Patents

Literature

339results about How to "Realize continuous processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

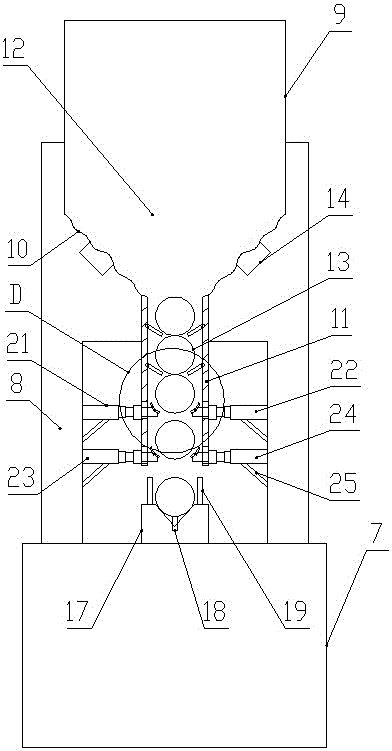

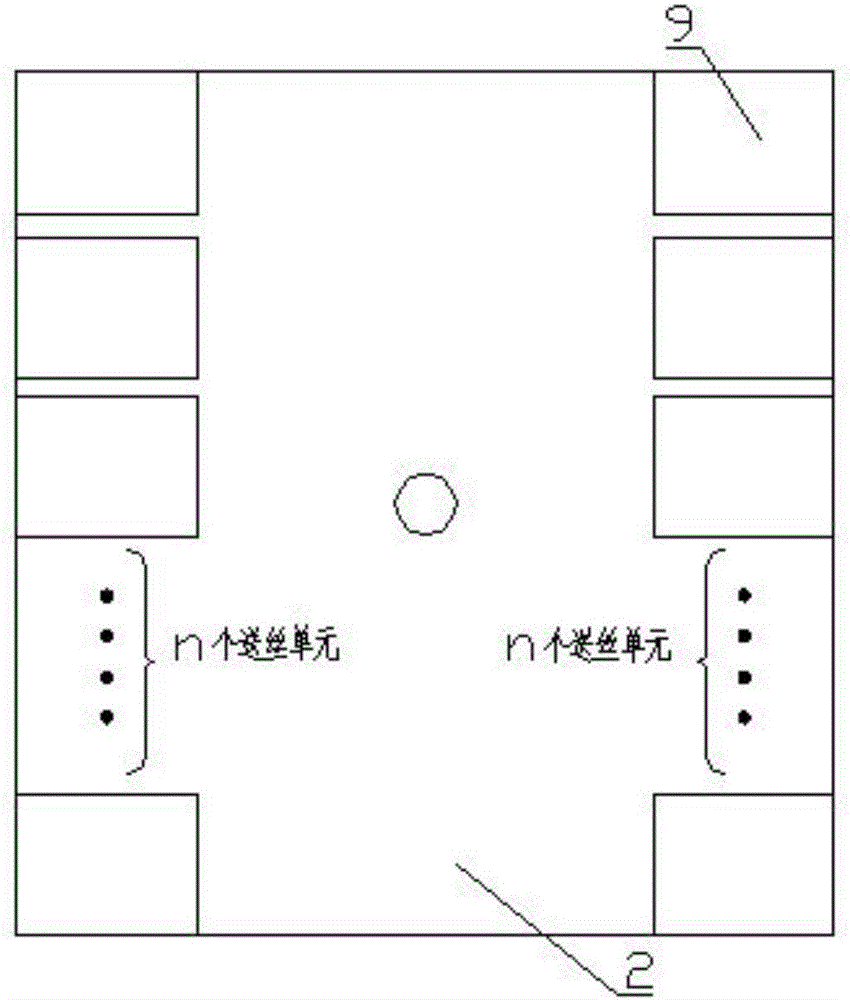

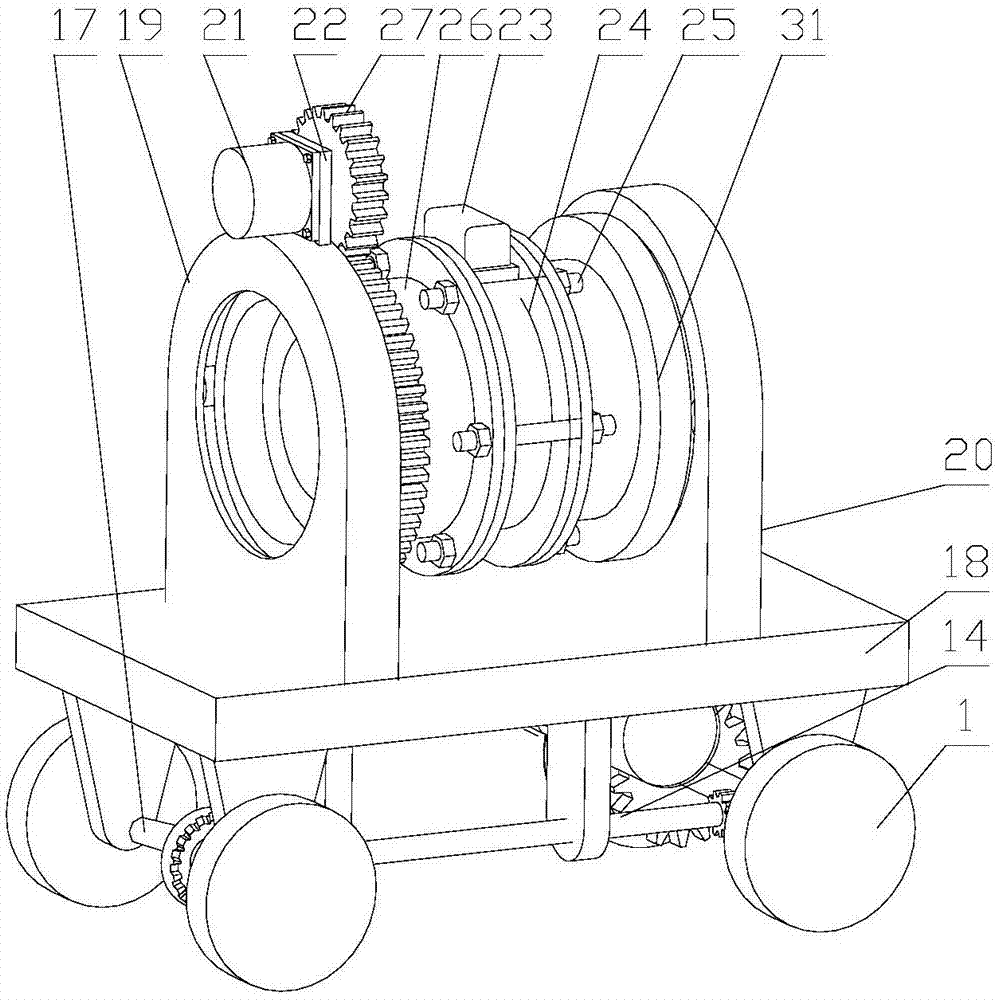

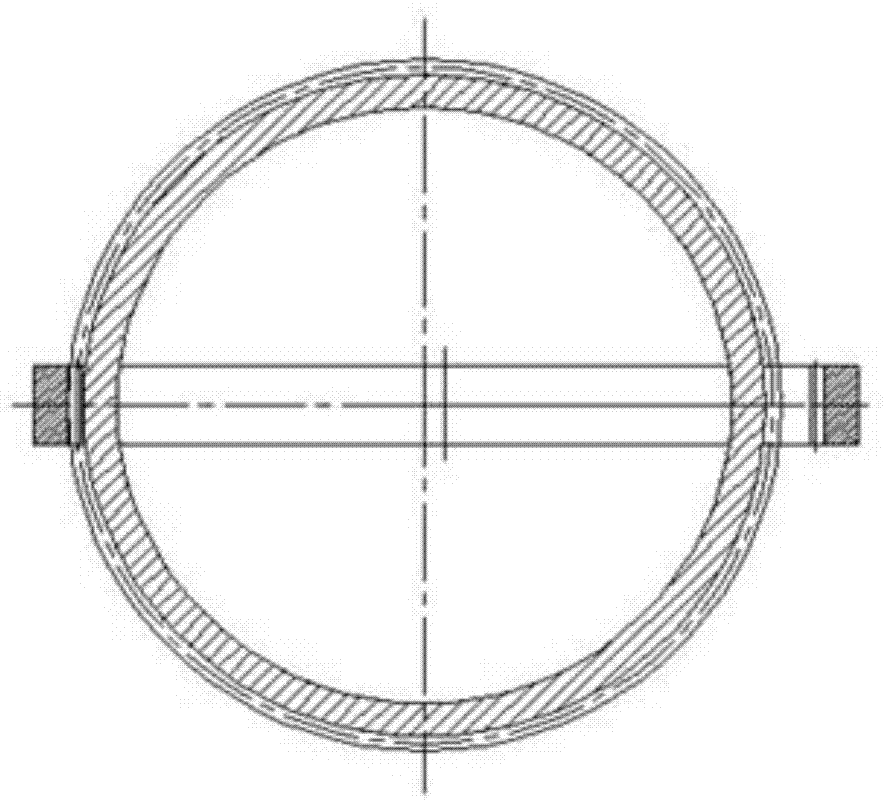

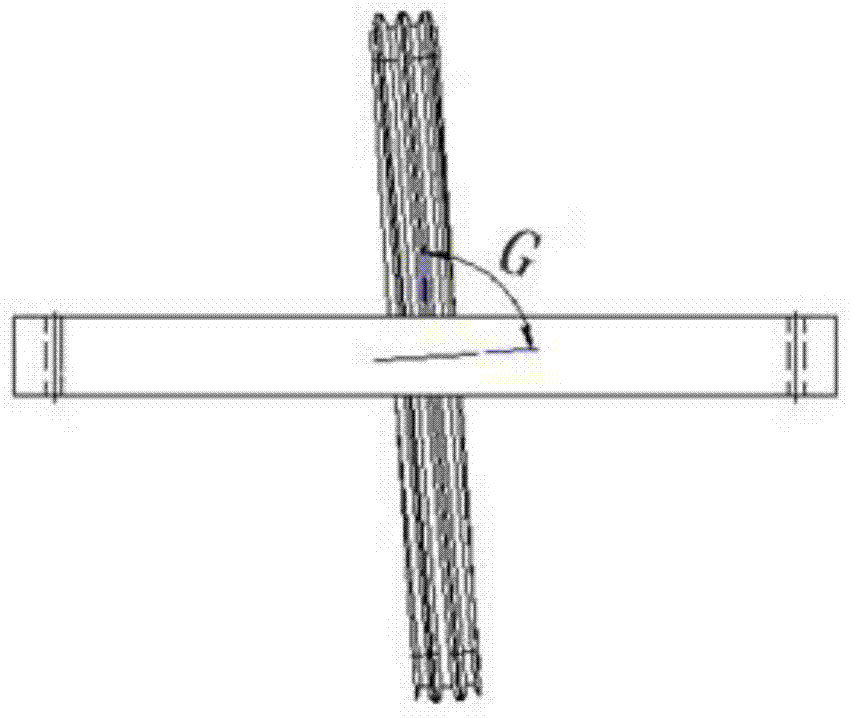

Spiral stirrup continuously and synchronously machining machine and machining method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

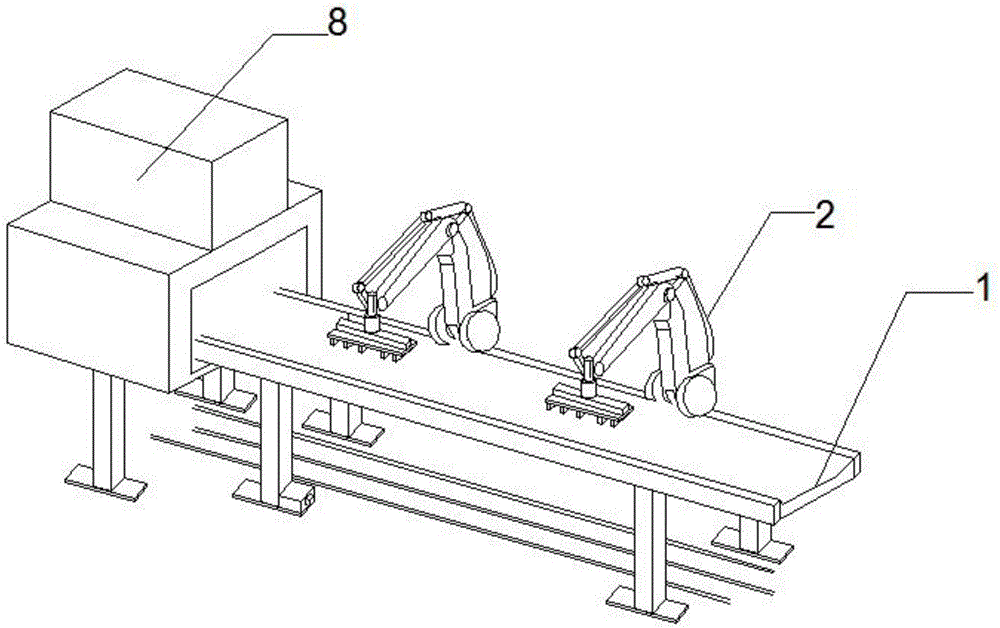

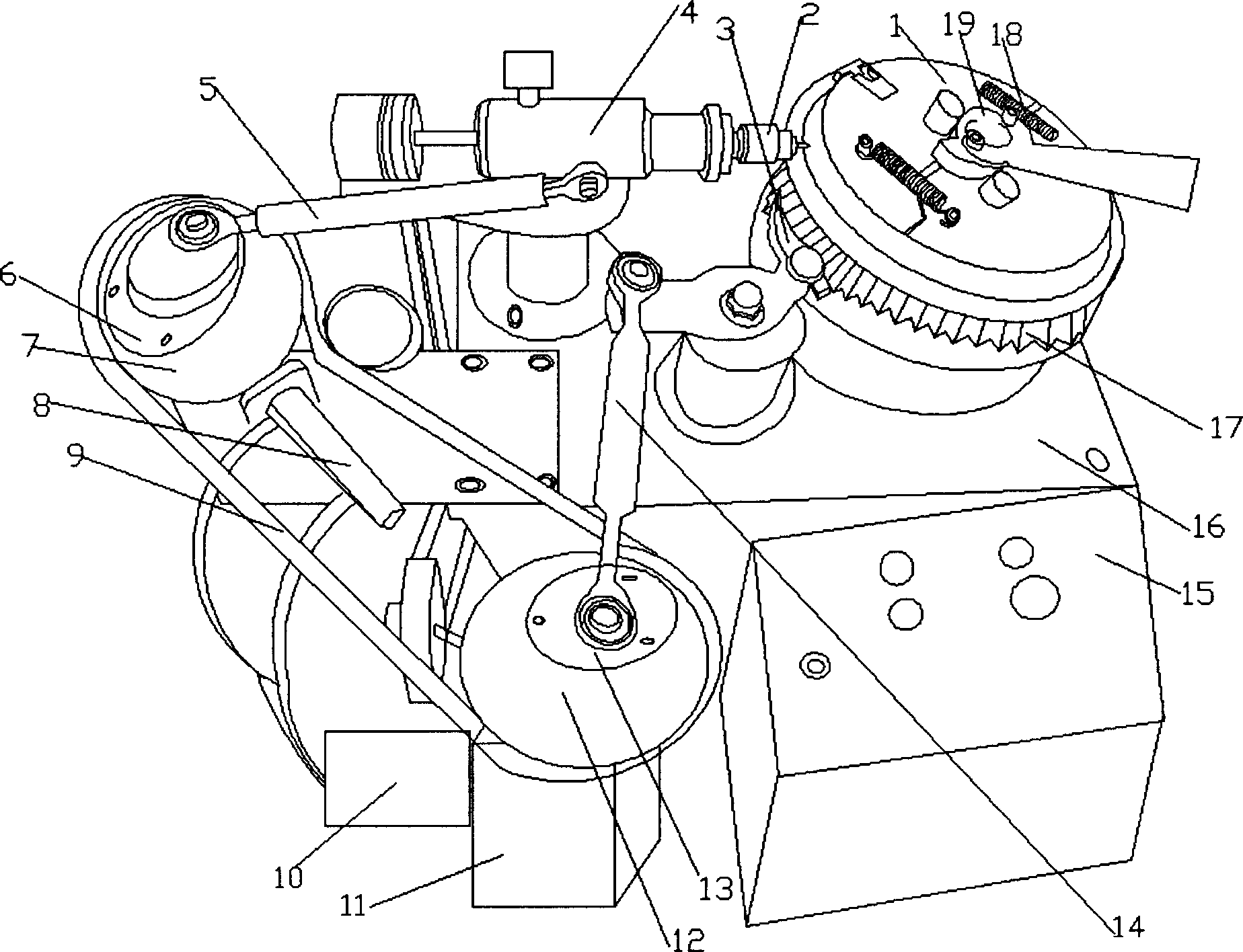

Punching machine

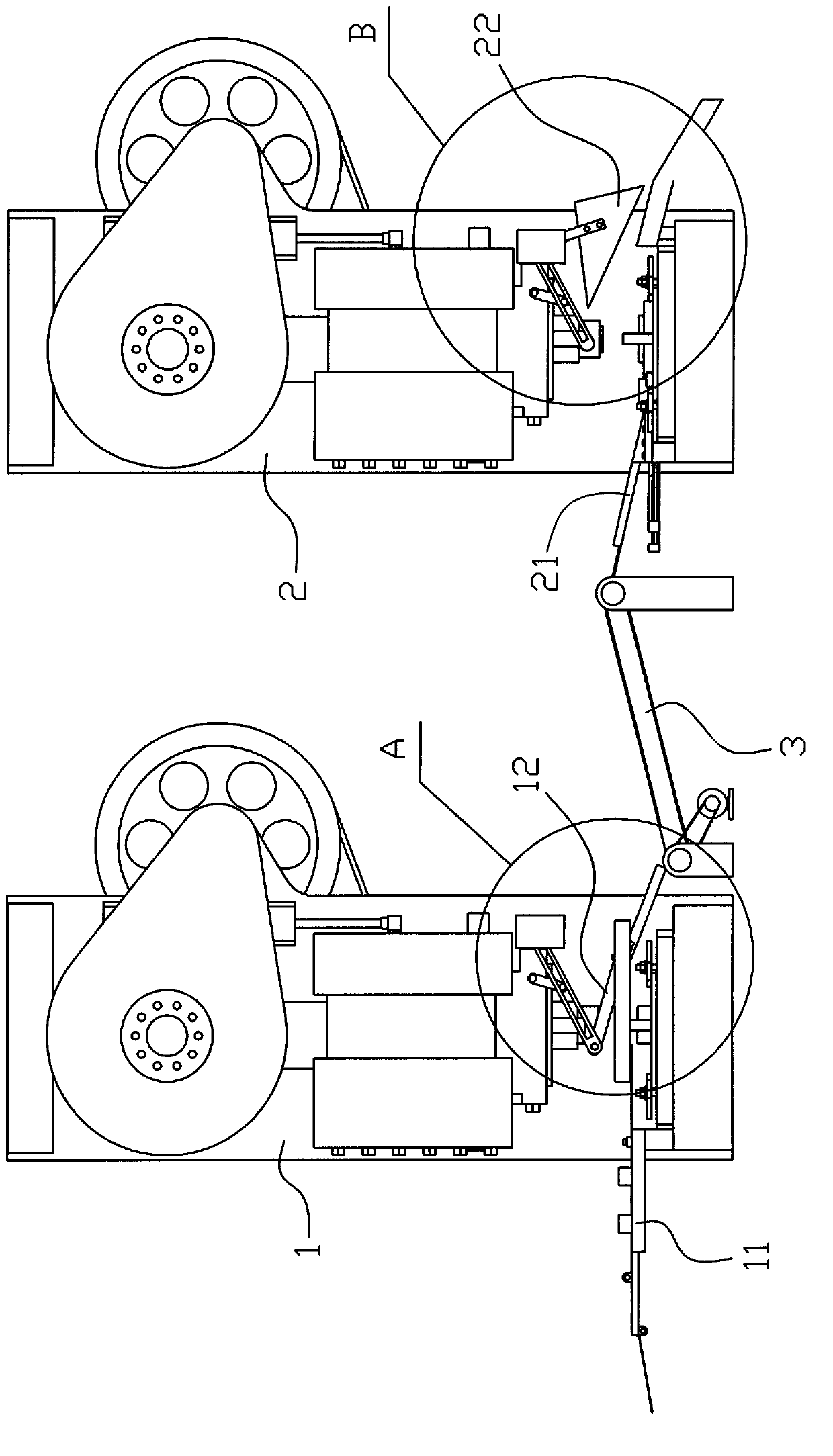

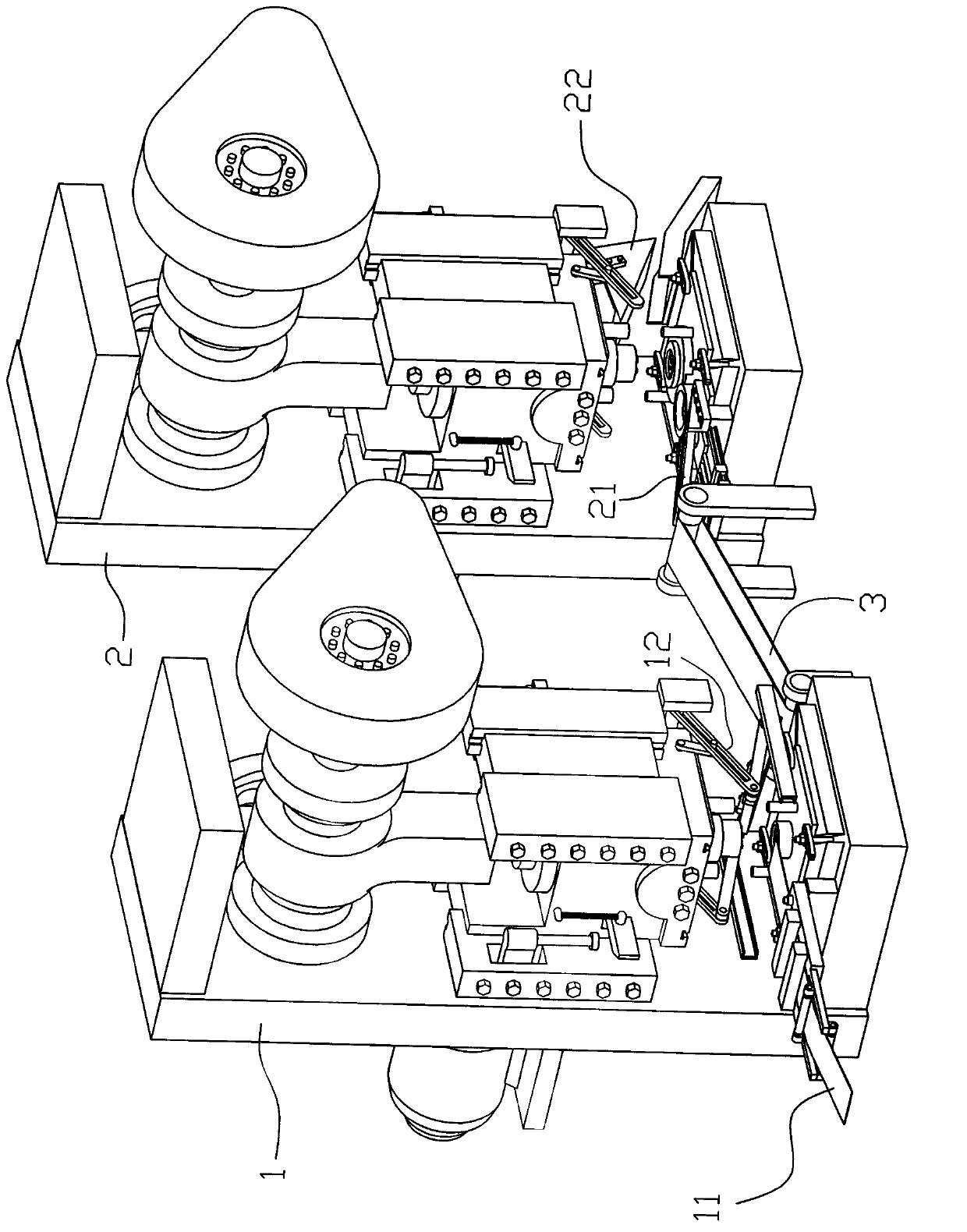

ActiveCN103341541AIngenious design structureRealize continuous processingMetal-working feeding devicesStripping-off devicesPunchingEngineering

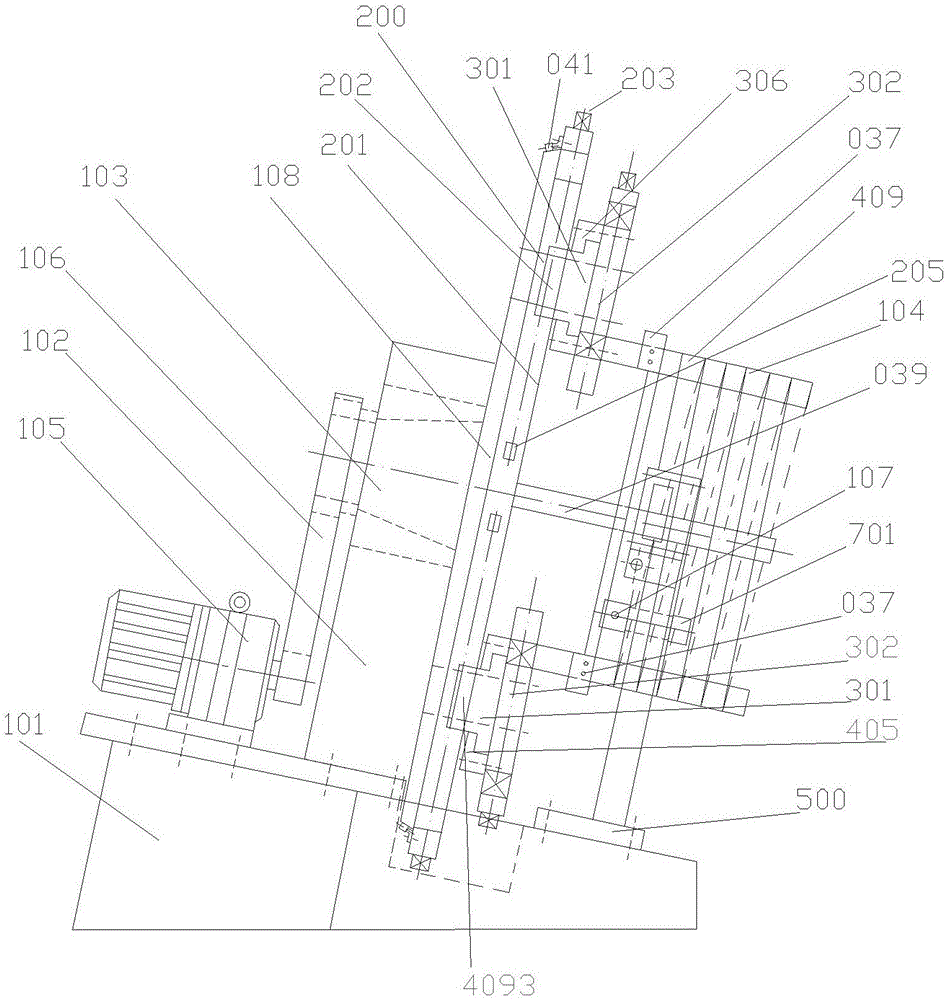

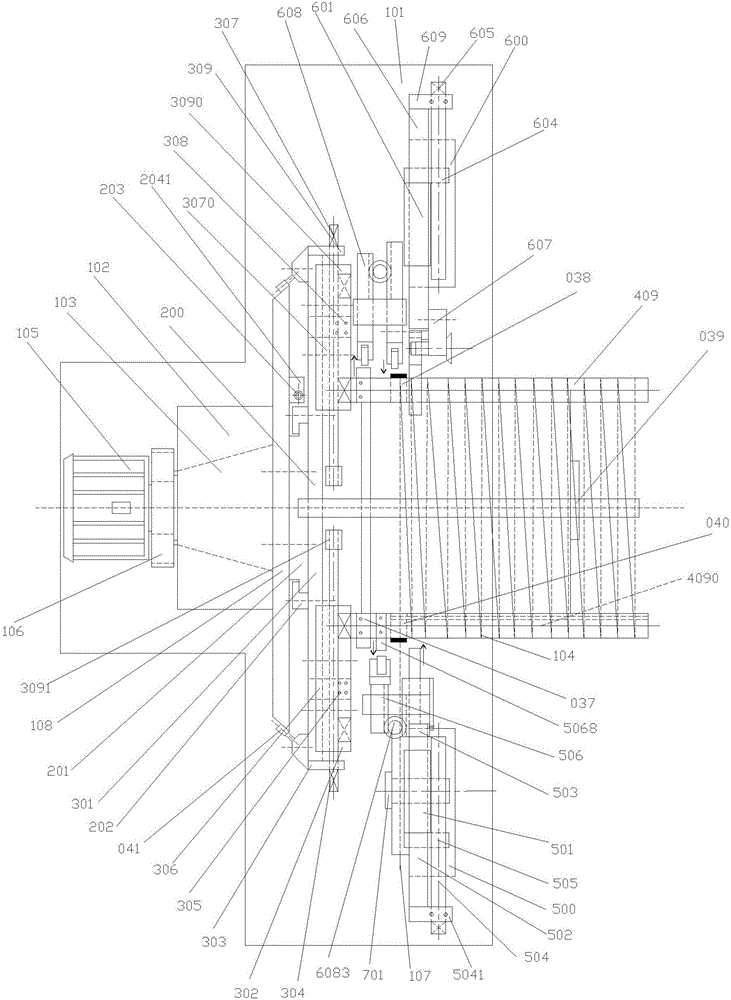

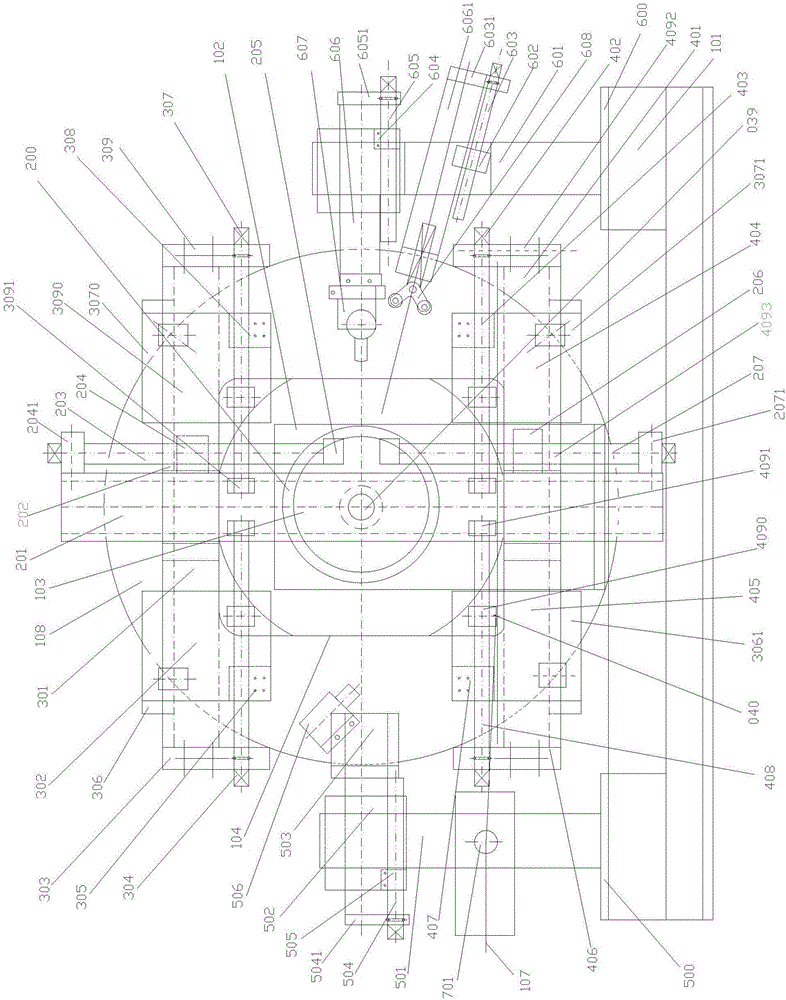

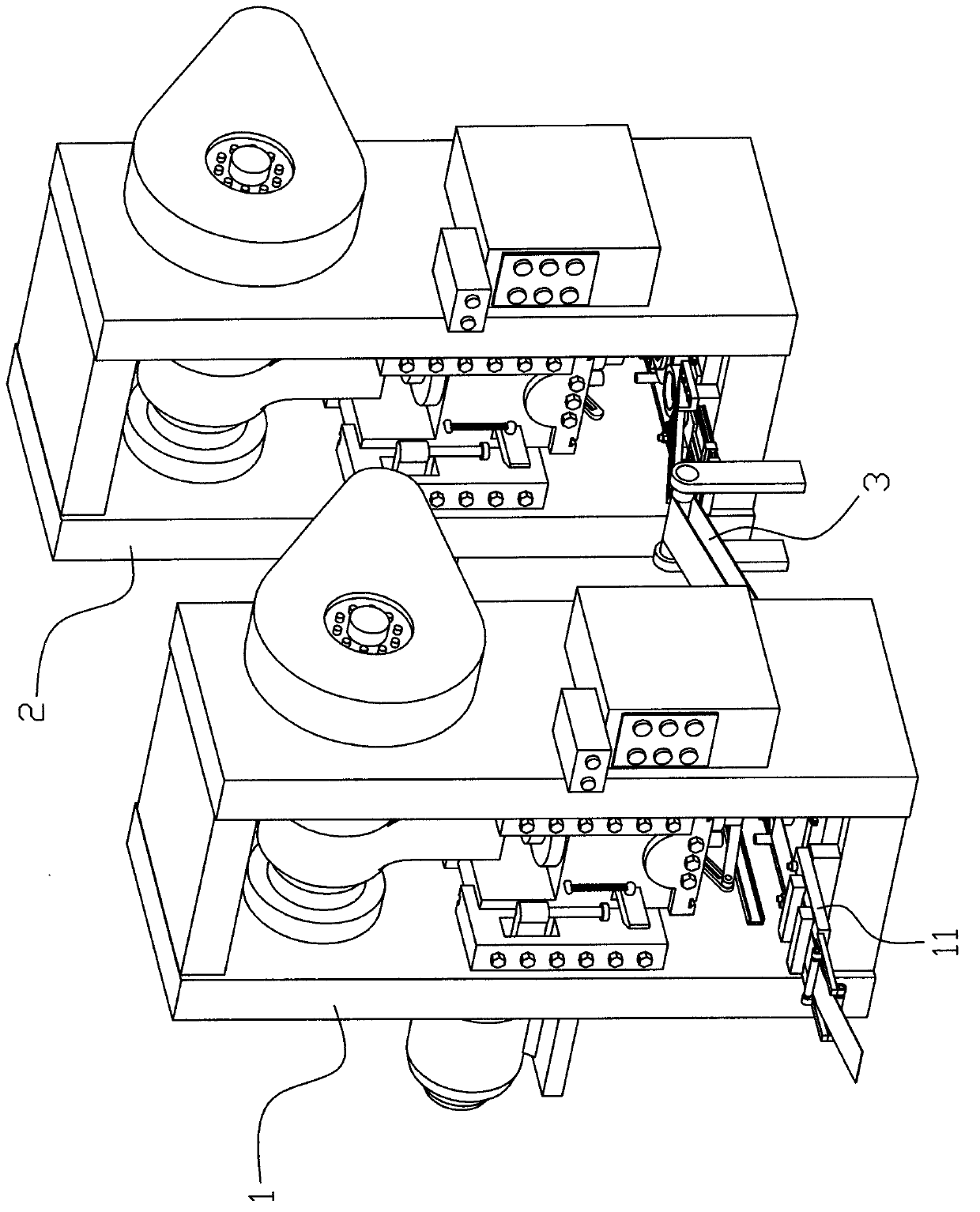

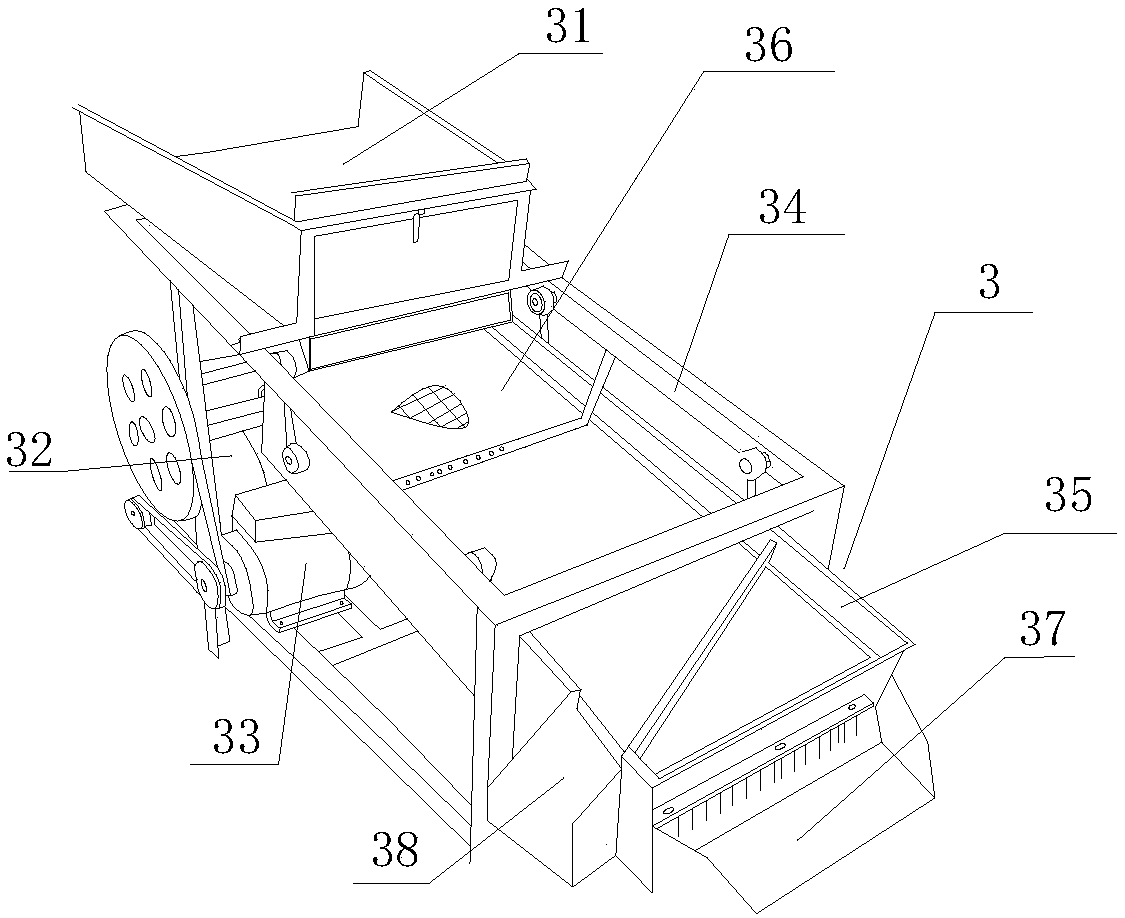

Disclosed is a punching machine. The punching machine comprises a first punching machine (1) and a second punching machine (2), and further comprises a steel strip feeding device (11), a first discharging device (12), a workpiece feeding device (21), a second discharging device (22) and a conveying device (3). The steel strip feeding device and the first discharging device are horizontally installed on the first punching machine and synchronously work with the first punching machine in a coordinated mode; the workpiece feeding device (21) and the second discharging device (22) are horizontally installed on the second punching machine (2) and synchronously work with the second punching machine (2) in a coordinated mode; the conveying device (3) is arranged between the steel strip feeding device (11) arranged on the first punching machine (1) and the workpiece feeding device (21) arranged on the second punching machine (2). The punching machine has the advantages of being ingenious in structural design because two punching machines are integrated through an automatic conveying device, and therefore the purpose of continuously machining workpieces is achieved, reducing labor intensity, substantially improving production efficiency of product machining, and effectively reducing production cost of labor force.

Owner:舟山神鹰滤清器制造有限公司

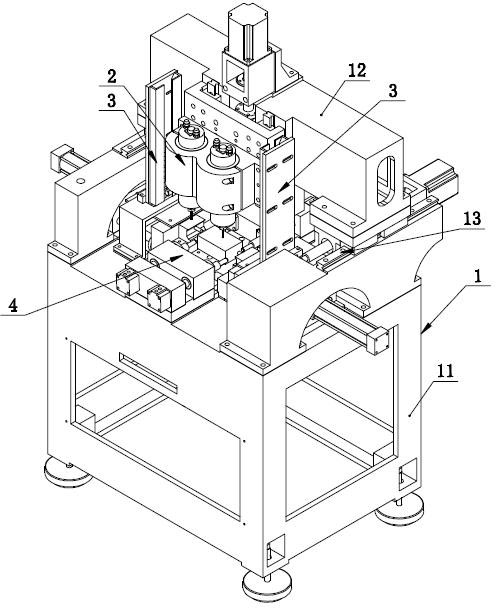

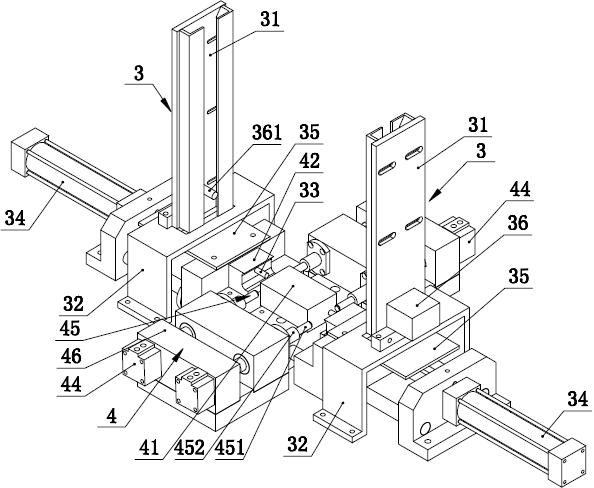

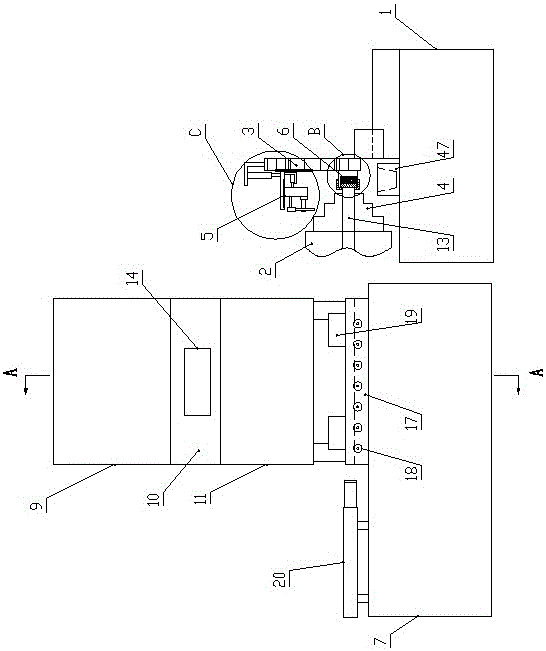

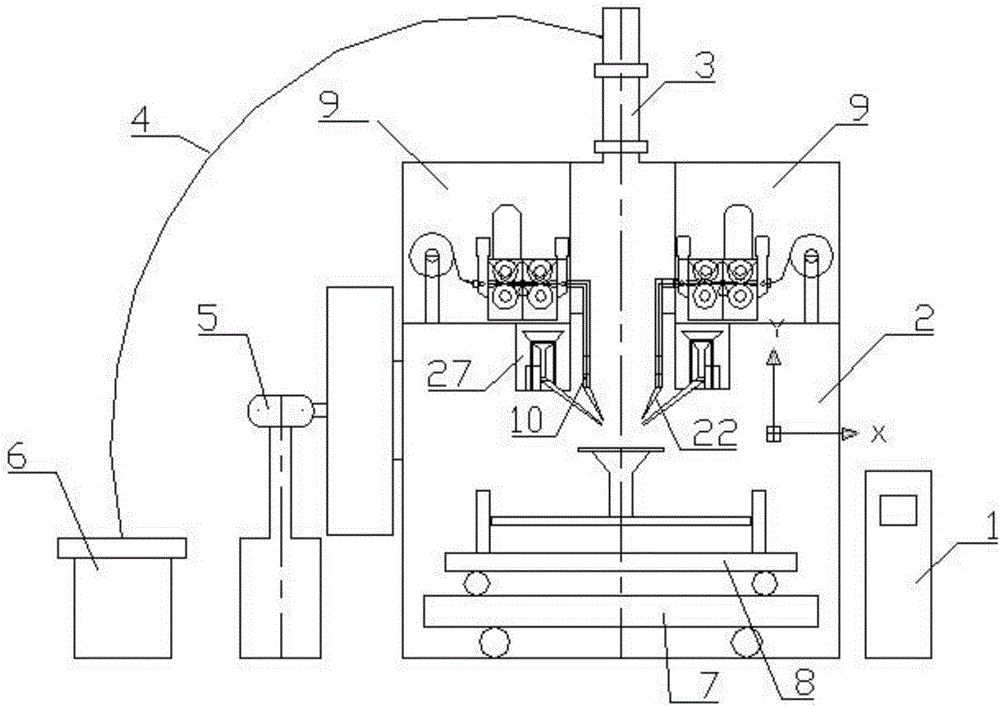

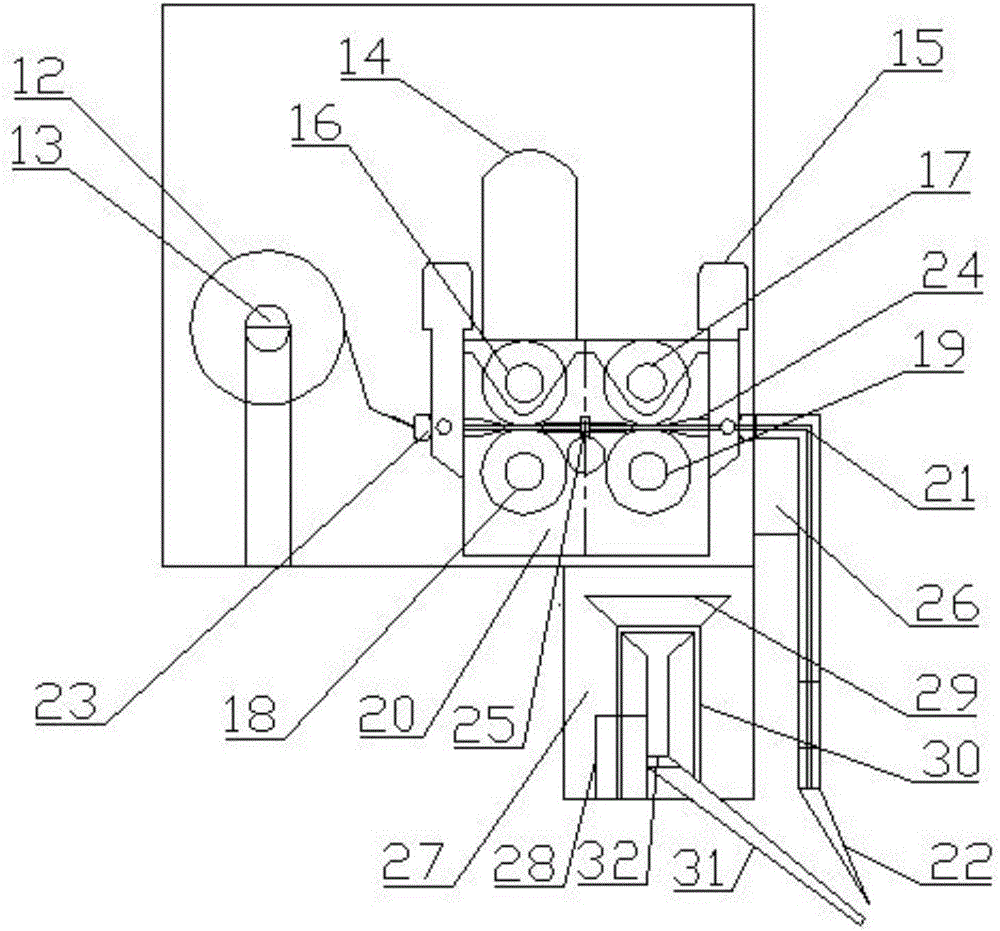

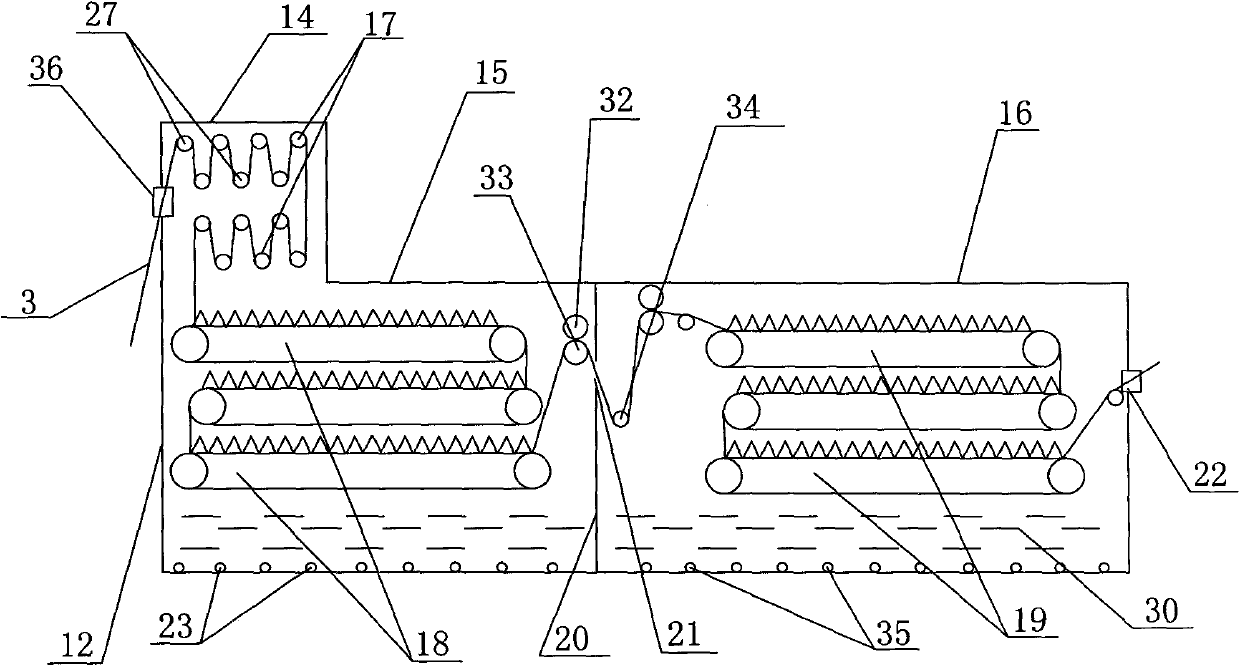

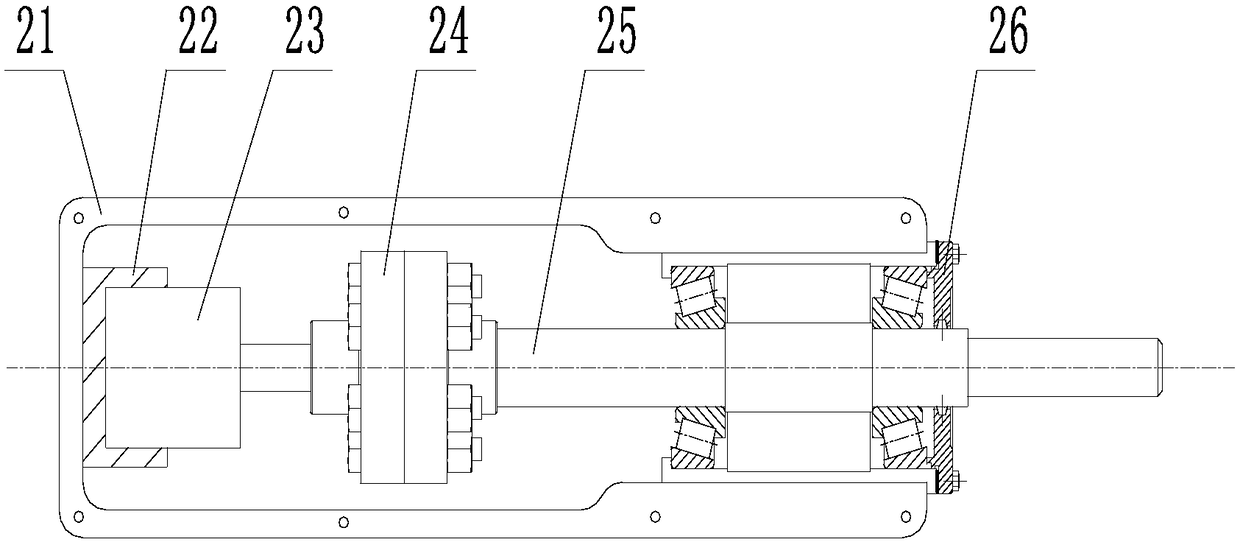

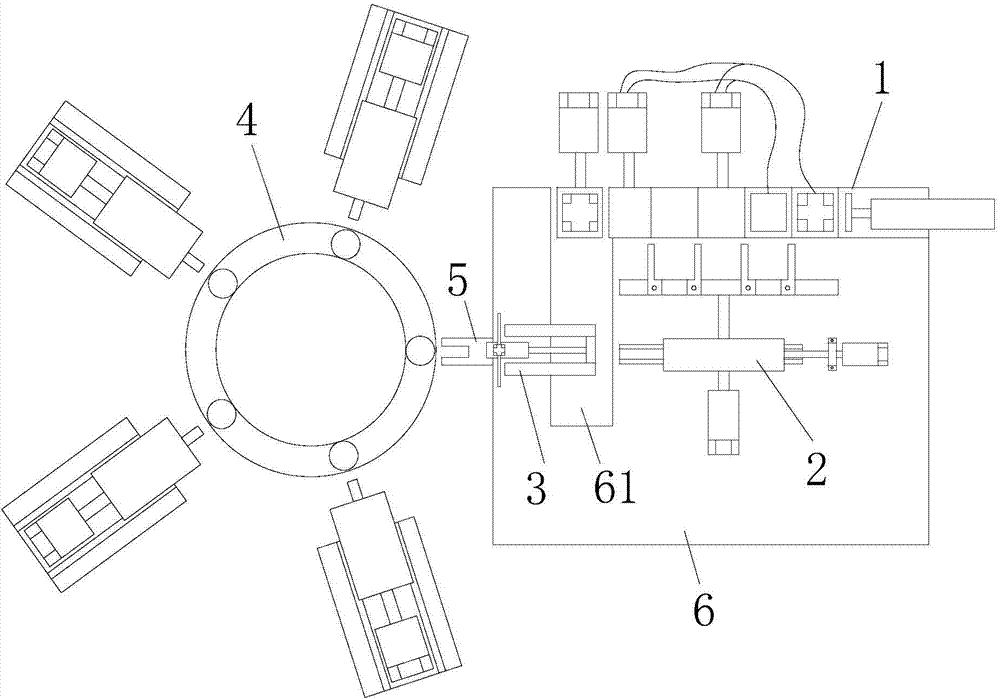

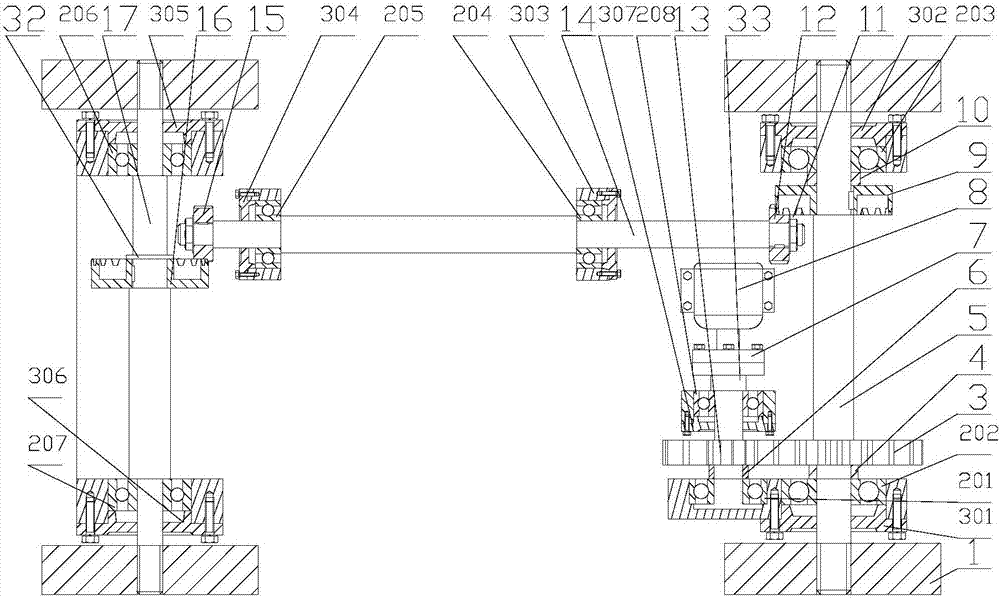

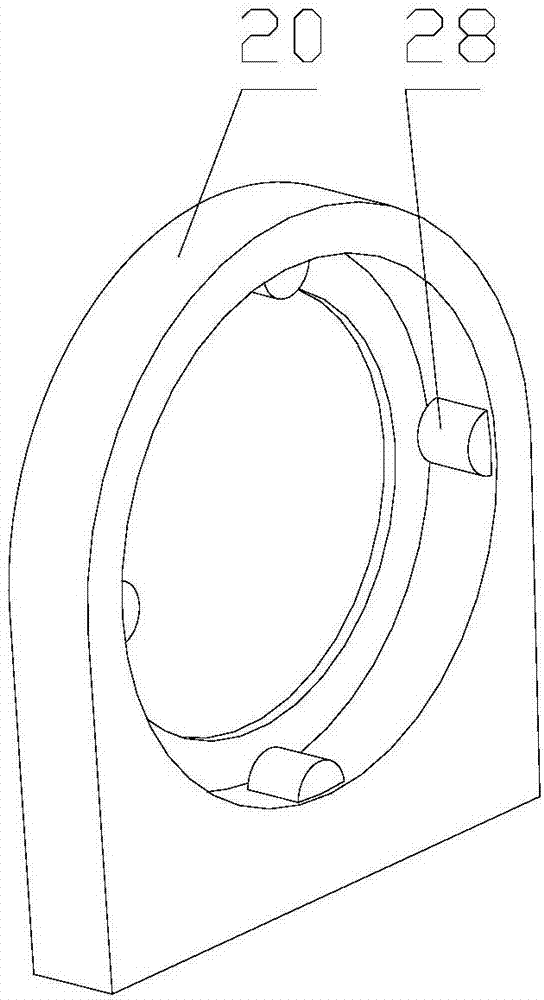

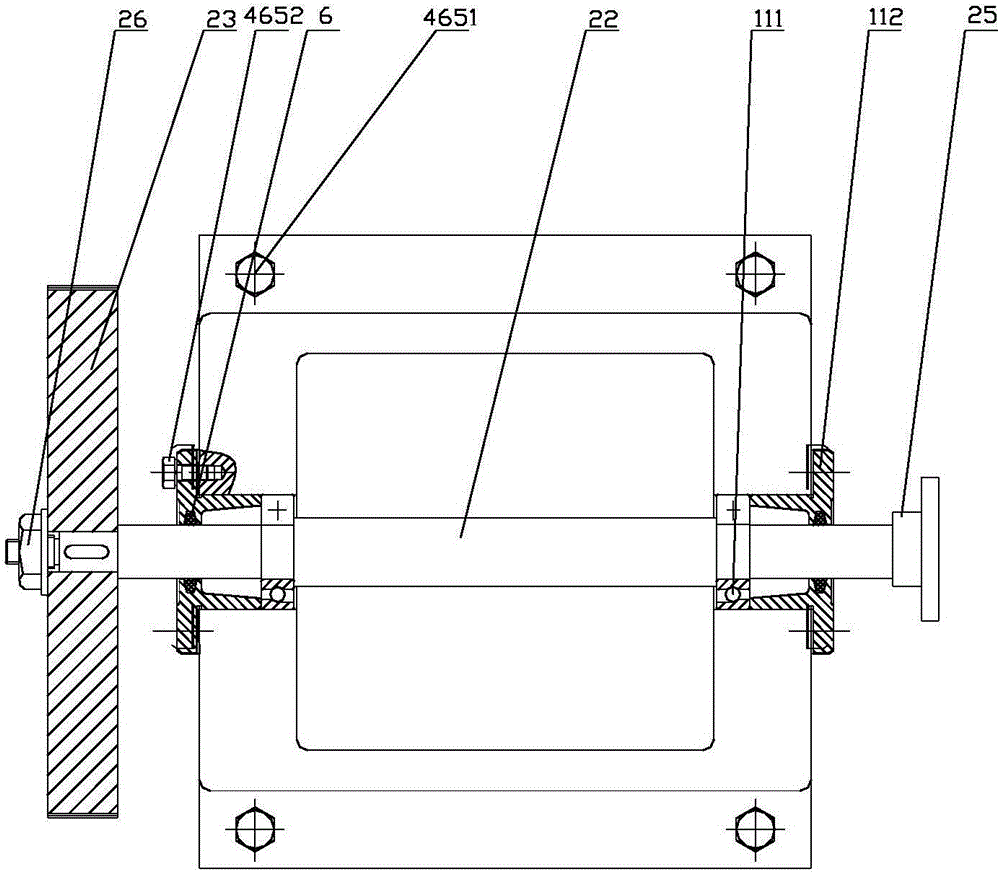

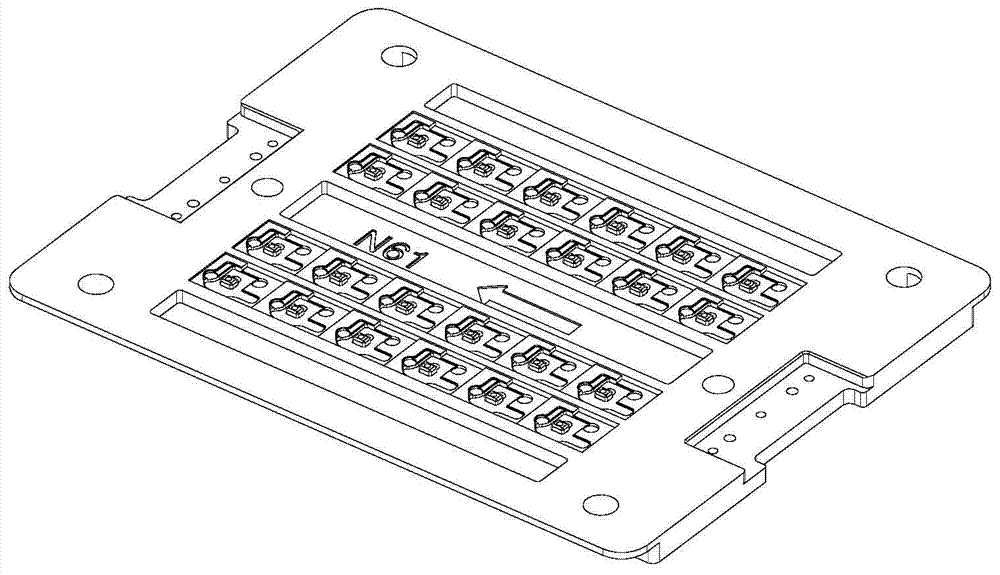

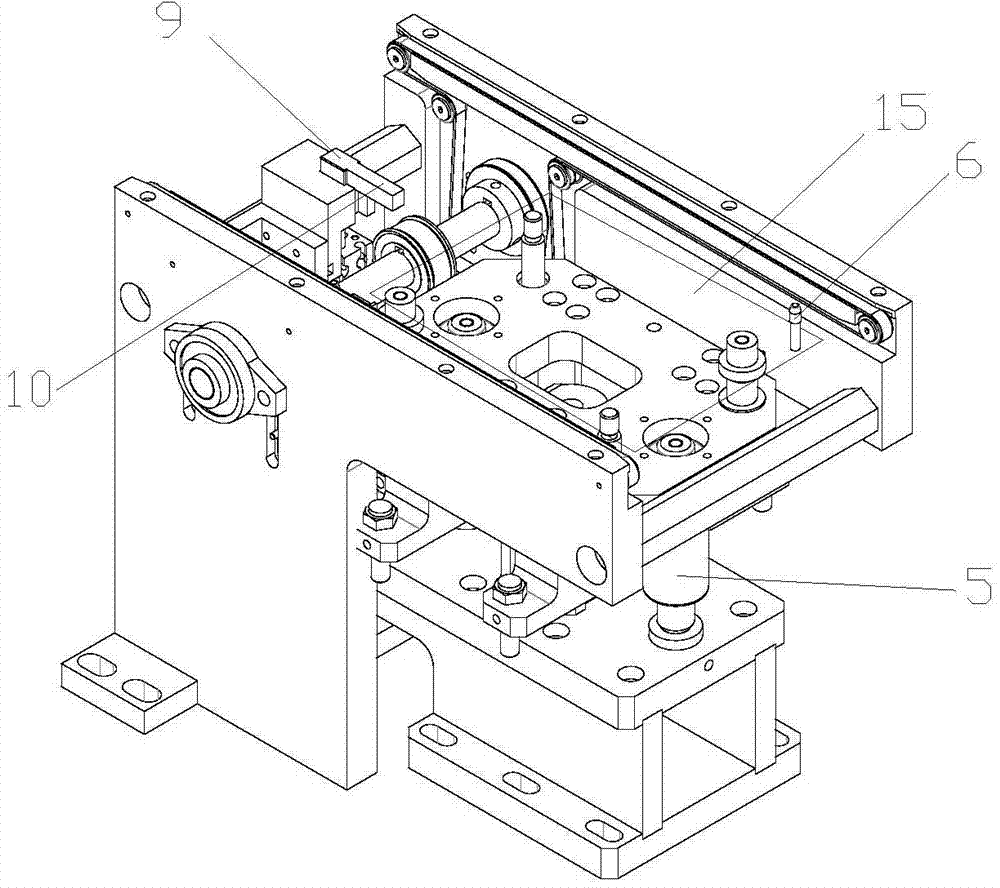

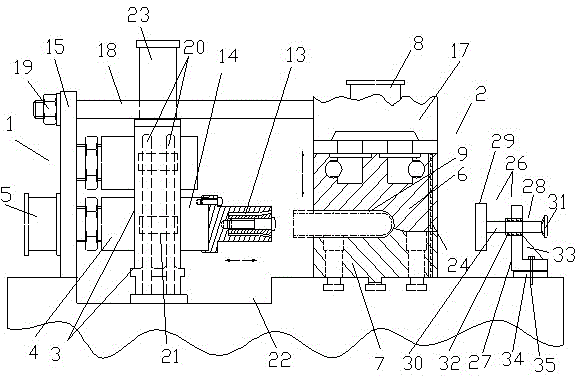

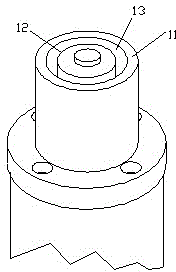

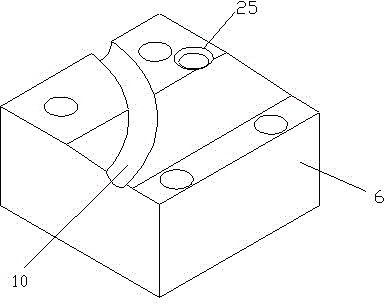

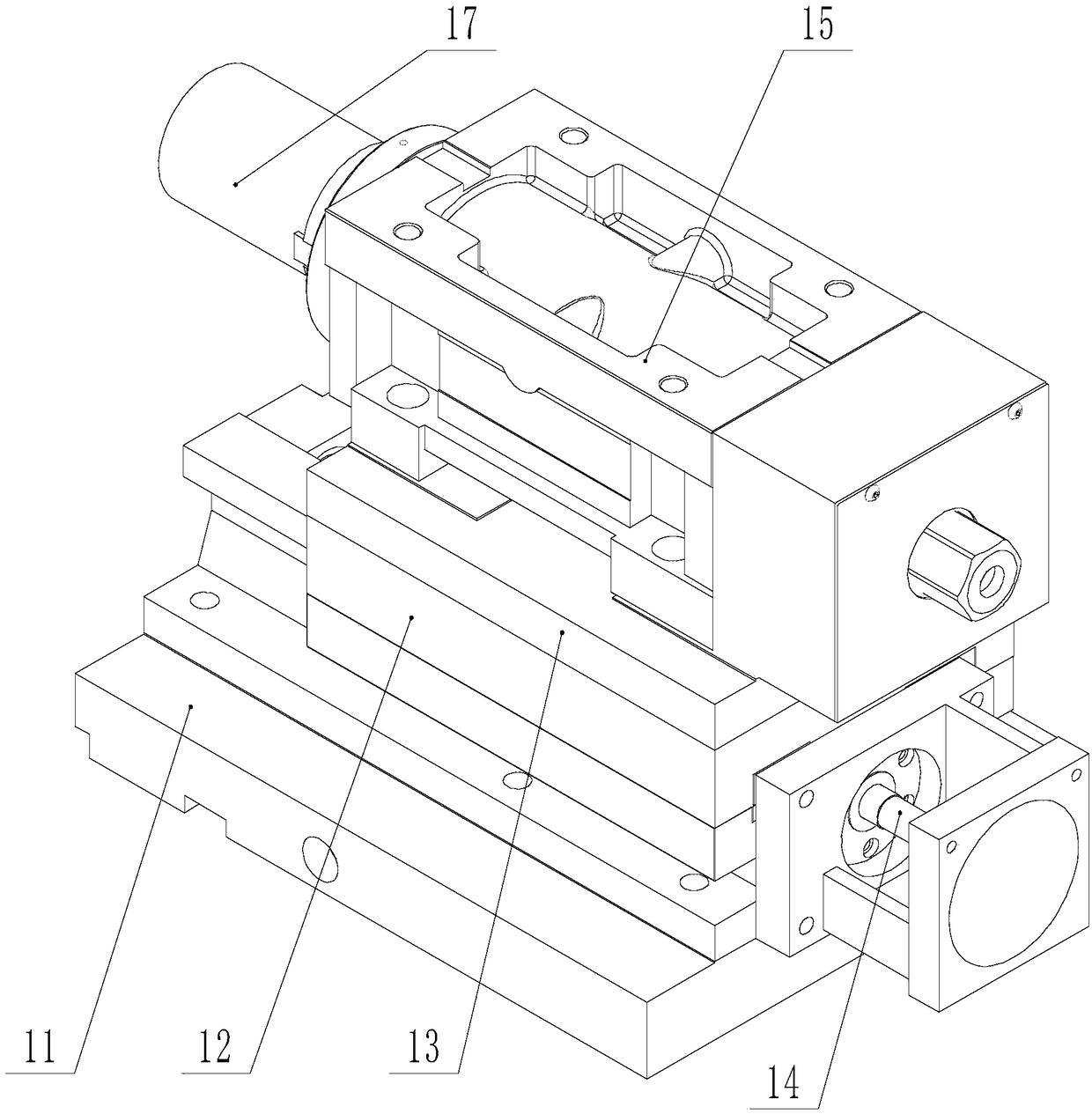

Lock core shell billiard hole drilling machine of numerical control mortise lock

ActiveCN102009203ASimplify the manual operation processImprove efficiencyBoring/drilling componentsBoring/drilling machinesNumerical controlControl system

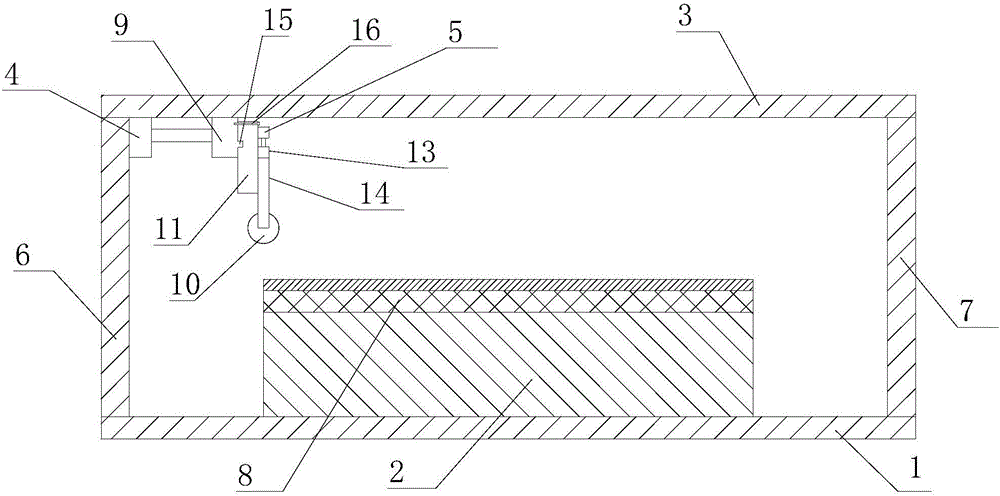

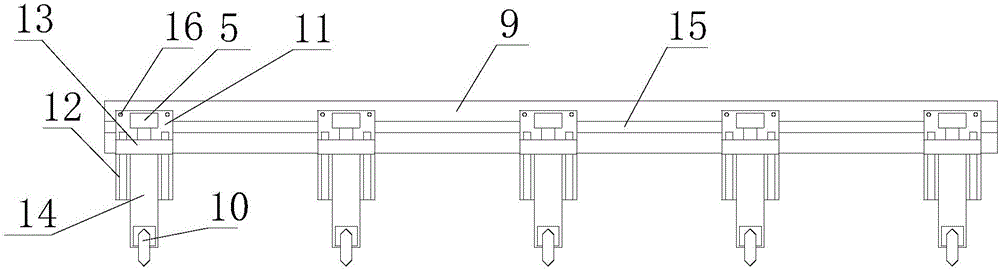

The invention discloses a lock core shell billiard hole drilling machine of a numerical control mortise lock. The machine comprises a machine body, a drilling mechanism, a feeding mechanism, a positioning and clamping mechanism and a control system, wherein the machine body consists of a pedestal and a gantry frame; a guide rail and a guide post which are matched with each other in a sliding way are arranged between the gantry frame and the pedestal; the drilling mechanism is fixed on the gantry frame; the feeding mechanism and the positioning and clamping mechanism are fixed on the pedestal; the output end of the feeding mechanism is connected with the positioning and clamping mechanism; a machined lock core shell conveyed out by the feeding mechanism is clamped and positioned by the positioning and clamping mechanism; and drilling operation of the machined lock core shell is finished by the drilling mechanism. By using the structure, only a lock core shell to be machined needs to be placed in a feeding groove frame, and the subsequent processes such as feeding, clamping and positioning, drilling, discharging and the like can be fully automatically operated; and compared with the conventional manual operation type lock core shell billiard hole drilling machine of the mortise lock, the machine simplifies the manual operation process, improves the efficiency and ensures that one person can simultaneously operate a plurality of machines.

Owner:温州杰拓数控设备有限公司

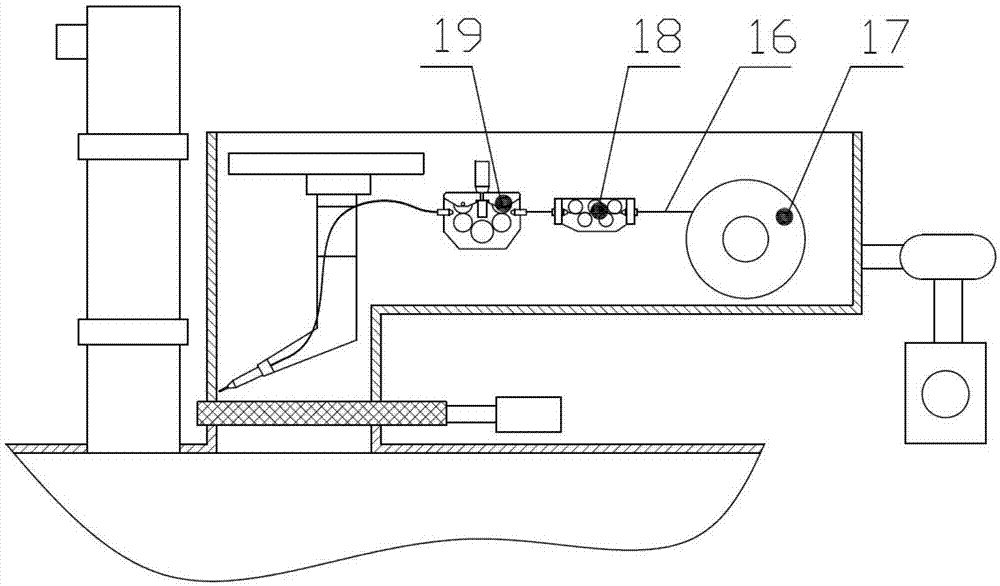

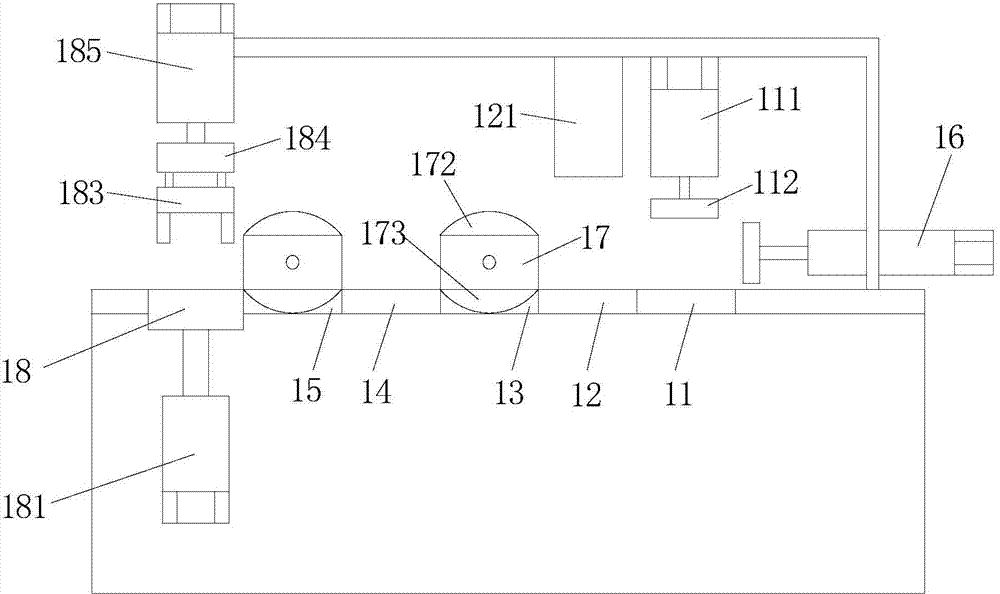

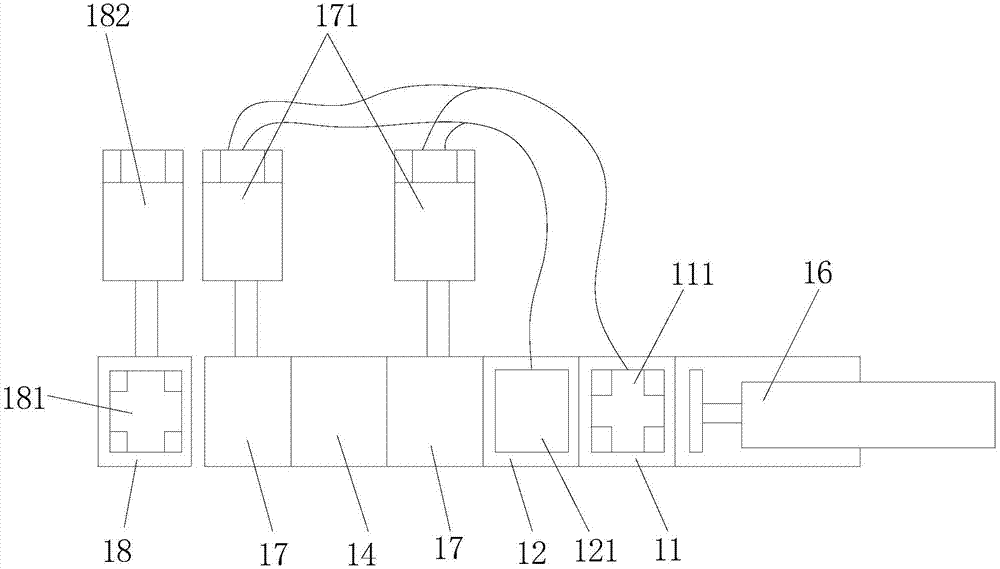

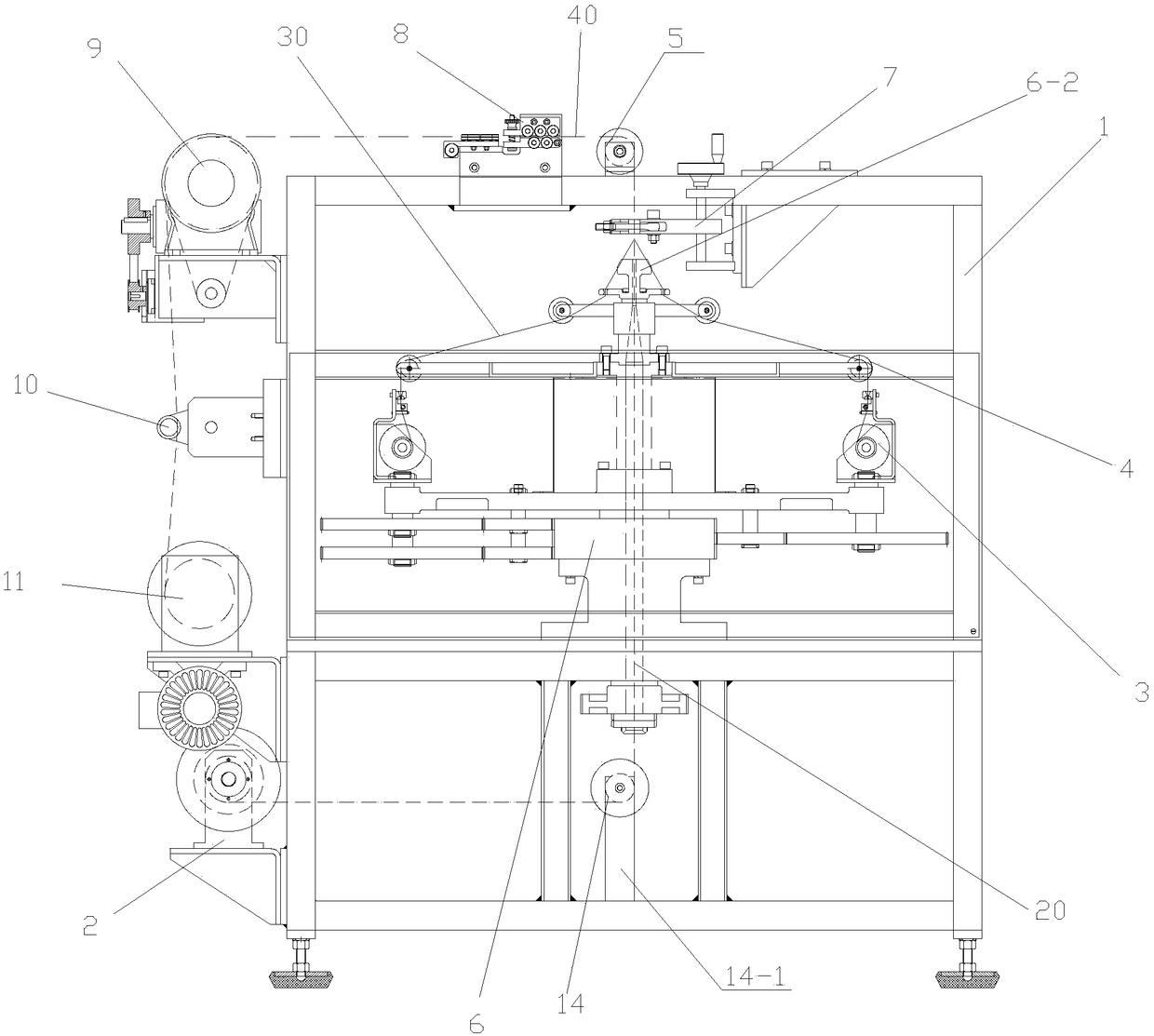

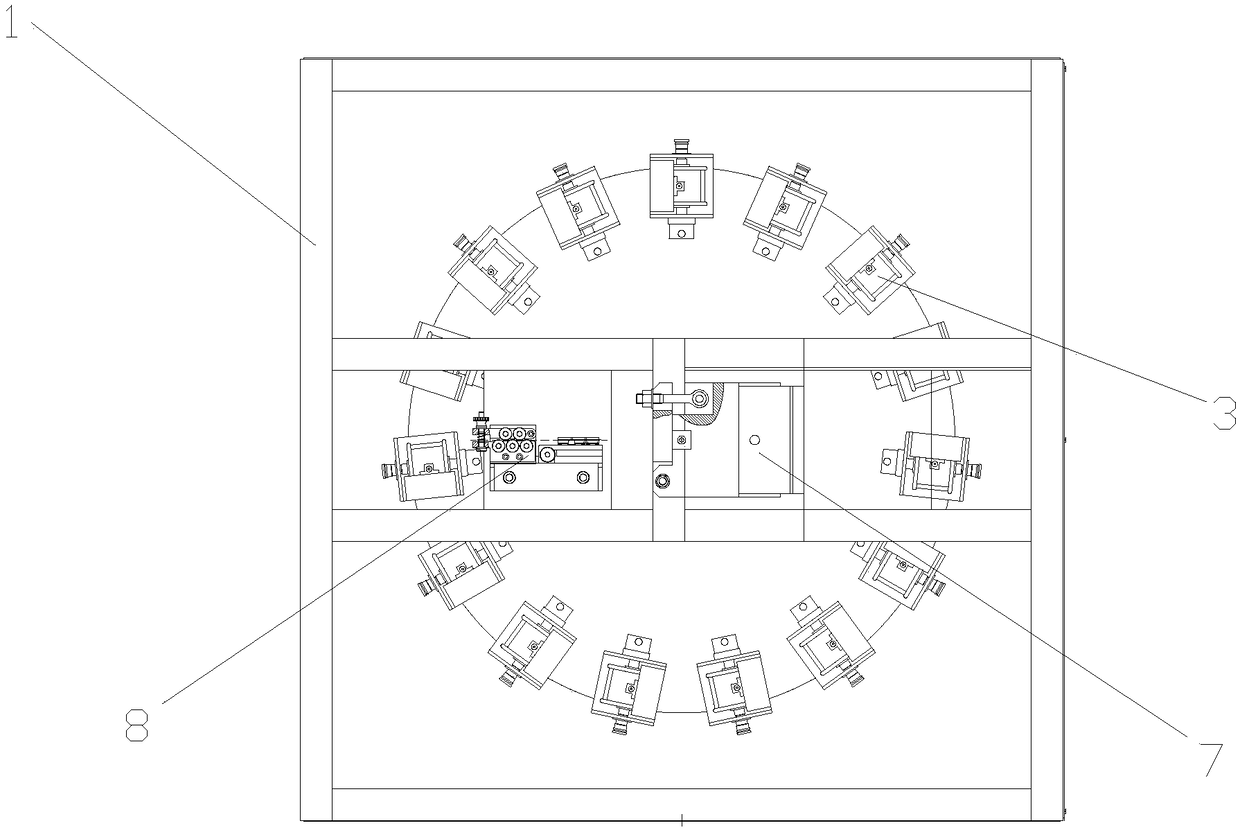

Automatic feeding numerical control lathe

InactiveCN105798332AAvoid shockPrevent flying outMetal working apparatusNumerical controlMaterial storage

The invention discloses an automatic feeding numerical control lathe. The automatic feeding numerical control lathe comprises a lathe body, wherein a hollow spindle is arranged on the lathe body; a sliding rail is arranged on the lathe body along the front and back horizontal direction; a knife rest is slidably arranged on the sliding rail; a hollow chuck is axially and fixedly connected to the front end of the hollow spindle; a cutting mechanism and an electromagnetic adsorption mechanism are arranged on the knife rest; an automatic feeding device is arranged behind the lathe body; the automatic feeding device comprises a material box base; a material box support is fixedly connected onto the material box base; a material storage box, a corrugated pipe elastic joint and a discharging box are sequentially arranged on the material box support from top to bottom in a fixed manner; a vibration motor is arranged on the outer wall of each of the left and right sides of the corrugated pipe elastic joint; a material baffle mechanism is arranged on the lower part of the discharging box; and a material pushing base which is right blow the discharging box is fixedly connected onto the upper surface of the material box base. The automatic feeding numerical control lathe is simple and convenient for operation, high in automatic degree and stable in work; automatic feeding can be realized; non-cutting time is effectively shortened; cutting can be performed rapidly; and the working efficiency is improved.

Owner:HUANGHE S & T COLLEGE

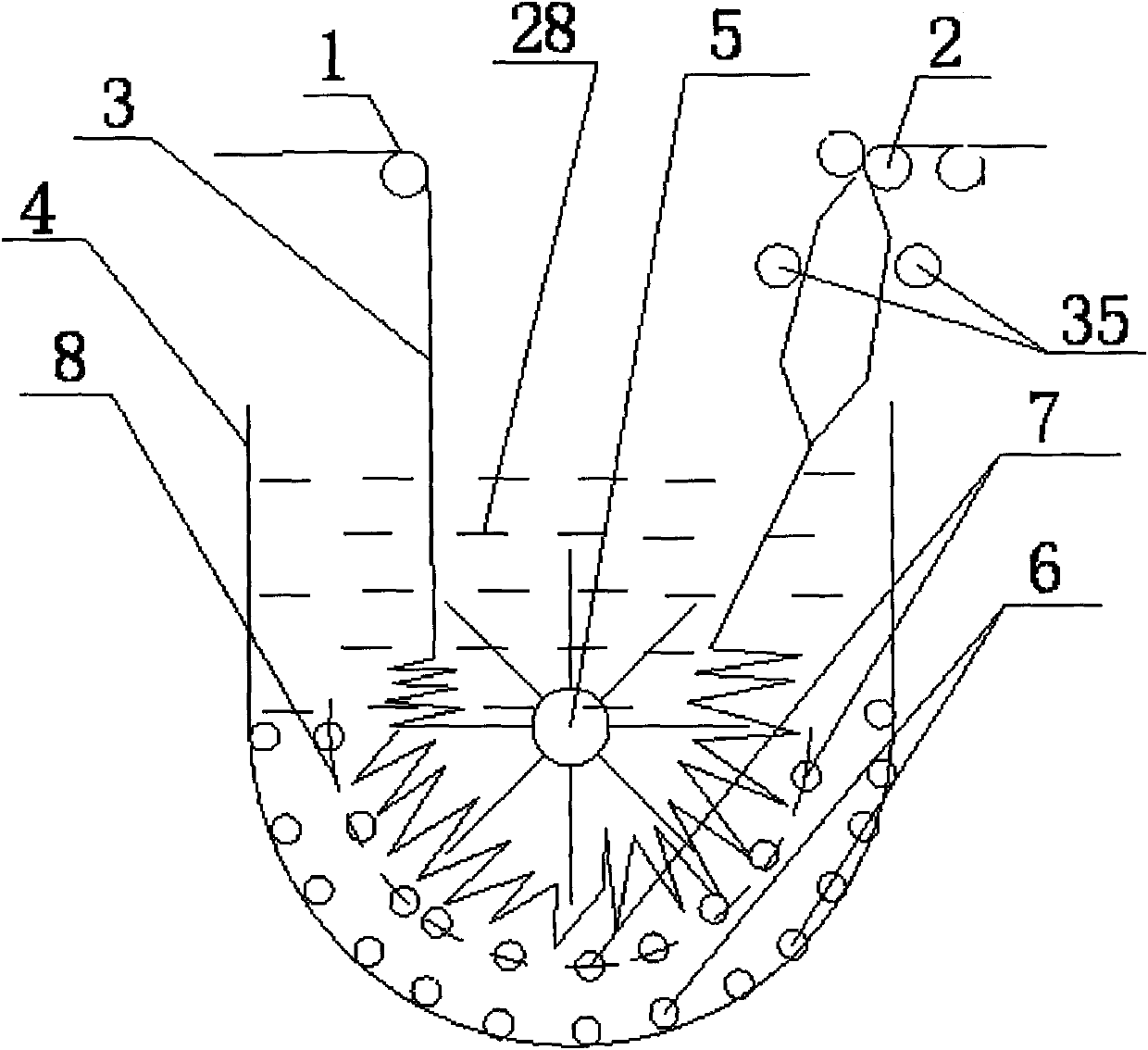

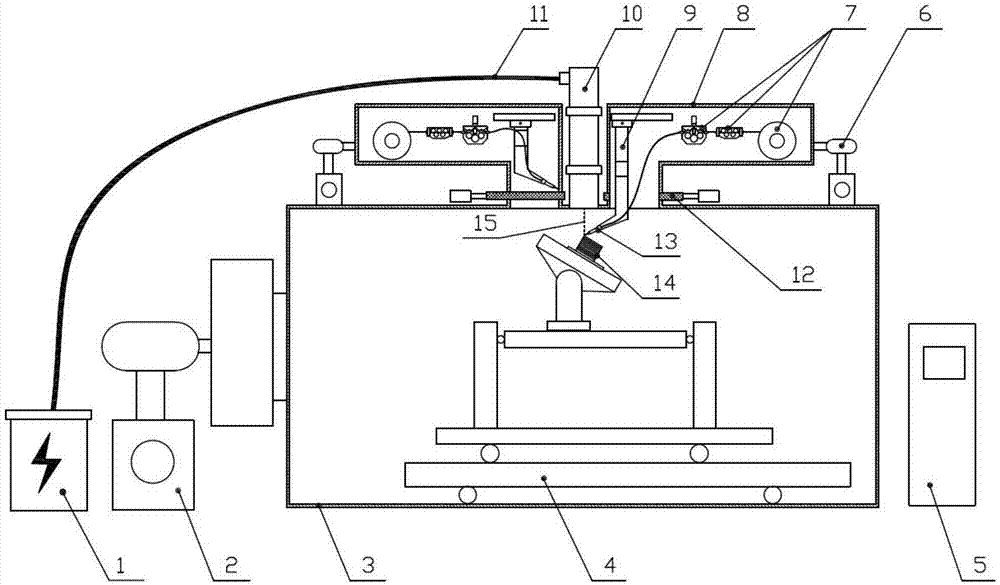

Fuse wire filled multifunctional controllable additive manufacturing device

InactiveCN106624323ARealize filler weldingFilling volume changeElectron beam welding apparatusSlagEngineering

The invention discloses a fuse wire filled multifunctional controllable additive manufacturing device. The fuse wire filled multifunctional controllable additive manufacturing device is composed of an electric control system, a vacuum chamber, an electronic gun, a high voltage power supply, a motion system, a wire feeding system and a particle feeding device. According to the device provided by the invention, metal particle included slag filling, particle included slag and wire rod mixed filling, single wire rod filling, multiple wire rod same material filling and multiple wire rod different material filling can be realized. By adjusting the wire feeding speed, the wire feeding mode and the filling amount of metal particles of each of wire feeding units, the filling material and the filling amount of a weld joint are changed; in an additive manufacturing process, the metal particles can be synchronously fed by virtue of the wire feeding system and the wire feeding system feeds the wires synchronously to realize metal particle included slag filling, and multiple wire rod same material same speed and multiple wire rod different material different speed addition, so that the components of the filling material of the weld joint are differently distributed, thereby realizing continuous processing of a functional gradient material.

Owner:NANJING UNIV OF SCI & TECH

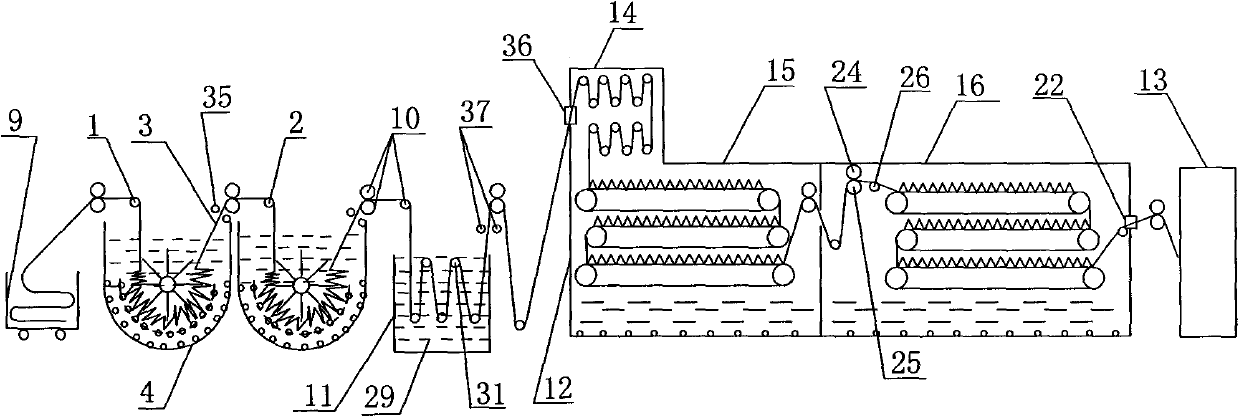

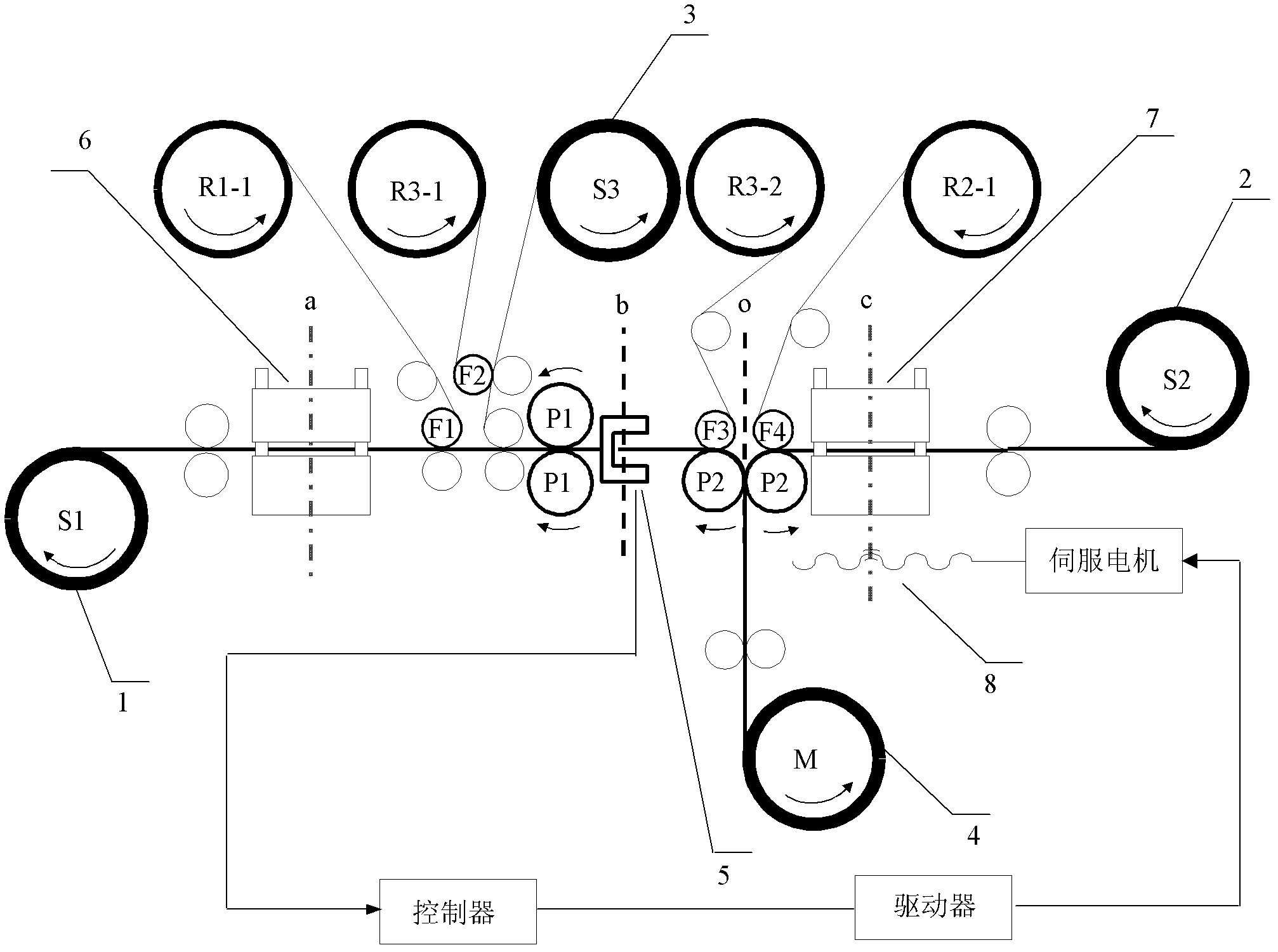

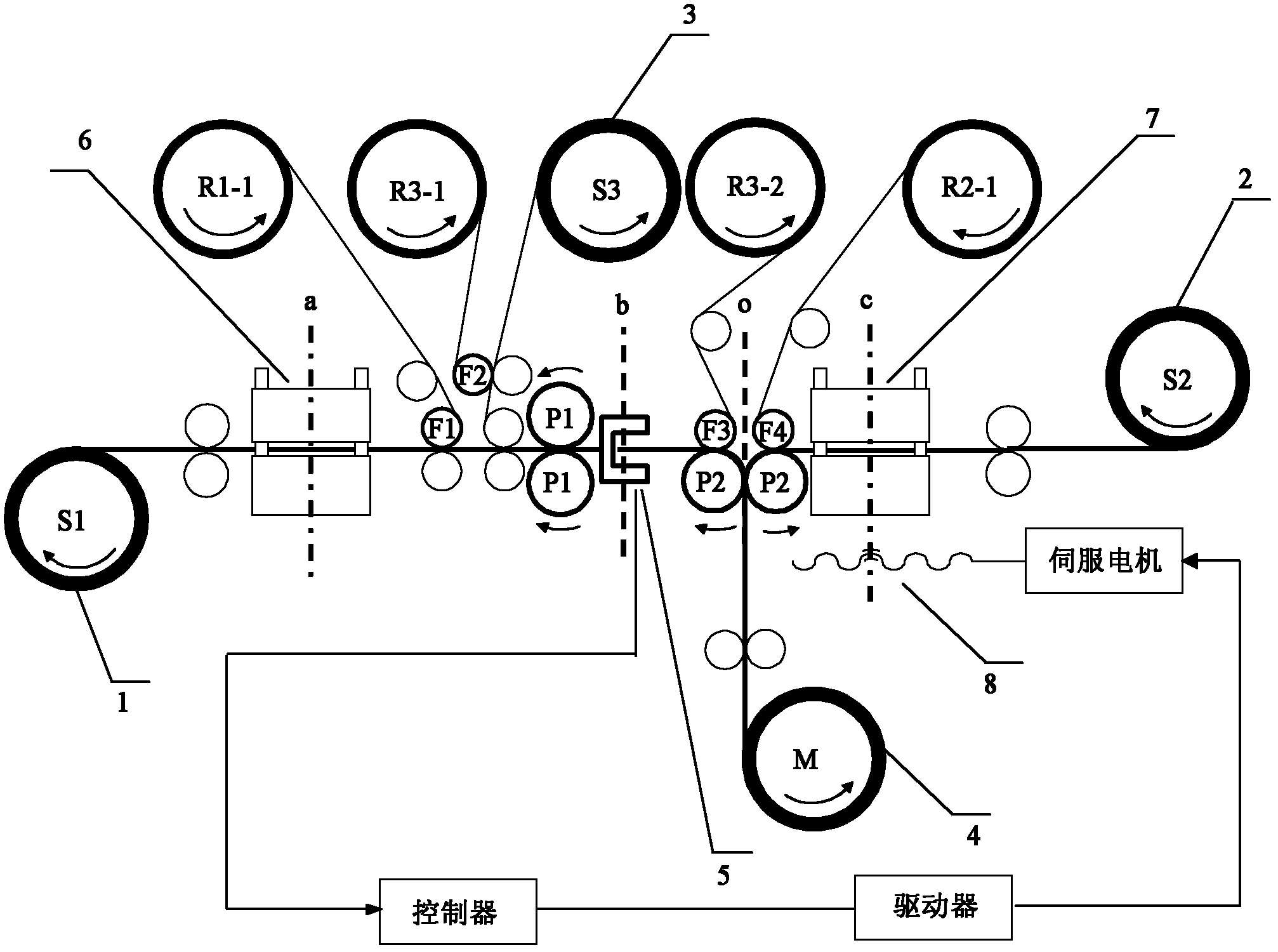

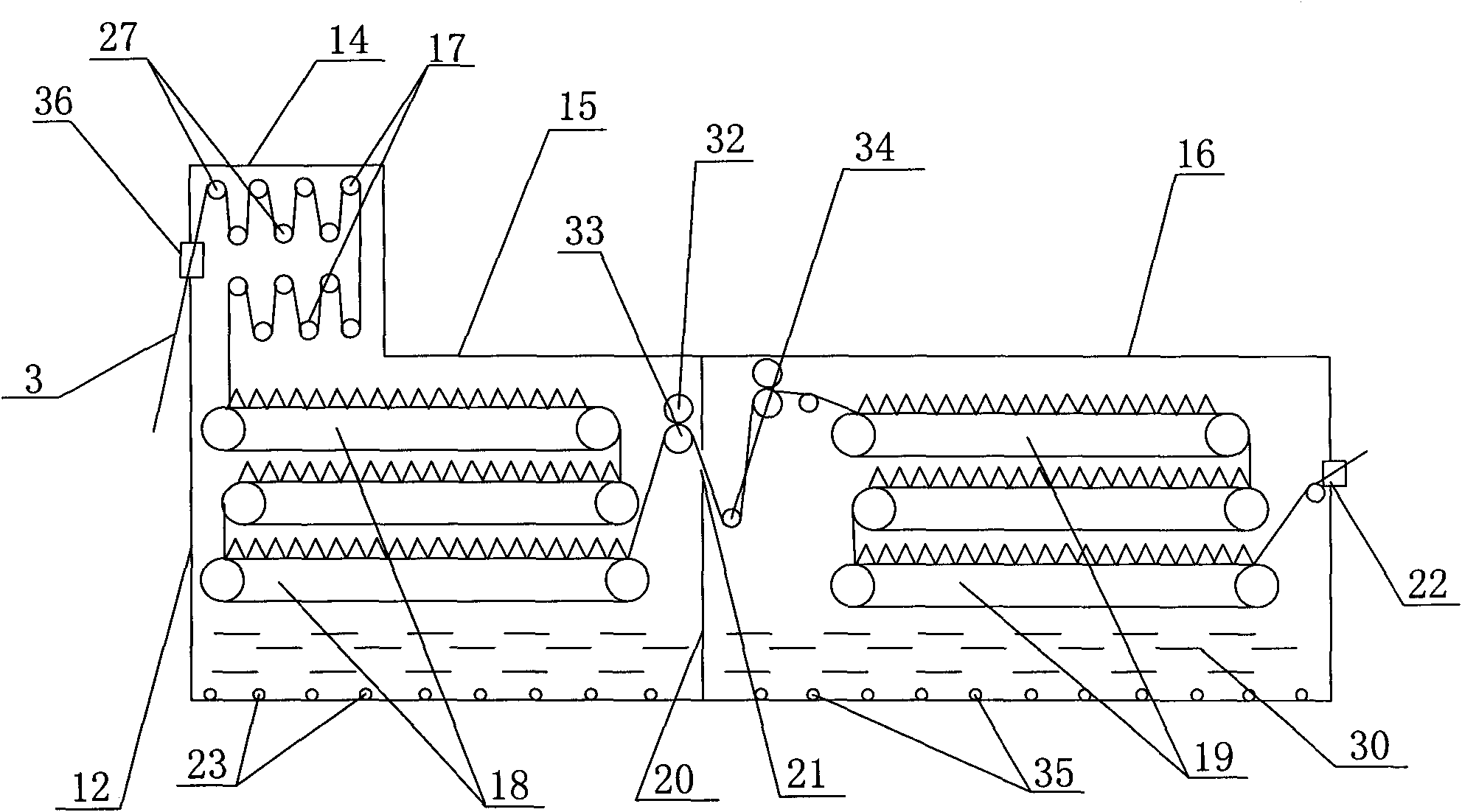

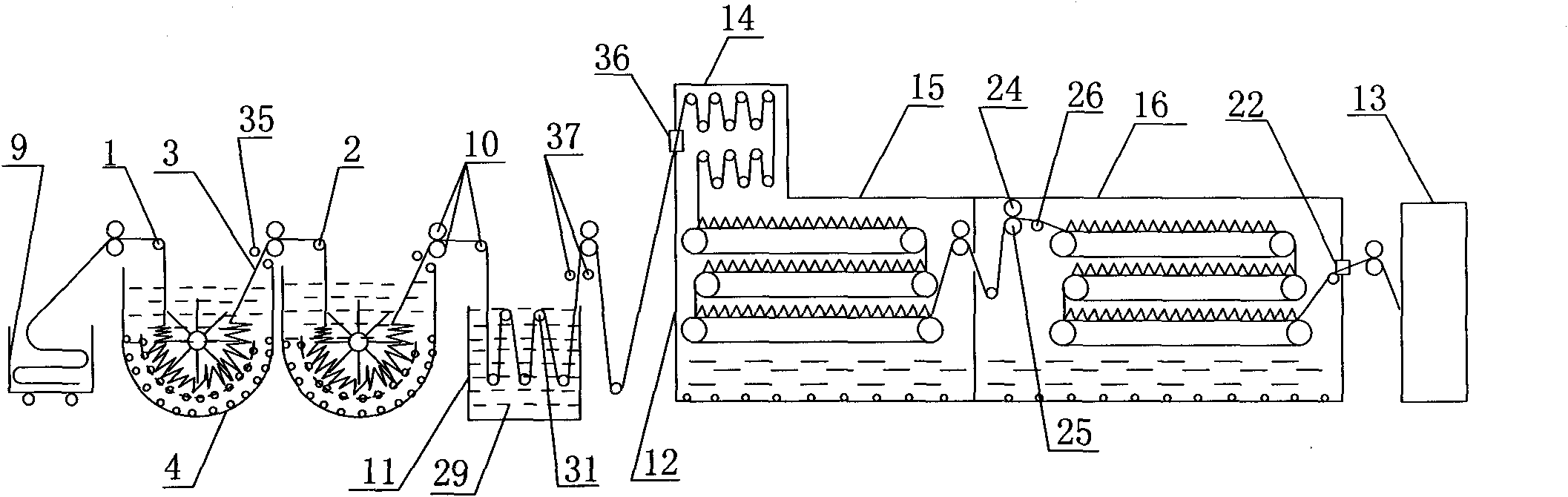

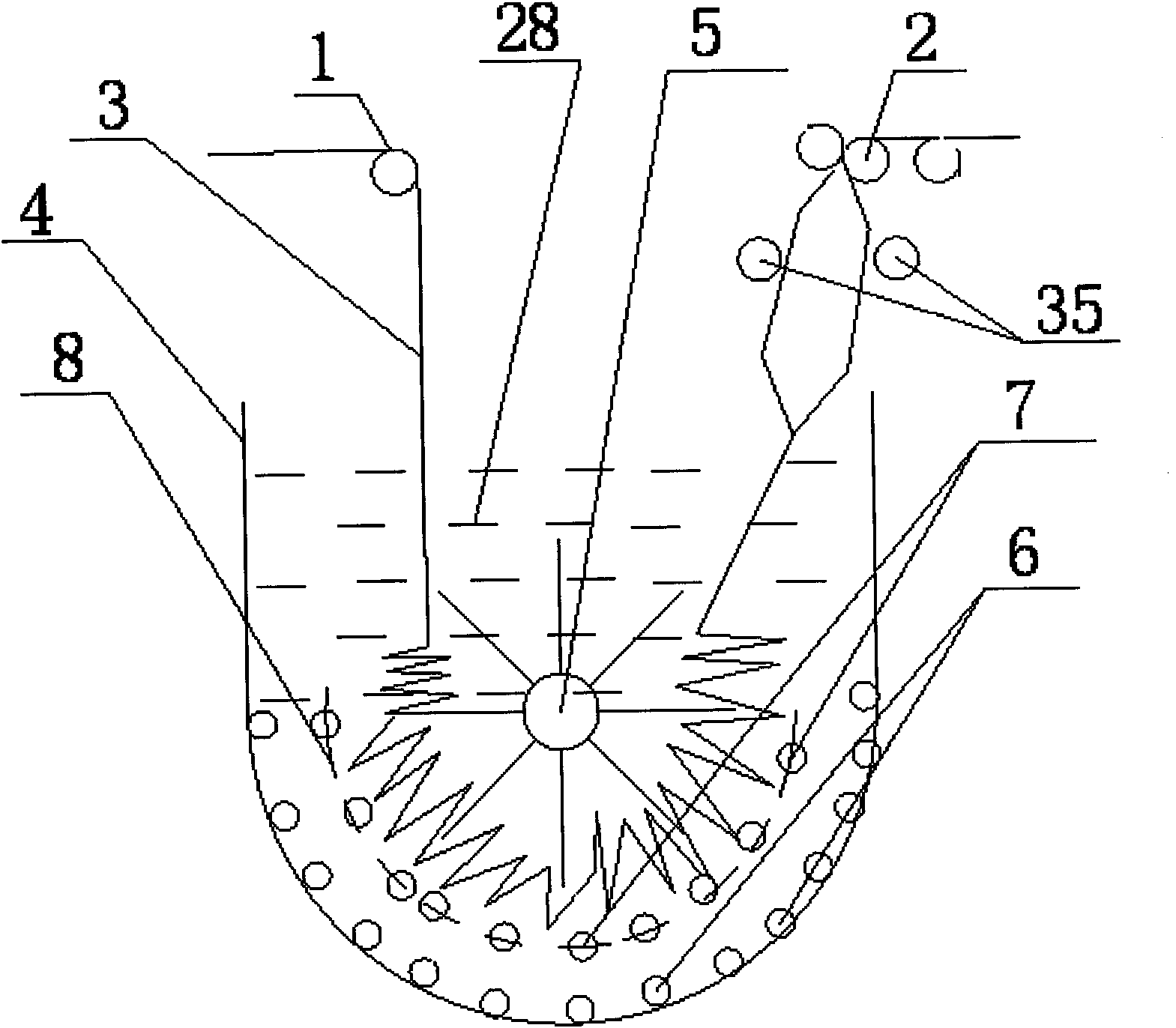

Crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and crease prevention method

ActiveCN101768845ALess chance of wrinklingImprove processing efficiencyTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentEngineeringTextile

The invention discloses a crease prevention device for scouring and bleaching equipment, scouring and bleaching equipment and a crease prevention method; a fabric is led in a fabric soaking vessel by a fabric lead-in roller; the fabric enters in hot water of the fabric soaking vessel and hot water flows through the fabric continuously under the condition that the fabric is in a loose state; the fabric in the fabric soaking vessel is led out to the next procedure by a fabric lead-out roller; the crease prevention device is arranged in the scouring and bleaching equipment, and the fabric is processed according to the process flows; in the invention, the fabric is fully self-swelled in the crease prevention device, the crease ratio of cotton knitted textile is reduced, the flatness of the cotton knitted textile is kept; in addition, the crease prevention device and a steam box in the scouring and bleaching equipment are improved, the fabric passes through a fabric trolley, an immersion device, the steam box and a rinsing machine sequentially by a delivery mechanism, so as to realize continuous processing and greatly improve the processing efficiency; under the condition of low cost operation, the fabric with no crease, high planeness, high whiteness and high capillary effect can be processed continuously.

Owner:QINGDAO UNIV

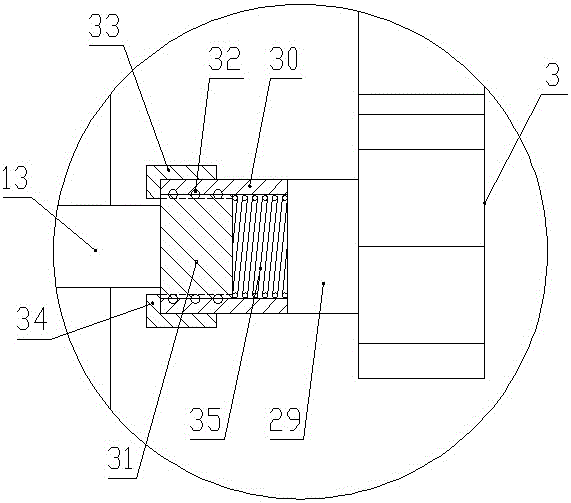

Wire filling machining device for rapidly forming electron beam

InactiveCN102756204ARealize continuous processingRealize multi-axis linkageElectron beam welding apparatusEngineeringHigh pressure

The invention provides a wire filling machining device for rapidly forming an electron beam. The device is characterized in that a multi-shaft worktable (4) is arranged inside a vacuum chamber (3); an electron gun (10) is mounted at the top of the vacuum chamber (3) and is connected with a high-voltage power supply (1) through a high-voltage cable (11); one or two wire feeding system vacuum chambers (8) are arranged at the outer part of the vacuum chamber (3); the wire feeding system vacuum chambers (8) are connected with the vacuum chamber (3) through a valve (12); each wire feeding system vacuum chamber (8) is internally provided with a wire feeding system (7) and a three-dimensional alignment mechanism (9); each three-dimensional alignment mechanism (9) is provided with two stations including a wire feeding station and a wire changing station; each three-dimensional alignment mechanism (9) can move between the two stations and is driven by a motor; when each three-dimensional alignment mechanism (9) is at the wire changing station, each three-dimensional alignment mechanism (9) is located in each wire feeding system vacuum chamber (8); and the valve (12) can be closed to separate the wire feeding system vacuum chambers (8) with the vacuum chamber (3). The wire filling machining device for rapidly forming the electron beam, disclosed by the invention, overcomes the defects that a wire feeding mechanism and parts in the conventional device are located in a same vacuum chamber all the time and the wire changing time is too long can be overcome.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

A film double-sided automatic positioning die-cutting lamination method

InactiveCN102275371AWide range of size variationsAdaptableLamination ancillary operationsControlling laminationComposite filmPunching

The invention provides a film double-sided automatic positioning die-cutting gluing method, which is used for gluing a first adhesion film (1), a second adhesion film (2) and a substrate film (3) which are provided with double-sided protective films. The method comprises the following steps of: firstly, punching windows on the first adhesion film (1) and the second adhesion film (2); secondly, removing the protective films on the window sides of the first adhesion film (1) and the second adhesion film (2); and finally, gluing to the two sides of the substrate film (3) of which the protective film is removed respectively, and thus obtaining a composite film which uses the substrate film as a middle layer and of which the two sides are provided with the adhesion films having positioning punching windows. Compared with the conventional multilayer film composite molding process method, the method has the advantages of simple process, high positioning die-cutting gluing accuracy, high applicability, capability of realizing continuous processing of multilayer film composite and the like.

Owner:WUHAN UNIV OF TECH

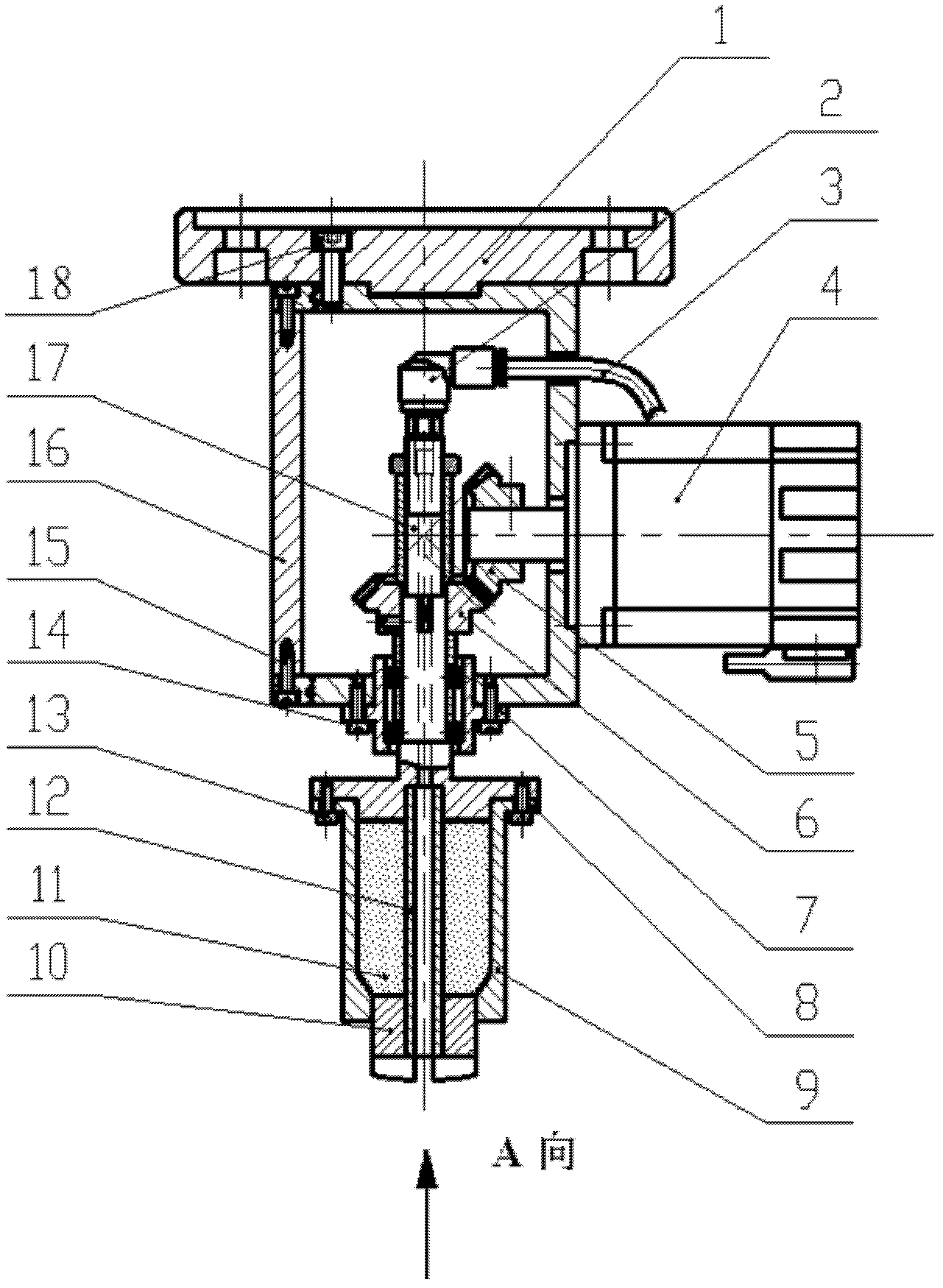

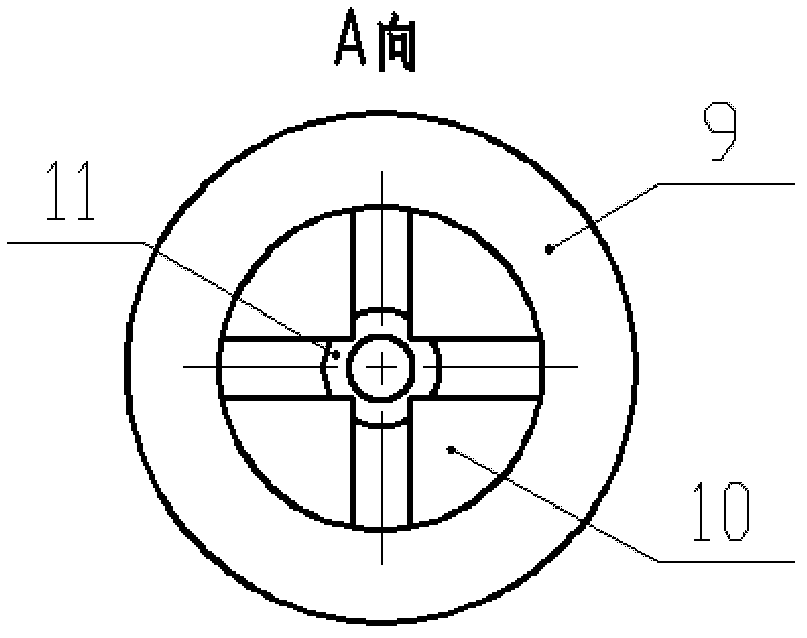

Magnetic grinding and polishing device for large curved surface

The invention discloses a magnetic grinding and polishing device for a large curved surface capable of continuously grinding and polishing a curved surface to obtain uniform surface quality finally. The magnetic grinding and polishing device comprises the following components: a main frame, a front-end supporting side plate, a side plate fixing bolt, a motor, a drive bevel gear, a driven bevel gear, a locating sleeve, a connecting bolt, a fastening bolt, a spindle, a magnetic pole, a grinding material and grinding liquid mixture conveying pipeline, a rotating joint, a magnetic shield, a flange disc, a flange locating bolt, a flange disc, a permanent magnet and a magnetic pole sleeve. The magnetic grinding and polishing device, provided by the invention, has the advantages of high processing efficiency, simple structure, low manufacturing cost and convenience for installation; the magnetic grinding and polishing device has an independent drive motor, convenience for connection with multiple processing equipment or devices, good university and no other external power. The magnetic grinding and polishing device can be widely applied to finish all kinds of curved surfaces, in particular to grind and polish a large-area complicated free curved surface. Technique grinding matched with the device has small temperature rise, high efficiency, difficulty in deformation of a processing work-piece, and no deterioration layer after processing.

Owner:UNIV OF SCI & TECH LIAONING

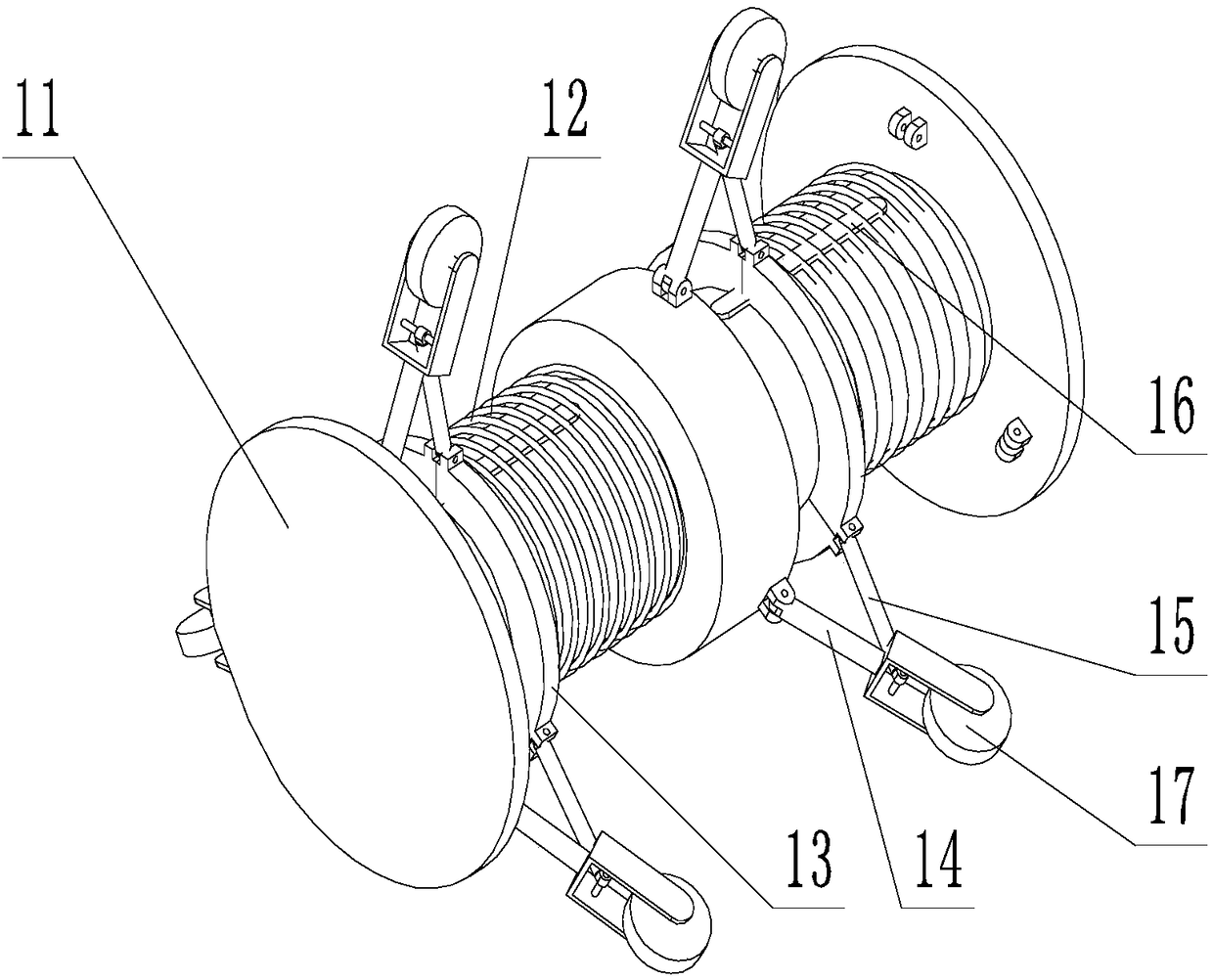

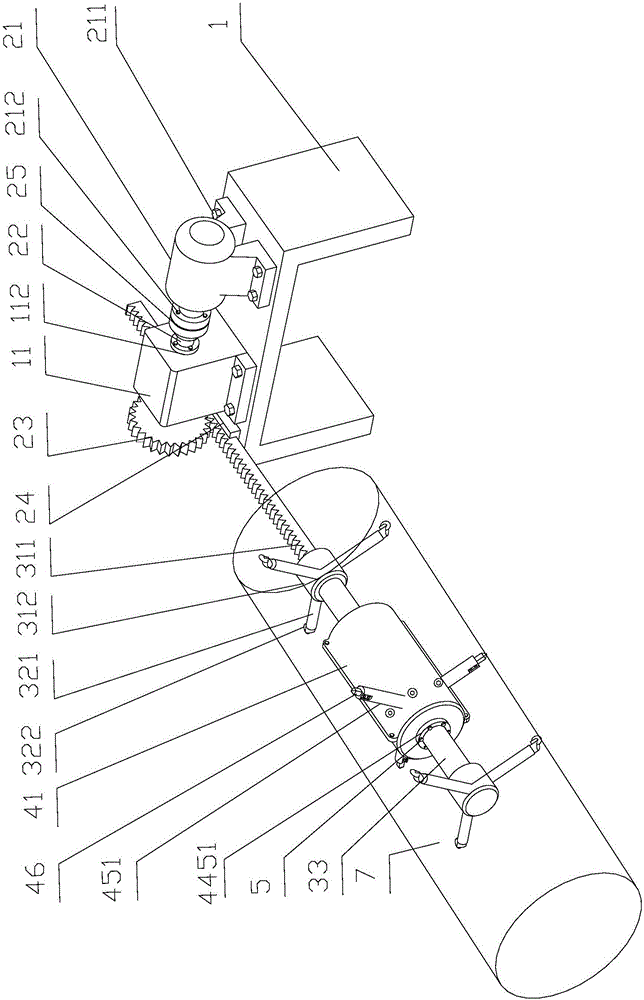

Processing device and processing method of simulated groove in inner wall of conical water inlet pipe of water pump

PendingCN108213534ARealize continuous processingSelf-lockingMilling equipment detailsSelf lockingEngineering

The invention discloses a processing device and a processing method of a simulated groove in the inner wall of a conical water inlet pipe of a water pump. The processing device comprises a supportingmechanism, a processing mechanism, a rotating mechanism and a feeding machine, wherein the supporting mechanism is arranged at the outer part of the rotating mechanism; an output end of the rotating mechanism is connected with one end of the processing mechanism; the other end of the processing mechanism is connected with an action end of the feeding mechanism; one end of the supporting mechanismis defined as a front part, and one end of the feeding mechanism is defined as a rear part. The processing method comprises the following steps: fixing well a pipeline requiring to be processed, and regulating the feeding mechanism until a cutting tool assembly arrives a to-be-processed position; regulating the shape of a supporting frame, and enabling the supporting frame to press the inner wallof the pipeline; regulating a cutting blade of a cutting tool to be in contact with the inner wall of a to-be-processed pipeline; starting a rotating part, and starting to process a groove in the inner wall of the pipeline; repeating the operation, thus realizing continuous processing of the simulated groove in the to-be-processed pipeline. The processing device and the processing method, disclosed by the invention, have the beneficial effects that an application range is extremely wide, and the processing device and the processing method are not influenced by the size of a pipe wall; a self-locking function is obtained, and the accuracy is higher; the processing quality is high.

Owner:ZHEJIANG UNIV OF TECH

Steam box used for scouring and bleaching equipment, scouring and bleaching equipment and steaming method

ActiveCN101781837AImprove flatnessHigh whitenessTextile treatment containersTextile treatment machine arrangementsEngineeringStretch rate

The invention discloses a steam box used for scouring and bleaching equipment, scouring and bleaching equipment and a steaming method. The steam box comprises a preheating zone, a first temperature zone and a second temperature zone; a steam box guide roller used for transmitting fabrics is arranged in the preheating zone; a first crawler belt set and a second crawler belt set are respectively arranged in the first temperature zone and the second temperature zone; the transmission directions of adjacent crawler belts in the first crawler belt set and the second crawler belt set are opposite; the crawler belts are staggered in parallel to form the continuous transmission of the fabrics, thereby enabling the fabrics to be stacked on the crawler belts and continuously transmitted; the steam box is arranged in the scouring and bleaching equipment and treats the fabrics according to certain process flows. The invention thoroughly solves the problems that the scouring and bleaching effect is not ideal, the cloth cover evenness of the fabrics is poorer, the dimensional stability is poor because the textile stretch rate is overlarge, the effects of energy saving and consumption reducing are not ideal and the like, thereby continuously producing the fabrics with high evenness, high whiteness and high capillary effect but without creases.

Owner:QINGDAO UNIV

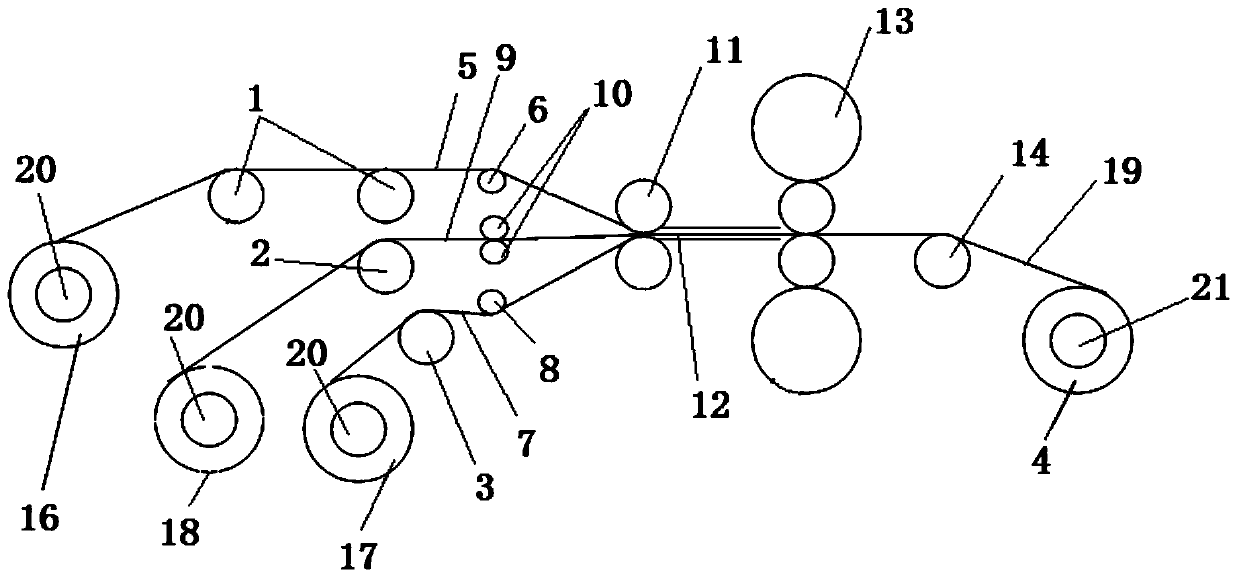

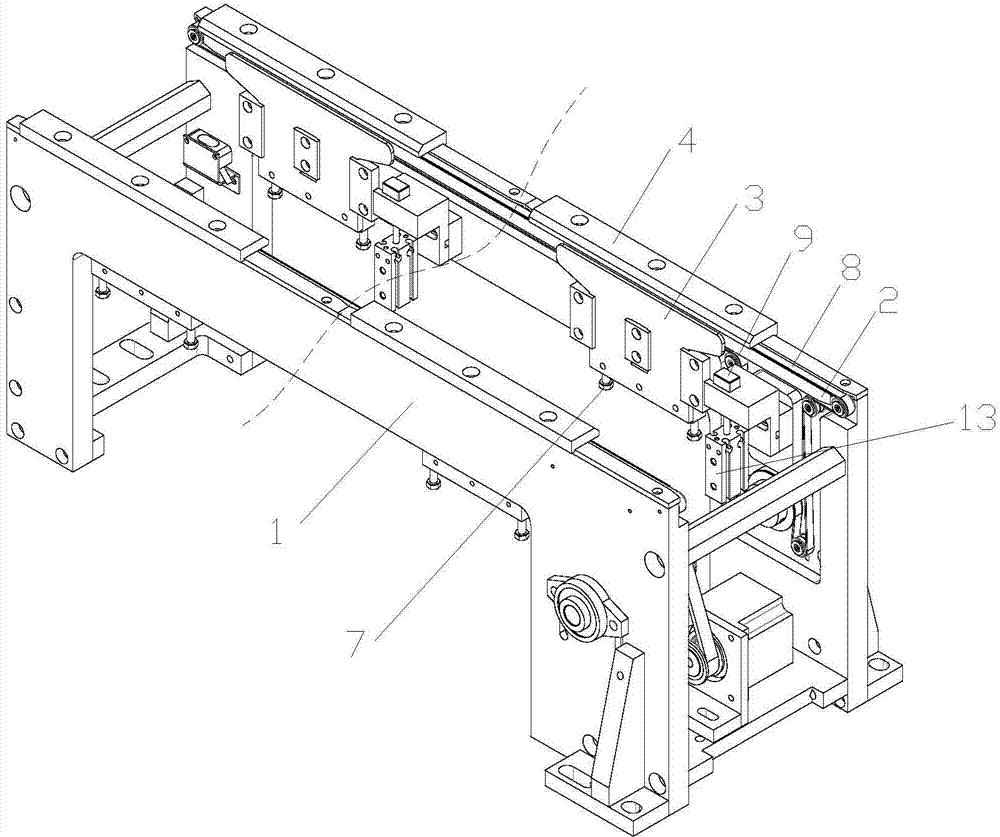

Device and method for producing high-frequency roll welding multilayer composite plate

The invention relates to a device and method for producing a high-frequency roll welding multilayer composite plate. The method comprises the following steps: feeding a strip coil into a corresponding uncoiling machine; performing tension control to ensure the flatness and favorable alignment of strips; feeding the strips into a conduction roll through a guide roll, and then performing on-line heating on the strips with high-frequency current, wherein the heating range is a loop from the conduction roll to the inlet of a guide and guard device, and the high-frequency current is introduced from the conduction roll to perform on-line quick heating on a shallow layer of the surface of the strips; when the strips reach a pinch roll, enabling that the strips are in contact with each other to achieve maximum heat, thus forming welding conditions; and welding the multiple layers of strips, then feeding into a rolling mill, and further rolling and compounding once to achieve optimal composite property of the different strips.

Owner:武汉钢铁有限公司

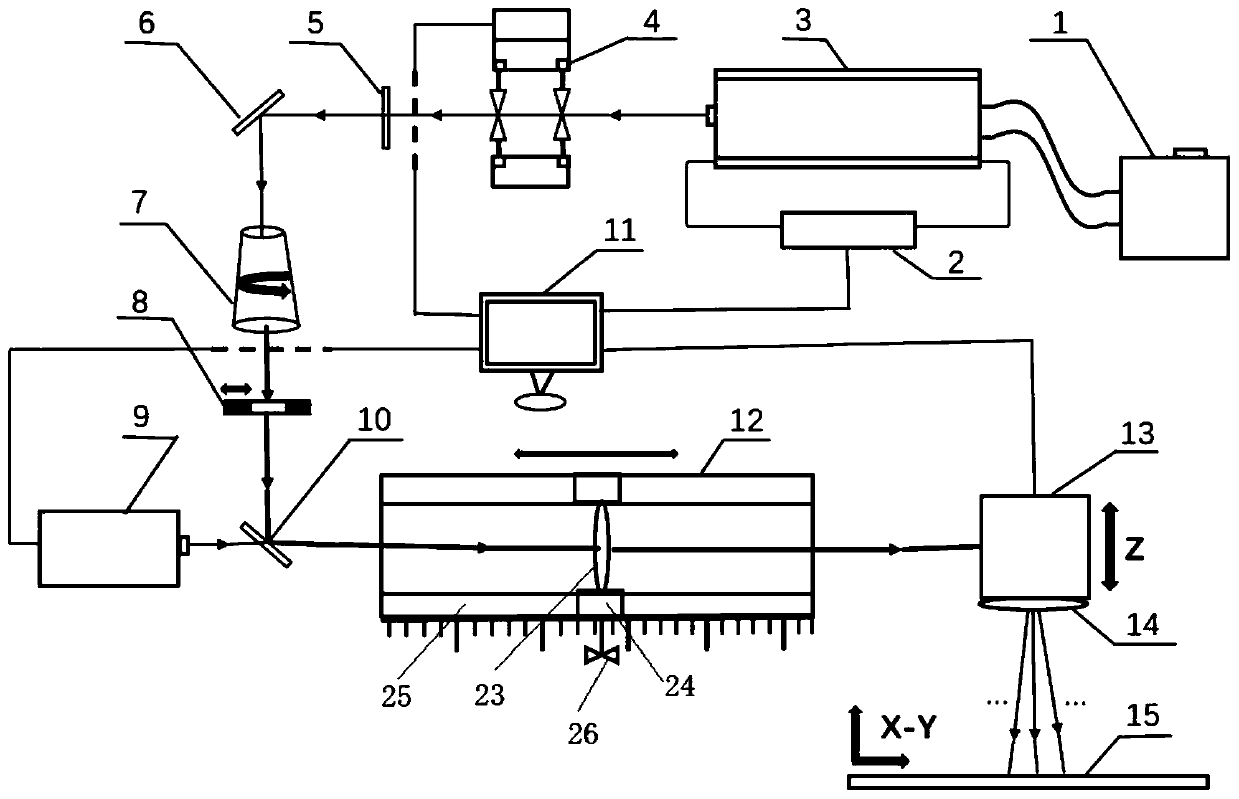

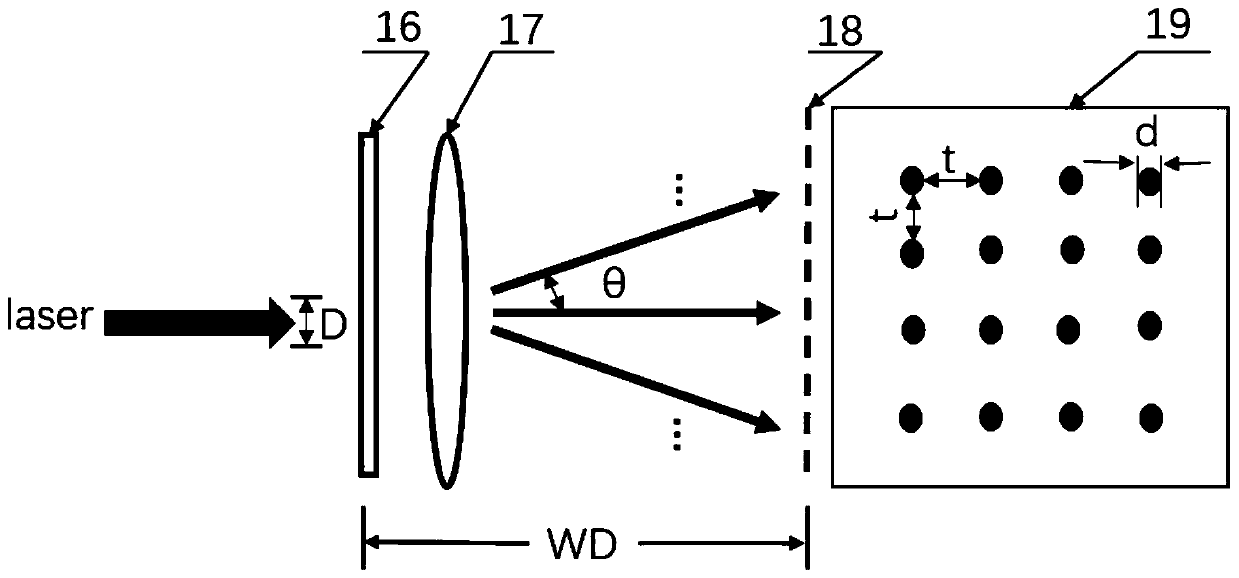

Laser parallel processing device and processing method for array air holes of leather product

ActiveCN110560936AMeet processing needsImprove drilling efficiencyLaser beam welding apparatusComputer control systemBeam expander

The invention discloses a laser parallel processing device and processing method for array air holes of a leather product. The laser parallel processing device comprises a laser system, an optical light guide system,an X-Y two-dimensional honeycomb adsorption platform system and a computer control system, wherein an optical path outlet of the laser system is opposite to an optical path inlet of the optical light guide system, and an optical path outlet of the optical light guide system is opposite to a working area of the X-Y two-dimensional honeycomb adsorption platform system; the optical light guide system involves a pneumatic optical shutter, a quarter slide, a reflector, an adjustable beam expander lens, an adjustable diaphragm, a dichroic mirror, a laser beam splitting unit and a scanning galvanometer; and a laser beam optical path output by the laser system sequentially passes through the pneumatic optical shutter, the quarter slide, the reflector, the adjustable beam expander lens, the adjustable diaphragm, a surface of the dichroic mirror, the laser beam splitting unit, the scanning galvanometer, and a to-be-processed leather surface, and the other surface of the dichroicmirror is provided with a red light unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

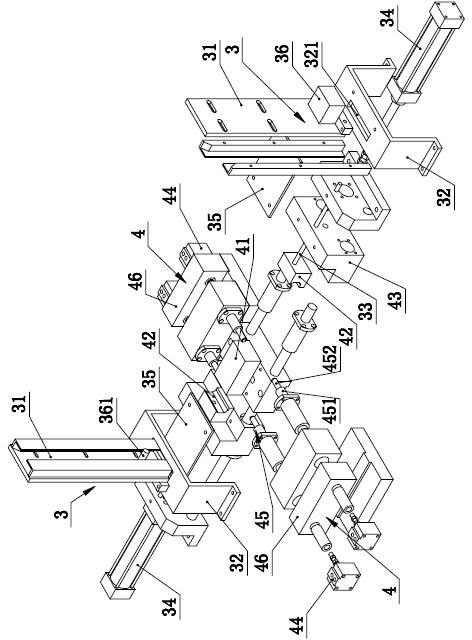

Angle-variable universal joint pin body full-automatic tapping machine

ActiveCN104708323ARealize automatic feedingRealize continuous processingMeasurement/indication equipmentsOther manufacturing equipments/toolsPunchingUniversal joint

The invention discloses an angle-variable universal joint body full-automatic tapping machine which comprises a feeding device, a conveying device, a loading device, a punching deice and a discharging device. The feeding device, the conveying device and the loading device are installed on a machining platform. The punching device and the discharging device are located on one side of the loading device. The discharging device is located below the machining platform. According to the angle-variable universal joint body full-automatic tapping machine, the feeding device, the conveying device, the loading device, the punching device and the discharging device are integrated, so that automatic feeding, loading, punching tapping and discharging are achieved; meanwhile, a plurality of fixing stations are arranged on the punching devices, so that continuous machining is achieved, and the production efficiency is greatly improved.

Owner:HANGZHOU ZHENGQIANG UNIVERSAL JOINT

Harmless treatment method for dead animal bodies

InactiveCN106140798ASolve the costSolve complexitySolid waste disposalResource utilizationEngineering

The invention discloses a harmless treatment method for dead animal bodies, and relates to the technical field of animal harmless treatment. The harmless treatment method comprises the following steps of: conveying the dead animal bodies into a crushing and stirring device to crush; in a crushing process, starting a heating device on the bottom of the crushing and stirring device, heating and drying the dead animal bodies; when a heating temperature reaches a preset value, smelting out oil in the dead animal bodies; discharging grease and residues generated after dead animal body smelting into a spiral conveying device; and in a conveying process of the spiral conveying device, realizing separation of grease and residues. The harmless treatment method disclosed by the invention is relatively low in cost; and the residues subjected to harmless treatment can be used for preparing products capable of being recycled, so that a resource utilization rate is increased.

Owner:四川金逸智科技有限公司

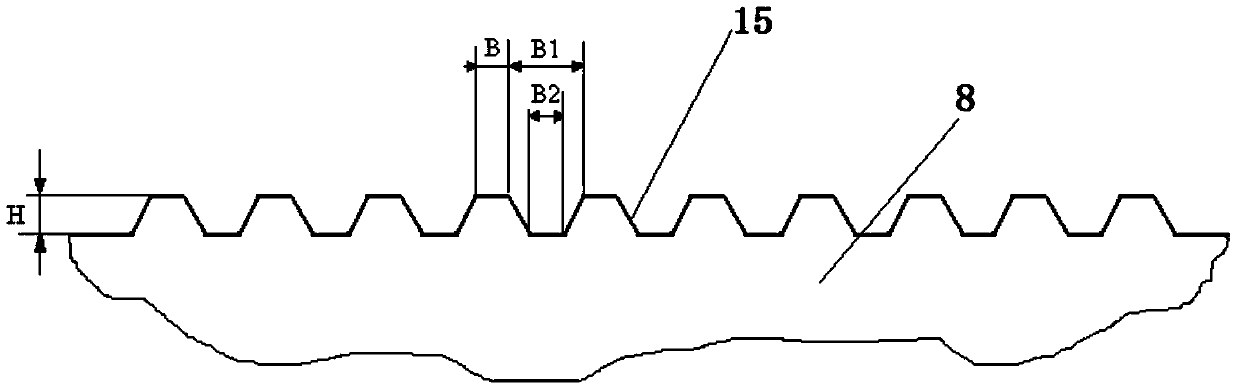

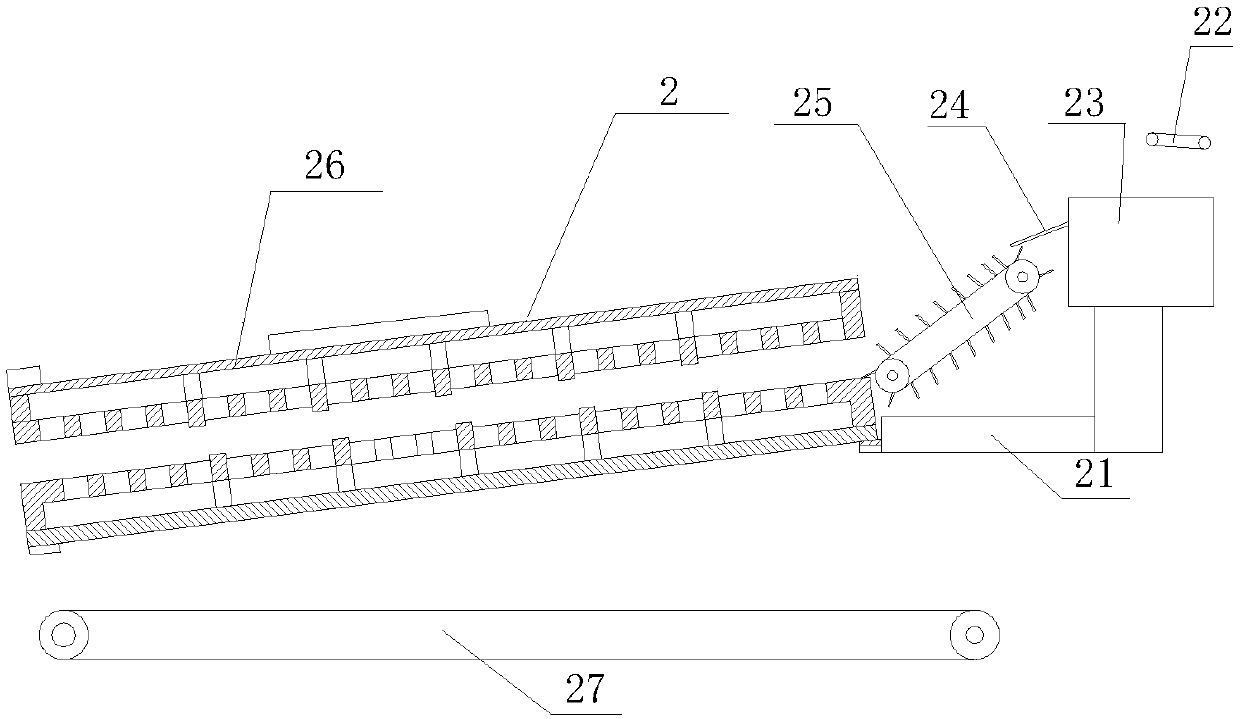

Pipeline outer wall bionic groove surface machining device and machining method thereof

ActiveCN107020409AImprove athletic abilityImprove stabilityFeeding apparatusLarge fixed membersEngineeringDrive motor

The invention relates to a pipeline outer wall bionic groove surface machining device and a machining method thereof. The pipeline outer wall bionic groove surface machining device comprises a driving mechanism used for providing driving force, a supporting base used for being connected with the driving mechanism and supporting a machining mechanism, the machining mechanism used for machining bionic grooves in a pipeline outer wall and a controller; a first supporting table and a second supporting table are installed above the supporting base and are coaxially and symmetrically arranged at the two ends of the supporting base; the driving mechanism is installed below the supporting base; the machining mechanism is installed between the first supporting table and the second supporting table in a clamped manner; the driving mechanism and the machining mechanism are both electrically connected with the corresponding control ends of the controller; and the machining method includes the steps that the devices are firstly placed, the positions of the device are adjusted, a driving motor is started, and the driving motor is stopped after the devices are adjusted to the appropriate positions; and the position of a cutter is adjusted through an adjusting pressure control device, and cutting is started. The pipeline outer wall bionic groove surface machining device has the beneficial effects that the structure is simple, operation is easy, and bionic groove structures can be machined on the pipeline outer wall protection coating surface.

Owner:ZHEJIANG UNIV OF TECH

Multi-head vertical digital control twisting and winding machine

PendingCN108134307ASimple structureReasonable designLine/current collector detailsWinding machineEngineering

The invention discloses a multi-head vertical digital control twisting and winding machine. The multi-head vertical digital control twisting and winding machine comprises a rack, a twisting and winding processing apparatus and a monitoring apparatus; the twisting and winding processing apparatus comprises a wire pay-off apparatus, a wire twisting apparatus, a correction traction apparatus and a wire take-up apparatus; the wire pay-off apparatus comprises a wire pay-off mechanism, shuttle frame mechanisms and guiding mechanisms, wherein the shuttle frame mechanisms and the guiding mechanisms are the same in number; the wire twisting apparatus comprises a rotary shaft, a rotating mechanism, a wire gathering plate and a power mechanism; the correction traction apparatus comprises a shaping mechanism, a straightening mechanism and a traction mechanism; the wire take-up apparatus comprises a wire arranging mechanism and a wire take-up mechanism for winding the twisted wires; and the monitoring apparatus comprises a control apparatus, a tension detection apparatus, a rotary speed measurement unit and a traction speed measurement unit. The multi-head vertical digital control twisting andwinding machine is simple in structure and capable of realizing continuous processing of the twisted wires, improving production efficiency, lowering manual labor, ensuring diameter consistency of twisted wire harnesses and satisfying the three-layer winding requirement of fried dough twist-like contact pins.

Owner:THE NORTHWEST MACHINE

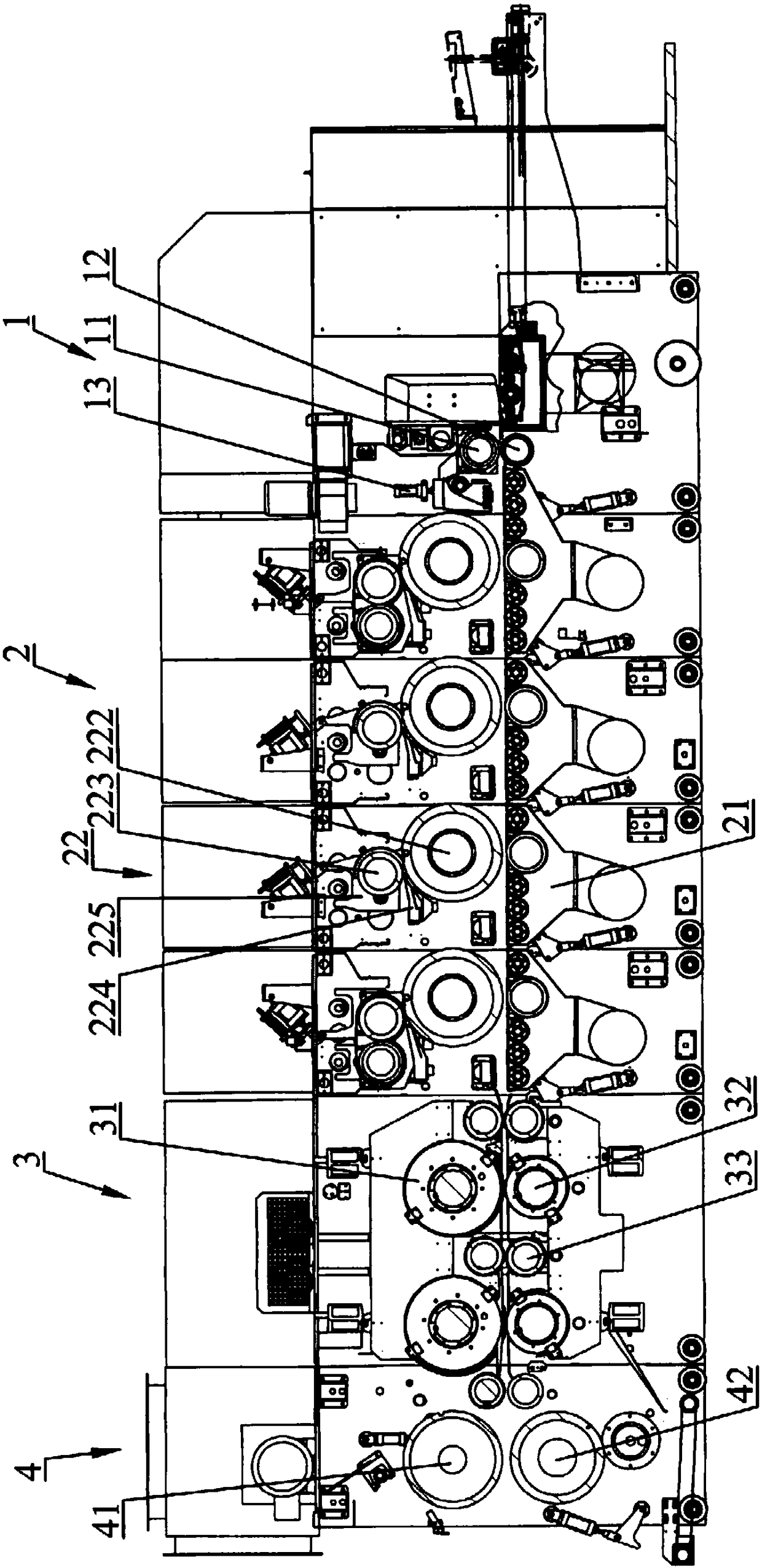

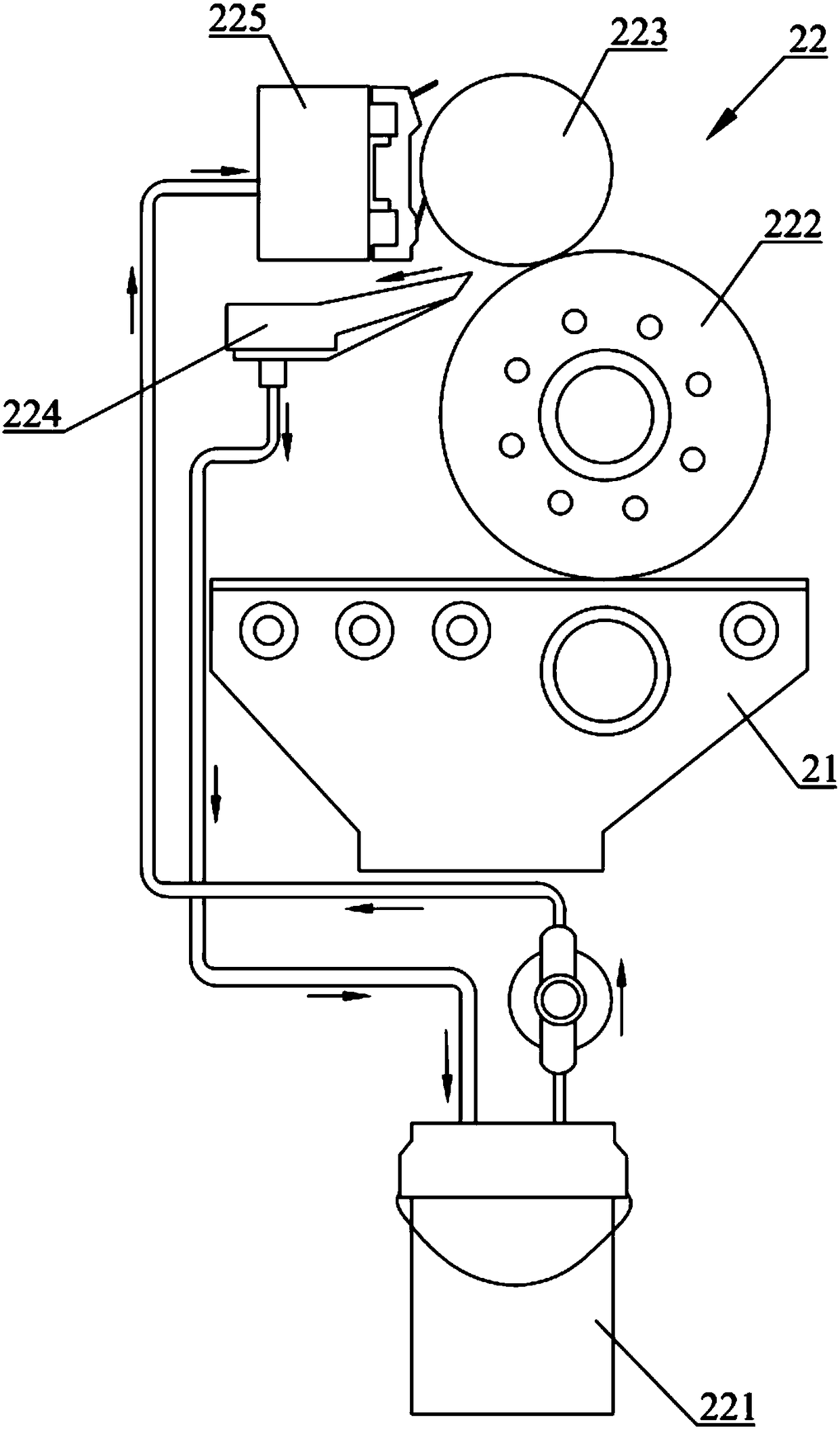

Corrugated board printing production line with environmental protection and energy saving functions

InactiveCN108394172ARealize continuous processingIncrease productivityRotary pressesMetal working apparatusProduction lineStack machine

The invention discloses a corrugated board printing production line with environmental protection and energy saving functions, and belongs to the technical field of corrugated board manufacturing. Thecorrugated board printing production line comprises a machine frame, a paper feeding mechanism, a printing mechanism, a slotting mechanism, a die cutting mechanism and an automatic stacking machine,wherein the paper feeding mechanism, the printing mechanism, the slotting mechanism, the die cutting mechanism and the automatic stacking machine are sequentially arranged on the machine frame. The printing mechanism comprises a printing portion, and the printing portion comprises an ink barrel, a plate cylinder, an anilox roller, an air bag type scraper and an ink fountain under the anilox rollerand the air bag type scraper. The plate cylinder and the anilox roller are rotatably connected to the machine frame, and the plate cylinder is pressed against a corrugated board. The anilox roller ispressed against the plate cylinder, the air bag type scraper communicates with the ink barrel and is in contact with the edge of the anilox roller, and the ink fountain communicates with the ink barrel. The corrugated board is subjected to paper feeding, printing, slotting and die-cutting, and finally, corrugated boards are neatly stacked by the automatic stacking machine. The air bag type scraper scrapes ink on the anilox roller, the amount of the ink is saved, and an ink layer is dried quickly; and the running speed of a machine is improved, the power consumption and labor cost are saved, and energy saving and environmental protection are achieved.

Owner:合肥丹盛包装有限公司

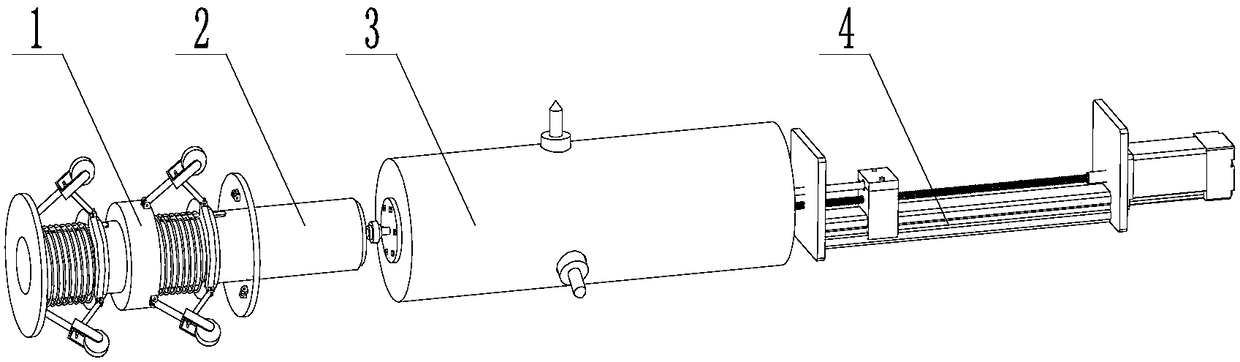

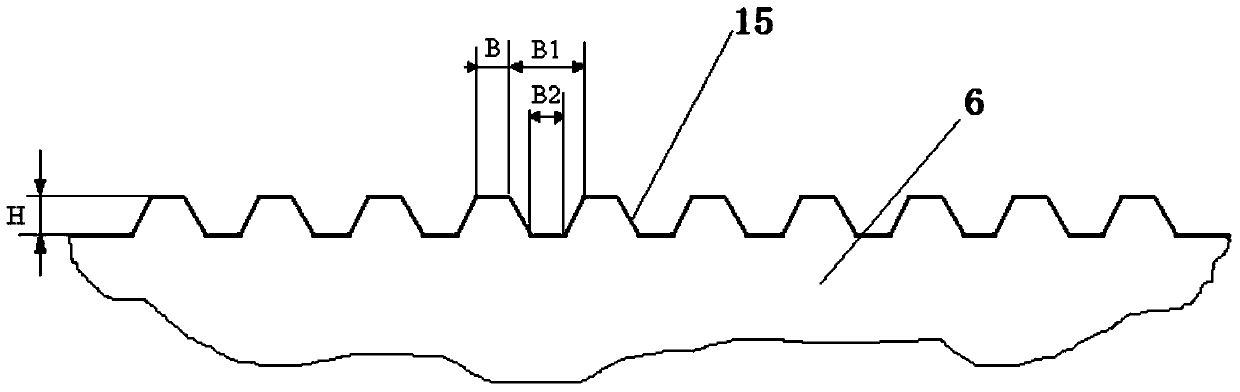

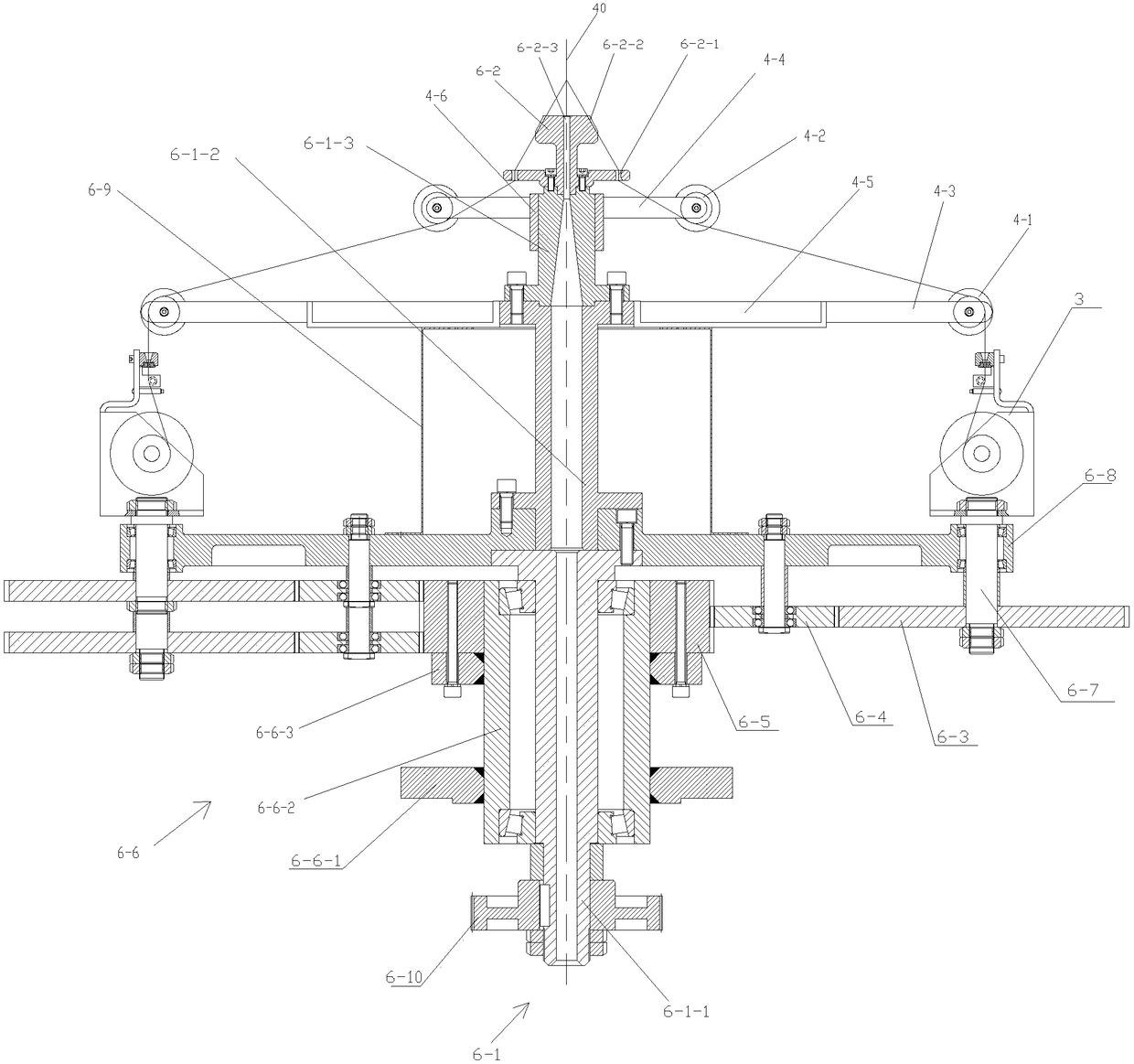

Short-distance pipeline inner wall bionic groove surface machining device and method

The invention provides a short-distance pipeline inner wall bionic groove surface machining device and method. The device comprises a supporting table with a supporting seat, an actuating mechanism for providing driving force, a traveling mechanism used for being supported on the inner wall face of a pipeline, a machining mechanism used for machining bionic grooves in the inner wall of the to-be-machined pipeline, and a controller. The actuating mechanism is installed on the supporting table. The traveling mechanism is connected with the movable end of the actuating mechanism. The machining mechanism is fixedly connected with the traveling mechanism. Both the actuating mechanism and the machining mechanism are electrically connected with corresponding control ends of the controller. The method comprises the steps that the pipeline inner wall bionic groove surface machining device is arranged in the pipeline, the actuating mechanism drives the traveling mechanism and the machining mechanism to move to corresponding positions, and then the inner wall of the pipeline is machined. The short-distance pipeline inner wall bionic groove surface machining device and method have the beneficial effects that the operation quality of the machining device is improved, the precision is high, and different tools can be installed specific to different resistance reduction structures so as to complete machining of the corresponding resistance reduction structures.

Owner:ZHEJIANG UNIV OF TECH

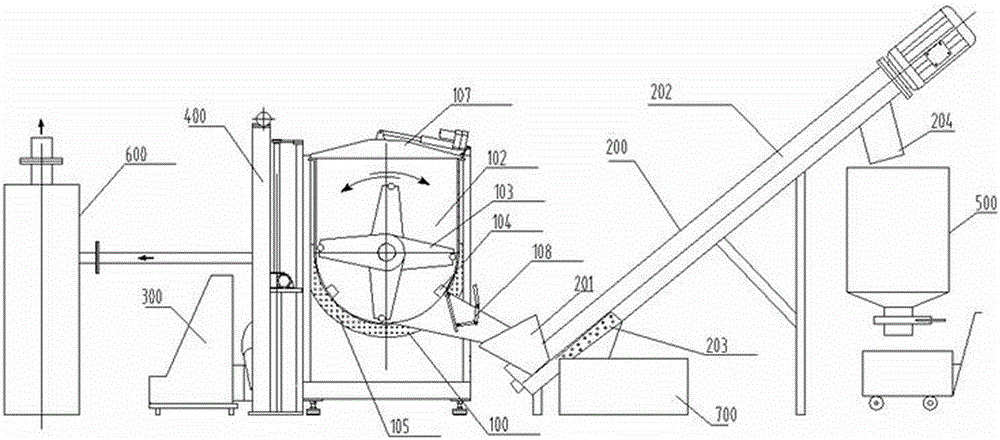

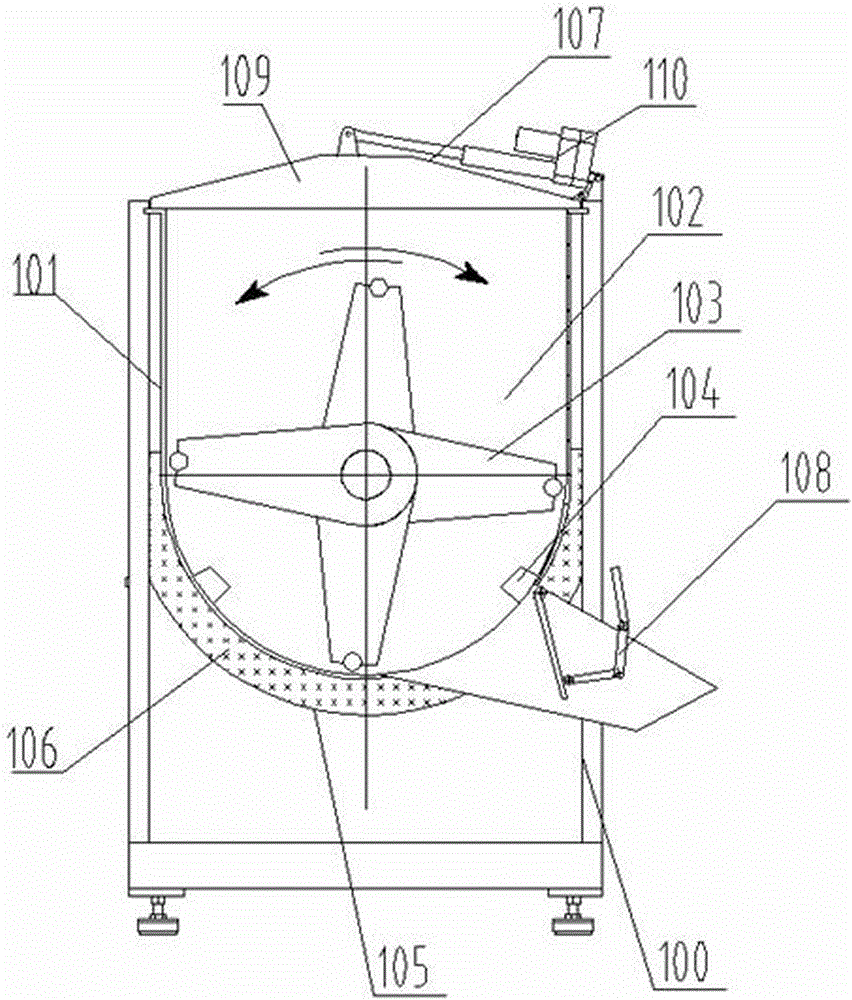

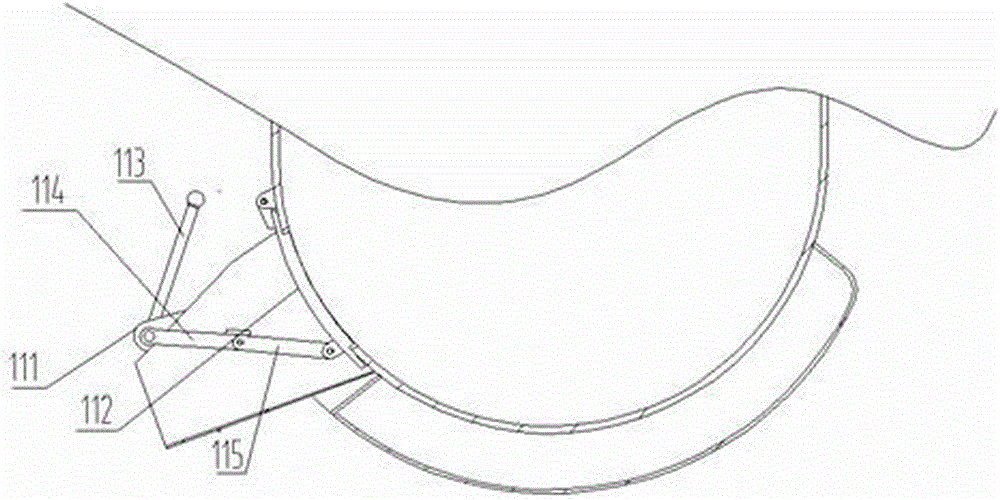

Processing production line for snake gourd fruit shells

InactiveCN107758018ARealize continuous processingLabor savingSievingGas current separationProduction lineSnake gourd

The invention provides a processing production line for snake gourd fruit shells. The processing production line comprises a snake gourd fruit cleaning machine, a snake gourd fruit shell and seed separator, a snake gourd fruit shell and seed picking machine, a food dryer, a snake gourd fruit shell shredder and a food vacuum packaging machine which are sequentially arranged and further comprises conveying mechanisms arranged between every two adjacent machines of the snake gourd fruit cleaning machine, the snake gourd fruit shell and seed separator, the snake gourd fruit shell and seed pickingmachine, the food dryer, the snake gourd fruit shell shredder and the food vacuum packaging machine. The conveying mechanisms comprise lifting devices and horizontal conveying devices, the lifting devices are obliquely-arranged conveyor belts, and the horizontal conveying devices are horizontal conveyor belts. All the machines are electrically connected with a control cabinet. Picked snake gourd fruits can be continuously processed so as to obtain the completely-packaged snake gourd fruit shells, a great deal of labor force is saved, and automatic operation is facilitated.

Owner:QIANSHAN YOUYU TRICHOSANTHES KIRILOWII MAXIM DEV CO LTD

Continuous type printing paperboard clipping processing equipment

ActiveCN106003824AGuaranteed flat and perfectImprove cropping accuracyPaper-makingBox making operationsPaperboardEngineering

The invention discloses continuous type printing paperboard clipping processing equipment. The continuous type printing paperboard clipping processing equipment comprises a base, a worktable, a first driving mechanism, a mounting frame, a clipping mechanism, a second driving mechanism, third driving mechanisms, a monitor and a control mechanism; a conveying roller group is arranged on the worktable; a detection station is arranged at a discharging end of the conveying roller group; the clipping mechanism comprises a movable plate and a plurality of cutting knives, wherein the movable plate is movably mounted on the mounting frame and is parallel to the base; the movable plate is arranged in the conveying direction of the conveying roller group; in the conveying direction of the conveying roller group, the cutting knives are arranged in parallel on the movable plate; the monitor is used for monitoring whether the paperboard reaches the detection station; the control mechanism is connected with the first driving mechanism, the second driving mechanism, the plurality of third driving mechanisms and the monitor and is used for controlling the first driving mechanism, the second driving mechanism, the third driving mechanisms and the monitor to act. The continuous type printing paperboard clipping processing equipment disclosed by the invention is high in clipping precision, fast in clipping speed and high in processing efficiency; and a clipped paperboard is discharged in time and is fed to the conveying roller group in time, thereby realizing continuous processing of the paperboard.

Owner:太湖县市场监督检验所(太湖县功能膜检测研究院)

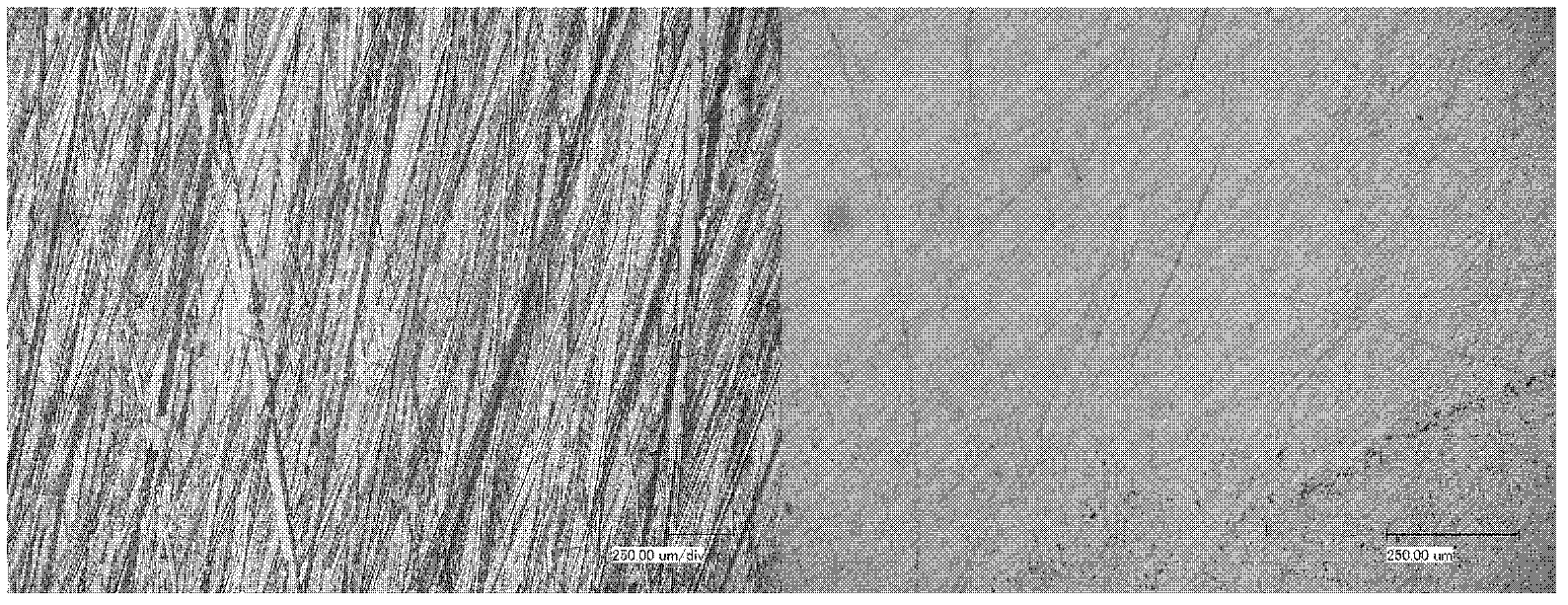

Magnetorheological chemical mechanical polishing solution used for SiC single crystal wafer and using method thereof

InactiveCN106281043ARealize continuous processingScratch freePolishing compositions with abrasivesMaterial removalSurface roughness

The invention provides a magnetorheological chemical mechanical polishing solution used for a SiC single crystal wafer and a using method thereof. A key formula of the magnetorheological chemical mechanical polishing solution is formed by a part A and a part B. The formula A comprises 3-10 wt% of abrasive particles, 5-30 wt% of magnetic particles, 1-10 wt% of dispersion stabilizer and base carrier liquid. The formula B comprises 1-30 wt% of oxidizing agent, 1-10 wt% of catalyst, 0.01-1 wt% of PH value modifier and base carrier liquid. By adoption of the magnetorheological chemical mechanical polishing solution, the formulas A and B can be used in a mixed mode or independently prior to processing according to different device and polishing requirements. The magnetorheological chemical mechanical polishing solution has the advantages that the surface roughness of the SiC single crystal wafer obtained after precision polishing processing, the material removal rate can reach 0.1-3.8 [mu]m / h, and the polishing finished surface is flat and smooth. A process for preparing the polishing solution is simple, and the magnetorheological chemical mechanical polishing solution is convenient to use and operate, low in cost and high in efficiency, can be used for processing the silicon surface and the carbon surface of the SiC single crystal wafer and have very high appcability and economic value.

Owner:GUANGDONG UNIV OF TECH

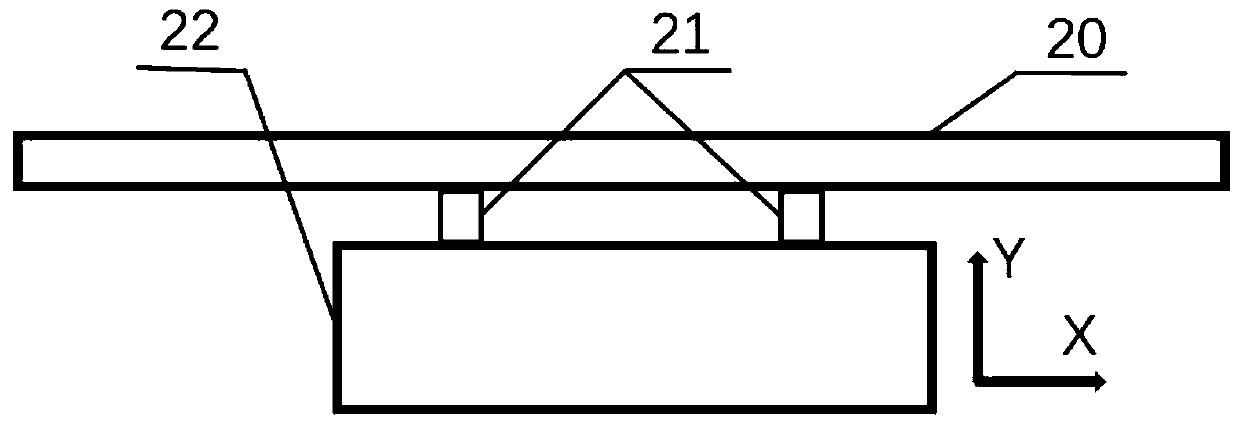

Conveying device for carrier plate

The invention relates to the technical field of conveying devices for carrier plates and provides a conveying device for a carrier plate. The conveying plate comprises at least one positioning table, wherein each positioning table comprises a positioning table body, a belt conveyor and a clamping plate positioning mechanism; each belt conveyor and each clamping plate positioning mechanism are arranged on the corresponding positioning table body; each positioning table body is used for bearing the carrier plate; each belt conveyor is used for conveying the carrier plate; each clamping plate positioning mechanism is used for clamping the carrier plate for positioning; after the carrier plate is placed on the conveying device for the carrier plate, the carrier plate is conveyed by the belt conveyor; when the carrier plate is conveyed to a position where each clamping plate positioning mechanism is positioned, the carrier plate is clamped and positioned by each clamping and positioning mechanism.

Owner:SUZHOU LINGHONG AUTOMATION EQUIP CO LTD

Pipe end hydraulic forming device for automobile pipe

The invention discloses a pipe end hydraulic forming device for an automobile pipe, and belongs to the field of automobile pipe machining equipment. The device comprises a hydraulic die and a clamping die which are arranged on a worktable. The hydraulic die comprises a die base, a die column and a hydraulic oil cylinder, the die column is axially and horizontally arranged on the die base in a sliding mode, and a piston rod of the hydraulic oil cylinder is connected with the die column. The clamping die comprises an upper die block, a lower die block and a clamping hydraulic oil cylinder, the upper die block is connected with a piston rod of the clamping hydraulic oil cylinder, the upper die block and the lower die block are provided with an upper clamping groove and a lower clamping groove respectively, and the upper clamping groove and the lower clamping groove correspond to a pipe to be machined in shape. An abutting die comprises a base and an abutting column installed in an installing hole of the base, and the abutting column sequentially comprises an abutting plate, a threaded column and a hand wheel. By means of the pipe end hydraulic forming device, the pipe can be reliably clamped, a die core and a die sleeve can be replaced conveniently, the application range is wide, continuous machining of the pipe end can be achieved, and production efficiency is improved.

Owner:ZIXING YUEXING AUTO PARTS MFG

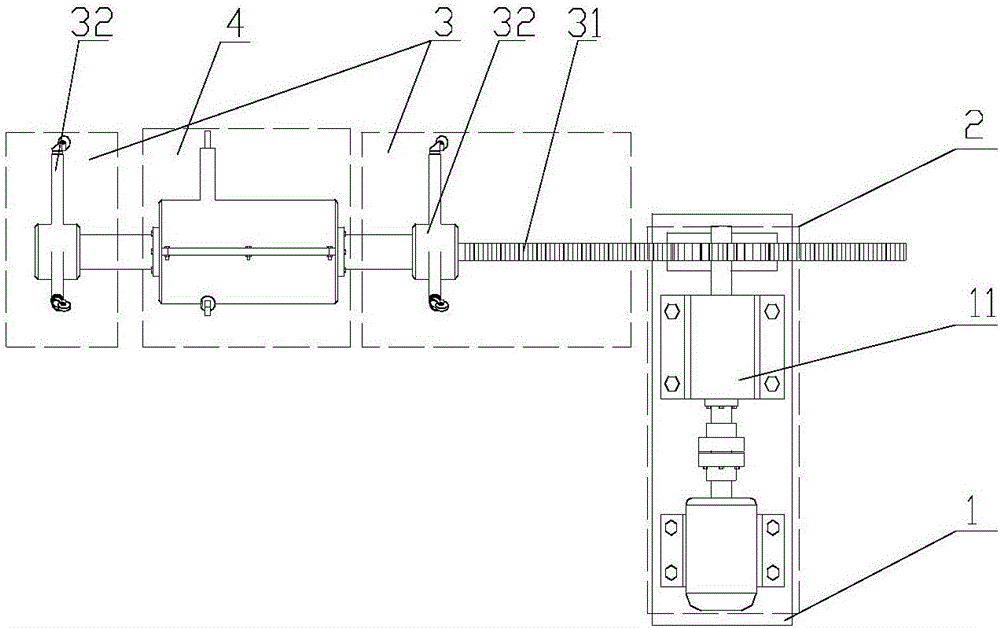

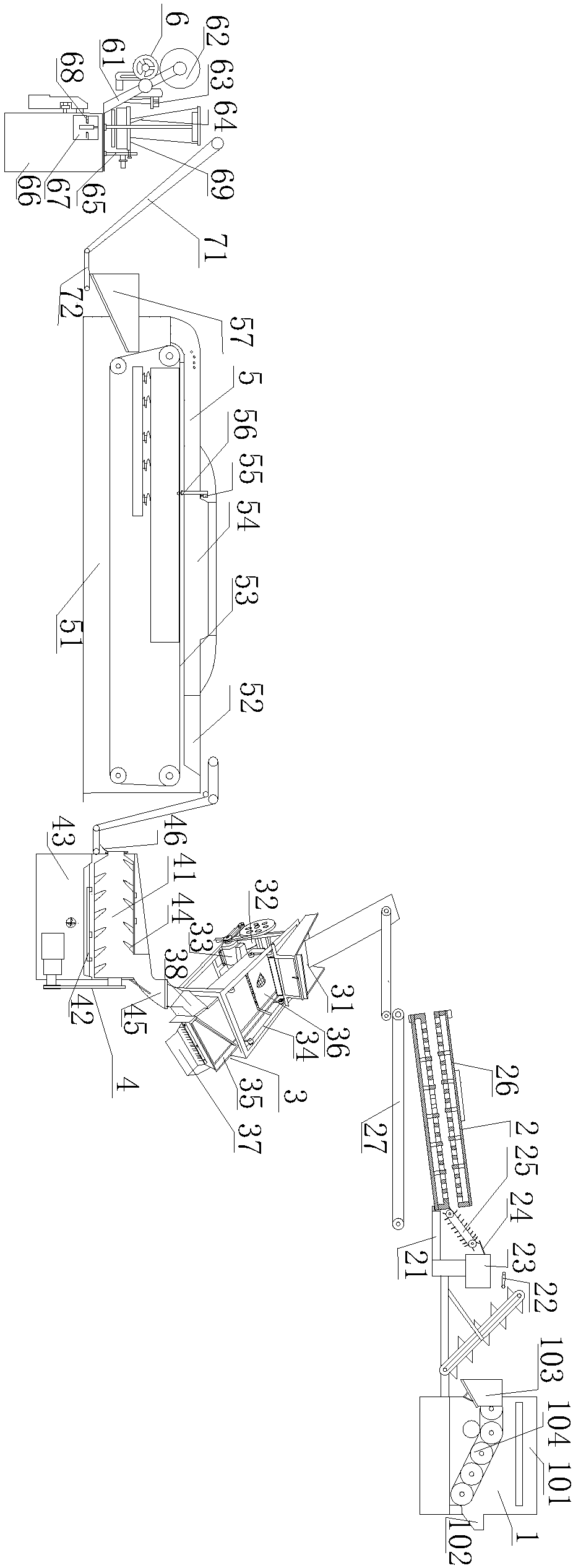

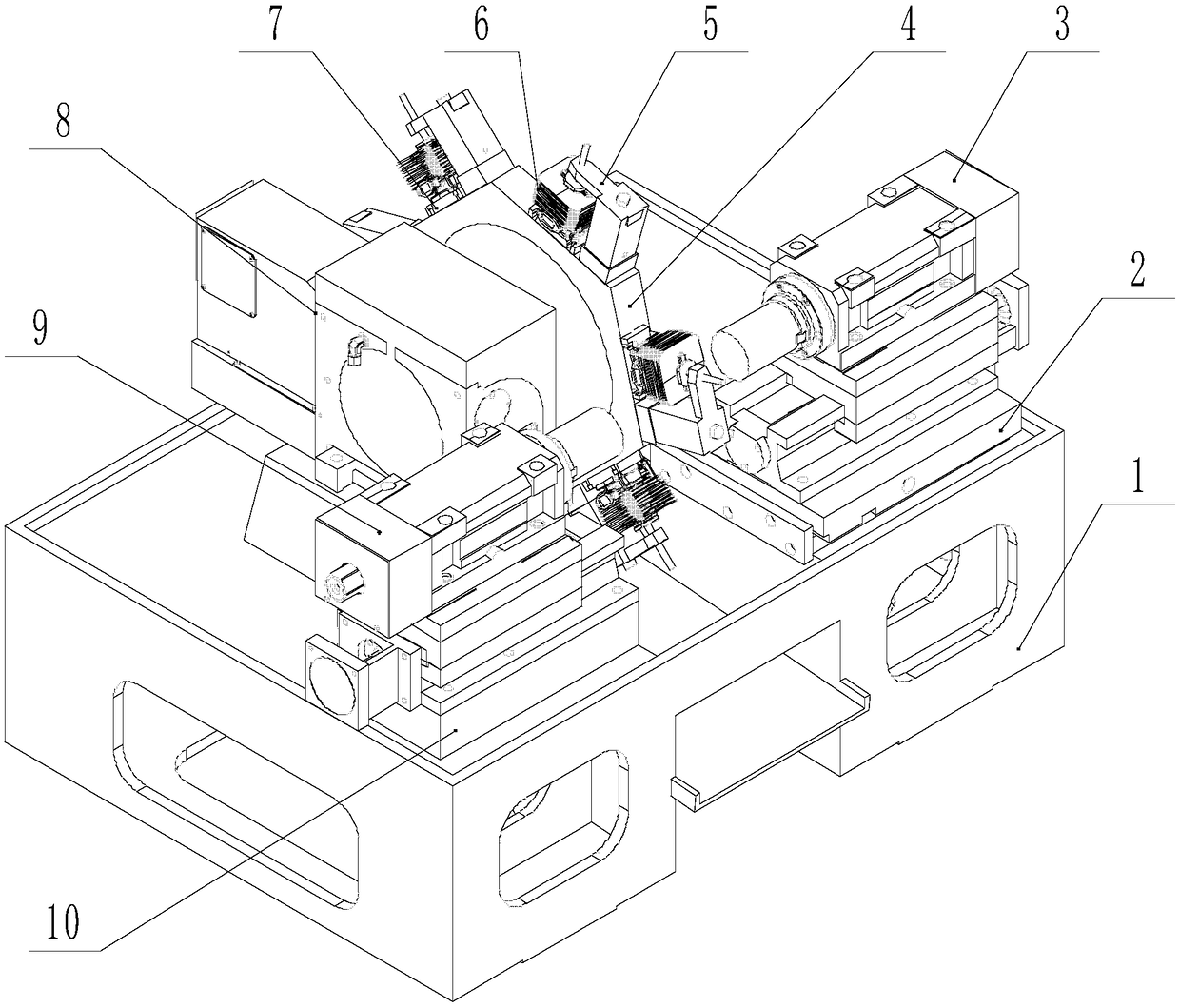

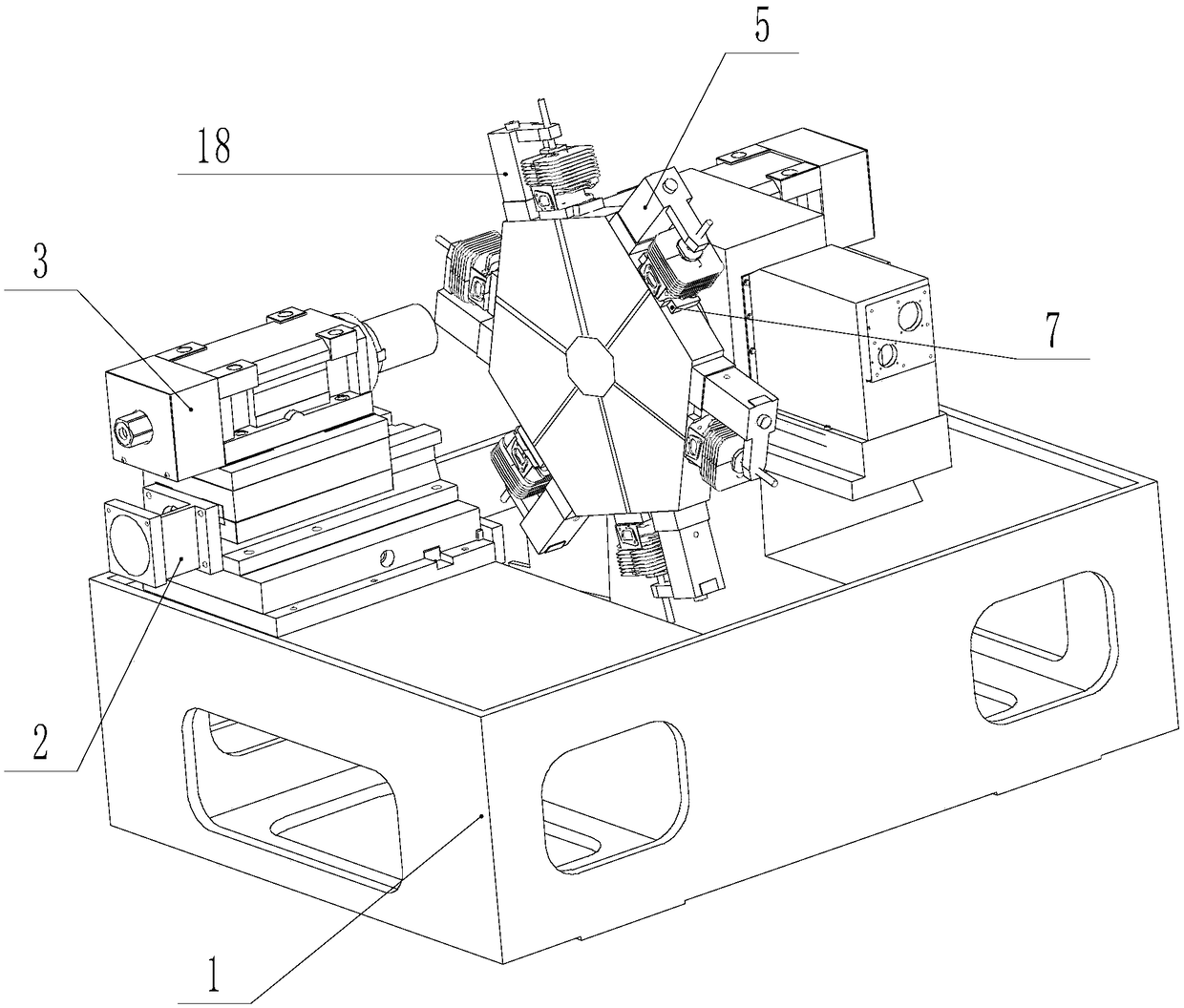

Method and device for machining tooth profile of inner gear with drum-shaped worm tool

ActiveCN103586546AIncrease radius of gyrationRealize continuous processingGear teethGear wheelEngineering

The invention discloses a device for machining the tooth profile of an inner gear with a drum-shaped worm tool. According to the device, a machine tool body is formed by a machine tool stand column (1) and a machine tool base (0), and the machine tool body is connected with a perpendicular feed motion unit (2), a worm tool driving power head (3), a workpiece rotation motion unit (4), a horizontal workpiece feed motion unit (5), a worm tool opening and closing unit (6) and a power head swing motion unit (7). A method for machining the tooth profile of the inner gear with the drum-shaped worm tool includes four major steps. The drum-shaped worm tool is divided into two parts and opened or closed in proper time before or after machining, the surface of the inner gear with a small diameter can be machined with a large-diameter tool, the inner gear can be machined continuously, and thus the machining efficiency is greatly improved; effects of worm rotation errors on the machining precision can be reduced by increasing the rotation radius of the drum-shaped worm tool, and therefore the method can also be used for machining precision inner gears.

Owner:陈谦 +1

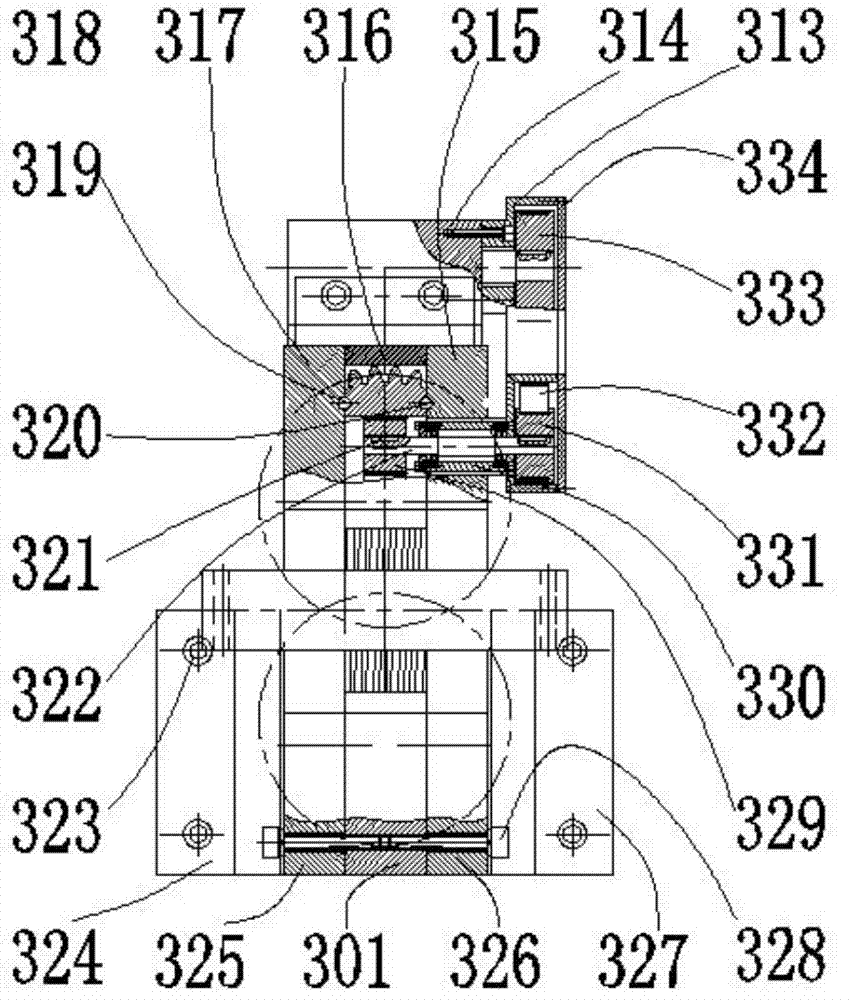

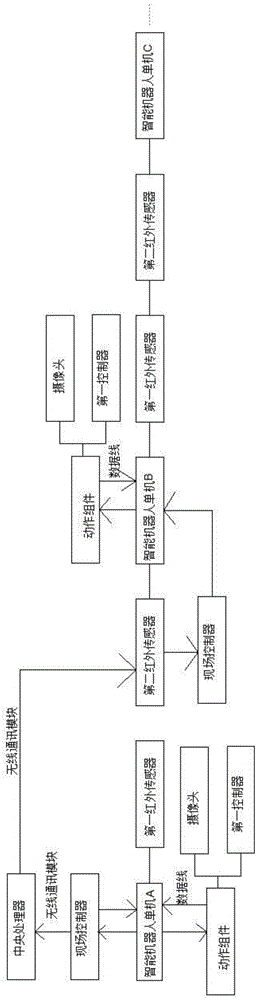

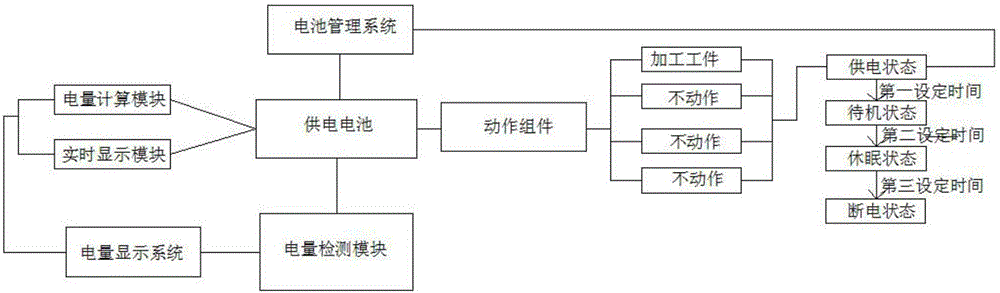

Intelligent robot production line scheduling system and method

ActiveCN106774191AImprove battery lifeRealize continuous processingCircuit monitoring/indicationDifferent batteries chargingProduction lineCommunications system

The invention discloses an intelligent robot production line scheduling system and method. The system comprises a conveying device, multiple intelligent robot single machines sequentially arranged along the conveying device and further comprises a shooting system, an infrared sensing system, and a control system, wherein each intelligent robot single machine comprises one processing station, the shooting system comprises a camera and a first controller, the infrared sensing system comprises a first infrared sensor and a second infrared sensor, and the control system comprises a field controller and a central processor. The system is advantaged in that scheduling of an intelligent robot production line is employed to replace manpower work in the prior art, continuous workpiece processing can be realized, the production line is made to be higher intelligentization and automation levels, through the cooperation effect of the shooting system, the infrared sensing system, the control system and a communication system, rapid start and standby of the intelligent robot single machines on the production line can be realized, electric power loss is saved, and endurance capability of intelligent robots is made to be better.

Owner:HUNAN TONGGANG TECH DEV

Processing method of aromatic black tea

ActiveCN104430967ARealize continuous processingStrong floral scentPre-extraction tea treatmentBlack teaFermentation

The invention relates to a processing method of aromatic black tea and aims at solving the problem of low aroma of the black tea. The processing method of the aromatic black tea comprises fixation on fresh leaves, rolling, fermentation, shaping, drying, and aroma extraction, thereby obtaining the aromatic black tea. The processing method of the aromatic black tea is capable of achieving the continuous production, and then capable of obtaining aromatic flat black tea or achieving the continuous processing of the flat black tea.

Owner:浮梁县农业开发有限公司

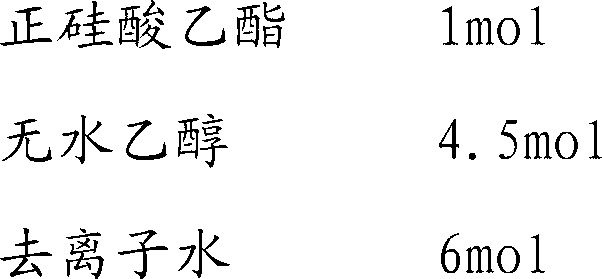

Processing method for high-efficiency polyester nonwoven thermal insulation material

ActiveCN102965911AContinuous productionDrying without supercritical technologyFibre typesPolyesterWater discharge

The invention discloses a processing method for a high-efficiency polyester nonwoven thermal insulation material, comprising the following steps: (1) carrying out aminolysis modification treatment on a polyester nonwoven fabric, and dewatering to form into the polyester nonwoven fabric which is carried out by aminolysis and modification with 40%-80% of mangle expression; (2) putting the polyester nonwoven fabric which is carried out by aminolysis and modification with 40%-80% of mangle expression into sol working solution to carry out an impregnation technology; and (3) adding 5%-10% (volume fraction) of perfluorinated compound into the working solution of the impregnation technology to improve the spontaneous water discharge capability of a capillary tube when the gel formed by the impregnation technology is dried, replacing the self removal of the solvent by nonpolar solvent through solvent, and drying in the manner of stepped heating and drying to obtain the high-efficiency polyester nonwoven thermal insulation material. According to the processing method, due to the technical means of the in-situ gelation, the problem that the fiber and the gel cannot be completely combined and easy to have the mechanical defect can be overcome, and the mechanical property of the thermal insulation material can be improved.

Owner:福建鑫华股份有限公司

Machine tool capable of achieving multi-station continuous automatic clamping and loosening and rotary milling of workpieces

PendingCN109396505ARealize continuous processingSimple structureMilling machinesMachine toolMachining

The invention discloses a machine tool capable of achieving multi-station continuous automatic clamping and loosening and rotary milling of workpieces, and belongs to the technical field of milling machine devices. The machine tool overcomes the defect in the prior art that the workpiece clamping auxiliary time is long, only one workpiece can be clamped once, only one side can be milled once, andthe efficiency is low when the traditional machine tool is adopted to mill two sides of the workpiece. A main structure of the machine tool comprises a base. The base is provided with a left lateral feeding mechanism, a right lateral feeding mechanism and a rotating mechanism. The left lateral feeding mechanism is provided with a left cutting mechanism, and the right lateral feeding mechanism is provided with a right cutting mechanism. The rotating mechanism includes a rotating unit and a tool plate which are connected, and the tool plate is provided with a pressing mechanism. The machine toolis mainly used for continuous machining of various workpieces.

Owner:LINYI JINXING MACHINE TOOL

Drilling machine for battledore

ActiveCN103212733AControl workReduced speed movementPrecision positioning equipmentPositioning apparatusProduction rateEngineering

The invention belongs to the field of production equipment for a battledore, and particularly relates to the field of equipment for production and machining of side holes of the battledore. A drilling machine for the battledore comprises a battledore clamping device, a drilling device and a hole spacing controlling device, wherein the battledore clamping device is arranged on a working table, and the drilling device and the hole spacing controlling device are connected with the battledore clamping device. The drilling device comprises a high-speed drilling machine which is provided with a high-speed drilling head facing toward the battledore clamping device. The high-speed drilling machine is provided with a first connecting rod, a clutch cam plate is connected at the end, far away from the high-speed drilling machine, of the first connecting rod, and the clutch cam plate is connected with the hole spacing controlling device. The battledore clamping device comprises a gear plate which is installed on the working table. The gear plate is provided with an interval displacement expansion device. The drilling machine for the battledore can achieve that one-step installation of the battledore can achieve machining of all the side holes of the battledore, and avoid the hole spacing error caused by multiple installation and clamping. Meanwhile, the drilling efficiency is high, and a production rate is improved greatly.

Owner:舒城县周瑜体育用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com