Transformation method of regular polygonal thin oil sealed gas cabinet

A regular polygon and sealed technology, which is applied to the reconstruction of regular polygon thin oil-sealed gas tanks, can solve the problems of stuck piston guide wheel, insufficient installation accuracy, long engineering time, etc., and achieves flexible pressure adjustment function and running speed. Fast, low running costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

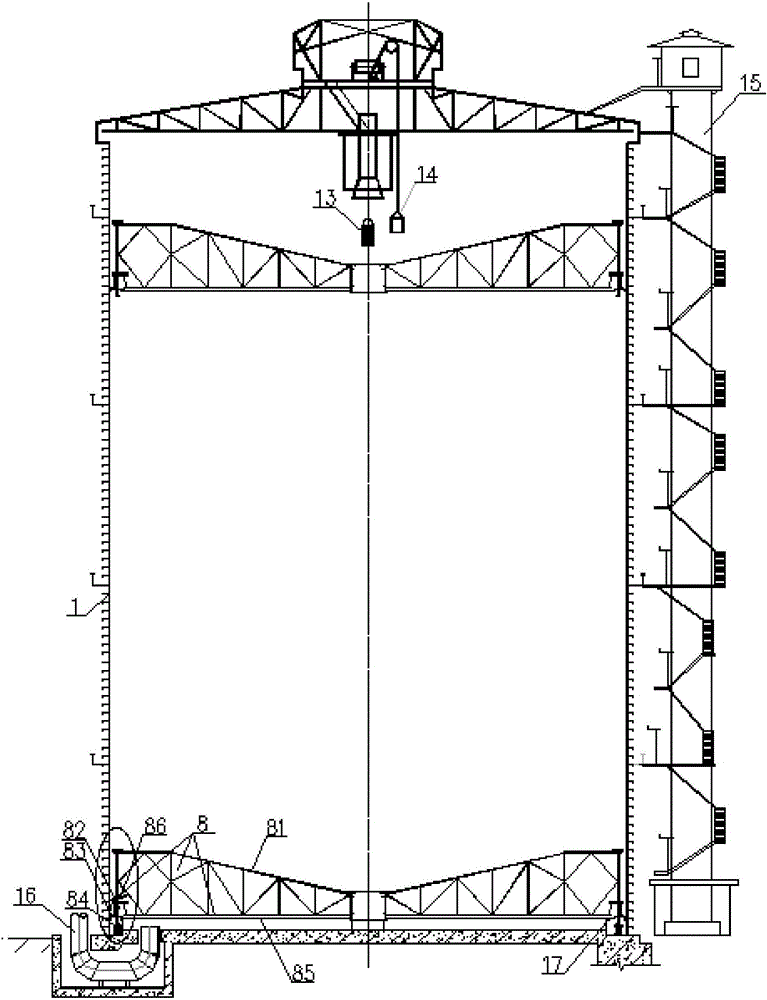

[0025] like figure 1 As shown, the existing regular polygonal thin oil-sealed gas cabinet includes a gas cabinet body 1, an internal hoisting cage 13, a temporary rescue device 14, an external elevator 15, an inlet and outlet pipe 16, an oil groove 17 at the bottom, and a piston 8. 8 includes the piston truss 81, oil groove support 82, piston oil groove 83, piston support bracket 84, piston bottom plate 85, thin oil-sealed gas cabinet sealing mechanism 86, etc. This kind of gas cabinet is a thin oil-sealed gas cabinet. If the cabinet body is greatly deformed, it will easily lead to reduced sealing effect or oil leakage. And for the regular polygonal thin oil-sealed gas holder that has been scrapped, if it is dismantled and then rebuilt a new gas holder, not only needs a large amount of funds, but also needs construction for a long time.

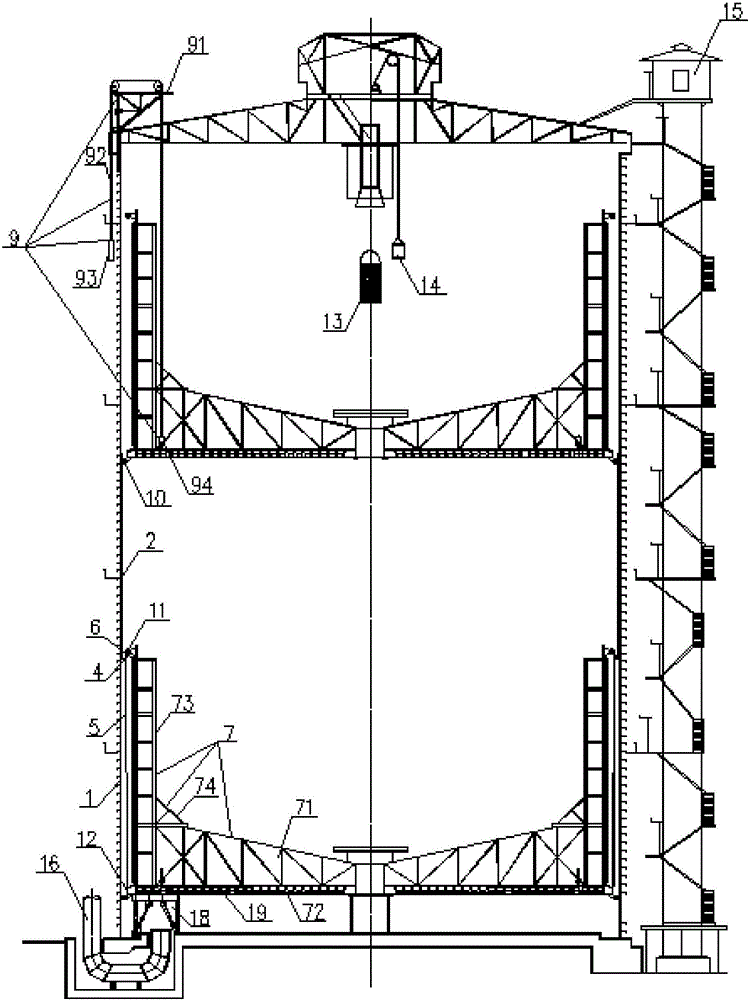

[0026] like figure 2 Shown: In the modification method of the regular polygonal thin oil-sealed gas cabinet provided in this embodiment, ...

Embodiment 2

[0035] On the basis of the above embodiments, a preparatory step is also included before step 1: stop production of the gas cabinet and perform gas replacement, and cut construction holes on the side wall of the gas cabinet body.

[0036] In this embodiment, construction holes are cut on the side wall of the gas cabinet body, and the construction holes can be used for the entry and exit of personnel, construction tools, and engineering materials, which facilitates the construction process.

Embodiment 3

[0038] On the basis of the above-mentioned embodiment, a bracket installation step is also included between the preparation step and step one: the piston bracket 18 is installed at a position corresponding to the edge of the one-piece gas cabinet piston 7, and the upper surface of each piston bracket is controlled to be in contact with the piston bracket. The lower chord contact of the piston truss.

[0039]In this embodiment, when the one-stage gas cabinet piston 7 is dropped, a piston support 18 is set at the position corresponding to the edge of the one-stage gas cabinet piston 7, so that the piston also keeps a certain distance from the bottom plate of the polygonal cabinet body for future maintenance when falling. Provide sufficient operating space for maintenance; in addition, it can also prevent the piston bottom plate from contacting the bottom plate of the gas cabinet body after the piston falls, and then the piston bottom plate and the gas cabinet body will be sucked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com