Patents

Literature

1367 results about "Phase change temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase Changes Between States of Matter. The point at which matter subjected to a particular temperature under conditions of constant pressure begins to change its phase is called the phase change threshold. At this temperature, every bit of the substance exposed to the heat will change its state.

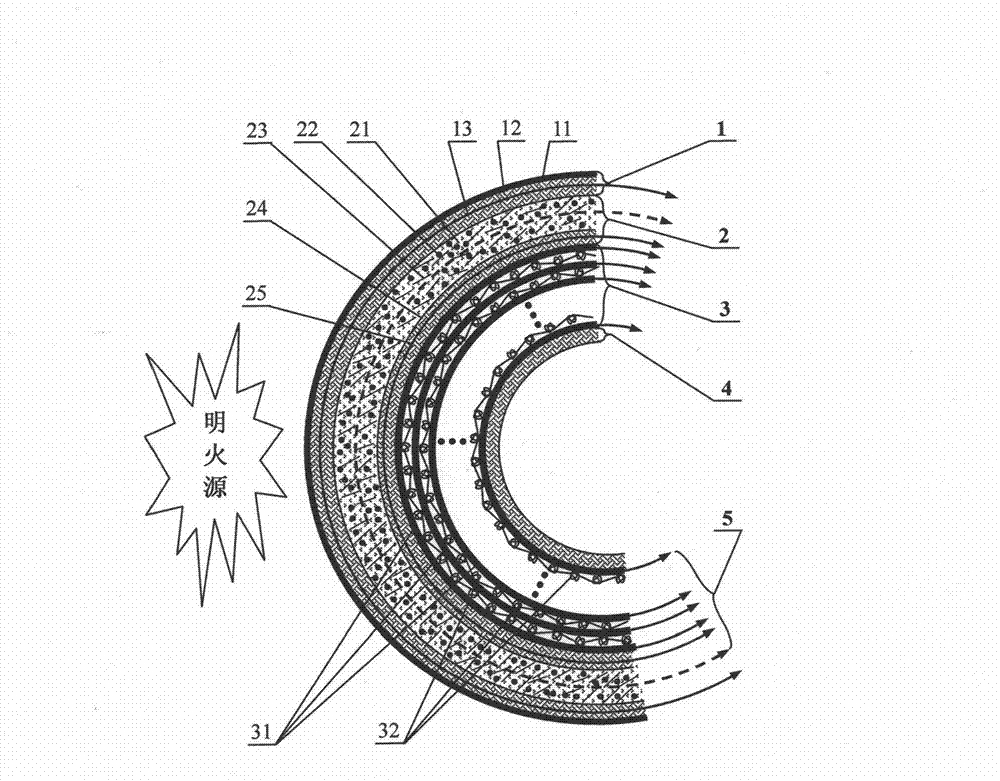

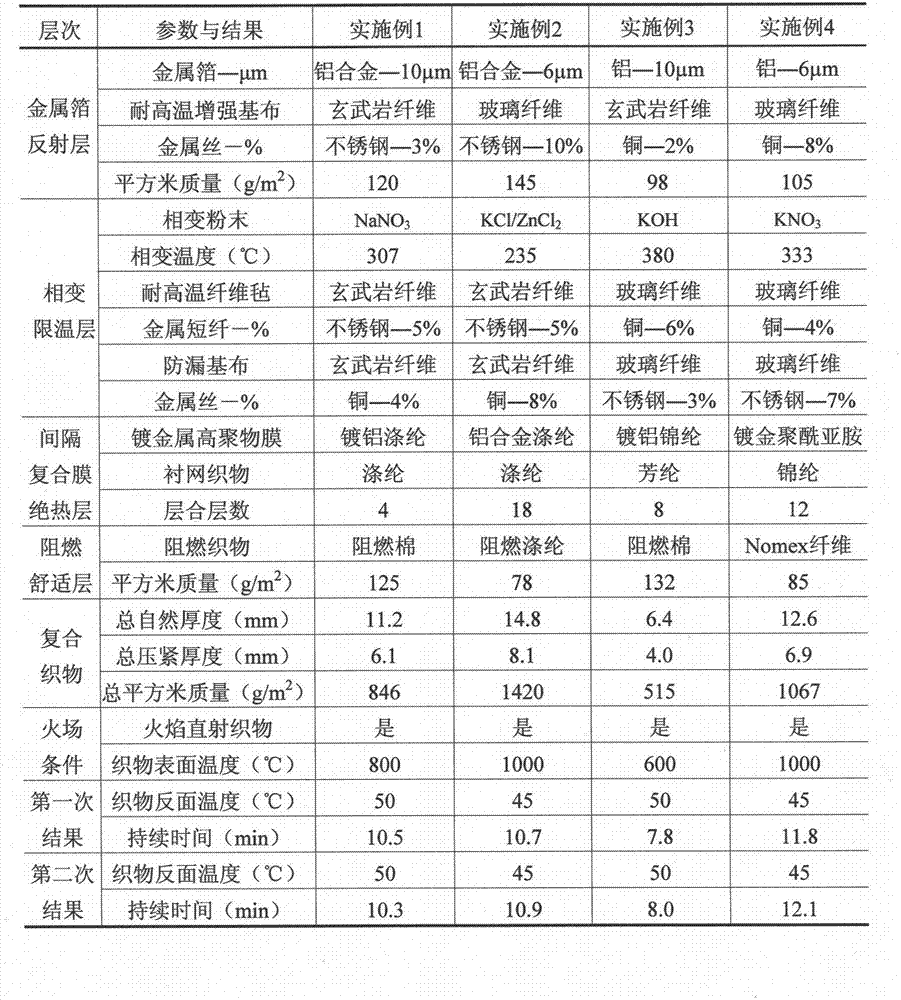

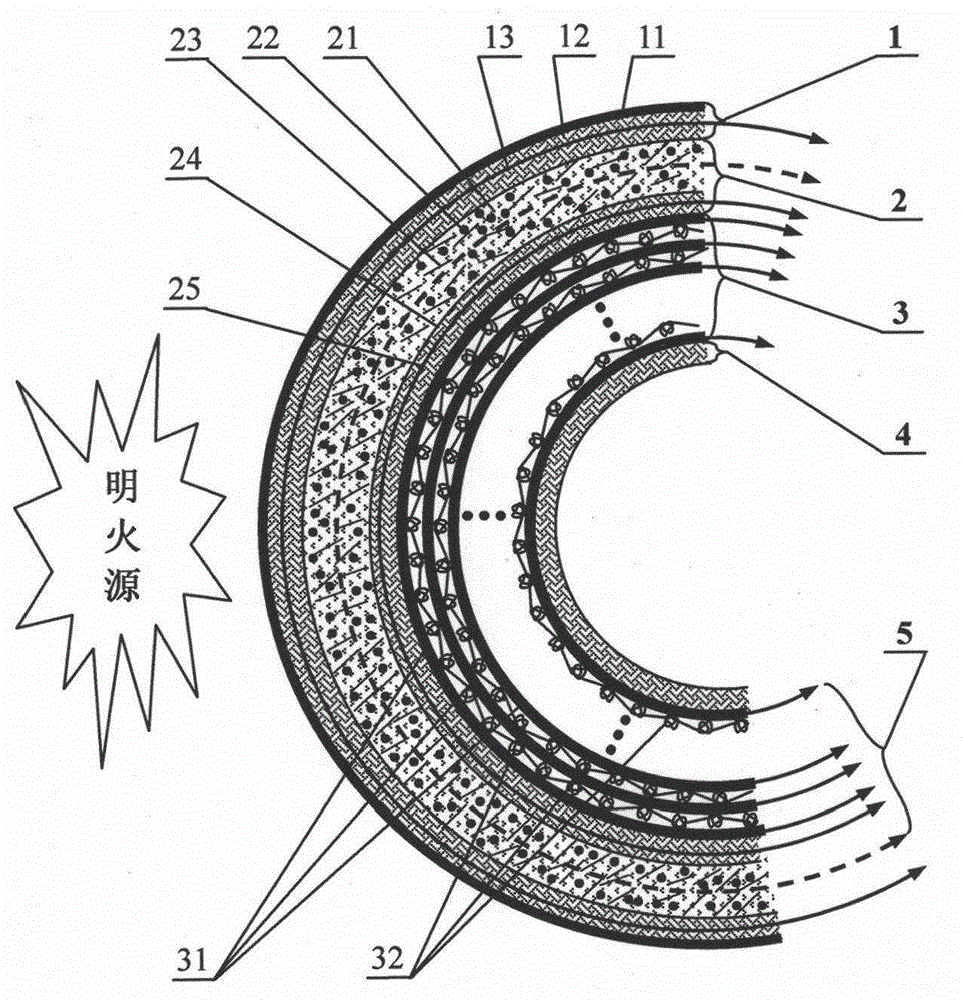

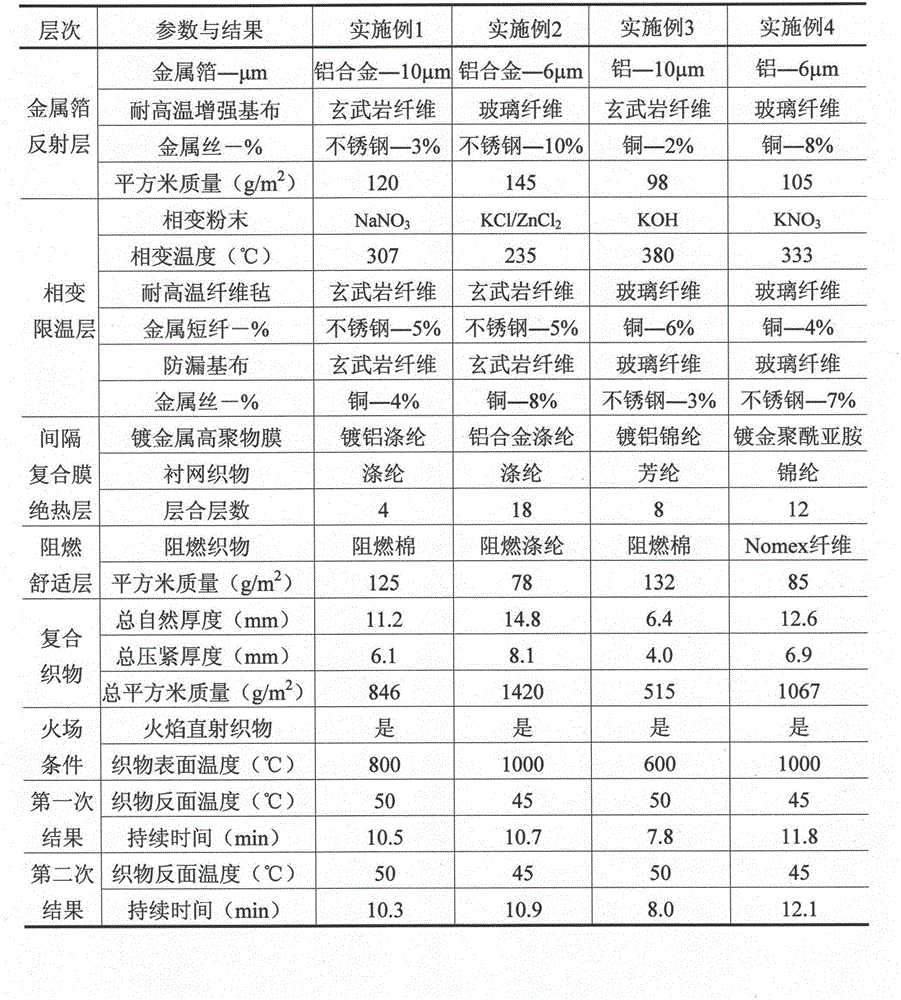

Multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric, preparation method and application

ActiveCN102783741AImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

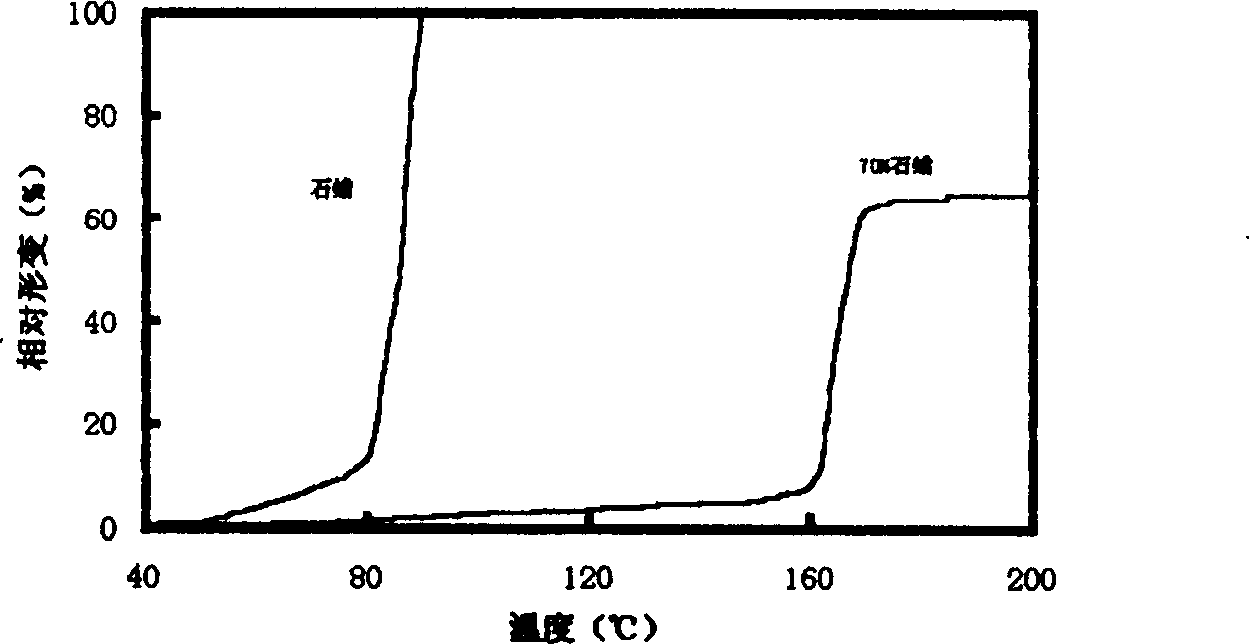

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

Fire-proof and heat-insulating composite fabric with multi-stage expansion and heat dissipation, preparation method and application

ActiveCN102783741BImprove permeabilityPromote absorptionLaminationLamination apparatusInsulation layerMetal foil

The invention relates to a preparation method and an application of multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric. The multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is formed by successively arranging and laminating a metal foil reflection layer, a phase change temperature limitation layer, an interval composite membrane heat-insulation layer and a flame-retardant comfortable layer, wherein the metal foil reflection layer has high reflectivity and an enhanced heat-dissipation function; the phase change temperature limitation layer has functions of high energy consumption absorption and evenly-distributed heat conduction; the interval composite membrane heat-insulation layer has the functions of reflection insulation and even distribution of heat; and the flame-retardant comfortable layer has the functions of low-contact heat conduction, heat insulation and comfort. When the front side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric is under the action of open fire and strong heat flow environment, the back side of the multistage-spreading heat-dissipation fire-proof heat-insulation composite fabric can be kept below 50DEG C which is near the safe temperature state of the human skin, and the integral structural form and the mechanical property are stable. The natural thickness of the composite fabric is 5-15mm, the compression thickness of the composite fabric is 3-8mm, and the square meter quality of the composite fabric is 400-1500g / m<2>. The composite fabric is fire-proof heat-insulation material which is totally sealed, stuck and sewn and can be used for individual protection and environment heat insulation in special high-temperature occasions, such as fire control, military, exploration, safe escape and industry and the like.

Owner:DONGHUA UNIV

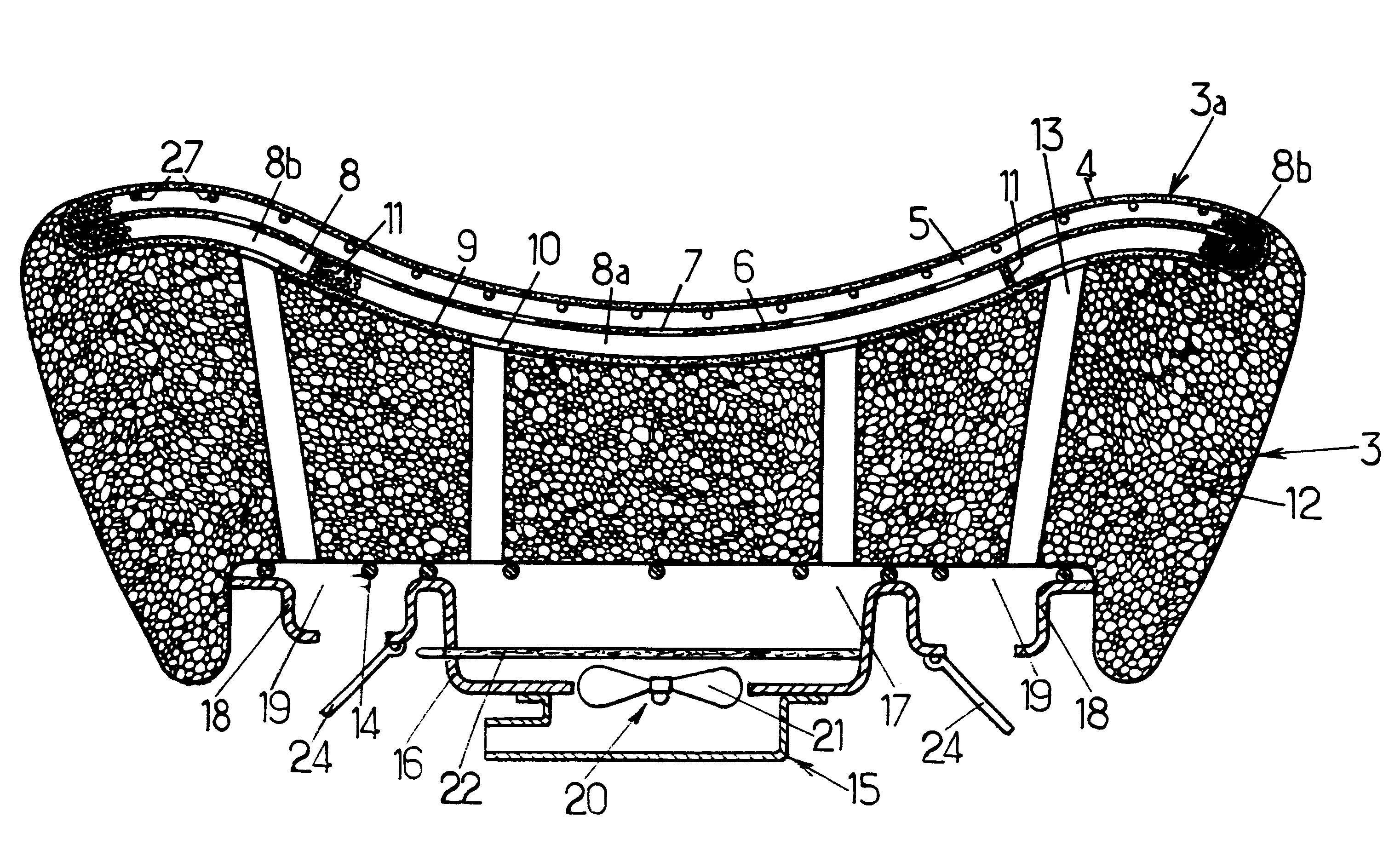

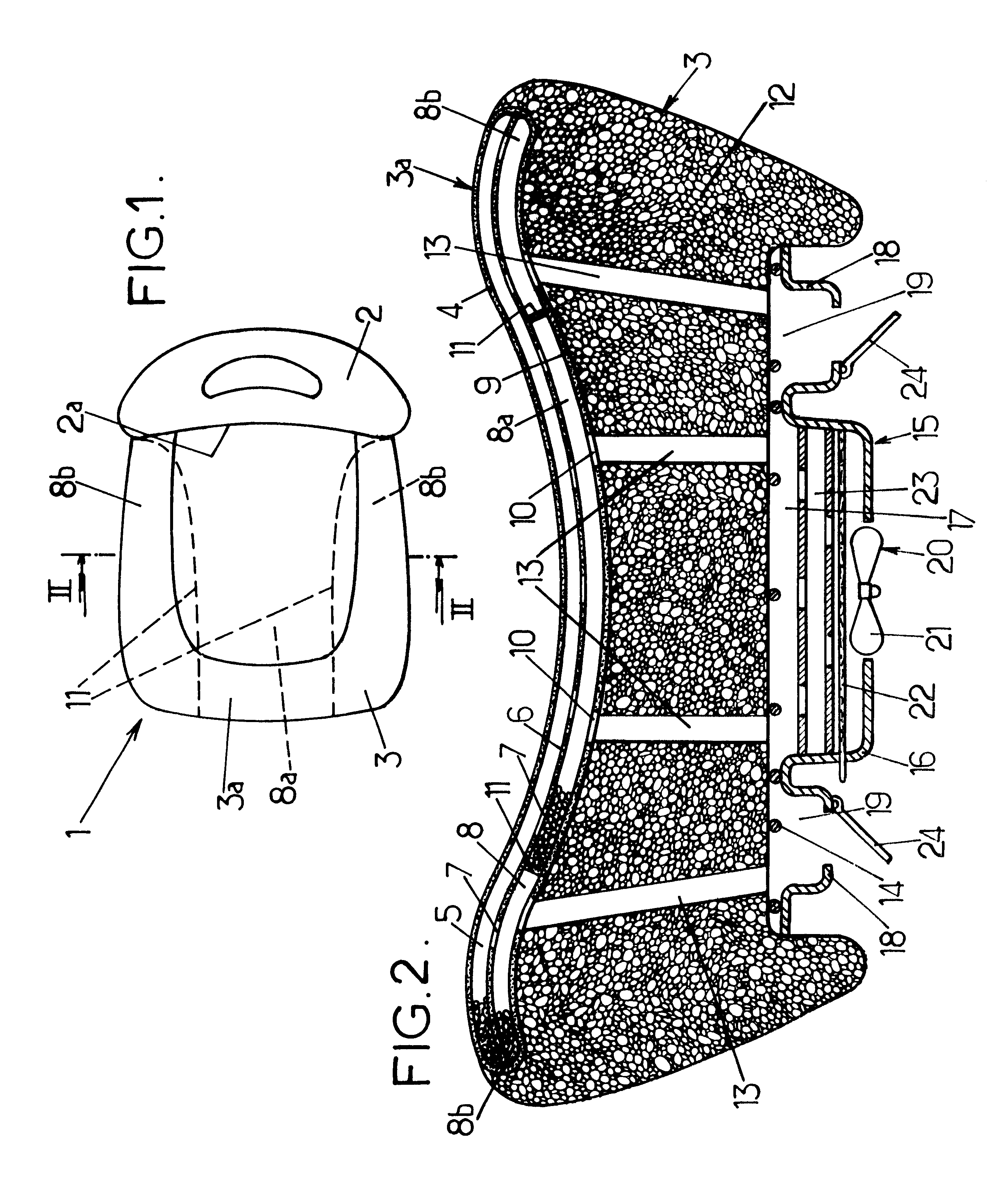

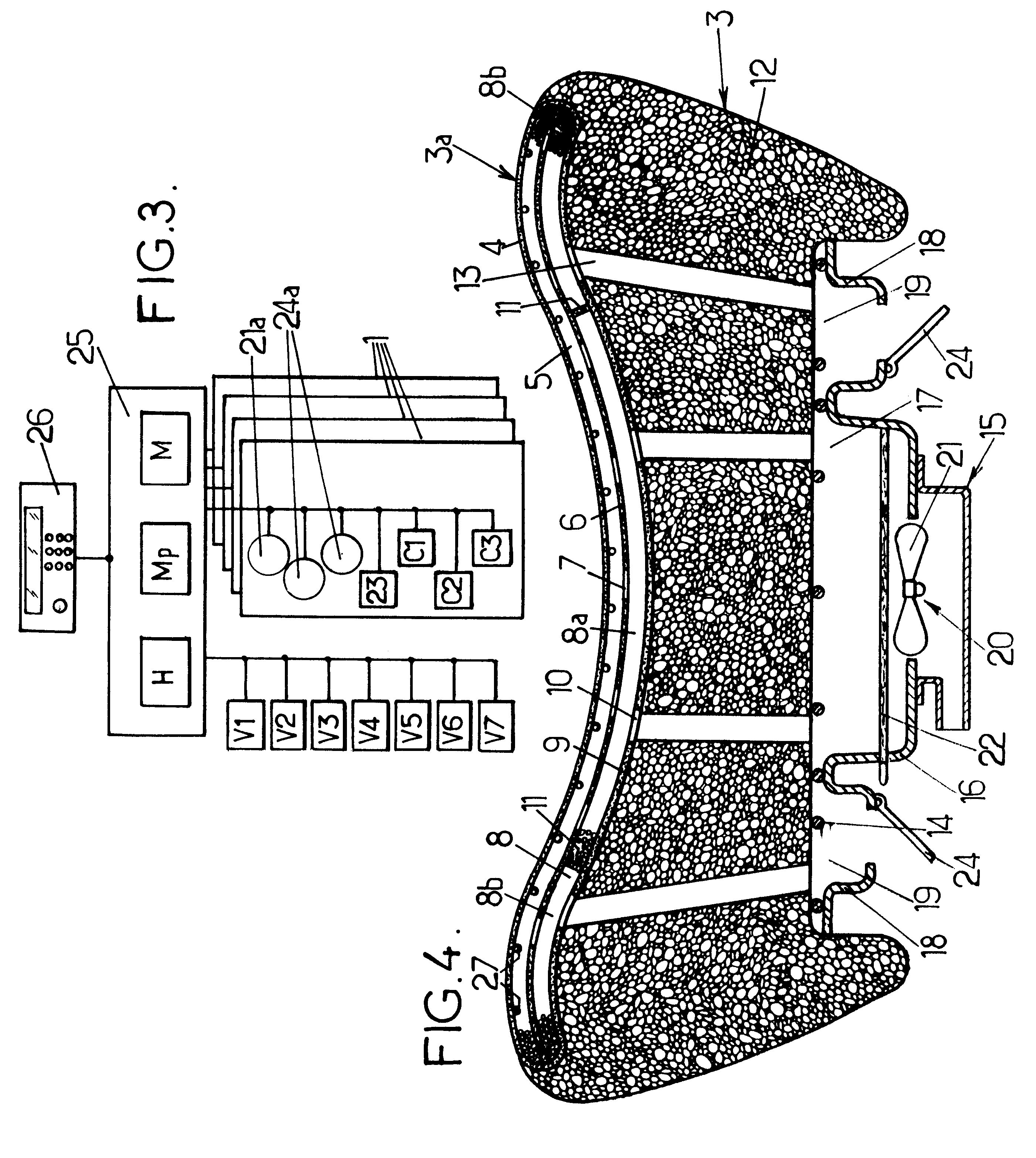

Method and system of regulating heat in a vehicle seat

In order to ensure that a vehicle seat, having a supporting face and incorporating microcapsules of phase-change material having a phase transition temperature between 15 and 37° C., is comfortable to use in terms of temperature, the support face is heated or cooled before the seat is used so that the phase-change material is at its transition temperature when a user subsequently sits on the seat.

Owner:BERTRAND FAURE EQUIP SA (FR)

Package system and method

InactiveUS6875486B2Effective maintenanceIntegrity guaranteedEnvelopes/bags making machineryHeat storage plantsRadiant barrierElectrical and Electronics engineering

Owner:MILLER DRAYTON +1

Novel package system and method

InactiveUS20040151851A1Envelopes/bags making machineryHeat storage plantsEngineeringPhase change temperature

A packaging system having a container, a first radiant barrier covering the exterior of the container, an insulator covering the interior of the container, a second radiant barrier positioned in the container within the insulator for surrounding a payload, a payload surrounded by the second radiant barrier, a first phase change material having a preselected phase change temperature surrounding the payload in close proximity therewith, and a second phase change material having a phase change temperature higher than the first phase change temperature surrounding the first phase change material in close proximity therewith and being in close proximity with the second radiant barrier.

Owner:MILLER DRAYTON +1

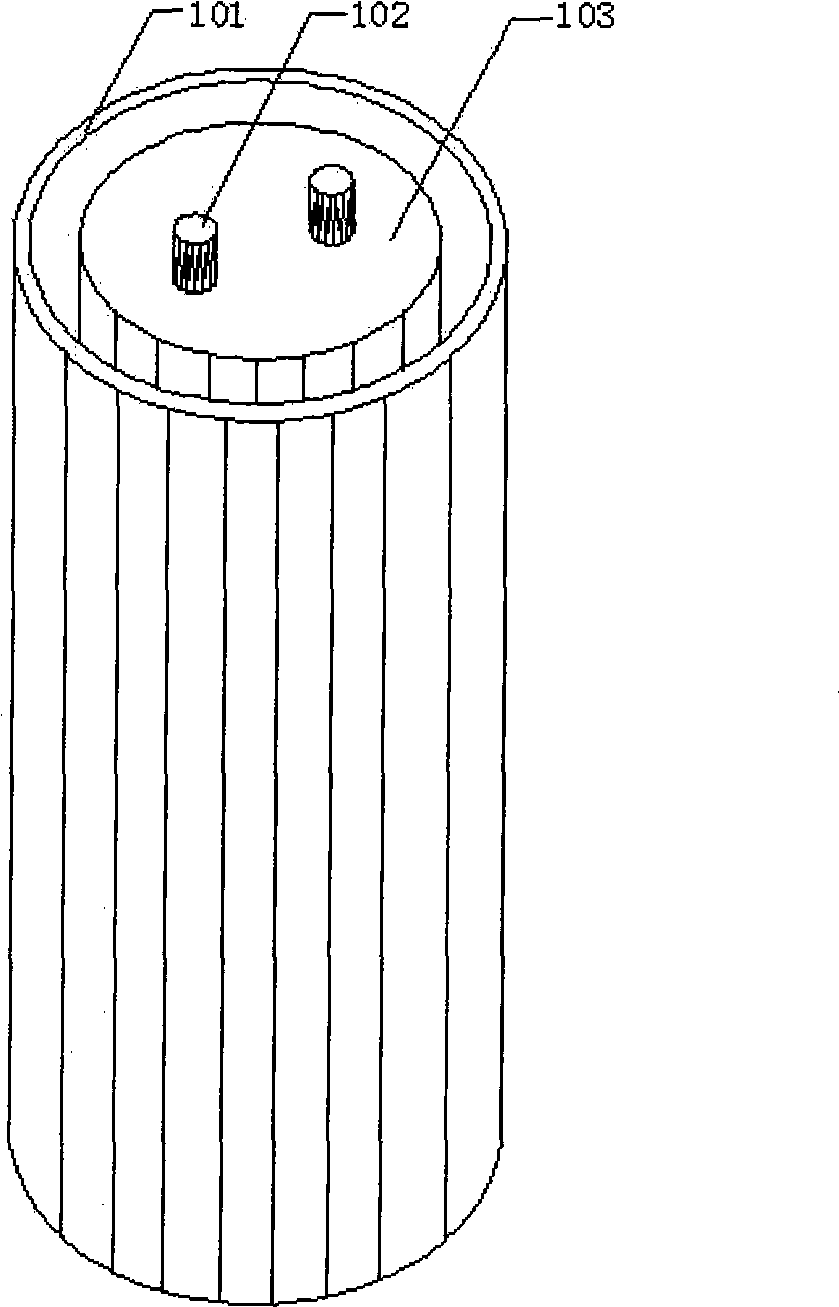

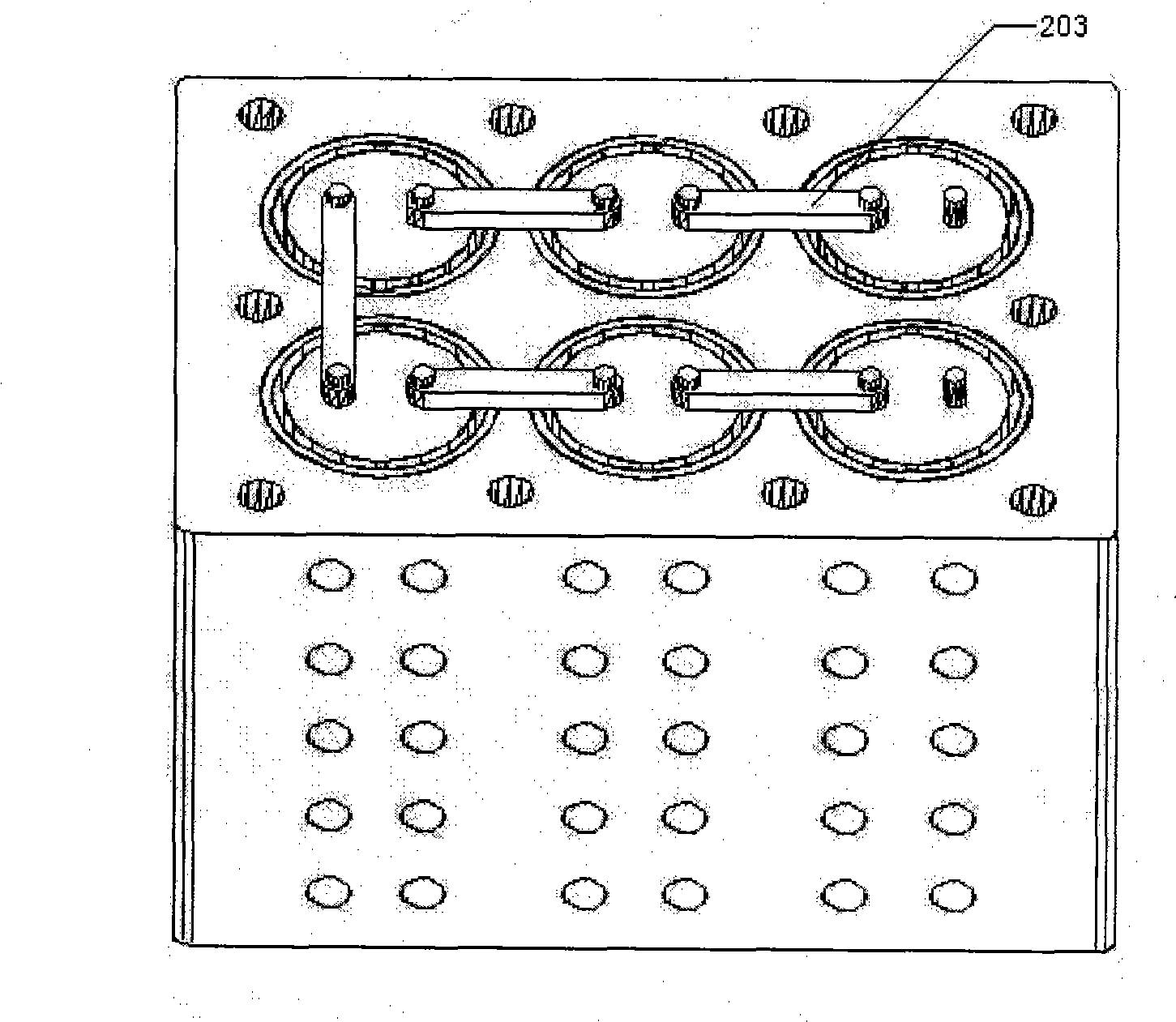

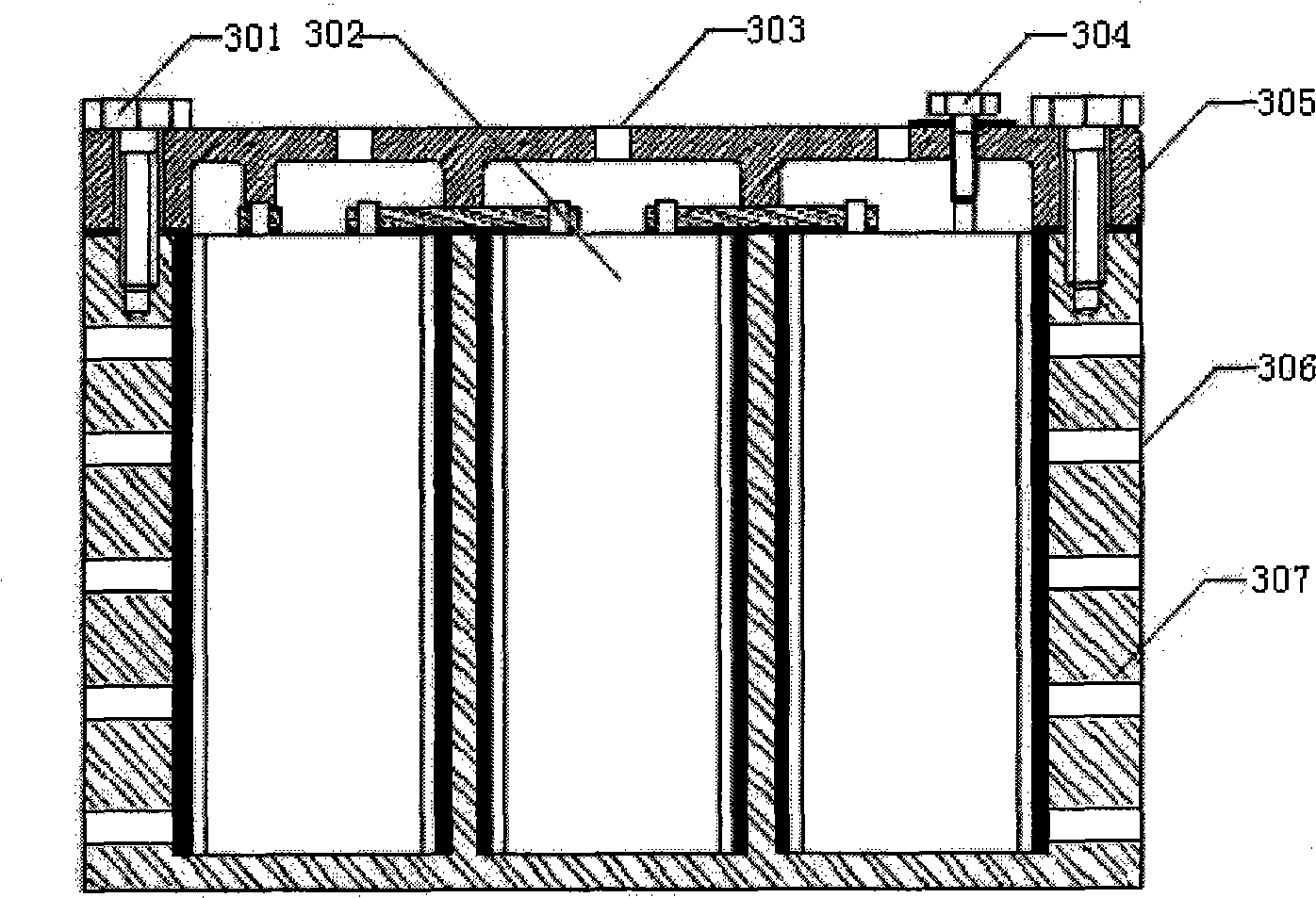

Power battery device with phase-change material cooling system

InactiveCN101546843AEffective coolingExtend your lifeFinal product manufactureSecondary cells manufacturePower batteryEngineering

The invention discloses a power battery device with a phase-change material cooling system, which comprises a bolt, a plurality of battery monomers, a box cover venting hole, an electrode connecting shaft, a box body top cover, a side venting hole and a frame body, wherein the battery monomers use batteries as base bodies, a shell is arranged outside the battery monomers, phase-change material is filled between the batteries and the shell and is sealed by insulating rubber; a battery box body is provided with the venting holes for radiating; the power battery device can realize that the temperature of batteries of a power device can be effectively reduced under more rugged thermal environment and can meet the requirement of the balance of temperature distribution among the battery monomers, thereby achieving the best operation condition of the power device, and prolonging the battery service life and improving the power performance of the power device. The adopted phase-change material has larger latent heat of phase-change, perfect phase-change temperature, economic and safe material, and high recycle utilization efficiency.

Owner:GUANGDONG UNIV OF TECH

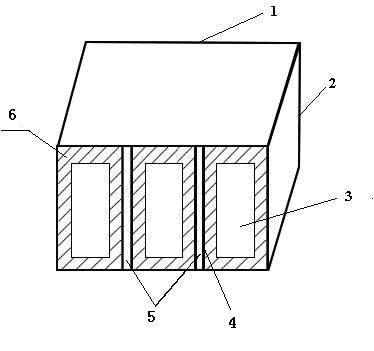

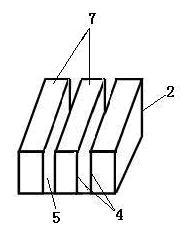

Composite phase change material for heat dissipation of lithium battery and device

InactiveCN102181270AImprove thermal conductivityIncrease heat storageSecondary cellsHeat-exchange elementsWork PerformancesPhase change

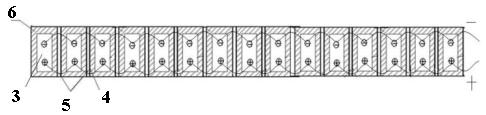

The invention discloses a composite phase change material for heat dissipation of a lithium battery and a device. The device comprises a top cap 1, a box body 2 and partition plates 4; and cavities of corresponding number are partitioned in the box body 2 according to the number of single batteries 3 to be radiated, an air runner 5 is formed between the adjacent partition plates, and the composite phase change material 4 with phase change temperature of between 40 and 70 DEG C is filled in the cavities. When the device starts working, the heat of the single batteries is transferred to the composite phase change material; and when the temperature is higher than the phase change temperature of the phase change material, the phase change material absorbs the heat, produces phase change and stores the heat so as to realize heat dissipation and cooling of the single batteries. The composite phase change material has high coefficient of heat conductivity, keeps the size in the phase change process, has high heat storage, heat release and heat dissipation rate, has no liquid liquidity or leakage, is easily encapsulated, is convenient to operate and maintain, and can improve the working performance and the reliability of the batteries when used for the heat dissipation of the high-power and quick charge / discharge power lithium batteries.

Owner:SOUTH CHINA UNIV OF TECH

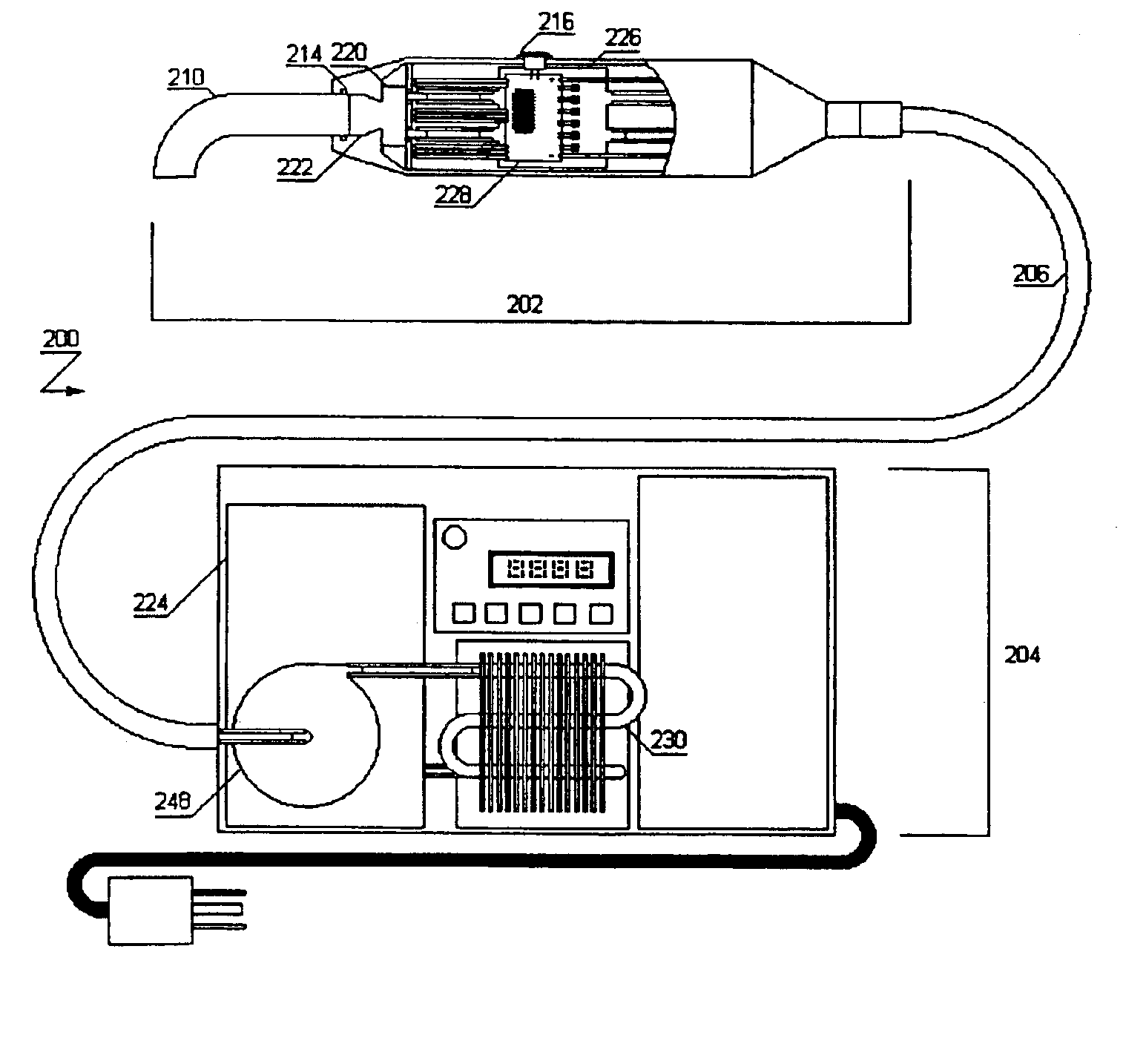

LED curing light

A light source which may be used as part of a dental curing lamp is comprised of at least one, and preferably a plurality, of LEDs. To increase the efficiency of the light output the LEDs are encapsulated in a beam converger including an extractor portion and a collimator portion. Light rays leaving the collimator portion have an angle which matches the entrance angle input requirements of an associated light guide. In another aspect, cooling of LEDs is accomplished by reservoirs located in a hand piece and in a base station. In another aspect of the invention, cooling is achieved by use of a heat pipe and a cooling jacket. The cooling jacket may contain a material having a high latent heat of fusion at a phase change temperature suitable for cooling the LEDs.

Owner:TSIMERMAN EFRAIM +1

Method and device relating to battery temperature regulation

InactiveUS20010033961A1Extended service lifeLow costCell temperature controlSecondary cells charging/dischargingThermal insulationEngineering

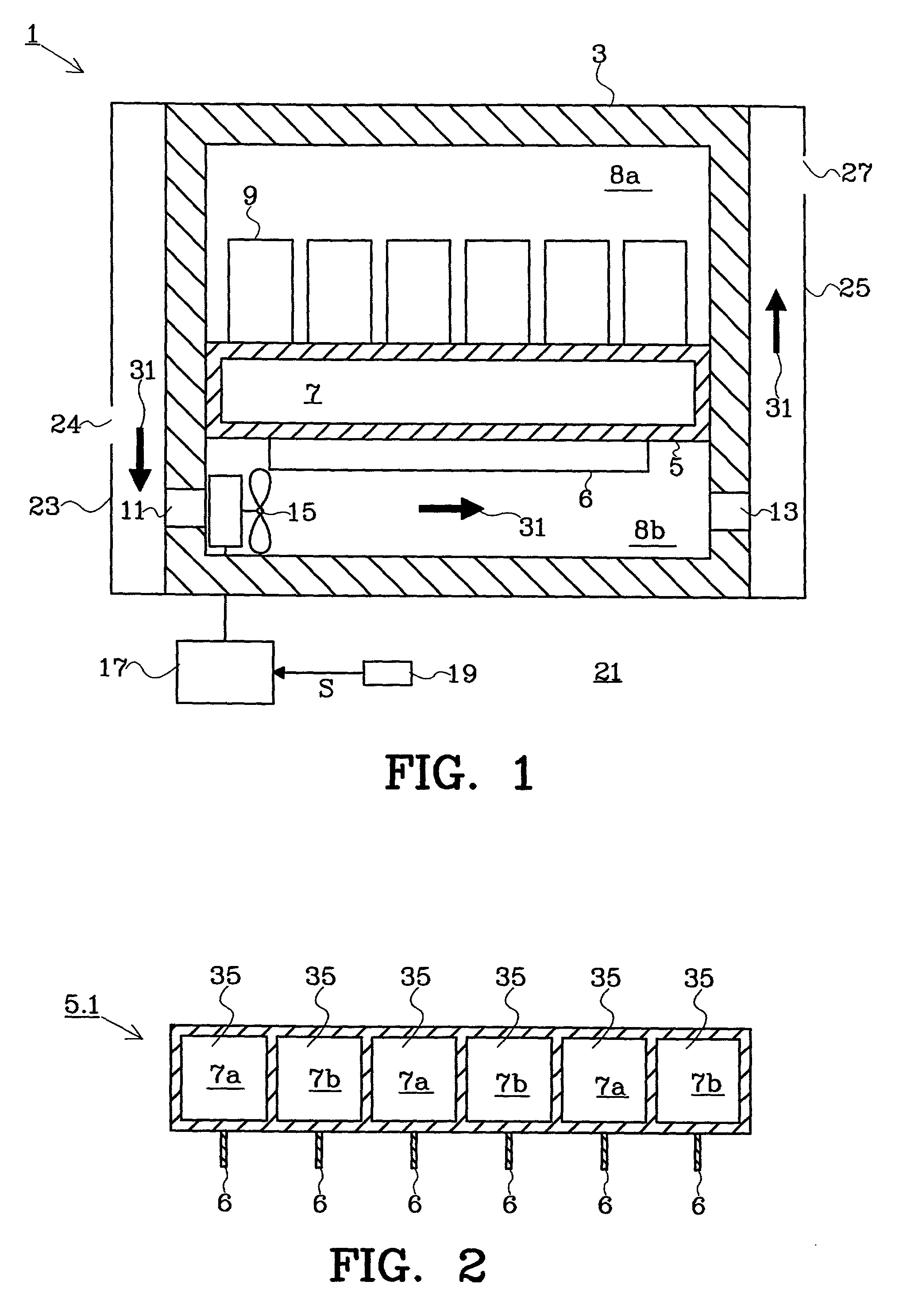

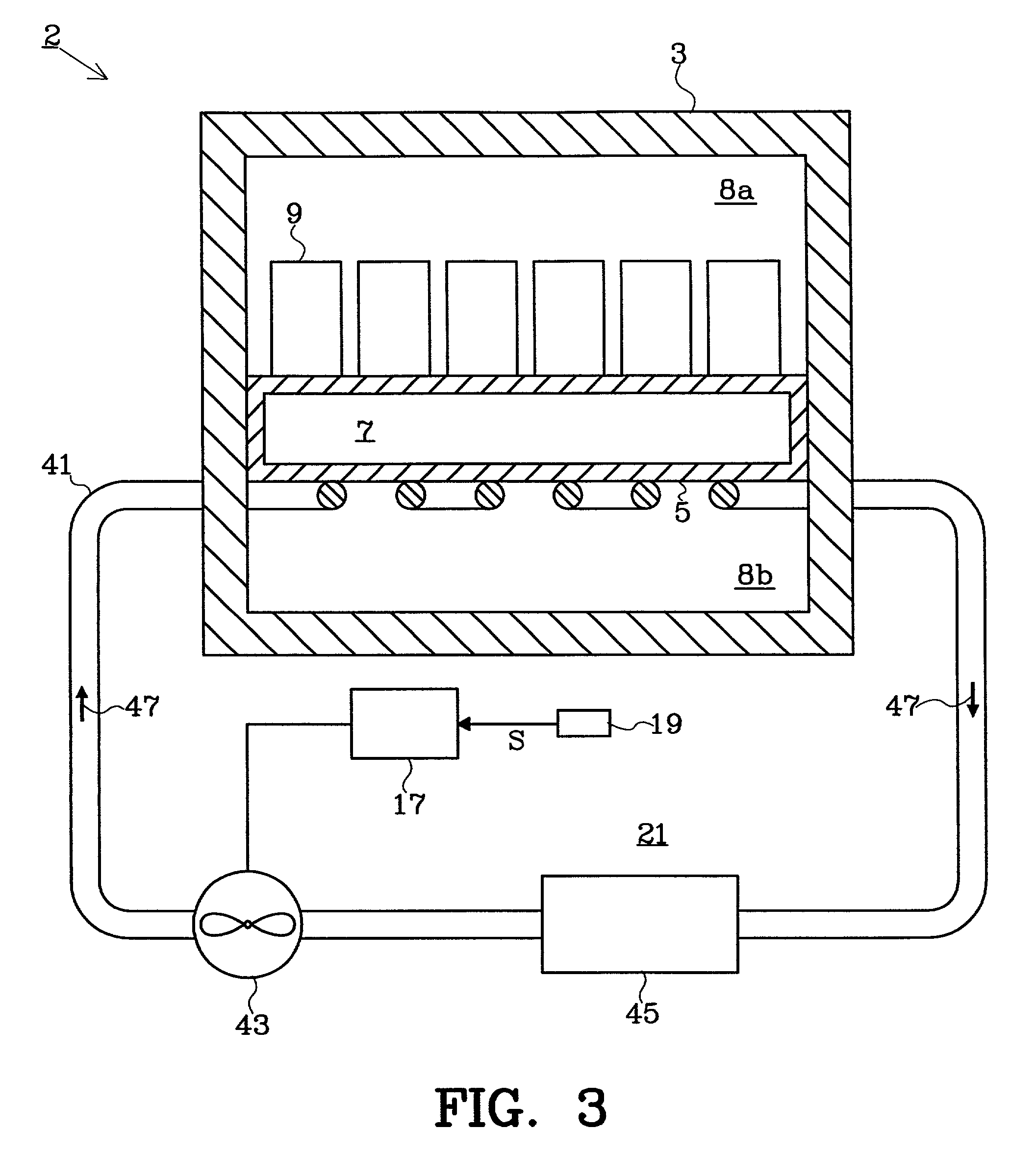

The present invention pertains to the field of methods and devices for battery (9) temperature regulation. Phase change material (7;7a,7b) having a phase change temperature within a preferred operating temperature range is employed in order to maintain the battery temperature within the preferred operating temperature range during extreme ambient temperature conditions. When the temperature of an ambient medium (21) so allows, a transfer of heat between the phase change material (7;7a,7b) and ambient medium (21) is effected for quickly restoring the capability of the phase change material (7;7a,7b) to maintain the battery temperature at the phase change temperature. Otherwise, thermal insulation between the phase change material (7;7a,7b) and the ambient medium (21) is provided.

Owner:TELEFON AB LM ERICSSON (PUBL)

High heat conductive fixed phase change heat storage material suitable for large scale industrial production

InactiveCN1587340ASolve processing technology problemsImprove thermal conductivityHeat-exchange elementsParaffin waxSodium Bentonite

The present invention relates to a high heat conductivity shaped phase change heat storing material suitable for large scale production, and belongs to the field of phase change material for building. The present invention consists of phase change heat storing material paraffin of phase change temperature 15-70 deg.c in 50-80 wt%; high molecular weight support material polyethylene, polypropylene, SBS and / or SEBS in 10-30 wt%; machining modifier alumina, montmorillonite, diatomite, clay, titania powder, calcium carbonate, bentonite and / or silica in 5-20 wt%; and heat conducting additive metal powder or graphite powder 5-15 wt%. The material may be well produced in large scale, has excellent heat conducting performance and is especially suitable for use in building.

Owner:TSINGHUA UNIV

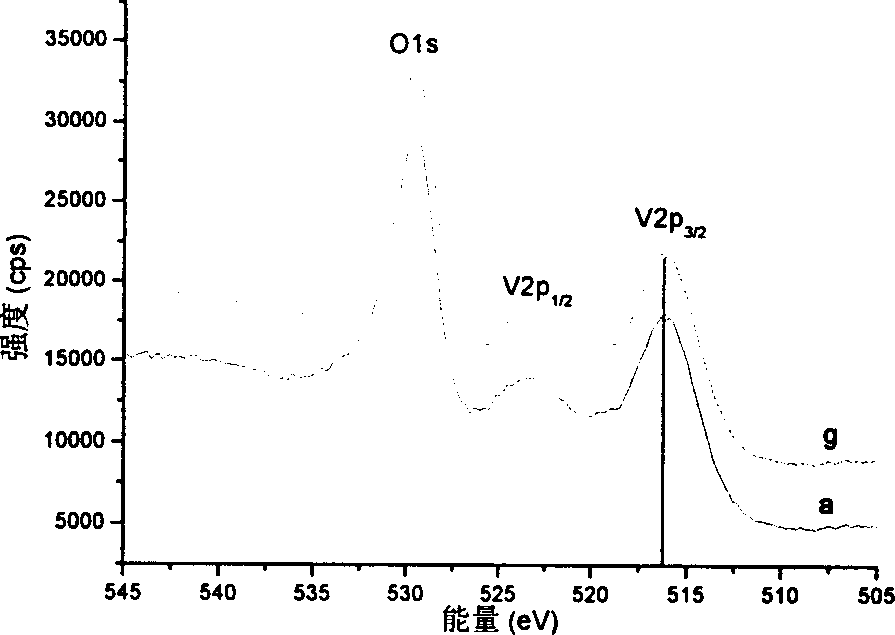

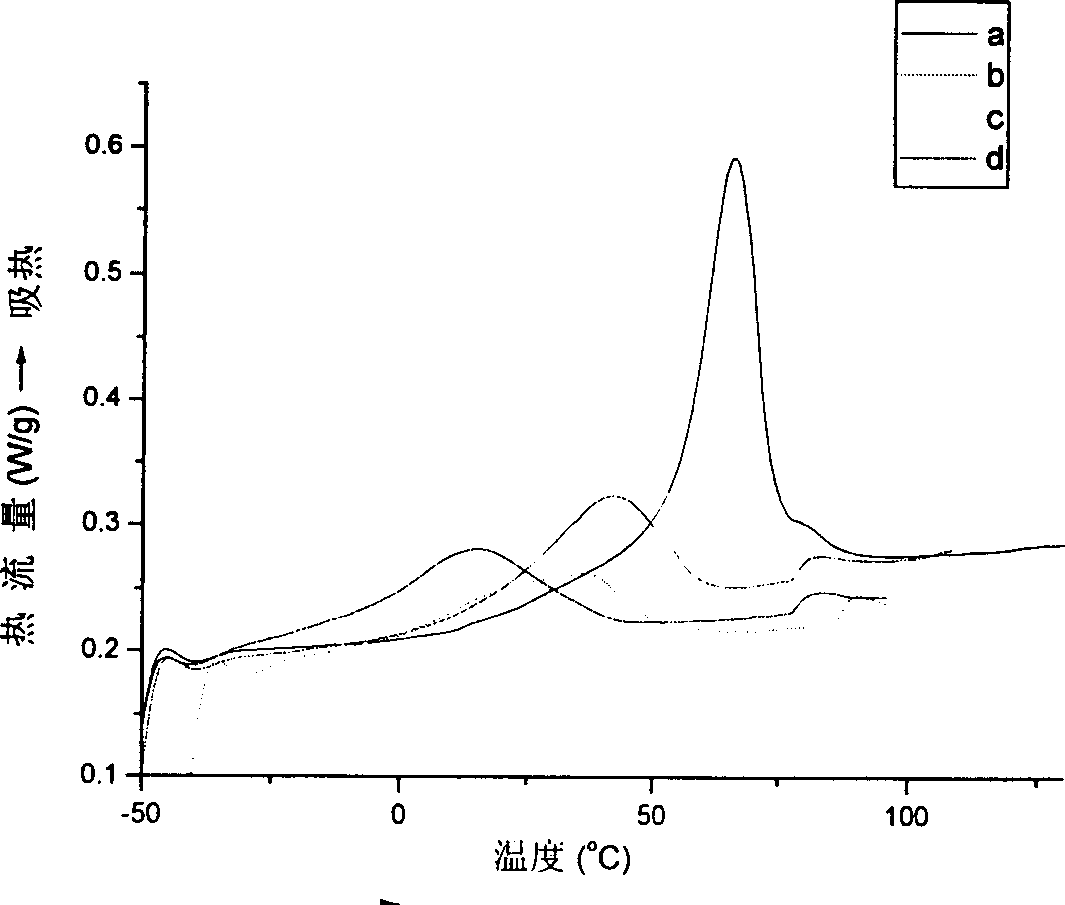

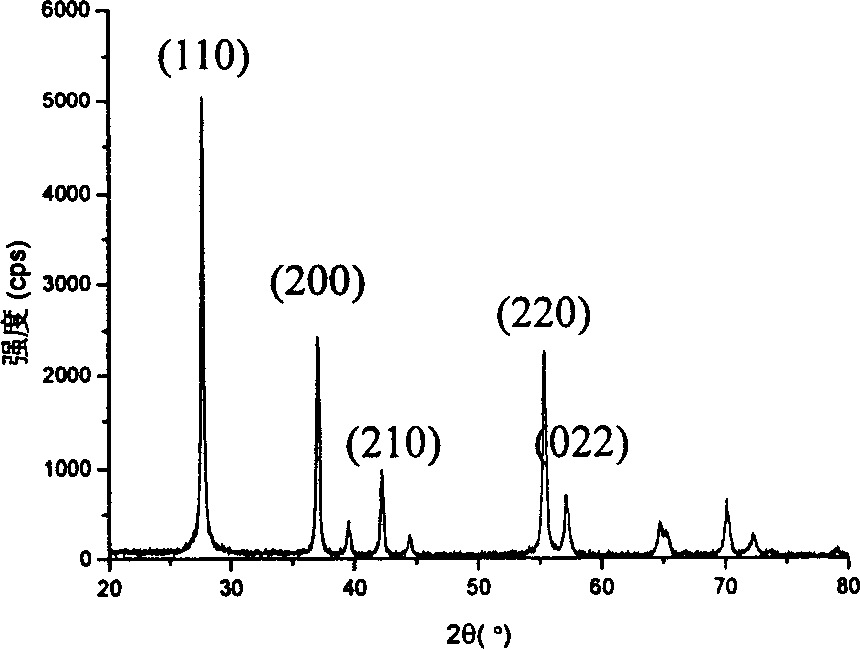

Phase-transition intelligent materials with adjustable phase-transition temperature and process for preparing same

InactiveCN1837061AReduce infrared transmittanceIt has the function of intelligent temperature controlOther chemical processesVanadium oxidesVanadium dioxideMaterials science

The invention relates to an intelligent phase-change material with adjustable phase-change temperature and its preparing process, which comprises making doped vanadium dioxide precursor through liquid phase precipitation method, carrying out filtering, scouring, drying, heating and crystallizing. The crystal grain dimension of the obtained phase-change material is less than 100 nanometers, thus can be applied into intelligent window coating material and temperature measurement resistors.

Owner:FUDAN UNIV

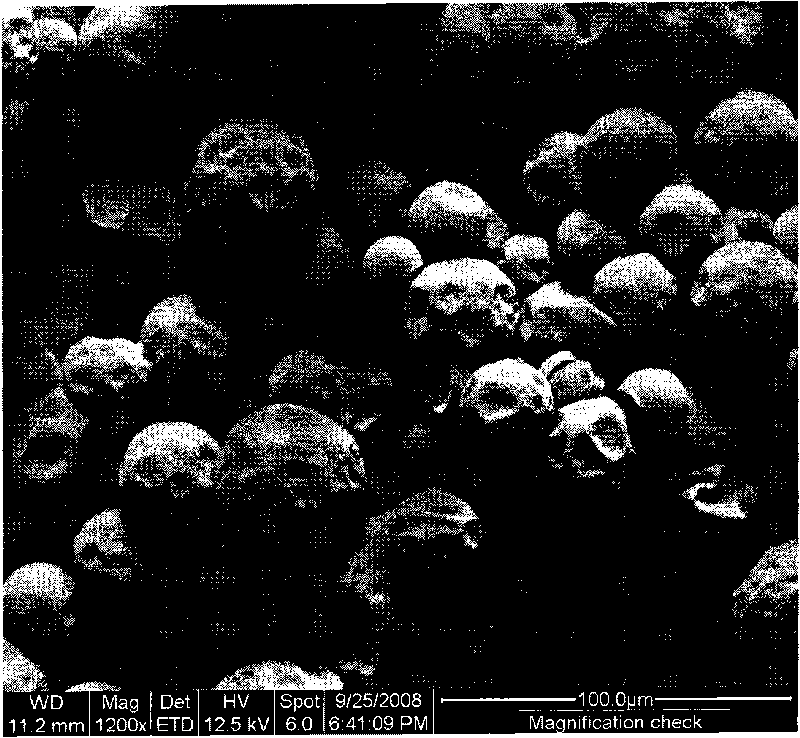

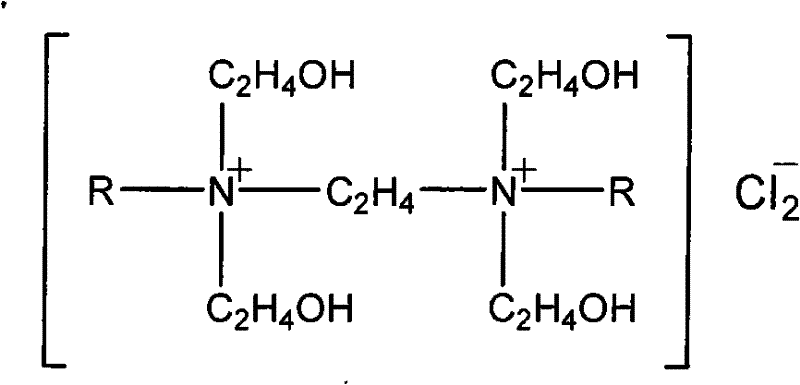

Preparation method of phase-change material microcapsule

InactiveCN101717618AImprove compactnessImprove hydrophilicityHeat-exchange elementsCoatingsSolubilityEmulsion polymerization

The invention discloses a preparation method of a phase-change material microcapsule, comprising the following steps of: mixing the core material and the monomer of a phase-change material designed with a phase-change temperature according to a certain proportion, uniformly stirring and heating to the temperature higher than the phase-change point of the core material of the phase-change material to enable the core material and the monomer to be fully dissolved and prepared into an oil phase; dissolving a functional surface active agent in water, heating the mixture to the temperature higher than the phase-change point of the phase-change material and then preparing the mixture into a water phase, wherein an oil-solubility initiating agent is only added in the oil phase preparing process or a water-solubility initiating agent is only added in the water phase preparing process; adding the oil phase in the water phase, preparing an emulsion with a high-shear emulsifying method or a pre-emulsifying and ultrasonic emulsifying method and then deoxidizing, wherein the water-solubility initiating agent is added, the emulsion is polymerized at a certain temperature, the polymerization reaction directionally occurs on the surface of the emulsion drip by adopting a emulsion polymerizing method, and then the phase-change material microcapsule with the required phase-change temperature is obtained.

Owner:TIANJIN POLYTECHNIC UNIV

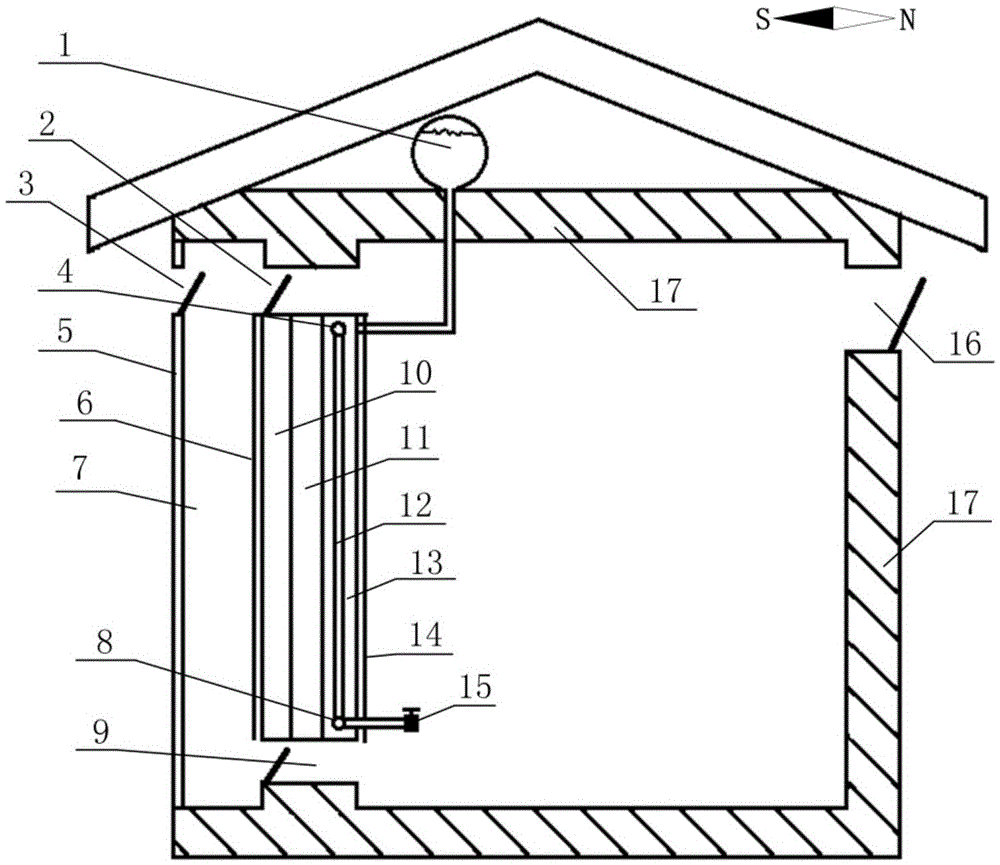

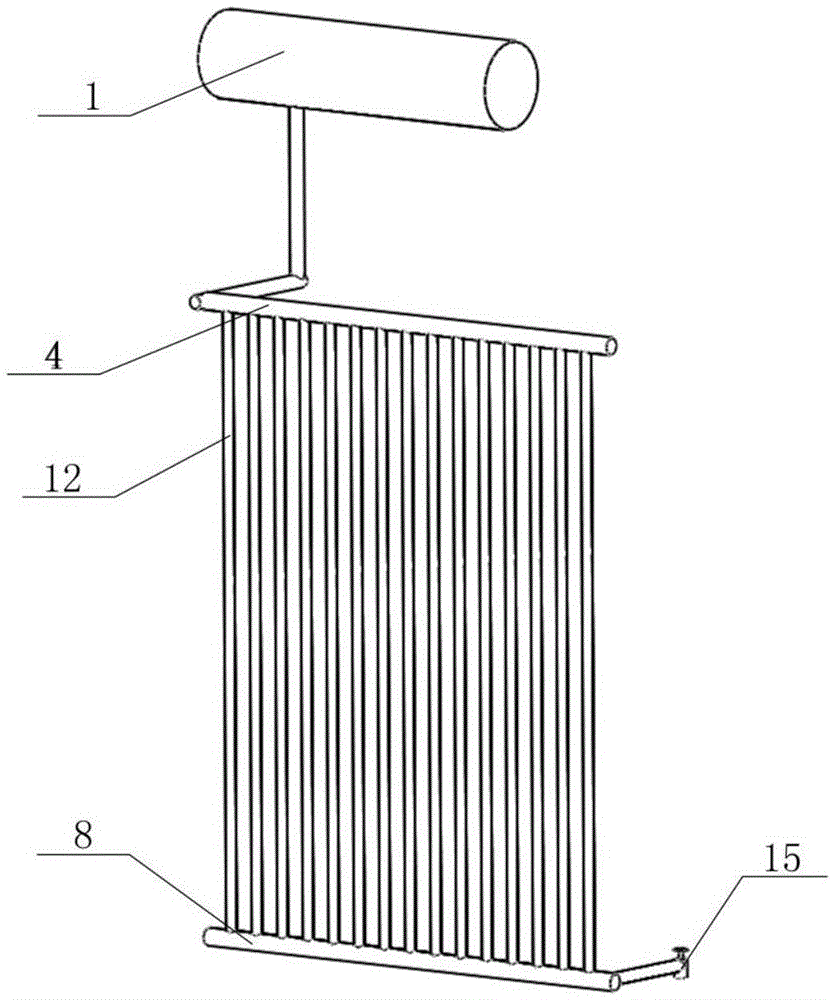

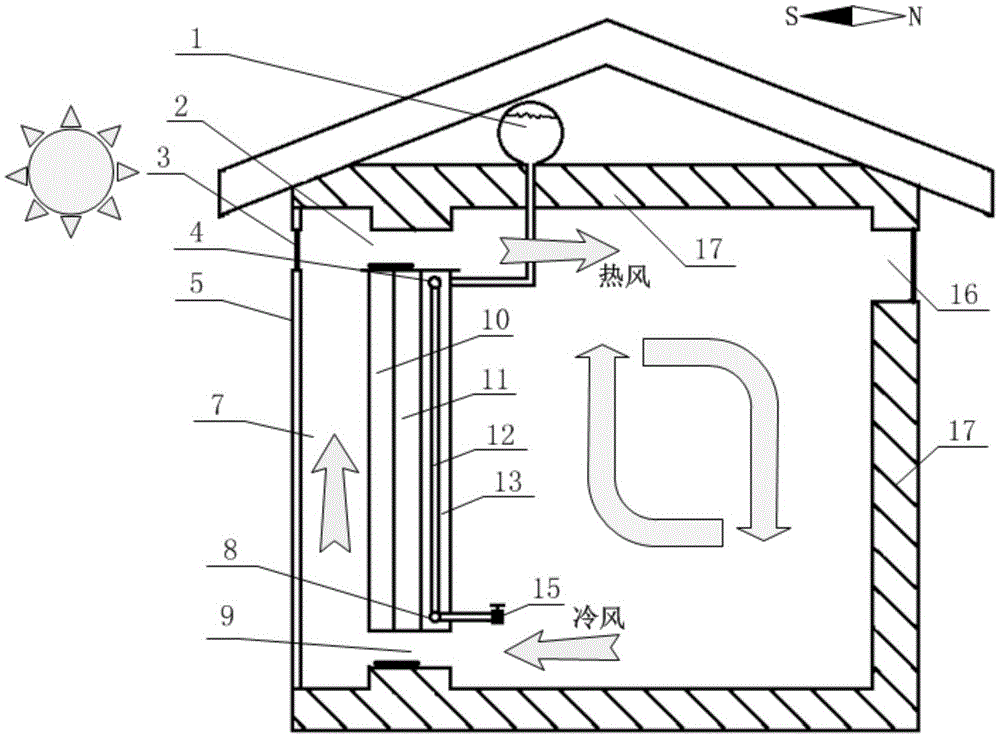

Solar phase change heat storage wall and ventilation system provided with same

ActiveCN105569213AAvoid instabilityIncrease heat storageSolar heating energyMechanical apparatusGlass coverEngineering

The invention provides a solar phase change heat storage wall and a ventilation system provided with the same. The solar phase change heat storage wall is formed by connecting a high-temperature phase change layer, a medium-temperature phase change layer and a low-temperature phase change layer sequentially, wherein the phase change temperatures of the high-temperature phase change layer, the medium-temperature phase change layer and the low-temperature phase change layer are set from high to low. A glass cover plate is arranged on the south side of the outer wall of the ventilation system; the rest part of the ventilation system is composed of an enclosure structure; an outdoor air inlet is formed in the upper part of the north side of the outer wall; and an outdoor air outlet is formed in the upper part of the south side. The solar phase change heat storage wall is positioned in the outer wall and close to the glass cover plate; the high-temperature phase change layer faces south; and an upper vent hole and a lower vent hole are formed in the upper part and lower part of the solar phase change heat storage wall respectively. A hot water system penetrates through the solar phase change heat storage wall to perform heat exchange. The solar phase change heat storage wall can overcome shortcomings of a conventional heat collection wall, has the advantages of good heat storage capability, diversified functions, simplicity for operation and no energy consumption, can achieve the effects of cooling by ventilation and domestic water heating in summer, and can be used for providing heat in winter, thereby having good application prospects.

Owner:陕西中为能源技术有限公司

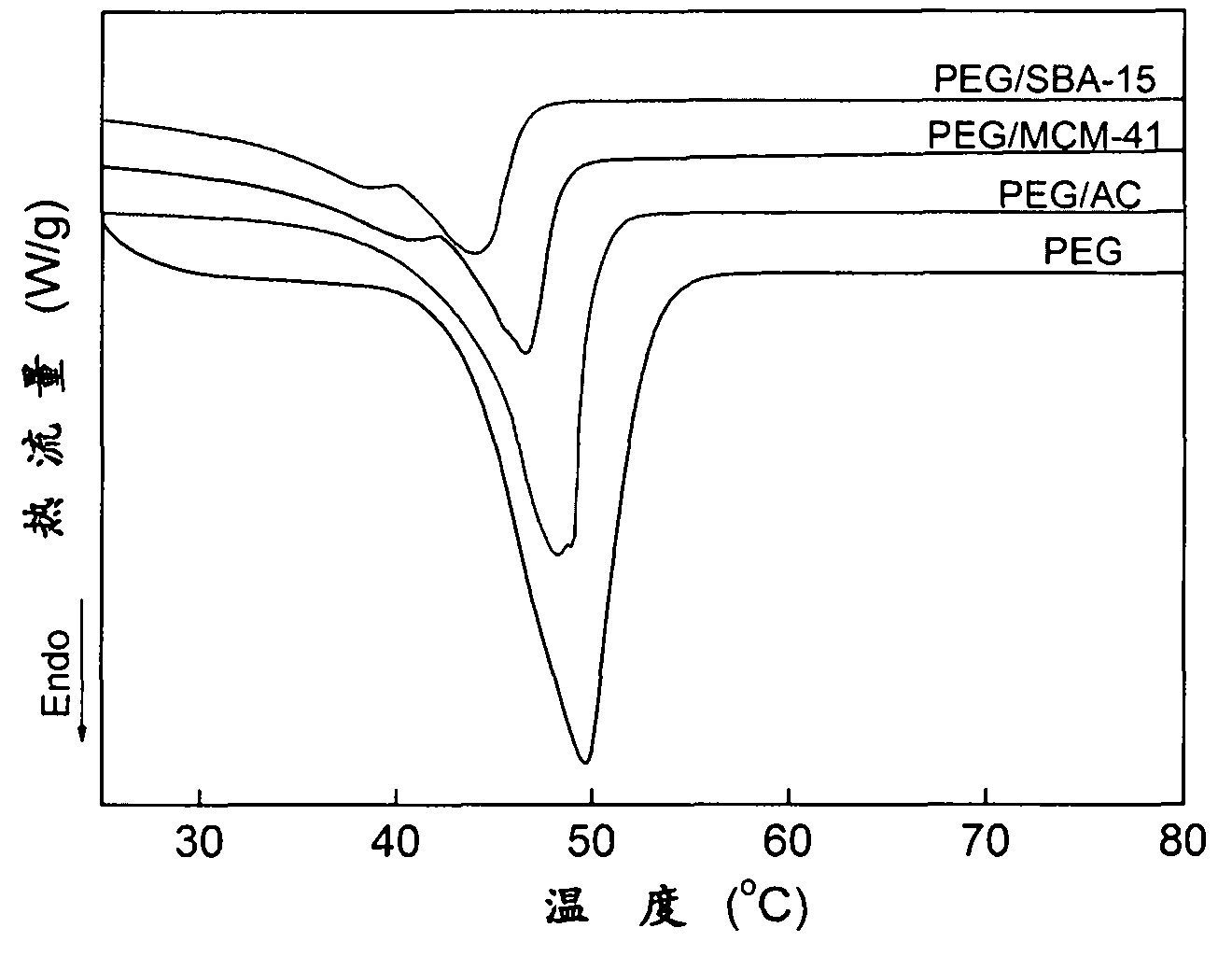

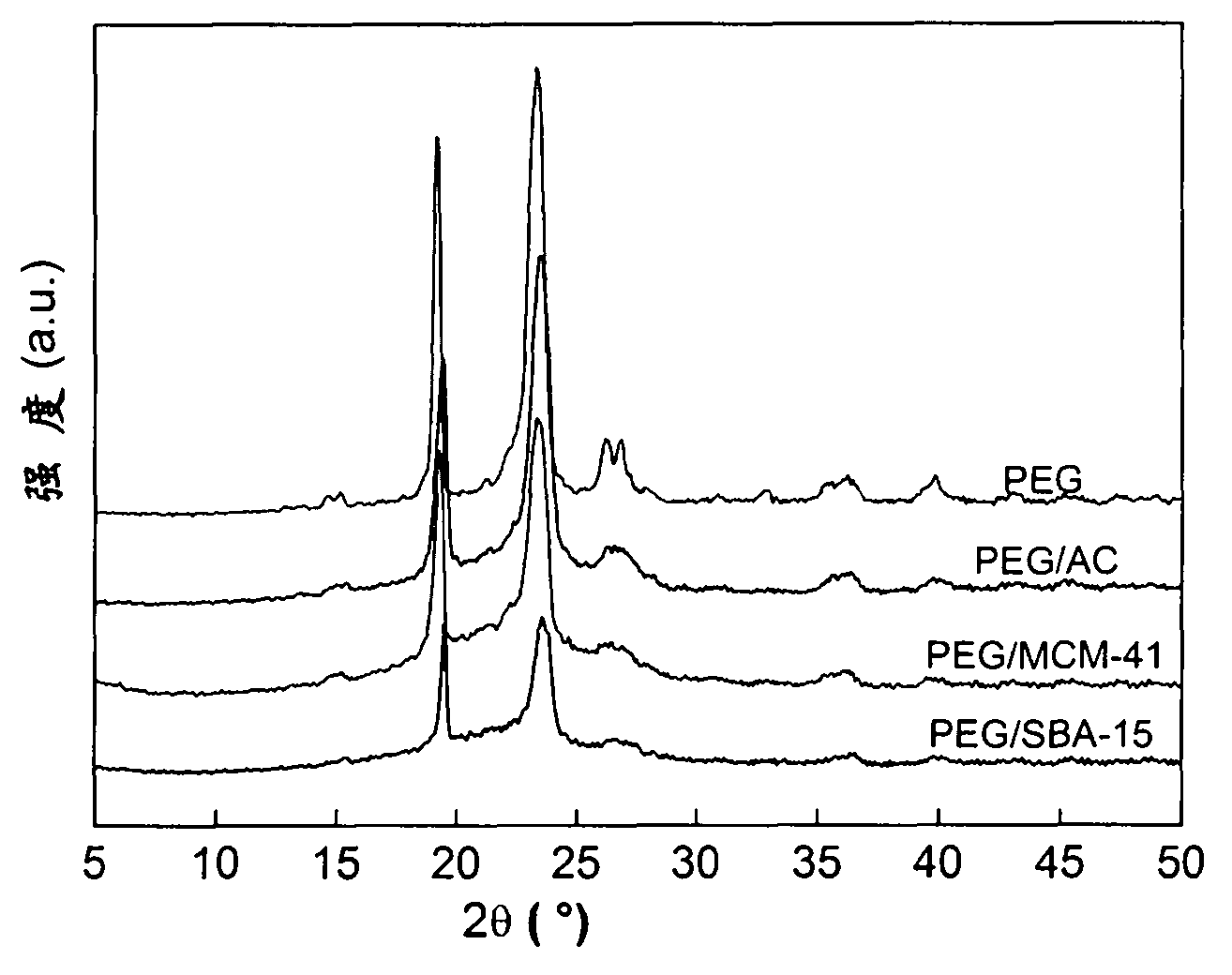

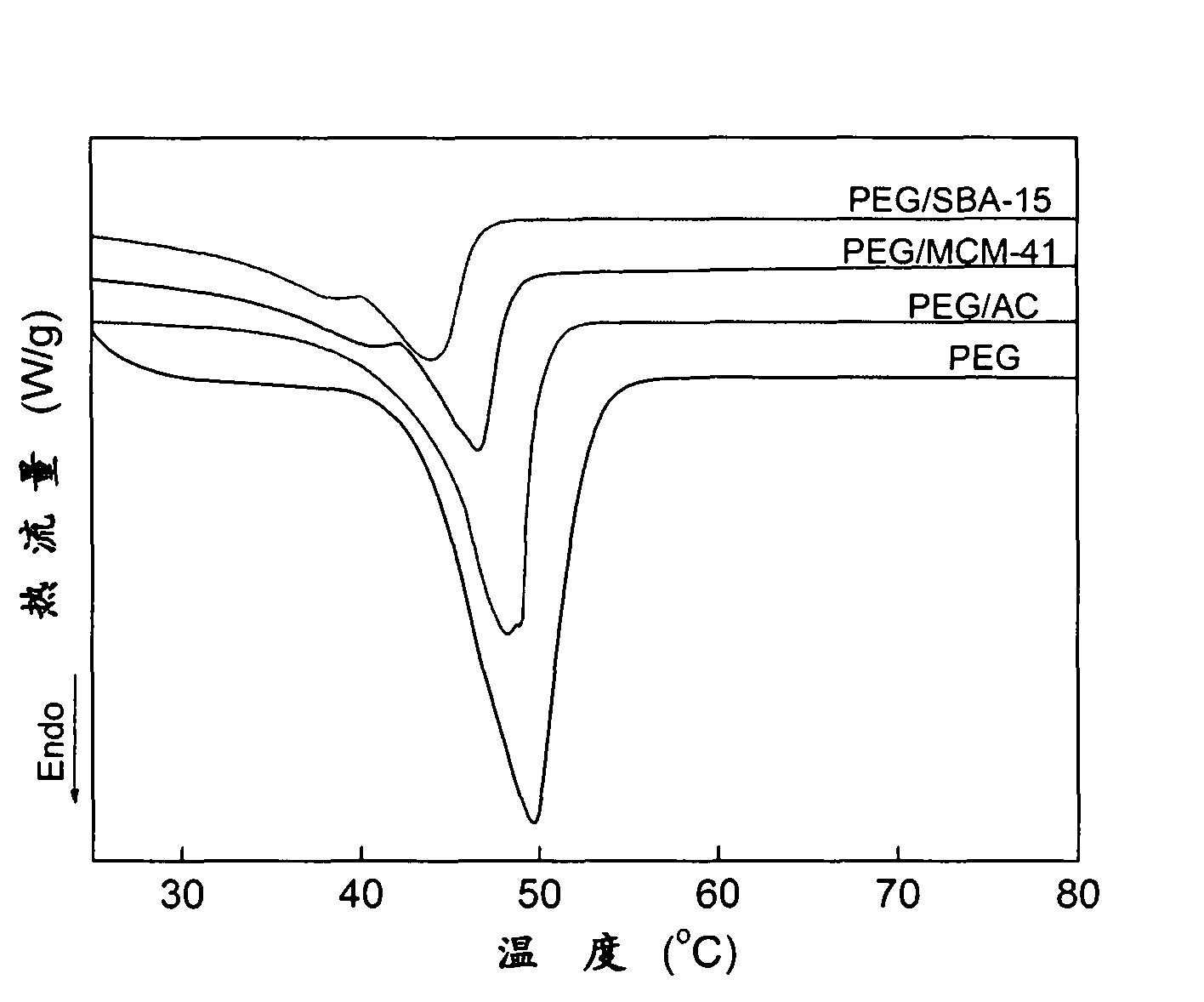

Mesoporous material-based composite phase change heat storage material and preparation method thereof

InactiveCN101812286AReduce contentSolving Phase Change Leakage ProblemsHeat-exchange elementsMesoporous materialHeat storage material

The invention discloses a mesoporous material-based composite phase change heat storage material and a preparation method thereof. The composite phase change heat storage material, which can still keep fixed shape even at the temperature higher than the melting point of phase change substance by 30 DEG C, is prepared by using mesoporous material as carrier matrix and organic substance as phase change substance according to methods of physical blending and impregnation. Compared with other technologies, reported in documents, for the preparation of shape-fixed composite phase change material, the preparation technology has the characteristics of great simplicity and saving time, and the prepared composite phase change heat storage material has high content of the phase change material, high latent heat of phase change and utilization rate of the latent heat, and obviously lowered phase change temperature.

Owner:PEKING UNIV

Secondary cooling method for reducing transverse cracks of corners of microalloy sheet billet

The invention relates to a secondary cooling method for reducing transverse cracks of corners of a microalloy sheet billet, which is characterized in that the cooling temperature of a casting blank is facilitated to reach a temperature for starting the transformation from gamma to alpha by controlling the secondary cooling speed at an earlier stage when the casting blank passes through a vertical section after being delivered out of a crystallizer; at the later stage, the cooling water quantity of the casting blank is reduced, potential heat produced by the solidification of the casting piece is used for reheating the casting piece, and the reheating temperature is controlled to make the casting blank reach more than an austenite phase changing temperature when the casting piece is delivered out of the vertical section; the entire process is under the transformation of gamma to alpha to gamma, so that crystal grains of a final transformation product are smaller; and after the casting blank leaves the vertical section, the casting blank enters the subsequent secondary cooling area in a slowly cooling mode. By optimizing the continuous-casting billet cooling mode, the crystal grains are refined, and second-phase particles in the steel are controlled, so that the high-temperature mechanical property of the casting blank can be improved, simpleness in operation is realized, and the transverse cranks on the surface of the casting blank can be effectively reduced.

Owner:WISDRI ENG & RES INC LTD

Sodium acetate trihydrate phase change energy storage material compositions

InactiveCN102212340AImprove performanceHeat-exchange elementsSodium acetrizoateSodium Acetate Trihydrate

The invention discloses sodium acetate trihydrate phase change energy storage material compositions. The compositions mainly comprises sodium acetate trihydrate, a nucleating agent, a thickening agent and the like; and the phase change temperature is between 56 and 58 DEG C, the degree of supercooling is less than 3 DEG C and the phase change latent heat is more than 220kJ / kg. 3,000 times of cold and heat cycle tests prove that the compositions have particularly excellent phase change stability.

Owner:WIDE SPACE PHASE CHANGE TECH

Intelligent vanadium dioxide solar temperature control coating

InactiveCN1621459AImprove reflection efficiencyImprove penetration efficiencyRubber derivative coatingsEpoxy resin coatingsEpoxyVanadium dioxide

The present invention present invention relates to one kind of intelligent solar heat temperature controlling phase change paint of vanadium dioxide and dopant. The paint consists of polymer filming material, dispersant, composite pigment, color regulator, solvent and plasticizer. Being different from traditional solar heat reflecting paint, it can reflect the infrared light of whole waveband at the temperature over the phase change temperature Tc of (V1-xMx)O2 to result in high reflecting efficiency and high temperature-lowering effect; and can pass the infrared light of whole waveband at the temperature below the phase change temperature Tc to result in high heating effect, so as to realize intelligent temperature control. The paint of the present invention may be coated to the surface metal, concrete, timber, foamed plastic, etc. and widely used for building, vehicle, ship, oil reservoir and other facilities exposed to sunlight.

Owner:SUN YAT SEN UNIV

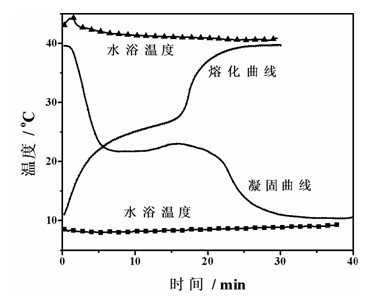

Inorganic phase-change material and preparation method thereof

InactiveCN102660231ALatent heat of fusion without decaySimple methodHeat-exchange elementsDisodium phosphateHydrogen phosphate

The invention discloses an inorganic phase-change material and a preparation method thereof. The inorganic phase-change material comprises at least one of a thickening agent and a water-retaining agent, and main thermit, nucleating agent, pH regulator, heat conducting agent, and water, wherein the main thermit is eutectic salt of sodium sulfate decahydrate and sodium hydrogen phosphate docecahydrate. The preparation method comprises the following steps: adding the main thermit in water, stirring in 40-45 DEG C water bath until completely fusing, adding the nucleating agent, the pH regulator, and the heat conducting agent and fully stirring to completely dissolve the nucleating agent and the pH regulator and uniformly disperse the heat conducting agent, then adding at least one of the thickening agent and the water-retaining agent and stirring to uniformly disperse the thickening agent or completely expanse the water-retaining agent, so as to obtain the inorganic phase-change material. The inorganic phase-change material of the invention has the characteristics of noninflammability and no toxicity, the phase change temperature is 21-27 DEG C, the latent heat of phase change is 214 kJ / kg, and the inorganic phase-change material has no attenuation of performance after 1000 weeks of the solidification-fusing cycle.

Owner:WUHAN UNIV

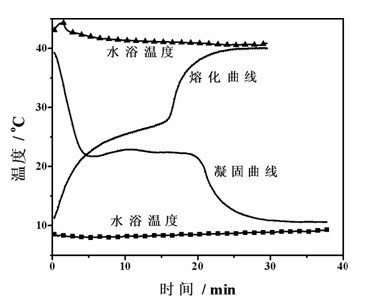

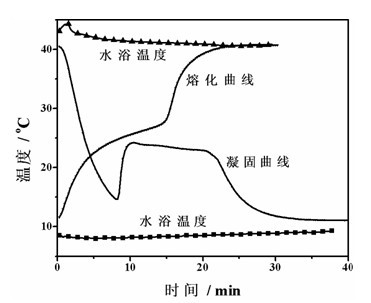

A cooling phase change material with a phase change temperature of 12-29°C and its preparation method

InactiveCN102268241AImprove cooling effectAvoid churnHeat-exchange elementsThermodynamicsCooling effect

The invention discloses a cooling phase change material with a phase change temperature of 12-29°C and a preparation method thereof. The components of the phase change material of the present invention are sodium sulfate decahydrate, a phase change temperature regulator, a moisturizing agent, a nucleating agent, a pH value regulator and a thickener, which are composed according to a certain weight ratio; the preparation method comprises the following steps : Mix humectant and nucleating agent, add pH adjuster to adjust pH value, add phase change temperature regulator and thickener, mix evenly, then add sodium sulfate decahydrate, stir at 12-29°C until melted , stop heating, continue to stir, and cool to obtain the phase change material of the present invention. The phase change material of the present invention has the advantages of non-toxicity, good stability, and large cold storage capacity. Adding a phase change temperature regulator makes the phase change temperature of the phase change material adjustable at 12-29°C, and has a long-term stable Physical cooling effect, can be used to absorb heat and cool down.

Owner:SOUTH CHINA UNIV OF TECH

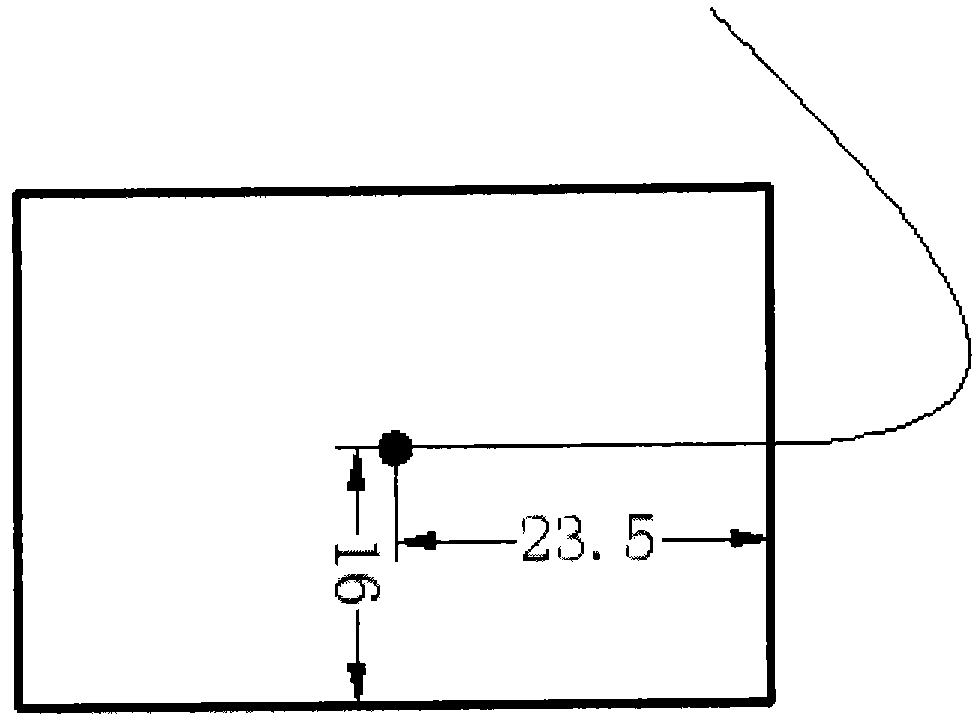

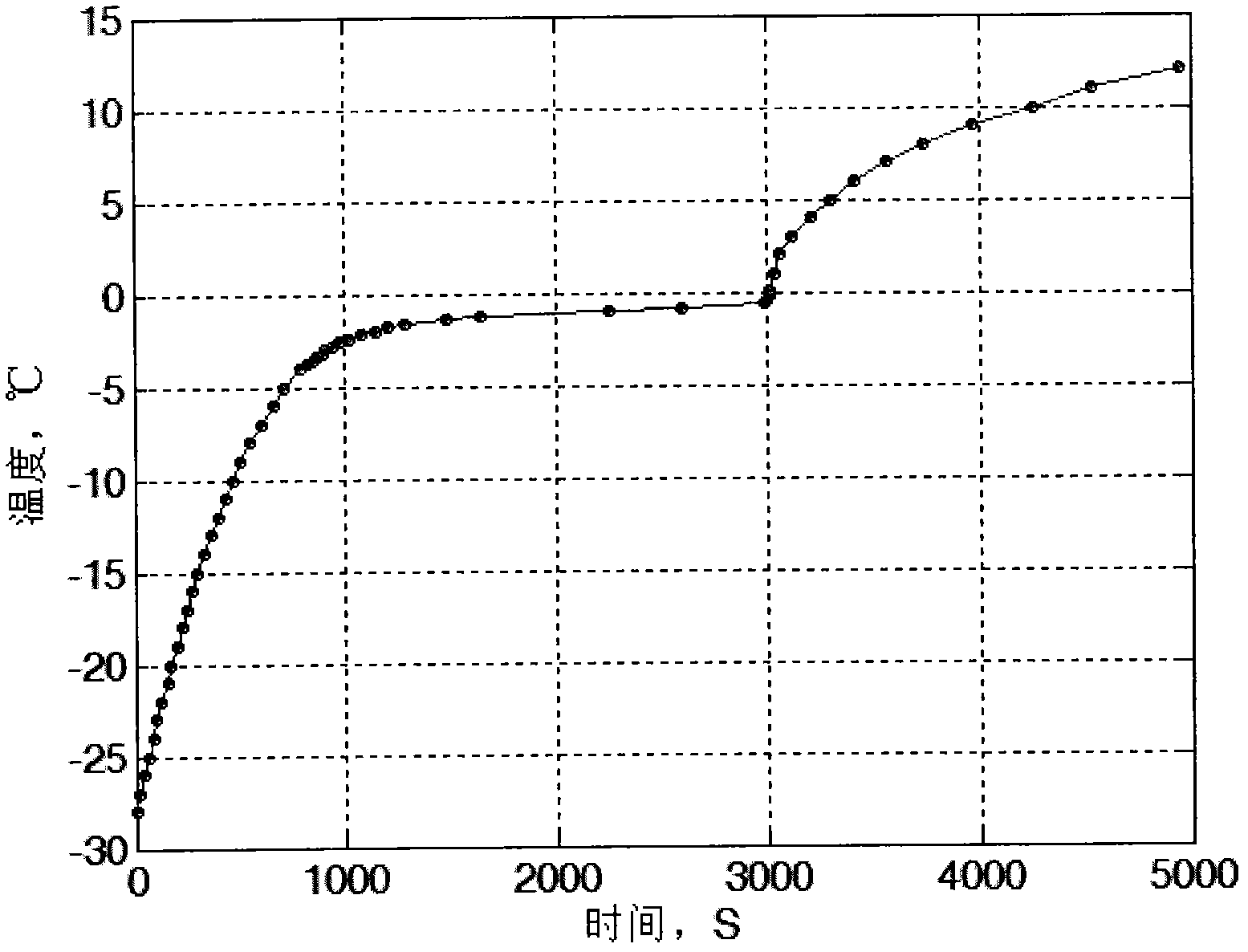

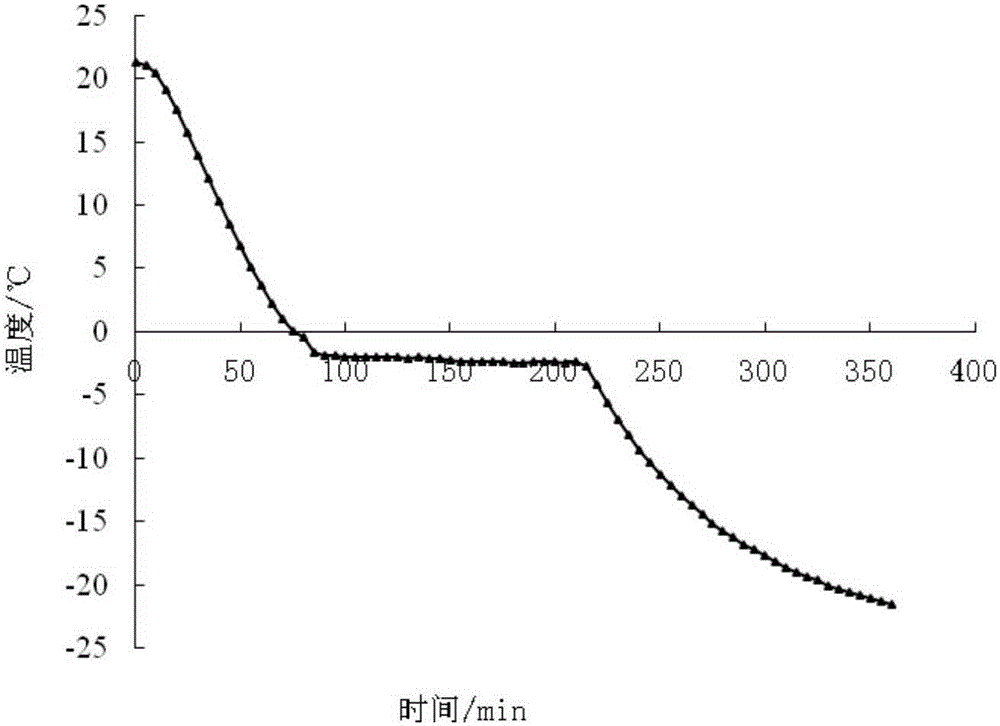

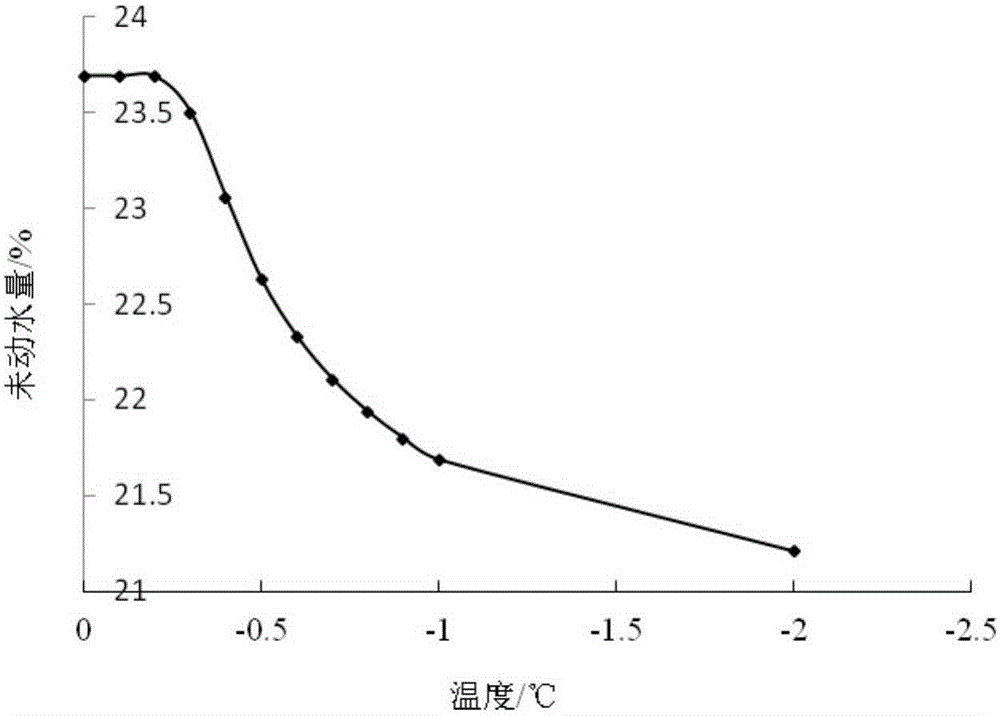

Method for testing content of unfrozen water in frozen earth

The invention provides a method for testing content of unfrozen water in frozen earth. The method is mainly applied to the testing on the content of unfrozen water in natural frozen earth and artificial frozen earth. The method comprises the steps of firstly processing the tested soil sample obtained in place according to the specified specification; subsequently freezing the tested soil sample to the low-temperature range of -30 to -15 DEG C; subsequently heating and melting the tested soil sample by natural convection under the room temperature air condition of 20 to 35 DEG C; recording thechange of the central temperature of the sample with the time; establishing a calculation model reflecting the temperature change process of the frozen earth according to a Newton cooling law; analyzing the convection heat transmission coefficient between air and soil; determining phase change time and phase change temperature so as to further calculate the content of unfrozen water under the frozen state; and finally calculating the characteristic curve of unfrozen water content during the melting process according to the test results. The method is simple and feasible and the testing resultis exact and reliable.

Owner:刘波 +1

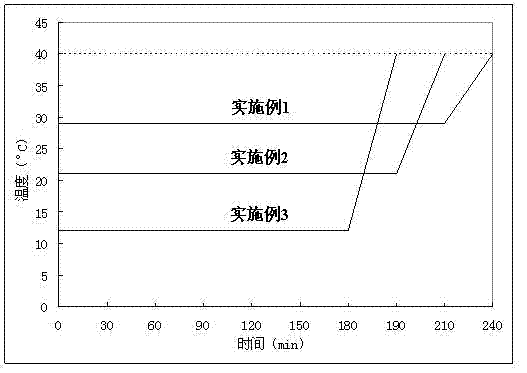

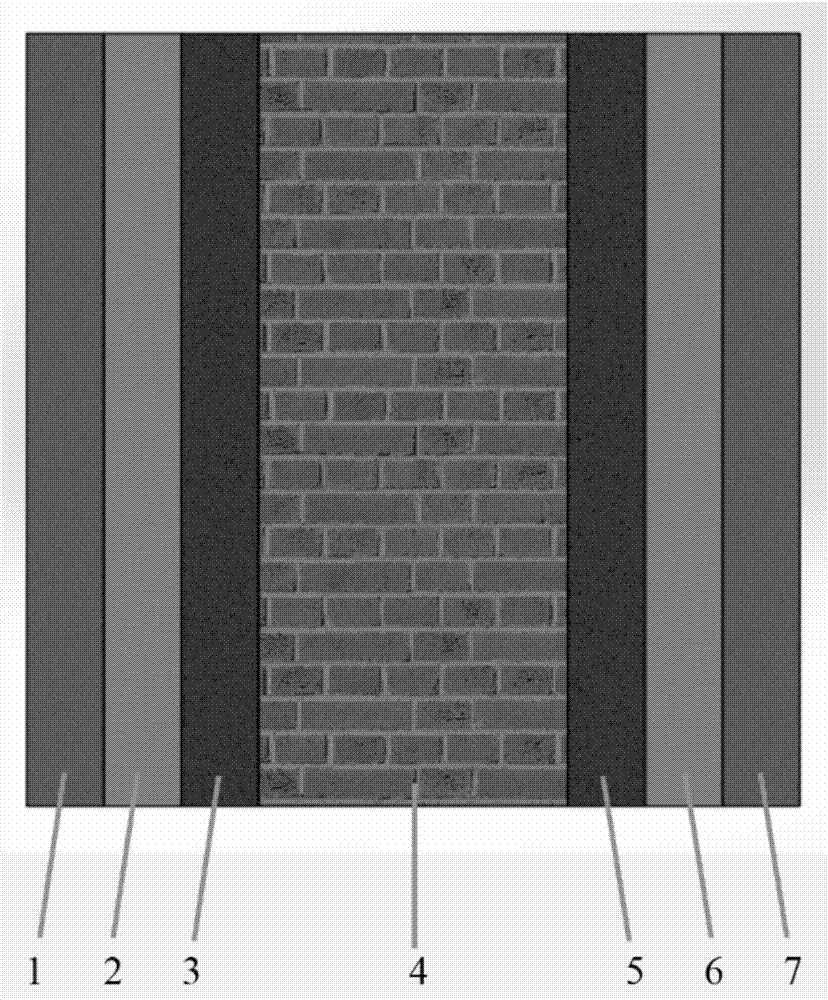

Energy-storing building wall structure containing double-layer phase-change material plate

Owner:SOUTH CHINA UNIV OF TECH

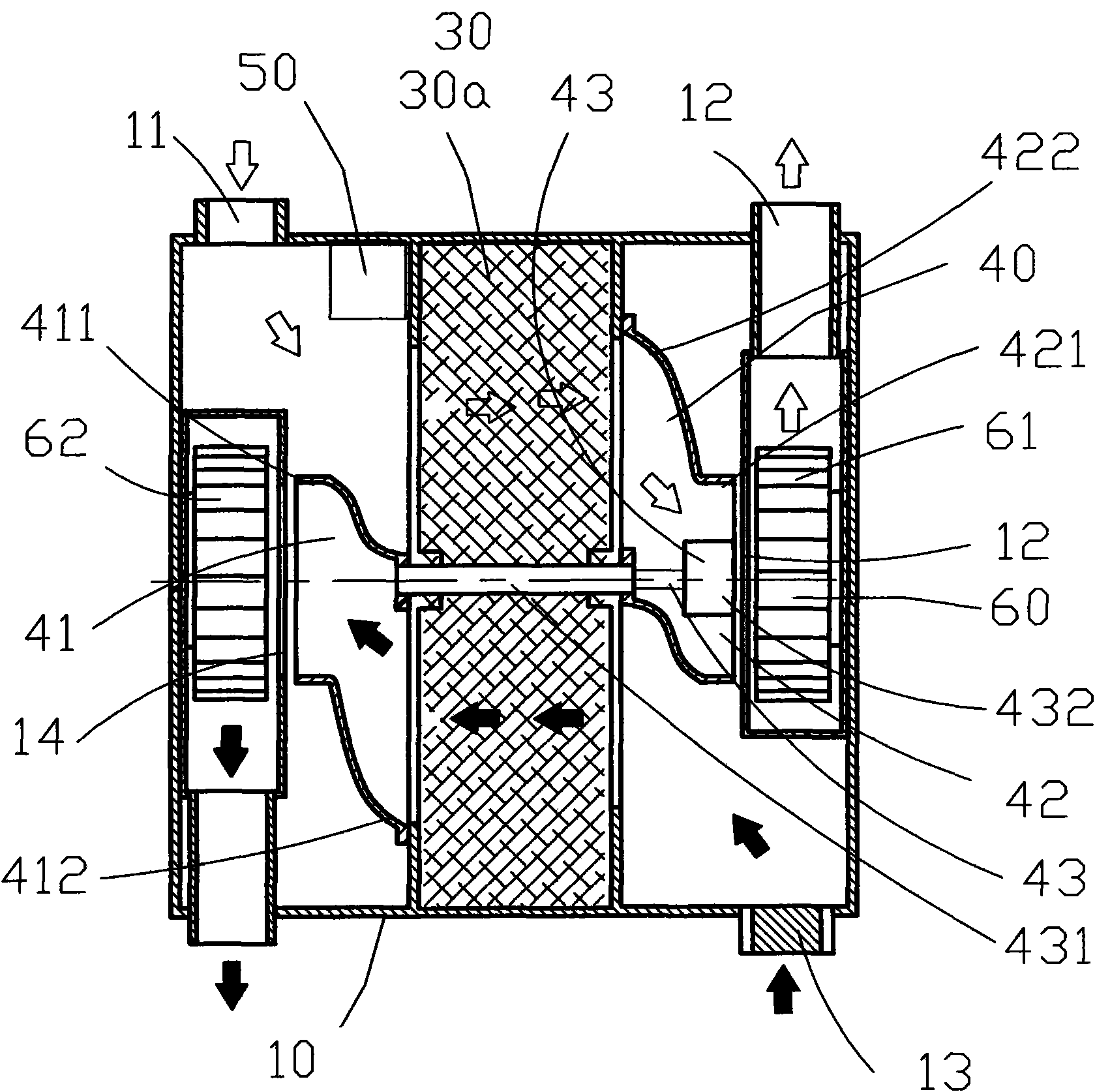

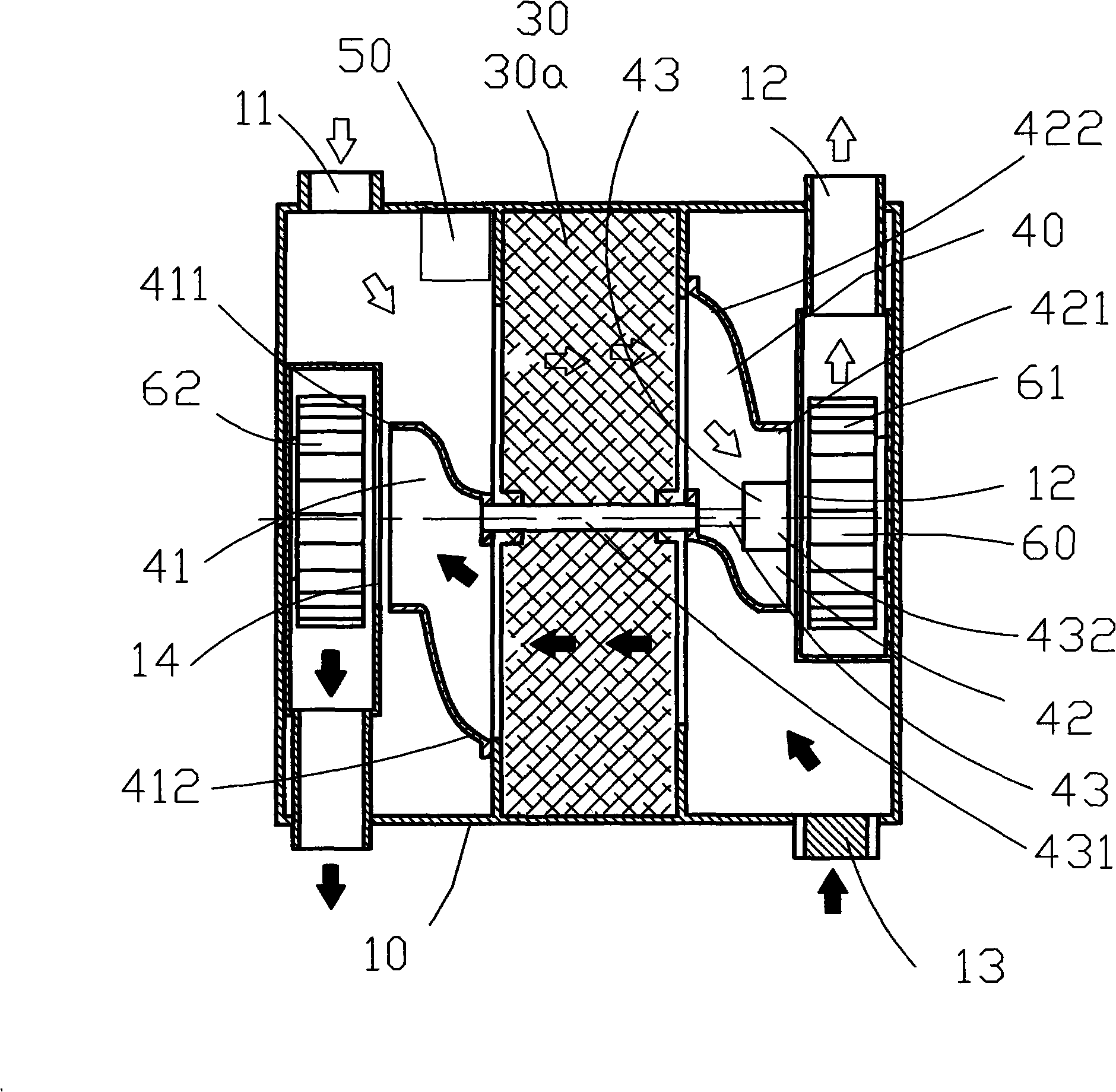

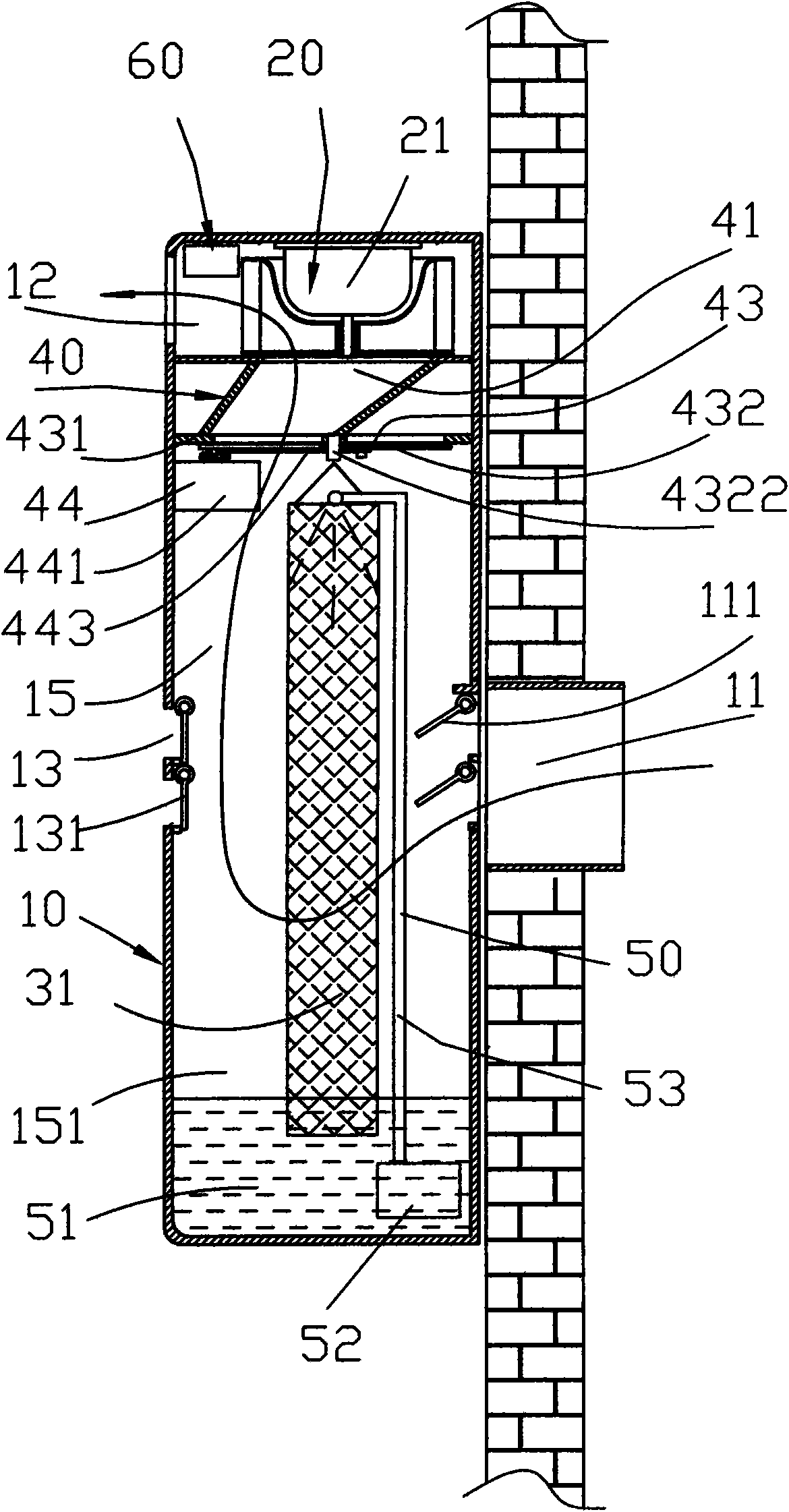

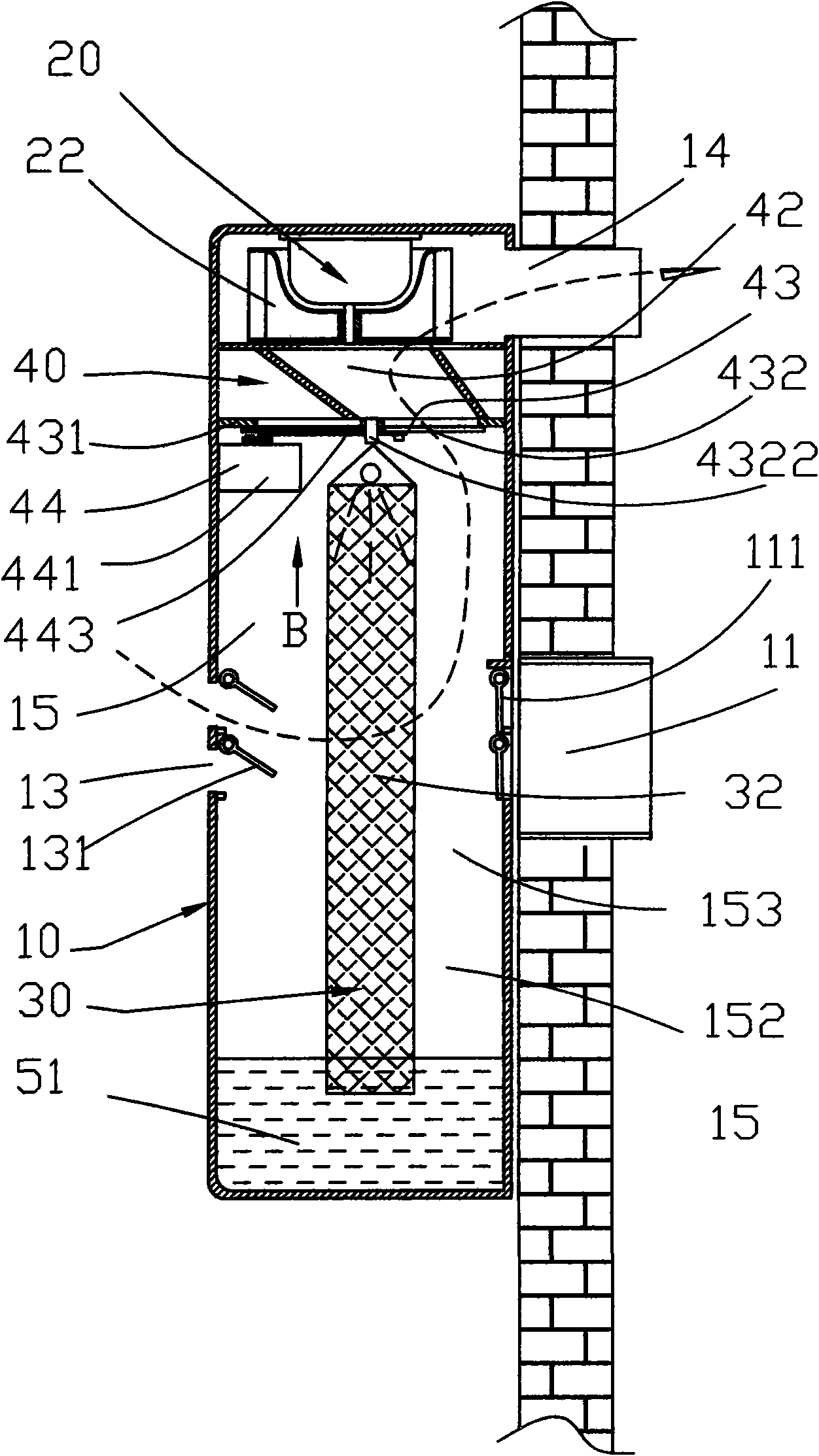

Energy-saving ventilator

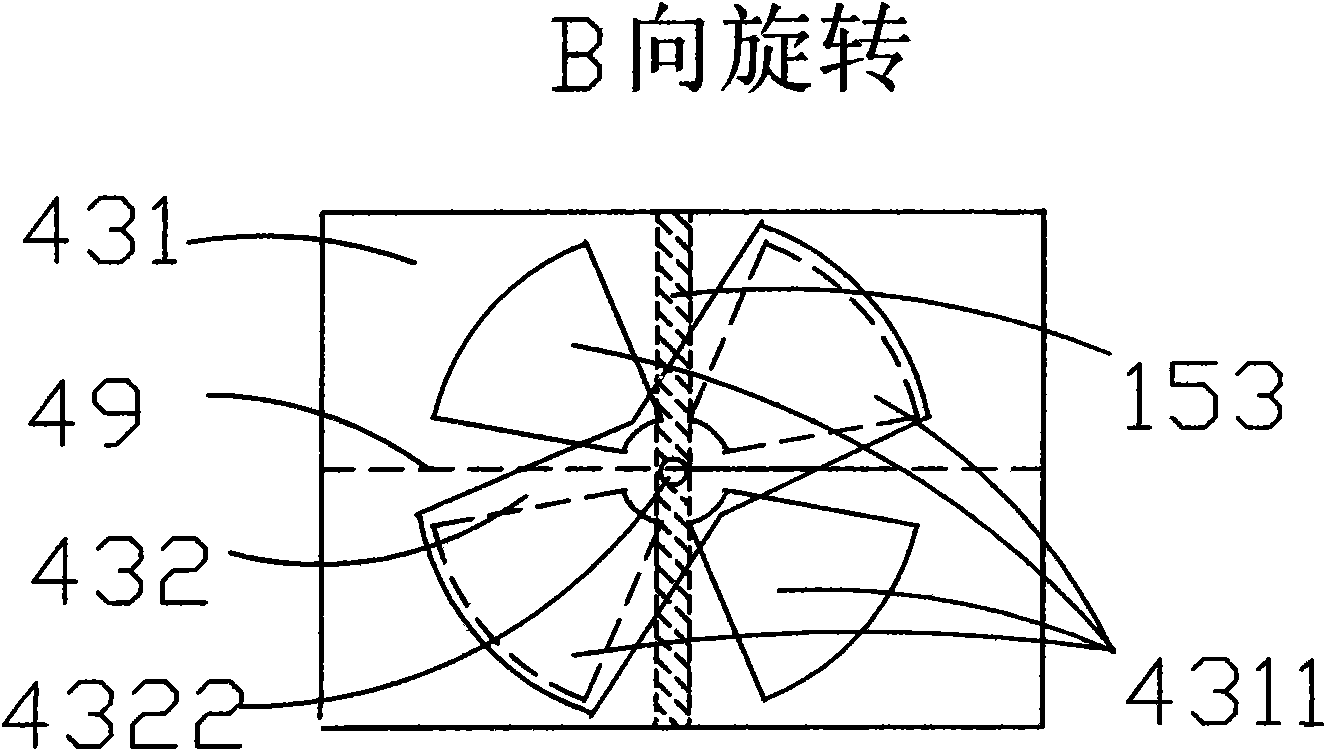

ActiveCN101813361ALow costImprove heat transfer effectEnergy recovery in ventilation and heatingHeat recovery systemsFiberAir filtration

The invention relates to an energy-saving ventilator for ventilating inside and outside an air conditioner room. The energy-saving ventilator comprises an enclosure (10), a heat exchange core (30), an air exchange device (40) and an electric control component (50), wherein the wall of the enclosure (10) is provided with a fresh air port (11) and an exhaust port (14) communicated with the outside and an air supply port (12) and an air return port (13) communicated with the inside; and through the air exchange device (40), the fresh air entering from the fresh air port and the polluted air entering from the air return port alternately exchange heat through each part of the heat exchange core from the opposite direction, and then are delivered into the inside through the air supply port and exhausted to the outside through the exhaust port. The energy-saving ventilator is characterized in that the heat exchange core is air filter cotton made of a fiber material, wherein heat exchange core contains a phase change substance of which the phase change temperature is between the indoor temperature and the outdoor temperature of the air conditioner room, the phase change substance is phase change salt or phase change polymer, and the phase change substance is added into the fiber material by using a filling method or a padding method, a microcapsule blending method or a microcapsule glue spraying method. The energy-saving ventilator has the advantages of high heat exchange efficiency, low cost, easy cleaning, long service life and capability of purifying air, so the energy-saving ventilator can be widely applied to various buildings and serve as an ideal energy-saving ventilating device for the environment-friendly energy-saving affairs.

Owner:深圳市金廷汇科技有限公司

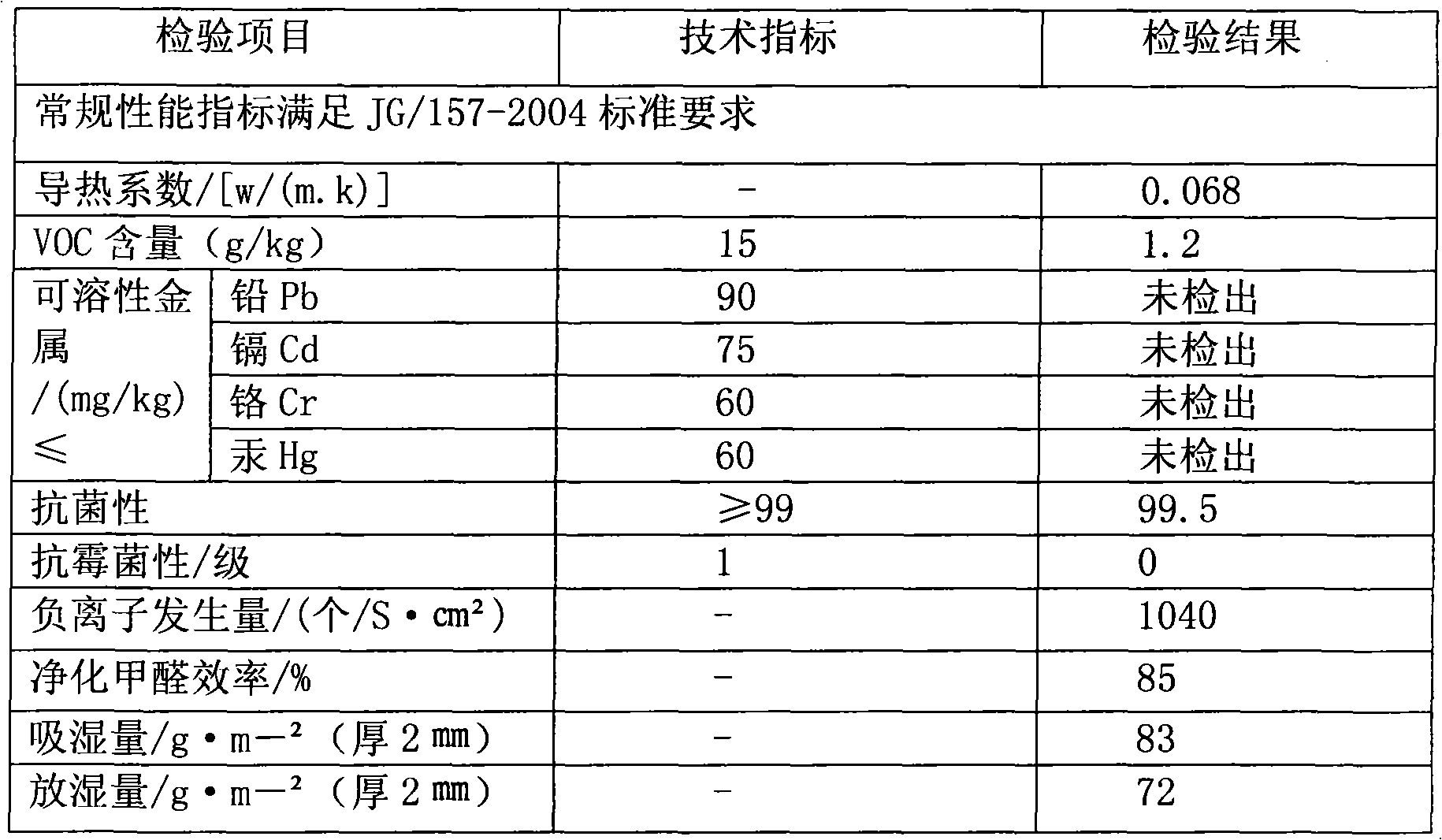

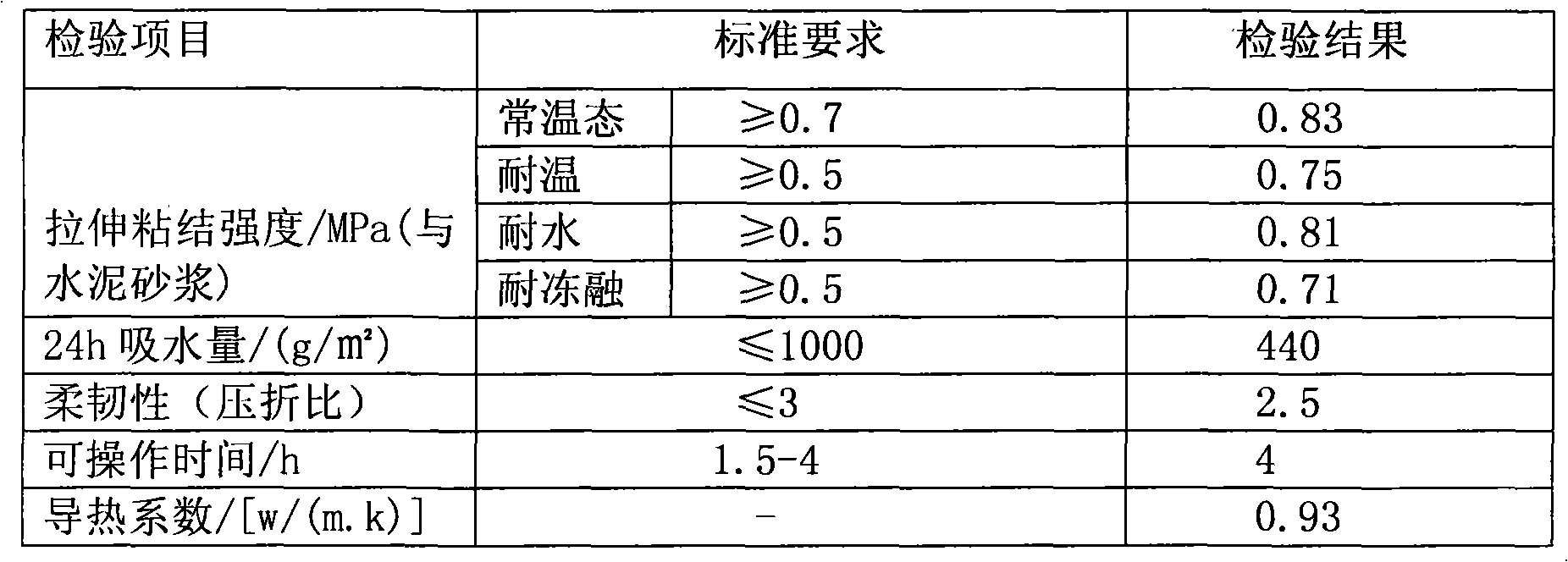

Construction method for heat-insulating wall body of building

InactiveCN102518220AReduce pollutionSave energyClimate change adaptationHeat proofingStructural engineeringMoisture absorption

The invention discloses a construction method for the heat-insulating wall body of a building. The method adopts the combined system of an inner wall heat-insulating decorative material and an outer wall heat-insulating decorative material for the wall body of the building, and comprises the following steps: plastering phase-change energy-storage inorganic / organic heat-insulating mortar, plastering phase-change energy-storage rendering mortar and mesh fabric, puttying phase-change energy-storage flexible water-fast putty, coating permeating-type elastic priming paint through rolling, and coating solar reflection heat-proof exterior wall coating through rolling on the outer wall of the wall body; plastering phase-change energy-storage desulphurized gypsum heat-insulating mortar, puttying temperature-regulating humidifying anti-bacterial flexible putty, and puttying temperature-regulating humidifying anti-bacterial interior wall coating on the inner wall of the wall body; and the like. Through the adoption of the construction method, the wall body has the functions of heat insulation, energy conservation, air purification, solar phase-change temperature adjustment, moisture absorption, moisture discharging, sound absorption, noise reduction, bacterium resistance, mold prevention, water prevention, and ventilation. Therefore, the method has the advantage that the functions of low carbon emission, pollution reduction, energy conservation, beautiful decoration and environment protection of the wall body are realized; and the method is convenient to popularize and apply.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Phase change energy storage material and preparation method thereof

InactiveCN101519581AReversible solid-solid phase change energy storage propertiesPhase transition temperature is suitableHeat-exchange elementsCellulosePolymer science

The invention discloses a phase change energy storage material and a preparation method thereof. The method comprises the following steps: 1) polyethylene glycol reacts with a crosslinking agent at the temperature of 50 DEG C to 80 DEG C for 4 hours to 8 hours and a polyethylene glycol prepolymer is obtained; and 2) the polyethylene glycol prepolymer and a cellulose ionic liquid solution react at the temperature of 60 DEG C to 80 DEG C for 4 hours to 8 hours. The mass portions of polyethylene glycol are 50 to 95 and the mass portions of the crosslinking agent are 1 to 20. The mass portions of cellulose are 2 to 40 and the concentration of the cellulose ionic liquid solution is 2 percent to 5 percent by mass percentage. The material realizes the storage and release of energy through reversible solid-solid phase conversion, the phase change temperature is at 25 DEG C to 60 DEG C, enthalpy of phase change can be up to 150 J / g, and the material is non-toxic or harmless and has high energy storage density, good thermal stabilization, no liquid leakage and phase separation, simple preparation technique and excellent application prospect in the fields of energy storage and temperature control.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Non-combustion type low temperature cigarette product based on phase change temperature-controlled fuel assembly and preparation method of aerosol generating section

InactiveCN105167182AAvoid conduction heatingLow conduction heatingCigar manufactureFiberProduct base

The invention relates to a non-combustion type low temperature cigarette product based on a phase change temperature-controlled fuel assembly. The cigarette product comprises a phase change temperature-controlled fuel assembly section, an aerosol generating section and a filter section which are sequentially connected. Energy released in a combustion process is transmitted to the aerosol generating section through mainstream smoke, and under the action of a phase change heat storage material, adsorbing purification and oxidation catalysis on CO are achieved, so that unexpected pyrolysis on a smoke matrix due to excessive temperature is avoided. The aerosol generating section is prepared by uniformly blending and mixing the smoke matrix and high-thermal-conductivity MPCF carbon fiber long filaments or short filaments, so that the temperature of an aerosol generating system is reduced in a gradient mode in the axial direction of the cigarette and the entire aerosol generating section is uniformly heated; therefore, a smoking experience is prevented from being rapidly decreased with increase in smoking times. The phase change temperature-controlled fuel assembly section and the aerosol generating section are integrally covered and rolled by virtue of heat-insulating cigarette paper, so that consumption of heat energy is reduced, and effective thermal excitation of the smoke matrix is achieved under relatively low heat distribution.

Owner:叶菁 +2

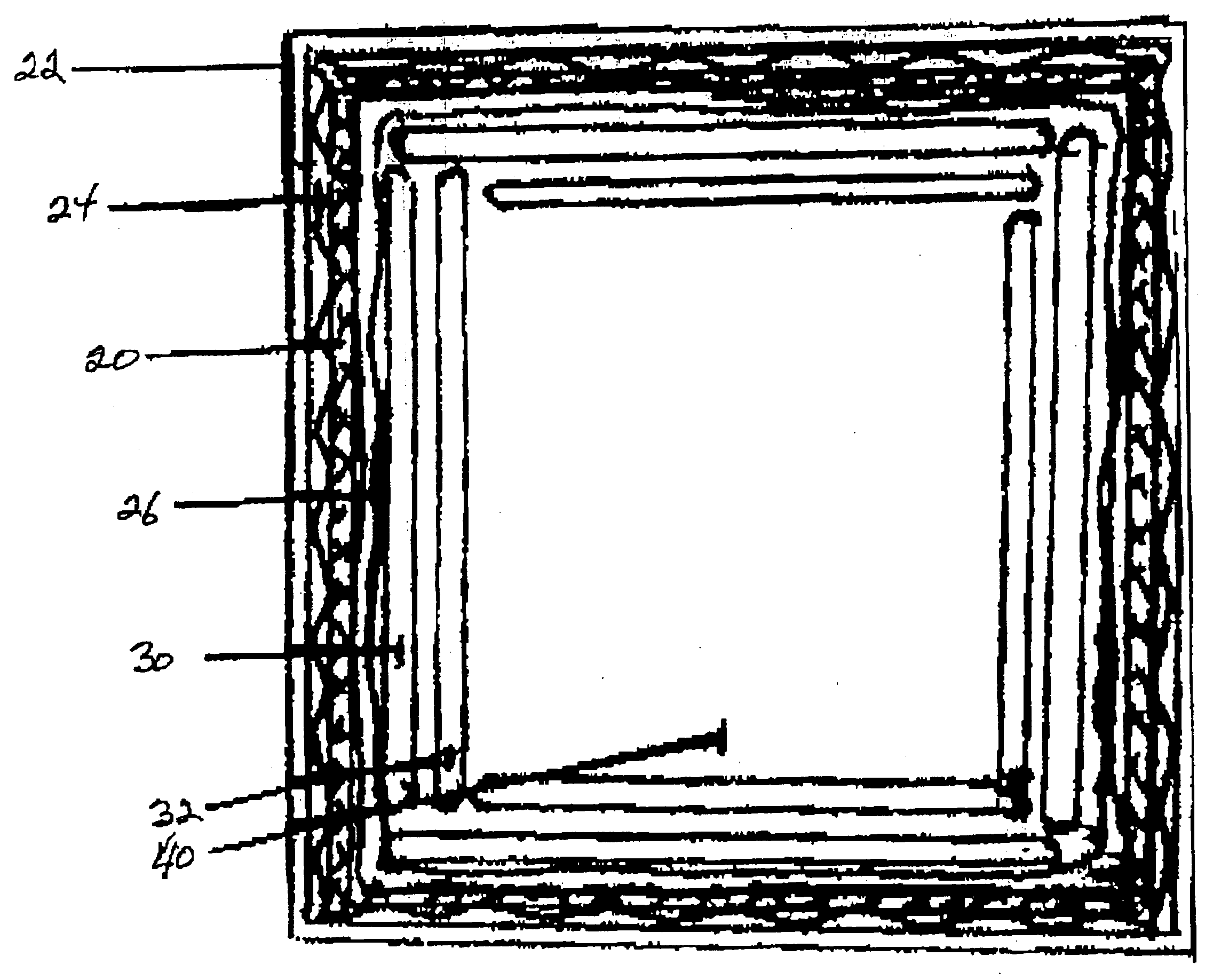

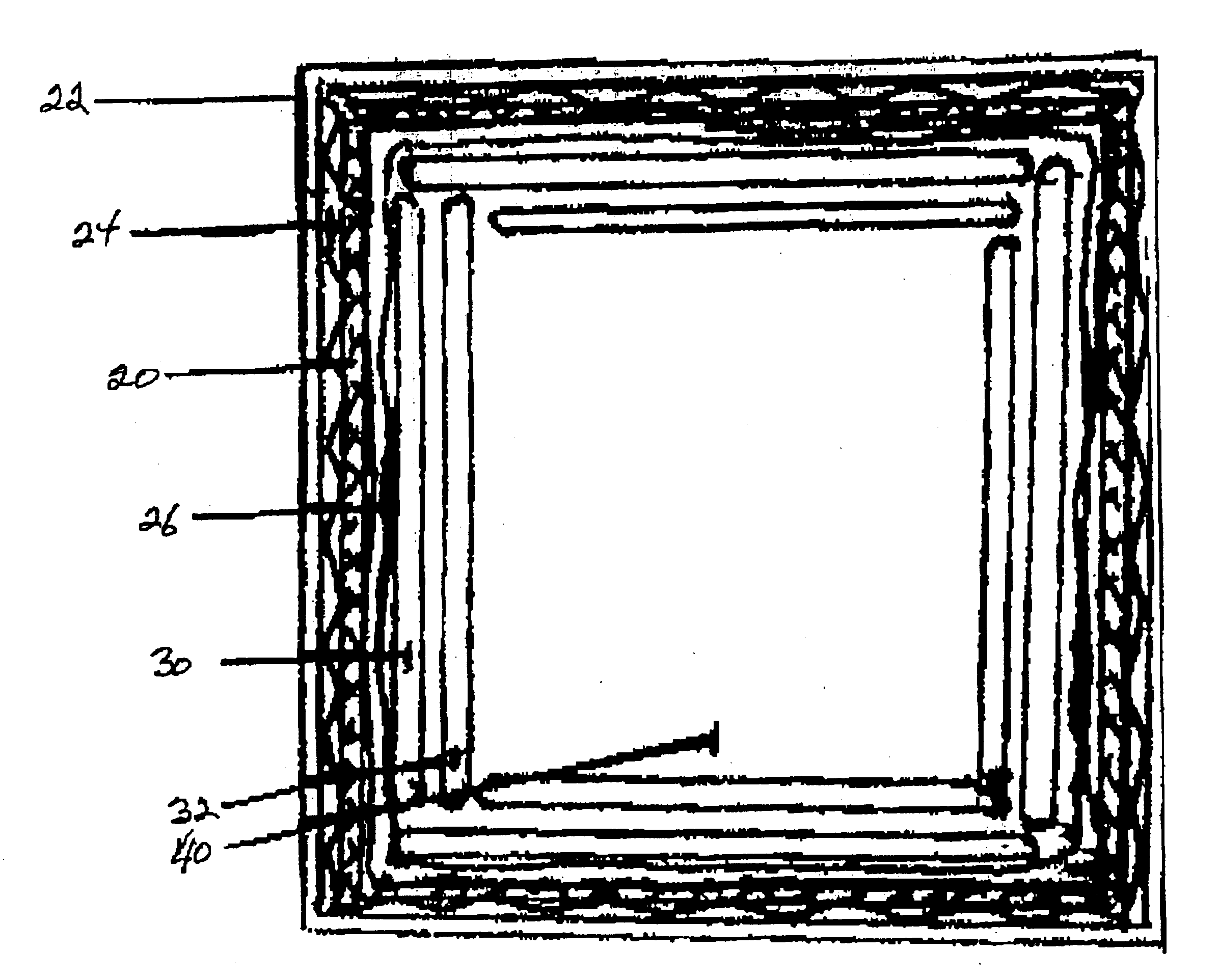

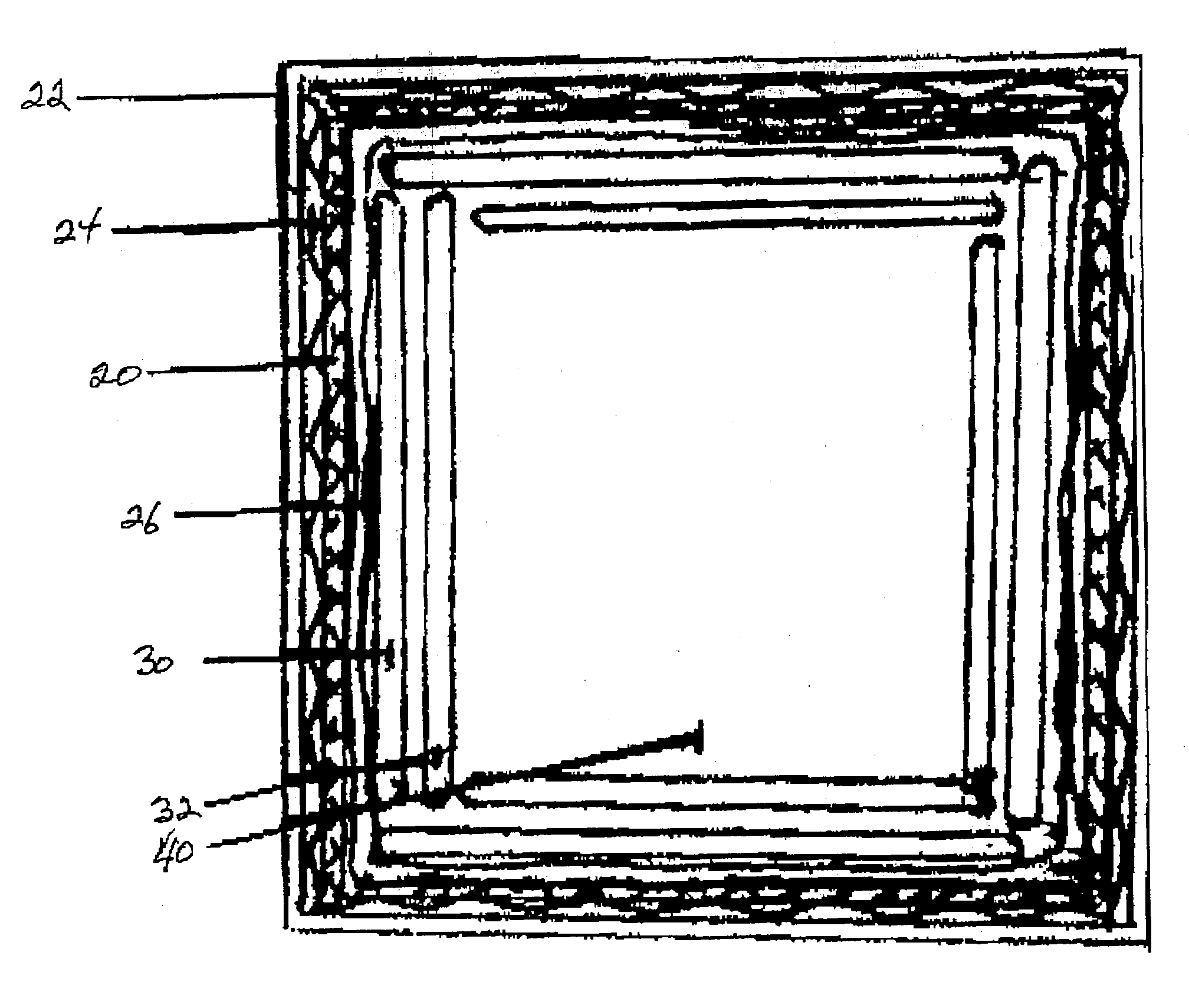

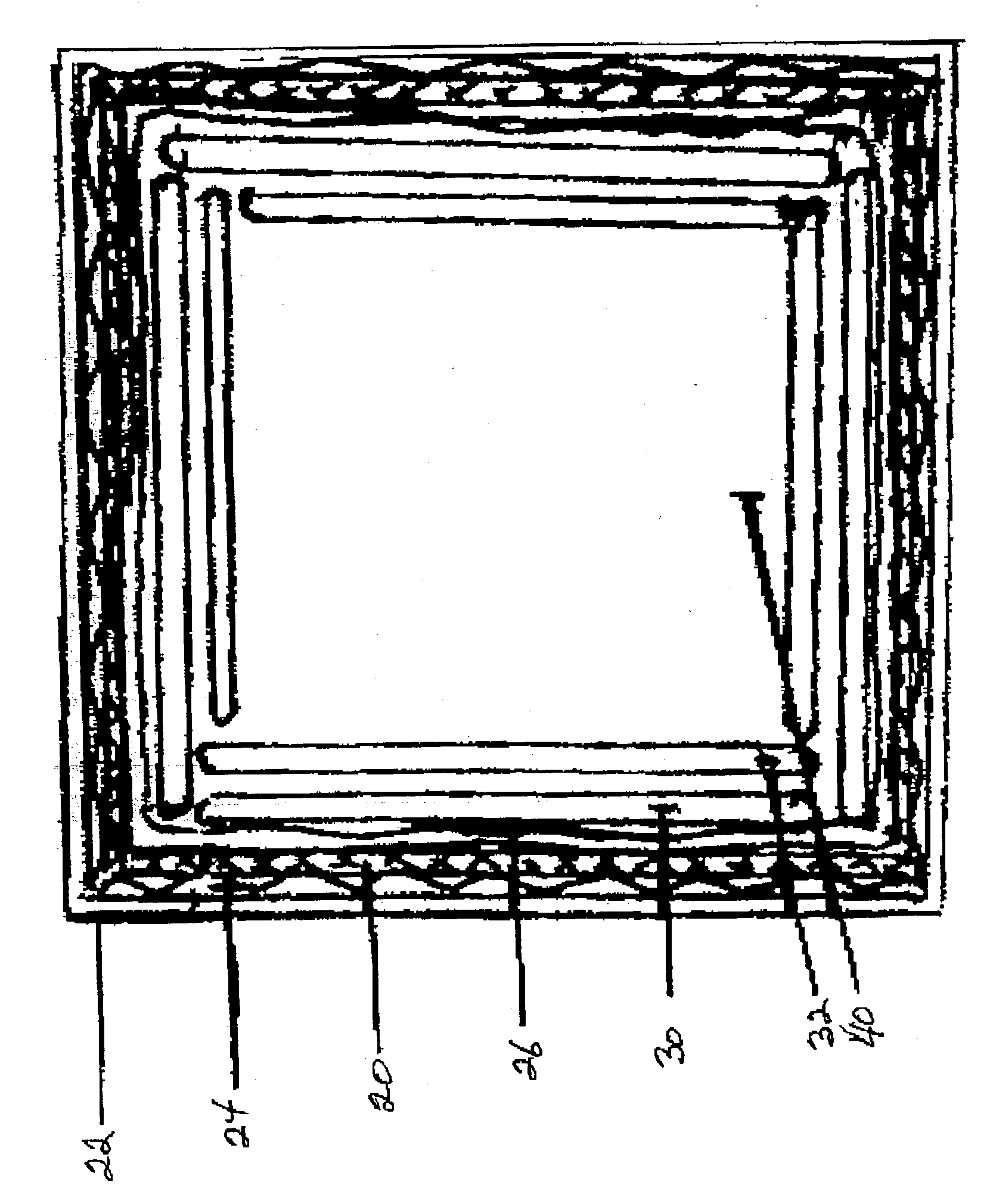

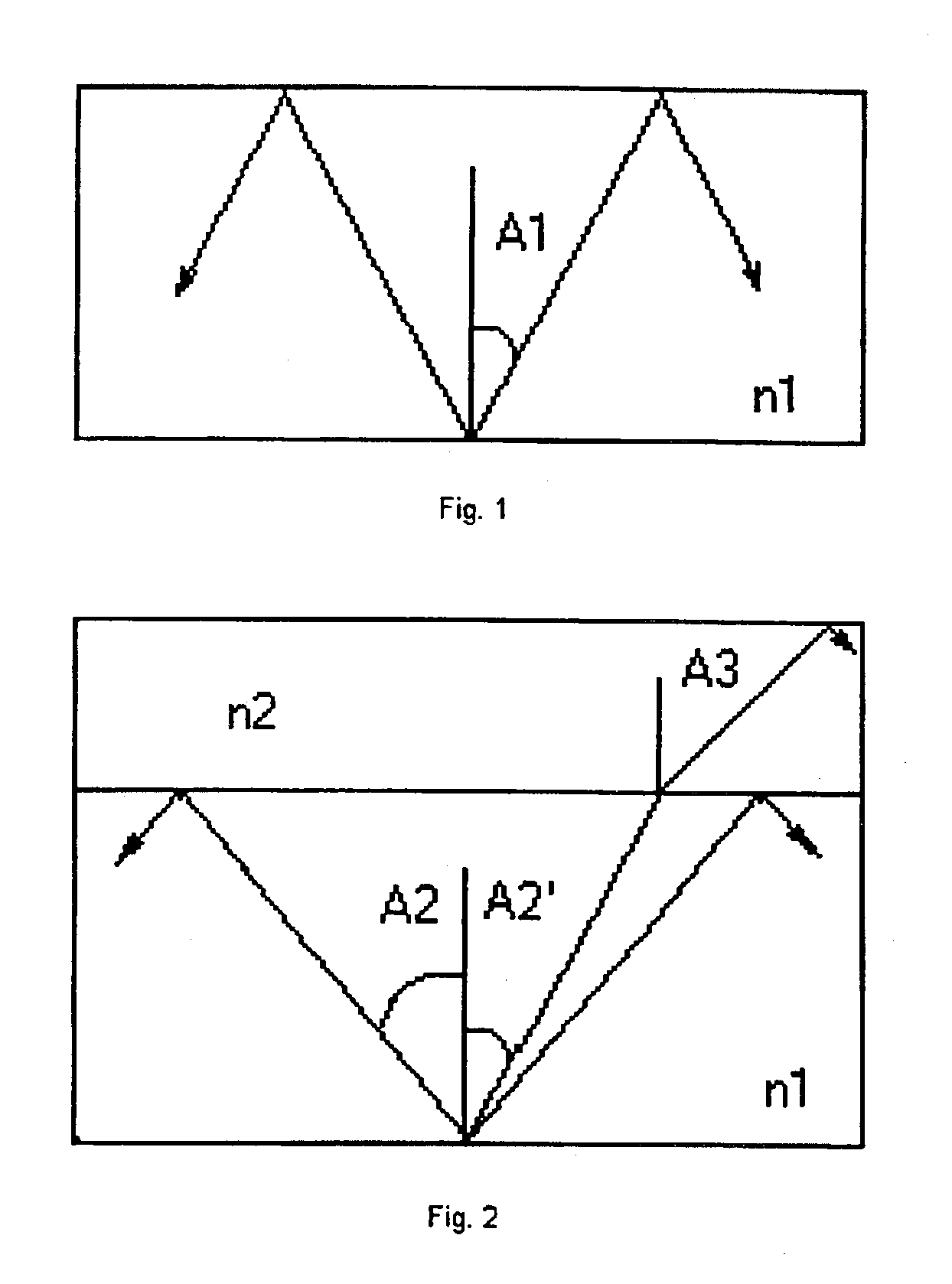

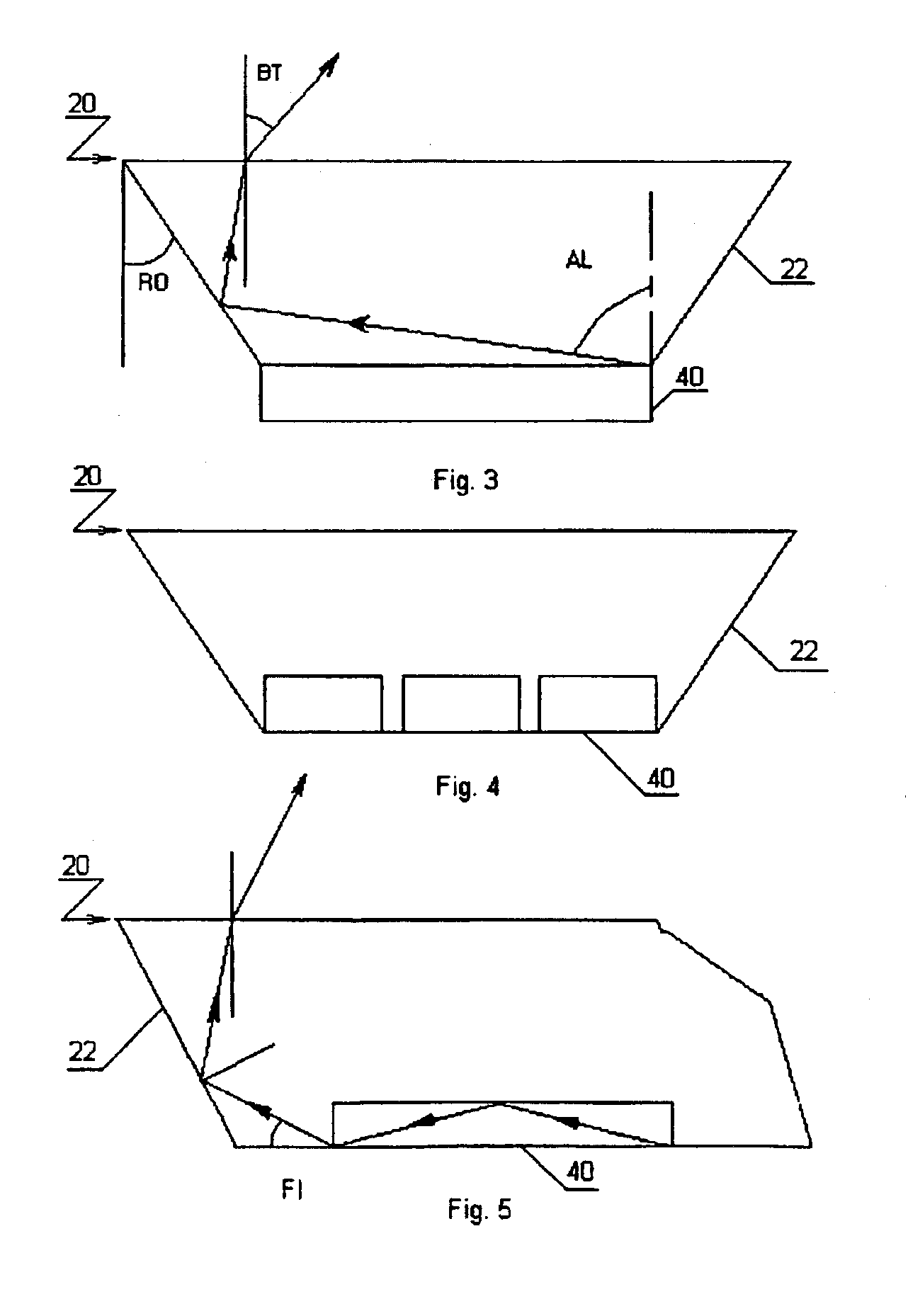

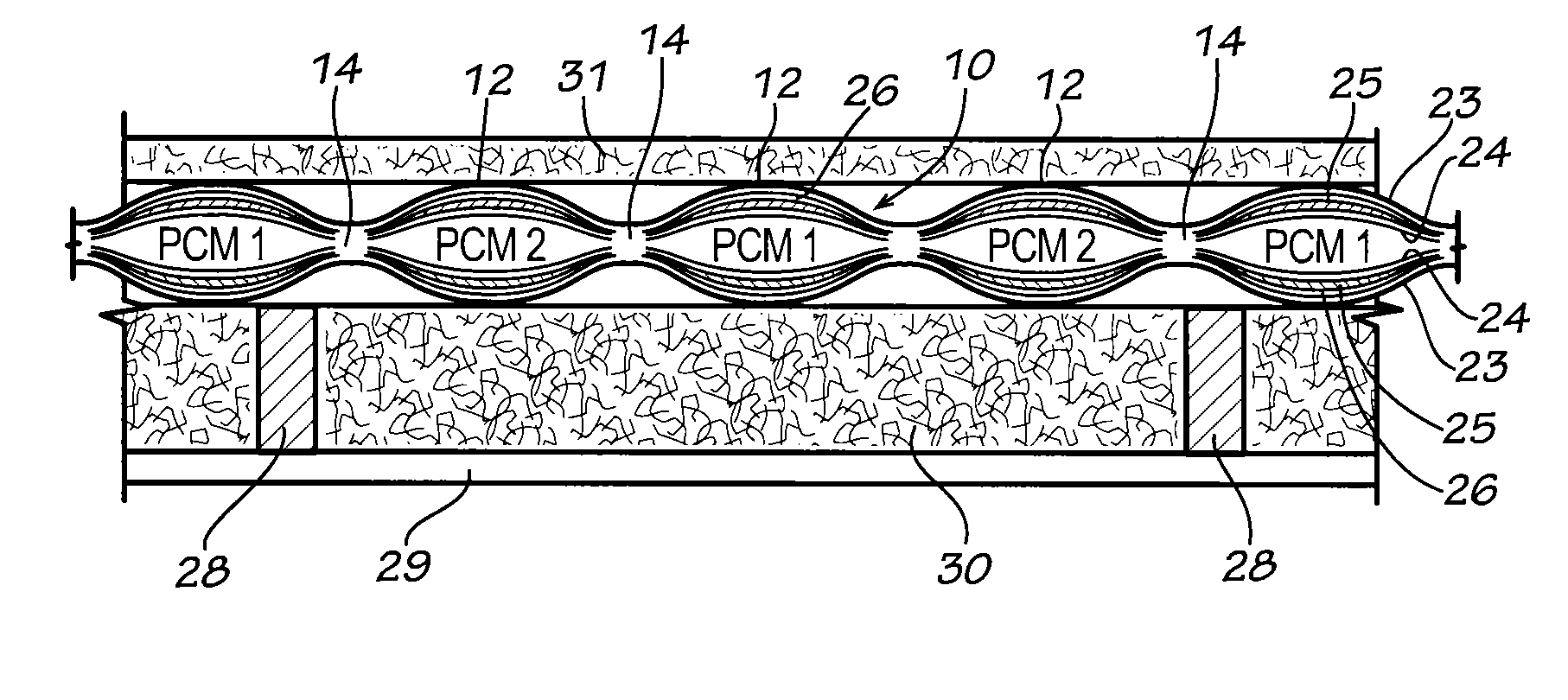

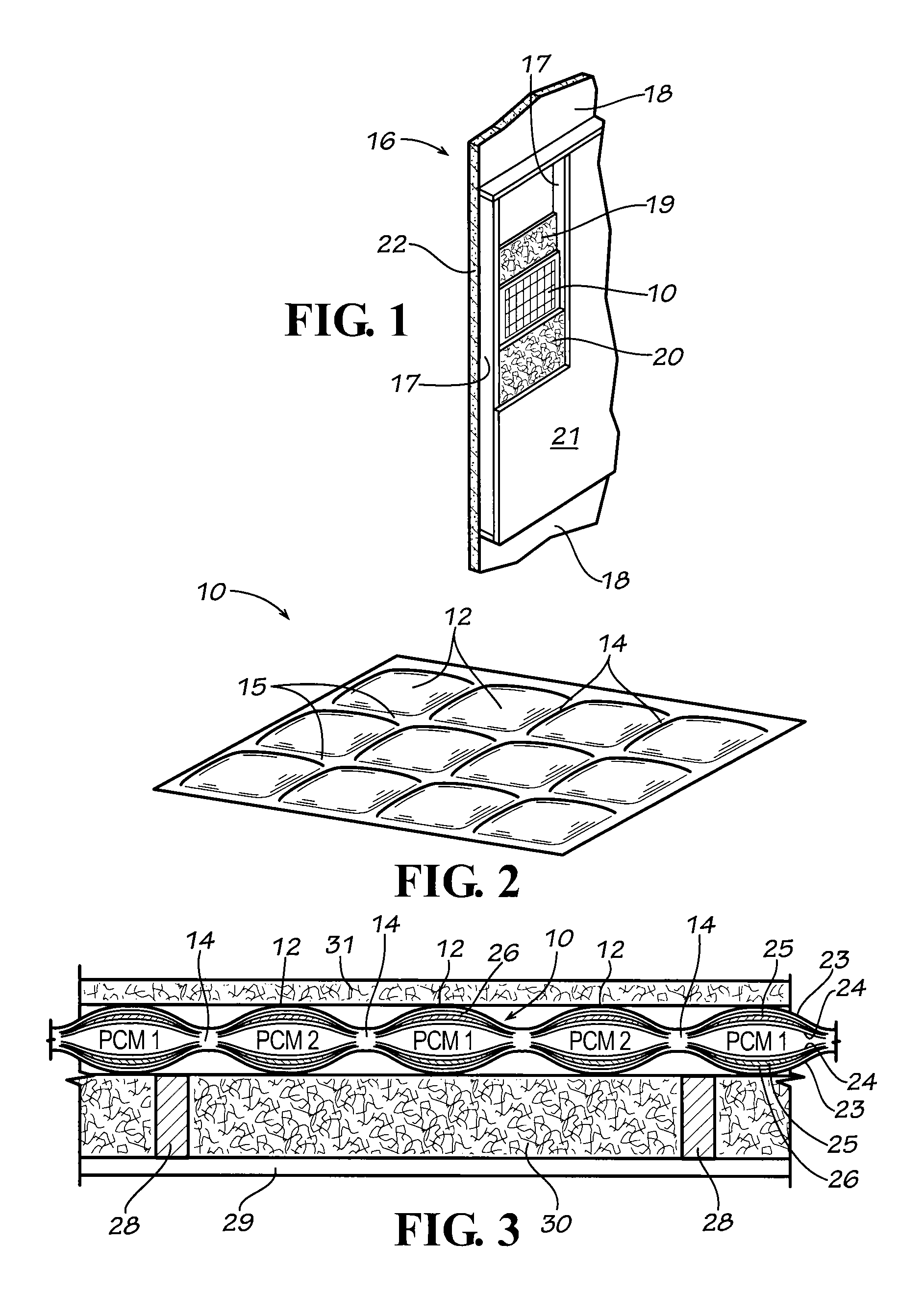

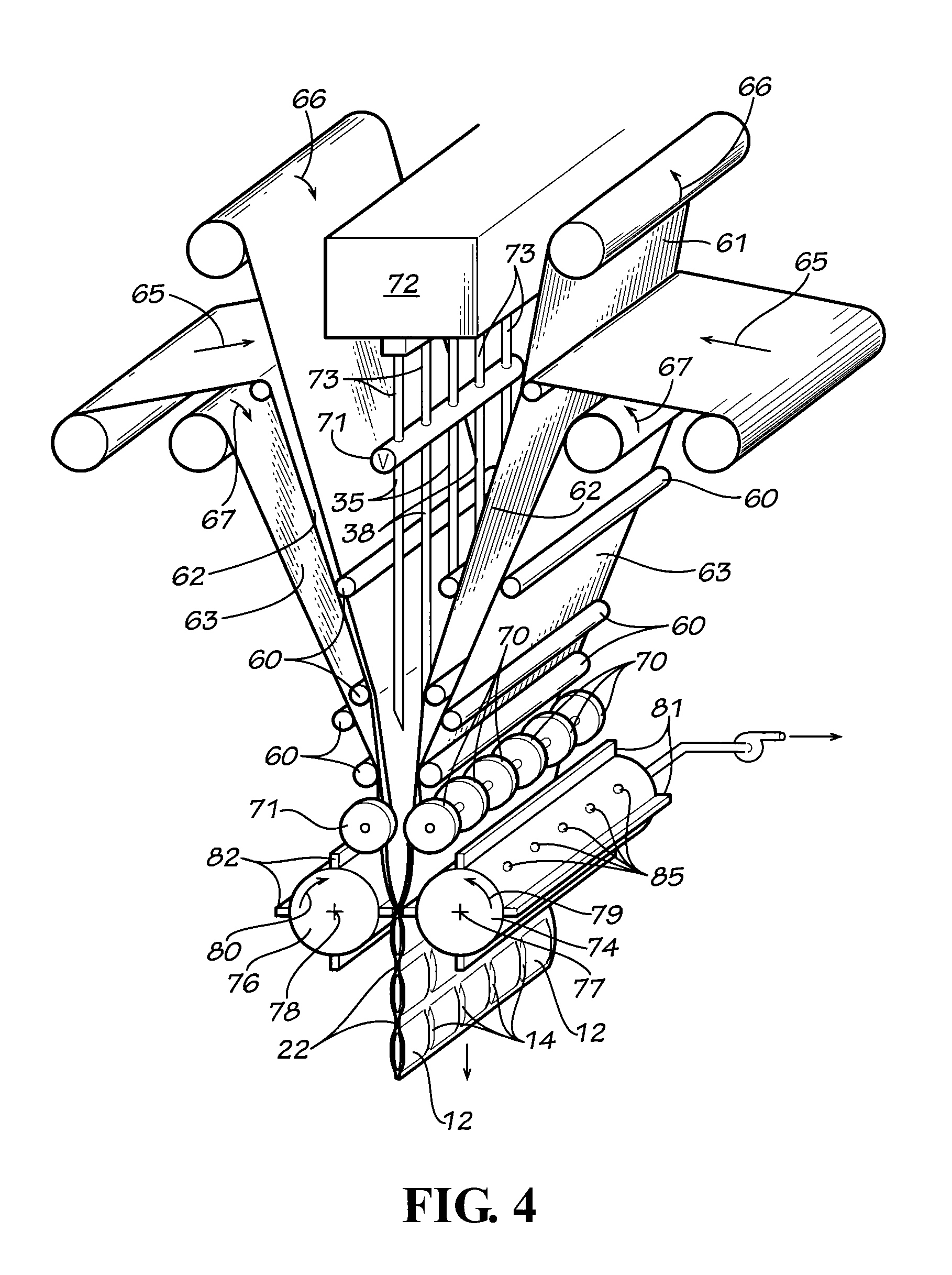

Multiple phase PCM heat insulation blanket

A PCM heat insulation blanket (10) is positioned in a wall structure of a building for modulating the transfer of heat to and from the controlled internal temperature of the building structure. The PCM heat insulation blanket includes an array of pods (12) with one group of pods 12A containing a first PCM and a second group of pods containing a second PCM 12B having a different phase change temperature than the first group of pods. The pods with different PCMs are substantially uniformly intermixed among each other. The pods are formed of laminated sheets, each of which may include a metal foil that is vapor impermeable and tends to maintain the PCMs in the blanket at approximately the same temperature, and which also functions to reflect radiant heat away from the temperature controlled internal space of the building structure.

Owner:ACTIVE INTEGRATION

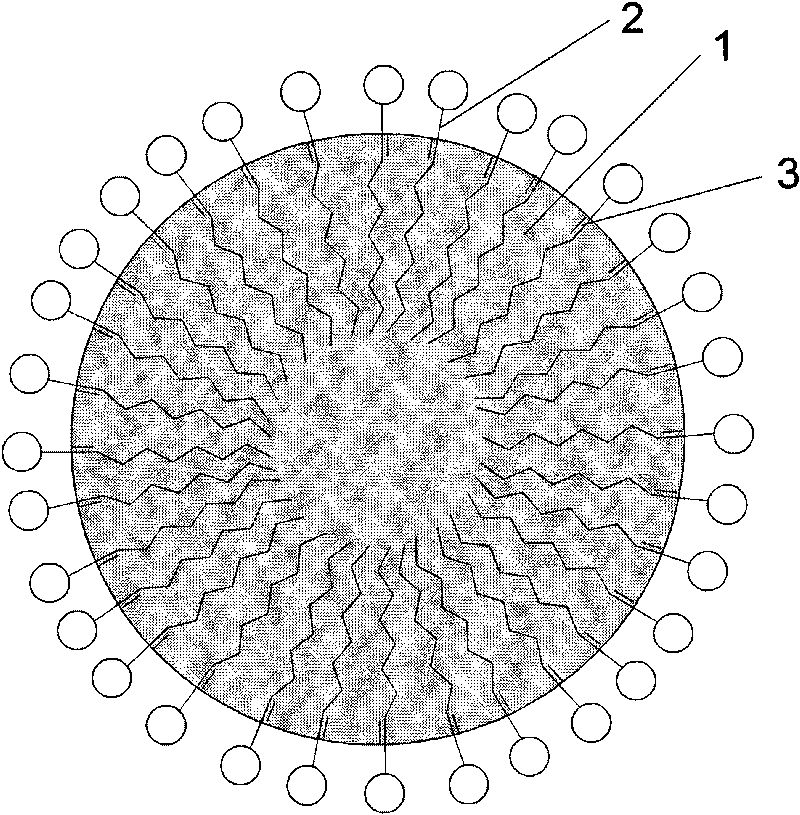

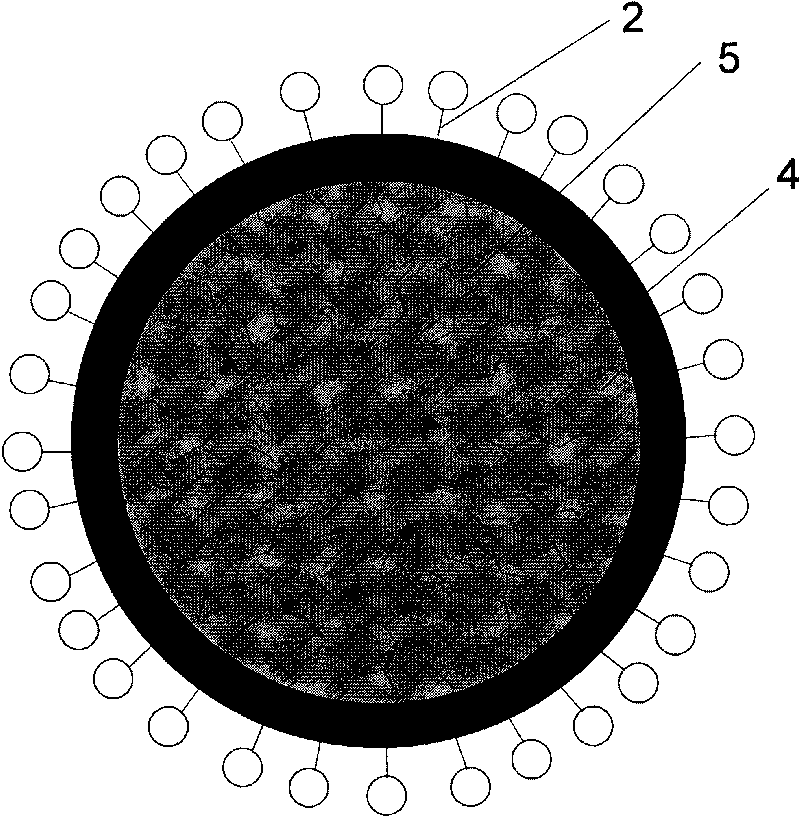

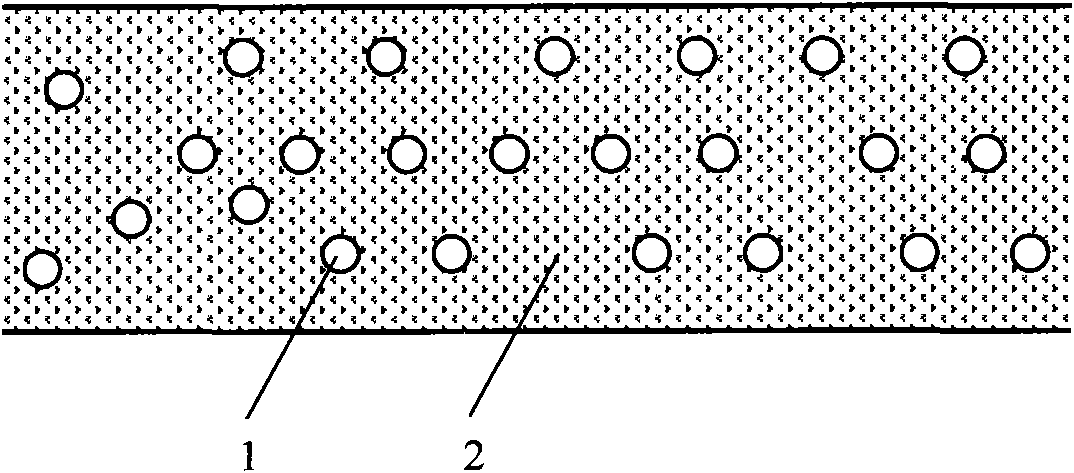

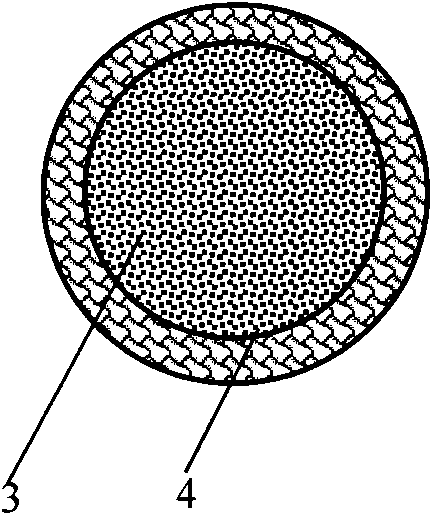

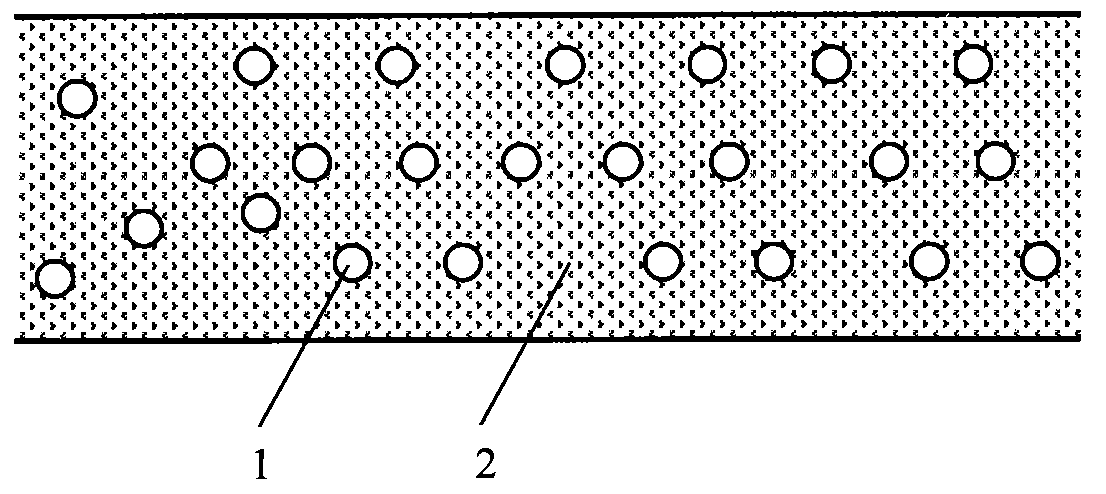

Liquid metal fluid containing phase-change microcapsules

InactiveCN101775270AHigh apparent specific heatIncrease surface tensionHeat-exchange elementsMicroballoon preparationIndiumIn situ polymerization

The invention discloses a liquid metal fluid containing phase-change microcapsules, which adopts phase-change microcapsules (1) as a solute and liquid metal (2) as a solvent, wherein the phase-change microcapsules (1), which are prepared by using an in-situ polymerization method or other methods to embed a phase-change material (3) into an outer casing (4), are spherical and has the diameter of 1nm-1mm; and the liquid metal (2) can be mercury, gallium, gallium-indium alloy or gallium-indium-tin alloy. The invention has the advantages that the liquid metal fluid containing the phase-change microcapsules has a large apparent ratio in the phase-change temperature area of a phase-change material, the phase-change microcapsules (1) are difficult to be deposited or aggregated, the liquid metal fluid has favorable performances in the aspects of calorifics, electrics, magnetics, and the like, and the thermal properties of traditional liquid metals can be enhanced greatly. The liquid metal fluid is a cooling medium suitable for various heat radiating occasions with high heat flux density, and can be widely applied to the fields of computer chips, satellites, rocket propulsion booster and lasers.

Owner:CHONGQING UNIV

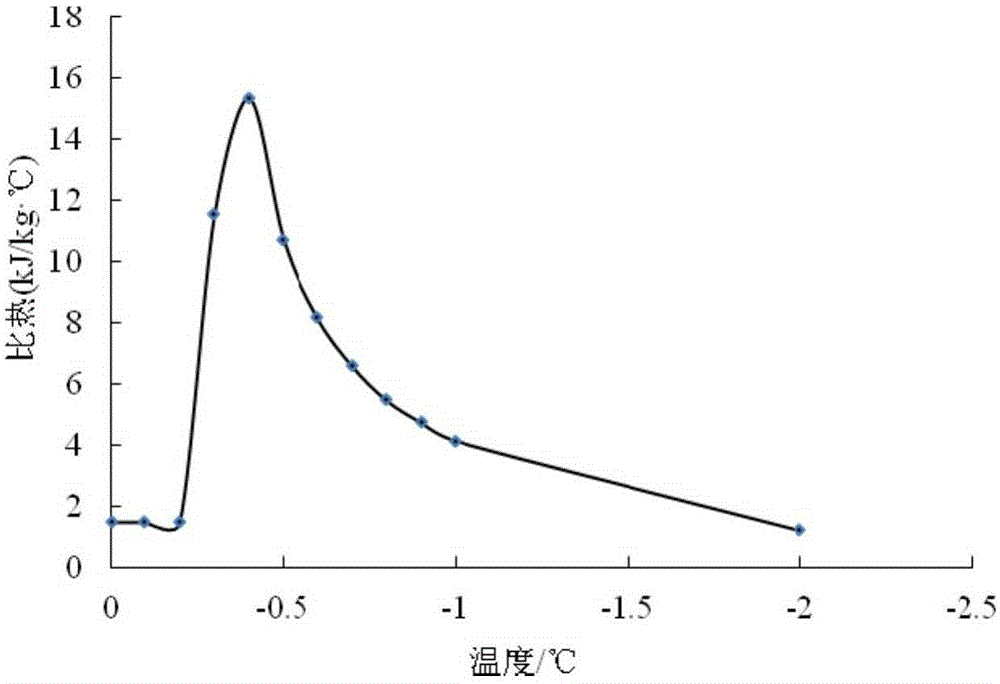

Method for determining content of unfrozen water in soil freezing process by using specific heat calculation

InactiveCN105241920ACalculations are clearThe theoretical basis is simple and sufficientMaterial heat developmentMaterial moisture contentPhase changePhysical property

The invention provides a method for determining the content of unfrozen water in a soil freezing process by using specific heat calculation. The method comprises the following steps: adopting the total heat of one temperature measuring point as the sum of soil particle heat, pore water heat, pore ice heat and heat released by phase change of water in soil; determining the physical properties of a soil sample by using indoor geotechnical test, and determining the phase change temperature range of the soil sample through freezing test; determining the specific heat of frozen heat at the corresponding temperature measuring point by using a calorimeter through mixed calorimetry; and expressing the four heats and the total heat by using the specific heat, deriving the unfrozen water content-specific heat function relation, and calculating to obtain the content of the unfrozen water at every temperature measuring point. The method for measuring the content of the unfrozen water has the advantages of simple operation and small test result error. General labs and construction units can use a simple calorimeter to measure and calculate the content of the unfrozen water.

Owner:TIANJIN CHENGJIAN UNIV

Energy-accumulating temp-controlled thermoplastic cross-link high-molecular composite material with solid-solid phase change and its preparing process

InactiveCN1482204AHigh energy storage densityImprove thermal stabilityHeat-exchange elementsCross-linkThermoplastic

The present invention features that the material has crosslinked crystalline polyolefin as base body and crystalline alkyl hydrocarbon dispersed inside the crosslinked net as the composite material for phase change energy accumulation. In the composite material, the phase change energy accumulating component accounting for 40-80 % has solid-solid phase conversion at phase change temperature of 20-80 deg.c and phase change enthalpy greater than 80 J / g. The composite phase change material has relatively high energy accumulating density and excellent heat stability, may be used as energy accumulating material for the accumulation of solar energy and industrial afterheat, constant temperature in building and energy saving in air conditioner and as temperature control material in electronic instrument, machinery, etc. widely.

Owner:云南玮昊能源发展有限公司

Multifunctional ventilation air-conditioning fan

ActiveCN101813362AGood energy saving effectSave enough costEnergy recovery in ventilation and heatingSpace heating and ventilation safety systemsFiberAir filtration

The invention provides a multifunctional ventilation air-conditioning fan which is used for air wetting and cooling or energy recovery and ventilation of an air-conditioning room. The multifunctional ventilation air-conditioning fan comprises a machine shell (10), a fan component (20), a ventilated carrier (30) of a medium for heat exchange or water certain for water evaporation, an air distributing device (40), a water supply system (50) and an electronic control component (60); a fresh air inlet (11), an air outlet (14), an air distributor (12) and a return air inlet (13) are arranged on the wall of the machine shell; the ventilated carrier is made of air filtering cotton comprising outlast containing a phase-change substance, wherein the phase change temperature of the phase-change substance is between the indoor temperature and the outdoor temperature of the air-conditioning room, the phase-change substance generates solid-liquid phase change when heated or cooled, the phase change can absorb or release large amount of latent heat, and therefore, large amount of heat energy can be transmitted between two flows of heat exchange air. The invention can be implemented in the structure types of a rotary valve type, a rotating wind channel type, a scroll type and a rotating wheel type and has the advantages of simple structure, low production cost and multiple functions of energy saving and ventilation, cooling and air wetting and fresh air purification; and moreover, the multifunctional ventilation air-conditioning fan can completely replace an air conditioner in a dry area and greatly save equipment investment and operation cost, therefore the multifunctional ventilation air-conditioning fan is an economical, environment friendly, high-efficiency and energy-saving product and has high social and economic benefits.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com