High-heat-conductivity inorganic phase-change energy storage material

An energy storage material and inorganic phase change technology, applied in the field of energy storage materials, can solve the problems of reducing cycle life, restricting practical application, phase separation, etc., to improve thermal conductivity, reduce free space for free movement, and solve the effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

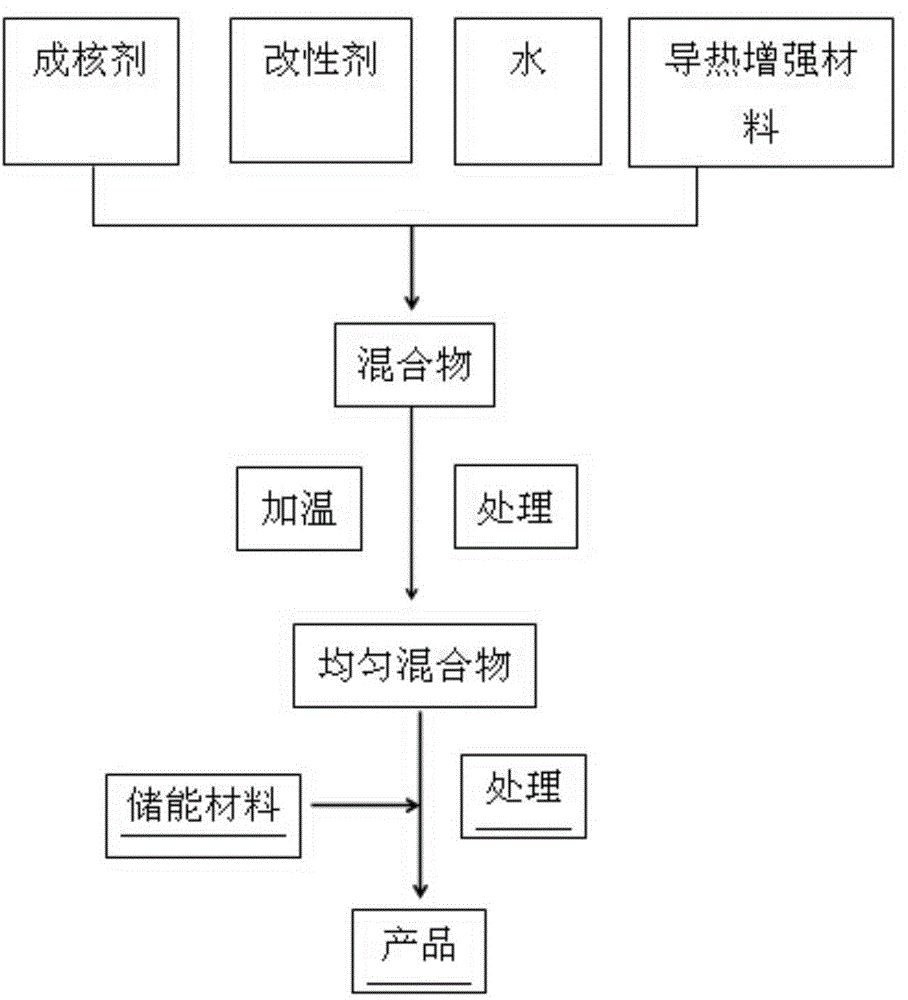

Method used

Image

Examples

Embodiment 1

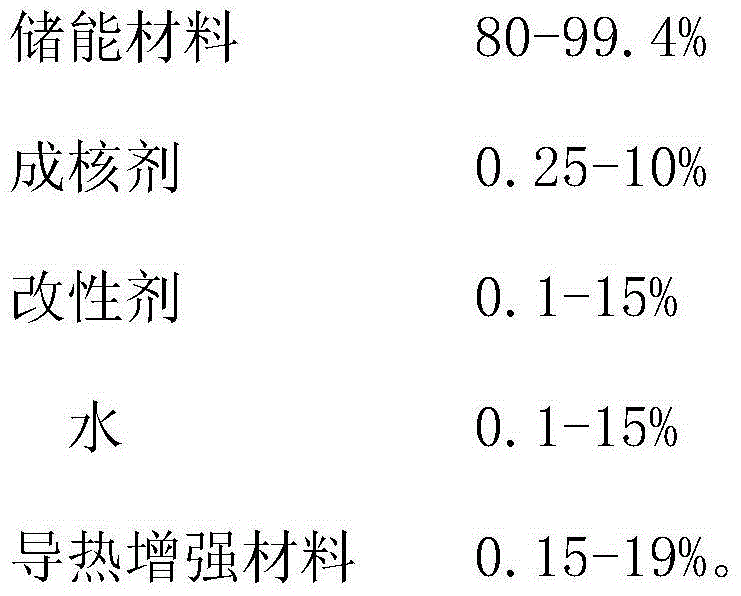

[0036] Mix 0.25Kg of barium carbonate, 0.1Kg of sodium polyacrylate emulsion and 0.15Kg of water, and then heat it to above 60°C to obtain a well-mixed mixture; then add 98.5Kg of barium hydroxide octahydrate to the mixture, Add 1Kg of expanded graphite, heat the mixture to about 90°C to fully melt the barium hydroxide octahydrate, and stir vigorously until the mixture of the four materials is uniform after melting, until the mixture is not delaminated, that is, the inorganic phase change storage tank with high thermal conductivity is obtained. Energy Materials Product A1.

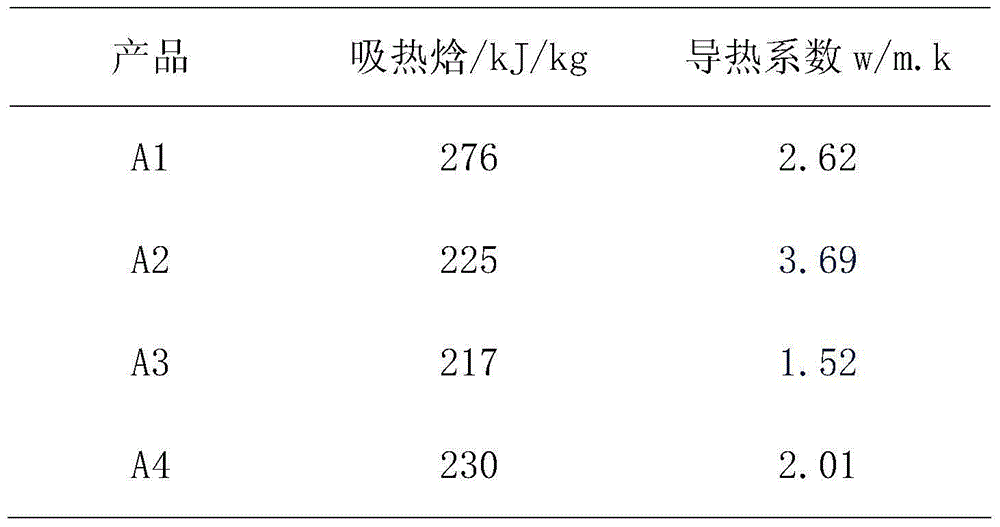

[0037] The above-obtained product A1 was subjected to DSC analysis, and the results are shown in Table 1.

Embodiment 2

[0039] Mix 3.0Kg of calcium carbonate, 2.0Kg of instant transparent thickening powder and 3.5Kg of water, and then heat it to above 60°C to obtain a well-mixed mixture; then add 90Kg of crystalline sodium acetate and 1.5kg copper powder (100 mesh), heat the mixture to about 80°C to fully melt the crystalline sodium acetate, after melting, stir vigorously until the mixture of the four materials is uniform, until the mixture has no delamination phenomenon, that is, the inorganic phase transition with high thermal conductivity is obtained Energy storage material product A2.

[0040] The above-obtained product A2 was subjected to DSC analysis, and the results are shown in Table 1.

Embodiment 3

[0042] Mix 6Kg of strontium carbonate (nucleating agent), 2.0Kg of sodium polyacrylate emulsion and 3.0Kg of water thoroughly, and then heat it to above 60°C to obtain a well-mixed mixture; then add 87Kg of decahydrate sulfuric acid to the mixture Sodium and 2kg of carbon powder, heat the mixture to about 80 ℃, so that the sodium sulfate decahydrate is fully melted, and after melting, vigorously stir until the mixture of the four materials is uniform, until the mixture is not delaminated, that is, the inorganic phase change storage tank with high thermal conductivity is obtained. Energy Materials Products A3.

[0043] The above-obtained product A3 was subjected to DSC analysis, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com