Energy-storing building wall structure containing double-layer phase-change material plate

A phase change material and building wall technology, applied in building components, building structures, buildings, etc., to reduce heat loss, make and install simple and fast, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

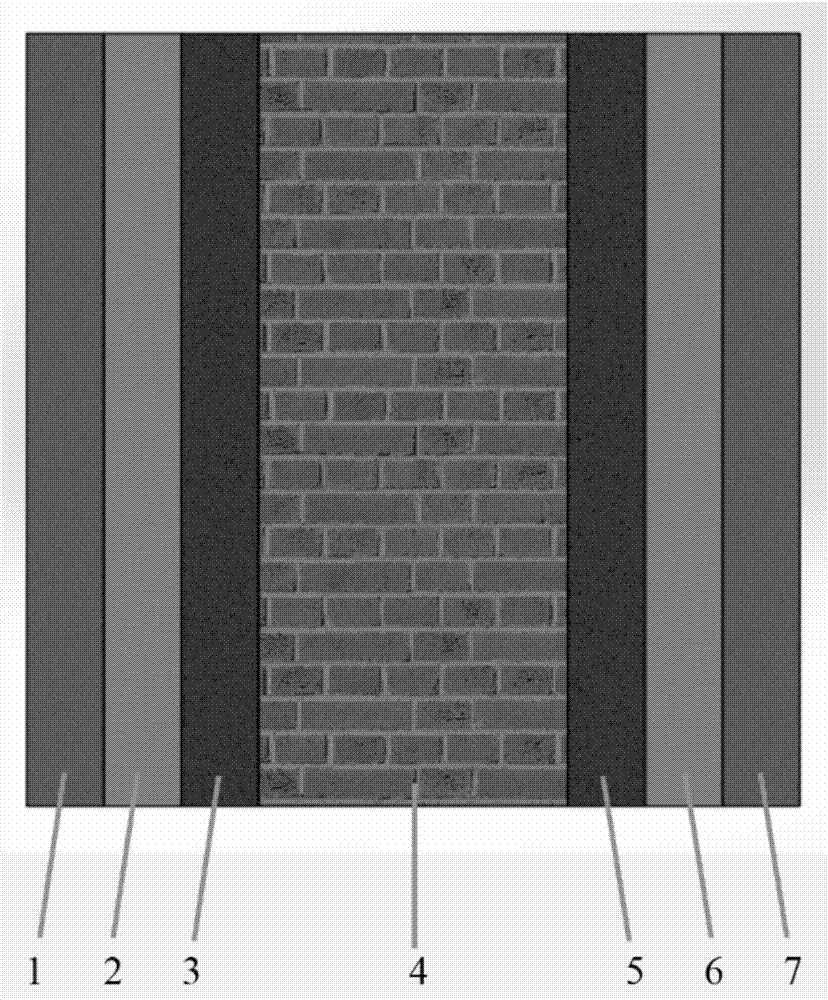

[0025] The aluminum veneer with a thickness of 3mm is selected as the exterior panel, the 10mm polystyrene foam board is used as the interior and exterior insulation panels, the 200mm concrete wall is used as the wall layer, and the 2mm aluminum gusset is used as the interior panel.

[0026] Mix anhydrous calcium chloride and distilled water in a molar ratio of 1:6 to obtain calcium chloride hexahydrate, add strontium chloride hexahydrate with 2% mass of calcium chloride hexahydrate as a nucleating agent, and calcium chloride hexahydrate 0.5% by mass of hydroxyethyl cellulose is used as a thickening agent, and the mixture is uniform to obtain an inorganic hydrated salt with low supercooling and no phase separation; % mass ratio of the two to obtain calcium chloride hexahydrate / expanded graphite composite phase change material. The obtained material has a phase transition peak temperature of 30° C., a phase transition enthalpy value of 120 J / g, no supercooling and phase separat...

Embodiment 2

[0031]With reference to Example 1, the difference is that the wall body does not have an internal thermal insulation board, and the inorganic hydrated salt adopted by the external shape-setting phase change material board is a co-mixture obtained by mixing calcium chloride hexahydrate and magnesium nitrate hexahydrate in a mass ratio of 92:8. Instead of crystalline salt, the phase transition peak temperature of the obtained material is 28°C, the phase transition enthalpy value is 100J / g, the degree of undercooling is small, there is no phase separation phenomenon, and the stability is good. The test results of Example 1 show that, compared with the reference room, in summer, the indoor temperature fluctuation of the phase change room is reduced by 2.6 °C, and the peak temperature appearance time is delayed by 1.5 hours; in winter, the indoor temperature fluctuation of the phase change room is reduced by 1.7 ℃. ℃, the peak temperature appeared time delayed by 1h. It can be seen...

Embodiment 3

[0033] The aluminum-plastic board with a thickness of 4mm is selected as the exterior panel, the 10mm mineral wool board is used as the external insulation board, the 240mm brick wall is used as the wall layer, the 20mm polystyrene foam board is used as the internal insulation board, and the 12mm gypsum board is used as the interior. panel.

[0034] After the sodium sulfate decahydrate is heated and melted at a constant temperature, borax of 3% by mass of sodium sulfate decahydrate is added as a nucleating agent, and carboxymethyl cellulose of 1% by mass of sodium sulfate decahydrate is used as a thickener to obtain low supercooling, no Phase-separated inorganic hydrated salt; according to the mass ratio of the obtained low-supercooled, non-phase-separated inorganic hydrated salt 50% and expanded perlite carrier 50%, the two are compounded to obtain sodium sulfate decahydrate / expanded perlite composite phase change material. The obtained material has a phase transition peak te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Phase transition peak temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com