Three-dimensional porous graphene-vanadium disulfide composite electrode material, and preparation method and application thereof

A technology of vanadium disulfide and composite electrodes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., and can solve problems such as poor rate performance, low cycle reversibility, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

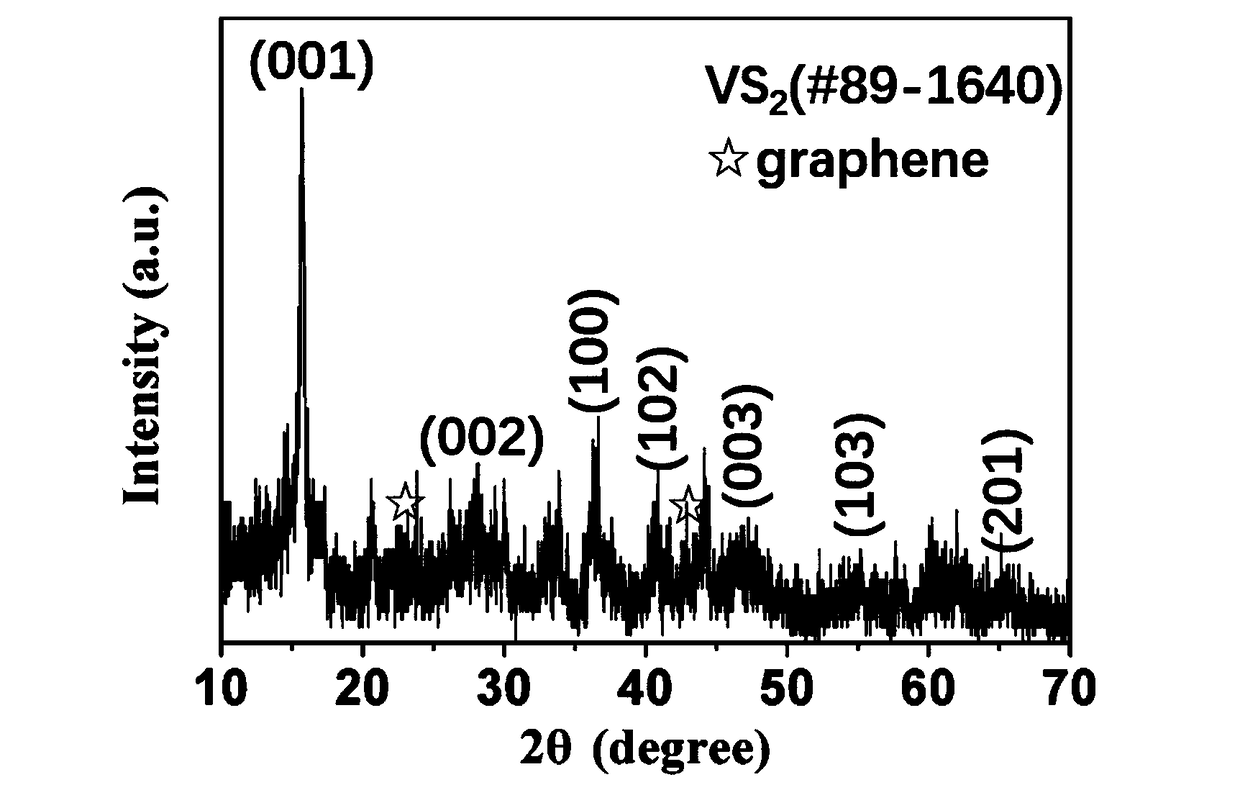

[0032] The invention provides a method for preparing a three-dimensional porous graphene-vanadium disulfide composite electrode material described in the above technical solution, comprising the following steps:

[0033] Mixing the vanadium source solution and the sulfur source to obtain a mixed solution;

[0034] The mixed solution, the porous graphene oxide and the surfactant are uniformly mixed, and hydrothermally reacted to obtain a three-dimensional porous graphene-vanadium disulfide composite electrode material.

[0035] The invention mixes the vanadium source solution and the sulfur source to obtain a mixed solution. In the present invention, the vanadium source solution is preferably prepared according to the following method:

[0036] The vanadium source and the solvent are mixed and stirred to obtain a vanadium source solution.

[0037] In the present invention, the vanadium source is preferably selected from one or more of ammonium metavanadate, sodium vanadate an...

Embodiment 1

[0054] Preparation of porous graphene oxide:

[0055] Take 44mg of graphene oxide to be treated, add 22mL of deionized water, put it into a 300W ultrasonic machine for 2 hours, and obtain a 2mg / mL graphene oxide dispersion, then add it to a three-necked flask and place it in a water bath, and adjust the temperature to room temperature Measure 4mL of 30% hydrogen peroxide with a graduated cylinder, and slowly add it into the above-mentioned three-necked flask with a peristaltic pump. After the dropwise addition is completed, raise the temperature of the water bath to 95-100°C, and the holding time is 2h. In the above process, the magnetic stirring of the water bath should be maintained and a condenser should be installed at the middle mouth of the three-necked flask to prevent the solvent from volatilizing due to the temperature rise of the solution. After the reaction is over, turn off the temperature control program of the water bath (keep magnetic stirring) and cool to room ...

Embodiment 2

[0065] Preparation of porous graphene oxide:

[0066] Take 44mg of graphene oxide to be treated, add 22mL of deionized water, put it into a 300W ultrasonic machine for 2 hours, and obtain a 2mg / mL graphene oxide dispersion, then add it to a three-necked flask and place it in a water bath, and adjust the temperature to room temperature Measure 4mL of 30% hydrogen peroxide with a graduated cylinder, and slowly add it into the above-mentioned three-necked flask with a peristaltic pump. After the dropwise addition is completed, raise the temperature of the water bath to 95-100°C, and the holding time is 2h. In the above process, the magnetic stirring of the water bath should be maintained and a condenser should be installed at the middle mouth of the three-necked flask to prevent the solvent from volatilizing due to the temperature rise of the solution. After the reaction is over, turn off the temperature control program of the water bath (keep magnetic stirring) and cool to room ...

PUM

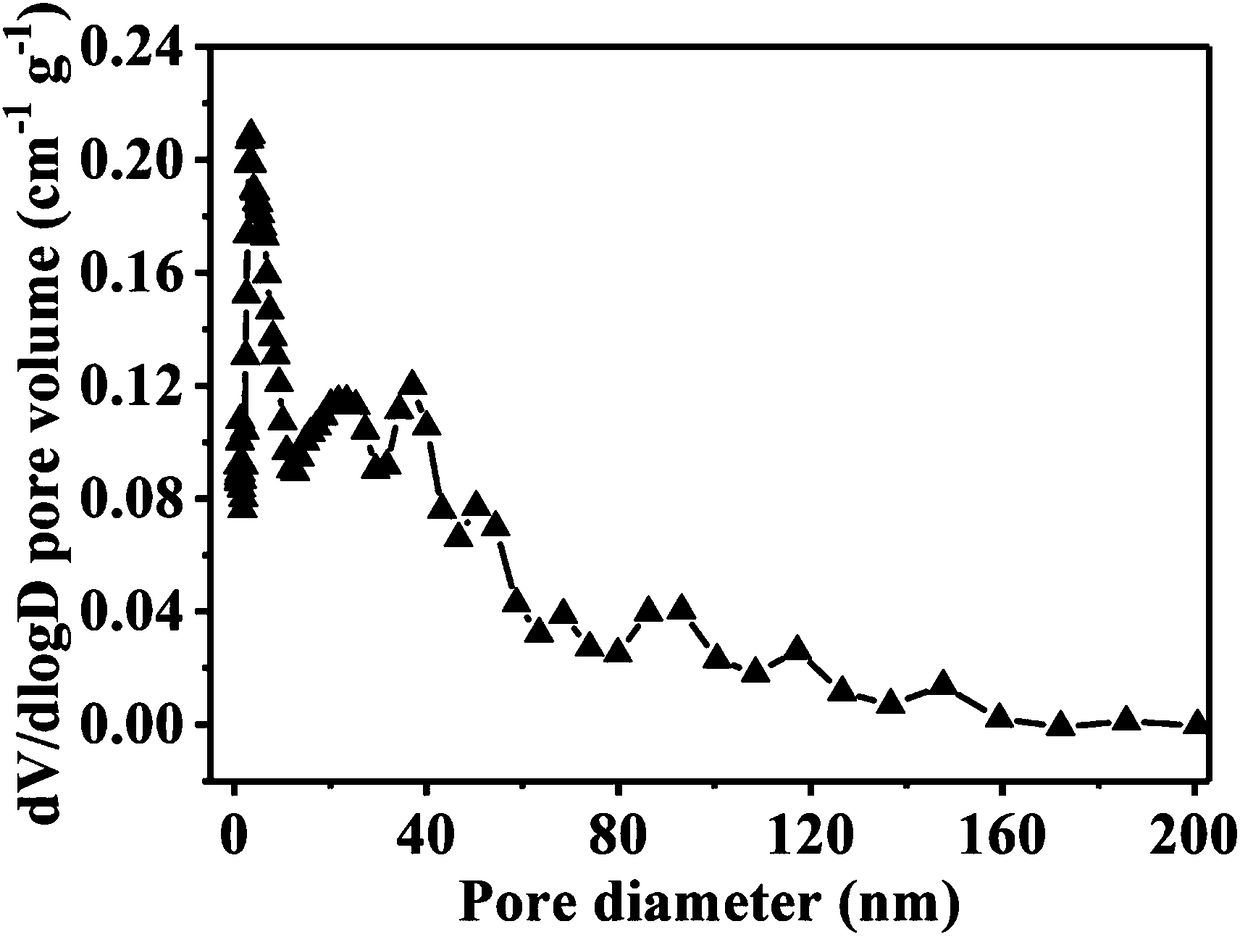

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com