Oxidized graphene or graphene/inorganic particle core/shell material and preparation method thereof

A technology of inorganic particles and graphene, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of preparation methods of hybrid materials with "core/shell" structure, etc., to change the physical and chemical properties of the surface and expand the application Space and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

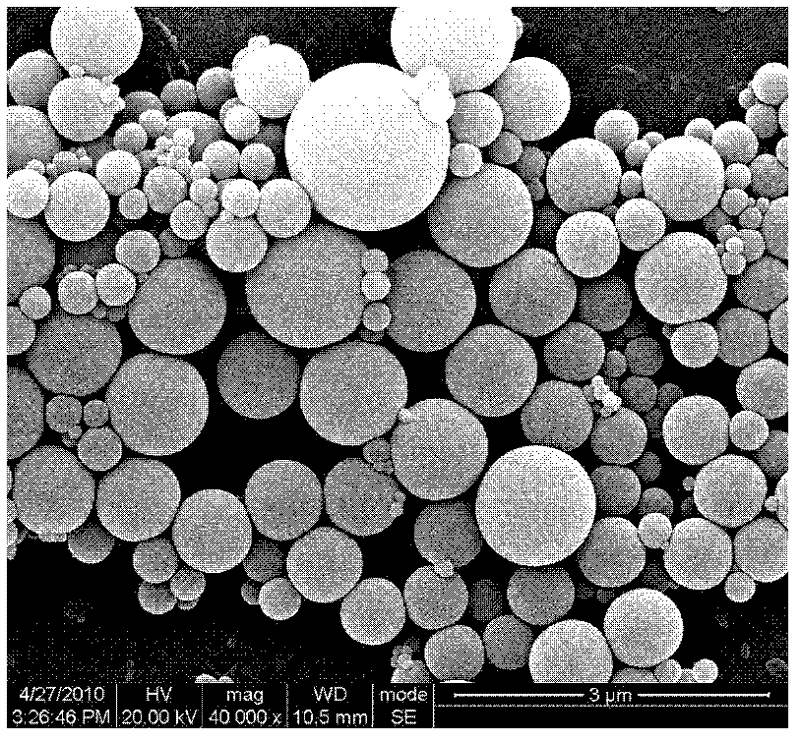

[0031] First, mix 10 g of submicron spherical silica (average particle size 500 nm) with 200 mL of ethanol / water solution (98 / 2, v / v) under high-speed stirring for 30 min to obtain a uniform suspension, and then add 0.2 g coupling agent KH550, heated to 60°C and stirred for 10 hours, then centrifuged and washed 3-4 times with deionized water to remove ungrafted coupling agent to obtain modified silica.

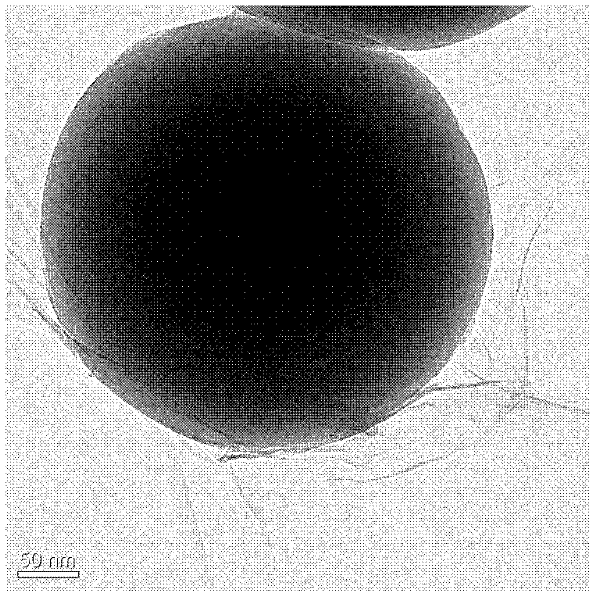

[0032] Prepare 200 mL of graphene oxide aqueous dispersion with a concentration of 0.5 mg / mL, and oscillate ultrasonically at room temperature to uniformly disperse it. Add the silica treated with the coupling agent KH550 into deionized water, stir to disperse evenly, and prepare 200 g of a suspension with a silica content of 5 wt%. Add the prepared silicon dioxide suspension dropwise into the graphene oxide dispersion under stirring. After the dropwise addition, let it stand for 10 minutes. It can be seen that the color of the supernatant becomes lighter, and the color of the...

Embodiment 2

[0034] First, mix 2.5g of titanium dioxide (average particle size 200nm) with 200mL of ethanol / water solution (98 / 2, v / v) under high-speed stirring for 30min to obtain a uniform suspension, then add 0.3g of coupling agent A1100 to the suspension , and heated up to 60° C. and stirred for 10 h, and centrifuged and washed with deionized water for 3-4 times to remove ungrafted coupling agent to obtain modified titanium dioxide.

[0035] 1000 mL of graphene oxide aqueous dispersion with a concentration of 0.05 mg / mL was prepared, and ultrasonically oscillated at room temperature to uniformly disperse it. Add the titanium dioxide treated with the coupling agent A1100 into distilled water, stir to disperse evenly, and prepare 500 g of a suspension with a titanium dioxide content of 0.5 wt%. Add the prepared titanium dioxide suspension dropwise into the graphene oxide dispersion under stirring. After the dropwise addition, let it stand for 10 minutes. It can be seen that the color of ...

Embodiment 3

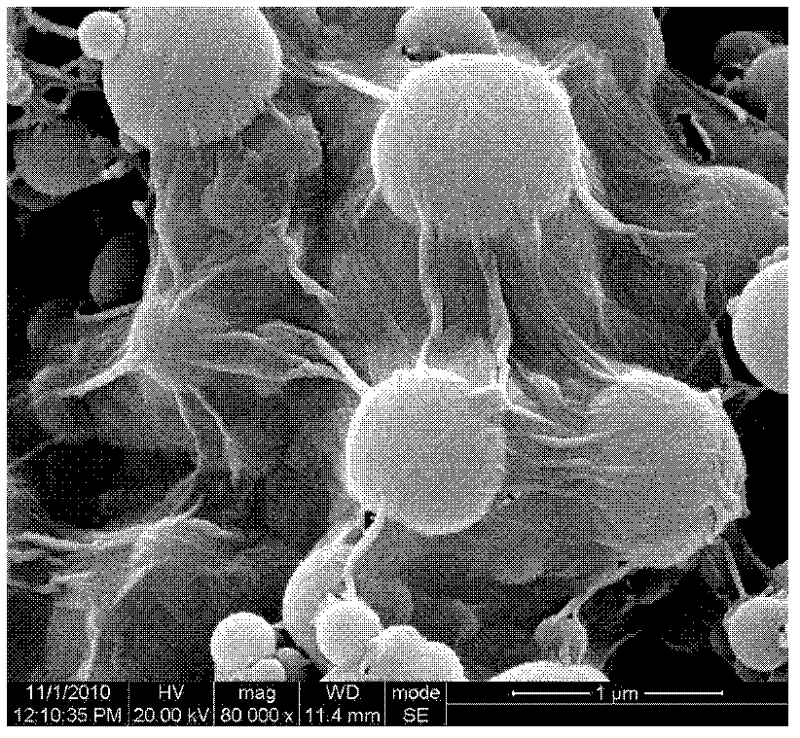

[0037] First, mix 10g of micron-grade alumina (average particle size 1μm) with 200mL of ethanol / water solution (98 / 2, v / v) under high-speed stirring for 30min to obtain a uniform suspension, and then add 0.2g of coupling Agent A1170, heated to 60°C and stirred for 10 hours, centrifuged and washed with deionized water for 3-4 times to remove ungrafted coupling agent to obtain modified alumina.

[0038] Prepare 25 mL of graphene oxide aqueous dispersion with a concentration of 2 mg / mL, and oscillate ultrasonically at room temperature to disperse it evenly. The alumina treated with the coupling agent A1170 was added into deionized water, stirred to disperse evenly, and prepared into 50 g of a suspension with an alumina content of 20 wt%. Add the prepared alumina suspension dropwise into the graphene oxide dispersion liquid under stirring. After the dropwise addition, let it stand for 10 minutes. It can be seen that the color of the supernatant becomes lighter, and the color of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com