Patents

Literature

1250 results about "Tungsten trioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungsten(VI) oxide, also known as tungsten trioxide or tungstic anhydride, WO₃, is a chemical compound containing oxygen and the transition metal tungsten. It is obtained as an intermediate in the recovery of tungsten from its minerals. Tungsten ores are treated with alkalis to produce WO₃. Further reaction with carbon or hydrogen gas reduces tungsten trioxide to the pure metal. Tungsten trioxide is a strong oxidative agent, it reacts rare-earth elements, iron, copper, aluminium, manganese, zinc, chromium, molybdenum, carbon, hydrogen and silver to make the pure tungsten metal, and gold and platinum to make the tungsten dioxide.

Supported palladium-gold catalysts and preparation of vinyl acetate therewith

InactiveUS20100121100A1High activity selectivityImproves oxygen selectivityOrganic compound preparationCarboxylic acid esters preparationTungsten trioxidePalladium

Disclosed is a catalyst. The catalyst comprises palladium, gold, and a support comprising titanium dioxide and tungsten trioxide. The support preferably comprises from 75 wt % to 99 wt % of titanium dioxide and from 1 wt % to 25 wt % of tungsten trioxide. A method for preparing the catalyst is also disclosed. The method comprises impregnating the support with a palladium compound and a gold compound, calcining the impregnated support, and then reducing the calcined support. Further disclosed is a method for preparing vinyl acetate with the catalyst. The catalyst exhibits improved catalytic activity and selectivity.

Owner:LYONDELLBASELL ACETYLS

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

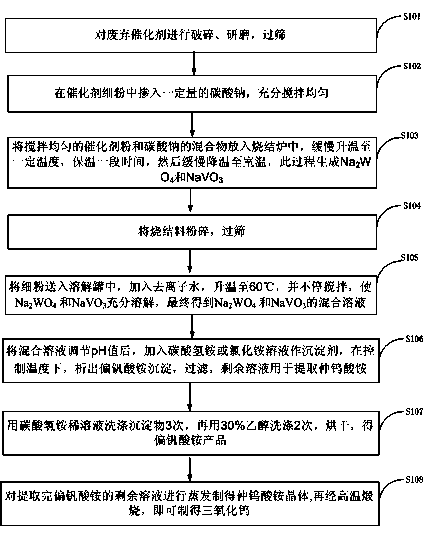

Method for recovering tungsten trioxide and ammonium metavanadate from selective catalytic reduction (SCR) denitration catalyst

ActiveCN102557142AEmission reductionTungsten oxides/hydroxidesDispersed particle separationWarm waterAmmonium paratungstate

The invention relates to a method for recovering tungsten trioxide and ammonium metavanadate from a selective catalytic reduction (SCR) denitration catalyst. The method comprises the following steps of: crushing the SCR denitration catalyst, sieving to obtain catalyst powder, mixing with sodium carbonate, and stirring fully and uniformly; putting the mixed powder into a sintering furnace, and sintering to obtain a sintered material; keeping temperature for 1 hour, and sieving to obtain sintered material powder; pouring warm water, so that Na2WO4 and NaVO3 in the sintered material powder are dissolved fully, filtering, and removing precipitates to obtain a mixed solution of Na2WO4 and NaVO3; regulating the pH value to be 6.5-7.5, adding an ammonium bicarbonate solution or an ammonium chloride solution, and precipitating ammonium metavanadate precipitate; filtering, washing by using a diluted ammonium bicarbonate solution for 2 to 3 times, washing by using 30 percent ethanol for 1 to 2 times, and drying to obtain an ammonium metavanadate finished product; and converting the Na2WO4 in the residual solution into ammonium paratungstate, evaporating the residual solution to obtain ammonium paratungstate crystals, and calcining to obtain the tungsten trioxide. By the method, the ammonium metavanadate and the tungsten trioxide can be recovered, and the discharge of pollutants is reduced.

Owner:江苏万德环保科技有限公司

Method for recovering tungsten component from selective catalytic reduction denitrification catalyst

The invention relates to a method for recovering a tungsten component from a selective catalytic reduction denitrification catalyst, belonging to the technical field of waste catalyst recovery. The invention achieves the purpose of separating and purifying a tungsten component by high-temperature sodium salt roasting, organic phase extraction, ammonia water back extraction and other operations. According to the invention, tungsten trioxide in a catalyst can be separated from other acidic metal oxide, the contained tungsten element can be selectively extracted, no effect can be made on the recovery of other metal elements, and the recovery of the tungsten component can be realized basically.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

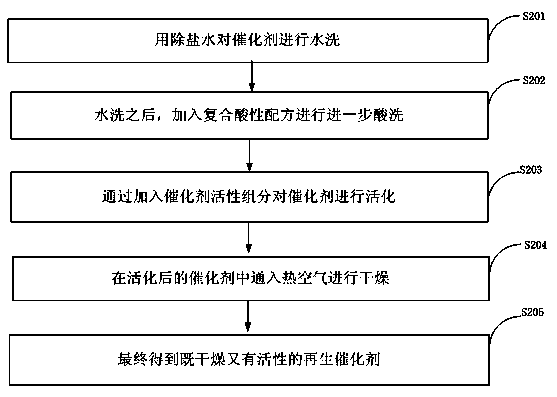

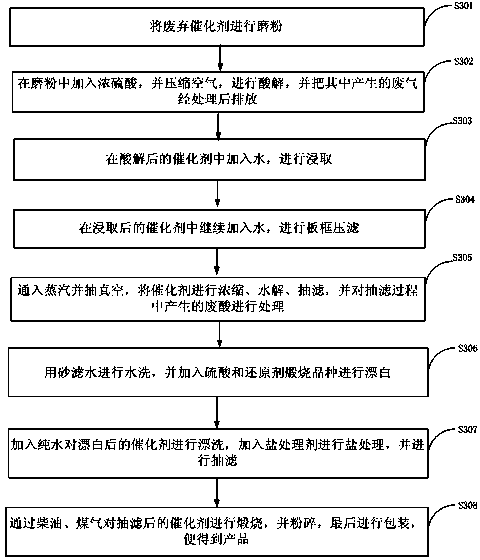

Method for regeneration and resource utilization of waste honeycombed denitrification catalyst

InactiveCN103508491ALow costRestore activityTungsten oxides/hydroxidesDispersed particle separationResource utilizationAmmonium paratungstate

The invention discloses a method for regeneration and resource utilization of a waste honeycombed denitrification catalyst. The method comprises the following steps of: crushing, grinding and sieving the waste catalyst; loading a mixture of the powdered catalyst and sodium carbonate into a sintering furnace to produce Na2WO4 and NaVO3, dissolving completely, adjusting the pH value to separate ammonium metavanadate precipitates, filtering, applying the remaining liquid to ammonium paratungstate extraction, washing the precipitates and oven-drying to obtain ammonium metavanadate, and making ammonium paratungstate crystals and tungsten trioxide. The regeneration method of the SCR catalyst comprises the following steps of: performing water-washing, pickling, activation and drying on the catalyst. The method for producing titanium pigment from the waste catalyst as raw material comprises the following steps of: performing pulverization, acidolysis and extraction on the waste catalyst, performing plate-frame pressure filtration; performing concentration, hydrolysis and suction-filtration on the catalyst, washing and blanching with sand leaching water, calcining, grinding and packaging. The method disclosed by the invention can effectively restore the activity of a deactivated catalyst and prolong the service life of the deactivated catalyst, which not only reduce the operating cost of a thermal power plant but also save the valuable rare earth resources.

Owner:YIXING YIGANG ENVIRONMENTAL PROTECTION ENG & MATERIALS

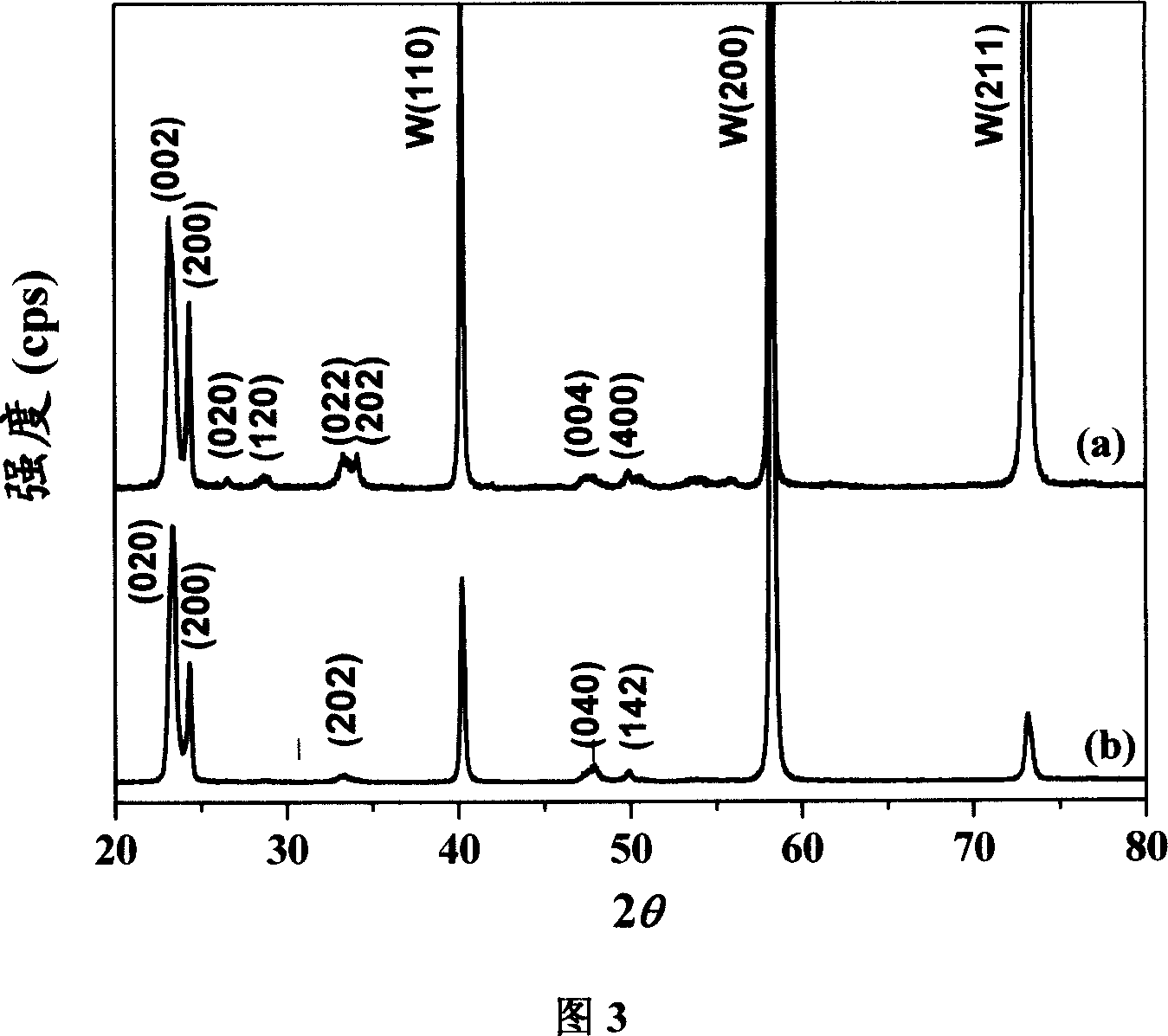

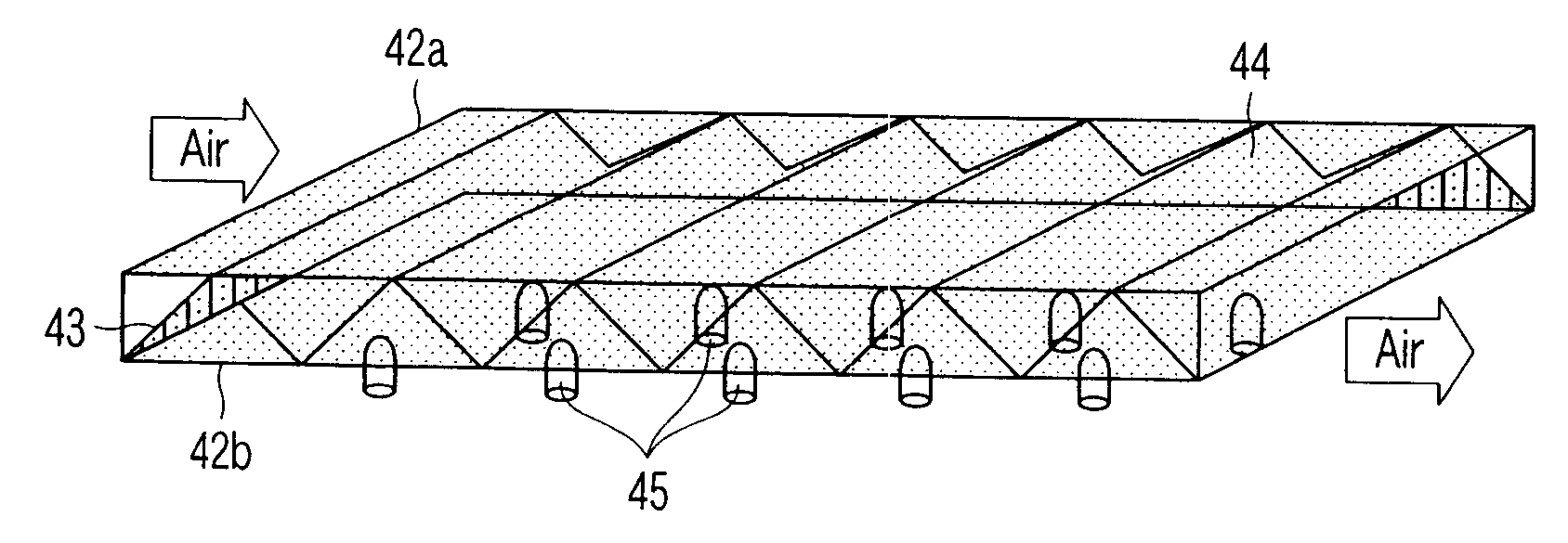

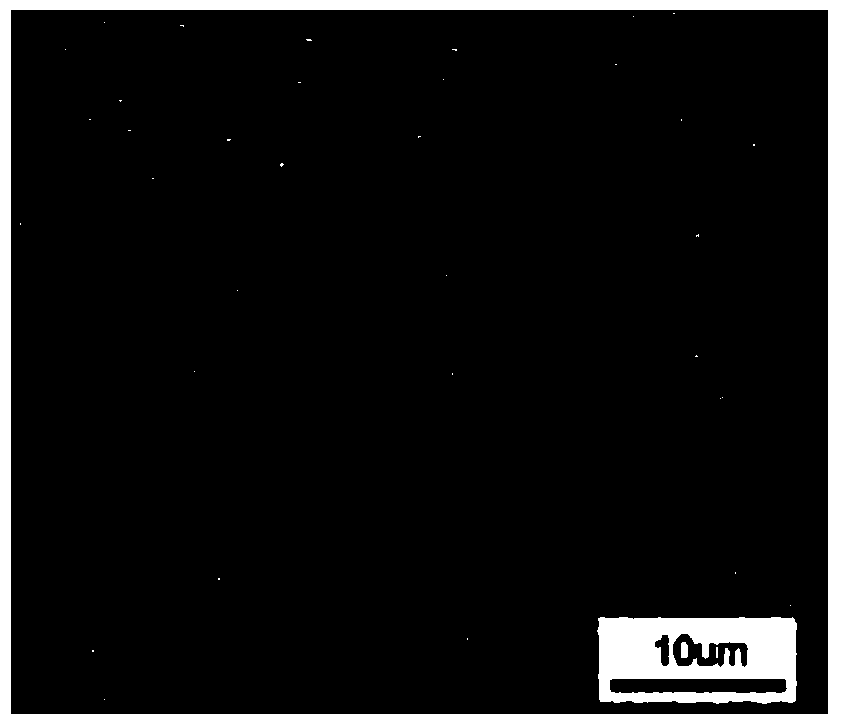

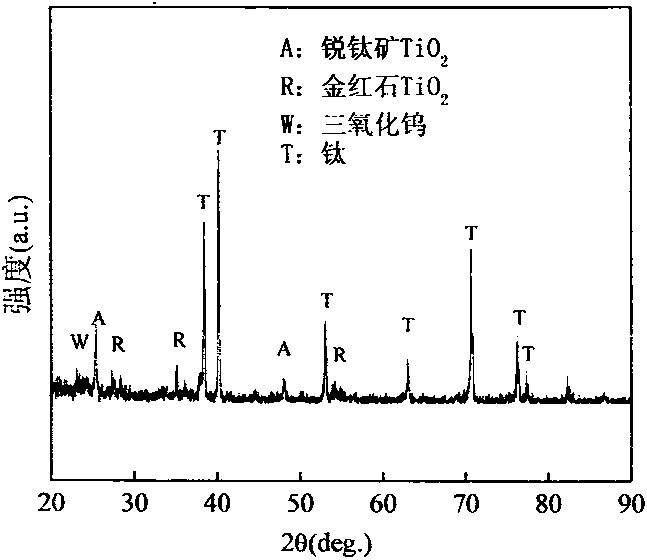

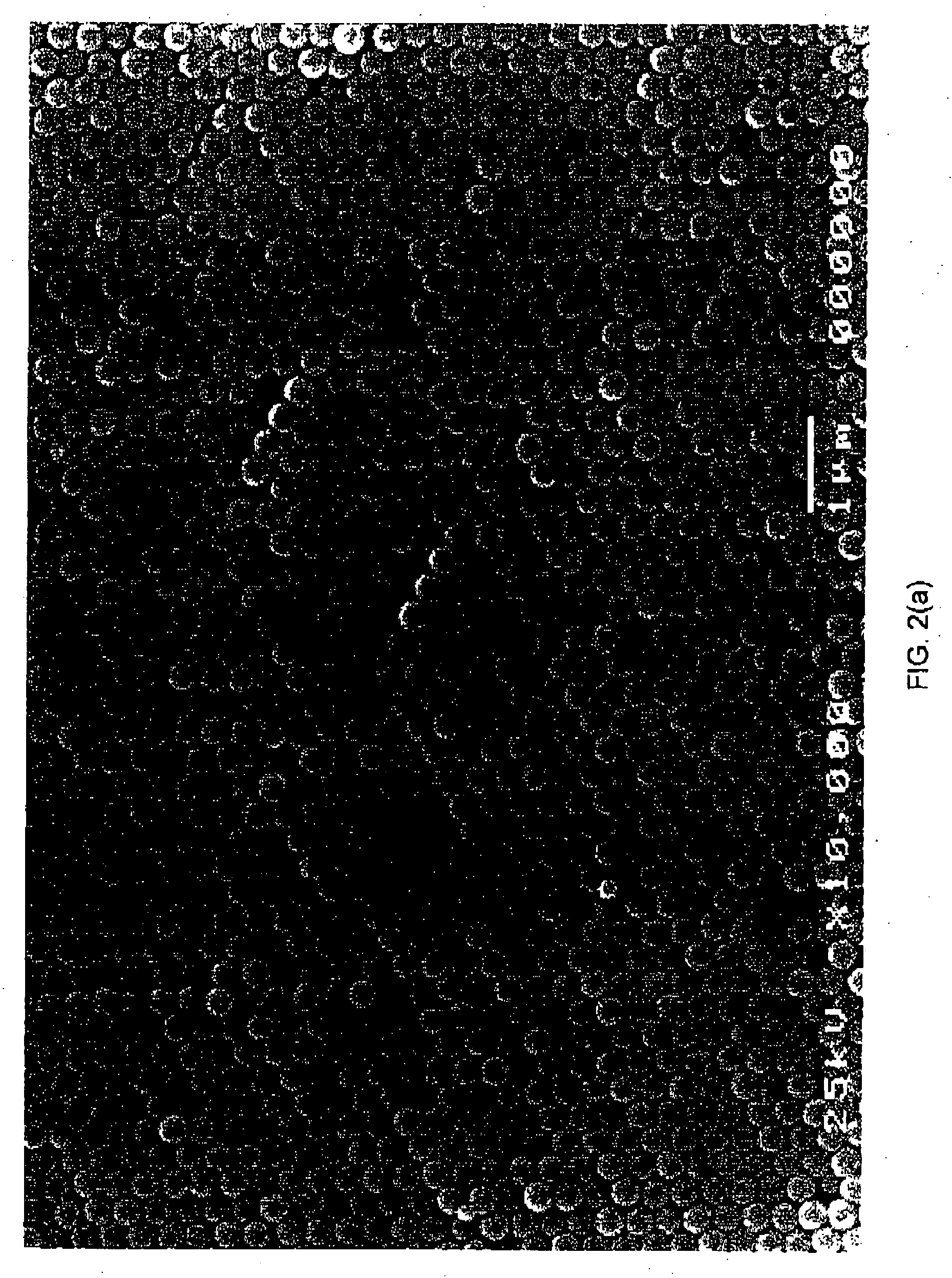

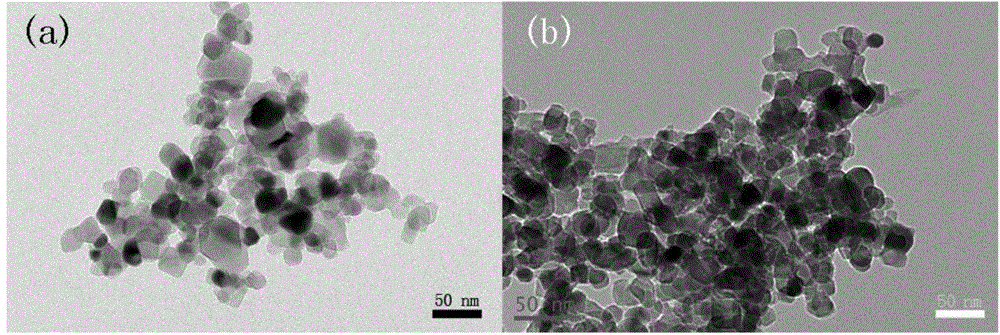

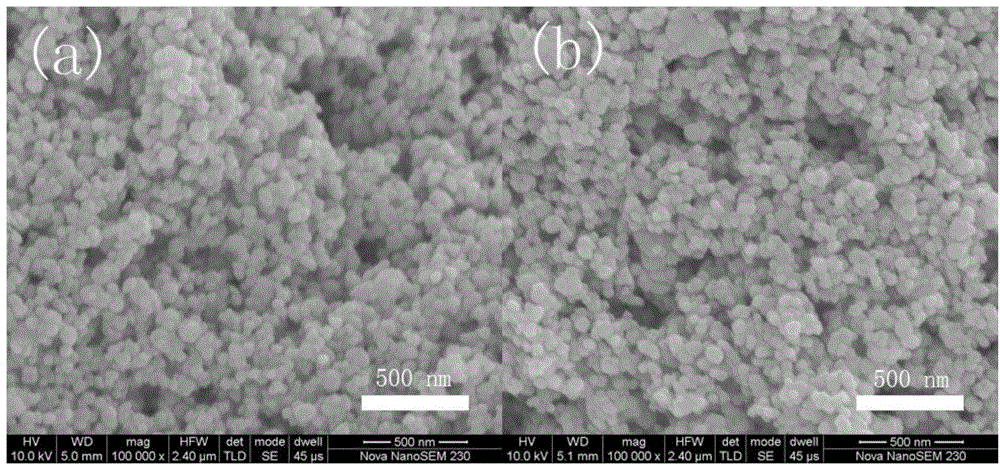

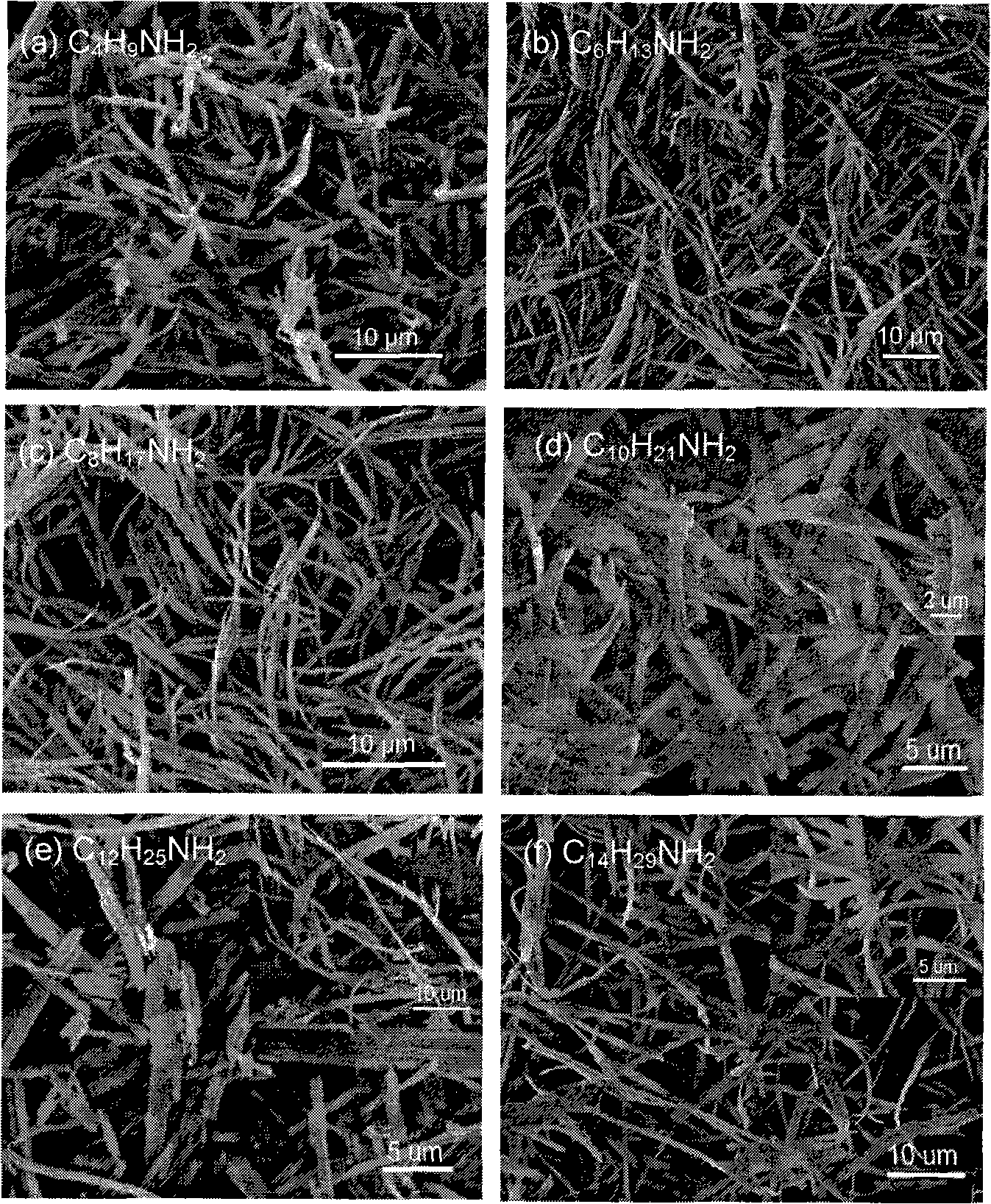

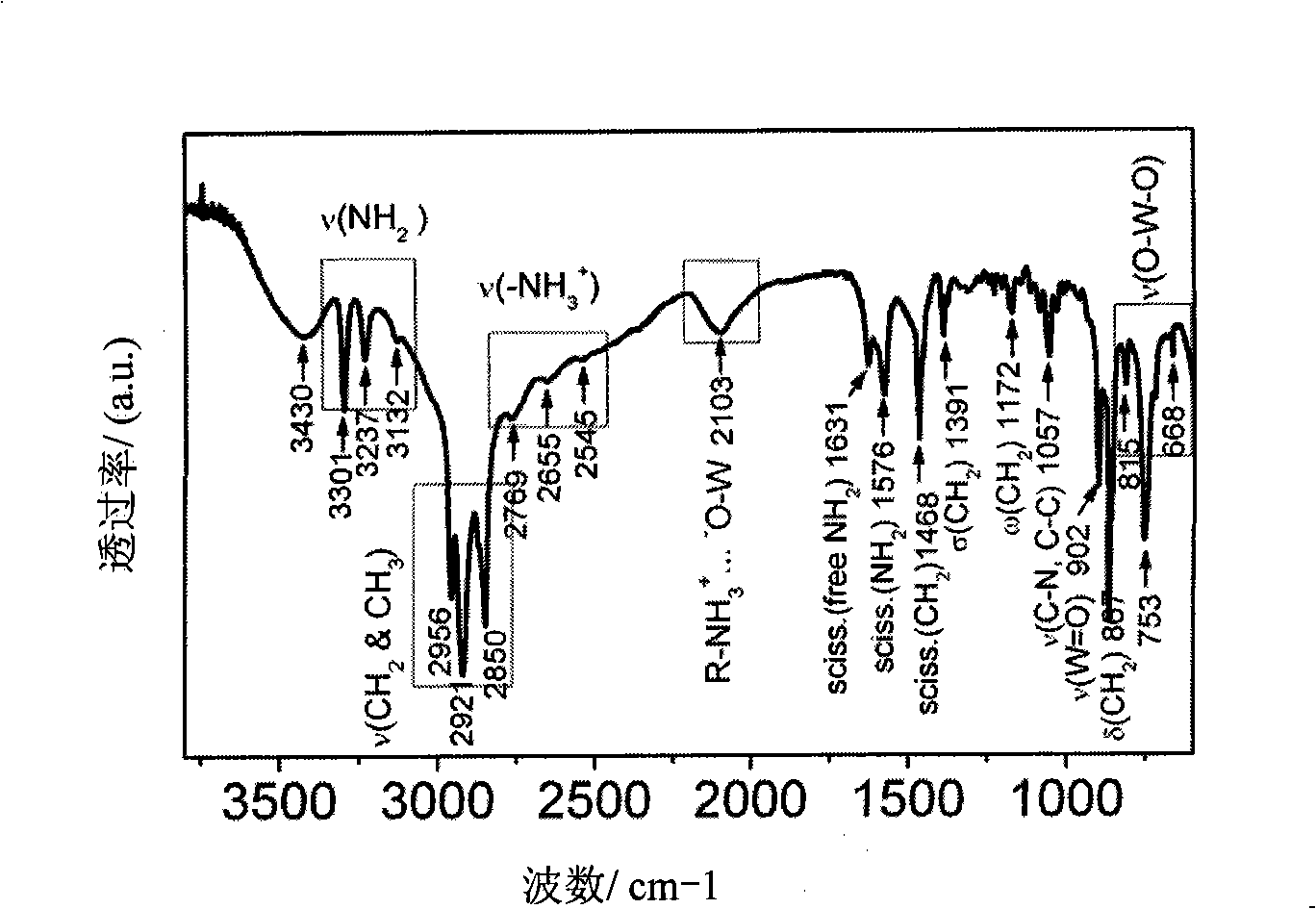

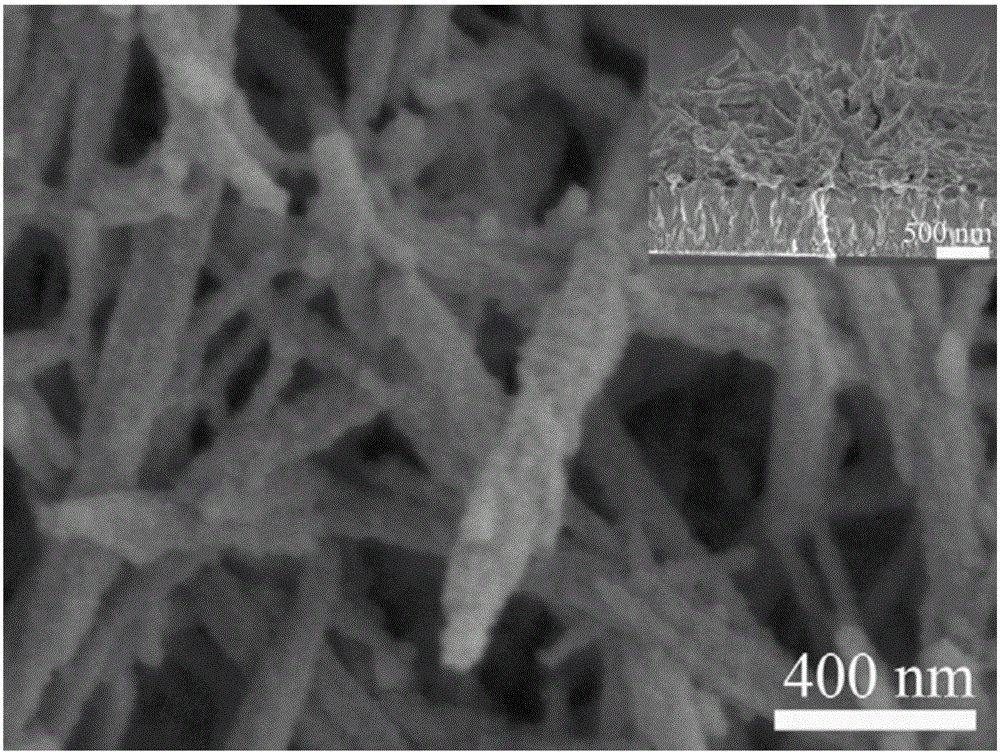

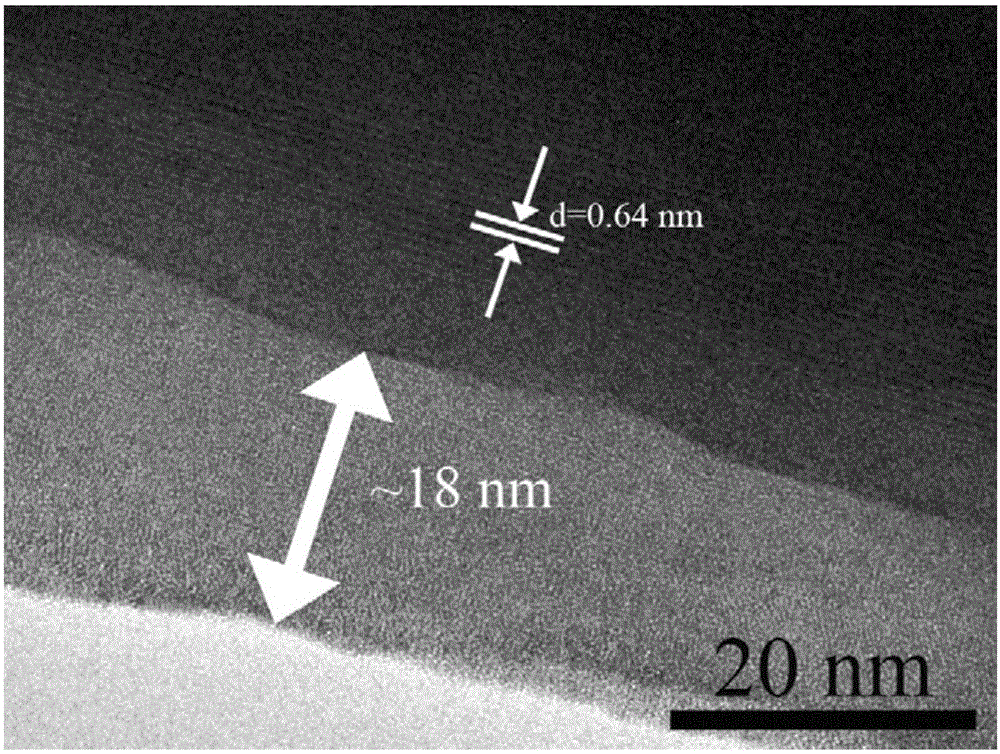

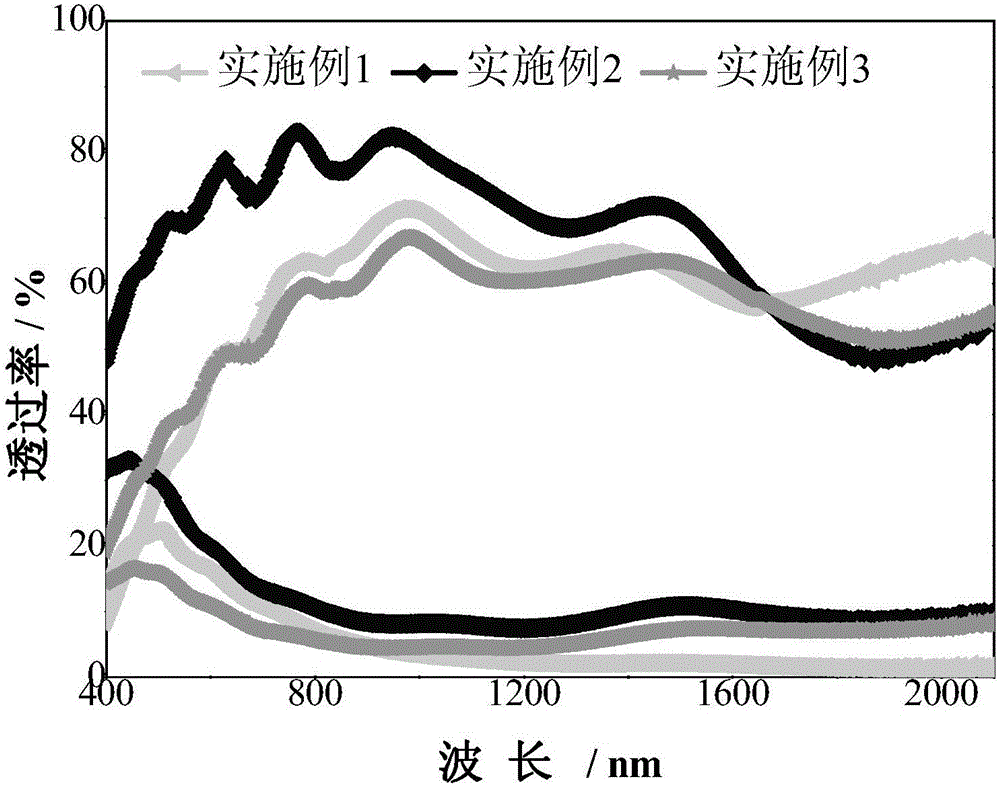

Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof

InactiveCN104874389AEasy to adjustEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsOxygen vacancyMesoporous silica

The invention discloses a mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and a preparation method thereof. The method comprises the following steps: calcinating at a controlled temperature of 350-600 DEG C in air so as to obtain a mesoporous silica molecular sieve KIT-6 loaded with tungsten trioxide by taking mesoporous silica molecular sieve KIT-6 as a hard template and a silicotungstic acid or phosphotungstic acid hydrate as a tungsten trioxide precursor; then calcinating at a controlled temperature of 450-550 DEG C so as to obtain a mesoporous silica molecular sieve KIT-6 provided with oxygen vacancy and loaded with tungsten trioxide by utilizing H2 as a reducing agent; and finally, removing the mesoporous silica molecular sieve KIT-6 by use of a 10wt% HF aqueous solution, thereby obtaining the mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and relatively large specific surface area and pore diameter. The mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy is capable of effectively utilizing lights to rapidly catalyze CO2 so as to generate methane, and is high in catalysis efficiency, simple in preparation process and needed equipment, environmentally friendly in preparation process and free from pollution.

Owner:SHANGHAI INST OF TECH

Nanometer porous tungsten trioxide material and its prepn and application

InactiveCN1974890ALower surface energyImprove surface topographyPolycrystalline material growthSurface reaction electrolytic coatingPotassium fluorideStrong acids

Owner:DALIAN UNIV OF TECH

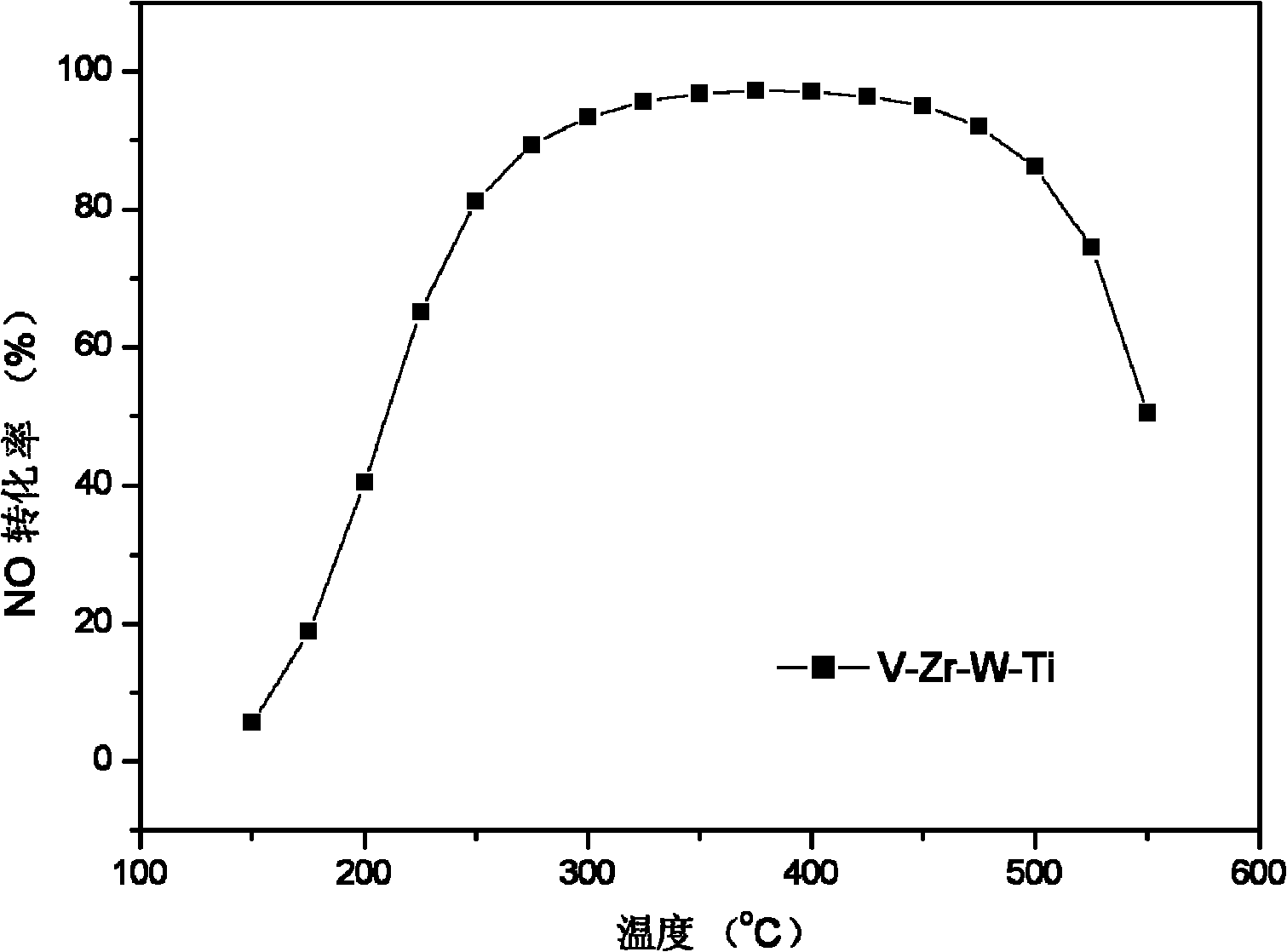

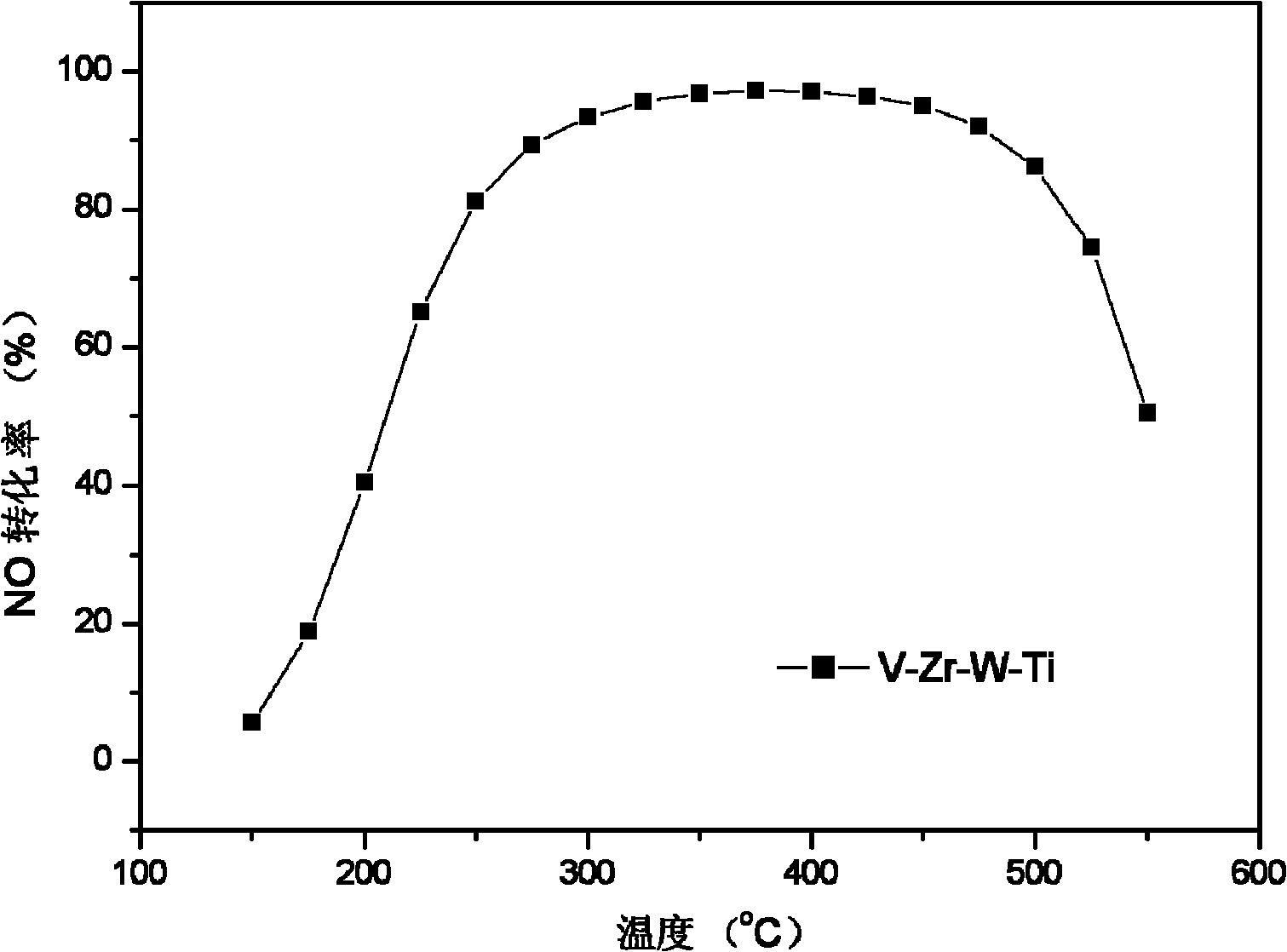

Selective catalyst for removing oxynitrides from tail gases of diesel vehicles and preparation method thereof

InactiveCN101912775AImprove smoothnessSatisfy and attain purifyingInternal combustion piston enginesDispersed particle separationWater vaporCordierite

The invention discloses a selective catalyst for removing oxynitrides from tail gases of diesel vehicles and a preparation method thereof. Cordierite honeycomb ceramic serves as a carrier, and the oxides of vanadium, zirconium, tungsten and titanium form a catalytic active site. The preparation method comprises the following steps of: sequentially dissolving vanadium pentoxide, a zircon salt, tungsten trioxide and titanium dioxide into the aqueous solution of oxalic acid, adding a bonder into the mixed solution to prepare pulp, impregnating the cordierite honeycomb ceramic in the pulp, drying the cordierite honeycomb ceramic for 1 to 3 hours at 100 to 150 DEG C, and roasting the cordierite honeycomb ceramic for 2 to 4 hours at 450 to 550 DEG C. In the invention, the preparation method is improved, and a powder catalyst is improved into a honeycomb selective catalytic reduction (SCR) catalyst applied to the removal of the oxynitrides from the tail gases of the diesel vehicles, so the high-efficiency catalytic removal of the oxynitrides can be realized at the temperature of 205 to 515 DEG C; and in the presence of steam or SO2, the activity of the catalyst is kept over 80 percent.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

Method for separating tungsten and molybdenum

ActiveCN105200246AEasy to separateThe operation process is easy to controlProcess efficiency improvementTungstateIon-exchange resin

The invention relates to a method for separating tungsten and molybdenum. The method comprises the following steps: (1) adding acid into a tungsten-molybdenum mixed solution and adjusting pH value to obtain mixed sediment of tungsten acid and molybdenum acid; (2) adding hydrogen peroxide and acid into the mixed sediment to form peroxide tungsten acid and peroxide molybdenum acid; (3) heating an obtained mixed solution, adding tungsten powder, reacting and filtering to obtain tungsten acid sediment and a molybdenum-containing acid solution; (4) calcining the prepared tungsten acid to prepare tungsten trioxide or dissolving by using ammonium hydroxide to obtain an ammonium tungstate solution and then evaporating and crystallizing to prepare APT; (5) extracting the molybdenum in the obtained molybdenum-containing acid solution by using an extraction agent / ion exchange resin; and (6) reversely extracting molybdenum-containing organic phase / resin by using ammonium hydroxide to obtain the ammonium molybdate solution, and carrying out acid precipitation to obtain ammonium tetramolybdate. The production process of tungsten-molybdenum products is taken into account in the method, so that the separated tungsten acid or molybdenum can be directly used for preparing the products thereof; the separation effect is excellent; the operation process is simple and is liable to control; the industrial popularization and application are liable to implement.

Owner:CENT SOUTH UNIV

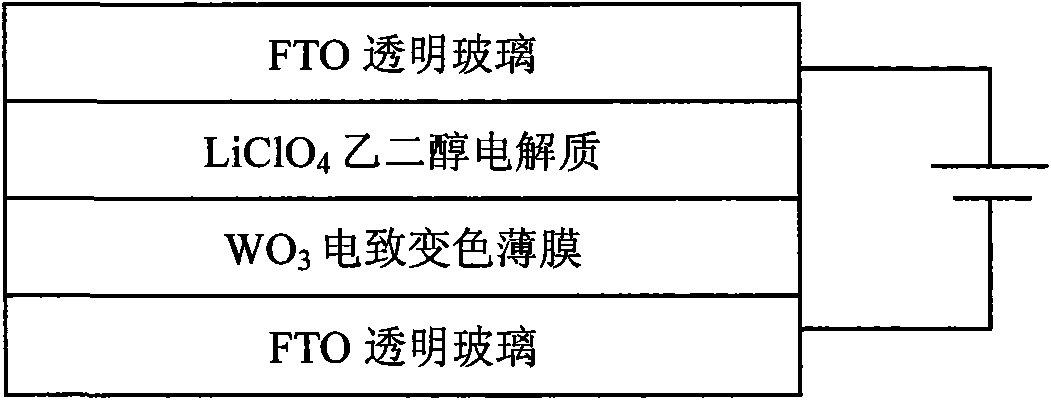

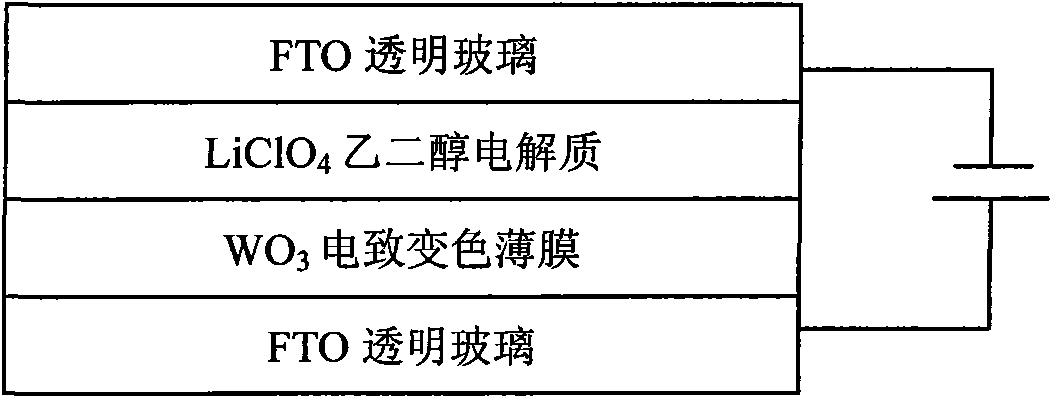

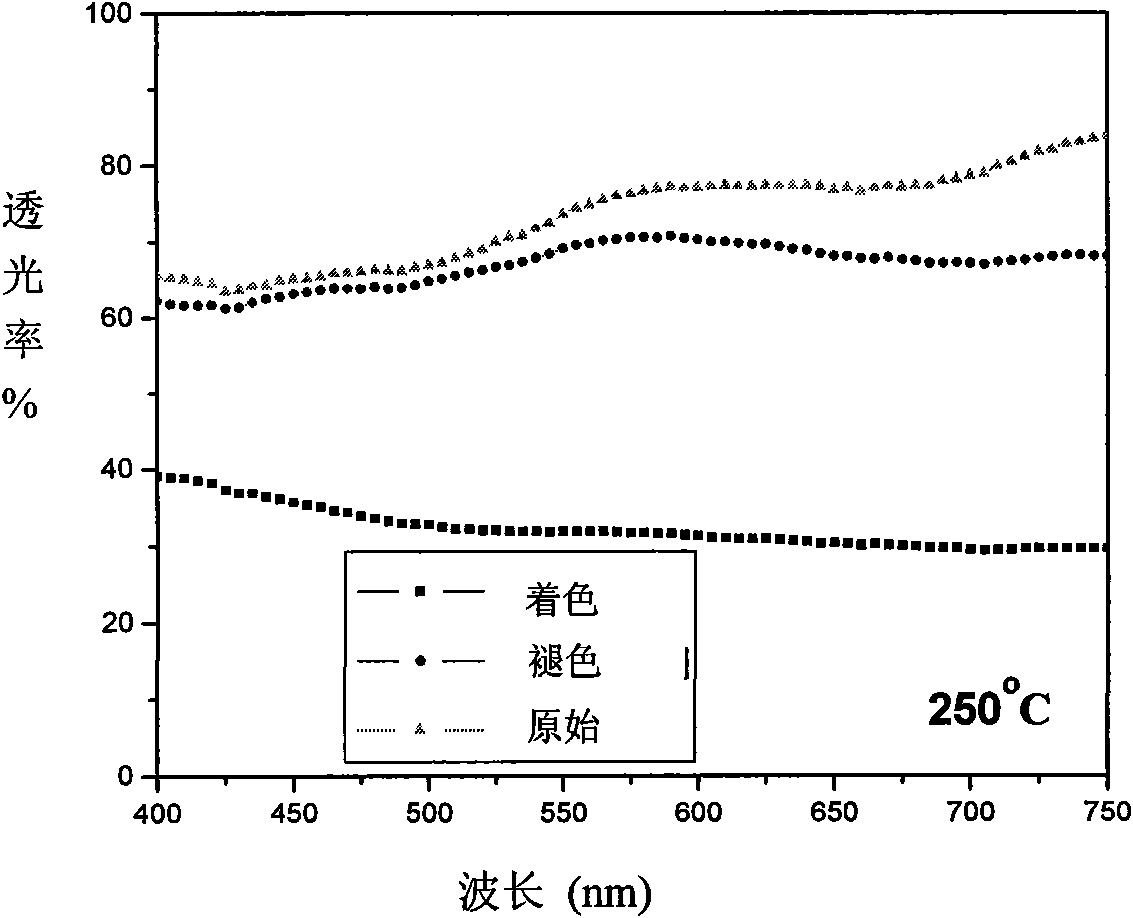

WO3 electrochromic thin film preparation method

A WO3 electrochromic thin film preparation method belongs to electrochromism technology and comprises the following steps of (1) washing a substrate; (2) conducting filtration after tungsten powder reacts with hydrogen peroxide for 5-7 hours in ice-water bath, then adding absolute ethyl alcohol and glacial acetic acid in the filtrate and stirring evenly; (3) using a reflux device for reflux at temperature of 50-60 DEG C for 5-6 hours to obtain uniform and transparent WO3 sol; (4) dipping the substrate of the step (1) in the sol obtained from the step (3) and pulling and drawing the substrate upwards with speed of 2-3cm / min; (5) repeating the step (4) for a plurality of times and then naturally drying the substrate in the air; and (6) heat treating the substrate obtained from the step (5) to obtain the WO3 thin film. The method adopts a sol-gel method to prepare the electrochromic thin film of tungsten trioxide, has simple device, low cost, easy preparation and good coloration efficiency, and is conducive to industrial large-area practical application and popularization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

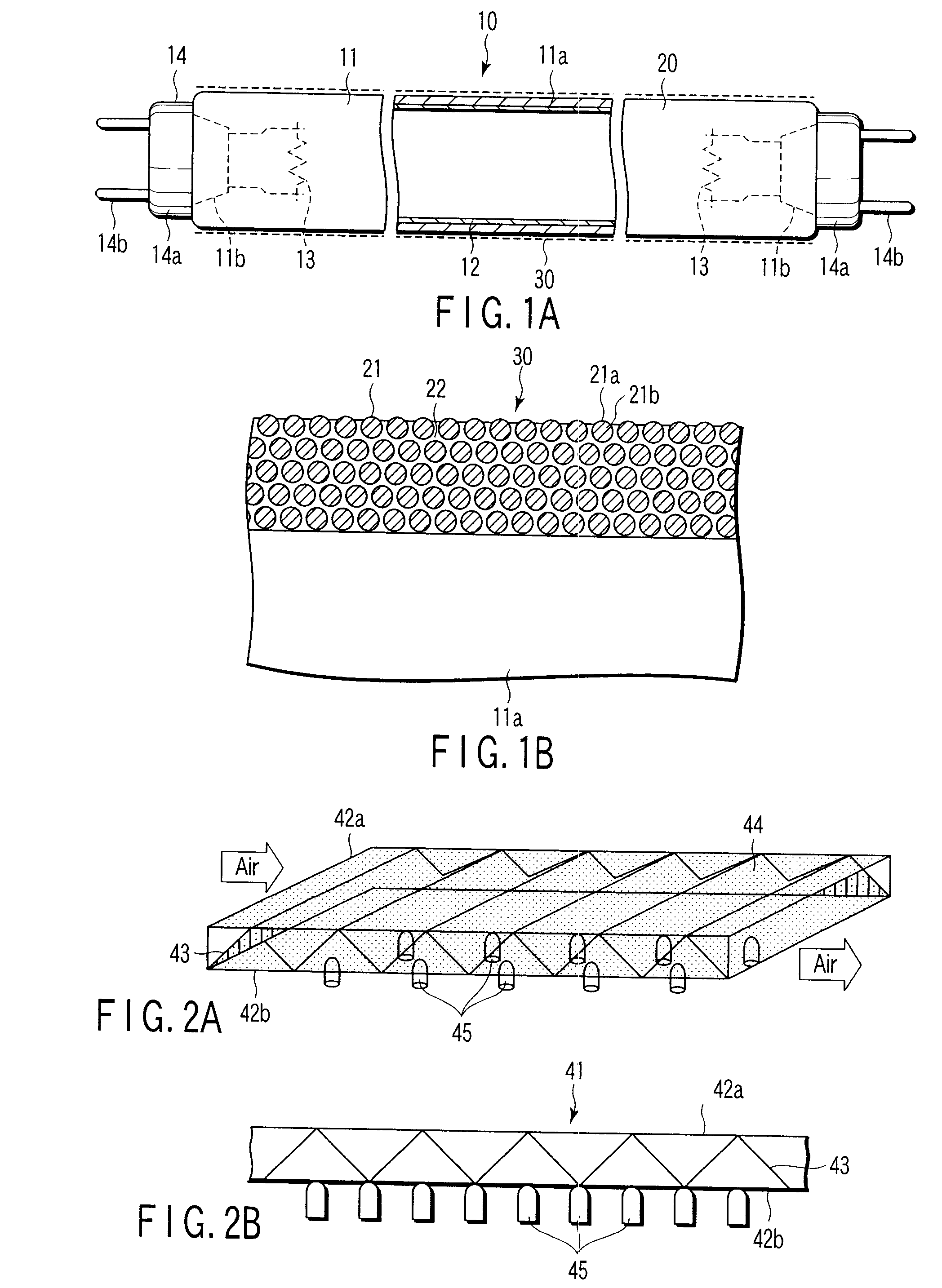

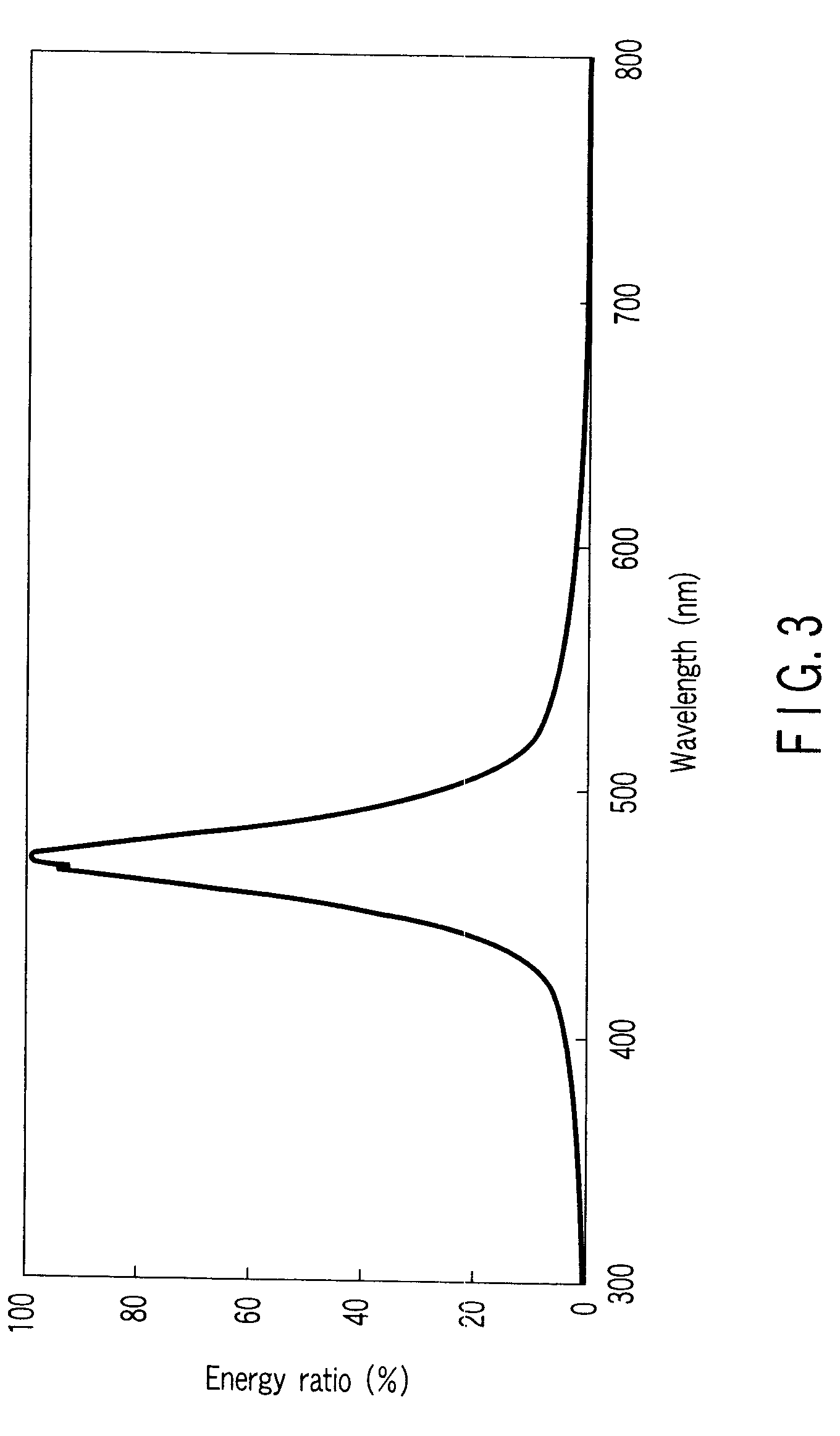

Photocatalytic material, photocatalyst, photocatalytic product, lighting apparatus, and method of producing photocatalytic material

InactiveUS20070177372A1Improve catalytic performanceImprove photocatalytic performanceMaterial nanotechnologyTungsten oxides/hydroxidesMicroparticleTungsten trioxide

A photocatalytic material containing tungsten trioxide fine particles having an average particle diameter of 0.5 μm or smaller and a crystal structure of a monoclinic crystal system as a main component.

Owner:TOSHIBA LIGHTING & TECH CORP

Preparation method of porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element

InactiveCN103424435ASimple methodLow process conditionsMaterial analysis by electric/magnetic meansGas detectorElectrochemical corrosion

The invention discloses a preparation method of a porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element. A porous silicon layer is prepared on a polished surface of a P-type single-side-polished monocrystalline wafer by double-channel electrochemical corrosion; tungsten oxide nanorods are grown in situ on porous silicon by hydrothermal process, so that composite-structure porous silicon-based tungsten trioxide nanorods are obtained; two platinum electrodes are deposited on the surface of the wafer by magnetron sputtering. The novel porous silicon-based tungsten trioxide nanorod composite-structure gas sensor element which has excellent gas-sensitiveness features, such as simplicity in preparation process, ease of control, capability of detecting nitride oxide gas at the room temperature and high flexibility, is provided.

Owner:TIANJIN UNIV

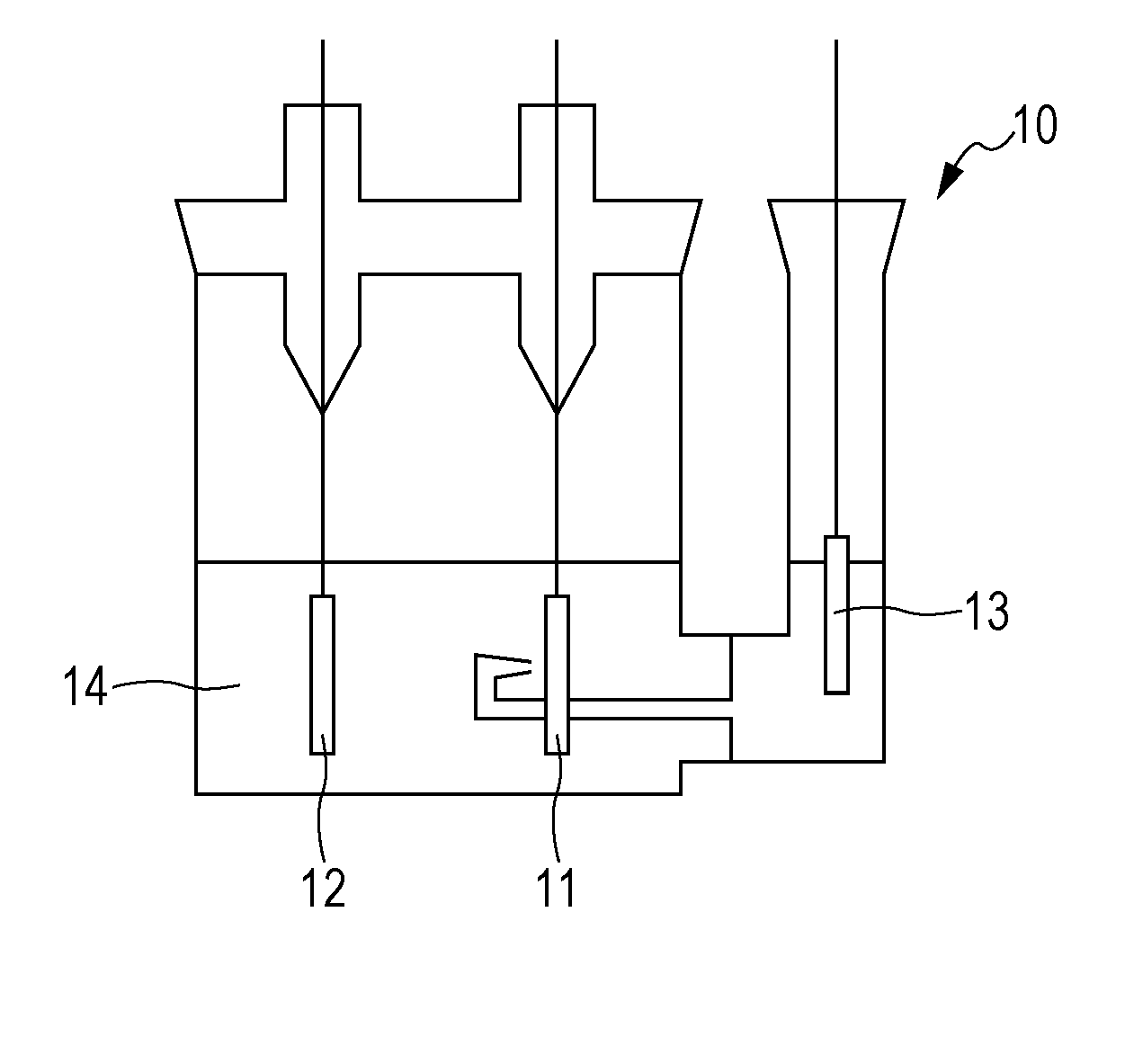

Nonaqueous electrolyte secondary battery

InactiveUS20140329146A1Improve output characteristicsGood effectPositive electrodesNon-aqueous electrolyte accumulator electrodesLithiumEngineering

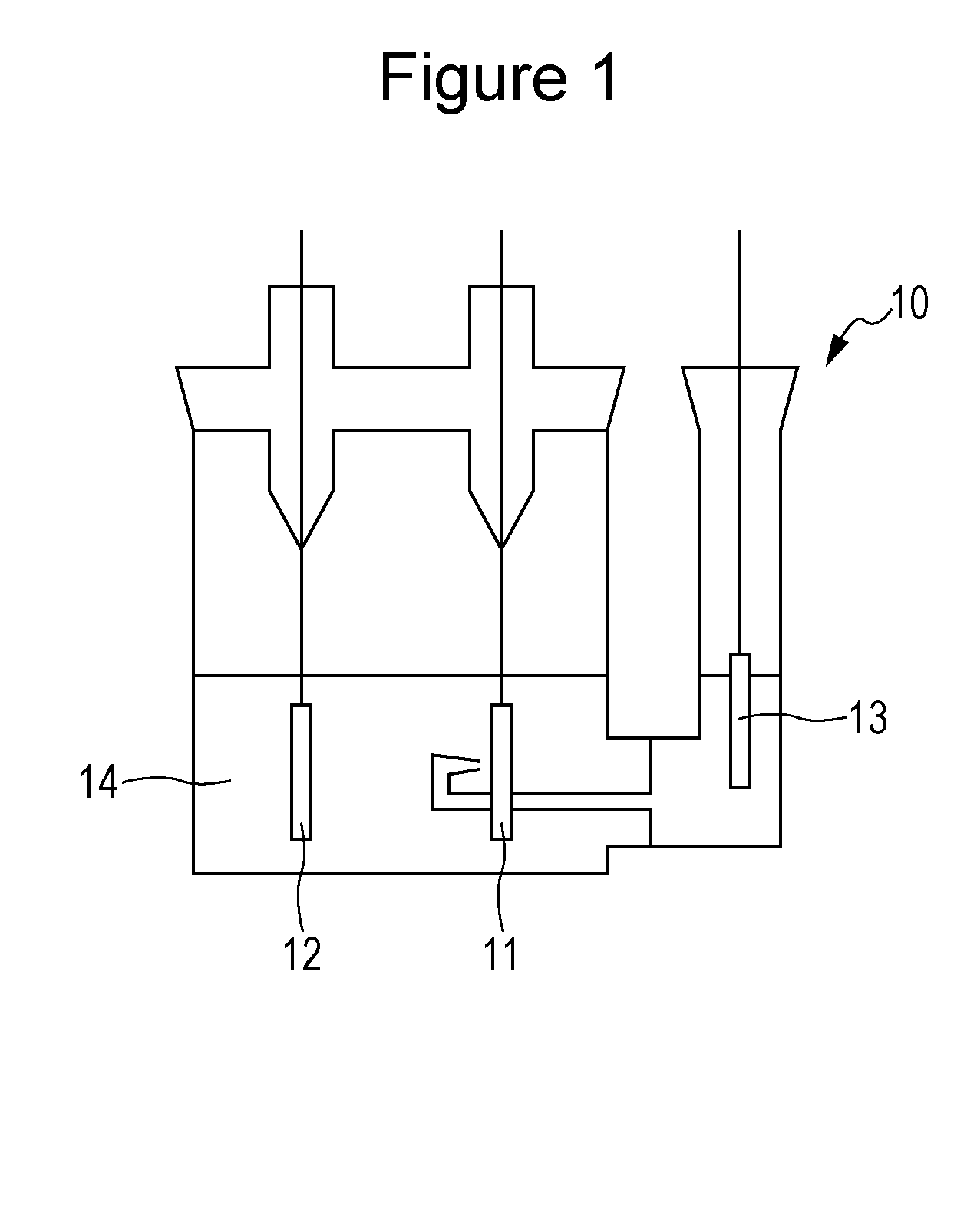

A positive-electrode active material of a nonaqueous electrolyte secondary battery is modified to improve the output characteristics under various temperature conditions, thereby making the nonaqueous electrolyte secondary battery suitable for a power supply for hybrid vehicles. The nonaqueous electrolyte secondary battery includes a working electrode 11, a counter electrode 12 containing a negative-electrode active material, and a nonaqueous electrolyte solution 14. In the working electrode 11, a positive-electrode mixture layer containing a granular positive-electrode active material and a binder is disposed on both sides of a positive-electrode collector. The positive-electrode active material contains a lithium transition metal oxide Li1.07Ni0.46Co0.19Mn0.28O2 and a tungsten trioxide attached to part of the surface of the lithium transition metal oxide.

Owner:SANYO ELECTRIC CO LTD

Method for preparing nano tungsten trioxide powder

The invention discloses a method for preparing nanometer tungstic oxide nanopowder. The method for producing the high-quality nanometer WO3 powder with high efficiency comprises the following steps: according to the rate of 1 to 1, 13.4 to15mol / L of ammonia and deionized water are prepared into the needed ammonia solution; tungstenic acid is dissolved into the prepared ammonia solution; citric acid which has the molar ratio with the tungstenic acid by 2 to 4 times is added into the solution, is heated at the temperature of between 80 and 90 DEG C and is stirred for 8 to 12 hours to obtain a yellowish transparent gel; the prepared gel is positioned in an infrared oven for roasting till brown expanded gel is obtained; and the gel obtained by the steps is calcined in a chamber furnace at the temperature of between 550 and 650 DEG C to obtain yellow nanometer tungstic oxide powder. Compared with the prior art, the method has the advantages of simple and feasible process,, less environmental pollution, less erosion to equipment and relatively low production cost.

Owner:SOUTHWEST JIAOTONG UNIV

Recovery method of waste SCR (Selective Catalytic Reduction) catalyst, recovery cleaning fluid and catalyst prepared from recovered catalyst

InactiveCN103962189AAchieve recyclingEmission reductionCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFatty alcohol

The invention discloses a recovery method of a waste SCR (Selective Catalytic Reduction) catalyst, recovery cleaning fluid and a catalyst prepared from the recovered catalyst. Effective cleaning for a waste honeycomb type SCR catalyst is realized with cleaning fluid prepared from an isomeric C13 fatty alcohol-polyoxyethylene ether emulsifier and hydrofluoric acid and by an ultrasonic cleaning method; the waste honeycomb type SCR catalyst is crushed, cleaned and ground, and is mixed with titanium dioxide, tungsten trioxide, glass fibers and vanadium pentoxide, so that the waste SCR catalyst incapable of working continuously becomes a material for producing a fresh catalyst and is recycled. The method is easy to operate, the production cost can be obviously reduced, the emission of pollutants is reduced, and the performance of the product prepared from the waste catalyst recovery material is the same as that of a new product. The product has an environment-friendly effect, and recycling of the waste catalyst is realized.

Owner:CHENGDU DONGFANG KWH ENVIRONMENTAL PROTECTION CATALYSTS

Tungsten trioxide nano-film with photocatalytic performance, and preparation method thereof

ActiveCN103708559ALarge specific surface areaIncrease profitMaterial nanotechnologyTungsten oxides/hydroxidesNanopillarPhotocatalytic water splitting

The invention discloses a tungsten trioxide nano-film with photocatalytic performance, and a preparation method thereof. The tungsten trioxide nano-film is characterized in that a WO3 nano layer with a WO3 nano structure is grown on a WO3 crystal seed layer, and the WO3 nano structure is shaped like a two-dimensional flying saucer including a middle main sheet and a nano-column. The preparation method of the tungsten trioxide nano-film comprises the steps of preparing a tungsten acid crystal seed layer precursor solution, preparing FTO (Fluorine-doped Tin Oxide) conductive glass with the crystal seed layer, preparing thermal tungsten acid solvent precursor solution, and finally performing hydrothermal synthesis to obtain the tungsten trioxide nano-film. According to the tungsten trioxide nano-film with photocatalytic performance, and the preparation method thereof, the specific surface area of the WO3 nano layer can be effectively enlarged; the efficiency of photocatalytic water splitting can be improved, the performance of photocatalytic water splitting in a photoelectric chemical pool is excellent, and excellent chemical stability can be achieved, the preparation method is simple, and the low-cost and large-scale application can be realized.

Owner:TIANJIN UNIV

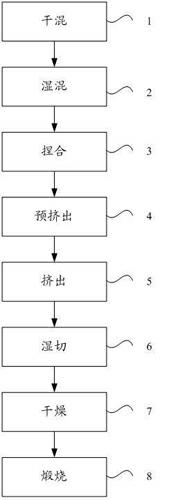

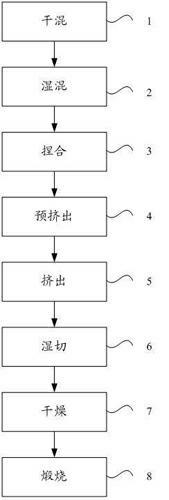

Recycling method of denitration catalyst waste and denitration catalyst prepared from denitration catalyst waste

InactiveCN102049317ALarge specific surface areaEasy to operateDispersed particle separationCatalyst activation/preparationGlass fiberPtru catalyst

The invention relates to the field of denitration catalyst, in particular to a recycling method of denitration catalyst waste. The recycling method comprises the following concrete steps: calcining unqualified denitration catalyst or denitration catalyst waste at the temperature of 500-700 DEG C for 10-20 hours; and grinding the calcined product into powder with particle size of 40-350 microns to obtain the recycled material of denitration catalyst. A method for preparing the denitration catalyst from the denitration catalyst waste comprises the steps of mixing, extruding, drying and calcining titanium dioxide, tungsten trioxide, denitration recycled material, vanadium pentoxide, glass fiber, citric acid solution and rare earth oxide by a conventional method. By adopting the recycling method, the operation is simple, and the production cost can be obviously lowered; the product prepared from the recycled material has the advantages of large specific area, large pore volume, strong compressive resistance and low wear rate; the catalyst is environment-friendly; and the waste is turned into wealth.

Owner:CHONGQING YUANDA CATALYST MFG

Method for preparing titanium dioxide nanotube array photoelectrode

ActiveCN103361689ANo pollution in the processImprove stabilitySurface reaction electrolytic coatingSolubilityVisible light photocatalytic

The invention discloses a method for preparing a titanium dioxide nanotube array photoelectrode. The method comprises the following steps of: 1, pretreating a titanium sheet; 2, by taking the pretreated titanium sheet as a substrate, preparing a titanium dioxide nanotube array by employing a constant current constant voltage anodic oxidation method; 3, calcining and cooling the titanium dioxide nanotube array, and obtaining a titanium dioxide nanotube array with different crystal structures; 4, by taking graphite powder as a raw material, preparing oxidized graphene with water solubility; 5, by taking the titanium dioxide nanotube array in the step 3 as a working electrode, taking a platinum electrode as a counter electrode, performing pulse deposition reduction in sodium tungstate and oxidized graphene solutions of different concentrations by utilizing a three-electrode system; 6, calcining the prepared photoelectrode under the vacuum condition of 100-300 DEG C to prepare graphene and tungsten trioxide modified titanium dioxide nanotube array photoelectrode. The raw materials in the preparation process are non-toxic, the preparation conditions are mild, the prepared electrode has high stability, the photocatalytic activity is high, and the electrode is environmentally-friendly and has high visible-light catalytic activity.

Owner:QINGDAO AGRI UNIV

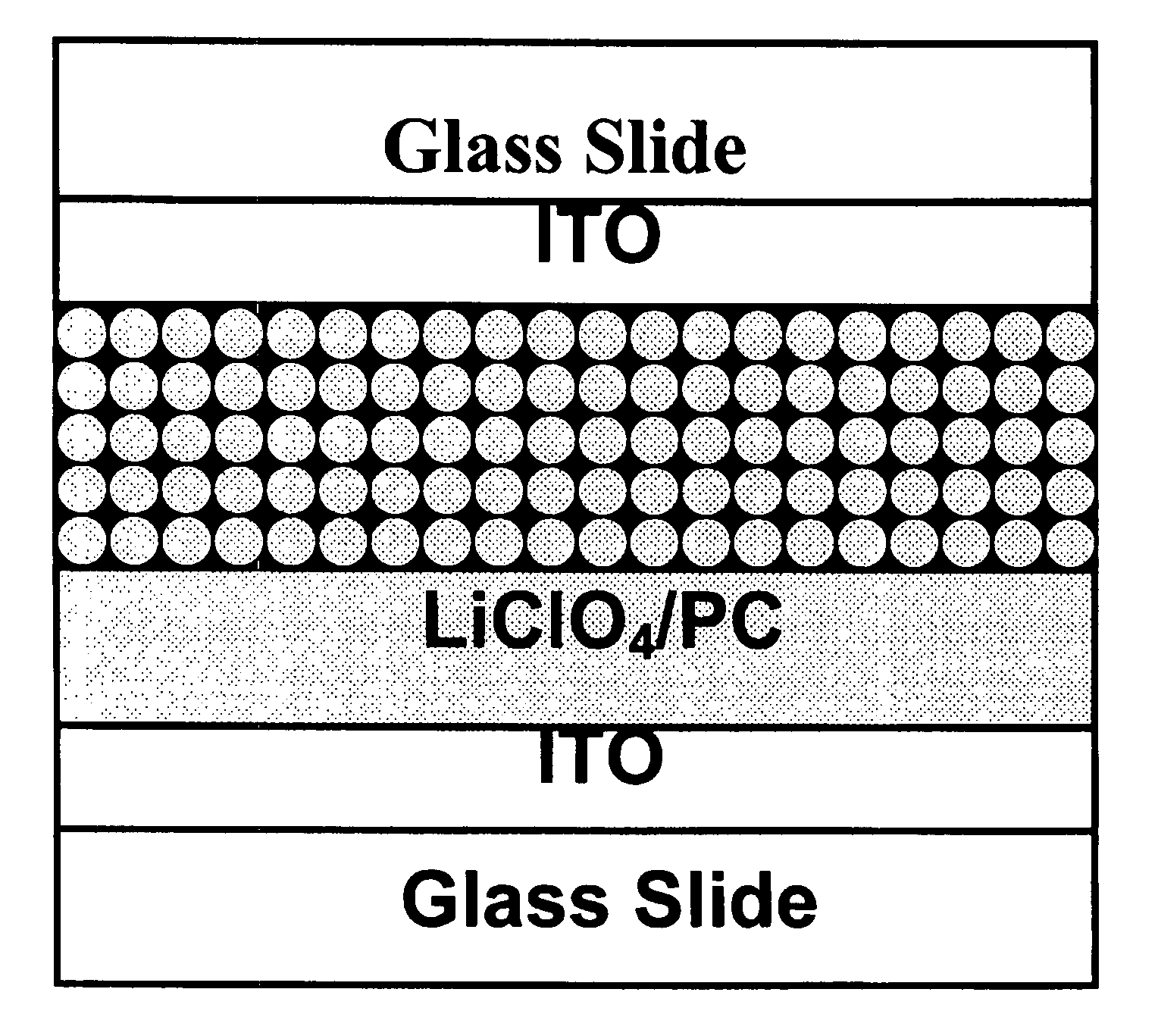

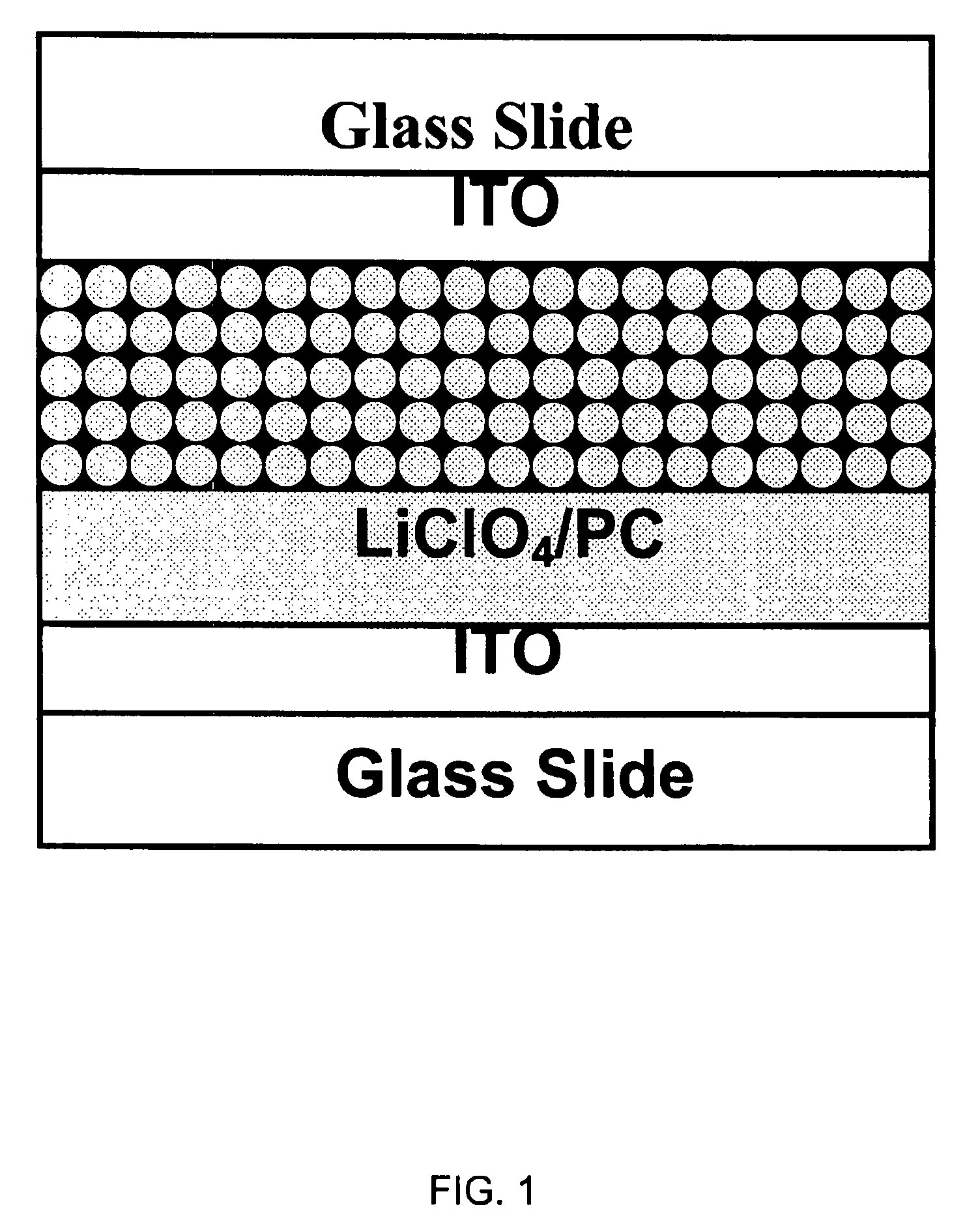

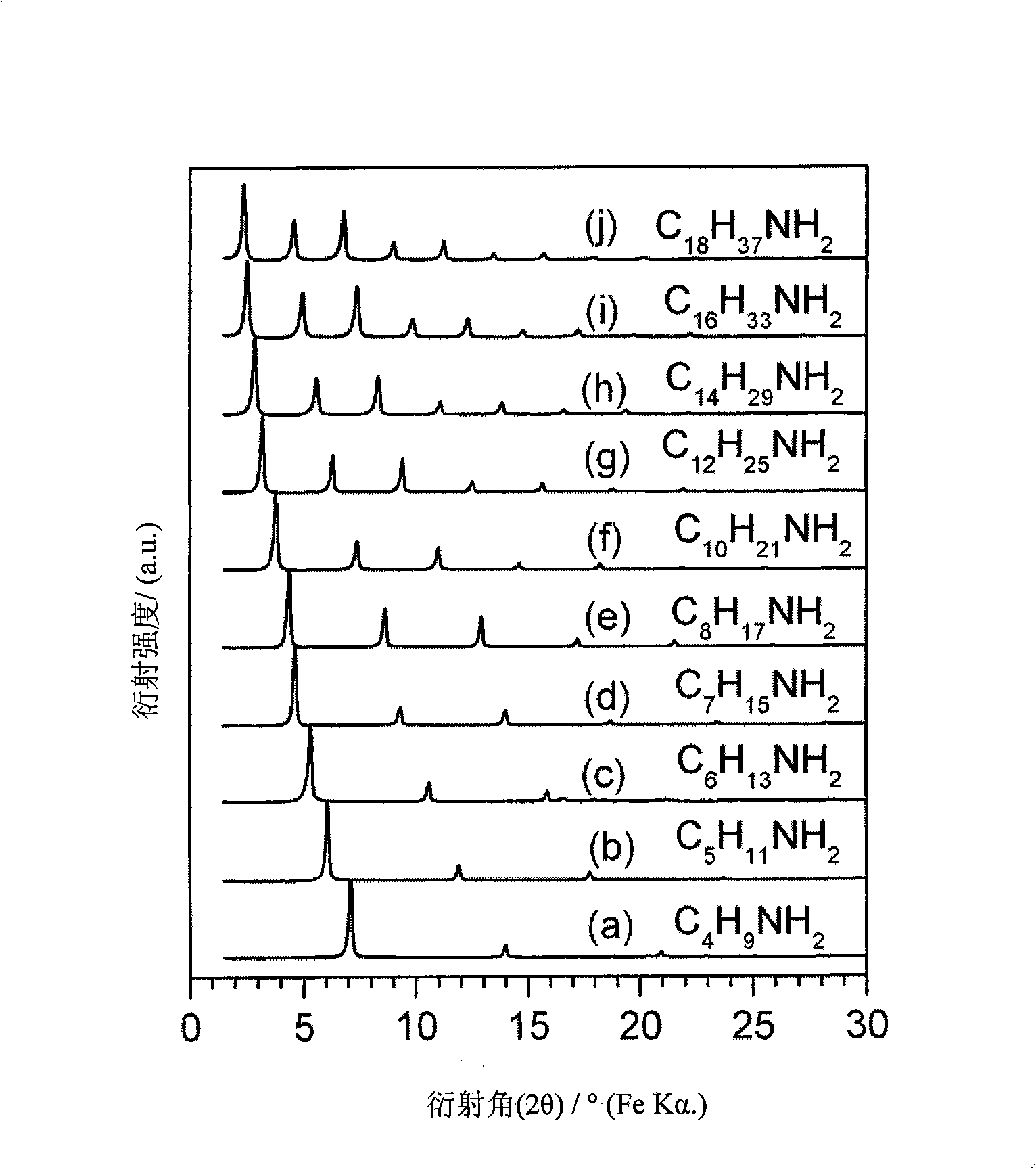

Chromogenically tunable photonic crystals

Owner:UNIVERSITE DE MONCTON

Catalytic agent for denitrating smoke and preparation technology thereof

ActiveCN102166516AGuaranteed denitrification effectImprove denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSurface-active agentsCoal

The invention provides a catalytic agent for denitrating smoke and a preparation technology thereof. The catalytic agent for denitrating the smoke comprises the raw materials based on parts by weight as follows: 60%-90% of titanium dioxide, 3%-9% of tungsten trioxide, 0.5-3% of vanadium pentoxide, 2%-5% of organic binder, 10%-20% of inorganic binder, 7%-10% of glass fiber, 2%-4% of plasticizer, 20%-40% of water, 2%-4% of lubricant, 0.1%-1% of surface active agent and 3%-9% of neutralizer. After the content of the tungsten trioxide is reasonably proportioned, on the premise of guaranteeing thedenitration performance of the catalytic agent for denitrating the smoke, the absorption to sulfur dioxide is reduced, the SO2 / SO3 conversion percentage is reduced, and the high-sulfur and high-ash use requirement of the coal quality in China is met.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

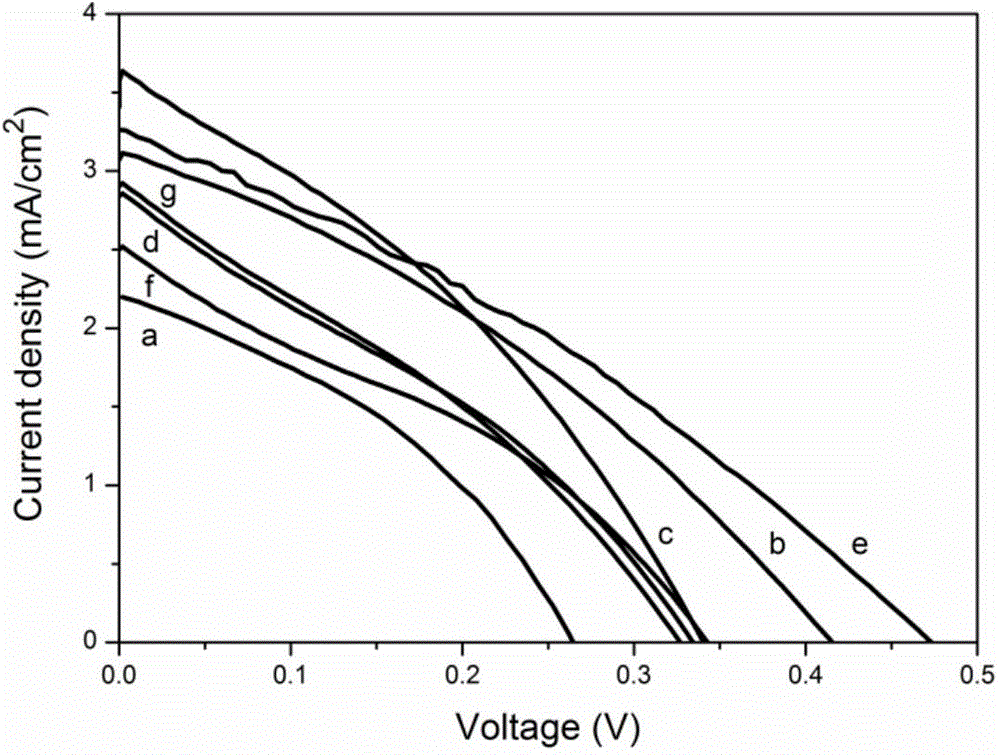

Dye-sensitized solar cell photo-anode and preparing method and application thereof

InactiveCN104465102AIncrease the potential gapSimple processLight-sensitive devicesPhotovoltaic energy generationAtomic orbitalDopant

The invention discloses a dye-sensitized solar cell photo-anode and a preparing method and application of the dye-sensitized solar cell photo-anode. The preparing method of the dye-sensitized solar cell photo-anode includes the following steps that heat treatment is carried out on a dopant and tungsten trioxide in acid to prepare powder, wherein the dopant is oxide or salt of metal M, the metal M can enter lattices of the tungsten trioxide after being dissolved in the acid, and the atomic orbital and the W5d orbital of the metal M can be hybridized; slurry is prepared from the powder; the surface of a conducting substrate is coated with the slurry to prepare the dye-sensitized solar cell photo-anode. The preparing method is simple in technology, and the prepared dye-sensitized solar cell photo-anode is applied to a dye-sensitized solar cell and has good photoelectric performance and good industrialization application prospects.

Owner:CENT SOUTH UNIV

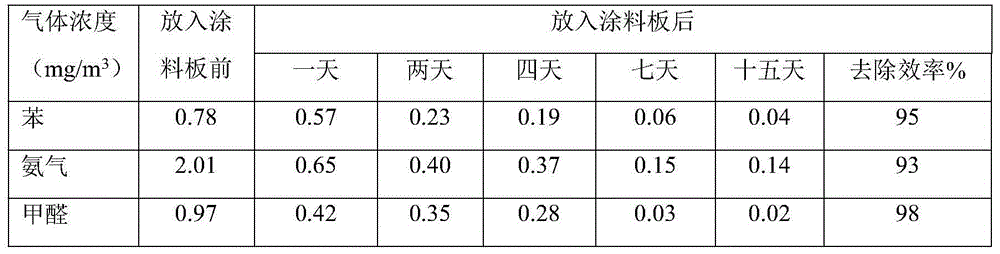

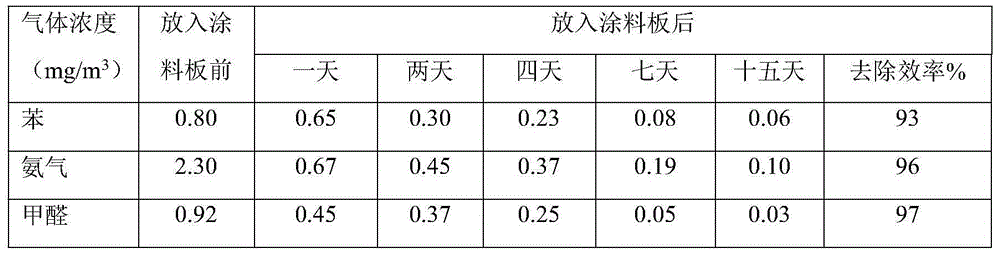

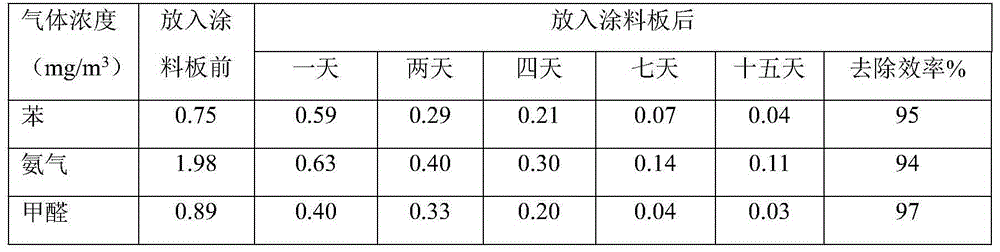

Diatomite coating capable of decomposing formaldehyde

InactiveCN104830161ALow costAvoid affecting the rate of decomposition of harmful gasesHyaluronic acid coatingsChitin coatingsOrganic compoundMaterials science

The invention discloses a diatomite coating capable of decomposing formaldehyde and relates to the field of coatings. The diatomite coating comprises the following components in percentage by mass: 5%-15% of titanium dioxide, 3%-10% of nano-titanium dioxide, 2%-8% of white carbon black, 1%-3% of nano-calcium carbonate, 2%-5% of nano-silicon dioxide, 6%-18% of nano-tungsten trioxide, 2%-8% of sepiolite material, 5%-7% of chitin, 3%-6% of graphene oxide, 0.5%-1.3% of mica powder, 1%-7% of nano-activated carbon, 0.1%-0.5% of a phthalocyanin compound and the balance of diatomite. The diatomite in the diatomite coating is capable of quickly decomposing organic compounds, purifying air and effectively improving the quality of indoor air; meanwhile, the indoor negative ion concentration can be increased, which is beneficial to the human body health.

Owner:胡世所

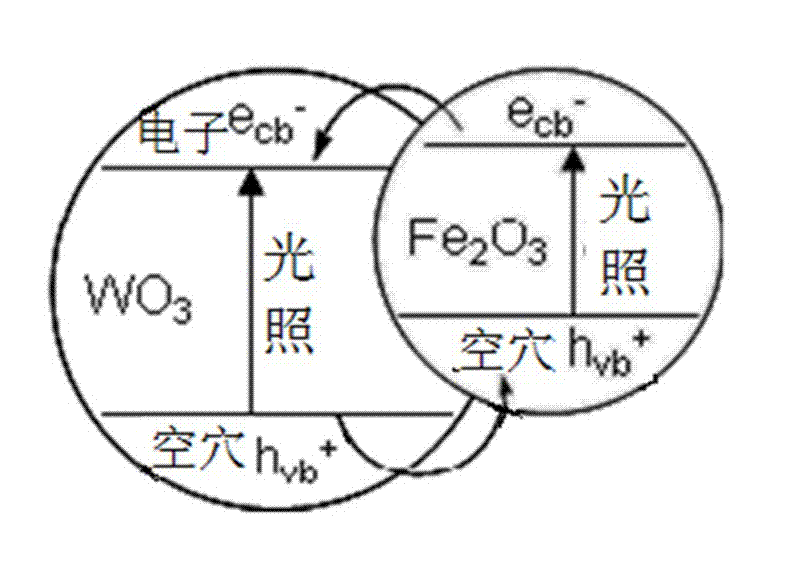

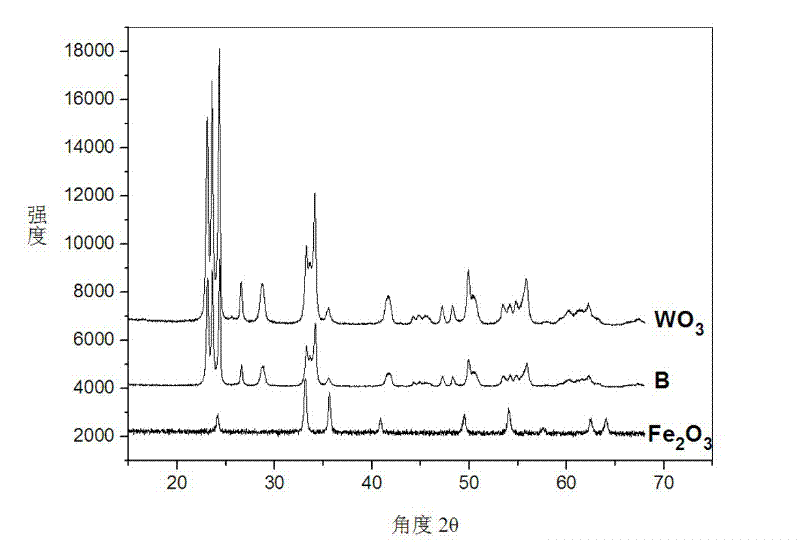

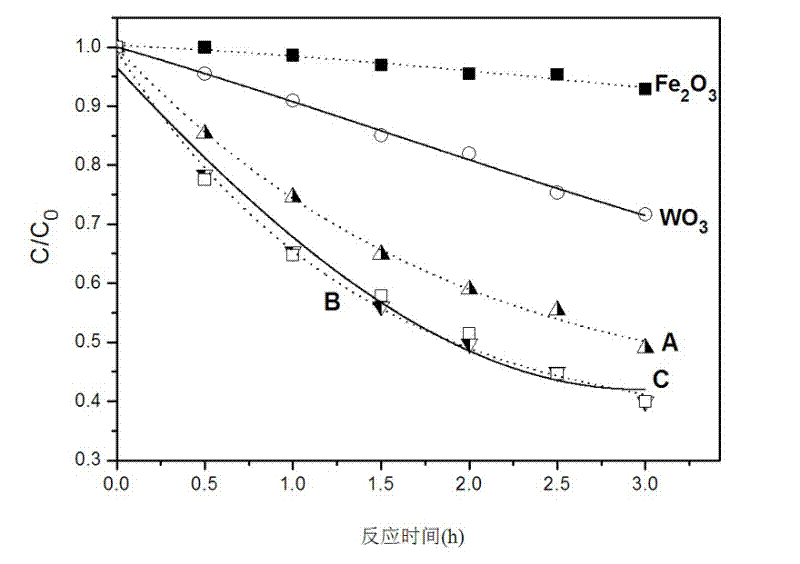

Iron-doped tungsten trioxide photocatalyst and preparation method thereof

InactiveCN102266783ALow costEasy to operateMetal/metal-oxides/metal-hydroxide catalystsPtru catalystUltraviolet lights

The invention provides an iron-doped tungsten trioxide photocatalyst. The photocatalyst comprises tungsten trioxide powder particles, and the tungsten trioxide powder particles comprise iron oxide with different contents and states. The photocatalyst of the invention has a significantly increased photocatalytic rate. The invention also provides a preparation method of the iron-doped tungsten trioxide photocatalyst; tungsten-containing and iron-containing compounds are used as precursors; the raw materials are finally transformed into forms of WO3 and iron oxide by processes of mixing the two compounds, grinding, high-temperature calcining and the like; and the iron oxide is distributed in WO3 in different forms so as to obtain the iron-doped tungsten trioxide photocatalyst. The raw materials used by the invention have low cost, and the equipment is simple and easy to operate; when the obtained photocatalyst is compared with simple tungsten trioxide and iron oxide, the photocatalytic activity in ultraviolet light and visible light is increased by several times.

Owner:ZHEJIANG UNIV

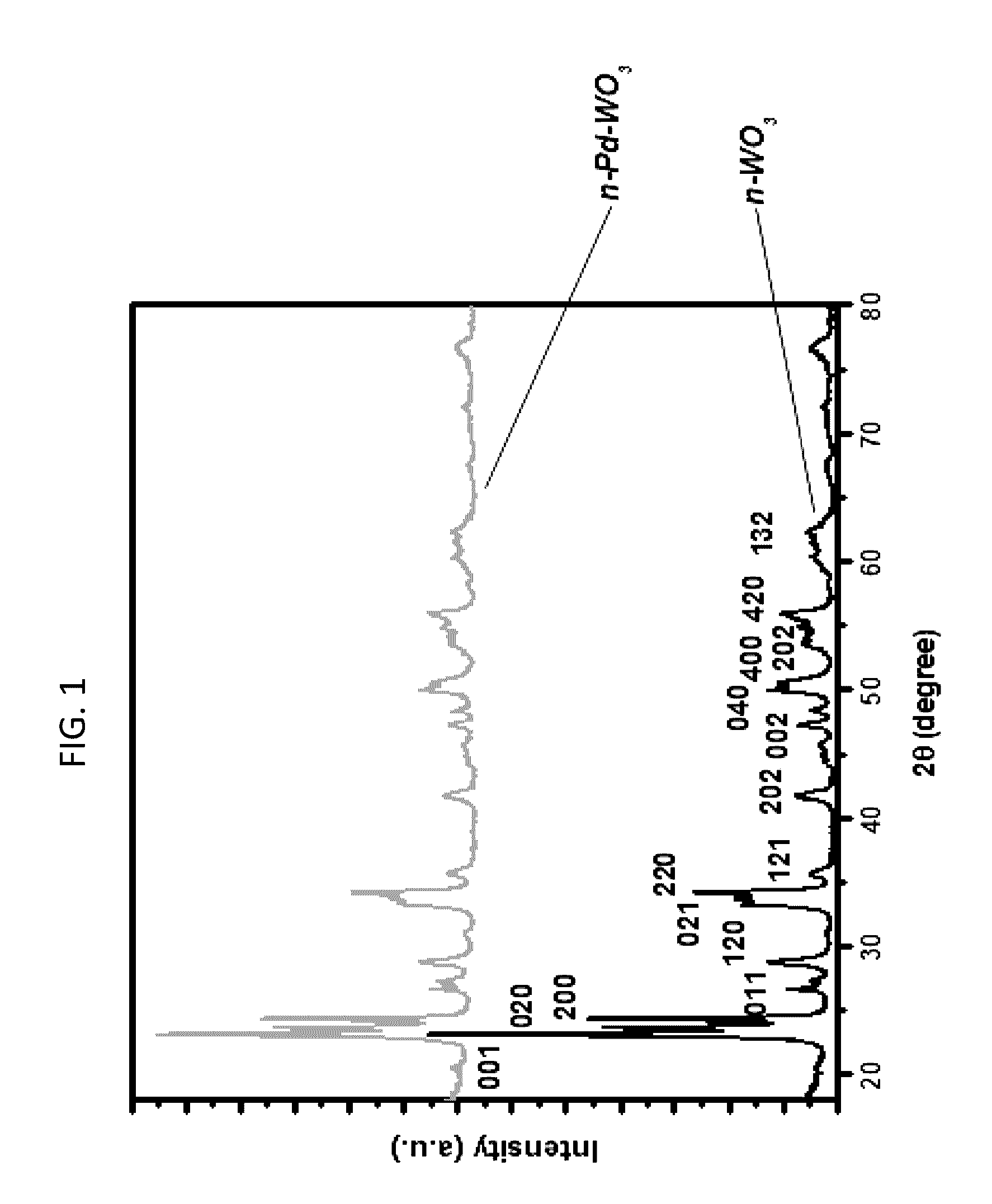

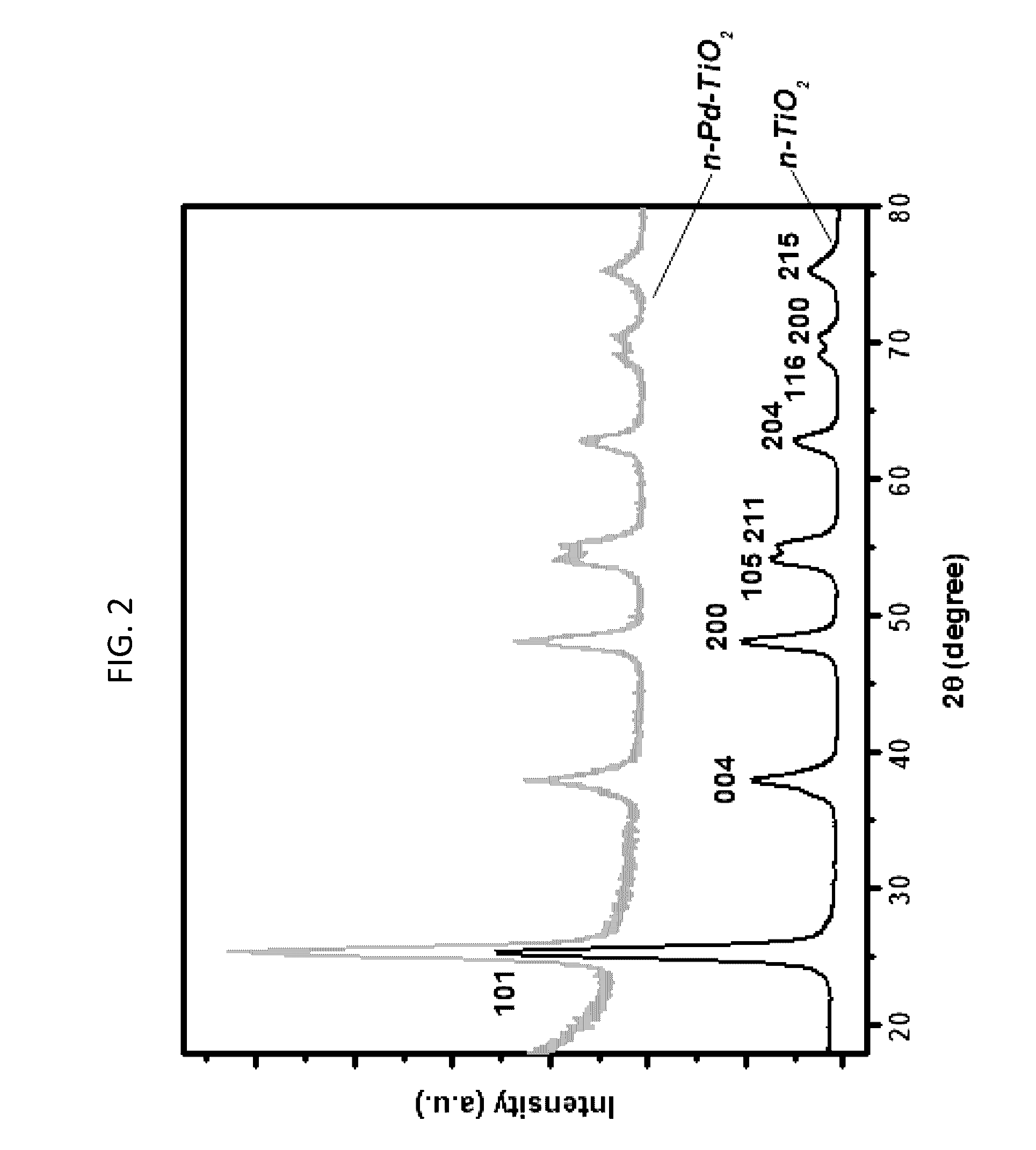

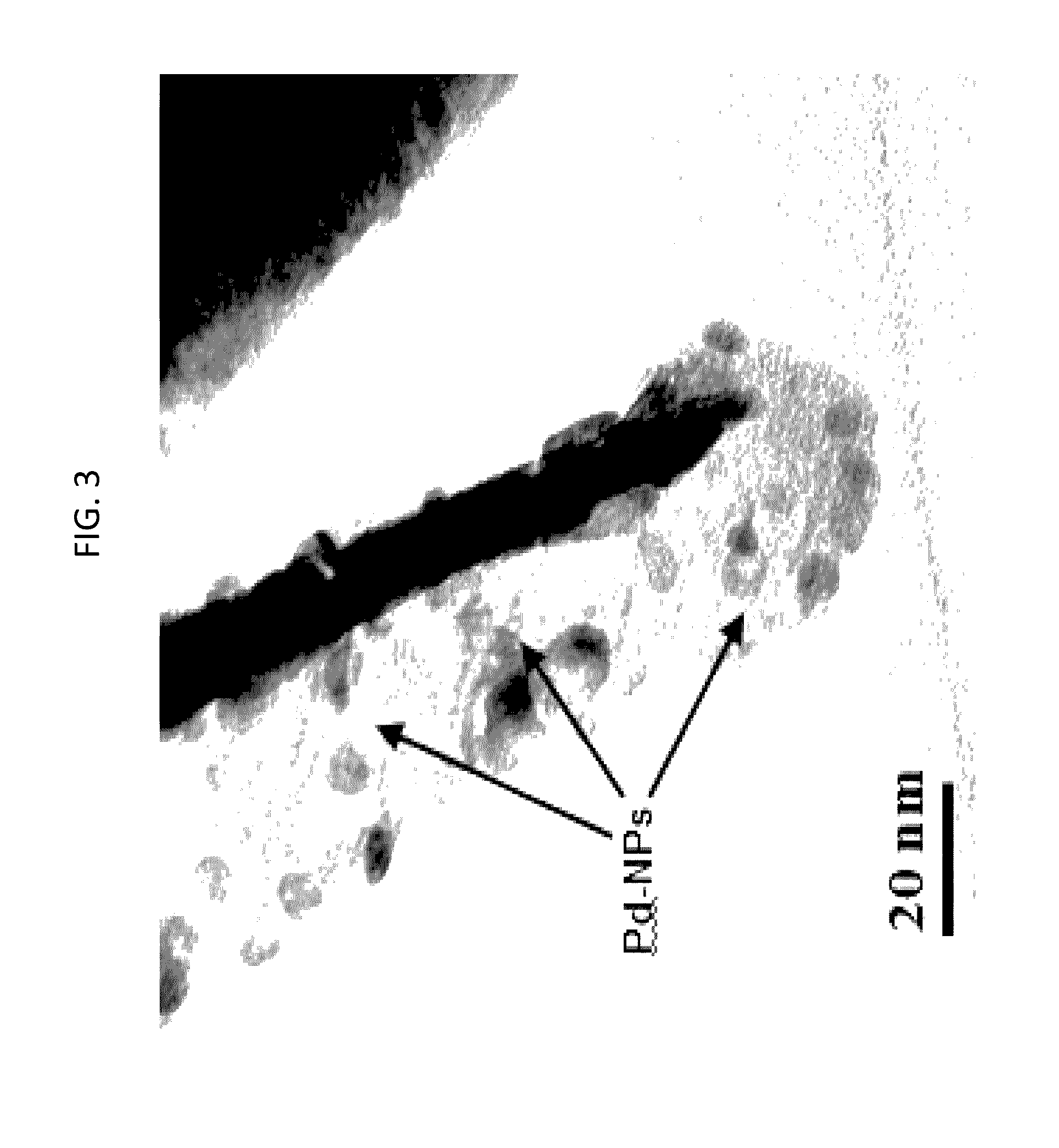

Method for disinfecting a fluid with a palladium-doped tungsten trioxide photo-catalyst

InactiveUS20160355409A1Reduce in quantityWater/sewage treatment by irradiationWater treatment compoundsNanoparticleTungsten trioxide

The present disclosure relates to a method of disinfecting a fluid comprising at least one live microbial organism. The method includes contacting the fluid comprising the at least one microbial organism with an effective amount of a photo-catalyst while exposing the fluid and the photo-catalyst to light from at least one light source with a wavelength of about 300-550 nm to reduce the number of the at least one live microbial organism to a predetermined level. The photo-catalyst comprises tungsten trioxide nanoparticles doped with palladium nanoparticles, and the palladium nanoparticles are present in an amount of about 0.1-5% of the total weight of the tungsten trioxide nanoparticles and the palladium nanoparticles.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Tungstic trioxide nano-slice and preparation method thereof

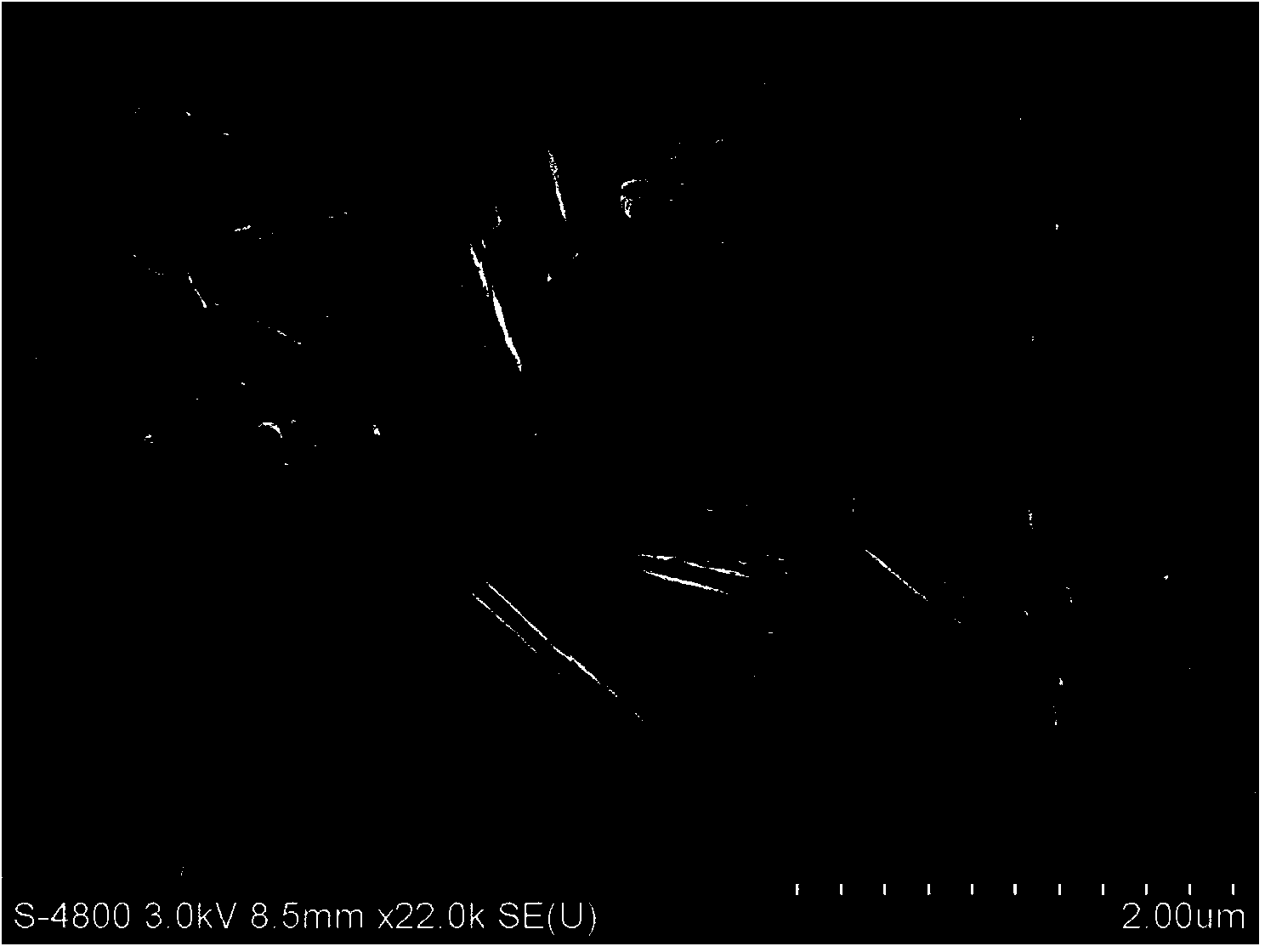

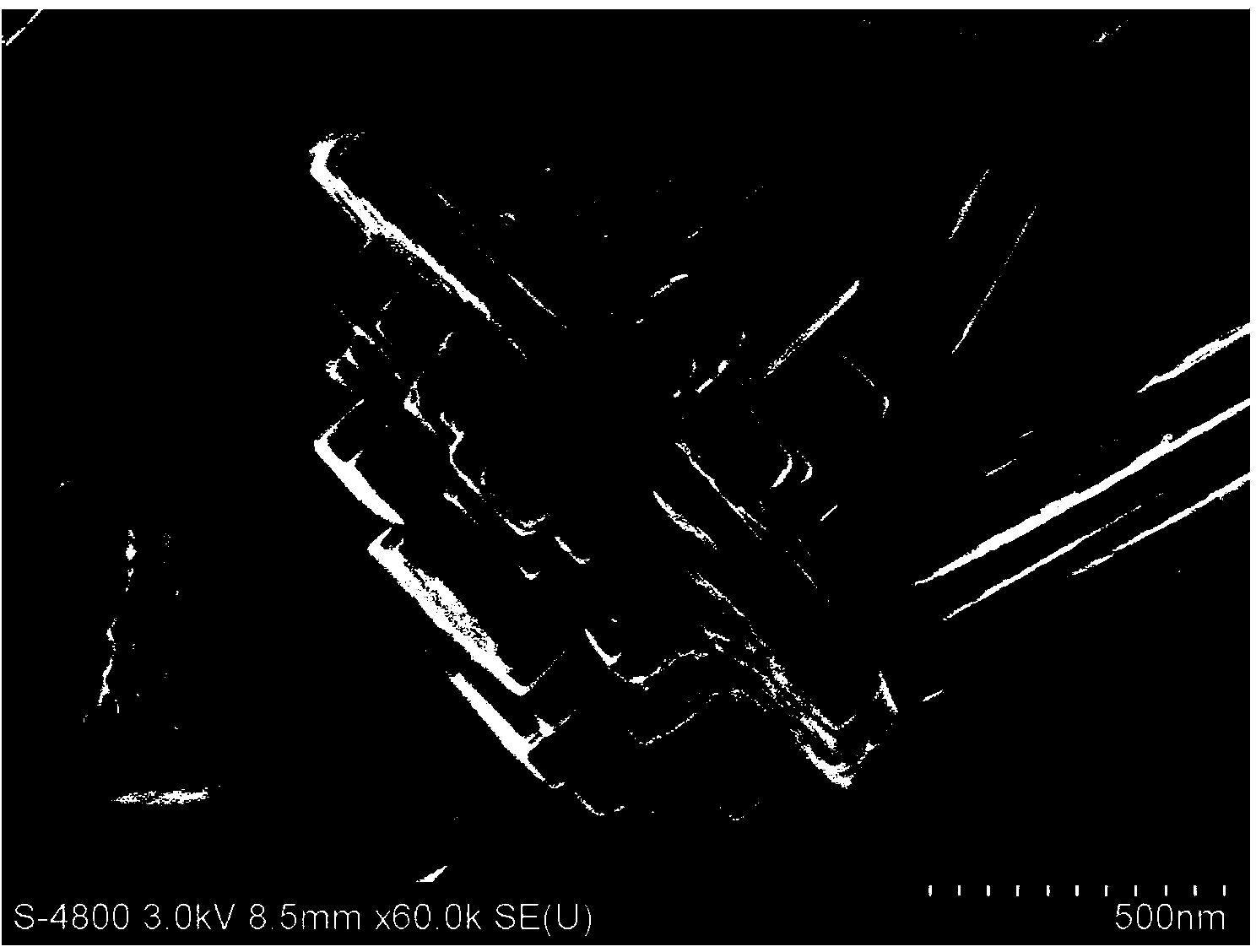

InactiveCN101318702AImprove efficiencyPerformance is not affectedNanostructure manufactureTungsten oxides/hydroxidesReaction temperatureSingle crystal

The invention relates to a tungsten trioxide (WO3) nano-plate and a preparation method thereof. The tungsten trioxide (WO3) nano-plate is characterized in that: the tungsten trioxide (WO3) nano-plate is monocrystal and monoclinic phase (JCPDS No.43-1035), and is shaggy and flocculent; the area is (100-800)nmx(100-800)nm; the apparent thickness is between 5 and 40 nanometers; and the BET specific surface area can reach 100-250 square meters per gram. The preparation method for the tungsten trioxide (WO3) nano-plate comprises the following steps that: a tungstenic acid organic or inorganic laminated mixed micron / nano belt (pipe) is taken as a precursor, and organic substances between precursor layers are removed through oxidation by a nitric acid, and then a tungstenic acid (WO3.H2O) nano-plate is prepared; the reaction temperature is between 15 and 50 DEG C, and the reaction time is between 5 and 120 hours; the tungstenic acid (WO3.H2O) nano-plate is heated up to between 250 and 600 DEG C at a heating rate of between 1 and 5 DEG C per minute, undergoes heat insulation for 1 to 5 hours, and finally naturally cooled to the room temperature so as to remove crystal water, and the tungsten trioxide nano-plate is prepared. The method has a simple technological process, a large variation range of operating parameters, strong adaptability, low facility requirement, controllable appearance of products, high repeatability, high efficiency and low cost.

Owner:ZHENGZHOU UNIV

Preparation method for high-performance transparent glass heat-insulating coating

ActiveCN102559025AImprove insulation performanceHigh transparencyPolyurea/polyurethane coatingsUltravioletSlurry

The invention discloses a preparation method for a high-performance transparent glass heat-insulating coating, comprising the following steps of: preparing a novel high-performance transparent mixed nano-slurry mixed and dispersed by blue WO3 (tungsten trioxide), ATO (antimony tin oxide) and ITO (indium tin oxide) at first, and then mixing, stirring and filtering by transparent polyurethane resinto obtain the transparent glass heat-insulating coating with high heat-insulating performance. The high-performance transparent glass heat-insulating coating prepared by the method disclosed by the invention has super-strong transparency, heat insulation and ultraviolet-preventing performance, and especially has very high heat-insulating performance in a near-infrared area ranging from 780 to 900nm; and the high-performance transparent glass heat-insulating coating can be widely applied to production for high-performance heat-insulating glass and high-performance heat-insulating window membrane, as well as has very important social and economic values.

Owner:上海沪正实业有限公司

Polymeric composition suitable for manufacturing pasteurizable containers

InactiveUS20090035502A1Improve thermal stabilityImprove barrier propertiesLayered productsFibre treatmentPolymer sciencePolyethylene naphthalate

A polymeric composition suitable for manufacturing pasteurizable containers comprising, polyethylene terephthalate (PET) in the ratio of about 80 to about 95 mass % by mass of the total composition; polyethylene naphthalate (PEN) in the ratio of about 20 to about 5 mass % by mass of the total composition; tungsten trioxide in the range of 10 to 100 ppm by mass of the composition and particle size of 2 to 20 microns; and optionally a nucleating agent and a polycondensation catalyst.

Owner:FUTURA POLYESTERS LTD PARAGON CONDOMINIUM

Electrochromic film adopting amorphous/crystalline tungsten trioxide core-shell structure and preparation method of film

InactiveCN105060733ALarge spectrum adjustment rangeImprove cycle performanceAmmonium sulfateChemistry

The invention discloses an electrochromic film adopting an amorphous / crystalline tungsten trioxide core-shell structure and a preparation method of the film. The method comprises steps as follows: white tungstic acid is dissolved in a hydrogen peroxide solution, the mixture is applied to a conductive surface of a conductive substrate, and a conductive substrate covered with a crystal seed layer is obtained; a tungsten source is dissolved in water, the pH value is adjusted, ammonium sulfate is added, a precursor solution is formed, a reaction is conducted in the precursor solution at the temperature of 150-250 DEG C for 4-10 h, and a tungsten trioxide nanowire array film is obtained. The tungsten source is dissolved in the water, the hydrogen peroxide is dropwise added, the pH value is adjusted, an electrodeposition solution is formed, and the film can be obtained through electrodeposition of amorphous tungsten oxide with a constant voltage method. The film prepared with the preparation method has the nanowire core-shell coating morphology, is good in electric connectivity and has the advantages of large spectrum adjusting range, high coloration efficiency and long cycle life, meanwhile, the preparation technology is convenient to control, the production cost is lower, massive production can be realized, and industrialization is easy to realize.

Owner:ZHEJIANG UNIV

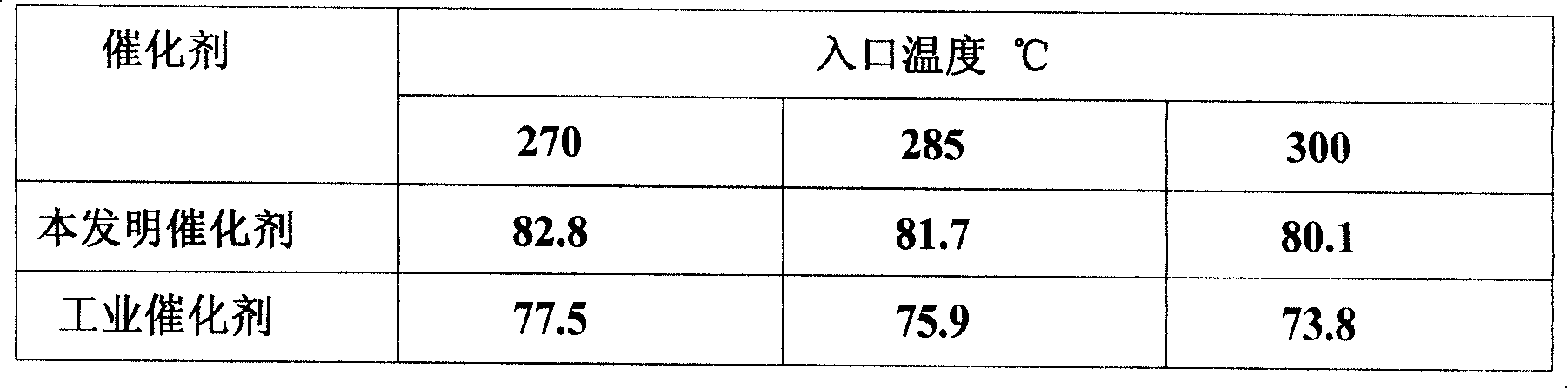

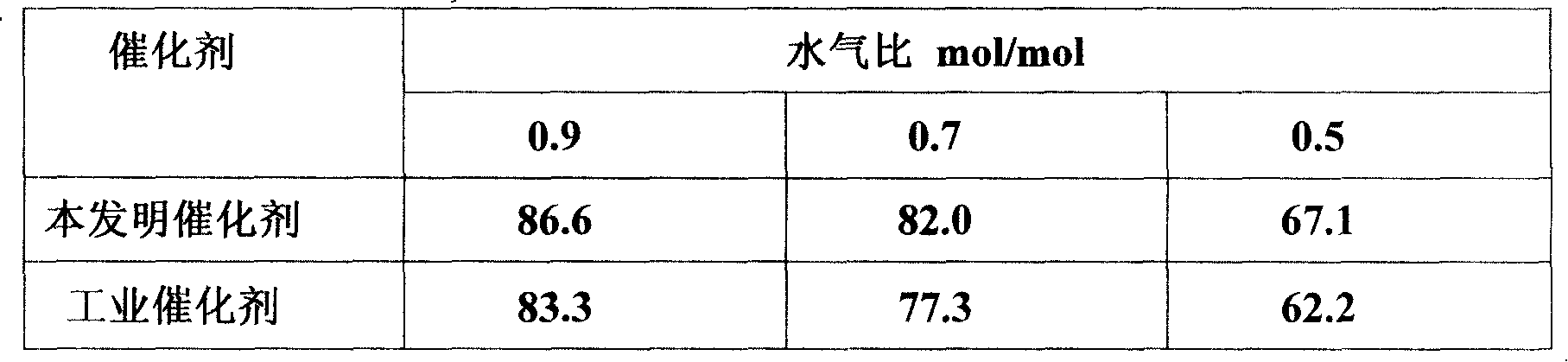

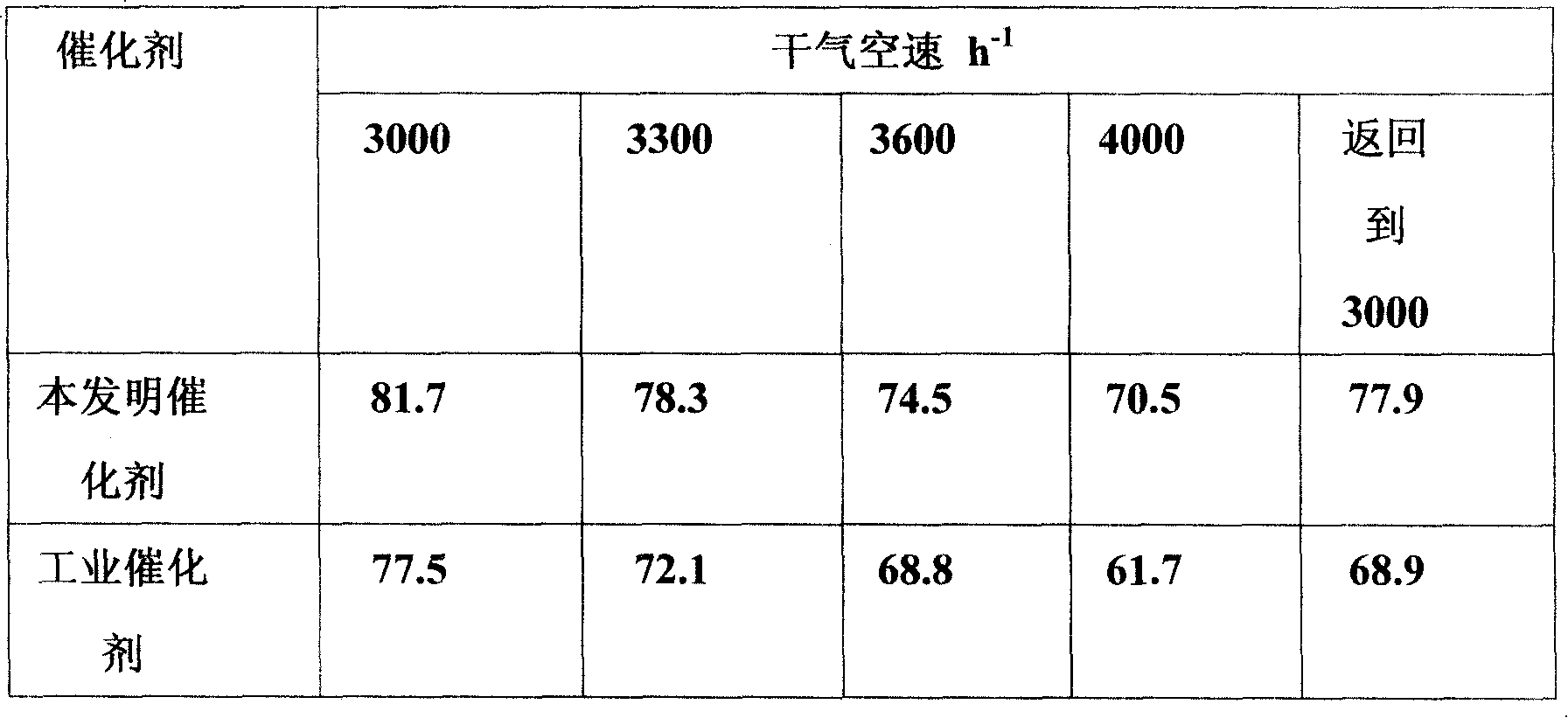

Polynary metal oxide catalyst and preparing process thereof

ActiveCN101199933AHigh activityHigh low temperature activityCatalyst carriersCombined combustion mitigationCerium(IV) oxideManganese

The invention discloses a multi-complex-metal-oxides catalyst and the preparation method. The catalyst carrier is multi-complex-metal-oxides solid alkali or surface solid alkali or the precursors of the solid alkali or surface solid alkali. The multi-complex-metal-oxides is complex oxides by combining two or more than two selections from alumina, titania, zirconium dioxide and ceria with one or more than one selections from magnesia, calcium oxide, baryta, potassium oxide and sodium oxide. Active ingredient is composed of cobalt oxides or / and nickel oxide and molybdenum trioxide or / and tungsten trioxide. The additive added to carriers or active components is the oxide of at least one of the following elements: cerium, lanthanum, zinc, zirconium, nickel or manganese. The invention has the advantages of high activity, high activity at low-temperature, high activity stability and wide temperature range of activity; high intensity, high intensity stability and high anti-hydration and anti-pulverization ability, wide water / gas ratio adaptability and wide range for impurity content. The catalyst of the invention is applied to the promotion of dirty water gas shift reaction.

Owner:汤海溶 +2

Dust removal and waste gas decomposition double-effect filter material and preparation method thereof

ActiveCN102512878AHigh catalytic activityImprove permeabilitySynthetic resin layered productsDispersed particle separationFiberDecomposition

The invention discloses a dust removal and waste gas decomposition double-effect filter material and a preparation method thereof. The filter material comprises a raw felt, catalyst powder and a coating. The filter material utilizes the raw felt as a carrier, the catalyst powder is adhered to the inside of the raw felt, and the coating is coated on the surface of the raw felt and is of a polytrifluorochloroethylene microporous film structure. The catalyst powder is in a grade of nanometer or micron and is selected from one or more of vanadium pentoxide, vanadium trioxide, tungsten trioxide, titanium dioxide and manganese dioxide. By utilizing the preparation method to prepare the filter material, the process is simple and easy to implement, and processing costs of preparation of catalyticfibers, film covering and the like are reduced. In addition, compared with a polytetrafluoroethylene microporous film, running resistance is low, and difficulties in follow-up sewing, transportation,installation and the like of the filter material are reduced simultaneously.

Owner:南京际华三五二一环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

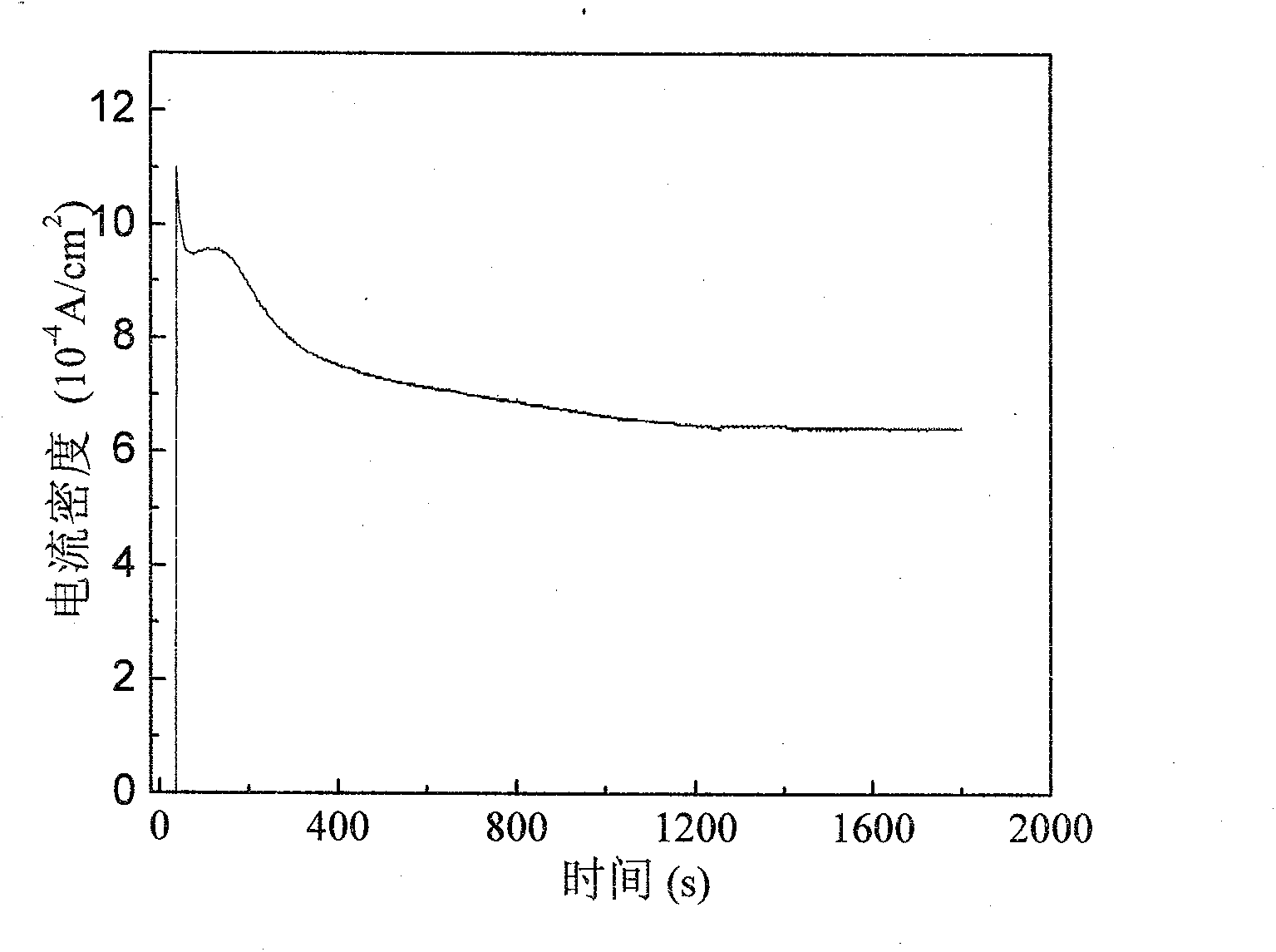

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449421.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449422.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449423.PNG)