Patents

Literature

1874results about How to "Improve thermal insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

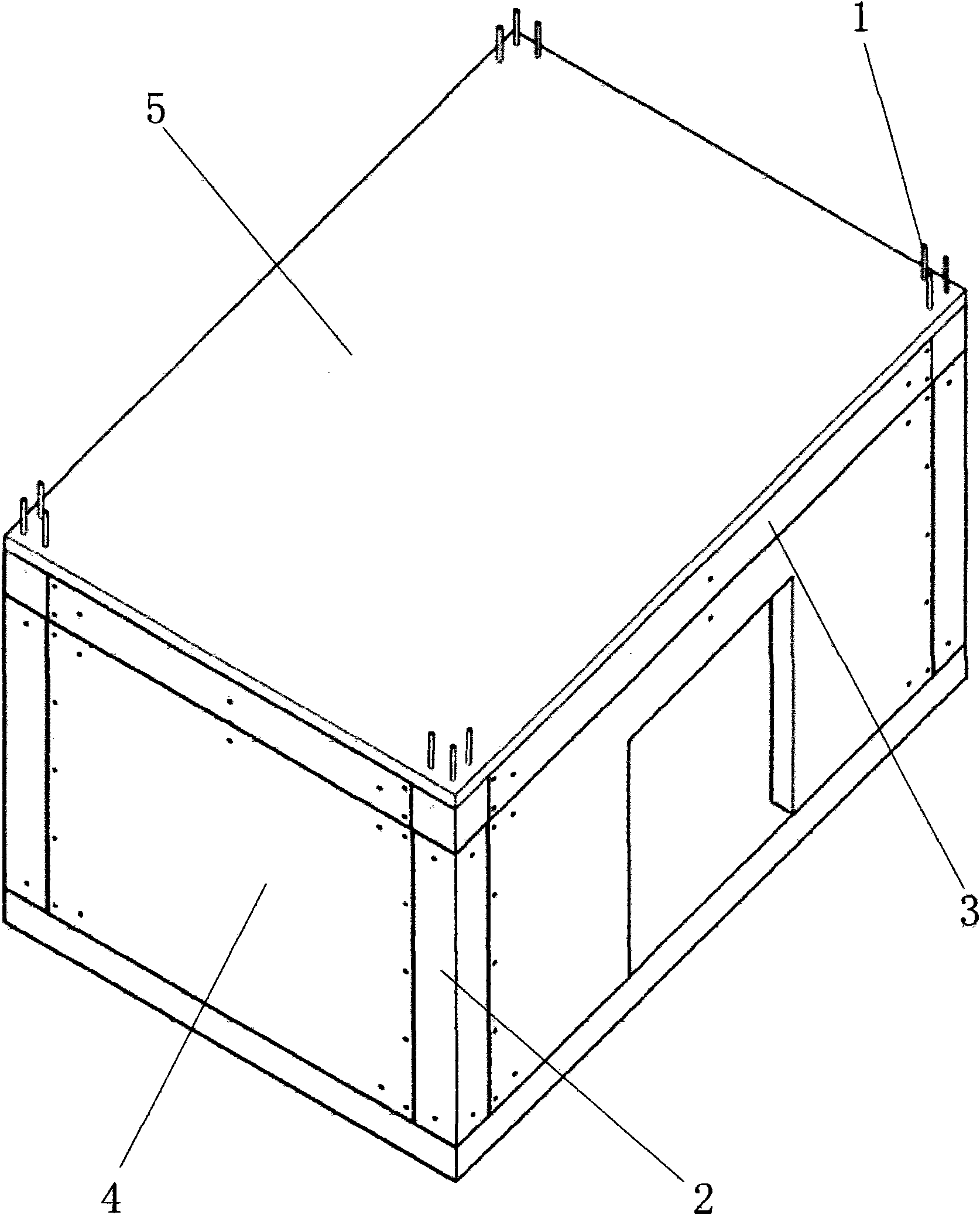

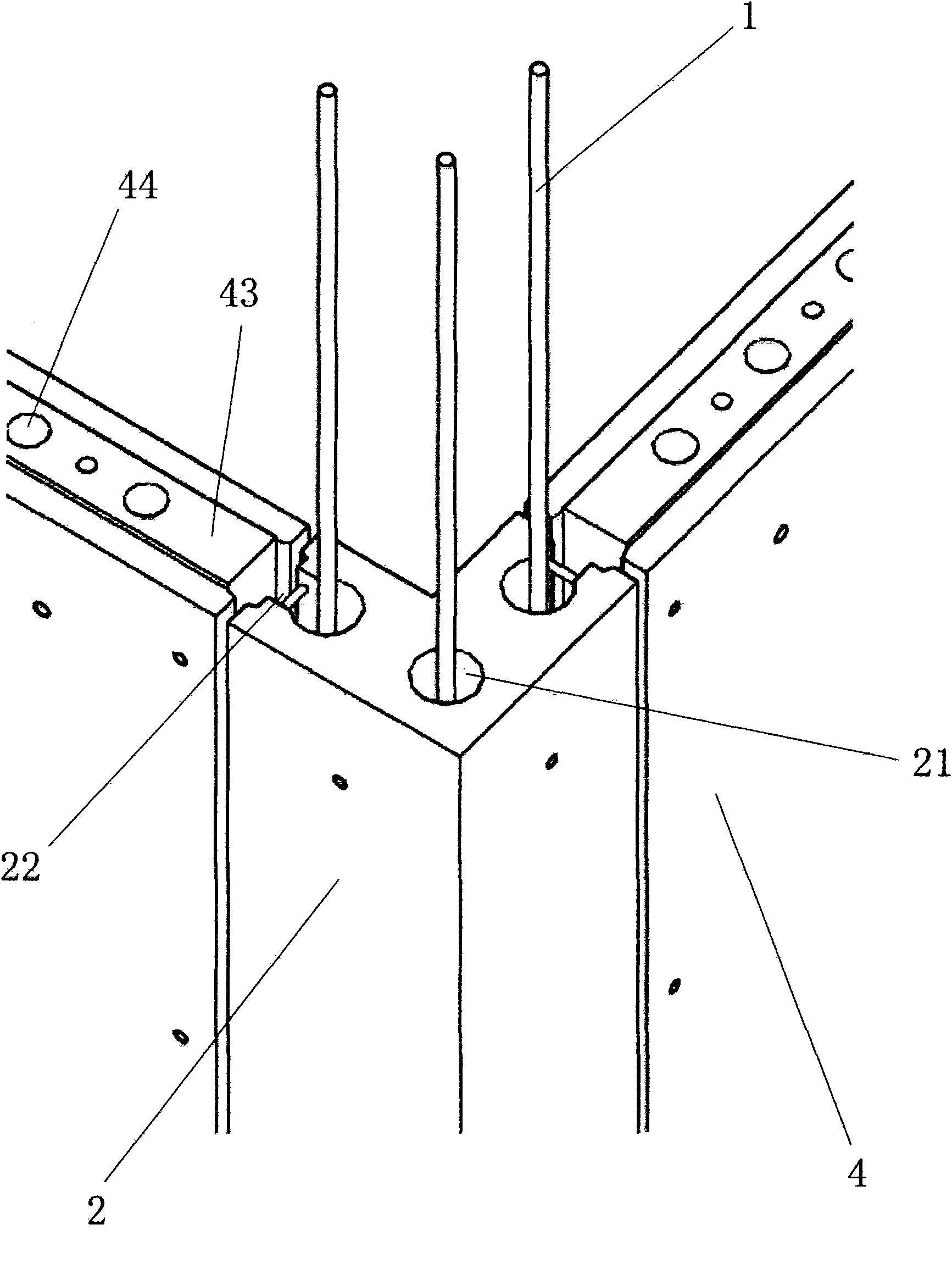

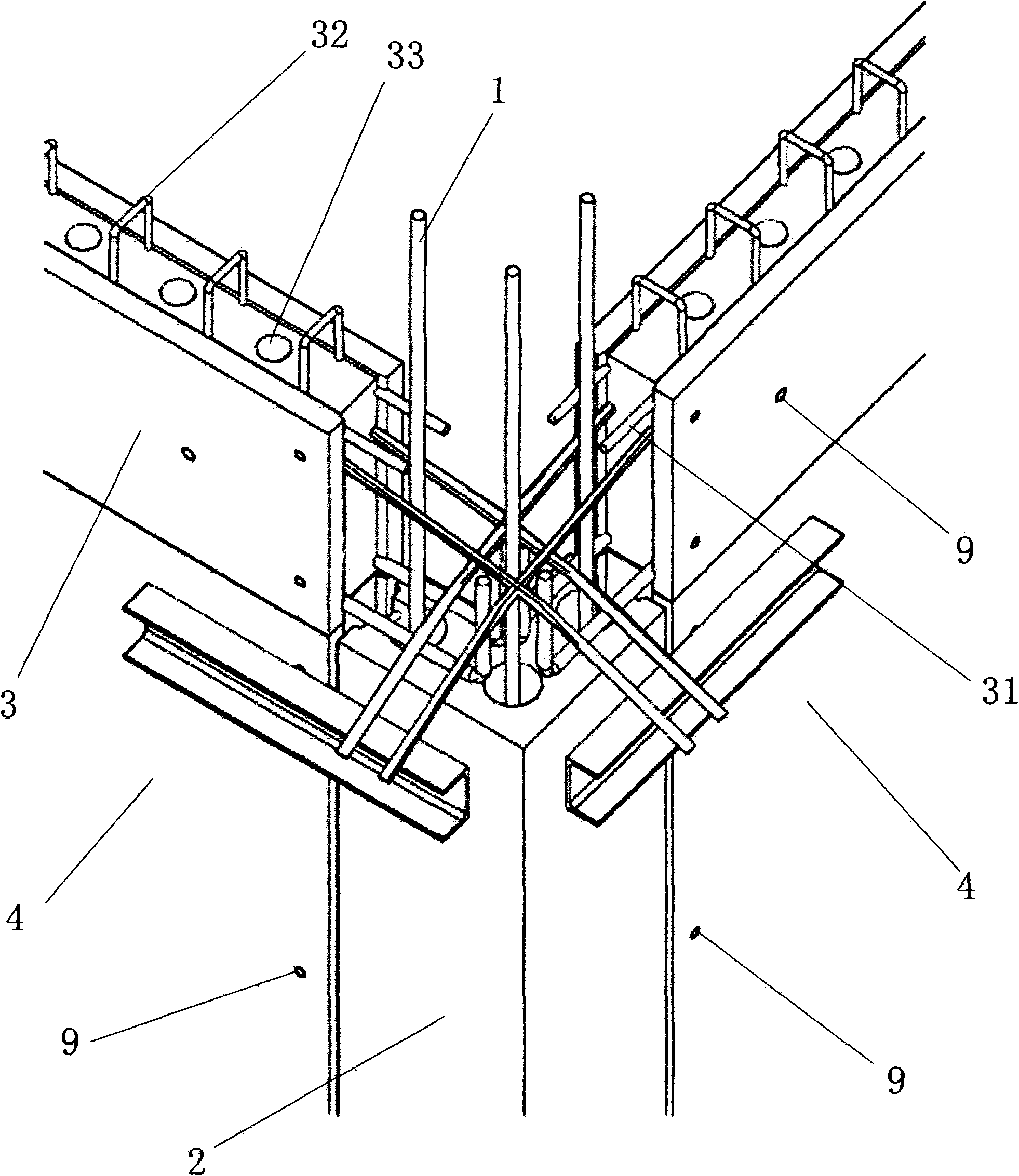

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

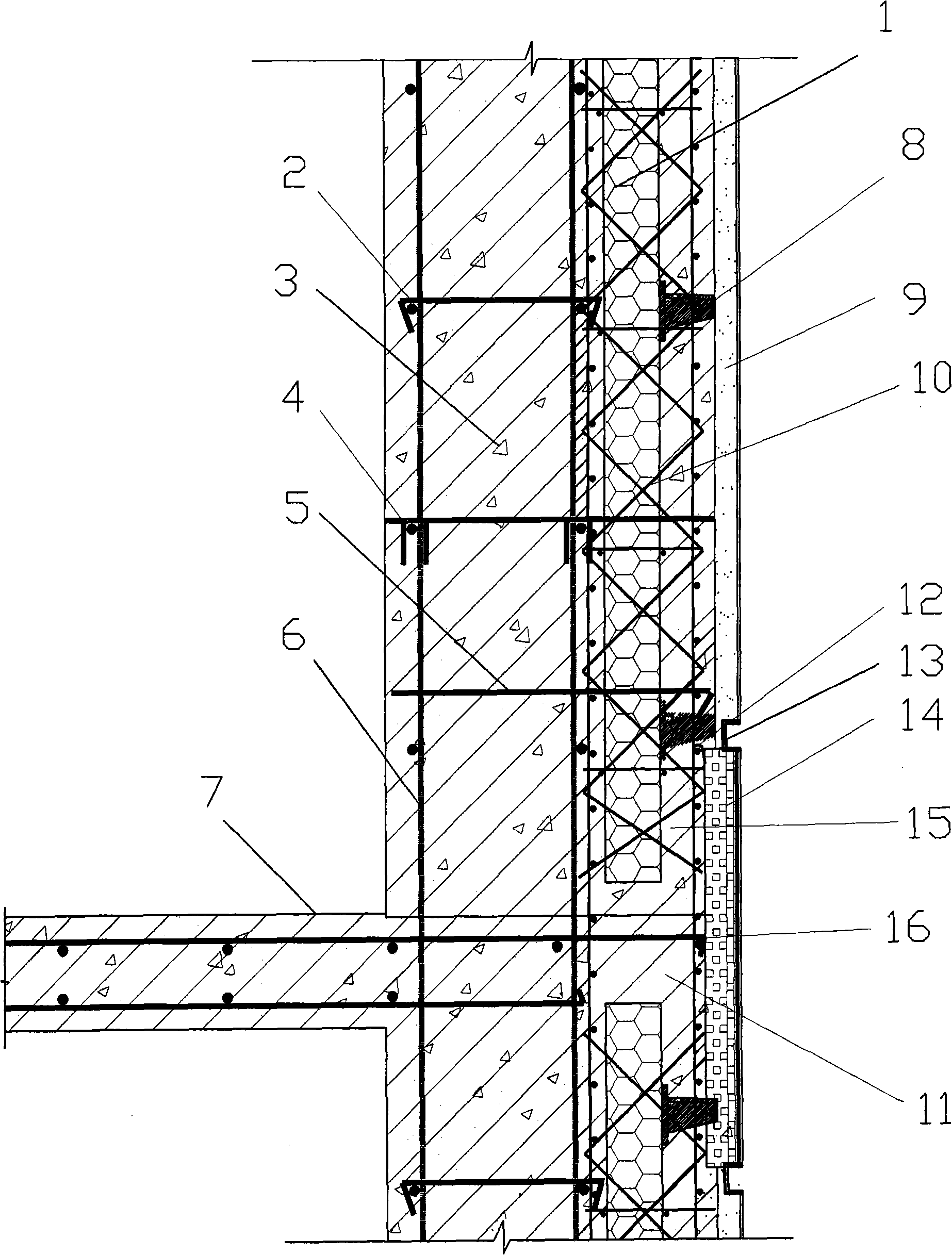

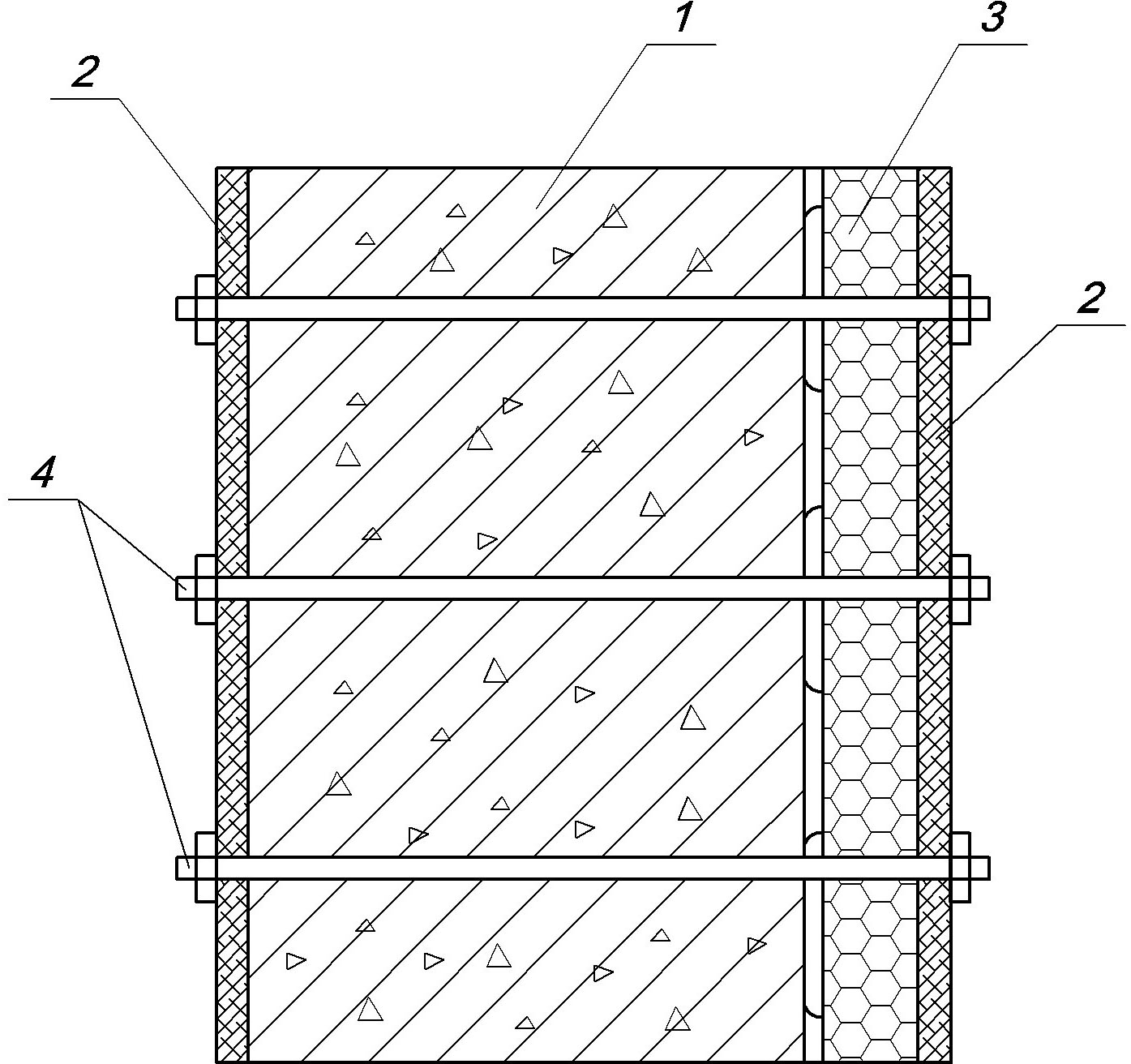

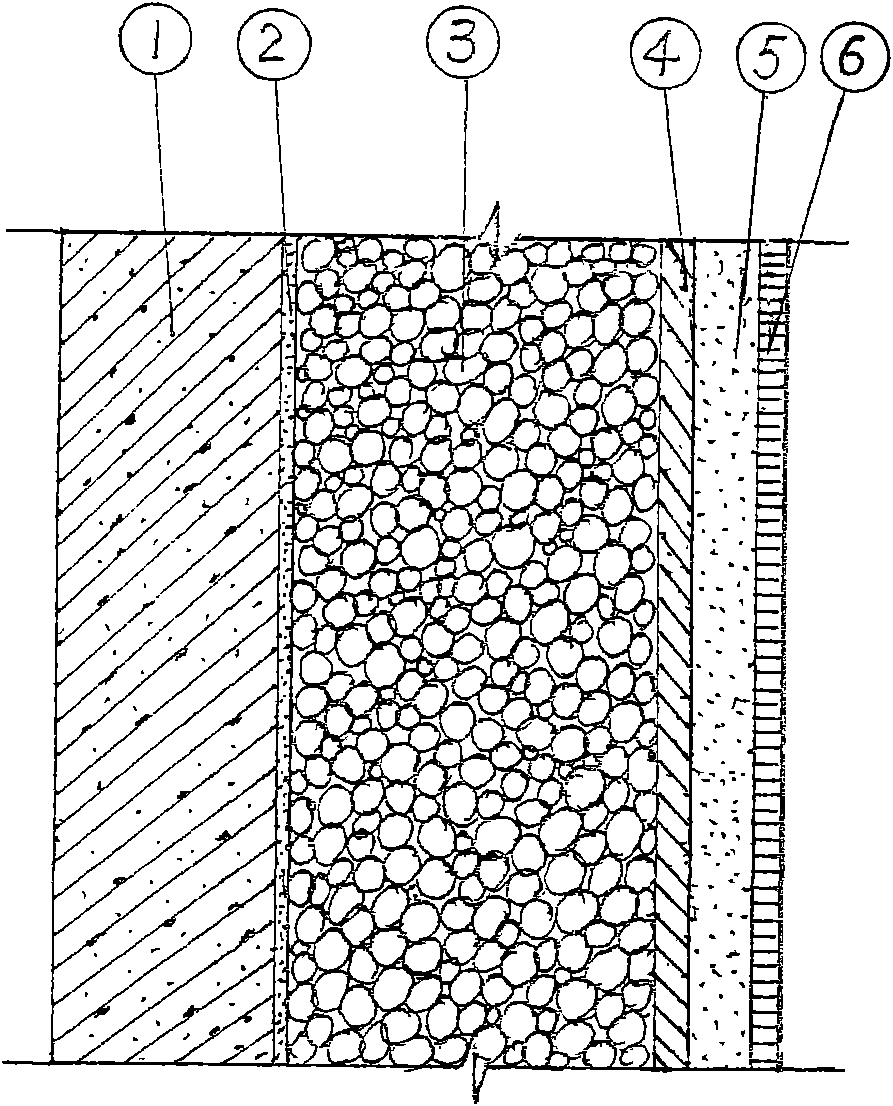

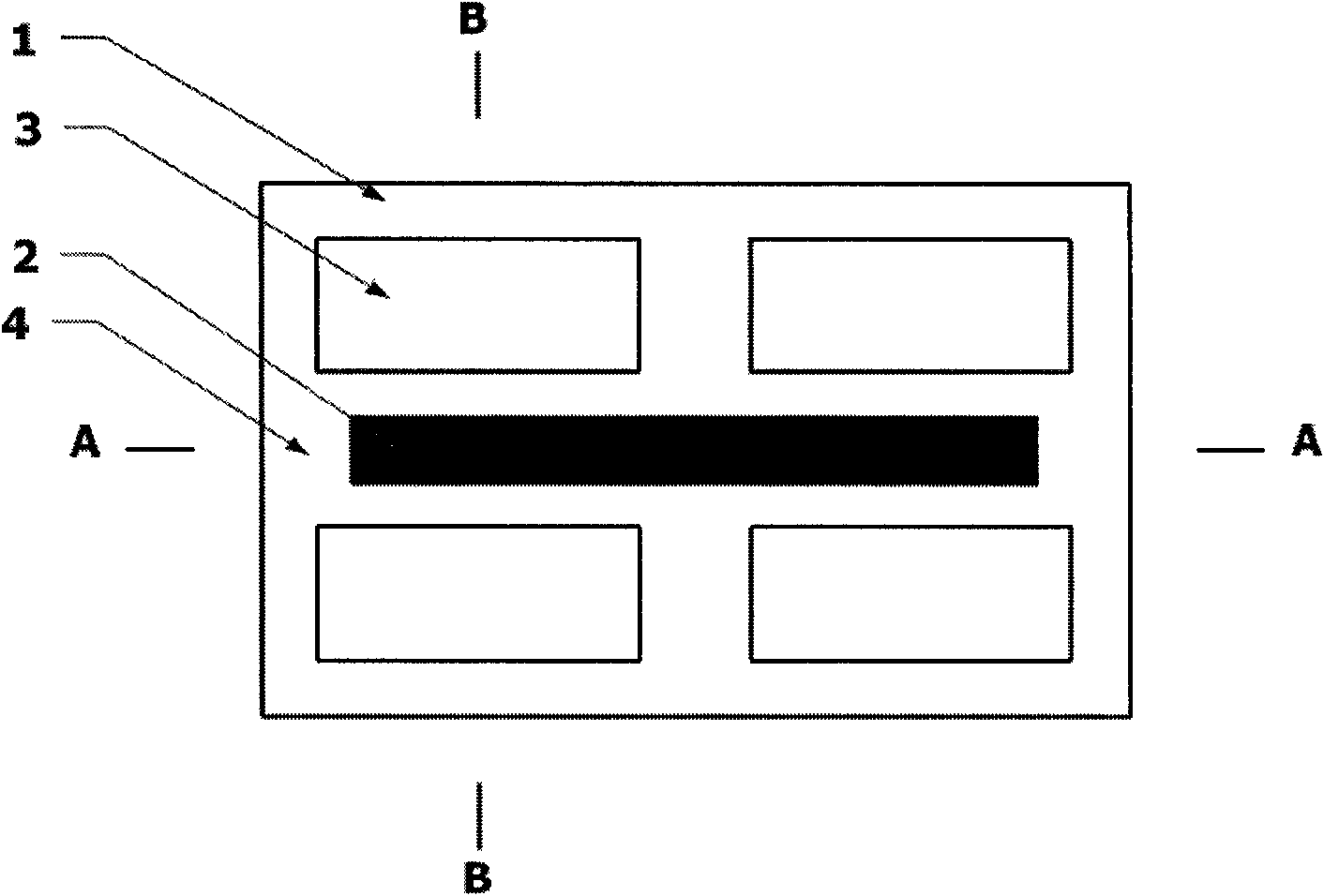

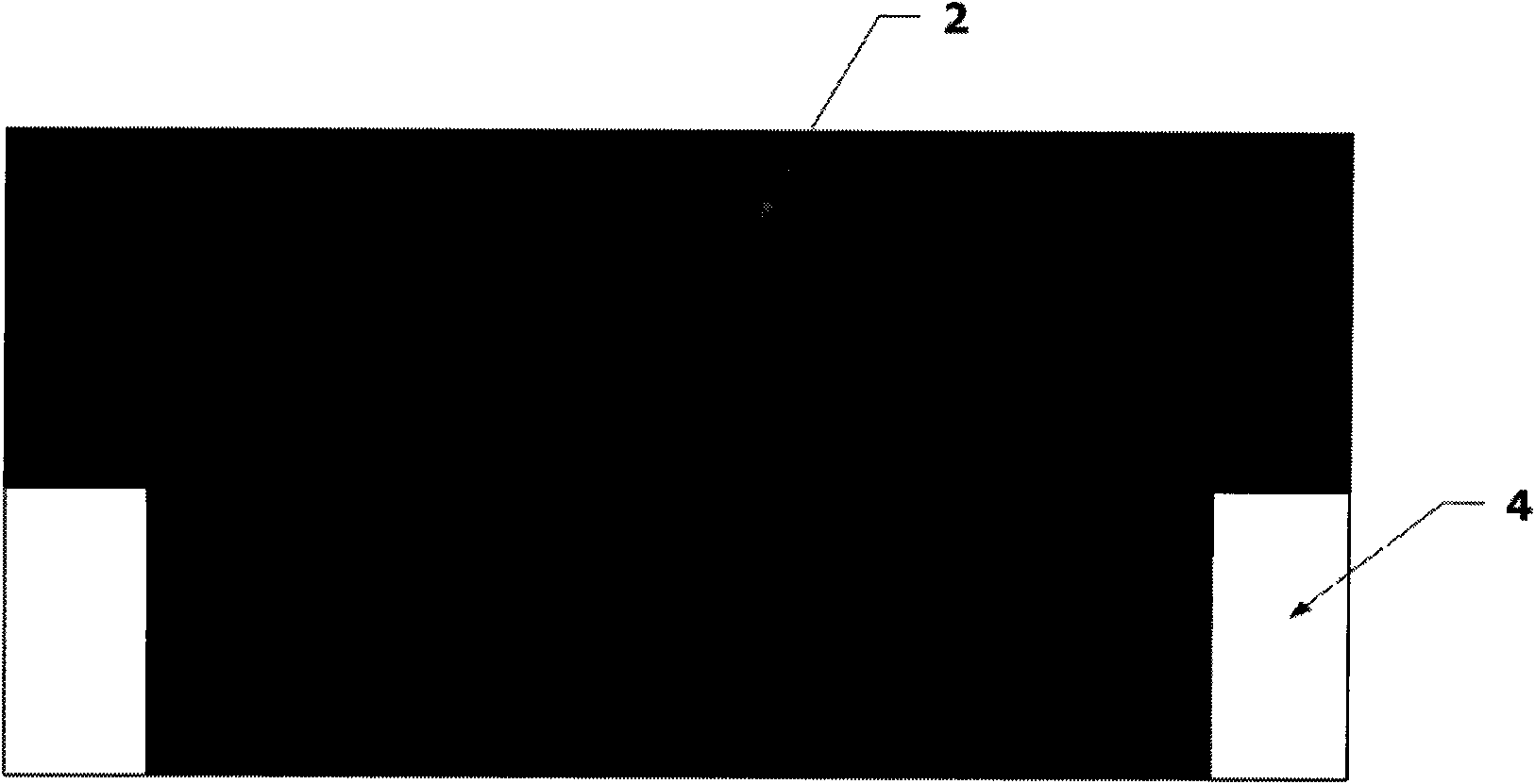

Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

ActiveCN101319525ANovel structureImprove thermal insulation performanceWallsClimate change adaptationInsulation layerSteel bar

The invention relates to an energy-saving system for a reinforced concrete outer-casting built-in heat insulation wall body structure and a construction method thereof, which can effectively solve the problems of external wall heat insulation of a high-rise building with high heat insulation requirement and cracking and falling of a heat insulation layer. The system is produced by a wall body and reinforcing steel bars in the wall body which are cast by concrete. The method comprises the following steps that: a reinforcing steel bar frame of the wall body is produced and arranged, namely parallel vertical reinforcing steel bars and indoor floor-connecting board tie bars perpendicular to the parallel vertical reinforcing steel bars are bound together, a grid board is hoisted and externally suspended outside the vertical reinforcing steel bars of the wall body, and is bound with the vertical reinforcing steel bars of the wall body by hooked bars and binding steel bars as well as framework positioning bearing bars, then a framework is arranged on the framework positioning bearing bars and is firmly bound with reinforcing steel bars of beams and boards of a floor, lapping bars are reserved, a heat insulation grid board is firstly arranged, then reinforcing steel bars of corbel brackets of a balcony and an air conditioning board external wall are bound, finally the concrete is cast, the curing is performed, and the framework is removed to repair the structure. The system has good heat insulation effect, energy conservation, environmental protection, simple method, and huge economic benefit and social benefit.

Owner:HENAN JINYUAN CONSTR

High-performance foaming cement and preparation method thereof

The invention relates to high-performance foaming cement, which comprises cement slurry and foams, wherein the cement slurry is prepared from the following raw materials in parts by weight: 100 parts of cement, 10-30 parts of gypsum powder, 10-50 parts of active admixtures, 10-40 parts of mineral admixtures, 1-5 parts of re-dispersible gelatine powder, 0.5-1.5 parts of cellulose ether, 0.2-1.0 part of water reducing agent, 0.1-0.5 part of water repellent and 40-90 parts of water; and the foams are prepared from the following components in parts by weight: 1 part of foaming agent, 0.2-0.8 part of foam stabilizer and 30-50 parts of water. A preparation method of the high-performance foaming cement comprises the steps of: (1) preparing the cement slurry; (2) preparing the foams by using a foaming machine; and (3) mixing and uniformly stirring the cement slurry and the foams according to the weight ratio of 1:(0.1-1), and pouring and molding. The high-performance foaming cement disclosed by the invention has high closed porosity and small shrinkage value, and integrates the performances of heat insulation, sound insulation, water repellent, shock resistance, fire protection, durability, low carbon and environmental protection into a whole.

Owner:辽宁际洲环保节能建材有限公司

Waterborne external thermal insulation coating and preparation method thereof

InactiveCN102329545AImprove waterproof and anti-corrosion performanceEasy constructionPolyurea/polyurethane coatingsReflecting/signal paintsThermal insulationDefoaming Agents

The invention provides a waterborne external thermal insulation coating. The coating consists of the following components in part by weight: 25 to 50 parts of functional filler, 30 to 50 parts of emulsion, 20 to 35 parts of filler, 8 to 20 parts of film-forming aid, 1 to 3 parts of wetting dispersant, 1 to 2 parts of propylene glycol, 1 to 2 parts of defoaming agent, 0.5 to 1.5 parts of mildew preventive, 1 to 5 parts of thickening agent and 10 to 20 parts of water. The invention is characterized in that: the coating is safe and environment-friendly, has excellent waterproof and anticorrosive properties, high thermal resistance and reflectivity, excellent thermal insulation property, and good weather resistance, is convenient to construct, and can be well adhered to various base materials, and the density of a dry film is low; an extremely thin hollow cavity layer is formed after the coating is coated on the surface of a base material and then is dried, so that an effective thermal barrier is formed; functional filler particles have large heated cathodes, low coefficient of thermal conductivity, and high heat reflectivity; the consumption of energy sources is remarkably reduced; the coating can reflect, refract and scatter thermal radiation and stop heat conduction; and the energy is saved.

Owner:QINGDAO AIR NEW MATERIALS

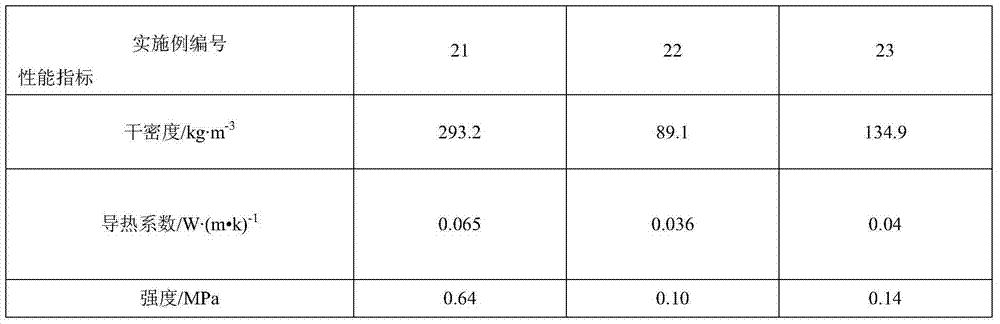

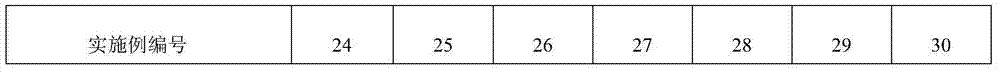

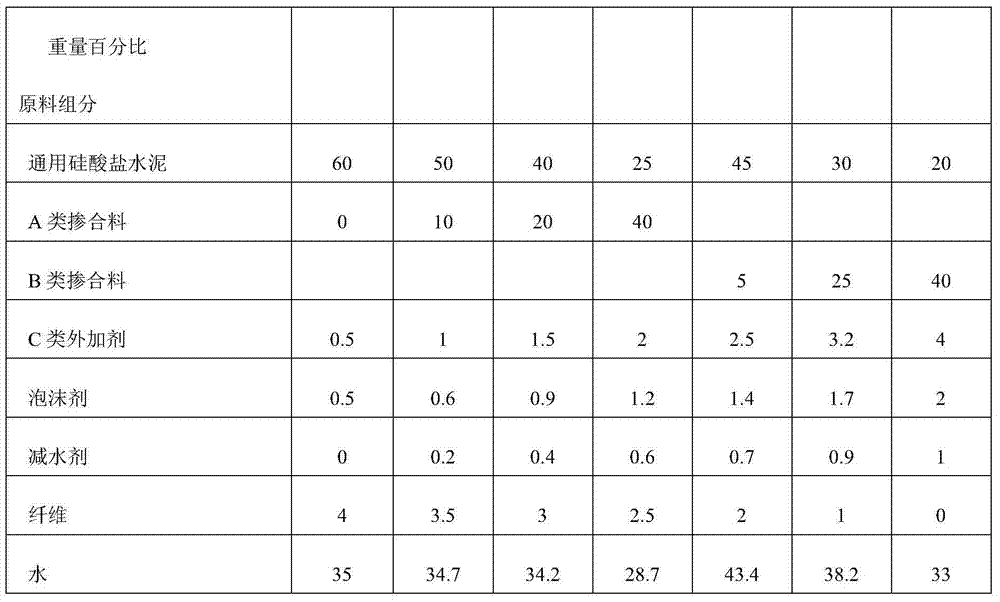

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Cellular concrete product

InactiveCN101353265AHigh strengthImprove thermal insulation performanceSolid waste managementCeramicwareMetakaolinAdjuvant

A foamed concrete product is characterized in that Portland cement or ordinary Portland cement is taken as gelling material; zeolite powder, metakaolin powder, limestone powder, fly ash or silicon ash powder are taken as admixtures; protein hydrolysate of hoof and horn of animals is taken as a foaming agent; an acrylate coagulator or a polycarboxylic acid type water reducing agent is taken as an adjuvant, and water is active water. In order to improve the early strength, the later compressive strength, the bending strength and the anti-tensile splitting strength of the low-density foamed concrete, a plurality of admixtures comprising the zeolite powder, the metakaolin powder, the silicon ash powder or the limestone powder are chosen, by mutual collocation of the components and contents of the admixtures, the comprehensive improvement of various strengths is achieved, and the multifunctional effects of insulating heat, adjusting moisture, preserving heat, and the like, are obtained. In the foamed concrete blocks of the ordinary Portland cement, the density is 500-800kg / m<3>, the compressive strength is 6-8MPa and the water absorption rate is 5-10%, the heat preserving property and the heat insulating property are obviously improved, the water absorption performance and the moisture adjusting index are remarkably improved, and the better cost performance ratio is obtained.

Owner:周照柱

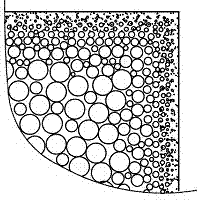

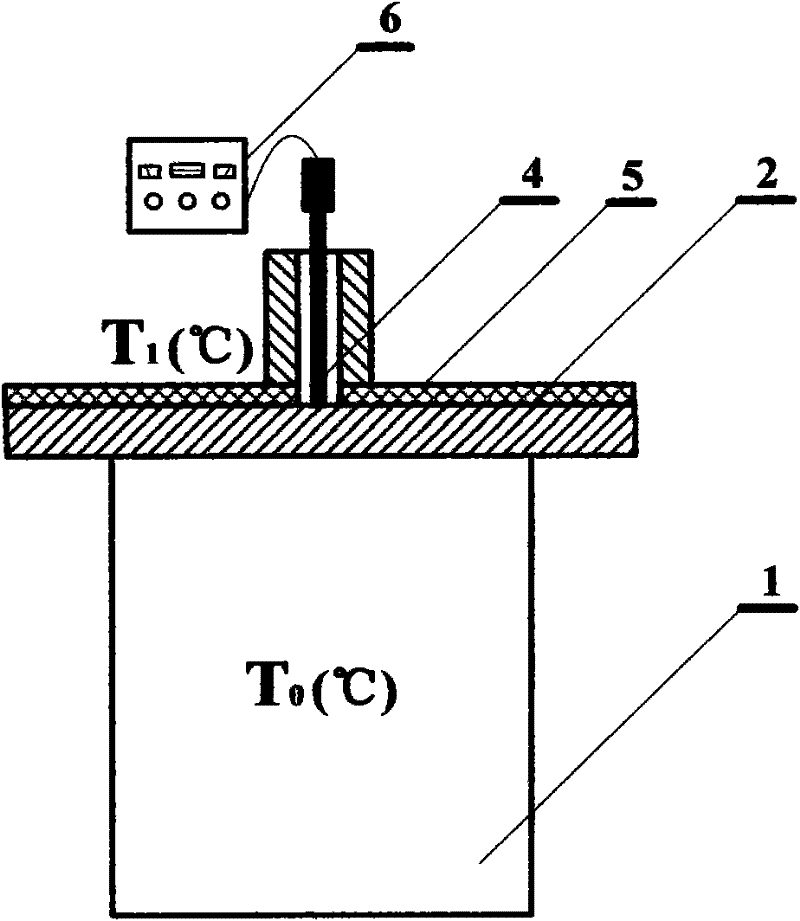

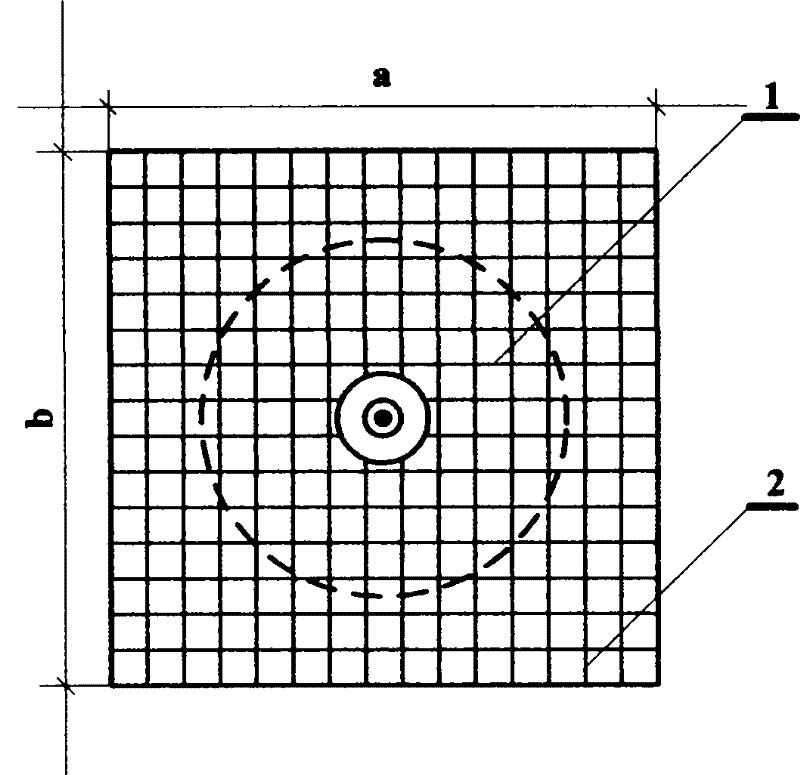

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

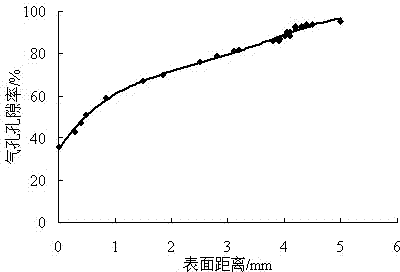

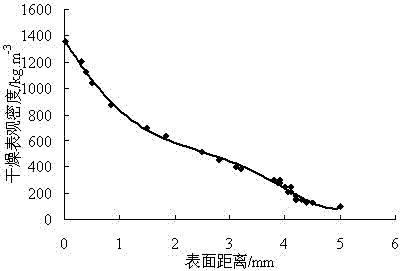

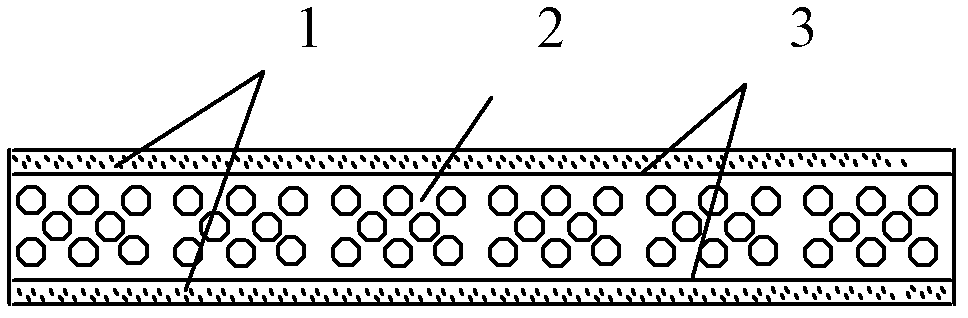

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Magnesium oxysulfate cement board and method for preparing same by using semidry method

InactiveCN102493598AAnti-bendingLower pH valueCeramic shaping apparatusBuilding componentsPlant fibreCement board

The invention relates to a magnesium oxysulfate cement board and a method for preparing the same by using a semidry method. The magnesium oxysulfate cement board comprises a heat insulation core layer and strength structure layers respectively compounded on the two surfaces of the heat insulation core layer. The heat insulation core layer is a layer structure formed by stirring and pressing magnesium oxysulfate which is used as a gelatinizing agent and a light material which is used as a filler. Each strength structure layer is a layer structure formed by the magnesium oxysulfate which is used as the gelatinizing agent. The magnesium oxysulfate cement board disclosed by the invention has the outstanding substantive characteristics that a plate material with a multilayer composite structure is formed by mixing the magnesium oxysulfate utilized as the gelatinizing agent with the light material and / or a reinforcing fiber; the structure of the core layer has the characteristics of light weight and good heat preservation and heat insulation effects; the strength structure layers on the two surfaces of the core layer have the characteristics of bending resistance and high compression strength; and meanwhile, the magnesium oxysulfate cement board is low in PH value and has no chlorine content. Therefore, the occurrence of the moisture absorption and the halogenation are avoided; the corrosion on materials, such as plant fibers, metal pieces and the like, is avoided; and the application range is widened and the service life is prolonged.

Owner:NG TERASUN AIR DUCT

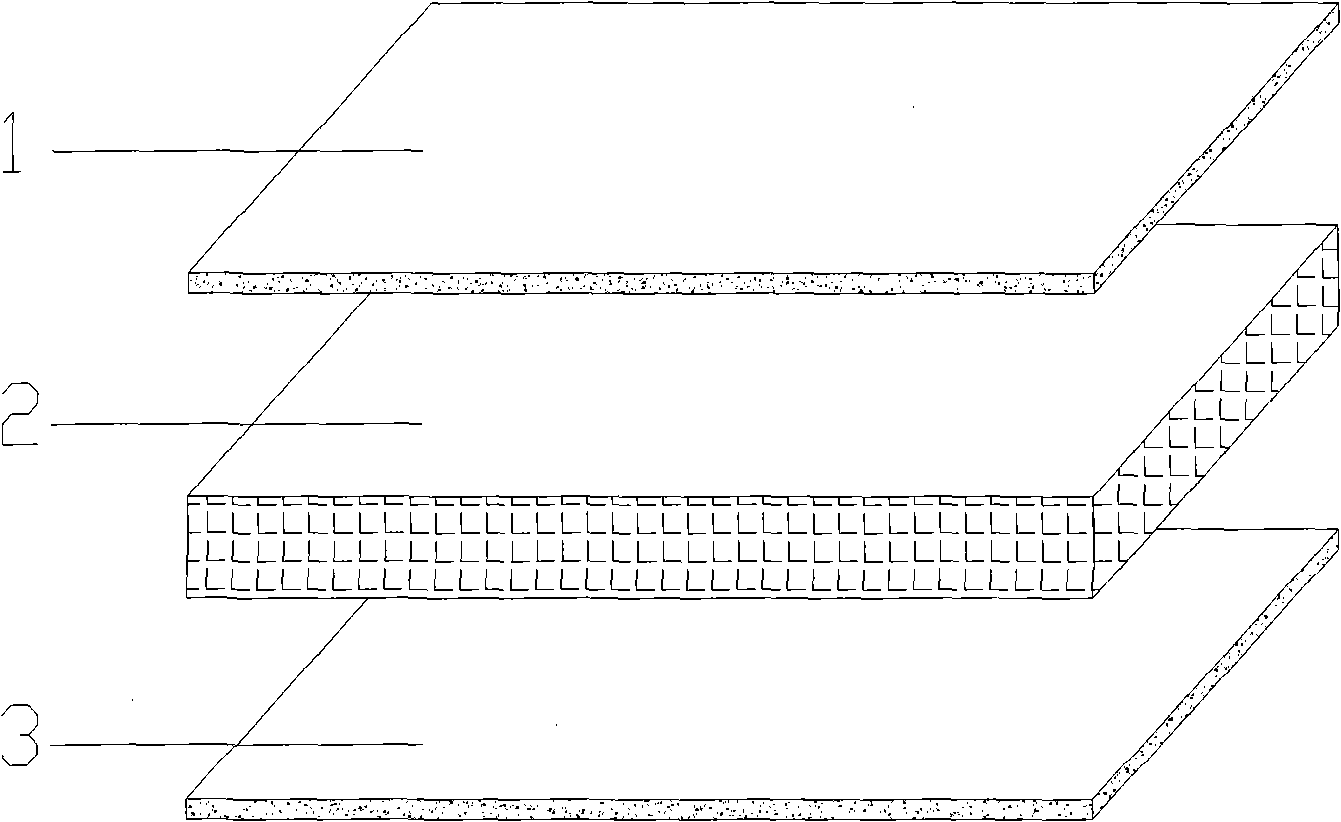

Double layer sandwich foamed concrete composite solid wall plate

InactiveCN1987008AShort demoulding timeIncrease productivityConstruction materialSolid waste managementFiberFoam concrete

A dual-layer sandwich-type solid wall slab is composed of two surficial thin cement slabs and a foam concrete core layer. It is proportionally made of fast hardening sulphoaluminate cement, powdered coal ash, river sand, fibers, hydrogen peroxide as foaming agent, and stabilizer. Its advantages are light weight, high surface strength and high insulating effect.

Owner:贵州华骏集团节能环保材料有限公司

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

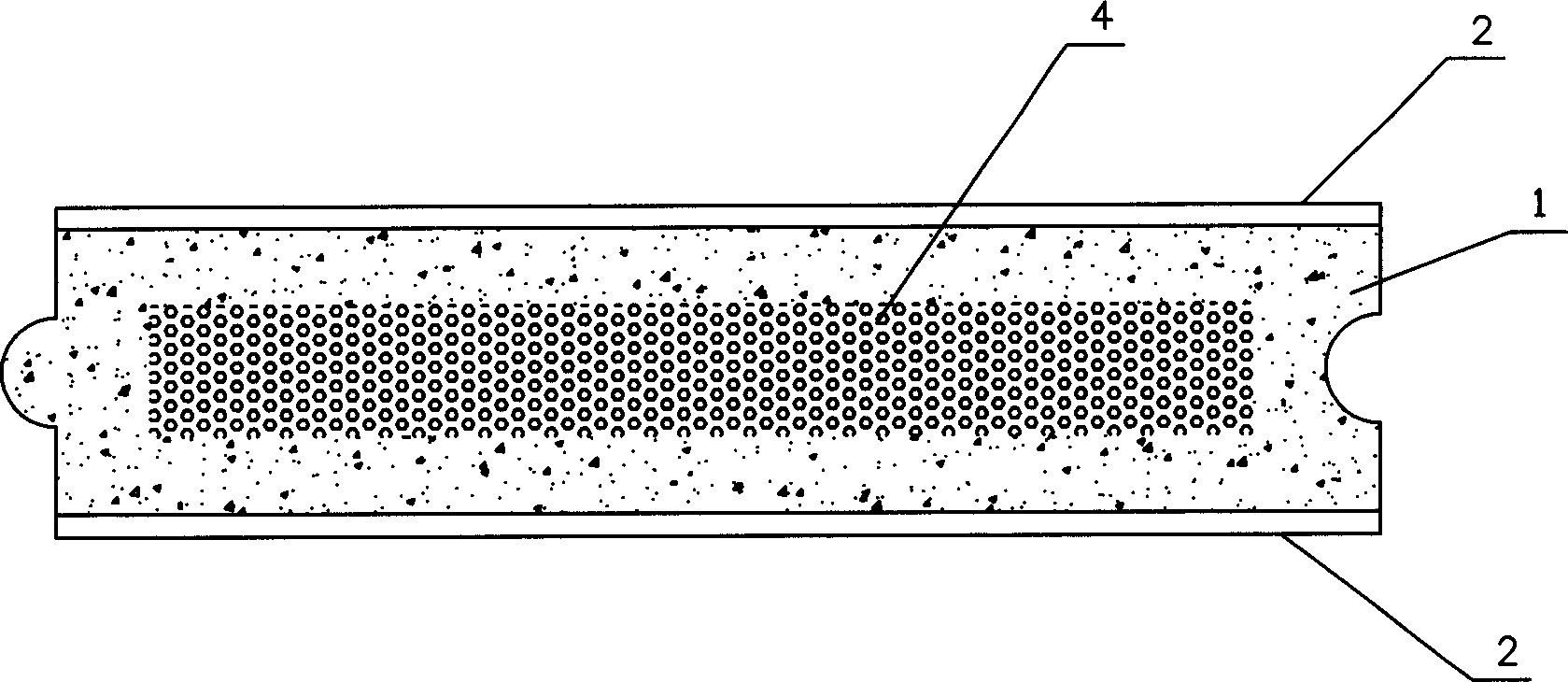

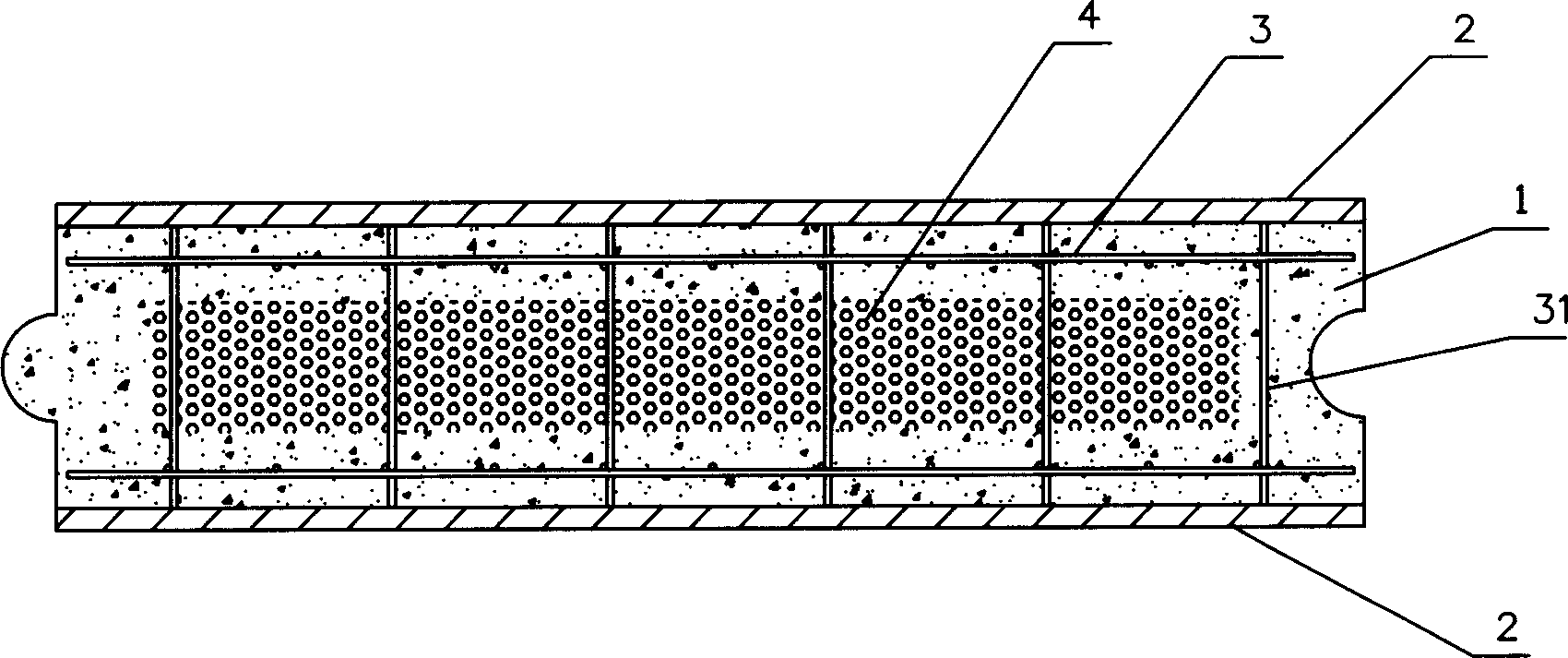

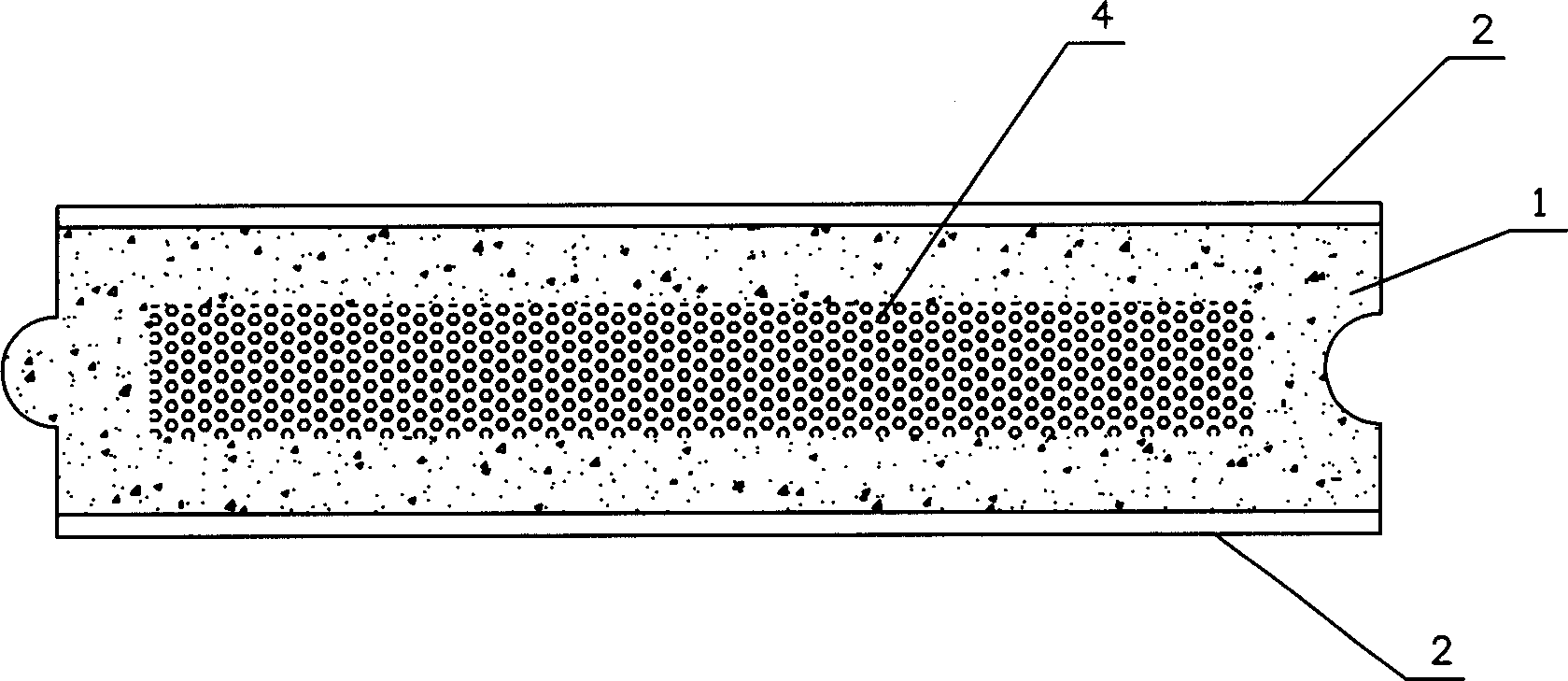

Light compound side fascia and its manufacturing method

ActiveCN1831270AReasonable structureSuperior performanceConstruction materialMouldsRebarHigh intensity

The invention relates to a lightweight compounded outer wallboard and the manufacturing method thereof. And it is compounded of fiber or wire fabric reinforced cement slab and bearing layer, where the bearing layer is made of reinforcing fabric reinforced light aggregate concrete, one or two sides of the bearing layer are combined with cement slabs and a cavity in the bearing layer is enveloped by light aggregate concrete and full of heat insulator. And its manufacturing method comprises a process as follows: A. placing cement slabs on one or two sides in a die space; B. placing reinforcing fabric provided with heat insulator in the middle by the cement slabs in the die space; C. pouring light aggregate concrete in the die space to bury the reinforcing fabric; and D. staying, curing and hardening and then demoulding to make it. And the method is simple, practical, high-efficiency and it has advantages of lightweight, high intensity, strong bearing capacity, good heat insulating property, seismic resistance, seepage prevention, etc.

Owner:广州益群板业有限公司

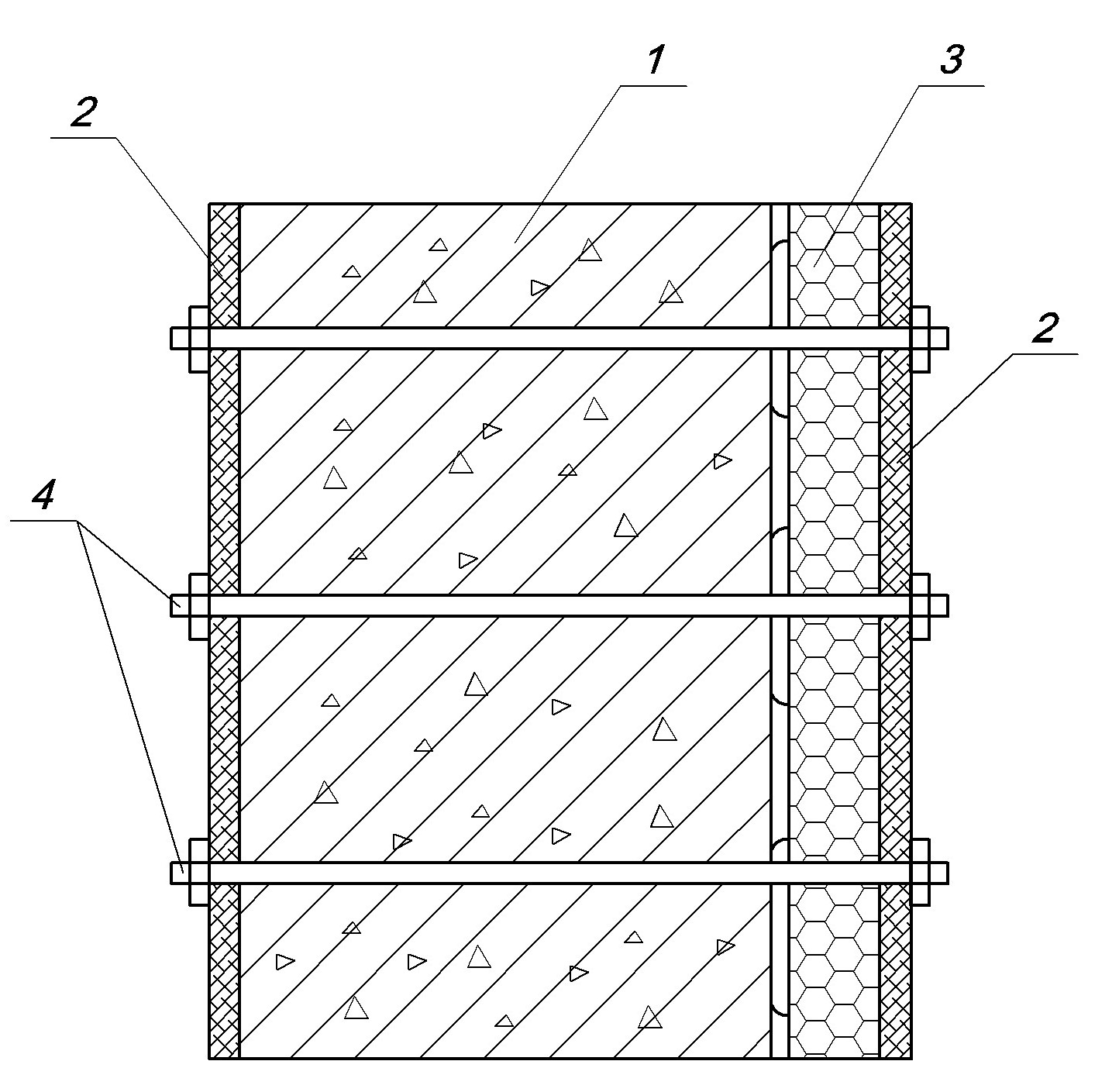

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

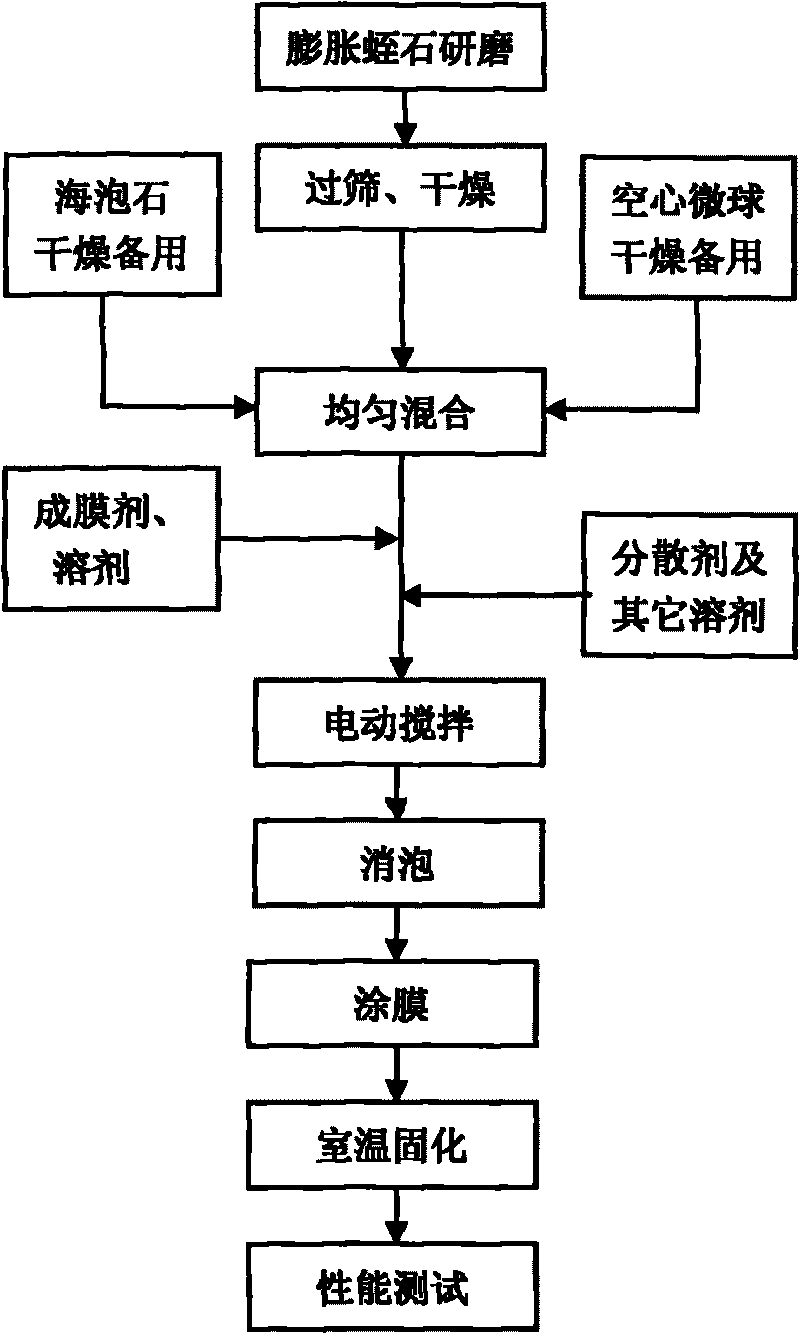

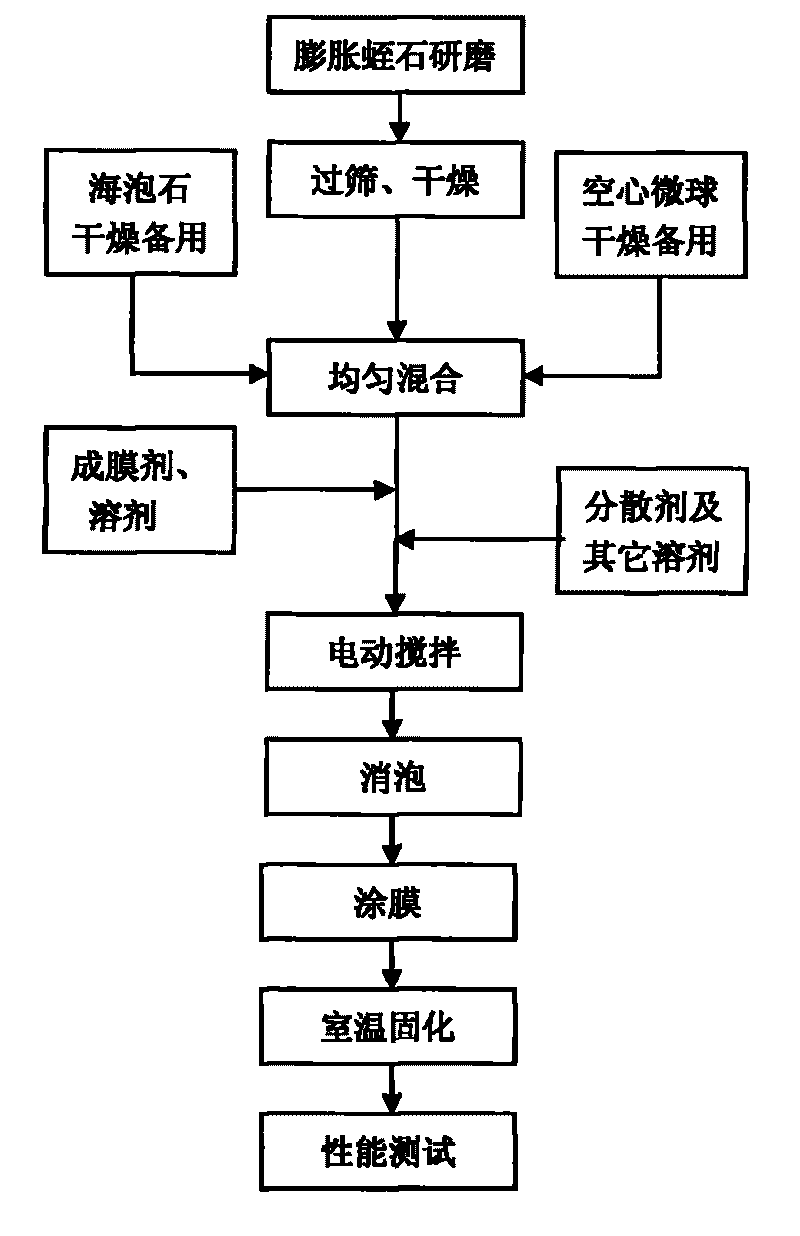

Novel environment-friendly heat insulating coating and preparation method thereof

InactiveCN101696336AGood heat insulationRich reservesAlkali metal silicate coatingsEpoxy resin coatingsMicrosphereSolvent

The invention relates to a novel environment-friendly heat insulating coating and a preparation method thereof. The novel environment-friendly heat insulating coating comprises the following components in percentage by weight: 10 to 50 percent of film forming matter, 1 to 3 percent of expanded vermiculite, 5 to 25 percent of meerschaum, 1 to 20 percent of hollow microspheres, 0.5 to 5 percent of wetting agent, 0.5 to 5 percent of dispersing agent, 0.5 to 5 percent of defoaming agent, 0.5 to 5 percent of silane coupling agent, 1 to 10 percent of auxiliary agents, and 10 to 50 percent of solvent. The preparation method comprises the following steps of: grinding, vacuum filtrating, drying, grinding, screening and drying the expanded vermiculite, and then evenly mixing the dried expanded vermiculite with the dried meerschaum and the hollow microspheres to form a component A; mixing the film forming matter, the solvent, the wetting agent, the dispersing agent, the defoaming agent, the silane coupling agent and other auxiliary agents to obtain a component B; and evenly mixing the components A and B, and defoaming the mixture to obtain the heat insulating coating of the invention. The prepared insulating coating is coated on the surface of a working surface, is cured at the normal temperature and completely dried to achieve the effects of heat preservation and heat insulation.

Owner:DONGHUA UNIV

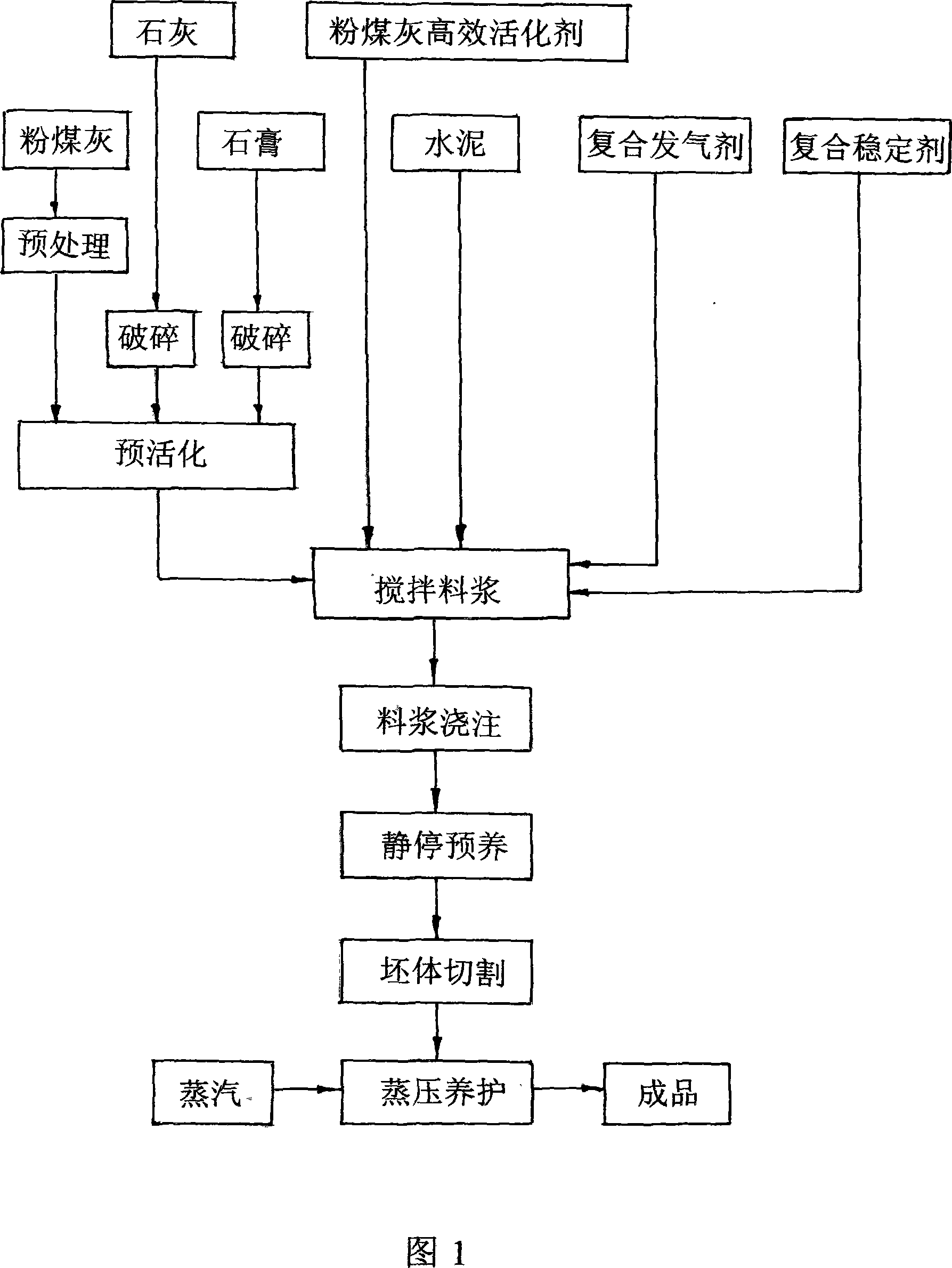

Aerated concrete block and its production process

InactiveCN101066886AHigh reactivityIncreased affinity and contact areaSolid waste managementCeramicwareGypsumPre treatment

The aerated concrete block is produced with fly ash 50-65 weight portions, lime 18-22 weight portions, gypsum 6-10 weight portions, cement 7-16 weight portions, composite gas former 4-8 weight portions, efficient fly ash activator 1-2 weight portions, composite stabilizer 1.5-3 weight portions and water in proper quantity; and through the production process including the steps of fly ash pre-treatment, crushing lime and gypsum, pre-activating fly ash, mixing the materials to prepare slurry and pouring, pre-curing, cutting, and steam curing to obtain the product. The production process adopts pre-activating and secondary activating and composite stabilizer, and the aerated concrete block product has low cement consumption, low cost and high strength.

Owner:张江

Straw cement based compound porous self-heat-insulating material and preparation method thereof

InactiveCN101941849AImprove thermal insulation performanceImprove thermal insulationSolid waste managementCeramicwareWater reducerMaterials science

The invention discloses a straw cement based compound porous self-heat-insulating material which is a new-type light, high-strength and porous building self-heat-insulating material prepared by foaming farmland straw, cement, industrial residue, foaming agent, waterproofing agent, coagulant, water reducer and water, and then mixing with gelled material slurry. The self-heat-insulating material comprises the following components by mass percent: 0.12-14.83% of farmland straw, 28.70-72.08% of cement, 0.40-43.52% of industrial residue, 0.04-0.40% of foaming agent, 0.06-0.89% of waterproof agent, 0.11-1.45% of coagulant, 0.06-0.13% of water reducer and 23.65-33.97% of water. The main raw materials, such as farmland straw, and industrial residue and other wastes used by the self-heat-insulating material prepared by the invention have wide resources, low cost and convenient preparation process, do not need high-temperature maintenance, simultaneously have excellent heat insulating performance, high mechanical strength, and have the outstanding properties of energy conservation, environmental protection, waste utilization, regeneration and the like.

Owner:SOUTHEAST UNIV

A kind of foam concrete and preparation method thereof

The invention relates to a foamed concrete and a preparation method thereof. The foamed concrete adopts a chemical foaming method, and a foam stabilizer, an early strength agent, and a water reducer are respectively added to ordinary Portland cement slurry and stirred evenly, and then chemical foaming agent is added. The foaming agent is fully stirred evenly, then injection molded, cured at room temperature, and hardened. The dry apparent density range of the foamed concrete prepared by this method is 150-300kg / m3, the corresponding compressive strength is 0.10-0.50MPa, and the thermal conductivity is lower than 0.10W / mK. It can be used as roof insulation project, floor heating project, light Cushion material, especially suitable for external wall insulation system, energy-saving composite panels, etc. used in building energy-saving projects.

Owner:NANJING UNIV OF TECH

Fiber reinforcement fire-proof thermal insulation plate and preparation process thereof

InactiveUS20150345132A1Low production costResistance to crackingSolid waste managementClimate change adaptationThermal insulationCalcium formate

The present invention discloses a fiber reinforcement fire-proof thermal insulation plate, which is prepared by raw materials having the following weight portions: 80-100 portions of fly ash, 30-50 portions of expanded perlite, 10-20 portions of haydite, 10-20 portions of vegetable fiber, 5-10 portions of winnowing beads, 5-8 portions of sepiolite, 3-5 portions of sodium fluorosilicate, 3-5 portions of calcium formate, 3-5 portions of flame-retardant, 0.1-0.5 portion of triisopropanolamine loeate and 0.1-0.3 portion of dimethoxy-ethane. According to the present invention, industrial production wastes are adopted as main raw materials, so that the production cost is reduced; and defects in the existing building thermal insulation plates can be effectively overcome through the cooperation effect produced by organic combination of the fly ash, light aggregates and additives.

Owner:GUANGDONG NO 1 CONSTRUCTION ENGINEERING CO LTD

Lightweight concrete exterior wall insulation building block and production method thereof

The invention discloses a lightweight concrete exterior wall insulation building block and a production method thereof. The lightweight concrete exterior wall insulation building block is prepared by mixing the following raw material components in proportion by weight: 20-50 of cement, 20-40 of fly ash, 8-20 of fine sand, 1-8 of calcareous material, 5-16 of plant filler, 0.2-0.5 of adjuvant, 8-15 of water and 0.3-0.7 of foaming agent. The production method of the lightweight concrete exterior wall insulation building block comprises the following steps of: forming raw material slurry by uniformly mixing production raw materials in mixing proportion; adding the water to the foaming agent, and generating uniform and stable bubbles by using a foaming device; mixing the bubbles with the raw material slurry so as to prepare bubble concrete slurry; and casting the bubble concrete slurry into a mold and curing. According to the lightweight concrete exterior wall insulation building block and the production method of the lightweight concrete exterior wall insulation building block, the plant filler, such as sawdust or crop straw powder, is mixed, so that the weight is reduced, the flexibility is improved, and the improvement on the strength of a finished product and the cracking prevention are favored; and the bubbles are enabled to be uniformly distributed in the raw material slurry by adding the foaming agent, so that not only is the weight of the building block reduced, but also the heat preservation and heat insulation effects are improved.

Owner:郑小东

Ultra-low-density foam concrete and preparation method thereof

InactiveCN102153363ALow densityConvenient construction requirementsCeramic shaping apparatusCeramicwareFoam concreteApparent density

The invention relates to ultra-low-density foam concrete and a preparation method thereof. The foam concrete is formed by mixing cement, a chemical foaming agent, a foam stabilizer and water in a mass ratio of (130-180):(10.3-15.2):(0.1-1.8):(60-90). The ultra-low-density foam concrete is prepared in a chemical foaming manner by the steps of: adding the foam stabilizer into sulfate aluminum cement slurry, stirring the slurry uniformly, then adding the chemical foaming agent, fully stirring the slurry and performing injection molding and natural curing. The dry apparent density of the ultra-low-density foam concrete prepared with the method is 130 to 150kg / m<3>, the compressive strength is more than 0.10MPa, and the heat conduction coefficient is less than 0.10W / mK; and the ultra-low-density foam concrete can be used as a material for roof heat preservation engineering, floor heating engineering and lightweight cushion layers, and is particularly suitable for an outer wall heat preservation system, an energy-saving composite board and the like.

Owner:NANJING UNIV OF TECH

Phosphogypsum sintering-free ceramsite light aggregate and preparation method thereof

InactiveCN110451864ALight weightImprove thermal insulation performanceSolid waste managementLower gradePhosphogypsum

The invention provides a phosphogypsum sintering-free ceramsite light aggregate. The phosphogypsum sintering-free ceramsite light aggregate comprises a mixture and water, wherein the mixture comprises, by weight percentage, 80-90% of phosphogypsum, 3.3-10% of mineral powder and 6.5-10% of cement, and the weight of the water is 17% of the total weight of the mixture. A method for preparing the phosphogypsum sintering-free ceramsite light aggregate is also provided. The phosphogypsum sintering-free ceramsite light aggregate is prepared by adopting the phosphogypsum as a main material, the cementas an alkaline activator and the mineral powder as an active material through the processes of modification, granulation, curing, crushing, sieving and the like. The produced phosphogypsum sintering-free ceramsite light aggregate can be widely used in highway subgrade materials, C40 and lower grade of concrete, cement concrete blocks and other products, a large amount of phosphogypsum inventoriescan be consumed, waste is turned into treasure, and the phosphogypsum sintering-free ceramsite light aggregate and the method have extremely important significance in saving resources and realizing optimized allocation of the resources and sustainable development.

Owner:HUBEI CHANG YAOXIN MATERIALS LIMITED BY SHARE

Vitrified micro-bead heat preserving and insulating material and method of preparing same

InactiveCN101665343AImprove thermal insulation performanceOvercoming the Achilles heel of flammabilitySolid waste managementCrack resistanceNew energy

The invention relates to vitrified micro-bead heat preserving and insulating material, in particular to heat preserving and insulating material for the wall and the roof of a building and a method ofpreparing the same, belonging to the field of the building energy saving technology. The heat preserving and insulating material comprises dry vitrified micro-bead heat preserving and insulating power, flexible seepage-prevention and crack-resistance mortar and alkali-resisting glass-fiber mesh cloth or hot-dip galvanized electrically-welded mesh; the dry vitrified micro-bead heat preserving and insulating power comprises the following raw materials by weight portion: 38-50 portions of special cement, 2-5 portions of pulverized coal ash, 8-10 portions of master batch and 35-55 portions of vitrified micro-beads; the flexible seepage-prevention and crack-resistance mortar comprises the following raw materials by weight portion: 28-40 portions of common silica cement, 3-6 portions of pulverized coal ash, 7-10 portions of polymer and 45-60 portions of quartz sand. The invention provides the new energy-saving and consumption-reducing environmental-friendly building material which has low thermal conductivity, good heat preserving and insulating effect, high strength, seepage prevention effect, crack resistance, fire resistance and stable performance, is convenient to use and easy to popularize and can be widely used for preserving and insulating the heat of the wall and the roof of the civil and industrial building.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Low-alkaline adhesive mortar compote vacuum heat insulation board and preparation method thereof

ActiveCN102979204AAvoid damageEasy constructionClimate change adaptationInsulation improvementAdhesiveHigh intensity

The invention relates to a low-alkaline adhesive mortar compote vacuum heat insulation board which comprises a vacuum heat insulation board and low-alkaline adhesive mortar which is coated on the periphery of the vacuum heat insulation board. The vacuum heat insulation board consists of core materials, a high-strength gas-blocking membrane and interface mortar, the high-strength gas-blocking membrane is coated on the periphery of the core materials and packed with the core materials in a vacuumizing mode, a layer of the interface mortar is coated on the periphery of the high-strength gas-blocking membrane, and the thickness of the interface mortar is 0.1-3 mm. The low-alkaline adhesive mortar compote vacuum heat insulation board has the advantages of overcoming a phenomenon that damage on traditional vacuum heat insulation materials occurs in the process of construction. The low-alkaline adhesive mortar compote vacuum heat insulation board is convenient to construct, good in heat insulation effect, and fireproof in class A.

Owner:ANHUI KERUIKE INSULATION MATERIAL

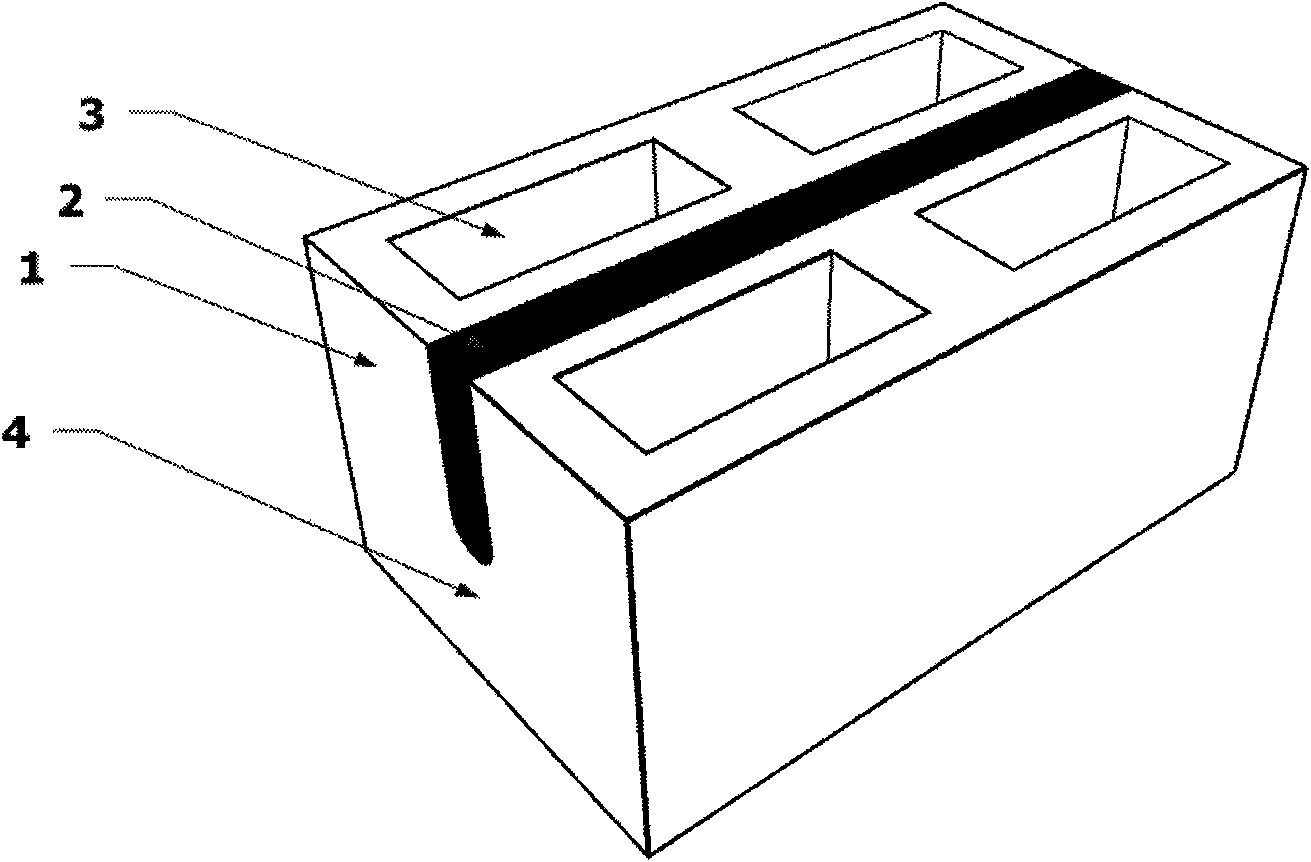

A composite self-insulating block

InactiveCN102261155ASimple structureReduce weightConstruction materialThermal insulationAgricultural engineering

The invention discloses a composite self-insulating block, which is composed of a block body and heat-insulating material. The block body is on both sides of the heat-insulating material, and there are connecting pieces at the bottom of both ends of the block body to connect the block bodies on both sides. The block has good thermal insulation effect, simple structure, convenient construction and does not increase the thickness of the wall body.

Owner:黄靓

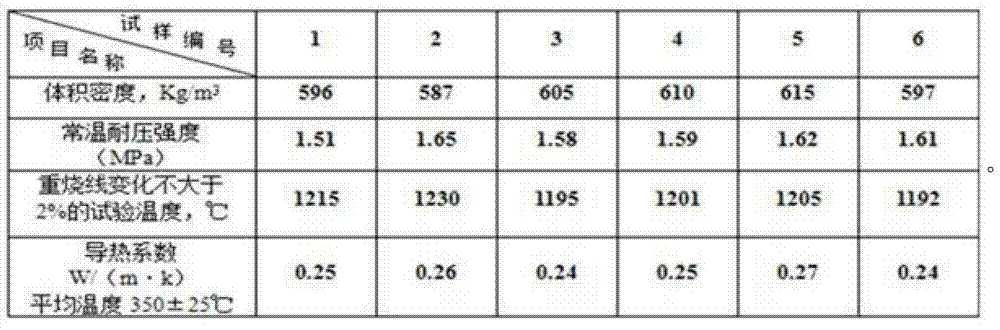

Foam light refractory casting material and preparation method thereof

The invention discloses a foam light refractory casting material. The foam light refractory casting material consists of a refractory raw material, a combined raw material and an auxiliary raw material, wherein the raw materials are pulped to be mixed with special foam at a high speed, and the mixture is hardened to obtain the microporous light refractory material. The foam light refractory casting material does not utilize a light refractory raw material but directly adopts the heavy refractory raw material, so that the raw material is abundant and easily available and is flexible in preparation, the production cost of the casting material is only half to one third of that of an original light refractory casting material, and the casting material has the characteristic that the cost is lower when the volume weight of the material is lighter, which is contrary to the characteristic that the cost is higher when the volume weight is higher of the original light refractory casting material; and light materials with different volume weights, different strengths and different application temperatures can be designed by selecting different material formulas and adding different quantities of foam. The foam light refractory casting material can be used for making a heat preserving layer and an insulation layer of a stove as well as an inner fire retardant coating of the stove.

Owner:MIANYANG HSBC FURNACES MATERIAL

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar

InactiveCN102690091AEliminate hot and cold bridgesEliminate hot and cold bridge phenomenonThermal insulationMicrosphere

A hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, especially a wall self-insulation system-matching hollow microsphere masonry dedicated thermal insulation mortar and a dedicated surface mortar, relate to a constuction energy-saving technology. The hollow microsphere masonry dedicated thermal insulation mortar comprises, by weight, 20-30% of special cement, 2-6% of coal ash, 20-35% of quartz sand, 5-8% of master batch, 35-45% of hollow microphere, and 3-6% of coarse whiting; and the hollow microsphere masonry dedicated surface mortar comprises, by weight, 28-40% of ordinary Portland cement, 3-6% of coal ash, 7-10% polymer, 40-55% of quartz sand, 10-16% of hollow microsphere, and 1-3% of coarse whiting. With a low heat conductivity coefficient, excellent thermal insulation effect, high compression strength, high bonding strength, low contractibility, environment-friendly and fire-proof properties and notable composite economic results, the wall self-insulation system-matching dedicated thermal insulation mortar and a dedicated surface mortar provided in the invention can be widely popularized and used in wall self-insulation system buildings.

Owner:HUBEI TIANQUAN NEW BUILDING MATERIALS

Water-based transparent heat-insulating paint used for energy-saving doors and windows and preparation method thereof

ActiveCN103351757AReduce usageRich varietyPolyurea/polyurethane coatingsWater basedAluminum doped zinc oxide

The invention discloses a water-based transparent heat-insulating paint used for energy-saving doors and windows. The paint comprises the following components by weight: 50 to 60% of an aqueous base latex, 20 to 30% of aqueous nanometer heat-insulating slurry, 0.5 to 1% of a defoaming agents, 1 to 5% of a thickening agent, 0.5 to 1% of a film forming auxiliary agent and 0.5 to 1% of a leveling agent, with the balance being deionized water, wherein the aqueous base latex is an aqueous acrylic resin emulsion with solid content of 30 to 60 wt% or an aqueous polyurethane resin emulsion with solid content of 30 to 60 wt%, and the aqueous nanometer heat-insulating slurry contains the two functional particles consisting of fluorine-doped tin oxide and aluminum-doped zinc oxide. The invention further discloses a preparation method for the paint. The paint prepared in the invention can be coated on the surface of door and window glass to form a transparent film; and the film can absorb the vast majority of ultraviolet light and obstruct more than 60% of infrared light and has average transmittance of more than 70% in a visible light area.

Owner:ZHEJIANG UNIV

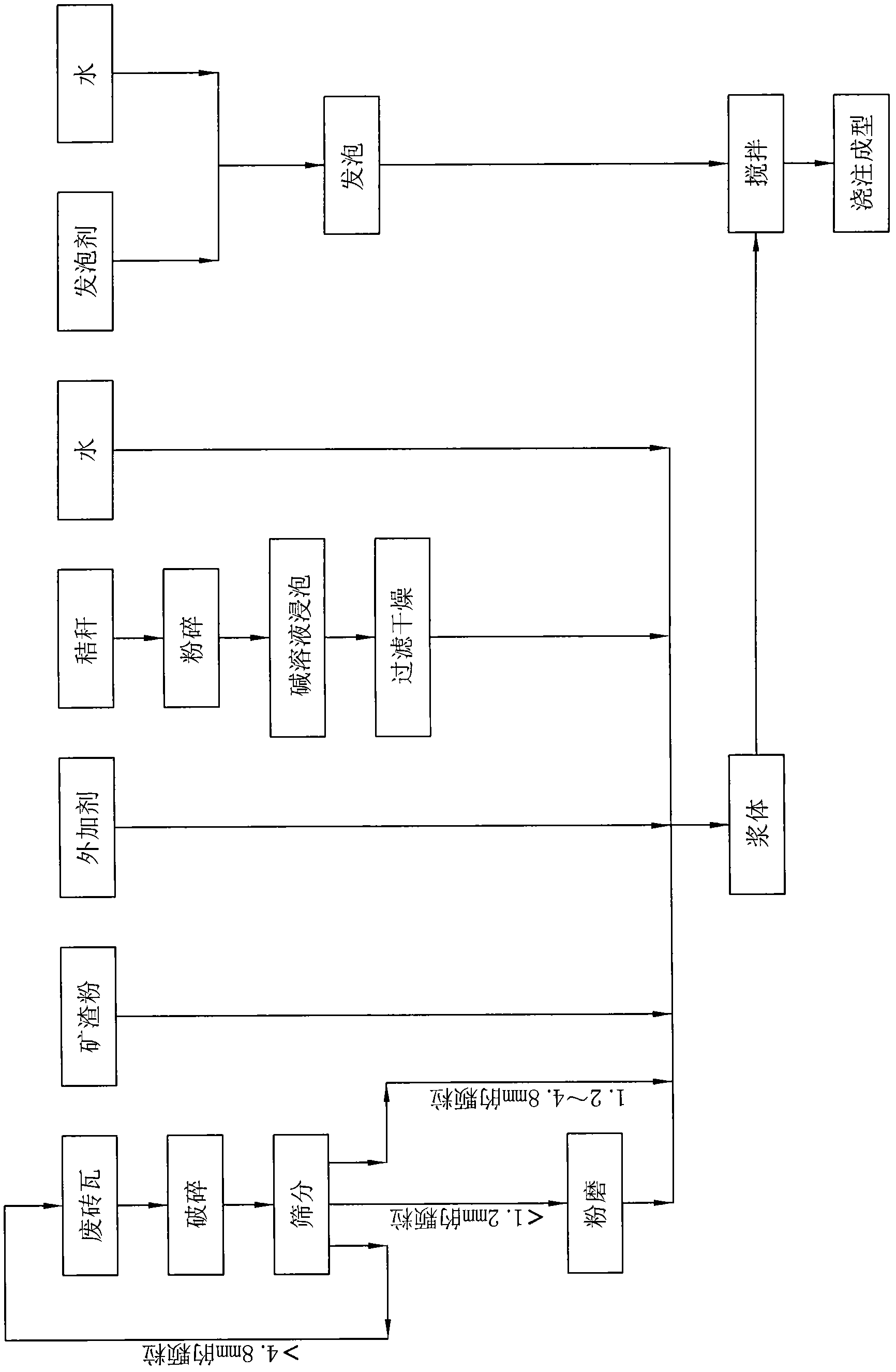

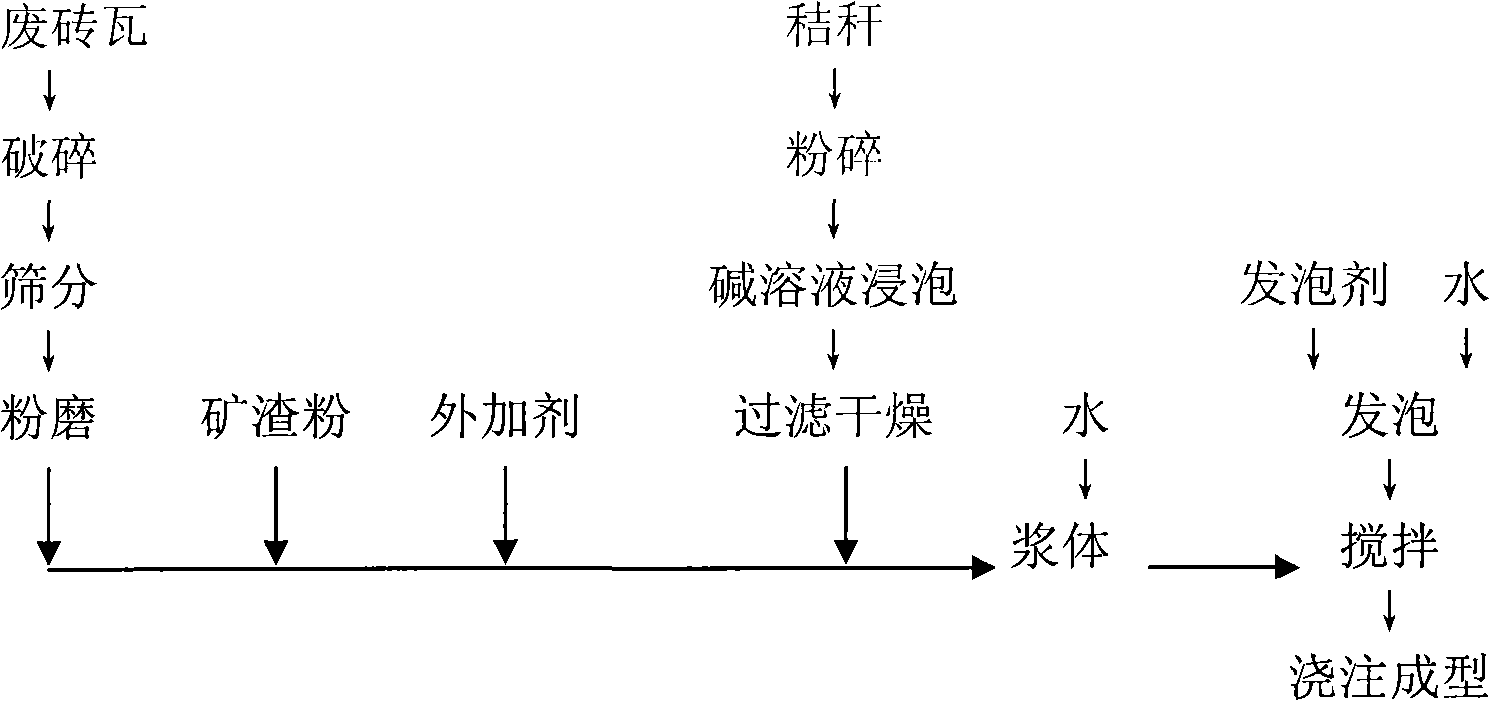

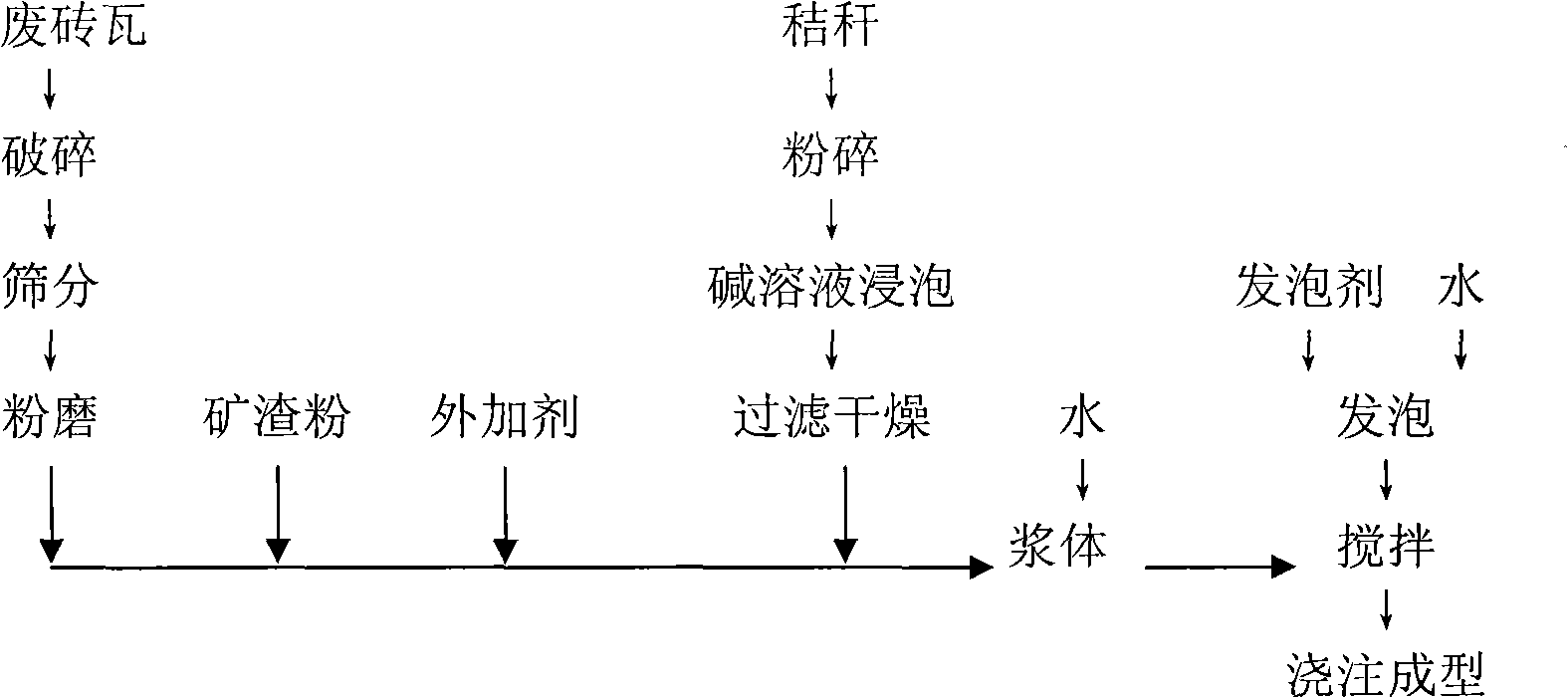

Waste brick tile/straw foam concrete and preparation method thereof

ActiveCN102464497AHigh strengthImprove thermal insulation performanceCeramicwareFoam concreteEcological environment

The invention which provides waste brick tile / straw foam concrete and a preparation method thereof relates to a lightweight building material. The foam concrete is a porous material obtained by mixing more than 90% of a main material comprising industrial and agricultural wastes of waste brick tiles, slag, straws and the like, an additive, a foaming agent and water according to a ratio, stirring,cast-molding and maintaining. The foam concrete which has the functions of light weight, low heat conduction coefficient, heat insulation, sound insulation and fire resistance, water resistance, freezing resistance, cracking resistance, shock resistance and the like and has the advantages of low production cost, simple manufacturing process, realization of onsite casting of prefabricated products, use convenience and safety, changing of wastes into valuables, reaching of energy-saving low-carbon effects, reduction of pollution of the wastes to the environment, ecological environment protection, and nation and civilian benefiting, contributes to the creation of the saving and low carbon society in China.

Owner:DAFENG YINGTAI STRAW STALK TECH DEV CO LTD

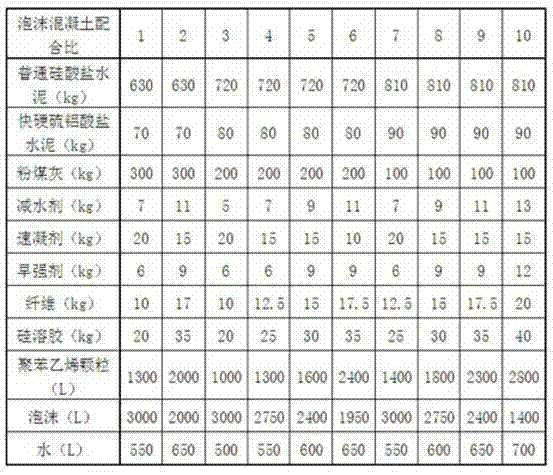

Foam concrete with large-dosage polystyrene particles and preparation method thereof

ActiveCN102503526AImprove thermal insulation performanceHigh electrical insulationCement mixing apparatusCeramicwareFoam concreteAluminate

The invention provides a foam concrete with large-dosage polystyrene particles and a preparation method thereof, which solve problems of water leakage and frost resistance of the foam concrete. The foam concrete comprises components in part as follows: 63-81 parts of ordinary portland cement, 63-81 parts of quick-hardening sulphoaluminate cement, 10-30 parts of coal ash, 0.5-1.3 parts of water reducing agent, 1-2 parts of accelerating agent, 0.6-1.2 parts of early strength agent, 1-2 parts of fiber, 2-4 parts of silica sol, and 50-70 parts of water. The percentage in volume (liter) of the polystyrene particles in added water is 200-400percent, and the percentage in volume (liter) of foam in the added water is 100-600percent. In the preparation process, the treated polystyrene particles stand for 10 min, and the foam can be added after standing uniformly-stirred cement slurry for 20 min. On the premise of ensuring the intensity, the foam cement disclosed by the invention has the advantages of higher heat preservation and heat-shielding performance, higher electric insulating performance, lower volume weight and lower water absorption. The problems of the water leakage and the frostresistance of the foam cement can be solved.

Owner:SHENYANG JIANZHU UNIVERSITY

Polyurethane composite insulation board and preparation method thereof

InactiveCN101570987ALight weightHigh strengthSynthetic resin layered productsHeat proofingFiberGlass fiber

The invention discloses a polyurethane composite insulation board, which consists of a surface layer and an insulating layer, wherein the surface layer is fiber reinforced polyurethane, the density range of the surface layer is between 0.1 and 1.2 g / cm, and the surface layer contains 5 to 50 percent of reinforcing fiber; and the insulating layer is low-density polyurethane, the density range of the insulating layer is between 0.01 and 0.4 g / cm, and the insulating layer contains 5 to 50 percent of reinforcing fiber. A preparation method comprises the following steps: (1) opening an upper mold and a lower mold, evenly laying the polyurethane and glass fiber in a female mold, closing the molds and foaming to manufacture the surface layer; (2) spraying and laying the low-density polyurethane or the fully-mixed reinforcing fiber or the low-density polyurethane of structural polyurethane on the surface layer by adopting special spraying equipment, forming and molding, and manufacturing the insulating layer to form the composite insulation board; and (3) taking out the insulation board. The insulation board has light dead weight, good effect of heat insulation, high strength, difficult deformation, simple manufacturing process and low cost.

Owner:董升顺

SBS (styrene-butadiene-styrene) modified asphalt waterproof coiled material filled with vitrified microbeads and preparation method thereof

InactiveCN102304288AImprove thermal insulation performanceImprove high temperature resistanceRoof covering using flexible materialsRoof covering insulationsPolymer scienceBituminous waterproofing

The invention relates to an SBS (styrene-butadiene-styrene) modified asphalt waterproof coiled material filled with vitrified microbeads and a preparation method thereof. The waterproof coiled material is prepared from the following raw materials in parts by weight: 30-50 parts of 90# asphalt, 10-20 parts of 10# asphalt, 5-8 parts of modifying agent SBS rubber, 3-5 parts of polypropylene resin, 8-12 parts of softening agent, 8-10 parts of rubber powder, 5-12 parts of hollow vitrified microbeads and 20-30 parts of light calcium carbonate. The preparation method comprises the following steps: sucking the asphalt and dewatered softening agent which are weighed into an asphalt preparing tank; melting, then heating to 175-185 DEG C, adding the modifying agent SBS rubber and polypropylene resin, further stirring and insulating heat for 1.5 hours until the SBS rubber and polypropylene resin are completely melted into the asphalt system; adding the rubber powder, hollow vitrified microbeads and light calcium carbonate which are weighed; and subsequently, carrying out production according to the equipment and process of the ordinary SBS modified asphalt waterproof coiled material. According to the invention, the SBS modified asphalt waterproof coiled material has the advantages of better high-temperature resistance and thermal insulation property because light hollow vitrified microbeads are added.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com