Patents

Literature

1362 results about "Cool temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold: Any temperature not exceeding 8°C (46 °F). Cool: Any temperature between 8° and 15° (46° and 59 °F) Room temperature: The temperature prevailing in a work area. Controlled room temperature: The temperature maintained thermostatically that encompasses at the usual and customary working environment of 20°-25° (68°-77 °F).

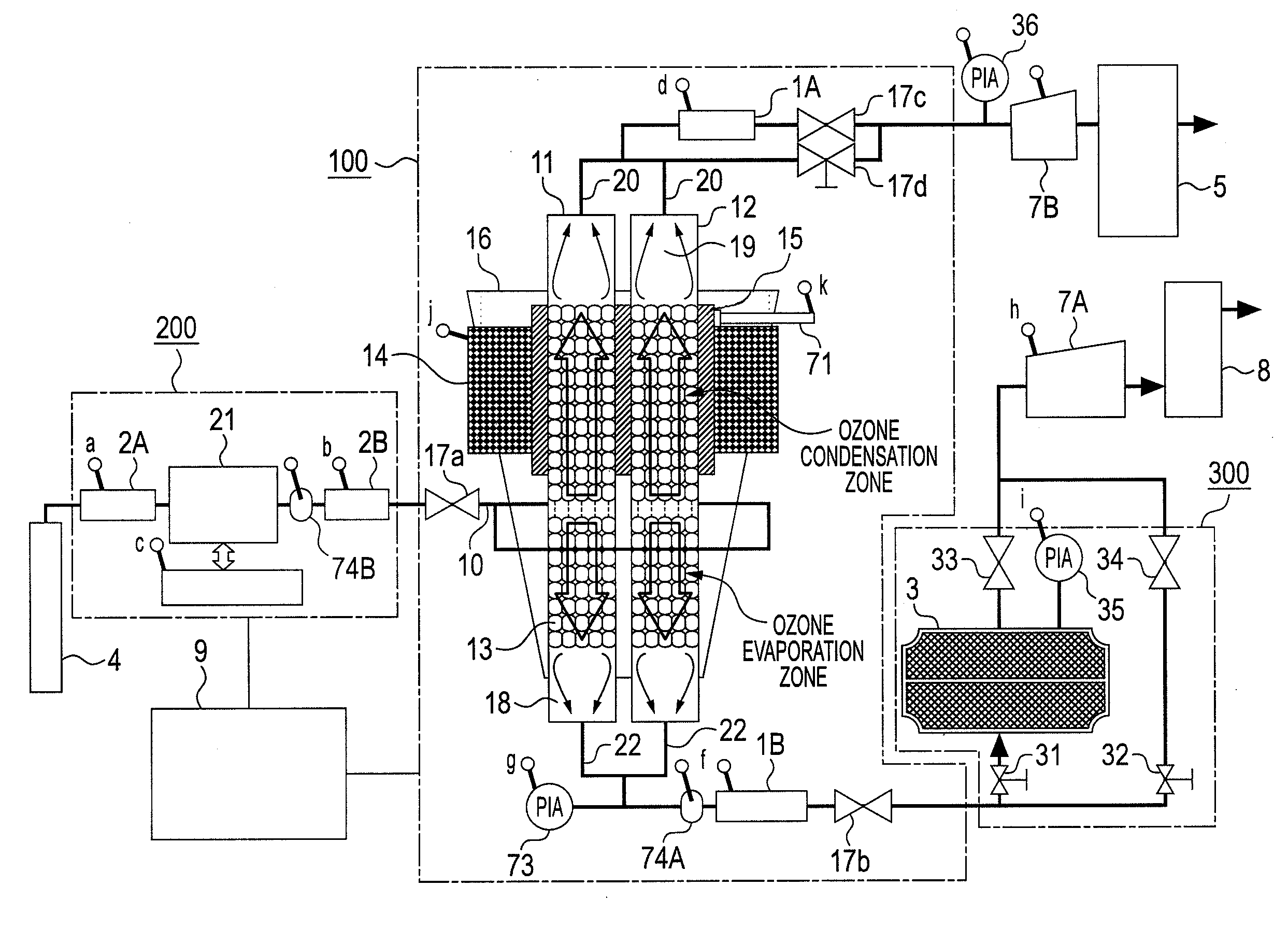

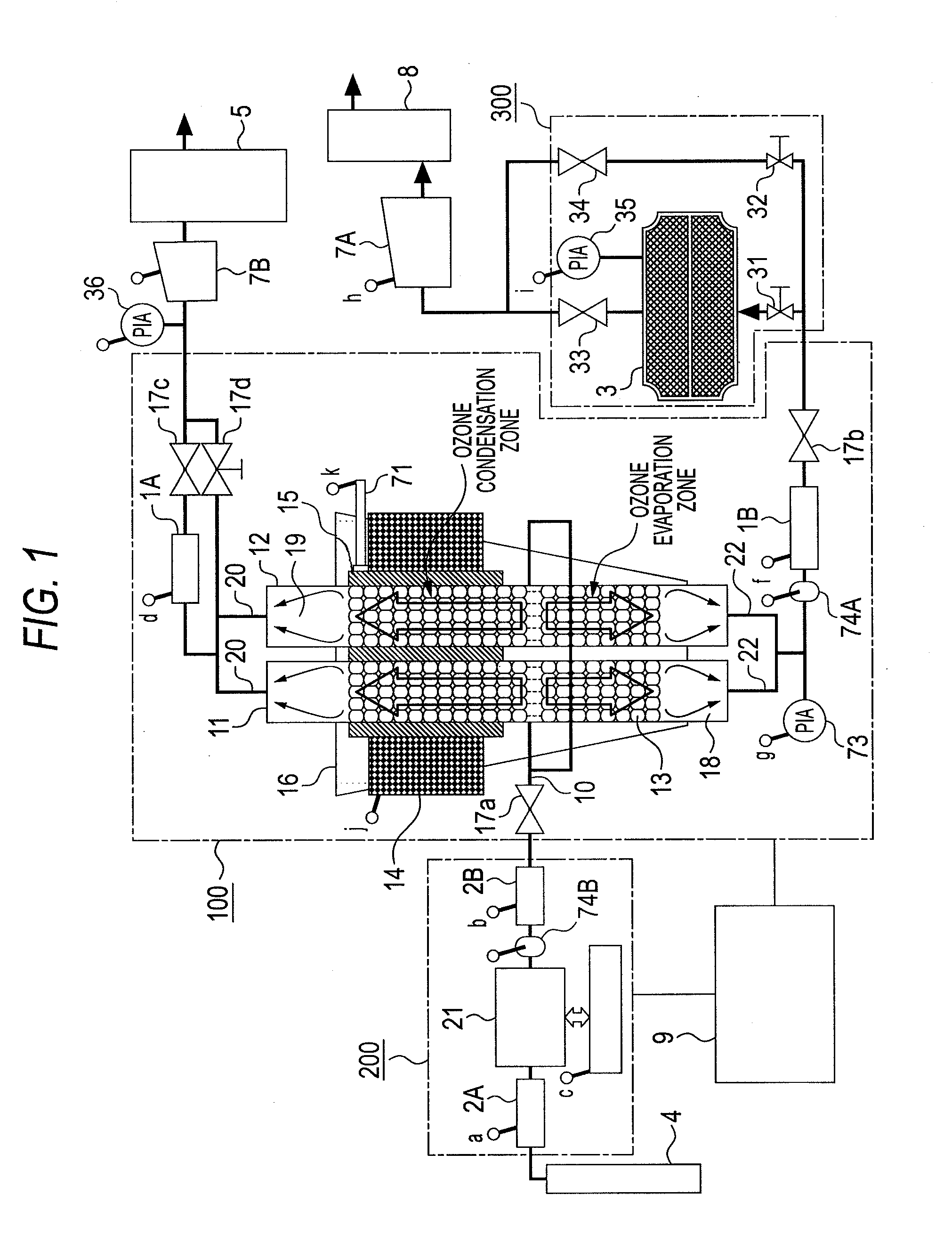

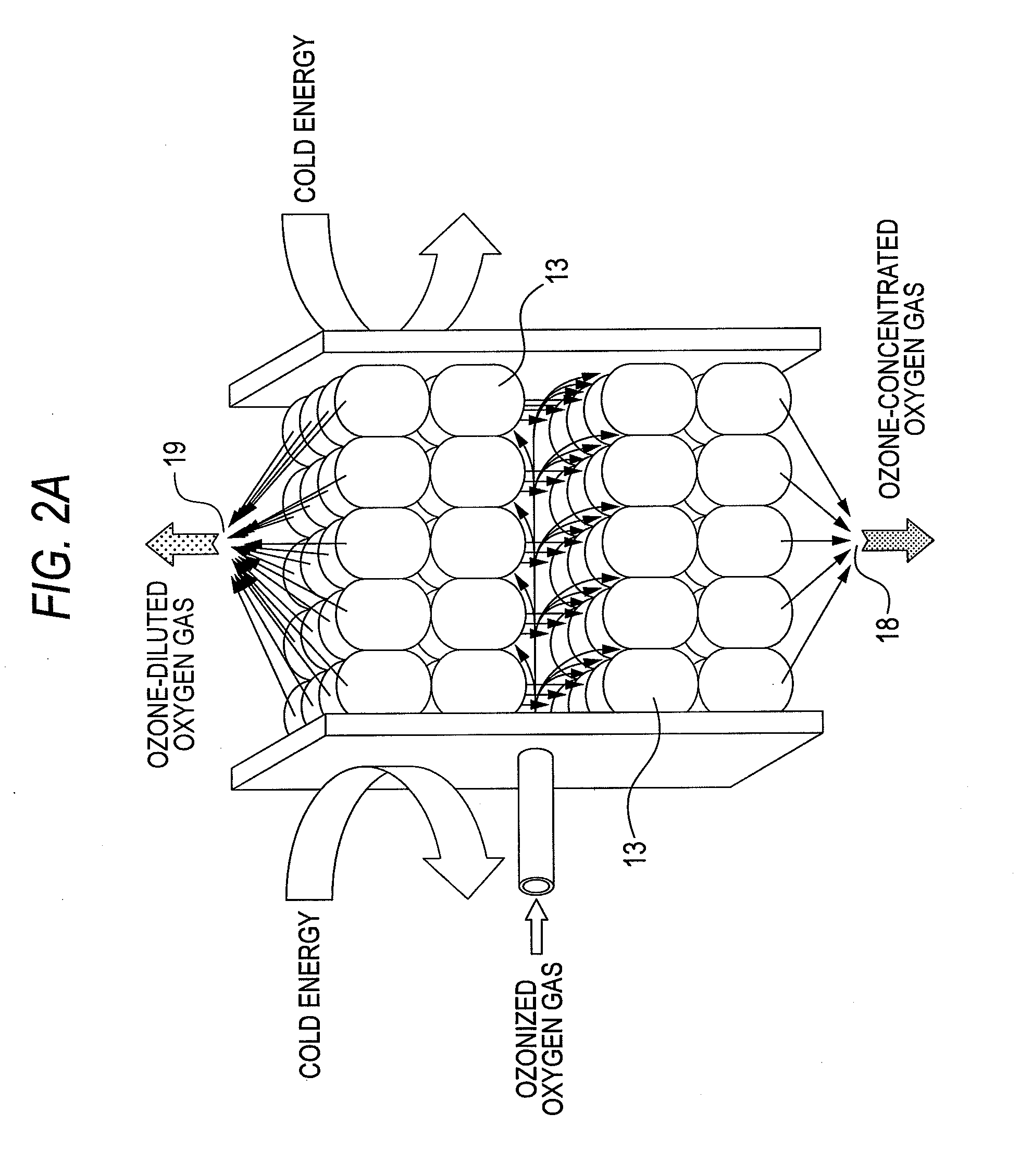

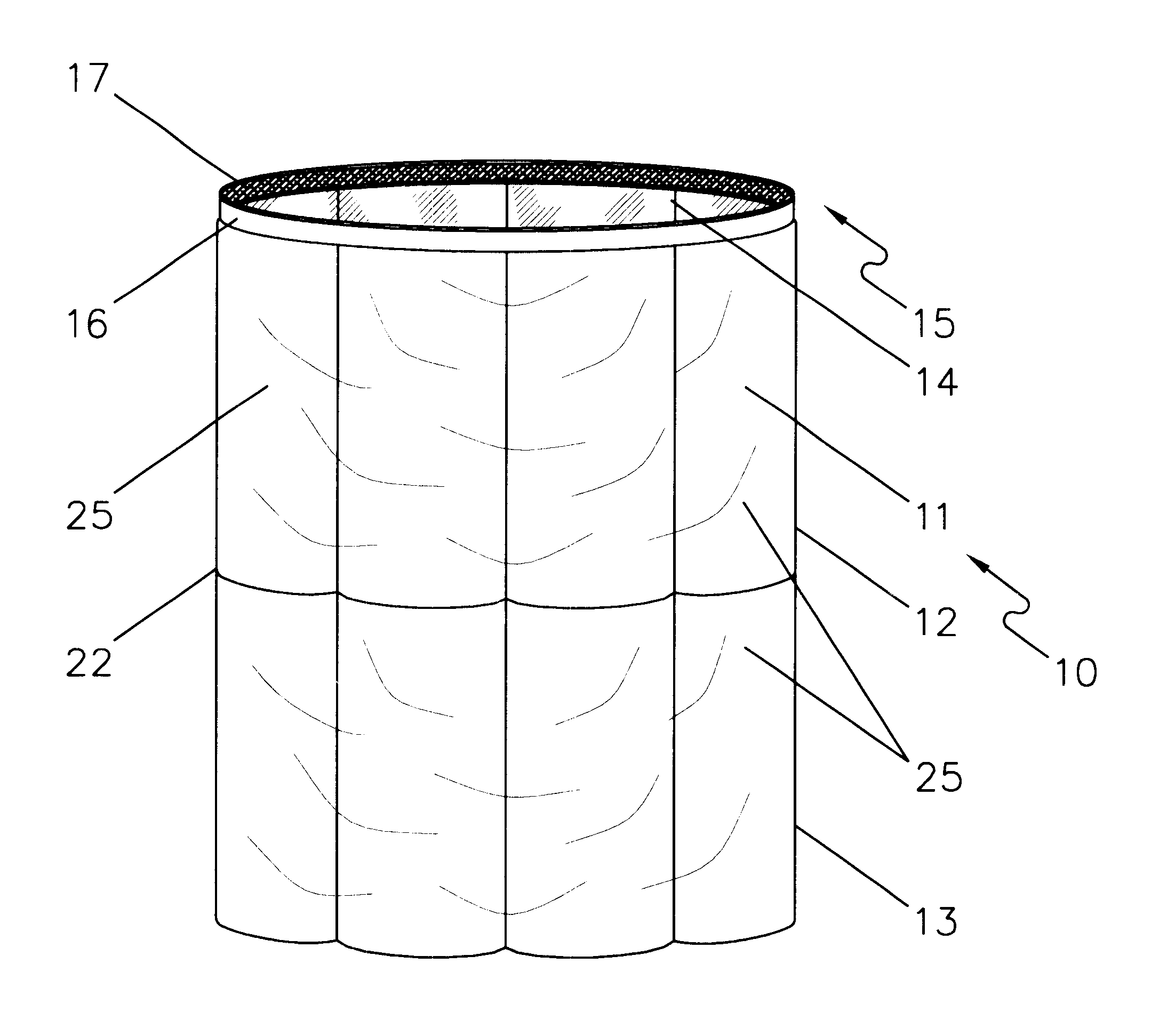

Apparatus for concentrating and diluting specific gas and method for concentrating and diluting specific gas

ActiveUS20100162752A1Improve processing efficiencySmall sizeSolidificationGas treatmentSpherical shapedVaporization

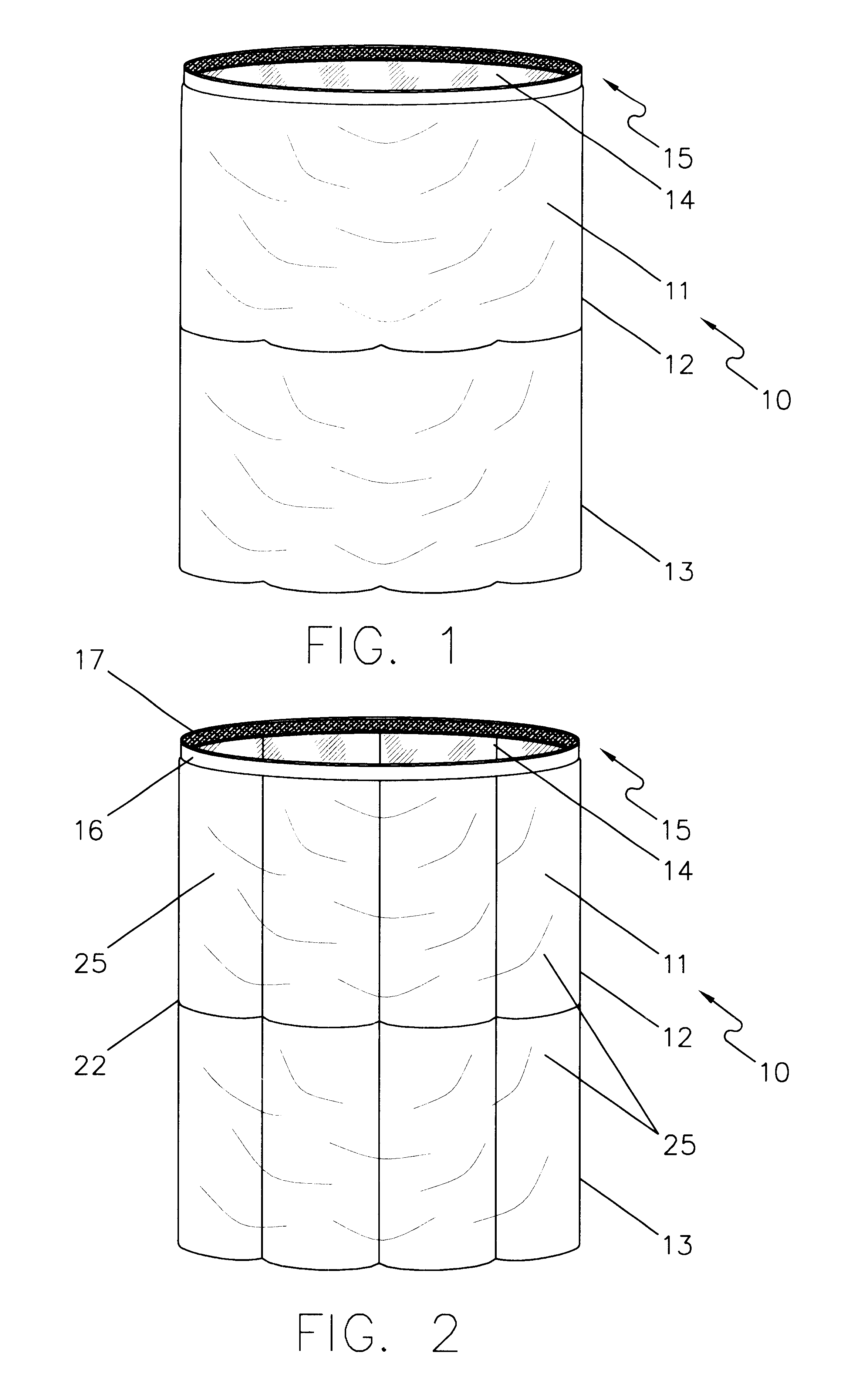

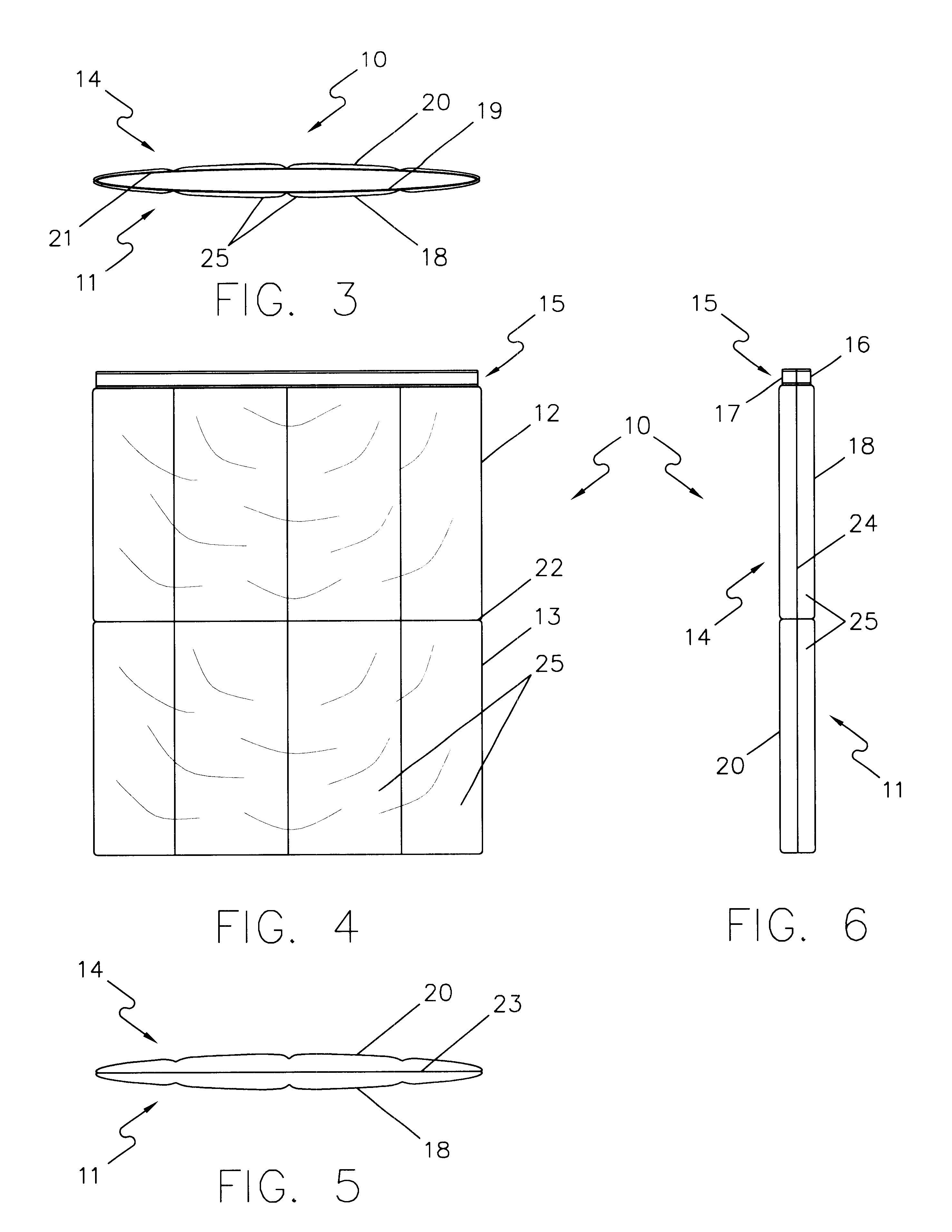

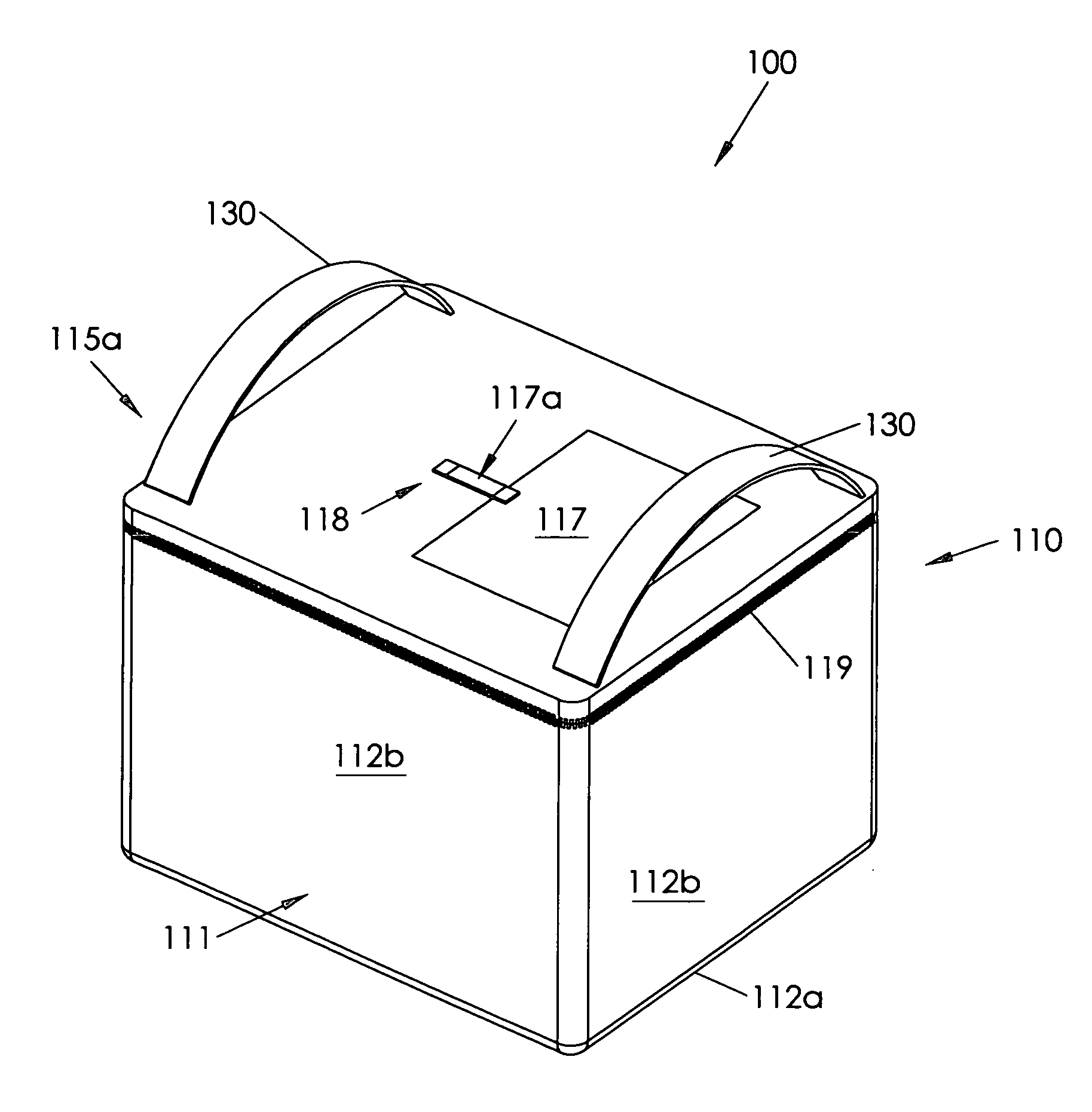

One ozone concentrating chamber is provided therein with a part of a cooling temperature range where ozone can be selectively condensed or an oxygen gas can be selectively removed by transmission from an ozonized oxygen gas, and a part of a temperature range where condensed ozone can be vaporized, and condensed ozone is vaporized by moving condensed ozone with flow of a fluid or by gravitation to the part where condensed ozone can be vaporized, whereby the ozonized oxygen gas can be increased in concentration. Such a constitution is provided that a particle material 13 for condensation and vaporization filled in the ozone concentrating chambers 11 and 12 has a spherical shape of a special shape with multifaceted planes on side surfaces, or an oxygen transmission membrane 130 capable of selectively transmitting an oxygen gas in an ozone gas is provided.

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Reusable cooler bag

InactiveUS6422032B1Lighting and heating apparatusCooling fluid circulationEngineeringCooling temperature

A reusable, multi-walled cooler bag for maintaining a cool temperature within the bag includes: (a) a front portion comprised of at least one front layer; (b) a rear portion comprised of at least one rear layer, the layers being identical to one another, the front portion being sealed to the rear portion along at least two of its edges, the bag having a closable opening at its upper end; and (c) a reclosable fastener mechanism for opening and closing the opening in the bag; wherein the front or rear portions hold nontoxic coolant material between the front and / or rear layers; and the bag has a water-tight interior for storing items to be kept cool.

Owner:GREENE GARY KEITH

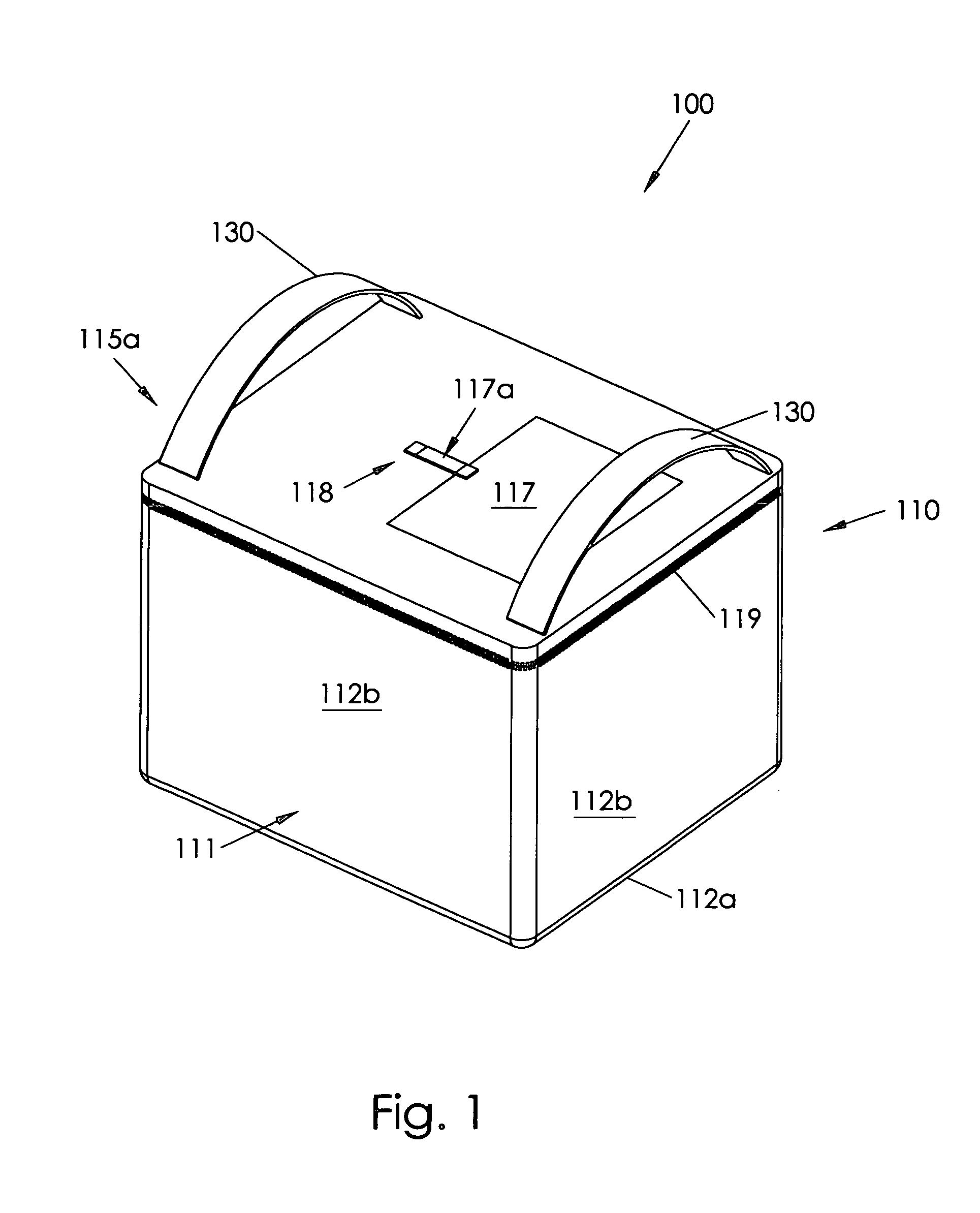

Insulating container

InactiveUS7677406B2Easy constructionEasy accessDomestic cooling apparatusClosuresRubber materialAuxiliary memory

Owner:MAXSON FLOYD S

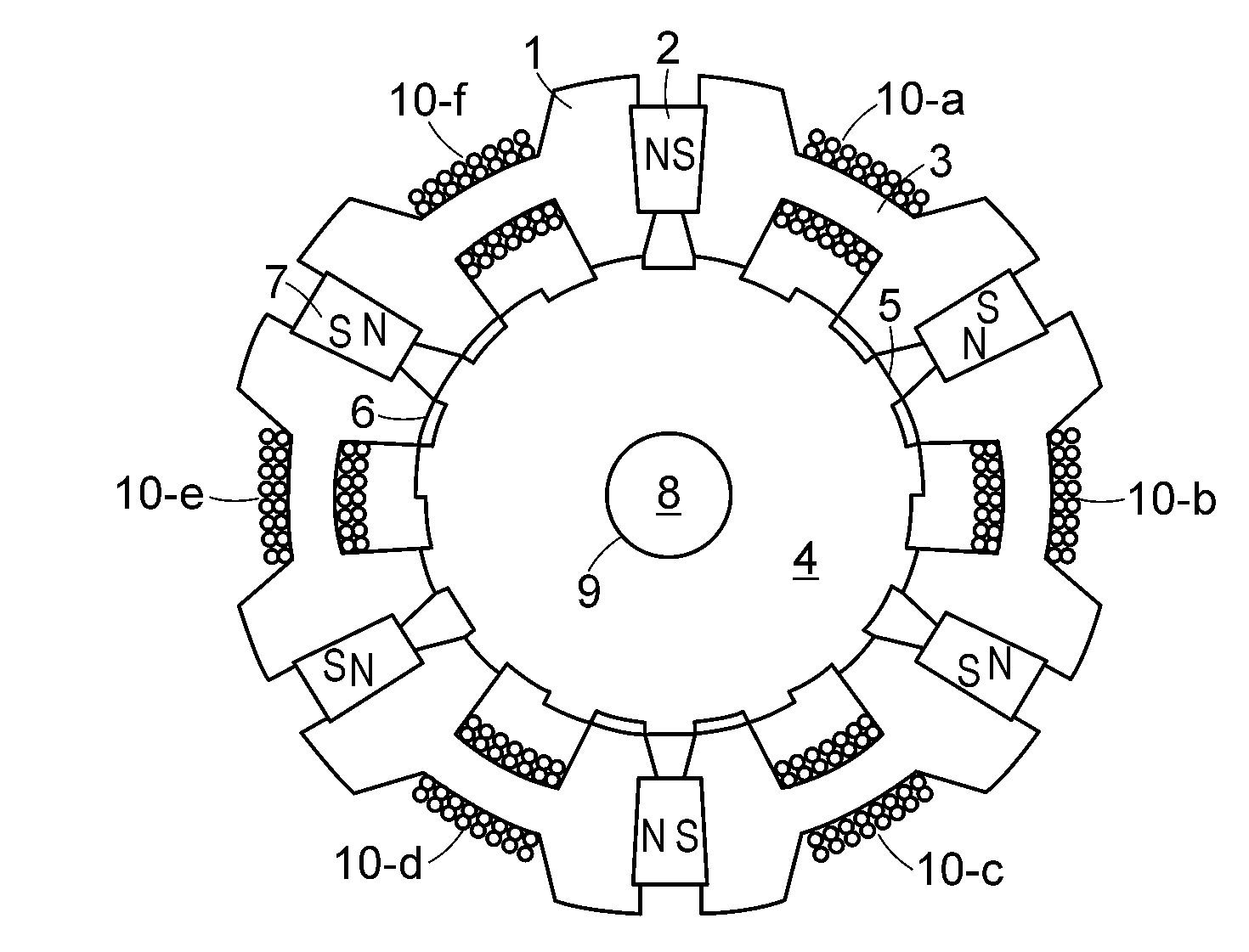

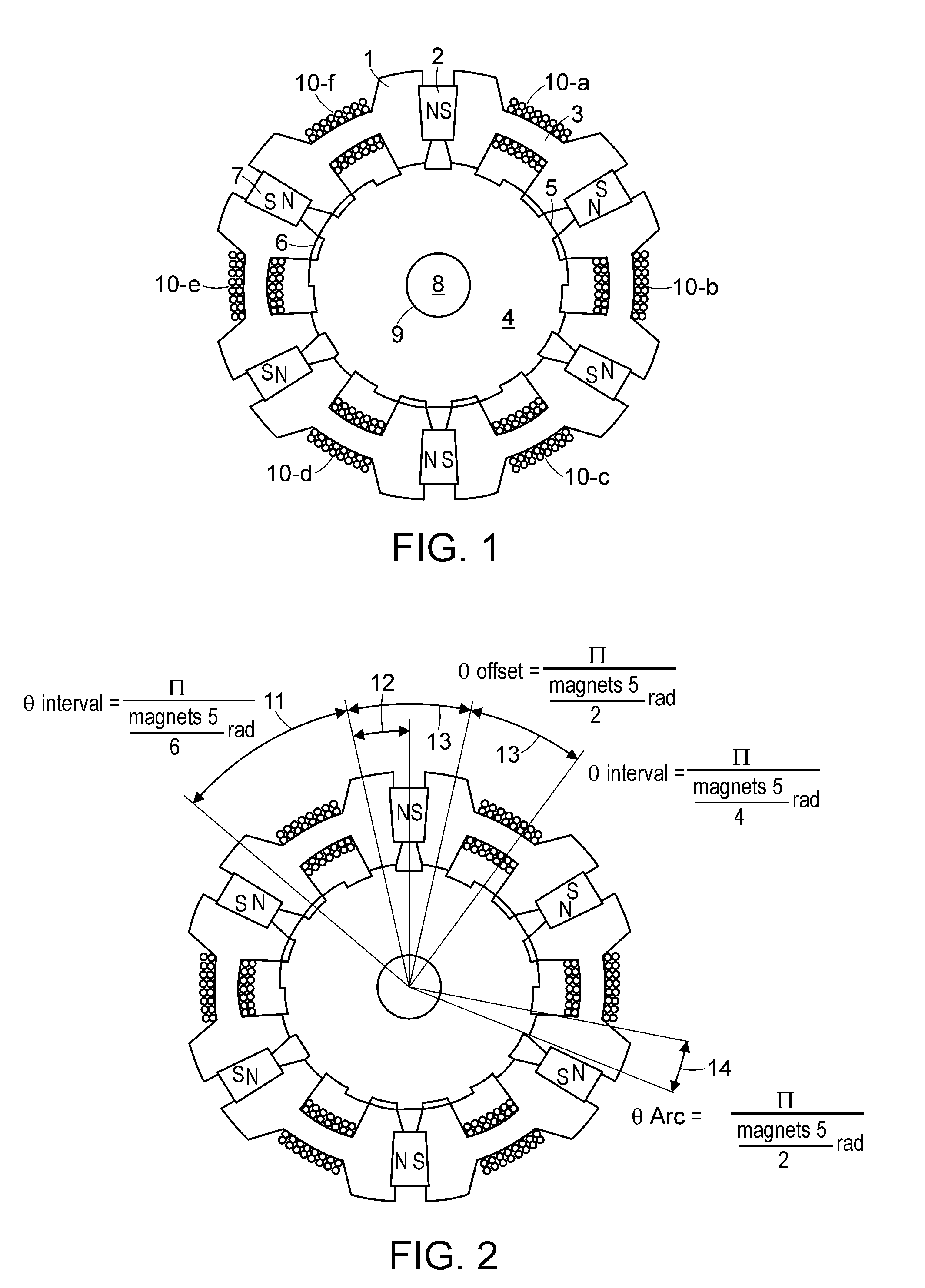

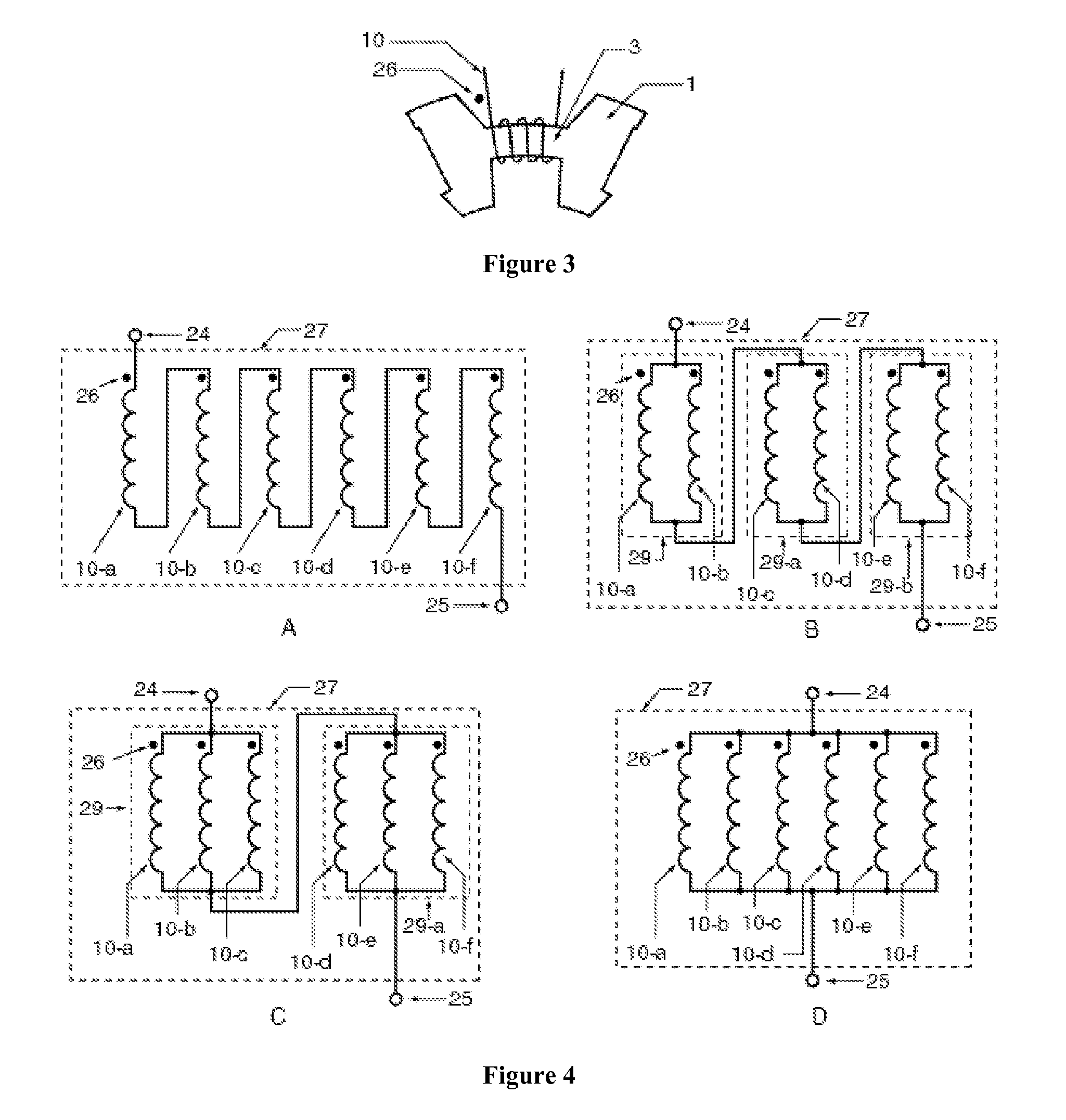

Permanent magnet electro-mechanical device providing motor/generator functions

InactiveUS20080272664A1DC commutatorSynchronous machines with rotating armatures and stationary magnetsMagnetic reluctanceCooling temperature

Owner:QM POWER

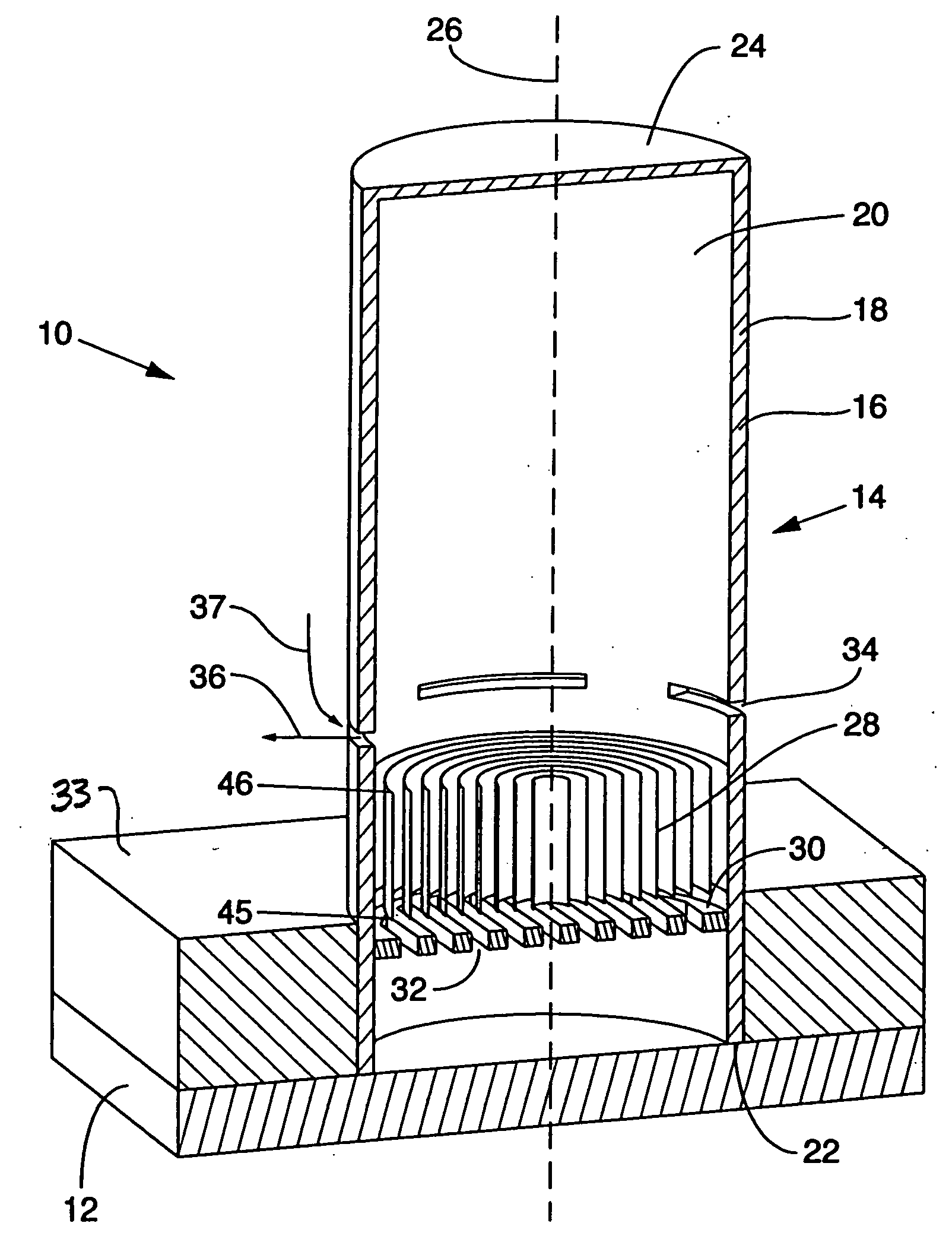

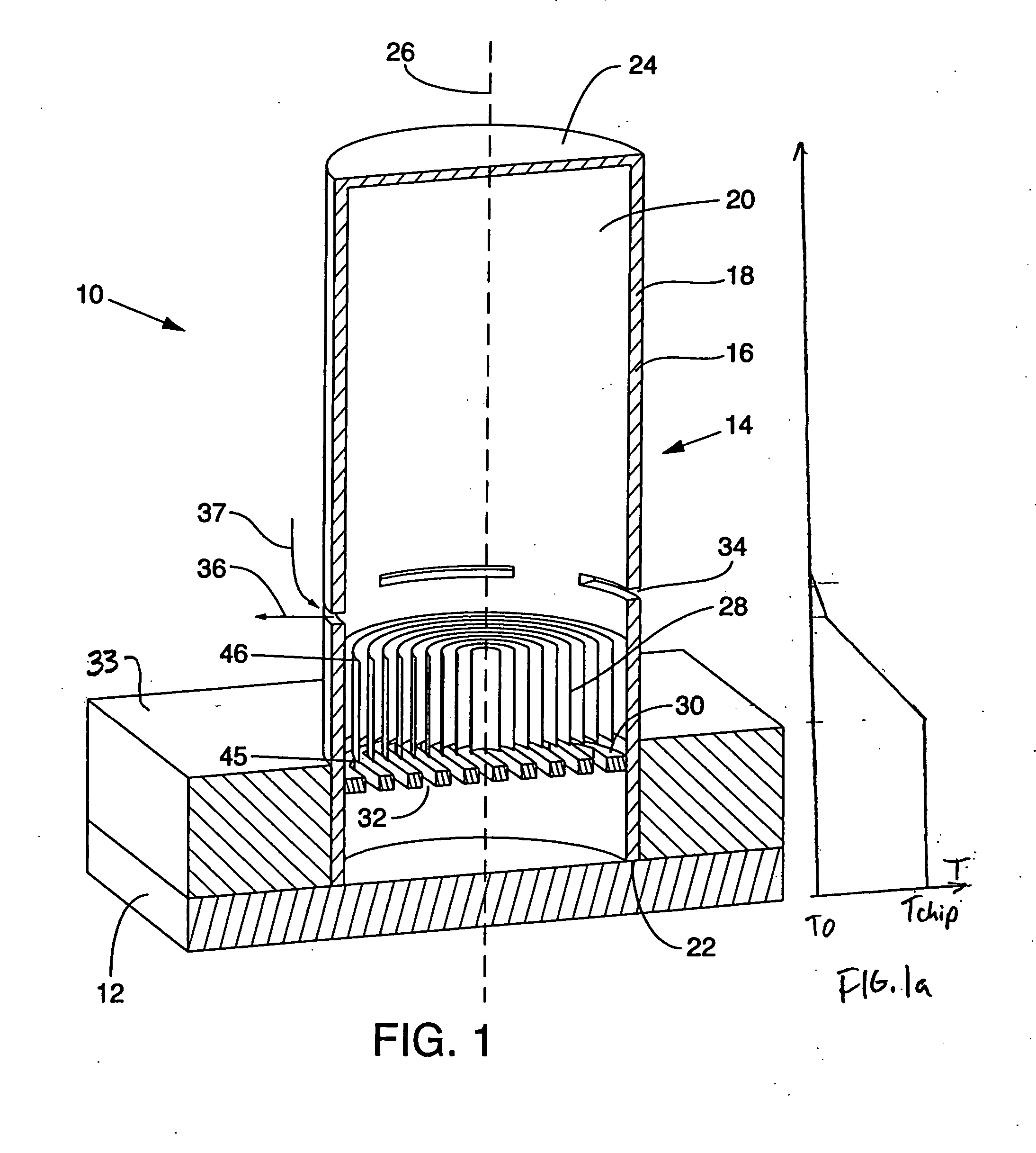

Thermoacoustic cooling device

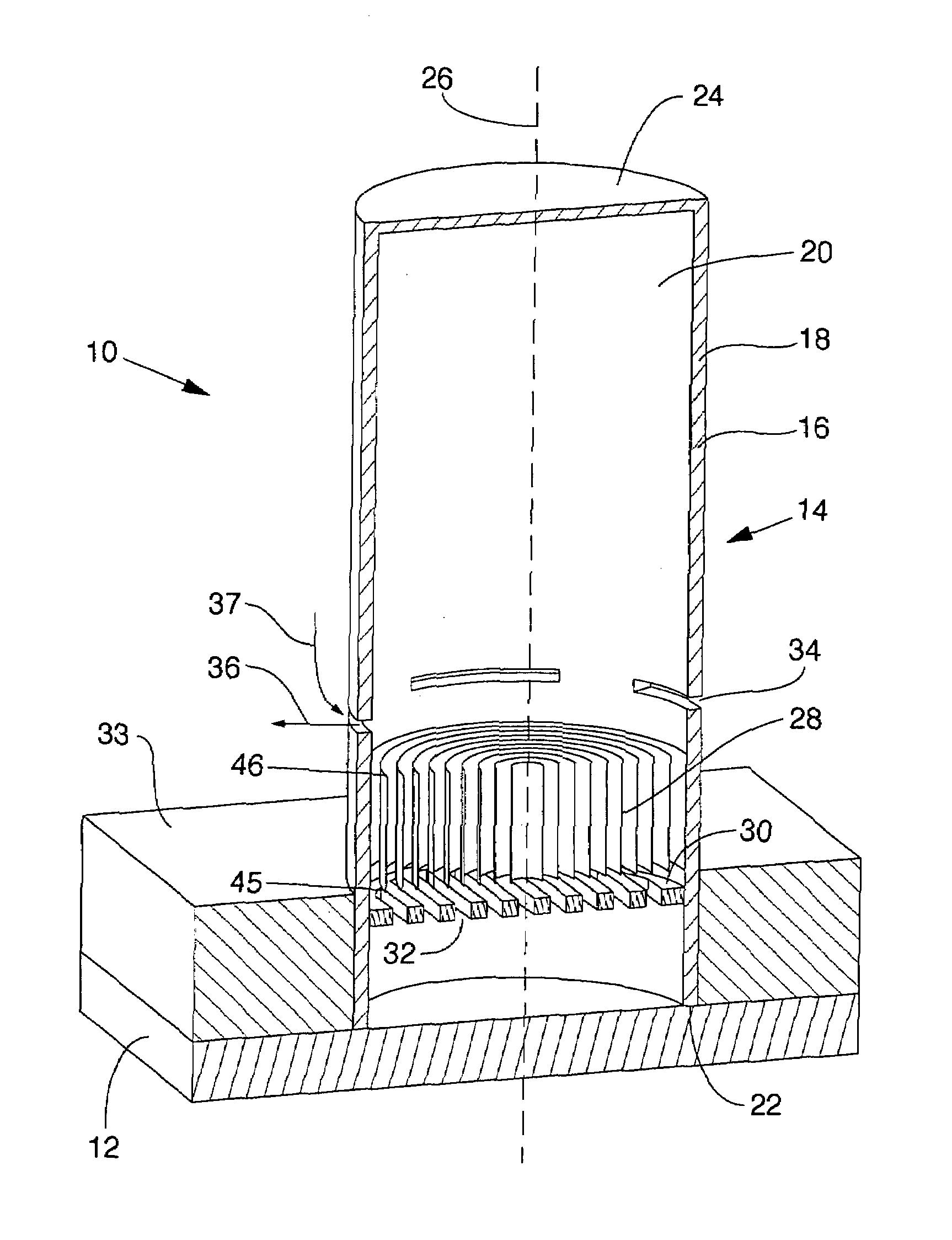

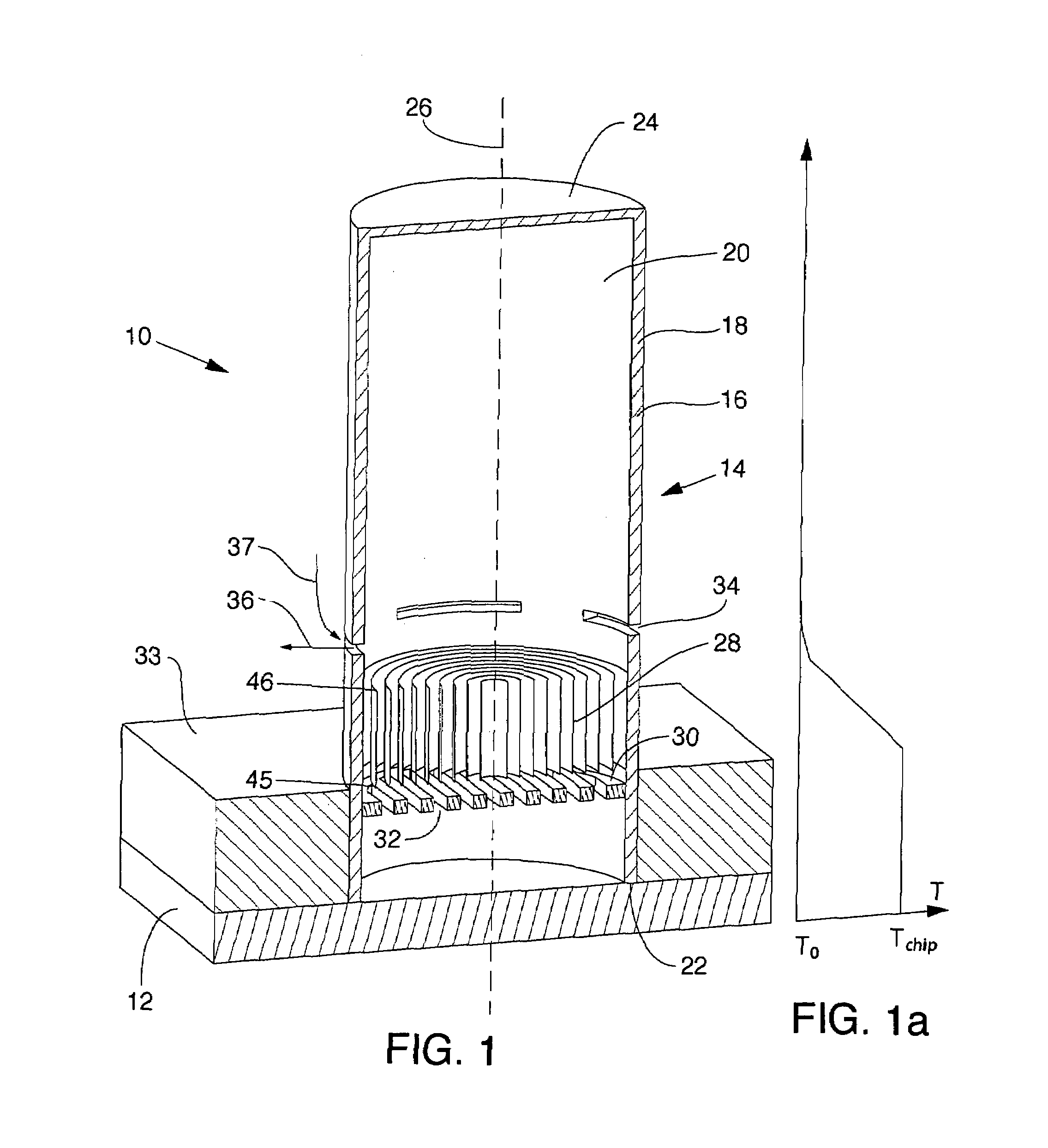

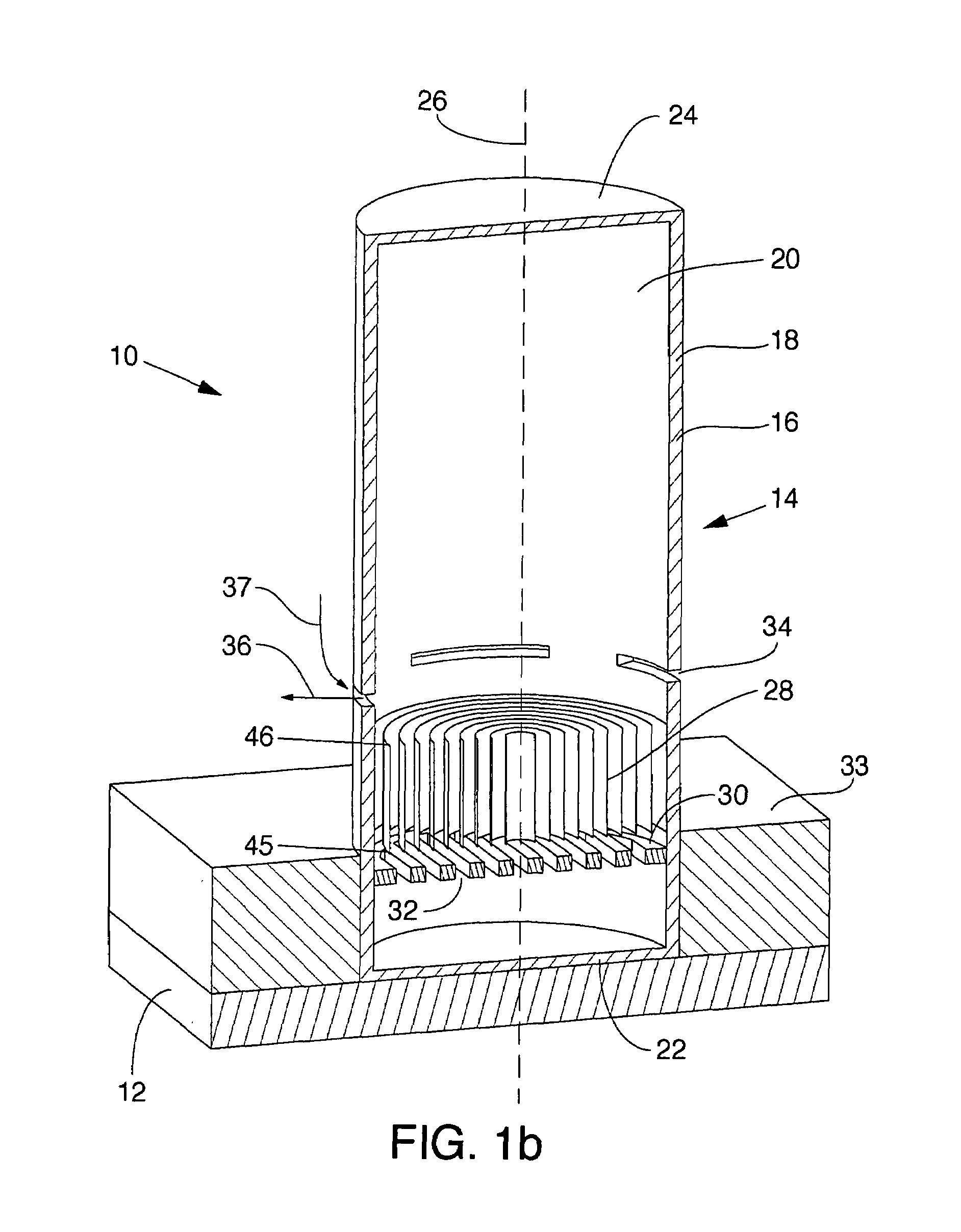

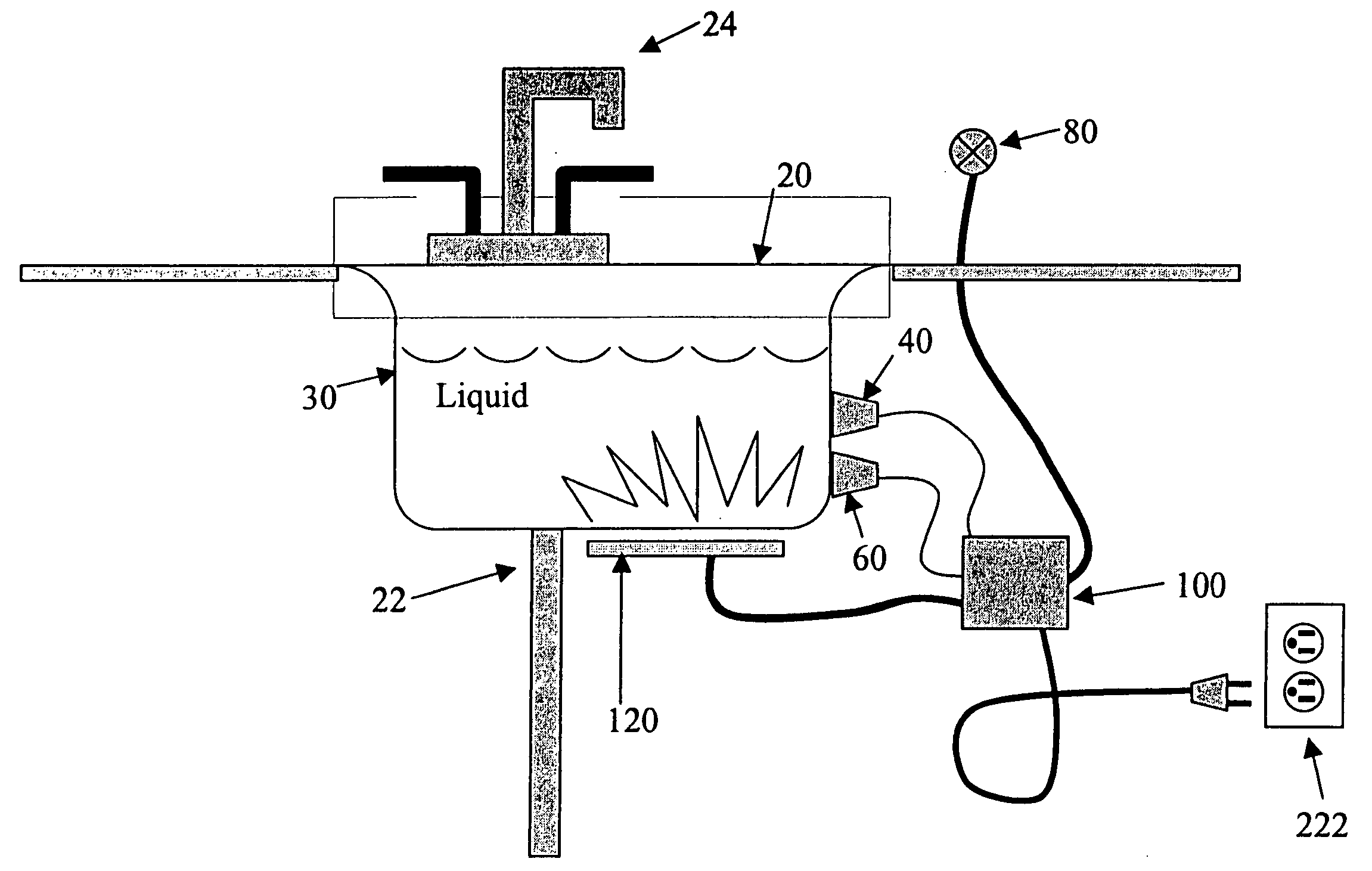

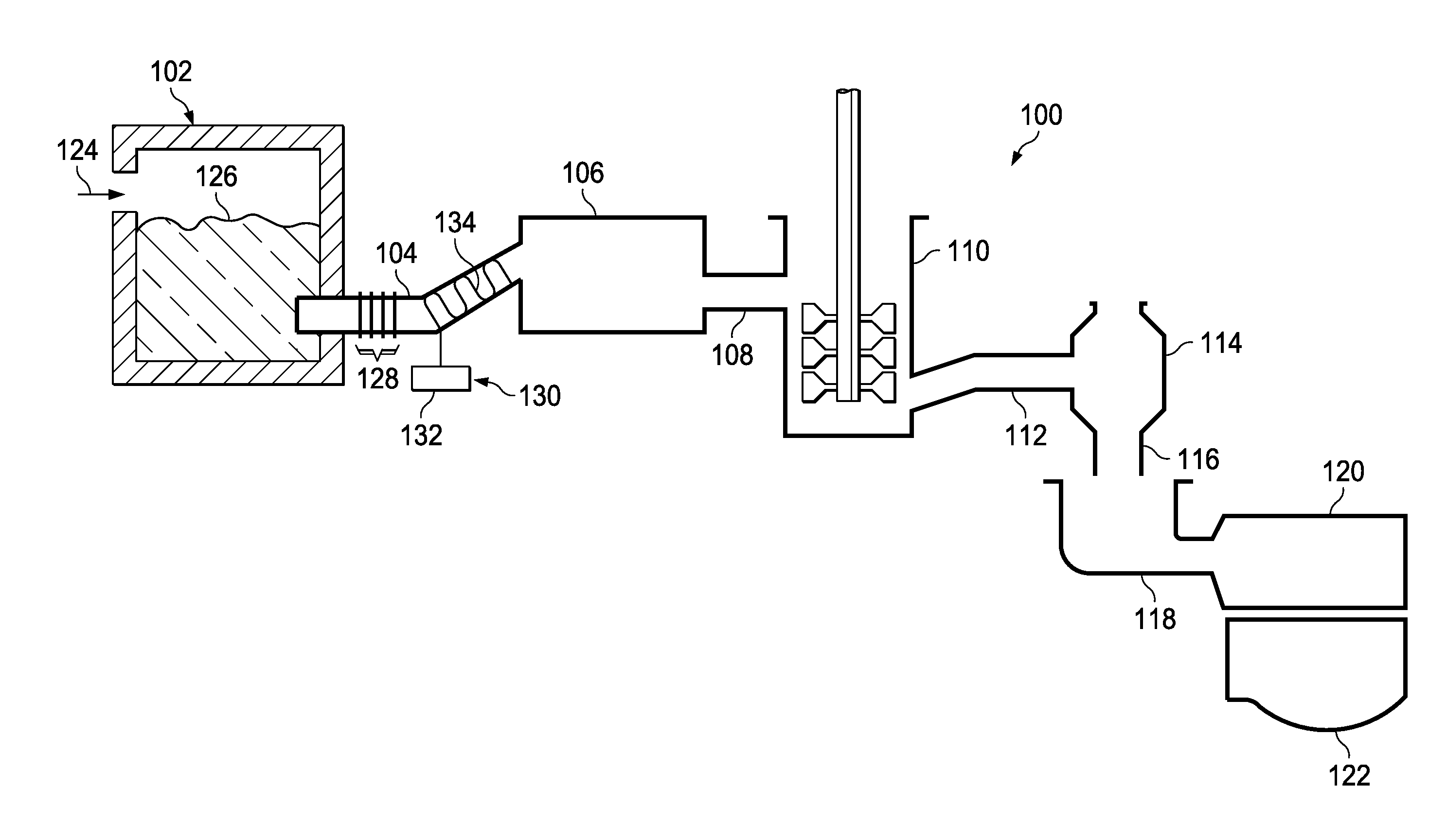

A thermoacoustic cooling system for cooling an object such as a microelectronic chip. Heat produced by the object is transferred to a thermoacoustic engine. The thermoacoustic engine may include a resonator defining a chamber. A stack may be positioned in the chamber with one side of the stack adjacent to the heat source, and the opposite side of the stack adjacent to air in the chamber having a relatively cooler temperature. One or more orifices may be formed in the resonator such that the acoustic power generated by the thermoacoustic engine creates a synthetic jet to circulate air and move the air away from the object being cooled. Thus, the heat produced by the object is used to power the thermoacoustic engine to thereby remove heat from the object. The thermoacoustic engine may use no moving parts and may require no external power source other than the object being cooled.

Owner:UTAH STATE UNIVERSITY

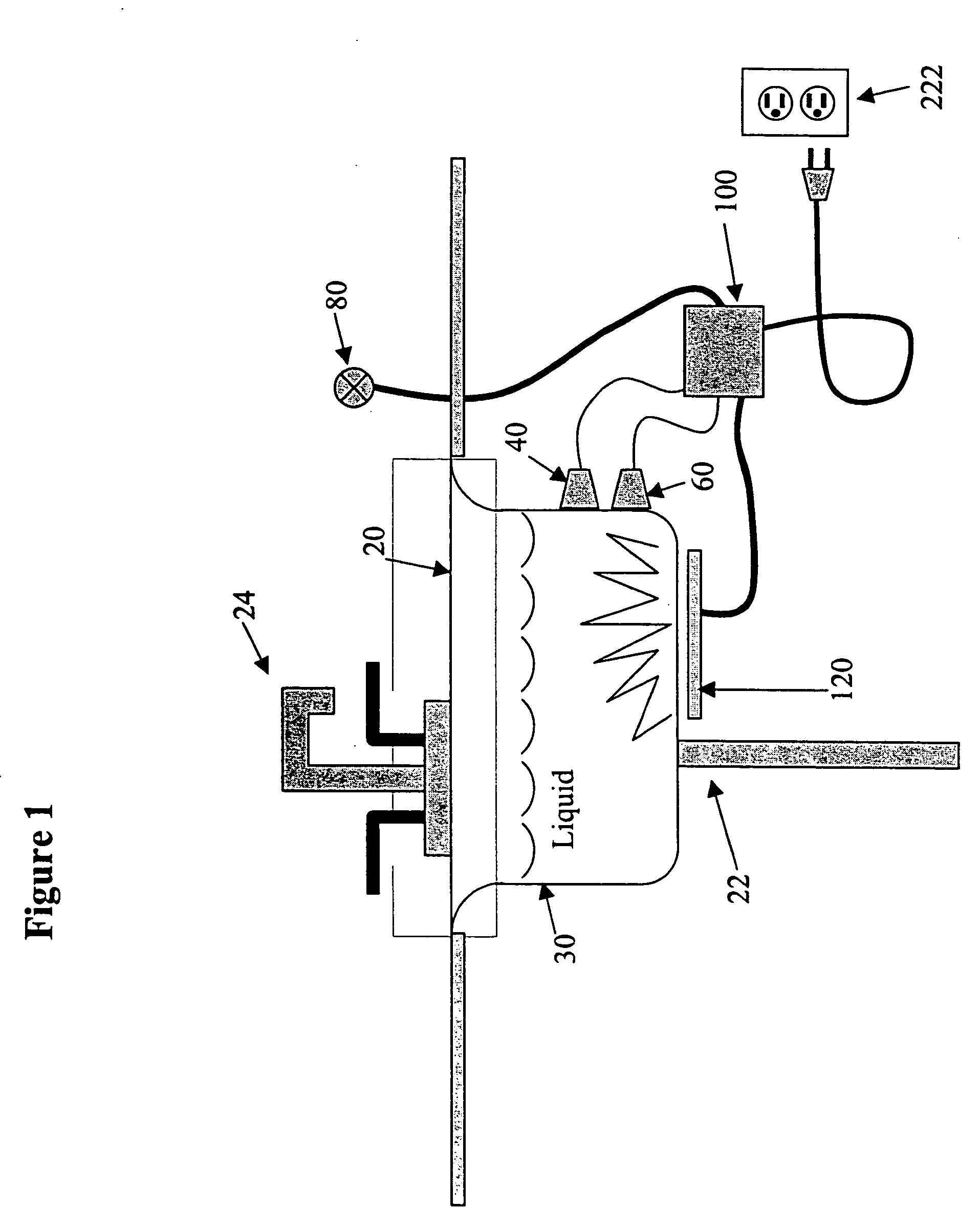

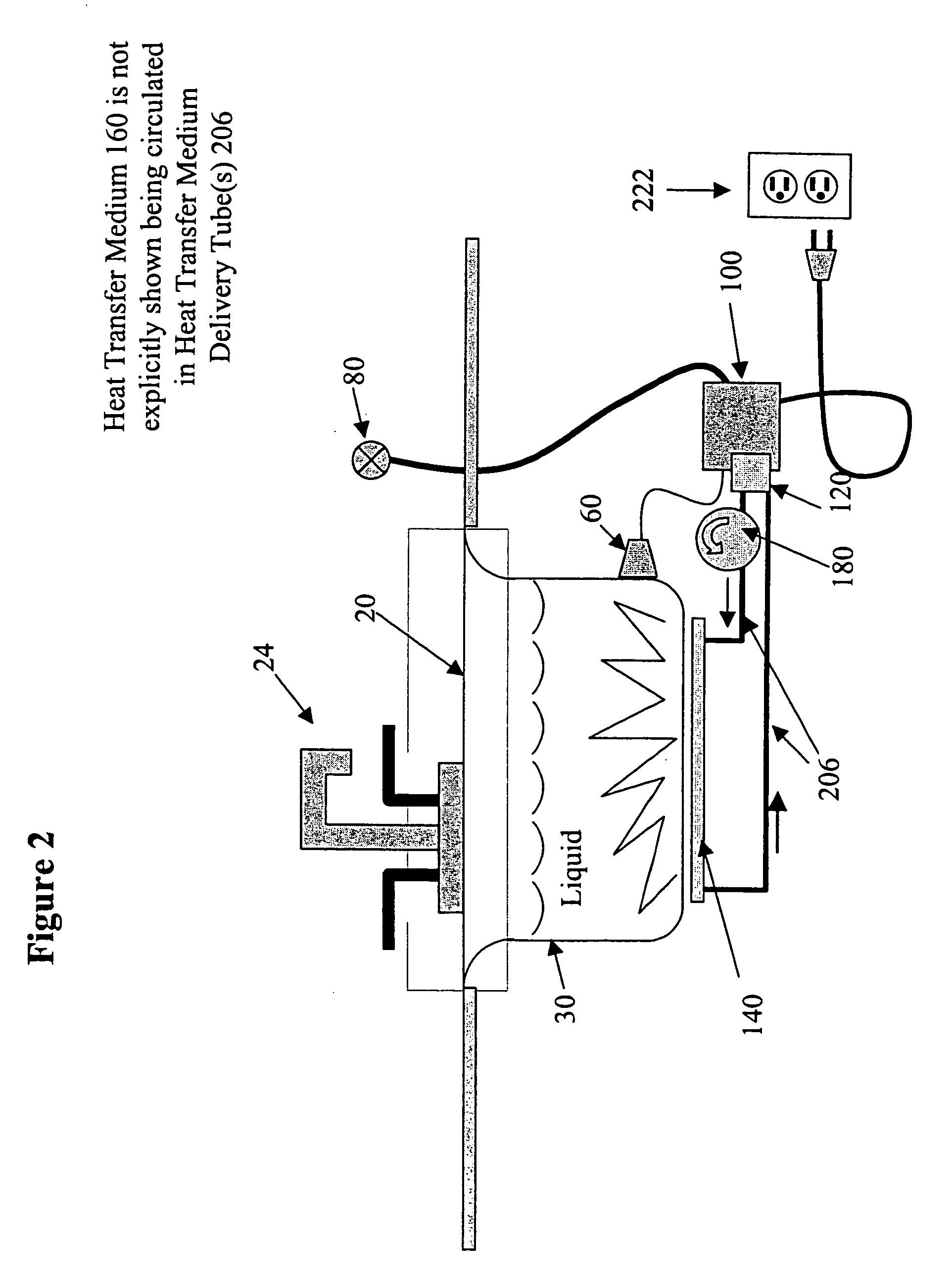

Apparatus for controlling the temperature of the water in a kitchen sink

InactiveUS20050044625A1Compensation for lossWash-standsDomestic plumbingTemperature controlFree cooling

Apparatus for use in controlling the temperature of the water in a kitchen sink (including a bathtub and / or other type of sink) for a reasonably extended period of time, without the necessity of adding additional hot water to the basin of the sink itself, to offset the loss of heat in the water as it naturally cools down over time. The invention also applies to the ability to maintain the water in a sink at a cool temperature, as opposed to a warm temperature. The preferred form of the invention provides a temperature controlling apparatus for a kitchen sink that can be integrally incorporated into the design of newly manufactured sink(s), and when activated by the user, automatically maintains the temperature of the water in the basin of a sink at an temperature level determined by the user.

Owner:KOMMERS WILLIAM JOHN

Thermoacoustic cooling device

A thermoacoustic cooling system for cooling an object such as a microelectronic chip. Heat produced by the object is transferred to a thermoacoustic engine. The thermoacoustic engine may include a resonator defining a chamber. A stack may be positioned in the chamber with one side of the stack adjacent to the heat source, and the opposite side of the stack adjacent to air in the chamber having a relatively cooler temperature. One or more orifices may be formed in the resonator such that the acoustic power generated by the thermoacoustic engine creates a synthetic jet to circulate air and move the air away from the object being cooled. Thus, the heat produced by the object is used to power the thermoacoustic engine to thereby remove heat from the object. The thermoacoustic engine may use no moving parts and may require no external power source other than the object being cooled.

Owner:UTAH STATE UNIVERSITY

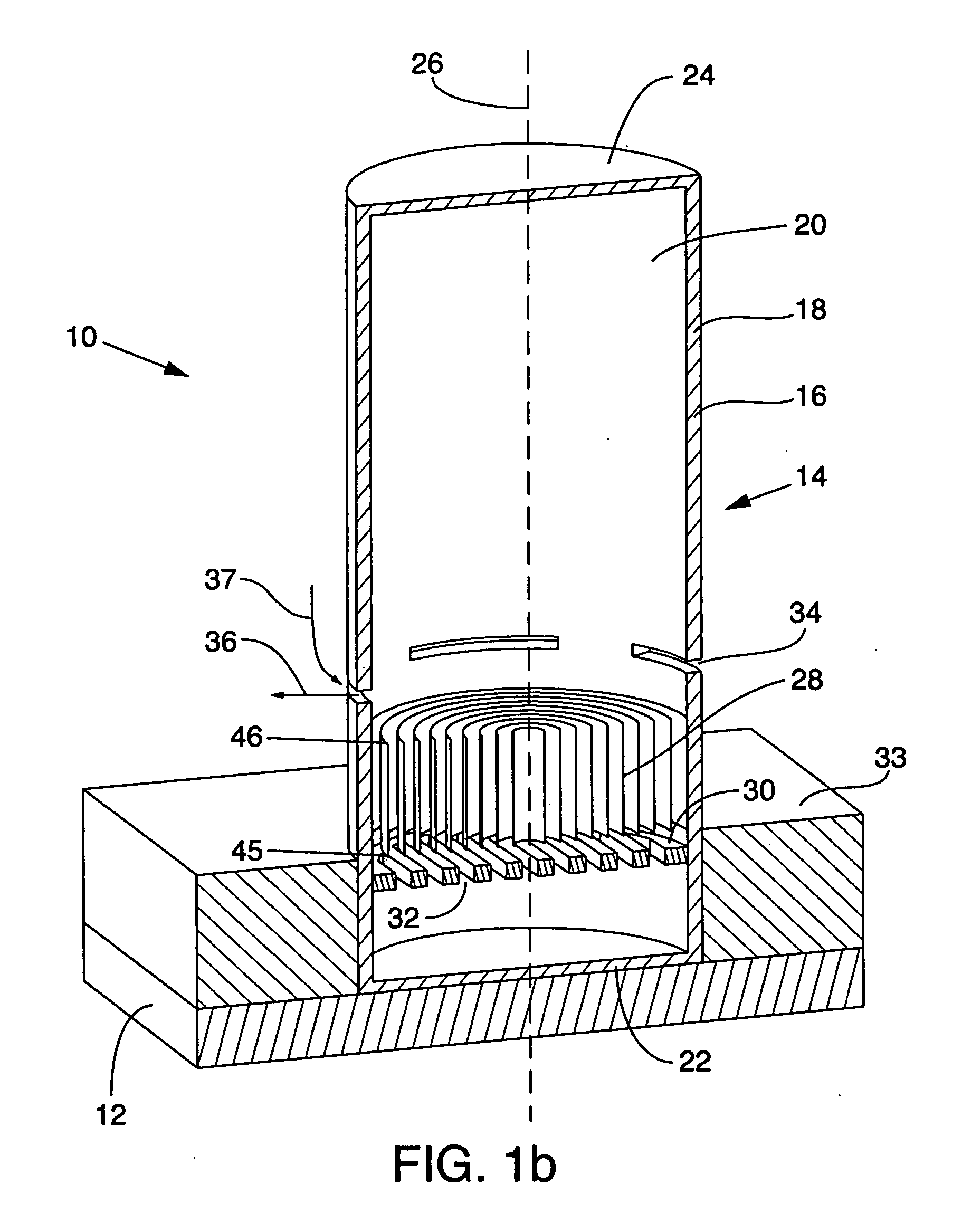

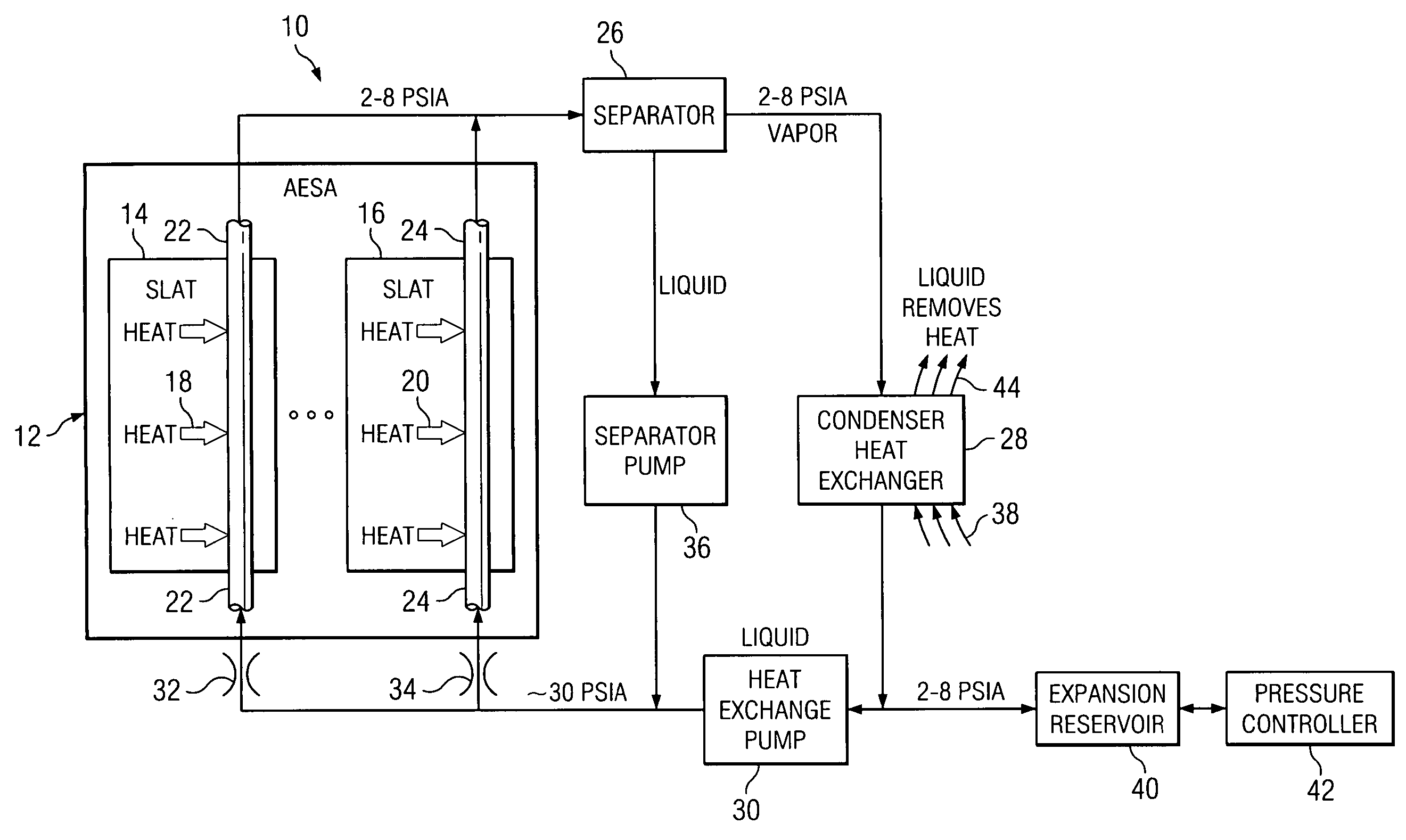

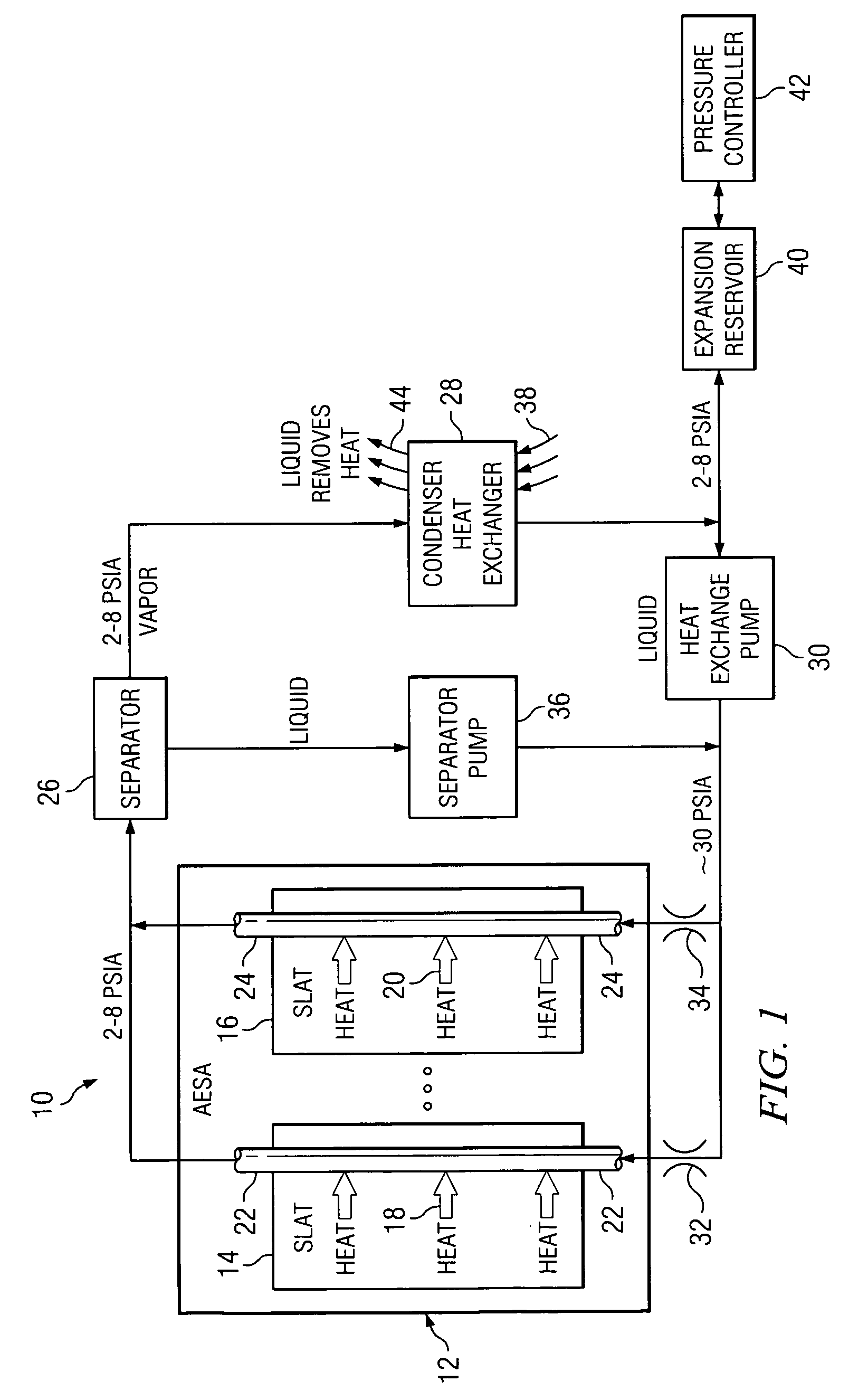

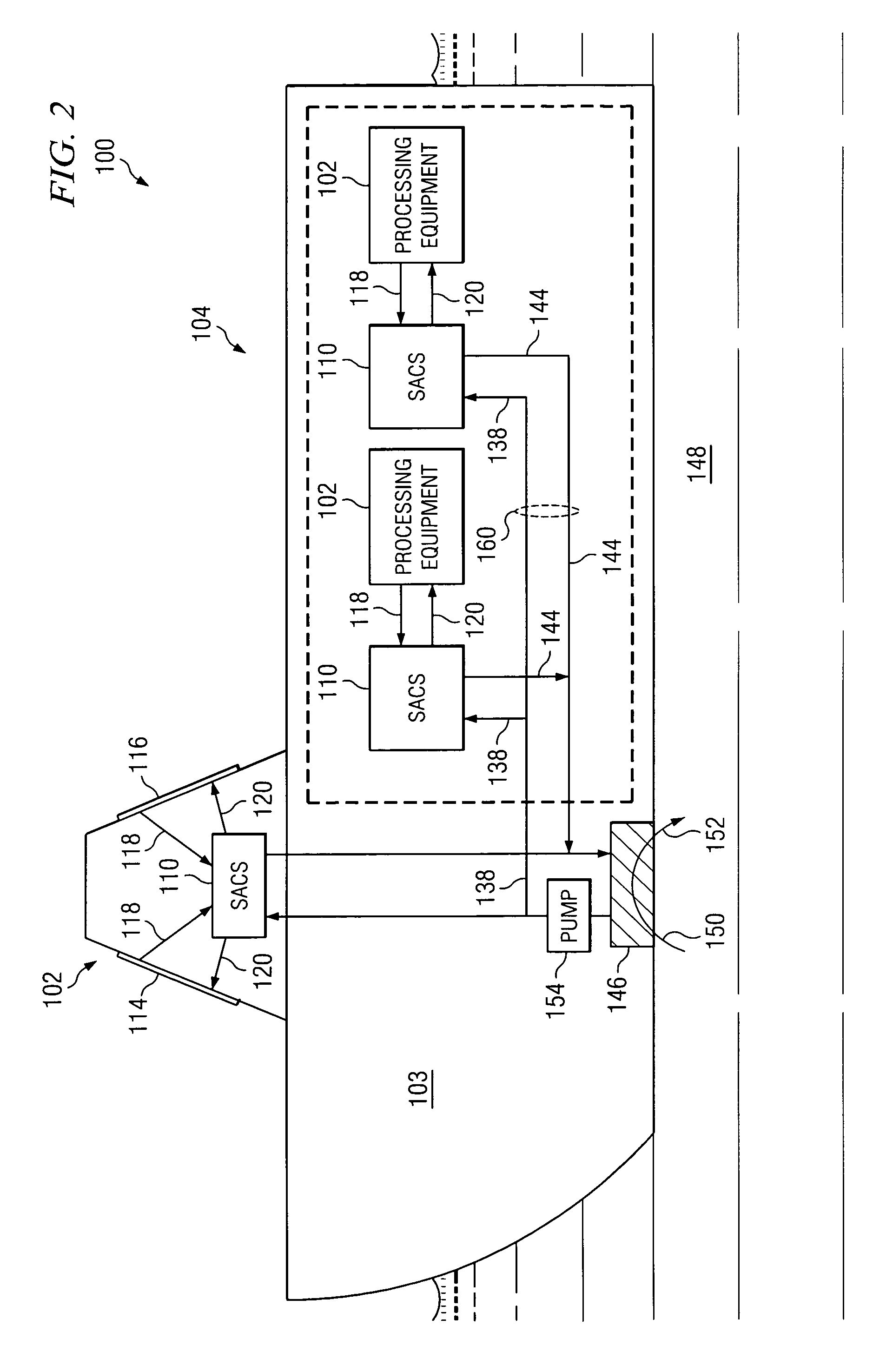

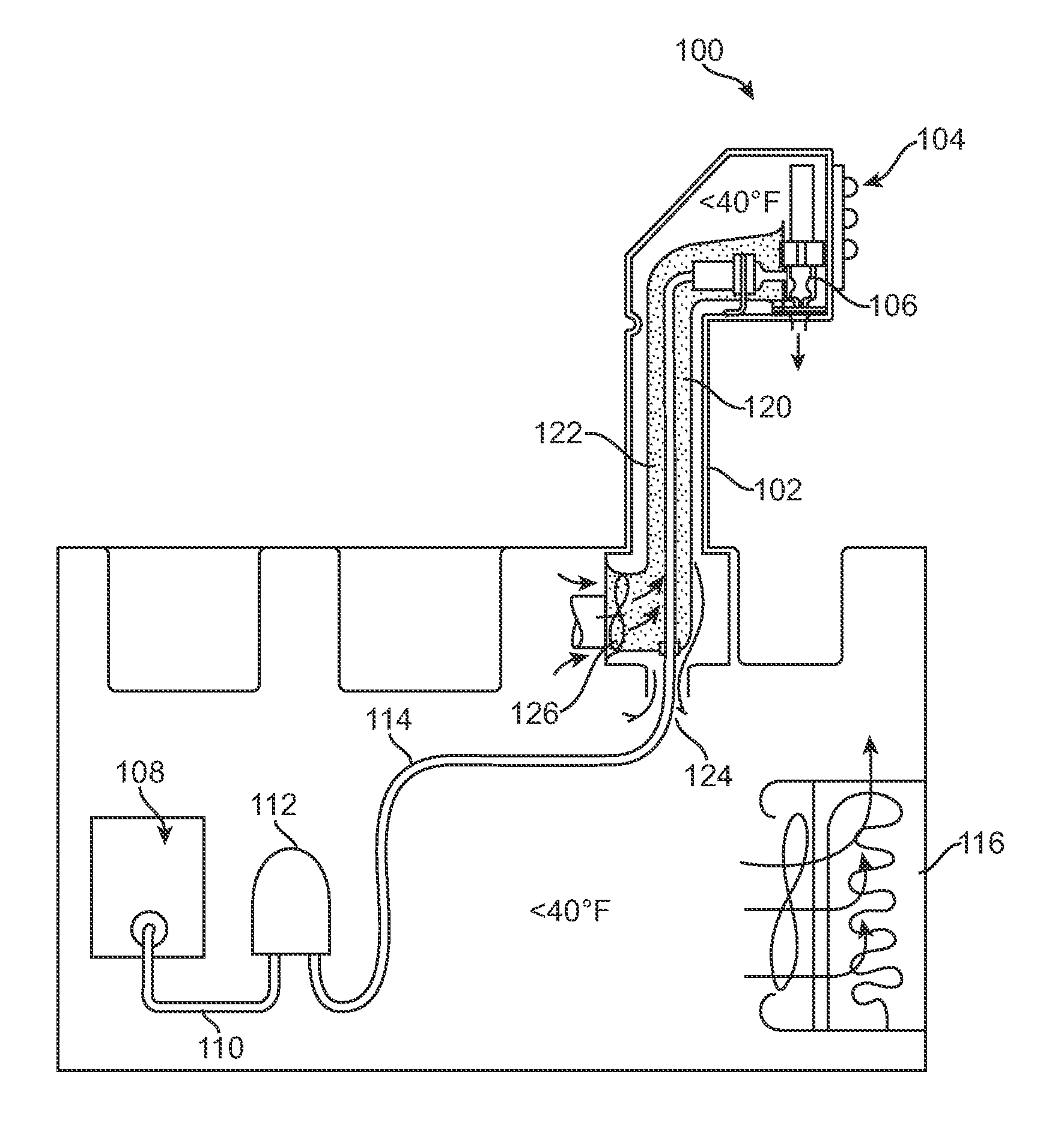

Method and apparatus for cooling with coolant at a subambient pressure

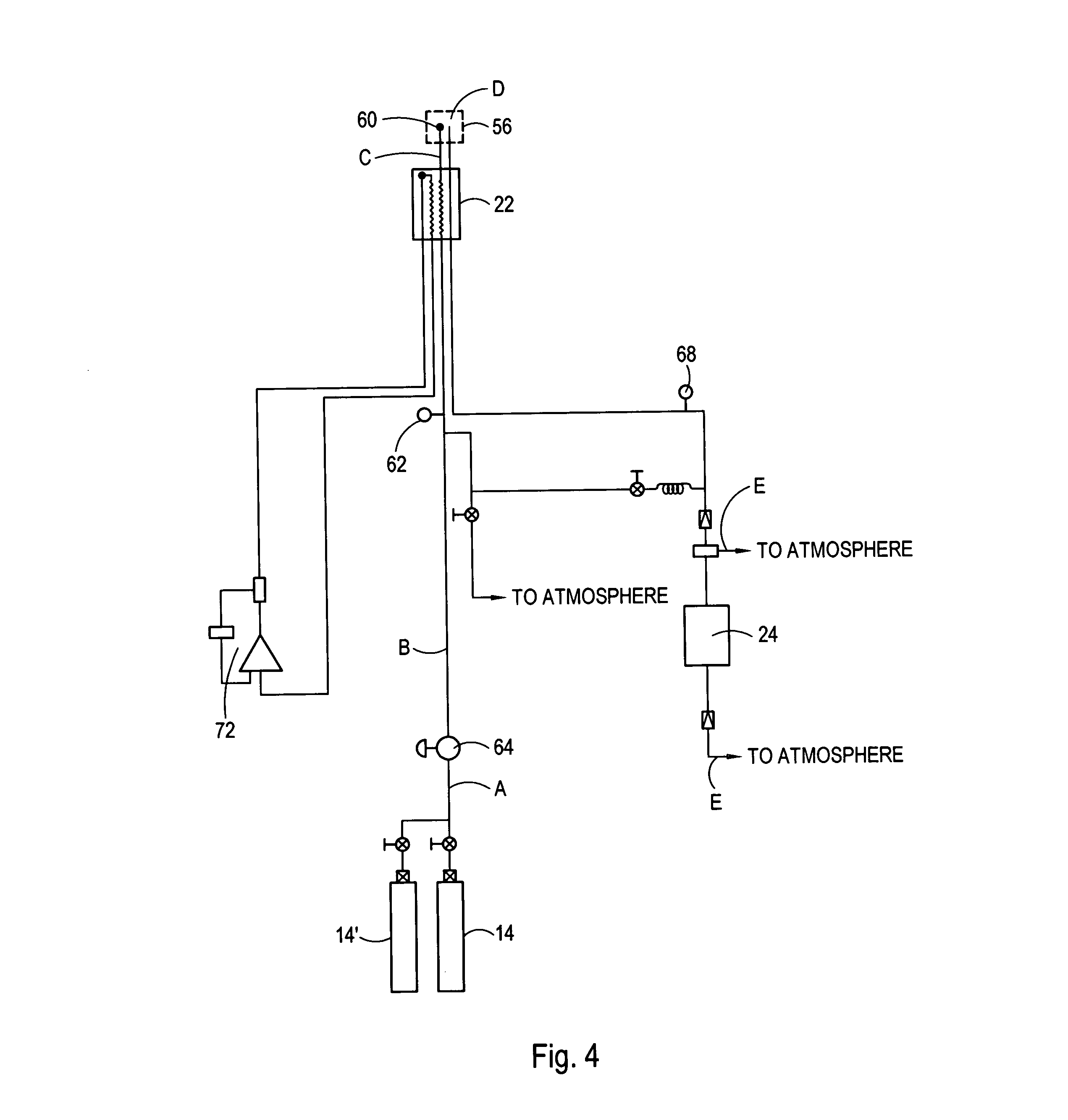

ActiveUS7254957B2Valuable spaceImprove cooling effectDomestic cooling apparatusAuxillariesCoolant flowAmbient pressure

According to one embodiment, an apparatus includes a fluid coolant and structure which reduces a pressure of the fluid coolant through a subambient pressure at which the coolant has a cooling temperature less than a temperature of the heat-generating structure. The apparatus also includes structure that directs a flow of the fluid coolant in the form of a liquid at a subambient pressure in a manner causing the liquid coolant to be brought into thermal communication with the heat-generating structure. The heat from the heat-generating structure causes the liquid coolant to boil and vaporize so that the coolant absorbs heat from the heat-generating structure as the coolant changes state. The structure is configured to circulate the fluid coolant through a flow loop while maintaining the pressure of the fluid coolant within a range having an upper bound less than ambient pressure. The apparatus also includes a first heat exchanger for exchanging heat between the fluid coolant flowing through the loop and a second coolant in an intermediary loop so as to condense the fluid coolant flowing through the loop to a liquid. The apparatus also includes a second heat exchanger for exchanging heat between the second coolant in the intermediary cooling loop and a body of water on which the ship is disposed.

Owner:RAYTHEON CO

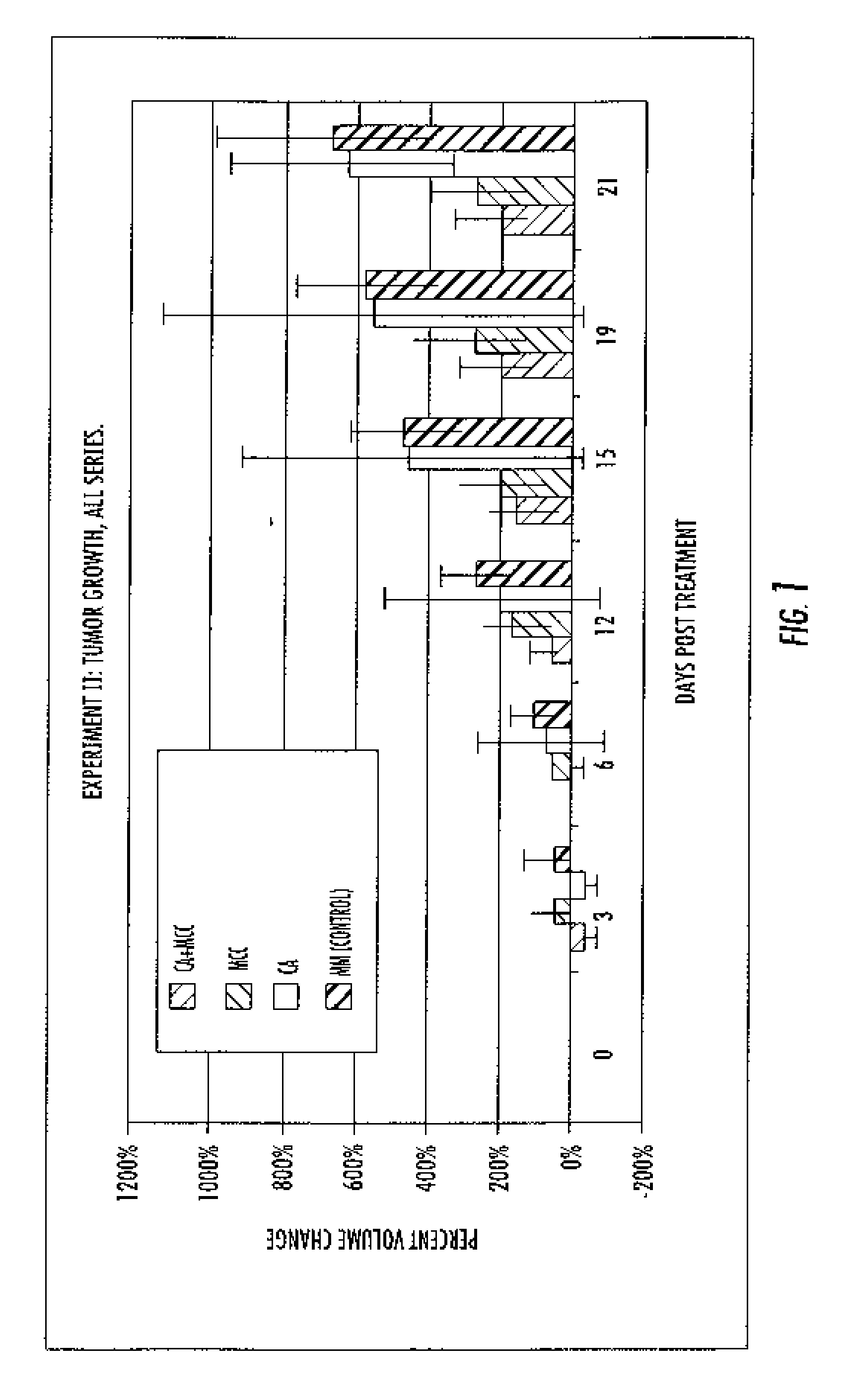

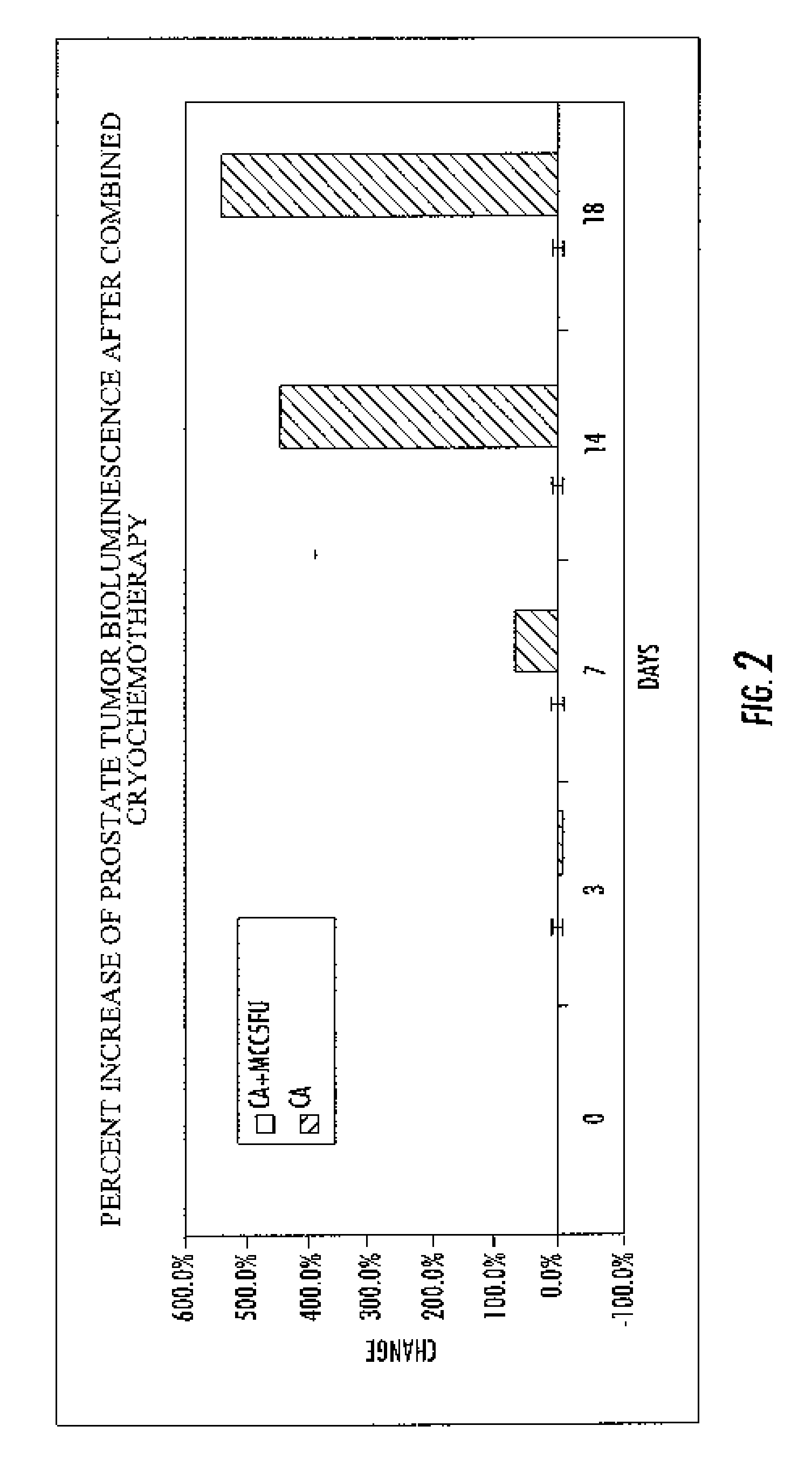

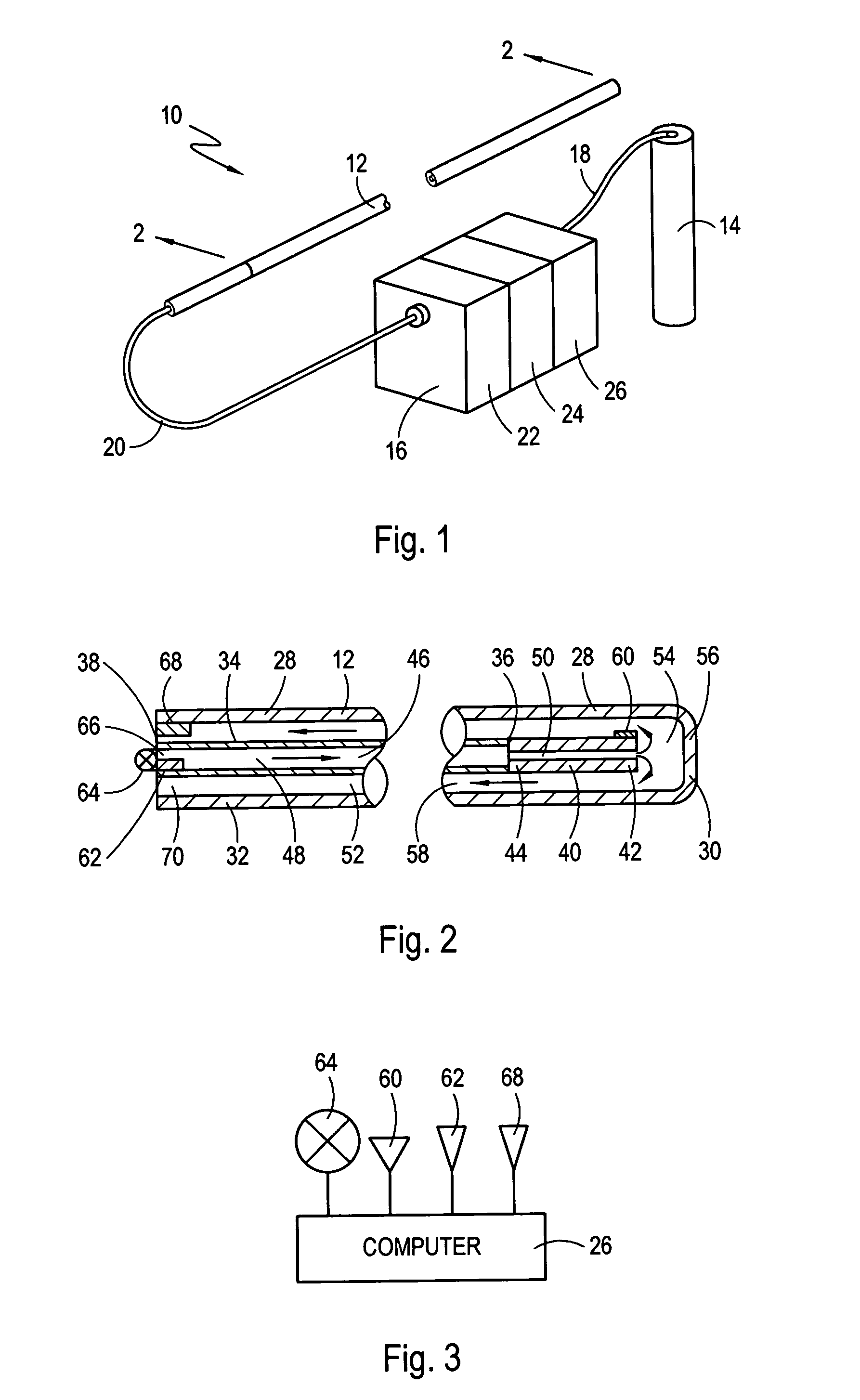

Systems and methods for improving image-guided tissue ablation

ActiveUS20080208052A1Enhanced safety and efficacyShorten operation timeUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasound imagingRegimen

The cryosurgical kit and method of use relates to the combined use of biodegradable, imageable, drug(s) carriers, vectors or microcapsules deposited into a target tissue region inside a body and the controlled cooling of the target tissue region. A minimally invasive method of treatment that applies a cooling device to a selected tissue region, uses a vibrating resonant frequency delivery device to inject drug(s) carriers (microcapsules) containing therapeutic and contrast agents into tissue region(s) submitted to cooling temperatures, successive real-time imaging of the microcapsule deposition and later detection of the progressive degradation of microcapsules with ultrasound imaging which provides estimation of sustained release rates and for planning re-dosing regimens. The thermosensitive microcapsules preferably contain ethiodol, a contrast agent for Ultrasound and / or X-Ray imaging, and cytotoxic drug(s).

Owner:NUVUE THERAPEUTICS

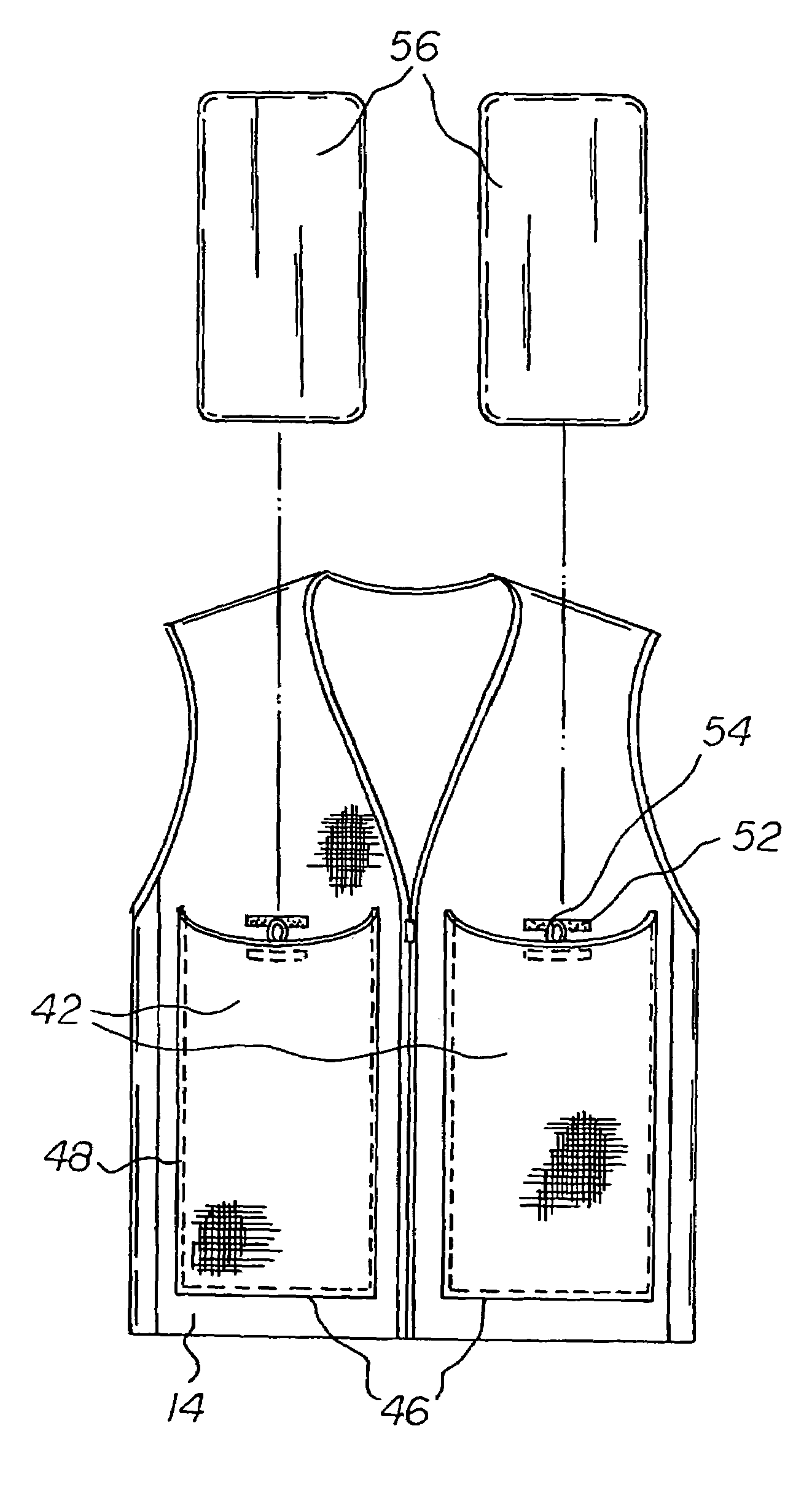

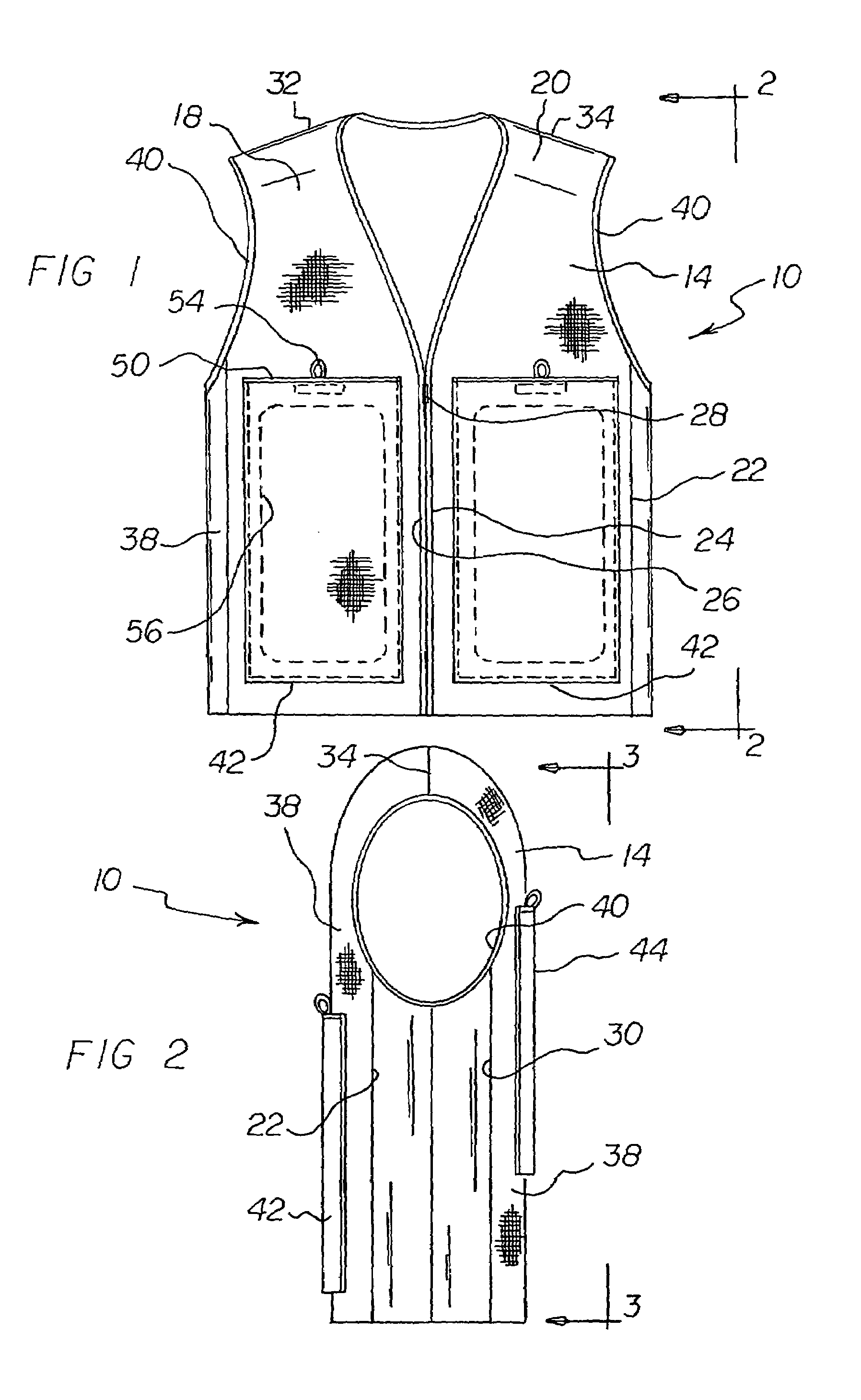

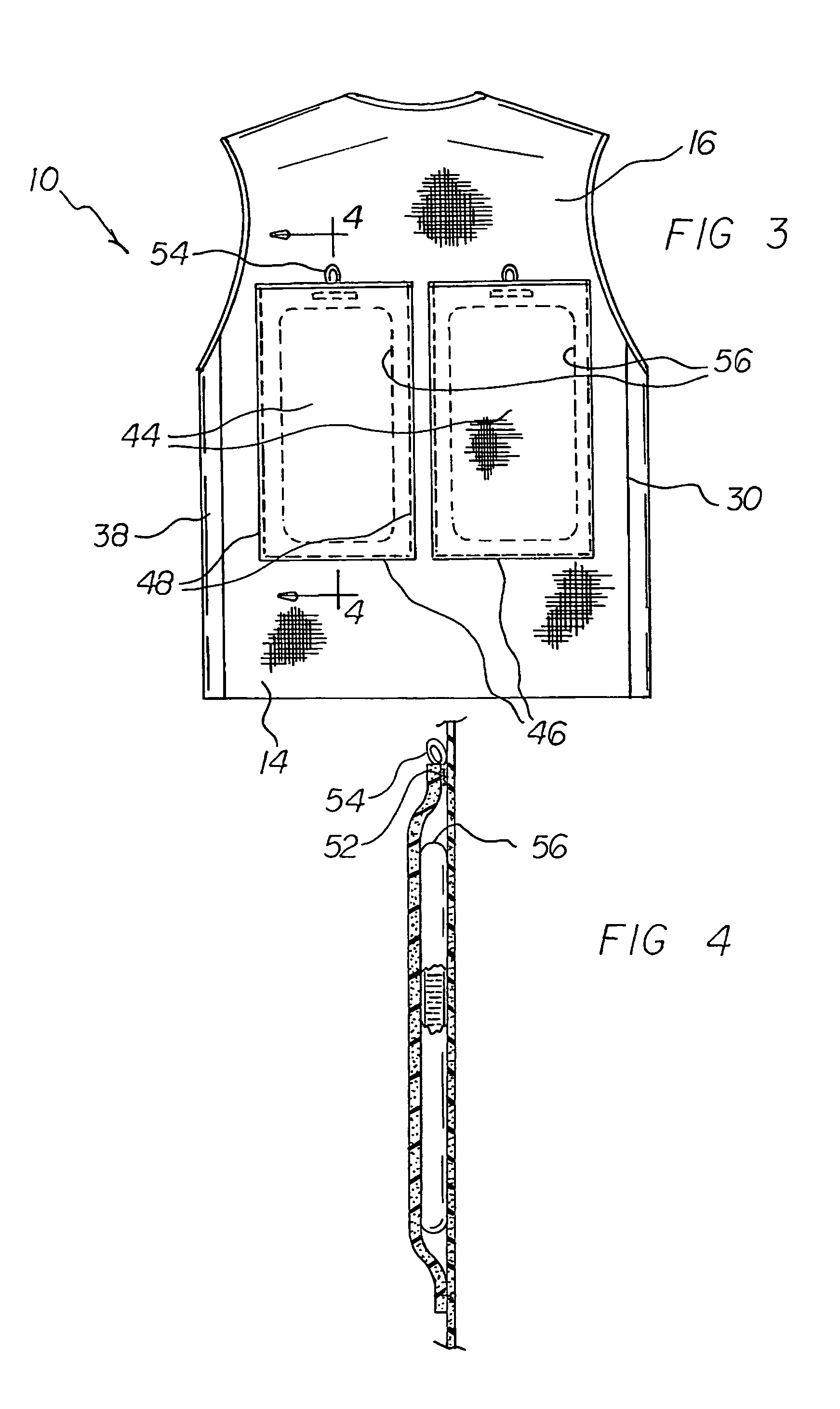

Cooling vest system

ActiveUS6931875B1Improve insulation effectImprove thermal efficiencyChemical protectionHeat protectionThermal insulationCooling temperature

A basic vest is formed of a rear panel and laterally disposed front panels. The panels are fabricated of a material of low thermal insulation capabilities. A plurality of pockets has two laterally spaced rectangular front sheets located on the exterior surface of the front panels and two laterally spaced rectangular rear sheets located on the exterior surface of the rear panel. Each sheet has peripheral edges stitched to an associated panel and a free peripheral edge. An opening with fasteners there adjacent allow a wearer to open and close the opening. The sheets are fabricated of a material of high thermal insulation capabilities. A plurality of cooling packs is adapted to be placed in the pockets for dissipating the cooling temperature to a wearer.

Owner:ALLEN JEFFREY +1

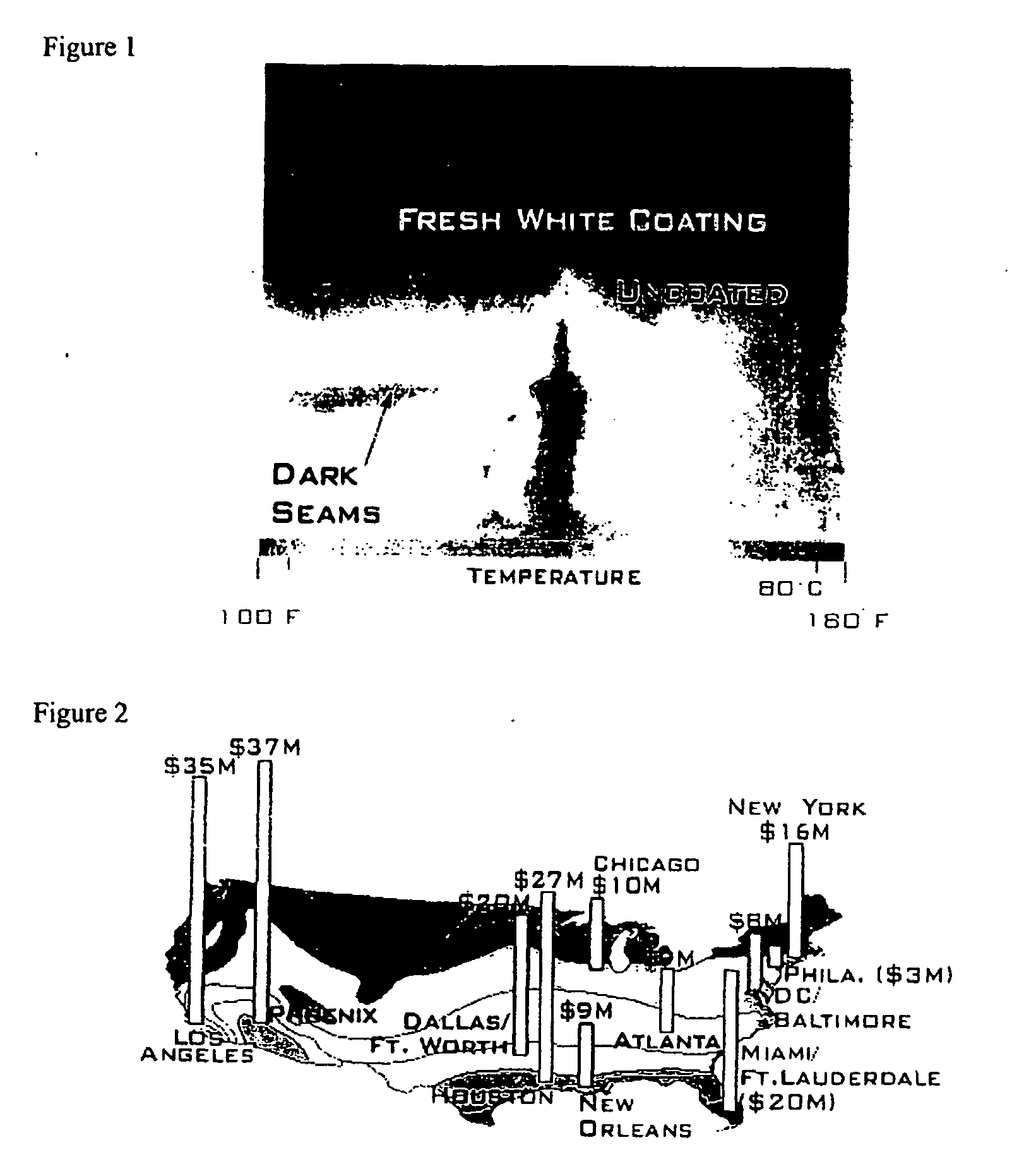

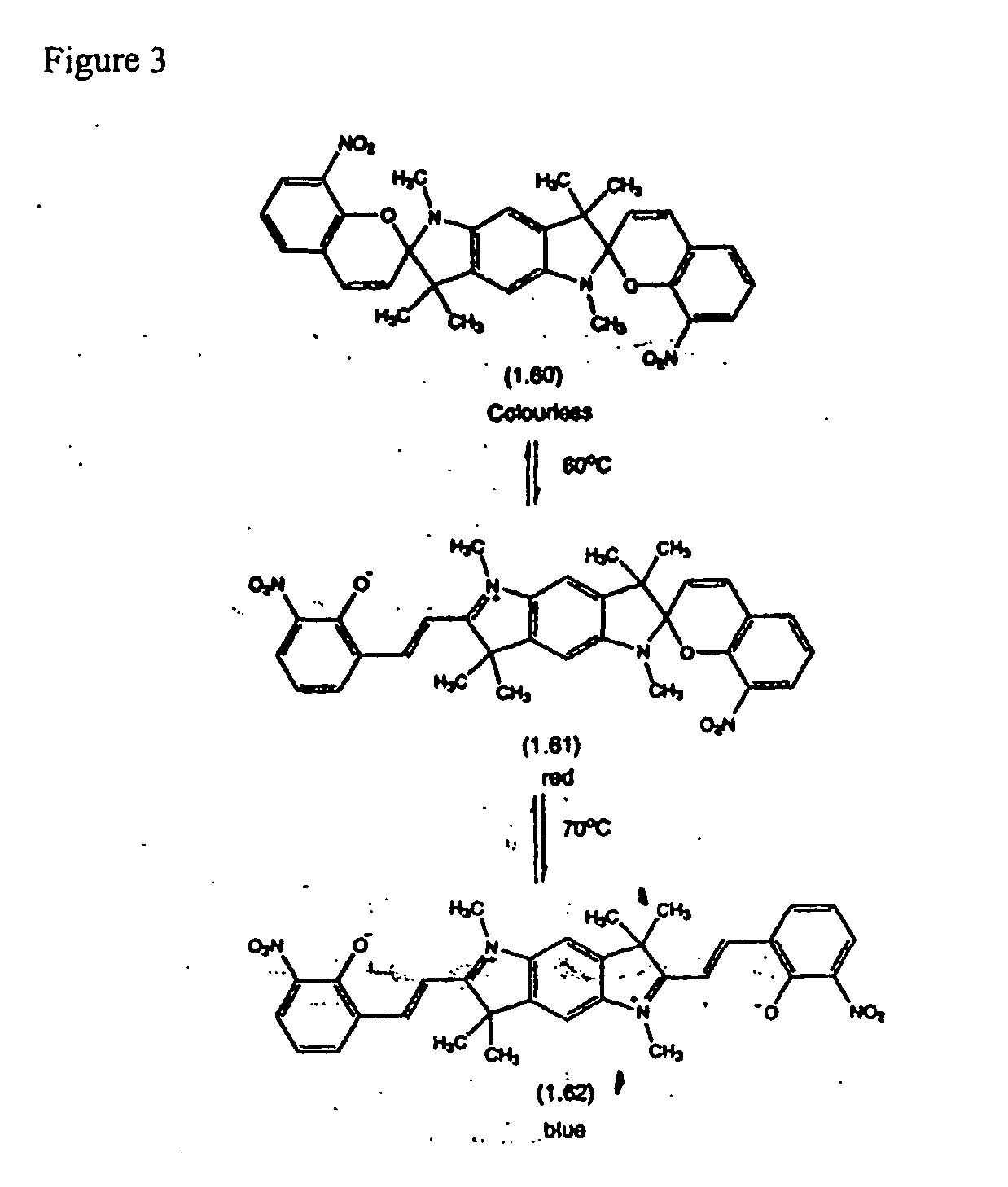

System and method for energy-conserving roofing

InactiveUS20050064175A1Reduce air pollutionLess cooling/heatingRoof covering using slabs/sheetsLayered productsAbsorbed energyEngineering

An energy-conserving building covering material includes a building panel, such as a roofing panel or a siding panel, coated with a thermomorphic material that can change its energy reflectance. The thermomorphic coating material can be combined with a carrier material, or it can be encapsulated with a solvent and optionally a color former in a microcapsule suspended in the carrier material. Alternatively, the building panel can include an electrophoretic material sandwiched between two transparent panels acting as electrodes. The building panel, when covered with said coating material and carrier material combination, can reflect radiant energy during warmer temperatures and can absorb radiant energy during cooler temperatures and re-radiate said absorbed energy into an interior of a building.

Owner:AZARI SHAUN +1

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

Method of Adjusting Temperatures of Products to Desired Product Temperatures

ActiveUS20090029016A1Lighting and heating apparatusDigital data processing detailsProcess engineeringProduct gas

A method of adjusting temperatures of products to a desired product temperature. The method may include enabling the selection of a product, enabling the selection of the desired product temperature, enabling the placement of the product into a temperature adjust device, circulating a liquid or a gas through the temperature adjust device, the liquid or the gas having been cooled to a cool temperature less than the desired product temperature or heated to a warm temperature greater than the desired product temperature, determining when the desired product temperature has been obtained, and ceasing circulation of the liquid or a gas through the temperature adjust device.

Owner:THE COCA-COLA CO

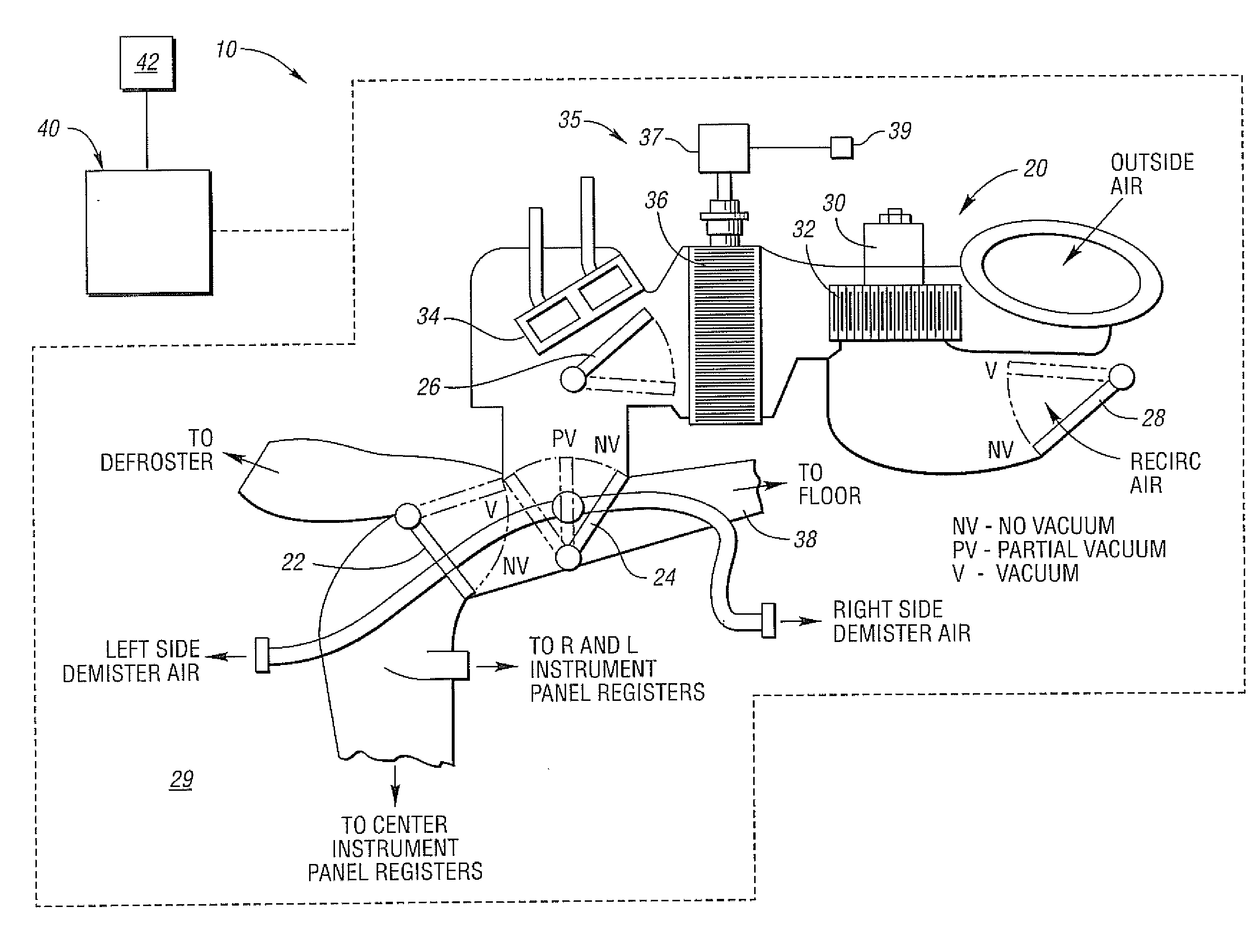

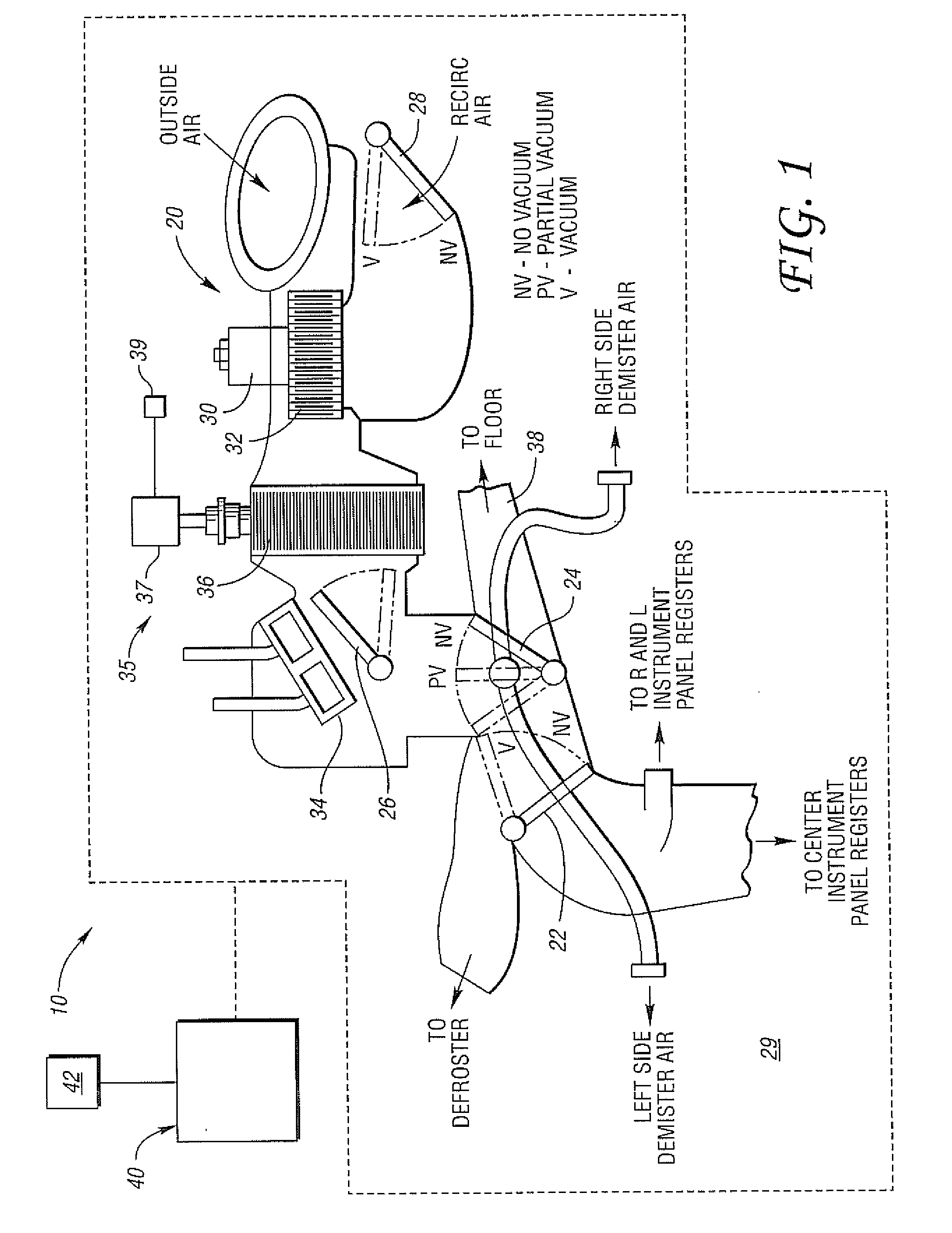

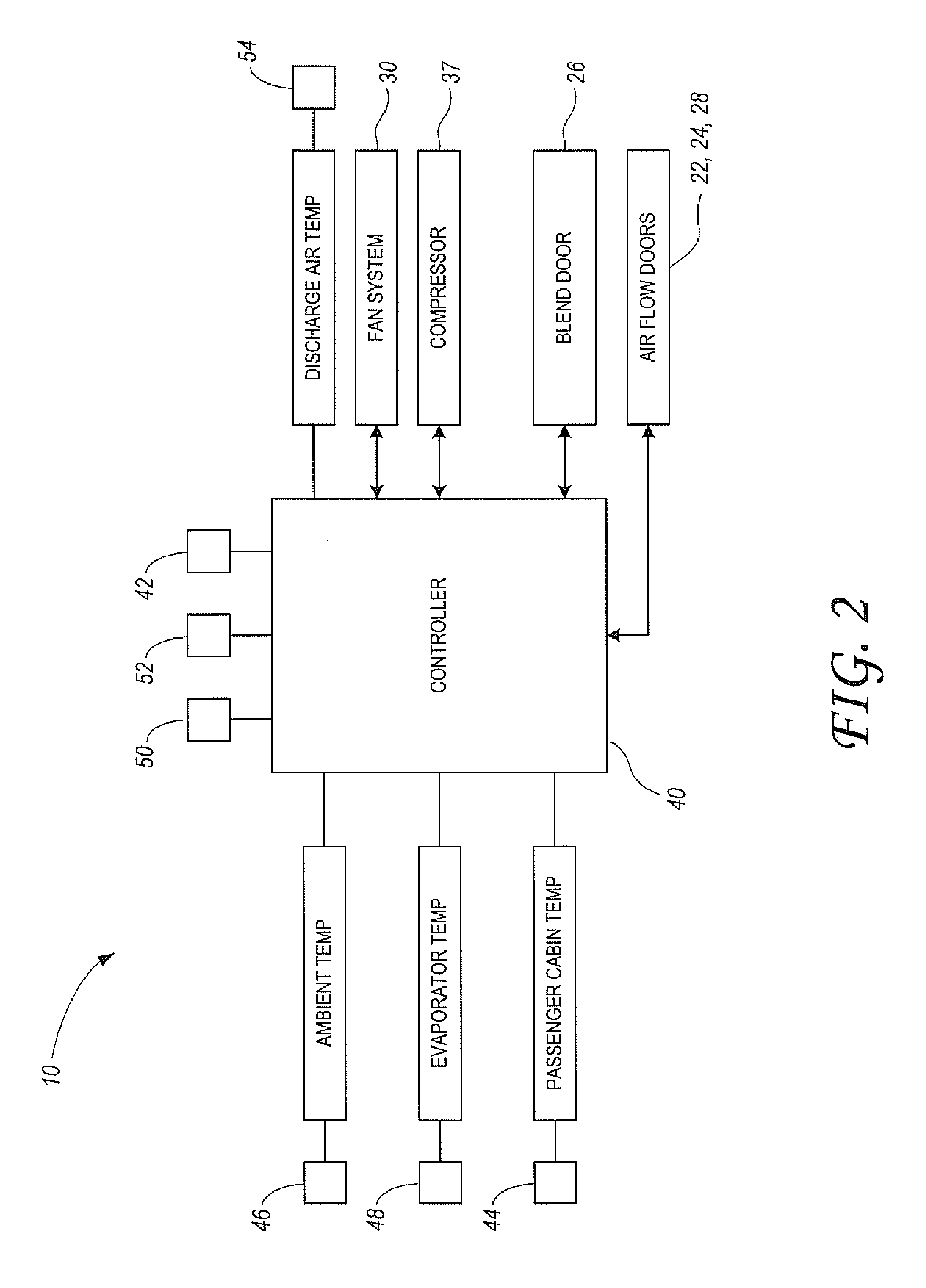

Climate Control System And Method For Optimizing Energy Consumption of A Vehicle

A climate control system includes a control head having a warmer / cooler temperature control for providing relative thermal comfort. A thermal comfort rating (TCR) corresponding to a range of passenger cabin temperatures is determined based upon a comfort level selection by an occupant using the control head. A control strategy employs look-up tables corresponding to the TCR to determine the speed of an electric compressor and the position of a temperature control blend door. The strategy provides for a relatively fast ramp down to a minimum compressor speed to improve fuel economy while maintaining a relative level of thermal comfort.

Owner:FORD GLOBAL TECH LLC

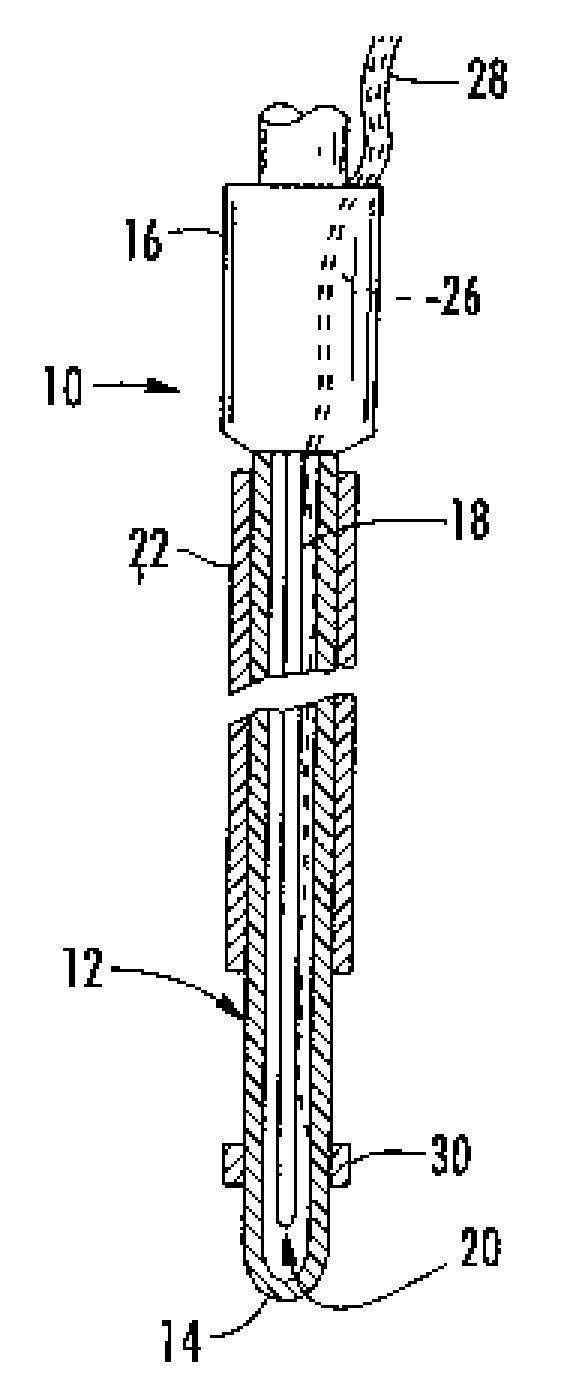

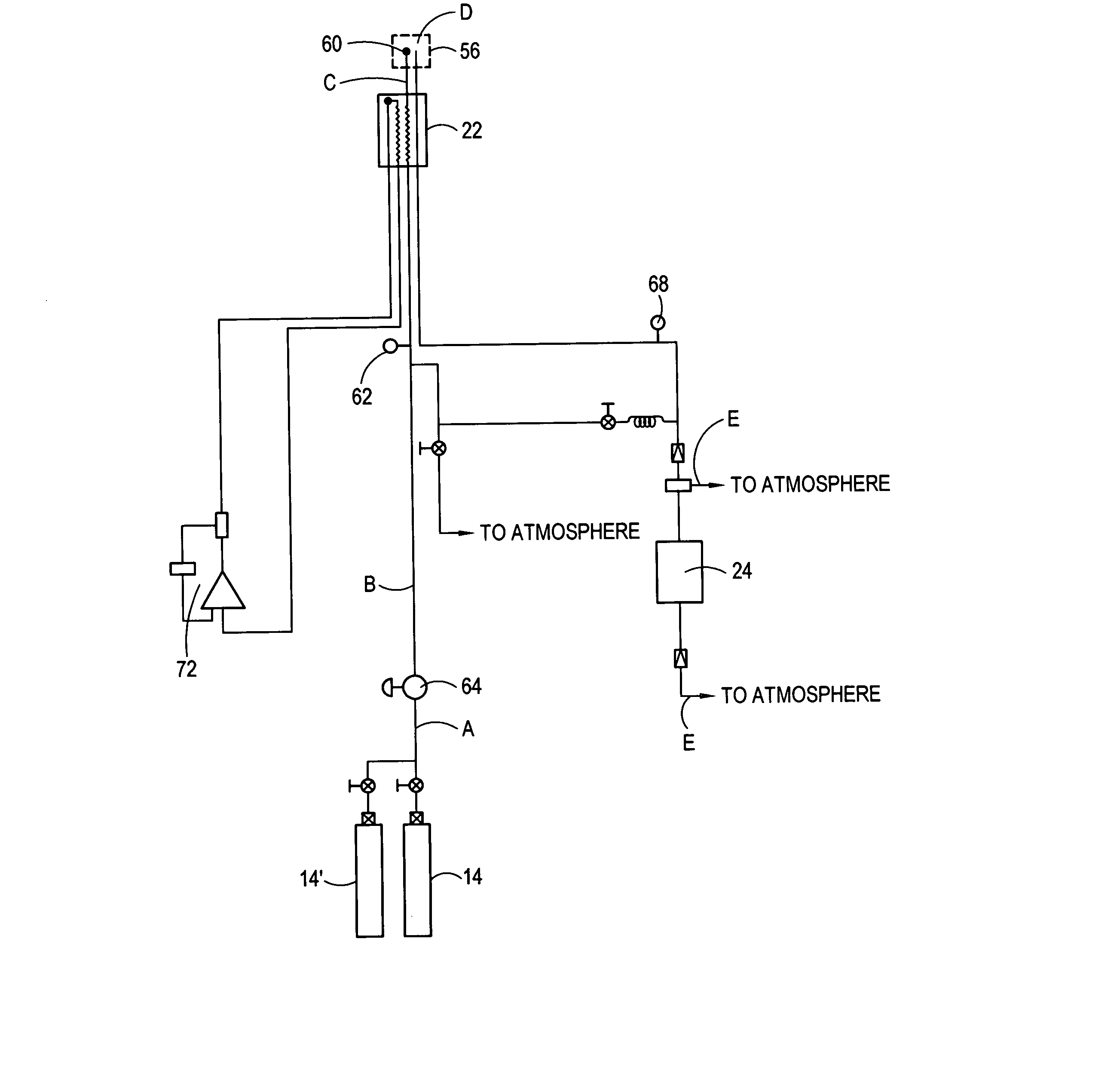

Refrigeration source for a cryoablation catheter

A catheter-based system for performing a cryoablation procedure uses a precooler to lower the temperature of a fluid refrigerant to a sub-cool temperature (−40° C.) at a working pressure (400 psi). The sub-cooled fluid is then introduced into a supply line of the catheter. Upon outflow of the primary fluid from the supply line, and into a tip section of the catheter, the fluid refrigerant boils at an outflow pressure of approximately one atmosphere, at a temperature of about −88° C. In operation, the working pressure is computer controlled to obtain an appropriate outflow pressure for the coldest possible temperature in the tip section.

Owner:CRYOCOR

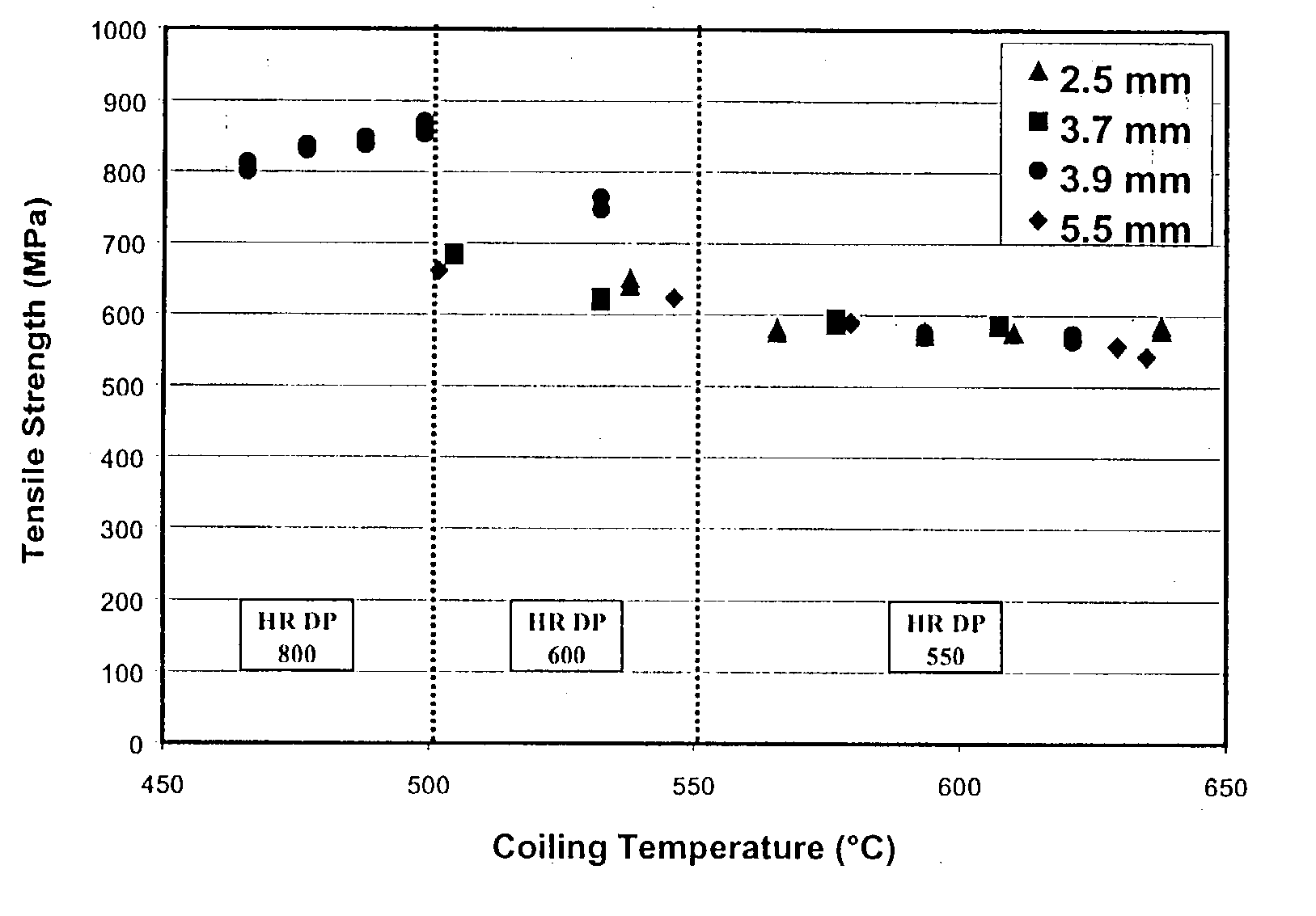

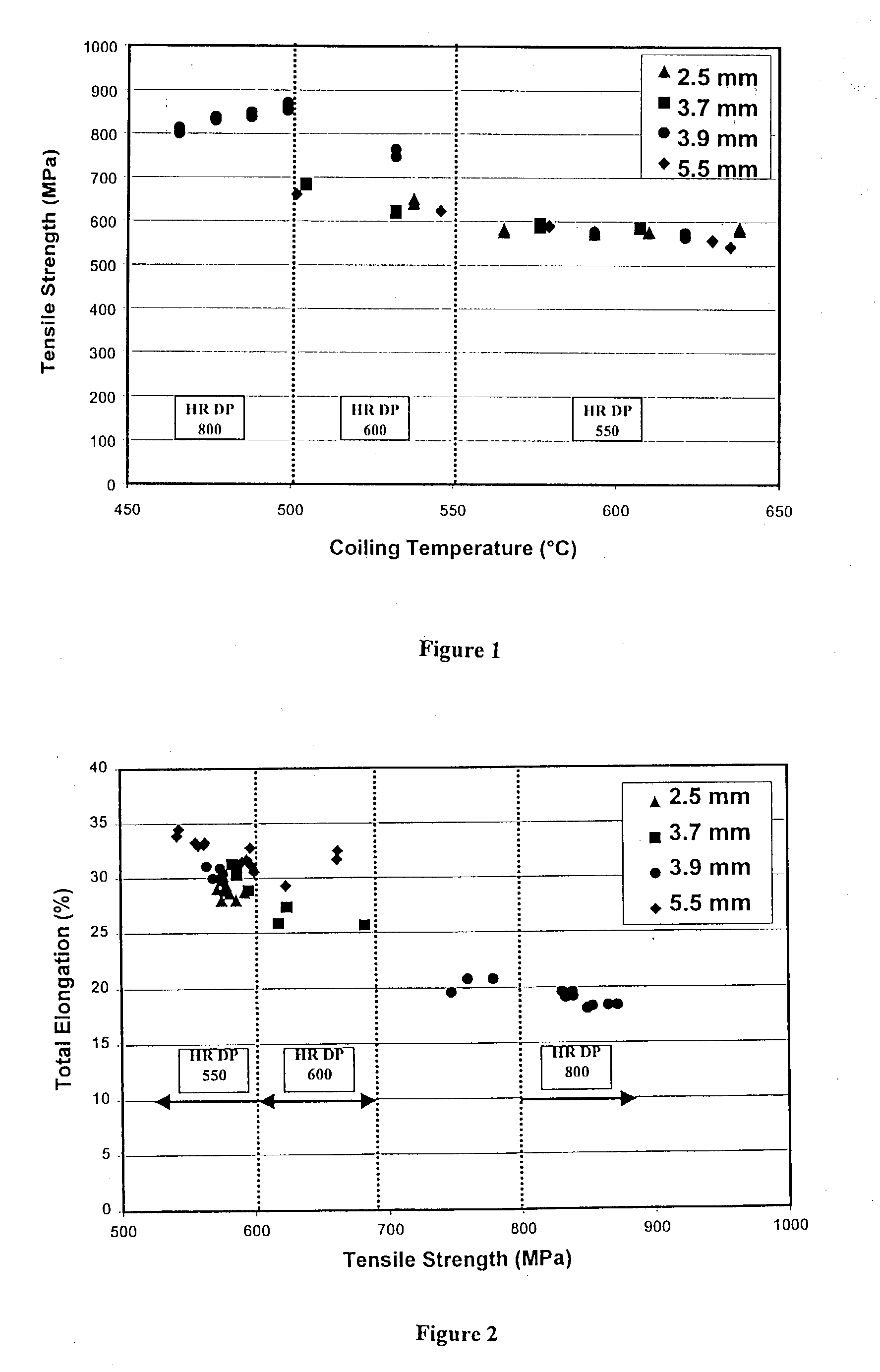

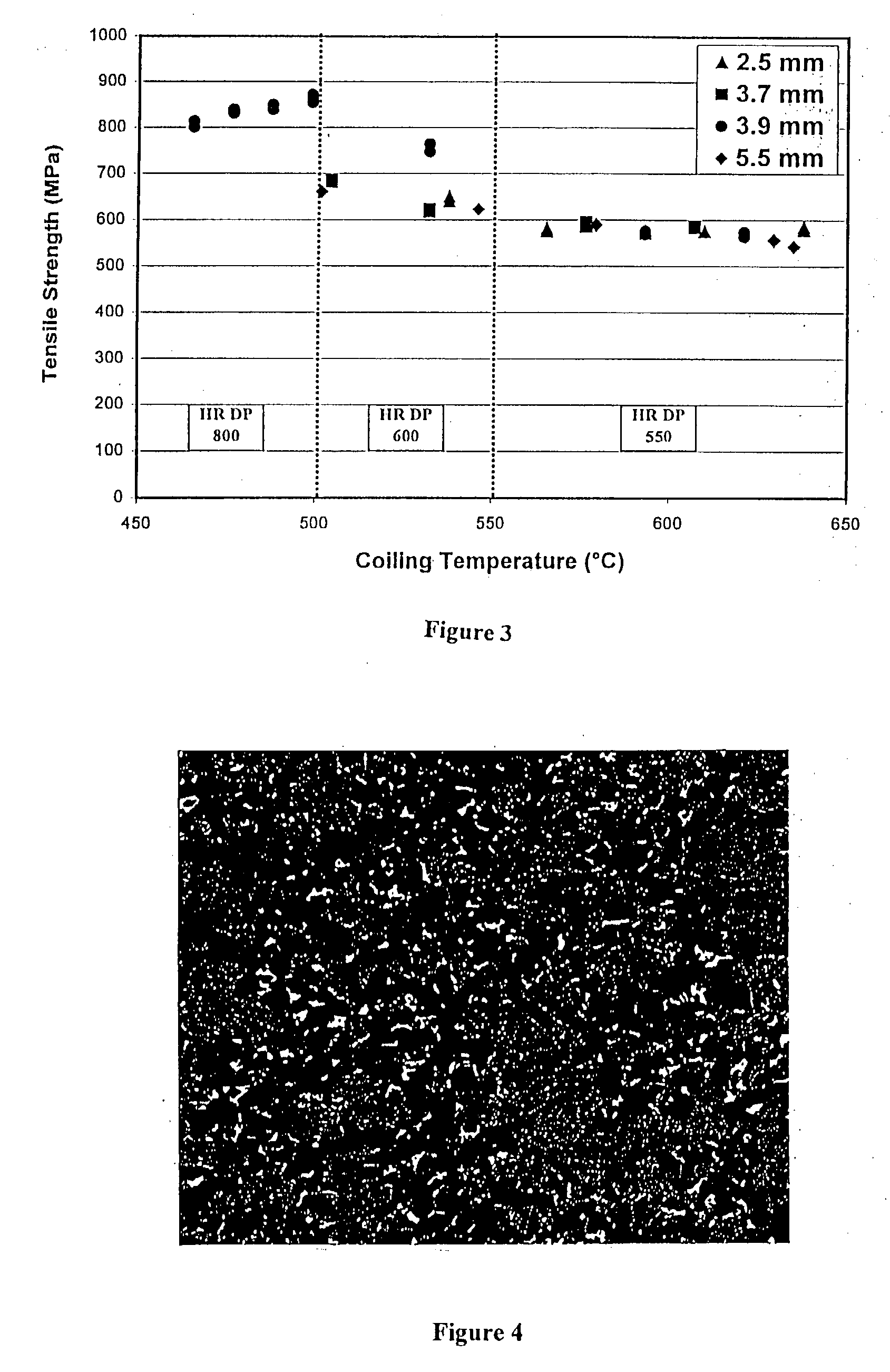

Dual phase hot rolled steel sheet having excellent formability and stretch flangeability

InactiveUS20040118489A1Few facilitiesGood formabilityFurnace typesHeat treatment furnacesIngotUltimate tensile strength

The present invention provides a process of producing a family of hot rolled dual phase steel sheets having excellent formability and stretch flangeability, with yield strengths of from about 500 MPa to about 900 MPa from a single steel chemistry consisting of, by weight percent, 0.02-0.15% of C, 0.3-2.5% of Mn, 0.1-2.0% of Cr, 0.01-0.2% Al, 0.001-0.01% Ca, not more than 0.1% P, not more than 0.03% S, not more than 0.2% Ti, not more than 0.2% V, not more than 0.2% Nb, not more than 0.5% Mo, not more than 0.5% Cu, not more than 0.5% Ni, the balance being Fe and unavoidable impurities. A slab or ingot of this composition is reheated to a temperature of between 1050° C. and 1350° C. and held at this temperature for at least 10 minutes, then hot rolled, completing the hot rolling at between 800° C. and 1000° C. The sheet is cooled, immediately after completion of hot rolling, at a rate of not lower than 10 C / sec., without requiring specific cooling patterns, and coiled at a temperature of not less than 450 C. The cooling temperature is controlled to produce the desired yield strength within the range of from about 500 MPa to about 900 MPa.

Owner:NATIONAL STEEL CORP +1

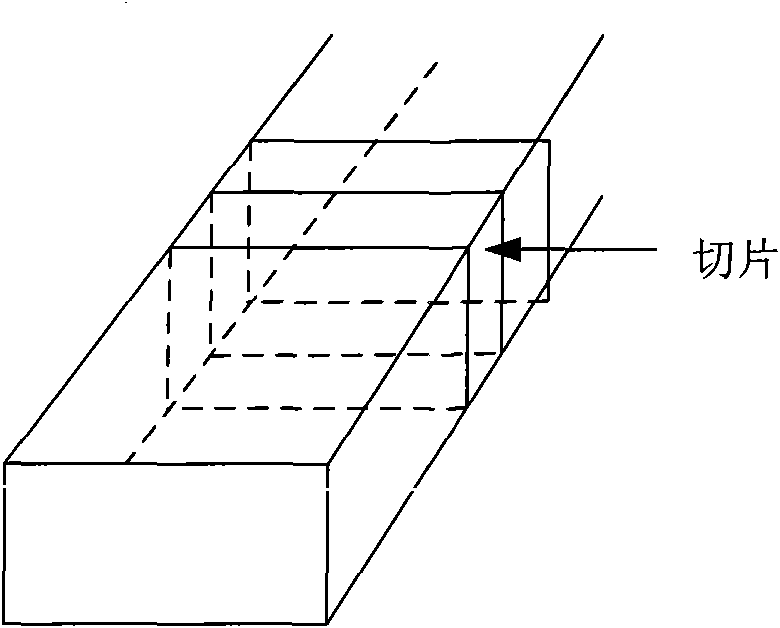

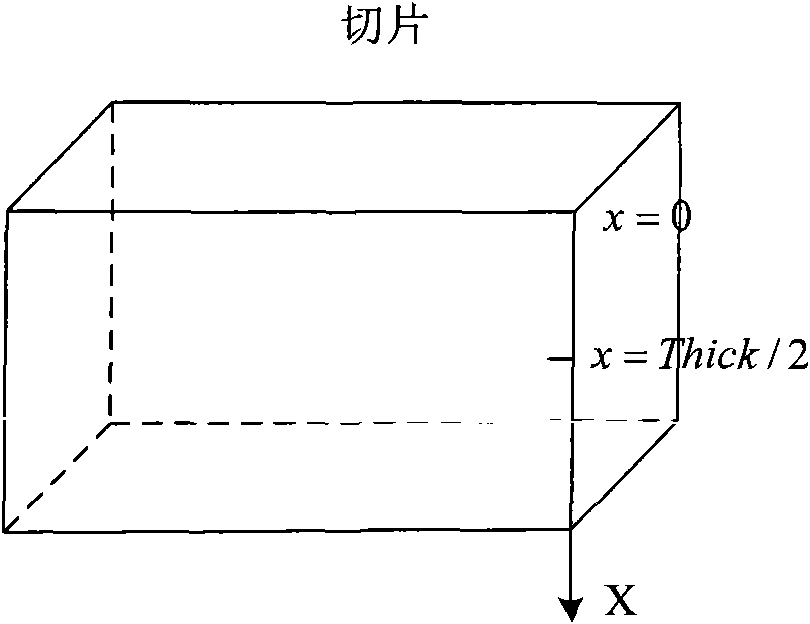

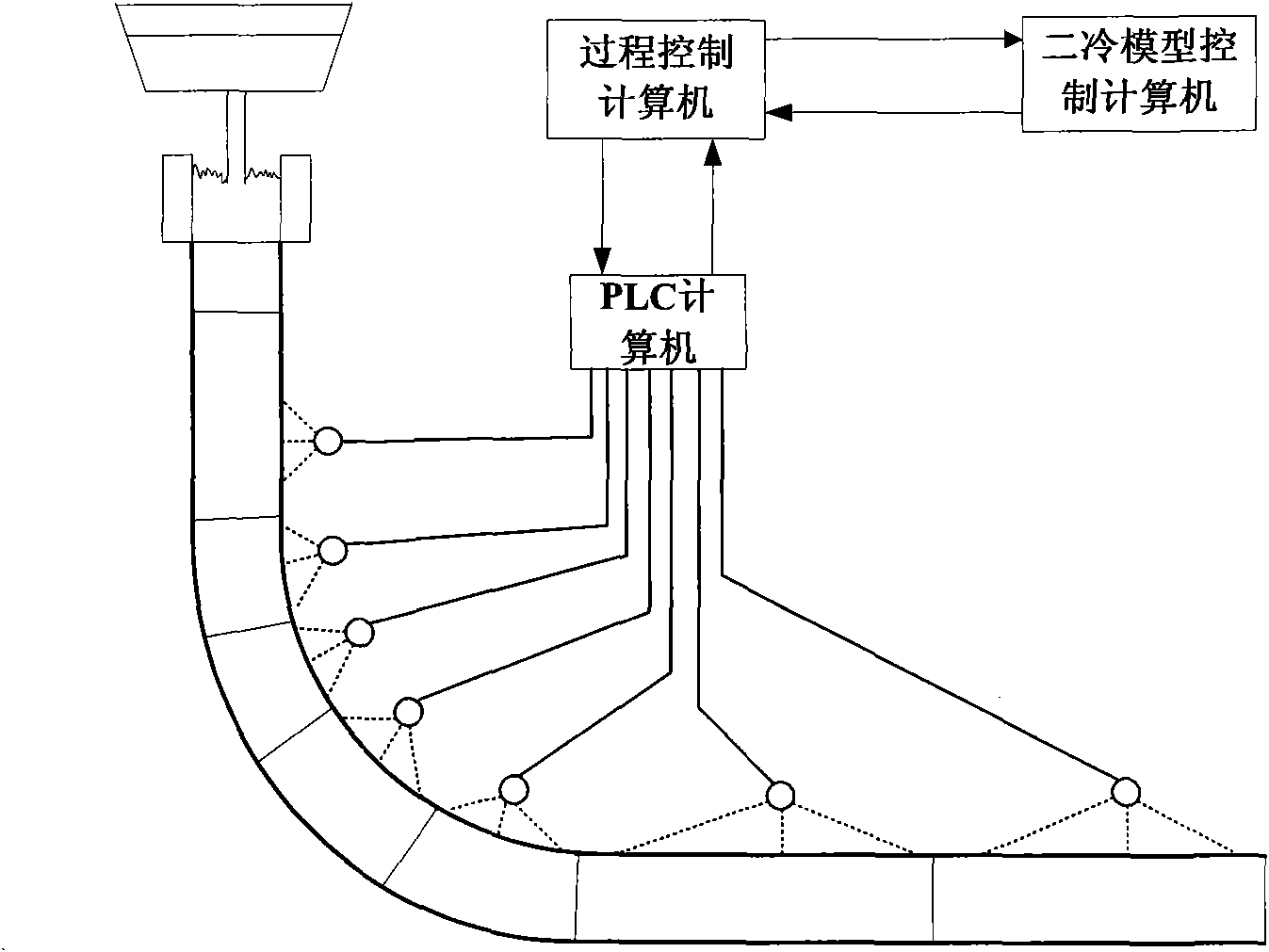

Secondary cooling method for reducing transverse cracks of corners of microalloy sheet billet

The invention relates to a secondary cooling method for reducing transverse cracks of corners of a microalloy sheet billet, which is characterized in that the cooling temperature of a casting blank is facilitated to reach a temperature for starting the transformation from gamma to alpha by controlling the secondary cooling speed at an earlier stage when the casting blank passes through a vertical section after being delivered out of a crystallizer; at the later stage, the cooling water quantity of the casting blank is reduced, potential heat produced by the solidification of the casting piece is used for reheating the casting piece, and the reheating temperature is controlled to make the casting blank reach more than an austenite phase changing temperature when the casting piece is delivered out of the vertical section; the entire process is under the transformation of gamma to alpha to gamma, so that crystal grains of a final transformation product are smaller; and after the casting blank leaves the vertical section, the casting blank enters the subsequent secondary cooling area in a slowly cooling mode. By optimizing the continuous-casting billet cooling mode, the crystal grains are refined, and second-phase particles in the steel are controlled, so that the high-temperature mechanical property of the casting blank can be improved, simpleness in operation is realized, and the transverse cranks on the surface of the casting blank can be effectively reduced.

Owner:WISDRI ENG & RES INC LTD

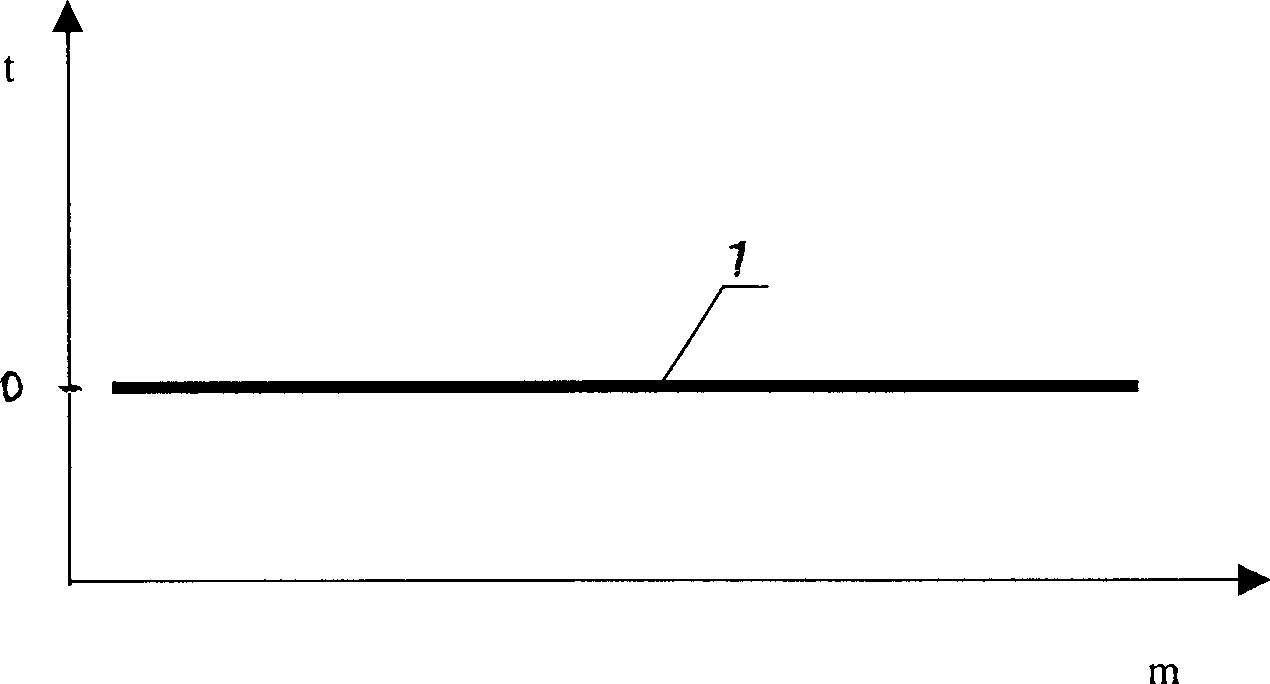

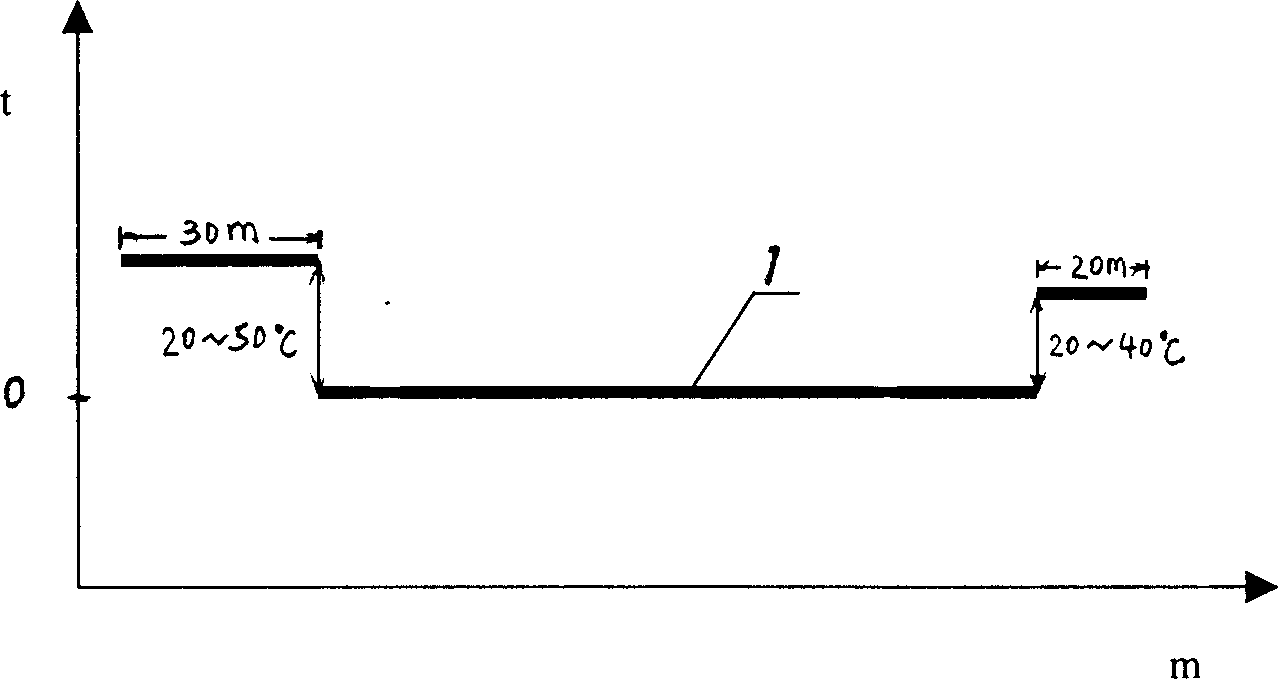

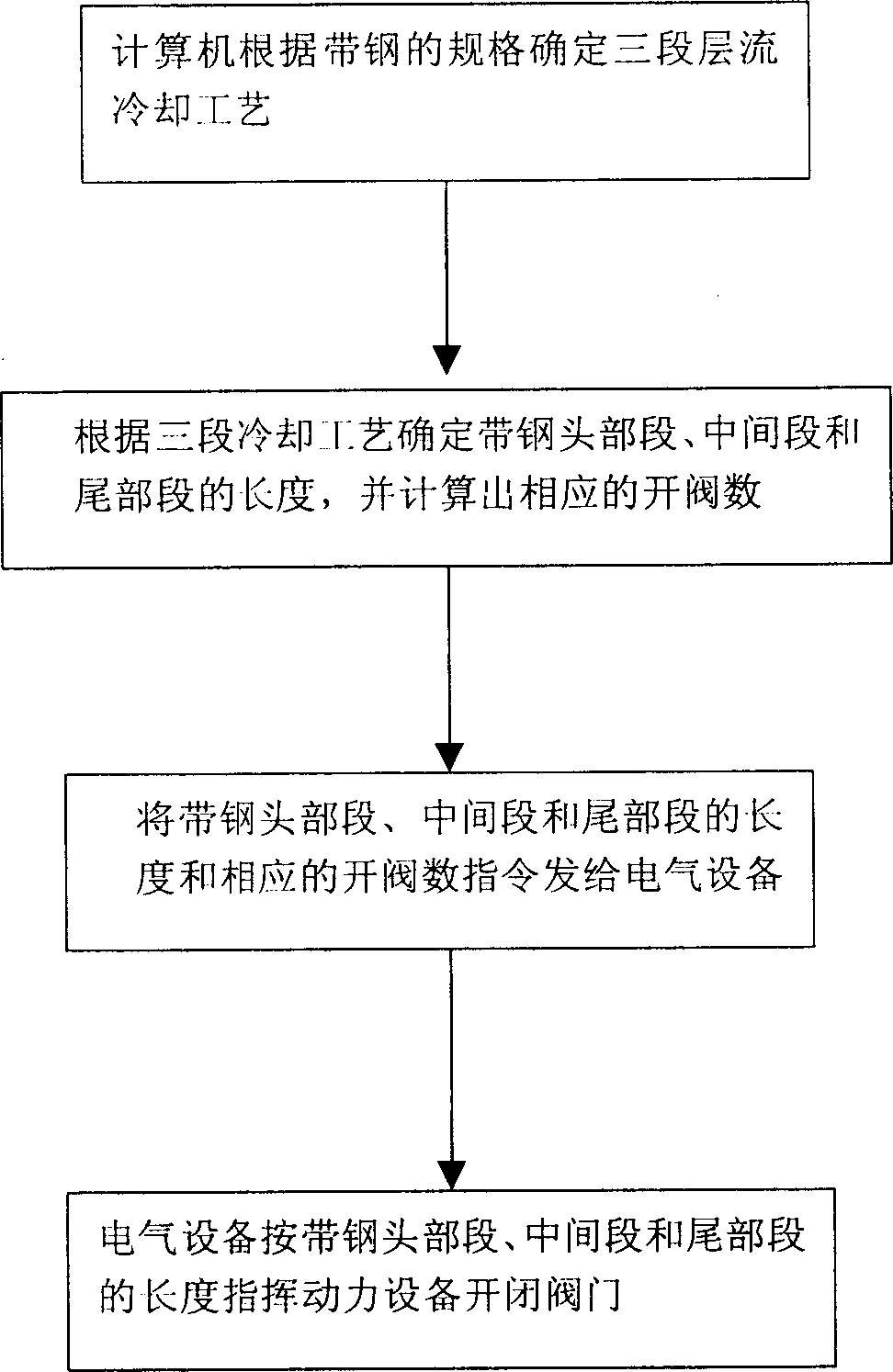

Three section laminar flow cooling technology for hot rolling band steel

InactiveCN1483528AImprove performance uniformitySolve productivityTemperature control deviceWork treatment devicesEngineeringStrip steel

The present invention provides a three-section cooling process by laminar flow for hot-rolled steel strip. Said process adopts the computer laminar flow cooling control, and is characterized by that the steel strip can be divided into three sections for cooling, first section is head portion section whose length is 30 m, second section is intermediate section of the steel strip, and third section is the tail portion section whose length is 20 m, and the cooling temperatures of said three sections are respectively controlled in that its intermediate section temp. is equal to the objective coiling temp., its head portion section temp. is 20-50 deg.C higher than that of objective coiling section, and its tail portion section temp. is 20-40 deg.C higher than objective coiling temp. Said invention can improve the performance uniformity of steel strip.

Owner:ANGANG STEEL CO LTD

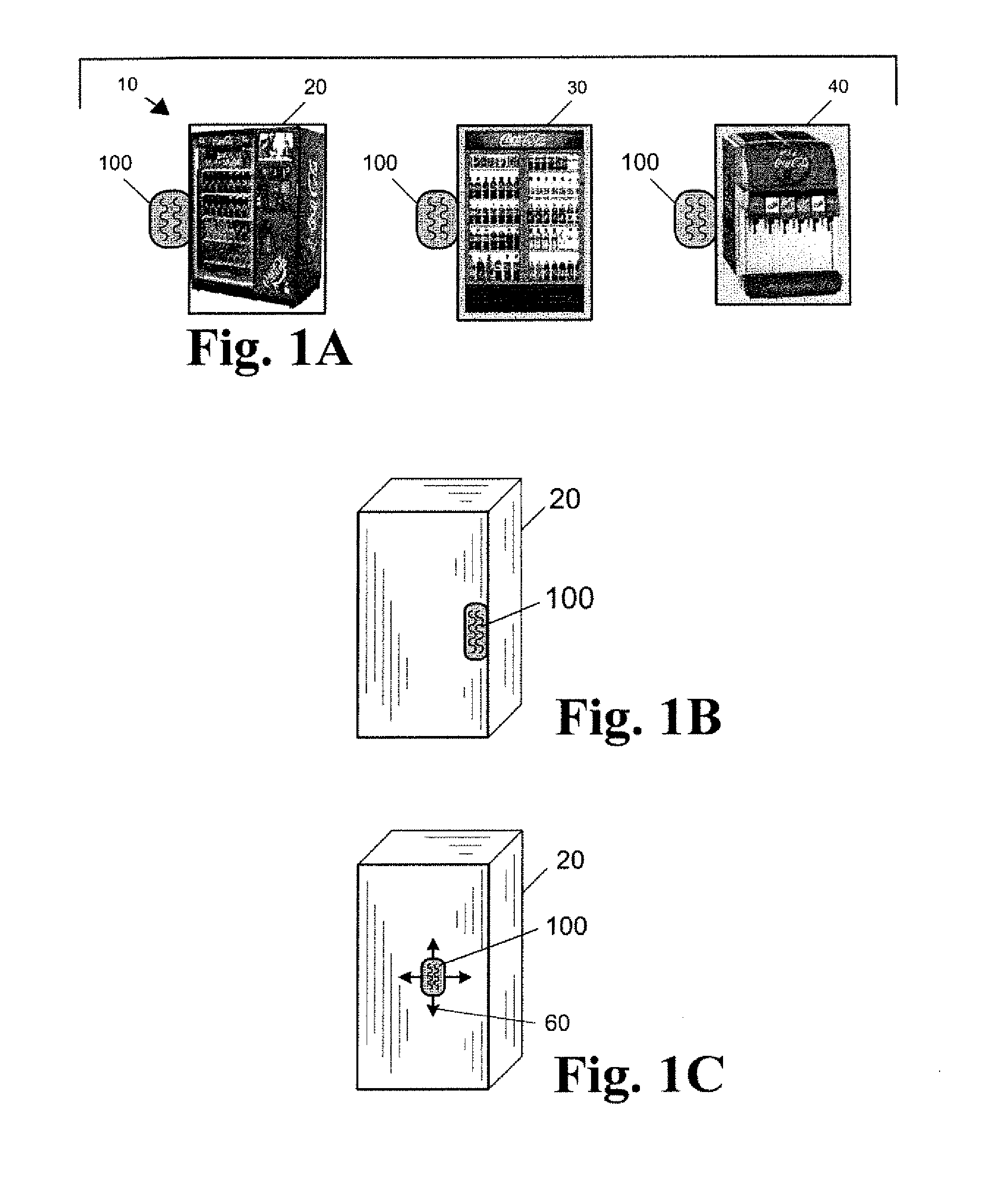

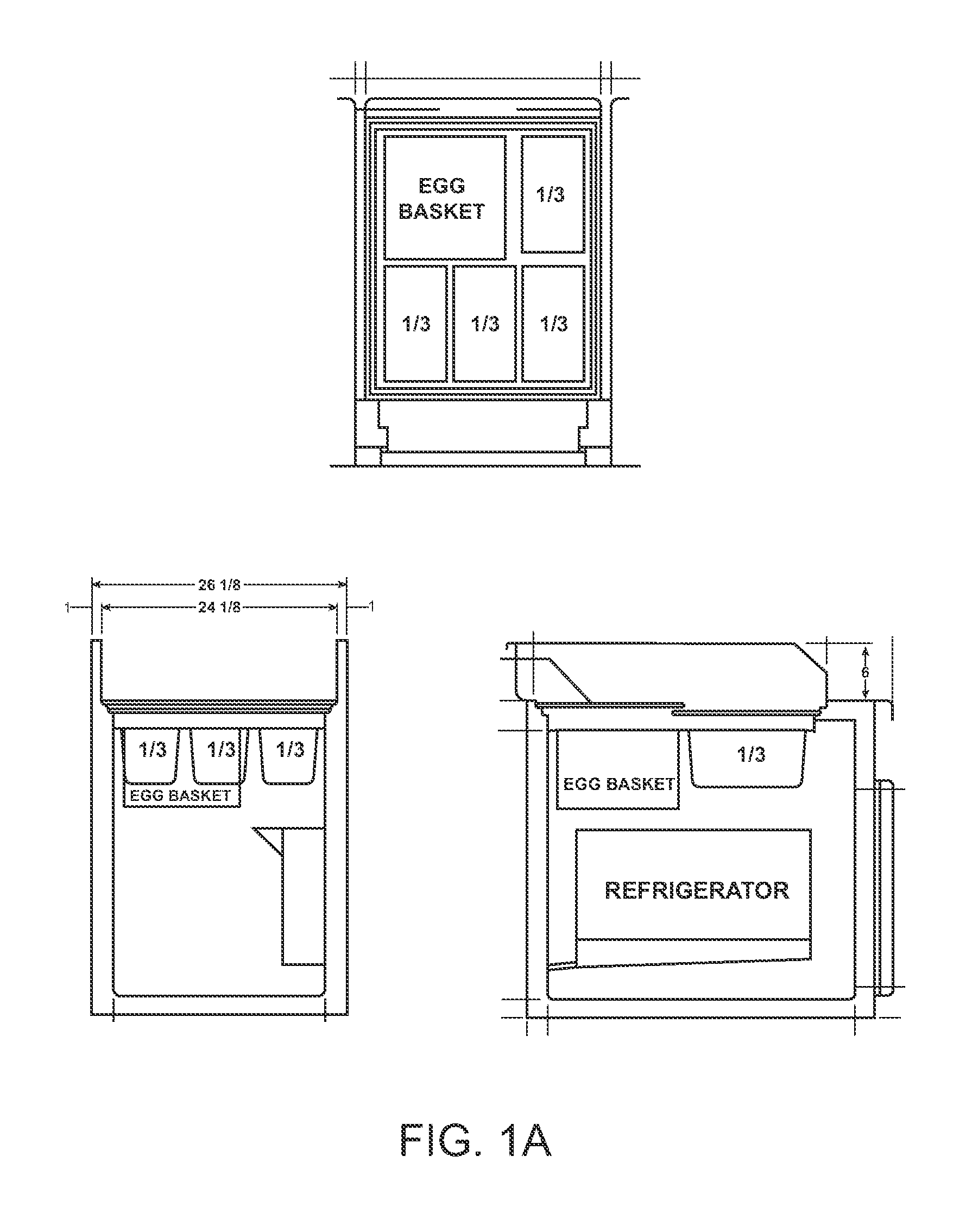

Refrigerated liquid product dispenser

ActiveUS7762431B1Avoid pollutionDomestic cooling apparatusLighting and heating apparatusLiquid productTower

A refrigerated liquid dispenser is disclosed. The dispenser has a pump configured for being in fluid communication with a source of a liquid product; a dispensing faucet configured for being in fluid communication with the pump, the dispensing faucet including a cold maintenance device located near the distal end of the dispensing faucet and an insulator device disposed adjacent to the cold maintenance device. The cold maintenance device has a distal end that projects beyond a lower surface of the insulator device. The dispenser also includes a dispensing tower for enclosing the dispensing faucet; and an auxiliary cooling circuit configured to direct cool airflow toward the dispensing faucet, the auxiliary cooling circuit having a passageway that is at least partially located within the dispensing tower and the passageway is configured to deliver cool airflow through the passageway onto the dispensing faucet, to shield the dispensing faucet from ambient temperature, thereby maintaining the dispensing faucet and the passageway at a cool temperature to avoid contamination of the liquid. The dispenser also includes a controller operatively coupled with the pump and the dispensing faucet to control the operation of the refrigerated liquid dispenser.

Owner:AUTOMATIC BAR CONTROLS

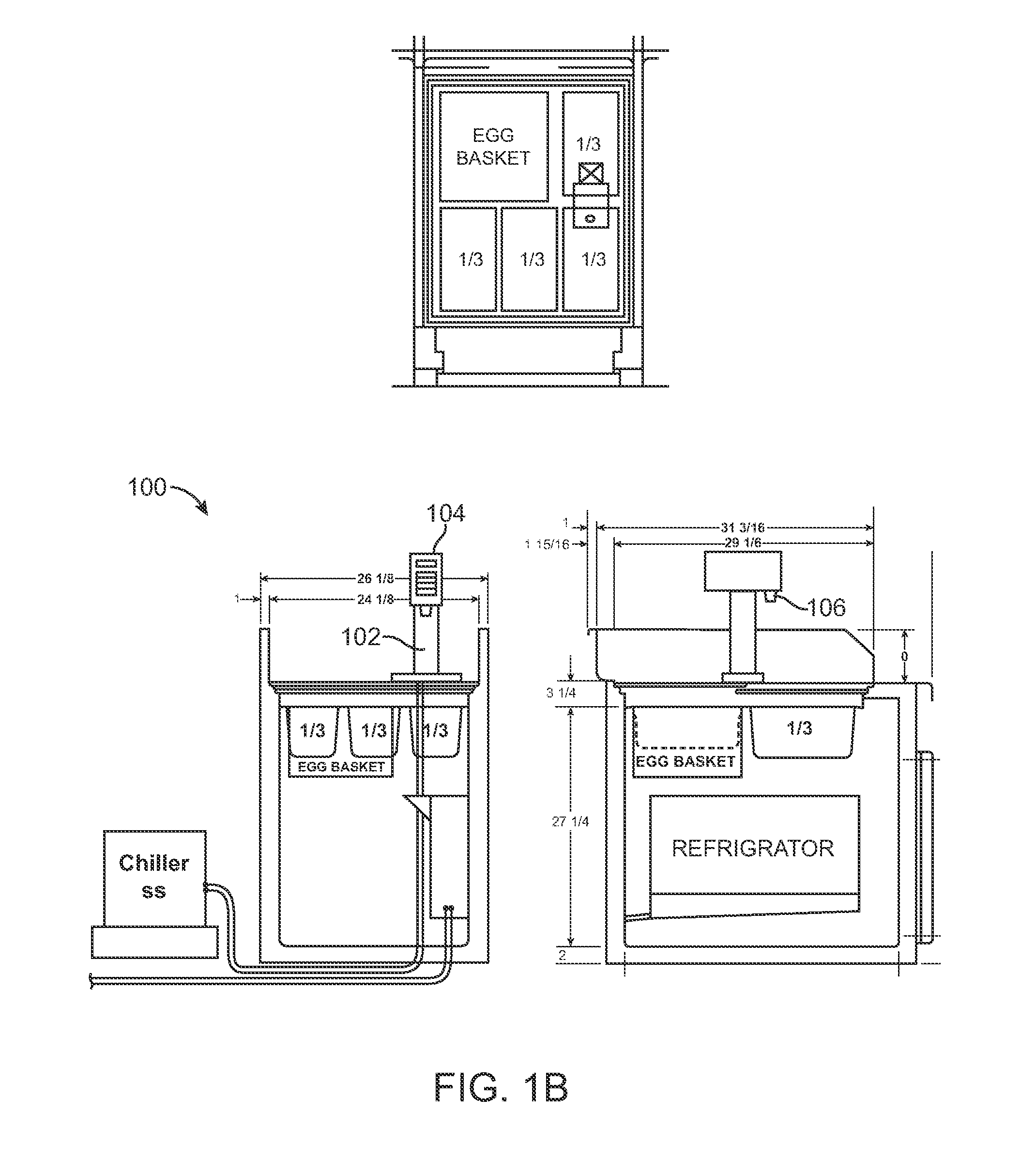

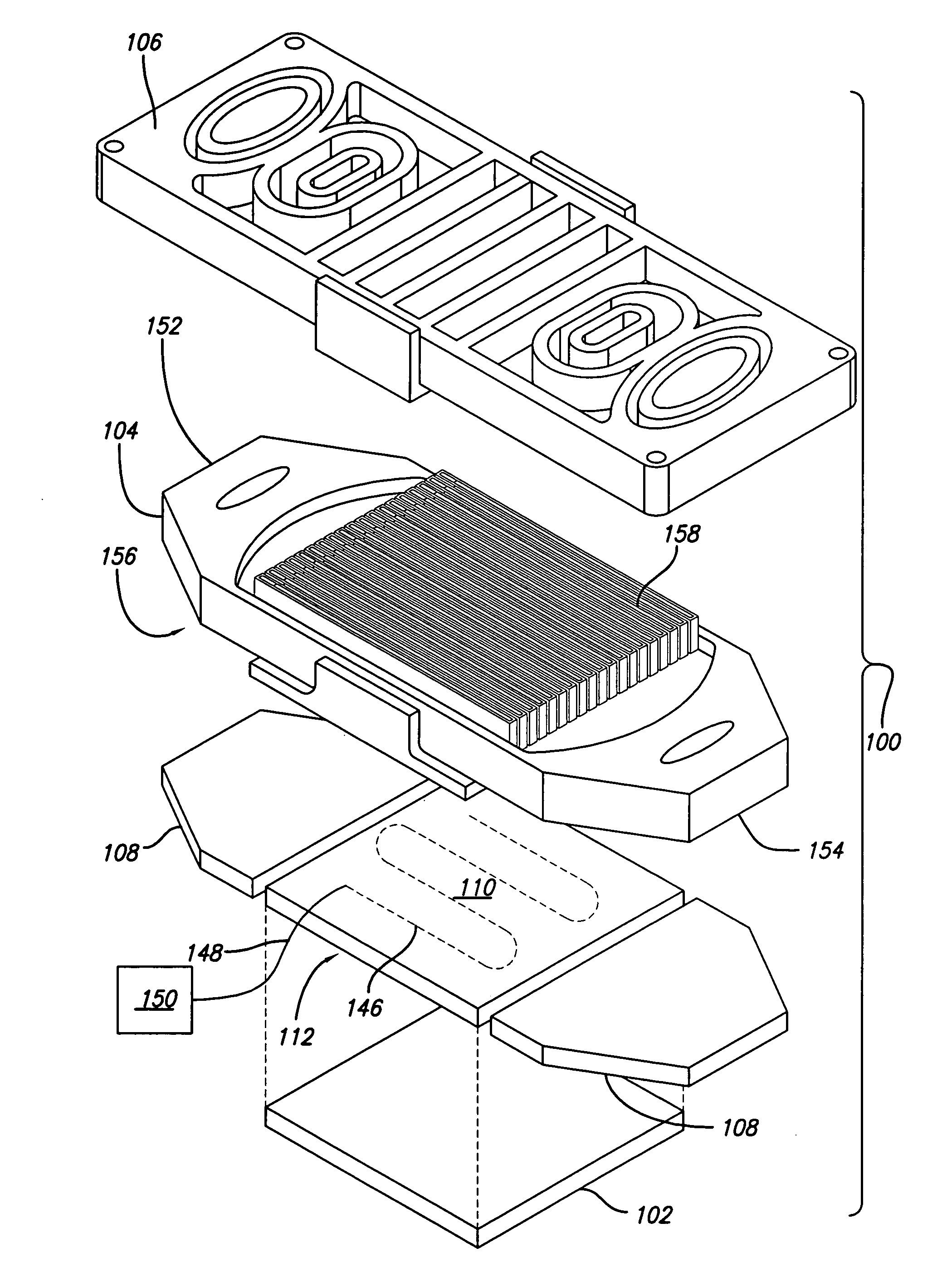

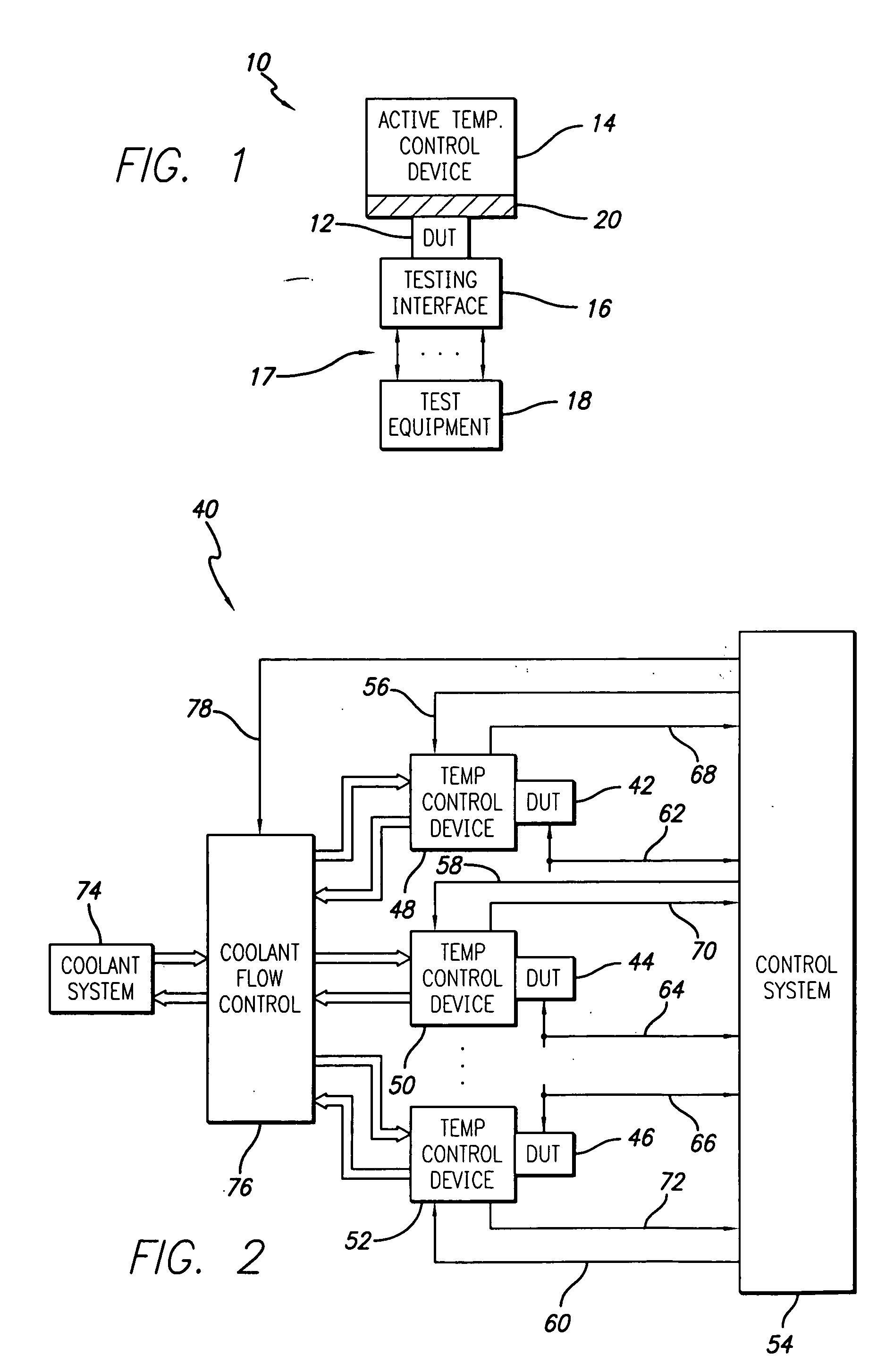

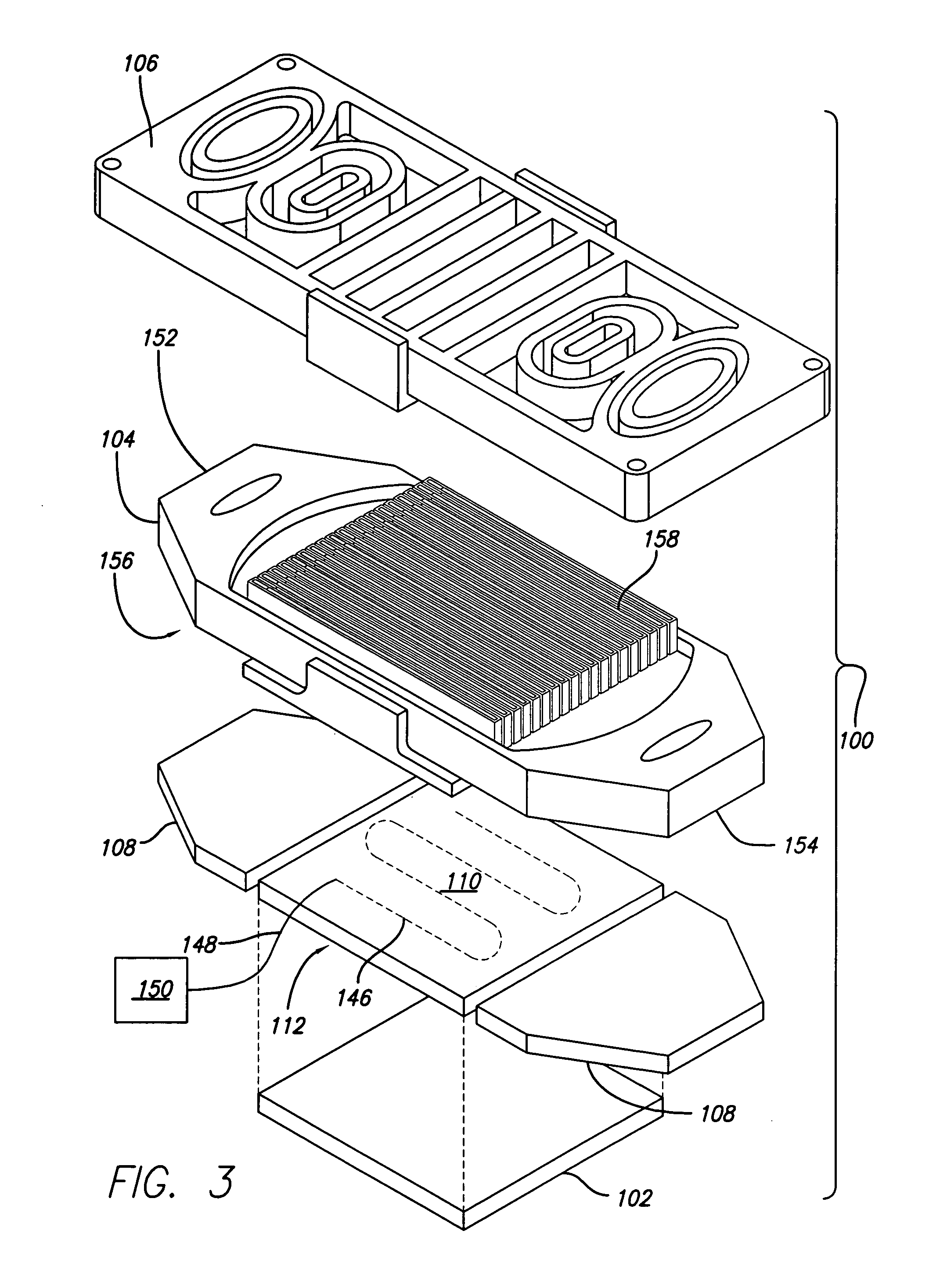

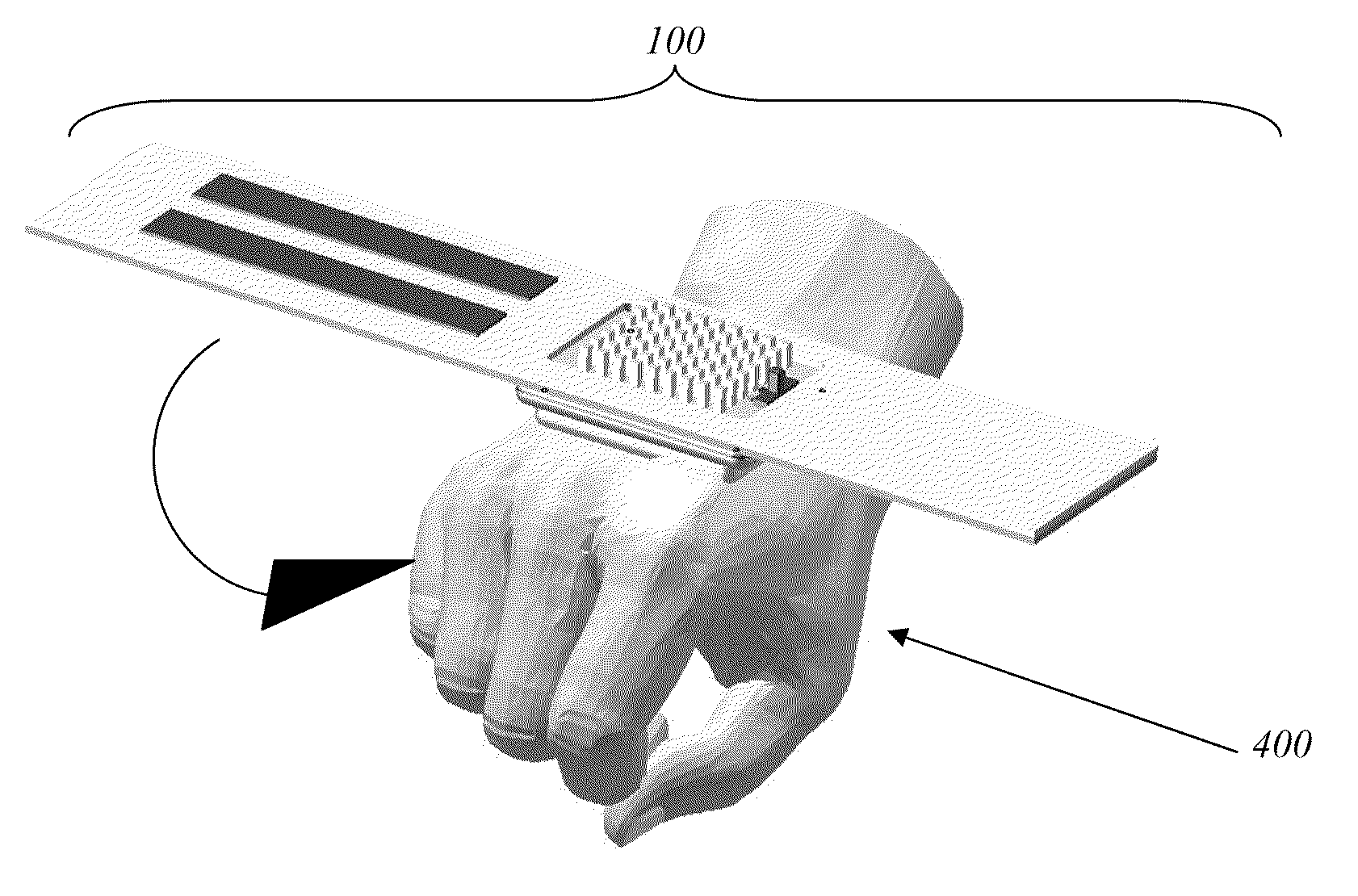

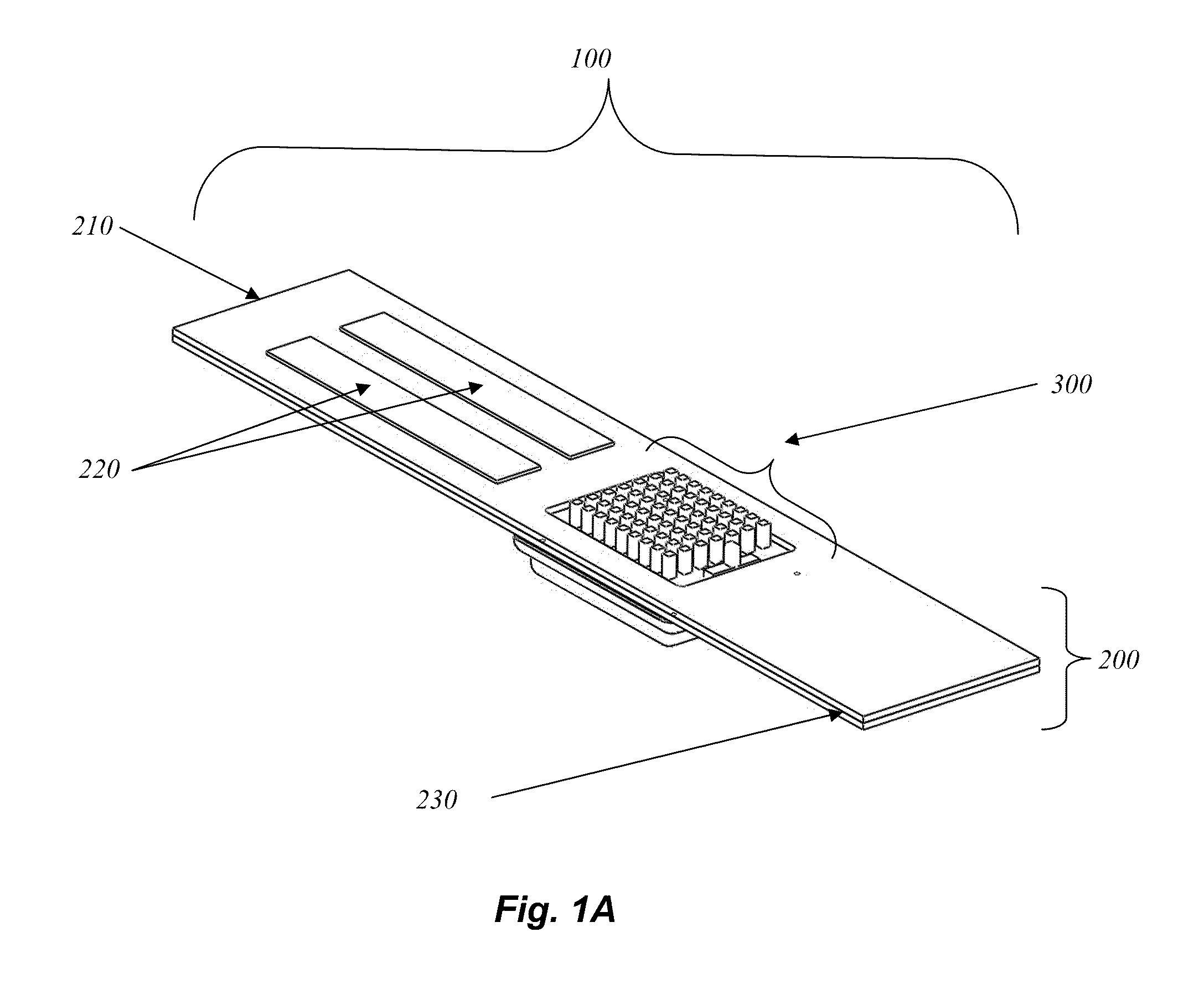

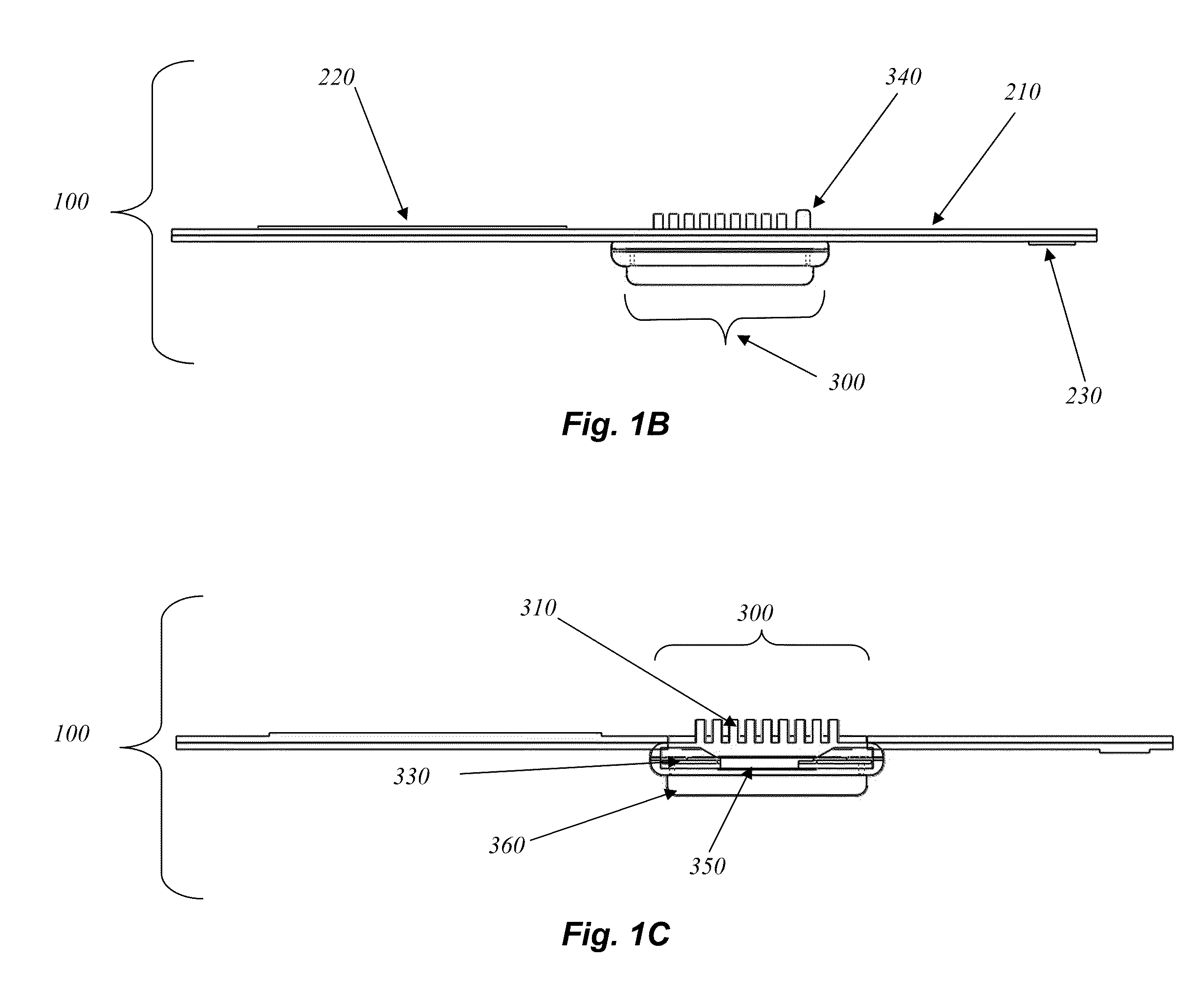

Active thermal control system with miniature liquid-cooled temperature control device for electronic device testing

InactiveUS20050151553A1Quick changeFault location by increasing destruction at faultHeat exchange apparatusCounter flowDevice material

A temperature control system, which includes a miniature liquid-cooled heat sink, is used to provide a controlled temperature surface to an electronic device, such as a semiconductor device, during the testing or bum-in phase. In one embodiment, the system includes a miniature liquid-cooled heat sink device having a monolithic counter-flowing structure. In other embodiments, the system includes a heater, a flow control valve, a controller, and / or sensors.

Owner:DELTA DESIGN

Dynamic secondary cooling control method for slab continuous casting based on double-cooling mode

The present invention discloses a dynamic secondary cooling control method for slab continuous casting based on a double-cooling mode, which comprises the following steps of: collecting casting process data and indexing target cooling temperatures and ABC parameters of each cooling area; dynamically calculating the heat conduction process of a continuously cast slab in the current period according to a heat conduction equation; calculating the temperature tracking error of each cooling area and calculating the water amount of each cooling area in a second cooling mode by taking the temperature tracking error as a regulation factor; respectively calculating the water amount of each cooling area in a first cooling mode based on the ABC parameters and the current casting speed; determining whether the temperature tracking error exceeds a preset threshold and comparing the water amounts in the two modes to determine the cooling mode and the controlled water amount in the current period; and validating the reasonableness of the controlled water amount, and correcting the controlled water amount to be a preset maximum water amount or minimum water amount if the controlled water amount exceeds the preset maximum water amount or minimum water amount. The invention guarantees the quality stability of the cast blank in secondary cooling process.

Owner:BAOSHAN IRON & STEEL CO LTD

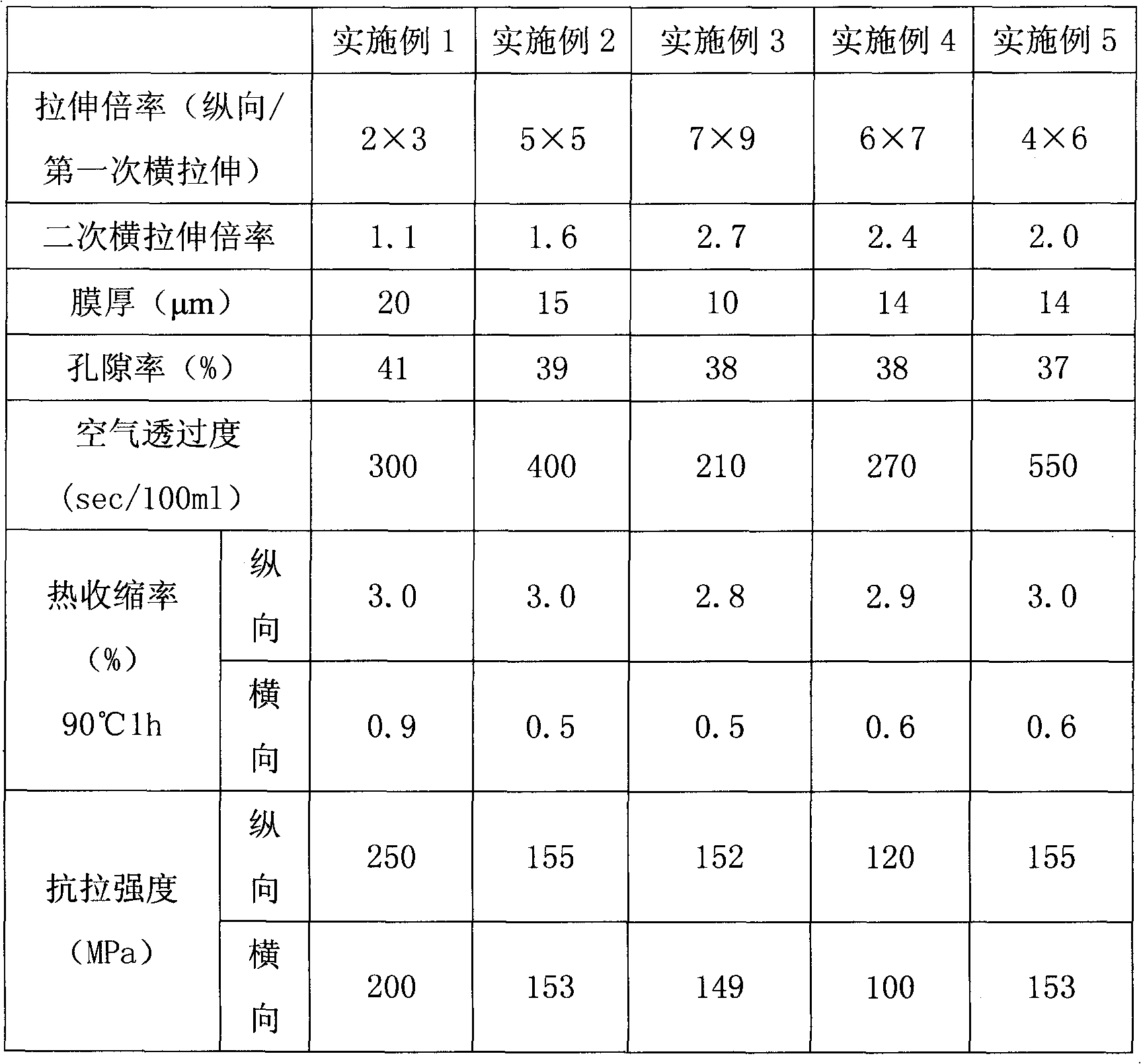

Polyolefin battery diaphragm and preparation method for the same

InactiveCN102320133AReduce porosityHigh elongation at breakCell component detailsFuel cell detailsPolymer sciencePolyolefin

The invention discloses a polyolefin battery diaphragm and a preparation method for the same. The preparation method is composed of the following steps of: (1) melting polyolefin resin, additive and dissolvent into uniform solution at 150-180 DEG C; (2) extruding the melt, which is obtained from the step (1), through a die head at 150-280 DEG C, and cooling and casting into a thick slice on a cooling roller, wherein the cooling temperature is in a range from -5 to 30 DEG C; (3) longitudinally stretching the thick slice obtained in the step (2), then, transversely stretching for the first time; (4) extracting the diaphragm obtained in the step (3) to remove the dissolvent, then, drying; (5) transversely stretching the diaphragm obtained in the step (4) for the second time, and executing heat shaping after stretching to obtain a polyolefin micro-porous membrane. With the preparation method provided by the invention, holes of the prepared micro-porous membrane are round, and have better ventilation effect; and mechanical strengths of the prepared micro-porous membrane in both longitudinal and transverse directions are uniform and consistent.

Owner:XINXIANG ZHONGKE SCI&TECH +1

Cyclic Heat Therapy Device

The therapy device enables the automatic application of customized and well controlled contrast therapy to localized areas of human and animal bodies. An electronic control circuit is used in conjunction with heat dissipating and heat absorbing surfaces to control the operation of a thermoelectric cooling module (TEC) to enable the administering of localized contrast therapy on human and animal bodies. The use of temperature sensors, timing circuits, and microprocessors in connection with the TEC and heat absorbing and dissipating surfaces allows precise control of the applied temperature and the time duration for cooling and heating cycles. The device is programmable and is capable of automatic cycling between desired heating and cooling temperatures for variable lengths of time.

Owner:MOORE JOSHUA JOHN EDWARD

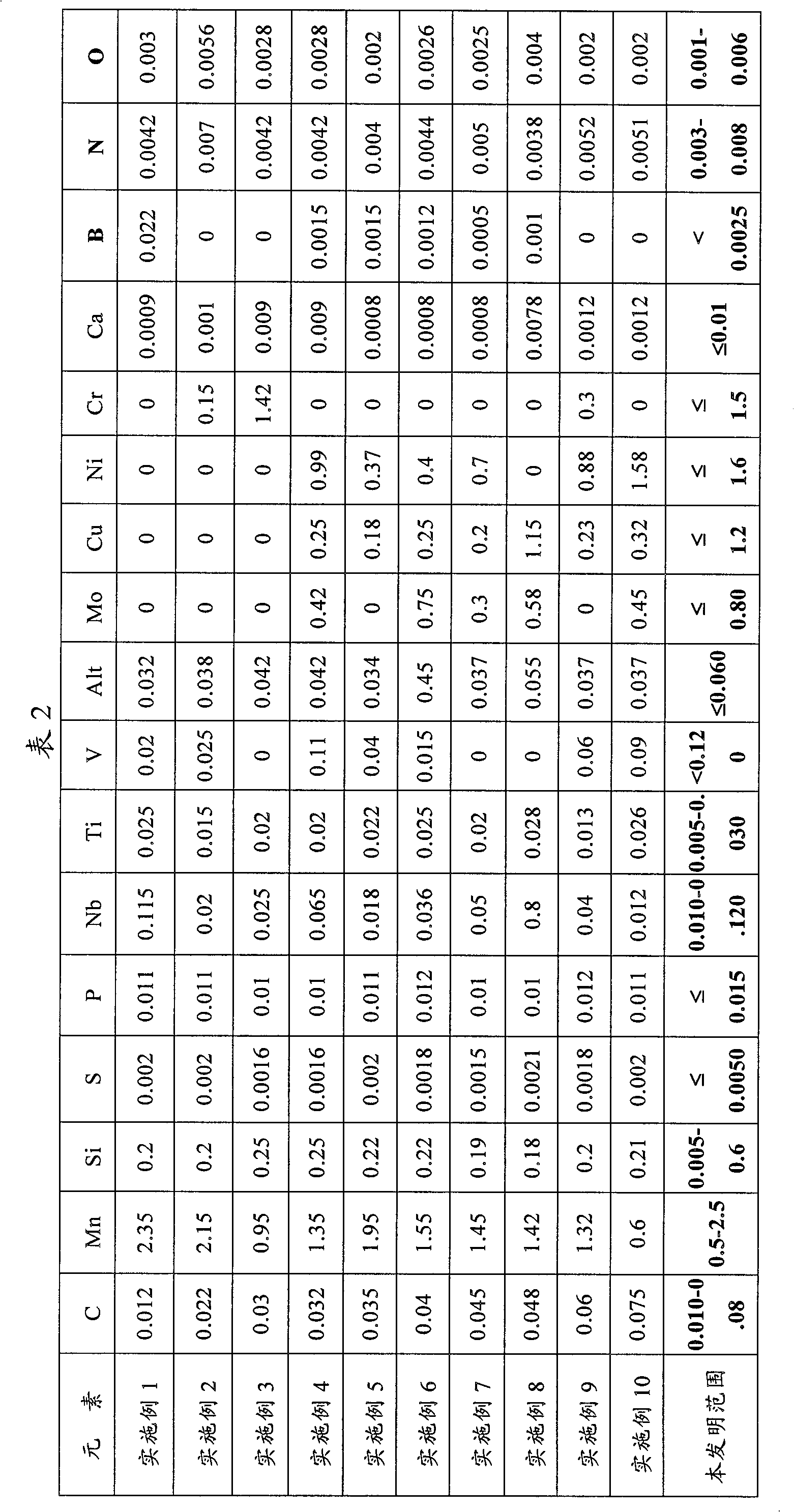

YP500MPa-level thick steel plate with excellent low-temperature toughness and manufacturing method thereof

InactiveCN102691015AImprove low temperature toughnessTemperature control deviceMetal rolling arrangementsCompound (substance)Toughness

The invention relates to a TMCP-type YP500MPa-level thick steel plate with excellent low-temperature toughness which comprises the following chemical components by weight: 0.010-0.08% of C, 0.005-0.6% of Si, 0.5-2.50% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.010-0.12% of Nb, 0.005-0.03% of Ti, less than 0.120% of V, not more than 1.50% of Cr, not more than 0.80% of Mo, not more than 1.2% of Cu, not more than 1.60% of Ni, not more than 0.06% of Al, not more than 0.01% of Ca, 0.003-0.008% of N, not more than 0.0025% of B, not more than 0.008% of O, and the balance of Fe and inevitable impurity elements. In the manufacturing process, a heating temperature of a continuous casting blank is 1100-1250 DEG C; a rolling temperature of a recrystallization zone is 920-1170 DEG C; a rolling temperature of a non-recrystallization zone is 680-910 DEG C; a finish rolling compression ratio is not less than 2 T, wherein T is a finished product thickness; a cooling speed is not less than 5 DEG C / s, and a finally cooling temperature is 300-600 DEG C. A TMCP-type YP500MPa-level thick steel plate with excellent low-temperature toughness is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

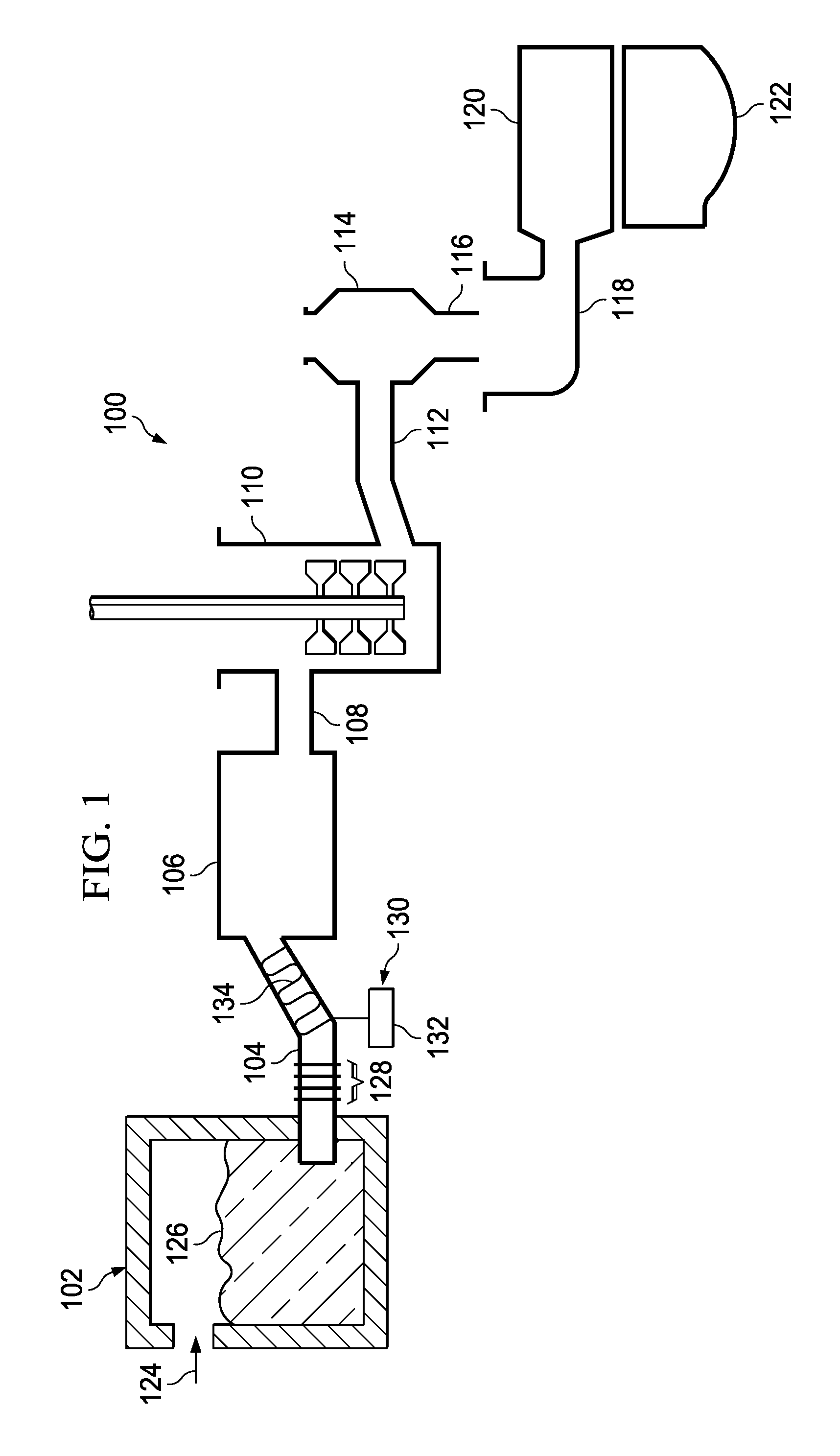

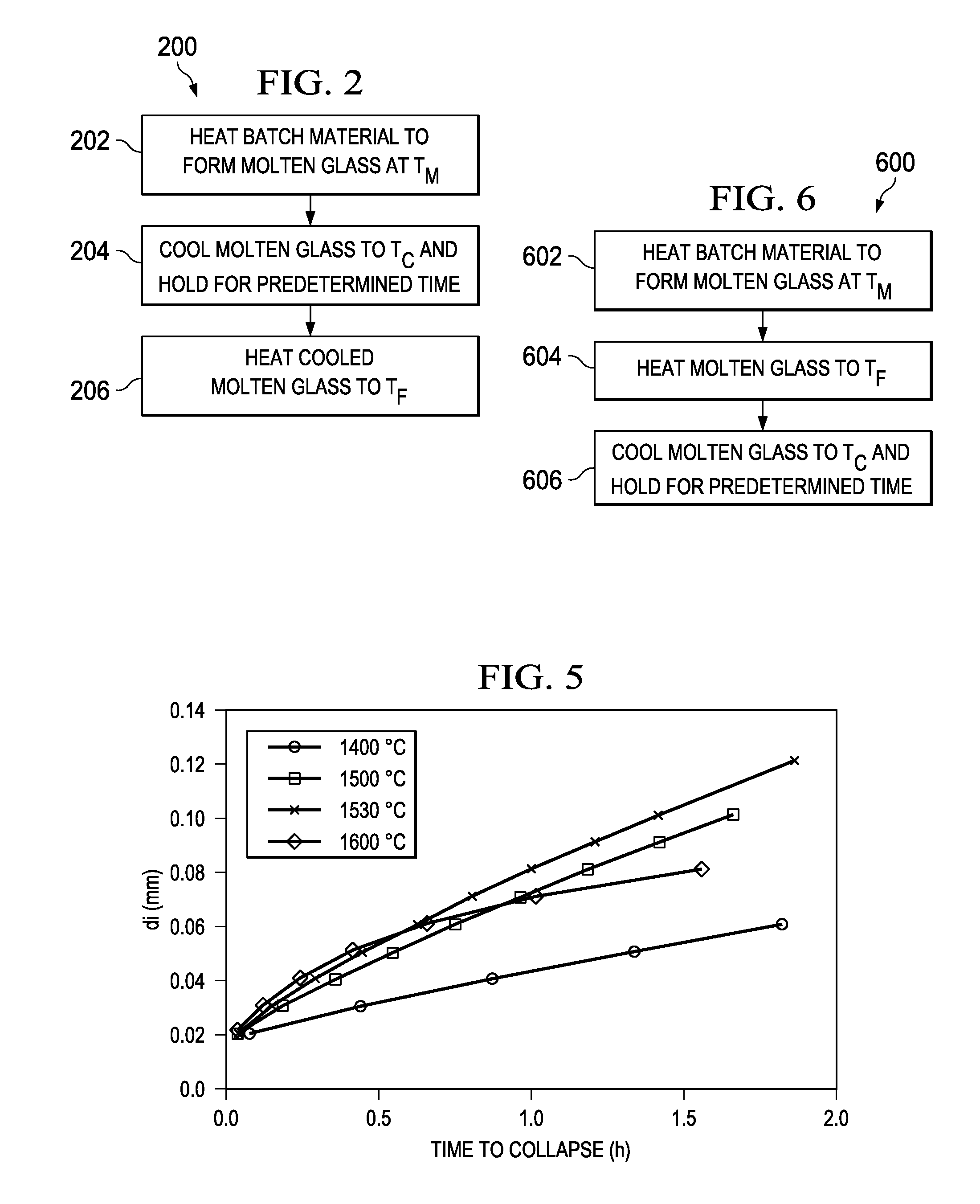

Apparatus and method for reducing gaseous inclusions in a glass

InactiveUS20100199721A1Lower the volumeForehearthsGlass furnace apparatusFlat panel displayGlass manufacturing

A glass manufacturing system and a method are described herein for reducing gaseous inclusions in high melting temperature or high strain point glasses, such as those that are used as glass substrates in flat panel display devices. In one embodiment, the method including the steps of: (a) heating a batch material within a melting vessel to form molten glass at a melting temperature TM, the molten glass comprising a multivalent oxide material; (b) heating the molten glass within a fining vessel to a fining temperature TF≧TM; and (c) cooling the molten glass within a refractory tube after the first heating step or after the second heating step to a cooling temperature TC less than TM, where the molten glass remains within the refractory tube for a predetermined resident time to reduce a volume of the gaseous inclusions in the molten glass and cause gas species to migrate out of the gaseous inclusions into the molten glass such that at least a portion of the gaseous inclusions collapse into the molten glass.

Owner:CORNING INC

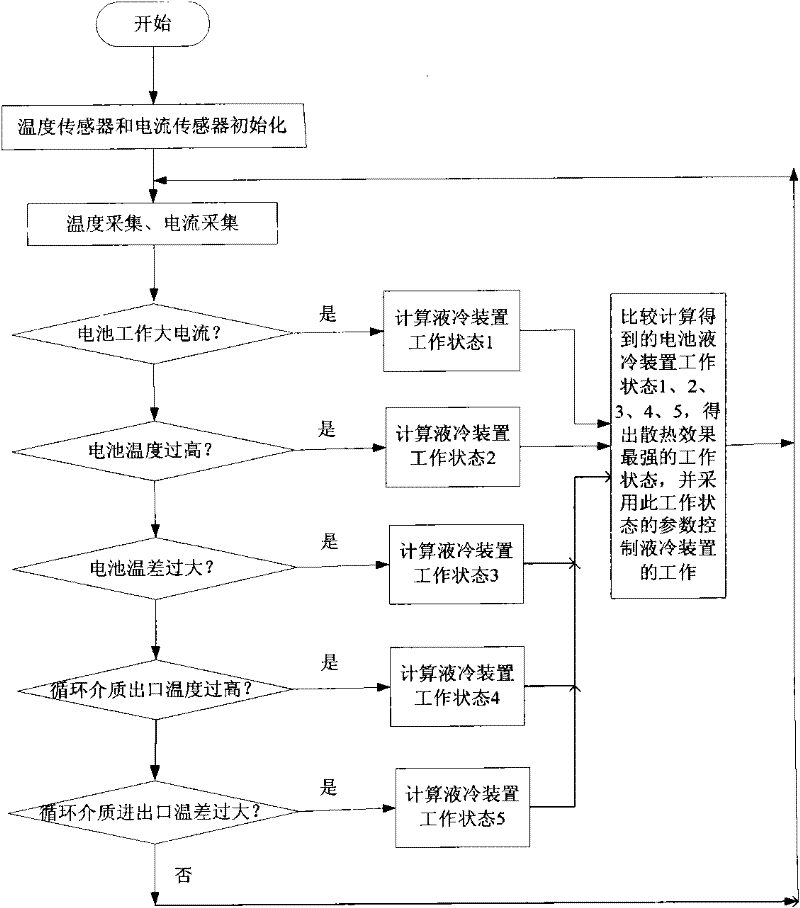

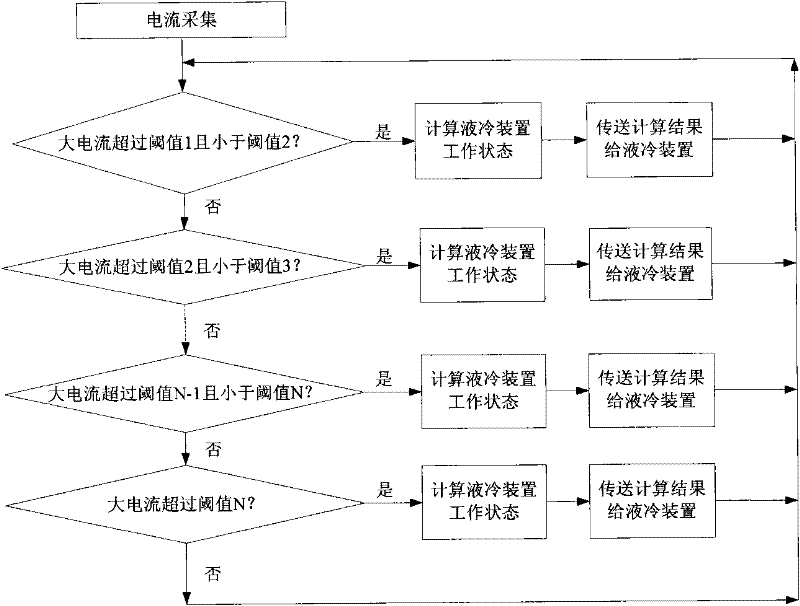

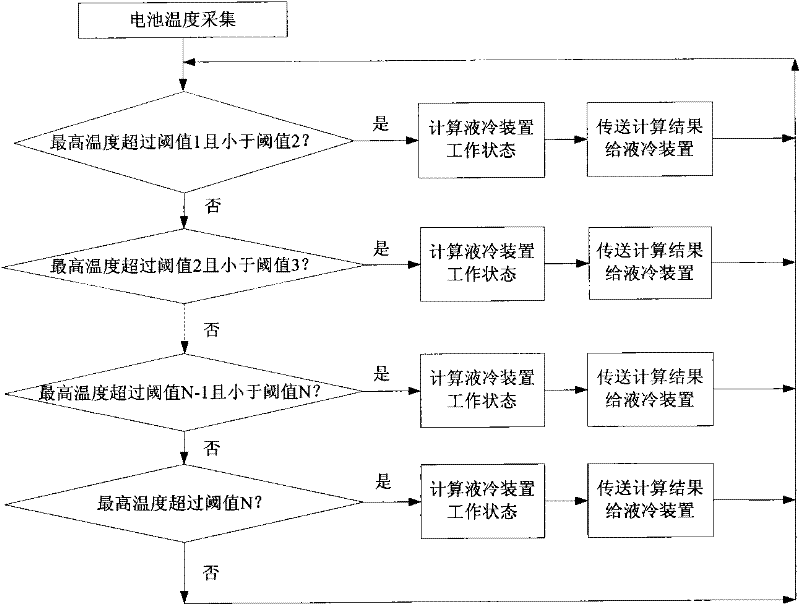

Liquid cooling temperature control and management method of power lithium ion battery

InactiveCN102544618AAvoid heat dissipationAvoid performance lossCell temperature controlTemperature controlPower flow

The invention discloses a liquid cooling temperature control and management method of a power lithium ion battery. The liquid cooling temperature control and management method comprises the steps of: 1) acquiring temperature and current; 2) obtaining a highest temperature value, a lowest temperature value, greatest temperature difference and liquid cooling system inlet and outlet temperature difference; 3) judging whether the current is large or not and computing a working state 1; 4) judging whether the temperature of the battery is high or not, computing a working state 2; 5) judging whether temperature difference of the battery is too great or not and computing a working state 3; 6) judging whether the outlet temperature of a battery pack is too high or not and computing a working state 4; 7) judging whether the temperature difference of circulating medium at the inlet and outlet of the battery pack is too great or not and computing a working state 5; and 8) comparing the computed working state 1, the working state 2, the working state 3, the working state 4 and the working state 5 to obtain a working state with the best heat dissipation effect for setting. The liquid cooling temperature control and management method of the power lithium ion battery solves the problems that the temperature of the battery is too high and the local temperature difference is too great, and has the beneficial effects that the performance of the battery is improved and the service life of battery is prolonged.

Owner:SHANGHAI AEROSPACE POWER TECH

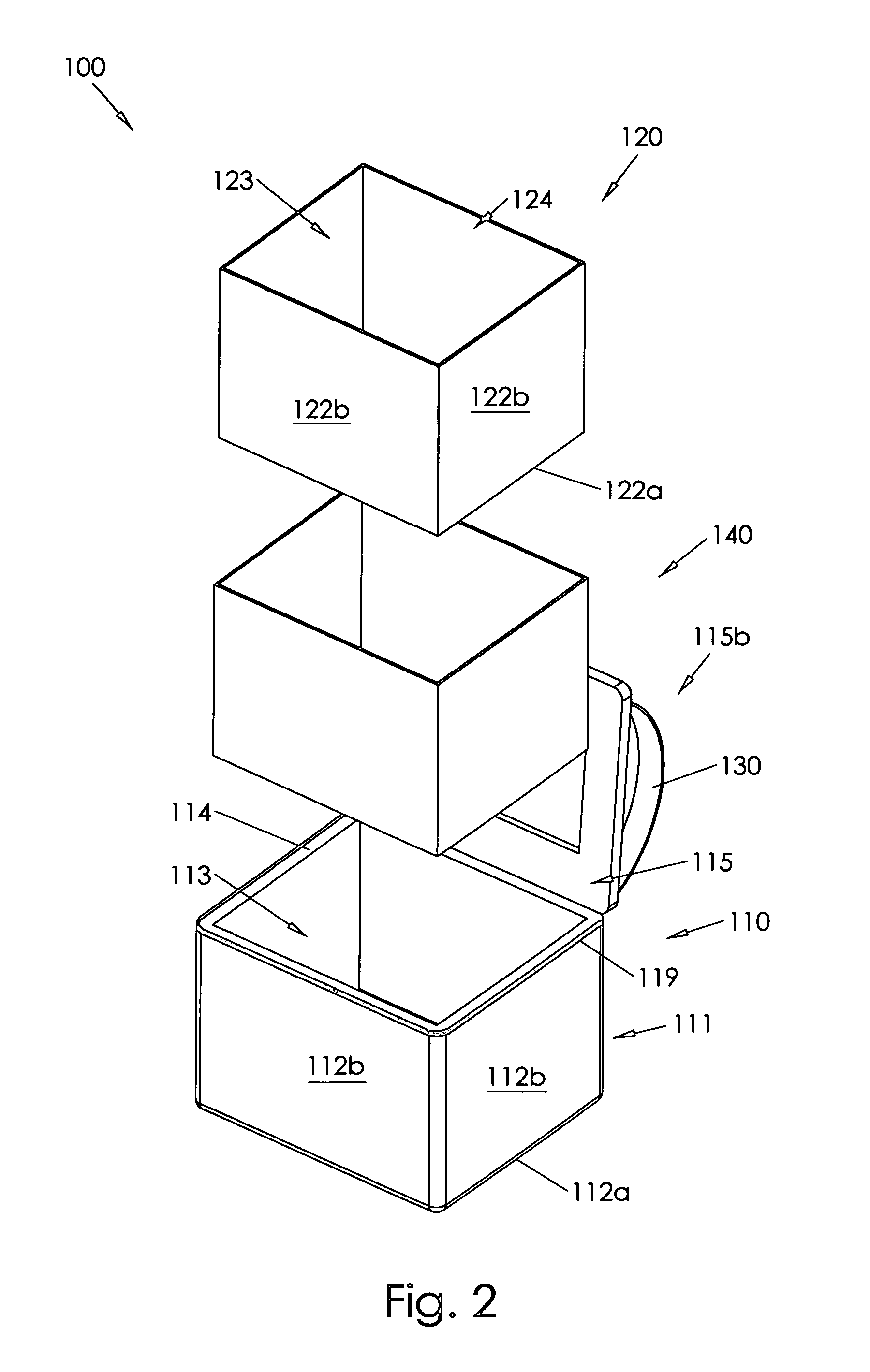

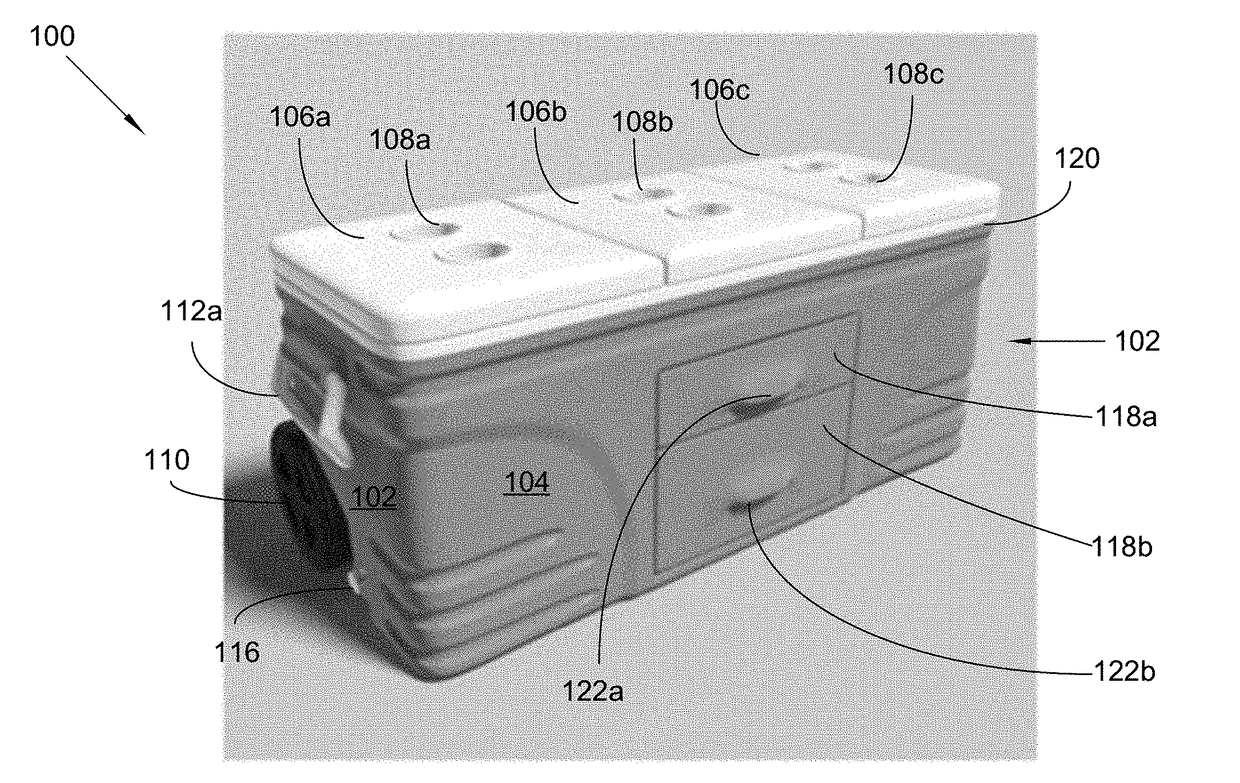

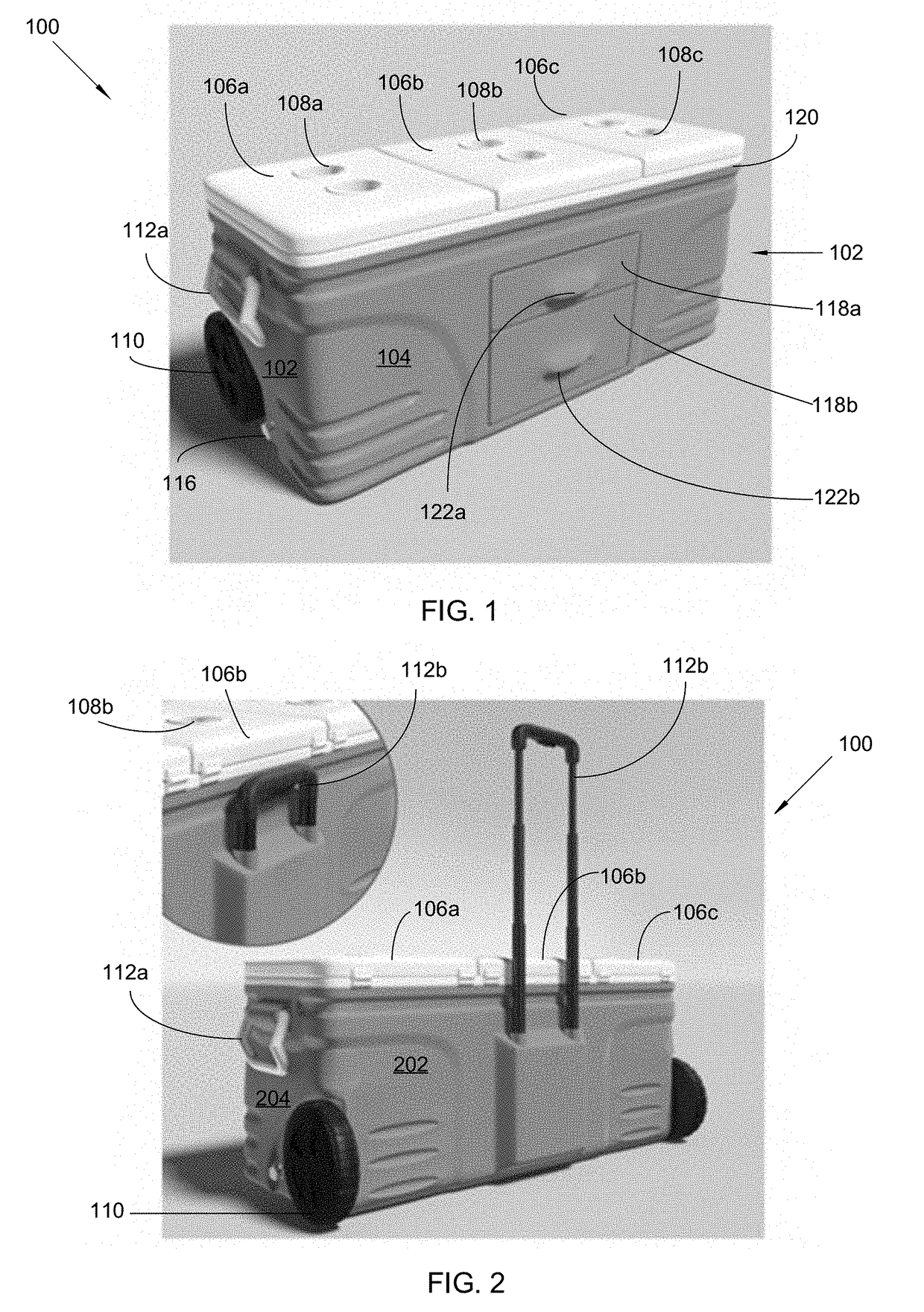

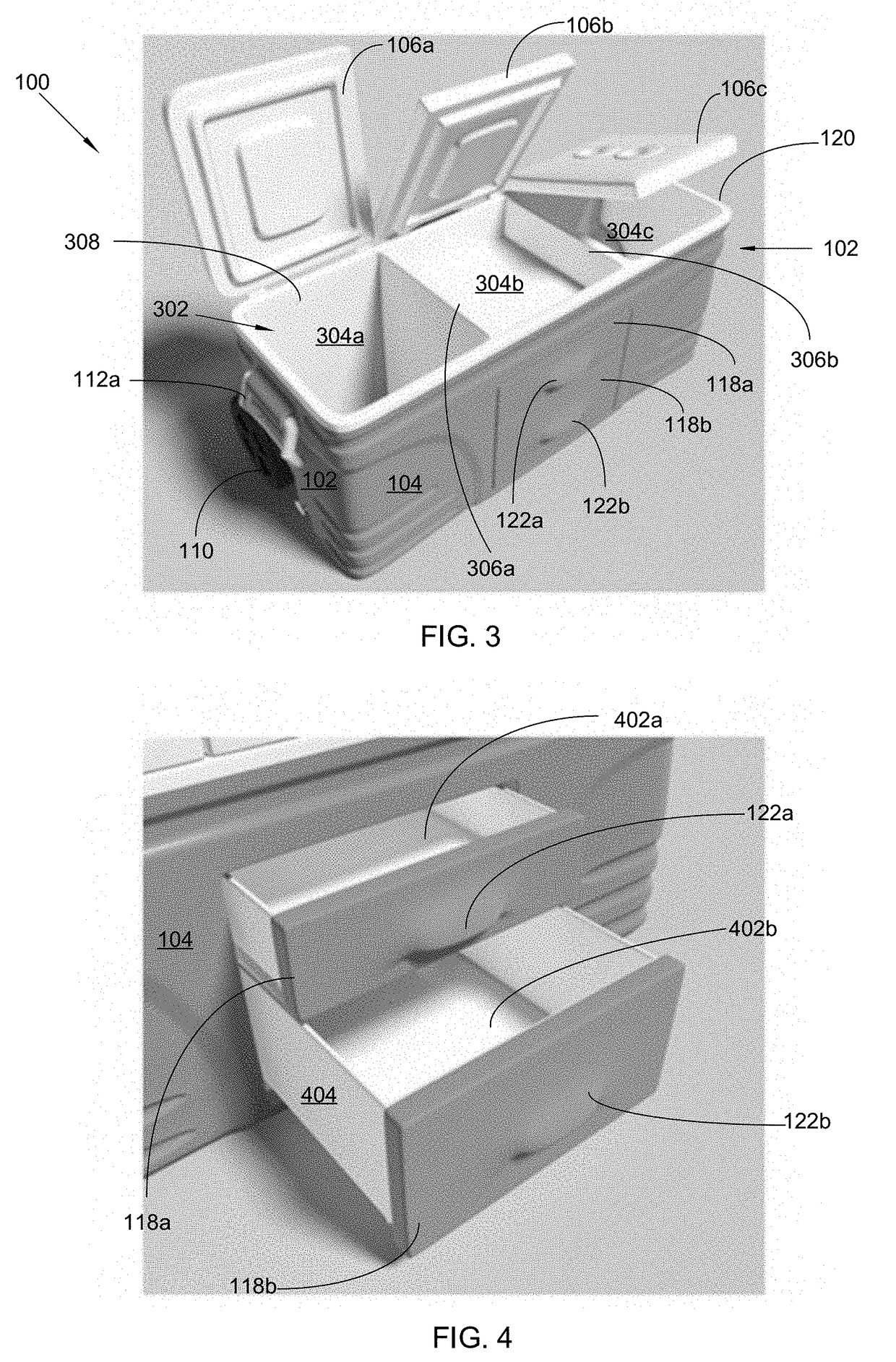

Multiple storage assembly

A multiple storage assembly provides an insulated housing comprising a plurality of segregated, independent compartments accessible by lids and drawers. The drawers provide a locking mechanism that helps inhibit accidental opening, and entry by children or animals. A housing stores food and beverages at cool temperatures. The housing includes an outer surface having a bottom wall, a first end wall, a second end wall, a first side wall, and a second side wall. The walls form a cavity. At least one barrier segregates the cavity into multiple lid compartments. Lids provide access to the lid compartments. Drawers having drawer compartments and a lower surface with a protruding lock slide in and out of housing on a rail. The protruding lock engages a depression in the rail to help restrain the drawers in the closed position. A mobile portion and a handle portion enable maneuvering and mobility of the housing.

Owner:VALENCIA SERGIO

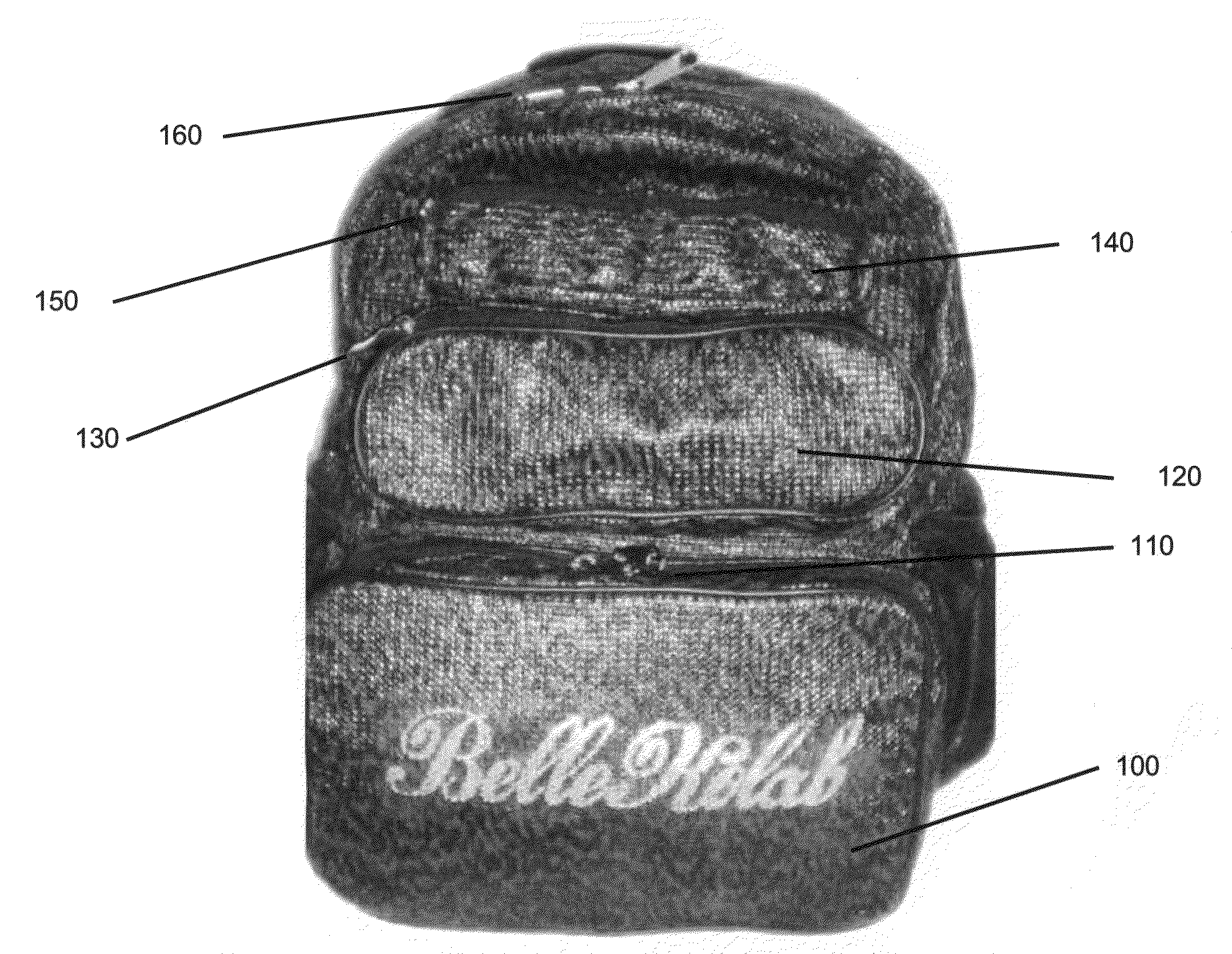

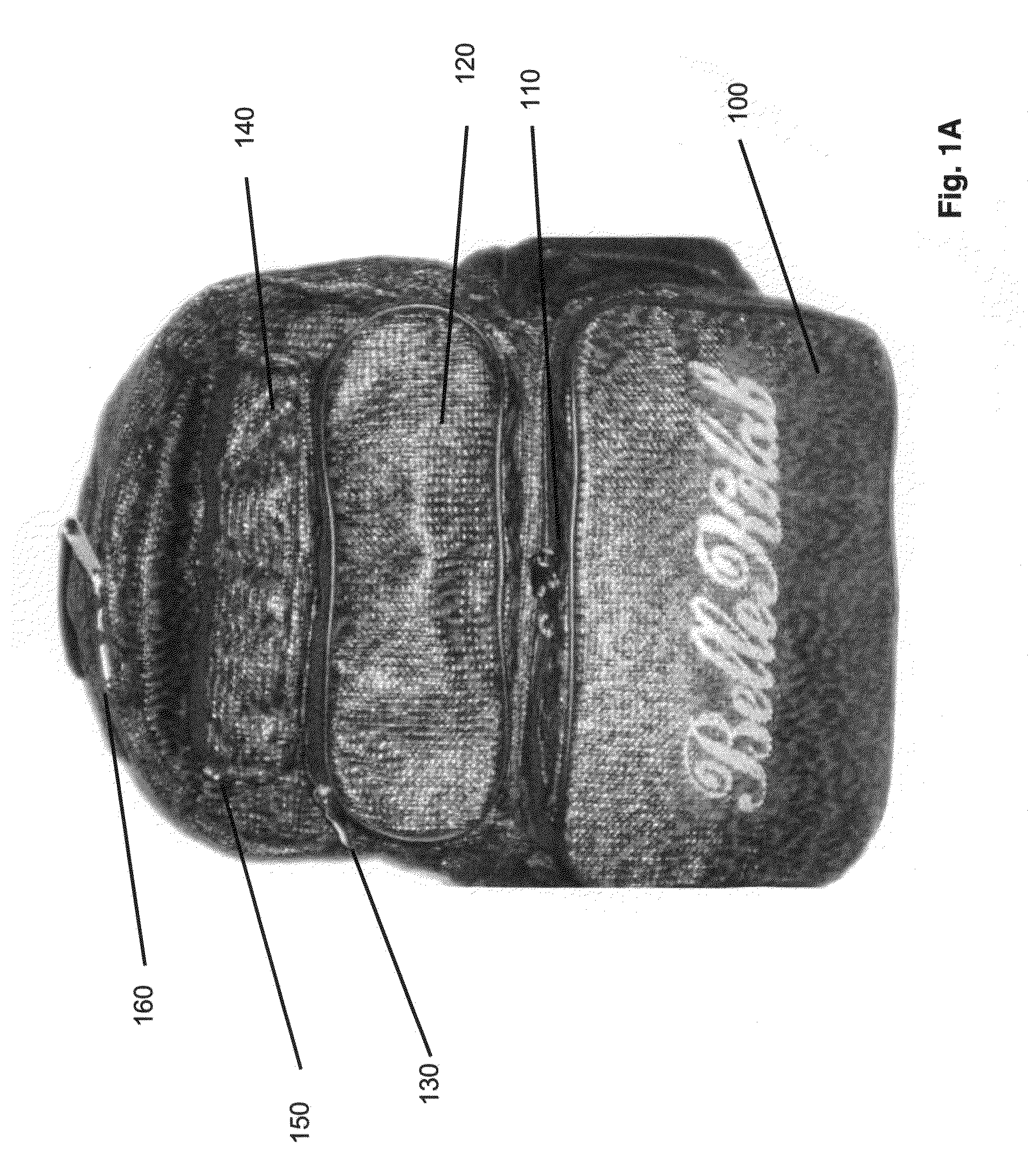

Bag with cooler compartment and uses thereof

The present invention provides a bag with a cooler compartment that can store perishable food or medicinal items with generous storage compartments in the interior and on the exterior front, back and sides of the bag. The cooler compartment is lined with thermal plastic lining to maintain cool temperature and is easily washable to clean up after spills. The cooler compartment is flexible and can be increased in size to accommodate larger items. Security features have been added to the bag, so that valuables can be carried safely in the padded exterior back compartments. All exterior and interior compartments feature quick access and ease of use through the use of double-headed zippers, which allow opening of the compartments in either direction. The bag can be worn on the back and is secured there by two padded shoulder straps, which individually have a hook for keys and a mesh pocket for a cell phone for added convenience.Another embodiment of the bag with a cooler compartment is smaller in size and has an adjustable shoulder strap for easier carrying. The cooler compartment is lined with washable thermal plastic lining. The cooler compartment is flexible and can be increased in size to accommodate larger items. Four exterior compartments are provided, of which one is a mesh pocket and three are zippered compartments. The interior compartment is zippered and has two additional storage compartments to further organize the interior area.

Owner:MEN JHENNA

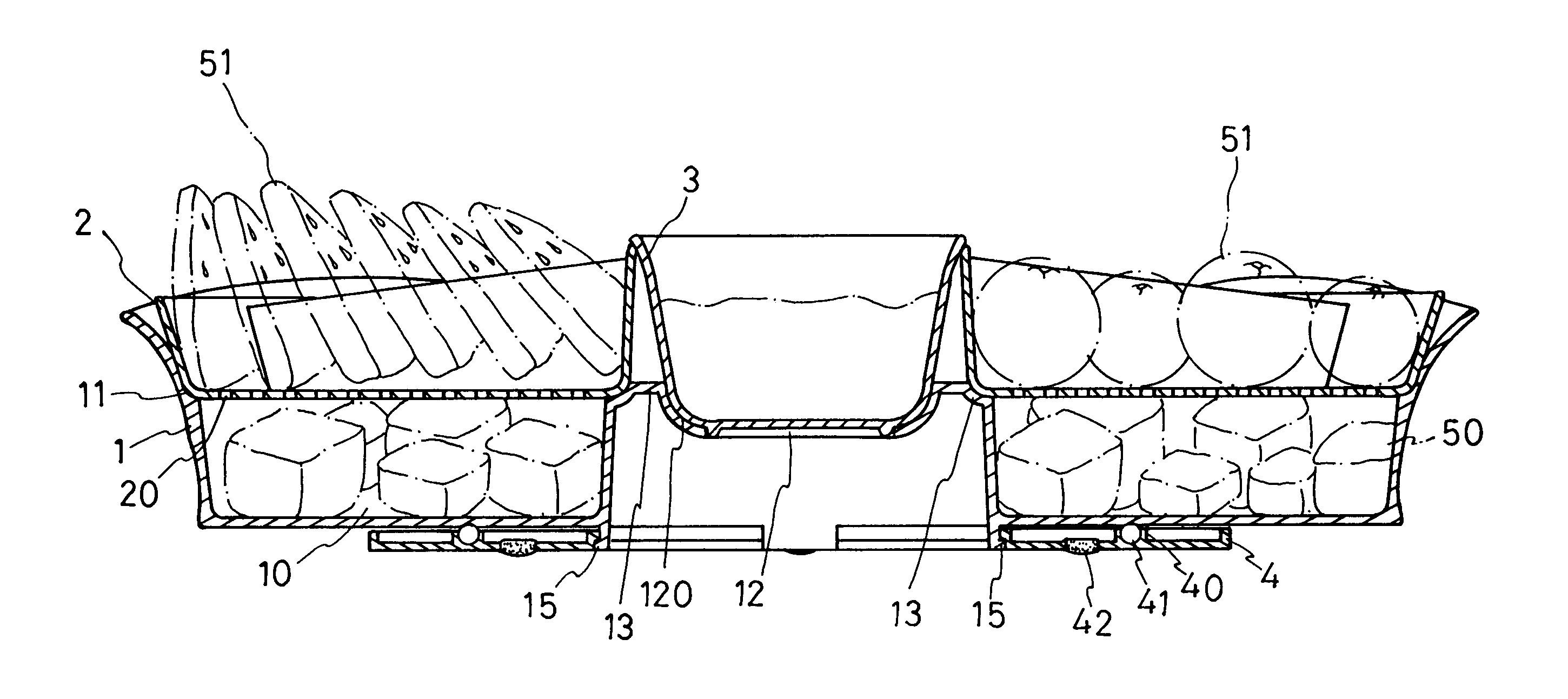

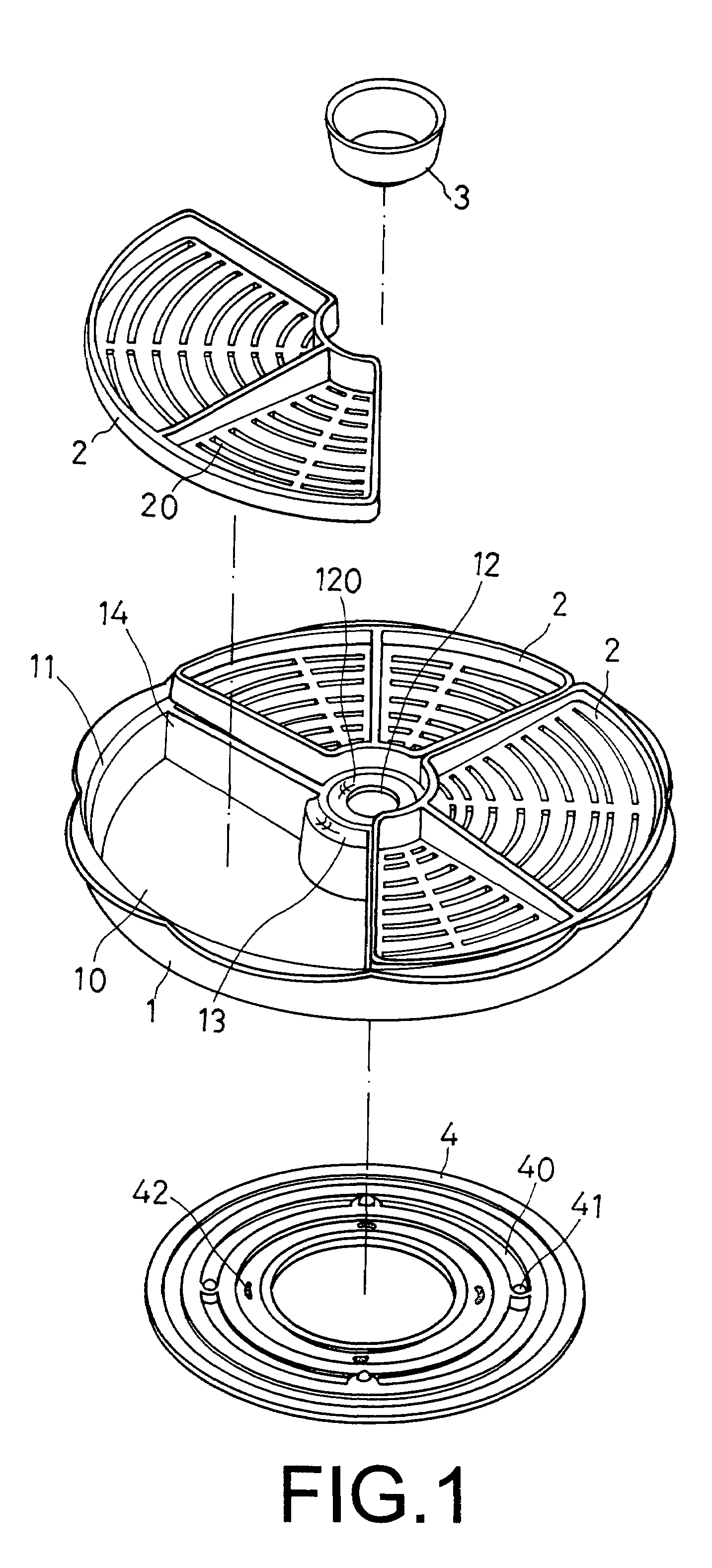

Serving tray with function of keeping food fresh

A serving tray with function of keeping food fresh in the present invention includes a rotary tray provided with at least one compartment; at least one receiving pan; and a base plate disposed below the rotary tray. In using, after a user puts ice cubes into the at least one compartment, places various food items, such as vegetables, fruits or the like, respectively in the at least one receiving pan, and then locates the at least one receiving pan above the at least one compartment, the food items will soon be spread with cool air coming from the ice cubes and penetrating through a plurality of perforated holes of the at least one receiving pan, thus enabling the food items to be kept fresh in cool temperature in a longer period for being tasted more delicious, and maintained with their individual unique flavors in a sanitary condition.

Owner:YANG HENG TE

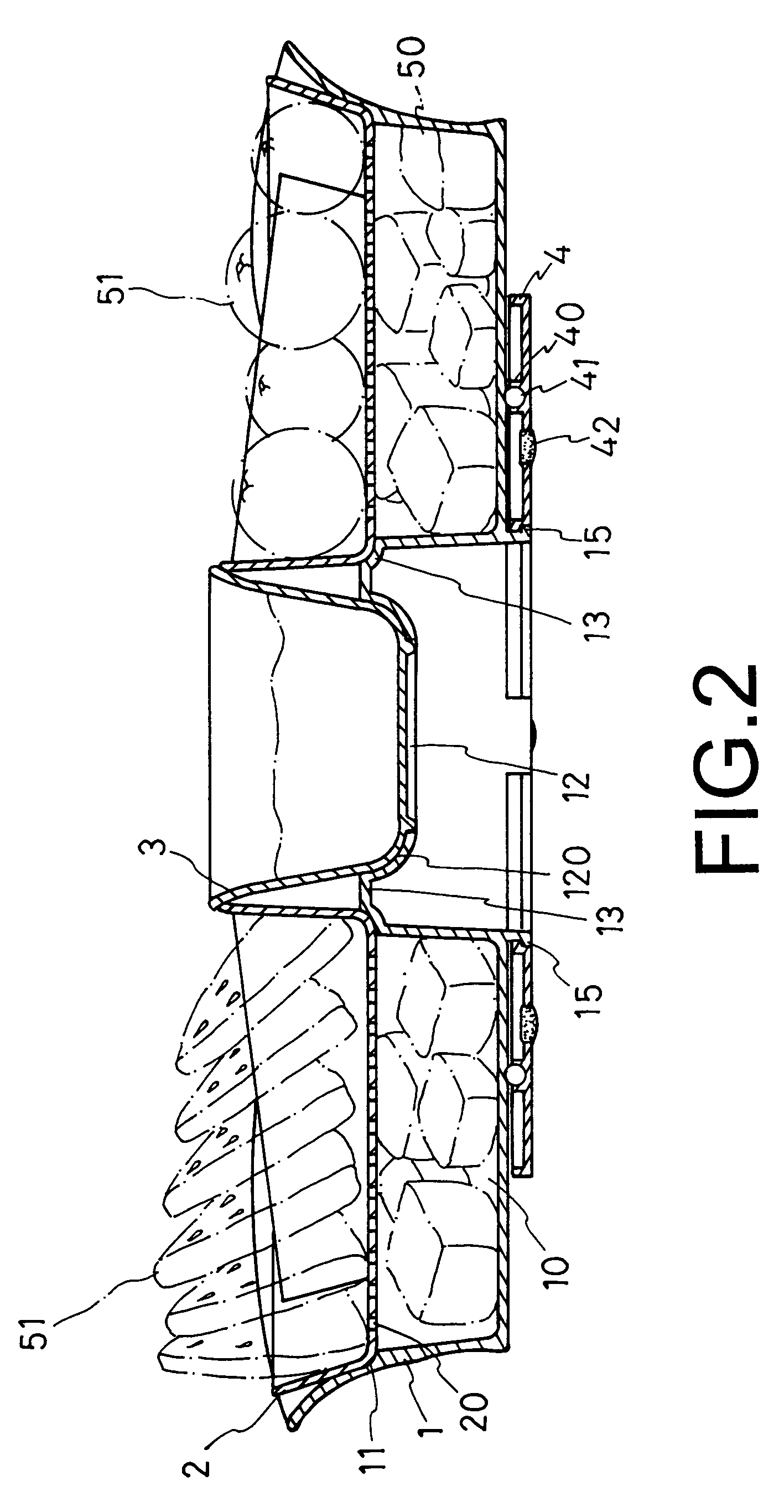

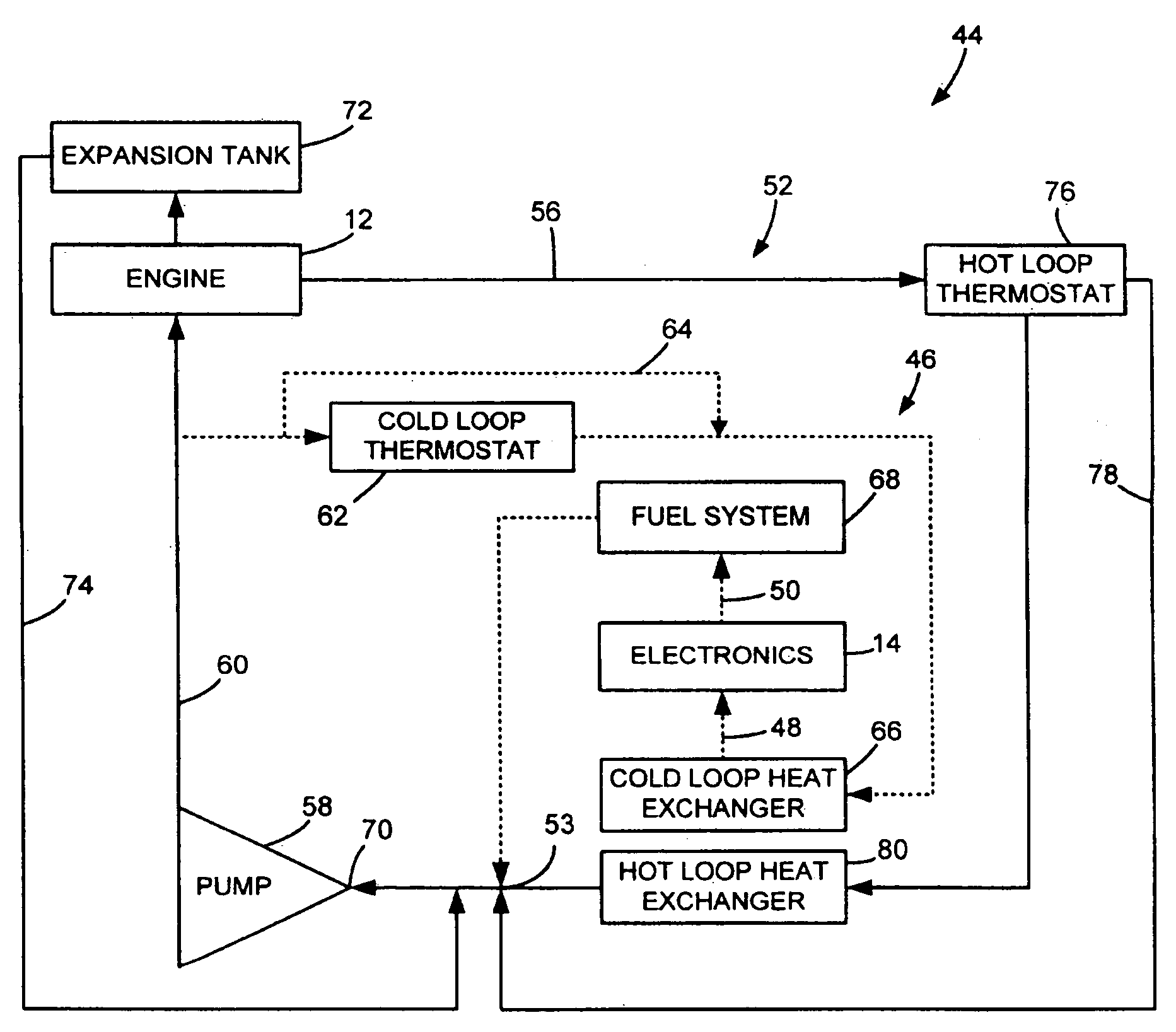

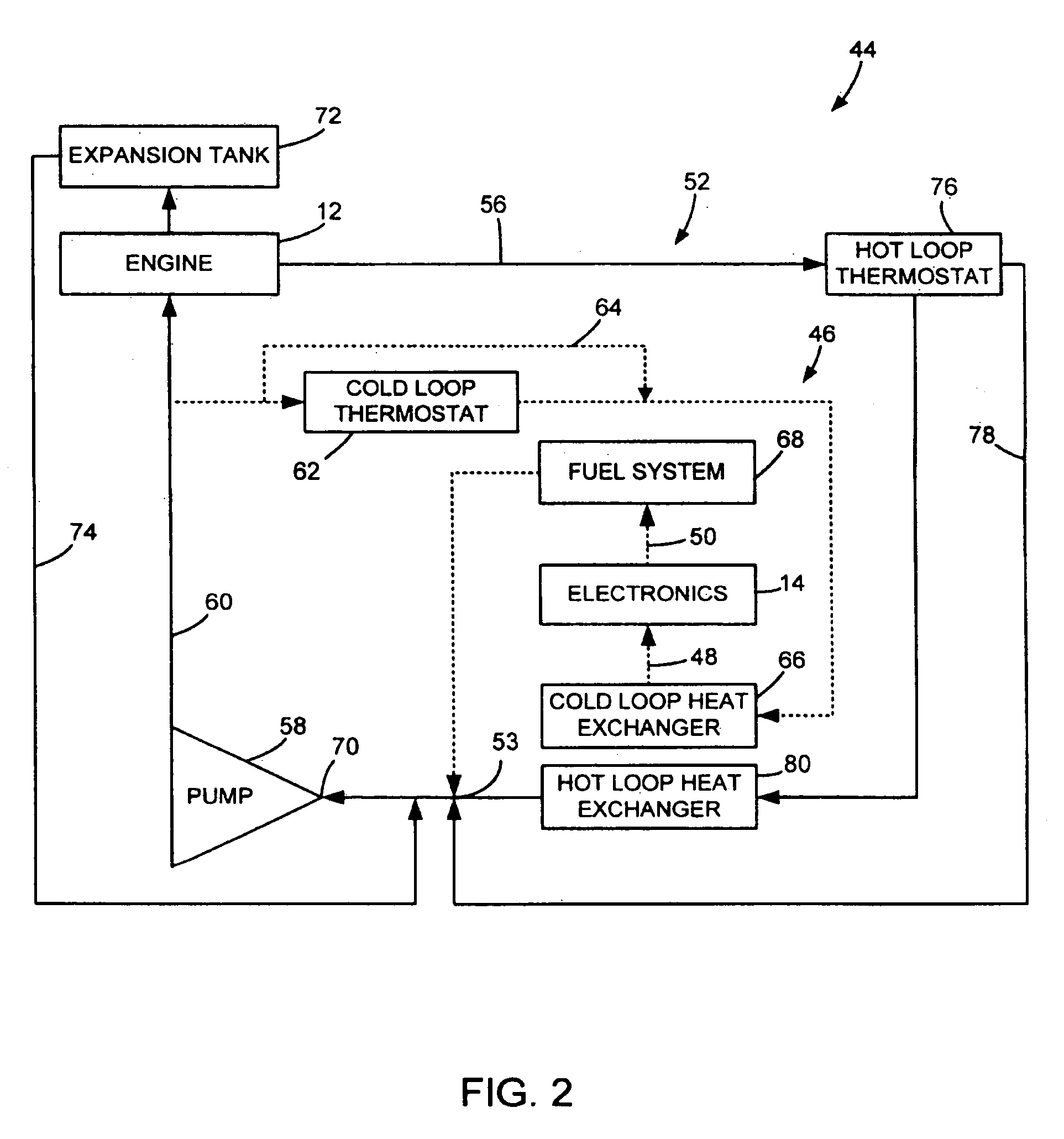

Dual temperature closed loop cooling system

A cooling system and method of cooling an engine are disclosed. The cooling system includes a first closed loop that circulates coolant at a first temperature and a second closed loop that circulates coolant at a second temperature that is different than the first temperature. Such a construction provides two separate cooling temperature circuits for cooling equipment at different cooling temperatures.

Owner:BRP US +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com