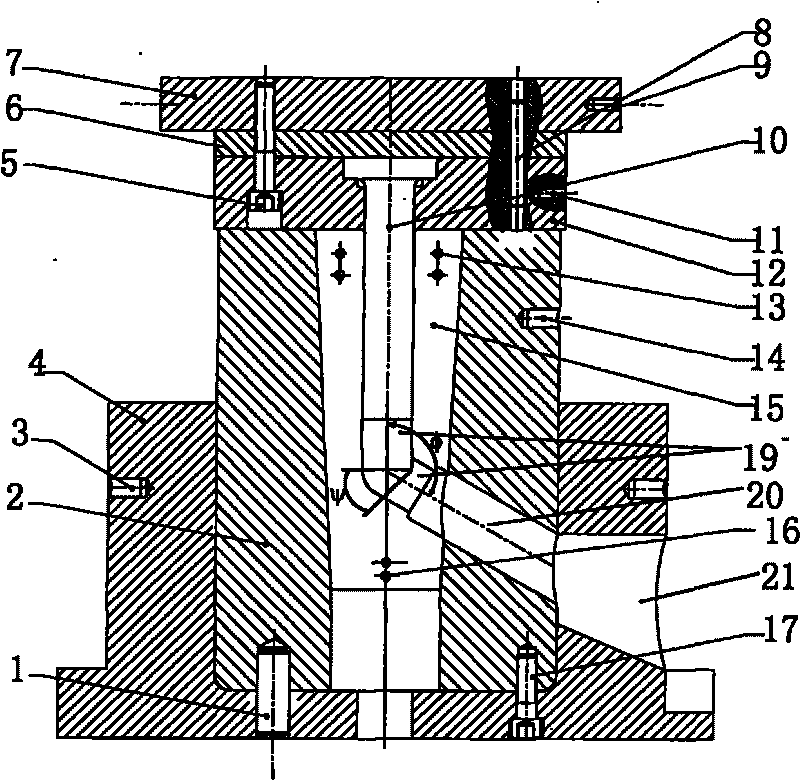

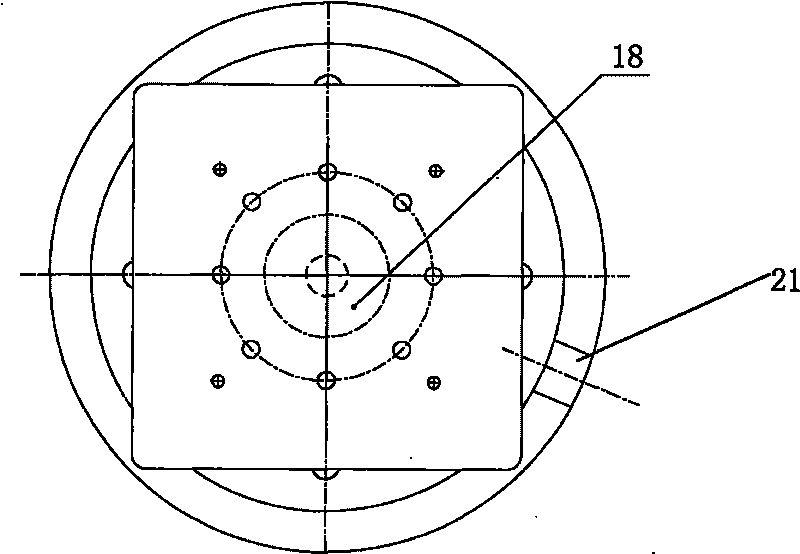

Large equal channel angular large-strain extrusion die

A technology with equal channel angle and large strain, applied in the direction of metal extrusion dies, etc., can solve the problems that low-hardness materials cannot achieve continuous production, lack of large-scale dies, and difficult to achieve industrialized production, etc. Toughness, smooth extrusion without blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

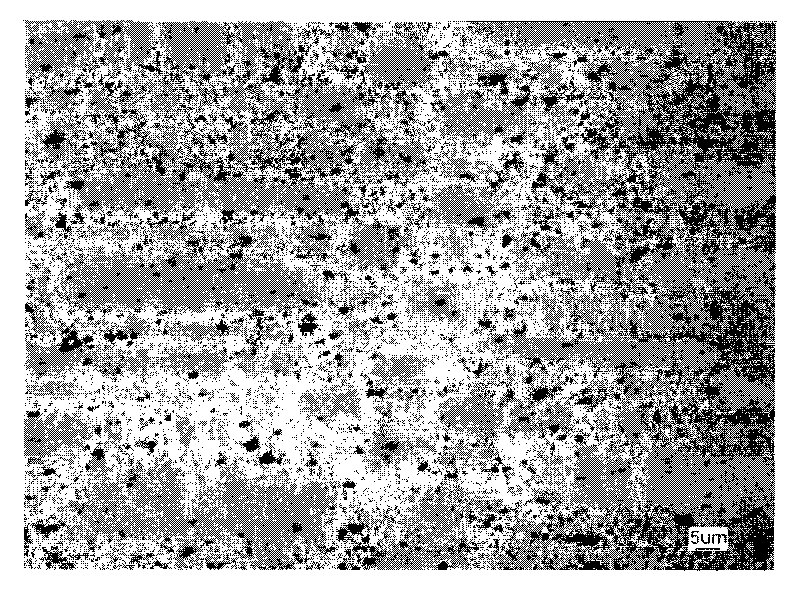

[0031] Example 1: The channel diameter of the equal-channel angular extrusion die is 90 mm, the inner angle φ of the mold is 120 degrees, and the outer angle ψ of the mold is 30 degrees. It can smoothly carry out continuous equal-channel large-strain extrusion processing of cast 3003Al and 6063Al with a diameter of 90mm, and crush the inclusions (AlFeMnSi) to less than 3μm and disperse them (see image 3 , 4 ).

example 2

[0032] Example 2: The channel diameter of the equal channel angular extrusion die is 20 mm, the inner angle φ of the die is 110 degrees, and the outer angle ψ of the die is 25 degrees. Continuous equal-channel large-strain extrusion processing can be carried out smoothly on as-cast 3003Al and 6063Al with a diameter of 20mm, and the hardness of 6063Al increases from 58.8Hv to 94.2Hv.

example 3

[0033]Example 3: The channel diameter of the equal channel angular extrusion die is 20 mm, the inner angle φ of the die is 100 degrees, and the outer angle ψ of the die is 24 degrees. The continuous equal-channel large-strain extrusion processing of as-cast 3003Al and 6063Al with a diameter of 20mm can be carried out smoothly, and the hardness of 6063Al increases from 58.8Hv to 96Hv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com