Patents

Literature

18623 results about "Cvd graphene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Description of CVD graphene. CVD, Chemical vapor deposition, is a chemical process used to produce high purity materials. When the CVD method is applied in graphene manufacturing, CH4 is often used as the carbon source. This method results in high-quality graphene with great homogeneity.

Method for preparing graphene compounds and graphene oxide compounds with high efficiency

The invention relates to a method for preparing graphene compounds and graphene oxide compounds with high efficiency, relating to the method for preparing the graphene compounds and the graphene oxide compounds. The invention solves the problems of easy composition of graphene or graphene oxide per se and many process steps, higher cost and difficult dispersedness for preparing the graphene compounds and the graphene oxide compounds by the traditional method at the same time. The invention adopts a mechanical stripping method to obtain the graphene compounds and the graphene oxide compounds. In the invention, an automatic machine is utilized, solid particles are used for assisting stripping, the contact area and the stripping number of the stripping process are greatly increased, and carbon material powder experiences a lot of stripping processes through the action of shear and impact, thereby obviously improving the stripping efficiency and achieving the purpose of uniform dispersedness to the composites. The method is suitable for industrial mass production of the graphene compounds and the graphene oxide compounds.

Owner:HARBIN INST OF TECH

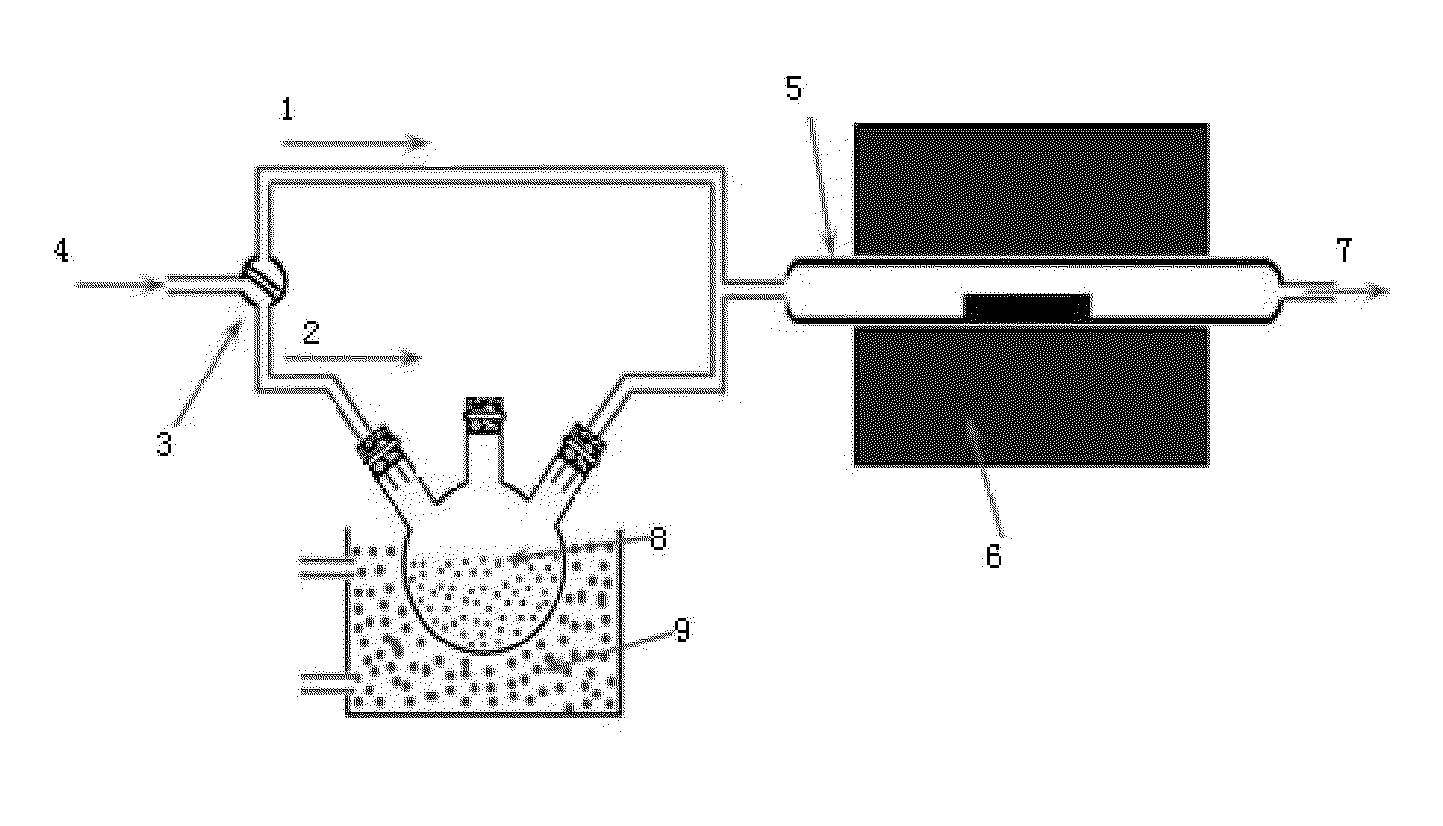

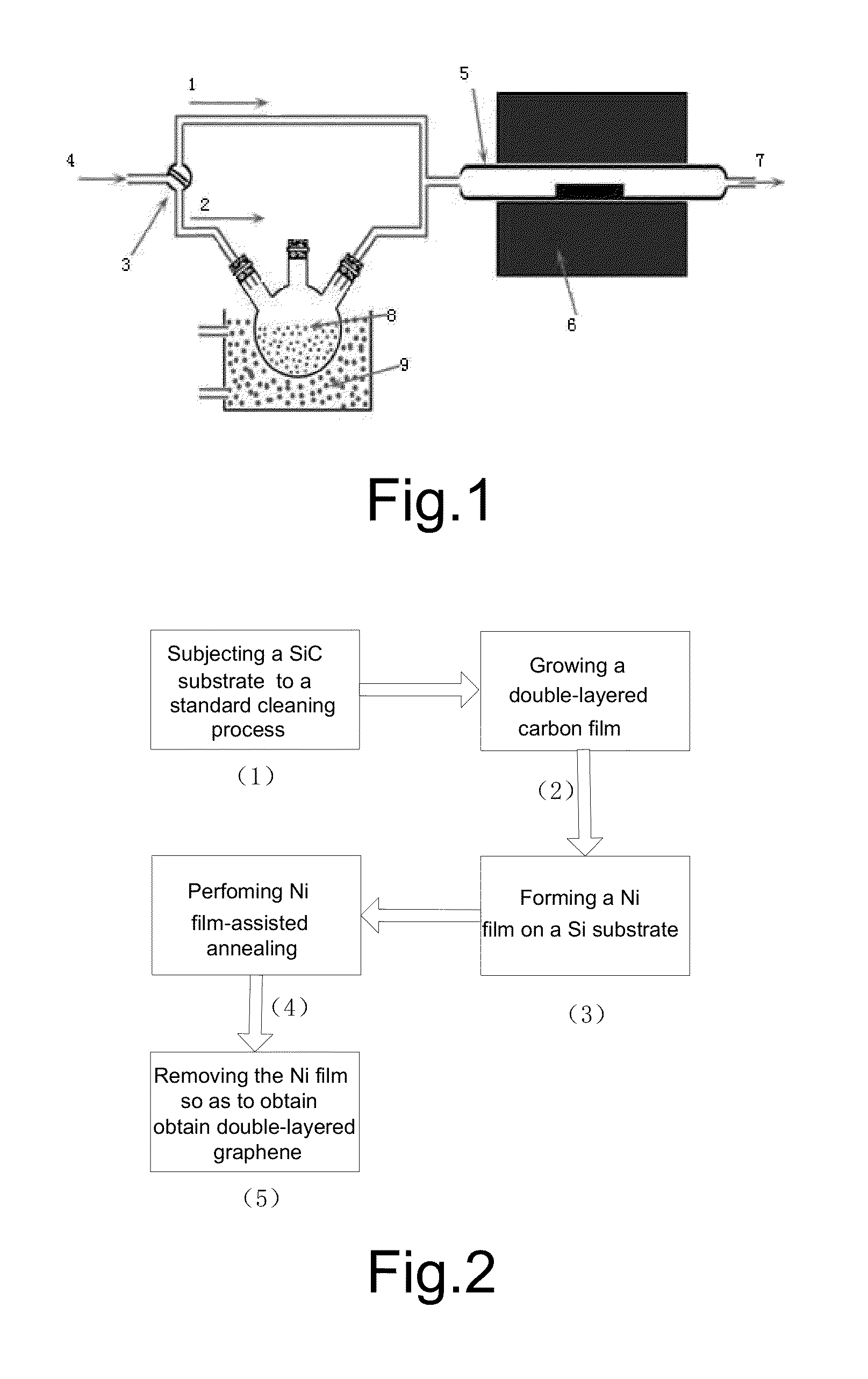

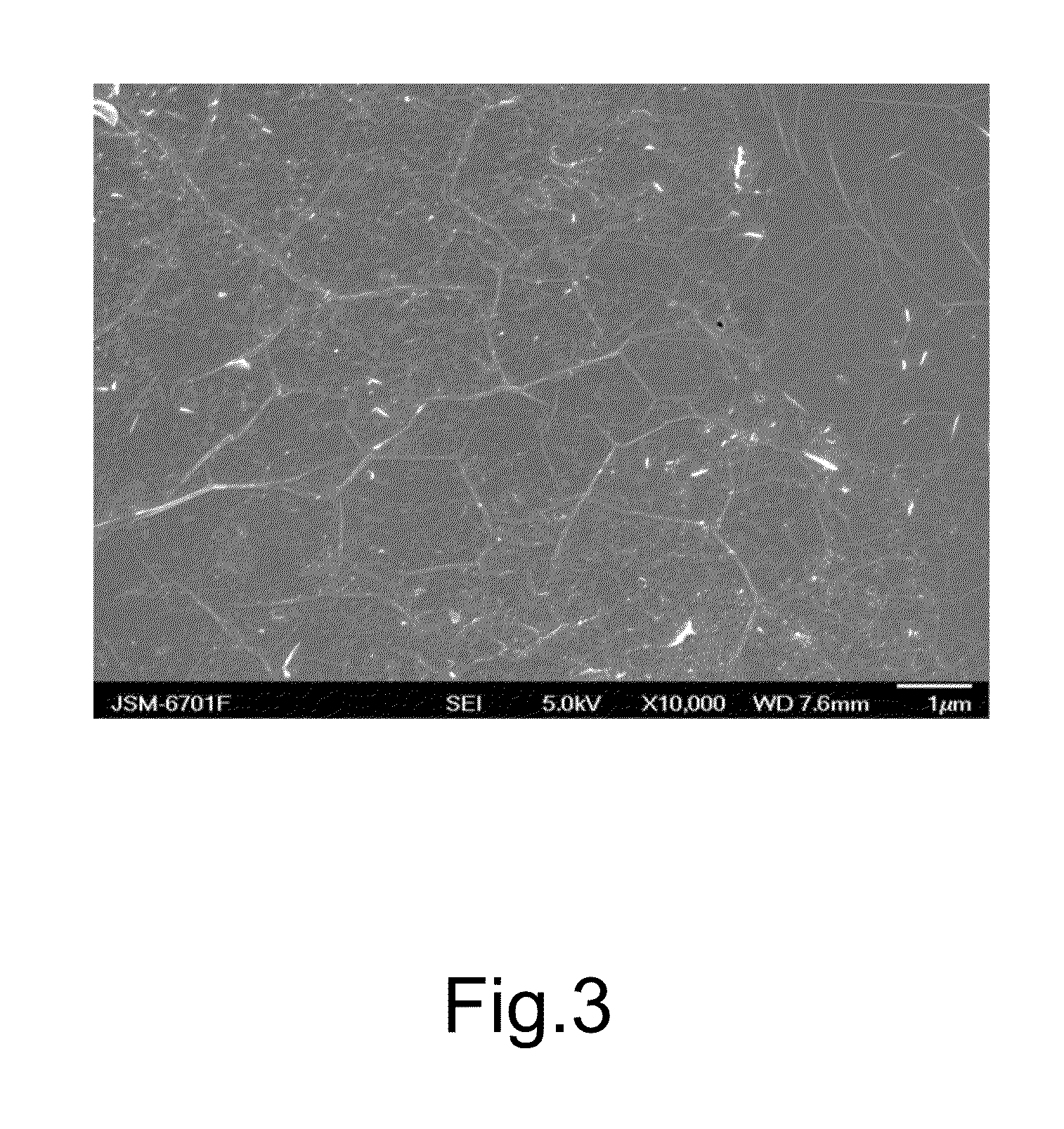

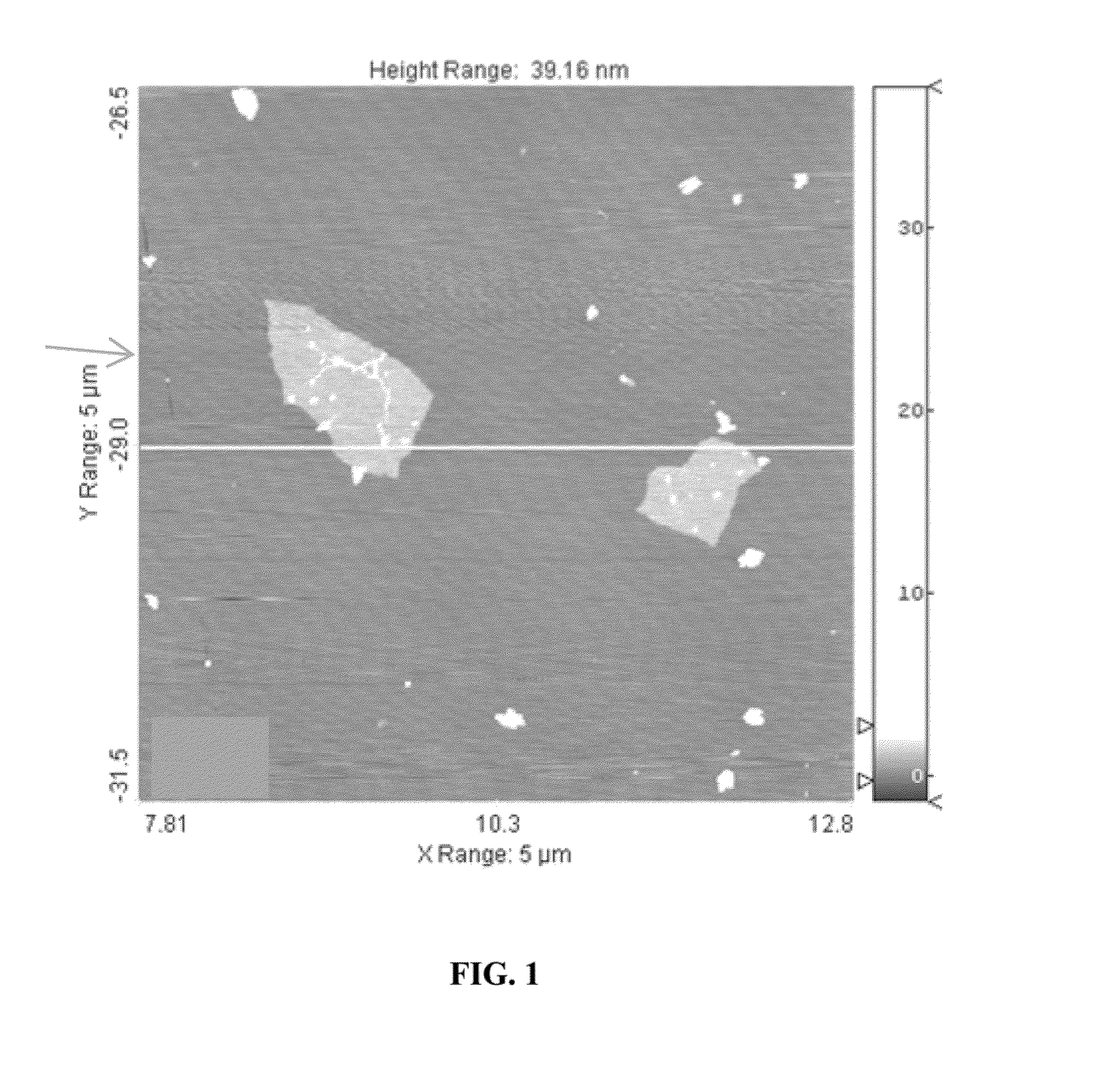

Process for Preparing Graphene on a SiC Substrate Based on Metal Film-Assisted Annealing

ActiveUS20140367642A1Simply and energy-efficientFlat surfaceMaterial nanotechnologyVacuum evaporation coatingCarbon filmElectron beam deposition

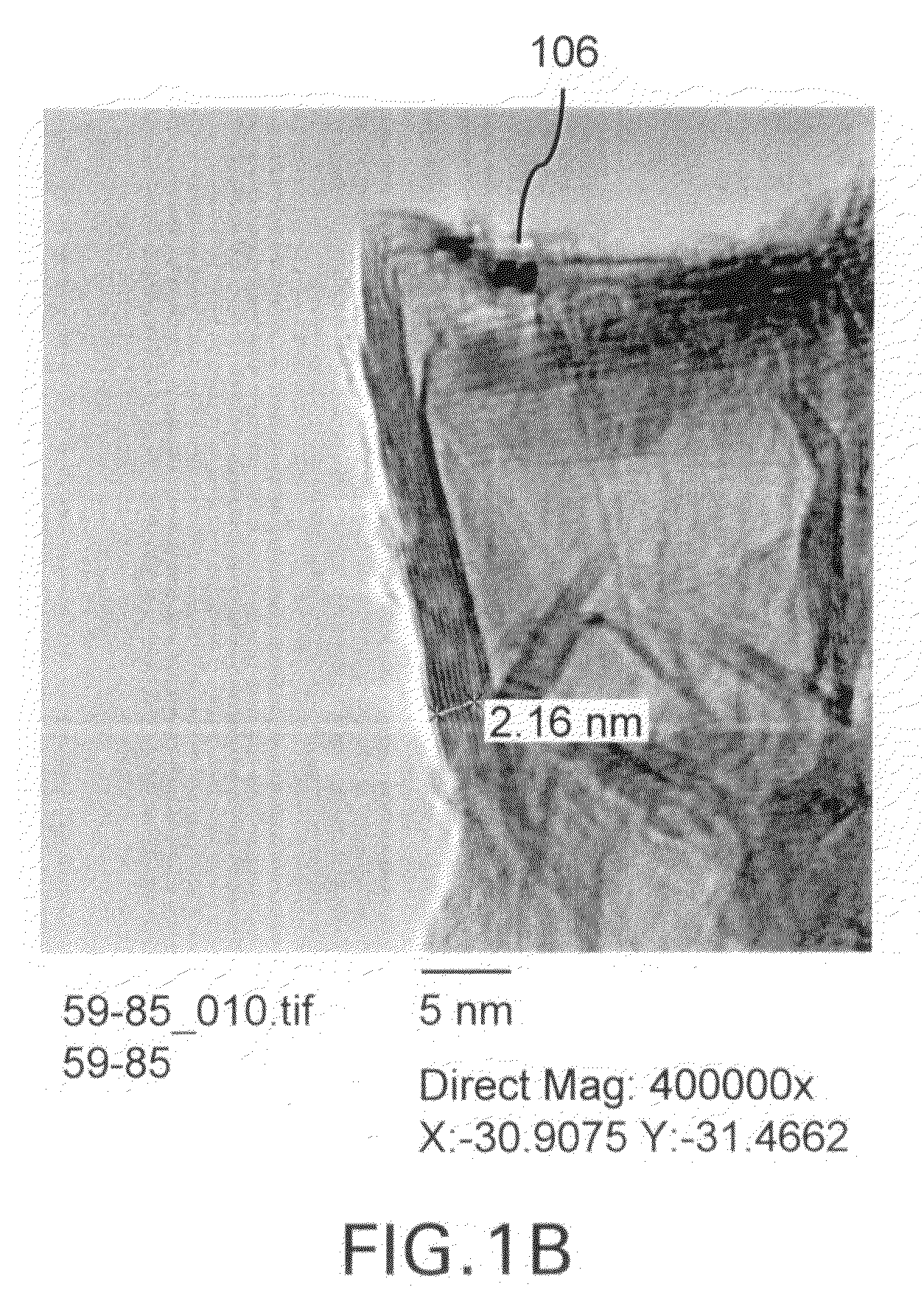

Provided is a process for preparing graphene on a SiC substrate, based on metal film-assisted annealing, comprising the following steps: subjecting a SiC substrate to a standard cleaning process; placing the cleaned SiC substrate into a quartz tube and heating the quartz tube up to a temperature of 750 to 1150° C.; introducing CCl4vapor into the quartz tube to react with SiC for a period of 20 to 100 minutes so as to generate a double-layered carbon film, wherein the CCl4 vapor is carried by Ar gas; forming a metal film with a thickness of 350 to 600 nm on a Si substrate by electron beam deposition; placing the obtained double-layered carbon film sample onto the metal film; subsequently annealing them in an Ar atmosphere at a temperature of 900 to 1100° C. for 10-30 minutes so as to reconstitute the double-layered carbon film into double-layered graphene; and removing the metal film from the double-layered graphene, thereby obtaining double-layered graphene. Also provided is double-layered graphene prepared by said process.

Owner:XIDIAN UNIV

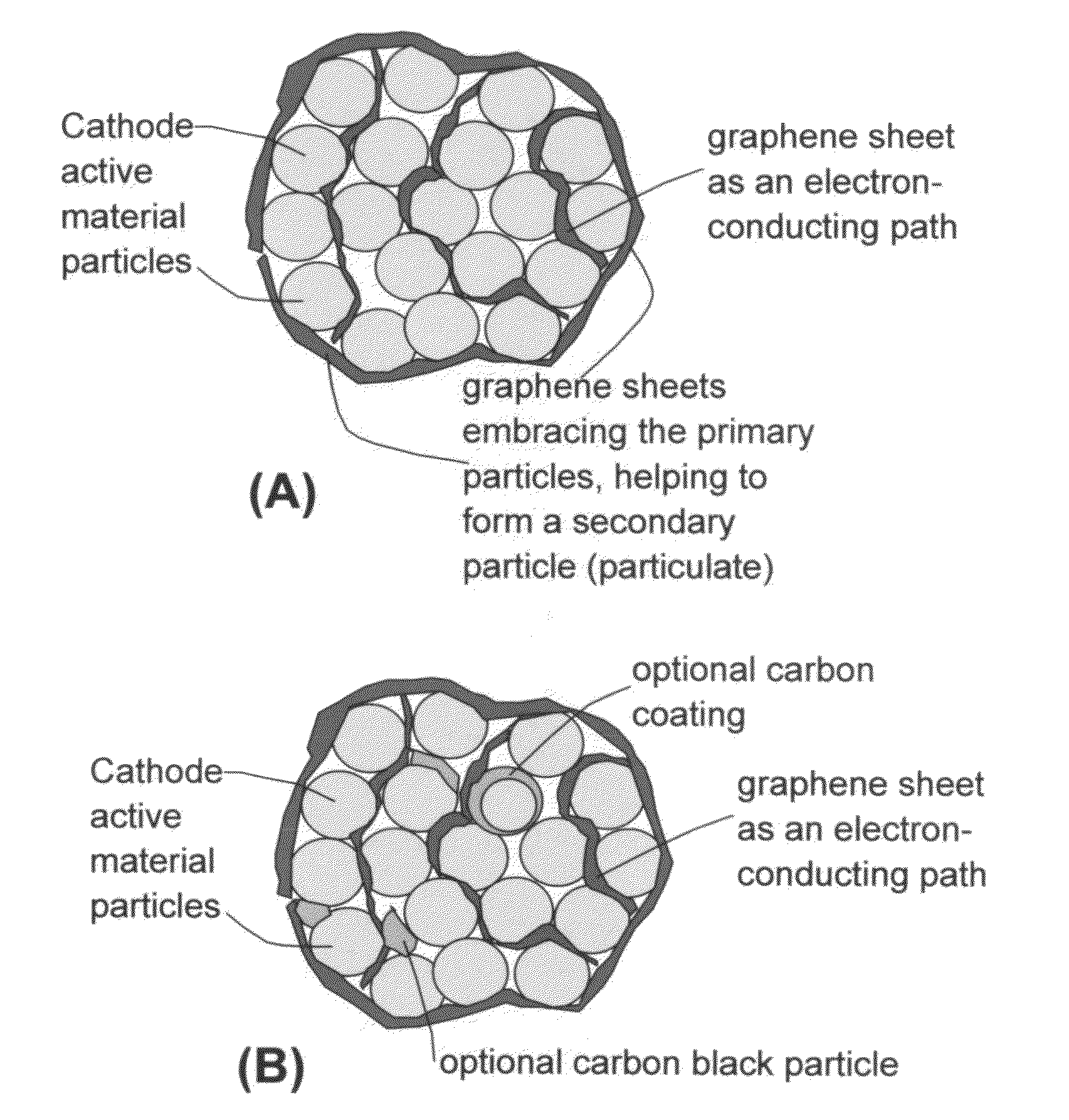

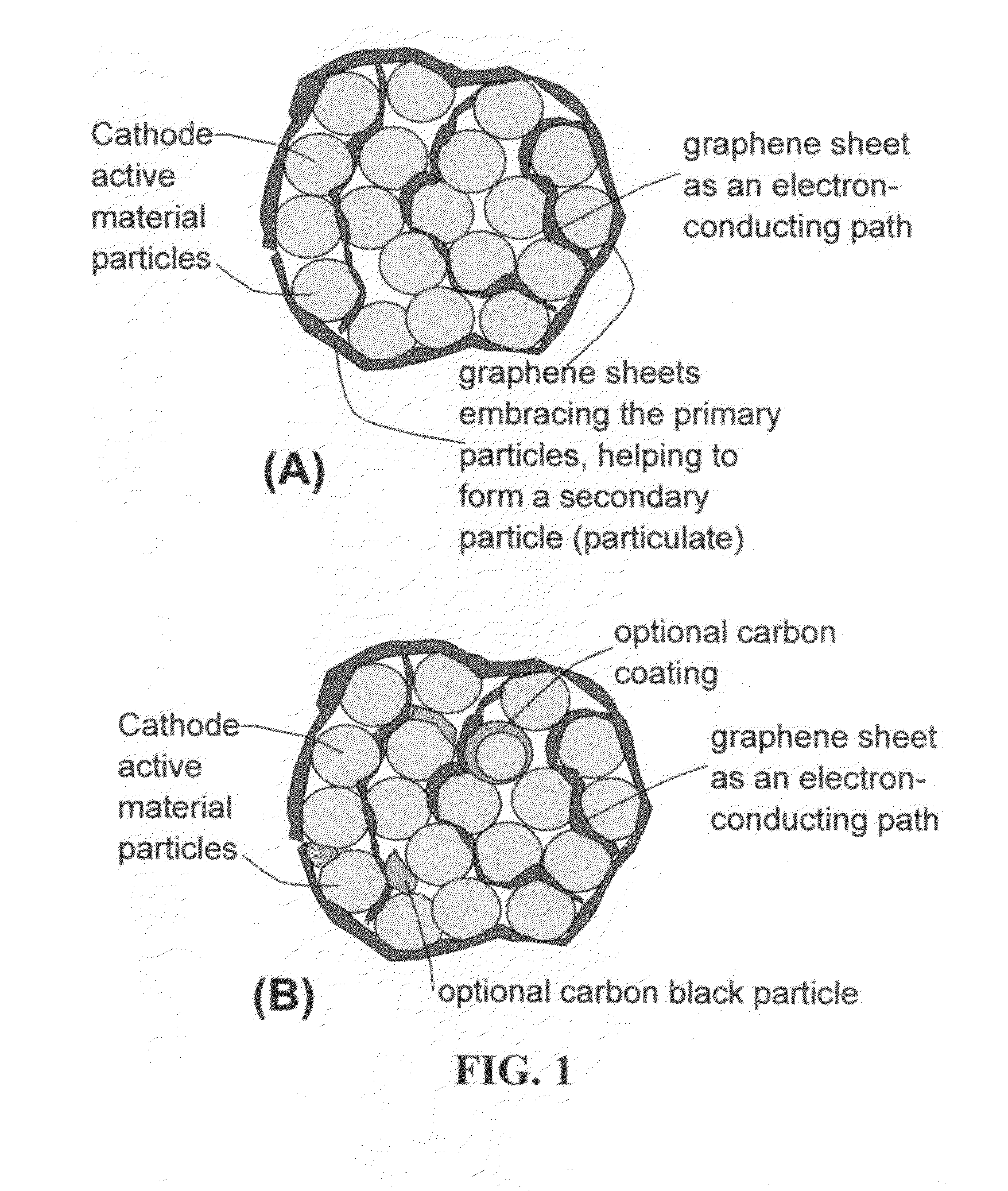

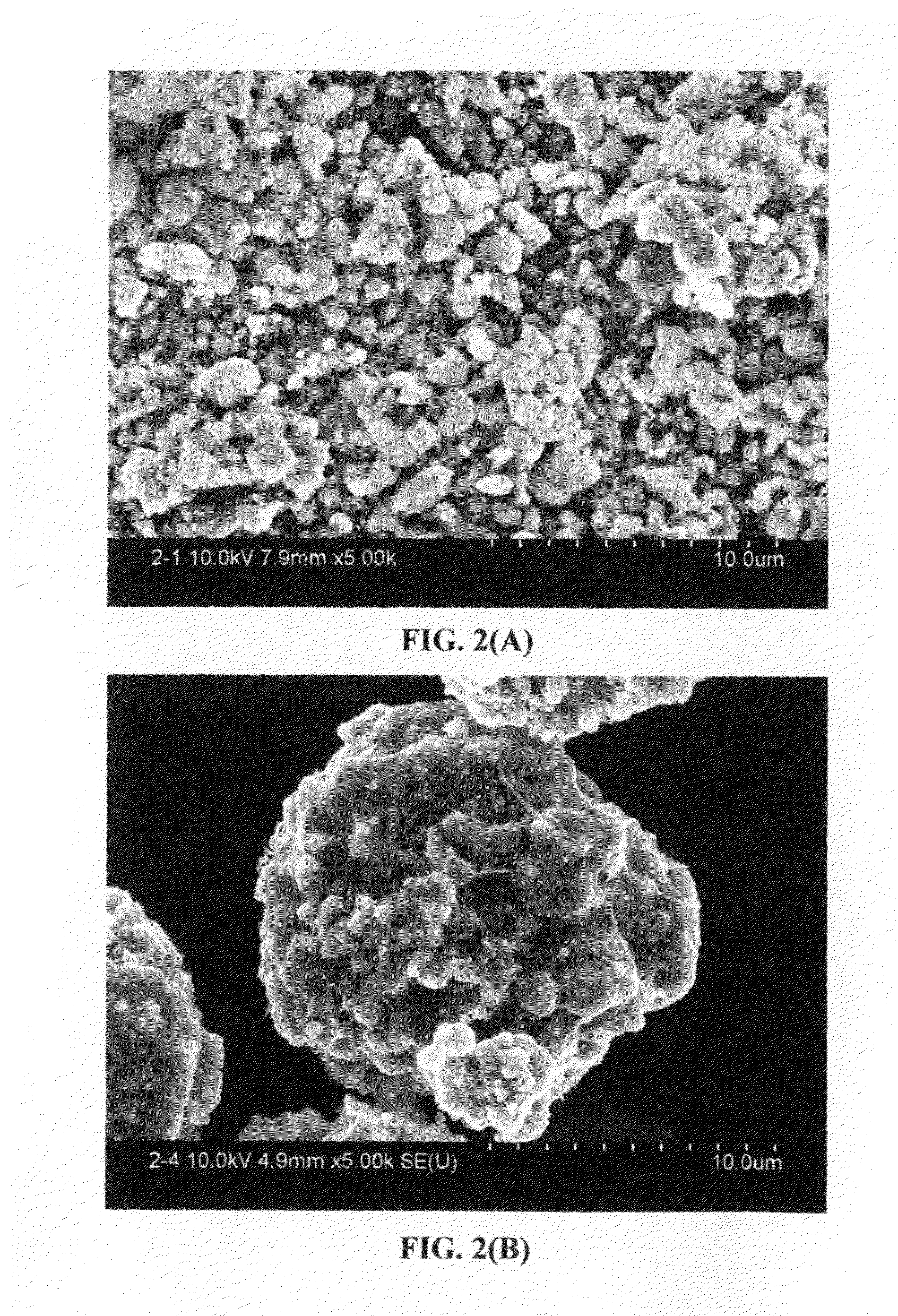

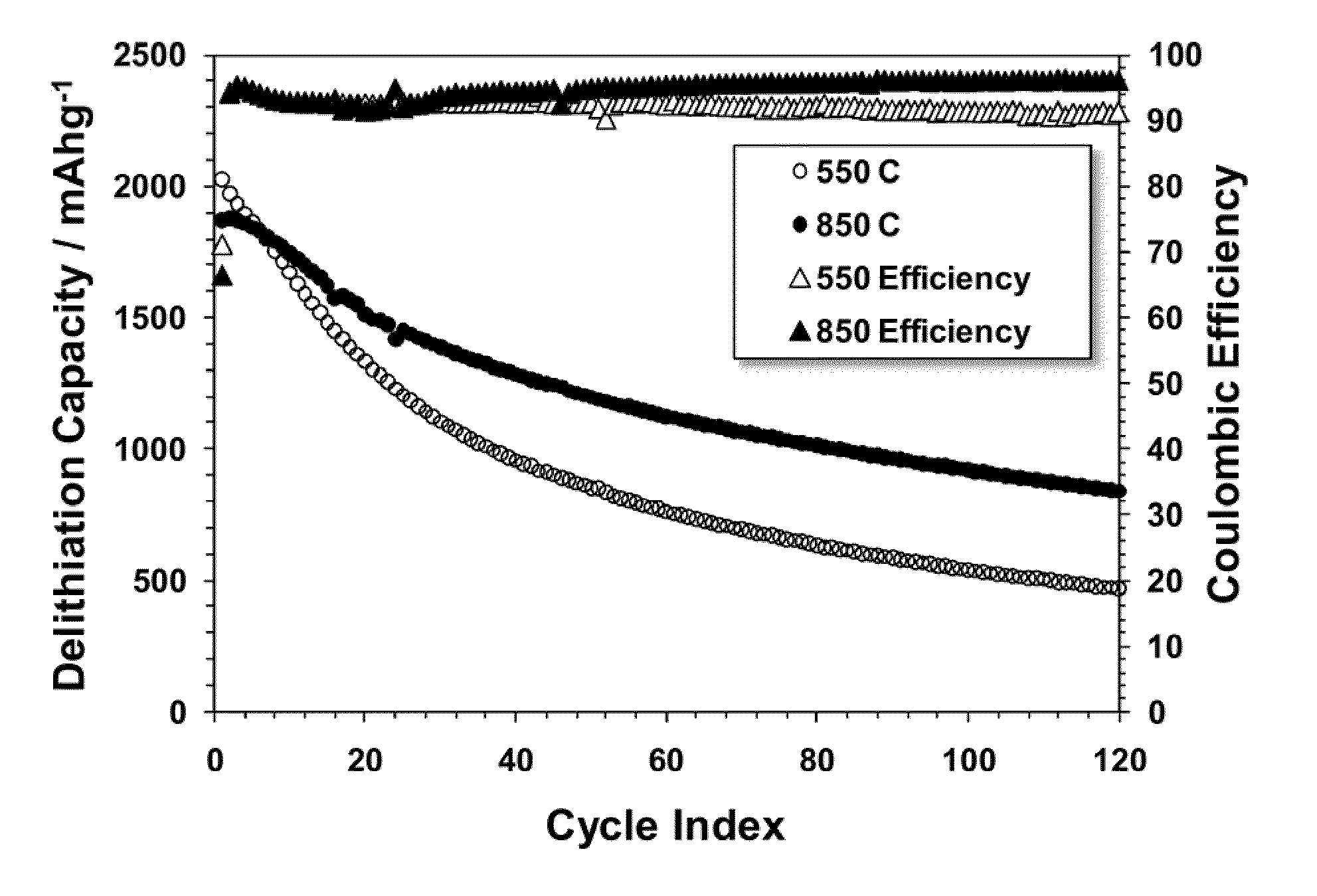

Graphene-Enhanced cathode materials for lithium batteries

ActiveUS20120058397A1Short timeEasy dischargeNon-metal conductorsMaterial nanotechnologyParticulatesCvd graphene

A nano graphene-enhanced particulate for use as a lithium battery cathode active material, wherein the particulate is formed of a single or a plurality of graphene sheets and a plurality of fine cathode active material particles with a size smaller than 10 μm (preferably sub-micron or nano-scaled), and the graphene sheets and the particles are mutually bonded or agglomerated into an individual discrete particulate with at least a graphene sheet embracing the cathode active material particles, and wherein the particulate has an electrical conductivity no less than 10−4 S / cm and the graphene is in an amount of from 0.01% to 30% by weight based on the total weight of graphene and the cathode active material combined.

Owner:GLOBAL GRAPHENE GRP INC

Electrode material comprising graphene composite materials in a graphite network formed from reconstituted graphene sheets

ActiveUS20110111303A1Weight increaseIncrease storage capacityConductive materialNon-conductive material with dispersed conductive materialGraphiteCvd graphene

A durable electrode material suitable for use in Li ion batteries is provided. The material is comprised of a continuous network of graphite regions integrated with, and in good electrical contact with a composite comprising graphene sheets and an electrically active material, such as silicon, wherein the electrically active material is dispersed between, and supported by, the graphene sheets.

Owner:NORTHWESTERN UNIV

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

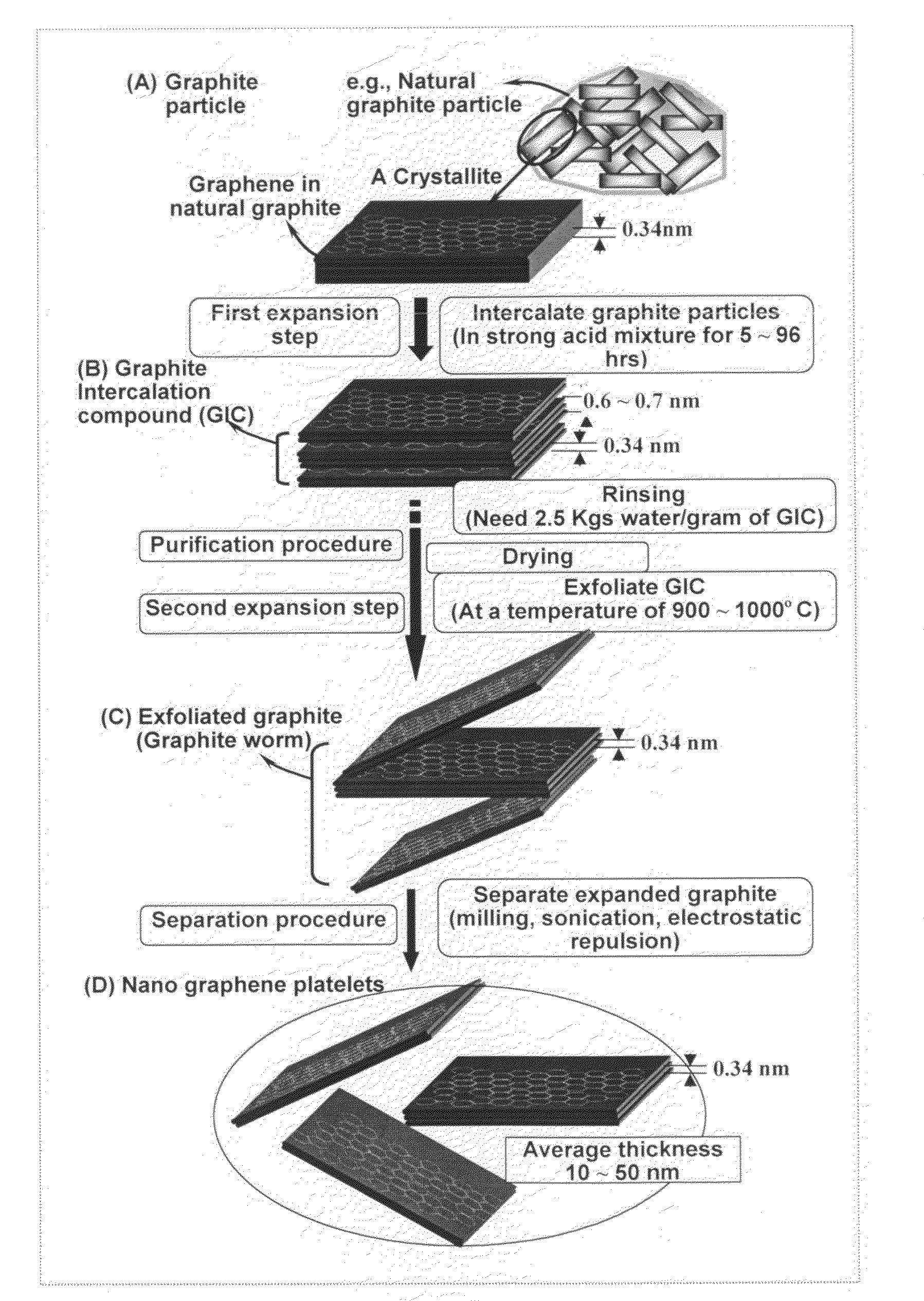

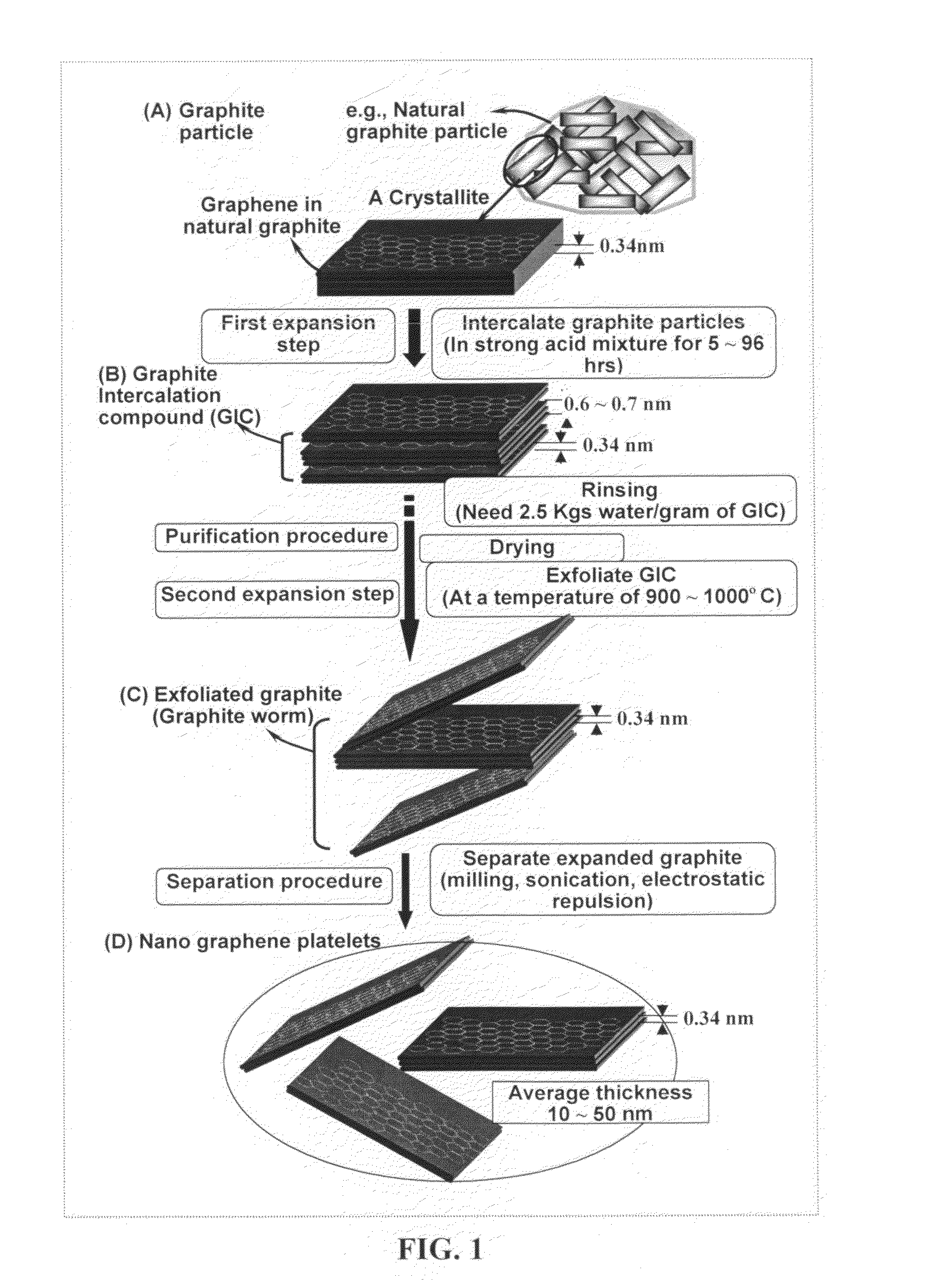

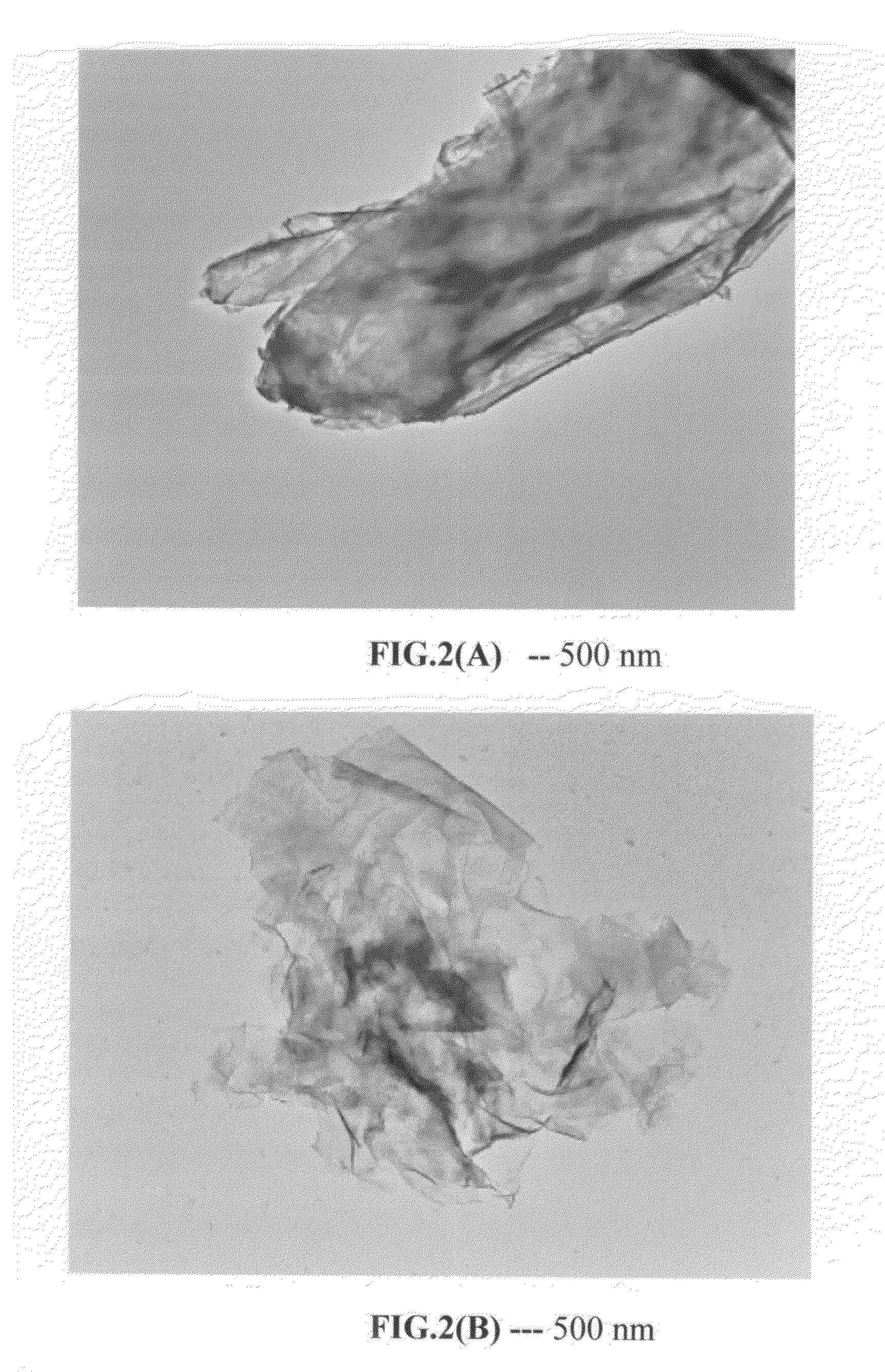

Method of producing exfoliated graphite, flexible graphite, and nano-scaled graphene platelets

ActiveUS20080279756A1Good dispersionImprove conductivityCarbon compoundsFibre chemical featuresFiberLiquid medium

The present invention provides a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm. The method comprises (a) dispersing particles of graphite, graphite oxide, or a non-graphite laminar compound in a liquid medium containing therein a surfactant or dispersing agent to obtain a stable suspension or slurry; and (b) exposing the suspension or slurry to ultrasonic waves at an energy level for a sufficient length of time to produce separated nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:GLOBAL GRAPHENE GRP INC

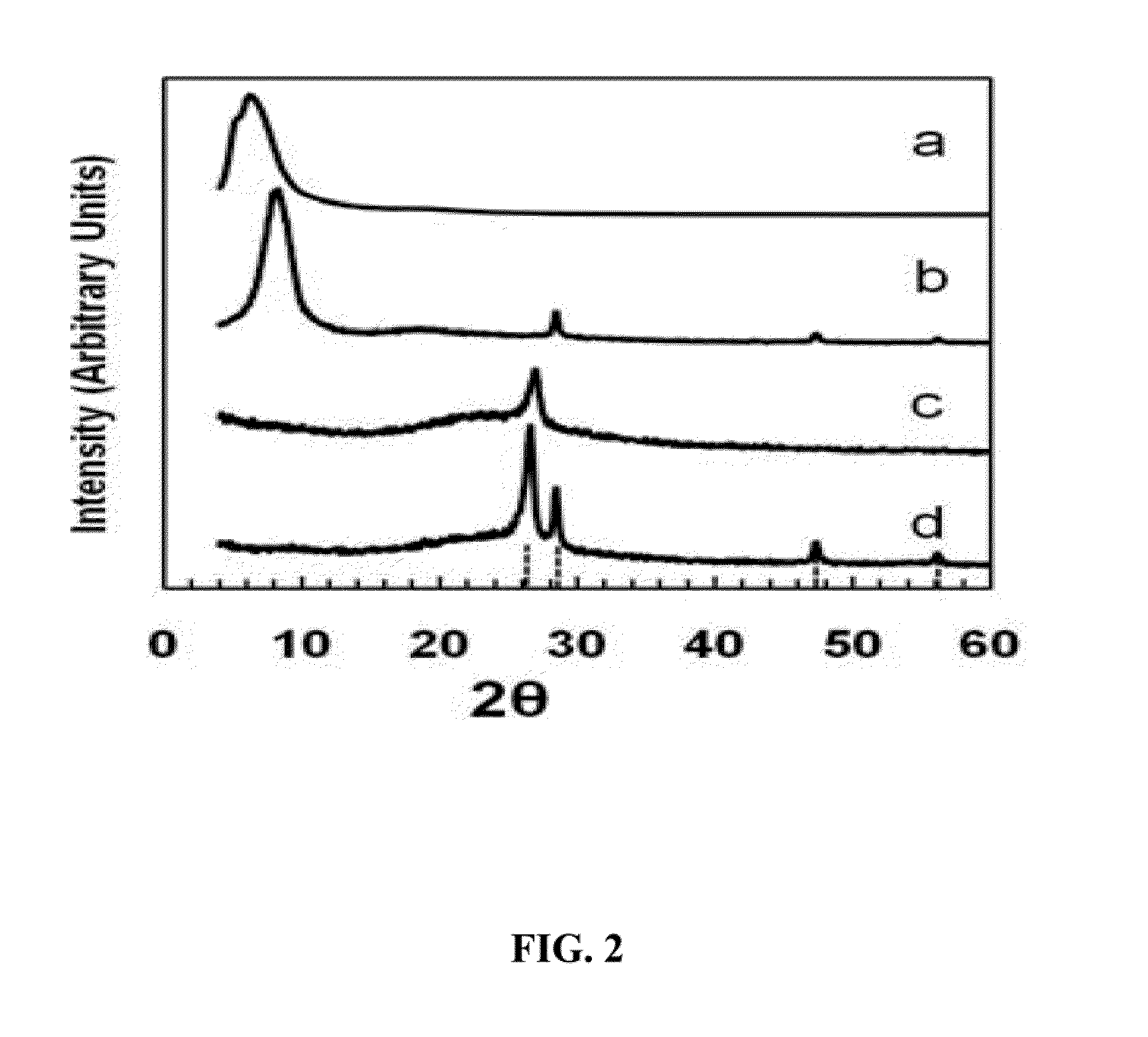

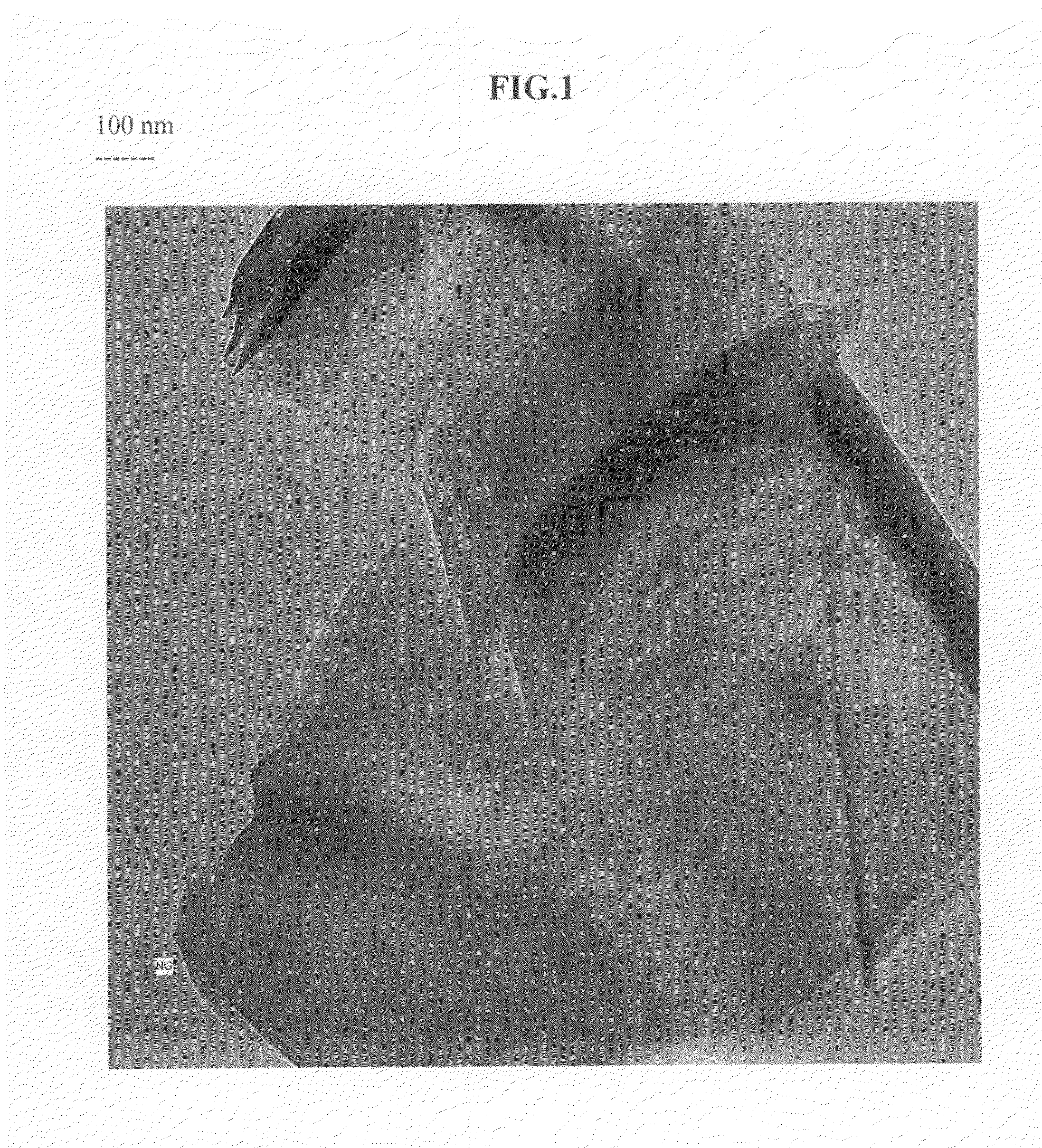

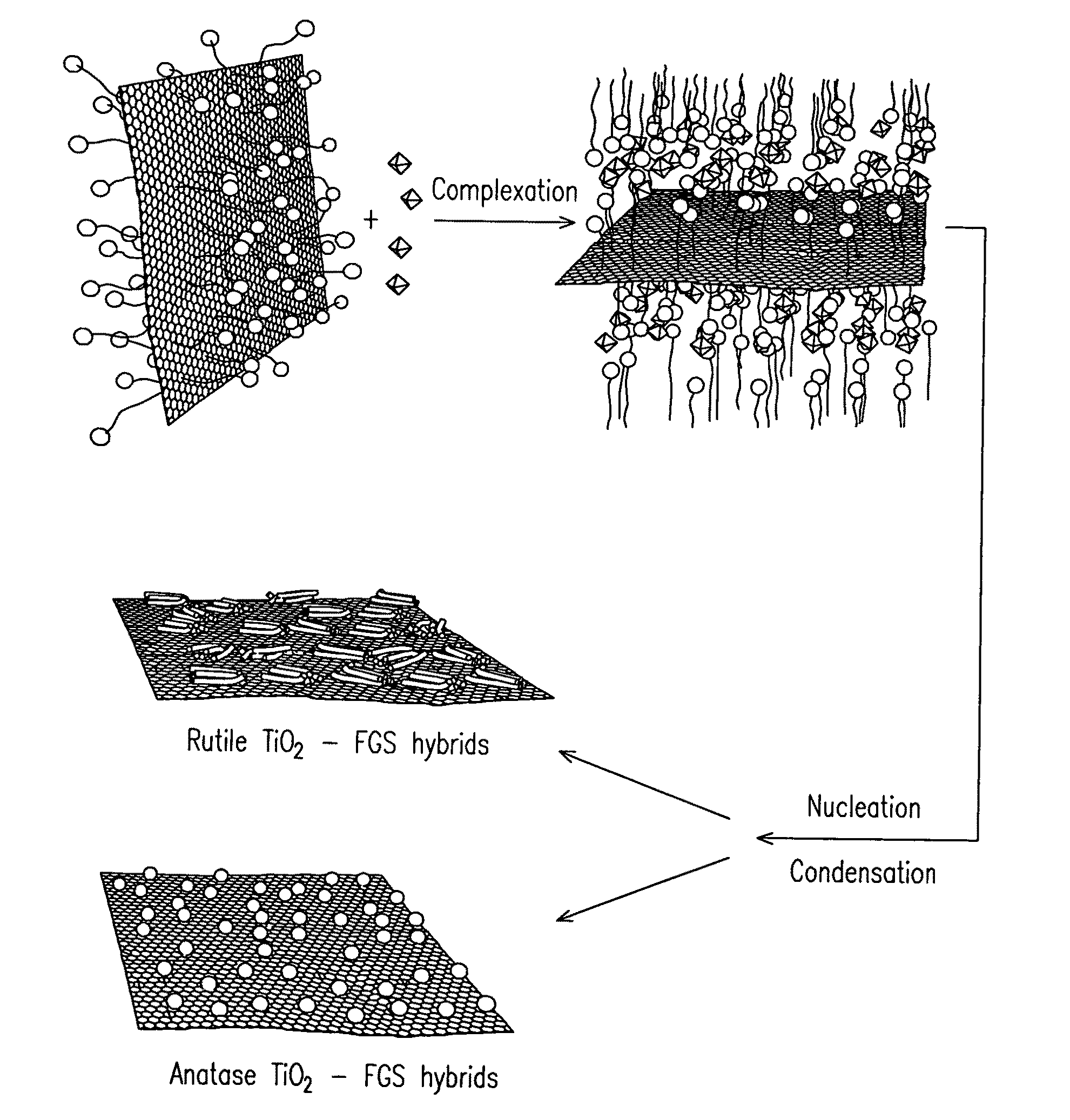

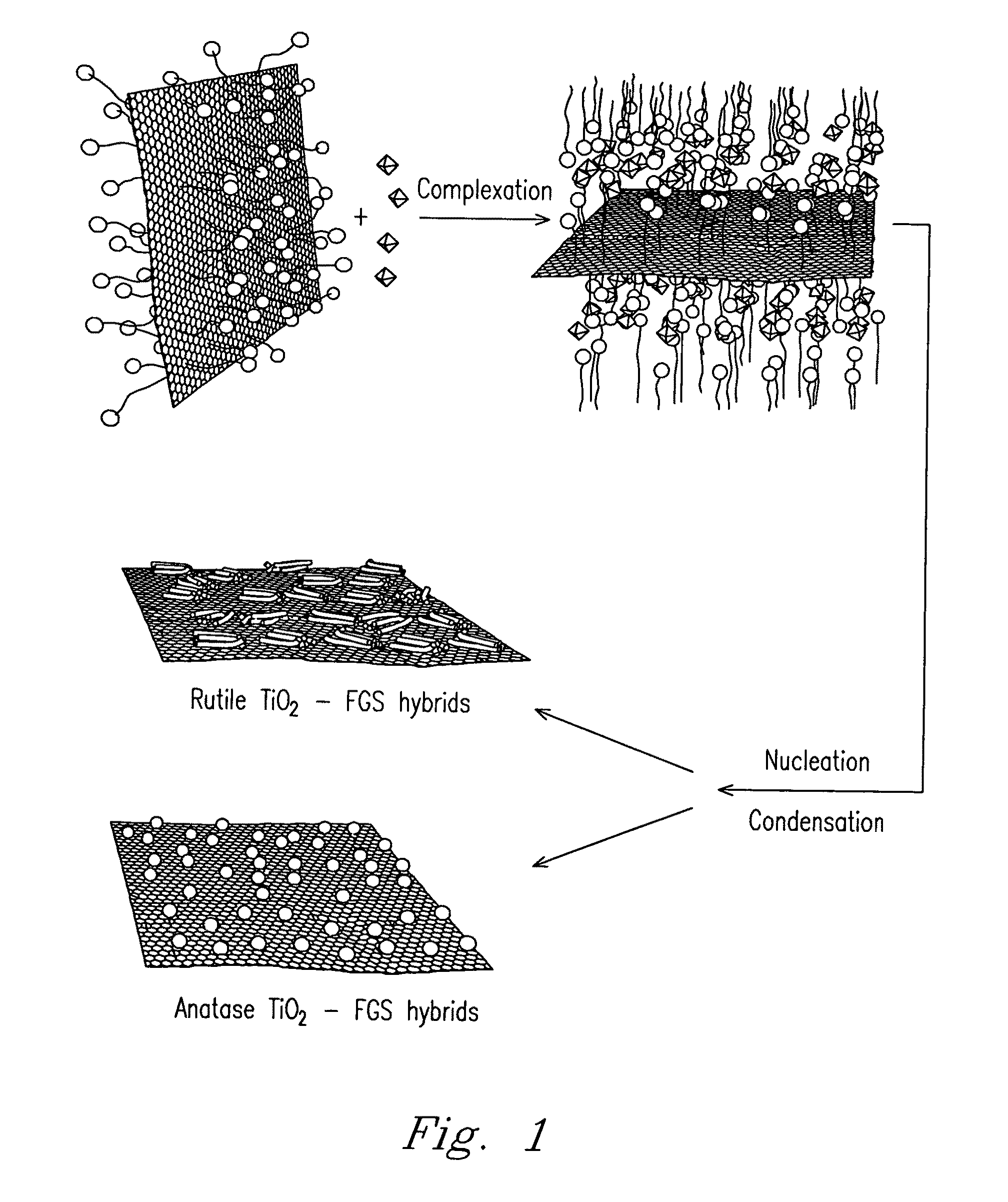

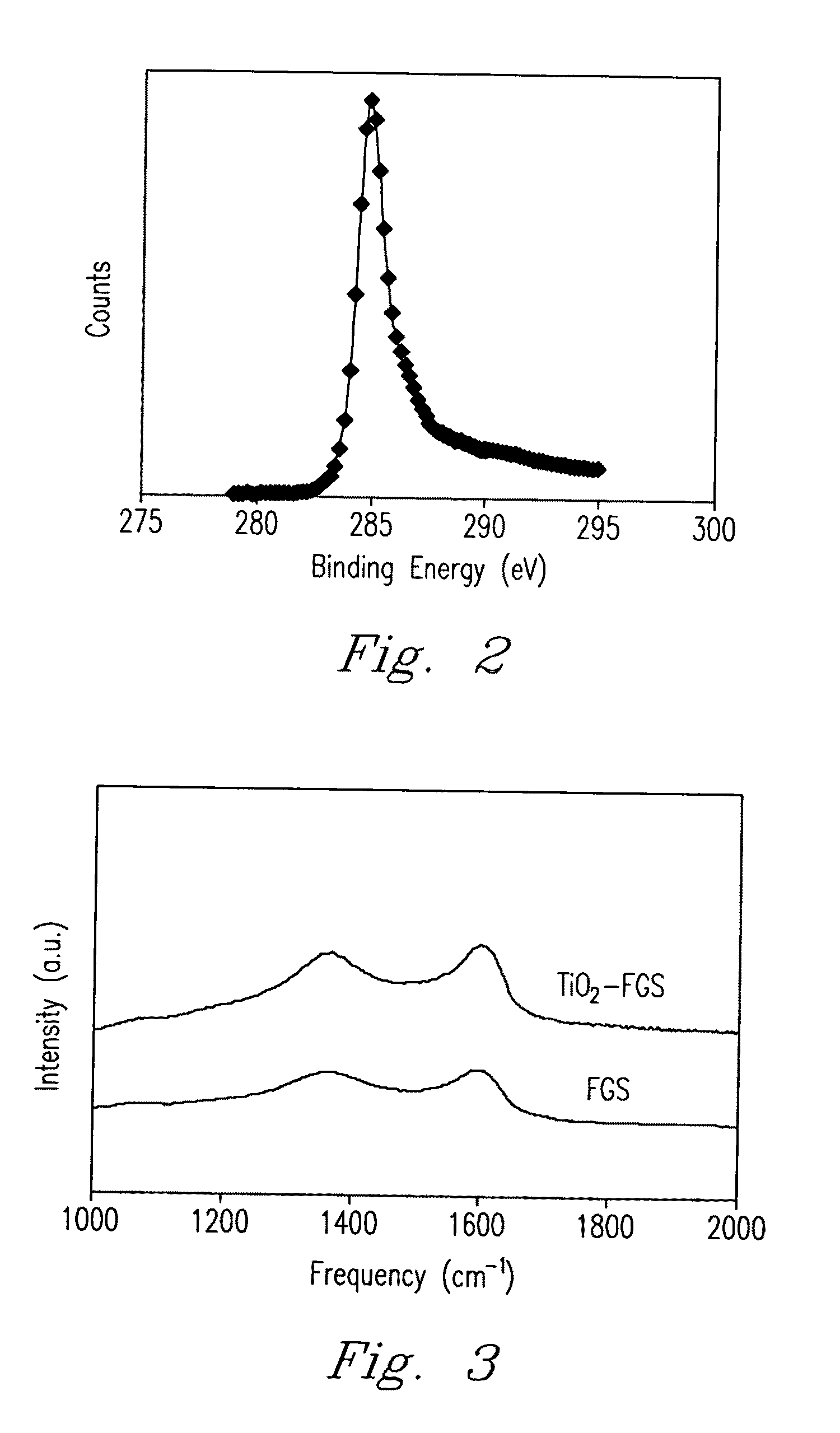

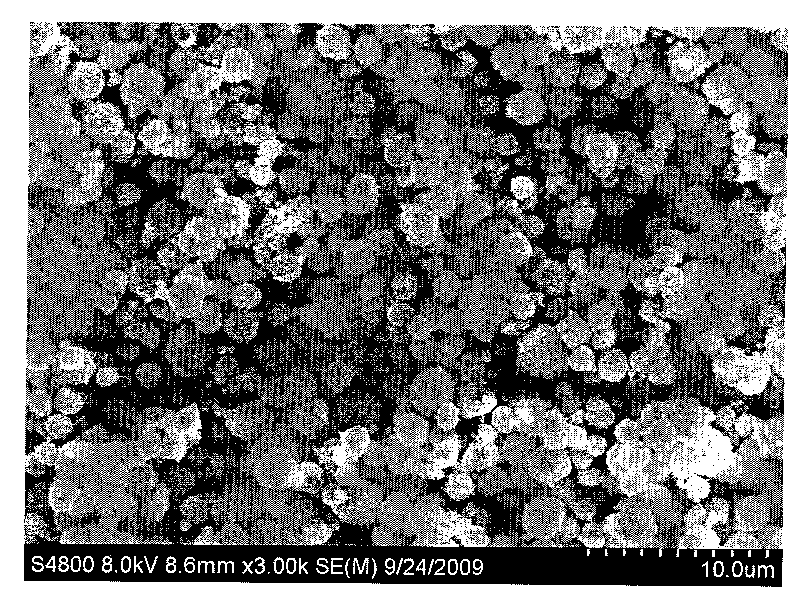

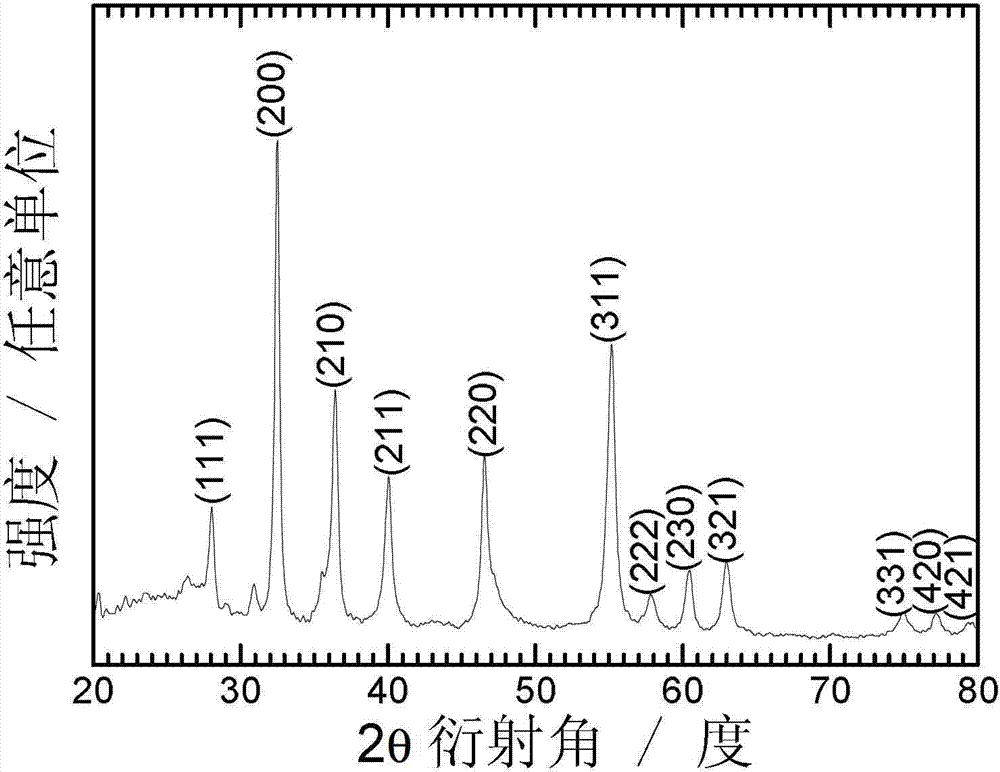

Nanocomposite of graphene and metal oxide materials

ActiveUS20100081057A1Easy to distinguishMaterial nanotechnologyRecord information storageDischarge rateCvd graphene

Nanocomposite materials comprising a metal oxide bonded to at least one graphene material. The nanocomposite materials exhibit a specific capacity of at least twice that of the metal oxide material without the graphene at a charge / discharge rate greater than about 10C.

Owner:THE TRUSTEES FOR PRINCETON UNIV +1

Method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping

InactiveCN101817516AImprove stripping efficiencyLight in massHigh volume manufacturingSolid particle

The invention provides a method for preparing graphene or graphene oxide by using high-efficiency and low-cost mechanical stripping and relates to a preparation method of the graphene or the graphene oxide, solving the problems that the traditional micro-mechanical stripping method has low efficiency and can not be used for large-batch production. The method comprises the following step of separating carbon materials by utilizing solid particles and a liquid working medium (or gas working medium) and adopting mechanical stripping to obtain the graphene or the graphene oxide, wherein the carbon materials comprise graphite powder, expanded graphite, expandable graphite or graphite powder oxide. By using automatic machinery and using a great deal of solid particles for assisting stripping processes, the invention greatly increases the contact areas and the stripping times of the stripping processes, the carbon materials are subject to a great amount of stripping processes in a short time through the shearing and impacting functions of the solid particles on the carbon materials, and thereby the method obviously improves the stripping efficiency, has low cost and is suitable for the industrial and large-batch production of the graphene or the graphene oxide.

Owner:HARBIN INST OF TECH

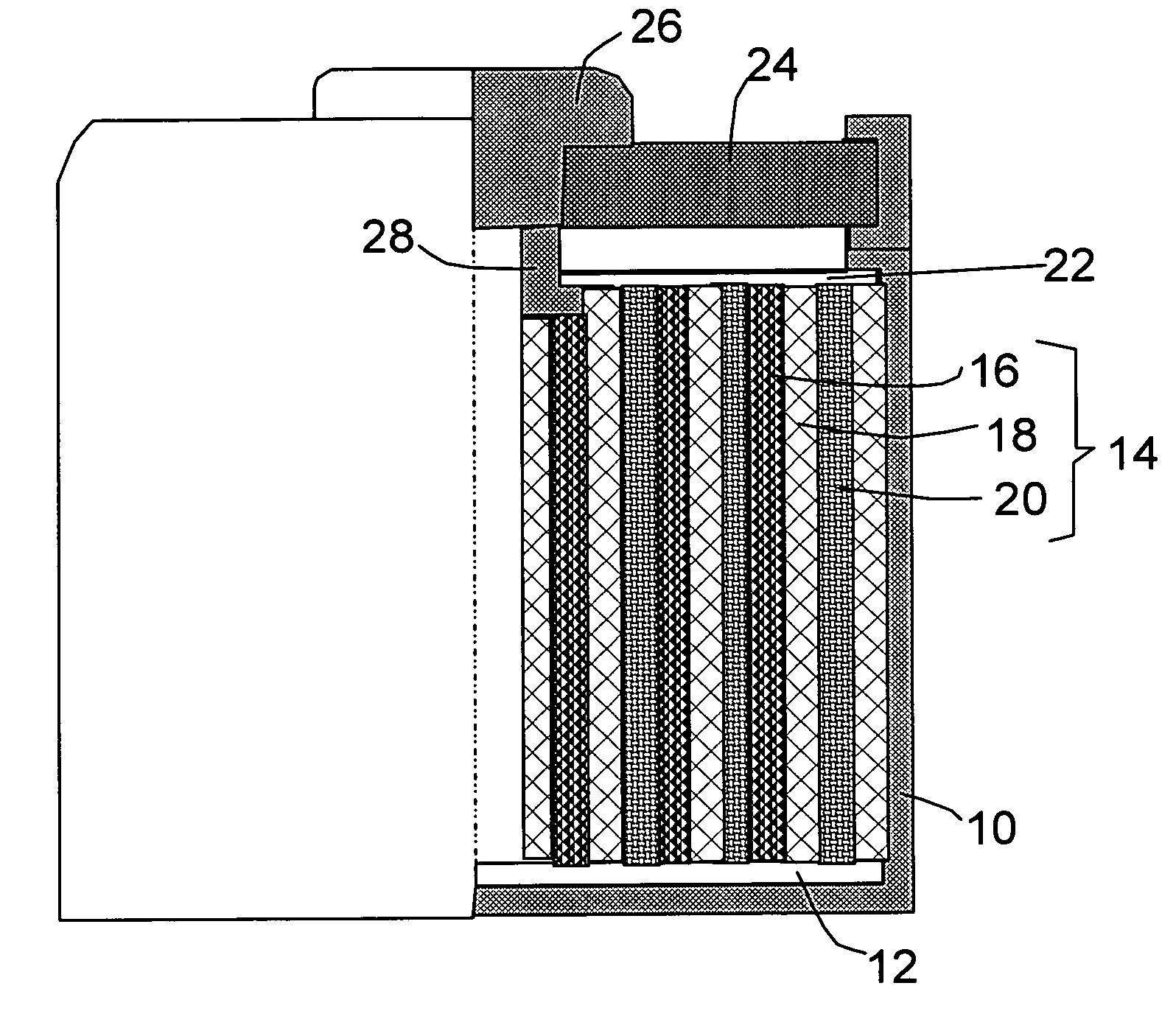

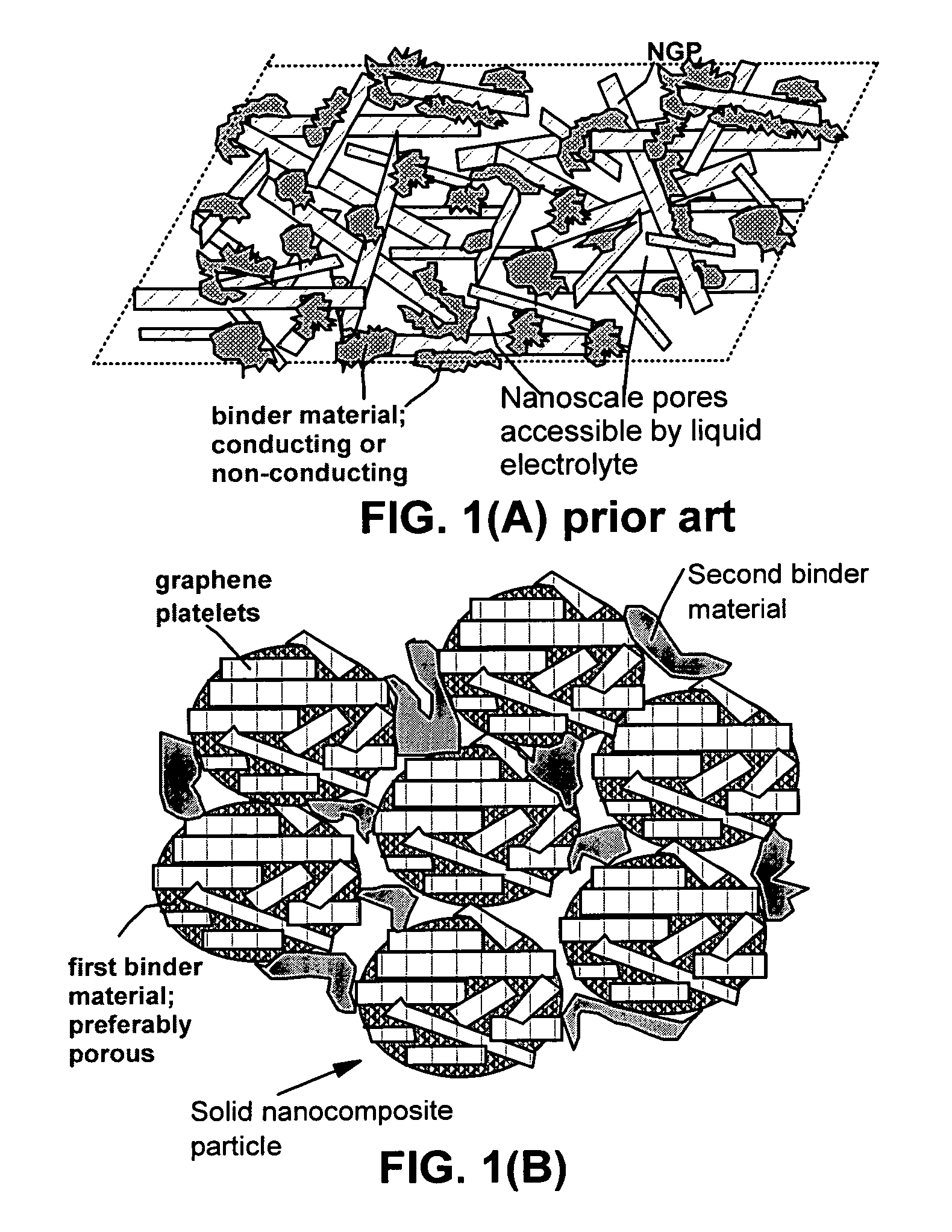

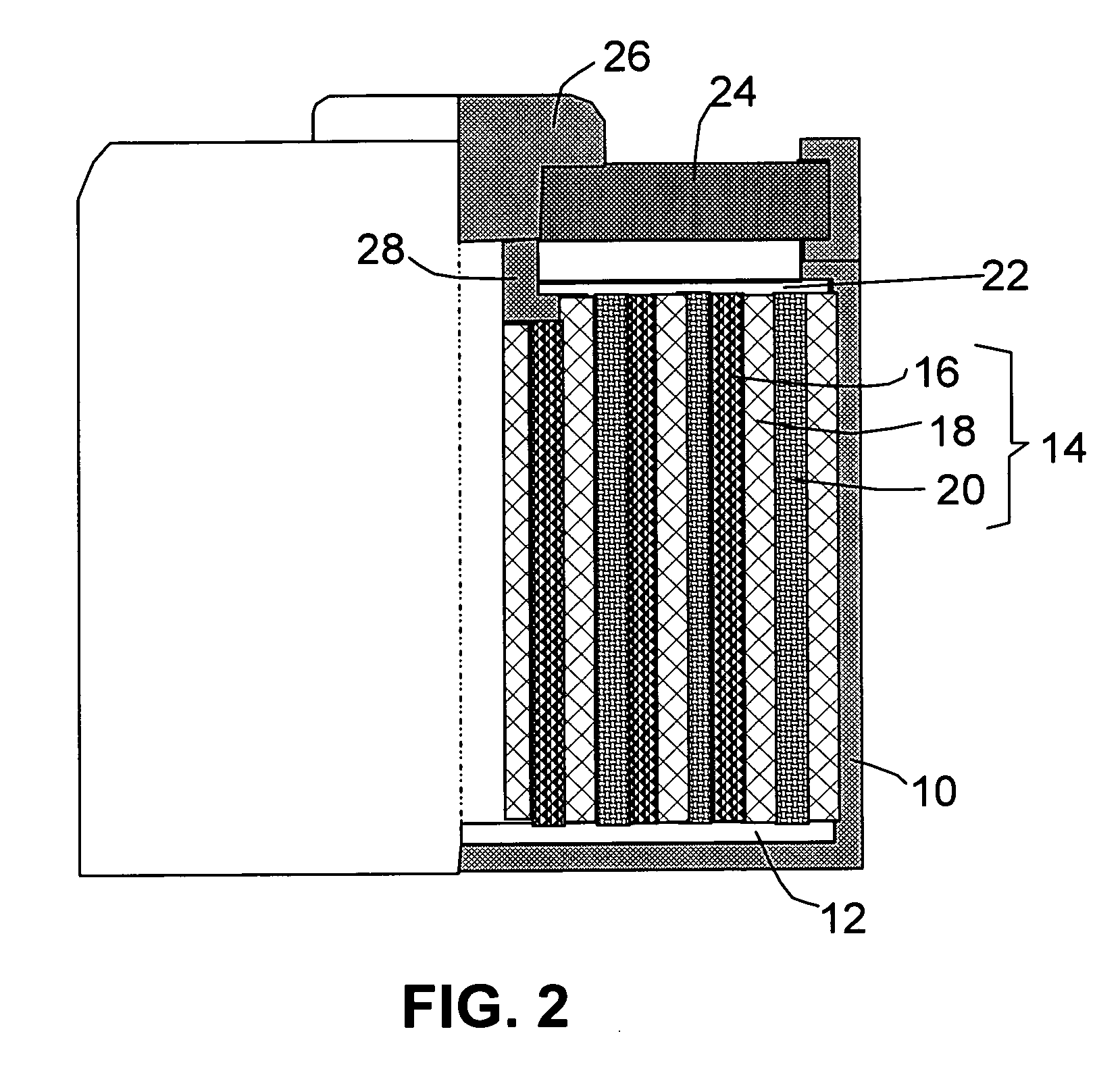

Graphene nanocomposites for electrochemical cell electrodes

ActiveUS20100021819A1High and reversible anode capacityTedious and energy-intensiveMicroscopic fiber electrodesHybrid capacitor electrodesGraphene nanocompositesSolid particle

A composite composition for electrochemical cell electrode applications, the composition comprising multiple solid particles, wherein (a) a solid particle is composed of graphene platelets dispersed in or bonded by a first matrix or binder material, wherein the graphene platelets are not obtained from graphitization of the first binder or matrix material; (b) the graphene platelets have a length or width in the range of 10 nm to 10 μm; (c) the multiple solid particles are bonded by a second binder material; and (d) the first or second binder material is selected from a polymer, polymeric carbon, amorphous carbon, metal, glass, ceramic, oxide, organic material, or a combination thereof. For a lithium ion battery anode application, the first binder or matrix material is preferably amorphous carbon or polymeric carbon. Such a composite composition provides a high anode capacity and good cycling response. For a supercapacitor electrode application, the solid particles preferably have meso-scale pores therein to accommodate electrolyte.

Owner:NANOTEK INSTR GRP LLC

Nano graphene-modified lubricant

ActiveUS20110046027A1Modulate viscosityImprove the lubrication effectAdditivesBase-materialsCarbon nanotubeSingle layer graphene

A lubricant composition having improved lubricant properties, comprising:(a) a lubricating fluid; and (b) nano graphene platelets (NGPs) dispersed in the fluid, wherein nano graphene platelets have a proportion of 0.001% to 60% by weight based on the total weight of the fluid and the graphene platelets combined. Preferably, the composition comprises at least a single-layer graphene sheet. Preferably, the lubricating fluid contains a petroleum oil or synthetic oil and a dispersant or surfactant. With the addition of a thickener or a desired amount of NGPs, the lubricant becomes a grease composition. Compared with graphite nano particle- or carbon nanotube-modified lubricants, NGP-modified lubricants have much better thermal conductivity, friction-reducing capability, anti-wear performance, and viscosity stability.

Owner:GLOBAL GRAPHENE GRP INC

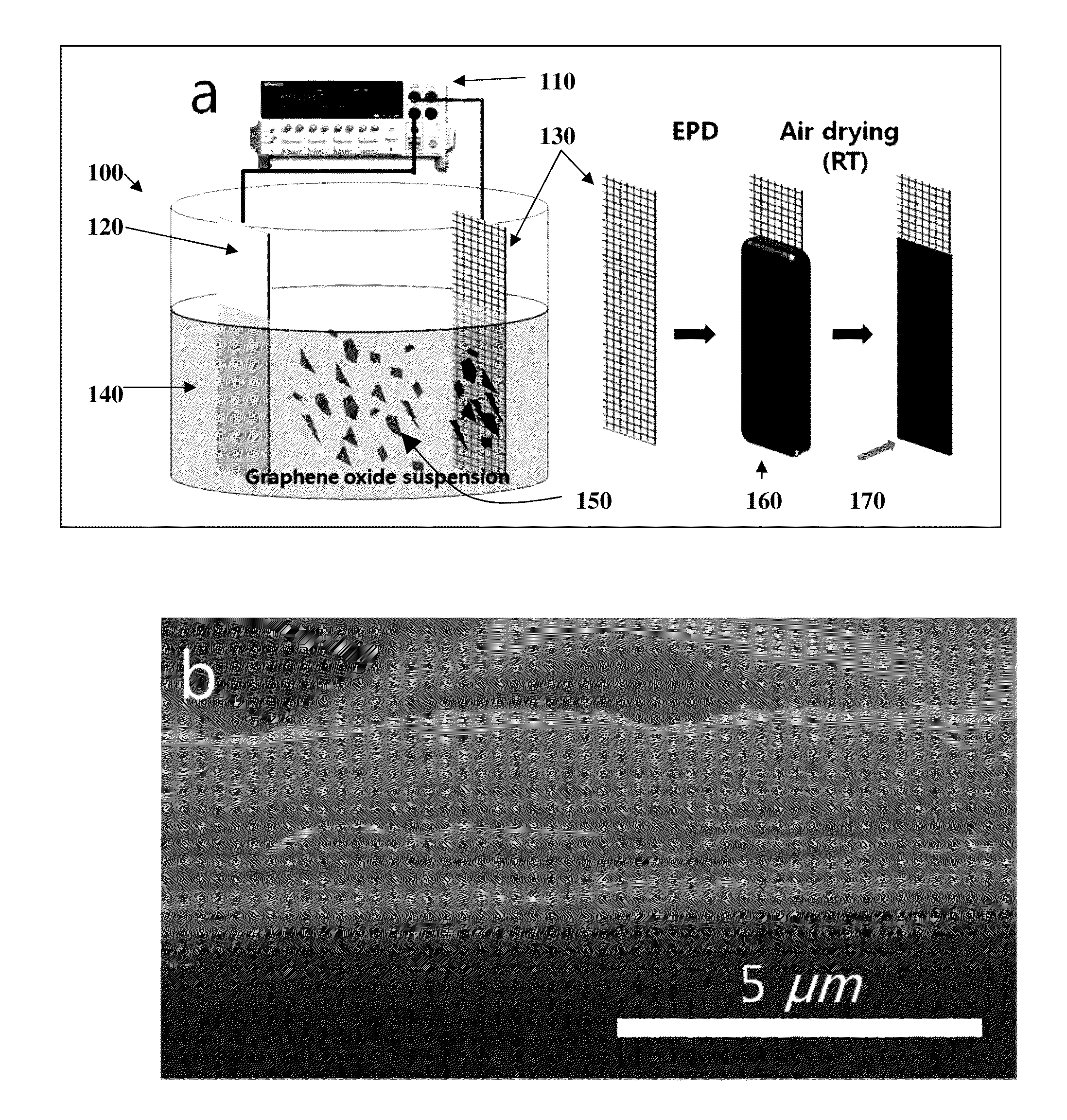

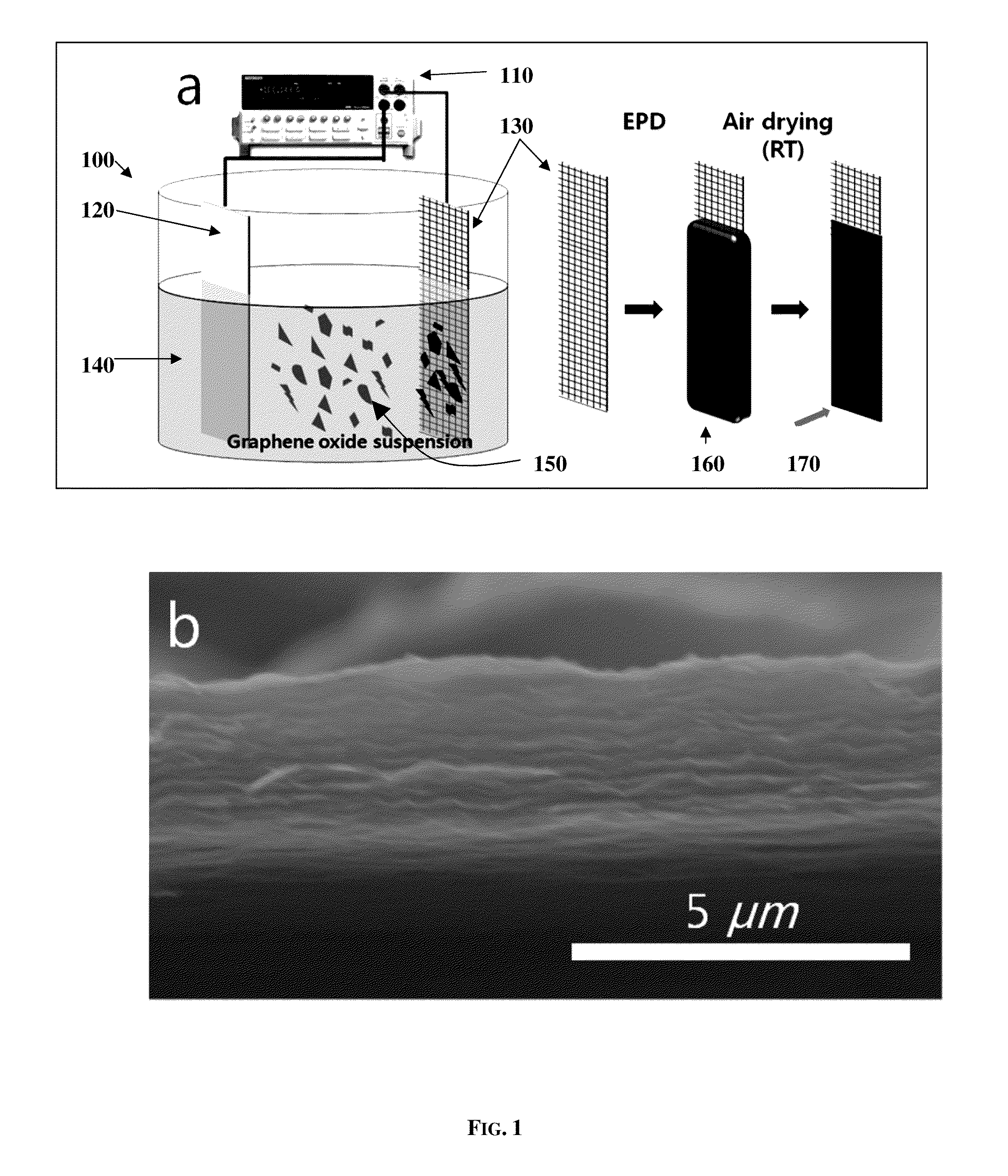

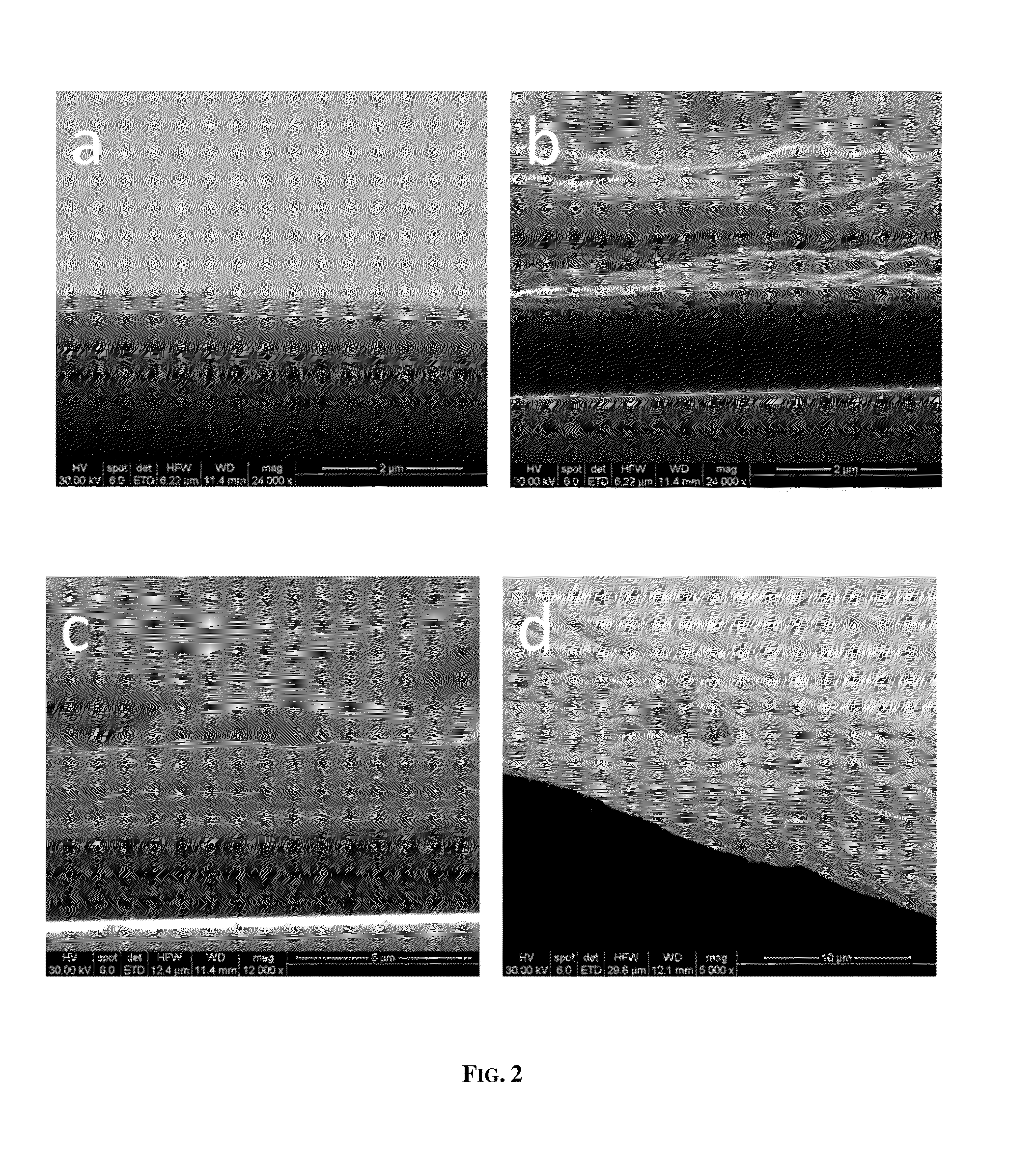

Electrophoretic deposition and reduction of graphene oxide to make graphene film coatings and electrode structures

Owner:RUOFF RODNEY S +4

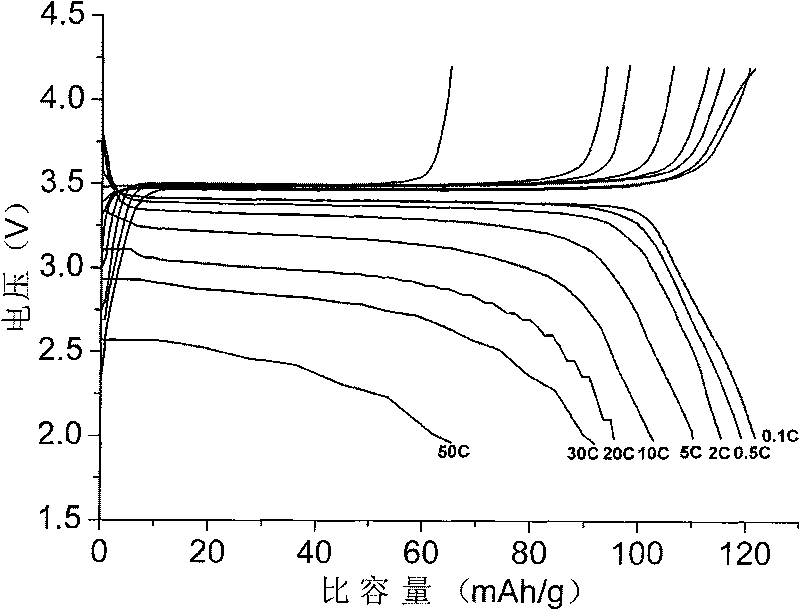

Graphite alkene iron lithium phosphate positive active material, preparing method thereof, and lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material

InactiveCN101752561AImprove conductivityImprove cycle stabilityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

The present invention relates to graphite alkene iron lithium phosphate positive active material, a preparing method thereof, and a lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material. Graphite alkene and iron lithium phosphate are dispersed into water solution to be mixed evenly by stirring and ultra audible sound, then, are dried to obtain iron lithium phosphate material compounded by the graphite alkene and the iron lithium phosphate to be annealed by high temperature, and finally, the graphite alkene modified iron lithium phosphate positive active material is obtained. Compared with traditional carbon coated and conductive polymeric adulteration modified lithium batteries, the lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material has the advantages of high battery capacity, good charging-discharging circulating performance, long life and high circulating stability, and has great utility value.

Owner:宁波艾能锂电材料科技股份有限公司

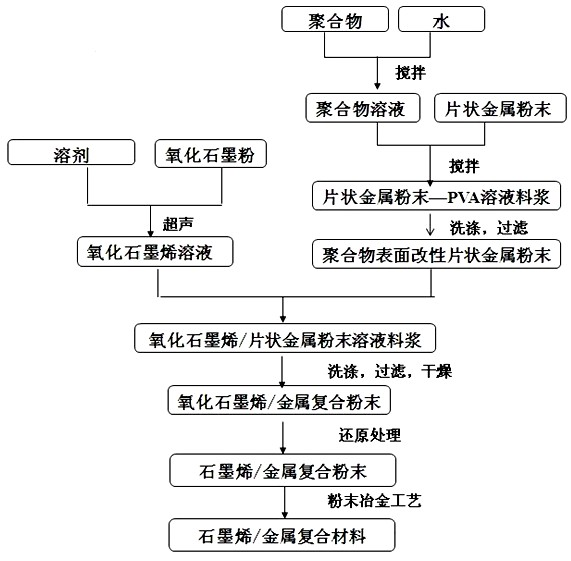

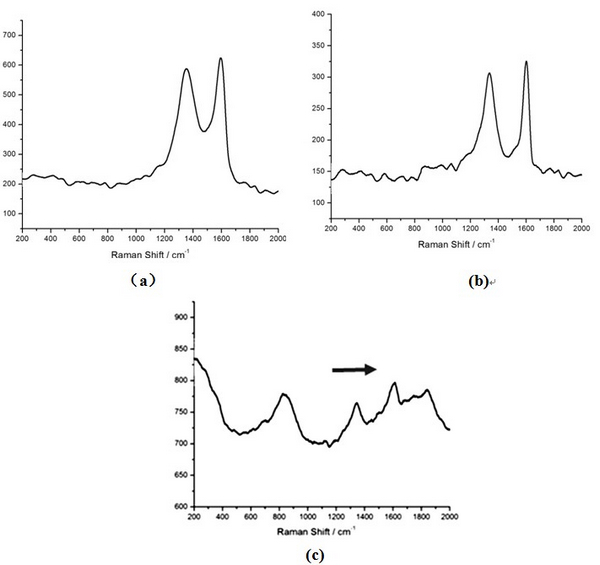

Preparation method of graphene reinforced metal-matrix composite

ActiveCN102329976AFacilitate induced orientation distributionPotential for large-scale applicationMetal matrix compositeCvd graphene

The invention discloses a preparation method of a graphene reinforced metal-matrix composite, which comprises the following steps of: firstly, dispersing the graphene oxide on the surface of the flaky metal powder; and then obtaining the graphene / metal composite powder through the reducing treatment; and at last, carrying out densification treatment by adopting a powder metallurgic technology to obtain the compact graphene reinforced metal-matrix composite. The flaky metal powder has the plane two-dimensional form, is inclined to the directional piling to form a laminated structure, and is helpful for inducing the graphene orientation distribution and giving play to the reinforcing effect. The preparation method disclosed by the invention is simple and feasible, is capable of regulating the graphene content and is suitable for preparing the massive composite.

Owner:SHANGHAI JIAO TONG UNIV

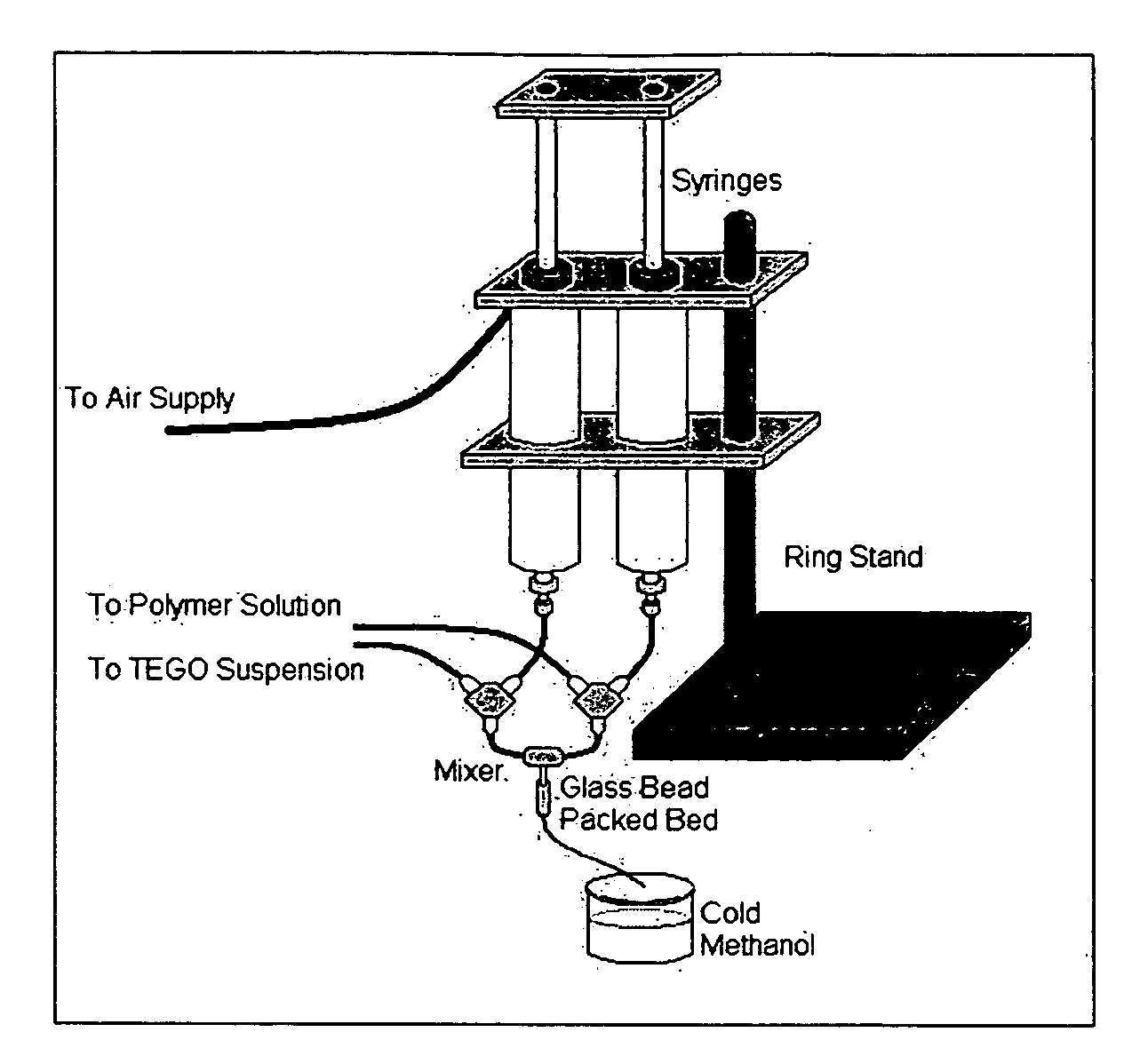

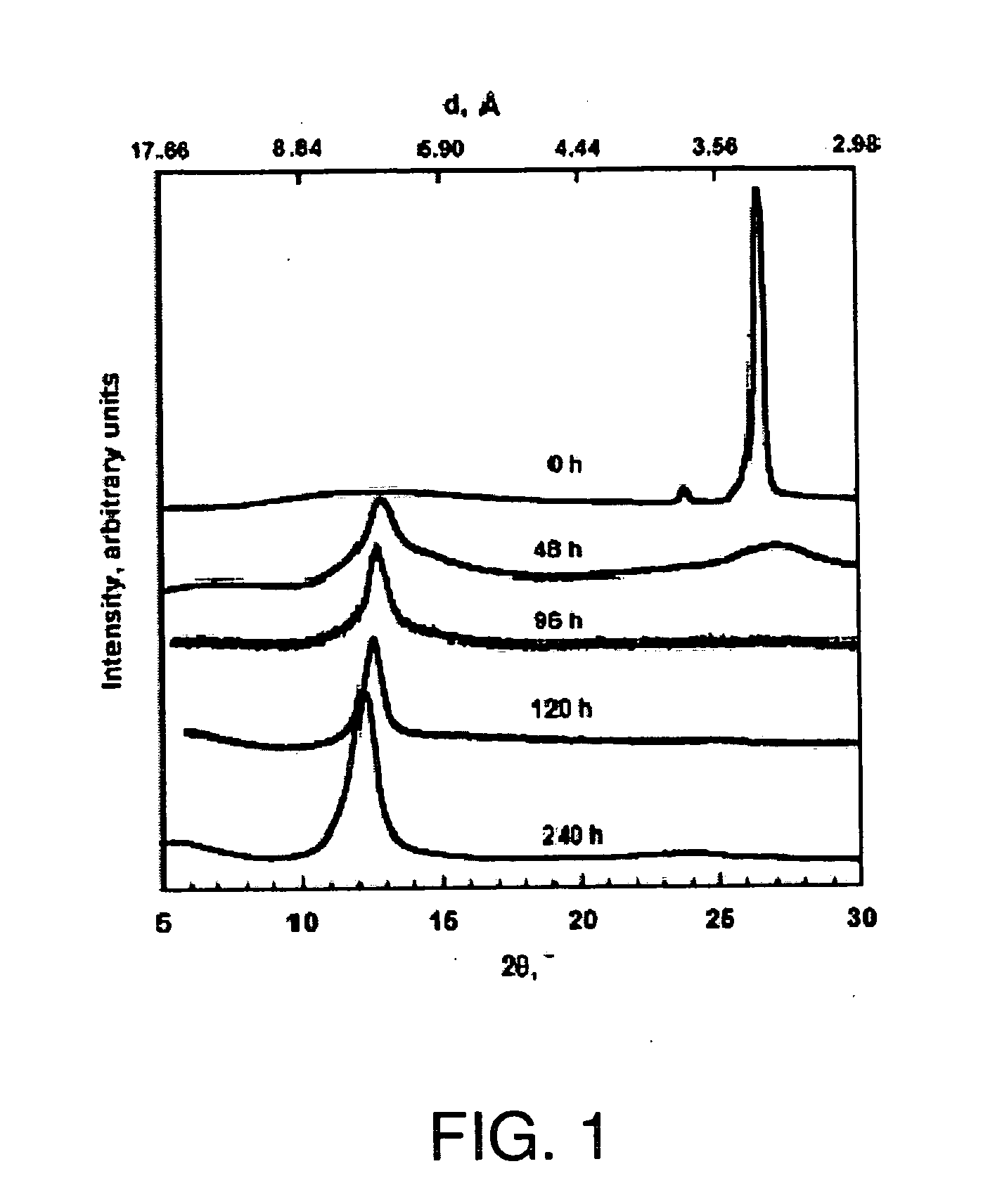

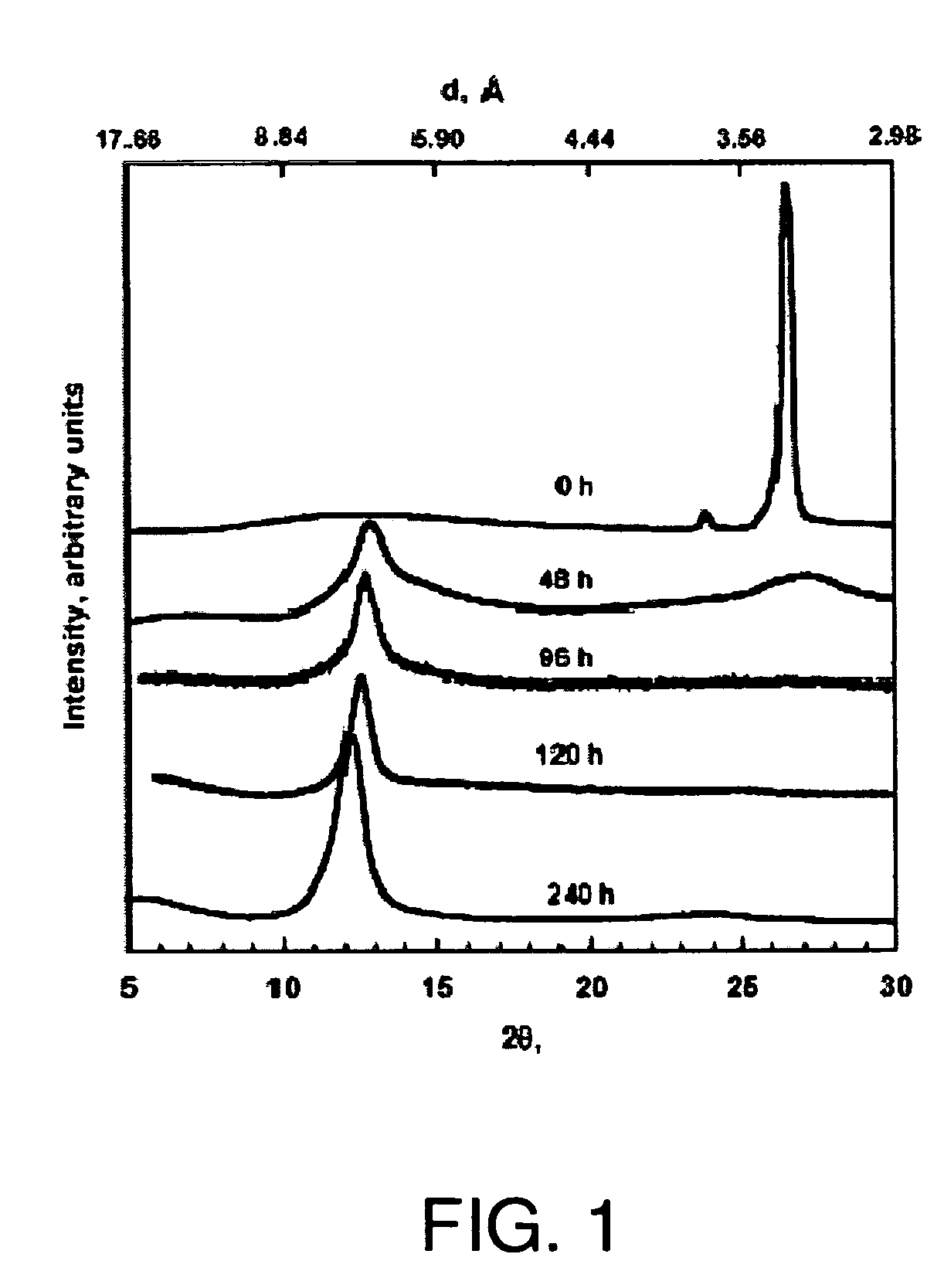

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveUS20100096595A1Excellent gas barrier performanceImprove suppression propertiesMaterial nanotechnologyNanostructure manufactureNano compositesX-ray

Owner:THE TRUSTEES FOR PRINCETON UNIV

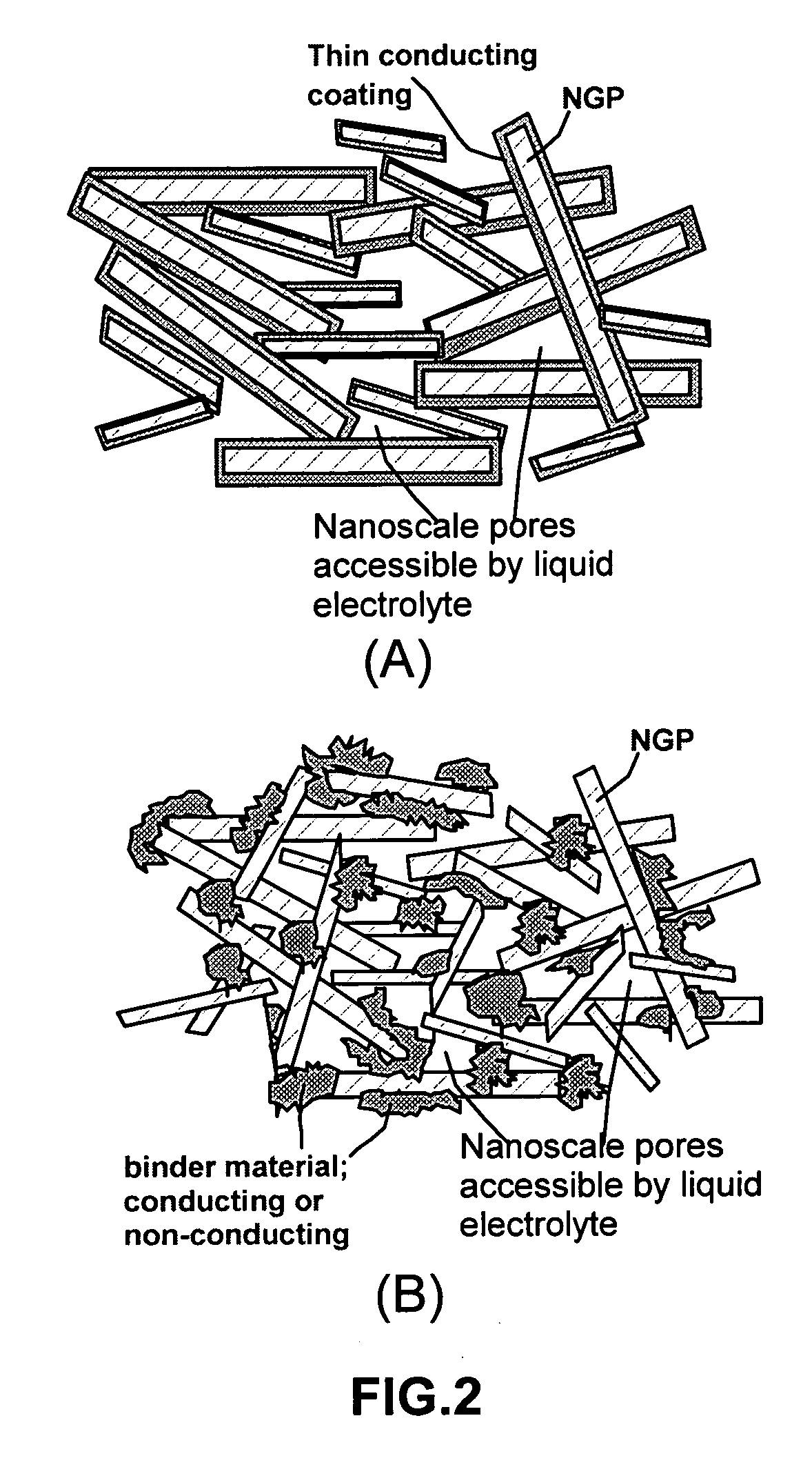

Process for producing nano-scaled graphene platelet nanocomposite electrodes for supercapacitors

ActiveUS20090092747A1Increase the areaImprove conductivityElectrolytic capacitorsHybrid capacitor electrodesHigh capacitanceCvd graphene

A process for producing meso-porous nanocomposite electrode comprising nano-scaled graphene platelets. The process comprises: (A) providing nano-scaled graphene platelets, wherein each of the platelets comprises a single graphene sheet or a stack of multiple graphene sheets, and the platelets have an average thickness no greater than 100 nm (preferably less than 5 nm and most preferably less than 2 nm in thickness); (B) combining a binder material, the graphene platelets, and a liquid to form a dispersion; (C) forming the dispersion into a desired shape and removing the liquid to produce a binder-platelet mixture; and (D) treating the binder material under a desired temperature or radiation environment to convert the binder-platelet mixture into a meso-porous nanocomposite electrode, wherein the platelets are bonded by the binder and the electrode has electrolyte-accessible pores characterized in that the nanocomposite has a surface area greater than about 100 m2 / gm (preferably greater than 200 m2 / gm, more preferably greater than 500 100 m2 / gm, and most preferably greater than 1,000 m2 / gm). A supercapacitor featuring such a nanocomposite exhibits an exceptionally high capacitance value.

Owner:SAMSUNG ELECTRONICS CO LTD +1

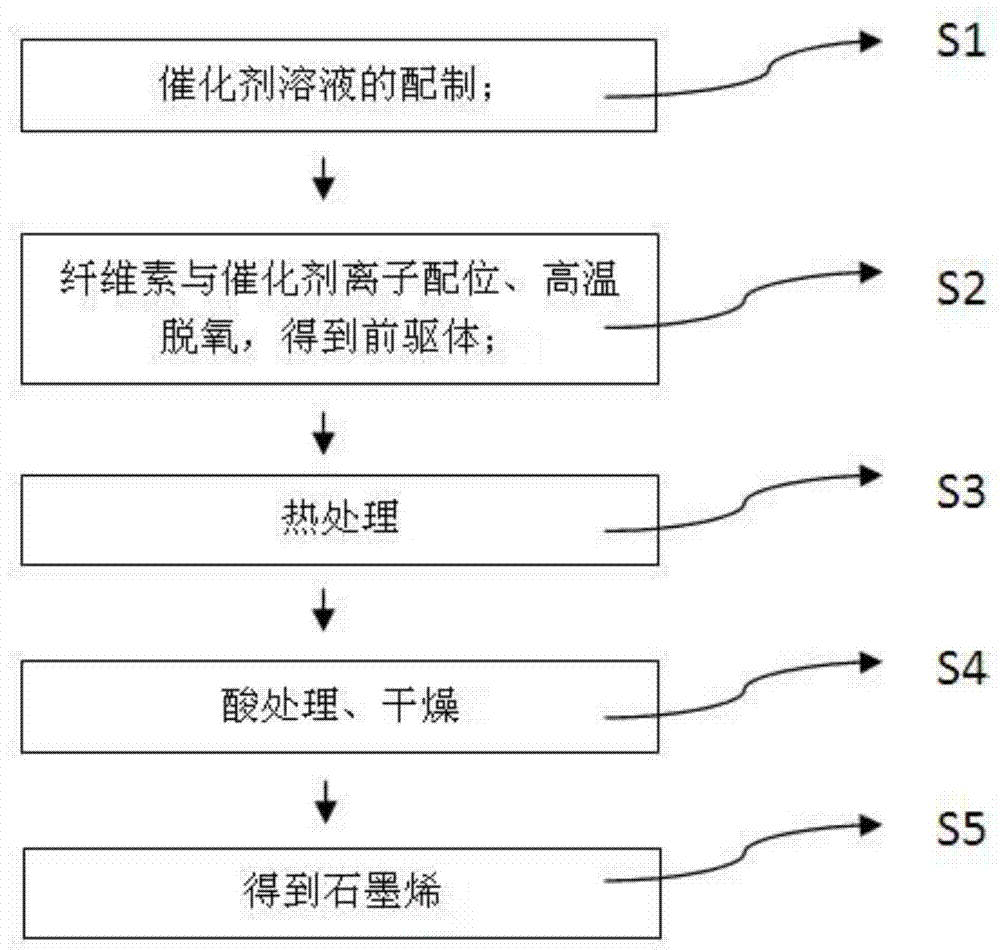

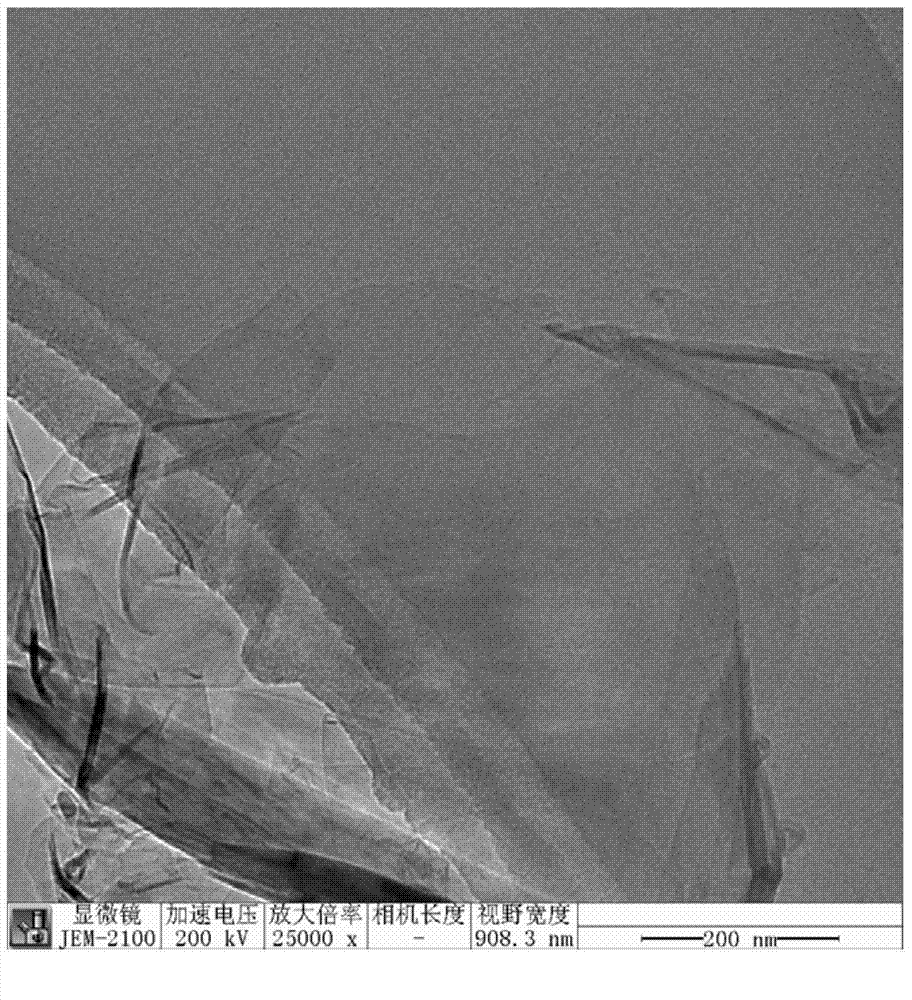

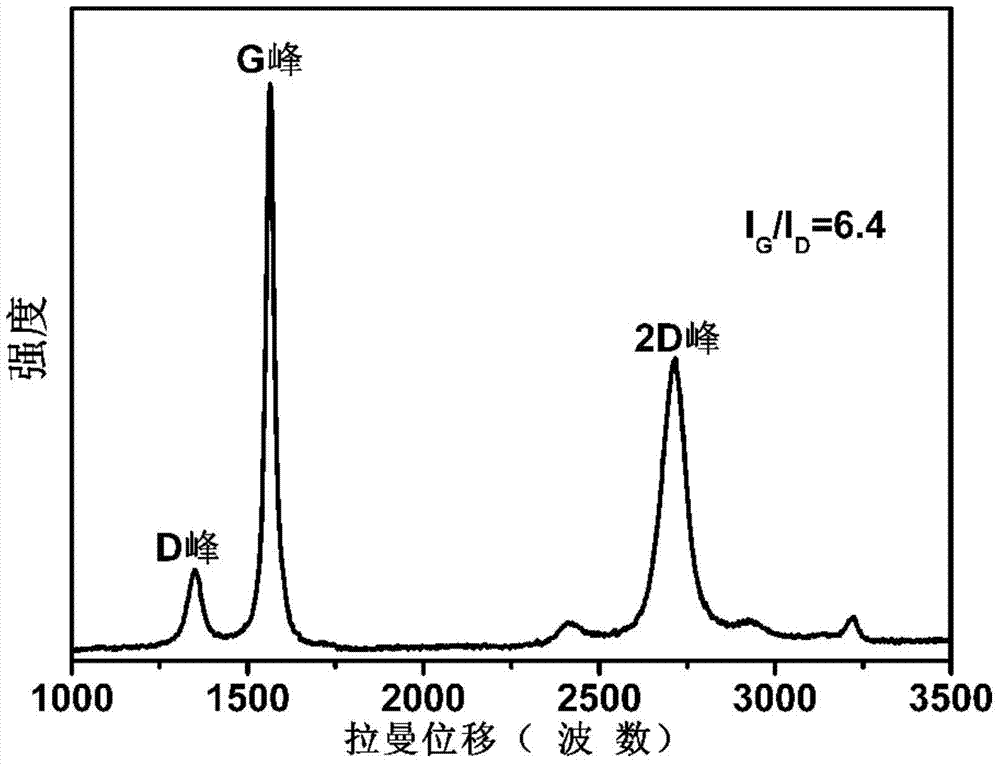

Method for preparing biomass graphene employing cellulose as raw material

ActiveCN104724699AUniform sizeIncrease productionPhysical/chemical process catalystsGrapheneCellulosePolymer science

The invention provides a preparation method of graphene, and particularly relates to a method for preparing biomass graphene employing cellulose as a raw material. The specific preparation method comprises the following steps: 1, preparing a catalyst solution; 2, carrying out ionic coordination and high-temperature deoxidization on cellulose and a catalyst, so as to obtain a precursor; 3, carrying out thermal treatment; 4, carrying out acid treatment, and drying to obtain the graphene, wherein the prepared graphene is uniform in morphology, has a single-layer or multi-layer two-dimensional layered structure; the dimension is 0.5-2 microns; and the electrical conductivity is 25,000-45,000S / m. The preparation method is simple in preparation technology, low in cost, high in yield, high in production safety, and controllable in product dimension and physical property; industrialized production can be realized; the graphene prepared by the method can be applied to electrode materials of super capacitors and lithium ion batteries, and can also be added to resin and rubber as an additive; and the physical property of the material can be improved.

Owner:HEILONGJIANG UNIV +1

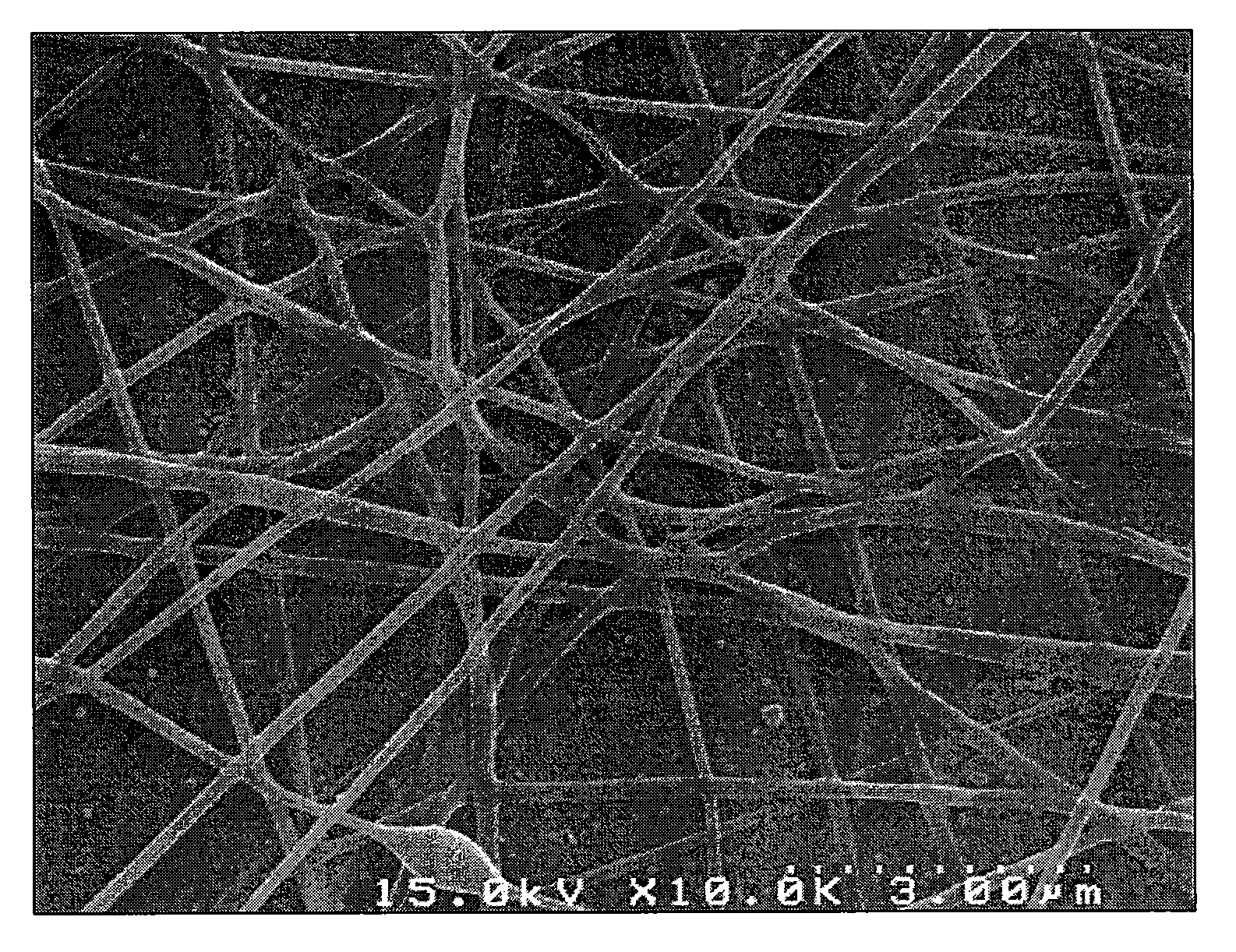

Graphene foam with three dimensional fully connected network and macroscopic quantity preparation method thereof

The invention relates to a graphene-based novel material and a chemical vapor deposition preparation technology thereof, in particular to graphene foam with a three dimensional fully connected network and a macroscopic quantity preparation method thereof. The method is suitable for a mass preparation of the graphene foam with high qualities. Three dimensional connected graphene can grow by catalytic cracking of carbon source gases on the surface of a three dimensional porous metal through the chemical vapor deposition technology, and a porous foam-shaped graphene three dimensional macroscopic body can be obtained after a porous metal base is removed by dissolving subsequently. According to the graphene foam with the three dimensional fully connected network and the macroscopic quantity preparation method thereof, a simple template replication method is used for preparing the three dimensional connected graphene macroscopic body, and the method has the advantages that the operation is simple and convenient, the rate of production is high, and the adjustment and control of the structure are easy. The graphene foam forms the fully connected network in a seamless connection mode, has a low density, a high porosity and specific surface area and excellent capabilities of charge conduction and heat conduction and establishes a foundation for applications of graphene in fields of electric conduction, thermally conductive composite materials, electromagnetic shielding, wave absorbing, catalysis, sensing and energy storage materials and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

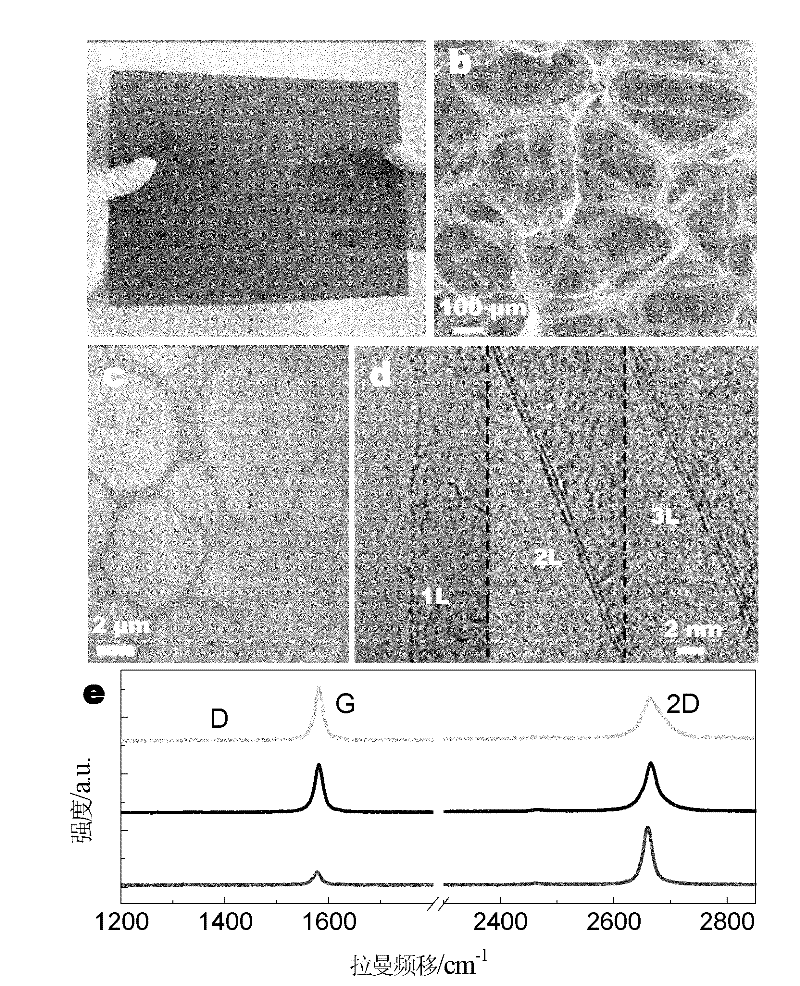

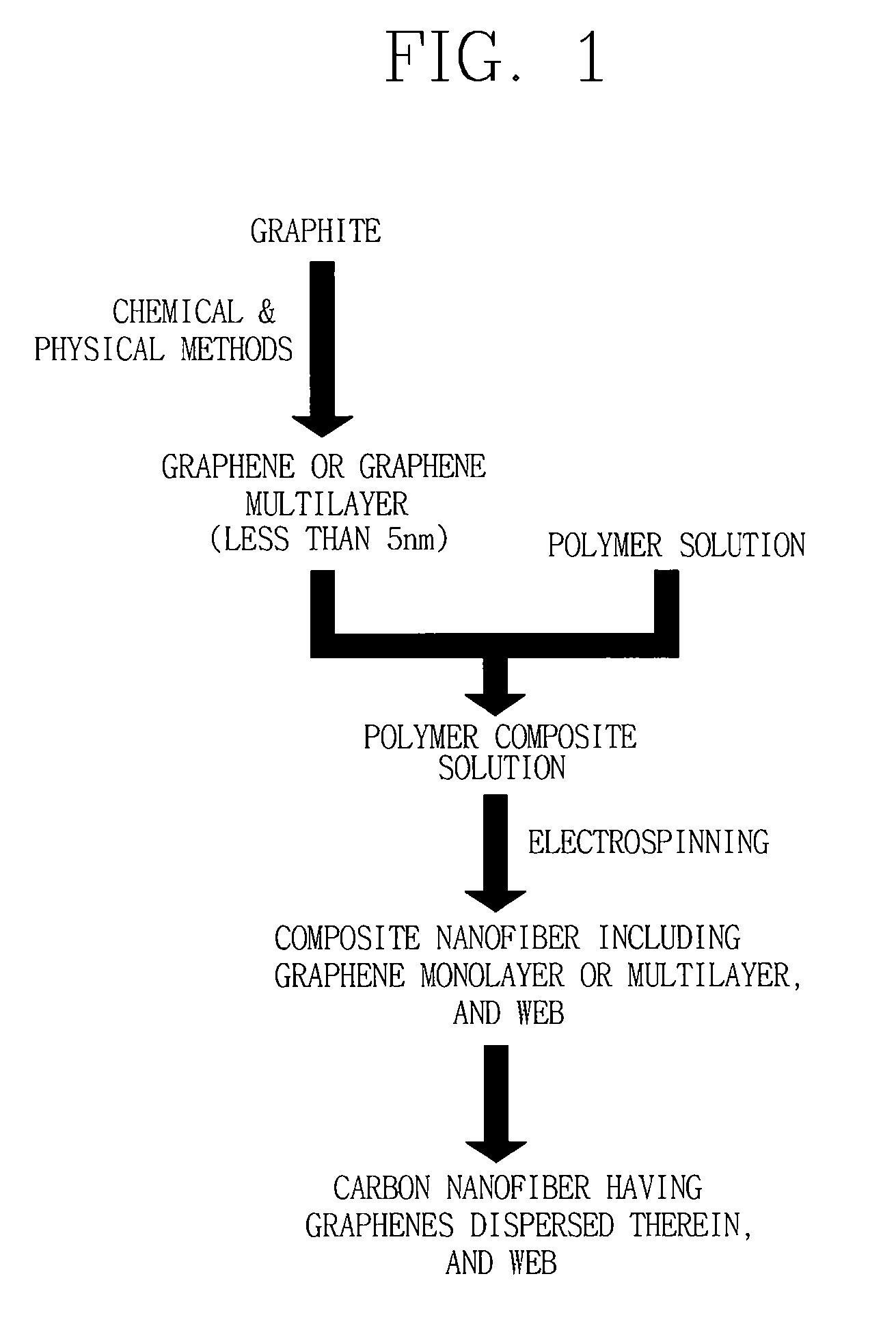

Graphene composite nanofiber and preparation method thereof

Disclosed are a graphene composite nanofiber and a preparation method thereof. The graphene composite nanofiber is produced by dispersing graphenes to at least one of a surface and inside of a polymer nanofiber or a carbon nanofiber having a diameter of 1˜1000 nm, and the graphenes include at least one type of monolayer graphenes, and multilayer graphenes having a thickness of 10 nm or less. The graphene composite nanofiber can be applied to various industrial fields, e.g., a light emitting display, a micro resonator, a transistor, a sensor, a transparent electrode, a fuel cell, a solar cell, a secondary cell, and a composite material, owing to a unique structure and property of graphene.

Owner:KOREA INST OF SCI & TECH

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

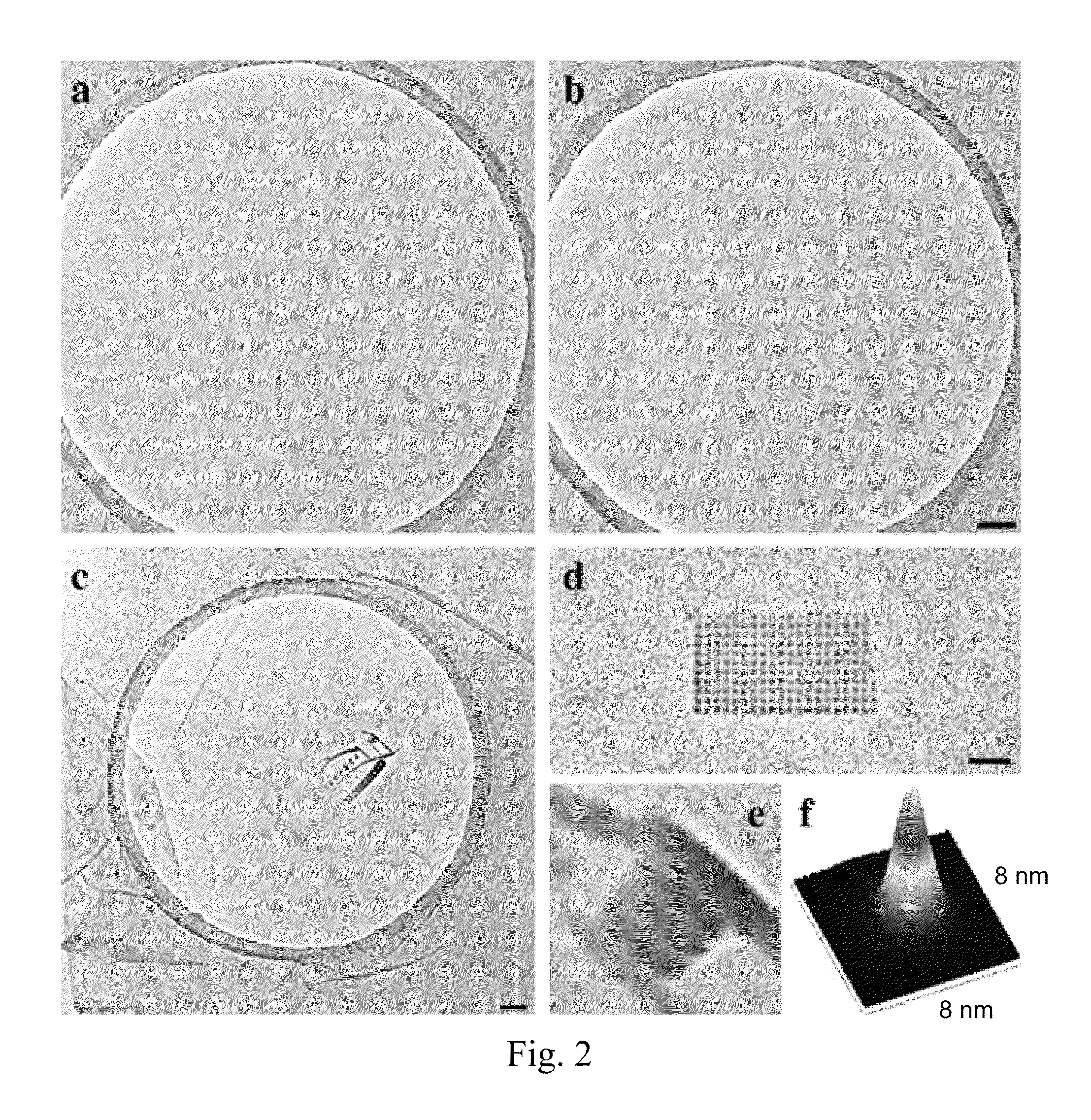

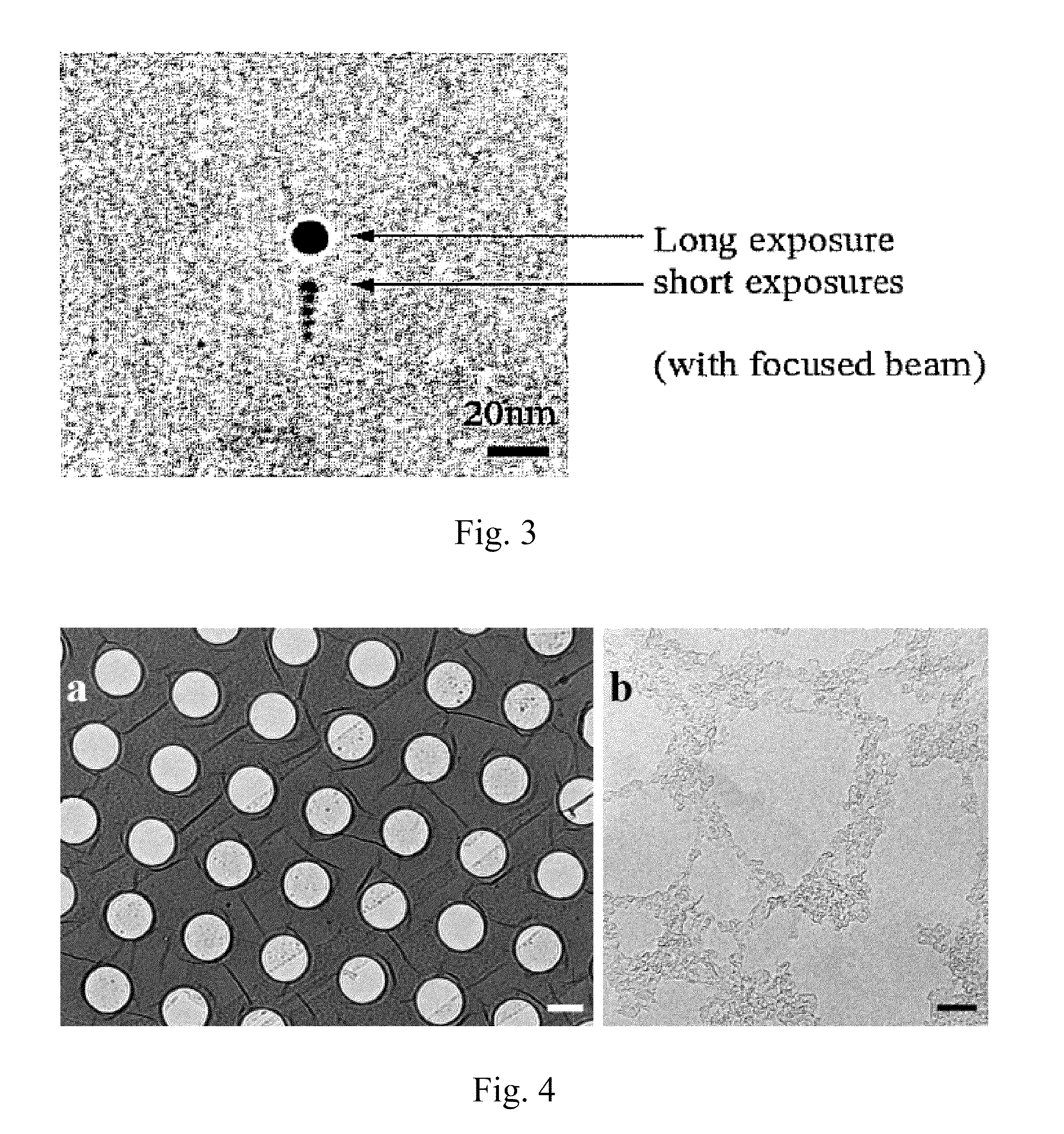

Graphene-based structure, method of suspending graphene membrane, and method of depositing material onto graphene membrane

An embodiment of a method of suspending a graphene membrane across a gap in a support structure includes attaching graphene to a substrate. A pre-fabricated support structure having the gap is attached to the graphene. The graphene and the pre-fabricated support structure are then separated from the substrate which leaves the graphene membrane suspended across the gap in the pre-fabricated support structure. An embodiment of a method of depositing material includes placing a support structure having a graphene membrane suspended across a gap under vacuum. A precursor is adsorbed to a surface of the graphene membrane. A portion of the graphene membrane is exposed to a focused electron beam which deposits a material from the precursor onto the graphene membrane. An embodiment of a graphene-based structure includes a support structure having a gap, a graphene membrane suspended across the gap, and a material deposited in a pattern on the graphene membrane.

Owner:RGT UNIV OF CALIFORNIA

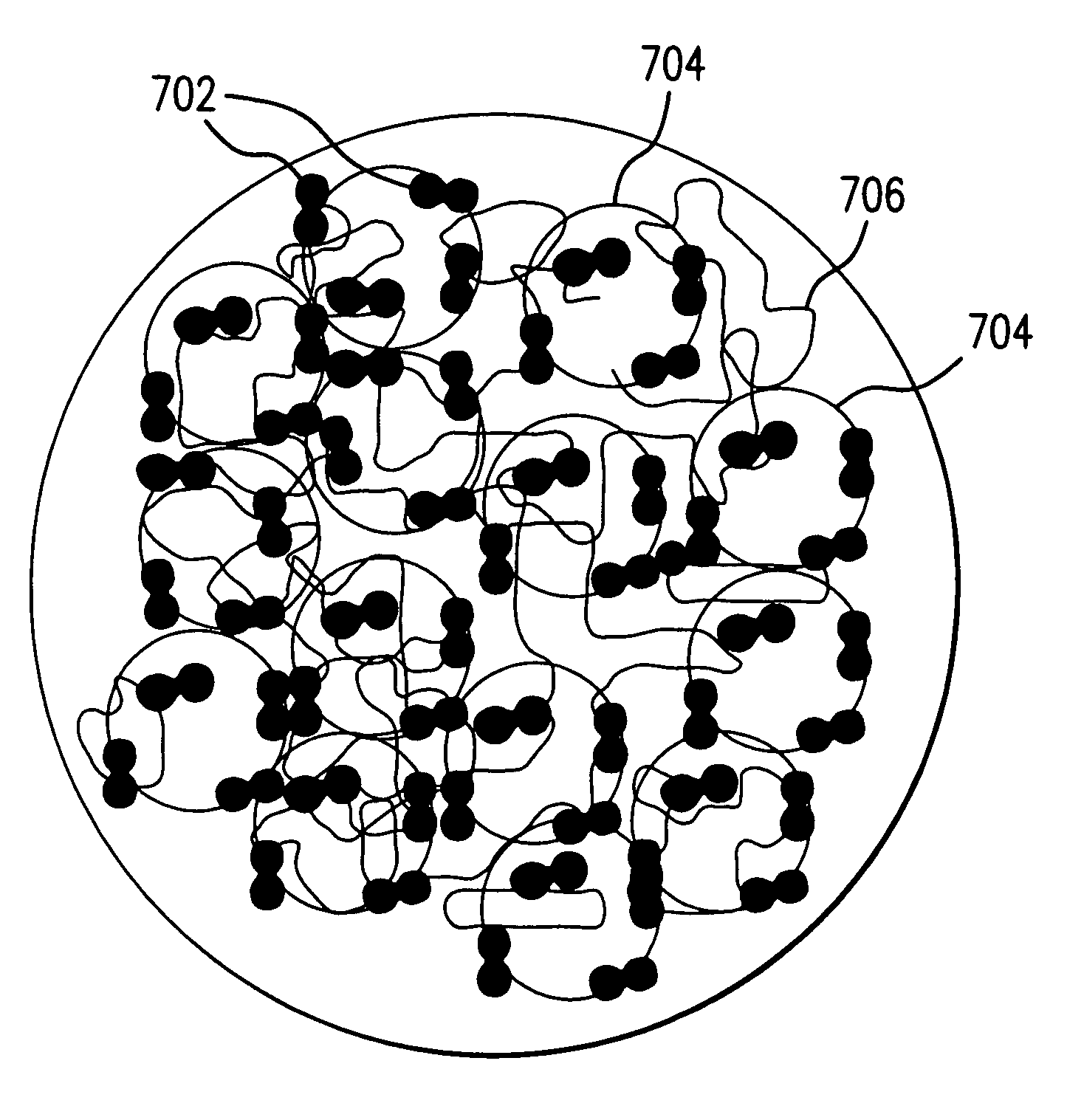

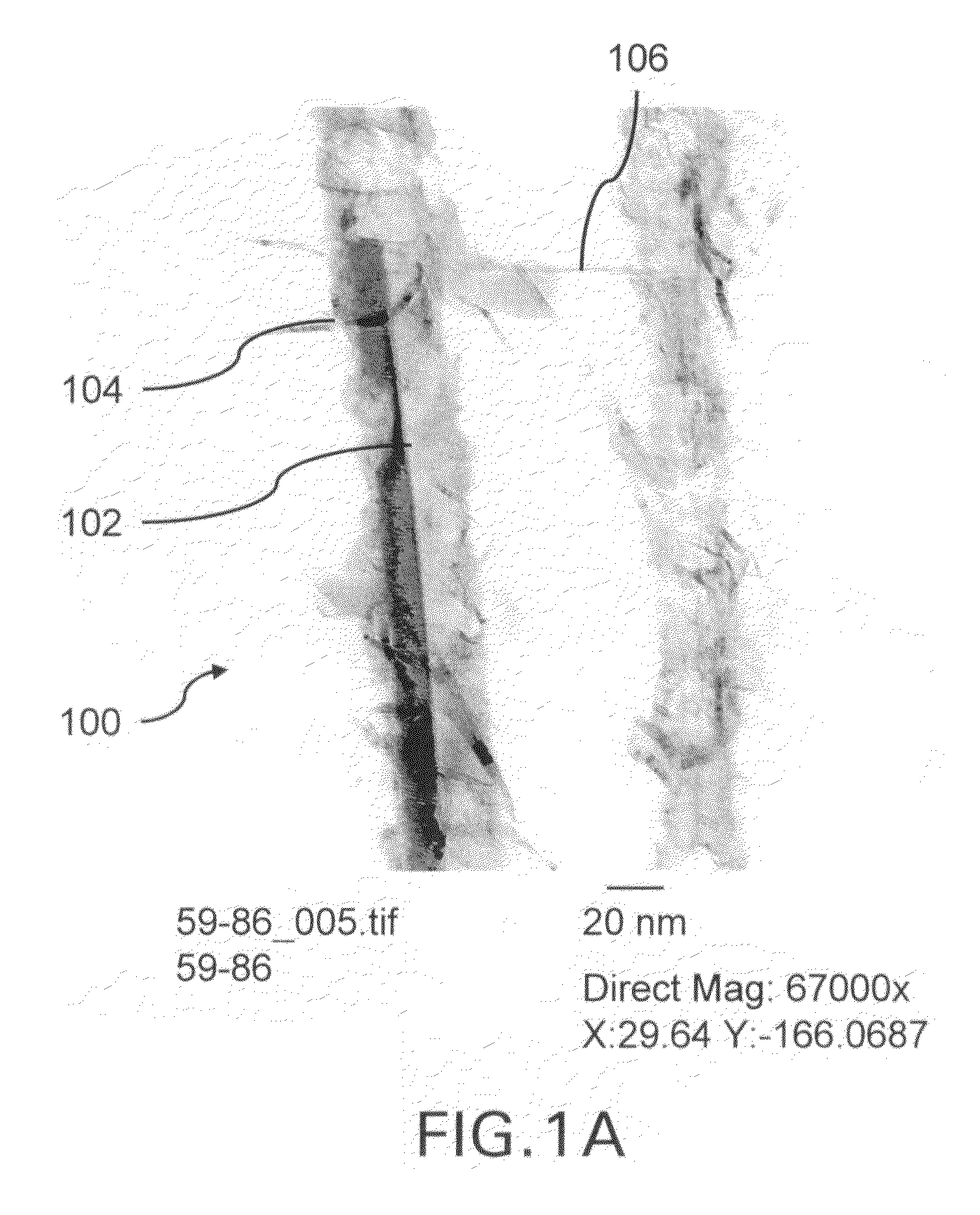

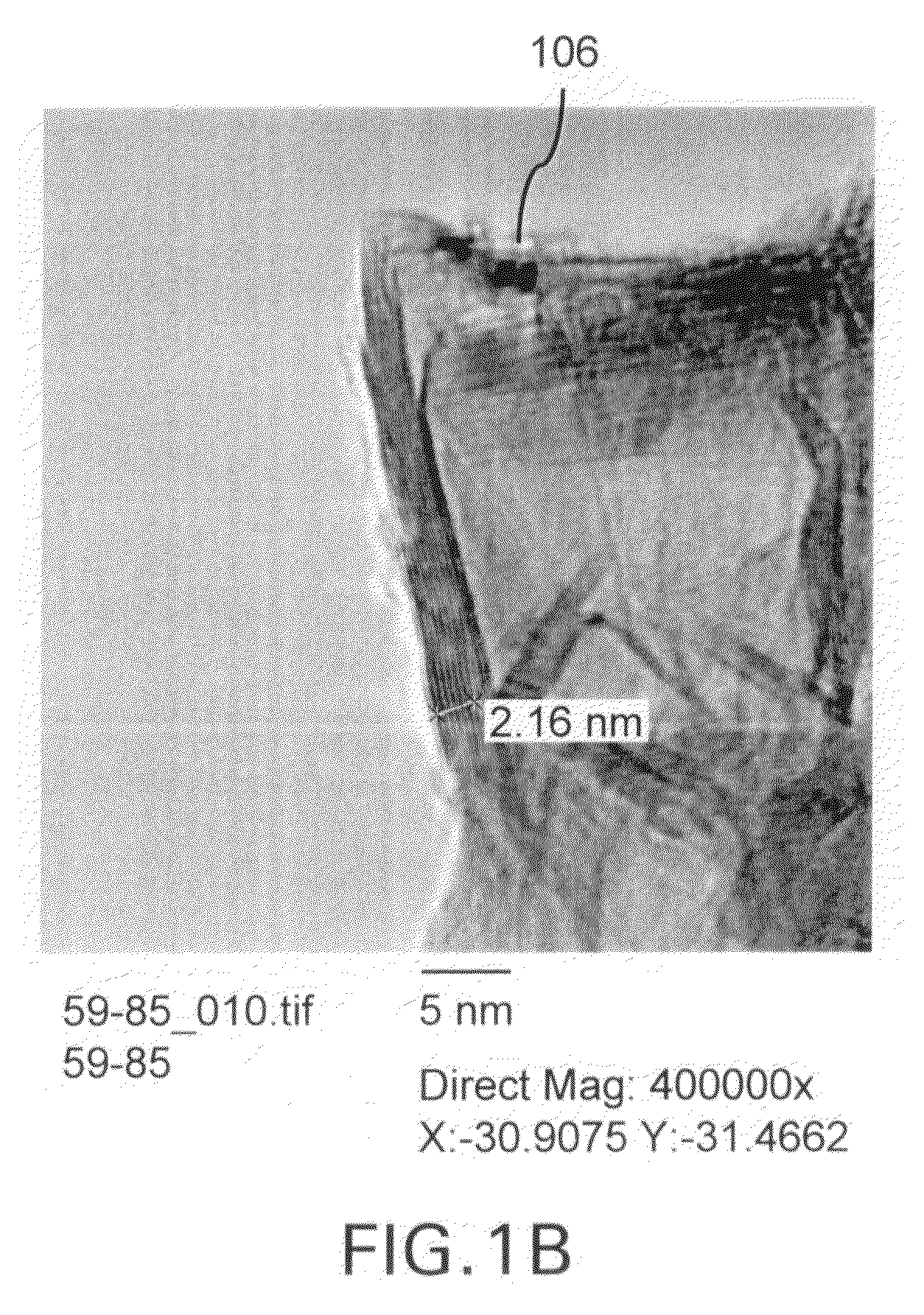

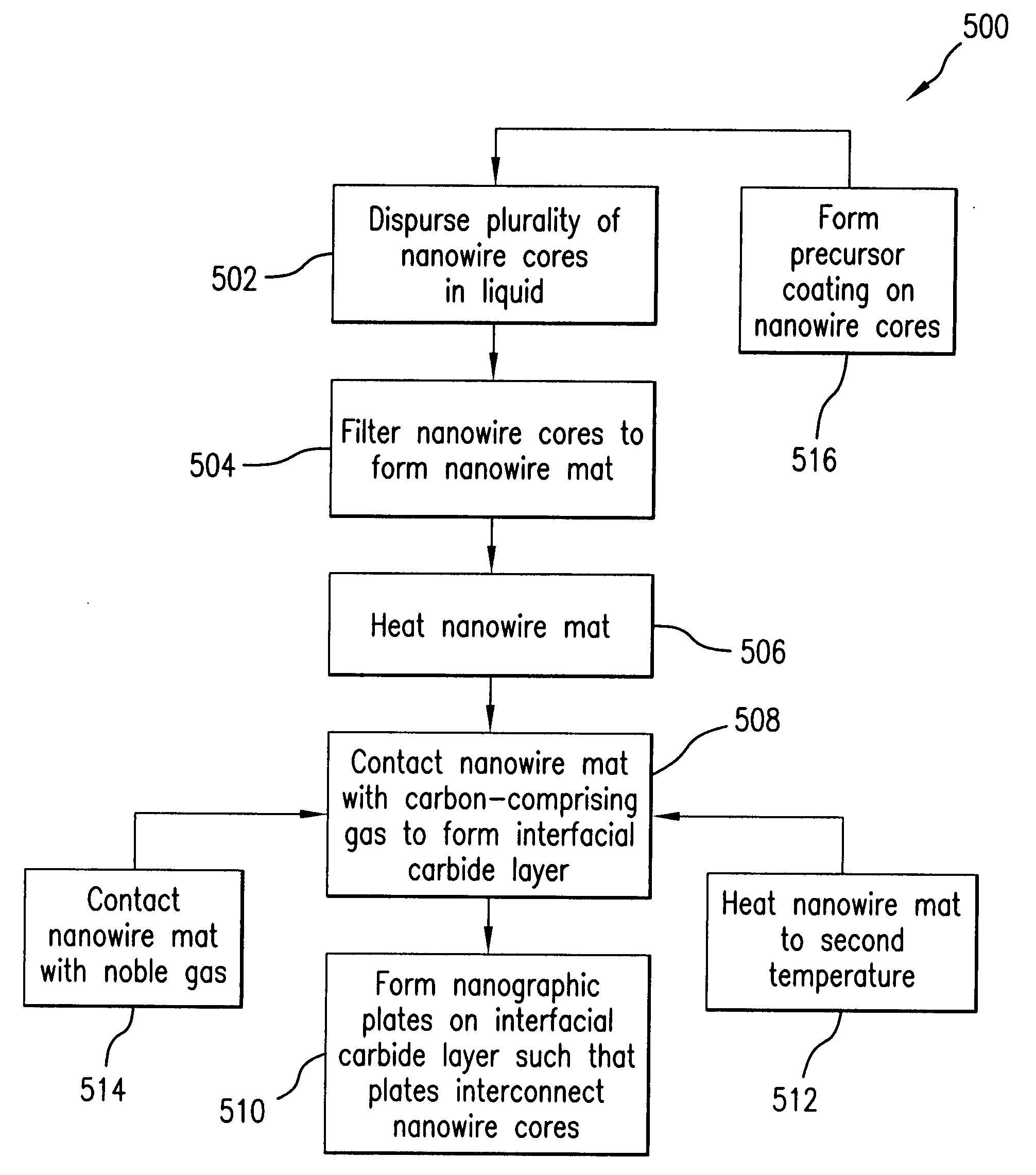

Nanowire structures comprising carbon

ActiveUS7842432B2High rateLow costFinal product manufactureFuel cell auxillariesField emission deviceNanowire

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Nanowire structures comprising carbon

ActiveUS20080280169A1Low overall diffusion resistanceLow costFinal product manufactureFuel cell auxillariesField emission deviceFuel cells

The present invention is directed to nanowire structures and interconnected nanowire networks comprising such structures, as well as methods for their production. The nanowire structures comprise a nanowire core, a carbon-based layer, and in additional embodiments, carbon-based structures such as nanographitic plates consisting of graphenes formed on the nanowire cores, interconnecting the nanowire structures in the networks. The networks are porous structures that can be formed into membranes or particles. The nanowire structures and the networks formed using them are useful in catalyst and electrode applications, including fuel cells, as well as field emission devices, support substrates and chromatographic applications.

Owner:ONED MATERIAL INC

Direct growth of graphene films on non-catalyst surfaces

The present invention provides methods of forming graphene films on various non-catalyst surfaces by applying a carbon source and a catalyst to the surface and initiating graphene film formation. In some embodiments, graphene film formation may be initiated by induction heating. In some embodiments, the carbon source is applied to the non-catalyst surface before the catalyst is applied to the surface. In other embodiments, the catalyst is applied to the non-catalyst surface before the carbon source is applied to the surface. In further embodiments, the catalyst and the carbon source are applied to the non-catalyst surface at the same time. Further embodiments of the present invention may also include a step of separating the catalyst from the formed graphene film, such as by acid etching.

Owner:RICE UNIV

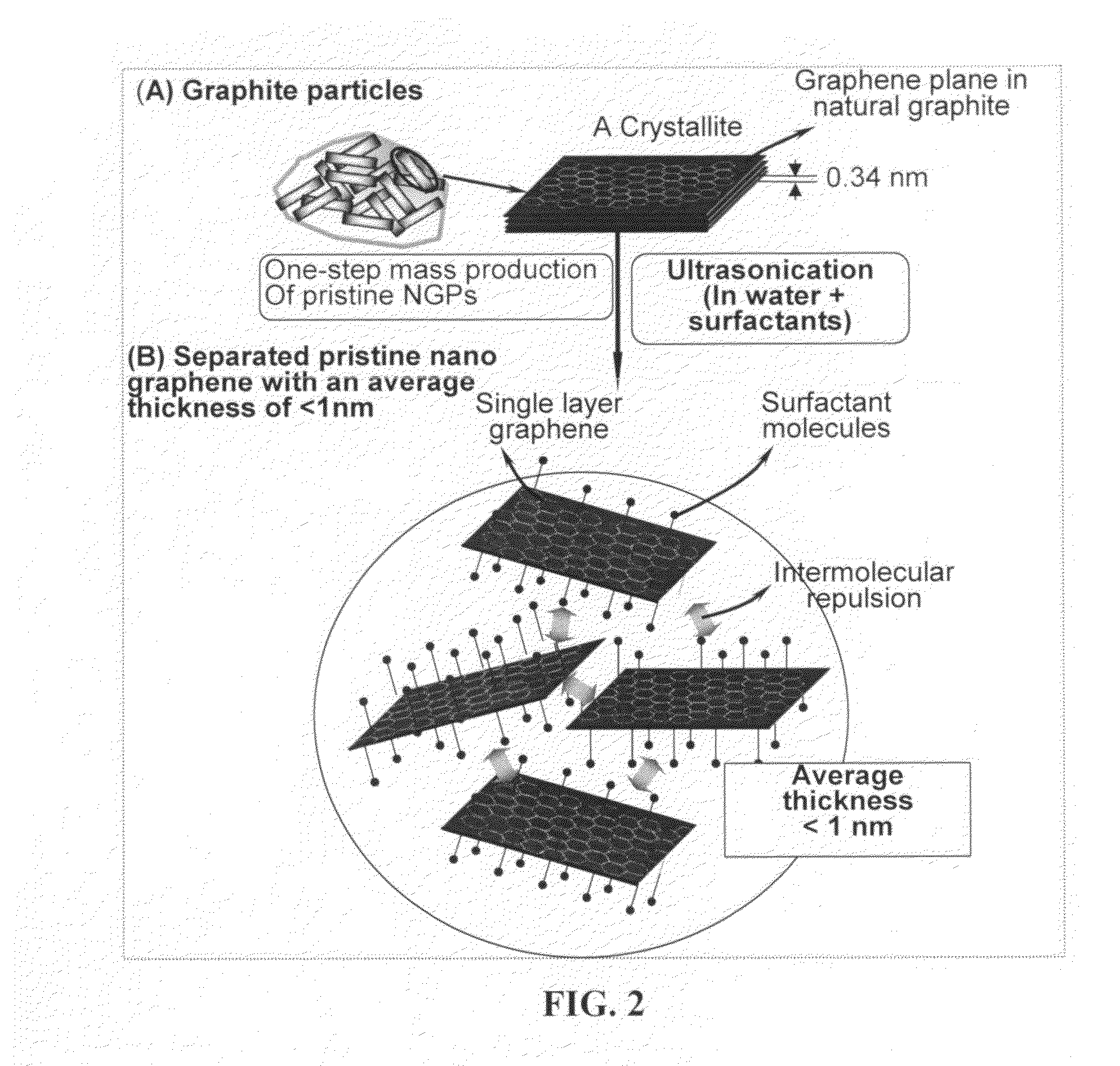

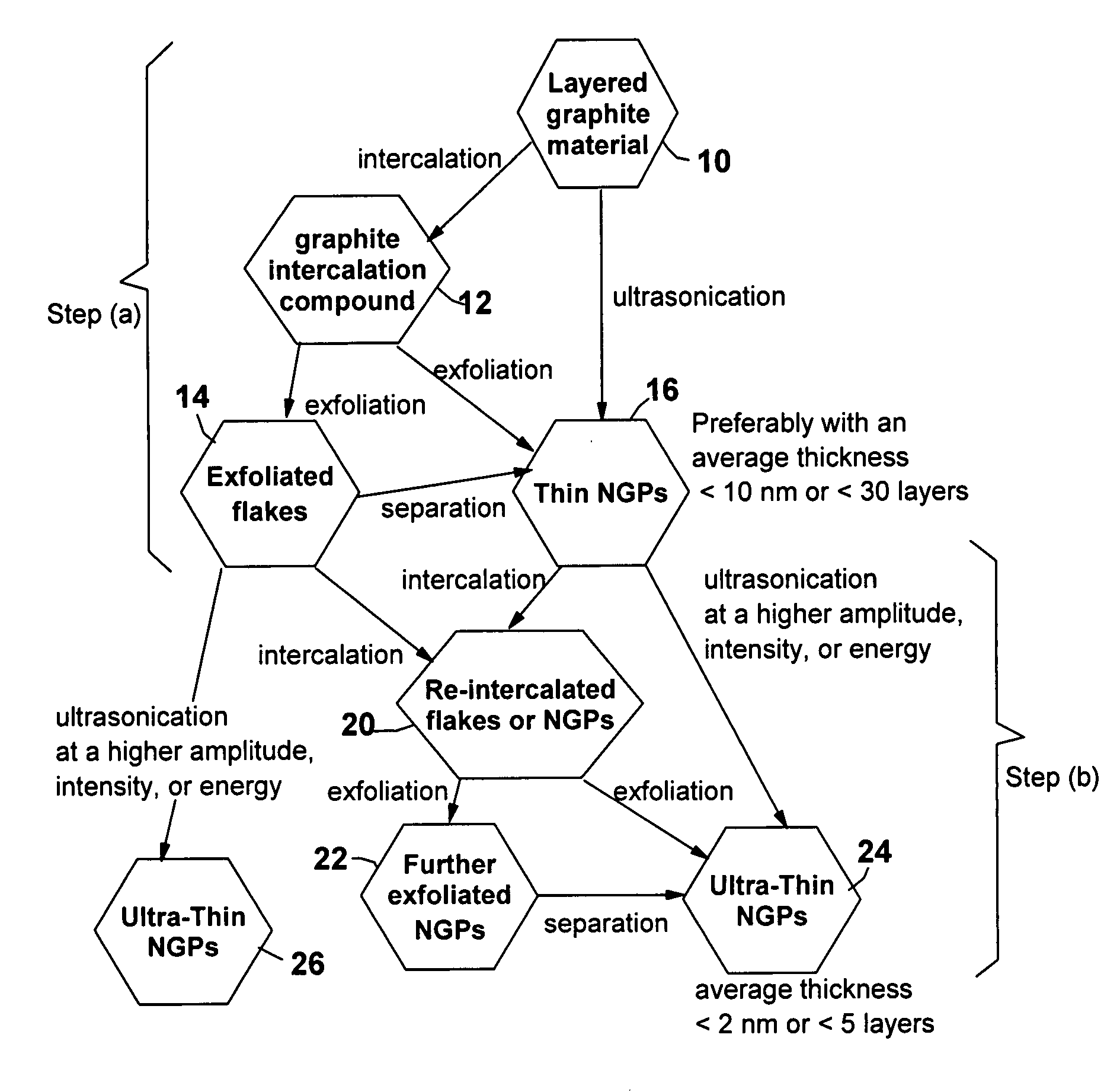

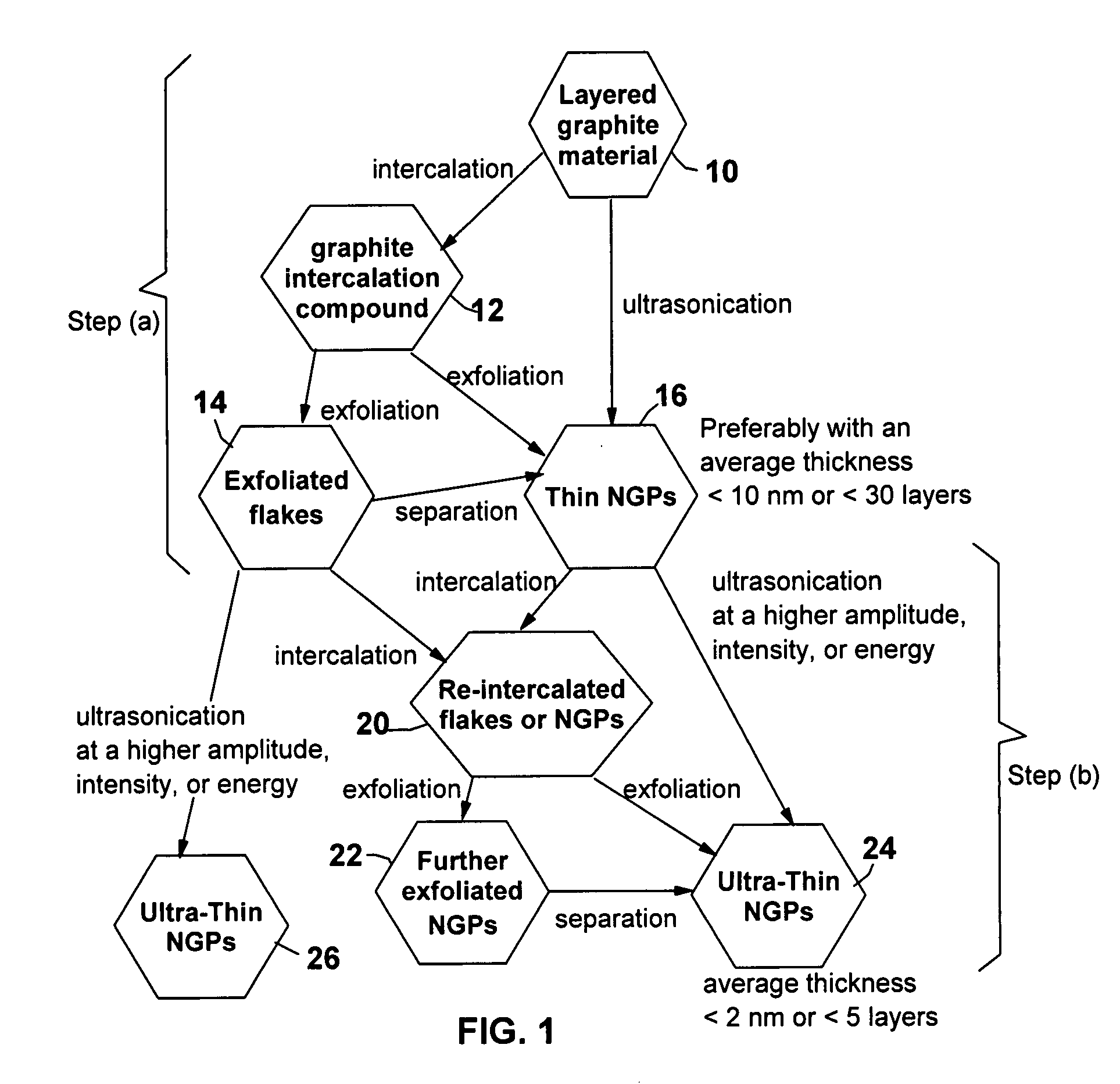

Method for producing ultra-thin nano-scaled graphene platelets

InactiveUS20090022649A1Good dispersionImprove conductivityMaterial nanotechnologyGraphiteFiberCarbon nanotube

A method of producing ultra-thin, separated nano-scaled platelets having an average thickness no greater than 2 nm or comprising, on average, no more than 5 layers per platelet from a layered graphite material. The method comprises: (a) providing a supply of nano-scaled platelets with an average thickness of no more than 10 nm or having, on average, no more than 30 layers per platelet; and (b) intercalating the supply of nano-scaled platelets to produce intercalated nano platelets and exfoliating the intercalated nano platelets at a temperature and a pressure for a sufficient period of time to produce the ultra-thin nano-scaled platelets. The nano-scaled platelets are candidate reinforcement fillers for polymer nanocomposites. Nano-scaled graphene platelets are much lower-cost alternatives to carbon nano-tubes or carbon nano-fibers.

Owner:NANOTEK INSTR

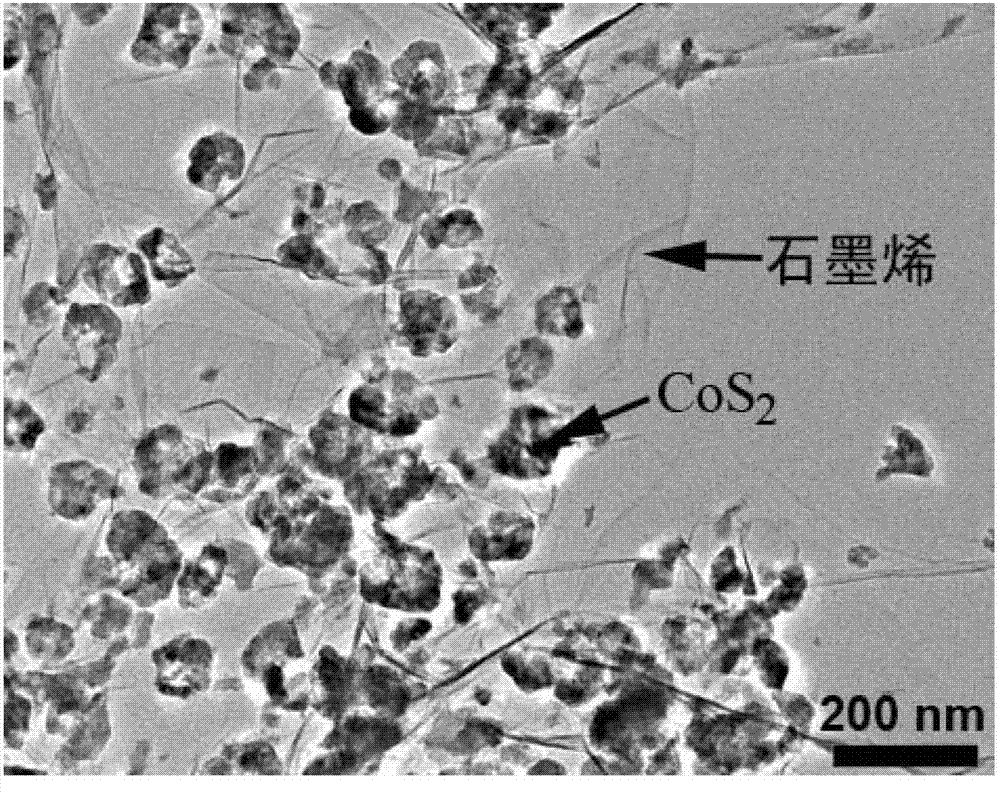

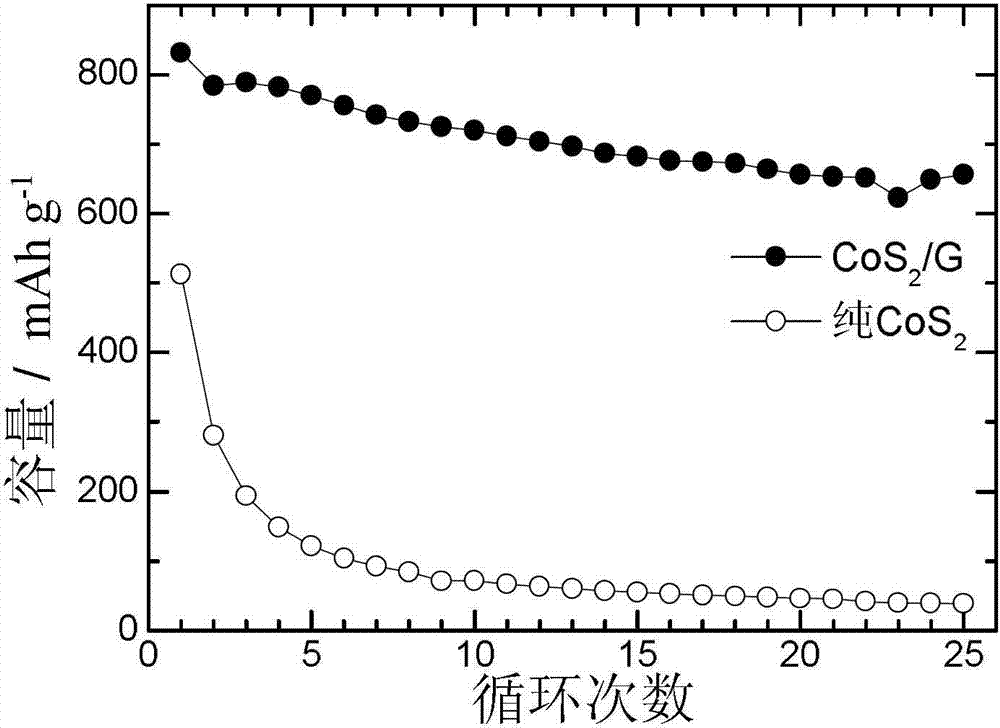

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

Functional graphene-rubber nanocomposites

ActiveUS7745528B2Increase modulusImprove toughnessMaterial nanotechnologyPigmenting treatmentElastomerX-ray

A polymer composition, containing a polymer matrix which contains an elastomer; and a functional graphene which displays no signature of graphite and / or graphite oxide, as determined by X-ray diffraction, exhibits excellent strength, toughness, modulus, thermal stability and electrical conductivity.

Owner:THE TRUSTEES FOR PRINCETON UNIV

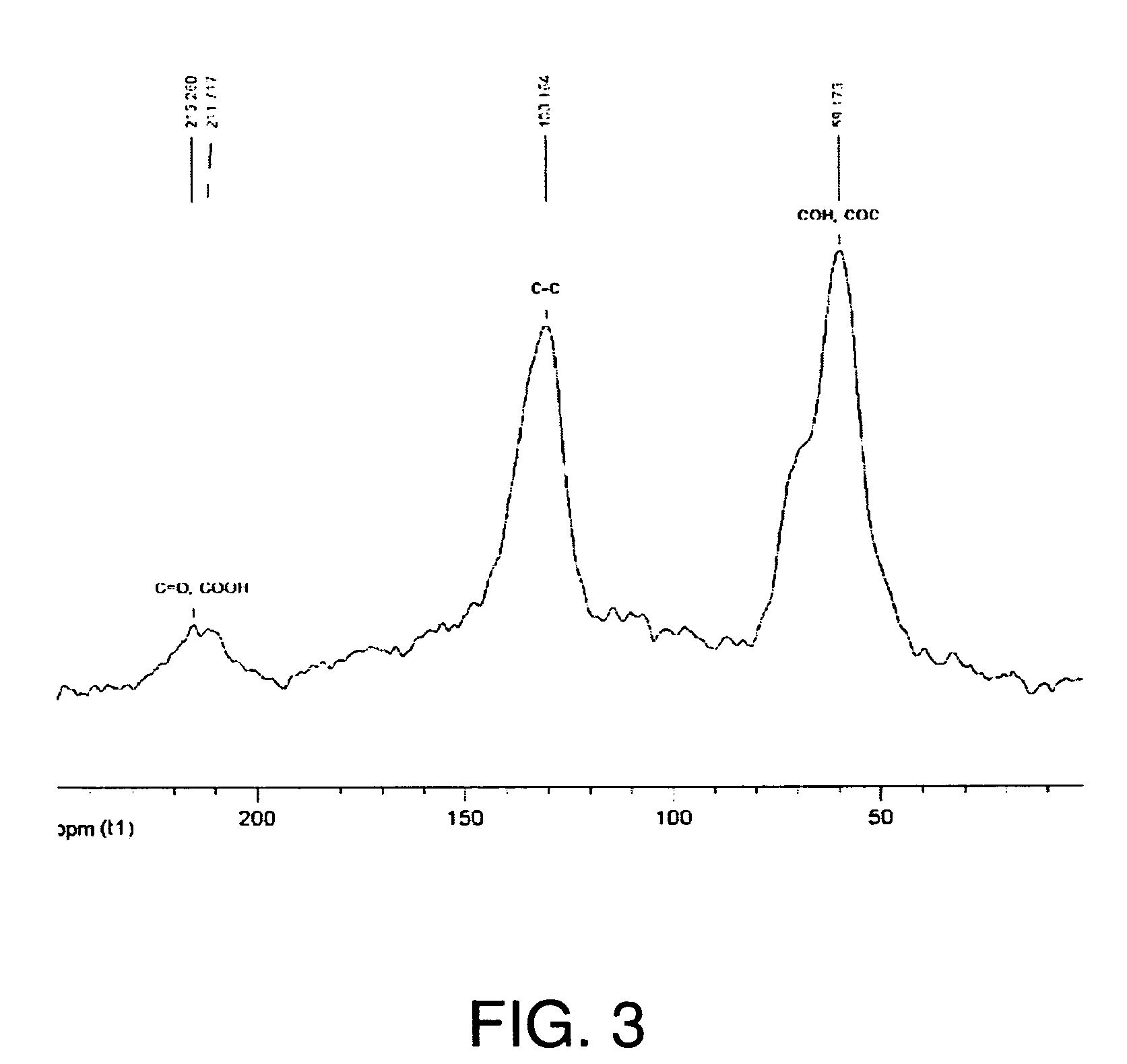

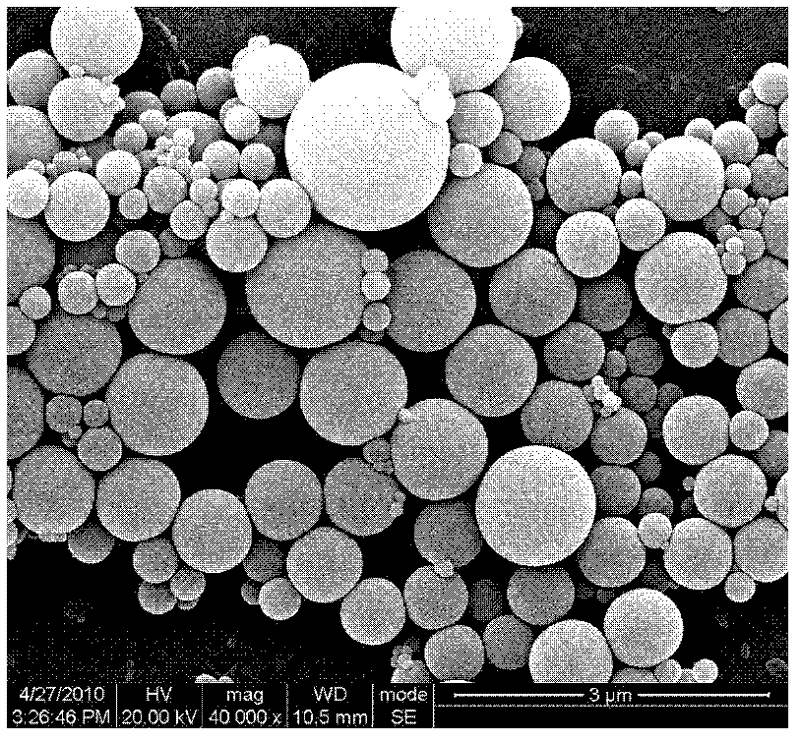

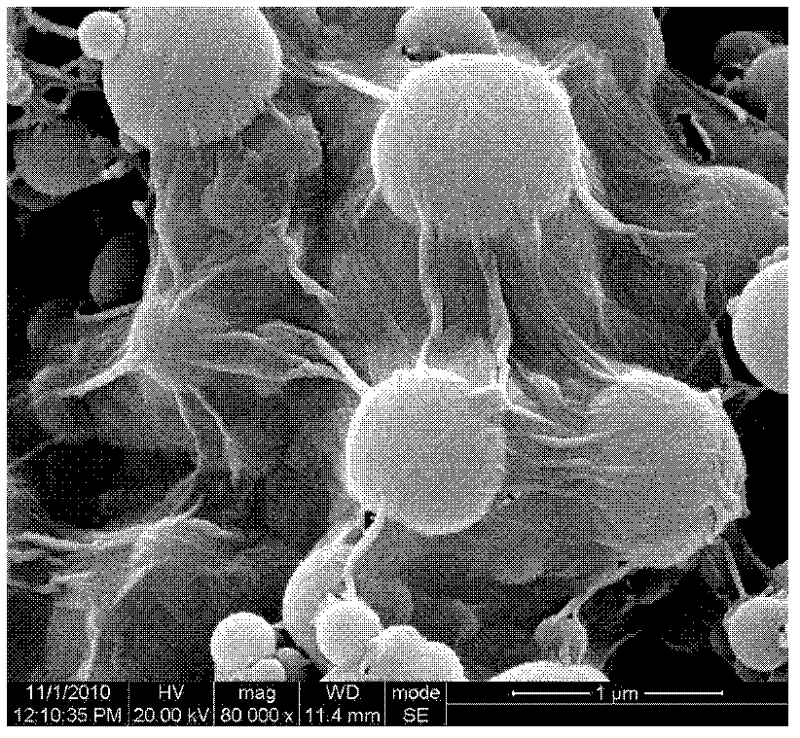

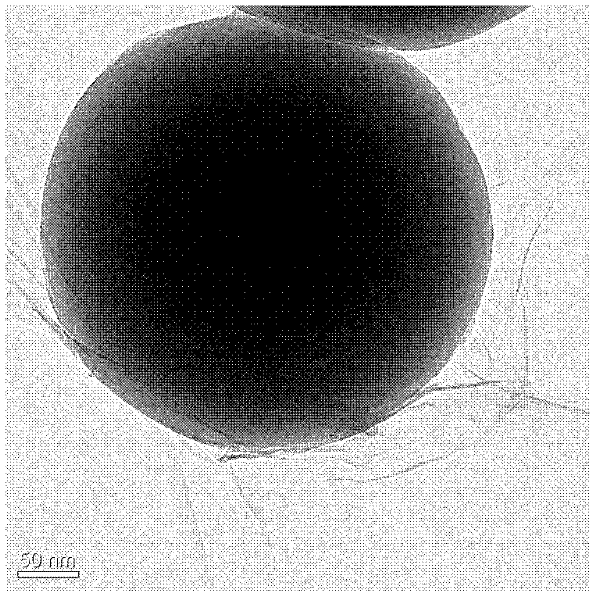

Oxidized graphene or graphene/inorganic particle core/shell material and preparation method thereof

ActiveCN102343239AExpand application spaceChange surface propertiesMicroballoon preparationMicrocapsule preparationInorganic particleInorganic particles

The invention firstly discloses an oxidized graphene or graphene / inorganic particle core / shell material which is formed by electrostatic self-assembly, wherein inorganic particles are taken as the core of the material, oxidized graphene or graphene is taken as a shell layer, and the content of the oxidized graphene or the graphene is 0.1-2wt% of that of the inorganic particles. The invention alsodiscloses a preparation method of the oxidized graphene or graphene / inorganic particle core / shell material. Therefore, a new species is added for outer-coated inorganic powder materials and the application space of the inorganic particles is expanded; furthermore, the electrostatic self-assembly technology is further applied to the preparation of the oxidized graphene or graphene-inorganic powderhybrid material, and the method simultaneously has the characteristics of being mature and environmentally-friendly in process, being simple to operate, having no need of complex equipment, being easy for realization of large-scale production and the like.

Owner:SICHUAN UNIV +1

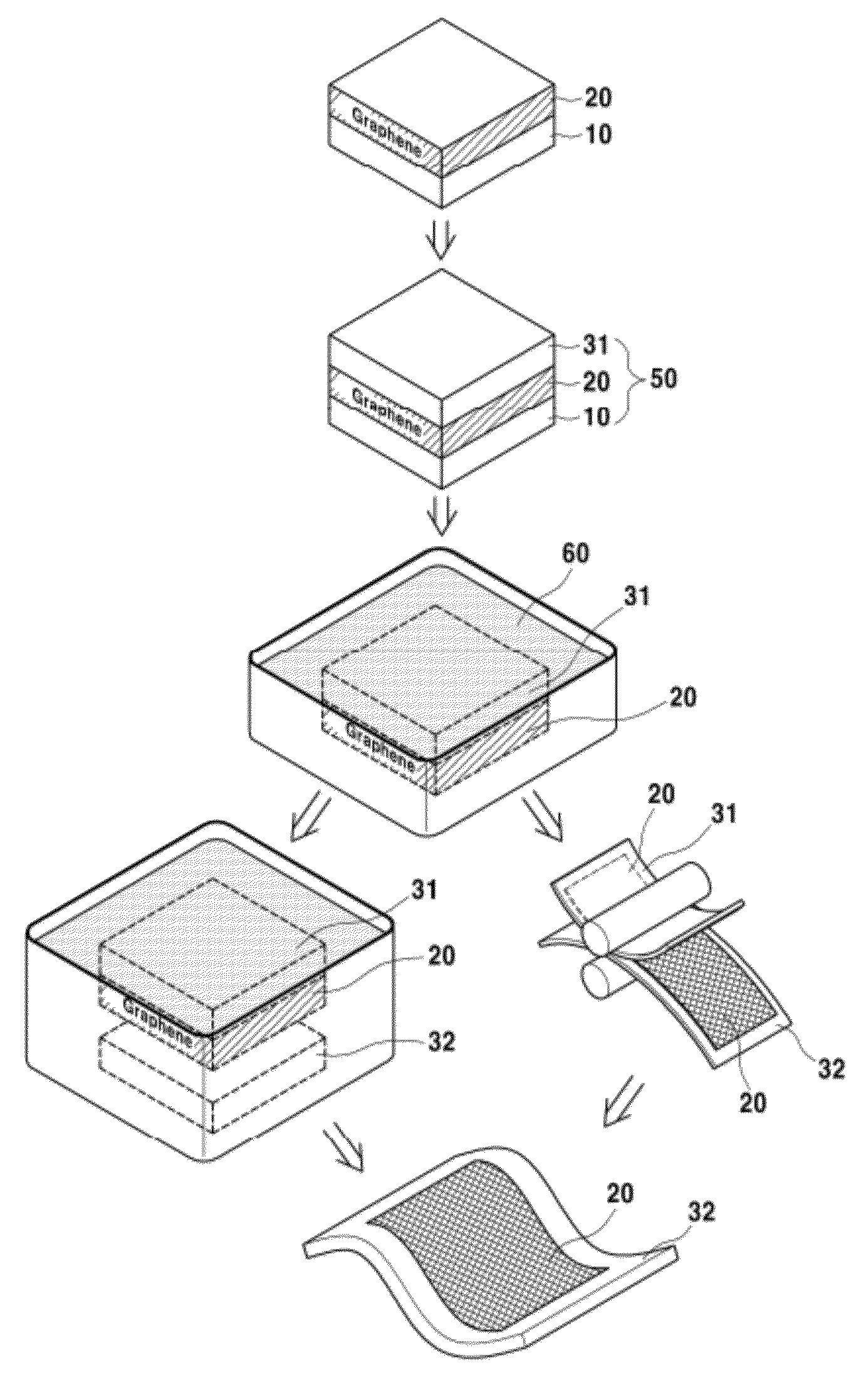

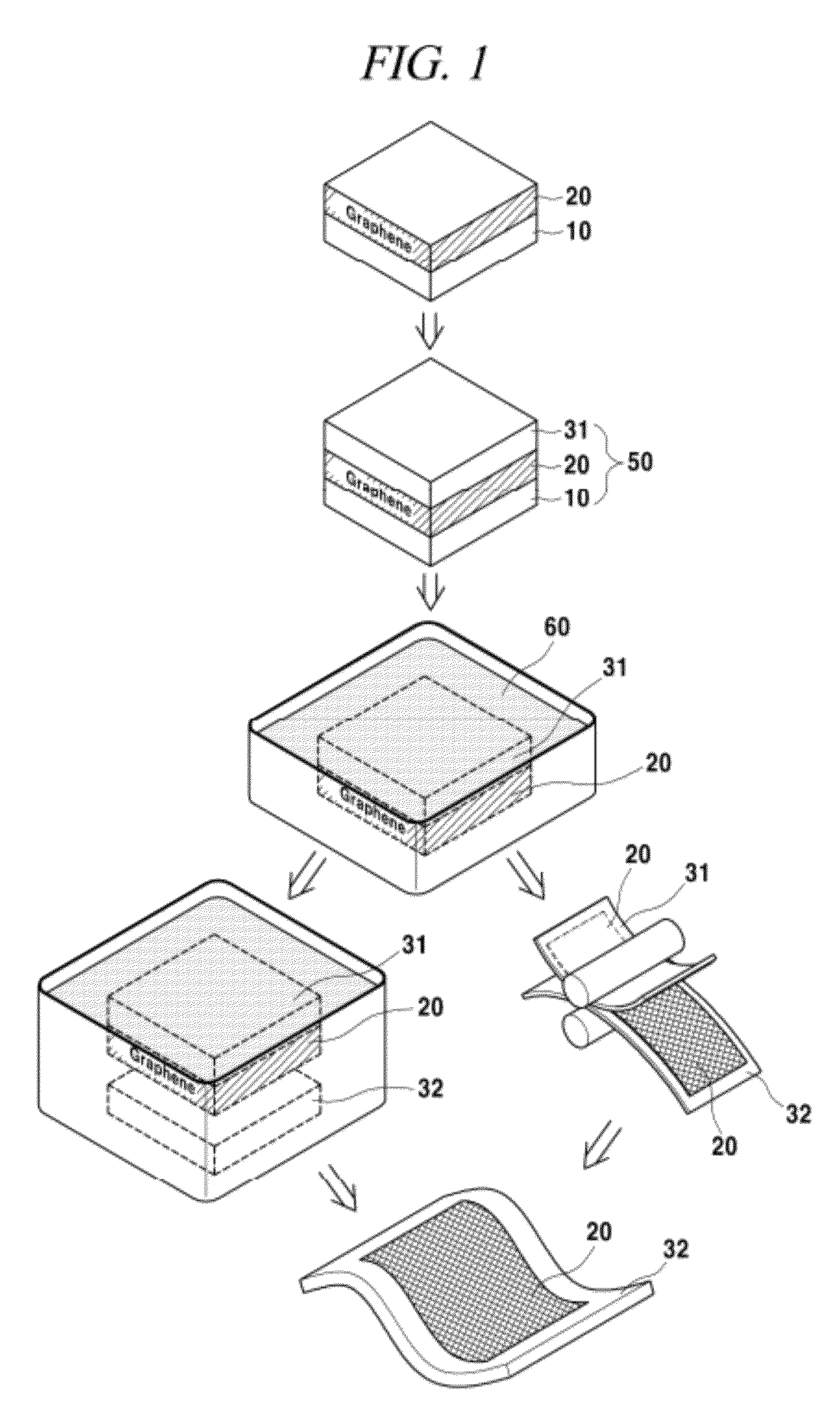

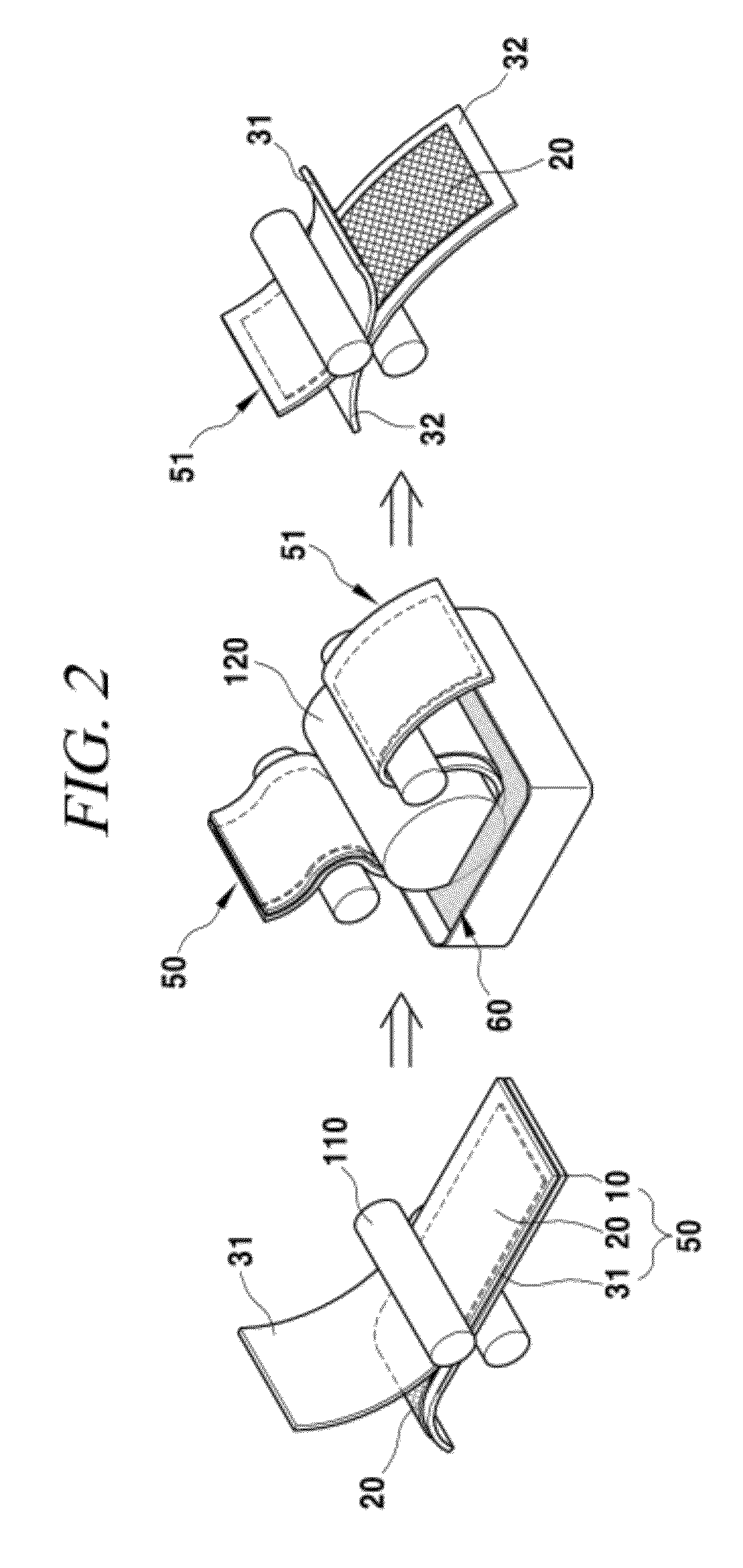

Graphene protective film serving as a gas and moisture barrier, method for forming same, and use thereof

ActiveUS20120282419A1Improve featuresImprove electrical characteristicsMaterial nanotechnologyDecorative surface effectsTectorial membraneGraphene

The present invention relates to a method for forming a graphene protective film having gas and moisture barrier properties, to a graphene protective film formed by the method, and to the use thereof. A single-layer or multi-layer graphene protective film can be used as a material for a barrier coating or bags, and improves the gas and moisture barrier properties of a variety of devices in a wide array of industrial fields to thereby maintain the electrical characteristics of devices over a long period of time.

Owner:GRAPHENE SQUARE

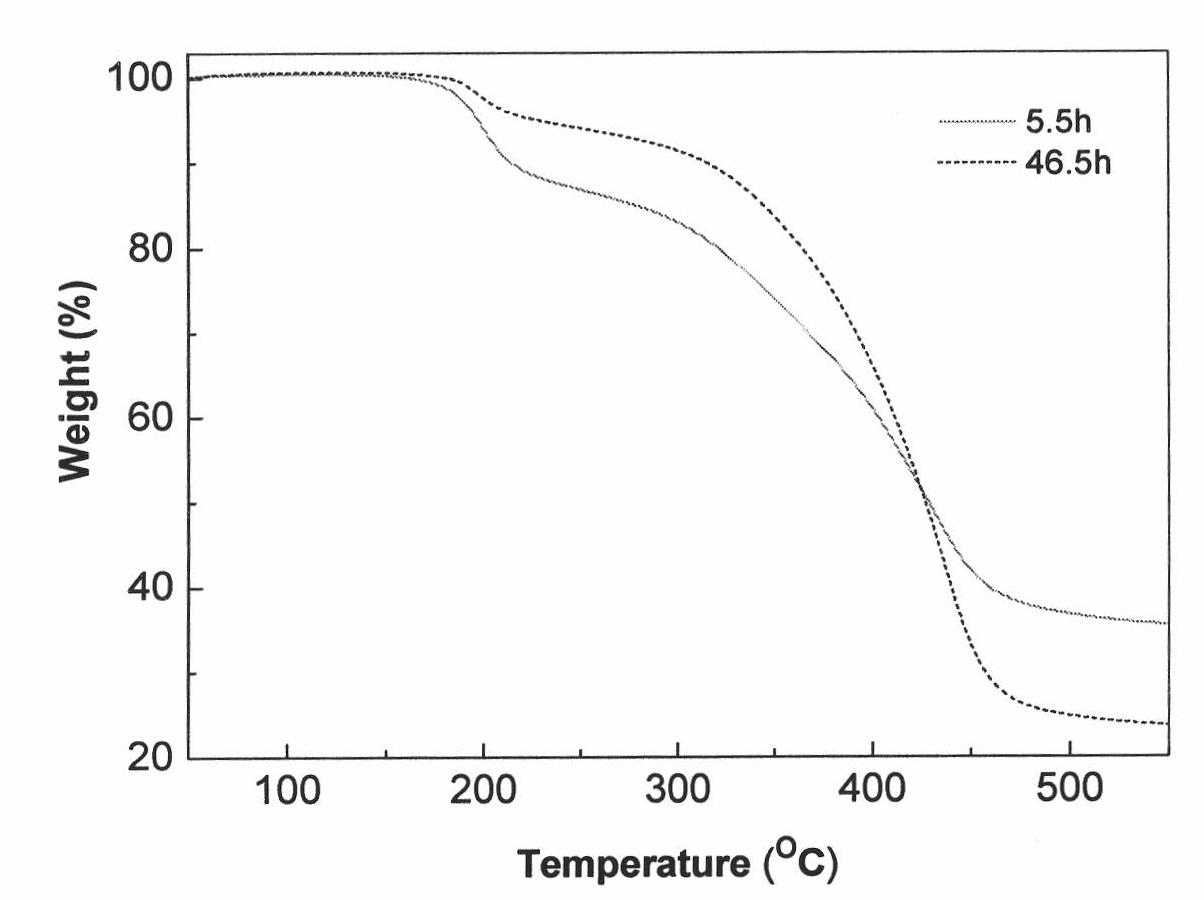

Preparation method of polymer-grafted graphene

The invention discloses a method for grafting a polymer ona surface of graphene. The method comprises the following steps: adding 1 part by weight of graphene or graphene oxide, 10-1000 parts by weight of solvent and 10-1000 parts by weight of vinyl monomer, and adding 0.01-10 parts by weight of initiator under introduction of nitrogen; heating to 55-90 DEG C, and carrying out reaction for 1.5-60hours; and precipitating, centrifugating, washing, and drying, thus obtaining a product of polymer-grafted graphene. The method is convenient and simple in process, can be used for the large-scale production, is the universal method and ensures that a variety of polymers can be grated onto the graphene. The obtained functionalized graphene has good solubility and good solution processability, is conducive and has extensive application value in micro-nano electronics, machinery, chemical industry, high-performance materials and other fields.

Owner:杭州德烯科技集团有限公司

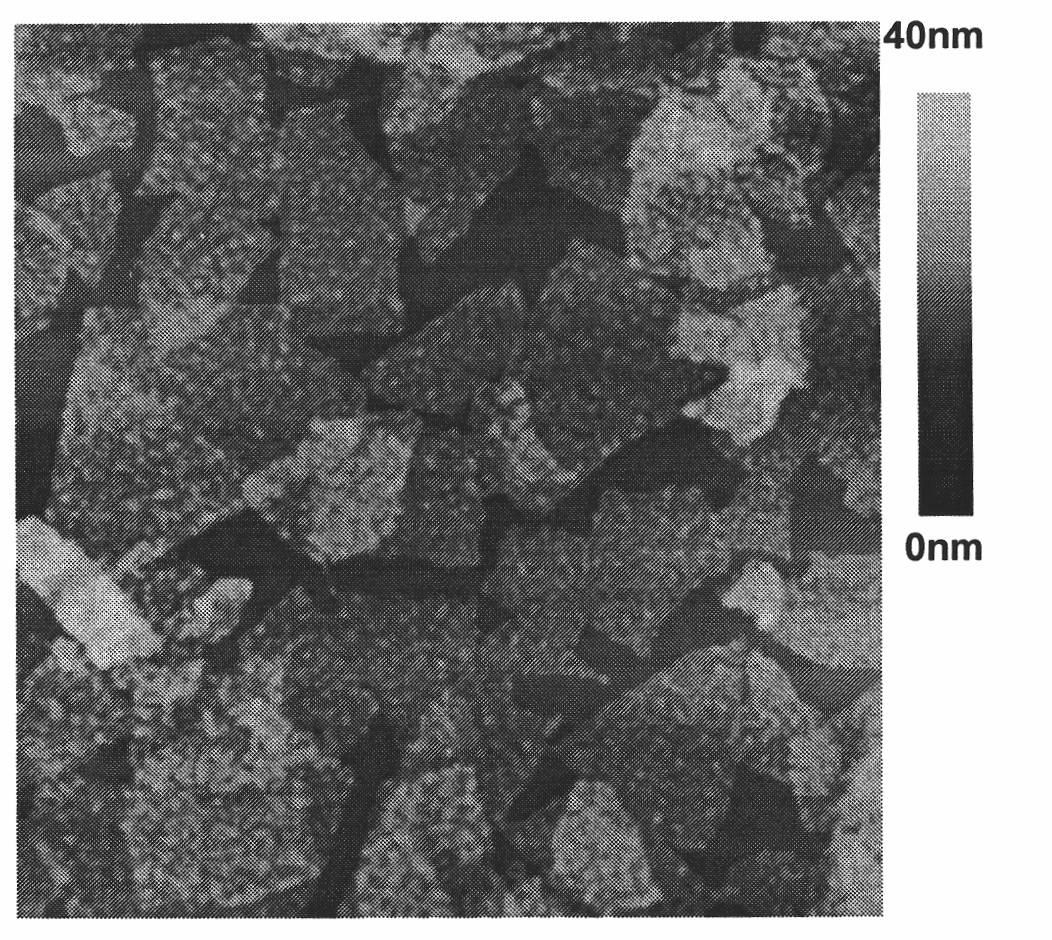

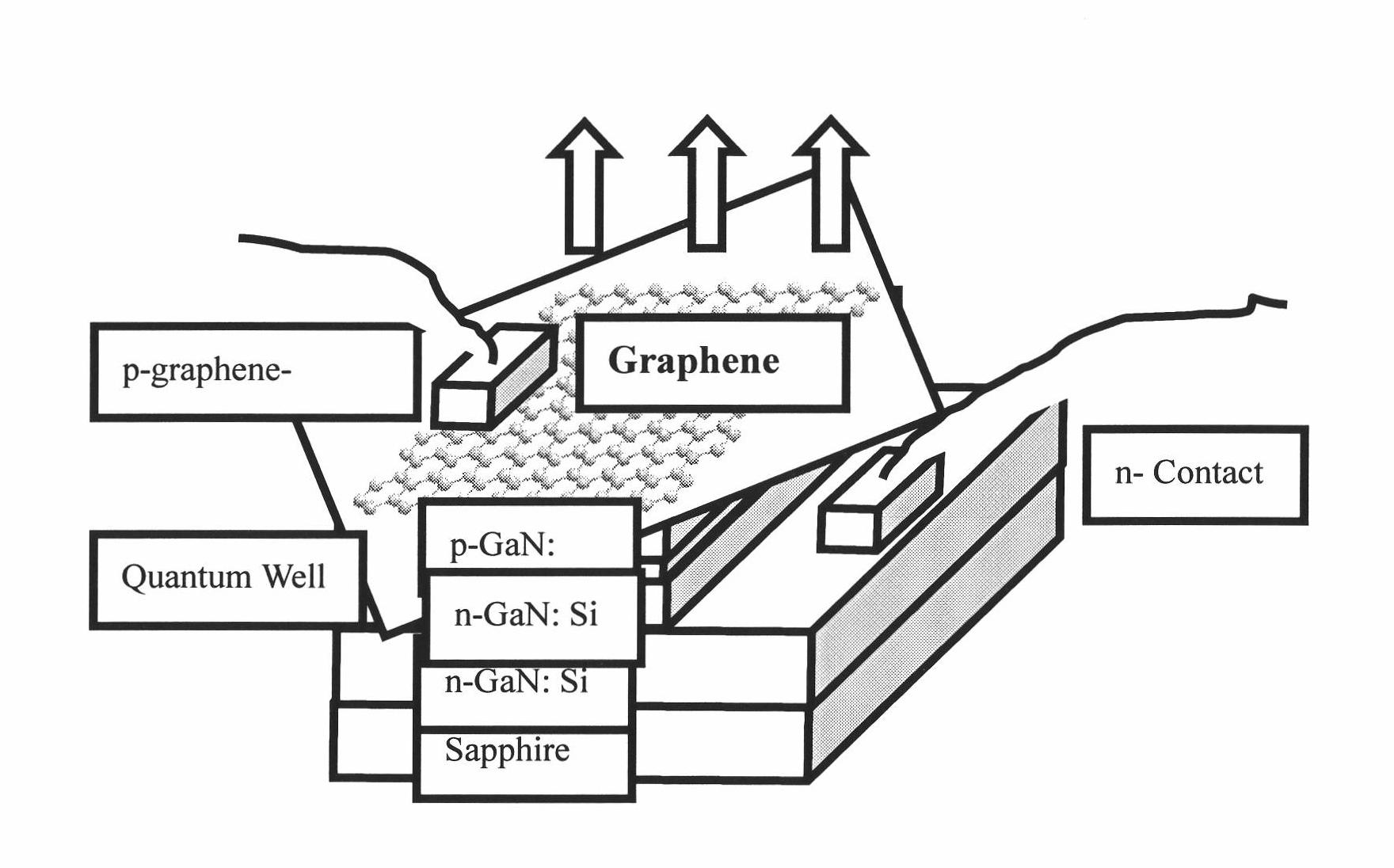

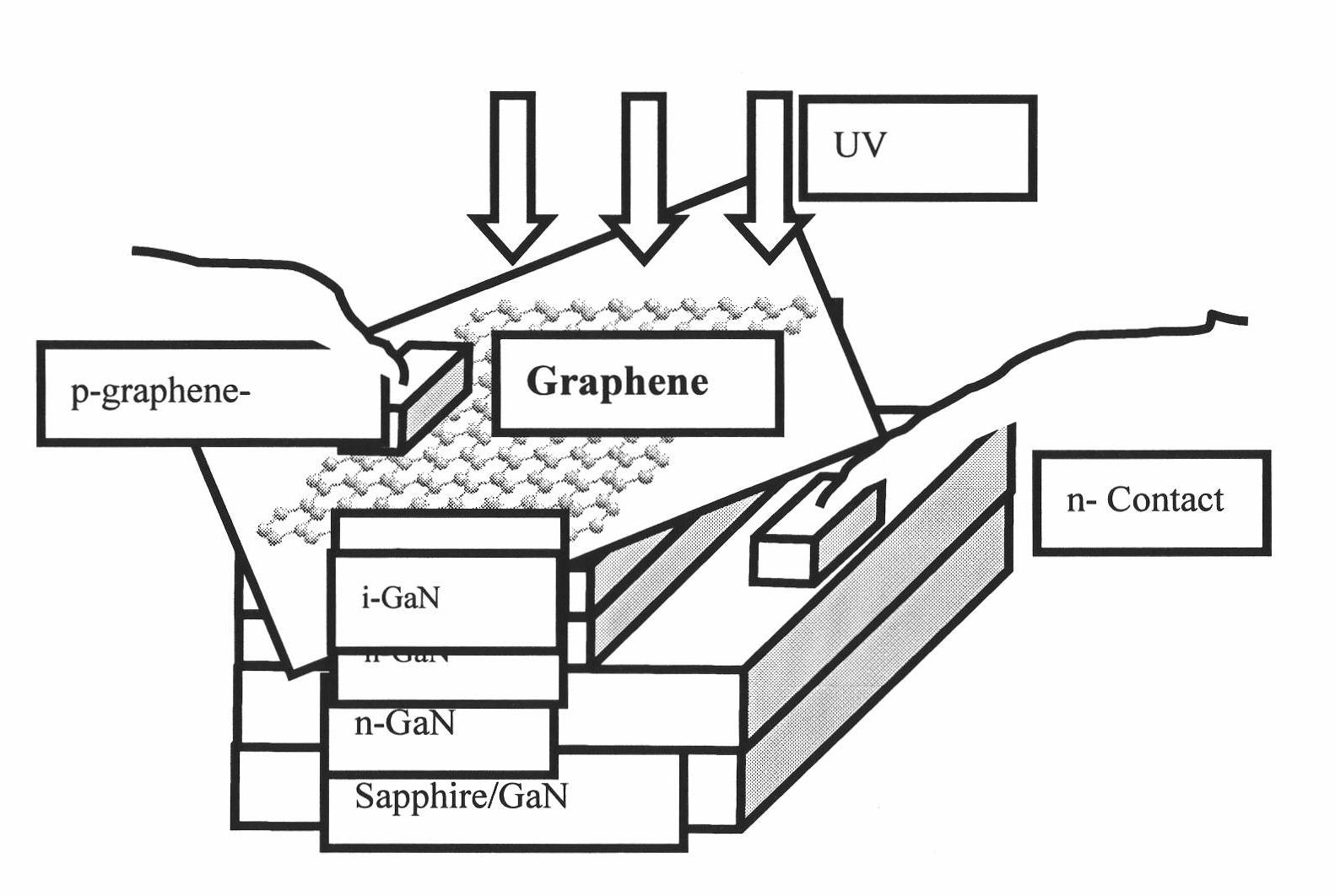

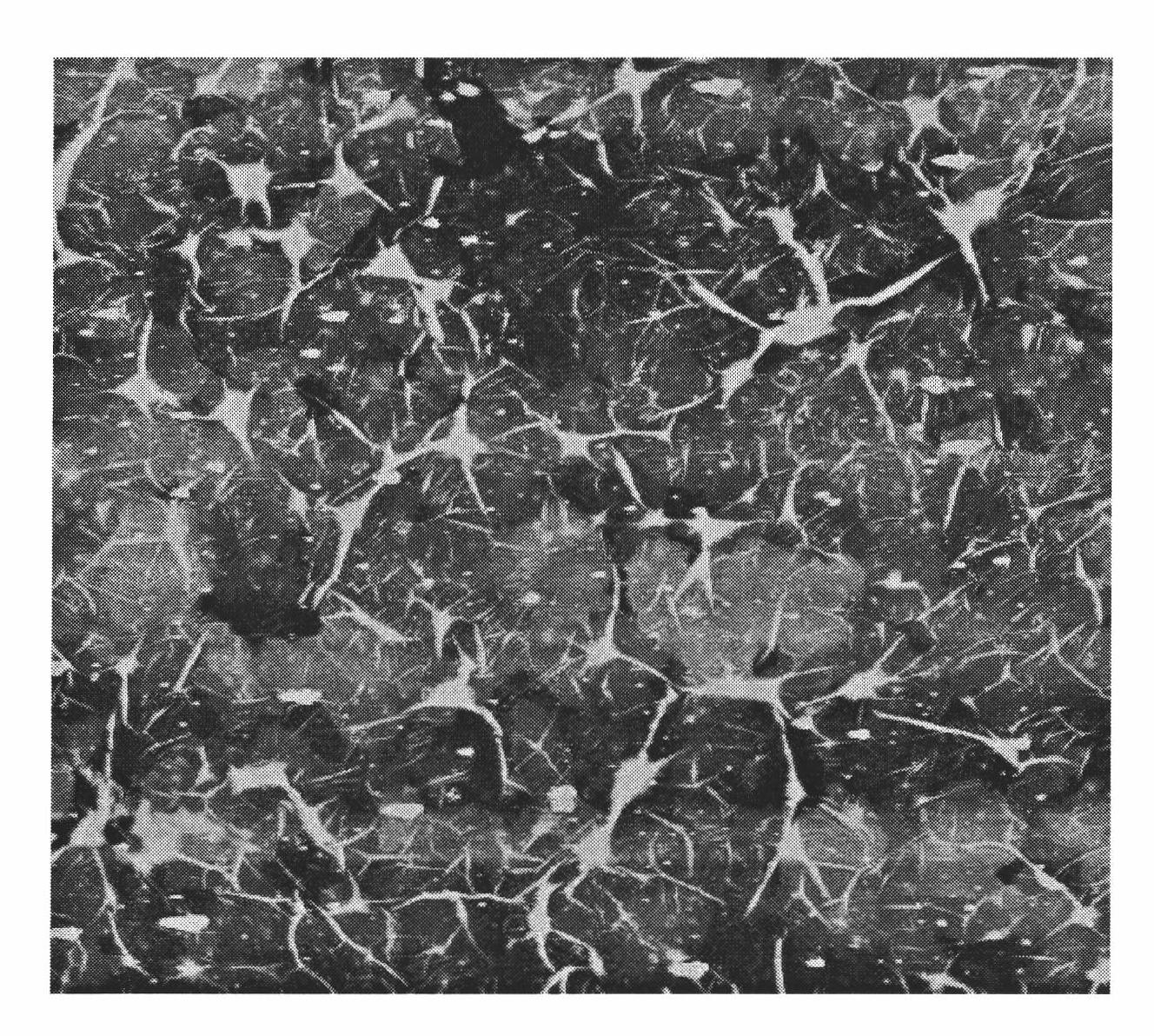

Transparent conducting electrode based on graphene and manufacture method and applications thereof

InactiveCN101859858ALow costIncrease brightnessFinal product manufactureSemiconductor devicesEtchingGas phase

The invention discloses a transparent conducting electrode using a graphene film as a GaN-based LED (light-emitting diode) or ultraviolet light detector and a manufacture method and applications thereof. The graphene film is solidified and bonded on the surface of the GaN substrate of the LED or ultraviolet light detector. The transparent graphene conducting film is prepared by adopting a chemical vapor deposition or reduction-oxidation method, and the GaN-based LED or ultraviolet light detector is manufactured by utilizing a micromachining photoetching, etching and metal deposition method; the graphene film is moved to the p-type GaN-based substrate of the LED or ultraviolet light detector to serve as the transparent conducting electrode instead of ITO or Ni / Au. In the invention, the graphene film is used as the transparent conducting electrode, which can realize low-cost and high-brightness luminescent devices and expands the applications of carbon nanometer materials in the field of GaN-based photoelectric devices.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com