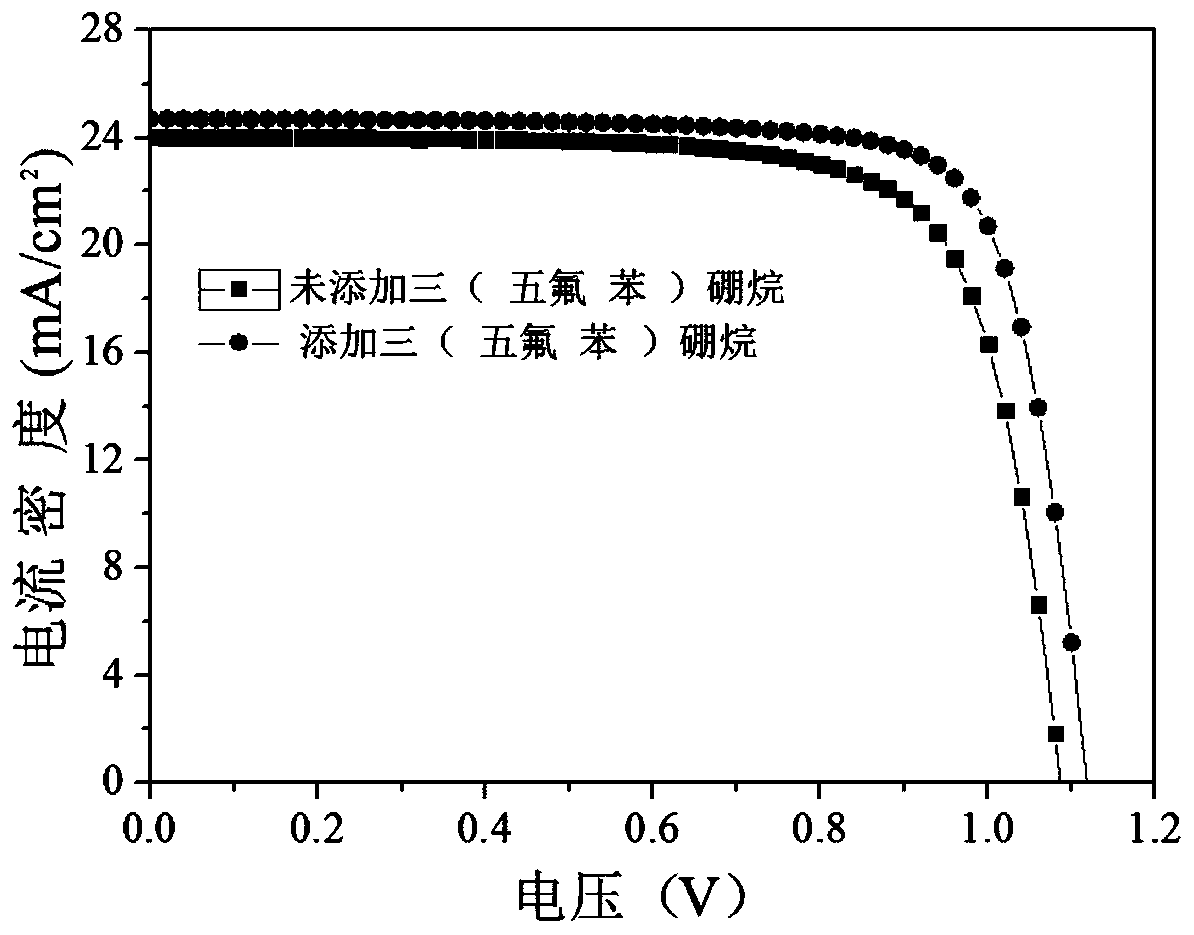

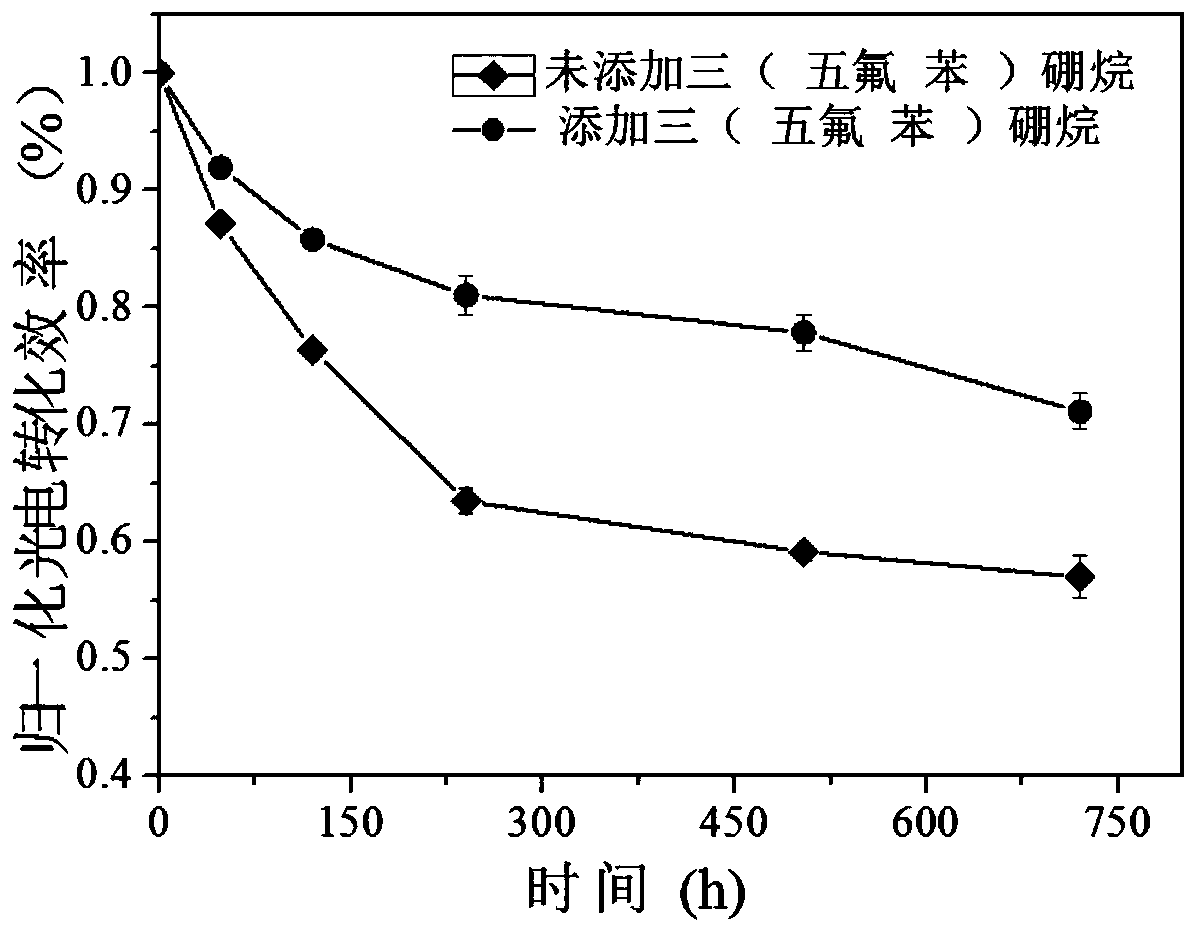

Novel passivated perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as poor stability of perovskite solar cells, and achieve the effects of improving air stability, improving quality, and reducing non-radiative recombination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1, ultrasonically clean the cut FTO conductive glass substrate in acetone, isopropanol and ethanol for 5 minutes respectively, and blow dry with nitrogen gas to obtain the cleaned conductive glass substrate;

[0052] Step 2, using the hydrothermal insulation deposition method to deposit a layer of TiO on the etched FTO surface at 70 °C 2 as electron transport material;

[0053] Step 3, take tris(pentafluorophenyl)borane powder, add chlorobenzene solvent, make tris(pentafluorophenyl)borane solution, its concentration is 1.25mg / mL, and stir 7h on the stirring platform, obtain tris(pentafluorophenyl)borane solution, (Pentafluorobenzene) borane solution;

[0054] Step 4, weigh NH according to the molar ratio 0.85:0.15 2 CHNH 2 I and CH 3 NH 3 I powder, form mixture A after mixing, then mix A and PbI according to molar ratio 1:1 2 Mixed, add a mixed solution of DMF and DMSO with a volume ratio of 6:1 as a solvent, and stir at room temperature on a stirring table f...

Embodiment 2

[0060] Step 1, ultrasonically clean the cut ITO conductive glass substrate in acetone, isopropanol and ethanol for 10 minutes respectively, and blow dry with nitrogen gas to obtain the cleaned conductive glass substrate;

[0061] Step 2, using the hydrothermal insulation deposition method to deposit a layer of TiO on the etched FTO surface at 70 °C 2 as electron transport material;

[0062] Step 3, take tris(pentafluorophenyl)borane powder, add chlorobenzene solvent, make tris(pentafluorophenyl)borane solution, its concentration is 0.625mg / mL, and stir on the stirring table for 8h, obtain tris(pentafluorophenyl)borane solution, (Pentafluorobenzene) borane solution;

[0063] Step 4, weigh NH according to the molar ratio 0.85:0.15 2 CHNH 2 I and CH 3 NH 3 I powder, form mixture A after mixing, then mix A and PbI according to molar ratio 1:1 2 Mixed, add a mixed solution of DMF and DMSO with a volume ratio of 8:1 as a solvent, and stir at room temperature on a stirring tabl...

Embodiment 3

[0068] Step 1, ultrasonically clean the cut FTO conductive glass substrate in acetone, isopropanol and ethanol for 15 minutes respectively, and blow dry with nitrogen gas to obtain the cleaned conductive glass substrate;

[0069] Step 2, using the hydrothermal insulation deposition method to deposit a layer of TiO on the etched FTO surface at 70 °C 2 as electron transport material;

[0070] Step 3: Weigh tris(pentafluorophenyl)borane powder, add chlorobenzene solvent to prepare tris(pentafluorophenyl)borane solution with a concentration of 1.875mg / mL, and stir on a stirring table for 8h to obtain tris(pentafluorophenyl)borane solution. (Pentafluorobenzene) borane solution;

[0071] Step 4, weigh NH according to the molar ratio 0.85:0.152 CHNH 2 I and CH 3 NH 3 I powder, form mixture A after mixing, then mix A and PbI according to molar ratio 1:1 2 Mixed, add a mixed solution of DMF and DMSO with a volume ratio of 4:1 as a solvent, and stir at room temperature on a stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com