Integrated extrusion and equal channel angular shear deformation large strain die

A technology of equal channel corners and shear deformation, applied in the field of channel corner shear deformation processing molds, can solve problems such as loose materials that are difficult to effectively press, lack of compressive stress, etc., and achieve the effect of convenient maintenance and optimized design of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

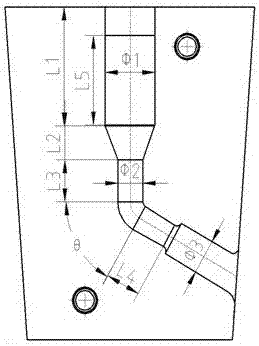

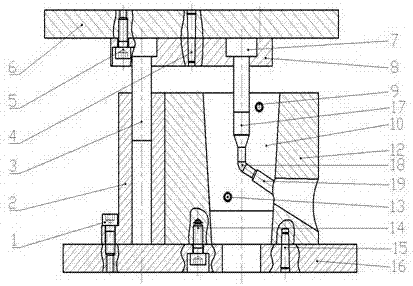

[0037] Example 1: Extrusion and Equal Channel Angle Shear Deformation Integrated Large Strain Die The extrusion channel diameter is 20mm, the extrusion ratio is 4:1, the channel angle is 120°, L3 and Φ 2 It is a 1:1 ratio. The 7075 aluminum alloy can be successfully extruded, and the effective strain and equivalent strain are both normal, the material strain effect is good, and the extrusion force is about 12t, which meets expectations. Figure 4 .

example 2

[0038] Example 2: Extrusion Channel Diameter Φ of Large Strain Die Integrated with Equal Channel Angle Shear Deformation 1 =20mm, the extrusion ratio is 4:1, the channel angle is 120°, L3 and Φ 2 It is a ratio of 1.2:1, L5=40mm, L2 / Φ 1 =0.5, L3=L4, θ=60°, Φ 3 =14mm. The 7075 aluminum alloy can be successfully extruded, and the effective strain and equivalent strain are both normal, but the extrusion force is about 25t, and the jump is large, and the material is difficult to extrude smoothly.

example 3

[0039] Example 3: Extrusion and Equal Channel Angle Shear Deformation Integrated Large Strain Die The extrusion channel diameter is 20mm, the extrusion ratio is 5:1, the channel angle is 120°, L3 and Φ 2 It is a ratio of 1:1, L5=40mm, L2 / Φ 1 =0.5, L3=L4, θ=60°, Φ 3 =14mm. During the extrusion process, the equivalent strain suddenly becomes larger, and the extrusion force is about 10t, but the jump is large, and the expected effect cannot be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com