Patents

Literature

55results about How to "Construction organization is convenient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Full-fabricated assembly overall reinforced concrete house and building method thereof

InactiveCN101806095ASmall sizeNo secondary plastering requiredBuilding material handlingFloor slabReinforced concrete

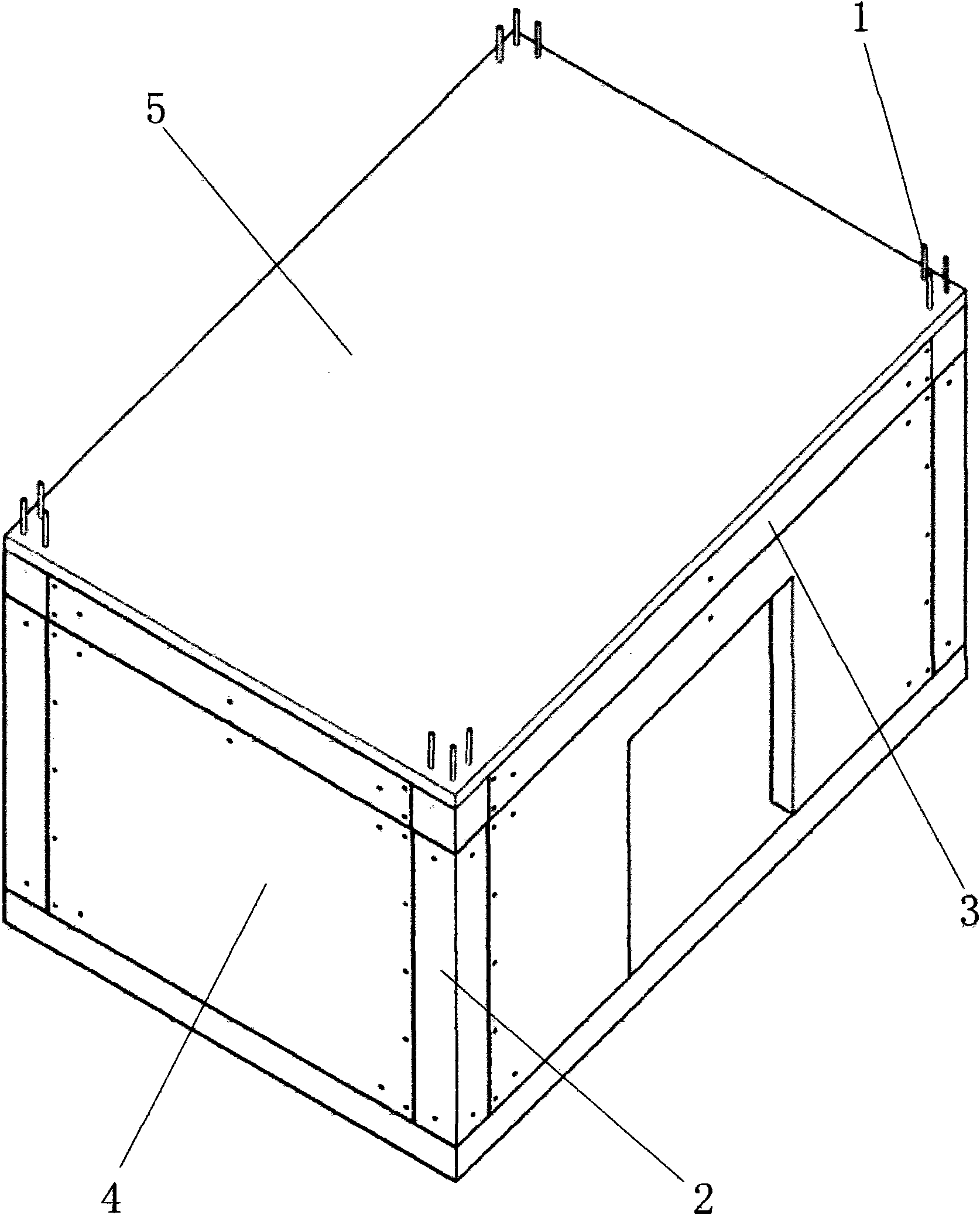

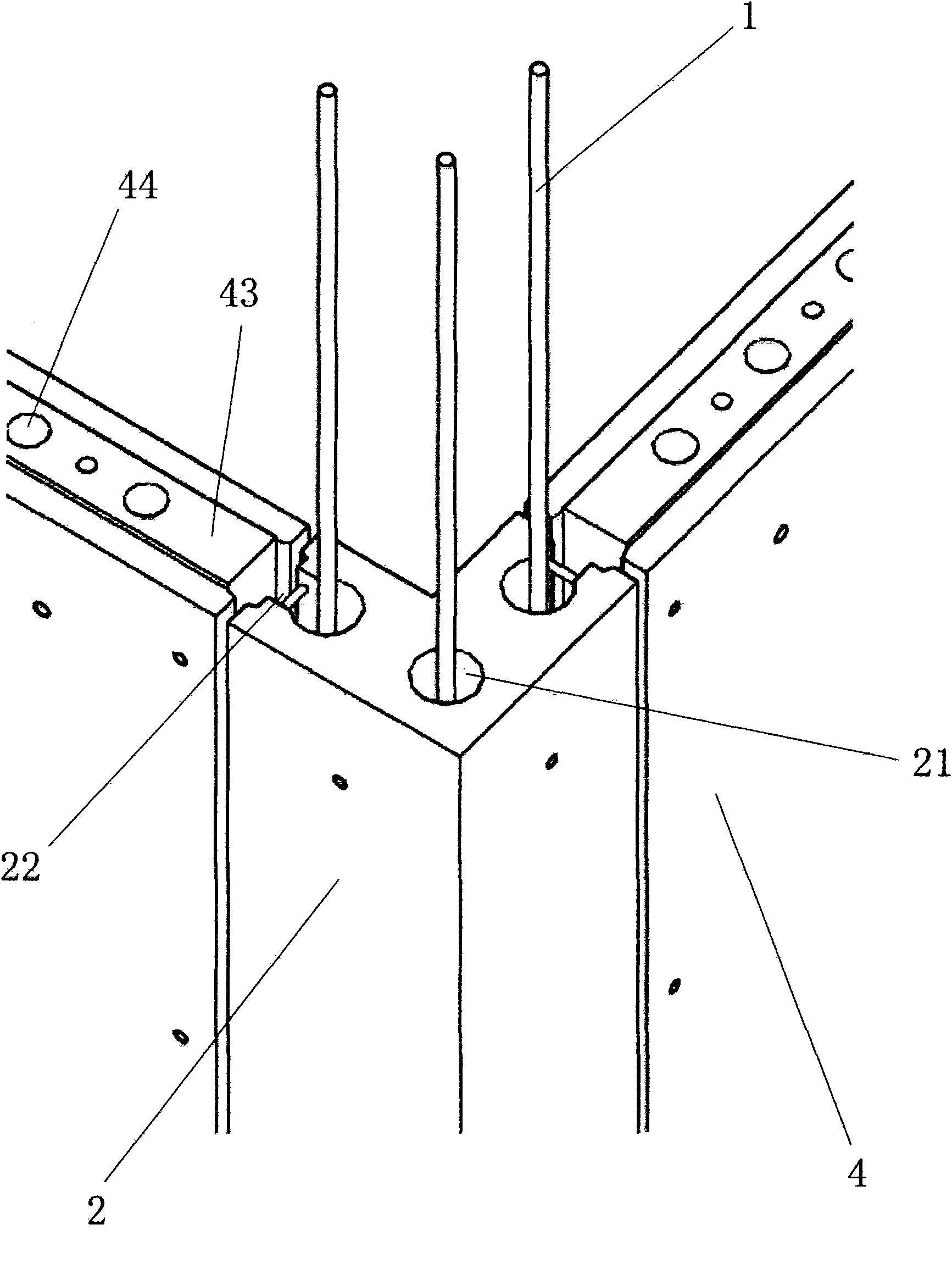

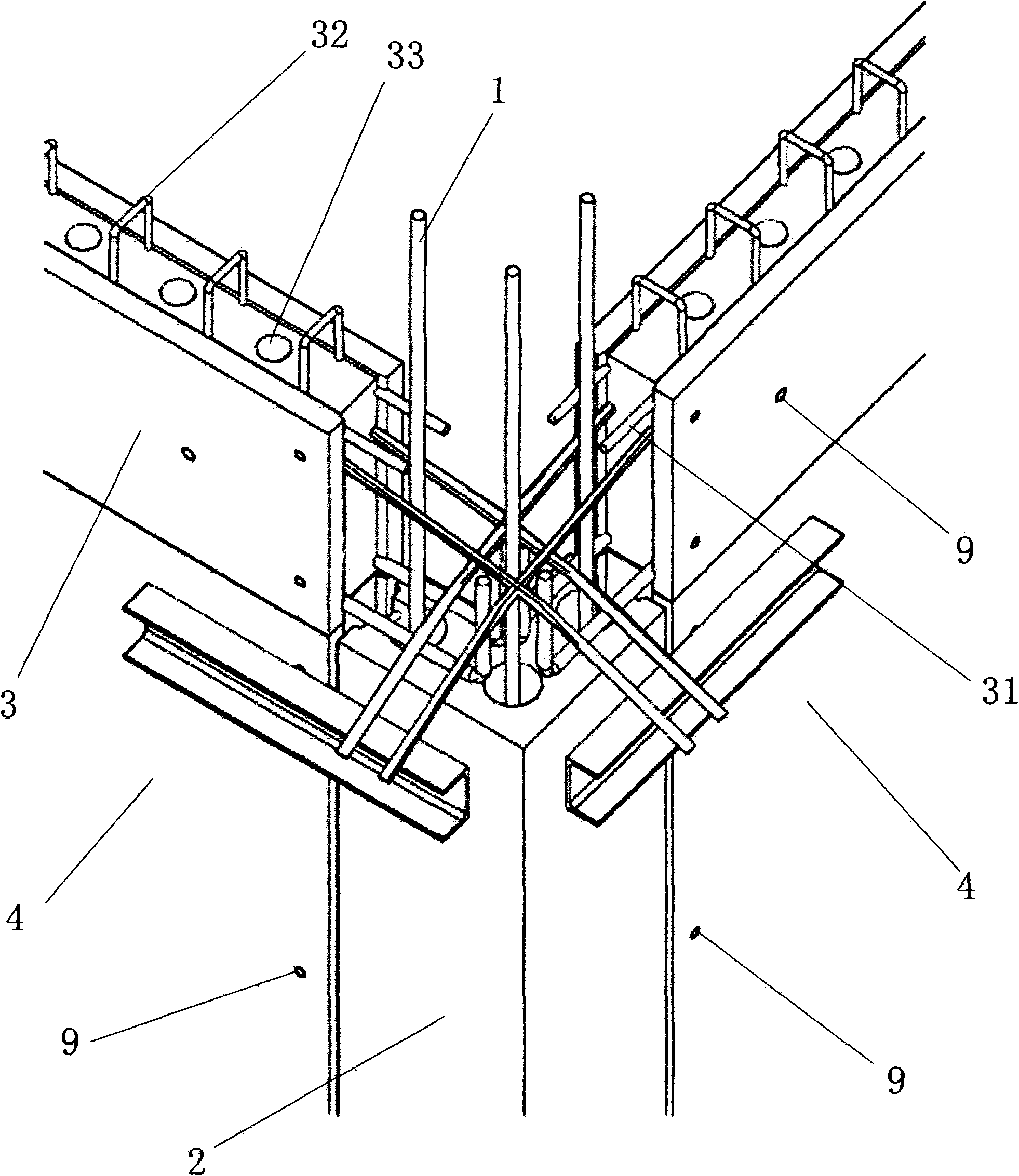

The invention discloses a full-fabricated assembly overall reinforced concrete house which comprises a plurality of column ribs arranged at intervals and respectively and fixedly connected with a foundation, a plurality of column bodies prefabricated in a modularized way, a plurality of wall bodies prefabricated in the modularized way, and a floor slab prefabricated in the modularized way. The invention aims to overcome the defects of the prior art, and improve the full-fabricated assembly overall reinforced concrete house which has simple structure, is convenient to install, saves building materials, is quick to build, and has good overall safety performance. Another purpose of the invention is to provide a method for building the house.

Owner:ZHONGSHAN FAST LIVING PREFABTED HOUSING

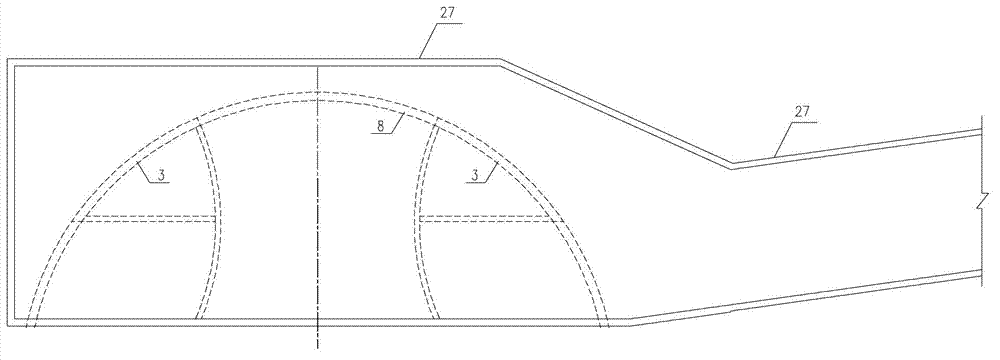

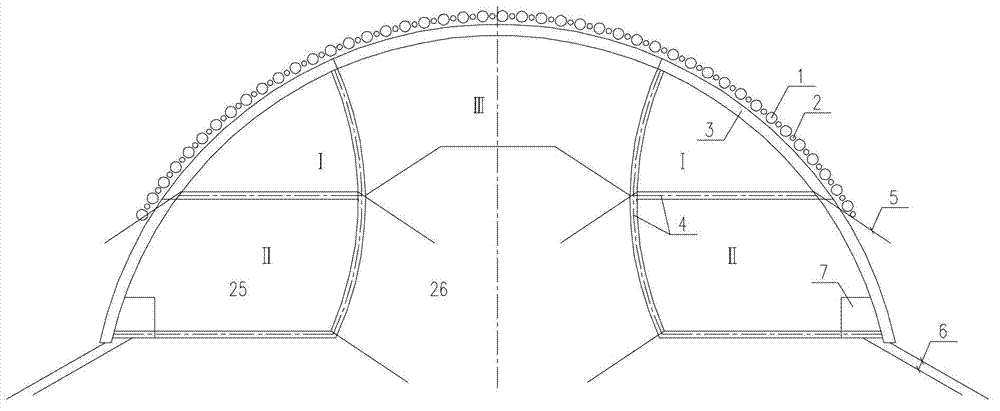

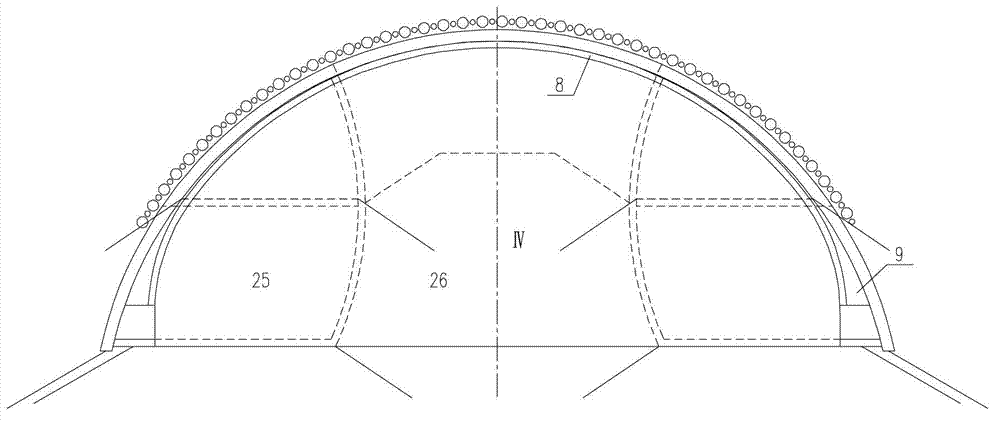

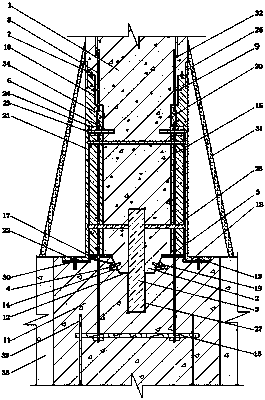

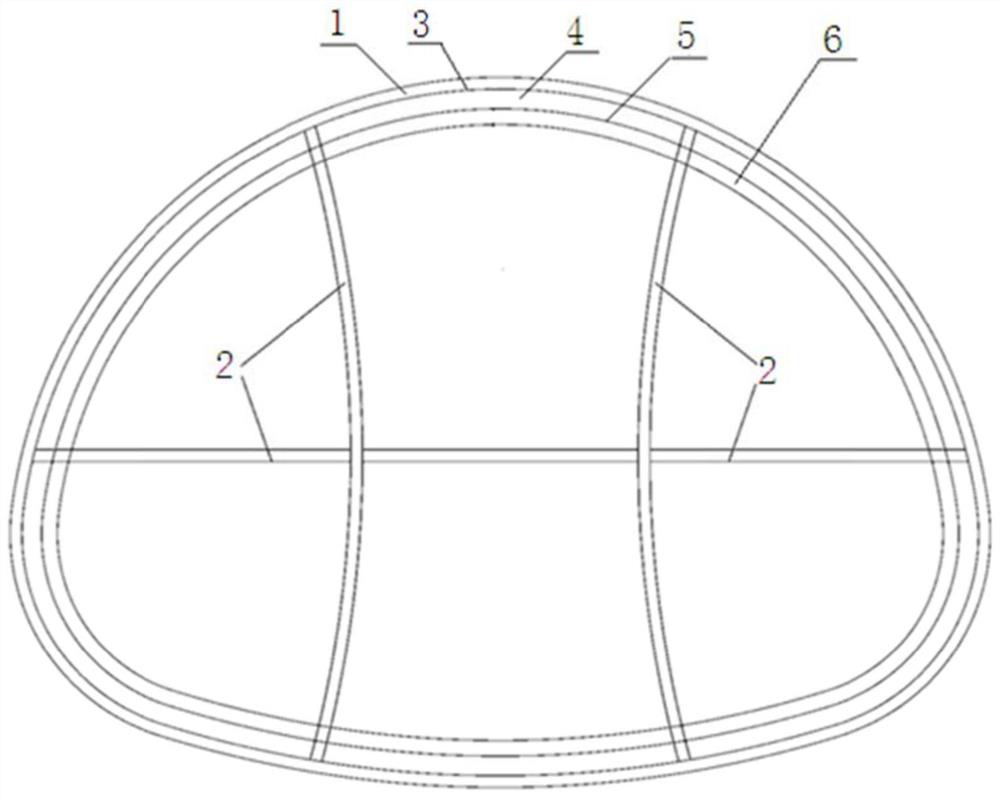

Rock stratum double initial support layering method for establishing large-scale underground structure

InactiveCN102758632ALow costSimple processUnderground chambersDrainageStructural deformationSteel tube

A rock stratum double initial support layering method for establishing a large-scale underground structure mainly includes the following steps: excavating the side headings of an arch part, excavating the upper steps on the middle heading of the arch part, setting the double-layer initial supports of the arch part, setting a mud jacking steel pipe, setting an arch springing girder, excavating the lower steps on the middle heading of the arch part, and three-layered excavating the foundation under the middle heading of the arch part and the two side headings of the arch part. The rock stratum double initial support layering method for establishing the large-scale underground structure combines multiple technologies as advanced small pipe, big pipe shed and section steel support with multiple mining excavation technologies such as PBA method, side drifts-support method, CRD method and step method, not only can satisfactorily control the structural deformation and the stratum settlement, but also has the advantages of simple process, convenience for construction and organization, high construction efficiency, saved project cost and the like.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

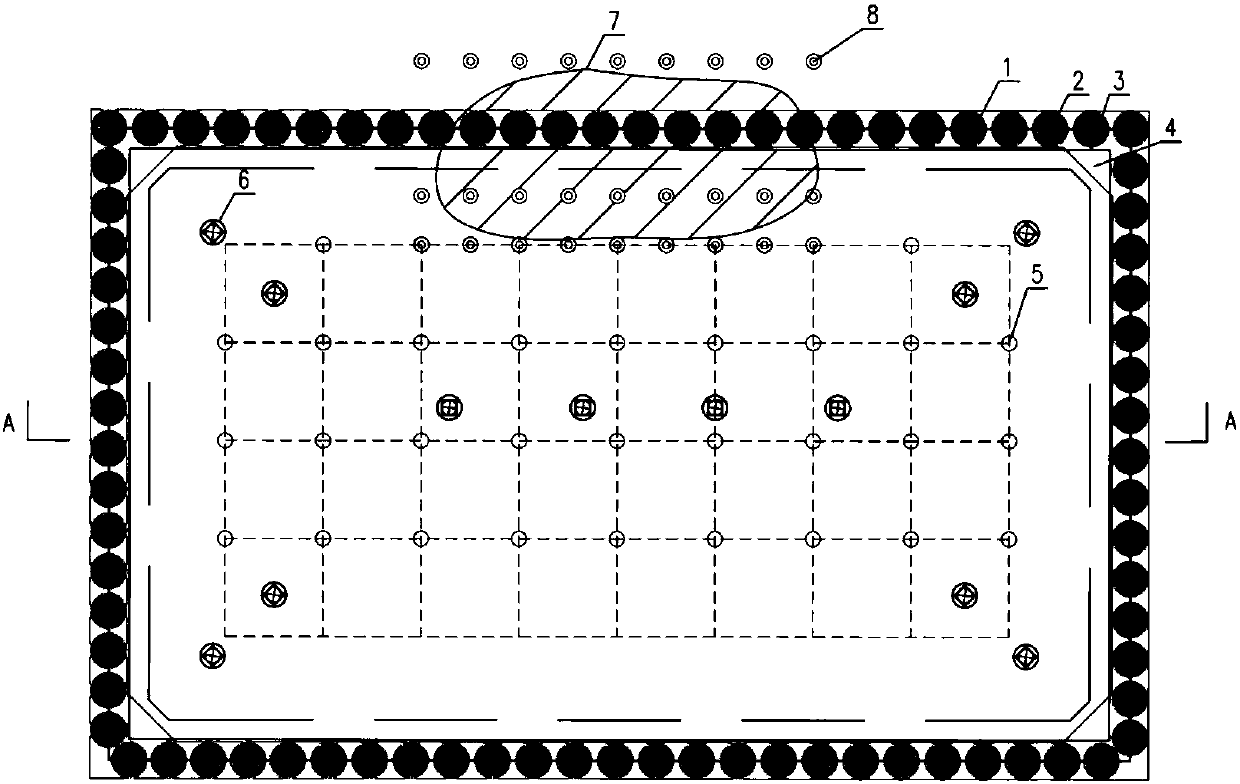

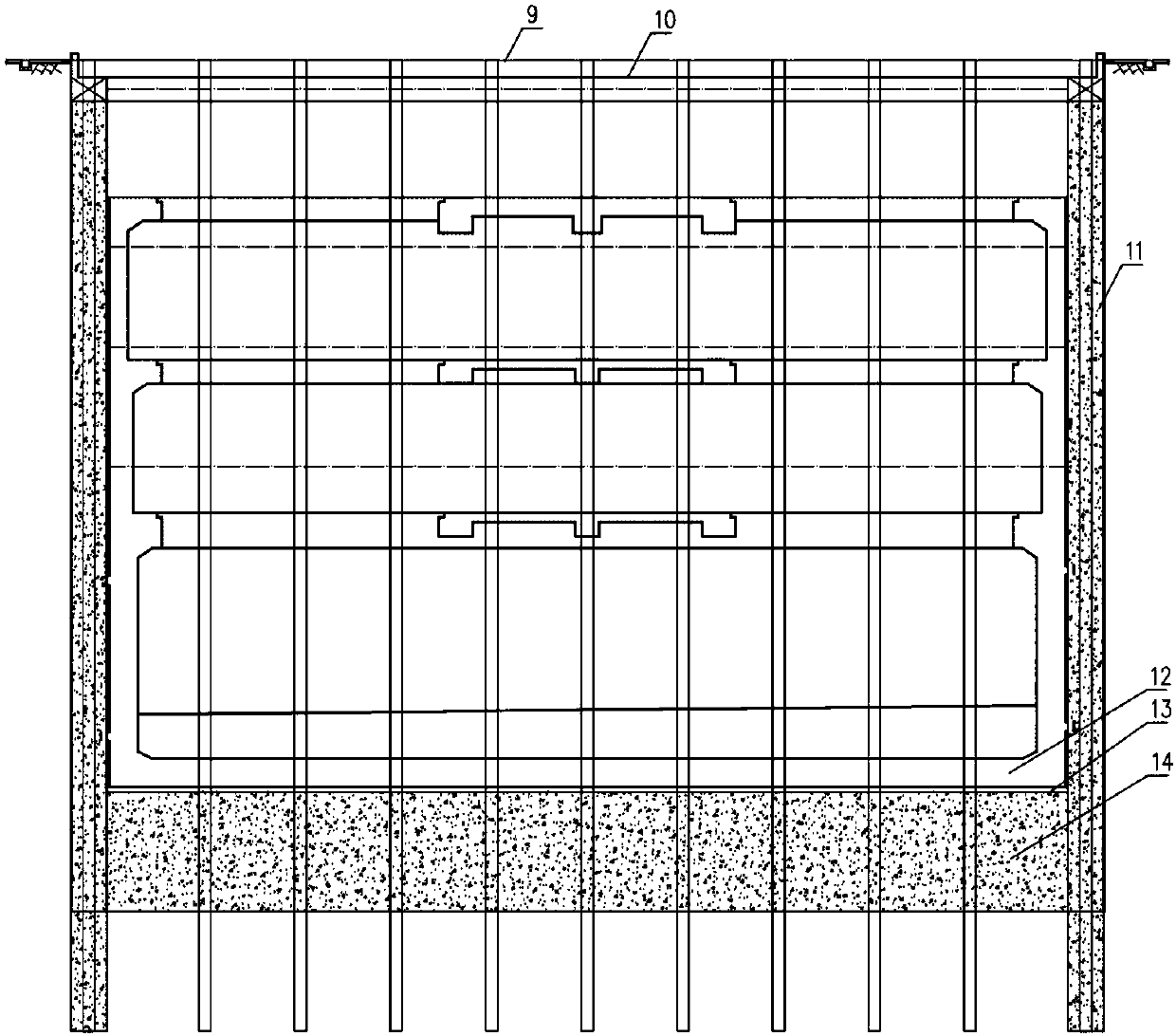

Three-dimensional treatment method of subway deep foundation pit in karst intense development region

InactiveCN105862722AEnsure construction safetyGuaranteed operational safetyExcavationsSoil preservationKarstEngineering

The invention discloses a three-dimensional treatment method of a subway deep foundation pit in a karst intense development region. The three-dimensional treatment method comprises the steps of karst cave / soil cave treatment; waterproof curtain construction; divisional grouting; and bottom sealing grouting. According to the three-dimensional stereo construction method, the foundation pit constriction safety and subway operation safety are guaranteed, the difficulty is low, the cost is low, the construction period is short, the method is the first one at home and abroad, the construction is convenient to organize, the construction procedure is scientific, the method is safe and reliable, the risks that a retaining structure collapses during construction and inrushing occurs in the foundation pit under the action of high-water head pressure confined karstic water are avoided, the capacity of the foundation pit for preventing partial karst collapse, the safety of a station structure, and the safety of subway operation are improved, and the method is applicable to karst treatment construction of the subway deep foundation pit.

Owner:CHINA CONSTR COMM ENG GRP UNITED

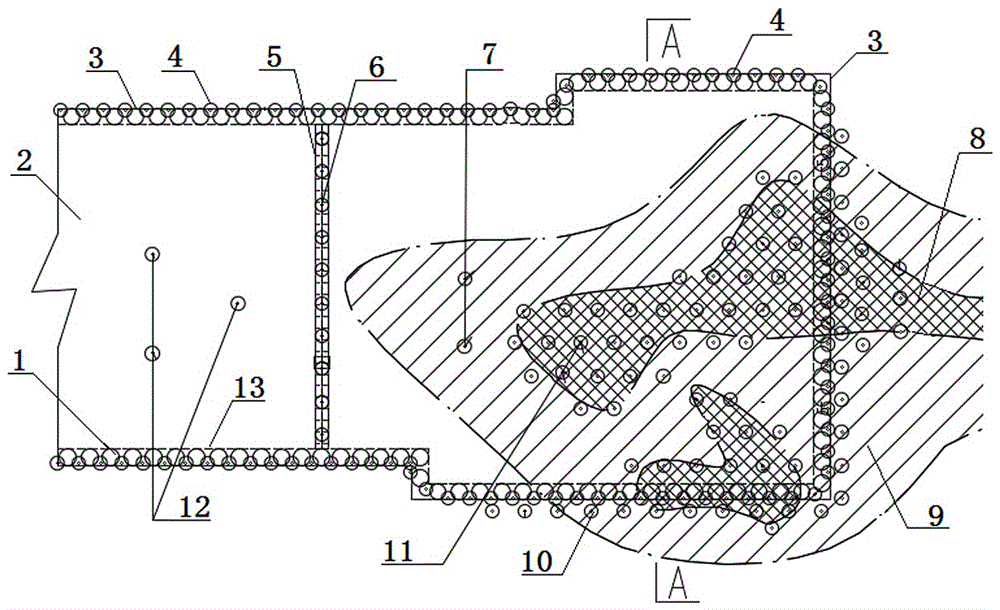

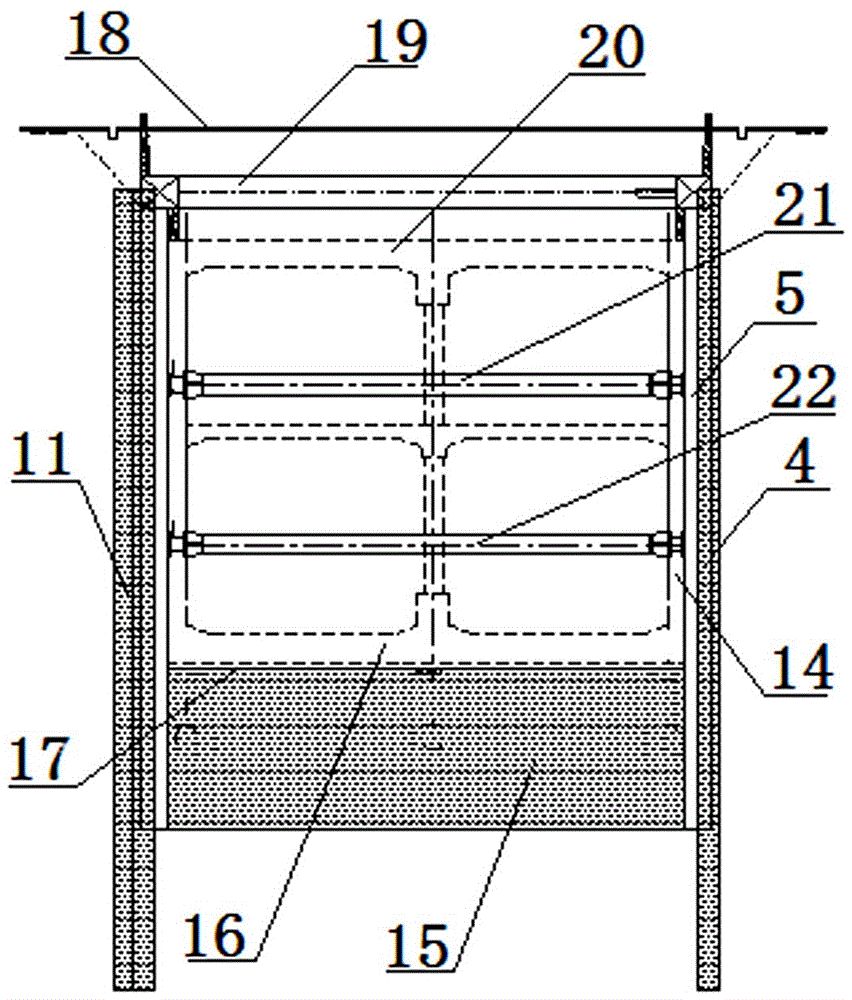

Super early receiving supporting structure of shield machine and super early receiving method

ActiveCN102322269AAchieve early receiptReduce construction proceduresTunnelsShield machineBuilding construction

The invention relates to a super early receiving supporting structure of a shield machine and a super early receiving method. The super early receiving supporting structure is characterized by comprising a receiving well foundation pit wall support, a bottom plate support and an outlet hole support, wherein the receiving well foundation pit wall support comprises a foundation pit envelope pile, at least two anchor cables and a steel pipe corner support; the outlet hole support is a temporary horizontal support; and the bottom plate support comprises an anti-pulling pile and a concrete bottom plate paved on a foundation pit bottom soil mass. By the super early receiving supporting structure and the super early receiving method, the construction problem that the shield machine cannot be received in advance when the shield machine arrives at a station in advance is successfully solved, the service life of the shield machine is prolonged, the construction cost of a shield interval is saved, and the construction period is shortened. The structure and the method can be applied to the advanced receiving of the shield machine when a receiving well structure is not completely constructed or finished.

Owner:北京城乡建设集团有限责任公司

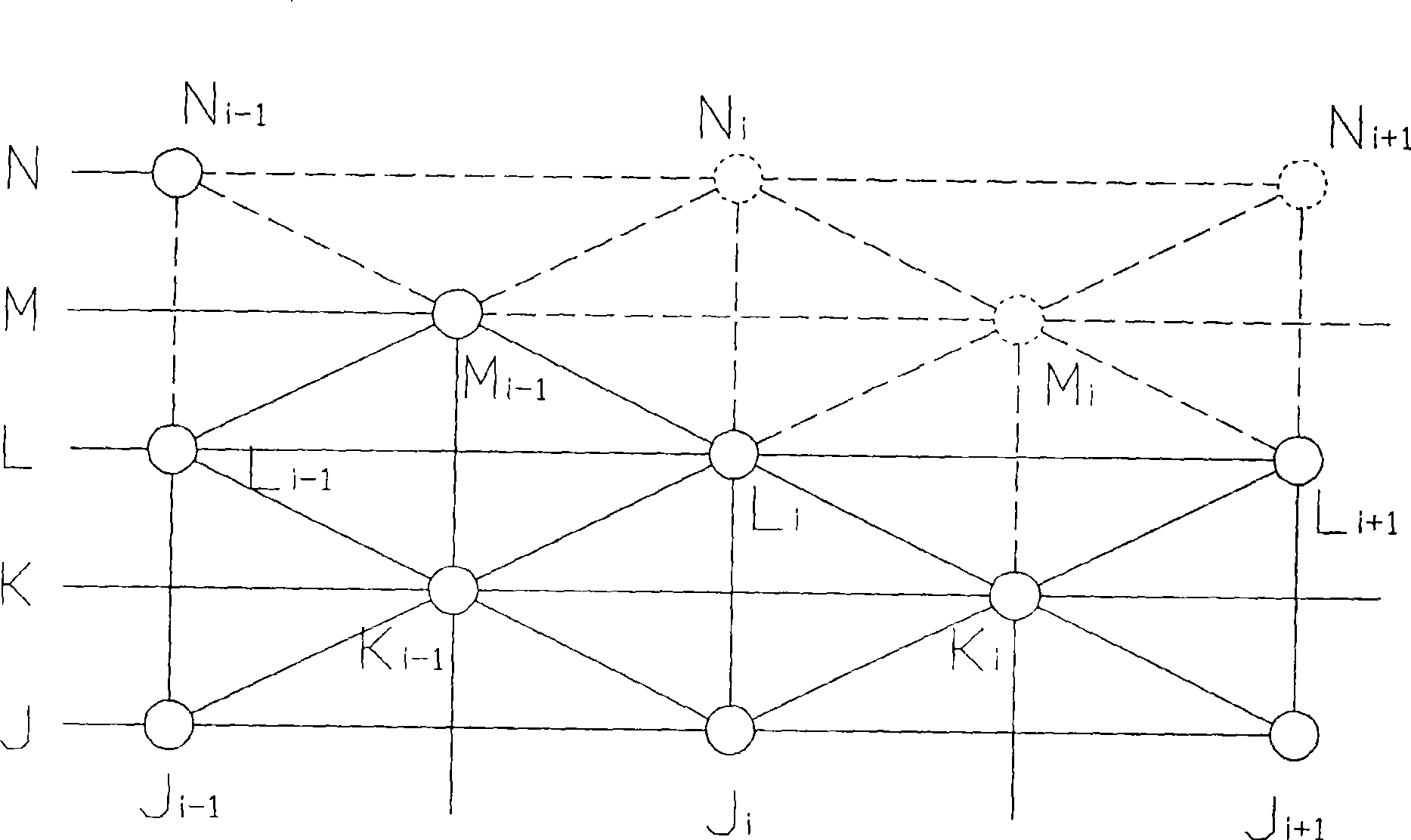

High altitude suspension selecting bulk construction method of barrel shell type bolt ball node network frame

InactiveCN101435224AImprove construction flexibilityImprove installation efficiencyBuilding constructionsSUSPENDING VEHICLESupport condition

The invention relates to a small assembling unit high suspending construction method for cylinder casing type bolt ball node grid. The cylinder casing type bolt ball node grid is divided into a plurality annuluses in longitudinal direction according to the support condition, a steel pipe scaffold is arranged in any one annulus, an upper net casing of the annulus is assemble on the annulus by a bulk method, and the scaffold is dismounted after the assembly is qualified; a second annulus is constructed by the small assembling unit high suspending method from the assembled first annulus, and the annulus is assembled one by one along the longitudinal direction, after the bolt balls on the lower boom loop wire in the annuluses are mounted in order, the bolt balls on adjacent upper boom loop wire are mounted in order, each bolt ball and a longitudinal boom, an annular boom and two web members are put together to form a one-ball-four-rod member on the ground before assembly, and then the formed members are suspended by crane to proper positions in the air to be connected to the bolt balls mounted on the periphery. The method of the invention is safe, flexible, convenient, fast, and has low cost.

Owner:河南中美铝业有限公司

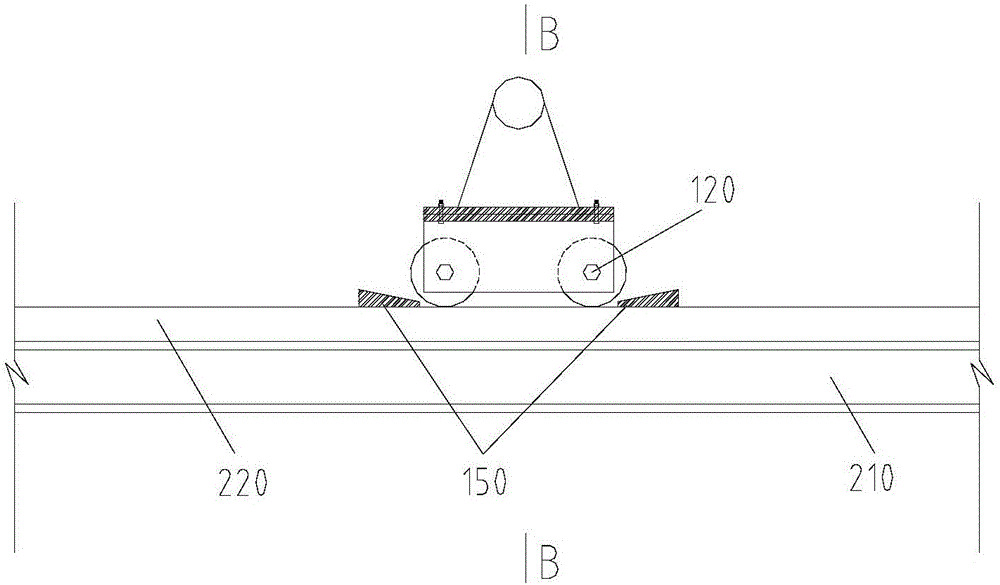

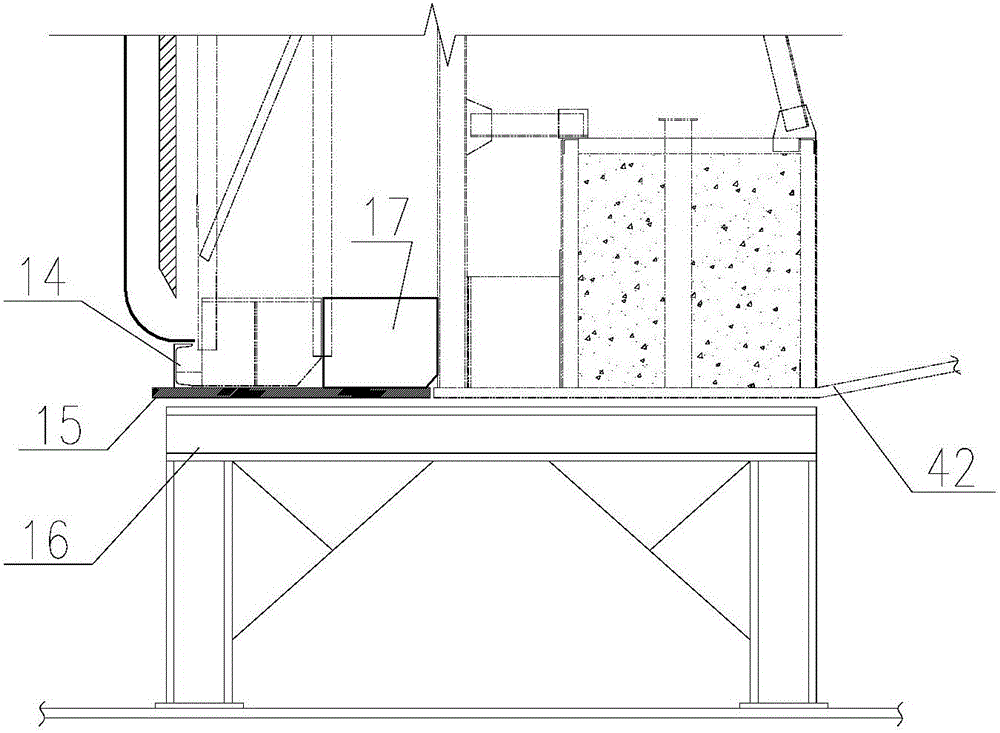

Sliding platform and construction method for separately mounting grid structures on high altitudes

ActiveCN106223595AMeet the requirements of continuous installationGood sliding safetyBuilding support scaffoldsOverhead craneIndustrial Factory

The invention discloses a sliding platform and a construction method for separately mounting grid structures on high altitudes. The sliding platform for separately mounting the grid structures on the high altitudes is arranged in an industrial factory building. The industrial factory building is provided with crane beams, and overhead crane tracks are arranged on the crane beams. The sliding platform for separately mounting the grid structures on the high altitudes comprises a grid structure type sliding platform, a scaffold operating platform and pulling equipment. The grid structure type sliding platform is slidably arranged on the overhead crane tracks via a plurality of sliding rollers; the scaffold operating platform is arranged on the upper surface of the grid structure type sliding platform; the pulling equipment is connected onto the grid structure type sliding platform, so that the grid structure type sliding platform can slide along the overhead crane tracks. The mounting quality of the grid structures, with bolt-sphere joints, of the industrial factory building can be sufficiently guaranteed, the time and labor can be saved, and the safety of staffs for constructing the grid structures on the high altitudes and the safety of construction staffs below the staffs can be guaranteed. The sliding platform and the construction method have the advantages of flexibility, convenience, speediness and low cost. Besides, merits can become obvious along with increase of ratios of the longitudinal lengths to the span of the grid structure.

Owner:CHINA IPPR INT ENG

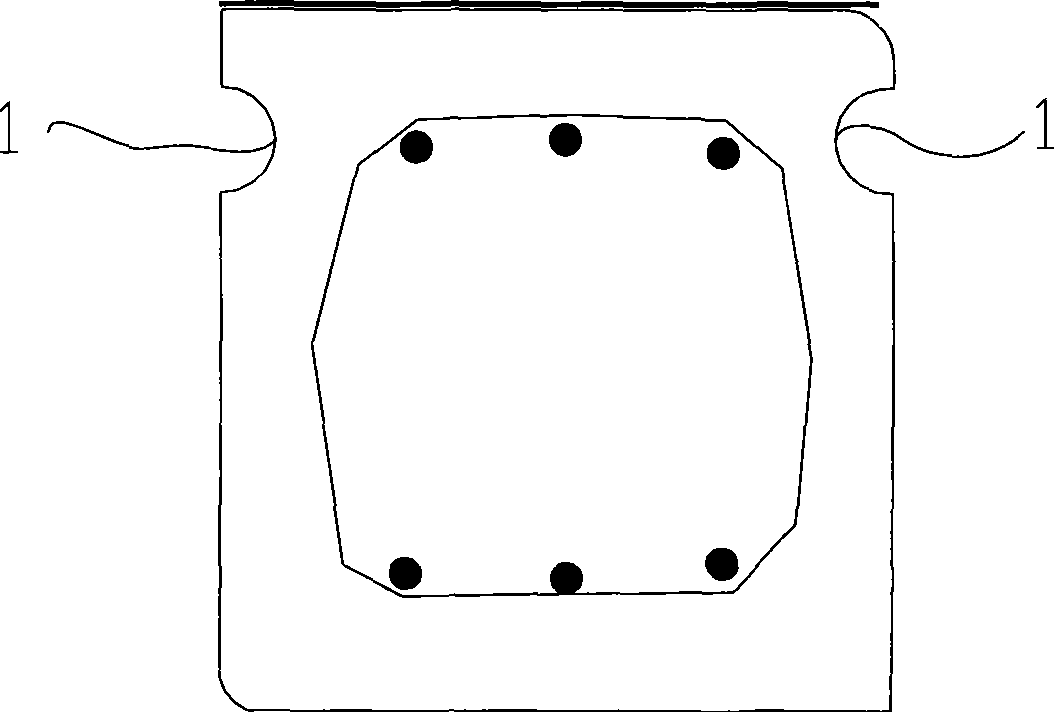

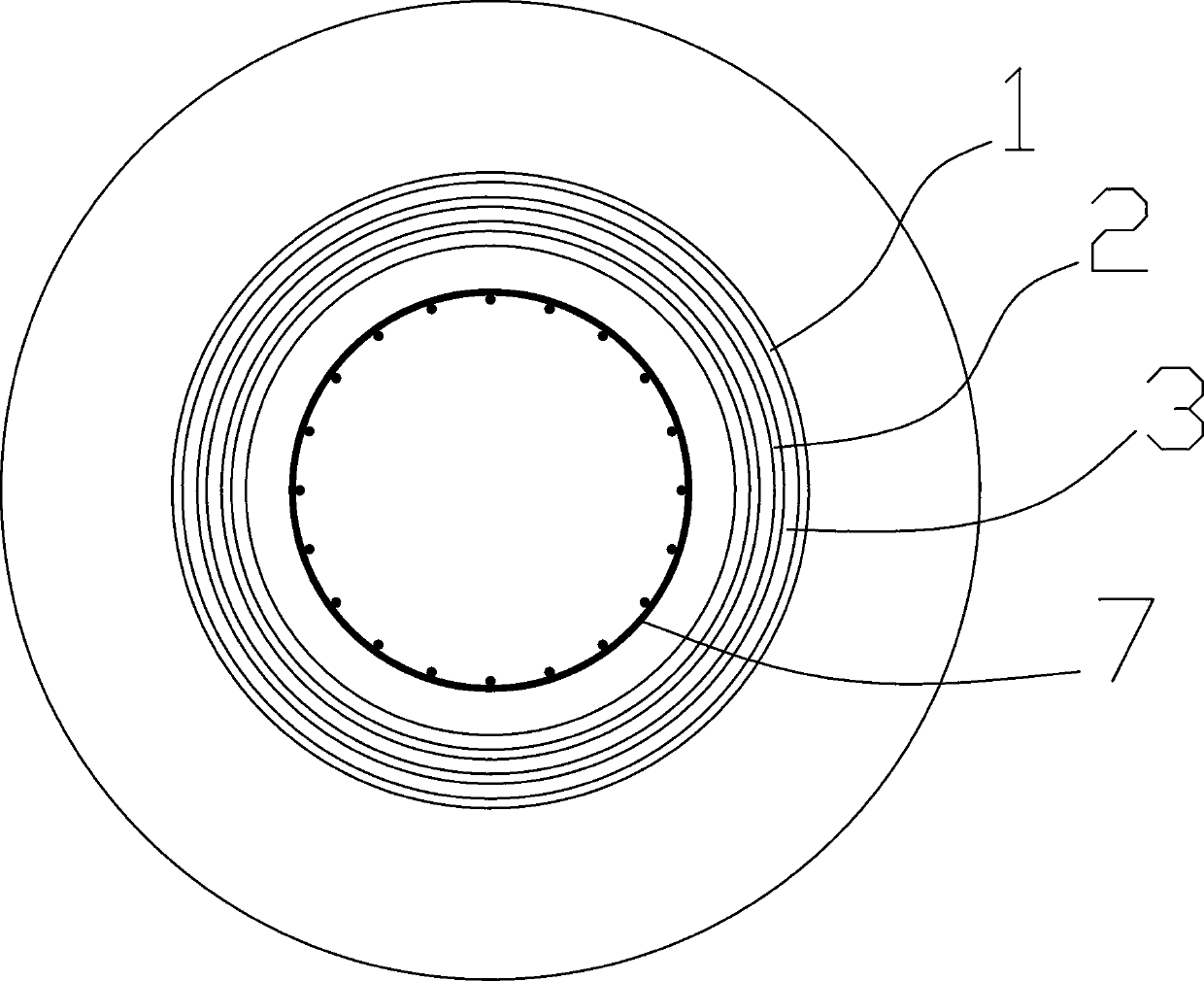

Preparation method for preformed hole fender pile

InactiveCN101544022AGood lateral pressure and shear resistanceShort construction periodMouldsShaping reinforcementsSEMI-CIRCLEPressure resistance

The invention provides a preformed hole fender pile, belongs to the field of building, in particular relates to a fender pile capable of barricading earth and water and applied to deep foundation pit engineering, and discloses a preparation method for the preformed hole fender pile. The cross section mode of the fender file is a square of which two semi-circles of opposite lateral surfaces are cut off. The fender pile is a preformed pile, has better compactness, permeability resistance, side pressure resistance and shearing resistance capacity, and does not need maintenance. The fender pile has simple construction, saves time and labor, and has short construction period and water retaining function; and the construction is completed by only driving a row of piles.

Owner:SHANGHAI ZHONGJI PILE IND

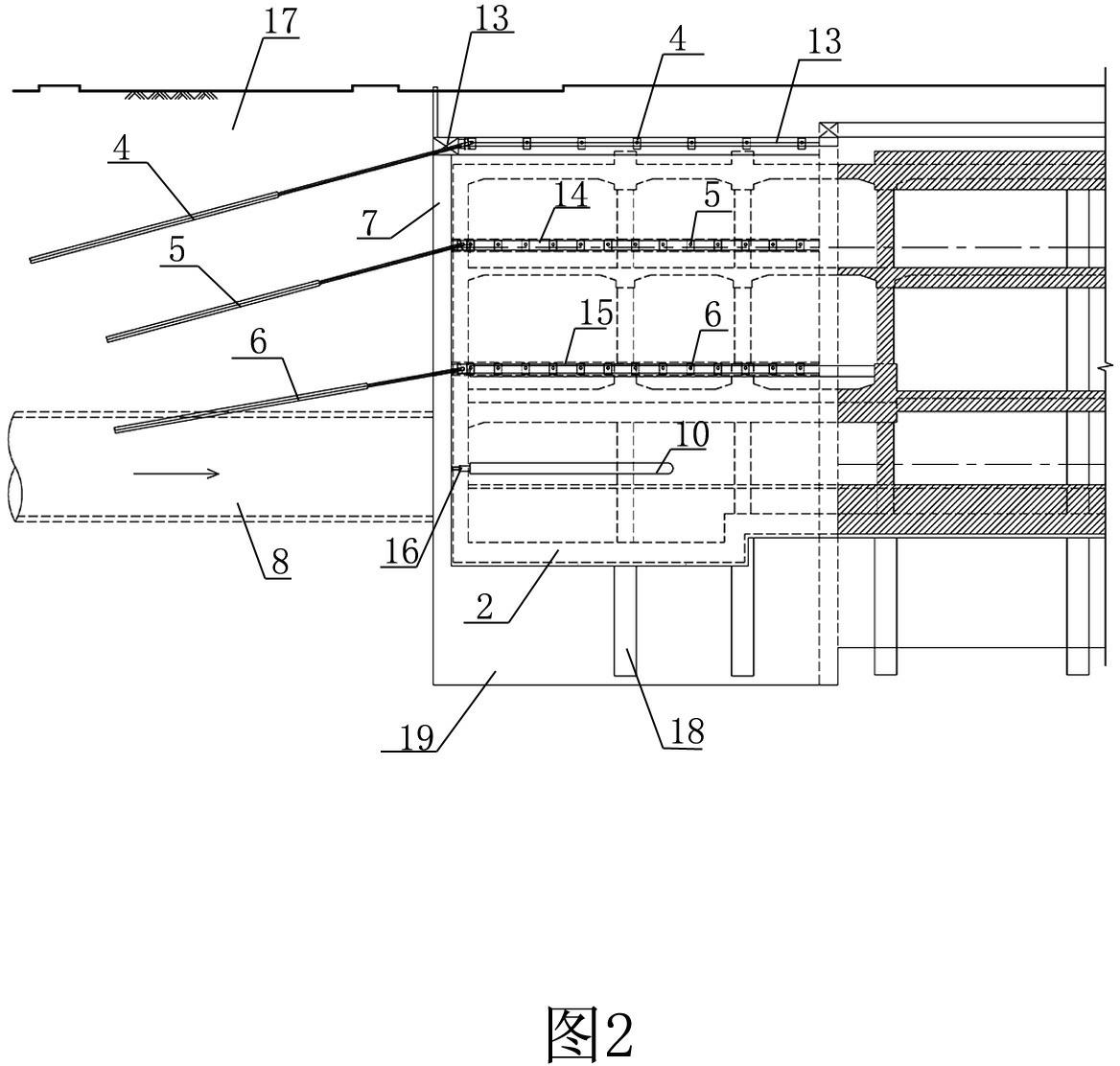

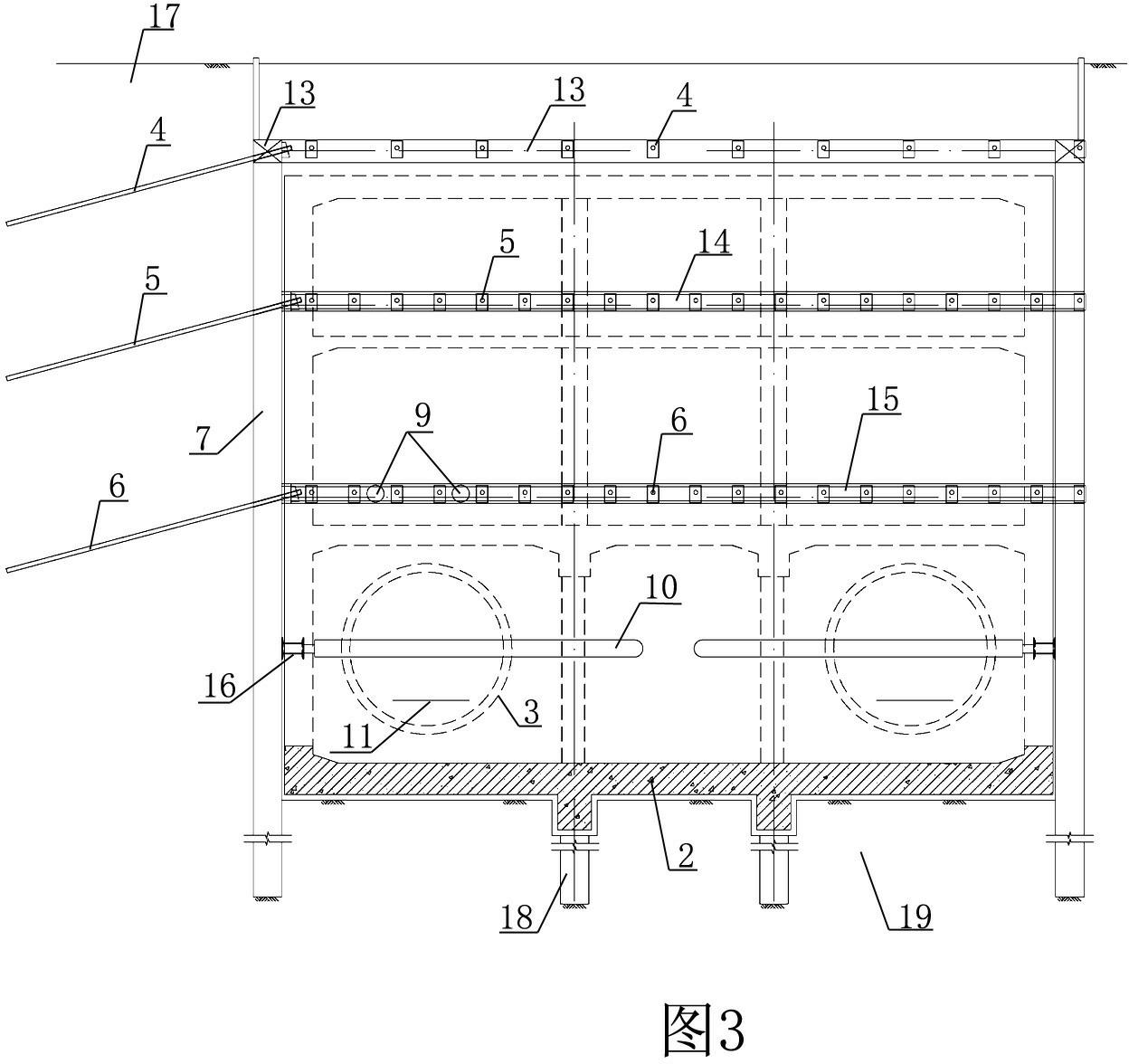

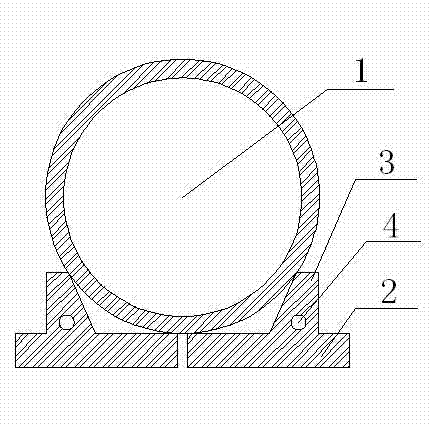

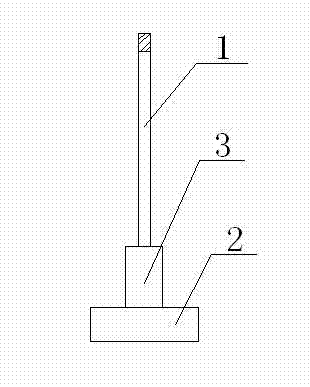

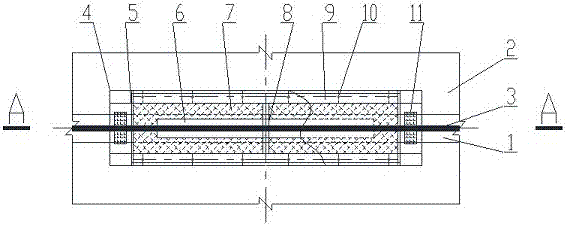

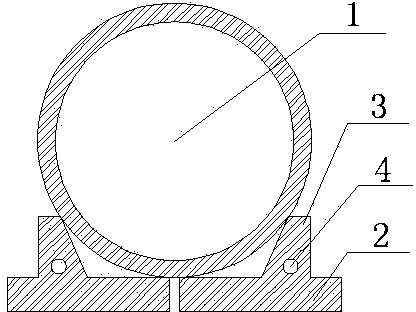

Large-caliber drainage pipeline construction assembly and construction method thereof

The invention belongs to the field of municipal rainwater-sewage pipeline engineering technology and particularly relates to a large-caliber drainage pipeline construction assembly and a construction method thereof. The large-caliber drainage pipeline construction assembly comprises a pipeline and is characterized in that the pipeline is arranged on two pipeline underlay pieces, pipeline stabilizing pieces are respectively and fixedly connected above the pipeline underlay pieces and respectively tangent with the pipeline, and hoisting holes are respectively formed in the pipeline stabilizing pieces. The large-caliber drainage pipeline construction assembly has the advantages of being high in installation efficiency, integrity and stability of the pipeline are high, pipeline installation straightness and smoothness can be guaranteed, inconvenience caused by concreting twice can be avoided, and manufacturing cost is low.

Owner:JINAN URBAN CONSTR GRP

Construction method of foundation pit support structure under karst and/or fissure development strata

The invention discloses a construction method of foundation pit support structure under karst and / or fissure development strata, and belongs to the field of rail traffic construction. The constructionmethod of the foundation pit support structure mainly includes the construction steps of advanced drilling, partition drilling, partition grouting, karst cave handling, and fissure handling. By meansof the construction method, accidents like sudden loss of arm protection mud and instability and collapse of a hole wall are not prone to occur, the stability of a foundation pit in an excavation process is good, and the safety of a main structure during the rail traffic operation is guaranteed. The construction method of the foundation pit support structure is easy to construct, low in cost, high in efficiency, convenient to organize, reasonable in procedure, safe and reliable, and wide in application scope.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +1

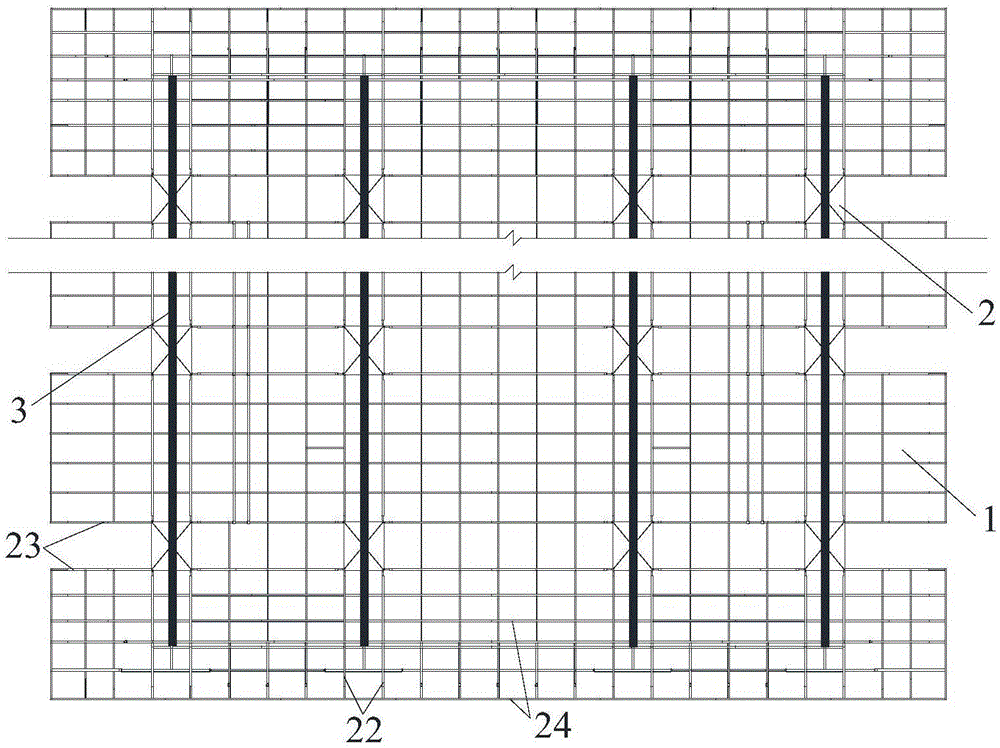

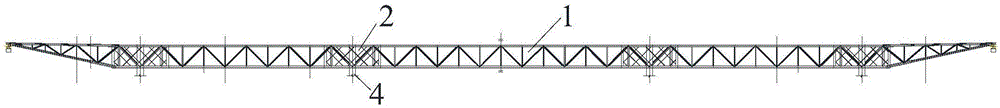

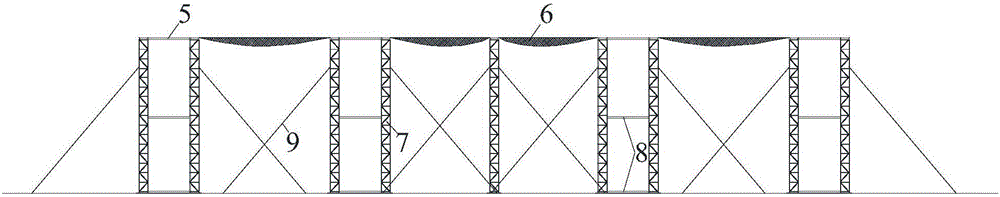

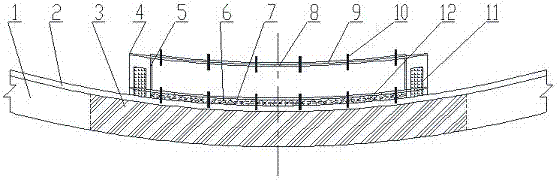

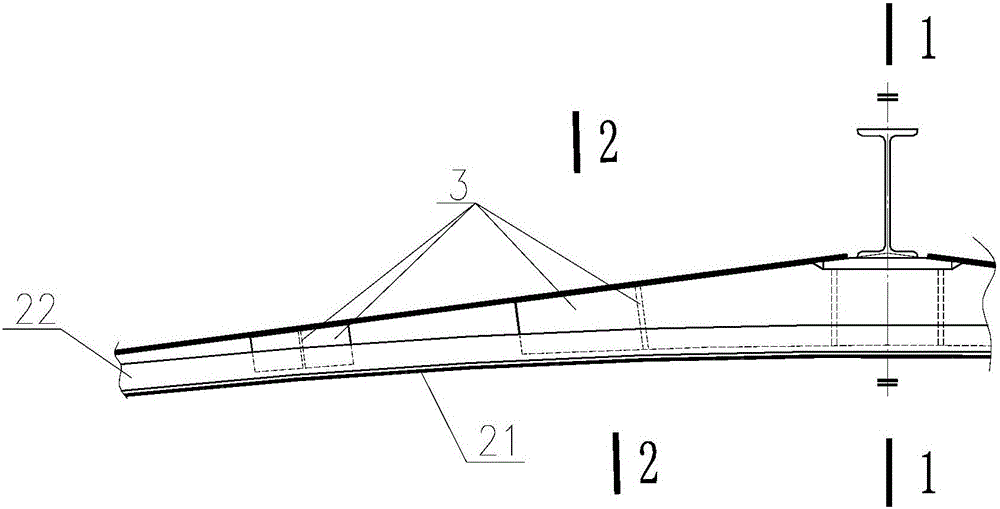

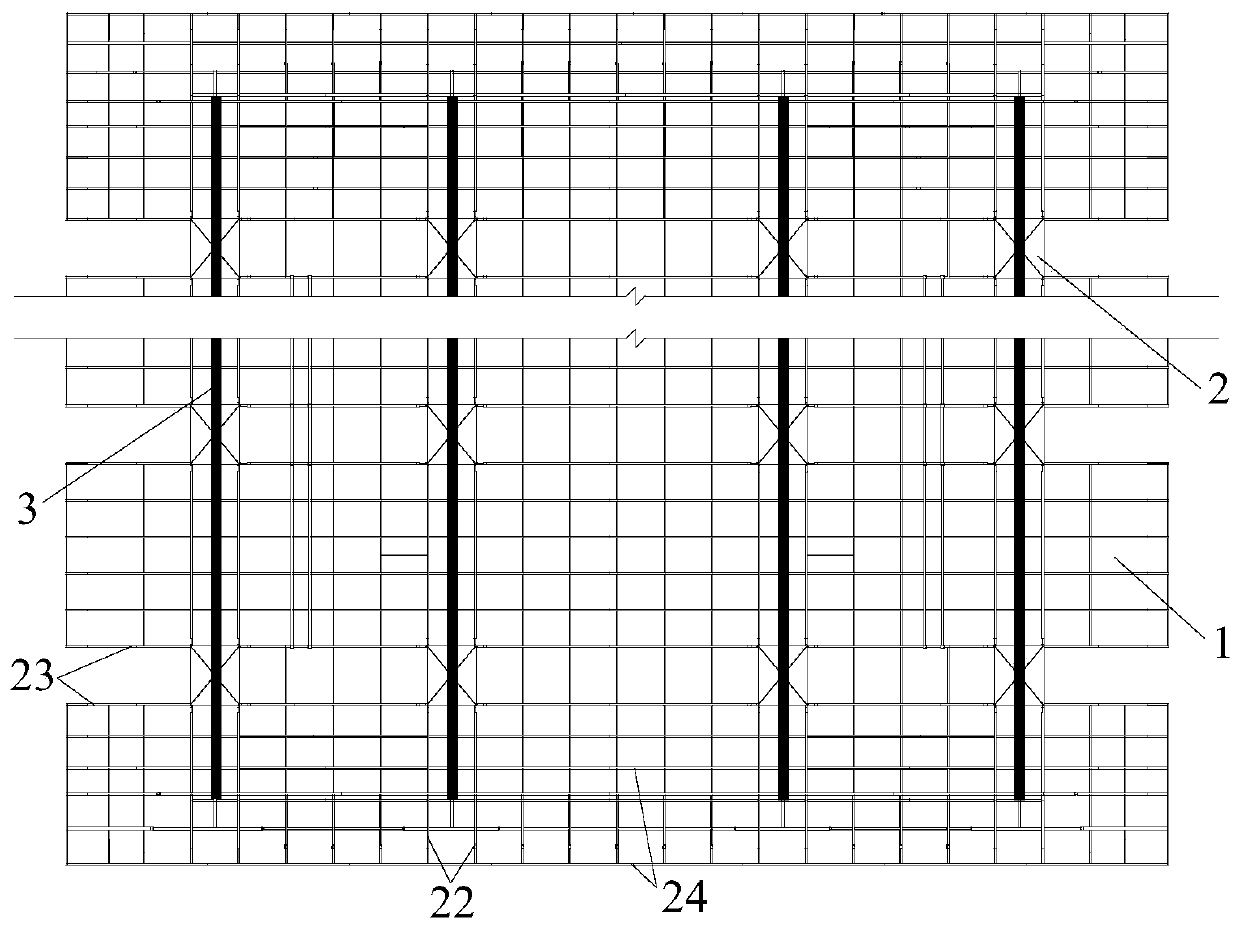

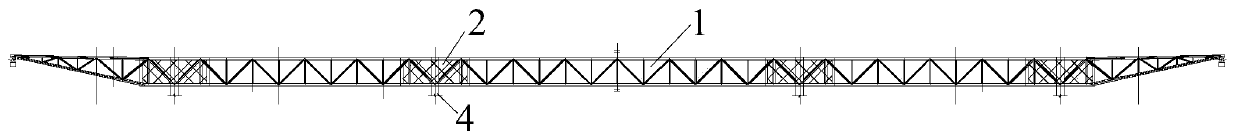

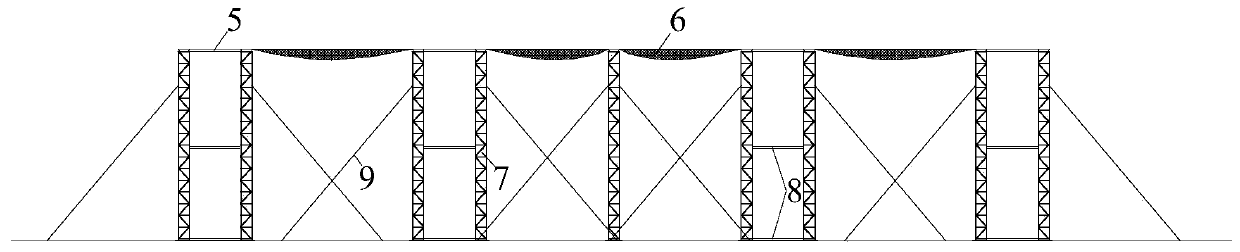

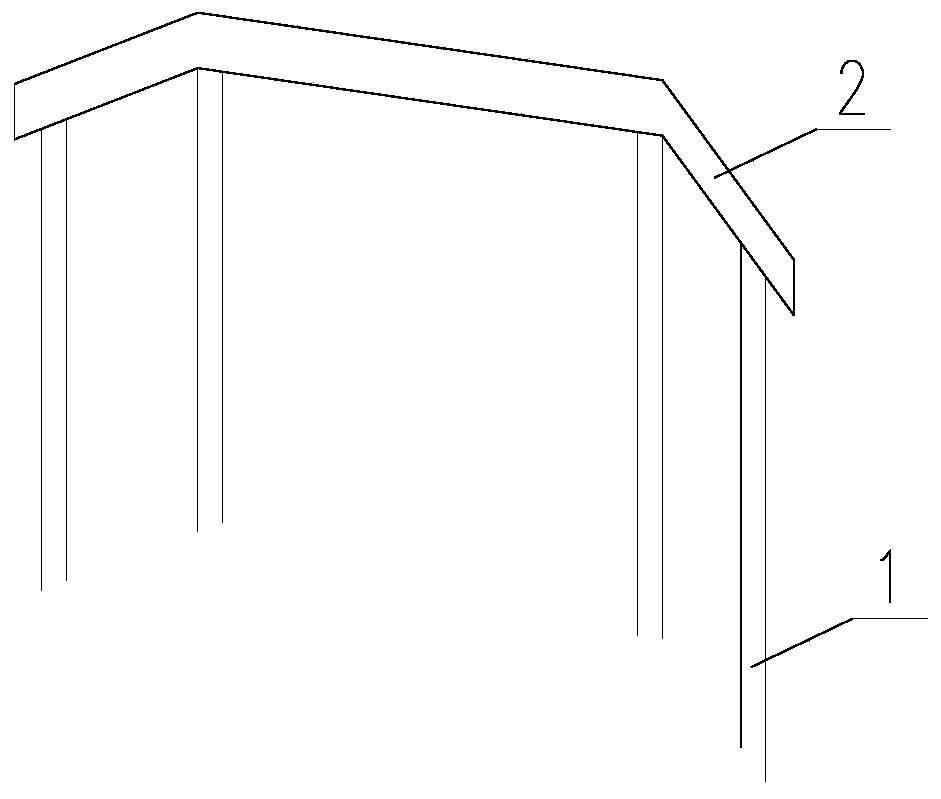

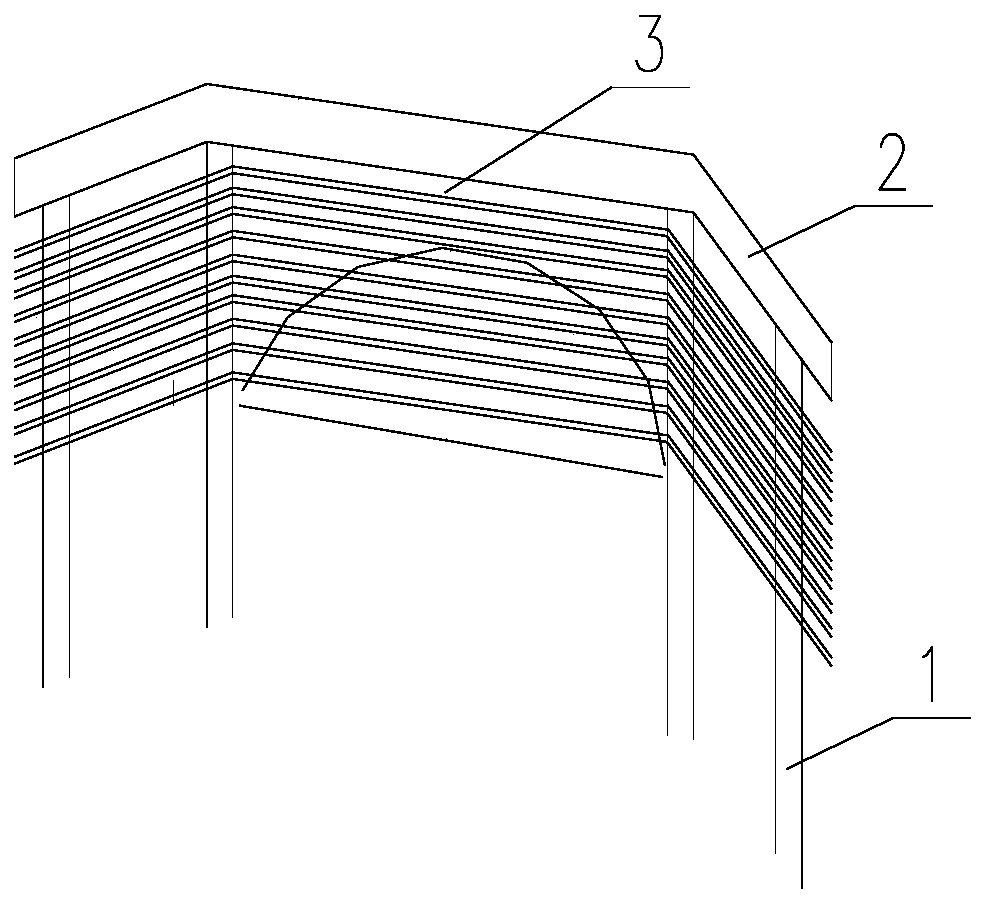

Sectional sliding roof steel truss assembling method

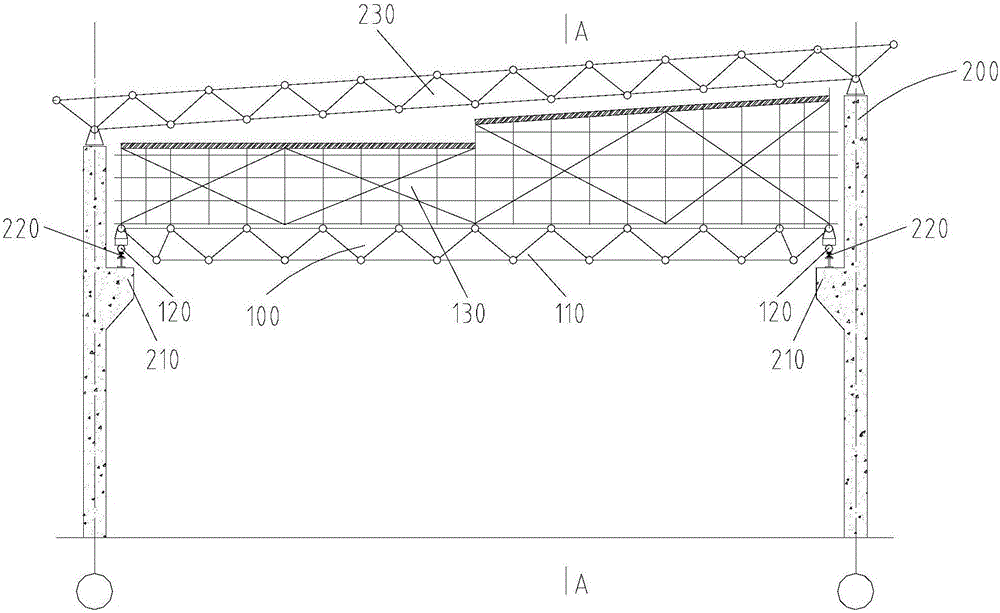

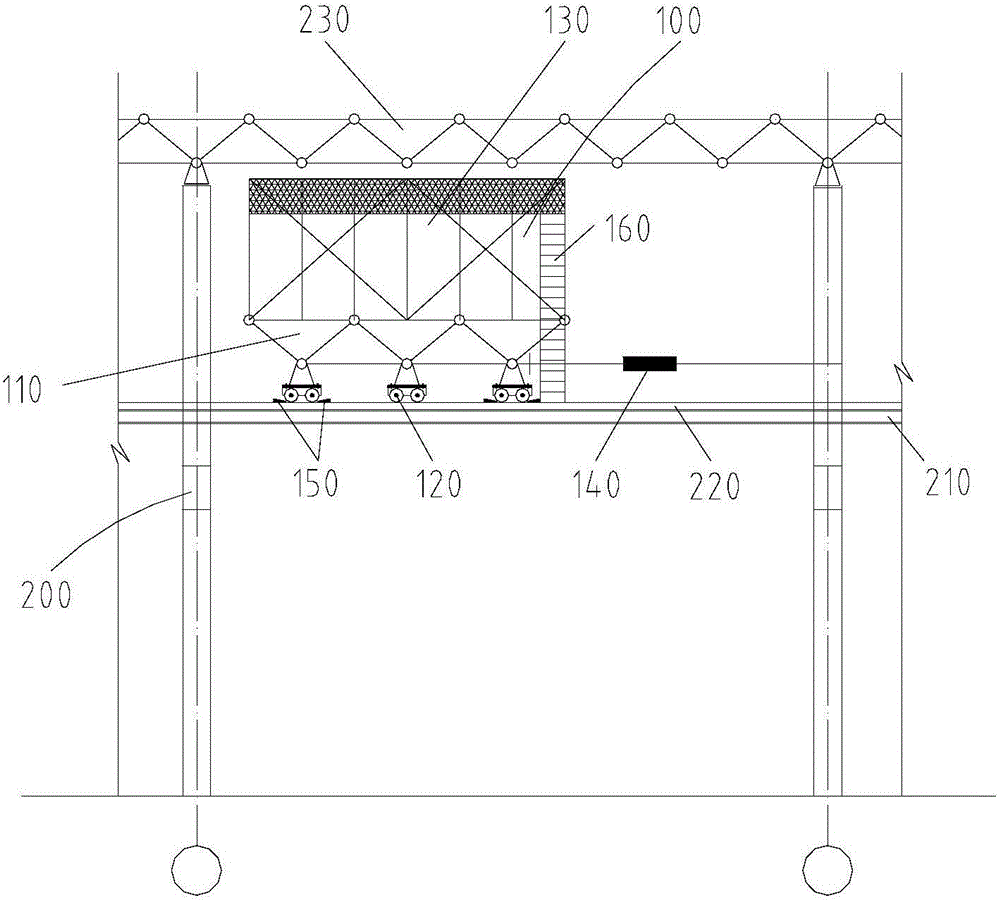

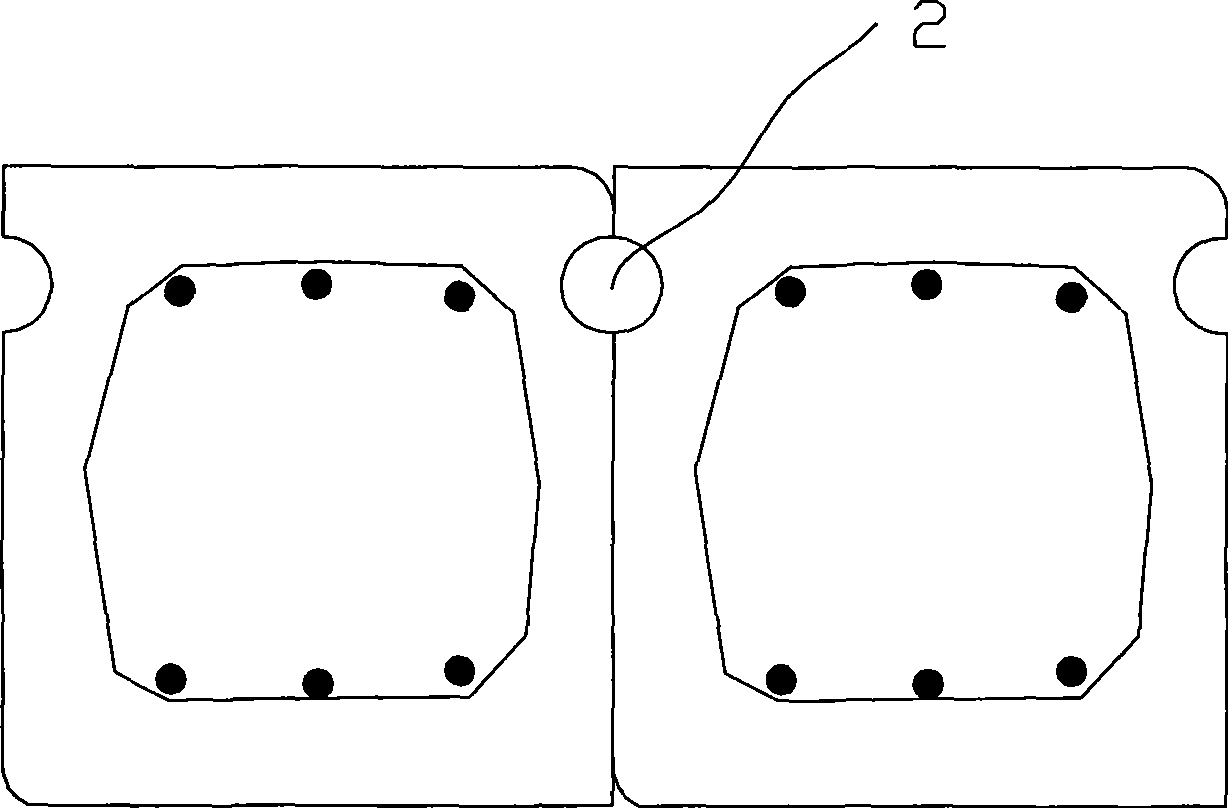

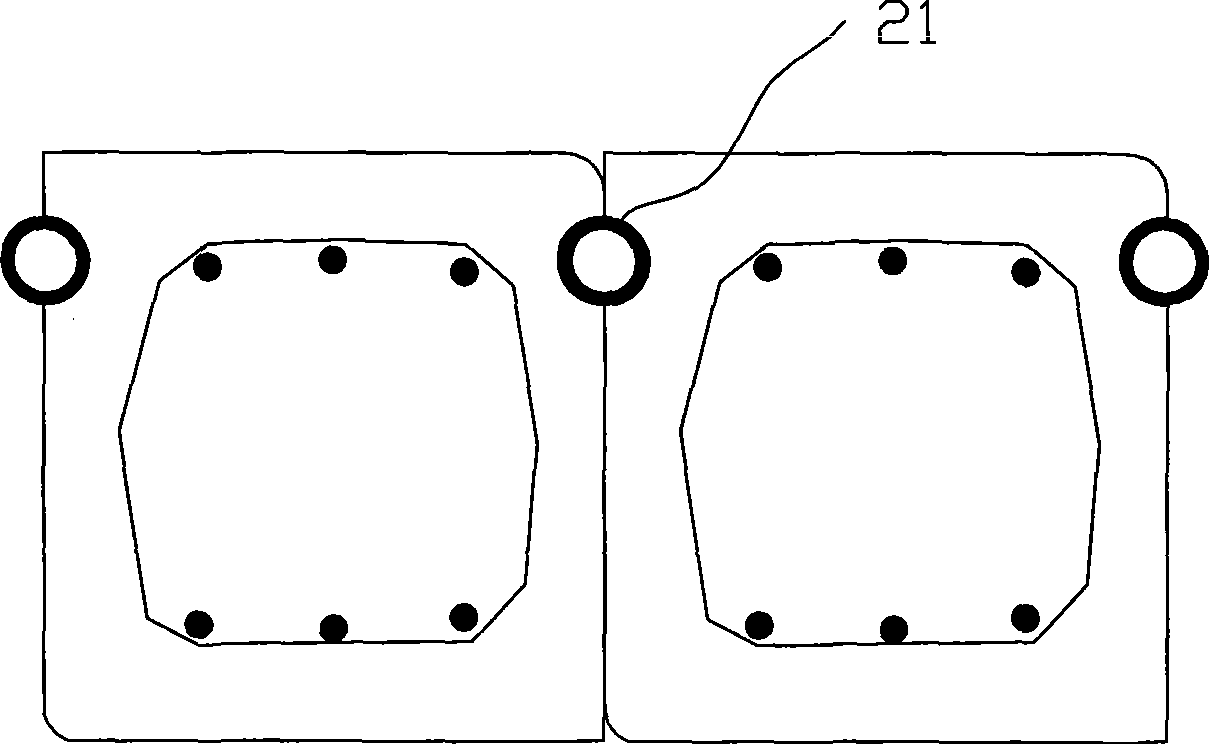

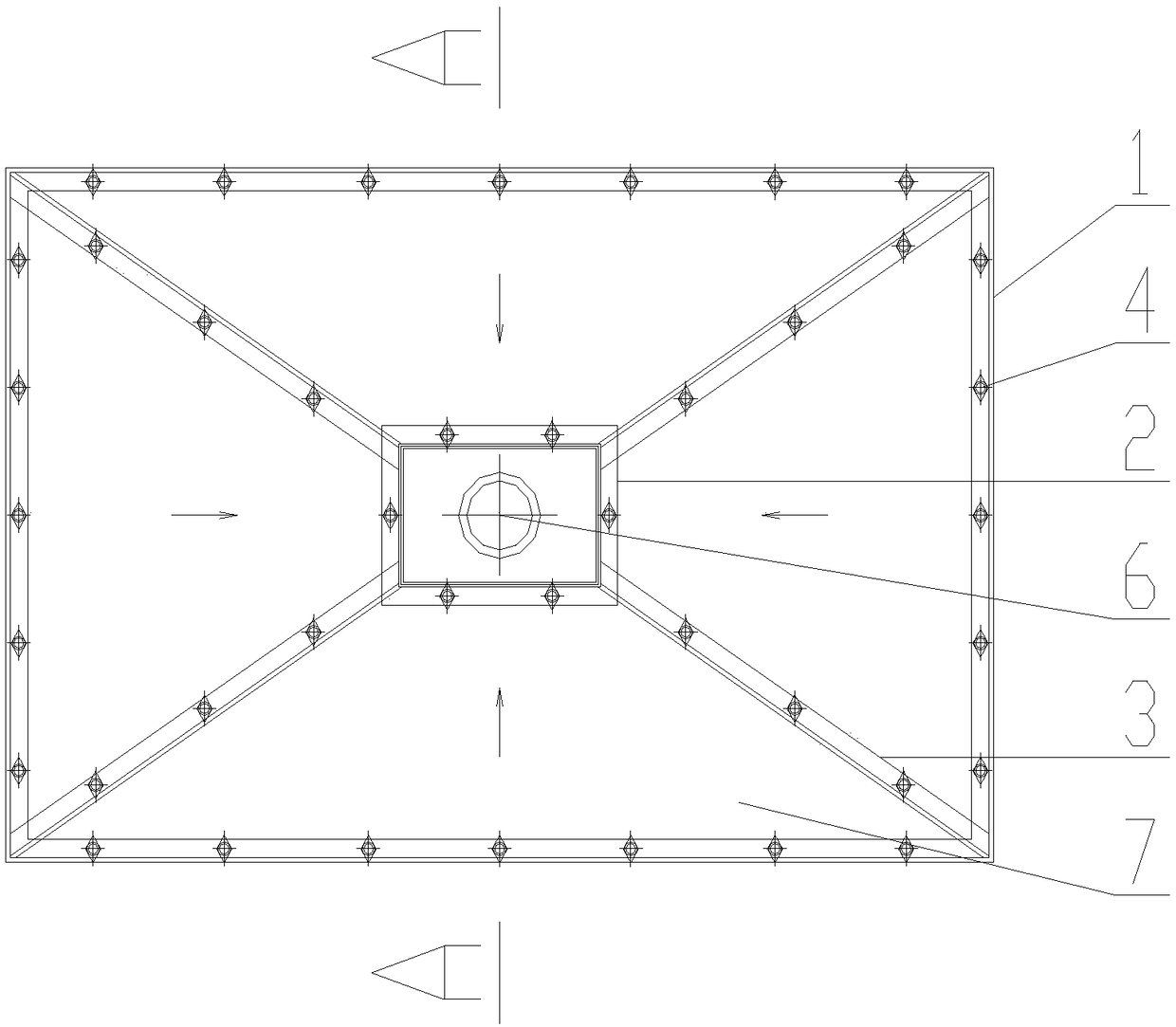

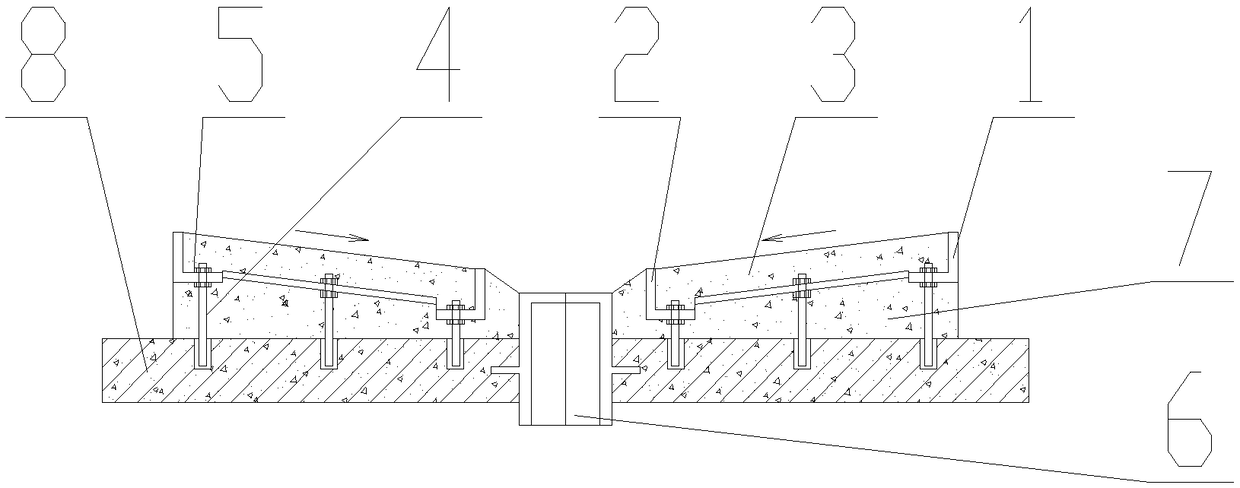

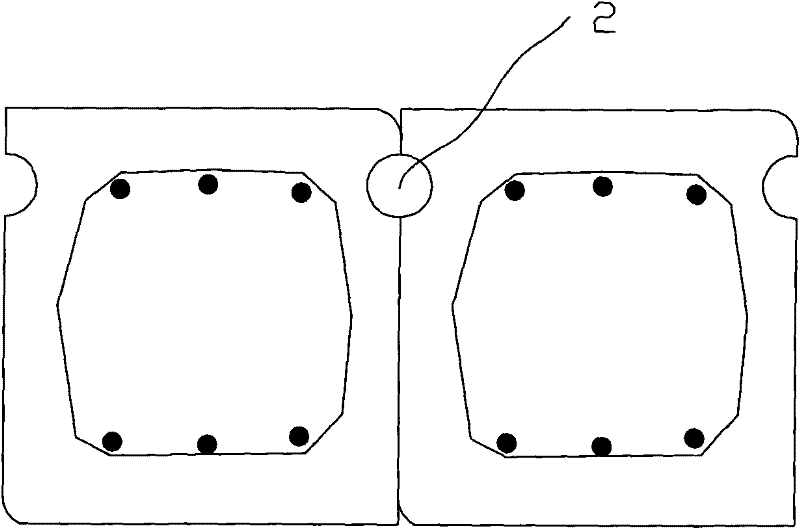

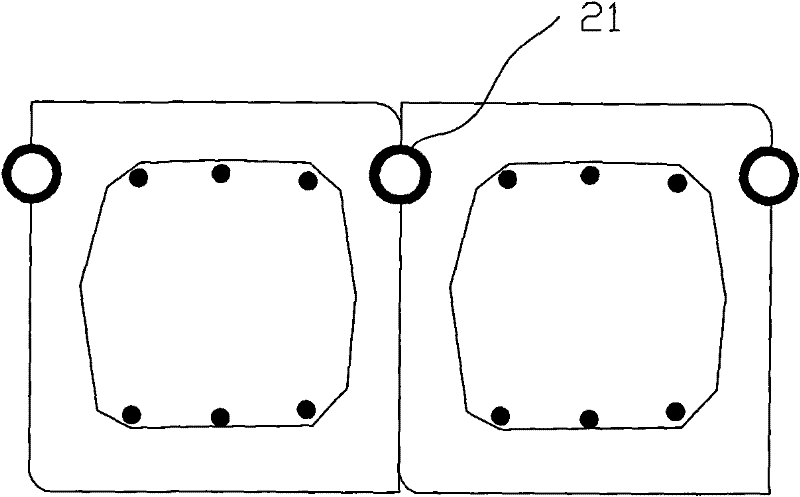

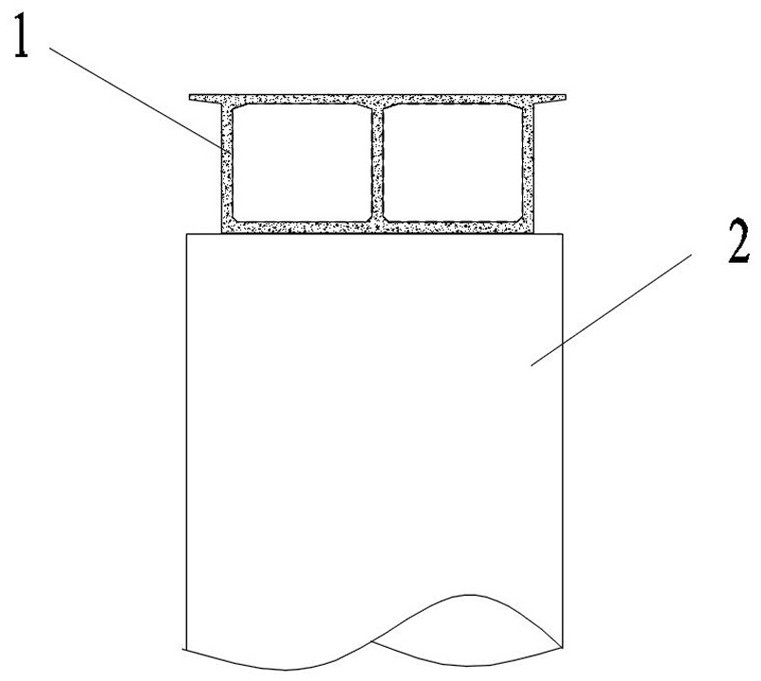

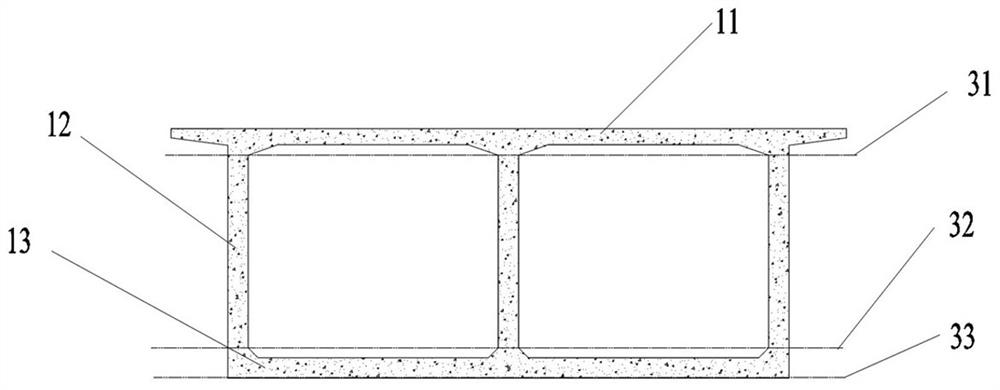

ActiveCN106760561AConstruction organization is convenientAvoid working at heightsGirdersJoistsPistonRoof window

The invention relates to a sectional sliding roof steel truss assembling method. The method is characterized by including the following steps of building a construction platform (5), preparing steel truss basic component units (24), installing first piston shoes (20) and second piston shoes (21), installing support trusses (2), installing longitudinal main trusses (22), installing transverse main trusses (23), lifting, assembling and transversely connecting the steel truss basic component units (24), sliding sectional steel trusses (1), putting the sectional steel trusses (1) in position, assembling the other sectional steel trusses (1), sliding the other sectional steel trusses (1), putting the other sectional steel trusses (1) in position, connecting transverse rods among the sectional steel trusses (1), disassembling second piston shoes (21) and sliding rails (3), and disassembling the construction platform (5). The method belongs to the field of steel structure engineering, roof steel trusses are prepared in sections and put in position by sliding, the problems that roof window construction time of an existing operating railway is short and difficulty of the construction is large are effectively solved, the construction efficiency is improved, and when applied in practical engineering, the method can obtain good technical and economic benefits.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY

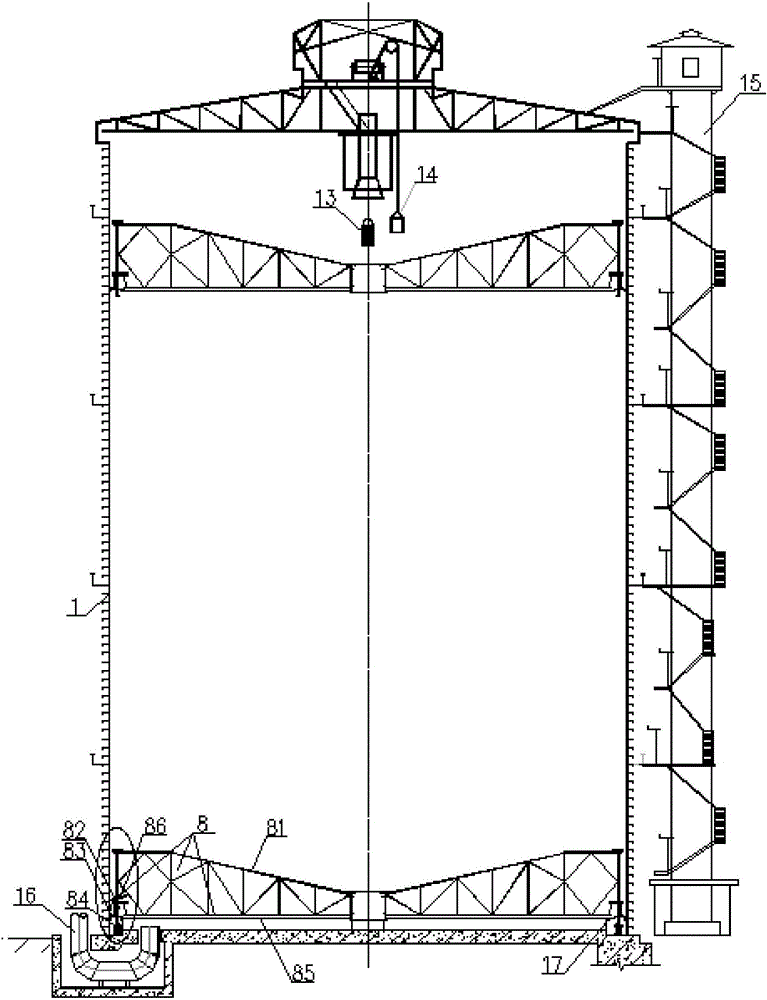

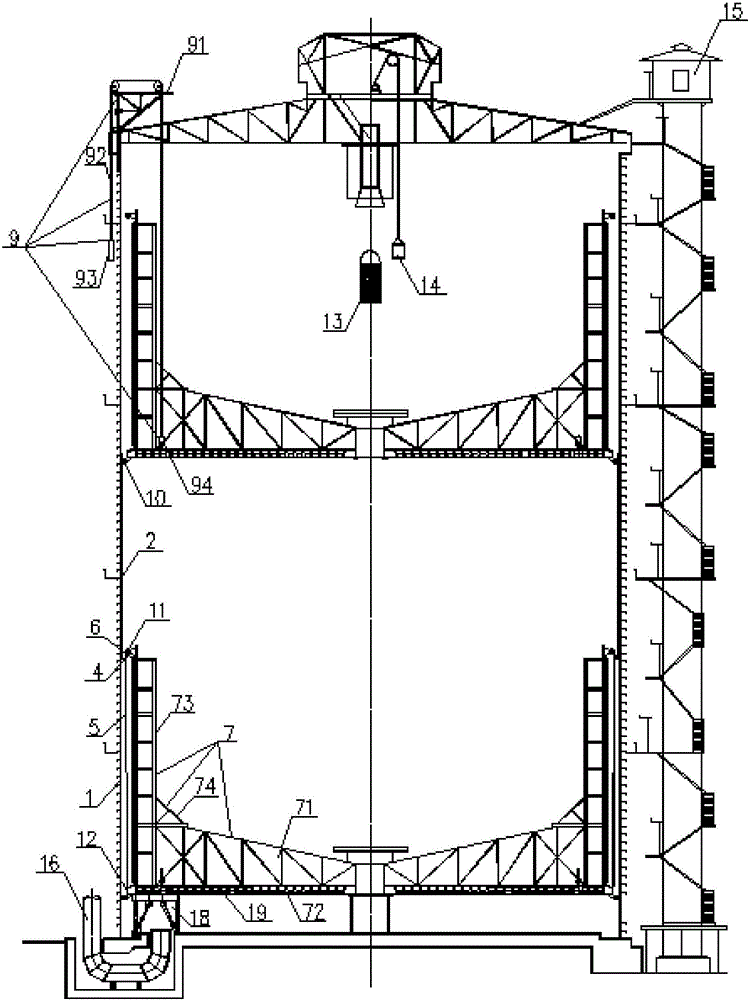

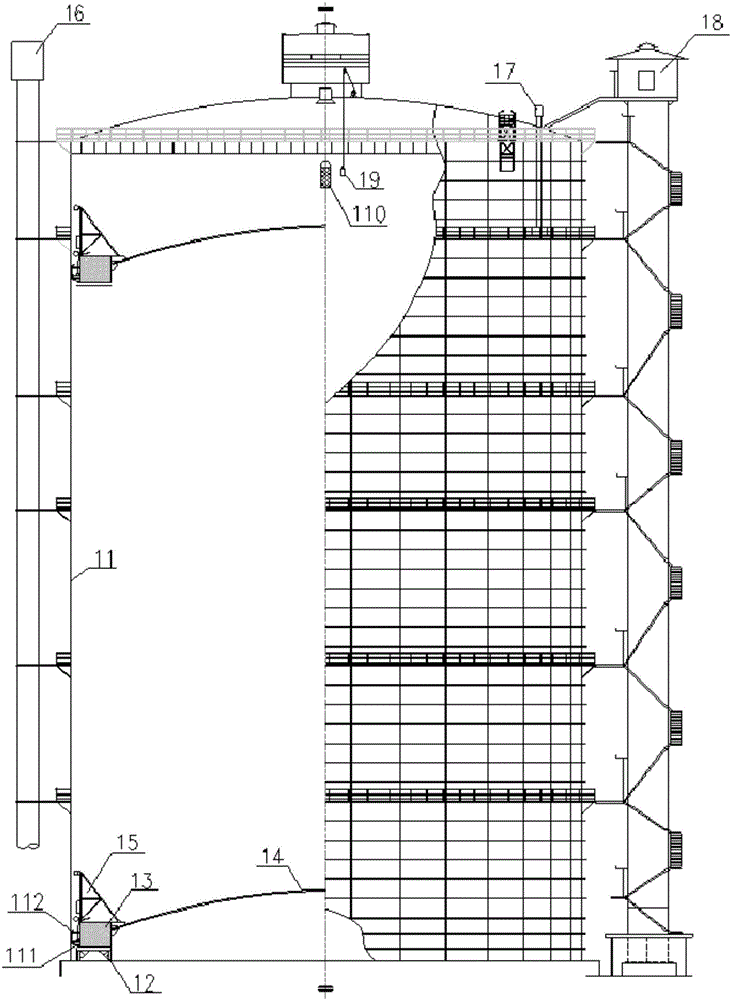

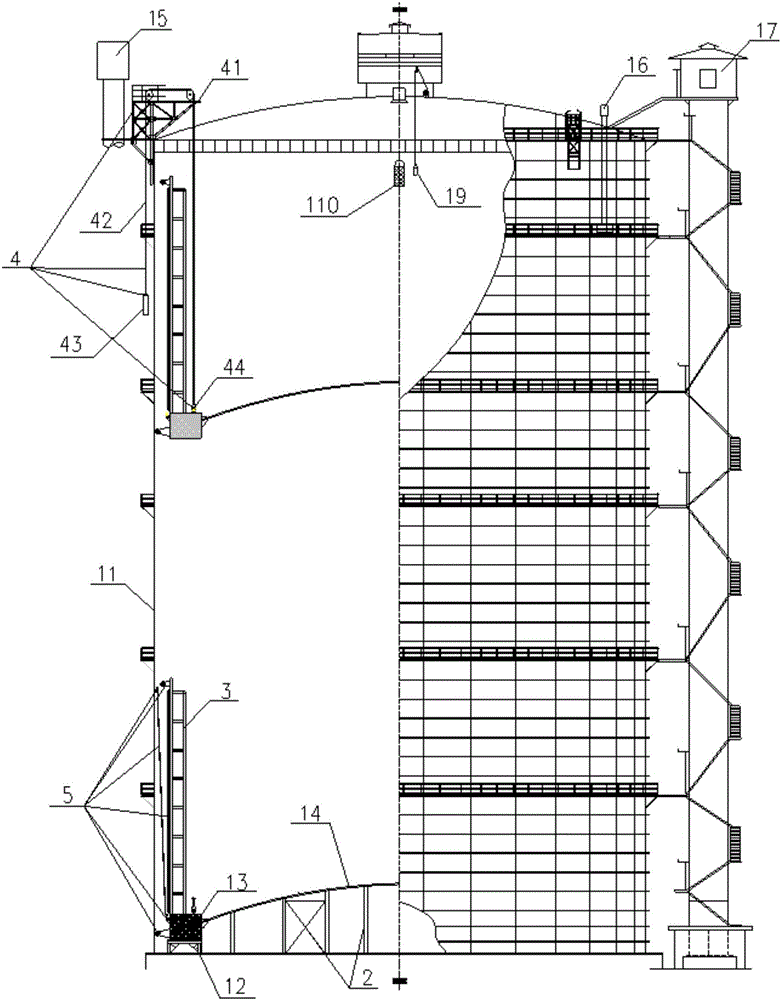

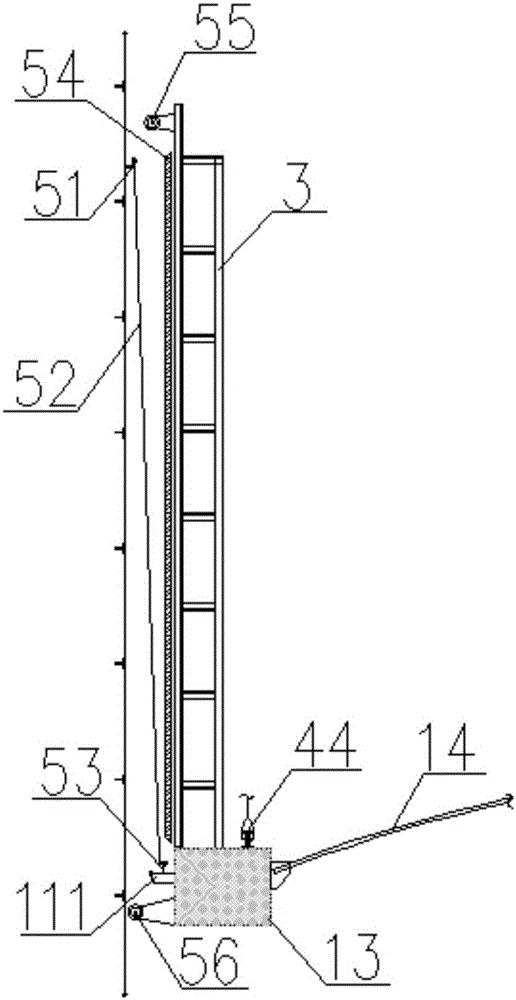

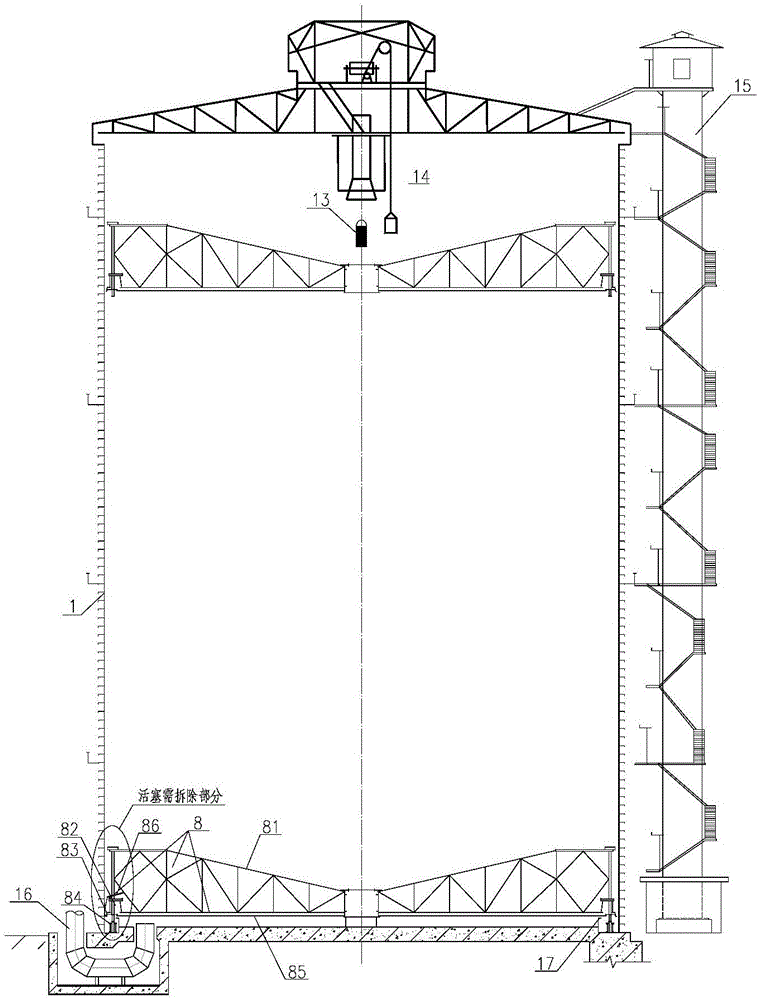

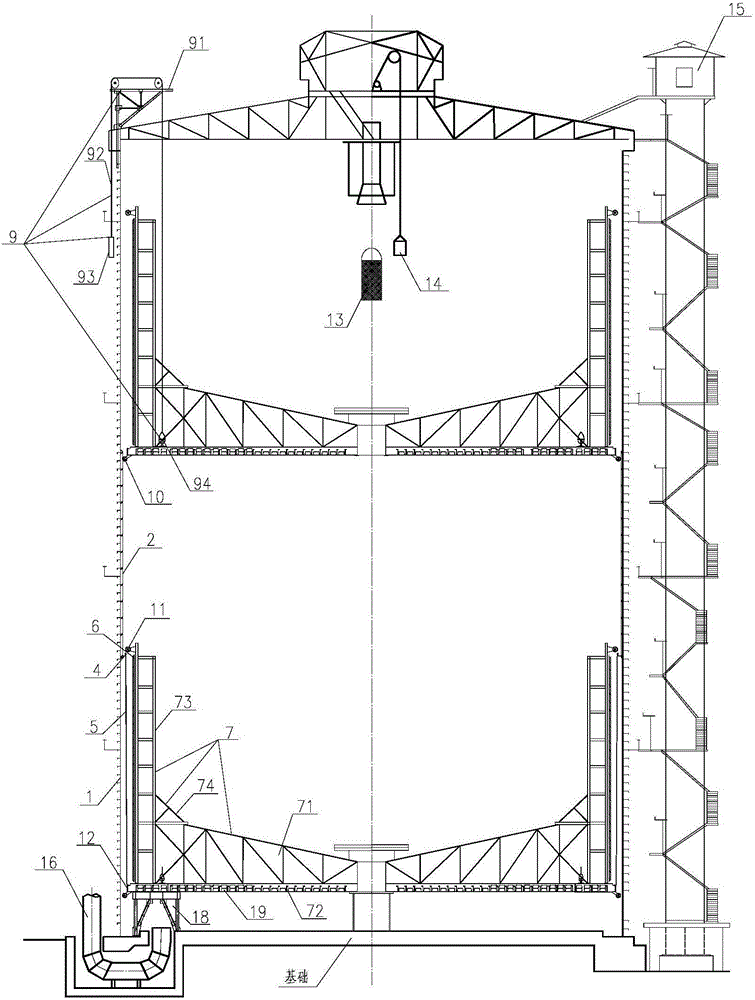

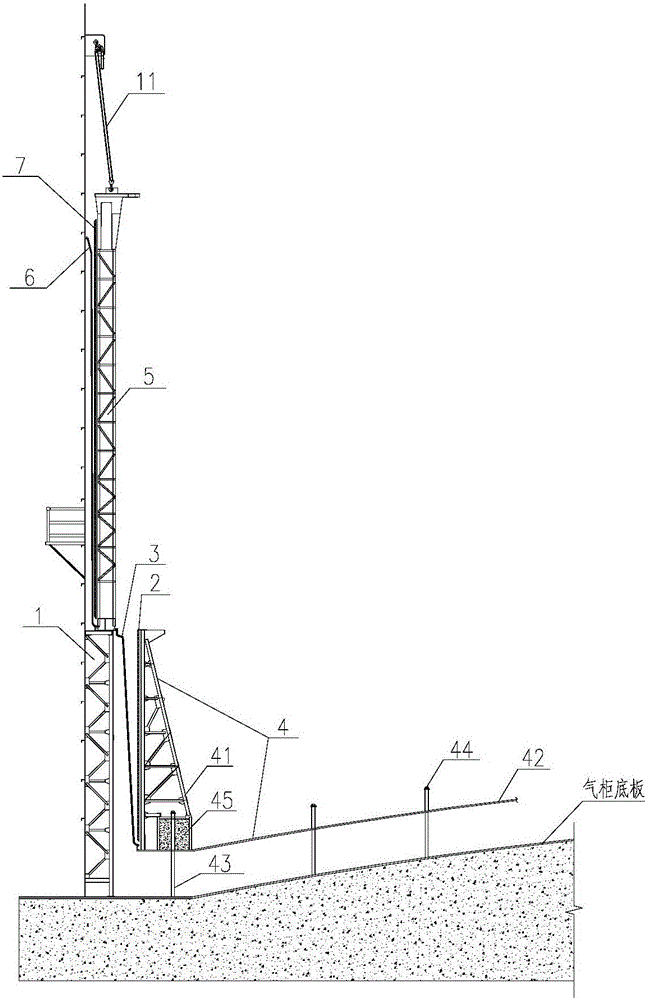

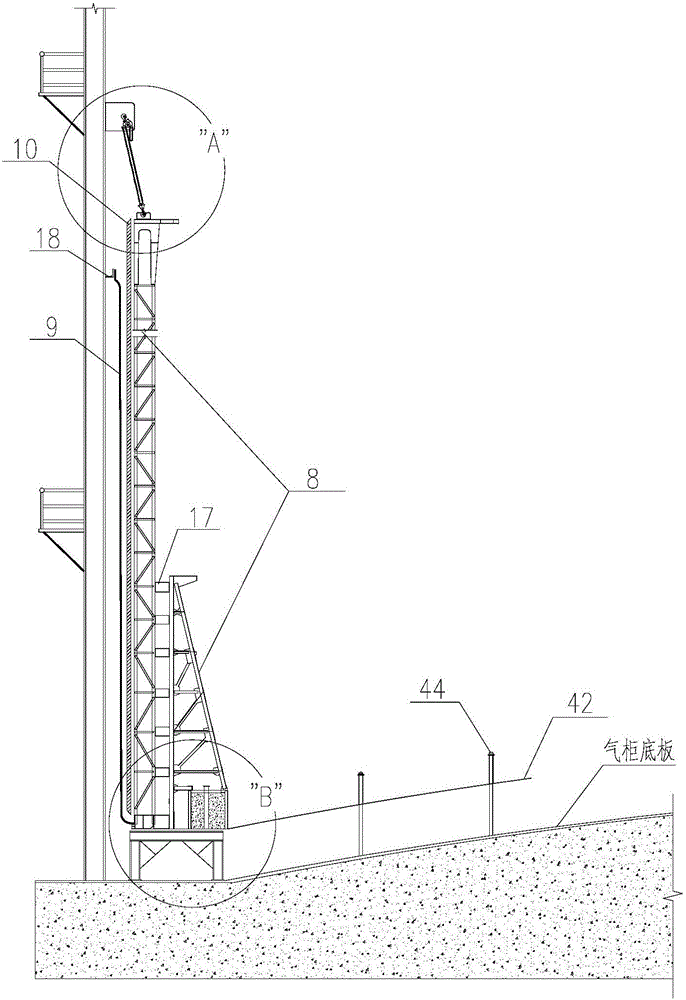

Transformation method of regular polygonal thin oil sealed gas cabinet

ActiveCN105927845ARun fastRunning speed is stableVariable capacity gas holdersRear quarterEconomic benefits

The invention discloses a transformation method of a regular polygonal thin oil sealed gas cabinet. The transformation method comprises the following steps: a piston oil groove support and a piston oil groove of the regular polygonal thin oil sealed gas cabinet are dismounted; an inner cylinder is mounted; brackets are mounted and connected to a side plate and a stand column of the gas cabinet; the connected brackets are connected with the inner cylinder; a truss of a piston and a piton baseplate are adjusted according to the shape of the inner cylinder, so that the shape of the piston is matched with the shape of the inner cylinder; a piston fence is arranged on the piston to form a one-section rubber film sealed gas cabinet piston; piston sealing profile steel is arranged at the bottom end of the piston fence; inner cylinder sealing profile steel is mounted on the inner cylinder in the peripheral direction; and a rubber film is unfolded, and two ends of the rubber film are respectively connected with the inner cylinder sealing profile steel and the piston sealing profile steel. The transformation method renewedly uses a cabinet body of the wasted polygonal thin oil sealed gas cabinet, and is low in construction investment, short in construction time and higher in economic benefit.

Owner:HUATIAN ENG & TECH CORP MCC

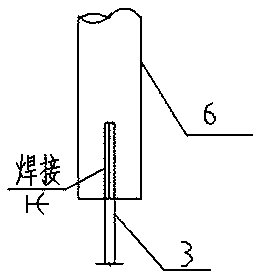

Protecting device of welding seam of titanium-steel composite plate of sleeve-type chimney and use method of protecting device

ActiveCN107052630ASimple structureImprove construction qualityWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

The invention discloses a protecting device of a welding seam of a titanium-steel composite plate of a sleeve-type chimney and a use method of the protecting device. After the titanium-steel composite plate of a smoke exhaust inner barrel of the sleeve-type chimney is subjected to edge rolling forming and is assembled, and before the titanium-steel composite plate is butted with a V-shaped welding seam, the protecting device is manufactured on a welding seam titanium plate surface by adopting galvanization C-shaped steel, and when a steel plate sealing welding seam of the titanium-steel composite plate is welded, the C-shaped steel of the protecting device is attracted to the titanium-steel composite plate by using a mightiness magnet on the welding seam titanium plate surface; when a steel plate back surface of the titanium-steel composite plate is subjected to back gouging, a thin steel plate at an opening of the C-shaped steel is removed, and the steel plate sealing welding seam can be subjected to the back gouging by using carbon arc air gouging along a strip-shaped notch. Since space between the C-shaped steel and the welding seam titanium plate surface is filled with a rock wool material, when the steel plate sealing welding seam and the steel plate back surface are subjected to the back gouging and the welding, pollutants like welding slag, splashes and smoke are not in contact with the titanium plate, and the disadvantages that weld cracks are generated and the corrosion resistance is lowered due to the fact that titanium steel interfusion occurs or titanium steel is polluted by iron during the welding can be avoided. The protecting device is simple in structure and easy to use, the construction quality is improved and the construction efficiency is improved.

Owner:CHINA MCC17 GRP

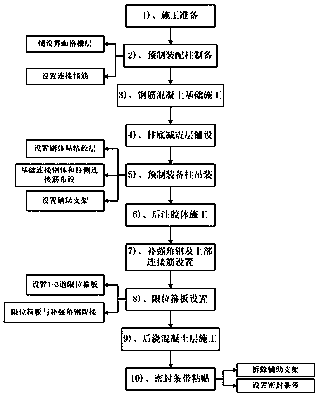

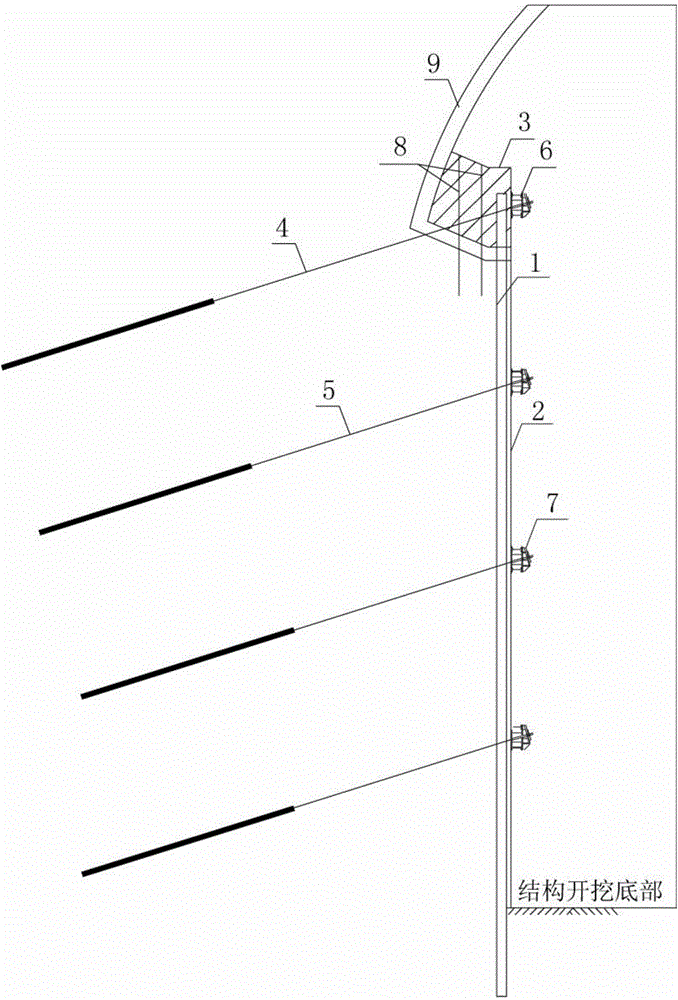

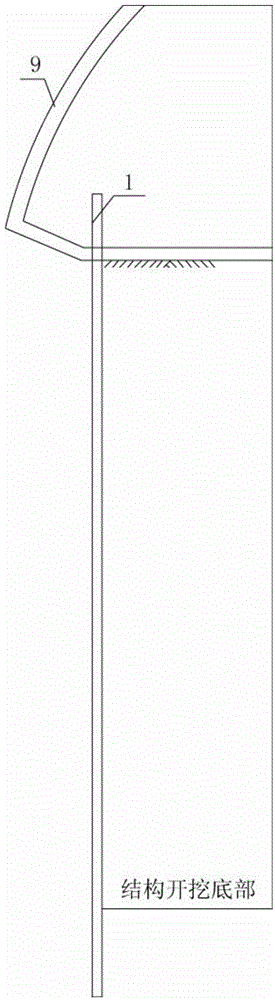

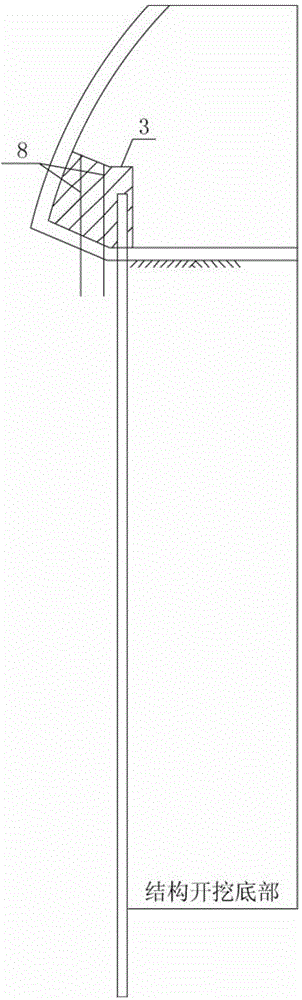

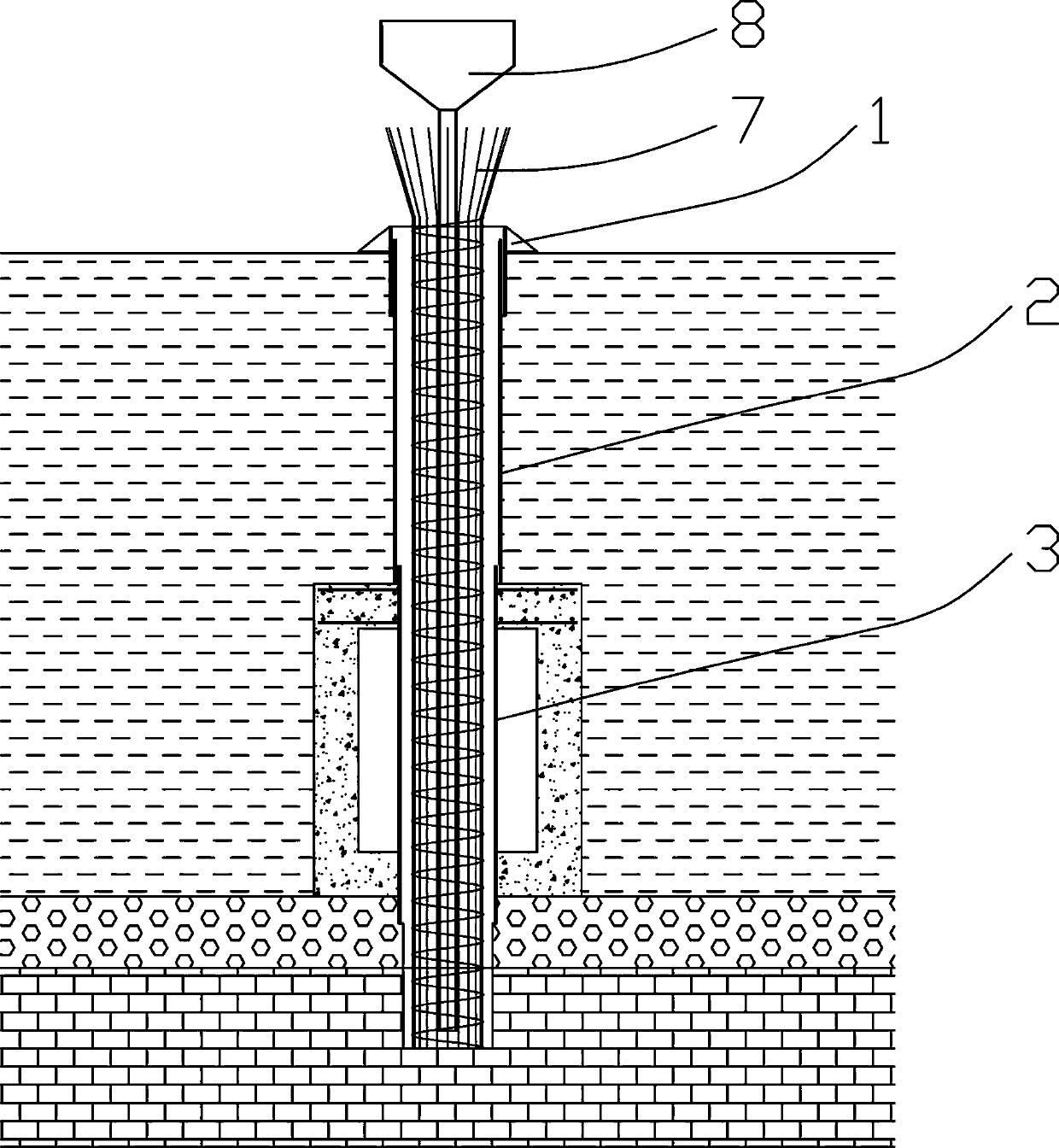

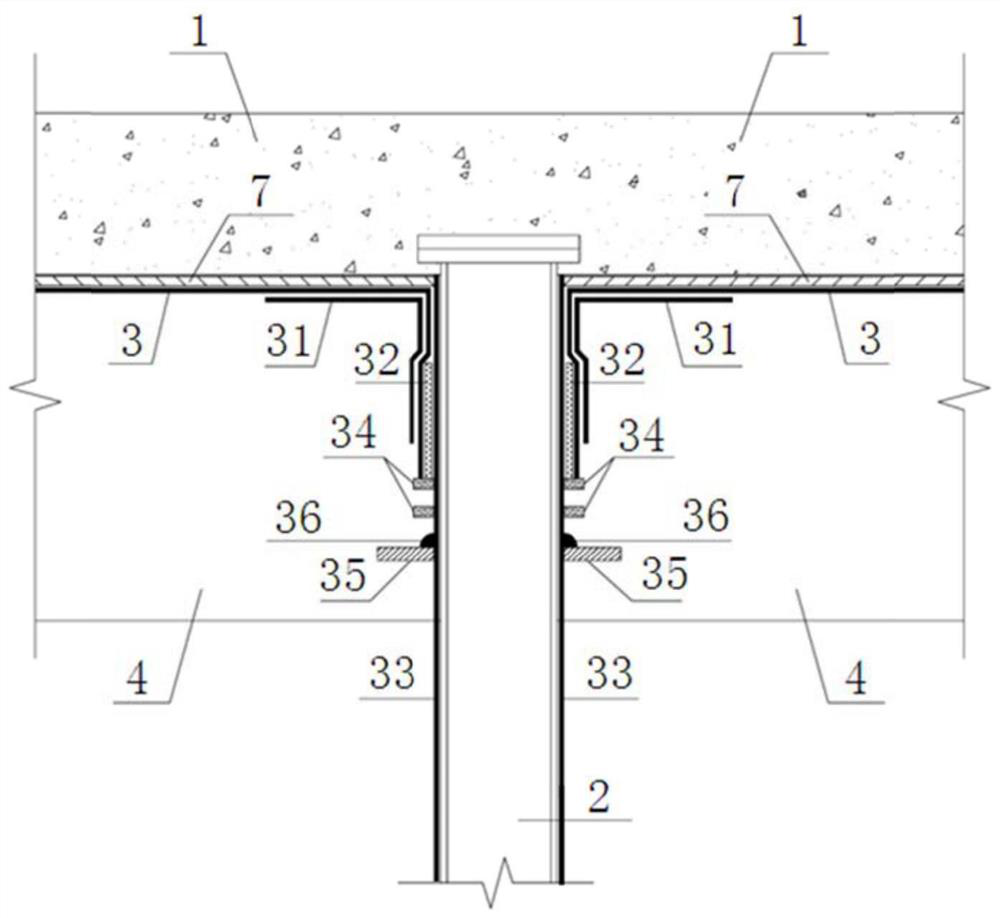

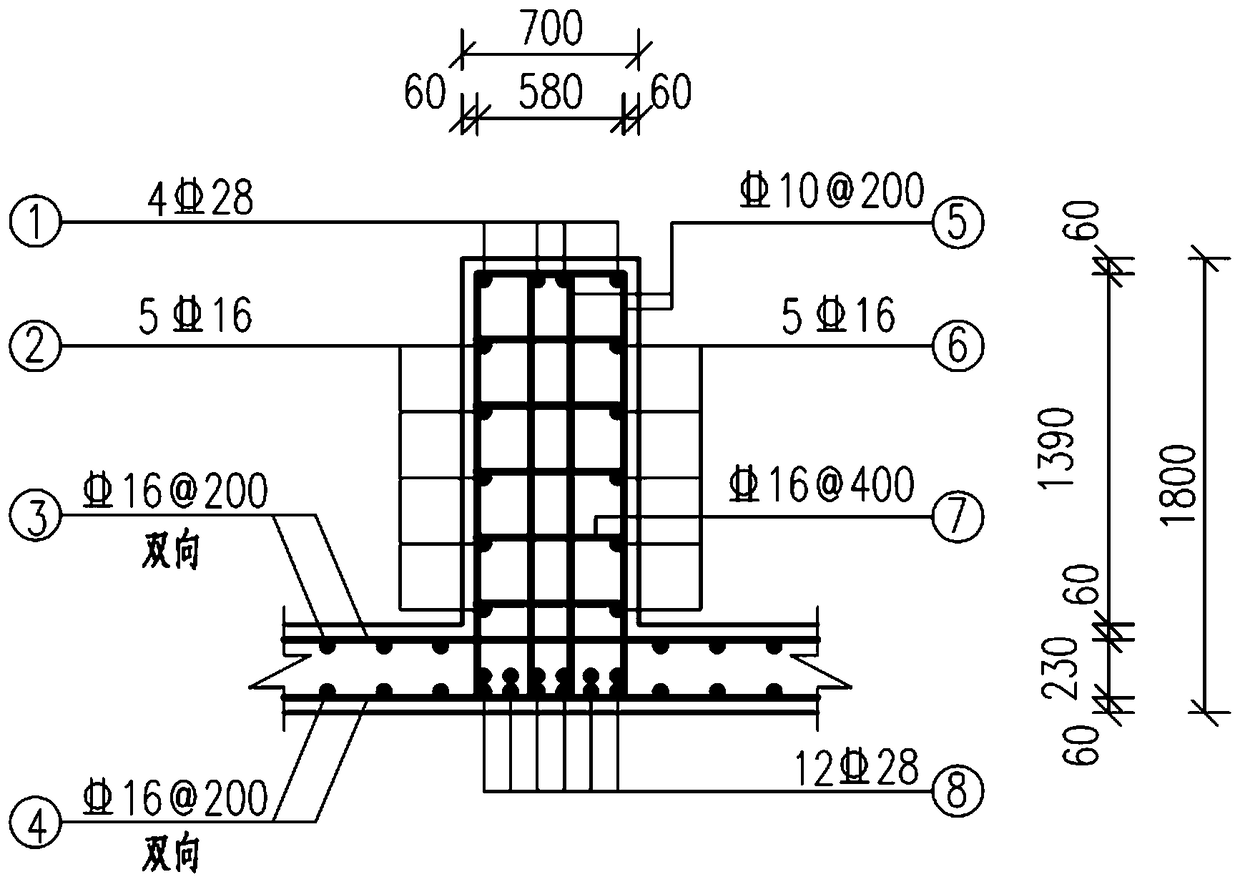

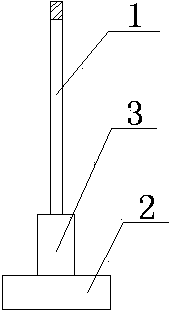

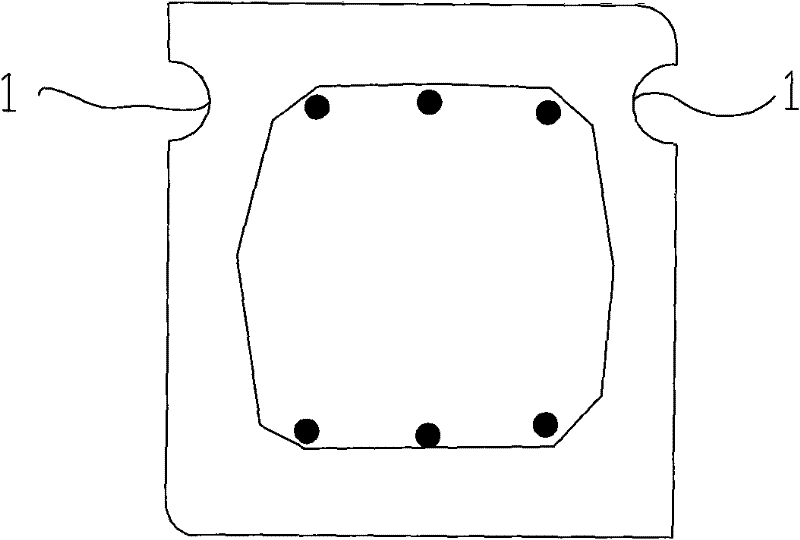

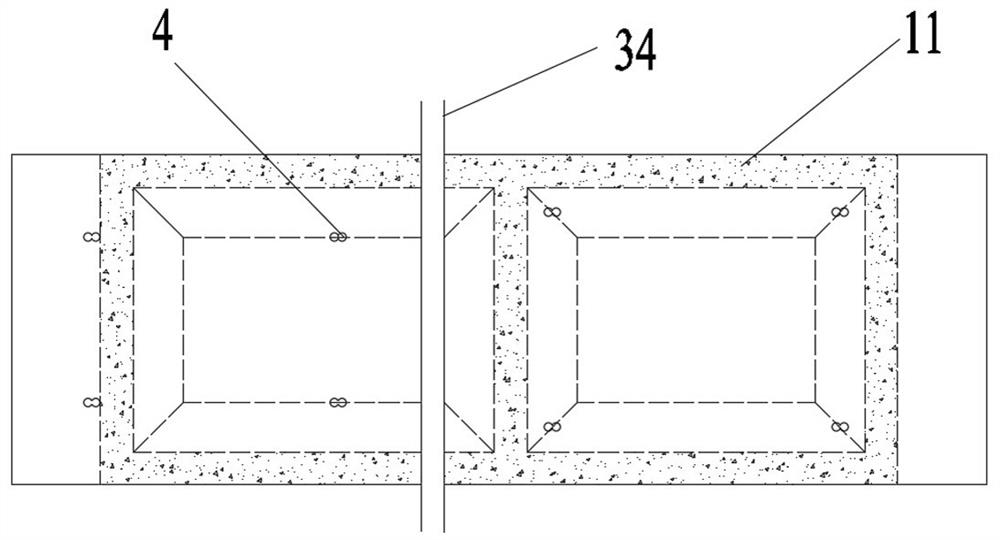

Connection structure of prefabricated assembly column and reinforced concrete foundation and construction method

ActiveCN107869150AImprove integrityAct as a stress spreaderFoundation engineeringProtective buildings/sheltersReinforced concreteShock resistance

The invention relates to a connection structure of a prefabricated assembly column and a reinforced concrete foundation. The connection structure is characterized in that the bottom surface of the prefabricated assembly column is provided with a connection tenon, a foundation connection steel body, column side connection ribs and a column bottom reinforcement plate, the top part of the prefabricated assembly column is provided with built-in connection bolts, connecting steps, column inner connecting reinforcement bars and connecting anchor bars, and an interface grid layer is arranged on the outer surface of the prefabricated assembly column; the upper surface of the reinforced concrete foundation is provided with a column bottom connection groove, a reinforcing angle steel arrangement groove and a column side connection rib insertion groove, the interior of the reinforced concrete foundation is provided with a foundation inner anchor plate, foundation connection ribs and post-glue-injection holes; a column bottom shock absorber layer and reinforcing angle steel are arranged at the junction of the reinforced concrete foundation and the prefabricated assembly column; a limiting hoopplate is arranged outside the reinforcing angle steel; the foundation connection bars are connected with the column inner connecting reinforcement bars through a steel bar connection section, and a closed strip is arranged at the intersection of a post-poured concrete layer and the prefabricated assembly column. The connection strength of the structure can be enhanced, and the shock resistance ofthe structure can be improved. The invention also discloses a construction method of the connection structure of the prefabricated assembly column and the reinforced concrete foundation.

Owner:NANCHANG HANGKONG UNIVERSITY

High-side-wall anchored primary support structure for rock strata underground excavation underground structure, and construction method of high-side-wall anchored primary support structure

ActiveCN104863613AImprove construction efficiencySimple structureUnderground chambersTunnel liningPre stressSurface layer

The invention belongs to the technical field of design and construction of tunnel and underground engineering, and particularly relates to a high-side-wall anchored primary support structure for a rock strata underground excavation underground structure, and a construction method of the high-side-wall anchored primary support structure. The high-side-wall anchored primary support structure is characterized in that the surface of a steel pipe pile and an adjacent steel pipe pile are sealed through a spray concrete surface layer; the tops of the steel pipe piles are vertically connected through a top ring beam; a ring beam grouting steel pipe is embedded into the top ring beam; a ring beam prestress anchor cable and a steel pipe pile prestress anchor cable are vertically arranged; one end of the ring beam prestress anchor cable is mounted on the top ring beam and locked by a ring beam fixing part; the steel pipe pile prestress anchor cable is positioned below the ring beam prestress anchor cable; the ring beam prestress anchor cable is fixed to the spray concrete surface layer through a concrete fixing part. The high-side-wall anchored primary support structure is suitable for a straight sidewall primary support structure of a large cross tunnel and an underground structure which are arranged at the weak fractured rock strata.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD

Method for reconstructing cylindrical gas holder

The invention discloses a method for reconstructing a cylindrical gas holder. The cylindrical gas holder comprises a holder body, a piston box beam, a piston center ball shell, a sealing device hanging ring beam, a piston guide wheel bracket and a sealing mechanism. According to the method, a reconstruction process comprises the following steps: disassembling the sealing mechanism of the cylindrical gas holder; disassembling the piston guide wheel bracket of the cylindrical gas holder; arranging a piston fence of a single-stage rubber sealed gas holder on the piston box beam of a cylindrical gas holder piston, and arranging a piston sealing steel section on the sealing device hanging ring beam of the piston; arranging a holder body sealing steel section on the holder body of the cylindrical gas holder; and spreading a rubber membrane, and connecting the two ends of the rubber membrane with the piston sealing steel section and the holder body sealing steel section in a sealing manner. The method provided by the invention has the advantages that the holder body and other auxiliary structures of the cylindrical gas holder are sufficiently utilized, so that the reconstructed cylindrical gas holder can be put into use again when the whole structure of the cylindrical gas holder is slightly reconstructed, neither a lot of construction capital nor long-term construction is needed, and the economic benefit is extremely high.

Owner:HUATIAN ENG & TECH CORP MCC

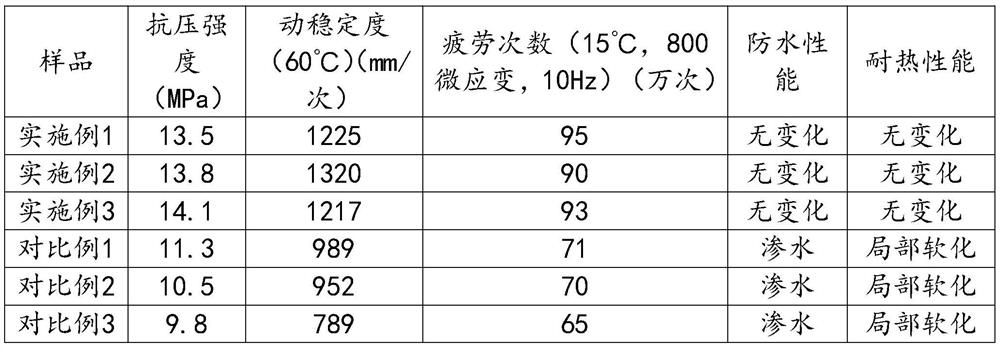

Preparation process of ceramsite asphalt pavement material

InactiveCN112551948AImprove mechanical propertiesImprove barrier propertiesCross linkerThermal stability

The invention discloses a preparation process of a ceramsite asphalt pavement material. The preparation proces comprises the following steps: preparing the following raw materials in parts by weight:30-50 parts of asphalt, 1-2 parts of modified nano filler, 10-13 parts of modified shale ceramsite, 5-10 parts of SBS modifier, 3-5 parts of basalt fiber, 2-4 parts of diatomite, 5-10 parts of rubberpowder, 0.3-0.5 part of dispersing agent, 0.1-0.3 part of cross-linking agent and 0.1-0.3 part of antioxidant; the ceramsite asphalt pavement material is prepared by mixing the modified shale ceramsite, the modified nano-filler, asphalt and other fillers, and the modified nano-filler is added into the ceramsite asphalt pavement material, so that the mechanical property, barrier property and thermal stability of the ceramsite asphalt pavement material are improved, and the ceramsite asphalt pavement material has fatigue resistance, low-temperature crack resistance and water stability by utilizing a special physical structure of the diatomite and high damping and shock absorption characteristics of the basalt fibers.

Owner:武汉极限光科技有限公司

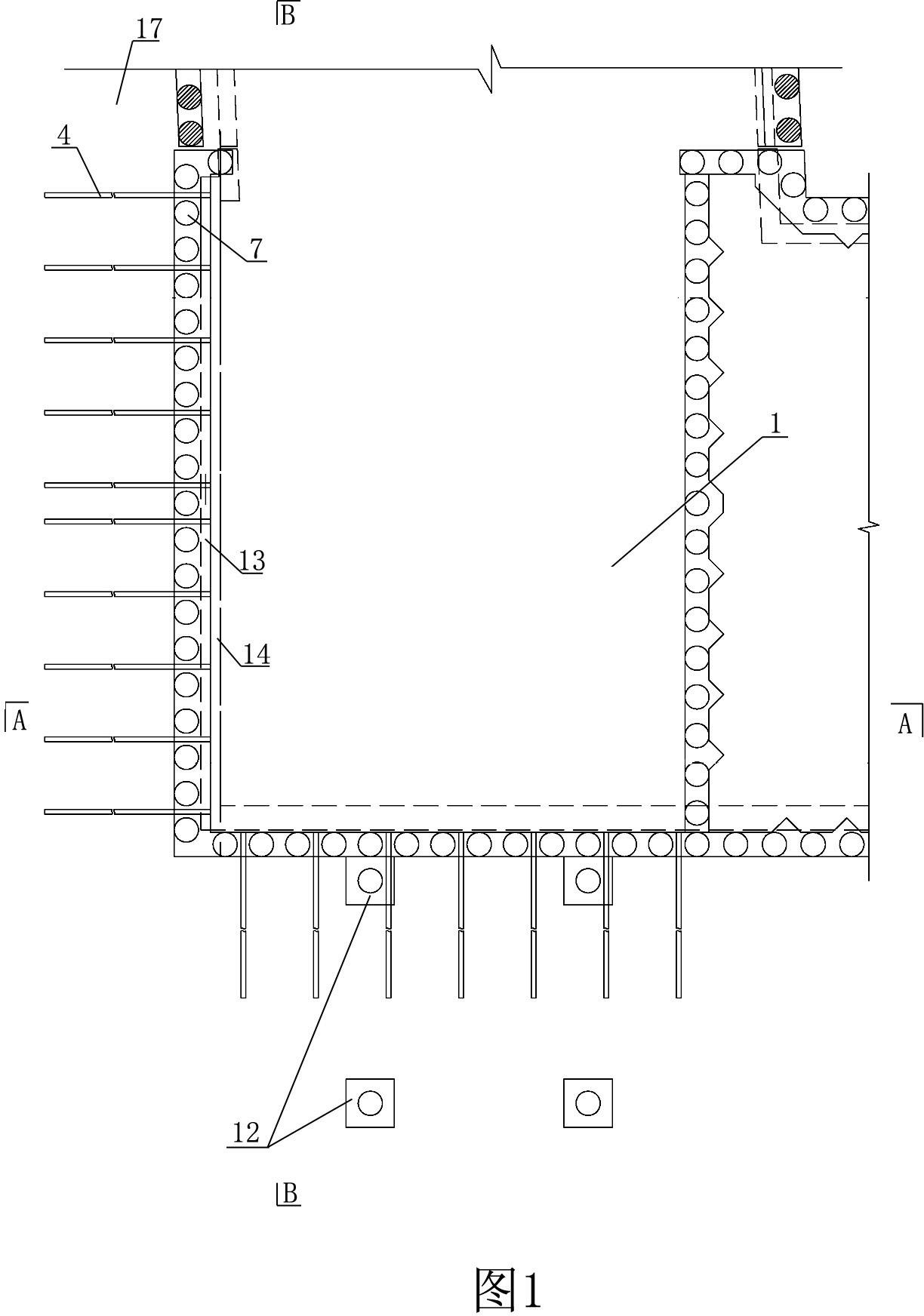

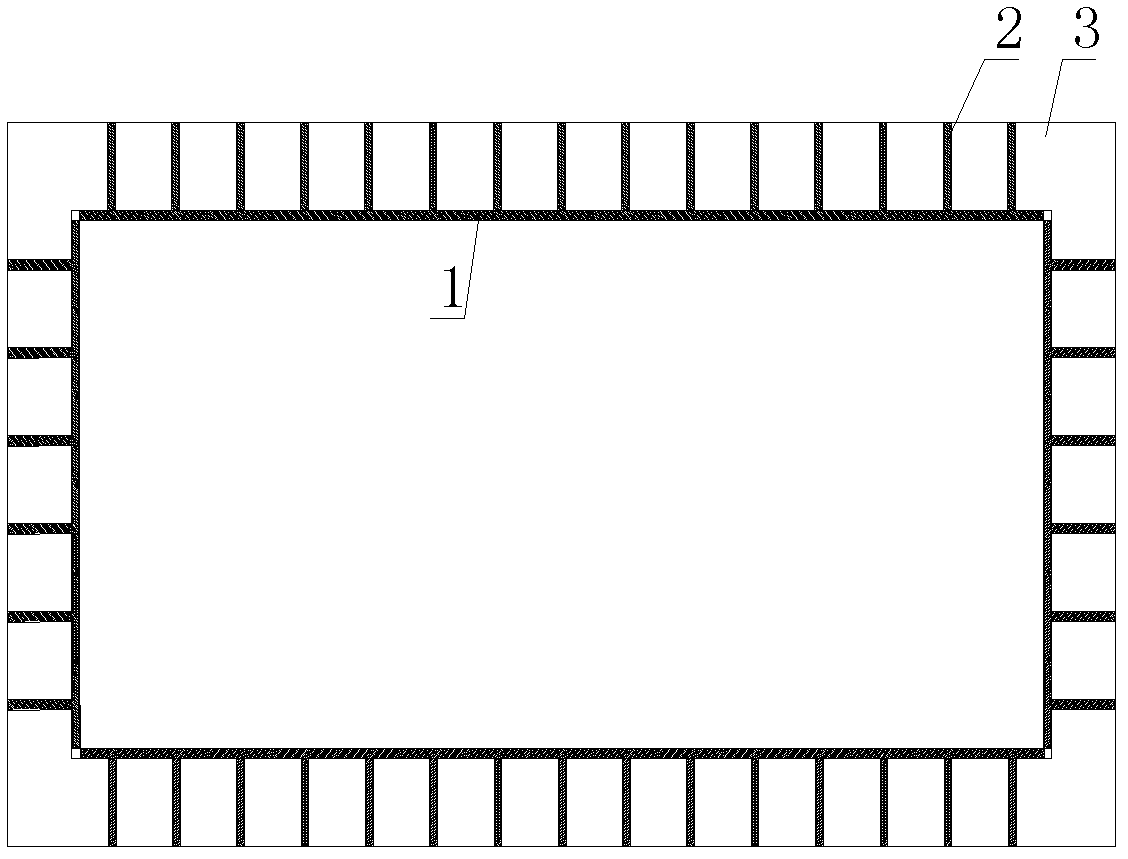

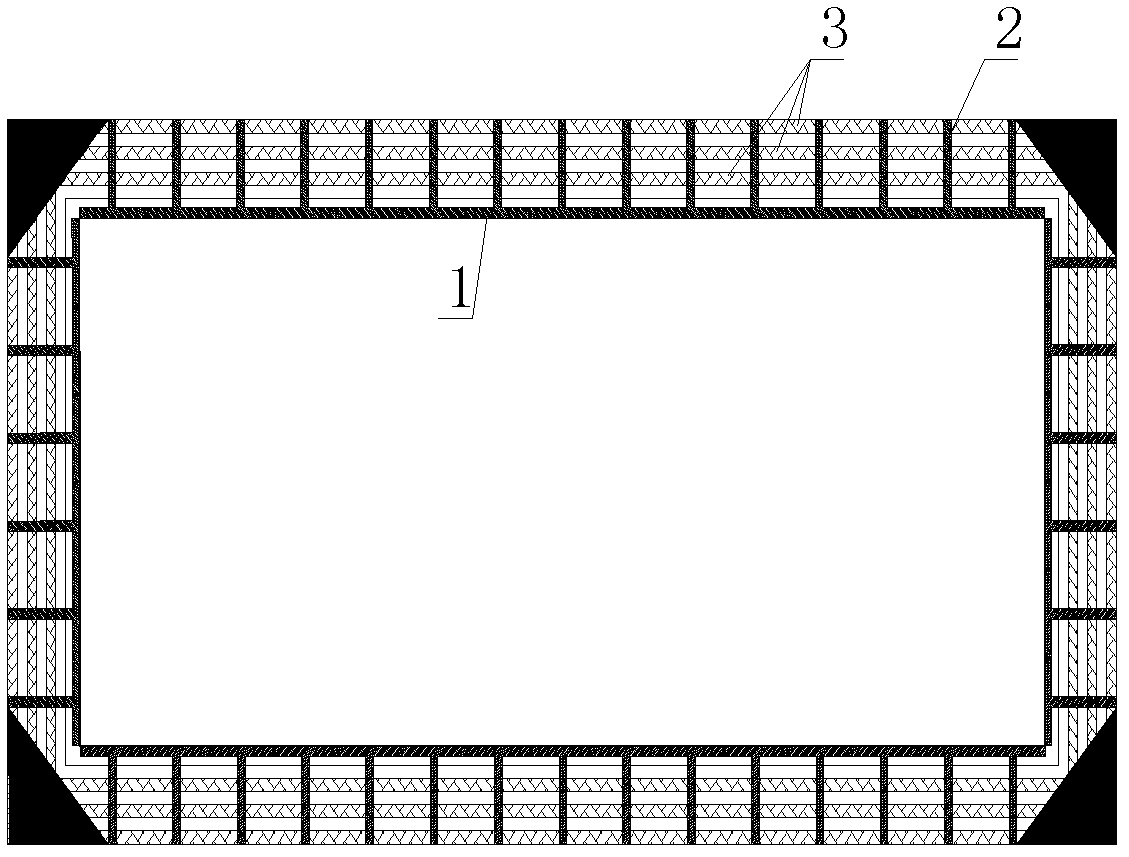

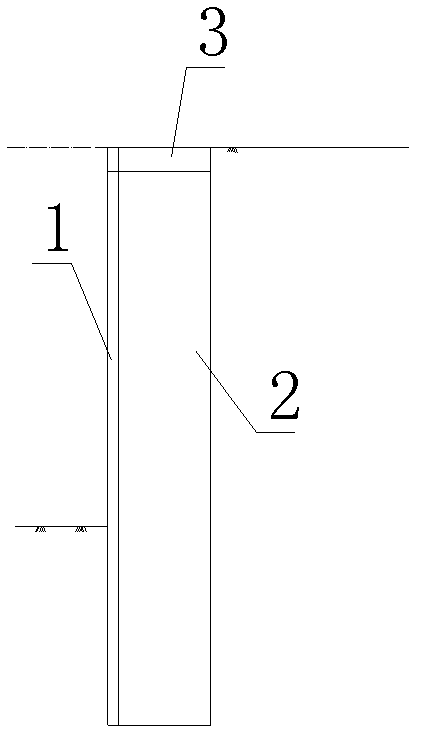

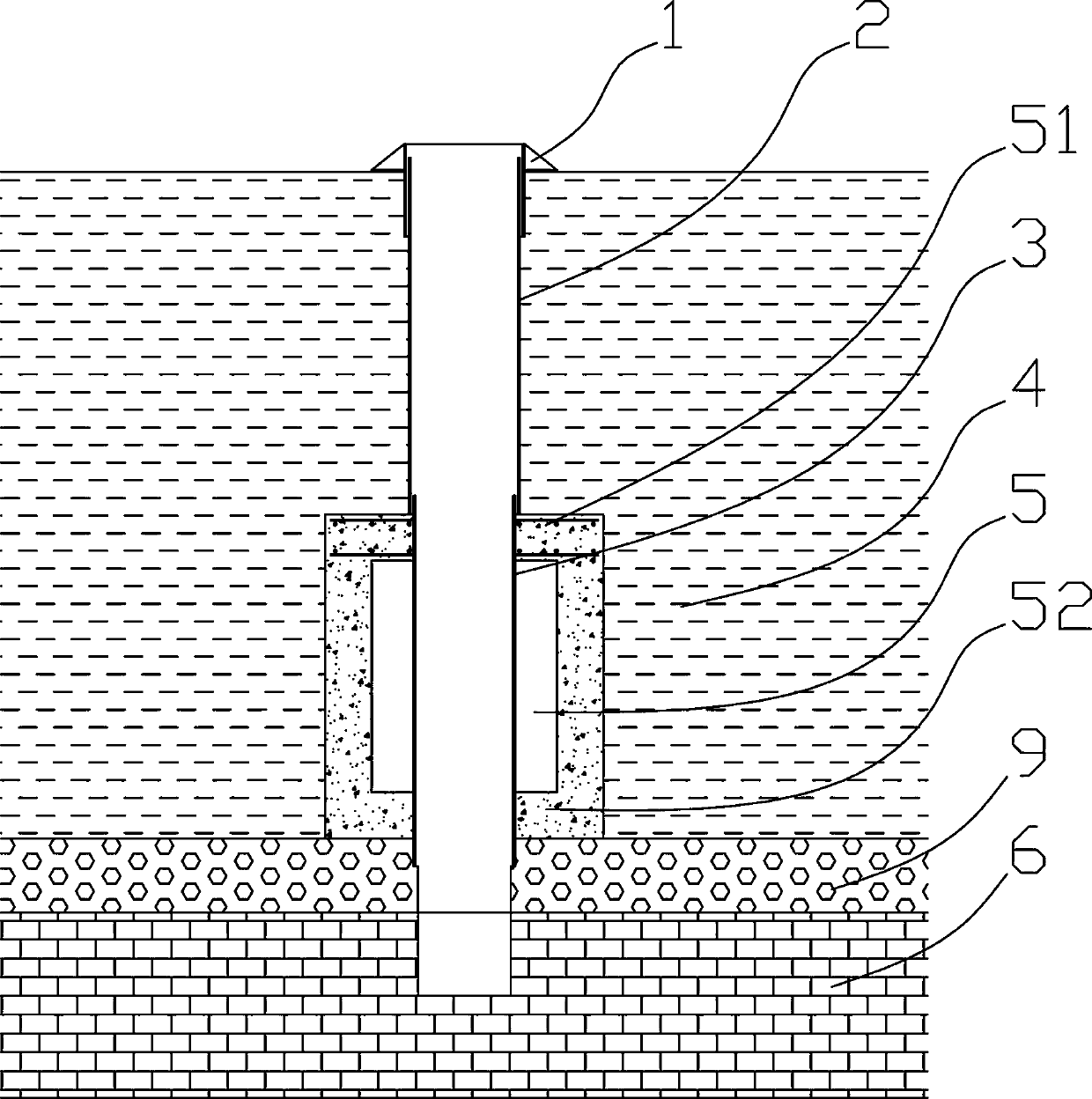

Outside-enhanced retaining supporting structure

InactiveCN102587390AImprove securityReasonable structural economyArtificial islandsExcavationsRetaining wallStructural system

The invention discloses an outside-enhanced retaining supporting structure which belongs to retaining supporting structures, and aims to provide a retaining supporting structural system, which is reasonable in structure, convenient in construction, short in construction period, low in construction cost and effective in leak proofing. The outside-enhanced retaining supporting structure is technically characterized in that a continuous retaining wall is formed by support wallboards by enclosing, longitudinal rib plates are distributed on the outer side of each support wallboard, connecting plates or connecting beams are further disposed on the periphery of each support wallboard, and the support wallboards, the longitudinal rib plates and the connecting plates or connecting beams form a rigid whole. The outside-enhanced retaining supporting structure is used for foundation pit or slope supporting.

Owner:中煤江南建设发展集团有限公司

Complete-set steel casing construction method of concrete cast-in-place bored pile passing through underground gallery

The invention provides a complete-set steel casing construction method of a concrete cast-in-place bored pile passing through an underground gallery. The method comprises the steps that a locating steel casing is buried; a rotary-digging drilling bucket or an auger bit is utilized to drill a hole in a soil body, and a protection steel casing follows up synchronously in the drilling process; when agallery top plate of the underground gallery is reached, a cylindrical coring bit is used instead for drilling on the gallery top plate, and the drilling tool is lifted up after penetration to take out a concrete core; the cylindrical coring bit continues to be utilized to drill through a gallery bottom plate of the underground gallery, and the drilling tool is lifted up to take out the concretecore; a partition steel casing is placed down; the rotary-digging drilling bucket is used instead to continue to drill into undisturbed soil and bed rock to a designed end hole position; a flat-bottomed rotary-digging drilling bucket is utilized to remove sediment at a hole bottom to ensure that the thickness of the sediment is controlled within a standard allowed range; a reinforcement cage is placed down; pile foundation concrete pouring is performed; the protection steel casing and the locating steel casing are taken out, and concrete is poured as supplement to finishing elevation; and construction of the concrete cast-in-place bored pile passing through the underground gallery is realized through the steps. Through the method, a working environment is obviously improved, and the methodis more environmentally friendly.

Owner:THREE GORNAVIGATION AUTHORITY

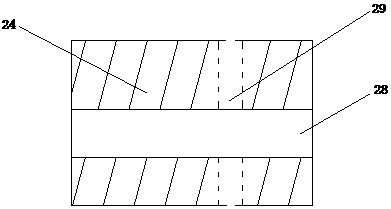

Single-stage rubber membrane sealed gas holder reconstructed from regular polygonal thin oil sealed gas holder

ActiveCN105715938ARun fastRunning speed is stableVariable capacity gas holdersSingle stageRubber membrane

The invention discloses a single-stage rubber membrane sealed gas holder reconstructed from a regular polygonal thin oil sealed gas holder. The single-stage rubber membrane sealed gas holder comprises a polygonal holder body, a circular piston arranged in the polygonal holder body, as well as a sealing mechanism arranged between the polygonal holder body and the circular piston, wherein a plurality of connecting brackets and an inner cylinder connected with the connecting brackets are arranged in the polygonal holder body; an inner cylinder sealing steel section is arranged on a lateral plate of the inner cylinder in the circumferential direction of the inner cylinder; the circular piston comprises a circular piston baseplate, a truss arranged on the circular piston baseplate and a piston fence connected with the truss; a piston sealing steel section is arranged at the edge of the circular piston baseplate; the sealing mechanism comprises a rubber membrane and a corrugated plate; the two ends of the rubber membrane are respectively connected with the inner cylinder sealing steel section and the piston sealing steel section in a sealing manner; the distance between the bottom end of the inner cylinder and the bottom of the polygonal holder body is not greater than the height of the rubber membrane; and the distance between the top end of the inner cylinder and the bottom of the polygonal holder body is not greater than the height of the piston fence. The single-stage rubber membrane sealed gas holder provided by the invention is low in investment, short in construction period and considerable in economic benefit.

Owner:HUATIAN ENG & TECH CORP MCC

Soft-rock large-span tunnel double-layer overlapped lining support removing method and structure

PendingCN112901205AImprove waterproof qualityAvoid the risk of demolition and constructionUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention provides a soft-rock large-span tunnel double-layer overlapped lining support removing method and structure. The method comprises the following steps that a primary support base face is leveled, a middle partition wall reinforcing mesh is mechanically broken and removed, wet spraying concrete is sprayed, and part of profile steel supports are detached; a geotechnical cloth buffer layer and a waterproof layer are sequentially laid close to the primary support base face, and waterproof treatment is conducted on the temporarily-reserved embedded support joints of the profile steel support; a formwork project is erected on the inner side of the primary support, steel bars are bound, and an outer layer secondary lining is molded; after the outer-layer secondary lining reaches the design strength, the profile steel support and the outer-layer secondary lining formwork project are dismantled; the base faces of the embedded support joints are flattened through cement mortar, and a waterproof reinforcing layer is laid on the base face of the outer layer secondary lining; and the formwork project is erected on the inner side of the outer layer second lining, the steel bars are bound, the inner layer second lining is molded, and after the inner layer second lining reaches the strength required by design, the formwork project of the inner layer second lining is removed. According to the method, the support dismounting construction risk can be effectively avoided, the overall waterproof quality of the lining can be improved, and the engineering, economic and social benefits are remarkable.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

Assembling method of segmental sliding roof steel truss

ActiveCN106760561BImprove construction efficiencyImprove stabilityGirdersJoistsArchitectural engineeringEconomic benefits

The invention relates to a sectional sliding roof steel truss assembling method. The method is characterized by including the following steps of building a construction platform (5), preparing steel truss basic component units (24), installing first piston shoes (20) and second piston shoes (21), installing support trusses (2), installing longitudinal main trusses (22), installing transverse main trusses (23), lifting, assembling and transversely connecting the steel truss basic component units (24), sliding sectional steel trusses (1), putting the sectional steel trusses (1) in position, assembling the other sectional steel trusses (1), sliding the other sectional steel trusses (1), putting the other sectional steel trusses (1) in position, connecting transverse rods among the sectional steel trusses (1), disassembling second piston shoes (21) and sliding rails (3), and disassembling the construction platform (5). The method belongs to the field of steel structure engineering, roof steel trusses are prepared in sections and put in position by sliding, the problems that roof window construction time of an existing operating railway is short and difficulty of the construction is large are effectively solved, the construction efficiency is improved, and when applied in practical engineering, the method can obtain good technical and economic benefits.

Owner:CONSTR & INSTALLATION ENG THE THIRD ENG GROUP OF CHINA RAILWAY

Transformation method of two-section rubber diaphragm sealed gas cabinet

ActiveCN106224755AGuaranteed uptimeSmall amount of structural changesVariable capacity gas holdersPiston GuideEconomic benefits

The invention discloses a transformation method of a two-section rubber diaphragm sealed gas cabinet. The transformation method comprises the following steps that a rubber diaphragm and a T baffle plate guide wheel between a cabinet body and a T baffle plate are dismounted; a rubber diaphragm and a piston guide wheel between the T baffle plate and a piston fence are dismounted; a corrugated plate on the piston fence is dismounted; the T baffle plate is lifted; a T baffle plate frame table is dismounted; cabinet body sealing profile steel on a side plate of the cabinet body is dismounted; a piston outer ring plate is machined and mounted, and is connected outside a piston baseplate; the T baffle plate is arranged on the piston outer ring plate, and is connected with the piston fence to form a piston of a one-section rubber diaphragm sealed gas cabinet; baffle plate sealing profile steel is arranged at the lower end of the T baffle plate in the peripheral direction; the cabinet body sealing profile steel is arranged on the side plate of the cabinet body; and two ends of the rubber diaphragm are respectively in sealing connection with the cabinet body sealing profile steel and the baffle plate sealing profile steel. The transformation method fully uses the cabinet body of the two-section rubber diaphragm sealed gas cabinet and accessory equipment, and is low in construction investment, short in construction time and high in economic benefit.

Owner:HUATIAN ENG & TECH CORP MCC

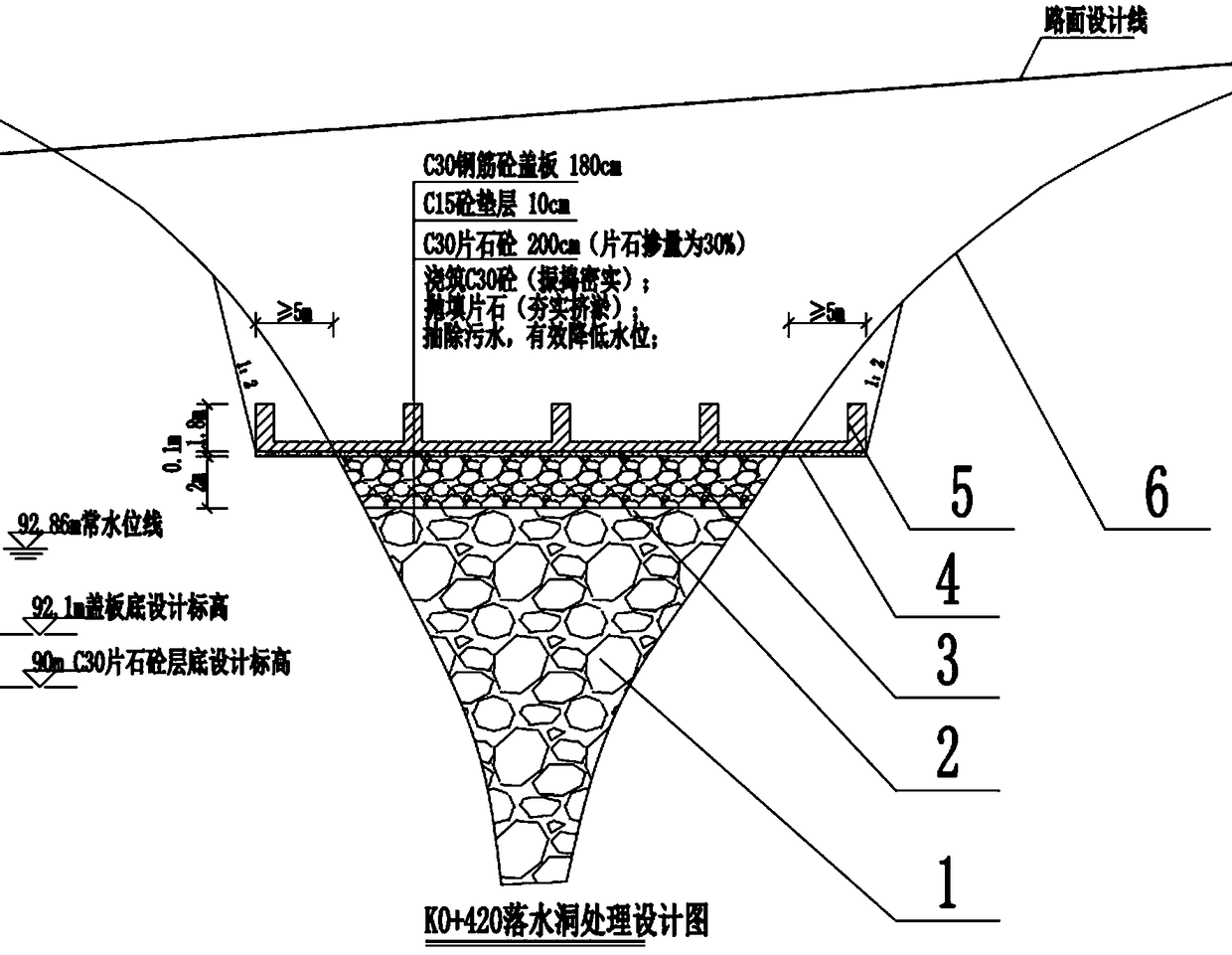

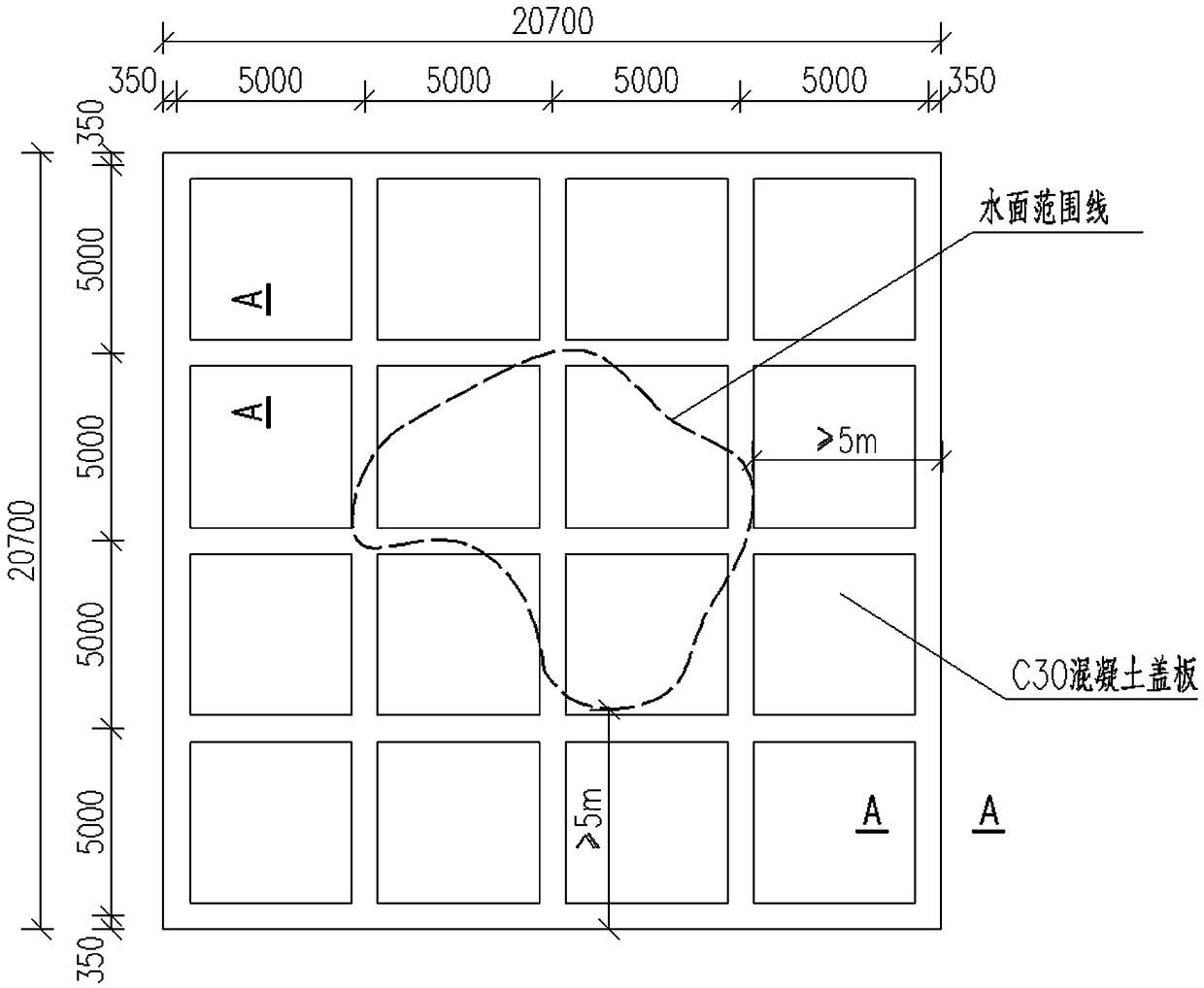

Treatment method of sinkhole in karst landform road roadbed range

ActiveCN108867225ASimple construction methodConstruction organization is convenientRoadwaysEmbankmentsSludgeRebar

The invention relates to a treatment method of a sinkhole in a karst landform road roadbed range. The treatment method of the sinkhole comprises the following steps: (1) pumping water and dischargingsewage to lower a water level in a sinkhole; (2) uniformly dispensing gravels along the sinkhole, tamping and squeezing the gravels into sludge; (3) after the gravels are dispensed to a designed standard height, pouring the concrete until the gravels are completely covered, and tamping and compacting; (4) pouring the gravel concrete to a cover plate bottom until reaching a designed standard height; (5) after the gravel concrete layer is solidified, flattening the field, constructing a reinforced concrete ribbed cover plate, and arranging a leveling layer between the cover plate and the gravelconcrete layer; (6) removing slope humus, wherein the slope on two sides is required to meet the design requirement; and (7) layering grinding, and refilling the roadbed to a designed standard height.By adopting the treatment method, the sinkhole in the roadbed range of the karst landform area can be effectively treated, and the problems of the underground water for the roadbed soil such as soaking, erosion, roadbed softening, loss and the like can be effectively solved.

Owner:HUALAN DESIGN GRP CO LTD

Construction method and structure of tunnel entering

PendingCN109869163AAvoid damageReduce earth and rock excavationUnderground chambersTunnel liningEcological environmentSteel frame

The invention discloses a construction structure and method of tunnel entering. A support is composed of filling piles, crown beams and grating steel frame net spraying concrete; an advanced pipe shedor a small guide pipe grouting or an anchor rod is constructed along an excavation line to be treated as an advanced support of underground excavation, and thus effective auxiliary measures are provided for underground excavation; and entering construction is conducted in a step-by-step mode. Earth-rock excavation and the protection workload are reduced, backfilling is reduced, land occupation isreduced, damage on ecological environments is reduced, side slope stability is facilitated, conservation of water and soil and environmental protection are facilitated, the built landscape effect isgood, and construction organization is simple and convenient.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

Large-caliber drainage pipeline construction assembly and construction method thereof

The invention belongs to the field of municipal rainwater-sewage pipeline engineering technology and particularly relates to a large-caliber drainage pipeline construction assembly and a construction method thereof. The large-caliber drainage pipeline construction assembly comprises a pipeline and is characterized in that the pipeline is arranged on two pipeline underlay pieces, pipeline stabilizing pieces are respectively and fixedly connected above the pipeline underlay pieces and respectively tangent with the pipeline, and hoisting holes are respectively formed in the pipeline stabilizing pieces. The large-caliber drainage pipeline construction assembly has the advantages of being high in installation efficiency, integrity and stability of the pipeline are high, pipeline installation straightness and smoothness can be guaranteed, inconvenience caused by concreting twice can be avoided, and manufacturing cost is low.

Owner:JINAN URBAN CONSTR GRP

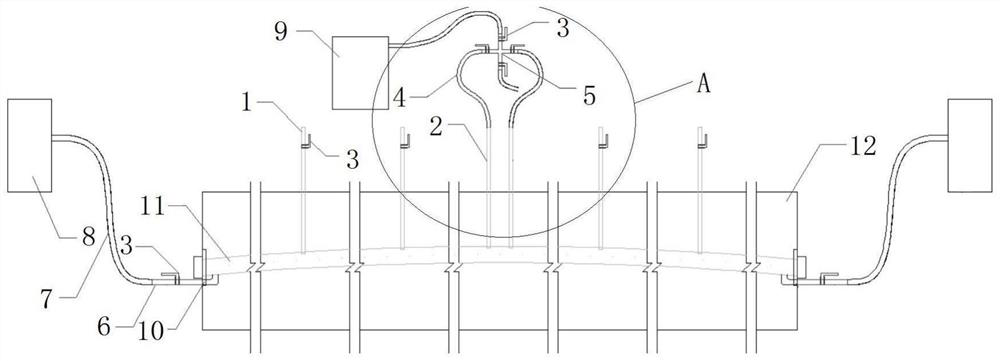

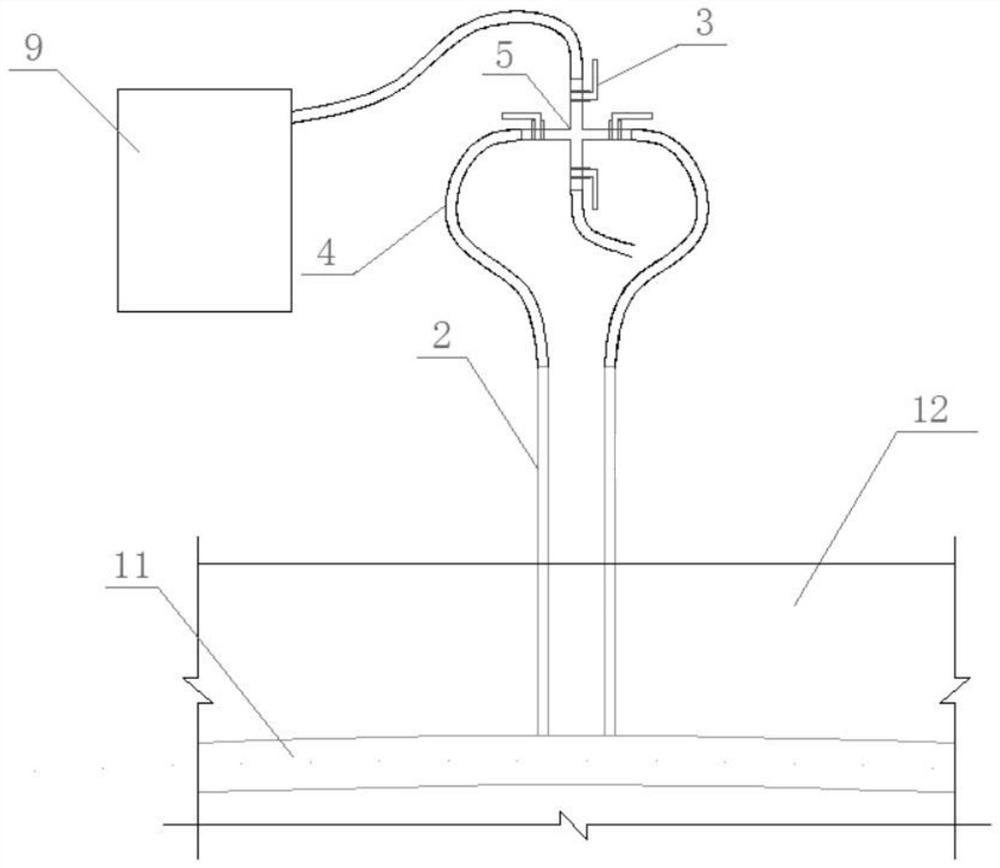

Grouting structure of prestressed concrete stiffening beam long duct and construction method thereof

PendingCN112227725AImprove the construction environmentIncrease productivityGirdersJoistsPumping vacuumGrout

The invention provides a grouting structure of a prestressed concrete stiffening beam long duct and a construction method thereof. The grouting structure comprises a grout supplementing pipe, grout discharging pipes, grout stopping valves, transparent steel wire hoses, a four-way connector, grouting devices, a vacuumizer, an ultra-long prestressed duct and a concrete stiffening beam, wherein the ultra-long prestressed duct is arranged in the concrete stiffening beam, grouting holes are formed in the two ends of the ultra-long prestressed duct, a grout stop valve is arranged on the grout supplementing pipe, two connectors of the four-way connector communicate with the two grout discharging pipes through the two transparent steel wire hoses respectively, in the other two connectors of the four-way connector, one connector communicates with the vacuumizer through the transparent steel wire hose, the other connector communicates with the outside through the transparent steel wire hose, four connectors of the four-way connector are provided with a grout stop valve respectively, and the two grouting devices communicate with the two ends of the ultra-long prestress duct respectively. Thegrouting structure can ensure the compactness of grouting.

Owner:CCCC FOURTH HIGHWAY ENG

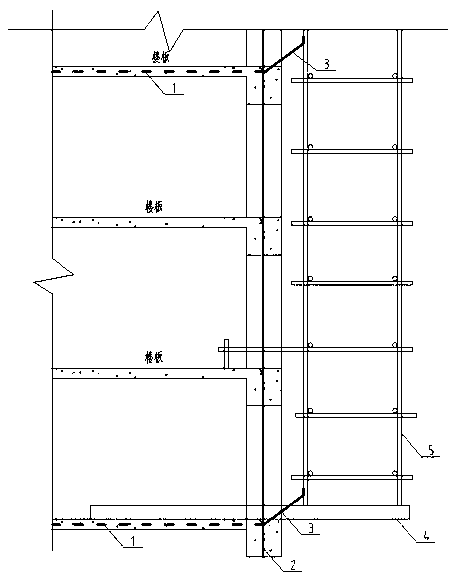

Lightning protection construction method for cantilever scaffold of high-rise building

InactiveCN105507588AConstruction organization is convenientSimple processBuilding material handlingBuilding support scaffoldsFalseworkArchitectural engineering

The invention discloses a lightning protection construction method for a cantilever scaffold of a high-rise building. In construction stage of a main structure of the high-rise building, the main structure of the high-rise building is designed into a structure that every other three floors are in equipotential connection through frame beam steel bars around the building to form internal grinding rings of the floors, and the internal grinding rings of the floors are connected with steel bars of cast-in-place piles of the high-rise building through in-column steel bar down leads; during construction of the internal grinding rings of the floors, the internal grinding rings of the floors are connected with vertical steel pipes of the cantilever scaffold through lightning protection leads. The lightning protection construction method for the cantilever scaffold of the high-rise building has the advantages that construction organization is facilitated, and connection with a body of the cantilever scaffold is completed during lightning protection construction of a body of the high-rise building, so that lightning protection is realized; technical simplicity and high operability are achieved, lighting protection of the body is made full use of to guarantee lightning protection effects, additional arrangement of grounding electrodes and down leads is avoided, and accordingly the cost is reduced to a great extent.

Owner:CHINA FIRST METALLURGICAL GROUP

Clean room micro slope terrace and construction method thereof

InactiveCN109025147AAvoid the lack of thickness increaseGuaranteed flatnessBuilding material handlingFlooringSteel barBlanket

The present invention provides a clean room micro slope terrace and a construction method thereof. In the large-area clean room terrace construction, a mode of drainage of a micro slope below 0.5% isemployed, prior to pouring of a terrace concrete leveling blanket, a concrete leveling blanket pouring surface is divided according to drainage exposure blocking; implanting a plurality of full-wire screws along each drainage slope intersecting line on a building structure layer by employing an adhesion agent, employing angle iron to make a location slope skeleton and an exposure floor drain alongan embedded steel bar screw, and employing an angle iron skeleton and the embedded steel bar screw to cooperate with double nuts to control the drainage slope; and integrally pouring the concrete leveling blanket, taking the angle iron skeleton as a reference for leveling of each drainage slop and each flatness, performing light collection, maintenance and forming, and performing finish coat construction after polishing. The structure is simple, the operation is convenient, the construction cost is saved while the clean room construction cleanness quality is improved and the construction efficiency is accelerated, it is convenient to achieve construction and organization, the integration benefit is very obvious, and therefore the clean room micro slope terrace and the construction methodthereof provide great convenience for the clean room terrace construction.

Owner:CHINA MCC17 GRP

Preparation method for preformed hole split pouring fender pile

InactiveCN101544023BImprove compactnessImprove impermeabilityMouldsShaping reinforcementsSEMI-CIRCLEEngineering

The invention provides a preformed hole split pouring fender pile, belongs to the field of building, in particular relate to a fender pile capable of barricading earth and water and applied to deep foundation pit engineering, and discloses a preparation method for the preformed hole split pouring fender pile. The cross section mode of the fender file is a square of which two semi-circles of opposite lateral surfaces are cut off. The fender pile is a preformed pile, has better compactness, permeability resistance, side pressure resistance and shearing resistance capacity, and does not need maintenance. The fender pile has simple construction, saves time and labor, and has short construction period and water retaining function; and the construction is completed by only driving a row of piles.

Owner:SHANGHAI ZHONGJI PILE IND

A construction method for dismantling and hoisting No. 0 block of a bridge

ActiveCN110984005BStable structureConstruction organization is convenientBuilding repairsBridge strengtheningArchitectural engineeringStructural engineering

The invention discloses a construction method for dismantling and hoisting No. 0 block of a bridge. The main steps are as follows: Step 1. Divide No. 0 block from top to bottom into three parts: the top plate, the middle plate and the bottom plate, and set a horizontal cutting line; step 2. Set the vertical cutting lines for the top plate, middle plate and bottom plate; Step 3: Select the hoisting equipment and design the lifting holes according to the size and weight of each cutting unit; Step 4: When cutting, the cutting direction is first the top plate, then the middle plate, and finally For the bottom plate, the cutting sequence is vertical cutting first, and then horizontal cutting; Step 5, lifting and disassembling after cutting, until all cutting units are disassembled. The invention divides No. 0 block vertically, which can facilitate the subsequent layered construction; when cutting, first cut vertically and then cut horizontally, which is convenient for on-site operation, and by cutting block by block, it is convenient for lifting; The setting of the cutting seam in the type structure style facilitates cutting and ensures the stability of the overall structure.

Owner:GUANGDONG GUANYUE HIGHWAY & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com