Method and device for removing steel strip oxidation tint

A technology to eliminate banding and oxidation color, applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., can solve problems such as product grade reduction and quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

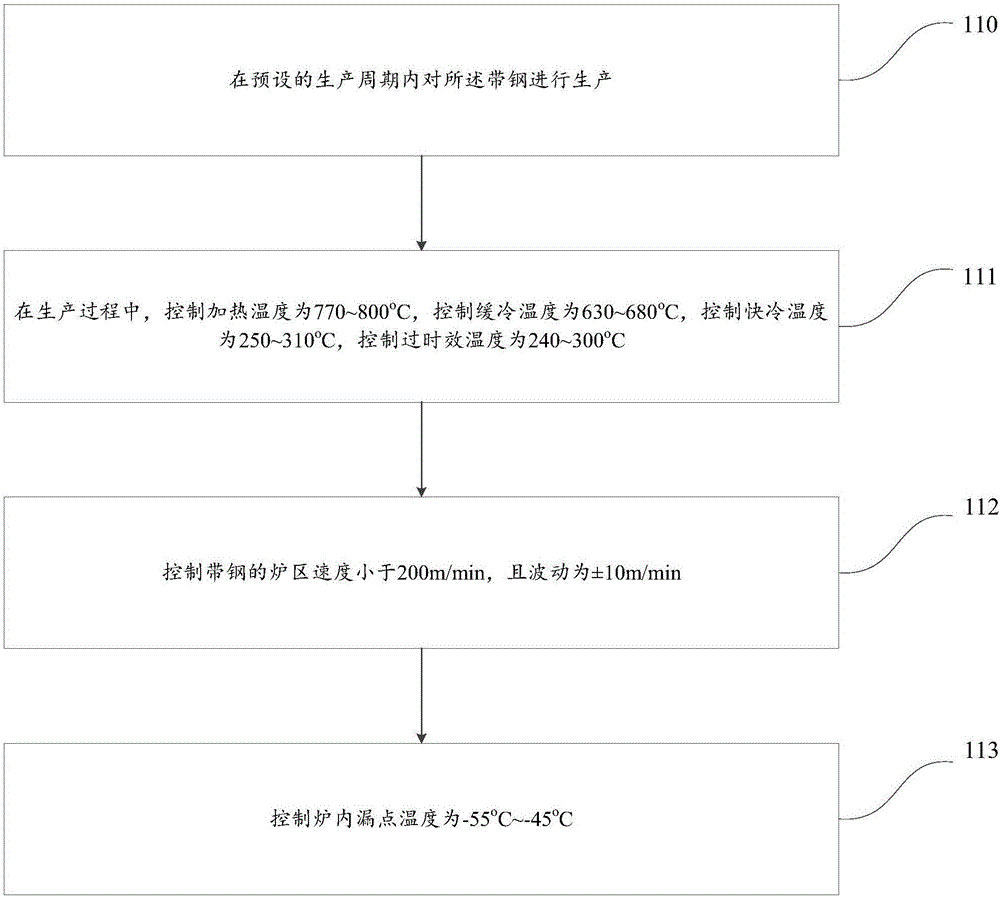

[0029] Present embodiment provides a kind of method for eliminating strip steel oxidation color, as figure 1 As shown, the method mainly includes the following steps:

[0030] Step 110, producing the steel strip within a preset production period.

[0031] In this step, due to the long-time shutdown and re-starting of the furnace (continuous annealing furnace), oxidized color is likely to appear on the edge of the strip, and after the start-up, oxidized color appears on the entire surface of the strip in contact with the furnace roll. Therefore, in the process of producing steel strips, the steel strips need to be produced within a preset production period. Wherein, the preset period is 24-48 hours after starting the production line (starting up). Preferably, it is 24h, 25h or 30h.

[0032] The strip steel may be high-strength steel, specifically including: high-strength steel with a tensile strength of 340MPa, 490MPa, 590MPa, 790MPa and 980MPa.

[0033] Here, the continuou...

Embodiment 2

[0043] Corresponding to Embodiment 1, this embodiment also provides a device for eliminating the oxidation color of strip steel, such as figure 2 As shown, the device includes: a first control unit 21, a second control unit 22, and a third control unit 23; wherein,

[0044] First of all, due to the long-time shutdown and restart of the furnace (continuous annealing furnace), oxidation color is easy to appear on the edge of the strip. After starting the machine, oxidation color appears on the entire surface of the strip in contact with the furnace roller. Therefore, in the process of producing steel strips, the steel strips need to be produced within a preset production period. Wherein, the preset period is 24-48 hours after starting the production line (starting up). Preferably, it is 24h, 25h or 30h. The strip steel may be high-strength steel, specifically including: high-strength steel with a tensile strength of 340MPa, 490MPa, 590MPa, 790MPa and 980MPa.

[0045] Here, t...

Embodiment 3

[0053] In practical application, when the strip steel tensile strength is respectively 340MPa, 590MPa, 980MPa, utilize the method that embodiment 1 provides and the device that embodiment 2 provides to produce described strip steel, concrete process is as follows:

[0054] First of all, due to the long-term shutdown and restarting of the furnace (continuous annealing furnace), oxidation color is likely to appear on the edge of the strip steel. After the start-up, oxidation color appears on the entire surface of the strip steel in contact with the furnace roller. Therefore, in the process of producing steel strips, the steel strips need to be produced within a preset production period. Wherein, the preset period is 24-48 hours after starting the production line (starting up). In this embodiment, it is 26h.

[0055] Here, the continuous annealing furnace is a vertical continuous annealing furnace, including: a preheating section, a heating section, a soaking section, a slow coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com