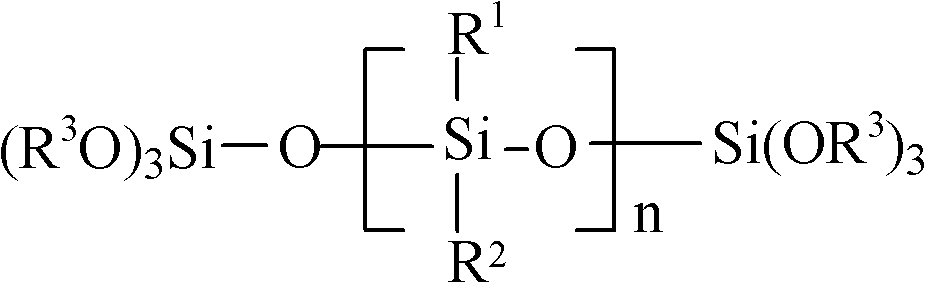

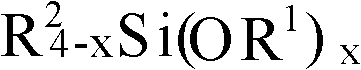

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

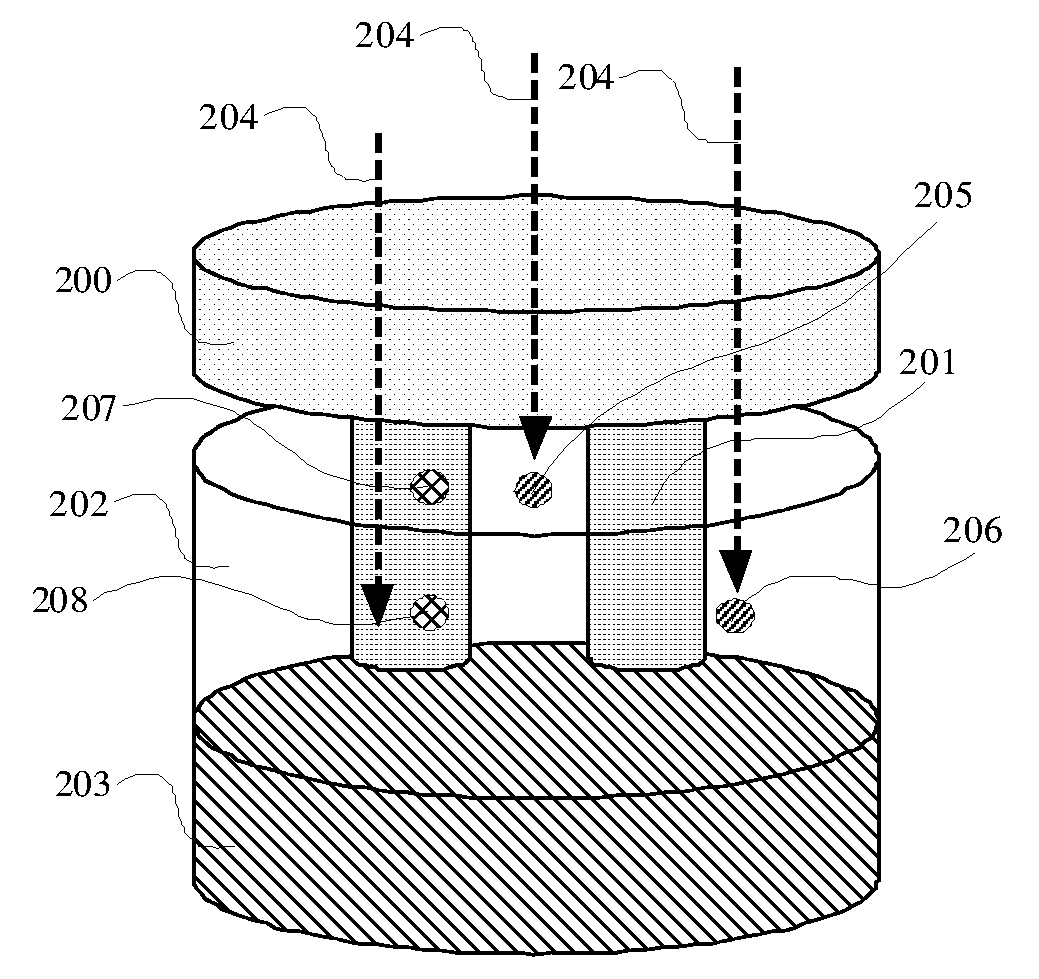

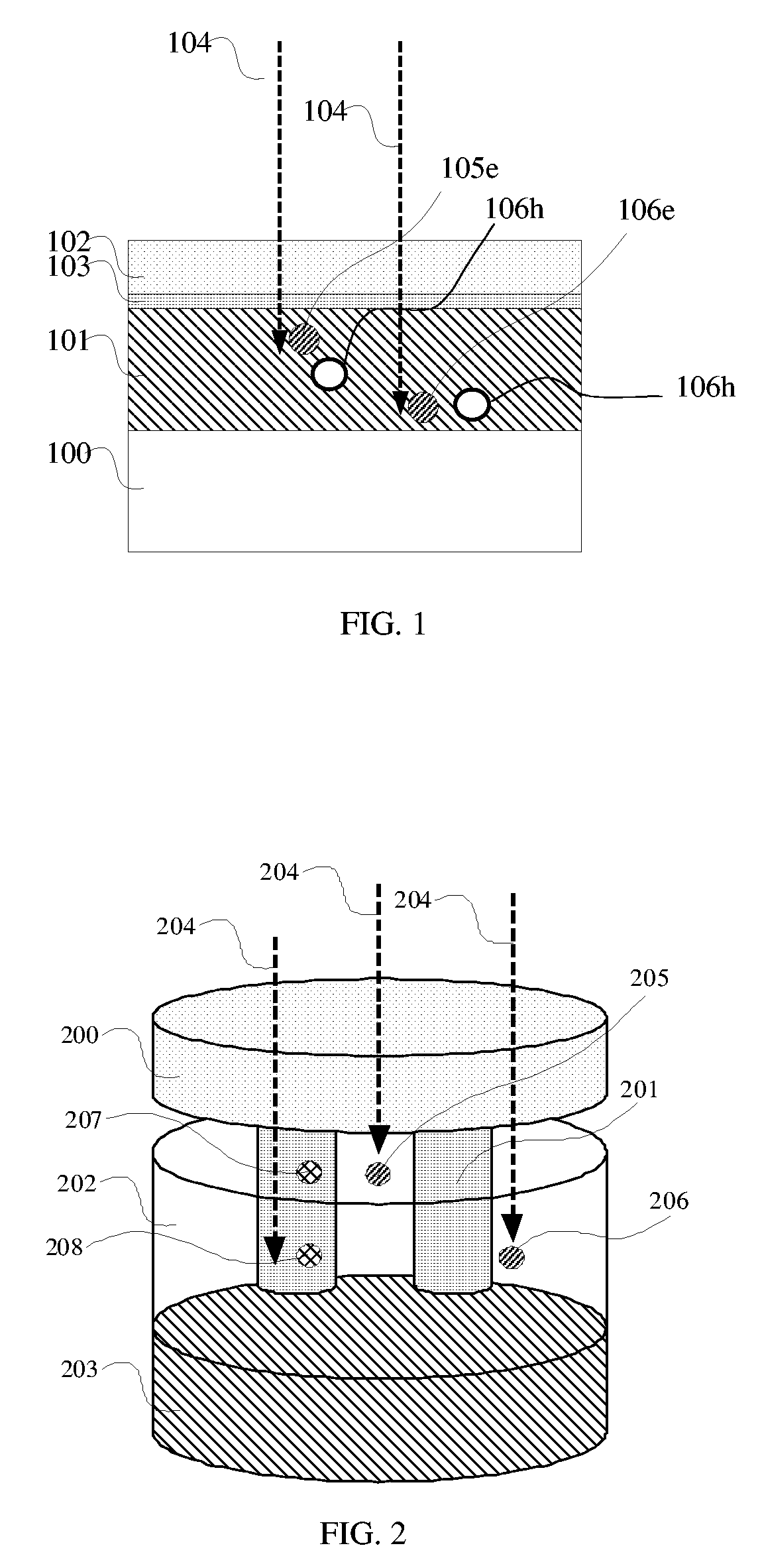

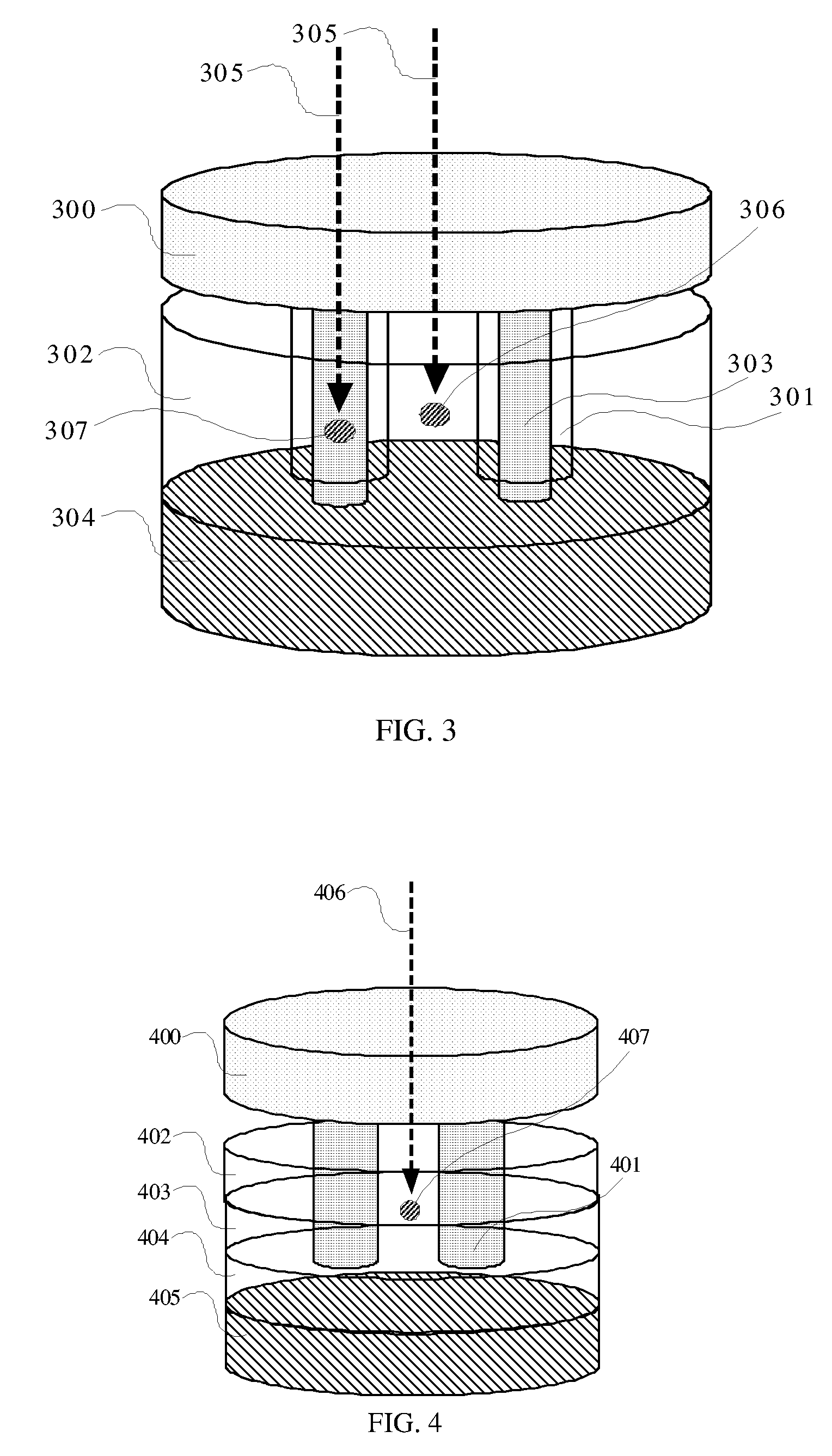

Photovoltaic cells based on nanoscale structures

ActiveUS20070012354A1High radiationIncrease the areaSolid-state devicesSemiconductor/solid-state device manufacturingCell basedElectronic materials

Novel structures of photovoltaic cells (also treated as solar cells) are provided. The Cells are based on the nanometer-scaled wire, tubes, and / or rods, which are made of the electronics materials covering semiconductors, insulator or metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells can have also high radiation tolerant capability. These cells will have enormous applications such as in space, in commercial, residential and industrial applications.

Owner:BANPIL PHOTONICS

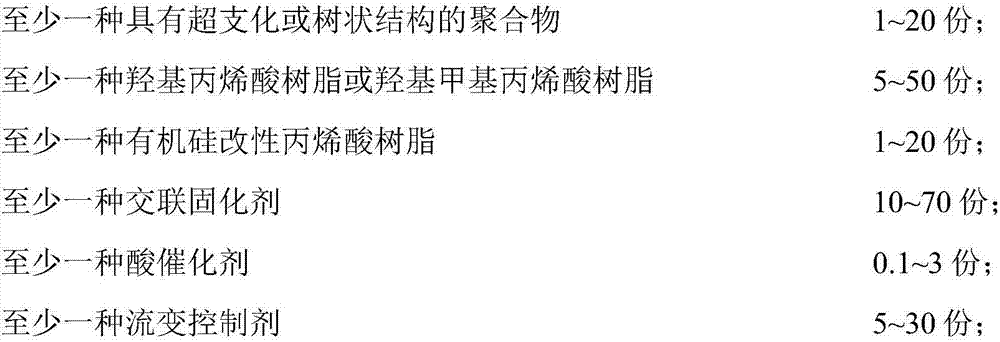

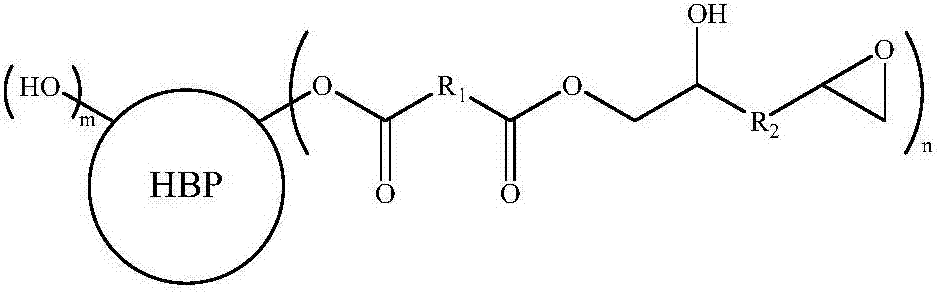

Mono-component varnish composition, preparation method and purpose thereof

ActiveCN106916503AImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsWeather resistanceAcrylic resin

The invention discloses a mono-component varnish composition, which comprises at least a polymer having a hyper branched or dendritical structure; at least one type of hydroxyl acrylic resin or hydroxyl methacrylate resin; at least one type of organosilicon-modified acrylic resins; at least a crosslinking curing agent; at least an acid catalyst; at least a rheological control agent; at least an auxiliary agent and at least a solvent; and the mono-component varnish composition has the advantages of high scratch resistance and high weather resistance. The provided mono-component varnish composition can effectively increase the smoothness of the surface of a varnish composition film, and increases the rub resistance of the film; in addition, the introduction of the organosilicon-modified acrylic resin can further increase the weatherability of the varnish composition film.

Owner:LANGFANG NIPPON PAINT +2

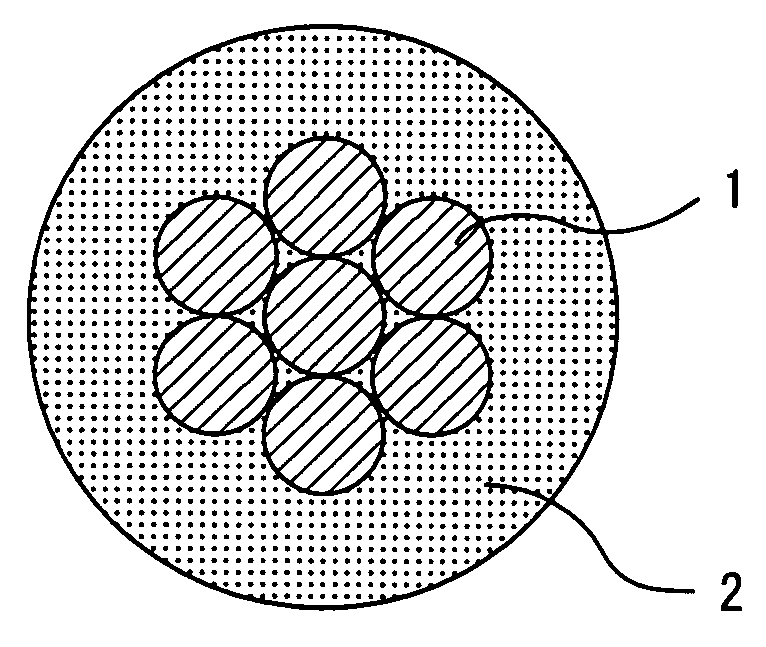

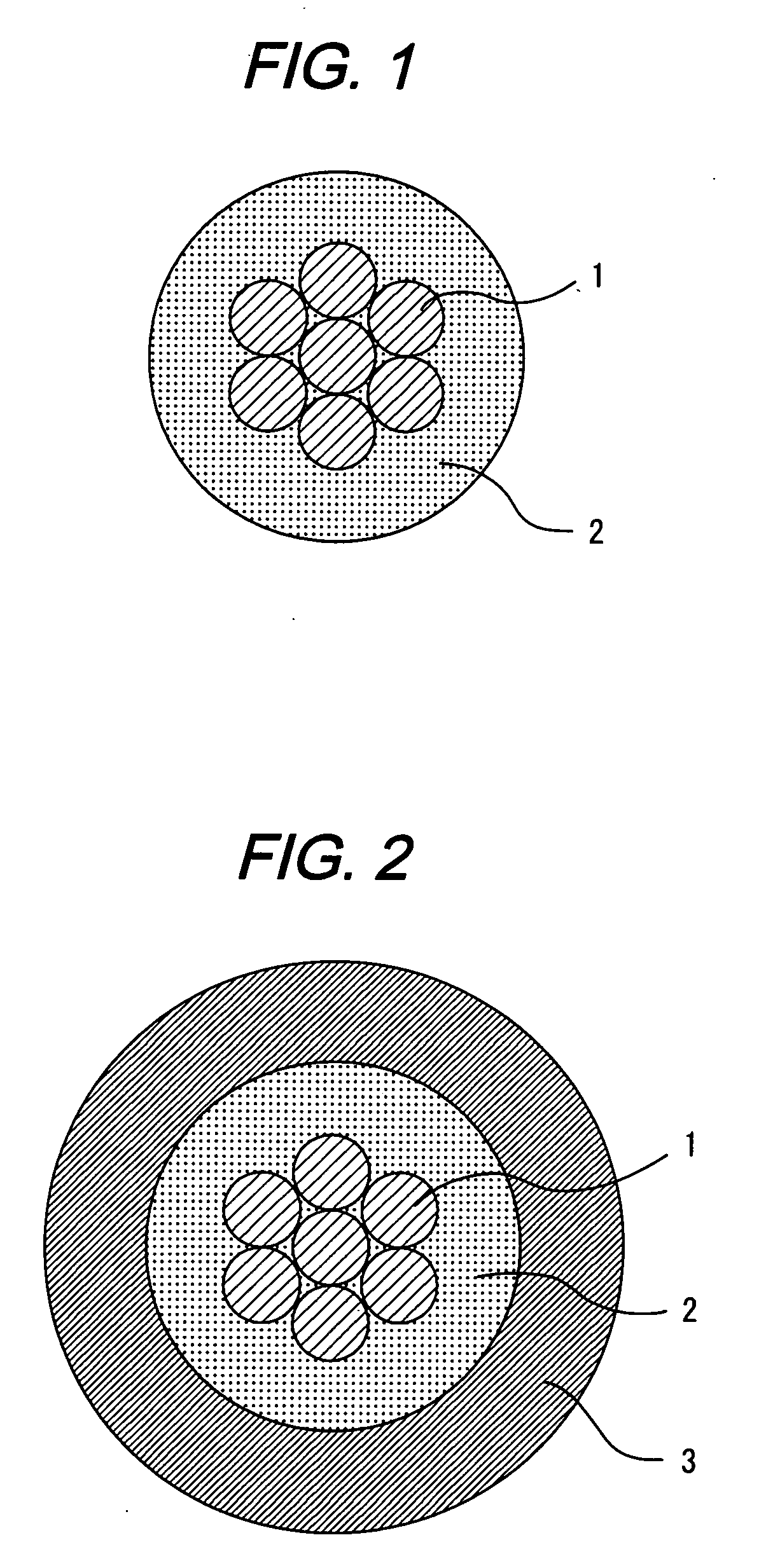

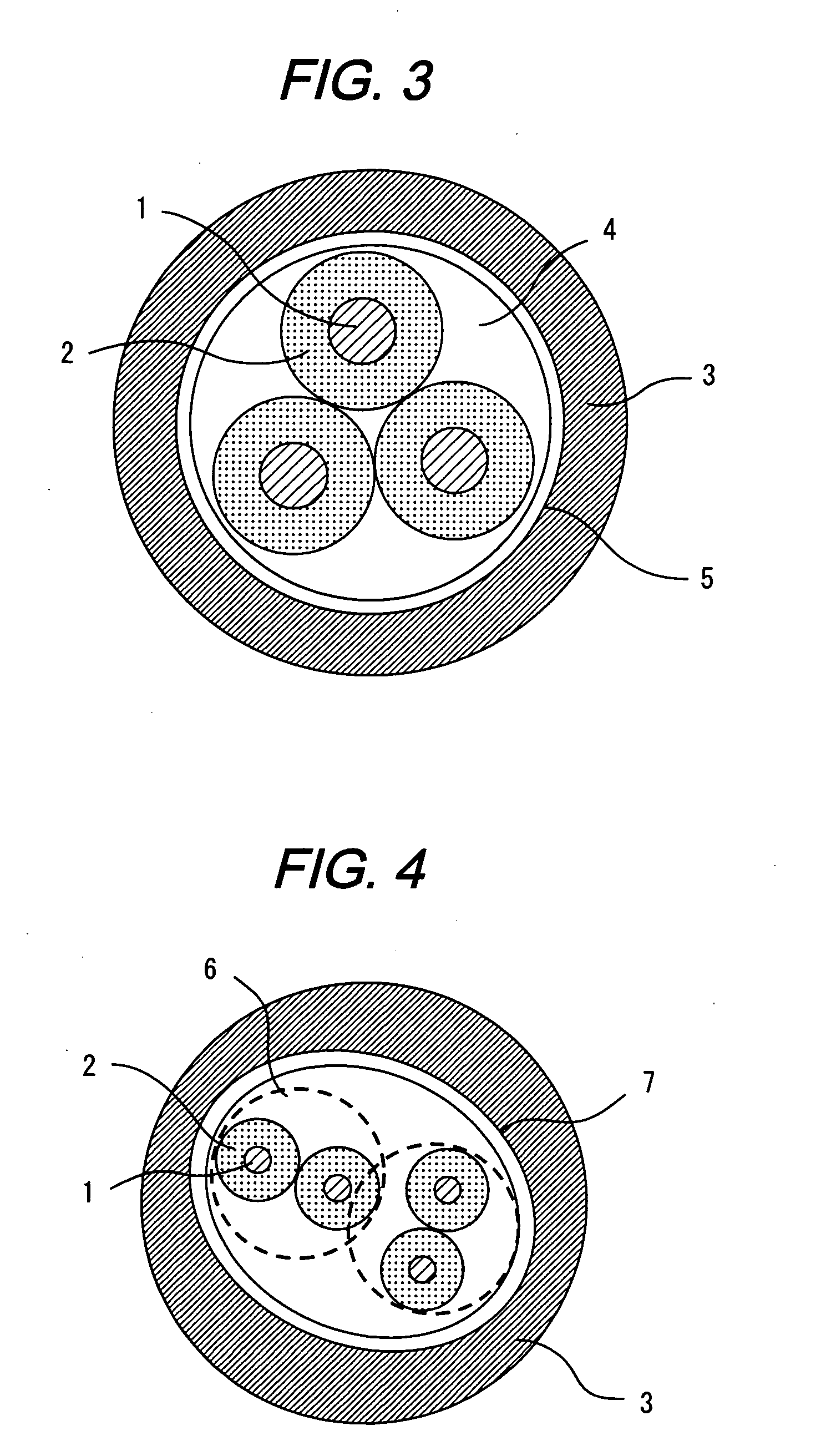

Irradiation-crosslinked low-smoke halogen-free inflaming retarding insulation material for nuclear power station cable and preparation method thereof

ActiveCN102108148AFulfil requirementsExcellent long-term heat aging resistancePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneCross-link

The invention provides an irradiation-crosslinked low-smoke halogen-free inflaming retarding insulation material for a nuclear power station cable. The insulation material comprises the following components in parts by weight: 100 parts of basic resin (A), 2-5 parts of antioxidant (B), 3-10 parts of irradiation-resisting agent (C), 110-170 parts of fire retardant (D), 2-10 parts of compatilizer (E), 0.1-0.8 part of anticopper agent (F), 0.2-2 parts of lubricant (G) and 2-10 parts of cross-linking sensitizing agent (H), wherein the basic resin (A) comprises a combination of polyethylene-octeneelastomer (POE) ethylene-butyl acrylate (EBA) and linear very low density polyethylene (VLDPE), and the weight ratio of the POE to the EBA to the VLDPE is (10-20):(65-80):(10-20).

Owner:上海至正新材料有限公司

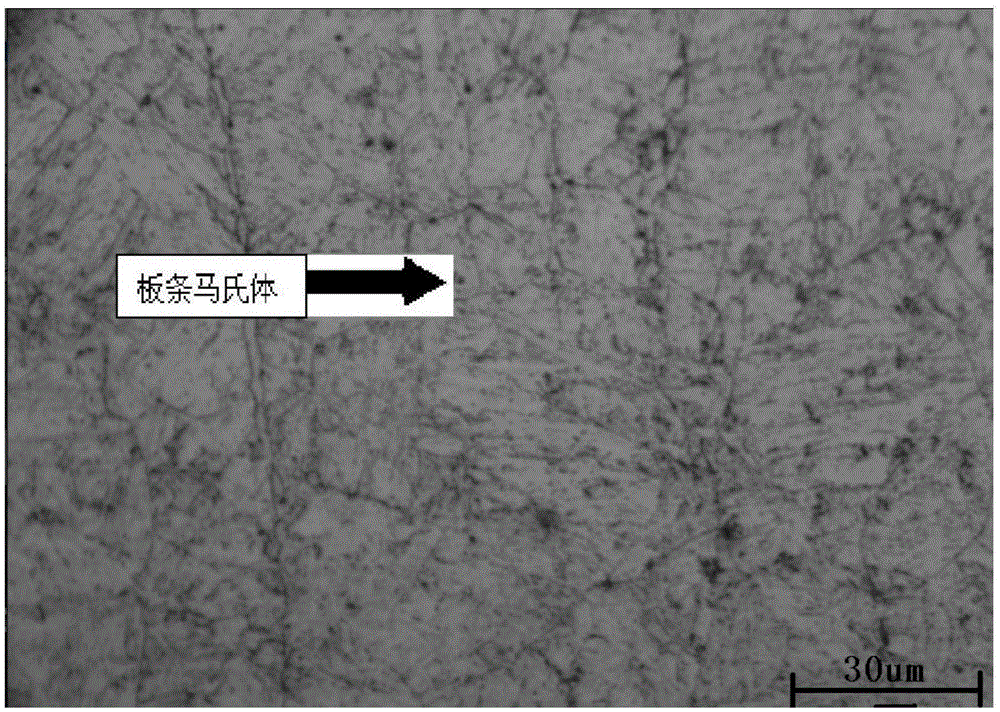

Structure steel material suitable for fusion reactor

InactiveCN1861825AImprove radiation resistanceImprove high temperature performanceHeat treatment process controlHalf-lifeAlloy

A structural steel material is suitable to fusion reactor, it is a martensite steel with low activation and is composed of element Fe, and it also contains the alloys Cr, W, V, Ta, Mn and C. It is suitable to use in the fusion reactor which has the resistance against the irradiation. The recipe of this steel replaces the elements Mo, Nb and Ni which are contained in the normal steels with W, Ta, V and Mn, so it assures the characteristic of low activation. Through optimization of the ingredients, the main nature of the steel increases. At the same time we strictly control the lever of long nuclear lifetime radioactive impurity which is created by irradiation with neutron. The half-life of the radioactive species which activated by irradiation with neutron is short, and the lever can be decreased to lower than the operational lever 10mSv / h in 100 years.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

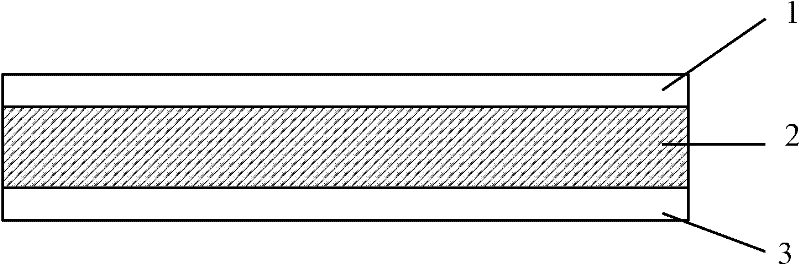

High-barrier polyester film and its preparation method

ActiveCN102225648AImprove barrier propertiesGood physical and mechanical propertiesSynthetic resin layered productsComposite constructionPolyester

The invention discloses a high-barrier polyester film, which has a three-layer composite construction, comprising a core layer, an upper cortex and a lower cortex. The core layer comprises the following components of: 60-100 wt% of PET polyester slices, 0-40 wt% of PEN polyester slices; the cortexes comprise the following components of: 92-98 wt% of PEN polyester slices, 0.2-2 wt% of a nucleating agent and 1-6 wt% of a nucleating modifier. The invention also discloses a coextruding-drawing preparation method of the above high-barrier polyester film. The invention has a simple preparation technology; in addition to excellent physical properties, the produced polyester film has better gas barrier property, heat resistance and radiation resistance performance, and can be applied in the fields of solar energy cell back-piece and the like.

Owner:JIANGSU YUXING FILM TECH

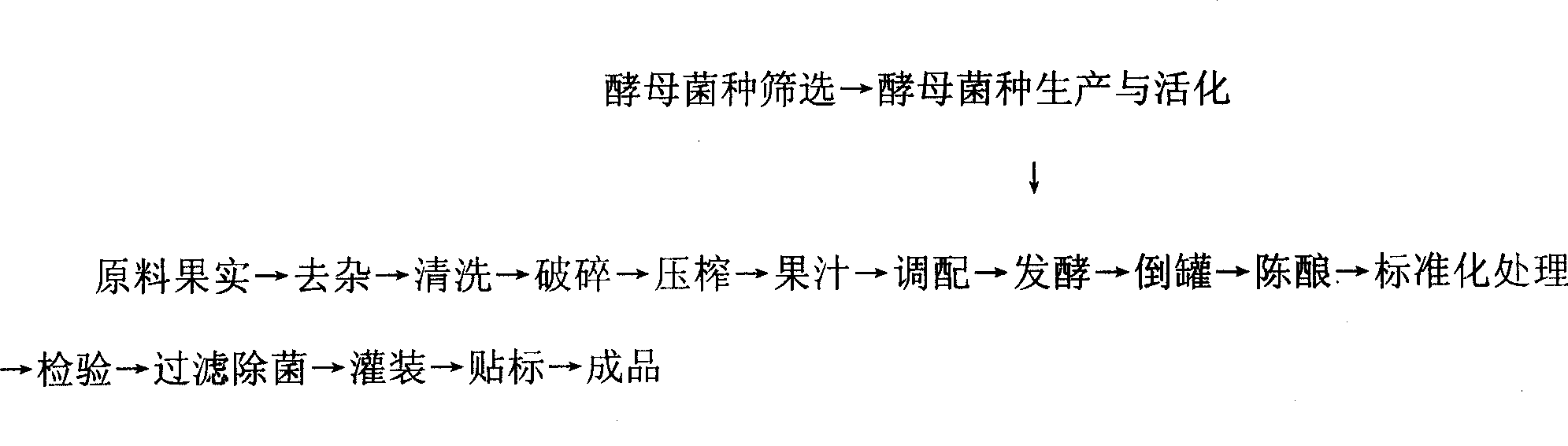

Aroniamelanocarpa fruit wine and brewing method thereof

InactiveCN101481643ARaw materials are uniqueFull of nutritionAlcoholic beverage preparationFruit juiceAntioxidant

The invention relates to an aroniamelanocarpa fruit wine and a brewing method thereof. The fruit of aroniamelanocarpa is taken as raw material and is made into fruit juice, fruit wine microzyme is selected for use and put into the fruit juice according to the proportion being 5-10% of the weight of the fruit juice, and the aroniamelanocarpa fruit wine is brewed with the alcohol content of 5-13% (v / v) and the total sugar content of 4.0-80.0g / L. The brewing technique of the invention comprises preparing the fruit juice, inoculation and fermentation, aging and store maturity, purifying wine body as well as filtration and sterilization, and the most advanced fermenting and purifying technique can be adopted by the production. The product of the invention has unique flavor, slightly acerbic and fresh taste, mellow mouthfeel, pleasing aroma and wide applicable people. The fruit wine contains multiple nutritional functional components such as anthocyanin, flavone, polyphenol active substance, vitamins antioxidant, mineral composition, polyoses, organic acid and the like which are rich in the fruit of aroniamelanocarpa, and has good effects of oxidation resistance, ageing prevention, blood pressure regulation, vessel relaxing, blood-fat reduction, anti-inflammation and detoxification, radiation resistance, etc.

Owner:辽宁省干旱地区造林研究所

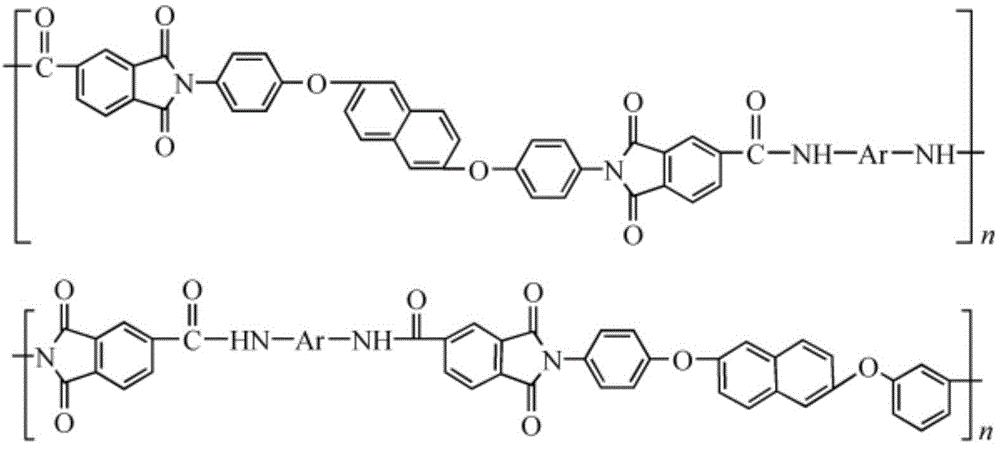

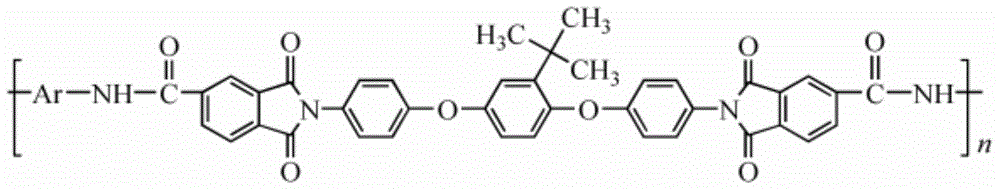

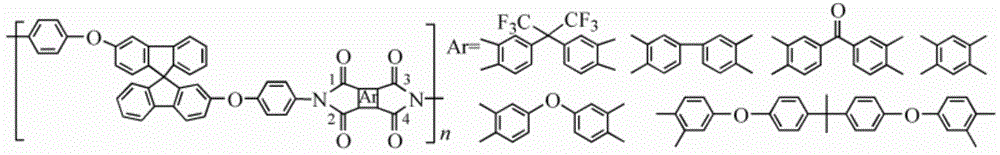

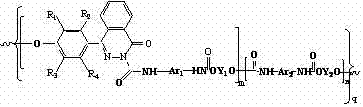

Low-melt-viscosity thermoplastic polyimide material and 3D printing moulding method thereof

ActiveCN103980489AOutstanding performanceHighlight application valueSolventUltimate tensile strength

The invention discloses a low-melt-viscosity thermoplastic polyimide material which is used for 3D printing. Molecular structure of the thermoplastic polyimide material is subjected to a modification process (such as introducing a special flexibility structure unit, a large side group or solvophilic group, a twisted and non-coplaner structure, characteristic atoms such as a heterocycle and a fluorine silicon and the like, and carrying out a main chain copolymerization reaction) to enable the polyimide material to be meltable and thus to have good processability a well processing performance. The polyimide material, after being mixed with a heat stabilizer and a reinforcing agent, is manufactured into a high-performance polyimide product in a manner of melting 3D printing technology. The polyimide material widens a selectable range of present 3D printing materials. With the high-performance and low-melt-viscosity thermoplastic polyimide as a 3D printing material, the high-performance polyimide product prepared from the polyimide material has excellent high temperature resistance performance, corrosion resistance performance and mechanical strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

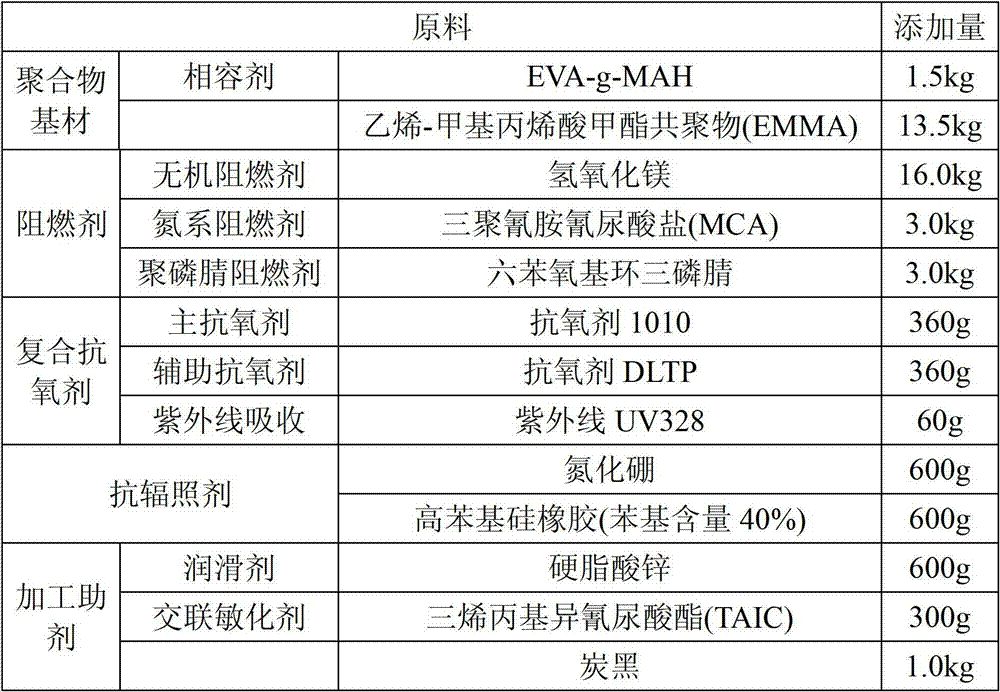

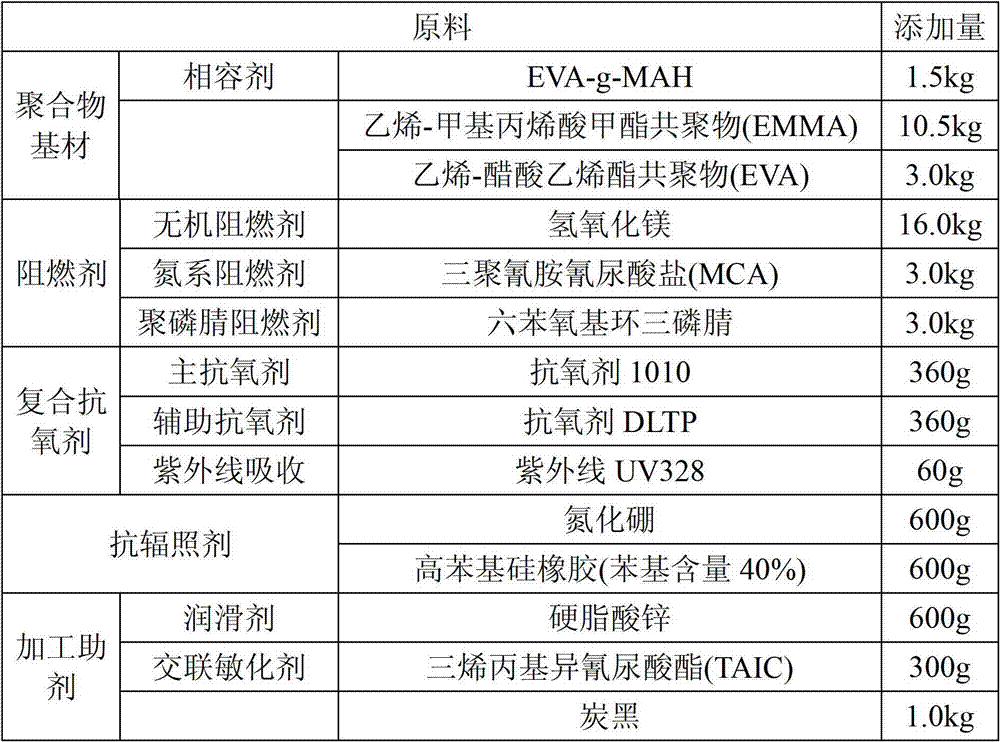

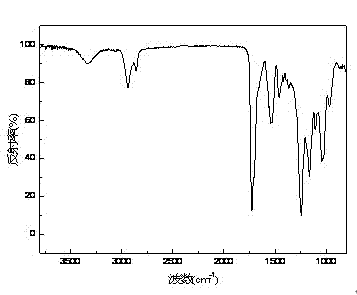

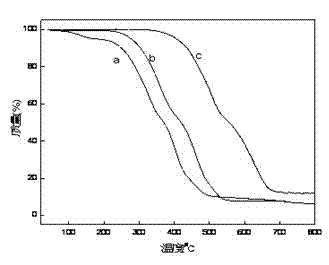

Halogen-free flame retardant sheath material for nuclear cable, cable sheath, preparation method and application

ActiveCN102875947AImprove performanceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesCross-linkProcedure Agents

The invention discloses a halogen-free flame retardant sheath material for a nuclear cable, a cable sheath, and a preparation method and an application of the cable sheath. The halogen-free flame retardant sheath material for the nuclear cable comprises the following raw materials: 100 parts of a polymer base material comprising ethylene vinyl acetate copolymer and ethylene methyl methacrylate copolymer, 100-140 parts of an inorganic fire retardant comprising magnesium oxide, 15-25 parts of phenoxycycloposphazene; 15-30 parts of nitrogen fire retardant comprising melamine cyanurate, 4-8 parts of a compound antioxidant comprising a main antioxidant, an auxiliary antioxidant and an ultraviolet light absorber, 5-15 parts of an anti-radiation agent comprising high phenyl siloxane rubber and an anti-radiation agent A, and 6-12 parts of a processing aid comprising a cross-linking sensitizing agent and a lubricant, wherein the anti-radiation agent A is boron carbide and / or boron nitride. The halogen-free sheath material for the nuclear cable disclosed by the invention is good in superior performance, good fire retardant performance, and stable anti-radiation performance, electrical performance and mechanical performance.

Owner:青岛中科汉缆高分子材料有限公司

Flame-retardant heat-resistance polyurethane resin and preparation method of aqueous emulsion of polyurethane resin

ActiveCN103242504AOvercome mechanical propertiesImprove heat resistancePolyureas/polyurethane adhesivesInksPolyesterPolymer science

The invention belongs to the field of high molecular materials and in particular relates to flame-retardant heat-resistance polyurethane resin. The resin structure contains a residue structure obtained after reaction of heterocyclic polyol A, flame-retardant polyol and polyisocyanate, and the resin is obtained by adding heterocyclic polyol B as a crosslinking agent at the post phase of polyurethane synthesis. The flame-retardant heat-resistance polyurethane resin and an aqueous emulsion thereof are prepared by carrying out a reaction on heterocyclic polyol, polyester or polyester polyol, flame-retardant polyol, polyisocyanate and the like. As the heterocyclic structure is introduced in a polyurethane molecule chain, except for the characteristics of the common polyurethane paint coating, the flame-retardant heat-resistant polyurethane resin further has excellent heat resistance, corrosion resistance and high mechanical strength and mechanism performance and is high-grade flame-retardant polyurethane aqueous resin. The defects of the existing polyurethane coating in terms of heat resistance and mechanical property are overcome; and the prepared flame-retardant heat-resistance polyurethane resin has the advantages of intrinsic flame retardance, high heat resistance, large hardness, excellent mechanical property and high cost performance, is convenient to use and can be dried at low temperature.

Owner:DALIAN UNIV OF TECH

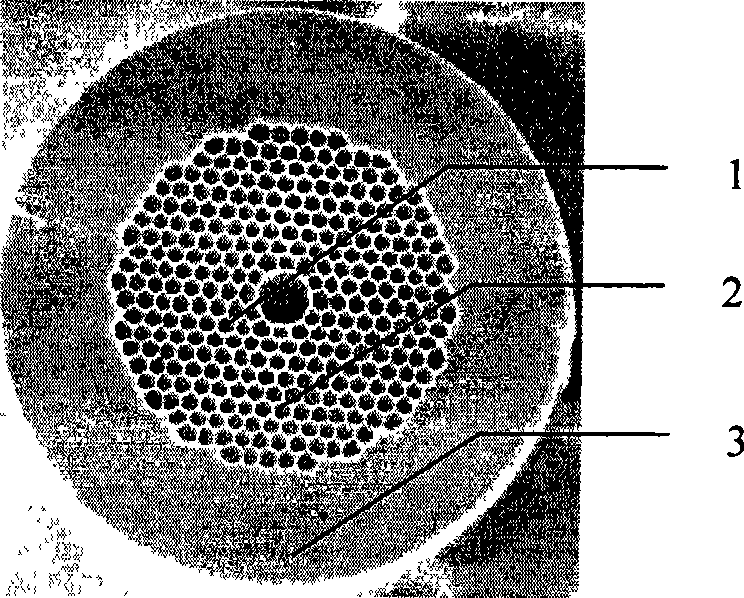

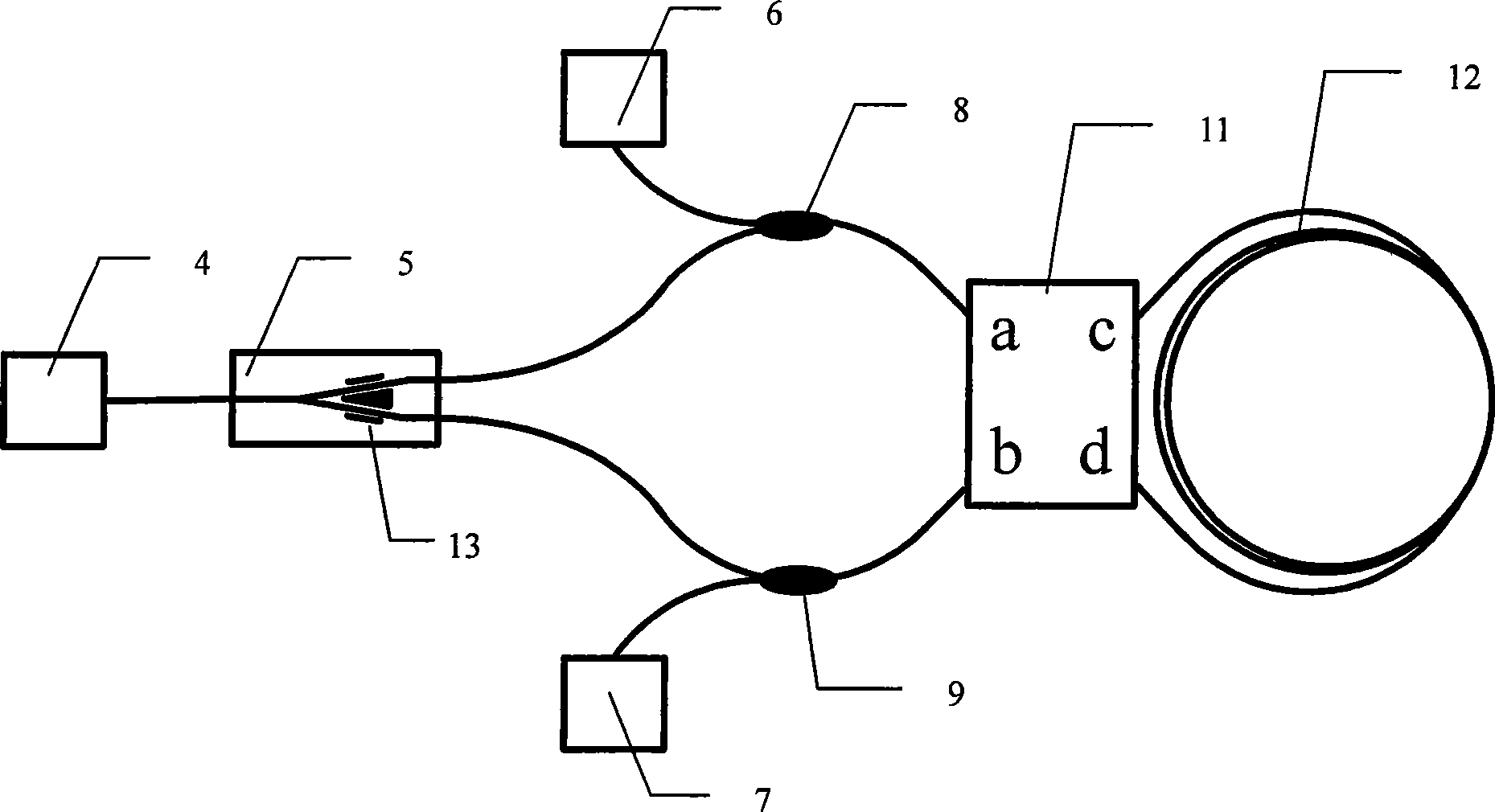

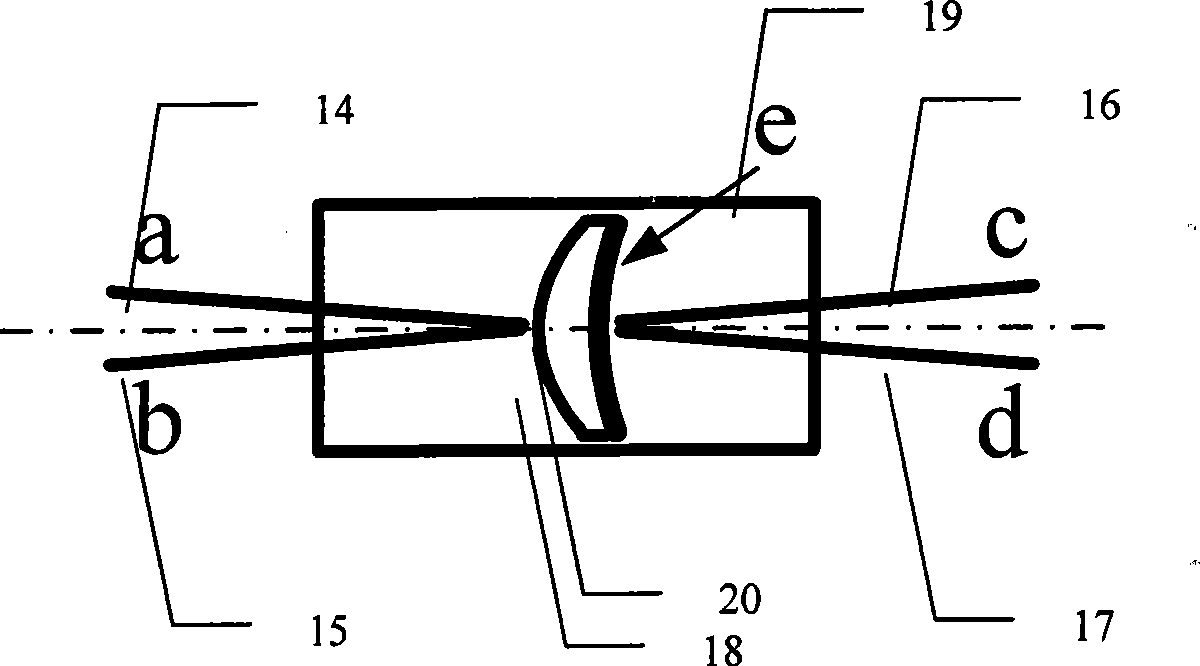

Hollow photonic crystal fiber gyroscope

InactiveCN101387519AHigh precisionReduce noiseCladded optical fibreSagnac effect gyrometersFiber couplerGyroscope

The invention relates to a hollow photonic crystal optical fiber gyro, which is characterized in that a hollow optical fiber resonant ring coiled by hollow photonic crystal optical fibers is adopted; laser light emitted by a tunable narrow linewidth laser is divided into two equal parts by an integrated optical modulator; the two parts enter an optical coupling module respectively through two polarization-maintaining fiber couplers, then are output from the optical coupling module and injected into the hollow optical fiber resonant ring; a convex spherical mirror adopted by the optical coupling module has high reflectivity and transmissivity, and a resonant cavity for the gyro is formed between the optical coupling module and the hollow optical fiber resonant ring to realize input and output of light; a small part of harmonic light penetrates the resonant cavity and returns to two detectors respectively through two polarization-maintaining fiber couplers, frequency difference of the harmonic light in the clockwise / anticlockwise direction is measured according to signals detected by the two detectors, and the angular speed of a carrier can be obtained through a testing circuit, so as to realize the function of a gyroscopic instrument. The optical fiber gyro has the advantages of small volume, convenient realization, high reliability, high radiation-resistant capacity and suitability of space application.

Owner:BEIHANG UNIV

Shaped ground plane for radio apparatus

ActiveUS7932863B2Small sizeImprove radiation resistanceSimultaneous aerial operationsAntenna supports/mountingsRadio equipmentGround plane

This invention refers to an antenna structure for a wireless device comprising a ground plane and an antenna element, wherein the ground plane has a slot with at least a short end, an open end and a length substantially close to a quarter wavelength. The feeding and ground connections of the antenna structure are placed at the two different sides of said slot and the distance of at least one of them to the short end of the slot is equal or smaller than an eighth of the wavelength. The invention further refers to an antenna structure for a wireless device comprising a ground plane and an antenna element, wherein the ground plane has a slot with at least two short ends, and a length substantially close to half wavelength. The feeding and ground connections of the antenna structure are placed at the two different sides of said slot and the distance of at least one of them to a short end of the slot is equal or smaller than a quarter of the wavelength. Further the invention refers to a corresponding wireless device, a corresponding mobile phone and to a method for integrating such an antenna structure within a wireless device.

Owner:FRACTUS

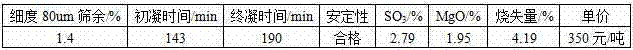

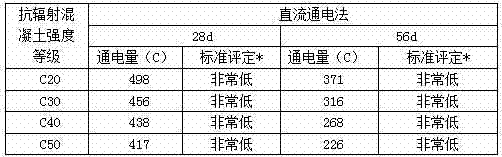

Barite anti-radiation pump concrete

The invention discloses barite anti-radiation pump concrete. The concrete comprises the following components: cement, water, barite powder, barite sand, barite, synergist and admixture according to a ratio of [340-450]:[110-170]:[75-150]:[1000-1400]:[1800-2000]:[2-4]:[7-19]. According to selection of raw materials and design of the ratio, the anti-radiation concrete which is high in density and high in liquidity and can be used for pumping is obtained.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

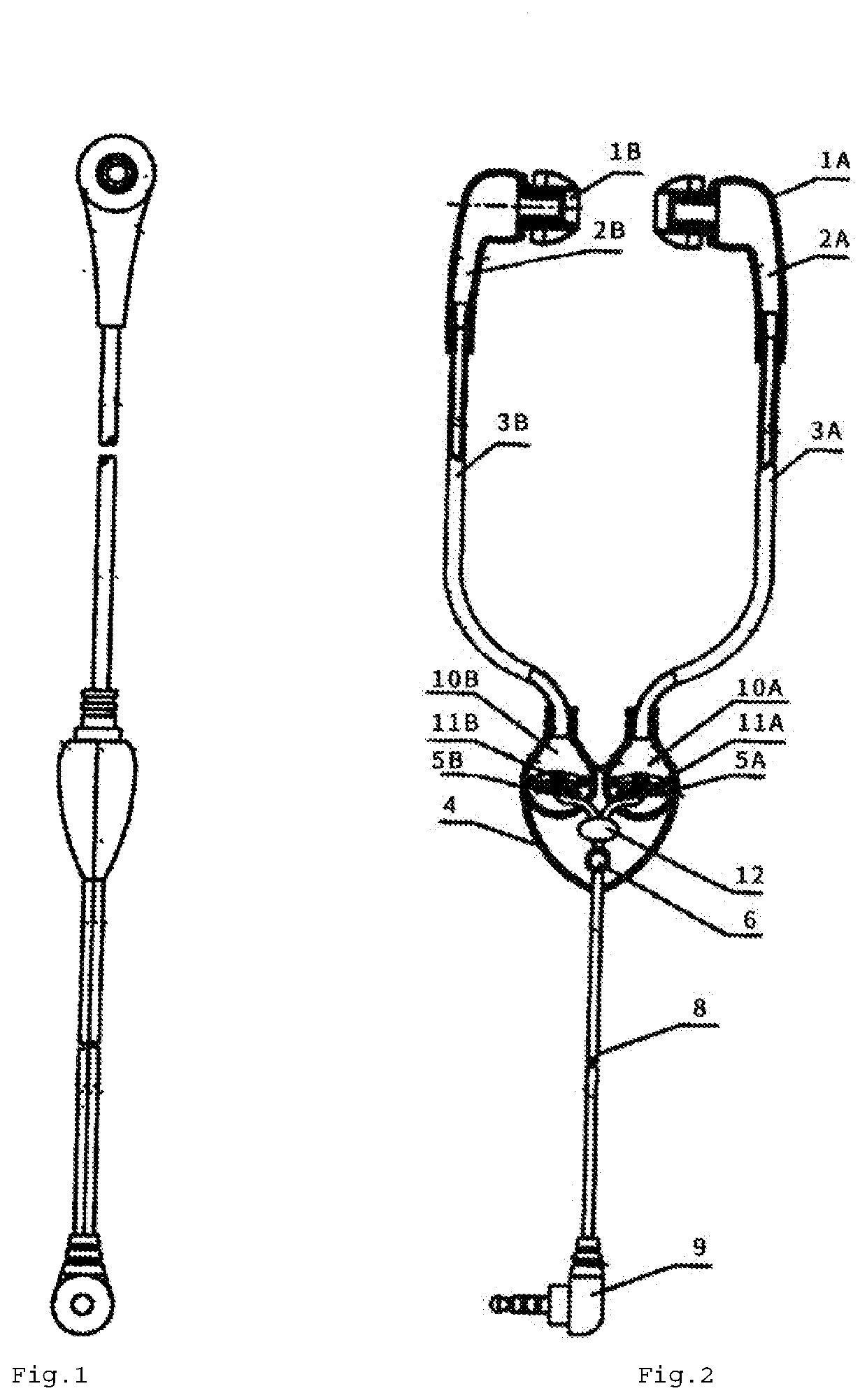

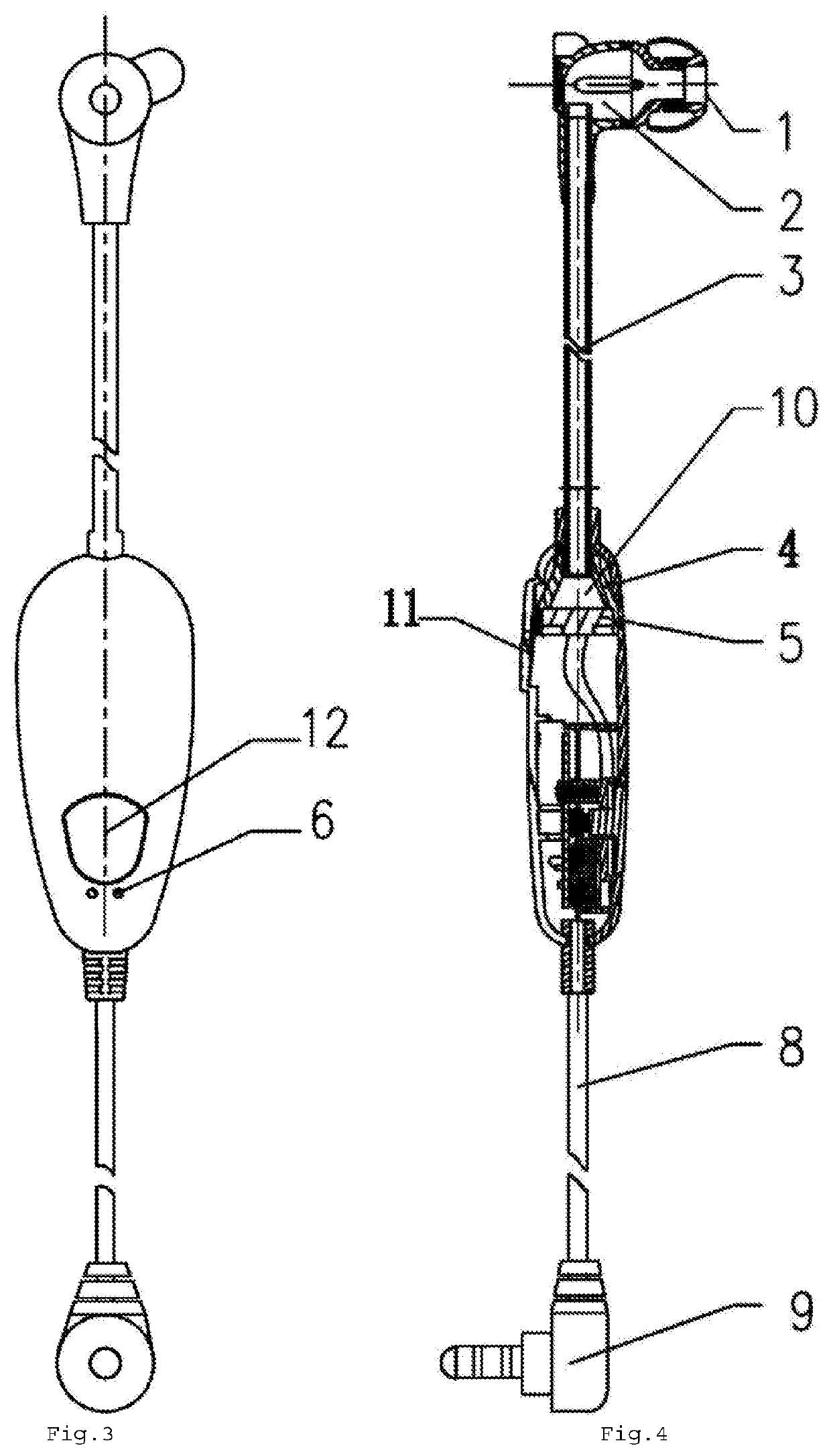

Noise reduction air tube microphone, noise-reduction safe headset and noise-reduction safe bluetooth headset

ActiveUS20200252708A1Improve frequency responseImprove noise reductionMicrophonesHeadphones for stereophonic communicationNoiseSound wave

A noise-reduction microphone, a noise-reduction safe earphone and a noise-reduction safe Bluetooth headset, comprising an acoustic wave concentrator which has a sound signal capturing unit at its big end used to capture sound wave signal and amplify the external sound wave signal, and then transmitted to the small end of the acoustic wave concentrator connected to the air tube, and the air tube is connected to the receiver device which receives the acoustic signal from the air tube and converts it into electrical sound signals transmitted to a voice terminal from the receiver device by a connector. The sound information is transmitted by the air tube, so the length of the air to be could be setted pretty long so that people can keep at a distance from electrical equipments with radiation, the remote air tube microphone can be separately used as microphone or mike.

Owner:ZHU AIDAO

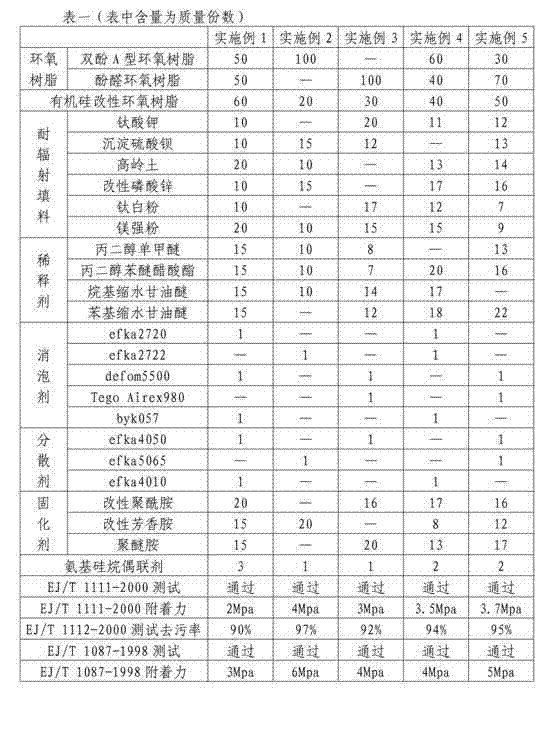

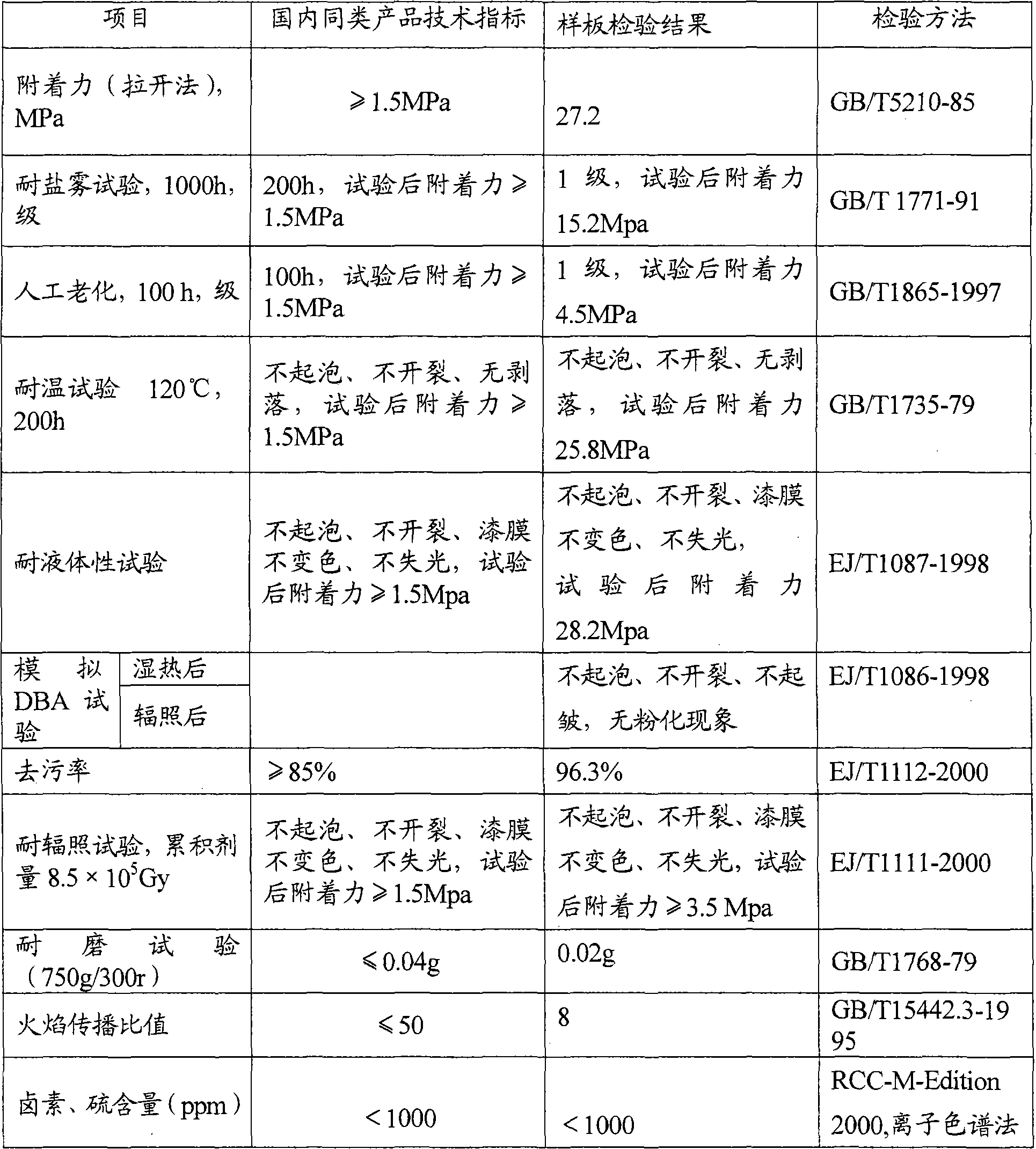

Steel-structure-use nuclear-radiation-resistant paint

InactiveCN102850910AImprove radiation resistanceGuaranteed service lifeEpoxy resin coatingsEpoxyNuclear radiation

The invention discloses a steel-structure-use nuclear-radiation-resistant paint which is characterized in that the paint comprises main agents, a curing agent, and a coupling agent. The main agents comprise epoxy resin, organosilicon modified epoxy resin, a radiation-resistant filling agent, a diluting agent, and a processing auxiliary agent. The paint is prepared from the components of, by mass: 100 parts of epoxy resin, 20-60 parts of organosilicon modified epoxy resin, 50-80 parts of radiation-resistant filling agent, 30-60 parts of the diluting agent, 2-5 parts of the processing auxiliary agent, 25-50 parts of the curing agent, and 1-3 parts of the coupling agent. A mass percentage ratio of the main agents to the curing agent is 6-11:1. The steel-structure-use nuclear-radiation-resistant paint provided by the invention has excellent radiation resistance and decontamination property. The paint does not precipitate environment-polluting harmful substances.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Preparation method for silicon carbide ceramic pipe

A preparation method for a silicon carbide ceramic pipe includes preparation of plasticity pug, vacuum pug milling of the plasticity pug, extrusion molding and shape keeping of pipe blank bodies, shade drying and drying of the pipe blank bodies and pressureless sintering. The plasticity pug is formed by adding deionized water into silicon carbide powder, sintering auxiliaries, adhesive, plasticizer, dispersing agent and lubricant and ball-milling and mixing the deionized water, the silicon carbide powder, the sintering auxiliaries, the adhesive, the plasticizer, the dispersing agent and the lubricant. The silicon carbide ceramic pipe prepared in the preparation method has the advantages of being highly-compact, super-thin in walls and high in precision and is applicable to industrial heat exchangers.

Owner:NINGBO VULCAN TECH CO LTD

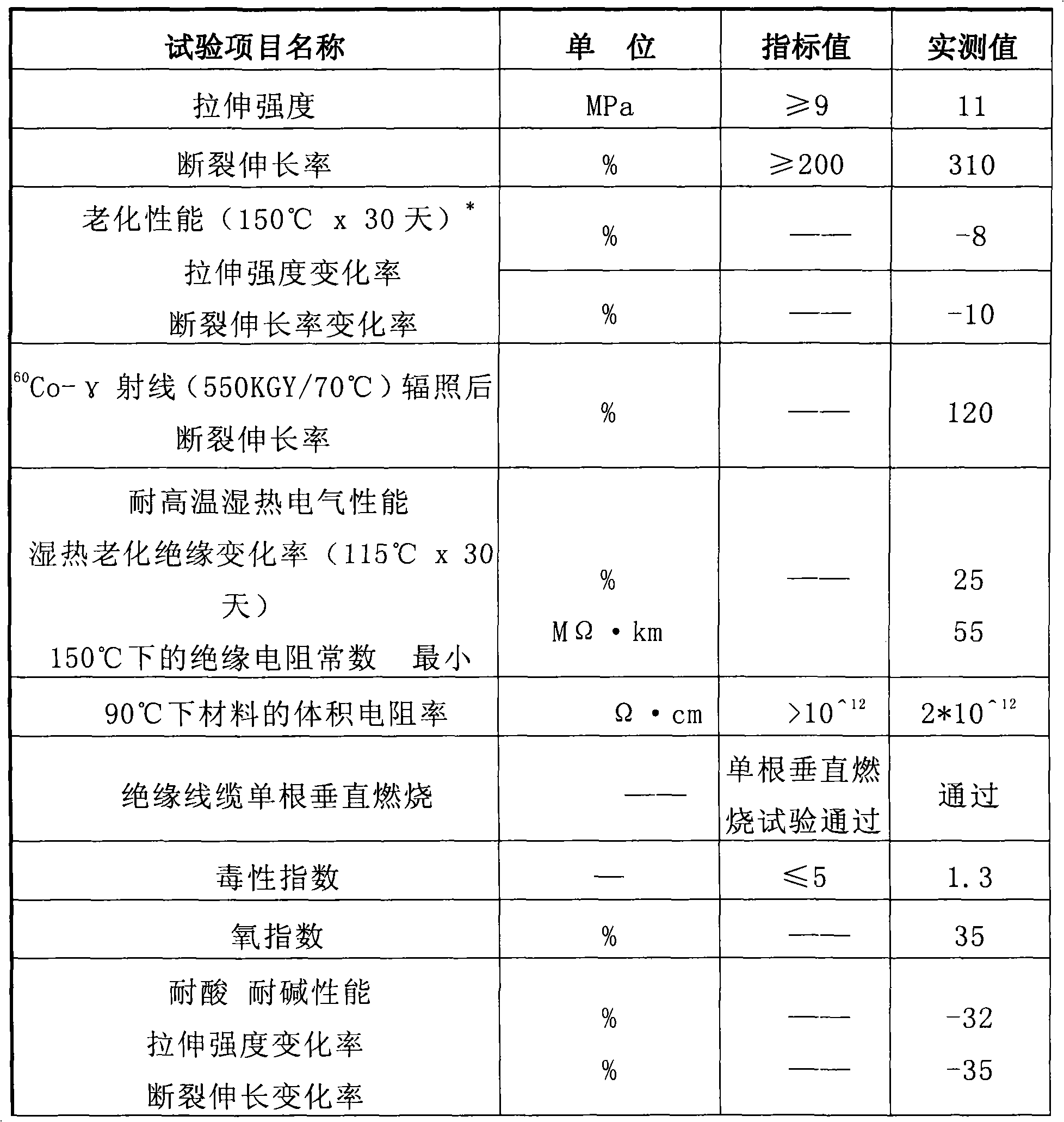

1E-level K1-type shrinkable tube used in nuclear power station and preparation method thereof

ActiveCN101661803AImprove flame retardant performanceImprove heat aging resistanceNuclear energy generationContainmentAging propertyFire retardant

The invention relates to a 1E-level K1-type shrinkable tube used in a nuclear power station, which comprises the following components by weight: 40 to 60 parts of base resin, 40 to 60 parts of hexyl-propyl rubber, 30 to 60 parts of flame retardant, 5 to 20 parts of antiradiation agent, 4 to 12 parts of antioxidizer, 2 to 5 parts of lubricant, and 3 to 8 parts of color masterbatch. The preparationmethod of the 1E-level K1-type shrinkable tube used in the nuclear power station comprises the following steps of: taking all the components by weight, carrying out mixed granulation by banburying ormixed granulation by a parallel double-screw extruder, then using a single-screw extruder for extrusion to form the tube, and carrying out radiation cross linking of cobalt 60 or electron accelerator50-180KGy to the tube, wherein the tube after the radiation cross linking expands by 2 to 6 times at the temperature of 90 to 150 DEG C. The shrinkable tube reaches and far exceeds the performance requirement of the 1E-level K1-type shrinkable tube used in the nuclear power station. The 1E-level K1-type shrinkable tube used in the nuclear power station has good flame retardant properties, can passV W-1 combustion test; has excellent heat-proof aging property, with the tensile strength and elongation at break of the product far stronger than the performance requirement; and outstanding intenseradiation-resistant function, and can pass AC withstand voltage test.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508AImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

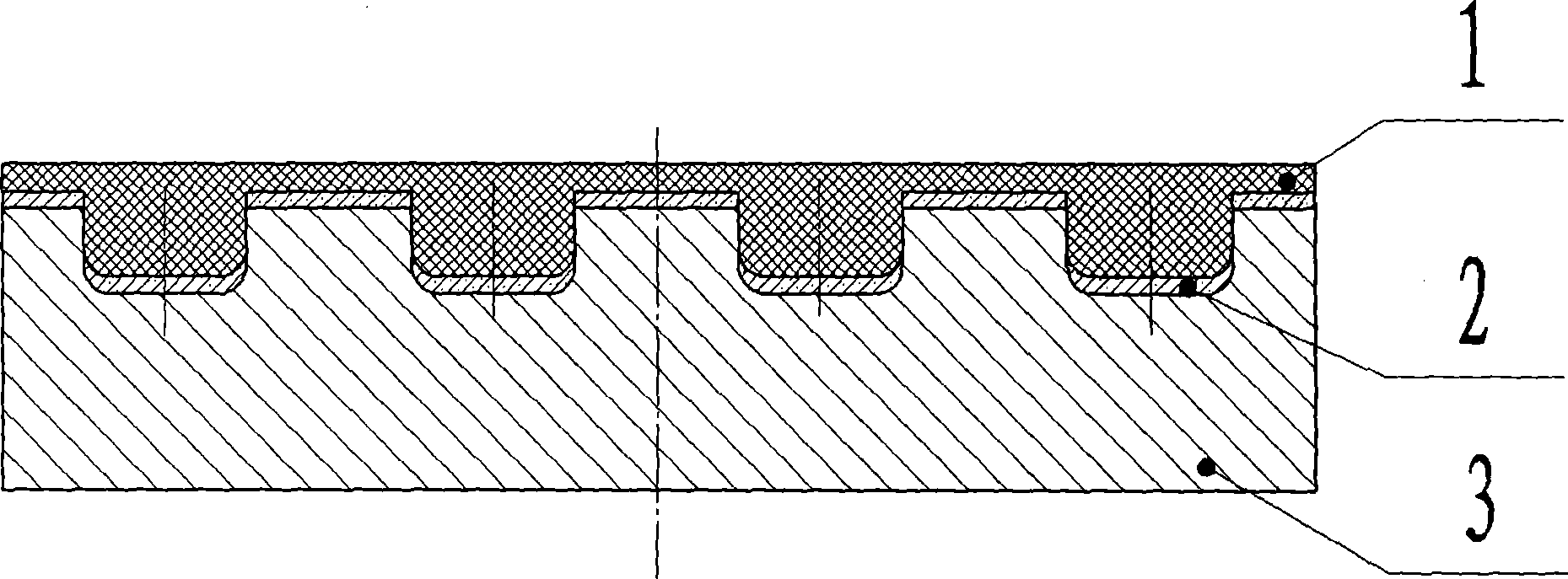

Metal and plastic composite self-lubricating material and preparation method thereof

ActiveCN101544080AHigh bonding strengthGood heat resistanceLiquid surface applicatorsLaminationThioetherPolyether ether ketone

The invention discloses a metal and plastic composite self-lubricating material and a preparation method thereof. The metal and plastic composite self-lubricating material comprises a metal layer, a plastic binding layer and a plastic working layer, wherein the plastic binding layer binds the metal layer and the plastic working layer together through a chemical bond of a molecule; one part of theplastic working layer is embedded in a drop pit of the metal layer; the plastic working layer includes the material components according to the mass percent as follows: 60-90 of polyether-ether-ketone, 5-20 of polyfluortetraethylene, 7 of graphite, 1 of MoS2 and 5-10 of aluminium oxide; and the plastic binding layer includes the material components according to the mass percent as follows: 70-90 of polyether-ether-ketone, 5-20 of polyphenyl thioether and 5-10 of aluminium oxide. By adding the plastic binding layer between the metal layer and the plastic working layer, the invention further improves the binding strength of metal and plastic, has favorable heat resistance and resistance to chemical corrosion, no environment pollution, low noise and energy saving; in addition, the usage temperature is -60 DEG C to 250 DEG C, the friction coefficient is 0.08-0.32 and the wear rate is 0.8-3.5*10<-6>mm<3> / N. m.

Owner:JIANGSU UNIV

Radiation-resistant non-halogen flame-retardant resin composition as well as electric wire and cable using same

InactiveUS20090114417A1Improve radiation resistanceImprove mechanical propertiesPlastic/resin/waxes insulatorsOther chemical processesAntioxidantAromatic amine

An electric wire and cable according to the present invention comprises a sheath made of a radiation-resistant non-halogen flame-retardant resin composition in which the radiation-resistant non-halogen flame-retardant resin composition includes one to 30 parts by weight of aromatic amine antioxidant with a melting point of 40° C. or higher and 50 to 300 parts by weight of metal hydroxide blended into 100 parts by weight of ethylene polymer.

Owner:HITACHI CABLE

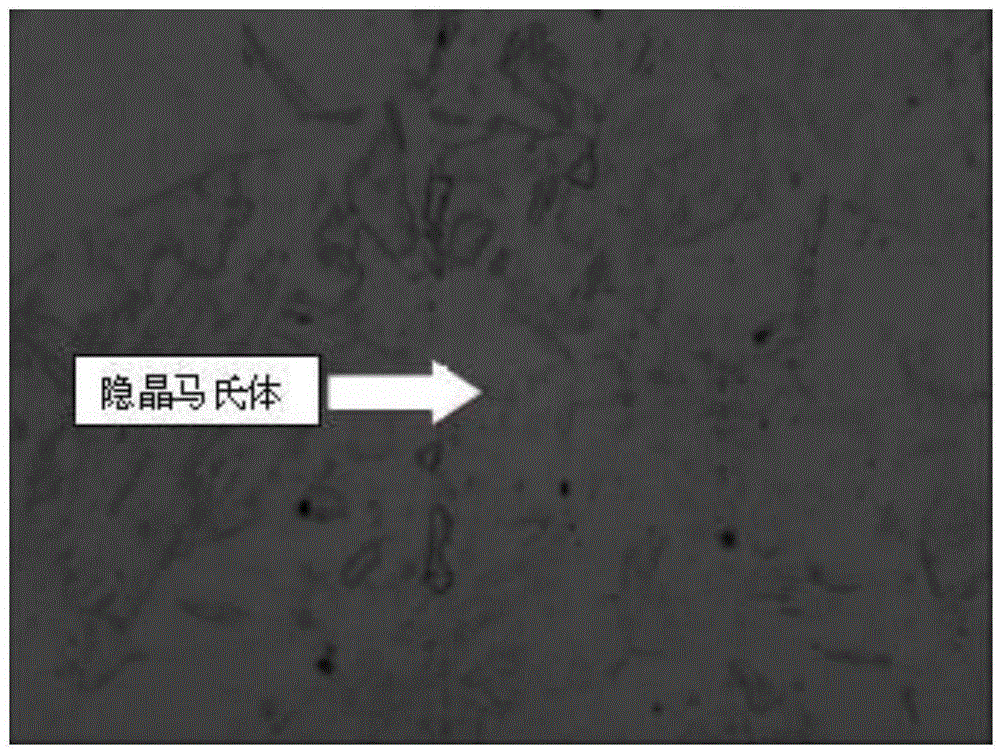

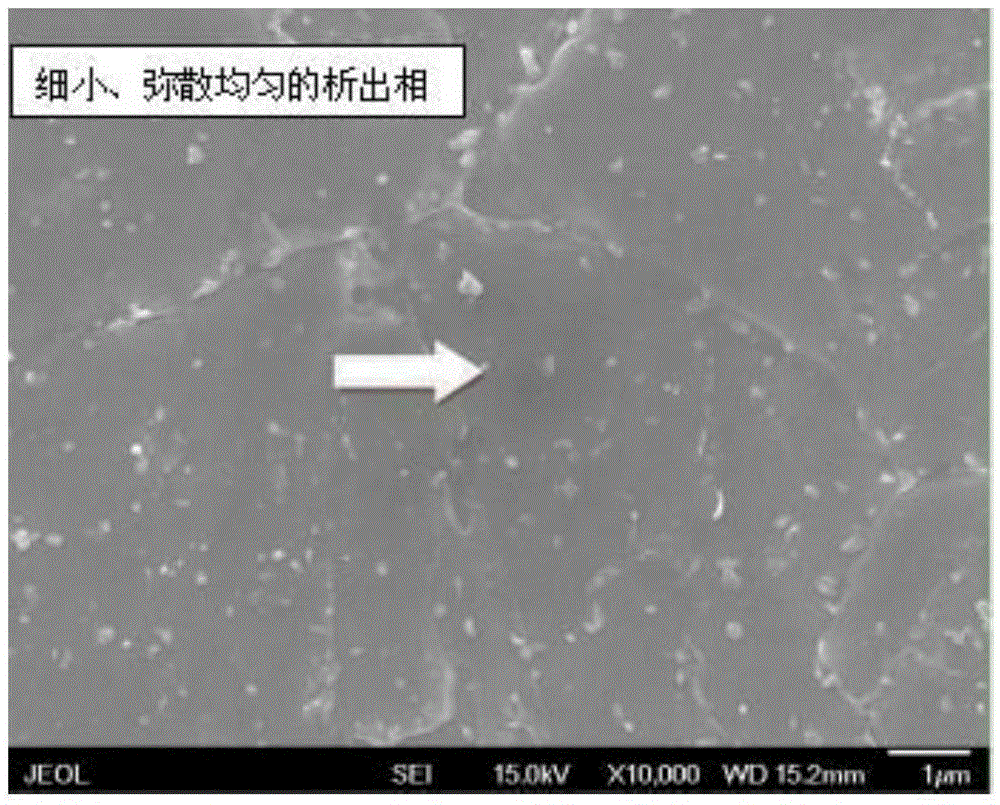

Oxide dispersion strengthened (ODS) steel preparing method and martensitic steel

The invention provides an oxide dispersion strengthened (ODS) steel preparing method and martensitic steel. The oxide dispersion strengthened steel preparing method includes the steps that iron oxides are added into a casting mould, a proper number of rare earth elements are added into a fully deoxidized molten steel, the mixture is rapidly cast into the casting mould, and the ODS steel is obtained through the reaction between the rare earth elements and the iron oxides. The martensitic steel is obtained by performing hot forging, hot rolling, hot machining and hot treatment on the ODS steel prepared through the method. The ODS steel prepared through the method is high in hardenability, the residual austenitic content is very low, and a full martensite structure can be obtained. W, V and Ta are strong carbide forming elements and have a remarkable strengthening effect, and the mechanical property is obviously higher than that of steel prepared through a traditional smelting technology. Meanwhile, the ductile-brittle transition temperature (DBTT) value is minus 80 DEG C and minus 90 DEG C, the good toughness of the traditional smelting technology is well inherited, and meanwhile good anti-radiation performance is achieved. By means of the ODS steel preparing method, the demands for preparing ODS steel in batches with stability, short process and low cost can be met.

Owner:UNIV OF SCI & TECH BEIJING

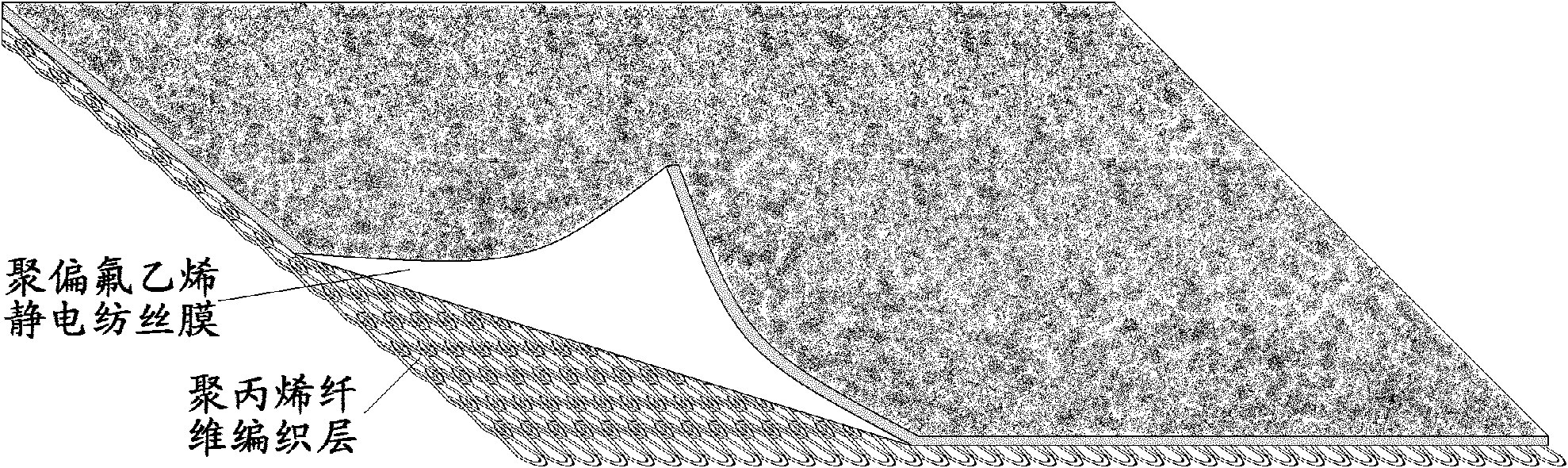

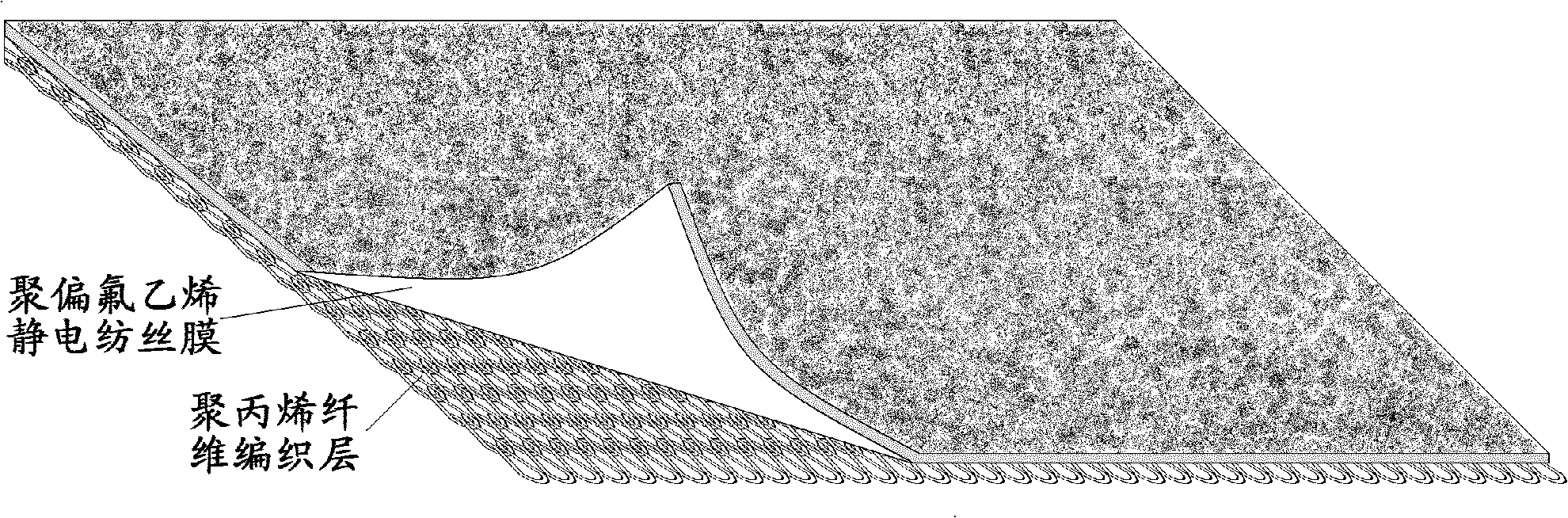

Polypropylene/polyvinylidene fluoride composite hernia patch and preparation method thereof

InactiveCN102085122AEasy to stickNot easy to stickProsthesisBiocompatibility TestingMechanical property

The invention relates to a polypropylene / polyvinylidene fluoride composite hernia patch and a preparation method thereof. The composite hernia patch has a bilayer structure, wherein the bottom layer is a plasma modified polypropylene braid and the surface layer is a polyvinylidene fluoride electrospinning film. The preparation method comprises the following steps: (1) dissolving polyvinylidene fluoride in the mixed solution of dimethylformamide and acetone to prepare polyvinylidene fluoride solution; (2) performing plasma modification to the polypropylene fiber braid; (3) adopting the electrospinning method to spray the polyvinylidene fluoride solution on the modified polypropylene fiber braid; and (4) shaping the composite fabric and drying. The hernia patch of the invention has stable structure and good mechanical properties and biocompatibility; by utilizing the good anti-adhesion property of polyvinylidene fluoride, the problem that the polypropylene hernia patch prepared from a single material is easy to be adhered with intestinal tissues can be overcome; and the preparation method is simple and is suitable for industrial production.

Owner:DONGHUA UNIV

Non-punch-through deep trench IGBT with field stop structure and manufacturing method thereof

InactiveCN101826552ALow costEasy to implementSemiconductor/solid-state device manufacturingSemiconductor devicesElectromagnetic interferenceEngineering

The invention discloses a non-punch-through deep trench IGBT with a field stop structure and a manufacturing method thereof. The IGBT is equivalent to one NMOS field-effect tube driving one PNP bipolar transistor or one PMOS field-effect tube driving one NPN bipolar transistor. The NMOS tube or the PMOS tube in the invention realizes a vertical gate and a vertical trench through a deep trench technology and a high voltage-resistant trench gate technology is adopted; the NMOS tube or the PMOS tube and the PNP tube or the NPN tube are directly manufactured on a polished wafer to form a non-punch-through IGBT structure; and a field stop layer with the same doping type as a base region and with doping concentration higher than the base region is formed in the base region of the PNP tube or the NPN tube at a position close to a collector region through ion implantation or diffusion. The invention has the advantages that the cost of the manufacturing method is low and the implementation is easy; and the area of the manufactured IGBT is small, the switching loss is small, the short-circuit tolerance is high, the anti-electromagnetic interference capacity and the radiation resistance are enhanced and the like. Thereby, the demand of the market on the high quality of IGBT products is satisfied.

Owner:TIANJIN HUANXIN TECH DEV

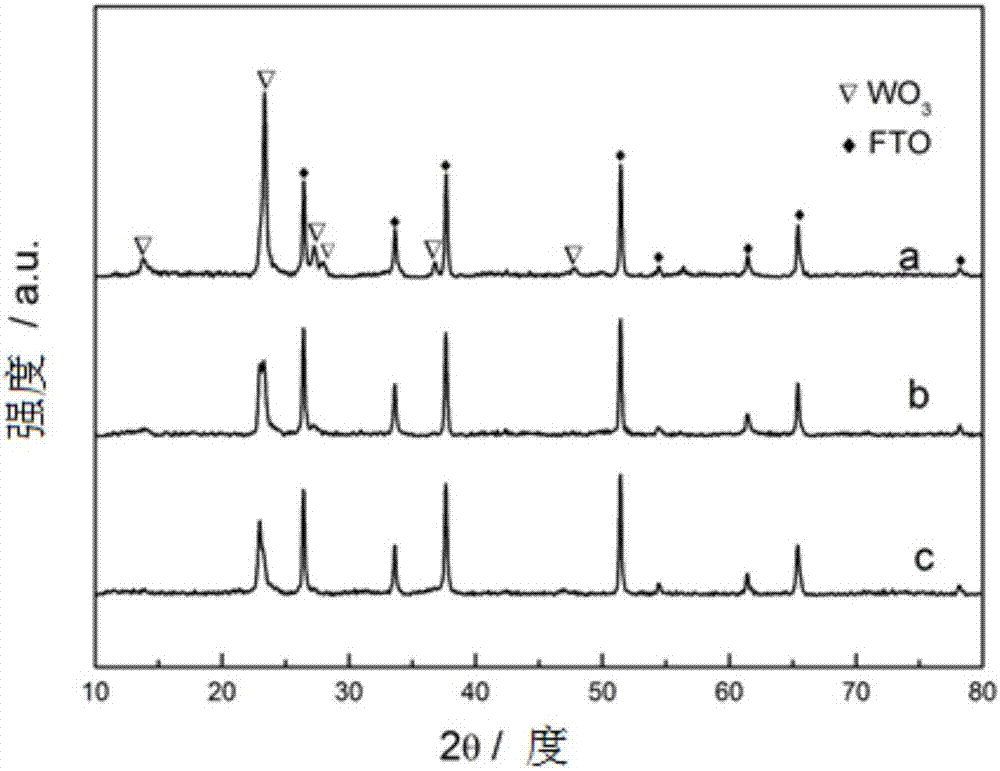

Preparation method for tungsten trioxide nanowire electrochromic film

InactiveCN107216045AIncrease the areaBarrier throughTungsten oxides/hydroxidesNanotechnologyNanowireTungstate

The invention discloses a preparation method for a tungsten trioxide nanowire electrochromic film, which includes the following steps: (Step 1) tungstic acid and hydrogen peroxide solution are mixed, and after water is added for dilution, stirring is carried out for aging, so that sol is obtained; (Step 2) the sol is applied on a conductive glass, and after annealing treatment, a conductive glass with a WO3 seed crystal layer is obtained; (Step 3) tungstate and water are mixed, pH is regulated to strong acidity, ammonium sulfate and alcohol are then added, and after stirring, tungsten precursor solution is obtained; (Step 4) the conductive glass with the WO3 seed crystal layer in the step 2 is immersed in the tungsten precursor solution in step 3 to carry out hydrothermal reaction, and thereby the tungsten trioxide nanowire electrochromic film is obtained. The prepared WO3 nanowire electrochromic film has an supramaximal optical modulation range and a high electrochromic rate; when applied as an electrochromic smart window, the tungsten trioxide nanowire electrochromic film can greatly reduce solar radiation, and can also play the role of saving energy and regulating temperature; moreover, the process is simple and controllable, the cost is low, and the preparation method is suitable for industrialized application.

Owner:ZHEJIANG UNIV

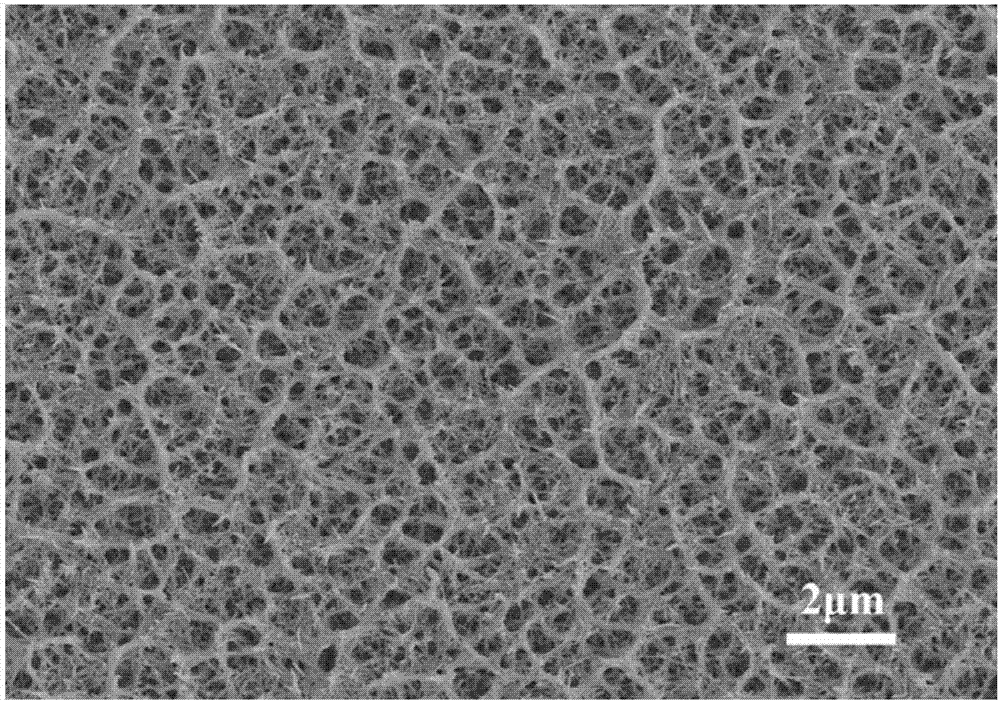

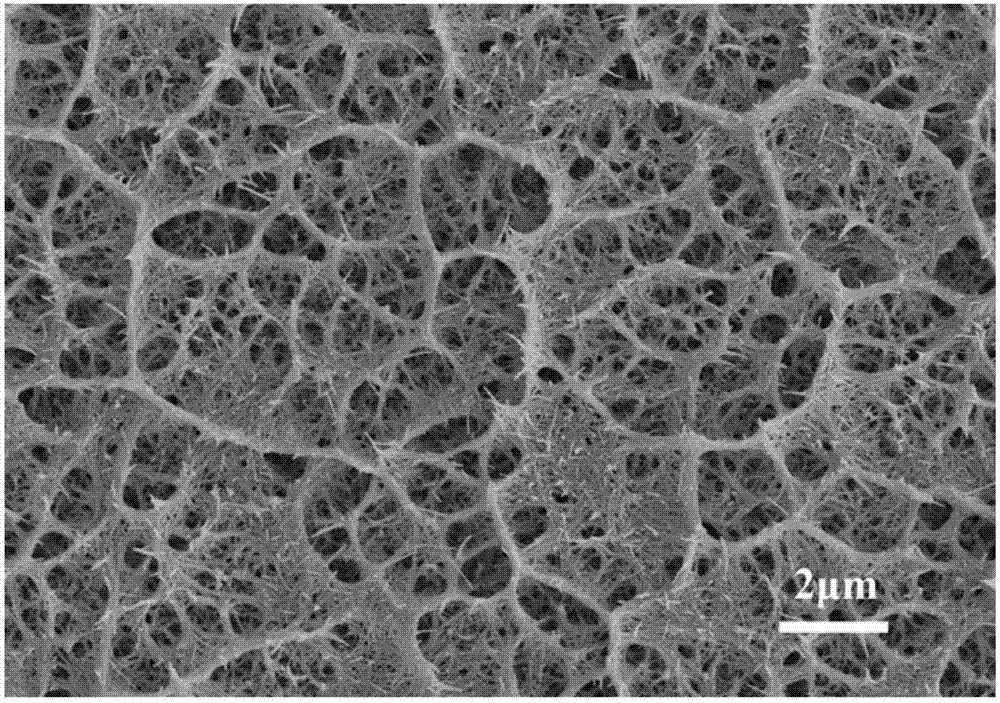

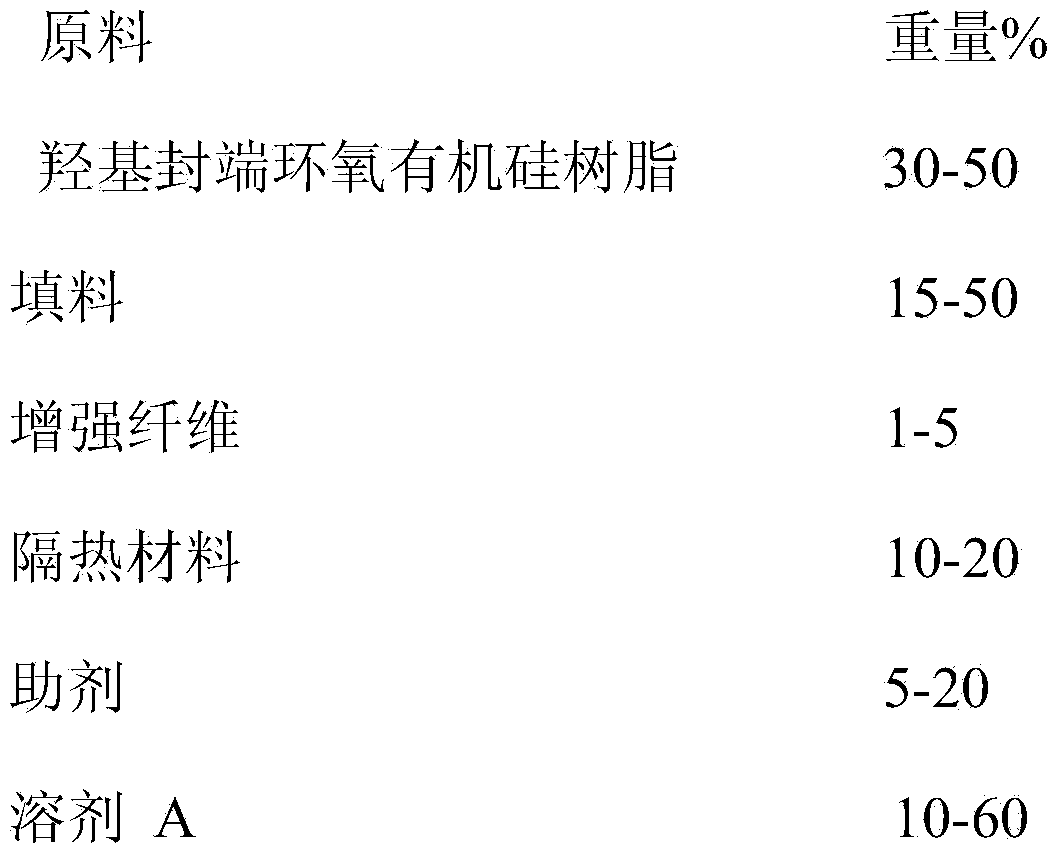

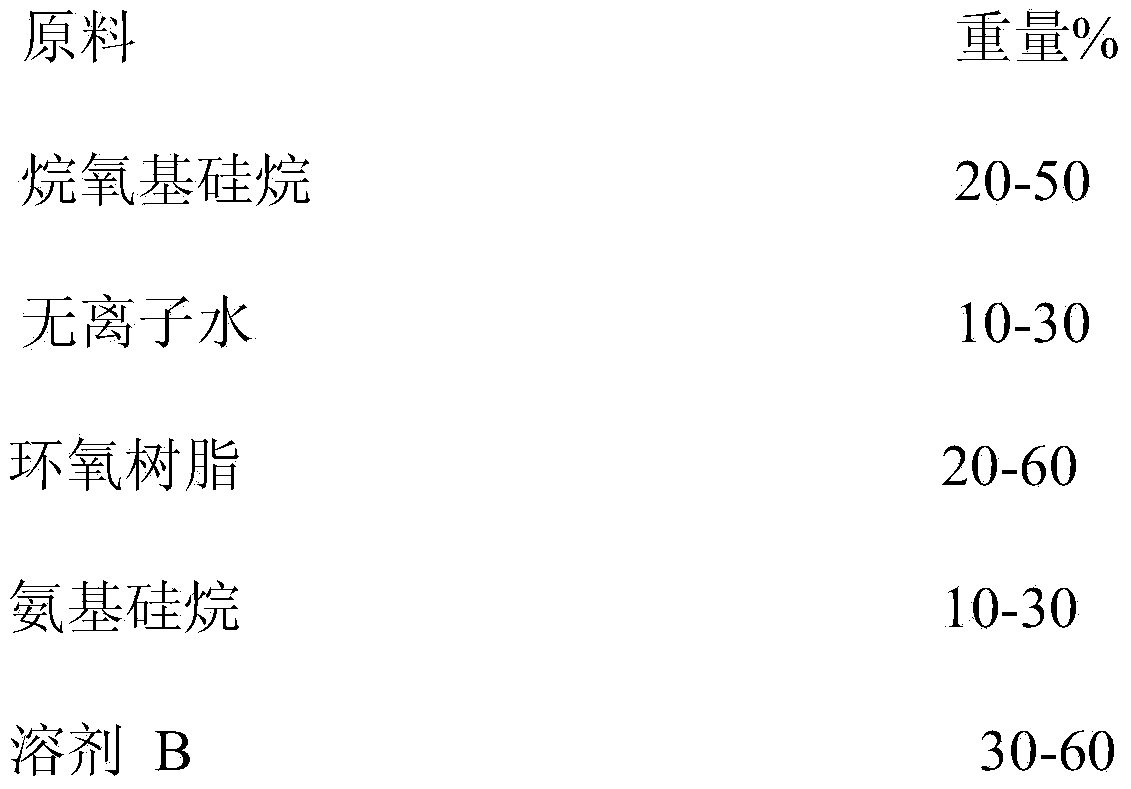

High-elasticity polyurethane modified epoxy-silicone ablation resistance paint

InactiveCN103725179AGood mechanical propertiesGood thermal stabilityPolyurea/polyurethane coatingsSolventSilicone resin

The invention discloses high-elasticity polyurethane modified epoxy-silicone ablation resistance paint. According to the invention, an organic silicon intermediate prepared through alkoxy silane hydrolysis and epoxy resin are condensed into hydroxyl-terminated epoxy-silicone resin with high char yield and excellent ablation resistance; the elongation at break and the tensile strength of the resin system are improved through selecting high-elasticity polyurethane resin to toughen the epoxy-silicone resin; filler, a reinforcing agent, a thermal insulation material, an additive and a solvent are also added, so as to obtain the high-elasticity polyurethane modified epoxy-silicone ablation resistance paint. While the requirement that an outer shell coating is subjected to relatively large deformation due to internal pressure when grains are burnt is met, the coating has excellent ablativity, very low density and high thermal insulation performance.

Owner:中昊北方涂料工业研究设计院有限公司

FeCrAl base alloy material for nuclear fuel cladding material

InactiveCN106319369AImprove antioxidant capacityExcellent fault toleranceOptical rangefindersNuclear energy generationNuclear powerPressurized water reactor

The invention relates to a FeCrAl base alloy material for a nuclear fuel cladding material. With the total weight of the FeCrAl base alloy material as a standard, the alloy material comprises 6%-16% of Cr, 3%-8% of Al, 0.001%-1% of Y, 0.1%-4% of Mo, 0.01%-0.5% of Si, 0.001%-0.5% of C, less than or equal to 500 ppm of N, less than or equal to 1000 ppm of O, less than or equal to 500 ppm of P, less than or equal to 500 ppm of S and the balance Fe. A FeCrAl base alloy shows the excellent antioxygenic property in the 1200 DEG C vapor environment, the excellent accident fault-tolerant ability is achieved and is obviously superior to that of a Zr base alloy, the machining performance is good, and the FeCrAl base alloy material can be used as core structural materials such as fuel element cladding, fuel element composite cladding, fuel cladding coatings and positioning grillage stripes in nuclear power station pressurized water reactors.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com