Patents

Literature

373results about How to "Improve surface topography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

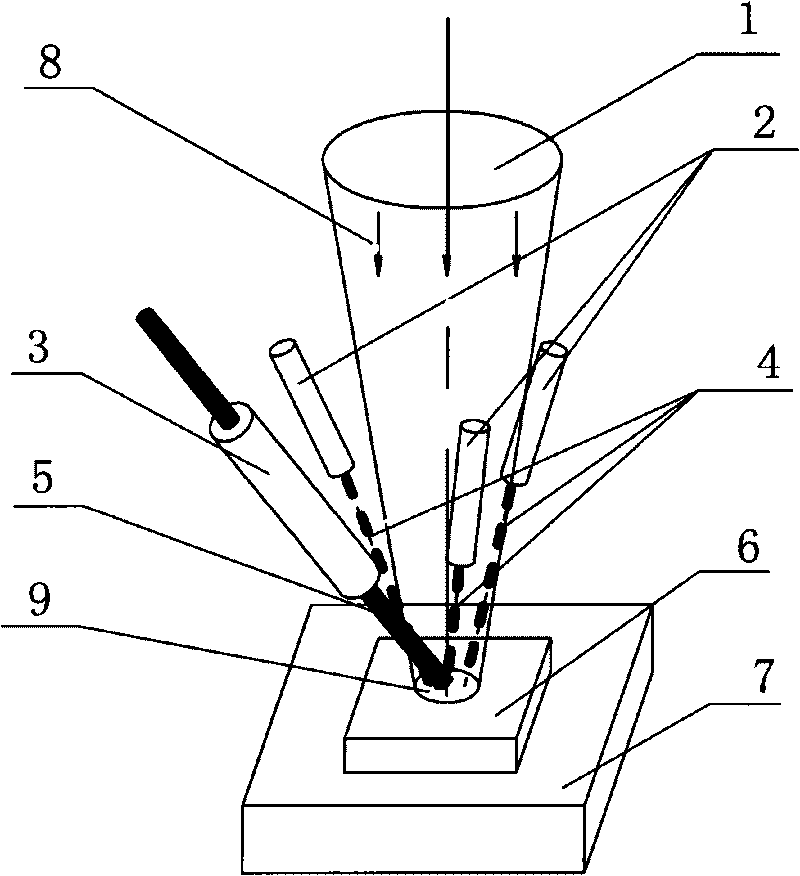

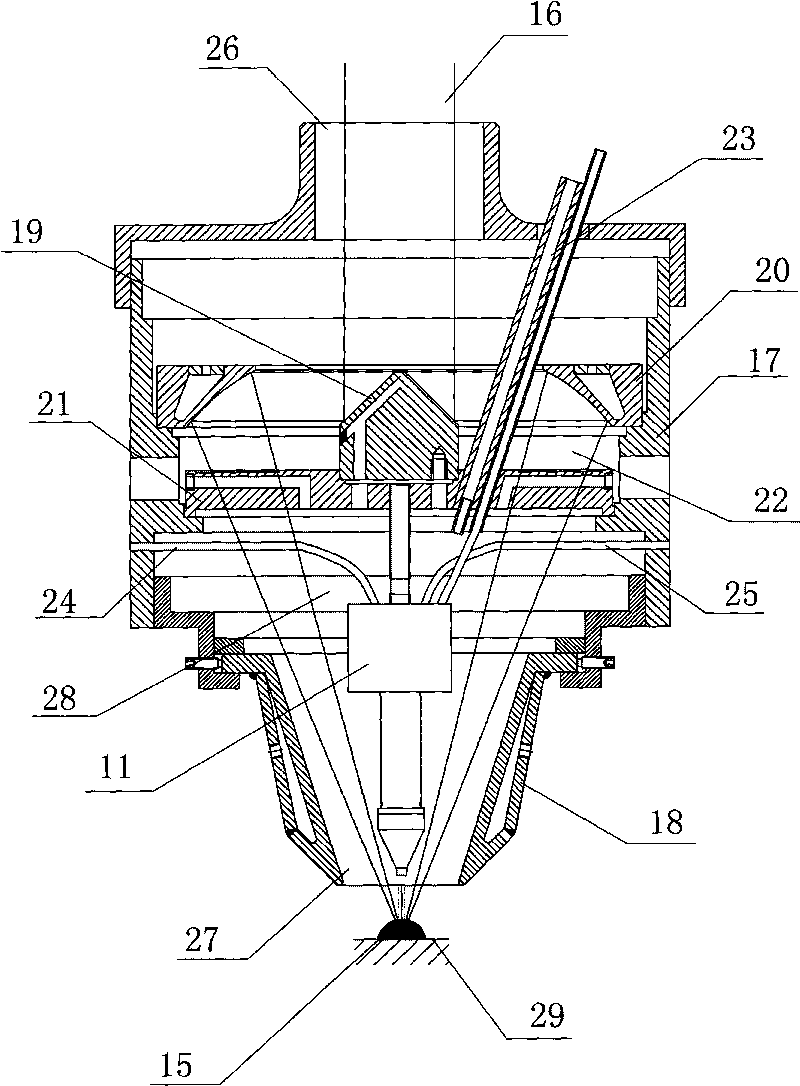

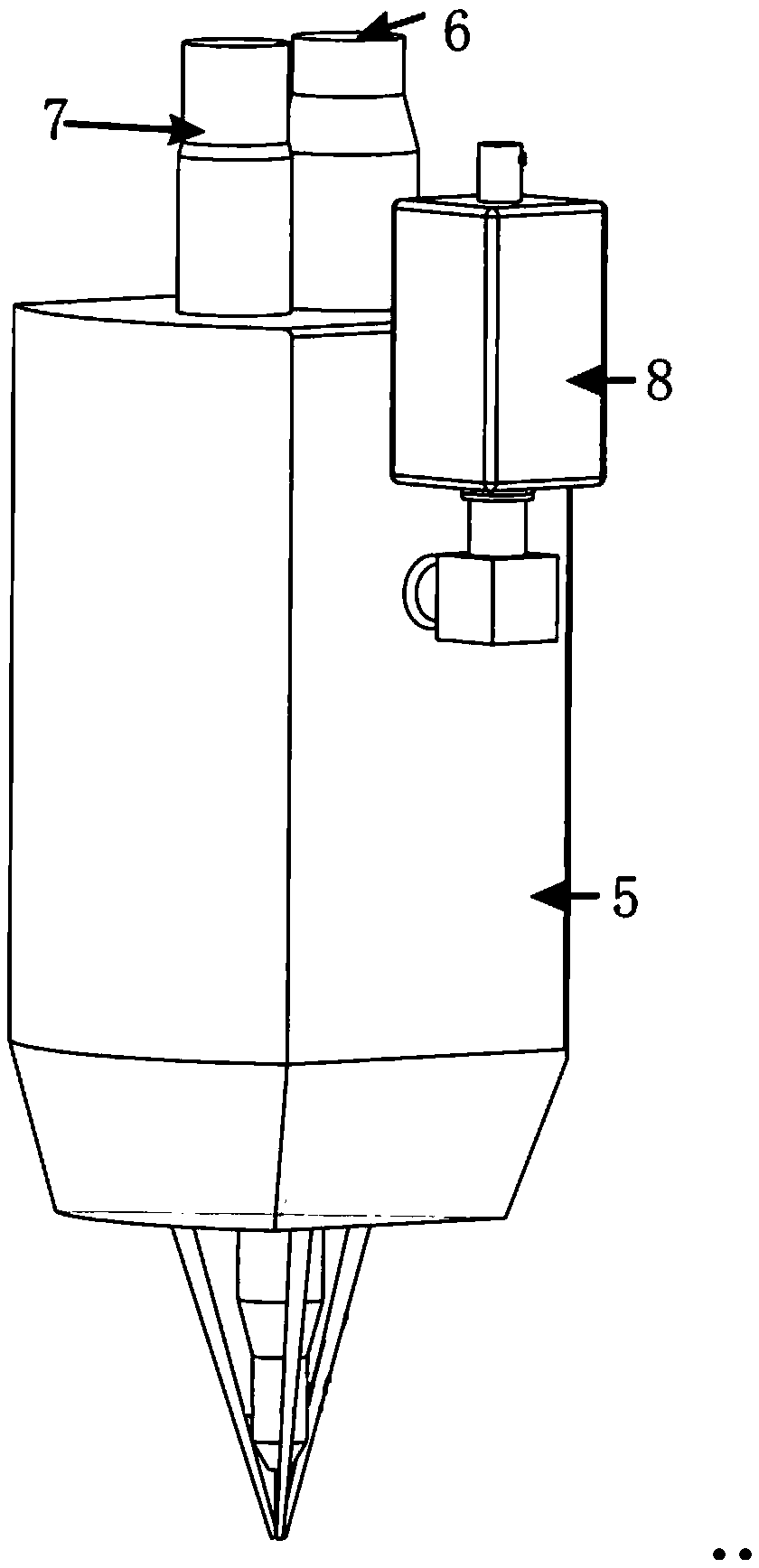

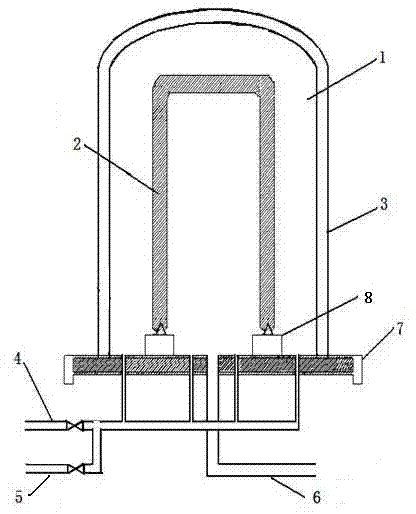

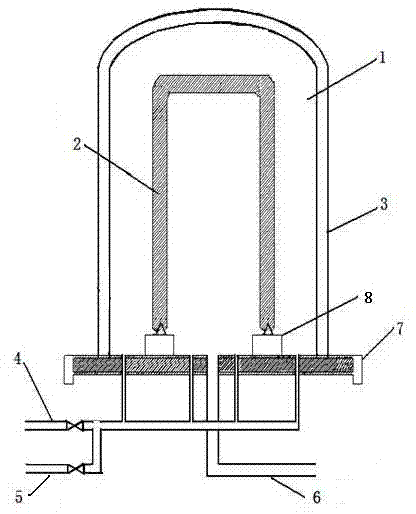

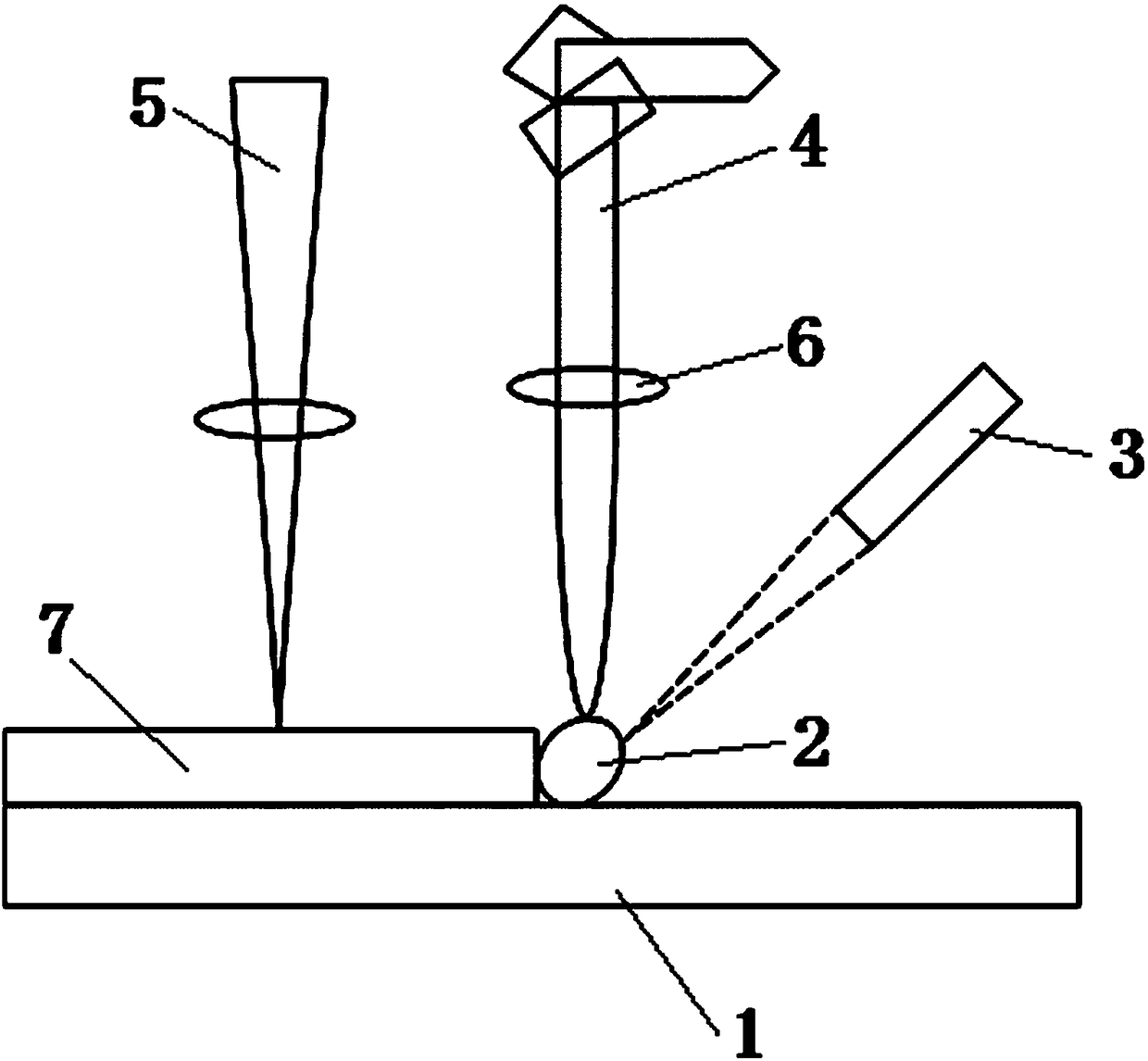

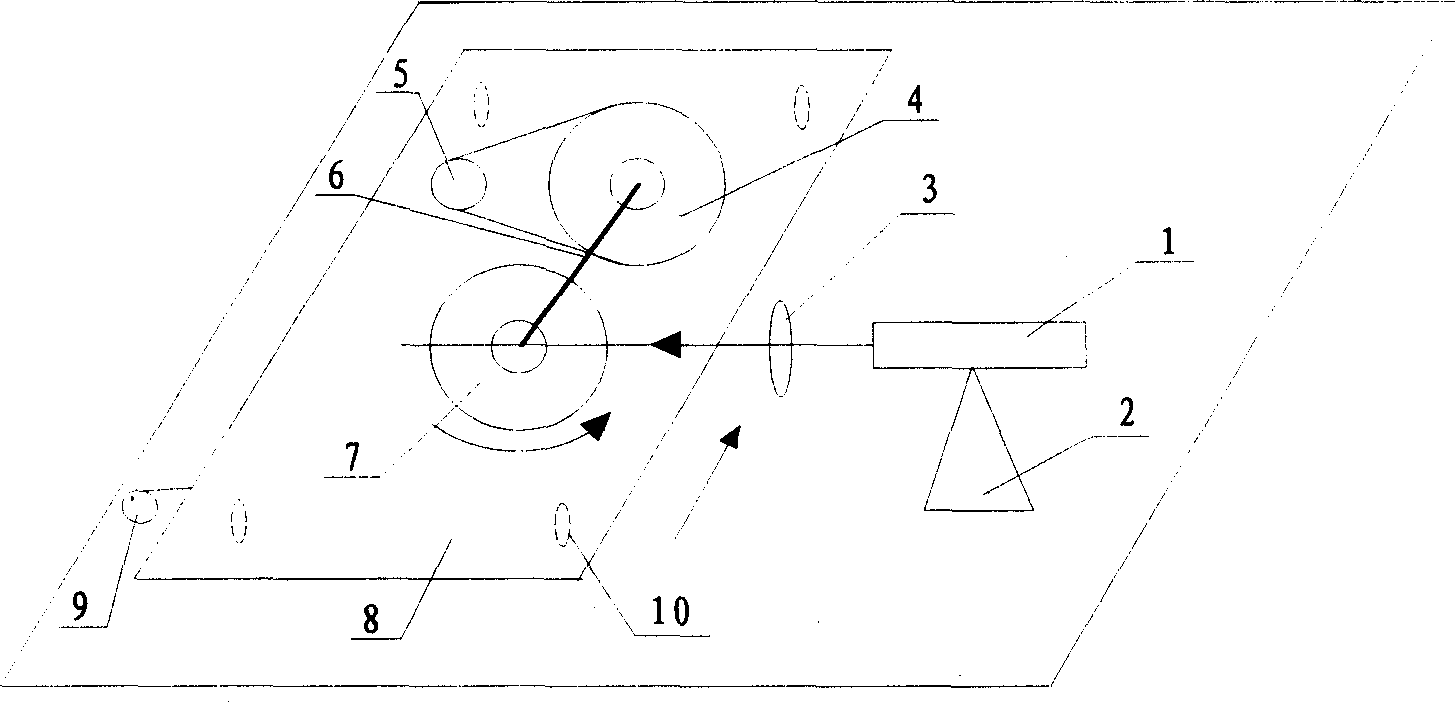

Welding wire sending and pulverized solder sending laser cladding forming method and device

InactiveCN101733550AIncrease peripheral light intensityOvercoming the deficiency of undermeltingLiquid spraying apparatusWelding/cutting media/materialsLight beamLaser beams

The invention discloses a welding wire sending and pulverized solder sending laser cladding forming method. The method is characterized in that a conscope is used to change a solid laser beam transmitted by a laser to an annular light beam through light path transformation, then an annular focus lens is used to focus the annular light beam to an annular conical light beam, a hollow conical aphotic zone is formed in the annular conical light beam, a welding wire sending and pulverized solder sending protective gas composite nozzle is arranged in the aphotic zone and has the same axis of the annular conical light beam, a welding wire sending hole is arranged in the center, parallel pulverized solder sending holes are around the welding wire sending hole, collimating protective gas holes are parallel to and around the pulverized solder sending holes, wire is sent to a molten pool through the welding wire sending hole along the axial direction of the light beam and vertically to a machining face, airborne pulverized solder is sent to the molten pool through the pulverized solder sending holes at the same time, and collimating protective gas surrounds the welding wire and pulverized solder and is blown to the molten pool. The invention adopts the welding wire sending and pulverized solder sending protective gas composite nozzle to realize welding wire, pulverized solder and protective gas composite cladding and solve the defects of the prior art.

Owner:SUZHOU UNIV

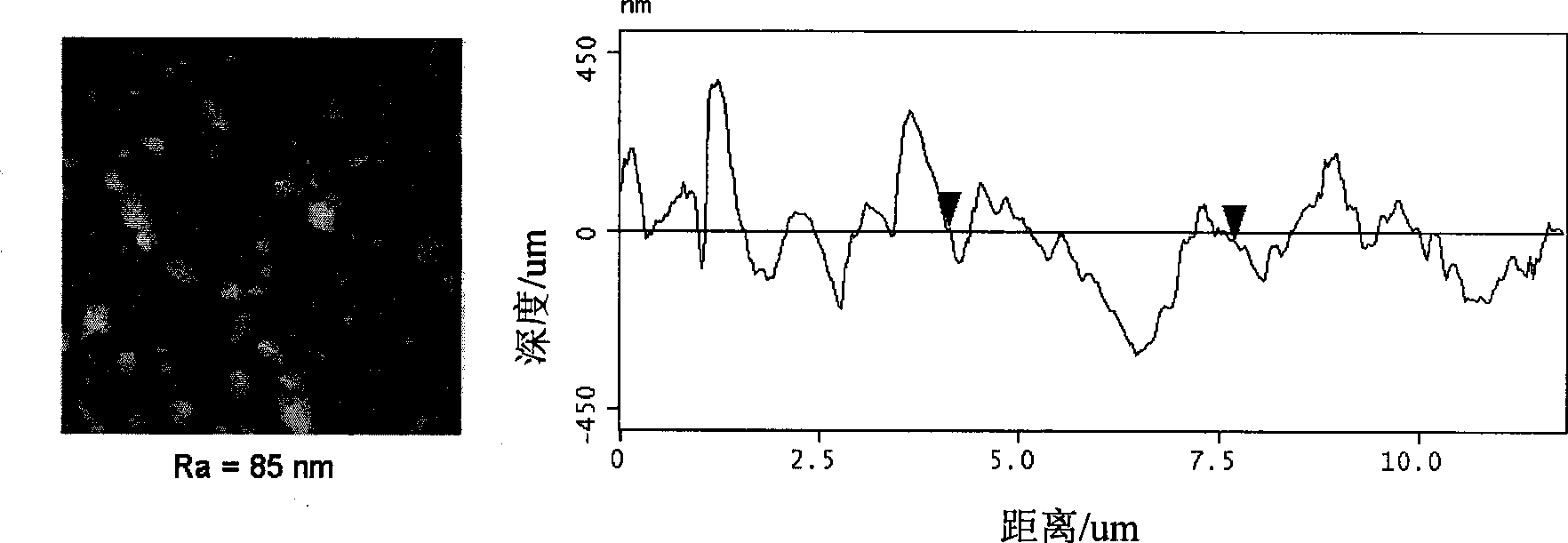

Electrolytic solution for integrated circuit copper wire laying electrodeposition

InactiveCN101481812AImprove surface topographyReduce roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesCopper wirePhysical chemistry

The invention provides an electrolyte used in integrated circuit copper cabling electrodeposition, which comprises the following components and contents: 50-200g / liter of copper sulphate, 50-220g / liter of sulphuric acid, 10-150 milligram / liter of chloridion, 5-200 milligram / liter of inhibitor, 5-50 milligram / liter of accelerator, 0.5-20 milligram / liter of leveling agent and the rest of deionized water. As the electrolyte contains the chloridion, inhibitor and accelerator, the surface appearance is improved after electrodeposition and the roughness concentration is reduced. And the leveling agent can increase the adsorption of the accelerator on the surface of electrodes in the deposition process, and then increases the surface improvement effect of the accelerator; the surface roughness of the clad layer is further reduced; the orientation of the clad layer obtained by deposition Cu (111) is dominant; after deposition, the surface dendrite growth mode disappears; and the surface has no hole defects.

Owner:TSINGHUA UNIV

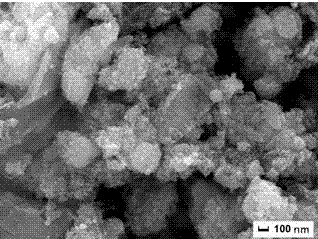

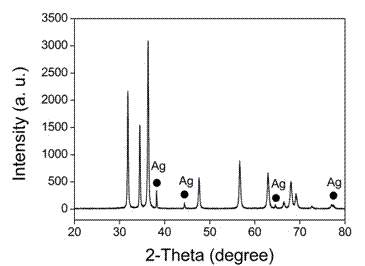

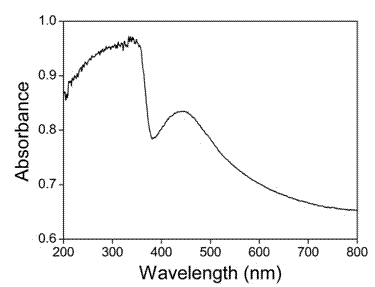

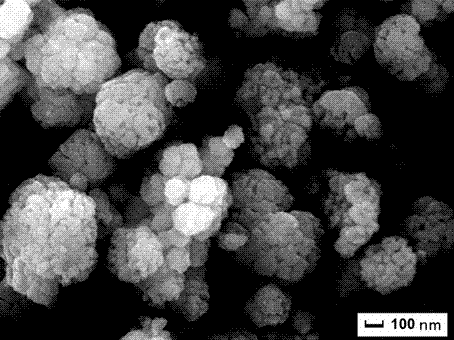

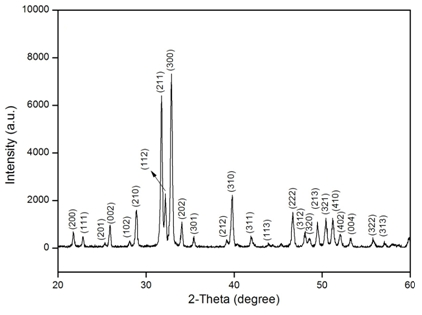

Nano composite photocatalytic material and method for preparing same

InactiveCN102921416AImprove surface topographyLarge specific surface areaWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsNano compositesPhotocatalytic degradation

The invention relates to a silver doped grapheme-zinc oxide nano composite photocatalytic material and a method for preparing the same and belongs to the technical field of nano composite materials and photocatalysis. Graphite oxide is subjected to ultrasonic dispersion to obtain a dispersion solution of graphene oxide; precursors of silver ions and zinc ions are added in the dispersion solution of the graphene oxide, and the mixture is placed into a reaction kettle to be subjected to hydro-thermal treatment to be prepared into the silver doped grapheme-zinc oxide nano composite photocatalytic material in situ after the pH is regulated to an alkaline condition. Photocatalytic degradation experiments show that the silver doped grapheme-zinc oxide nano composite photocatalytic material prepared through the method has good adsorption and visible light photocatalytic degradation effects on rhodamine B and is an ideal nano composite photocatalytic material.

Owner:JIANGSU UNIV

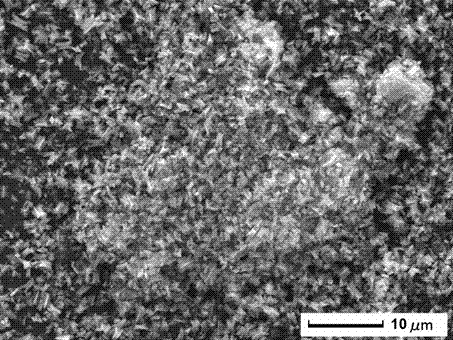

Graphene/titanate nanometer composite visible-light activated photocatalyst and preparation method thereof

InactiveCN102847529AGood surface morphologyLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationCvd graphene

The invention discloses a graphene / titanate nanometer composite visible-light activated photocatalyst and a preparation method thereof, and belongs to the fields of nanometer composite materials and photocatalysis technology. The composite photocatalyst is prepared by compounding titanate and graphene, and the preparation method comprises the following steps: reacting tetrabutyl titanate with ammonia water to obtain a titanium hydroxyl compound; performing ultrasonic dispersion of graphene oxide in water, adding nitrate, stirring, mixing with the titanium hydroxyl compound and a potassium hydroxide aqueous solution, stirring, finally transferring the mixed solution into a reaction vessel to perform a hydrothermal reaction, after the reaction, performing centrifugation, filtration, washing, and vacuum drying of the product to obtain the composite photocatalyst. Photocatalytic degradation experiments show that the graphene / titanate composite photocatalyst prepared by the method has good photocatalytic degradation effect on rhodamine B under visible light irradiation. The photocatalyst of the invention has the advantages of relatively simple operation process, controllable morphology, no requirements for other reducing agents, and good visible-light activated photocatalysis performance.

Owner:JIANGSU UNIV

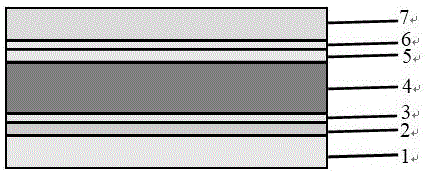

Perovskite solar cell and preparation method thereof

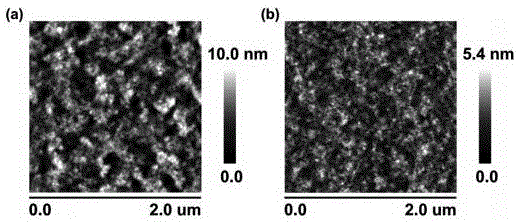

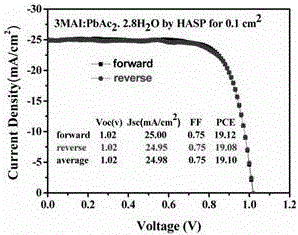

InactiveCN106684247AInhibitory complexImprove photoelectric conversion efficiencySolid-state devicesSemiconductor/solid-state device manufacturingHysteresisSpray coating

The invention discloses a perovskite solar cell and a preparation method thereof. The perovskite solar cell comprises a transparent conductive substrate, a hole transport layer, a decoration layer, a perovskite layer, an electron transport layer, a barrier layer and a metal electrode. The surfaces of PEDOT: PSS, NiOx and the hole transport layer are decorated by ionic liquid based on imidazole, atomic force microscope graphs before and after the decoration are compared, and the decorated surface appearance is more smooth, which is conducive to inhibiting the compounding of dark current. The perovskite layer is a new perovskite material 3MAI: PbAc2.xH2O (x is not smaller than 0 and is not greater than 3), and is prepared by quickly preheating a substrate and heating a perovskite precursor solution, namely instant heating assisted spray coating technology (HASP) at a low temperature (lower than 100 DEG C), which is conducive to increasing the grain size of perovskite and reducing the defects between perovskite grains so as to greatly improve the efficiency of the perovskite battery. The photoelectric conversion efficiency of the final battery device is greater than 19%, the flexible device efficiency is 10.8%, no hysteresis effect is formed, and thus the preparation method has a broad application prospect.

Owner:CENT SOUTH UNIV

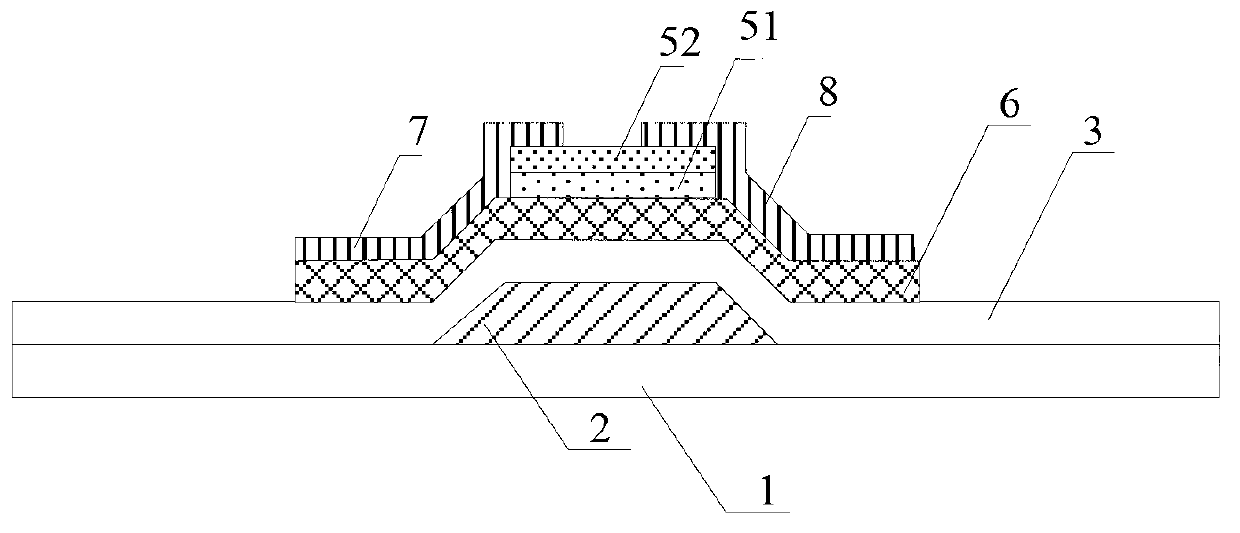

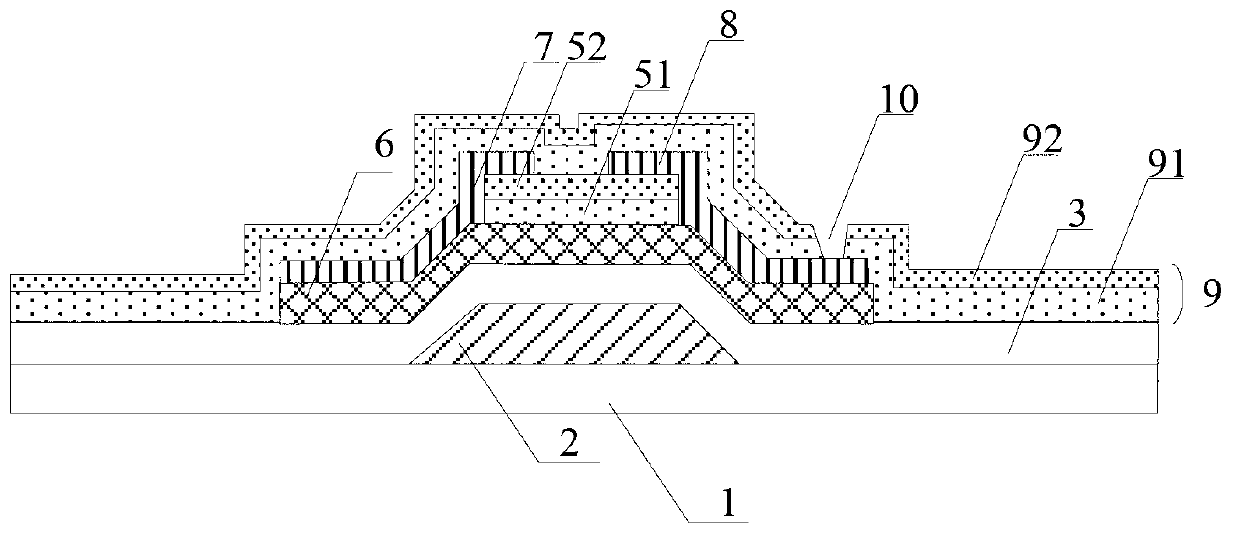

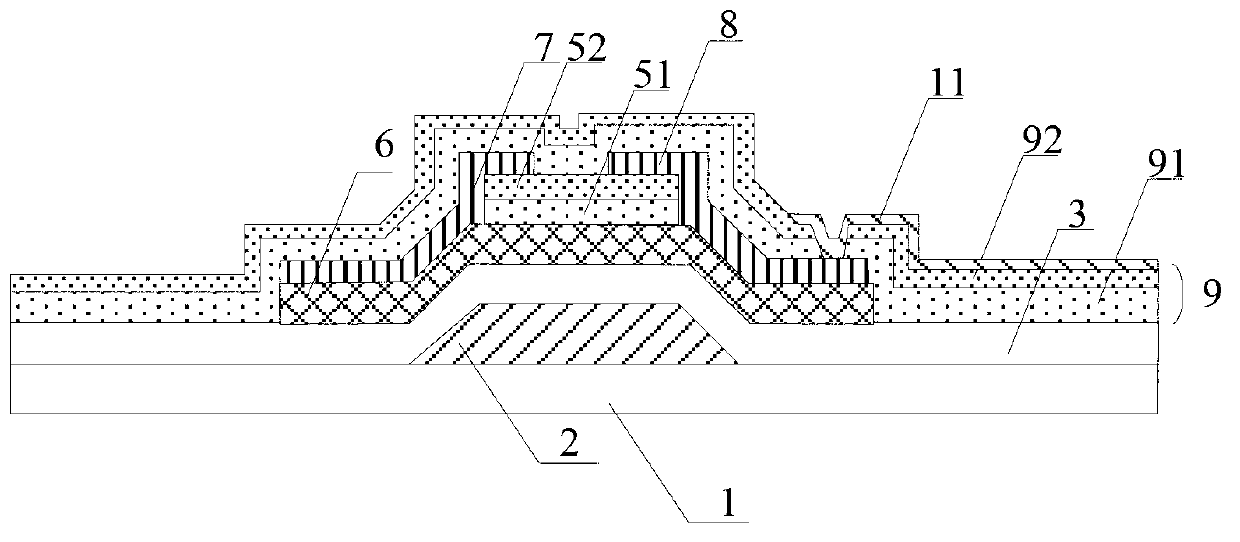

Thin film transistor and manufacture method, array substrate and display device thereof

ActiveCN103000694AGood film qualityGood surface morphologyTransistorSolid-state devicesVoltage stabilityEngineering

The invention discloses a thin film transistor and a manufacture method, an array substrate and a display device thereof. The thin film transistor, the manufacture method, the array substrate and the display device are used for improving drive voltage stability of the thin film transistor and prolonging service life of the thin film transistor. The manufacture method of the thin film transistor includes forming a picture containing a grid electrode, an active layer and a source drain electrode layer and forming a picture containing a grid electrode insulation layer and an etching barrier layer. The grid electrode insulation layer is located between the grid electrode and the active layer, the etching barrier layer is located between the active layer and the source drain electrode layer, the grid electrode insulation layer is located above the active layer, the gride electrode insulation layer is manufactured by at least two insulation layers, or the etching barrier layer is located above the active layer and is manufactured by at least two insulation layers.

Owner:BOE TECH GRP CO LTD

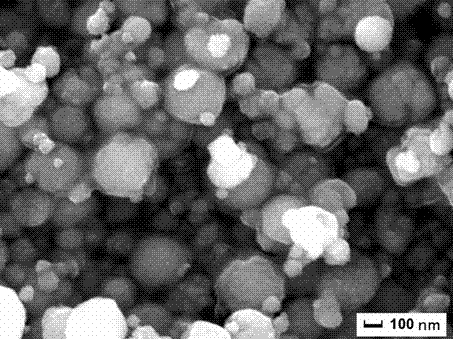

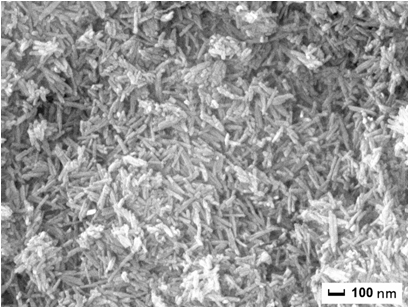

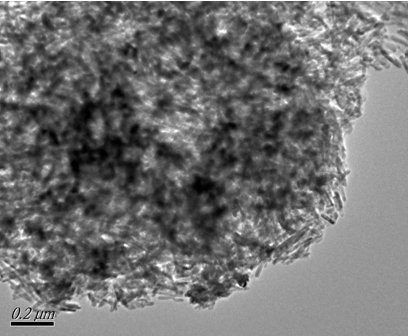

Graphene/hydroxyapatite nano composite and preparation method thereof

InactiveCN102569749AImprove surface topographyLarge specific surface areaMaterial nanotechnologyCell electrodesO-Phosphoric AcidBiological materials

The invention relates to a graphene / hydroxyapatite nano composite and the preparation method thereof, particularly relates to a hydrothermal method for preparing graphene / hydroxyapatite nano composite through the assistance of amino acid, and belongs to the field of nano composite and biological material. According to the invention, graphene oxide is placed in deionized water for ultrasonic dispersion, and calcium chloride anhydrous is added for stirring, so as to form mixed solution A; amino acid is added into dilute phosphoric acid for stirring so as to form solution b, the dilute hydrochloric acid solution is used for adjusting the solution to enable the PH value to be 7.5 to 8.5, finally the mixed solution A and the mixed solution B are mixed to transfer into a polytetrafluoroethylene reaction kettle for hydro-thermal reaction, and after the reaction is finished, the composite can be obtained through centrifugating, cleaning and vacuum drying the product. The invention has the advantages that the operating process is relatively simple, the structure is controllable, the surface appearance is better, the specific surface area is larger, the dimension is even, and the like.

Owner:JIANGSU UNIV

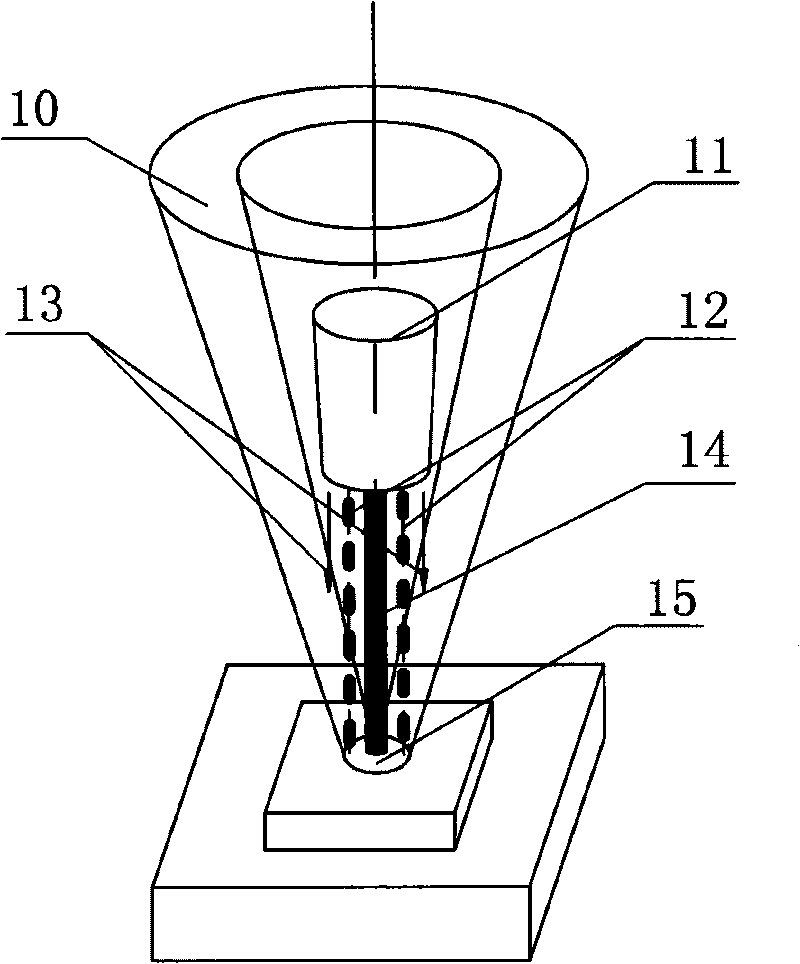

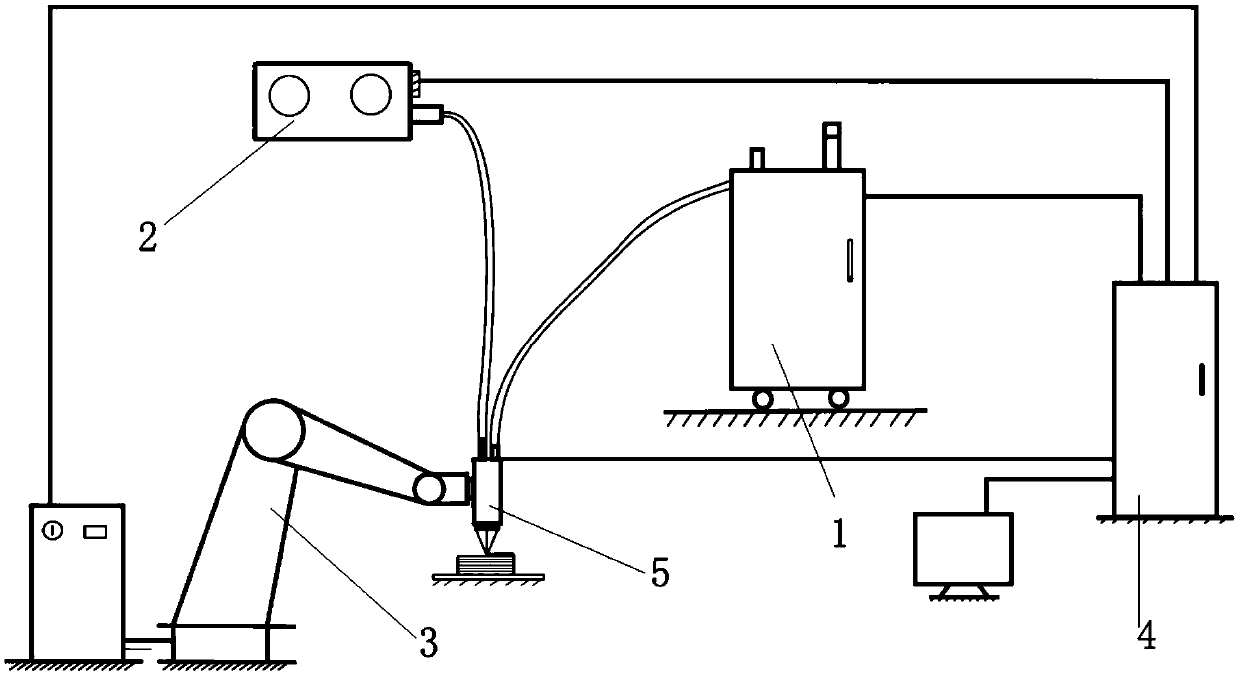

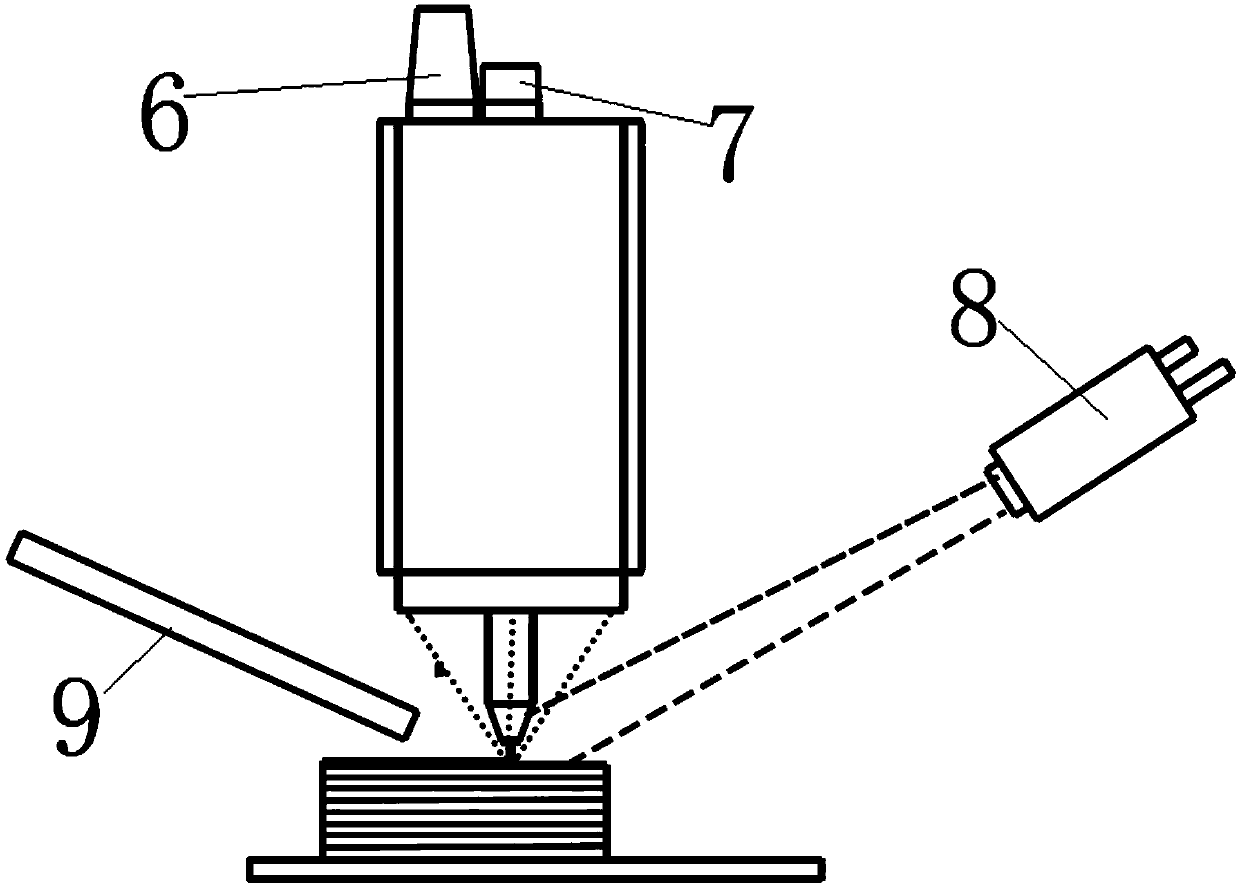

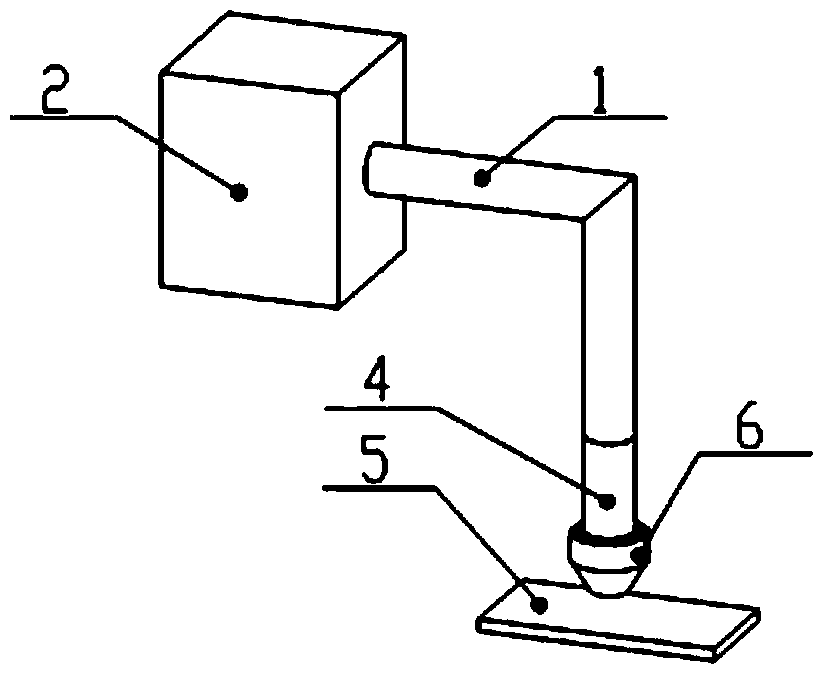

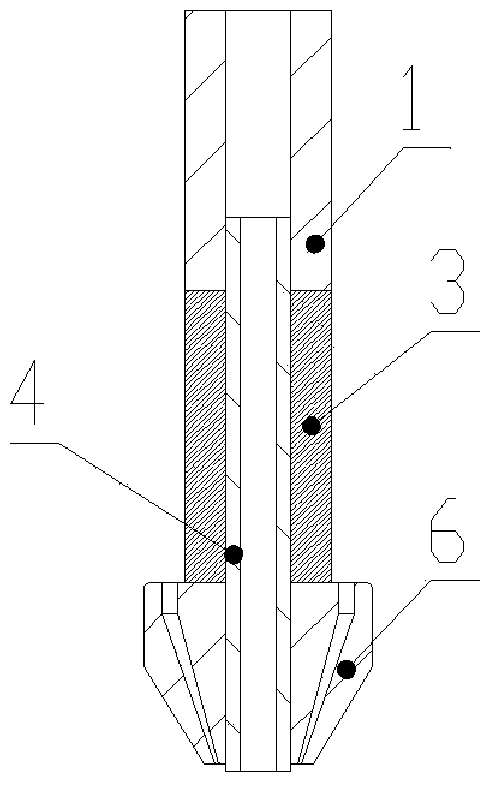

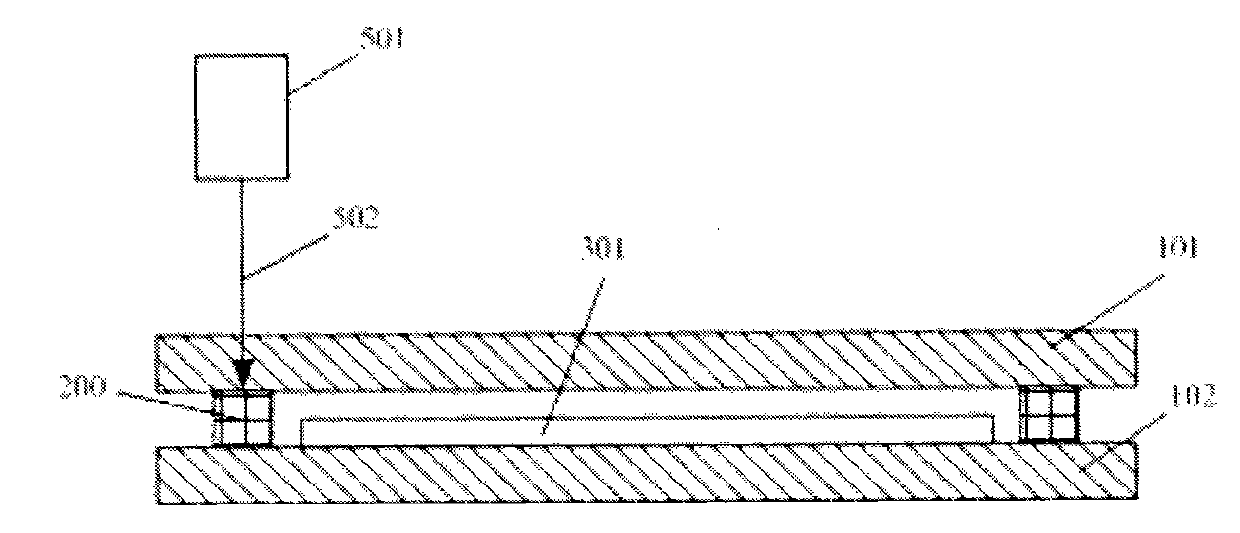

Laser-based inside-laser coaxial wire-feeding additive manufacturing system and forming method

InactiveCN109530918AReduce unevennessImprove deposition qualityAdditive manufacturing apparatusLaser beam welding apparatusMelting tankFeature structure

The invention discloses a laser-based inside-laser coaxial wire-feeding additive manufacturing system and a forming method. The laser-based inside-laser coaxial wire-feeding additive manufacturing system is formed by a laser, a wire feeder mechanism, a movement actuating mechanism, a molten pool shape monitoring feedback module and a system control module. After a part model is cut into slices, aninitial path is planned, input parameters and technological parameters in a technology database are compared, the molten pool temperature corresponding to technological parameters and input technology parameters under different feature structures is optimized, printing parameters and a robot code under an optimal path are generated, a high-speed infrared camera acquires molten pool shape parameters during the printing process and transmits to the system control module, the system control module compares the acquired molten pool shape data and the technology data of the technology database module, meanwhile, the molten pool temperature change is monitored, and the molten pool temperature is corrected through feedback-adjusting laser power and is monitored and feedback-adjusted in real time, so that the molten pool shape is uniform and consistent and the printing process is stably controlled during the printing process.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

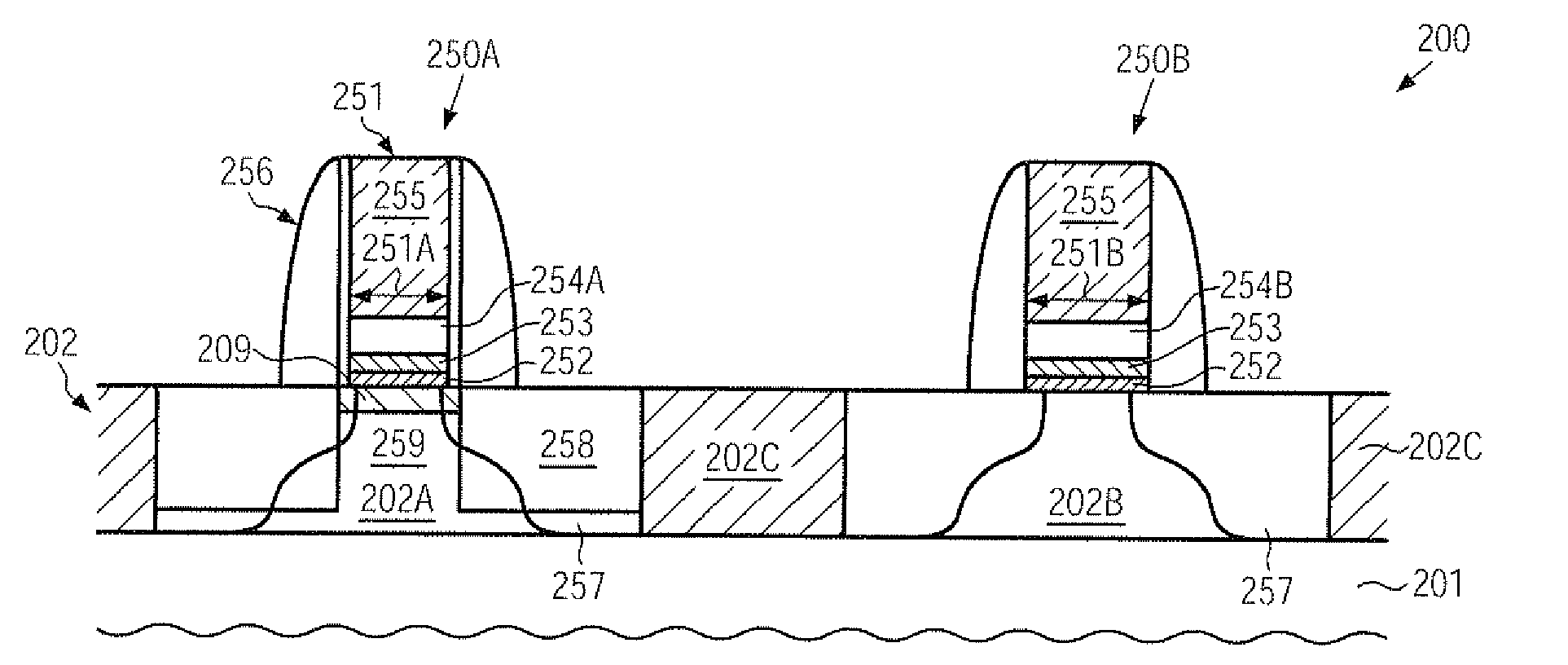

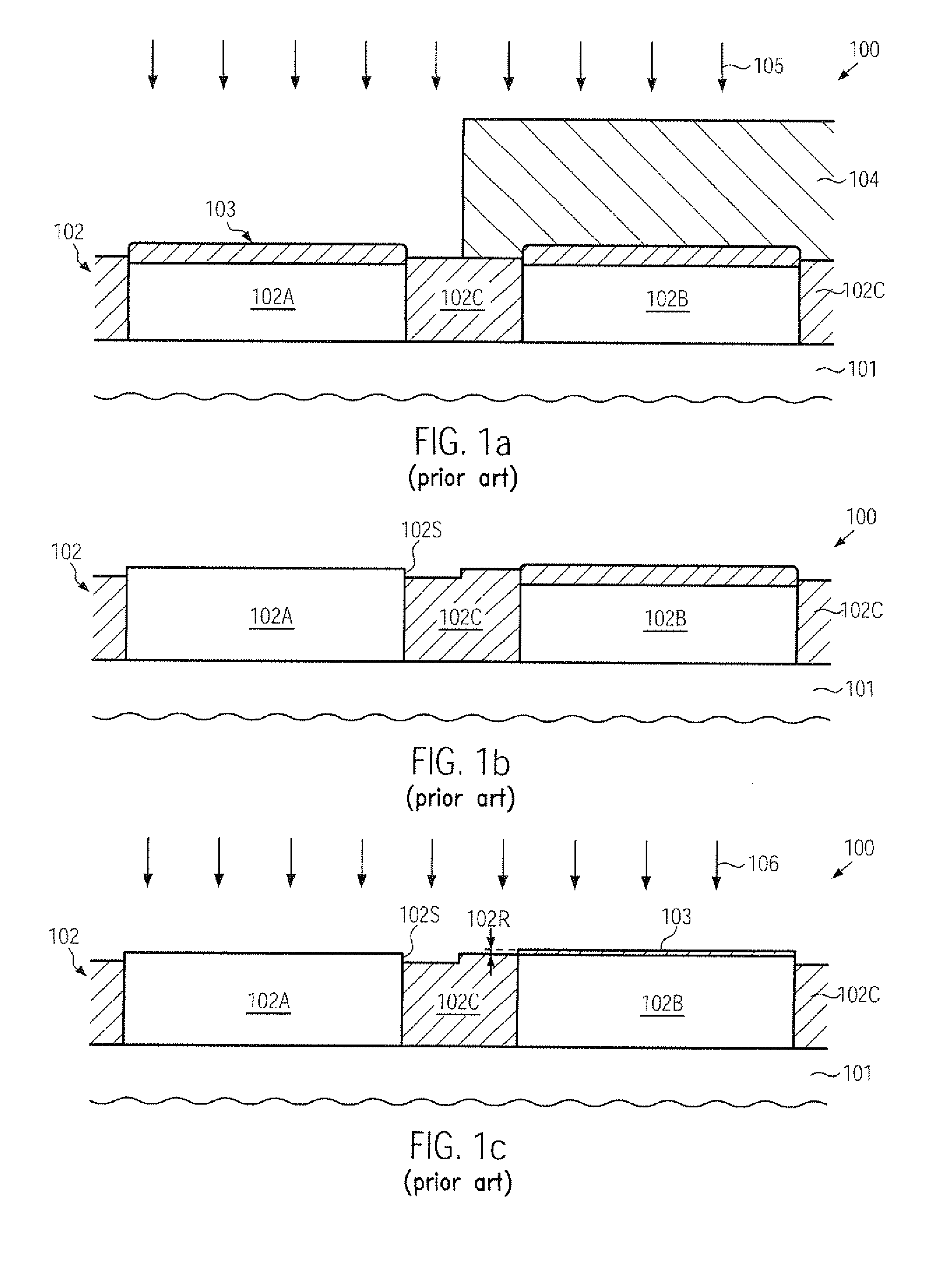

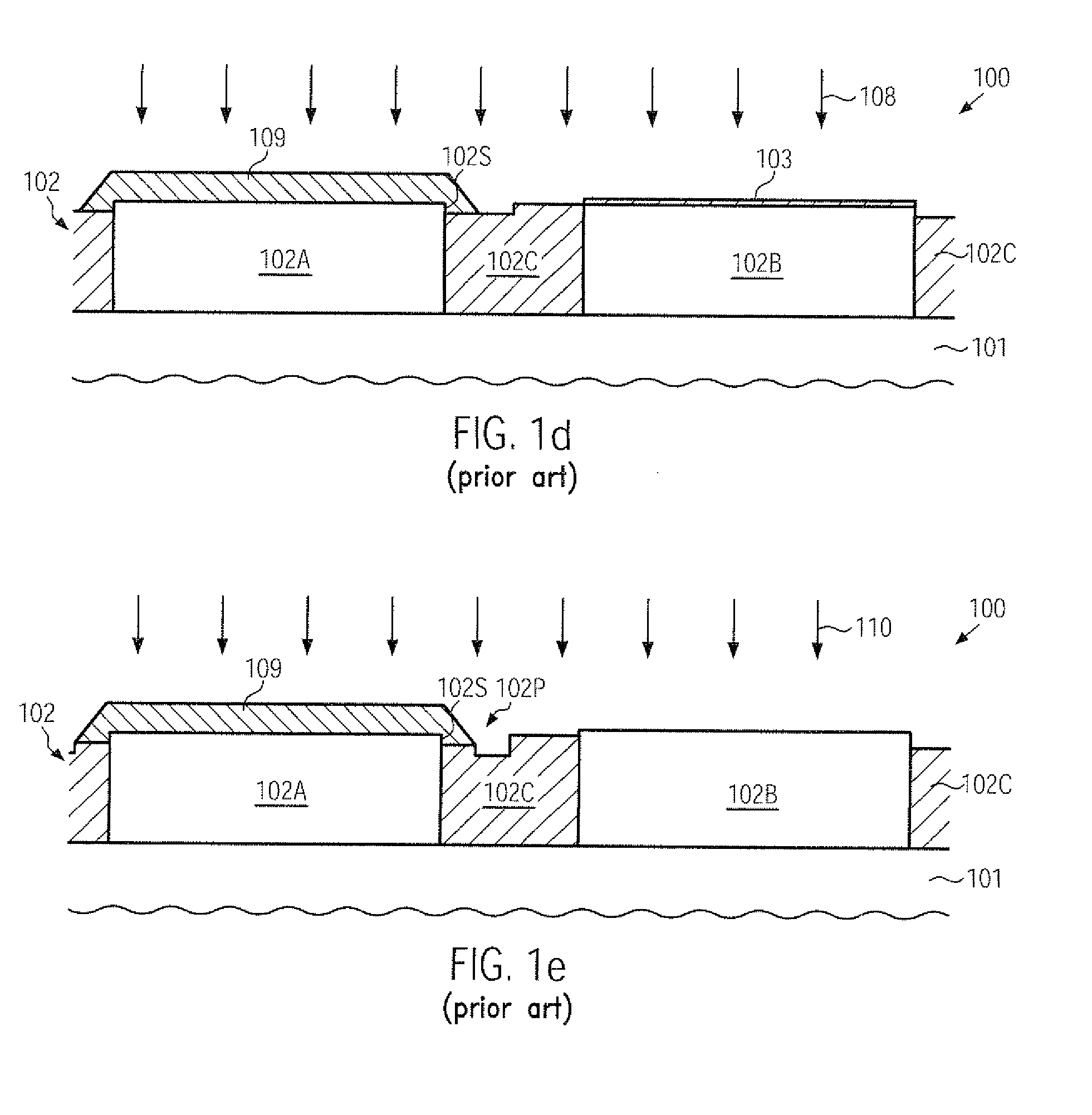

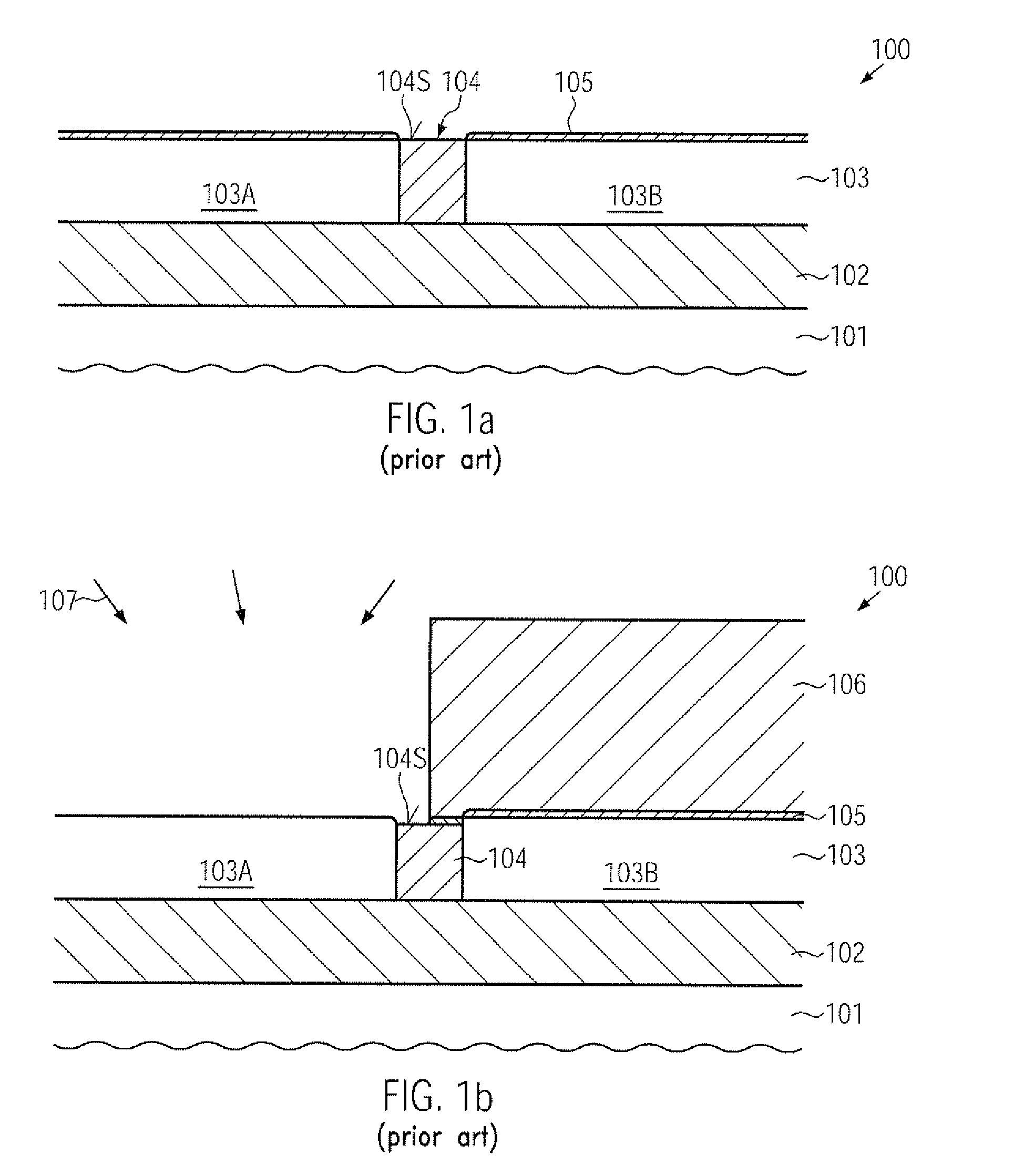

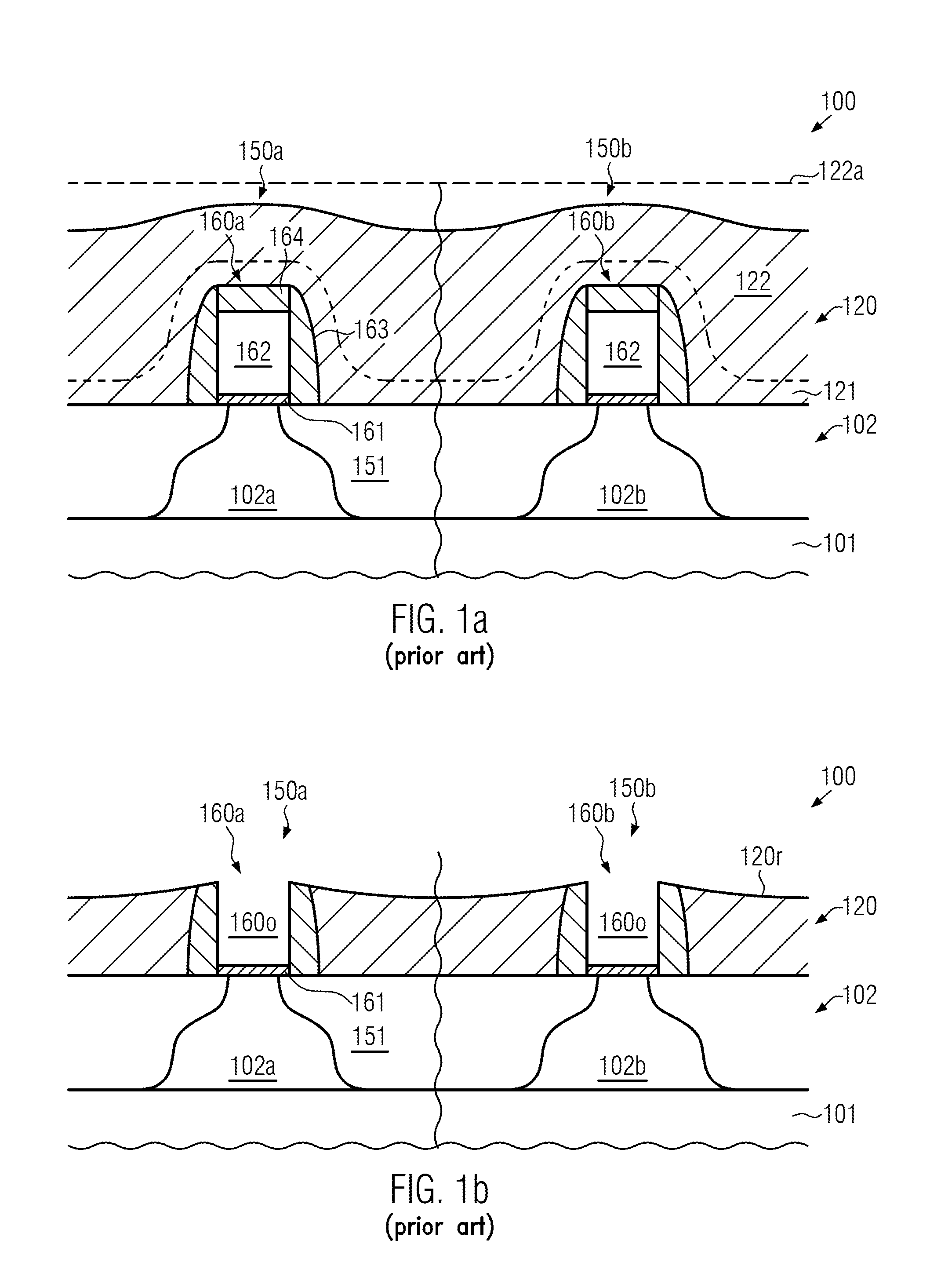

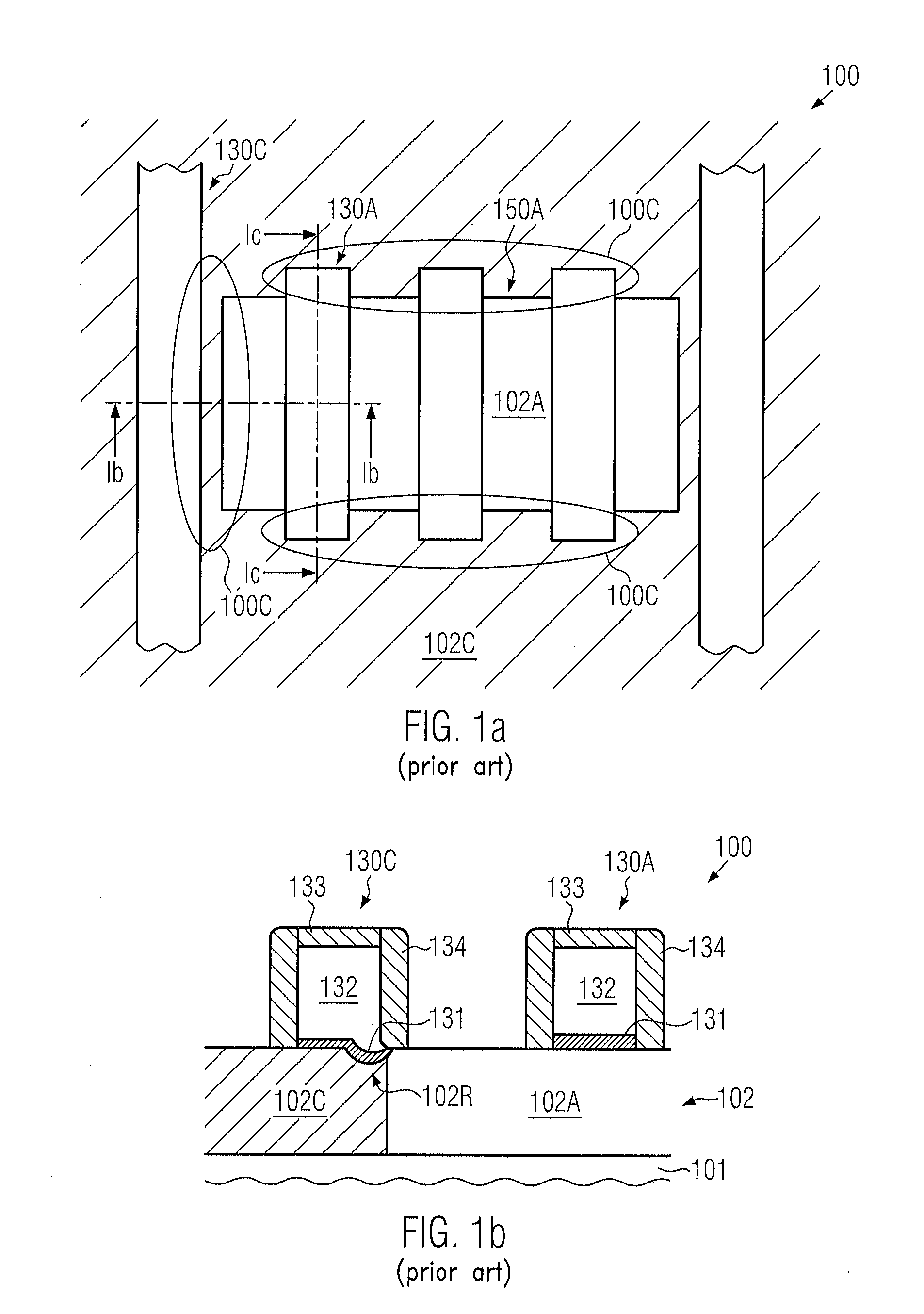

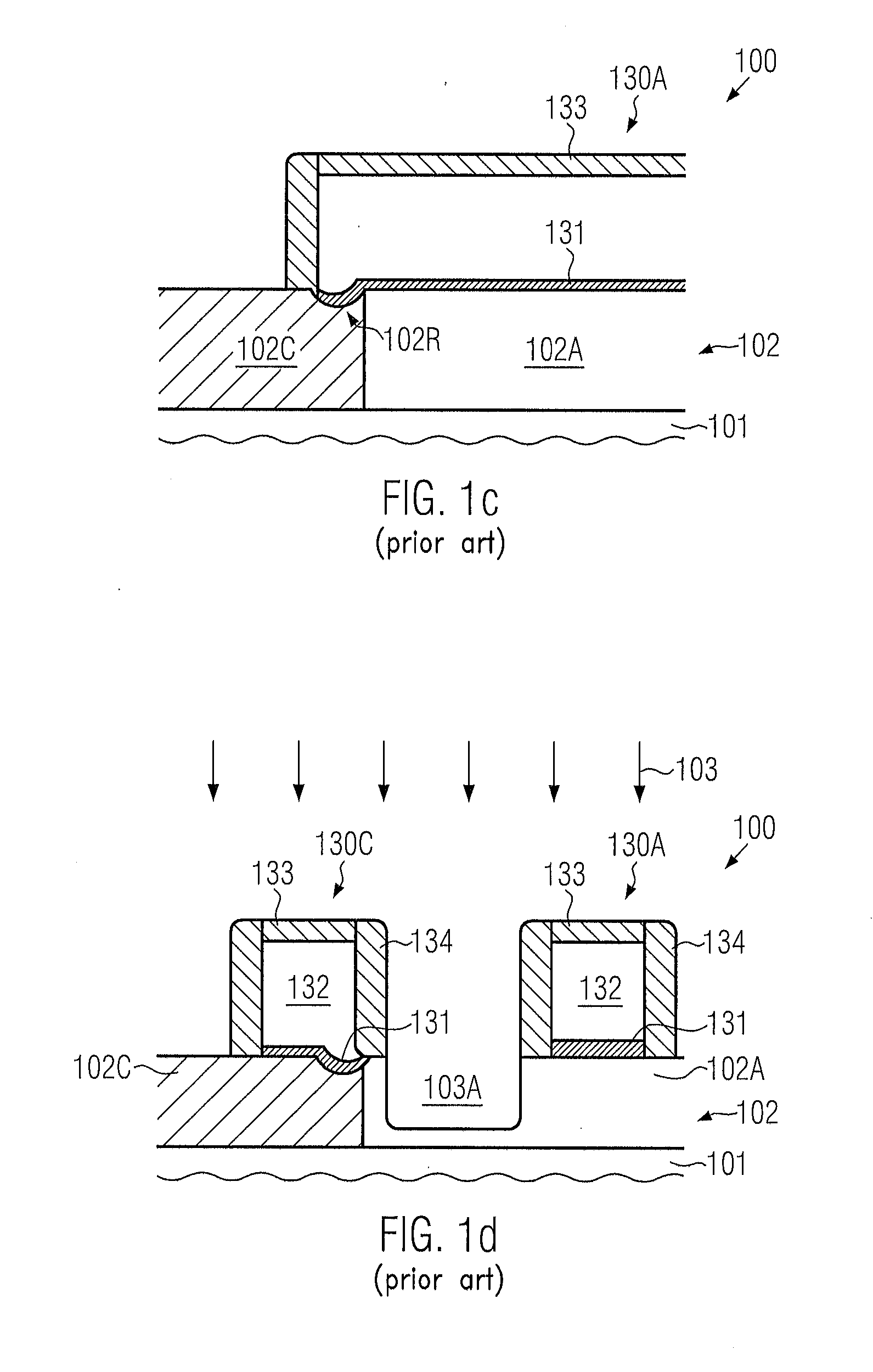

Enhancing deposition uniformity of a channel semiconductor alloy by an in situ etch process

InactiveUS20100289094A1Superior deposition conditionEfficient overall manufacturing flowTransistorSemiconductor/solid-state device manufacturingSemiconductor materialsSemiconductor alloys

When forming sophisticated gate electrode structures requiring a threshold adjusting semiconductor alloy for one type of transistor, a recess is formed in the corresponding active region, thereby providing superior process uniformity during the deposition of the semiconductor material. Due to the recess, any exposed sidewall surface areas of the active region may be avoided during the selective epitaxial growth process, thereby significantly contributing to enhanced threshold stability of the resulting transistor including the high-k metal gate stack.

Owner:GLOBALFOUNDRIES INC

Preparation method of polycrystalline silicon

ActiveCN102557038AReduce deposition energy consumptionSuppress or eliminate foggingChemical industrySilicon compoundsEtchingHydrogen

The invention discloses a preparation method of polycrystalline silicon. The method comprises the following steps of: undergoing a chemical vapor deposition reaction on trichlorosilane and high-purity hydrogen serving as raw materials at the high temperature of 1,050-1,250 DEG C and under the pressure of 0-0.8 MPa in a reduction furnace reactor; and depositing polycrystalline silicon on the surface of a heat-emitting silicon core. The method is characterized in that: 0.1-20 percent of hydrogen halide gas is introduced into a reduction furnace in a chemical vapor deposition process. According to method, silicon powder produced in the bulk phase of the reduction furnace can be suppressed effectively, an atomization phenomenon is eliminated, heat produced by reacting can be applied to deposition of polycrystalline silicon, the energy utilization efficiency and silicon depositing rate are increased, and the reaction temperature and the halogenated silane concentration are not required to be lowered; and due to etching of hydrogen halide on the surface of a silicon stick, the surface appearance is improved, and a dense polycrystalline silicon stick is obtained.

Owner:新疆戈恩斯能源科技有限公司

Ink for inkjet printing and preparation method as well as zirconia film printed by ink for inkjet printing

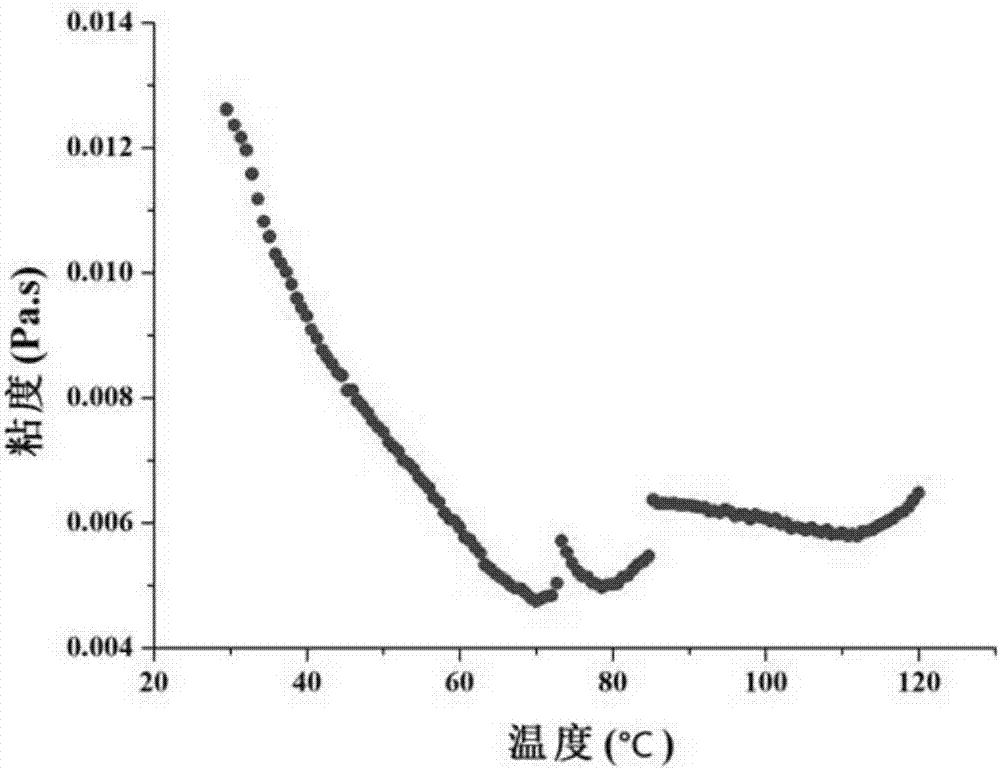

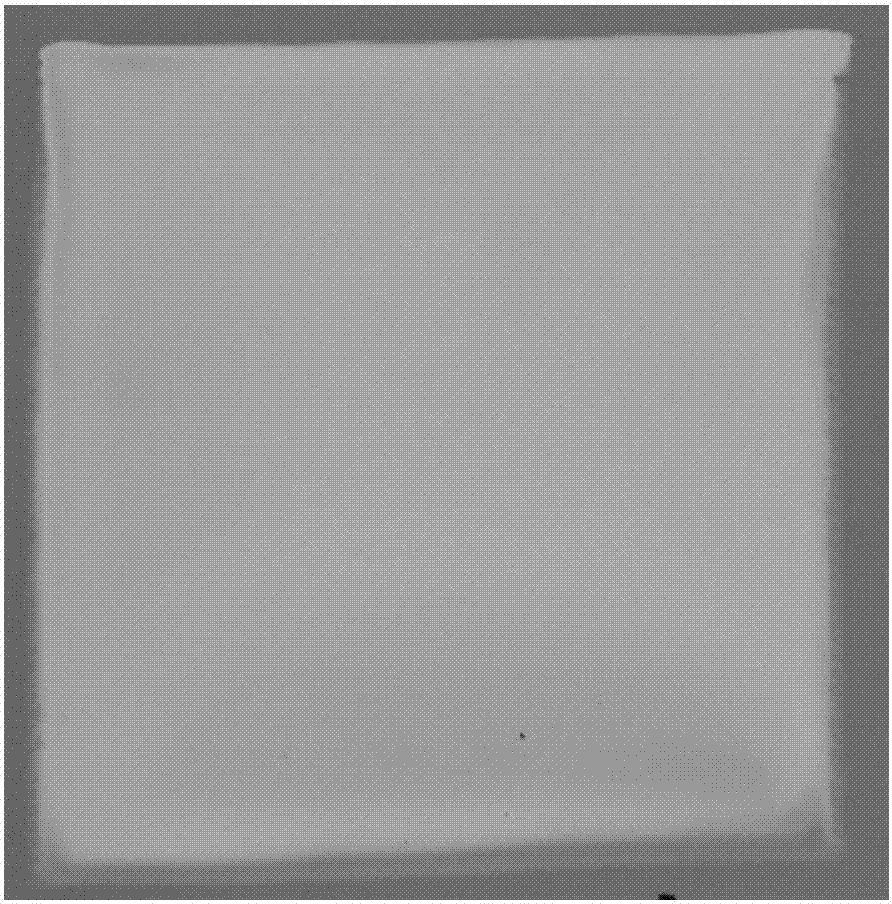

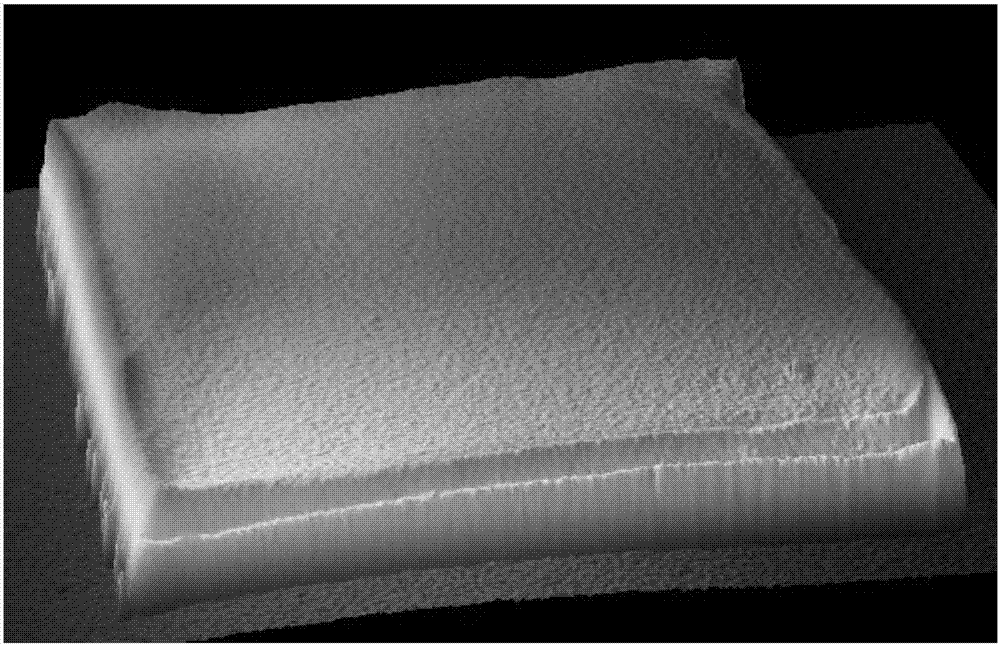

ActiveCN107151483AImprove flatnessImprove surface topographyInksPrintingPolymer scienceCoffee ring effect

The invention discloses an ink for inkjet printing and a preparation method as well as a zirconia film printed by the ink for the inkjet printing. The preparation method for the ink for the inkjet printing comprises the steps: (1) dissolving zirconium oxychloride in a mixed solvent to obtain a mixed solution, wherein the mixed solvent is prepared from ethylene glycol monomethyl ether and ethylene glycol in a volume ratio of (0.5 to 2) to (2 to 1)1; (2) adding PVP to the mixed solution obtained in the step (1), dissolving and standing to aging, and obtaining the ink for the inkjet printing. According to the ink for inkjet printing and the preparation method as well as the zirconia film printed by the ink for the inkjet printing, the polymer PVP is introduced in the process of preparing the ink for the inkjet printing, the viscosity and the dispersion of the solution are adjusted by due to the existence of the polymer, the system is more likely to generate gelatinization, and the flow of the liquid phase is restricted and the coffee-ring effect is weakened, so that the flatness of the surface of the zirconia film printed by the ink is improved.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of double-high-energy-beam metal additive material

InactiveCN108115137AQuality improvementImprove surface topographyAdditive manufacturing apparatusIncreasing energy efficiencyMathematical modelControl system

The invention discloses a manufacturing method of a double-high-energy-beam metal additive material. The manufacturing method comprises the following steps: (a) determining a three-dimensional entitymodel of a forming component, and modeling; and (b) manufacturing an additive material of the forming component: carrying out slicing and layering on a mathematical model in the step (a), so as to obtain two-dimensional outline information of a section of each layer and generate a machining route, inputting information into a control system of additive material manufacturing equipment, and manufacturing the double-high-energy-beam metal additive material by taking metal powder as the raw material according to a preset machining route. According to the manufacturing method, the internal defectsof pores, incomplete fusion, cracks and the like of a formed part are avoided, the system error of the formed part and an original design is small, and the formed part is relatively high in dimensional accuracy, small in residual stress, low in surface roughness and high in comprehensive quality; and compared with the prior art, the manufacturing method has significant progress and industrial application values.

Owner:SHANGHAI UNIV OF ENG SCI

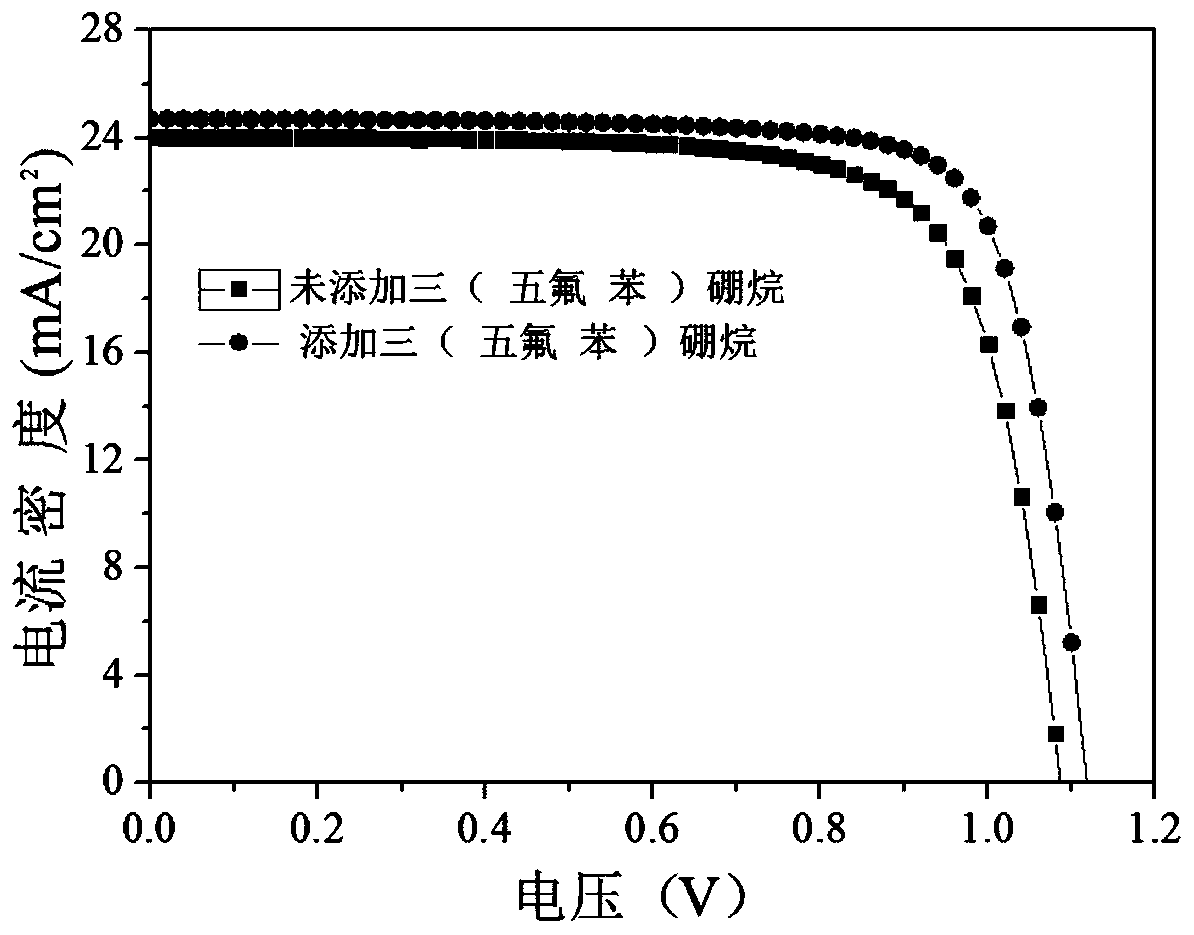

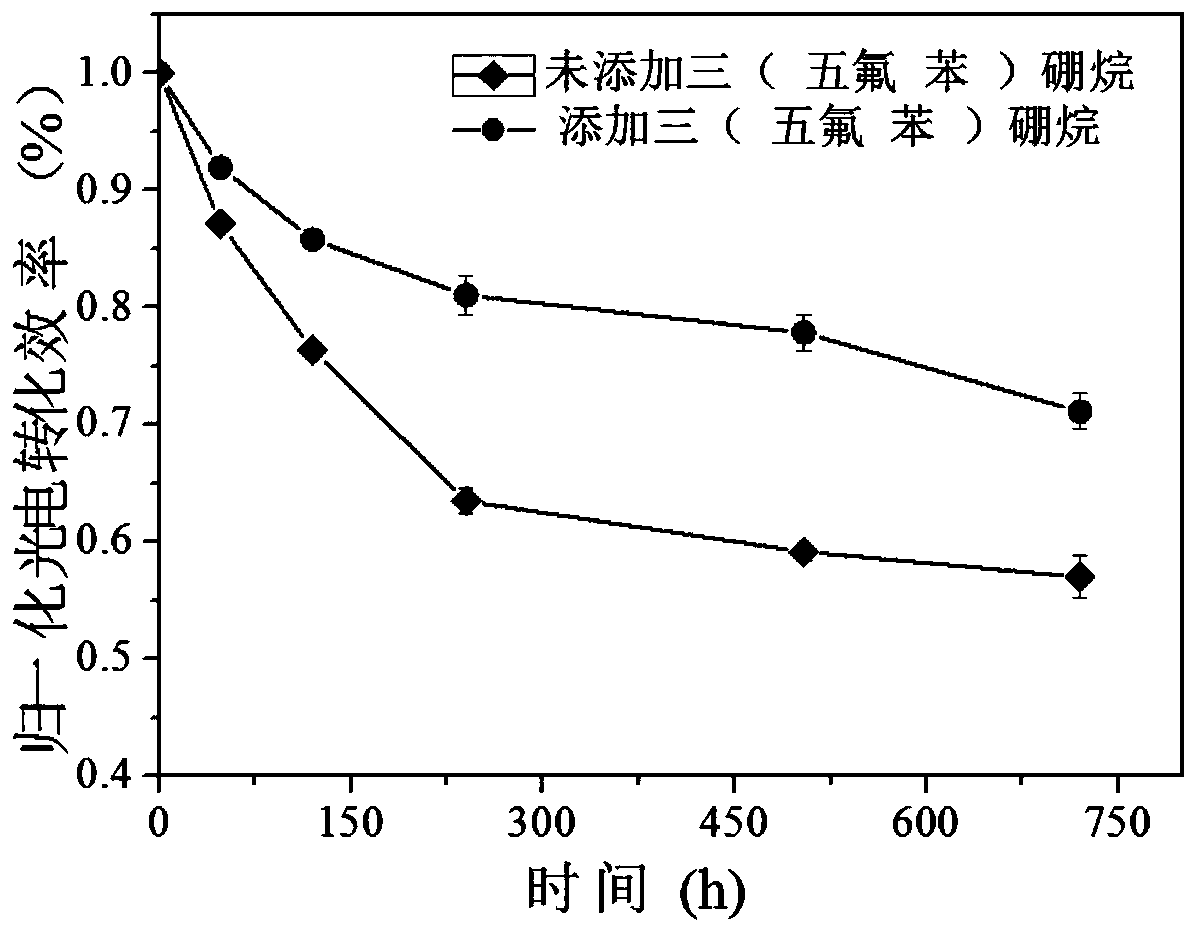

Novel passivated perovskite solar cell and preparation method thereof

ActiveCN109888105AInhibition of phase transitionEnhanced light absorptionFinal product manufactureSolid-state devicesAnti solventPerovskite solar cell

The invention discloses a novel passivated perovskite solar cell and a preparation method thereof. The perovskite solar cell optimizes the absorption of perovskite, so that a perovskite absorption layer contains an anti-solvent tris(pentafluorophenyl)borane to serve as a novel additive. On one hand, the addition of fluoride ions can change the crystallinity and the defect state of a perovskite film to form a high-quality perovskite film with a large grain size; the anti-solvent tris(pentafluorophenyl)borane can enhance the surface appearance of the perovskite and plays a passivation function at the grain boundary; and on the other hand, the fluoride ions can improve the hydrophobicity of the perovskite film and inhibit the phase change of the perovskite to better protect the perovskite from being destroyed by water, thereby further improving the air stability and the light stability of the cell to obtain a high-efficiency perovskite solar cell.

Owner:SHAANXI NORMAL UNIV

Static magnetic field-laser coaxial composite fusion covering method and device

ActiveCN103741138AWide range of applicationsFlexible regulationMetallic material coating processesSurface shapeElectromagnet

The invention relates to a static magnetic field-laser coaxial composite fusion covering method and a device and belongs to the technical field of laser processing. A static magnetic field is provided by an electromagnet, and the coaxial compositing of the magnetic field and a laser beam is realized through a device. When in magnetic field-laser coaxial fusion covering, the magnetic field generation device moves coaxially and synchronously with the laser beam, the coupling of the magnetic field and a laser-induced molten pool flow field can be completed, the laser fusion covering process is completed through a preset or coaxial powder delivery way, the flowing of the laser-induced molten pool can be inhibited, so that a purpose for controlling the solidification structure, improving the surface shape of the fuse covering layer, optimizing the distribution of the stress and reducing the splashing phenomenon in the fuse covering process can be realized. The coaxial synchronous motion of the magnetic field and the laser can be realized. The static magnetic field-laser coaxial composite fusion covering method and device have the characteristics of good capacity for controlling the fuse covering layer, wide application range, simplicity in structure, convenience in popularization and the like.

Owner:HANGZHOU BOHUA LASER TECH

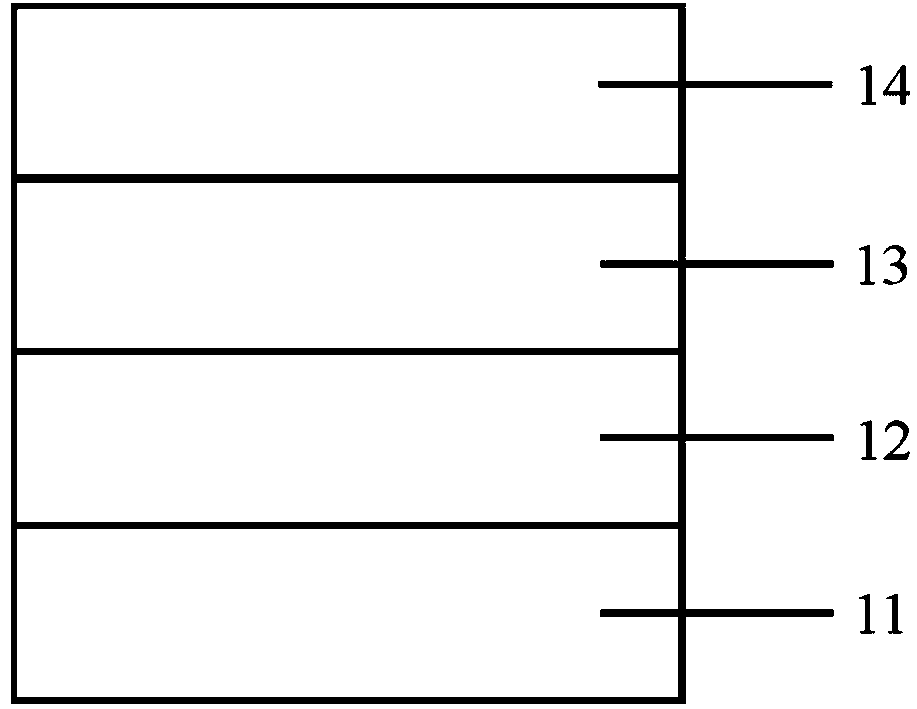

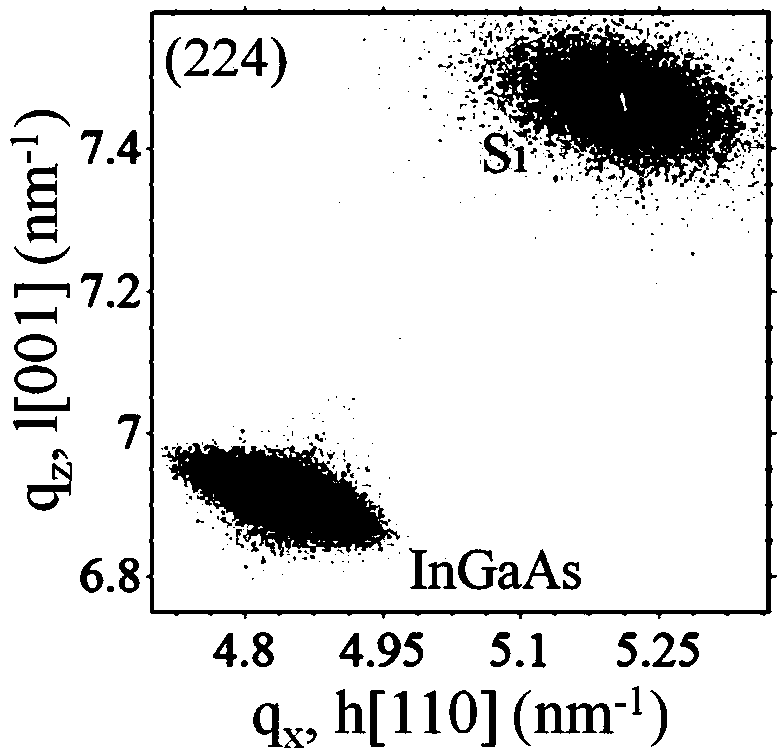

InGaAs film grown on Si substrate and preparation method thereof

ActiveCN103762256AEffectively filter dislocationsFacilitated releasePolycrystalline material growthSemiconductor/solid-state device manufacturingNanotechnologySi substrate

The invention discloses an InGaAs film grown on a Si substrate which comprises the Si substrate, a low-temperature In0.4Ga0.6As buffering layer, a high-temperature In0.4Ga0.6As buffering layer and an In0.53Ga0.47As expitaxial film. The low-temperature In0.4Ga0.6As buffering layer is grown at the temperature of 350 DEG C-380 DEG C. The high-temperature In0.4Ga0.6As buffering layer is grown at the temperature of 500 DEG C-540 DEG C. The sum of the thickness of the low-temperature In0.4Ga0.6As buffering layer and the thickness of the high-temperature In0.4Ga0.6As buffering layer is 10nm-20nm. The invention further discloses a preparation method of the InGaAs film. The InGaAs film grown on the Si substrate is good in crystalline quality, almost completely relaxes and is simple in preparation technology.

Owner:SOUTH CHINA UNIV OF TECH

Method for reinforcing laser cladding layer on surface of titanium alloy

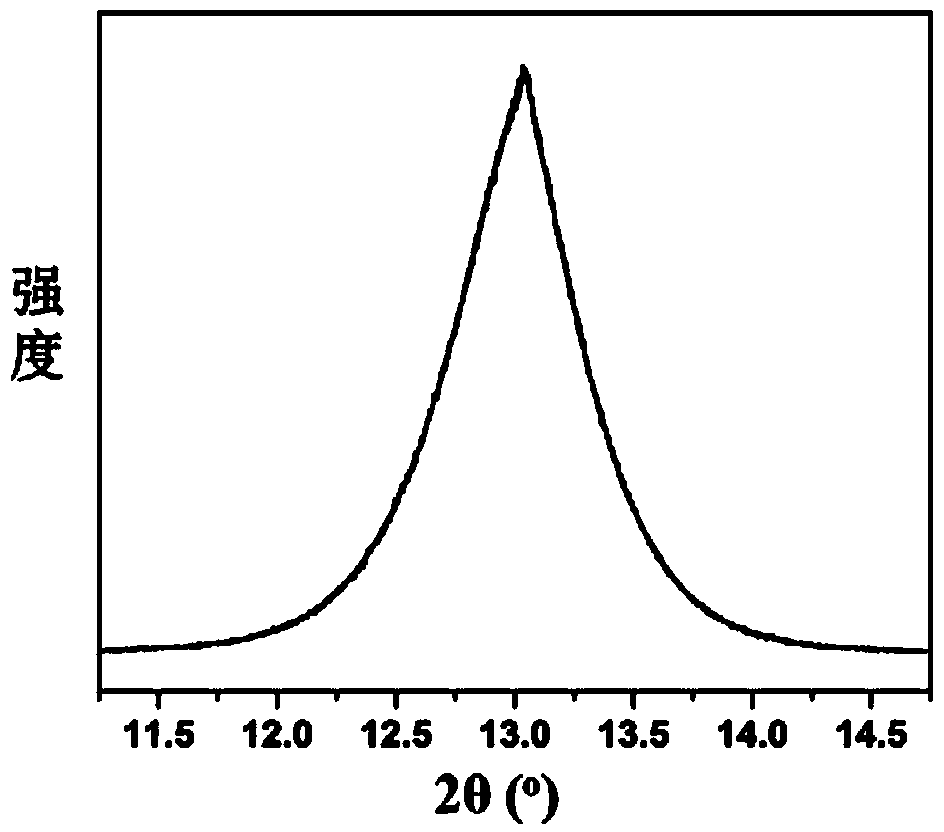

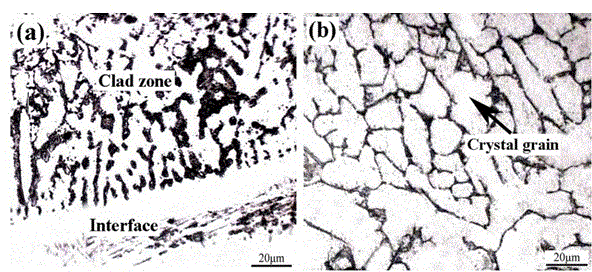

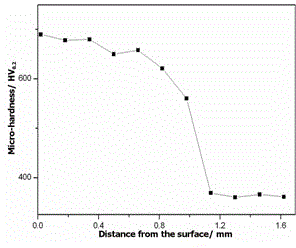

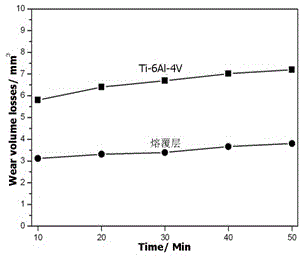

ActiveCN102618866AImprove wear resistanceImprove surface topographyMetallic material coating processesLight spotTitanium alloy

The invention discloses a method for reinforcing a laser cladding layer on a surface of a titanium alloy, which comprises the following steps that base powder is evenly mixed with mixed powder of C, TiB2 and Cu with a certain quantity proportion to form a paste shape by utilizing sodium silicate solution; the base powder is a Ti-Al intermetallic compound or Fe and Al mixed powder, the size of thebase powder is 20-30mum, and the size of the mixed powder of C, TiB2 and Cu is 20-30mum; the paste-shaped mixed powder is evenly coated on the surface of the titanium alloy, the thickness of a coating is 0.3-2mm, and the coating is naturally aired; laser beams are utilized to perform laser cladding on the surface of a titanium alloy sample pre-provided with the coating, and during the vertical scanning process of the laser beams, argon is laterally and coaxially blown to protect a molten pool and a lens barrel; and the process parameters are that laser power is 650-1500W, scanning speed is 2-11mm / s, light spot diameter is 2-9mm, and argon protection air pressure is 0.2-0.9MPa. The method for reinforcing the laser cladding layer on the surface of the titanium alloy can obtain a titanium alloy surface reinforcing coating layer with good abrasion resistance and a surface shape, and is convenient and simple in process, strong in adaptability and convenient to popularize and apply.

Owner:SHANDONG UNIV

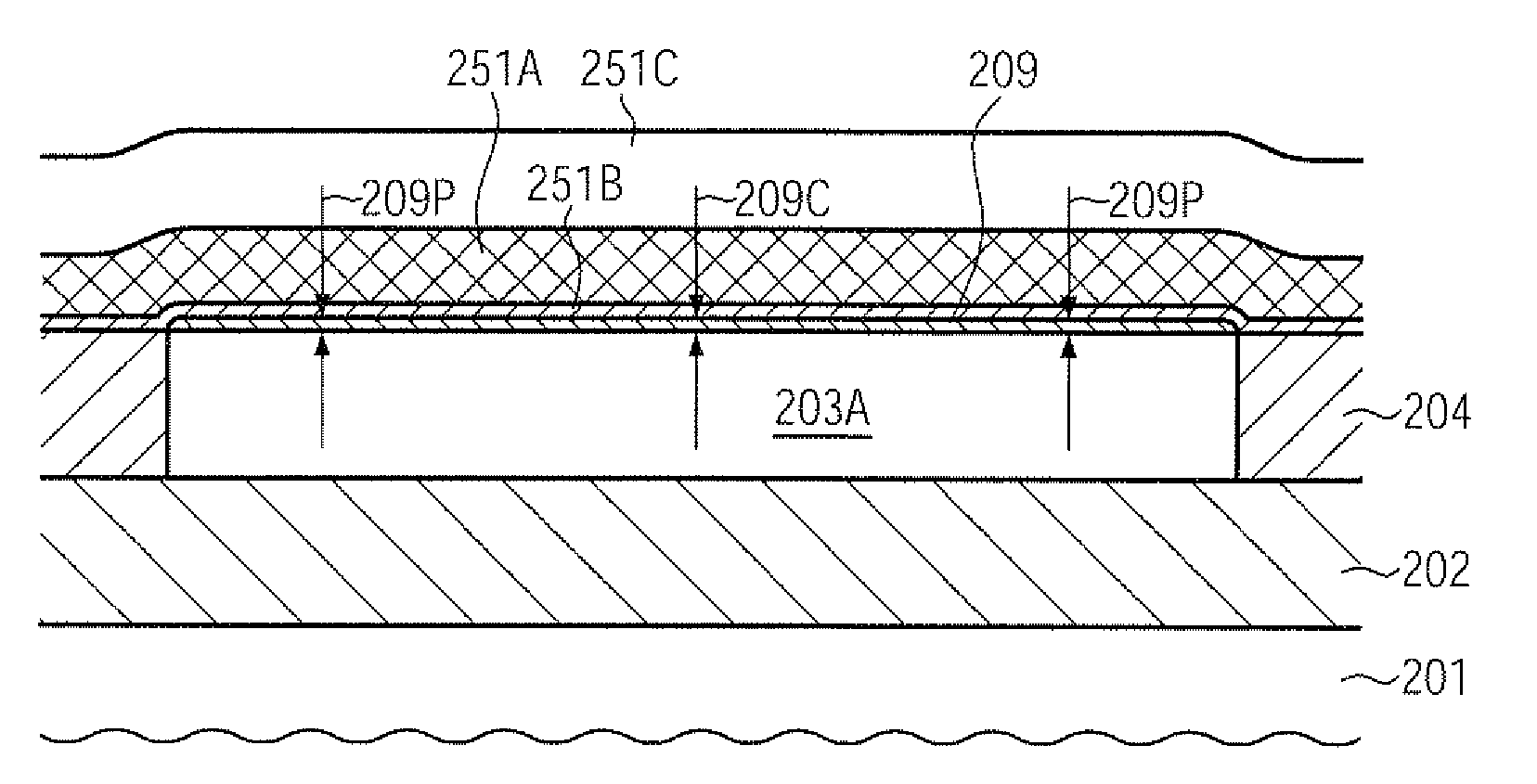

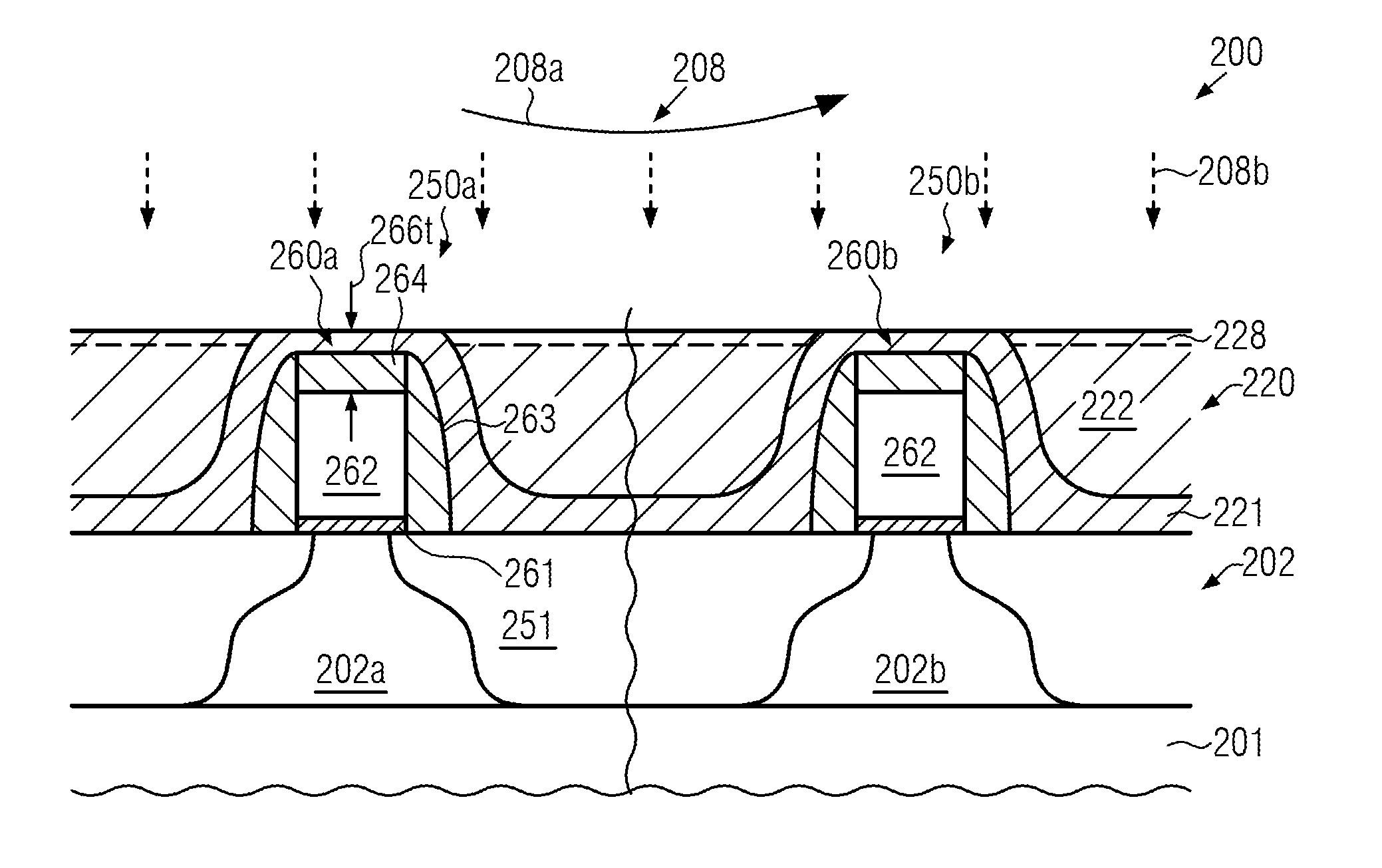

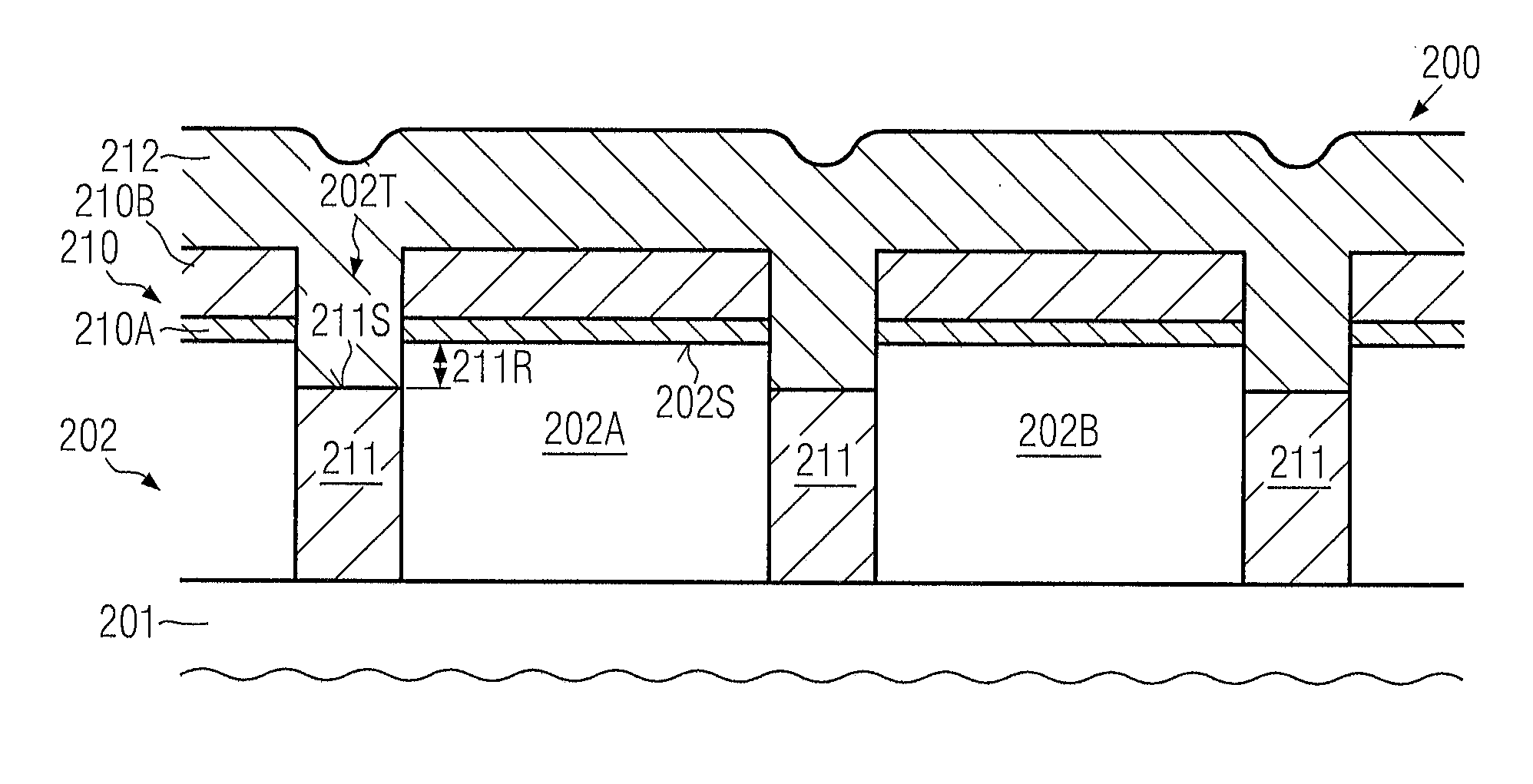

Reduction of thickness variations of a threshold semiconductor alloy by reducing patterning non-uniformities prior to depositing the semiconductor alloy

ActiveUS20100193881A1Low variabilityImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor alloysAlloy

The growth rate in a selective epitaxial growth process for depositing a threshold adjusting semiconductor alloy, such as a silicon / germanium alloy, may be enhanced by performing a plasma-assisted etch process prior to performing the selective epitaxial growth process. For example, a mask layer may be patterned on the basis of the plasma-assisted etch process, thereby simultaneously providing superior device topography during the subsequent growth process. Hence, the threshold adjusting material may be deposited with enhanced thickness uniformity, thereby reducing overall threshold variability.

Owner:ADVANCED MICRO DEVICES INC

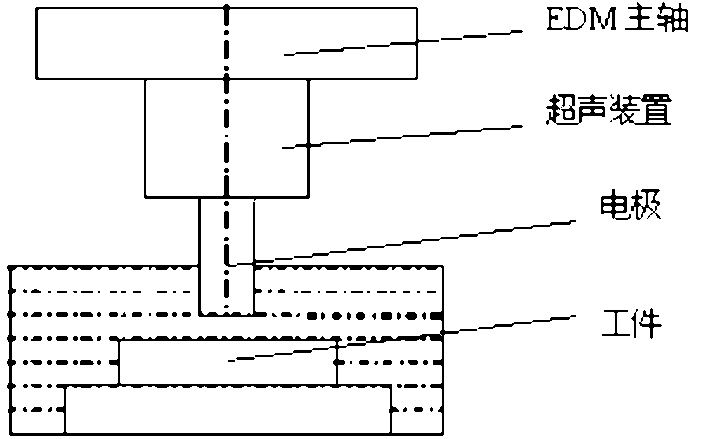

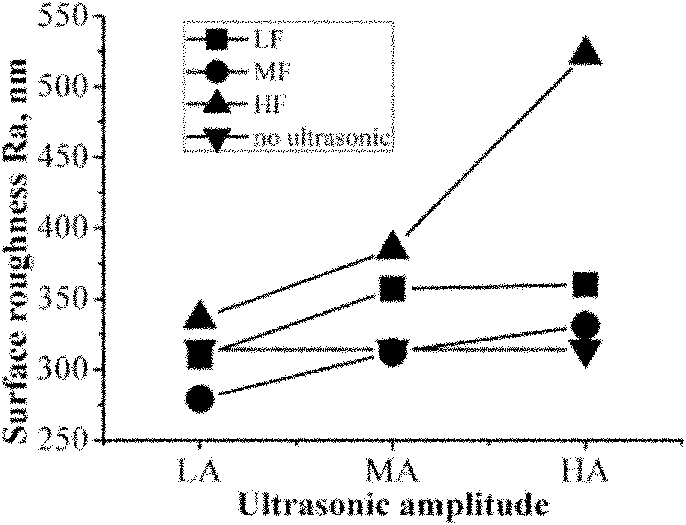

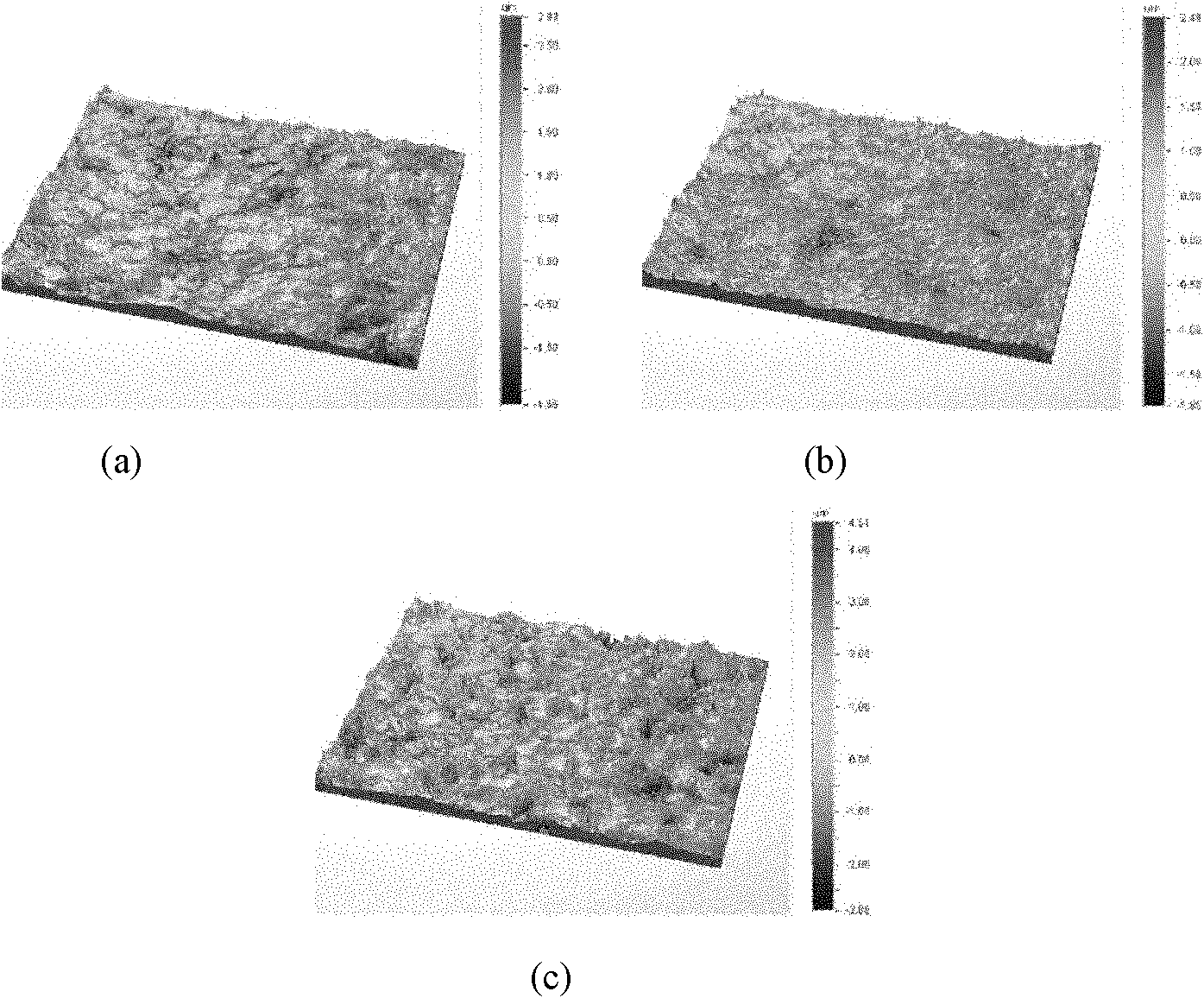

Process for intensifying ultrasonic vibration assisted electric spark pulse discharging surface

The invention discloses a process for intensifying an ultrasonic vibration assisted electric spark pulse discharging surface, comprising the following steps of: selecting 65Mn steel subjected to medium temperature tempering treatment after quenching, as a workpiece electrode and a monocrystal Si as a tool electrode; additionally arranging an ultrasonic vibration device on the tool electrode to assist the electric spark surface intensification; and with coal oil as a working solution, carrying out positive electrode electric spark surface intensification on the 65Mn steel by utilizing an electric spark processing machine tool, wherein the intensifying electricity parameters are that the pulse width is more than or equal to 4.2 mu s and less than 7.5mu s, the pulse width intrapulse ratio is between 0.21 and 0.56, a peak value current is more than or equal to 3.2A and less than 14.2A, the intensifying time is between 15min and 25min, the tool electrode-assisted ultrasonic vibration amplitude range is between 1mu m and 2mu m, and the frequency range is between 15 kHz and 60kHz. The invention improves the surface topography of an intensified layer so that the thickness distribution of the intensified layer is more uniform and more compact, increases the quantity of an intensifying phase and improves microhardness, abrasive resistance and surface Si content of the intensified layer.

Owner:SHANDONG UNIV

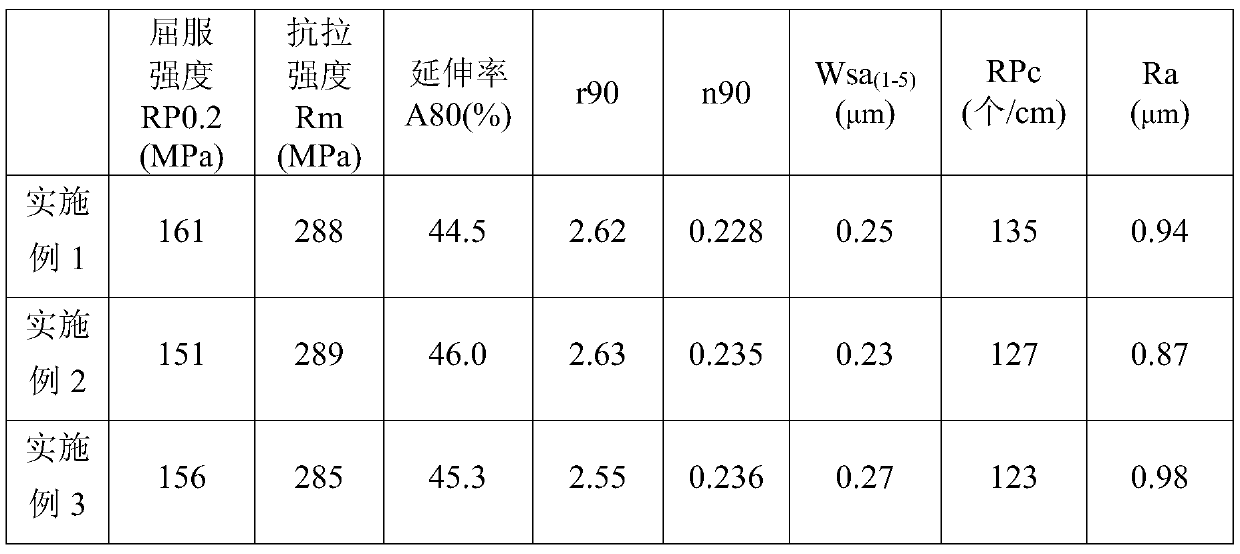

Method for controlling surface appearance of hot-dip galvanized ultra-deep drawing steel for automobile panel

ActiveCN110527921AImprove surface topographyGuaranteed cooling rateHot-dipping/immersion processesSurface roughnessProcess conditions

The invention discloses a method for controlling the surface appearance of hot-dip galvanized ultra-deep drawing steel for an automobile panel. The hot-dip galvanized steel strip comprises the following chemical components in percentage by mass: C is smaller than or equal to 0.0025%, Si is smaller than or equal to 0.020%, Mn is 0.10-0.15%, P is smaller than or equal to 0.012%, S is smaller than orequal to 0.010%, Als is 0.020-0.050%, Ti is 0.055-0.080%, N is smaller than or equal to 0.0040%, and the balance Fe and inevitable impurities. The manufacturing method comprises the steps of smelting, continuous casting, hot rolling, acid continuous rolling, hot galvanizing and the like. By controlling the production process, especially the process conditions of the cold continuous rolling stageand the hot galvanizing stage, the surface roughness and waviness of the hot galvanizing ultra-deep drawing steel can meet the requirements of automobile factories besides good tensile property.

Owner:SD STEEL RIZHAO CO LTD

Prevention of ILD Loss in Replacement Gate Technologies by Surface Treatmen

InactiveUS20130115773A1Improve surface topographyHigh resistivitySemiconductor/solid-state device manufacturingSemiconductor devicesDielectricMetal

When forming sophisticated high-k metal gate electrode structures on the basis of a replacement gate approach, pronounced loss of the interlayer dielectric material may be avoided by inserting at least one surface modification process, for instance in the form of a nitridation process. In this manner, leakage paths caused by metal residues formed in the interlayer dielectric material may be significantly reduced.

Owner:GLOBALFOUNDRIES INC

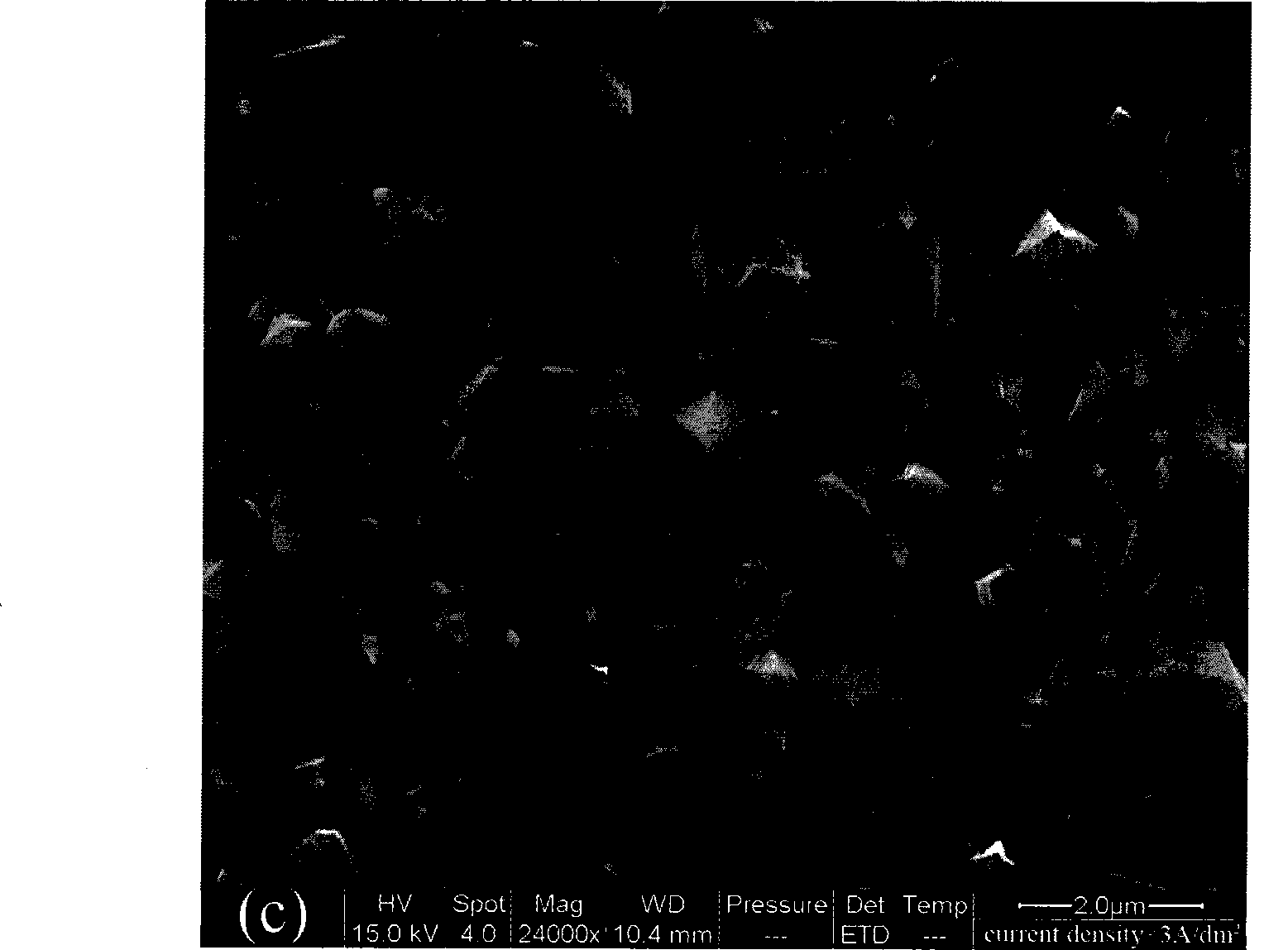

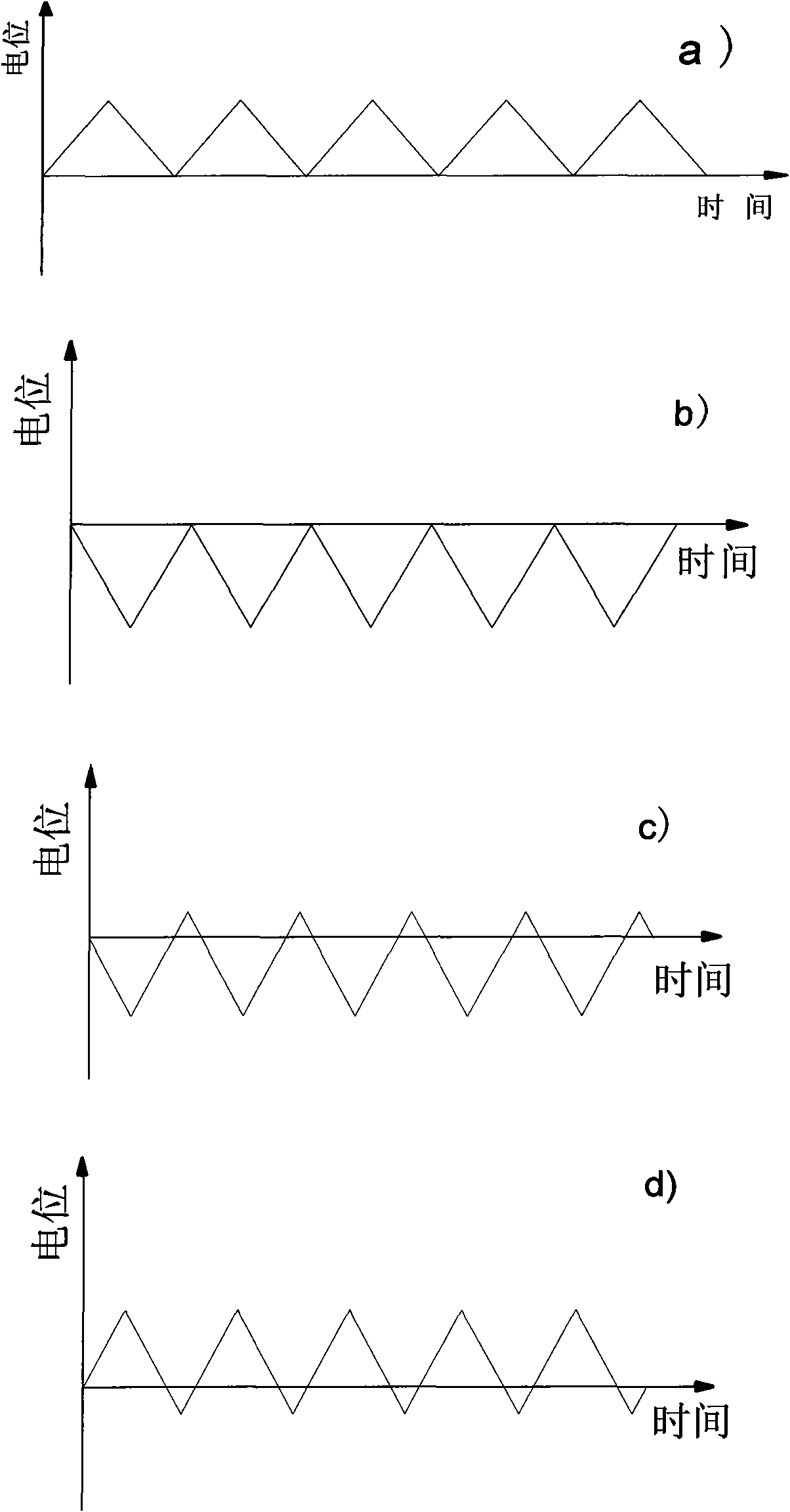

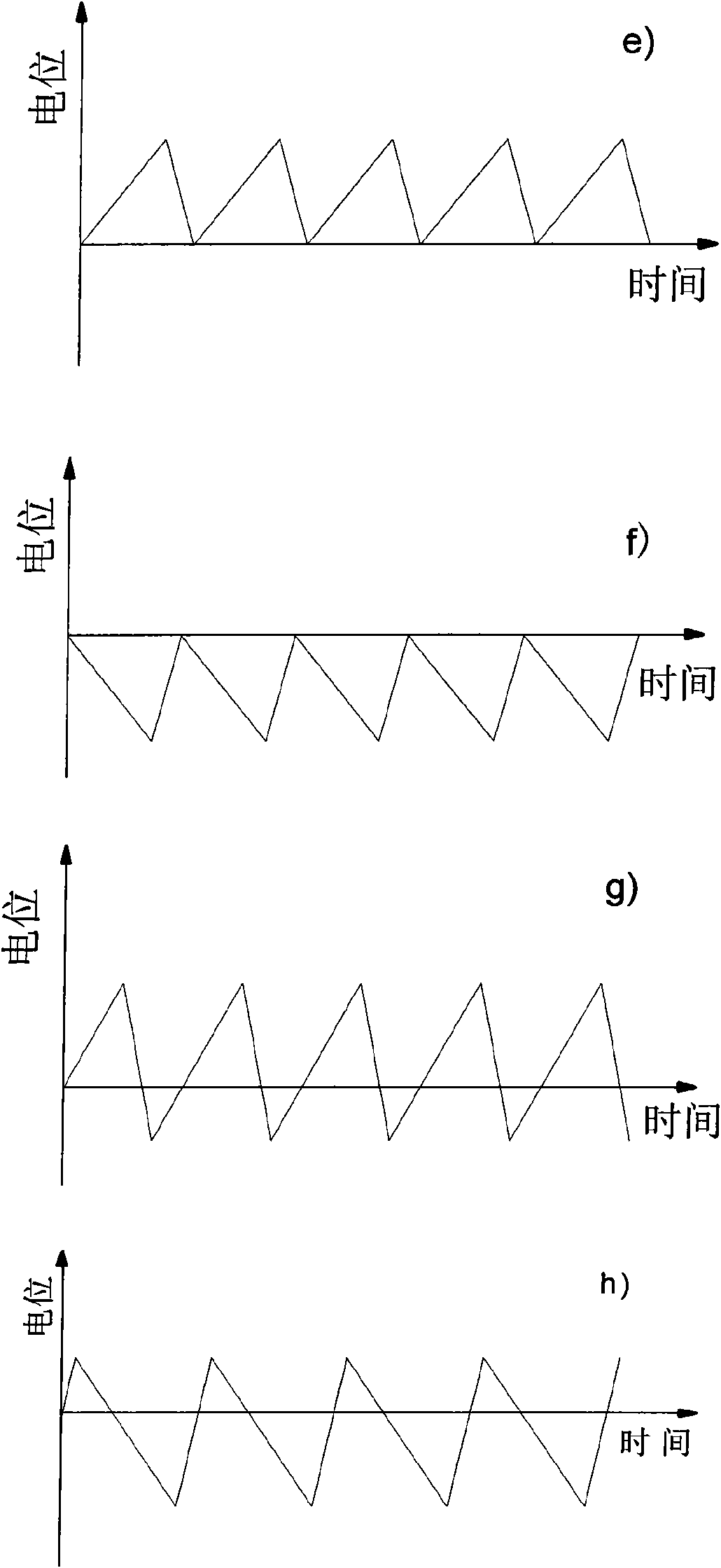

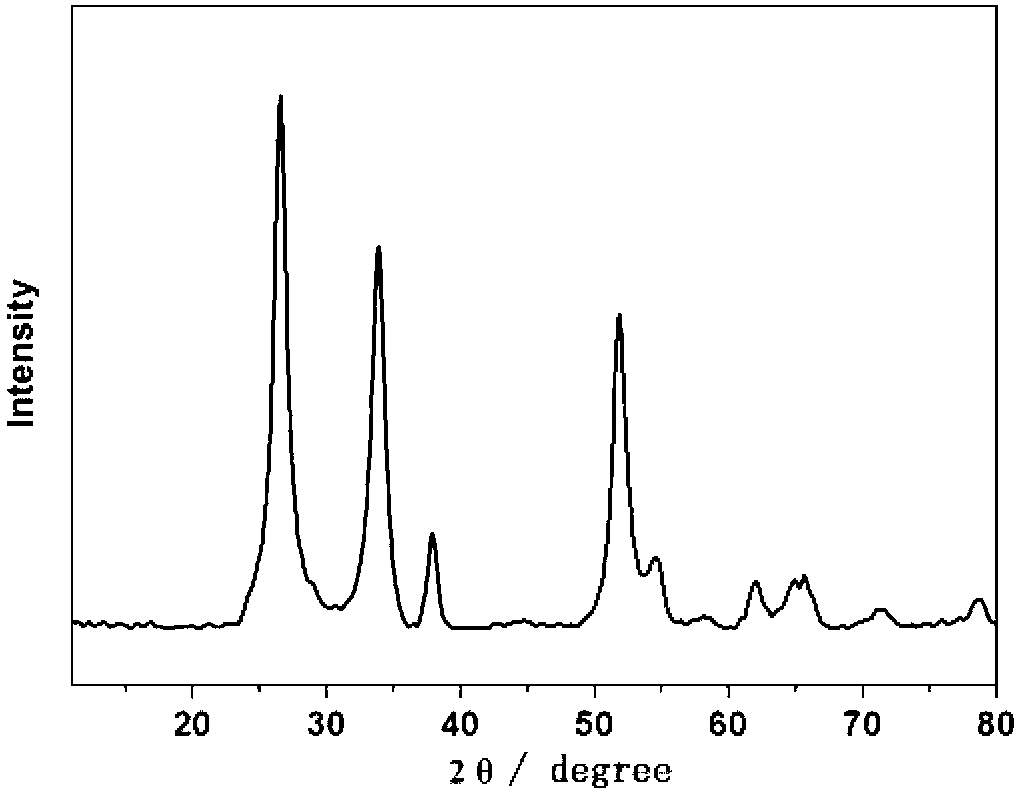

Preparation method of electrodepositing Bi2Te3 mixed with thin-film thermoelectric material

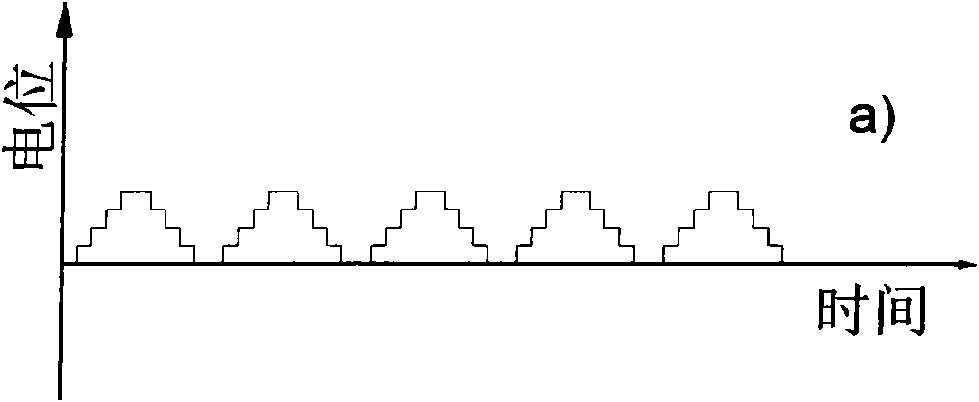

InactiveCN101613867AImprove surface topographyImprove thermoelectric performanceElectrolytic inorganic material coatingThermoelectric device manufacture/treatmentElectricityContinuous scanning

The invention relates to an electrodepositing method of electrodepositing Bi2Te3 mixed with thin-film thermoelectric material, which uses electrokinetic potential or galvanic current in an electrodepositing system. The electrokinetic potential waveform output by a power supply in the electrodepositing system is a continuous scanning potential waveform or a step scanning potential waveform; and the potential of a cathode electrode ranges from minus 1V to 1V. The galvanic current waveform output by a power supply in the electrodepositing system is a continuous scanning current waveform or a step scanning current waveform; and the current density of the cathode electrode ranges from minus 50mA / cm<2> to 100mA / cm<2>. The Bi2Te3 mixed with thin-film thermoelectric material prepared by the invention has the advantages of low manufacturing cost, good surface appearance of the material, high thermoelectricity performance and easy large-scale production. The thin-film thermoelectric material is very applicable to preparing micro-thermoelectric batteries, micro-thermoelectric cooling (heating) devices, and thermoelectric detectors.

Owner:TIANJIN UNIV

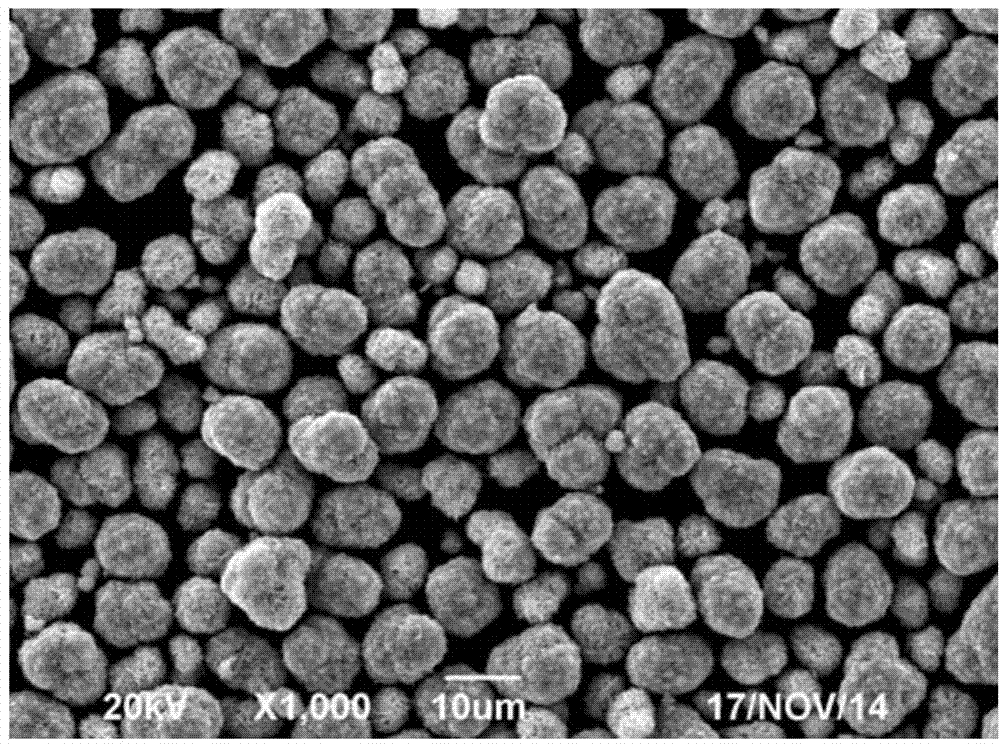

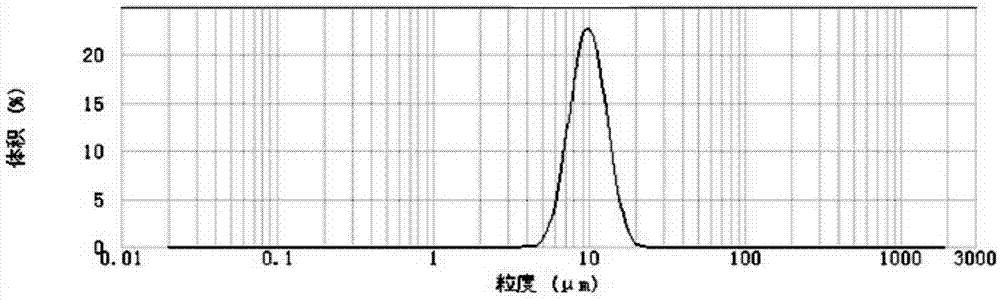

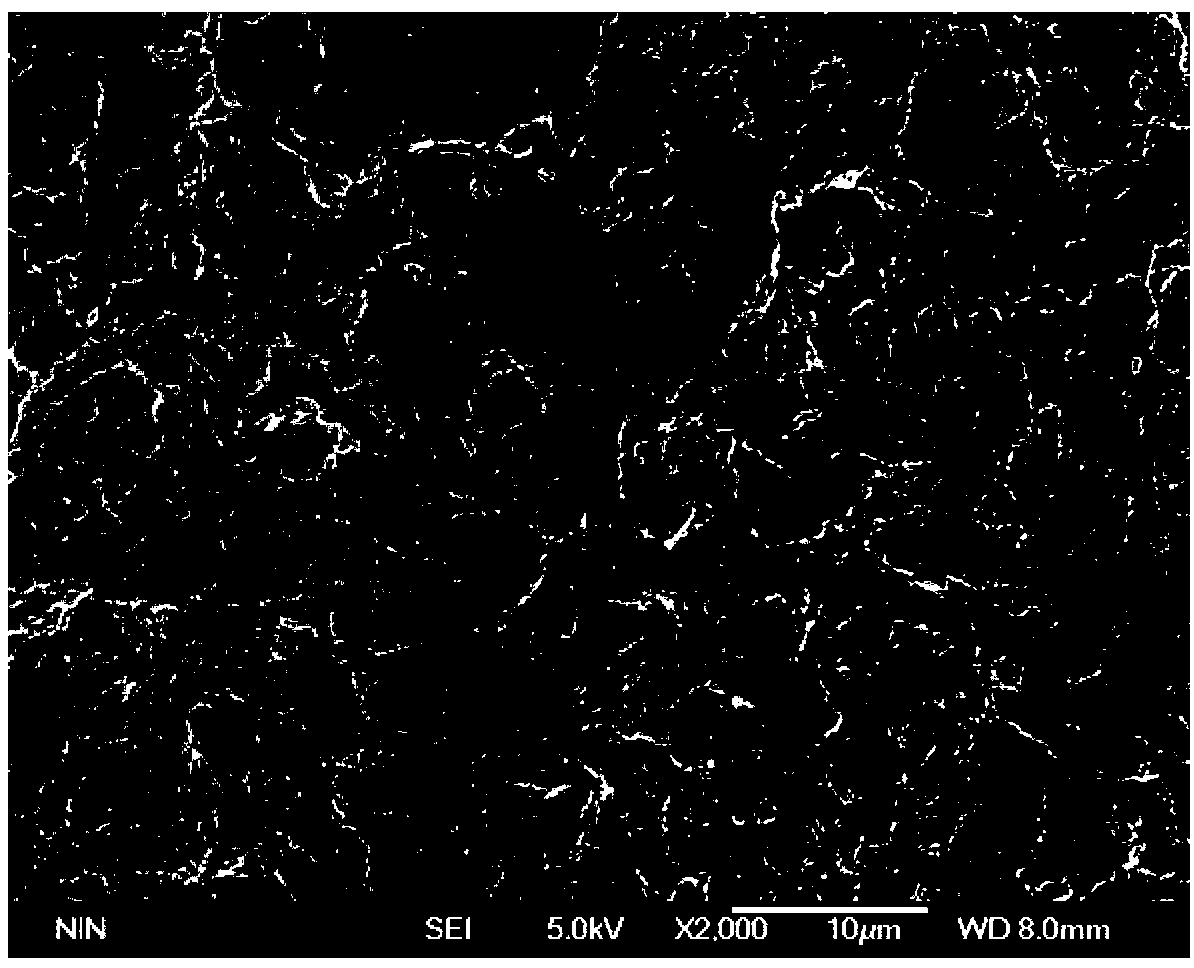

Nickel and cobalt binary anode material precursor preparing method and nickel and cobalt binary anode material precursor prepared through method

The invention provides a nickel and cobalt binary anode material precursor preparing method and a nickel and cobalt binary anode material precursor prepared through the method. According to the nickel and cobalt binary anode material precursor preparing method, the pH value of a solution at the early stage of a reaction is regulated so that the grain size of a nickel and cobalt binary anode material precursor crystal nucleus in the obtained solution can be in normal distribution, then a subsequent reaction is performed with the obtained solution as a base solution, subsequent preparing conditions are regulated, and therefore the grain size of the crystal nucleus is increased in a balanced mode under the distribution condition, and the grain size of the nickel and cobalt binary anode material precursor prepared through the method can be in normal distribution.

Owner:HUNAN RESHINE NEW MATERIAL

Preparation method and application of wear resistant hydroxyl terminated polyurethane resin used for protection coating of silica key

InactiveCN102516489AEasy to prepareReaction is easy to controlPolyurea/polyurethane coatingsCyclohexanonePolyester

The invention discloses a preparation method and an application of wear resistant hydroxyl terminated polyurethane resin used for a protection coating of a silica key. The resin is prepared by addition polymerization in a toluene solution through selecting different diisocyanate, polyester polyol, a chain extender and a cross-linking agent, and takes dibutyltin dilaurate as a catalyst. The application of the wear resistant hydroxyl terminated polyurethane resin is characterized in that the hydroxyl terminated polyurethane resin, an enclosed type curing agent, a catalyst and a leveling agent are dissolved in a mixed solvent of acetic ester, toluene and cyclohexanone, and uniformly mixed to obtain the protection coating of the silica key. By introducing surface modified gas phase silica, the compatibility of gas phase silica and polyurethane resin can be enhanced, thereby the wear resistant performance of a polyurethane coating can be raised with a large degree.

Owner:SOUTH CHINA UNIV OF TECH

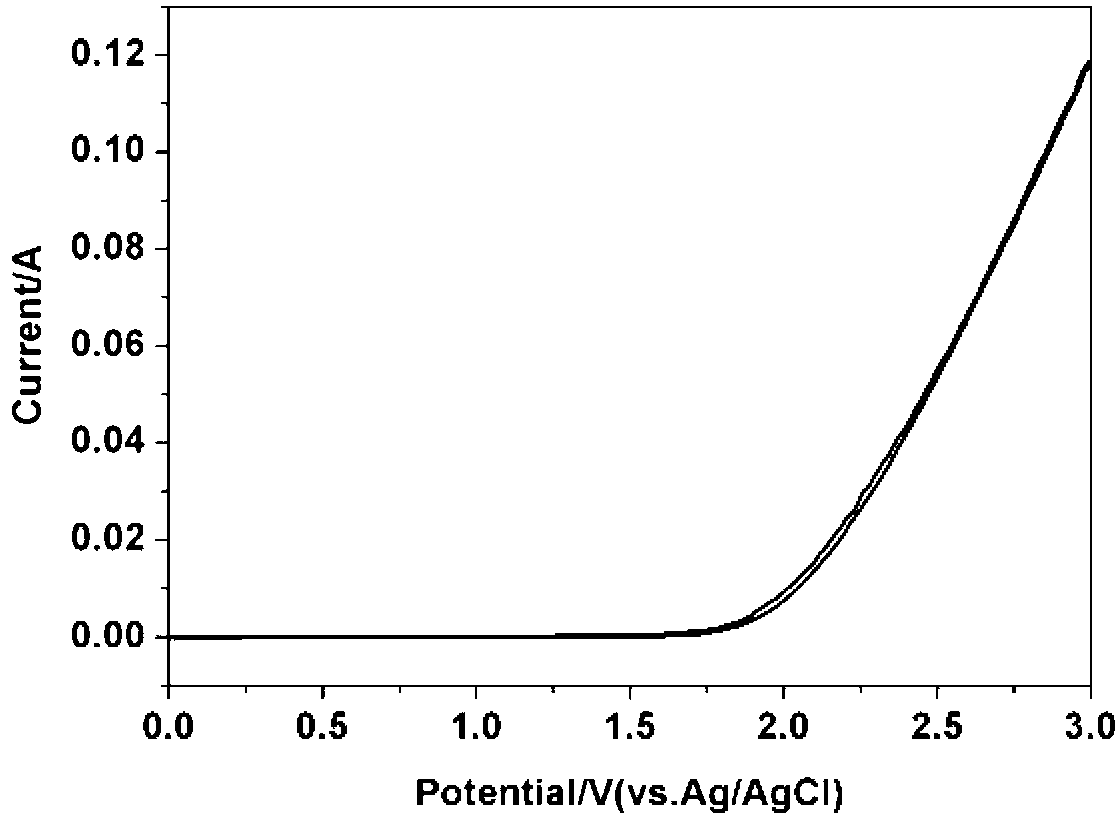

Fabrication method of long-life titanium base electrode

The invention discloses a fabrication method of a long-life titanium base electrode, which comprises the steps of fabricating a titanium oxide layer on a titanium substrate by a dipping-thermal decomposition method, reducing the titanium oxide layer in a reducing atmosphere, synchronously depositing a tin metal simple substance and an antimony metal simple substance in proportion on the surface of the titanium oxide layer by an electrodeposition method, and conducting thermal oxidation to allow an antimony doped tin oxide layer to be tightly combined with the titanium oxide layer connected with the titanium substrate to form a solid solution structure. The prepared titanium base tin dioxide electrode has the advantages of long service life, high oxygen evolution potential, high electrocatalytic activity, high generation efficiency of ozone from electrolyzed water, and the like. In addition, the cost of the fabrication process is low, the requirement of equipment is low, the operation is easy to control, and industrial mass production is facilitated.

Owner:XI AN JIAOTONG UNIV

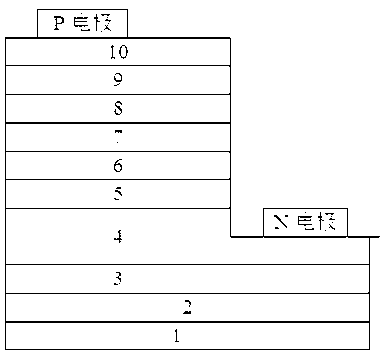

Growing method of GaN-based light-emitting diode extensional structure

ActiveCN103227251AImprove surface topographyQuality improvementSemiconductor devicesPotential wellPower flow

The invention discloses a growing method of a GaN-based light-emitting diode extensional structure. The extensional structure disclosed by the invention comprises a substrate, a low-temperature GaN buffering layer, a GaN non-doped layer, an N-type GaN layer, a light quantum well layer, a light-emitting quantum well layer, a low-temperature P-type GaN layer, a PAlGaN current blocking layer, a high-temperature P-type GaN layer and a P-type contact layer in sequence from bottom to top, wherein the light quantum well layer comprises a plurality of quantum well structures overlapped in sequence; the quantum well structures are formed by growing InxGa1-xN potential well layers, wherein x is greater than 0 and smaller than 1 and GaN barrier layers sequentially grow with a gradient growth rate; and a Ga source extensionally grow by using TMGa or TEG A. by adopting the growing method disclosed by the invention, the crystal quality, the light-emitting efficiency and the luminance can be better improved.

Owner:宁波安芯美半导体有限公司

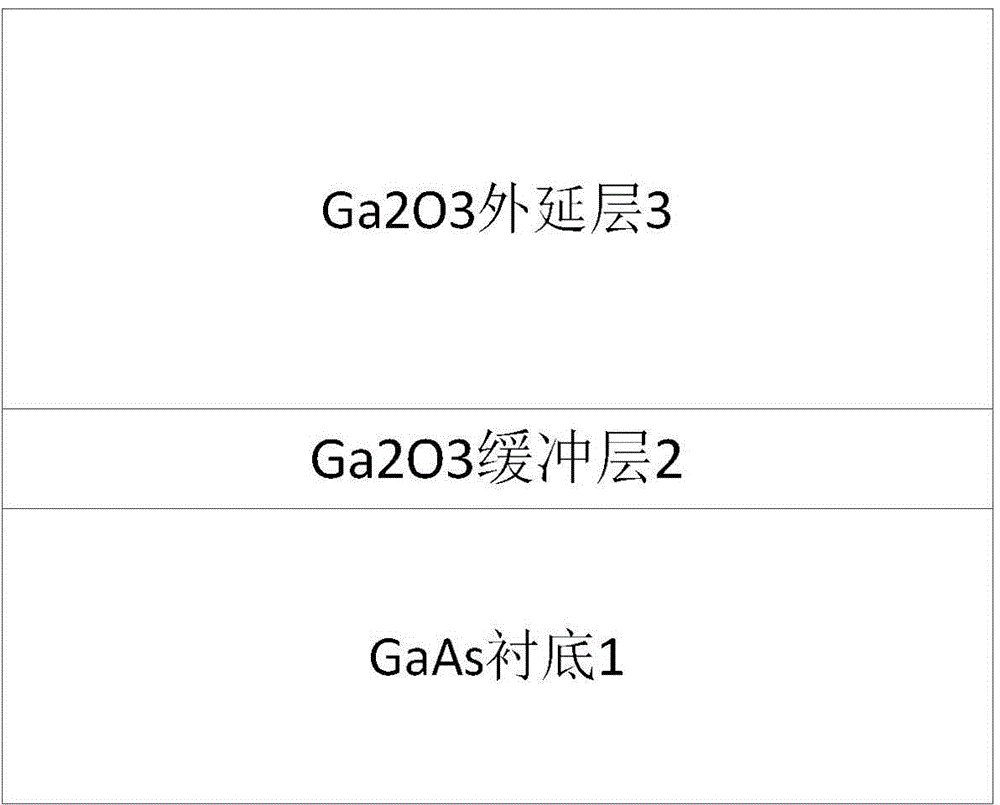

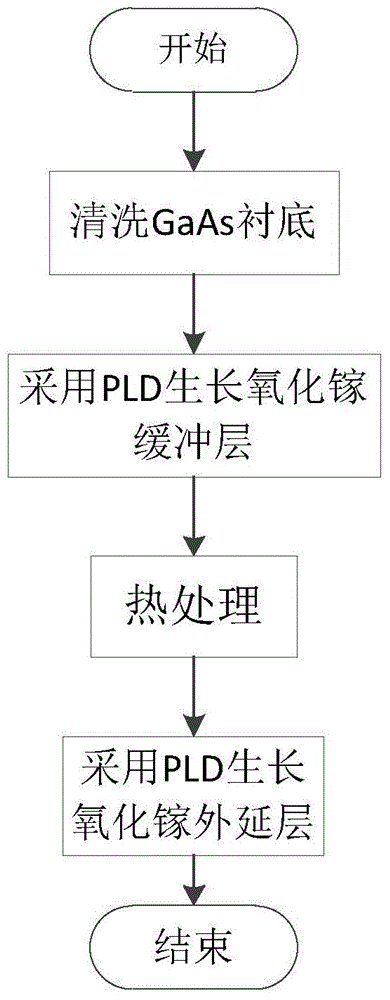

GaAs substrate-based gallium oxide thin film and growing method thereof

InactiveCN104962858AImprove crystal qualitySmall sizeVacuum evaporation coatingSemiconductor/solid-state device manufacturingSurface roughnessSemiconductor

The invention discloses a GaAs substrate-based gallium oxide thin film and a growing method thereof, and mainly solves the problems of poor surface appearance and small grain size of an existing gallium oxide thin film. The gallium oxide thin film comprises a GaAs substrate (1) and a gallium oxide epitaxial layer (3), and is characterized in that a gallium oxide buffer layer (2) of 6 to 12 nm is arranged between the GaAs substrate (1) and the gallium oxide epitaxial layer (3), and the crystal quality of the gallium oxide buffer layer is improved by utilizing thermal annealing. The surface roughness of a Ga2O3 thin film is reduced, the surface appearance of the Ga2O3 thin film is improved, and the Ga2O3 grain size is increased; the GaAs substrate-based gallium oxide thin film and the growing method can be used for making semiconductor power devices.

Owner:XIDIAN UNIV

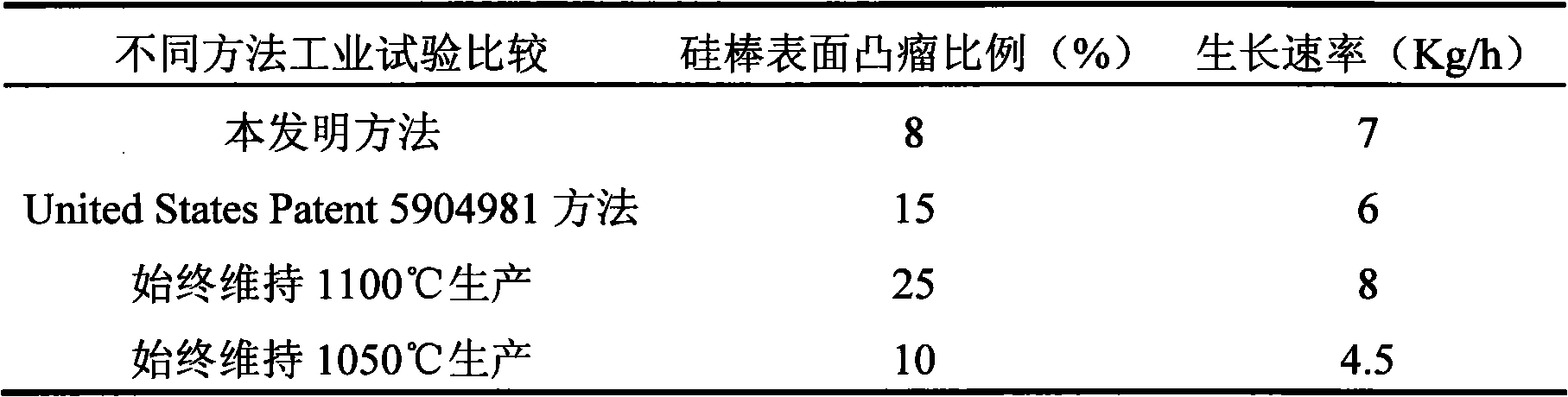

Production method of polysilicon rod

ActiveCN101654249AImprove surface bumpsImprove surface topographySilicon compoundsHydrogen flowPolycrystalline silicon

The invention discloses a production method of a polysilicon rod, comprising the following steps: when the surface temperature of a silicon core is 1100-1250 DEG C, leading in hydrogen to react with trichlorosilane for 30-45 hours; when the silicon core grows to have the diameter of 50mm, stopping current, and adding hydrogen flow rate to continuously react for 3-10 hours; when the surface temperature of the polysilicon rod is reduced to1000-1050 DEG C, applying the current, reducing the hydrogen flow rate, raising the surface temperature of the polysilicon rod to about 1080-1100 DEG C and keeping the surface temperature of the polysilicon rod for 30 hours; stopping the current, and increasing the hydrogen flow rate again to react for 2-6 hours; when the surface temperature of the polysilicon rod is reduced to 970-1020 DEG C, reducing the hydrogen flow rate again, applying the current, raising the surface temperature of the polysilicon rod to 1050-1080 DEG C, and then keeping the surface temperature of the polysilicon rod till a reduction reactor is stopped. The production method of the polysilicon rod can obviously improve the surface appearance of solar polysilicon in the production process, and the surface bump area of the polysilicon can be controlled within 8 percent.

Owner:JIANGSU ZHONGNENG POLYSILICON TECH DEV

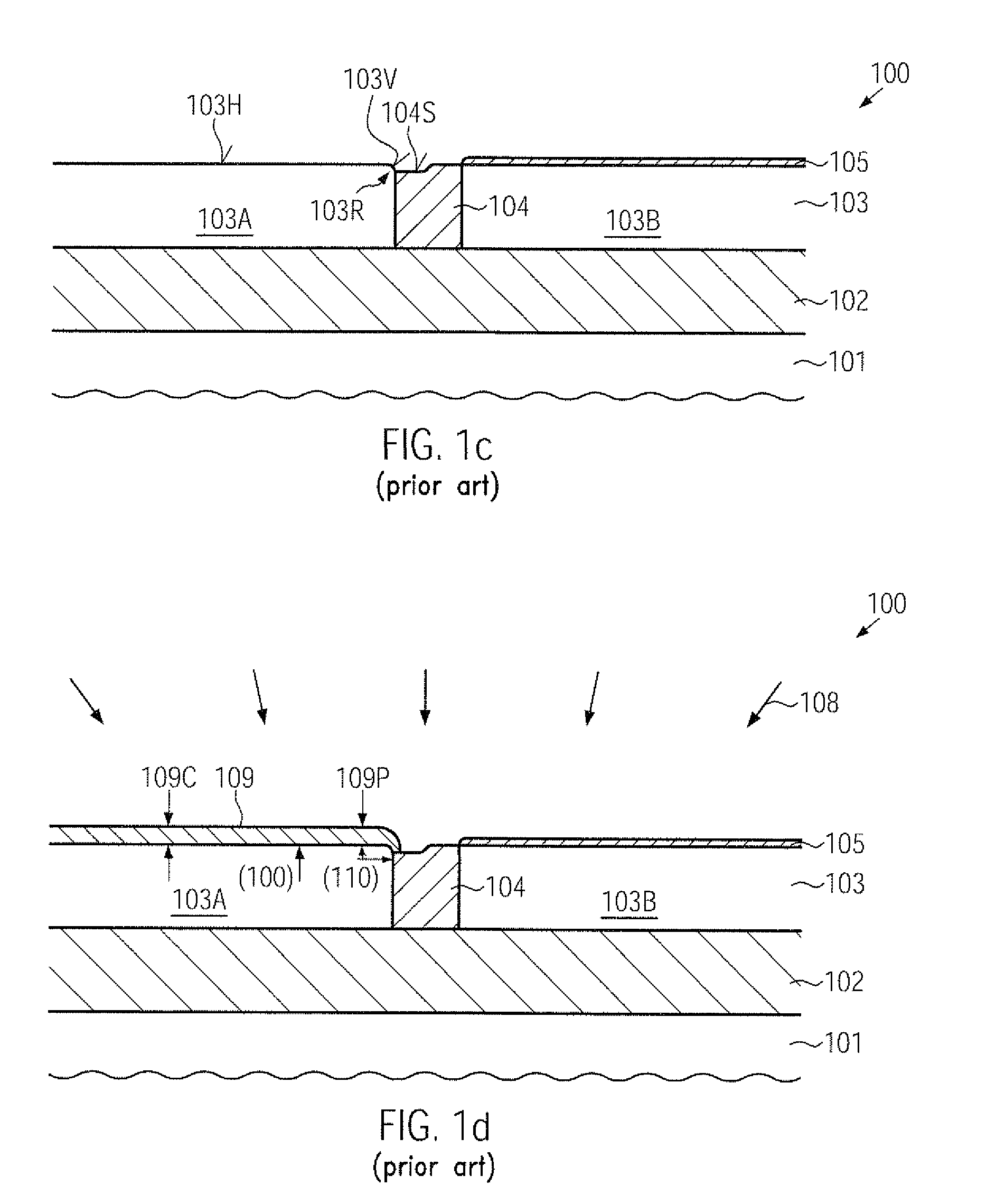

Superior Integrity of High-K Metal Gate Stacks by Capping STI Regions

ActiveUS20120223407A1Improve efficiencyReduce saggingSemiconductor/solid-state device manufacturingSemiconductor devicesSilicon dioxideMetal gate electrodes

When forming high-k metal gate electrode structures in an early manufacturing stage, integrity of an encapsulation and, thus, integrity of sensitive gate materials may be improved by reducing the surface topography of the isolation regions. To this end, a dielectric cap layer of superior etch resistivity is provided in combination with the conventional silicon dioxide material.

Owner:GLOBALFOUNDRIES US INC

Device and method for continuous laser sharpening resin binder grinding wheel

InactiveCN1586816AMeet the requirements of sharpeningImprove surface topographyAbrasive surface conditioning devicesThree phase asynchronous motorEngineering

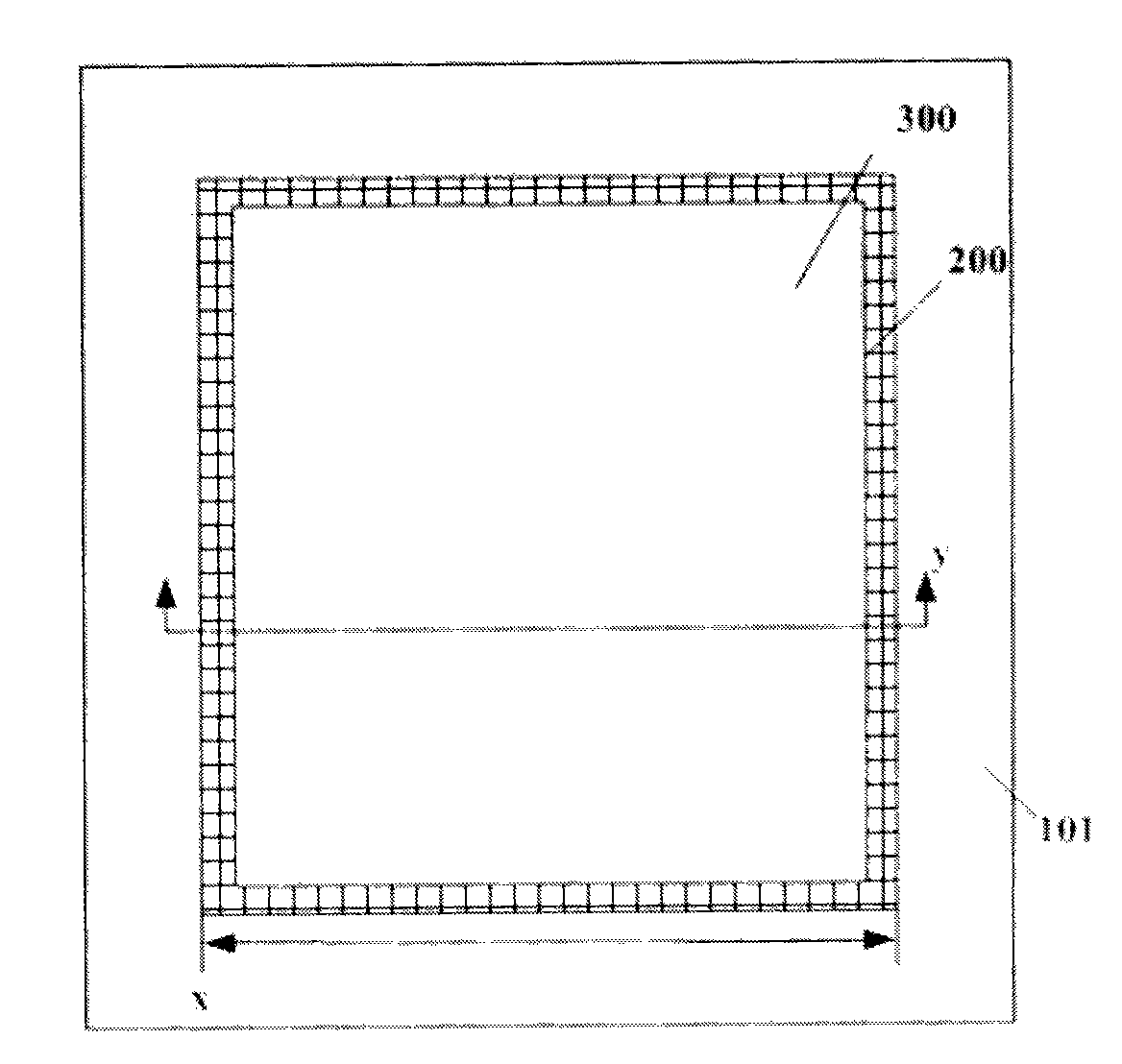

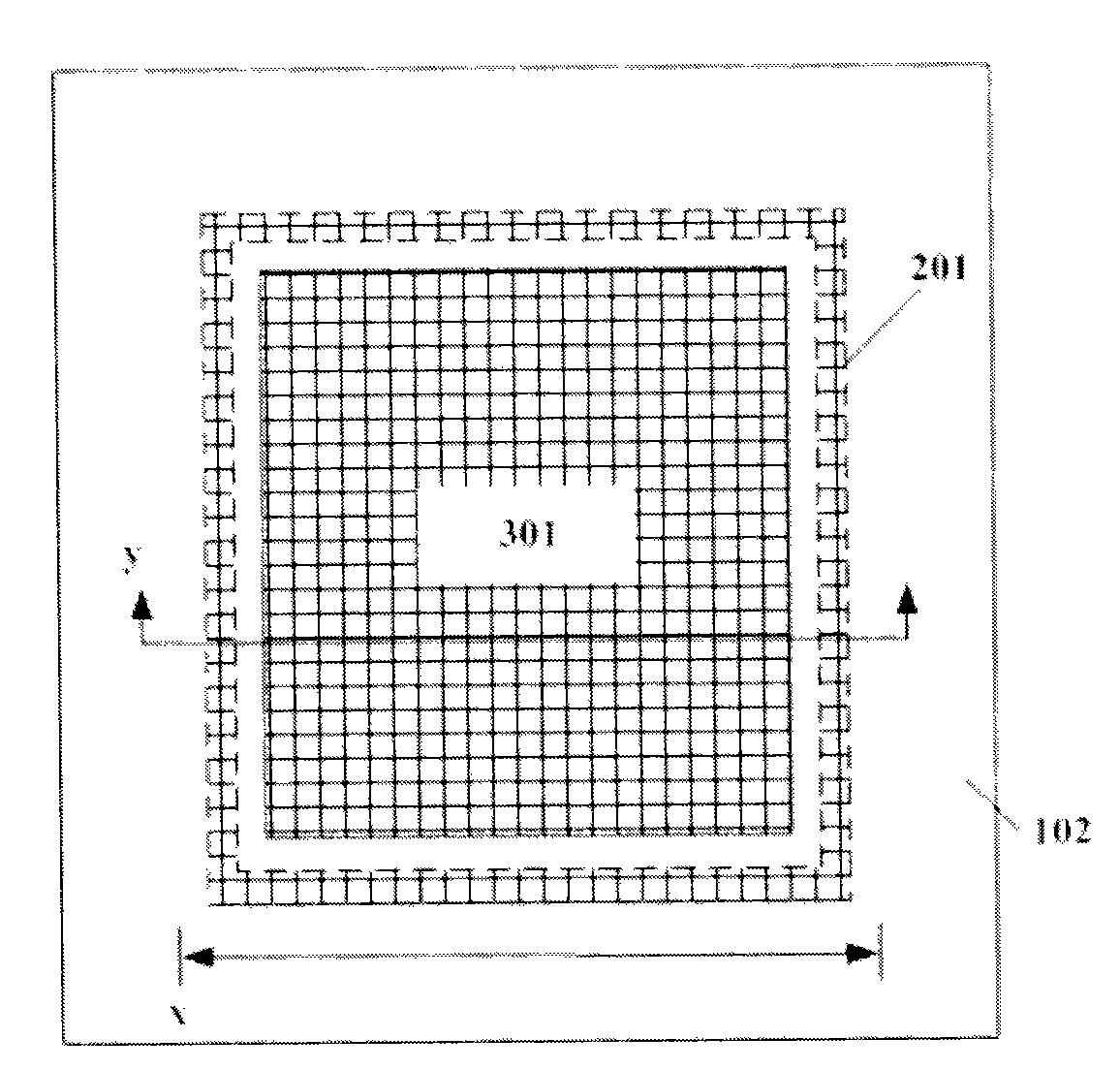

The present invention belongs to the field of mechanism engineering technology. The grinding wheel sharpening apparatus includes CO2 laser, fixing rack, focusing lens, belt wheel, frequency regulating motor, main shaft, grinding wheel frame, and triphase asynchronous motor. Through grinding wheel sharpening digital simulation to obtain the proportional relation between the groove depth and E1, selecting output power and light spot diameter of CO2 laser to determine the linear speed of the grinding wheel, regulating output power and light spot diameter of CO2 laser, regulating the rotation speed of the frequency regulating motor to regulate the surface linear speed of the grinding wheel, regulating the rotation speed of the triphase asynchronous motor to regulate the axial speed of the grinding wheel, and regulating performance parameters of the laser to control the sharpening effect precisely, ideal grinding wheel may be obtained.

Owner:SHANGHAI JIAO TONG UNIV

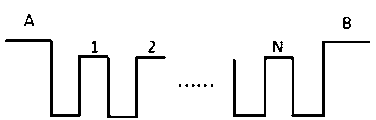

Packaging method

ActiveCN102690044AImprove surface topographyIdeal for height non-uniformitySolid-state devicesSemiconductor/solid-state device manufacturingLaser scanningMaterials science

A packaging method comprises the following steps of: preparing a finely pulverized powder, preparing a finely pulverized powder paste by the use of the finely pulverized powder, coating a packaging wire of cover lens by with the finely pulverized powder paste and glass paste, presintering the coated cover lens in vacuum, folding the cover lens which is presented in vacuum with a glass substrate, and carrying out laser scanning and packaging on the folded combination of the cover lens and the glass substrate. By the adoption of the packaging method, height inhomogeneities of the presentered packaging wire can be controlled within an ideal range and requirements on laser power when packaging is obviously reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com