Patents

Literature

427results about How to "Solve productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

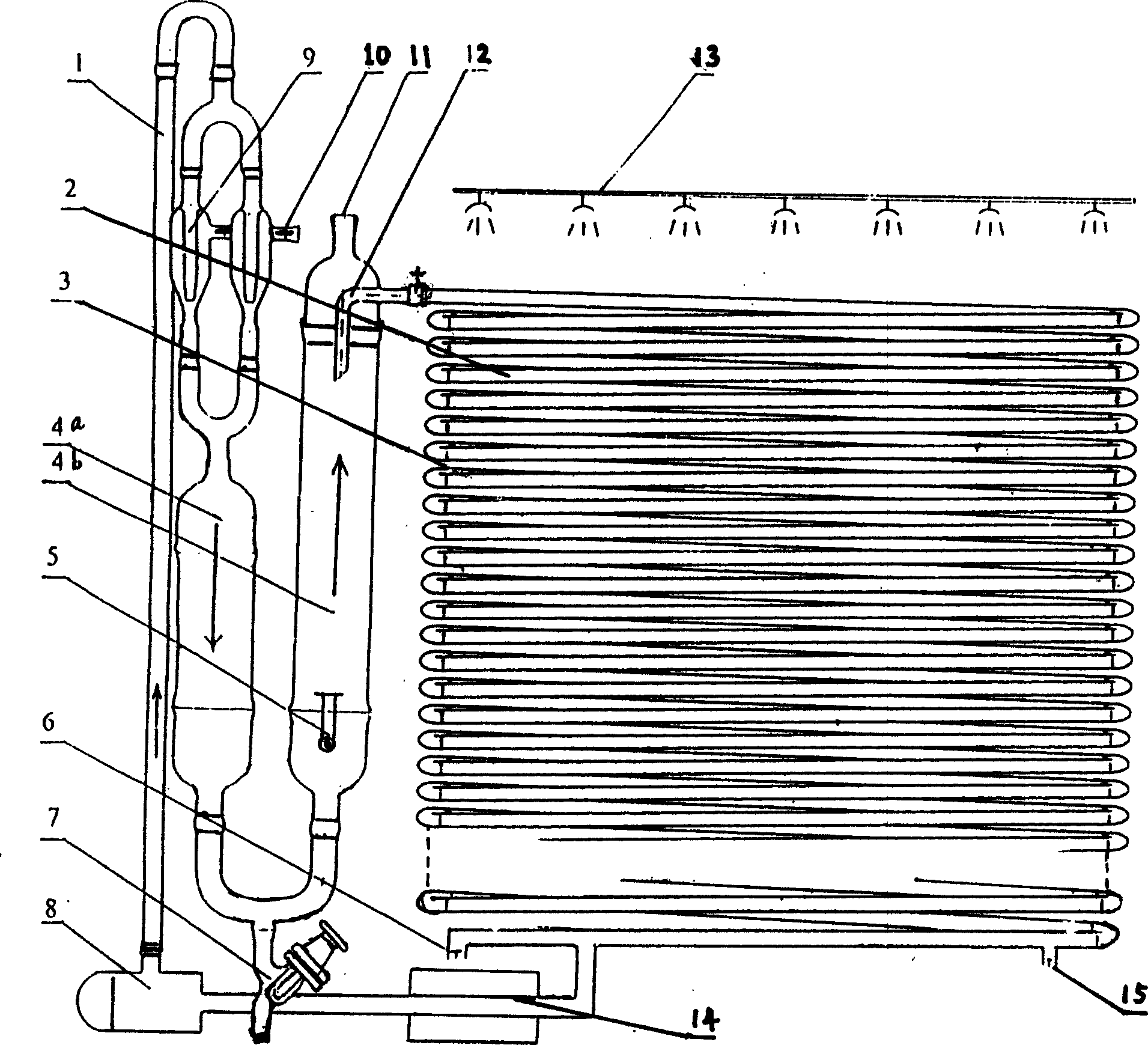

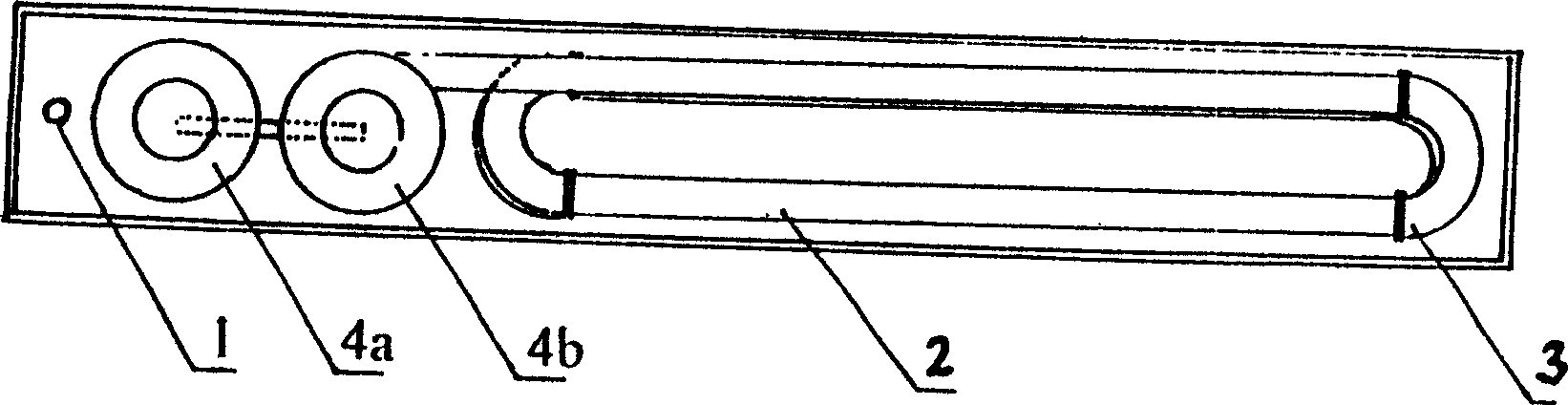

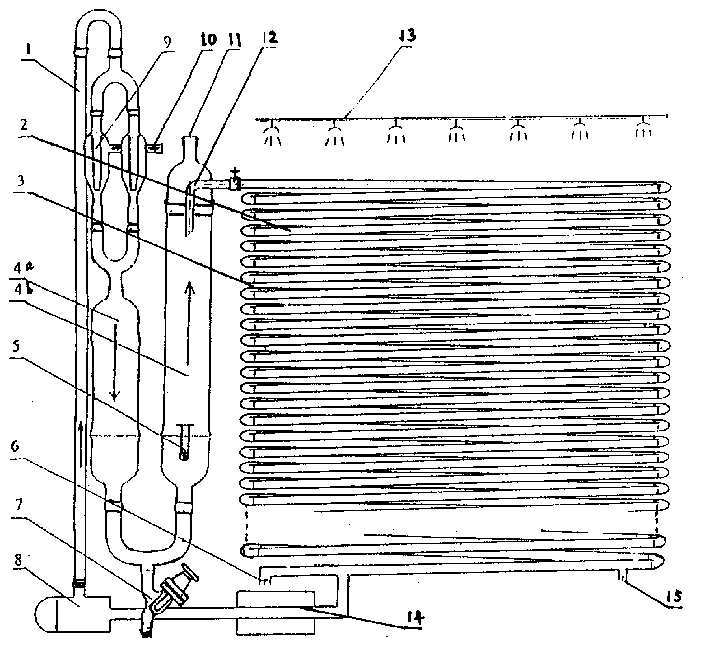

Photosynthesis bioreactor system for industrial production of micro algae

ActiveCN1475558ASolve the problem of not being able to upgrade and enlargeSolve productivityBioreactor/fermenter combinationsBiological substance pretreatmentsPhotosynthesisAlgae

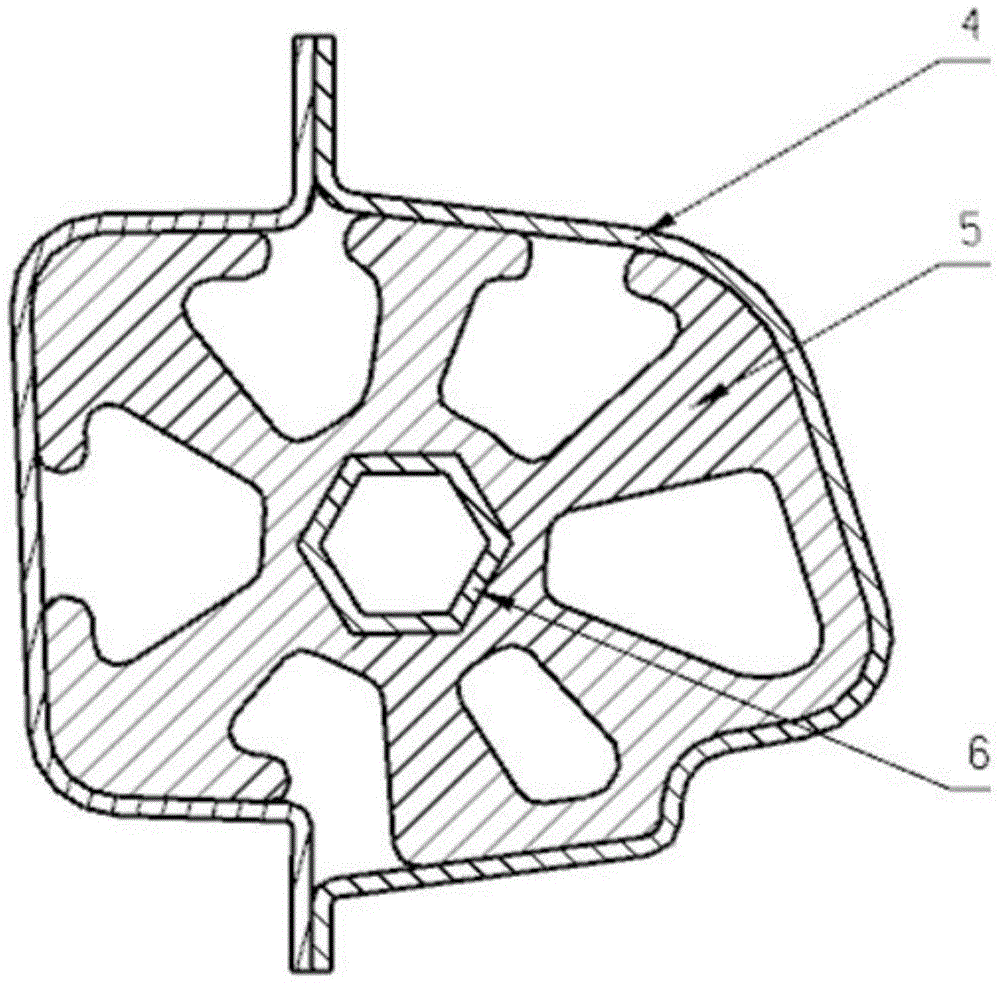

A photosynthesizing bioreactor system for industrial culturing microlgae is composed of dual lines of 3D spiral pipeline with unique U-shaped joint elbow, dual reaction towers including oxygen exhausting tower and regulating tower, liquid delivering pump with zero shear force, CO2 filler, artificial lighting unit and cold (or heat) exchanger. Its advantages are less possessed ground area, high output rate, low energy consumption, and low pollution.

Owner:南昌新生生物科技有限公司 +1

Three section laminar flow cooling technology for hot rolling band steel

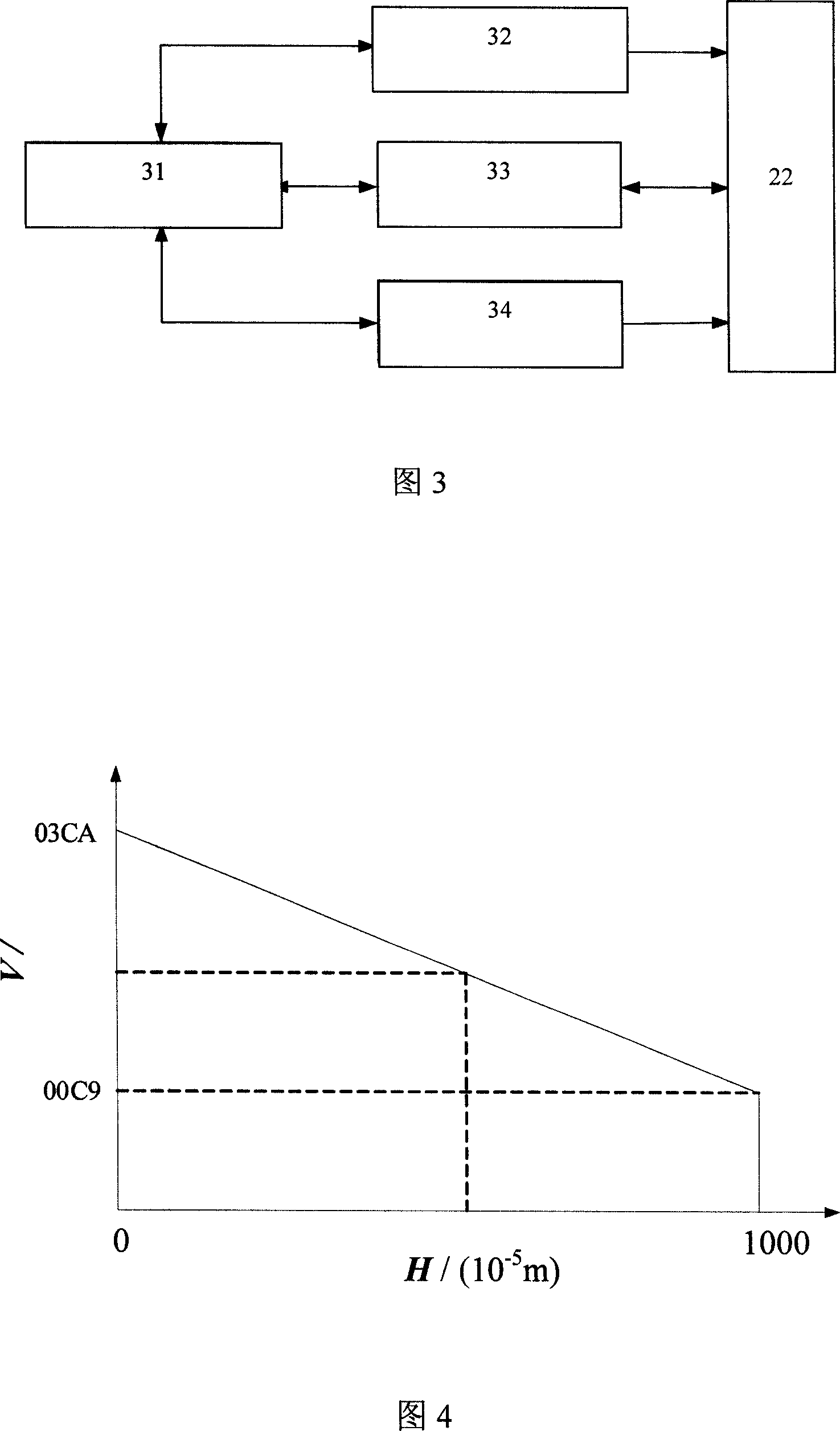

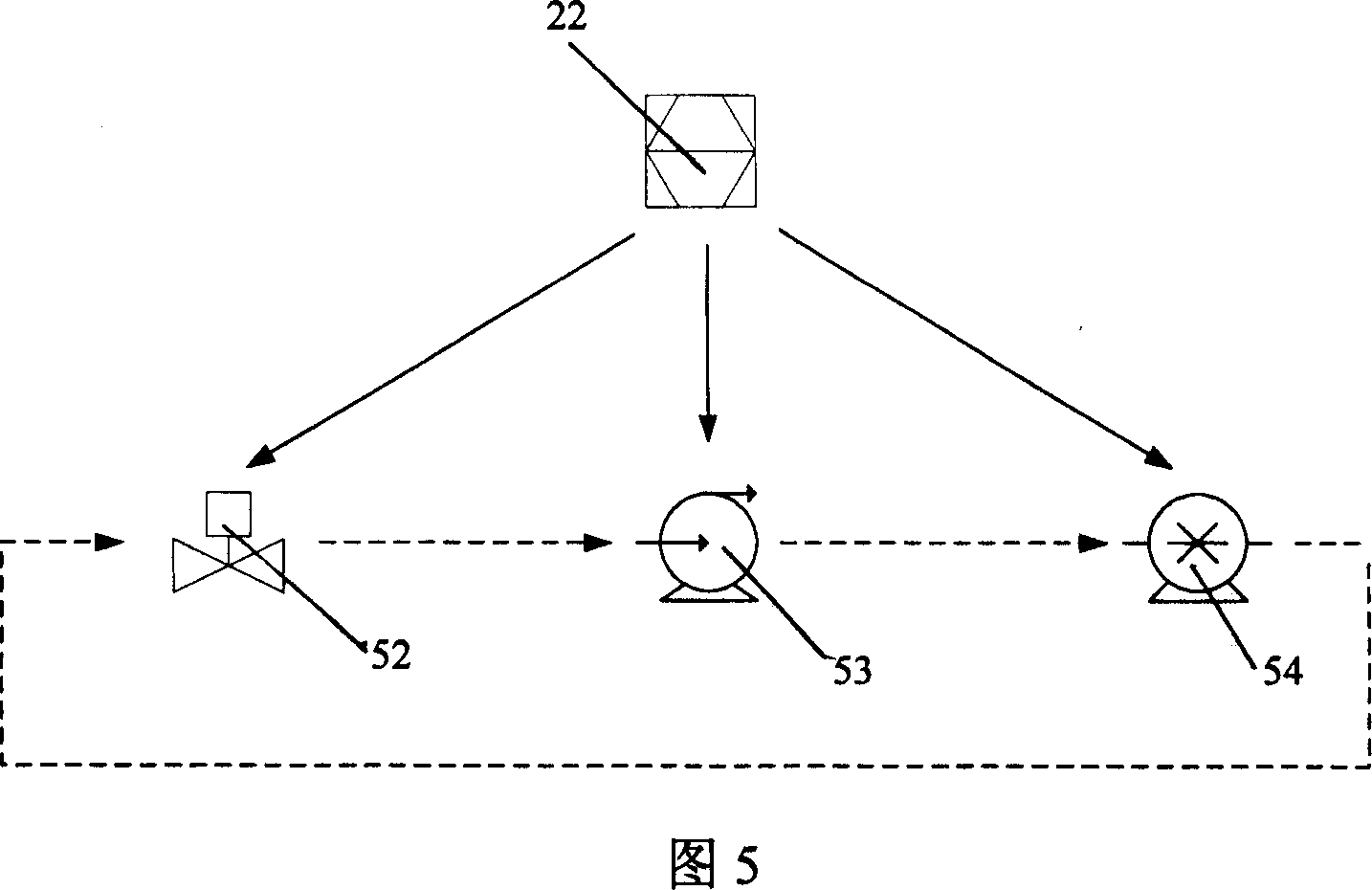

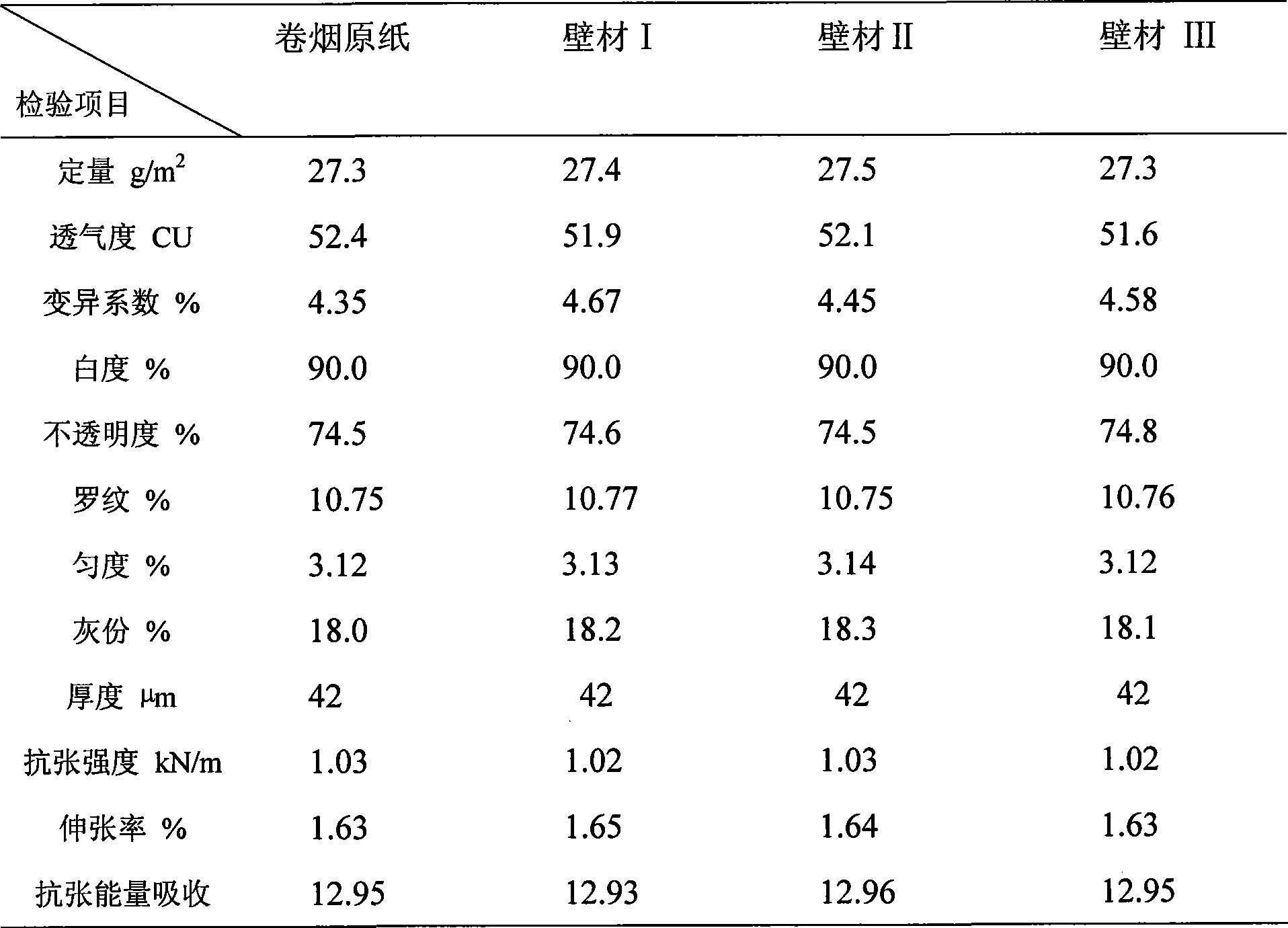

InactiveCN1483528AImprove performance uniformitySolve productivityTemperature control deviceWork treatment devicesEngineeringStrip steel

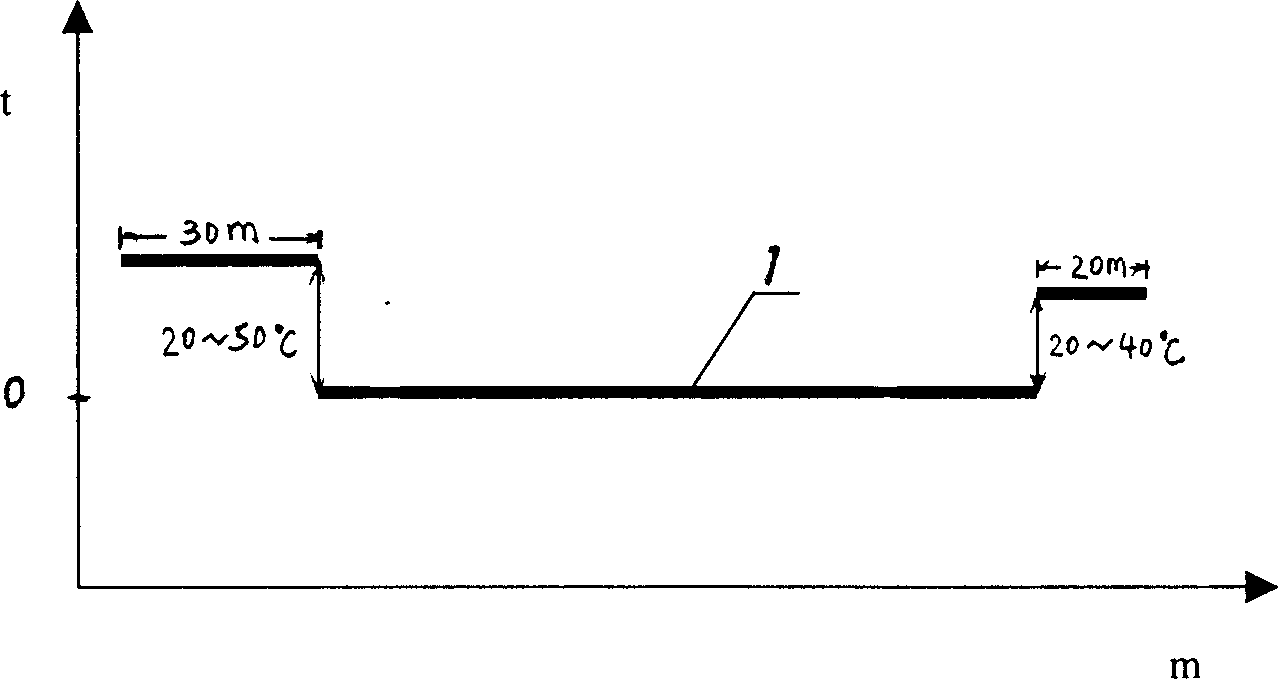

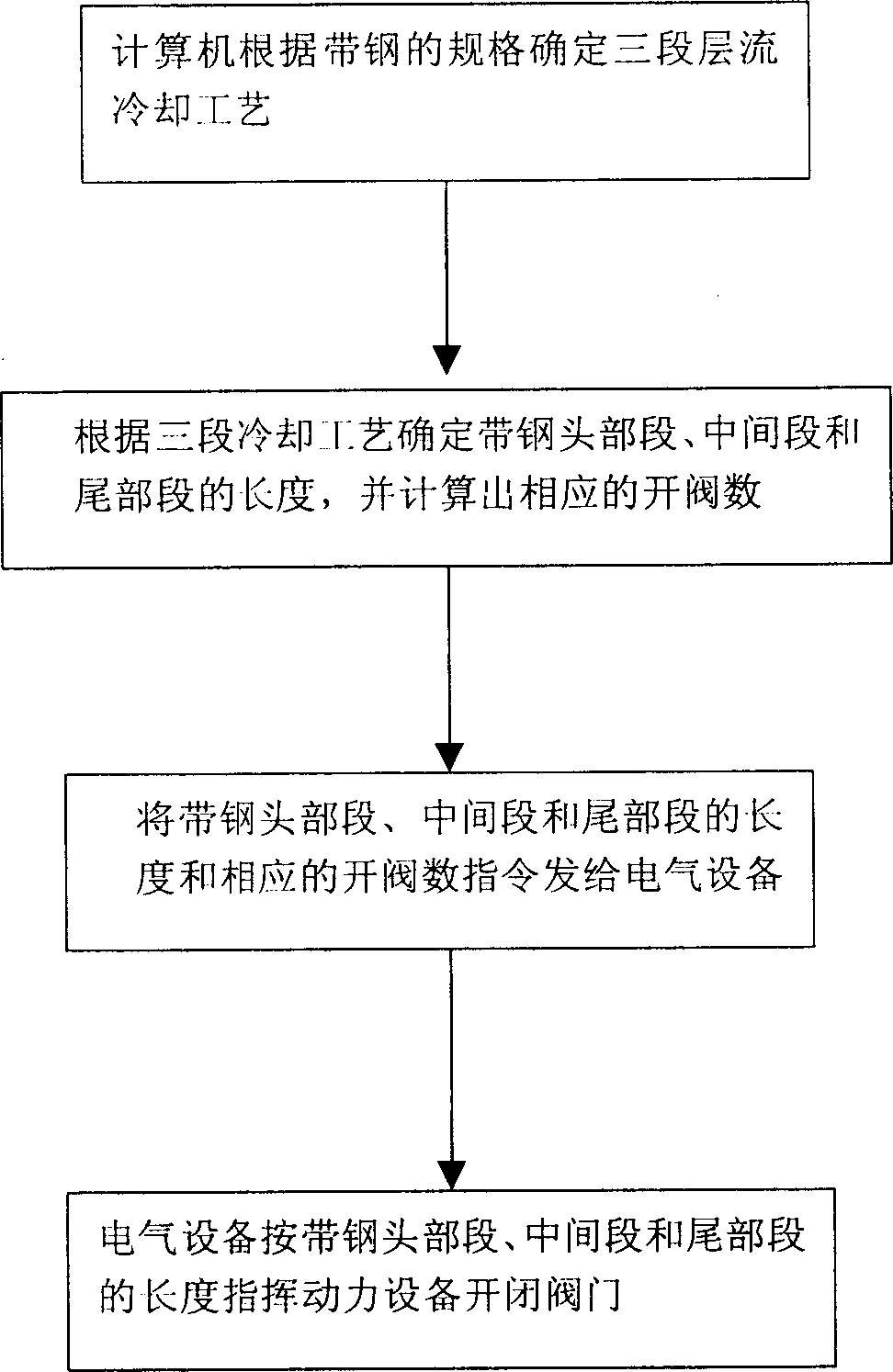

The present invention provides a three-section cooling process by laminar flow for hot-rolled steel strip. Said process adopts the computer laminar flow cooling control, and is characterized by that the steel strip can be divided into three sections for cooling, first section is head portion section whose length is 30 m, second section is intermediate section of the steel strip, and third section is the tail portion section whose length is 20 m, and the cooling temperatures of said three sections are respectively controlled in that its intermediate section temp. is equal to the objective coiling temp., its head portion section temp. is 20-50 deg.C higher than that of objective coiling section, and its tail portion section temp. is 20-40 deg.C higher than objective coiling temp. Said invention can improve the performance uniformity of steel strip.

Owner:ANGANG STEEL CO LTD

Preparation method of oxidized graphene and sodium alginate composite absorbing material capable of removing ciprofloxacin in aqueous solution

PendingCN105536726ARaw materials are easy to obtainLow costOther chemical processesAlkali metal oxides/hydroxidesPeristaltic pumpFreeze-drying

The invention provides a preparation method of an oxidized graphene and sodium alginate composite absorbing material capable of removing ciprofloxacin in an aqueous solution. The preparation method comprises the following steps: dispersing a certain amount of oxidized graphene samples in deionized water, putting the oxidized graphene samples into an ultrasonic cleaner, and performing ultrasonic treatment for 6-10 hours; dissolving a certain amount of sodium alginate into an oxidized graphene solution subjected to ultrasonic treatment, and performing ultrasonic treatment for 20 minutes; dropewise adding the mixed solution into a 0.2mol / L calcium chloride solution by virtue of a peristaltic pump, soaking for 1-3 days, and cleaning with deionized water for 3-4 times, thereby obtaining a sodium alginate and oxidized graphene sphere hydrogel material; and freeze-drying, thereby obtaining oxidized graphene and sodium alginate sphere aerogel. The preparation method is performed under a relatively mild condition, and oxidized graphene is packaged in a sodium alginate network structure by an ion bridge method, so that the nano toxicity of graphene powder is avoided, and a new nano material capable of efficiently absorbing ciprofloxacin antibiotics in the aqueous solution is prepared. The preparation process is simple, easily controllable in condition, low in cost and suitable for large-scale batch production.

Owner:SHANGHAI INST OF TECH

Fixed bacterial fertilizer and preparing method thereof

InactiveCN1490279ASave raw materialsHigh effective bacteria countOn/in organic carrierOrganic fertilisersActivated carbonHigh resistance

An immobilized bacterial fertilizer is prepared from the sodium alginate, activated carbon, bacteria, CaCl2 and H2O. Its advantages are high resistance to ambient condition, great number of living bacteria, long storage time, and durable acting.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

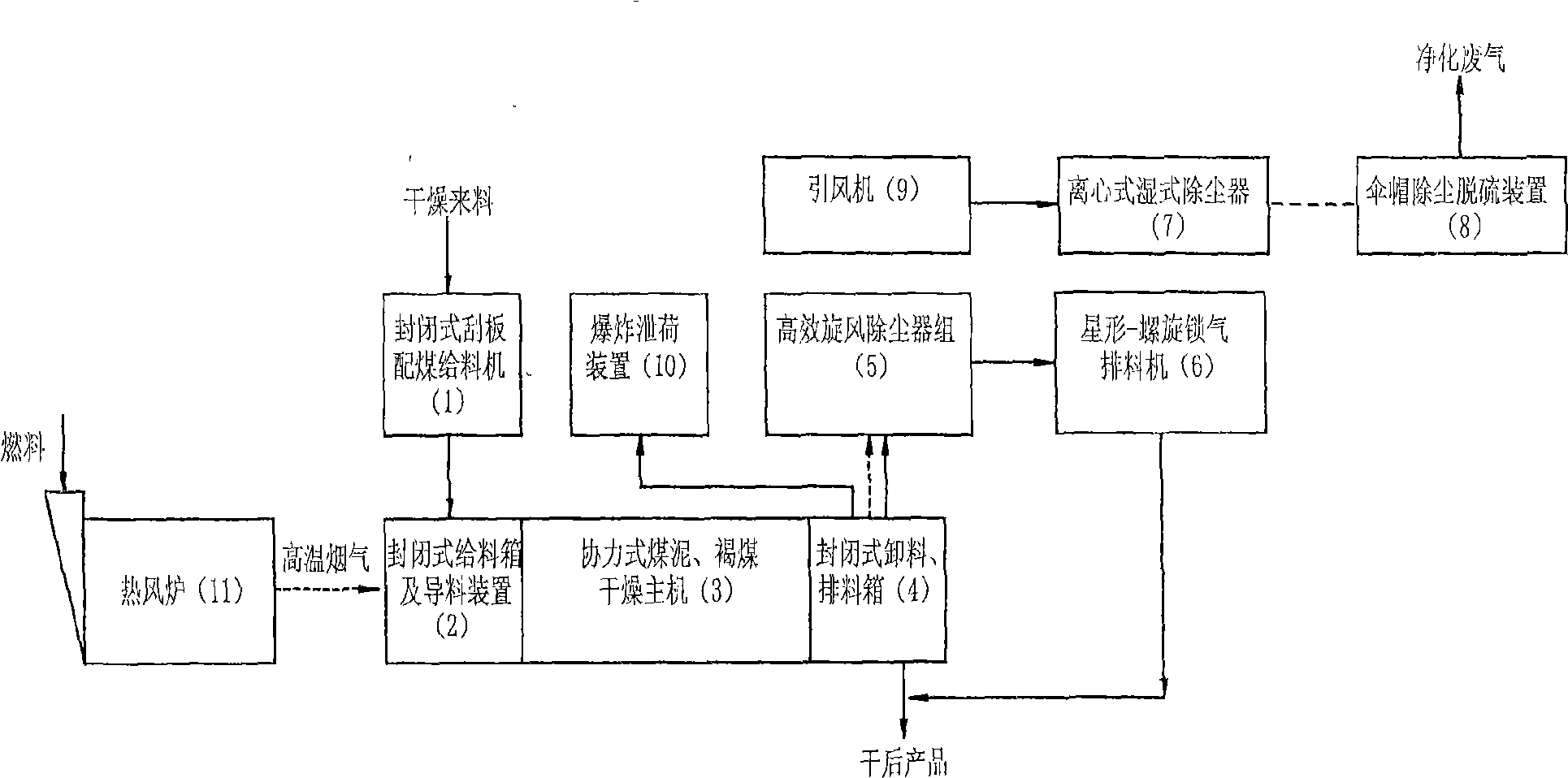

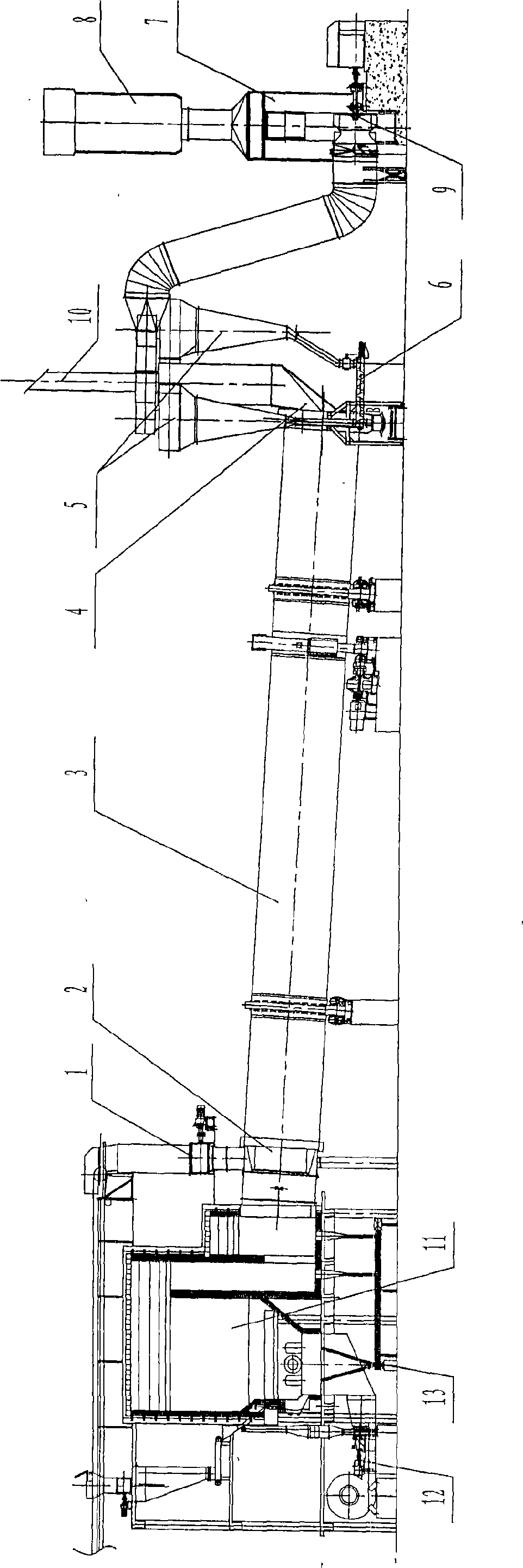

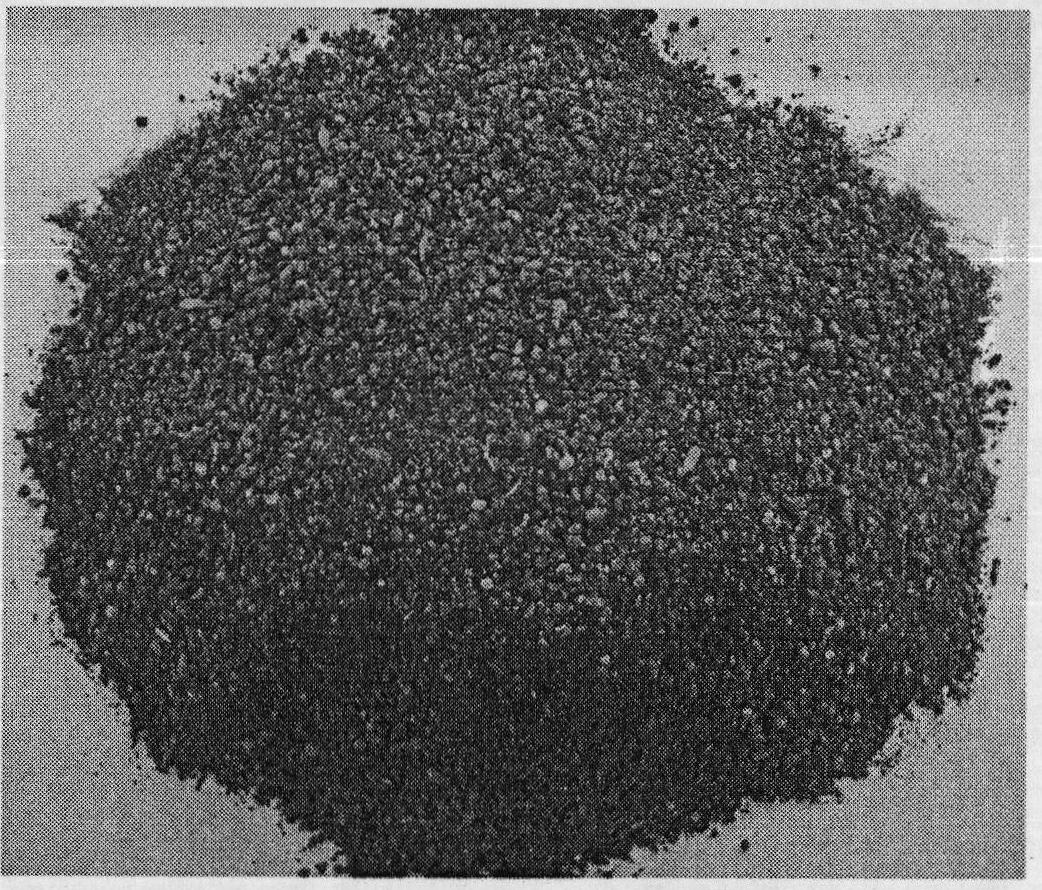

Process and equipment for improving the quality of coal slurry and lignite through drying same

InactiveCN101519617ASolve frequent blockagesSolve the burning problemSolid fuelsDrying peatEconomic benefitsProcess engineering

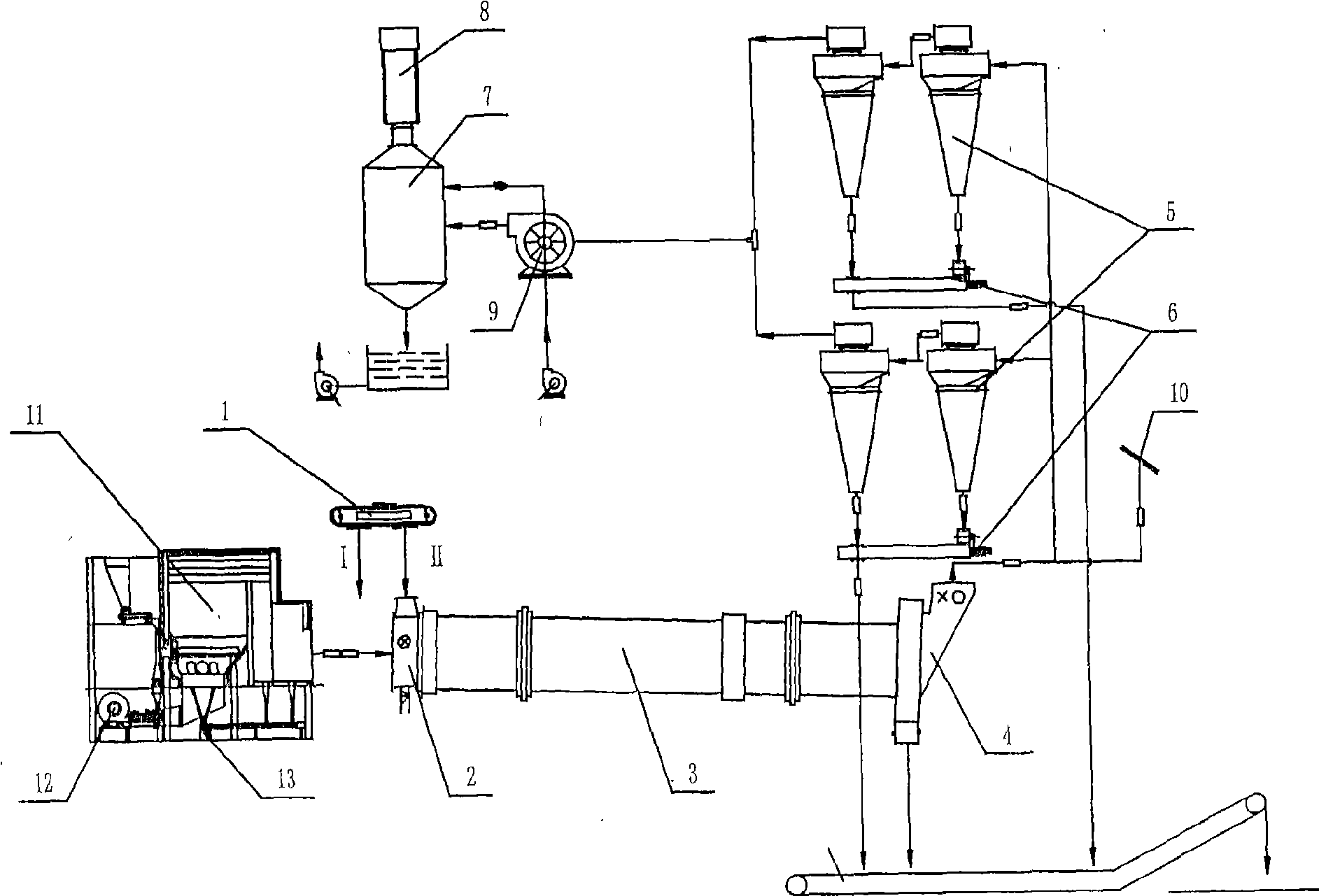

The invention relates to process and equipment for improving the quality of coal slurry and lignite through drying the same. The process comprises the following steps: (1) the coal slurry and the lignite are predried and then quantitatively fed to a drying system; (2) the coal slurry and the lignite are dried to be improved in quality by a material drying system; and (3) products are produced from the dried coal slurry and lignite of improved quality. The coal slurry and the lignite are dried and dewatered according to the physical and chemical properties of the same and the coal slurry and the lignite can not adhered to the wall of a cylinder of the equipment and can be cleaned automatically; the equipment is arranged integrally lineally on a plane so that the height of a factory building is lowered and the investment on the equipment is reduced by half compared with investment on the equipment arranged in a laminated mode; in addition, the equipment integrates feeing equipment, drying equipment and discharging equipment, has good sealing performance and high thermal efficiency which is increased to over 70 percent from the original 30-40 percent, saves energy to be consumed by one third, is environmentally friendly, can efficiently dewater the coal slurry and the lignite to improve the quality thereof and can be used safely and reliably so as to obtain obvious economic benefits.

Owner:张兆奇

Compound microbial fertilizer and preparation method thereof

InactiveCN101891509AHigh effective bacteria countSimple production processBio-organic fraction processingOrganic fertiliser preparationDiseaseGrowth promoting

The invention relates to a compound microbial fertilizer and a preparation method thereof. The compound microbial fertilizer is characterized by being prepared from the following materials in percentage by weight: 40.0-50.0 % of rape seed cakes, 10.0-20.0% of crops straws, 1.5-3.0% of mycothallus, 0.5-1.0% of bacterium thallus and 35.0-40.0% of water. By using the solid fermentation method twice, the invention organically combines the fungi (Trichoderma harzianum and Aspergillus aculeatus for biological control effect) and the bacteria (Bacillus subtillis and Bacillus megatherium for growth-promoting effect), and realizes a simple preparation method. The compound microbial fertilizer has the advantages of environmental condition resistance, high count of active viable bacteria, less influence by the environment after application, slow release of thallus and long-term effective colonization at rhizosphere of plants, promotes plant growth and simultaneously has a certain biological control effect on soil-borne diseases.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

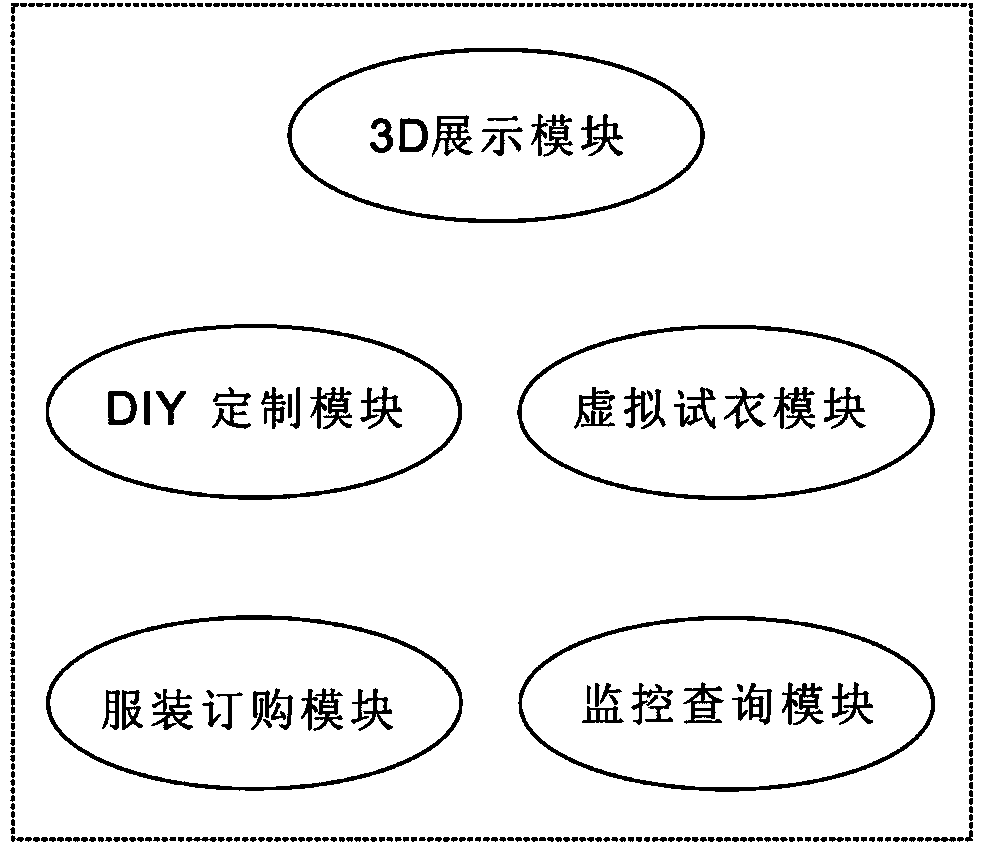

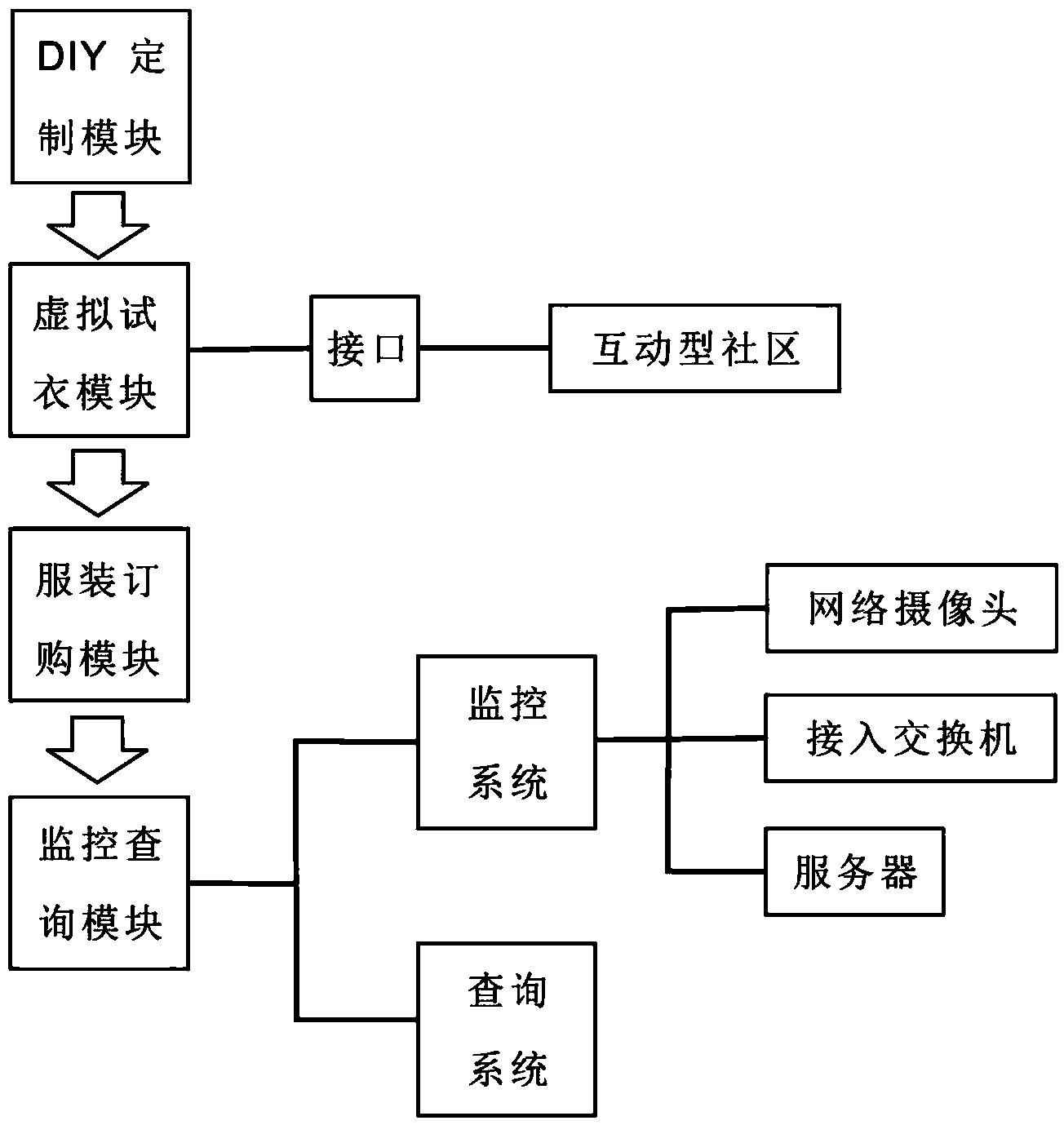

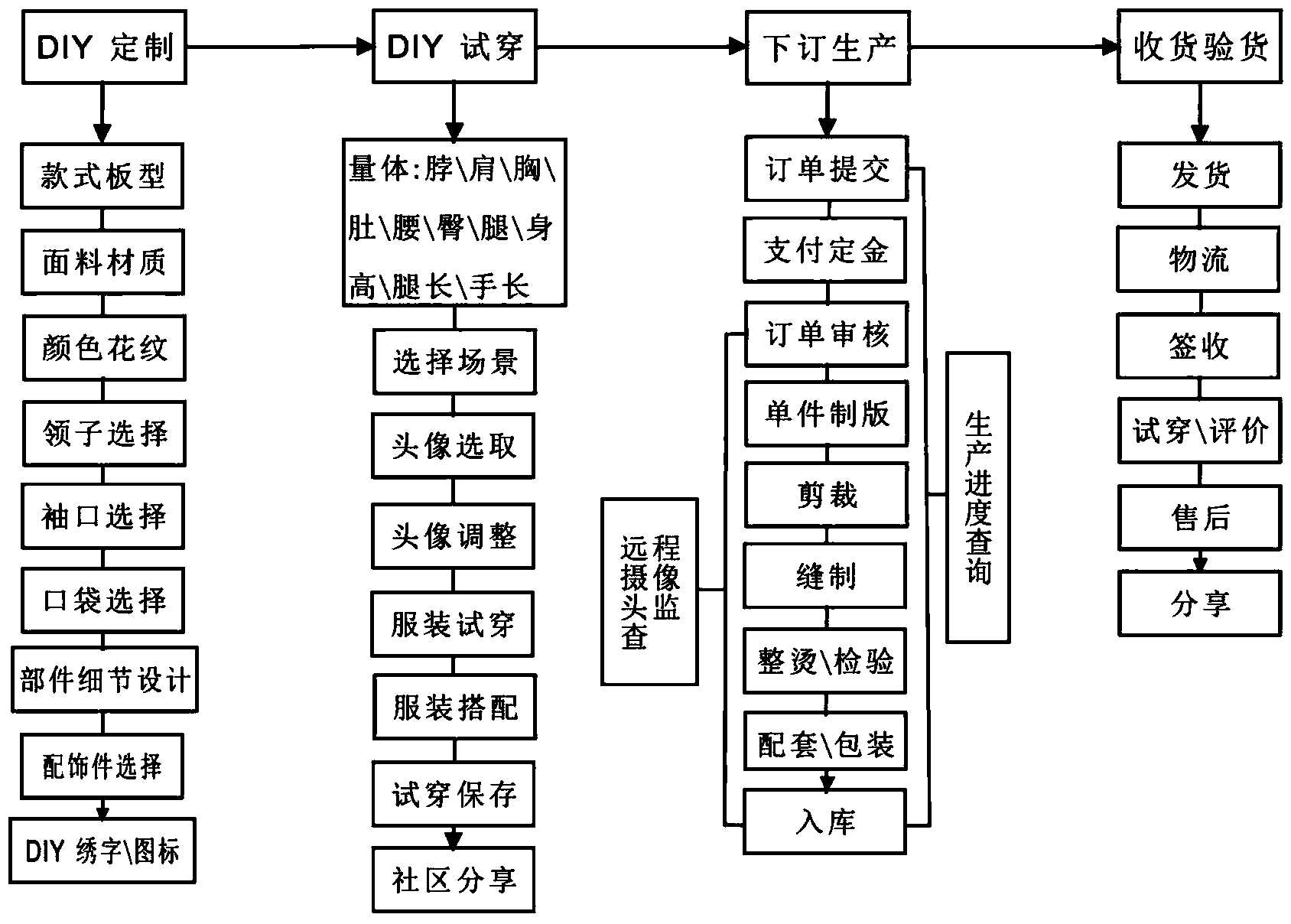

Touch interaction type garment DIY (Do It Yourself) ordering system

InactiveCN104391594ASolve productivitySolve technical problemsCommerceInput/output processes for data processingHuman–computer interactionInteraction type

The invention relates to a touch interaction type garment DIY (Do It Yourself) ordering system. The touch interaction type garment DIY ordering system comprises a garment sale physical store, a virtual fitting module and an online interaction module, wherein the online interaction module comprises a touch display screen. The touch interaction type garment DIY ordering system is characterized in that a DIY customizing module and a garment ordering module are arranged on the online interaction module; the DIY customizing module is mainly used for optionally designing the style of garment, cloth materials, color patterns, pattern words, sleeves, a collar, pockets and ornamental parts by a customer according to own requirements to achieve DIY customizing of a complete article of garment; the garment ordering module is mainly used for submitting an order of the garment with which the customer is satisfied after trying on and paying a manufacturing production deposit for the DIY customized garment. According to the system, the problem of a production sale mode for garment popularization personalized customization and the technical problem are solved, and the psychological problems that consumers focus on the garment customizing production process are solved.

Owner:GUANGZHOU UDL GARMENT

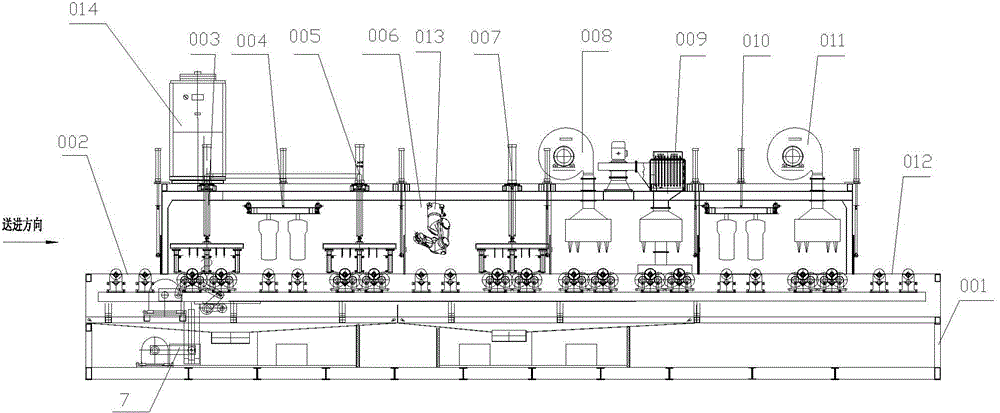

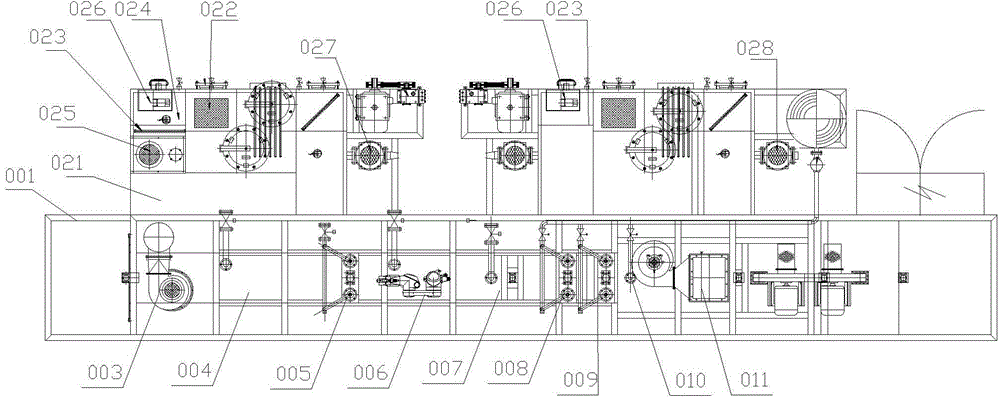

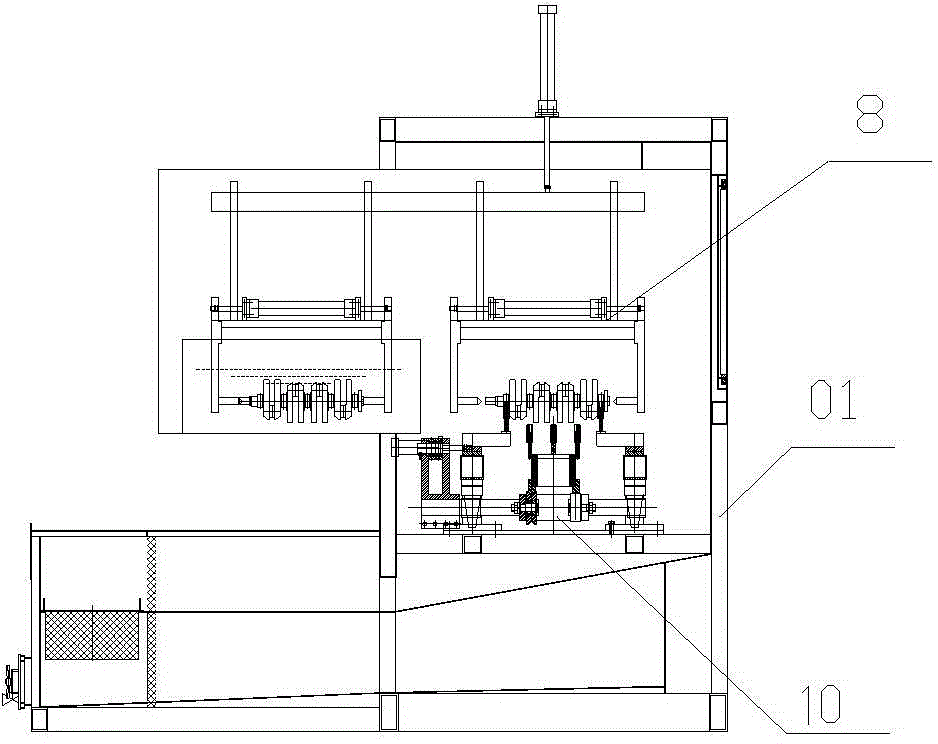

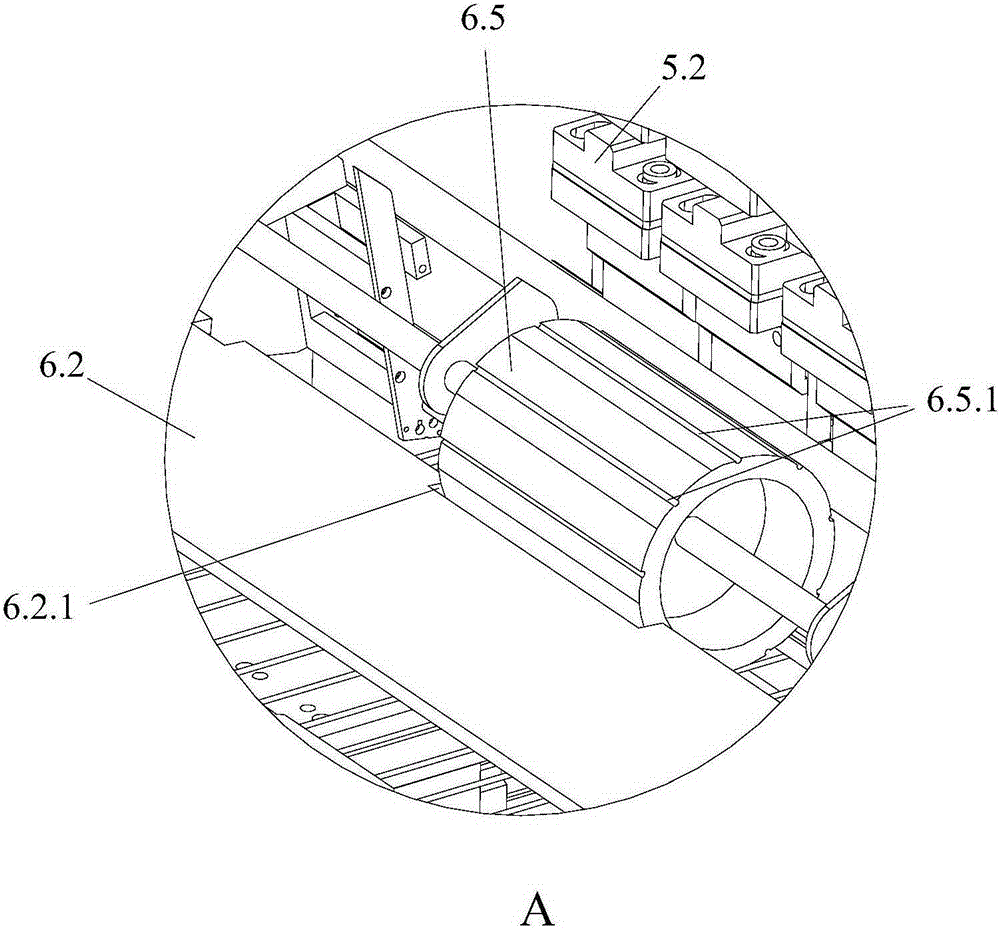

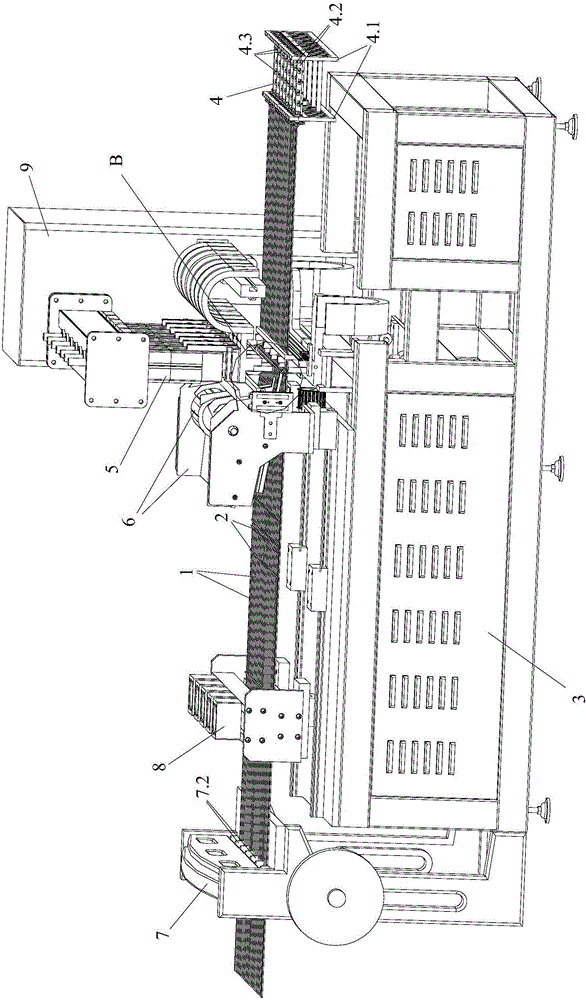

Crankshaft cleaning machine

ActiveCN105312269ASolve cleaningSolve productivityLiquid surface applicatorsCoatingsSurface cleaningWind shear

The invention provides a crankshaft cleaning machine. The crankshaft cleaning machine comprises a rack as well as a first surface cleaning system, a surface ultrasonic cleaning system, a second surface cleaning system, an oil duct cleaning system, a surface rinsing system, a surface blow-drying system, a hot air drying system, an ultrasonic oil immersion system and a wind-shear oil blowing system which are arranged on the rack sequentially, a workpiece conveying system for conveying workpieces is further arranged on the rack and comprises a lifting and conveying mechanism and a tool adjusting mechanism. The crankshaft cleaning machine is designed for cleaning an automobile crankshaft and integrates advanced combined means such as ultrasonic waves, high-pressure spray, ultrahigh-pressure spray, rotation, flexible robot hole alignment, ultrasonic oil immersion, oil blowing and the like so as to be applied to crankshaft cleaning, drying and rustproofing processes, and the tool adjusting mechanism of the conveying system can adjust the width automatically to adapt to cleaning of products in various specifications.

Owner:CHONGQING KEBEN TECH

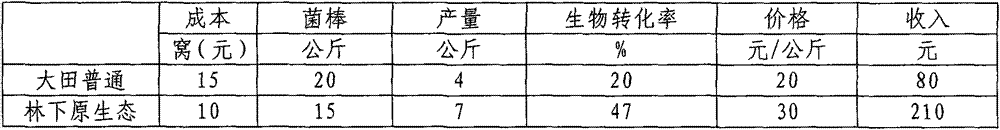

Under-forest original ecology gastrodia elata planting method

The invention discloses an under-forest original ecology gastrodia elata planting method. The method includes the steps that a field of which one half backs to the sun and the other half faces the sun and a piece of shady mountainous forest land are selected for planting, wherein the altitude of the field and the altitude of land range from 1000m to 2000m; fungus-growing materials are prepared, specifically, tree sticks are cut in November to February and are then cut into short wood sections with the lengths ranging from 18cm to 20cm, the prepared tree sticks are placed along slopes, every 6-8 tree sticks is subject to a bottle of halimasch with the volume of 750ml, and homozygous zero-generation seeds and homozygous one-generation seeds are sown for planting, wherein the homozygous zero-generation seeds and the homozygous one-generation seeds are cultivated by carrying out artificial pollination on wild gastrodia. According to the method, the natural environment can be fully used, natural shading is achieved, and accordingly produced commodities can reach the quality standard of purely natural, pollution-free, environment-friendly, organic and authentic traditional Chinese medicinal materials due to abundant compost soil, leaves, sloped places and beneficial bacteria under a forest.

Owner:LUEYANG COUNTY RONGCHANG EDIBLE FUNGUS CULTIVATION FARMER SPECIALIZED COOP

Grain saving type feedstuff substituting food to reduce greenhouse gases

InactiveCN101107969APromote resource utilizationEasy constructionFood processingAnimal feeding stuffGrazingForest industry

The invention discloses a grain-saving type feed replacing the grain to deduce the greenhouse gasses, which is mainly composed of a lees and / or Jerusalem artichoke, drugs reducing the emission of animal waste gas, straws, grazing, tree or normal feeds. The invention, besides suits the normal feeding, is also applicable for multi-functional grain-saving type ''carbon culture'' and ''lees or Jerusalem artichoke;; feed, fuel and ethanol industrial integrating livestock breeding, forest industry and firedamp with compact shaped fuel as ''alcohol to gasline'', ''ordure to electricity'', ''fart to cylinder gas'', ''branch to coal'', ''forest to meats'' co-produced meat, eggs and milk, ethanol and canned firedamp. Farmers, besides using feeding with castoff and planting trees and grasses to resolve the meat demanding in China, also can become the industrial worker for planting ''energy'' by conducting the multi-functional production for reducing the greenhouse gases, which is beneficial for the reusing the castoff, promoting the construction of the energy forest and fast-growing and high-yield plantation with low cost, small investment, simpleness and practicability and conforms to the harmonious circulation between human and nature.

Owner:窦观一

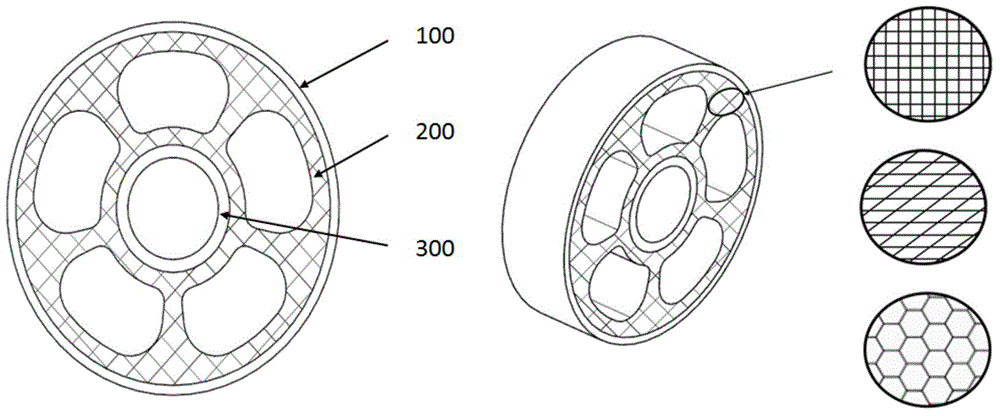

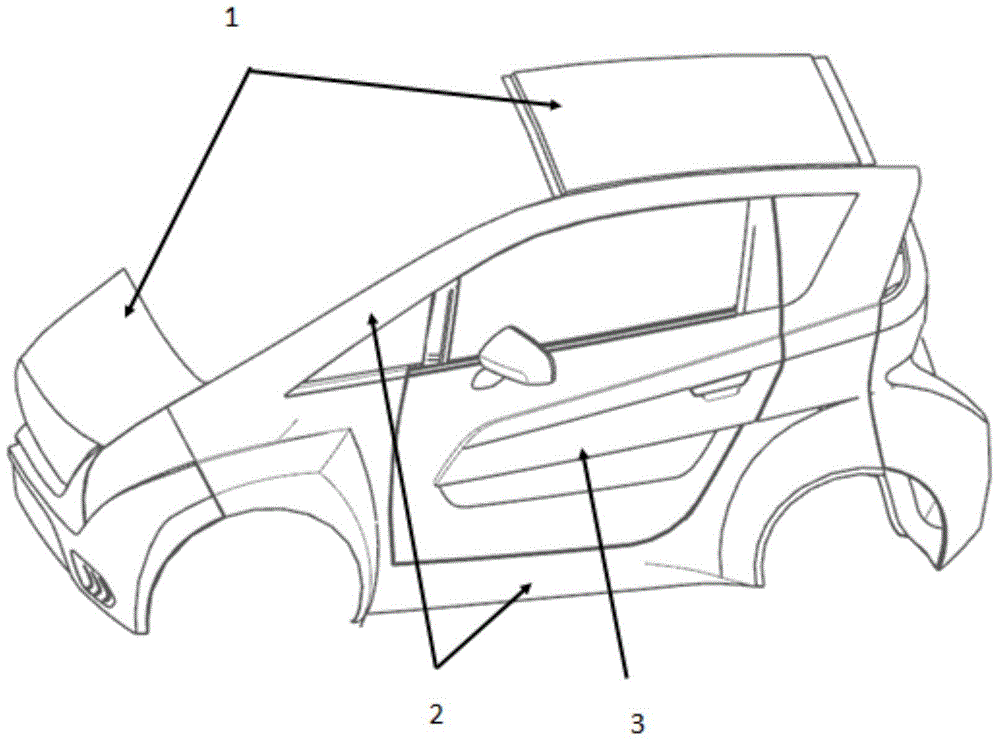

Section structure of lightweight car body and application method thereof

The invention provides a lightweight car body structure, which comprises a core layer (300), a middle layer (200) and an outer layer (100), wherein the core layer (300) is a support framework which is made of aluminum magnesium alloy, the core layer (300) is of a hollow structure of which the section is in a circular, quadrilateral or hexagonal shape; the middle layer (200) is made of plastic, the middle layer is made into a rib structure through a 3D (three dimensional) print technology, and the rib structure is of a honeycomb structure, a mesh structure or a spatial cell body structure; the outer layer (100) is formed by adhering a carbon fiber sheet to the surface of the resin material. In the invention, the weight of the car body is reduced; the high-polymer carbon fiber material and the aluminum magnesium alloy are rationally applied to the structure design of the car body, and properly replace the previous sheet metal structure material; in the condition of guaranteeing the safe strength and rigidity property, the weight of the car body is reduced and the fuel consumption is reduced.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

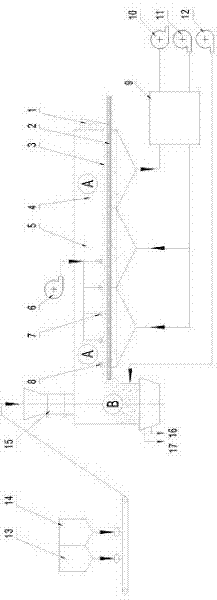

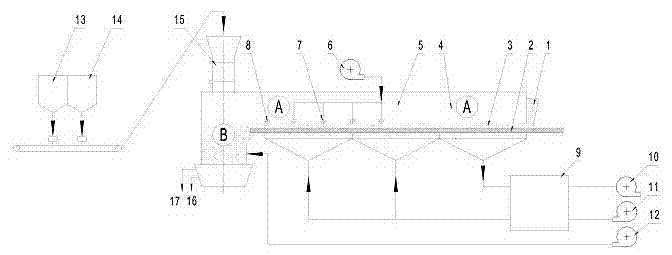

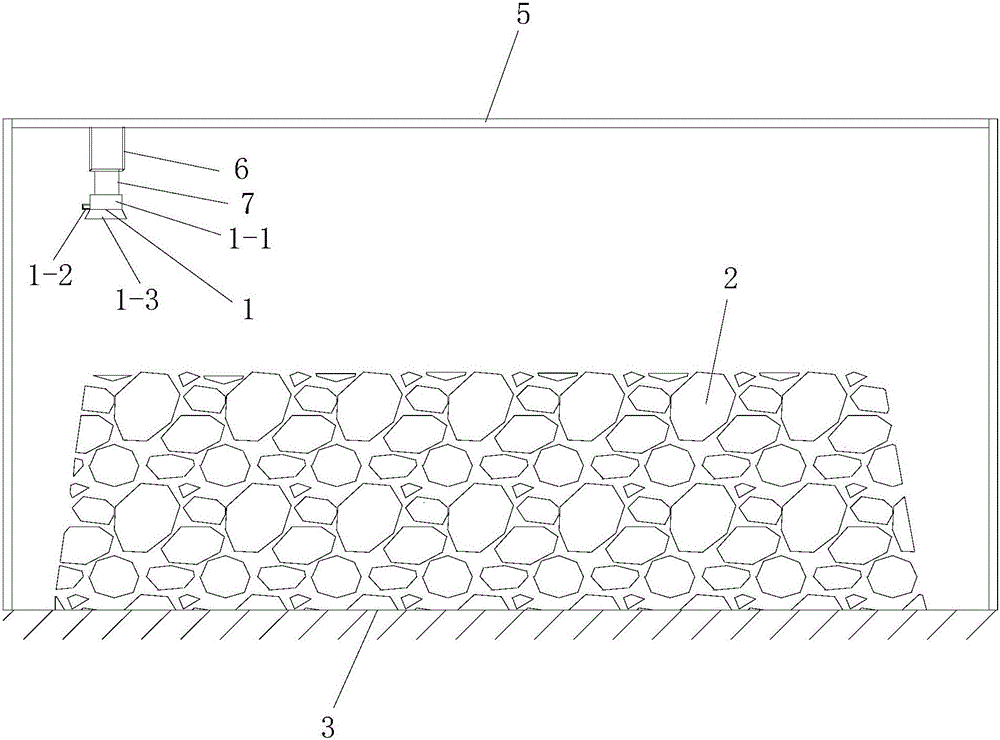

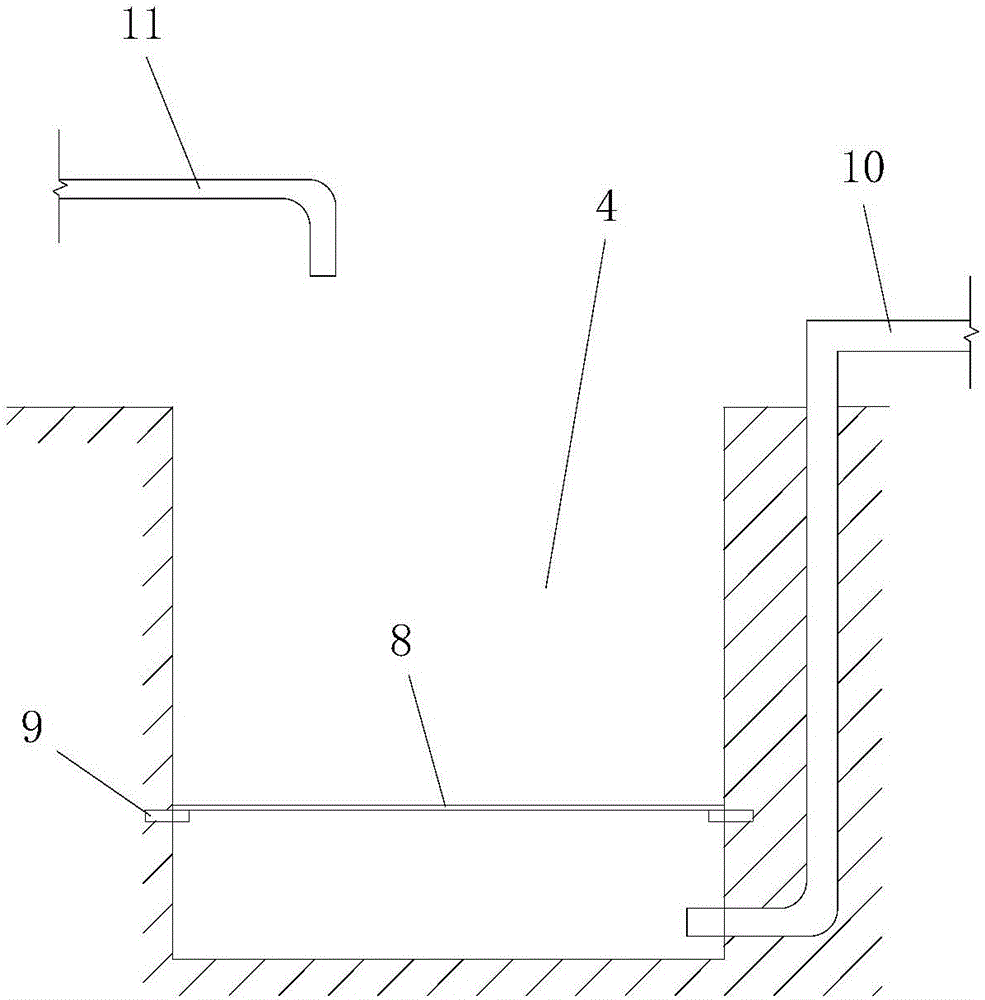

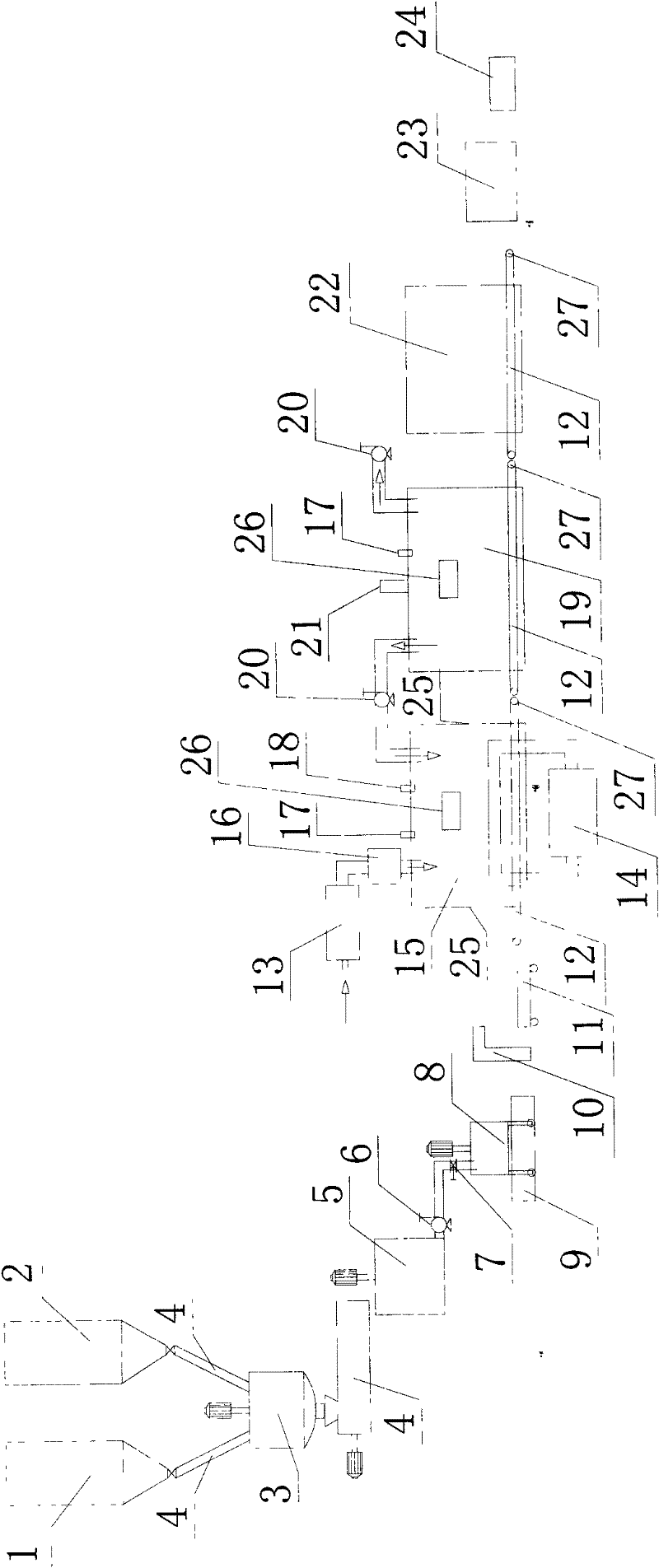

Continued ironmaking device based on melting reduction

The invention relates to a continued ironmaking device based on melting reduction of iron oxide containing carbon iron oxide balling (blocks). In the invention, the device is a continued ironmaking device based on melting reduction and can carry out continual tapping by pre-reducing furnace burden (3) through continually adding the furnace burden (3), extracting air, preheating, blasting and carrying out downstream roasting, and directly conveying the pre-reduced furnace burden (3) into a smelting-separating furnace (B) for continuous smelting-separation; a preheat area (4), a roasting area (5) and the smelting-separation areas behind the preheat area and the roasting area form a connected hearth; a combustion-supporting burner (8) and a secondary tuyere (7) are arranged also; preferably, the high-temperature coat gas generated in the smelting-separation area is subjected to secondary combustion in a pre-reduced furnace (A) for preheating and roasting the furnace burden (3); then the furnace burden (3) is discharged into the smelting-separation area for the further reduction, carburization and melting to separate the slag and iron; in the preheated area (4), the fuse passes through a bed of material to directly heat the furnace burden (3), and then the fuse enters a heat exchanging device (9) and a fuse process system; and a fan blasts the cool air below the bed into a hearth bottom (2) through the heat exchange device (9). The device has the advantages of short flow, reduced energy consumption, low carbon emission, low production cost, simple equipment, less occupied space, less investment and short building period.

Owner:李振洪

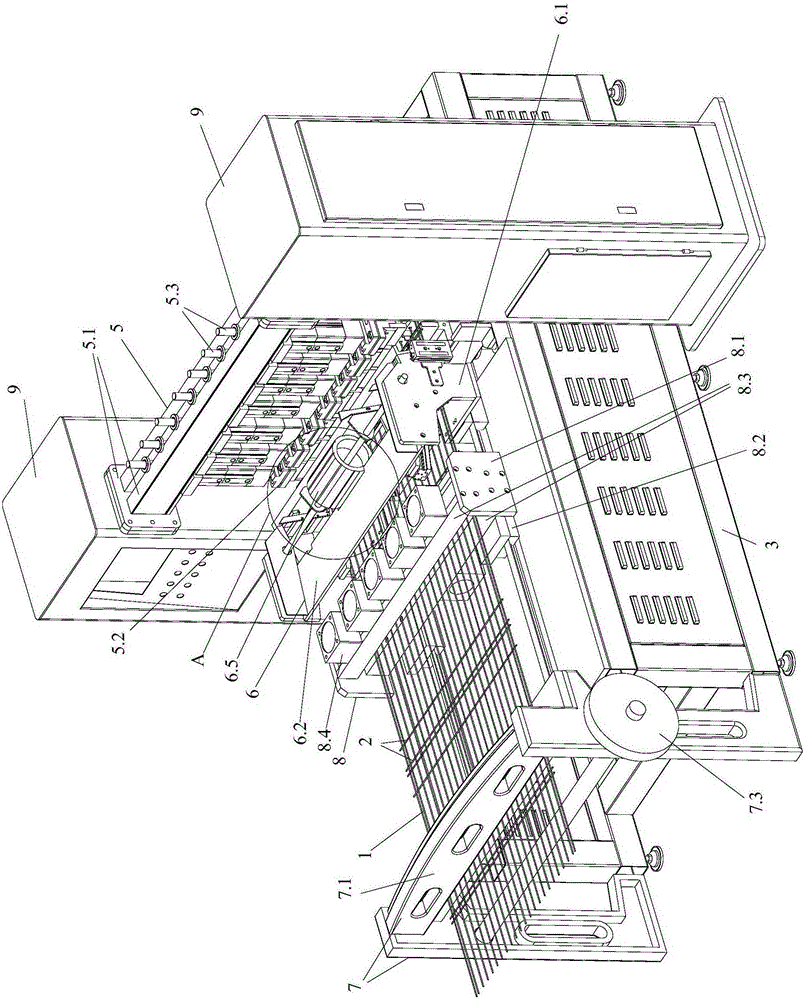

Automatic network-arranging welding equipment

ActiveCN105171263ASimple structureFast welding speedWelding/cutting auxillary devicesWire networkEngineeringWire mesh

The invention provides automatic network-arranging welding equipment which comprises the components of a frame; a longitudinal network wire arranging mechanism which is arranged at the front end of the frame and is used for straightening and arranging longitudinal network wires; a welding mechanism which bestrides the frame; a transverse network wire blanking mechanism which bestrides the frame and is arranged at one side of the welding mechanism and is used for conveying transverse network wires to the welding mechanism and performing positioning; a cutting mechanism which is arranged at the tail end of the frame and is used for cutting a metal wire network that is formed through welding; a wire drawing mechanism which is movably connected with the frame and is used for clamping the network wire and pushes the network wires to penetrate the welding mechanism and the transverse network wire blanking mechanism to the cutting mechanism; and control mechanisms which are arranged at two sides of the frame. The network-arranging welding equipment can realize full-automatic network-arranging welding of the metal wire network according to a production requirement, thereby replacing a traditional manual network-arranging welding process, improving production efficiency and settling the problems of low automatic degree and low production efficiency in an existing welding machinery industry.

Owner:佛山煜宁智能科技有限公司

Waterborne polyurethane decorative leather and manufacturing method thereof

The invention provides waterborne polyurethane decorative leather and a manufacturing method thereof. The manufacturing method includes the steps of 1), performing base cloth treatment; 2), coating; 3), agglomerating; 4), conducting washing and drying, namely removing residual solidification liquid on the base cloth through a washing trough, drying and setting so as to obtain waterborne polyurethane decorative leather base; 5), conducting dry-process direct coating, namely applying the waterborne polyurethane decorative leather base with waterborne direct coating topcoat slurry and drying; 6), subjecting the waterborne polyurethane decorative leather base obtained after dry-process direct coating to high-temperature embossing to shape surface effect grain so as to obtain the waterborne polyurethane decorative leather. The manufacturing method has the advantage that the waterborne polyurethane resin slurry and a waterborne environment-friendly auxiliary are used for enabling the decorative leather to be free of organic solvents during preparation and use, so that the problems of contamination and residues of solvent-type decorative leather are solved. The waterborne polyurethane decorative leather has the advantages of compact structure, less proneness to cracking and wear and flexibility in hand feel and can meet the demands of existing market on the decorative leather completely.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +1

Coupling compound moulded coal binder and preparation method thereof

InactiveCN101798538AWater evaporates quicklyIncrease production capacitySolid fuelsCross-linkCellulose

The invention discloses a coupling compound moulded coal binder and a preparation method thereof. The coupling compound moulded coal binder is a mixture prepared by mixing bentonite, tackifier, sodium carbonate, kaolin and sodium humate; the mixture comprises the following components in parts by weight: 350-600 parts of the bentonite, 45-55 parts of the tackifier, 3-5 parts of the sodium carbonate, 280-320 parts of the kaolin and 100-125 parts of the sodium humate; the tackifier is prepared by smashing 10-15 parts by weight of polyacrylate, 5-10 parts by weight of acrylamide, 3-5 parts by weight of cellulose, 20-25 parts by weight of cassava stalk, 3-5 parts by weight of modified starch and 0.2-0.5 part by weight of cross-linking agent into 50-100 meshes, and mxing the smashed materials. The preparation method comprises the following steps: preparing the tackifier, stocking, pretreating parts of the components, mixing, stirring and the like. The moulded coal binder has favorable waterabsorbtion performance, the moisture of an extruded and shaped coal bar is quickly evaporated and is easy to dry, thus solving the problems of high raw coal moisture, difficult moulded coal production and low shaping rate in rainy days in the south of China.

Owner:柳州化工股份有限公司 +2

Method for preparing carbon nanotube on glass substrates

InactiveCN1558441ASolve growth problemsSolutions for Growing Carbon NanotubesDischarge tube/lamp detailsCold cathode manufactureMischmetalHigh volume manufacturing

The invention discloses a method for preparing carbon nanotube on glass substrates, in particular the preparation of carbon nanotube emission cathode, which comprises, using glass as substrate, depositing a fluoride film of II main group metals or rare-earth metals on the glass substrate, then depositing ferrum, cobalt, nickel, palladium or using the alloy film composing these material as catalyst, growing carbon nanotube on the film by utilizing the conventional growing technology, or first depositing a layer of ferrum, cobalt, nickel, palladium on the glass substrate or using the alloy film composing these material as catalyst, then depositing a fluoride film of II main group metals or rare-earth metals, then growing carbon nanotube on the film, wherein the substrate temperature during carbon nanotube growing is 400-650 deg. C.

Owner:TSINGHUA UNIV

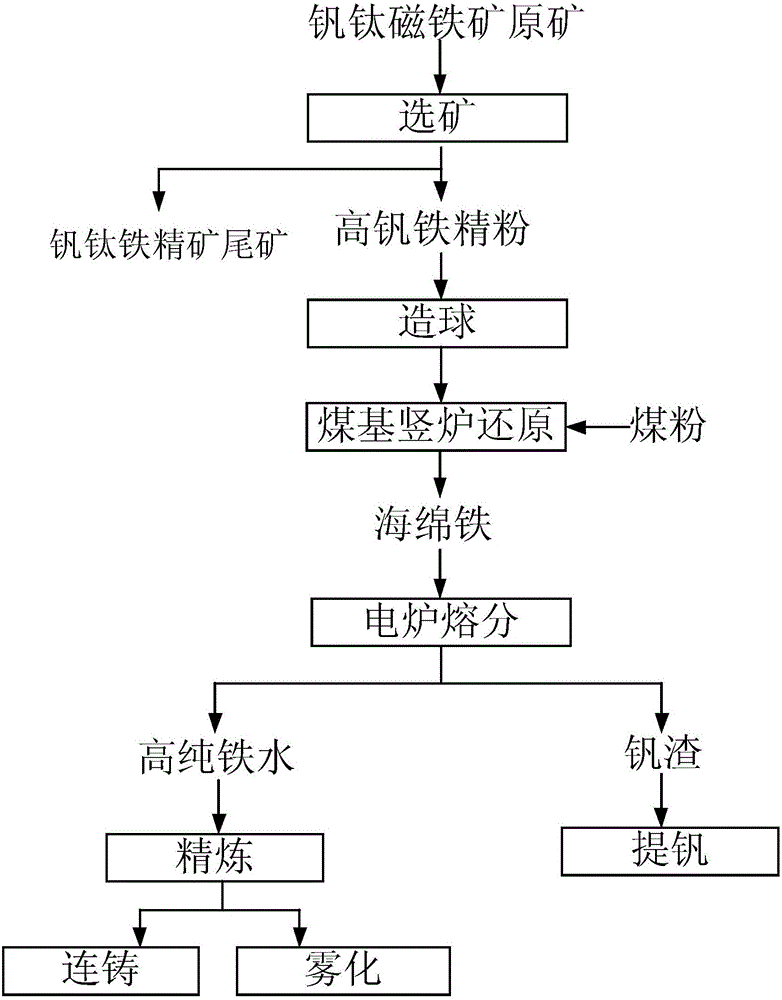

Process for comprehensively utilizing vanadium-titanium magnetite

The invention relates to a process for treating and comprehensively utilizing a vanadium-titanium magnetite. The process is characterized by comprising the following steps: (1) treating a raw vanadium-titanium magnetite by crushing, tailings discarding, fine grinding, low-intensity magnetic separating, high-intensity magnetic separating, and separating by a shaking table, so as to obtain a titanium concentrate and a high-vanadium-ferrum concentrate; (2) adding an adhesive to the high-vanadium-ferrum concentrate; uniformly mixing and pelletizing; drying; uniformly mixing with pulverized coal or coke powder; distributing; performing controlled reduction that V is not reduced through a coal based shaft furnace so as to obtain sponge iron, wherein the amount of used reducing agents such as the pulverized coal is 30 to 70% of the weight of high-vanadium-ferrum concentrate powder, and the reduction is performed for 10 to 18 hours at the temperature of 850 to 1060 DEG C; (3) heating the obtained sponge iron for 0.5 to 1.0 hour at the temperature less than 1050 DEG C through an intermediate frequency / main frequency furnace under a weak reduction atmosphere; then heating until the temperature is more than 1500 DEG C; performing melt separation to enable vanadium to enter slag, thus obtaining high-grade vanadium slag and high-purity molten iron. With the adoption of the process, a plurality of valuable elements in the vanadium-titanium magnetite can be effectively separated and utilized with high additional value.

Owner:WUHAN COSRED SCI & TECH LTD

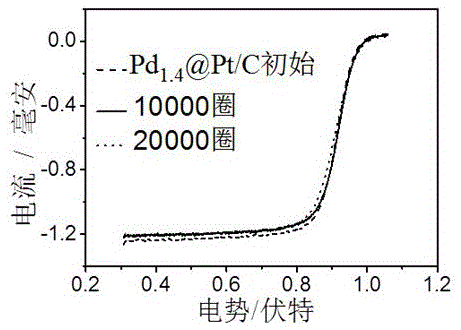

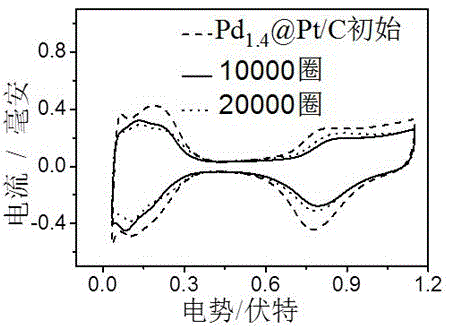

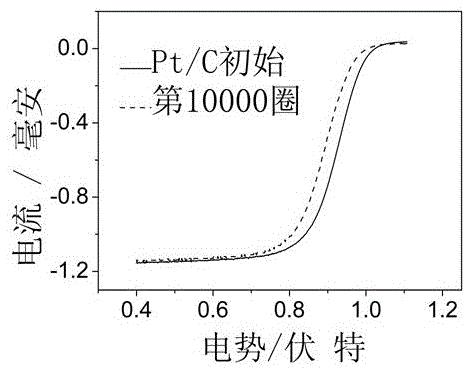

Pdx@Pt/C core-shell structure cathode catalyst for fuel cell and preparation method of Pdx@Pt/C core-shell structure cathode catalyst

ActiveCN105633425AEasy to prepareSolve resource problemsMaterial nanotechnologyCell electrodesPrimary cellAniline

The invention discloses a Pdx@Pt / C core-shell structure cathode catalyst for a fuel cell and a preparation method of the Pdx@Pt / C core-shell structure cathode catalyst. The method comprises the following steps: (1) adding a palladium precursor and a conductive carrier to N,N-dimethyl formamide or ethanol, carrying out ultrasonic mixing, and then adding borane.N,N-diethyl aniline or sodium borohydride, reacting at a room temperature for 0.5-1.5h, carrying out centrifugal washing and vacuum drying and then obtaining a carbon-supported Pd catalyst, namely Pd / C; and (2) ultrasonically dispersing the Pd / C prepared in the step (1) into a formic acid solution with the concentration of 1-5ml formic acid / 20ml water, adding a water solution of a platinum compound at the atomic ratio of Pt to Pd being 1 to 1 or 1 to 2 or 1 to 3, reacting at the room temperature for 2-6h, and carrying out centrifugal washing and vacuum drying to obtain the product. The catalyst with high catalytic activity and stability is prepared by a primary cell reaction principle; the catalyst is lower than a pure Pt catalyst in cost; the preparation method is simple, convenient, mild in condition and easy to operate; and the problem that a high temperature and a surfactant are required for preparation of the core-shell structure catalyst by a conventional chemical reduction method is solved.

Owner:WUHAN UNIV

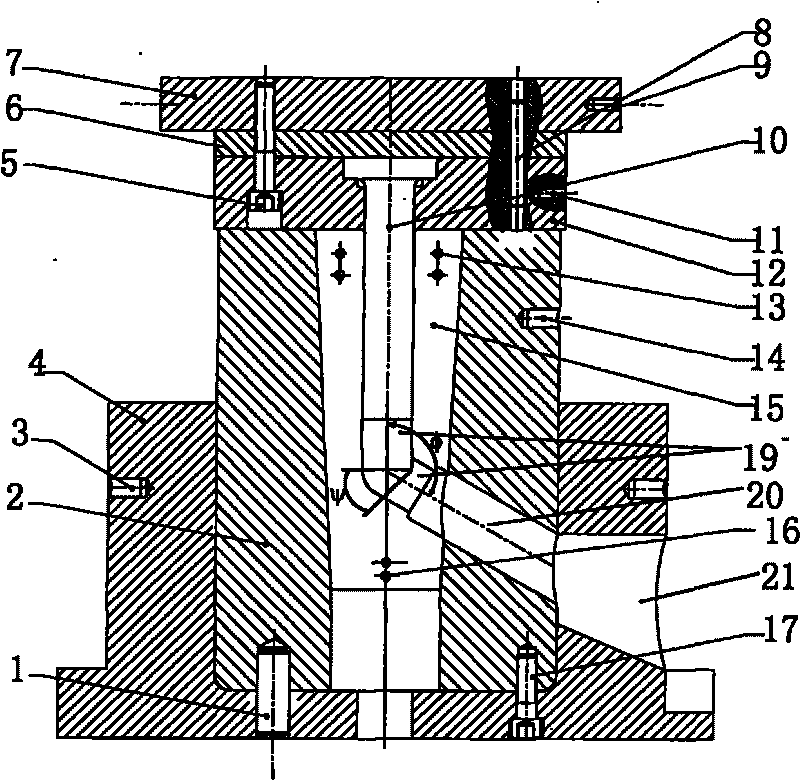

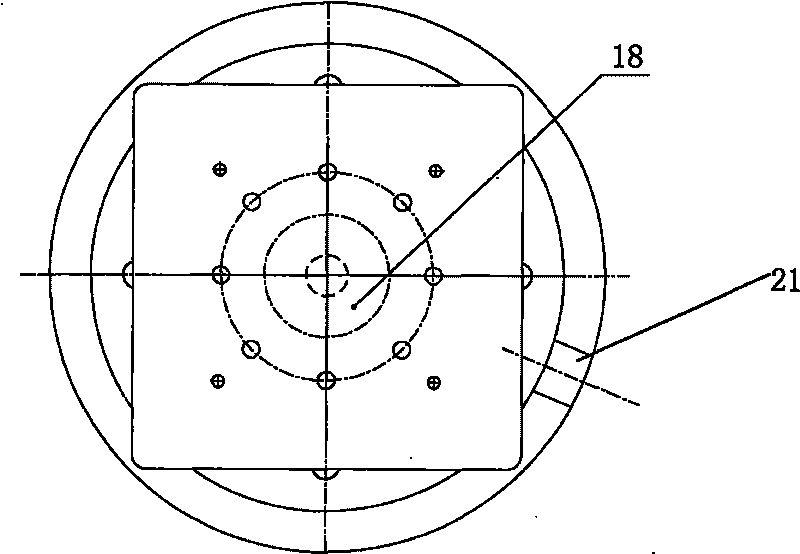

Large equal channel angular large-strain extrusion die

The invention relates to a large equal channel angular large-strain extrusion die comprising an upper die holder (7), a die case (2), a punch (10) and a lower die holder (4). The large equal channel angular large-strain extrusion die is characterized in that the upper end of the punch (10) is fixedly mounted in a punch fixing board (12); the upper die holder (7), a punch backing plate (6) and the punch fixing board (12) are tightly connected to form a whole body; a front die core (15) and a rear die core (18) are embedded in the die case (2); the lower end of the punch (10) is inserted in an extrusion cavity (19) formed between the front die core (15) and the rear die core (18); the die case (2) is provided with a slantwise arranged extrusion channel (20) which is communicated with the extrusion cavity (19) and embedded in the lower die holder (4); the front die core (15), the rear die core (18) and the die case (2) are in taper fit; the lower die holder (4) is connected with the die case (2); and a discharge cavity (21) which is communicated with the extrusion channel (20) on the die case (2) is arranged on the lower die holder (4). The invention has the advantages of high strength, smooth extrusion and simple structure.

Owner:JIANGSU UNIV

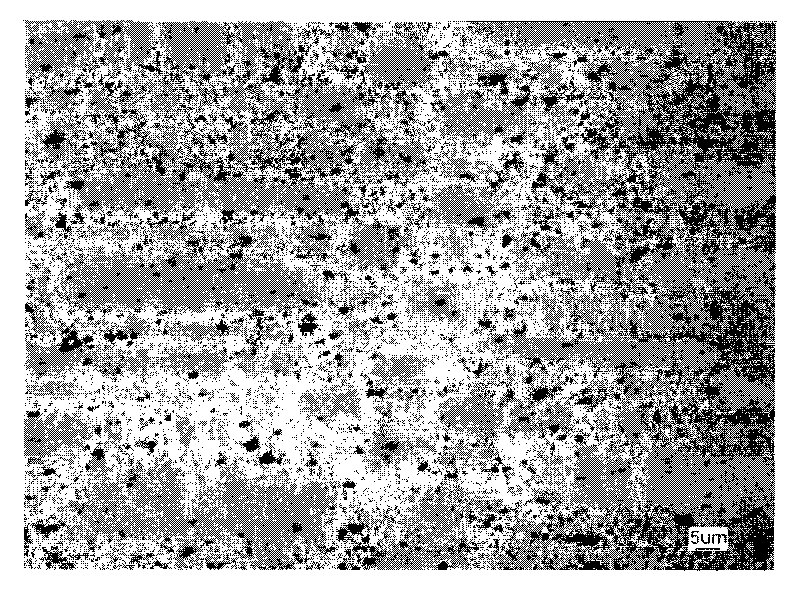

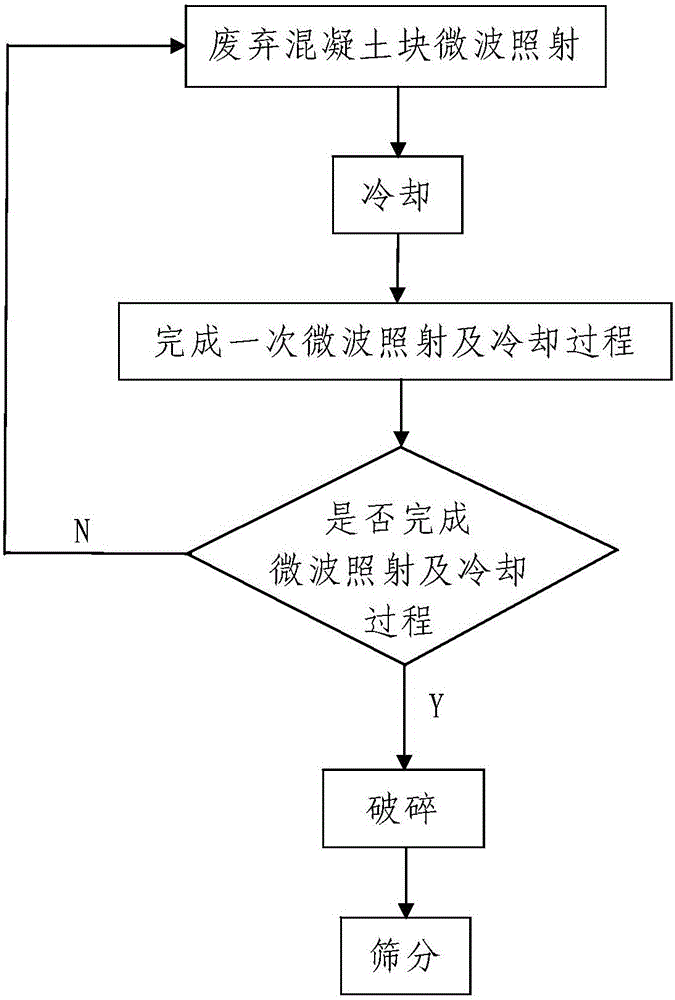

Microwave-assisted recycled concrete coarse aggregate picking method

InactiveCN105776930AThe method steps are simpleLow input costSolid waste managementMicrowave emissionMicrowave irradiation

The invention discloses a microwave-assisted recycled concrete coarse aggregate picking method. The method comprises the following steps of: firstly, carrying out microwave irradiation and cooling, namely 101, carrying out microwave irradiation for the first time and cooling, namely 1011 carrying out microwave irradiation on waste concrete blocks and 1012 cooling, wherein the step 1011 comprises the steps of transporting and piling the waste concrete blocks in a microwave irradiation region and then carrying out microwave irradiation on the waste concrete blocks by adopting a microwave transmitting device, and the step 1012 comprises the steps of transporting and soaking the waste concrete blocks subjected to microwave irradiation in a cooling water tank for cooling; 102, carrying out microwave irradiation for the next time and cooling; and 103, repeating the step 102 for once or twice; secondly, breaking; and thirdly, screening. The method disclosed by the invention is simple in steps, reasonable in design, easy to realize and good in use effect, and the problems of an existing recycled concrete aggregate picking method that the picking efficiency is low, mass production of recycled concrete aggregate is not applicable and the quality of the picked recycled concrete aggregate is difficult to guarantee can be effectively solved.

Owner:XIAN UNIV OF SCI & TECH

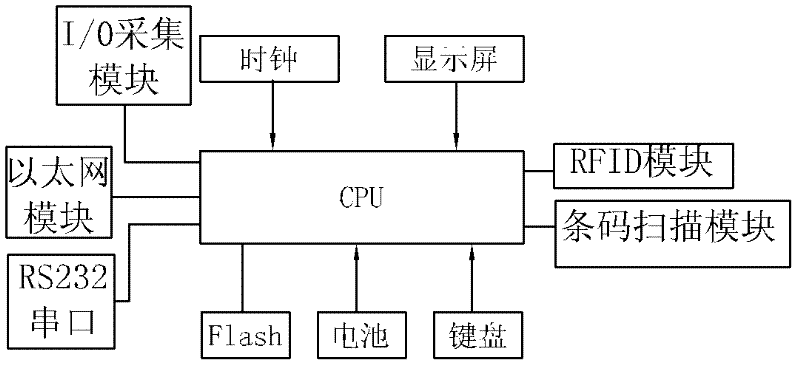

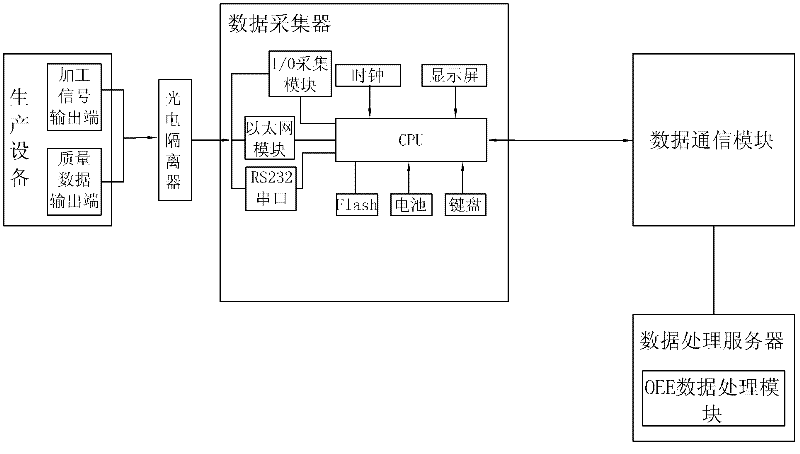

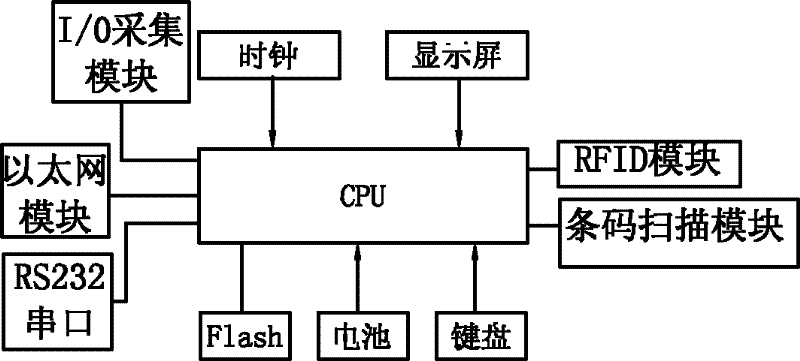

IoT (Internet of Things) service terminal for factory

InactiveCN102411364ATimely collectionTimely uploadTotal factory controlProgramme total factory controlData acquisitionComputer terminal

The invention discloses an IoT (Internet of Things) service terminal for a factory. The IoT service terminal comprises a data acquisition unit which comprises a CPU (central processing unit) as well as a keyboard, a battery, a flash, an RS232 (recommend standard 232) serial port, an Ethernet module, an I / O (input / output) acquisition module, a clock and a display screen which are respectively connected with the CPU. The IoT service terminal for the factory has the functions of receiving instruction information about production service plan as well as acquiring, uploading and processing information of a production field and can be used for acquiring data such as equipment state, production Takt time, alarm information, equipment utilization rate and the like, thereby saving labor and reducing the data acquisition cost.

Owner:浙江力太工业互联网有限公司

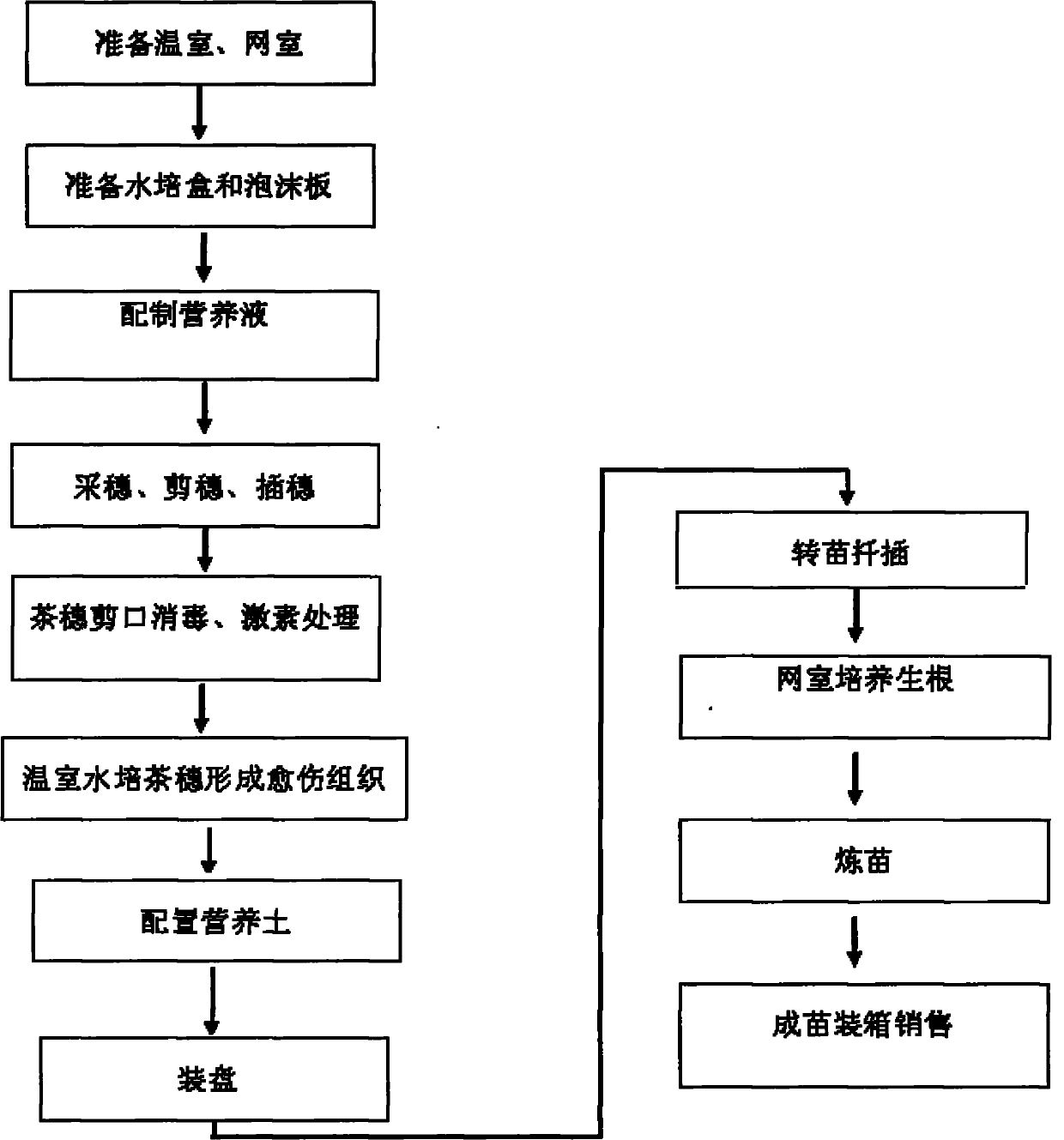

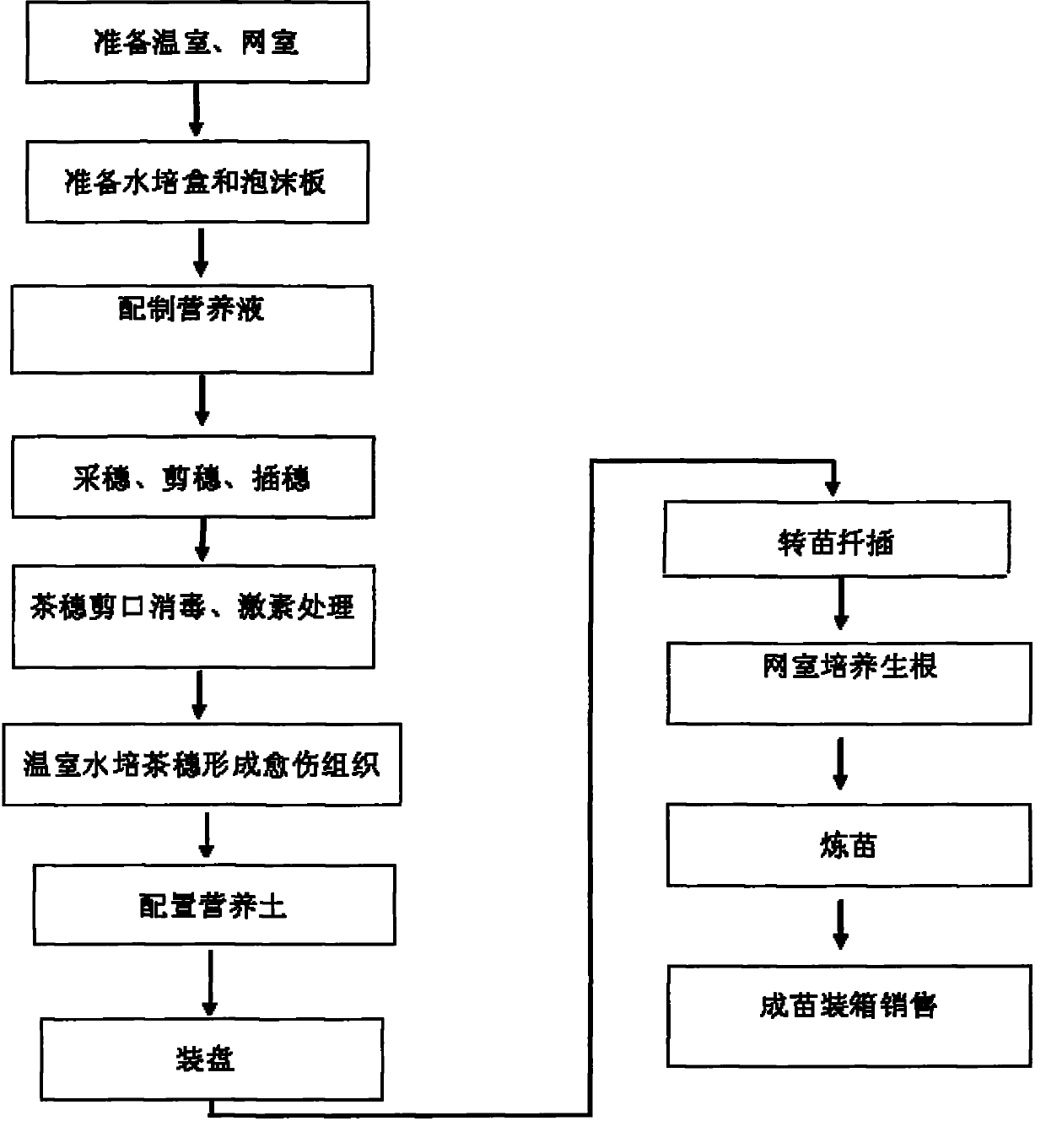

Industrial fast breeding method for white tea

InactiveCN101946661AIncrease incomeReduce occupancyCultivating equipmentsWide areaEcological environment

The invention discloses an industrial fast breeding method for white tea. The method comprises the following process routes: preparing a greenhouse and a net house; preparing a water planting box and a foam plate; preparing a nutrient solution; collecting fringes, cutting fringes and inserting fringes; sterilizing the cutting surface of the tea fringes and processing the cutting surface of the tea fringes with hormone; planting the tea fringes in water in the greenhouse to form calluses; adding nutrient soil; putting the calluses into a dish; sticking the calluses; culturing the calluses in the net house to take roots; hardening the seedlings; and packaging the grown seedlings for sales. Because the technical requirement in the implementation and the demonstration of the technical scheme is high, the modern technical means and installation construction are adopted, which is exactly matched with the principles of environmental protection and sustainable agricultural development. Compared with the traditional wide area breeding method, the method avoids the loss of soil and water and the damage of the ecological environment. The industrial fast breeding method for white tea seedlings with high quality has the advantages of big unit area breeding capability, a few occupied land, good social effect, economic effect and environmental protection effect, shortens the breeding period by 30-40%, improves the qualification rate of the tea seedlings, saves the land resource and protects the environment.

Owner:LIYANG TIANMU LAKE TEA RES INST

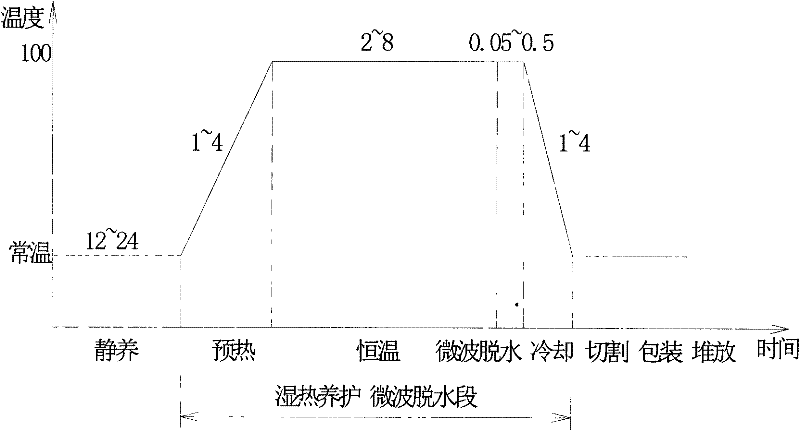

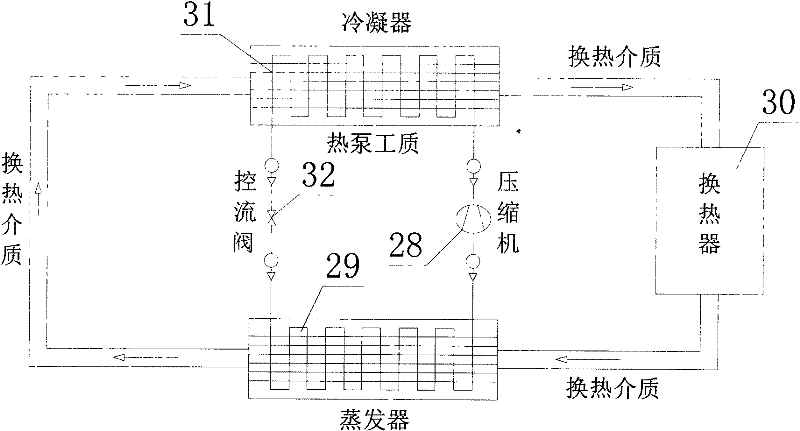

Continuous production method for foam concrete

InactiveCN102503272AFix stability issuesSolve efficiency problemsCeramic shaping apparatusCeramicwareTunnel kilnFoam concrete

The invention discloses a continuous production method for foam concrete and belongs to the technical field of building materials. The method is characterized in that concrete, coal ash and ore powder are dispersed in advance and the workability is compactly enhanced before raw materials are mixed and stirred in the production process. Furthermore, a tunnel kiln or box type structure is used for performing damp-heat curing and electromagnetic wave dehydration processes, instead of an original natural curing process, on a de-molded foam concrete blank, so as to quickly and continuously produce the foam concrete heat-insulating building material. The method has the advantages that the problems of a present method of manual workshops for producing the foam concrete, such as unstable quality, low production efficiency, big floor area of a production workshop, incapability of realizing standardized production, poor working condition, large investment of project construction and high cost of products are solved by the continuous production method for foam concrete, the continuous production method for foam concrete is importantly promoted and improved, the continuous and modernized production is realized, and the continuous production method for foam concrete is worthy of application and popularization.

Owner:王峰 +2

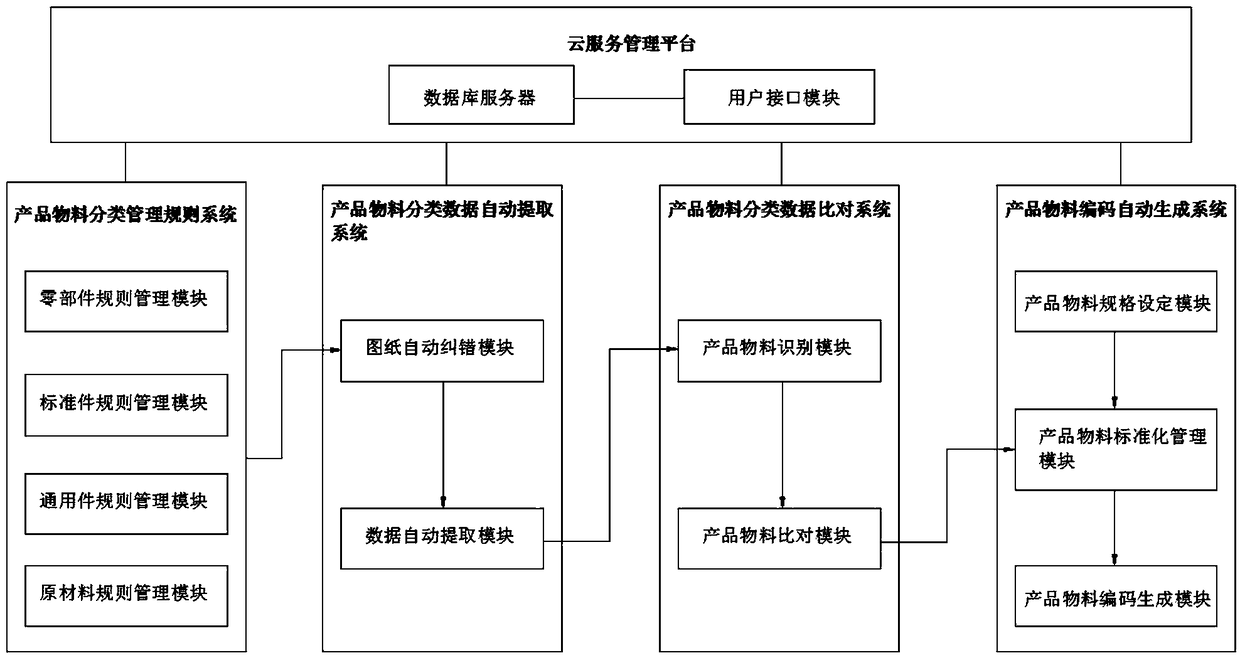

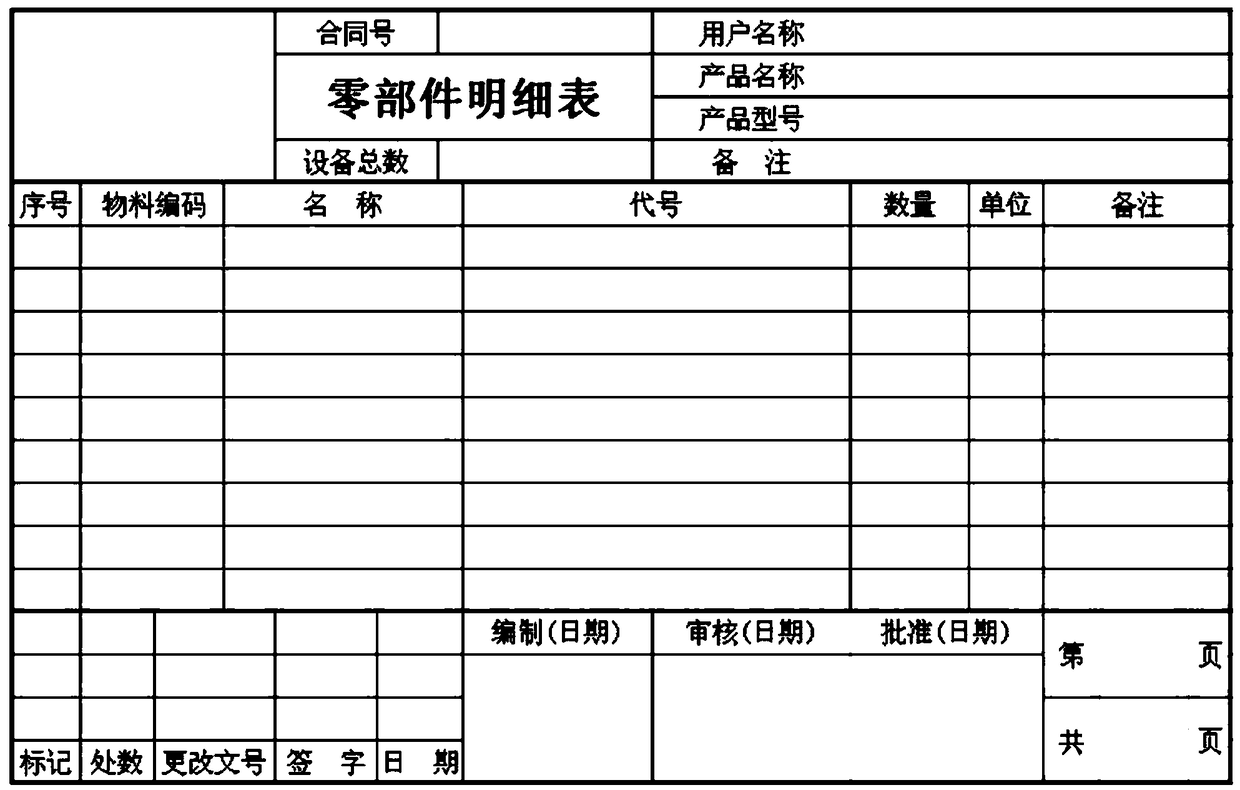

Product material code management method and system

ActiveCN108764773ASolve coding messSolve the difficult control of materialsLogisticsManufacturing computing systemsMaterial classificationDatabase server

The invention relates to a product material code management method and system. Product data can be extracted automatically from a design drawing which satisfies product material classification rules,a product material is identified, product material information is compared with that stored in a database server, and a code is matched or a new code is generated for the product material via an automatic code generation system. A computer cloud platform information technology is used, the product material code is managed scientifically, efficiently and conveniently via a simple flow control method, the problem that that a product cannot be delivered timely due to the fact that enterprise product data and product materials cannot be provided timely is solved, and the working efficiency of an enterprise is improved.

Owner:SAIMO ELECTRIC

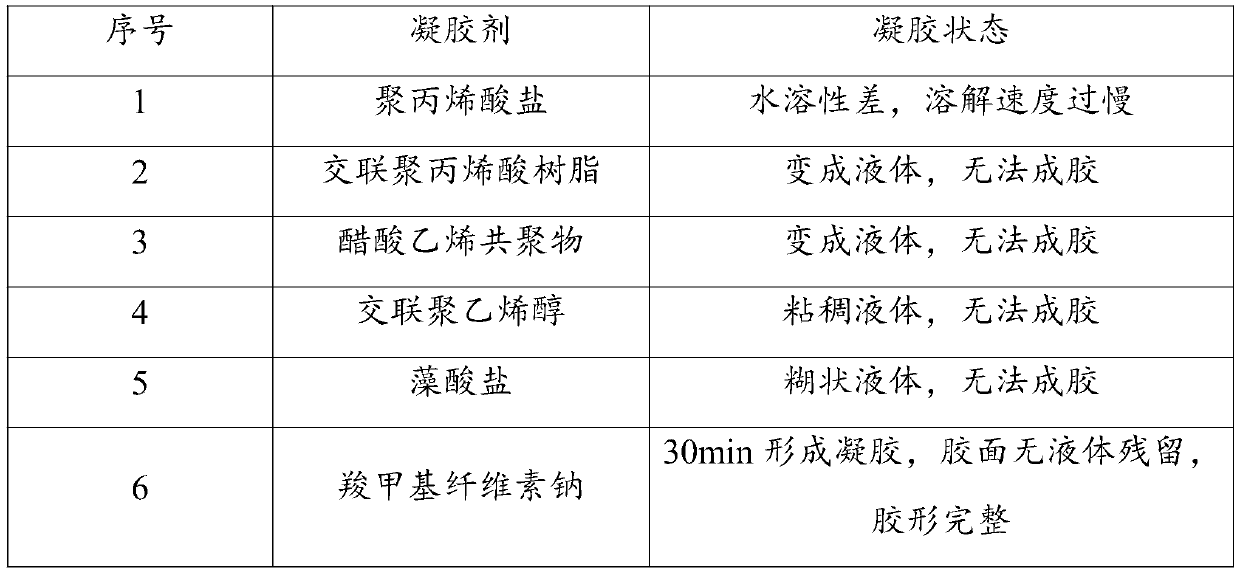

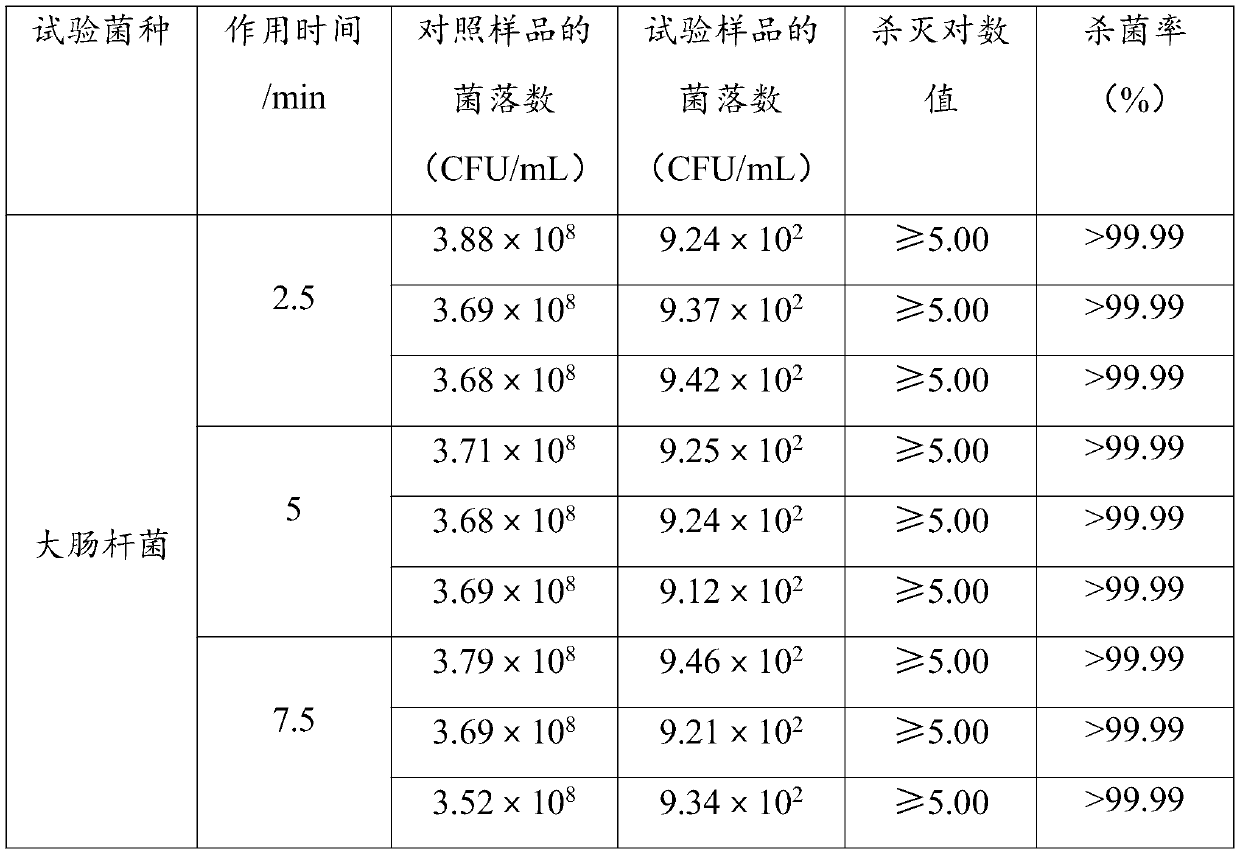

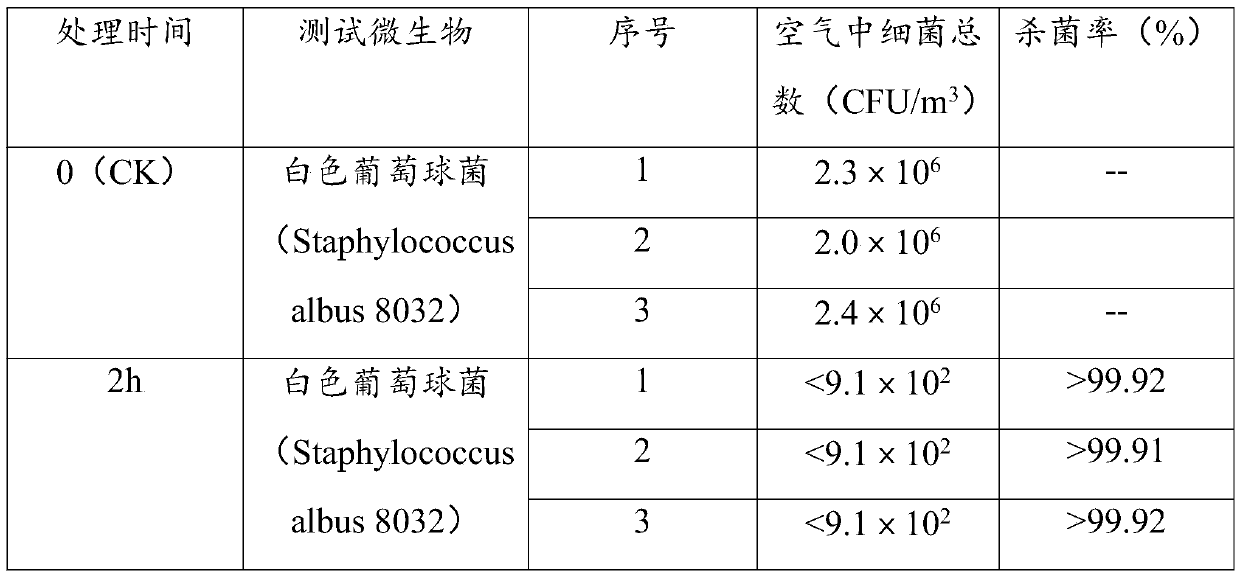

Slow-release chlorine dioxide air purification gel and preparation method thereof

InactiveCN111567552AImprove gel performanceImprove the bactericidal effectBiocideGas treatmentSodium bicarbonateCellulose

The invention discloses slow-release chlorine dioxide air purification gel and a preparation method thereof, and belongs to the technical field of air disinfection. The slow-release chlorine dioxide air purification gel is prepared from the following components in percentage by weight: 1.8 to 3 percent of chlorine dioxide disinfectant; 10.3 to 14.7 percent of slow-release agent; 6.4 to 9.6 percentof gel; and 72.7 to 81.5 percent of deionized water. The chlorine dioxide disinfectant is prepared from the following components: sodium chlorite, citric acid, sodium chloride, sodium bicarbonate andmagnesium sulfate which are in a weight ratio of 4-6:8-10:1-3:0.5-2:2-4. The slow-release agent is prepared from the following components of sodium dihydrogen phosphate, polyethylene glycol and citric acid which are in a weight ratio of 0.5-1.5:0.5-1.5:0.5-1.5. The gel is sodium carboxymethyl cellulose. The preparation method comprises the following steps of: mixing powder; preparing a semi-finished product; transferring the semi-finished product to a PE bottle; pasting an identifier; printing a code; and carrying out thermoplastic packaging.

Owner:中节能(唐山)环保装备有限公司

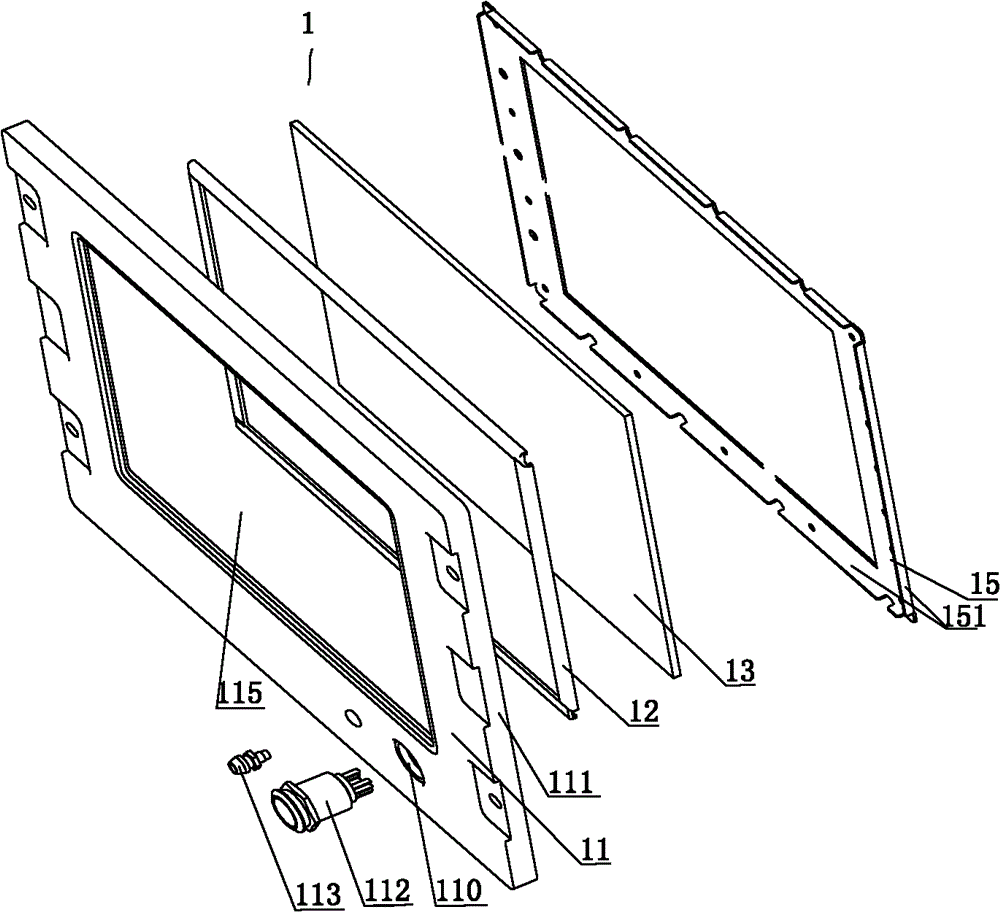

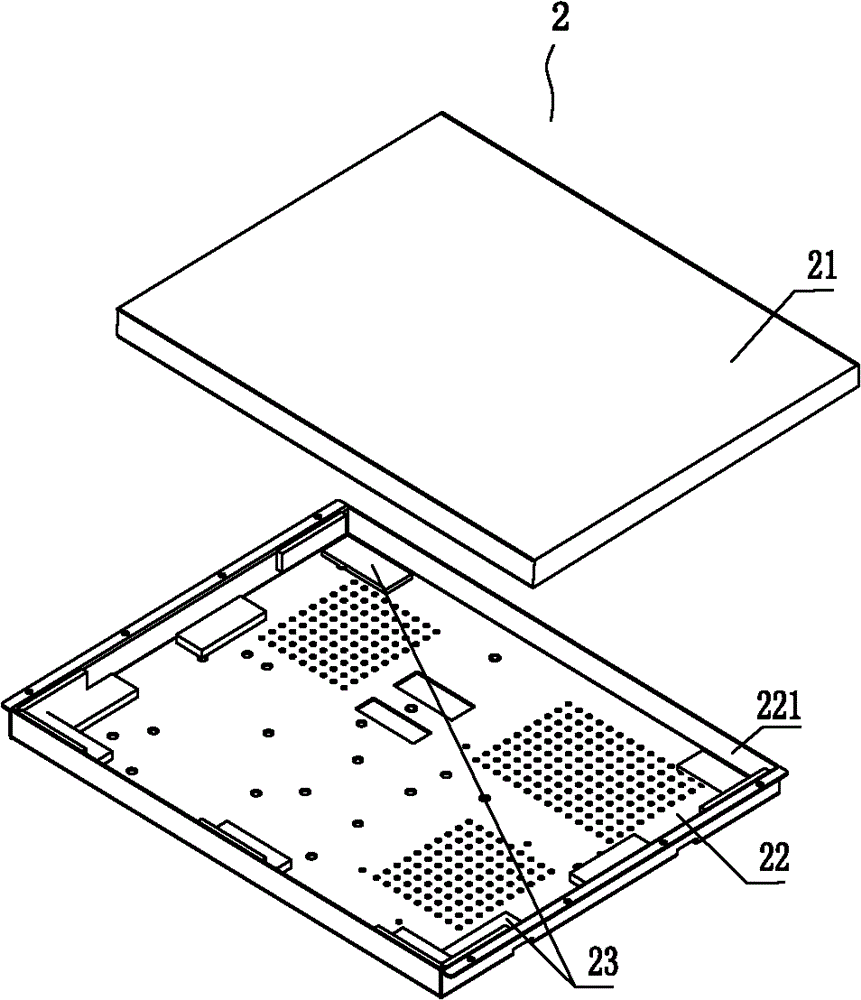

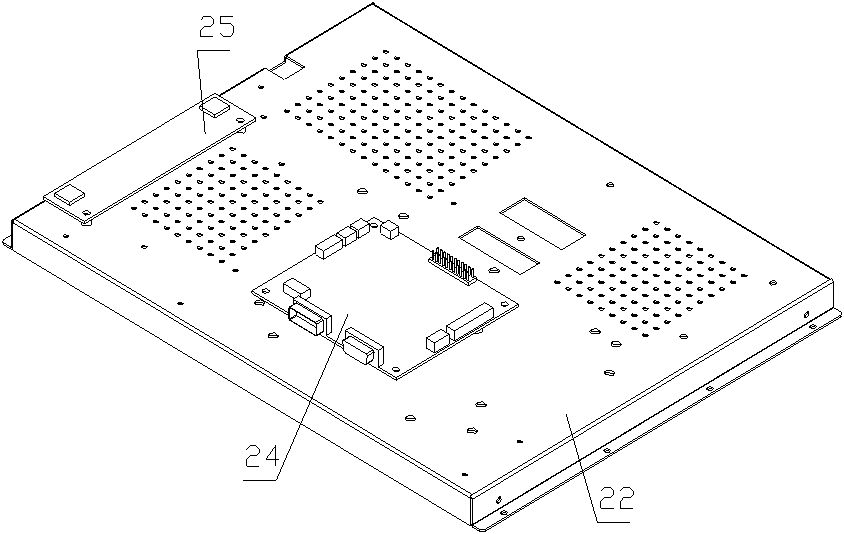

Display module and rugged tablet personal computer thereof

ActiveCN102749962AImprove assembly efficiencyImprove maintenance efficiencyDigital data processing detailsTablet computerDisplay device

The invention discloses a display module and a rugged tablet personal computer thereof. The display module comprises a panel module unit and an LCD (Light Crystal Display) module unit which are independent mutually, wherein the panel module unit is arranged in front of the LCD module unit and is detachably and fixedly connected with the LCD module unit. The rugged tablet personal computer comprises a host module and a display module, wherein the host module and the display module are independent respectively and are detachably and fixedly connected together; the host module comprises a rear cover and a host unit arranged in the rear cover; the host unit comprises a mainboard, a rigid disk, an IO (Input / Output) interface board, a power source and a power filter; the mainboard is respectively and electrically connected with the IO interface board, the power source and the power filter; and the mainboard is spliced with the IO interface board. The display module provided by the invention is strong in compatibility and easy to maintain and replace. The rugged tablet personal computer has the characteristics of complete computer modularization, high assembling efficiency, easiness for maintaining and replacing and balanced customization and industrialization.

Owner:深圳市研祥智慧科技股份有限公司

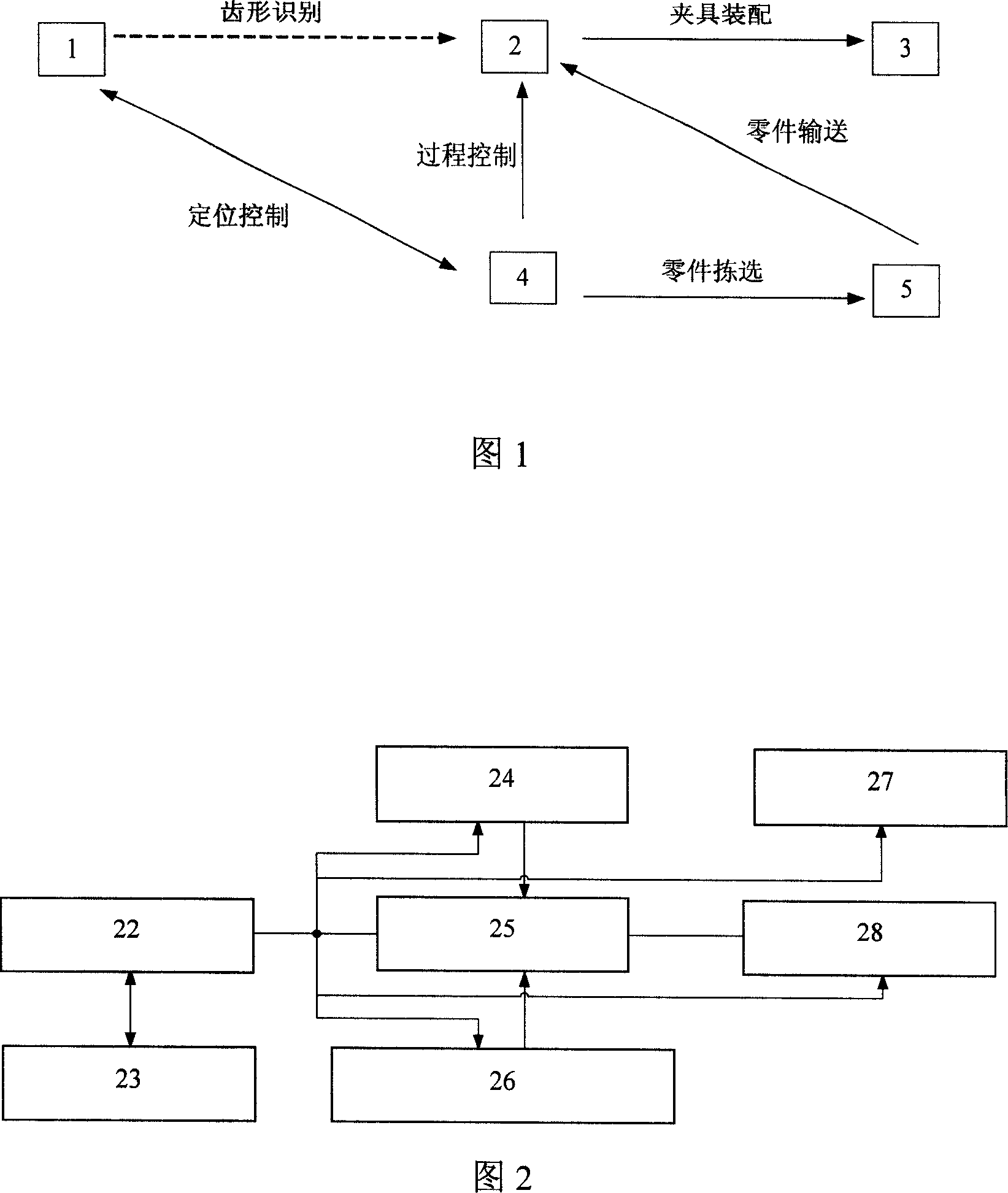

Automatic assembly apparatus system and method for automobile door lock

InactiveCN101011788AImprove detachabilityImprove maintainabilityComputer controlAssembly machinesComputer control systemProduction rate

The invention relates to the mechanical assembly of the door lock of vehicles, which comprises locking plate snap clip, key teeth identification device, locking plate automatic choosing device, automatic spring discharging and delivery device, locking plate snap clip moving device and its thrusting device, lock core jig and location exchange device, and embedded computer control system, with the method composed of key automatic location and identification, snap clip feeding and assembly, lock plate feeding and assembly, to finish the assembly of vehicle doors with accurate matching. Through lock core jig and location exchange device with the repetition of above procedures, it can get to the operation of next lock core. It is accurate, highly efficient, easy for operation, convenient for maintenance.

Owner:ZHEJIANG UNIV

Preparation of peppermint type cigarette tissue

ActiveCN101487203AMeet the requirements of dryingReduce volatilityNon-fibrous pulp additionPaper coatingMentholAlcohol

The invention discloses a method for preparing mint-typed cigarette paper. A new material: functional molecule encapsulation menthol is selected; the performances of the molecule encapsulation menthol such as low volatility, low transitivity and thermal stability are utilized and alcohol is used as a solvent; furthermore, new technologies such as internal machine coating or external machine coating, low-temperature drying of a baking cylinder and the like are utilized during the production of the cigarette paper, therefore, the adding uniformity and remaining performance of the menthol on the cigarette paper are ensured, the shortages that the mint ingredients in the original mint cigarette are easy to be volatilized, have unstable effect and the like are overcome, and the mint cooling feeling of the cigarette is always kept during smoking process. The mint-typed cigarette paper greatly improves the quality of the mint-typed special cigarette and the good running performance of the production process, becomes one highlight for the special cigarette paper and is expected to be a new economic growing point for the cigarette paper products.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Method for carbon dioxide fertilization in plastic tunnel by organic agricultural waste fermentation

InactiveCN1582623AIncrease productionImprove qualityFertilising methodsHorticulture methodsPlastic filmFermentation

A method for applying gas-state CO2 fertilizer in plastic-film hot shed includes such steps as proportionally mixing the straw or stalk of agricultural crops with the droppings or dung of fowls or animals, fermenting in said plastic-film hot shed to release CO2 fertilizer, and periodically discharging dregs from fermentor while adding raw material into it.

Owner:ZHEJIANG UNIV

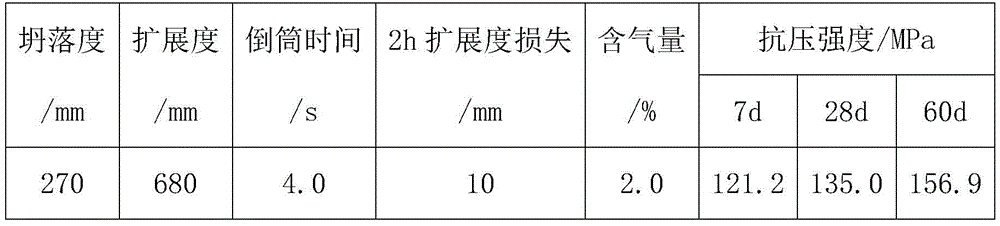

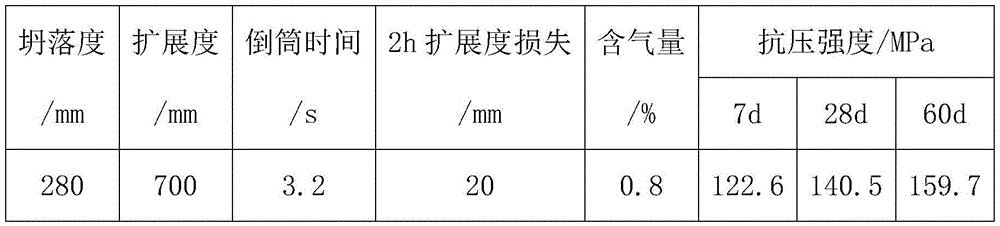

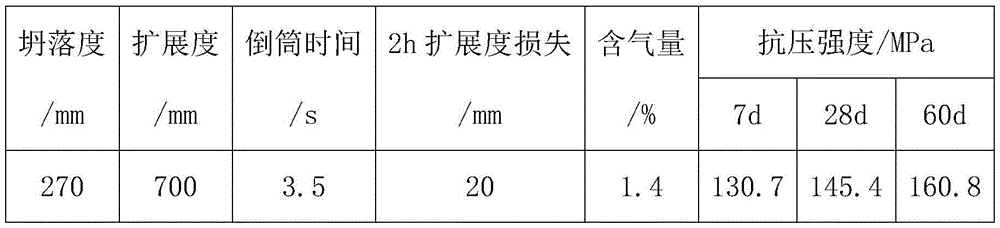

Preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping

The invention provides a preparation method of ultra-high-strength steel fiber reinforced concrete for super-high pumping. According to the method, the ultra-high-strength steel fiber reinforced concrete with the strength grade of C150 is prepared by changing proportion of a cementing material and a feeding sequence and can be prepared with conventional production process through a mixing plant, and the problem that concrete with the strength grade of C150 or higher cannot be produced with the conventional process is solved. Common Portland cement as well as coarse and fine aggregate is adopted, and the cement is prepared through technological approaches such as reduction of a water-binder ratio, density enhancement and the like under double-doping actions of a polycarboxylate superplasticizer and a superfine mineral admixture. The prepared concrete has good working performance, the slump flow is 670-700 mm, and loss is basically avoided within 2 h; the viscosity is low, and rewinding time is 3.2-4.2 s; 28 d compressive strength reaches the strength grade of C150, and requirements for pumping construction of super high-rise buildings with height of 600 m or higher can be met.

Owner:中建西部建设北方有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com