Patents

Literature

485results about How to "Expand application space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxidized graphene or graphene/inorganic particle core/shell material and preparation method thereof

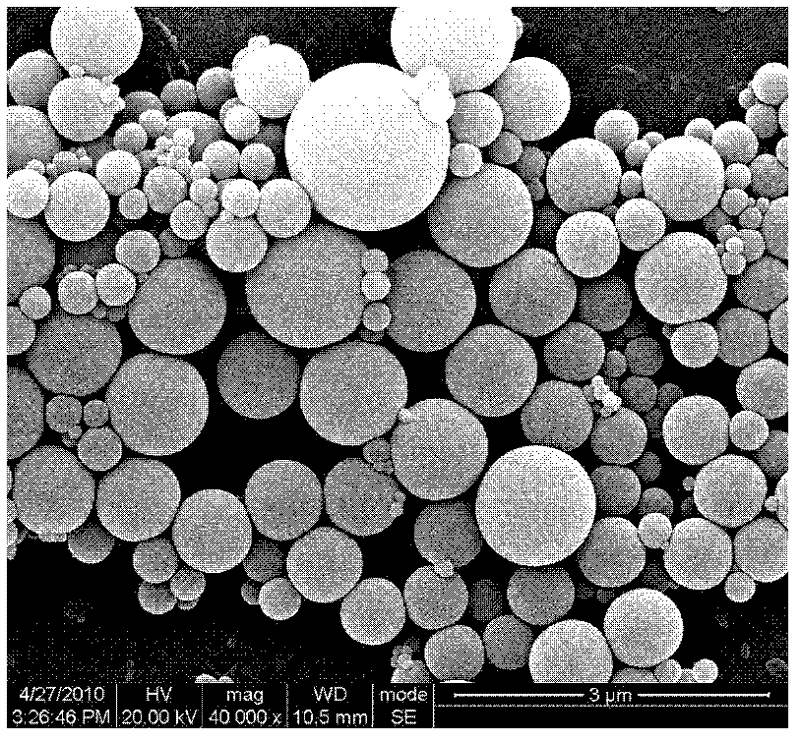

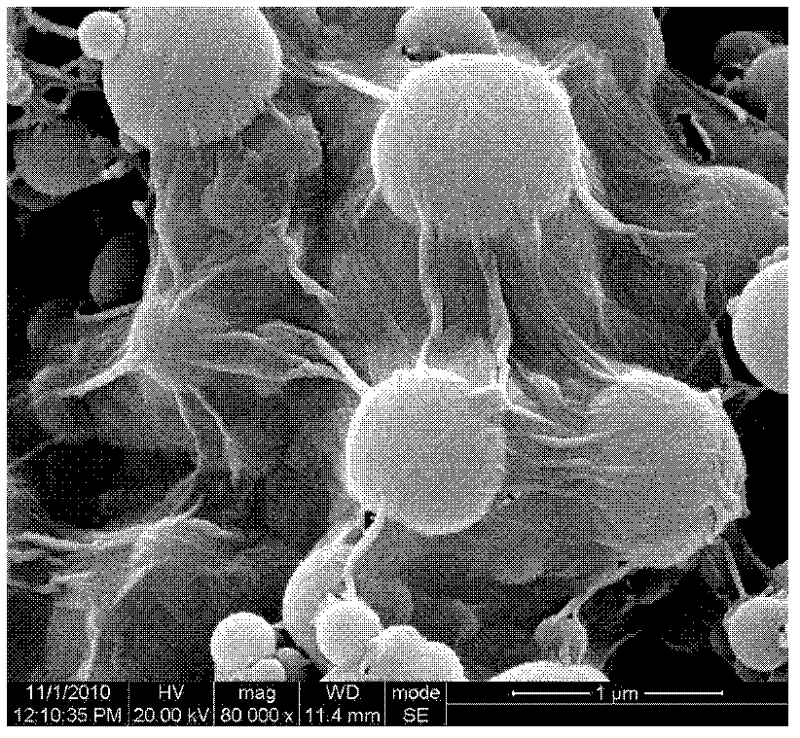

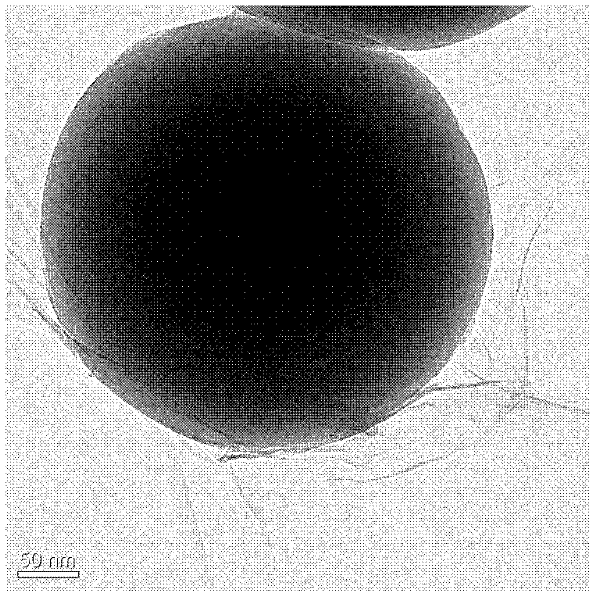

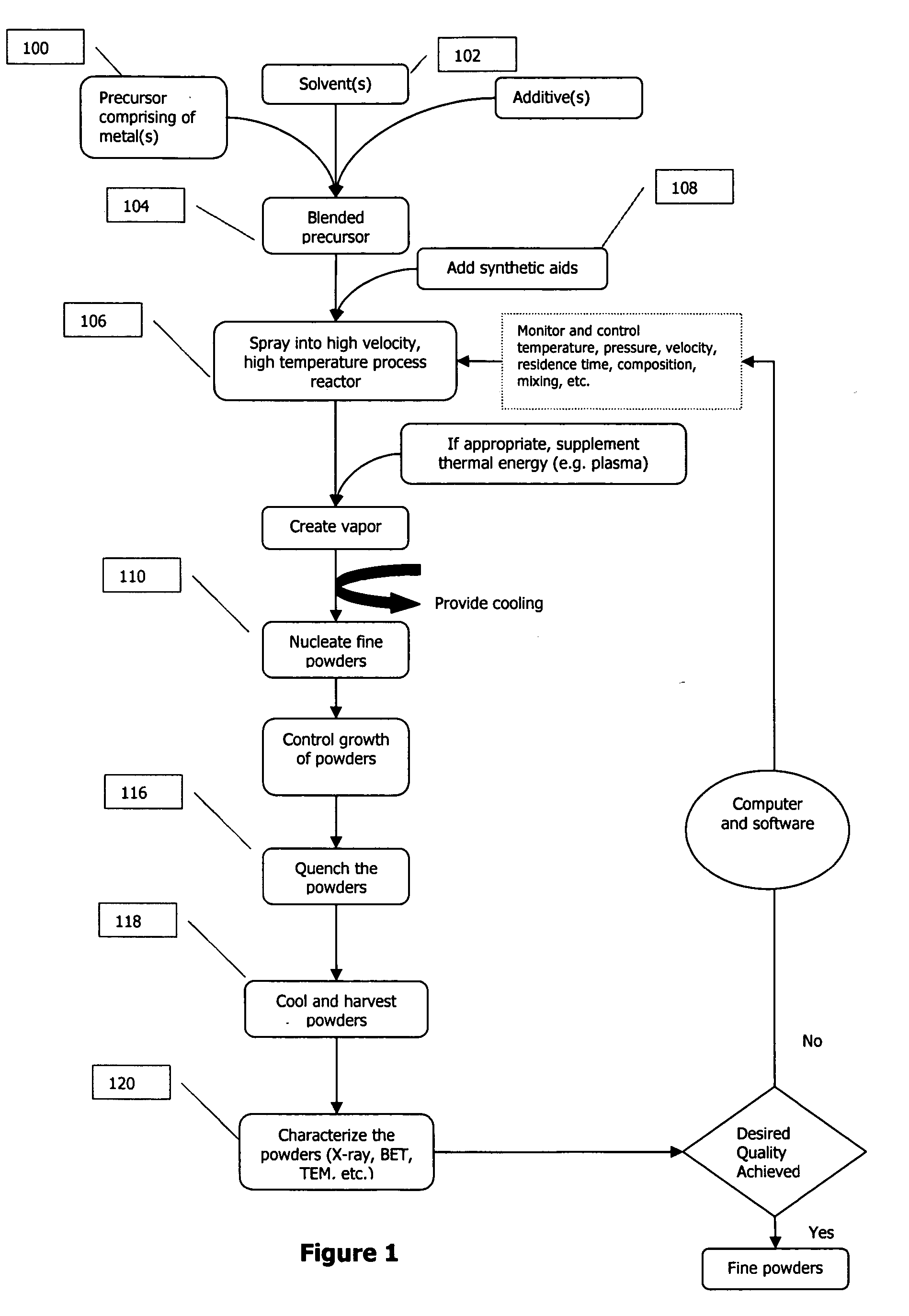

ActiveCN102343239AExpand application spaceChange surface propertiesMicroballoon preparationMicrocapsule preparationInorganic particleInorganic particles

The invention firstly discloses an oxidized graphene or graphene / inorganic particle core / shell material which is formed by electrostatic self-assembly, wherein inorganic particles are taken as the core of the material, oxidized graphene or graphene is taken as a shell layer, and the content of the oxidized graphene or the graphene is 0.1-2wt% of that of the inorganic particles. The invention alsodiscloses a preparation method of the oxidized graphene or graphene / inorganic particle core / shell material. Therefore, a new species is added for outer-coated inorganic powder materials and the application space of the inorganic particles is expanded; furthermore, the electrostatic self-assembly technology is further applied to the preparation of the oxidized graphene or graphene-inorganic powderhybrid material, and the method simultaneously has the characteristics of being mature and environmentally-friendly in process, being simple to operate, having no need of complex equipment, being easy for realization of large-scale production and the like.

Owner:SICHUAN UNIV +1

Adhesives & sealants nanotechnology

ActiveUS20060035087A1Increase volumeLow costNon-macromolecular adhesive additivesOther chemical processesAdhesiveSealant

Adhesives and sealants comprising submicron particles and nanomaterials, methods of making such adhesives and sealants, and methods of using such adhesives and sealants are provided.

Owner:PPG IND OHIO INC

Graphene-containing insulated radiating composition and preparation and application thereof

ActiveCN103804942AHigh thermal conductivityImprove mechanical propertiesCoatingsPigment treatment with organosilicon compoundsHeat conductingGraphene

The invention discloses a graphene-containing insulated radiating composition and preparation and application thereof. The composition comprises the components of silica-coating graphene, insulated heat-conducting filler, a surface treating agent, and a function additive. The preparation method comprises the following steps of: hydrolyzing ethyl silicate on the graphene surface by the sol-gel method to obtain graphene coated with a silica film on the surface; adding the surface treating agent to a mixture of the insulated heat-conducting filler and modified graphene; uniformly agitating; then adding the function additive; and uniformly dispersing to obtain the insulated radiating composition. The composition has the advantages that the graphene is processed by insulating and coating, and the insulated heat-conducting filler and additive of other forms are coordinately added, thus the composition shows high radiating improvement effect in the plastic cement and coating fields; and the composition can be widely applied to a heating element and a radiating facility of various electronic products and electrical equipment, and can greatly improve the radiating effect as well as prolong the service life of devices.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

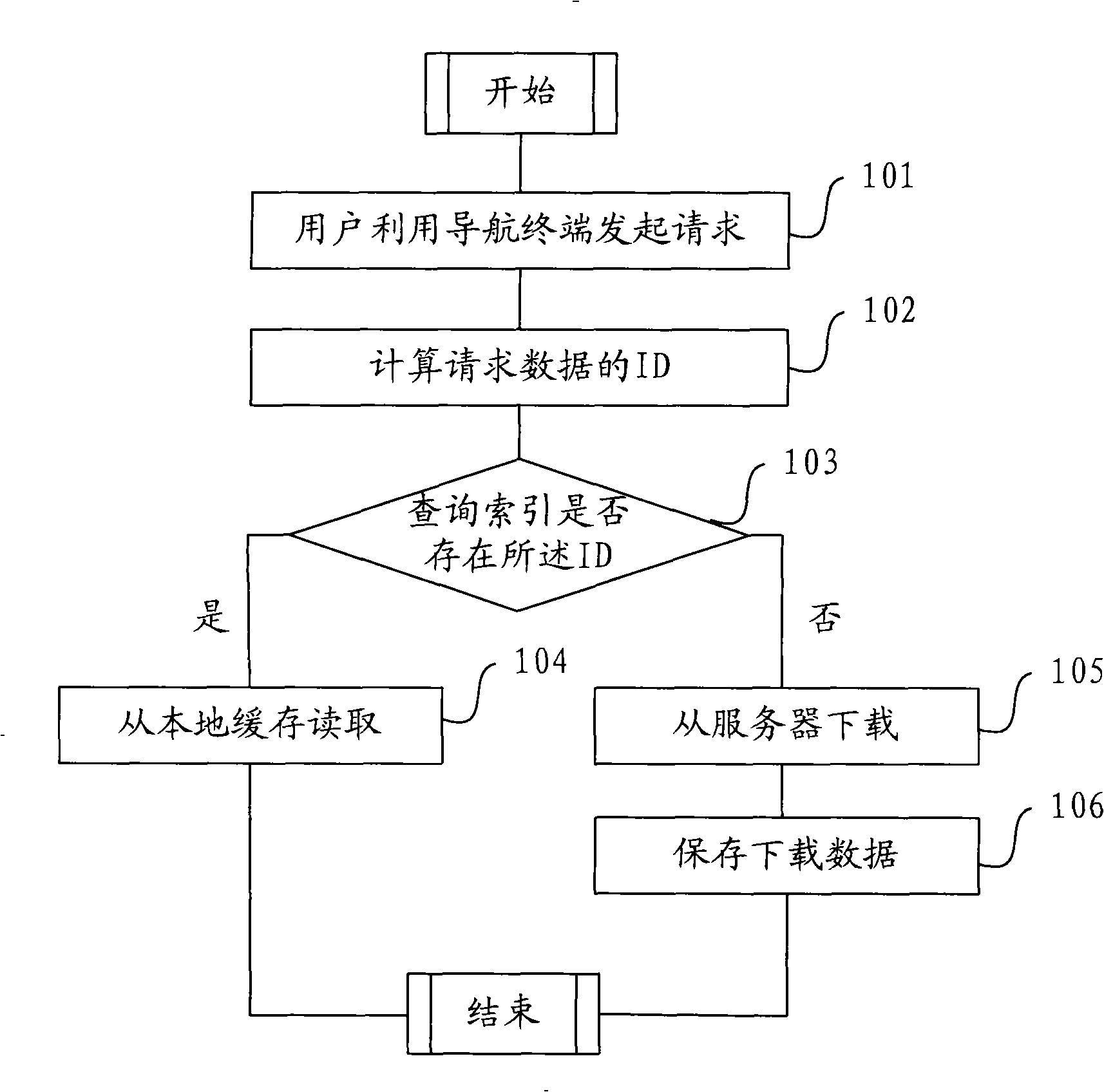

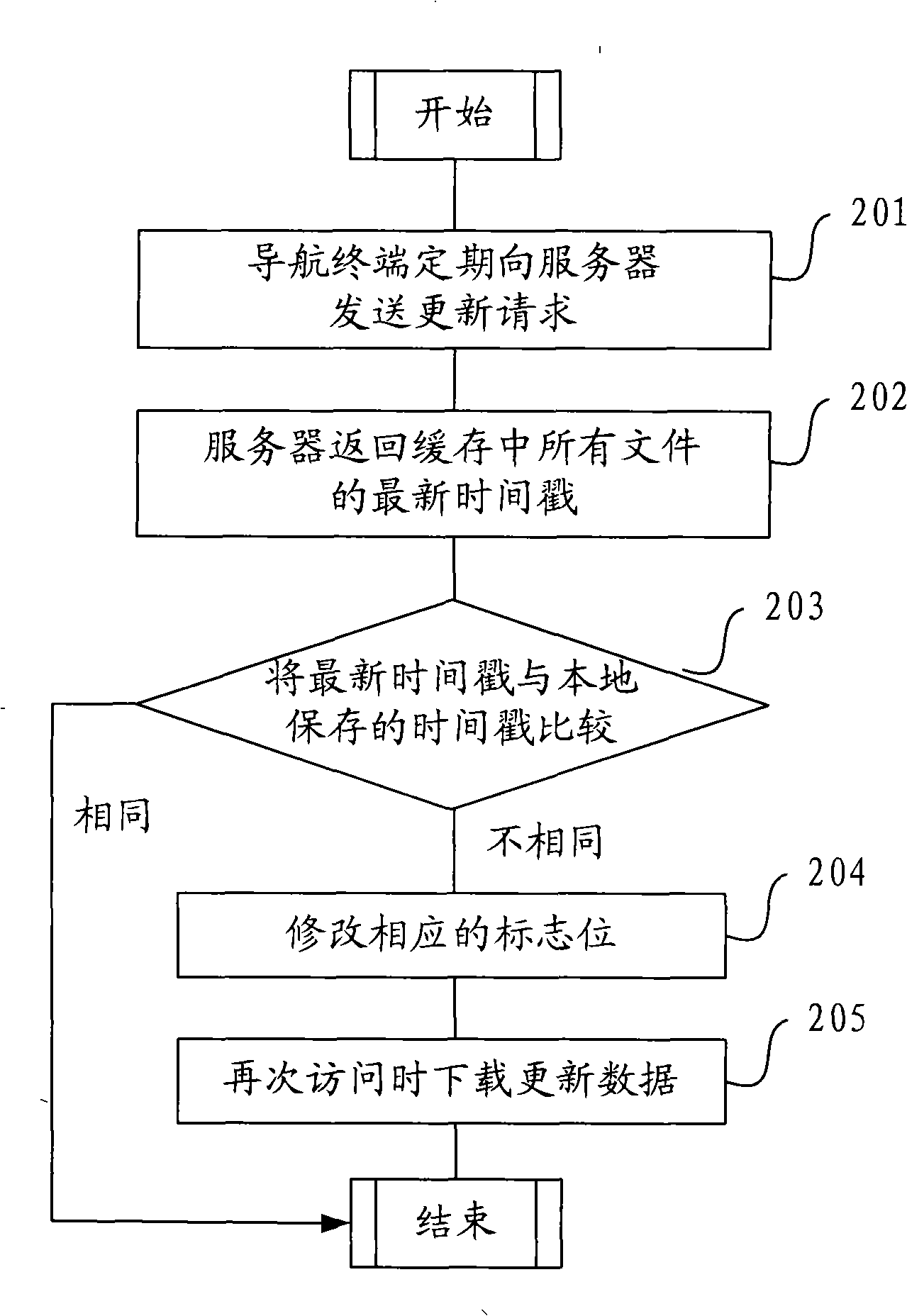

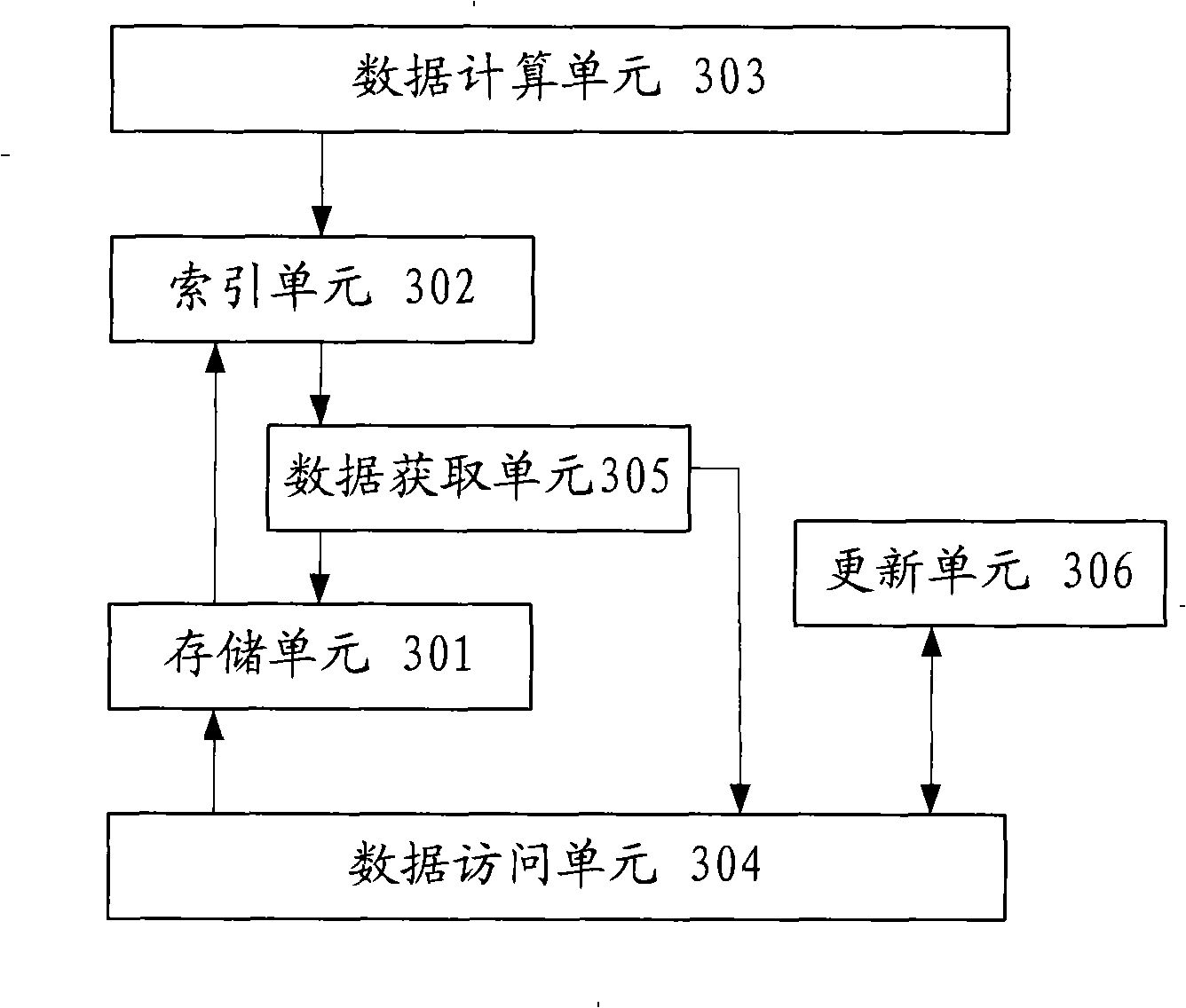

Method for navigating data in local caching, system and customer terminal device

InactiveCN101358851AEasy to useQuick responseInstruments for road network navigationBeacon systems using radio wavesTerminal equipmentComputer terminal

The present invention discloses a method, a system and a customer terminal device for buffer memorizing the local navigation data, which aims at resolving the problems of the prior navigation device that the downloading speed is slow causing poor experience of the user. The method comprises the steps: the navigation data is stored in the server end in different layers and in different blocks, and each layer corresponds to different map scale, and the navigation data is classified into different sub-blocks in each layer, and an exclusive ID is calculated according to the layer level and the position of the sub-block at each layer; the downloaded navigation data is memorized at the navigation terminal in order, and the index for the navigation data is established according to the ID; the navigation terminal responds to the request of the user and calculates the ID according to the layer level and the position information in the request; the ID is searched in the local index, and if the index is found, the navigation data corresponding to the ID is obtained in the local area, and if the index is not found, the navigation data corresponding to the ID is downloaded from the server and is buffer memorized. The buffer memory method effectively resolves the problems of the communication navigation area that the bandwidth is limit, and the speed for the navigation terminal to download the navigation data from the server is slow, and improves the responding speed, and improves the application experience of the user.

Owner:BEIJING LINGTU SOFTWARE TECH CO LTD

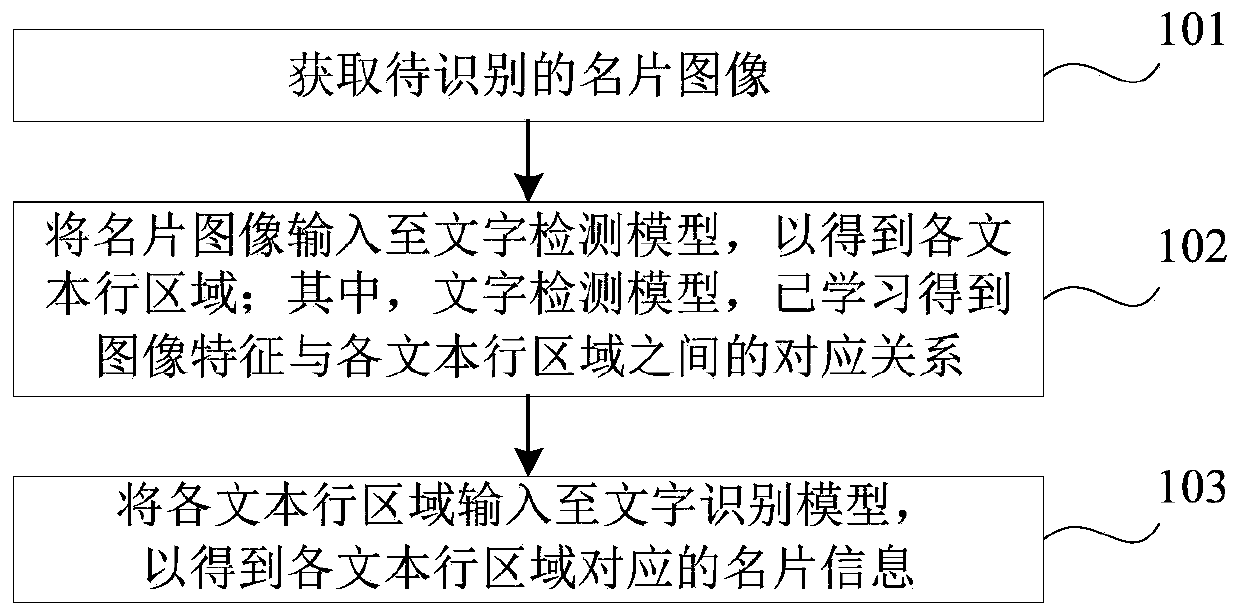

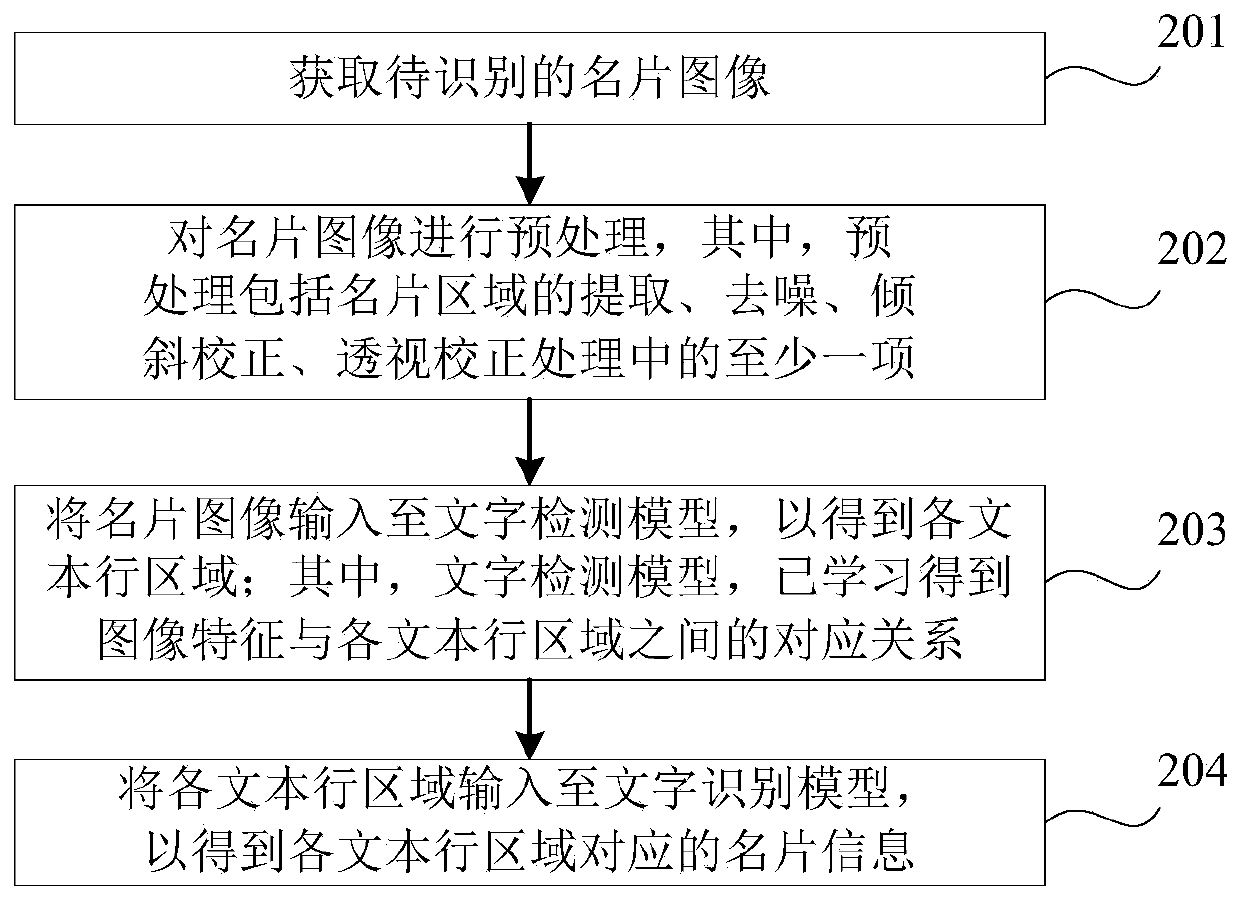

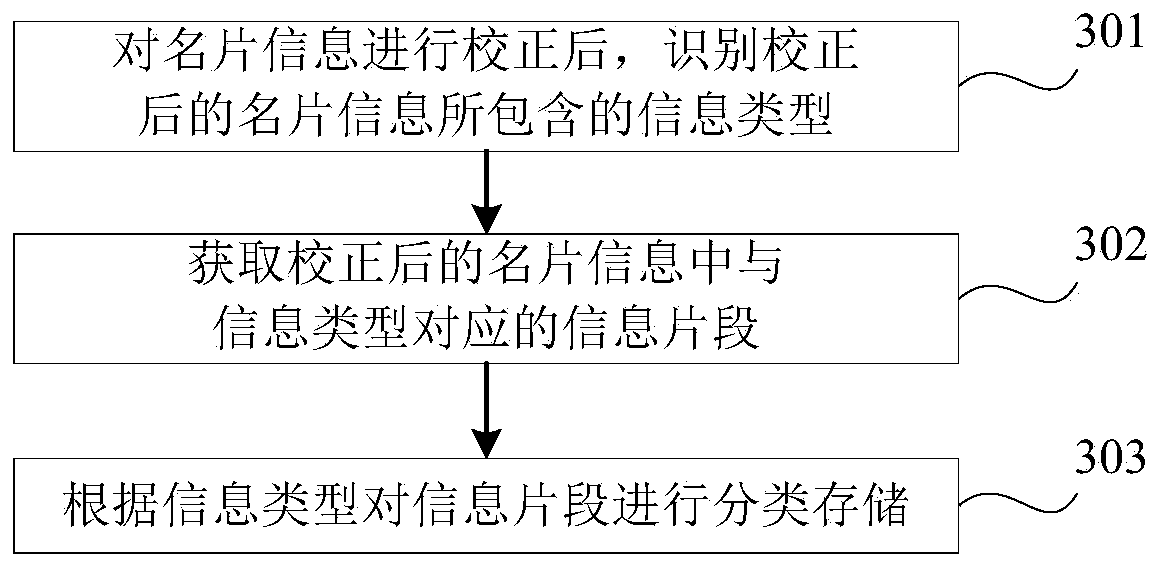

Business card identification method and device

ActiveCN110135411AReduce the impact of extractionImprove robustnessCharacter and pattern recognitionRobustificationBusiness card

The invention provides a business card identification method and device, and the method comprises the steps: obtaining a to-be-identified business card image; inputting the business card image into acharacter detection model to obtain each text line area, wherein the character detection model learns and obtain a corresponding relation between image features and each text line area; and inputtingeach text line area into the character recognition model to obtain business card information corresponding to each text line area. According to the method, the text line areas in the business card image can be identified through the text detection model based on deep learning, the robustness is high, the influence of low-quality and noise data on text extraction can be reduced, and therefore the universality and the application space of the method are improved. Moreover, the text line areas are subjected to end-to-end recognition based on the deep learning character recognition model, single word segmentation is not needed, higher accuracy is achieved, higher recognition capability is achieved for various complex changes, and the universality and the recognition effect of the method are improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

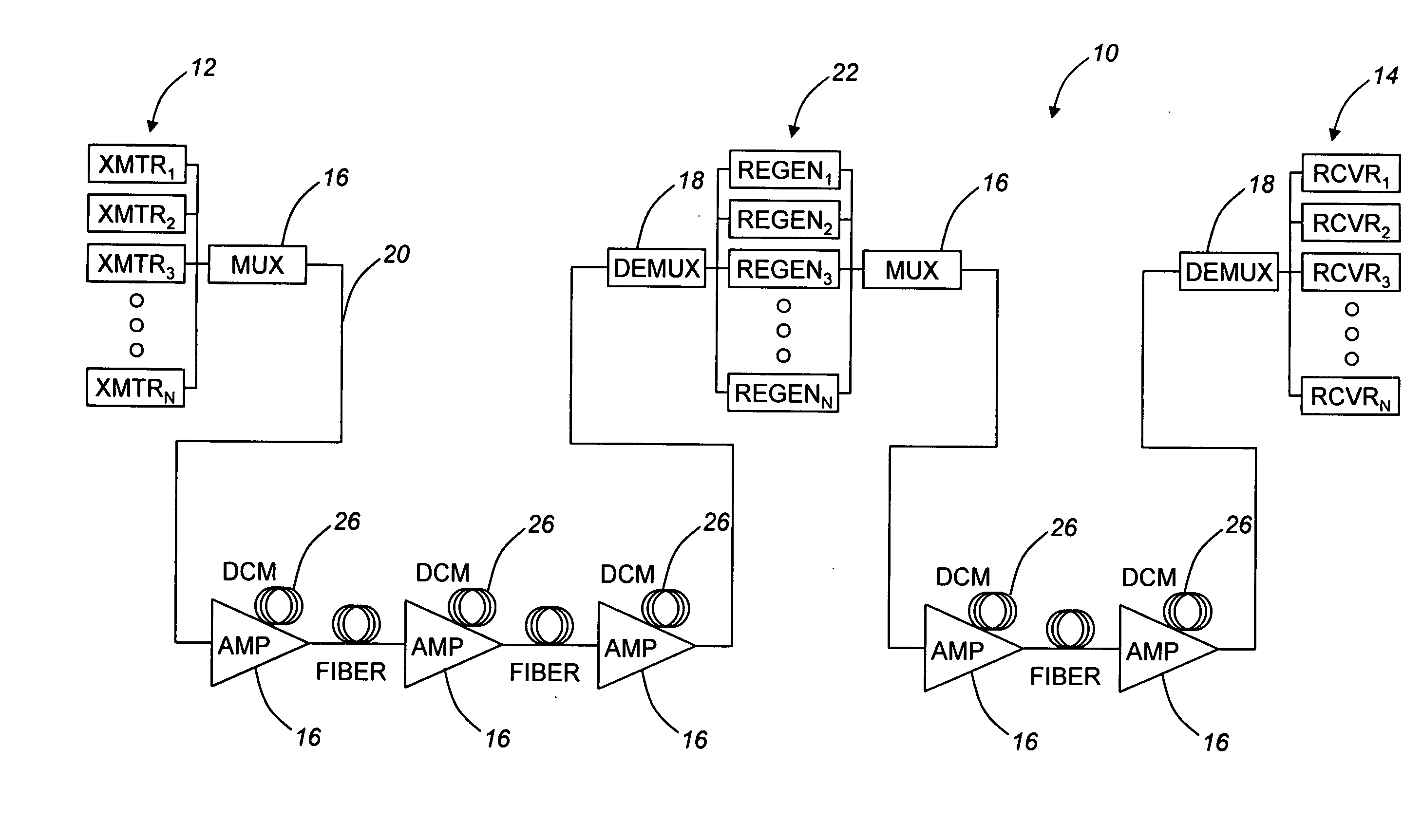

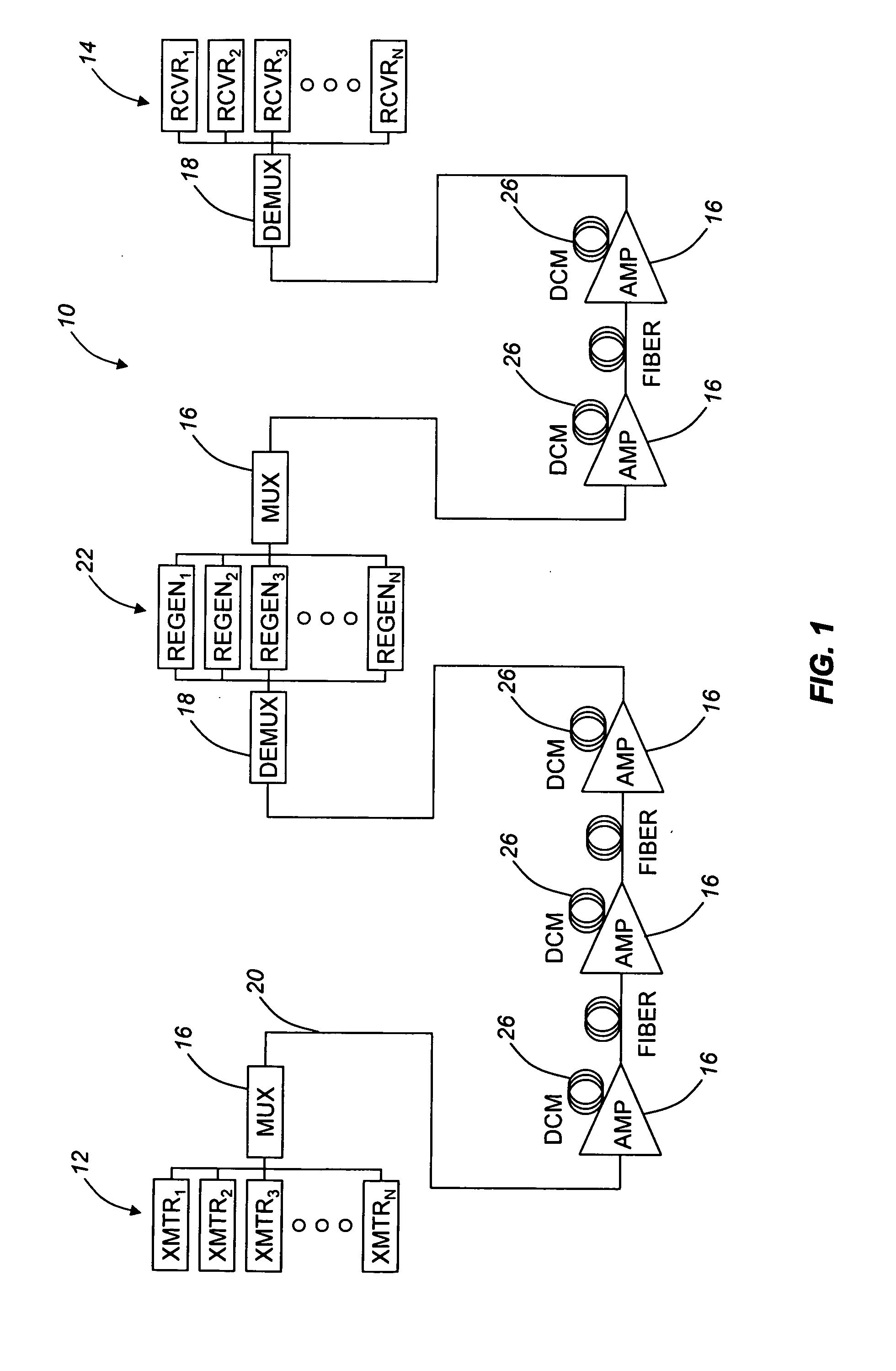

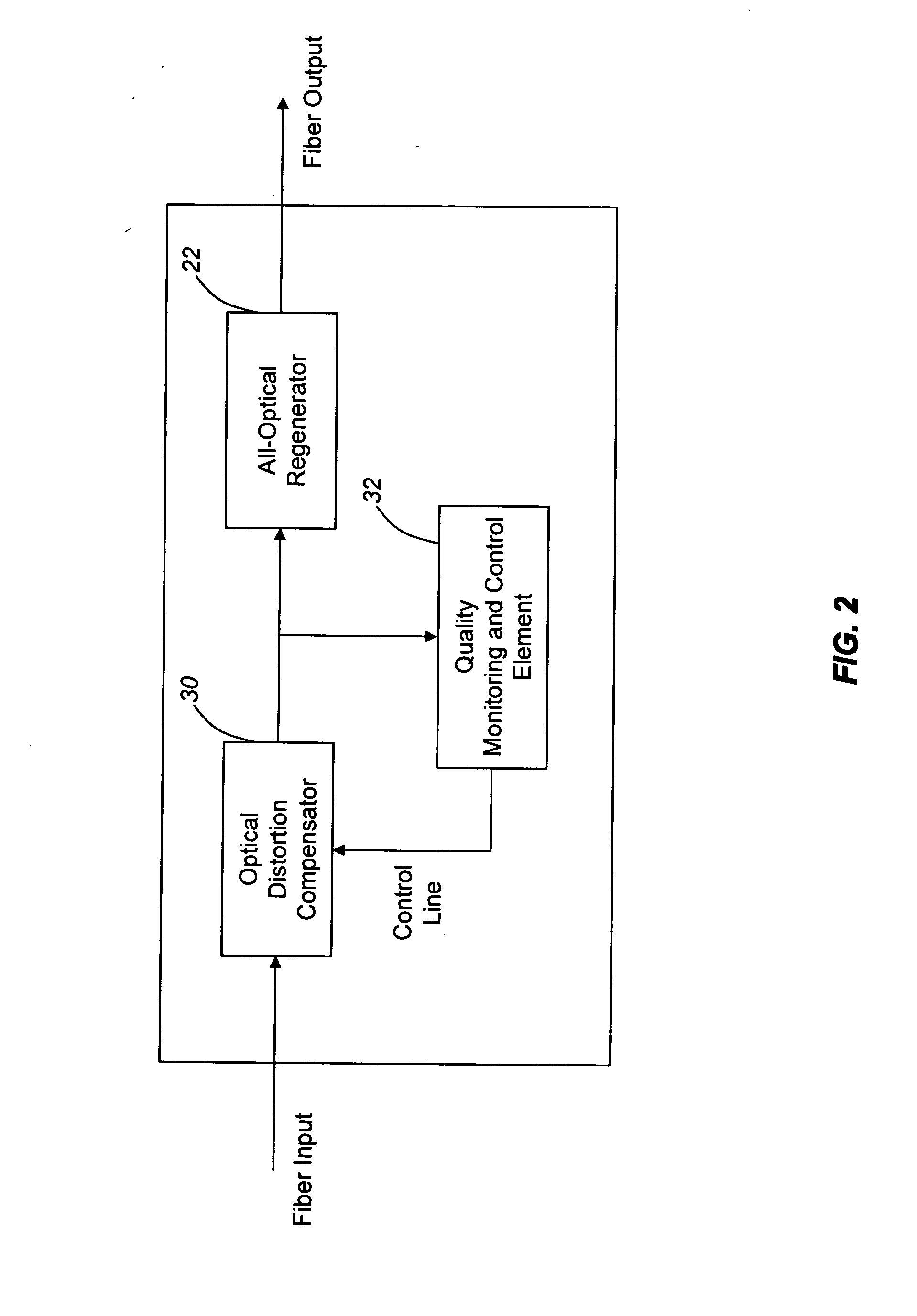

All-optical regenerator and optical network incorporating same

ActiveUS20080085125A1Increase in sophistication and complexityImprove distortionElectromagnetic transmissionAudio power amplifierSignal quality

The present invention provides an optical networking device for re-amplifying, re-shaping, and re-timing an optical signal, as well as providing distortion compensation and performance monitoring of the optical signal. The optical networking device includes an all-optical regenerator device for one or more of re-amplifying, re-shaping, and re-timing the optical signal; a distortion compensator device for compensating for distortion associated with the optical signal; and a quality-of-signal monitoring device for measuring the quality of the optical signal. Preferably, the all-optical regenerator device, the distortion compensator device, and the quality-of-signal monitoring device are disposed within a single module. The quality-of-signal monitoring device measures the optical signal subsequent to distortion compensation. Alternatively, the quality-of-signal monitoring device measures the optical signal subsequent to distortion compensation and all-optical regeneration. In various embodiments, the quality-of-signal monitoring device provides feedback to the distortion compensator device, a distortion compensator device disposed along a line system, one or more of an optical amplifier and a distortion compensator device disposed along the line system, and a transmitter device disposed along the line system.

Owner:CIENA

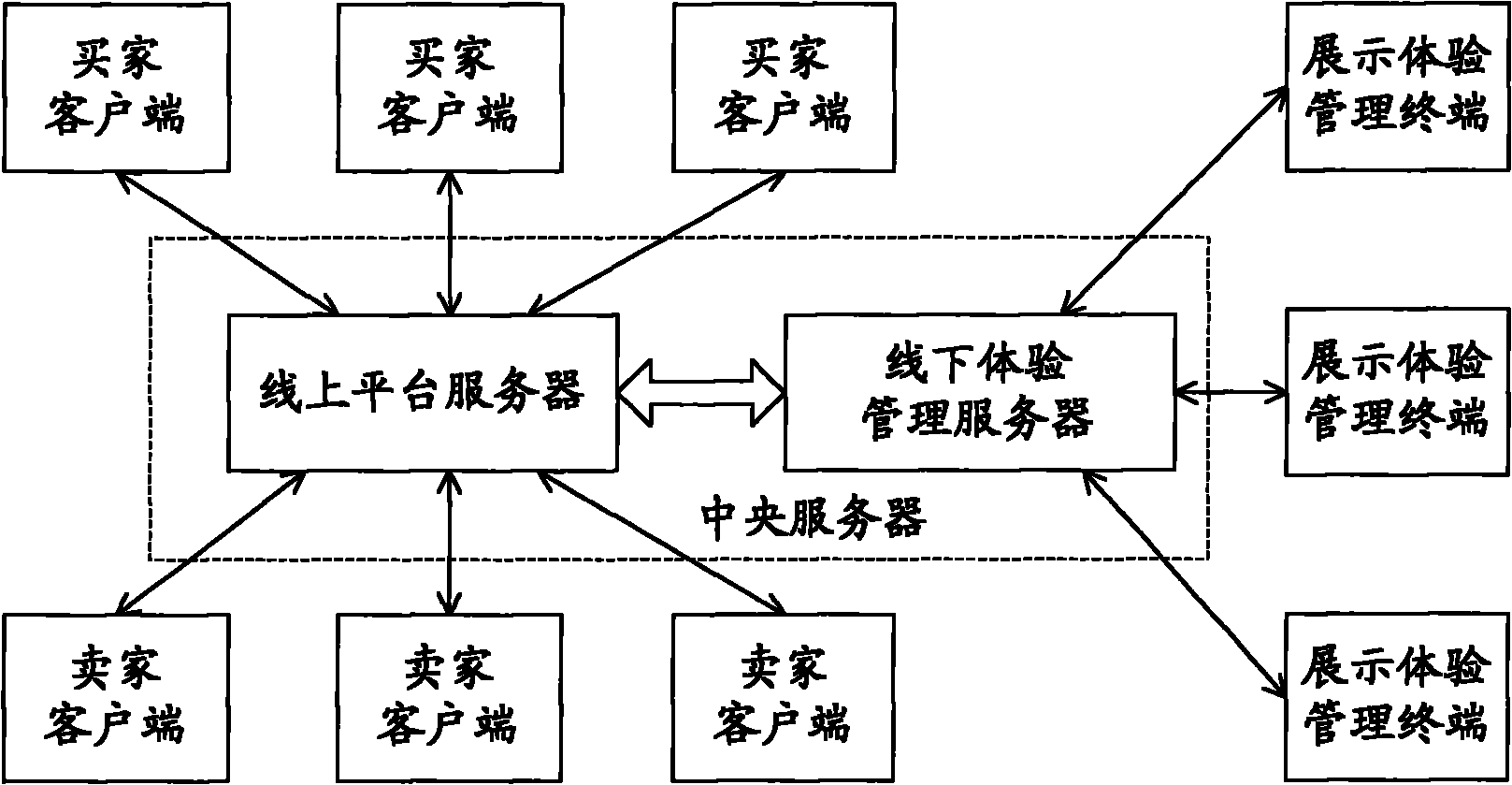

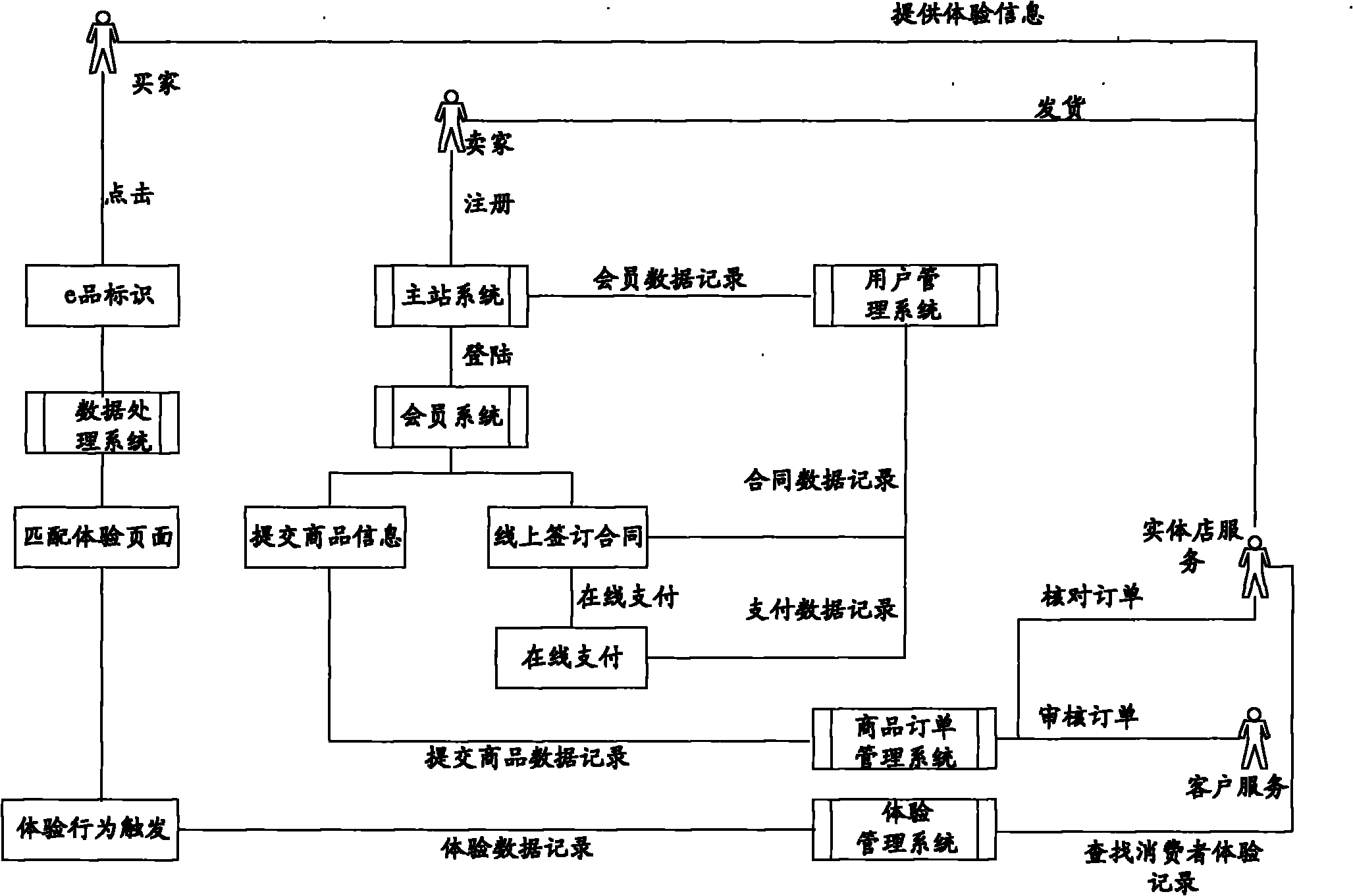

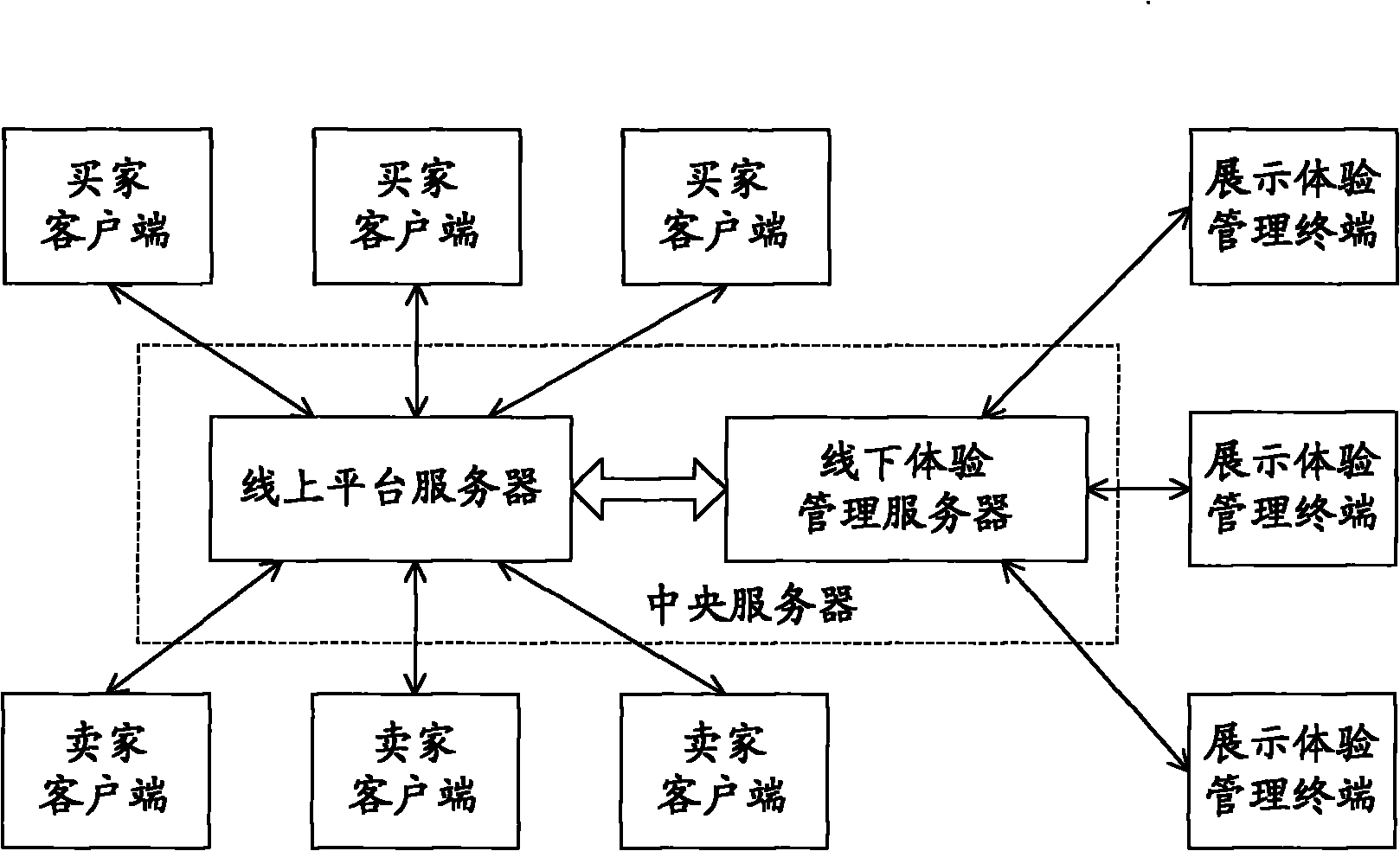

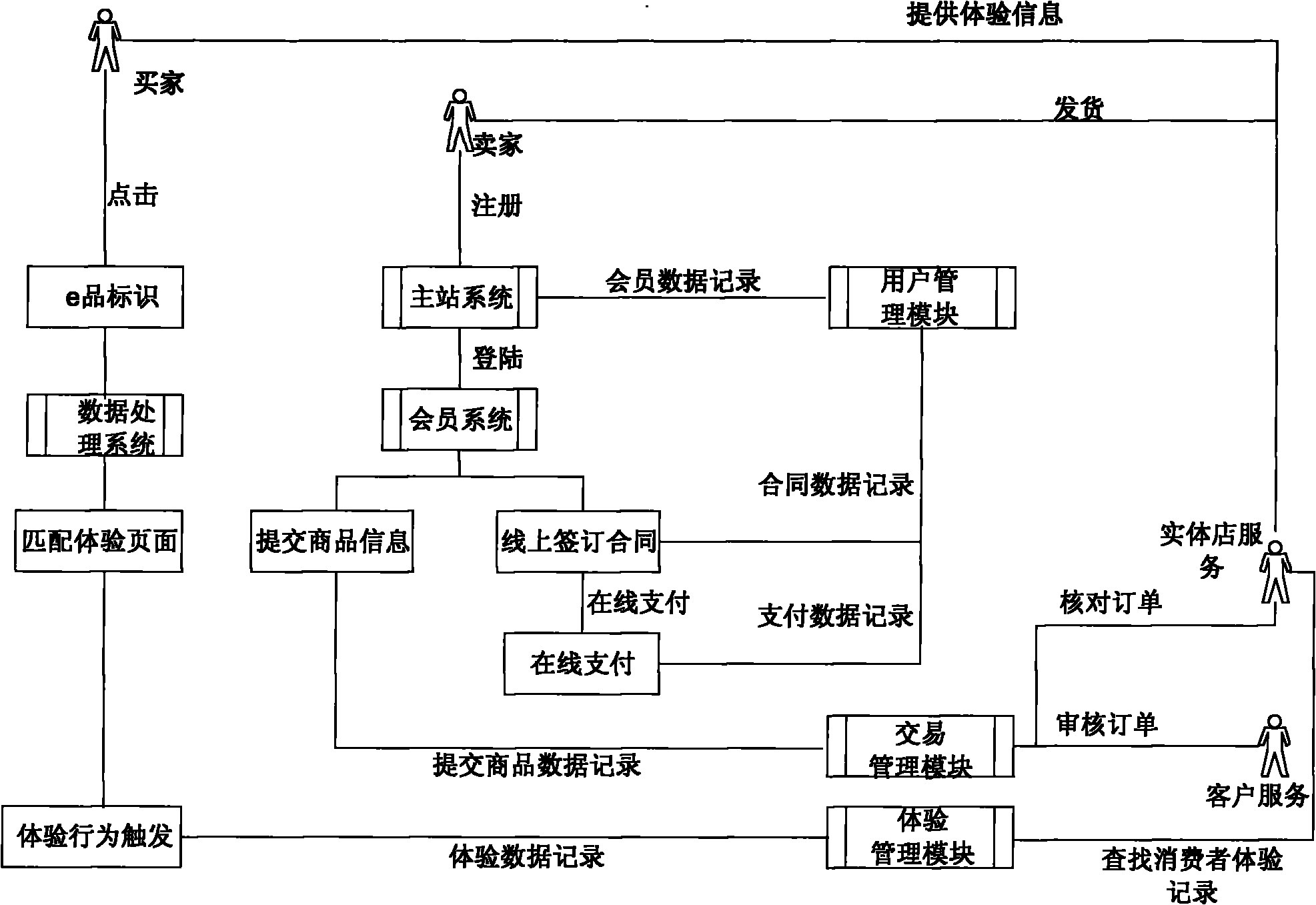

System and method for combining online and offline exhibition

InactiveCN101901438AExpand application spaceMeet operating costsMarketingCommunication interfaceTransaction management

The invention discloses a service system for combining online and offline exhibition, which comprises a central server, a seller client communicated with the central server, a purchaser client and an exhibition experience management terminal which is communicated with the central server, wherein the central server comprises a server database and a management system; the management system comprises a user management module, a transaction management module, an experience management module and a communication module; the communication module is used for providing corresponding data exchange service; the transaction management module matches the supply and demand of goods, generates goods orders and manages the orders; the experience management module queries corresponding information of an exhibition experience shop according to the goods orders, transmits the experience goods information to the experience management terminal, and carries out experience reservation; and the exhibition experience management terminal provides a communication interface between the worker of the exhibition experience shop and the central server, and manages the goods storage and delivery of the exhibition experience shop and the purchaser experience.

Owner:BEIJING HUSNG CHUANGZHAN TECH

Basic biomass synthetic resin and preparation method and application thereof

ActiveCN101629019AGood film formingIncrease stickinessProtein adhesivesGlue/gelatin preparationPolymer scienceAdhesive

The invention belongs to the material science field, in particular to a basic biomass synthetic resin and a preparation method and an application thereof. The basic biomass synthetic resin is prepared by the following steps: taking acidity regulator to prepare a water solution with pH value of 6.0-10.0, adding plant protein powder in the water solution under the stirring state; adding a molecular structure modifying agent under the stirring state, performing the modifying reaction for 15-240 min at 5-75 DEG C; sequentially adding modified starch and a resin assistant, performing the polymerization reaction for 15-240min at 5-90 DEG C, adding preservative in a reaction system within the last 5-20min of the polymerization reaction; adding or not adding packing after finishing the reaction, and stirring uniformly to obtain the basic biomass synthetic resin, wherein the part of the materials is taken by weight. The basic biomass synthetic resin has wide application range on the respect of preparing bonding adhesive or coating.

Owner:郑州佰沃科技发展有限公司

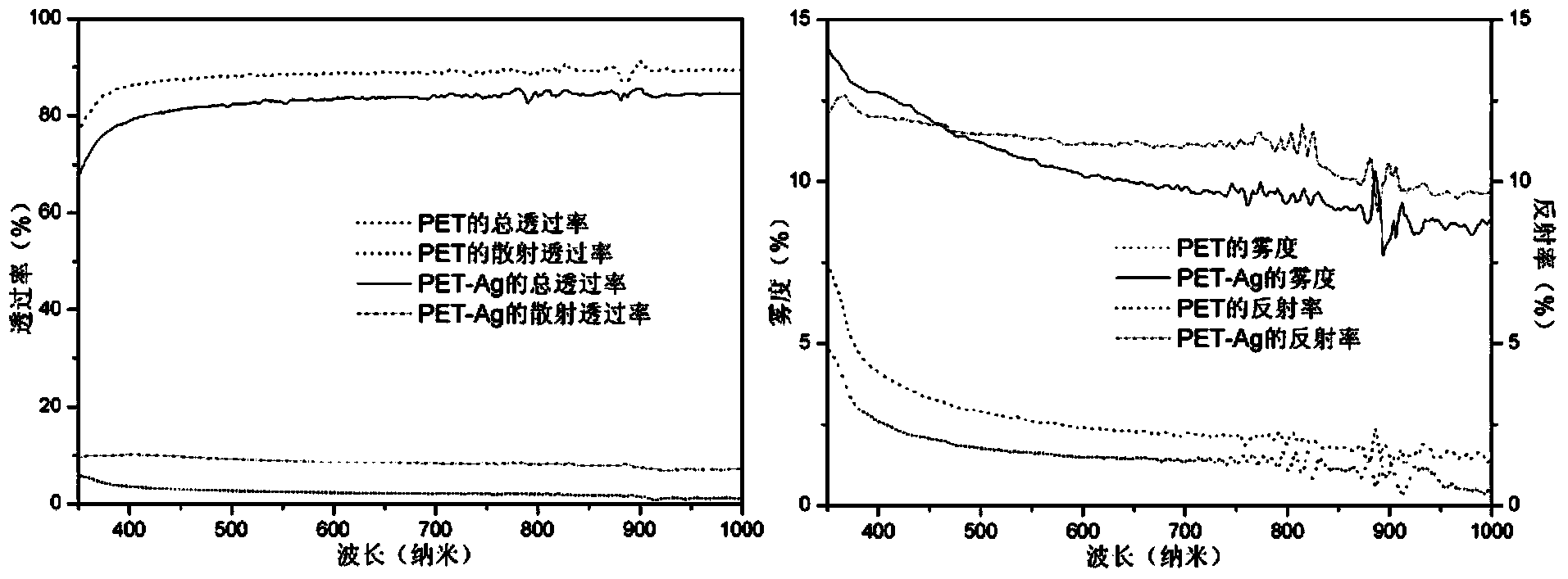

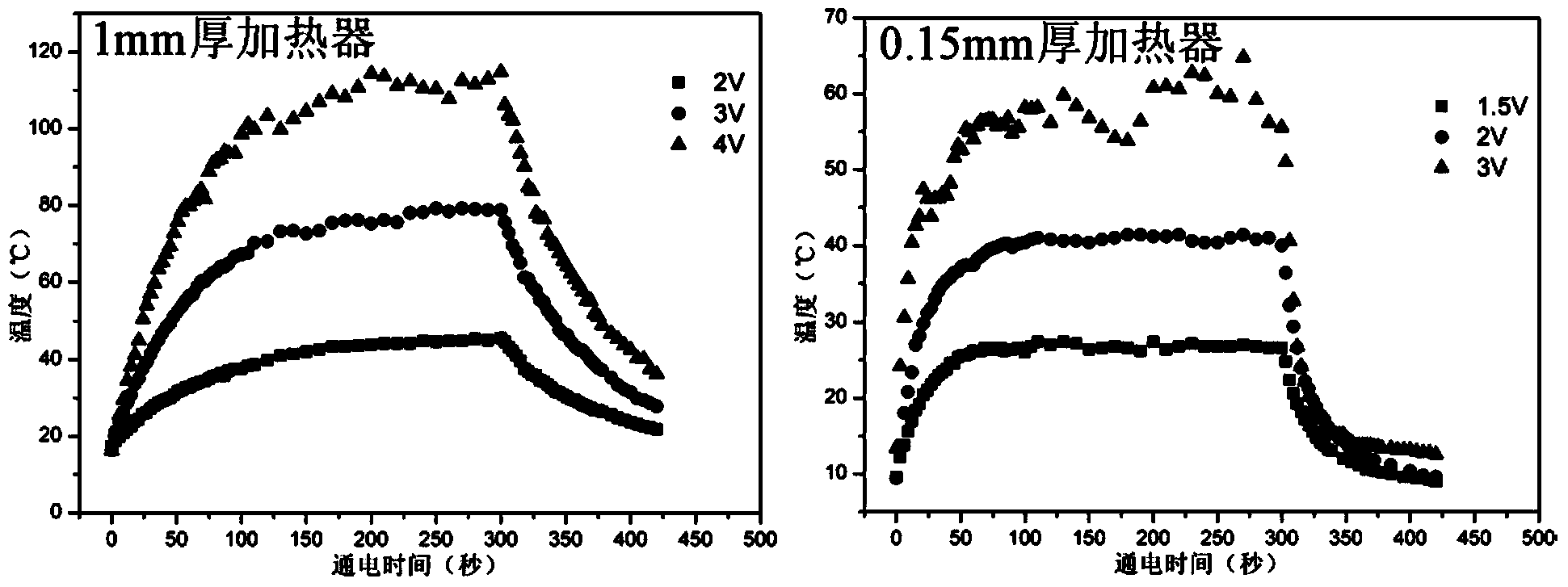

Heater based on transparent silver nanowire conducting thin film and preparation method thereof

ActiveCN104053256ALow costExpand application spaceTransparent/reflecting heating arrangementsHeating element materialsHydrophilizationConductive polymer

The invention discloses a heater based on a transparent silver nanowire conducting thin film and a preparation method of the heater. The heater is simple in structure, uniform in heating and resistant to corrosion. The heater comprises a transparent substrate, the transparent conducting thin film, a conducting electrode and a protective layer. The heater is applied to defogging glass, a thermochromic substrate, a sensor substrate and the like. The preparation method of the heater comprises the steps of hydrophilization processing of the substrate, preparation of the transparent conducting thin film, preparation of the conducting electrode and preparation of the protective layer. According to the heater, silver nanowires synthesized through a low-temperature liquid phase method are used as raw materials, the transparent substrate is coated with the transparent conducting thin film through a non-vacuum non-high-temperature filming technology, the heating uniformity of the thin film is improved through technically mature and commercial conducting polymers, and the thin-layer protective film is obtained by means of liquid phase coating of cheap organic polymers. The heater is simple in structure, the raw materials are cheap, the requirement for preparation technological conditions is low, and large-scale production is facilitated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

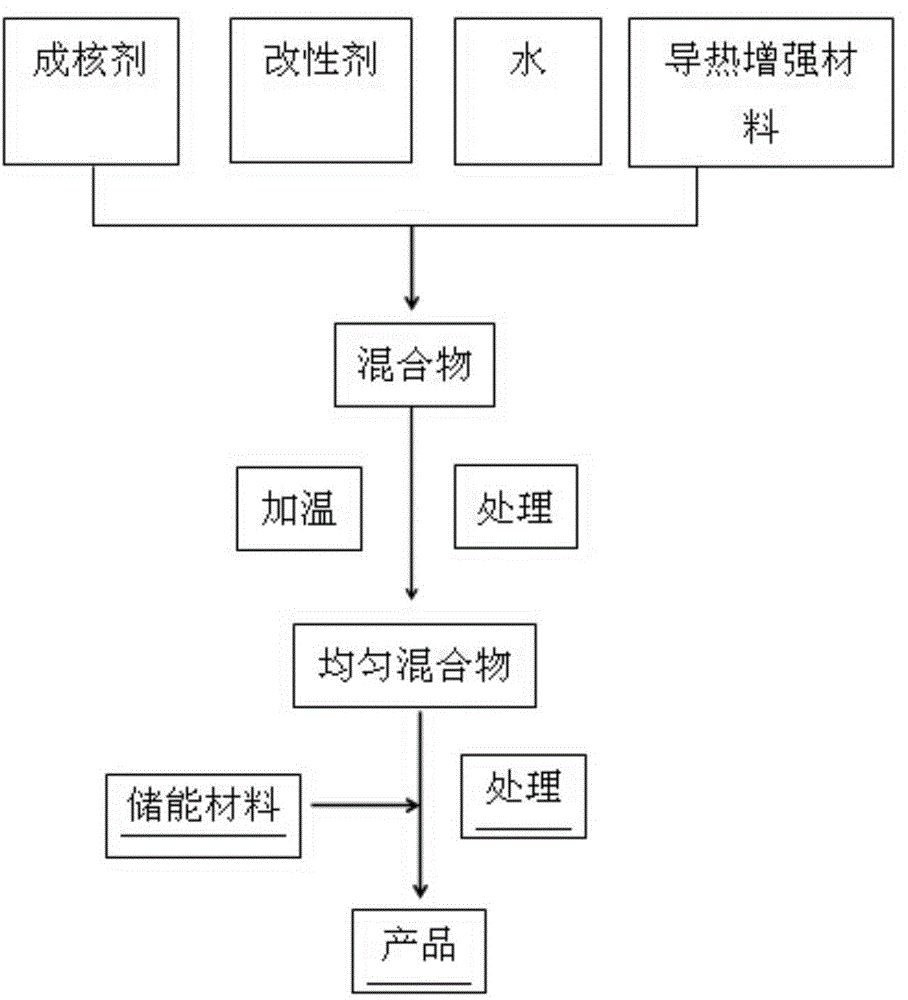

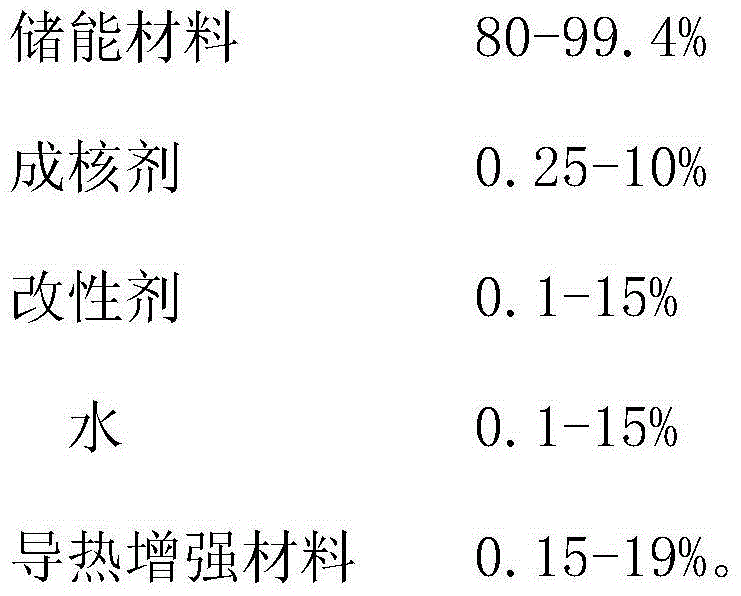

High-heat-conductivity inorganic phase-change energy storage material

InactiveCN104087254AImprove liquidityIncrease fluid volumeHeat-exchange elementsFiberHeat conducting

The invention relates to the technical field of energy storage materials, particularly a high-heat-conductivity inorganic phase-change energy storage material. The high-heat-conductivity inorganic phase-change energy storage material is composed of the following components in percentage by mass: 80-99.4% of energy storage material, 0.25-10% of nucleating agent, 0.1-15% of modifier, 0.1-15% of water and 0.15-19% of heat-conducting reinforcing material. The energy storage material is crystalline hydrated salt, the nucleating agent is carbonate or borate, the modifier is a polyacrylic acid emulsion or thickening powder, and the heat-conducting reinforcing material is one or mixture of more of graphite, carbon powder, copper powder, carbon fiber and silicon carbide powder. Compared with the prior art, the energy storage material has the advantages of high stability, low tendency to supercooling, high latent heat energy, high heat conductivity and the like. By selecting the proper modifier and proportion thereof, the heat-conducting reinforcing material and nucleating agent material can be successfully dispersed uniformly in the system, thereby solving the problem of the phenomenon of phase separation of the material due to long-term cycle, further enhancing the heat-conducting property of the material and being worthy of popularization and application.

Owner:PIONEER ENERGY JIANGSU

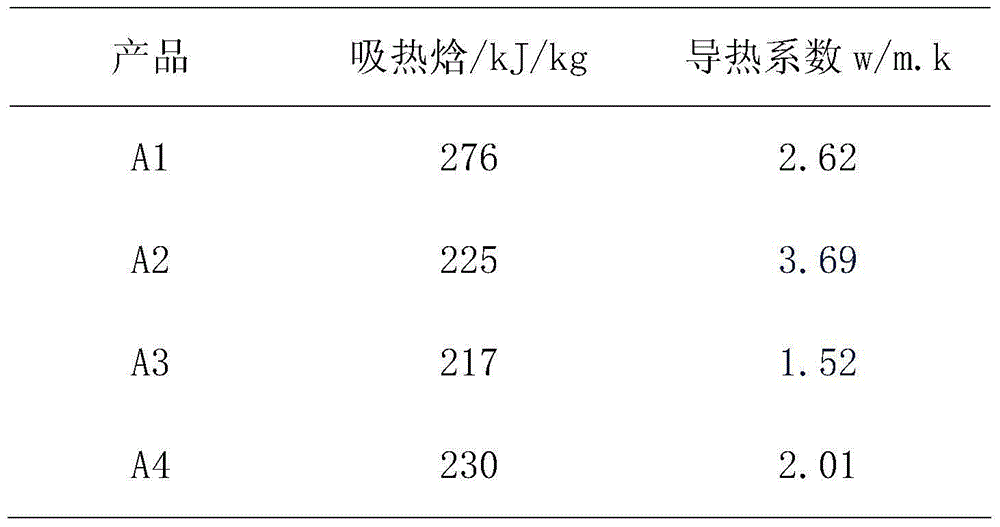

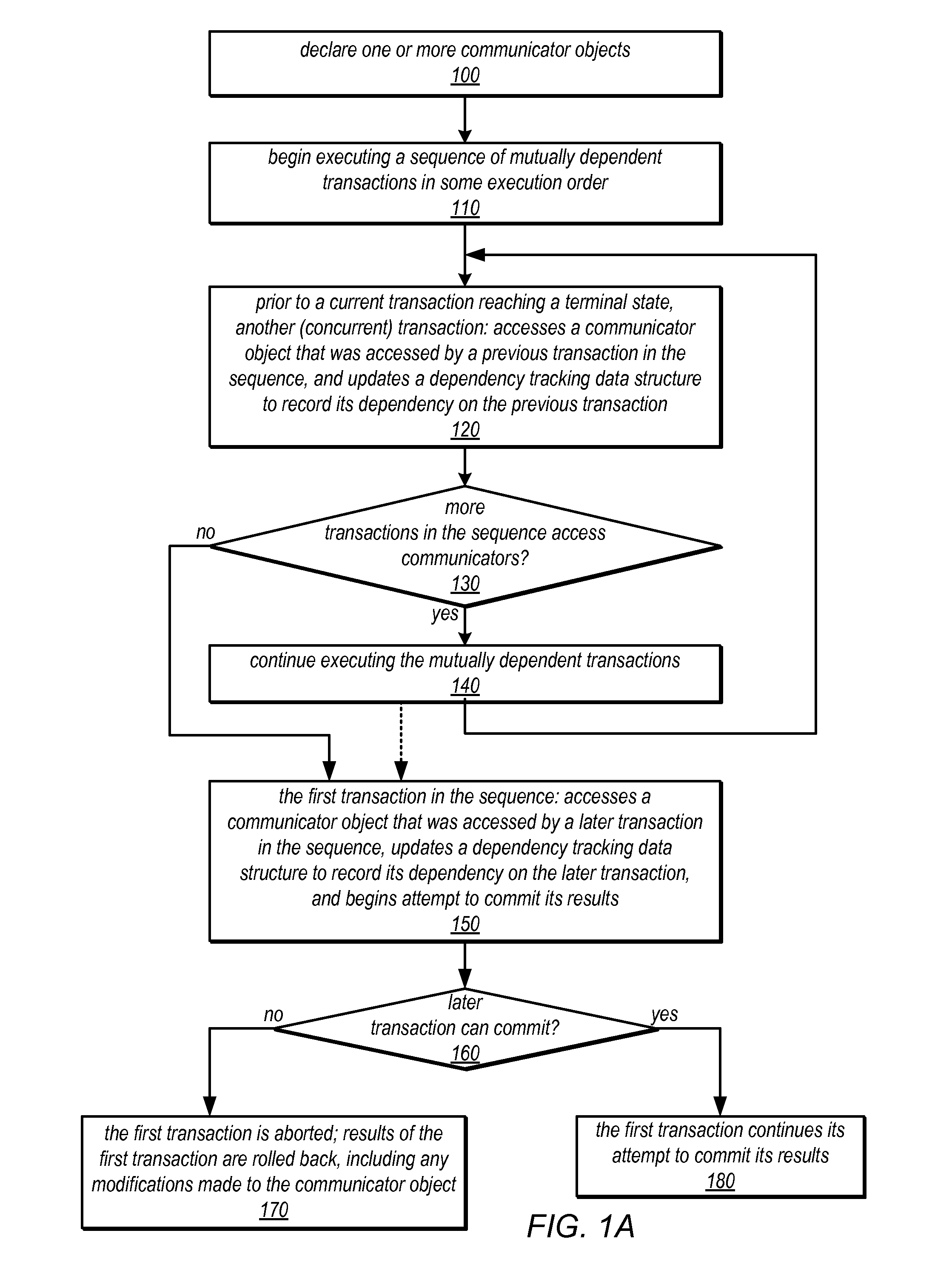

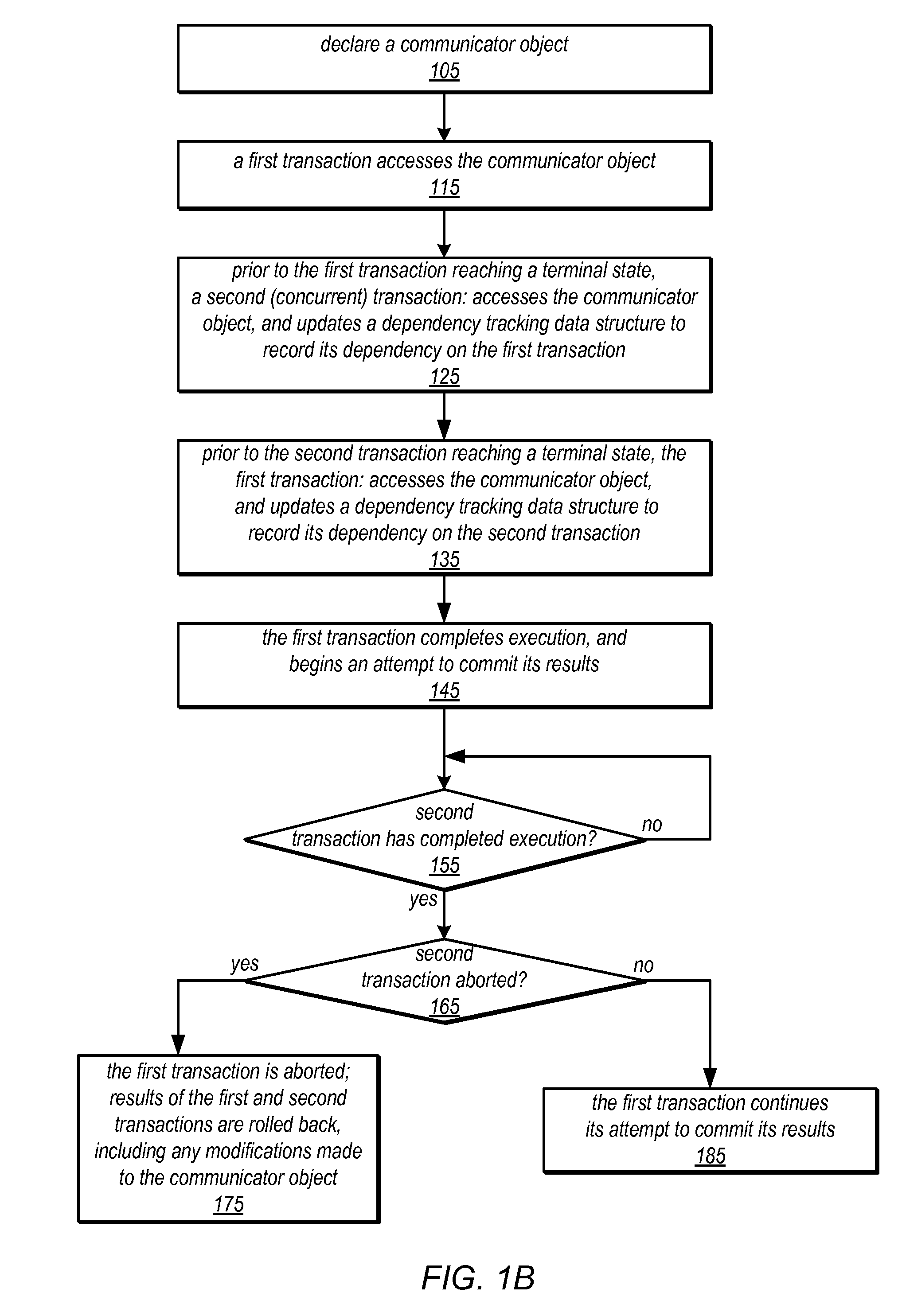

System and Method for Communication Between Concurrent Transactions Using Transaction Communicator Objects

ActiveUS20120005530A1Expand application spaceEnsure isolationDigital computer detailsRedundant operation error correctionTransactional memoryDependency graph

Transactional memory implementations may be extended to include special transaction communicator objects through which concurrent transactions can communicate. Changes by a first transaction to a communicator may be visible to concurrent transactions before the first transaction commits. Although isolation of transactions may be compromised by such communication, the effects of this compromise may be limited by tracking dependencies among transactions, and preventing any transaction from committing unless every transaction whose changes it has observed also commits. For example, mutually dependent or cyclically dependent transactions may commit or abort together. Transactions that do not communicate with each other may remain isolated. The system may provide a communicator-isolating transaction that ensures isolation even for accesses to communicators, which may be implemented using nesting transactions. True (e.g., read-after-write) dependencies, ordering (e.g., write-after-write) dependencies, and / or anti-dependencies (e.g., write-after-read dependencies) may be tracked, and a resulting dependency graph may be perused by the commit protocol.

Owner:ORACLE INT CORP

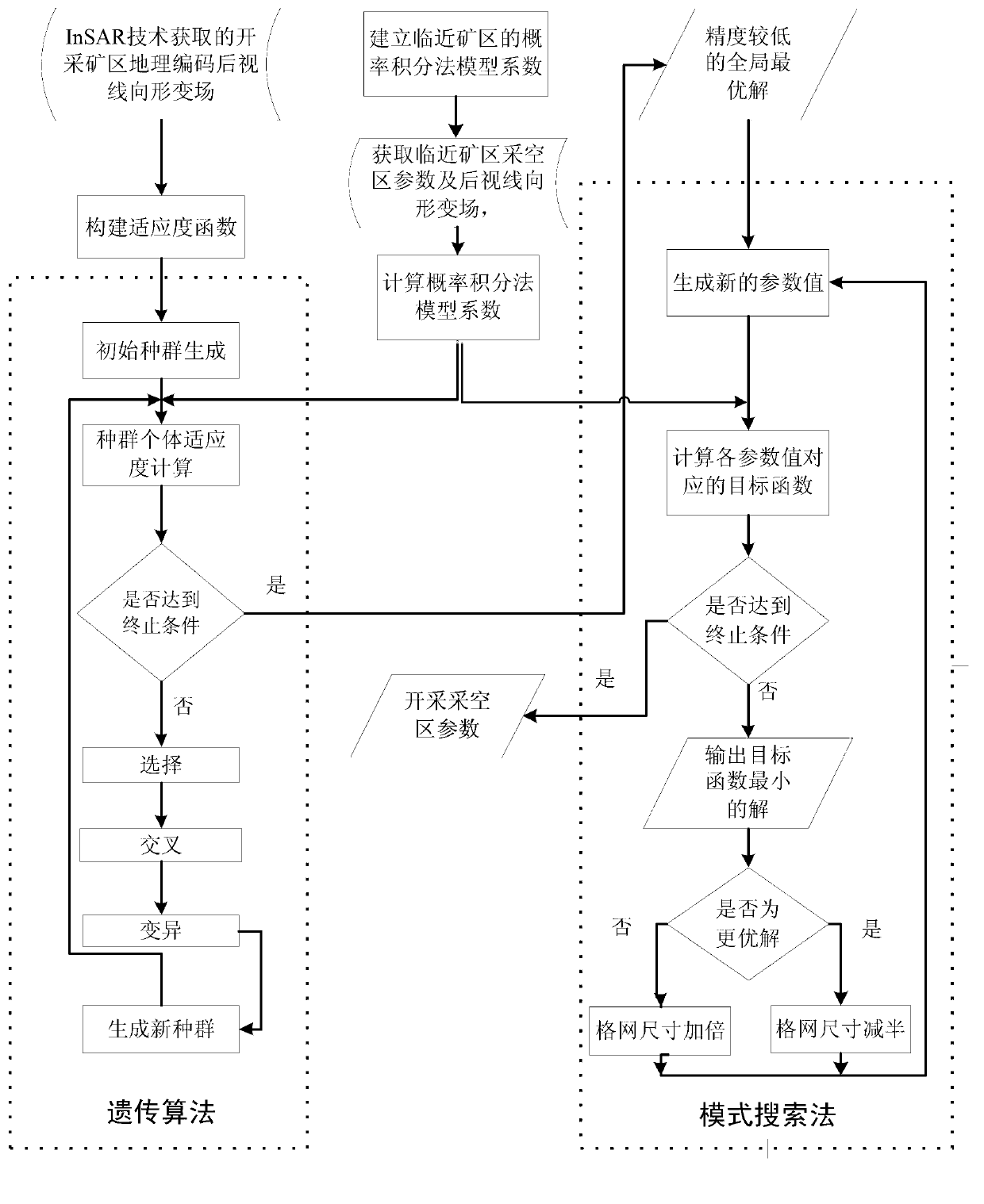

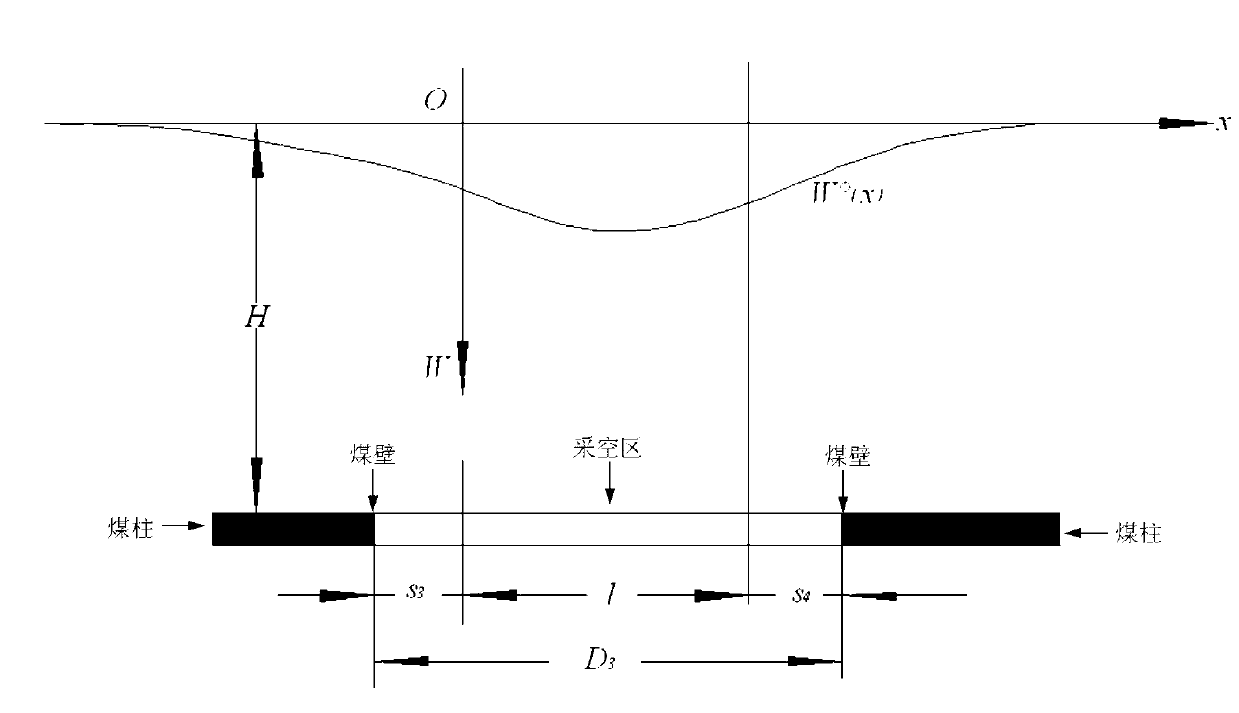

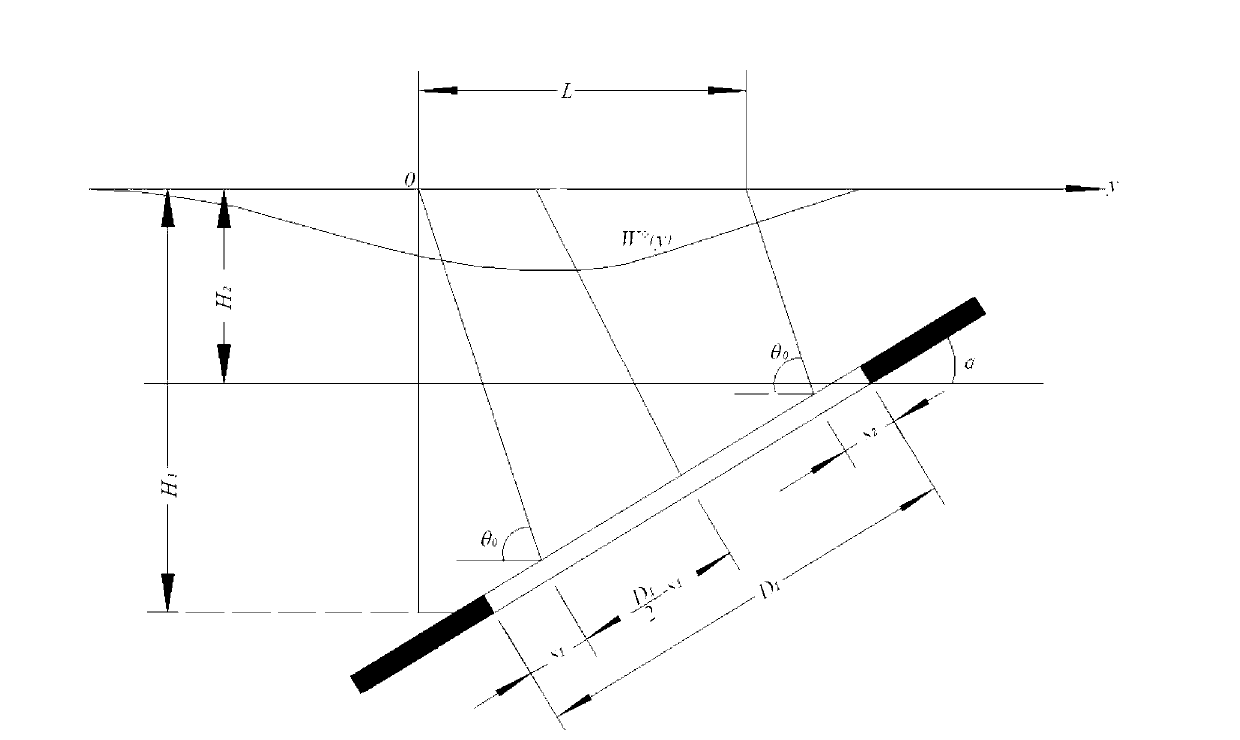

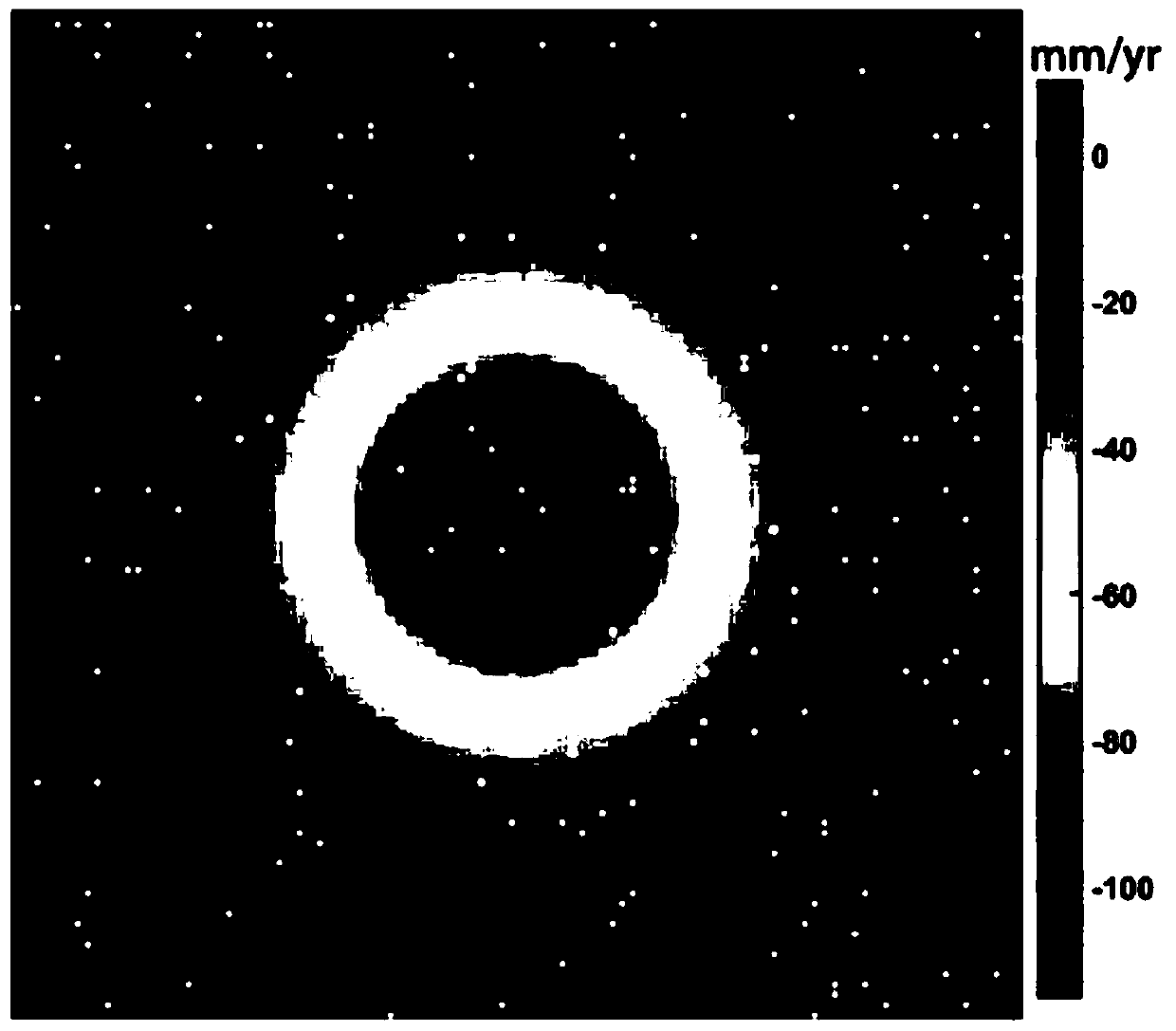

Mining lot exploiting and monitoring method based on interferometric synthetic aperature radar (InSAR) technology

ActiveCN103091675AExpand application spaceLow costRadio wave reradiation/reflectionInterferometric synthetic aperture radarRadar

The invention provides a mining lot exploiting and monitoring method based on interferometric synthetic aperature radar (InSAR) technology. The method includes the steps of obtaining a probability integral method model coefficient of a mining area adjacent to a mining area to be detected, using a radar sight line directional deformation field, obtained through the InSAR technology, of a mining lot to be detected, using the length, the width, the thickness, an exploiting depth, a trend azimuthal angle and a central point coordinate of a working face of the mining area to be detected as unknown numbers, and enabling the unknown numbers and a probability integral method model coefficient of the mining area adjacent to the mining area to be detected to be brought in the probability integral method model, then using a genetic algorithm to search and obtain a parameter value of the working face of the mining area to be detected, finally, using the working face parameter value obtained through the genetic algorithm as an initial value of a mode searching method, and obtaining the accurate working face parameter value of the mining area to be detected through iterative search. The mining lot exploiting and monitoring method overcomes the defects in the prior art that only an approximate exploiting location can be obtained in the process of exploiting monitoring to the mining area, and underground goaf detailed parameter information can not be obtained accurately, greatly expands the application space of the InSAR technology in the mining area, and provides a mining area exploiting fine monitoring method which is low in cost and large-scale.

Owner:经通空间技术(河源)有限公司

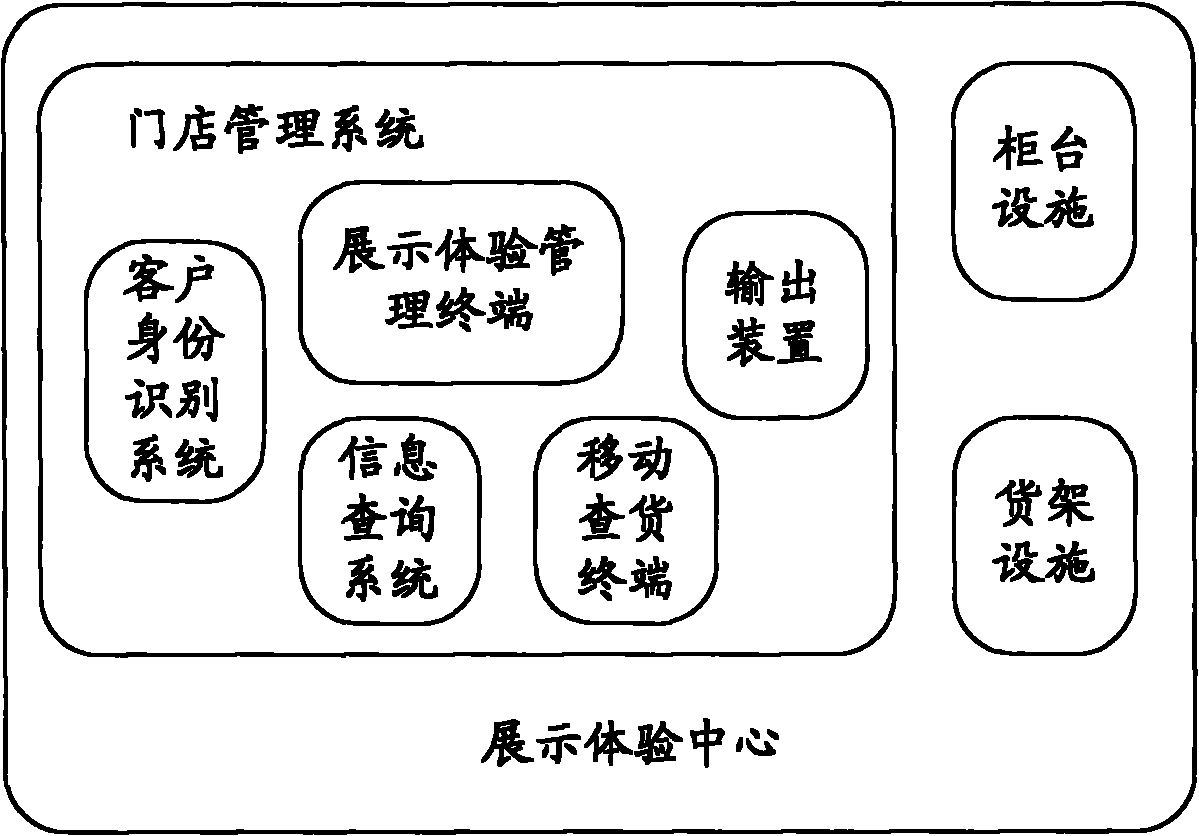

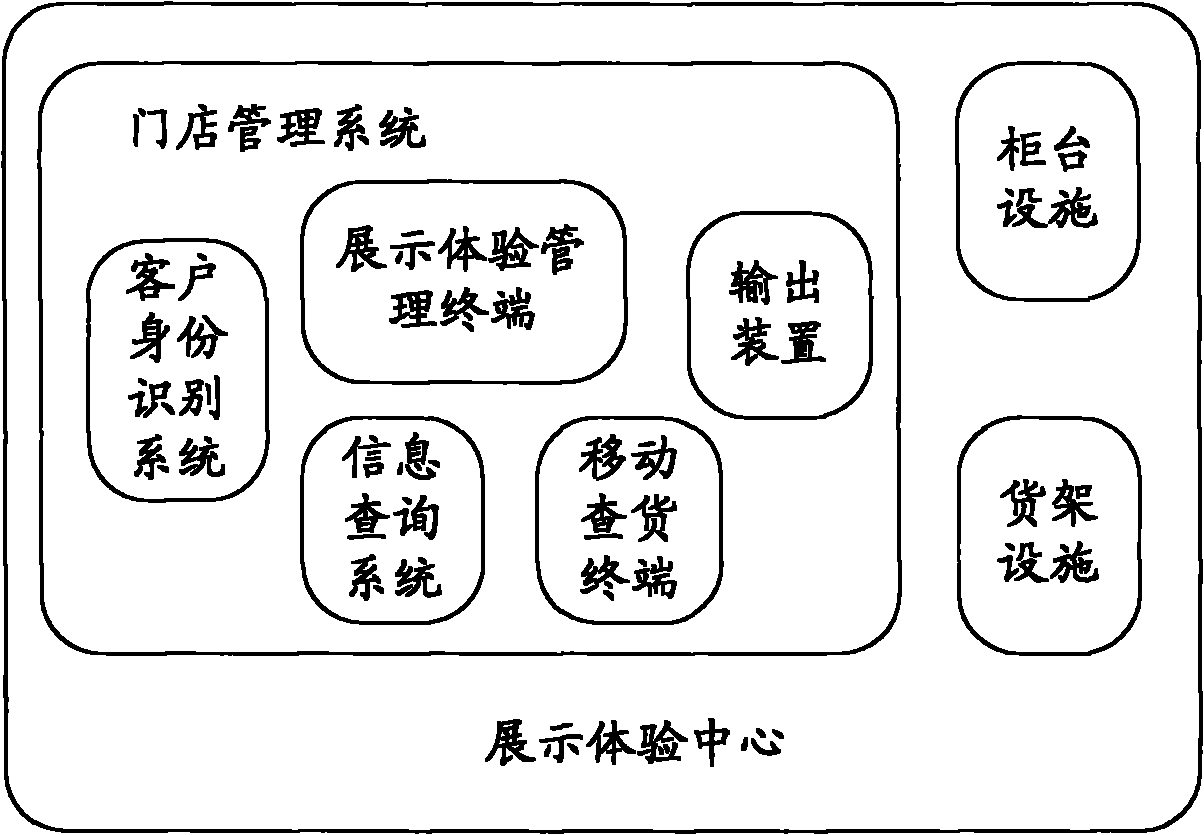

Off-line experience store management system and method

The invention relates to an off-line experience store management system. The system comprises an experience management system terminal and a client identification system, an information query system, a mobile query terminal and an output device which are connected with the experience management system terminal in a communication way, wherein the experience management system terminal is connected with a remote central server in a communication way and performs data interaction and the synchronization of an experience goods database; the client identification system is used for identifying experience sheet numbers of clients coming into a store, transmits the experience sheet numbers to the experience management system terminal and generates experience serial numbers of the clients; the output device is used for displaying information to users in the store according to instructions of the experience management system terminal; the information query system is communicated with the experience management system terminal and is used for providing real-time query of store inventories and experience information for the clients or salesclerks; and the mobile query terminal is used for reading all the goods information of the store and uploading the goods information to the experience management system terminal. Therefore, the system can realize mutual combination of an on-line system and an off-line system and provides an integrated shopping platform.

Owner:BEIJING HUSNG CHUANGZHAN TECH

A two-component abnormity hollow high moisture absorption curling composite fiber and a preparation method thereof

InactiveCN105177740AThree-dimensional apparent curl effect is goodBeautiful curly structureHollow filament manufactureFilament/thread formingFiberMoisture absorption

The invention provides a two-component abnormity hollow high moisture absorption curling composite fiber and a preparation method thereof; the preparation method comprises the following steps: spinning on a two-component composite spinning machine; enabling terylene melt to pass a first diversion hole of a first diversion slot on a melt distributing board, and to enter a first O-shape spinneret hole of a 8-shape spinneret hole; enabling polyamide 56 melt to pass a second diversion hole of a second diversion slot on the melt distributing board, and to enter a second O-shape spinneret hole of the 8-shape spinneret hole; using a bonding agent to firmly bond the melt flowing from the first and second O-shape spinneret holes into one body; using a side blowing mode to cool off the melt so as to obtain nascent fiber; carrying out post-treatment so as to obtain the two-component abnormity hollow high moisture absorption curling composite fiber. Finished product fabrics using the two-component abnormity hollow high moisture absorption curling composite fiber and the method has good moisture absorbable and breathable effect, is ventilating, anti-static, hollow, and warming.

Owner:DONGHUA UNIV

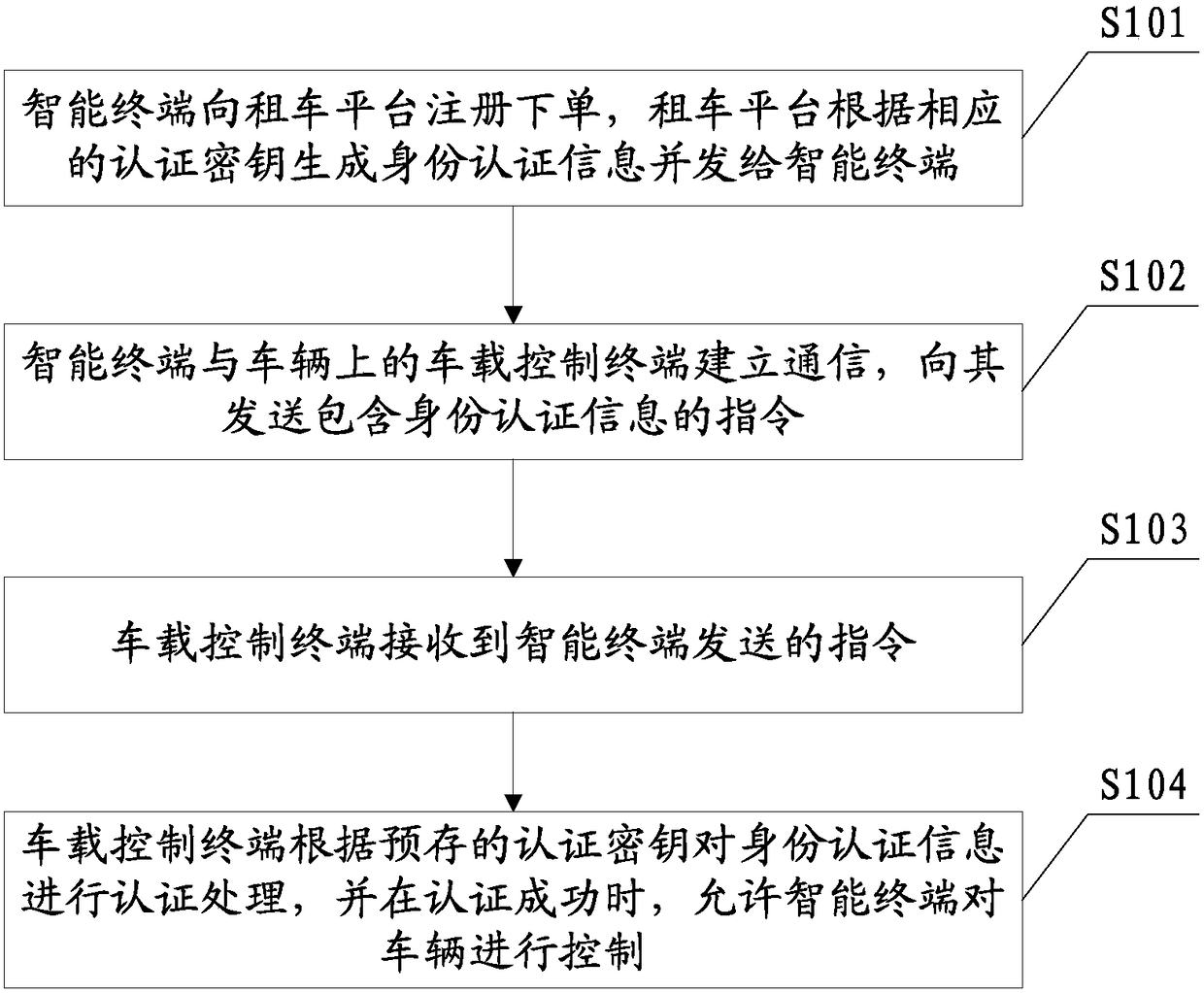

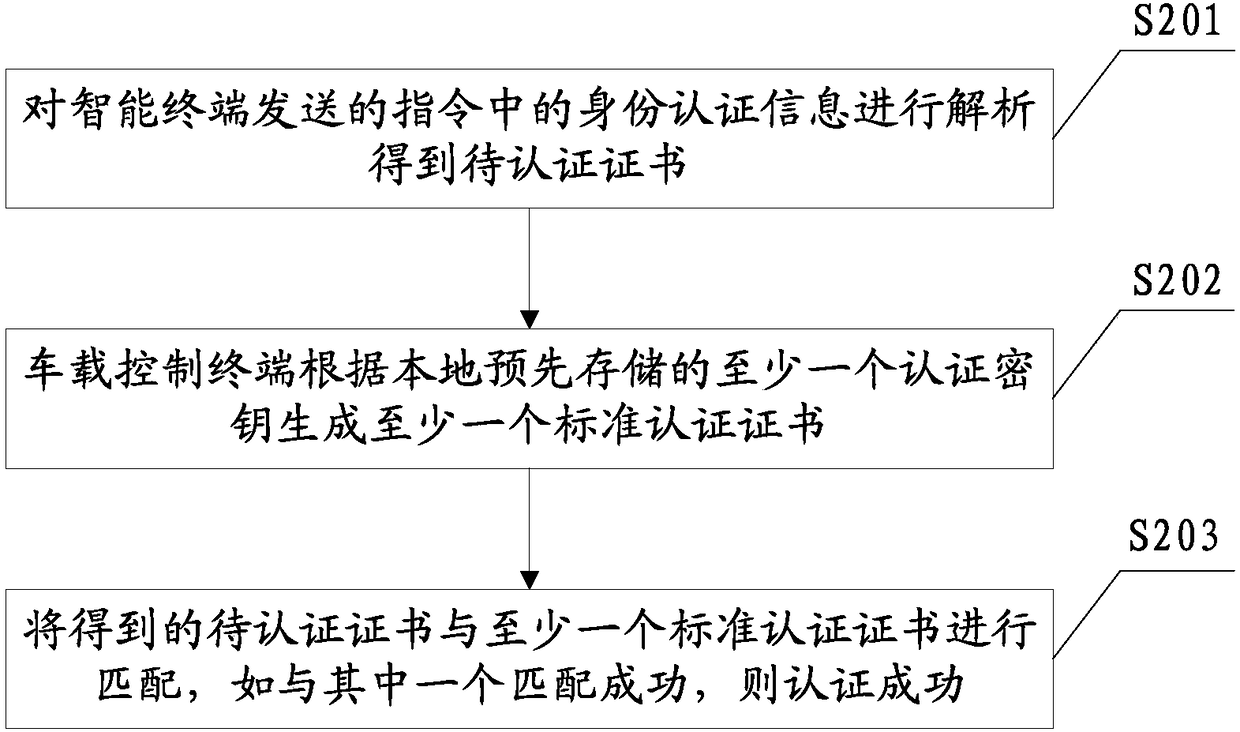

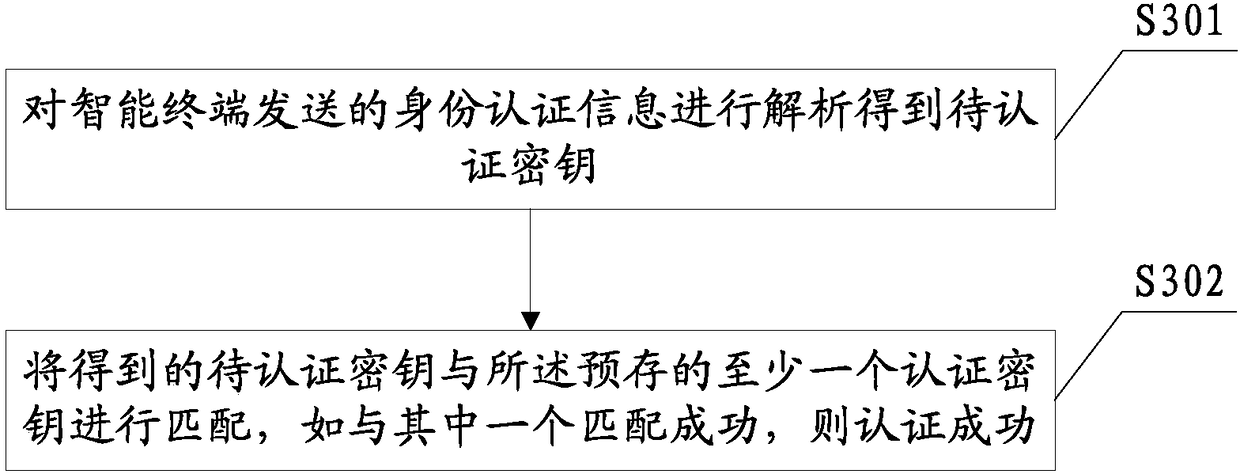

Vehicle system and virtual key authentication method thereof

InactiveCN108665337AImprove leasing efficiency andConducive to developmentIndividual entry/exit registersBuying/selling/leasing transactionsAuthentication informationComputer science

The invention provides a vehicle system and a virtual key authentication method thereof. As a vehicle virtual key, an intelligent terminal can register and order in a vehicle rental platform. After receiving the order request of the intelligent terminal, the vehicle rental platform generates identity authentication information according to a corresponding authentication key and sends the identityauthentication information to the intelligent terminal. The intelligent terminal transmits an instruction including identity authentication information to a vehicle-mounted control terminal on a vehicle, the vehicle-mounted control terminal performs authentication processing on the identity authentication information according to a pre-stored authentication key, and when authentication is successful, the intelligent terminal is allowed to control the vehicle. A user can directly use the intelligent terminal to interact with the vehicle rental platform and the vehicle-mounted control terminal on the vehicle, authentication is completed to achieve vehicle rental, improving rental efficiency, and avoiding various security risks caused by an entity key being cracked in the vehicle rental process; and the authentication key is only stored on the vehicle rental platform and the vehicle-mounted control terminal in the whole process, further ensuring the security of the key system.

Owner:CHONGQING WIRELESS OASIS COMM TECHCO

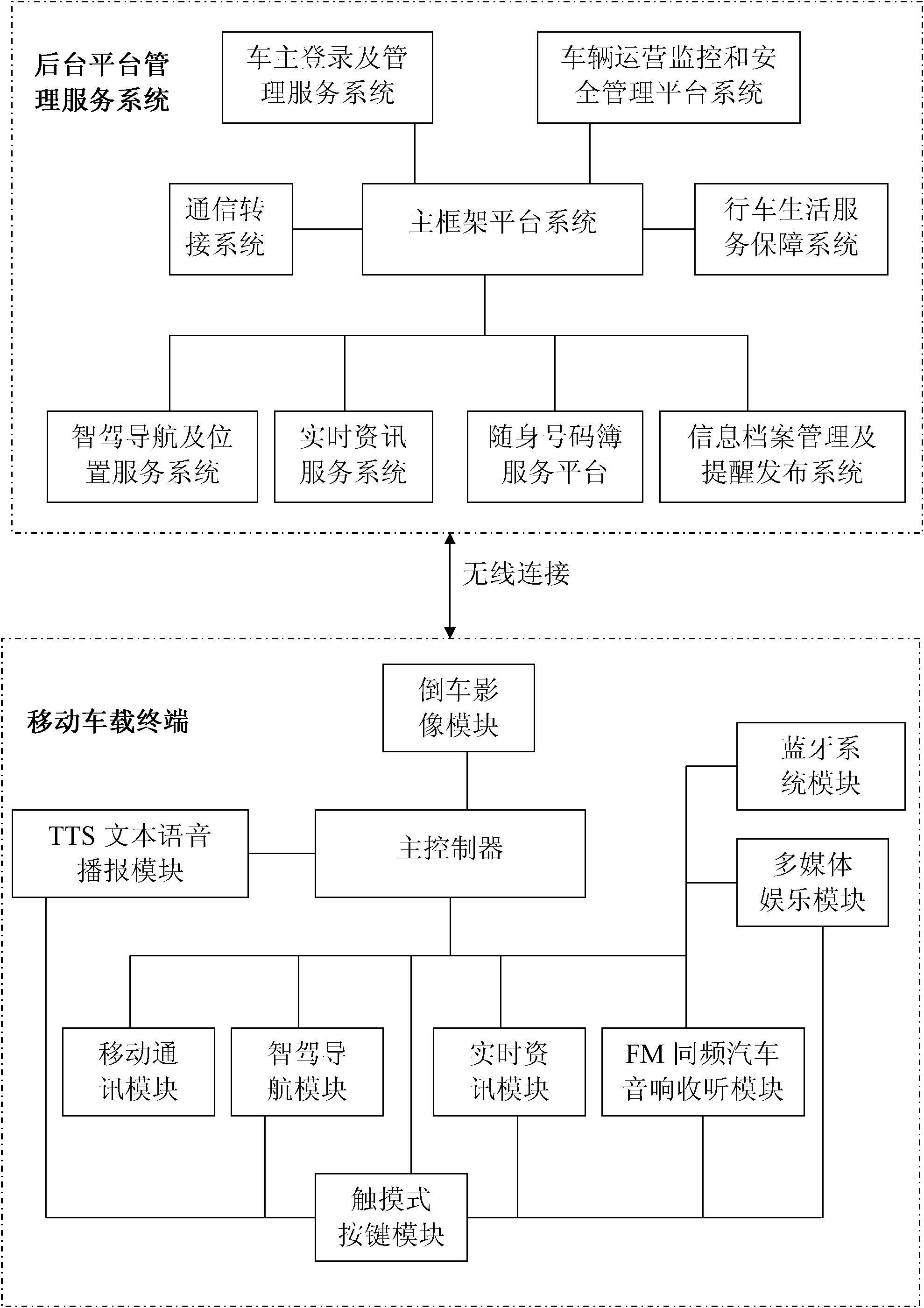

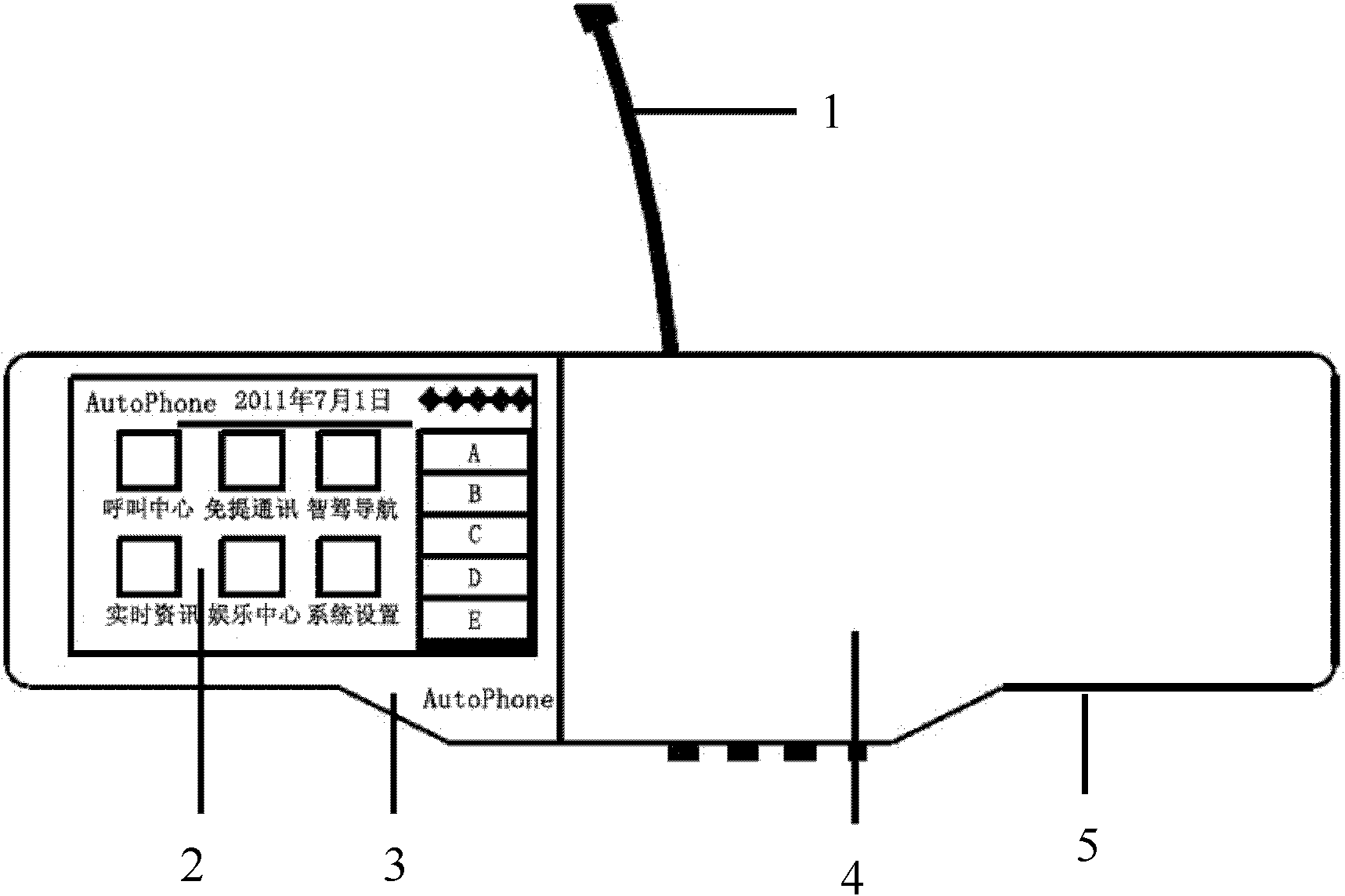

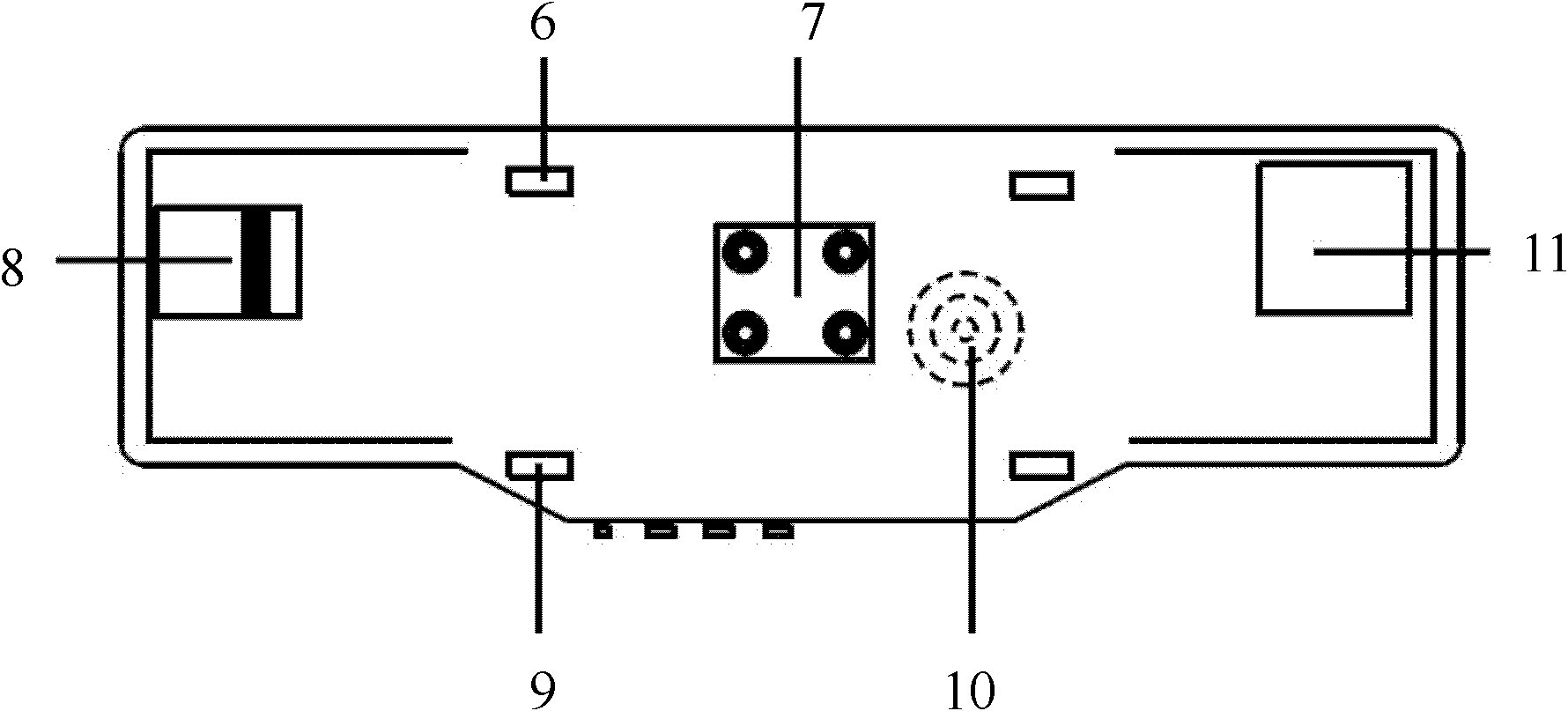

Mobile vehicle-mounted terminal and platform management service system

InactiveCN102325151AMeet needsInnovative service application modelBroadcast specific applicationsTransmissionTime informationMobile vehicle

The invention discloses a mobile vehicle-mounted terminal and a platform management service system. The system is up equipment which is suitable for installation on any model of cars, the after-service application scope is wider, the equipment functions are more and the operation is more safe, simple and convenient. The mobile vehicle-mounted terminal and the platform management service system mainly comprise the mobile vehicle-mounted terminal and a background platform management service system. The mobile vehicle-mounted terminal mainly comprises a main controller, a mobile communication module, an intelligent driving navigation module, a real-time information module, a frequency modulation (FM) common-frequency automobile sound box listening module, a multimedia entertainment module and a touch key module. The background platform management service system mainly comprises a platform main frame system, a communication switching system, an intelligent driving navigation and position service system, a real-time information service system, a carry-on number book service platform, an information file management and prompt distribution system, a driving life service guarantee system, an owner login and management service system and a vehicle operation monitoring and safety management platform system.

Owner:江苏一信科技有限公司

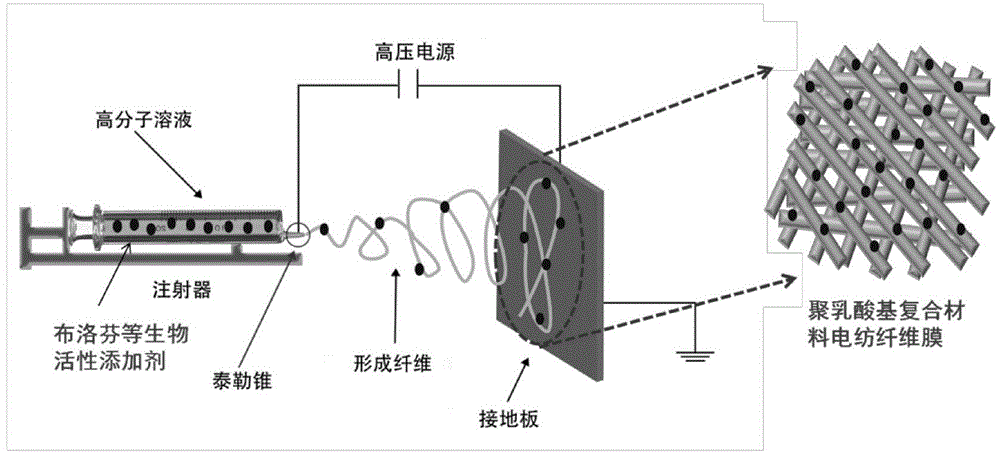

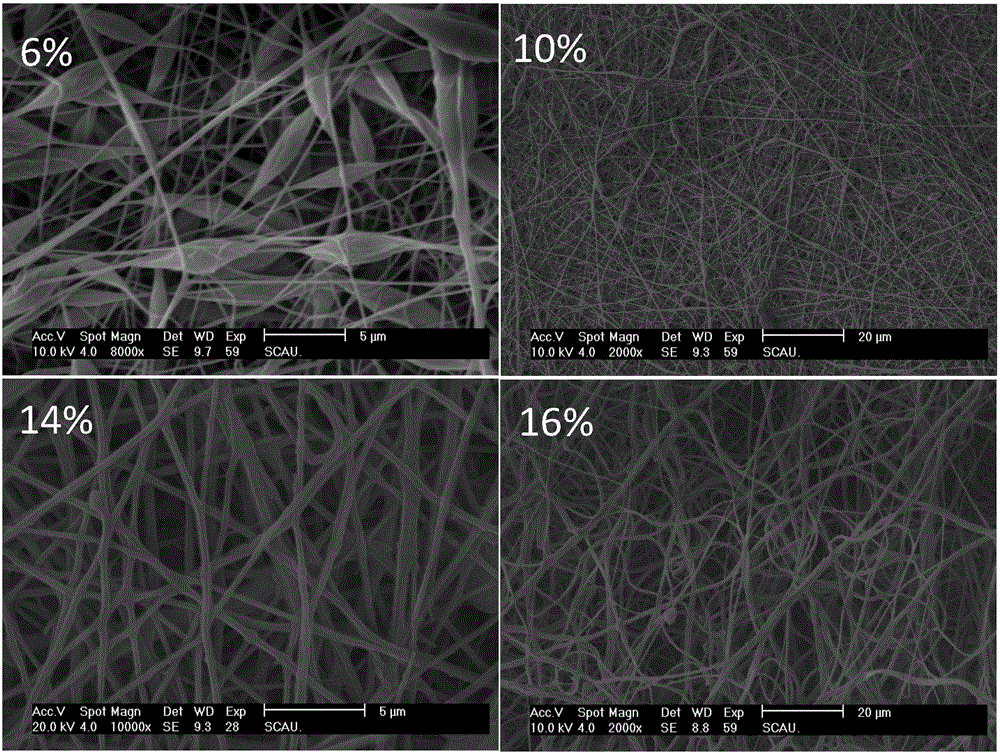

Polylactic acid-based composite material surgical medical film and preparation method thereof

InactiveCN104056297AImprove performanceGood flexibilityAbsorbent padsNon-woven fabricsFiberEnvironmental resistance

The invention discloses a polylactic acid-based composite material surgical medical film and a preparation method thereof. By adopting electrostatic spinning equipment and exploring proper technological parameters, different types of polylactic acid-based composite material macromolecular fiber thin films are finally formed and are applied to the field of biomedicine. In addition, by regulating and controlling composition of a macromolecular composite material system and thickness of an electro-spinning thin film, the surgical medical film which has good flexibility, high tensile strength, controllable degradation rate as well as excellent waterproof, antibacterial and air permeable performances is obtained finally. The surgical medical film is applicable to the field of various biomedicines such as healing film, wound surface dressing and anti-adhesion medicine; the medical film not only can be better adhered to tissues and avoid biotoxicity, but also can effectively promote transmission functions of blood, nutrients and growth factors in a human body due to the nature of semipermeable membrane. The process of the invention is simple and environment-friendly; the preparation method is easy to operate, low in cost, applicable to large-scale production and good in controllability, and is expected to be widely applied to various medical fields.

Owner:SICHUAN UNIV

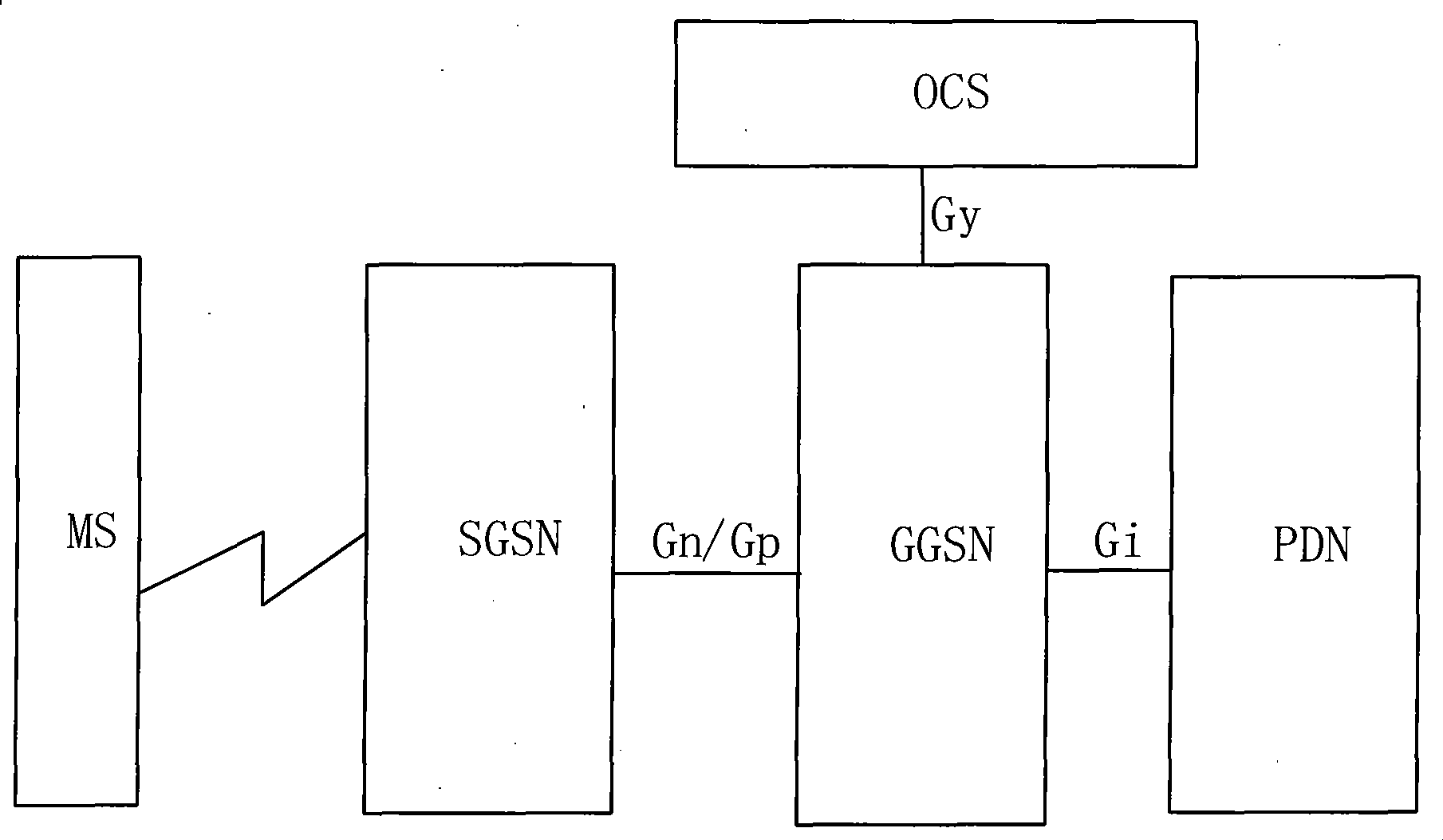

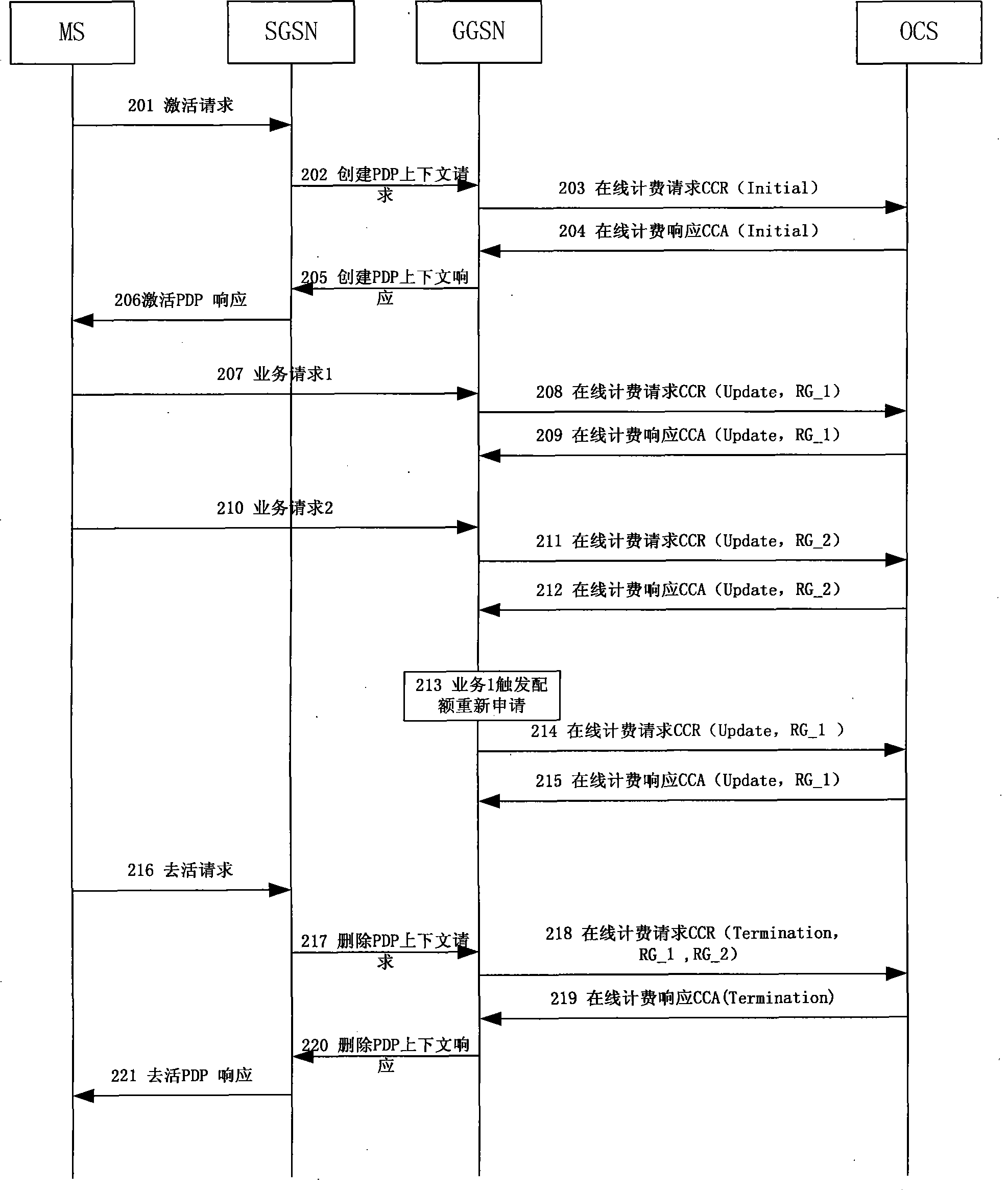

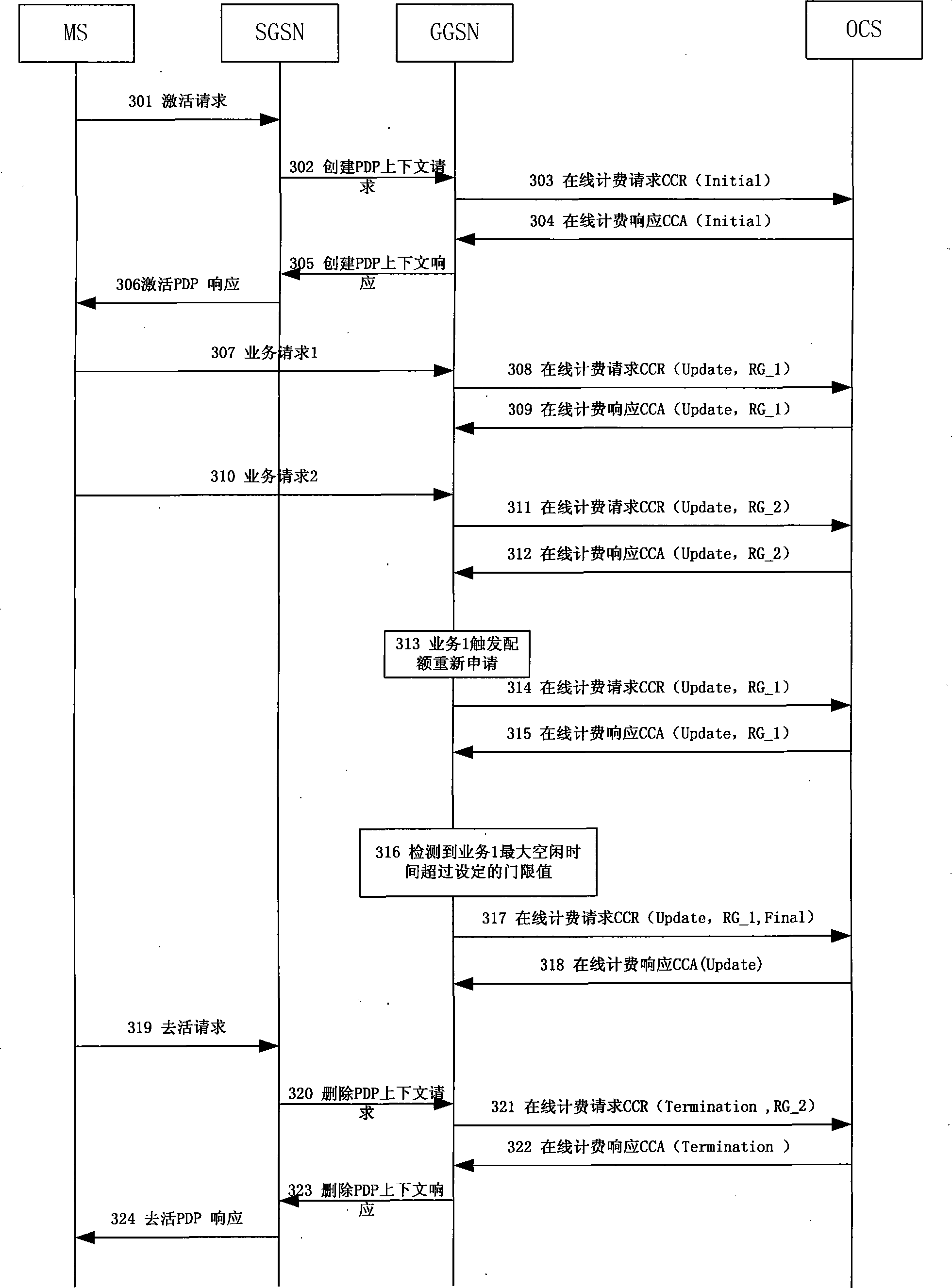

Method for implementing on-line charging of control business stream and network system thereof

InactiveCN101378323AReduce loadImprove experienceMetering/charging/biilling arrangementsRadio/inductive link selection arrangementsService flowInformation quantity

The invention discloses a realization method for controlling the on-line charging of service flows, and a network system thereof. Service ending conditions are set in the local site by general packet radio system gateway support nodes; when detecting that the service meets the service ending conditions, the general packet radio system gateway support nodes report a credit control request message and a service ending message to a real-time on-line charging system; the real-time on-line charging system ends the service according to the received credit control request message and the service ending message. By adopting the realization method for presetting the service ending conditions in the local site, the information quantity carried by CCR is reduced in the flow, thus reducing the interaction of the on-line credit control messages between GGSN and OCS, and the load of the OCS and the GGSN for processing the on-line charging, and improving the message interaction efficiency between the GGSN and the OCS, and the accuracy of system charging.

Owner:ZTE CORP

Low-melting-point alloy with melting point being 40-60 DEG C and preparation method of low-melting-point alloy

The invention relates to the field of heat conduction materials and provides low-melting-point alloy. The low-melting-point alloy comprises, by mass, 47.0-50.8% of indium, 29.5-32.3% of bismuth, 13.5-16.3% of tin and 0.67-10% of gallium. A preparation method of the low-melting-point alloy comprises the steps that A, all the constituents are weighed according to requirements; B, the furnace temperature is increased to 350 DEG C, the bismuth and the tin are placed into a ceramic crucible, the ceramic crucible is placed into a smelting furnace to be heated, after the bismuth and the tin are melted, surface oxide is removed, and stirring is conducted; C, the furnace temperature is adjusted to 200 DEG C, the indium is added, and after the indium is completely melted, surface slagging-off and stirring are conducted; D, the furnace temperature is adjusted to 100 DEG C, the gallium is added, and slagging-off and standing are conducted after stirring; and E, the crucible is taken out, the alloy is poured into a mold, and cooling is conducted. The melting point of the low-melting-point alloy is 40-60 DEG C, the low-melting-point alloy is used for low-junction-temperature occasions in a phase-change mode, and the application space of liquid metal thermal interface materials is enlarged; harmful elements such as lead and cadmium are not contained in the low-melting-point alloy product, and environment protection is facilitated. The preparation method is simple in technological requirement, and the whole process can be conducted in the atmospheric environment.

Owner:SUZHOU TIANMAI THERMAL TECH

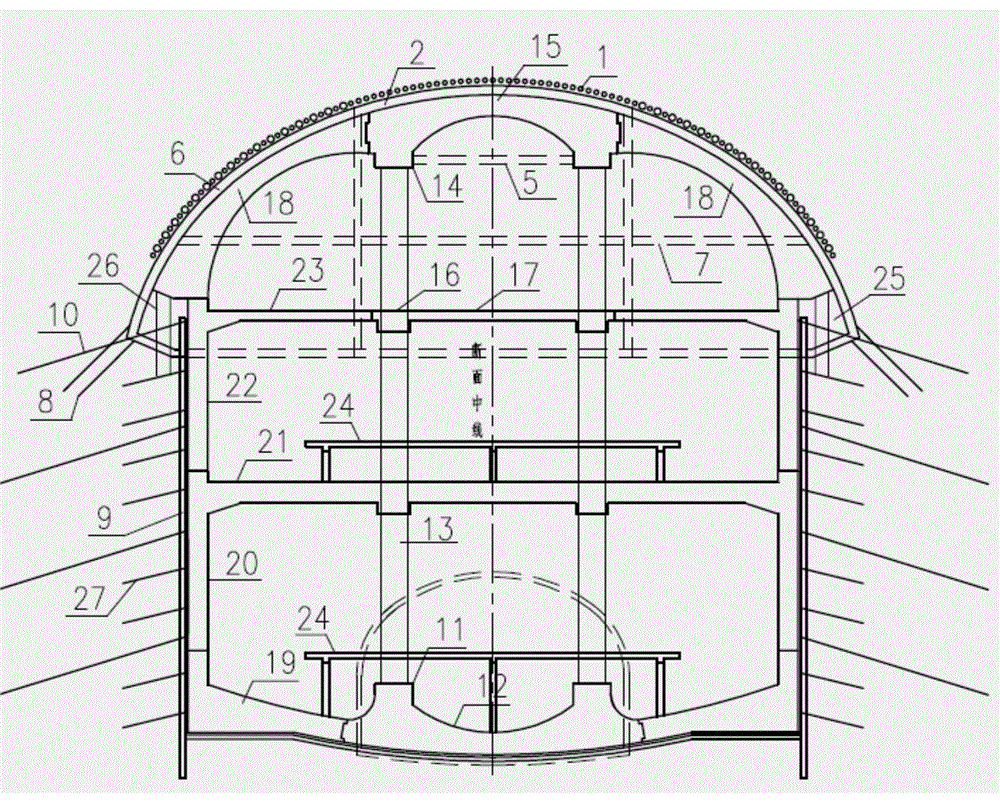

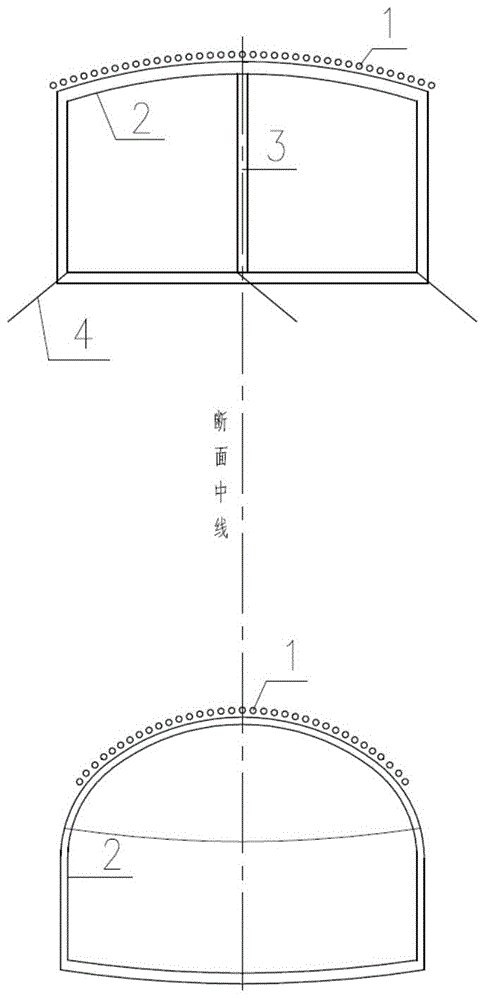

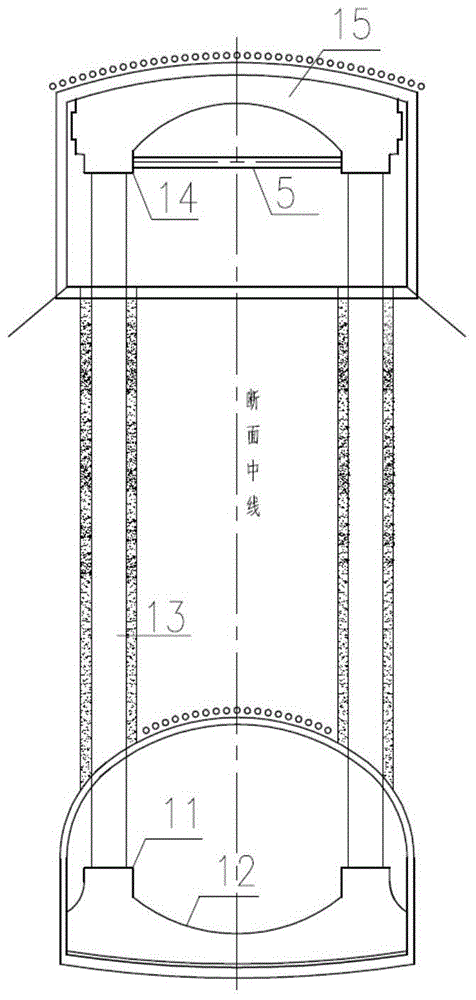

Rock stratum underground excavation three-story subway station umbrella cover structure and construction method thereof

ActiveCN106337686AReasonable structural designImprove stabilityUnderground chambersTunnel liningReinforced concreteSubway station

The invention belongs to the technical field of design and construction of tunnel and underground engineering and especially relates to a rock stratum underground excavation three-story subway station umbrella cover structure and a construction method thereof. The structure comprises a main arc structure and a reinforced concrete inverted arch. an underground two-story side wall and an underground three-story side wall are installed between the main arc structure and the reinforced concrete inverted arch. The main arc structure comprises an arch portion second lining middle segment and arch portion second lining side segments; the arch portion second lining side segments are positioned at two sides of the arch portion second lining middle segment; the reinforced concrete inverted arch comprises an inverted arch second lining middle segment and inverted arch second lining side segments; the top of the inverted arch second lining middle segment is provided with two bottom girders; the bottom of the arch portion second lining middle segment is provided with two top girders; steel-pipe columns are installed between the top girders and the bottom girders. The structure and the method of the invention is suitable for supporting structure and construction of weak rock stratum dug three-story subway station and large sections of underground space; the structure has good stability and increased construction efficiency.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

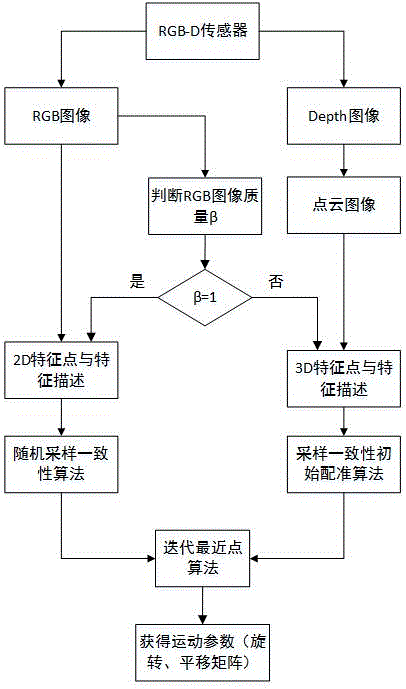

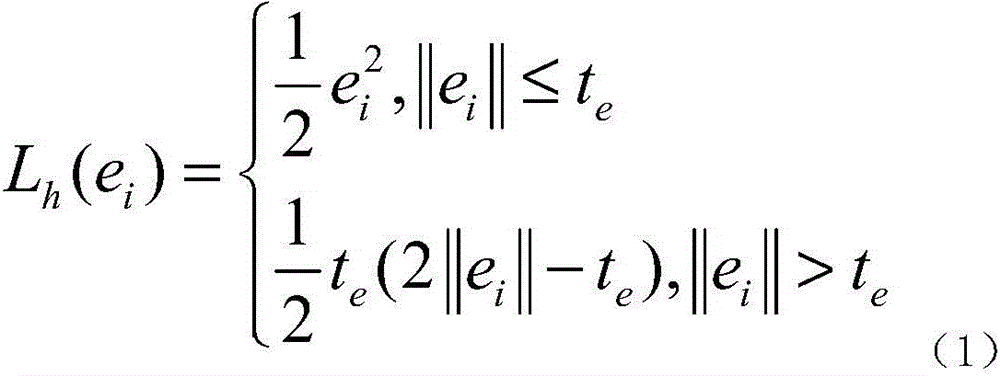

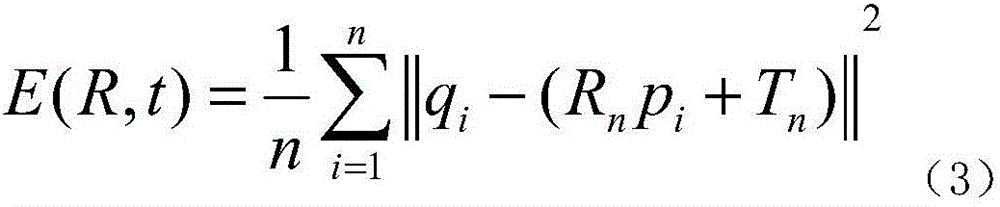

Visual odometer realization method based on fusion of RGB and depth information

InactiveCN105938619ABreak through the dependence of lighting conditionsImproved robustness and practicalityImage enhancementImage analysisMature technologyMobile robot

The invention discloses a visual odometer realization method based on fusion of RGB and depth information. According to the existing visual odometer realization method, only environmental RGB information can be obtained based on a monocular or binocular camera and three-dimensional information of the environment can not be obtained directly, so that the application environment of the method is limited and the precision is high. Besides, an RGB-image-matching-based positioning method has characteristics of mature technology and fast processing speed; and a Depth-image-matching positioning method has the characteristic of high environment changing robustness. According to the invention, with combination of the advantages of the RGB-image-matching-based positioning method and the Depth-image-matching positioning method, an RGB-D sensor is used for obtaining RGB and Depth information of a scene simultaneously and a visual odometer realization method based on fusion of RGB and depth information is provided. Information of 2D and 3D modes is utilized reasonably; the dependence on the illumination condition by the visual system is broken; precision, robustness, and practicability of the speedometer system can be improved substantially; and the application time and space for the mobile robot can be expanded.

Owner:CHINA UNIV OF MINING & TECH

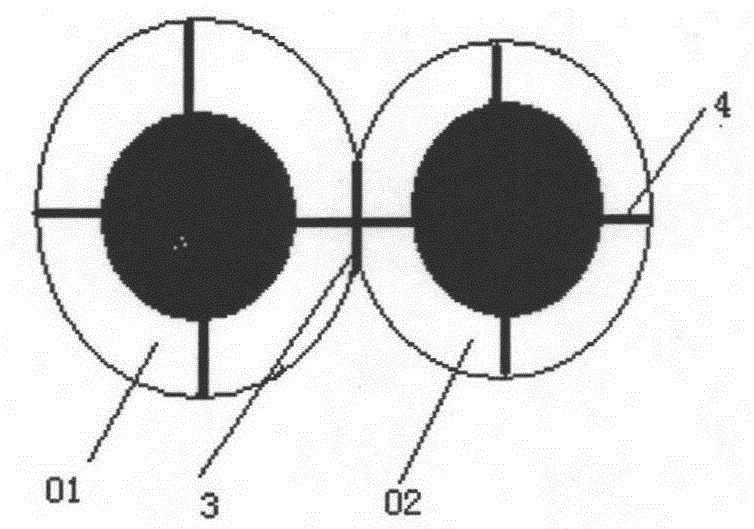

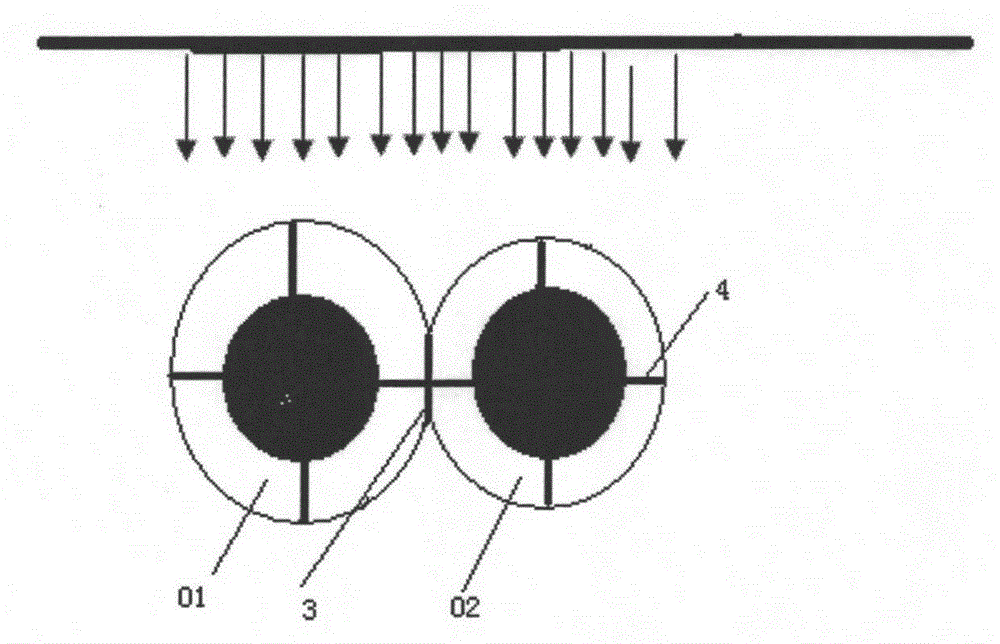

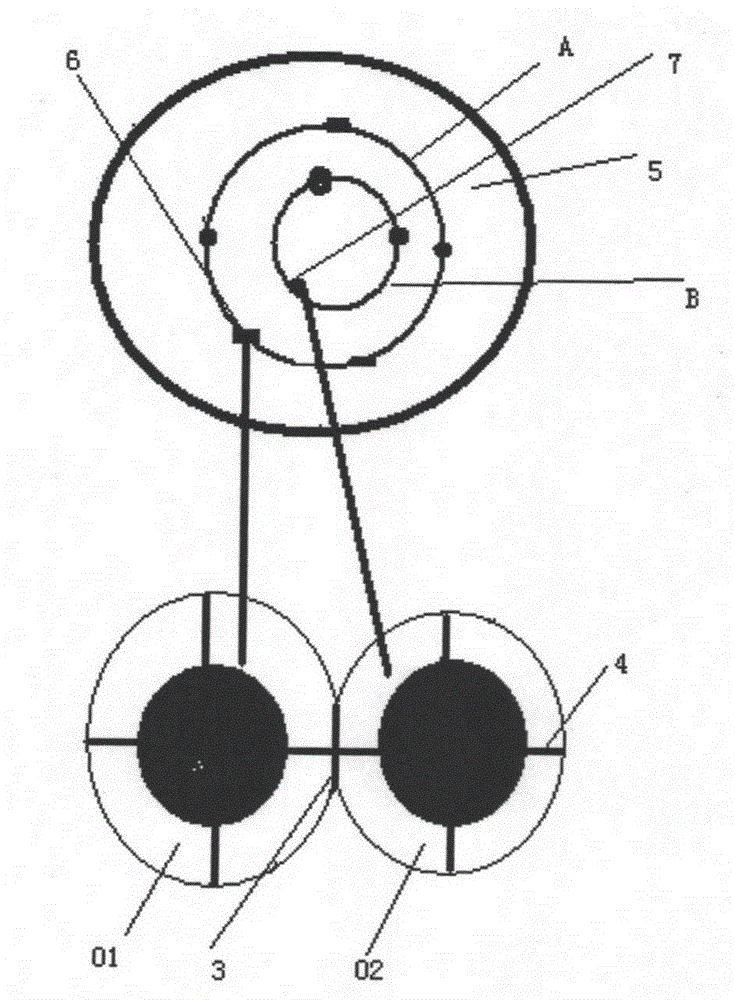

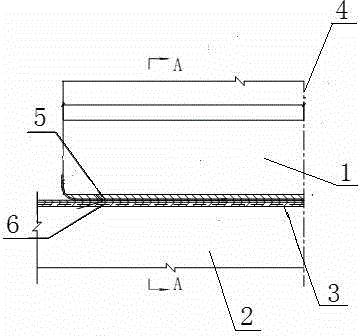

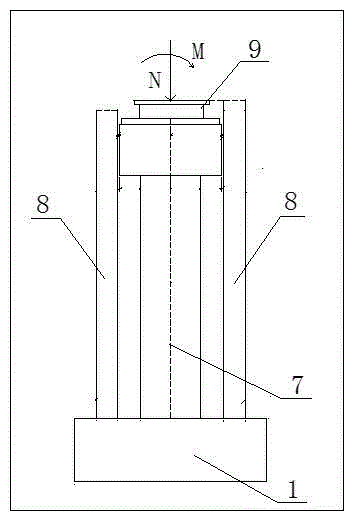

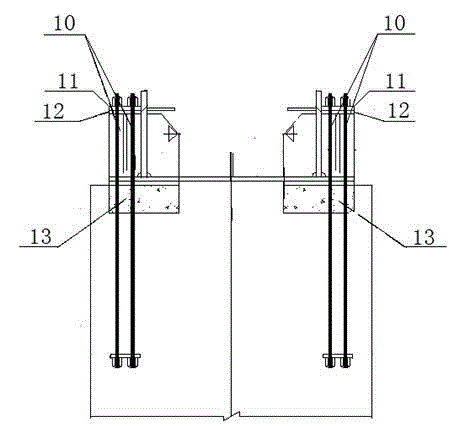

Special structural explosive for explosive cladding, explosive cladding method and explosive cladding device

ActiveCN103317222ASave explosivesReduce critical thicknessNon-electric welding apparatusShock waveExplosive cladding

The invention discloses special structural explosive for explosive cladding, an explosive cladding method and an explosive cladding device. The structural explosive comprises a filling plate, a plurality of cavities filled with the explosive are formed in the filling plate and distributed in a matrix. The special structural explosive for explosive cladding is formed by filling or injecting the explosive in the cavities of the filling plate. A layer of composite plate is mounted on each of two sides of the structural explosive, and the two composite plates are driven to move reversely after explosion to composite with two base plates in reserve directions. By the aid of an explosive filling method, explosive filling quality is guaranteed, critical thickness of stable explosive detonation is reduced, and energy utilization rate of explosive explosion is improved. The special structural explosive is convenient to use, and mechanized batch production can be realized. By the aid of the explosive cladding device, usage amount of the explosive is lowered, production cost is reduced, shock wave and noise pollution are reduced, and working environment of workers is improved.

Owner:UNIV OF SCI & TECH OF CHINA

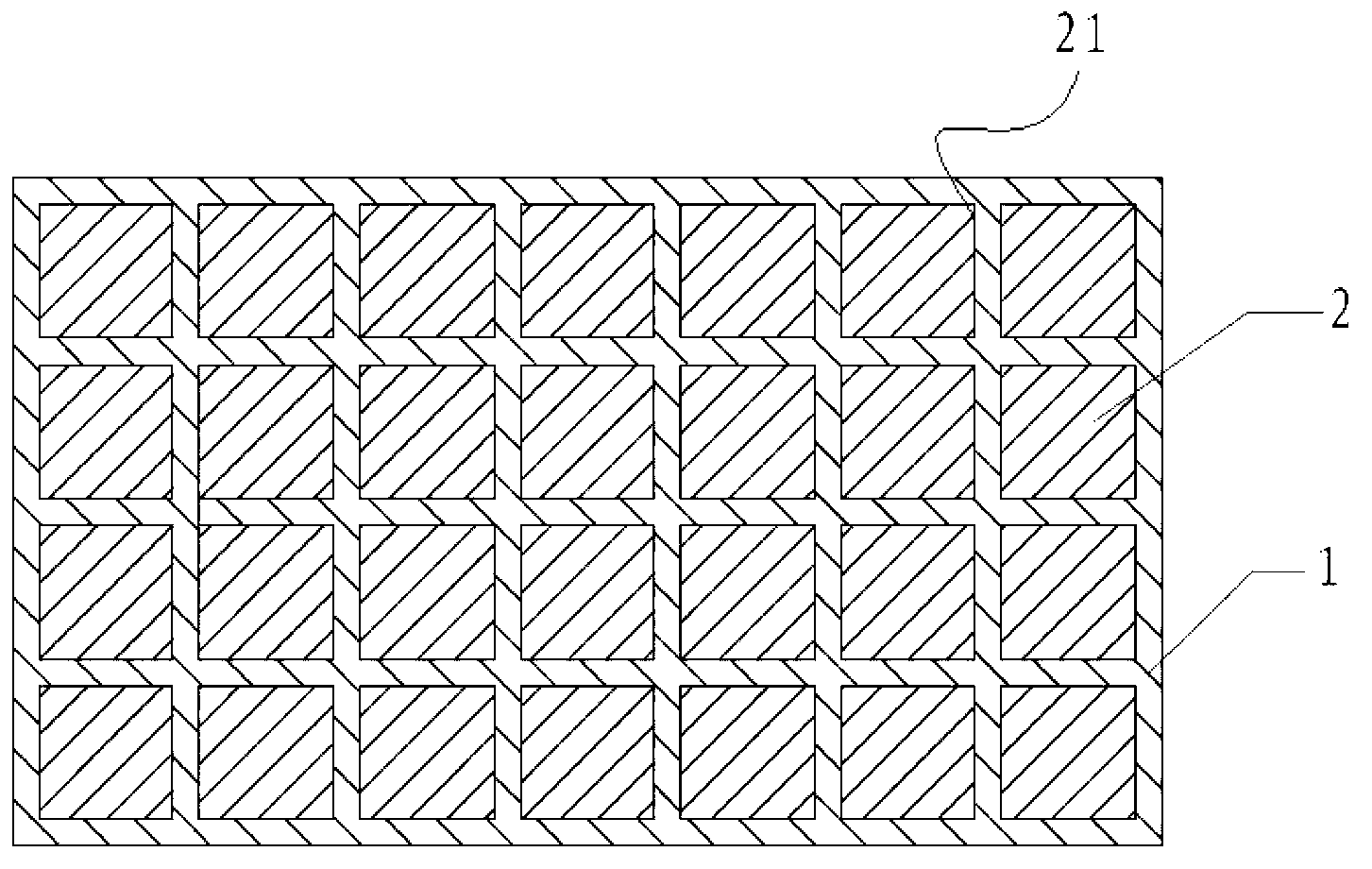

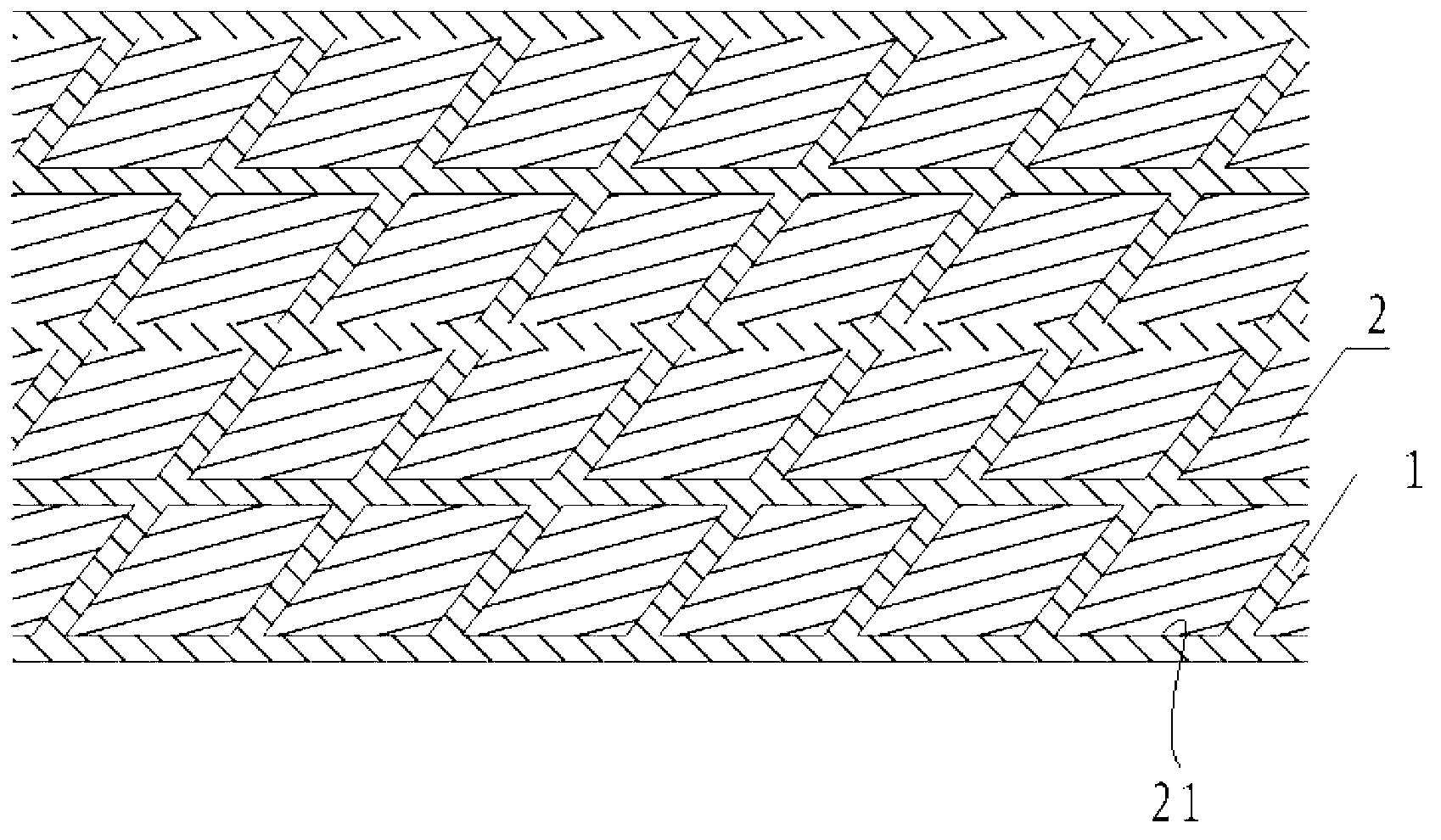

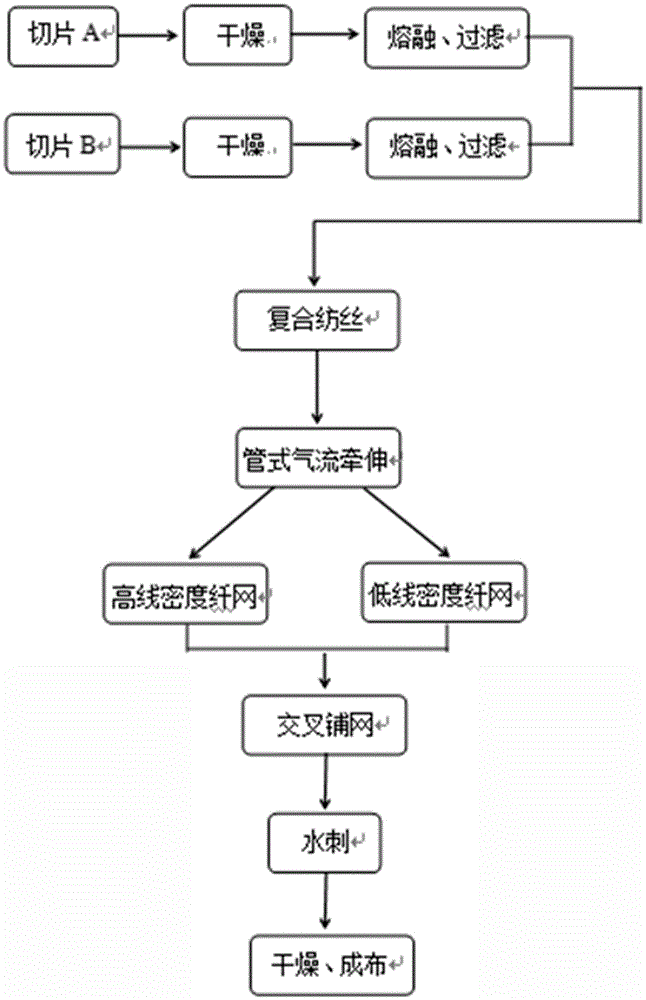

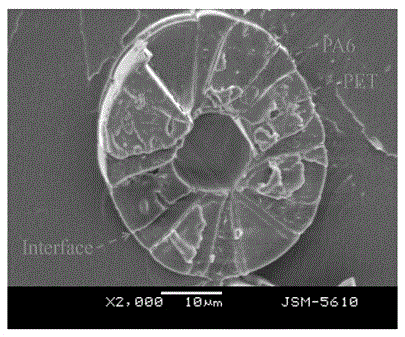

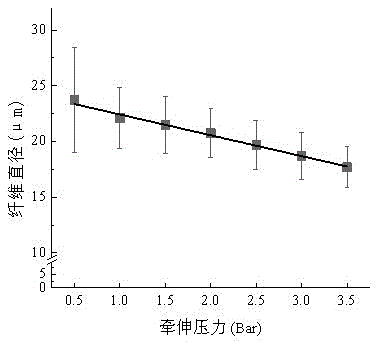

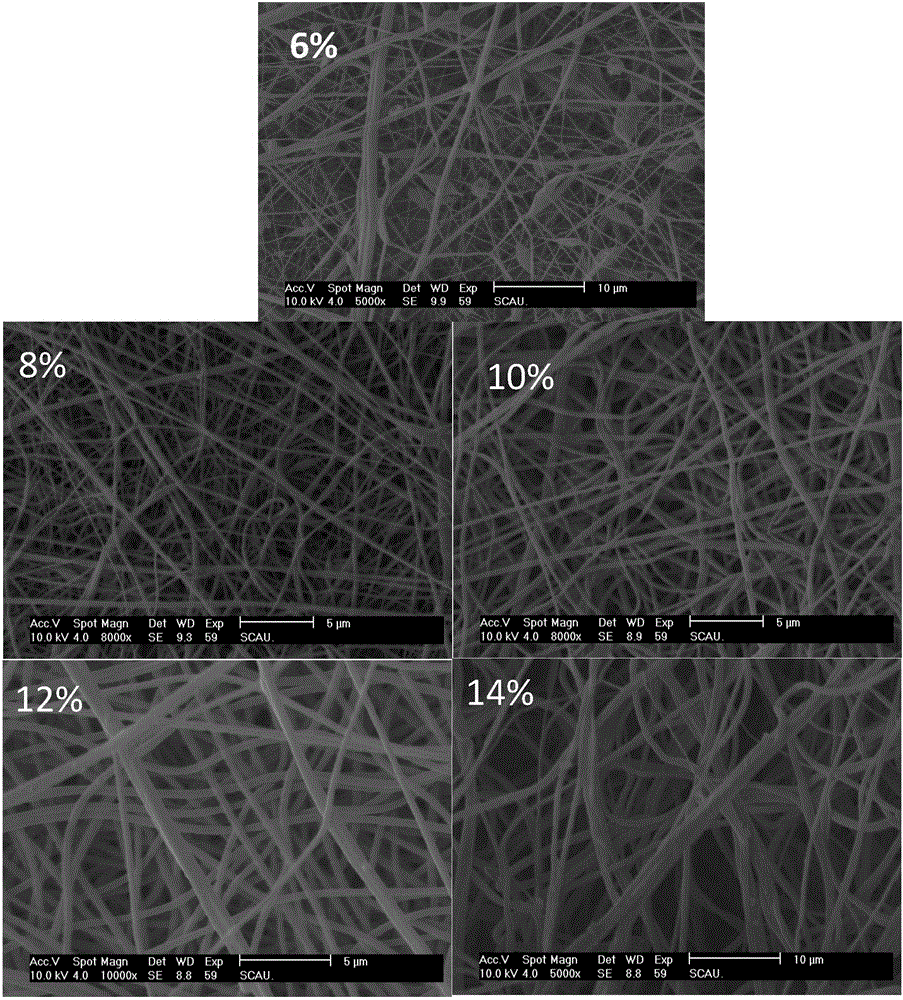

Manufacturing method of two-component superfine non-woven filtering material

InactiveCN105671791AImprove filtration efficiencyExpand application spaceNon-woven fabricsPolyesterSpinning

The invention discloses a manufacturing method of a two-component superfine non-woven filtering material. Any two of polyester (PET), polyamide (PA6) and polyethylene (PE) serve as raw materials for composite spinning, the pressure in the airflow drafting process is controlled, and two types of spun viscose webs which are greatly different in fiber line density are obtained; lapping is conducted on the two types of spun viscose webs, multiple cycles of spunlace splitting and solidification formation are conducted, and the superfine non-woven filtering material is finally formed. According to the two-component superfine non-woven filtering material manufactured through the method, due to the fact that two-component hollow orange-slice fibers are cracked and separated into superfine fibers under the spunlace pressure, a special three-dimensional stereo structure is formed after solidification, different fiber density gradients exist, and the manufacturing method has the advantages of being high in filtering efficiency, small in resistance, large in dust containing capacity and the like.

Owner:ZHEJIANG SCI-TECH UNIV

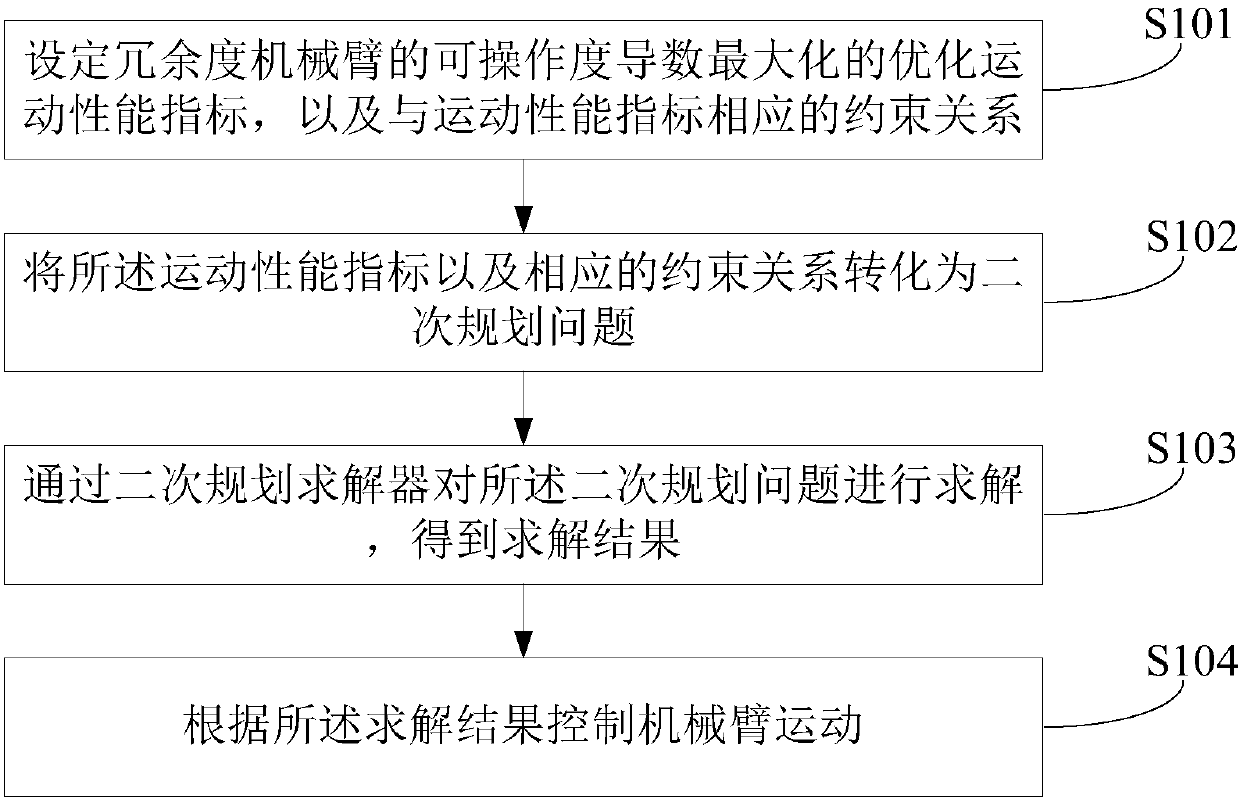

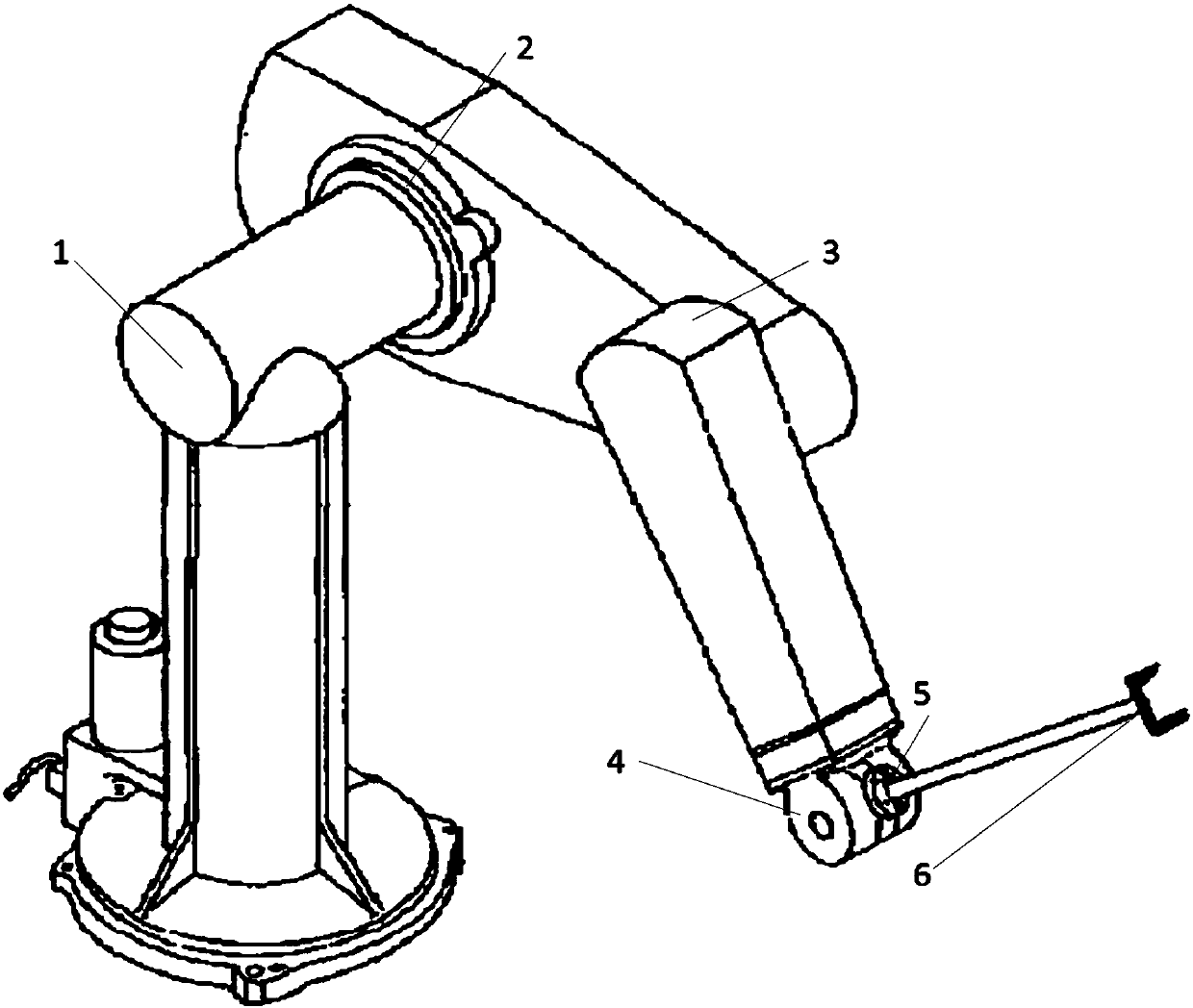

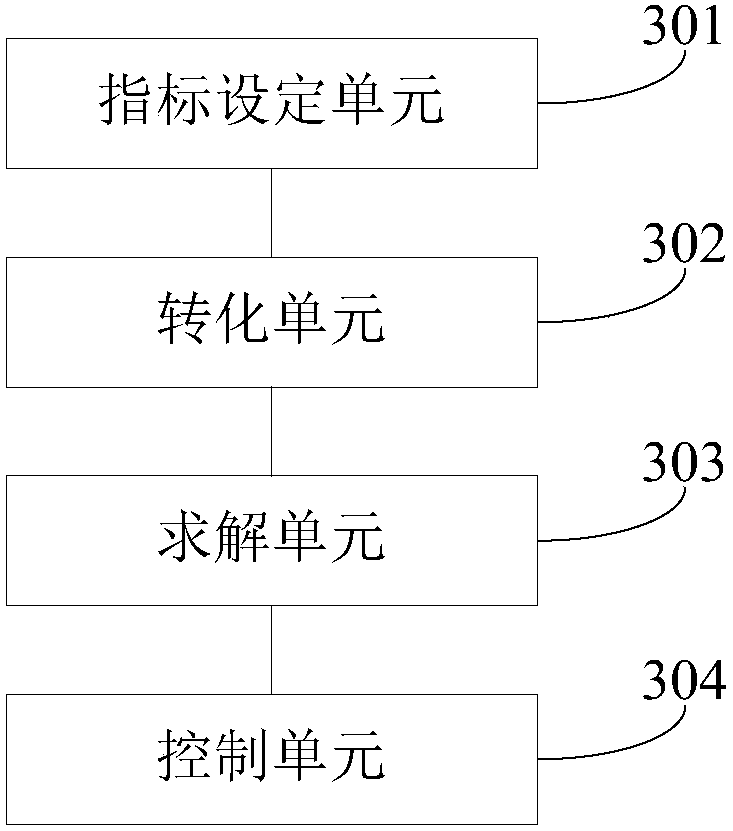

Operability optimization motion programming method and device for redundancy mechanical arm

ActiveCN108326844AAvoid physical constraintsExpand application spaceProgramme-controlled manipulatorOperabilityPerformance index

The invention discloses an operability optimization motion programming method for a redundancy mechanical arm. The operability optimization motion programming method comprises the steps of setting anoptimized motion performance index for maximizing the operability derivative of the redundancy mechanical arm and a constraint relation corresponding to the motion performance index; converting the motion performance index and the corresponding constraint relation into a quadratic programming problem; solving the quadratic programming problem through a quadratic programming solver, so that a solving result is obtained; and controlling the mechanical arm to move according to the solving result. By means of the method, various physical constraints of the redundancy mechanical arm can be effectively avoided, and the application space for conducting operability optimization motion programming on the redundancy mechanical arm is effectively expanded.

Owner:THE HONG KONG POLYTECHNIC UNIV SHENZHEN RES INST

Horizontal rotating construction method for steel truss beam bridge

ActiveCN104652290AReasonable structureClear forceTruss-type bridgeBridge erection/assemblyReinforced concreteConstruction engineering

The invention discloses a horizontal rotating construction method for a steel truss beam bridge. The horizontal rotating construction method comprises the following steps: constructing a reinforced concrete pile foundation, a cushion cap, a slideway, a main pier and a cap beam in a rotating system by using a conventional construction technology, and mounting a rotating spherical hinge as a core part for rotating; mounting an upper rotating plate on the slideway for construction; constructing the main pier and the cap beam; mounting a permanent support saddle of the main pier; preparing safety measures before rotating; determining a weight scheme before rotating; preparing a jack; rechecking before rotating; performing rotating construction operation. Compared with other processes, the horizontal rotating construction method for the steel truss beam bridge, provided by the invention, has the advantages of high construction speed and low construction cost. The construction of a lower structure can be synchronously finished in the manufacturing process of a steel beam in a factory; the hoisting operation of symmetrical cantilevers can be performed when a spliced site is hardened to reach the traveling strength of cranes like crawler crane; main expenses are rental expenses of the cranes, so the cost is reduced.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD +1

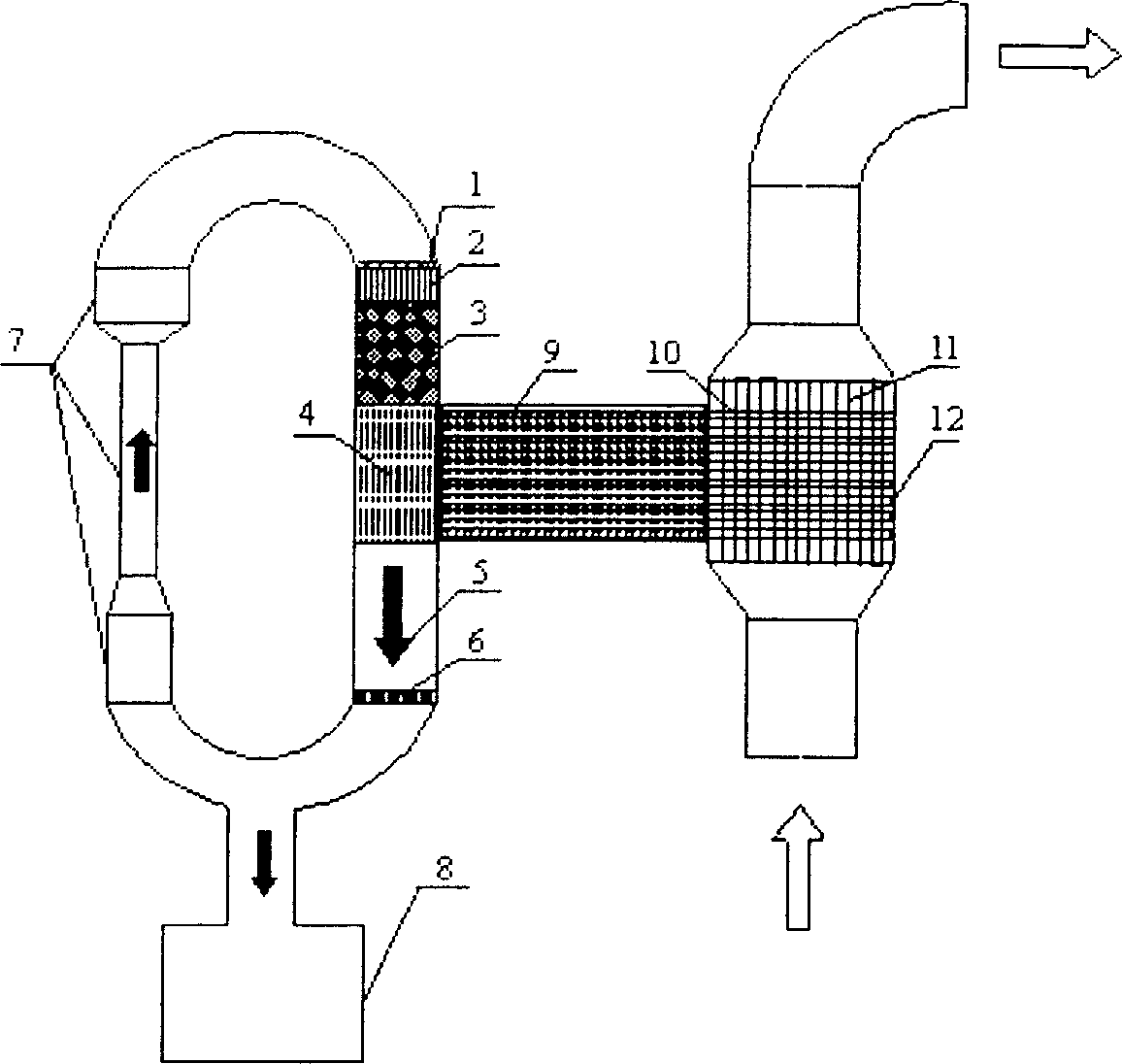

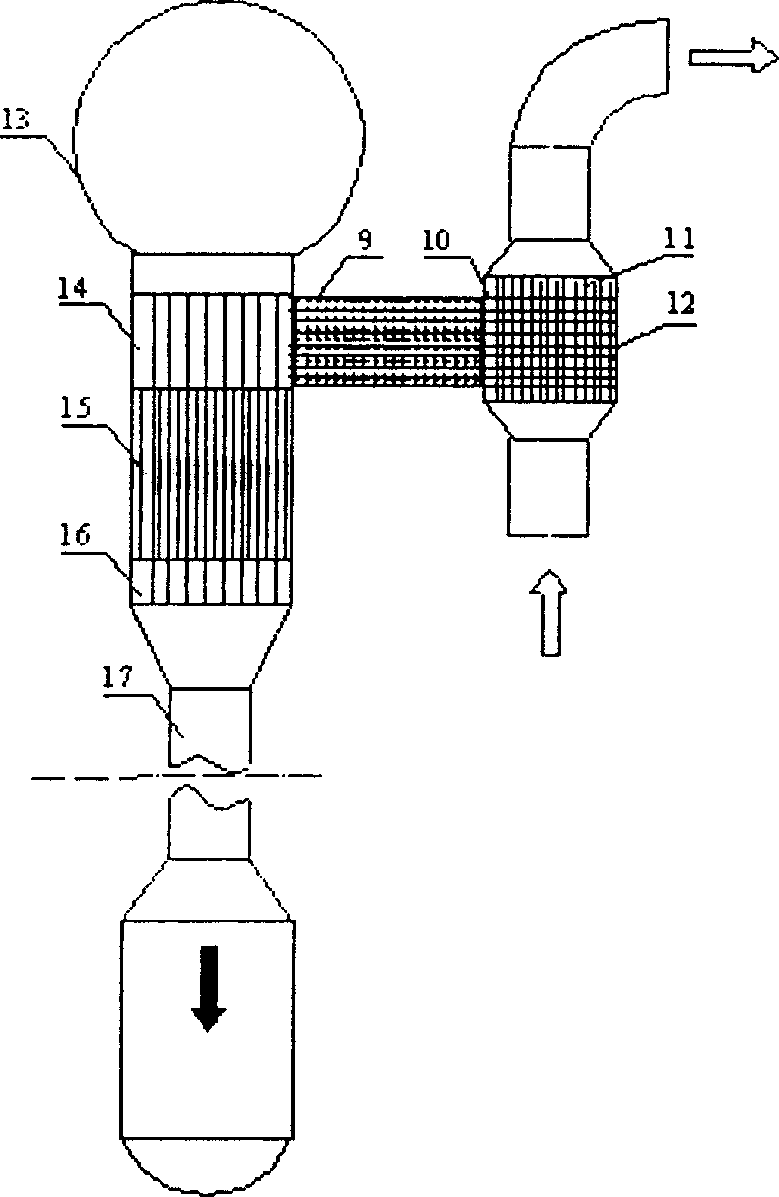

Heat-phonomotor driven by heat transfer through heat pipe

InactiveCN1916404AEliminate the constraints of small heating spacesExpand application spaceMachines/enginesMechanical power devicesThermal energyNuclear reactor

A thermo acoustic engine driven by heat conduction of heat tube consists of traveling-wave loop and resonant branch. It is featured as forming said traveling-wave loop by connecting in sequence of DC controller, master cooler, heat regenerator, heater, heat buffer tube, sub cooler and feedback loop; connecting heater of engine to heating source through heat tube.

Owner:ZHEJIANG UNIV

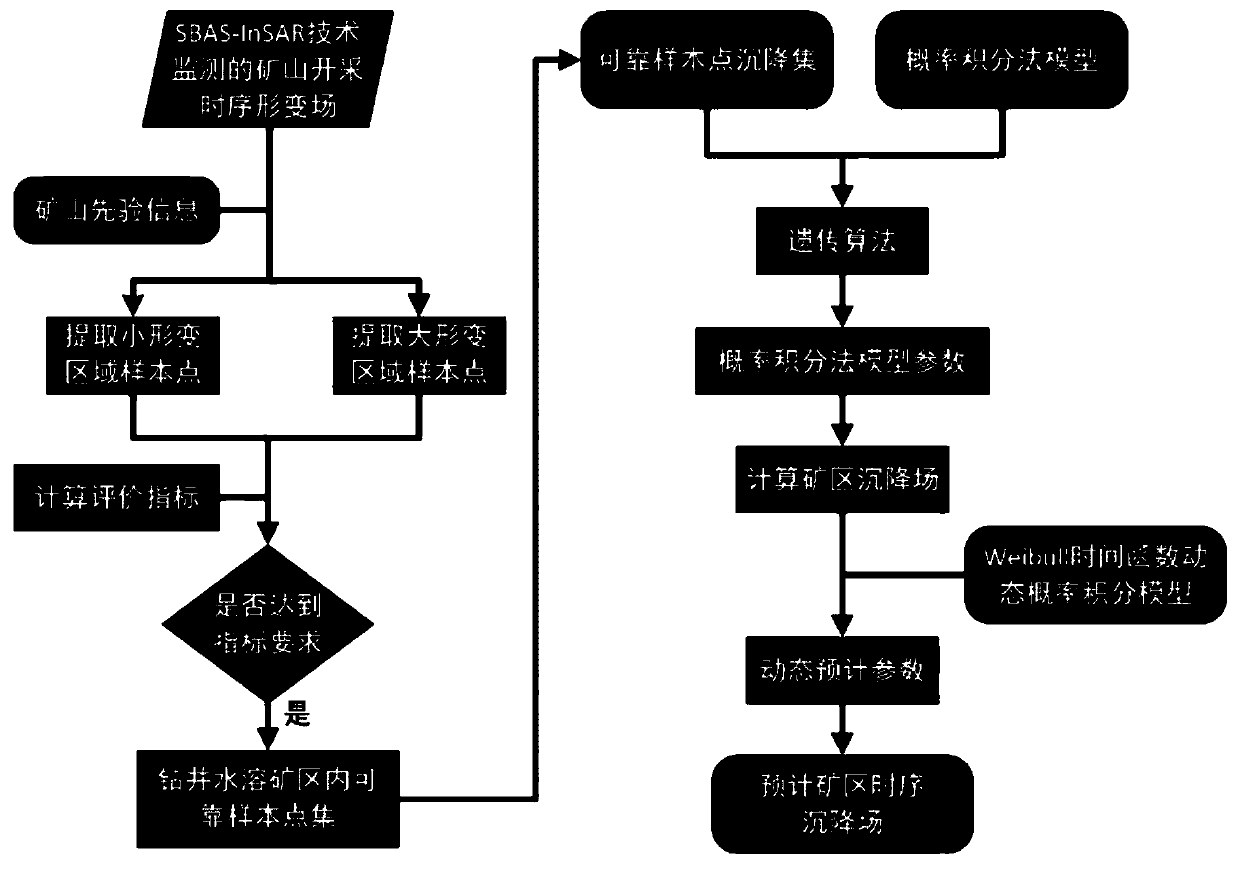

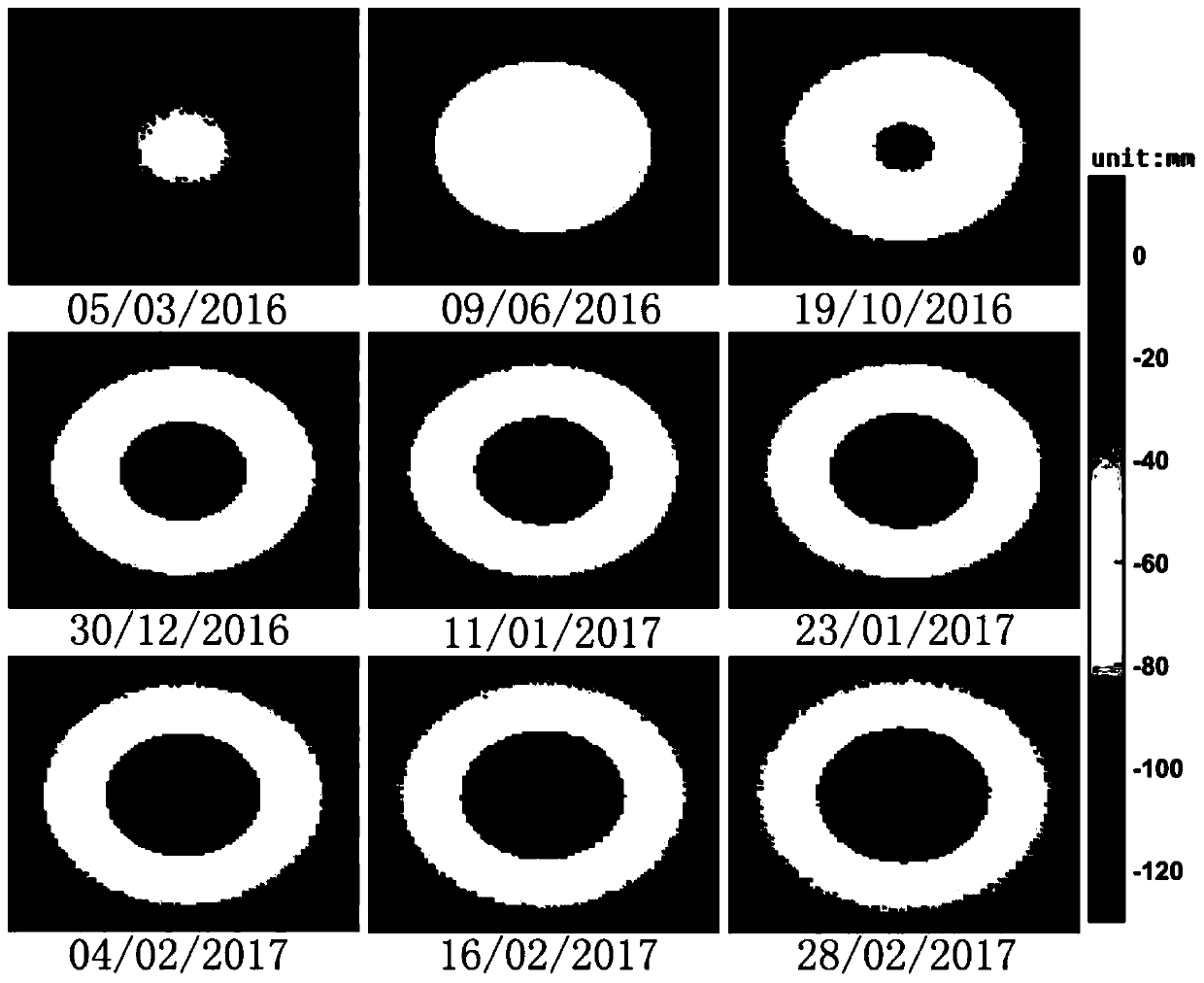

drilling water soluble salt mine mining subsidence InSAR prediction method

ActiveCN109918781AExpand application spaceOvercome limitationsGenetic modelsComplex mathematical operationsEcological environmentCoal

The invention provides a drilling water soluble salt mine mining subsidence InSAR prediction method, which comprises the following steps: inverting the surface time sequence settlement of a salt minearea by using a time sequence InSAR technology, and obtaining a radar line-of-sight direction time sequence deformation quantity; extracting reliable deformation sample points near the drilling layoutposition; constructing a traditional static probability integral method model; calculating the settling volume of the high-coherence point in the vertical direction; utilizing unknown parameters of agenetic algorithm estimation model to construct a Weibull time function dynamic probability integral model, substituting all parameter result values obtained through calculation into the Weibull timefunction dynamic probability integral model, the settlement amount of all point positions at any time is calculated, and predicting a mining area time sequence deformation field. The defect that a traditional probability integral method model is mostly applied to a coal mine area and limited to a static sinking basin to mine subsidence prediction is overcome, the application space of the InSAR technology in mining area subsidence prediction is widened, and the ecological environment and production safety of the drilling water soluble rock salt mine are guaranteed.

Owner:湖南天湘和信息科技有限公司

Representing and processing method for semantic data of semantic-oriented web service program design

InactiveCN101526898ALess development workPromote resultsSpecific program execution arrangementsSpecial data processing applicationsXML schemaSemantic web services

The invention discloses a representing and processing method for semantic data of semantic-oriented Web service program design, which comprises the following steps of: (1) formulating XML Schema mode standard of semantic data types and semantic variables; (2) defining semantic data types on the basis of basic body; (3) declaring semantic variables; (4) using the semantic variables; and (5) processing the semantic data. According to the characteristics of semantic program design of semantic-oriented Web service, the invention formulates the semantic data representation standardizing and processing method for semantic-oriented Web service, can be convenient to carry out actual development of semantic software for developers conveniently. The use of the semantic data representation standard can assist to develop a semantic Web application system, can precisely debug various semantic Web program and process the semantic data related to service process and realize the automation of semantic information processing.

Owner:WUHAN UNIV

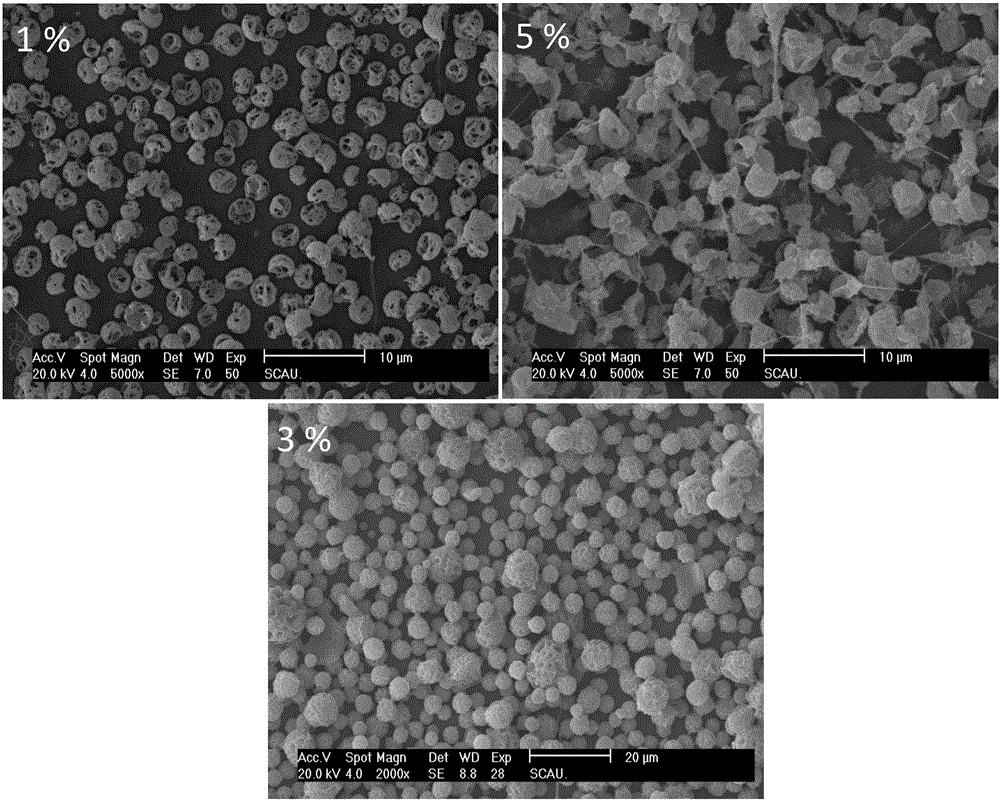

Static spraying composite film and preparation method and application thereof

ActiveCN105908363AAvoid breedingAchieve bi-directional performanceElectro-spinningAbsorbent padsFiberComposite film

The invention discloses a static spraying composite film and a preparation method and application thereof. A PVDF nanofiber thin film is spun on a roller receiver through electrostatic spinning to serve as a supporting material, then a layer of Cur-PLA microspheres is sprayed through an electrostatic spraying method, and a double-layer film is obtained; an Enro-PLA nanofiber film is spun on the double-layer film through an electrostatic spinning method, drying is carried out, and the electrostatic spraying composite film is obtained. Medicine is carried on polylactic acid fibers and the microspheres, so that the biological activity and antibacterial property of the electrospinning film are achieved; compared with like products, a hydrophilic face formed by the PLA microspheres and the PLA fibers is not single in medicine release capacity, wider in antibacterial performance and larger in contact area with the skin surface. PVDF is adopted as an outer layer for isolating invasion of water vapor and bacteria. The preparation method is simple, the production cost is low, large-scale production can be achieved, application and popularization are convenient, and the final product can completely meet various clinical needs.

Owner:SOUTH CHINA AGRI UNIV

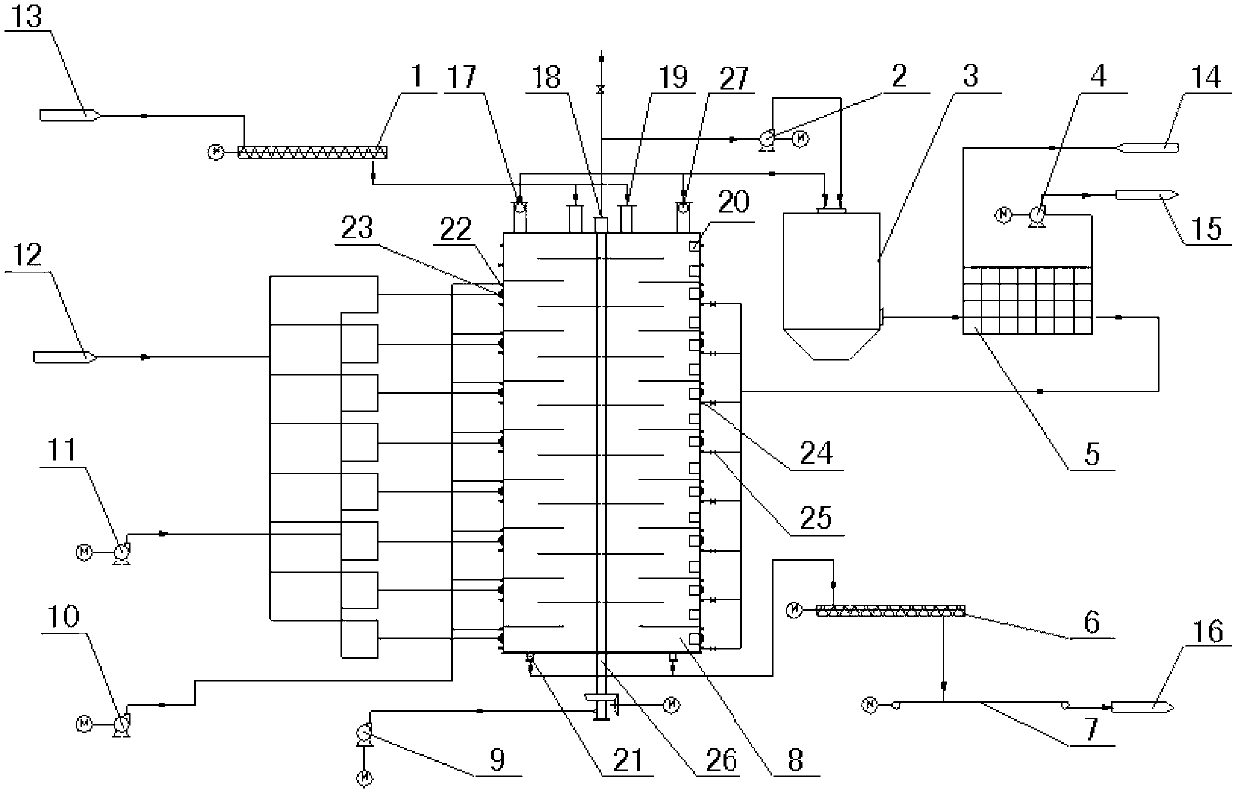

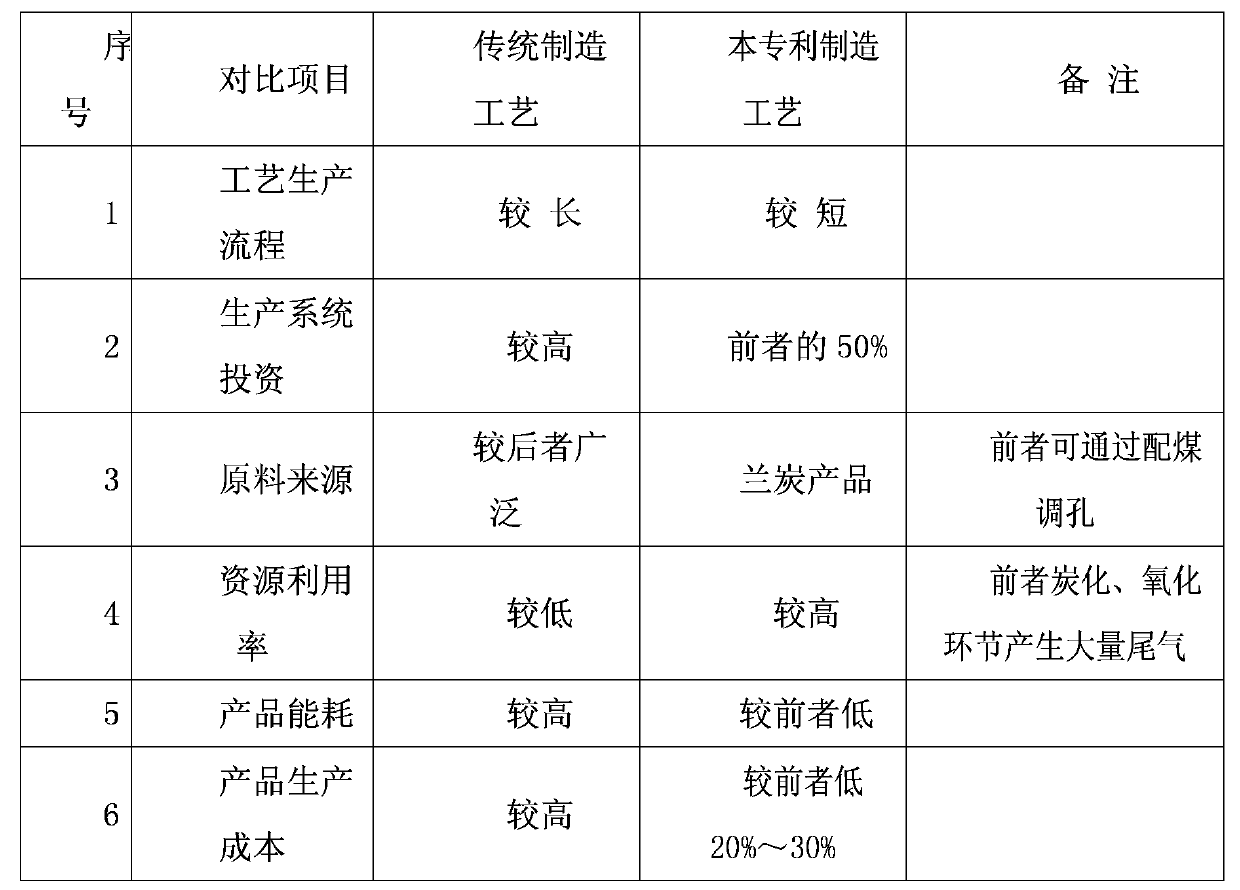

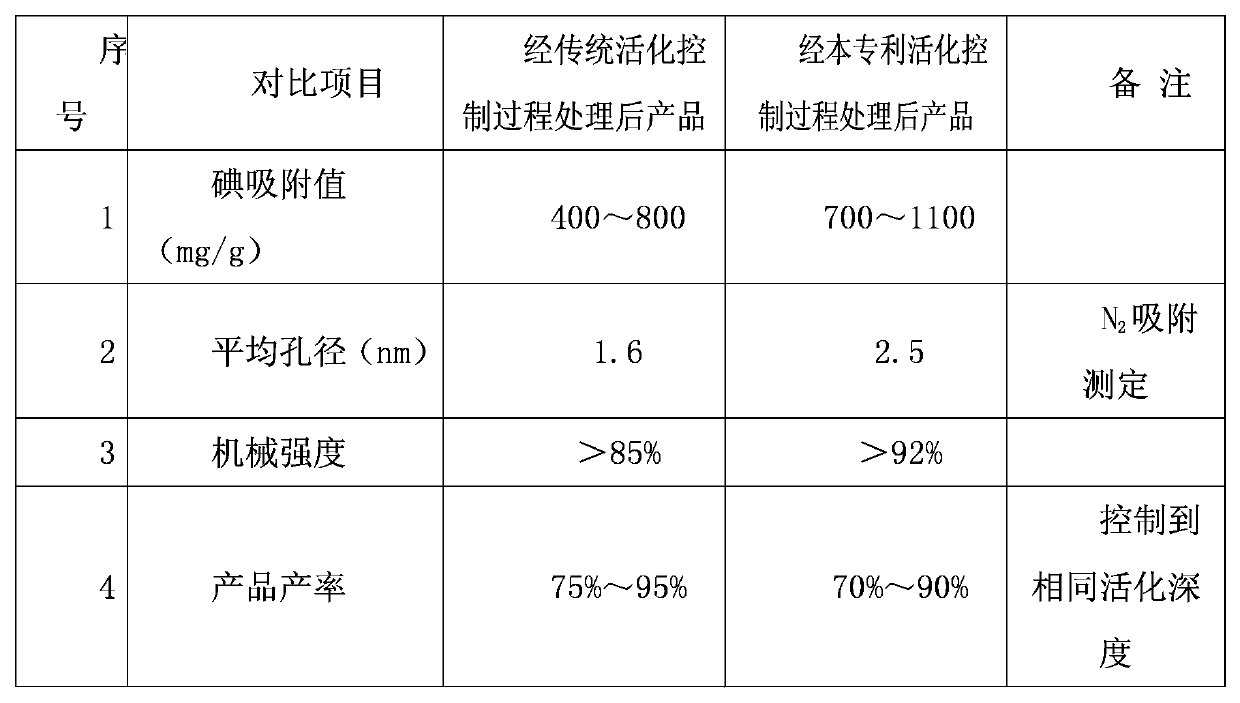

Method for preparing activated carbon from semi-coke and device used in same

ActiveCN103130222ABig market demandTo satisfy the market's needsCarbon compoundsActivated carbonCoke

The invention discloses a method for preparing activated carbon from semi-coke and a device used in the method. The method comprises the following steps of: taking semi-coke of which the volatile matter is greater than 5% and the thermal stability is greater than 70%, screening and feeding the semi-coke of which the granularity is 5-20mm into a rake-type activating furnace (8) to be subjected to activation treatment to generate the activated carbon; discharging the activated carbon from the rake-type activating furnace (8), cooling at a helix cooling machine (6) and conveying through a belt conveyer (7); and finally entering an activated carbon packaging period to be selected and packaged. According to the method, the structural characteristics of organic matter components and micro-pores of a semi-coke product are sufficiently utilized, and with the combination of the operation control principle of the domestic activation furnace, a novel process control method is innovated, and the activation process of the rake-type furnace is applied to the production process of the semi-coke-made activated carbon, so that the activation process control precision of a product is greatly improved, activated carbon products of higher quality are produced, the additional value of a semi-coke product is greatly increased, the application space of the semi-coke is widened, and the market requirements of the activated carbon are met.

Owner:HUADIAN HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com