Patents

Literature

104results about How to "Running speed is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

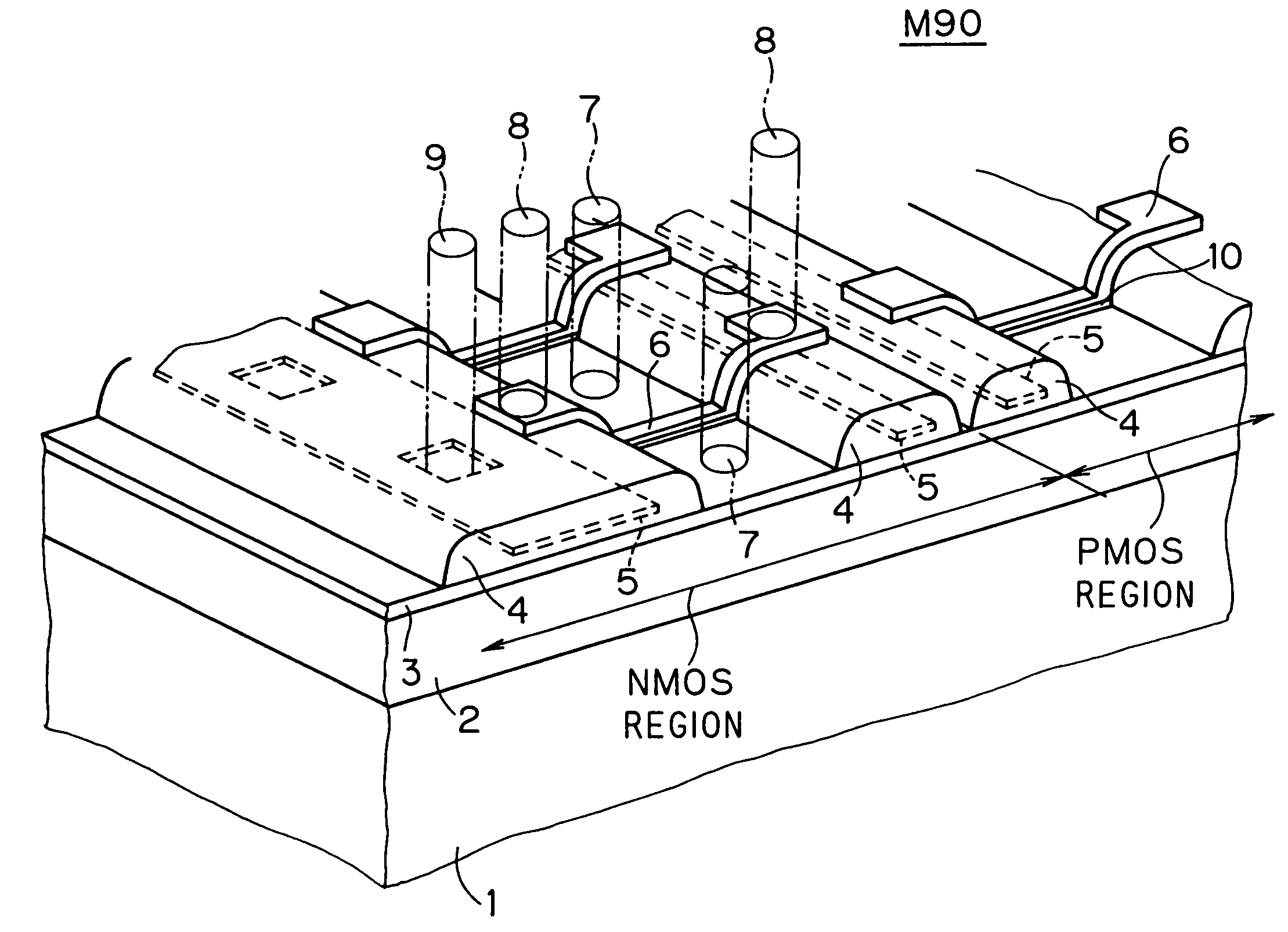

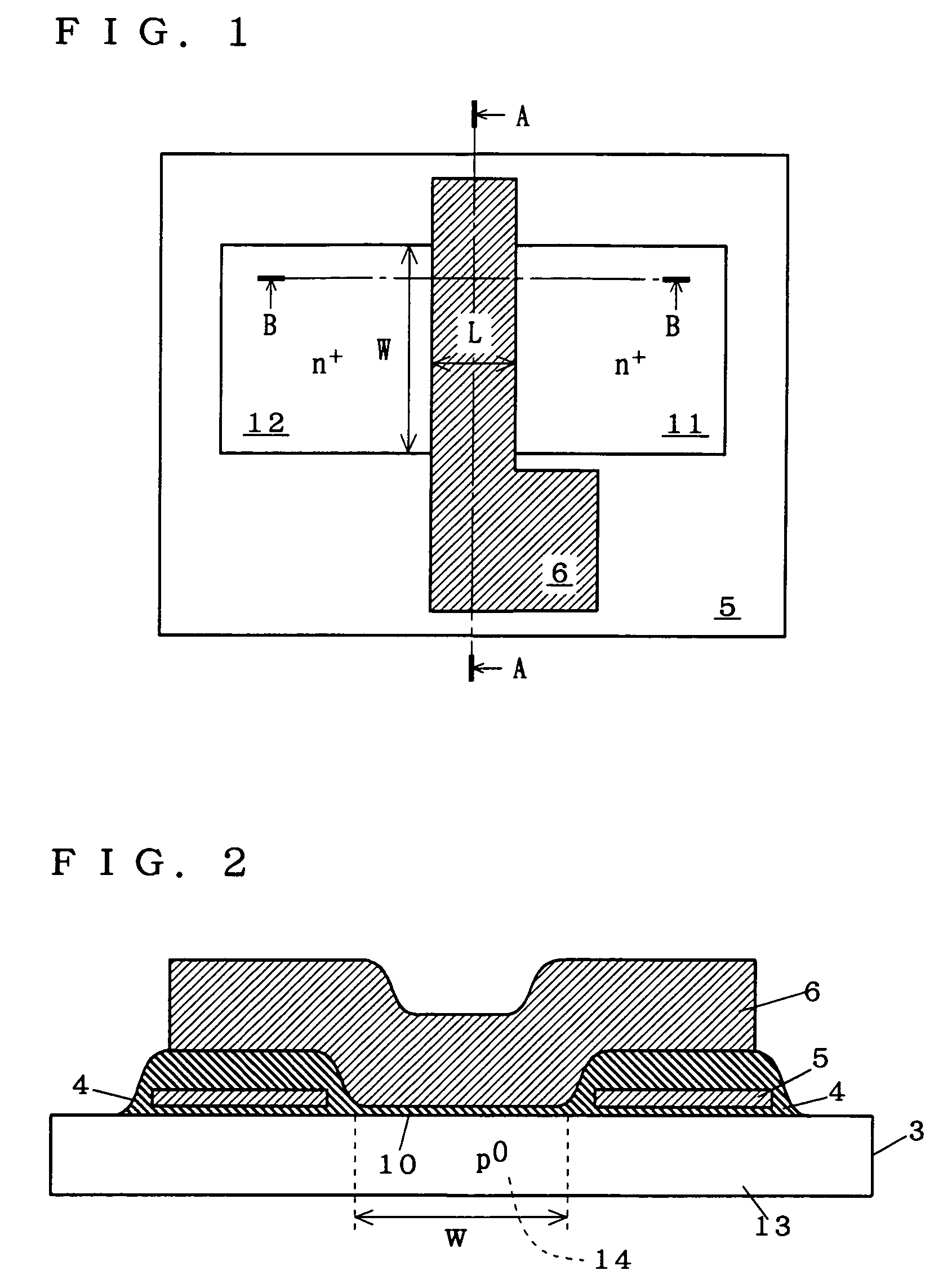

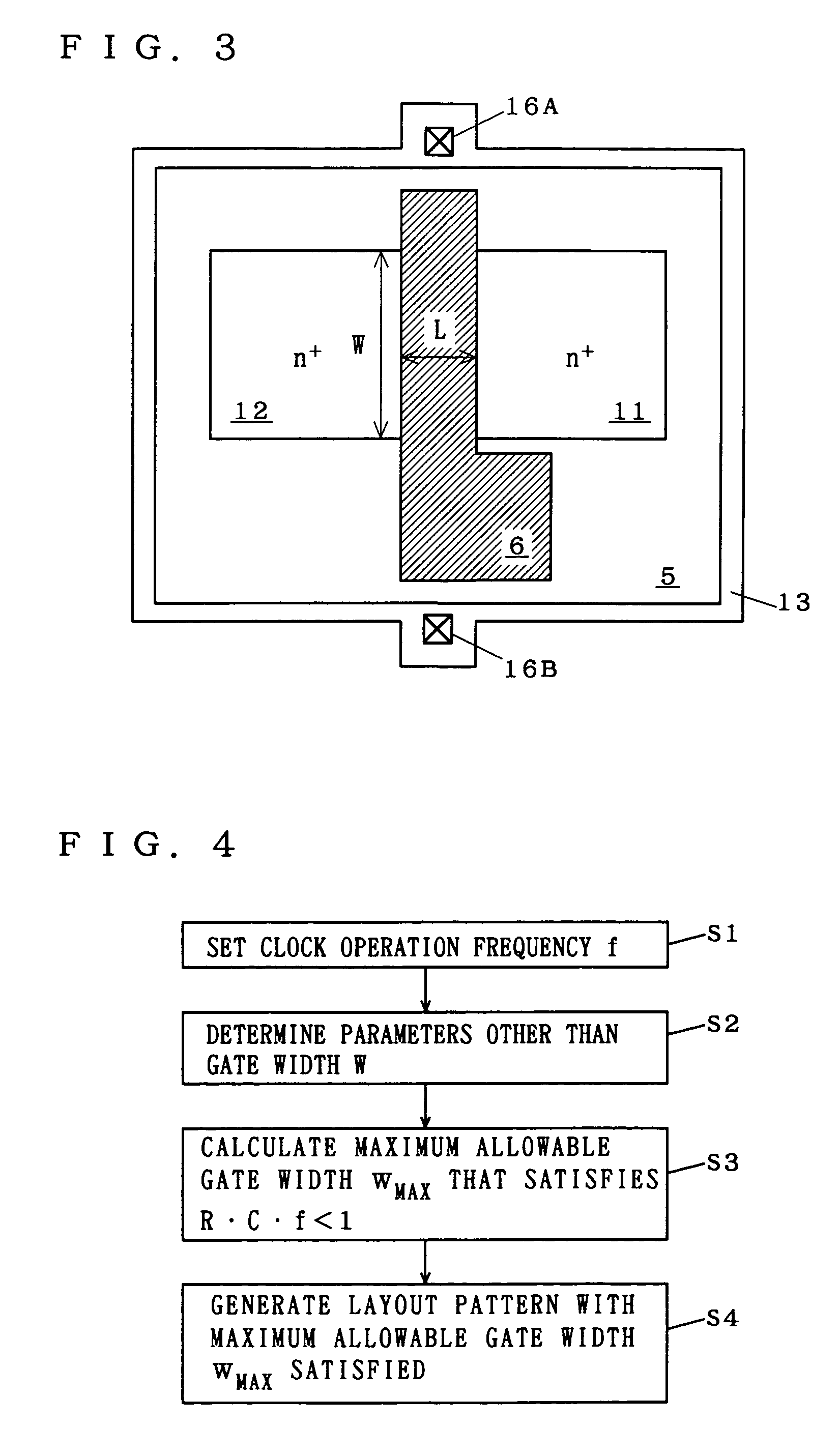

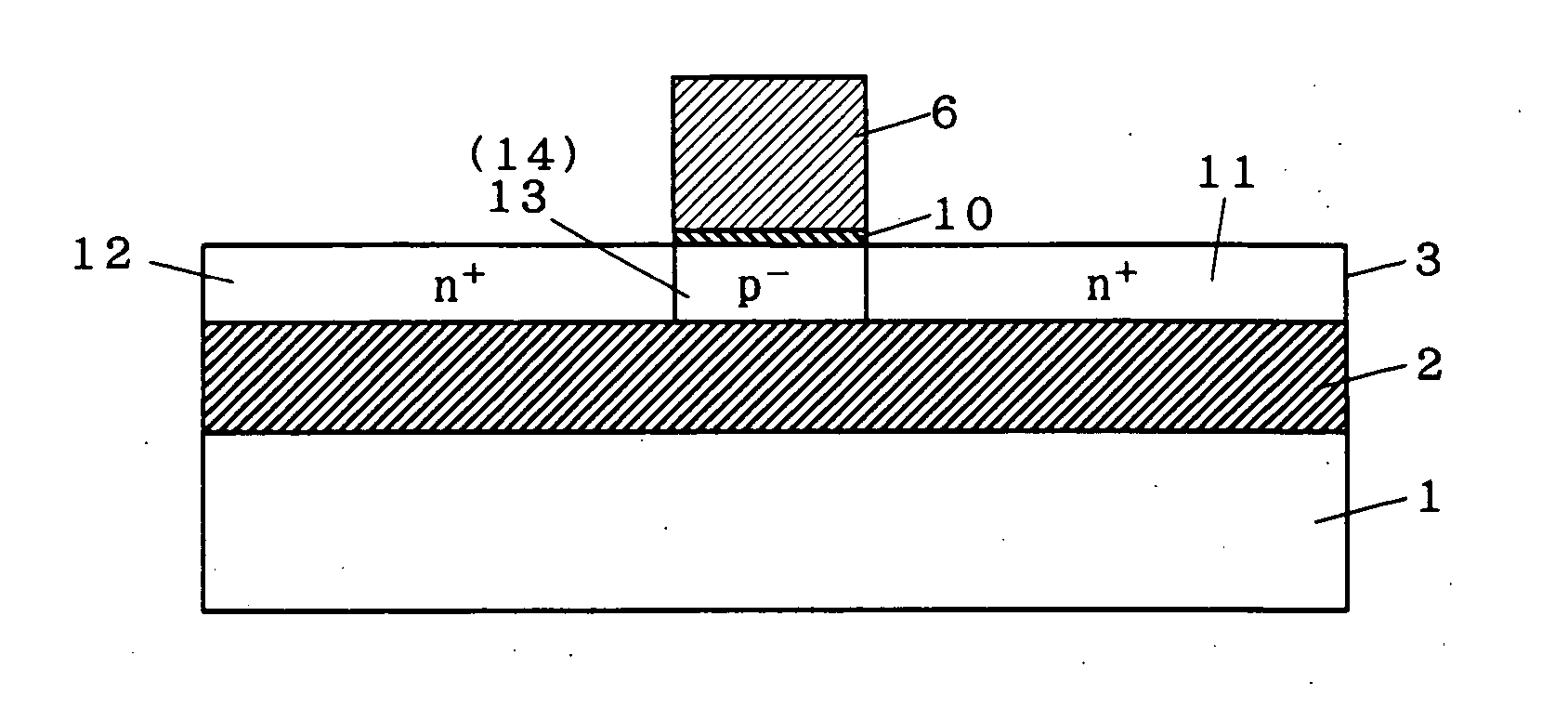

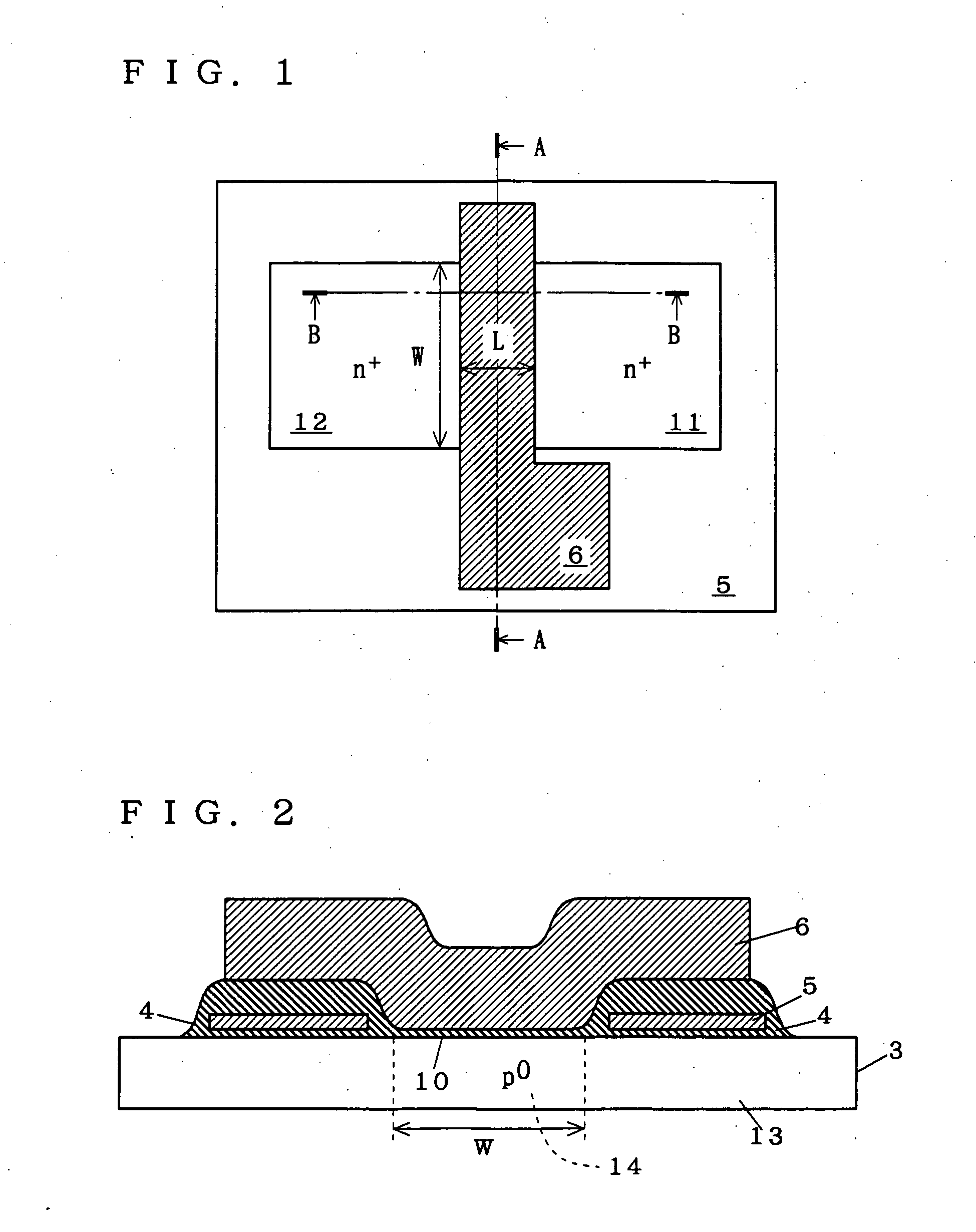

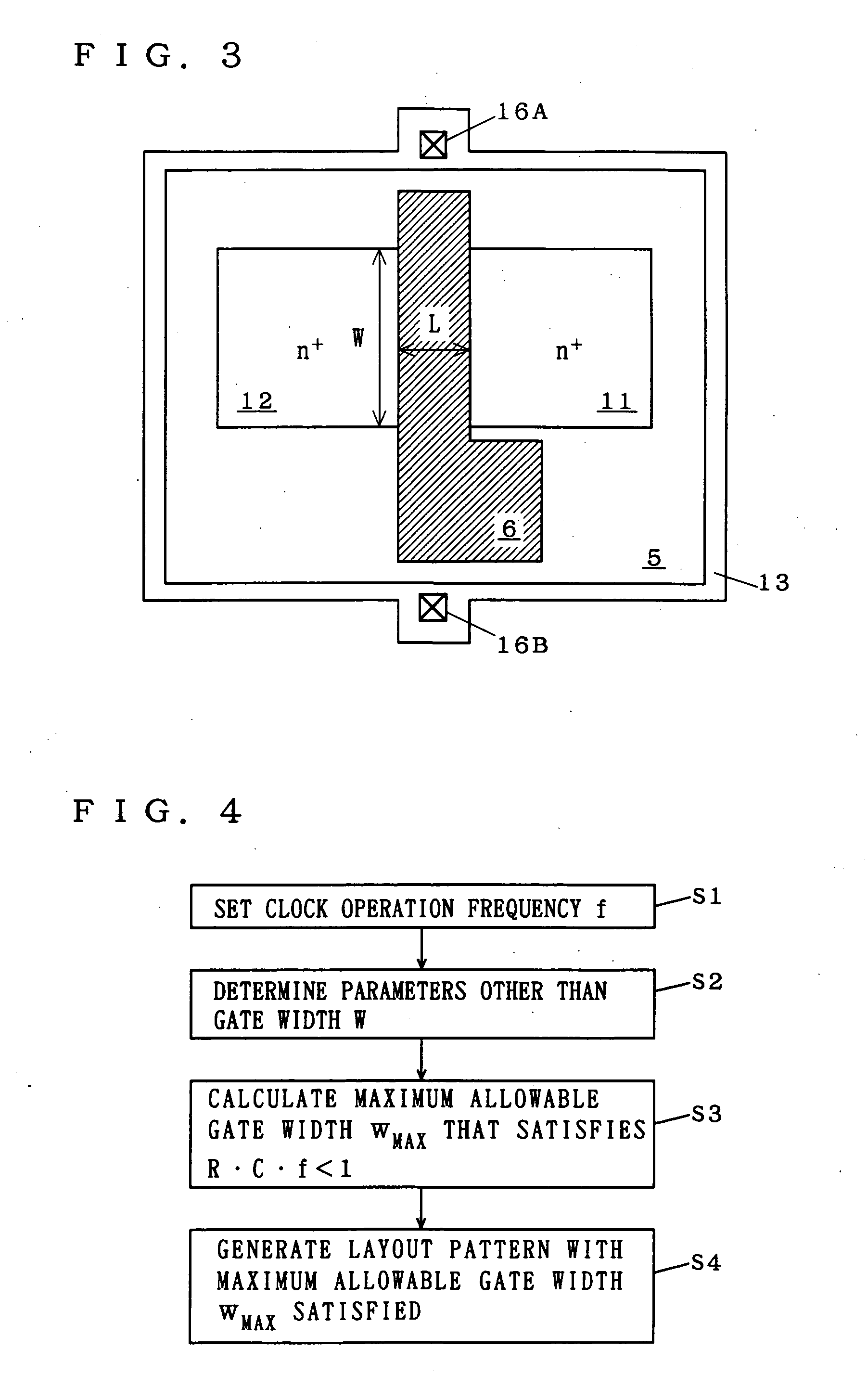

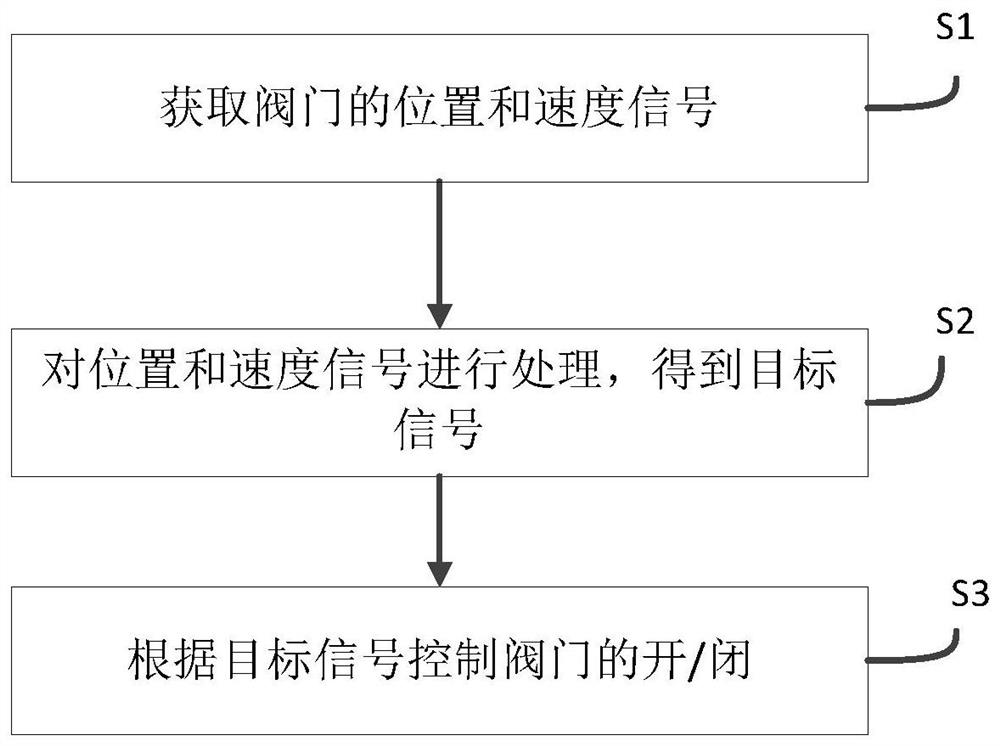

Method of designing semiconductor device, semiconductor device and recording medium

InactiveUS7129543B1Stable in operating speedRunning speed is stableTransistorSolid-state devicesGate capacitanceCapacitance

A semiconductor device including a transistor having an SOI structure the operating speed of which is not affected is provided. A MOS transistor having the SOI structure is formed which satisfies R·C·f<1 where C is a gate capacitance (F), R is a body resistance (Ω), f is a clock operating frequency (Hz), and f≧500 MHz.

Owner:TESSERA ADVANCED TECH

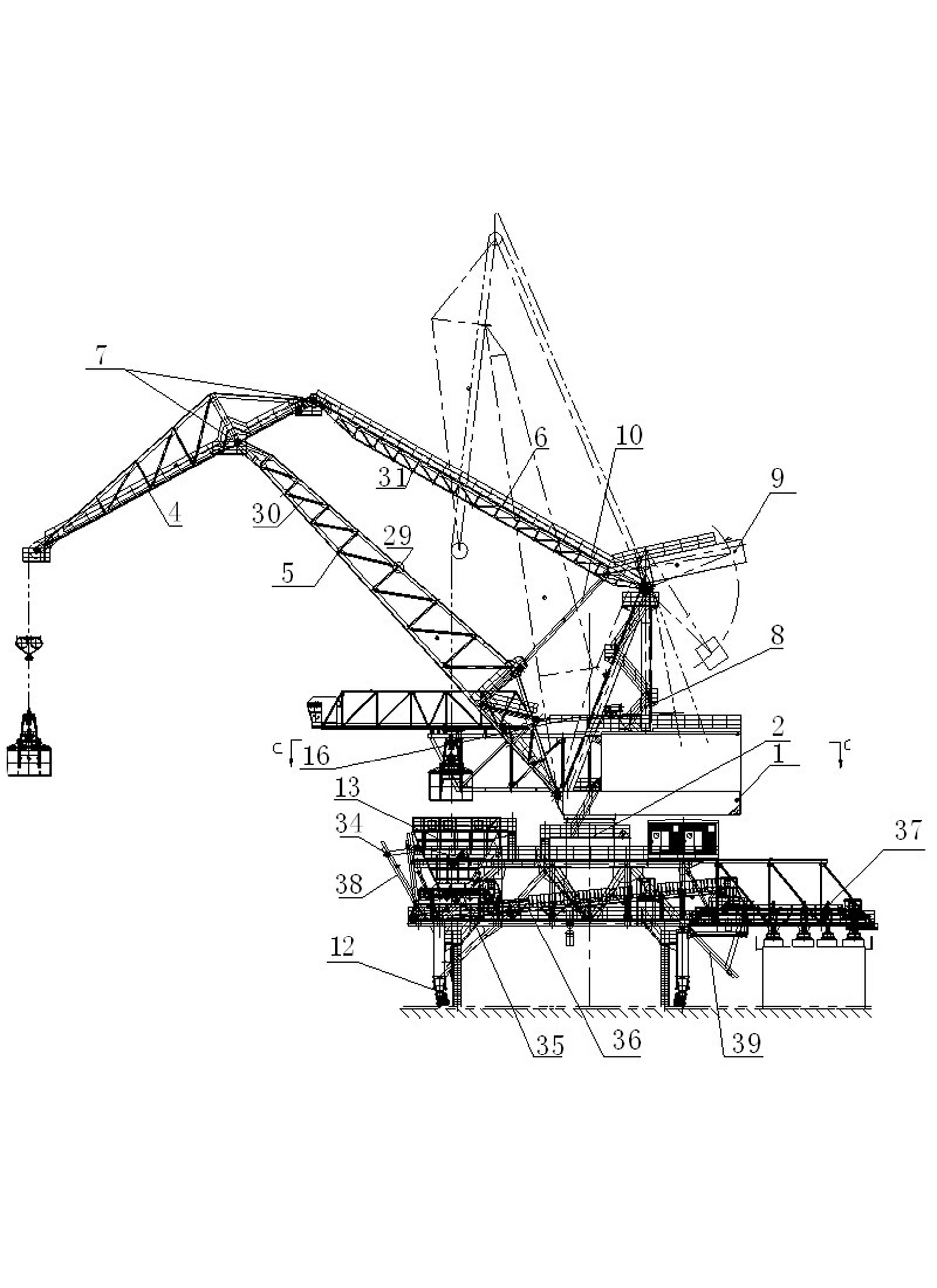

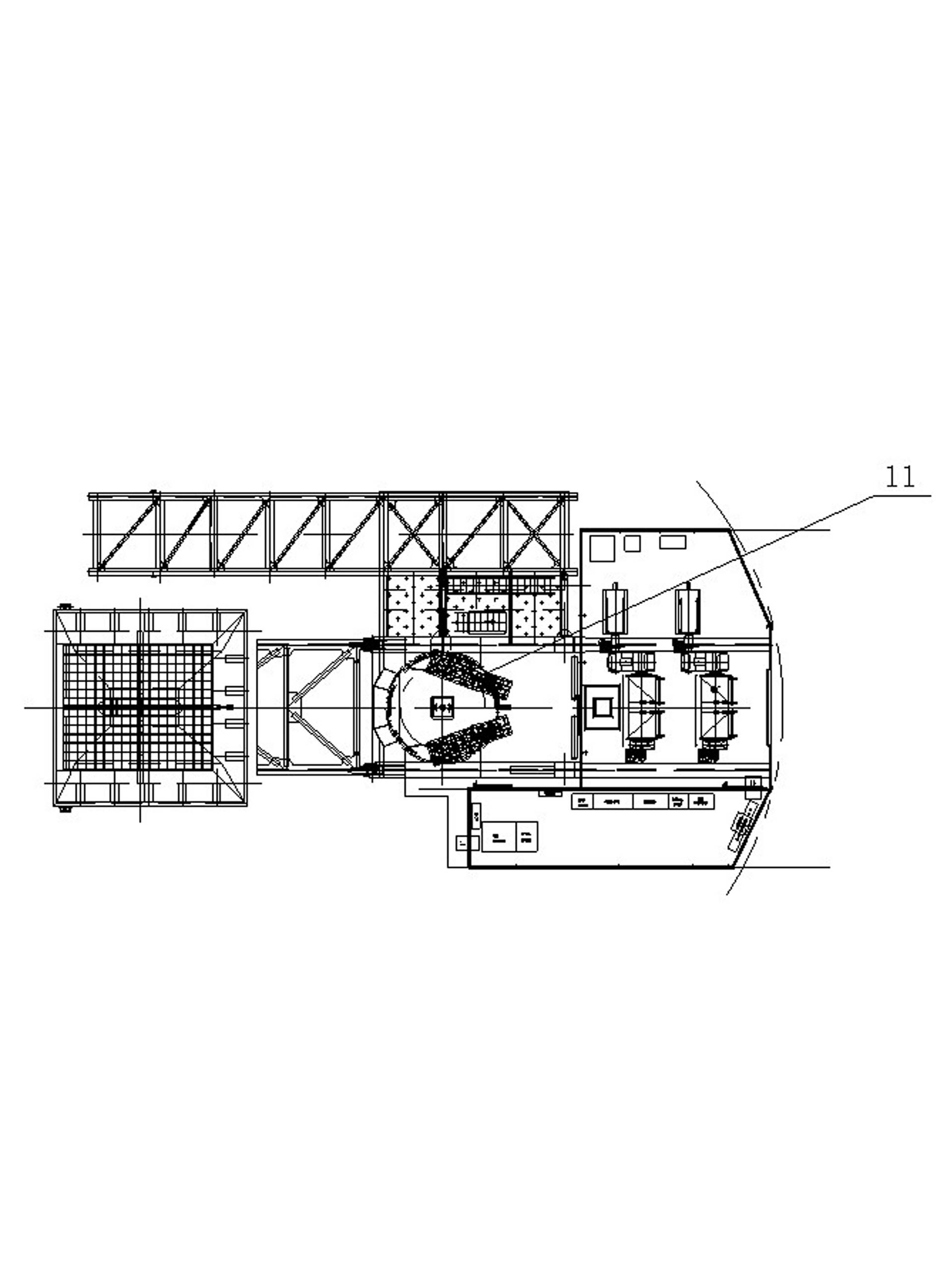

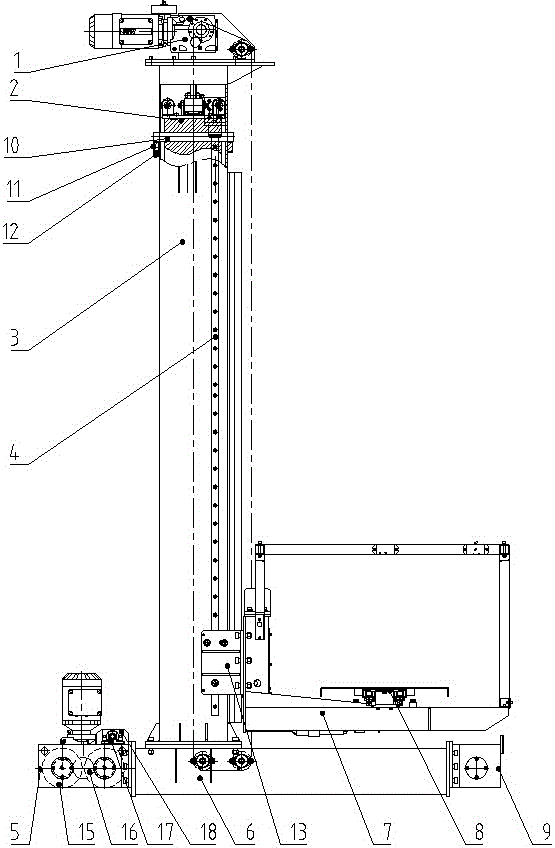

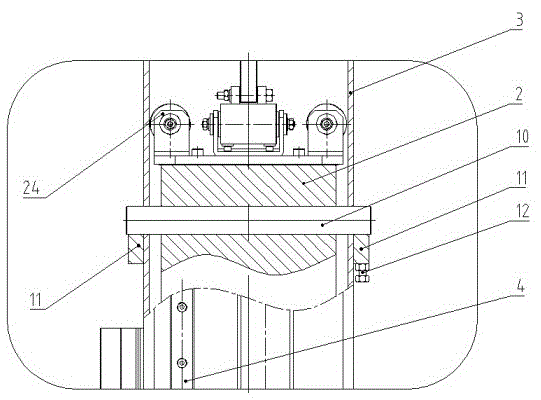

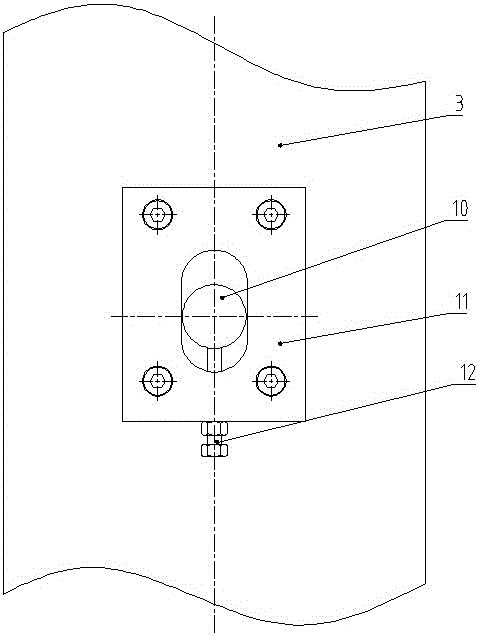

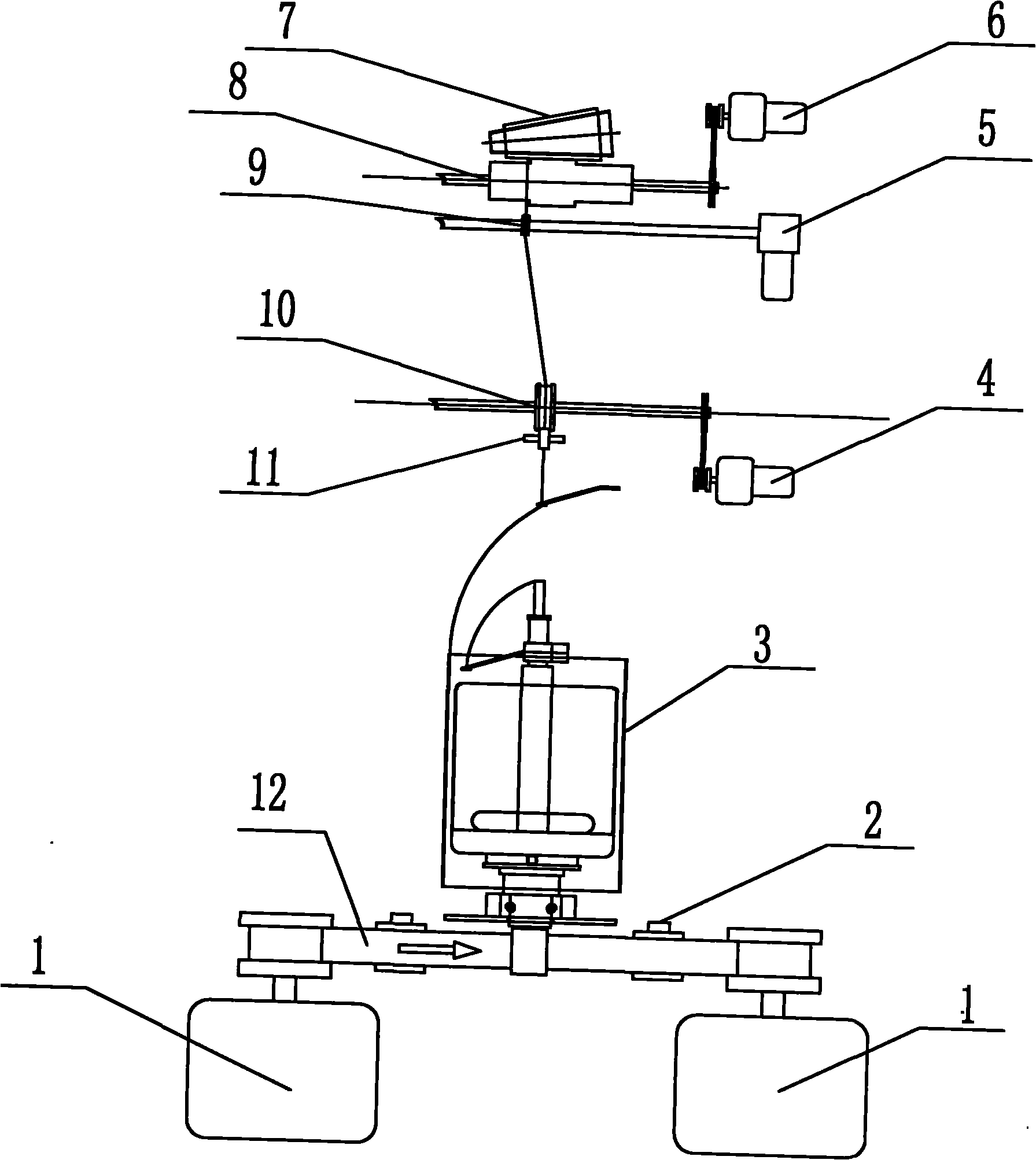

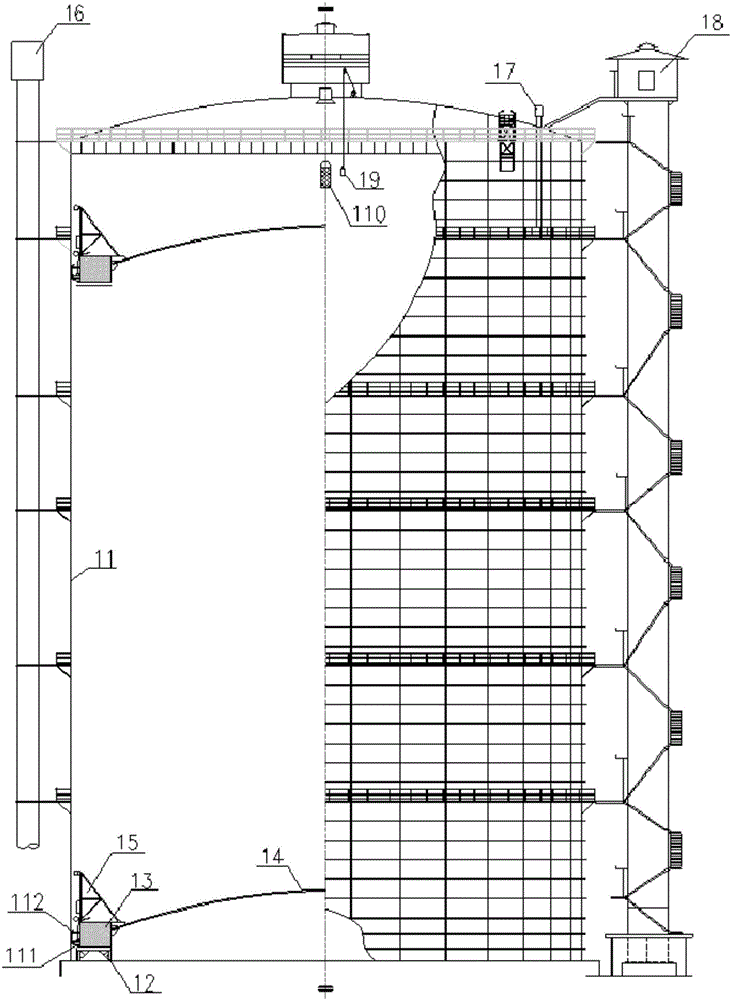

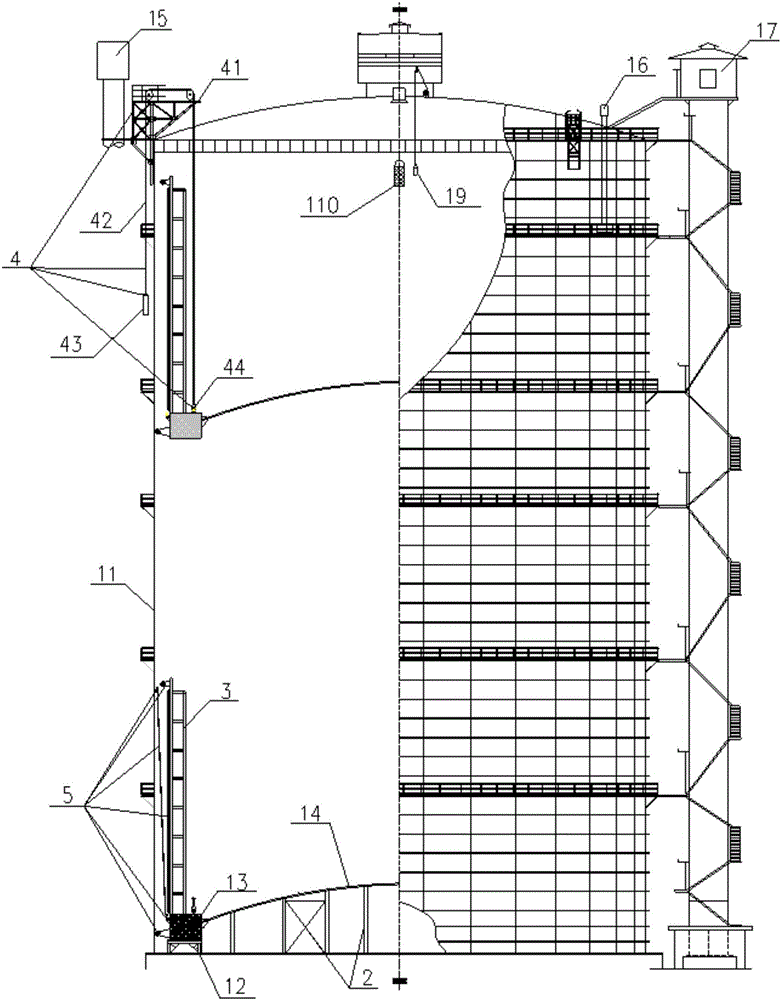

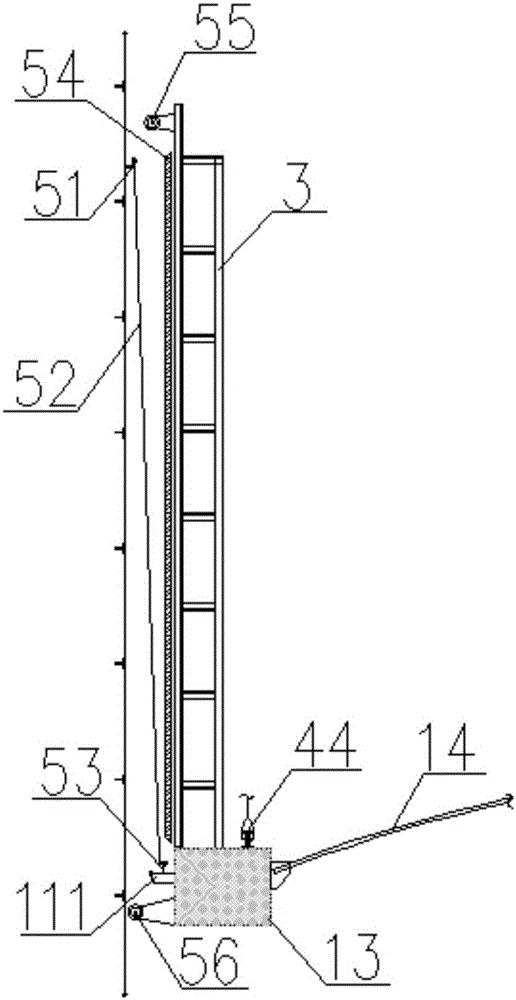

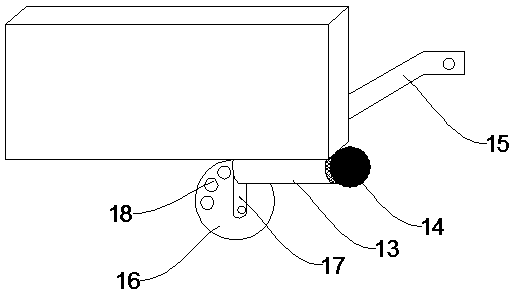

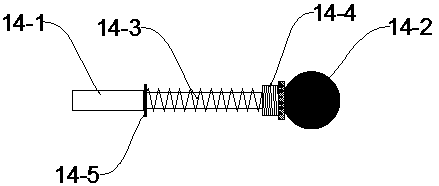

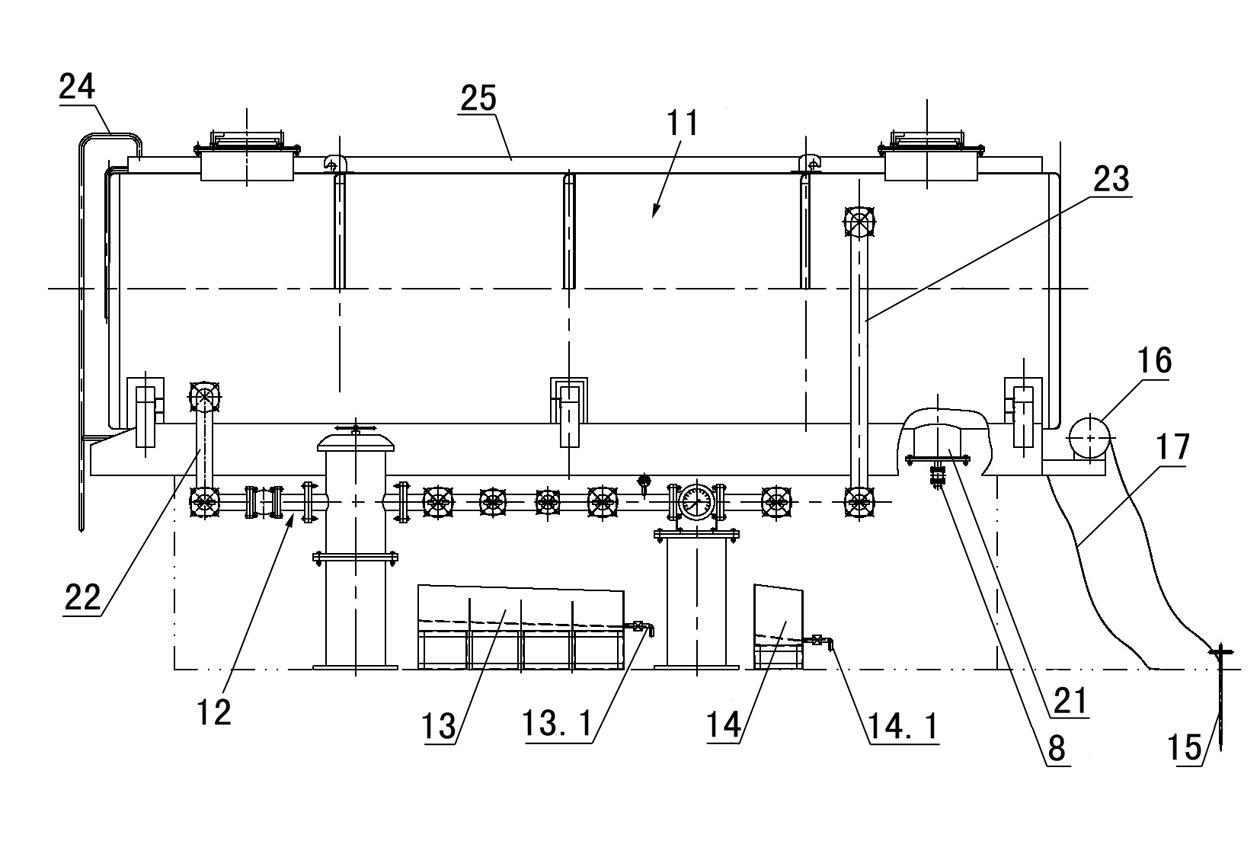

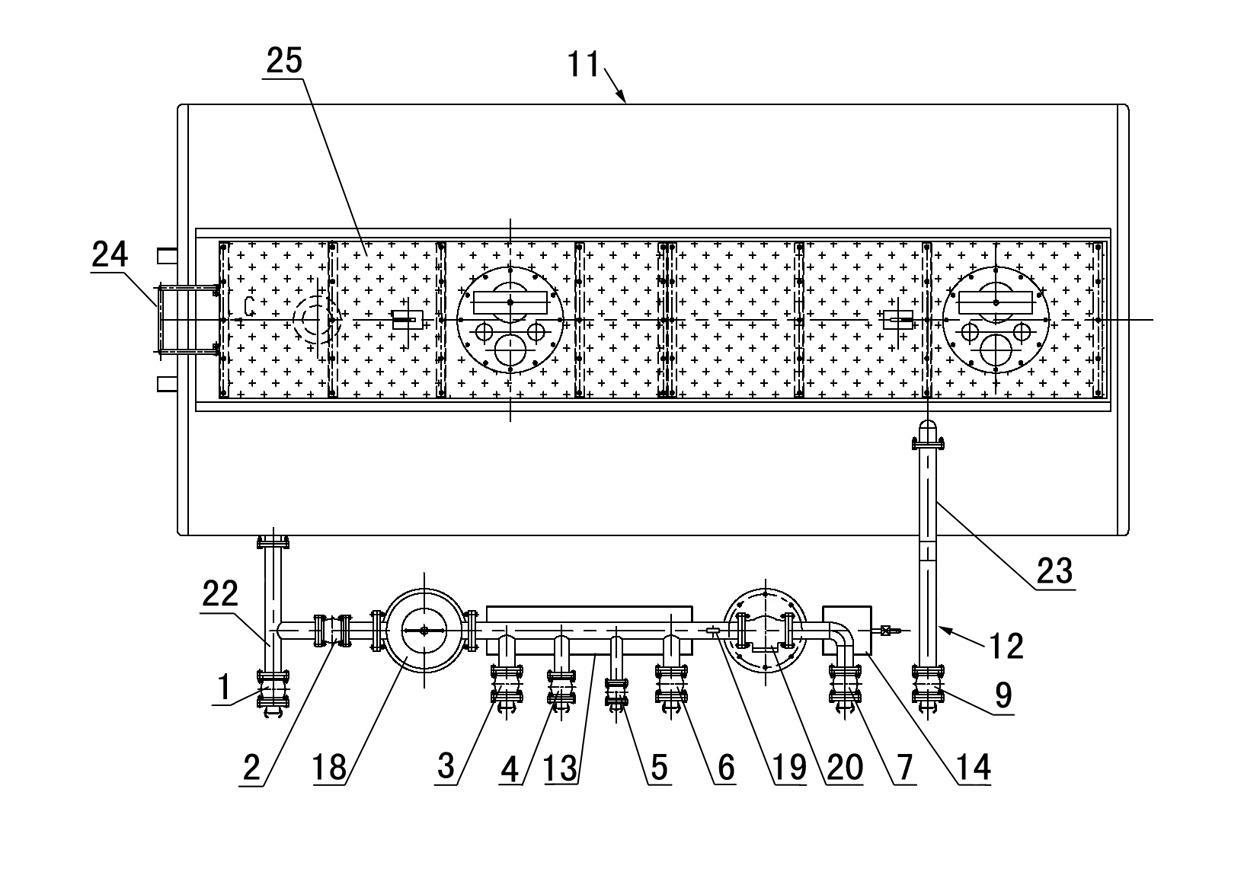

Horizontal luffing grab portal crane

InactiveCN102229412AImprove transmission efficiencyHigh transmission efficiency and high telescoping speedCranesNumerical controlGusset plate

The invention relates to a horizontal luffing grab portal crane, including a four-bar linkage level luffing boom system, a travelling mechanism and a gantry structure. The crane is characterized in that: a luffing mechanism comprises a triple screw, a screw pedestal and an electric transmission mechanism. The outside of the triple screw is provided with a telescopic cover, the inside of the screw pedestal is equipped with a sleeve with nuts, and two ends outside the sleeve are provided with bearings in the screw pedestal. The electric transmission mechanism comprises a motor, a driving gear and a brake apparatus. The end of the triple screw is hinged to a boom, and the luffing mechanism is equipped with a speed adjustable control system. The four-bar linkage boom system and a gantry beam are both girder construction which employs a T-shaped structure and a rectangular pipe. The T-shaped structure is a main chord member, and the rectangular pipe as a web member is welded on a web member gusset plate. In the blanking process, the T-shaped structure and the web member gusset plate are integrated through numerical control cutting. The crane of the invention has high operating cycle frequency which can reach 6 million times, high luffing speed, smooth running of grab bucket, high operating efficiency and long service life.

Owner:江苏海隆重机有限公司

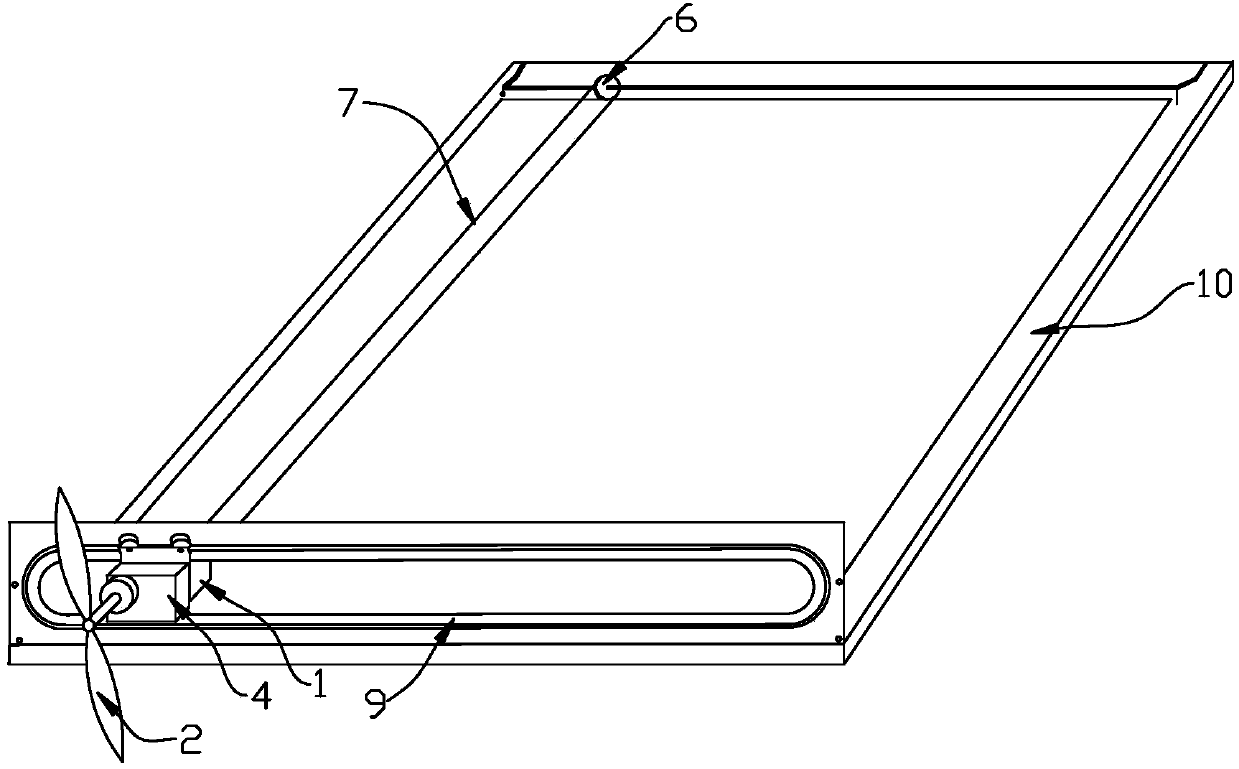

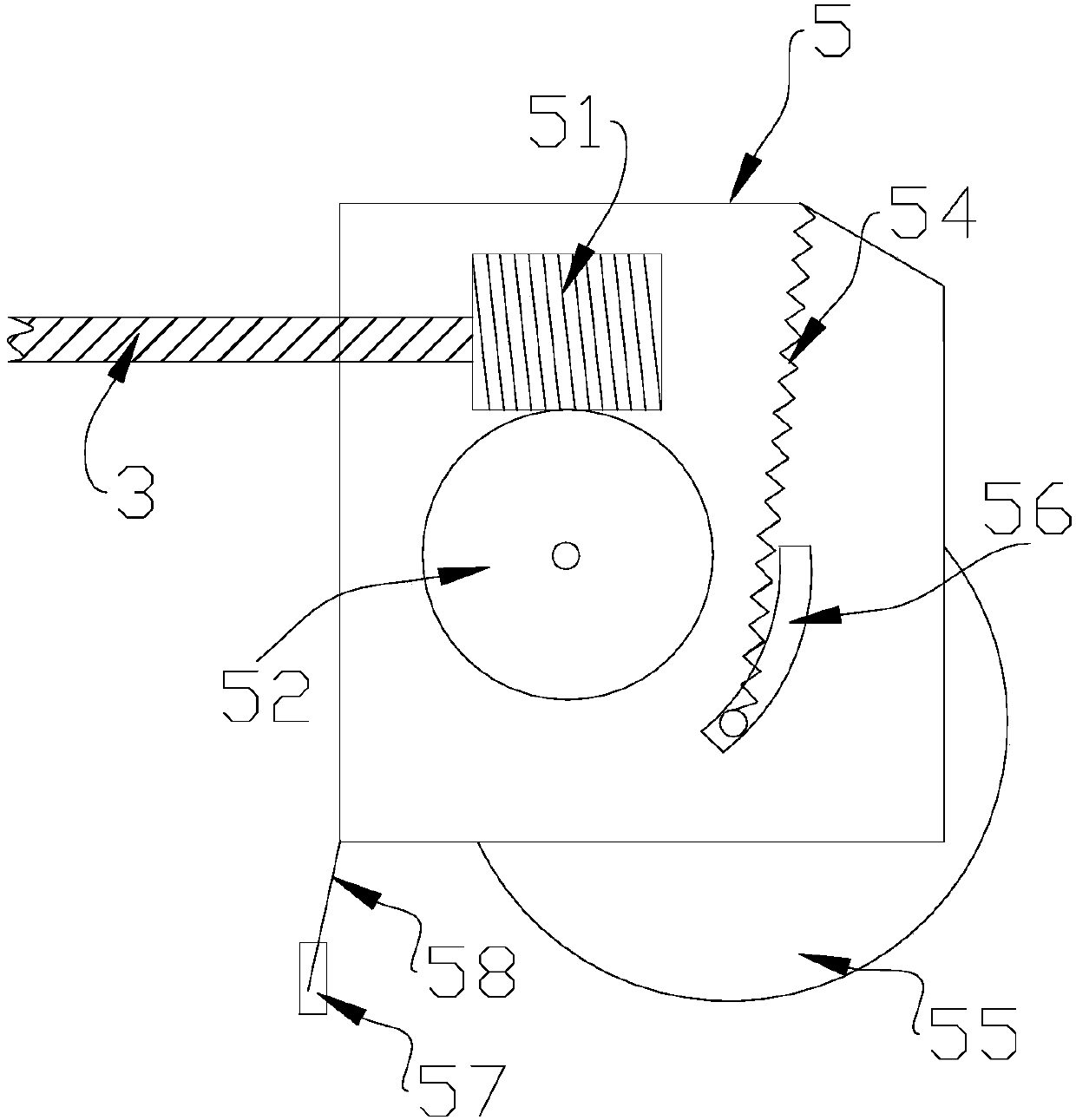

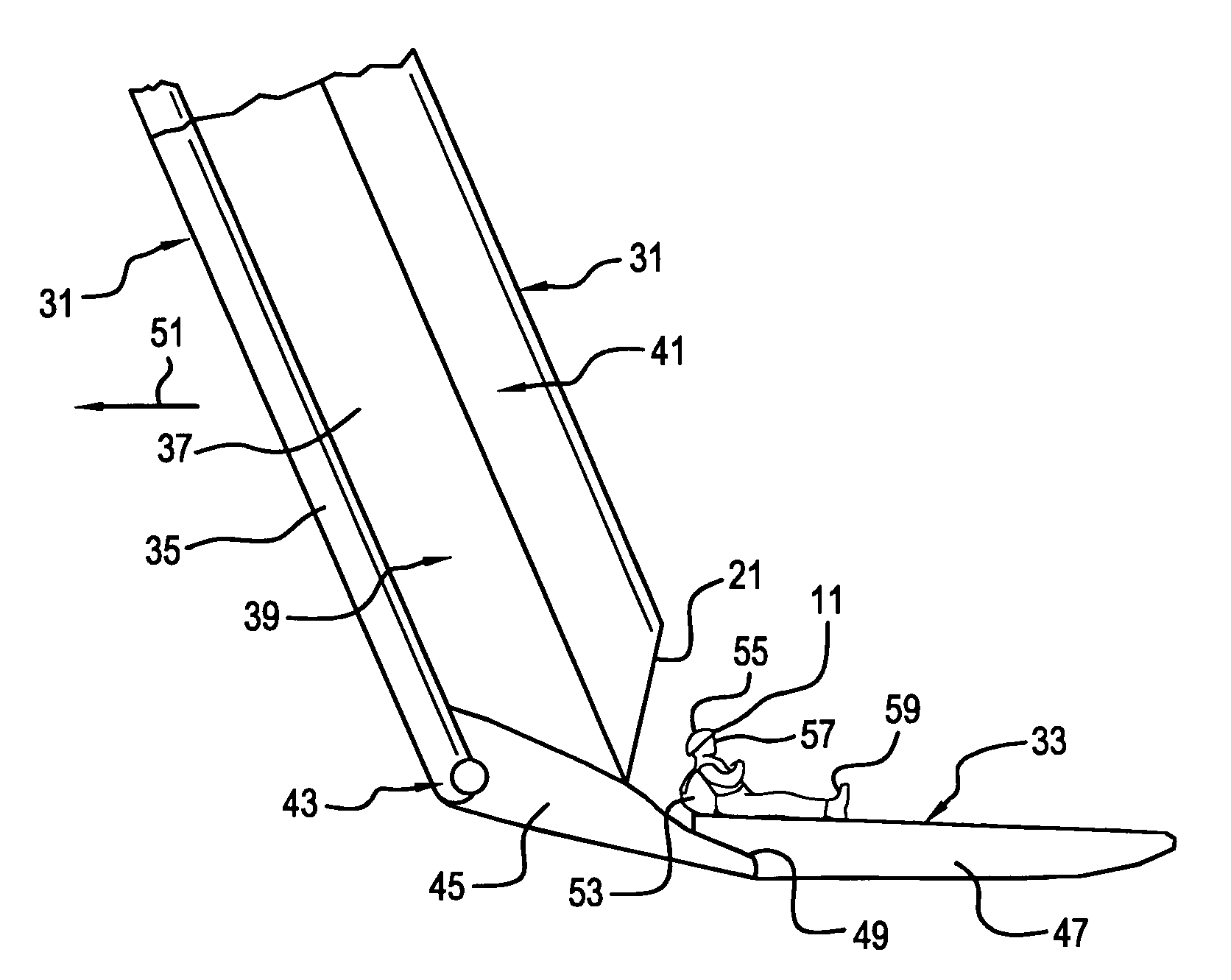

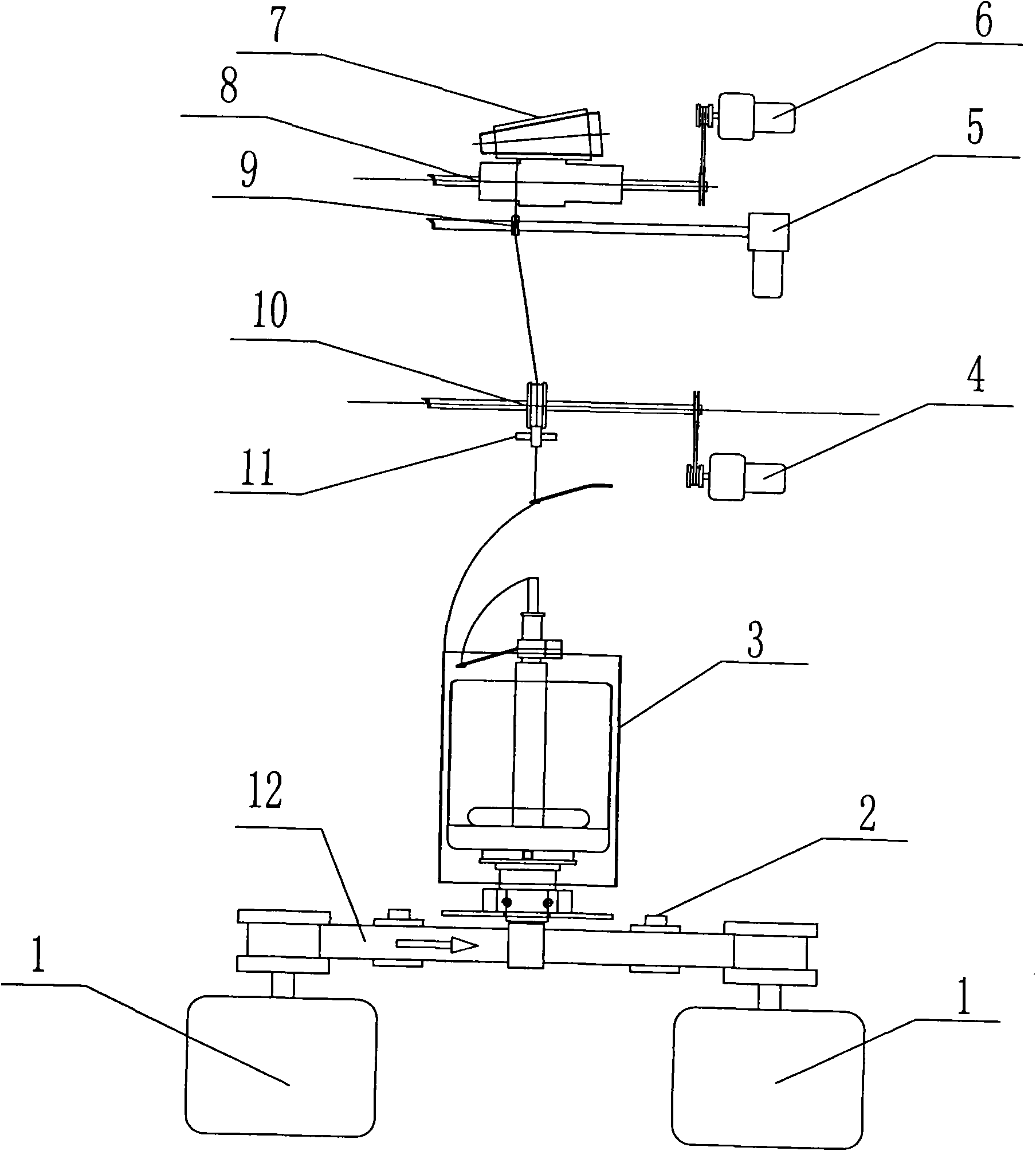

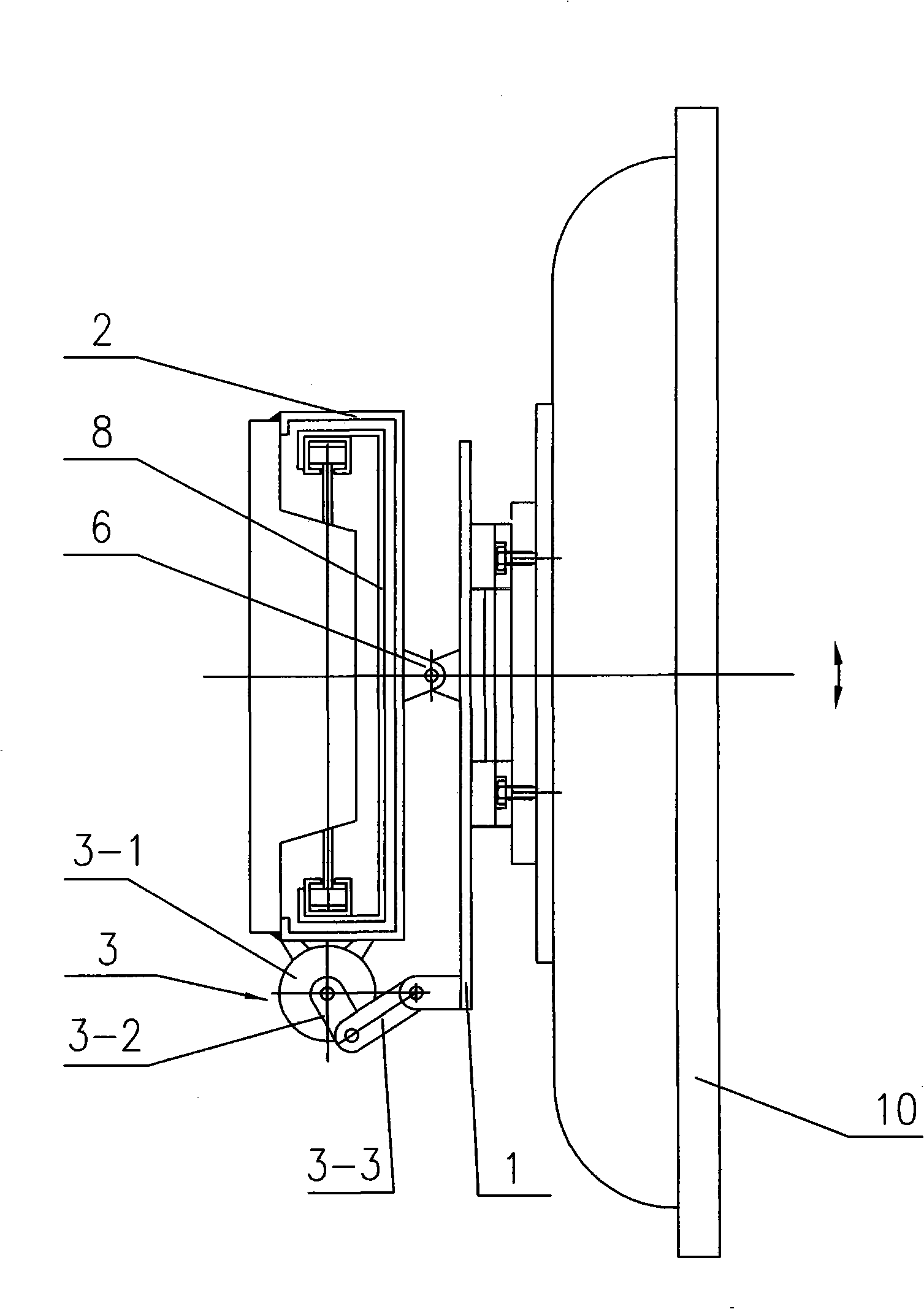

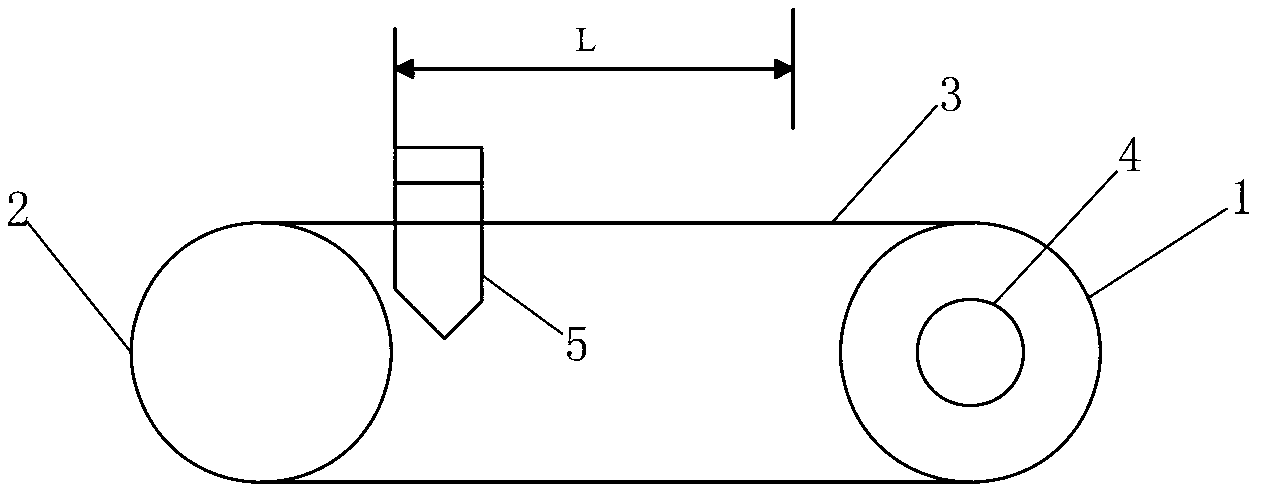

Photovoltaic panel cleaning device driven by wind power

PendingCN107774594AEfficient cleaningEffective brushingPhotovoltaicsMachines/enginesEngineeringWind force

The invention aims at providing a photovoltaic panel cleaning device driven by wind power with the advantages that the structure is simple; the manufacturing cost is low; the automatic cleaning is performed by natural wind power. The photovoltaic panel cleaning device driven by wind power comprises a wind power driving mechanism, a circulation rail mechanism, a sliding mechanism and a cleaning mechanism, wherein the sliding mechanism is matched with the circulation rail; the wind power driving mechanism drives the sliding mechanism to do reciprocating operation on the circulation rail; the sliding mechanism connects and drives the cleaning mechanism to do reciprocating operation so as to automatically clean the panel surface.

Owner:张德昌

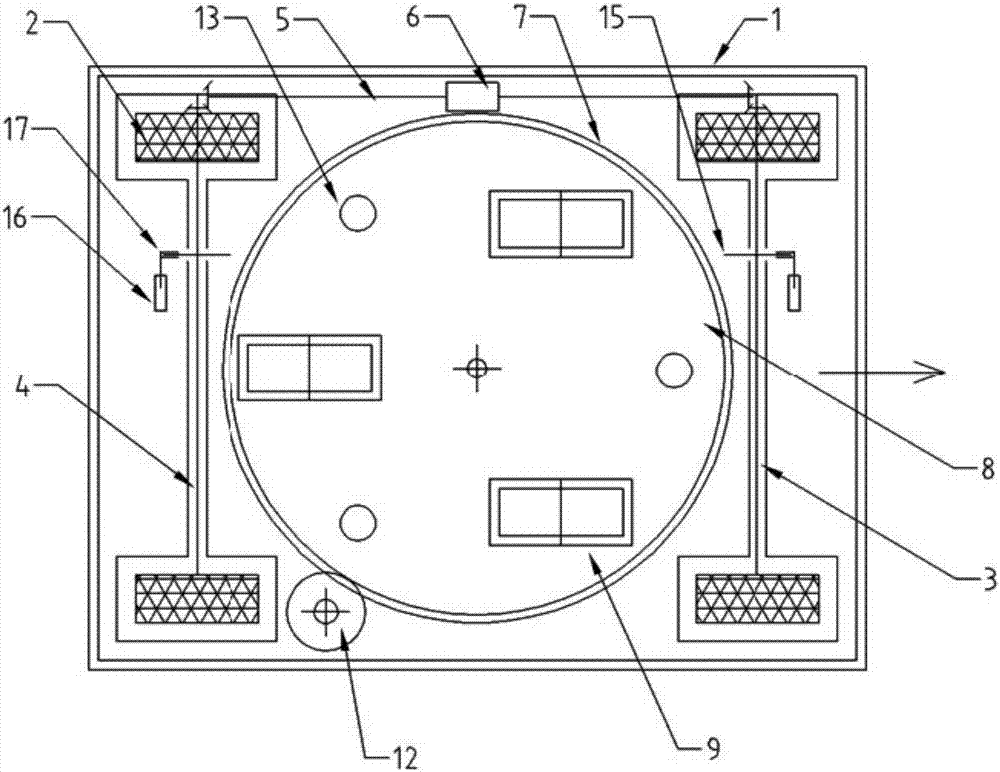

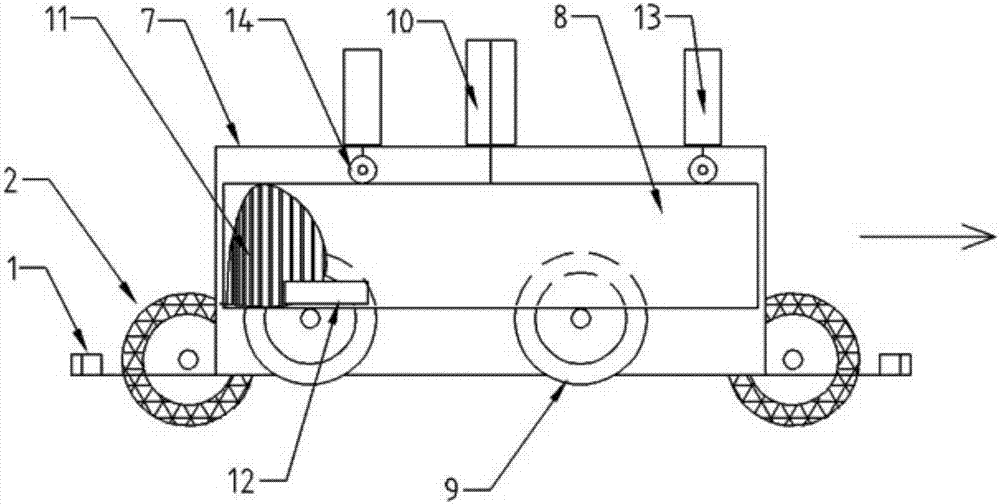

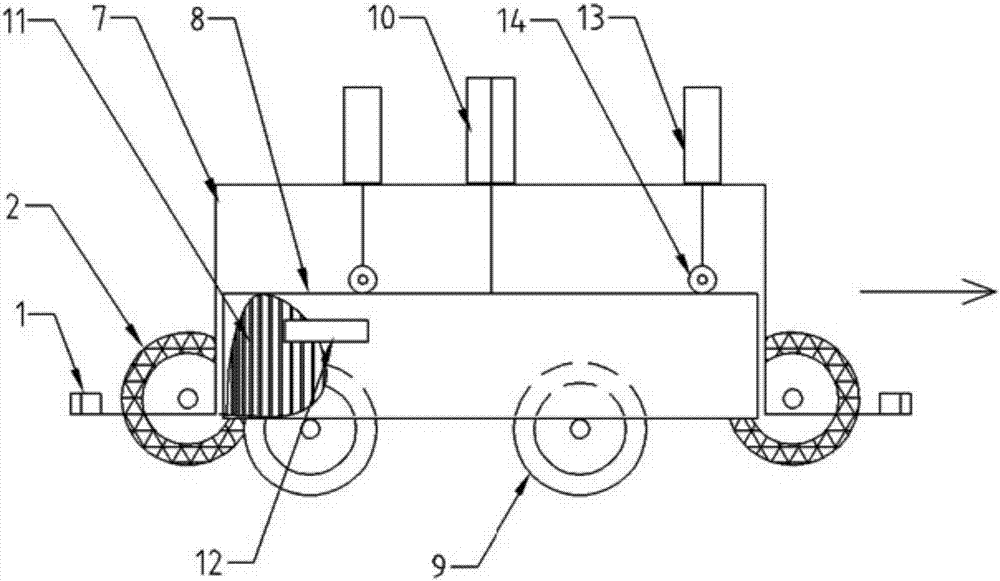

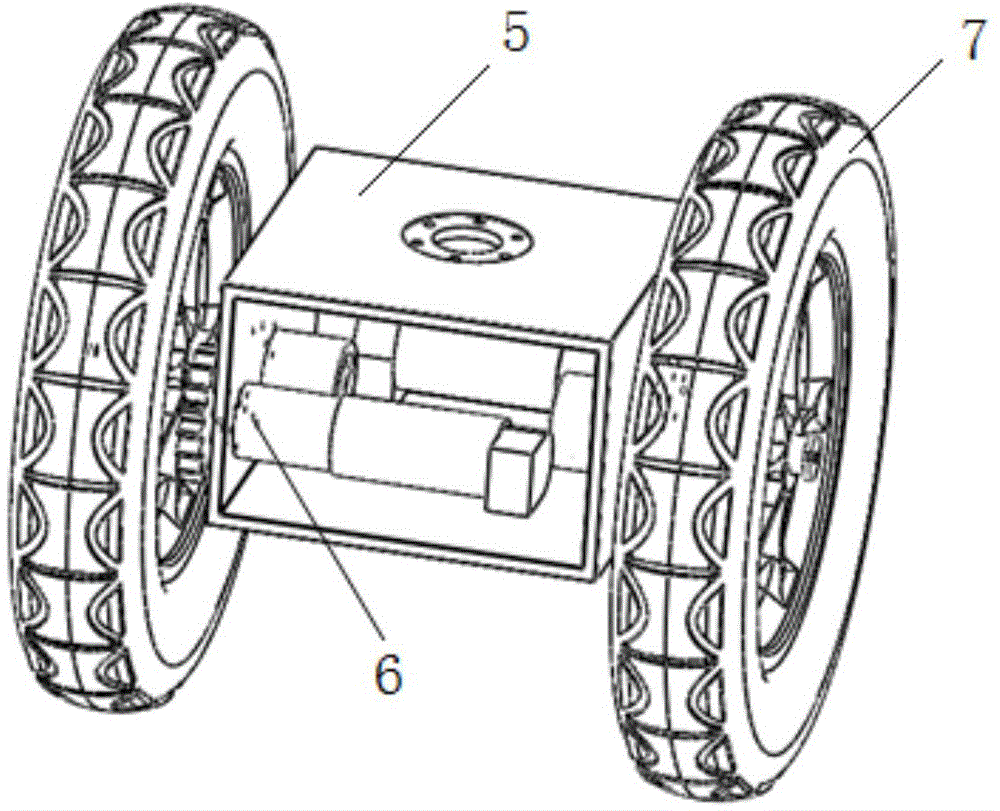

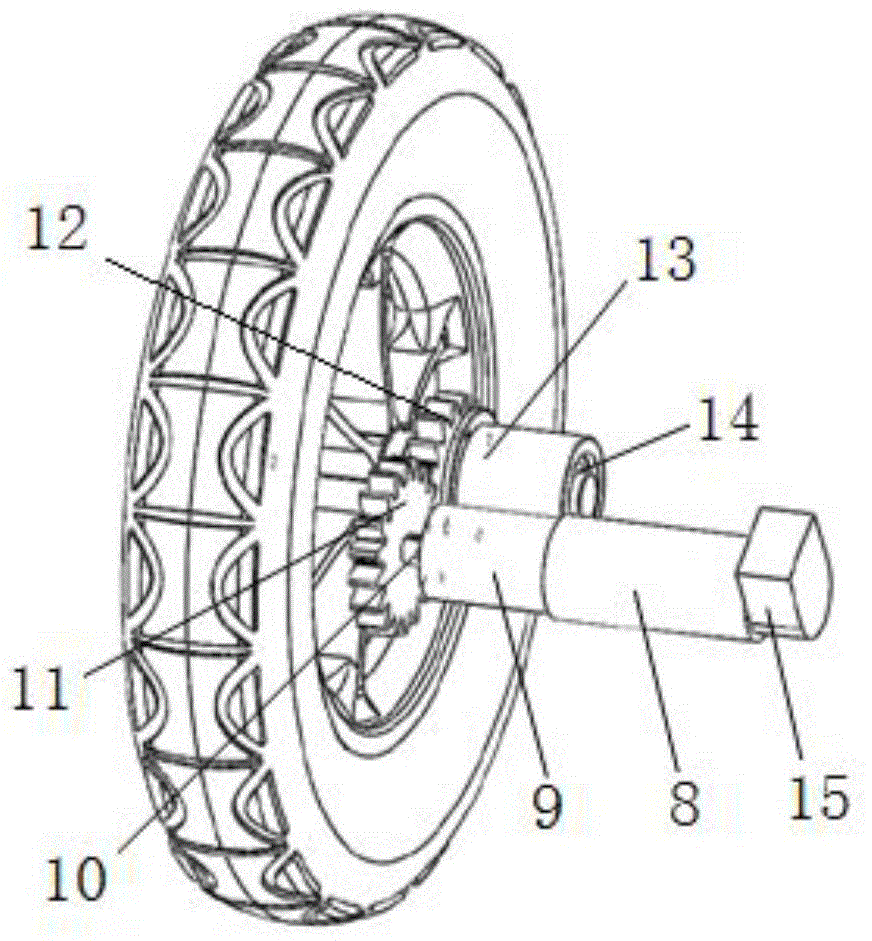

Travelling mechanism of mobile robot

ActiveCN107215407AGood load propertiesImprove overload capacitySteering linkagesVehiclesDrive wheelSteering wheel

The invention relates to a travelling mechanism of a mobile robot. The travelling mechanism comprises a chassis, a travelling system, a steering system and a control system; the travelling system comprises four drive wheels, a front main shaft and a back main shaft which are connected with the drive wheels, a coupling and a travelling drive motor; the steering system is a large upward and inward concave cylindrical hole which is formed in the center of the chassis, a balance steering wheel is arranged in the large cylindrical hole, and three driven wheels are arranged on the portion, away from the circle center, of the bottom face of the balance steering wheel respectively; according to the steering work mode of the travelling mechanism, driving wheels always work in a straight line driving mode with highest energy utilization, the driven wheels always work in a dangling or half-dangling steering mode, the driving wheels and the driven wheels work alternately in turn and work independently, and the structure is simple.

Owner:曹治

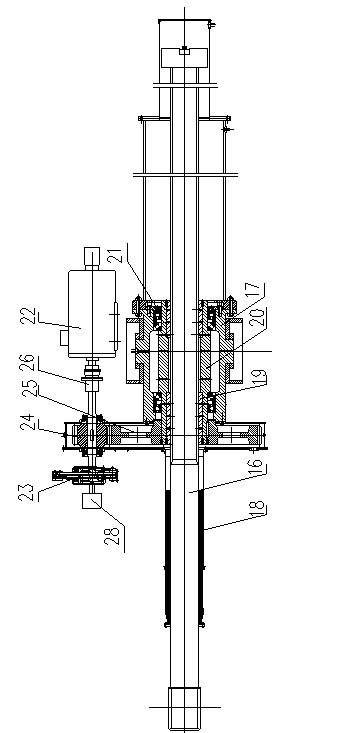

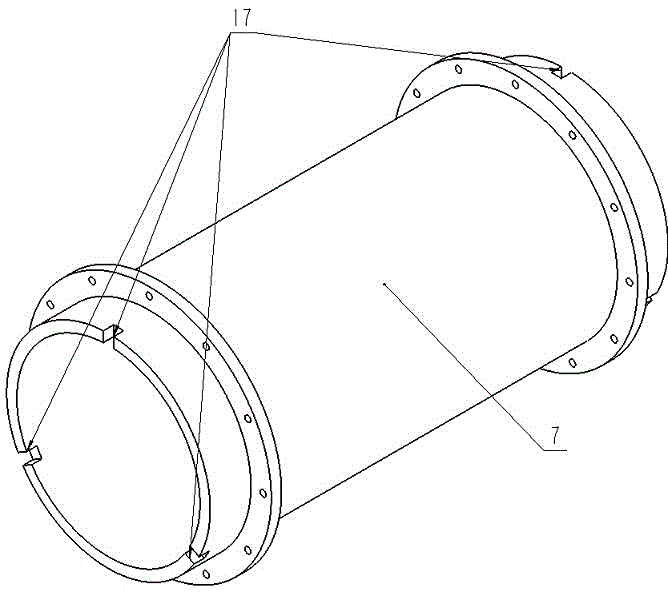

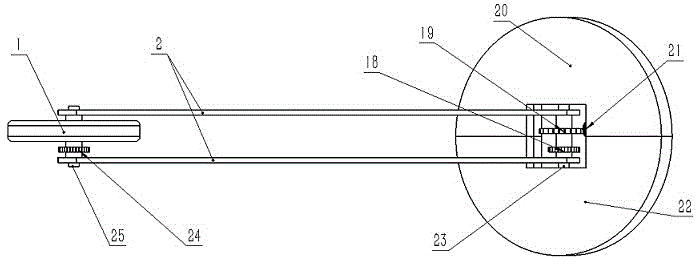

Pulling tool capable of generating power of pipeline detector

InactiveCN105587968AReduce battery qualityImprove passabilityMachines/enginesEngine componentsReduction driveElectric machine

The invention discloses a pulling tool capable of generating power of a pipeline detector, and the pulling tool is used for pulling the pipeline detector. The pulling tool consists of a supporting body, a power generating system and a speed regulating system, wherein the two ends of a framework are provided with leather cups to form the supporting body; a motor is sequentially connected to a speed reducer and a speed regulating valve so as to form the speed regulating system with a speed sensor and a control unit; a pressing wheel mechanism, a power generator gearbox and a power generator are sequentially connected so as to form the power generating system with a storage battery. The control unit, the power generator, the storage battery and the motor are sealed in a sealed cabin; and the sealed cabin is mounted in the framework. Under the action of a tension spring, a pressing wheel clings to a pipeline inner wall; when a fluid in a pipeline drives the pulling tool to move, the pressing wheel is driven to rotate, and the power generator is driven to generate powder after the speed of the pulling tool changes, and the electric energy is stored in the storage battery. Under the action of the speed regulating system, the whole detector is almost stable in operation speed, so that the detection data is more precise and reliable; and meanwhile, in the operation process of the detector, the power generating system is always in a power generating state, so that sufficient electric quantity is provided for the whole detector.

Owner:XIHUA UNIV

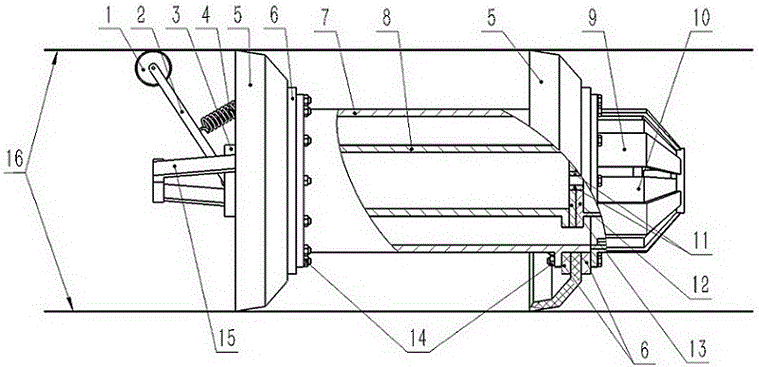

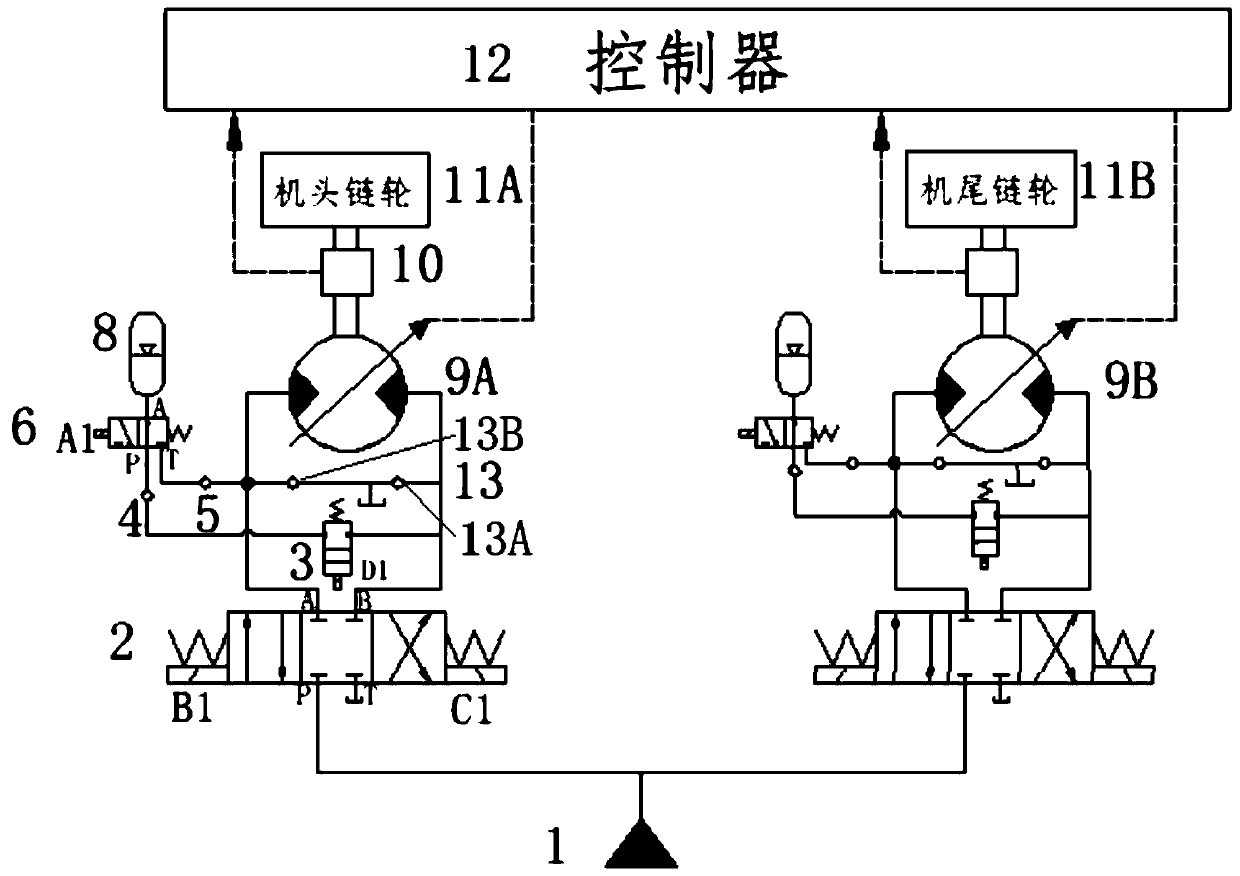

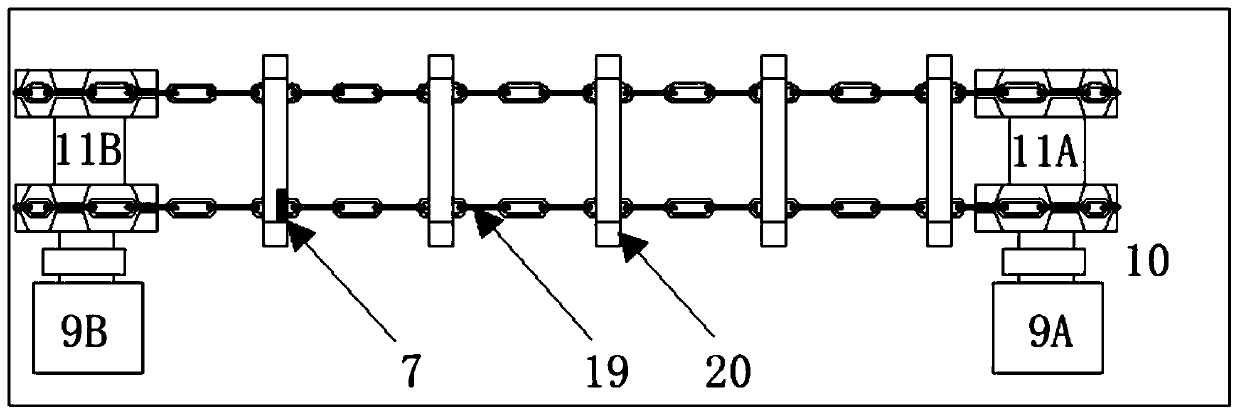

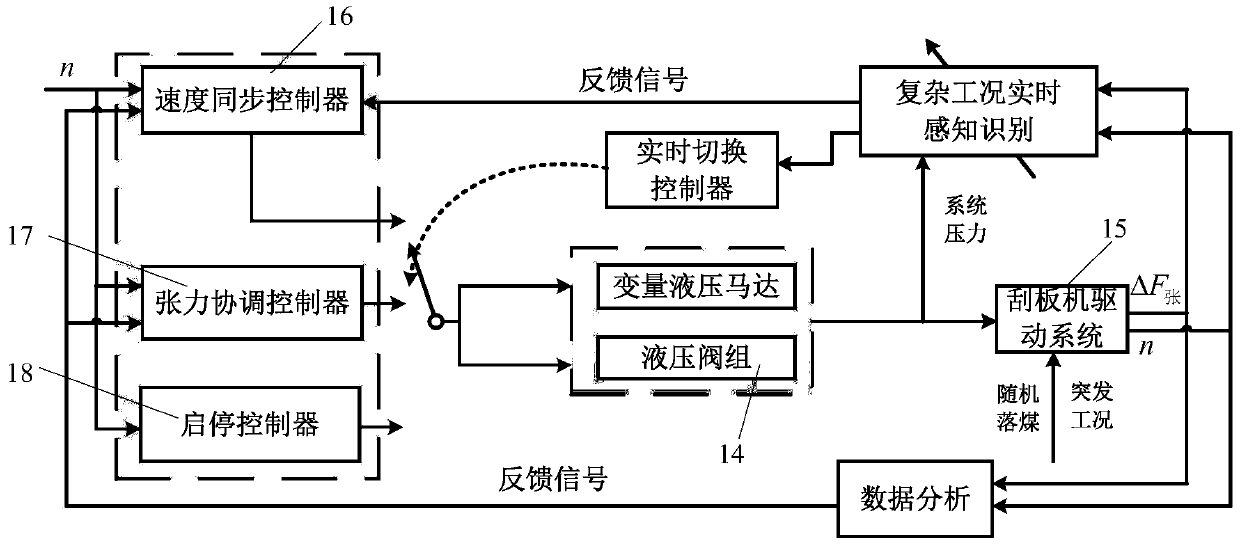

Driving system of scraper conveyor and control method

ActiveCN110817343AStart fastRunning speed is stableConveyorsServomotor componentsHydraulic motorSprocket

The invention discloses a driving system of a scraper conveyor and a control method. The driving system comprises a machine head chain wheel, a machine tail chain wheel, a machine head chain wheel driving mechanism and a machine tail chain wheel driving mechanism. The machine head chain wheel driving mechanism is a first hydraulic motor, and the machine tail chain wheel driving mechanism is a second hydraulic motor. A hydraulic system for driving the first hydraulic motor and a hydraulic system for driving the second hydraulic motor include identical hydraulic components and each comprise a three-position four-way electromagnetic directional valve, a two-position two-way electromagnetic directional valve, a two-position three-way electromagnetic directional valve, an energy accumulator andan oil supplementing valve group. The driving system is applicable to rapid starting and stopping of a scraper conveyor under the heavy-load condition, meanwhile, the chain tension can be adjusted inreal time, the problem of power unbalance in a dual-driving system is solved, and the driving system is simple in structure and long in service life.

Owner:CHINA UNIV OF MINING & TECH

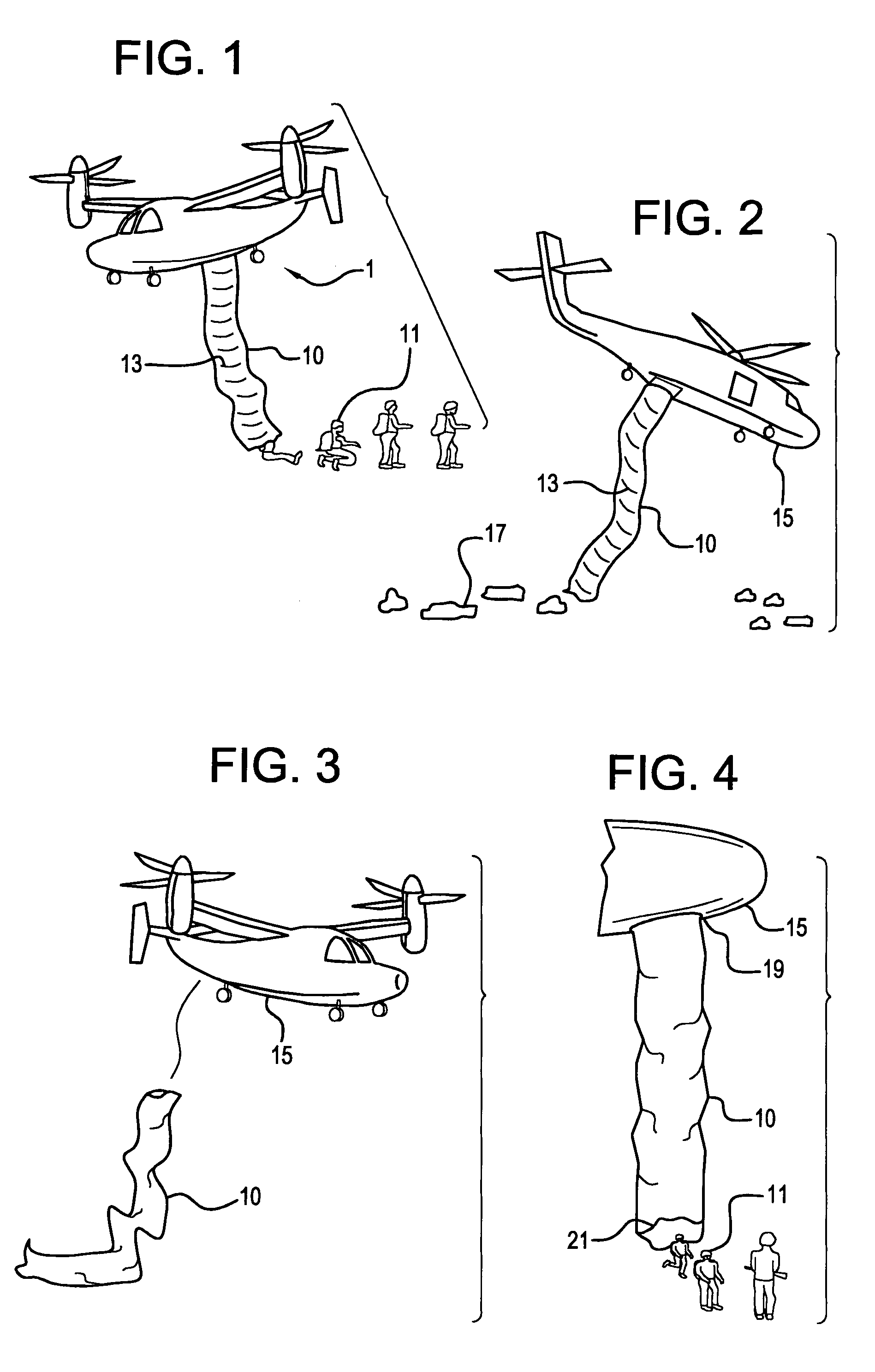

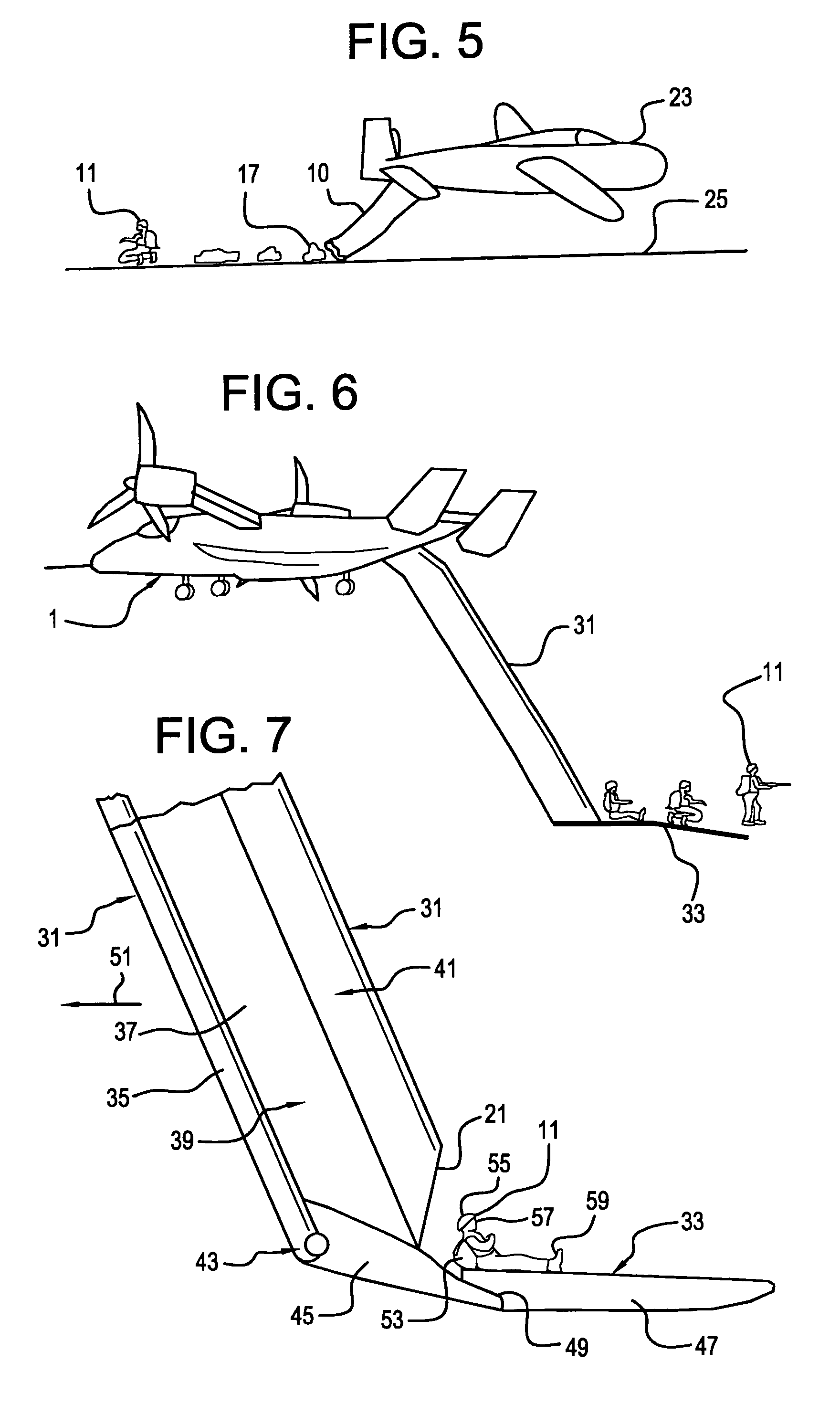

Rapid deployment of troops and cargo

InactiveUS7159823B1Rapid safe egressRunning speed is stableAircraft ejection meansBuilding rescueMultiple layerAirplane

A rapid deployment system has an inflatable landing tube with an inflatable exit slide coupled to an aircraft. Connectors couple the landing tube to the aircraft. Flexible retarders extend inward from the inner surface of the tube for retarding gravitational descent of cargo and / or personnel from the aircraft. The tube has tubular segments, with ribs and reinforcements, forming a continuous descent tube. A spine along the tube is retractable telescopically allowing for the tube to be retracted within the aircraft. The tube is connected to exterior edges of any exit port of the aircraft. A window coaming adapter is positioned around the exterior edges and a membrane extending between sides of the adapter expands with the landing tube as the landing tube is inflated. The membrane is of multiple layers with expansion cells between adjacent layers for allowing independent expansion of the layers. The entry port has a shield behind the membrane and connected to the aircraft for protecting the membrane. The shield has a couple of arms lying in a straight line when the landing tube is inactivated and separating and swinging outward from each other when the landing tube is activated. Another shield extends between edges of the exit port sandwiching the membrane between the two shields. An override lock on the one shield prevents that shield from opening automatically.

Owner:CERBERUS INST FOR RES & DEV

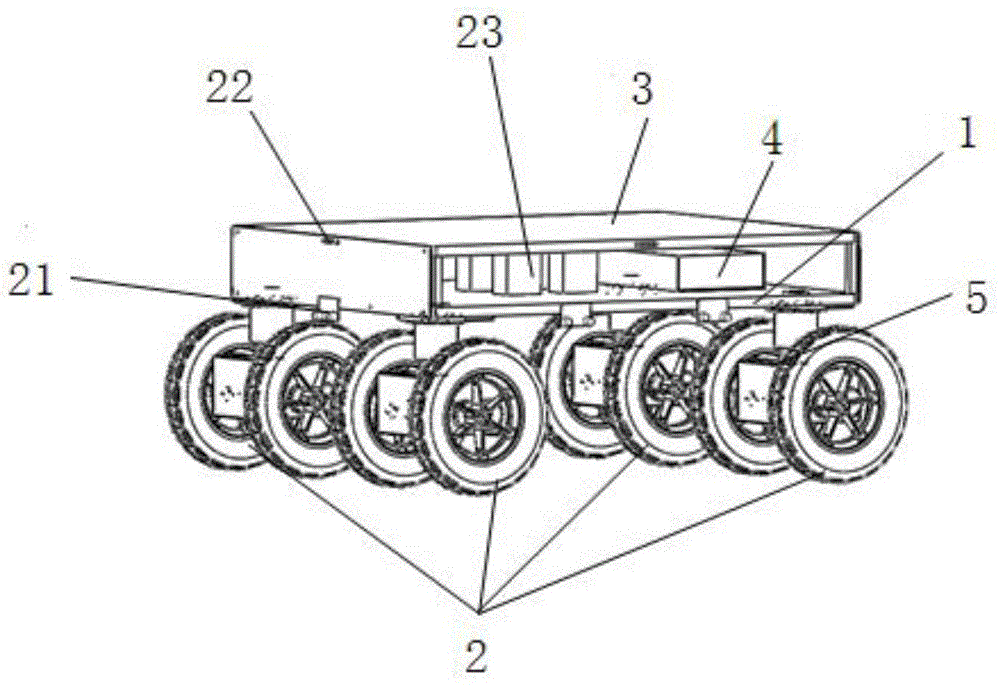

Transport cart with omnibearing movement function

InactiveCN104973123AEasy to controlImprove transport efficiencySteering linkagesUltrasonic sensorEmbedded controller

The invention discloses a transport cart with an omnibearing movement function. The transport cart with the omnibearing movement function comprises a cart body platform, dual differential driving units, a goods platform, a control cabinet, an acceleration sensor, a battery power set and a wireless communication module. An embedded controller and a servo motor driver are arranged in the control cabinet. The four dual differential driving units are movably connected with the cart body platform. Both the control cabinet and the battery power set are fixedly connected into the cart body platform. An ultrasonic sensor, the acceleration sensor and the wireless communication module are fixed to the cart body platform. Numerical values measured by the acceleration sensor are transmitted to the embedded controller through the wireless communication module, and the servo motor driver drives the dual differential driving units according to the control quantity worked out by the embedded controller so as to achieve omnibearing movement of the cart body platform. According to the transport cart with the omnibearing movement function, through the coordinated control of the four dual differential driving units, the control performance of the system is improved, and the moving speed of the cart body platform is made more stable.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

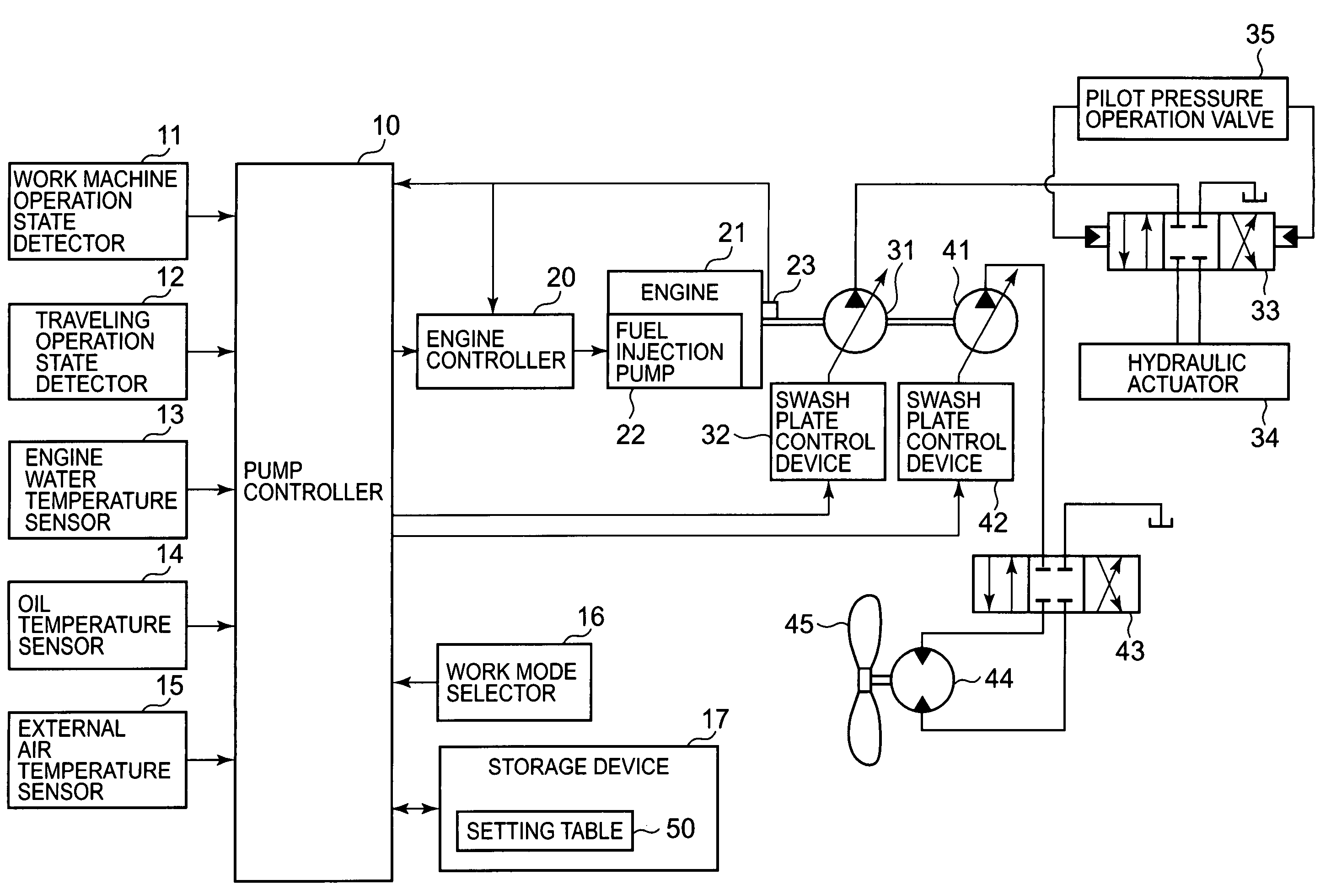

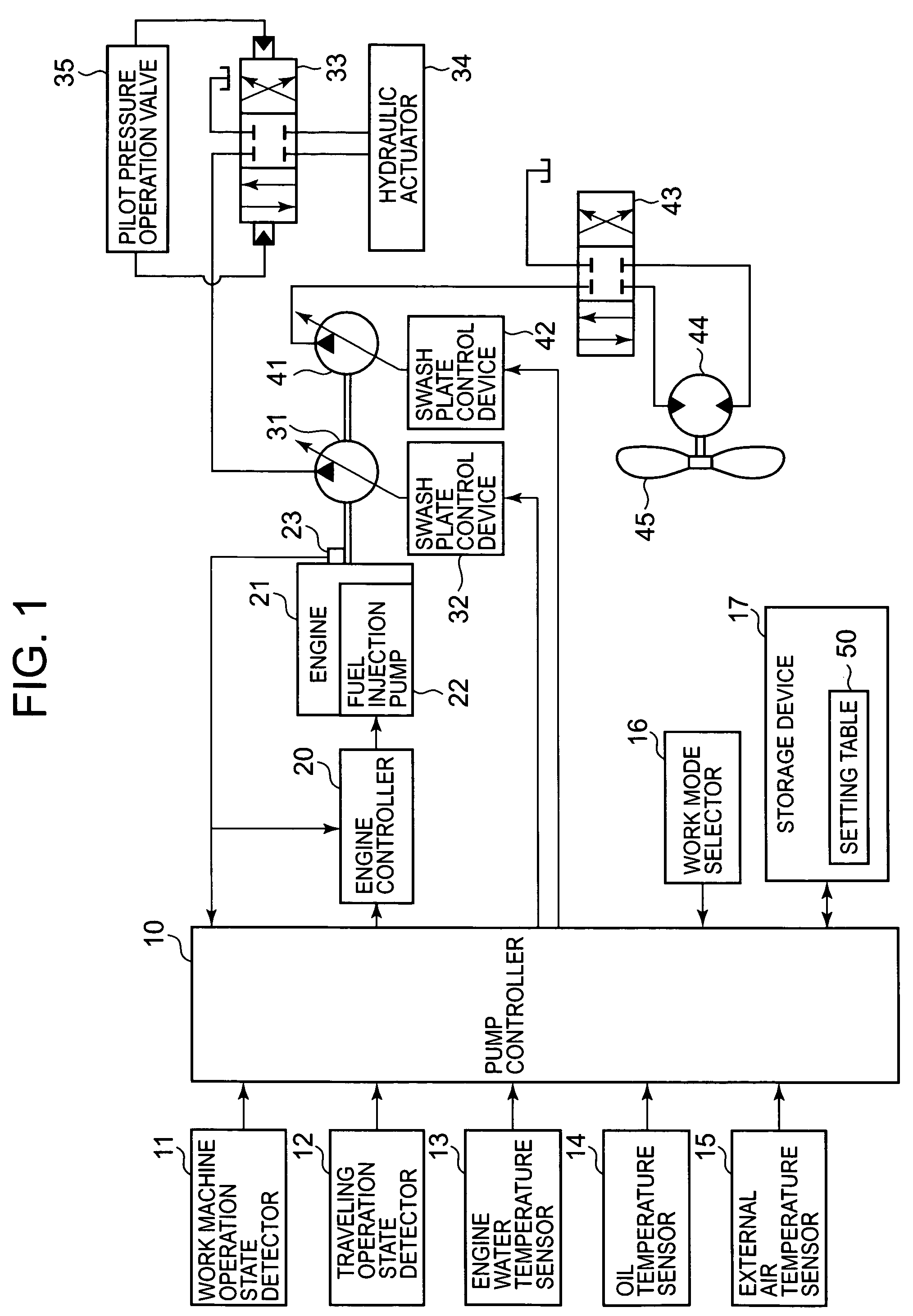

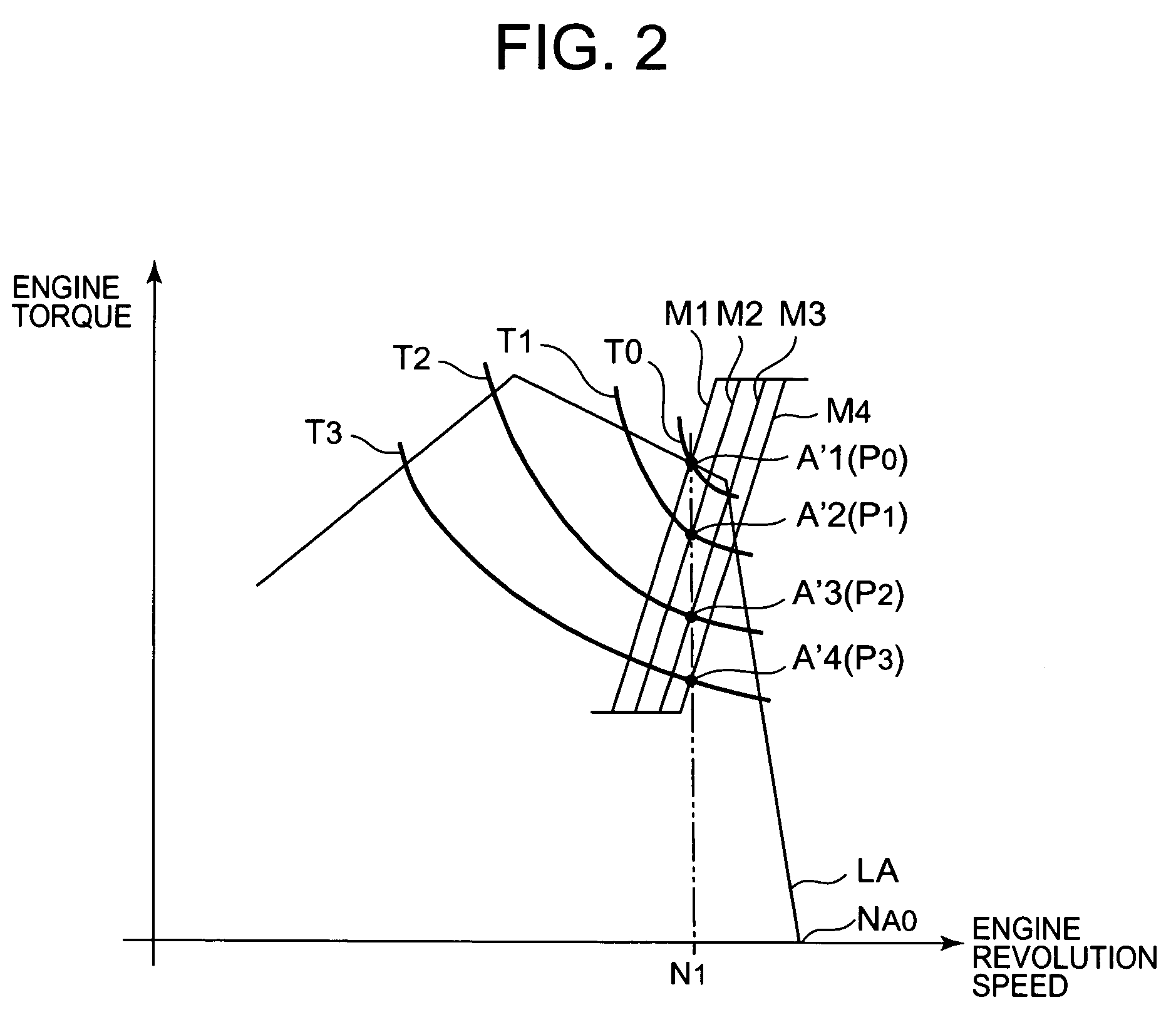

Device and method of controlling hydraulic drive of construction machinery

ActiveUS7607296B2Low maneuverabilityRunning speed is stableElectrical controlFluid couplingsControl theoryType selection

In construction machinery, control is conducted to keep a work machine to operate at a constant speed regardless of the operation thereof. Different engine output lines T0-T3 and pump torque lines M1-M4 are defined for different operation types. All the matching points of the engine output lines T0-T3 and pump torque lines M1-M4 designate a constant engine speed N1. One engine output line and one pump torque line are selected according to the operation type presently selected. An output horsepower of the engine is controlled on an equal horsepower line corresponding to a sum of a horsepower for an auxiliary machine and a horsepower at a matching point of the selected lines. The pump torque for the work machine is controlled on the selected pump torque line. The engine operates at a constant speed N1 even when the operation type varies or the horsepower for the auxiliary machine changes.

Owner:KOMATSU LTD

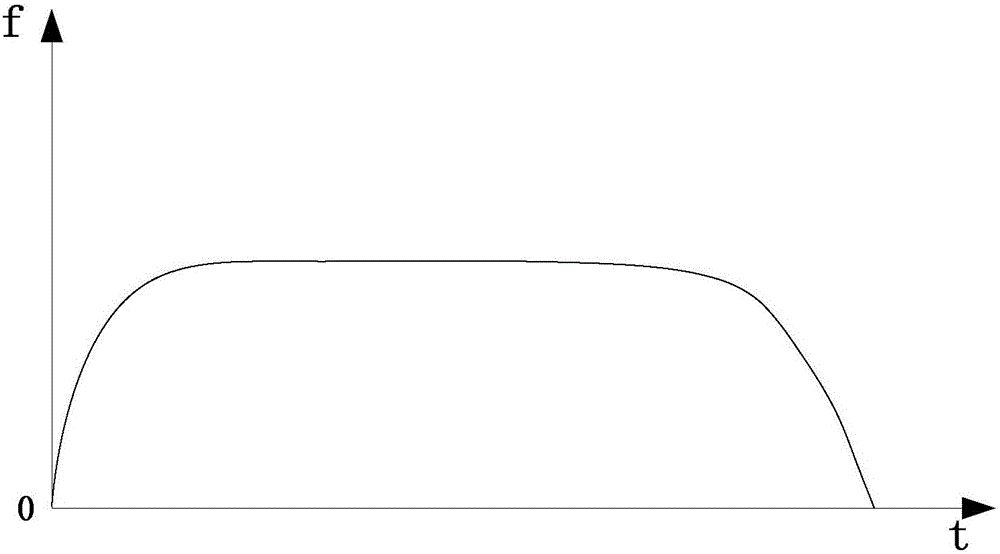

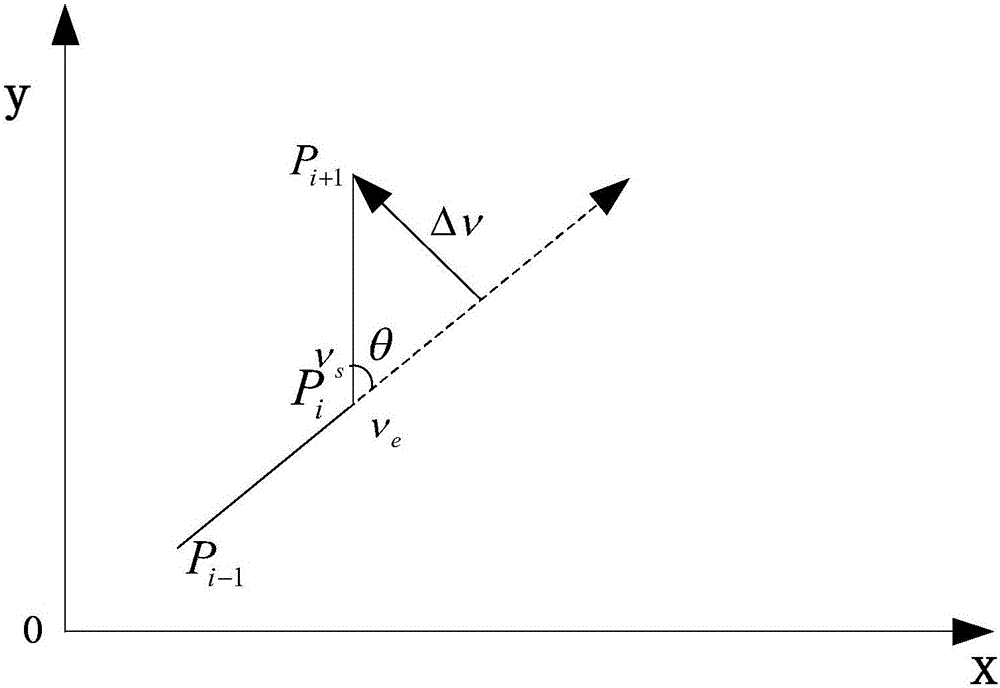

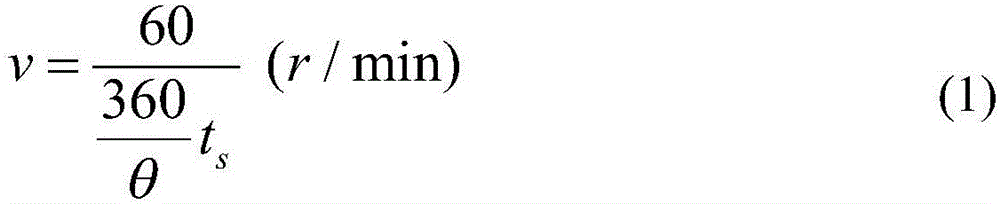

Automatic feeding speed control method based on template sewing machine controller

InactiveCN105717873AReduce volumeImprove real-time performanceNumerical controlElectric machineryControl theory

A automatic feeding speed control method based on a template sewing machine controller includes the following steps that 1, a speed chart (v1,...,vm) is established by combining with the best frequency raising law of a servo motor according to a S-shaped acceleration and deceleration control algorithm, and a ladder-shaped step length table (l1,..., lm) is established according to the speed chart and movement characteristics of the motor; 2, the maximum sudden-change speeds Delta argument x and Delta argument y allowable for the motor in the directions of two shafts are determined through debugging according to the mechanical structure of a mobile platform of the automatic template sewing machine and model of the servo motor; 3, the maximum speed of every turning point of a sewing track is calculated; 4, a regression method is adopted to recalculate and determine the speed of each coordinate point (shown in the description) according to the step length table, and finally speed control is achieved. The automatic feeding speed control method can effectively solve the problems of severe shaking, poor stability, low precision and the like occurred during high-speed movement of a feeding platform of the automatic template sewing machine.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

Method of designing semiconductor device, semiconductor device and recording medium

InactiveUS20060267096A1Running speed is stableTransistorSolid-state devicesCapacitanceDevice material

A semiconductor device including a transistor having an SOI structure the operating speed of which is not affected is provided. A MOS transistor having the SOI structure is formed which satisfies R·C·f<1 where C is a gate capacitance (F), R is a body resistance (Ω), f is a clock operating frequency (Hz), and f≧500 MHz.

Owner:RENESAS TECH CORP

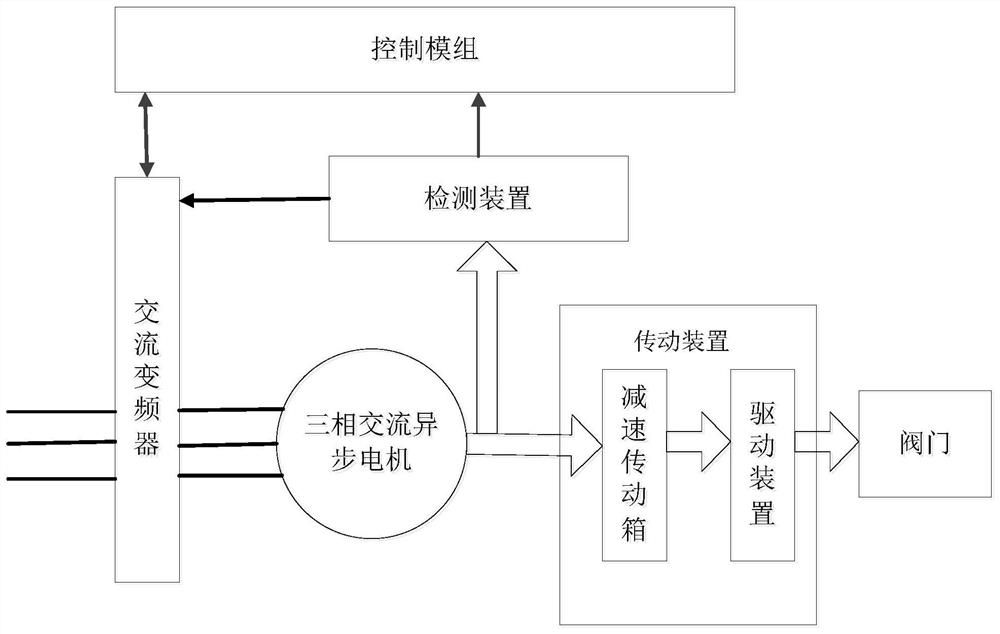

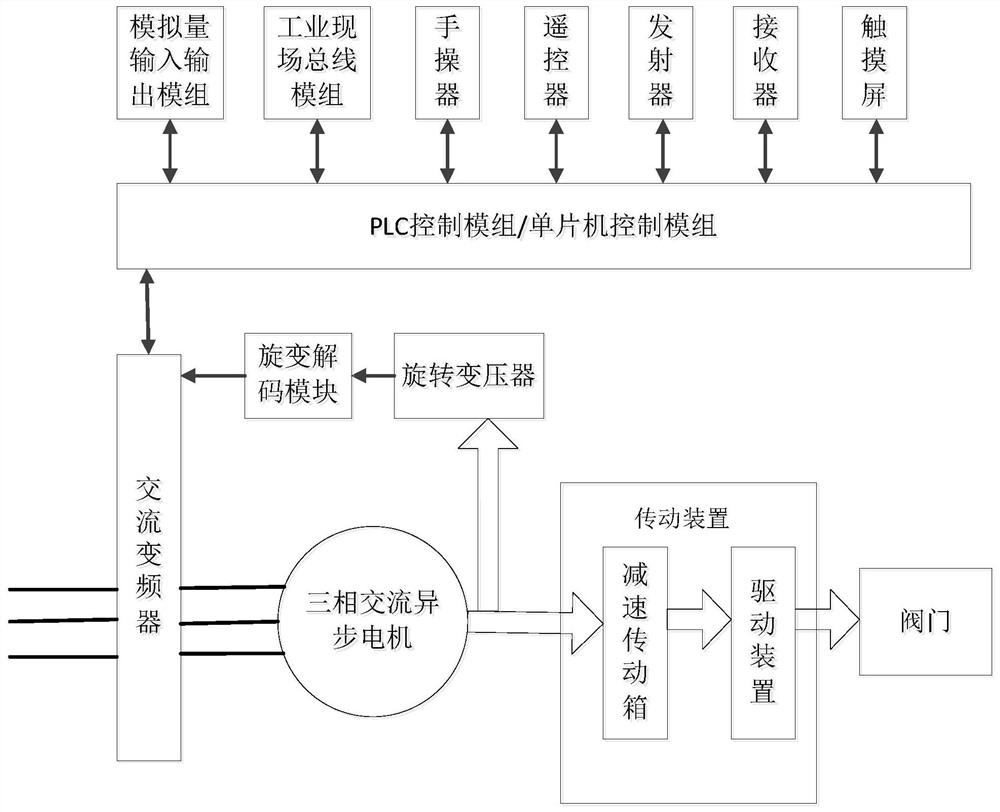

Valve actuator automatic control method

ActiveCN112113019ARunning speed is stableAvoid the problem of not being able to open after being closedOperating means/releasing devices for valvesValve members for absorbing fluid energyFrequency changerAutomatic control

The invention provides a valve actuator automatic control method which is applied to a valve actuator automatic control system. The control system comprises a control module; an alternating-current frequency converter connected with the control module; a three-phase alternating-current asynchronous motor connected with the alternating-current frequency converter; a transmission device connected with the three-phase alternating-current asynchronous motor; and a valve connected with the transmission device. The method comprises the steps that position and speed signals of the valve are obtained;the position and speed signals are treated to obtain a target signal; and opening / closing of the valve is controlled according to the target signal. Meanwhile, the embodiment of the valve actuator automatic control method has the characteristics that full-stroke continuous monitoring of the valve position can be realized by adopting a rotary transformer, and the position control precision is improved.

Owner:BEIJING RAYMOND CBE MECHANICAL & ELECTRIC TECH

Double-drive counterweight high-speed stacking machine

PendingCN106586903AHigh positioning accuracyHigh repeat positioning accuracyLifting devicesDrive wheelGear drive

The invention discloses a double-drive counterweight high-speed stacking machine, and aims to reduce energy consumption and facilitate mounting and maintenance of a counterweight. The double-drive counterweight high-speed stacking machine comprises a lifting system, the counterweight, a counterweight adjusting device, an upright post, linear guide rails, a sliding block, a lower cross beam, a cargo carrying table, a fork, an active travelling system and a driven travelling system, wherein the lifting system comprises a lifting gear motor, a synchronous belt, synchronous pulleys and a lifting bracket; the synchronous pulleys mesh with the synchronous belt; the linear guide rails are mounted on the two sides of the upright post; the active travelling system comprises a driving wheel box, a gear drive wheel train, travelling wheels and a travelling gear motor; the travelling wheels and the gear drive wheel train are mounted in the driving wheel box; the driven travelling system comprises a driven wheel box and driven wheels; the driven wheels are mounted in the driven wheel box; a lower cross beam hinge lug ring, an upright post mounting plate and a driven wheel box mounting plate are arranged on the lower cross beam; the counterweight adjusting device comprises a hinge pin, a fixed block and an adjusting bolt; the fixed block is mounted on the upright post of the stacking machine; and the hinge pin is connected with the fixed block and the counterweight.

Owner:TAIYUAN OTTLE LOGISTICS TECH CO LTD

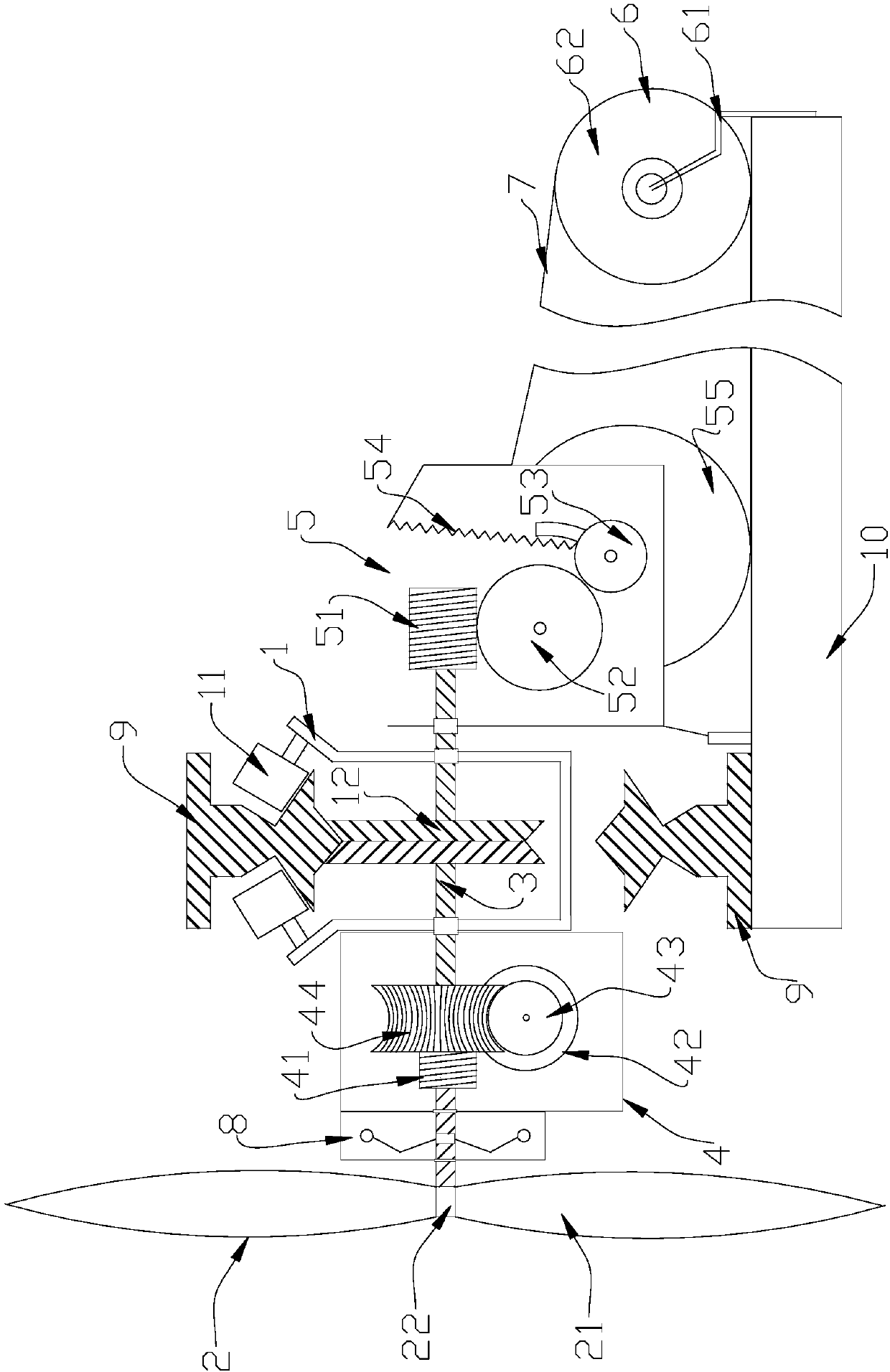

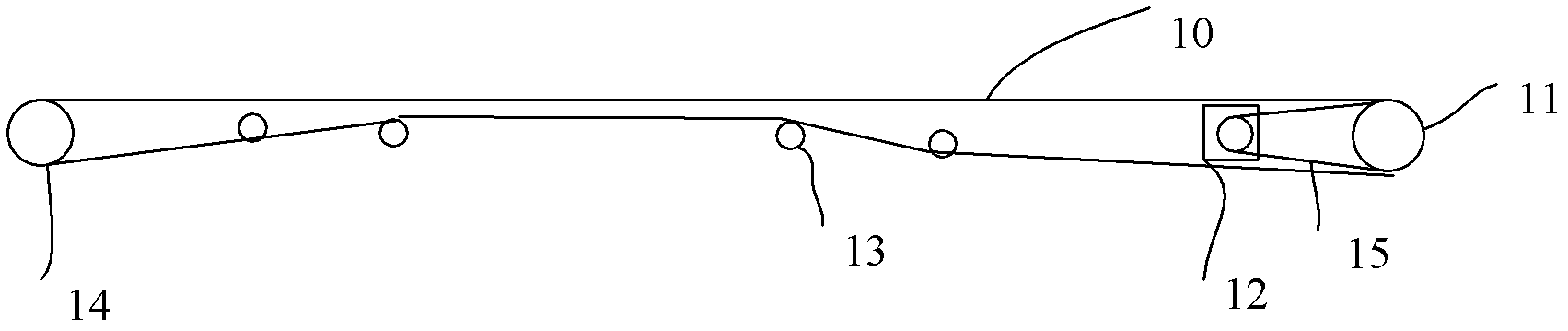

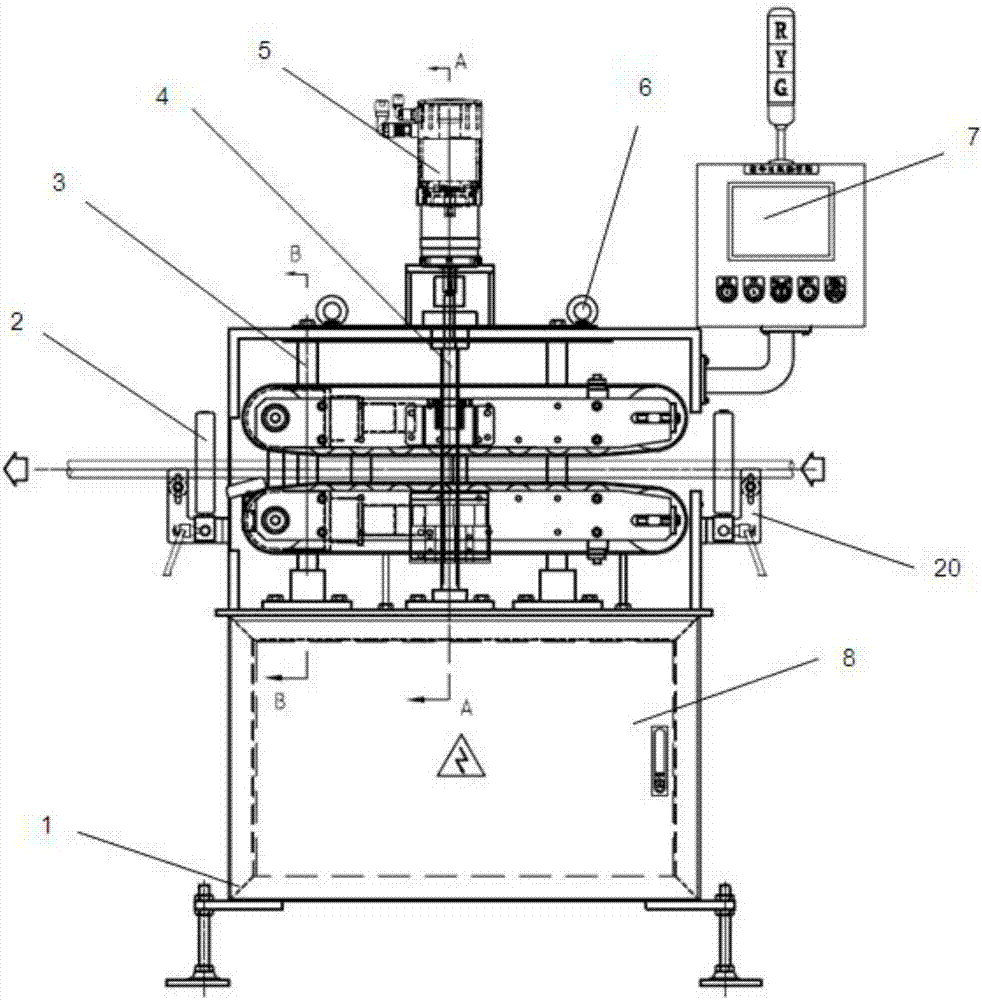

Double twister

InactiveCN101831735ADoes not affect running speedEasy to adjust winding densityTextiles and paperPolyesterYarn

The invention relates to a double twister, which is suitable for double twisting procedure of pure cotton and blended yarn of cotton, wool, polyester and the like in textile industry. The double twister comprises a double twisting mechanism, a traction mechanism, a transversal moving mechanism and a winding mechanism, wherein the double twisting mechanism comprises a spindle component (3), a nylon belt (12) and two nylon belt driving motors (1), wherein the transversal moving mechanism comprises a yarn guiding device (9), a transversal moving device and a transversal moving motor (5); the traction mechanism comprises a traction driving wheel (10), a traction rubber pressing wheel (11) and a traction motor (4); the traction driving wheel (10) and the traction rubber pressing wheel (11) form compression driving; the traction driving wheel (10) is connected with the traction motor (4); the winding mechanism comprises a winding driving wheel (8), a yarn winding barrel (7) and a winding motor (6); and the winding driving wheel (8) is connected with the winding motor (6). The traction driving wheel and the winding driving wheel are respectively driven by the independent motors, the traction motor and the winding motor are combined with electrical control to conveniently adjust the winding density, the yarn running speed is not affected, and the nonuniform twisting index is not affected.

Owner:江阴祥盛纺印机械制造有限公司

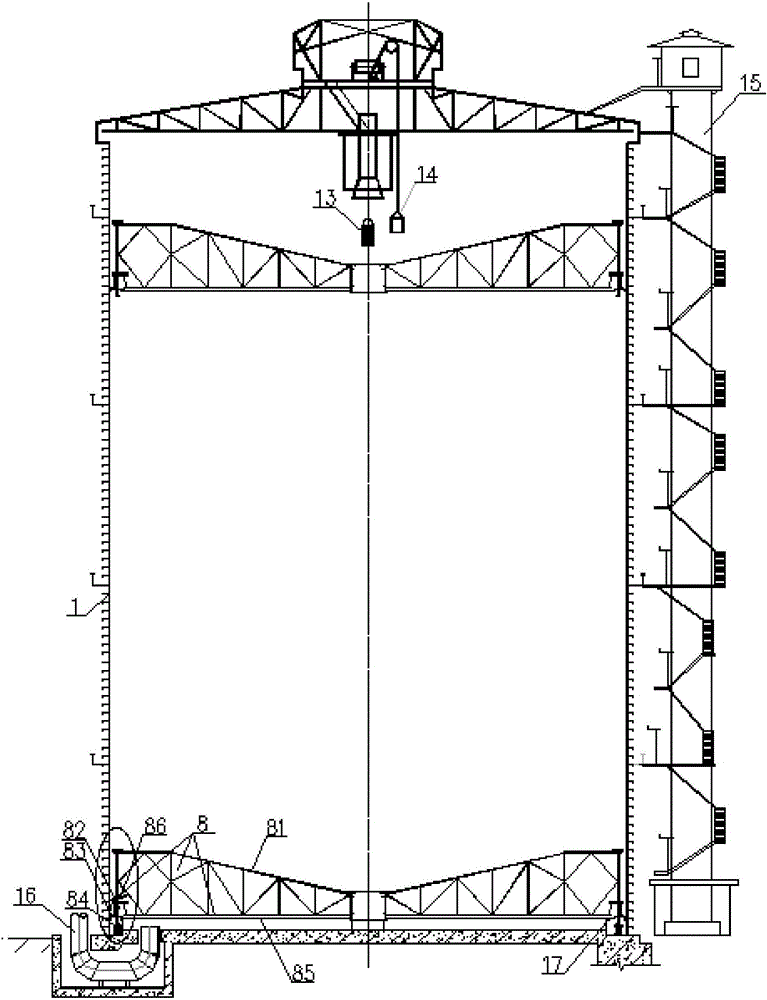

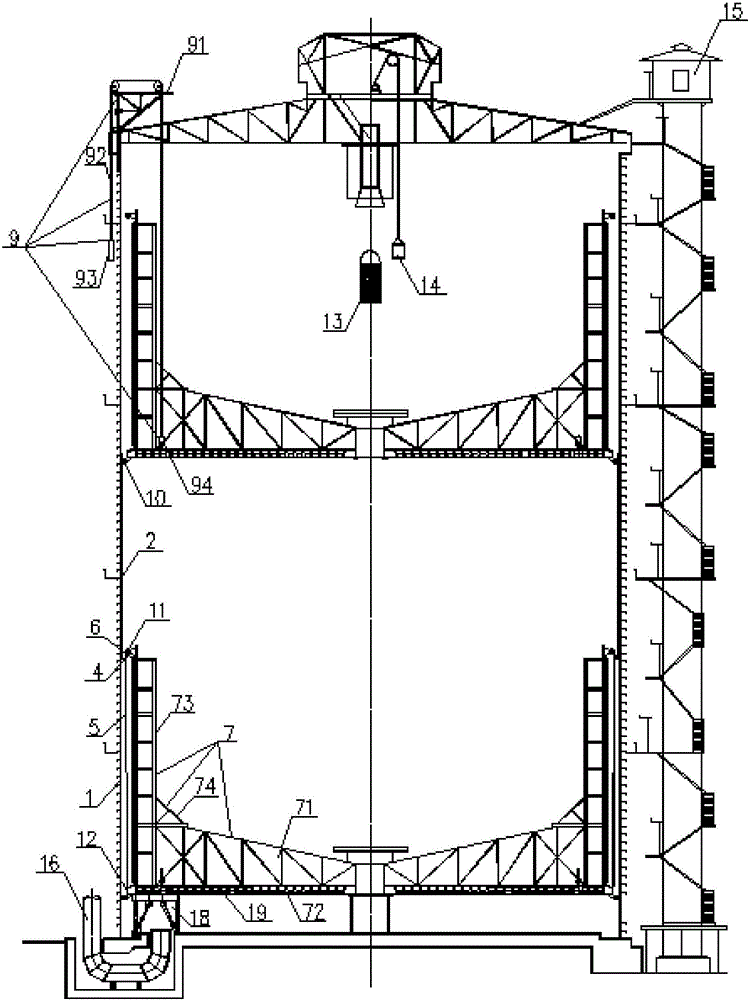

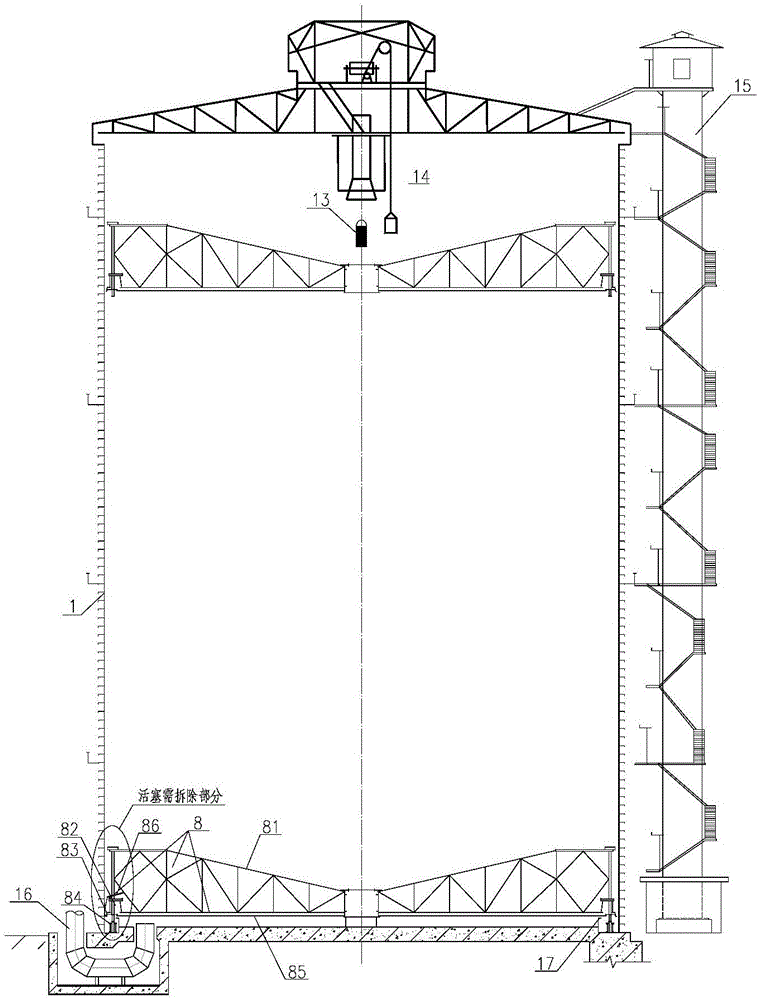

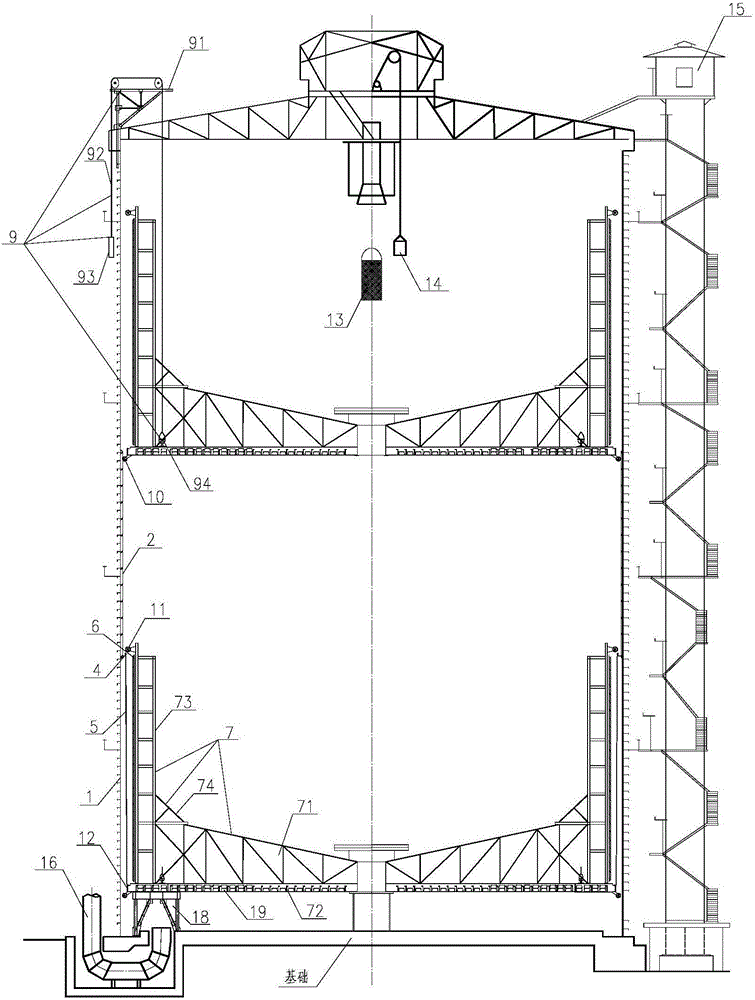

Transformation method of regular polygonal thin oil sealed gas cabinet

ActiveCN105927845ARun fastRunning speed is stableVariable capacity gas holdersRear quarterEconomic benefits

The invention discloses a transformation method of a regular polygonal thin oil sealed gas cabinet. The transformation method comprises the following steps: a piston oil groove support and a piston oil groove of the regular polygonal thin oil sealed gas cabinet are dismounted; an inner cylinder is mounted; brackets are mounted and connected to a side plate and a stand column of the gas cabinet; the connected brackets are connected with the inner cylinder; a truss of a piston and a piton baseplate are adjusted according to the shape of the inner cylinder, so that the shape of the piston is matched with the shape of the inner cylinder; a piston fence is arranged on the piston to form a one-section rubber film sealed gas cabinet piston; piston sealing profile steel is arranged at the bottom end of the piston fence; inner cylinder sealing profile steel is mounted on the inner cylinder in the peripheral direction; and a rubber film is unfolded, and two ends of the rubber film are respectively connected with the inner cylinder sealing profile steel and the piston sealing profile steel. The transformation method renewedly uses a cabinet body of the wasted polygonal thin oil sealed gas cabinet, and is low in construction investment, short in construction time and higher in economic benefit.

Owner:HUATIAN ENG & TECH CORP MCC

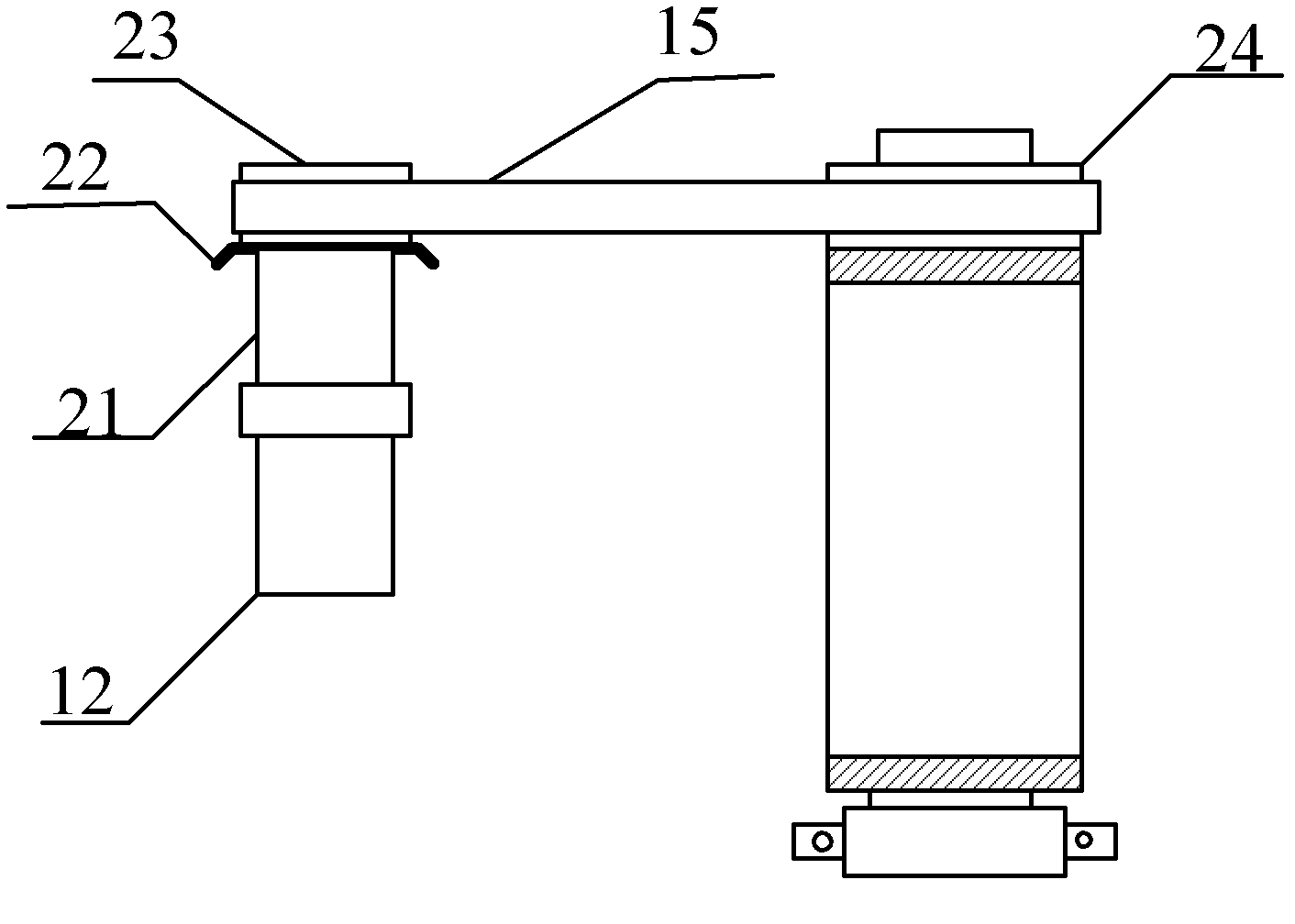

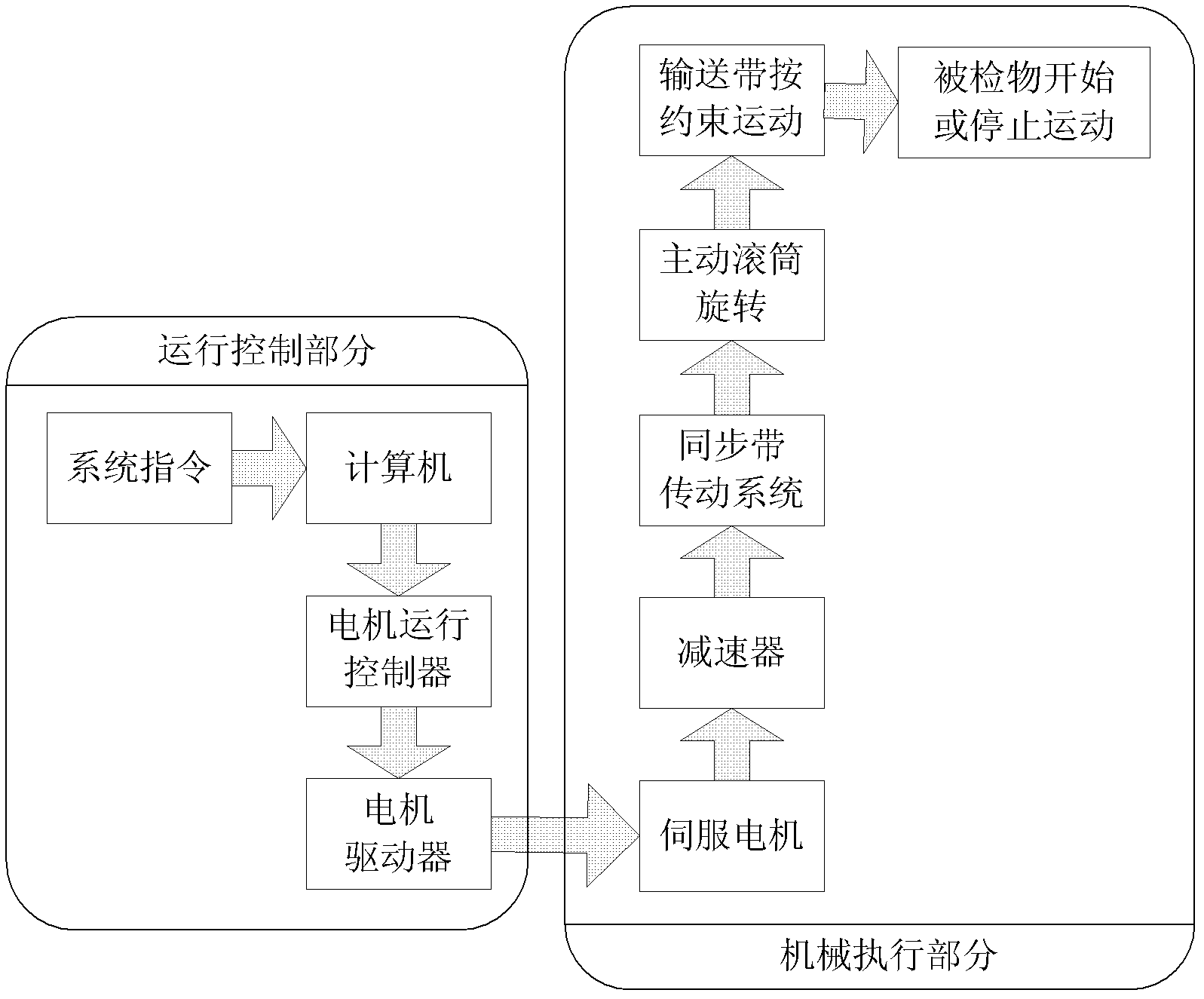

CT security inspection instrument delivery system

InactiveCN102426394AImprove imaging effectRunning speed is stableNuclear radiation detectionControl theoryDelivery system

The invention provides a CT security inspection instrument delivery system. The system comprises: a control computer, at least one servo motor, at least one power roller, a plurality of tensioning roller, at least one turnabout roller and a conveyer belt. The servo motor is connected with the control computer. Under control of the control computer, the servo motor is connected with the power roller through a synchronous belt. The conveyer belt respectively bypasses the power roller, then passes through the tensioning rollers located on two sides of the conveyer belt and then is redirected through the turnabout roller so as to form a delivery pathway. In the invention, stability is high and positioning precision is high too.

Owner:THE FIRST RES INST OF MIN OF PUBLIC SECURITY +1

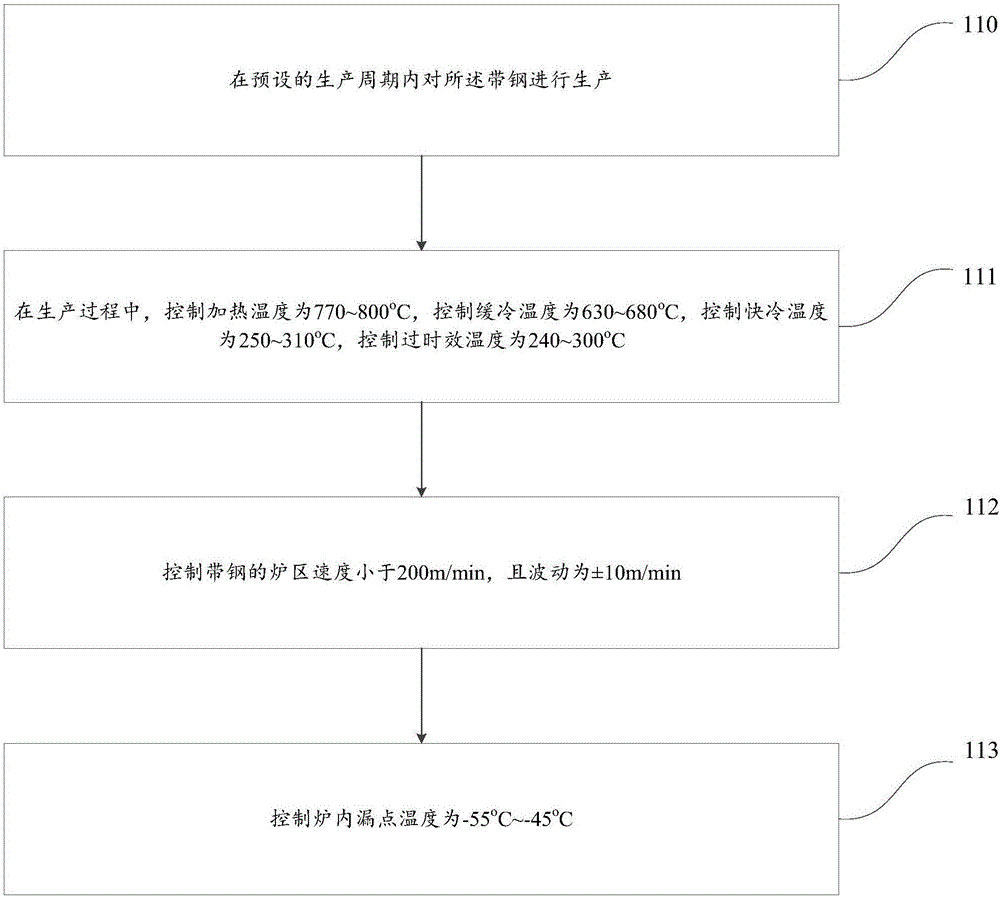

Method and device for removing steel strip oxidation tint

ActiveCN106636574ARunning speed is stableQuality improvementFurnace typesHeat treatment process controlProduction lineStrip steel

The invention provides a method and device for removing steel strip oxidation tint. The method comprises the steps of producing the steel strip in a preset production period; controlling heating temperature of 770-800 DEG C, slow cooling temperature of 630-680 DEG C, fast cooling temperature of 250-310 DEG C, and over-aging temperature of 240-300 DEG C in the production process; controlling the steel strip speed of less than 200 / min at a furnace area, with the deviation of + / -10m / min; controlling leakage temperature of -55 - -45 DEG C in the furnace; in this way, if the steel strip to be produced is high-strength steel, producing the high-strength steel 24-48h after starting the steel strip production line so as to effectively avoid the oxidation tint of the contact part between the steel strip and furnace rollers; controlling the steel strip running speed at the furnace area and the fast cooling temperature of <=320 DEG C in the production process, and preventing atmosphere in the furnace from being oxidized through controlling the leakage temperature in the furnace, so that the problem of the oxidation tint occurred on the surface of the steel strip is solved basically, and the quality and grade of the steel strip are improved so as to avoid economic loss.

Owner:BEIJING SHOUGANG COLD ROLLED SHEET

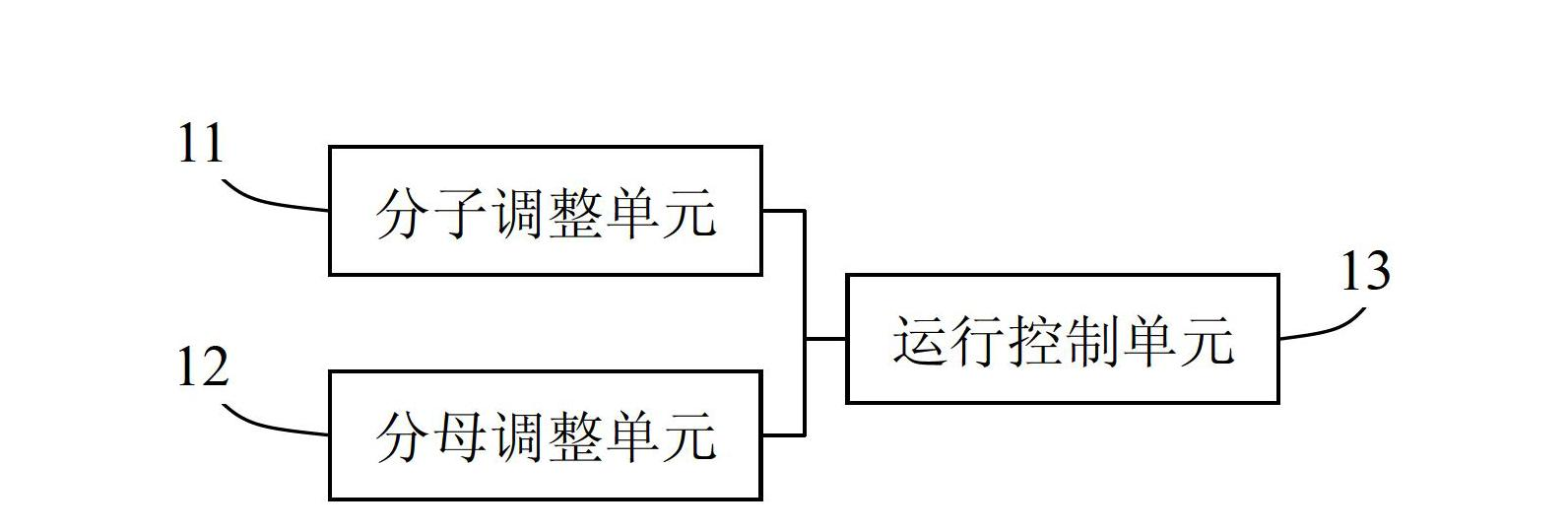

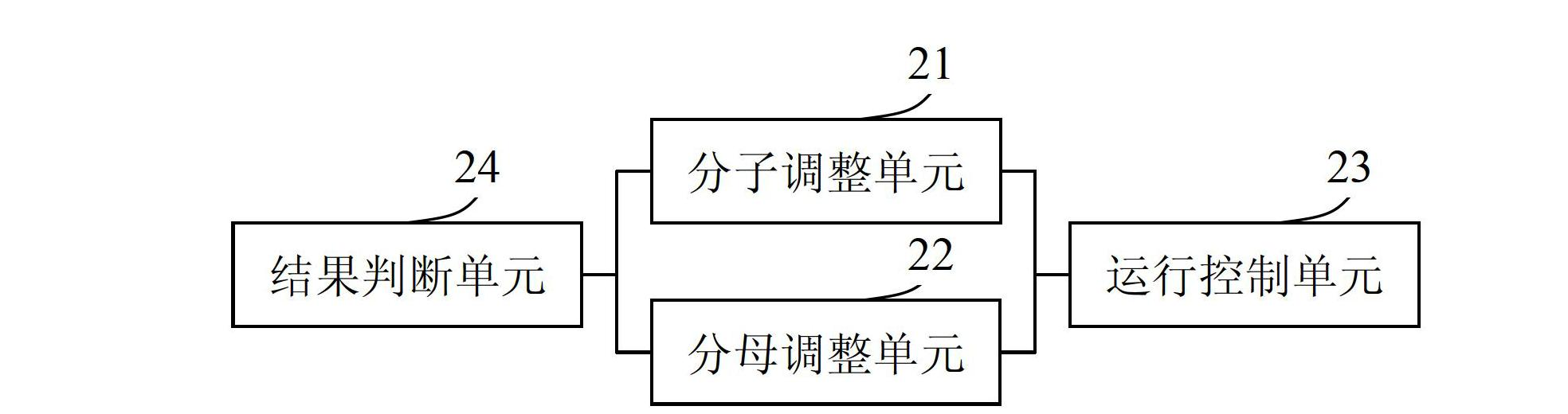

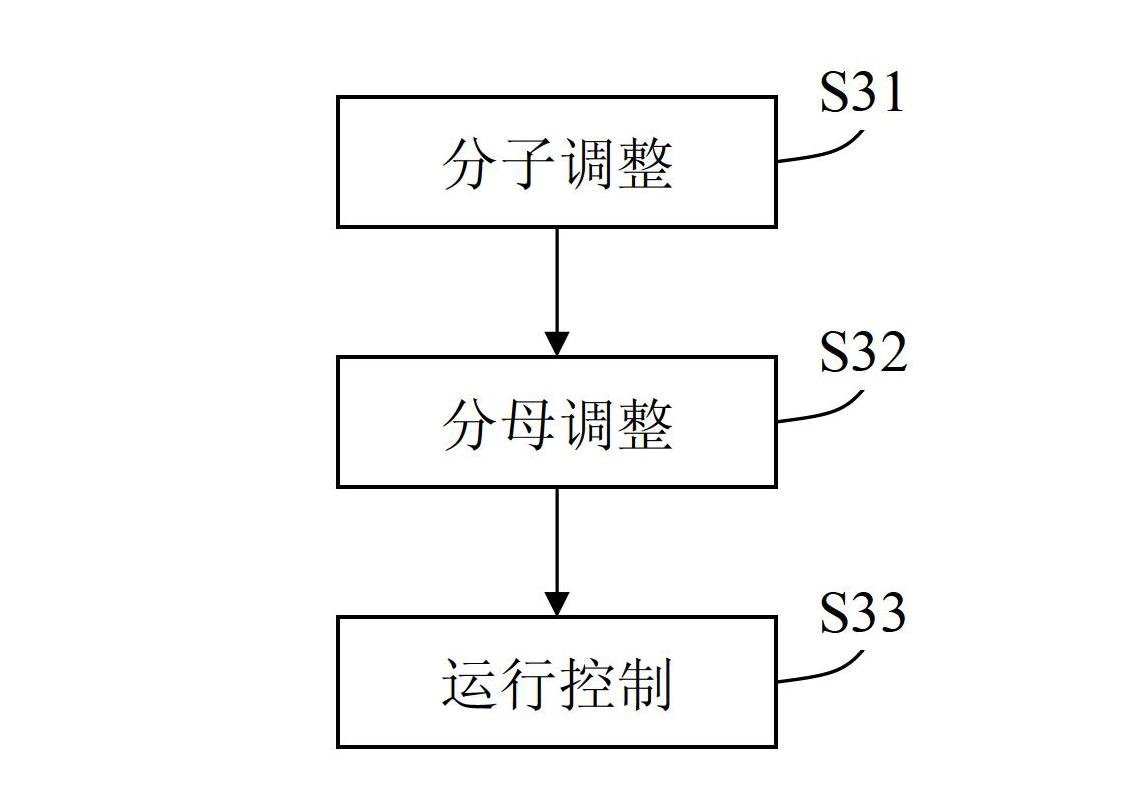

Electronic gear proportion smooth switching system and method

ActiveCN102664483ARunning speed is stableWill not falsely report the fault of excessive follow-up deviationMechanical energy handlingElectric machineControl theory

The invention provides an electronic gear proportion smooth switching system, which is used for controlling a servo motor to realize smooth switching from an initial electronic gear proportion to a target electronic gear proportion. The electronic gear proportion smooth switching system comprises a numerator adjusting unit, a denominator adjusting unit and an operation control unit, wherein the numerator adjusting unit is used for adjusting the numerator of the initial electronic gear proportion to the numerator of the target electronic gear proportion by one unit; the denominator adjusting unit is used for adjusting the denominator of the initial electronic gear proportion to the denominator of the target electronic gear proportion by one unit; the operation control unit is used for running the servo motor by using the adjusted initial electronic gear proportion; and the numerator adjusting unit, the denominator adjusting unit and the operation control unit are executed once at every scheduling period. The invention further provides a corresponding method. The numerators and denominators of the electronic gear proportions are gradually adjusted respectively, so that the motor running speed can be smoothened effectively, and excessive following deviation failures are not misreported.

Owner:SUZHOU INOVANCE TECH CO LTD +1

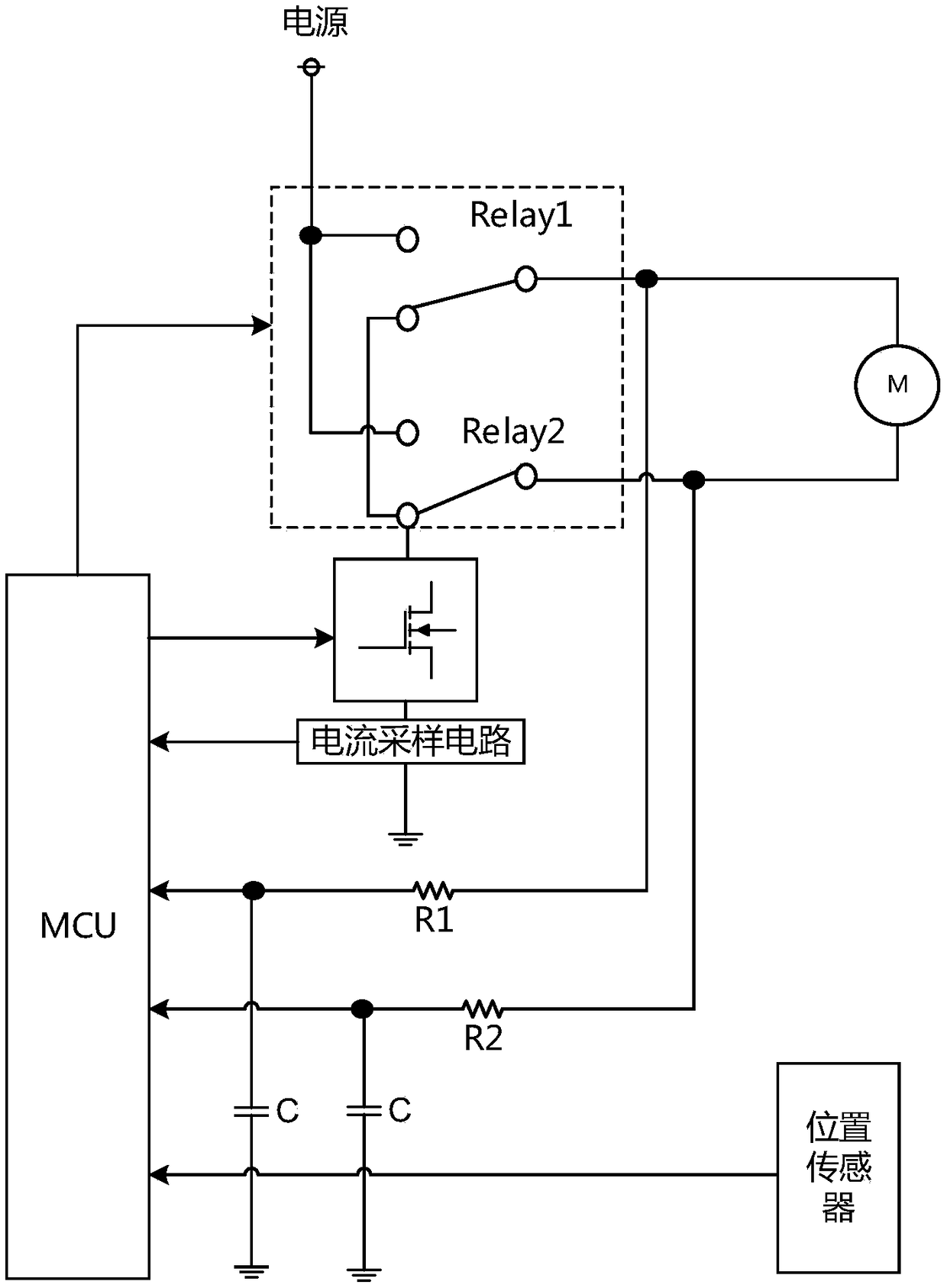

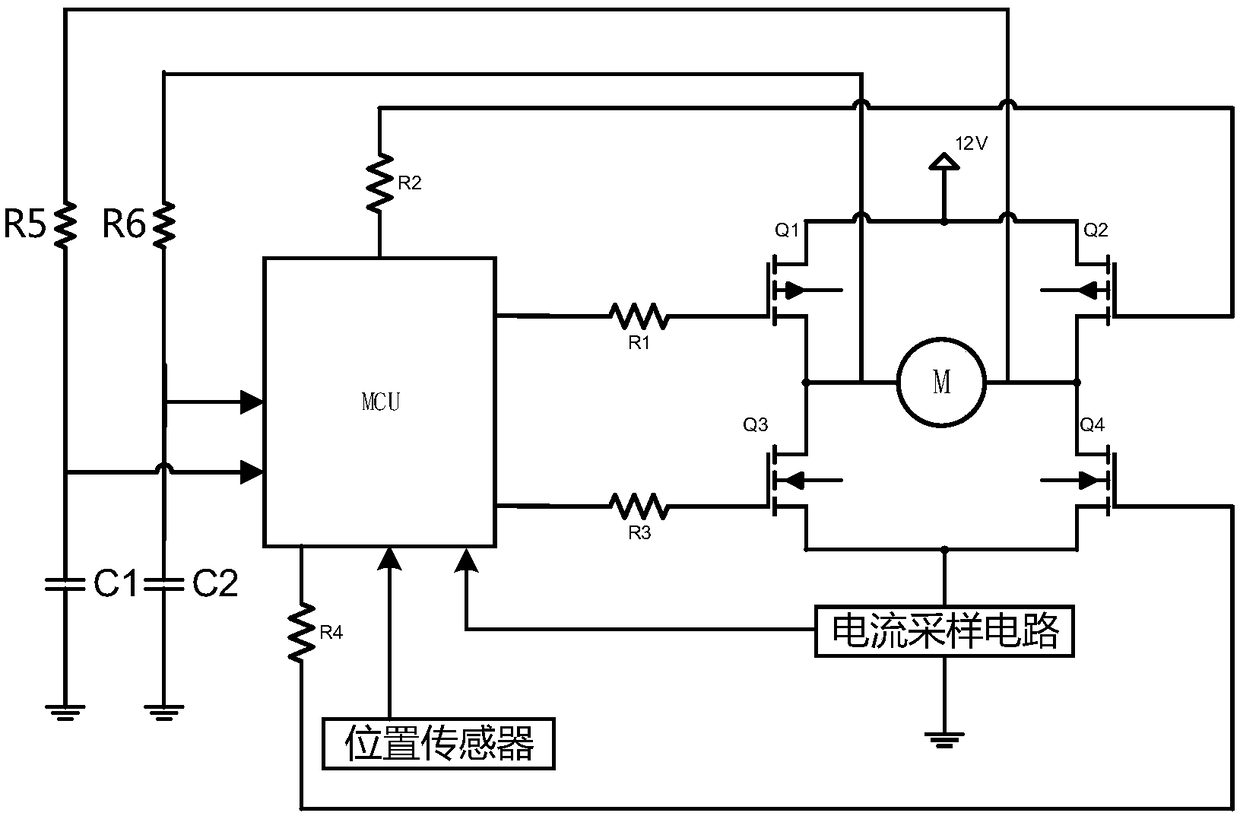

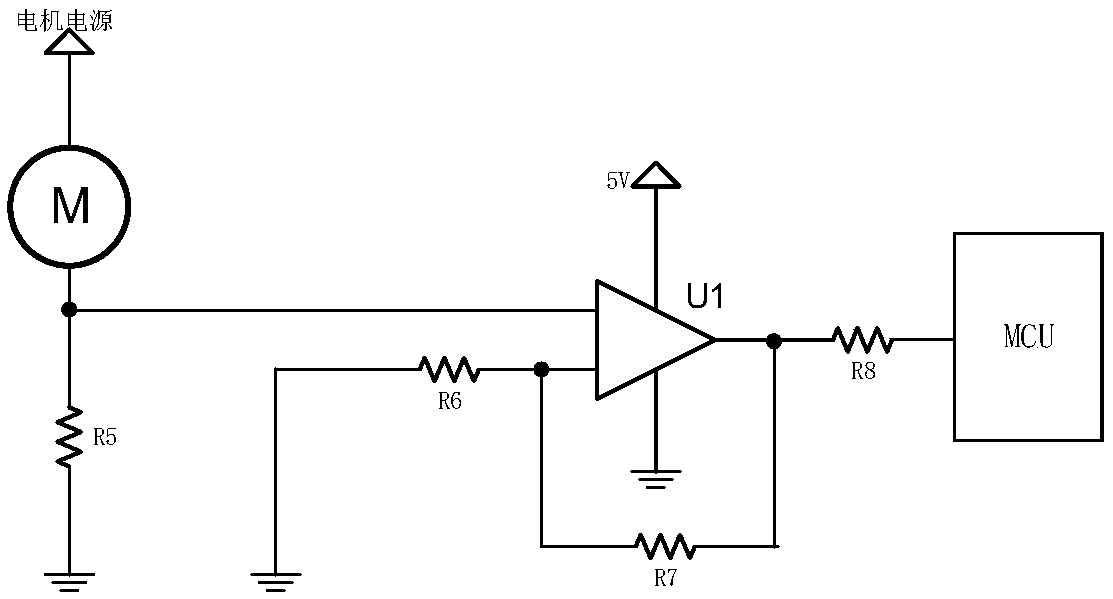

Car window speed control circuit and method

ActiveCN108798351AThe average voltage does not changeRunning speed is stablePower-operated mechanismMOSFETMotor drive

The invention discloses a car window speed control circuit and method. The car window speed control circuit comprises an MCU, a car window motor driving circuit, a car window motor rotating speed adjusting circuit and a position sensor; the MCU is used for pre-writing the target speed of the operation of a motor, the MCU calculates the actual speed of the operation of the motor according to the square waves generated by the position signals in the operation process of the car window, the speed of the motor is automatically adjusted by adopting the PID control, namely, when the actual speed ofthe motor is smaller than the target speed of the motor, the MCU increases the duty ratio output of the MOSFET to increase the average voltage at the two ends of the motor to increase the rotating speed of the motor, and when the actual speed of the motor is larger than the target speed of the motor, the MCU increases the duty ratio output of the MOSFET so as to reduce the average voltage at the two ends of the motor and reduce the rotating speed of the motor. According to the car window speed control circuit and method, the running speed of the car window in the whole stroke can be kept stable, the running speed of the car window cannot be slowed due to the change of the load of the car window, and the operation comfort of the car window is improved.

Owner:CHONGQING HI LEX CABLE SYST GRP CO LTD

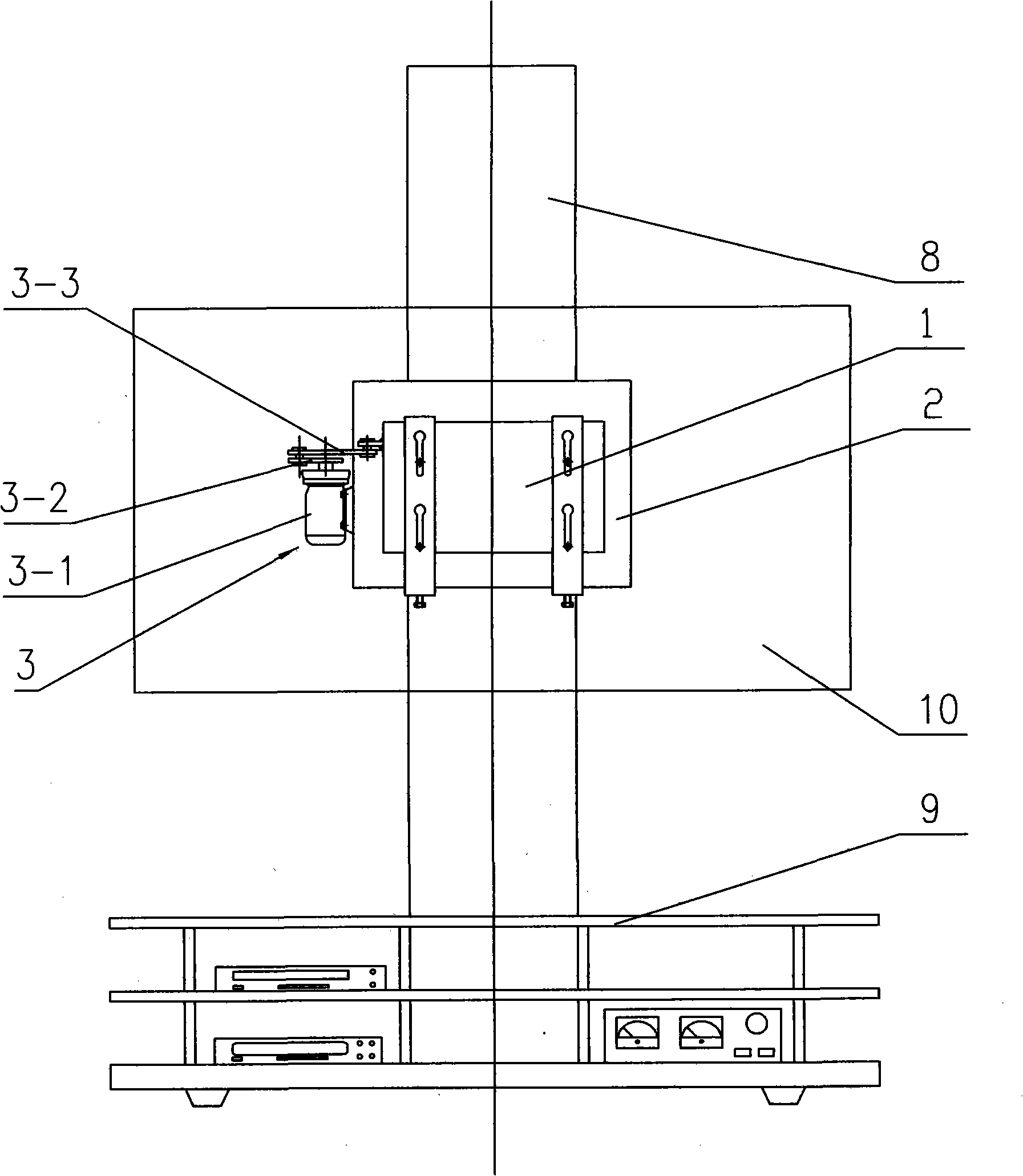

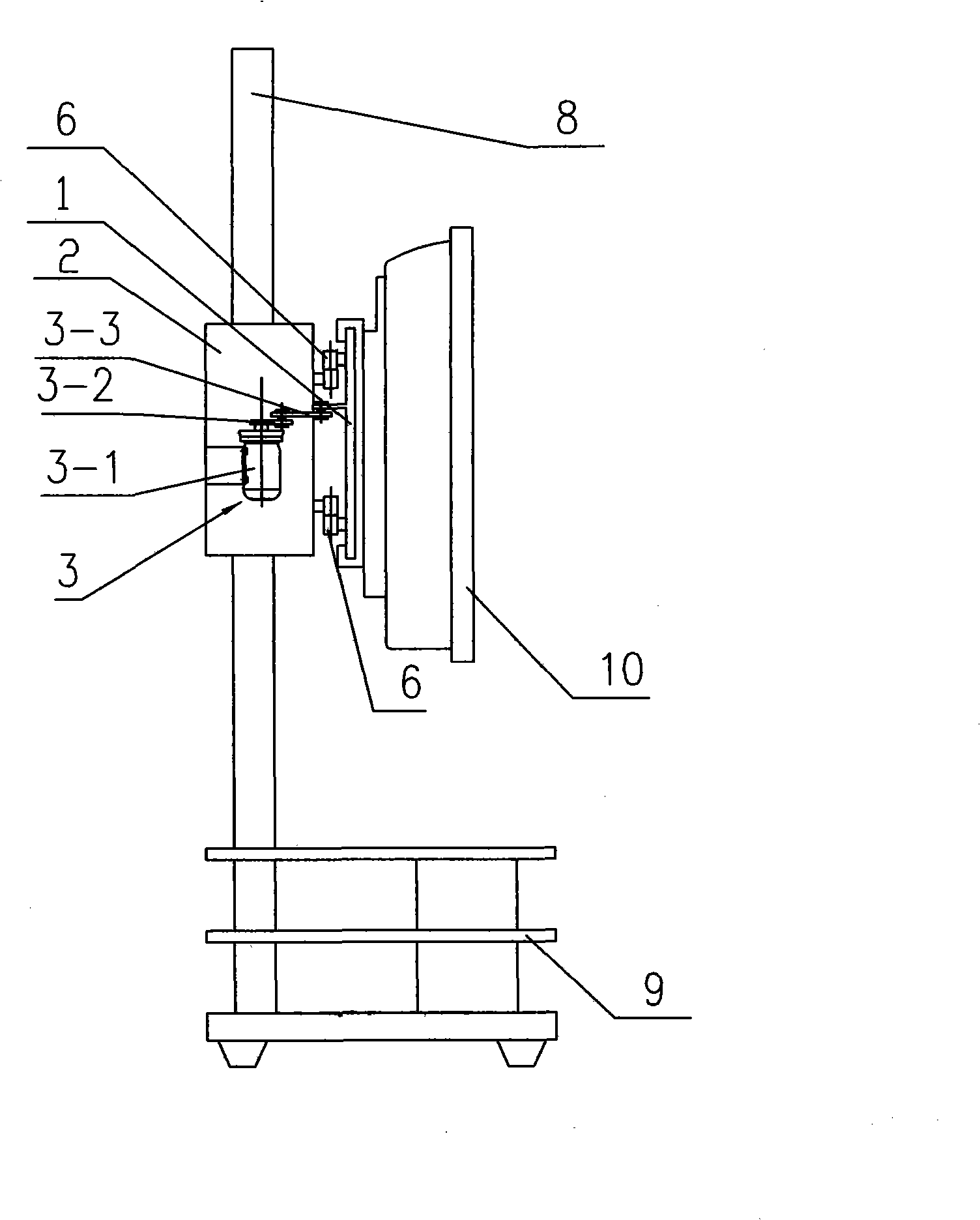

TV set rack

InactiveCN101324300ASimple structureLow costTelevision system detailsColor television detailsEngineeringTelevision set

The invention discloses a TV stand, the angle of which can be adjusted. The TV stand comprises a TV bracket and a support of the bracket; an angle demodulator is connected between the TV stand bracket and the support; the angle demodulator comprises a motor; a crank is installed on an output shaft of the motor; a connecting rod is movably connected to the crank; the support is fixedly connected with the motor of the angle demodulator; the TV bracket is hinged with the connecting rod of the angle demodulator, or the TV bracket is fixedly connected with the motor of the angle demodulator; and the support is hinged with the connecting rod of the angle demodulator. The TV stand has the advantages of simple structure, light weight, low cost, easy manufacture, less possibility of abrasion and convenient maintenance.

Owner:CHANGZHOU NEW DISTRICT SAIEN ELECTROMECHANICAL EQUIP

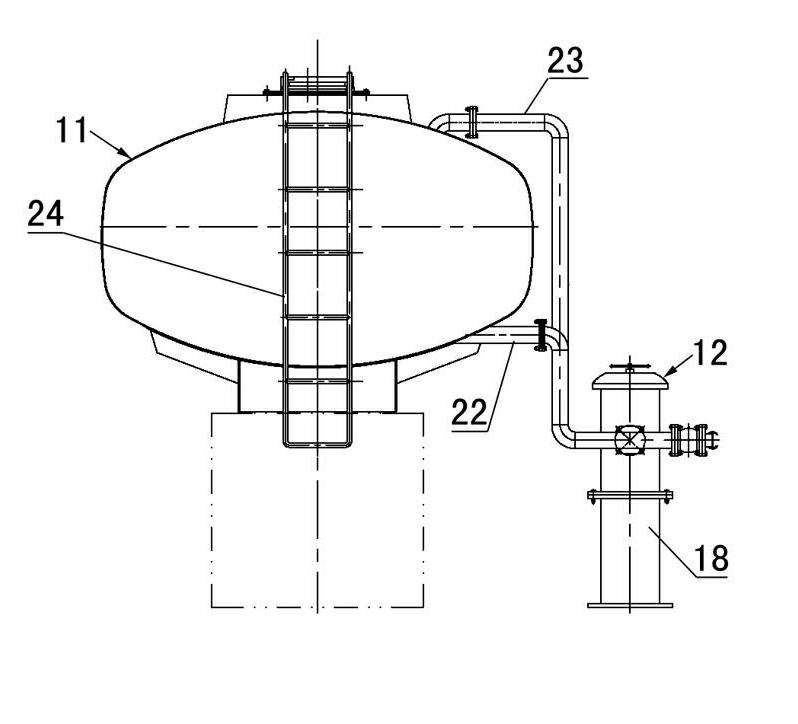

Method for reconstructing cylindrical gas holder

The invention discloses a method for reconstructing a cylindrical gas holder. The cylindrical gas holder comprises a holder body, a piston box beam, a piston center ball shell, a sealing device hanging ring beam, a piston guide wheel bracket and a sealing mechanism. According to the method, a reconstruction process comprises the following steps: disassembling the sealing mechanism of the cylindrical gas holder; disassembling the piston guide wheel bracket of the cylindrical gas holder; arranging a piston fence of a single-stage rubber sealed gas holder on the piston box beam of a cylindrical gas holder piston, and arranging a piston sealing steel section on the sealing device hanging ring beam of the piston; arranging a holder body sealing steel section on the holder body of the cylindrical gas holder; and spreading a rubber membrane, and connecting the two ends of the rubber membrane with the piston sealing steel section and the holder body sealing steel section in a sealing manner. The method provided by the invention has the advantages that the holder body and other auxiliary structures of the cylindrical gas holder are sufficiently utilized, so that the reconstructed cylindrical gas holder can be put into use again when the whole structure of the cylindrical gas holder is slightly reconstructed, neither a lot of construction capital nor long-term construction is needed, and the economic benefit is extremely high.

Owner:HUATIAN ENG & TECH CORP MCC

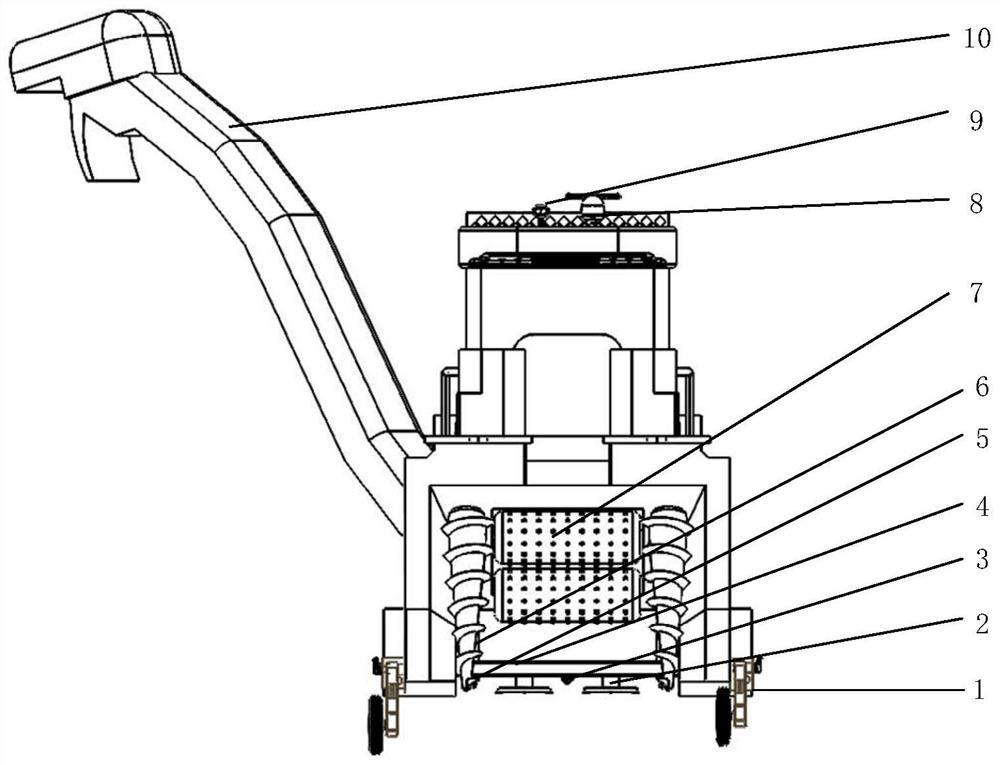

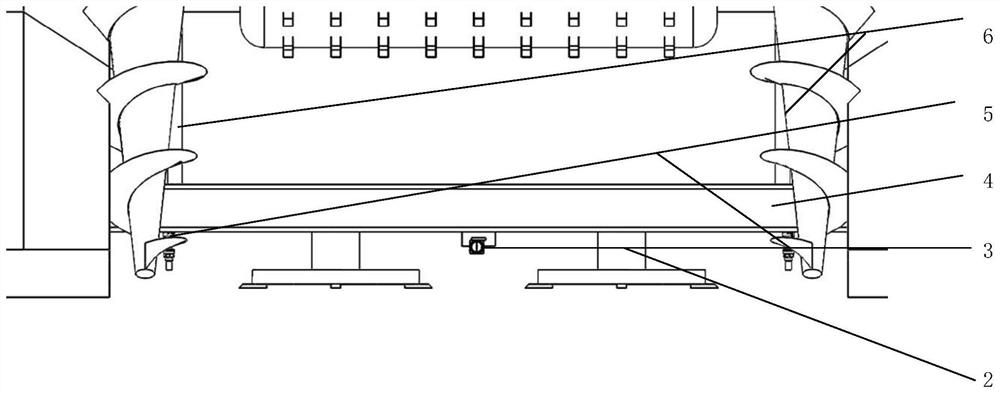

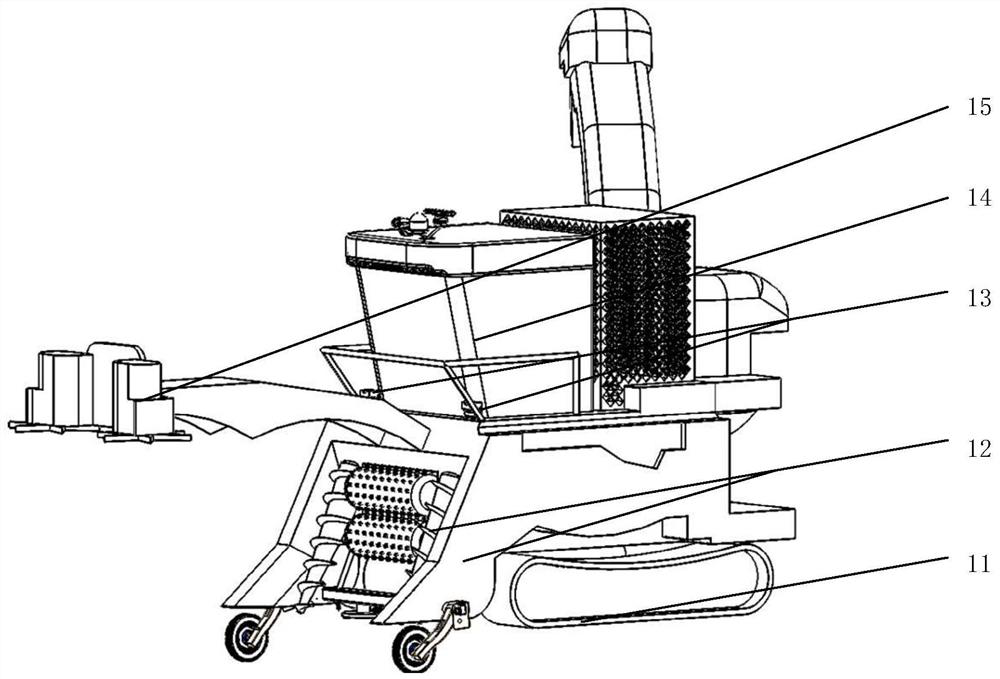

Induction system of small-sized section-cutting type crawler sugarcane harvester and control method

PendingCN112056087ARunning speed is stableAdjust in timeHarvestersAcoustic wave reradiationAgricultural scienceMachine vision

The invention relates to an induction system of a small-sized section-cutting type crawler sugarcane harvester and a control method. The induction system comprises a follow-up profiling device, a machine vision recognition device, an ultrasonic height measuring device, and a machine vision auxiliary navigation device. The follow-up profiling device, the machine vision recognition device, and the ultrasonic height measuring device are applied to follow-up of a header of the small-sized section-cutting type crawler sugarcane harvester, fusion analysis is conducted on information fed back by sensors through a multi-source information fusion method, the stability and precision of follow-up control over the header are improved, and therefore the harvesting quality and harvesting efficiency of sugarcanes are effectively guaranteed. The machine vision auxiliary navigation device is applied to assisting navigation of the small-sized section-cutting type crawler sugarcane harvester and is for preventing the small-sized section-cutting type crawler sugarcane harvester from generating overlarge turning to damage an unharvested area during harvesting operation.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

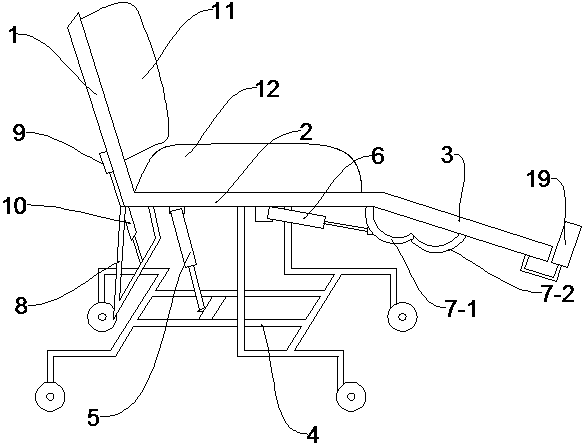

Flat electric wheelchair

PendingCN109172175ARunning speed is stableSimple structureWheelchairs/patient conveyanceWheelchairRest frame

The invention relates to the field of medical rehabilitation devices, in particular to a rehabilitation wheelchair. The invention relates to a flat electric wheelchair, comprising an electric seat frame, wherein the electric seat frame comprises a backrest frame, a cushion frame and a leg rest frame arranged in sequence; the backrest frame is rotatably connected with the cushion frame through a rotating shaft, and the leg rest frame is rotatably connected with the cushion frame through the rotating shaft; the seat rest frame is rotatably connected with the leg rest frame through the rotating shaft; the lower part of the cushion frame is fixedly connected with a movable frame, and three electric push rods are arranged, wherein the expansion and contraction of the electric push rods controlthe lifting ting and lowering of the cushion frame, the expansion and contraction of the electric push rods and the rotating of the movable push rods realize the turning over of the leg frame relativeto the cushion frame, and the expansion and contraction of the electric push rods 3 realize the turning over of the backrest frame relative to the cushion frame. The invention has the advantages of simple overall design, replacing the traditional complex connecting rod structure, lightweight and flexible turning of the whole wheelchair, stable running speed of the electric push rod, stable and smooth wheelchair in the process of unfolding and lying flat, and increased user comfort.

Owner:嘉兴邦泽科技有限公司

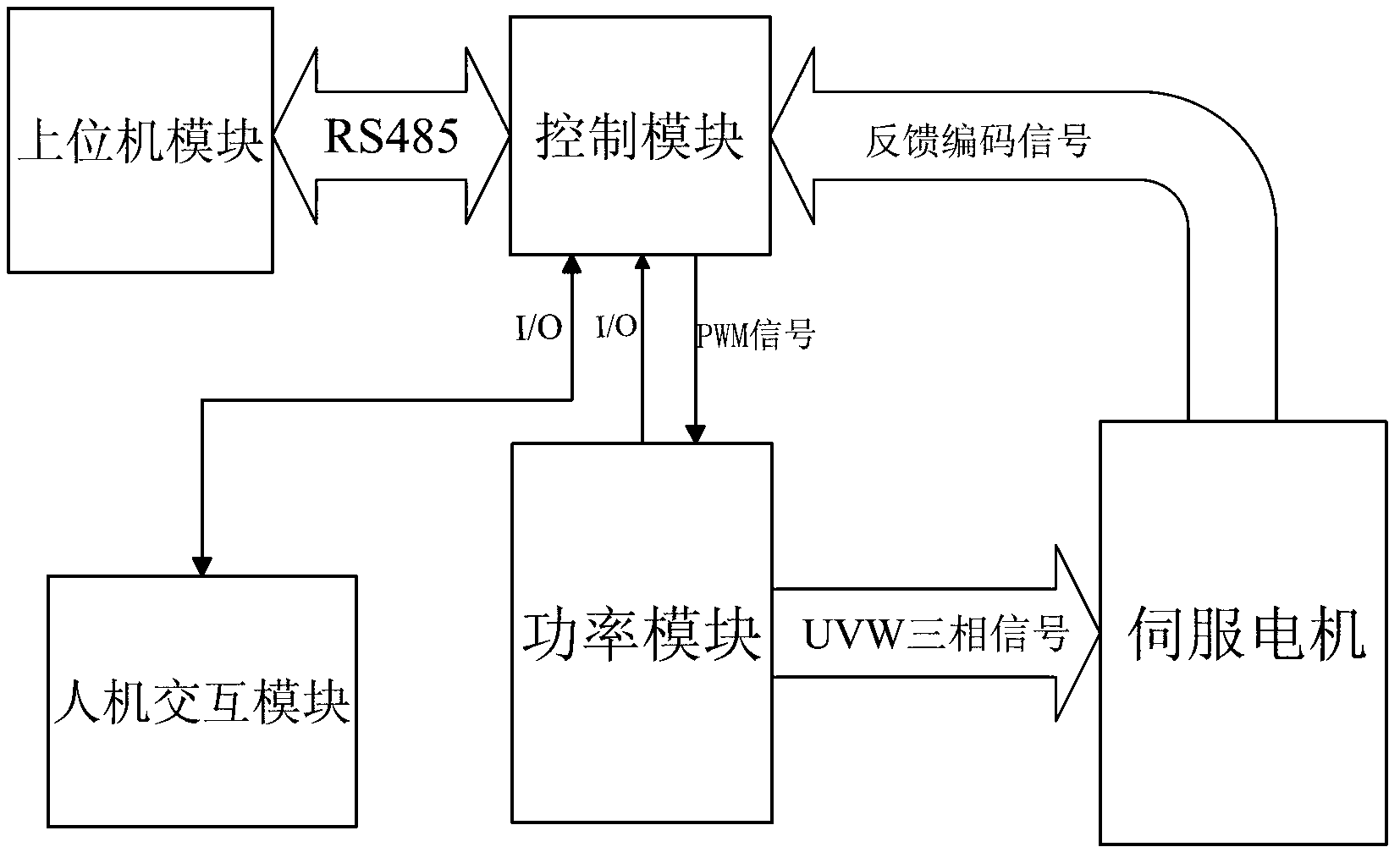

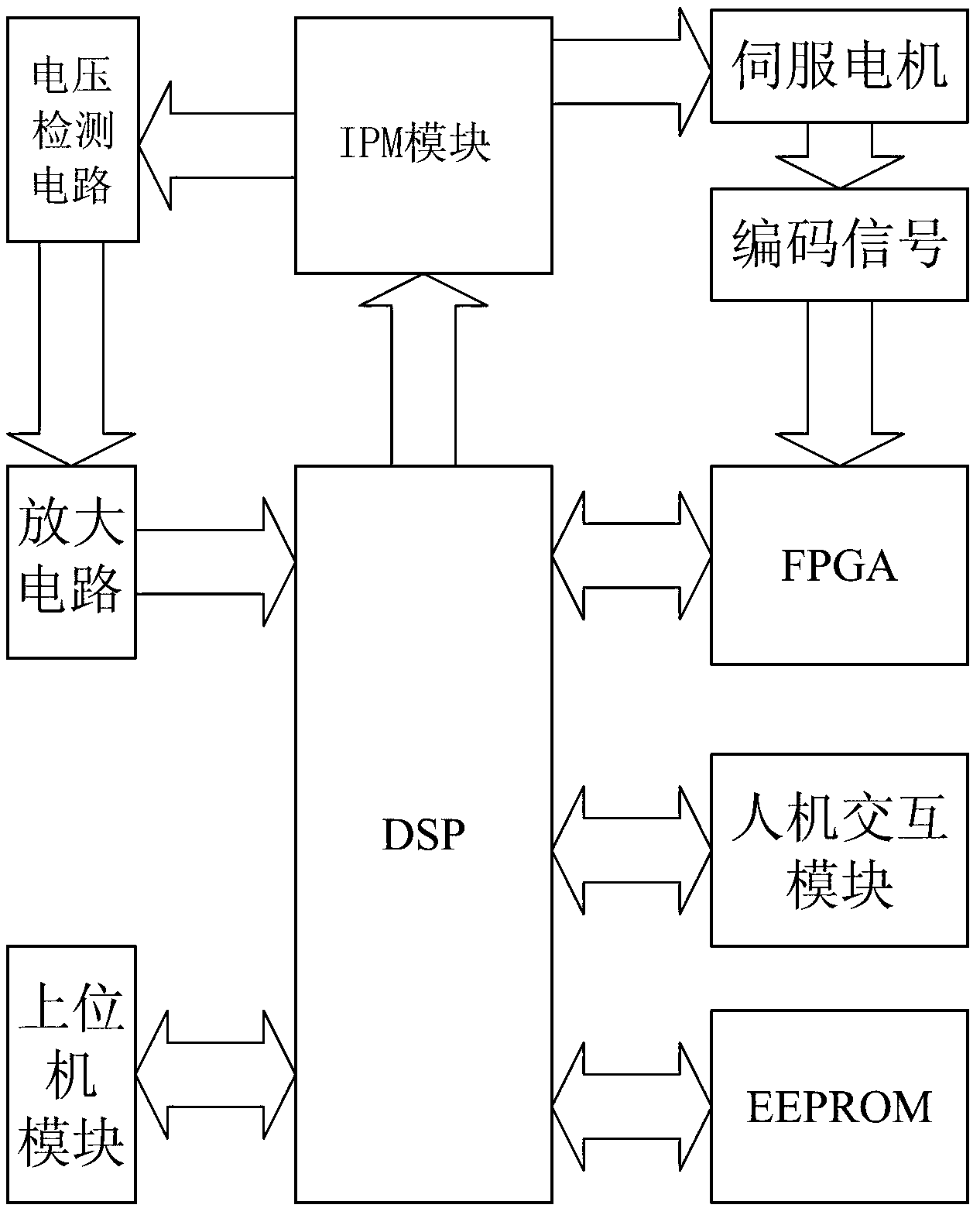

System and method for controlling motion of yarn guide of full-automatic computerized flat knitting machine

ActiveCN103268126AMobile real-time controlMobile Quick ResponseWeft knittingControl using feedbackYarnMotor drive

The invention discloses a system and a method for controlling the motion of a yarn guide of a full-automatic computerized flat knitting machine. The system comprises an upper computer module, a human-computer interaction module, a control module, a power module and a servo motor. The upper computer module sends a message of the position which the yarn guide is going to arrive at to the control module; the control module calculates a variable value of the position of the yarn guide and a variable quantity of a coded signal corresponding to the variable value, and then outputs a PWM signal; the power module converts the PWM signal into a UVW three-phase signal and controls the servo motor to rotate; the servo motor drives a mechanical transmission device to move the yarn guide; meanwhile, a motor encoder continuously feeds back the coded signal to the control module; when the variable value of the coded signal received by the control module reaches a set value, the yarn guide arrives at the position which the yarn guide is going to arrive at; the control module stops sending the PWM signal, the servo motor is locked at the moment, and the yarn guide stops motion at the same time. The system and method for controlling the motion of the yarn guide of the full-automatic computerized flat knitting machine have the advantages of being capable of controlling the motion of the yarn guide in real time and quickly responding to the motion of the yarn guide.

Owner:FUJIAN RAYNEN TECH

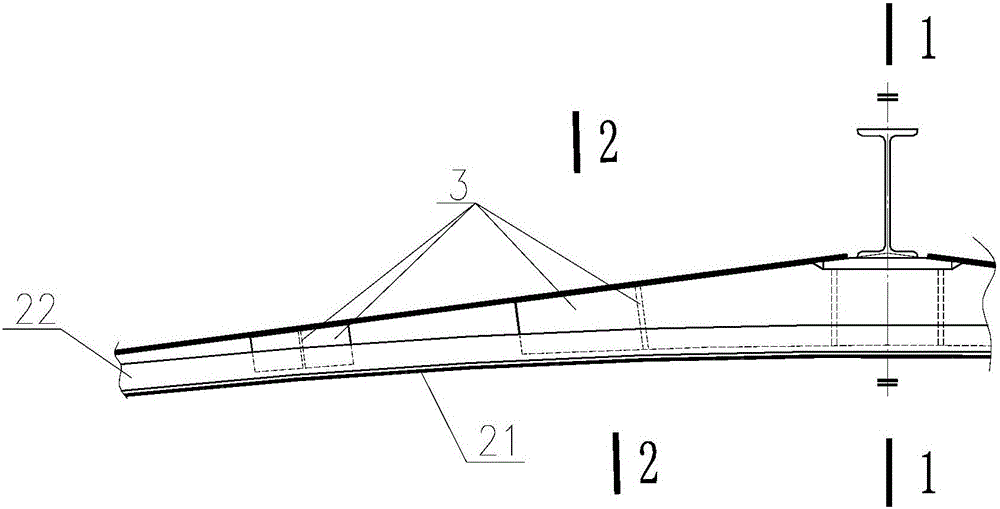

Single-stage rubber membrane sealed gas holder reconstructed from regular polygonal thin oil sealed gas holder

ActiveCN105715938ARun fastRunning speed is stableVariable capacity gas holdersSingle stageRubber membrane

The invention discloses a single-stage rubber membrane sealed gas holder reconstructed from a regular polygonal thin oil sealed gas holder. The single-stage rubber membrane sealed gas holder comprises a polygonal holder body, a circular piston arranged in the polygonal holder body, as well as a sealing mechanism arranged between the polygonal holder body and the circular piston, wherein a plurality of connecting brackets and an inner cylinder connected with the connecting brackets are arranged in the polygonal holder body; an inner cylinder sealing steel section is arranged on a lateral plate of the inner cylinder in the circumferential direction of the inner cylinder; the circular piston comprises a circular piston baseplate, a truss arranged on the circular piston baseplate and a piston fence connected with the truss; a piston sealing steel section is arranged at the edge of the circular piston baseplate; the sealing mechanism comprises a rubber membrane and a corrugated plate; the two ends of the rubber membrane are respectively connected with the inner cylinder sealing steel section and the piston sealing steel section in a sealing manner; the distance between the bottom end of the inner cylinder and the bottom of the polygonal holder body is not greater than the height of the rubber membrane; and the distance between the top end of the inner cylinder and the bottom of the polygonal holder body is not greater than the height of the piston fence. The single-stage rubber membrane sealed gas holder provided by the invention is low in investment, short in construction period and considerable in economic benefit.

Owner:HUATIAN ENG & TECH CORP MCC

Detecting assembly for whole body of transporting and fuelling vehicle at test center

InactiveCN102636354AMeet vehicle testing requirementsOvercome speedVehicle testingMachine gearing/transmission testingEngineeringInlet valve

The invention relates to a detecting assembly for a whole body of a transporting and fuelling vehicle at a test center. The detecting assembly comprises a test oil tank assembly, an oil-way assembly, an anti-static system and an oil collecting tank assembly, wherein the oil-way assembly is connected with the test oil tank assembly; the anti-static system is connected with the test oil tank assembly; the oil collecting tank assembly is arranged under the oil-way assembly; the oil-way assembly comprises an oil outlet pipe which is communicated with the test oil tank assembly and an oil return pipe which is communicated with the test oil tank assembly; a test oil tank self-flowing oil-draining valve, an oil outlet valve, a flowmeter inlet valve and a flowmeter outlet valve are arranged on the oil outlet pipe in sequence along the oil outlet direction of the oil outlet pipe; a stop valve and a filter are arranged on the oil outlet pipe between the test oil tank self-flowing oil-draining valve and the oil outlet valve; and a pressure gauge and a flowmeter are arranged on the oil outlet pipe between the flowmeter inlet valve and the flowmeter outlet valve. The detecting assembly can meet the whole body detecting demands for various transporting and fuelling vehicles; the defects of low detecting speed and high labor intensity of detectors existed in the traditional detecting method are completely overcome; and the detecting assembly is particularly suitable for the condition with a large quantity of transporting and fuelling vehicles.

Owner:BEIJING SANXING AUTOMOBILE

Servo drive traction machine

InactiveCN107953534AEasy to adjust clamping pressureStable line speedTubular articlesEngineeringControl theory

The invention discloses a servo drive traction machine. The servo drive traction machine comprises a machine frame, an electric box, an operation box and a transmission mechanism, wherein the electricbox is arranged on the machine frame. The transmission mechanism comprises a linear polish rod, a screw rod, an opening and closing servo motor, an upper side traction device, a lower side traction device, a driving servo motor and a reduction gearbox, wherein the linear polish rod is connected with the upper side traction device and the lower side traction device through a linear bearing, the opening and closing servo motor is connected with the screw rod, the lower side traction device and the lower side traction device are installed on the side part of the screw rod through a nut and a nutseat, an air cylinder is further connected between the lower side traction device and the nut seat, and the air cylinder is driven by the opening and closing servo motor to provide the transaction opening and closing power for the upper side traction device and the lower side traction device. A belt pulley of the upper side traction device and a belt pulley of the lower side traction device provide the driving power by the driving servo motor and the reduction gearbox, the belt pulleys drive belts to carry out traction, and guide mechanisms are further arranged at the two ends of the upper side traction device and the lower side traction device. According to the servo drive traction machine, the clamping pressure is conveniently adjusted, the constant clamping force can be provided, and the stable wire production speed can be provided.

Owner:NANJING ORIENTLEADER TECH CO LTD

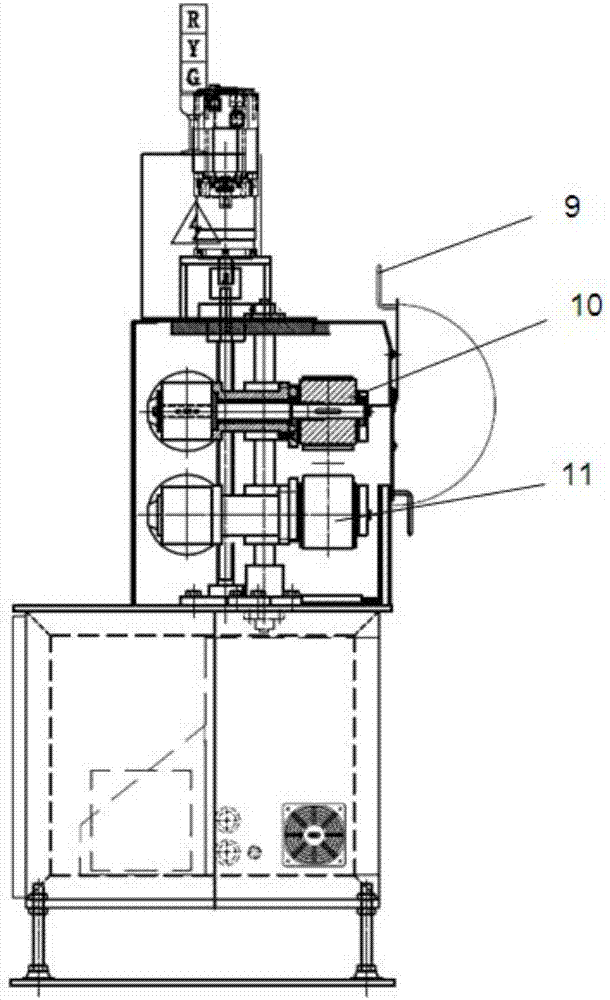

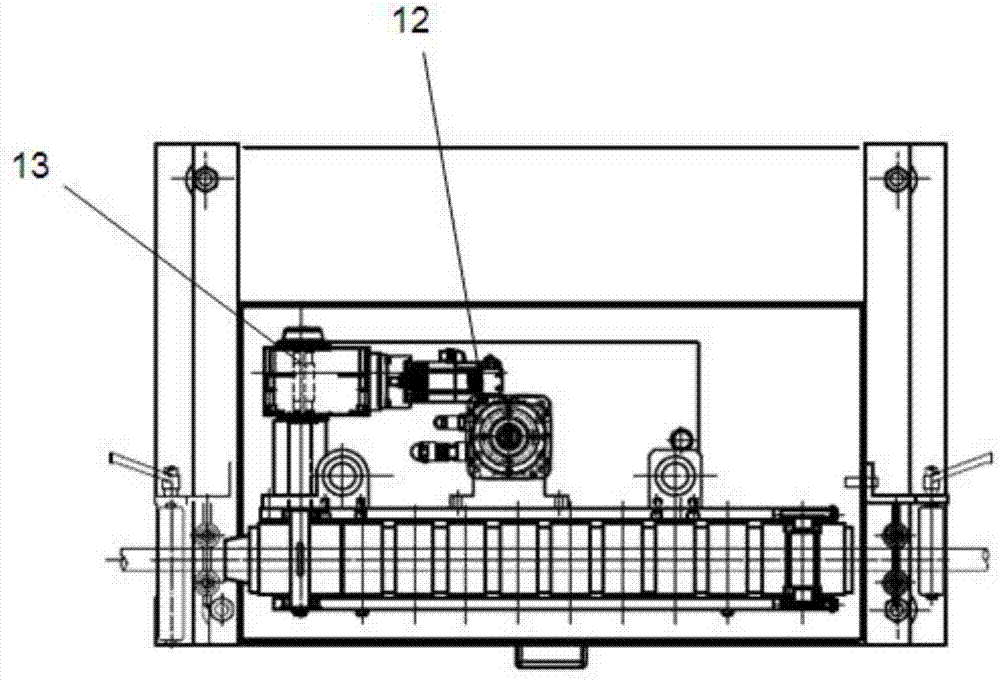

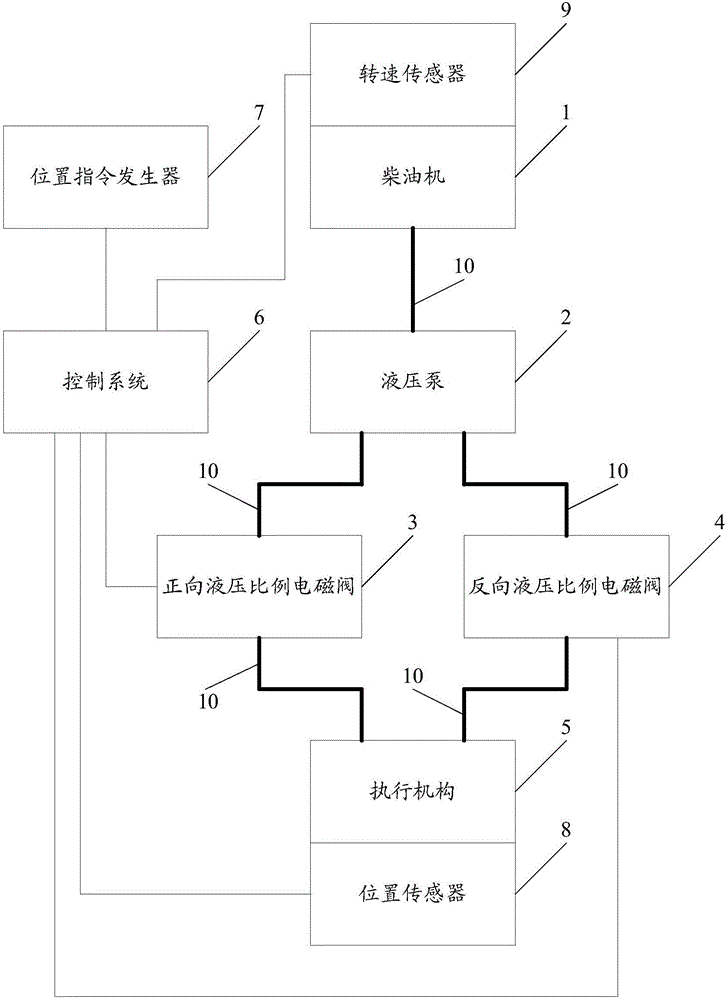

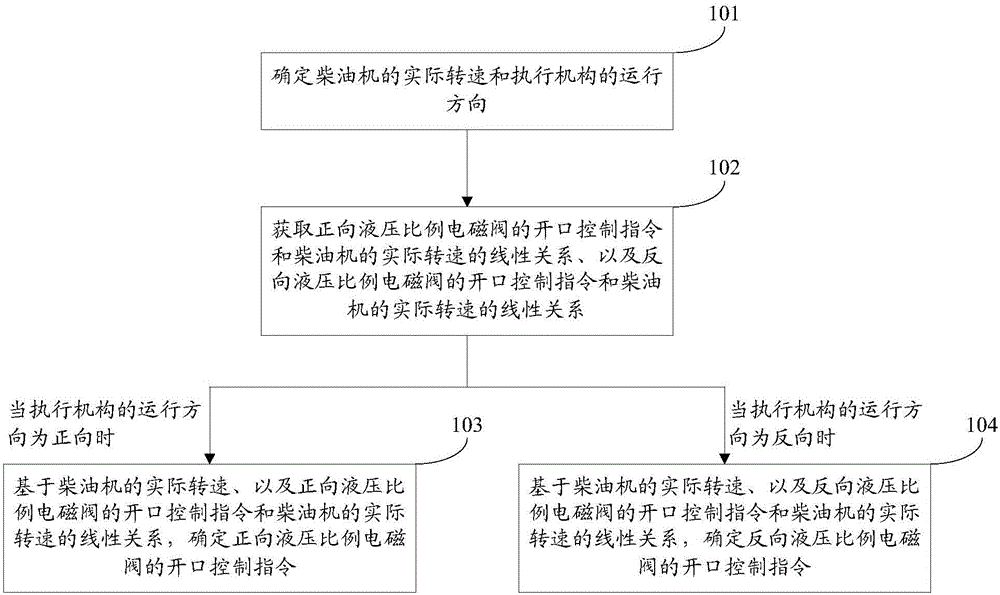

Method and device for controlling hydraulic system

ActiveCN106122126ARunning speed is stableReduce shockServomotorsServometer circuitsHydraulic pumpControl theory

The invention discloses a method and device for controlling a hydraulic system, and belongs to the technical field of hydraulic control. The hydraulic system comprises a diesel engine, a hydraulic pump, a forward direction hydraulic proportional electromagnetic valve, a reverse direction hydraulic proportional electromagnetic valve and an executing mechanism. The control method includes the steps that the actual rotation speed of the diesel engine and the moving direction of the executing mechanism are determined, and the moving direction of the executing mechanism comprises the forward direction and reverse direction; the linear relation of an opening control instruction of the forward direction hydraulic proportional electromagnetic valve and the actual rotation speed of the diesel engine and the linear relation of an opening control instruction of the reverse direction hydraulic proportional electromagnetic valve and the actual rotation speed of the diesel engine are obtained; and when the moving direction of the executing mechanism is the forward (or reverse) direction, the opening control instruction of the forward (or reverse) direction hydraulic proportional electromagnetic valve can be determined based on the actual rotation speed of the diesel engine and the linear relation of the opening control instruction of the forward (or reverse) direction hydraulic proportional electromagnetic valve and the actual rotation speed of the diesel engine. By the adoption of the method and device, the moving speed of the executing mechanism can be kept stable.

Owner:WUHAN MARINE MACHINERY PLANT

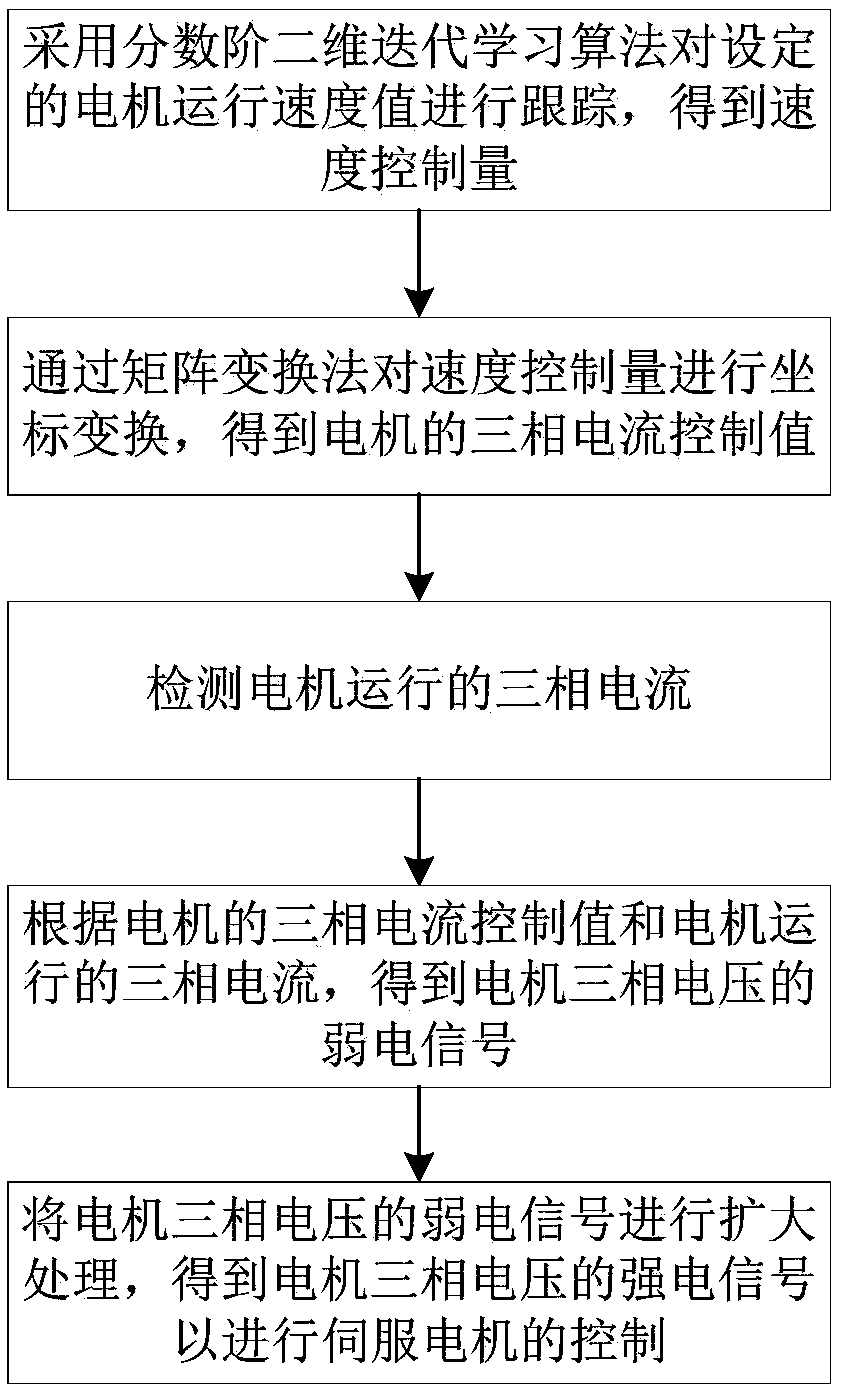

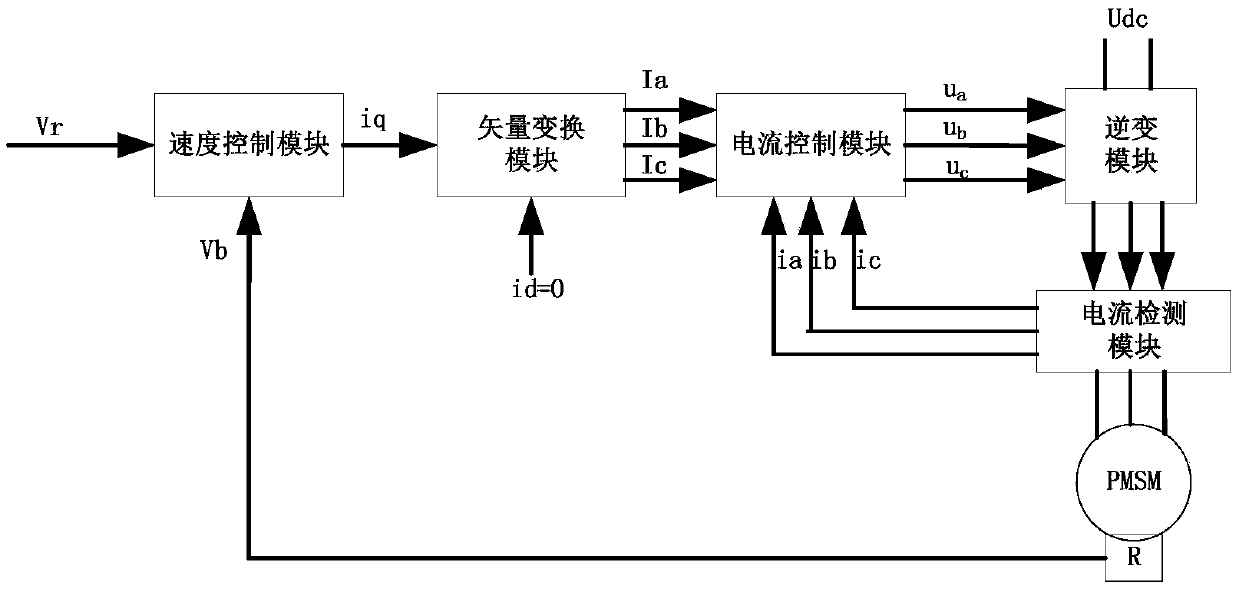

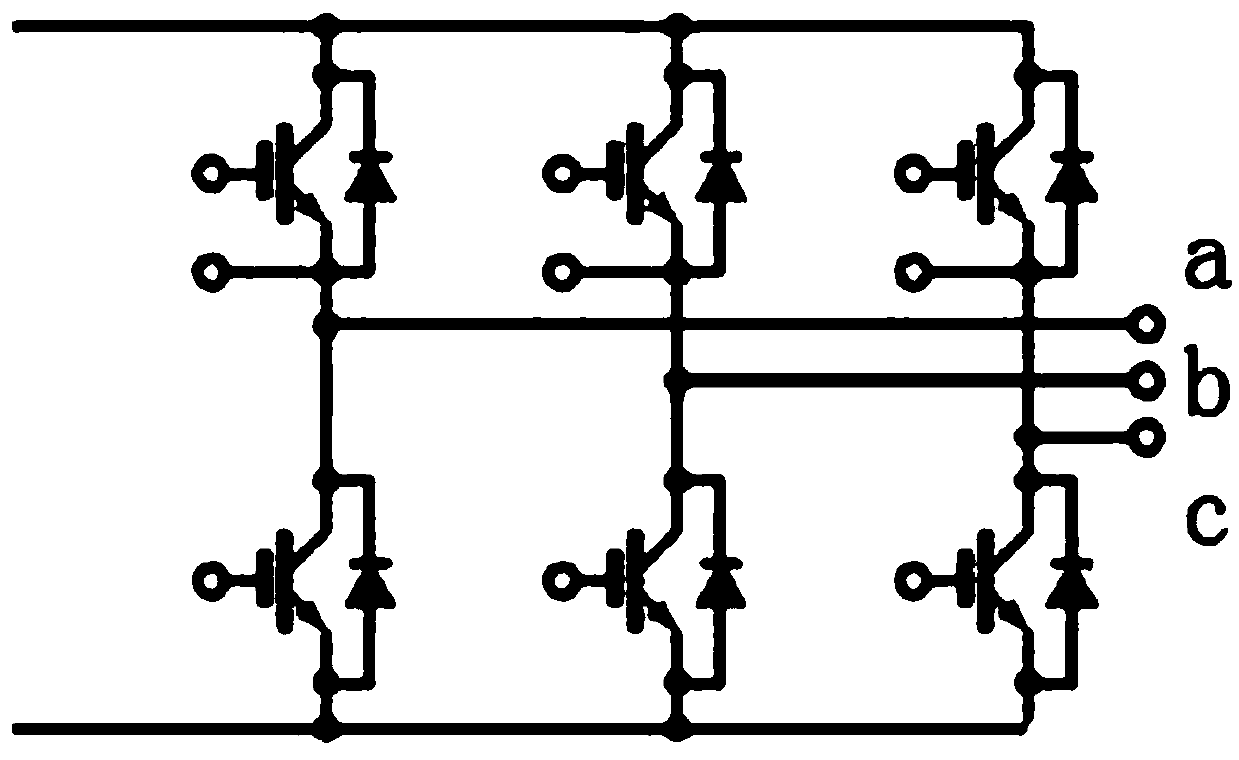

Servo motor control method and system based on fractional iterative learning

ActiveCN108736785ARunning speed is stableImprove real-time performanceElectronic commutation motor controlVector control systemsIterative learning algorithmThree-phase

The invention discloses a servo motor control method and system based on fractional iterative learning. The method comprises the following steps: using a fractional iterative learning to track a set motor operation speed value to obtain a speed controlled quantity; carrying out coordinate transformation on the speed controlled quantity through a matrix transform method so as to obtain the three-phase current control value of a motor; detecting three-phase current for motor operation; obtaining the weak current signal of motor three-phase voltage according to the three-phase current control value of the motor and the three-phase current for motor operation; and carrying out amplification processing on the weak current signal of motor three-phase voltage to obtain the strong current signal of motor three-phase voltage so as to control a servo motor. The system comprises a speed control module, a vector transformation module, a current detection module, a current control module and an inverter module. The system is high in instantaneity, the motor can keep stable operation speed under the condition of disturbance, the reliability is high, and the system can be widely applied to technical field of servo motor control.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

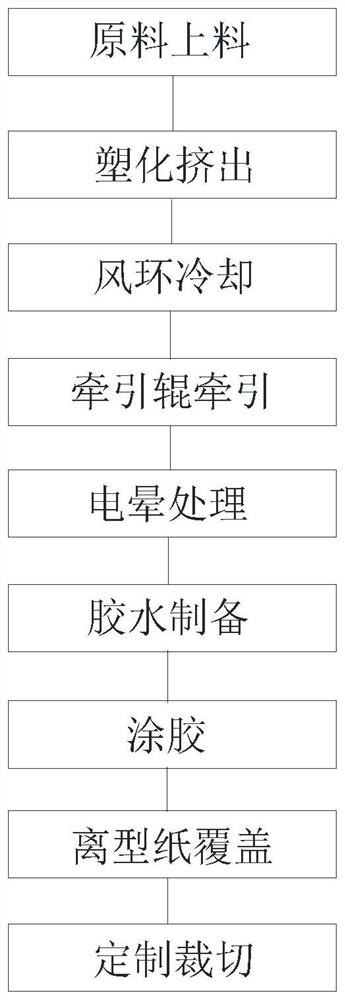

Preparation method of coating protective plastic capable of being bonded with metal

The invention relates to the technical field of coated plastic production, in particular to a preparation method of coated protective plastic capable of being bonded with metal, which comprises the following steps: S1, feeding raw materials; raw materials for manufacturing wrapping plastic are subjected to kneading and cold mixing treatment, kneading of the raw materials is completed through a kneading machine, side-by-side tangent differential arrangement is adopted, namely, the speed of one stirring paddle is high, the speed of the other stirring paddle is low, so that shearing force is generated, the mixed materials can be rapidly sheared due to different paddle speeds, and therefore the materials can be evenly mixed; cold mixing of raw materials is completed through the cold mixing machine, the cold mixing machine is provided with a cooling pipe, a cooling system is used for injecting a cooling agent into the cooling pipe through a water inlet, then the raw materials in a machine body are cooled, an automatic cutting machine is used for cutting a plastic film covered with release paper into a preset shape, and leftover materials are recycled; and the cut wrapping plastic finished products are collected and wrapped in a centralized mode, the metal parts can be directly wrapped after the release paper is torn off, and use is convenient.

Owner:重庆华众新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com